Patents

Literature

1070results about How to "Easy to trim" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

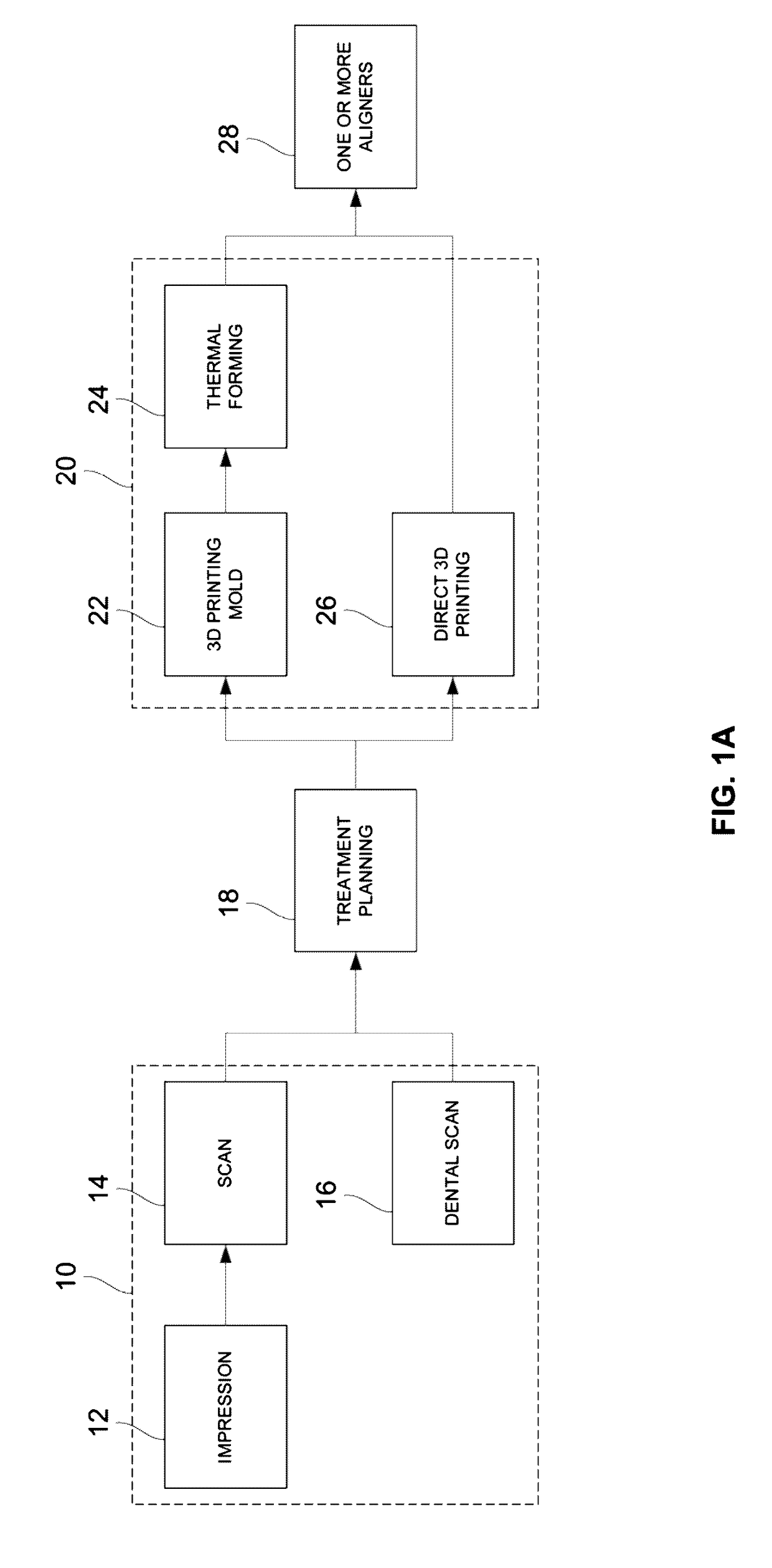

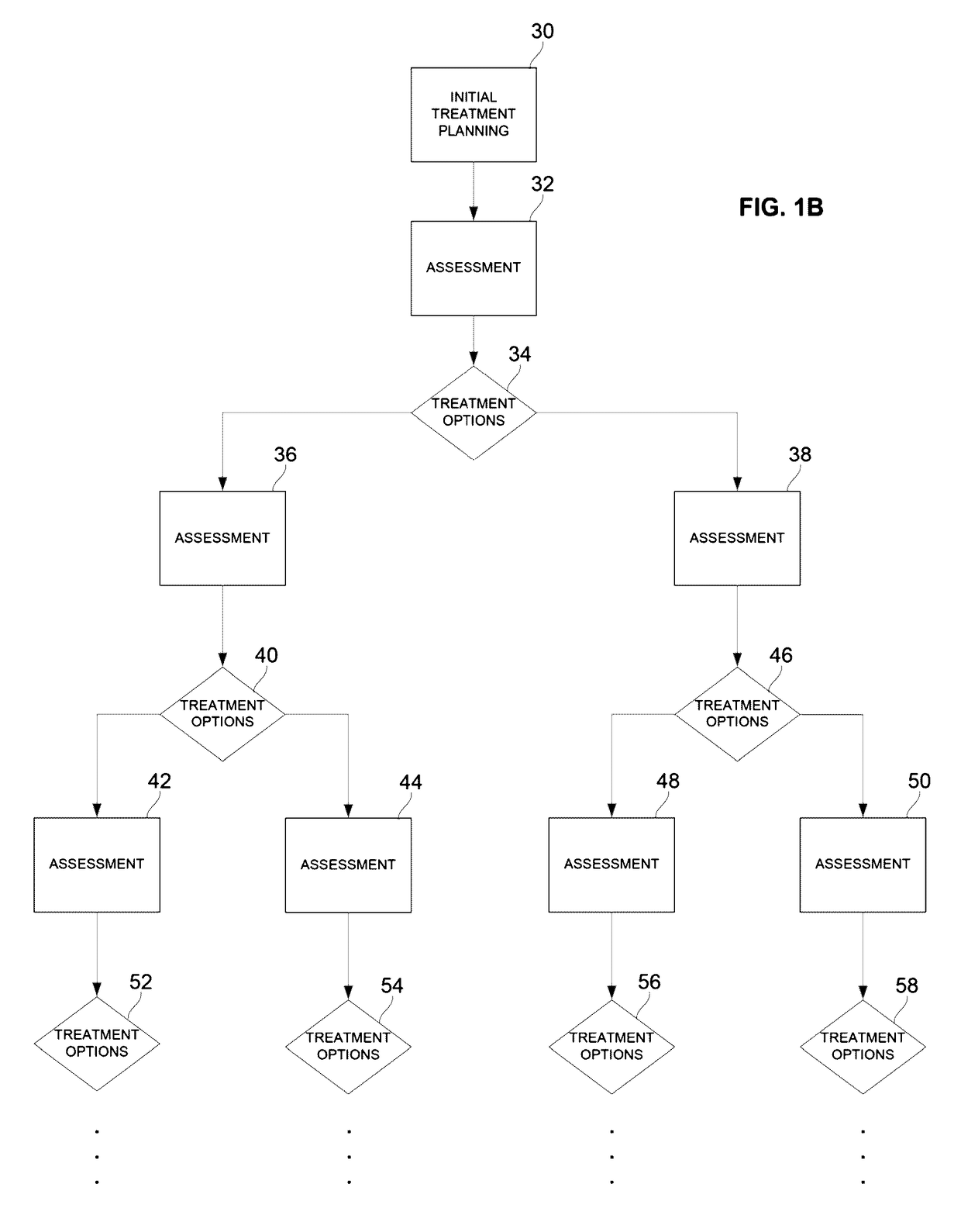

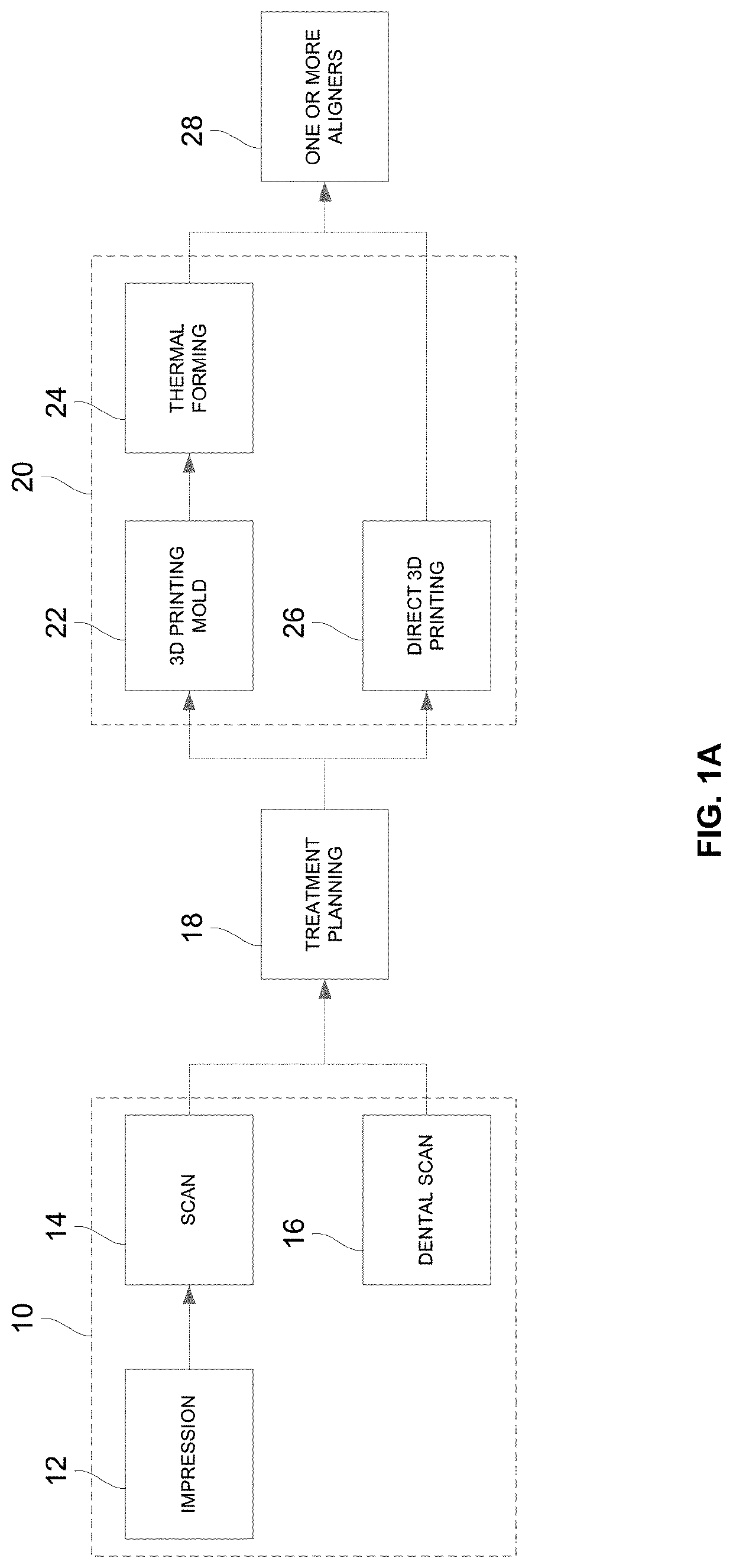

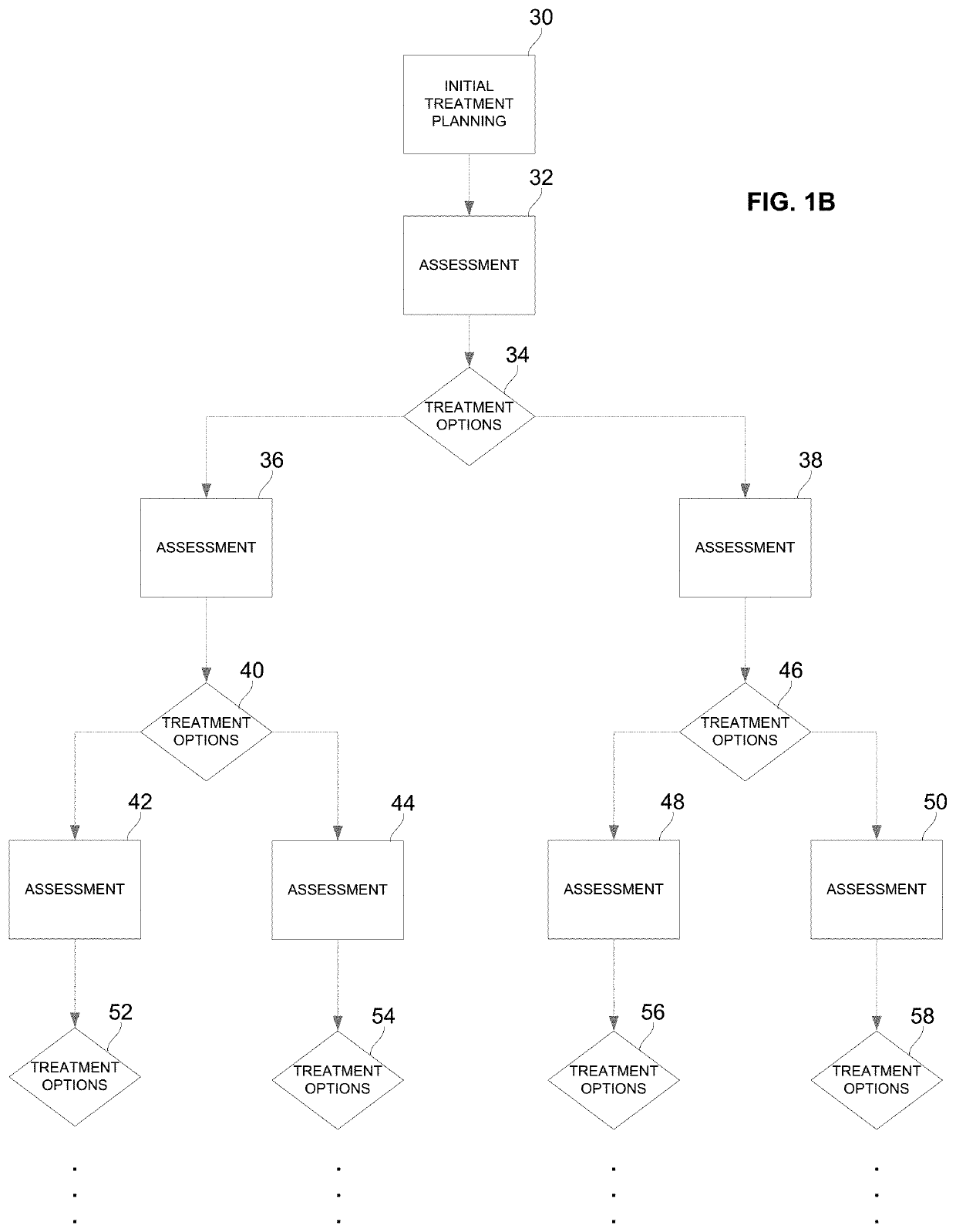

Orthodontic planning systems

ActiveUS20170100214A1Reduce riskMinimal forceMedical simulationOthrodonticsProgram planningDentition

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished in one variation by receiving a scanned dental model of a subject's dentition, determining a treatment plan having a plurality of incremental movements for repositioning one or more teeth of the subject's dentition, and fabricating one or more aligners correlating to a first subset of the plurality of incremental movements.

Owner:ULAB SYST INC

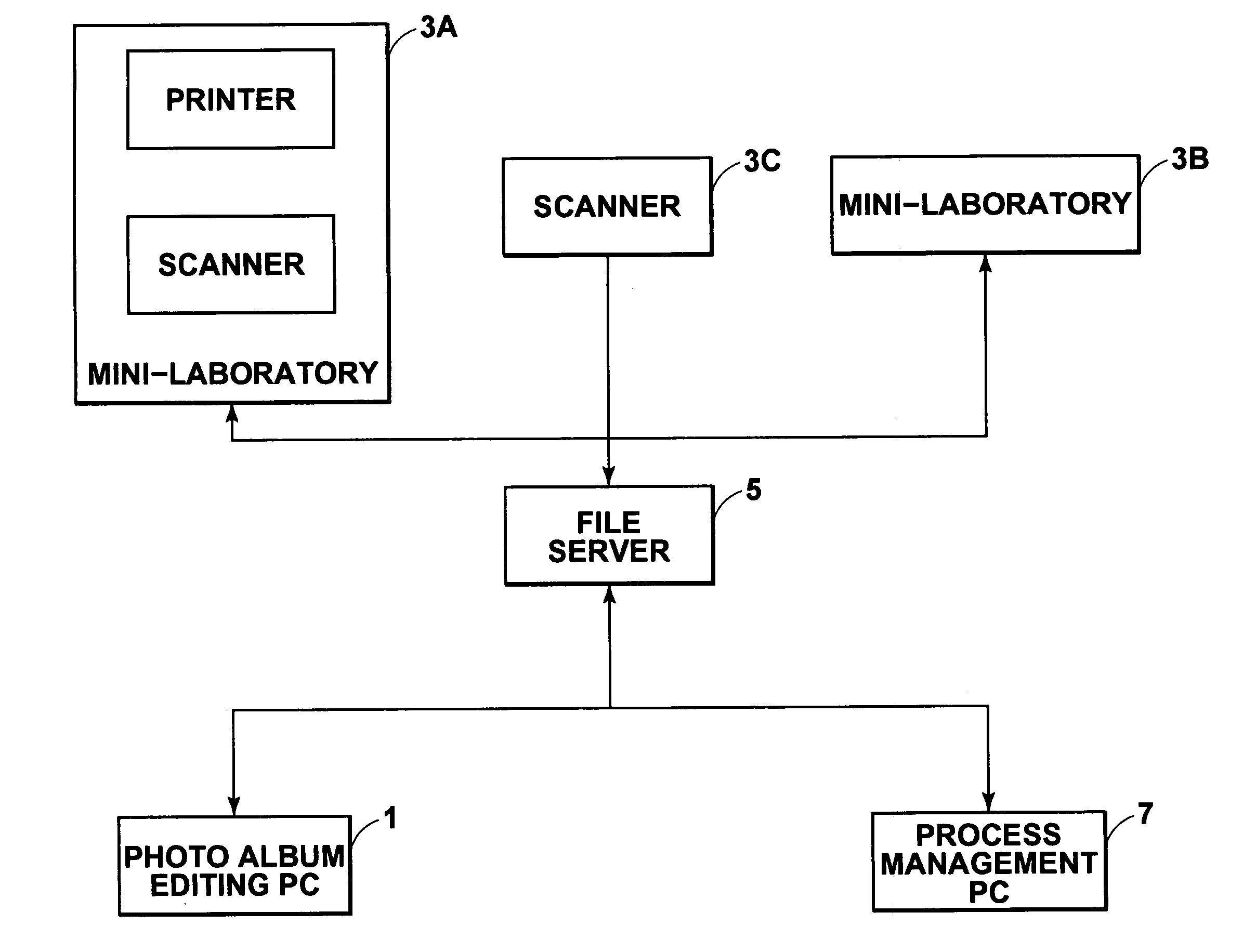

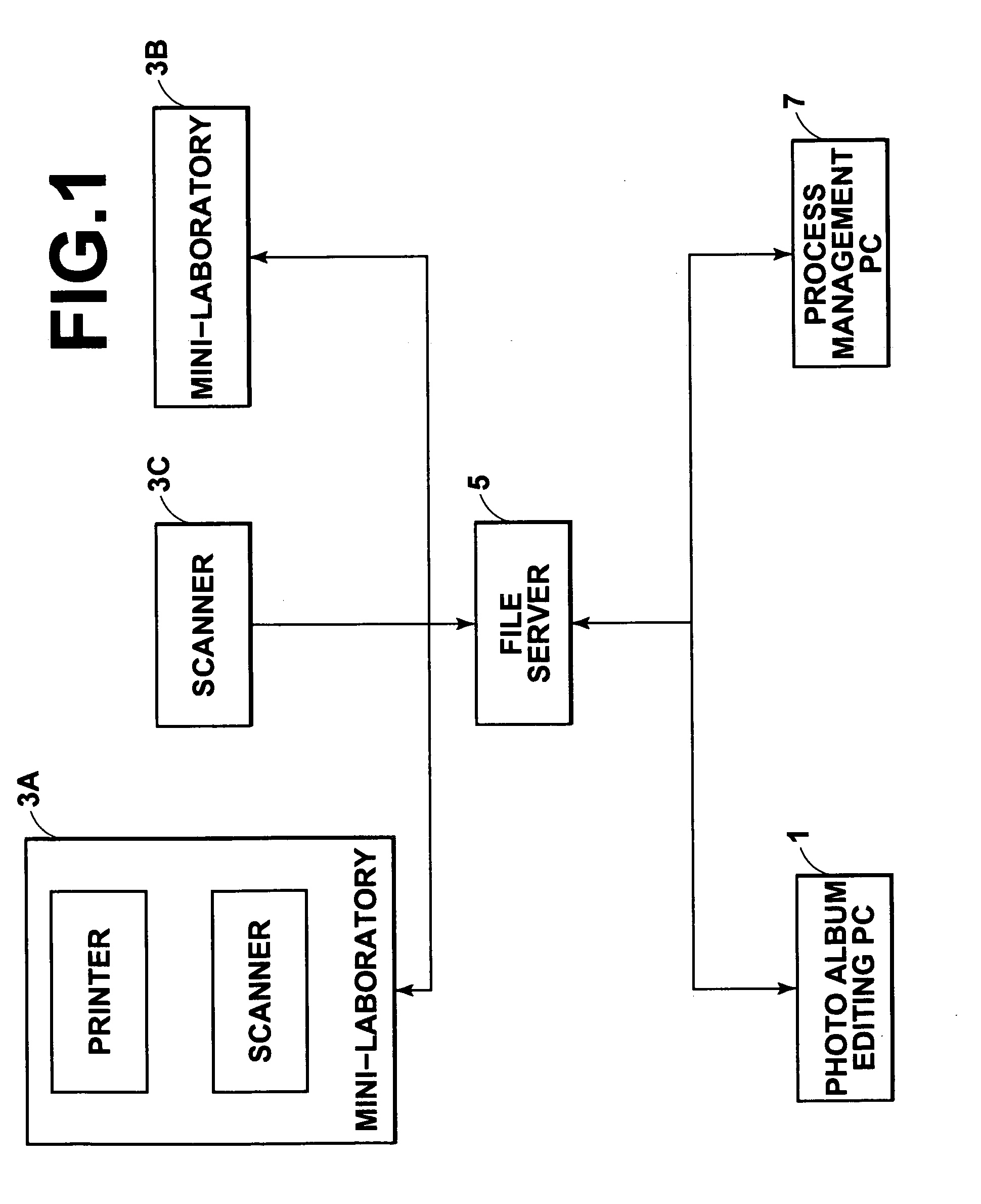

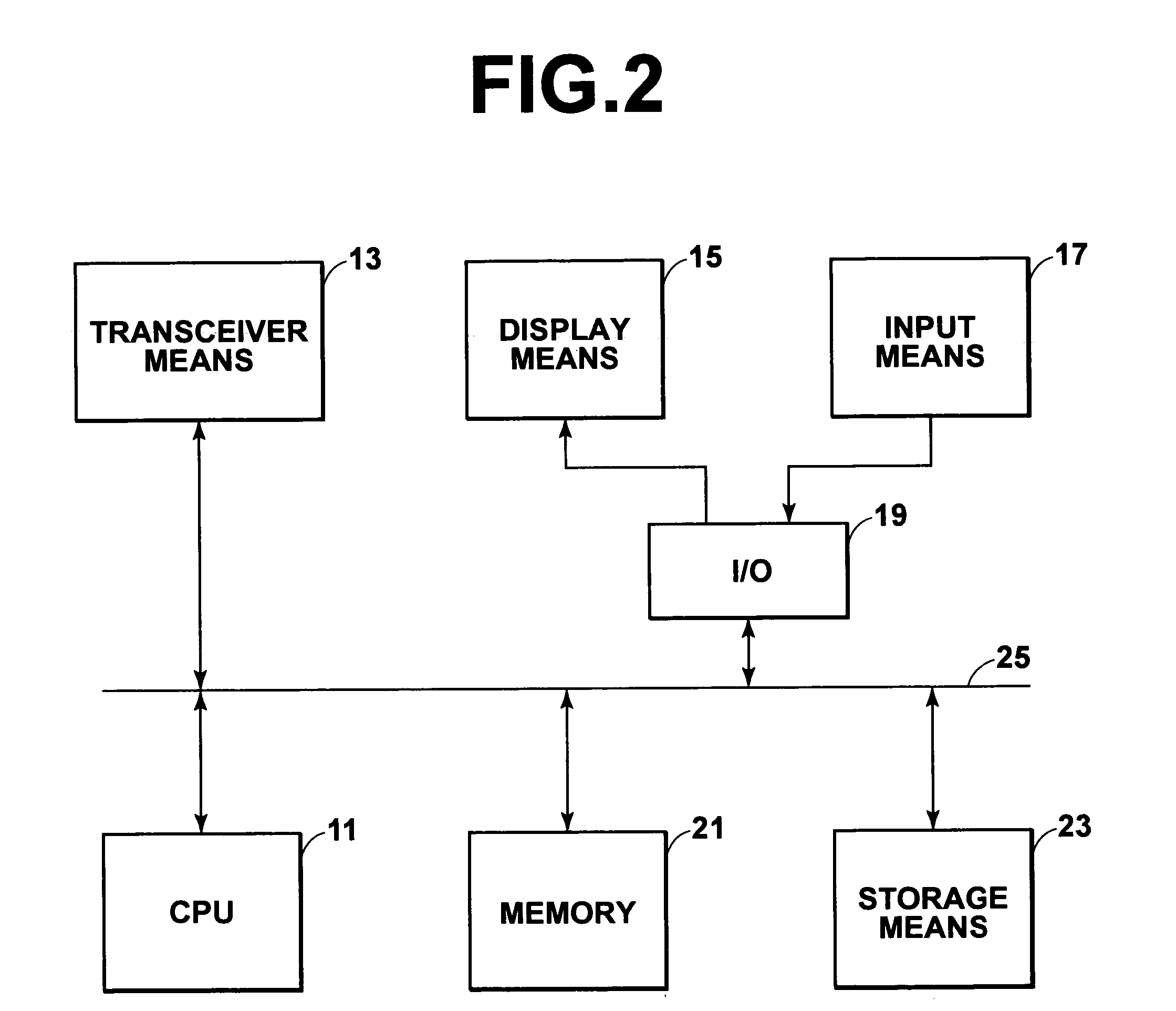

Apparatus, method and program for editing images

InactiveUS20050128518A1Efficiently editEffective imagingDigitally marking record carriersGeometric image transformationImage editingComputer science

When a user who once ordered generation of a photo album of an event such as a wedding orders generation of another photo album of the same event by using a different template, image editing can be carried out efficiently. In each order, the template ID used in the order and image specification information identifying selected images are recorded. Correspondence between image insertion areas in templates is recorded as correspondence information. When the order using the differential template is placed, the image specification information and the correspondence information is referred to, and an image editing screen is displayed by inserting the selected images used in the previous order in the image insertion areas in the template used in the present order.

Owner:FUJIFILM HLDG CORP +1

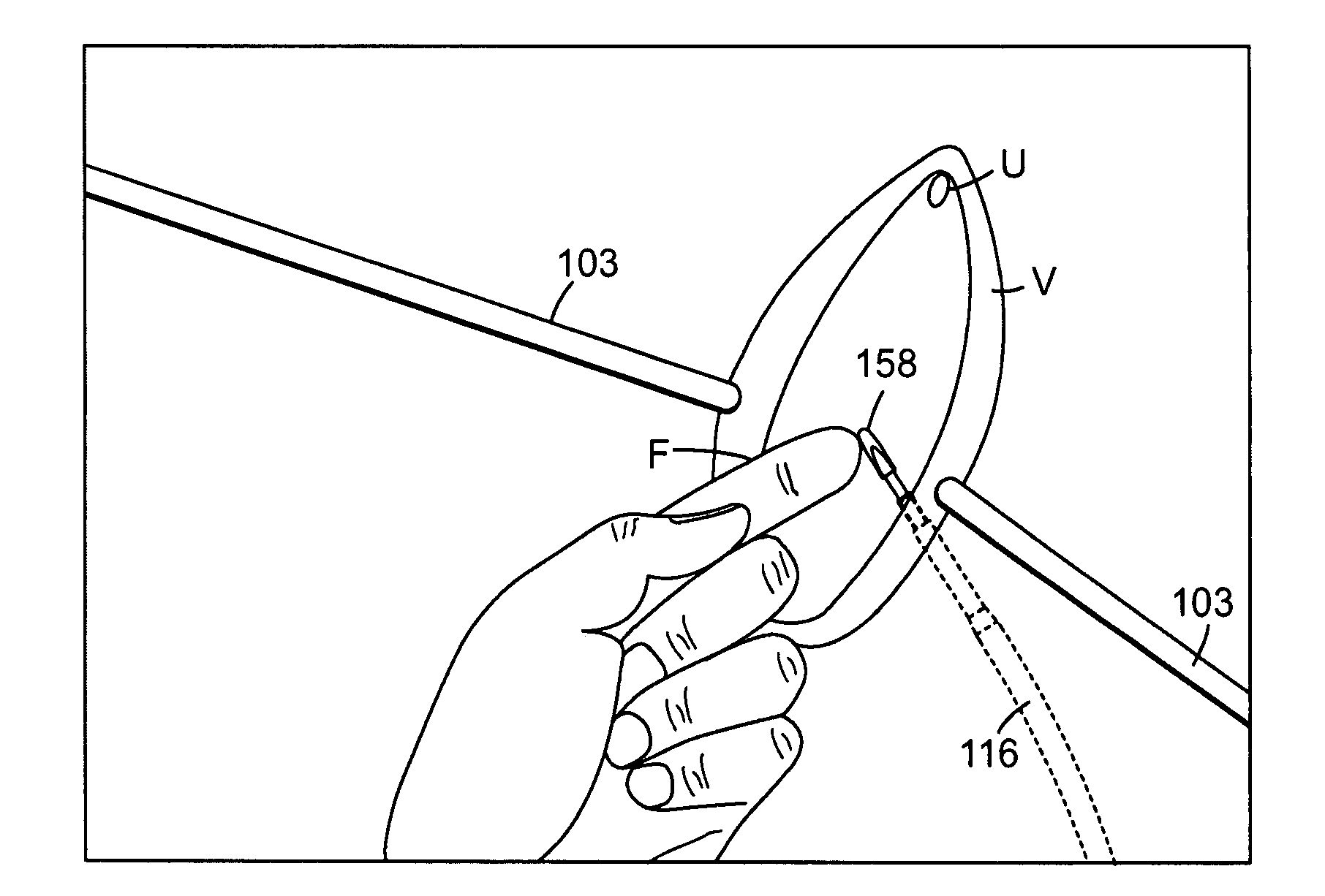

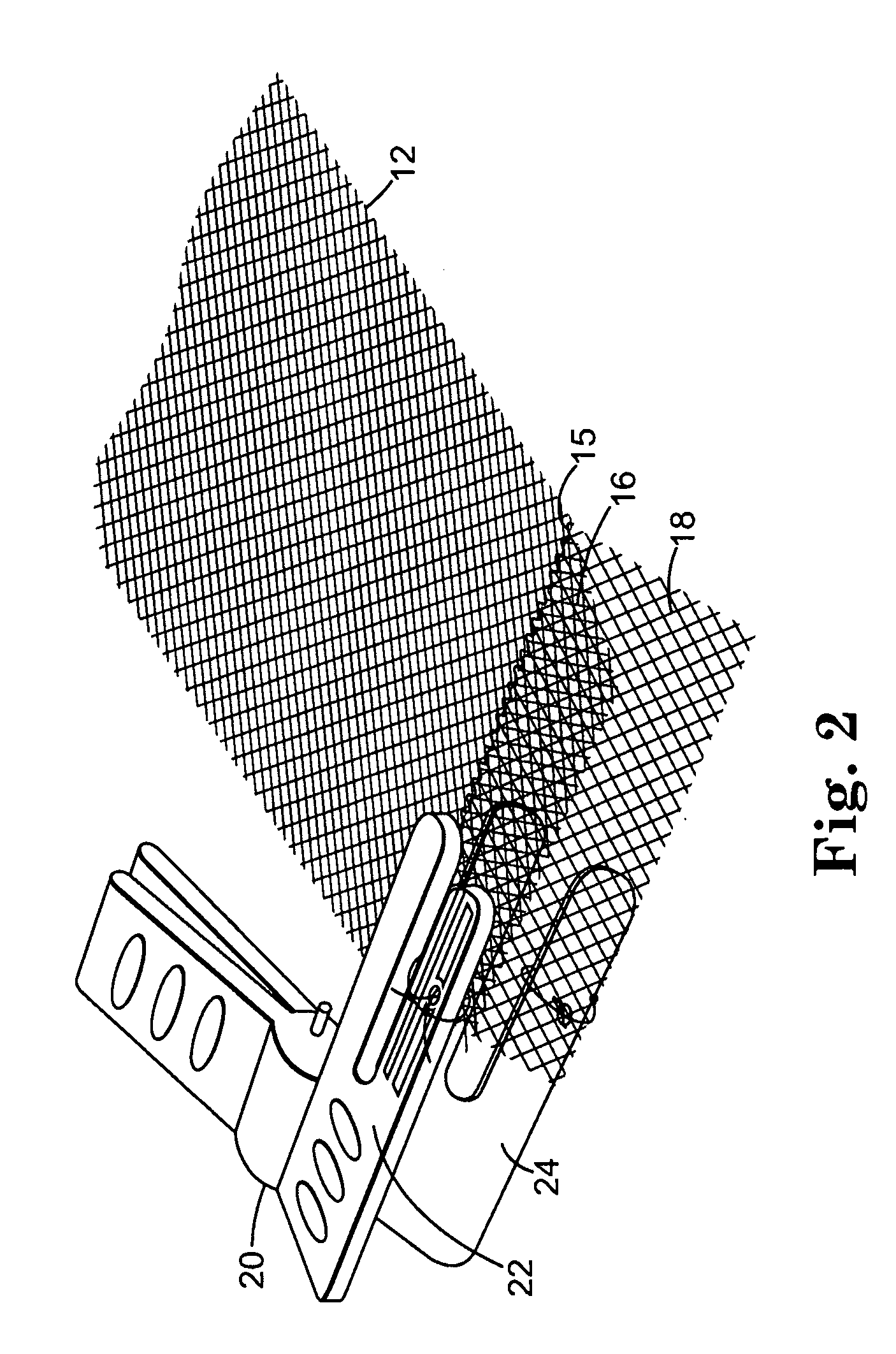

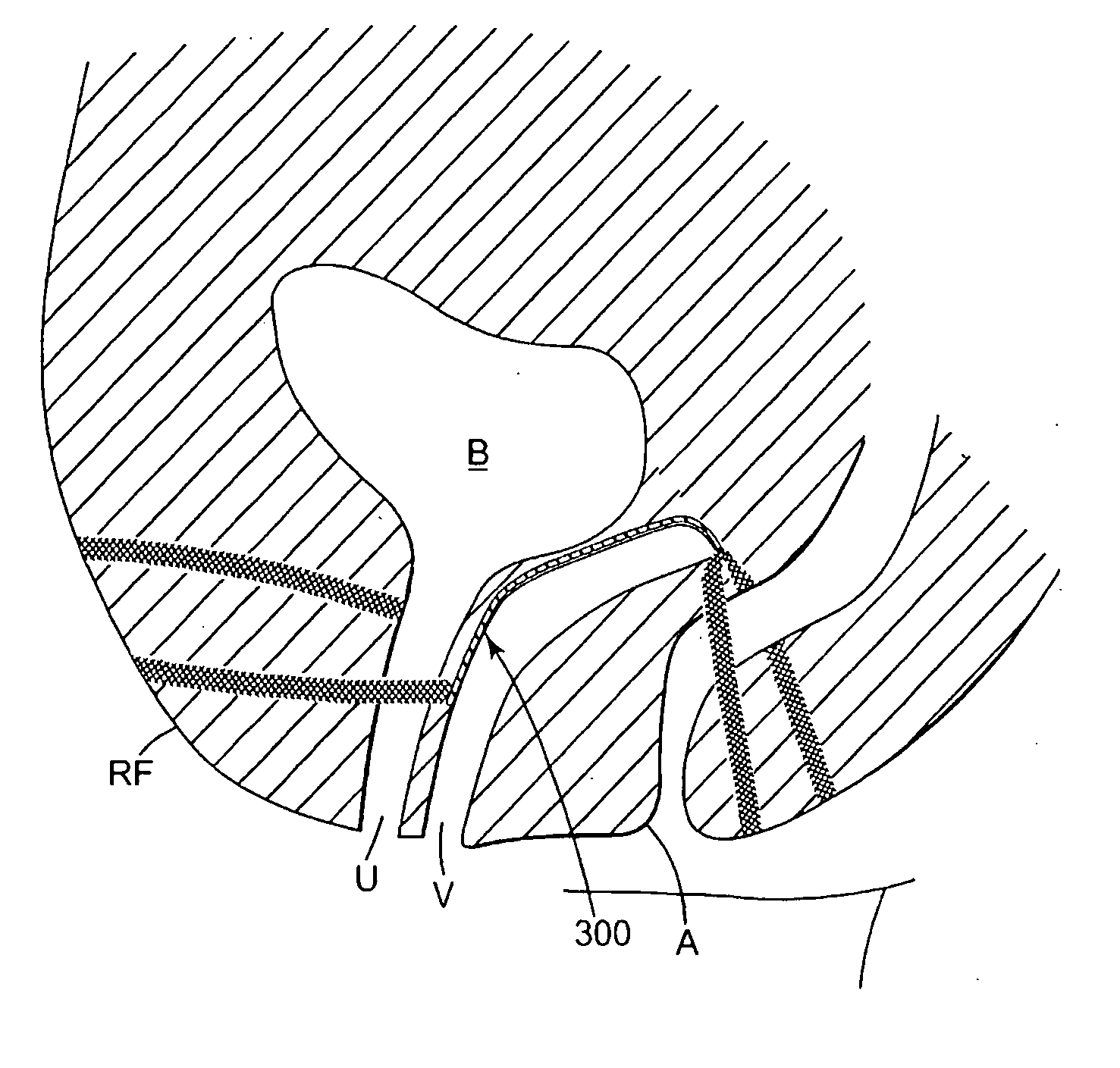

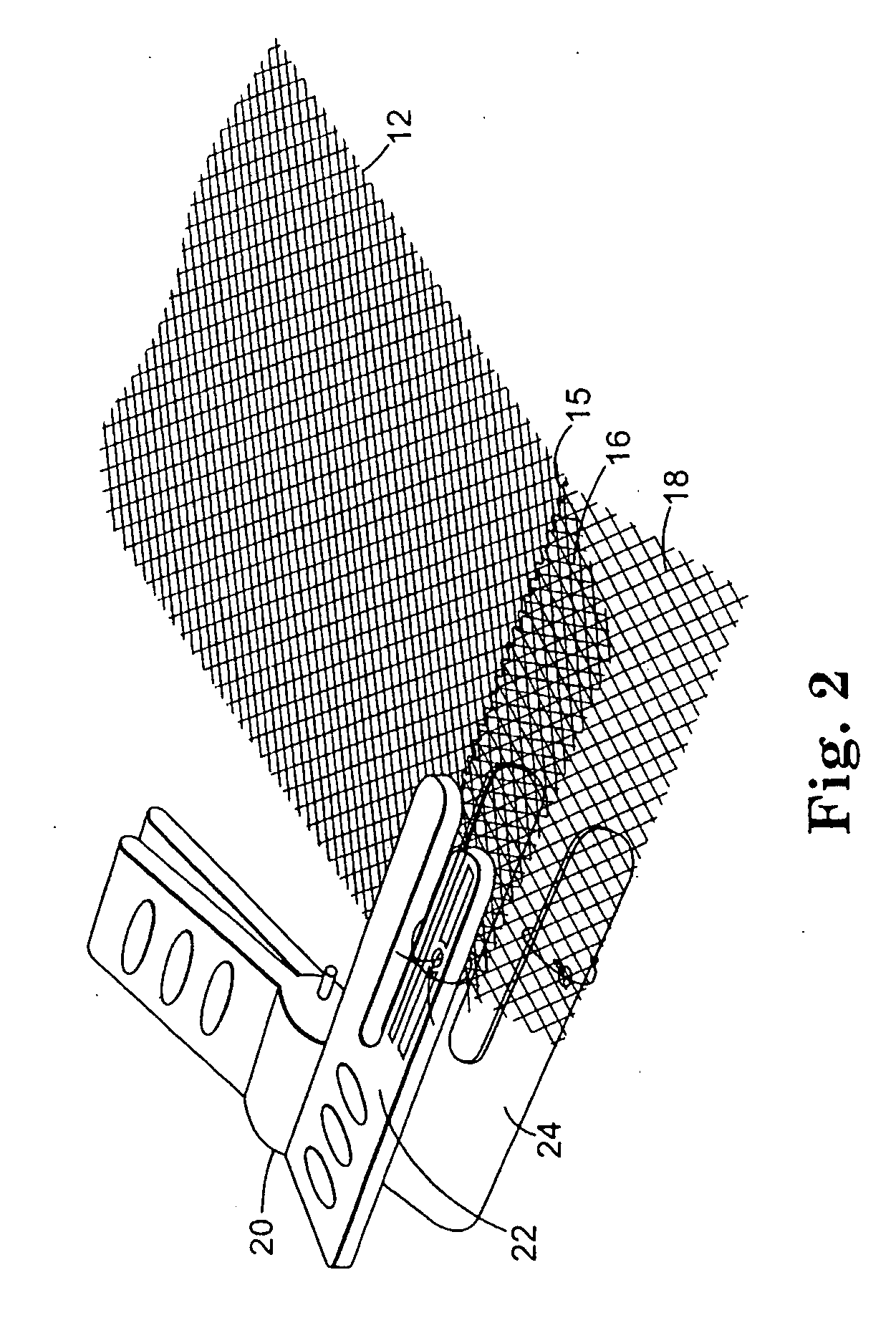

Pelvic health implants and methods

ActiveUS20080140218A1Easy to useEasy to assembleSuture equipmentsSurgical furniturePelvisSurgical department

Owner:STASKIN DAVID MD DR

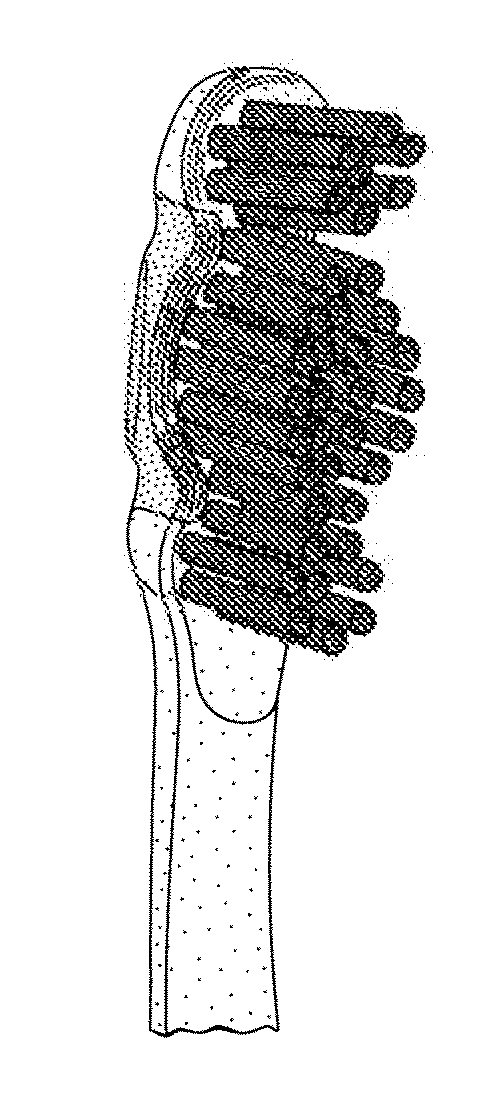

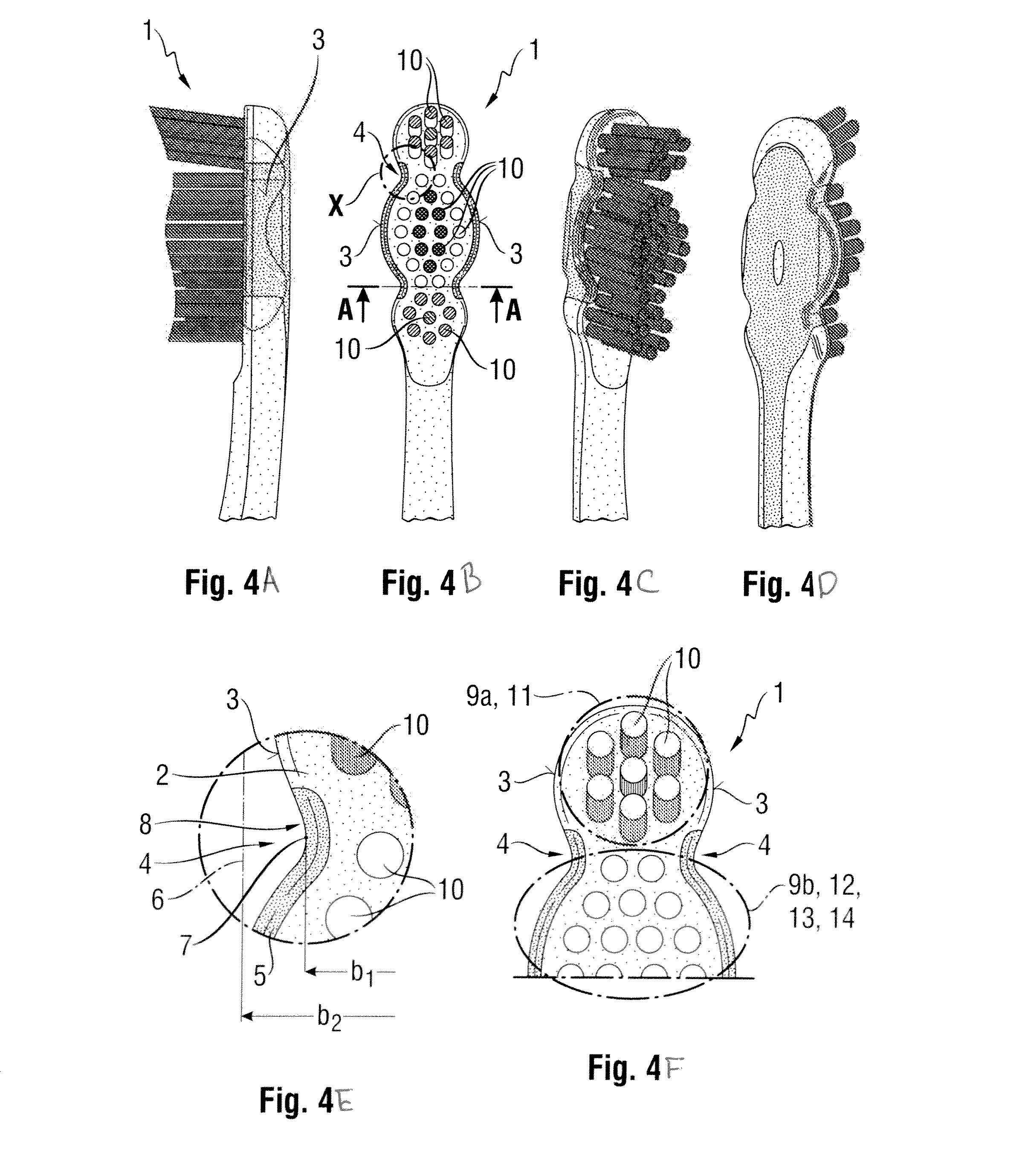

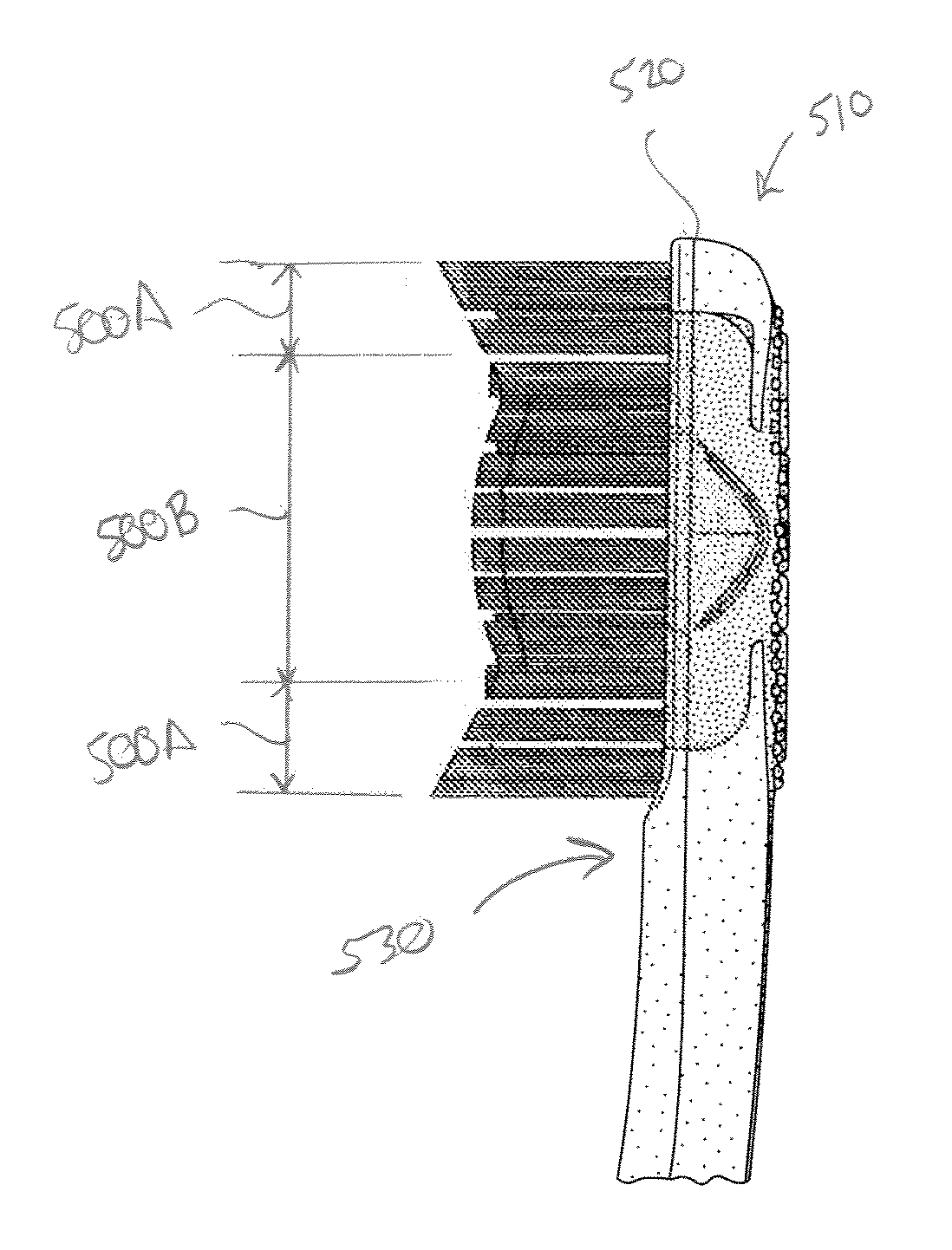

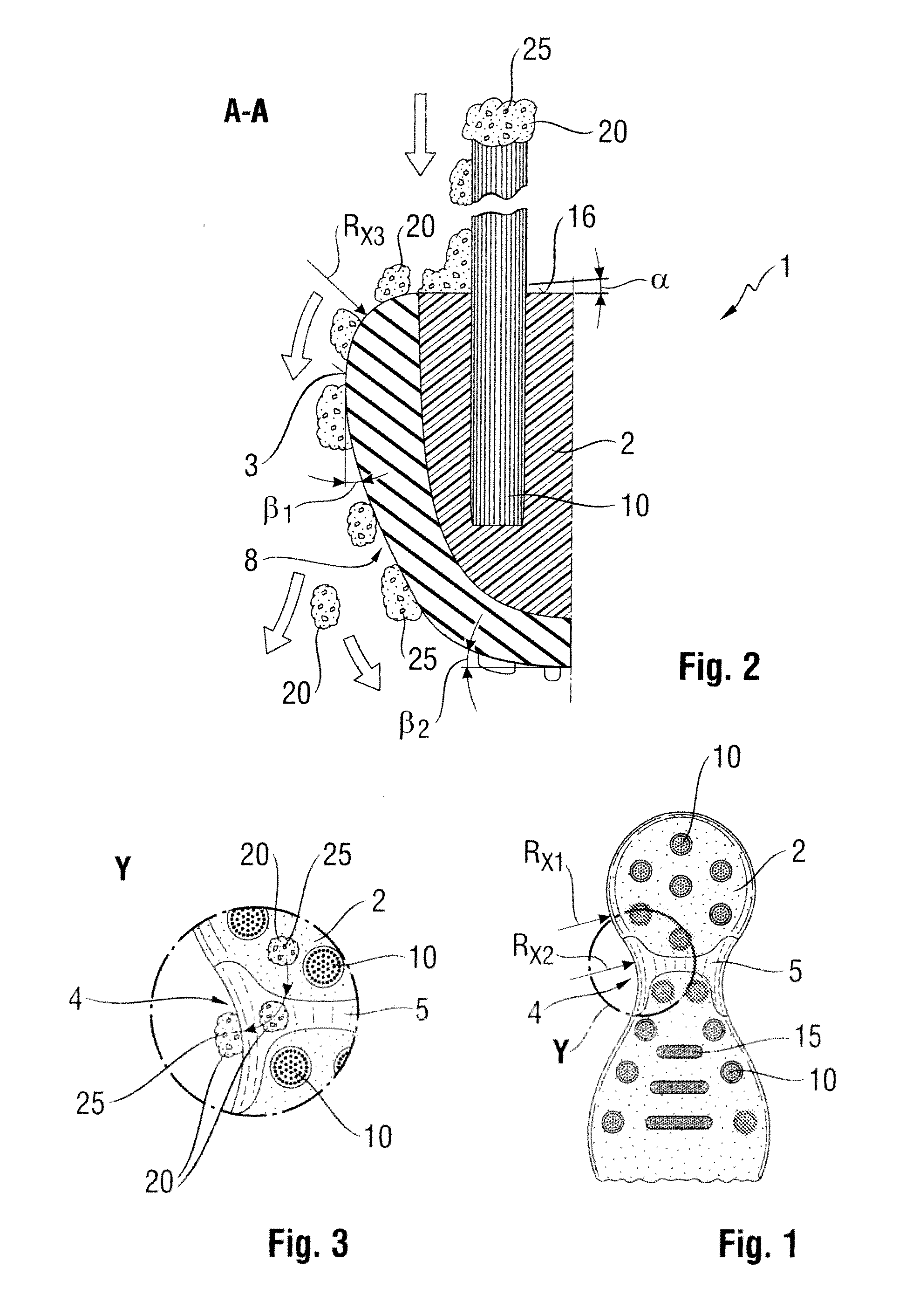

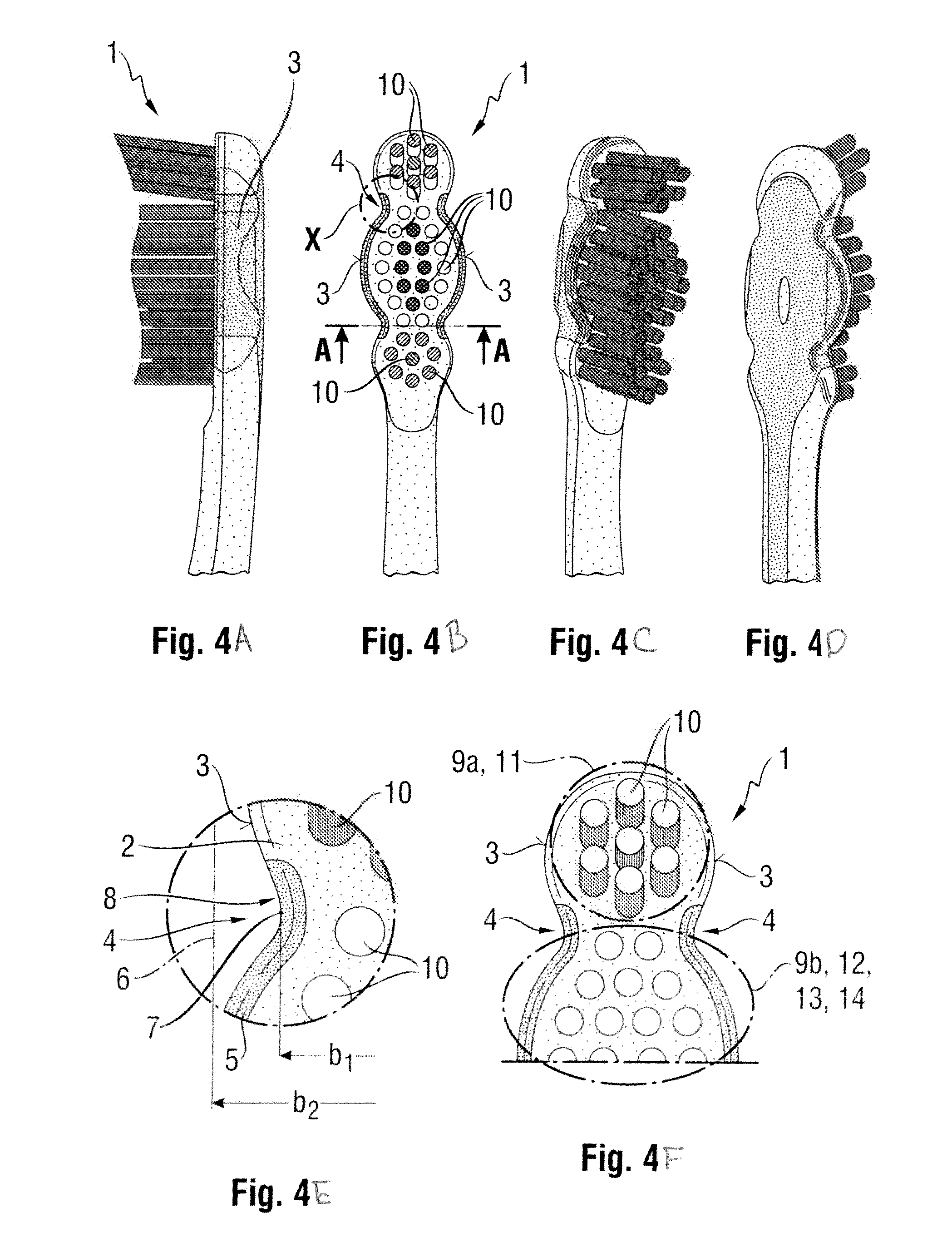

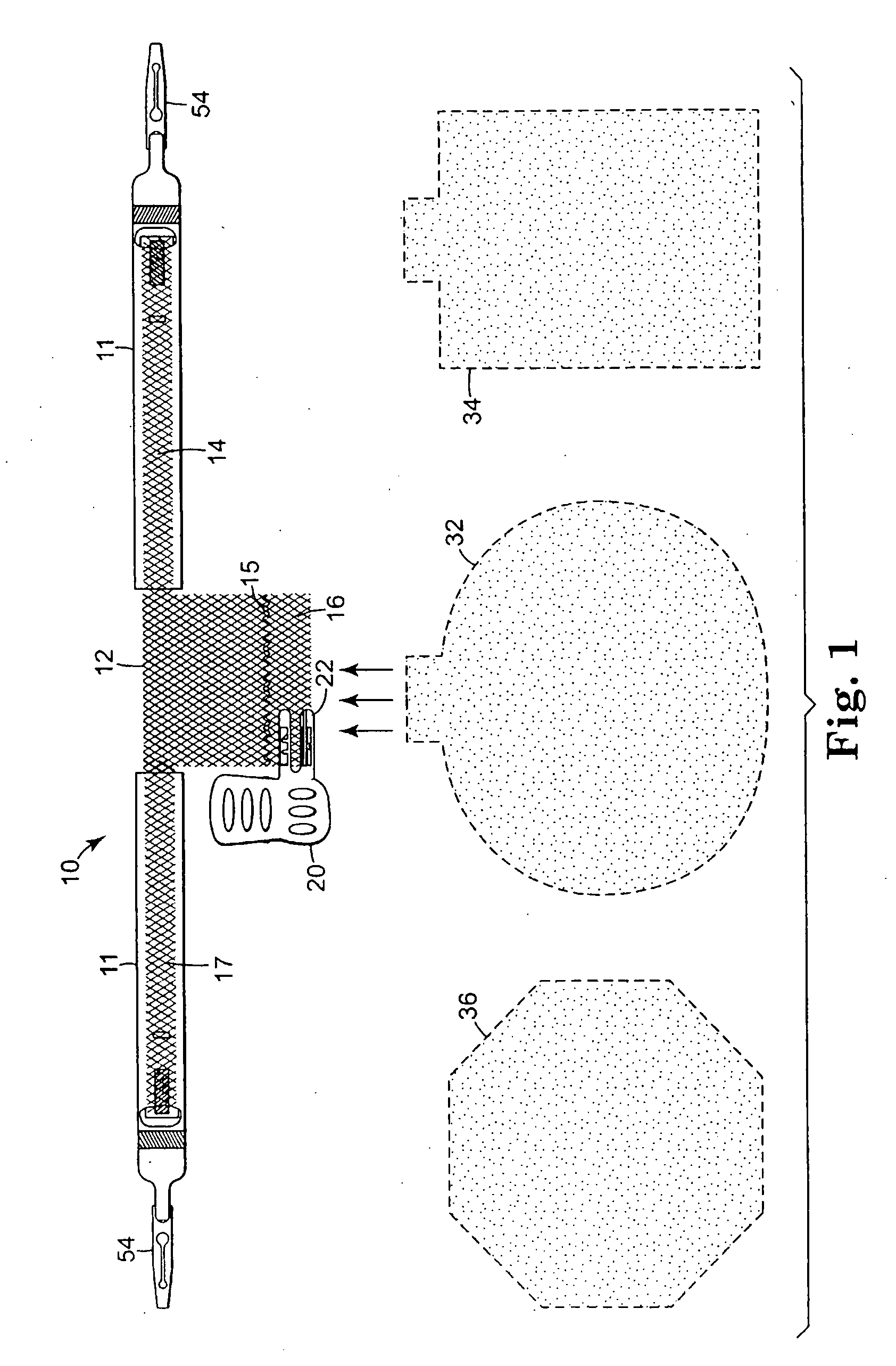

Toothbrush

InactiveUS20110138560A1Easy to manufactureEasy to disassembleBristleEngineeringMechanical engineering

A toothbrush having a toothbrush head with a top side at which cleaning elements for cleaning teeth are arranged. The cleaning elements form various zones of care or arrangements to meet specific cleaning and manufacturing requirements.

Owner:BRAUN GMBH

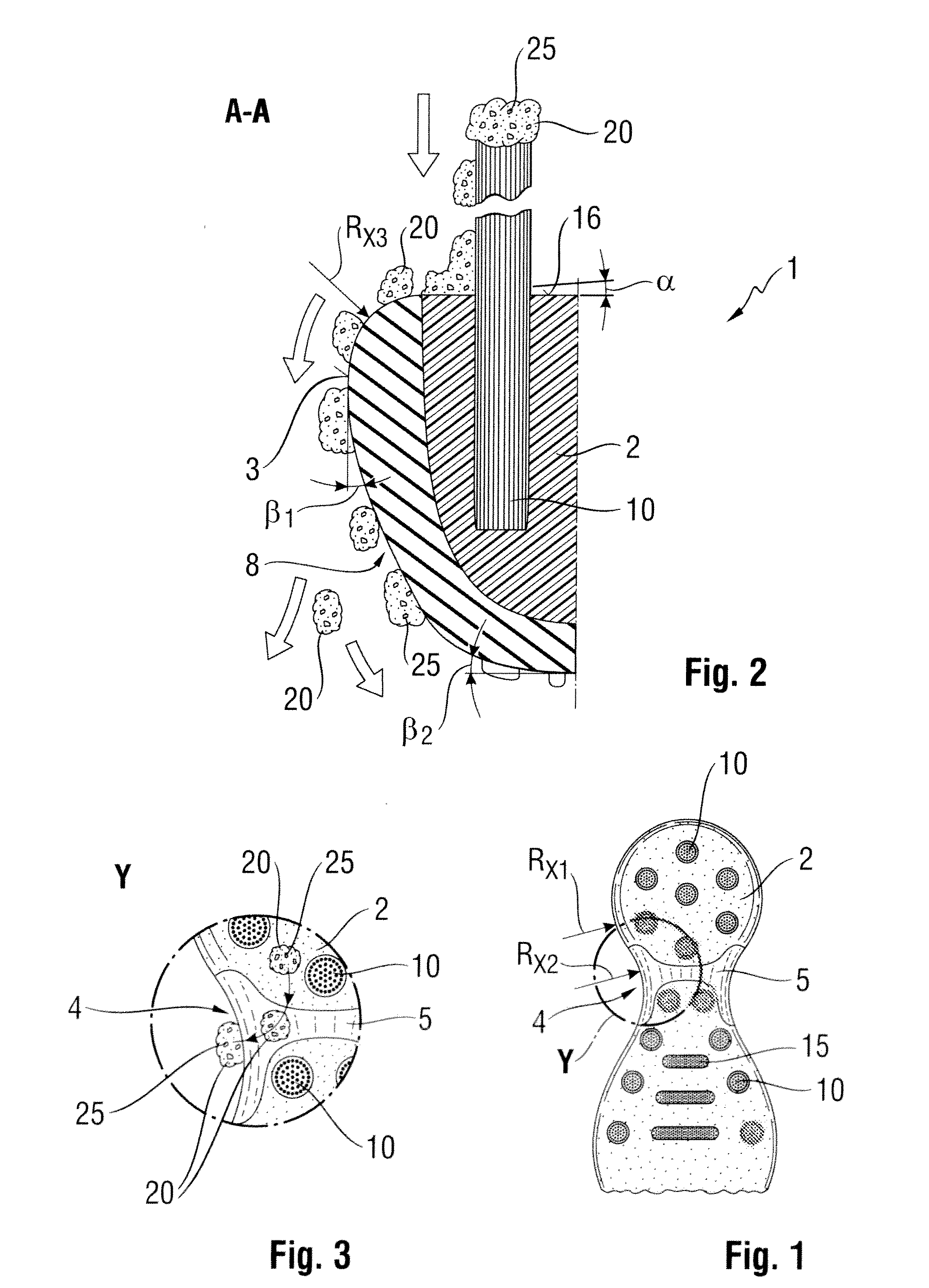

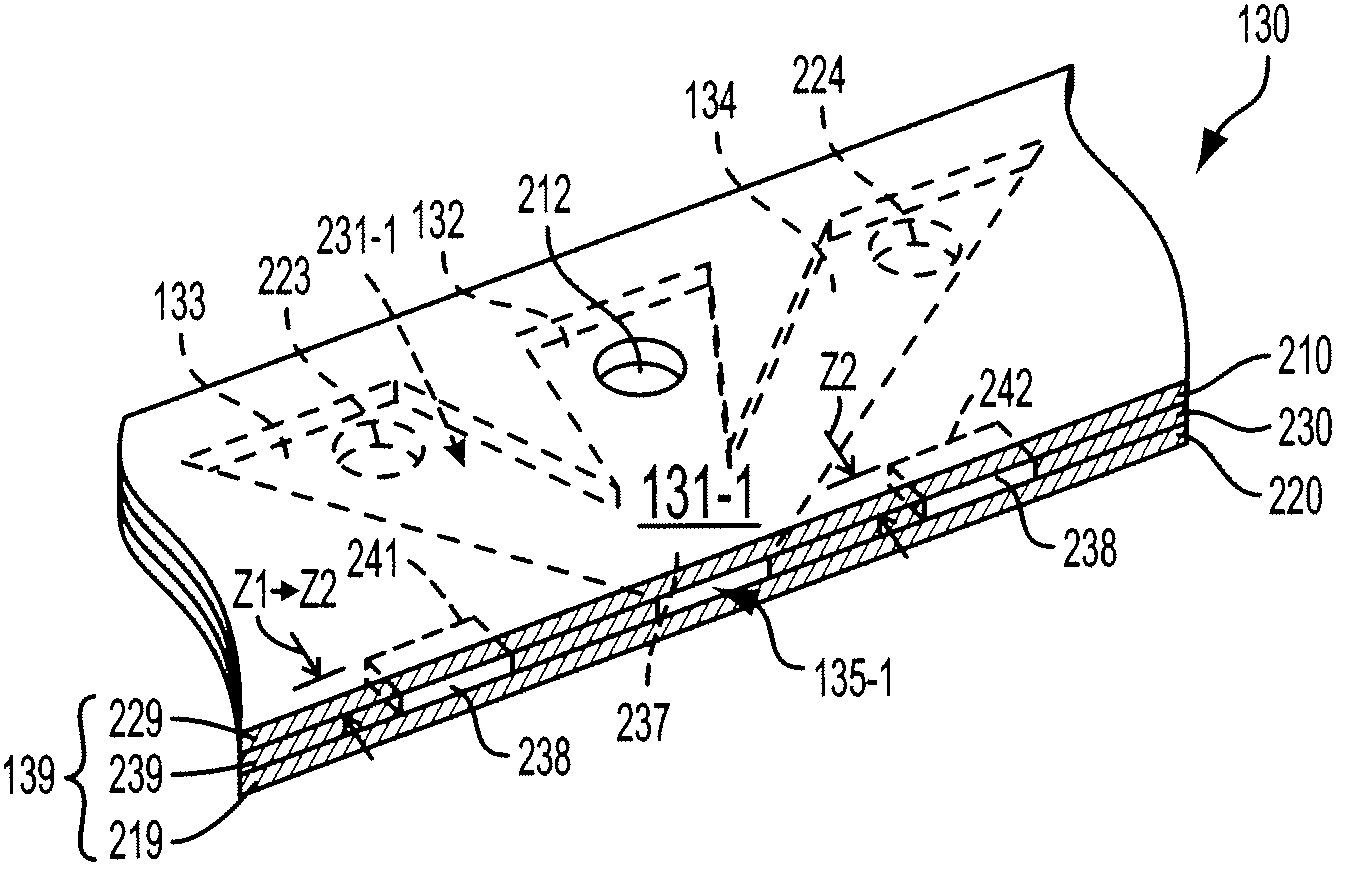

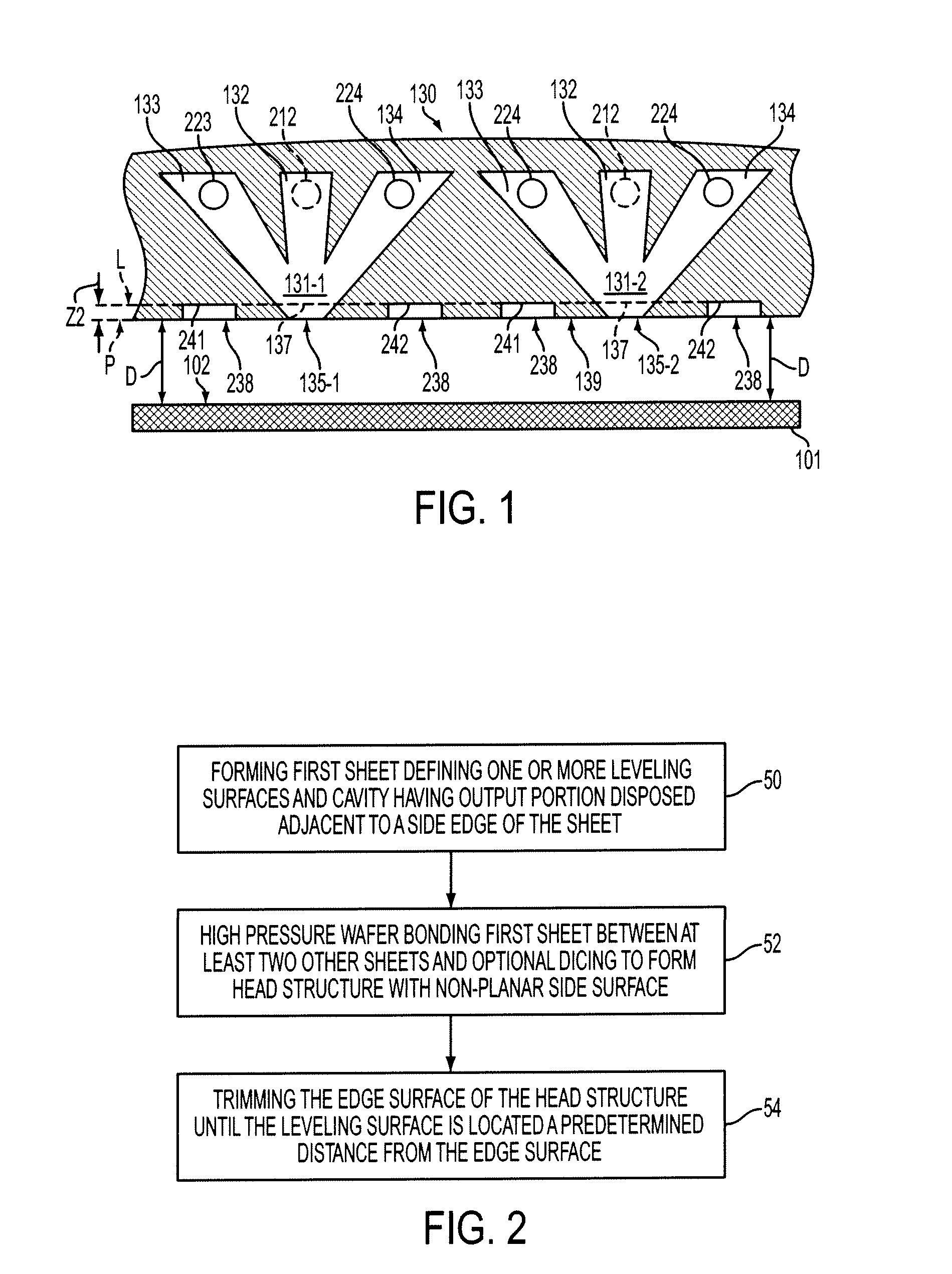

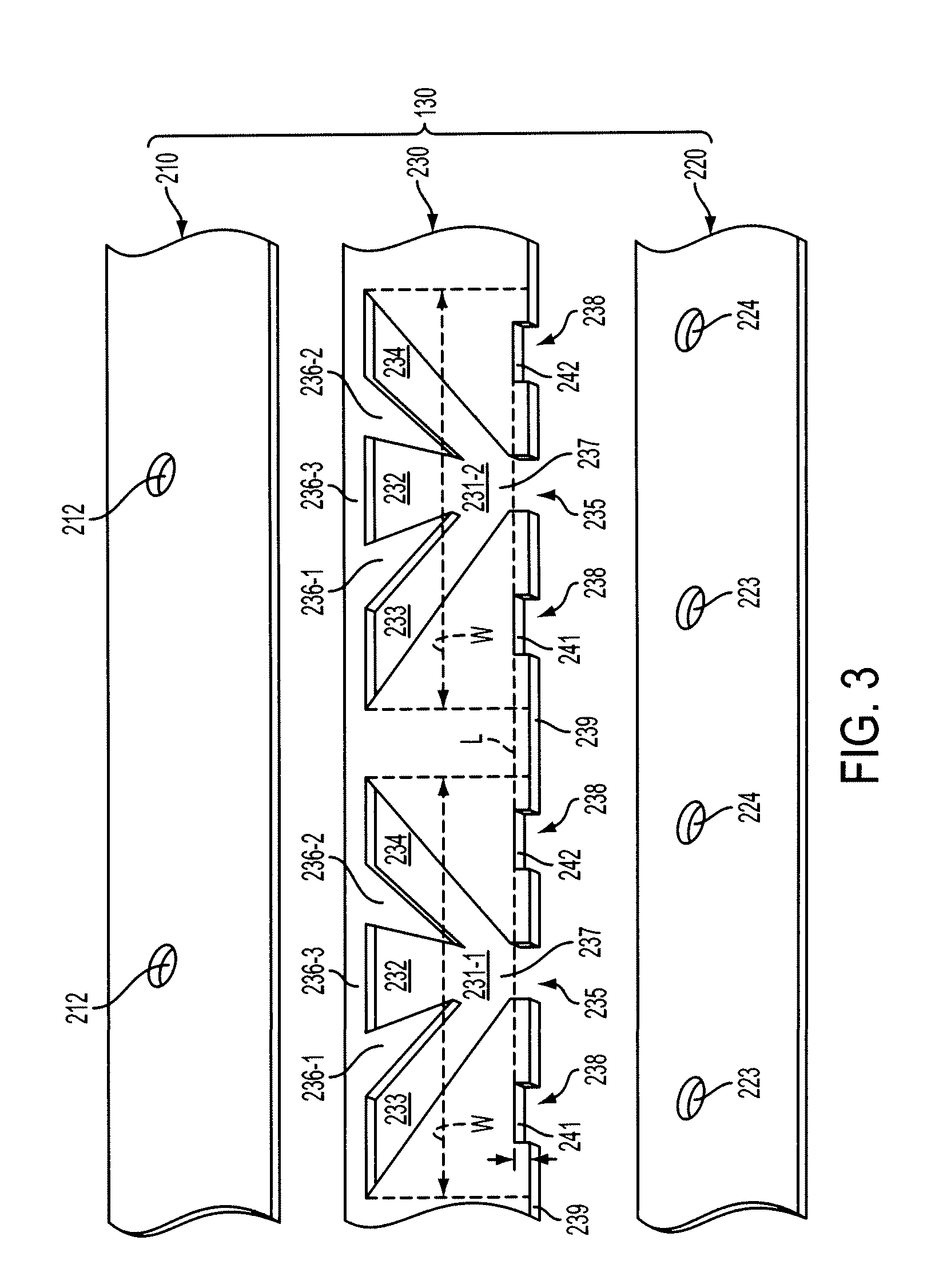

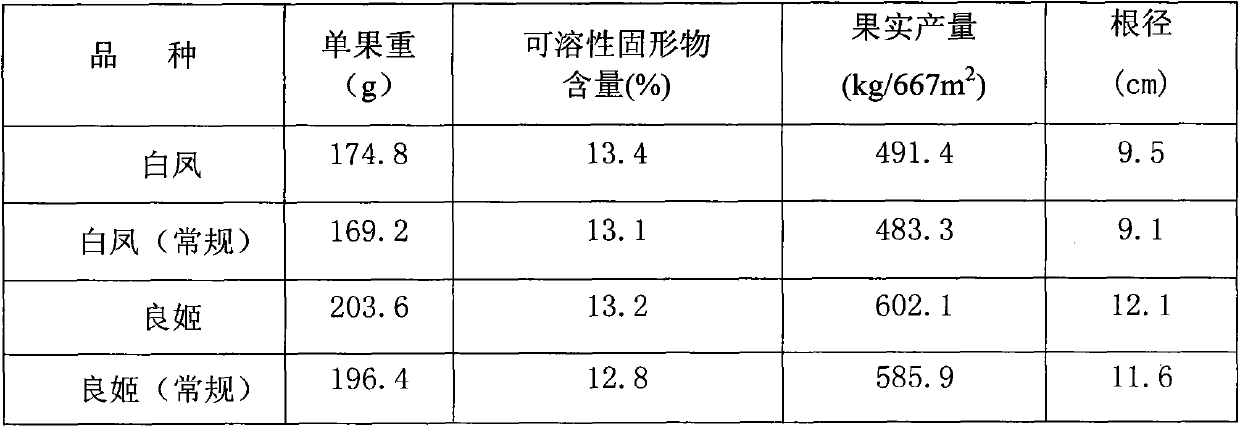

Extrusion head with planarized edge surface

InactiveUS7780812B2Easy to trimUnified positionConfectioneryCeramic shaping apparatusEdge surfaceHigh pressure

A co-extrusion head for forming high-aspect ratio gridline structures in a micro extrusion apparatus includes multiple sheets (e.g., metal plates) that are machined and assembled to define three-part fluidic channels having associated outlet orifice disposed along an edge surface of the head. Reference surfaces are also etched in the sheets and are aligned in a straight line that intersects output junctions of the three-channel cavities. After assembly (e.g., using high pressure bonding techniques), each reference surface is located inside a notch defined in the edge surface. The edge surface of the co-extrusion head is then trimmed (e.g., machined by wire EDM) using the reference surfaces as a precise guide, thereby producing uniform length outlet orifices with uniform flow impedance.

Owner:SOLARWORLD INNOVATIONS

Toothbrush

A toothbrush having a toothbrush head with a top side at which cleaning elements for cleaning teeth are arranged. The cleaning elements and the head can facilitate the removal of foam, plaque and undesired particles.

Owner:BRAUN GMBH

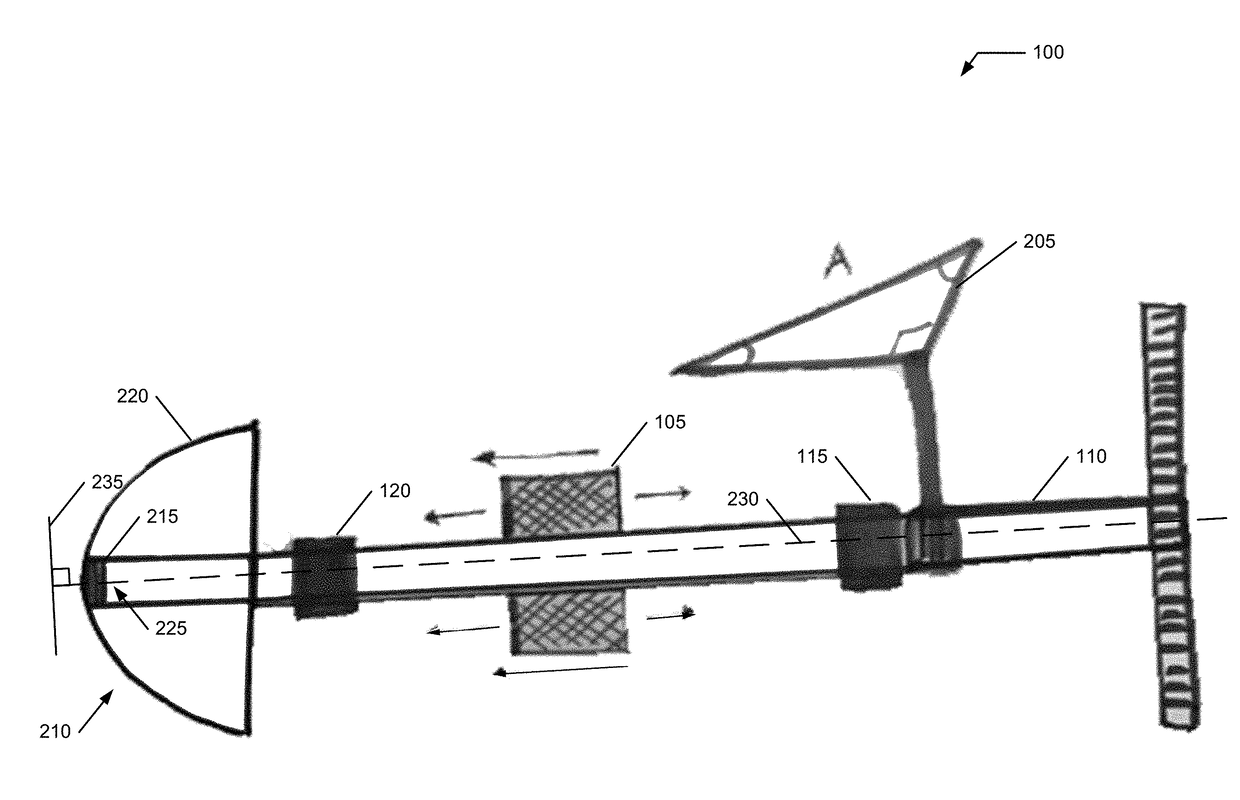

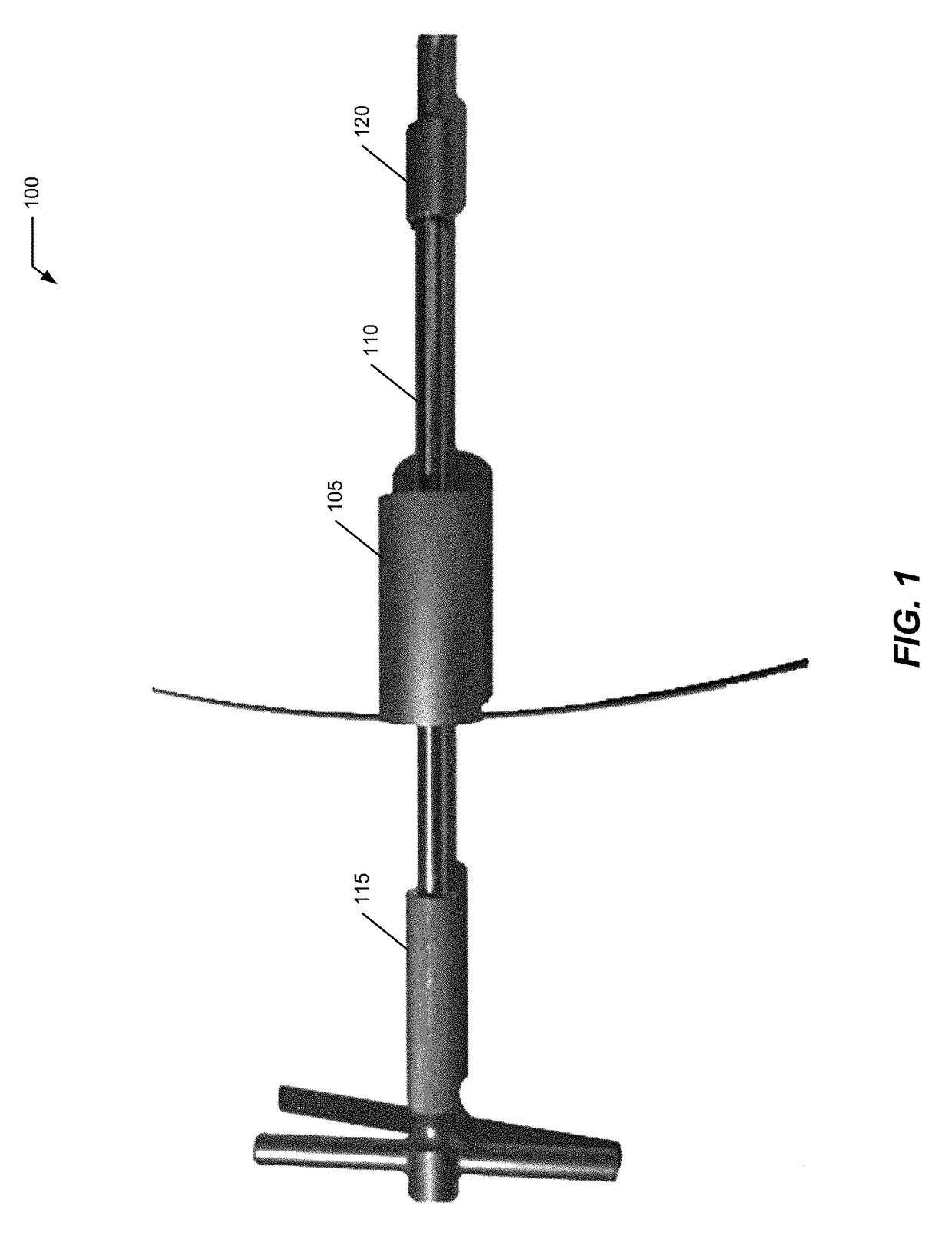

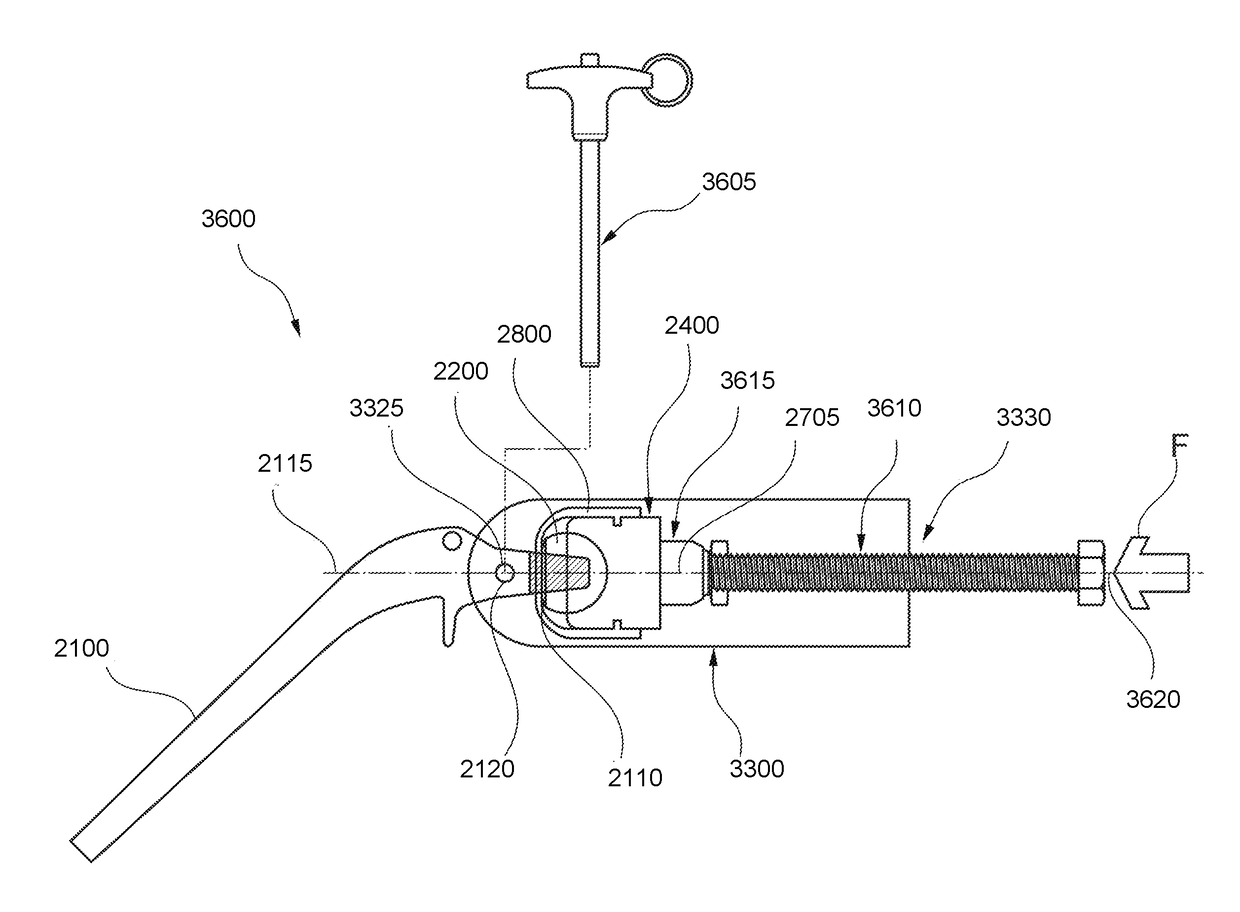

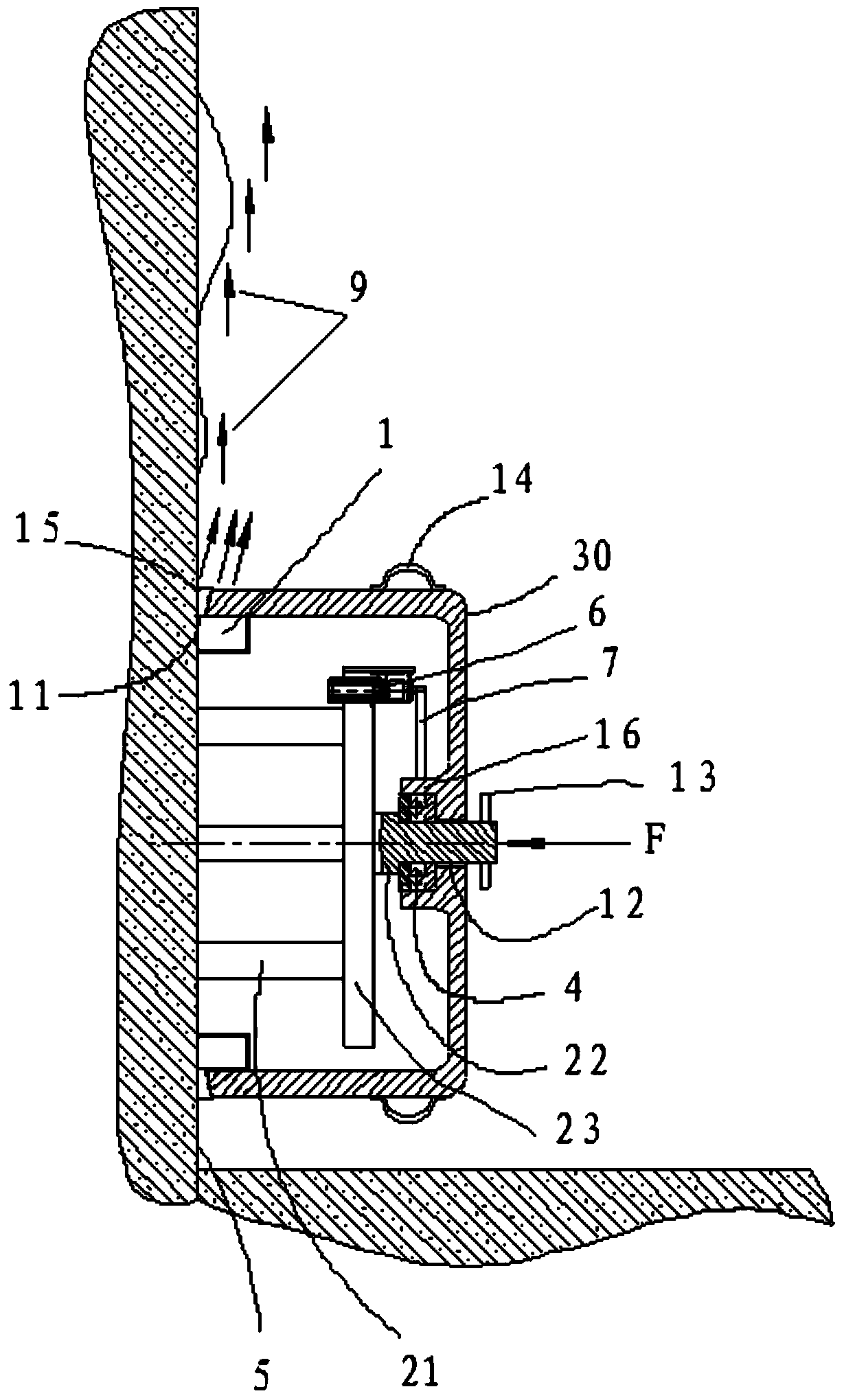

Bone preparation apparatus and method

ActiveUS20170196705A1Assembly precisionImprove site preparationJoint implantsFemoral headsProsthesisPower tool

A system and method for improving installation of a prosthesis. Devices include prosthesis installation tools, prosthesis assembly tools, site preparation systems, and improved power tools used in implant site preparation.

Owner:BEHZADI KAMBIZ

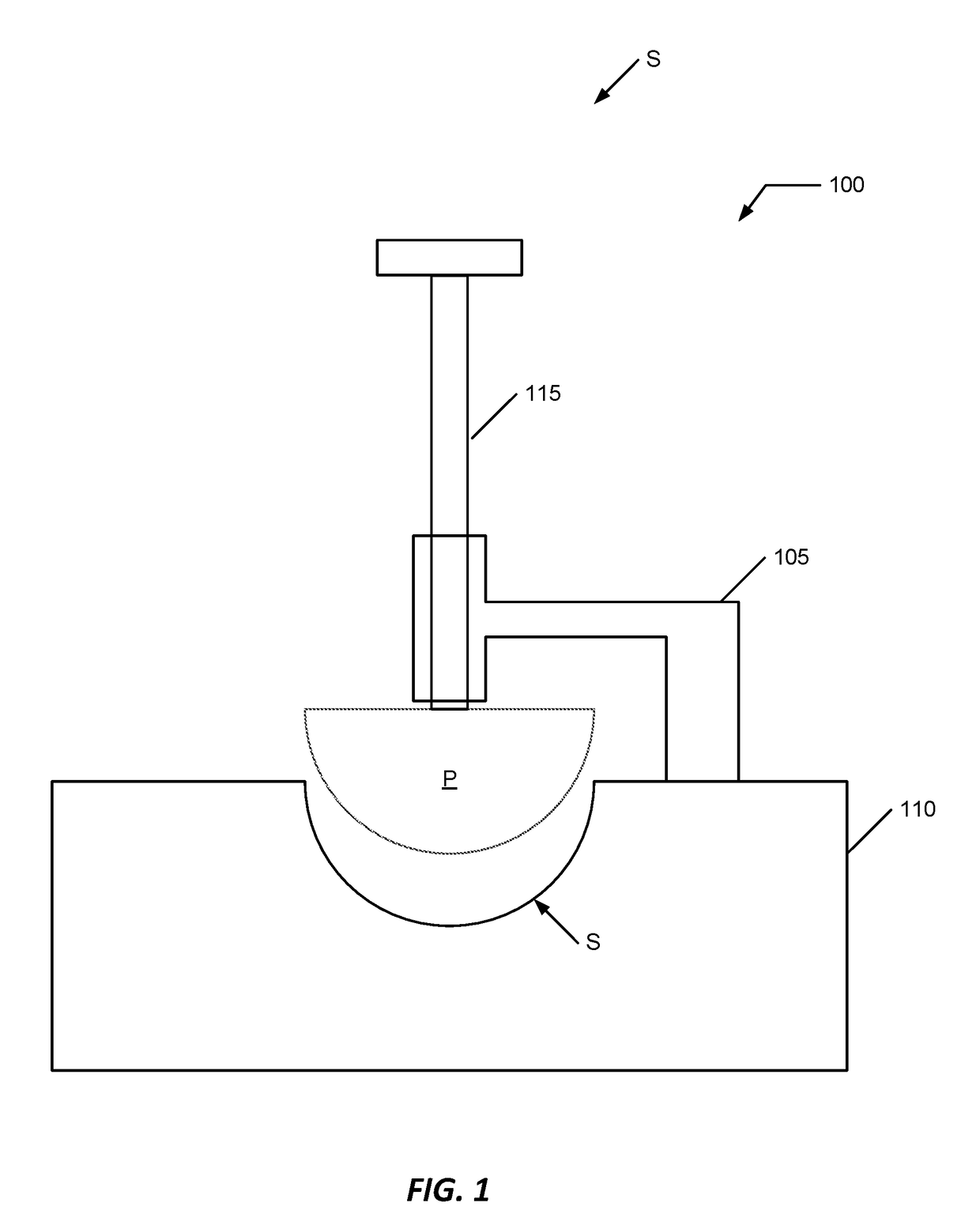

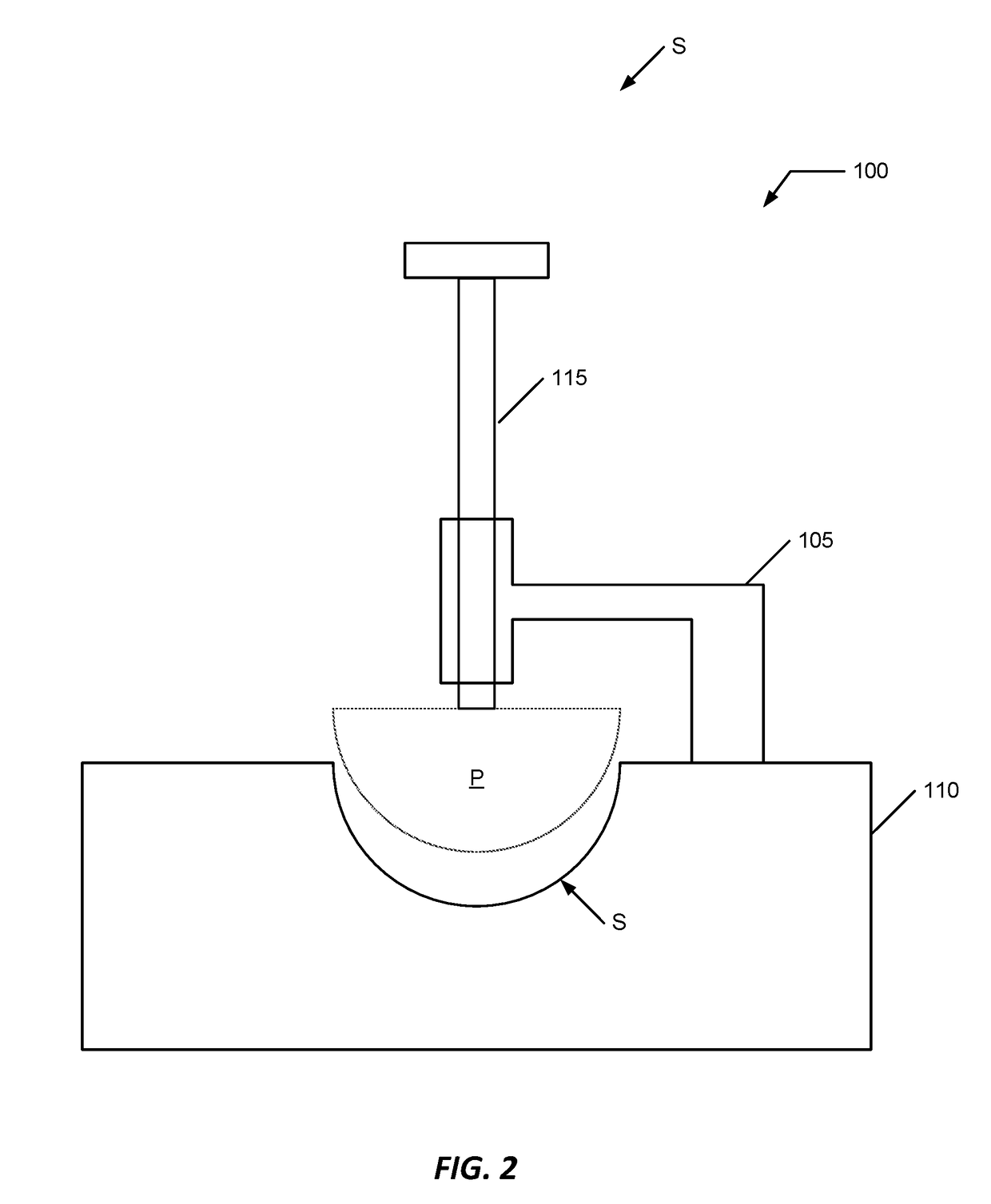

Prosthesis installation

ActiveUS20170196711A1Assembly precisionImprove site preparationJoint implantsFemoral headsProsthesisRelative motion

A system and method for improving installation of a prosthesis, particularly an acetabular cup. The system and method may include implementation of a constant velocity relative motion between a prosthesis and an installation site. For example, an installation system may be fixed relative to the installation site, with the prosthesis fixed into an initial position. The prosthesis is moved at constant speed (i.e., with minimal if any acceleration or applied impulses) relative to the installation site. That is, one or both of the prosthesis or the installation site may be in motion. Resistive forces to installation of a prosthesis may thus be reduced by maintaining the prosthesis constantly in motion relative to the installation site. Securing a processing / implanting tool directly to the installation site may offer advantages.

Owner:BEHZADI KAMBIZ

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

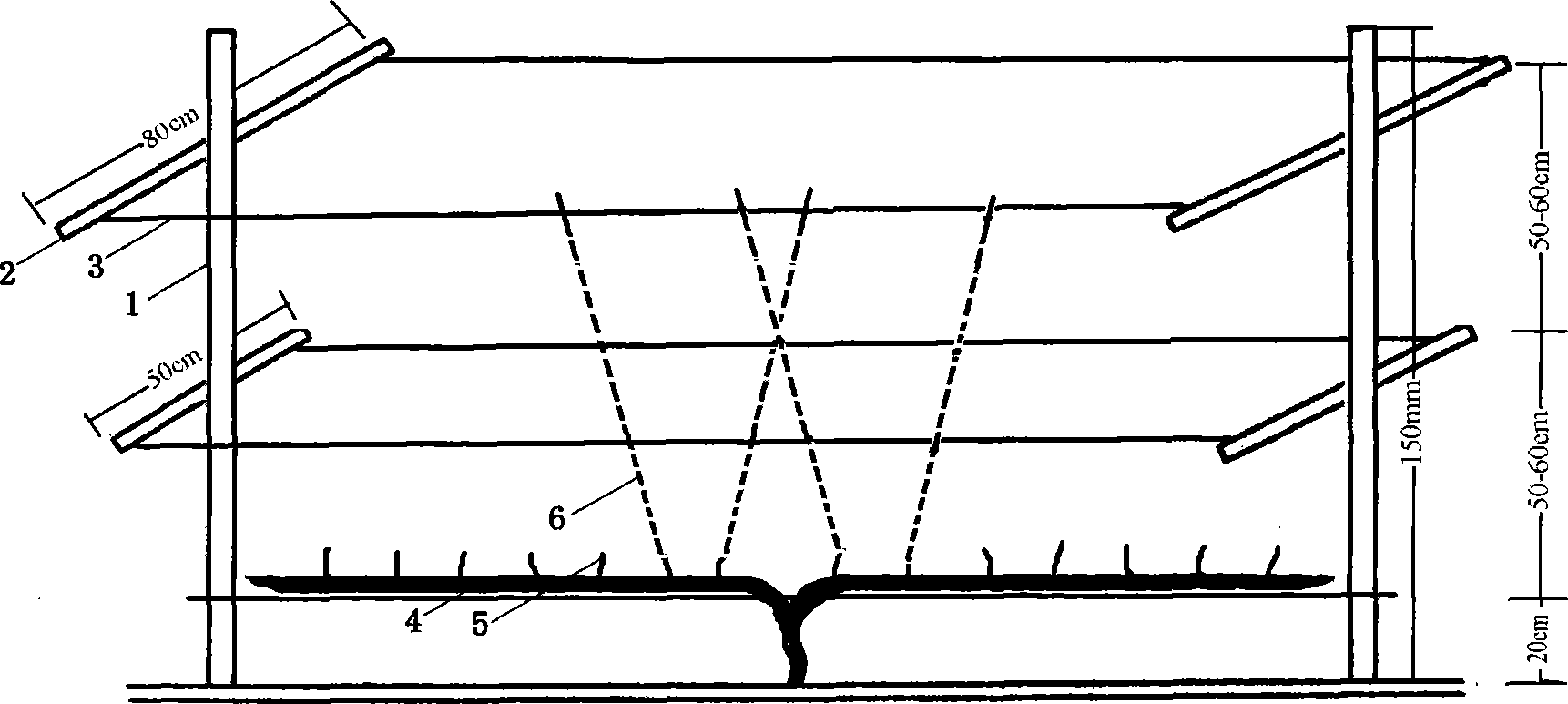

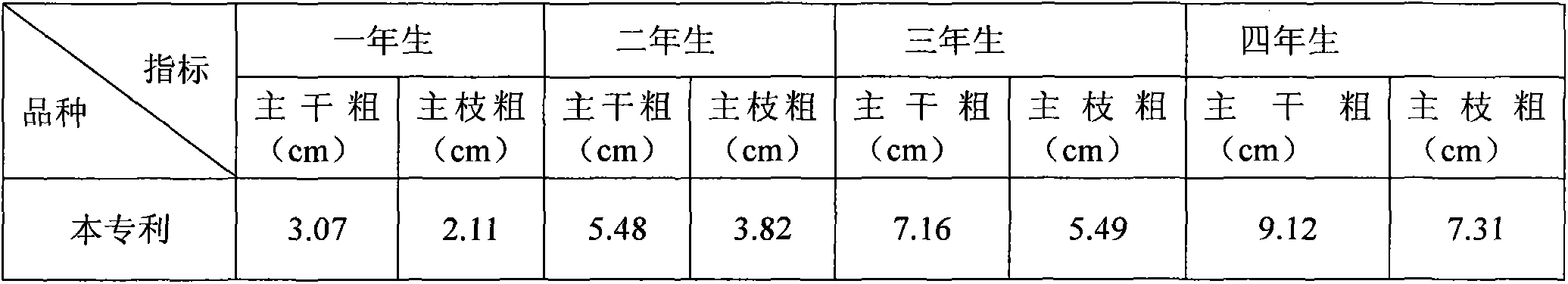

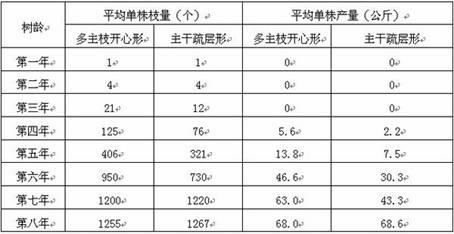

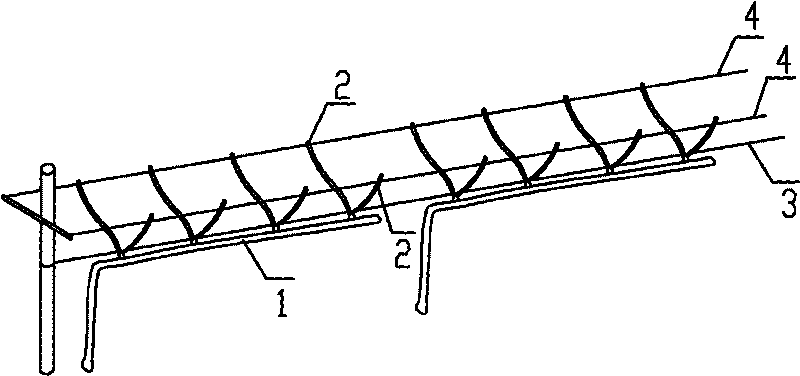

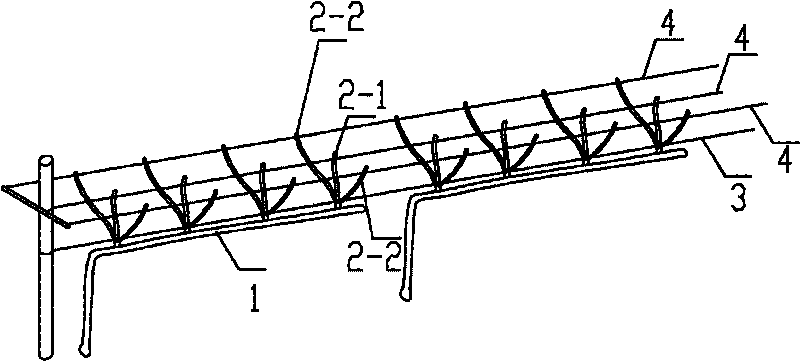

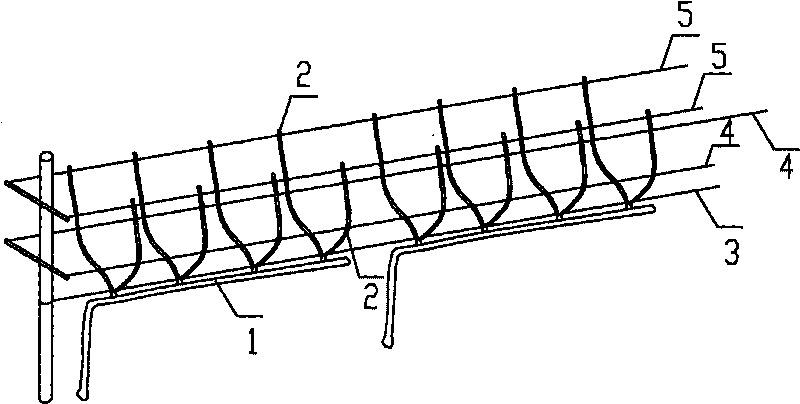

Cultivation method for pruning fig to be in line-shaped tree form

ActiveCN103518577AEasy to trimFast formingCultivating equipmentsHorticulture methodsFruit treeAgricultural engineering

The invention relates to a cultivation method for pruning a fig to be in a line-shaped tree form, and belongs to the technical field of fruit tree pruning. The cultivation method for pruning the fig to be in an I-shaped tree form comprises the following steps that the land is leveled, and ridges are made; the reasonable plantation density is determined, wherein 1.5m of line spacing and 3m of row spacing are preferred; the height of a trunk is 10-20cm after plantation, and two strong branches or strong buds are selected and reserved to be cultivated into two principal branches in an upright luring mode; a frame suitable for energy-saving pruning is built, a cross arm with the length being 50cm and a cross arm with the length being 80cm are horizontally erected on a stand column with the height being 1.5m on the ground, bracing wires are arranged on the two sides of each cross arm in a pulling mode, a main bracing wire is arranged at the position with the height being 20cm on the trunk in a pulling mode, and a U-shaped small trellis surface is formed. A tree form obtained through the cultivation method for pruning the fig to be in the line-shaped tree form has the advantages of being simple and convenient to prune, fast in forming, early in fruit yielding, convenient to manage, saving in labor, good in ventilation and light transmitting condition and the like.

Owner:邵阳启灵生物科技有限公司

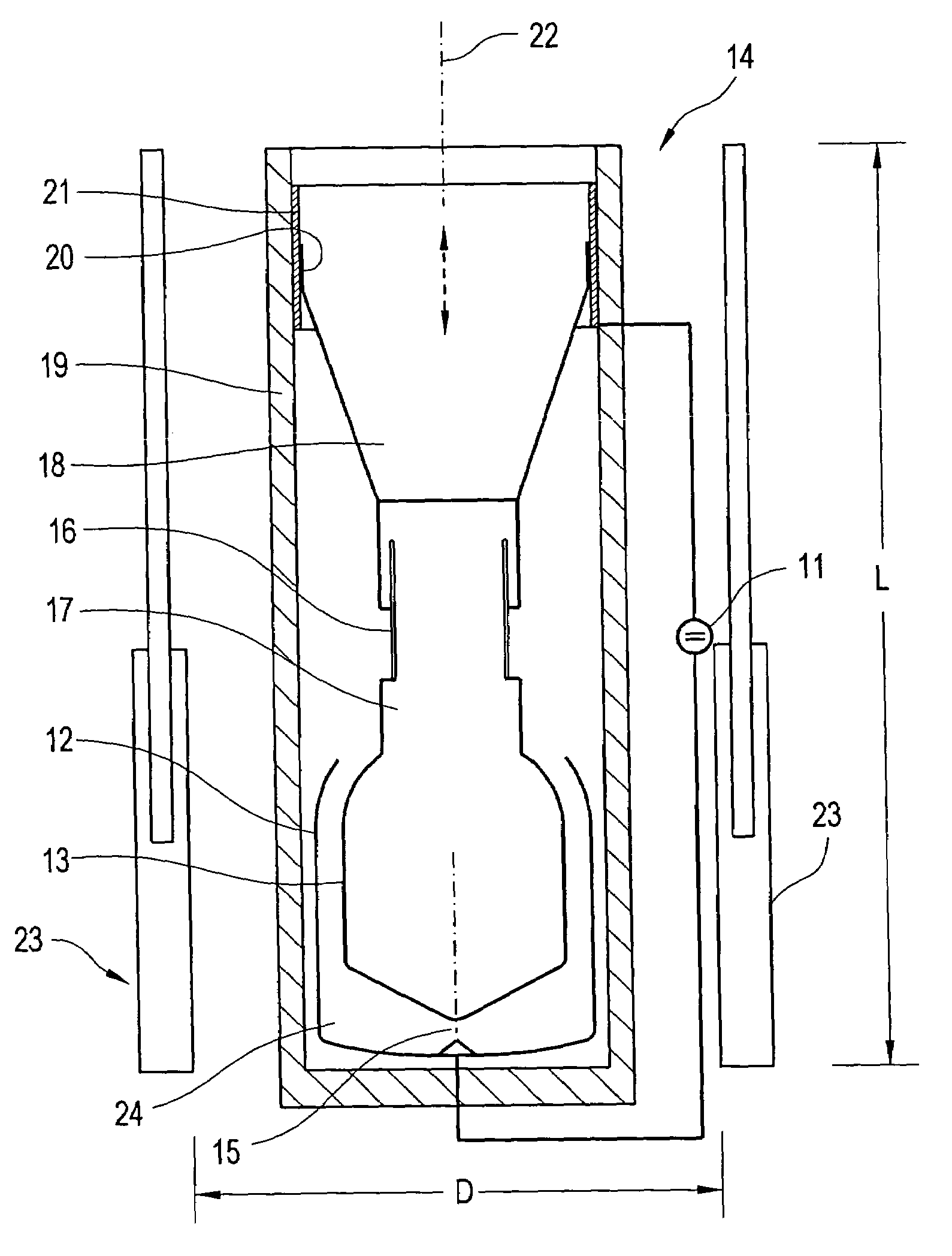

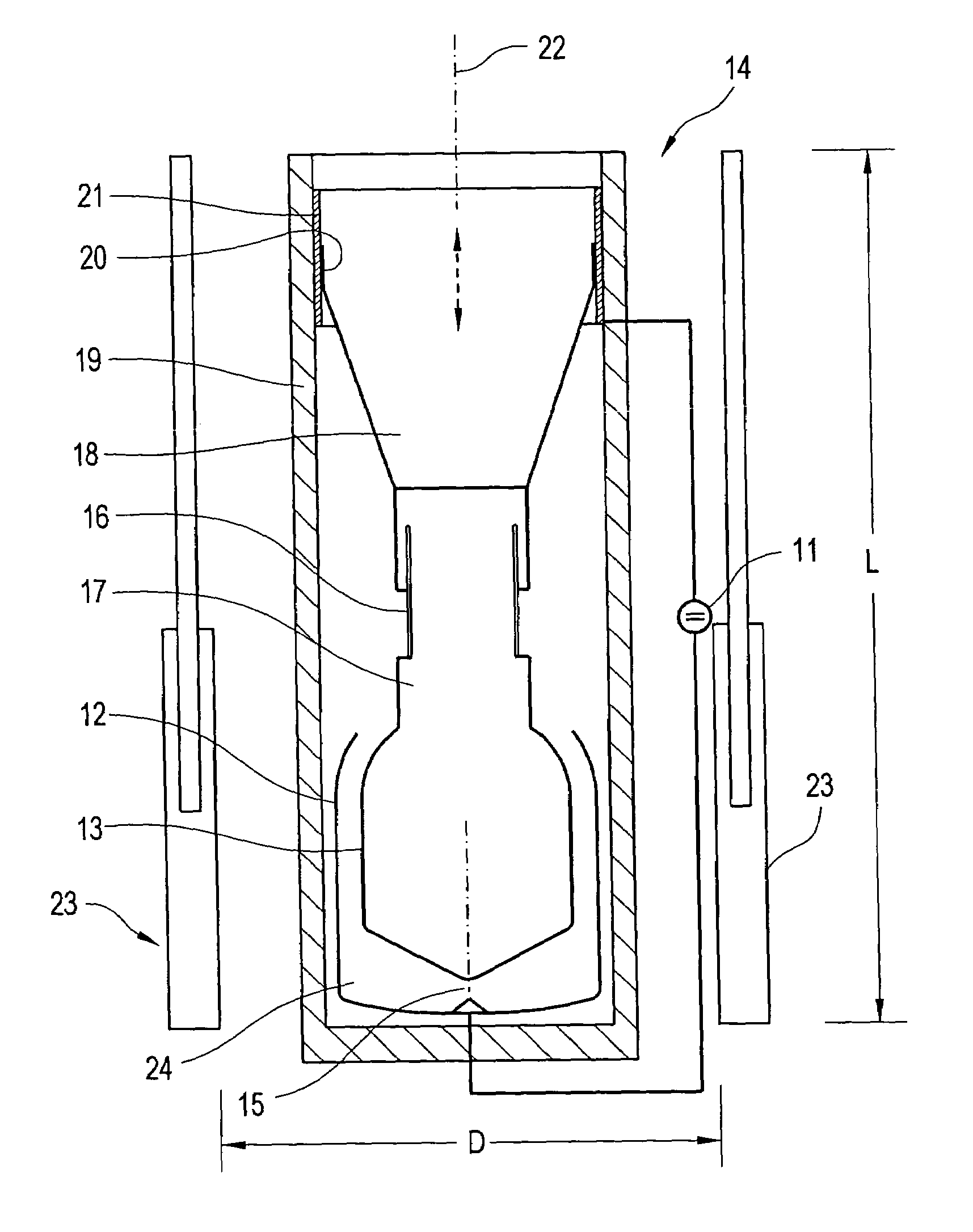

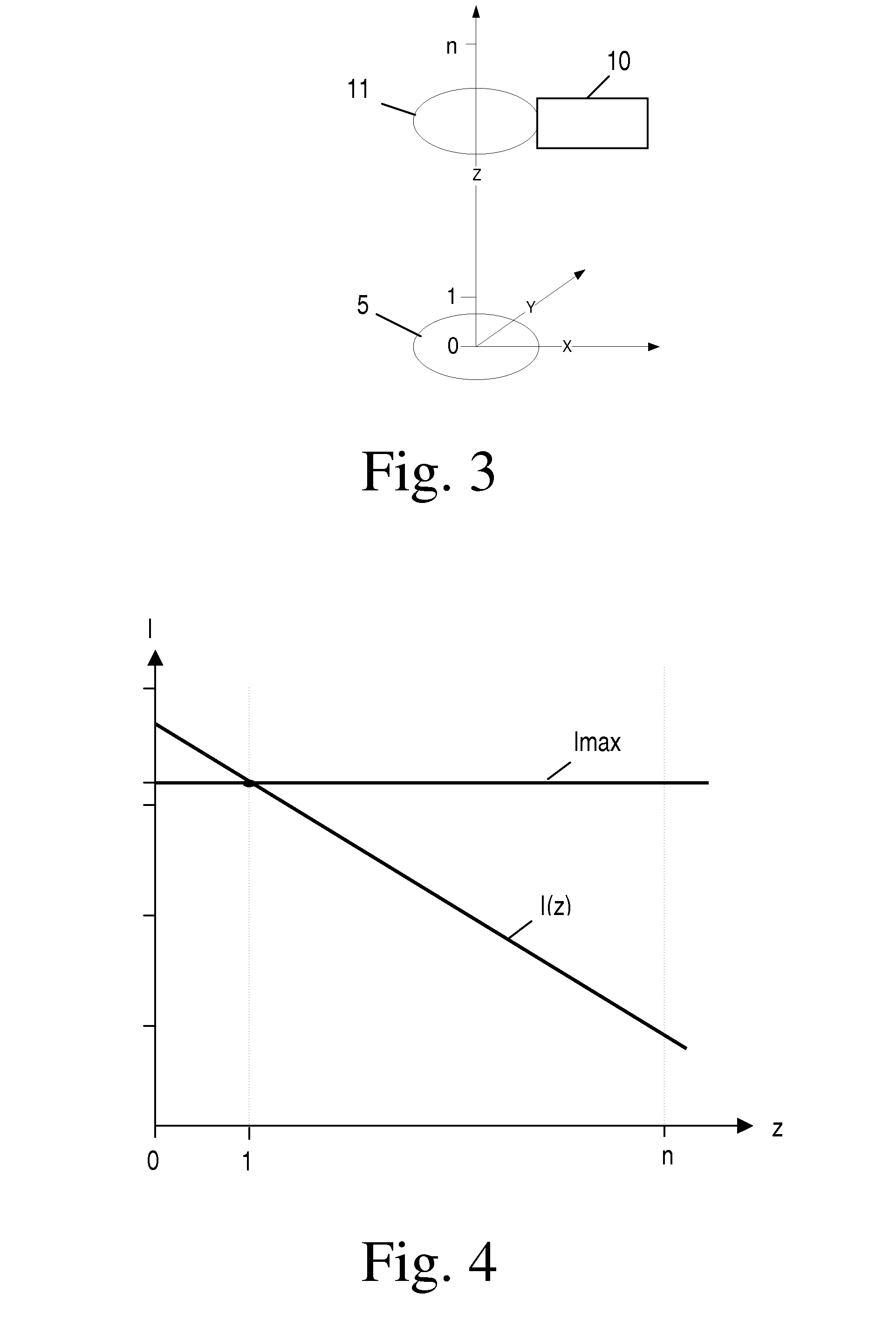

Microwave generator with variable frequency emission

InactiveUS7626468B2Improve matchEasy to trimPulse generation by gas-filled tubesOscillations generatorsMicrowaveResonance

The median frequency in the emission from a microwave generator (14), which operates in a pulsed manner, is shifted when the generator (14) operates between passive reflectors (23) whose axes are parallel thereto. In the axial direction, the reflectors (23) are approximately the same length (L) as the generator (14), with length matching through telescopic rods being preferable. However, the frequency is governed primarily by the distance (D) between the reflectors (23-23) between which the generator (14) is operated. Once desired resonance conditions have been found, for example for injection of microwave radiation into the mechanical structure of an external arrangement, this frequency relationship can be fixed by the magnitude of the length of the preferably telescopic coupling piece (16) between the resonator (13) and the antenna (18).

Owner:DIEHL BGT DEFENCE GMBH & CO KG

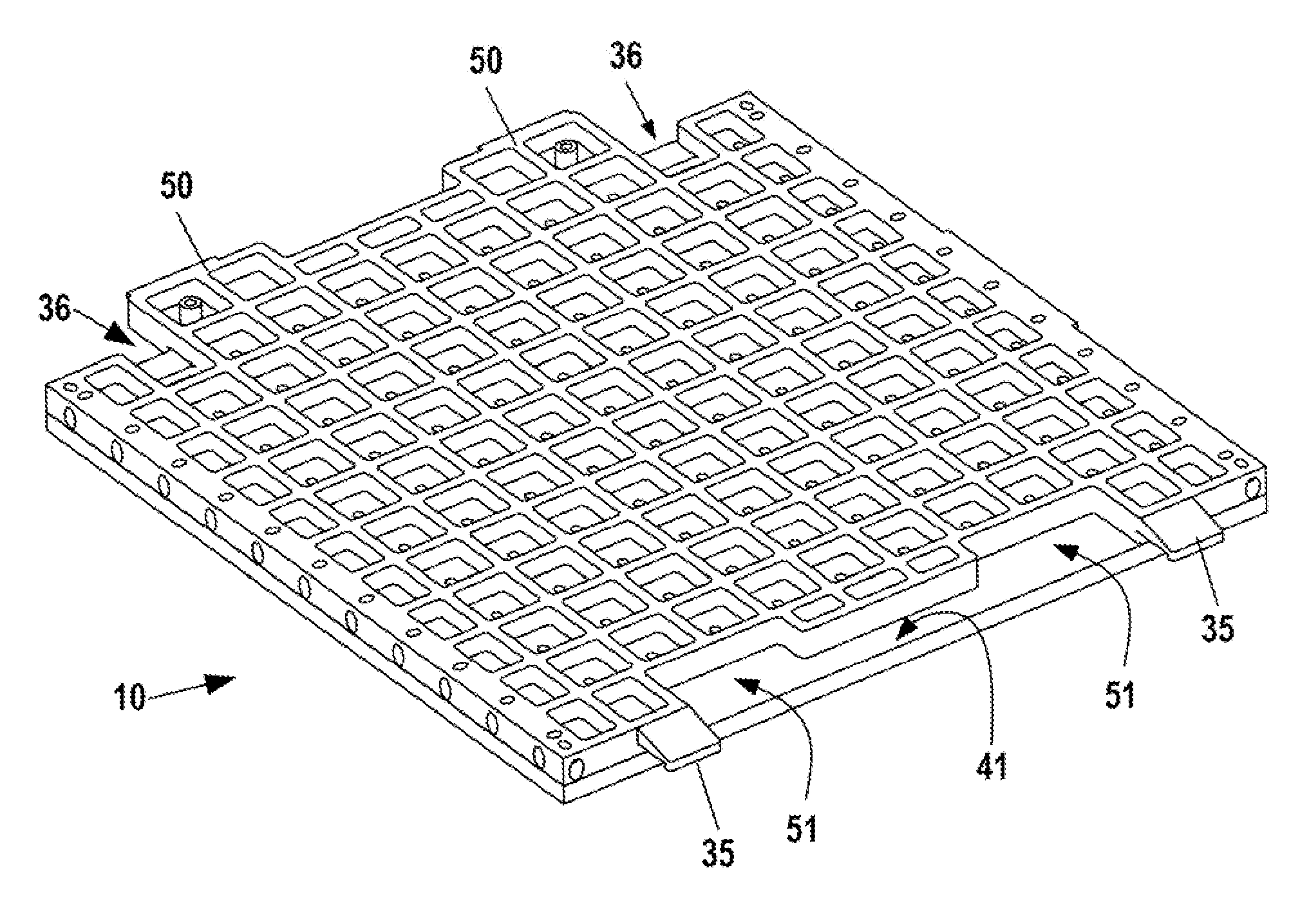

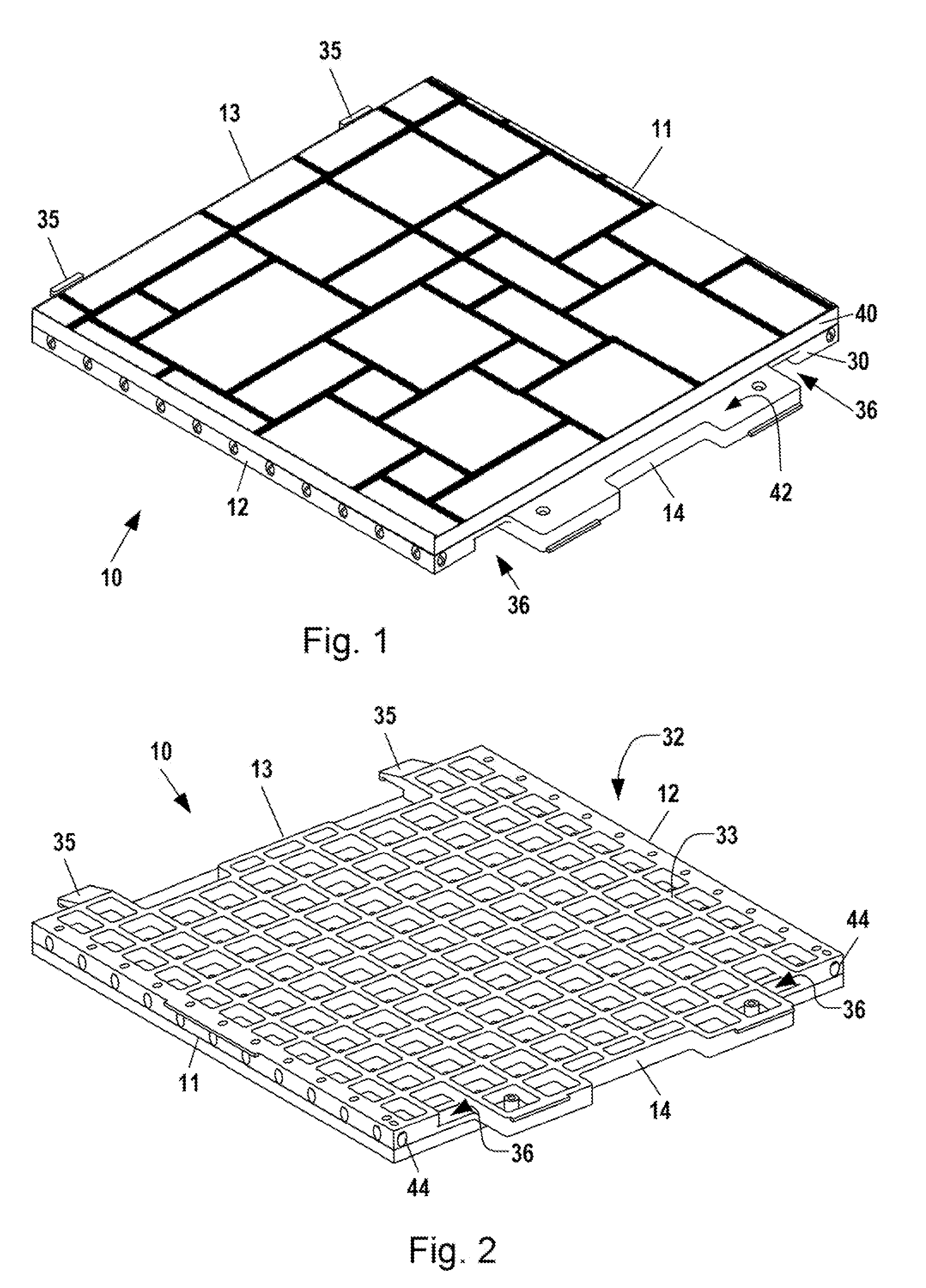

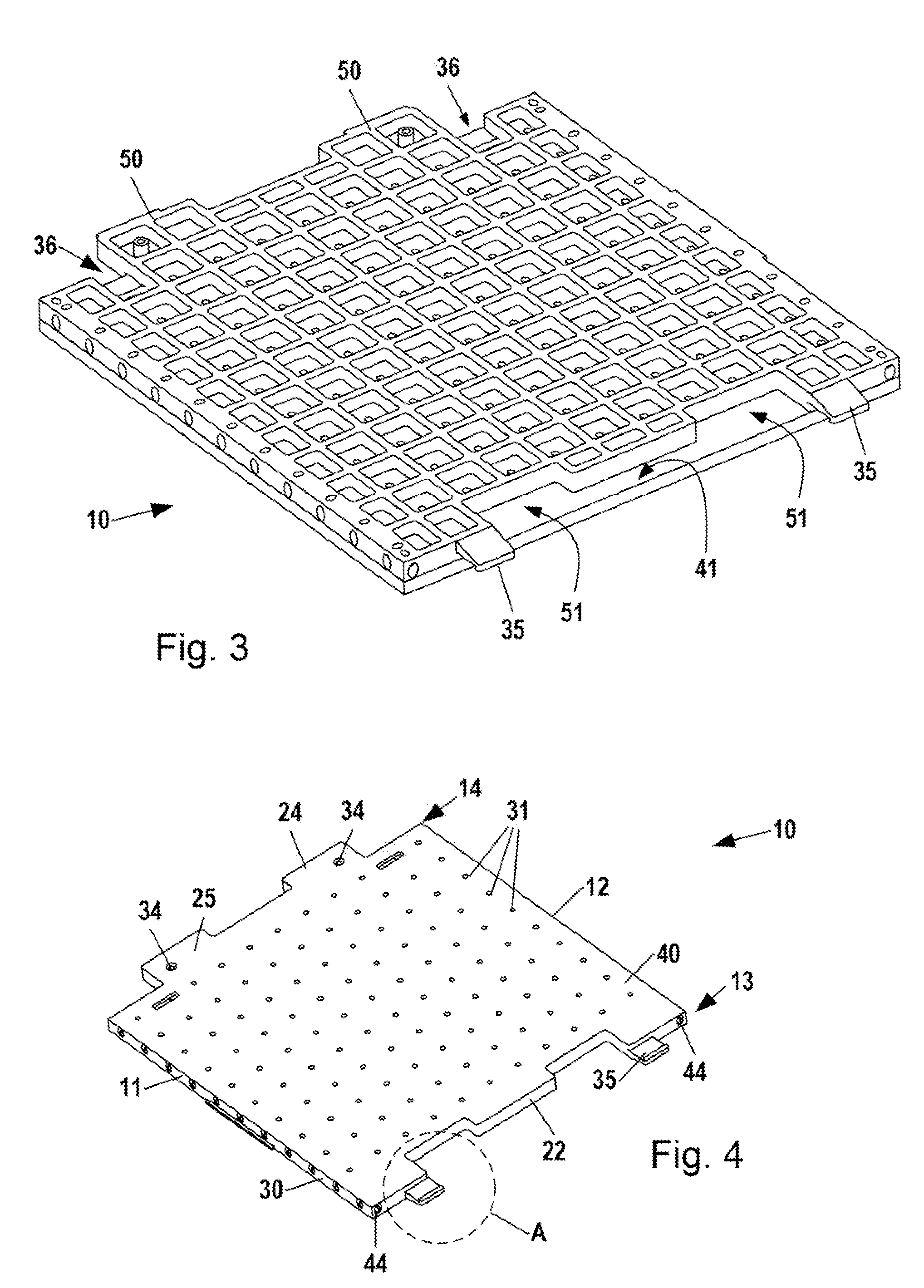

Interlocking platform panels and modules

A platform panel or module is provided to construct a surface for a deck, floor, wall, ceiling, or roof. The panel or module comprises a decorative top layer integral with or joined to a structural, composite molded platform. Each platform panel or module has two complementary module-coupling sides that take advantage of the full width of each joist that supports the platform. Also, male and female connecting members are disposed along the module-coupling sides that enable one platform panel or module to be efficiently and positively interlocked with an adjacent panel or module. Each panel or module can be fastened on one side to a single joist while being secured on its opposite side to an adjoining panel or module. The panels or modules are also designed to cover over an entire joist substructure, including the beginning-of-sequence and end-of-sequence joists.

Owner:MCFARLAND CASCADE HLDG

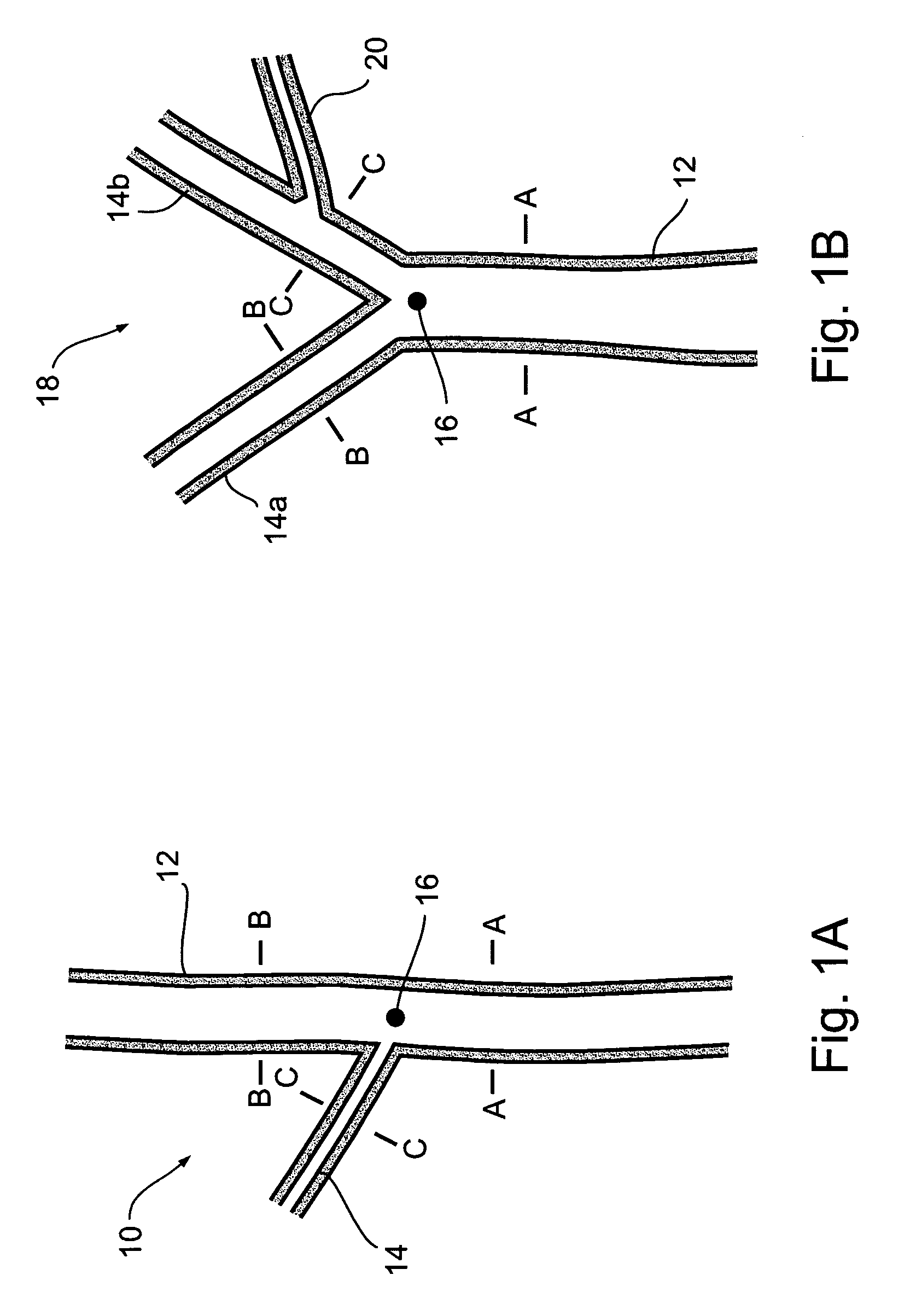

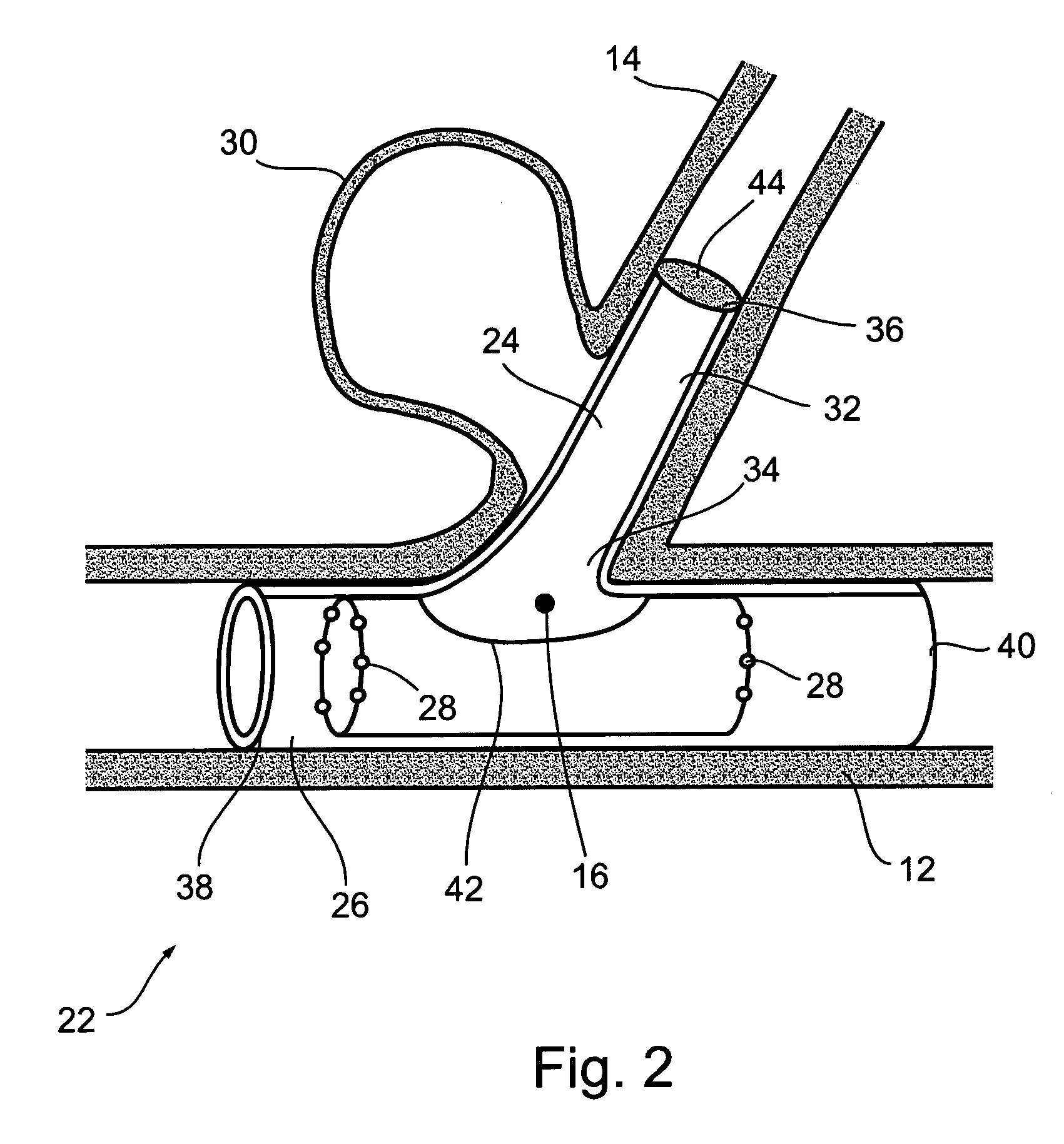

Graft-stent assembly

A graft-stent assembly comprising a stent and a substantially tubular graft branching therefrom is disclosed. The stent is preferably deployed in a trunk vessel to support trunk vessel patency while the tubular graft is preferably deployed in a branching vessel. In embodiments, the downstream end of the tubular graft is provided with an expandable ring-shaped support member to anchor the downstream end of the tubular graft in place.

Owner:DESIGN & PERFORMANCE CYPRUS

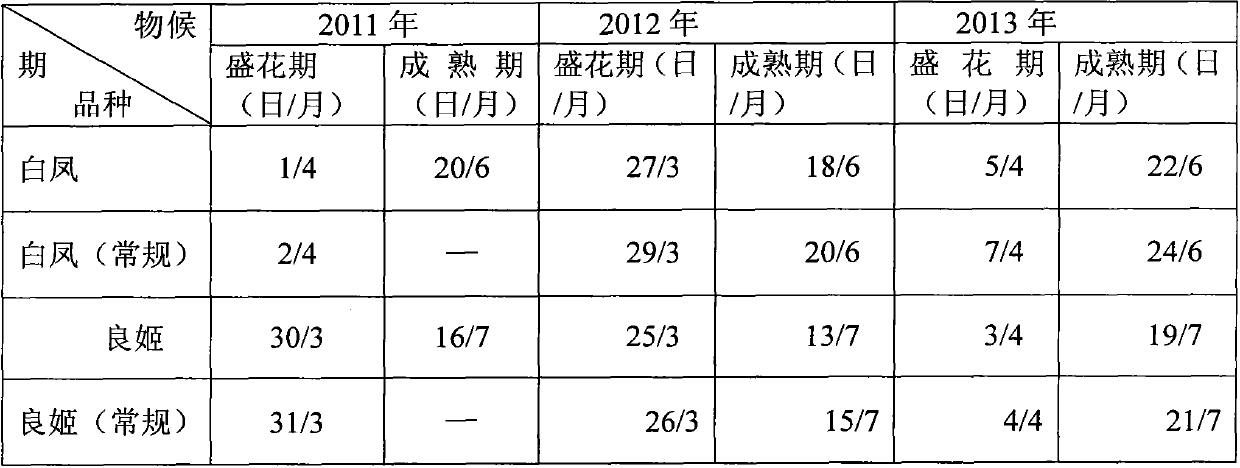

Shaping cultivation method of peach tree shape with three boughs and one center truck

ActiveCN103430803AImprove qualityIncreased main branch openingCultivating equipmentsHorticulture methodsSmall branchTree shaped

The invention relates to a shaping cultivation method of a peach tree shape with three boughs and one center truck. The method concretely comprises the following processes: the height of a stem of the tree shape is determined to be 20-30cm; a leafbud at the top end of the determined stem part germinates young sprouts; the center truck is cultivated to vertically grow upwards; three strong branches or strong buds are selected from the young sprouts germinated on a base part and cultivated into three boughs; small and medium fruiting branch groups are evenly configured at two sides of the boughs; the intervals of the medium branch groups on the boughs are 60-80cm; the intervals of the small branch groups are 20-30cm; the angles between the boughs and the center truck are 60-70 degrees; the height of the center truck is controlled at about 2.2m. Compared with the traditional three-bough natural opening heart tree, the opening of each bough is improved by about 15%; the tree shape is easily formed; a branching group is directly connected to a skeleton branch; pruning is simple and convenient, fruiting is early, management is convenient, and fruit quality is excellent.

Owner:盖南南

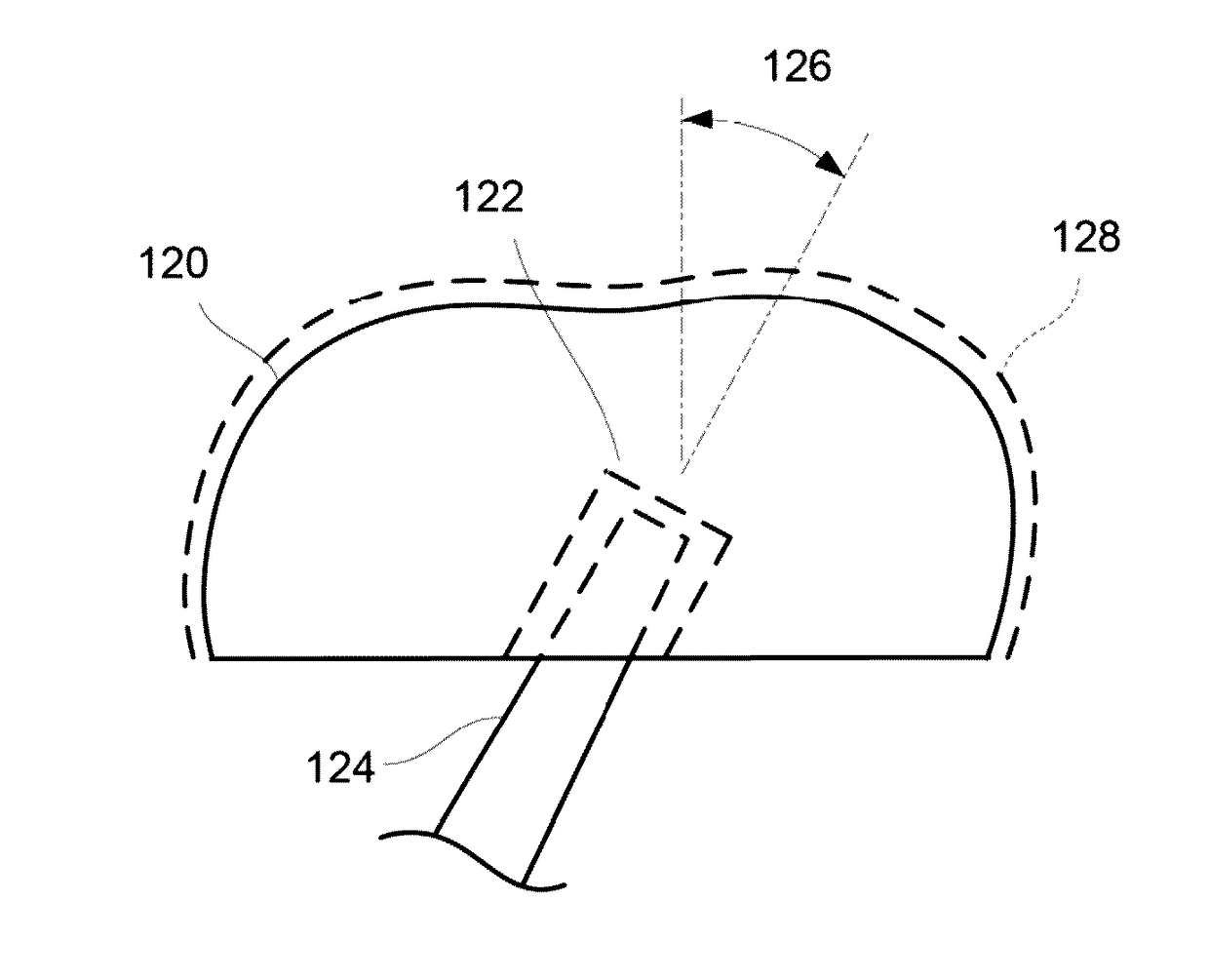

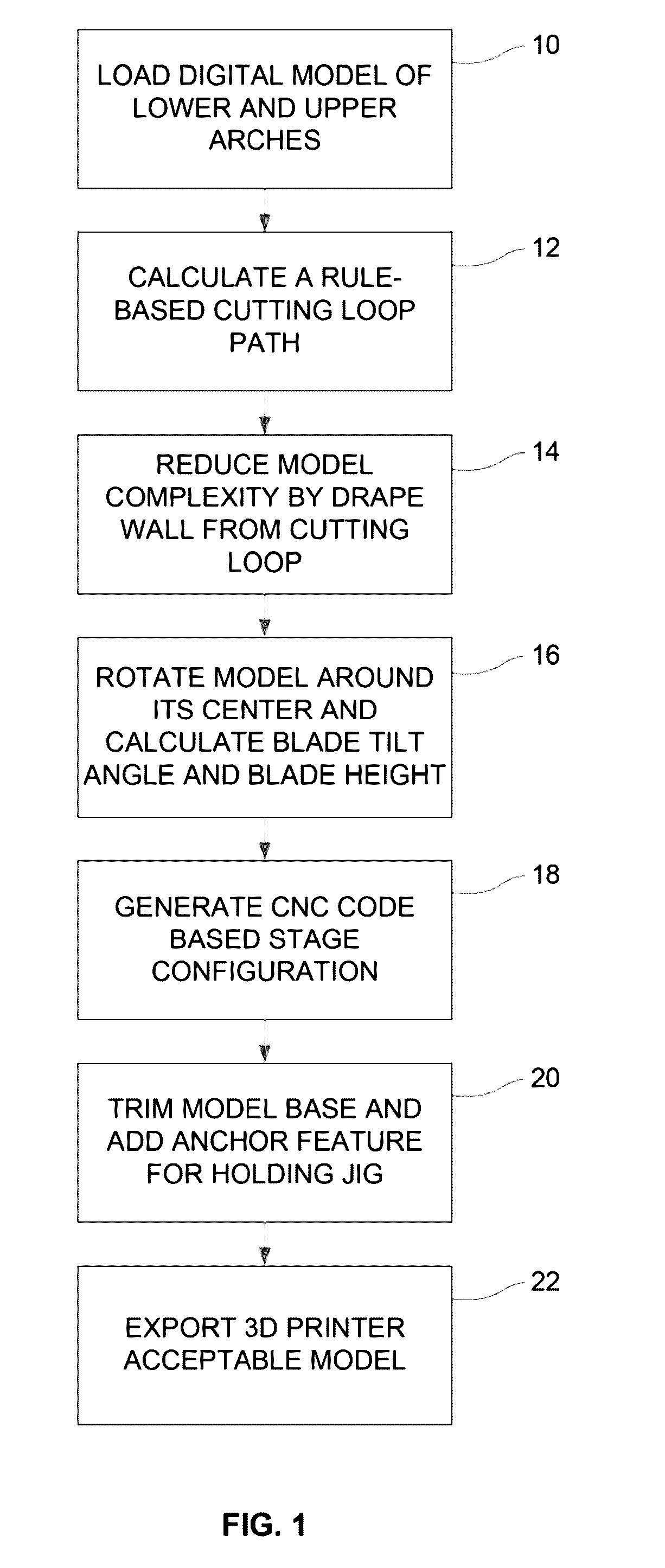

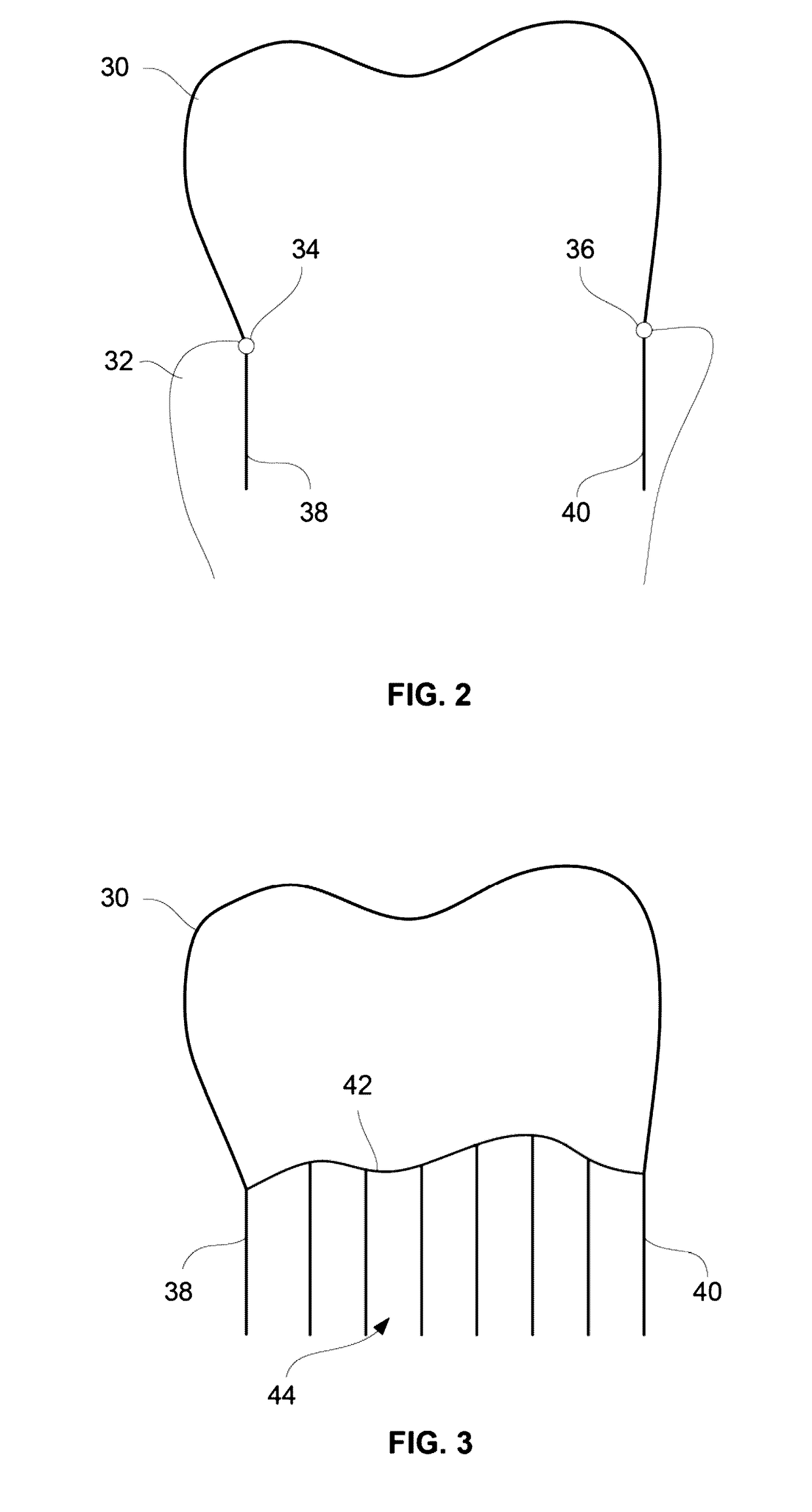

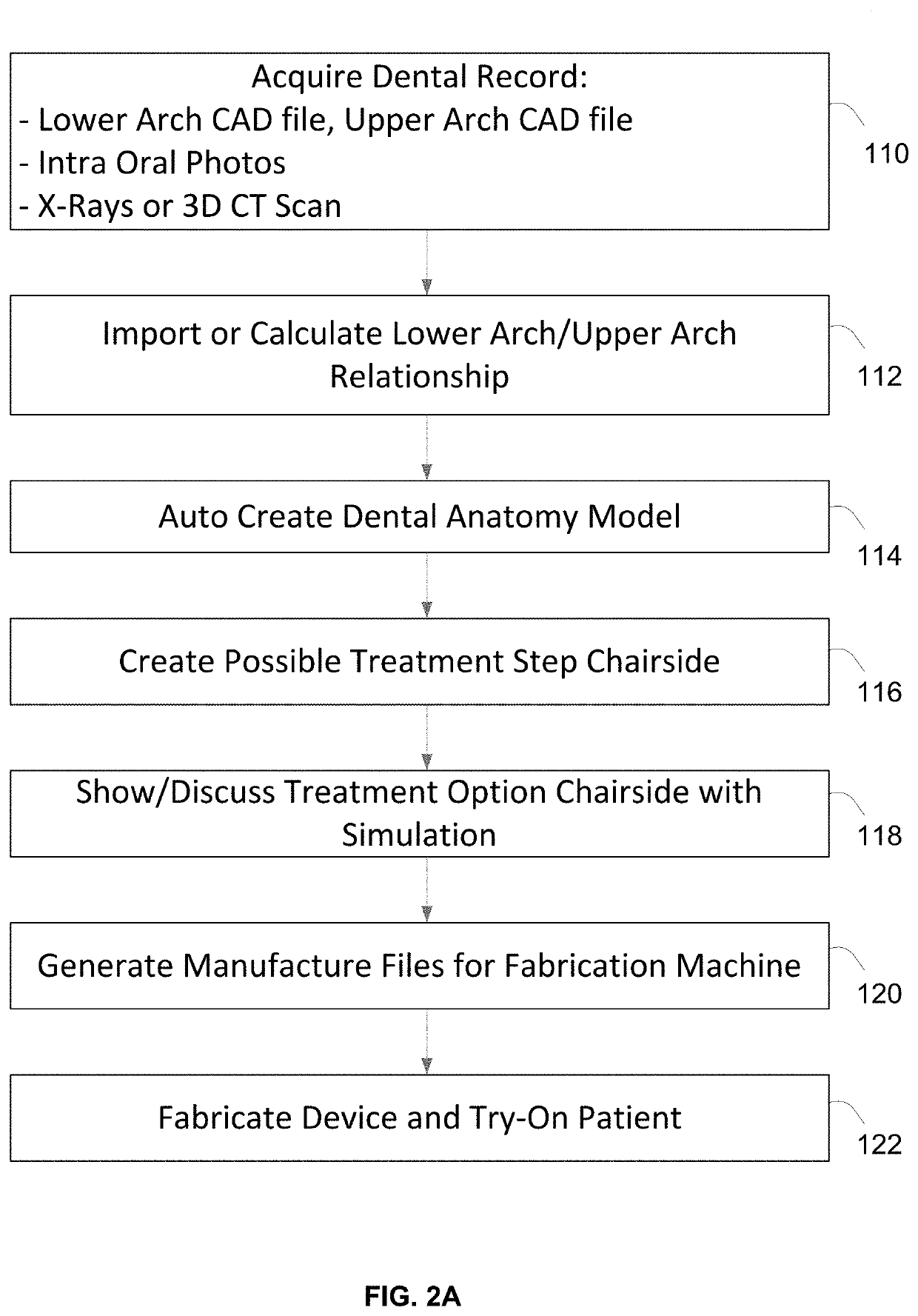

Systems and methods for fabricating dental appliances or shells

Systems and methods are disclosed for cutting and trimming dental molds and oral appliances by receiving a digital model of teeth, determining a cutting loop path and applying a drape wall to the cutting loop to generate a simplified tooth base in a dental mold having an inner arch curve and an outer arch curve. The oral appliance may be formed on the dental mold and a cutter may be applied using a sweeping motion across the inner and outer arch curves.

Owner:ULAB SYST INC

Pelvic health implants and methods

ActiveUS20080103351A1Easy to useEasy to assembleSuture equipmentsSurgical furniturePelvisSurgical department

Owner:STASKIN DAVID MD DR

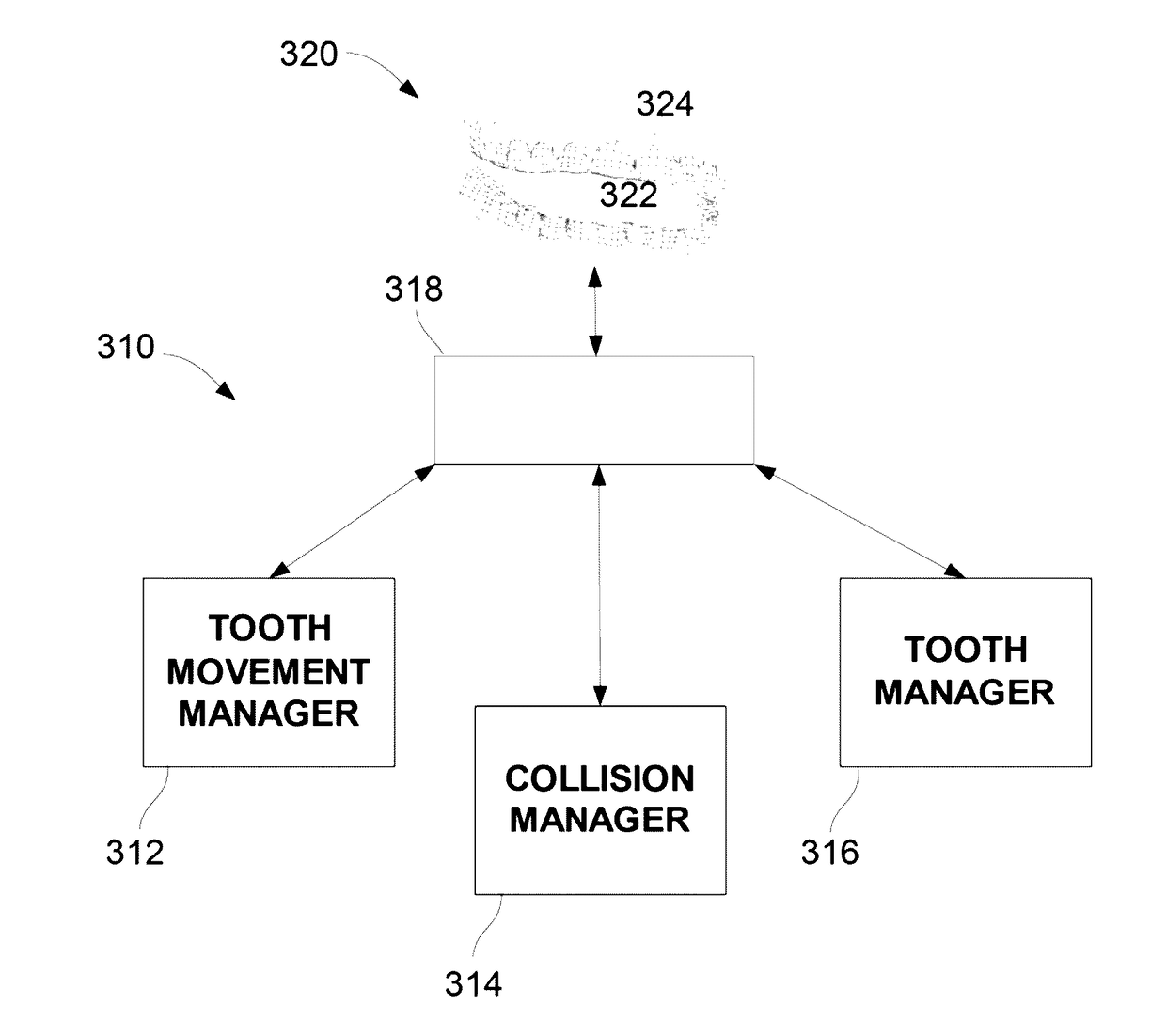

Orthodontic planning systems

ActiveUS10548690B2Reduce complexityAvoid collisionMedical simulationOthrodonticsDental malocclusionDentition

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished in one variation by receiving a scanned dental model of a subject's dentition, determining a treatment plan having a plurality of incremental movements for repositioning one or more teeth of the subject's dentition, and fabricating one or more aligners correlating to a first subset of the plurality of incremental movements.

Owner:ULAB SYST INC

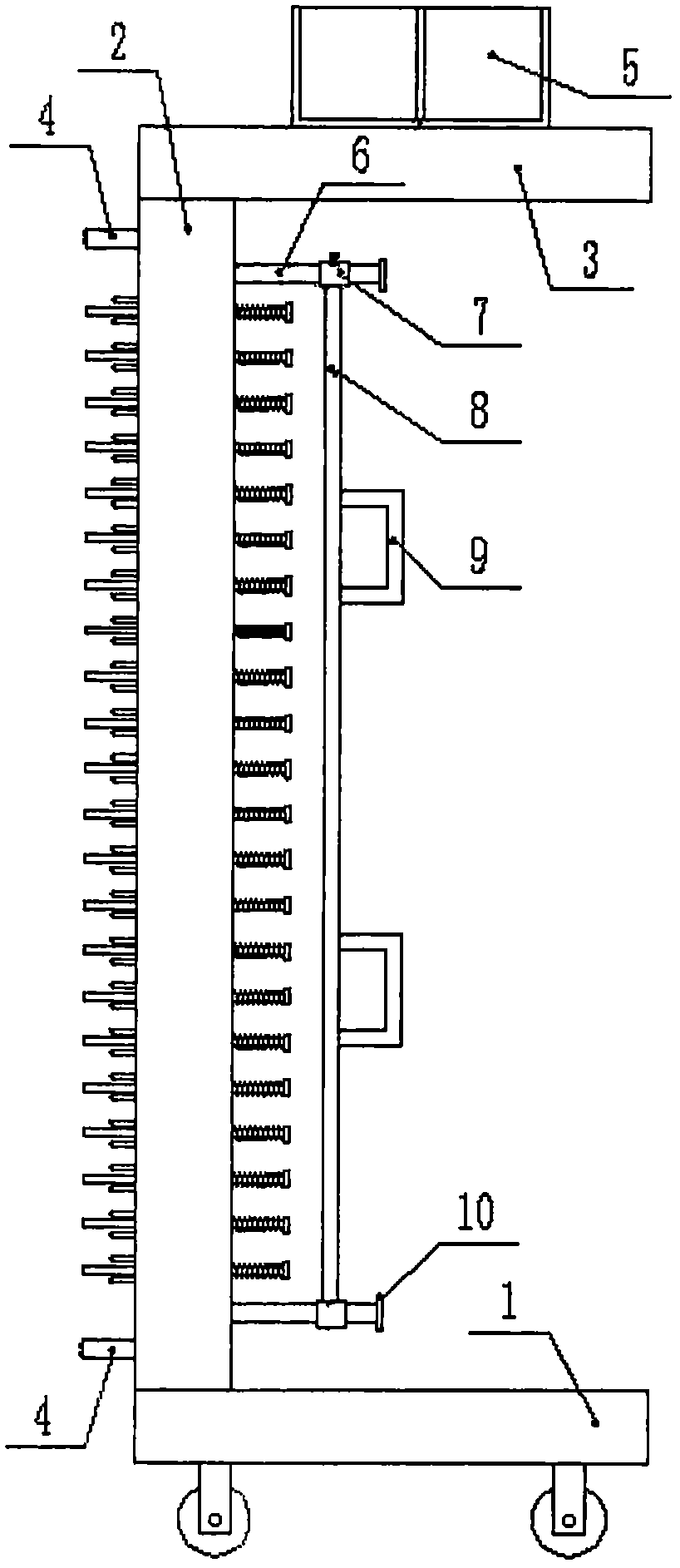

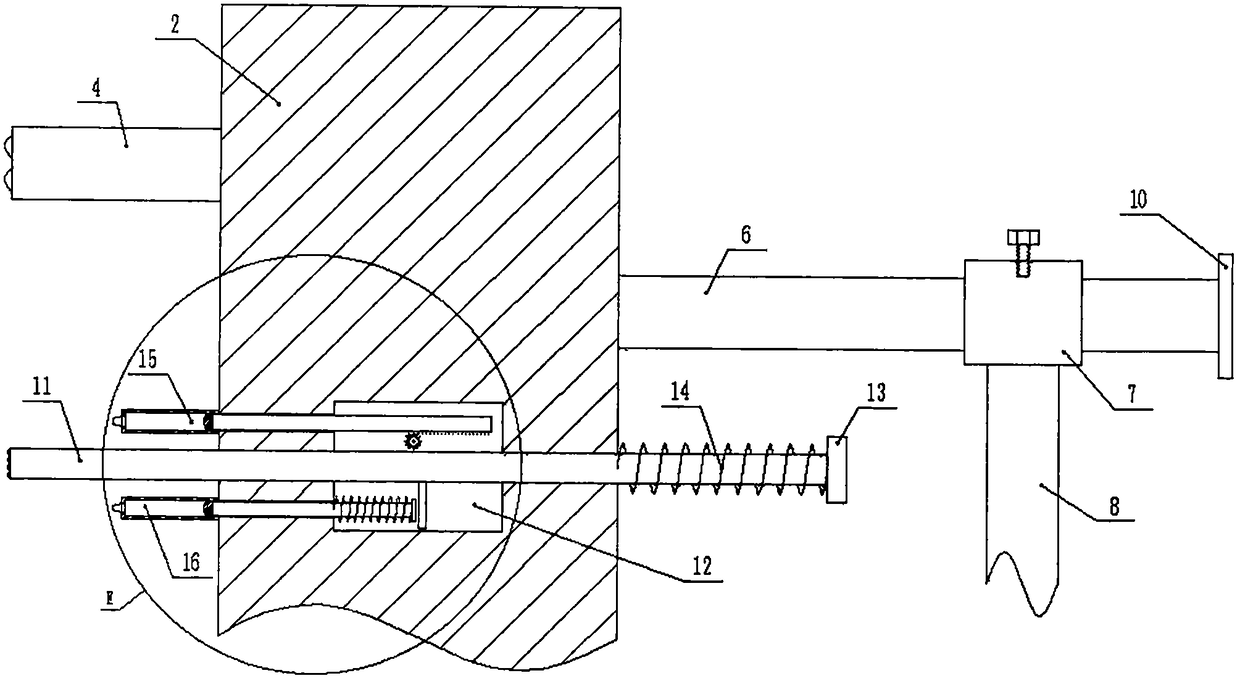

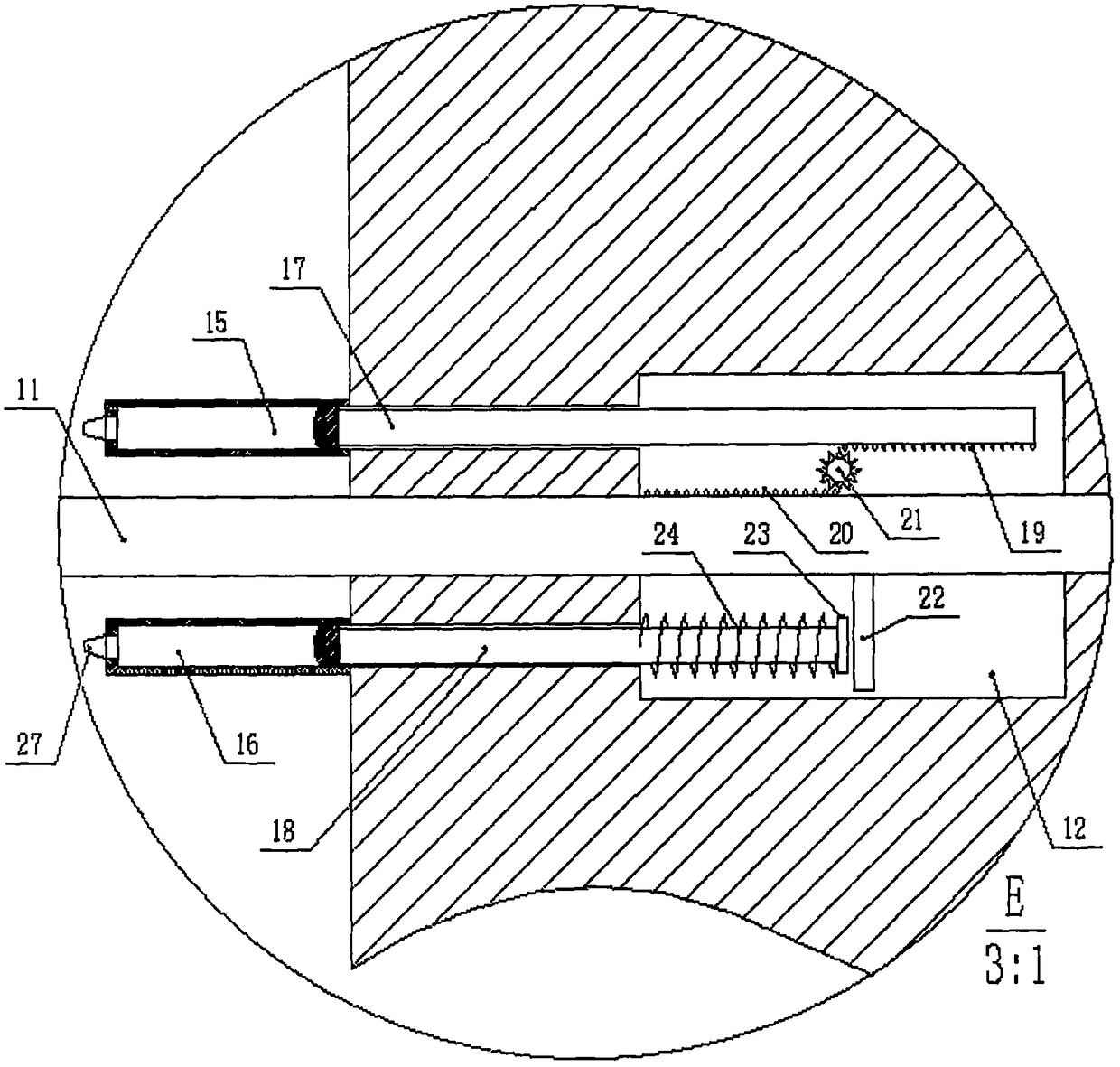

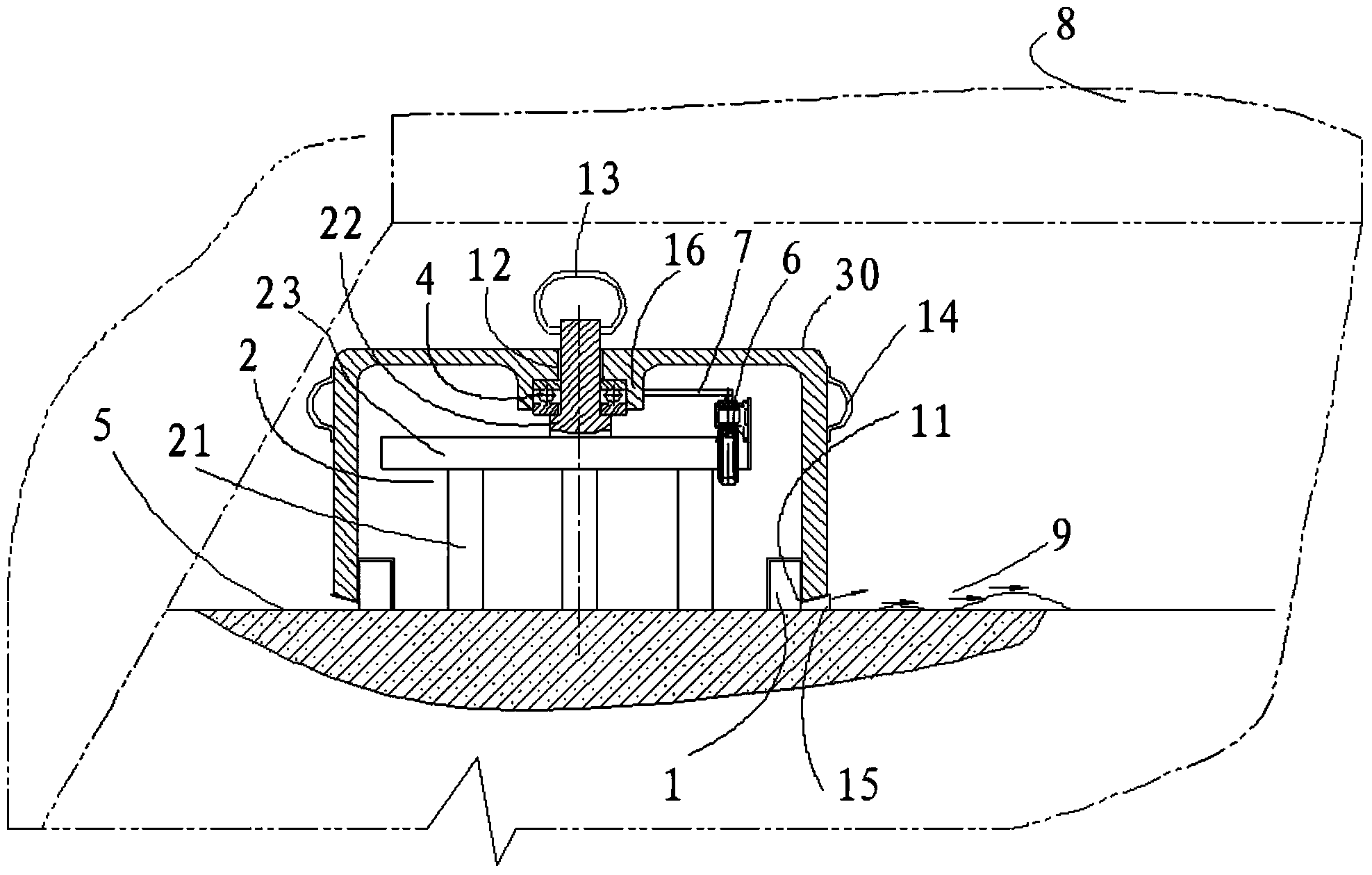

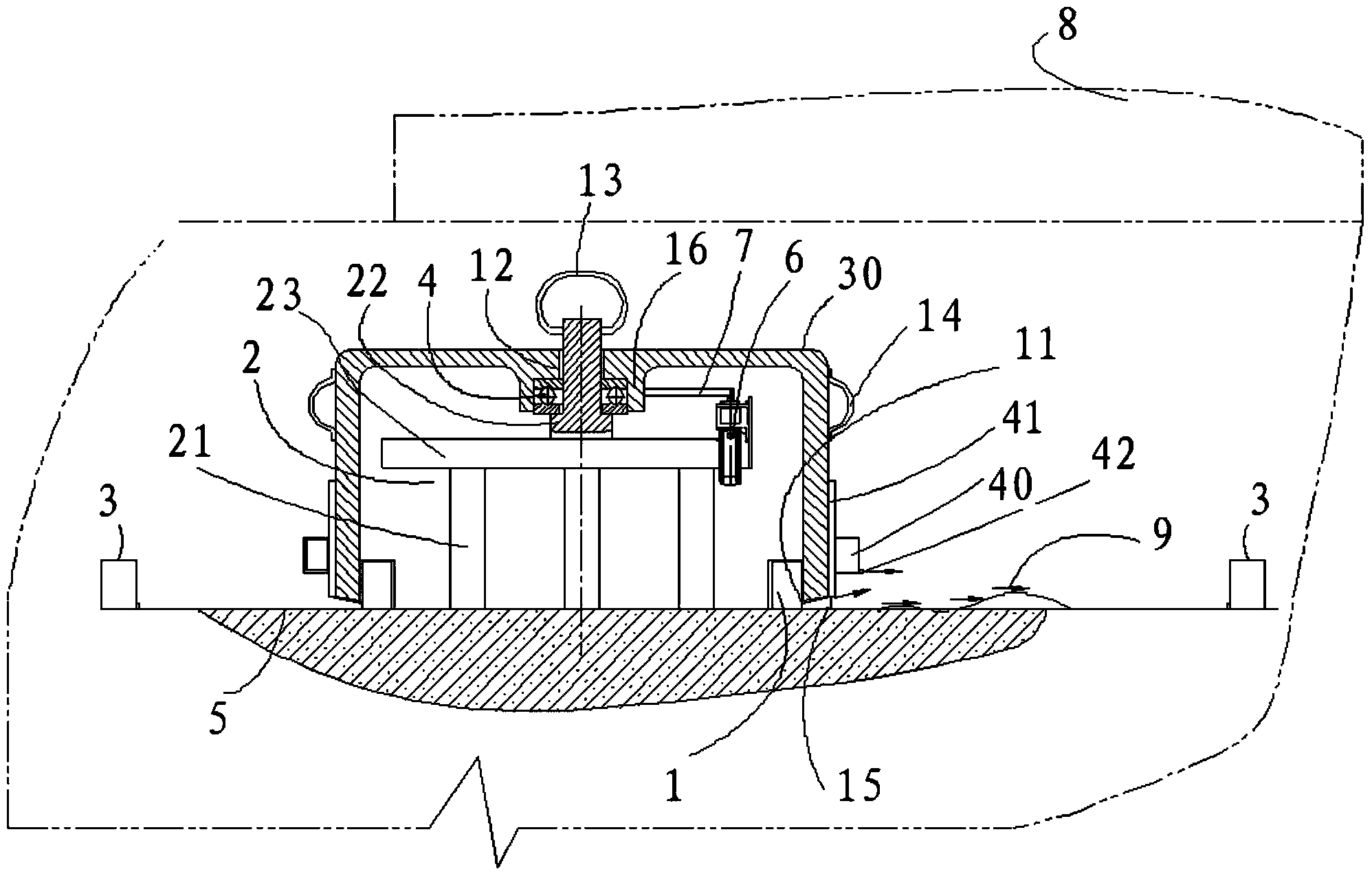

Wall surface roughness detection apparatus

InactiveCN108801124AEasy to trimReasonable designMechanical roughness/irregularity measurementsVertical barArchitectural engineering

The invention discloses a wall surface roughness detection apparatus. The wall surface roughness detection apparatus includes a base plate, wherein a vertical plate is vertically fixed at the upper end of the base plate; a top plate is fixed at the upper end of the vertical plate; support rods are horizontally fixed on the upper and lower ends of one side of the vertical plate, and cross bars arehorizontally fixed on the upper and lower ends of the other side of the vertical plate; a hopper is fixed on the upper end of the top plate; two cavities are arranged in the hopper; a sleeve is slidably connected with each cross bar; a vertical bar is fixed between the sleeves; the vertical bar is made of iron material, and a handle is fixed on the vertical bar; the each sleeve is locked through abolt which is in threaded connection with the sleeve; a retaining plate A for preventing the sleeve from falling off is fixed on each cross bar; a plurality of detecting rods are inserted in the vertical plate horizontally; a plurality of cavities corresponding to the detecting rods are arranged in the vertical plate; one end, located on the corresponding support rod, of each detecting rod is connected with a plurality of balls in a rolling manner; and during the movement detection process, the rough locations of the wall can be marked at the same time, and after the detection is completed, the wall mark can be directly observed, so as to obtain the determination result which is clear at a glance, and at the same time, the mark is more conspicuous, thus being convenient to repair the rough parts in the later stage.

Owner:桐乡市龙翔众心纺织有限公司

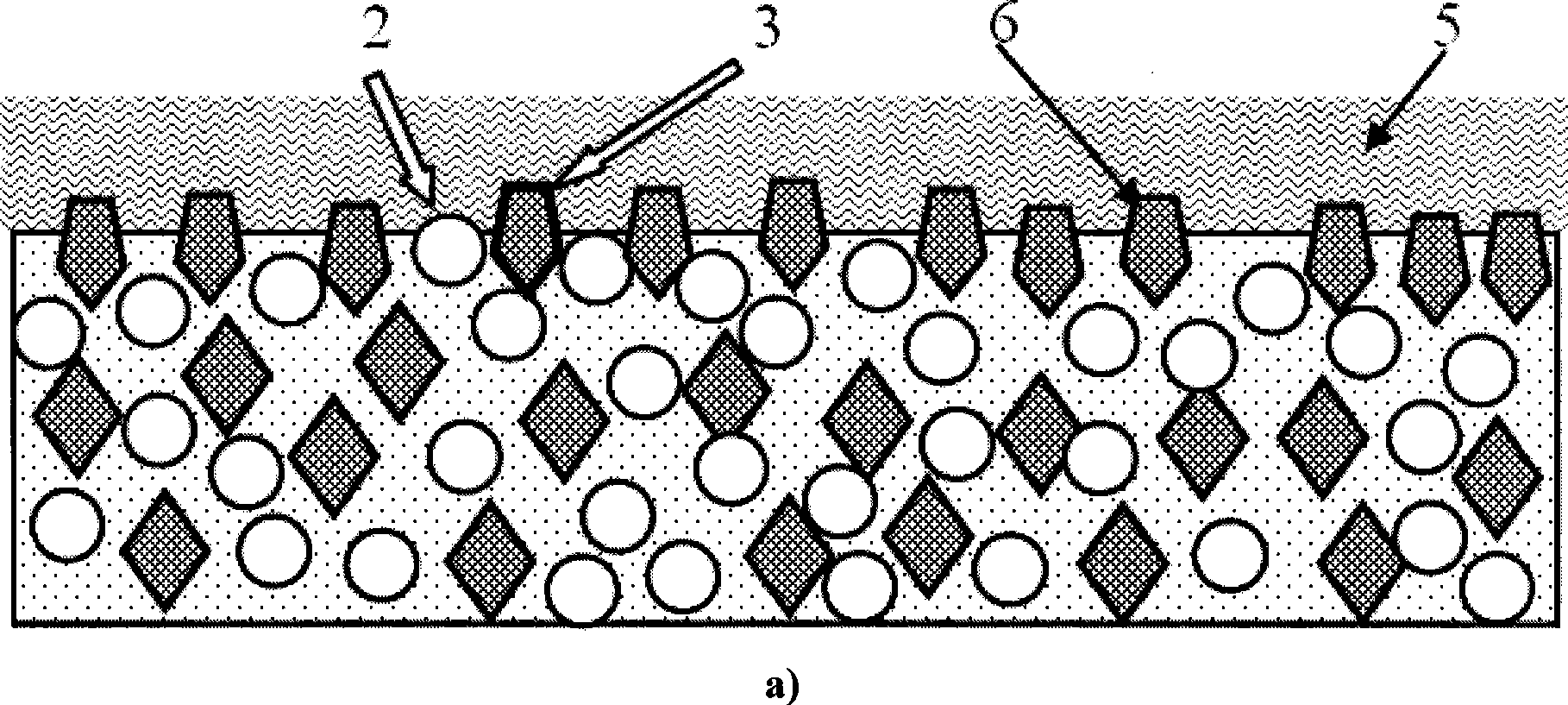

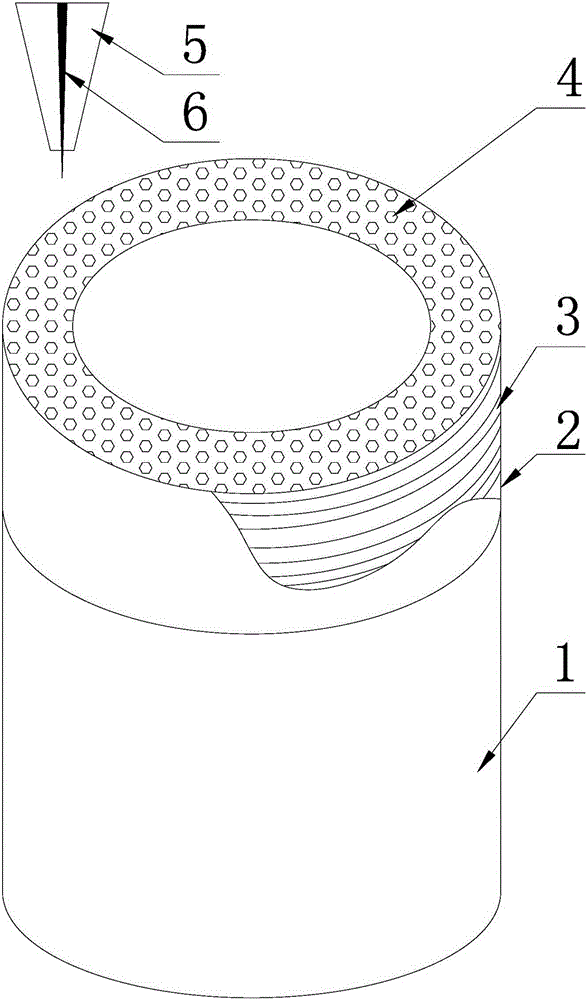

Pore self-generation superhard abrasives grinding tool and shaving method thereof

The invention discloses an automatic pore generation ultrahard abrasive grinding tool and a method for dressing the same. The grinding tool at least consists of abrasive grains, a bonding agent and a 'soluble' filling agent. The 'soluble' agent soluble in a certain solvent is added into the bonding agent of the automatic pore generation ultrahard abrasive grinding tool, and a layer of the 'soluble' filling agent can be coated on the ultrahard abrasive grain surface layer according to requirement. The 'soluble' filling agent and the bonding agent act together to hold the abrasive grains and ensure excellent strength of the grinding tool. In a grinding process of the grinding tool, when the abrasive grains on the surface of the grinding tool are passivated and the grinding tool needs to be dressed, the method can deliver the certain solvent to the surface of the grinding tool to dissolve the 'soluble' filling agent on the surface layer of the grinding tool and generate pores in the bonding agent to reduce the structural strength of the bonding agent and holding force of the bonding agent to the sounding abrasive grains and make the abrasive grains on the surface layer of the grinding tool easy to fall off, thereby automatically dressing the grinding tool and revealing new abrasive grains.

Owner:吴寿麟

Device for measuring wall or ground flatness by lasers

ActiveCN103925892AConvenient flatness measurementConvenient flatness inspection and measurementUsing optical meansLaser transmitterBall bearing

The invention discloses a device for measuring the wall or ground flatness by lasers. The device comprises a base and a laser transmitter, the lower portion of the base is supported on a standard supporting face, the standard supporting face is the plane which is locally leveled and ground, and has the qualified flatness, the laser transmitting point of the laser transmitter is arranged in the plane of the standard supporting face, a stepped shaft is arranged in the middle of the upper portion of the base, a thrust ball bearing is arranged at the position of a small shaft of the stepped shaft, a boss is arranged on the upper portion of the laser transmitter, a stepped hole is formed in the boss, the position of a large hole of the stepped hole is matched with the thrust ball bearing, and the laser transmitter rotates around the axis of the stepped shaft through the thrust ball bearing. The device is simple and compact in laser, a constructor can conveniently conduct wall or ground flatness measurement in the construction process, meanwhile, an inspector can conveniently check and measure the flatness in the inspection and acceptance process, the measured face can be rapidly and accurately measured, and the measuring and repairing efficiency can be improved.

Owner:STATE GRID CORP OF CHINA +1

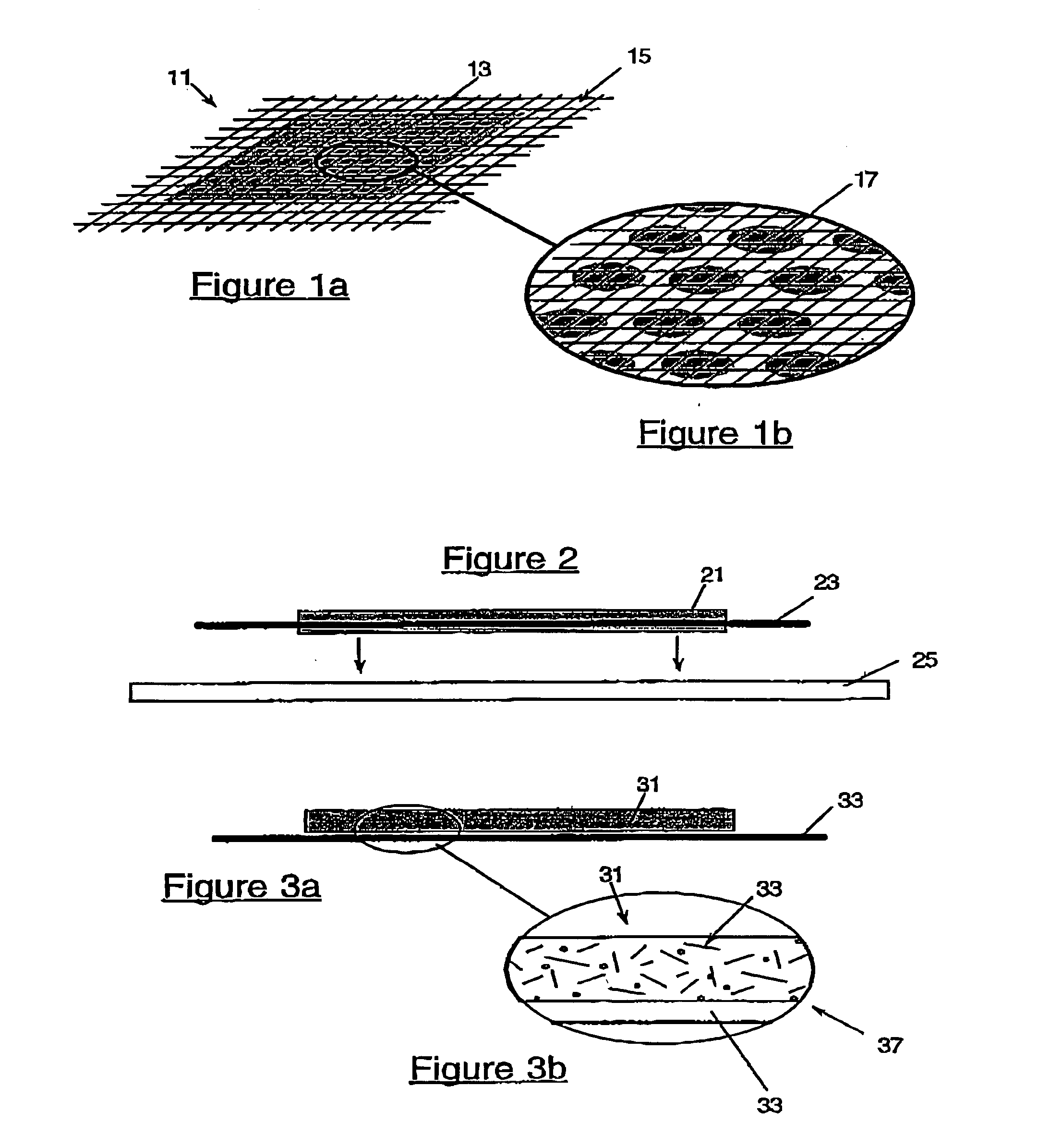

Honey based wound dressing

InactiveUS20040054313A1Easy to trimDegree of flexibility be variedAerosol deliveryOintment deliveryWound dressingMedicine

The present invention is directed to the use of honey in medical dressings. Preferred embodiments modify honey with a viscosity increasing agent, resulting in a range of possible compositions including ointments and salves, self-adhesive gels such as for use on mouth ulcers and pustules, and pliable or flexible sheets which can be used as a wound covering. Preferred viscosity increasing agents include both particulate and continuous gels, respective examples of each including agars and alginates. Selected honeys preferably, but not necessarily, exhibit antibacterial properties other than what is merely conferred by osmolarity and sugar concentration effects.

Owner:APIMED MEDICAL HONEY

Multi-main-branch open center tree shape of pear tree and pruning method for pear tree

The invention discloses a multi-main-branch open center tree shape of a pear tree, and belongs to the field of pruning of fruit trees. The trunk height of the tree shape is 0.7 to 0.9 meter, the central trunk height is 1.7 to 1.9 meters, 7 to 9 main branches are uniformly grown on the central trunk, and medium and small branch groups are directly grown on the main branches; the angle between each main branch and the central trunk is 70 to 80 degrees; and the thickness of a leaf curtain is 1.8 to 2.3 meters, and the height of the tree is 2.2 to 2.7 meters. The intervals of the medium branch groups on the main branches are 50 to 70 centimeters, and the intervals of the small branch groups are 10 to 20 centimeters. The tree shape has the advantages of simplicity and convenience in pruning, quickness in formation, earliness in fruiting, convenience in management, good ventilation and light transmission conditions and the like.

Owner:SHIJIAZHUANG POMOLOGY INST OF HEBEI ACADEMY OF AGRI & FORESTRY SCI

Camellia grafting method by utilizing buxus sinica stock

InactiveCN103314768AEasy to trimMeet the needs of admiring a variety of camelliasHorticultureRootstockBuxus sinica

The invention discloses a camellia grafting method by utilizing a buxus sinica stock. A camellia with a certain thickness can be obtained in a relatively short time. A tea tree serving as the stock can grow into needed thickness in a short time, several even dozens of kinds of camellias can grow on the same tea tree, the demands for enjoying various camellias in a small space can be met, and branches and leaves can be trimmed conveniently. The success rate of grafting is improved under the premise that the cultivating period is obviously shortened, and double indexes of the cultivating period and the success rate are guaranteed.

Owner:隆林盈荣种养农民专业合作社

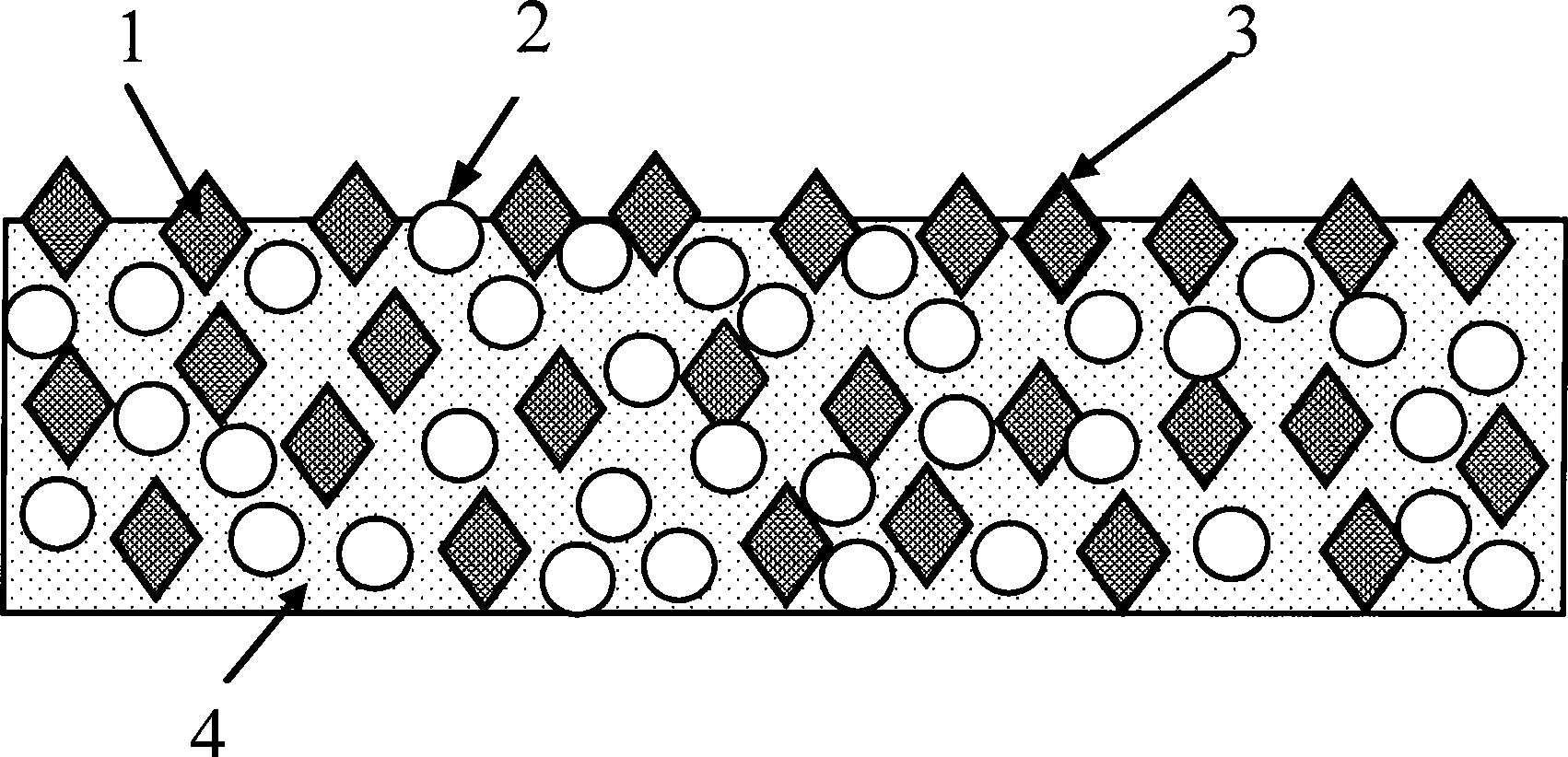

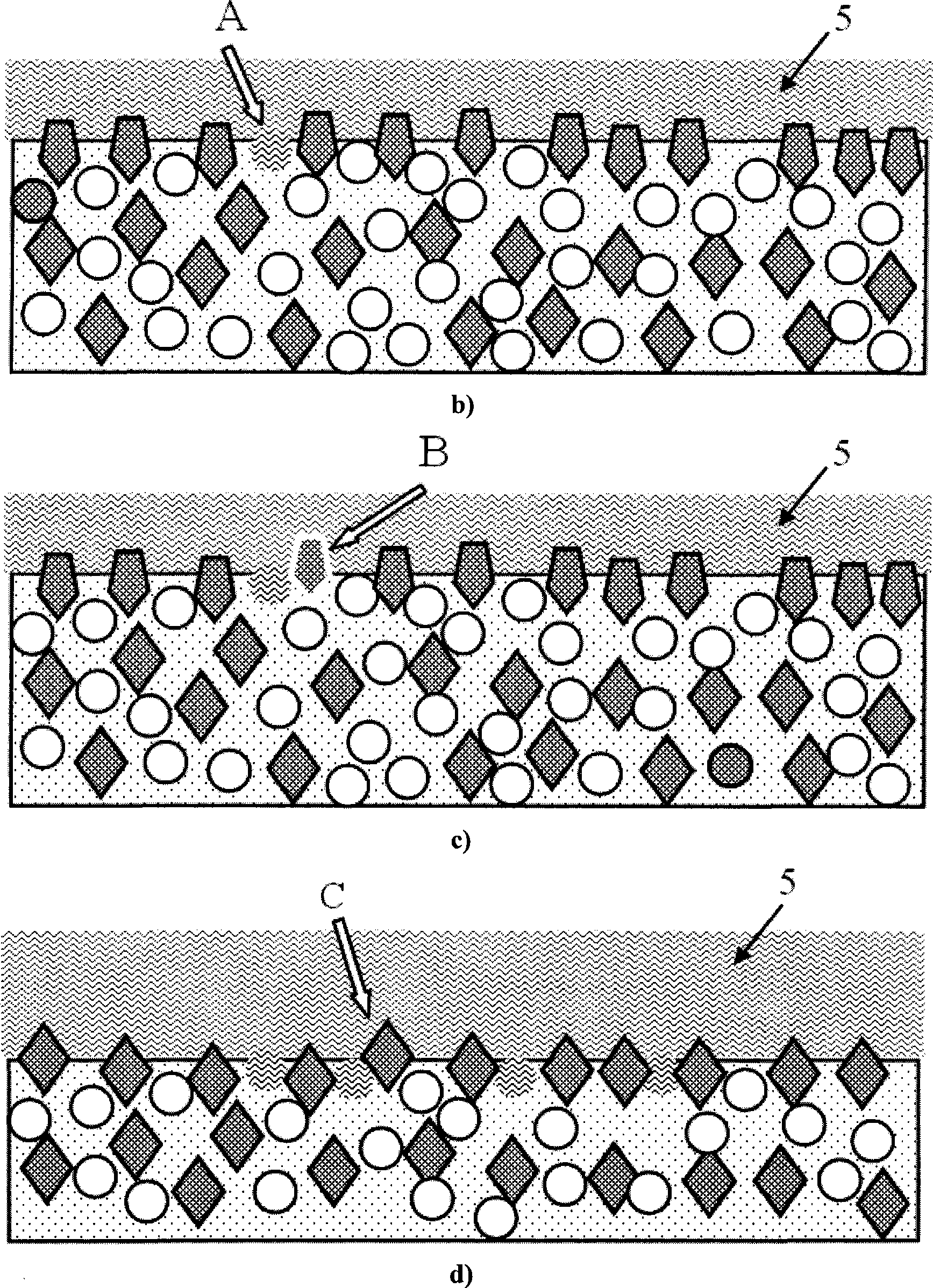

Diamond grinding wheel and production method thereof

InactiveCN106312843AAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesDiamond grindingBonding strength

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

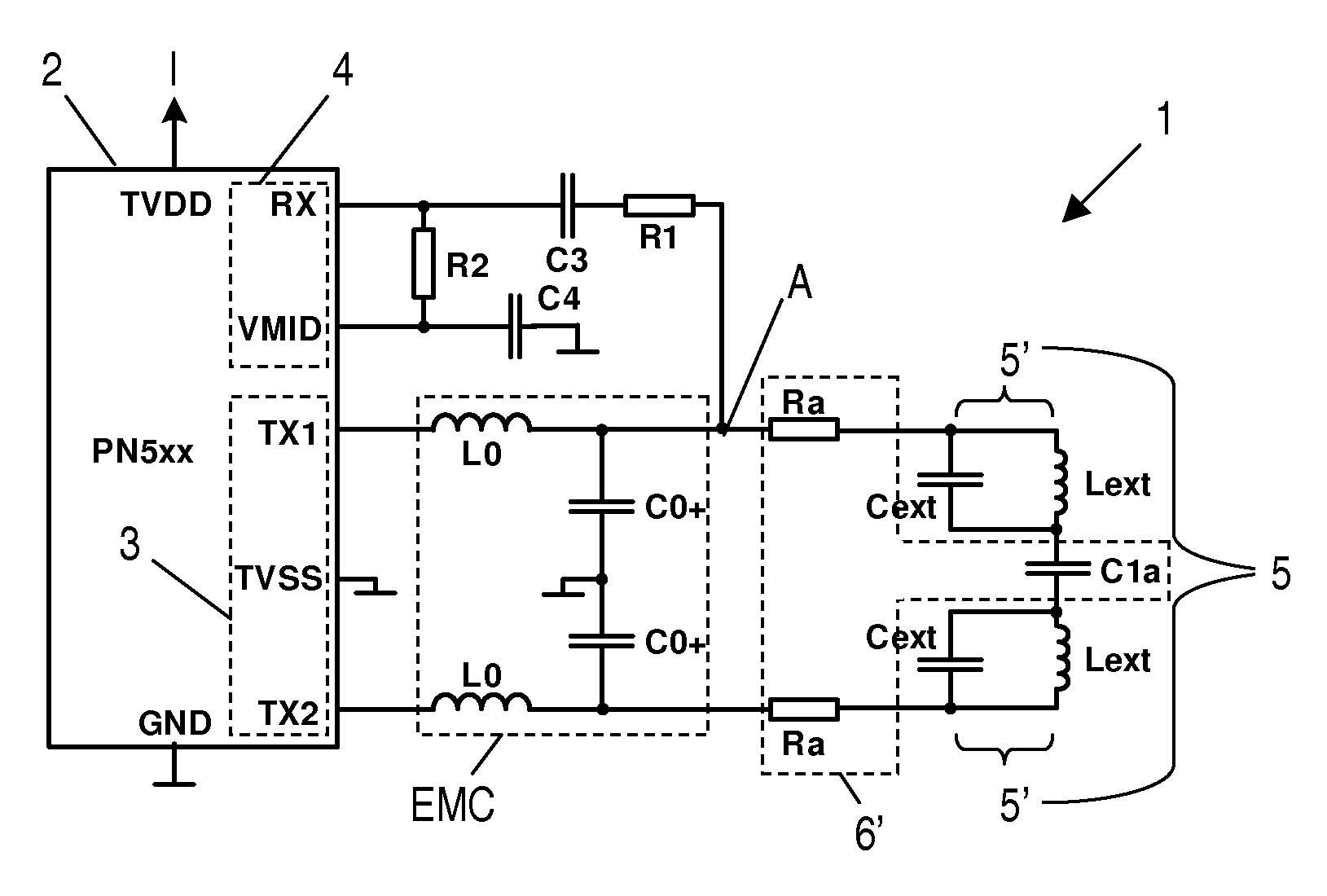

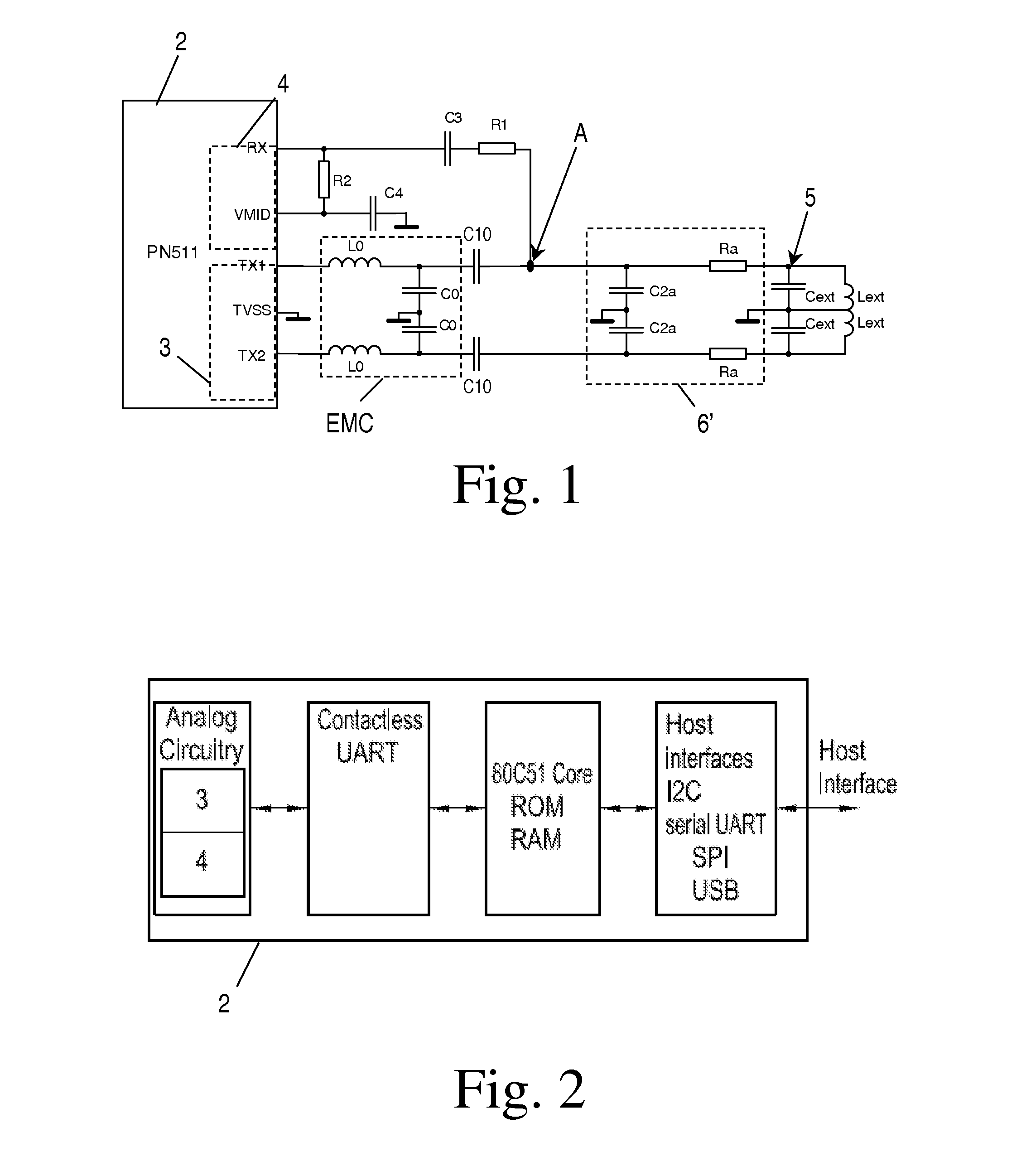

Transceiving circuit for contactless communication and NFC device or RFID reader/writer device comprising such a transceiving circuit

ActiveUS20110043429A1Avoid disadvantagesMore currentAntennas earthing switches associationRecord carriers used with machinesCarrier signalEngineering

A transceiving circuit (1, 1′) for contactless communication comprises transmitter means (3) being adapted to generate an electromagnetic carrier signal and to modulate the carrier signal according to transmitting data, and an antenna (5) being connected to and driven by the transmitter means (3) with the modulated carrier signal. At least one impedance-matching capacitor (C1a) is arranged serially to the antenna (5).

Owner:QUOTAINNE ENTERPRISES

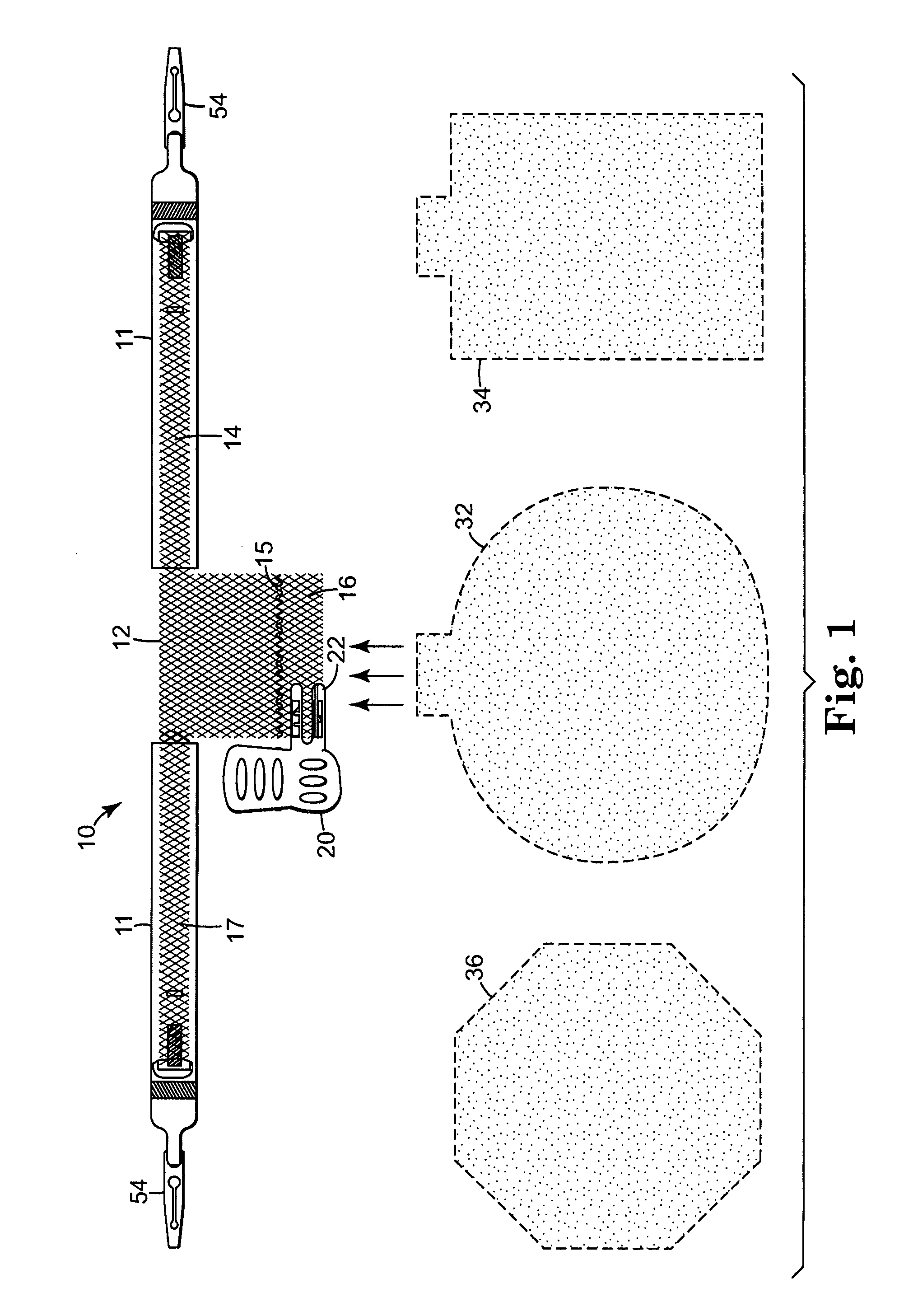

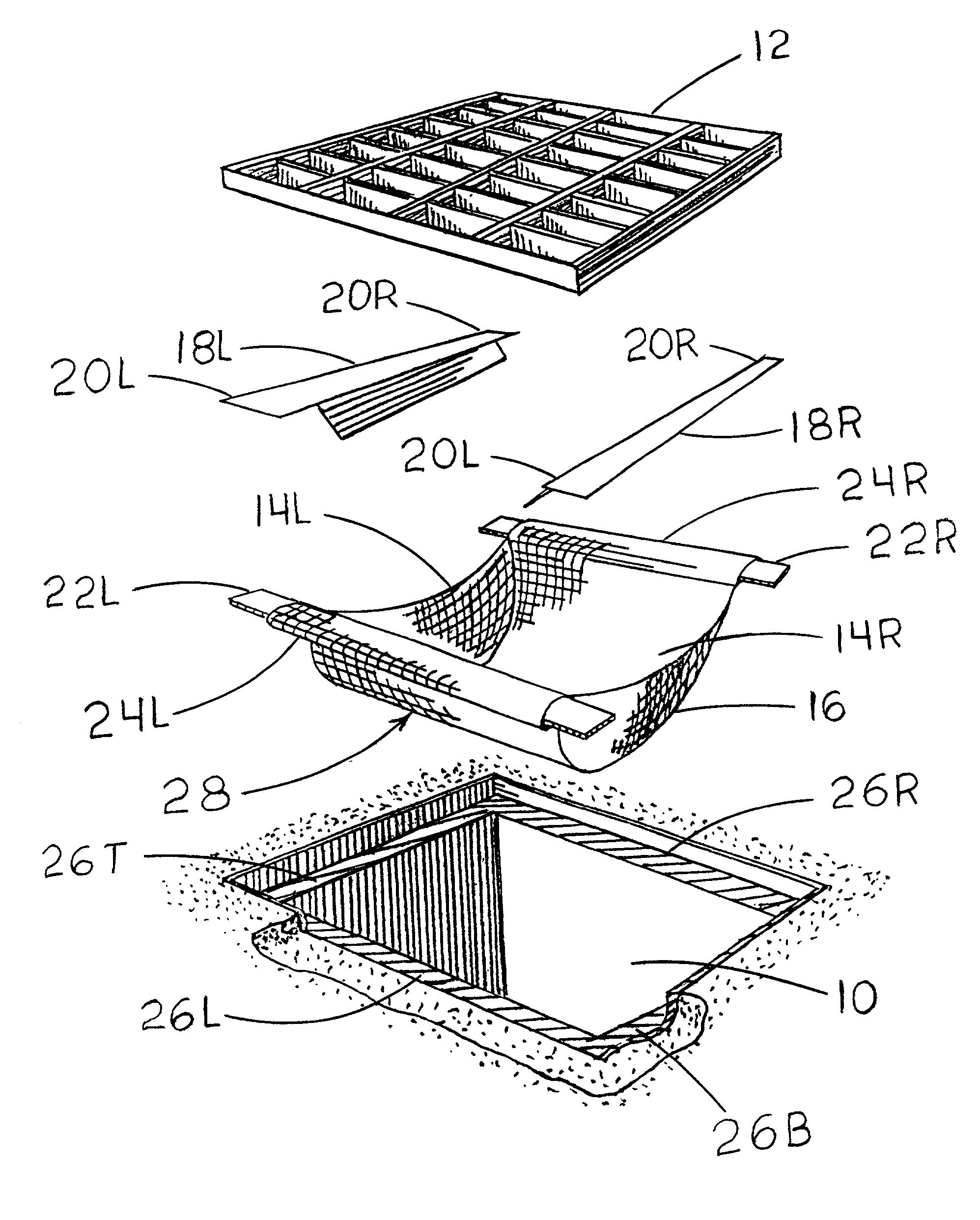

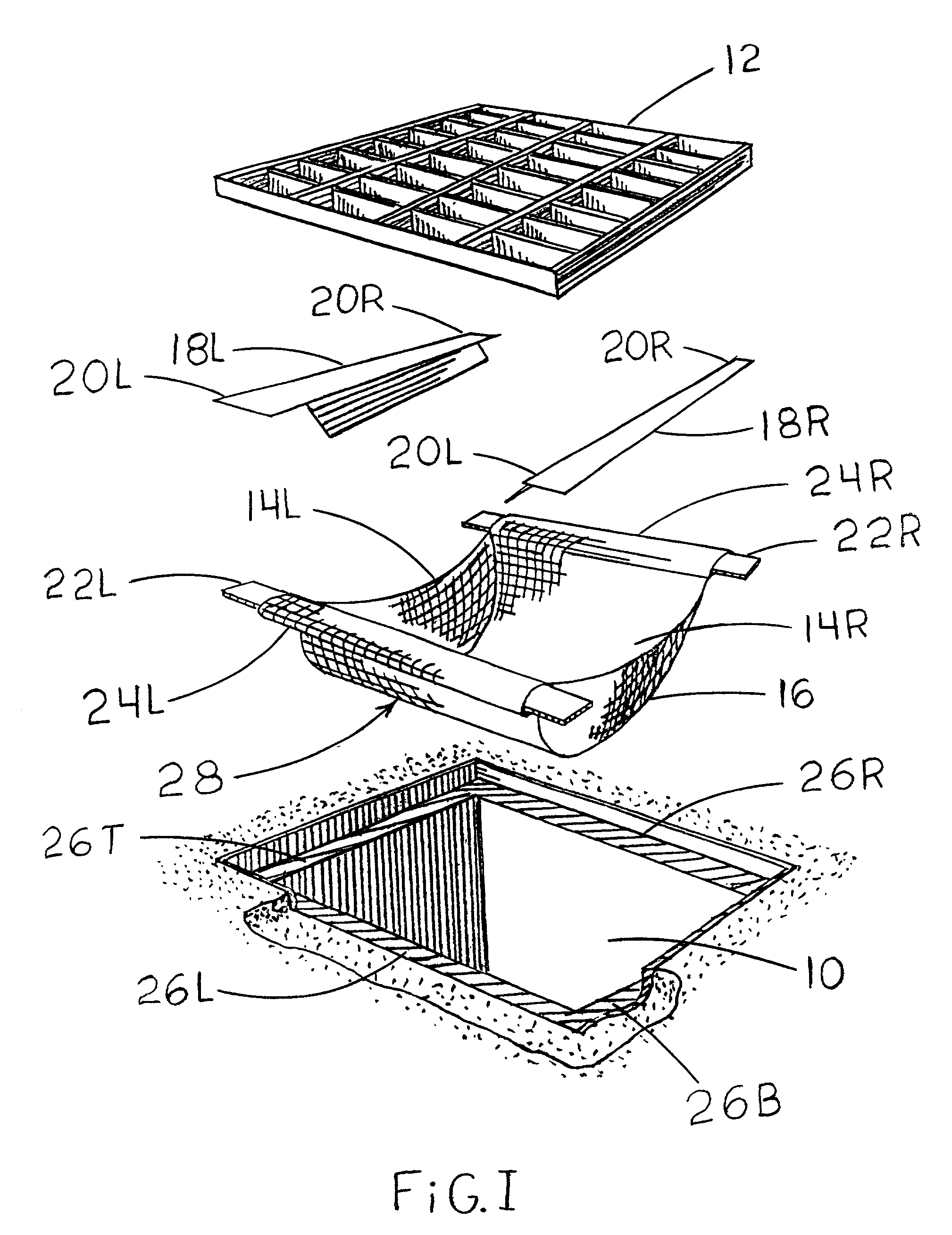

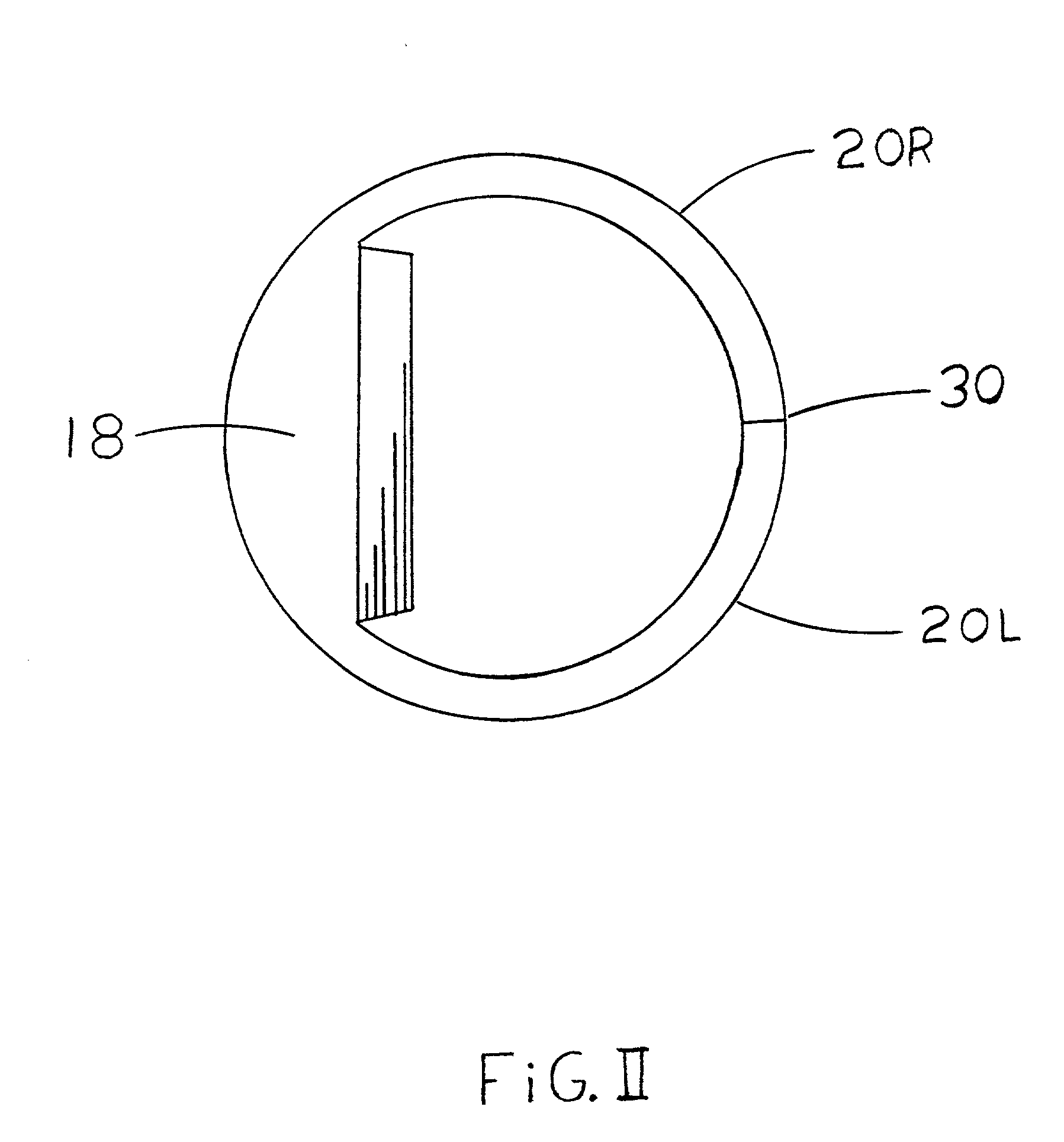

Subgrate drain basin filter

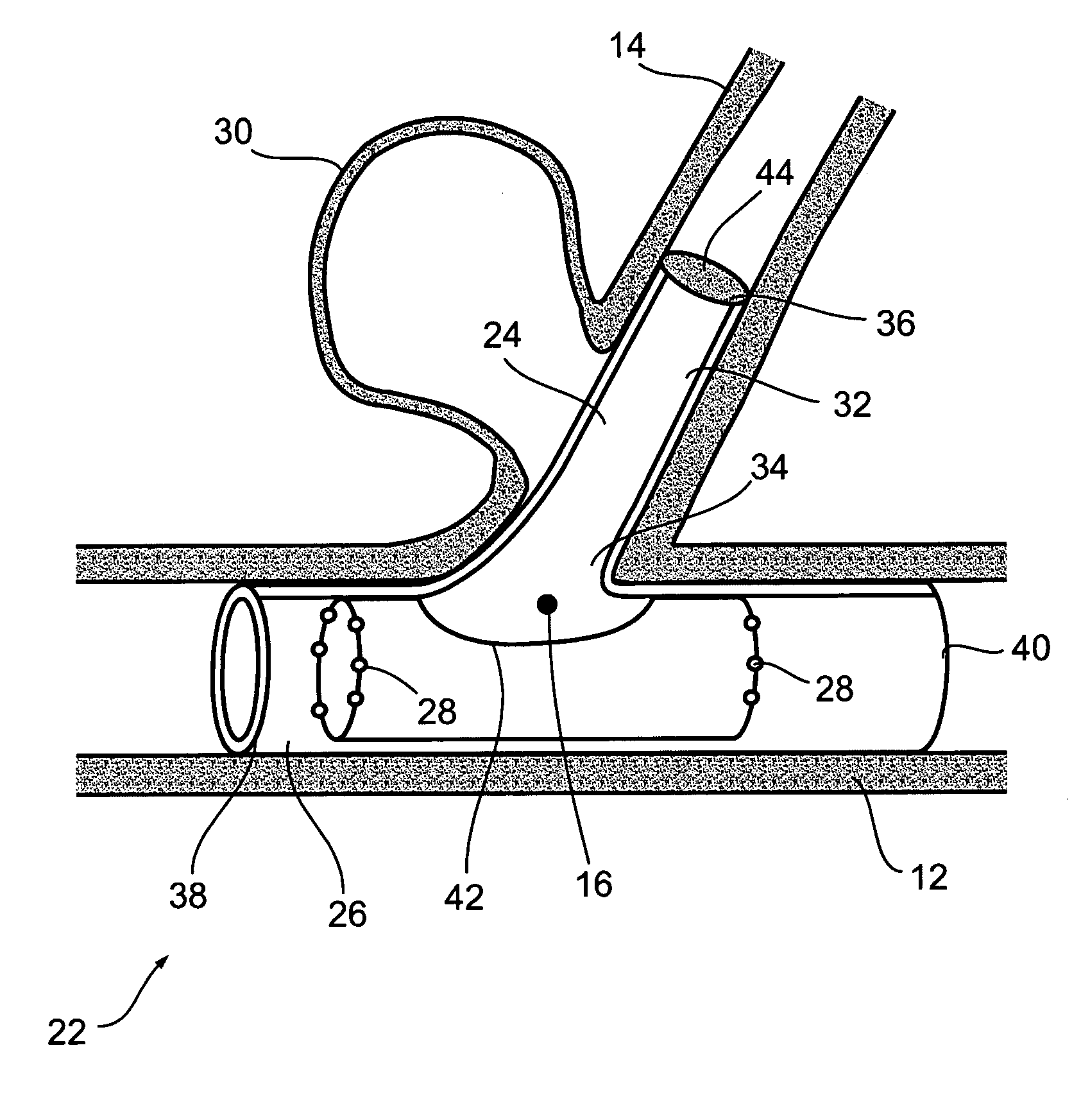

InactiveUS20030098267A1Easy to installEasy to trimFatty/oily/floating substances removal devicesGround-workWaste managementStorm

The invention is a filter mounted below a perforated basin cover (12) of a storm water inlet basin (10) suspended from two ridged support bars (22) which rest upon a cover support (26) which are connected to a bag assembly (28) by inserting the support bars (22) into two bar sleeves (24) on a periphery of a filter basket (16) with a storm water bypass comprising a loop (14) and a bridge (18) which channels water above and over the loop into the inside of a filter basket (16).

Owner:PAGE ARDLE E

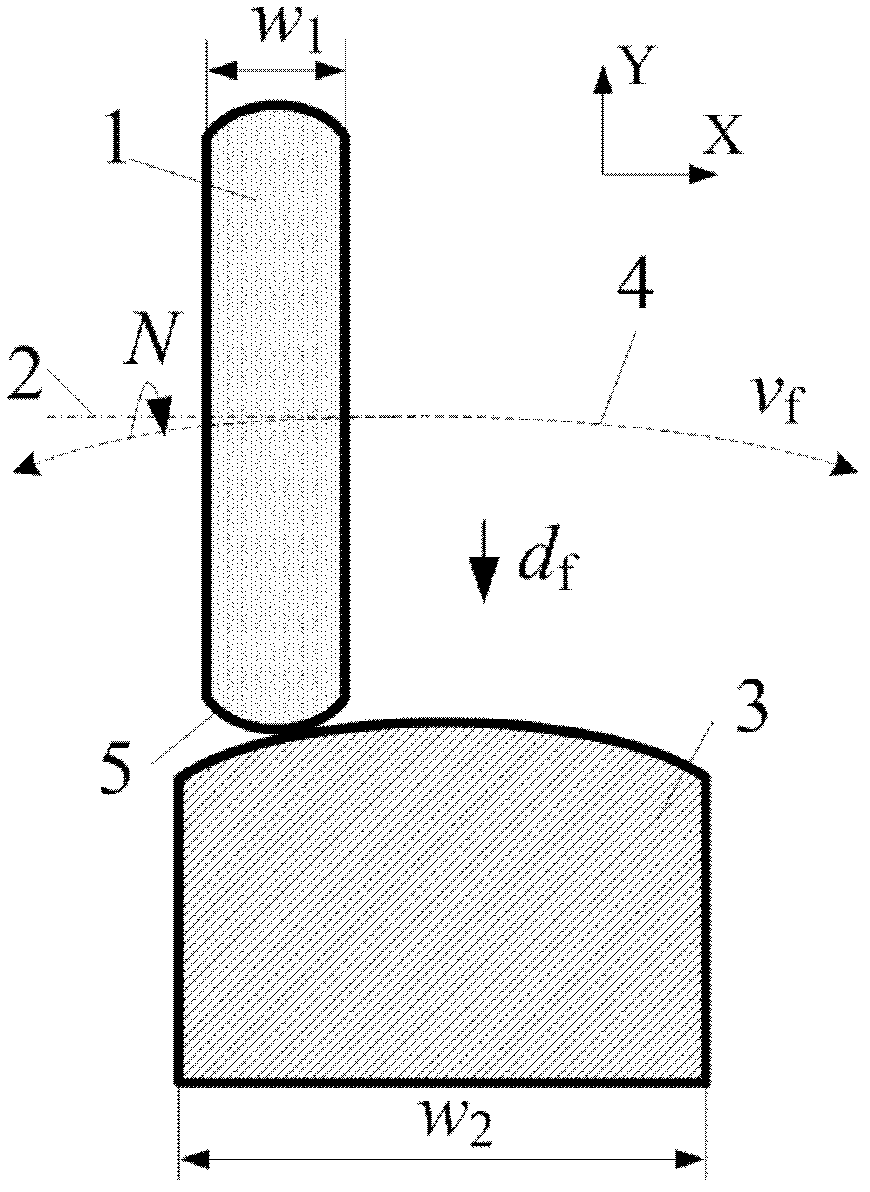

Trellis type grape cultivation method

InactiveCN101715707AIncrease the light areaImprove completenessCultivating equipmentsViticultureEngineering

The invention discloses a trellis type grape cultivation method, which is realized by leading and binding wires parallelly arranged between vertical posts in a grapery. Each grape tree grows a main vine which is led and bound to a first leading and binding wire; and young sprouts of the main vine are led and bound to at least two leading and binding wires above the first leading and binding wire. The cultivation method of the invention has the advantages of convenient management, reasonable space utilization, concreteness, effectiveness and convenient promotion and application.

Owner:杨润高

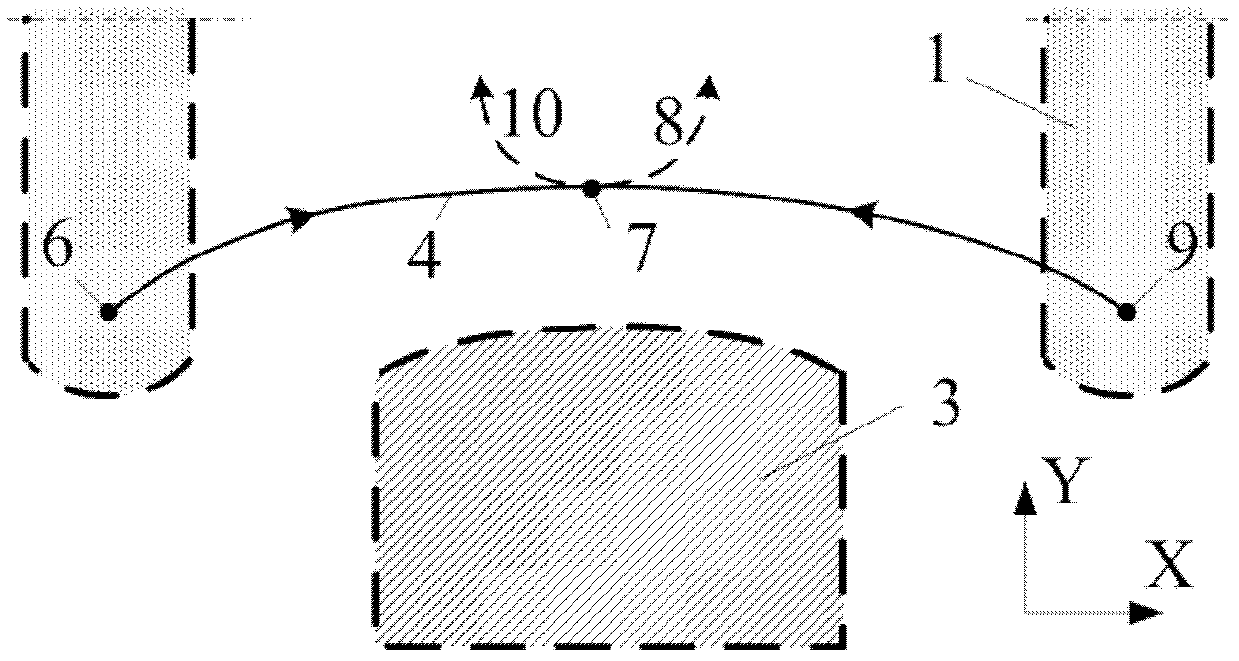

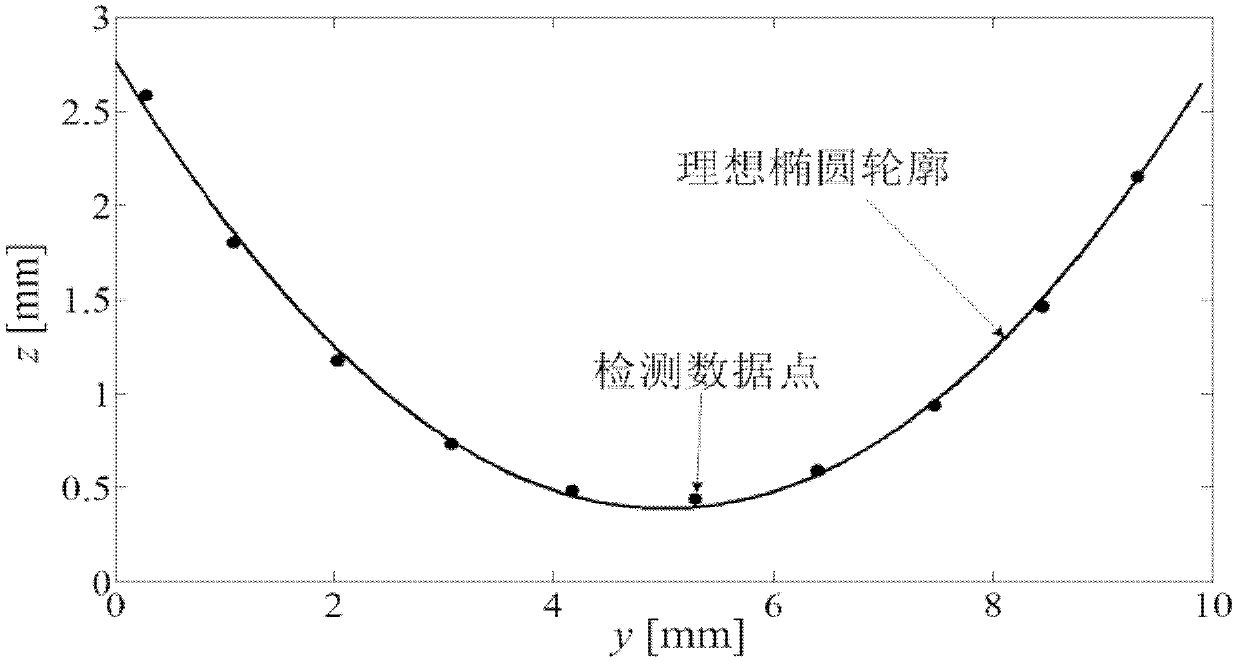

Diamond grinding wheel of elliptical working face and mutual wear forming and trimming method thereof

ActiveCN102350666AEasy to trimTrimming is effectiveAbrasion apparatusAbrasive surface conditioning devicesCarbide siliconStructural engineering

The invention discloses a diamond grinding wheel of an elliptical working face and a mutual wear forming and trimming method thereof. The profile of an axial section of a working face of the diamond grinding wheel is an elliptical arc profile; an end face of the diamond grinding wheel is an elliptical face; in the method, a diamond grinding wheel tool travels from left to right to a top point of an elliptical arc at a first starting point outside one side of a silicon carbide grinding stone along an elliptical arc traveling path, is then lifted along a first circular arc tangential to the top point and with a radius of more than 2mm, next travels from right to left to the top point of the elliptical arc from a second starting point outside the other side of the grinding stone along the elliptical arc traveling path and is lifted along a second circular arc tangential to the top point and with a radius of more than 2 mm. Compared with the conventional circular face diamond grinding wheel, the elliptical face diamond grinding wheel has the advantages that: a flatter grinding wheel elliptical working face and a workpiece curved surface can be used for complexing to grind, the number of effective grinding particles is increased, and the surface quality and the shape accuracy of curved surface grinding are improved.

Owner:SOUTH CHINA UNIV OF TECH

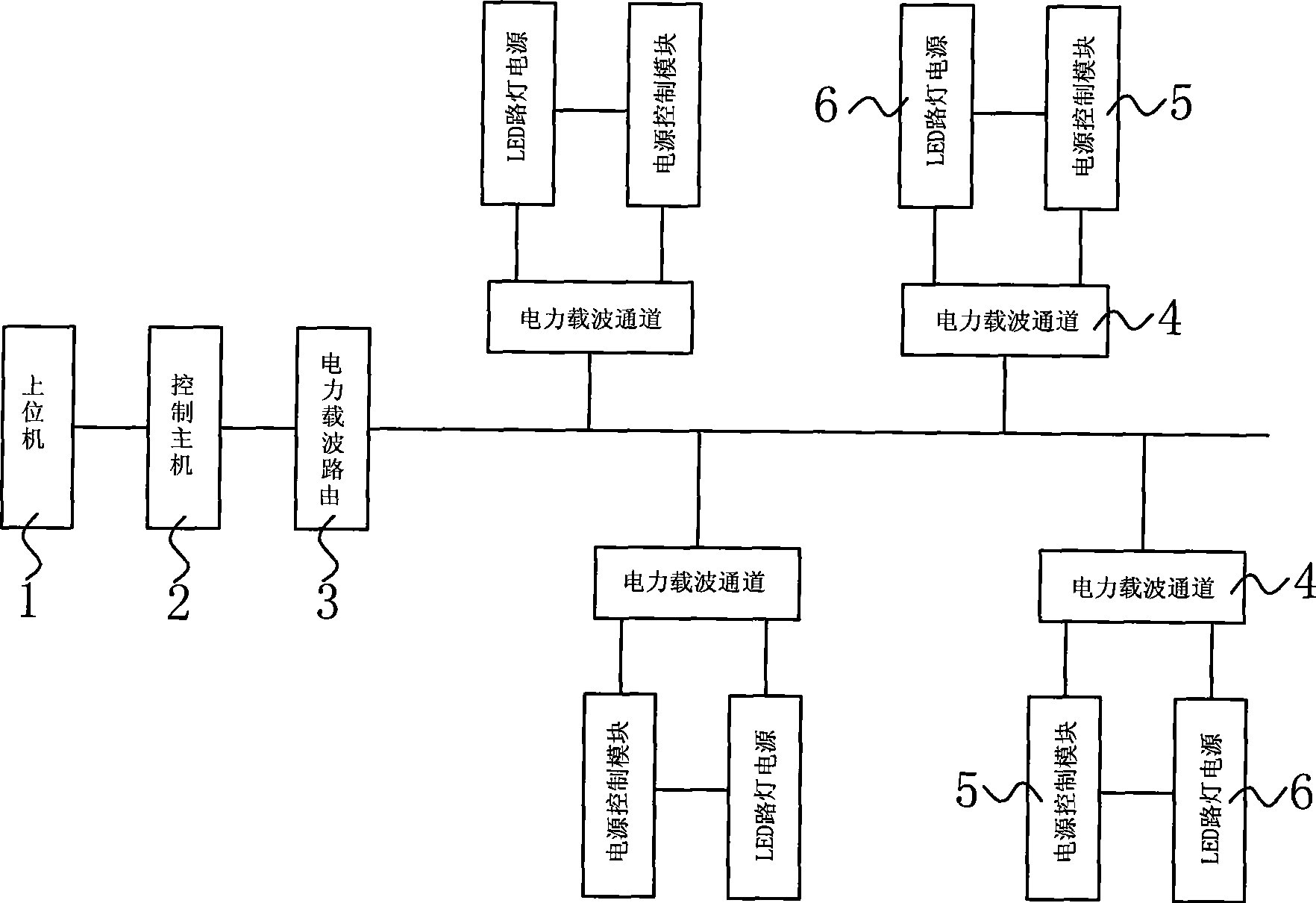

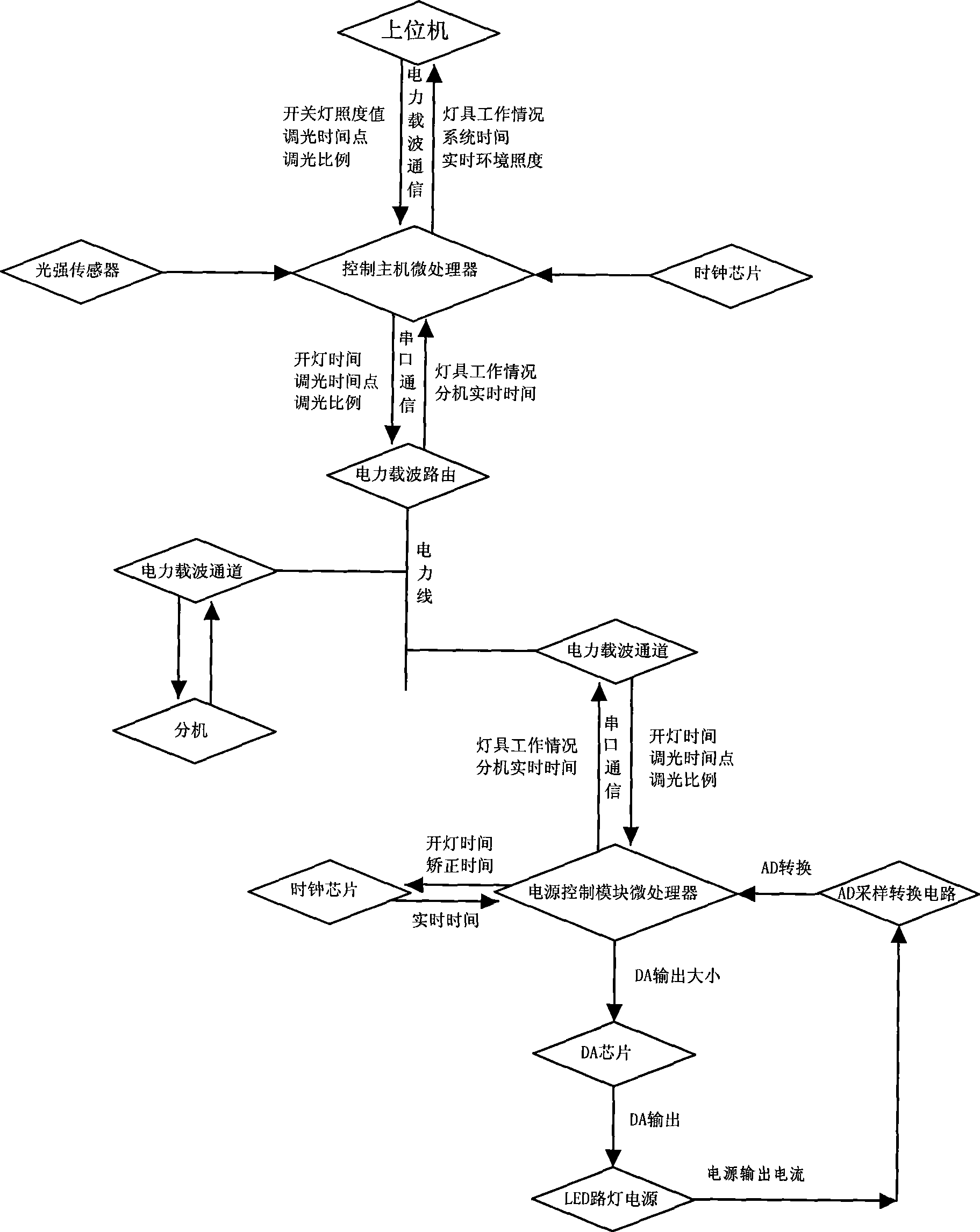

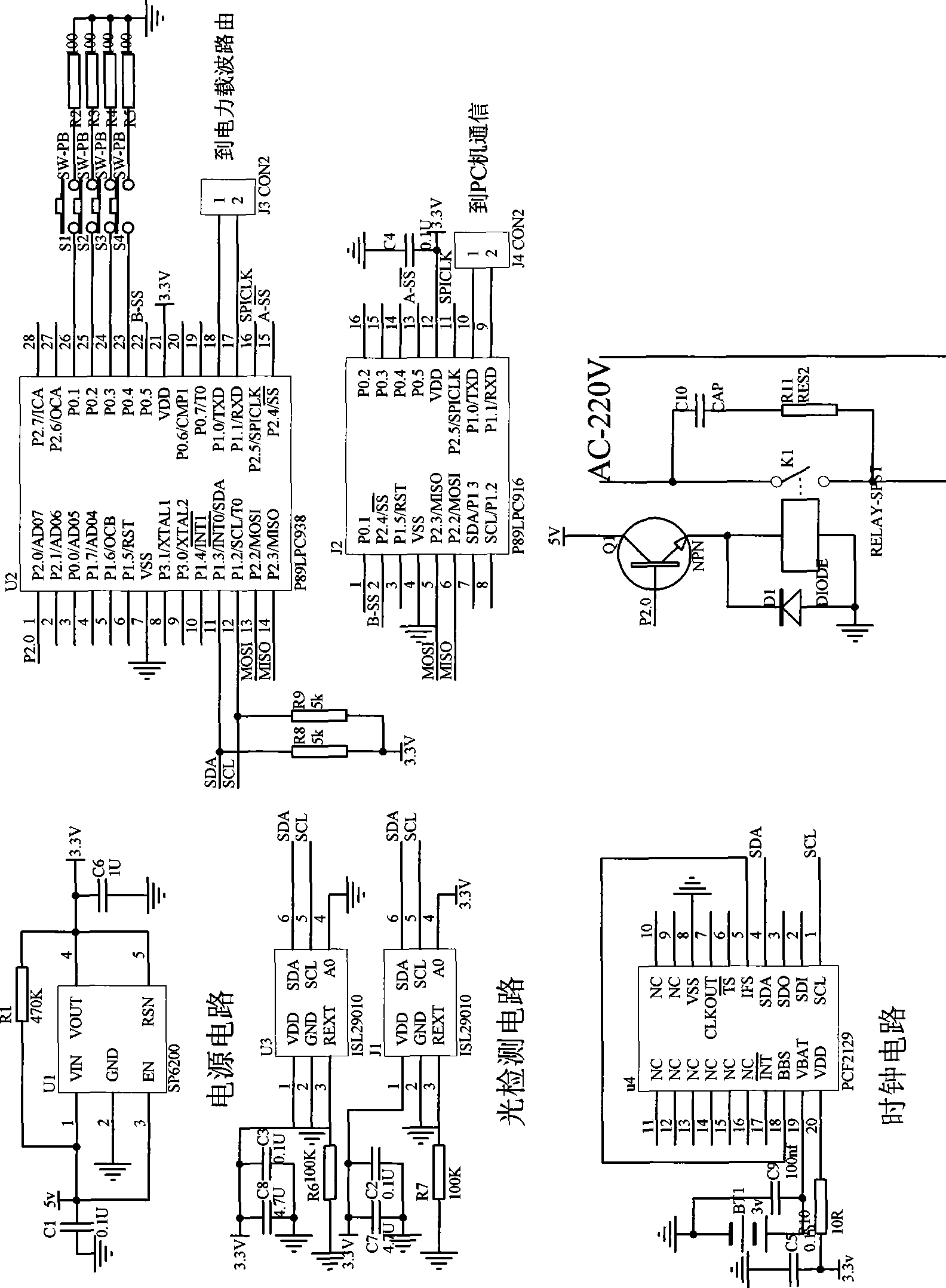

LED automatic control system

InactiveCN101511144ALow costImprove reliabilityPower distribution line transmissionElectric light circuit arrangementCommunication interfaceAutomatic control

The invention provides a LED automatic control system which includes an upper computer, the upper computer belongs to a computer hardware equipment which is installed with an intelligent system control software in inner. The upper computer communicates with a control host by way of electrical power carrier, the control host is installed in a distribution cabinet, the control host connects with a series communication interface of the electrical power carrier router, the electrical power carrier router is jointed to the electrical power carrier channel of each branch computer through the electrical power line, each electrical power carrier channel connects with the control module with electrical power source through the series communication interface, the electrical power source control module connects with the LED router electrical power source. The control system can process category setting according with grade and characteristic of the road for controlling the road lamp opening or closing automatically. The system also can adjust the lamp brightness and working power, and monitor using condition of the road lamp and the line in time, the system also can jump the control system and control the road lamp switch by hand.

Owner:重庆乔亚电子有限公司

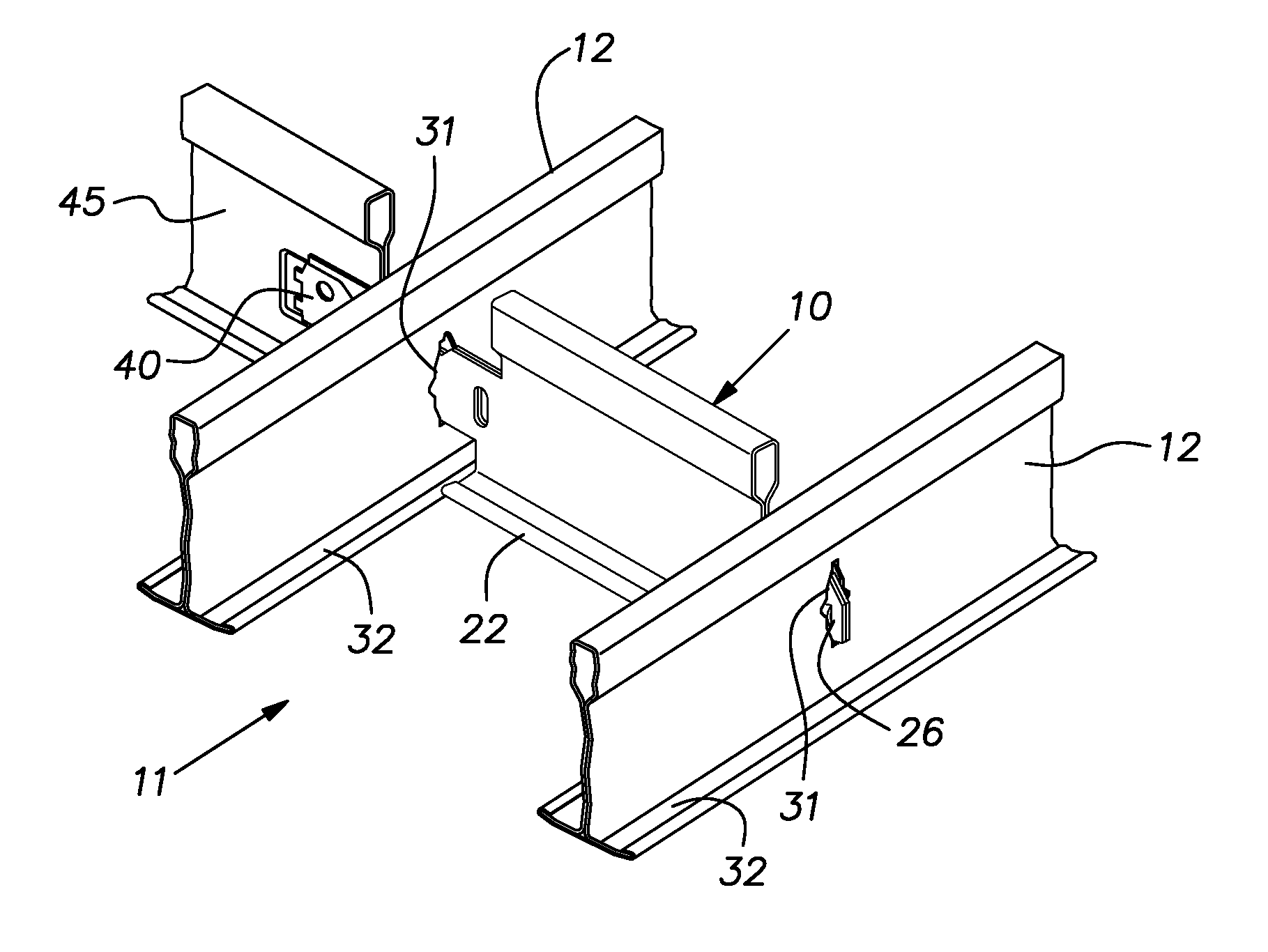

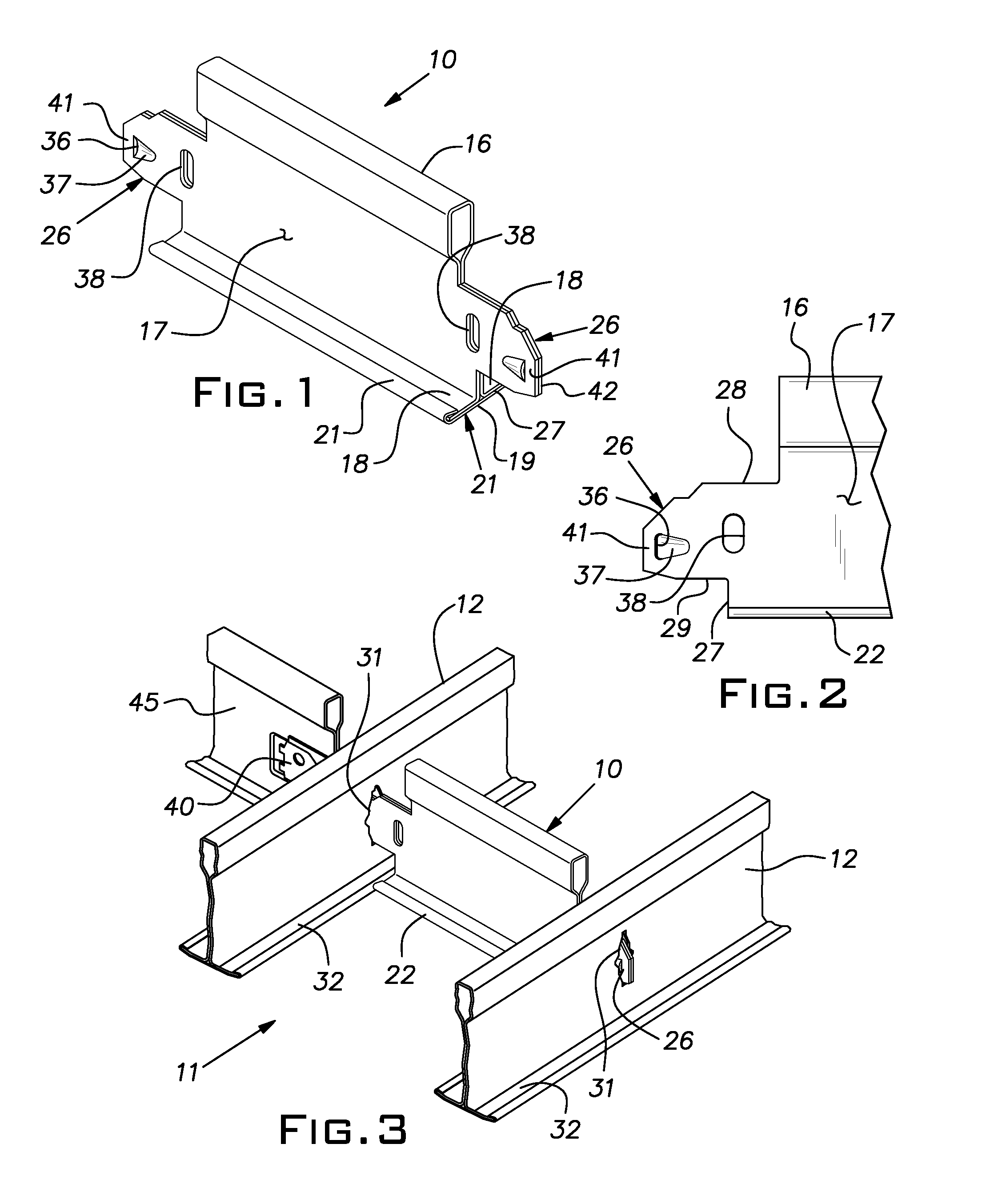

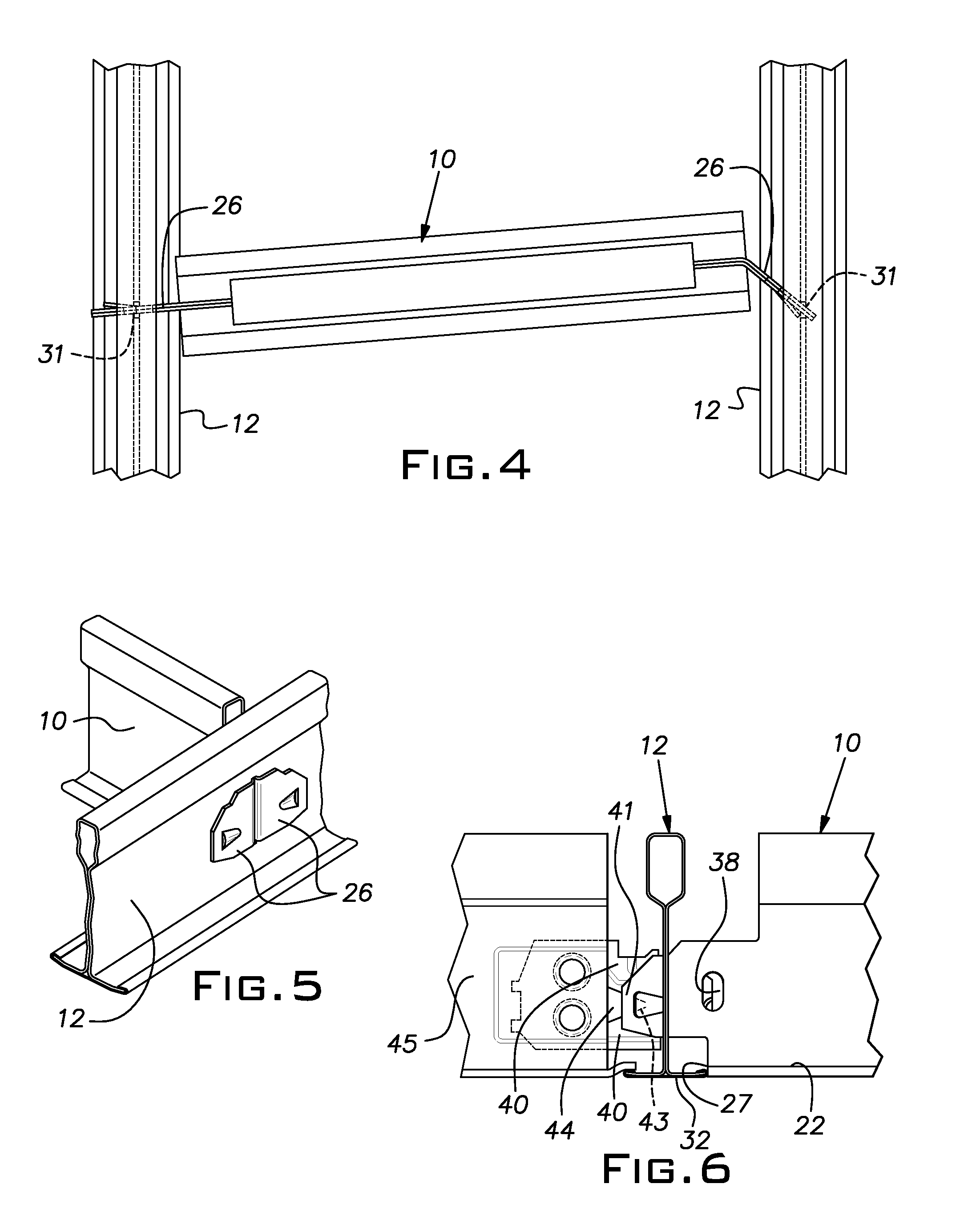

Channel cross member

ActiveUS8955273B1Facilitate installation and connectionEasy to trimCeilingsWallsEngineeringNarrow channel

A short cross member for a narrow utility channel formed of malleable sheet metal and having a vertical double ply web and a horizontal flange symmetrically disposed on both sides of a lower edge of the web, integral end connectors formed on each end of the cross member from sheet material contiguous with the web, the integral end connectors being arranged to support the flange in coplanar relation with flanges of the channel, the end connectors and the web being weakened at a predetermined vertical line whereby the cross member can be assembled in a narrow channel by bending at the associated line of weakness to shorten the effective overall length of the cross member.

Owner:USG INTERIORS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com