Method and apparatus for roll grinding

A roll and grinding wheel technology, which is used in the field of roll grinding and devices, can solve the problem of increasing the total time, and achieve the effects of increasing consistency, long wheel life, and long roll life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

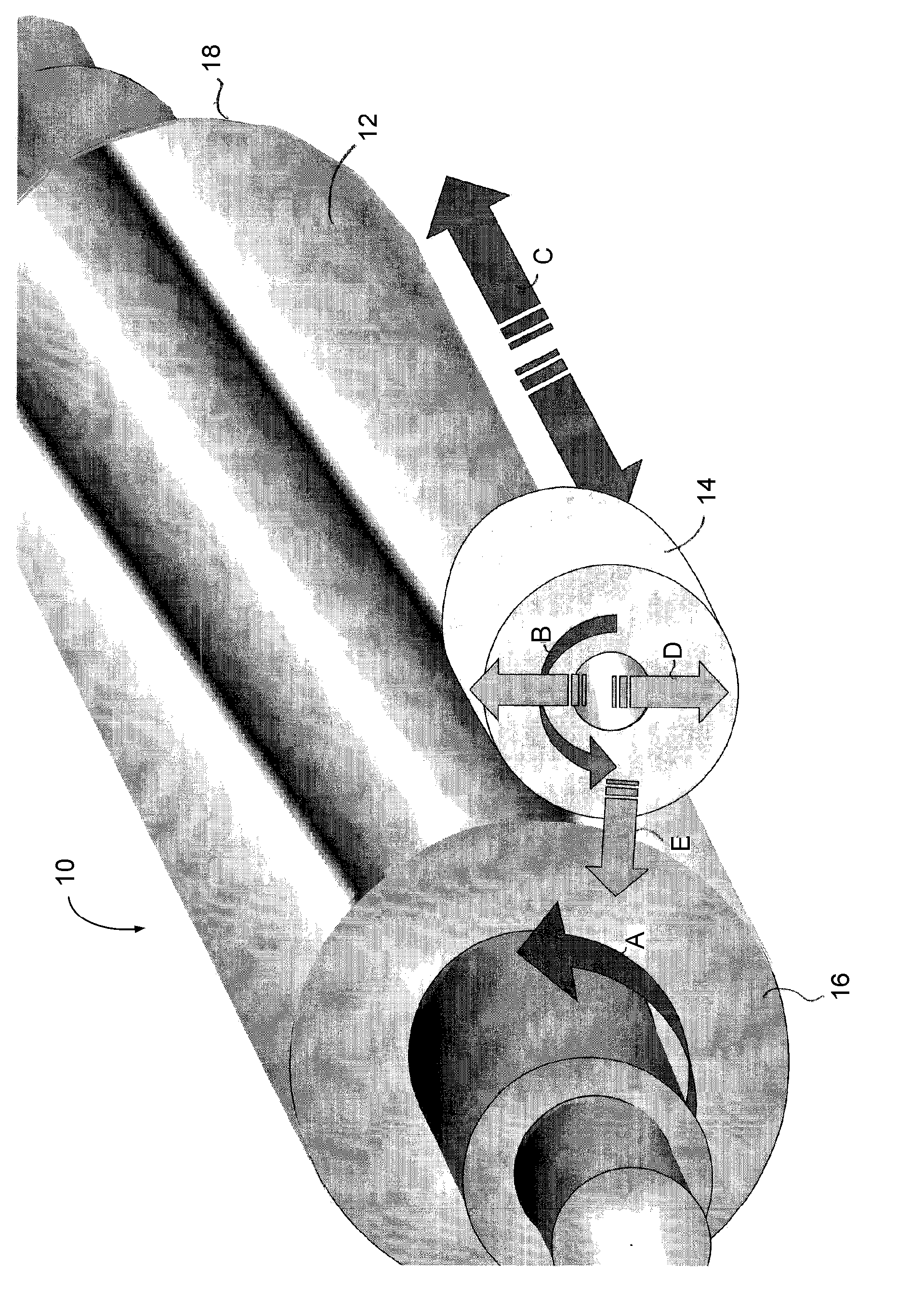

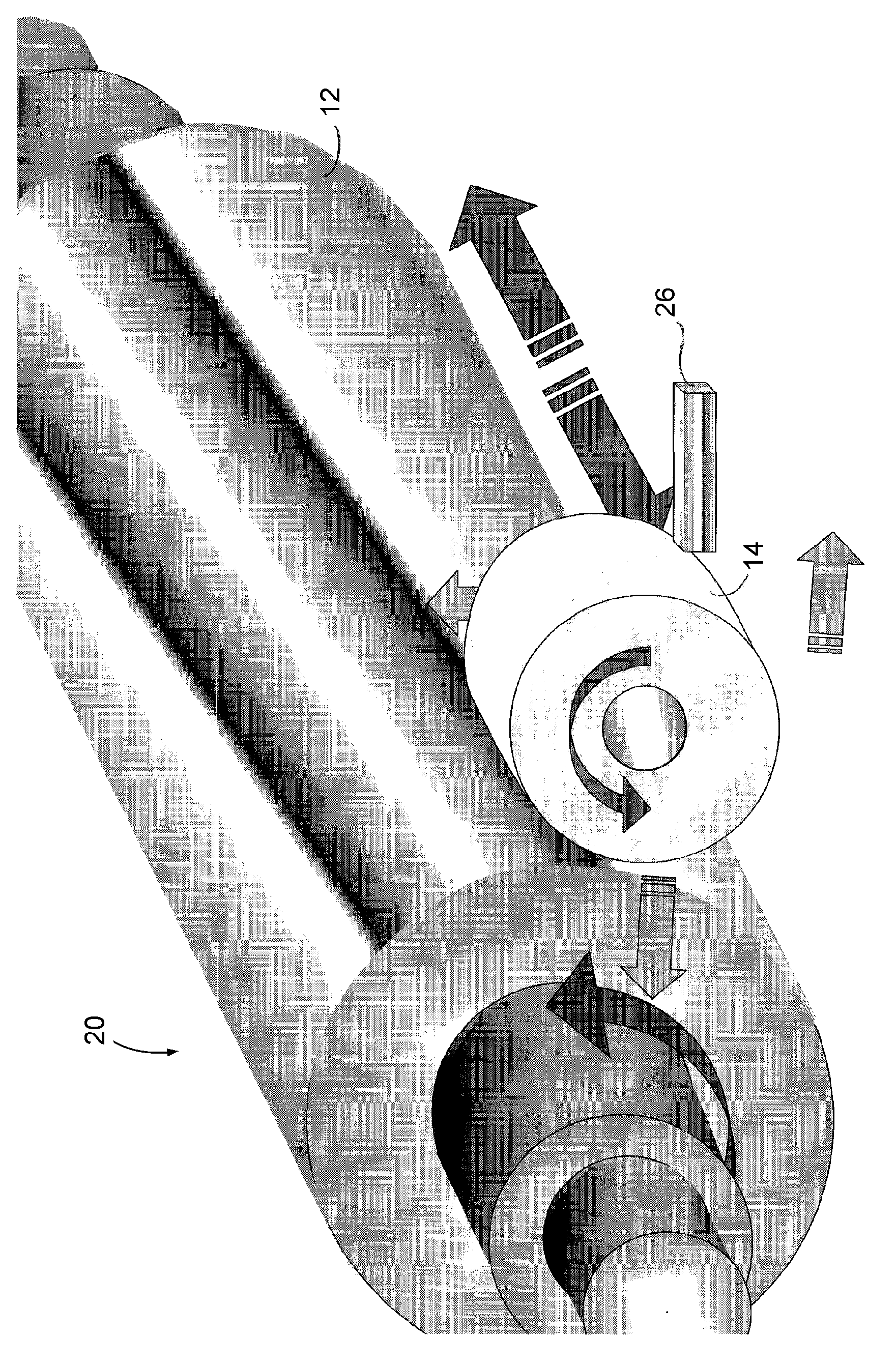

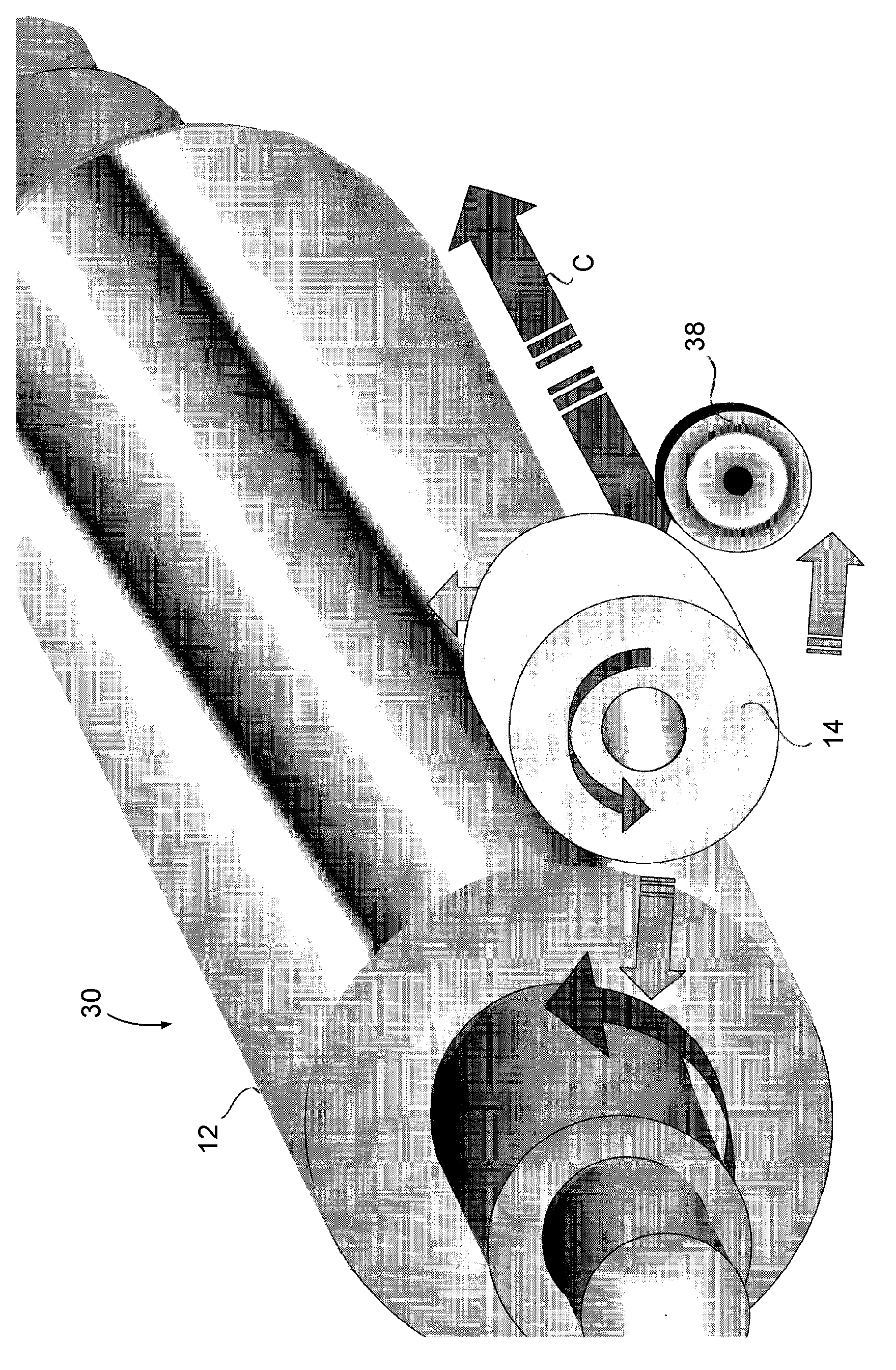

[0130] In one instance, using the Figure 5A and 5B A single type wheels and a continuous dressing arrangement to process 1400 rolls. About 0.12 mm was removed from the roll radius at a material removal rate (MRR') of 12 mm3 / s / mm. The G ratio is about 35 and the total processing time is about 15 minutes. The wheel works on all profiles and a desired Ra can be achieved by varying the speed of the wheel.

[0131] In another example, a single type of wheel, such as Figure 5A and 5B Trimming as shown in , 60 rolls were machined and about 0.2mm was removed from the roll radius with an MRR' of 5mm3 / s / mm. The G ratio is about 2. The grinding wheel works on all profiles and a desired Ra can be achieved by varying the speed of the wheel.

[0132] In yet another instance, such as Figure 5A and 5B A single Quantum grinding wheel (organic size) shown in Figure 1 was dressed, 250 rolls were machined, and about 0.25mm was removed on the roll radius. The MRR' is 8mm3 / s / mm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com