Electrically driven motors and pumps having such motors

a technology of electric motors and motors, which is applied in the direction of positive displacement liquid engines, pumping machines, machines/engines, etc., can solve the problems of a large number of parts and a limitation in the attempt to downsize the motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first representative embodiment

[0027] First Representative Embodiment

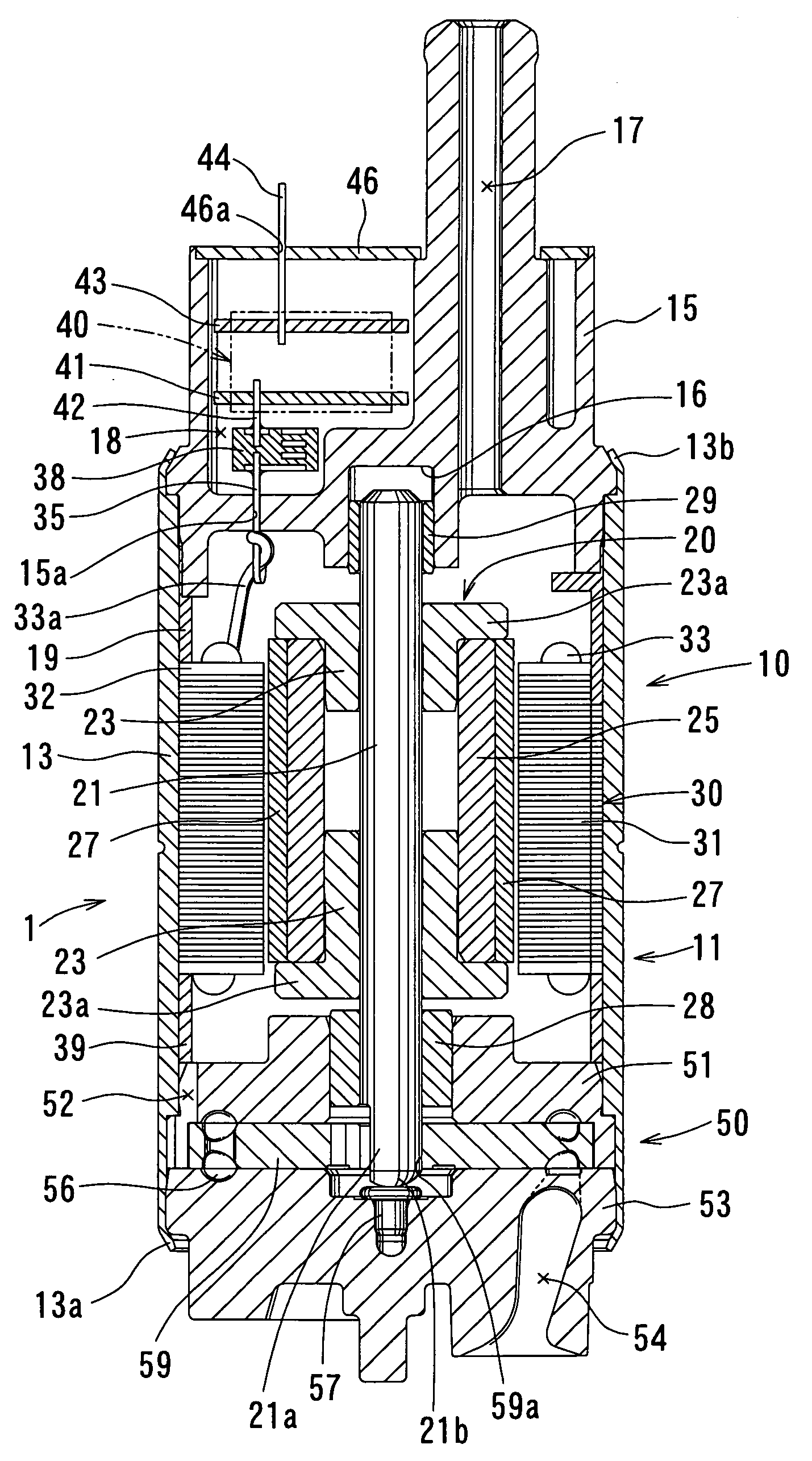

[0028] Referring to FIG. 1, a fuel pump 1 according to a first representative embodiment is mountable on an automobile (not shown) and has a brush-less DC motor as a motor section 10. As shown in a vertical sectional view in FIG. 1, the fuel pump 1 includes a pump section 50 in addition to the motor section 10. The pump section 50 is disposed on the lower side of the motor section 10.

[0029] The motor section 10 will now be described. The motor section 10 generally includes a housing 11, a rotor 20 rotatably supported within the housing 11, and a stator 30 fixedly mounted within the housing 11. The housing 11 has a substantially cylindrical housing tube 13, an upper end cover 15 mounted to the upper end of the housing tube 13, and a pump casing 51 and a pump cover 53 mounted to the lower end of the housing tube 13. An axial support hole 16 is formed in an inner wall of the upper end cover 15 (the lower wall as viewed in FIG. 1) and extends subst...

second representative embodiment

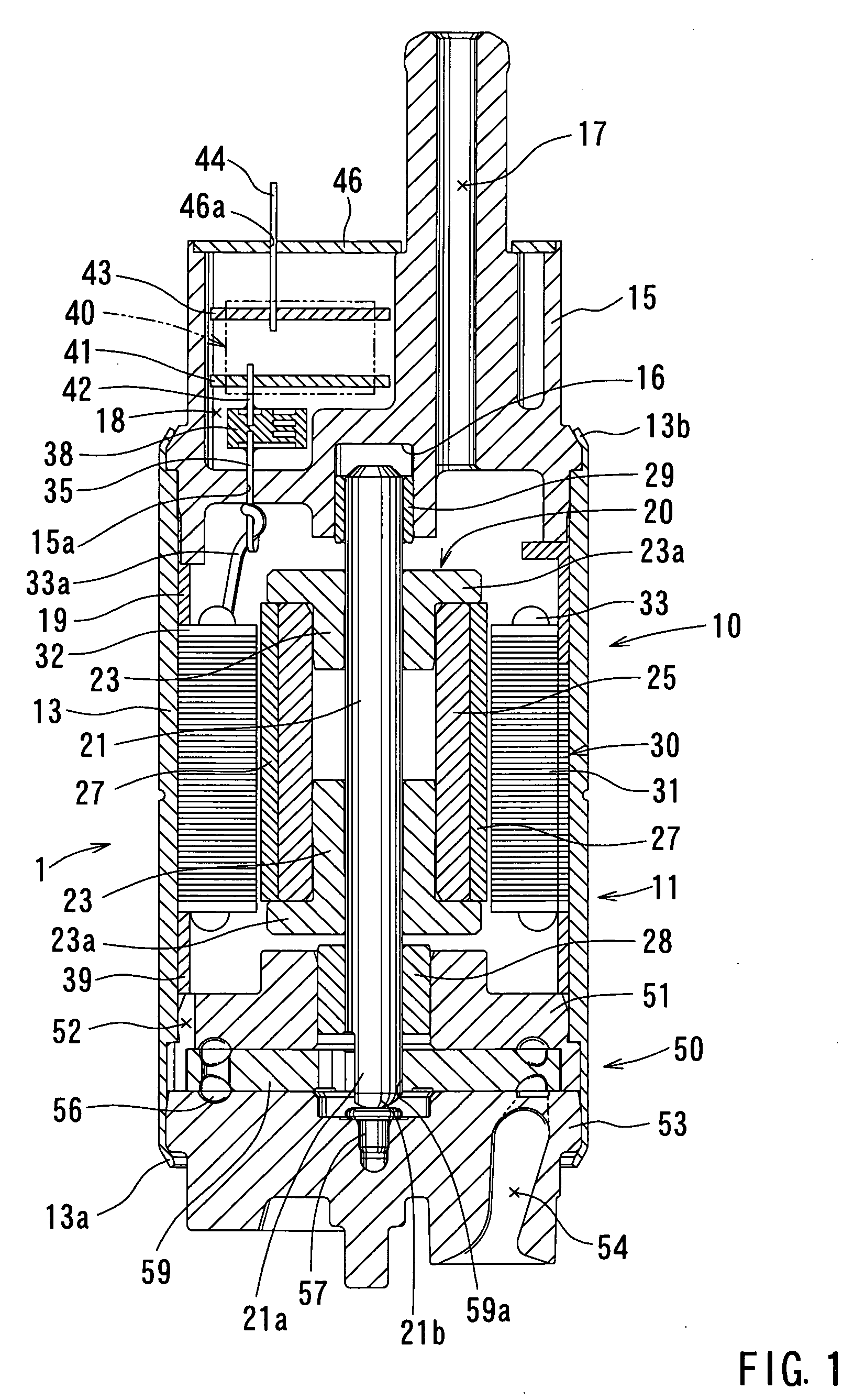

[0047] Second Representative Embodiment

[0048] The second representative embodiment will now be described with reference to FIG. 2. The second representative embodiment is different from the first representative embodiment only in that the connecting circuit board 38 is disposed within the housing 11. Therefore, the connecting circuit board 38 is connected to the terminal 35 at a location within the housing 11. In this case, the connecting terminal 42 of the coil-side circuit board 41 extends through the terminal hole 15a formed in the upper end cover 15 so as to be electrically connected to the connecting circuit board 38. Also with this second representative embodiment, substantially the same operation and advantages may be attained as with the first representative embodiment.

third representative embodiment

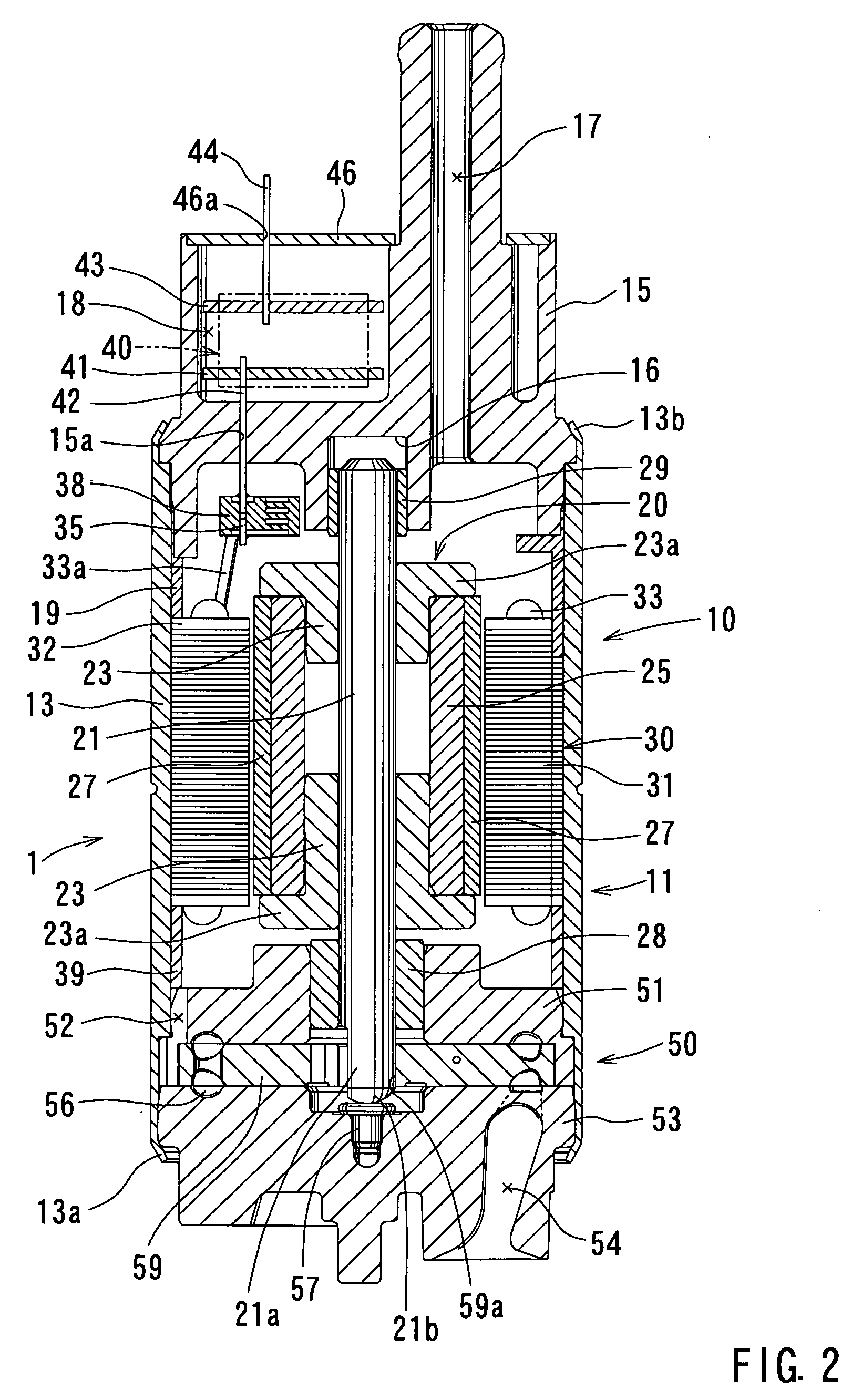

[0049] Third Representative Embodiment

[0050] The third representative embodiment will now be described with reference to FIG. 3. The third representative embodiment is different from the first representative embodiment in that the housing tube 13 and the upper end cover 15 of the housing 11 are molded integrally with each other into an integral housing member 12 via a resin molding process. In addition, the upper spacer 19 and the lower spacer 39 are also molded integrally with the housing member 12. Further, the stator 30, including the terminal end 33a of the stator coil 33 connected to the terminal 35, is integrated within the housing tube 13, i.e., the housing member 12, using an insertion molding process. For example, the stator 30 may be set into a cavity of the mold used for molding the housing member 12. A resin material may then be injected into the cavity, consequently integrating the stator 30 with the housing member 12. FIG. 4 shows a vertical sectional view of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com