Device for removing burr in straight welded pipe

A straight seam welded pipe and burr technology, which is applied in the field of burr scraping equipment for straight seam welded pipes, can solve the problems of damage to the inner burr scraping blade, high labor intensity of employees, and poor quality of burr scraping, so as to reduce labor intensity of employees, Improve scraping quality and work efficiency, prolong the effect of use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

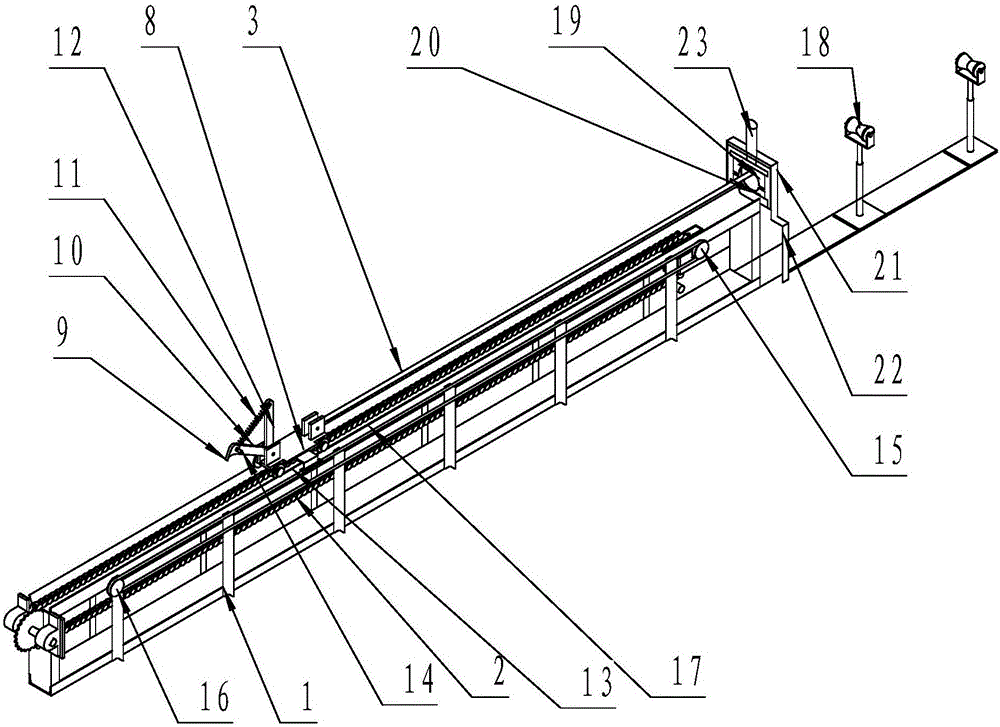

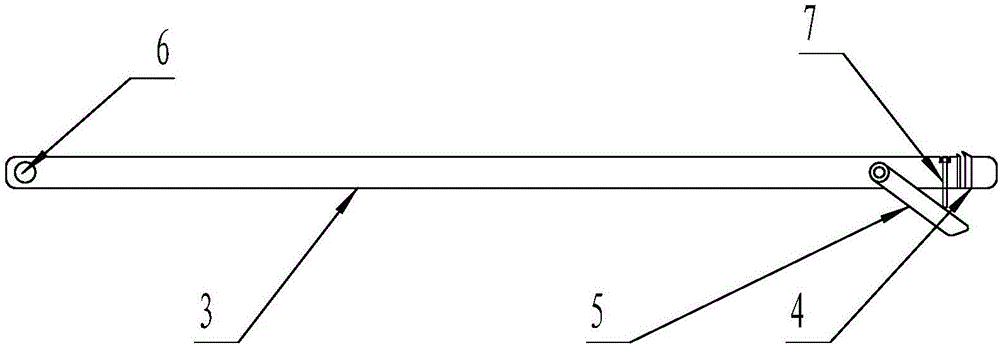

[0019] Such as figure 1 , figure 2 As shown, a device for removing burrs in a straight seam welded pipe includes a frame 1 and a chain 2. The sprocket mounted on the front end of the frame 1 is a driving wheel, and the sprocket mounted on the rear end of the frame 1 is The driven wheel is characterized in that: the frame 1 is a strip frame, the chain 2 is a double-row roller transmission chain, and the double-row roller transmission chain is set on the driving wheels arranged at the front and rear ends of the strip frame And the driven wheel, also includes the straight seam welded pipe internal burr scraping device, the pulling device of the straight seam welded pipe internal burr scraping device installed on the bar frame, also includes the straight seam welded pipe internal burr scraping device pushed into The propulsion device for straight seam welded pipes also includes conveying and clamping devices for straight seam welded pipes installed at the rear end of the bar fra...

Embodiment 2

[0025] Such as figure 1 , figure 2 As shown, a device for removing burrs in a straight seam welded pipe includes a frame 1 and a chain 2. The sprocket mounted on the front end of the frame 1 is a driving wheel, and the sprocket mounted on the rear end of the frame 1 is The driven wheel is characterized in that: the frame 1 is a strip frame, the chain 2 is a double-row roller transmission chain, and the double-row roller transmission chain is set on the driving wheels arranged at the front and rear ends of the strip frame And the driven wheel, also includes the straight seam welded pipe internal burr scraping device, the pulling device of the straight seam welded pipe internal burr scraping device installed on the bar frame, also includes the straight seam welded pipe internal burr scraping device pushed into The propulsion device for straight seam welded pipes also includes conveying and clamping devices for straight seam welded pipes installed at the rear end of the bar fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com