Patents

Literature

182 results about "Furring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In construction, furring (furring strips) are thin strips of wood or other material to level or raise surfaces of another material to prevent dampness, to make space for insulation, or to level and resurface ceilings or walls. Furring refers to the process of installing the strips and to the strips themselves. Firring is a U.K. term for wood strips which are usually 50 mm wide, tapered and fixed above wood roof joists to provide drainage falls below roof boarding. Furring strips themselves are typically referred to as battens in the U.K. and sometimes the material is called strapping in the U.S.

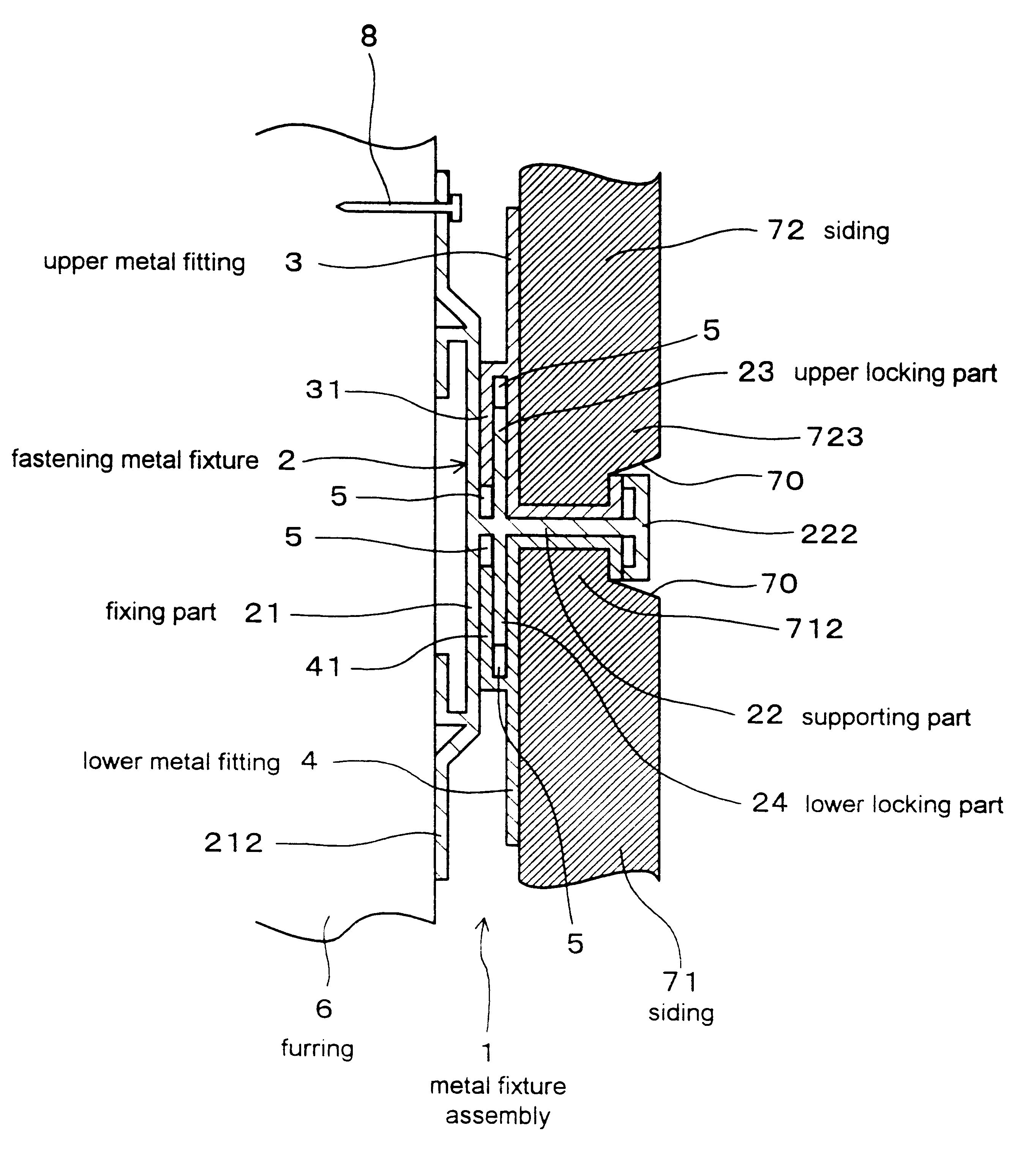

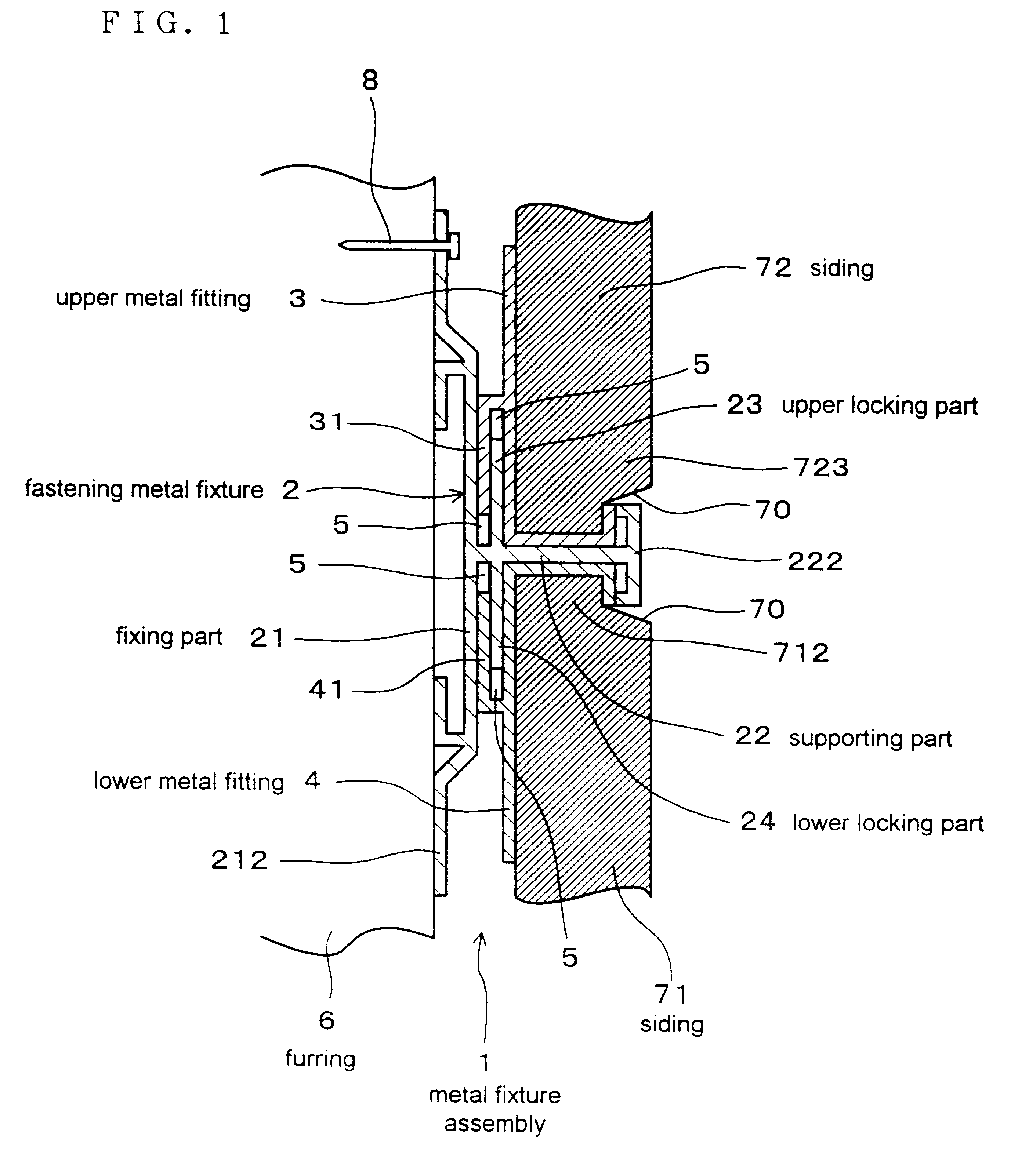

Metal fixture assembly for installation of vertical sidings, construction and method of installation

InactiveUS6289646B1Safe installationGood lookingCeilingsRoof covering using tiles/slatesArchitectural engineeringFurring

A metal fixture assembly for installation of vertical sidings to fix the siding to a furring, which is capable of providing a construction of the installation having excellent appearance and weathering, and a method using the metal fixture assembly to facilitate the installation. A metal fixture assembly for installation of a vertical lower siding and a vertical upper siding vertically adjacent to each other on a furring is positioned therebetween. The metal fixture assembly includes a fastening metal fixture to be fixed to the furring, an upper metal fitting provided between the fastening metal fixture and the upper siding and fittingly fixed on a bottom portion thereof, and a lower metal fitting provided between the fastening metal fixture and the lower siding and fittingly fixed on a top portion thereof. The fastening metal fixture has a fixing part to be fixed to the furring, a supporting part projecting from the fixing part to support the lower and upper sidings, an upper locking part provided between the fixing part and the supporting part and locking the upper metal fitting thereto, and a lower locking part provided between the fixing part and the supporting part and locking the lower metal fitting thereto.

Owner:NICHIHA CORP

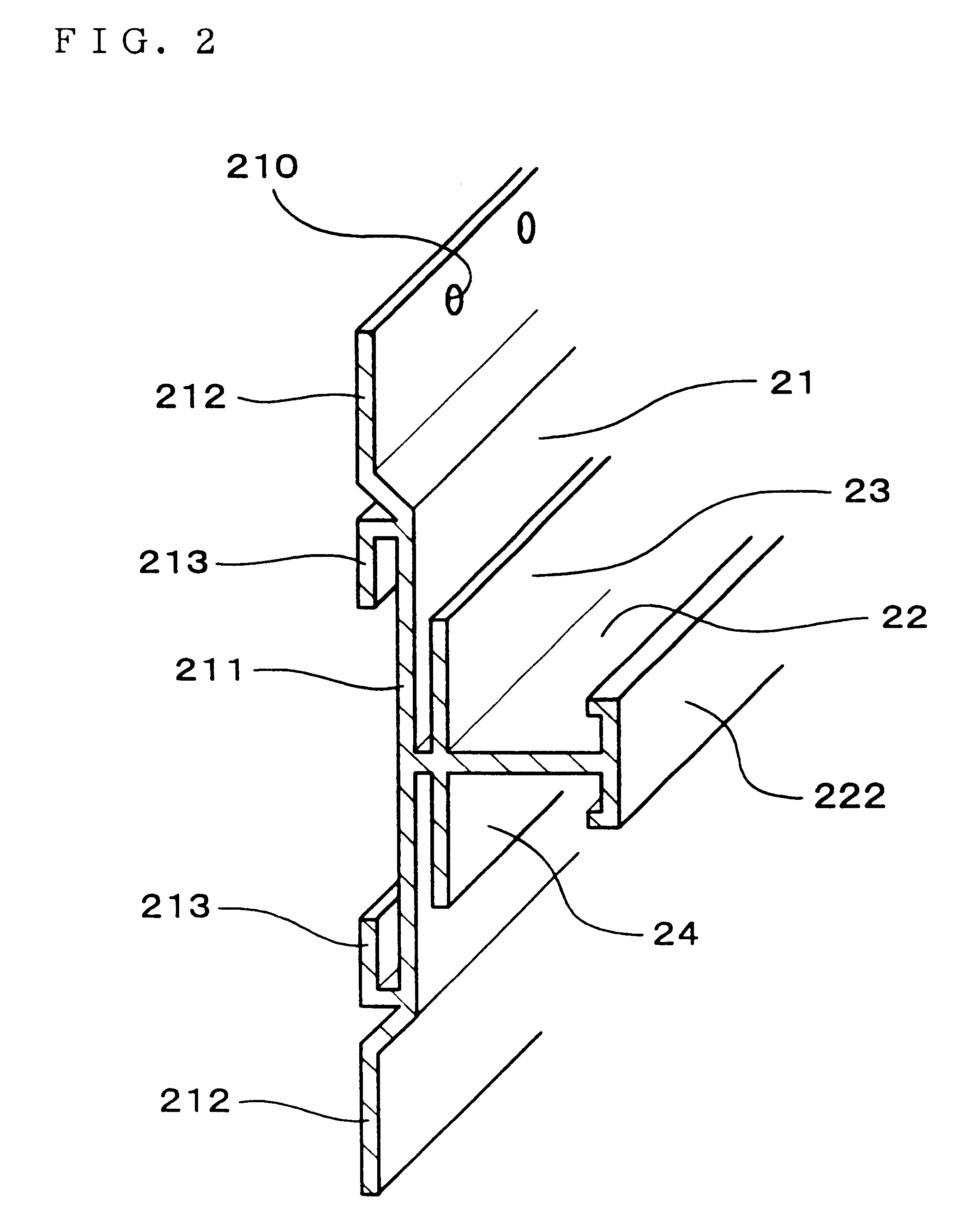

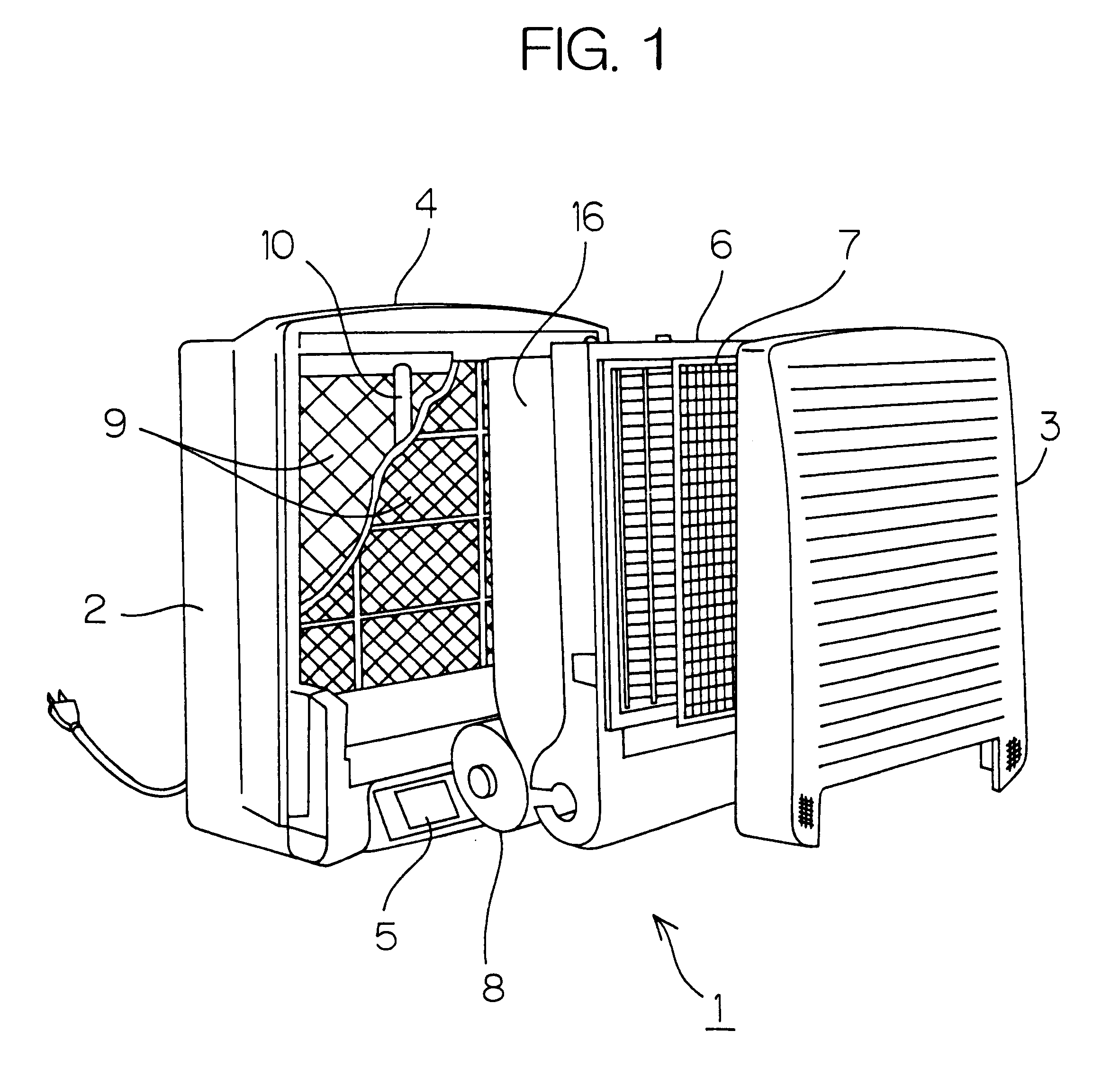

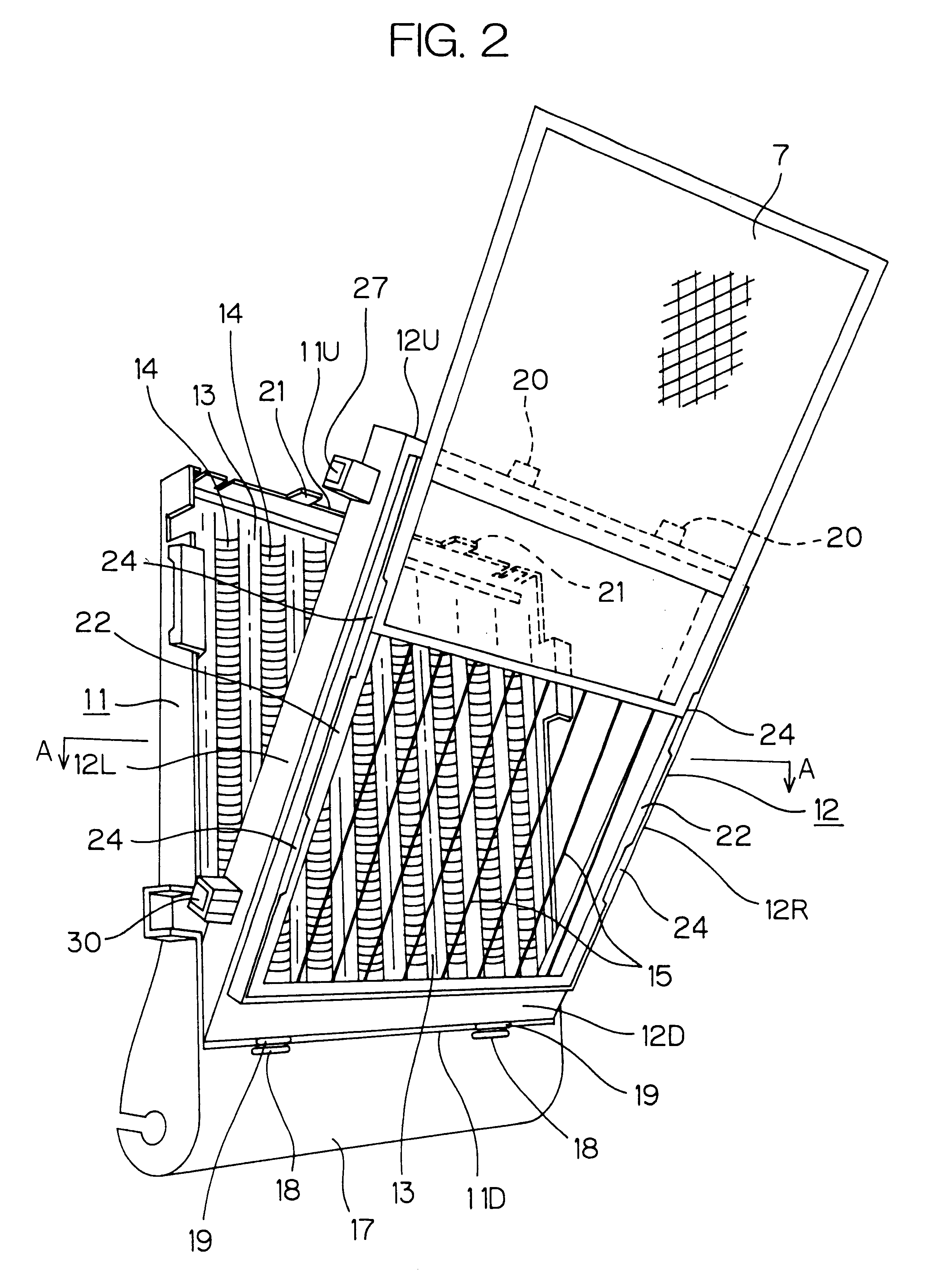

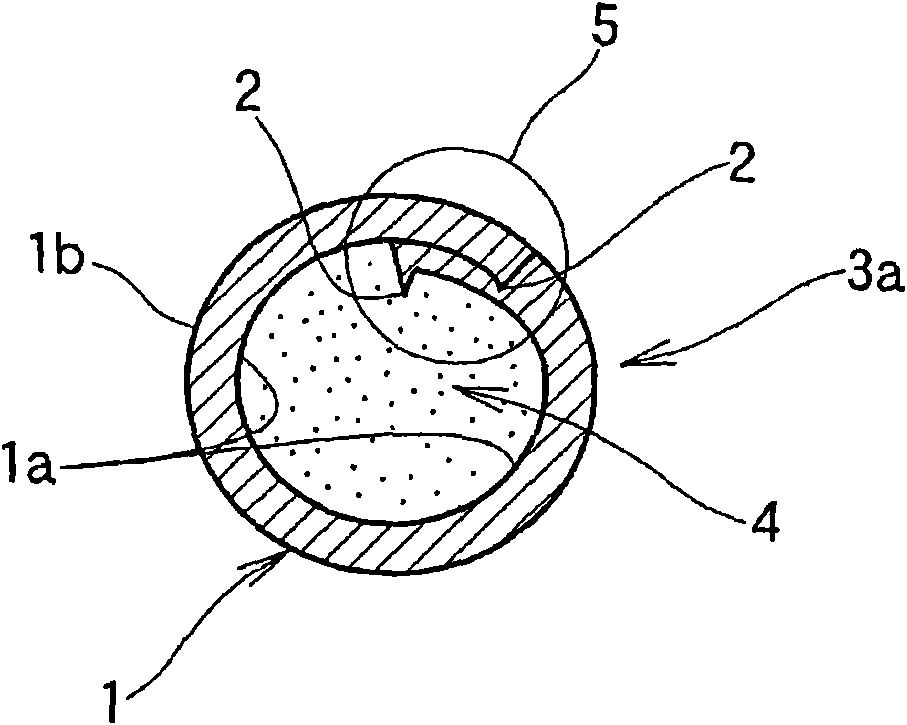

Air cleaner and its ionizing unit

InactiveUS6679940B1Easy to installWashing the unit easyElectrostatic separation housingDeodrantsFurringEngineering

When an ionization section is taken out of a main body housing of a conventional air cleaner in order to wash the ionization section, an ionization line may be cut by being accidentally touched. In order to avoid this problem, a pre-filter (7) is mounted on a front surface of an ionization and dust collection unit (6) so as to be detachable. The pre-filter (7) is slidably guided by guide furrings (23) in a sub-frame (12), and is mounted on a front surface of the sub-frame (12). When the pre-filter (7) is mounted, ionization lines (15) are not exposed, so that the pre-filter (7) protects the ionization lines (15). When the ionization and dust collection unit (6) is detached from the main body housing, therefore, there is no problem that the ionization lines (15) might be cut by being accidentally touched with worker's hands, for example.

Owner:DAIKIN IND LTD

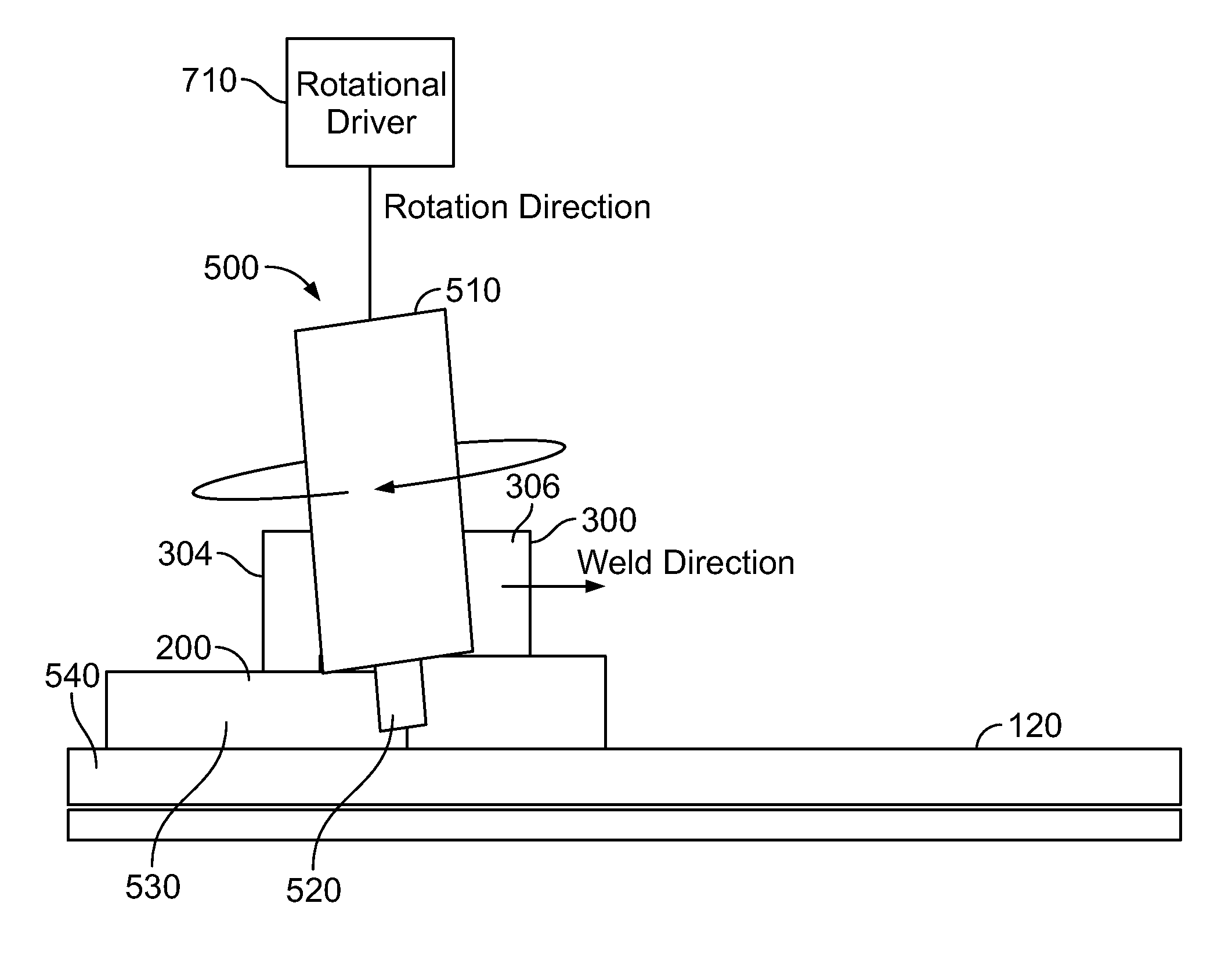

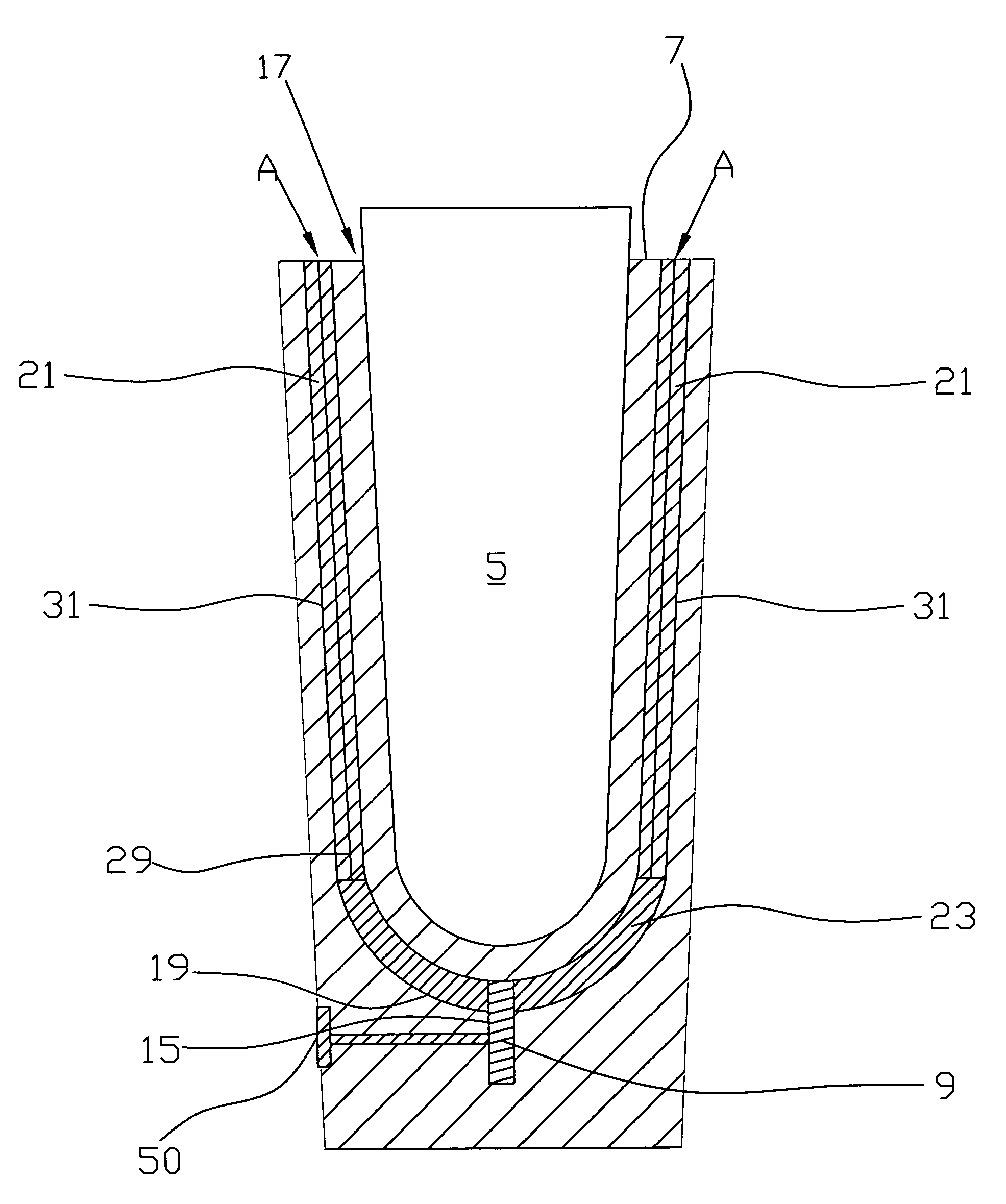

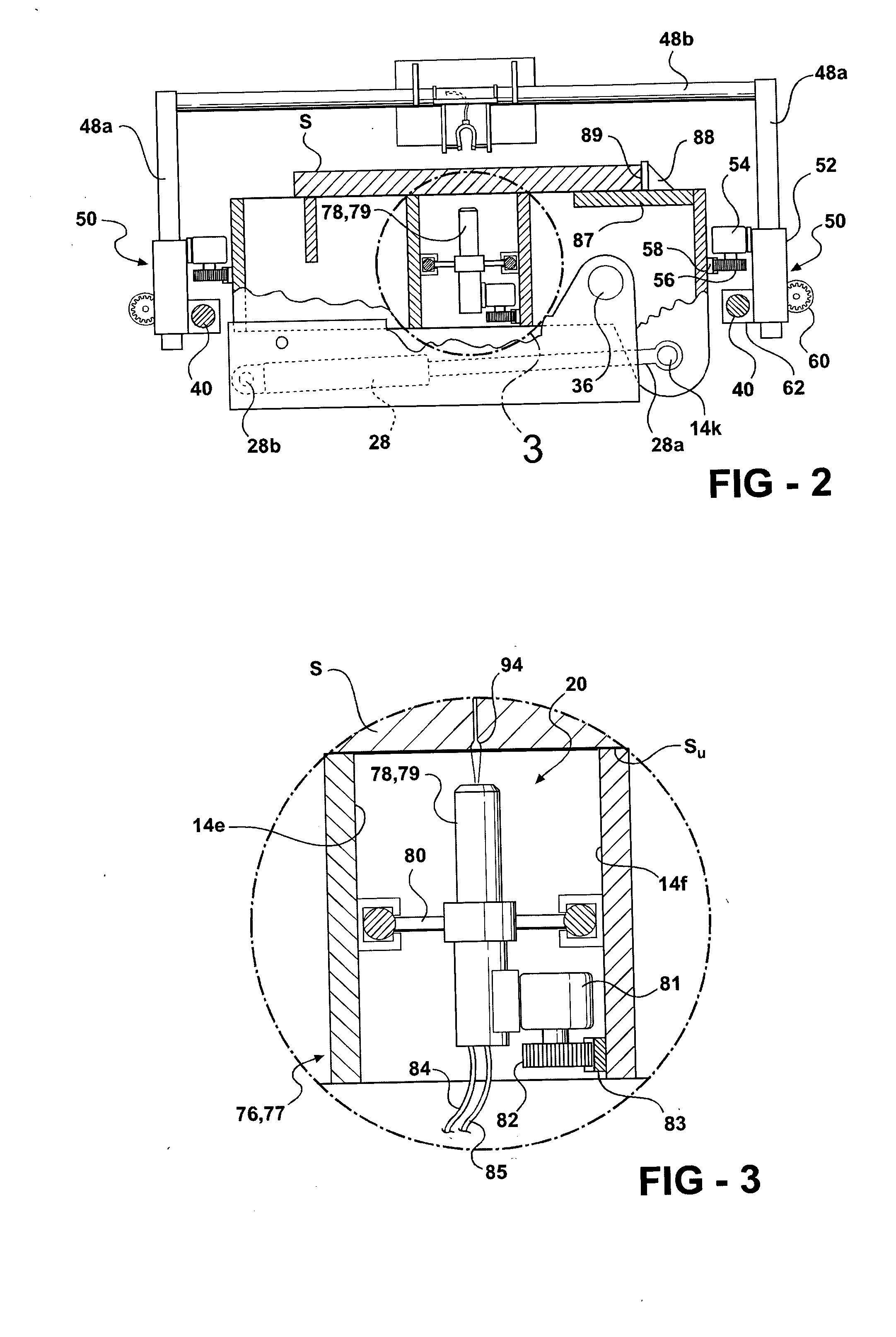

Method and apparatus for friction stir welding tube ends for a heat exchanger

ActiveUS20130037601A1Eliminates significant costReduce defectsCooking-vessel materialsWelding/cutting auxillary devicesFurringEngineering

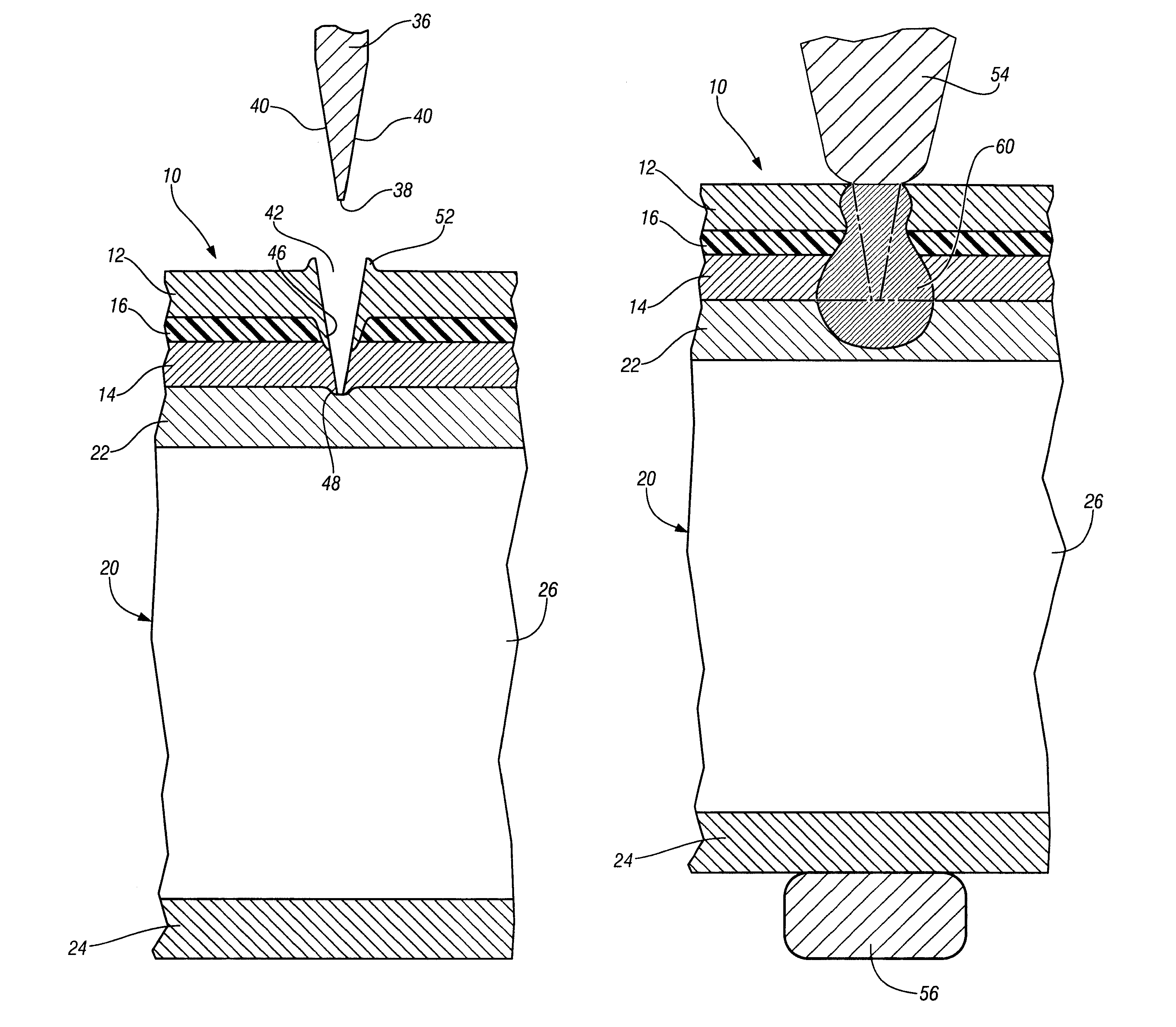

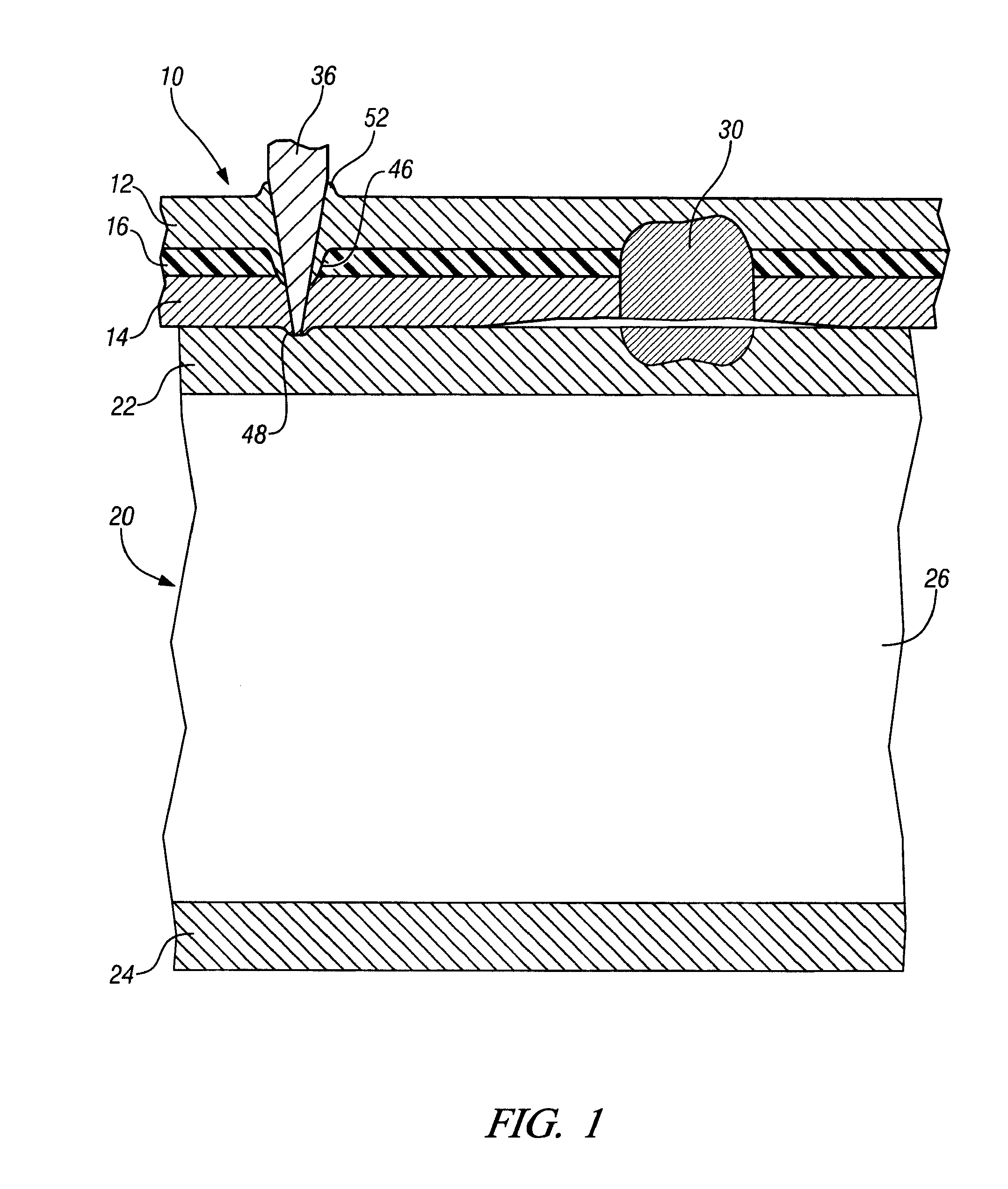

A method for forming a joint between a tube and a sheet includes forming an anvil at least within the tube, and welding the tube to the sheet in the presence of the anvil. The anvil includes an anchor which is placed within the tube near or at the joint to be formed. At least one washer is placed over the end of the anchor that is near the joint to be formed. A threaded fastener is then placed into the anchor to securely hold the anchor within the tube and to provide a backing substantial enough so that a friction stir weld can be formed. The threaded fastener and the washer can be used as a guide for the friction stir weld. Once the weld is completed, the anvil can be removed. The weld can be further processed to remove burrs and other material.

Owner:LOCKHEED MARTIN CORP

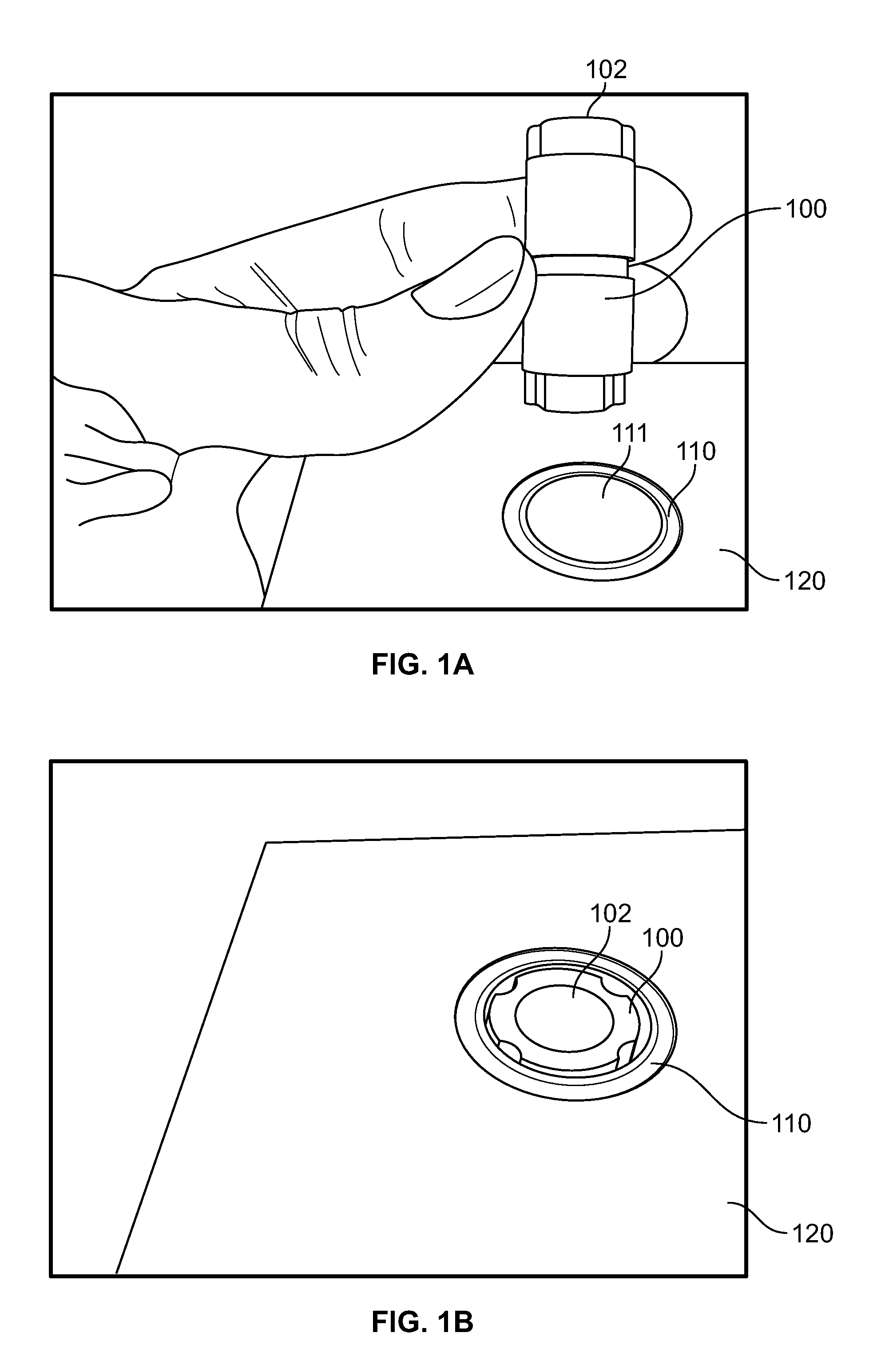

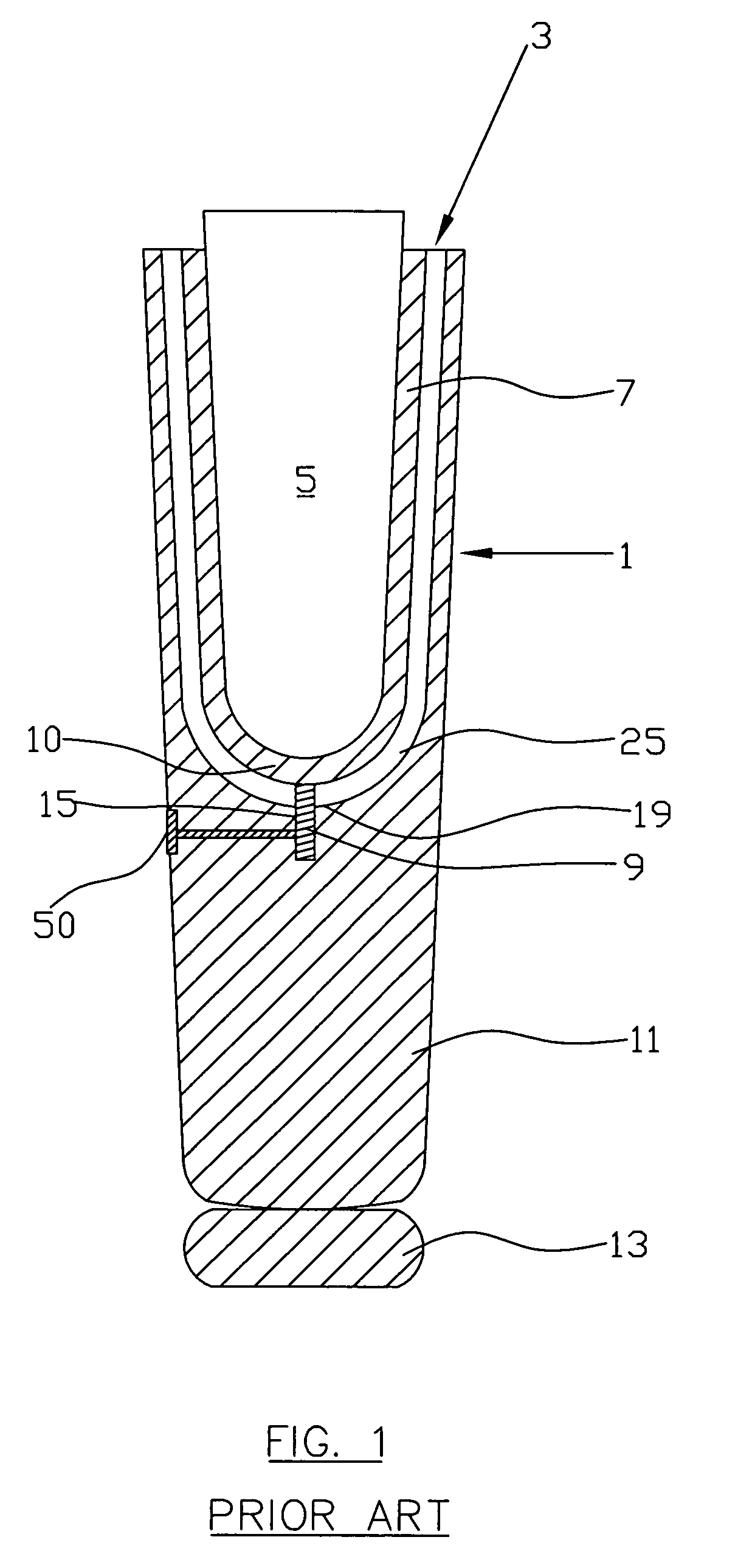

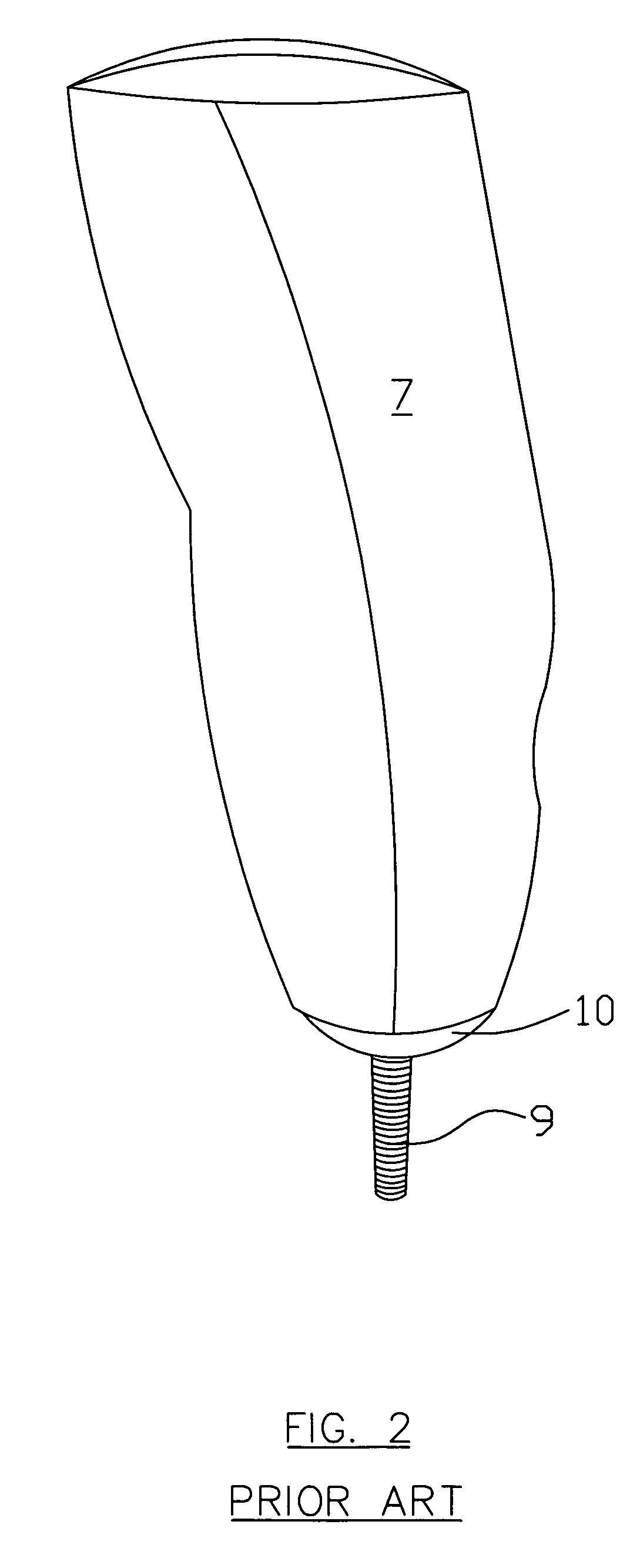

Prosthetic interior casting process and product

InactiveUS7240414B2Low costExtend equipment lifeMetal rolling stand detailsArc welding apparatusShell moldingFurring

A method of sizing, resizing or reshaping the interior of a prosthetic device includes placing a lightweight moldable or shape assuming, pliable material that adheres and hardens on the interior sides of a socket of a prosthetic device. An end of a residual limb is placed into the socket causing the moldable material to conform to the shape of the residual limb. The limb is maintained in position for a few minutes in the socket until the moldable material has sufficiently hardened. After hardening, the molded material is dressed down, sanded or feathered to remove any burrs or sharp edges. Low spots or holes may be filled in with more moldable material and the fitting process repeated.

Owner:TAYLOR SR MATTHEW T

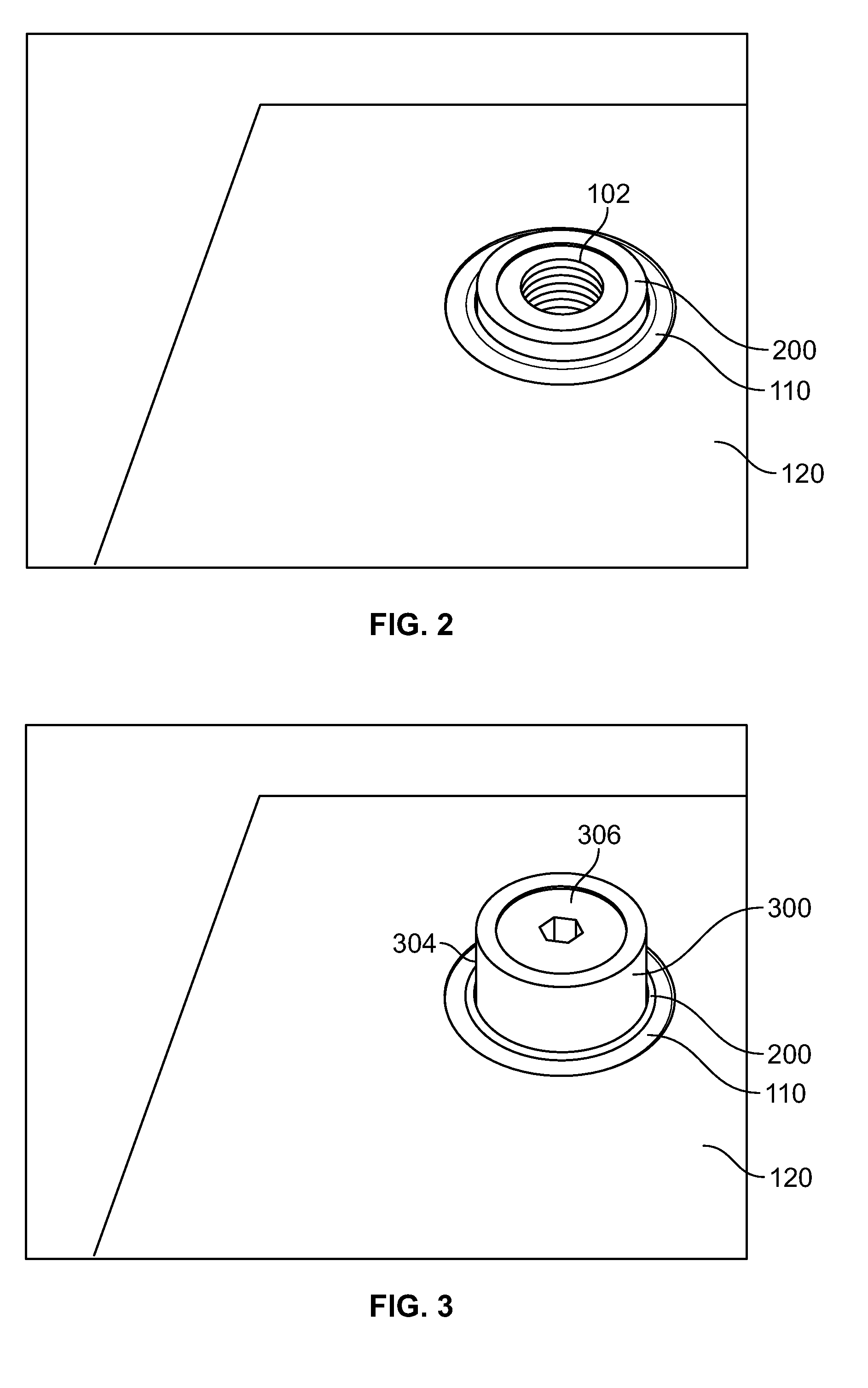

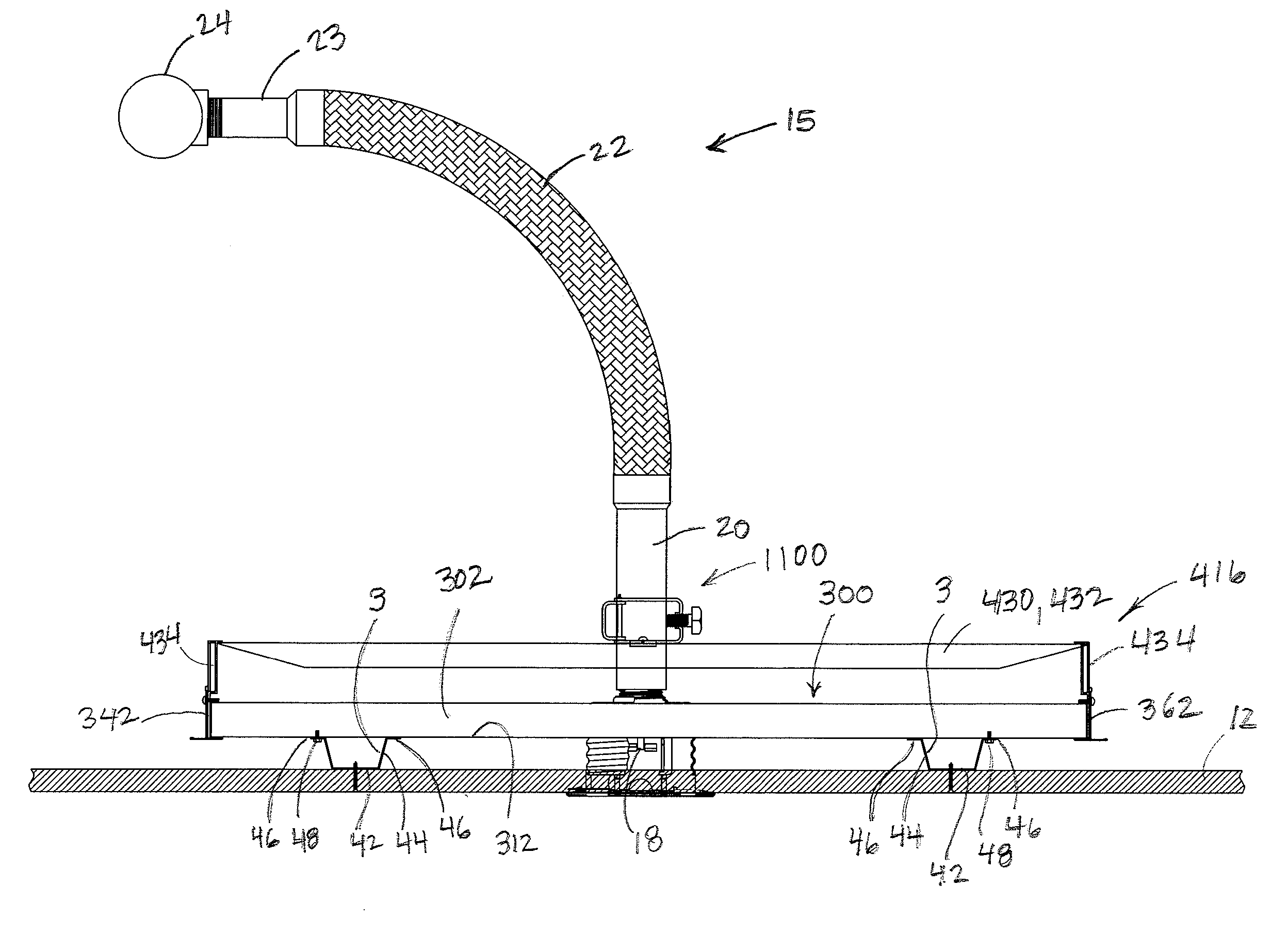

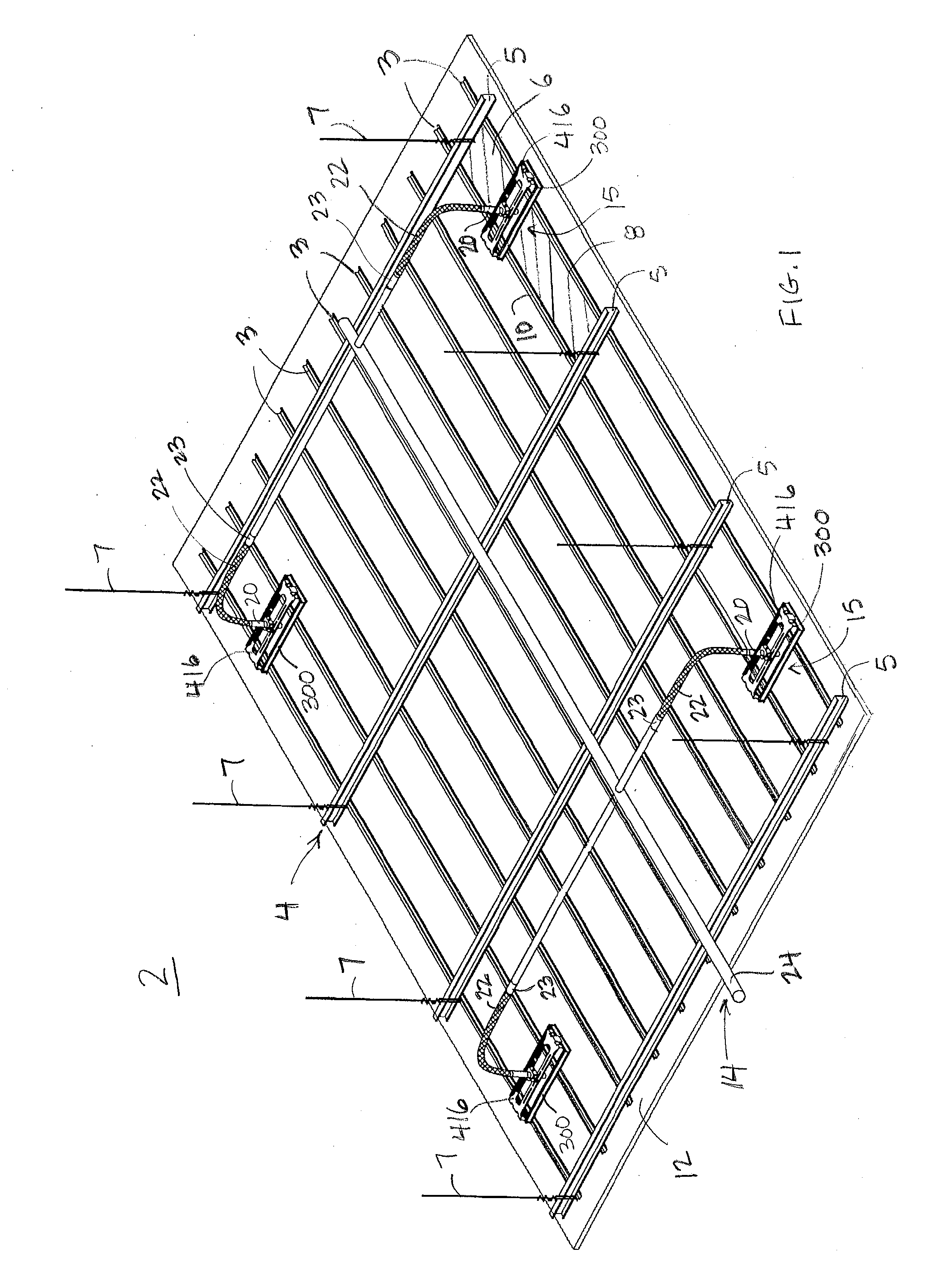

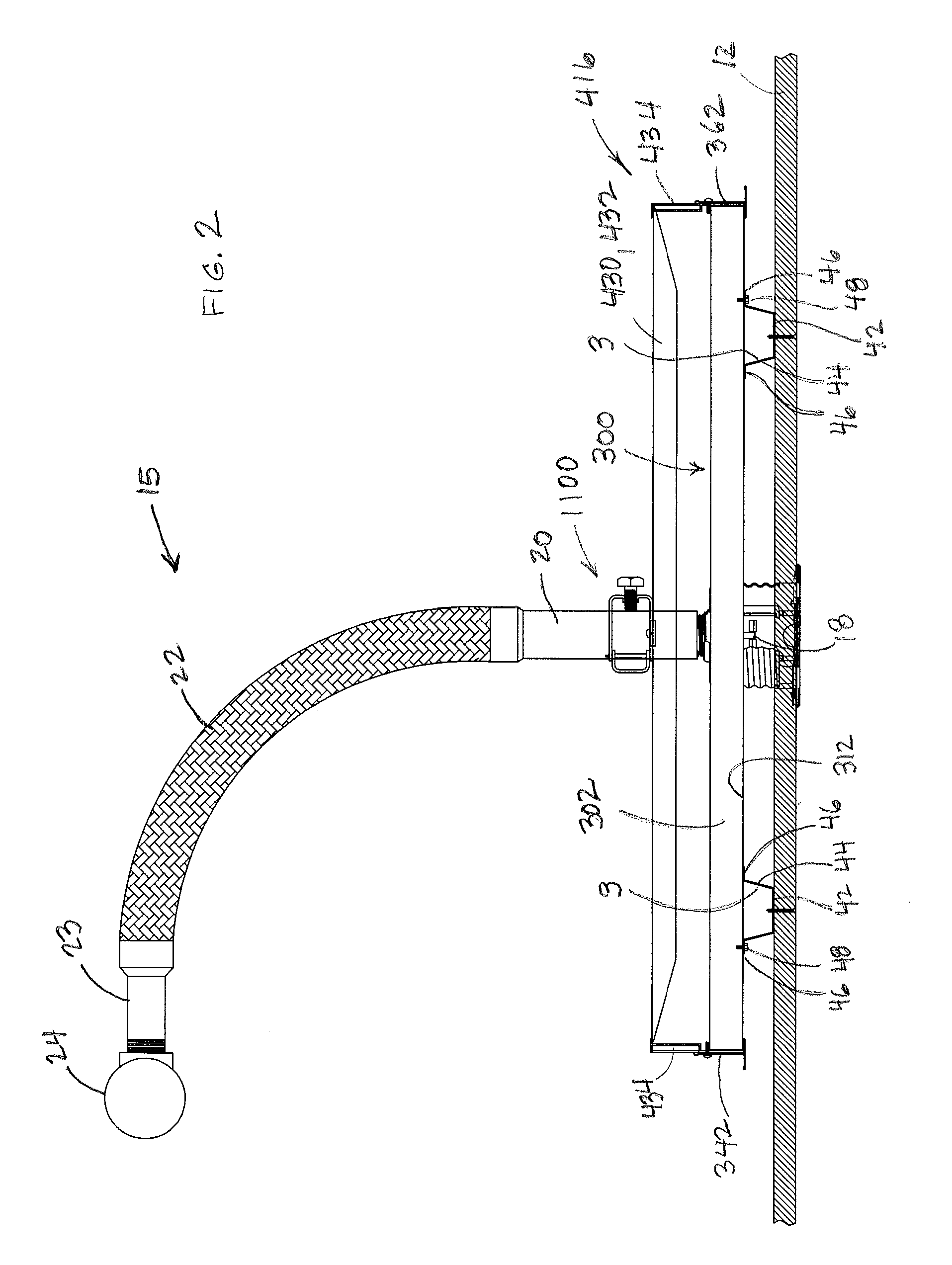

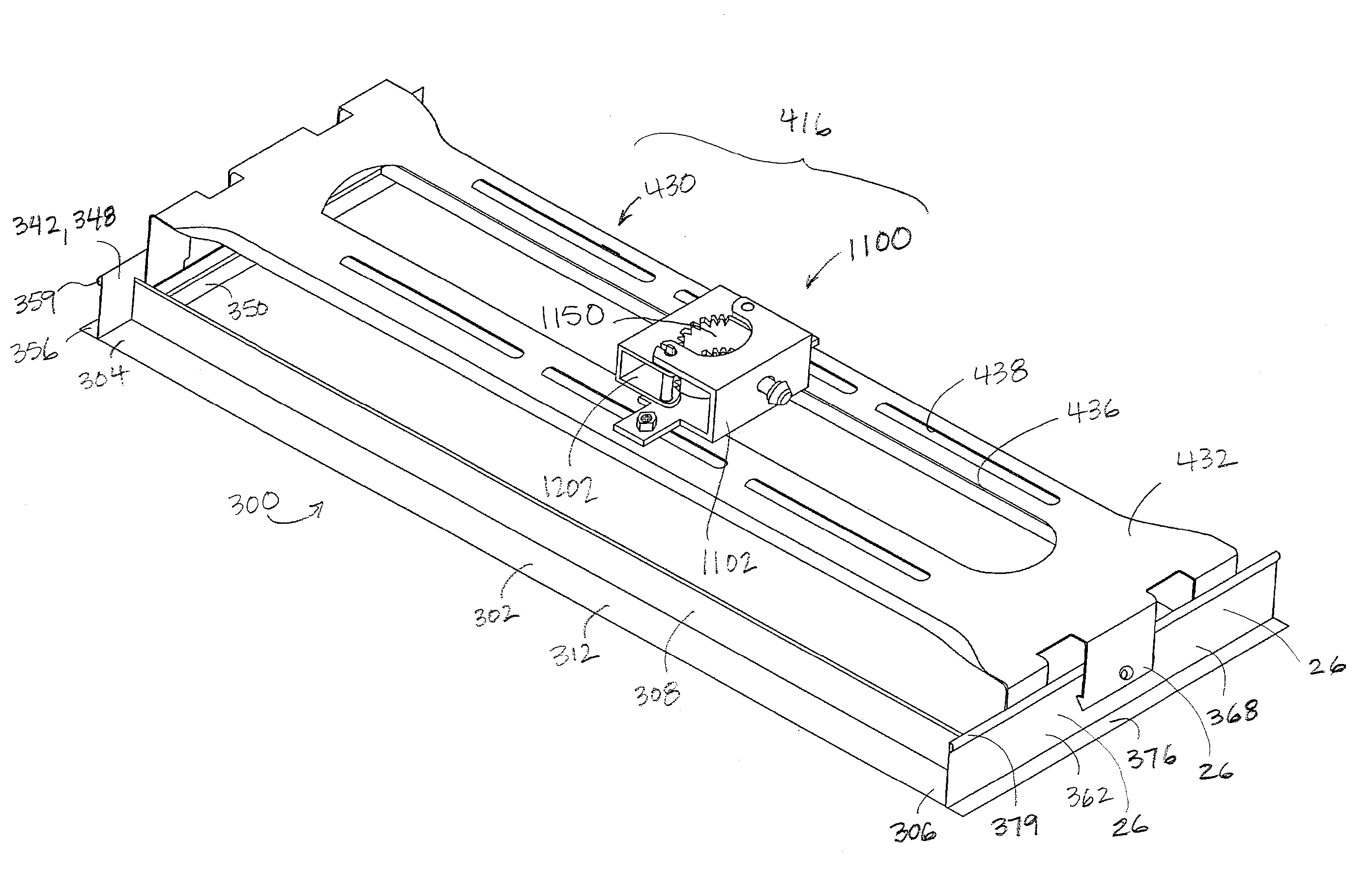

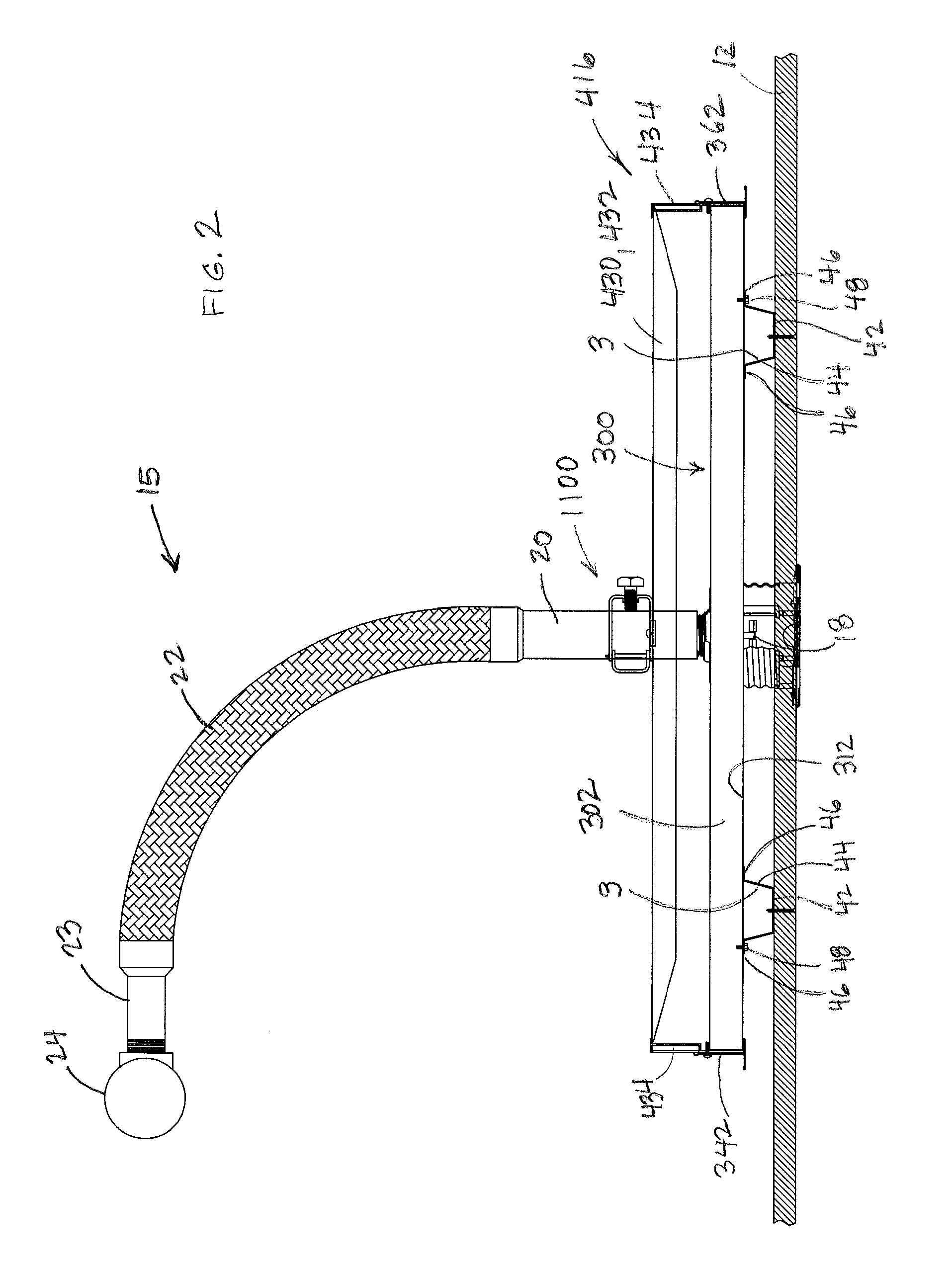

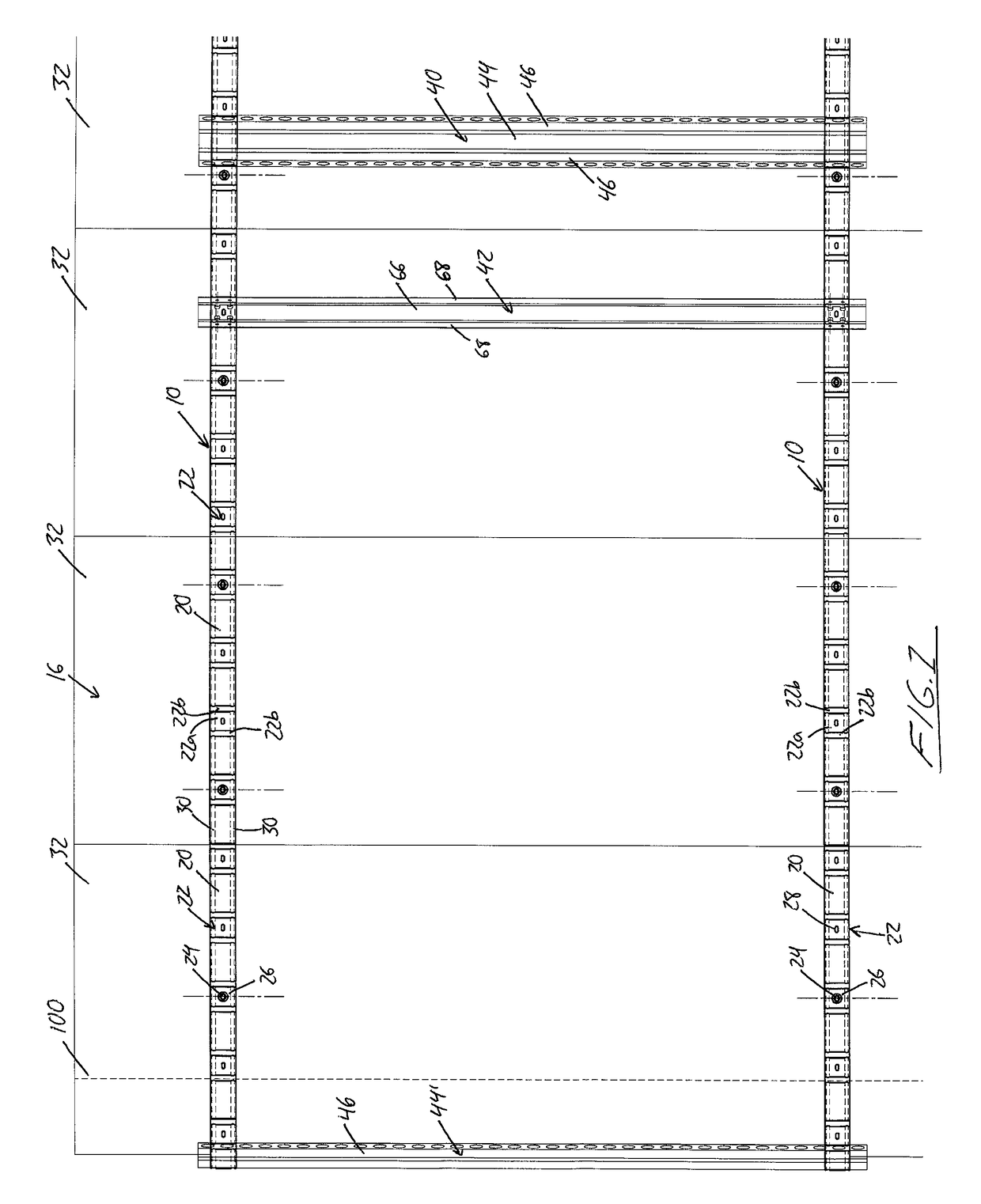

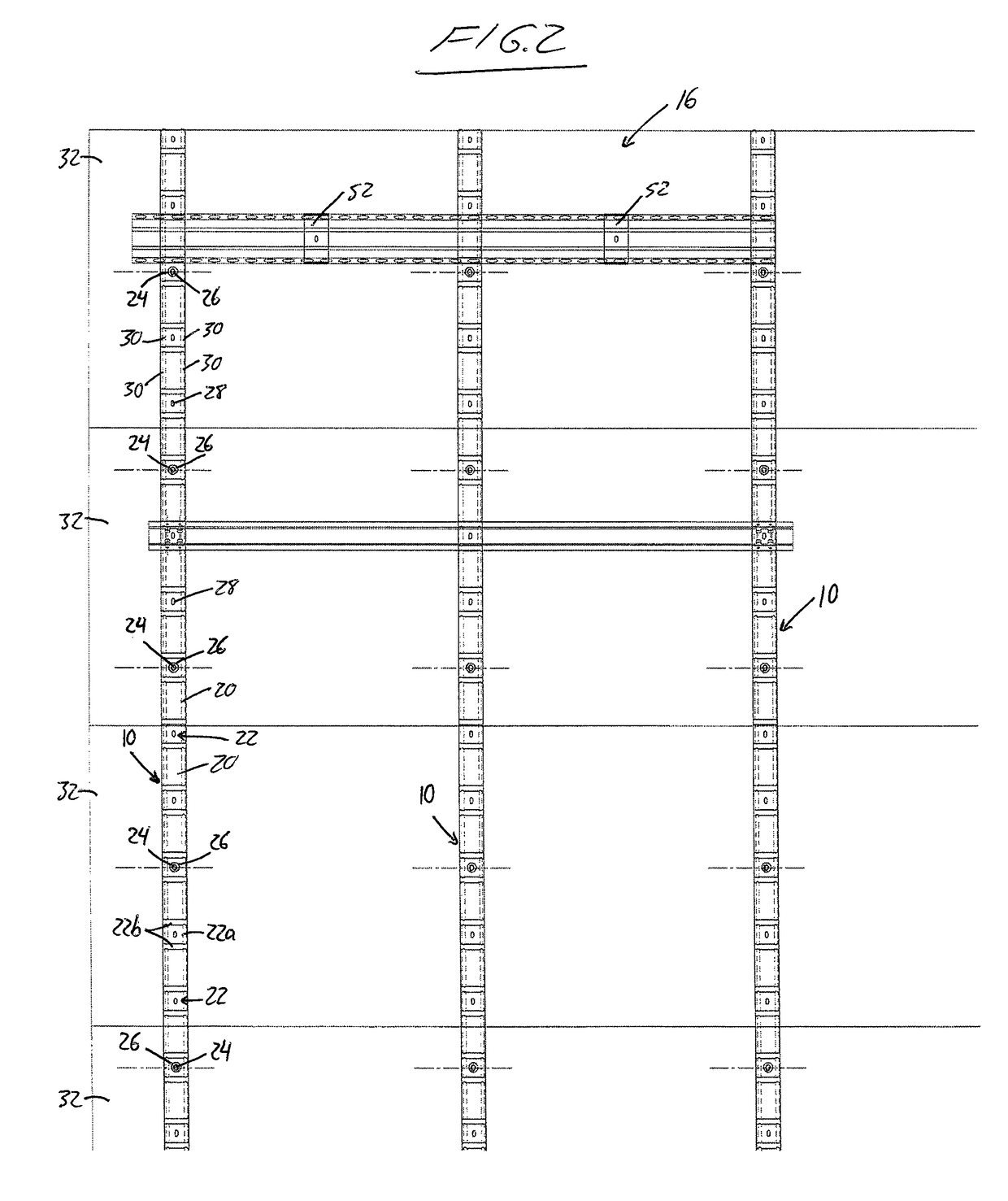

Hat channel adaptor for sprinkler support assembly

An adaptor is provided that is configured to receive a support assembly for mounting a flexible fire sprinkler fitting in a ceiling support structure formed of parallel, spaced beams. The adaptor includes first and second long sides configured to be secured to each beam of an adjacent pair of beams, and first and second short sides configured to be secured to the support assembly. One end of each long side is joined by the first short side, and an opposed end of each long side is joined by the second short side such that the first and second long sides are parallel to each other and perpendicular to the first and second short sides, whereby the adaptor is a generally elongated, hollow, rectangular structure. The adaptor permits the support assembly to be mounted in a suspended ceiling formed of hat channel or metal stud furring.

Owner:ASC ENGINEERED SOLUTIONS LLC

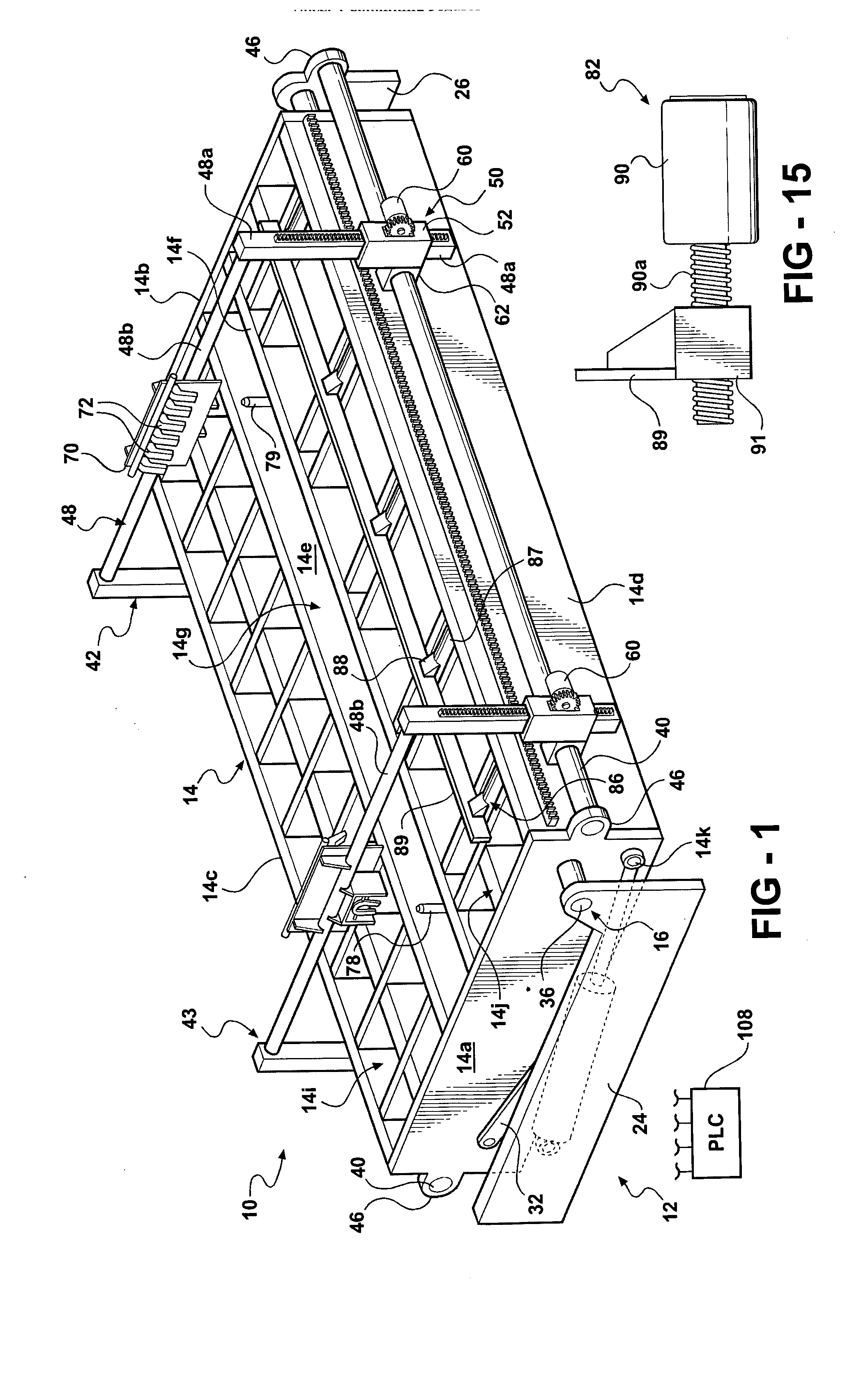

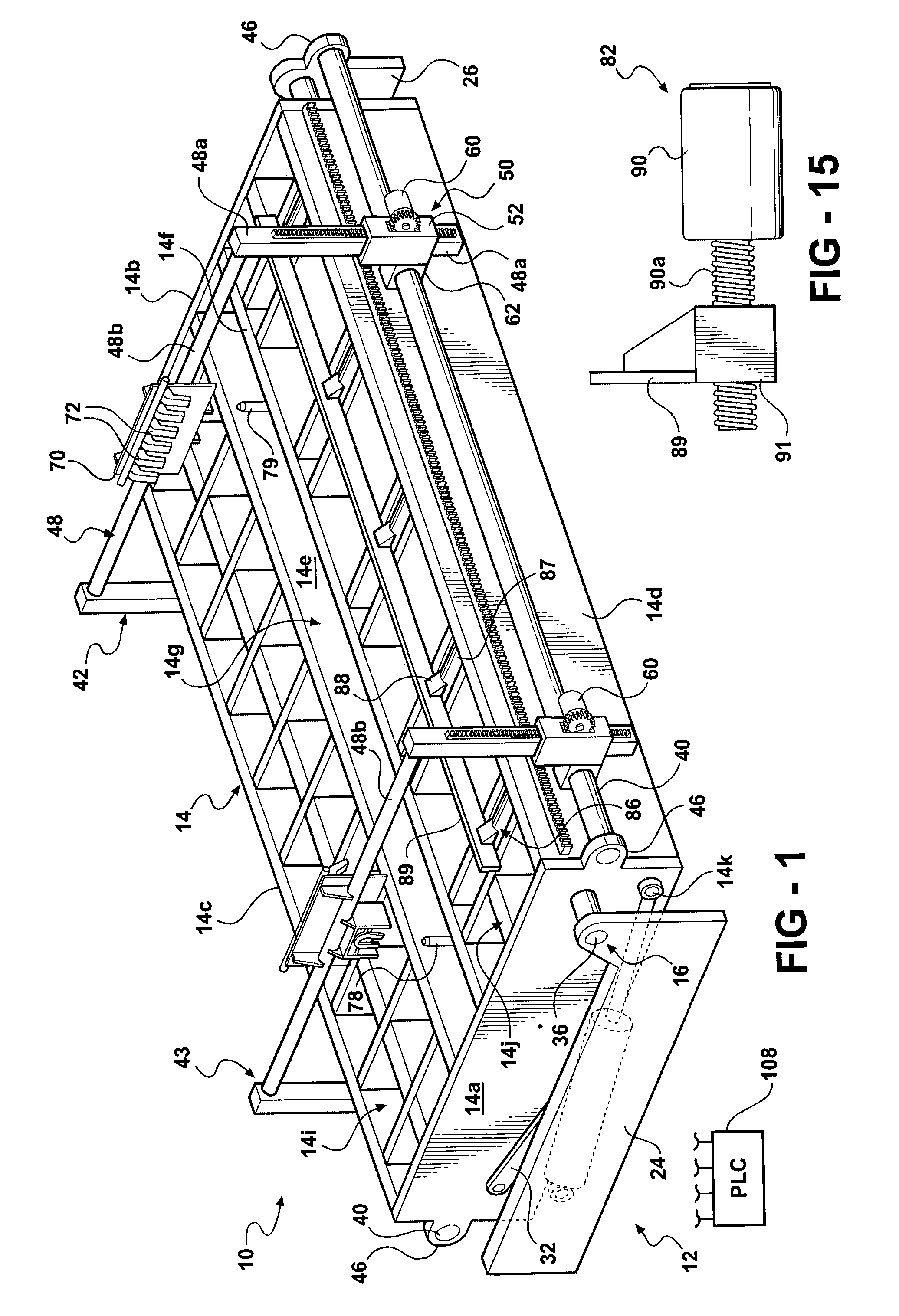

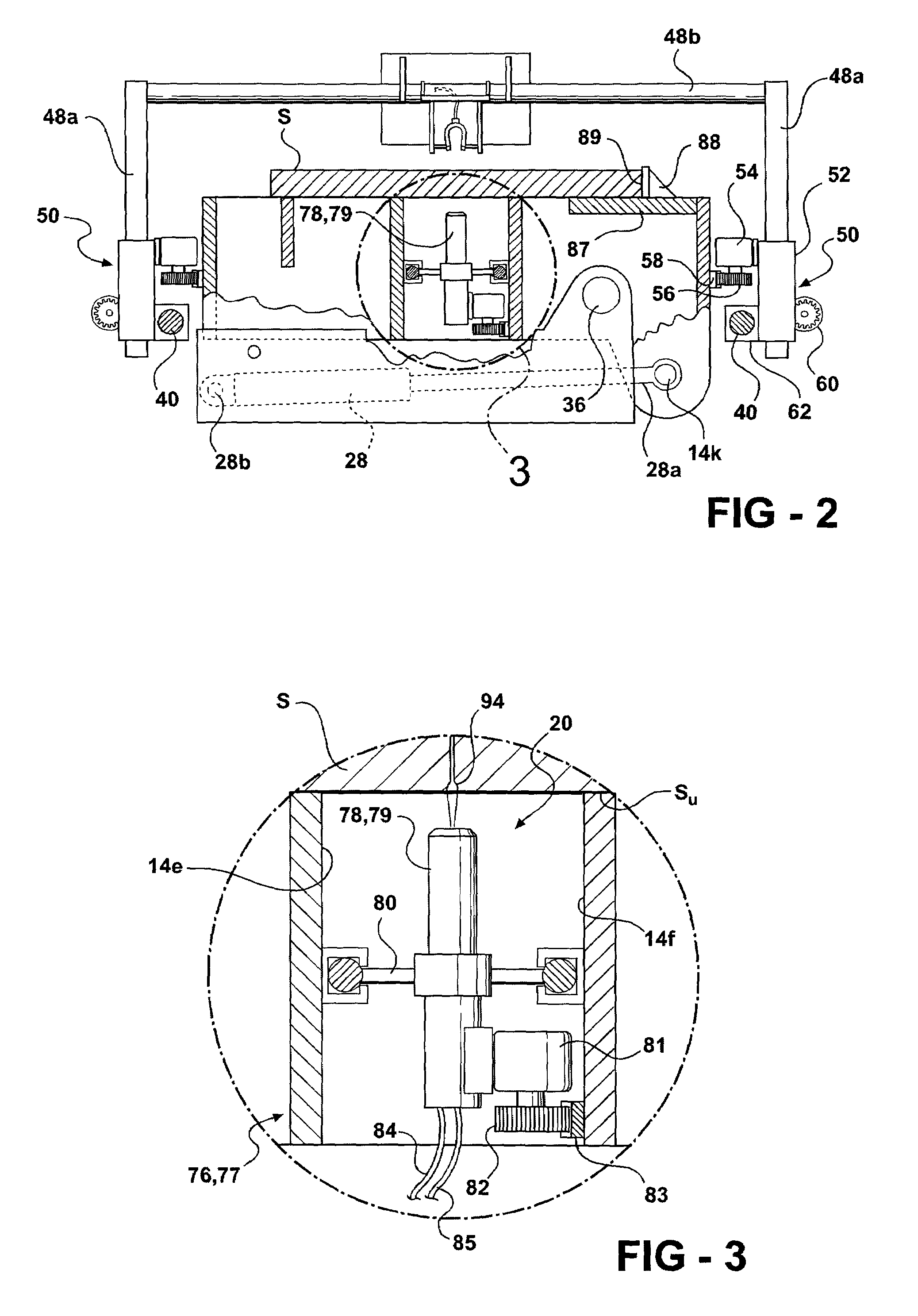

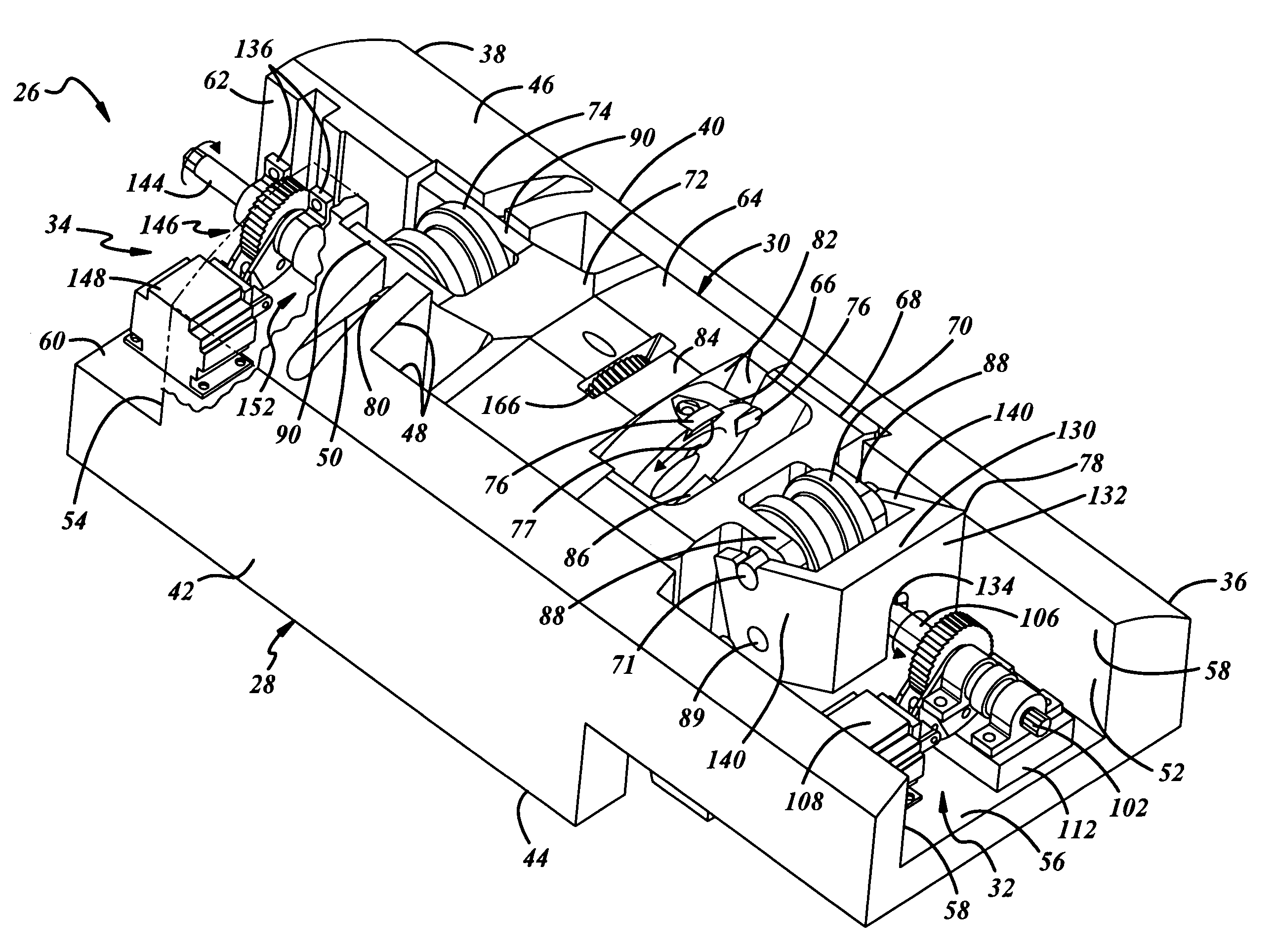

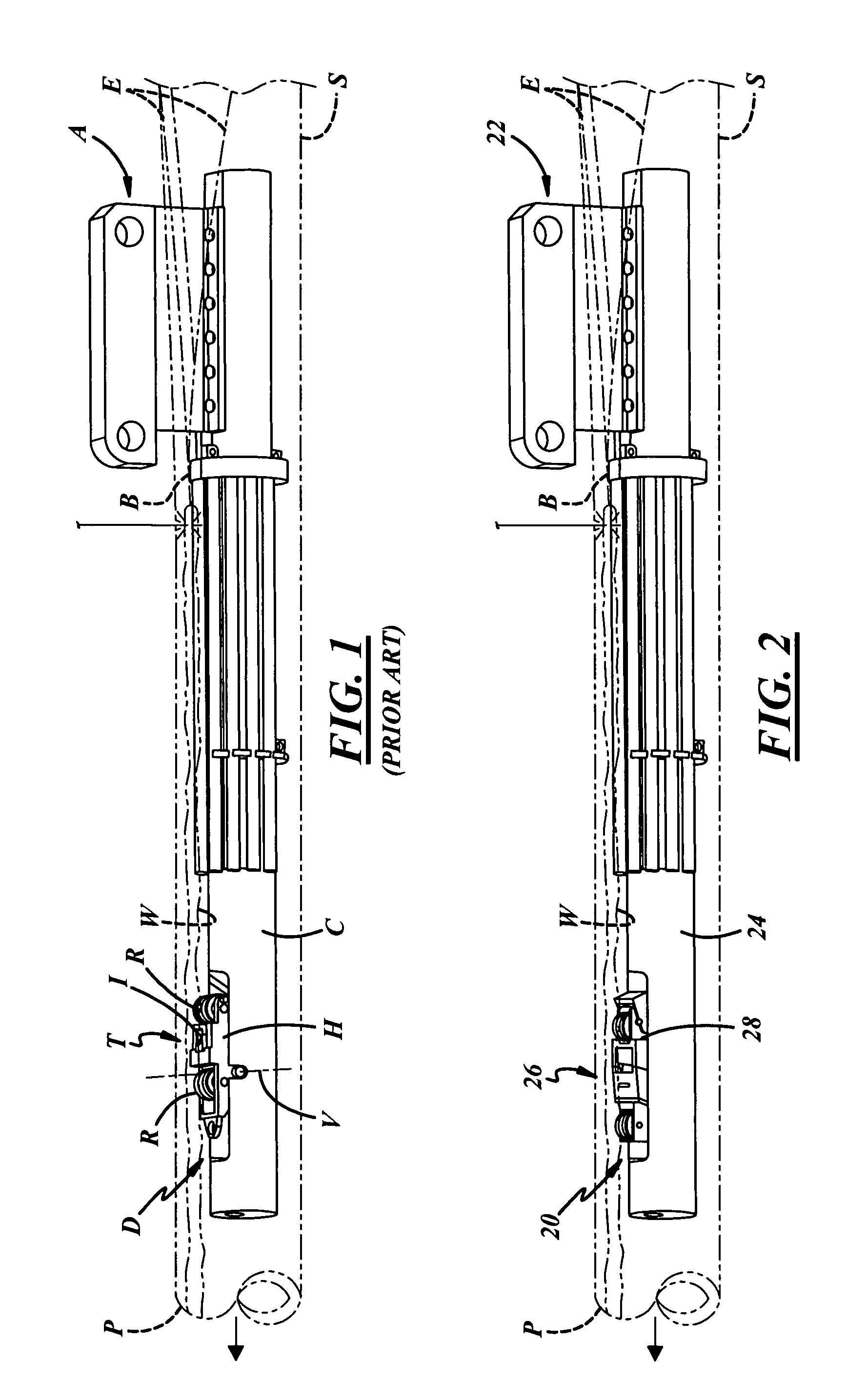

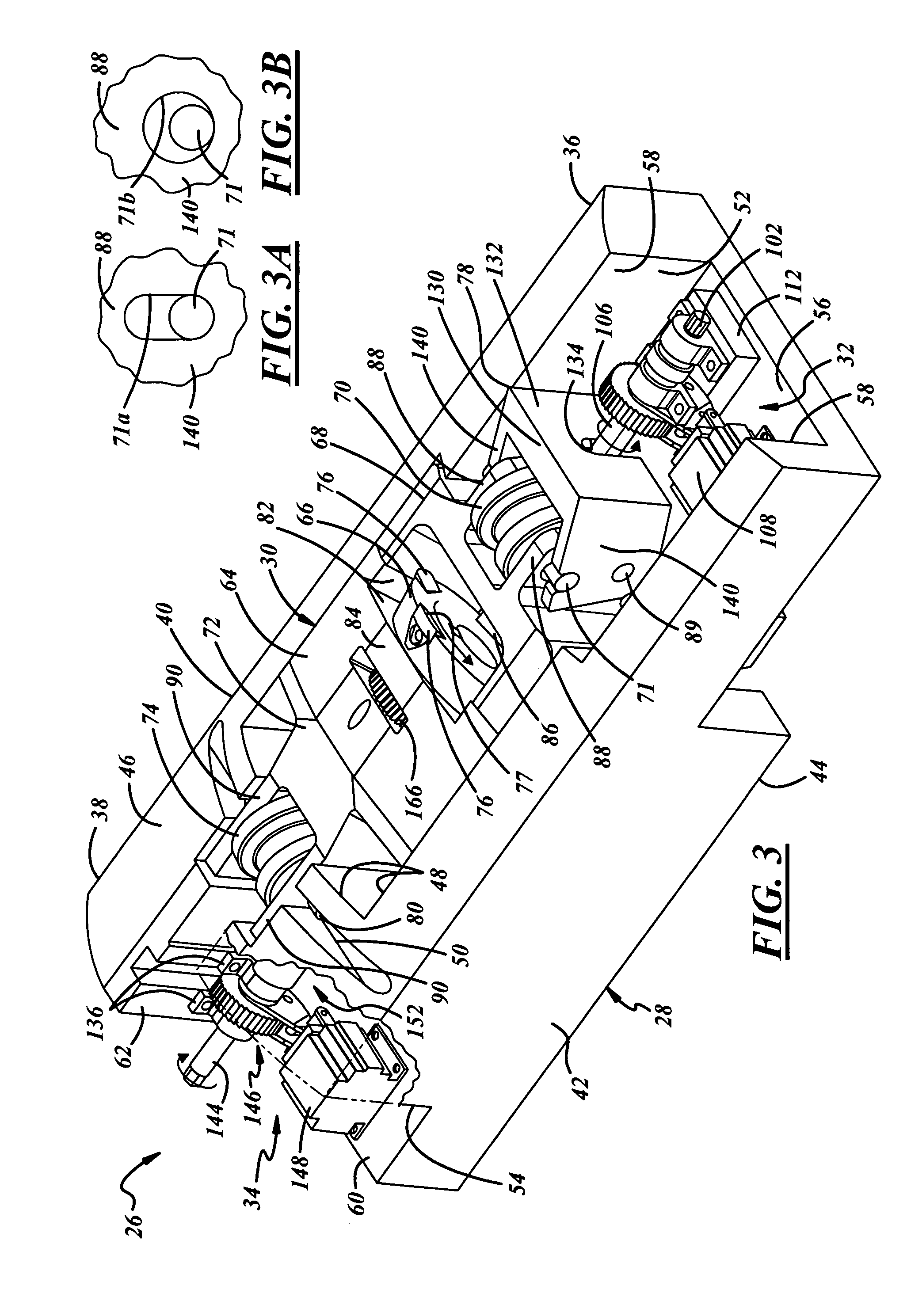

Method and apparatus for slitting steel slabs

A cutting table assembly for oxy cutting comprising a cutting table having a slab loading face and mounted for pivotal movement between a loading position in which the loading face is generally horizontal and a cutting position in which the face is oblique, and a pair of torches mounted on the table. The loading face is constituted by a pair of loading subfaces separated by a slot and the torches are mounted in the slot below the loading face. The torches are positioned at opposite ends of the slot prior to the initiation of the cutting action and, upon the initiation of the cutting action, move toward each other and cut into opposite ends of the slab. A pair of gantries are mounted on the table and each carries a deburring device positioned in overlying opposition to a respective torch. Each gantry further includes a plurality of spaced downwardly directed nozzles which are supplied with compressed air to generate an air curtain.

Owner:EDWARD C LEVY

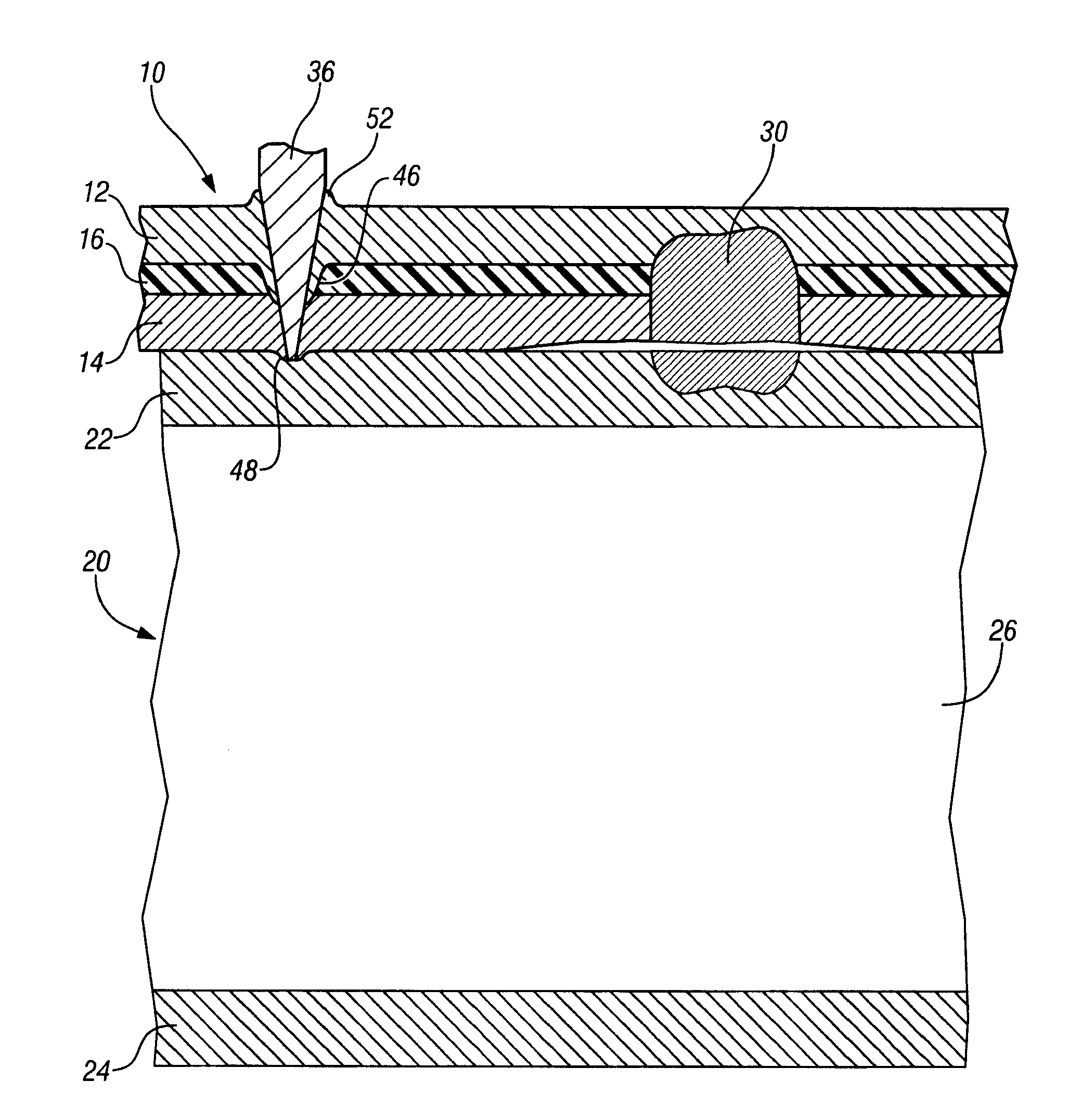

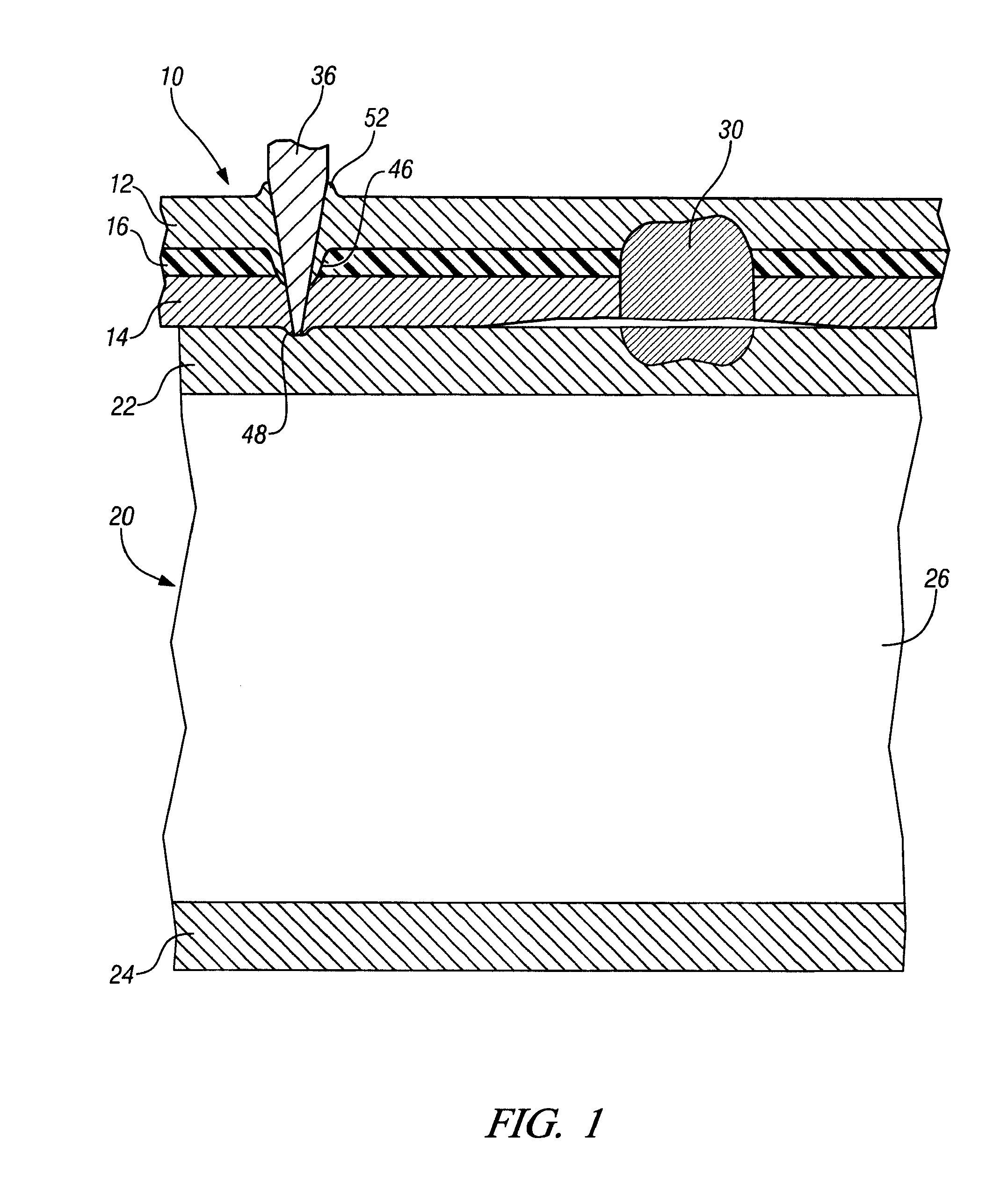

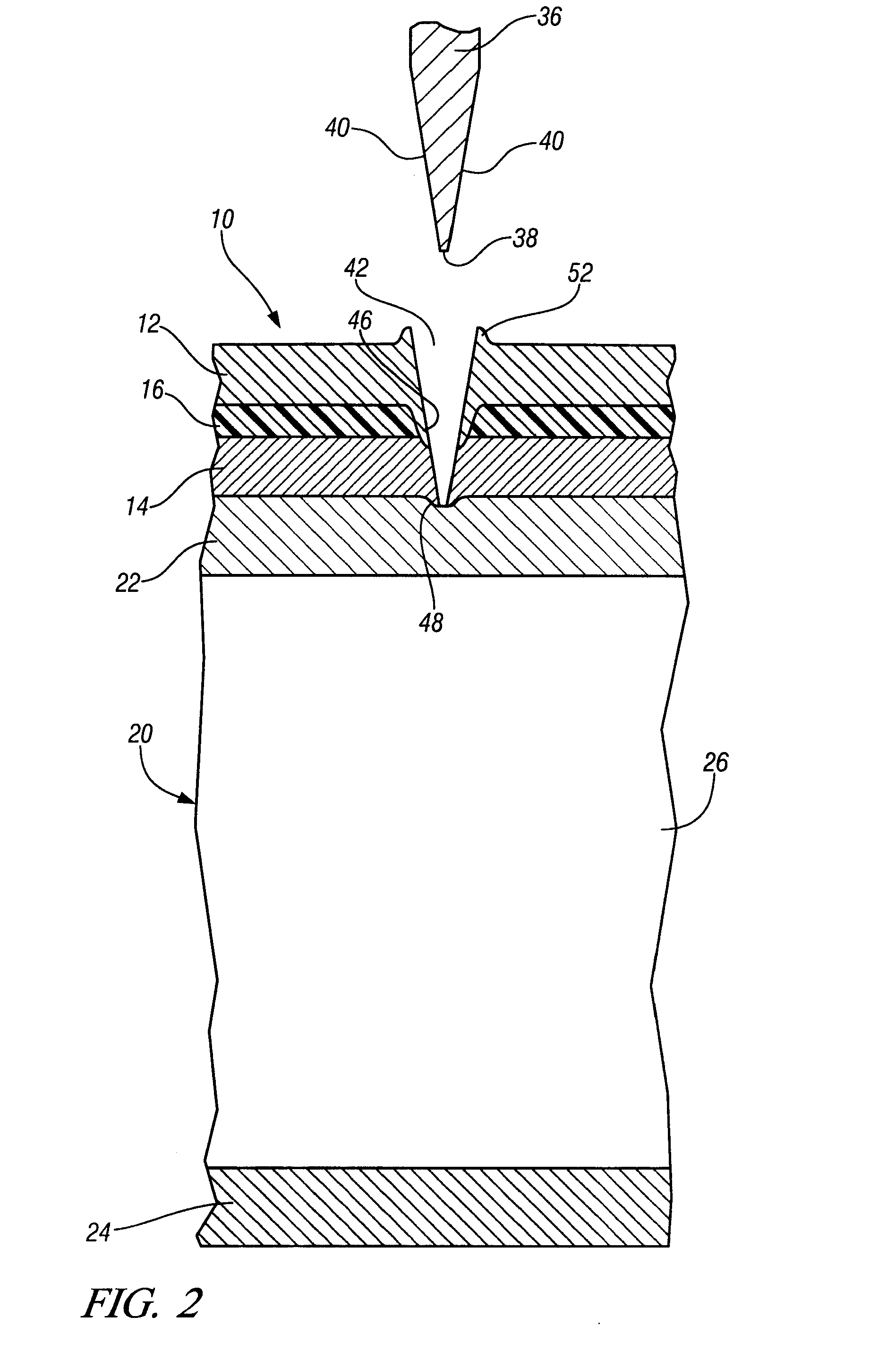

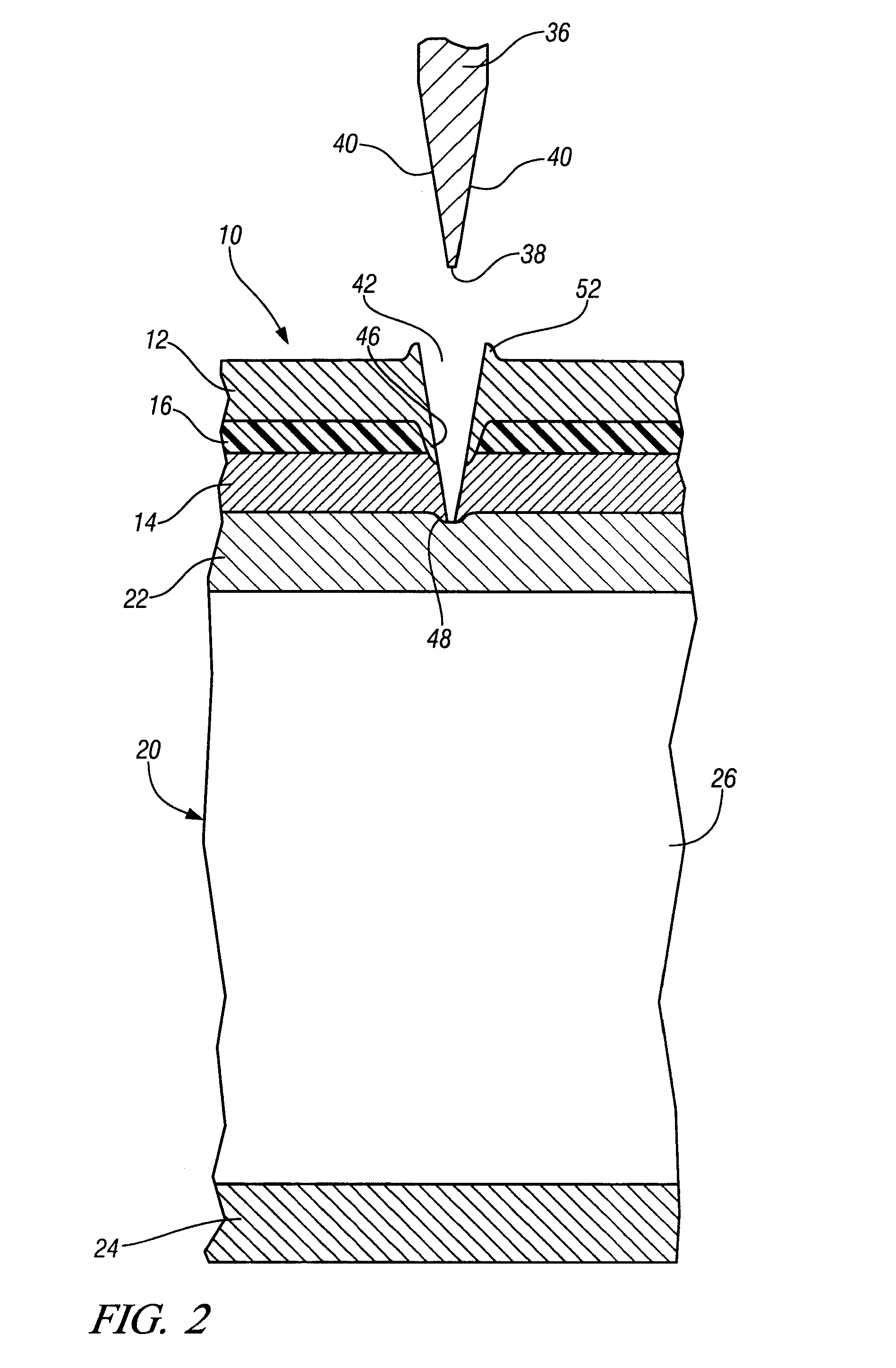

Method for single side welding of laminate steel

A method is provided for welding a laminated metal sheet to a workpiece. The laminated metal sheet includes an outer metal sheet and an inner metal sheet bonded together by a polymer material that impedes the flow of weld current. A punch is applied against the outer metal sheet and driven through the laminated metal sheet to create a hole and also create an annular metallic burr that bridges across the polymer material layer between the outer metal sheet and the inner metal sheet. A weld electrode is positioned against the outer metal sheet at the punched hole and weld current is conducted through the first annular metallic burr to create an electric resistance weld between the laminated metal and the workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hat channel adaptor for sprinkler support assembly

An adaptor is provided that is configured to receive a support assembly for mounting a flexible fire sprinkler fitting in a ceiling support structure formed of parallel, spaced beams. The adaptor includes first and second long sides configured to be secured to each beam of an adjacent pair of beams, and first and second short sides configured to be secured to the support assembly. One end of each long side is joined by the first short side, and an opposed end of each long side is joined by the second short side such that the first and second long sides are parallel to each other and perpendicular to the first and second short sides, whereby the adaptor is a generally elongated, hollow, rectangular structure. The adaptor permits the support assembly to be mounted in a suspended ceiling formed of hat channel or metal stud furring.

Owner:ASC ENGINEERED SOLUTIONS LLC

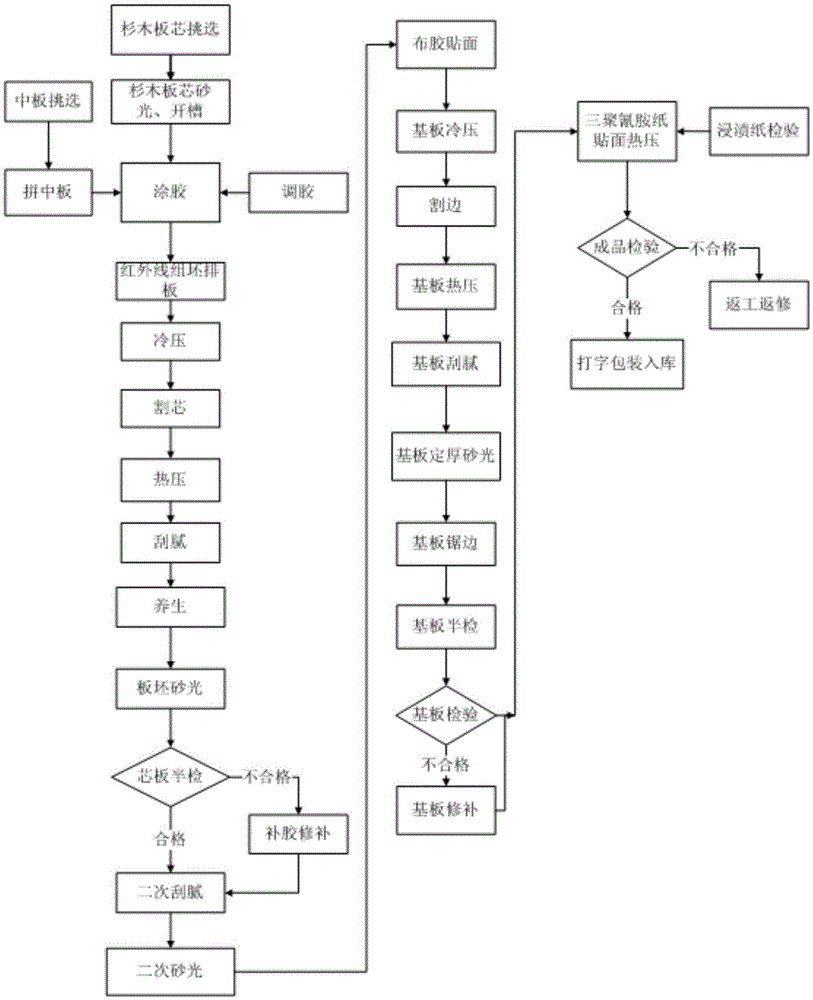

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

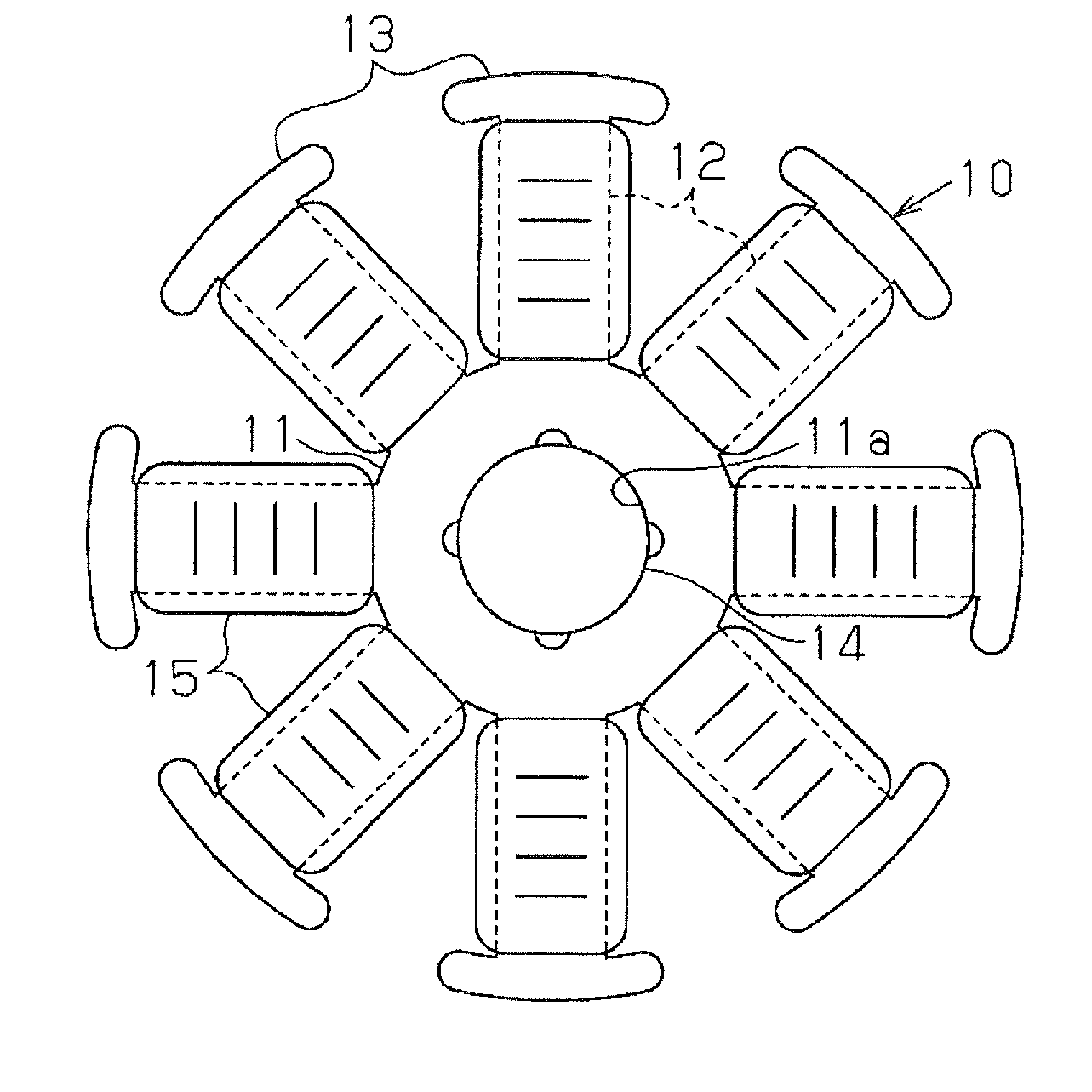

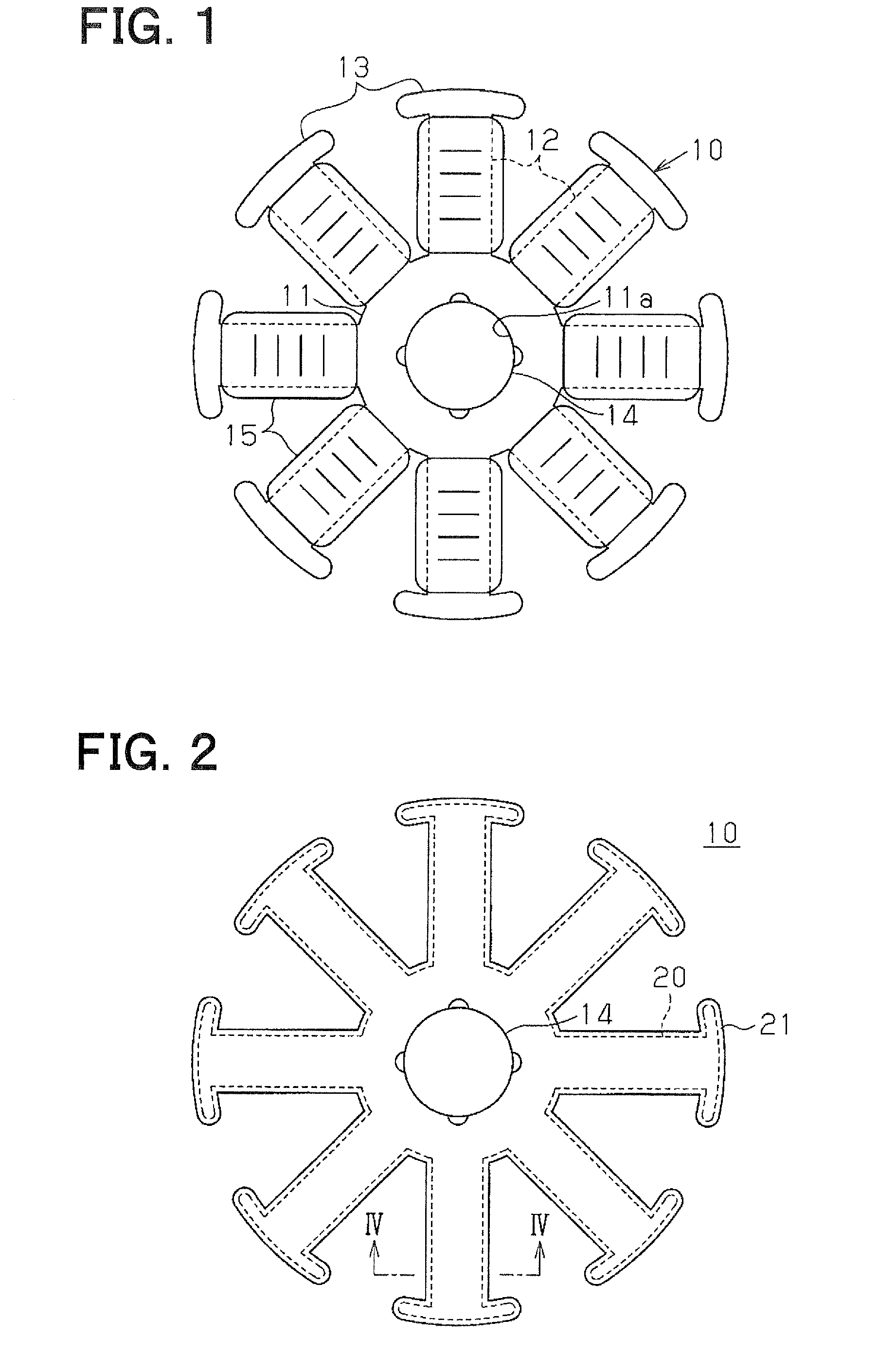

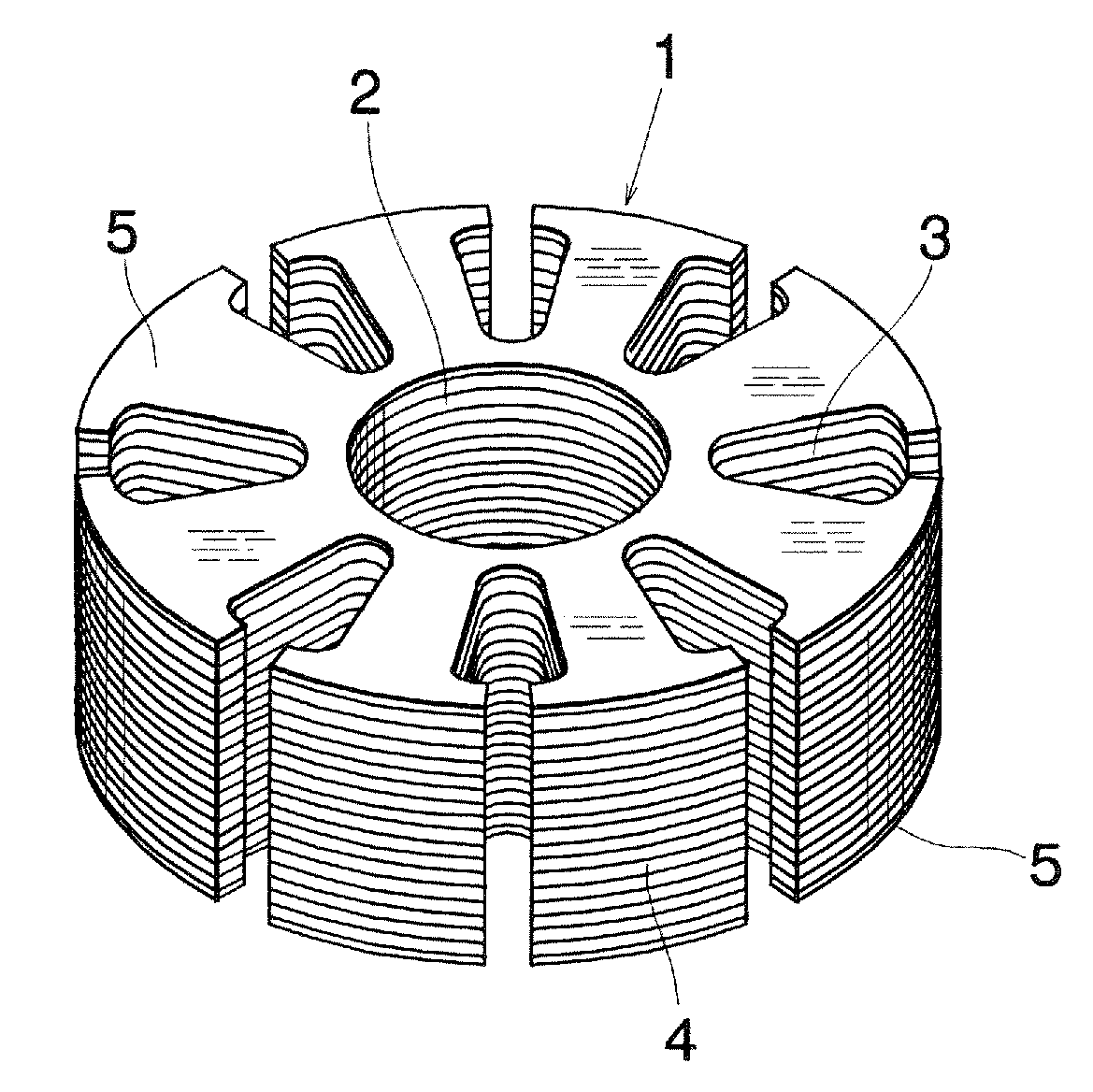

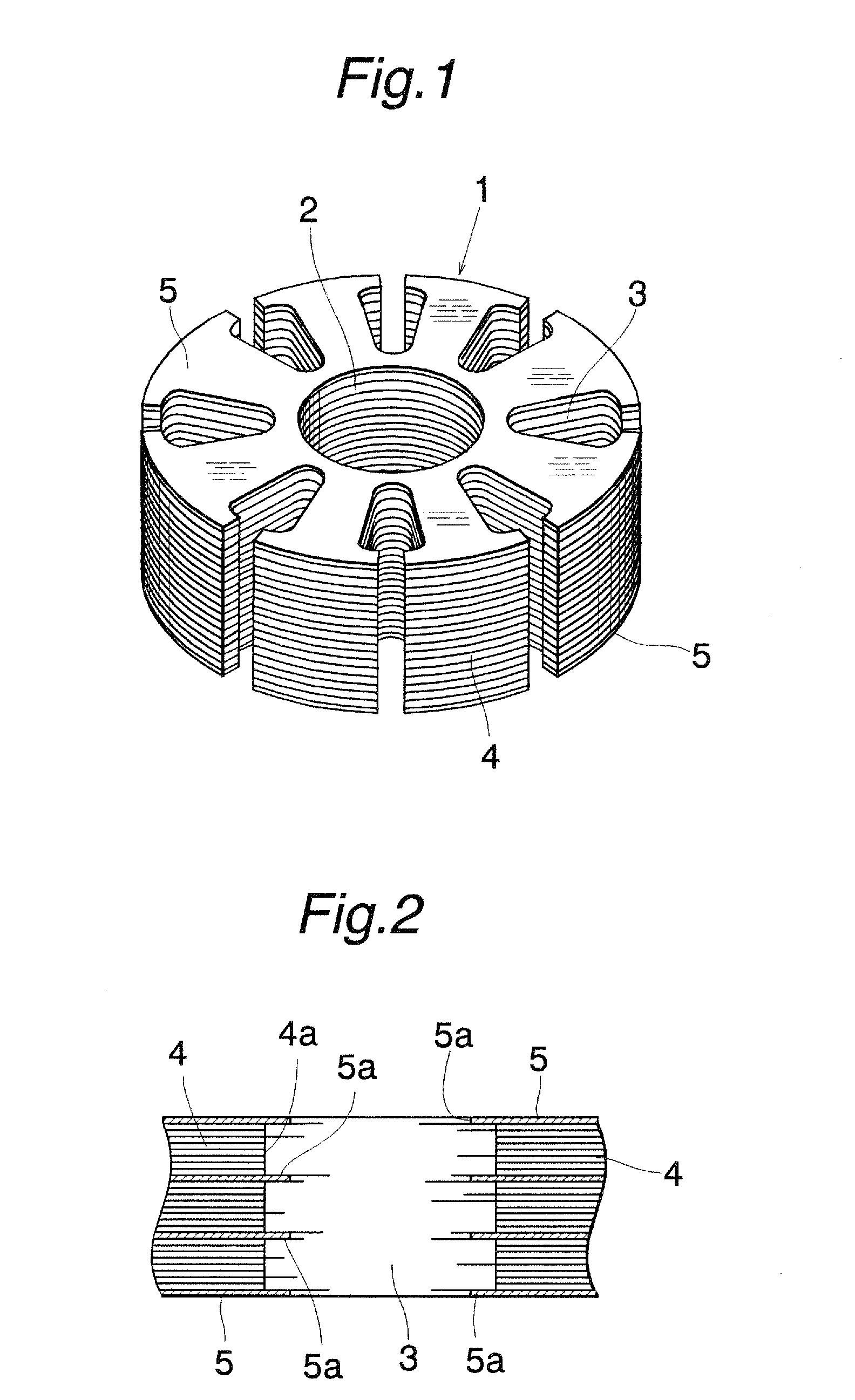

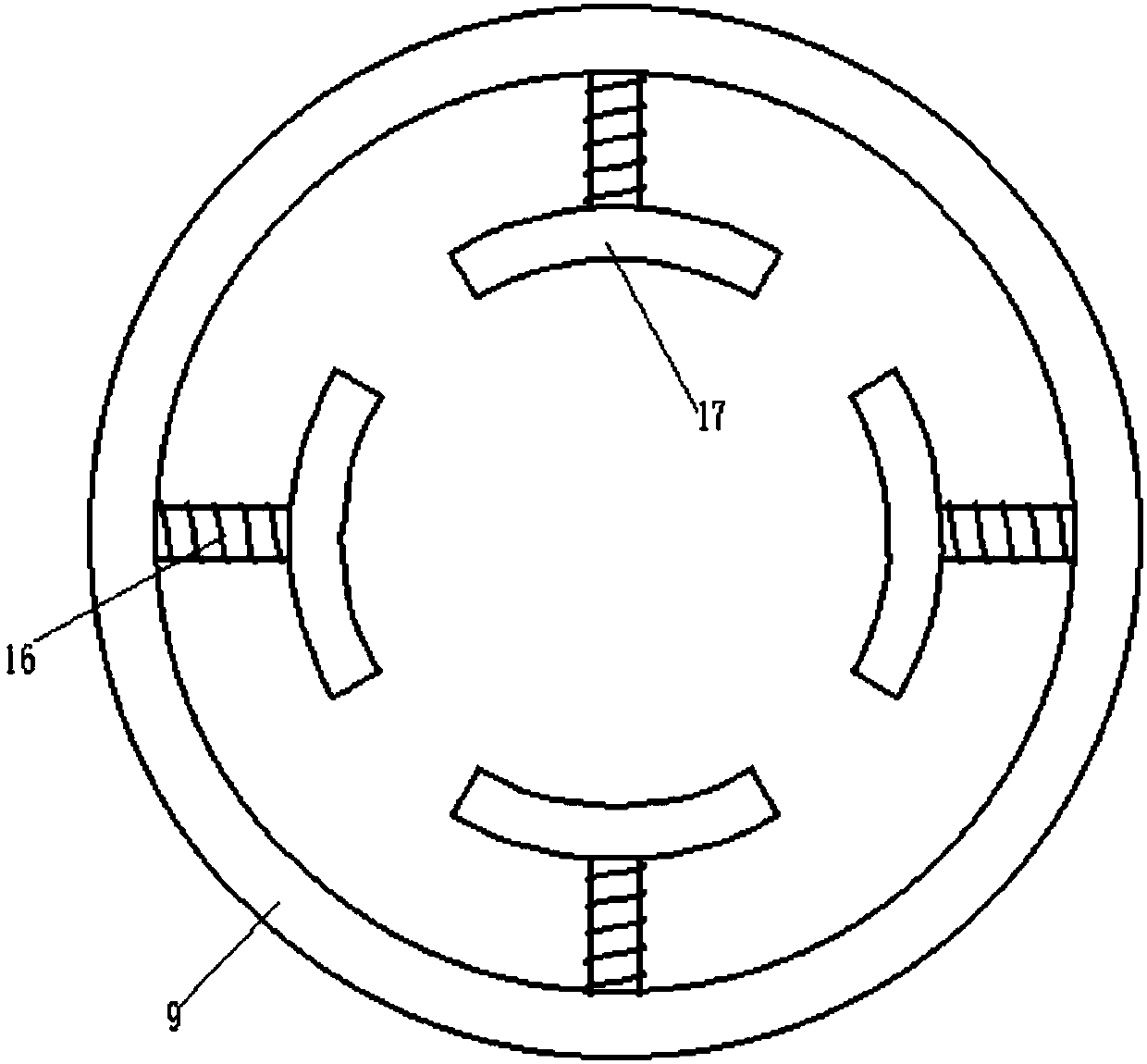

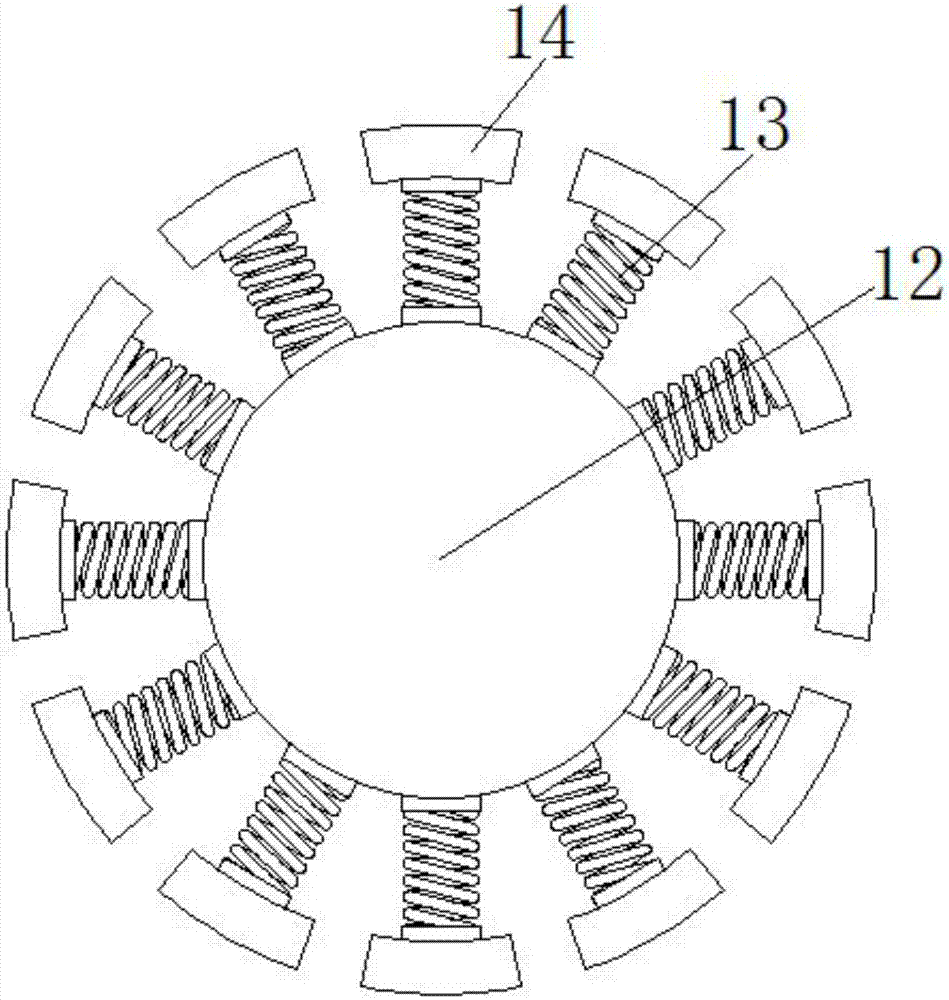

Armature for rotary electric apparatus and manufacturing method for the same

InactiveUS20120080973A1Limiting projectionReduce the amount requiredWindingsMagnetic circuit rotating partsFurringEngineering

Owner:ASMO CO LTD

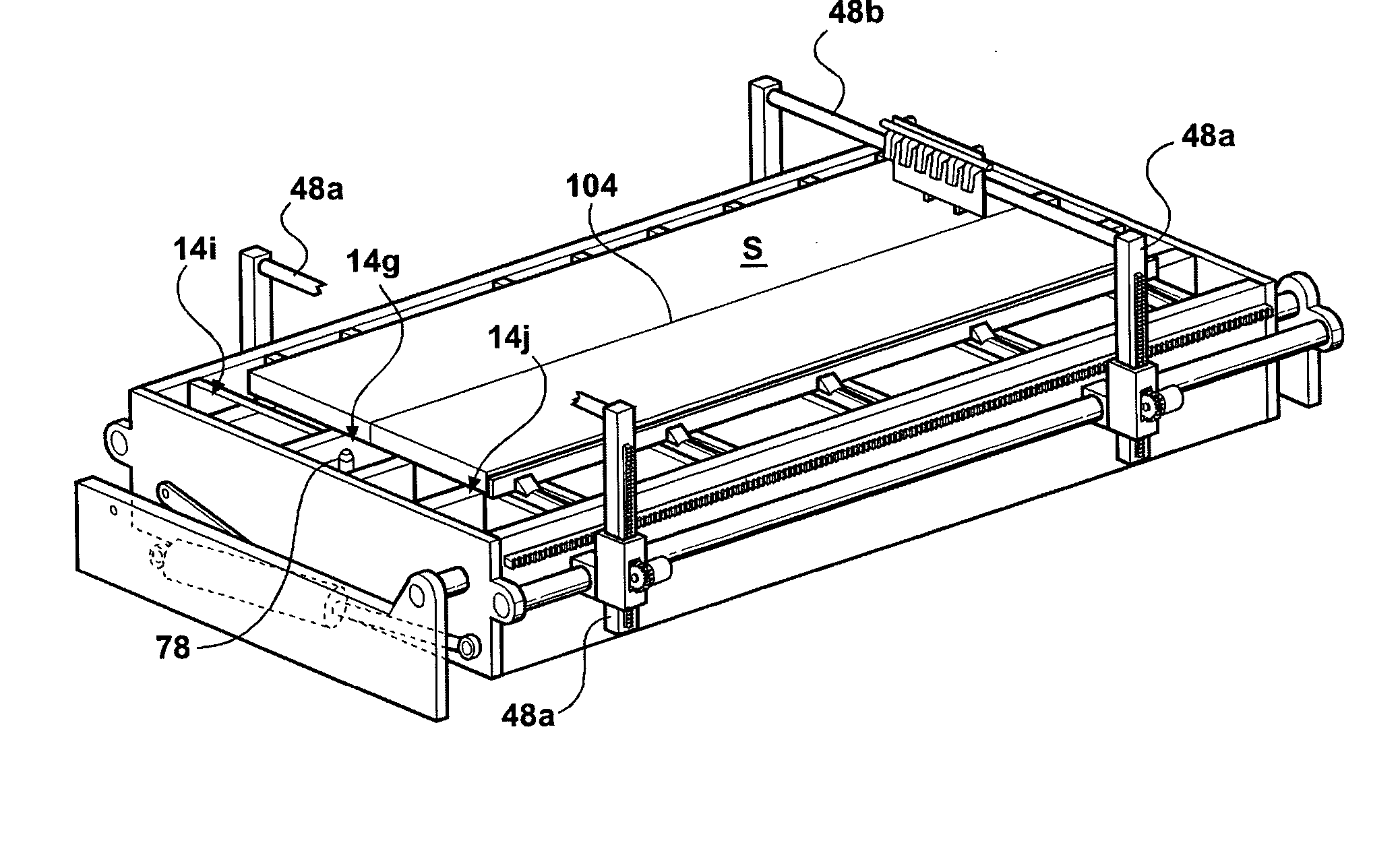

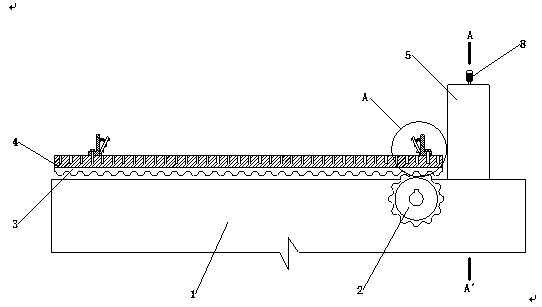

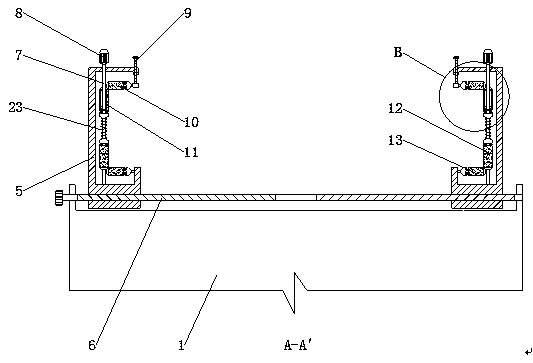

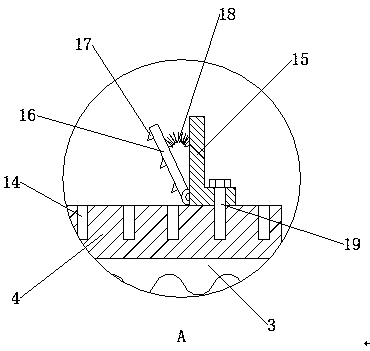

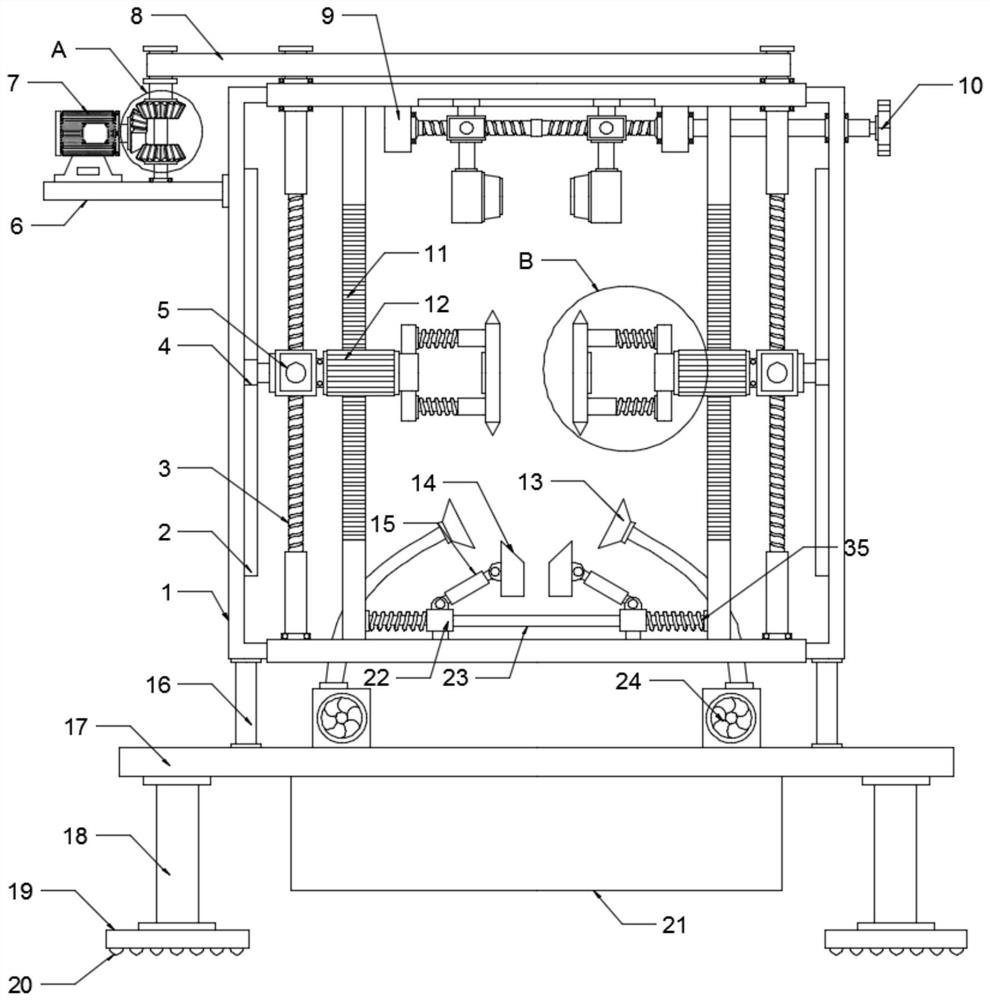

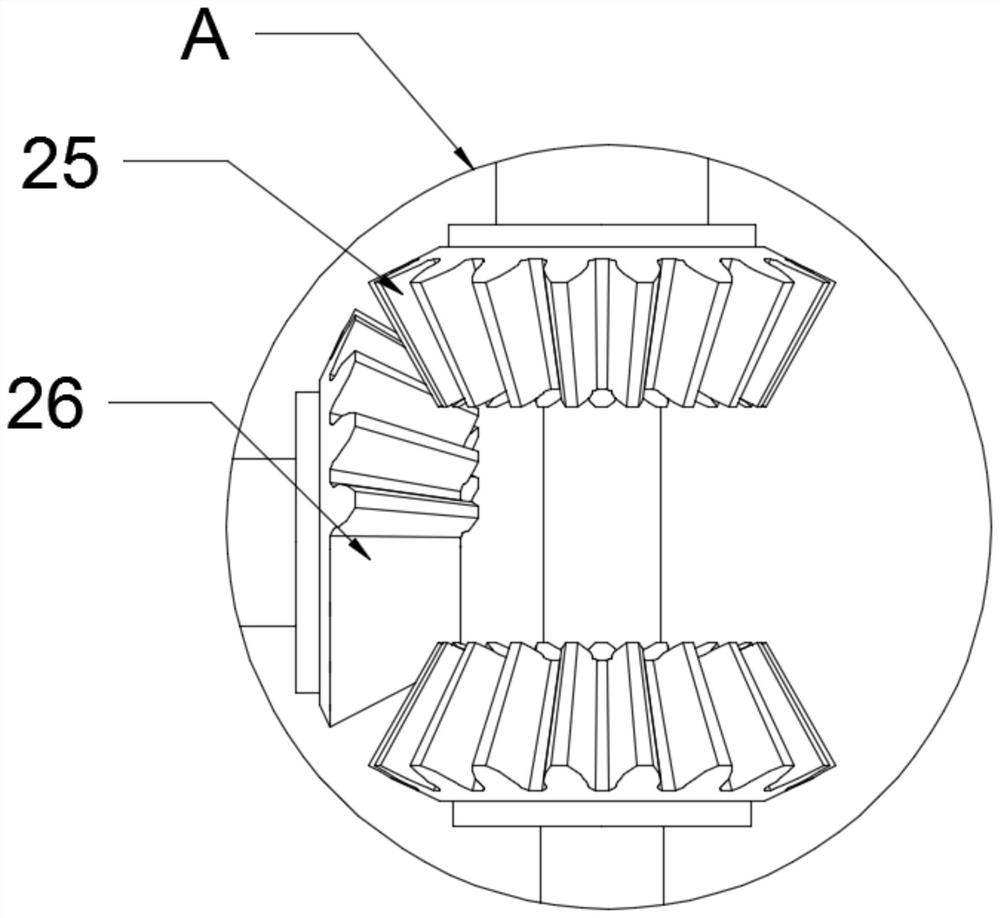

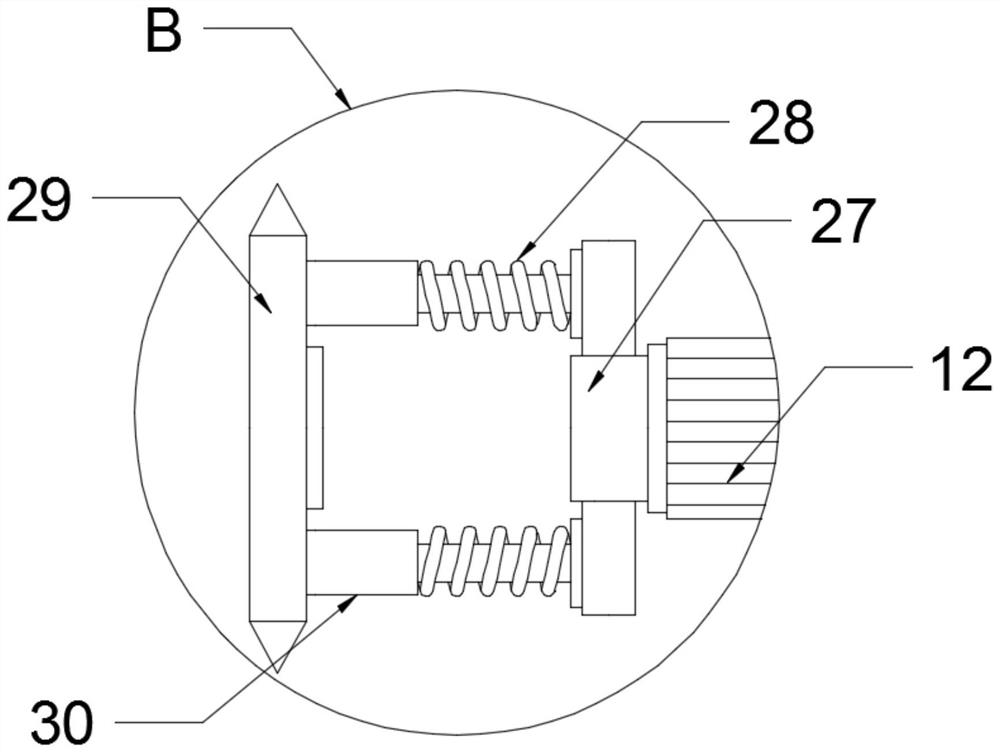

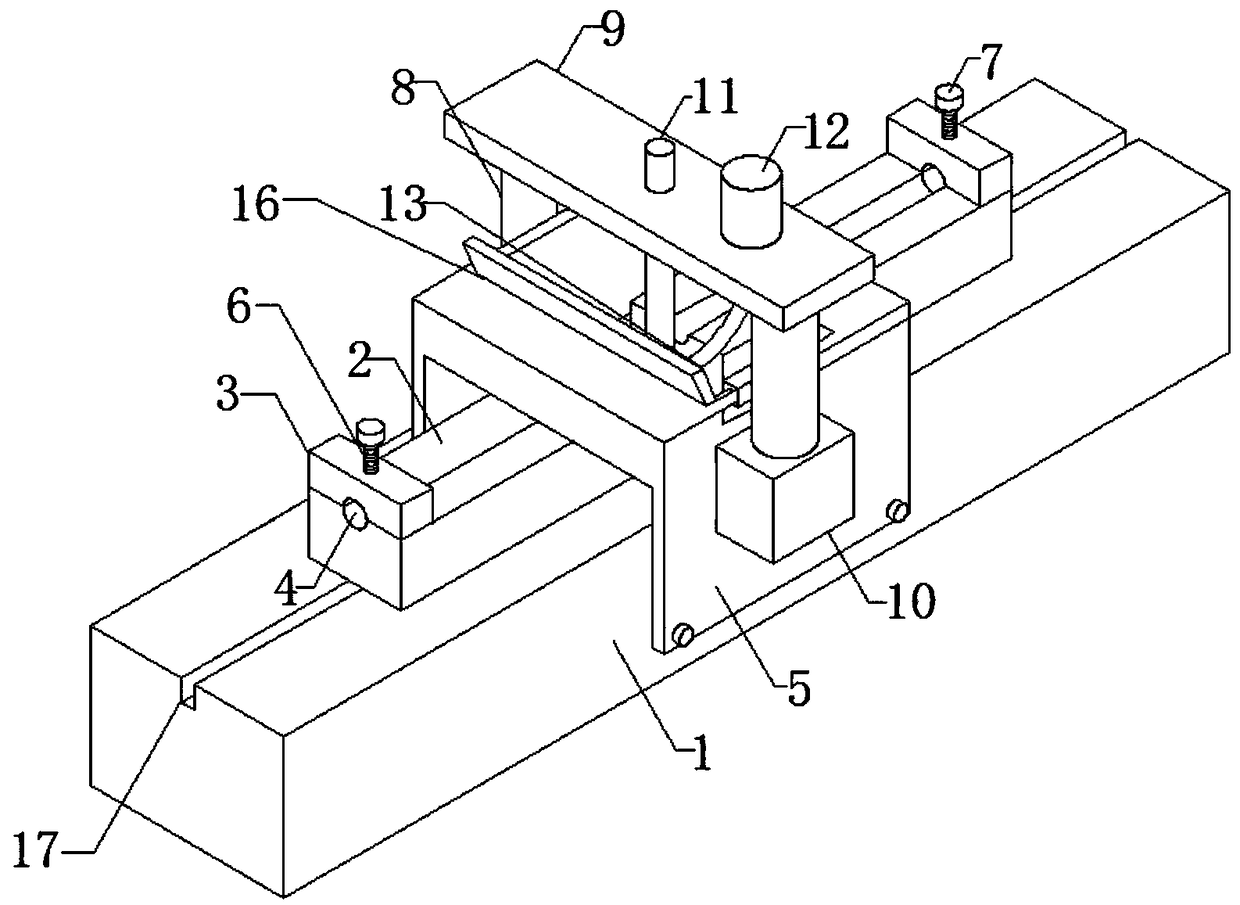

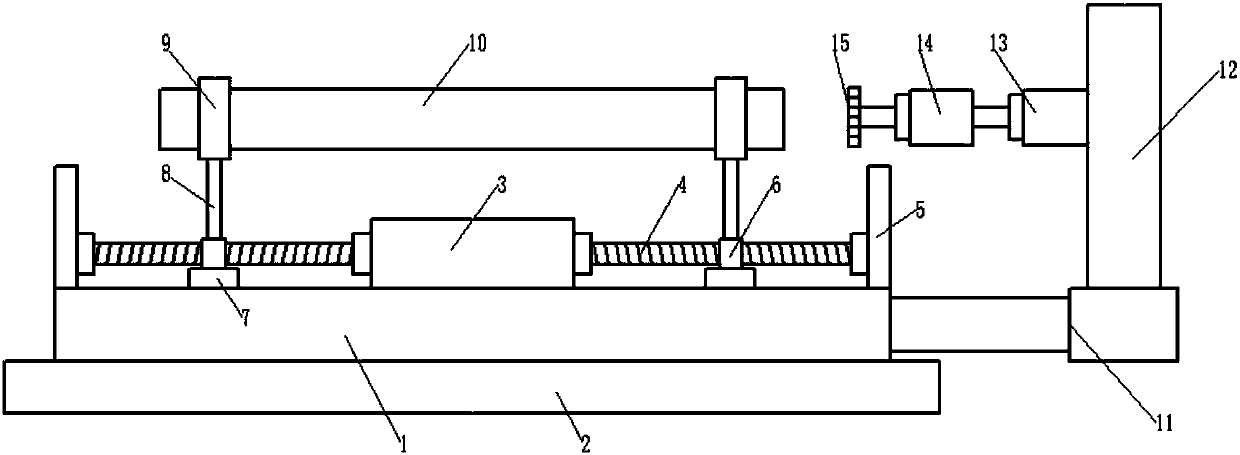

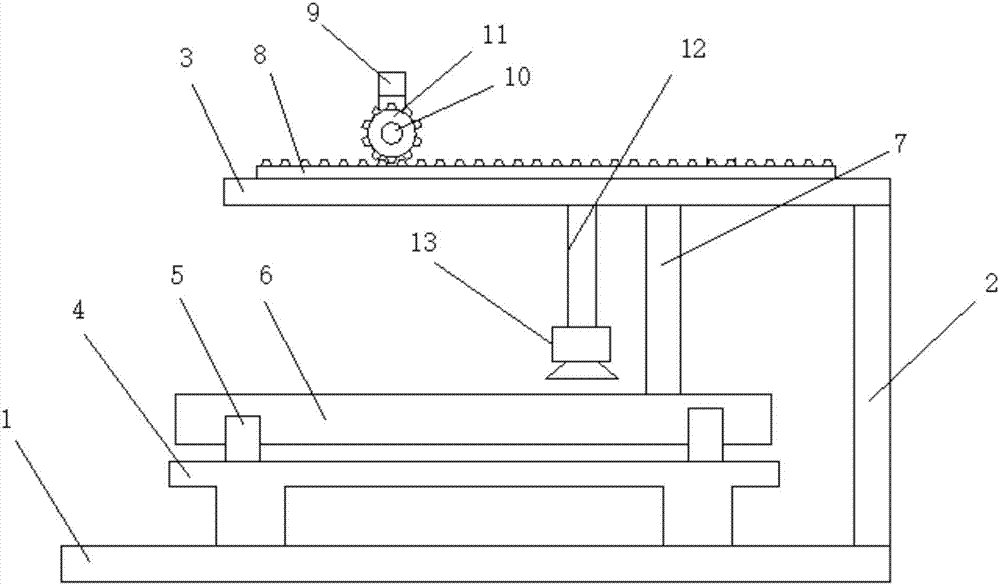

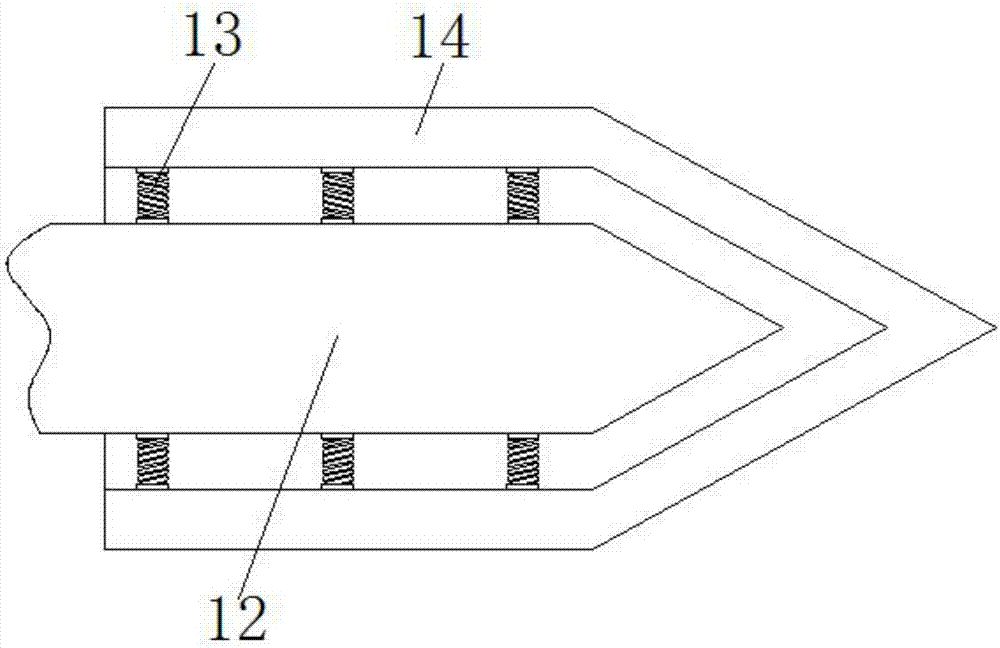

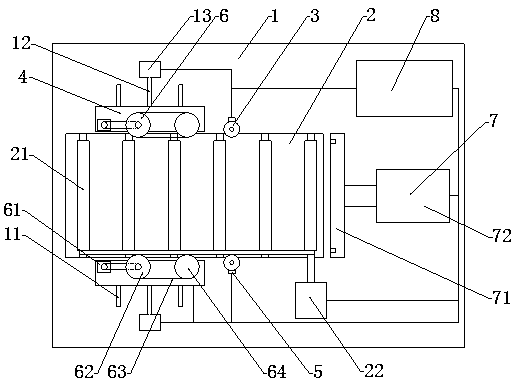

Deburring device for wood board processing

InactiveCN109732436AAvoid affecting the working environmentQuick clampingEdge grinding machinesGrinding drivesFurringPulp and paper industry

The invention provides a deburring device for wood board processing. The deburring device includes a workbench, a feeding flat board, two deburring frames, a moving transverse-grinding roller, a moving vertical-grinding roller, a fixed vertical-grinding roller and a fixed transverse-grinding roller, the feeding flat board is slidably arranged at the upper portion of the workbench, a rack is fixedly connected with the bottom of the feeding flat board, two L-shaped supporting boards are fixedly connected with the upper portion of the feeding flat board, and an elastic splint is rotatably connected with the inner side of each L-shaped supporting board; and a return stopping strip is fixedly connected with the surface of each elastic splint, the two deburring frames are movably arranged at oneend of the workbench, the moving vertical-grinding roller is slidably connected with the upper end of a rotating shaft, the moving transverse-grinding roller meshes with outer periphery of a cone gear, a fixed vertical-grinding roller is fixedly connected with the outer periphery of the lower end of the rotating shaft, and the fixed transverse-grinding roller meshes with the bottom of the fixed vertical-grinding roller. According to the deburring device, the feeding flat board is matched with the deburring frames, the wood board can be fixed on the feeding flat board through the elastic splints and the L-shaped supporting boards, so that the side end surface of the wood board can be scraped and polished in a reciprocating mode, and the deburring effect is improved.

Owner:江山市标龙装饰材料有限公司

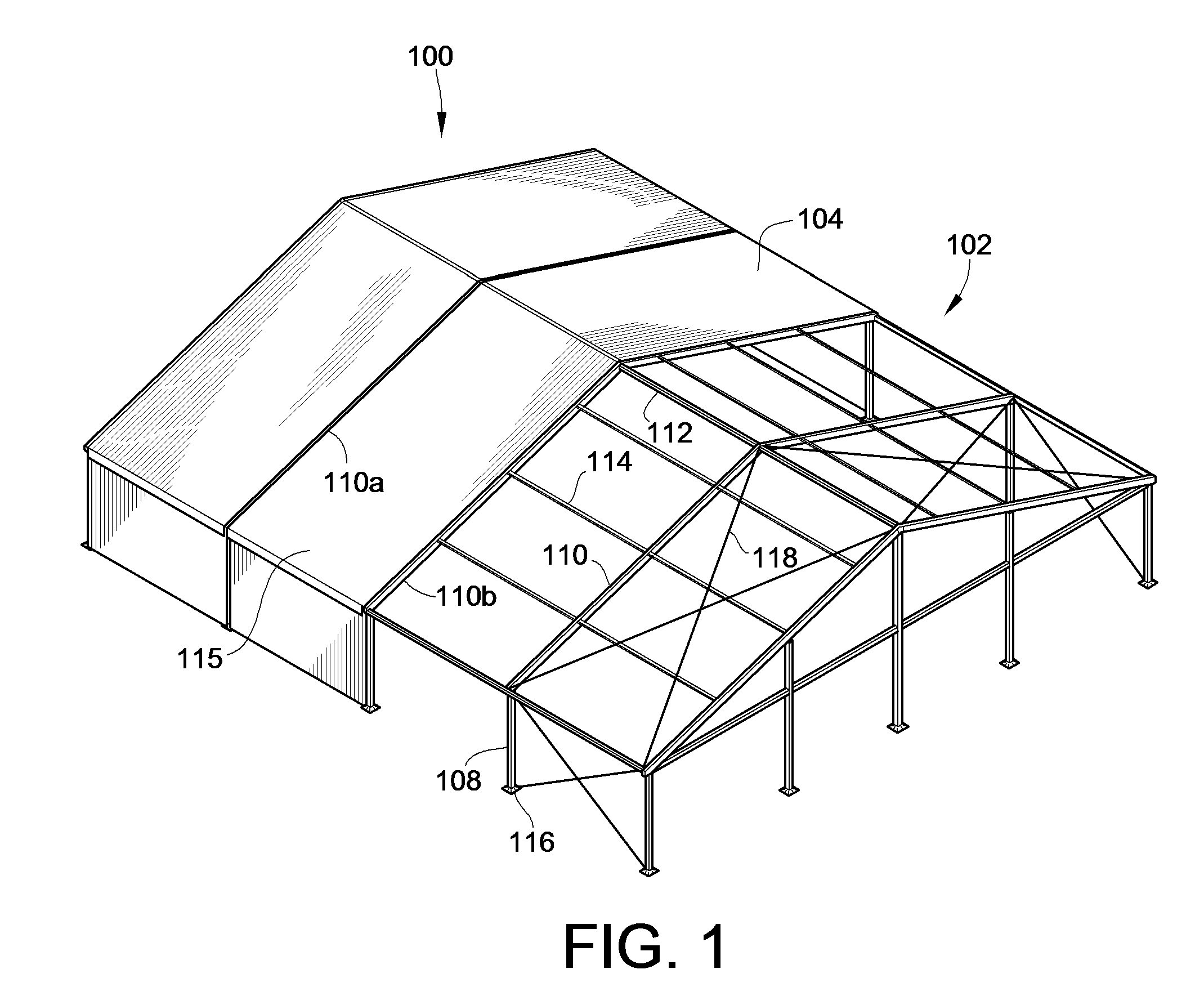

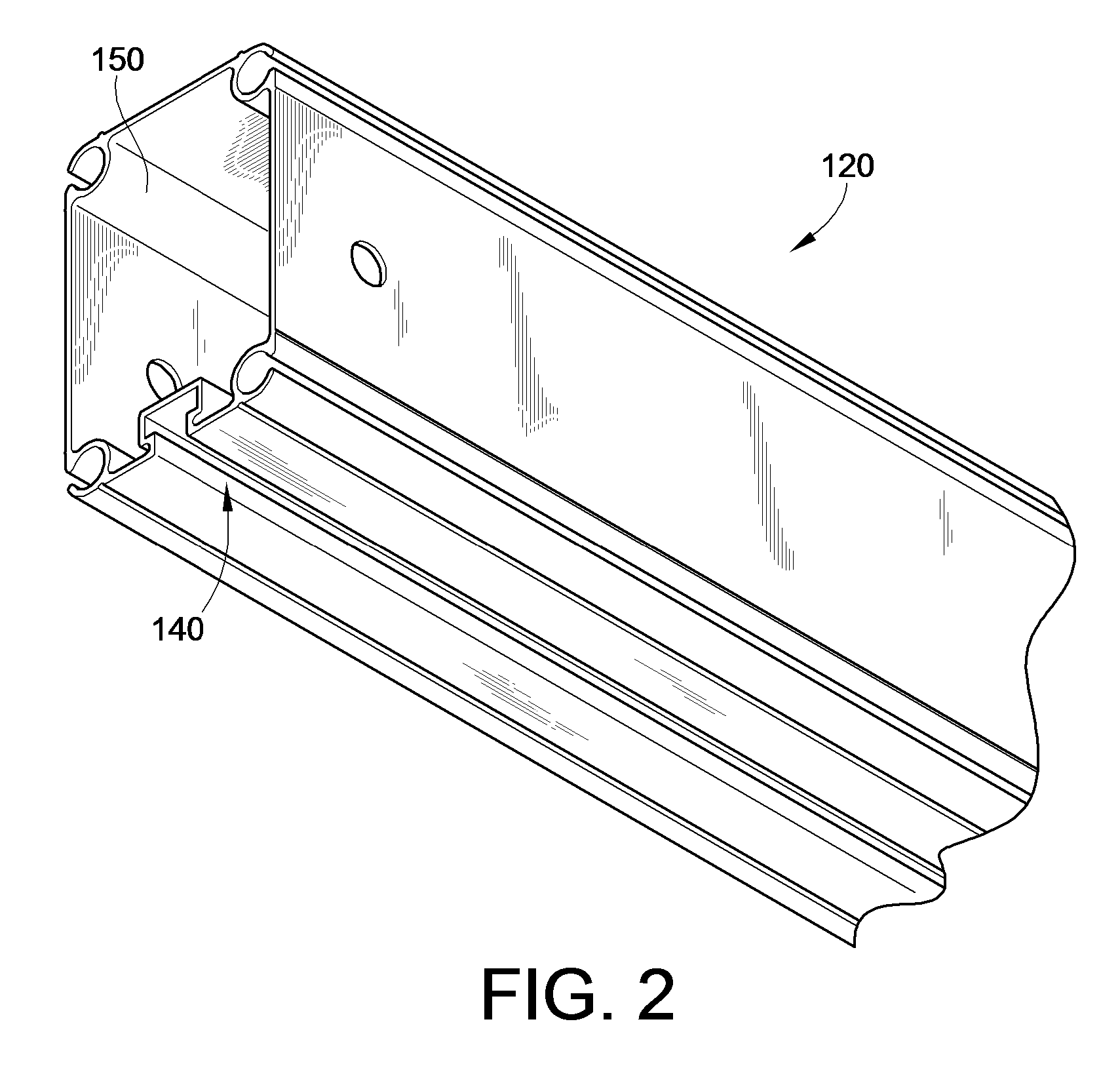

Tent rafter end cap and tent incorporating same

A tent including a structural member and an end cap insertable into the structural member and a method of forming a tent are provided. The structural member is preferably a rafter. The rafter has C-channels aligned with support troughs of the end cap. The C-channels and support troughs receive edge portions of a fabric panel therein to secure the fabric panel to the rafter. The end cap supports the weight of the fabric panel during assembly to reduce or avoid engagement of the fabric panel with corners of the C-channel or burs formed in the end of the C-channel of the rafter as the fabric panel is fed through the C-channel. The end cap may also include an optional tension push down bar assembly for providing additional tensioning of the fabric panel.

Owner:JOHNSON OUTDOORS

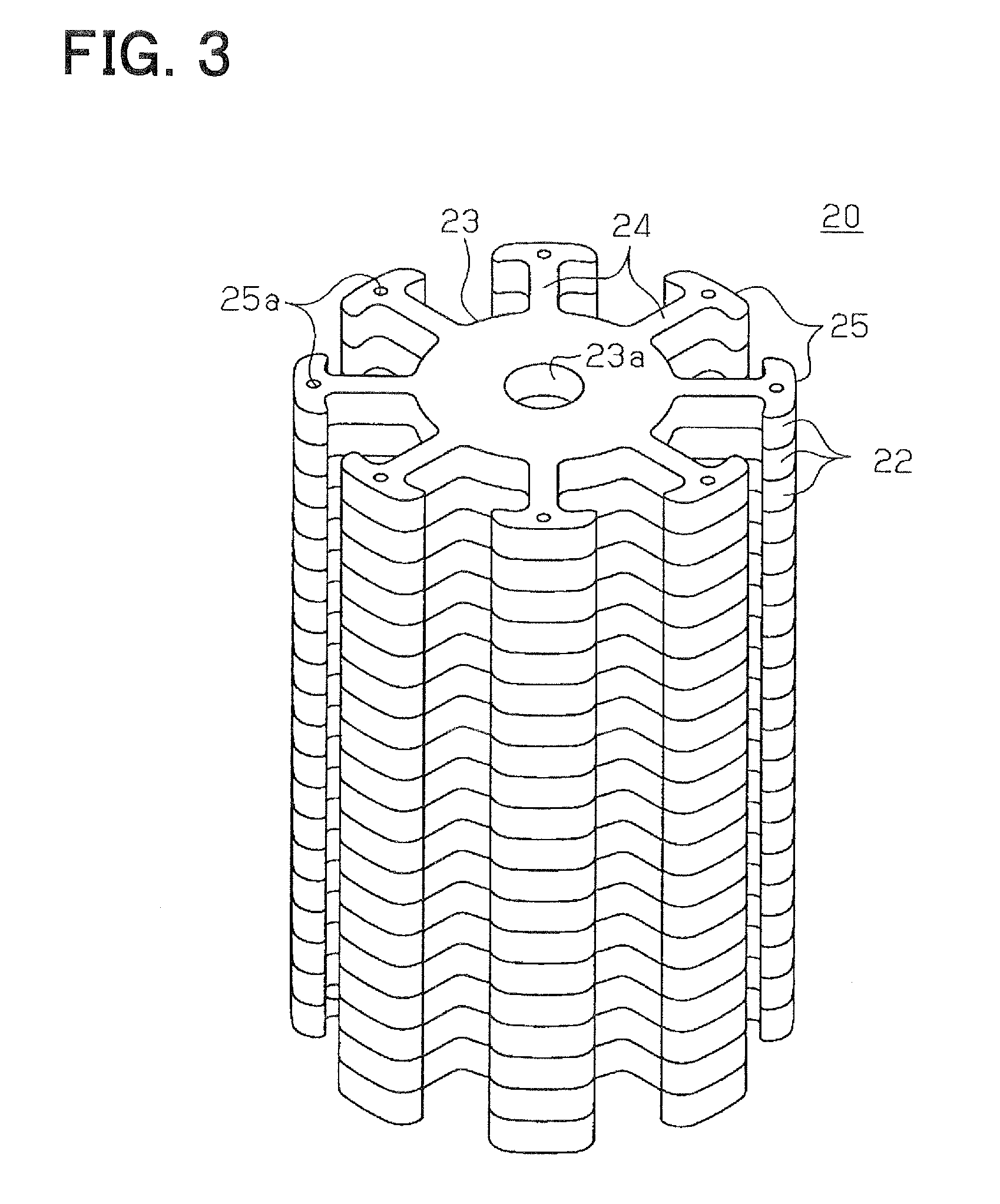

Laminated iron core, method and die machine for manufacturing the same

InactiveUS20080307634A1Small sizeElectrical insulationWindings insulation shape/form/constructionInductances/transformers/magnets manufactureFurringEngineering

A laminated iron core includes a plurality of stacked iron core pieces punched out from a thin steel sheet material, each iron core piece including a plurality of slot holes for receiving coil windings. At least one electrically insulating sheet piece is stacked on an outer surface of a lowermost iron core piece. The electrically insulating sheet pieces include a spindle hole and a plurality of slot holes which have a substantially similar configuration to, but are smaller than, the slot holes of the iron core pieces whereby edges of slot holes of electrically insulating sheet pieces extend outwardly beyond edges of slot holes of iron core pieces. Burrs formed at edges of slot holes of iron core pieces are covered with edges of slot holes of electrically insulating sheet pieces so that a coil can be wound safely without directly contacting the burrs.

Owner:KURODA PRECISION INDS

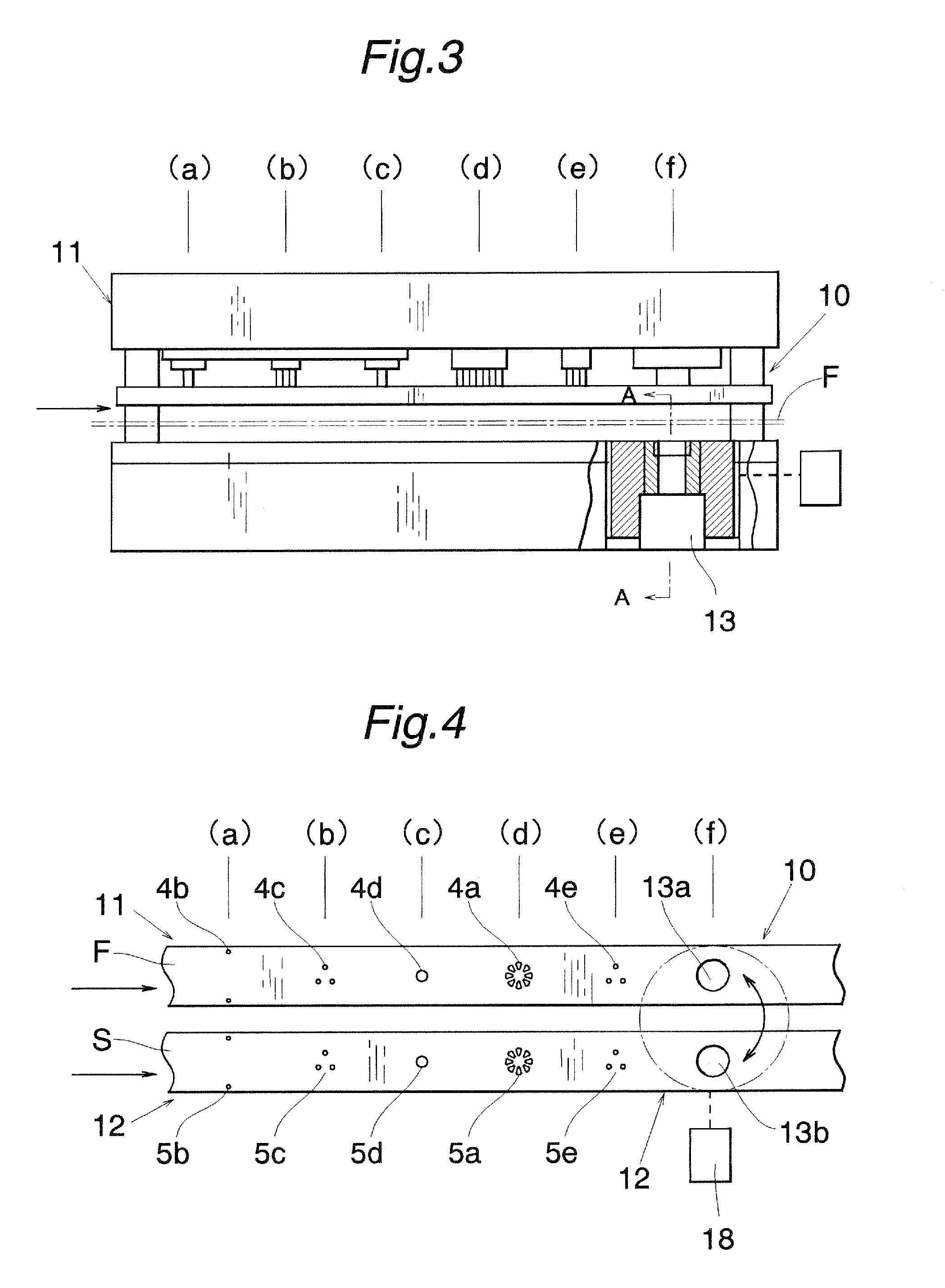

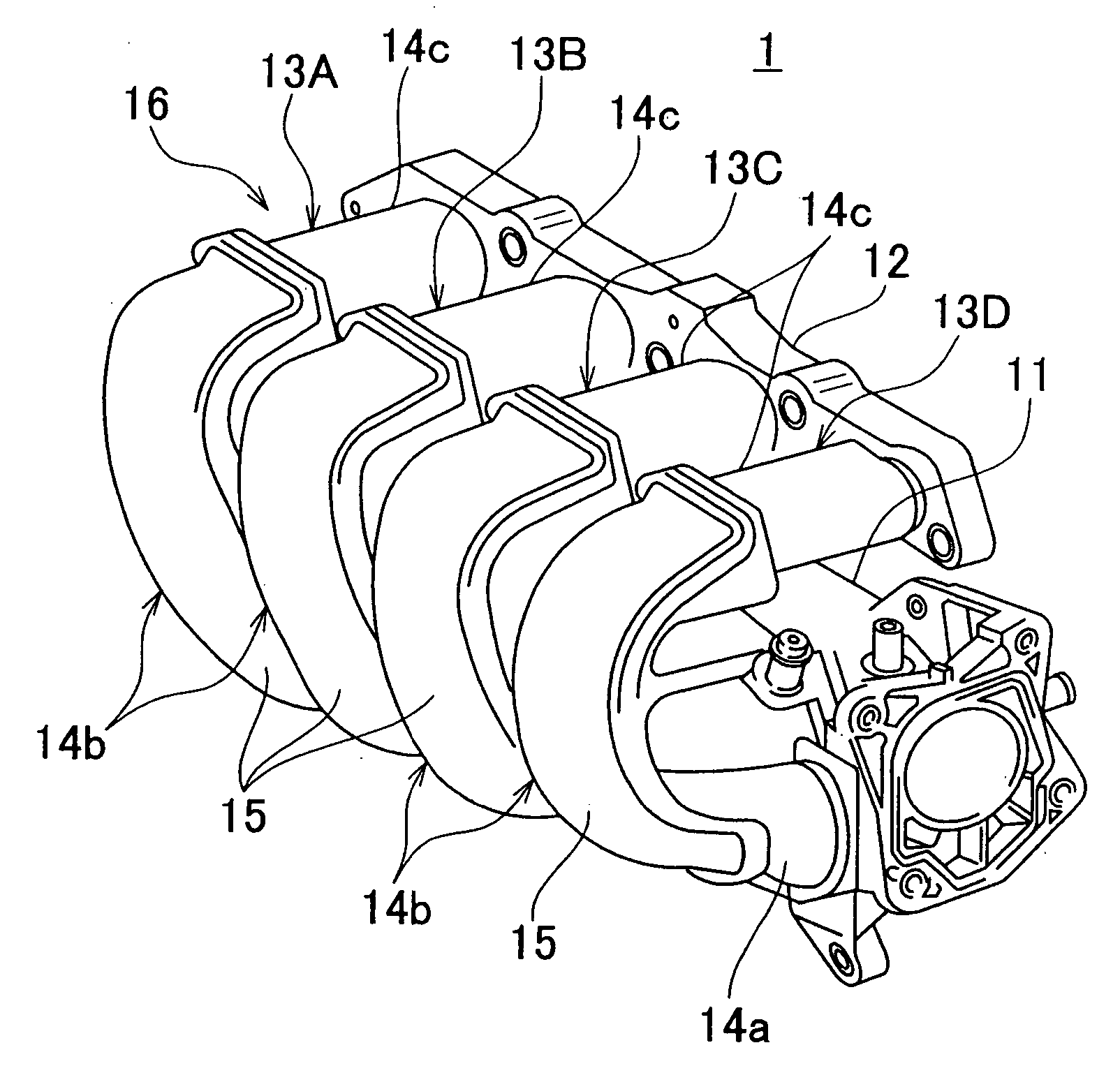

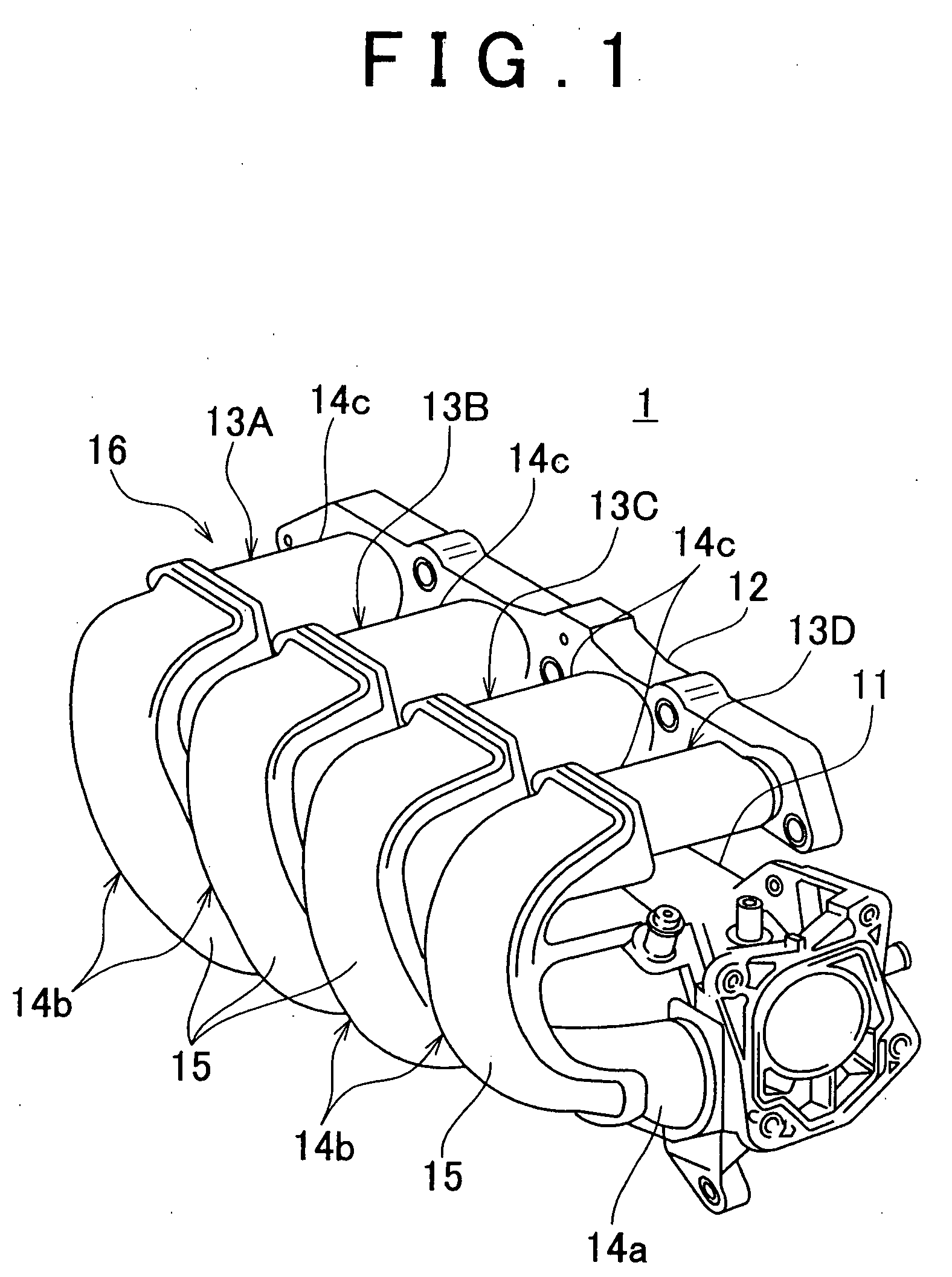

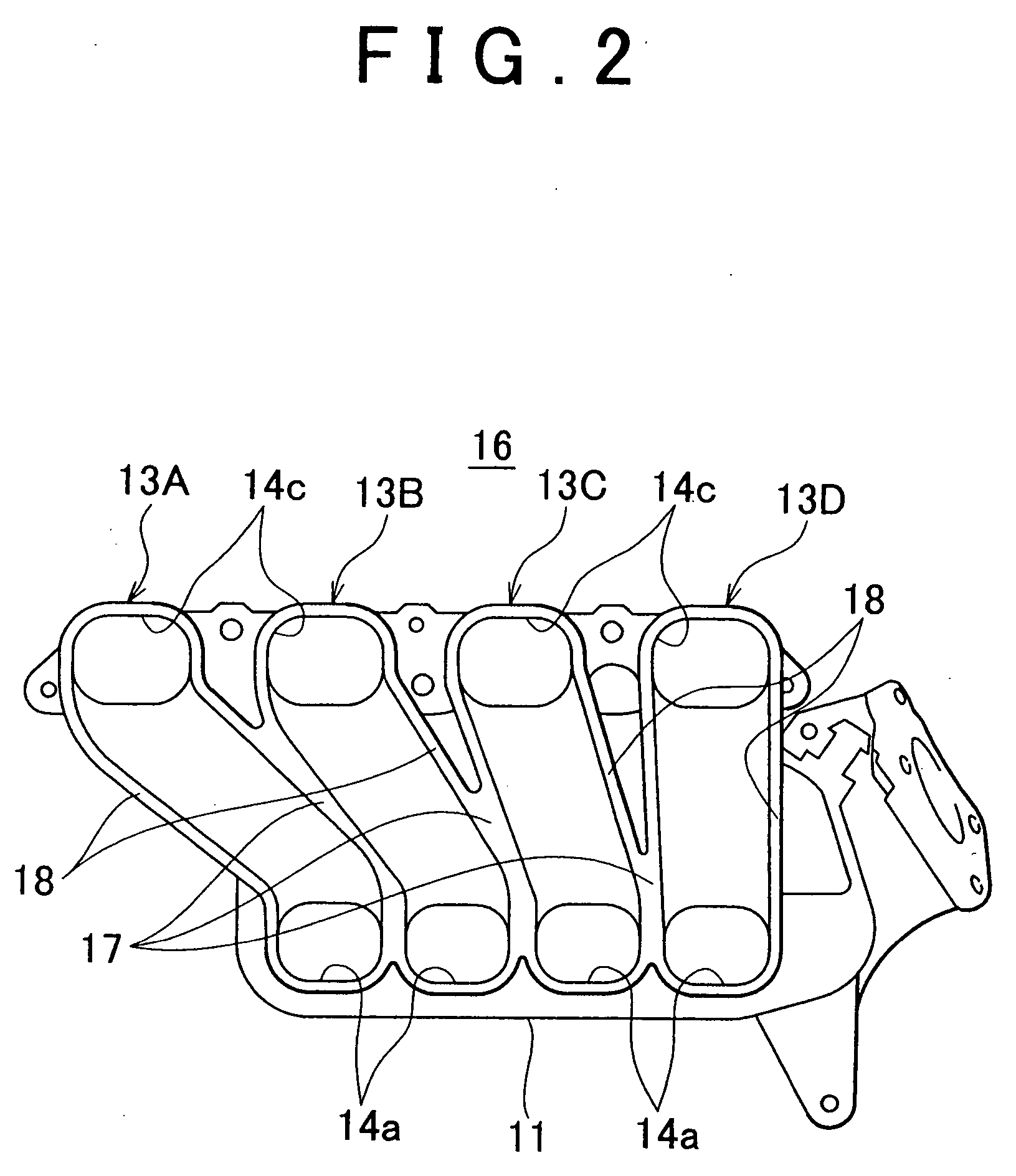

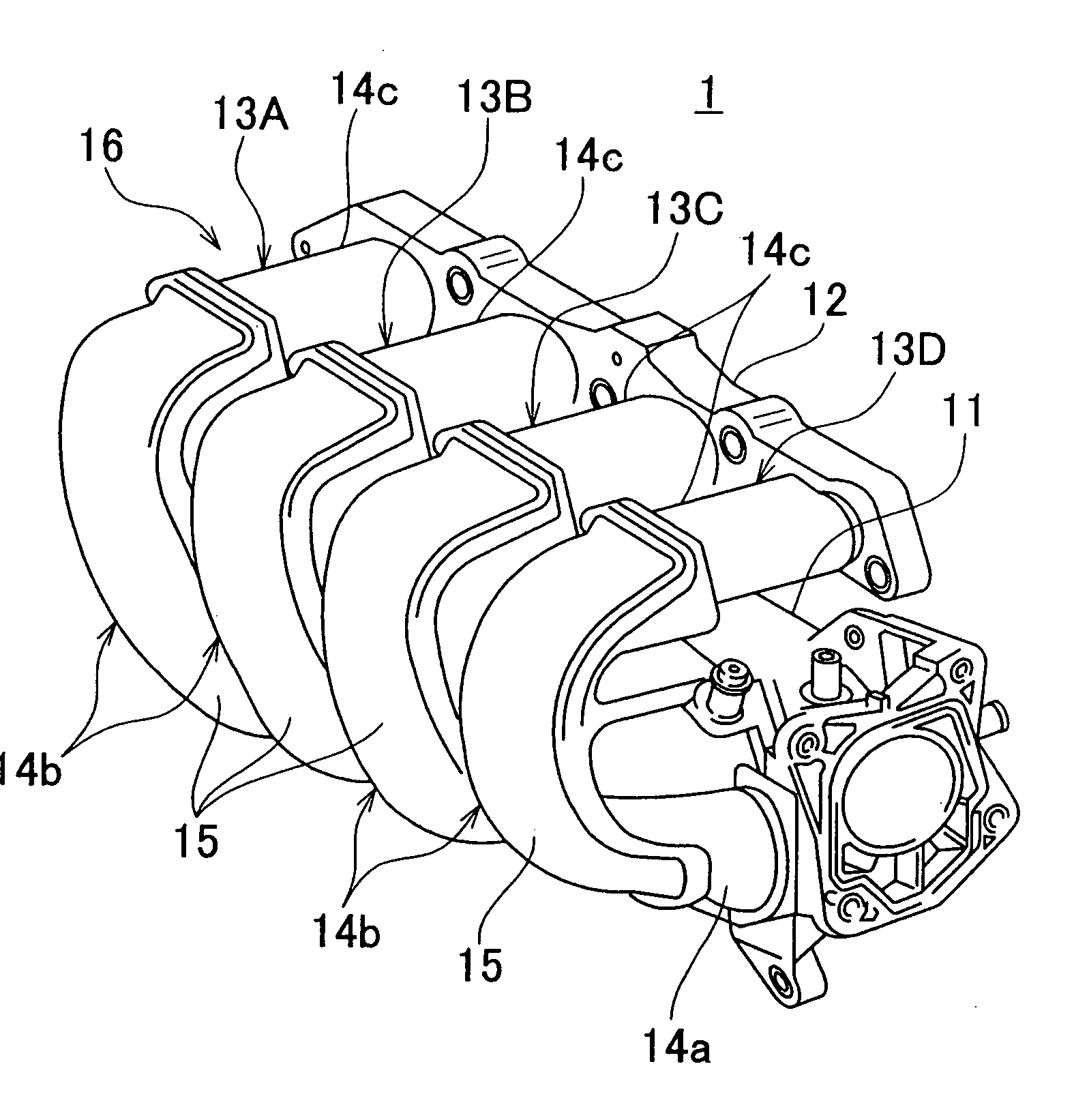

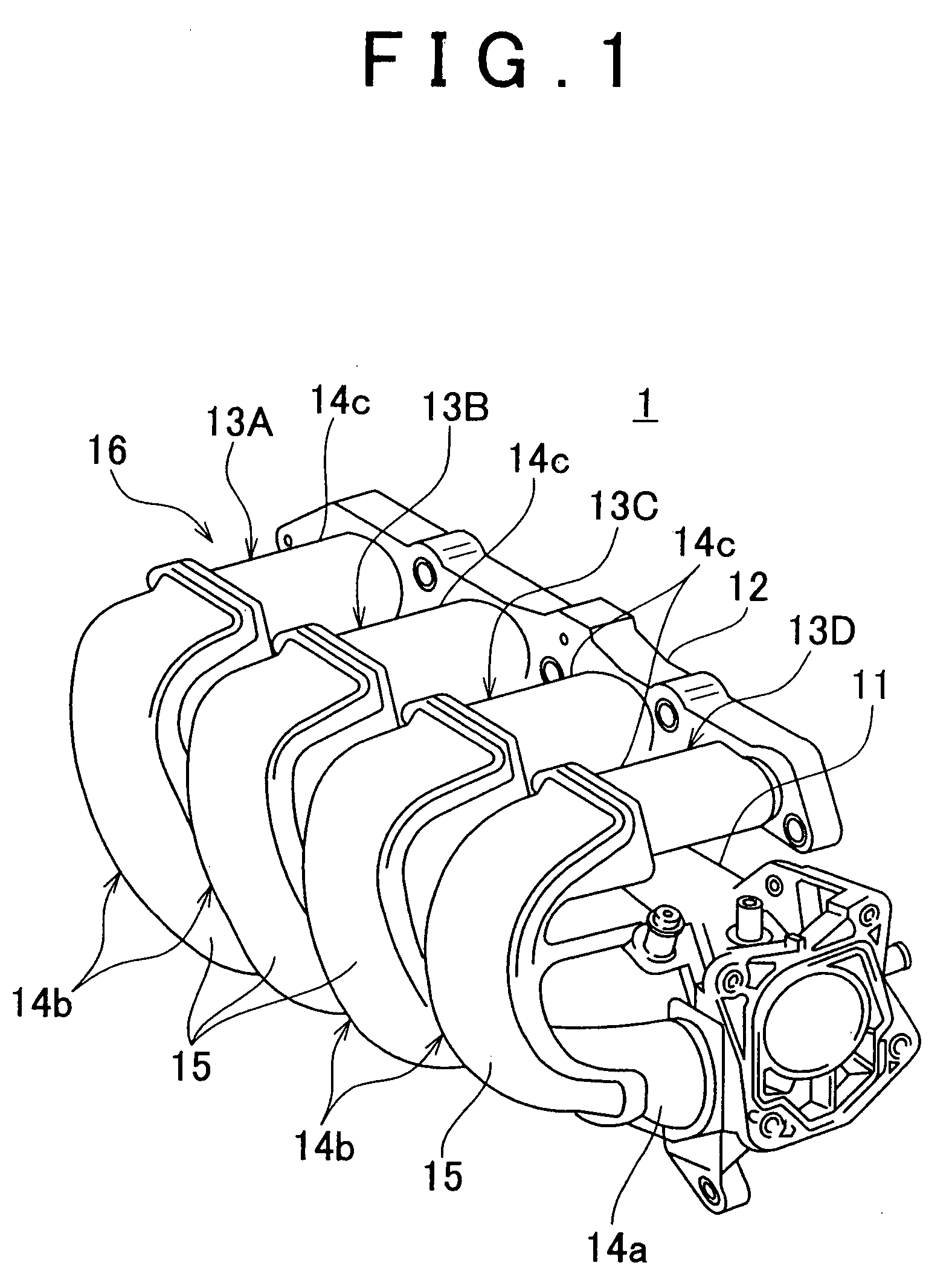

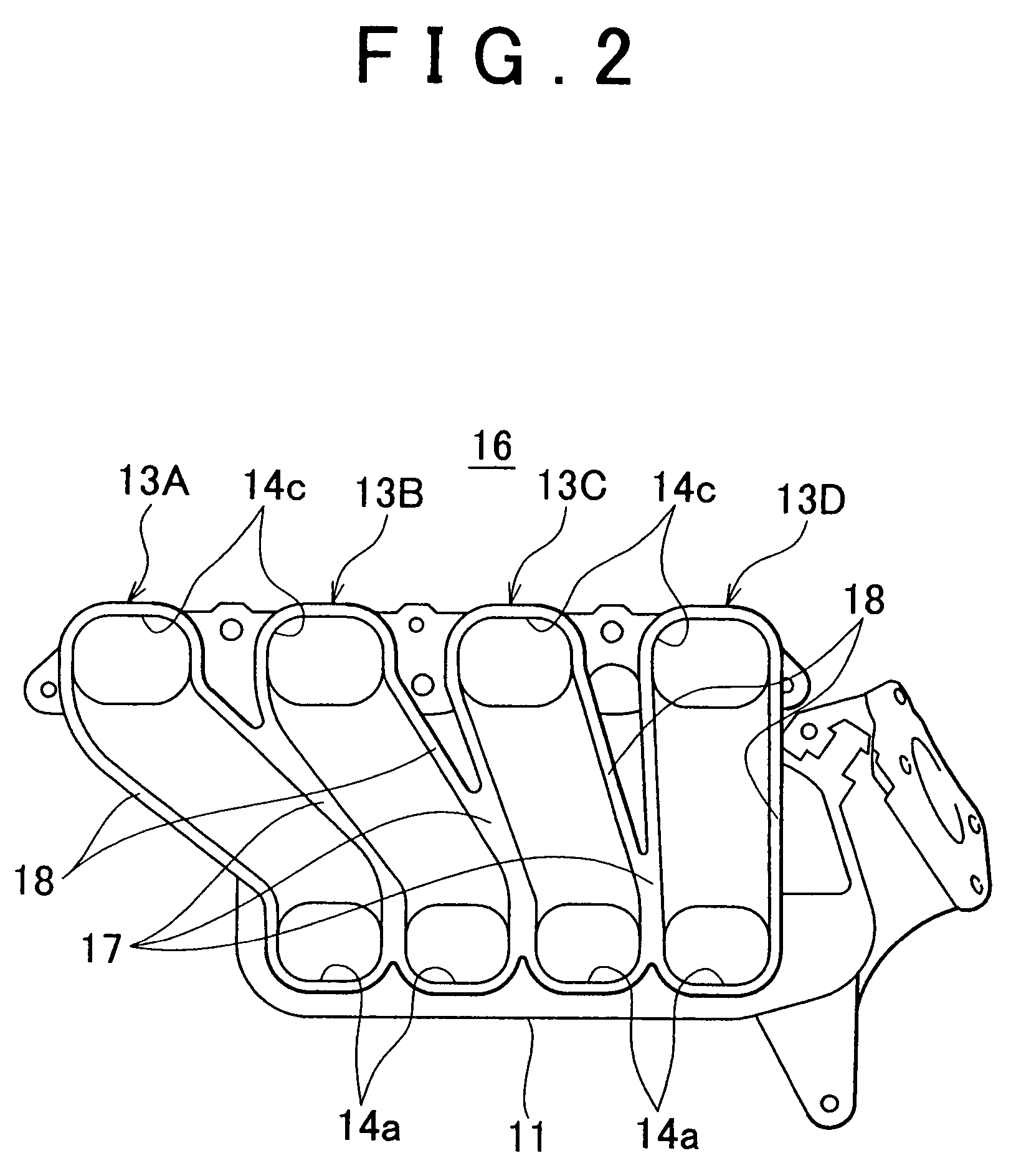

Welding structure for synthetic resin intake manifold

InactiveUS20060086334A1Inhibition formationWorsening of intake air flow resistanceMachines/enginesDomestic articlesFurringSynthetic resin

A synthetic resin intake manifold body and a synthetic resin passage structural member are respectively provided with a body side joining flange and a structural member side joining flange that are continuously formed along a joining line. A protrusion is provided on the body side joining flange and a welding protrusion and an inside and an outside control wall are provided on the structural member side joining flange. When the synthetic resin passage structural member is positioned and aligned with respect to the synthetic resin intake manifold body along the joining line prior to welding, a volume of an inside burr retaining groove is set to be larger than a volume of an outside burr retaining groove.

Owner:TOYOTA JIDOSHA KK

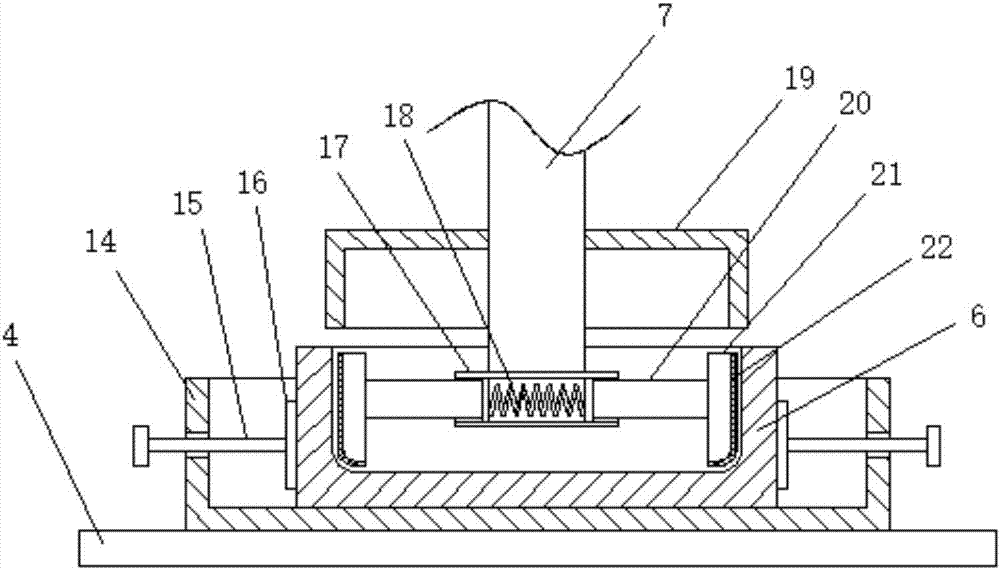

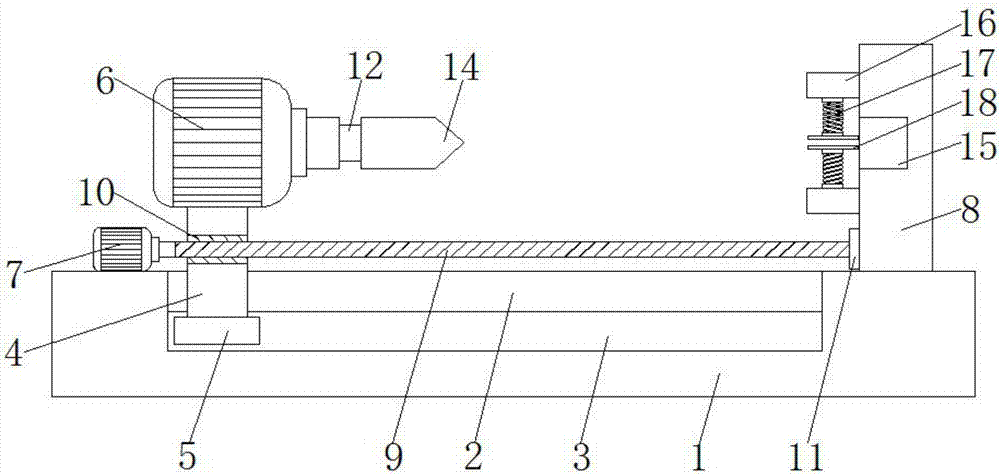

Efficient wood board deburring equipment for building construction

InactiveCN112355778AImprove deburring efficiencySpeed up the construction processEdge grinding machinesGrinding drivesGear driveGear wheel

The invention discloses efficient wood board deburring equipment for building construction, and relates to the technical field of building construction equipment. The efficient wood board deburring equipment comprises a treatment box and a supporting base, supporting seats are symmetrically arranged on the left side and the right side of the upper portion in the treatment box, a screw rod is arranged between the supporting seats and rotationally connected with the supporting seats, nuts are symmetrically arranged on the left side and the right side of the surface of the screw rod, clamps are fixedly connected to positions below the nuts, lead screws are symmetrically arranged on the left side and the right side in the treatment box, lead screw nuts are arranged on the surfaces of the leadscrews, and rack plates are arranged on one sides of the lead screw nuts. Wood boards are clamped and fixed in the clamps, the lead screw nuts drive gears to move up and down on the surfaces of the rack plates in the vertical direction, the rack plates mesh with the gears to drive the gears to rotate, the gears drive a grinding wheel to rotate on the surfaces of the wood boards, the grinding wheelcarries out deburring treatment on the wood boards, a dust suction machine sucks chippings generated in the grinding process into a material collecting groove through a dust suction port, unified collection treatment is carried out, the deburring efficiency is effectively improved through double-face grinding of the wood boards, and the construction process is accelerated.

Owner:刘先贵

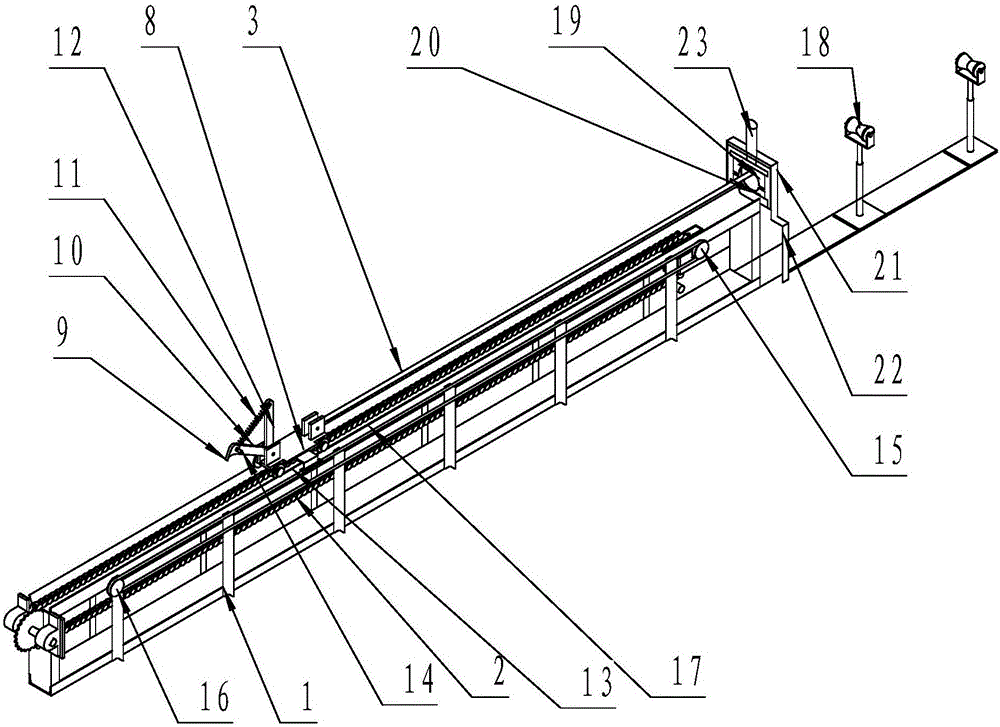

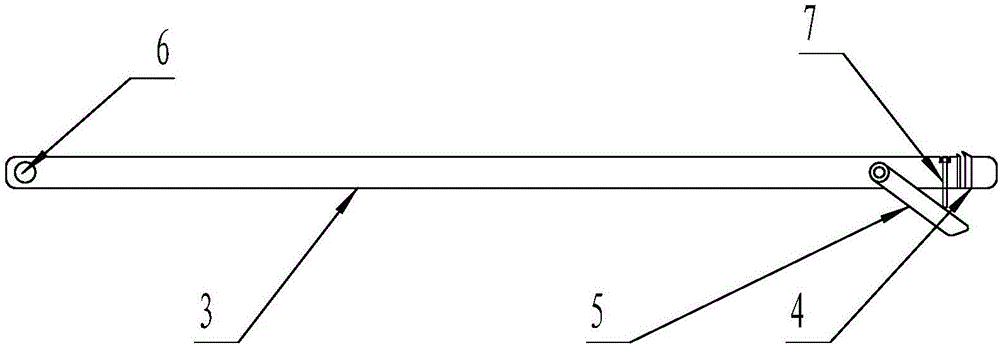

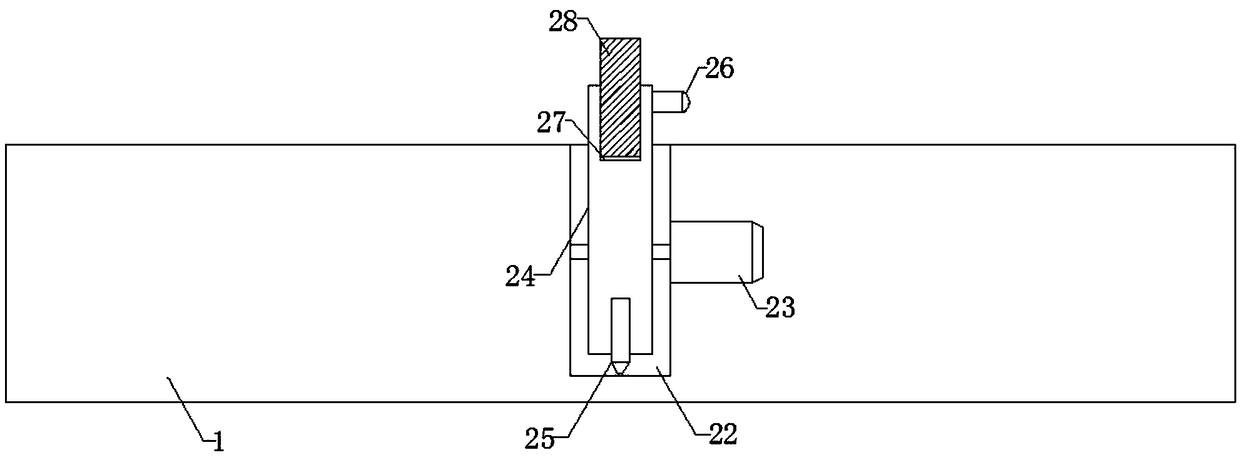

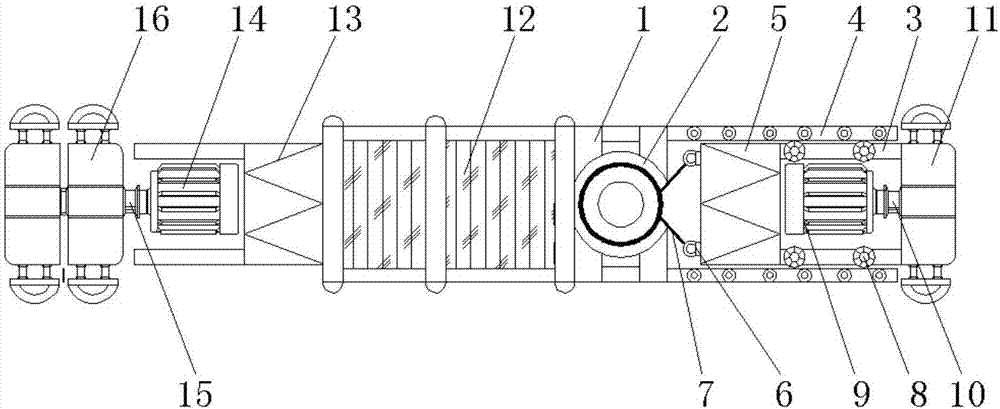

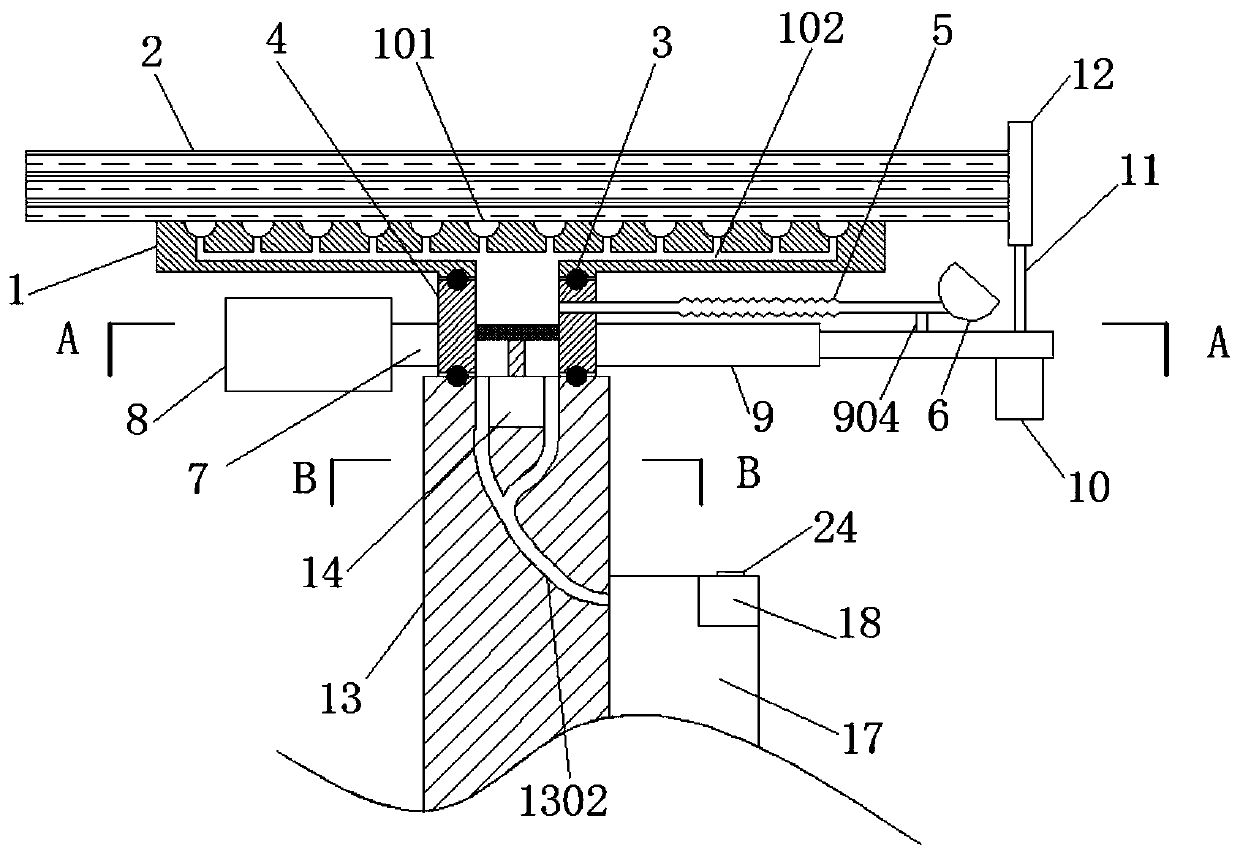

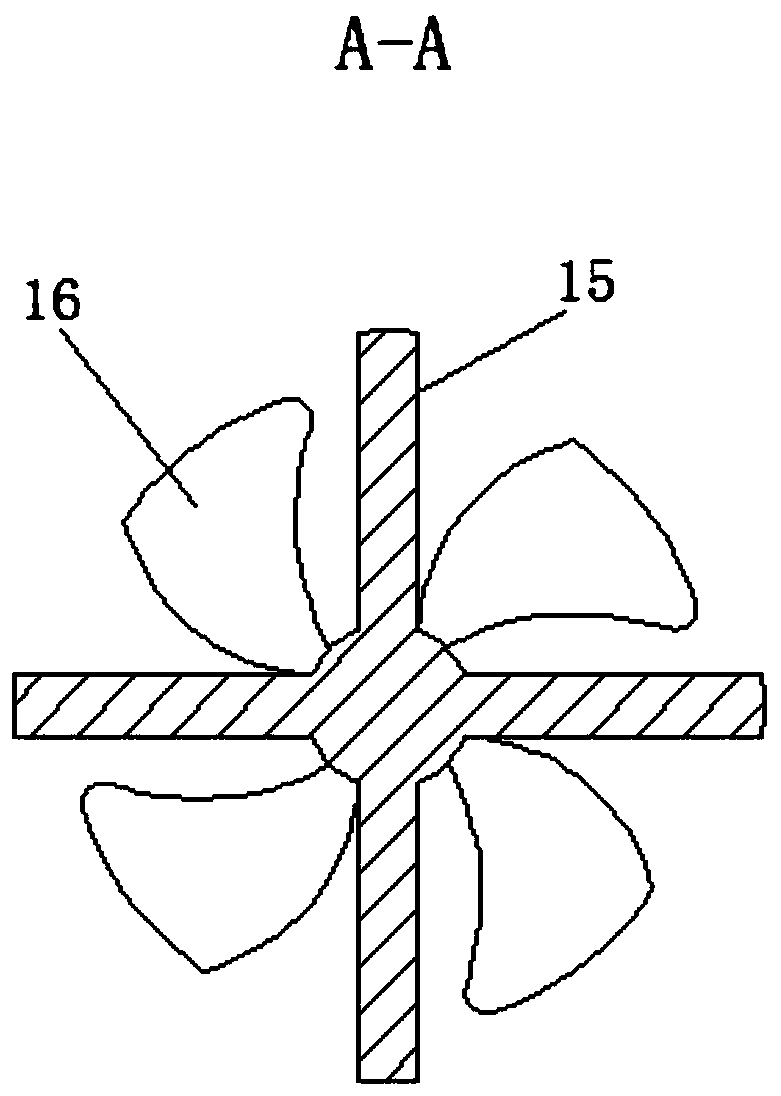

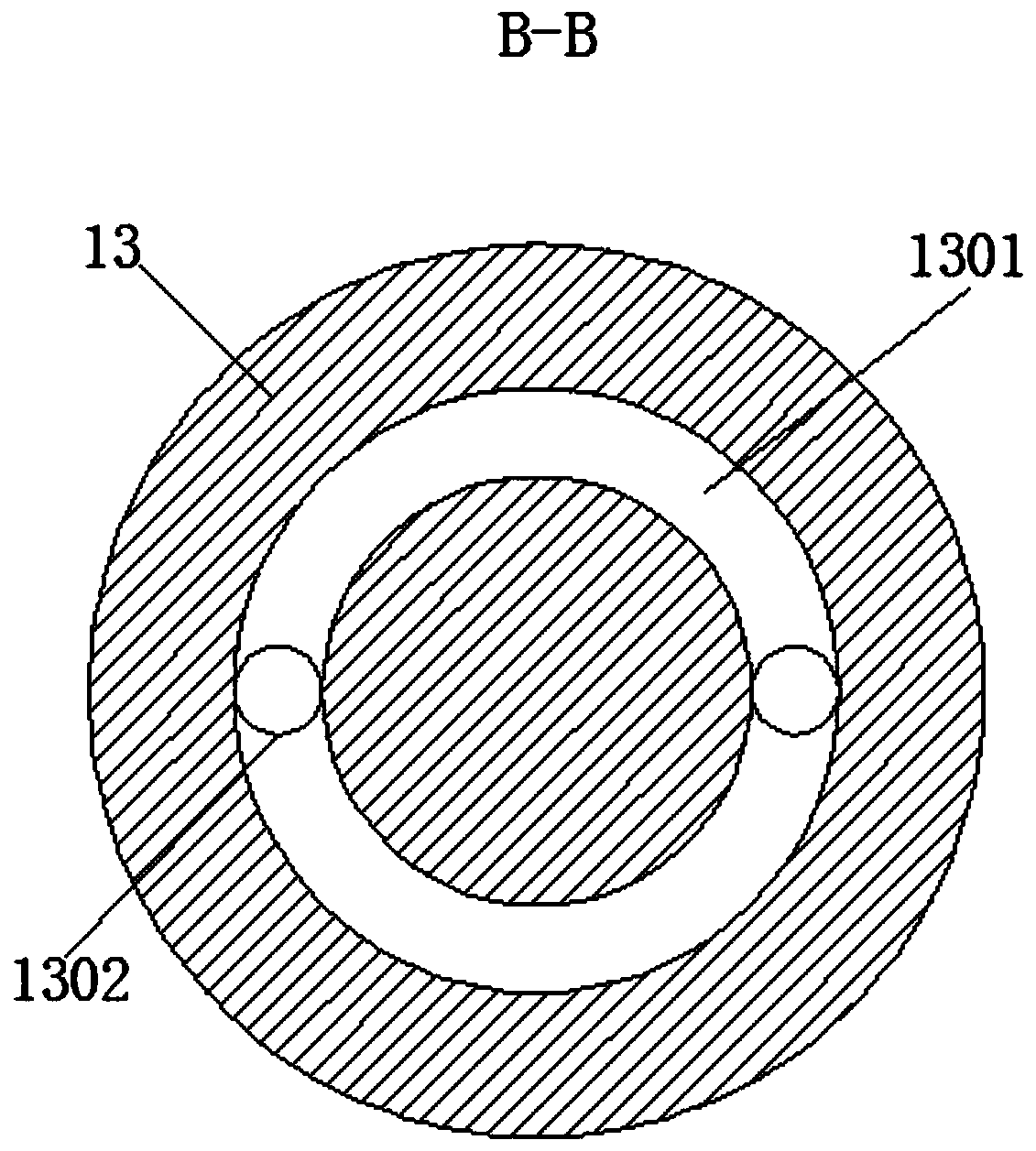

Device for removing burr in straight welded pipe

ActiveCN106475727AImplement automatic cleanupImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelFurring

The invention discloses a device for removing a burr in a straight welded pipe. The device comprises a frame and a chain, wherein the frame is arranged as a bar-shaped frame; the chain is arranged as a double-row roller driving chain; the double-row roller driving chain is sleeved on a driving wheel and a driven wheel arranged at the front and rear ends of the bar-shaped frame; the device further comprises a removing device for the burr in the straight welded pipe, a pulling device, a pushing device and a straight welded pipe conveying and clamping device; the pushing device for the removing device for the burr in the straight welded pipe is arranged on the bar-shaped frame; the pushing device is used for pushing the removing device for the burr in the straight welded pipe into the straight welded pipe; the straight welded pipe conveying and clamping device is arranged on the end part at the rear end of the bar-shaped frame. The device provided by the invention is capable of realizing the automatic removal of the burr in the straight welded pipe, increasing the quality and working efficiency of removing the burr in the straight welded pipe, reducing the labor intensity of the worker, preventing the scraper for removing the inner burr from being damaged and prolonging the service life of the scraper for removing the inner burr.

Owner:济南迈科管道科技有限公司

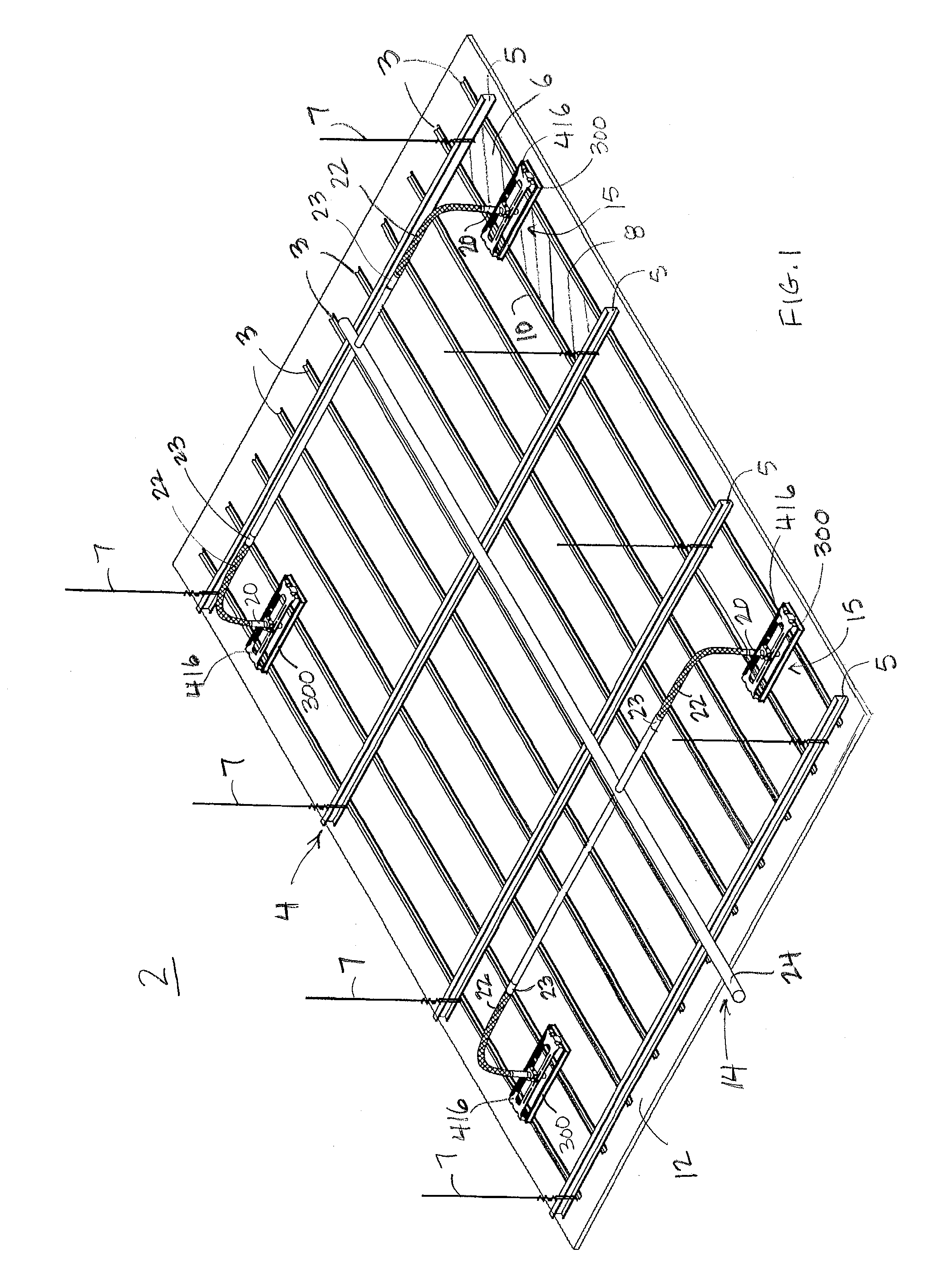

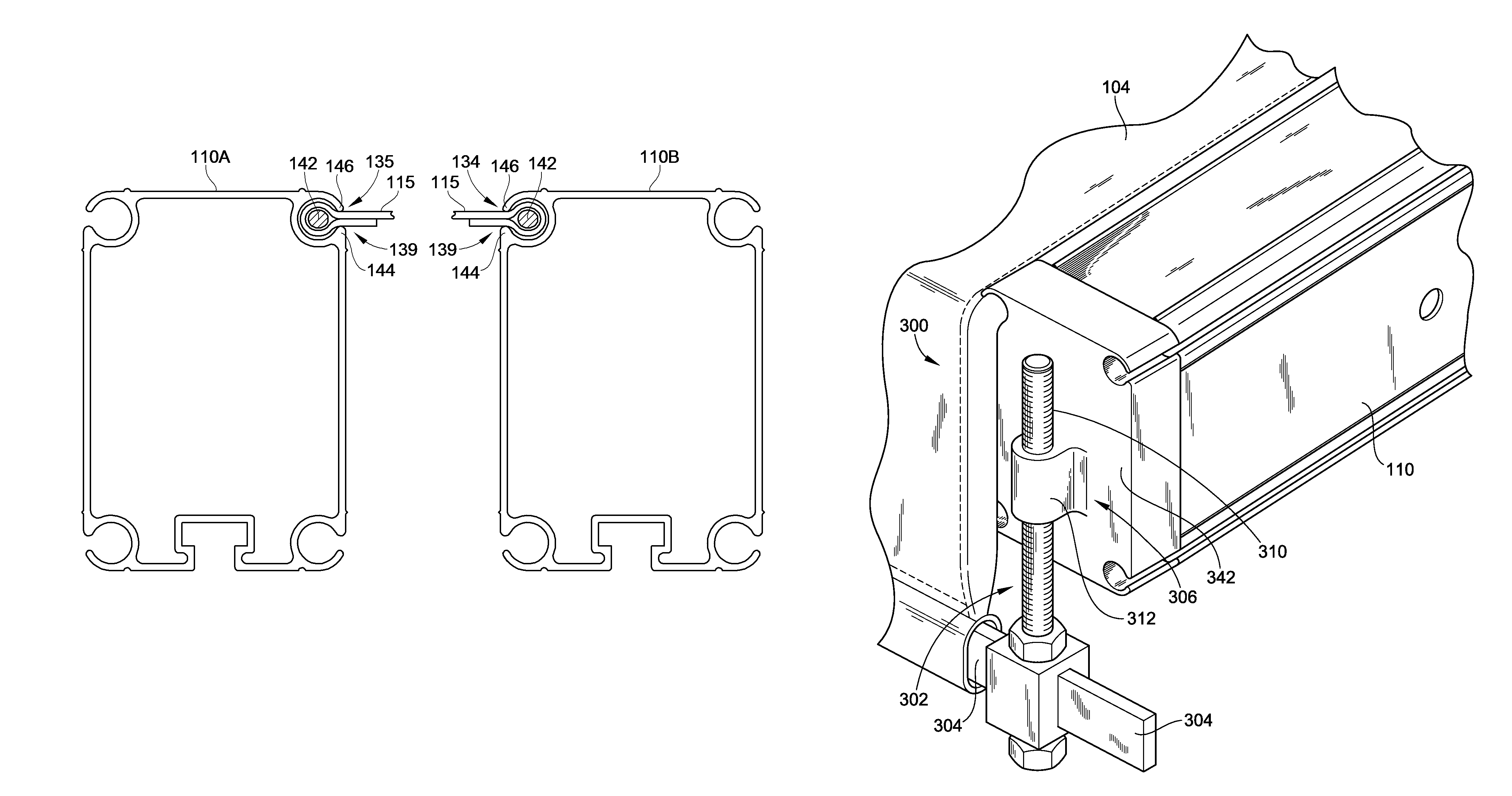

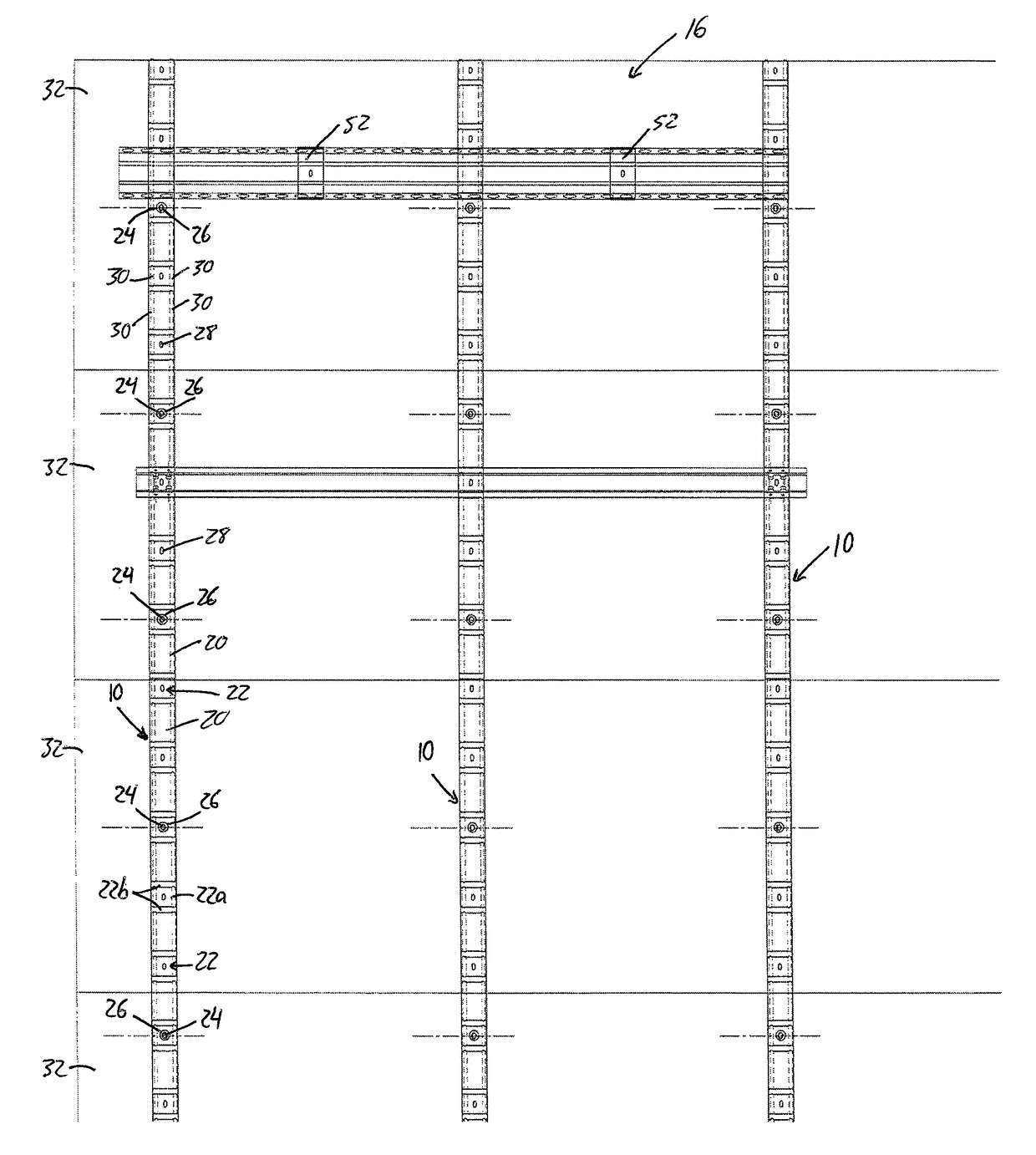

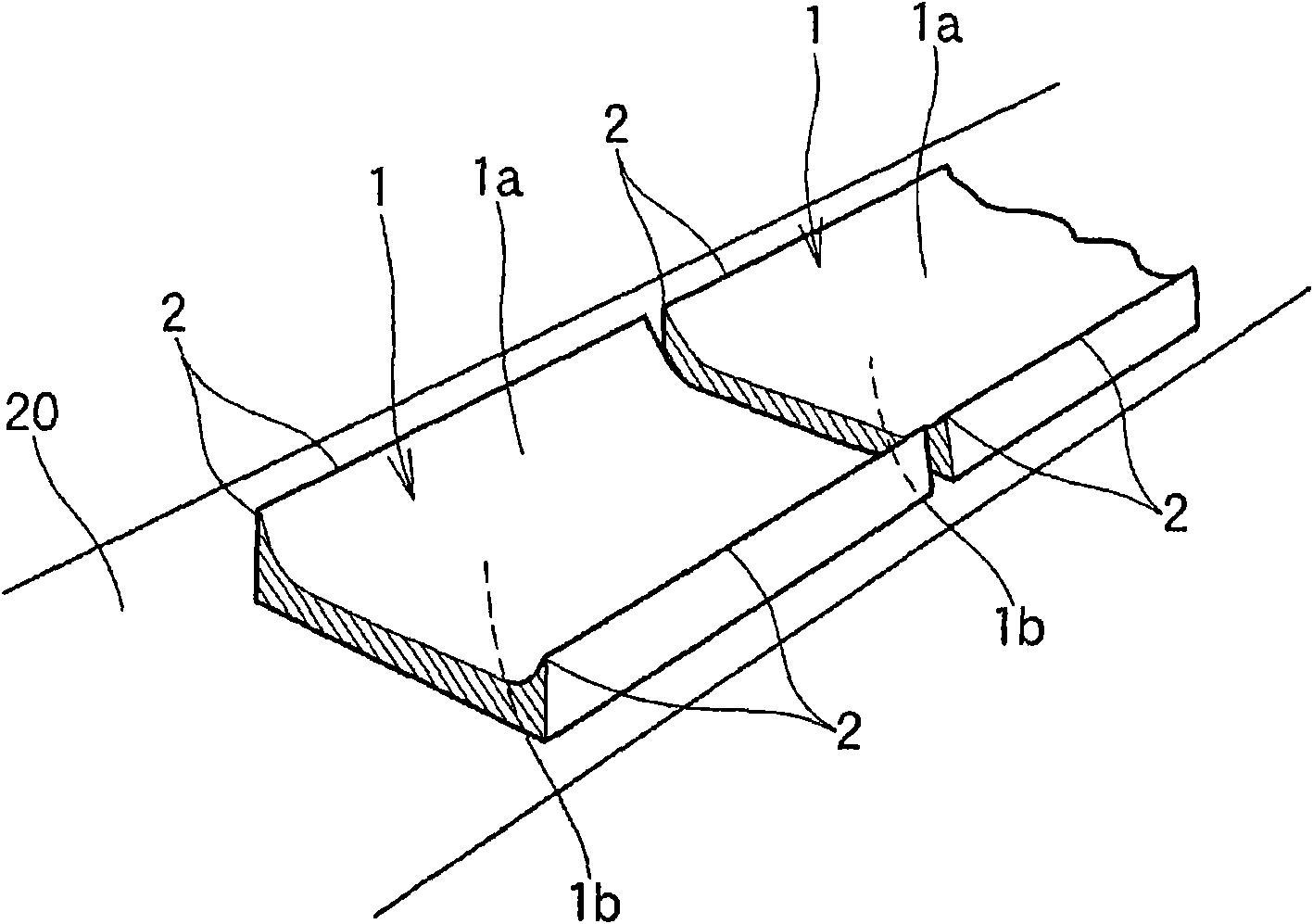

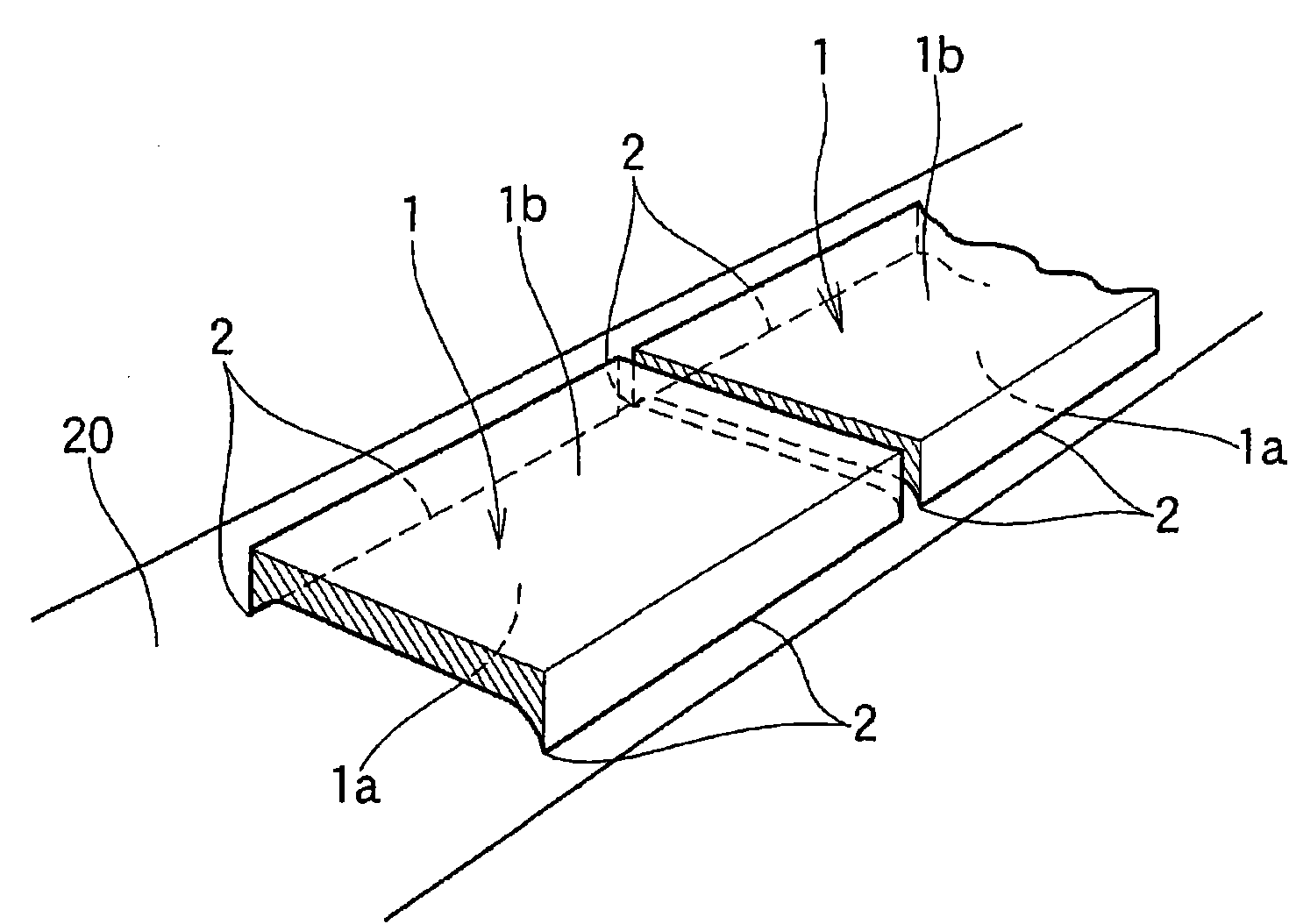

Corrugated furring strips and use of same in upright wall structures

Corrugated furring strips are used on the outer side of an exterior insulation layer in an exterior wall construction. The corrugated furring strips support a final cladding layer at an offstanding position from the insulation, thereby providing a rainscreen. The corrugated furring strips are fastened to the framework of the wall through the exterior insulation layer. Optional bridging members shaped to conformingly mate with lands and grooves of the corrugated furring straps cooperate therewith to define a support grid with improved load capacity for heavier cladding materials and more fastening location options. The insulation layer is free of any thermal bridges other than the insulation-penetrating fasteners used to support the furring and optional bridges. Thermally insulative washers isolate the furring and optional bridges from the fasteners to further improve the insulating effect of the wall.

Owner:UKRAINETZ MICHAEL WAYNE

Method for making a flux cored wire

ActiveCN101804534AEliminate burrsArc welding apparatusWelding/cutting media/materialsSheet steelButt joint

the ends of strip steels are butt-jointed with each other in the longitudinal direction in order and are connected by welding, when such long strip steel raw material is used for continuously making a thin flux-cored wire, the burr generated due to the shearing of the steel plate and continuously existing at the end of the width direction of the strip steel along the whole longitudinal direction of the strip steel faces the upper part of the connecting strip steels, then the ends of strip steels are butt-jointed with each other in the longitudinal direction, and are connected by welding, no burr toward the outside of the thin flux-cored wire exists. By adopting the method, the circularity of the flux-cored wire can be ensured, in case of thin flux-cored wire, no bad influence on the supply of the extending-out welding wire in the welding construction for a welding machine is caused, and the supply is good.

Owner:KOBE STEEL LTD

Welding device for building reinforcing steel bar precise localization

ActiveCN109352196APrecise positioningAvoid artificialEdge grinding machinesWelding/cutting auxillary devicesCircular discArchitectural engineering

The invention discloses a welding device for building reinforcing steel bar precise localization. The welding device comprises a work platform, sliding grooves are formed in the two sides of the top end of the work platform, the two sliding grooves are in sliding connection with four sliding blocks, the four sliding blocks are fixedly arranged on the bottom end of a first stand, the bottom end ofa second stand, the bottom end of a third stand and the bottom end of a fourth stand, the first stand and the second stand are fixedly connected through a mechanical telescopic rod, and the third stand and the fourth stand are fixedly connected through a mechanical telescopic rod. According to the welding device for building reinforcing steel bar precise localization, through a grinding wheel, after heat treatment of a welding opening of reinforcing steel bars, the welding opening is ground, burrs on the welding opening are removed, and the phenomenon that during taking of the reinforcing steel bars, a worker is hurt by the burrs is avoided; a flame spraying gun is fixedly arranged on a disc, a first motor is started, the flame spraying gun and the grinding wheel can be replaced back and forth, back and forth heat treatment and preheating of the welding opening by manual work can be avoided, and work efficiency of welding is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

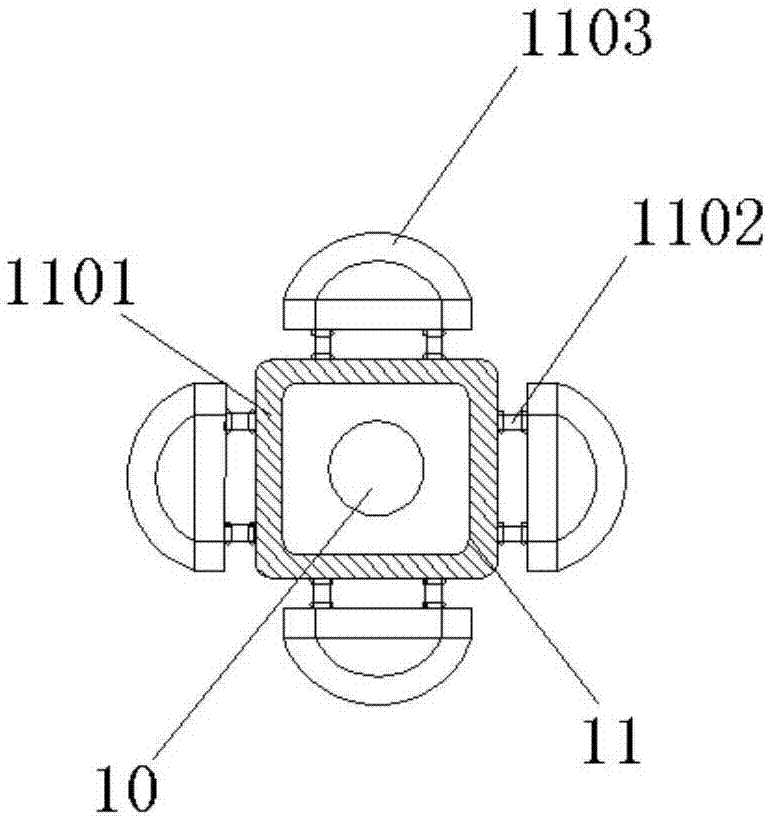

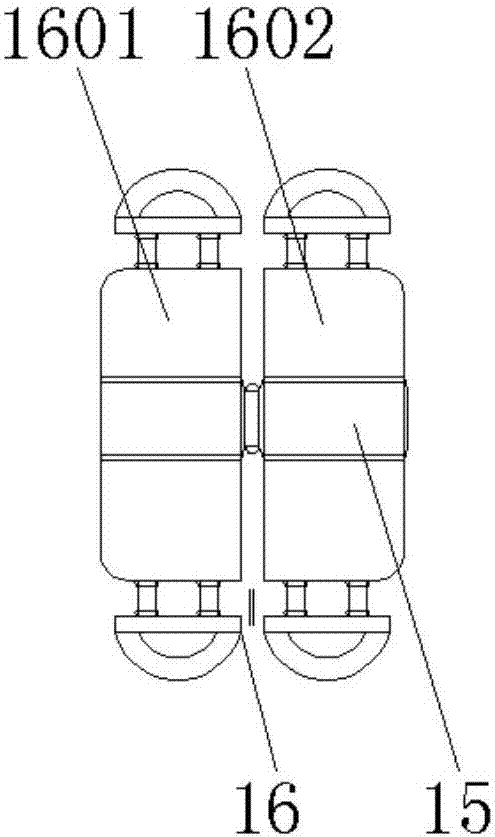

Steel pipe inner burr removing device

InactiveCN107855860AEasy to installEasy to useEdge grinding machinesGrinding carriagesFixed frameFurring

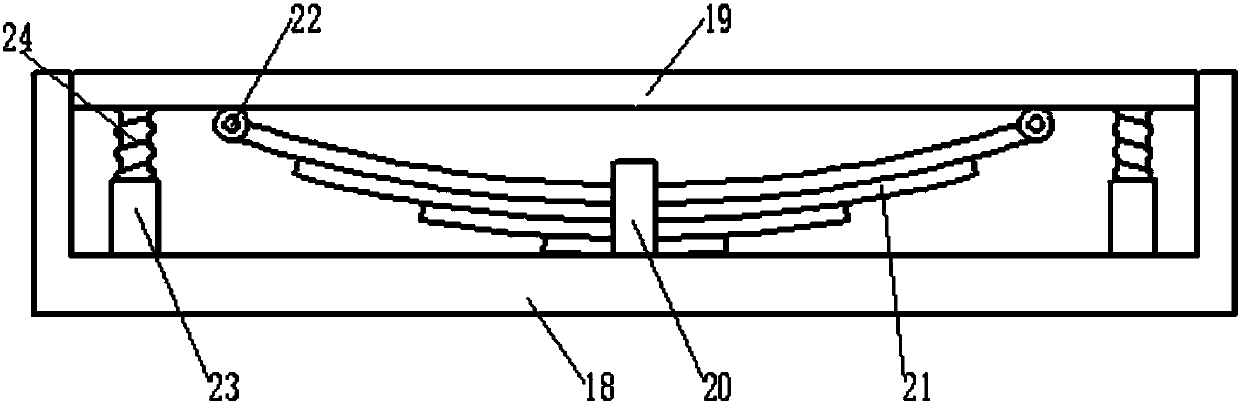

The invention discloses a steel pipe inner burr removing device comprising a fixed base and a grinding wheel. The two sides of the surface of the fixed base are fixedly connected with side plates. A double-shaft motor is fixedly connected to the surface of the fixed base. Rotary shafts are connected to the two ends of the double-shaft motor and are sleeved with movable parts. Sliding blocks are fixedly connected to the bottoms of the movable parts. The sliding blocks and the surface of the fixed base are connected slidably. Connecting rods are fixedly connected to the movable parts. Fixed parts are fixedly connected to the tops of the connecting rods. Telescopic rods are fixedly connected to the inner walls of the fixed parts. Clamping plates are fixedly connected to the tail ends of the telescopic rods. A support is fixedly connected to the fixed base. A fixed frame is fixedly connected to the support. An electric telescopic device is fixedly connected to the fixed frame. A micro motor is fixedly connected to the tail end of the electric telescopic device. The shaft-extension end of the micro motor is connected with the grinding wheel. In the process that burrs on the inner wall of a steel pipe are removed through the steel pipe inner burr removing device, the steel pipe is convenient to install, vibration reducing performance is good, vibratility in the removal process of theburrs in the steel pipe is small, and practicability is high.

Owner:成都市龙泉星源机械厂

Method for single side welding of laminate steel

Owner:GM GLOBAL TECH OPERATIONS LLC

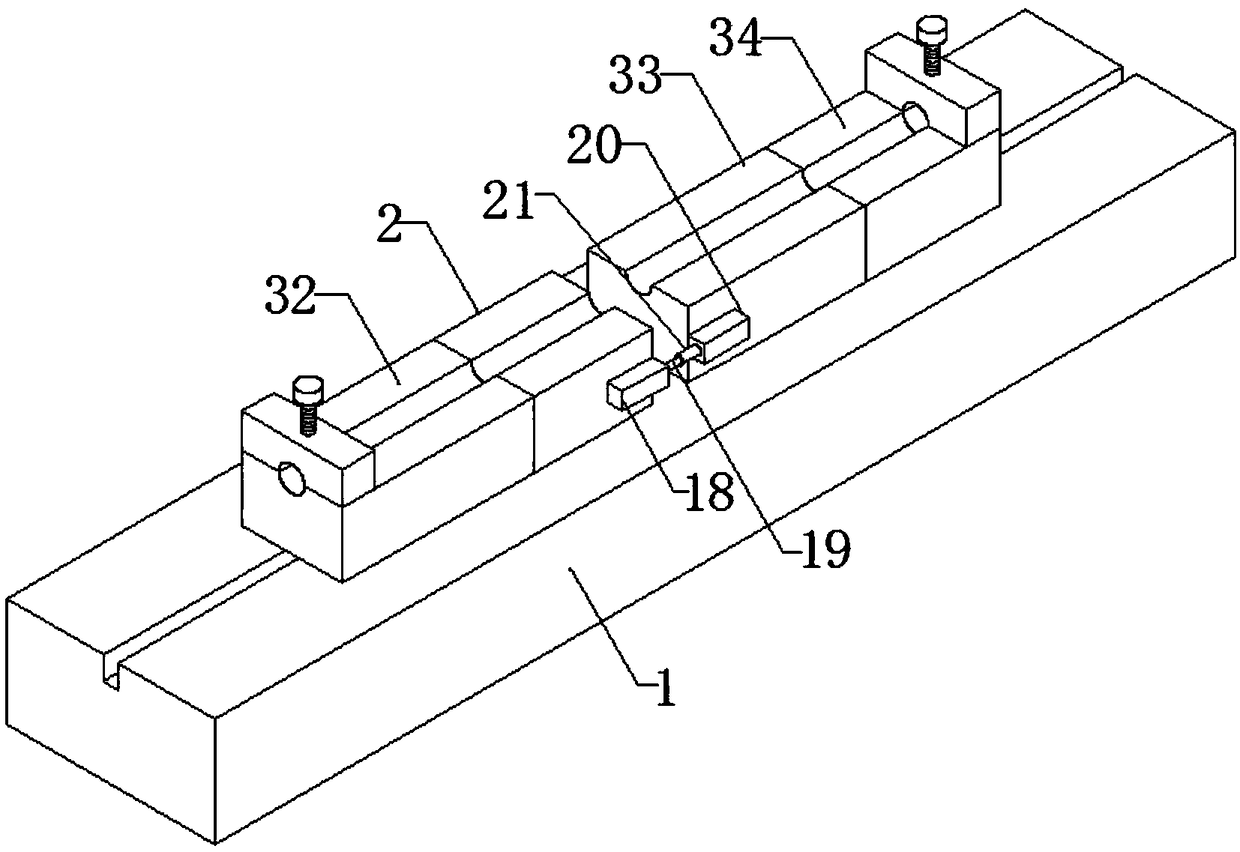

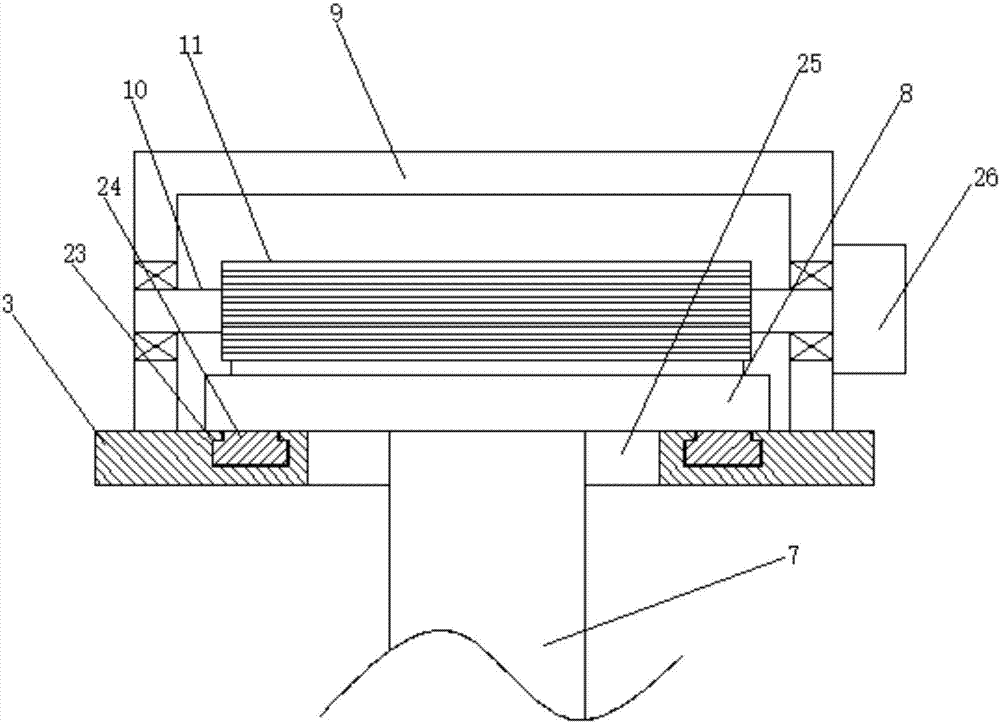

Deburring device for inner side wall of C-shaped guide rail

InactiveCN107150272ATimely processingImprove grinding effectEdge grinding machinesGrinding drivesFurringPulp and paper industry

The invention discloses a deburring device for the inner wall of a C-shaped guide rail, which comprises a bottom plate, a side plate, a top plate and an operation platform. Both ends of the upper end surface of the operation platform are provided with clamping devices for fixing the two ends of the guide rail. A rack and a mounting frame are arranged, and a horizontal shaft is installed on the mounting frame, and a driving gear is arranged on the horizontal shaft. And the driving gear is meshed with the rack, the lower end surface of the rack is connected with the upper surface of the top plate through a sliding mechanism, the bottom end of the rack is provided with a vertical bar, and the bottom end of the vertical bar is provided with a guide cylinder perpendicular to it, and the guide cylinder Both ends are provided with connecting rods, the opposite ends of the two connecting rods are provided with mounting plates, the mounting plates are provided with friction plates, the bottom end of the rack is also provided with a suspension rod, and the lower end of the suspension rod is provided with a vacuum cleaner. The invention has a simple structure, can be repeatedly deburred and polished, has a good grinding effect, does not need manual grinding, has high grinding efficiency, can process debris after grinding in time, is simple to operate, and has strong practicability.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

Method and apparatus for slitting steel slabs

A cutting table assembly for oxy cutting comprising a cutting table having a slab loading face and mounted for pivotal movement between a loading position in which the loading face is generally horizontal and a cutting position in which the face is oblique, and a pair of torches mounted on the table. The loading face is constituted by a pair of loading subfaces separated by a slot and the torches are mounted in the slot below the loading face. The torches are positioned at opposite ends of the slot prior to the initiation of the cutting action and, upon the initiation of the cutting action, move toward each other and cut into opposite ends of the slab. A pair of gantries are mounted on the table and each carries a deburring device positioned in overlying opposition to a respective torch. Each gantry further includes a plurality of spaced downwardly directed nozzles which are supplied with compressed air to generate an air curtain.

Owner:EDWARD C LEVY

Steel pipe inner wall edge burr grinding device

InactiveCN107971861AEasy to installEasy to useEdge grinding machinesGrinding carriagesFurringDrive motor

The invention relates to the technical field of steel pipe machining equipment and discloses a steel pipe inner wall edge burr grinding device. The steel pipe inner wall edge burr grinding device comprises a pedestal; the upper surface of the pedestal is provided with a first sliding chute; the bottom of the first sliding chute is provided with a second sliding chute; a first sliding plate is inserted into the first sliding chute; and the bottom end of the first sliding plate penetrates through the first sliding chute and is fixedly connected with the upper surface of a second sliding plate which is positioned inside the second sliding chute. The steel pipe inner wall edge burr grinding device is provided with a driving motor, a positive and negative rotating motor, a threaded rod, a grinding bar and a second spring; the driving motor can move, so convenience is provided for installation of a steel pipe; meanwhile, the second spring and the grinding bar are matched with each other, sothe steel pipe inner wall edge burr grinding device is high in applicability and can be applicable to different specifications of steel pipes; burrs are ground in a rotation process of the driving motor, and manual operation is not needed, so the work intensity and the work difficulty are reduced; and meanwhile quicker grinding is realized, the grinding efficiency is improved, and the steel pipe inner wall edge burr grinding device is more convenient to use.

Owner:惠州市世育五金制品有限责任公司

Polishing and cleaning device for inner walls of steel pipes

InactiveCN107297657AImprove applicabilityEdge grinding machinesGrinding machine componentsArchitectural engineeringFurring

The invention discloses a grinding and cleaning device for the inner wall of a steel pipe. The left side of the block is fixed with a lock, the upper and lower sides of the right mounting block are equipped with self-propelled wheels, the first motor is connected to the first grinding head through a rotating shaft, and the left end of the hydraulic telescopic column is fixed with a left The installation block, the inside of the left installation block is equipped with a second motor, and the second motor is rotatably connected to the grinding device through a bearing, and the grinding device is located on the left side of the second motor. The steel pipe inner wall grinding and cleaning device can not only grind the burrs of the steel pipe welding joint or cutting edge, but also go deep into the inside of the steel pipe to polish the burrs on the inner wall of the steel pipe. At the same time, the device does not need to replace the grinding head. The diameter of the steel pipe is ground to increase the applicability of the device.

Owner:HEFEI YONGWEI MACHINERY EQUIP

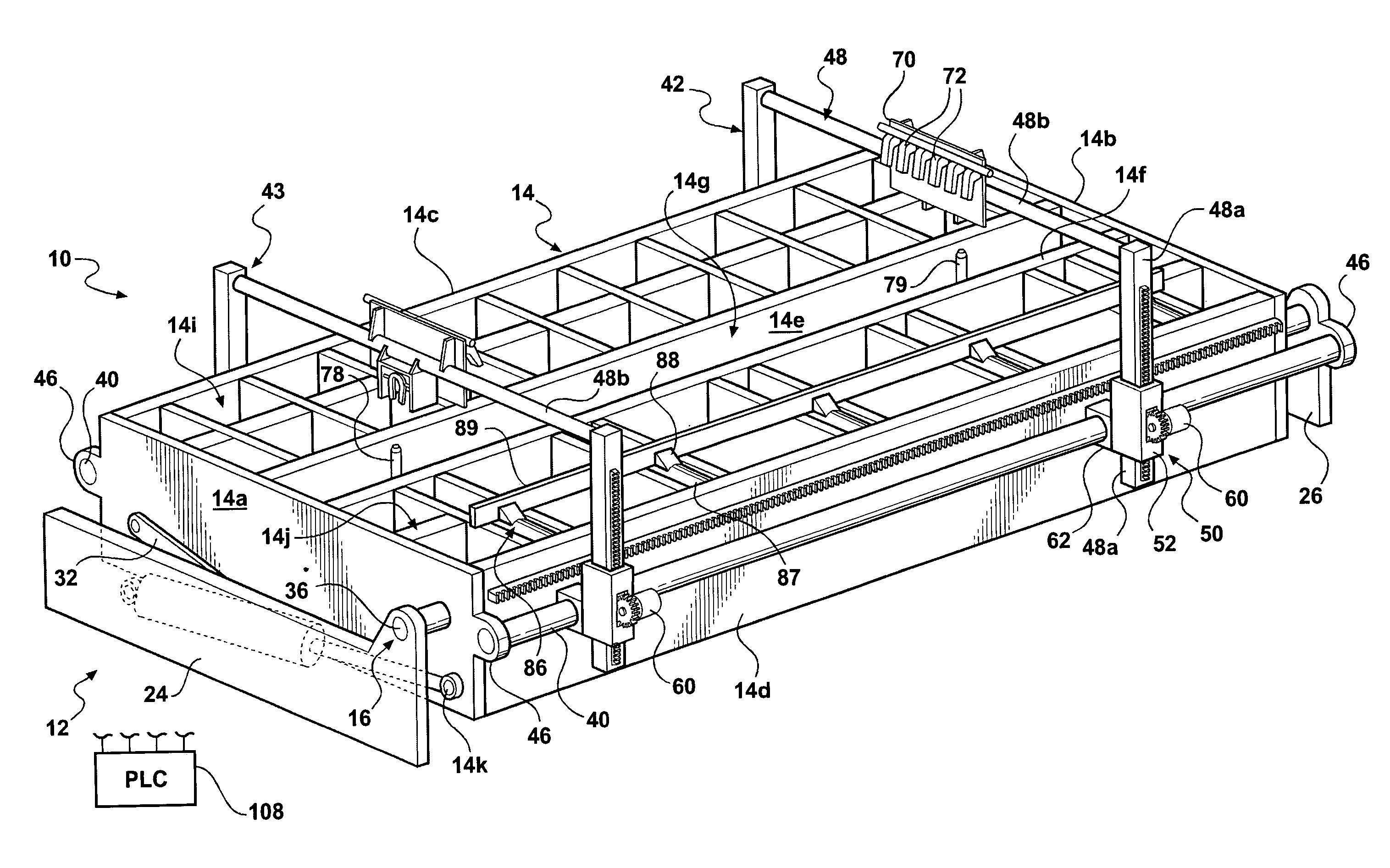

Plank side and corner polishing device for wood packages

InactiveCN107775498AReduce labor inputReduce glitchesGrinding carriagesBelt grinding machinesFurringEngineering

The invention relates to a wood board edge grinding device for wood packaging, which belongs to the technical field of wood packaging processing. It includes a frame, the frame is provided with conveying rollers, guide rollers are arranged on both sides of the conveying rollers, a grinding mechanism is arranged on the side of the guide rollers, pressure sensors are arranged on the guide rollers, The grinding mechanism connection includes grinding units symmetrically arranged on both sides of the conveying roller table, a pushing mechanism is arranged at the entrance of the conveying roller table, and the conveying roller table, the pressure sensor, the grinding mechanism and the pushing mechanism are jointly connected by a PLC controls the control box for the four. The advantages of the invention are: it can reduce manual input, automatically grind after feeding, has high grinding efficiency, can quickly reduce the burrs on the edge of the board, has high automation, low vibration during the grinding process, and good grinding stability.

Owner:苏州卫刚木包装制品有限公司

Automatic arc-edge wood board grinding device with grinding degree detection function

ActiveCN111002152AGuaranteed internal exhaustAvoid settingEdge grinding machinesGrinding feed controlFurringElectric current flow

The invention relates to the technical field of whole wood home furnishing manufacturing tools. The invention discloses an automatic arc-edge wood board grinding device with a grinding degree detection function. The device comprises a placing frame, a detection device is connected to the upper right portion of a collection box, a rotating column is arranged on the right side of the detection device, a drum layer is connected to the left end of the detection device, a U-shaped metal rod is connected to the outer side of the rotary column, coils are arranged at the upper, lower and left ends ofthe U-shaped metal rod, a second spring is connected to the left end of the lower portion of the U-shaped metal rod and the bottom of the detection device, magnetic sets are connected to the front andrear inner walls of the detection device, and a prompt lamp is connected to the upper end of the detection device. Collected burrs impact the drum layer, sound generated by the drum layer drives theU-shaped metal rod to swing on the second spring, the coil on the U-shaped metal rod cuts a magnetic induction line in the magnetic set in the swing process, alternating current generated when the coil cuts the magnetic induction line flows into the prompt lamp and a diode, and the structure solves the problem that the grinding degree needs to be manually detected.

Owner:阜南县富昌恒业工艺品有限公司

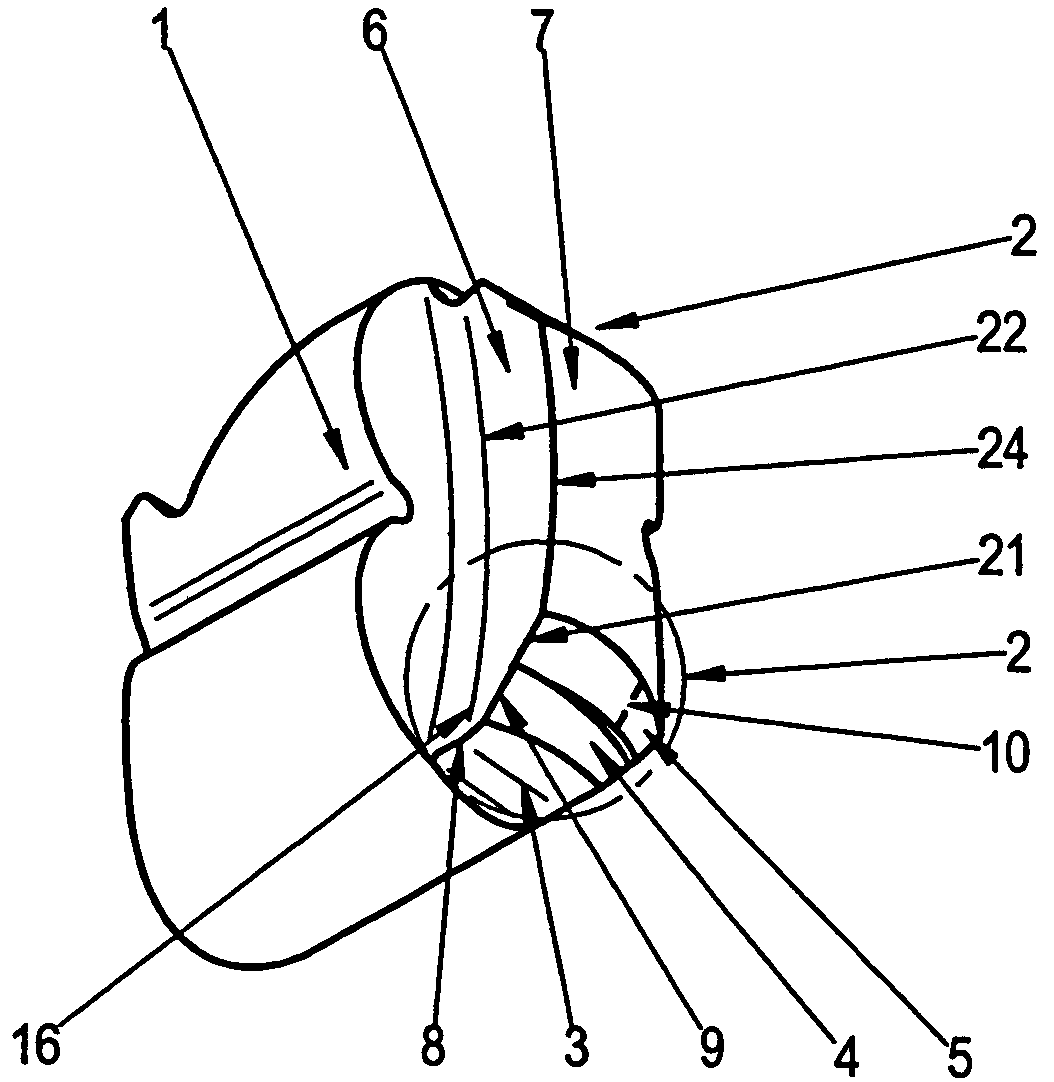

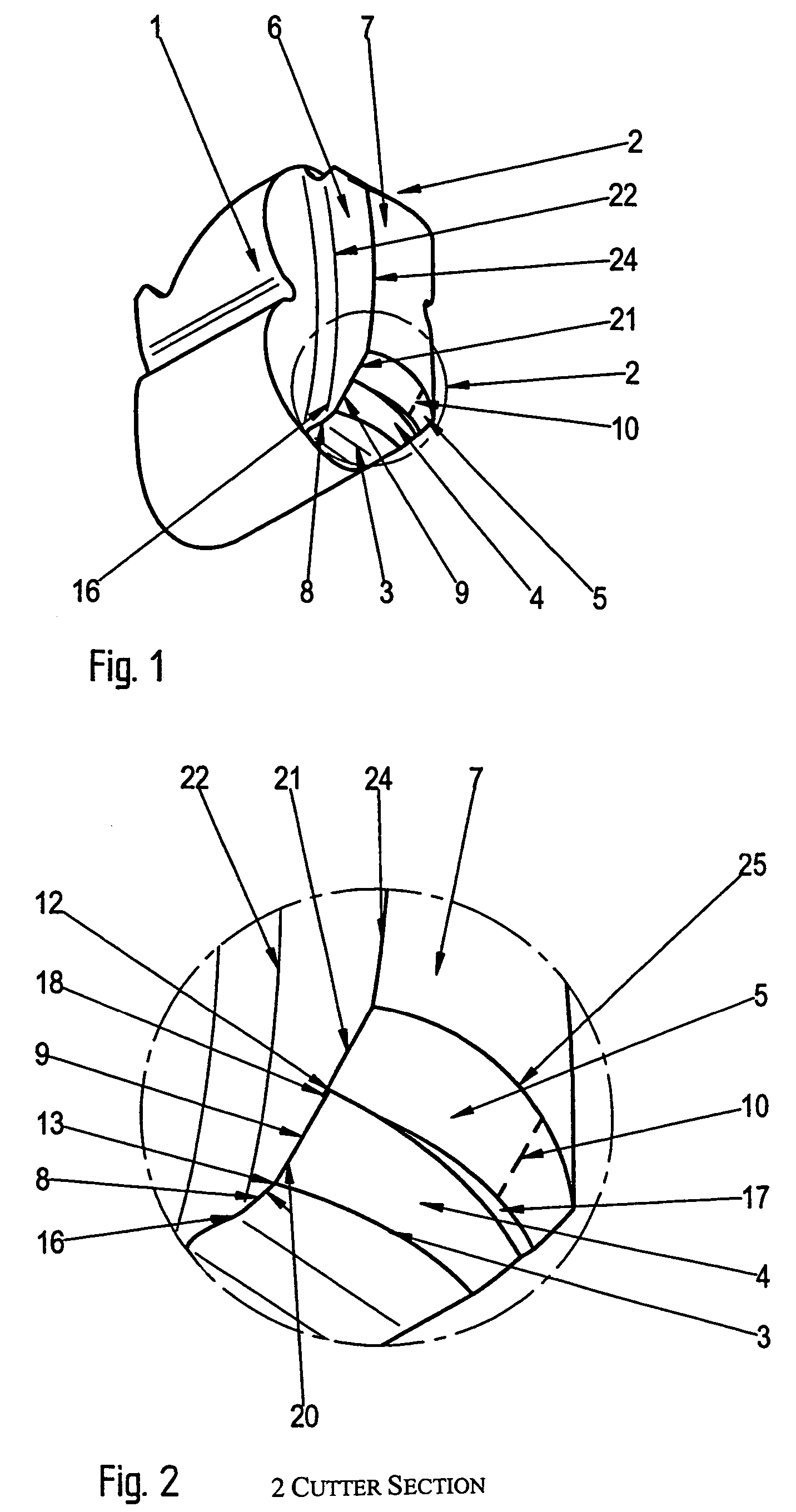

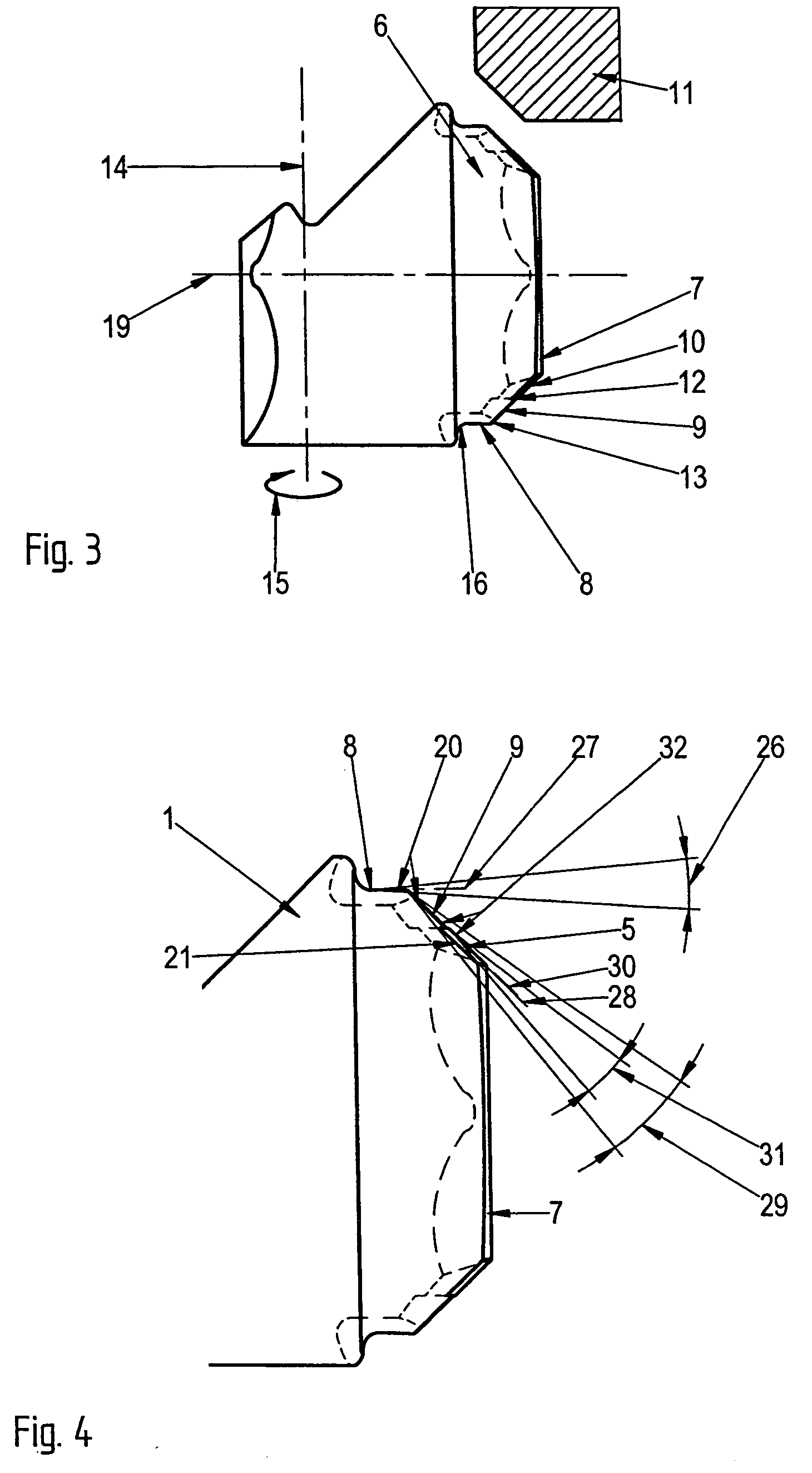

Deburring cutter for deburring edges of drilled holes

ActiveUS7273334B2Effectively remove unusually large burrAggressive cutting actionThread cutting toolsWood turning toolsFurringEngineering

The first cutting edge can advantageously remove a large burr from the edge of a drilled hole with high effectiveness, because of the particularly aggressive cutting action of the first cutting edge. The following inclined second cutting edge advantageously allows precise chamfers to be cut, i.e., the surface and the angle of the counter bore can be precisely maintained, independent of the wear on the cutting edges. A control surface located adjacent to the cutting edge in the forward region enables a precise control of the cutter.

Owner:HEULE WERKZEUG

Welding structure for synthetic resin intake manifold

InactiveUS7174873B2Inhibition formationWorsening of intake air flow resistanceMachines/enginesDomestic articlesFurringSynthetic resin

A synthetic resin intake manifold body and a synthetic resin passage structural member are respectively provided with a body side joining flange and a structural member side joining flange that are continuously formed along a joining line. A protrusion is provided on the body side joining flange and a welding protrusion and an inside and an outside control wall are provided on the structural member side joining flange. When the synthetic resin passage structural member is positioned and aligned with respect to the synthetic resin intake manifold body along the joining line prior to welding, a volume of an inside burr retaining groove is set to be larger than a volume of an outside burr retaining groove.

Owner:TOYOTA JIDOSHA KK

Deburring welded pipe

InactiveUS7695224B2Simple designEconomical manufacture and assemblyWelding/cutting auxillary devicesPlaning/slotting machinesButt weldingFurring

Owner:LUMCO MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com