Metal bond-containing arachnoid plane diamond grinding wheel and 3D printing production process thereof

A metal bond and diamond grinding wheel technology, applied in the field of mechanical processing, can solve the problems of grinding wheel failure, grinding heat, working surface clogging, affecting the processing quality and processing efficiency of parts, and achieve the effect of solving grinding wheel clogging and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

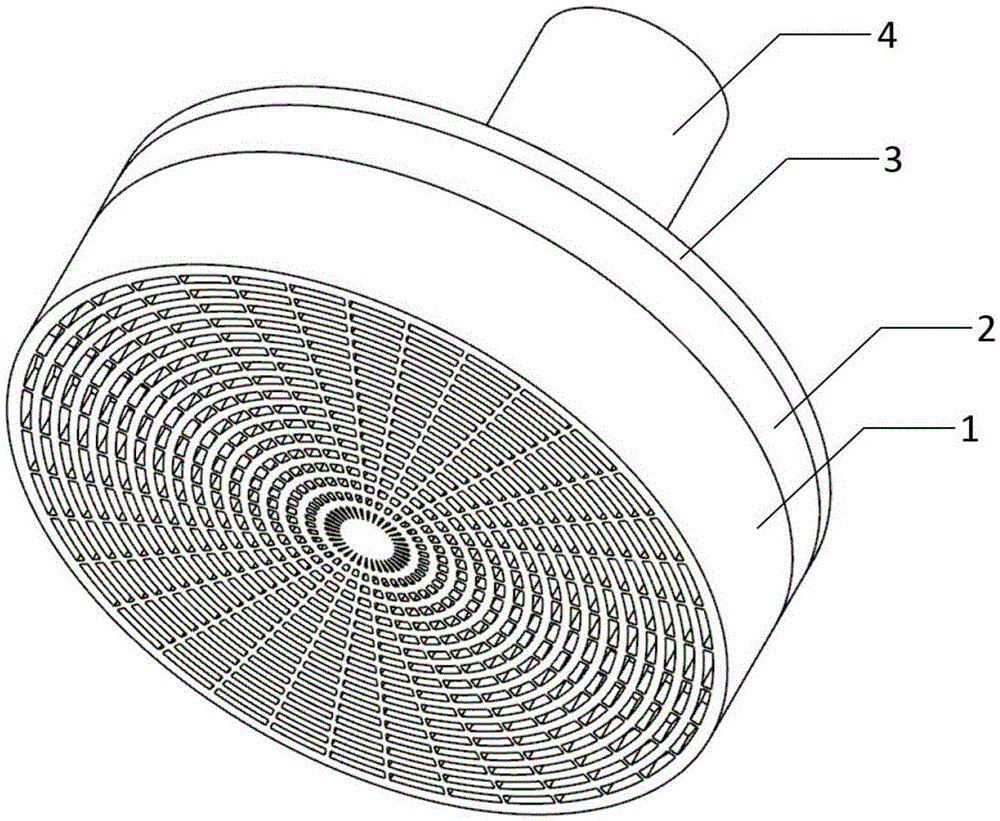

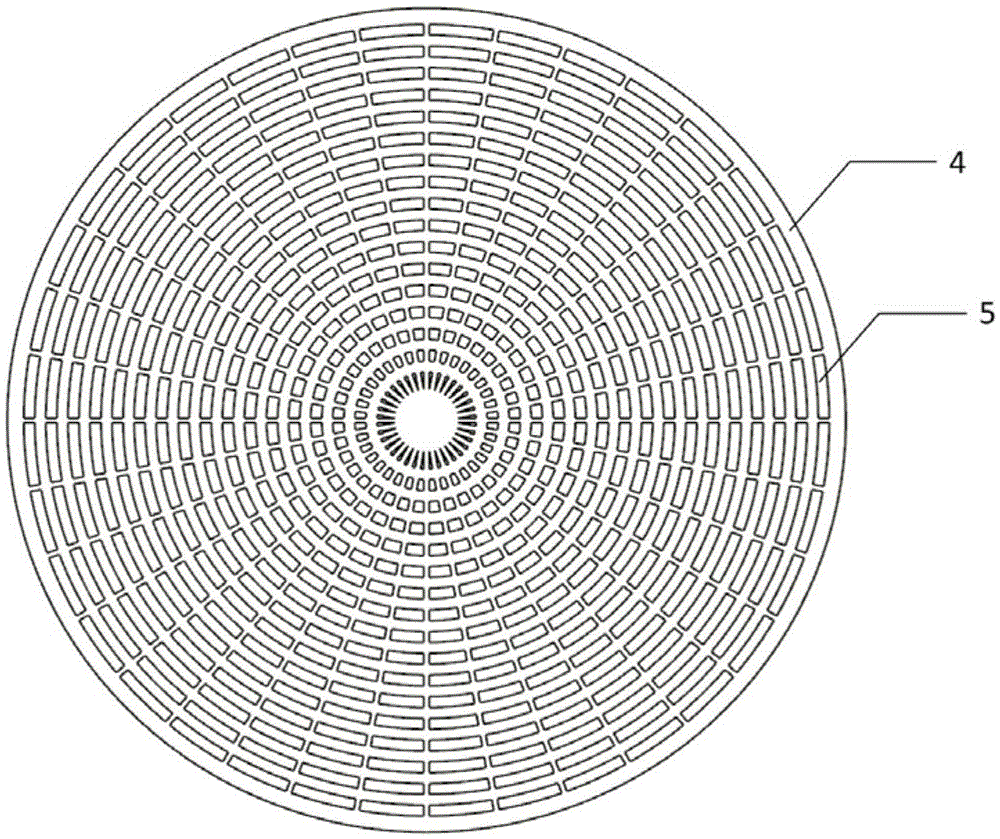

[0015] Such as figure 1 with figure 2 As shown, the metal-bonded spider web-shaped plane grinding wheel includes three parts: a spider web-shaped working layer 1 , a transition layer 2 and a metal matrix 3 . The spider web-shaped working layer is composed of cutting entities 4 and gaps 5 distributed along the radial and circumferential directions. In the radial direction, the cutting entities are distributed concentrically from the center of the grinding wheel working layer plane to the outside. The thickness of each cutting entity is 0.5 mm, two The distance between cutting entities is 0.05mm; in the circumferential direction, the cutting entities are radiated from the center of the working layer of the grinding wheel to the outer diameter of the plane. The thickness of each cutting entity is 0.5mm, and the distance between two cutting entities is 0.05mm; The depth in the axial direction is 0.05mm; at the outer diameter circumference side of the working level, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com