Method for preparing diamond grinding wheel ceramic bond with low sintering temperature and high strength

A technology of diamond grinding wheel and low sintering temperature, which is applied in the direction of metal processing equipment, manufacturing tools, grinding/polishing equipment, etc. It can solve the problems of increasing the economic cost of firing, thermal damage of diamond abrasive, and affecting the performance of abrasive, so as to achieve porosity Good tonality, few correction times, and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with examples.

[0018] The embodiment of the present invention provides a low sintering temperature and high strength diamond grinding wheel vitrified bond with good performance.

Embodiment 1

100

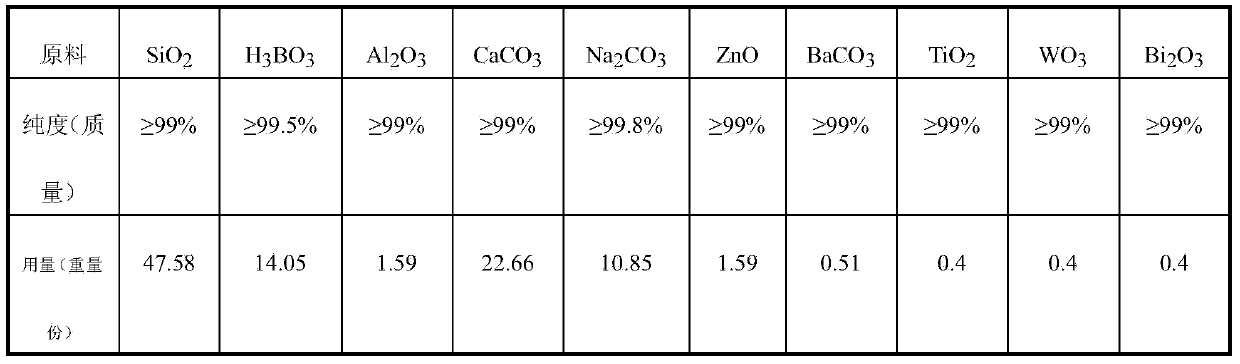

[0022] According to the formula shown in the above table, select raw materials and calculate the ingredients. The list of raw materials and ingredients is shown in the following table:

[0023]

[0024] Put the raw materials in the above table into the high-temperature furnace for melting according to the proportion of ingredients. The heating process in the high-temperature furnace is as follows: raise the temperature to 800°C at a rate of 5°C / min; continue to raise the temperature to 1350°C at a rate of 3°C / min. hours; and then heated up to 1500°C at a rate of 3°C / min, and kept at 1500°C for 2 hours to obtain a molten liquid. Then the molten liquid is water-quenched and dried at 70° C. for 24 hours, ground by a ball mill and passed through a 200-mesh sieve to obtain powder, which is a low sintering temperature and high-strength diamond grinding wheel vitrified bond.

[0025] The present invention further provides a diamond grinding wheel containing the abov...

Embodiment 2

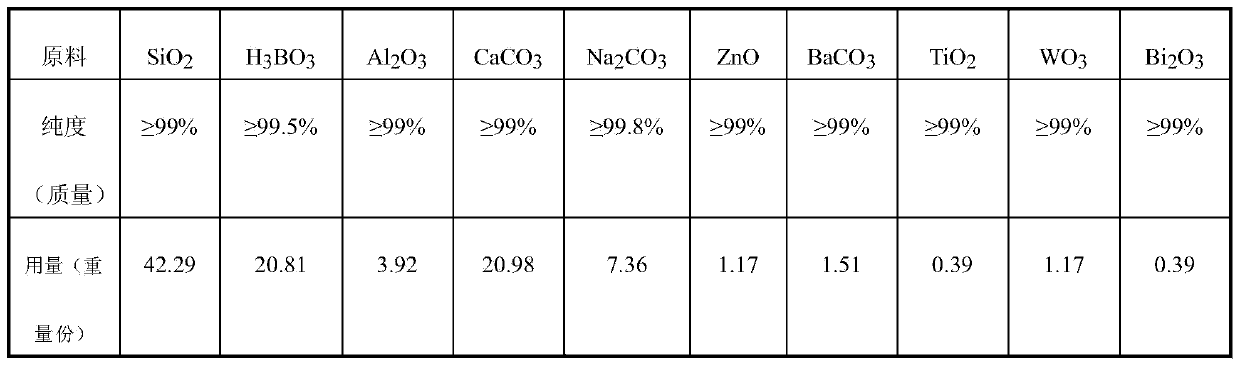

[0029] Step 1: Select raw materials according to the formula shown in the above table and calculate the ingredients. The list of raw materials and ingredients is shown in the following table:

[0030]

[0031] Step 2: Put the raw materials in the above table into the high-temperature furnace according to the proportion of ingredients for melting. The heating process in the high-temperature furnace is as follows: heat up to 800°C at a rate of 5°C / min; continue to heat up to 800°C at a rate of 3°C / min. Insulate at 1350°C for 2 hours; then raise the temperature to 1500°C at a rate of 3°C / min, and keep at 1500°C for 2 hours to obtain a molten liquid.

[0032] The third step: quench the molten liquid in water and dry it at 70°C for 24 hours, grind it with a ball mill, and pass through a 200-mesh sieve to obtain powder, which is a vitrified bond for diamond grinding wheels with low sintering temperature and high strength.

[0033] The present invention further provides a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com