Diamond grinding wheel of elliptical working face and mutual wear forming and trimming method thereof

A diamond grinding wheel and forming method technology, applied in abrasives, manufacturing tools, metal processing equipment and other directions, can solve the problems of difficult surface quality and shape accuracy, difficult processing, low efficiency, etc., to improve the grinding curved surface quality and shape Accuracy, increase the effective number of abrasive grains, the effect of simple dressing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

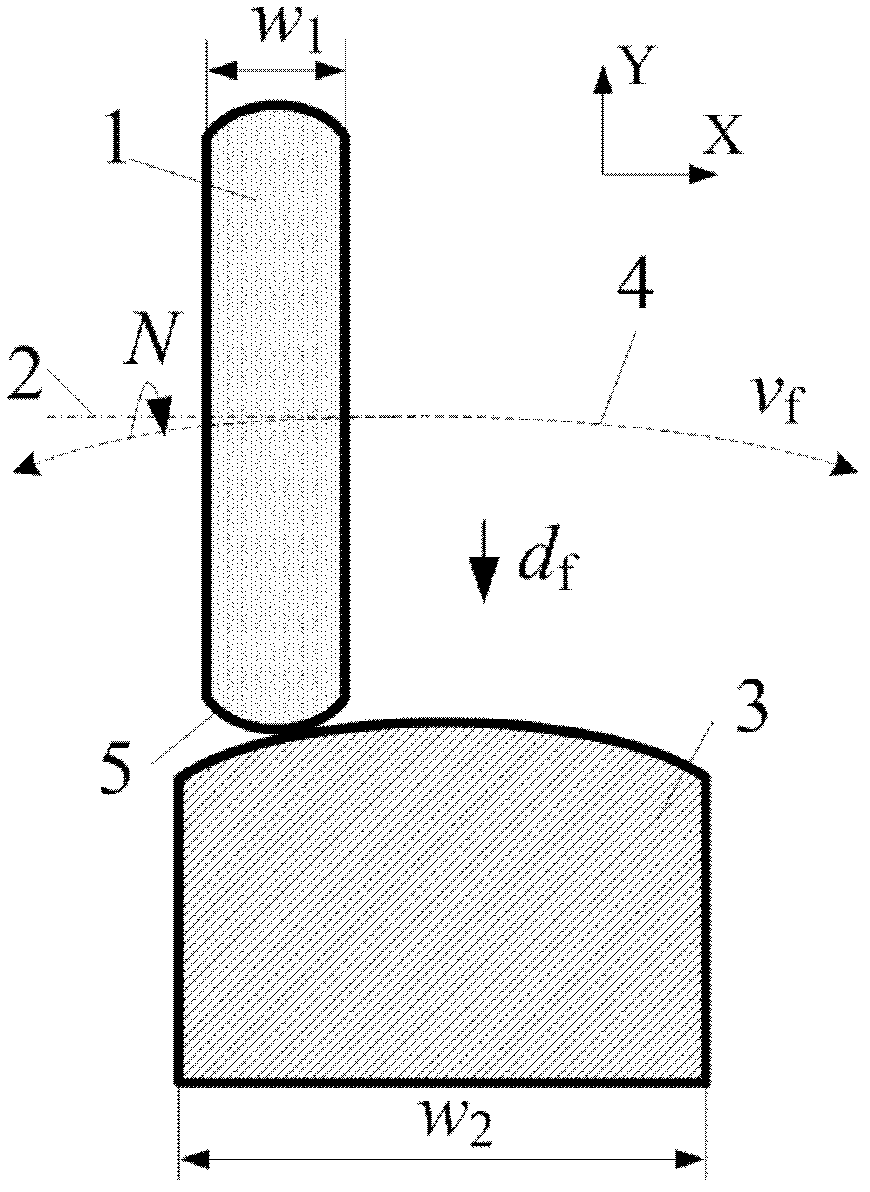

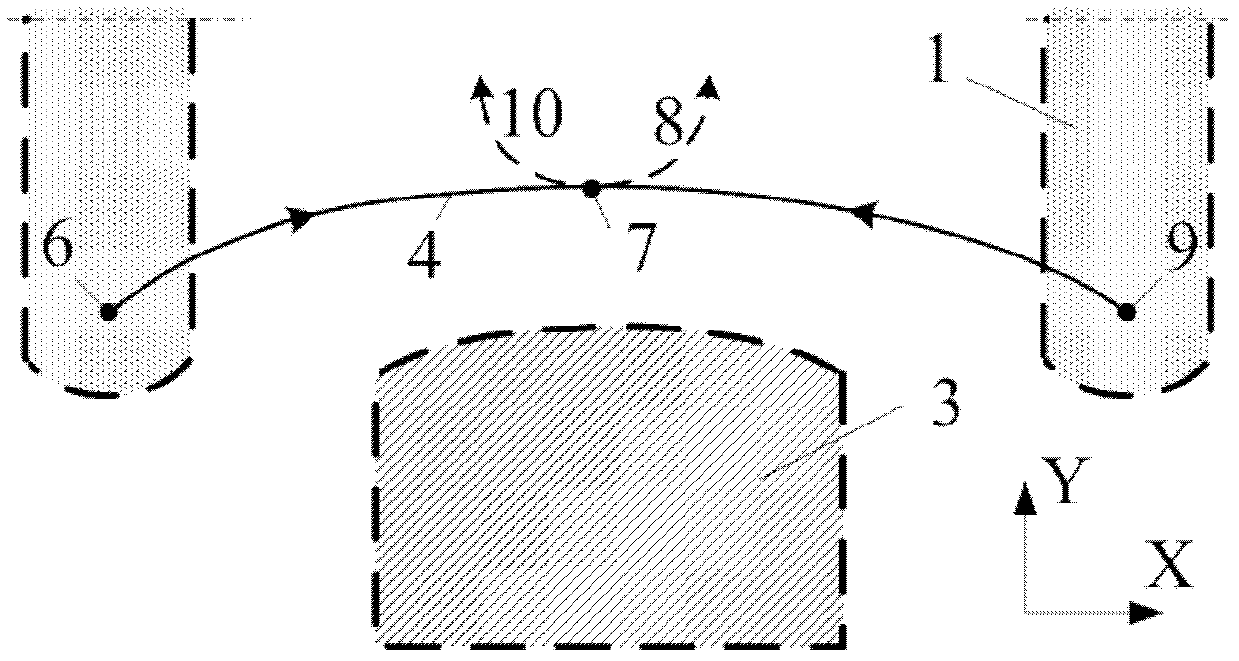

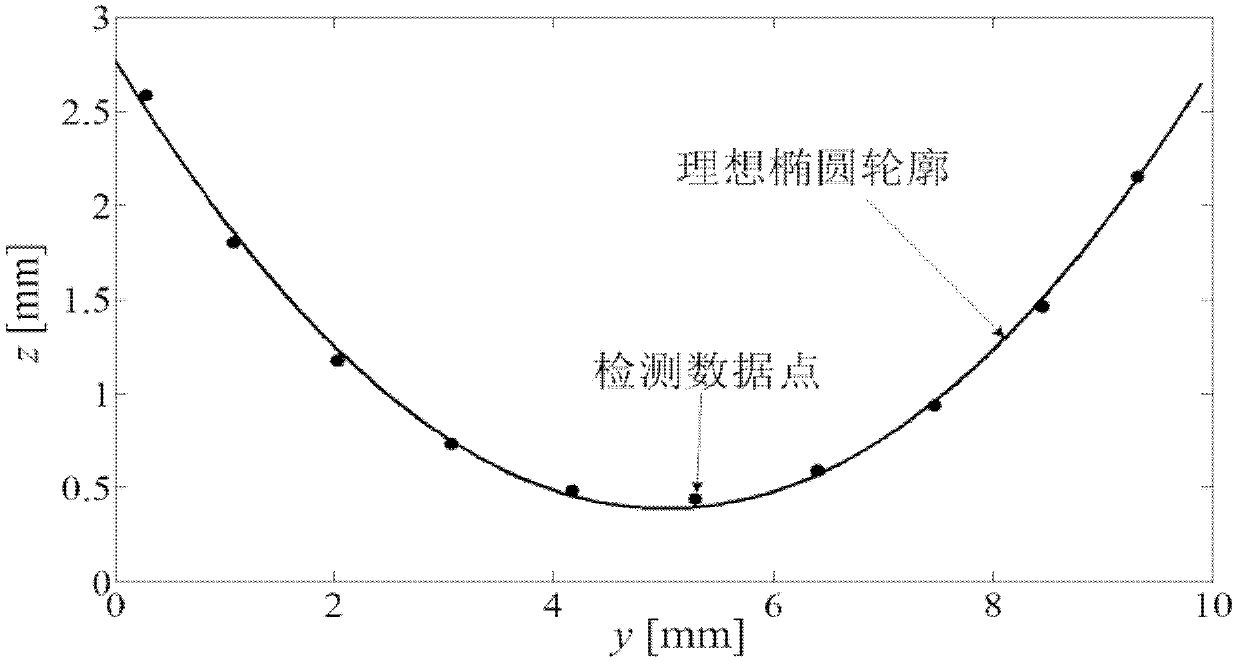

[0028] Installed on a CNC precision grinding machine (SMRART B818) with a diameter of 150mm and an axial width of w 110 mm diamond wheel cutter 1, axial thickness w 2 The rectangular silicon carbide grinding stone 3 of 25 mm is placed on the horizontal plane of the workbench, and the thickness direction along the middle part of the grinding stone is kept consistent with the diamond grinding wheel axis on the workbench. The particle size of the diamond grinding wheel is #320, the binder is resin, and the concentration is 100. The silicon carbide grinding stone 3 is a green silicon carbide grinding stone, and the bonding agent is ceramics. The objective of trimming the axial section profile of the grinding wheel is the standard ellipse equation is The elliptical arc, a=6mm, b=2.62mm, the working surface of the grinding wheel is an elliptical torus. In order to dress the elliptical torus of the grinding wheel, the walking path 4 of the center of the grinding wheel is designed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com