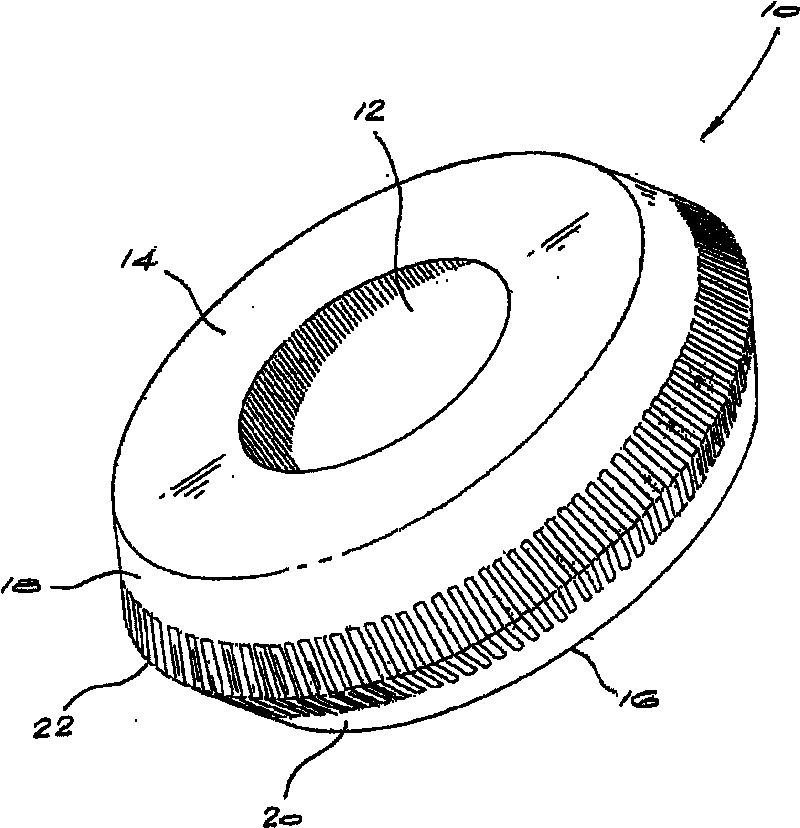

Cutting disk for forming a scribed line

A technology of cutting discs and engraving lines, which can be used in glass cutting devices, glass manufacturing equipment, stone processing tools, etc., and can solve problems such as crack offsets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

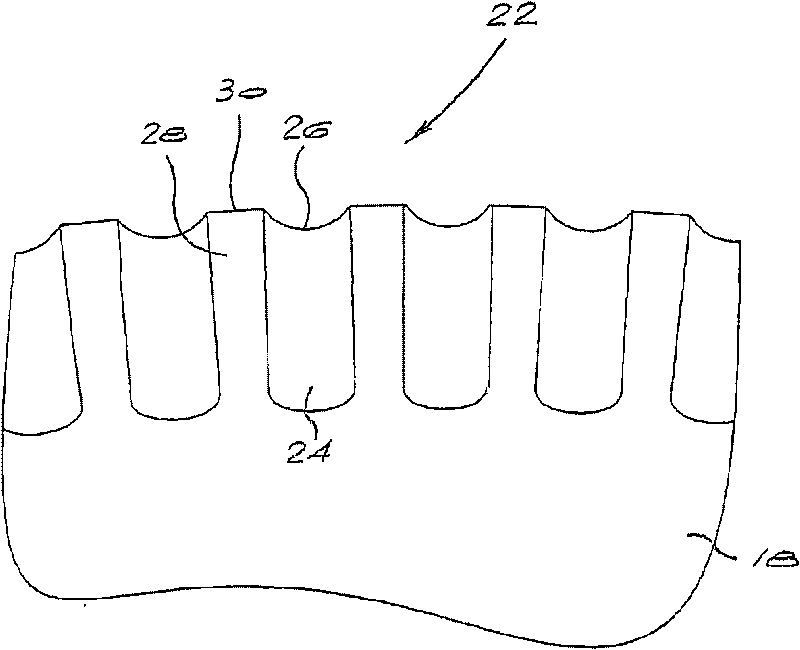

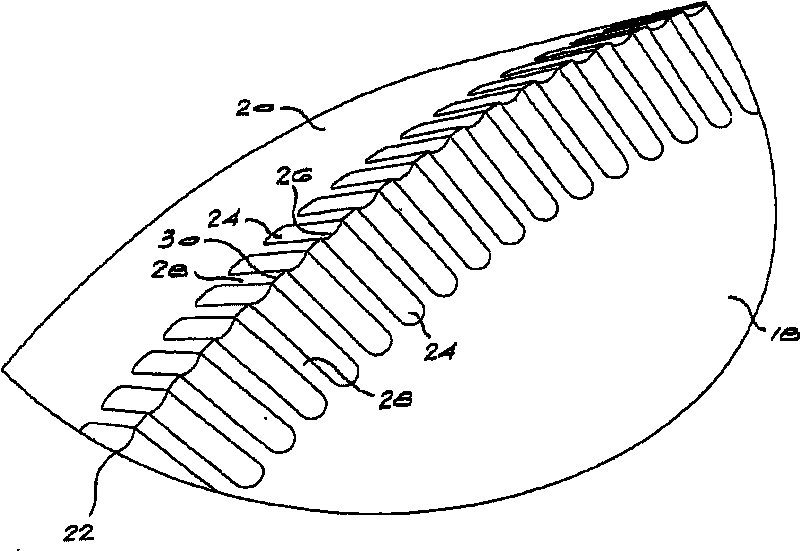

[0082] 1. Cutting disc with 110 grooves and sharp cutting edges using finely ground cobalt bonded sintered diamond

[0083]Cutting disc blanks shaped according to the prior art with continuous peripheral ridges were prepared using finely ground, cobalt-bonded sintered diamond. The size of the diamond particles used is substantially less than 1 micron. A plate of this material was first ground to a thickness of 0.6 mm, then EDM was used to cut a cylinder with a central hole, then, on each of these cylinders, at the intersection of the peripheral ridges Tapered or inclined tapered areas with a total included angle of 125° are ground on both sides of the surface. The radius of curvature at the intersection is substantially less than 1 micron. The cutting disc blank had a center hole of 0.8 mm and a diameter of 2.0 + / - 0.02 mm. Five of these disks, formed according to the prior art, were cleaned to remove adhering dust and contaminants and were subsequently mounted on shafts ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com