Special ceramic bond diamond grinding wheel for grinding diamond

A ceramic bond and diamond grinding wheel technology, applied in the field of diamond grinding wheels, can solve the problems of high temperature resistance of resin bond, falling off of abrasive grains, loss of diamonds, etc., and achieve good thermal conductivity and heat resistance, high strength and grinding speed. , the effect of improving comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

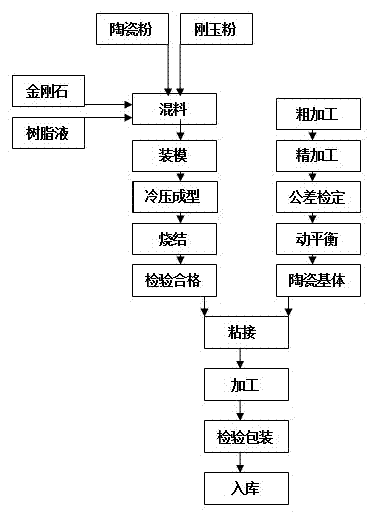

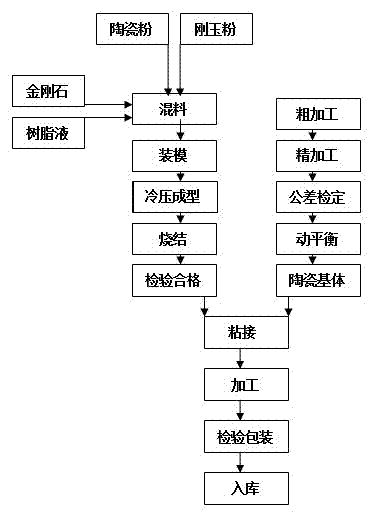

[0050] Embodiment one: see figure 1 As shown, the method for preparing vitrified bonded diamond grinding wheel includes: preparing the grinding wheel substrate, preparing the grinding layer, bonding the grinding layer to the grinding wheel substrate, and then processing it to the shape and size required by the drawing, and passing the inspection according to the national standard of diamond grinding wheel After storage.

[0051] (1) Prepare the grinding wheel base: use Norton (Norton) high-strength ceramic white corundum grinding wheel as the grinding wheel base, and then obtain a qualified grinding wheel base after rough machining, finishing, tolerance verification, and testing dynamic balance; the tensile strength of the grinding wheel base The strength is 45MPa-70MPa, and the expansion coefficient is 8.3×10 -6 ~9.0×10 -6 .

[0052] Prepare the grinding layer:

[0053] (a) Preparation of vitrified bond: mix the raw materials according to the following proportions to obta...

Embodiment 2

[0067] Embodiment two: see figure 1 As shown, the method for preparing a vitrified bonded diamond grinding wheel includes: preparing a grinding wheel base, preparing a grinding layer, bonding the grinding layer to the grinding wheel base, and then processing it to the shape and size required by the drawing, and putting it into storage after passing the inspection.

[0068] (1) Preparation of grinding wheel substrate: adopt white dove white corundum grinding wheel as the grinding wheel substrate, and then obtain a qualified grinding wheel substrate after rough machining, finishing, tolerance verification, and test dynamic balance; the tensile strength of the grinding wheel substrate is 40MPa- 80MPa, the expansion coefficient is 7.9×10 -6 ~9.8×10 -6 .

[0069] Prepare the grinding layer:

[0070] (a) Preparation of vitrified bond: mix the raw materials according to the following proportions to obtain the mixture:

[0071] Silica 41%;

[0072] Borax 16%;

[0073] Lithium hy...

Embodiment 3

[0084] Embodiment 3: A method for preparing a vitrified bond diamond grinding wheel, comprising: preparing a grinding wheel substrate, preparing a grinding layer, bonding the grinding layer to the grinding wheel substrate, and then processing to the shape and size required by the drawing, after passing the inspection storage.

[0085] (1) Preparation of grinding wheel substrate: adopt white dove white corundum grinding wheel as the grinding wheel substrate, and then obtain a qualified grinding wheel substrate after rough machining, finishing, tolerance verification, and test dynamic balance; the tensile strength of the grinding wheel substrate is 40MPa- 80MPa, the expansion coefficient is 7.9×10 -6 ~9.8×10 -6 .

[0086] Prepare the grinding layer:

[0087] (a) Preparation of vitrified bond: mix the raw materials according to the following proportions to obtain the mixture:

[0088] Silica 41%;

[0089] Borax 16%;

[0091] Zinc oxide 12%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com