Downhole tool bearing system containing diamond enhanced materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

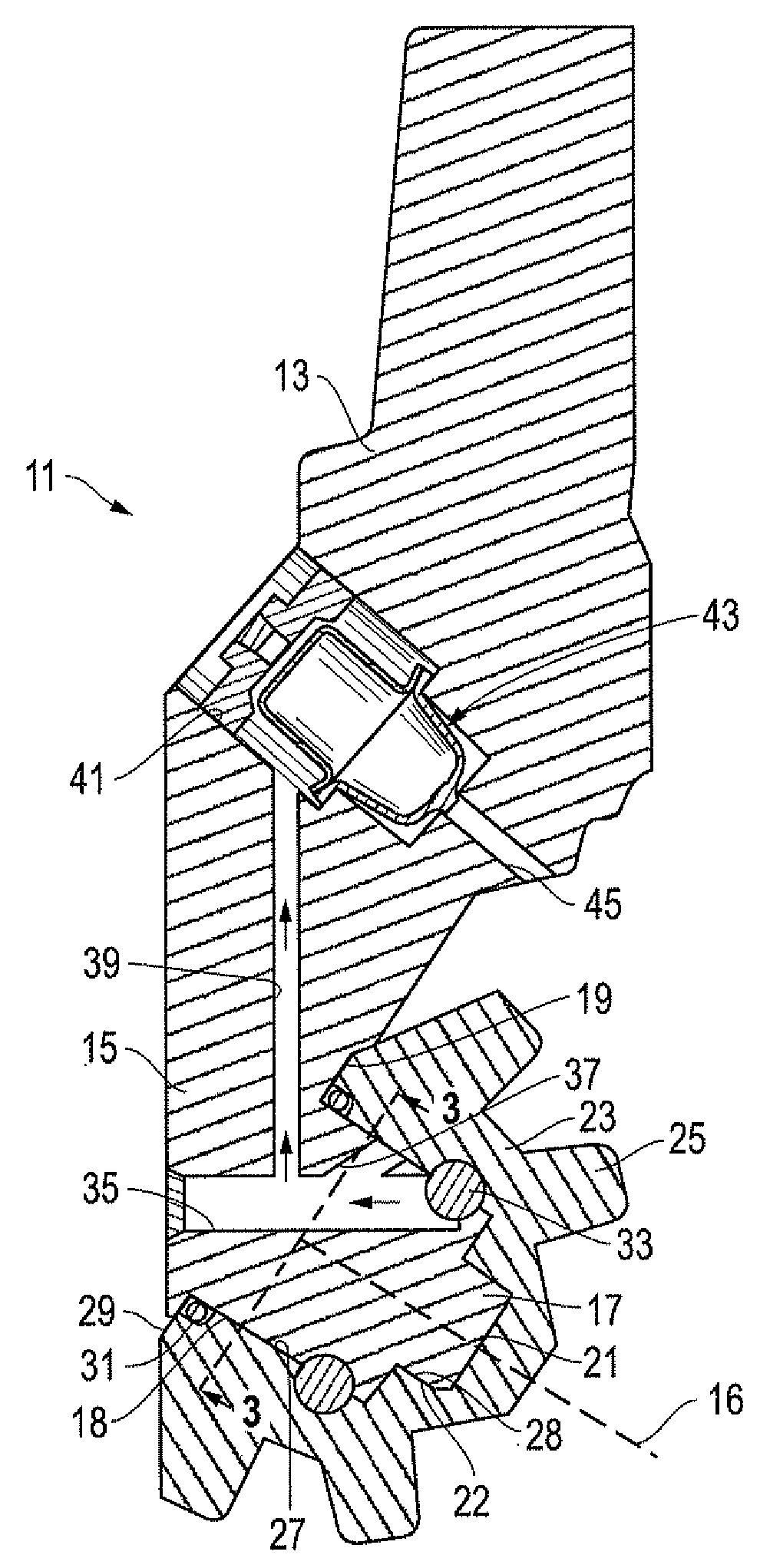

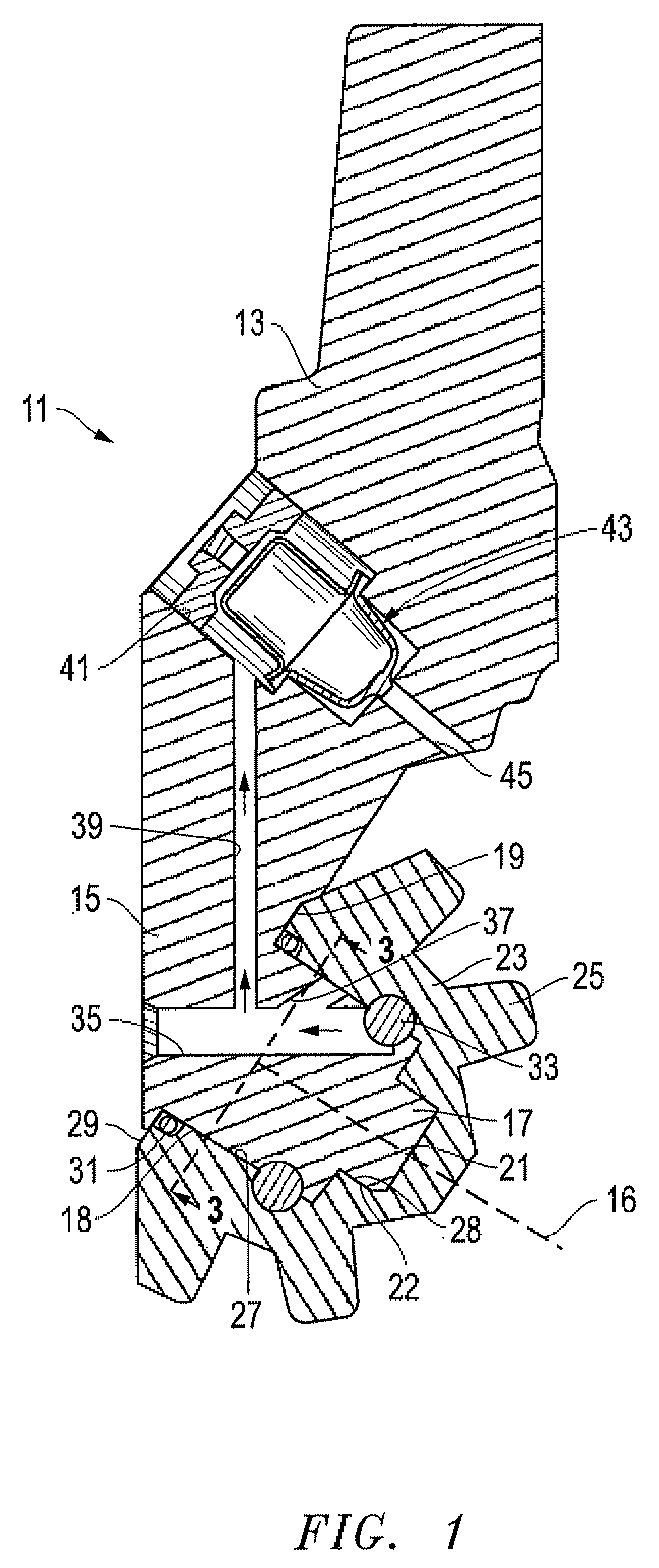

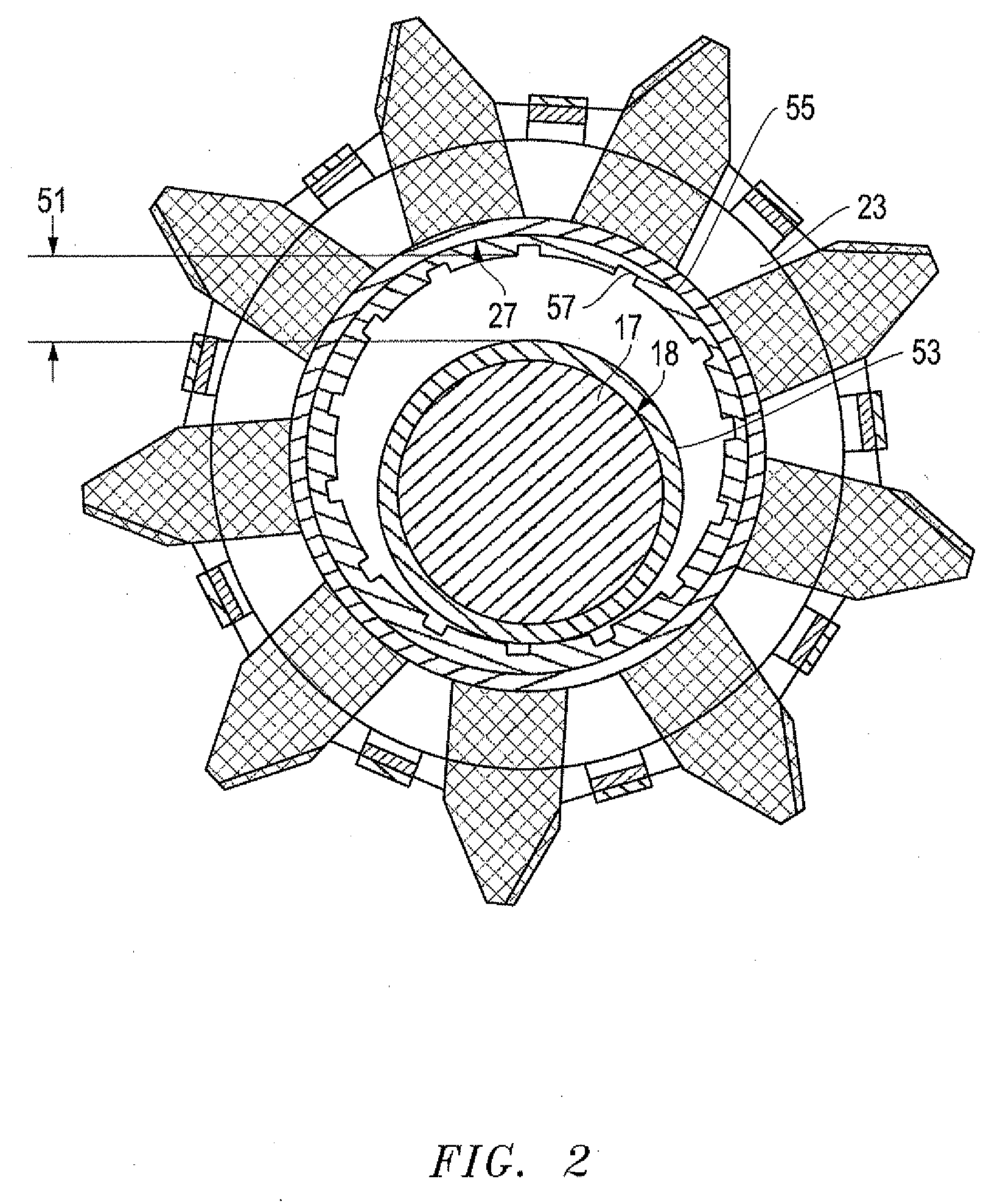

[0015]Referring to FIGS. 1-4, embodiments of a system, method and apparatus for downhole tool bearings containing diamond enhanced materials are disclosed. The diamond enhanced materials may comprise diamond grains in a matrix of tungsten carbide, silicon carbide, etc. For example, such materials may be provided by the company Element Six (E6) under such commercially available product names as SYNDAX (i.e., a high temperature, high pressure sintered silicon bonded polycrystalline diamond), or SCD (i.e., a low pressure, low concentration diamond enhanced polycrystalline material). Another such material may be aluminum nitride intermetallic bonded diamond and carbide composite.

[0016]In another embodiment, a brazed diamond grit may be utilized for bearing applications. The E6 company provides still another type of diamond enhanced surface that is formed by applying diamond particles coated with a reactive braze. The braze is activated and a layer of brazed diamond particles forms a wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com