Patents

Literature

572results about How to "Grind evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

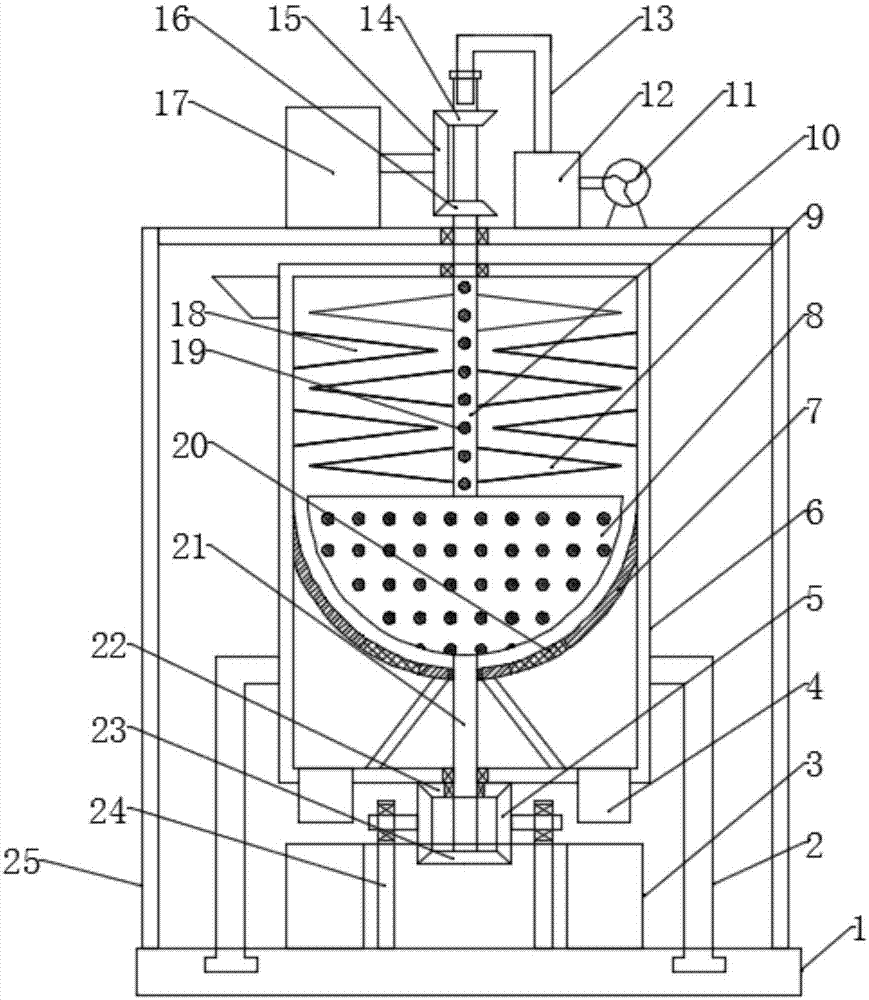

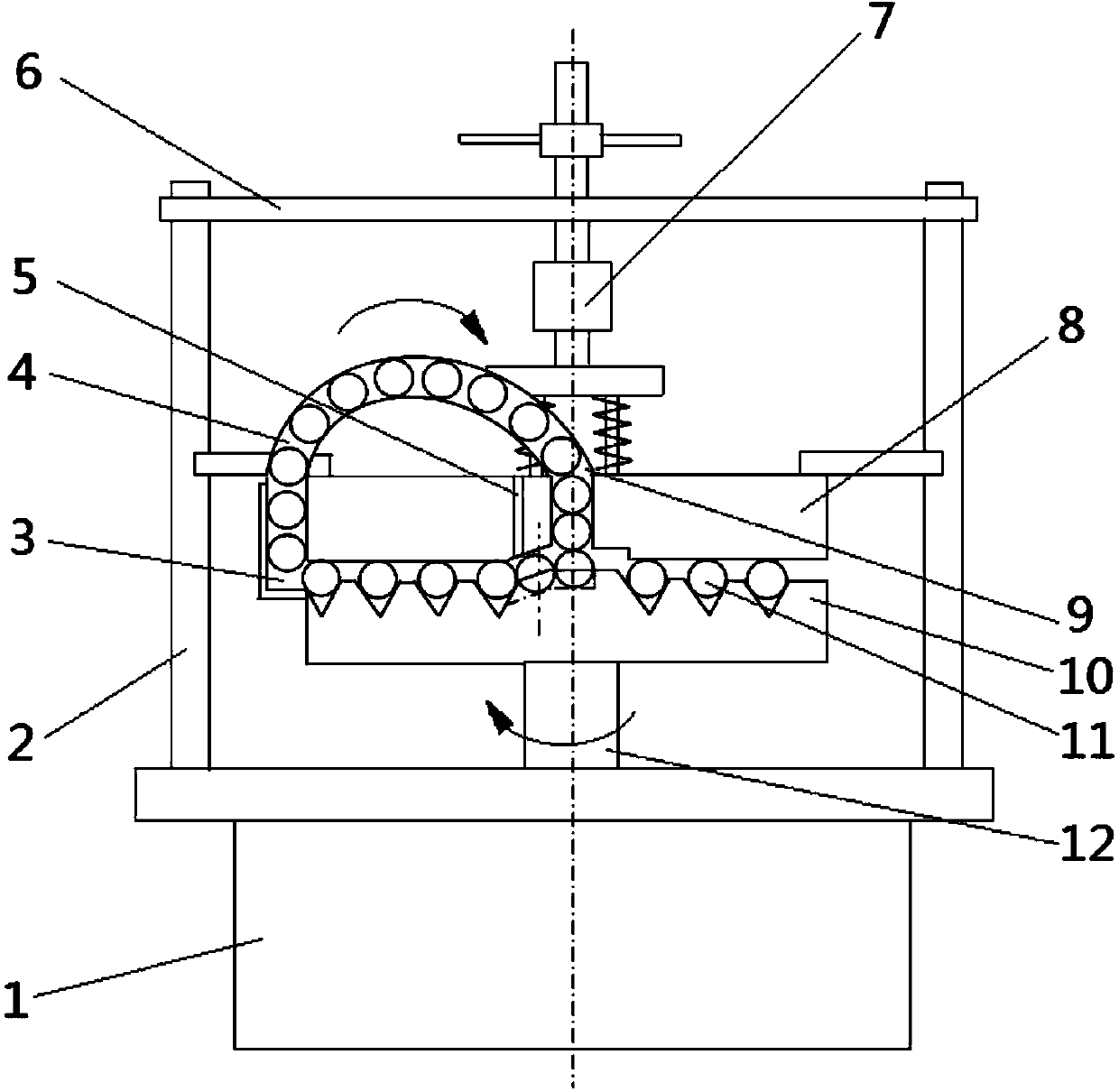

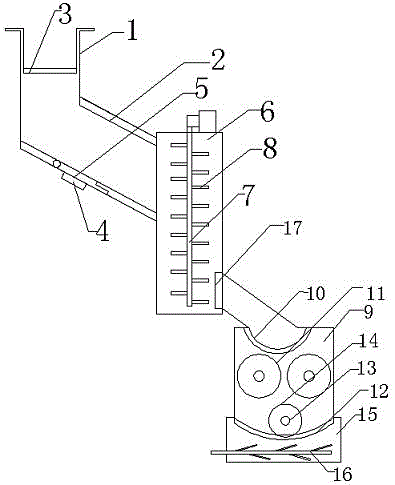

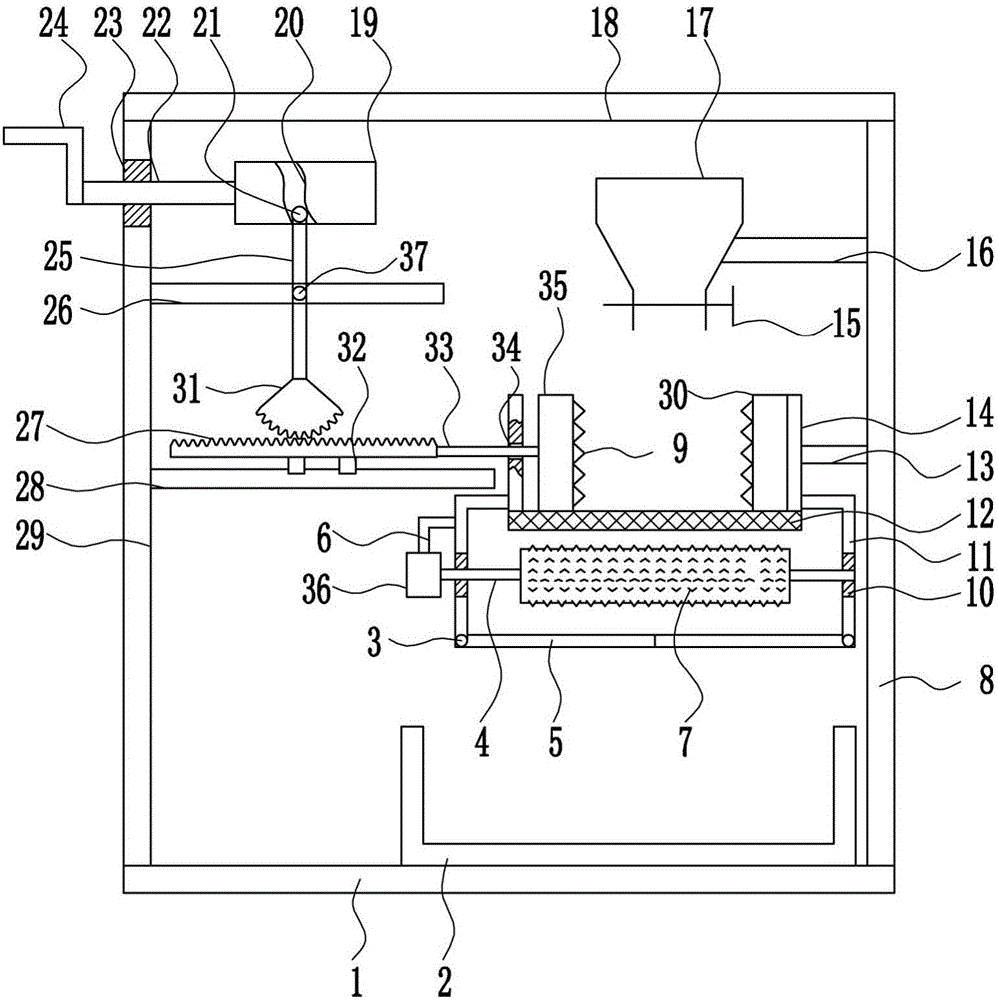

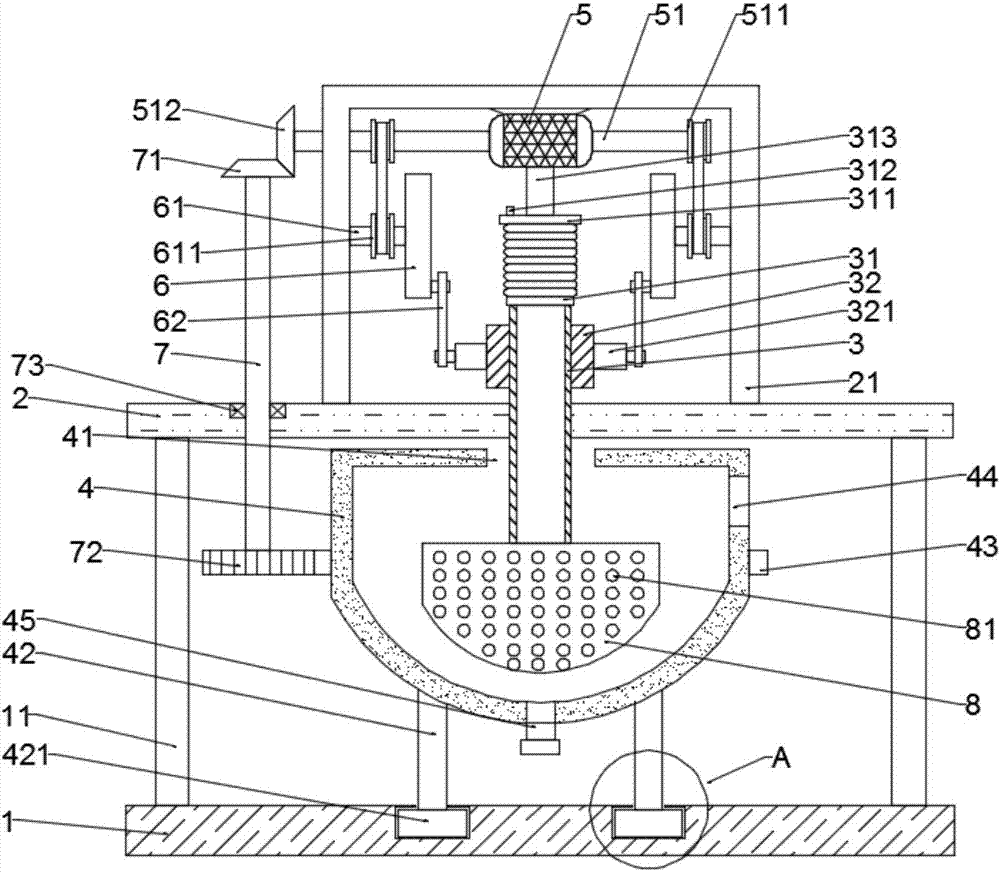

Traditional Chinese medicine smashing-grinding-drying integrated equipment

InactiveCN107570308AImprove crushing and grinding efficiencyImprove drying efficiencyDrying gas arrangementsGrain treatmentsEngineeringTraditional Chinese medicine

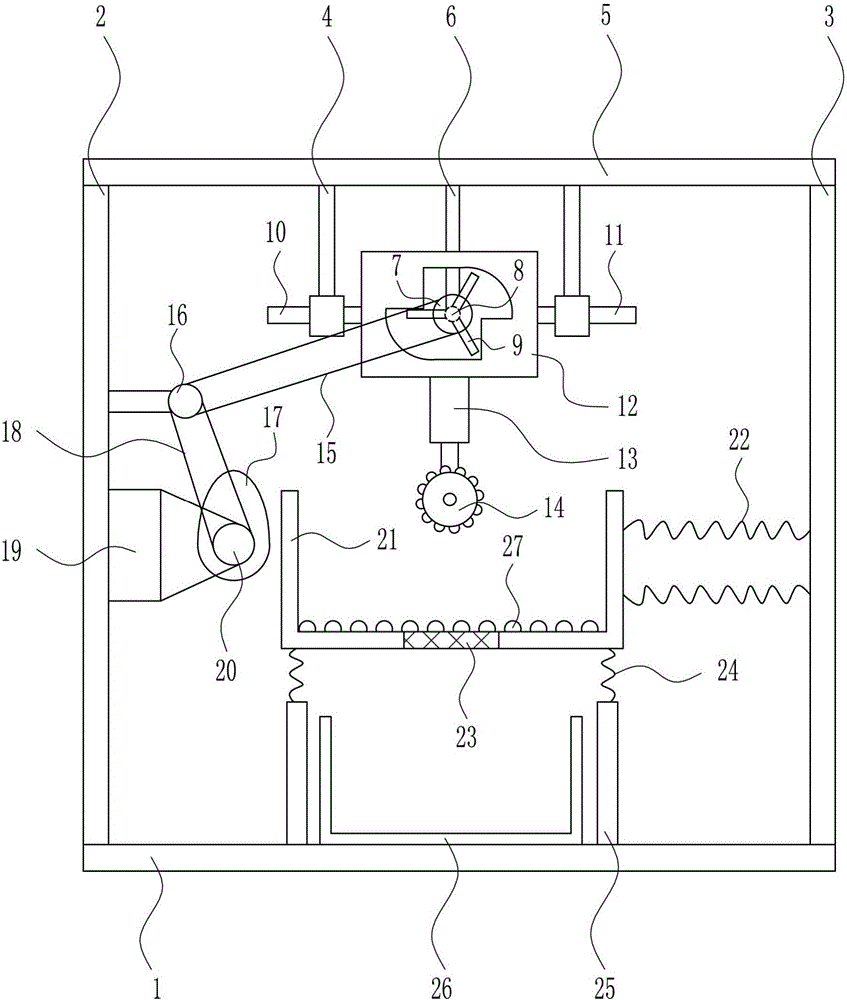

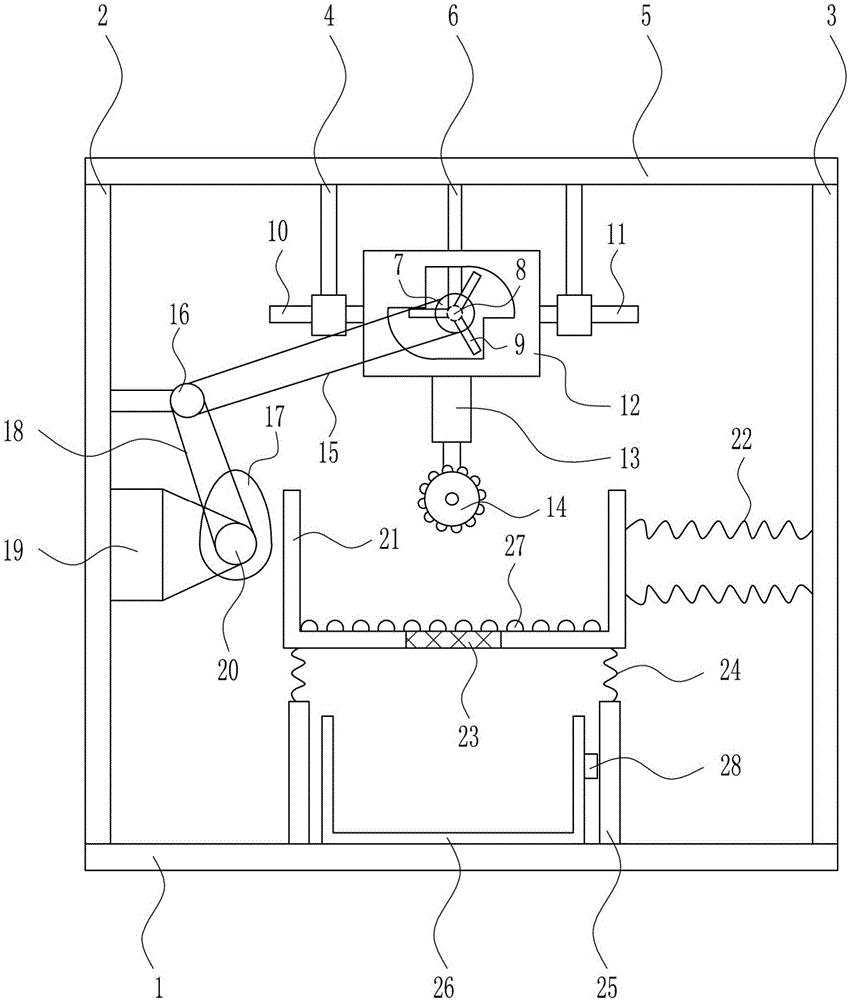

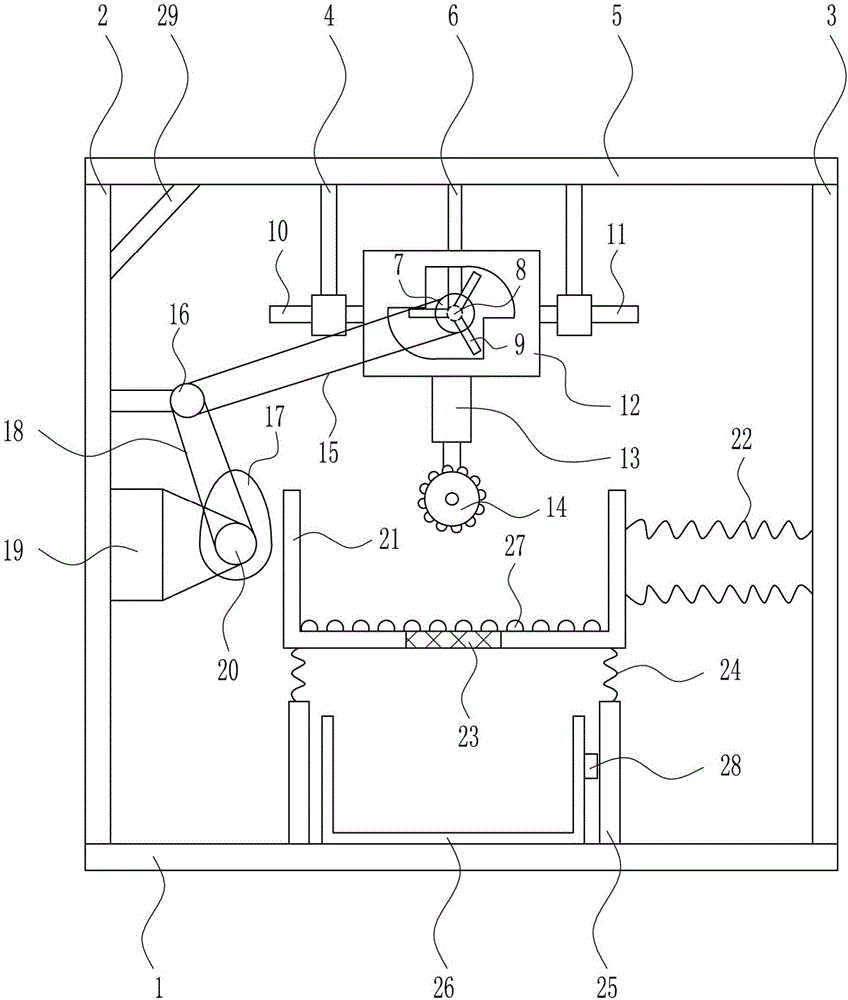

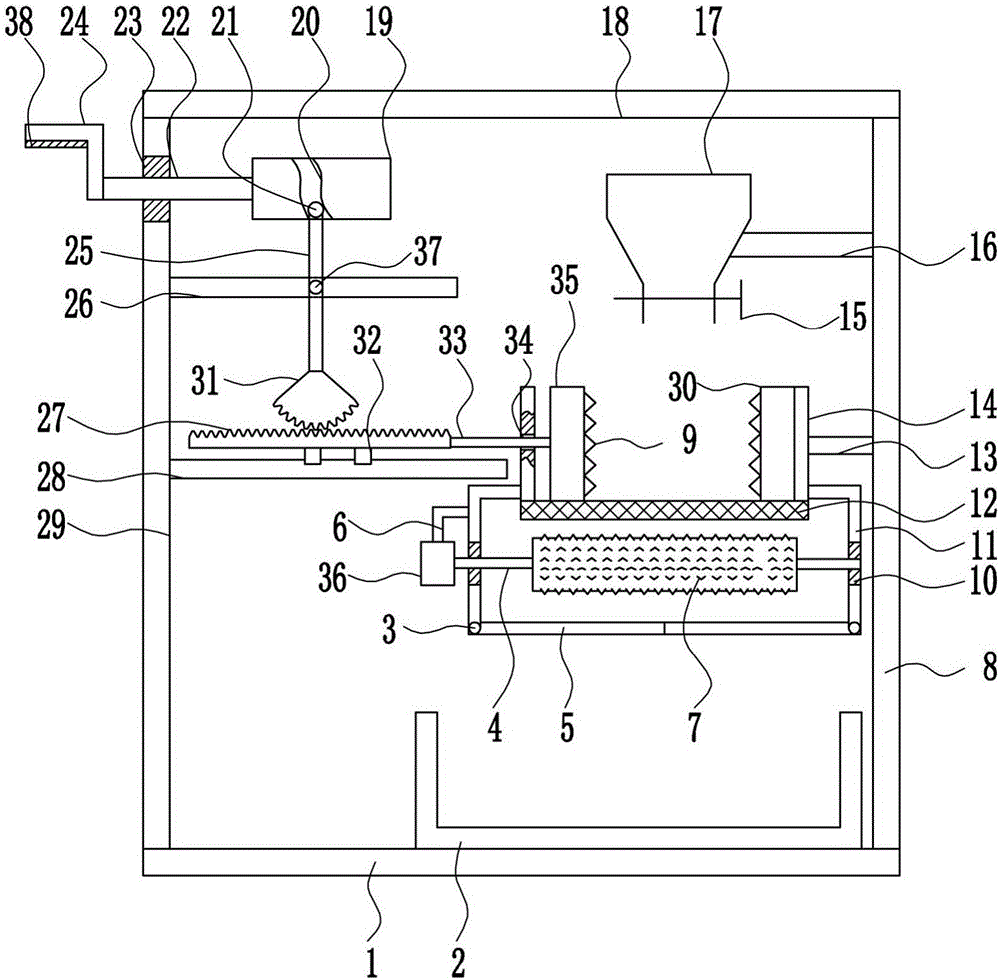

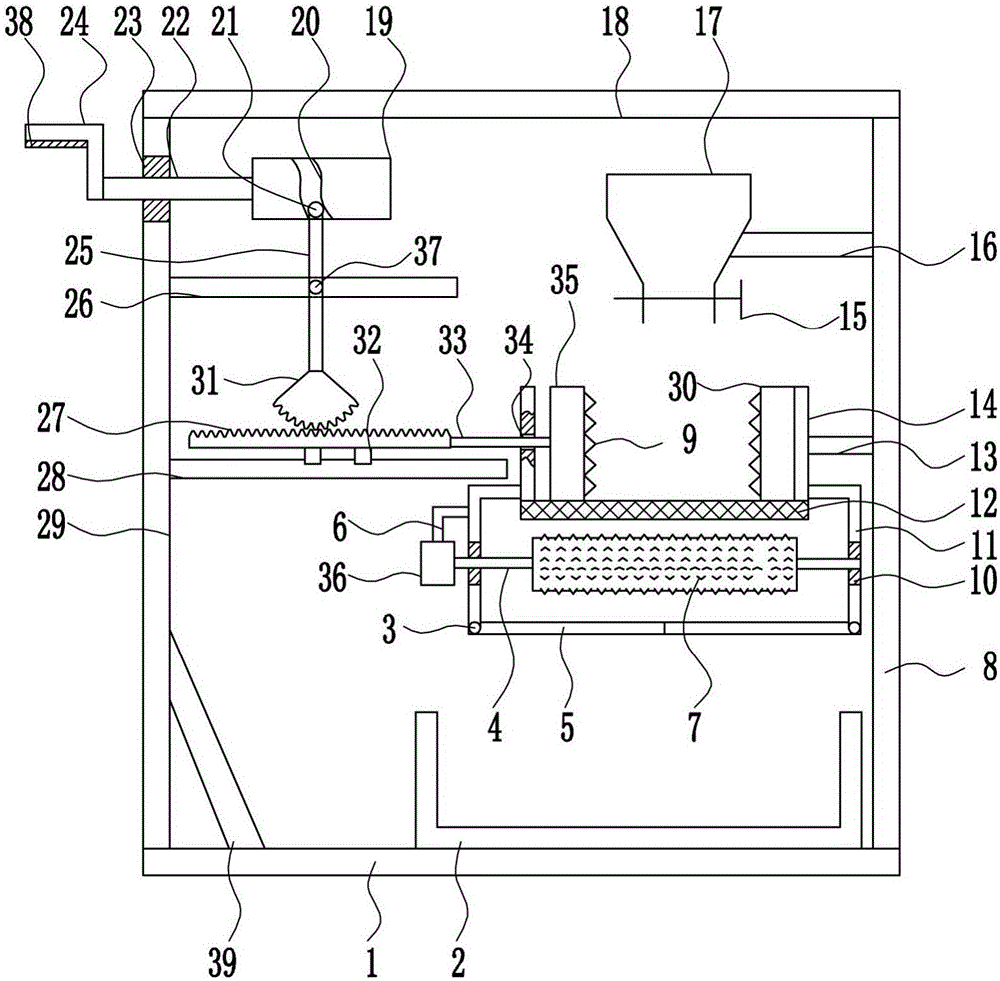

The invention discloses traditional Chinese medicine smashing-grinding-drying integrated equipment. The traditional Chinese medicine smashing-grinding-drying integrated equipment comprises a bottom plate, a cylinder body, a motor, an incomplete bevel gear, a first bevel gear, a second bevel gear, a hollow rotary shaft, a first smashing blade, a second smashing blade, a grinding hemisphere, a grinding shell, a filter screen, a third bevel gear, a fourth bevel gear, a fifth bevel gear and a drying device. The drying device comprises a draught fan, a heating device and air outlet holes. Accordingto the traditional Chinese medicine smashing-grinding-drying integrated equipment, the motor, the incomplete bevel gear, the first bevel gear, the second bevel gear, the hollow rotary shaft and the grinding hemisphere cooperate to drive the first smashing blade and the grinding hemisphere to rotate positively and negatively, the smashing and grinding efficiency is improved, so that traditional Chinese medicine is smashed and grinded more sufficiently and rapidly. The third bevel gear, the fourth bevel gear and the fifth bevel gear cooperate to drive the cylinder body and the hollow rotary shaft to rotate reversely, and thus the smashing and grinding efficiency is further improved. The drying device is used for drying the traditional Chinese medicine while the traditional Chinese medicineis smashed and grinded, and thus the drying efficiency is high.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

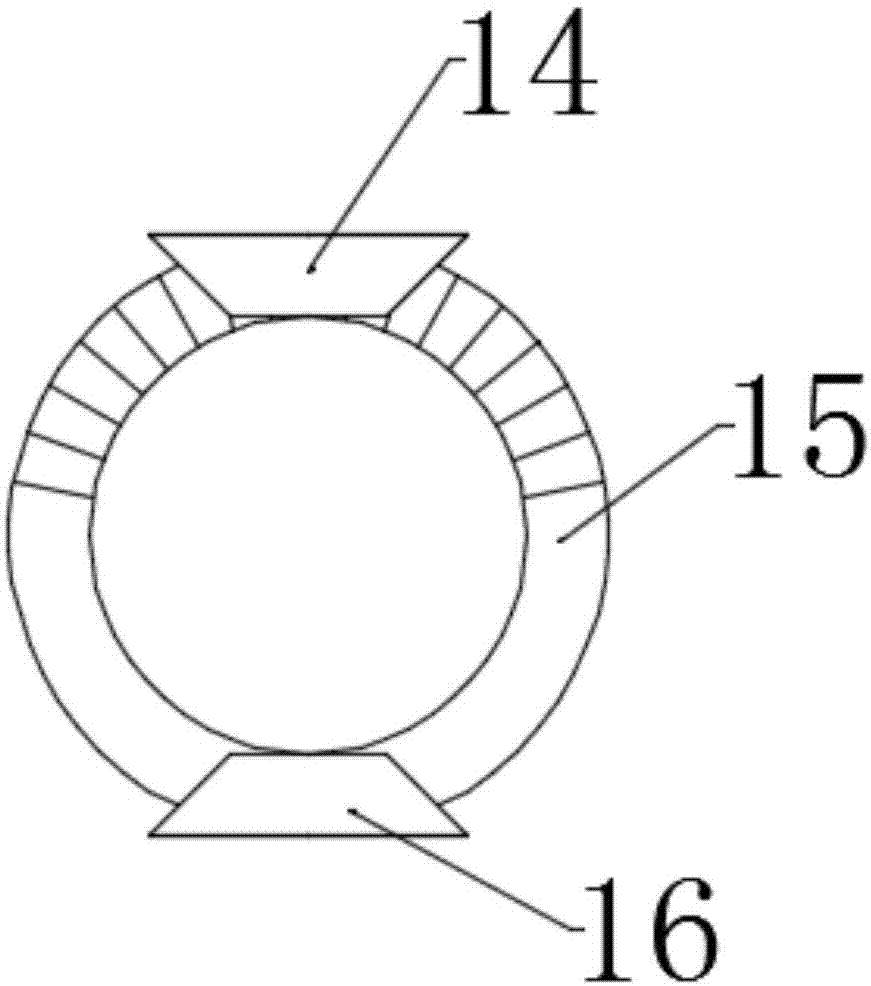

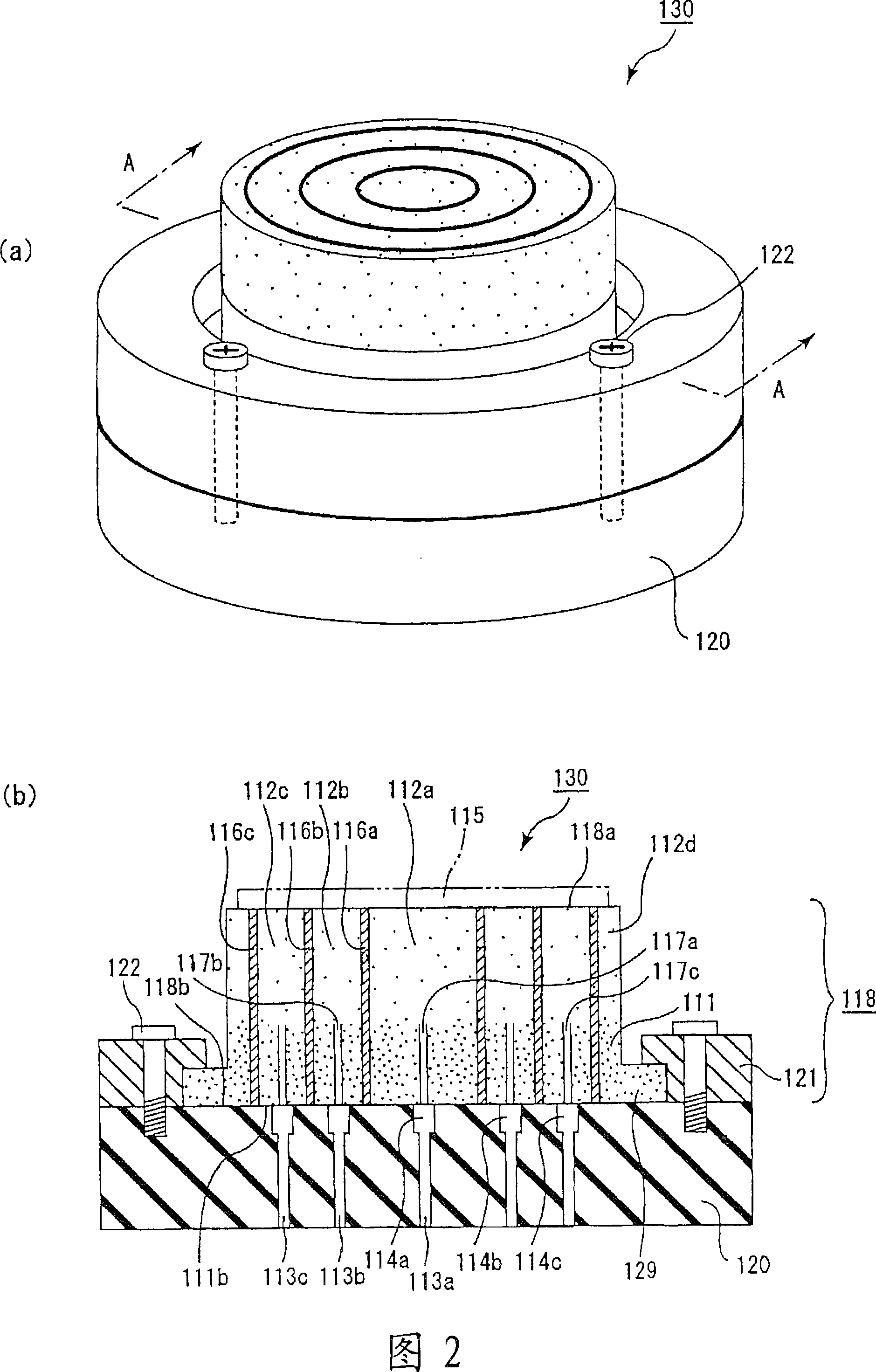

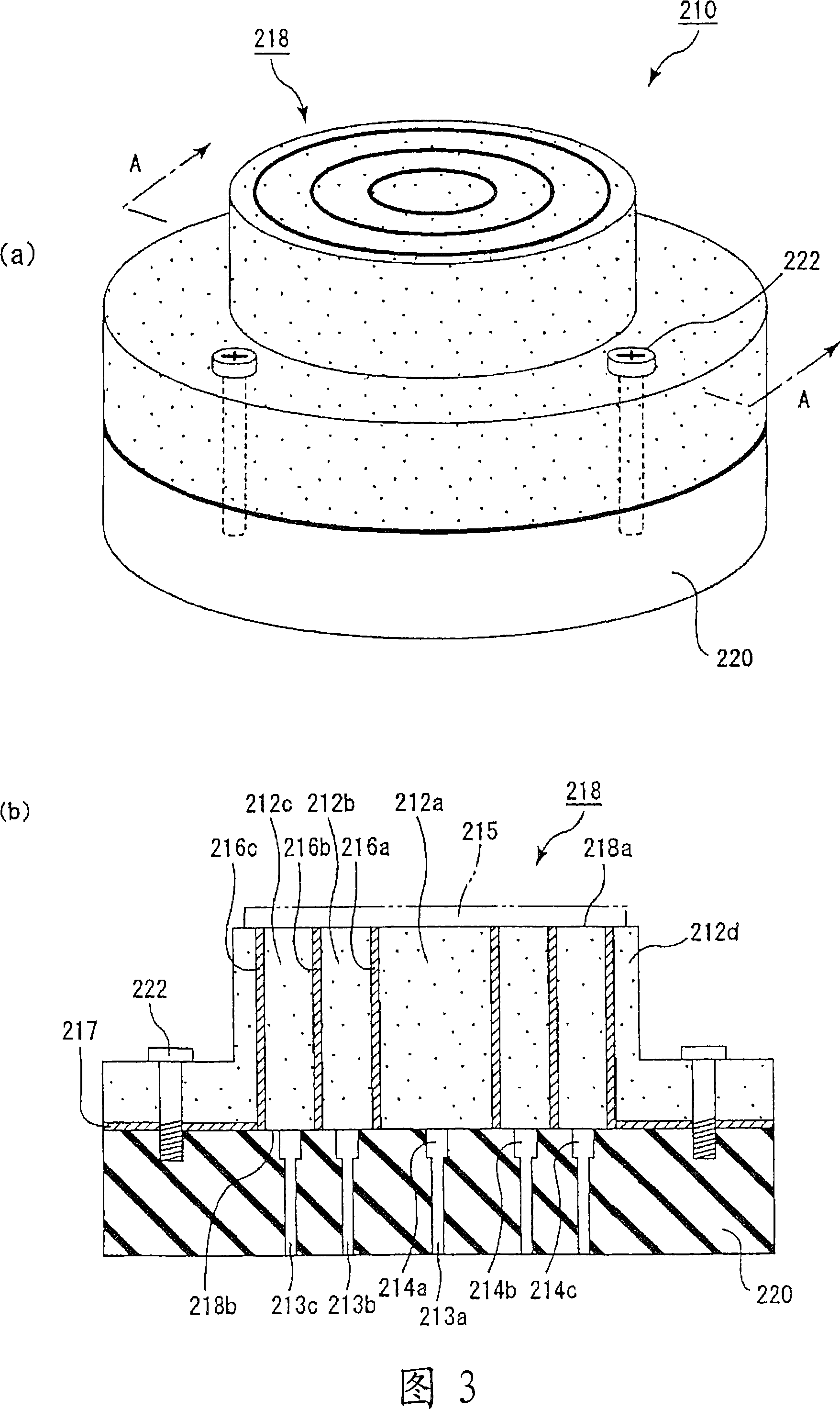

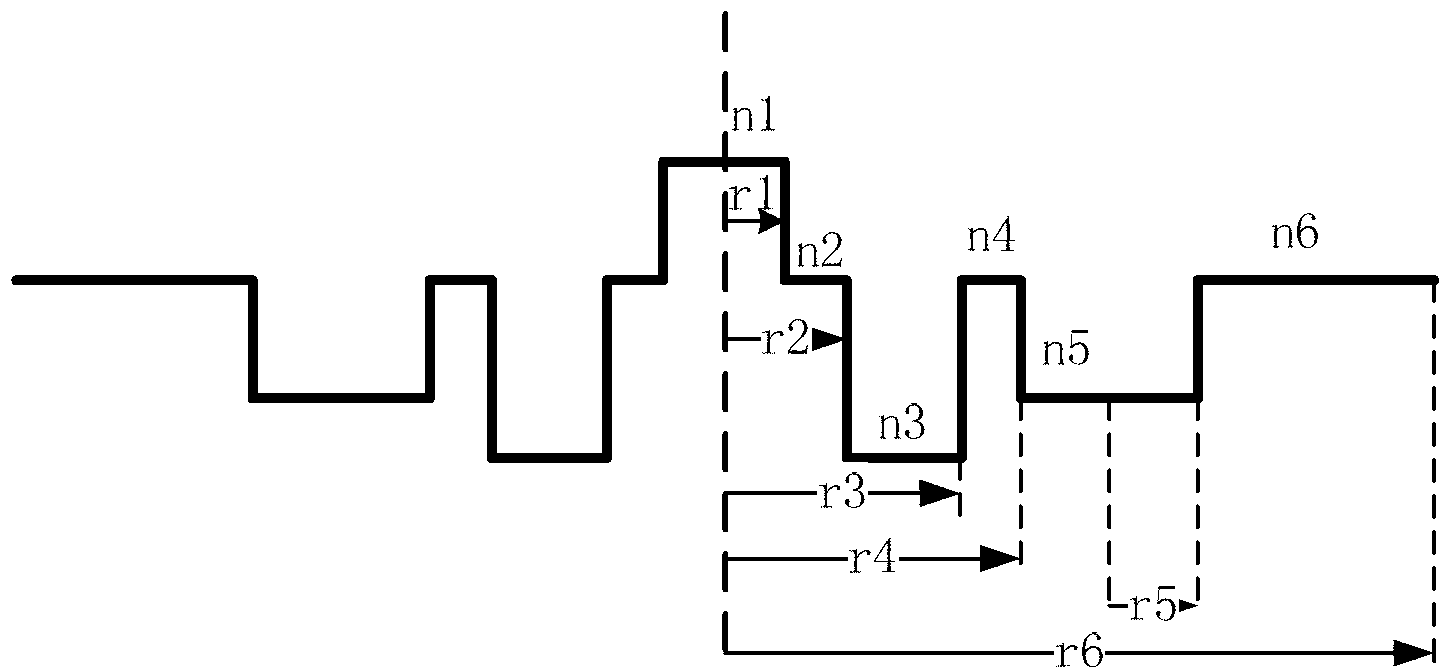

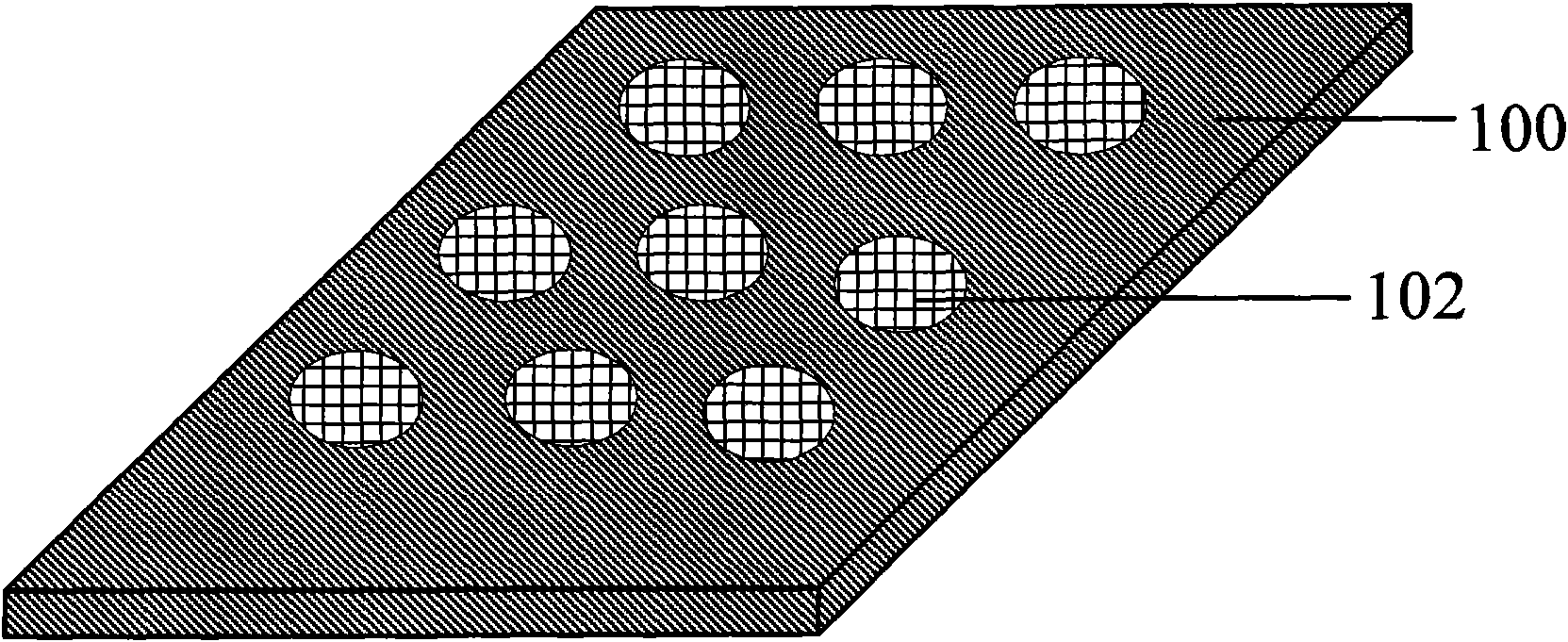

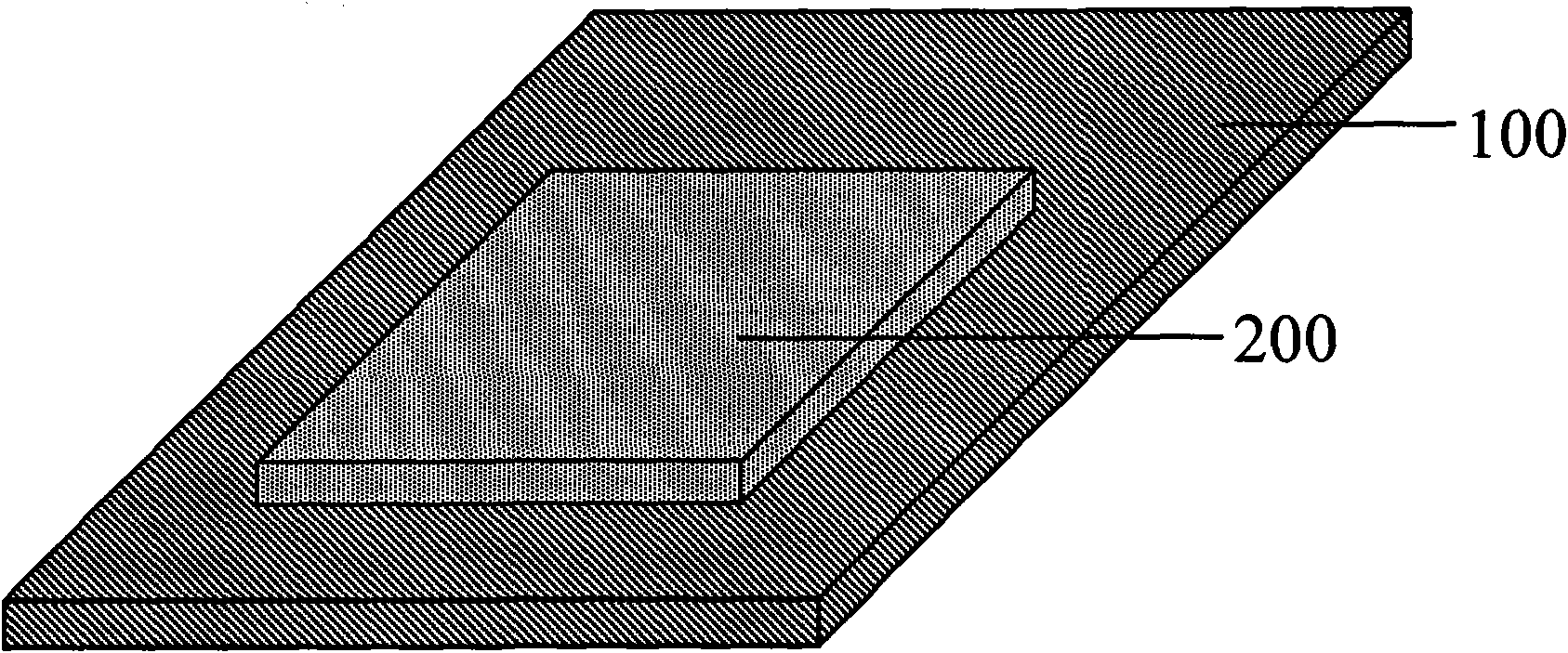

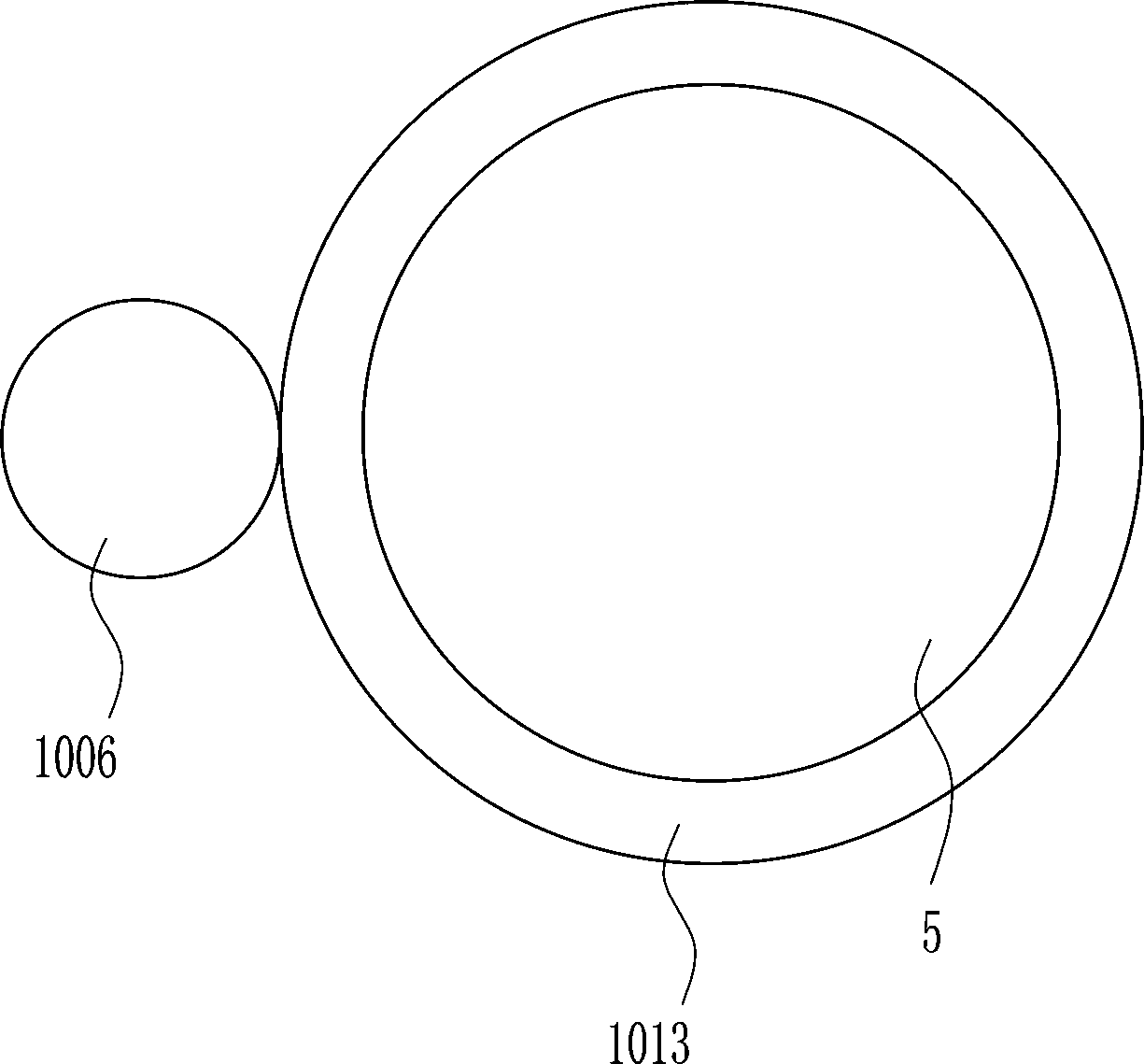

Vacuum chuck and suction board

ActiveCN1938122ADoes not produce uniformityNo situationSleeve/socket jointsSemiconductor/solid-state device manufacturingPorous ceramicsMaterials science

A vacuum chuck is provided for attaining uniform polishing of an object to be sucked. The vacuum chuck is provided by integrating a suction layer and a compact substance layer, which are formed of a porous ceramics, and positioning the suction layer on a side of sucking the object to be sucked. The vacuum chuck is provided with a suction board for sucking and holding the object to be sucked. The compact substance layer is formed by impregnating the porous ceramics with a metal.

Owner:IBIDEN CO LTD

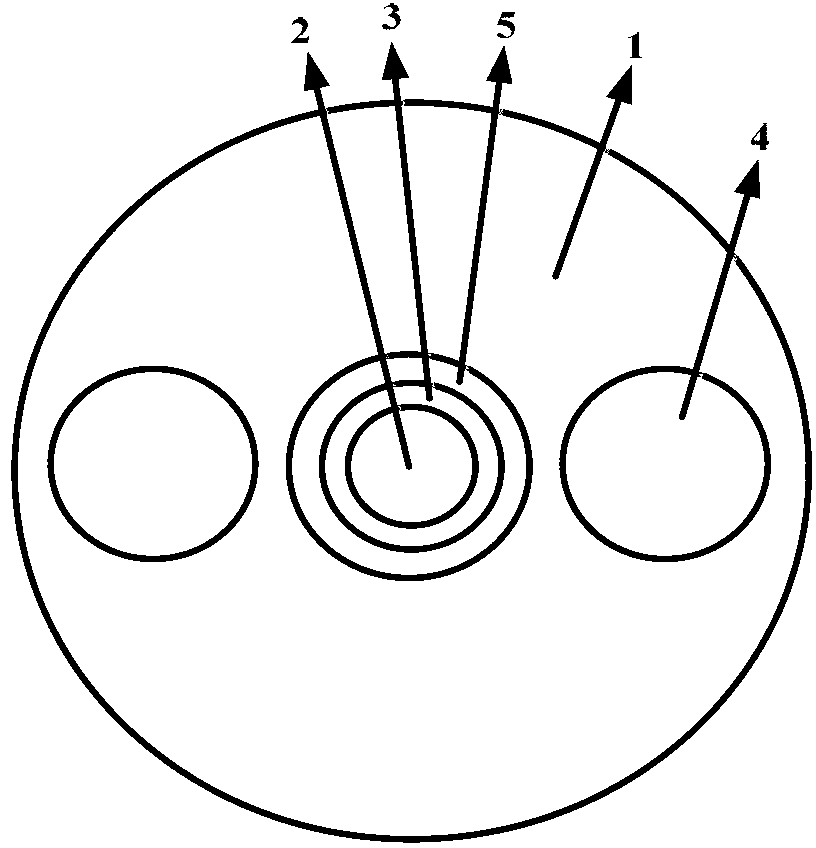

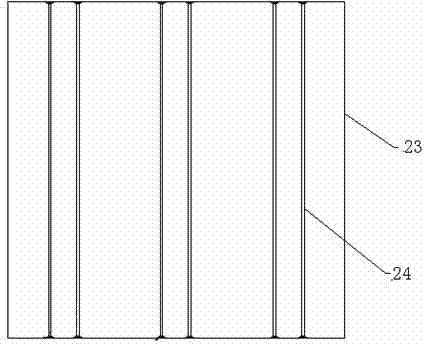

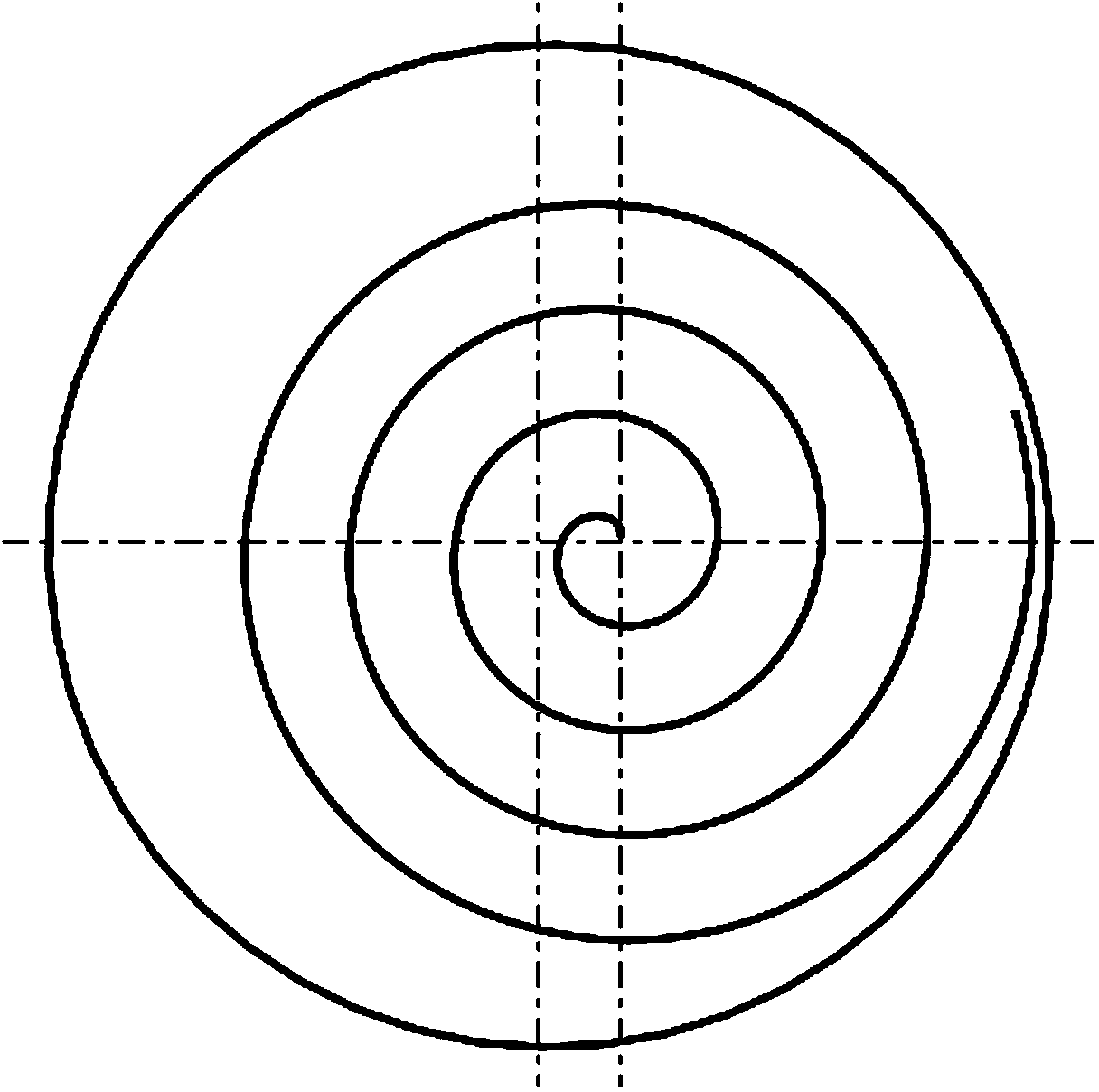

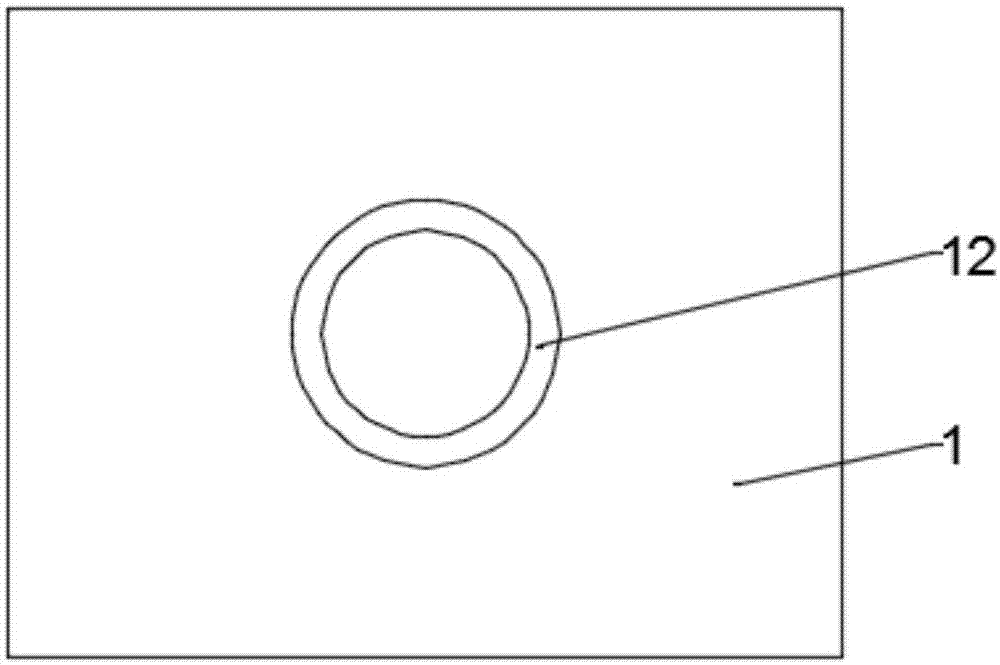

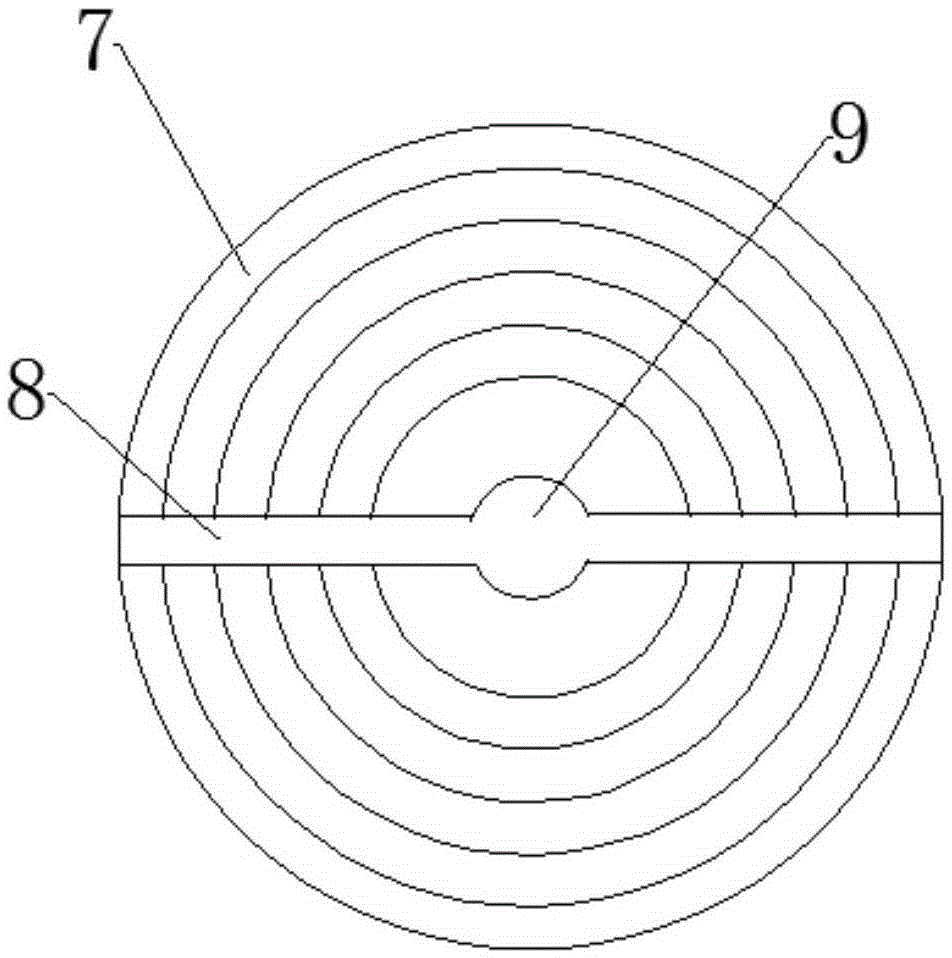

Polarization maintaining optical fiber with small bending radius and manufacture method of polarization maintaining optical fiber

ActiveCN103018821AImprove bending resistanceReduce disturbanceGlass making apparatusOptical fibre with polarisationInformation transmissionPolarization-maintaining optical fiber

The invention discloses a polarization maintaining optical fiber with a small bending radius and a manufacture method of the polarization maintaining optical fiber and relates to the field of optical fiber manufacture. The polarization maintaining optical fiber comprises a silica cladding, a core layer, a second silica cladding ring, a third fluorine-doped silica cladding ring and two stress cat eyes are sequentially arranged in the silica cladding from inside to outside, and the two stress cat eyes are in central symmetry with the core layer. By means of the manufacture method, the bending radius of the manufactured polarization maintaining optical fiber is smaller than 5mm, operating wavelength of the polarization maintaining optical fiber is 1550nm, and supplementary deterioration of the polarization maintaining optical fiber is under 0.4dB / km. According to the polarization maintaining optical fiber, under the condition that the bending radius is small, low-loss information transmission of the polarization maintaining optical fiber is achieved, low supplementary deterioration and good crosstalk characteristics of the polarization maintaining optical fiber are guaranteed, fiber optic sensors with small sizes can be manufactured by means of the polarization maintaining optical fiber, and requirements of users are satisfied.

Owner:RUIGUANG TELECOMM TECH CO LTD

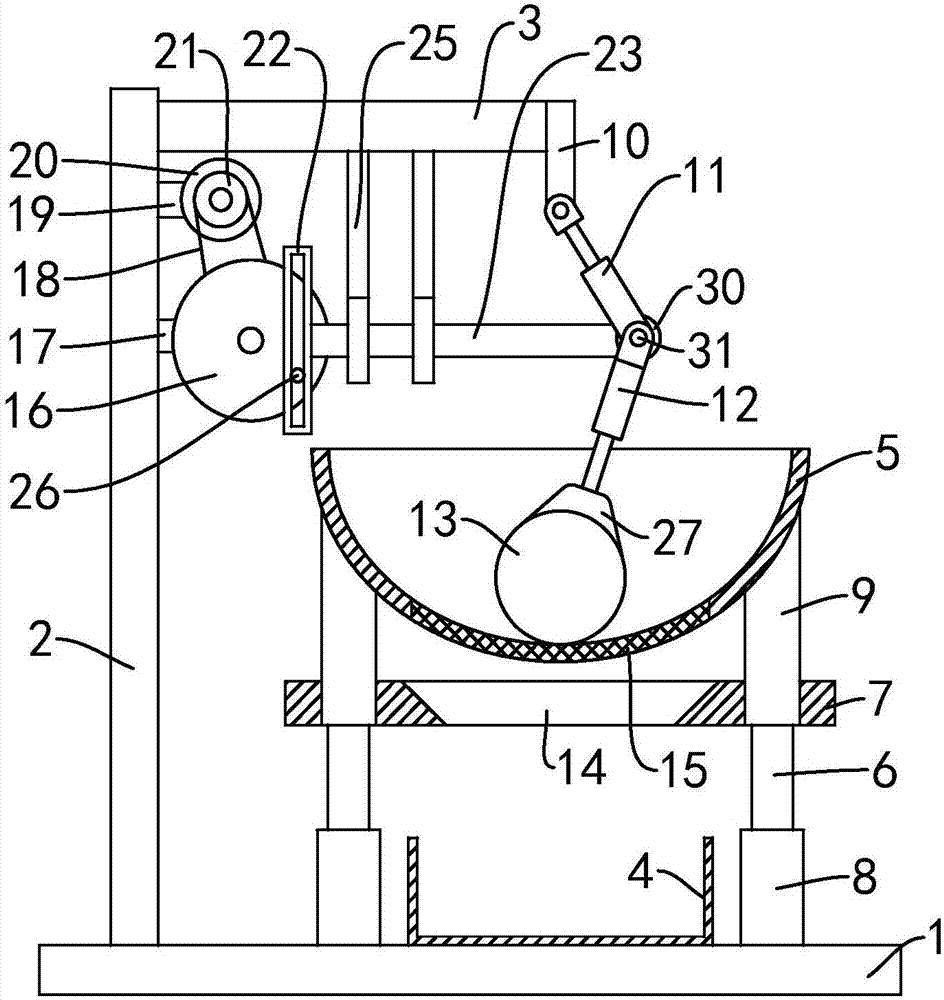

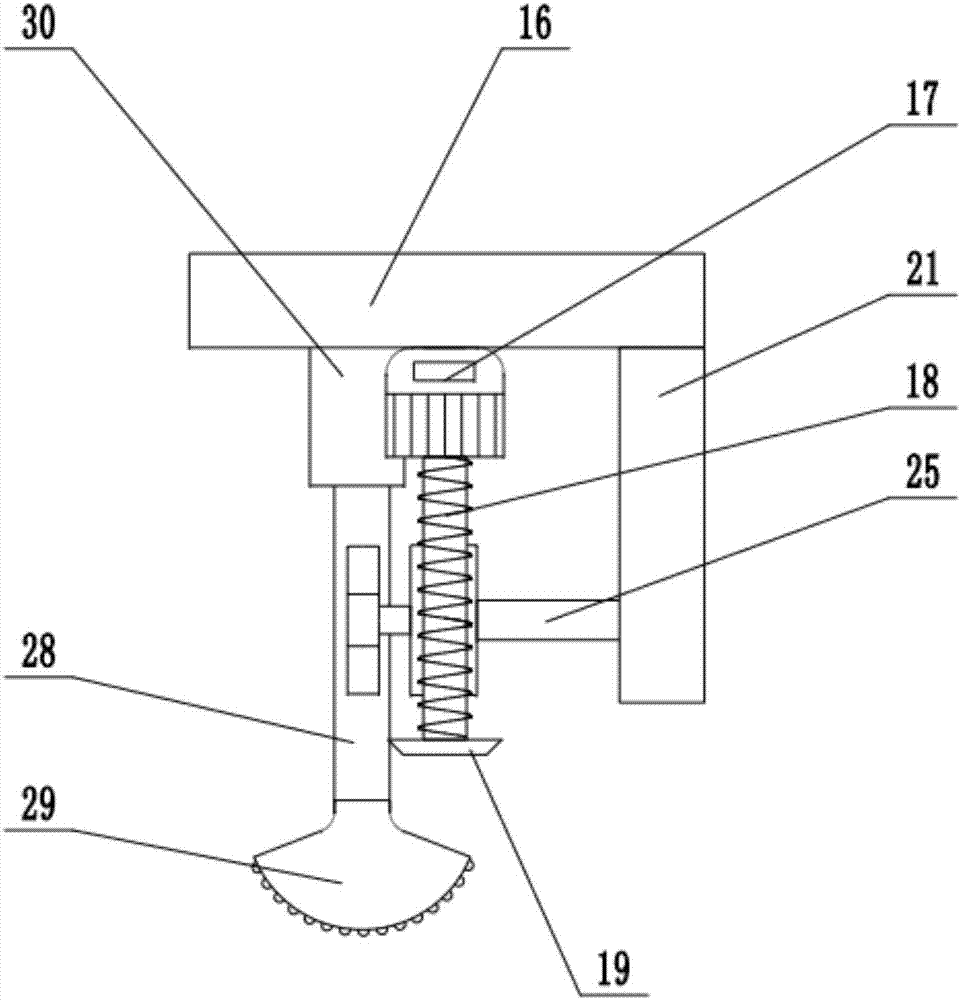

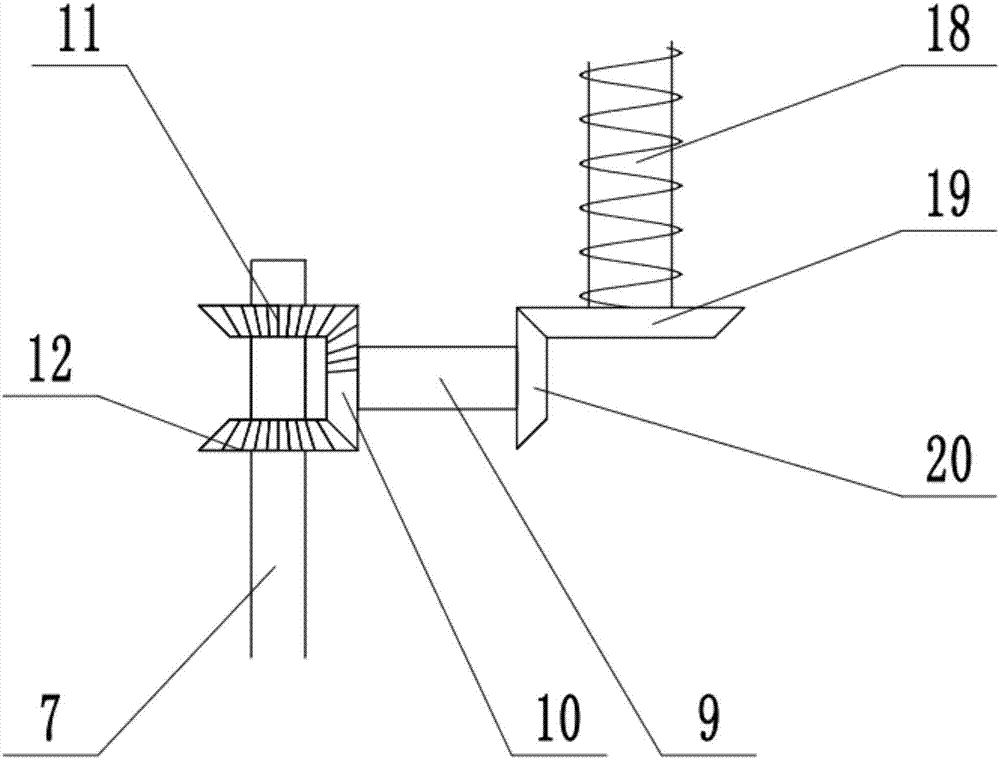

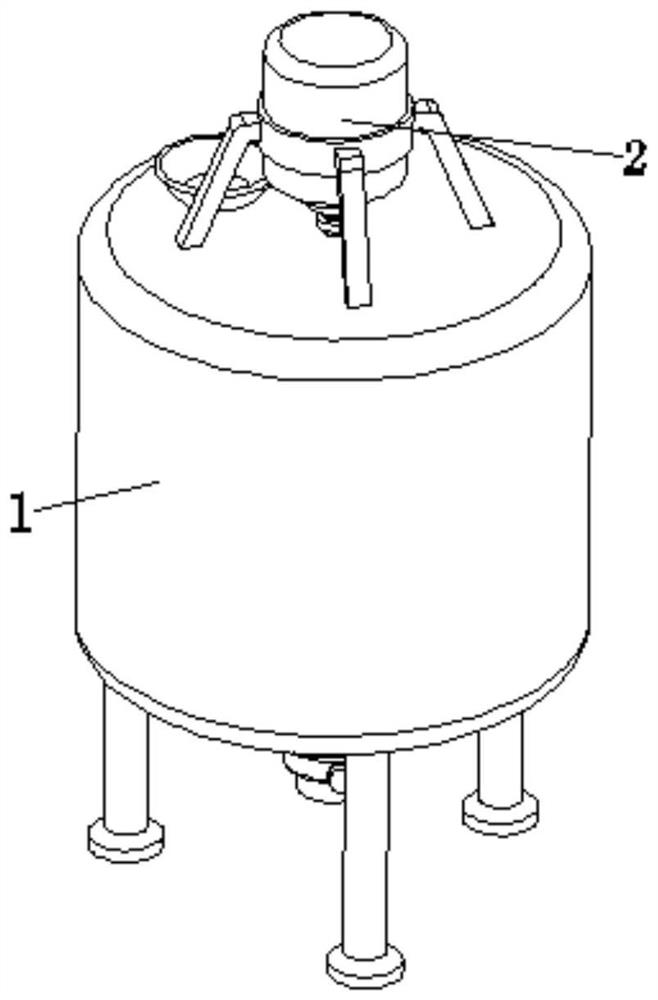

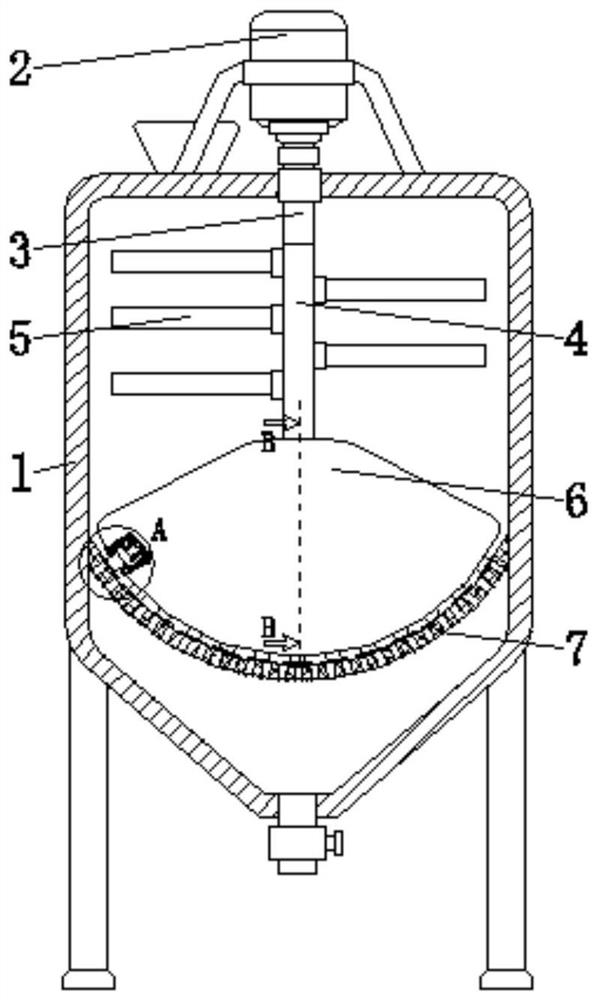

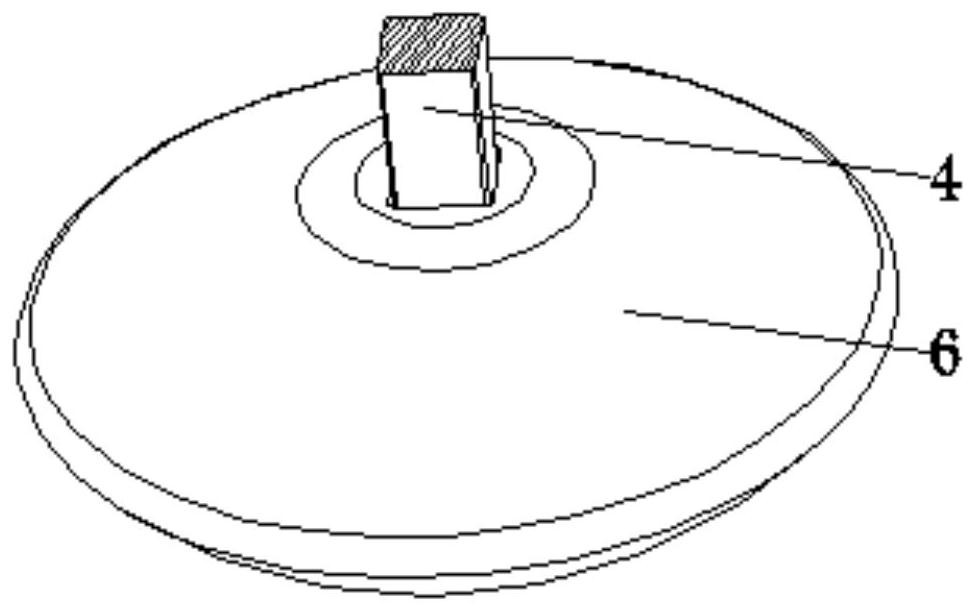

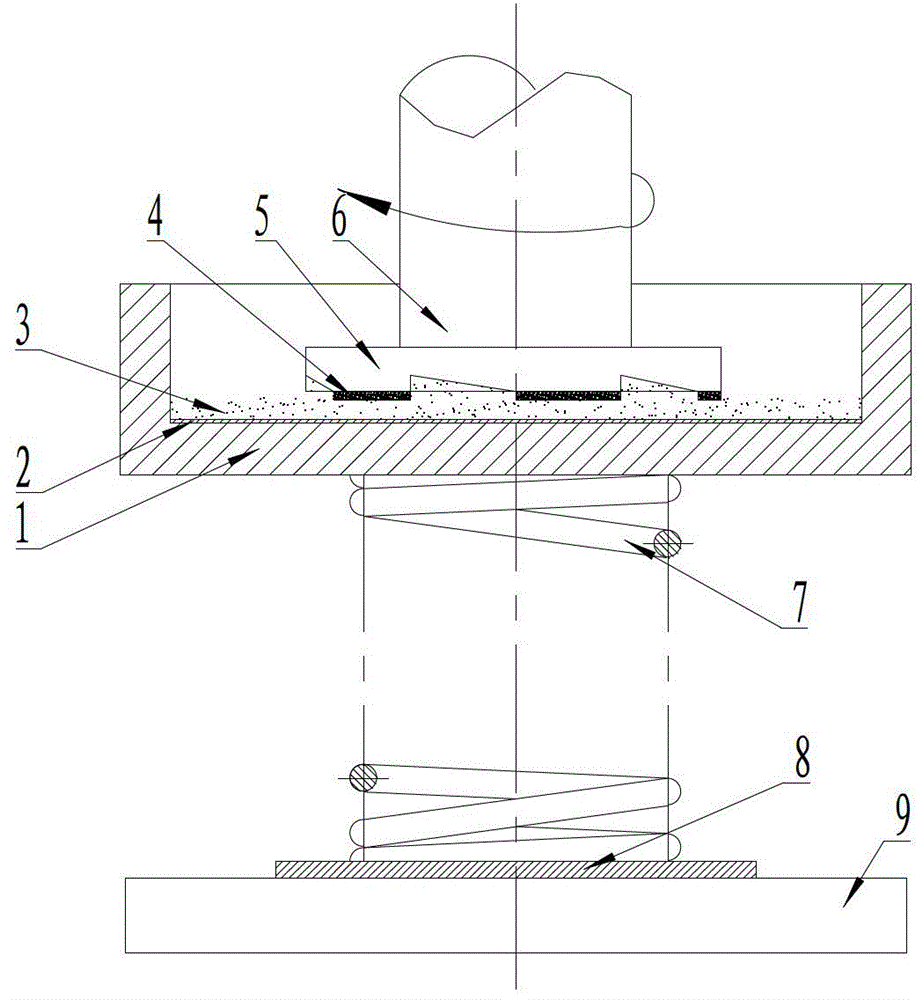

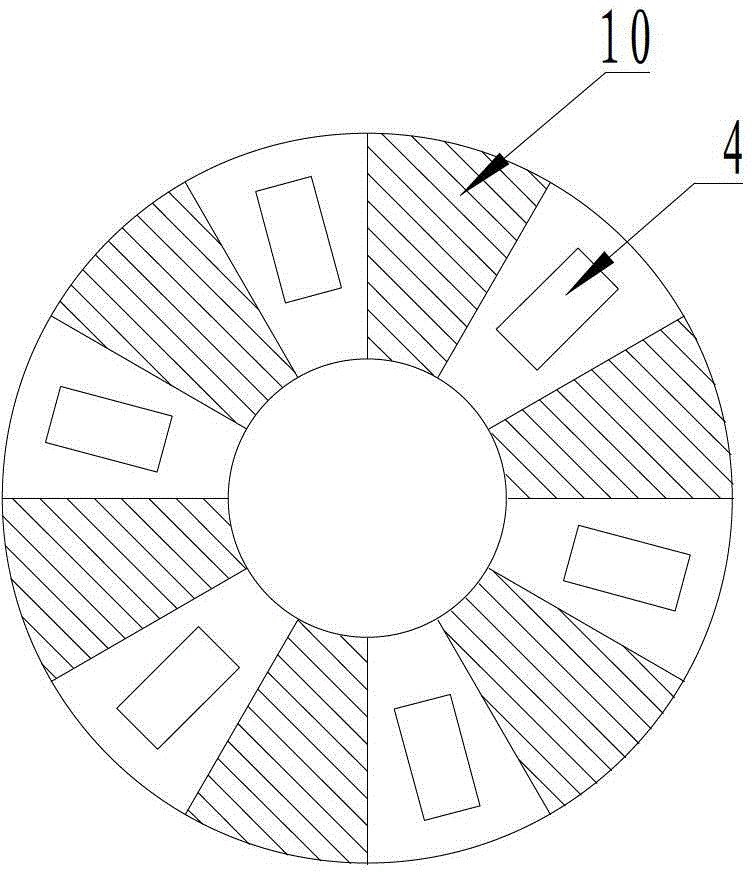

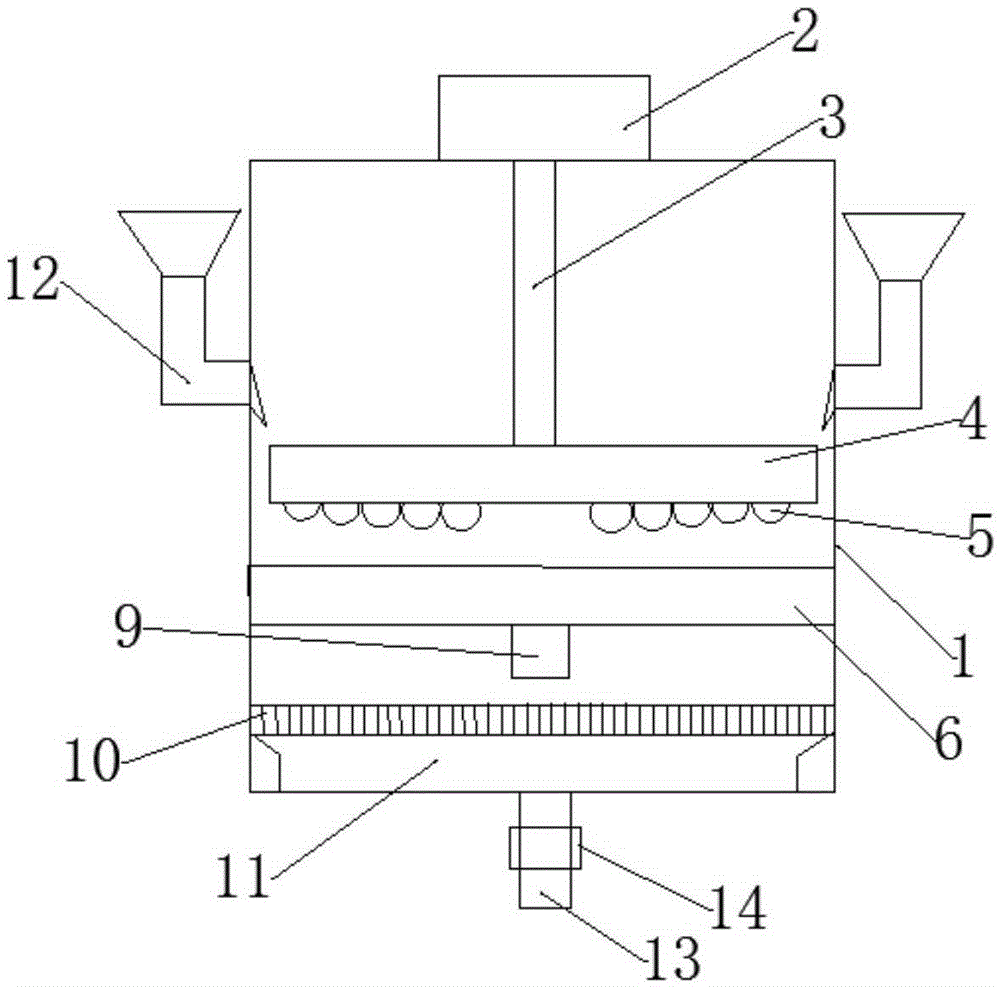

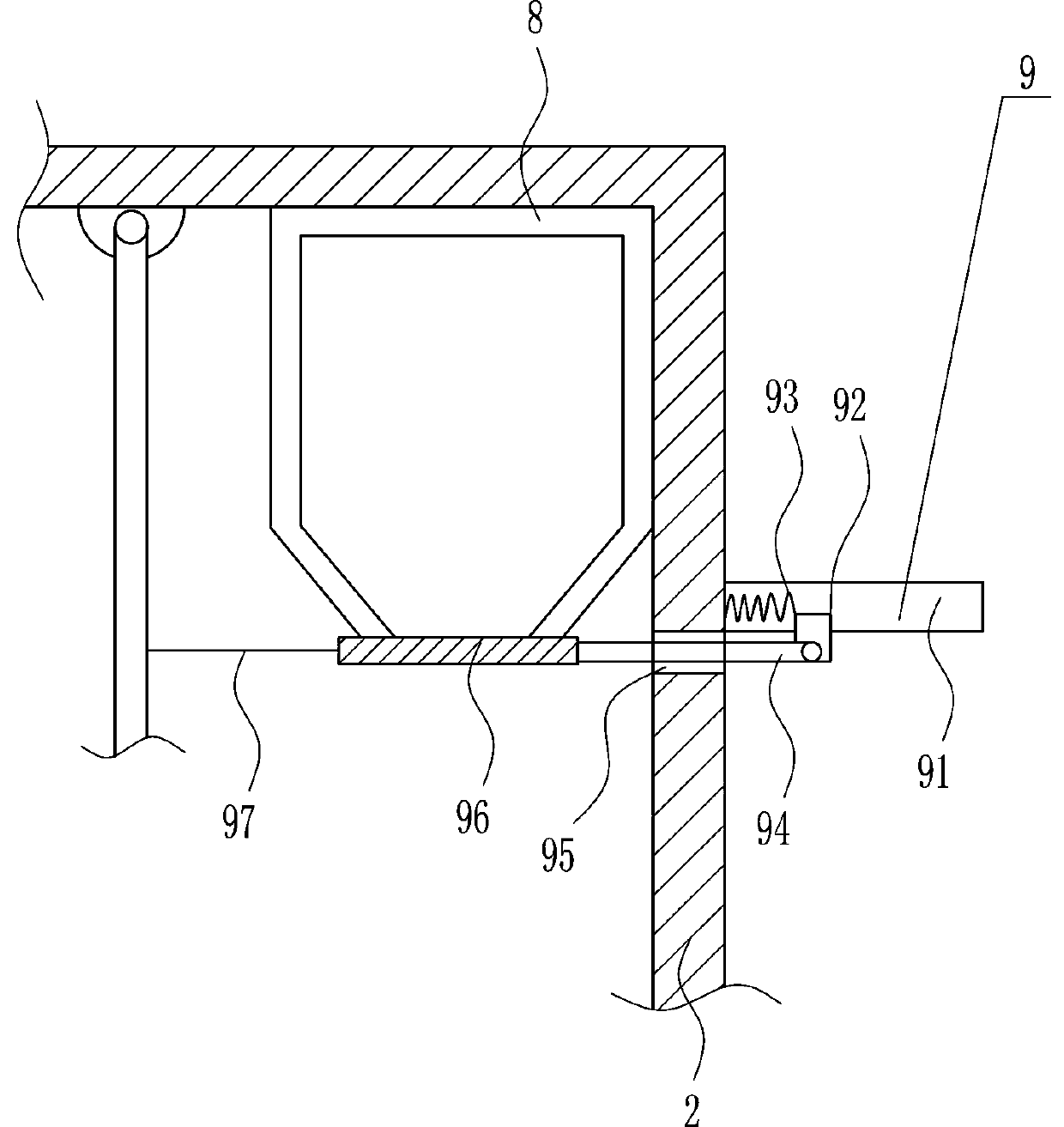

Refined grinding device for Chinese medicinal herbs

InactiveCN107282250AImprove grinding effectRealize the grinding operationGrain treatmentsCircular discMedicinal herbs

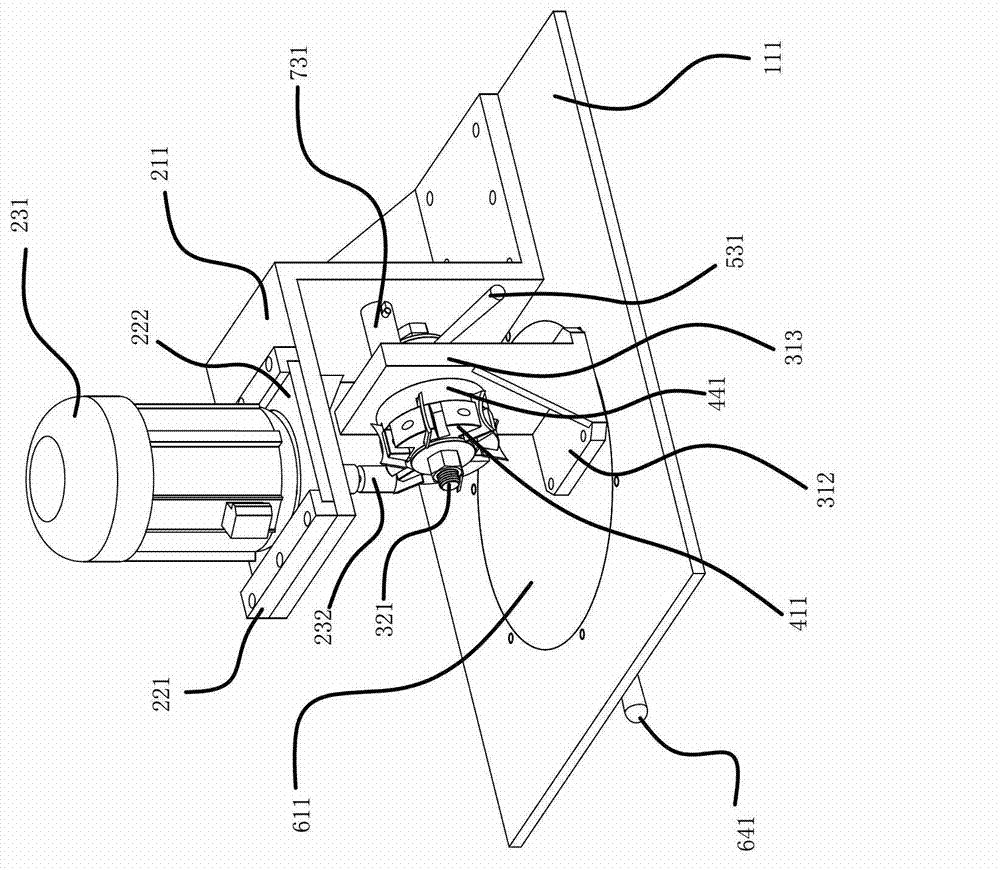

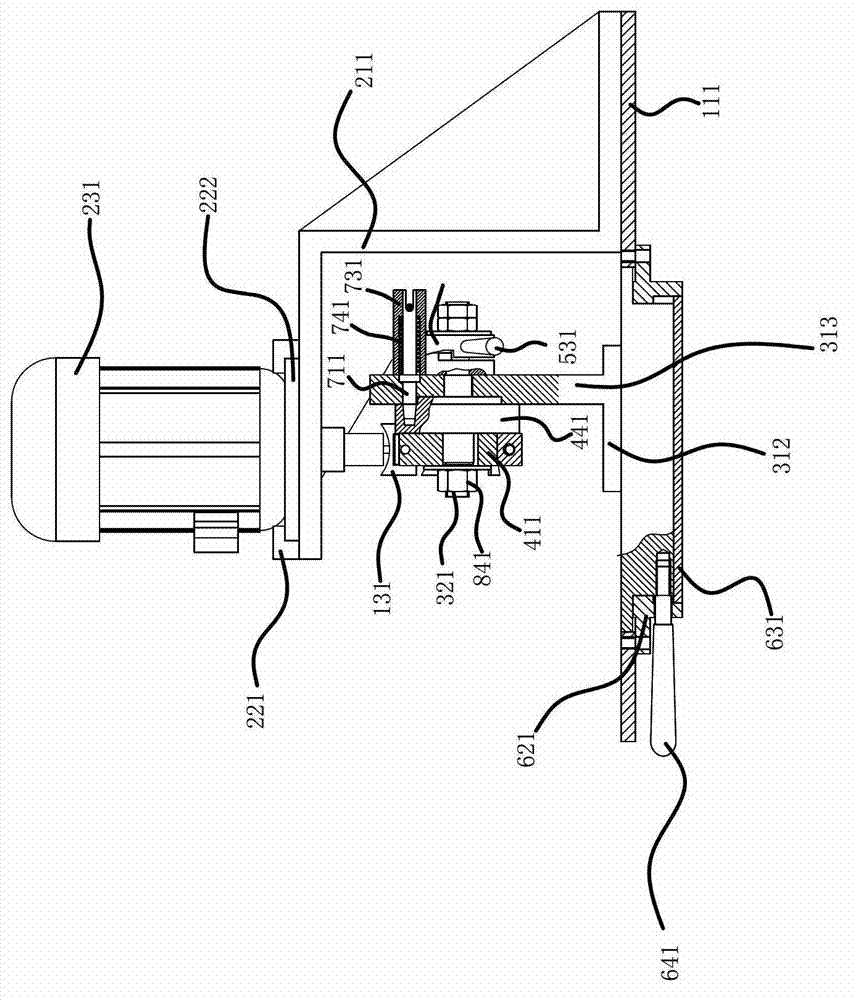

The invention discloses a refined grinding device for Chinese medicinal herbs. The refined grinding device comprises a base, a collecting box, a grinding groove, a support platform, a first telescopic sleeve rod, a second telescopic sleeve rod, grinding balls, a rotating disk, a movable sleeve plate and a push-pull rod. The bottom end of a coupling sleeve on the first telescopic sleeve rod is rotatably hinged with the top of the coupling sleeve on a second telescopic sleeve through an articulated shaft, and the end of the articulated shaft is fixedly provided with a connecting block; the upper part of the grinding balls is fixedly provided with a connecting plate, and the bottom end of a connection sliding rod on the second telescopic sleeve rod is connected to the connecting plate; the outer ring surface of the grinding balls is fixedly provided with a guide pillar, and the movable sleeve plate is sheathed on the guide pillar; and the movable sleeve plate is fixedly installed on one end of the push-pull rod of which the other end is fixedly connected to the connecting plate. The refined grinding device disclosed by the invention has the advantages of simple structure, easy operation, smart design, full and uniform grinding, and time and labor saving in the grinding process, and is suitable for popularization and application.

Owner:侯添有

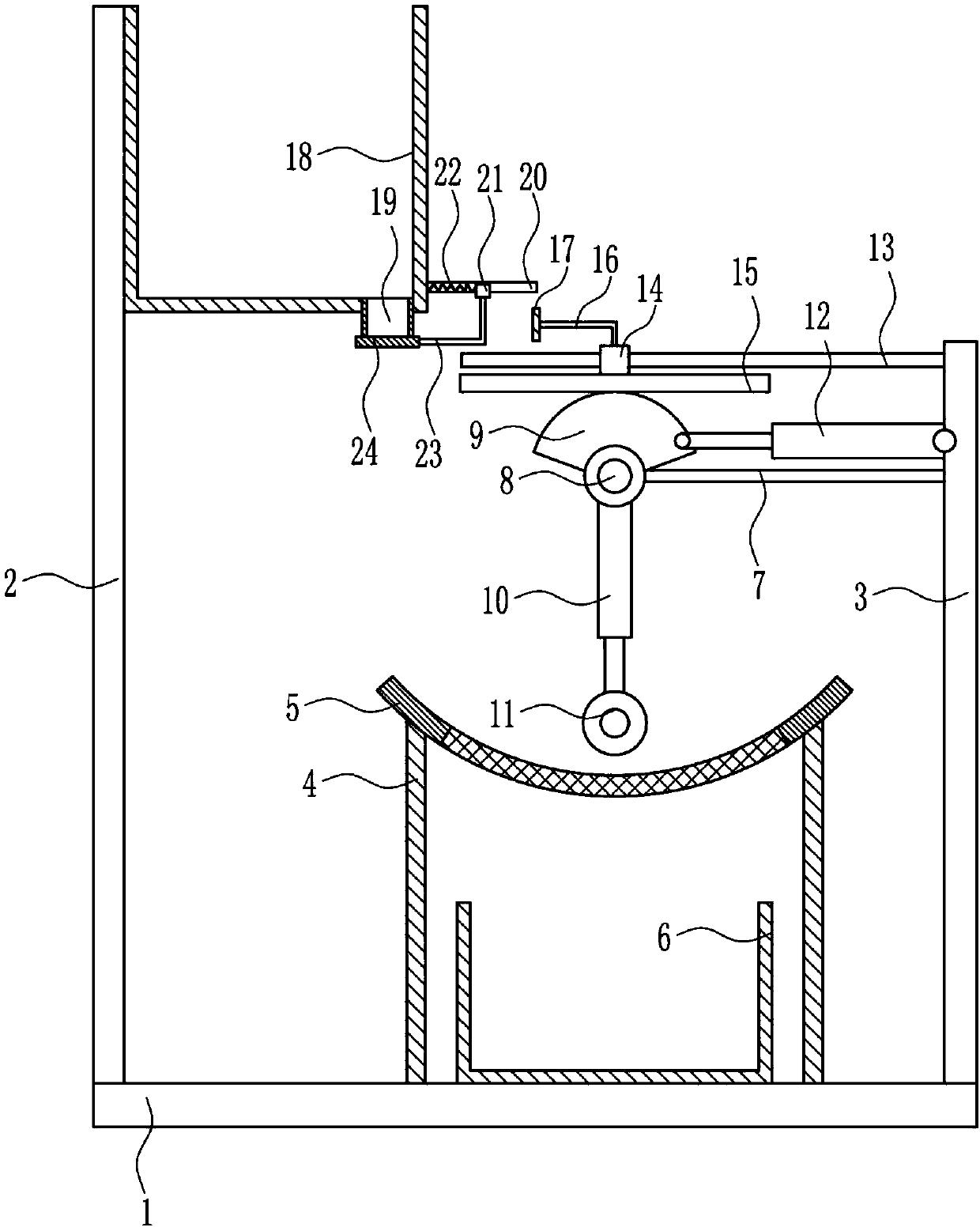

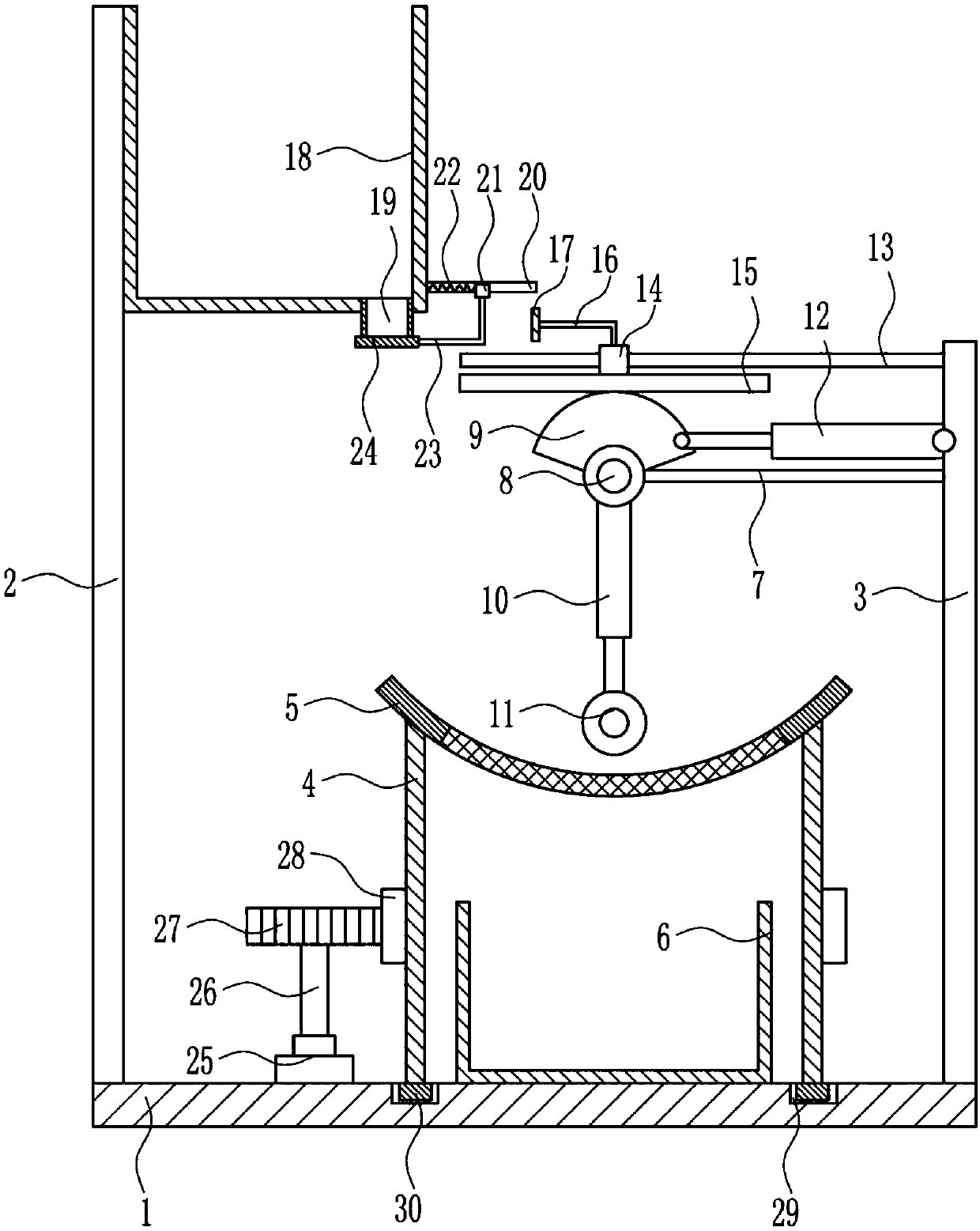

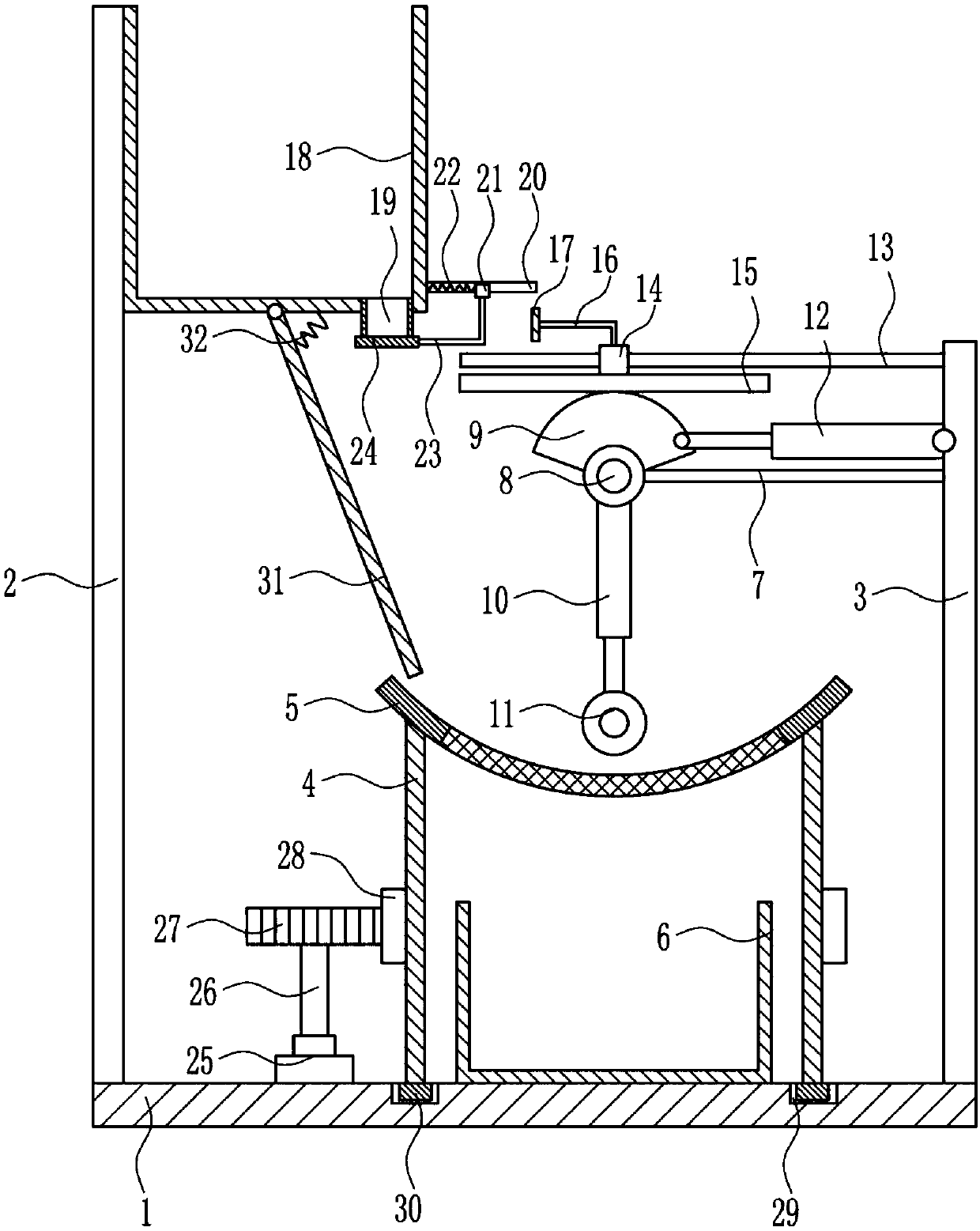

Swing grinding device for traditional Chinese medicines

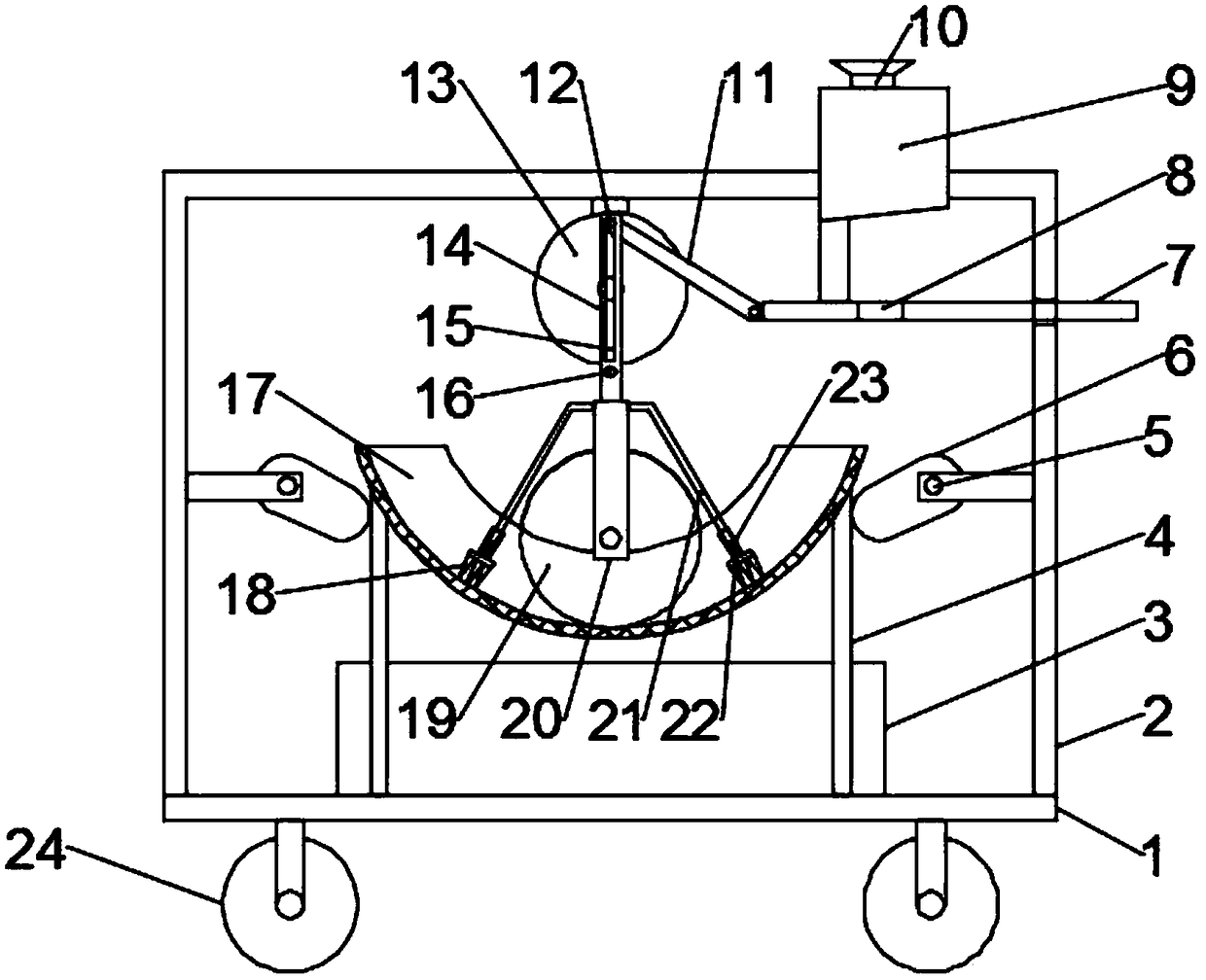

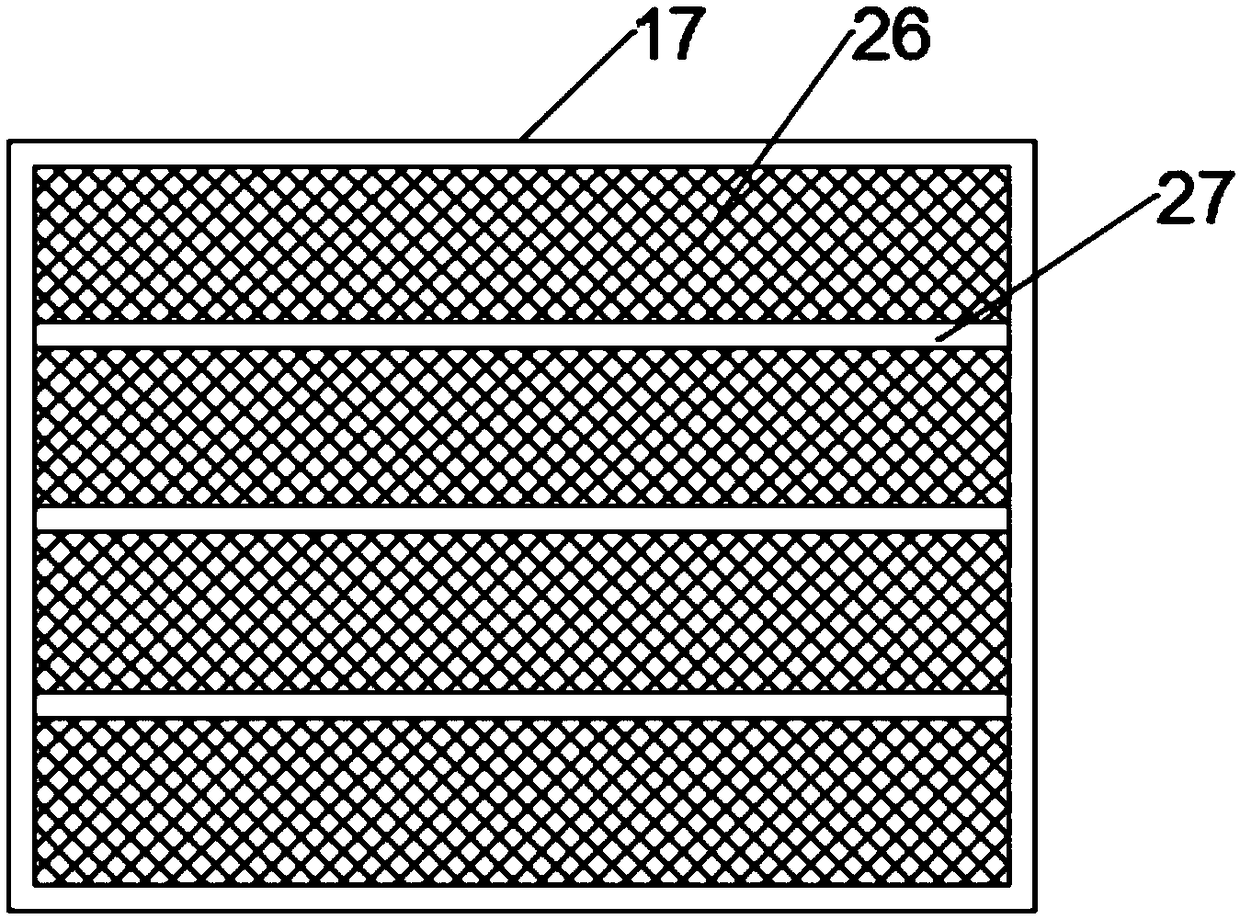

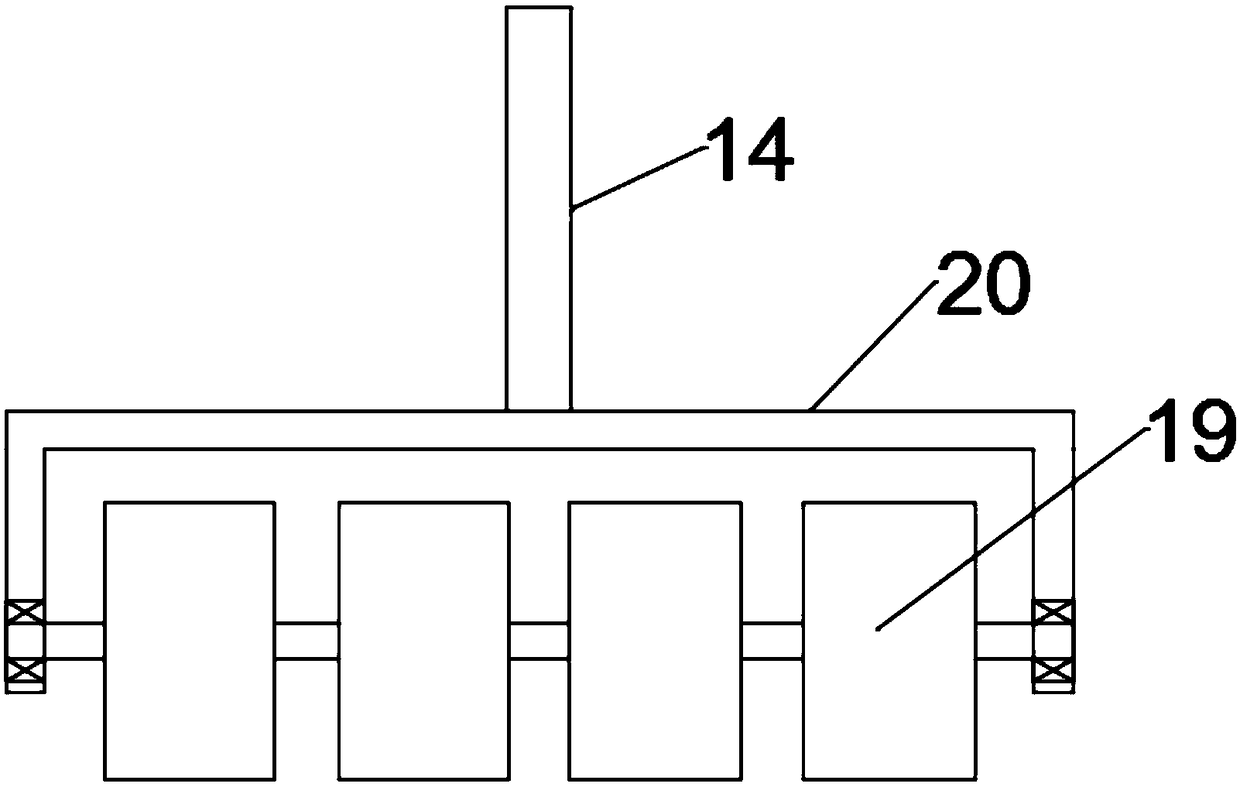

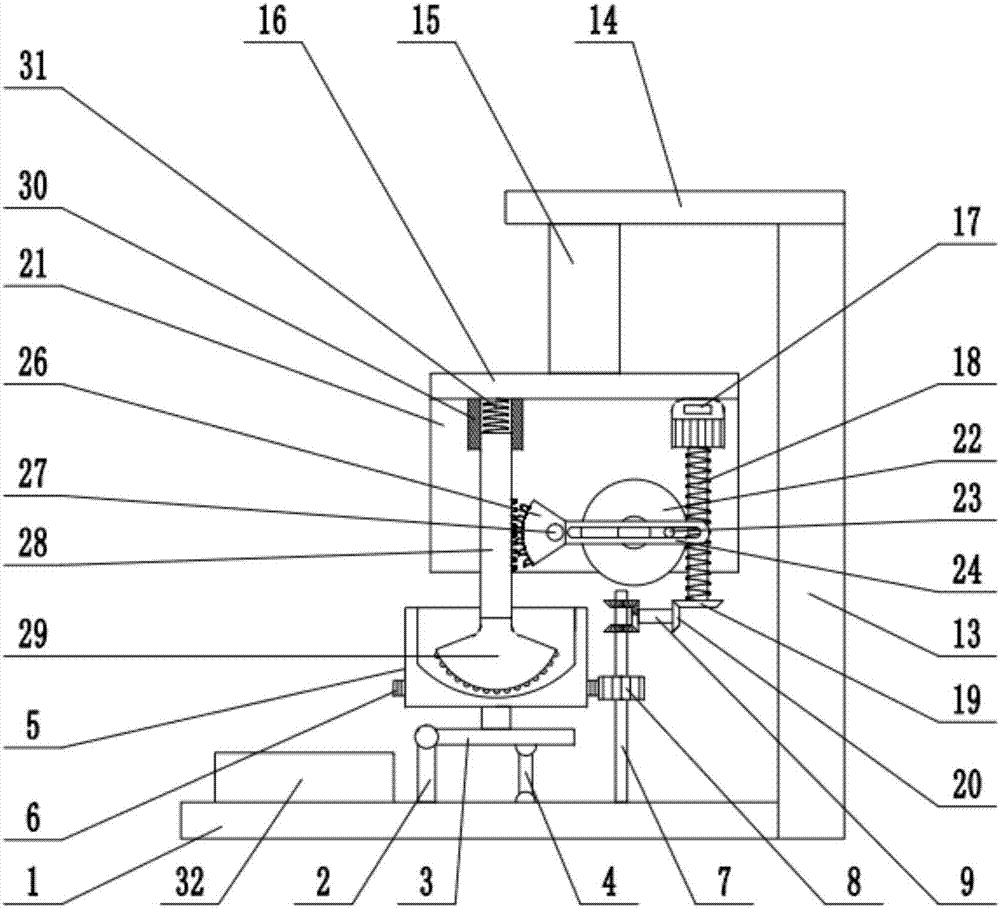

The invention discloses a swing grinding device for traditional Chinese medicines. The device comprises a base plate, an arc grinding frame, a grinding wheel, a mounting frame, a collecting frame, a separation plate, a first motor, a disc, a connecting rod, a baffle plate, traditional Chinese medicine hoppers, medicine outlet holes, a dowel pin, a swing rod, a rotating shaft, an inverted U-shapedplate, a poking rod and vibration devices; the vibration devices comprise second motors, second rotating shafts and cams; different traditional Chinese medicines are added in different traditional Chinese medicine hoppers for synchronously grinding different types of traditional Chinese medicines to improve the working efficiency; meanwhile, the traditional Chinese medicines in the traditional Chinese medicine hoppers intermittently fall down from the medicine outlet holes to prevent insufficient grinding caused by excessive continuous medicine discharging; the grinding wheel repeatedly grindsthe traditional Chinese medicines in the arc grinding frame, and meanwhile, the poking rod can overturn the traditional Chinese medicines, so that the traditional Chinese medicines are grinded more fully and uniformly; and the vibration devices are arranged on the two sides of the arc grinding frame for continuously beating a screen at the bottom of the arc grinding frame to prevent blockage of the screen at the bottom of the arc grinding frame and to improve the screening and grinding efficiency.

Owner:安徽汉盛药业有限公司

Conveniently unloading traditional Chinese medicine grinder

The invention discloses a traditional Chinese medicine grinding machine which is convenient for unloading, which comprises a base, a grinding cylinder, a support plate, a top plate, a motor, a hammer head and a collecting box; There is a transmission shaft, the left end of the transmission shaft is covered with an incomplete bevel gear, the right end of the base is fixedly connected with a support plate, the top of the support plate is fixedly connected with a top plate, and the lower surface of the top plate is fixedly connected with a second telescopic mechanism. The lower end of the mechanism is fixedly connected with a mounting plate, the lower surface of the mounting plate is fixedly connected with a side plate, the left side of the worm is provided with a worm wheel, the surface of the worm wheel is fixedly connected with a fixed rod near the edge, and the left side of the worm wheel is provided with a half gear, hammer The lower end of the handle is fixedly connected with a hammer head, which adjusts the distance between the hammer head and the bottom of the grinding cylinder, and then adjusts the diameter of the traditional Chinese medicine grinding particles. The grinding cylinder rotates forward and backward to make the grinding more uniform. Falling into the collection box, the unloading is convenient and quick.

Owner:朱玥

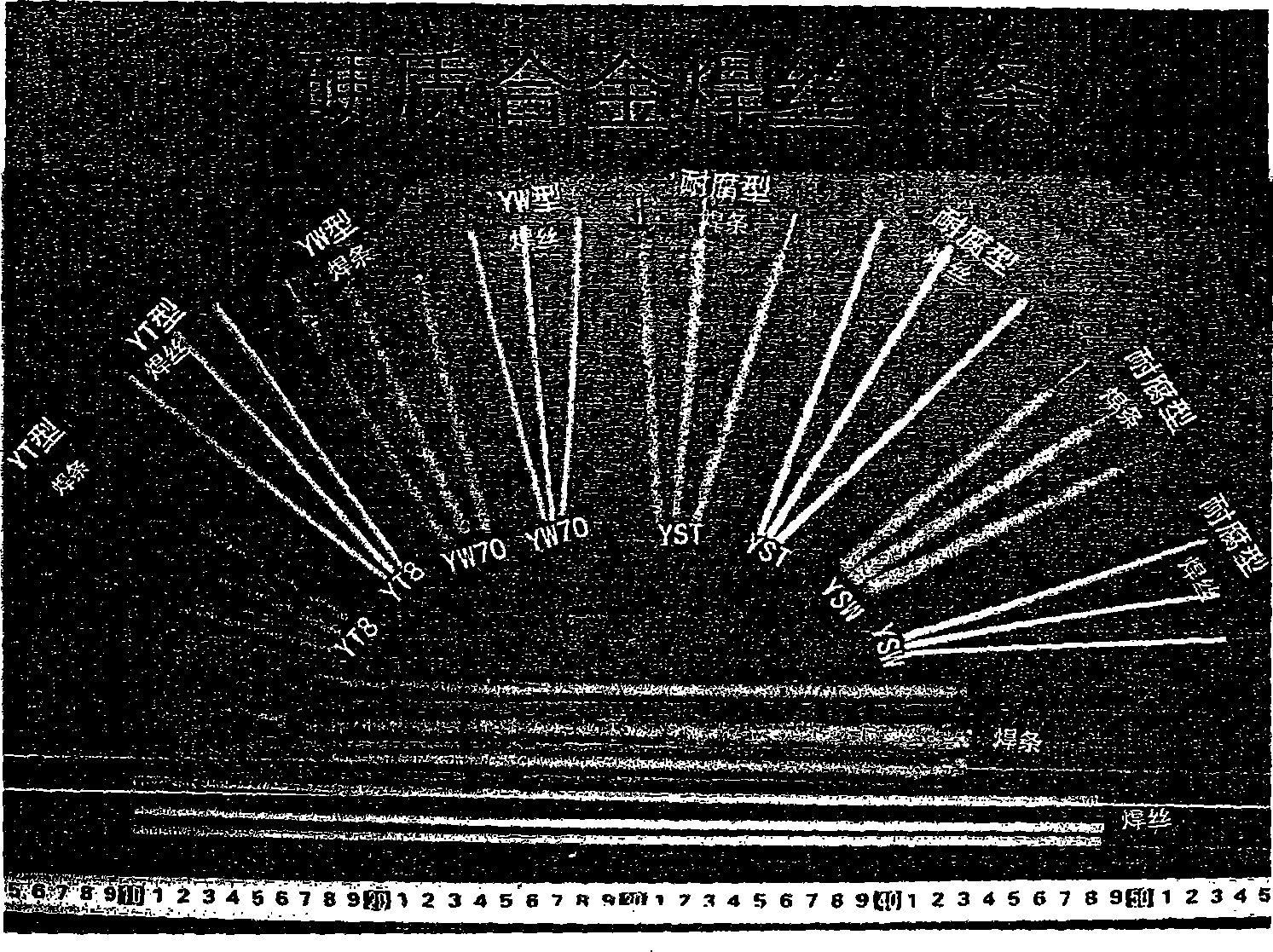

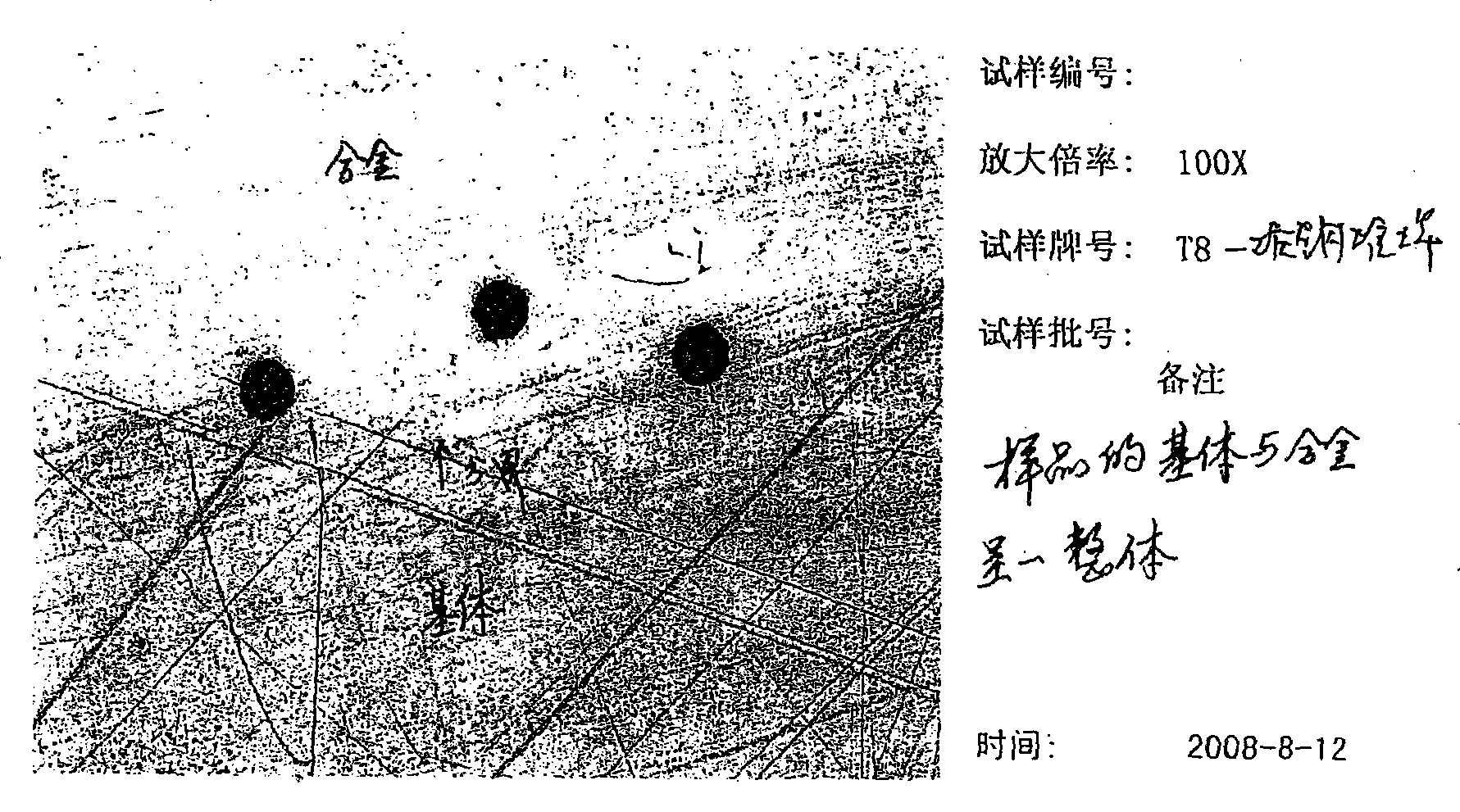

Carbide alloy welding wire or welding rod as well as manufacturing method and application thereof

InactiveCN101462206AImprove bindingHigh strengthWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention relates to a hard alloy welding wire or welding rod. The welding wire or welding rod is prepared from the following compositions: tungsten carbide, titanium carbide or tungsten carbide and titanium carbide is used as a hard phase; one, two or three of iron, nickel and cobalt are used as a bonding phase; specific compositions have the following weight percentage accounting for the gross weight: 30 to 85 percent of the hard phase and 15 to 70 percent of the bonding phase; and in the mixture ratio of the hard phase or the bonding phase, the hard phase or the bonding phase comprises one or more of chrome, manganese, copper, molybdenum, vanadium, tantalum, niobium and carbide accounting for less than 15 percent of the gross weight and C with proper amount is added. The hard alloy welding wire or welding rod has the advantages of high rigidity, high wearing resistance, impact resistance, corrosion resistance, easy welding, low cost, simple operation and wide application range.

Owner:郭庆虎 +2

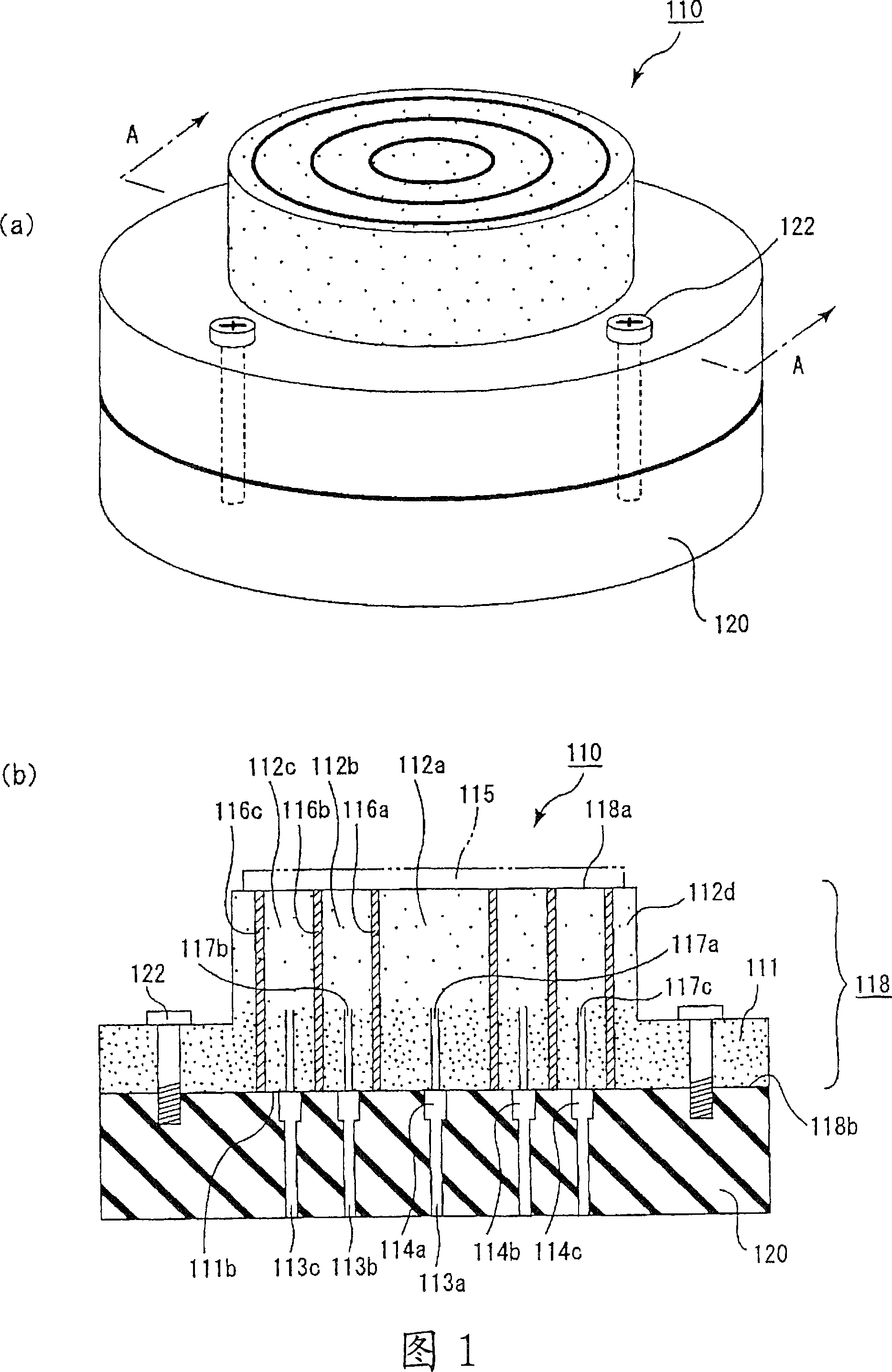

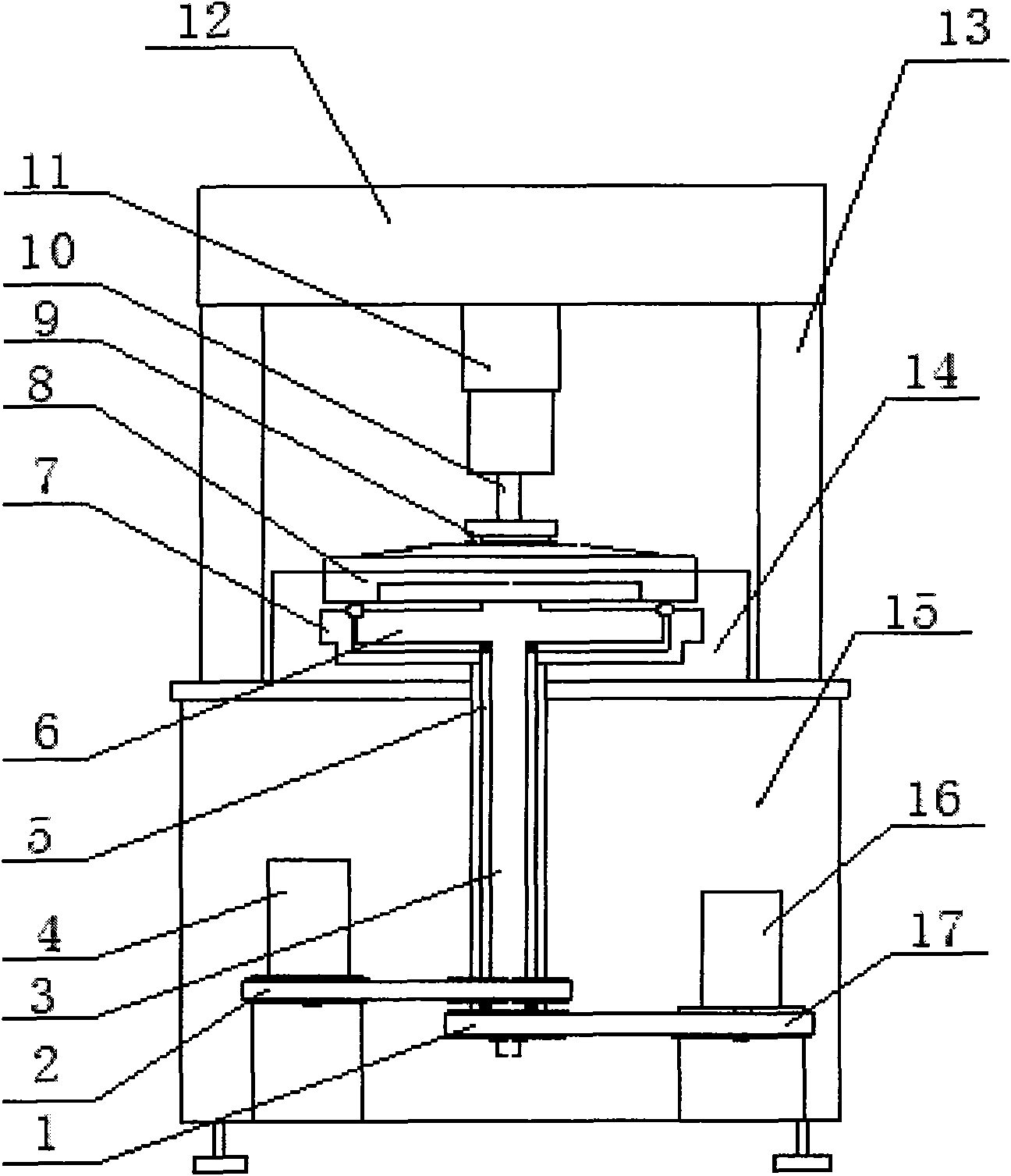

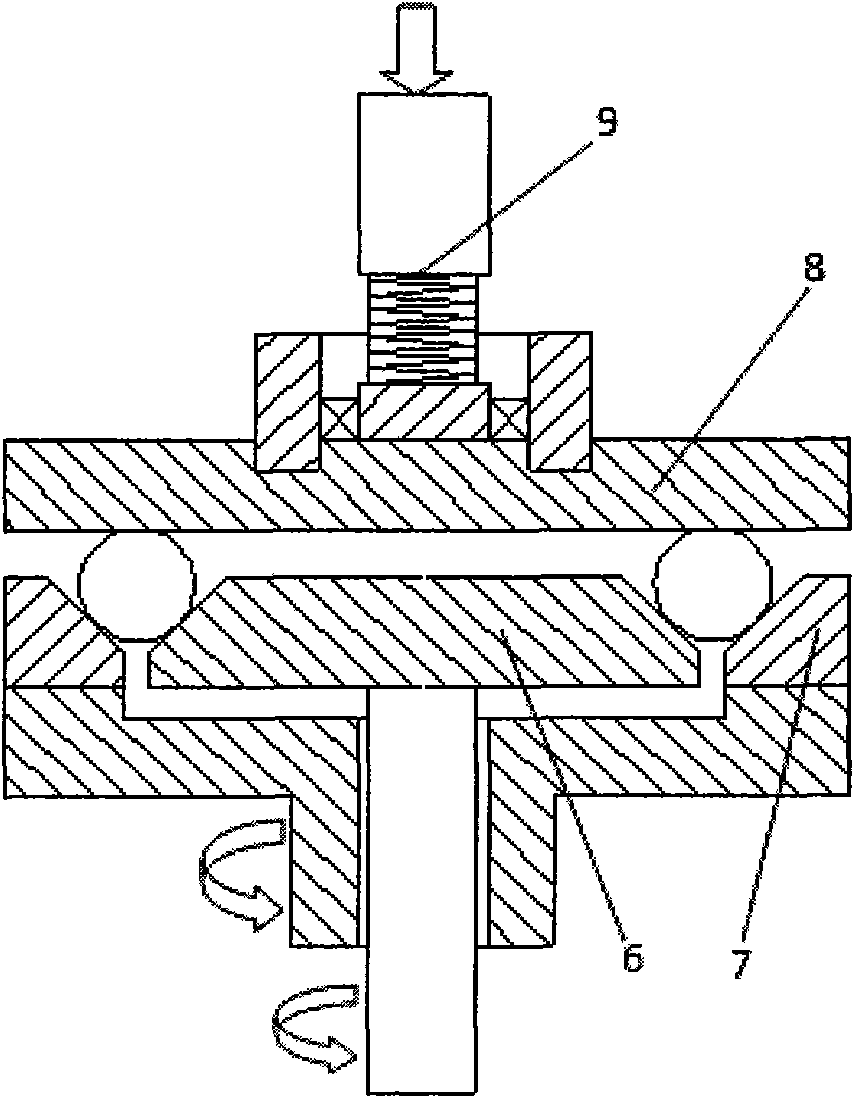

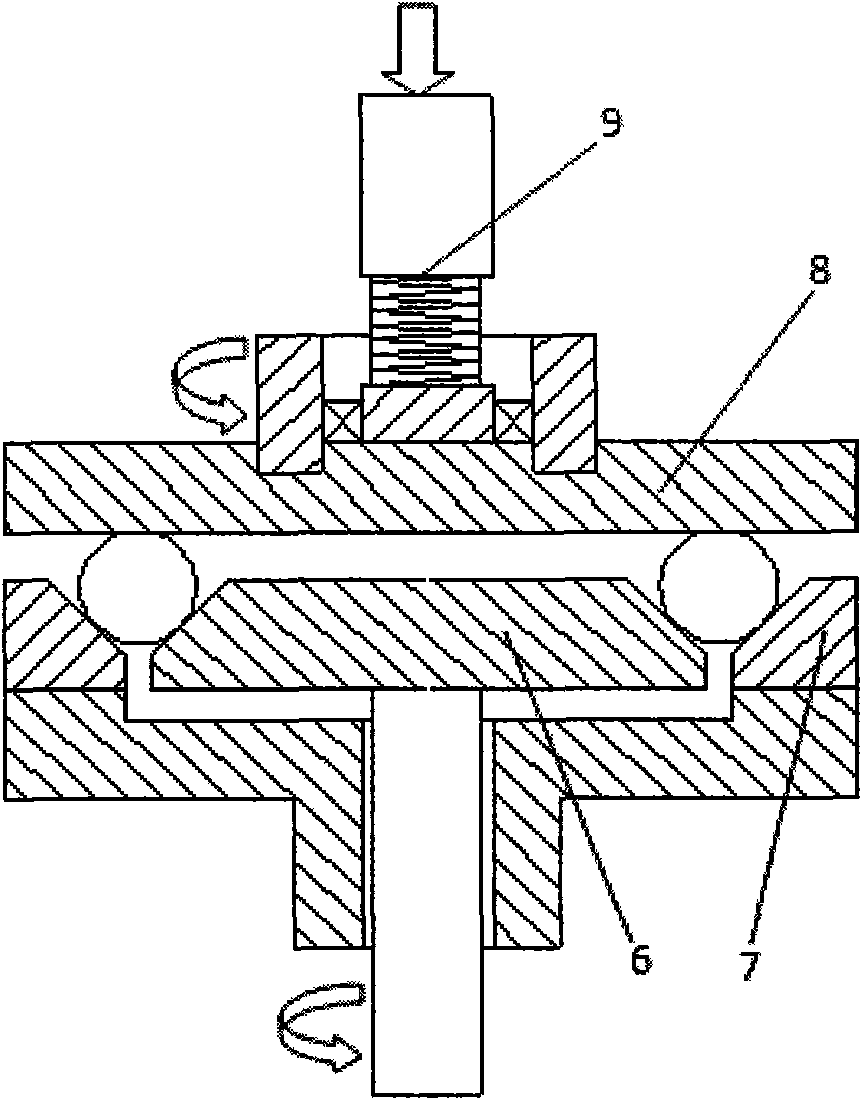

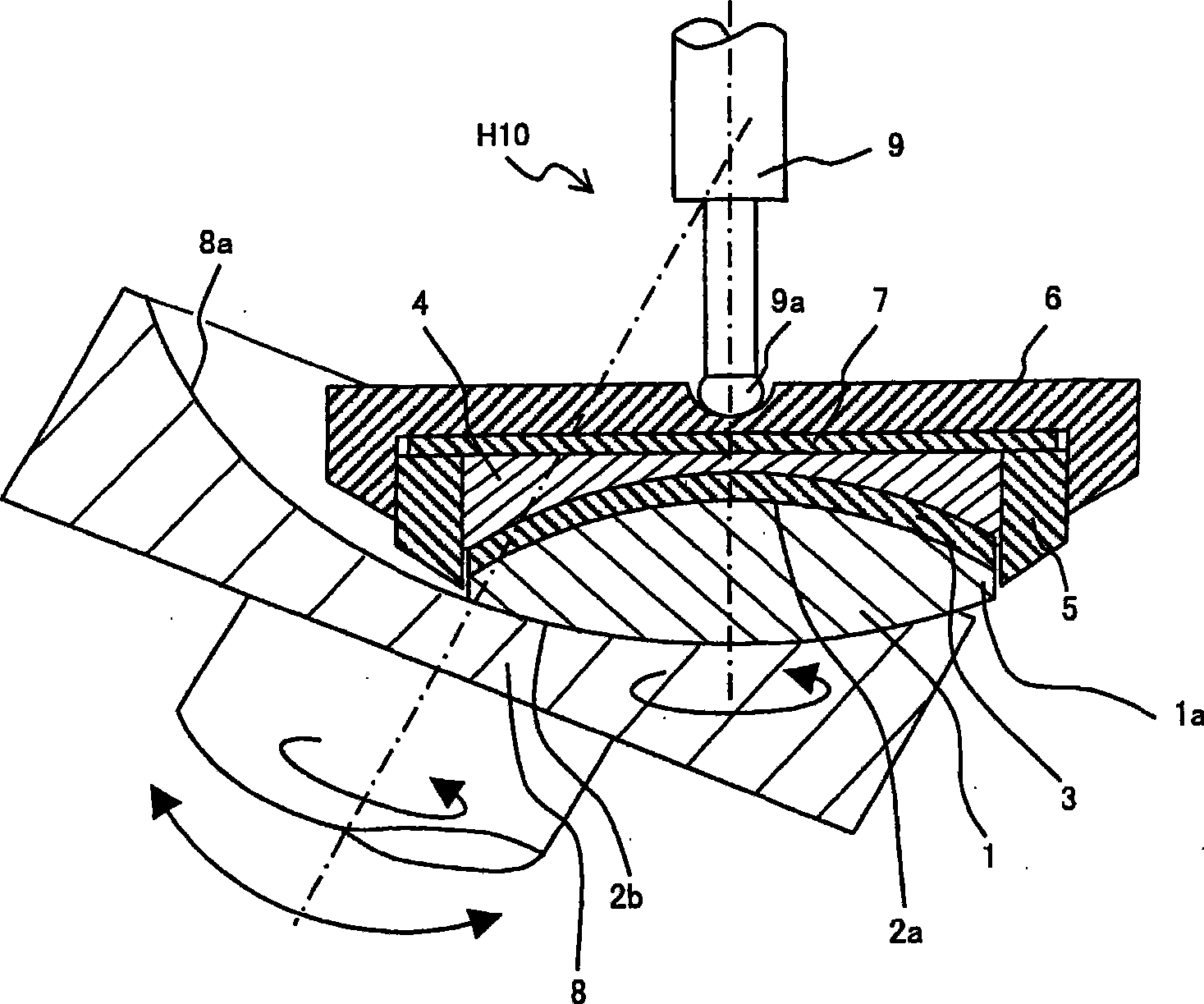

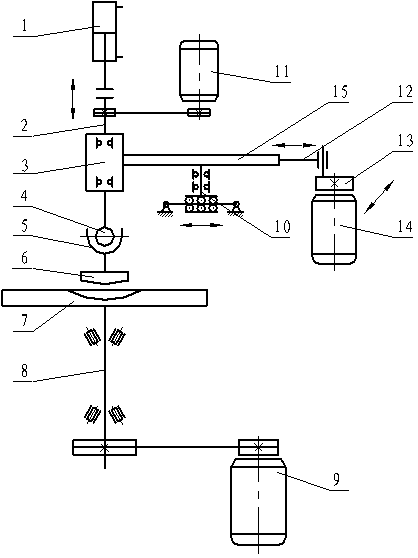

High-precise ball highly-efficient grinding and polishing processing method

InactiveCN101579840AImprove efficiencyImprove machining accuracyPolishing machinesSpherical surface grinding machinesEngineeringElectric motor

The invention discloses a high-precise ball highly-efficient grinding and polishing processing method, in the processing devices for realizing the processing method, a V-shaped groove is formed by a pyramidal face abrasive surface of the outer of an inner plate of a lower grinding plate and a pyramidal face abrasive surface of the inside of an outer plate of the lower grinding plate, a loading pressure device acts on a ball billet through an upper grinding plate, three processing contact points of the grinding ball are formed by the V-shaped groove and the upper grinding plate, the upper grinding plate, the outer plate of the lower grinding plate and the inner plate of the lower grinding plate share a same rotary shaft; a rotating shafts of two plates among the upper grinding plate, the outer plate of the lower grinding plate and the inner plate of the lower grinding plate are driven by an electric motor; relative orientation changing is carried out on a ceramic ball through adjusting the velocity combination of the omega[B] and omega[C], so that the grinding trails are distributed on the face of the ball uniformly, thus grinding the surface of the ceramic ball uniformly. In the invention, the higher processing precision and processing efficiency can be realized, and the processing device has simple structure and low manufacturing cost.

Owner:ZHEJIANG UNIV OF TECH +1

Efficient grinding device for graphite for 3D printing

The invention relates to a grinding device for graphite for 3D printing, in particular to an efficient grinding device for the graphite for 3D printing. The efficient grinding device for the graphite for 3D printing is even, thorough and fast in grinding. The efficient grinding device for the graphite for 3D printing comprises a bottom plate, a left rack, a right rack, guiding sleeves, a top plate, a first supporting rod, a first large belt pulley, a motor, rotating rods, a first guiding rod, a second guiding rod and a movable frame. Two second supporting rods are arranged in symmetry with respect to the center of the top of the bottom plate; a collecting frame is arranged on the top, located between the two second supporting rods, of the bottom plate; a second spring is arranged at the top end of each second supporting rod; a grinding frame is arranged at the top ends of the second springs; and a net plate is arranged in the center of the bottom of the grinding frame. According to the efficient grinding device, the effects of even, thorough and fast grinding are achieved due to the action of a first reinforcing rib and a second reinforcing rib.

Owner:浙江泰嘉光电科技有限公司

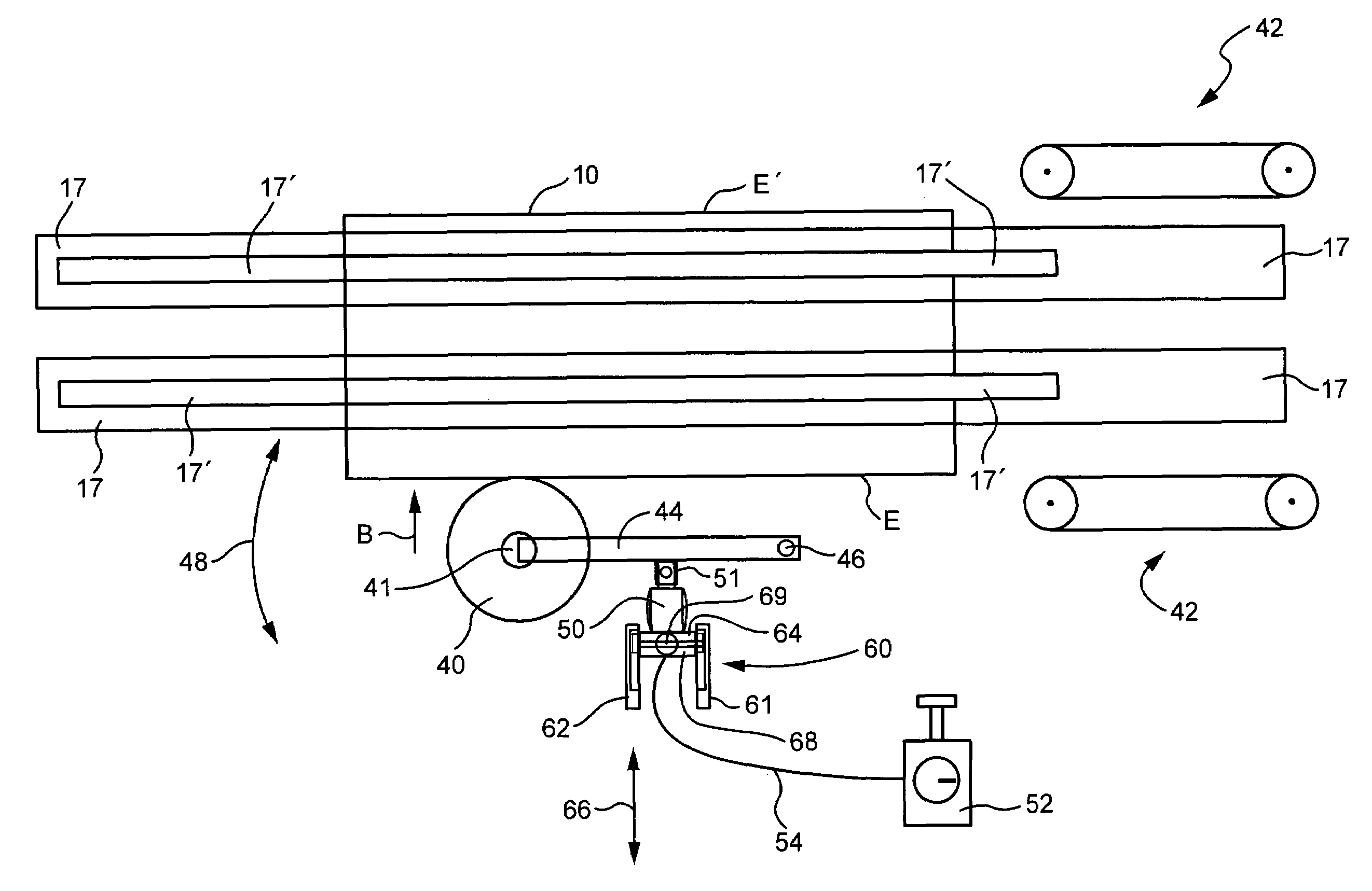

Method and system for making glass sheets including grinding lateral edge(s) thereof

ActiveUS7235002B1Grinding of lateral edge(s) of glass sheets is improvedReduces unnecessary wearEdge grinding machinesGrinding headsEngineeringAirbag

A method and system for making glass sheets is provided. At least one grinding wheel is provided for grinding a lateral edge of a glass sheet. An airbag and corresponding air pressure regulator are provided for biasing the grinding wheel against the lateral edge of the glass sheet being ground. In certain example embodiments, the airbag is advantageous in that it permits the grinding wheel to be biased against the lateral edge of the glass sheet with a substantially constant pressure, where this pressure does not substantially fluctuate due to small changes in the location of the edge of the passing glass.

Owner:GUARDIAN GLASS LLC

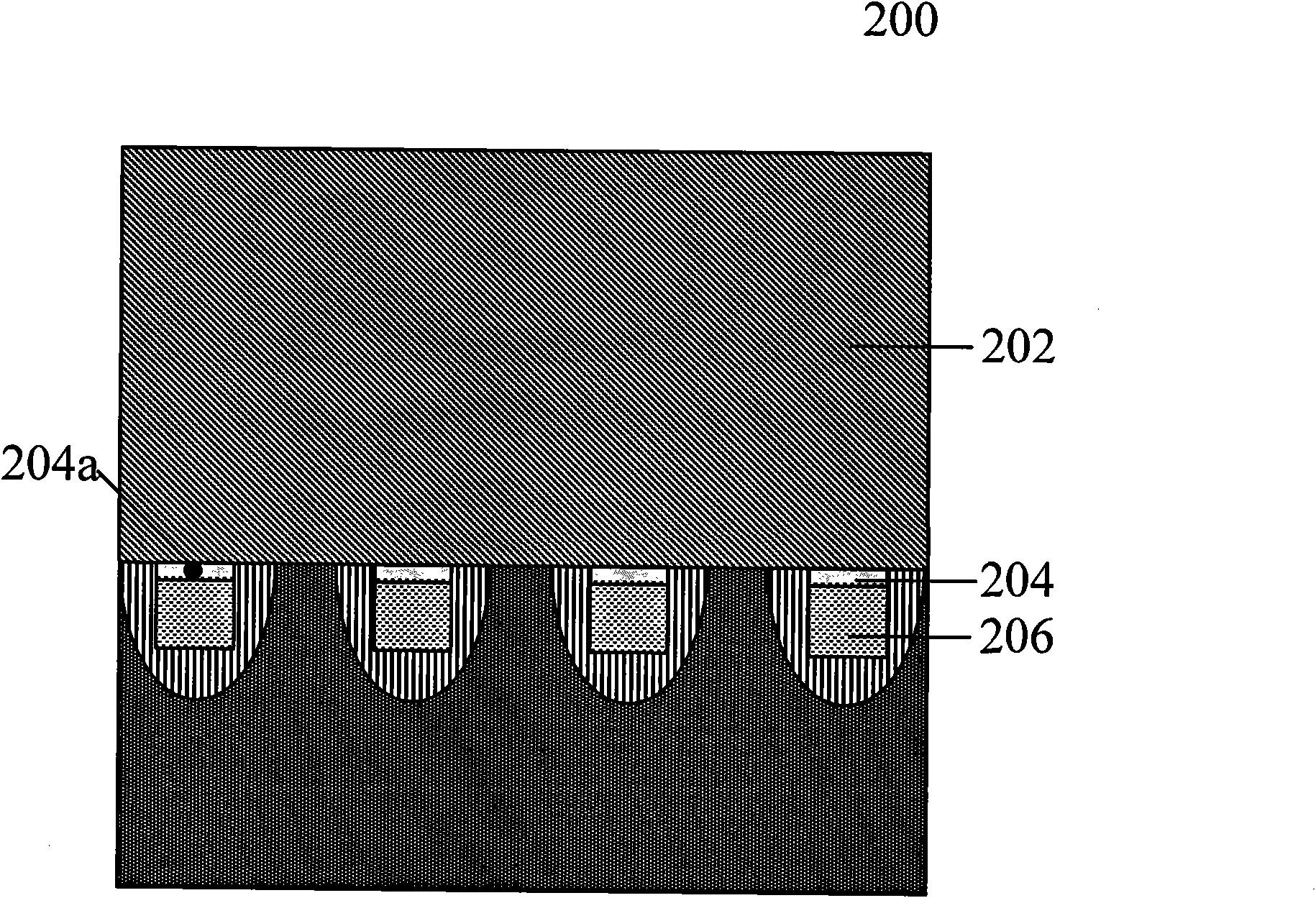

Failure analysis method of gate oxide

ActiveCN101996911ADefect retentionGrind evenlySemiconductor/solid-state device testing/measurementPreparing sample for investigationFailure analysisGate oxide

The invention provides a failure analysis method of a gate oxide, which ensures that problems of extremely complicated detection process of a failure chip, relatively long detection period, easy occurrence of failed detection results, higher detection cost and the like in the prior art can be solved. The failure analysis method comprises the following steps: pasting the failure chip reversely on a substrate by hot gel, wherein, the failure chip comprises a substrate and the gate oxide on the substrate; grinding the substrate of the failure chip to certain thickness or fully removing the substrate; soaking the surface of the chip with alkaline solution; and observing the failure chip, wherein, the gate oxide is defective when a control gate is damaged, and the gate oxide is intact when the control gate is undamaged. The detection method of the failure chip has the advantages of simplicity, shorter time consumption, less possibility of failure and lower cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP

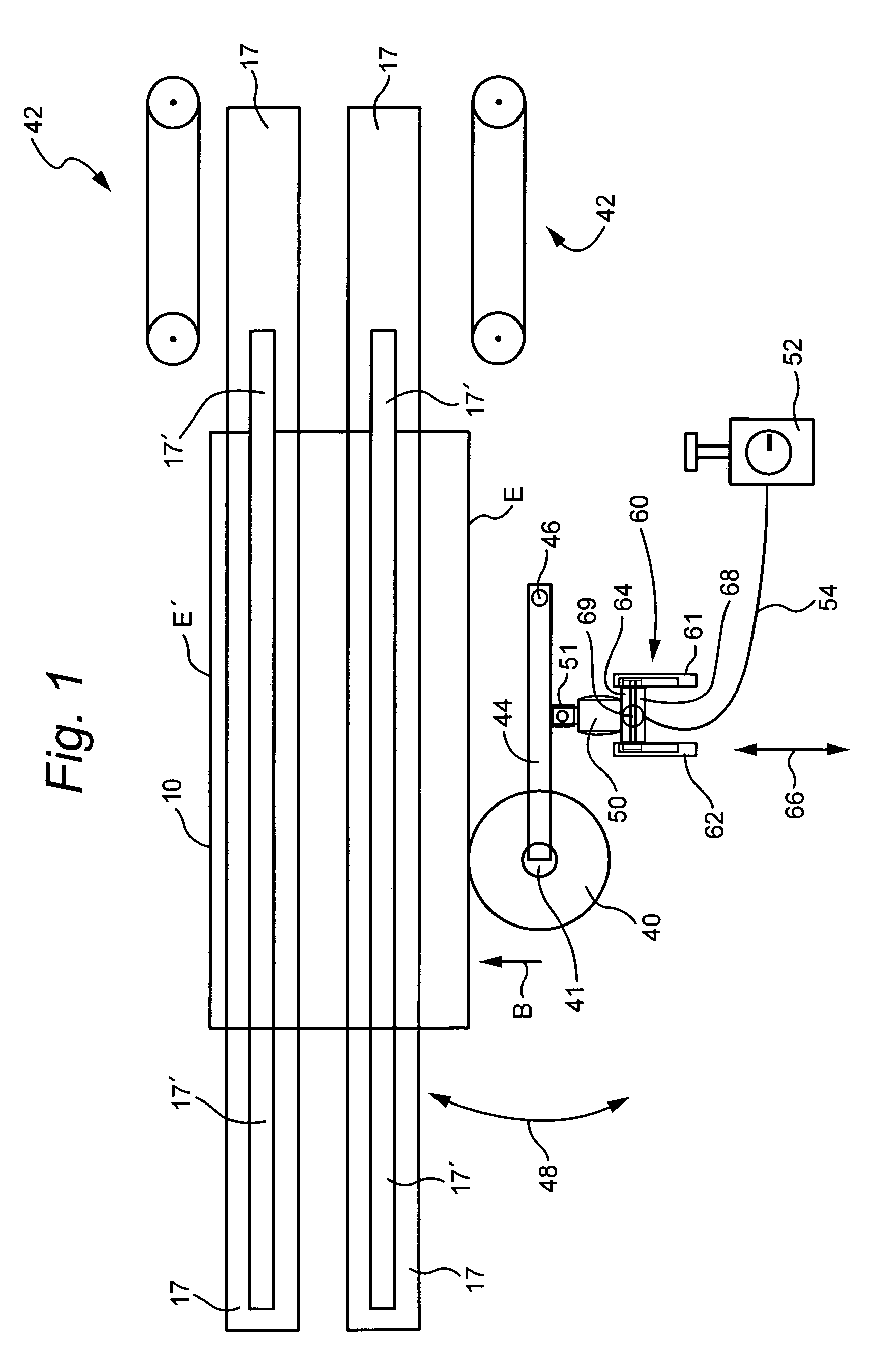

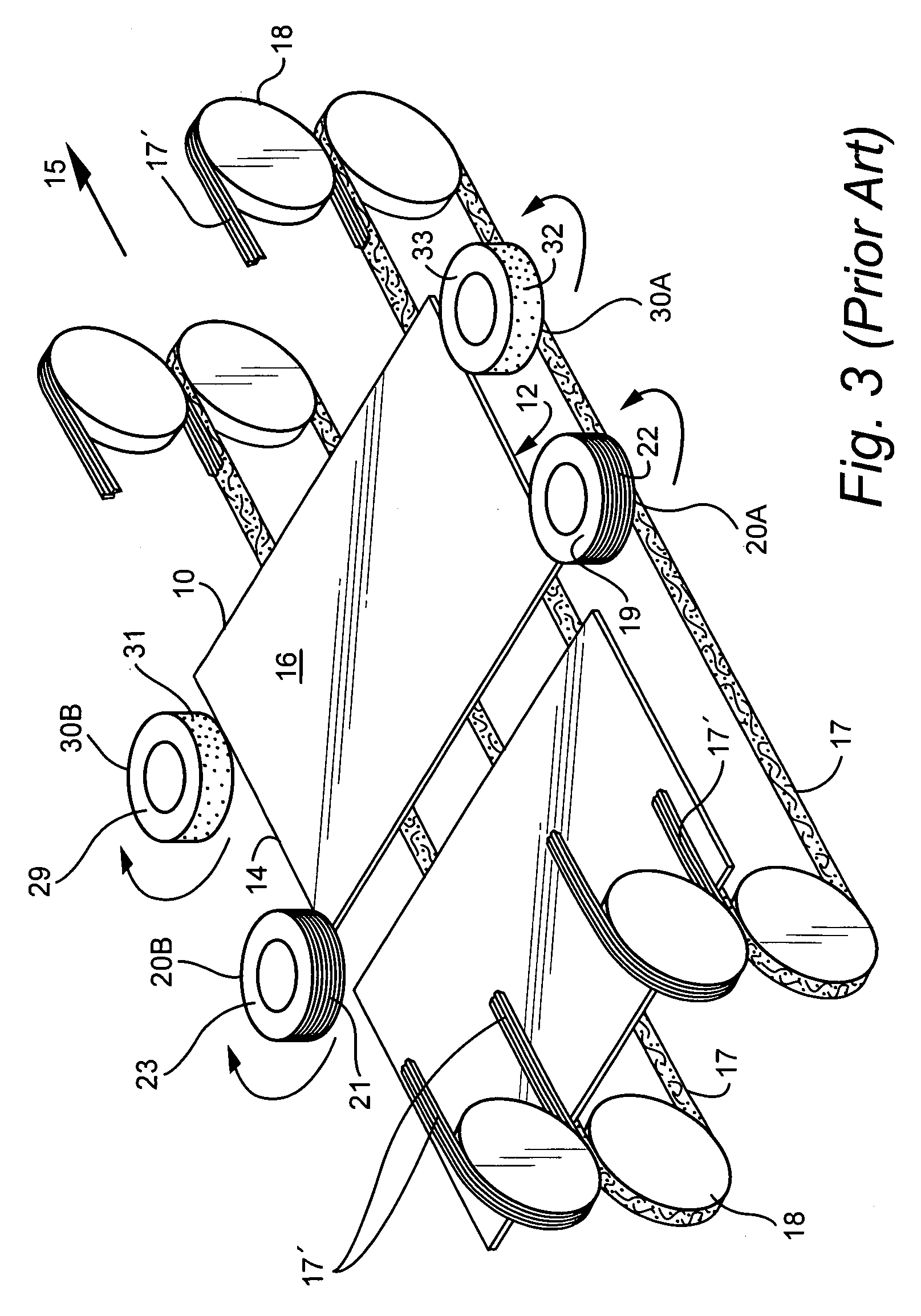

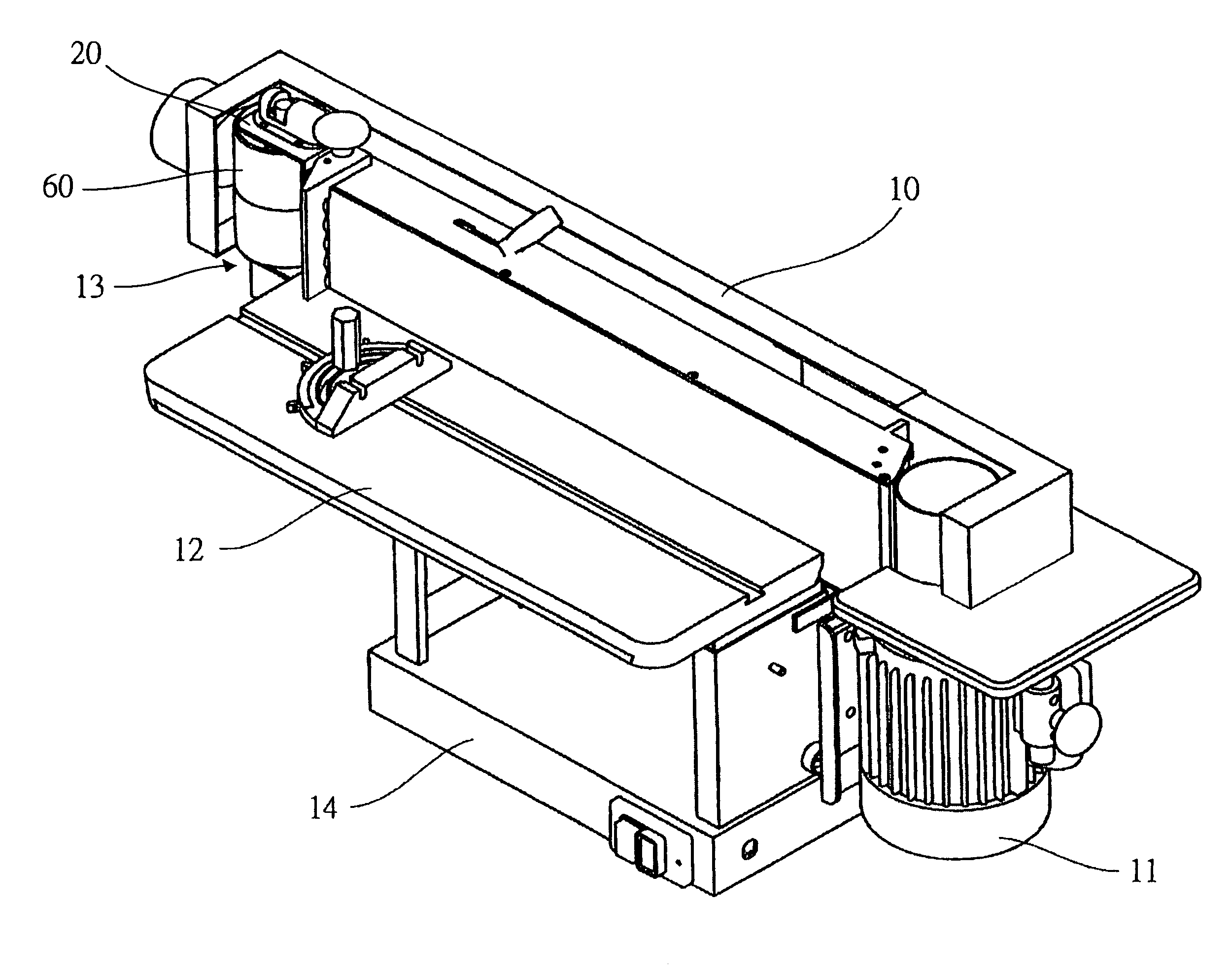

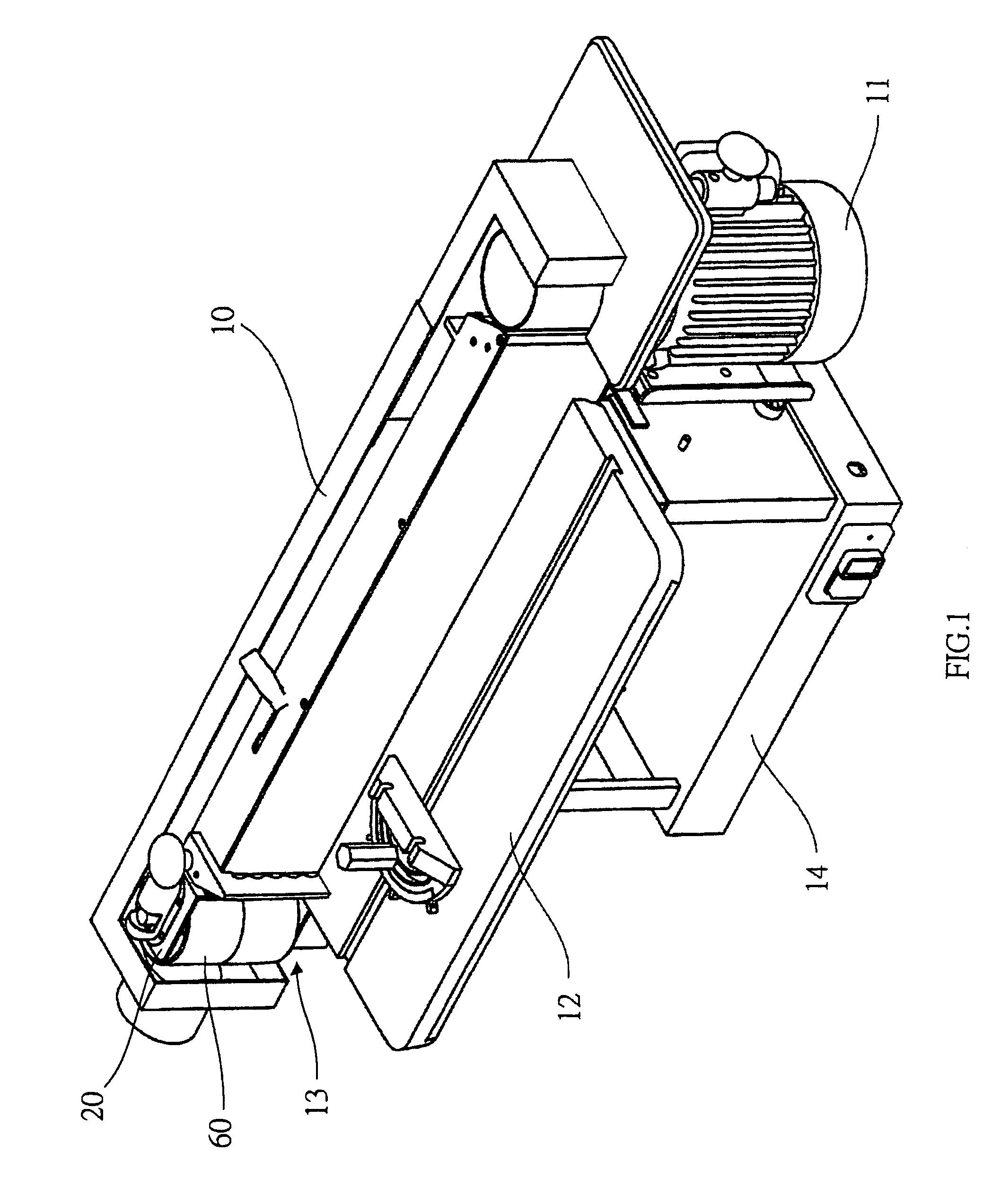

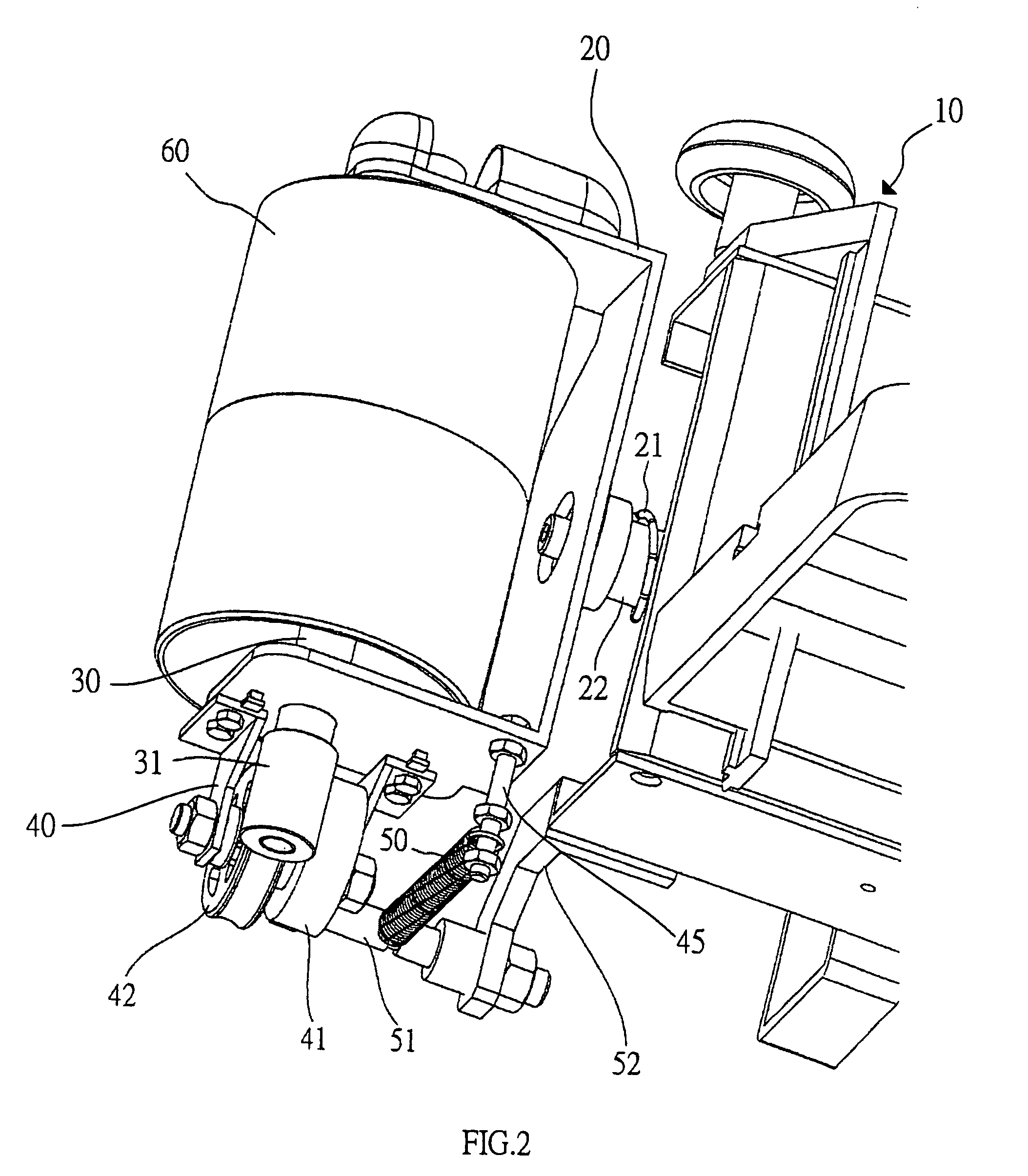

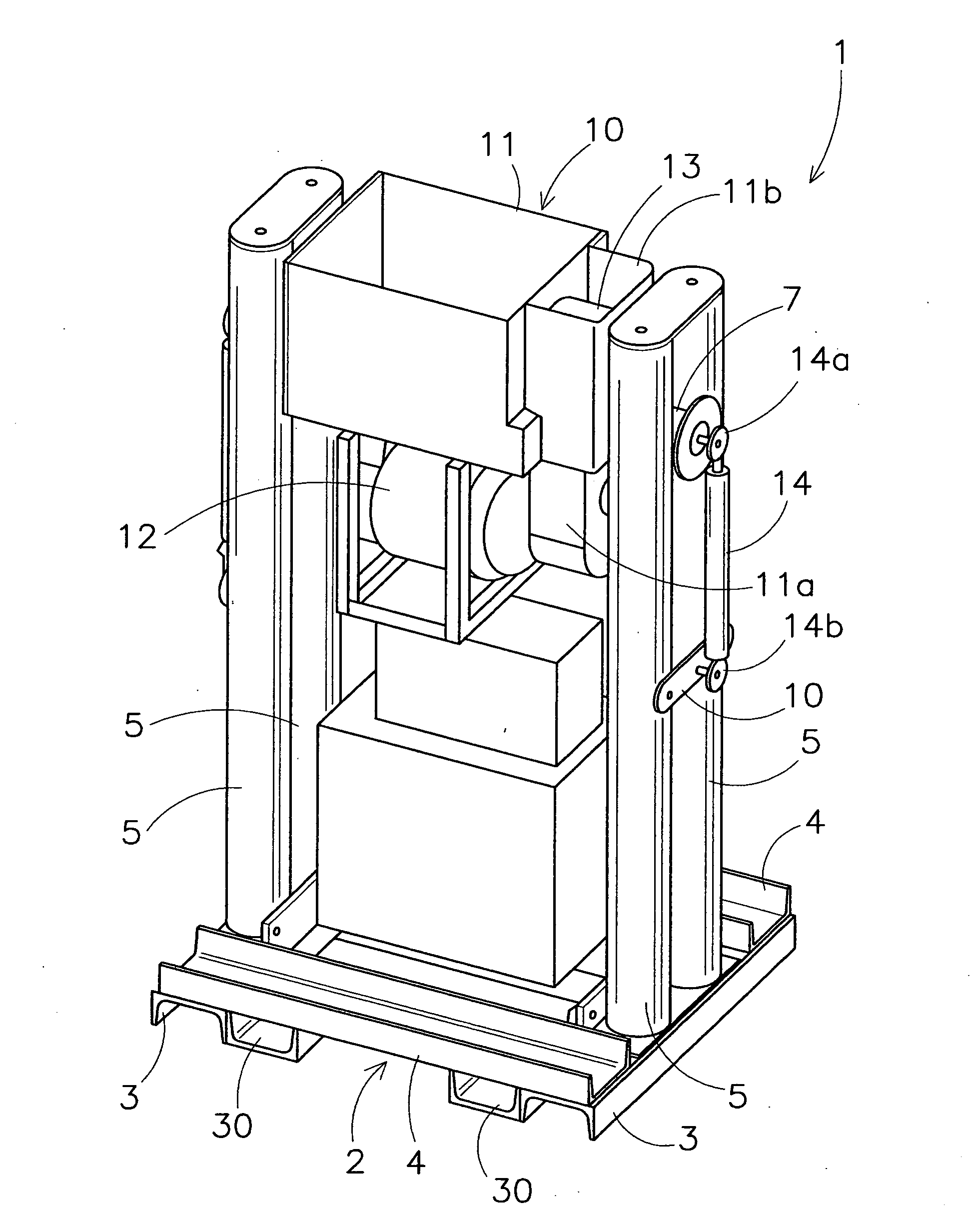

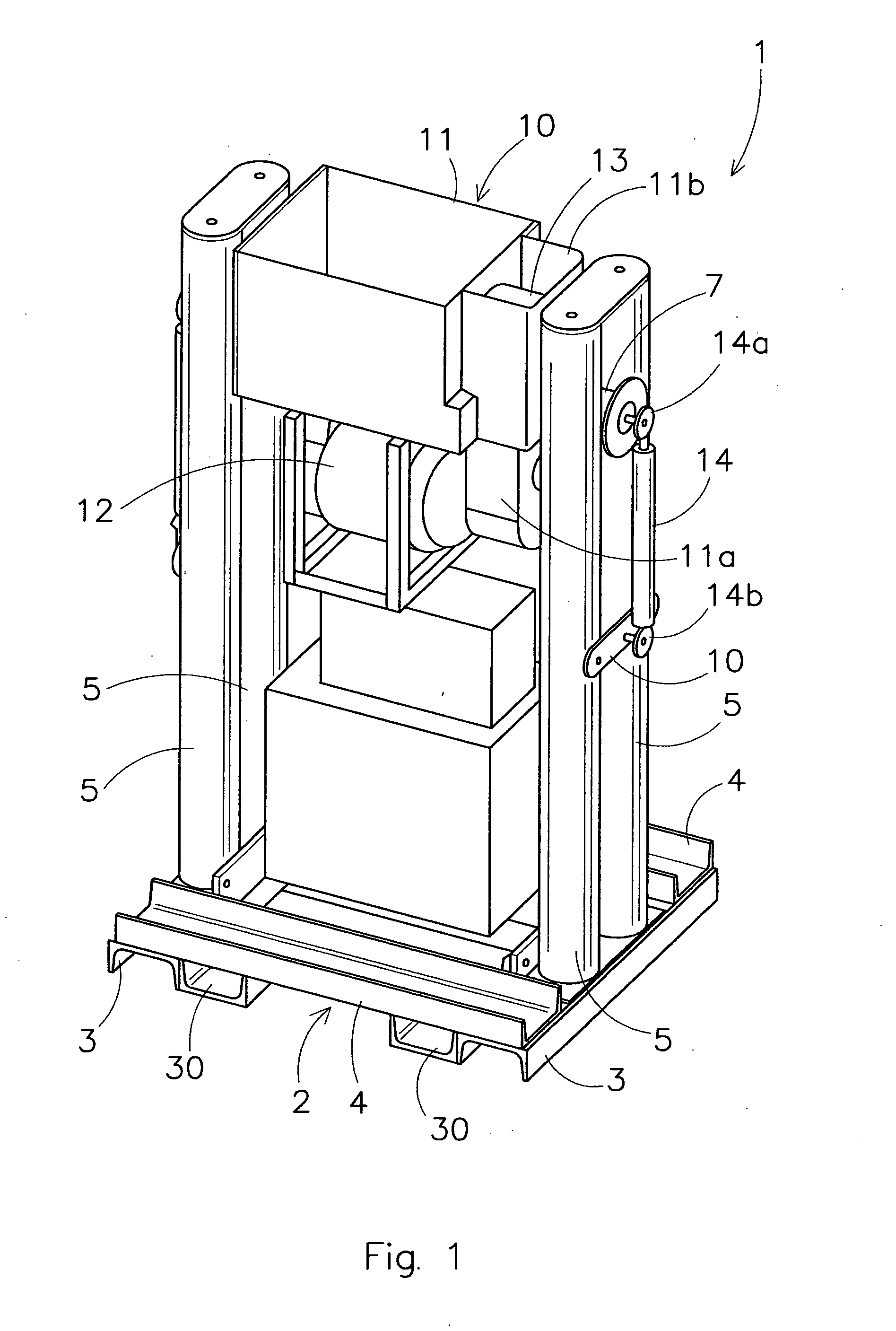

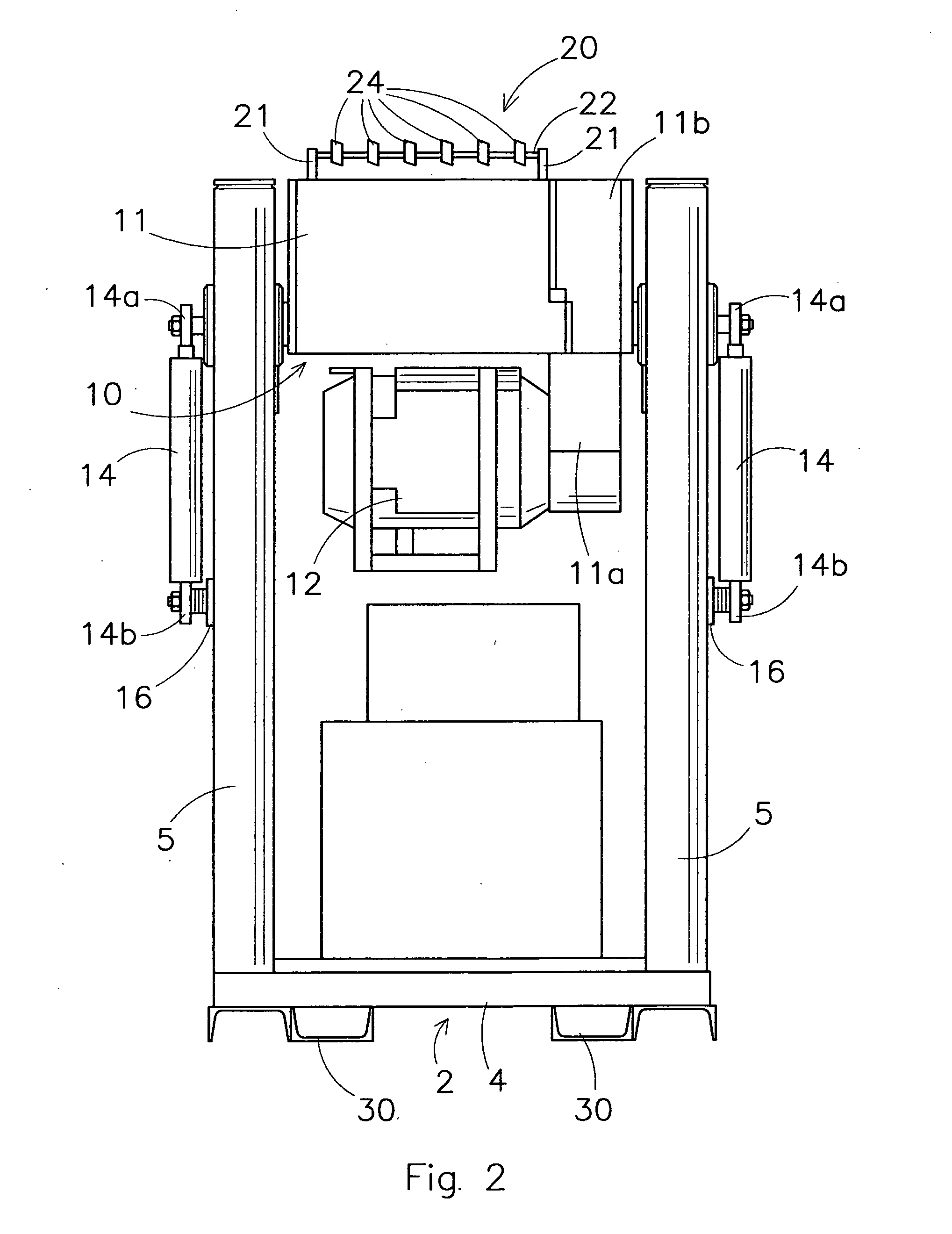

Belt sander

ActiveUS7090571B1Increase the areaGood effectBelt grinding machinesPortable grinding machinesSanderEngineering

A belt sander includes a base, a sanding device, a worktable, a tipping drive device, and a swinging device. The swinging device includes a cylindrical roller, a central shaft, a toothed ring, a drive gear, a cam, and a fixing rod. The swinging device drives the sanding device to produce a slightly reciprocally swinging action during operation of the sanding device. Thus, the grinding path and area of the sand belt are increased largely by the reciprocally and successively swinging action of the swinging device and the sanding device, so that the sand belt can be used to grind the wooden material exactly and efficiently, thereby greatly enhancing the grinding and finishing effect of the belt sander.

Owner:WANG TIAN WANG

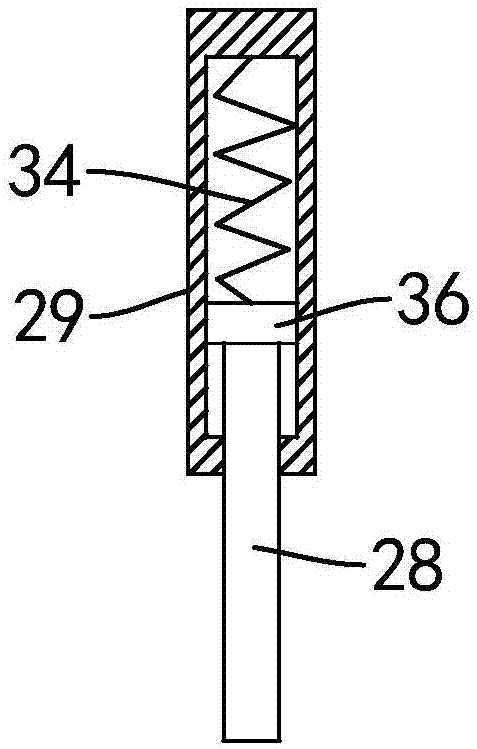

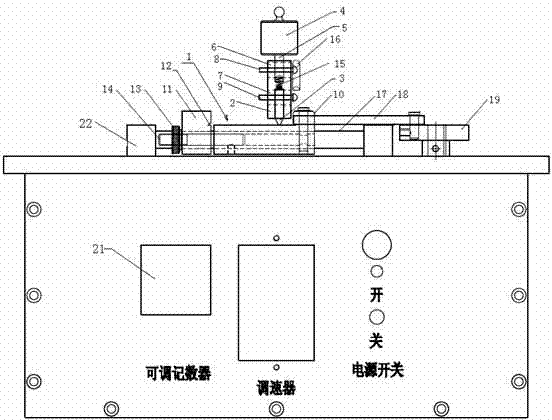

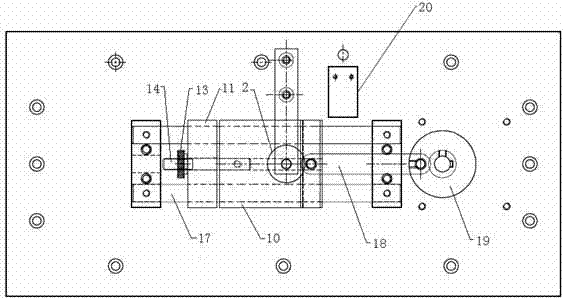

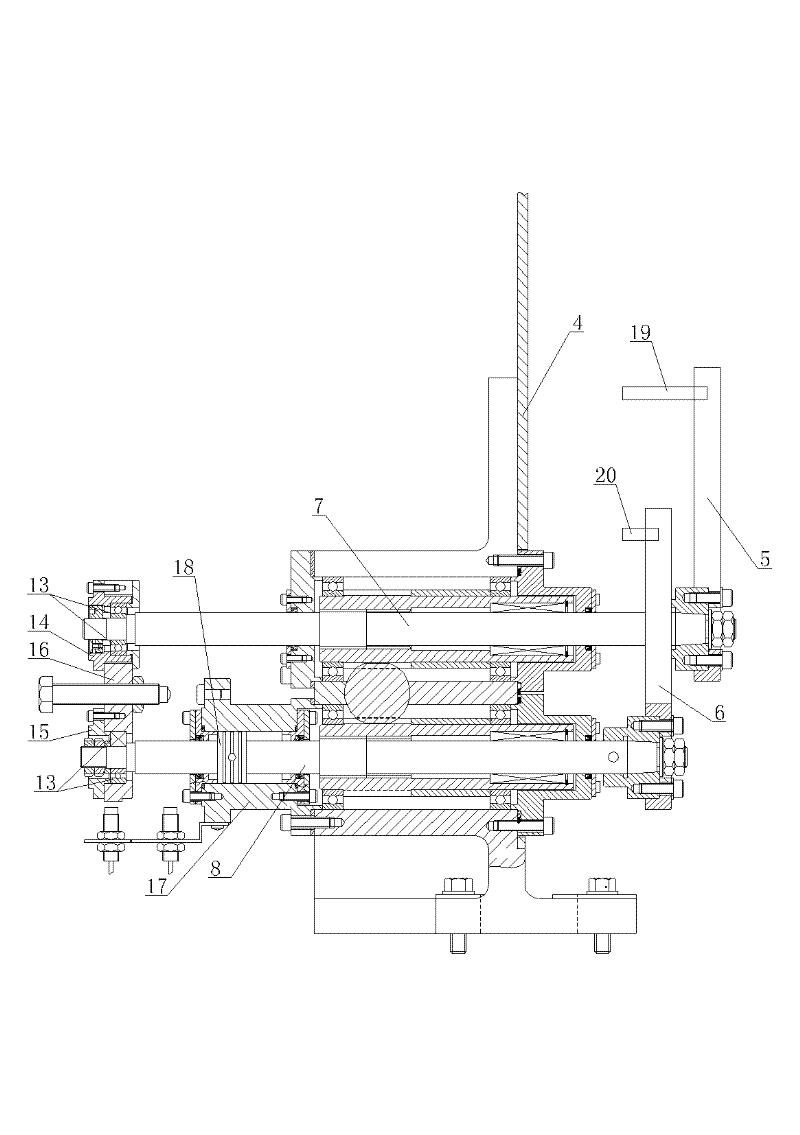

Plating surface wear resistance tester

InactiveCN102507357ATest stableReduce shockInvestigating abrasion/wear resistanceStructural engineeringWear resistance

The invention relates to a plating surface wear resistance tester, which comprises a sample carrying platform, a grinding mechanism, a driving mechanism and a limiting connector, wherein the grinding mechanism is arranged above the sample carrying platform by a support and comprises a sleeve which is arranged on the support and a grinding head and a weight which are arranged on the sleeve; the weight is arranged above the grinding head and adds a load onto the grinding head; the driving mechanism drives the sample carrying platform or the grinding mechanism to do reciprocal movement so that reciprocal sliding friction is generated between the grinding head and a sample to be tested; the lower end of the weight is provided with a fixed rod, and the upper end of the sleeve is suitable for the fixed rod to be inserted into; the lower end of the sleeve is suitable for the upper end of the grinding head to be inserted into; a shock absorbing device is arranged between the upper end of the grinding head and the fixed rod; and the limiting connector is used for connecting the fixed rod and the grinding head to the sleeve respectively and allowing the fixed rod and the grinding head to make up and down displacement along the axial direction of the sleeve. The plating surface wear resistance tester can operate quietly in a test process and delivers an accurate test result.

Owner:WENZHOU YIHUA CONNECTOR

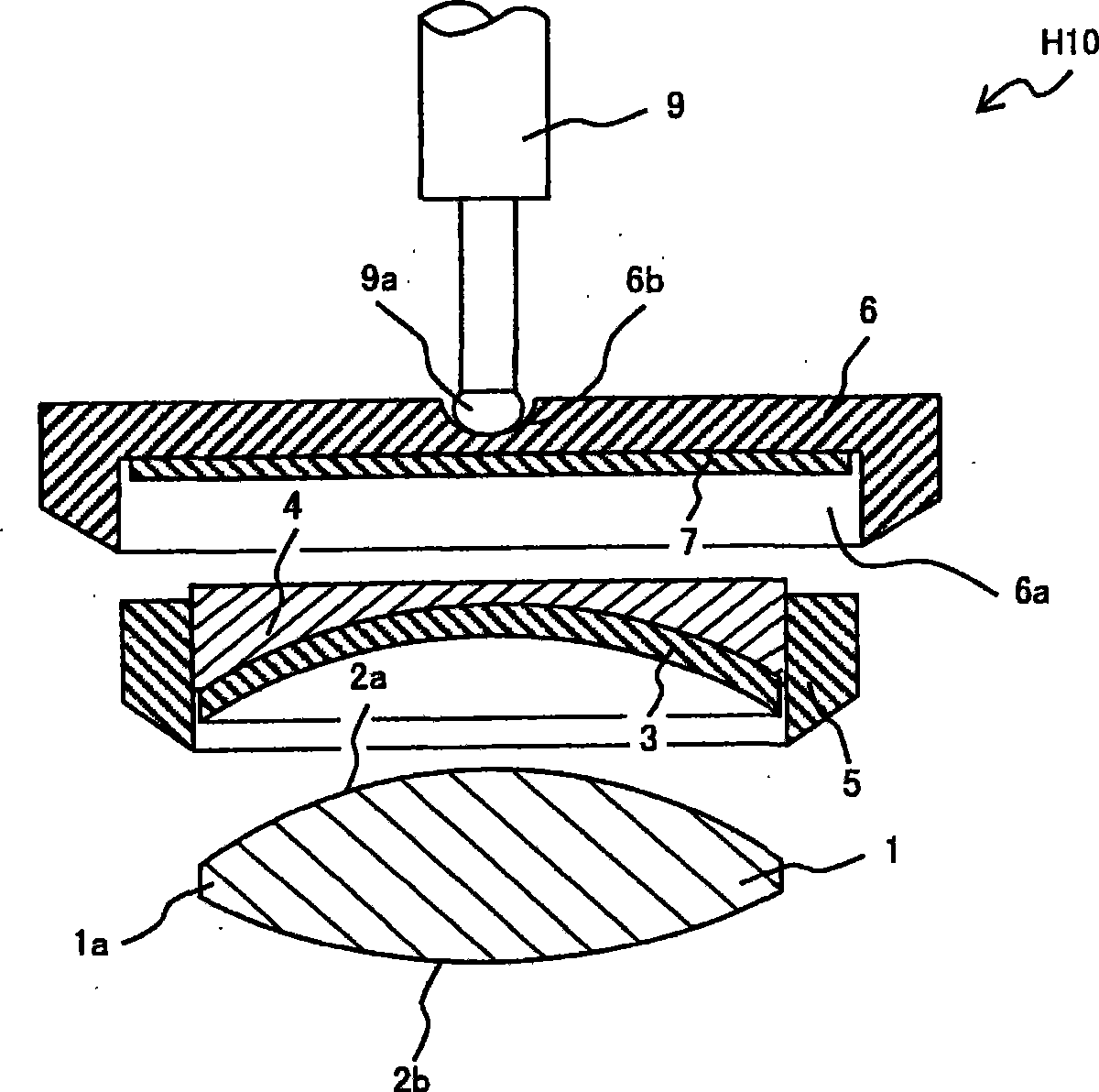

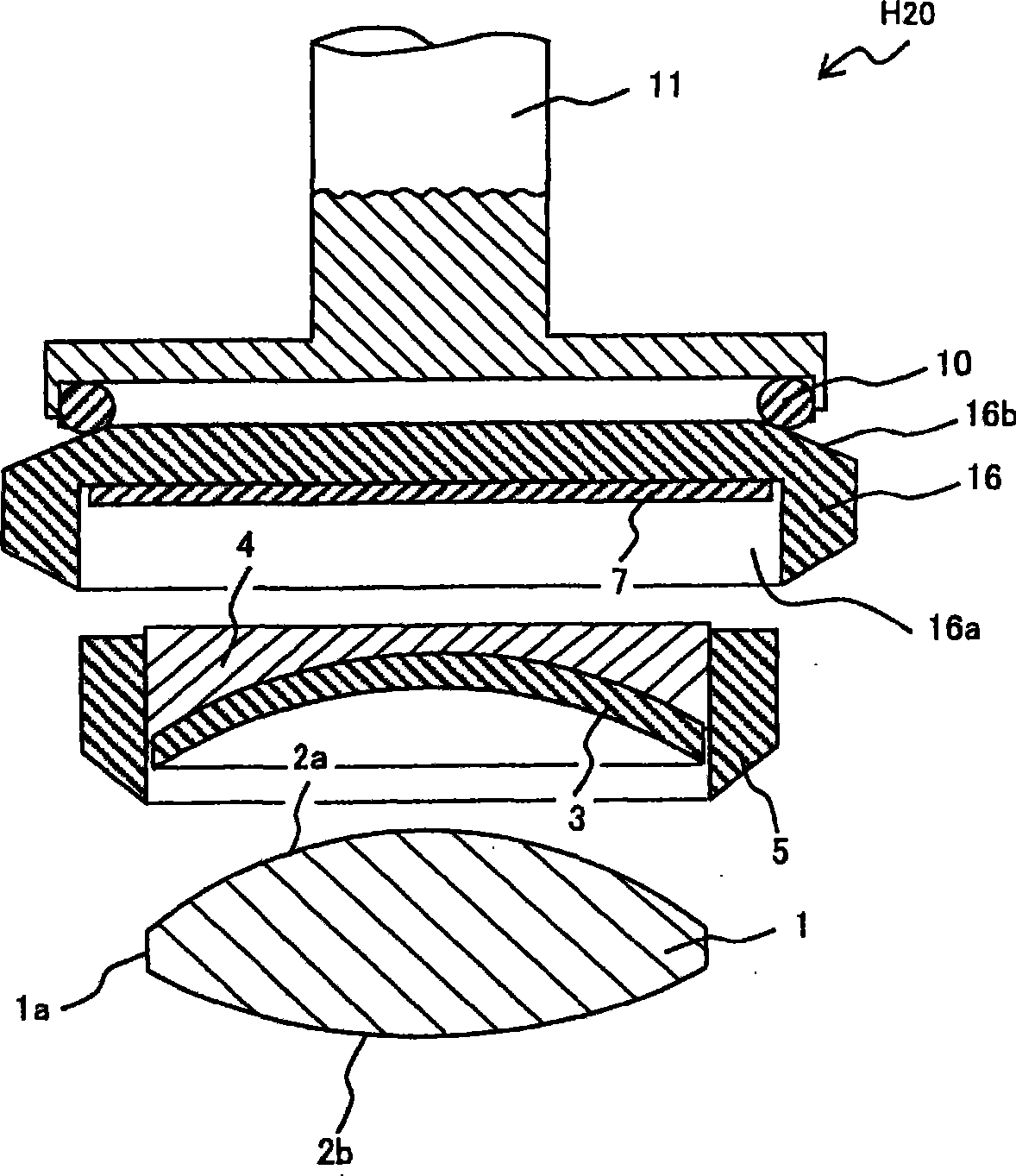

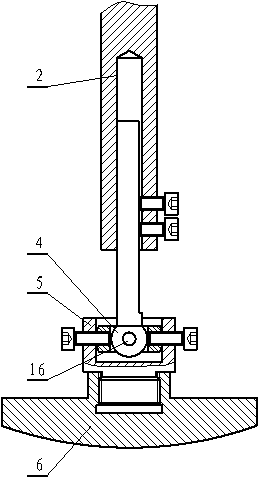

Retaining apparatus

ActiveCN101518884ASmooth rotationGrind evenlyOptical surface grinding machinesEngineeringSliding contact

The invention provides a retaining apparatus for lapping-in between optical elements and process tools. The retaining apparatus comprises: a sheet-shaped component in contact with the retaining surface on the opposite side of the optical element process surface which is in sliding contact with the process tools; a support component for supporting the optical element by said sheet-shaped component; an outer-diameter ring for supporting the outer edge of the optical element supported on said support component; an outer cylinder for supporting the outer-diameter ring in the mode of covering the periphery of the outer-diameter ring, the back of the outer cylinder having a concave spherical surface part cooperated with the outer oscillating axle; and a sliding part located between the outer cylinder and the support component for connecting the two components so that they can rotate.

Owner:OLYMPUS CORP

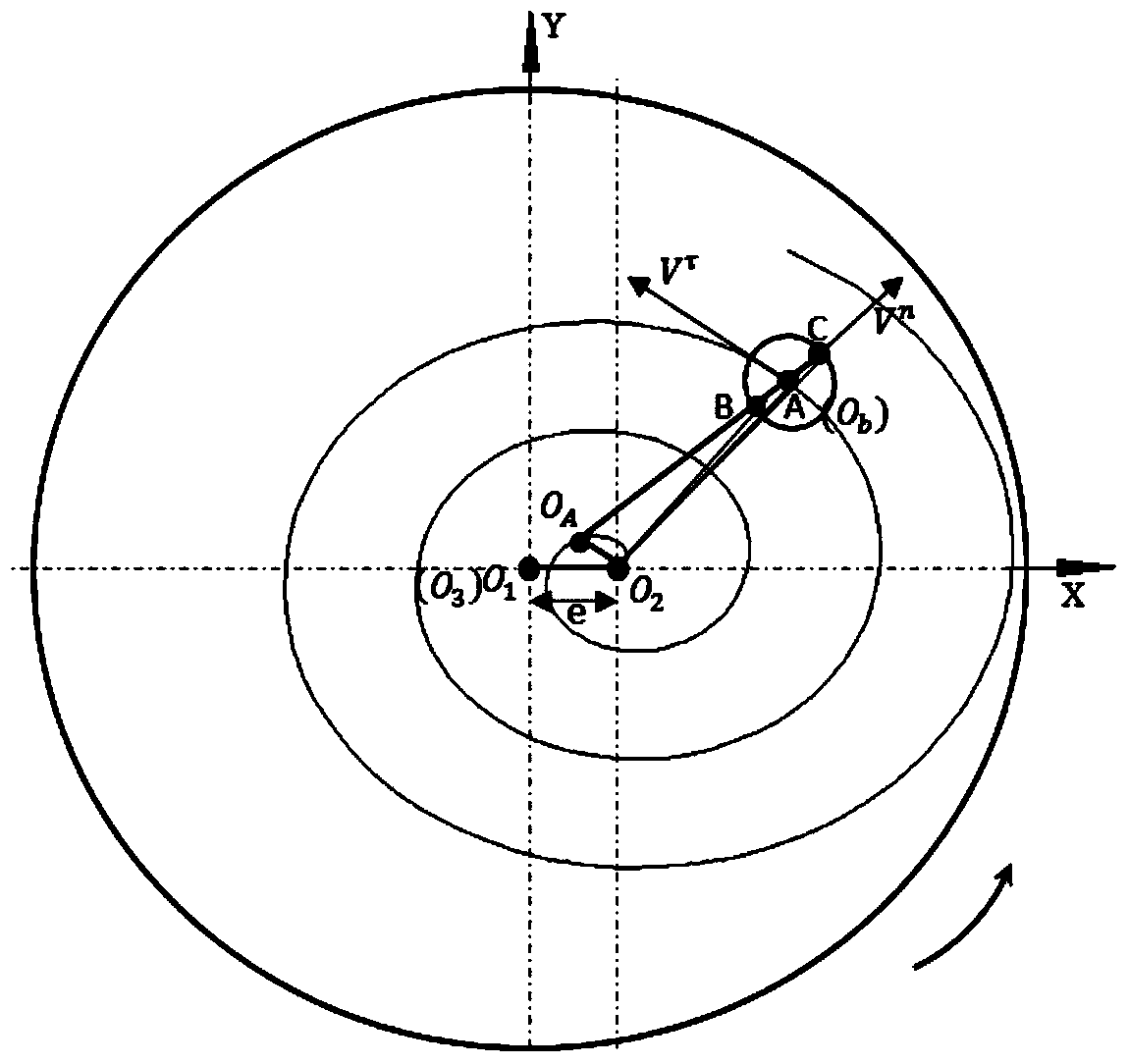

High-accuracy sphere machining device based on eccentric variable-curvature V-shaped grooved disc

InactiveCN103991018AHigh precisionImprove consistencyGrinding carriagesSpherical surface grinding machinesEngineeringMachining

A high-accuracy sphere machining device based on an eccentric variable-curvature V-shaped grooved disc comprises a rack, an upper grinding disc, a lower grinding disc and a loading system, wherein the upper grinding disc is peripherally and fixedly installed on the rack, the lower grinding disc is connected with a lower grinding disc spindle, the lower grinding disc spindle is rotatably installed on the rack, the lower grinding disc spindle is connected with a driving mechanism, the upper grinding disc is located right above the lower grinding disc, the loading system is located on the upper grinding disc, a sphere inlet is formed in the center of the upper grinding disc, a machining liquid inlet is arranged nearby the sphere inlet, the top face of the lower grinding disc is provided with a variable-curvature V-shaped groove, an eccentric distance exists between a starting point of the variable-curvature V-shaped groove and the center of the lower grinding disc, the lower end of the sphere inlet is communicated with an inlet of the variable-curvature V-shaped groove, an inlet of a sphere blank circulating system is connected with an outlet of the variable-curvature V-shaped groove, and an outlet of the sphere blank circulating system is connected with the upper end of the sphere inlet. The high-accuracy sphere machining device can achieve high machining accuracy and machining efficiency and have low device requirement.

Owner:ZHEJIANG UNIV OF TECH

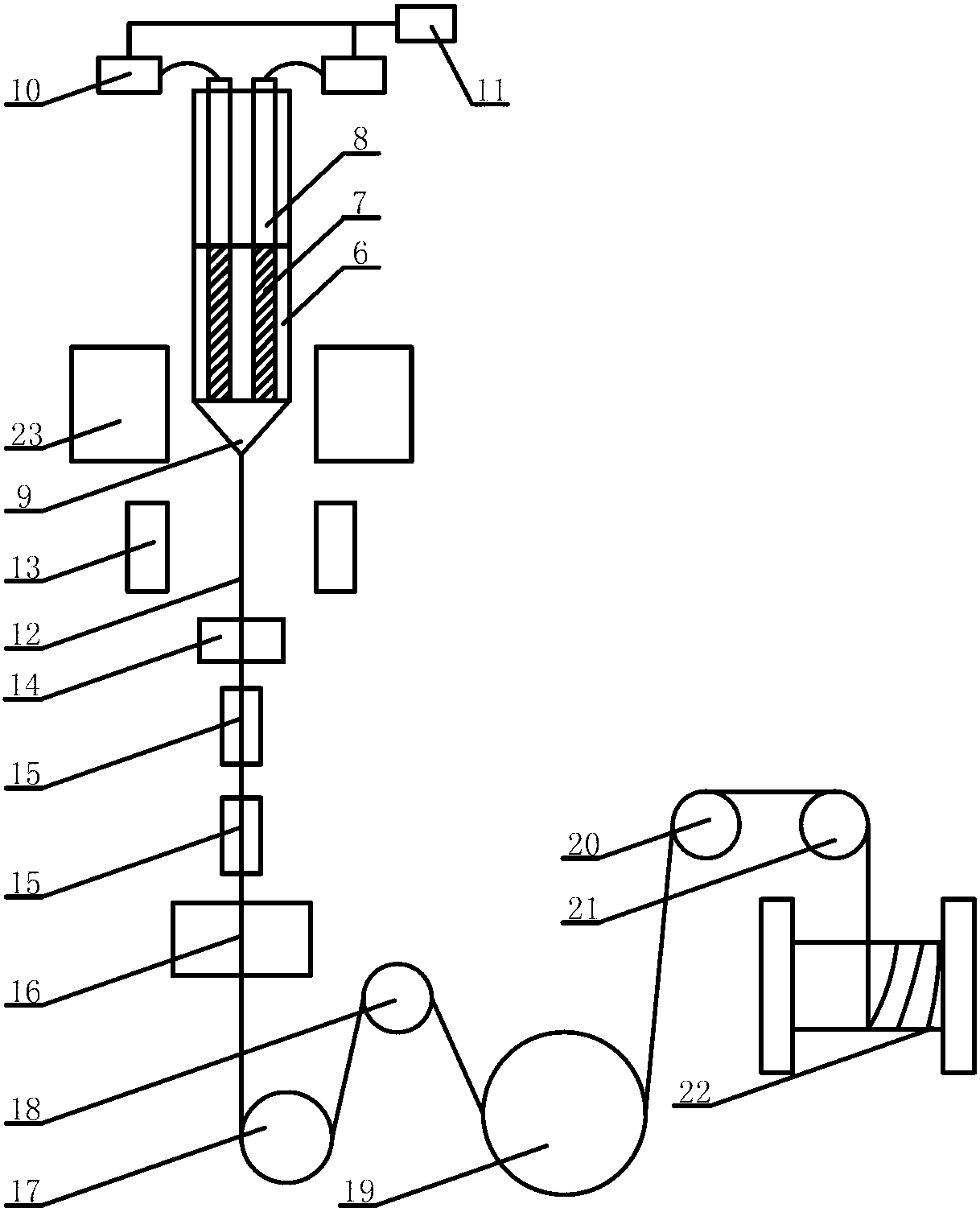

Making equipment for spices

The invention relates to making equipment for spices. The equipment comprises a feeding device, a smashing device and a grinding device, wherein the feeding device consists of a feeding pipeline and a sliding pipeline, a rotating closing plate is arranged on the wall of the sliding pipeline, a permanent magnetic iron remover is arranged on the rotating closing plate, a smashing tank of the smashing device is connected below the sliding pipeline, the lower end of one side of the smashing tank is connected with a grinding tank of the grinding device through a smashing screen and a pipeline, a rectangular hopper is arranged on the inner upper end of the grinding tank, two grinding rolls are arranged below the hopper, arc-shaped grinding screens are arranged inside the grinding tank and below the two grinding rolls, a motion shaft is arranged on the grinding tank in a penetrating manner, a plurality of grinding discs are arranged on the motion shaft, and a material storage tank is arranged on the outer side of the grinding tank and below the arc-shaped grinding screens. The making equipment is simple in structure and reasonable in design, materials are evenly ground, and no spicy flavor is generated to cause harm to the health of working staffs.

Owner:吉林省杞参食品有限公司

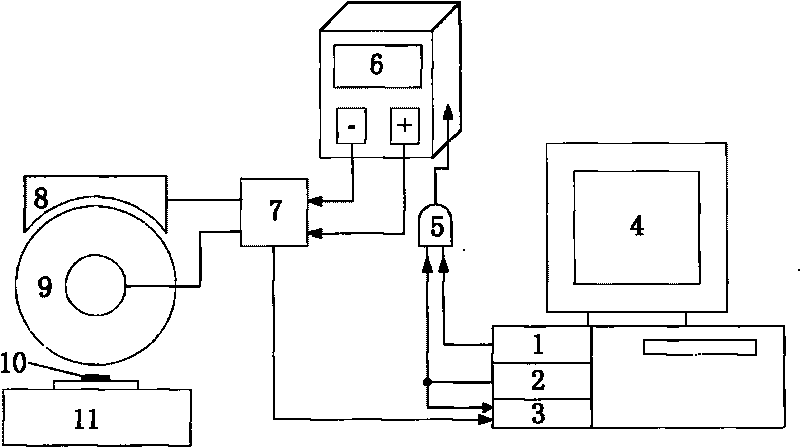

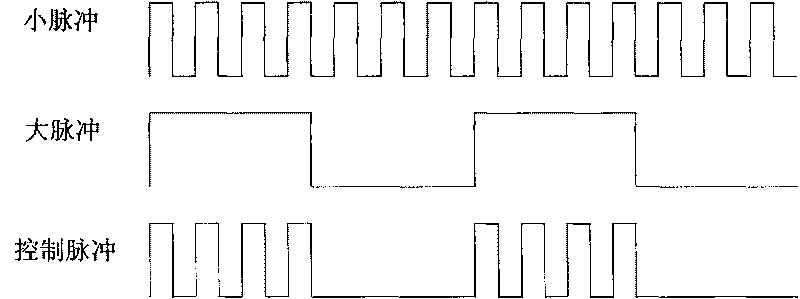

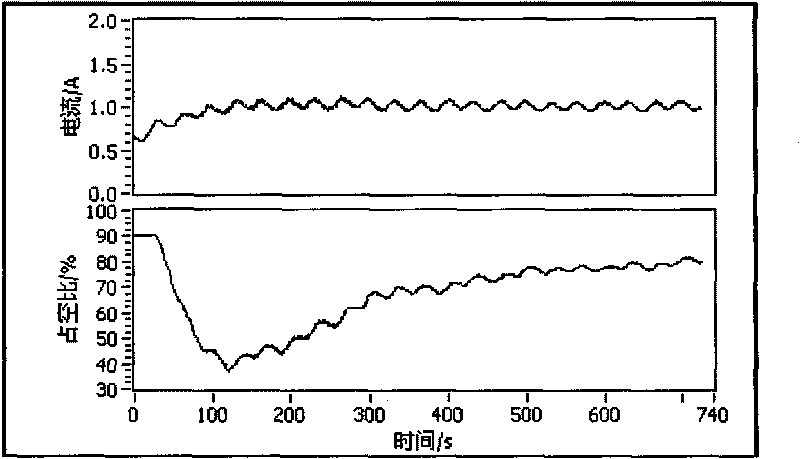

Control device and method of electrolytic current in grinding process of ELID

InactiveCN101722474AGrind evenlyStable stateComputer controlAbrasive surface conditioning devicesElectrolysisPower flow

The invention relates to control device and method of electrolytic current in the grinding process of electrolytic in-process dressing (ELID). The control device comprises a host computer, a pulse signal generating card, a data acquiring card, an AND gate driving circuit, a pulse power source and a hall sensor. The control method is characterized in that the pulse generated by the pulse signal generating card drives the pulse power source through an AND gate superimposed circuit, the data acquiring card acquires current and pulse signals through the hall sensor and a pulse card, and the pulse power source is connected with electrodes and a cast iron based grinding wheel for the ELID. In the invention, the large pulse is used for realizing the purpose of periodically starting and stopping the electrolytic action to control the electrolytic current in the grinding process, thereby controlling the state of an oxidation film to be maintained near the set target value, and ensuring the stable grinding process.

Owner:TIANJIN UNIV

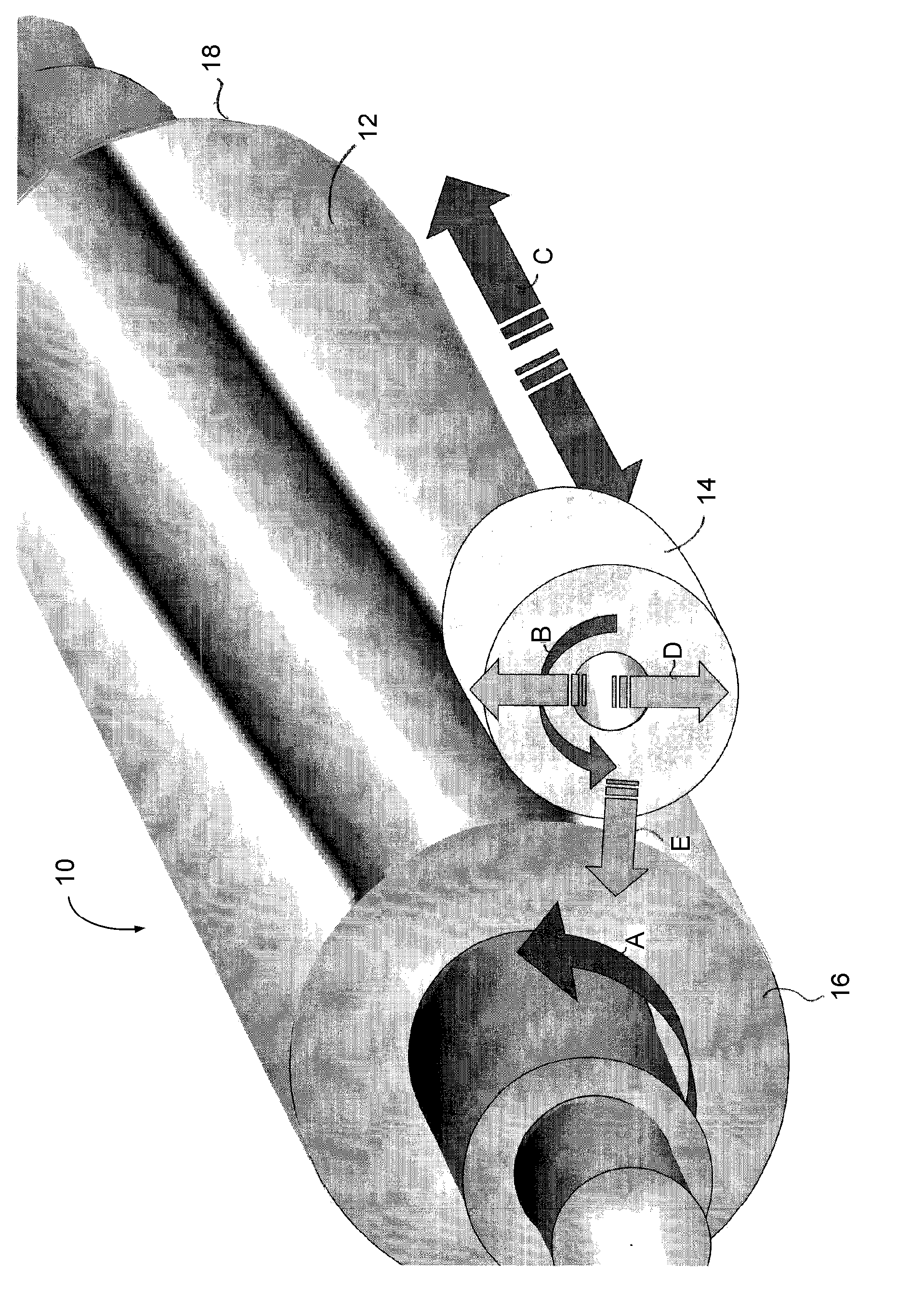

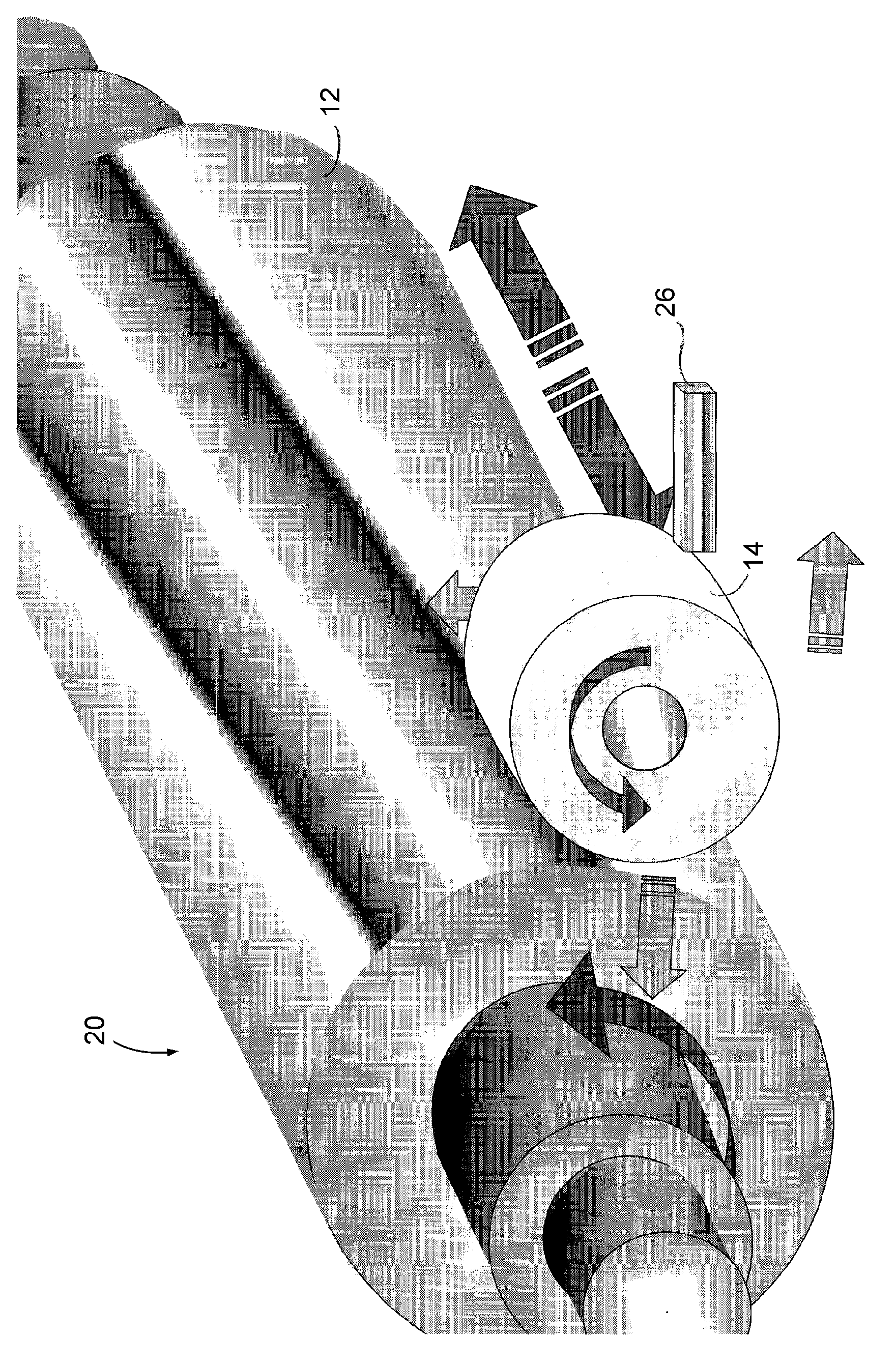

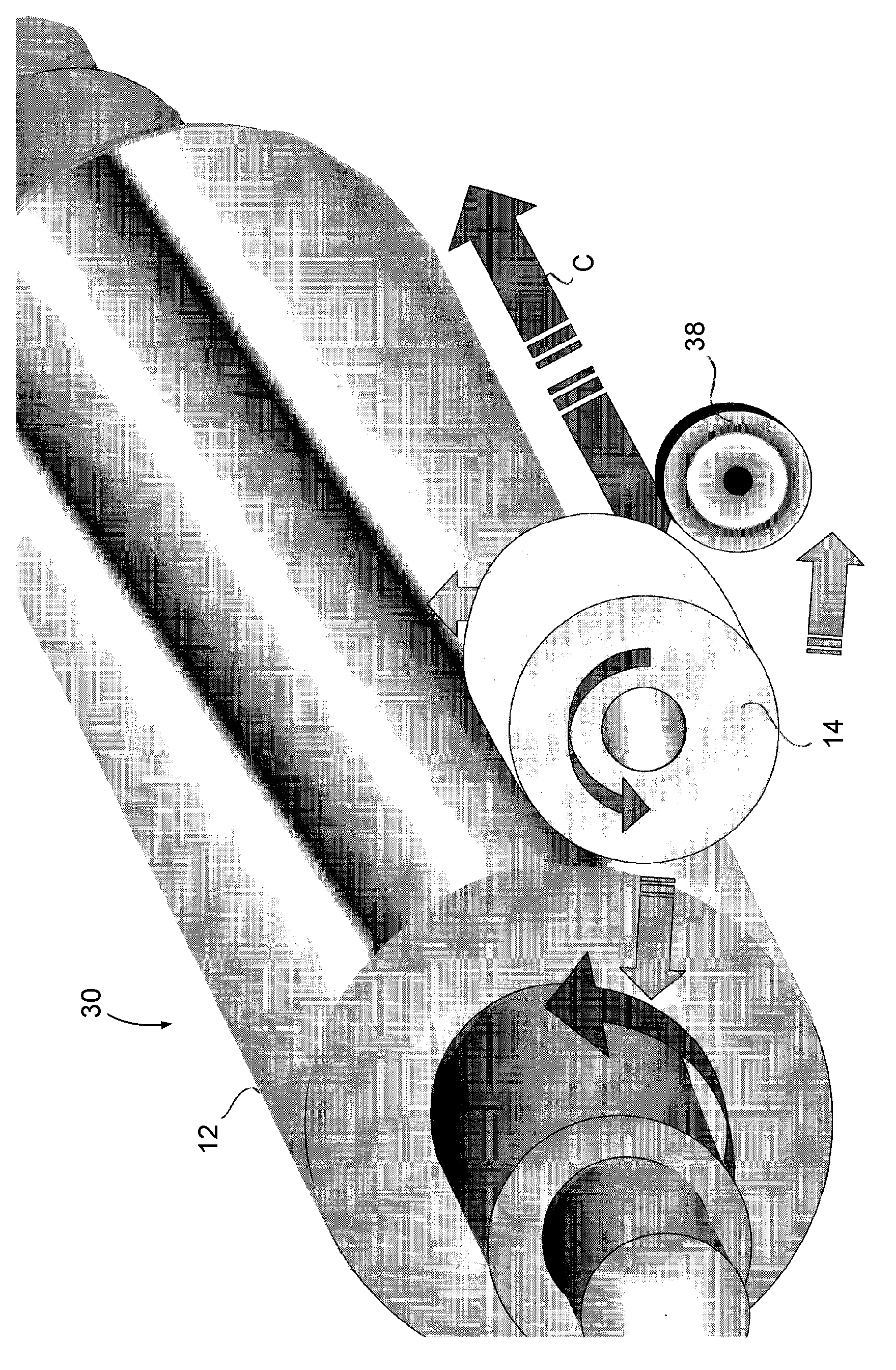

Drive type reversion polisher

ActiveCN103707170AReduce adverse effectsHigh speedPolishing machinesOptical surface grinding machinesEngineeringMechanical engineering

The invention discloses a drive type reversion polisher. The drive type reversion polisher comprises an upper disc part and a lower disc part both of which rotate in opposite directions. The upper disc part comprises a polishing die, an upper shaft and a swinging mechanism, wherein the polishing die is connected with the upper shaft through a spherical surface mechanism, and the upper shaft is further connected with a pressurizing mechanism and a rotating mechanism. The unfavorable effect caused by vibration produced by eccentricity, inertia and the like of a large workpiece is overcome due to the low-velocity rotation of the lower disc part, the grinding process is more stable, the upper disc part and the lower disc part are rotated in the opposite directions, the relative speed between the polishing die and the workpiece is effectively improved, and the machining efficiency is greatly improved under the condition that the polishing quality is guaranteed. The consistency of the relative revolving speed of the polishing die and the workpiece can be effectively guaranteed, and the occurrences that according to a traditional polisher, the passive revolving speed of a polishing die is fluctuated due to the different linear velocity differences, and polishing is uneven are avoided.

Owner:铜陵亚摩管业有限公司

Multi-stage crushing equipment for solid veterinary drugs for livestock farm

The invention relates to veterinary drug crushing equipment, in particular to multi-stage crushing equipment for solid veterinary drugs for a livestock farm. The multi-stage crushing equipment aims at achieving the technical purposes that the crushing effect is good, crushing is uniform, and the structure is novel. To achieve the technical purposes, the multi-stage crushing equipment for the solid veterinary drugs for the livestock farm is provided. The multi-stage crushing equipment comprises a bottom plate, a collecting frame, hinges, a first rotating shaft, baffles, a second L-shaped bracket, a roller, a right frame, crushing teeth, first bearing seats, first L-shaped brackets and the like. A left frame is welded to the left end of the top of the bottom plate. A second bearing seat is connected to the upper portion of the left frame in a bolt connecting manner. A bearing in the second bearing seat is in interference fit with a second rotating shaft. The multi-stage crushing equipment has the beneficial effects of being good in crushing effect, uniform in crushing and novel in structure. The multi-stage crushing equipment plays an important role, not only has the good crushing effect, but also improves the working efficiency and has high safety.

Owner:庄永和

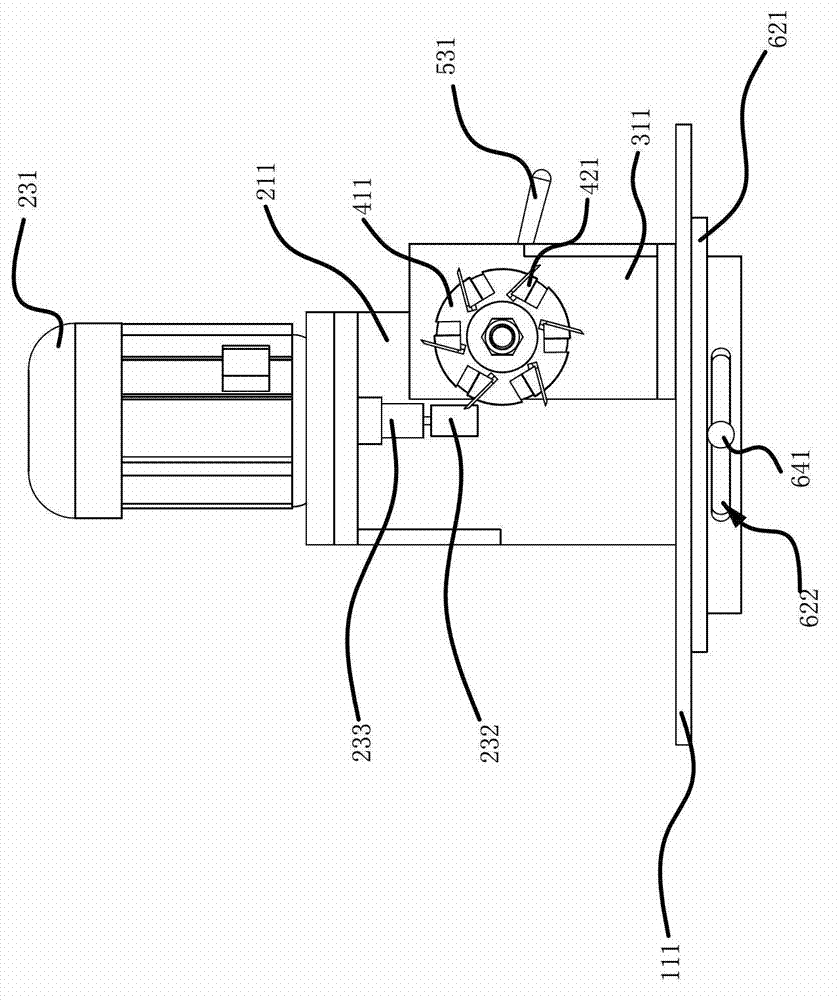

Knife grinder for grinding formed blade

InactiveCN103084937AAchieve grindingEasy to processOther manufacturing equipments/toolsElectric machineryEngineering

Owner:台州市奕帆帝门工业设计股份有限公司

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

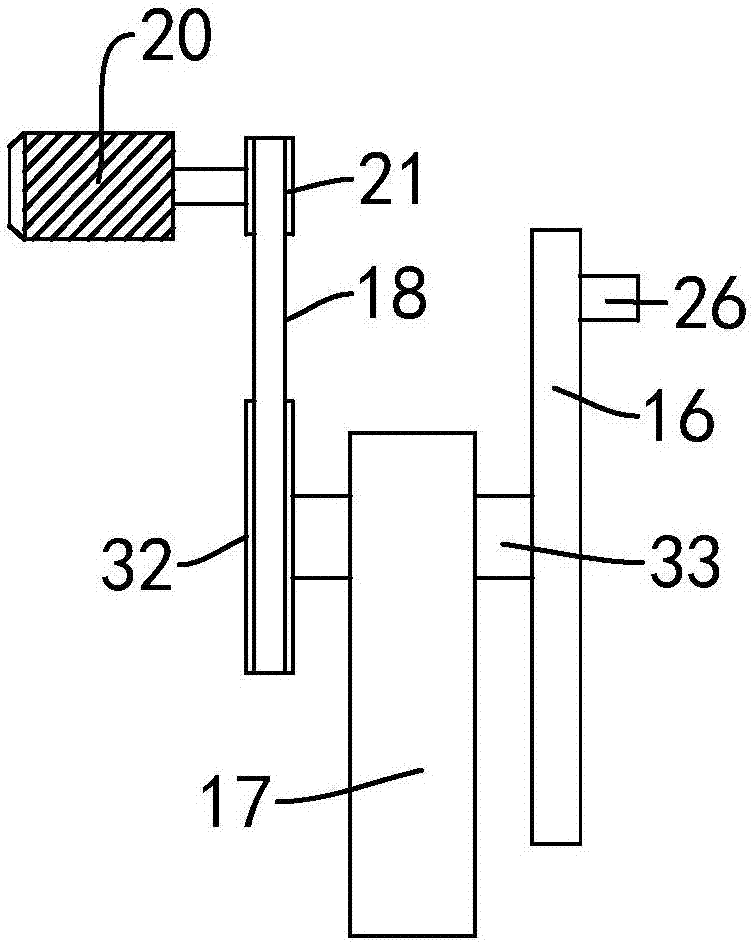

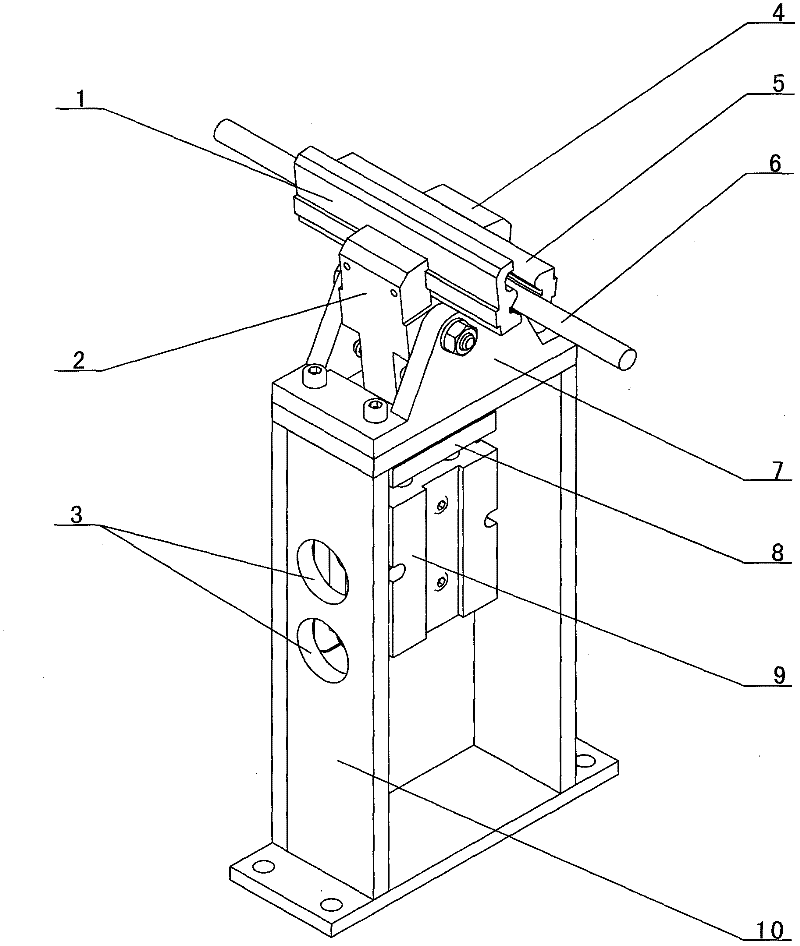

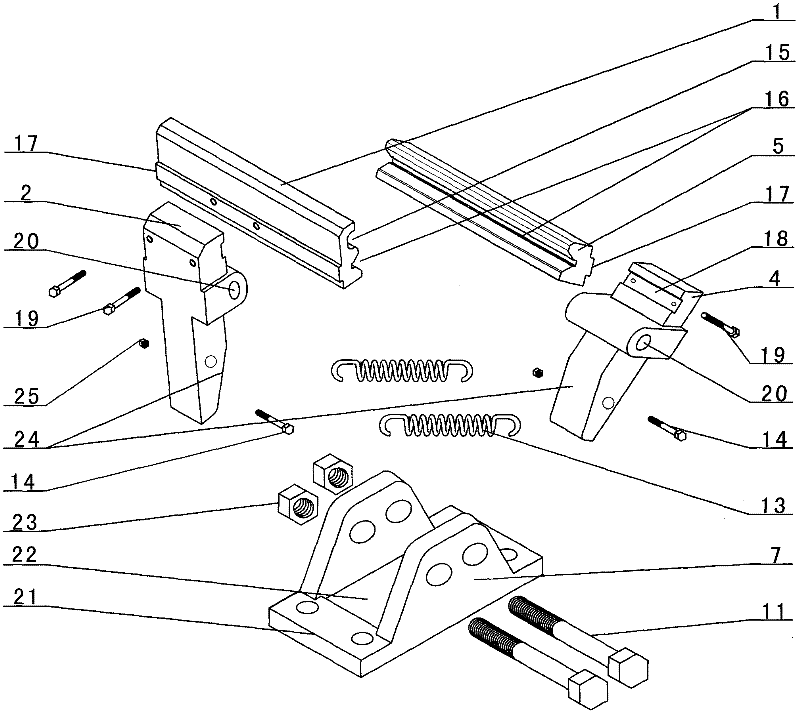

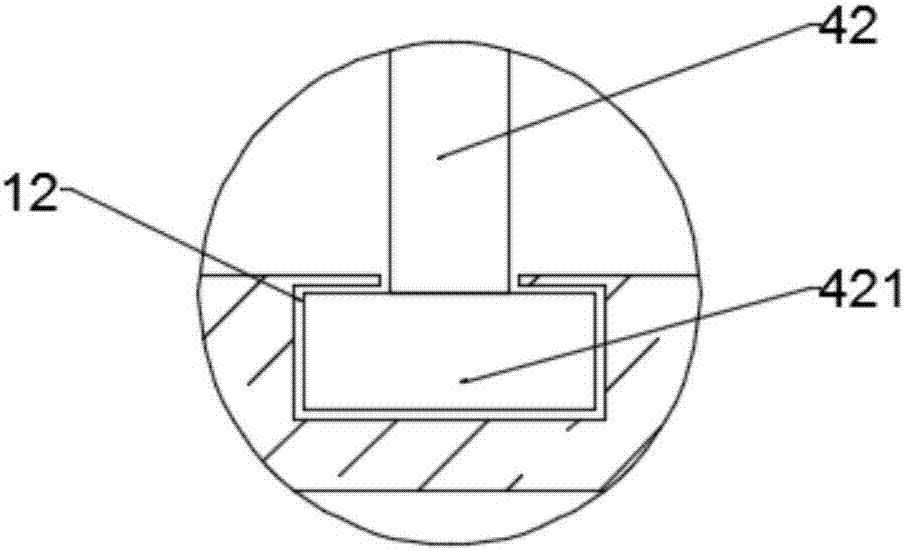

A centering clamping device for crystal material processing

ActiveCN102294761AImprove work efficiencyGrinding evenlyWorking accessoriesGrinding work supportsCrystalline materialsRocker arm

The invention relates to a fixture for a crystal material, in particular to a centering and clamping device used for processing the crystal material. The fixture is characterized in that the opposite faces of the upper parts of a rocker arm (2) at one side and a rocker arm (4) at the other side are respectively fixedly connected with a big clamping piece (1) and a small clamping piece (5), the opposite faces of the big clamping piece and the small clamping piece are respectively provided with slots (16), the lower part at a hinge joint of rocker arm support plates (7) on the bases of the rocker arm at one side and the rocker arm at the other side is respectively connected with the two ends of an elastic body; a corresponding lower part between the rocker arm at one side and the rocker arm at the other side is provided with a wedge-shaped block (8) which is small at the top and big at the bottom, and the lower part of the wedge-shaped block (8) is provided with a power mechanism which moves up and down. In the invention, by virtue of the big clamping block on the rocker arm at one side and the small clamping block on the rocker arm at the other side, stable positioning on a silicon core is realized, and accurate drilling or grooving or grinding on the silicon core is realized; and the defect that a hole or grinding groove on a transverse or vertical silicon core is non-standard due to the traditional manual operation mode is overcome by using the fixture provided by the invention.

Owner:LUOYANG JINNUO MECHANICAL ENG

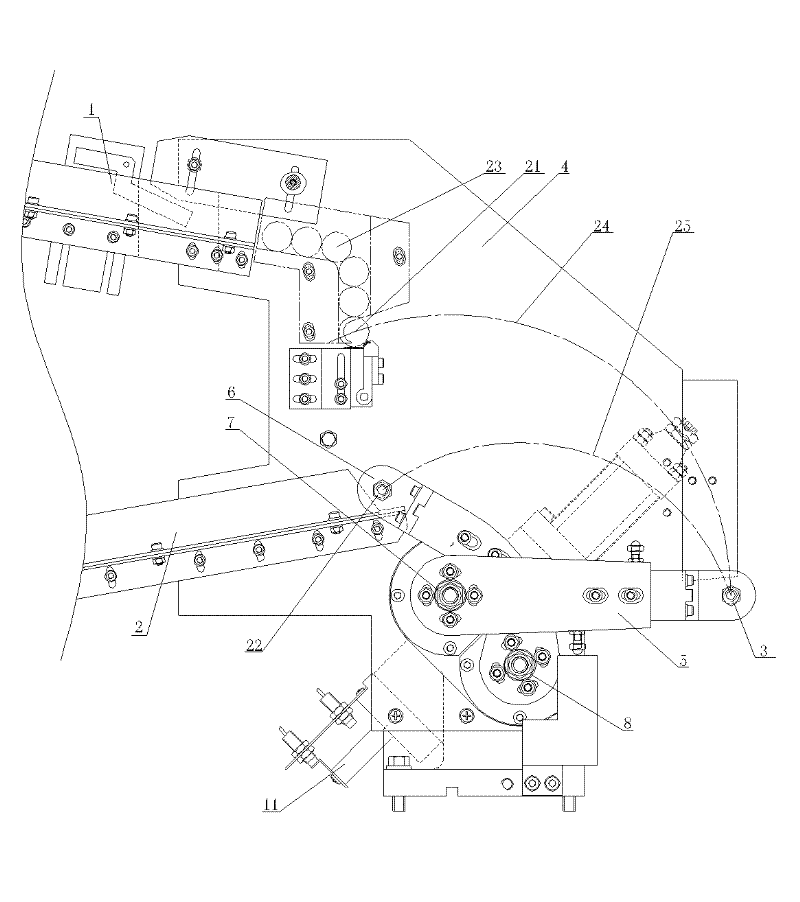

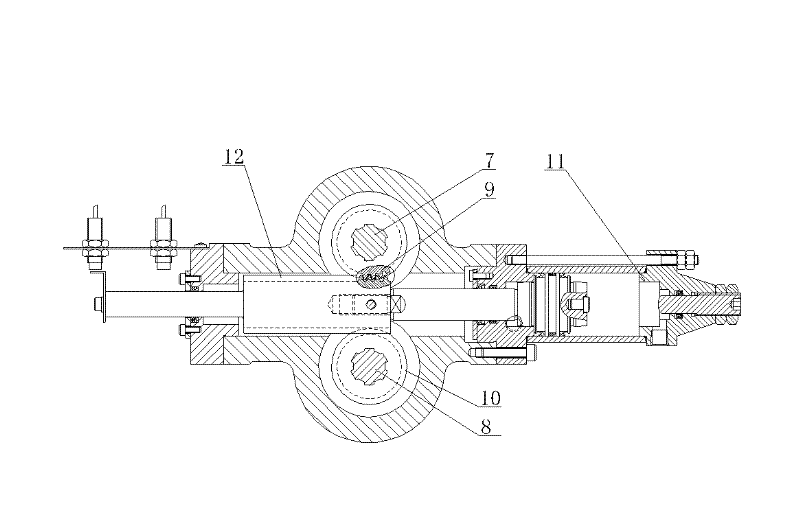

Milling arrangement for tunnel walls

InactiveUS20070138857A1Grind evenlyPossible to moveGrinding machinesTunnel liningSurface roughnessEngineering

The invention relates to a vehicle with a milling arrangement on top. The milling arrangement includes a milling device for grinding an upper tunnel wall surface like tunnel ceilings of traffic tunnels. Such a vehicle with the milling arrangement according to the invention is suitable for treating tunnel walls such that a desired surface roughness and the removal of carbon black results. This assures that a lining which is applied to the tunnel ceiling and wall surface is sufficiently attached to said surfaces.

Owner:BLASTRAC

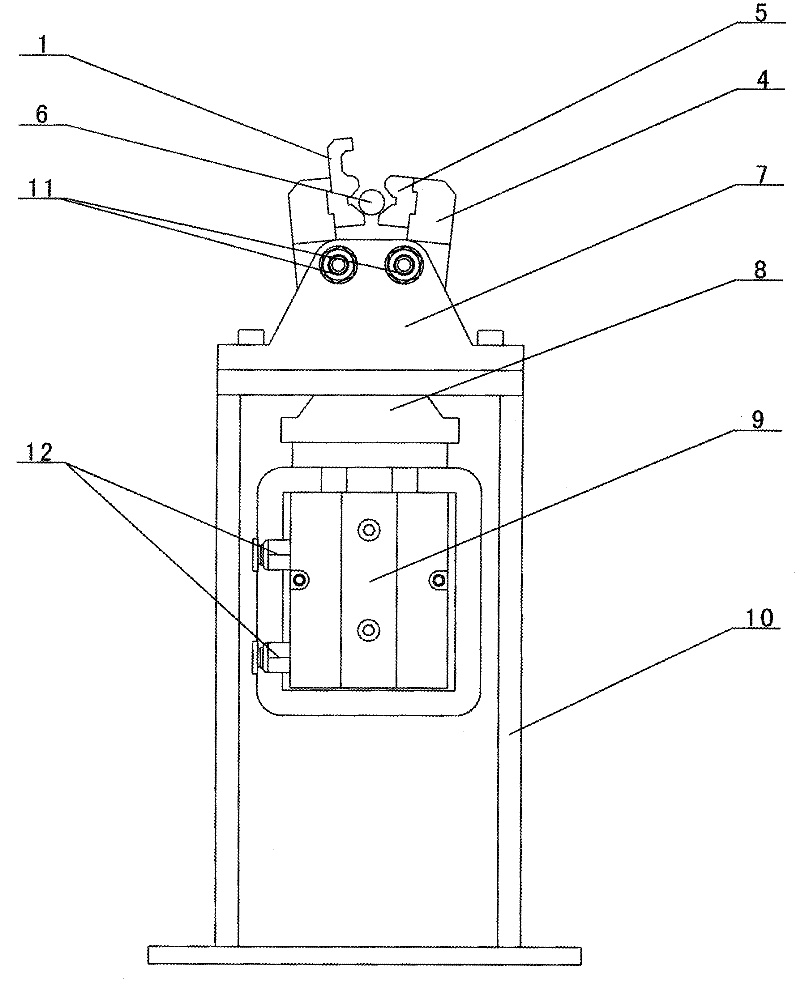

Double-material arm charging and blanking mechanism for grinding machine

InactiveCN102416584ALow costGrind evenlyRevolution surface grinding machinesEngineeringMechanical engineering

The invention provides a double-material arm charging and blanking mechanism for a grinding machine. By the double-material arm charging and blanking mechanism, only the cost of machines is needed in the grinding process, so the integral grinding cost is reduced, the integral grinding process is smooth, and a normal production progress is ensured. The double-material arm charging and blanking mechanism comprises a charging channel, a blanking channel, a grinding station of the grinding machine, a panel and a charging arm, wherein the charging channel and the blanking channel are formed on the front side of the panel respectively. The double-material arm charging and blanking mechanism is characterized by also comprising a blanking arm, wherein the charging arm and the blanking arm are positioned on the front side of the panel; a charging rotation shaft and a blanking rotation shaft are sleeved in rotation centers of the charging arm and the blanking arm respectively; the charging rotation shaft and the blanking rotation shaft pass through the panel; a charging gear and a blanking gear which are positioned on rear side of the panel are sleeved on the charging rotation shaft and the blanking rotation shaft respectively; a rack is arranged at the driving end of a material arm rotation oil cylinder; and two lateral teeth of the rack are correspondingly meshed with the charging gear and the blanking gear respectively.

Owner:无锡市锡山区鹅湖镇荡口新华机械厂

Soybean grinding device capable of preventing soybean powder from hanging on wall

InactiveCN107362863AAvoid hanging on the wallPlay the role of turning soybean flourGrain treatmentsEngineeringMechanical engineering

The invention discloses a soybean grinding device for preventing soybean powder from hanging on the wall, which comprises a base, a supporting platform, a movable column, a grinding frame and a double-axis motor; Above the base, a movable column is inserted in the center of the supporting platform, and the movable column is slidingly connected with the supporting platform. The lower end of the movable column is connected with a grinding block with air holes. The movable column is a hollow structure, and the top of the movable column is connected with a telescopic hose. There is a blind plate on the top of the telescopic hose, and the left side of the blind plate is connected to the intake pipe with a one-way valve installed. The motor is located above the blind plate, and a pressing rod is connected between the biaxial motor and the blind plate. The invention can effectively solve the wall-hanging phenomenon in soybean grinding, ensure the uniformity of grinding, and meanwhile has good grinding effect, and is worth popularizing and using.

Owner:胡忠义

Dry powder raw material grinding device for producing fire extinguisher

InactiveCN108672054AGrind evenlyGrinding speed is fastSievingScreeningFire extinguisherGrinding wheel

The invention relates to a powder grinding device, in particular to a dry powder raw material grinding device for producing a fire extinguisher. The dry powder raw material grinding device for producing the fire extinguisher is high in smashing efficiency, smashing is uniform, and raw materials are not stacked easily in the smashing process. According to the technical scheme, the dry powder raw material grinding device for producing the fire extinguisher comprises a bottom plate, a left support, a right support, a round supporting plate, a grinding box, a collecting box, a supporting rod, a first rotating shaft, a fan-shaped gear, an air cylinder, a grinding wheel, an electric pushing rod and the like. The left support is arranged on the left side of the top of the bottom plate. The rightsupport is arranged on the right side of the top of the bottom plate. The round supporting plate is arranged in the middle of the top of the bottom plate. According to the dry powder raw material grinding device, the electric pushing rod serves as the main power source to drive the grinding wheel to swing to carry out grinding, meanwhile, by means of mutual cooperation of the fan-shaped gear and arack, a baffle moves left and right indirectly, the raw materials are discharged intermittently, the raw materials are ground while being discharged, and the raw materials are not stacked easily in the grinding process.

Owner:胡智晶

Floating disc suspension polishing device

ActiveCN103331691AAvoid damageImprove machined surface qualityLapping machinesEngineeringMechanical engineering

A floating disc suspension polishing device comprises a polishing base disc and a floating disc, wherein wedge grooves and processing stations for placing workpieces to be processed are formed and arranged on the surface, opposite to the floating disc, of the polishing base disc in the circumferential direction; the wedge grooves are filled with polishing solutions; the wedge grooves and the processing stations are arranged at intervals; the polishing device further comprises a spring, a force sensor, a lifting platform and a master driver; the polishing base disc and the master driver are connected and can rotate around a spindle; the polishing base disc is positioned on the floating disc; the floating disc is connected with the upper end of the spring; the lower end of the spring is connected with the force sensor; and the force sensor is fixedly connected with the lifting platform. The floating disc suspension polishing device presses precisely, grinds stably, and is small in surface damage and high in quality.

Owner:奥特贝(天津)机器人有限公司

Method and apparatus for roll grinding

InactiveCN102725102ASolution to short lifeReduce the numberRevolution surface grinding machinesRolling equipment maintainenceEngineeringGrinding wheel

In one aspect, a process for roll grinding employs a grinding wheel that is porous and permeable. In another aspect, a process for grinding mill rolls includes dressing the grinding wheel as the wheel traverses the surface of a mill roll. Other aspects relate to a system, e.g., a mill roll grinding machine, or parts thereof, in which a dressing tool contacts the wheel as the wheel grinds the surface of the mill roll. In specific examples, the wheel and a rotary dressing tool are maintained in contact as the wheel traverses the surface of the mill roll.

Owner:SAINT GOBAIN ABRASIVES INC +1

Medicine grinding device

The invention provides a medicine grinding device. The medicine grinding device comprises a case, a rotating motor, a lifting rod and a grinding disk; feeding ports of the case are formed in two sides of the case; a discharging port of the case is formed in the bottom of the case; the rotating motor is arranged at the top of the case; the lifting rod is connected onto the rotating motor; the other end of the lifting rod is connected with the top of the grinding disk; the medicine grinding device is characterized in that grinding balls are arranged on the bottom layer of the grinding disk; a grinding tank is arranged at the lower part of the grinding disk; circular grooves are formed in the grinding tank; the grinding balls are opposite to the circular grooves; flow guiding channels are formed in the grinding tank; a through hole is formed in the center of the grinding tank; the flow guiding channels communicate with the circular grooves and extend to the through hole; a storage box is arranged at the bottom of the case; and the top of the storage box communicate with the inner cavity of the case through a screen.

Owner:TIANJIN MAOLIN AQUATIC PROD CULTURE CO LTD

Petroleum asphalt grinding device for producing waterproof coiled material

The invention relates to a grinding device, in particular to a petroleum asphalt grinding device for producing a waterproof coiled material. The technical problem to be solved is to provide the petroleum asphalt grinding device which is used for producing the waterproof coiled material and is uniform in grinding effect, convenient to move, capable of preventing petroleum asphalt from being adheredto tools during machining and capable of achieving uniform discharging. To solve the technical problem, the petroleum asphalt grinding device for producing the waterproof coiled material is provided.The petroleum asphalt grinding device for producing the waterproof coiled material comprises a bottom plate, an L-shaped plate, a collection frame, a first support rod, a grinding disc, a filtering net and the like. The collection frame is arranged in the middle of the top of the bottom plate. The first support rod is arranged on the top of the bottom plate. The first support rod is located on the rear side of the collection frame. The grinding disc is arranged on the top of the first support rod. The filtering net is arranged on the grinding disc. The petroleum asphalt grinding device for producing the waterproof coiled material has the beneficial effects that the grinding is uniform, movement is convenient, the petroleum asphalt can be prevented from being adhered to the tools during machining, and uniform discharging can be achieved.

Owner:湖南弘百实业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com