Milling arrangement for tunnel walls

a technology for tunnel walls and milling arrangements, applied in the direction of tunnel linings, cutting machines, stone-like material working apparatuses, etc., can solve the problems of carbon black layer and concrete starting to bum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

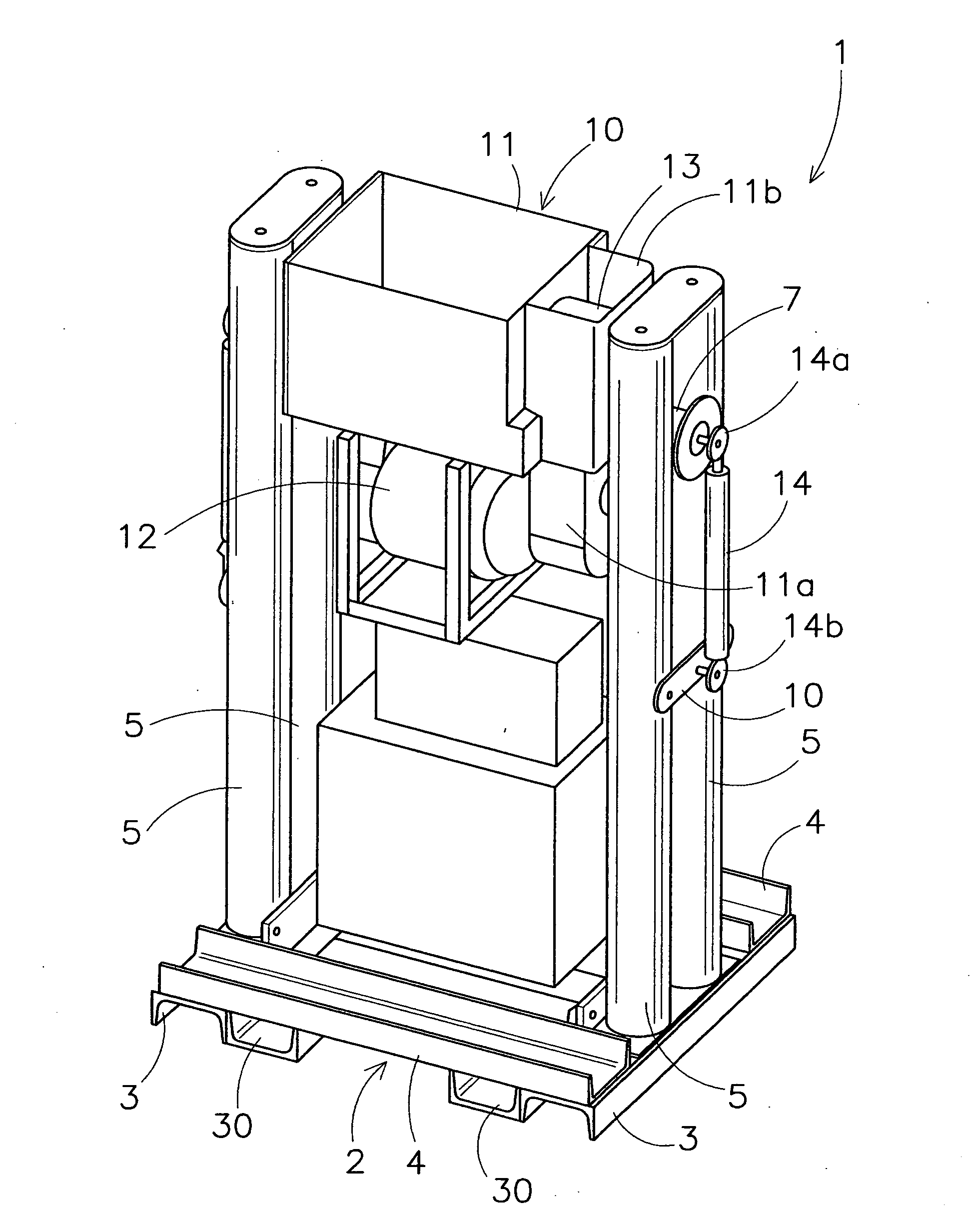

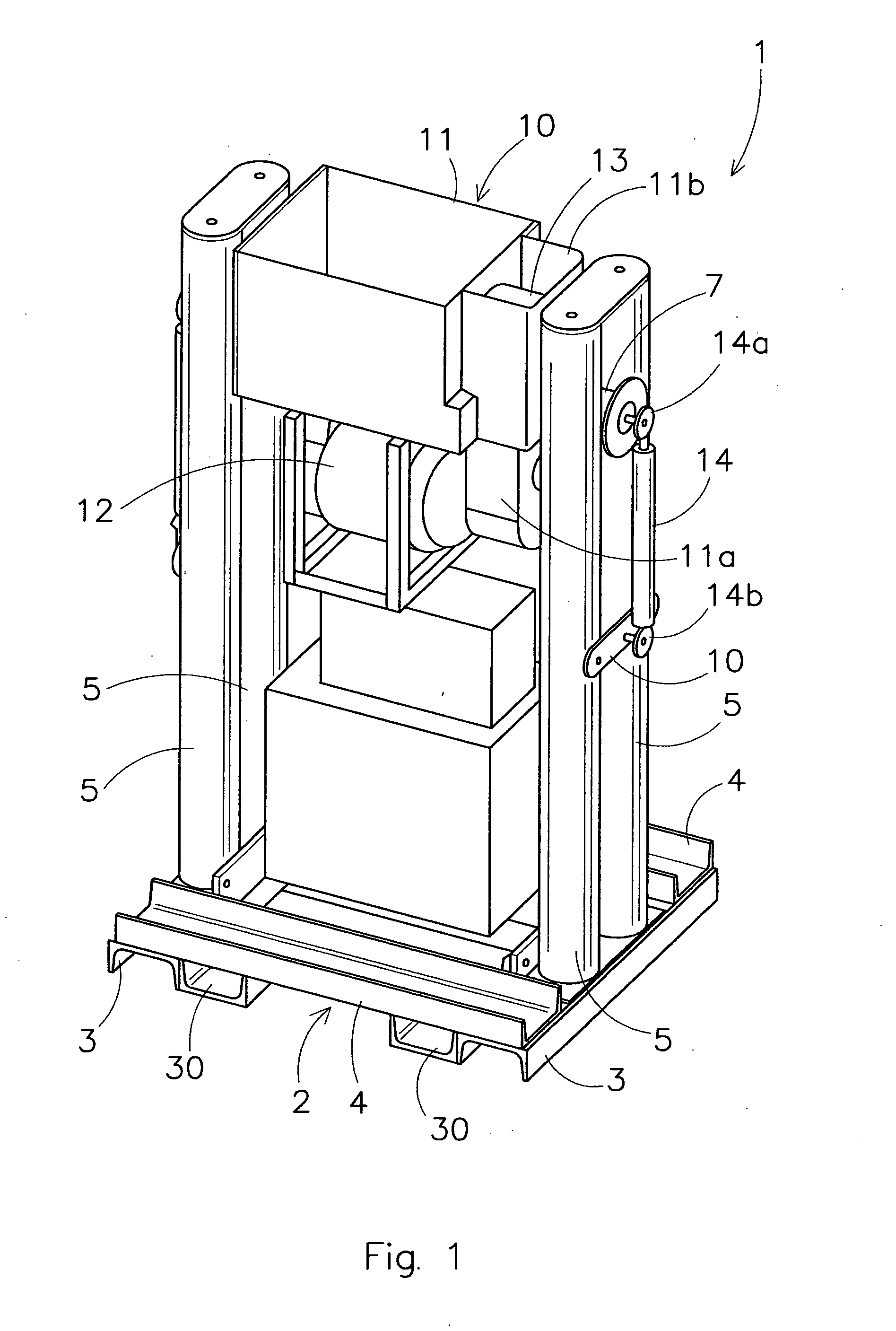

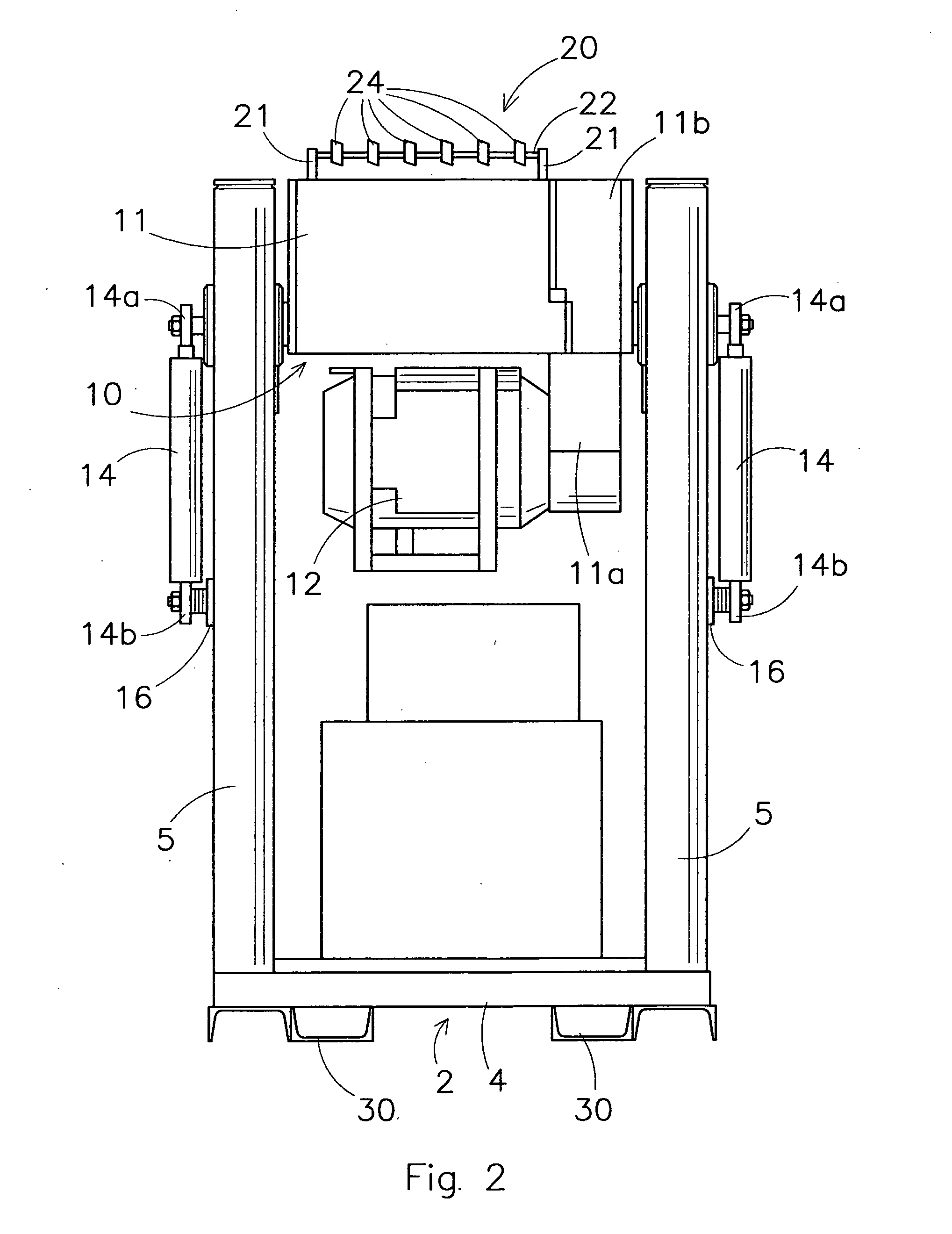

[0025] In FIGS. 1-3 is shown a milling arrangement 1. The milling arrangement 1 comprises a support base 2. In the shown example the support base 2 comprise a support frame which is formed of longitudinal beams 3 and lateral beams 4 in this particular example each with a U-shaped cross section. The support base 2 could however also be of a different structure, e.g. out of other types of beams or even formed as a single support plate.

[0026] On each side of the base 2 on the beams 3 is placed a pair of two spaced apart tubular guiding elements 5 with a cylindrical outer shape. The tubular guiding elements 5 extend from the support base 2 upwardly and parallel to each other. As is best seen in FIG. 3 between the tubular guiding elements 5 a space 6 is present in which a guiding roll 7 is moveable.

[0027] The milling arrangement 1 comprises a milling device 10. The milling device 10 comprises a casing 11 in which the milling tool 20 that will be described in more detail below is rotata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| movement | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com