Patents

Literature

274 results about "Diamond grit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-Layer Encapsulation of Diamond Grit for Use in Earth-Boring Bits

ActiveUS20080202821A1High retention rateOptimize allocationDrill bitsTransportation and packagingCarbideAtmospheric pressure

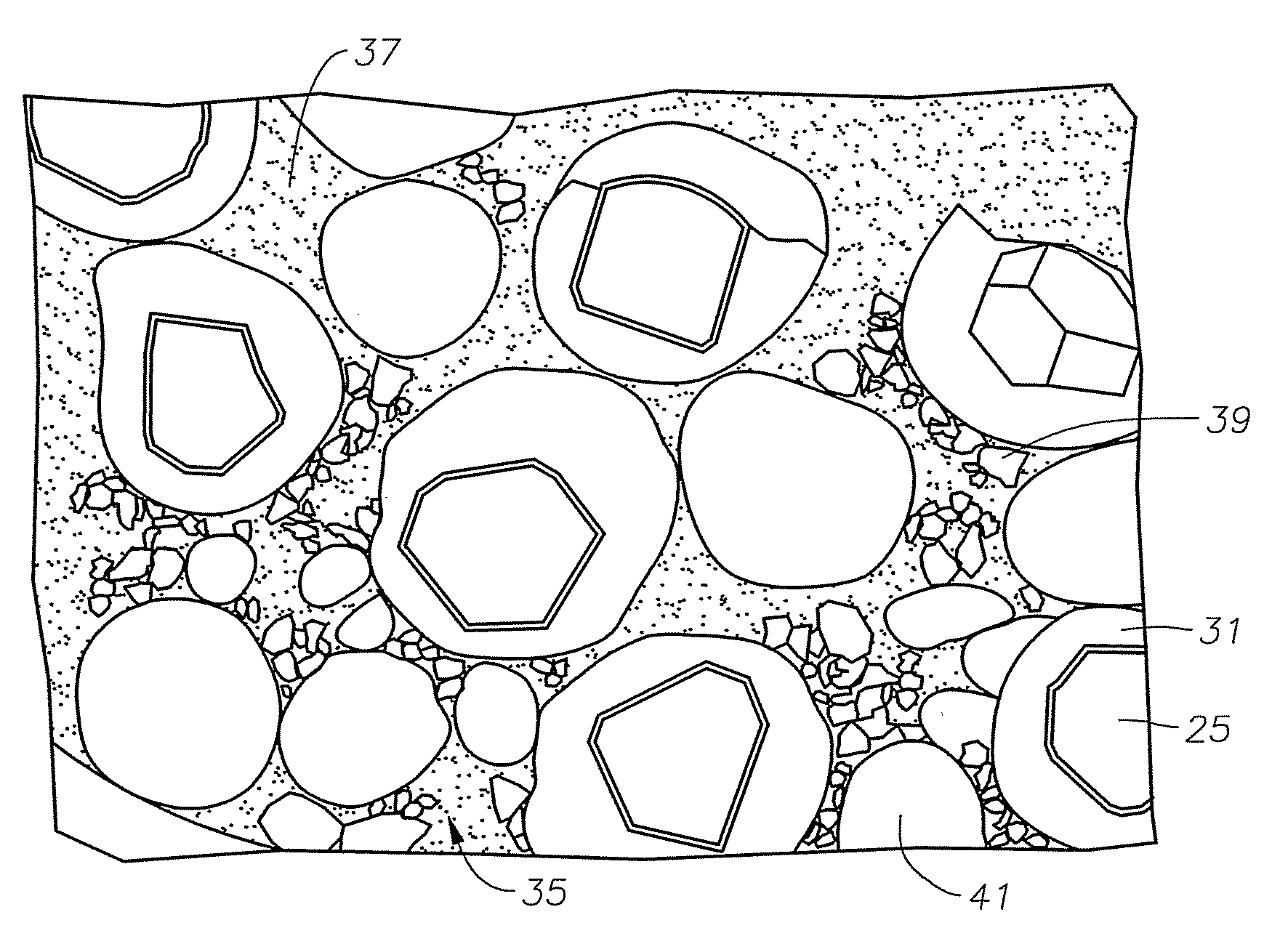

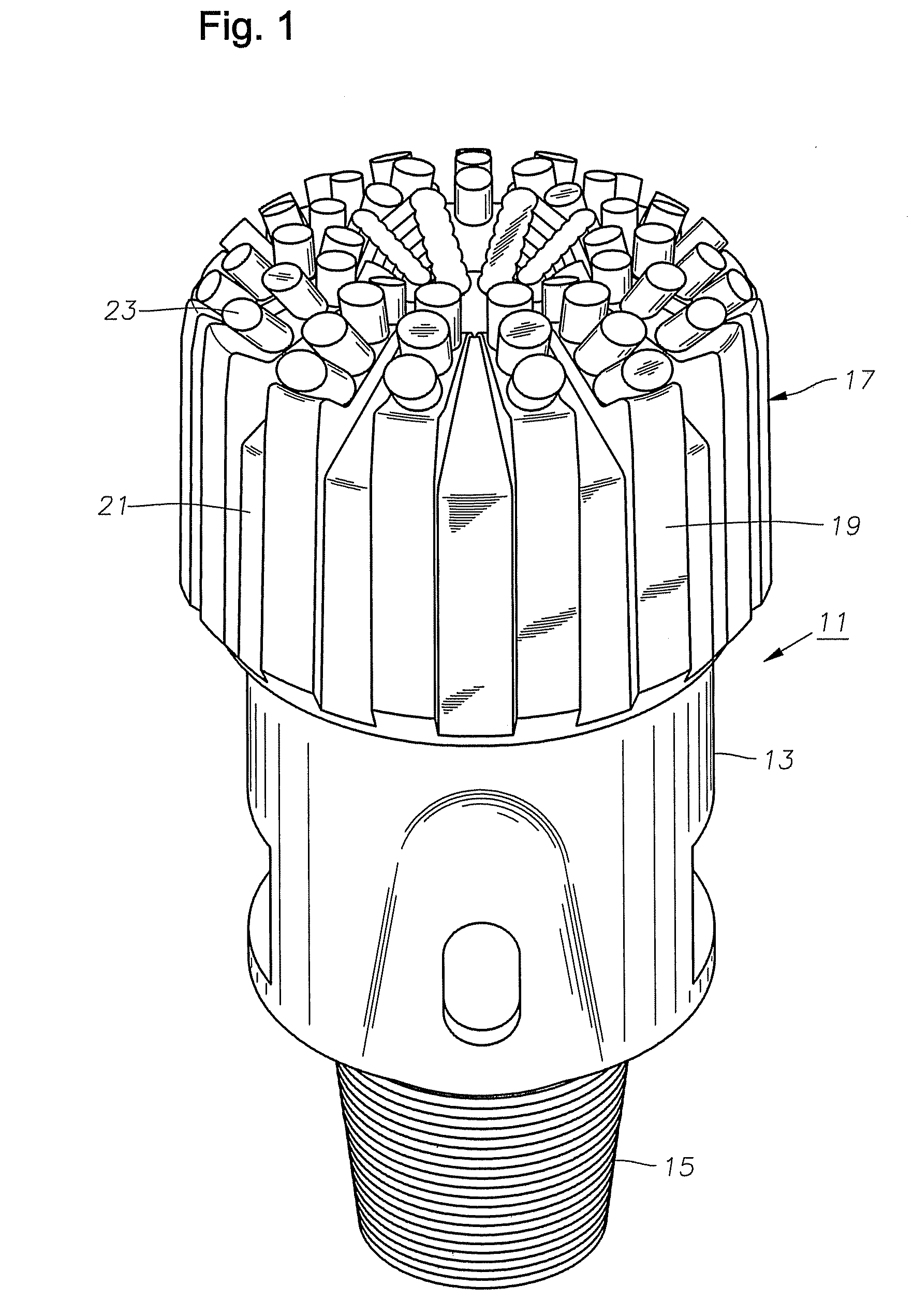

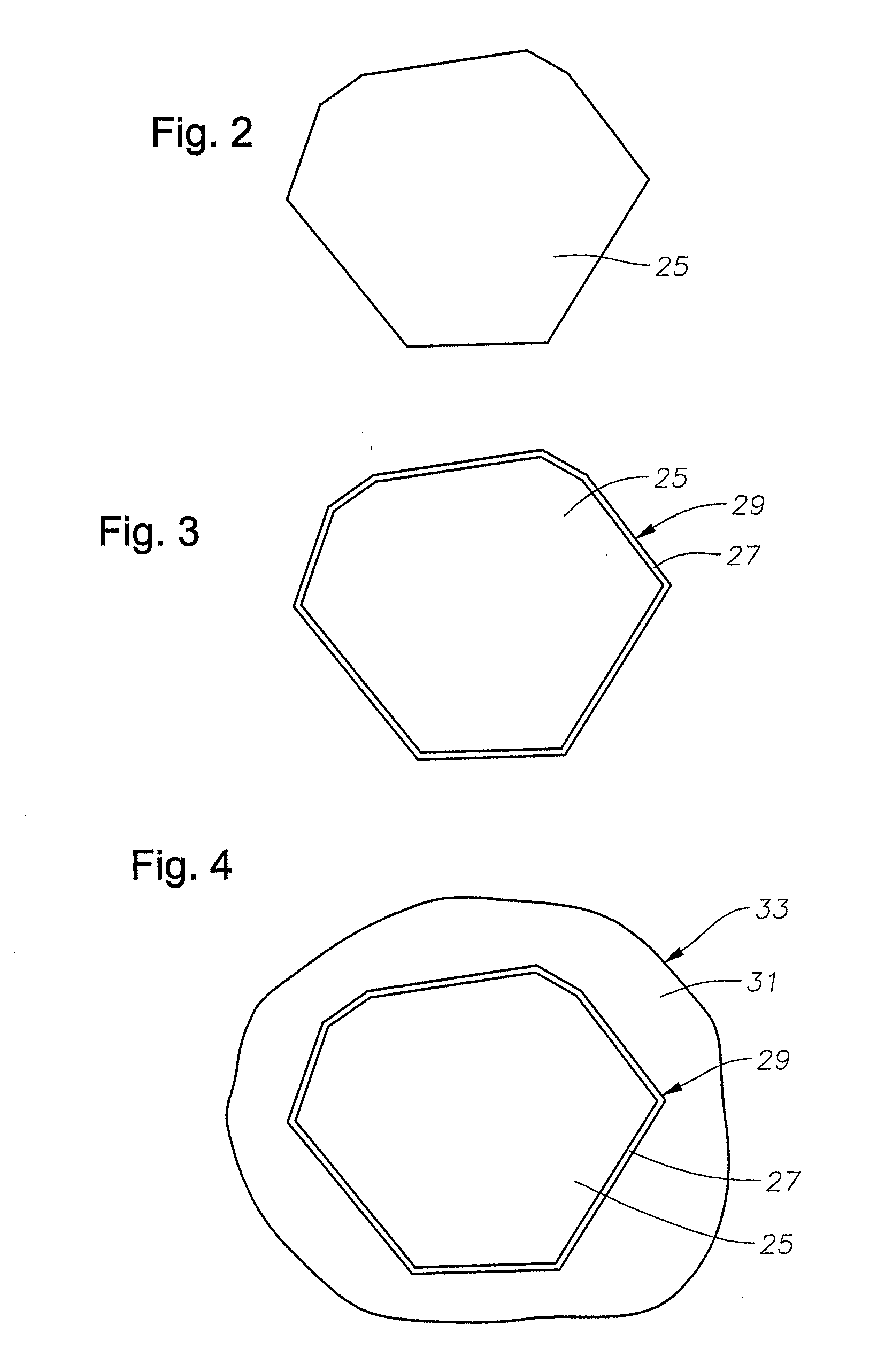

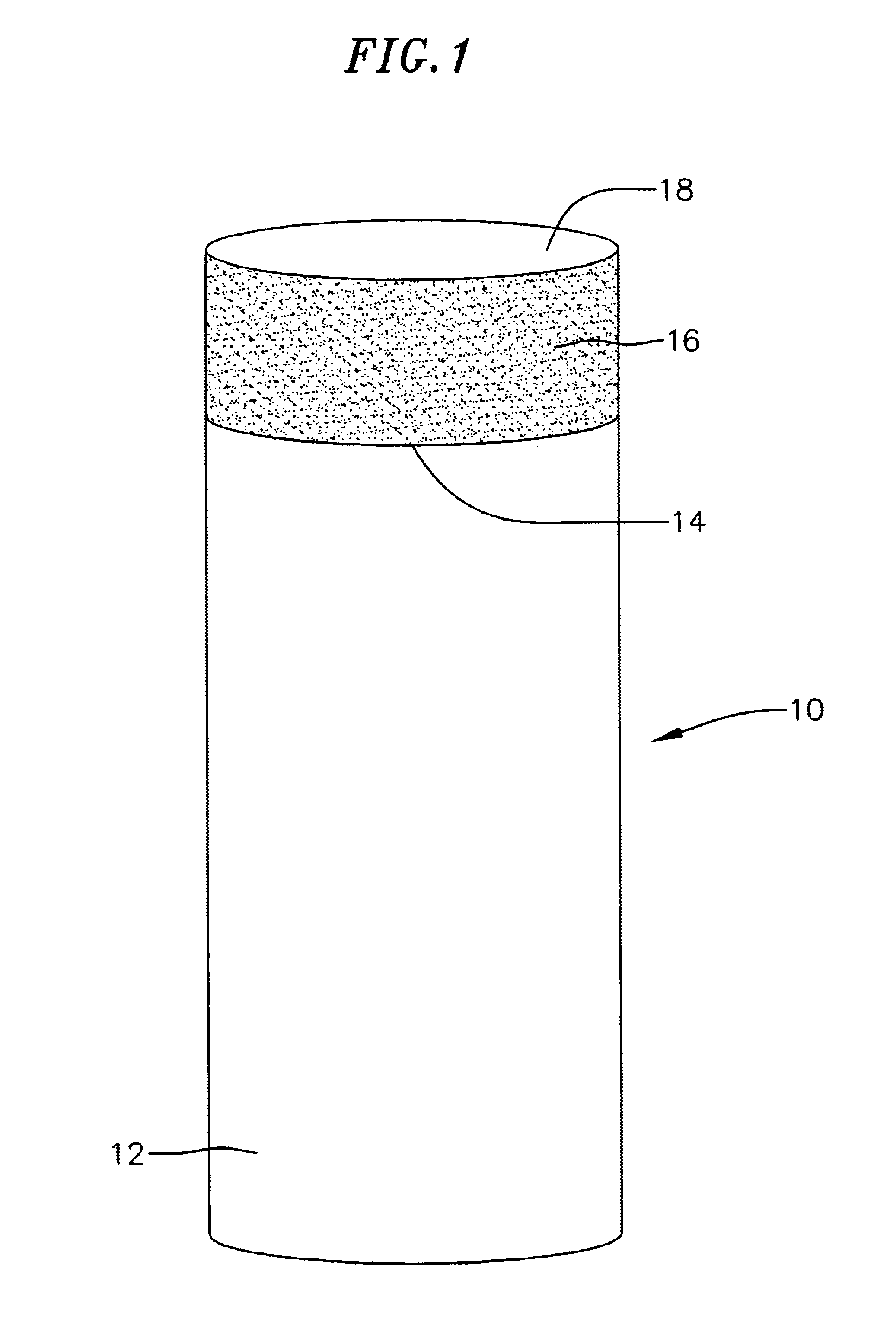

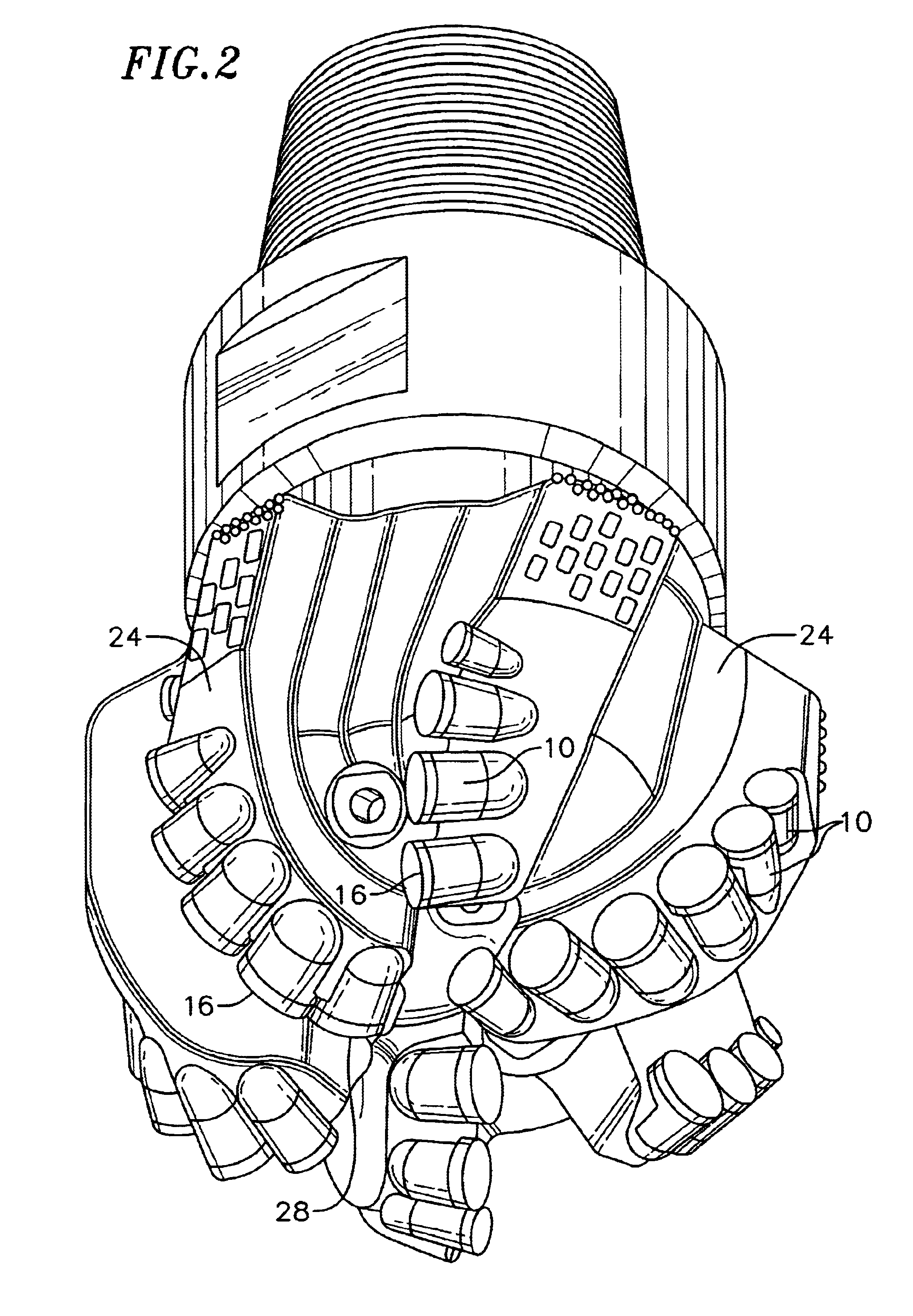

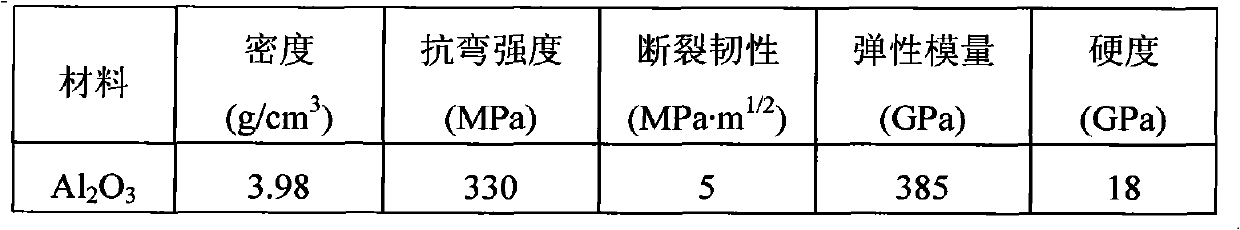

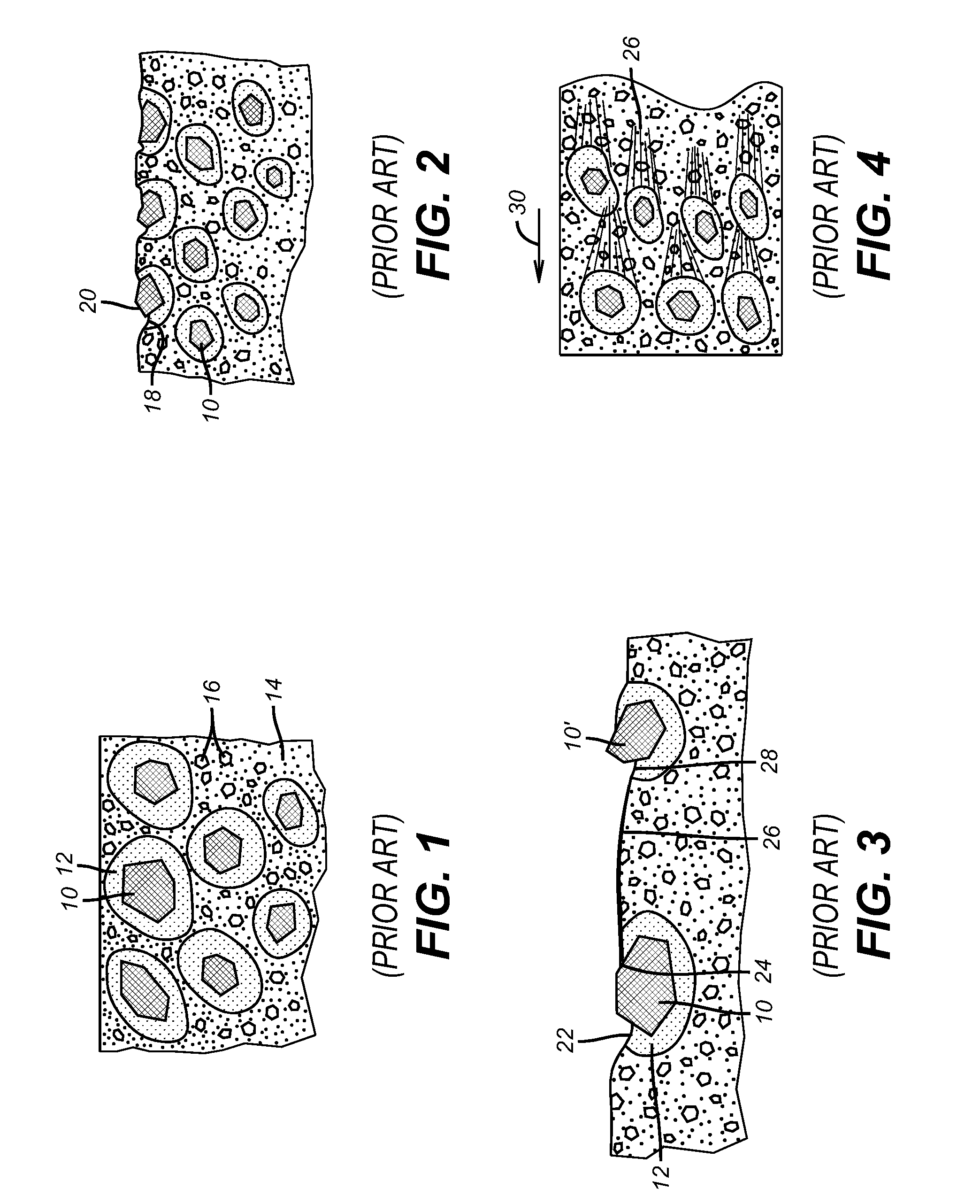

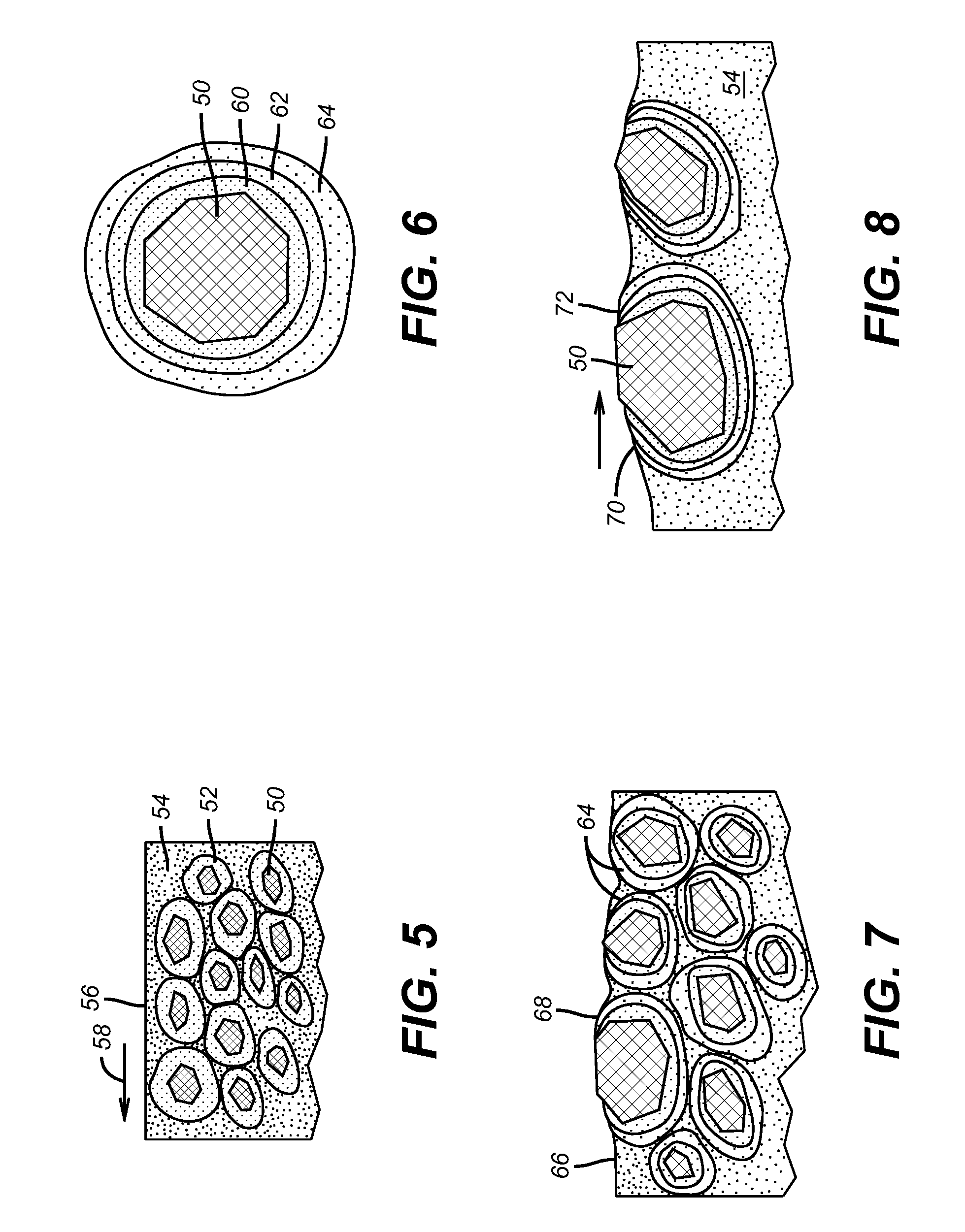

A method of constructing an earth-boring, diamond-impregnated drill bit has a first step of coating diamond grit with tungsten to create tungsten-coated diamond particles. These coated particles are then encapsulated in a layer of carbide powder held by an organic green binder material. The encapsulated granules are then mixed along with a matrix material and placed in a mold. The matrix material includes a matrix binder and abrasive particles. The mixture is heated in the mold at atmospheric pressure to cause the matrix binder to melt and infiltrate the encapsulated granules and abrasive particles.

Owner:BAKER HUGHES INC

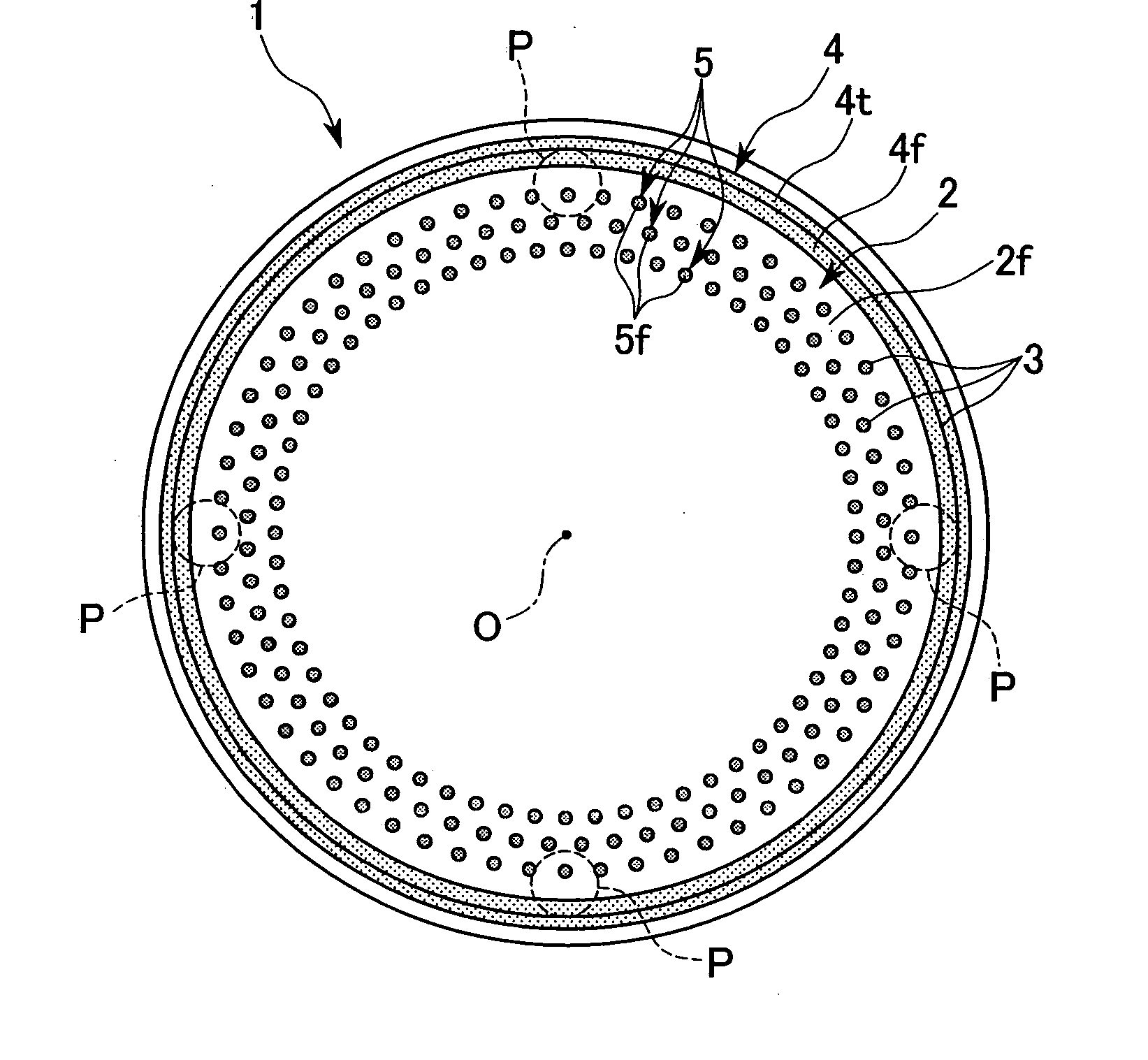

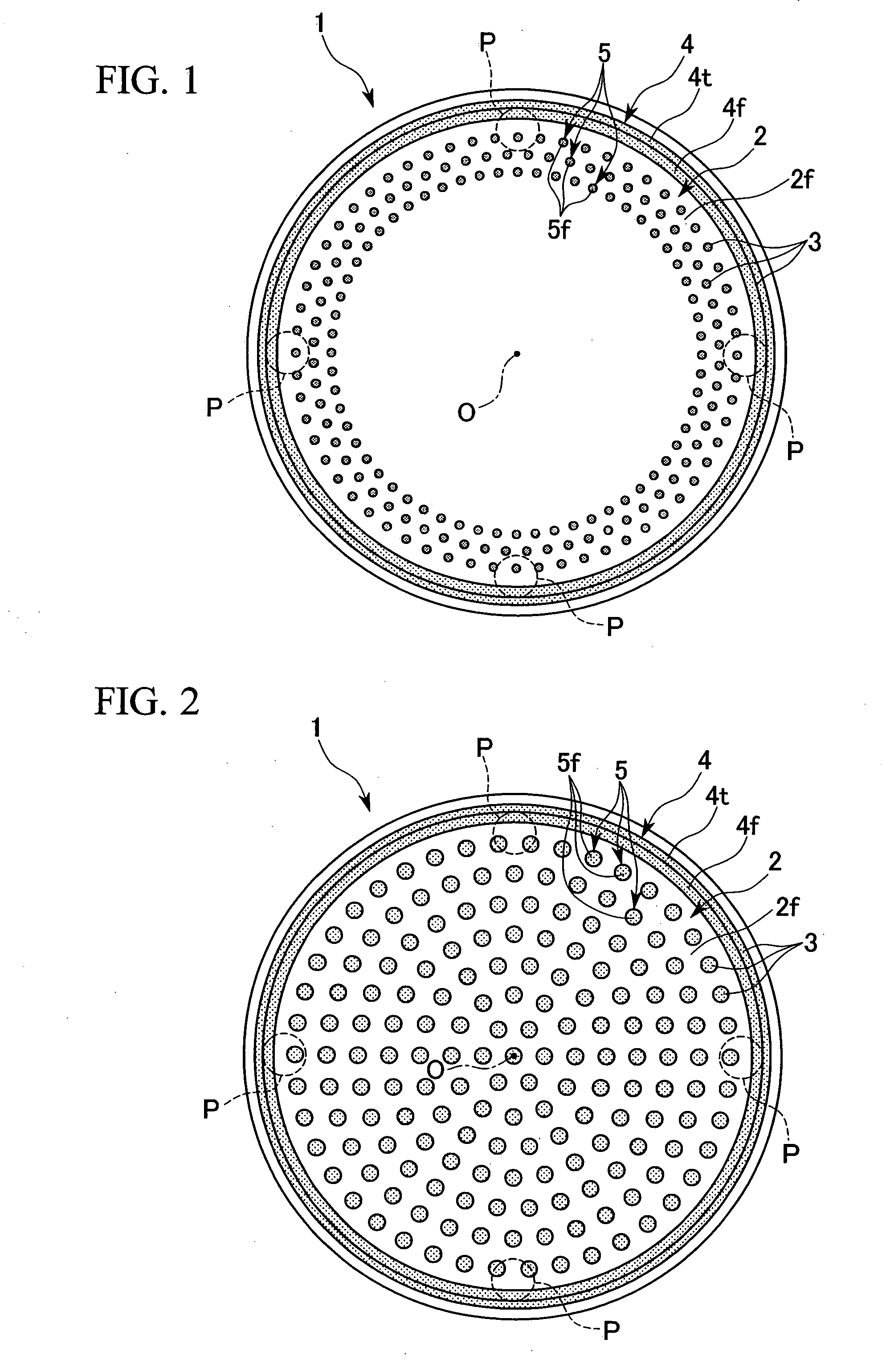

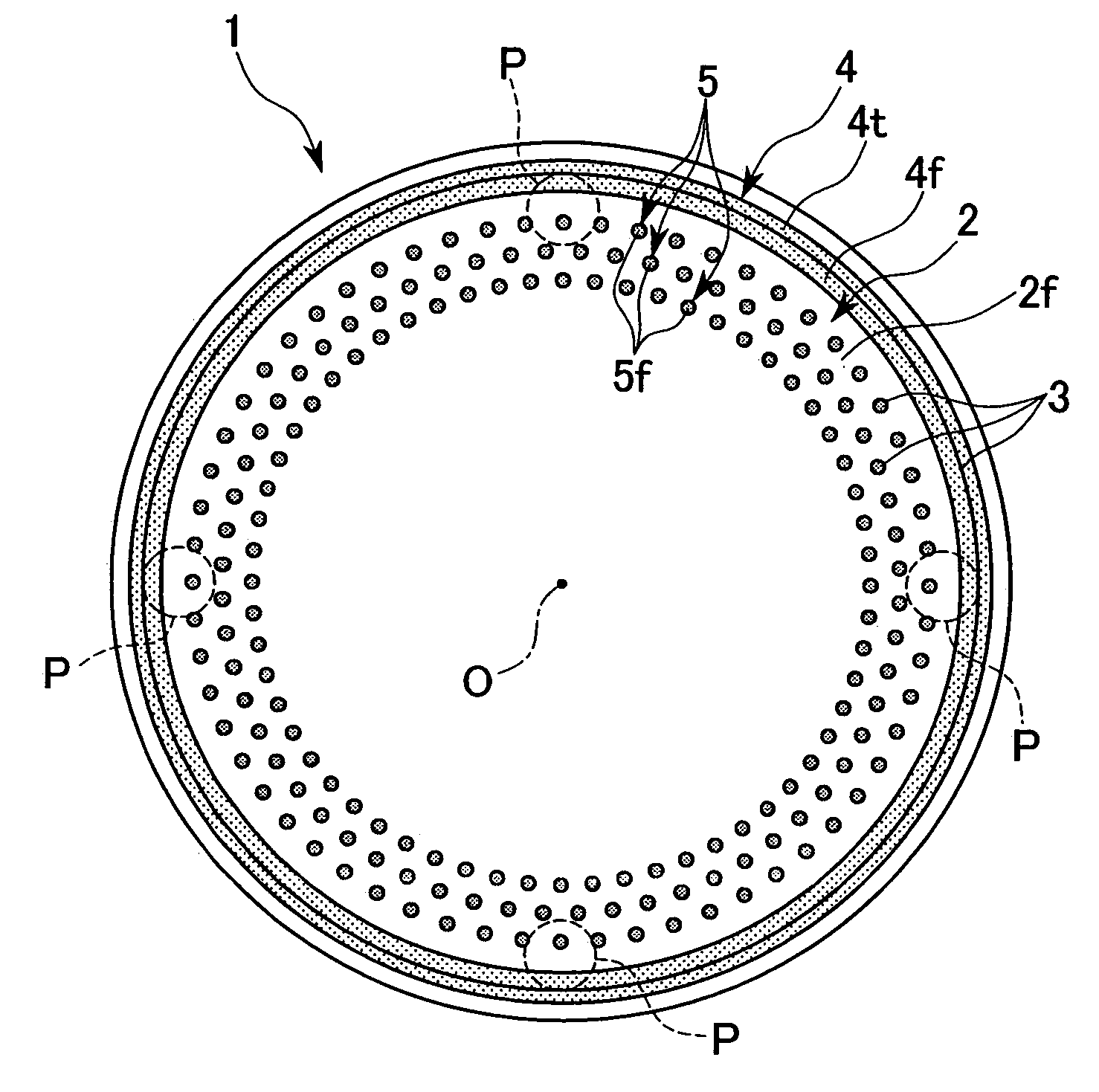

CMP conditioner

ActiveUS20060079162A1Avoid it happening againCorrosion resistanceRevolution surface grinding machinesGrinding drivesMechanical engineeringDiamond grit

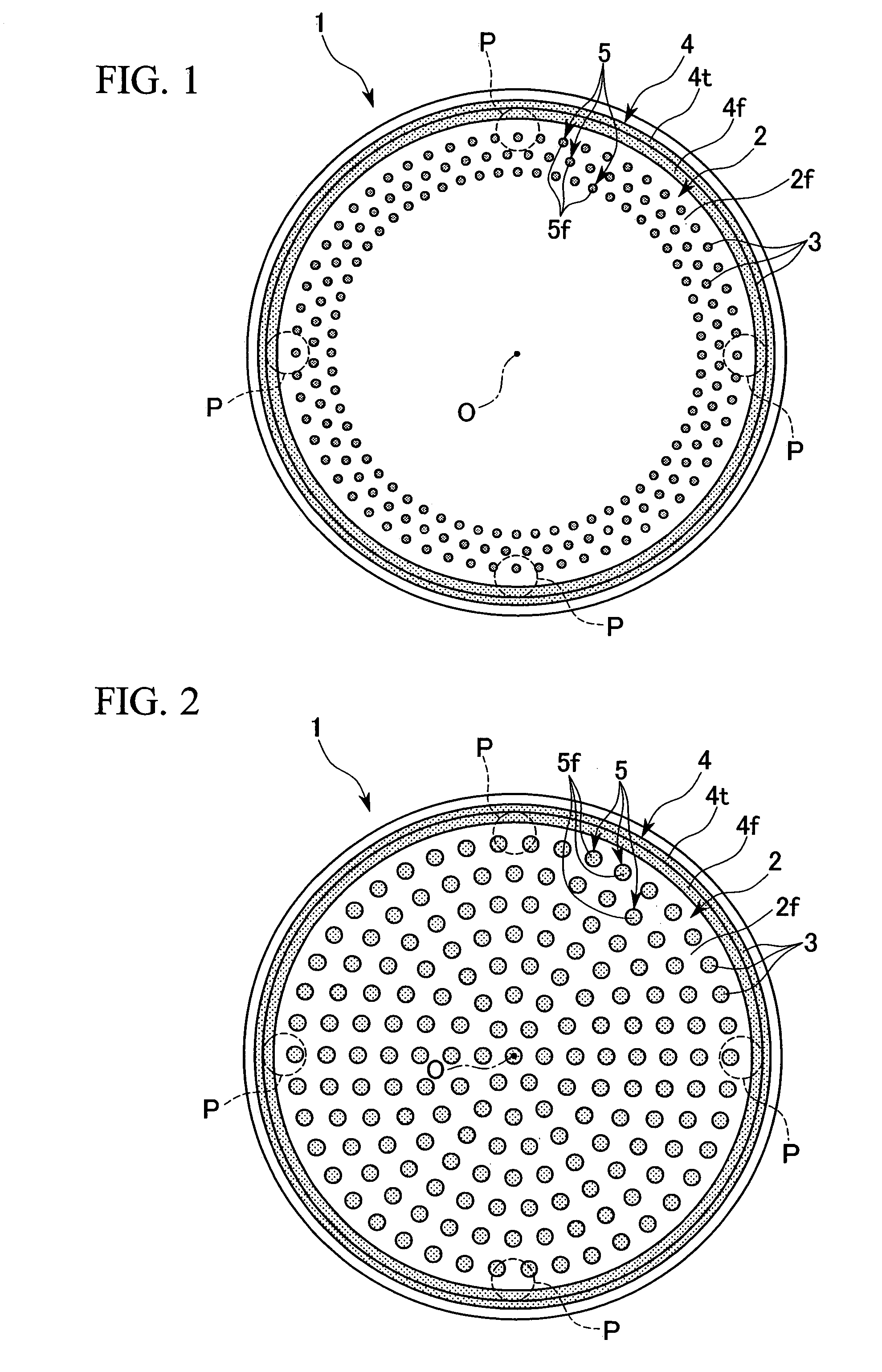

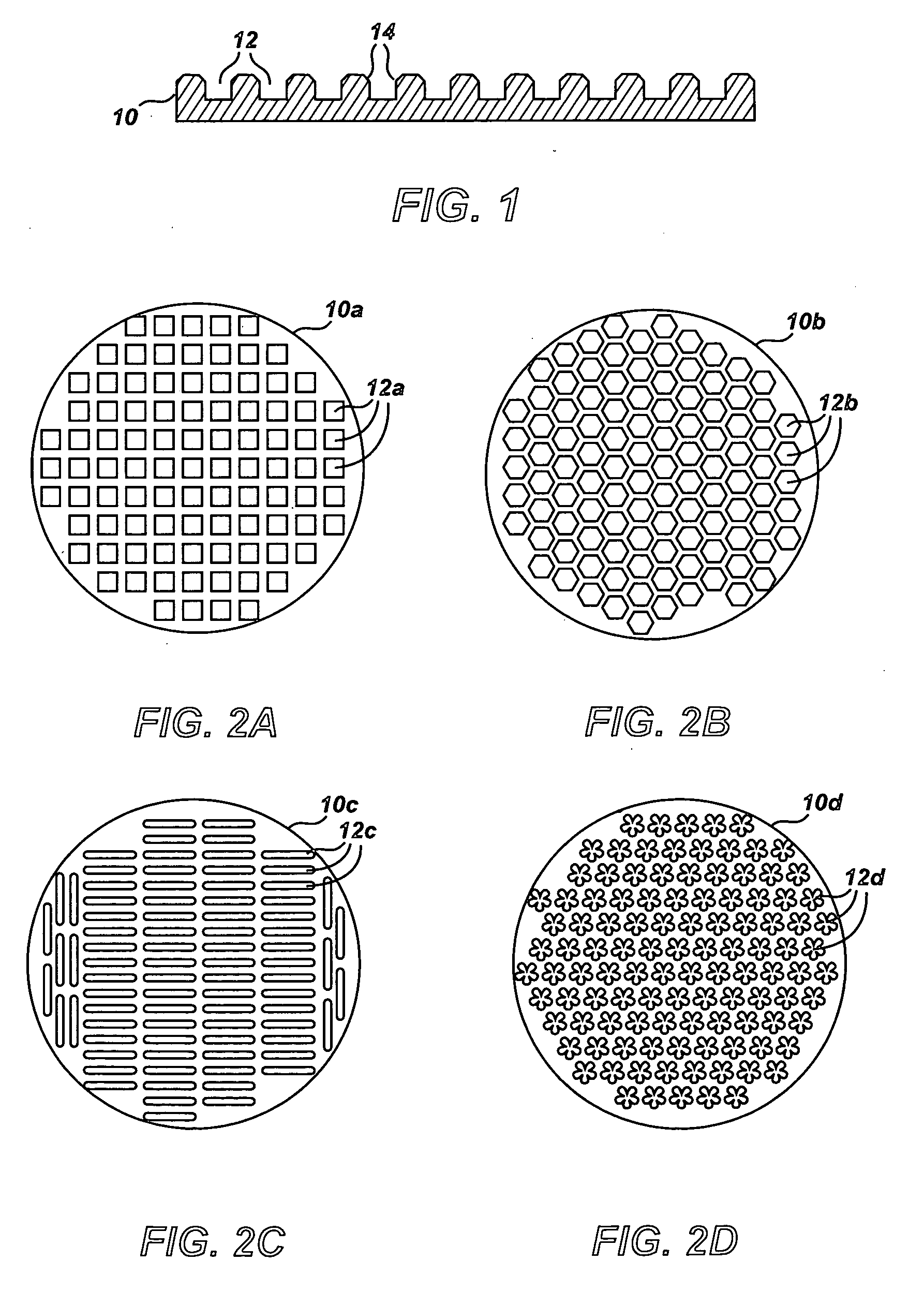

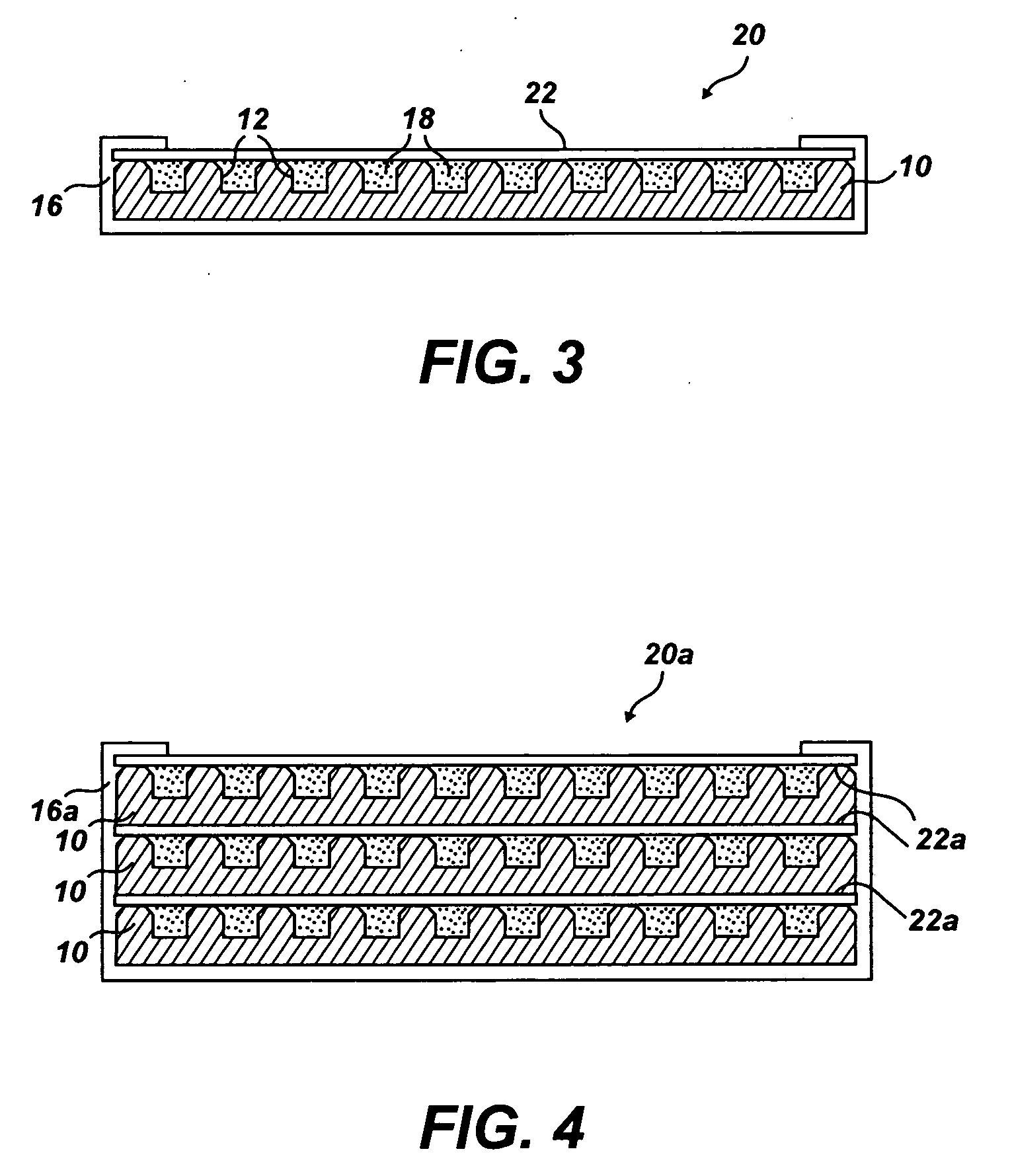

A CMP conditioner is provided in which diamond grit that is adhered to a conditioning surface so as to face and be in contact with a polishing pad of a CMP apparatus is adhered such that 111 surfaces of crystal surfaces of the diamond grit are substantially parallel with the conditioning surface and face in a direction faced by the conditioning surface.

Owner:MITSUBISHI MATERIALS CORP

Carbonaceous composite heat spreader and associated methods

InactiveUS20050189647A1Low melting pointSemiconductor/solid-state device detailsSolid-state devicesGraphiteMetal

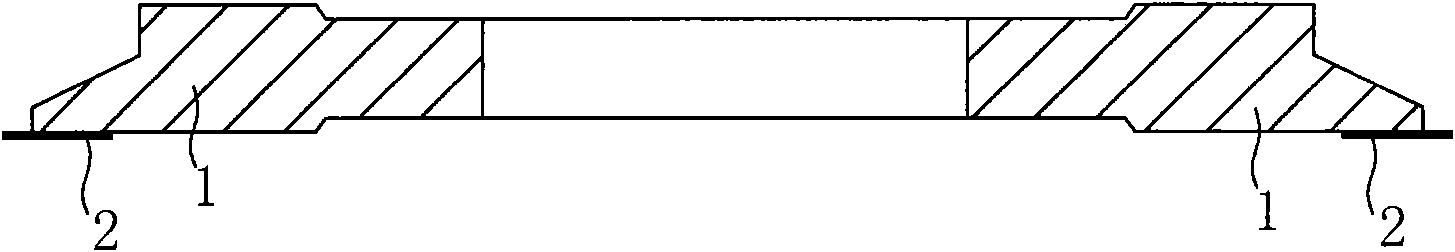

A carbonaceous composite heat spreader includes a plurality of diamond grits present in an amount greater than about 50% by volume of the heat spreader and a metal matrix holding the diamond grits in a consolidated mass. The metal matrix contains at least about 50% aluminum by volume. The heat spreader can include a quantity of graphite, with the plurality of diamond grits being in substantially intimate contact with the graphite and with the metal matrix holding the graphite and the diamond grits in a consolidated mass. The quantity of graphite can include at least two distinct layers of graphite and the diamond grits can be arranged in a layer disposed between the layers of graphite.

Owner:SUNG CHIEN MIN

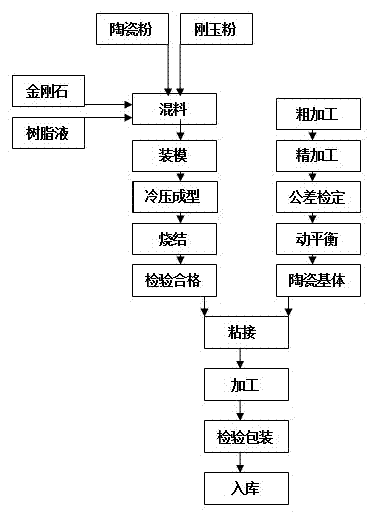

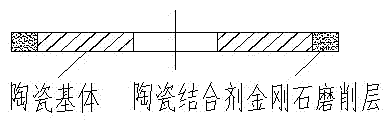

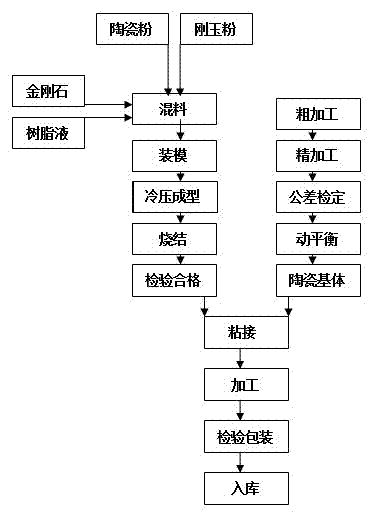

Special ceramic bond diamond grinding wheel for grinding diamond

InactiveCN102229122AHigh strengthSmall expansion coefficientAbrasion apparatusGrinding devicesDiamond grindingCeramic

The invention belongs to the field of diamond grinding wheels, and particularly relates to a ceramic bond and a method for manufacturing a ceramic bond diamond grinding wheel for grinding a diamond by adopting the ceramic bond. The ceramic bond is prepared from the following raw materials in percentage by weight: silicon dioxide, borax, lithium hydroxide, zinc oxide, calcium oxide and aluminum oxide; and the ceramic bond is obtained through the steps of: mixing the raw materials, then smelting at the high temperature of 1300+ / -5 DEG C, cooling, then performing ball milling to prepare ceramic powder, and sieving through a standard sieve of 180 meshes. The ceramic bond provided by the invention has high intensity and a low coefficient of expansion, so that the ceramic bond can be perfectly matched with the adopted ceramic grinding wheel basal body. The diamond grinding wheel manufactured by adopting the ceramic bond has good heat conductivity and heat resistance; and compared with the traditional resin bond diamond grinding wheel, the ceramic bond diamond grinding wheel not only ensures that the diamond is excellently sintered at the temperature of not being carbonized, but also ensures that grinding grains are always at an excellent holding state without falling off when grinding is carried out. The special ceramic bond diamond grinding wheel has the grinding efficiency and service life far higher / longer than that of the traditional grinding wheel, and has a comprehensive benefit which is increased by over 50%.

Owner:SUZHOU SAILI PRECISION TOOLS

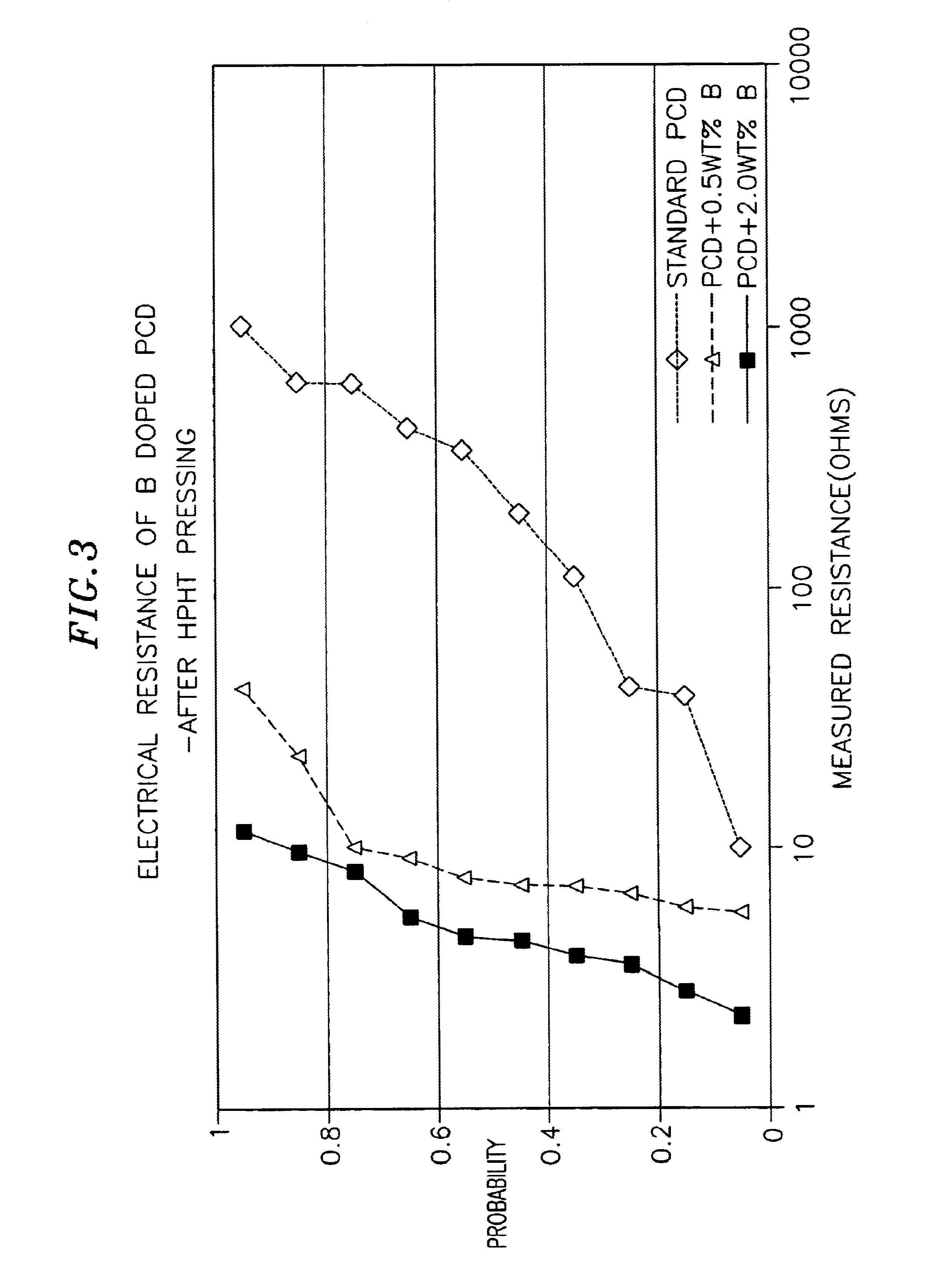

Method of forming cutting elements

InactiveUS6846341B2Improve conductivityExcellent cuttabilityPigmenting treatmentTransportation and packagingDiamond crystalPolycrystalline diamond

An ultra-hard semiconductive polycrystalline diamond (PCD) material formed with semiconductive diamond particles doped with Li, Be or Al and / or insulative diamond particles having semiconductive surfaces, tools incorporating the same, and methods for forming the same, are provided. The ultra-hard PCD material may be formed using a layer of insulative diamond grit feedstock that includes additives therein, then sintering to convert a plurality of the diamond crystals to include a semiconductive surface. In another embodiment, the ultra-hard PCD material is formed by sintering semiconductive diamond grit feedstock consisting of diamond crystals doped with Li, Al or Be. The ultra-hard semiconductive PCD cutting layer exhibits increased cuttability, especially in EDM and EDG cutting operations.

Owner:SMITH INT INC

CMP conditioner

ActiveUS7150677B2Prevents any large-scale reductionReliably prevents scratchesRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

Owner:MITSUBISHI MATERIALS CORP

Method and apparatus for removing trip hazards in concrete sidewalks

InactiveUS7000606B2Smooth transitionMetal sawing devicesRevolution surface grinding machinesAngle grinderEngineering

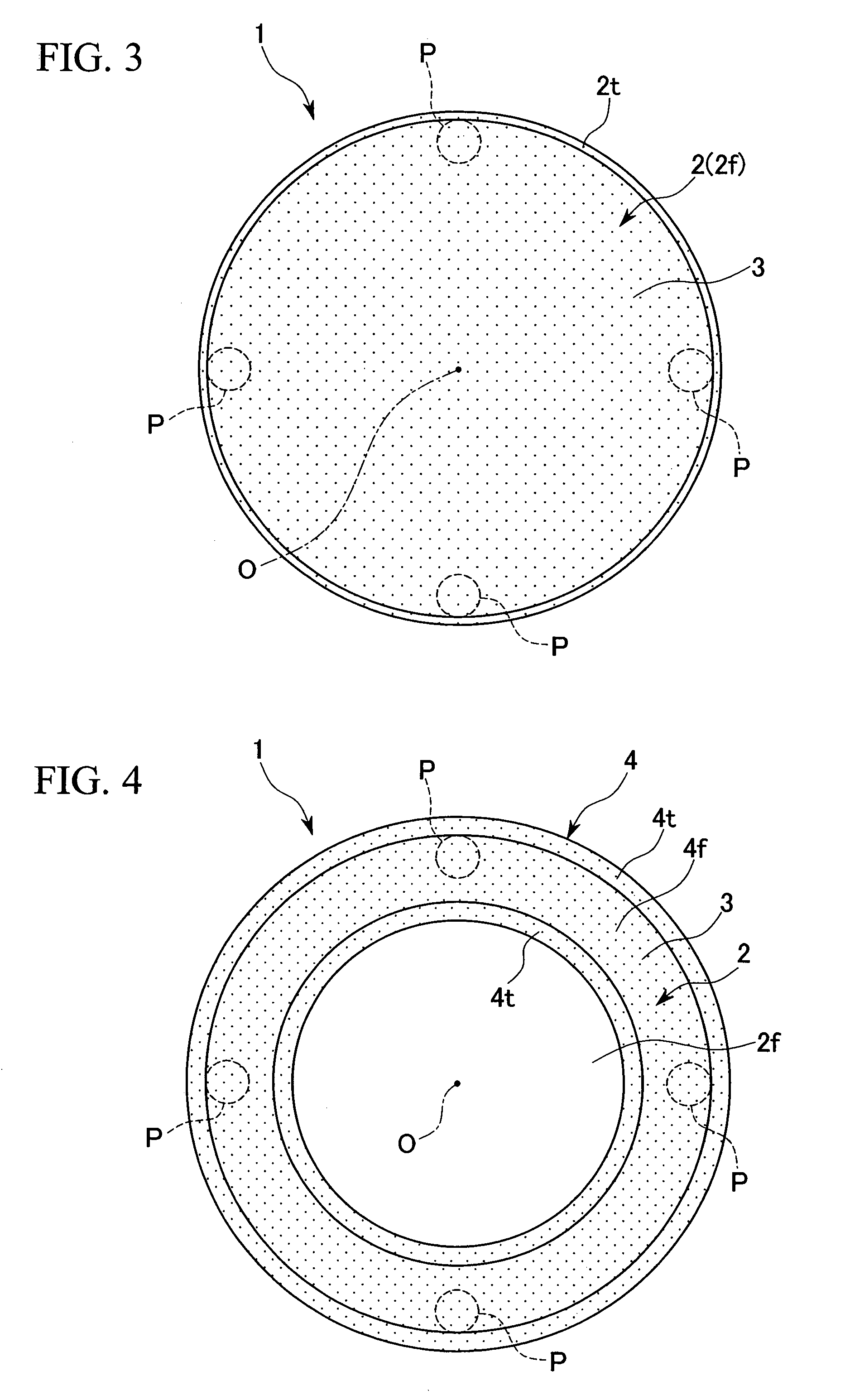

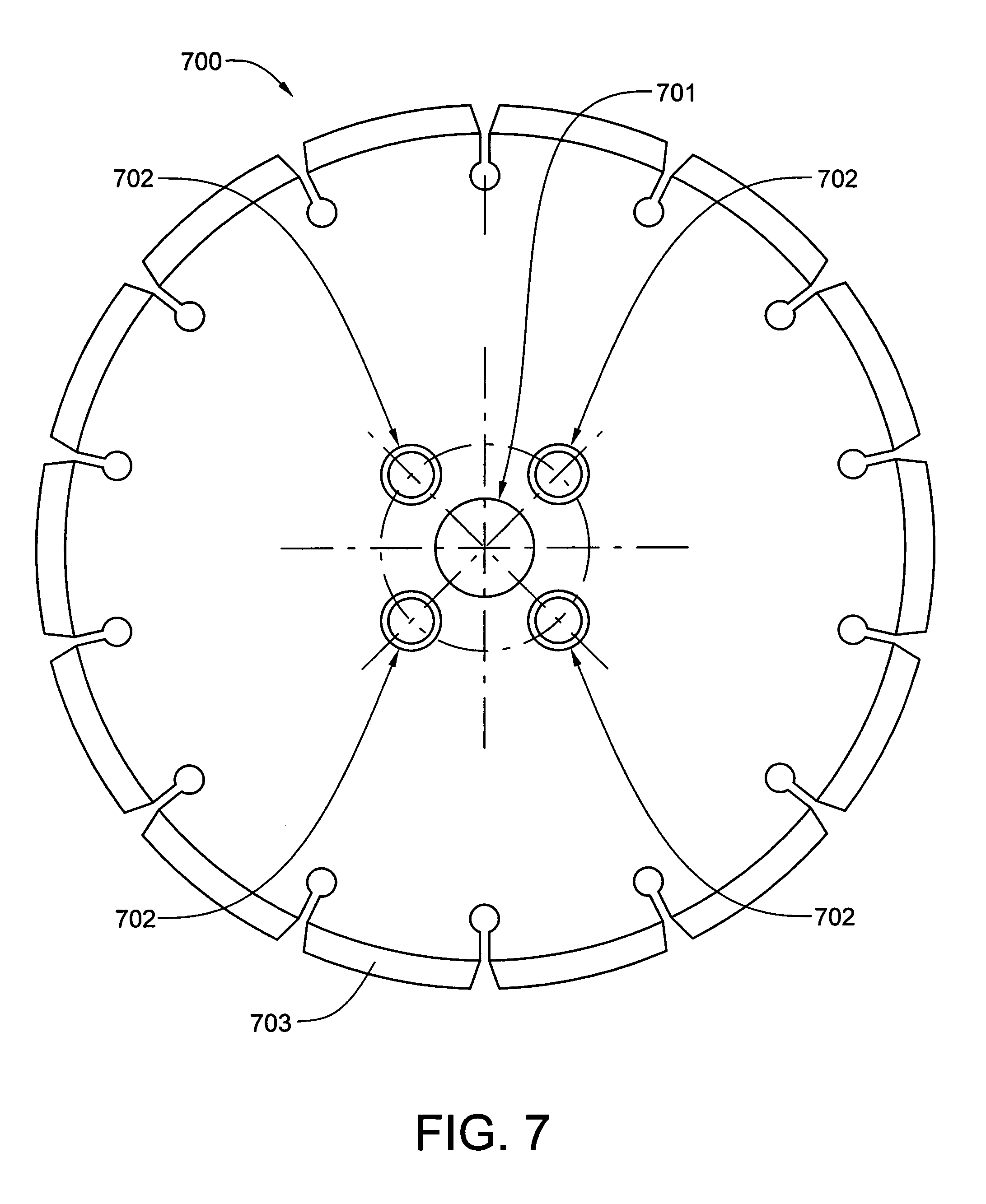

An apparatus for cutting a chamfer on an upper edge of a concrete slab includes a hub designed for installation on the threaded output spindle of an angle grinder, and a specially-modified diamond-grit-edged rotary blade which mounts on the hub. For a preferred embodiment of the hub, an attachment collar is unitary and concentric with both a blade mounting flange having countersunk attachment screw holes and a blade centering shoulder on the flange. The attachment collar has at least one pair of flattened parallel sides for receiving a wrench used to tighten the hub on the output spindle. The blade, which is equipped with both countersunk attachment holes and a central positioning aperture sized to fit closely over the blade centering shoulder, is attachable with countersinking screws to the mounting flange so that the head of each screw is flush with the surface of the blade.

Owner:PRECISION CONCRETE CUTTING

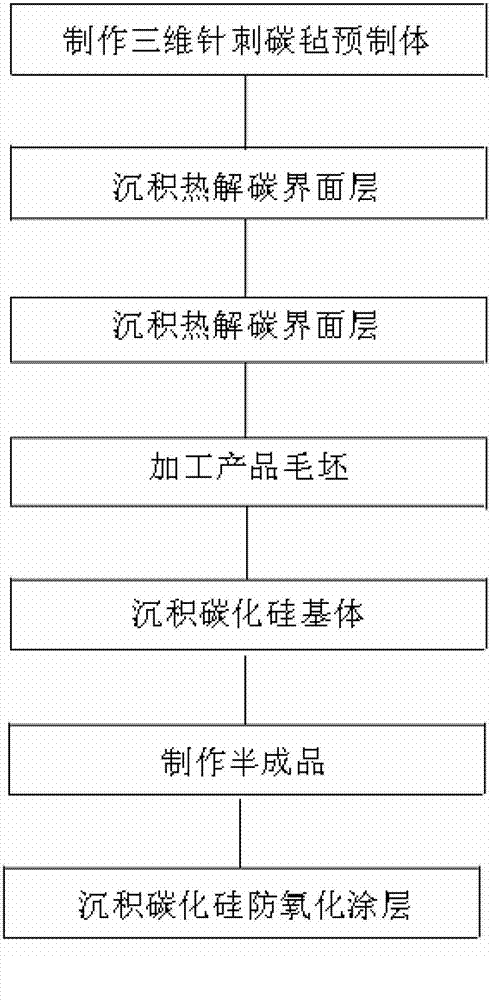

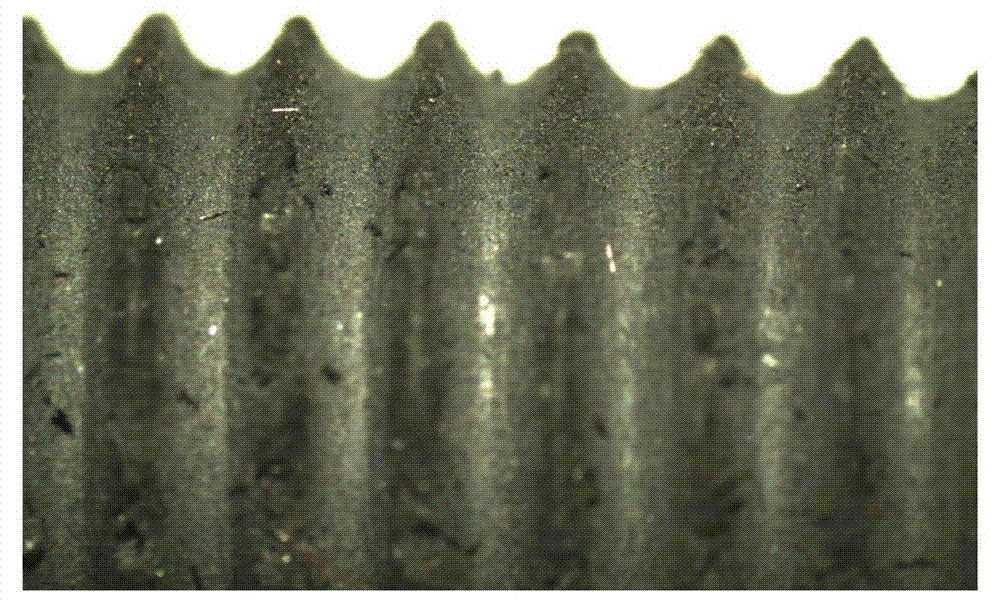

Preparation method of three-dimensional needling carbon/carborundum composite material bolt

ActiveCN102775176AIncreased shear strengthReduce wearScrewsChemical vapor infiltrationMaterials science

A preparation method of a three-dimensional needling carbon / carborundum composite material bolt adopts a three-dimensional needling fiber prefabrication body to prepare the composite material bolt. Pyrolytic carbon is deposited on the prefabrication body, carborundum substrates are deposited through chemical vapor infiltration (CVI), and a bolt bar blank and a bolt cap blank are obtained. The carborundum substrates of the bolt bar blank and the bolt cap blank which are obtained through machining are deposited through the CVI, a carborundum anti-oxidation coating is deposited through the CVI, and a three-dimensional needling C / SiC composite material bolt end product with the shear strength being 80-100MP is obtained. Compared with the prior art, the preparation method has the advantages that the number of times for getting into a furnace is reduced by 6-10, the densifying period is shorter, and the production cost is reduced. By means of a test of a CK6180-3000 numerically controlled lathe, the preparation method is small in diamond grinding wheel abrasion, hour norm for machining 30 bolt threads is reduced by about 10 hours, and as the abrasion of a grinding wheel is less, the working accuracy is improved, and industrialized batch production is achieved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Polyimide resin diamond grinding wheel and preparation method thereof

ActiveCN102814763AHigh mechanical strengthImprove heat resistanceAbrasion apparatusGrinding devicesCorundumPolyimide

The invention discloses a polyimide resin diamond grinding wheel and a preparation method of the polyimide resin diamond grinding wheel. The polyimide resin diamond grinding wheel is prepared from the following components in parts by weight: 50-60 parts of diamond grinding material, 5-10 parts of white corundum grinding material, 5-10 parts of garnet sand, 5-15 parts of polyimide resin powder, 2-6 parts of furfuryl alcohol, 1-2 parts of trioctyl trimellitate, 5-10 parts of cryolite, 5-10 parts of gypsum powder, 2-5 parts of nano siliceous shale powder and 2-5 parts of copper powder. According to the polyimide resin diamond grinding wheel and the preparation method of the polyimide resin diamond grinding wheel, as polyimide resin serving as a binding agent has higher mechanical strength and excellent heat resistance, the durability of the prepared resin grinding wheel is improved greatly; as ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, and cracks formed by rigid grinding are reduced, thereby the use efficiency and service life of the resin grinding wheel are improved further; and in addition, since copper power is added, fast heat dissipation effect is achieved, a great deal of heat generated in a cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is achieved.

Owner:安徽威铭耐磨材料有限公司

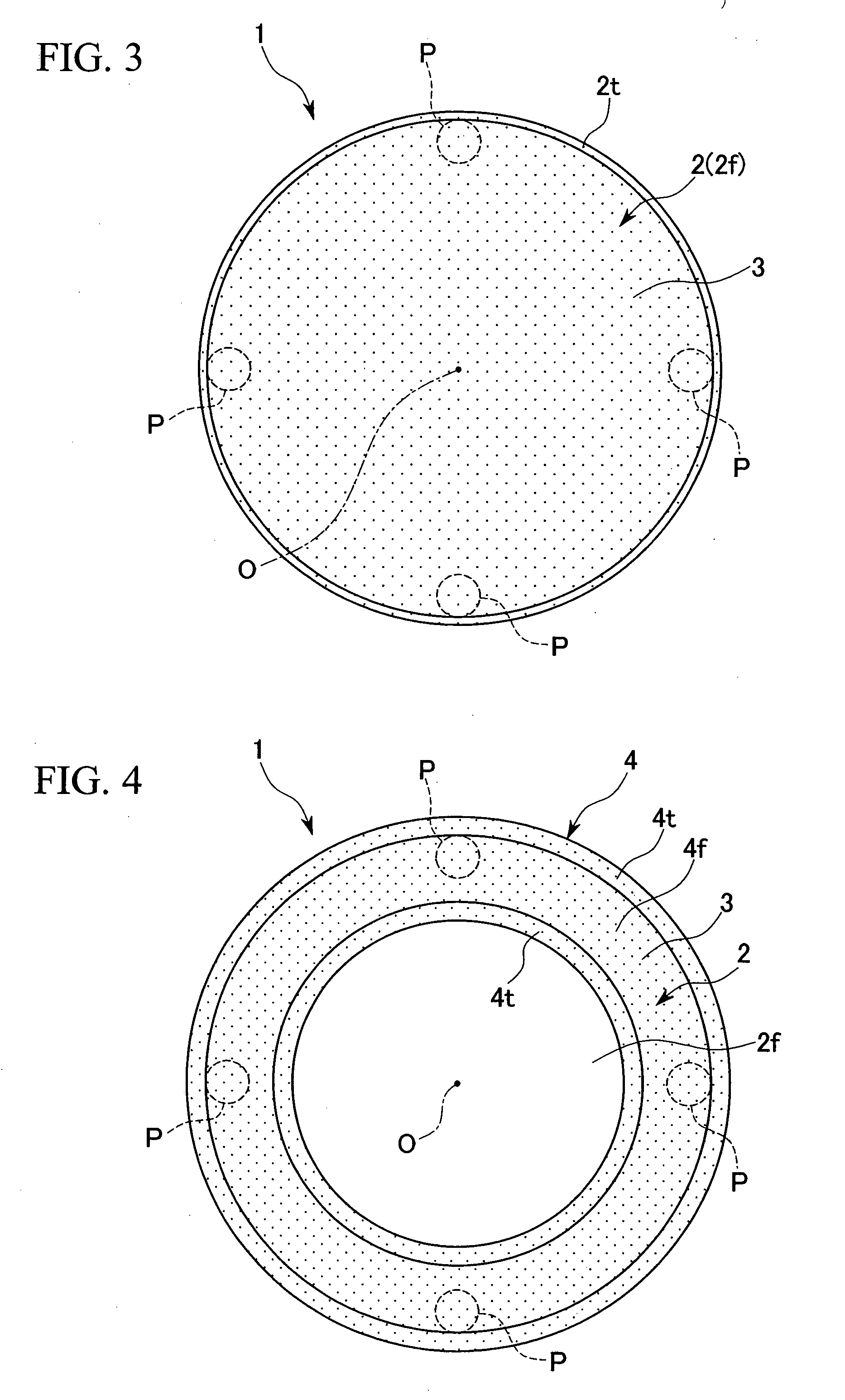

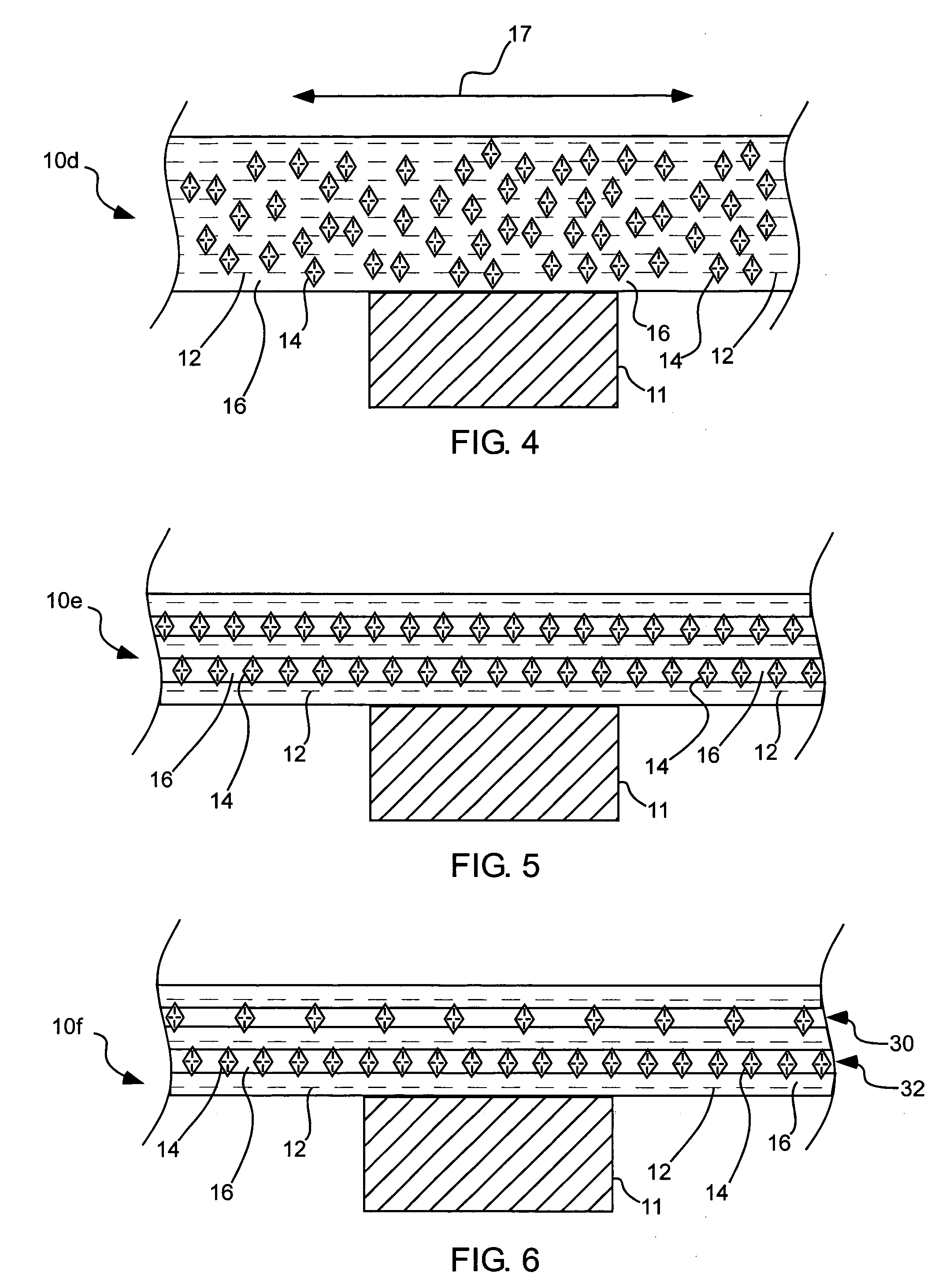

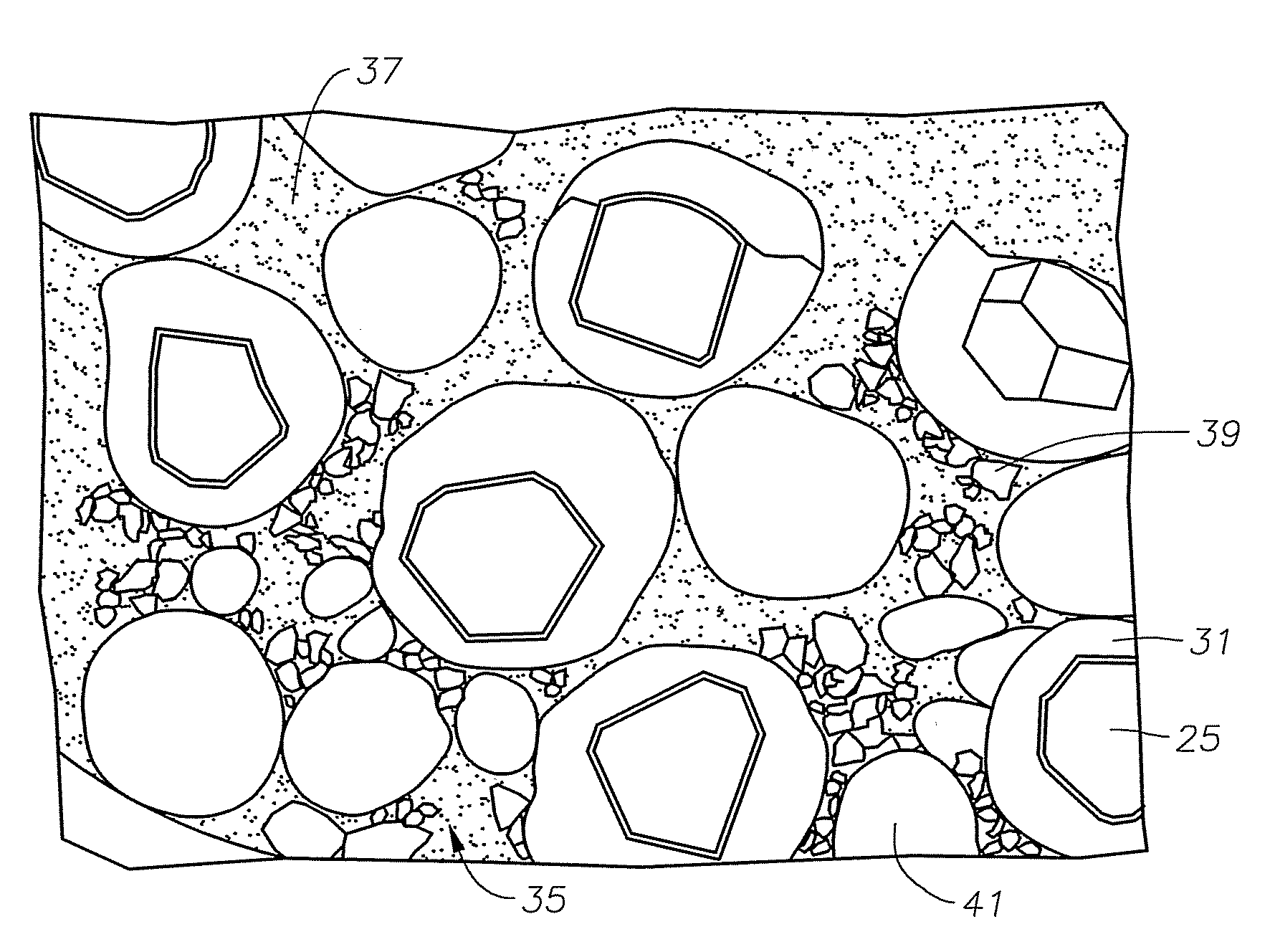

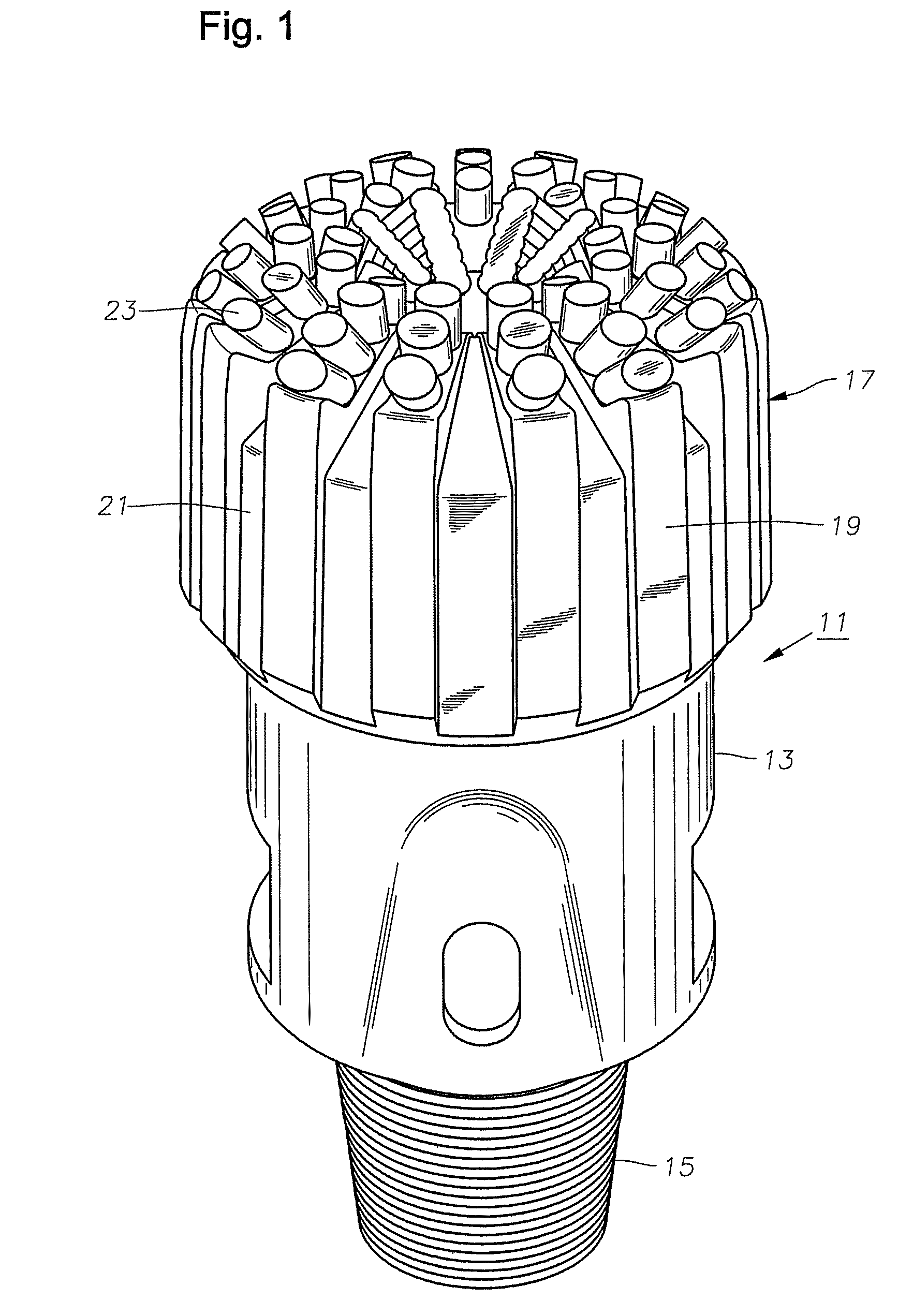

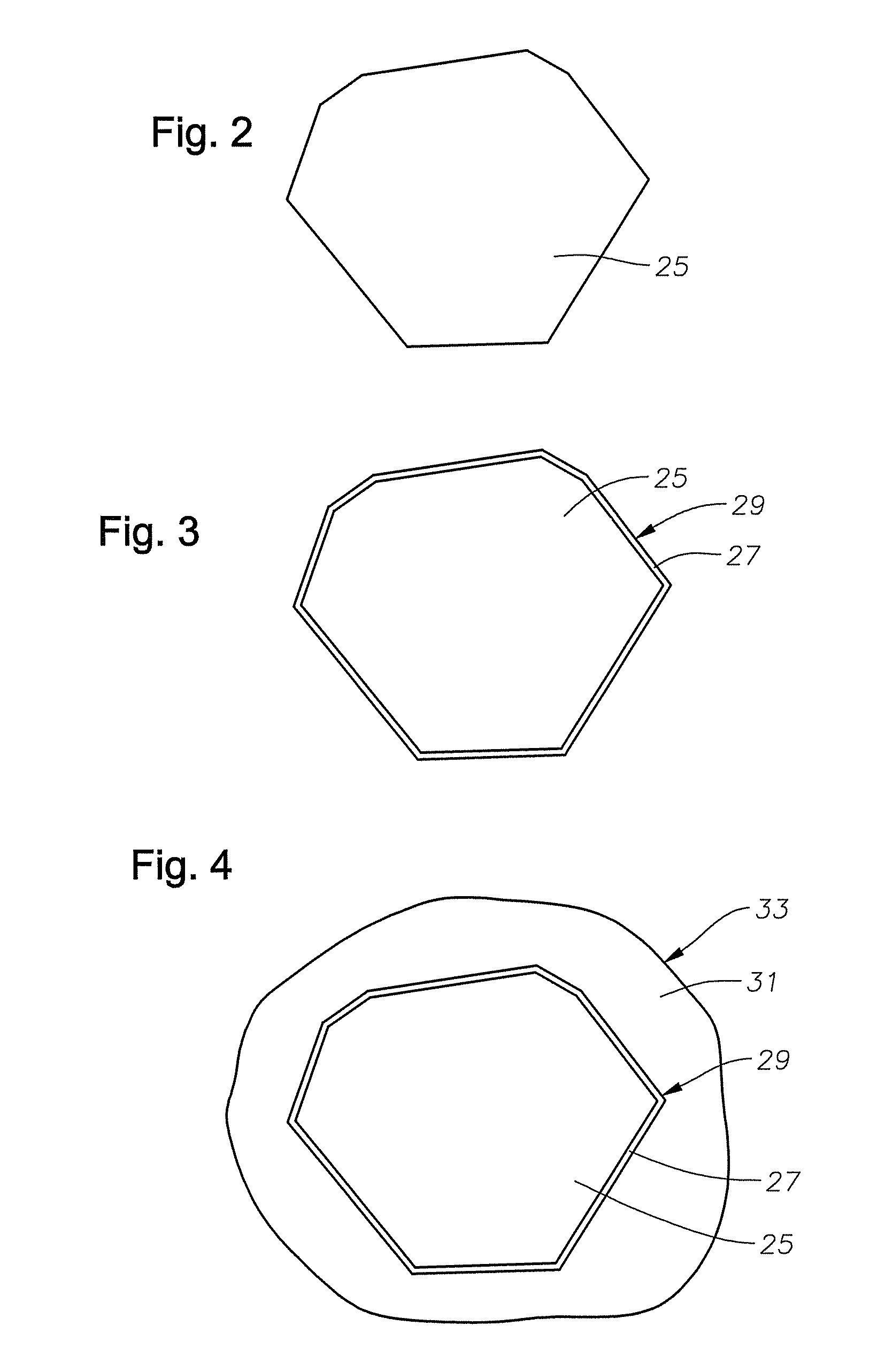

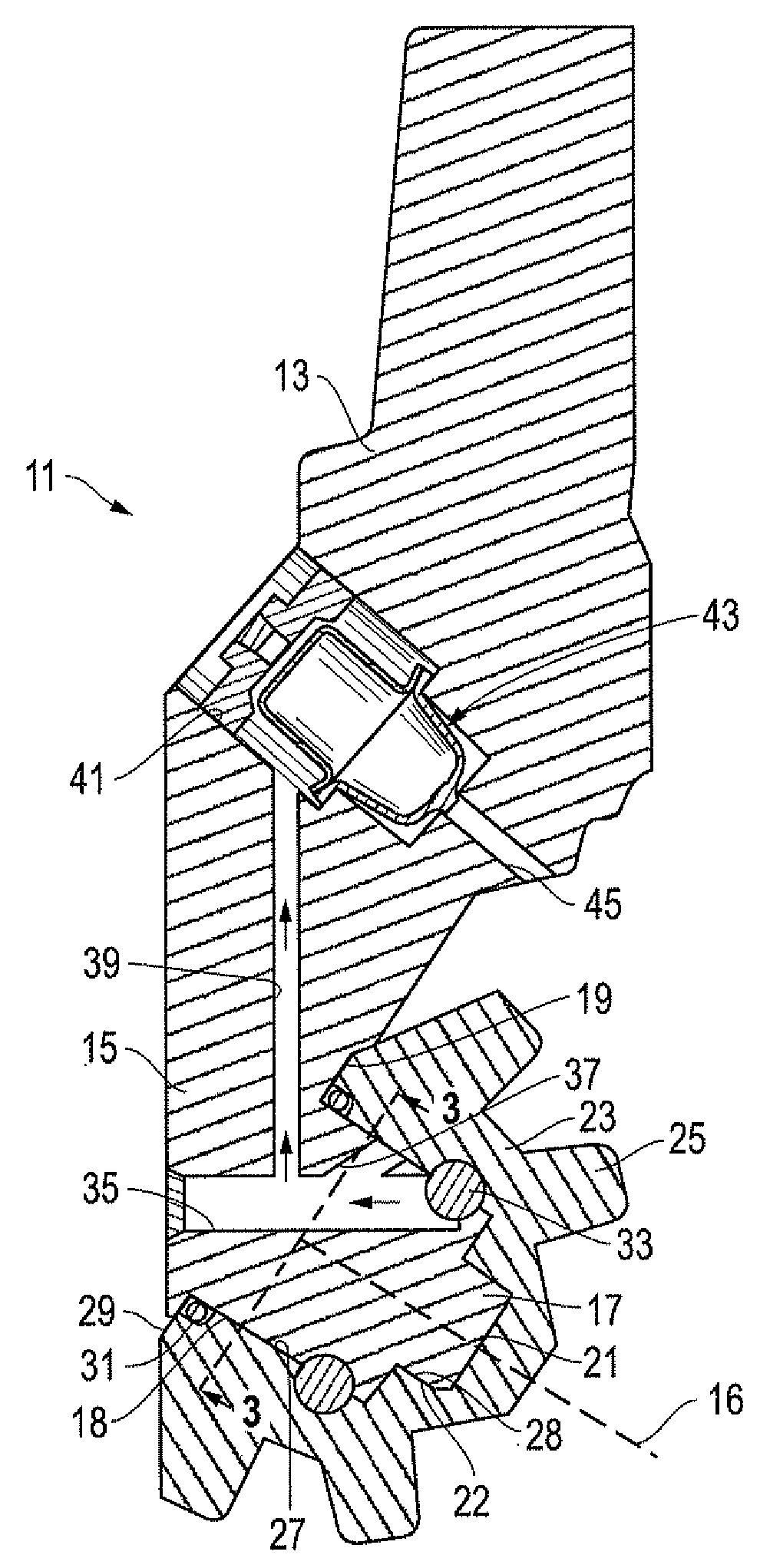

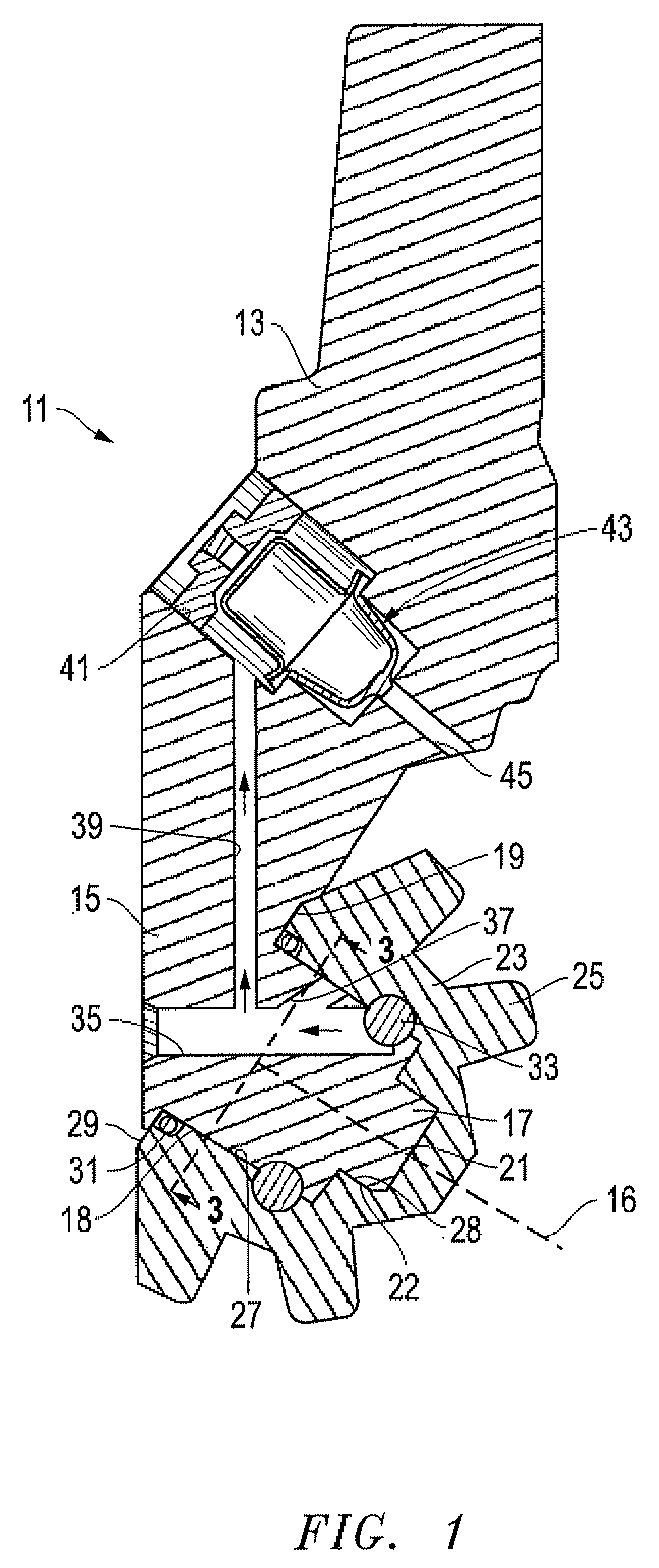

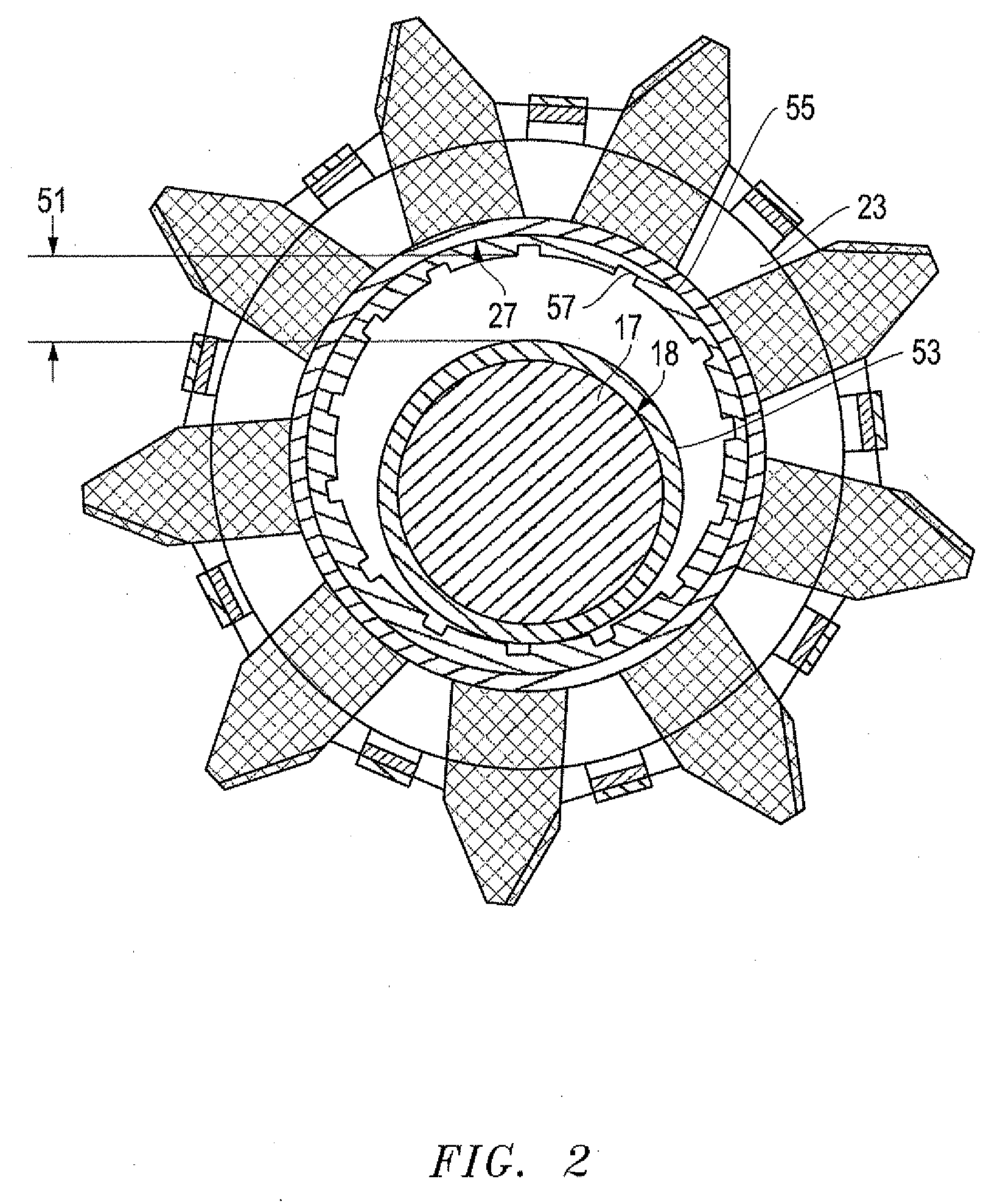

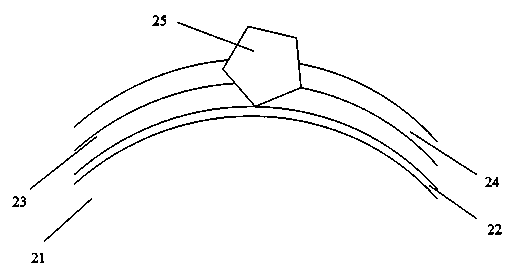

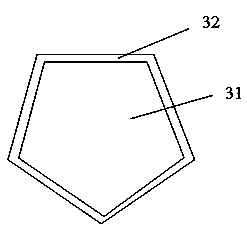

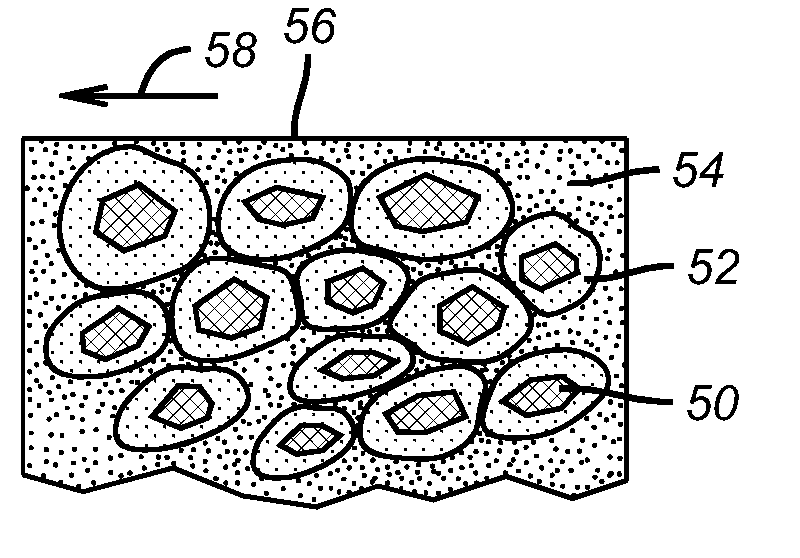

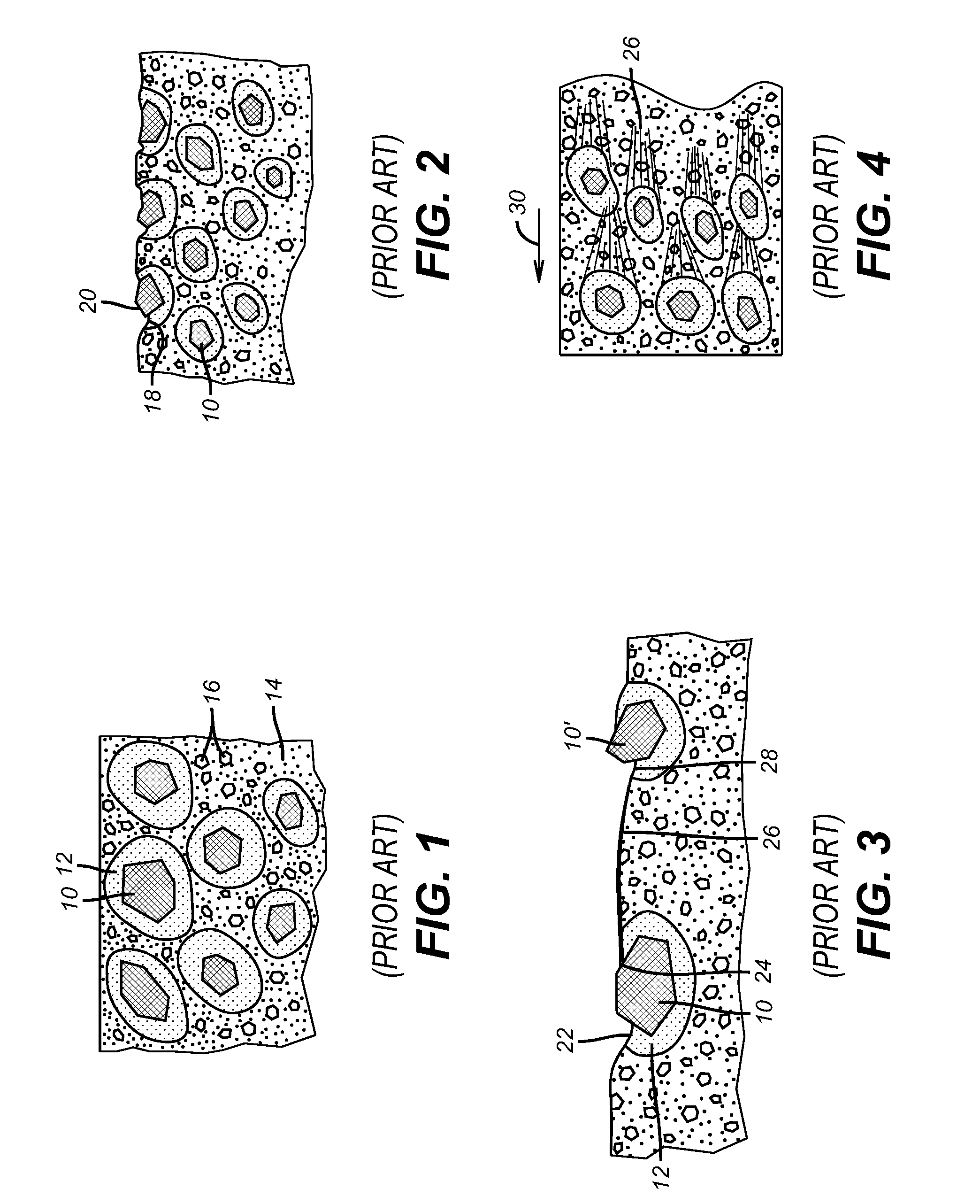

Multi-layer encapsulation of diamond grit for use in earth-boring bits

ActiveUS7810588B2High retention rateOptimize allocationDrill bitsMetal-working drilling toolsCarbideAtmospheric pressure

A method of constructing an earth-boring, diamond-impregnated drill bit has a first step of coating diamond grit with tungsten to create tungsten-coated diamond particles. These coated particles are then encapsulated in a layer of carbide powder held by an organic green binder material. The encapsulated granules are then mixed along with a matrix material and placed in a mold. The matrix material includes a matrix binder and abrasive particles. The mixture is heated in the mold at atmospheric pressure to cause the matrix binder to melt and infiltrate the encapsulated granules and abrasive particles.

Owner:BAKER HUGHES HLDG LLC

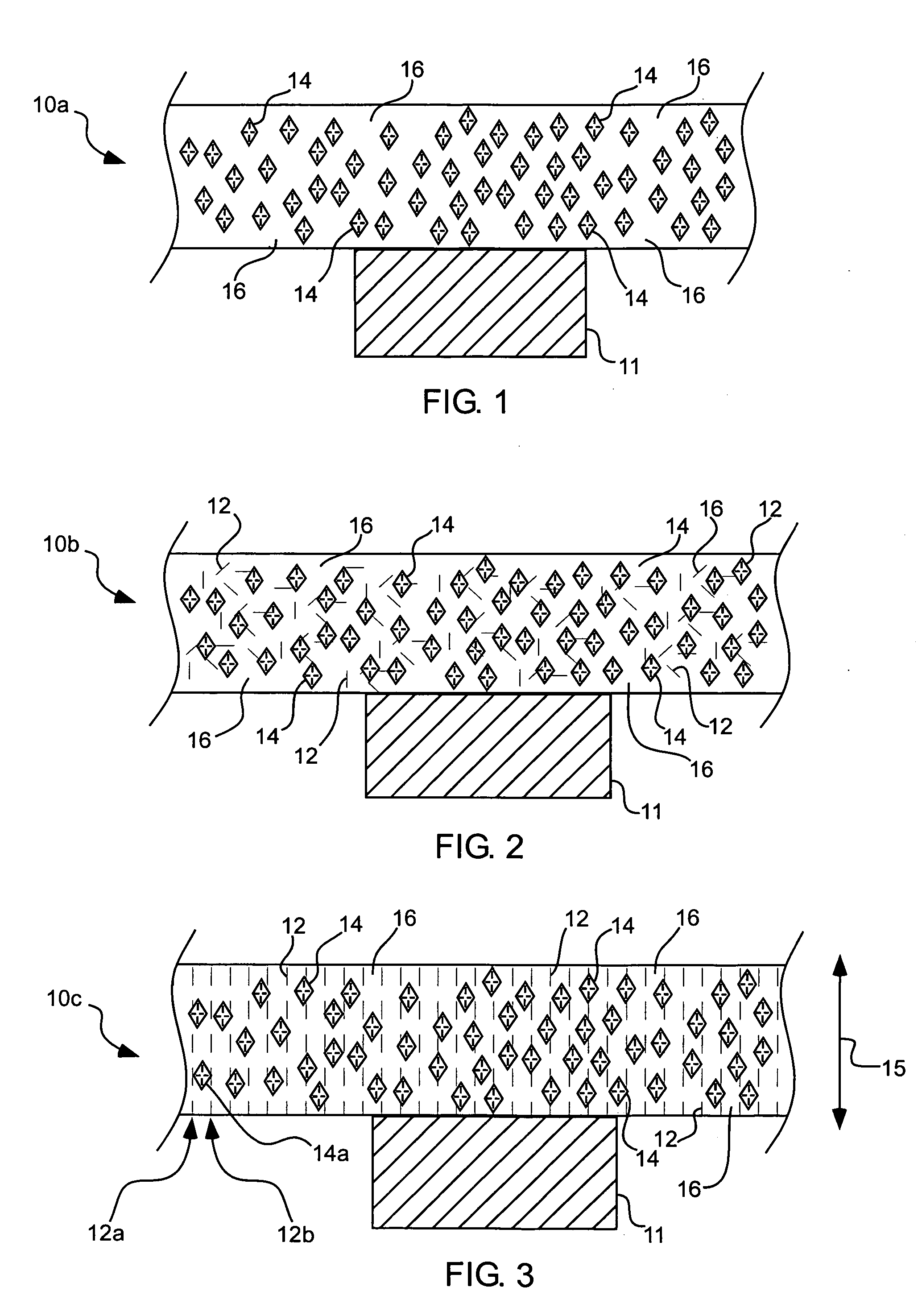

Shaped thermally stable polycrystalline material and associated methods of manufacture

InactiveUS20060272571A1Tailored strengthGood self-cutting behaviorPigmenting treatmentPolycrystalline material growthPolycrystalline diamondThermal stability

A new industrial thermally stable polycrystalline diamond (TSP) is disclosed and described as a replacement of natural as well as synthetic diamond grit in concrete cutting, grinding, polishing, and surface-set grinding or core bit drilling applications. Conventional diamond is too strong and brittle for self-sharpening and polishing and has a lower thermal stability inferior to the industrial standard for high temperature tool segment bonding. TSP grits can be tailor-made having unique properties as well as an engineered shape of grits over naturally or synthetically produced diamond grits. The TSP grits have a high thermal stability of up to 1200° C. and are self-sharpening. Further, economical production of coarse TSP grit size up to 1-2 mm from 50 / 60 mesh size in almost any preferred shape such as blocky, round, hexagonal, thin elongated, spherical, needle like, and any desirable tailor-made shaped etc can be realized. The use of a partition member during production of the TSP grits allows for the effective manufacturing of desired shaped grits as compared to laborious and ineffective low yield crushing of TSP material. Advantageously, the process time can also be exceptionally shorter than conventional HPHT processes.

Owner:ADICO ASIA POLYDIAMOND

Preparation method of porous metal binding agent braze welding diamond grinding wheel

The invention provides a preparation method of a porous metal binding agent braze welding diamond grinding wheel, comprising the following steps of preparing a grinding wheel segment block and connecting the grinding wheel segment block with a grinding wheel base body. The prepared porous metal binding agent braze welding diamond grinding wheel has 45-70 percent of porosity, and the bending strength of three points of the grinding wheel segment block is 75-200 MPa. Because of the introduction of a pore structure, the trimming and sharpening ability, the grinding material exposure ability and a chips-containing space of the novel grinding wheel are greatly improved compared with the compact metal binding agent grinding wheel, the grinding wheel has favorable self-sharpening property, favorable durability and high processing efficiency, and can bear heavier load when crisp and hard materials are grinded; meanwhile, the grinding wheel segment block has high strength, the metal binding agent has favorable holding force on the grinding material, and the grinding material does not fall off easily and prematurely.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

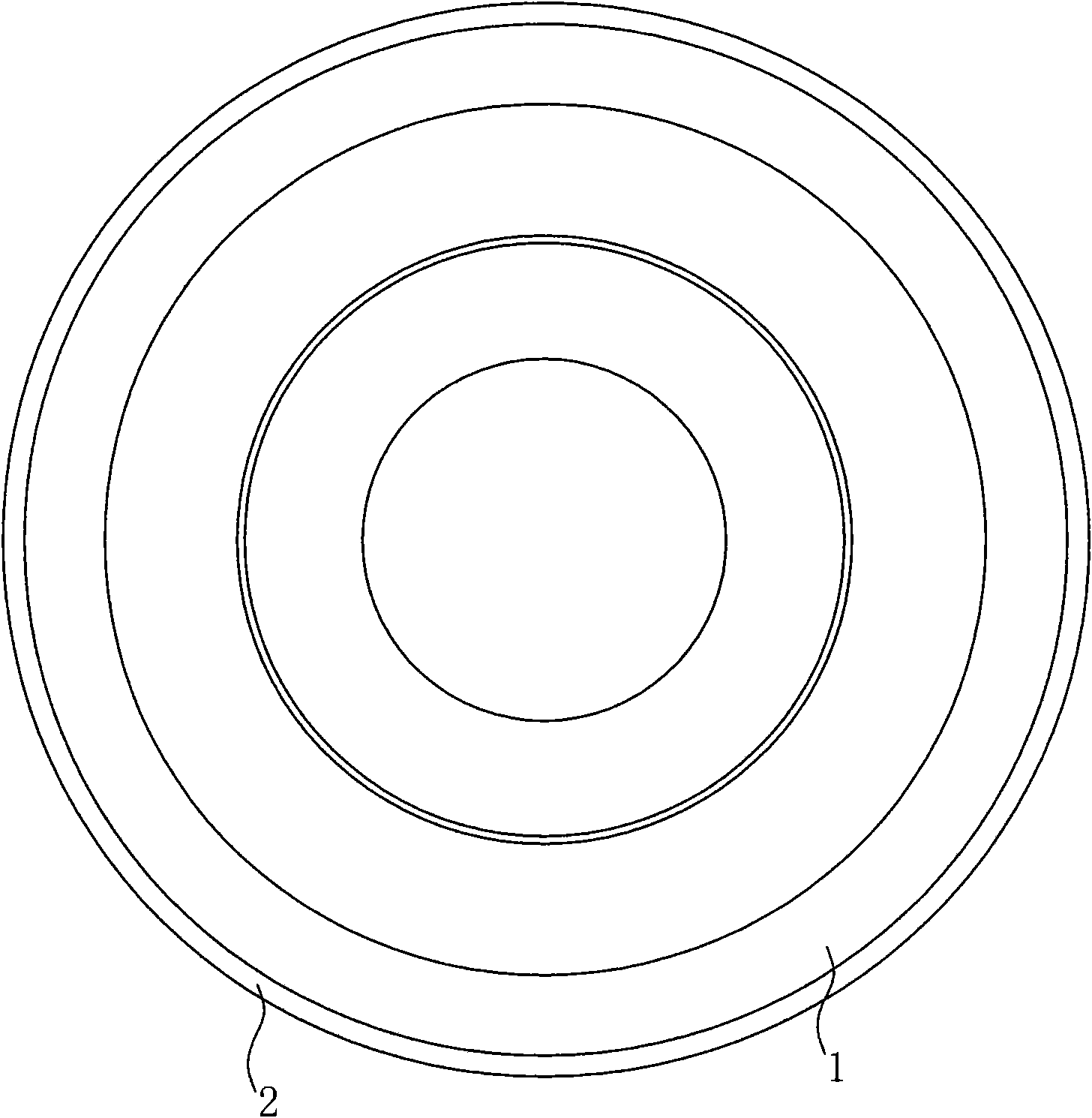

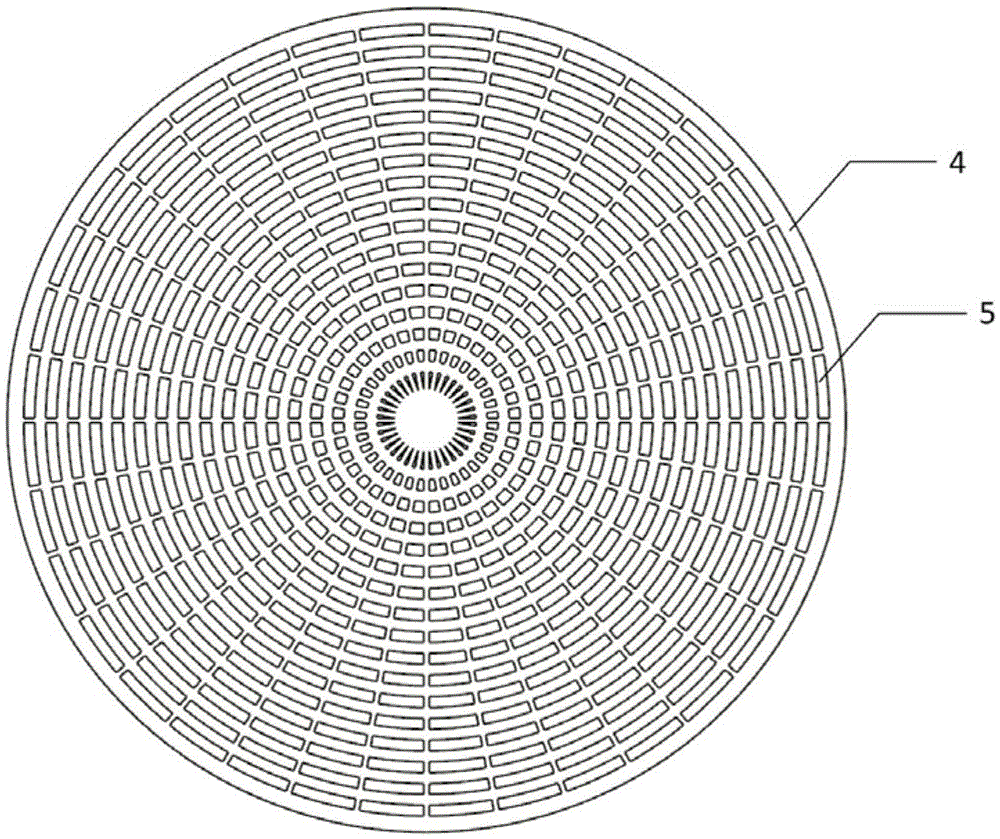

Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

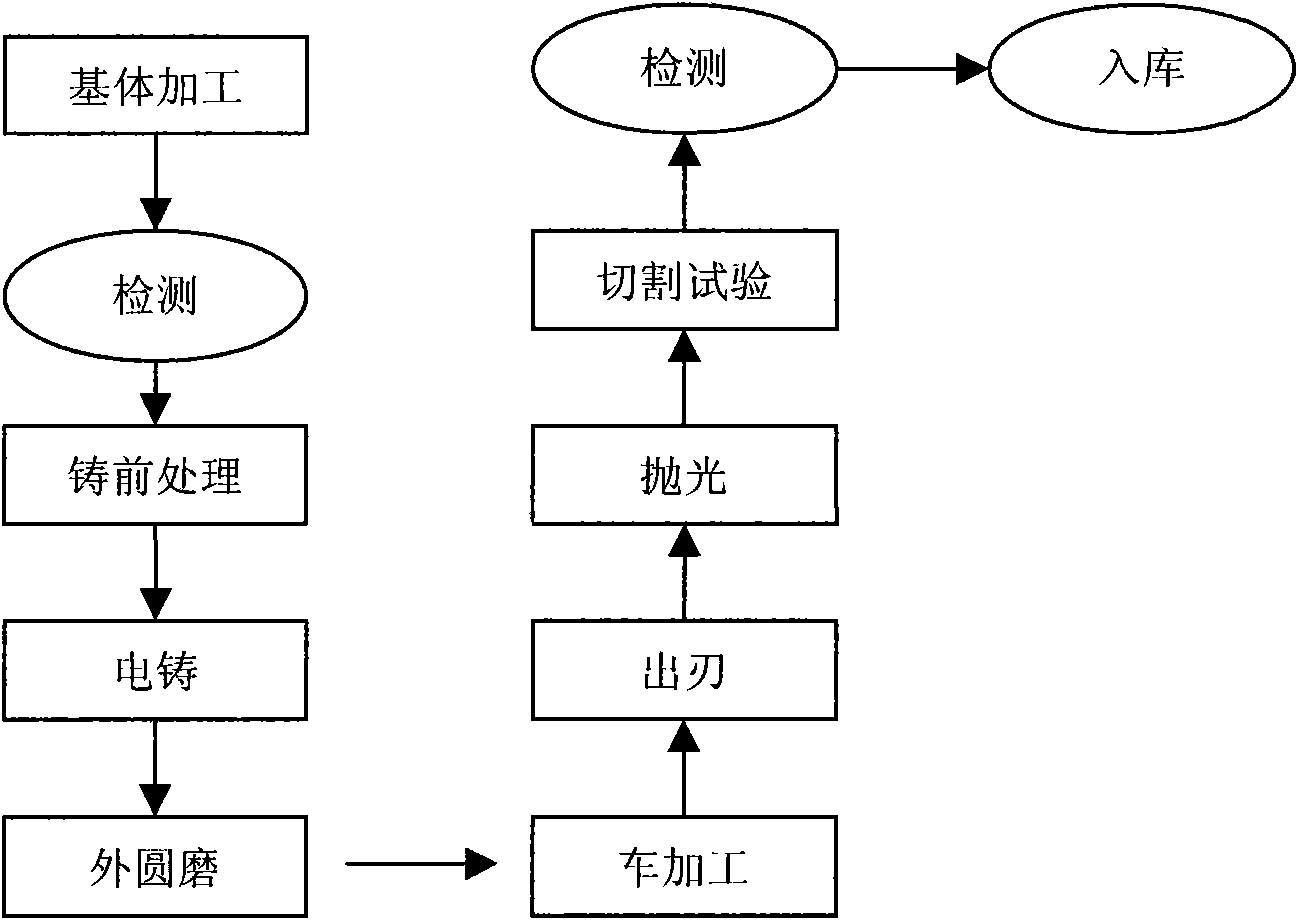

ActiveCN101633158AHigh strengthImprove rigidityGrinding devicesGrinding machinesNumerical controlCobalt sulphate

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal body obtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Owner:赛尔科技(如东)有限公司

Diamond grinding wheel for ceramic grinding and preparation method thereof

ActiveCN102335885AIncrease productivityReduce processing costsAbrasion apparatusGrinding devicesWear resistanceCeramic

The invention discloses a diamond grinding wheel for ceramic grinding and a preparation method thereof. The diamond grinding wheel consists of the following components in percentage by weight: 18.7 to 27 percent of diamond abrasive, 14 to 20 percent of polyimide resin, 8 to 13 percent of Cu powder, 9 to 14 percent of Co powder, 3 to 8 percent of Al2O3, 3 to 6 percent of rare earth, 0.7 to 1.2 percent of carbon black and the balance of Cr2O3. The preparation process for the diamond grinding wheel comprises the following steps of: (1) fully mixing the components; and (2) putting the mixture into a mold, heating, pressing, curing, and machining. The diamond grinding wheel can effectively overcome the defects of the conventional diamond grinding wheel, improving feed amount to 0.1-0.8mm each time during grinding, is difficult to block, has wear resistance of a grinding wheel, improves the production efficiency of zirconium oxide structural ceramic grinding, and greatly reduces the machining cost of zirconium oxide structural ceramic.

Owner:树熊新材料科技(河源)股份有限公司

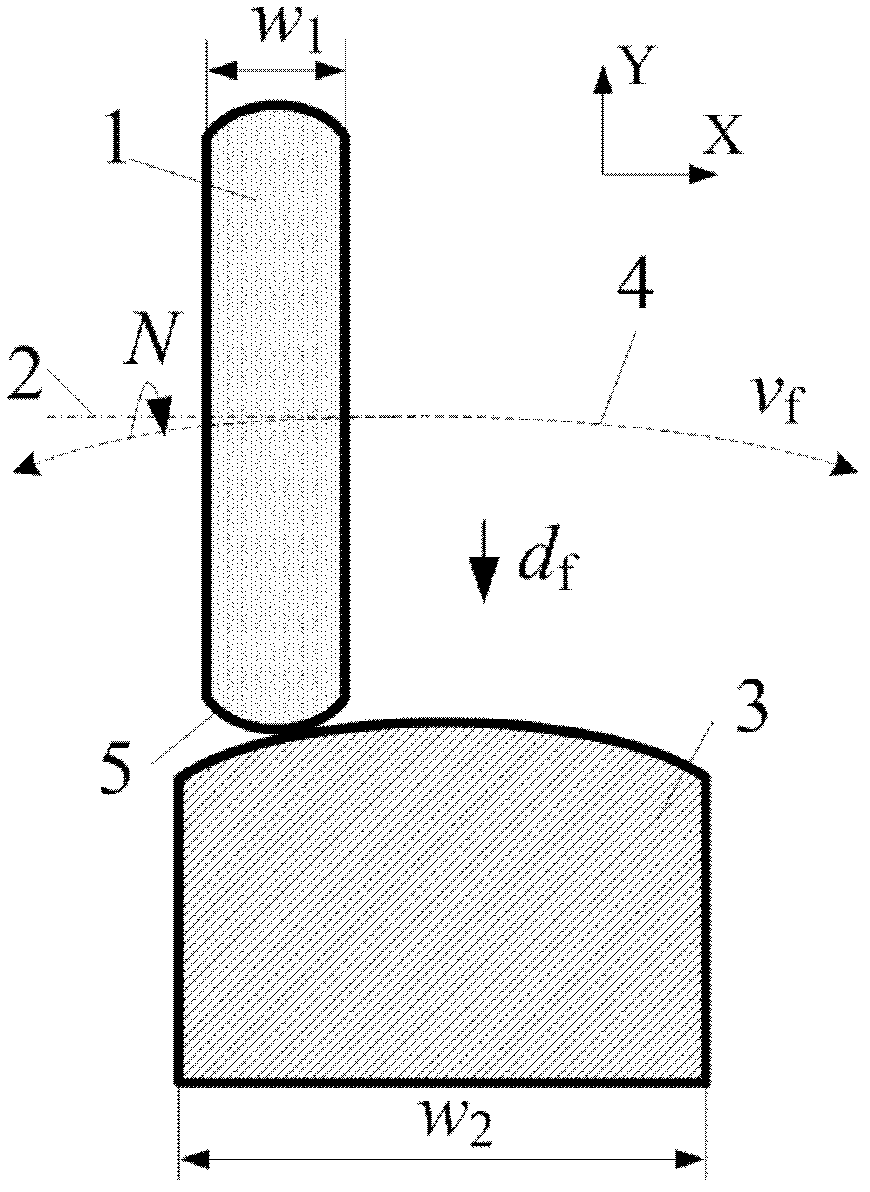

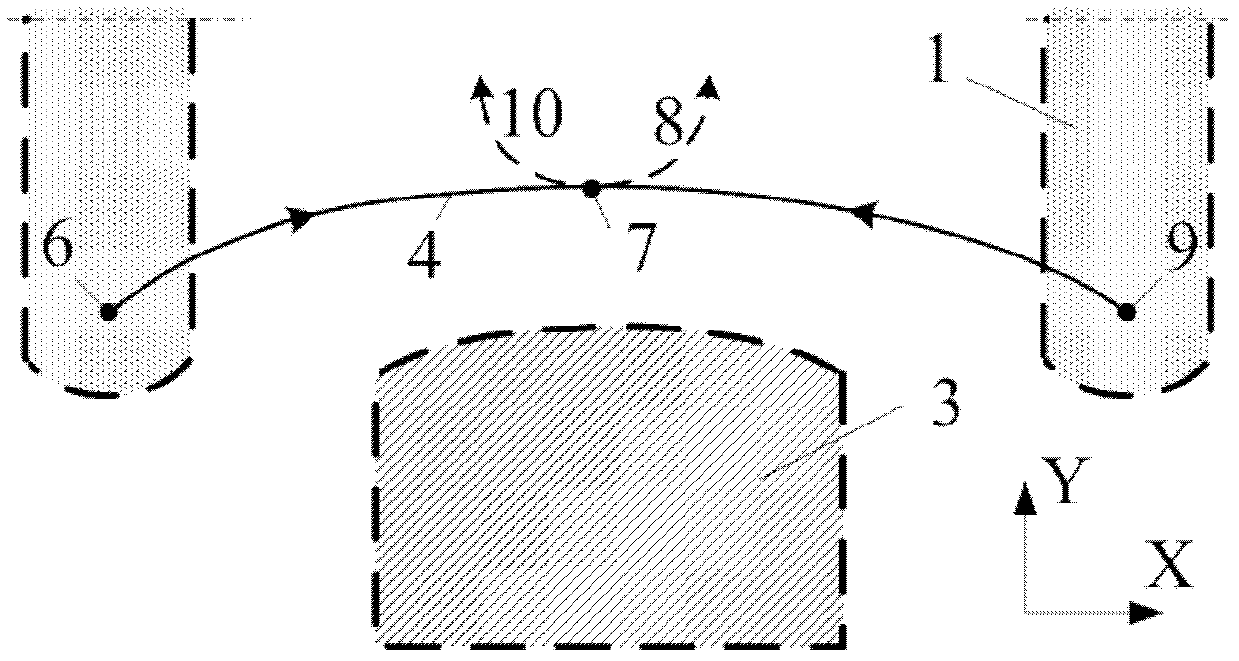

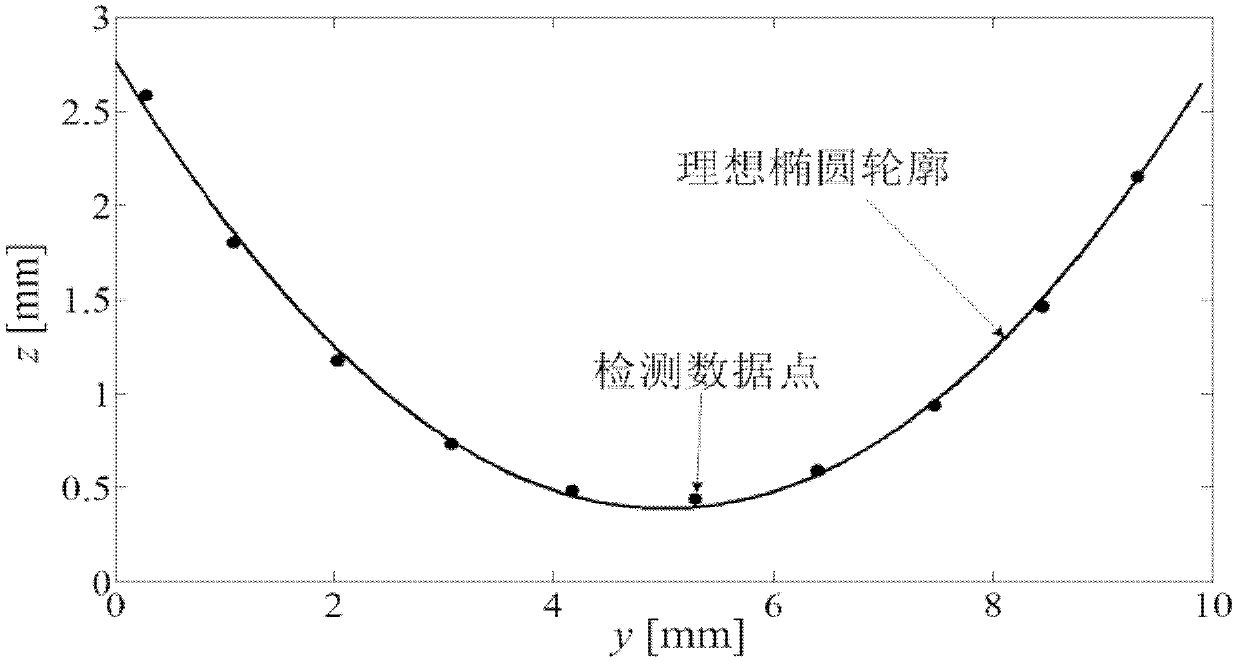

Diamond grinding wheel of elliptical working face and mutual wear forming and trimming method thereof

ActiveCN102350666AEasy to trimTrimming is effectiveAbrasion apparatusAbrasive surface conditioning devicesCarbide siliconStructural engineering

The invention discloses a diamond grinding wheel of an elliptical working face and a mutual wear forming and trimming method thereof. The profile of an axial section of a working face of the diamond grinding wheel is an elliptical arc profile; an end face of the diamond grinding wheel is an elliptical face; in the method, a diamond grinding wheel tool travels from left to right to a top point of an elliptical arc at a first starting point outside one side of a silicon carbide grinding stone along an elliptical arc traveling path, is then lifted along a first circular arc tangential to the top point and with a radius of more than 2mm, next travels from right to left to the top point of the elliptical arc from a second starting point outside the other side of the grinding stone along the elliptical arc traveling path and is lifted along a second circular arc tangential to the top point and with a radius of more than 2 mm. Compared with the conventional circular face diamond grinding wheel, the elliptical face diamond grinding wheel has the advantages that: a flatter grinding wheel elliptical working face and a workpiece curved surface can be used for complexing to grind, the number of effective grinding particles is increased, and the surface quality and the shape accuracy of curved surface grinding are improved.

Owner:SOUTH CHINA UNIV OF TECH

Metal ceramic composite binding agent and composite binding agent diamond grinding wheel

InactiveCN104128892AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesCeramic compositeCopper

The invention discloses a metal ceramic composite binding agent and a composite binding agent diamond grinding wheel manufactured by adoption of the metal ceramic composite binding agent. The metal ceramic composite binding agent is composed of, by weight, 65 percent to 75 percent of metal powder and 25 percent to 35 percent of ceramic powder. The metal powder is composed of, by weight, eight percent to ten percent of tungsten, five percent to eight percent of tin, five percent to eight percent of zinc, three percent to five percent of lead, and the balance copper. The ceramic powder is formed by mixing and melting, by weight, 40 percent to 50 percent of SiO2, 20 percent to 30 percent of Al2O3, 10 percent to 20 percent of K2O, five percent to 15 percent of MgO, and three percent to eight percent of Fe2O3. According to the composite binding agent diamond grinding wheel manufactured by adoption of the metal ceramic composite binding agent, the good sharp and self-sharpness characteristics of a ceramic composite binding agent diamond grinding wheel can be kept, and the high-rigidity and good-shape-maintaining advantages of a metal binding agent diamond grinding wheel are achieved.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

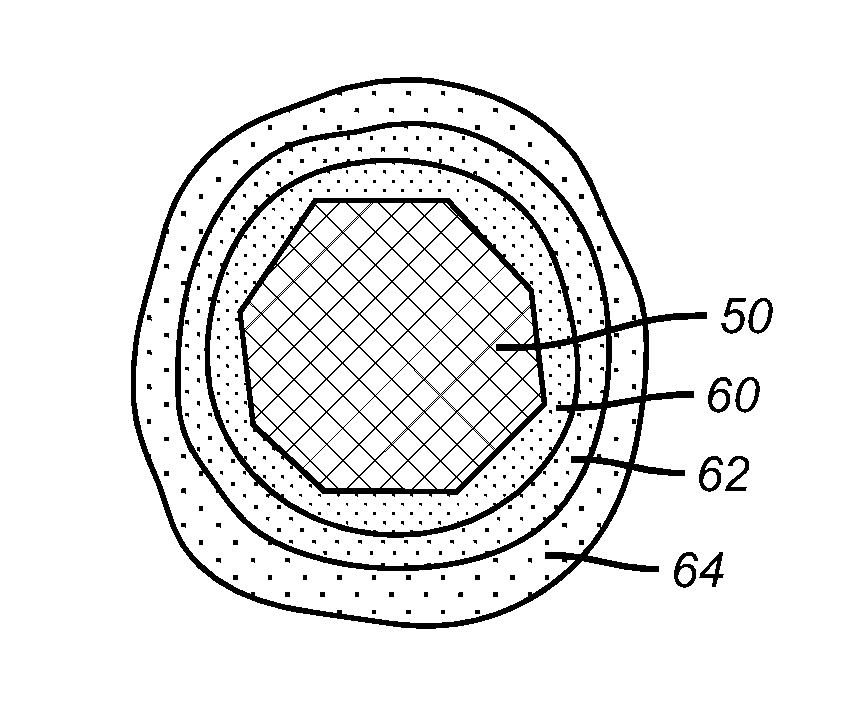

Downhole tool bearing system containing diamond enhanced materials

Downhole tool bearings are provided with diamond enhanced materials. The diamond enhanced materials comprise diamond grains in a matrix of tungsten or silicon carbide. A brazed diamond grit or diamond particles coated with a reactive braze may be utilized for bearing applications. Bearing rings formed at least in part with diamond enhanced material are installed on at least one of the bearing pin journal, the nose and the cone cavity. The bearing rings may be continuous rings or partial rings and attached to the journal pin or cone cavity. These may include thrust bearings, rollers, roller race, balls and ball races made of diamond enhanced material. These bearing surfaces also are formed at least in part with diamond enhanced material and attached to portions of the journal or cone bearing surfaces.

Owner:BAKER HUGHES INC

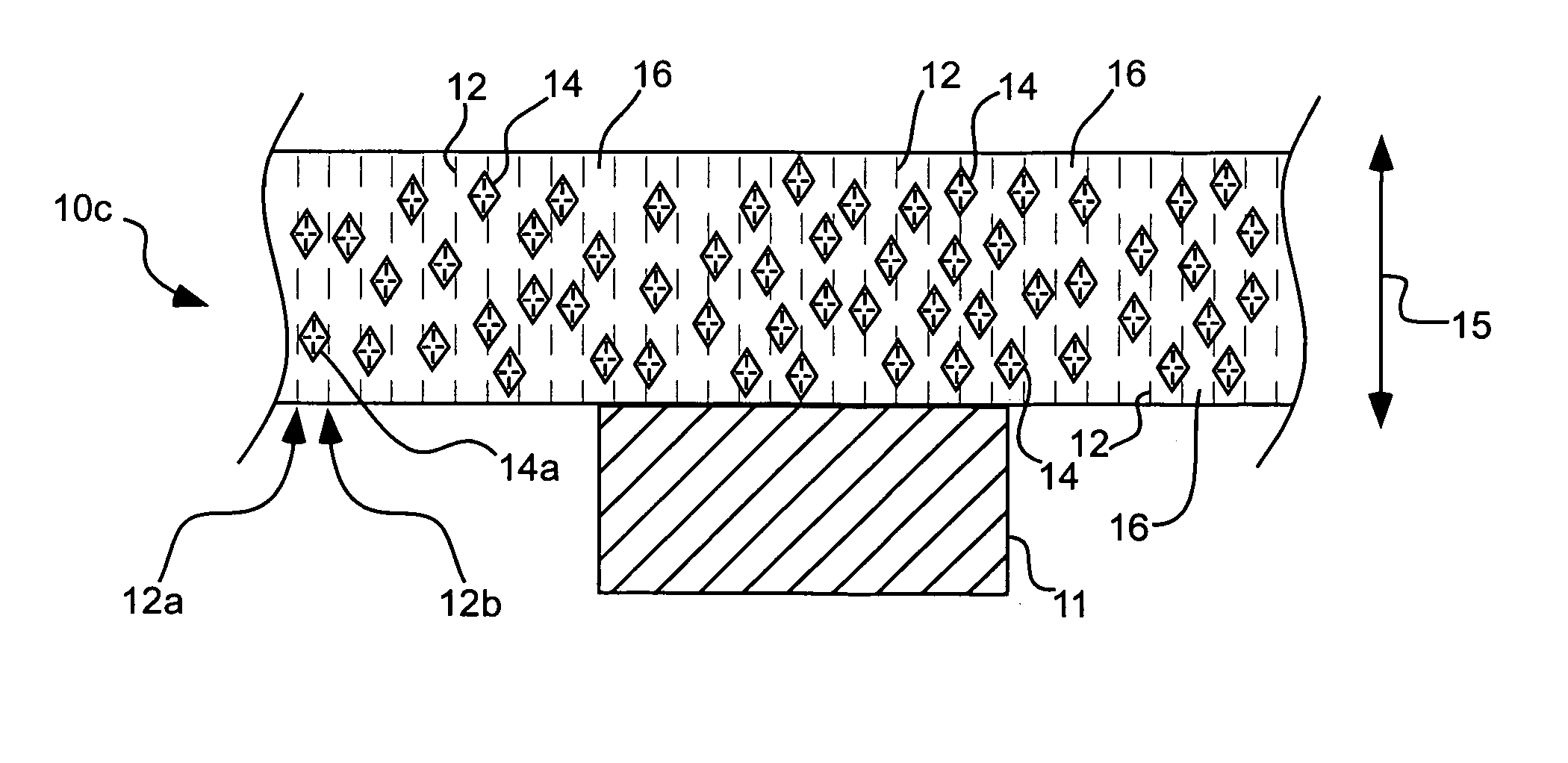

Diamond core drill bit

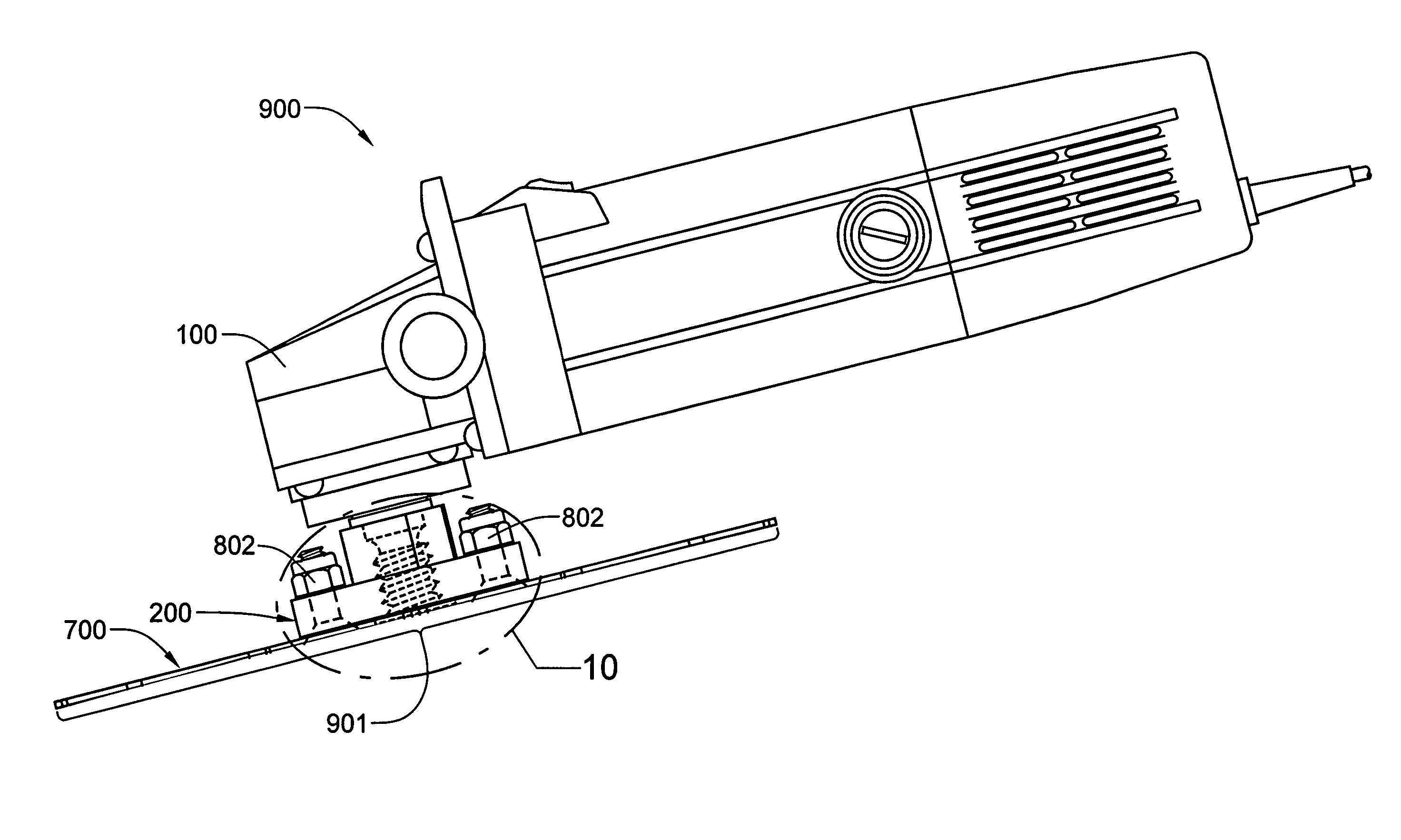

ActiveUS7204244B1Improve drilling efficiencyReduce wasteRevolution surface grinding machinesHoning machinesDrive shaftLubrication

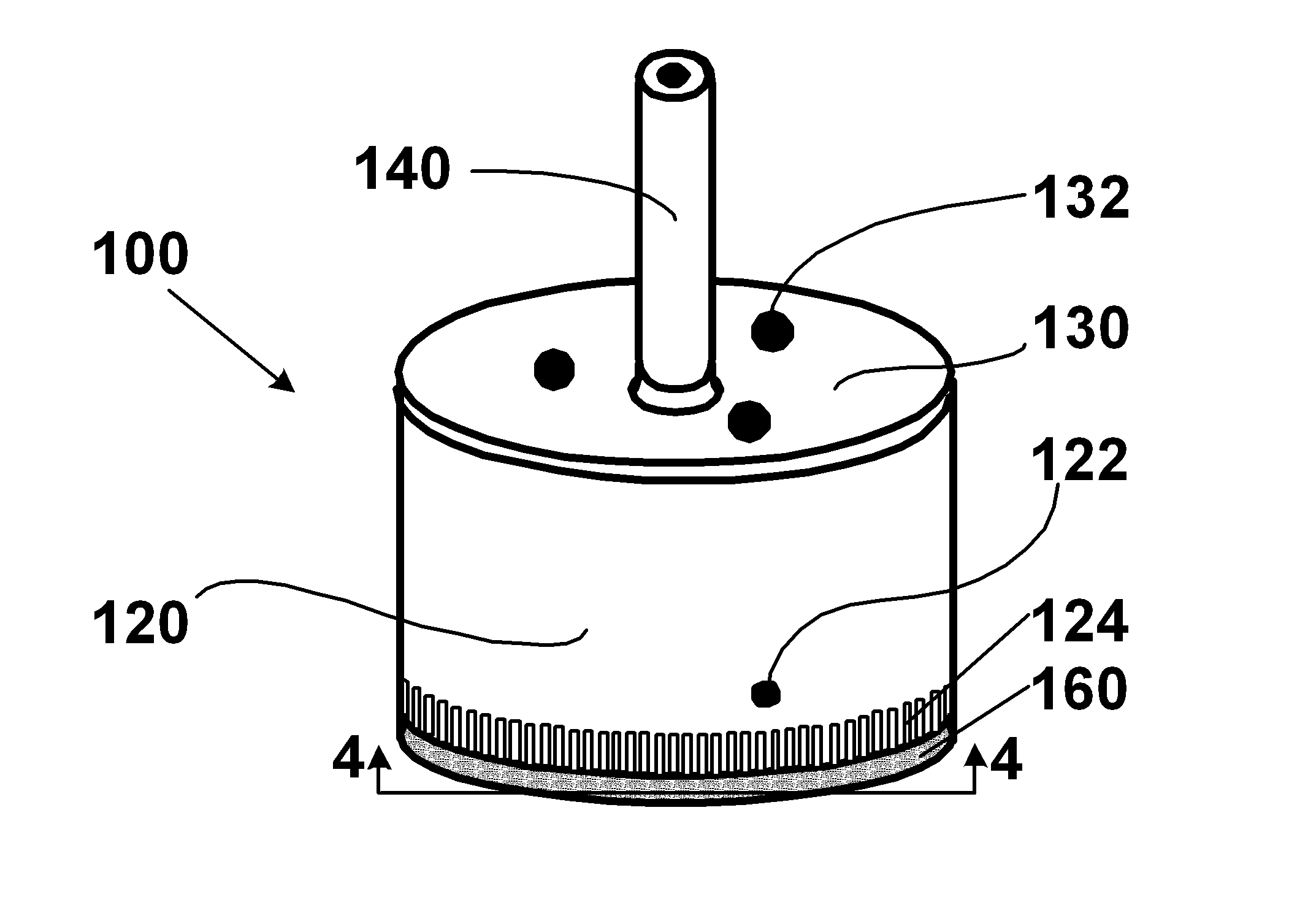

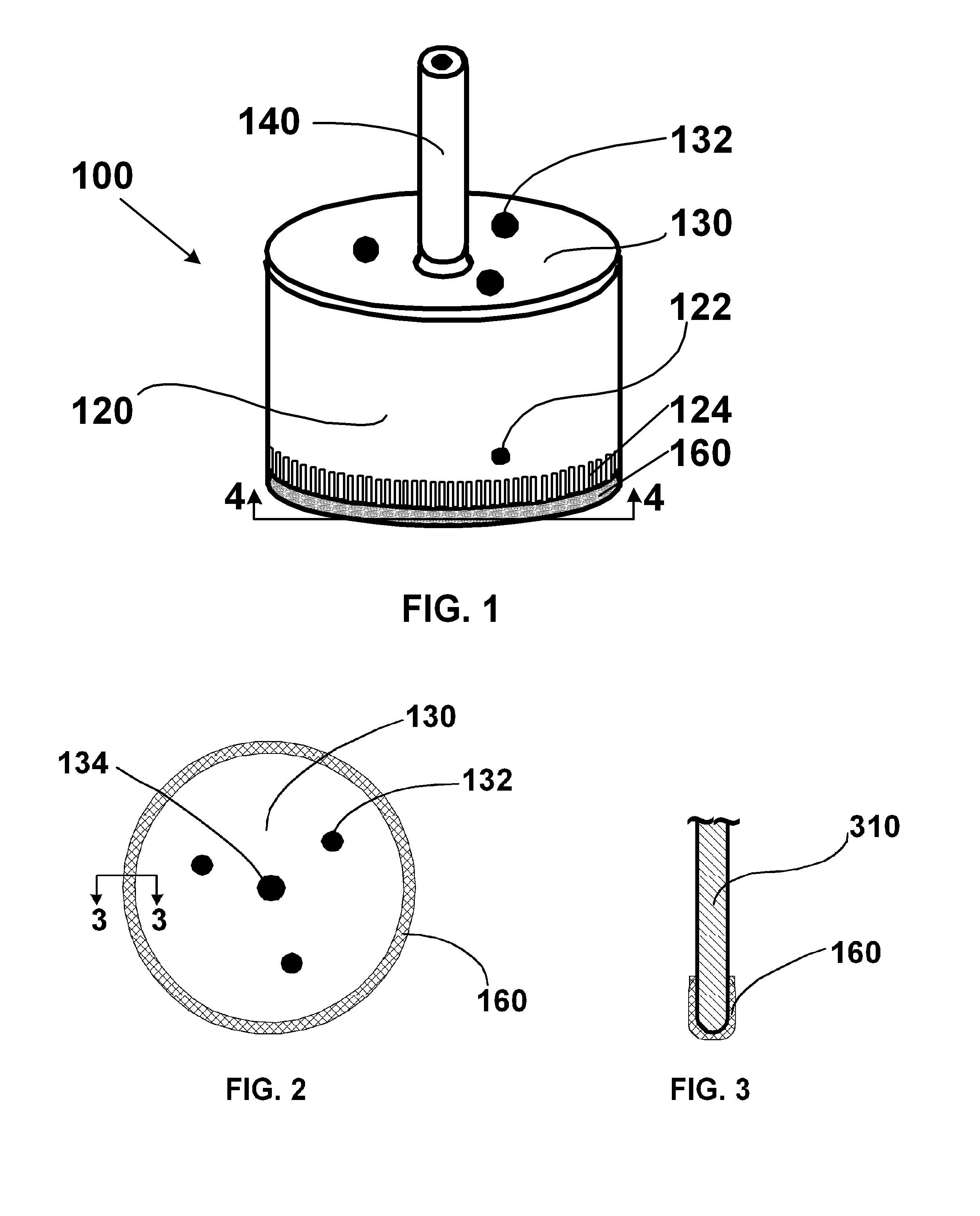

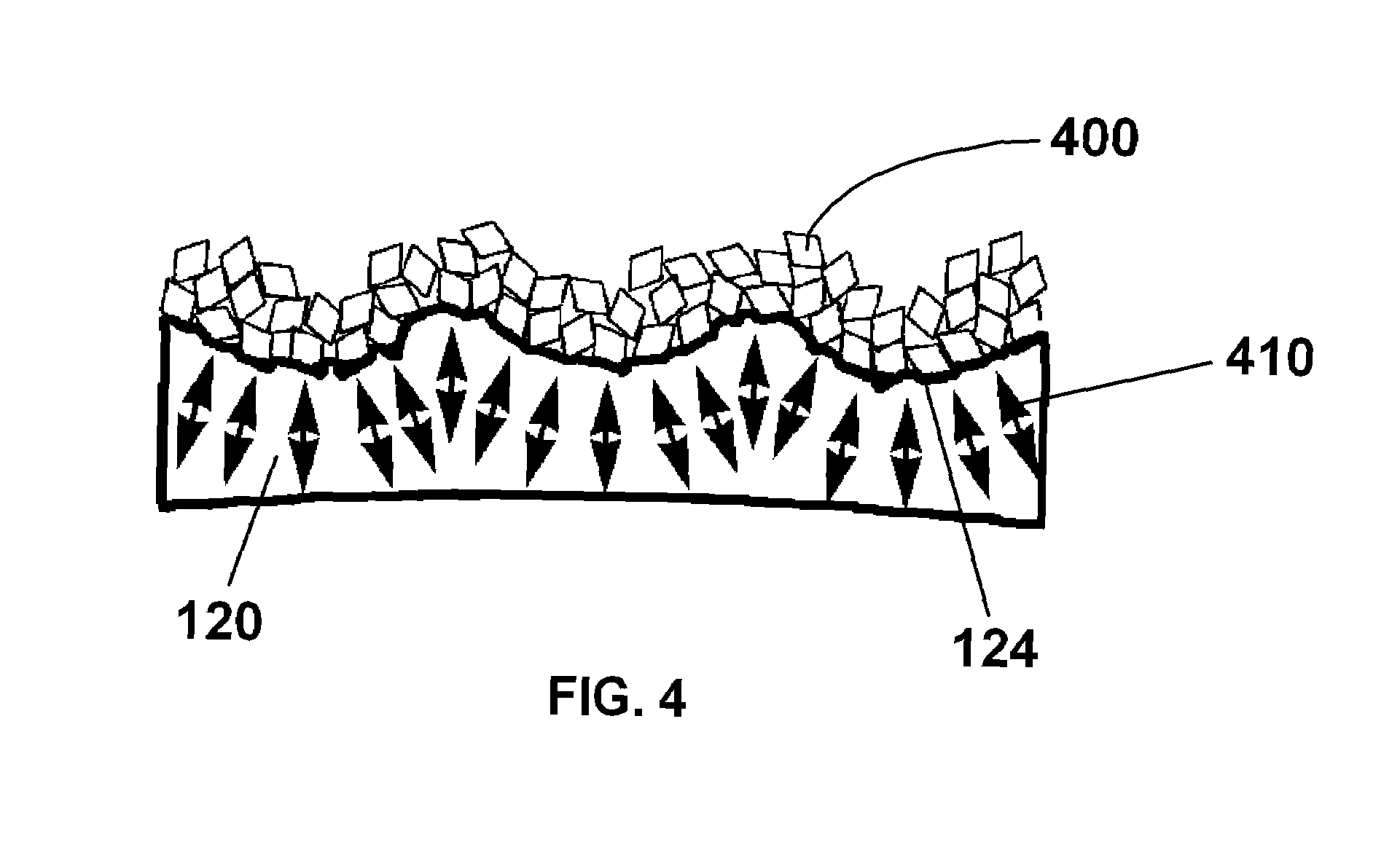

A diamond core drill bit (100) is disclosed. The drill bit has a right-circular cylindrical body (120) with at least one side lubrication hole (122) toward the bottom of the body and a plurality of parallel grooves (124) oriented in an axial direction at the bottom circumferential sidewall of the body. A cap (130) at the top of the cylindrical body (120) closes one end of the body. The cap has a central lubrication hole (134) and alternative embodiments have at least one core extraction hole (132). These holes extend through the cap to the interior of the body. A hollow drive shaft (140) is mated to the cap (130) over the central lubrication hole (134), such that a lubricant can flow through the hollow shaft and into the internal volume of the body and out a side lubrication hole (122). Diamond grit (160) is bonded around the bottom edge on a portion of the internal and external sidewall surfaces at the bottom circumferential edge of the body (120) in such a way that the diamond grit (160) is bonded over a portion of the axial height of the grooves (124).

Owner:LUMINARE SUPPLY CORP

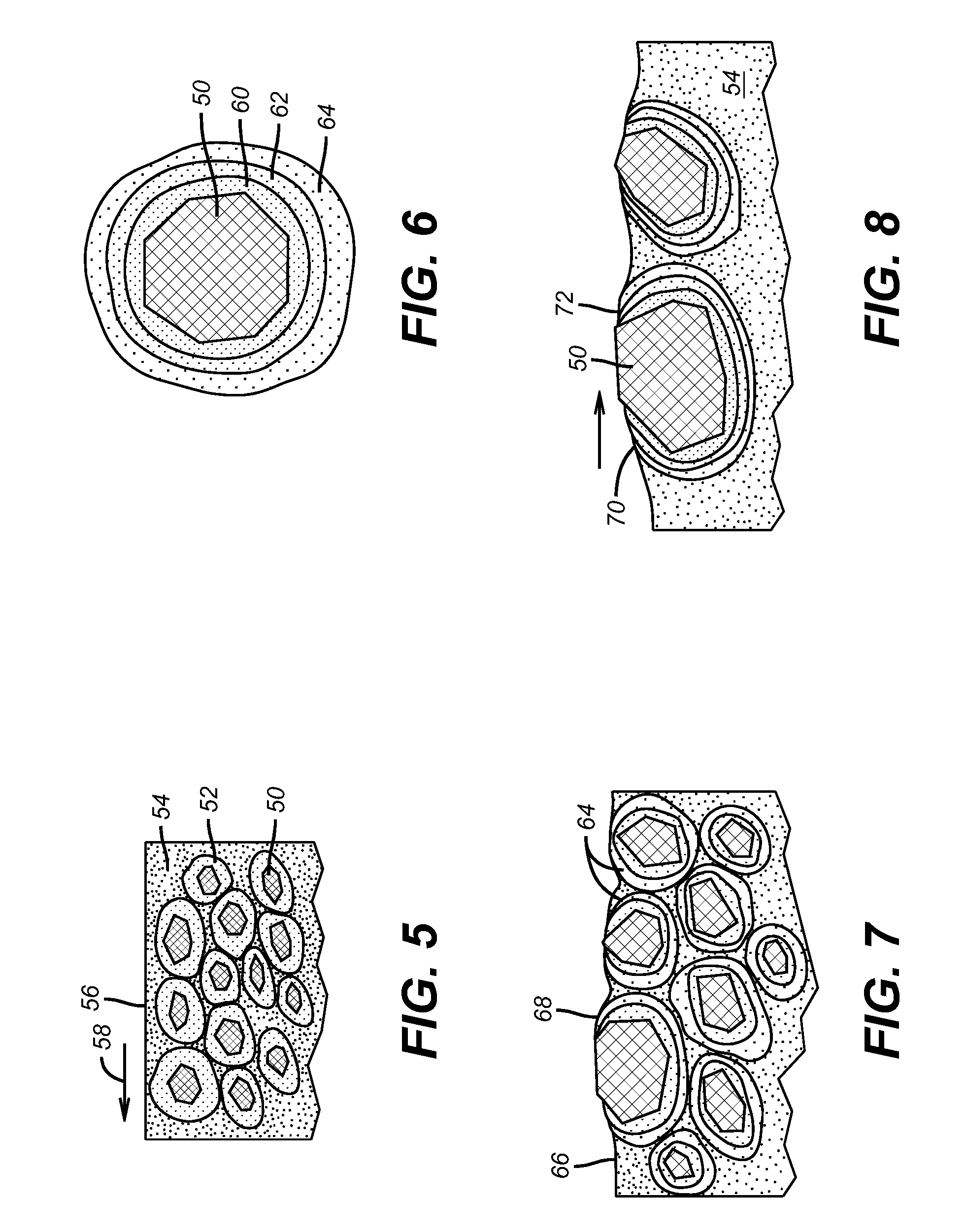

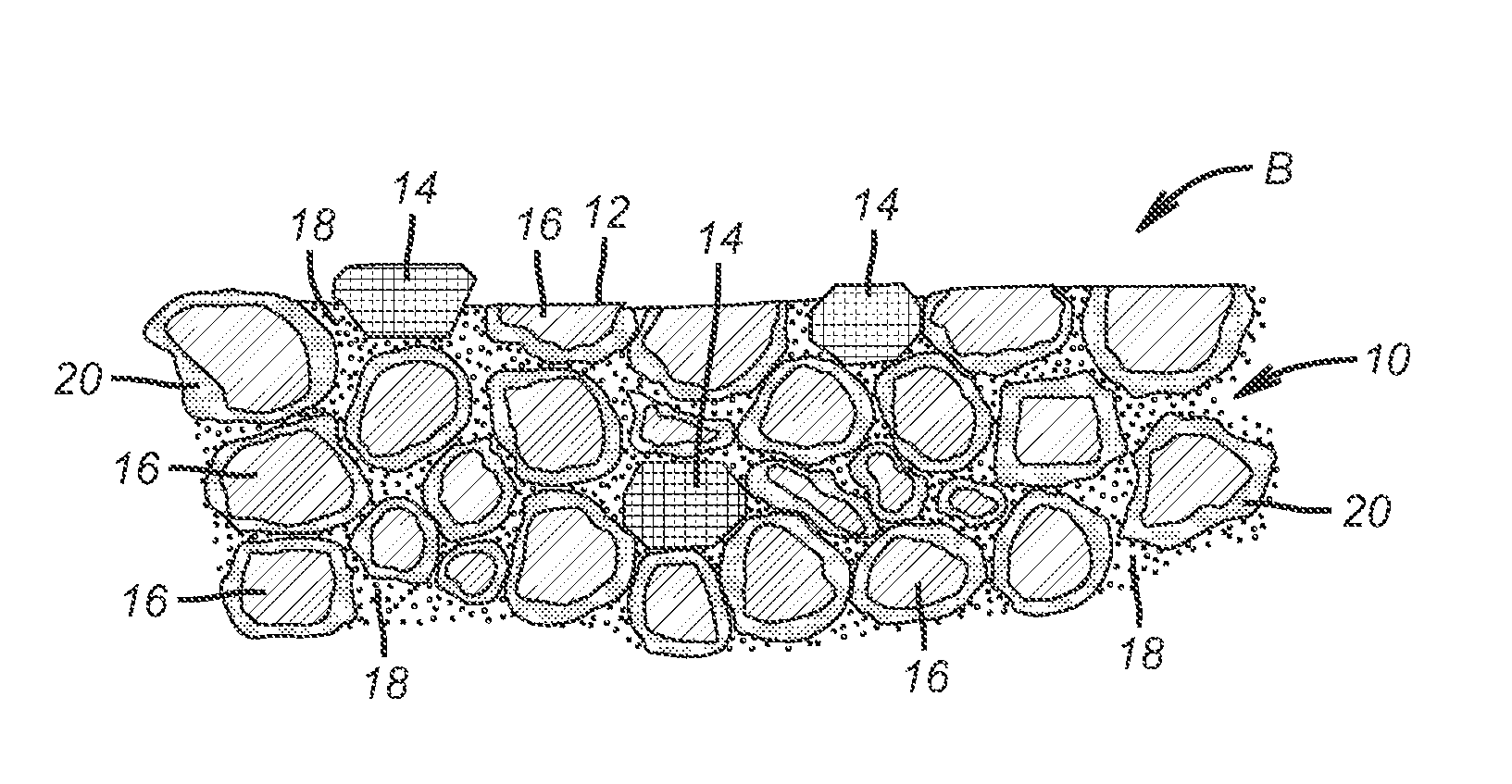

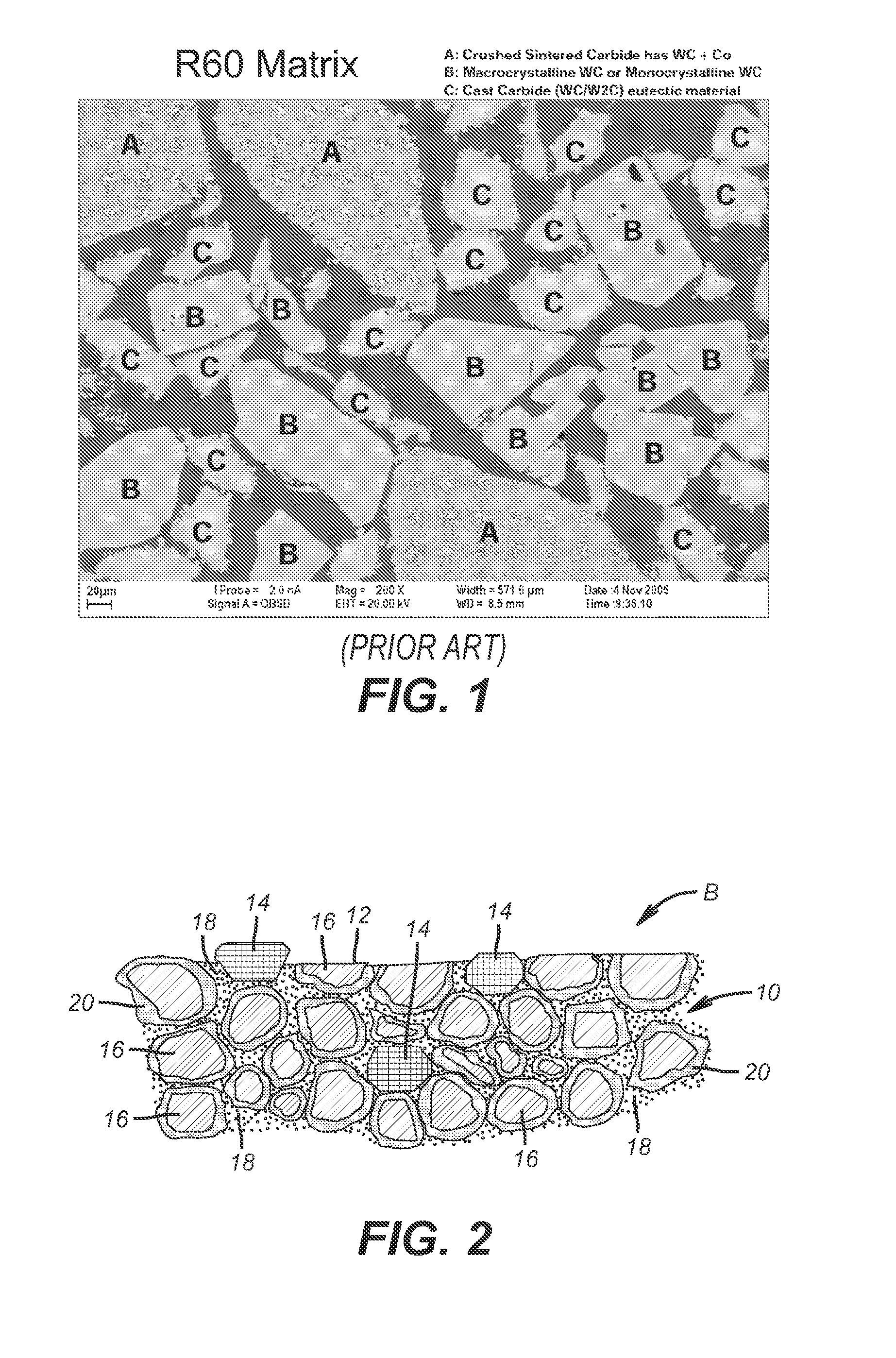

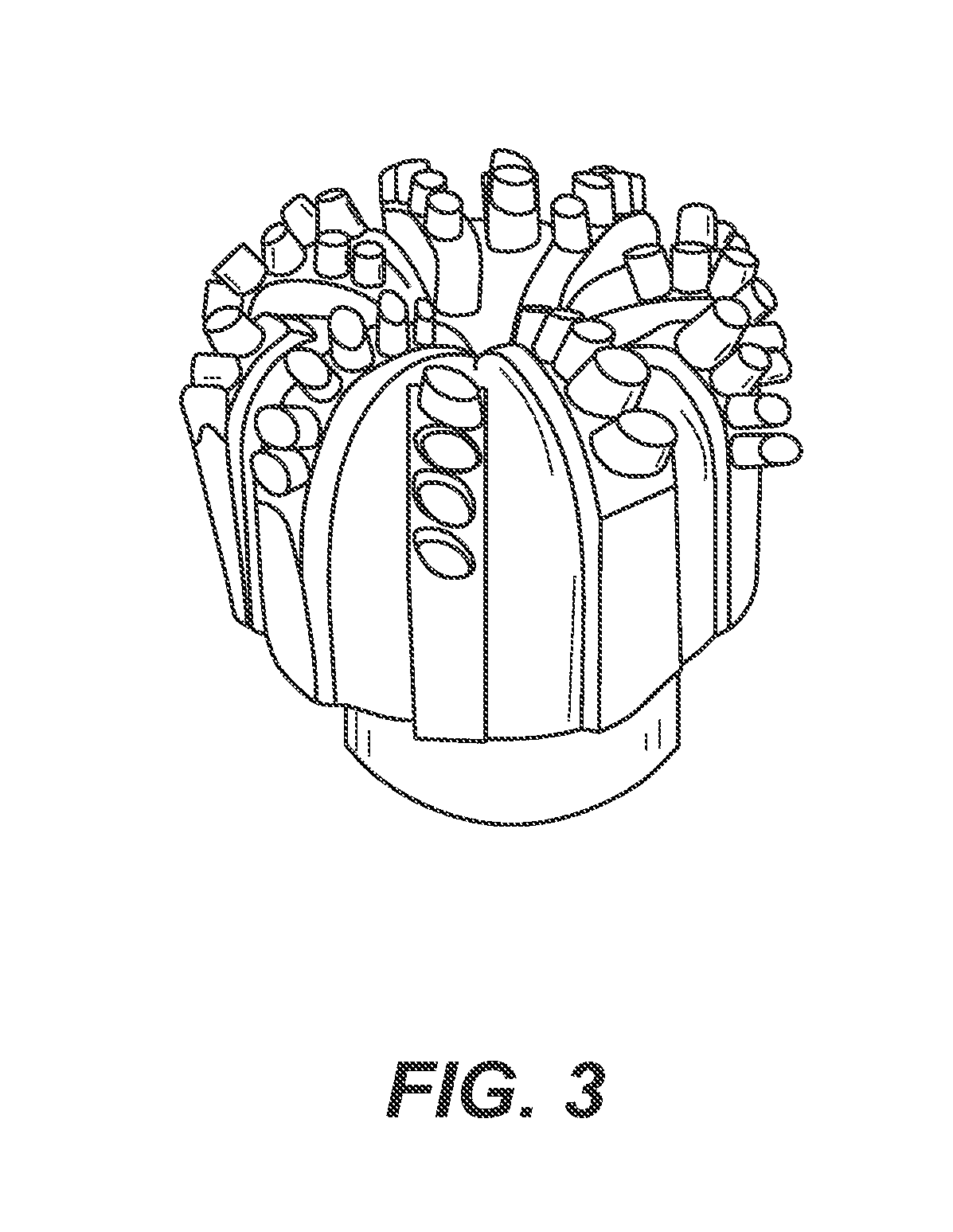

Impregnated bit with improved grit protrusion

A diamond impregnated drill bit features layered encapsulation of the diamond grit where the innermost layer is hardest or most abrasion resistant while succeeding layers are generally softer and less wear resistant. This can be accomplished by manipulating several variables in the encapsulation layers such as particle size or hard particle concentration. The outer layers can have added binder to make them softer. The encapsulated grit can be sintered or pre-sintered to make it less friable when handled.

Owner:BAKER HUGHES INC

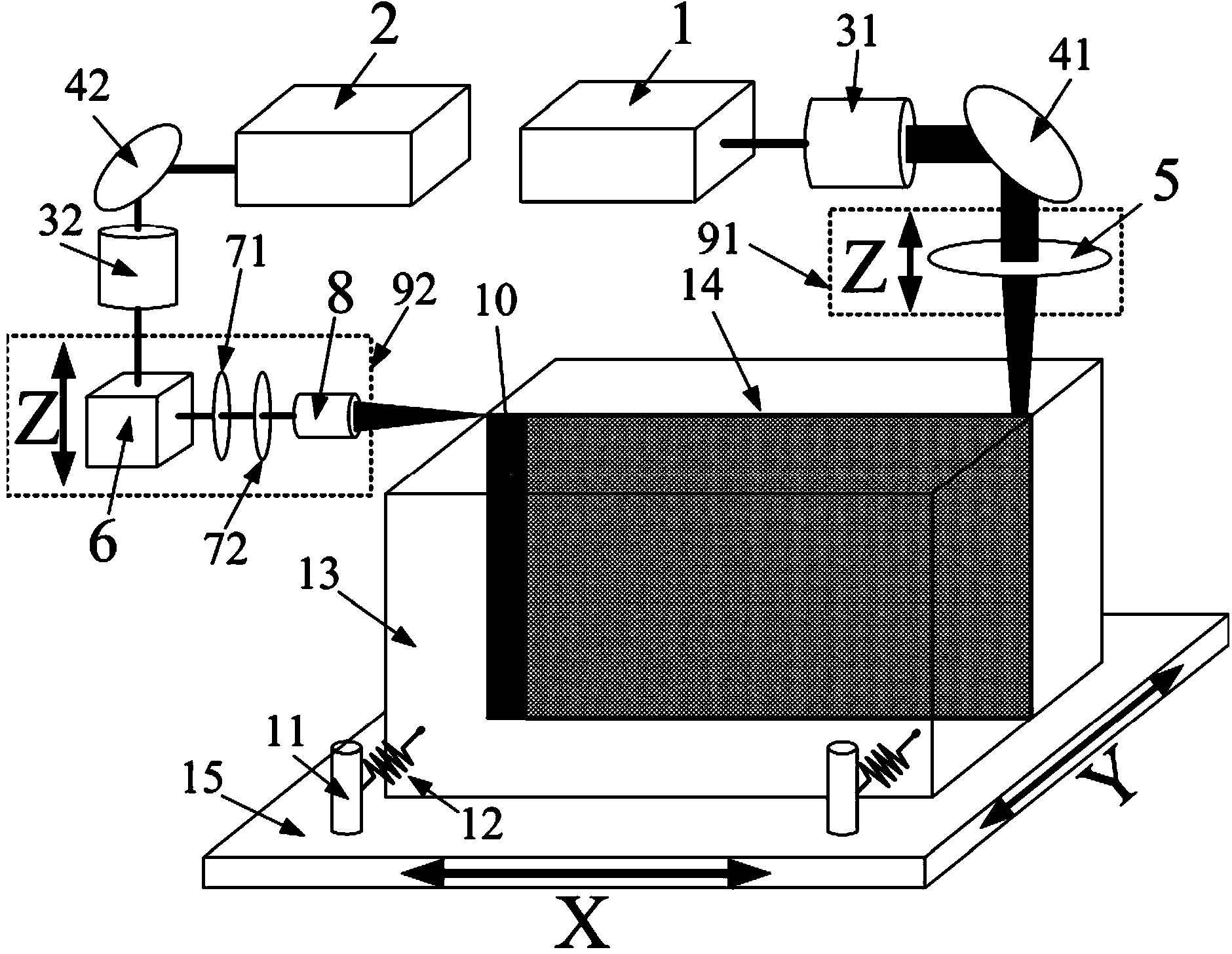

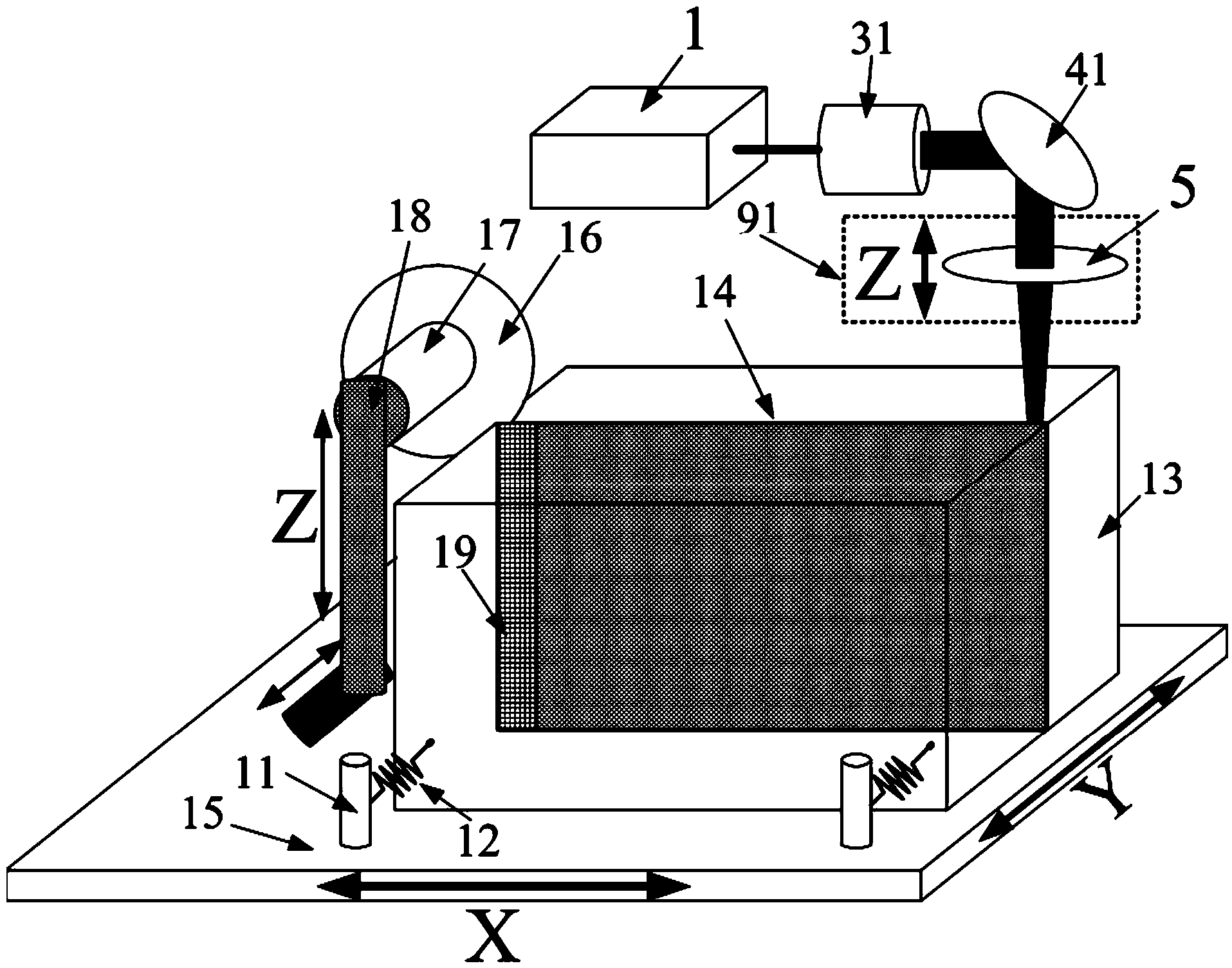

Method and device for quickly separating optical crystals by using laser light

ActiveCN103831527ARelieve mechanical stressPrecise Separation SizeWelding/soldering/cutting articlesLaser beam welding apparatusLaser lightThermal expansion

The invention discloses a method for quickly separating optical crystals by using layer light. The method comprises the following steps of setting the separating direction of the optical crystals by using ultrafast laser light or a miniature diamond grinding wheel; forming a precast microcrack with the direction along a to-be-separated path at a separation starting end; performing scanning heating on the preformed microcrack by using focusing laser light to form a laser-induced microcrack; quickly moving the focusing laser light along the to-be-separated path until the laser moving speed is the same with the crack expansion speed; enabling the focusing laser light to always follow the foremost end of the microcrack; performing thermal expansion effect on materials on two sides of the microcrack; generating forward squeezing force and lateral pulling stress on the tip of the microcrack; and pulling materials of the crystals so as to realize high-quality separation of the crystals. A device comprises a microcrack preforming mechanism, a single-focus-point laser machining system and a two-dimensional worktable. By using the method and the device, the separation speed, the separation accuracy, the machining safety and the machining quality of the optical crystals can be improved, non-loss separation of the optical crystals is realized, and a quasi-polishing-level finishing separation surface is formed.

Owner:武汉飞能达激光技术有限公司

Diamond grinding wheel

ActiveCN106625296AHigh thermal conductivityGood grinding temperatureAbrasion apparatusGrinding devicesSuperhard materialHigh load

The invention relates to the field of superhard materials, in particular to a diamond grinding wheel which is excellent in impact resistance and shape retention, can bear higher load during a high-speed grind process, and comprises a steel core and an abrasive material ring adhered together through a resin adhesive; the abrasive material ring is characterized by being prepared from the following raw materials in mass percent: 25-50% of diamond abrasive material, 44-72% of a metallic bond and 3-6% of an auxiliary adhesive. The diamond grinding wheel has excellent heat conductivity to facilitate reduction of grinding temperature so as to reduce power loss and increase grinding speed; the auxiliary adhesive in the formula facilitates formation of pores, and the characteristic of high holding force of the metallic bond is combined, so that the chip space can be effectively increased, and the utilization of the abrasive material is more sufficient; and the grinding wheel has the characteristics of high grinding efficiency, low grinding temperature and power loss, high machining precision and long service life.

Owner:磐维科技(青岛)有限公司

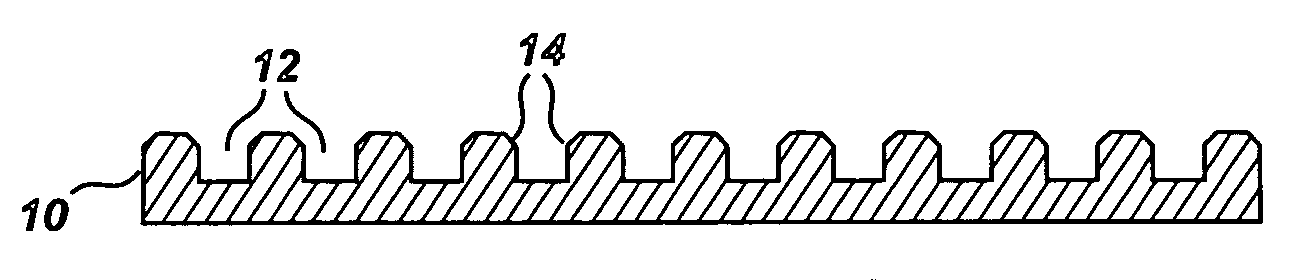

Cutting disk for forming a scribed line

ActiveCN101730616AGlass severing apparatusStone-like material working toolsEngineeringMechanical engineering

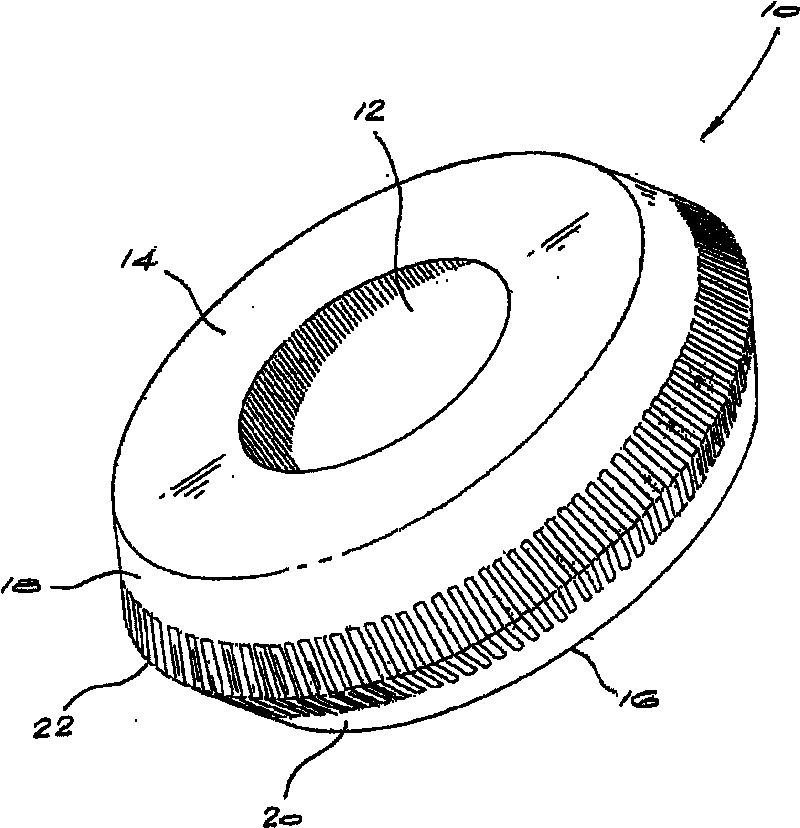

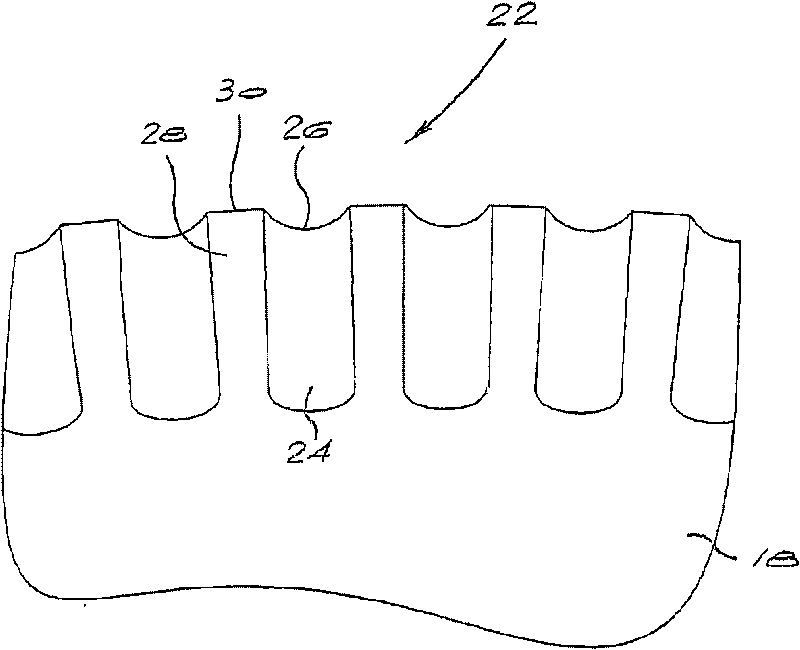

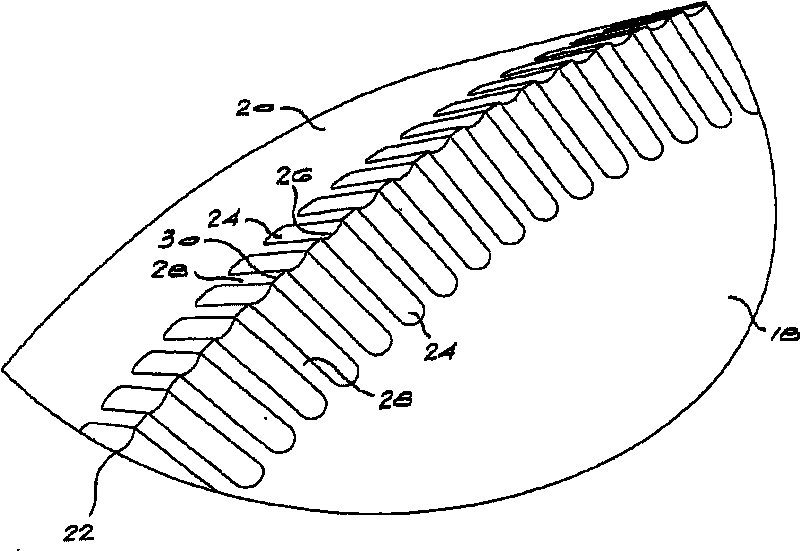

A cutting disk is provided for. forming a scribed line on a surface of a body or object. The cutting disk comprises a disk shaped body (10) having a peripheral portion having first and second circumferentially extending tapered surfaces (18,20) that converge radially outwardly. The peripheral portion defines a scribing edge (22) with adjacent raised (30) and recessed (26) circumferentially extending cutting elements. A plurality of outwardly extending grooves (24) are formed in the first and second tapered surfaces (18, 20), and the outer ends of opposed- grooves (24) in the respective tapered surfaces (18, 20) being aligned to define between them the recessed (26) cutting elements. As a result, the scribing edge (22) defined by the cutting disk is a continuous sharp edge having alternating raised (30) and recessed (26) cutting elements, aligned circumferentially with one another. The cutting disk can be manufactured ' from sintered or cemented diamond grit, or other hard materials. Apparatus and a method for manufacturing the cutting disks' are also disclosed.

Owner:劲钻科技股份有限公司

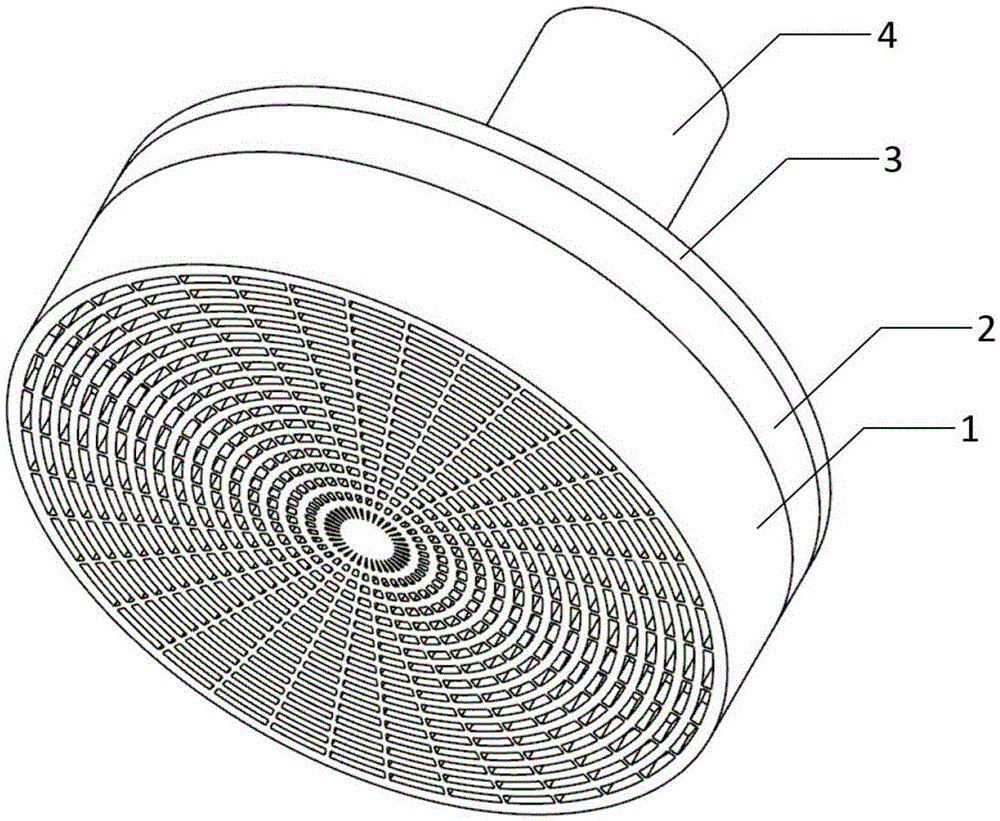

Metal bond-containing arachnoid plane diamond grinding wheel and 3D printing production process thereof

InactiveCN105563352AImprove cooling effectSolve the blockageAdditive manufacturing apparatusAbrasion apparatusCooling effectTransition layer

The invention relates to a metal bond-containing arachnoid plane diamond grinding wheel and a 3D printing production process thereof, and belongs to the field of machining. According to the invention, an arachnoid working layer is composed of solids and gaps in a manner of being distributed on the working surface of the working layer along a radial direction and a peripheral direction, directly produced on a transition layer by virtue of a laser sintering 3D printing technology, and form the integrated plane diamond grinding wheel with the transition layer and a metal matrix. A precise arachnoid structure is realized on the working surface of the plane grinding wheel by virtue of 3D printing, the gaps are provided, and intermittent grinding is realized; the heat dissipation and cooling effects can be effectively improved; the thermal damages of grinding machining are reduced and the grinding efficiency is improved; and the problem of blockage of the grinding wheel can be effectively solved.

Owner:CENT SOUTH UNIV

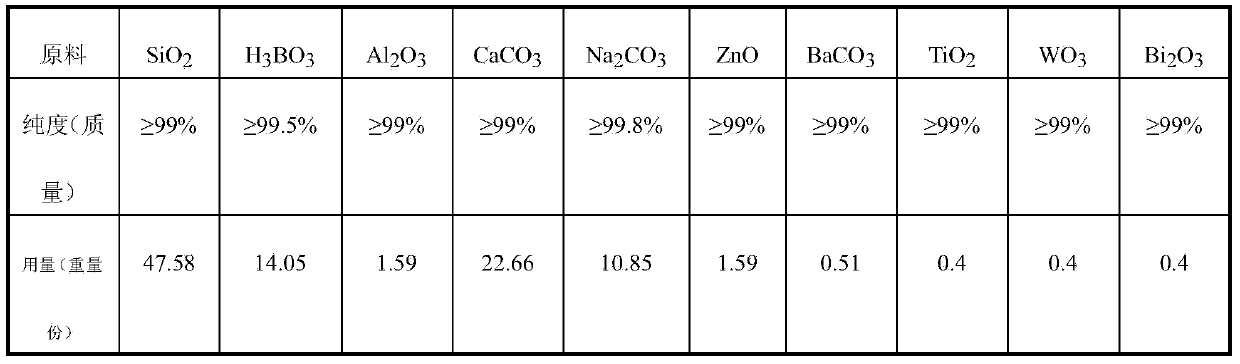

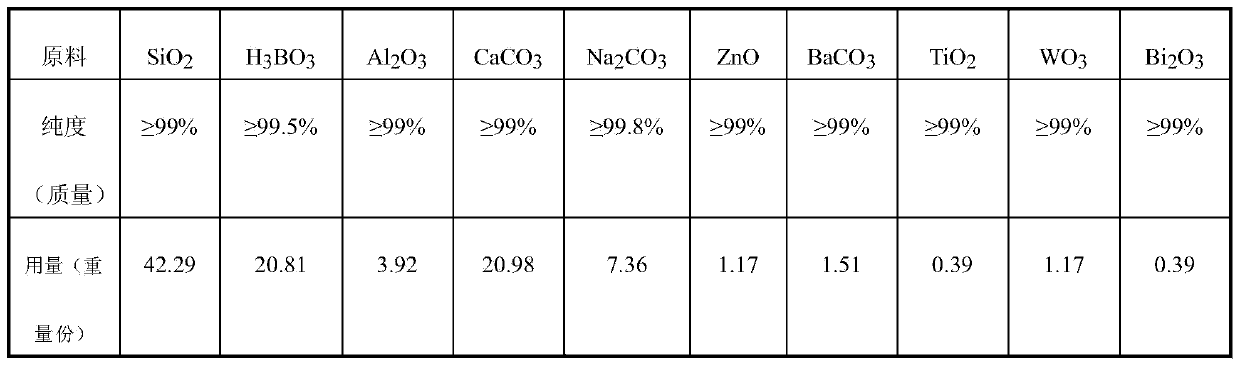

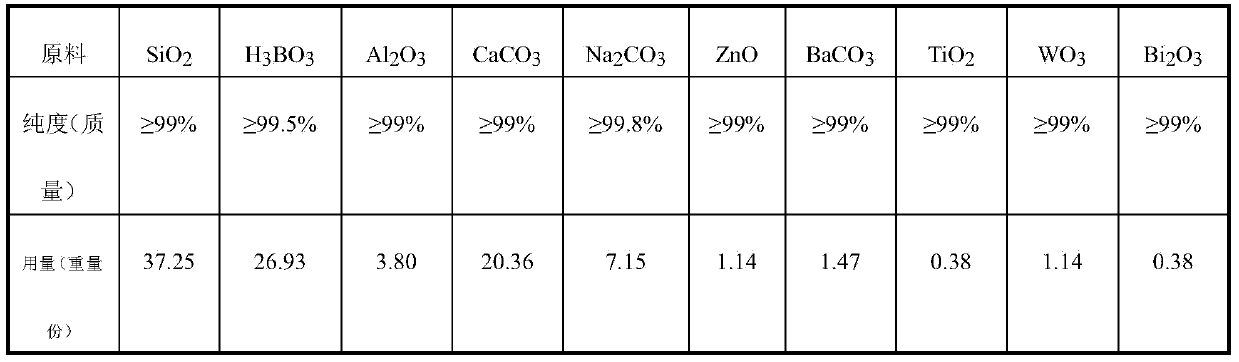

Method for preparing diamond grinding wheel ceramic bond with low sintering temperature and high strength

InactiveCN103770035ASolve complexitySolve the costAbrasion apparatusGrinding devicesBoron trioxideTungsten trioxide

The invention provides a method for preparing diamond grinding wheel ceramic bond with low sintering temperature and high strength. The method includes the following steps of (1) mixture calculation, (2) melting and (3) water quenching and grinding, wherein the step (1) includes that raw mineral materials and chemical materials are used as the source of oxide, the mixture calculation is performed according to the oxide and the content thereof in the raw mineral materials and the chemical materials, and oxide compositions and contents thereof by weight part in the materials meet the following requirement, that is to say 40-60 parts of silicon dioxide, 10-30 parts of diboron trioxide, 2-6 parts of aluminum oxide, 12-16 parts of calcium oxide, 2-8 parts of sodium oxide, 0.5-2 parts of zinc oxide, 0.5-1.5 parts of barium oxide, 0.5-1 part of titanium dioxide, 0.5-2 parts of tungsten trioxide and 0.5-1 part of bismuth oxide, and after the step (3), the diamond grinding wheel ceramic bond with the low sintering temperature and the high strength can be obtained. The method is simple in preparing process and low in costs, and the obtained diamond grinding wheel ceramic bond is good in performances.

Owner:WUHAN UNIV OF TECH

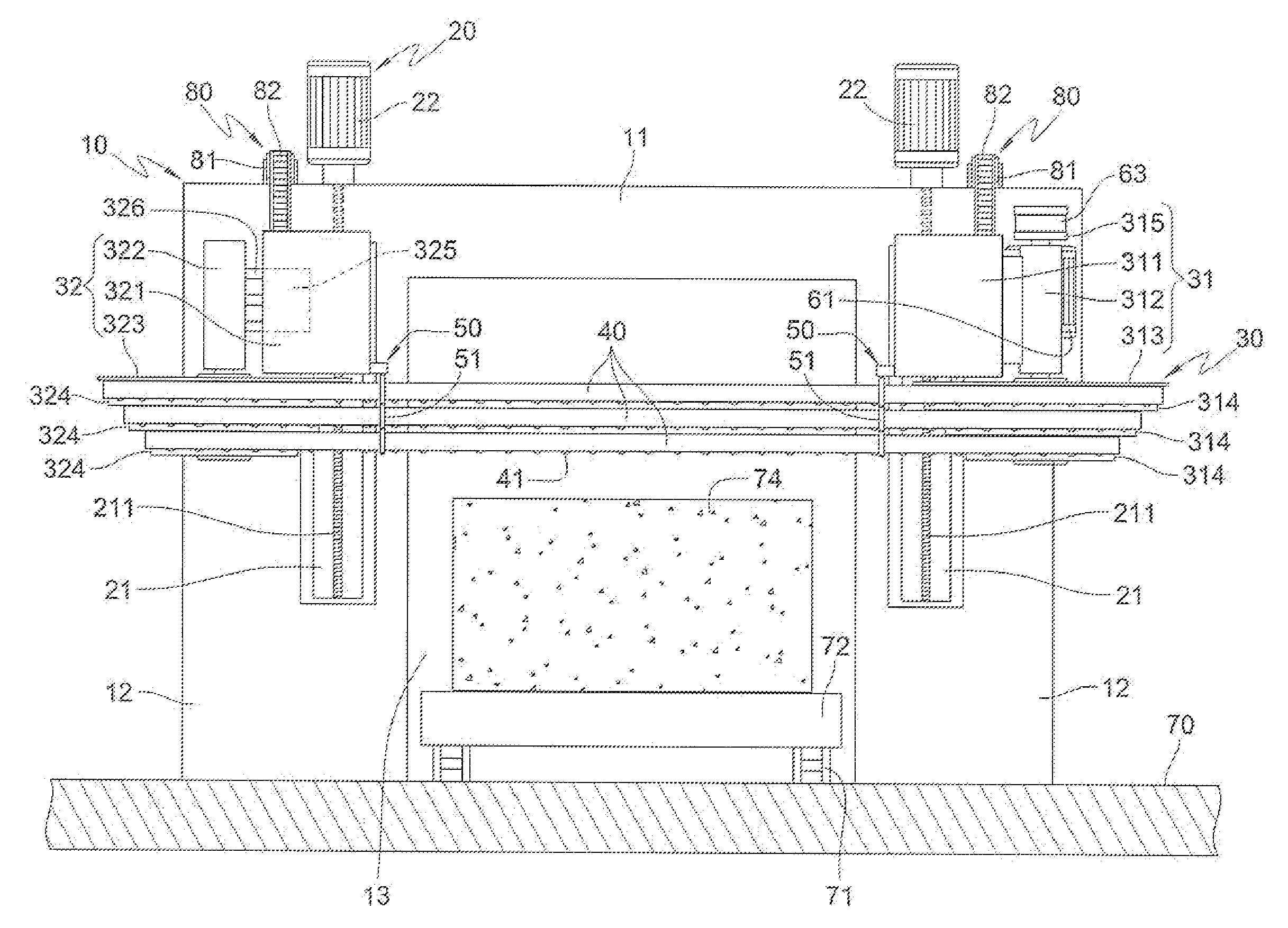

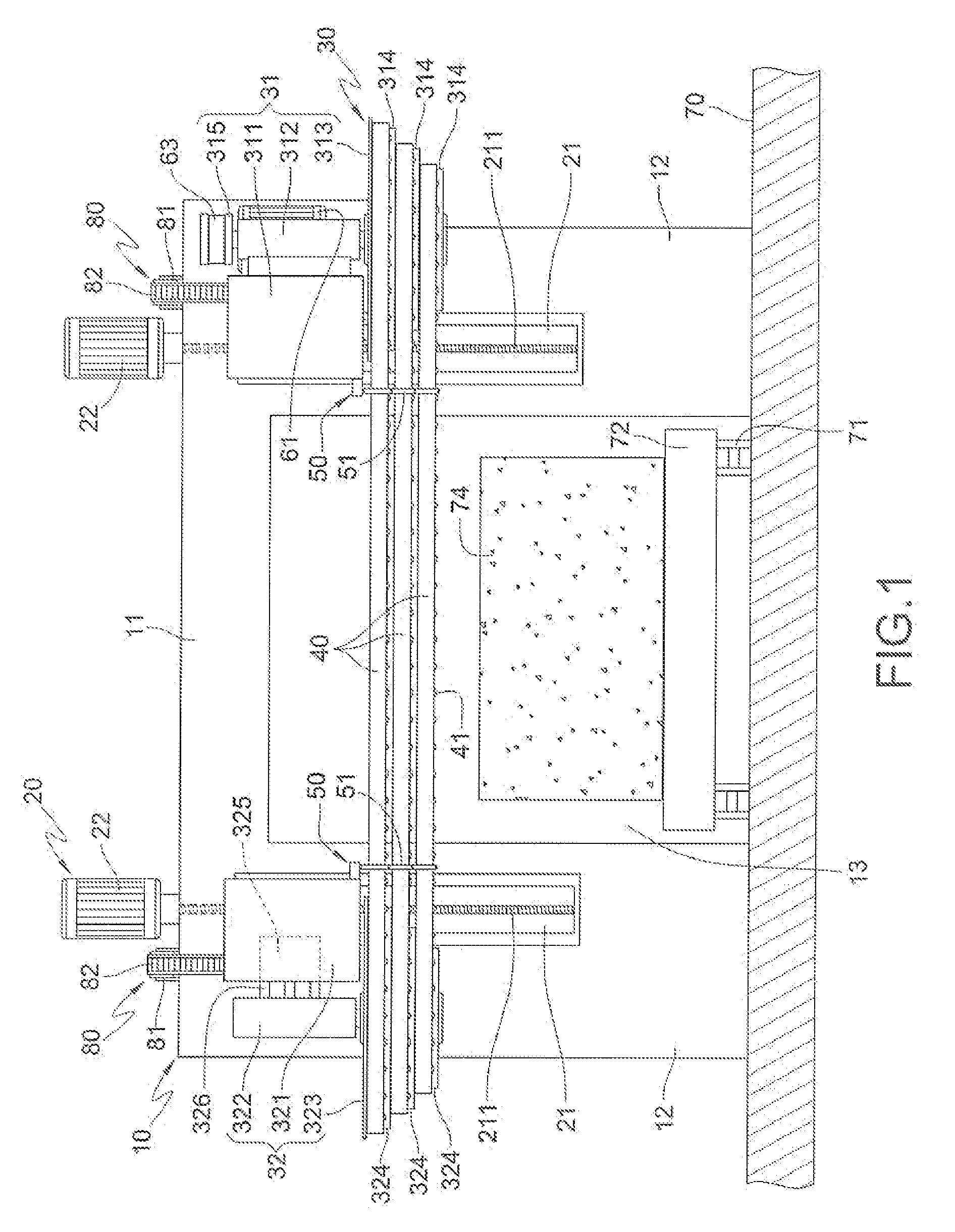

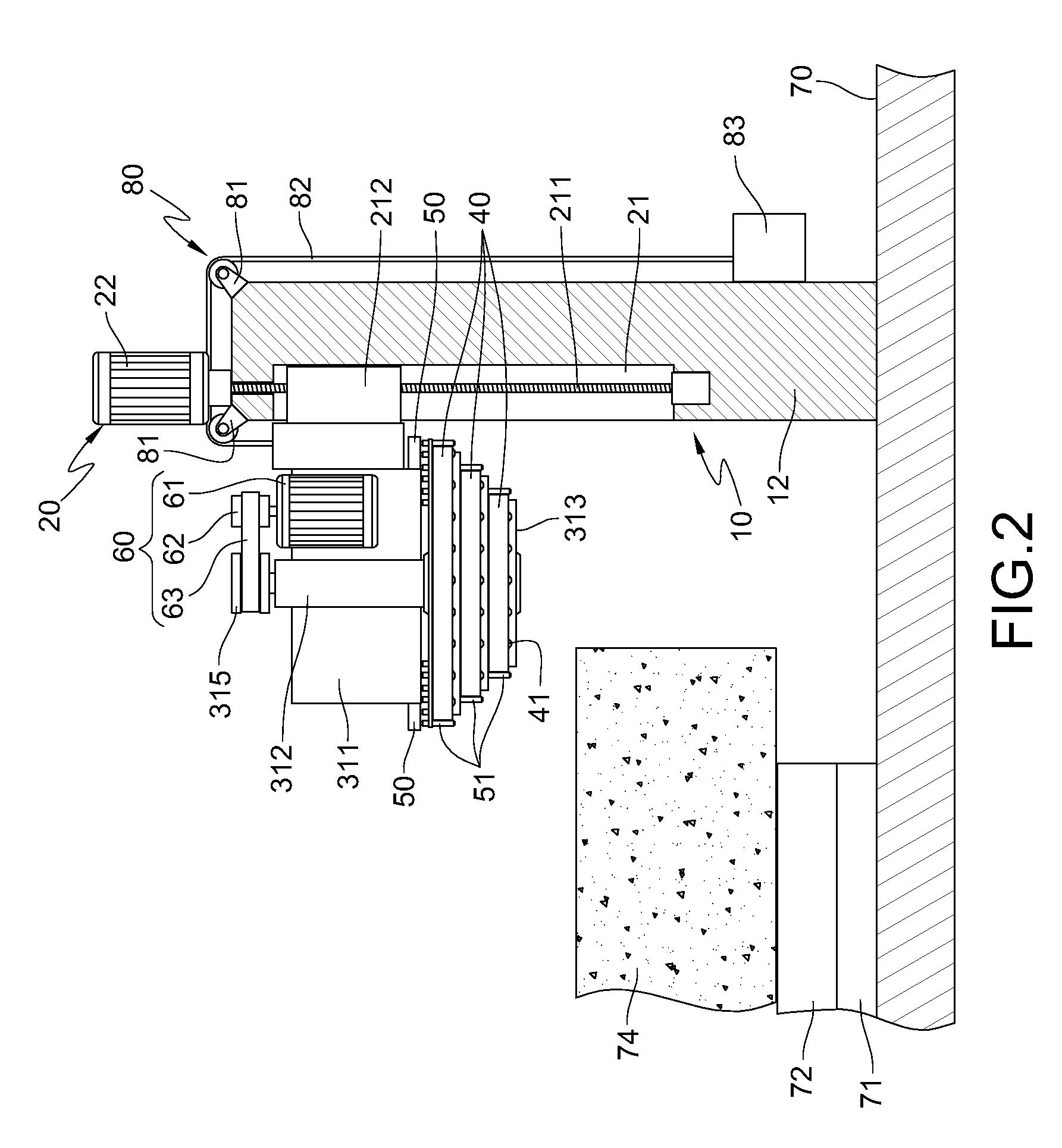

Multi-Bandsaw Machine

InactiveUS20110000355A1Cutting efficiency can be affectedIncrease manufacturing costMetal sawing devicesGang saw millsSingle processEngineering

A multi-bandsaw machine includes several bandsaws, for cutting a material into a plurality of plates in a single process. At least one side edge of each bandsaw has a plurality of diamond grits, and the bandsaws rotate in a single direction on the multi-bandsaw machine, so as to cut the material with the diamond grits and form a cutting notch on the material. The cutting notch has a depth to kerf ratio at least larger than 100:1 during the process of cutting the material with the diamond grits in each hour.

Owner:KINIK

Diamond wire saw and rapid production method thereof

ActiveCN103388170AIncreased chance of collisionIncrease capture rateElectrolytic coatingsChemical platingHeat treated

The invention discloses a diamond wire saw and a rapid production method thereof. The surfaces of diamond grits are respectively coated with a nickel layer by chemical plating, the nickel layers are fixed on a copper-plated piano wire substrate pre-plated with a nickel layer through electroplating, and then the nickel layers are thickened, so that the diamond grits are solidified more firmly. The rapid production method of the diamond wire saw comprises the following steps of: 1, removing greases and oxides on the surfaces of diamond grits, and carrying out sensitization, activation and chemical nickel plating on the diamond grits; 2, removing greases and oxides on the surface of a metal substrate, and pre-plating nickel layers as buffer layers; and 3, carrying out composite electroplating, thickened electroplating and heat treatment on the diamond wire saw. According to the invention, diamond grits are subjected to chemical nickel plating to achieve an effect of electric conduction, so that the diamond grits carry out sequential movement under the action of an electric field, and chemical consolidation is realized; and in addition, intense agitation is introduced in an electroplating process, so that high-current / density electroplating is realized, and a highly efficient and rapid method is provided for the industrial production of diamond wire saws.

Owner:江西核工业兴中科技有限公司

Impregnated Bit with Improved Grit Protrusion

InactiveUS20100230174A1Less friableImprove bit longevityDrill bitsCutting machinesWear resistantWear resistance

A diamond impregnated drill bit features layered encapsulation of the diamond grit where the innermost layer is hardest or most abrasion resistant while succeeding layers are generally softer and less wear resistant. This can be accomplished by manipulating several variables in the encapsulation layers such as particle size or hard particle concentration. The outer layers can have added binder to make them softer. The encapsulated grit can be sintered or pre-sintered to make it less friable when handled. As a result the encapsulated diamonds are retained in the matrix longer with higher protrusion to improve bit longevity and penetration rates.

Owner:BAKER HUGHES INC

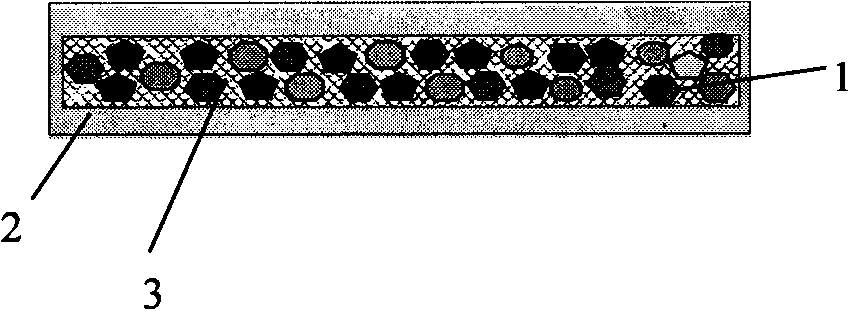

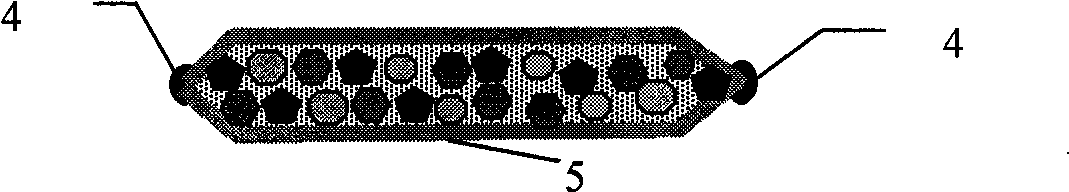

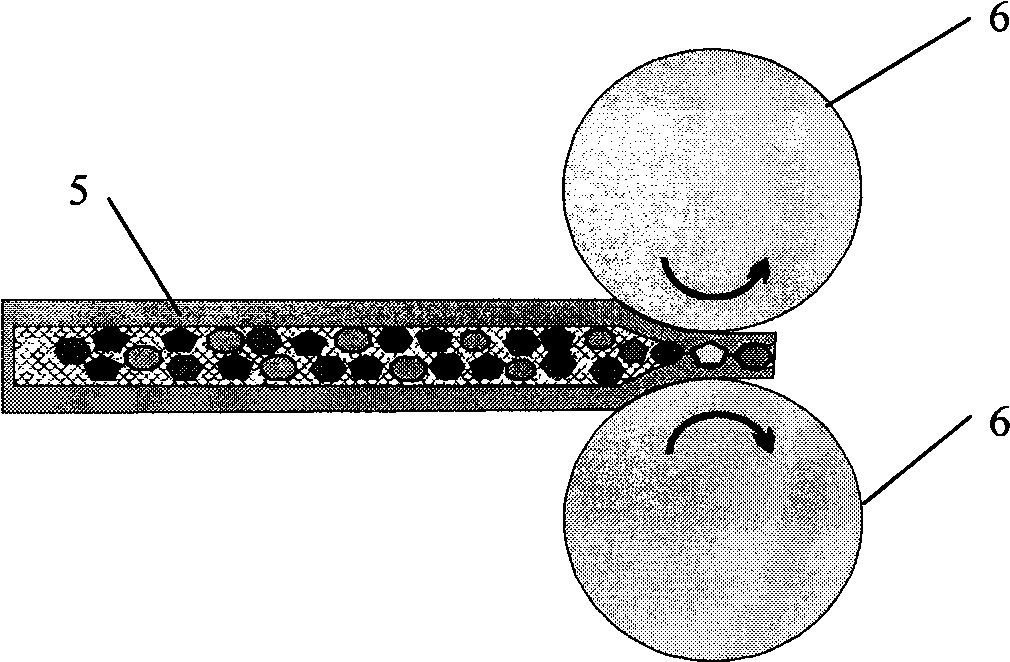

Method for producing metal and diamond composite body

InactiveCN101480744AAvoiding problems with reduced sintering qualityQuality improvementSoldering apparatusMetal rolling arrangementsHardnessLarge deformation

The invention discloses a method for manufacturing a composite body of metal and diamond, comprising the following steps: diamond grits and metal powder bonds are arranged between two metal plates which can be copper plates or low-carbon steel plates, the metal plates are rolled to be in a flat pipe shape, braze welding and sealing are carried out on the round seaming part to manufacture a prefabricated piece, and multi-time cold rolling is carried out so that the thickness of the metal plates in a flat pipe shape is a little bigger than that of a particle and the metal plates in a flat pipe shape are sintered at the temperature ranging from 700-900 DEG C. The invention abandons a traditional powder metallurgy like method, instead, the capability feature that great difference exists between the rigidity of the diamond and the rigidity of the copper plate or the low-carbon plate is utilized, thereby the diamond embedded into a copper block or a low-carbon block in the rolling process and the combination of a little amount of metal powder bonds and high-speed flow deformation and large deformation rate which are unique in the rolling process enable the metal plates to be mutually welded so that the problem in the traditional method that the metal powder is prone to be oxidized to cause the sintering quality to be reduced is avoided. The invention is favorable for the mechanized and automated manufacturing and lowers the manufacturing cost.

Owner:YANSHAN UNIV

Impregnated bit with increased binder percentage

InactiveUS8225890B2Increase the soft binder percentageMore diamond gritDrill bitsCutting machinesCarbideLow volume

Control of the carbide volume in the matrix in an impregnated bit is accomplished by coating the hard particles in the matrix to space them further apart to increase the soft binder percentage in a controllable manner. The softer binder due to lower volume content of hard particles allows more rapid matrix wear in the softer formations to allow more diamond grit to cut better before getting flat spots and to be replaced faster with additional diamond grit further into the matrix as the higher content of the softer binder and the softer coating on the hard particles in the matrix promotes more effective cutting with more frequent emergence of diamond grit on the bit face as cutting progresses.

Owner:BAKER HUGHES INC

Diamond grinding wheel for high-speed four-edge grinding and manufacturing method thereof

InactiveCN104440601AHigh hardnessHigh impact strengthAbrasion apparatusGrinding devicesBronzeMachine tool

The invention discloses a diamond grinding wheel for high-speed four-edge grinding and a manufacturing method of the diamond grinding wheel. The diamond grinding wheel comprises a base body and a work layer, and the work layer is composed of, by volume, 75 percent to 93 percent of bronze bond dedicated alloyed powder and seven percent to 25 percent of diamonds. Firstly, the diamonds are dumped into a grinding bowl, and liquid paraffin is added to be fully wetted with the diamonds. Then, the bronze bond dedicated alloyed powder is dumped for even mixing, and mixtures are obtained. The mixtures are dumped into an assembled mold, the mixtures are placed in a dual-body sintering furnace to be sintered after striking and prepressing, and mold unloading is carried out after sintering and cooling. An obtained semi-finished product is ground and finished, and the diamond grinding wheel for high-speed four-edge grinding is obtained. The diamond grinding wheel for high-speed four-edge grinding has the advantages of being stable in performance, sharp in grinding, high in efficiency, low in cost and the like, and the machining requirement that sheet glass machined by imported and domestic high-speed four-edge grinding machine tools is 30 m / min to the maximum degree can be fully met.

Owner:河南新源超硬材料有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com