Patents

Literature

533 results about "Boron trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron trioxide (or diboron trioxide) is one of the oxides of boron. It is a white, glassy solid with the formula B₂O₃. It is almost always found as the vitreous (amorphous) form; however, it can be crystallized after extensive annealing (that is, under prolonged heat).

Lithium ion battery composite cathode material and preparation method

InactiveCN101604743APromote circulationImprove cycle performanceElectrode manufacturing processesActive material electrodesFuranEpoxy

The invention relates to a lithium ion battery composite cathode material and a preparation method. The cathode material comprises a hard carbon precursor material containing hetero atoms, and natural spherical graphite, wherein the hard carbon precursor material selects one or more than two of phenolic resin, polyfurfural, furan resin, polyvinyl alcohol, epoxide resin or polyacrylonitrile as raw materials, and accounts for 5 to 45 percent of the natural spherical graphite by mass; modifier of the hetero atoms is boron-containing modifier including boric acid and diboron trioxide, phosphor-containing modifier including phosphoric acid and phosphorus pentoxide, and nitrogen-containing modifier HNO3; and one of the modifiers accounts for 5 to 35 percent of the hard carbon precursor by mass. An analog battery formed by the cathode material which is prepared by the method has the capacity over 350 mAH / g and first coulomb efficiency up to 95.8 percent, and has good circulation performance. The preparation method has the advantages of low cost and simple process.

Owner:珠海华丽新能源科技有限公司

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

Thin and thermal insulation inner wall paint, preparation method and construction method thereof

ActiveCN101085892AImprove the decorative effectLow costFireproof paintsEmulsion paintsPolymer scienceMicrosphere

The invention discloses a kind of thin thermal insulating inner wall paint. The comprised components and their weight proportion are as follows: styrene-acrylic emulsion 28- 35%, titanium dioxide 8- 13%, fillings 10- 18%, borosilicate hollow microsphere 6- 12%, water- brone nanometer anti- pollution agent 0.5- 2%, defoaming agent 0.3- 0.5%. Said hollow microsphere is hollow white spherical powder with thin wall, the main component is silicon dioxide and diboron trioxide, the real density is small and heat conductive coefficient is 0.04- 0.08 w / m.k. The invention aslo discloses the preparation and construction method for said paint. It employs high pressure airless painting process for construction, the aperture of employed gunjet nozzle is 0.6- 0.8 mm, atomization pressure is 15- 18 Mpa, and when the coating layer is 0.3- 1.0 mm, the coating layer is homogeneous and tight, and the thermal insulating effect is good. The paint is especially suitable for building inner wall and ceiling painting.

Owner:上海秀珀化工有限公司

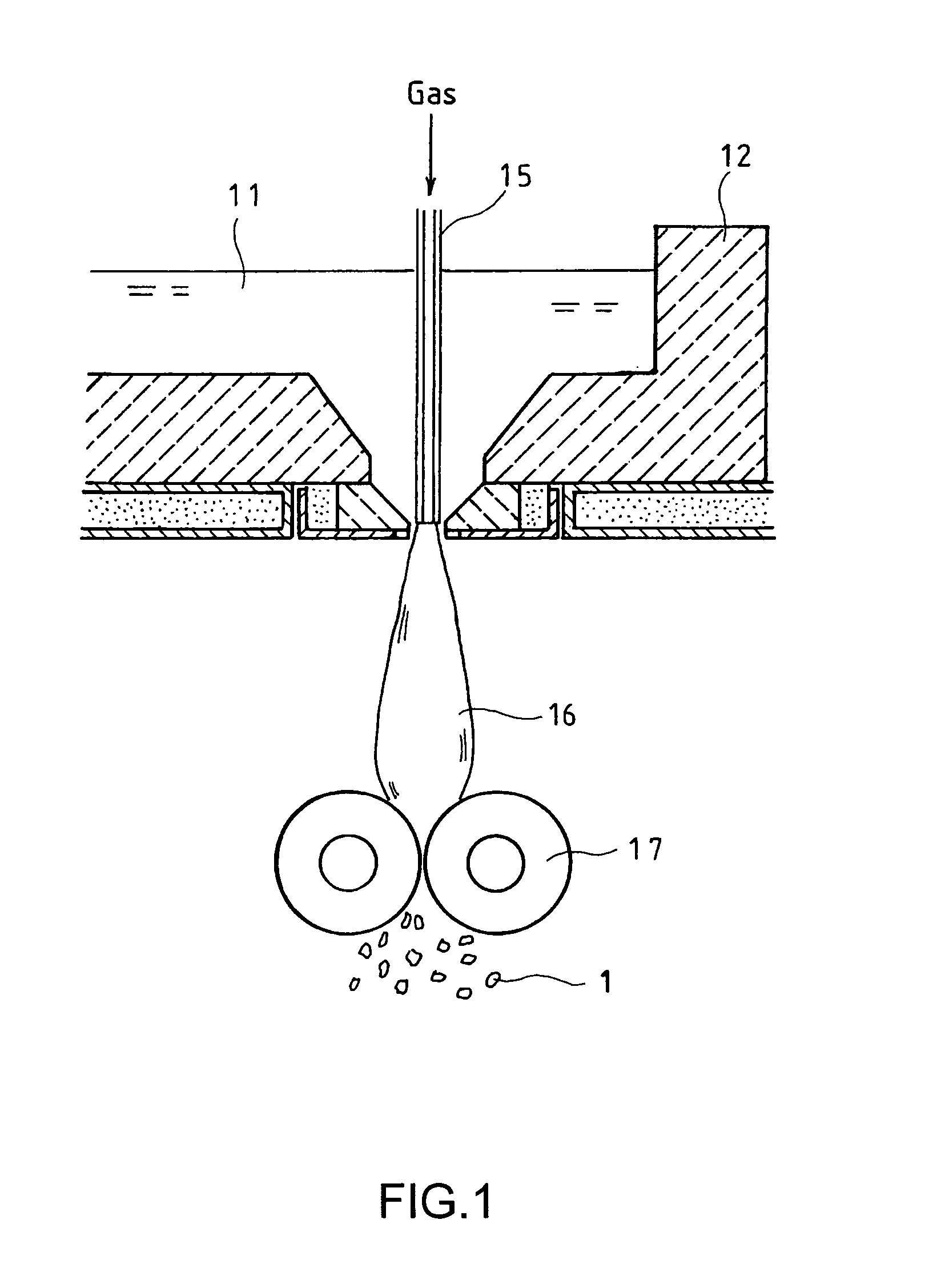

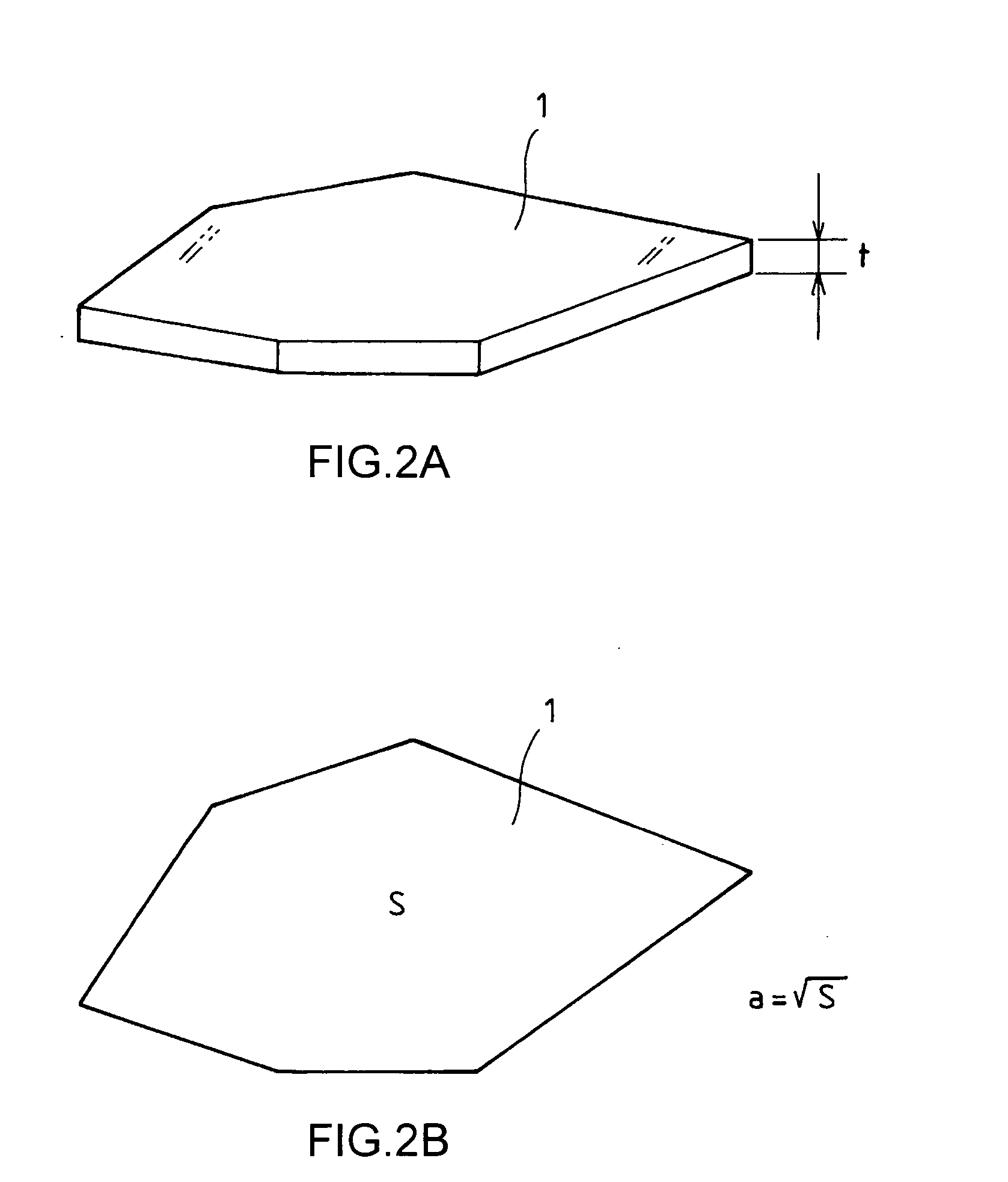

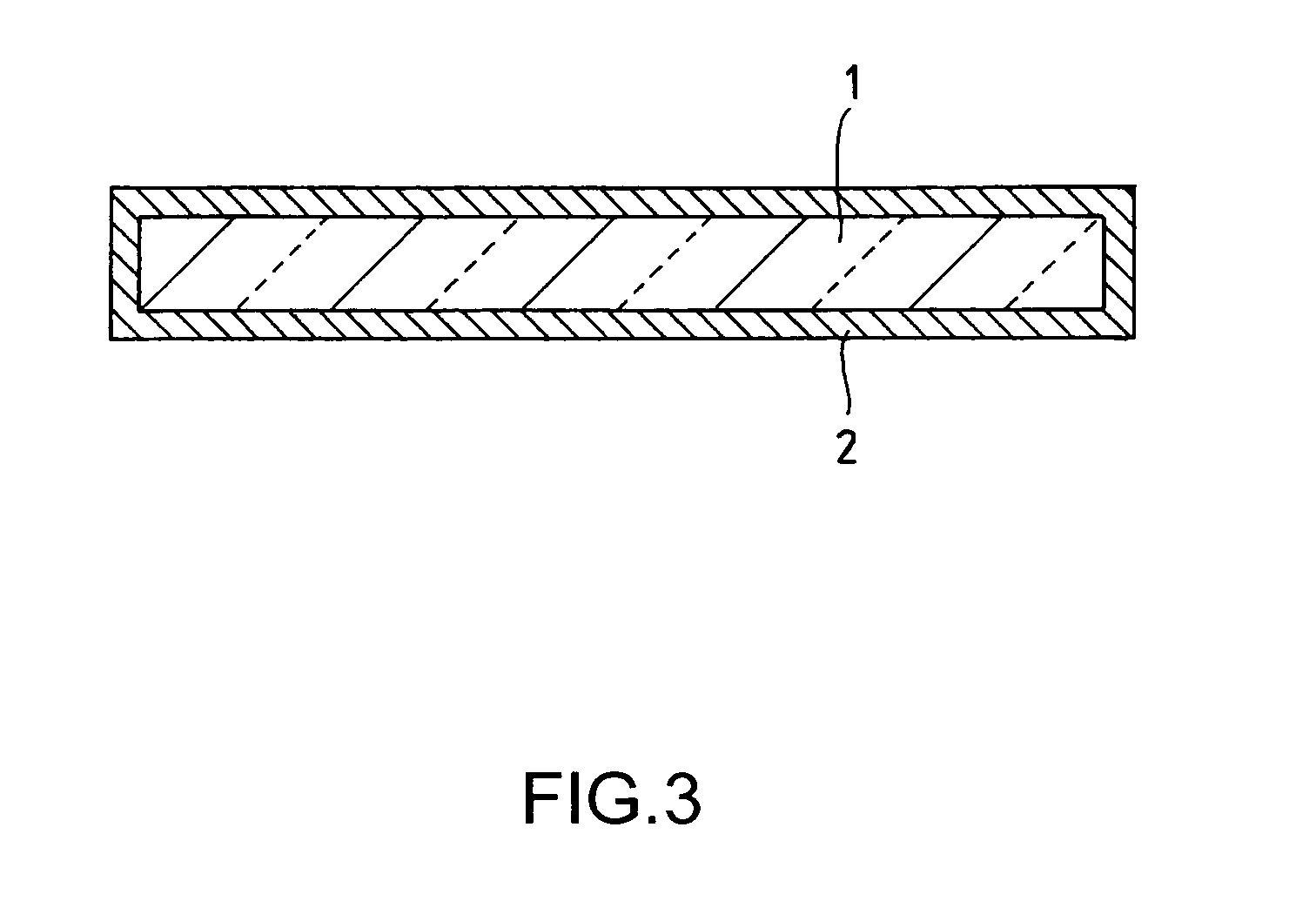

Glass flake

InactiveUS20050049133A1Overcome lack of heat resistanceGood molding effectPigmenting treatmentOther chemical processesHeat resistanceBoron trioxide

The present invention provides a glass flake that is substantially free of boron trioxide (B2O3), barium oxide (BaO), zinc oxide (ZnO), and fluorine (F) and has sufficient heat resistance and good formability for glass flake. The glass flake of the present invention includes a glass composition that contains the following components, expressed in mol %; 50≦SiO2≦65; 4≦Al2O3<12; 5≦SrO≦25; 10<(MgO+SrO)≦30; 20≦(MgO+CaO+SrO)≦45; and 0<(Li2O+Na2O+K2O)<2; wherein the glass composition is substantially free of B2O3, BaO, ZnO, and F. This glass flake is useful for resin compositions, paints, cosmetics, ink compositions, and the like.

Owner:NIPPON SHEET GLASS CO LTD

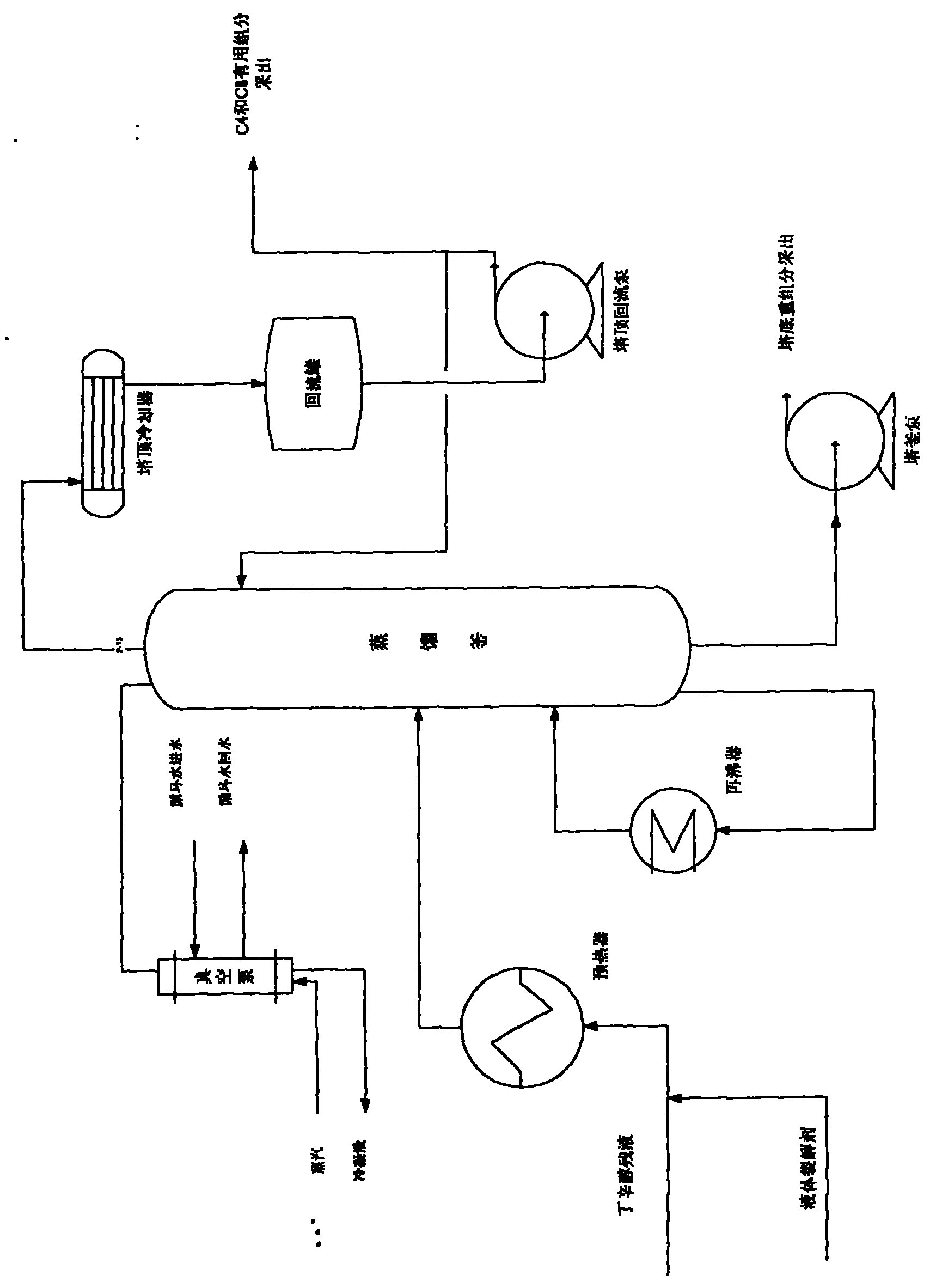

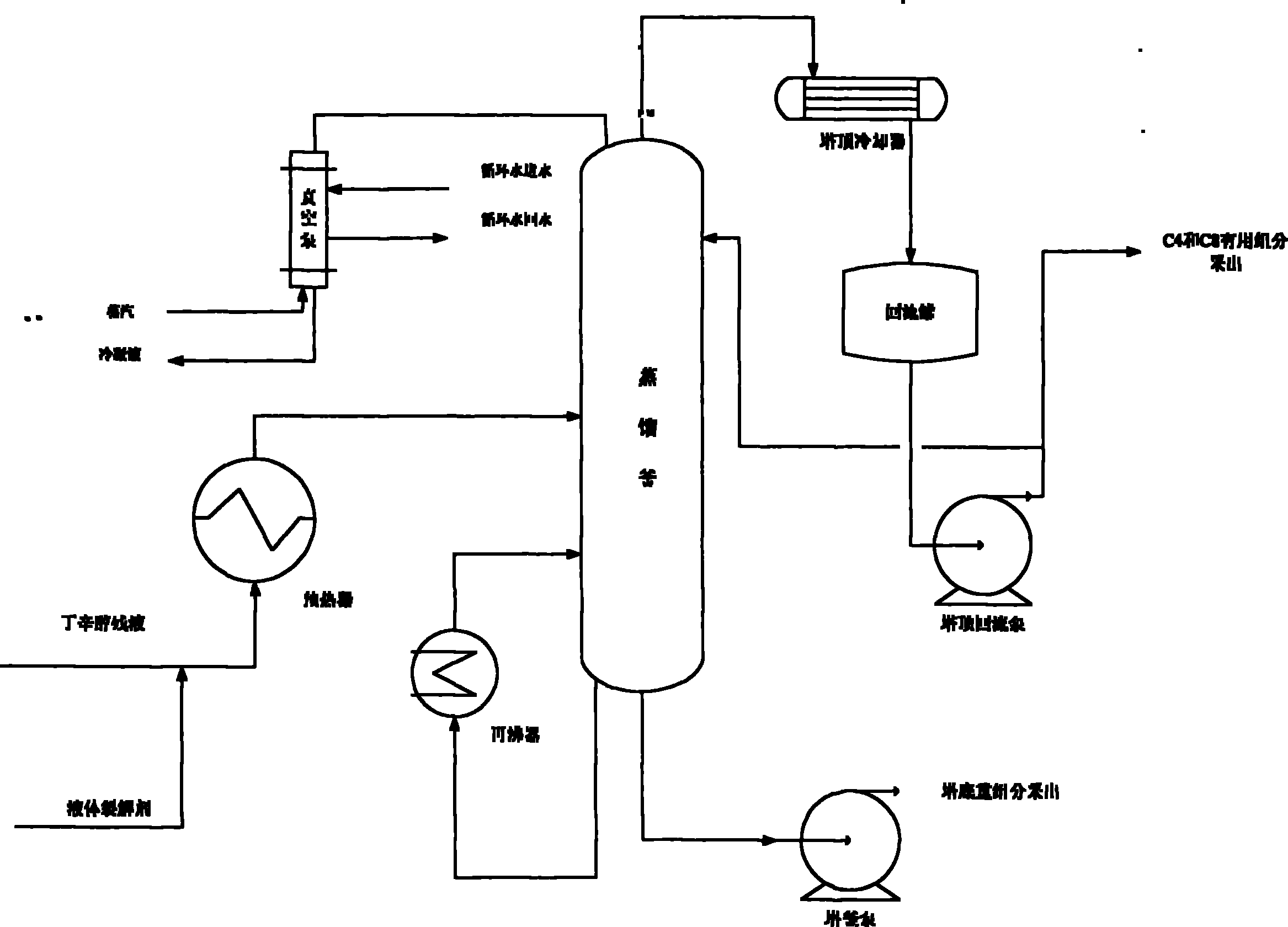

Production technology for cracking butyl octanol residual liquid into C4 and C8 by means of alkaline liquid cracking agent

ActiveCN101892066AReasonable useEmission reductionThermal non-catalytic crackingFractionationPotassium hydroxide

The invention relates to production technology for cracking butyl octanol residual liquid into C4 and C8 by means of an alkaline liquid cracking agent. The technology is characterized by comprising the following steps of: preparing the alkaline liquid cracking agent, wherein the alkaline liquid cracking agent consists of sodium hydroxide, potassium hydroxide, water, isopropanol, ethylene glycol, potassium permanganate, ethanol, barium nitrate and diboron trioxide; preheating the alkaline liquid cracking agent and the butyl octanol residual liquid through a preheater and adding into a distilling still, wherein the tower bottom temperature of the distilling still is between 200 and 280 DEG C, the tower top temperature is between 130 and 190 DEG C, and the tower top pressure is between 0.08 and 0.1Mpa below zero; and extracting the C4 and C8 generated by cracking from the tower top of the distilling still, pumping the C4 and C8 into a fractionating column at the downstream for fractionation, and extracting a small amount of uncracked heavy components from a tower bottom pump. The production technology has the advantages of high production capacity, high cracking selectivity, high content of the cracked useful components, low cost, simple process, and batch distillation or continuous distillation.

Owner:山东瑞利尔石油装备有限责任公司

Preparation method of ceramic bond for low-temperature high-strength cubic boron nitride (CBN) grinding tool

The invention discloses a preparation method of ceramic bond for a low-temperature high-strength cubic boron nitride (CBN) grinding tool, which comprises the following steps: evenly mixing 35-75% of a, 2-15% of b, 5-20% of c and 5-25% of d by weight percent, grounding and sieving, melting at 1200-1400 DEG C for 1-6h, carrying out water quench, drying, secondary grinding and secondary sieving to obtain basic ceramic bond, and evenly mixing the obtained basic ceramic bond with nano oxide the weight of which accounts for 0.2-15% of that of the basic ceramic bond to obtain the ceramic bond of theinvention, wherein the a is silica or silicon dioxide, the b is aluminum hydroxide or aluminum oxide, the c is anhydrous sodium carbonate or sodium oxide, and the d is boric acid or boron trioxide. Through adding nano oxide to the basic ceramic bond, the refractoriness of the basic ceramic bond is reduced by 10-50 DEG C, the fluidity is improved by 5-25%, and the breaking strength is improved by 5-45%.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing oxidation-resistant ceramic-matrix composite material capable of resisting 1,200 DEG C

The invention belongs to preparation technologies for continuous fiber reinforced ceramic matrix composite materials and particularly relates to a method for preparing an oxidation-resistant ceramic-matrix composite material capable of resisting 1,200 DEG C. According to the method, a continuous fiber reinforced ceramic matrix composite material is prepared by adopting a polymer impregnation and pyrolysis process, an adopted impregnant is a xylene solution of polycarbosilane or a xylene solution of a polycarbosilane and polyborazine mixed precursor, the solubility of the polycarbosilane and the polyborazine in xylene is relatively high, and thus, a polymer precursor can be uniformly dispersed in a solution, so that the maintaining of uniformity of composition and a structure of a ceramic matrix, formed after the precursor is subjected to pyrolysis, is facilitated. According to the method, the obtaining of the continuous fiber reinforced ceramic matrix composite material with excellent mechanical properties is facilitated; and then, the polycarbosilane and polyborazine mixed precursor is subjected to vacuum impregnating and pyrolysis, and the high-temperature stability of the material in oxidizing environments at the temperature of 1,200 DEG C is improved by making full use of a synergistic anti-oxidation action of an oxidizing ingredient, i.e., boron trioxide of the ceramic matrix and borosilicate.

Owner:AVIC COMPOSITES

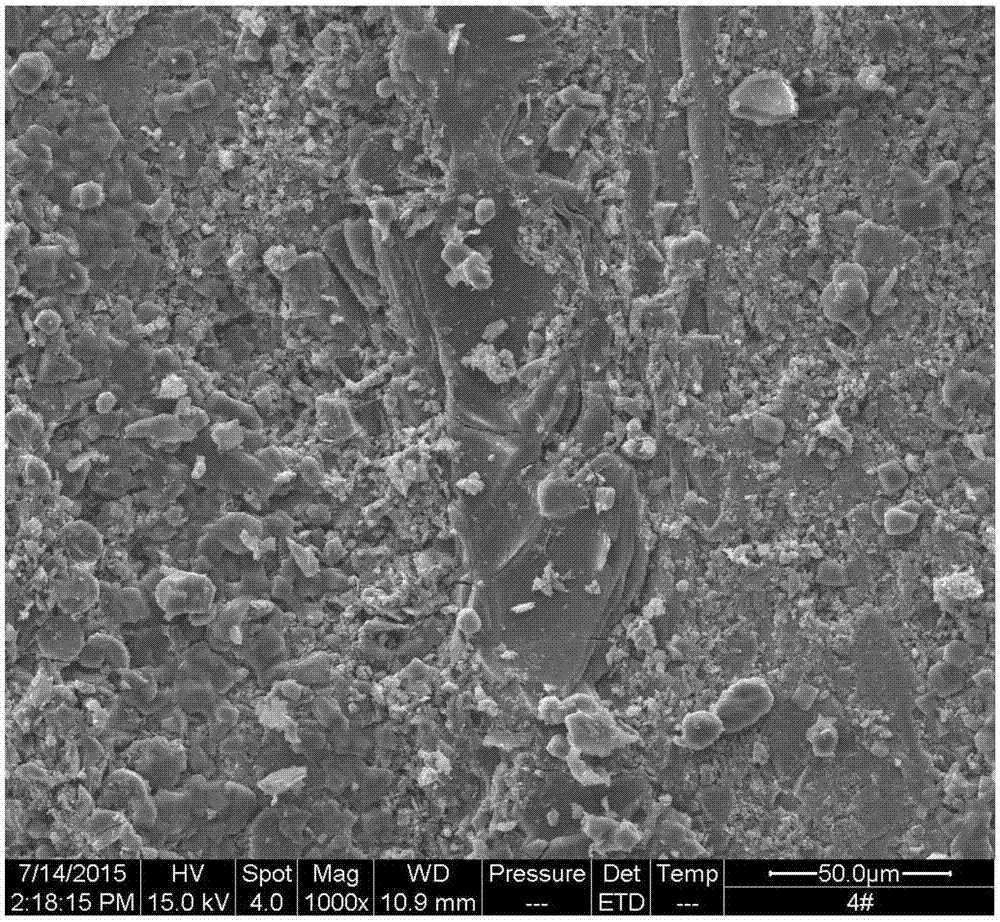

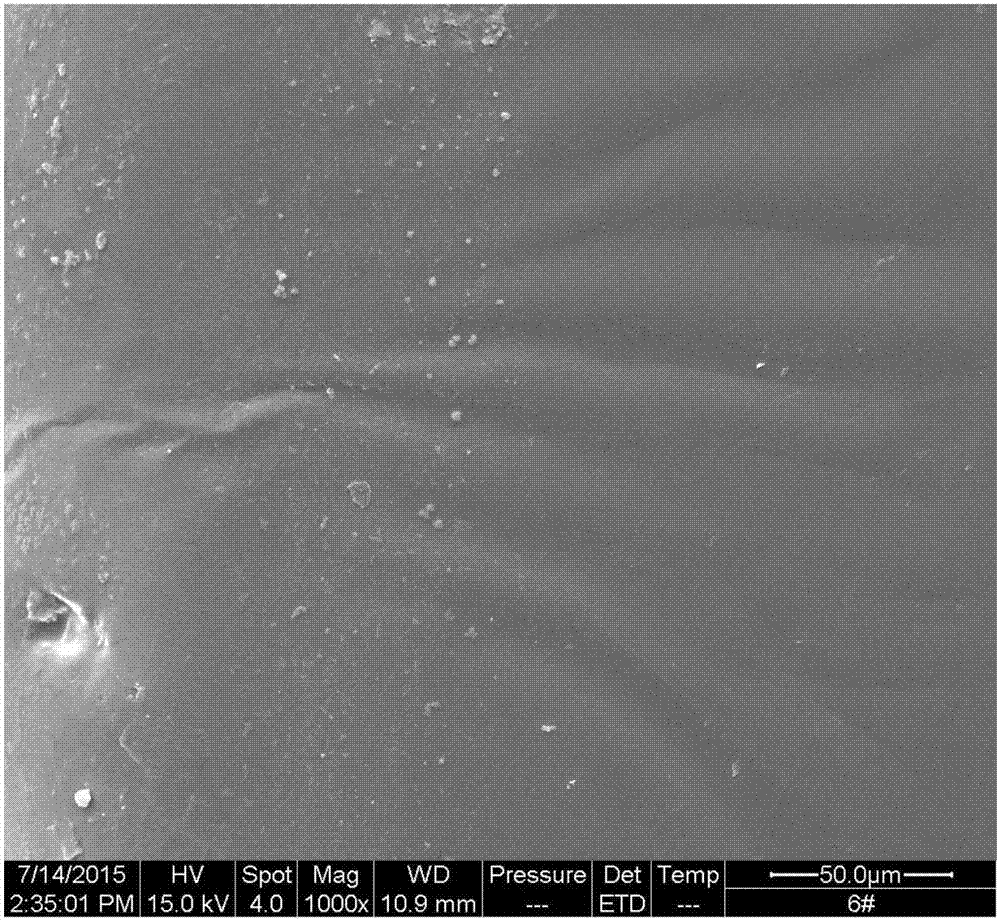

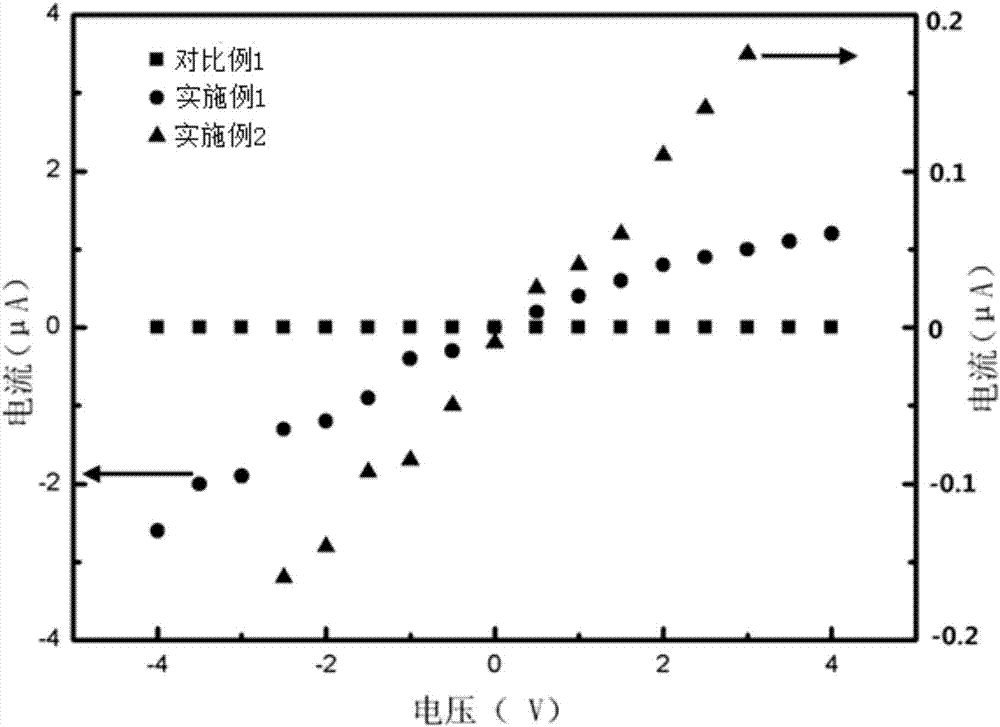

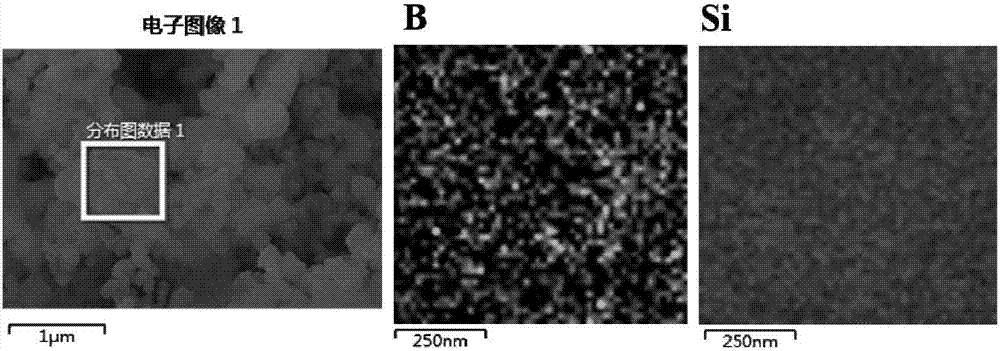

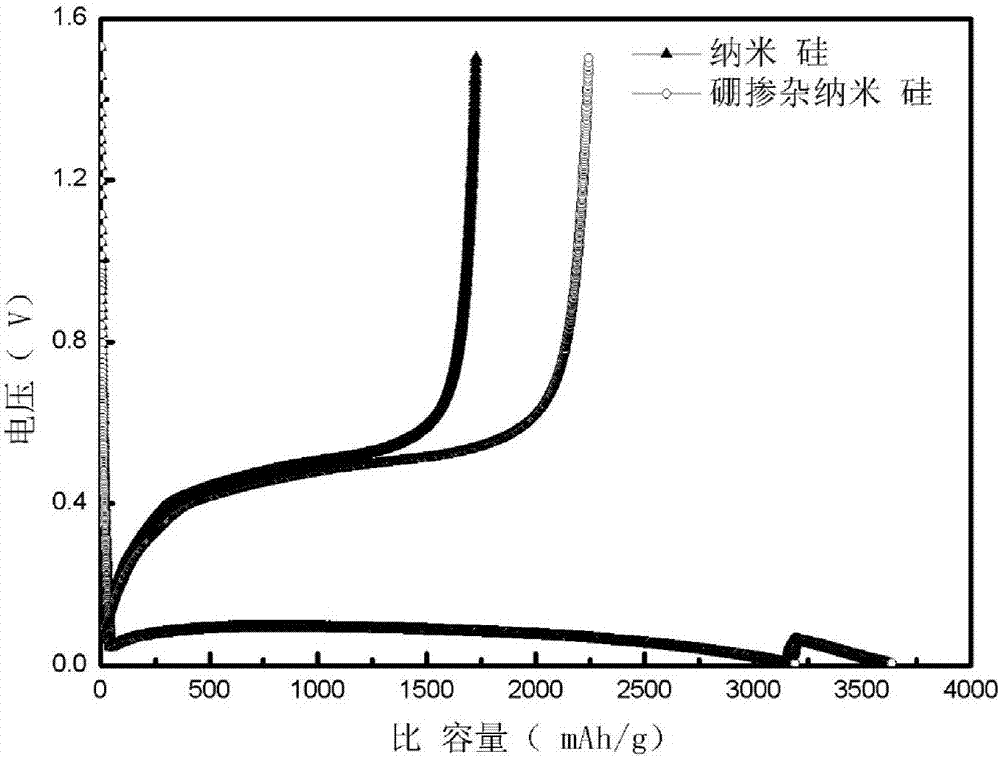

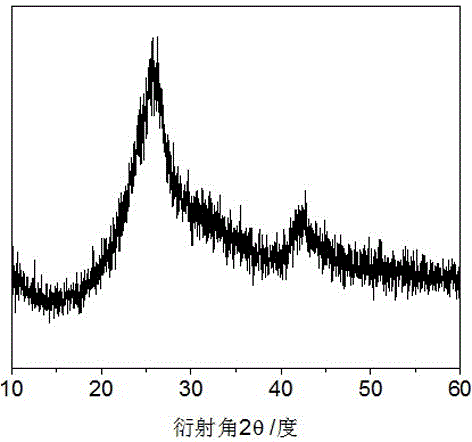

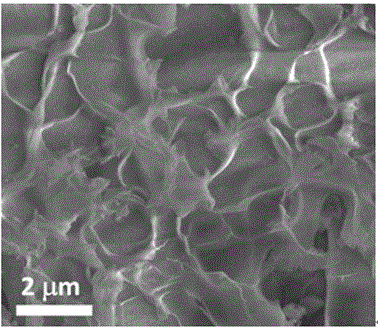

Boron-doped silicon-based negative electrode material used for lithium ion battery

InactiveCN107195893ASimple preparation processEasy to operateMaterial nanotechnologyCell electrodesGraphiteBoron trioxide

The invention discloses a boron-doped silicon-based negative electrode material used for a lithium ion battery. The boron-doped silicon-based negative electrode material is prepared from a boron-doped nanometer silicon material and graphite in a compounding manner, wherein the mass percentage of the boron-doped nanometer silicon material is 3-100%, and the balance is graphite. Diboron trioxide is gradually diffused to the silicon negative electrode material in a high-temperature sintering process to replace a part of silicon atoms to form displacement type doping, so that vacancy carrier concentration in the nanometer silicon material is improved, thereby improving the intrinsic electron conductivity of the silicon material; volume expansion of the silicon material can be buffered by graphite; and the boron-doped silicon-based negative electrode material has simple preparation process, convenience in operation, natural and easily available raw materials, low cost, convenience in subsequent processing mode, and easy realization of large-scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Magnesium oxide foam ceramic filter

InactiveCN101164656AImprove protectionEasy to operateFiltration separationCeramicwareBoron carbideMethyl cellulose

The present invention relates to an aluminium oxide foamed ceramic filter with special high-temperature chemical stability. Said aluminium oxide foamed ceramic filter is made up by adopting the following steps: using magnesium oxide, boron carbide and boron trioxide to form ceramic powder, then adding methyl cellulose and water to prepare slurry, using soft polyurethane foamed plastics as carrier, impregnating said carrier with said slurry, extruding to make blank material, drying and sintering so as to obtain the invented magnesium oxide foamed ceramic filter. The invented foamed ceramic filter has good high-temperature stability in the molten magnesium alloy, does not contaminate alloy and possesses good filtering and adsorption efficiency for removing oxide impurity and flux impurity form molten magnesium alloy, so that its filtering purification effect is good.

Owner:晋城市富基新材料股份有限公司

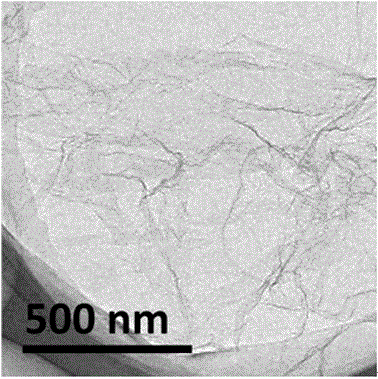

Compounding method for nanometer ultrathin boron carbon nitrogen sheet

ActiveCN106430128AThe synthesis process is simpleGood controllabilityNitrogen and non-metal compoundsOrganocatalysisBoron trioxide

The invention discloses a compounding method for a nanometer ultrathin boron carbon nitrogen sheet and belongs to the technical field of material preparation. The method comprises the following steps: mixing diboron trioxide, melamine, glucose and the mixed salt of NaCl and KCL, then grinding, and performing heat treatment on the acquired powder under the atmosphere of ammonia gas, thereby acquiring the nanometer ultrathin boron carbon nitrogen sheet. According to the invention, the low-cost mixed salt and the boron carbon nitrogen precursor have a heating reaction under the atmosphere of ammonia gas, and the fused mixed salt is utilized as a template of the boron carbon nitrogen sheet, is evaporated at high temperature and is peeled, so that the nanometer ultrathin boron carbon nitrogen sheet characterized by having a graphite like phase crystal structure, the thickness of an atom-level ultrathin sheet, a huge size and a high specific area can be prepared. The compounding method disclosed by the invention is simple in operation; complex and expensive instruments and equipment are not required; the adopted raw materials are low in cost and are easily acquired; the environmental pollution is little; the method is suitable for large-scale production; and the compounding method has significance in boosting the application of the nanometer ultrathin boron carbon nitrogen sheet in the fields of photoelectric materials, organic catalysis, hydrogen storage carriers, detection analysis, and the like.

Owner:FUZHOU UNIV

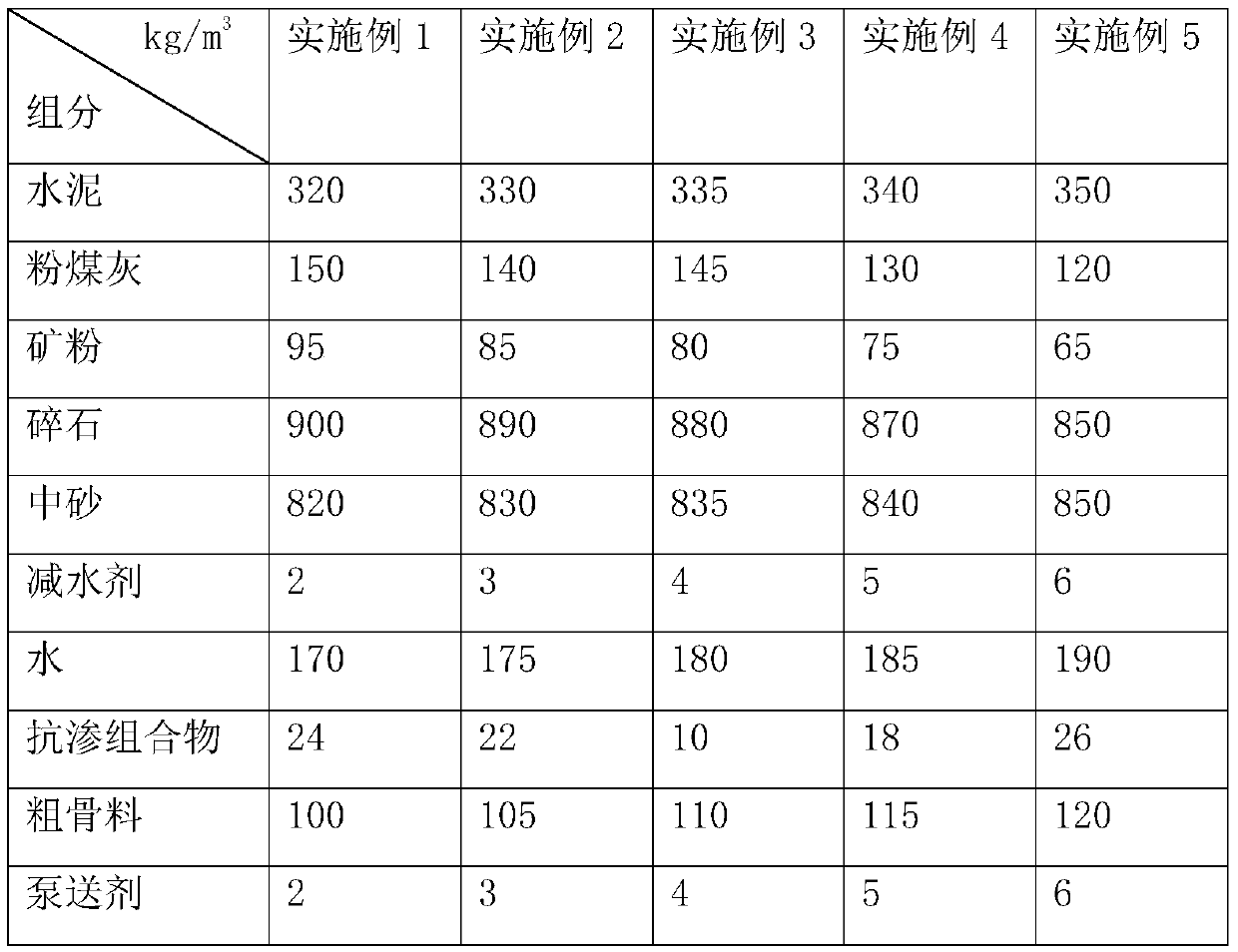

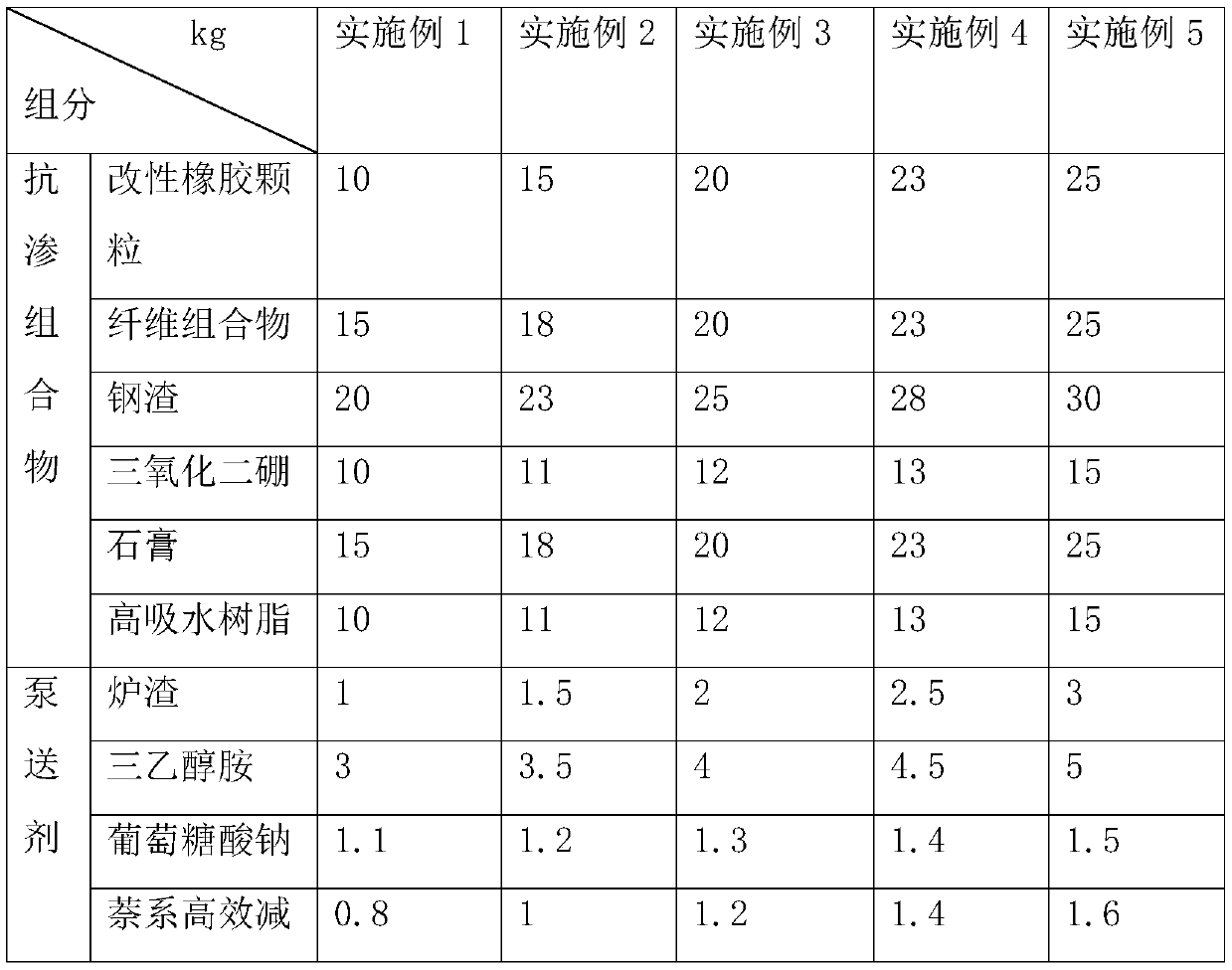

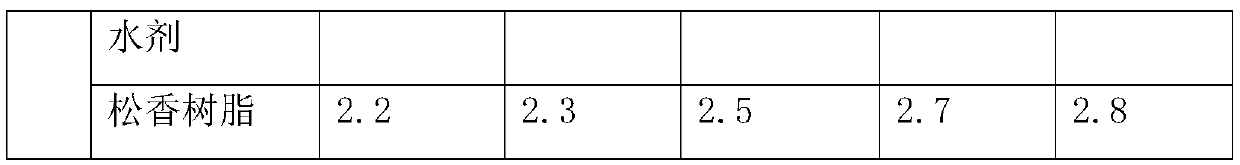

High-strength impervious concrete and preparation method thereof

The invention discloses high-strength impervious concrete and a preparation method thereof. the high-strength impervious concrete comprises the following components in parts by weight: 320-350 parts of cement, 120-150 parts of fly ash, 65-95 parts of mineral powder, 850-900 parts of crushed stone, 820-850 parts of medium sand, 2-6 parts of a water reducing agent, 170-190 parts of water, 10-26 parts of an impervious composition, and 100-120 parts of a coarse aggregate, wherein the impervious composition comprises the following components in parts by weight: 10-25 parts of modified rubber particles, 15-25 parts of a fiber composition, 20-30 parts of steel slag, 10-15 parts of boron trioxide, 15-25 parts of gypsum, and 10-15 parts of superabsorbent resin, and the fiber composition comprises carbon fiber, polypropylene fiber, calcium formate and polyamide with a mass ratio of 1:0.7-1.4:0.4-0.8:1.5-2.5. The high-strength impervious concrete has the advantages of high strength, good impermeability and easy pumping.

Owner:青岛金磐石新型建材有限公司

Sealing glass material and preparation method thereof

The invention discloses a sealing glass material and a preparation method thereof; silicon dioxide and boron trioxide are used as a skeleton structure and a network forming body for glass, wetting property and interface stability of the glass and titanium and a titanium alloy can be increased by adding of the boron trioxide, phase separation and crystallization problems are not easy to cause afterannealing and other heat treatment steps; alkali metal elements are used to lower melting temperature and increase expansion coefficient, and positive ions Mg<2+>, Ca<2+>, Sr<2+>, and Ba<2+> are filled into network spaces to produce mixed alkali effect and pressing effect to hinder the activity of alkali metal ions and improve the insulation performance of the glass; Al2O3 is added to form AlPO4units in the glass, and a linear structure is changed into a network structure, so that the structure of the glass tends to be stable, and the chemical stability is improved; ZnO and TiO2 oxides are added to improve the chemical stability and electrical insulation of the glass. The expansion coefficients of the sealing glass are matched, and the mechanical strength and chemical stability of the sealing glass are enhanced.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Unleaded glass powder used for electronic paste and preparation method thereof

The invention provides an unleaded glass powder used for electronic paste and a preparation method thereof. The unleaded glass powder is composed of the following components by mass ratio: 10-60% of diboron trioxide, 2.5-30% of silicon dioxide, 30-75% of bismuth trioxide, 0.1-5% of sodium oxide, 0.1-3% of calcium oxide, 0.5-10% of strontium oxide, 1.5-20% of titanium dioxide, 0.5-8% of zirconium oxide, 0.1-5% of stannic oxide, 0.5-6% of aluminium oxide, 0.5-5% of antimonous oxide and 0.1-5% of calcium fluoride, the components are fully mixed to be uniform and then heated to 1050-1250 DEG C, and heat preservation is carried out for 30-120min, so that raw material is fully melted into glass metal, the glass metal is poured into deionized water to be quenched into glass granules, and ball milling into 320-400 meshes is carried out, thus obtaining the unleaded glass powder. The invention provides an unleaded glass powder with low softening temperature, good chemical stability, appropriate expansion coefficient, acid-base resistance, good abrasive resistance, wide sintering temperature range, low manufacturing cost and no toxic heavy metal oxide, and the unleaded glass powder has wide application range.

Owner:KUNMING UNIV OF SCI & TECH

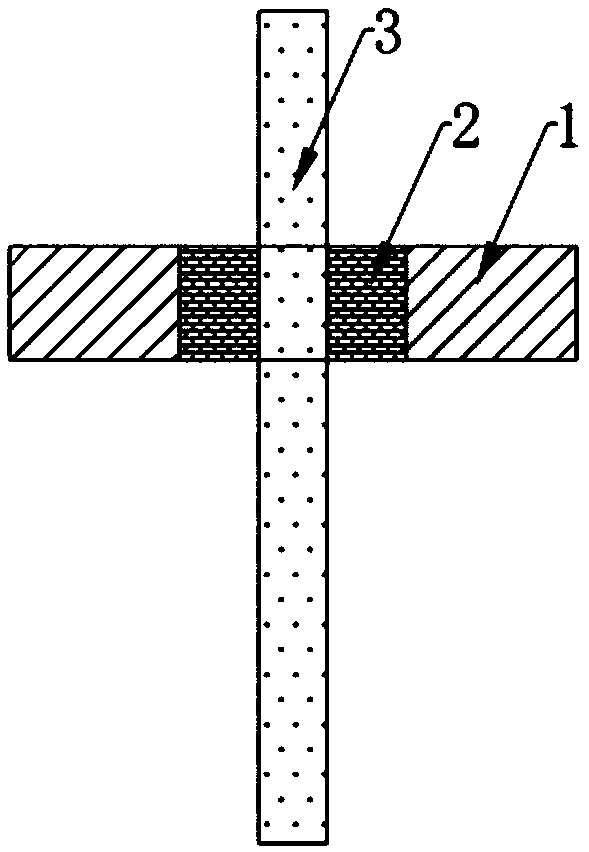

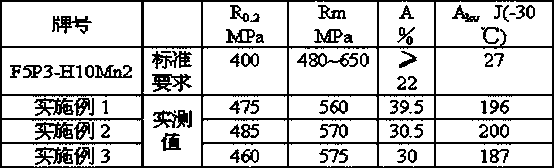

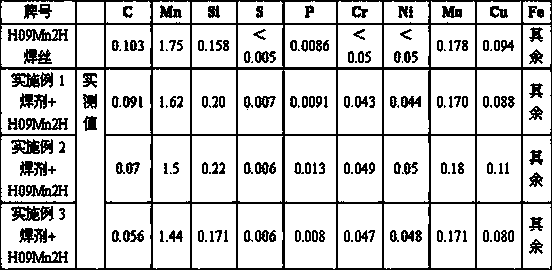

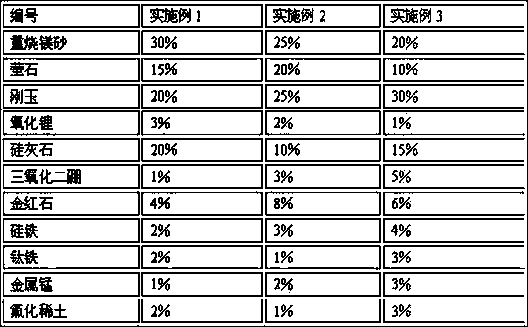

High-toughness sintered flux for submerged-arc welding, and preparation method thereof

The invention relates to a high-toughness sintered flux for submerged-arc welding. The high-toughness sintered flux comprises dry powder and a binding agent, wherein the dry powder comprises the components by weight percent: 20-30% of dead-burned magnesite, 20-30% of corundum, 10-20% of fluorite, 10-20% of wollastonite, 1-3% of lithium oxide, 4-8% of rutile, 2-4% of silicon iron, 1-3% of ferrotitanium, 1-3% of manganese metal, 1-5% of diboron trioxide and 1-3% of rare earth fluoride; potash water glass is adopted as the binding agent. The sintered flux is good in welding technology performance. When being used for welding, the high-toughness sintered flux is stable in electric arc, attractive in weld joint formation and moderate in weld joint infiltration angle, and enables slag at the bottom layer in a groove of a thick plate to be very easily cleaned. The high-toughness sintered flux can be matched with most carbon steel welding wires for use, is good in comprehensive mechanical properties, and especially has higher low temperature impact toughness.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Medicinal glass pipe prepared by full electric melting wilo method and manufacturing method thereof

InactiveCN101033115ASolve the problem of small expansion coefficient and acid resistanceSolve the problem of weak alkali resistanceTank furnacesGlass furnace apparatusPotassiumBoron trioxide

This invention relate to a medical glass tube drawn by the Wieluo method and its preparation method, in which, the weight percentage includes: SiO2 71-77.1, Al2O3 5.2-7.1, B2O3 8.2-11.6, BaO 0.6-2.6, CaO 1.2-2.4, Li2O 4.6-7.7, K2O 5.0-7.4 and Na2O 5.1-7.6, and the preparation method includes: preparing raw materials, smelting the materials, drawing the tube to molding and cutting the gouge accurately, checking and packaging.

Owner:沧州四星玻璃股份有限公司

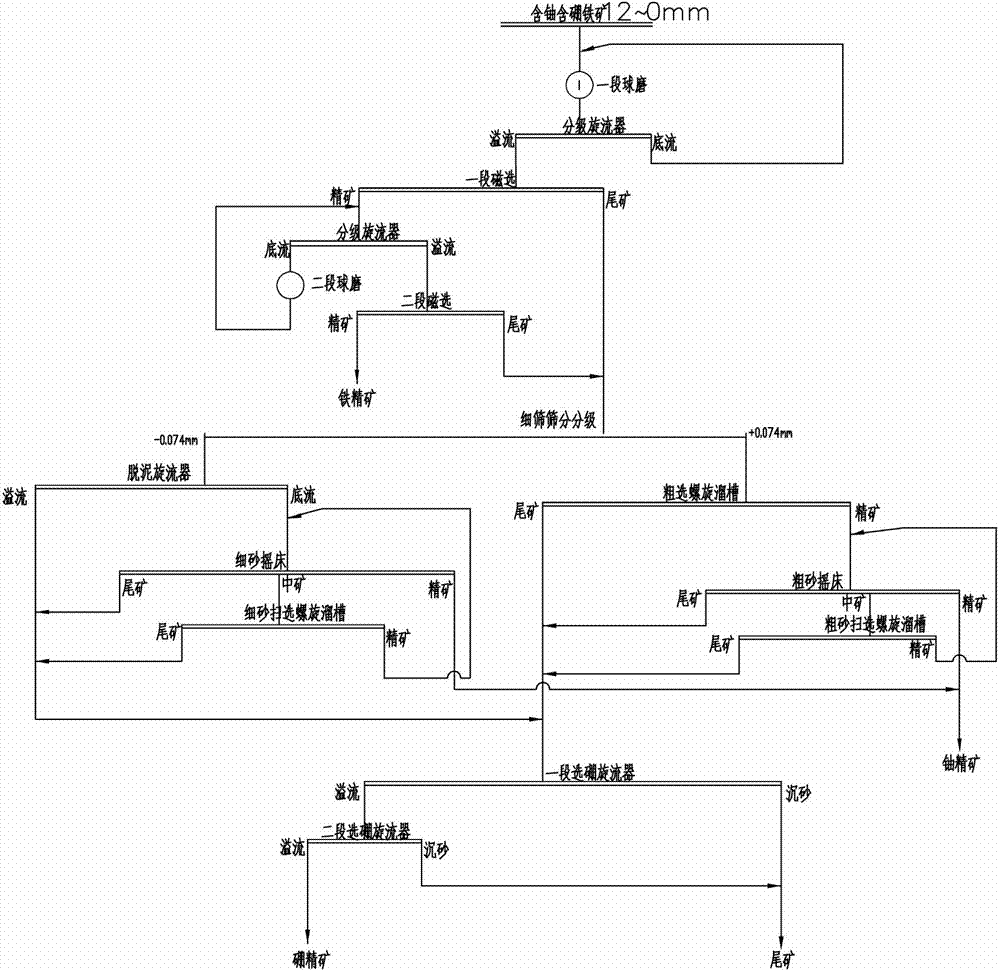

Growing method and growing device for indium phosphide single crystal

ActiveCN104911690AReduce dosageSimple processPolycrystalline material growthFrom frozen solutionsDopantVertical gradient

The invention provides a growing method for an indium phosphide single crystal. The method comprises the following steps: using a vertical gradient freeze method for heating indium phosphide seed, indium phosphide polycrystal, diboron trioxide and red phosphorus, and growing crystals to obtain the indium phosphide single crystal, wherein the red phosphorus takes up 0.05-0.1% of the total mass of the indium phosphide polycrystal, the diboron trioxide and the red phosphorus. By the provided growing method, the indium phosphide single crystal with substantially lower dislocation density can be obtained without adding dopant such as ferrum or sulfur, thereby simplifying the technology and saving the cost; moreover, the few red phosphorus (only one tenth of the dosage of the red phosphorus in the prior art) is used in the preparation method, thereby reducing the danger during the production. It is shown by experiments that the average dislocation density of the indium phosphide single crystal obtained by the provided growing method is 2000-4000 / cm2, with the local dislocation density being less than 500 / cm2. The invention further provides a growing device of the indium phosphide single crystal.

Owner:威科赛乐微电子股份有限公司

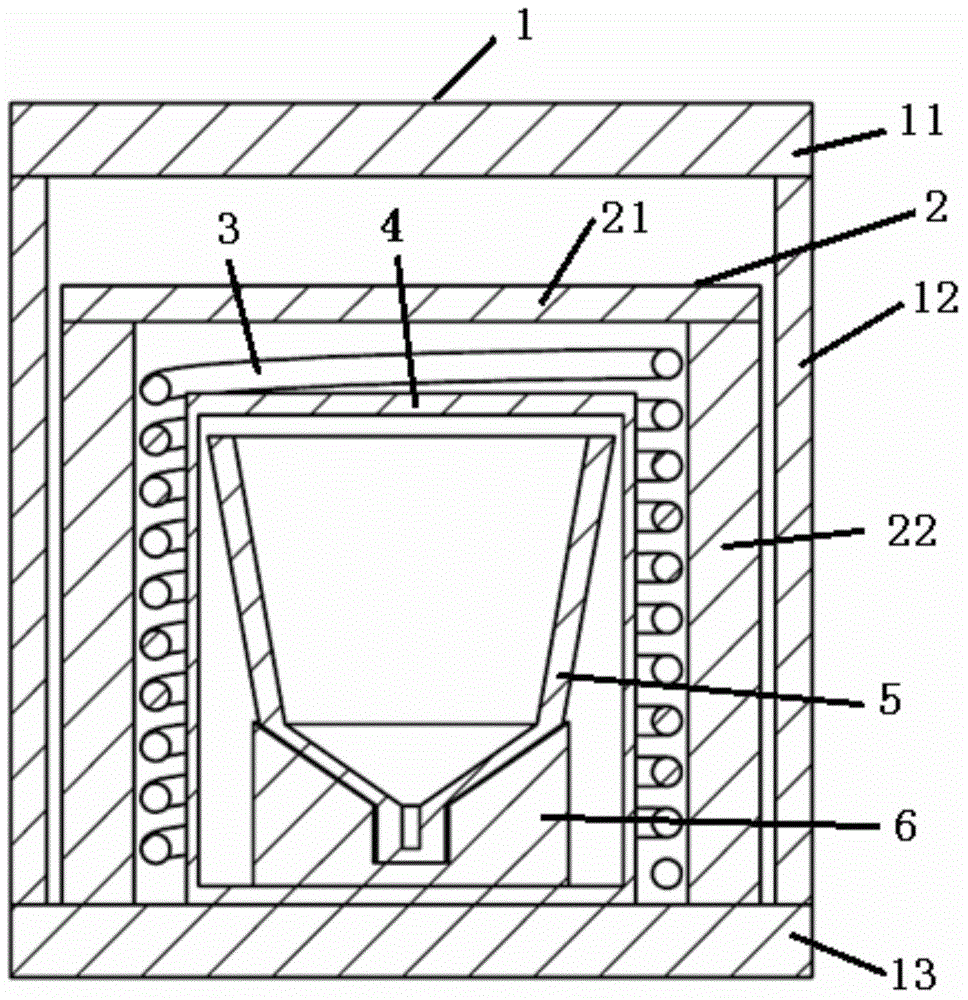

Uranium-bearing paigeite separating process

ActiveCN104258980AMeets granularity requirementsGood sorting indexWet separationEconomic benefitsBoron trioxide

The invention relates to a uranium-bearing paigeite separating process. The uranium-bearing paigeite separating process is characterized by comprising an iron concentrate separating process, a uranium concentrate separating process and a boron concentrate separating process. The iron concentrate separating process comprises two-section ball grinding and adopts a sectional grinding and sectional separation process, wherein the two-section ball grinding guarantees that the -0.043 mm fraction content of final boron concentrate can be less than 80% and meets the granularity requirements of boron industry on the boron concentrate; a uranium concentrate separating system utilizes a fine screening and grading process to perform pre-gravity-separation processing and treatment on magnetic-separated tailings to achieve hierarchical separation and improve the separation indexes; the recovery rate of both diboron trioxide and uranium inside the comprehensive magnetic-separated tailings of an iron concentrate separating system can reach up to more than 66%, the recovery rate of diboron trioxide inside the comprehensive tailings of the uranium concentrate separating system can reach 60%-65%, the recovery rate of final iron concentrate can reach more than 80%, the recovery rate of final uranium concentrate can reach 35%, and the recovery rate of the final boron concentrate can reach 35%. Therefore, good economic benefits can be obtained.

Owner:中冶北方(大连)工程技术有限公司

Low-temperature sintered composite microwave dielectric ceramic material and preparation method thereof

The invention discloses a low-temperature sintered medium-dielectricconstant high-quality-factor microwave dielectric ceramic material and a preparation method thereof. The low-temperature sintered composite microwave dielectric ceramic material is composed of an Li2O-Nb2O5-TiO2 material and a composite burning reducer which accounts for 1-10 wt% of the main crystal phase. The low-temperature sintered composite microwave dielectric ceramic material is obtained by solid-phase reaction. The composition of the Li2O-Nb2O5-TiO2 material is LiaNbbTicO3, wherein 2<a<2.2, 0.2<b<0.3, and 0.6<c<0.7. The composite burning reducer is prepared from the following raw materials: lithium carbonate (Li2CO3), zinc oxide (ZnO), aluminum oxide (Al2O3), calcium oxide (CaO), silicon dioxide (SiO2), boron trioxide (B2O3) and trace amounts of additive components. The low-temperature sintered LTCC (low temperature co-fired ceramic) microwave dielectric ceramic disclosed by the invention has the advantages of good sintering property at 850-900 DEG C, the medium dielectric constant (Epsilonr is 18-24), high quality factor Qf and low temperature coefficient of resonance frequency, can be used for manufacturing a LTCC system, multilayered medium resonator, microwave antenna, filter or any other microwave device, and has great industrial application value.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

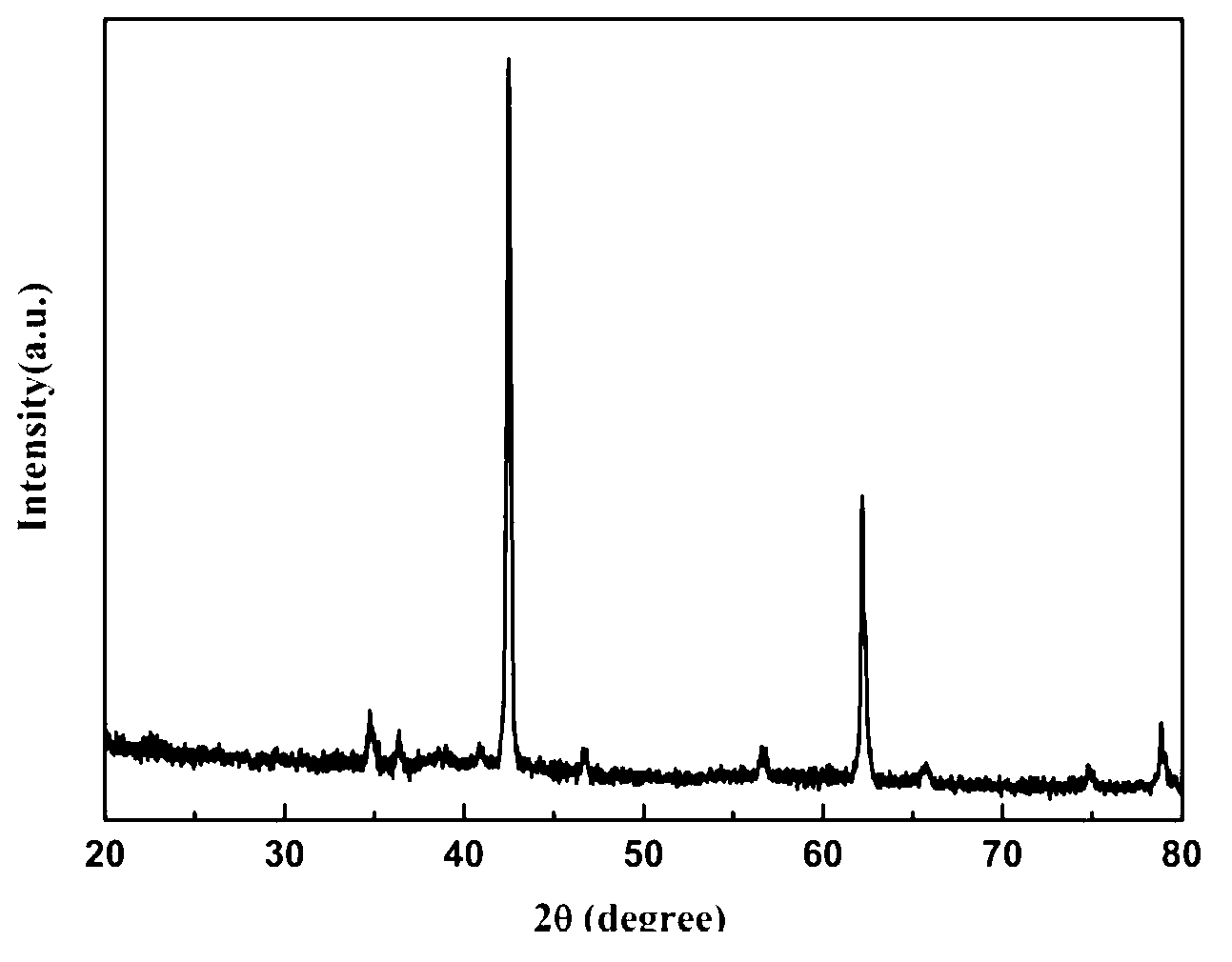

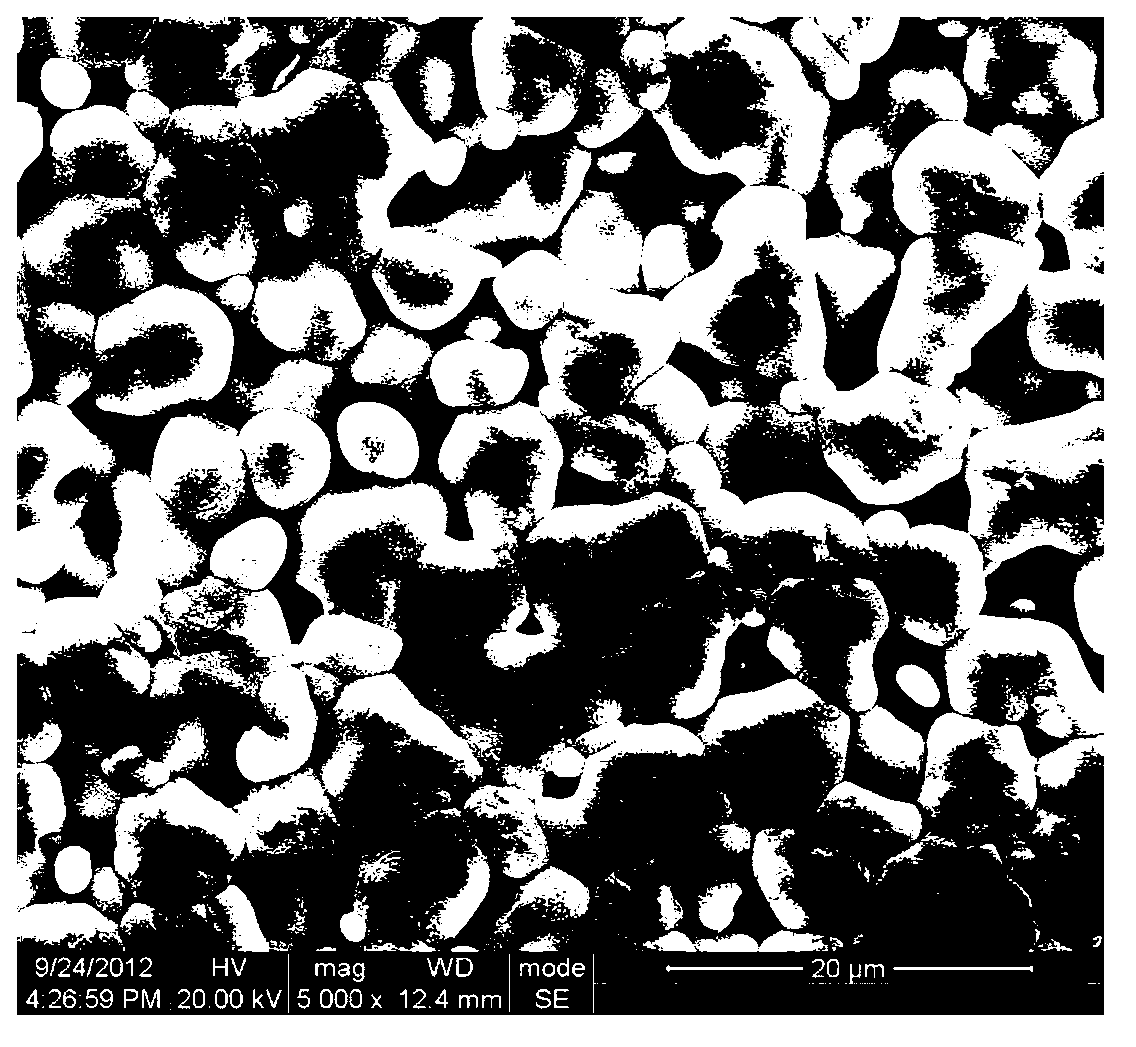

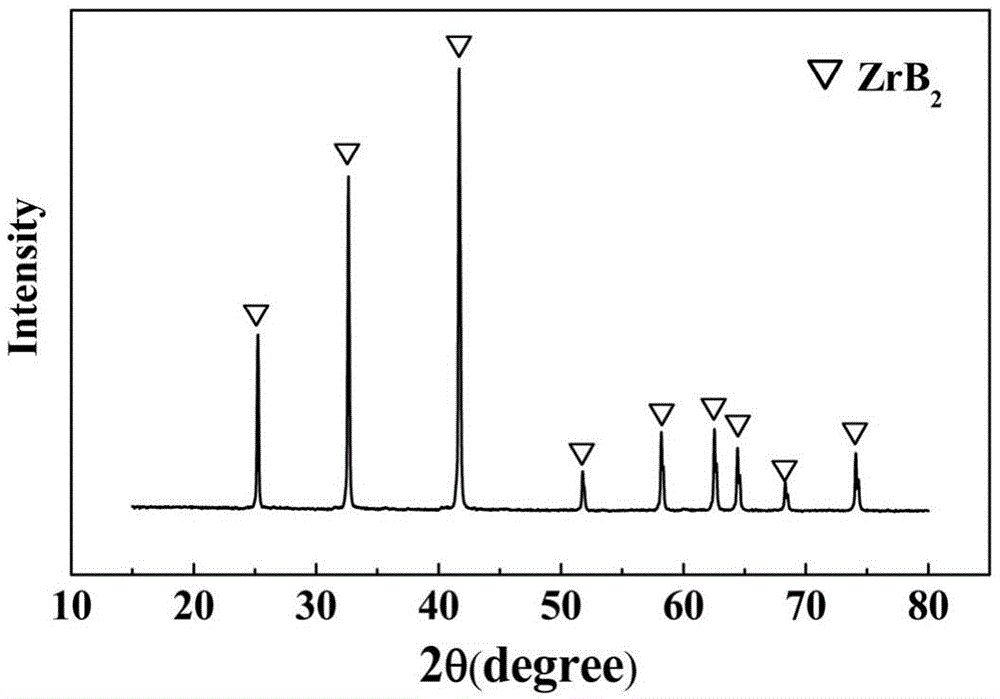

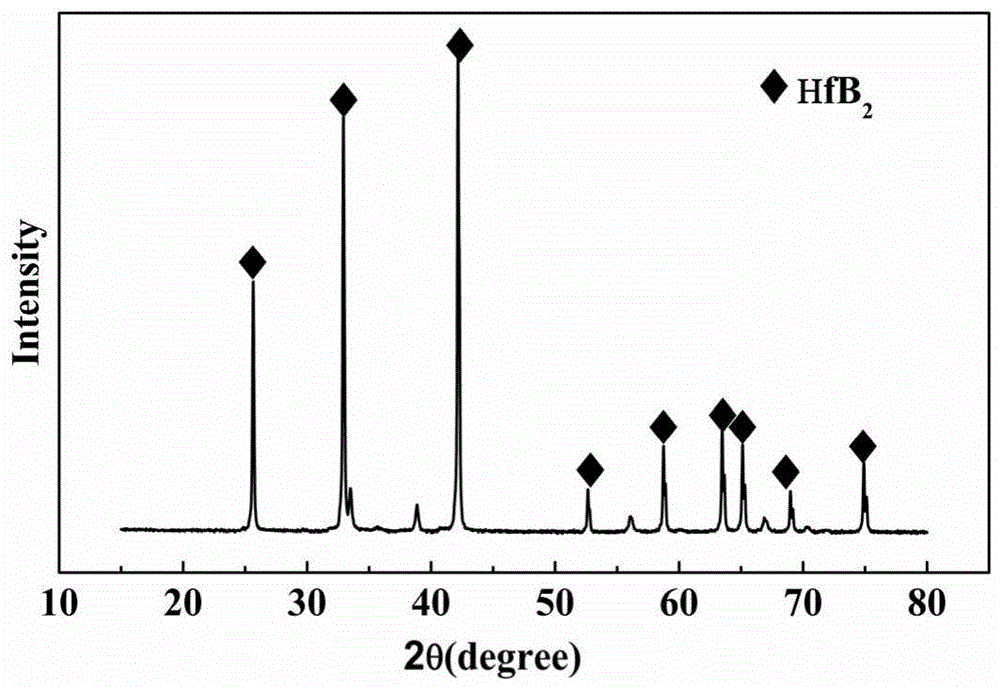

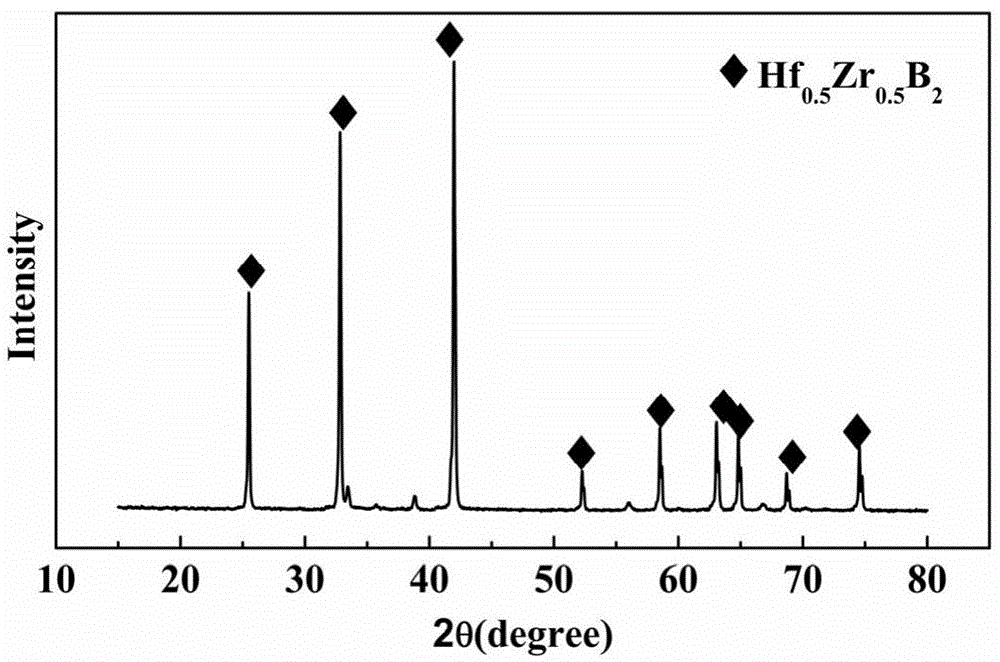

Preparation method and application of boride ceramic precursor

The invention provides a preparation method and application of a zirconium (Zr) and hafnium (Hf) boride superhigh-temperature ceramic liquid-phase precursor. According to the preparation method disclosed by the invention, the boride ceramic precursor is prepared by taking water-soluble inorganic salts of zirconium (Zr) and hafnium (Hf) as the sources of metal elements in corresponding ceramics, a mixture of water-soluble hydroxycarboxylic acid and water-soluble polyalcohol as a carbon source, diboron trioxide and boric acid as corresponding boron sources and distilled water as a solvent; corresponding boride ceramic powder is prepared through crosslinking splitting. The ceramic precursor provided by the invention has the advantages of low cost, low toxicity and environmental protection, simplicity in preparation, good stability in air, long-time placing and the like. The prepared boride ceramic powder has the characteristics of relatively high purity, good crystallinity, small particle size and the like. The preparation method of the boride precursor is expected to be applied to the synthesis and preparation of a superhigh-temperature ceramic precursor, preparation of a composite material through precursor transformation, preparation of superfine superhigh-temperature ceramic powder and the like.

Owner:NAT UNIV OF DEFENSE TECH

Porcelain enamel glaze composition, film coating material and preparation thereof

ActiveCN101497496AImprove wear resistanceImprove corrosion resistanceElectrophoretic coatingsLiquid/solution decomposition chemical coatingLithium oxideSilicon oxide

The invention provides a porcelain enamel glaze material composition, which contains zinc oxide, diboron trioxide, zirconium oxide, silicon oxide and sodium oxide, wherein the composition also contains aluminum oxide or a compound which can generate the aluminum oxide after sintering, calcium oxide or a compound which can generate the calcium oxide after sintering, barium oxide and lithium oxide. The invention also provides a film coating material prepared from the porcelain enamel glaze material composition and a method for preparing the same. The film coating material has the advantages of better bonding force, wear resistance and corrosion resistance, and small surface roughness.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

All-electric viilo drawn medicinal glass tube and method for making the same

ActiveCN101182115ASolve acid resistanceSolve weak alkalineGlass drawing apparatusLithium oxideSesquioxide

The invention provides a medicinal glass tube which is made through a whole fused villo method and a preparation method, belonging to the medicine packing technical field and aiming at solving problems of weak acid-resistance and alkaline-resistance, low mechanical-resistance strength and easy break of a present medicinal glass tube. Used raw materials in weight portion include 71.0-77.1 portions of silicon dioxide (SiO2), 5.2-7.1 potions of aluminium sesquioxide (Al2O3), 8.2-11.6 potions of boron trioxide (B2O3), 0.2-2.6 potions of barium oxide (BaO), 0.2-2.4 portions of calcium oxide (CaO), 0.2-1.0 portions of lithium oxide (LiO), 0.5-7.4 portions of potassium oxide (K2O) and 5.1-7.6 portions of sodium oxide (Na2O). The manufacturing method consists of procedures of the raw materials preparation, the fused melting plastics heating, the villo stretching forming, the precise cutting, the mouth rounding and the packing. The invention has the advantages of optimal expansion coefficient and high mechanical-resistance strength and is applied to the manufacturing of medicinal glass vessels for containing medicine liquids and medicines, the chemical pipes, etc.

Owner:沧州四星玻璃股份有限公司

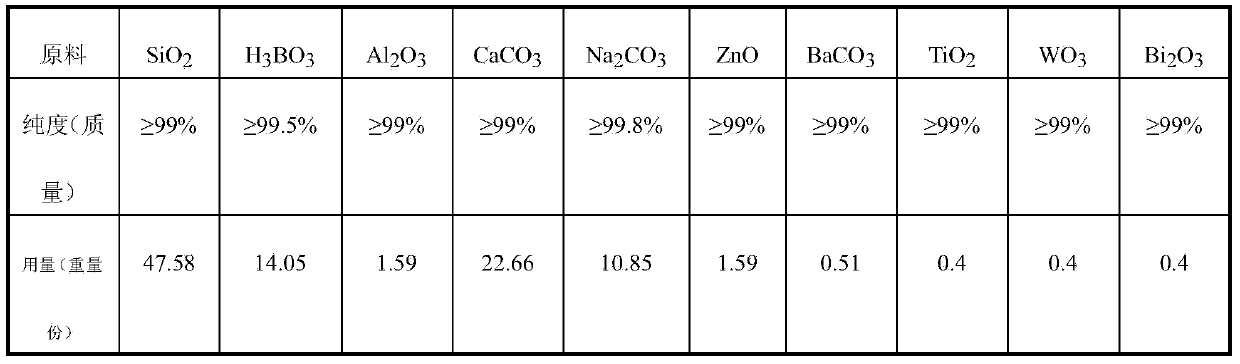

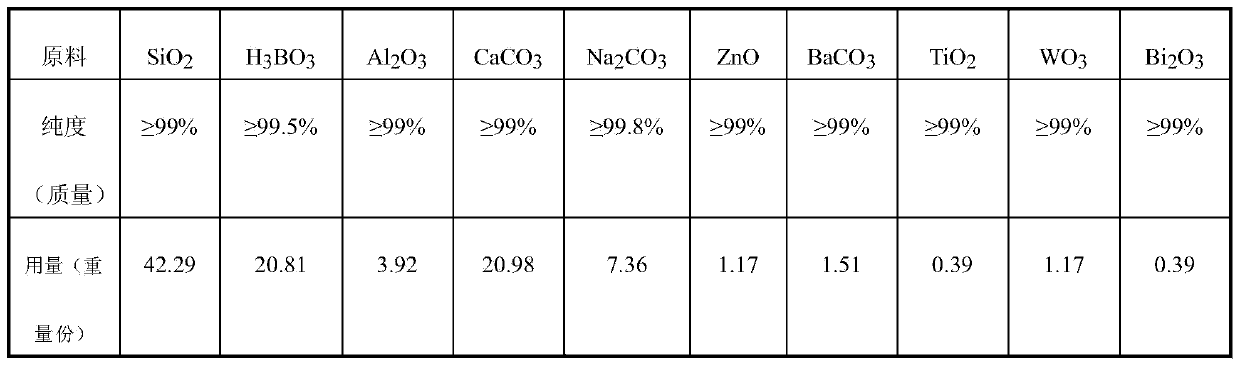

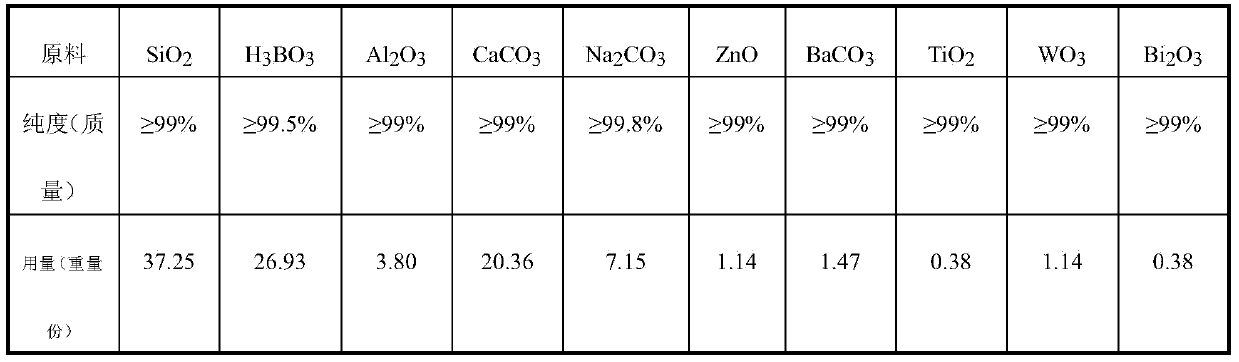

Method for preparing diamond grinding wheel ceramic bond with low sintering temperature and high strength

InactiveCN103770035ASolve complexitySolve the costAbrasion apparatusGrinding devicesBoron trioxideTungsten trioxide

The invention provides a method for preparing diamond grinding wheel ceramic bond with low sintering temperature and high strength. The method includes the following steps of (1) mixture calculation, (2) melting and (3) water quenching and grinding, wherein the step (1) includes that raw mineral materials and chemical materials are used as the source of oxide, the mixture calculation is performed according to the oxide and the content thereof in the raw mineral materials and the chemical materials, and oxide compositions and contents thereof by weight part in the materials meet the following requirement, that is to say 40-60 parts of silicon dioxide, 10-30 parts of diboron trioxide, 2-6 parts of aluminum oxide, 12-16 parts of calcium oxide, 2-8 parts of sodium oxide, 0.5-2 parts of zinc oxide, 0.5-1.5 parts of barium oxide, 0.5-1 part of titanium dioxide, 0.5-2 parts of tungsten trioxide and 0.5-1 part of bismuth oxide, and after the step (3), the diamond grinding wheel ceramic bond with the low sintering temperature and the high strength can be obtained. The method is simple in preparing process and low in costs, and the obtained diamond grinding wheel ceramic bond is good in performances.

Owner:WUHAN UNIV OF TECH

High alumina slag ball and preparing method thereof

InactiveCN1521279AAvoid bursting phenomenonReduce inclusionsProcess efficiency improvementSlagSesquioxide

The high-aluminum slag ball used as molten steel surface heat insulating and refining agent in smelting pure steel contains metal aluminum, alunina, titania, boron sesquioxide, calcium carbonate, fluorite powder and evitable impurity. With controlled silica, carbon, sulphur and phosphorus contents, the high-aluminum slag ball is suitable for use in smelting low-carbon and low-silicon pure steel or other super-pure steel. It has low water content to avoid molten steel sputtering and content of deoxygenating and alloying elements capable of being altered in wide range to suit for steel variety change. It has excellent performance of heat insulating for the surface of molten steel, and makes the deoxygenation and refining completed simultaneously to reduce included oxide in molten steel.

Owner:梅一峰

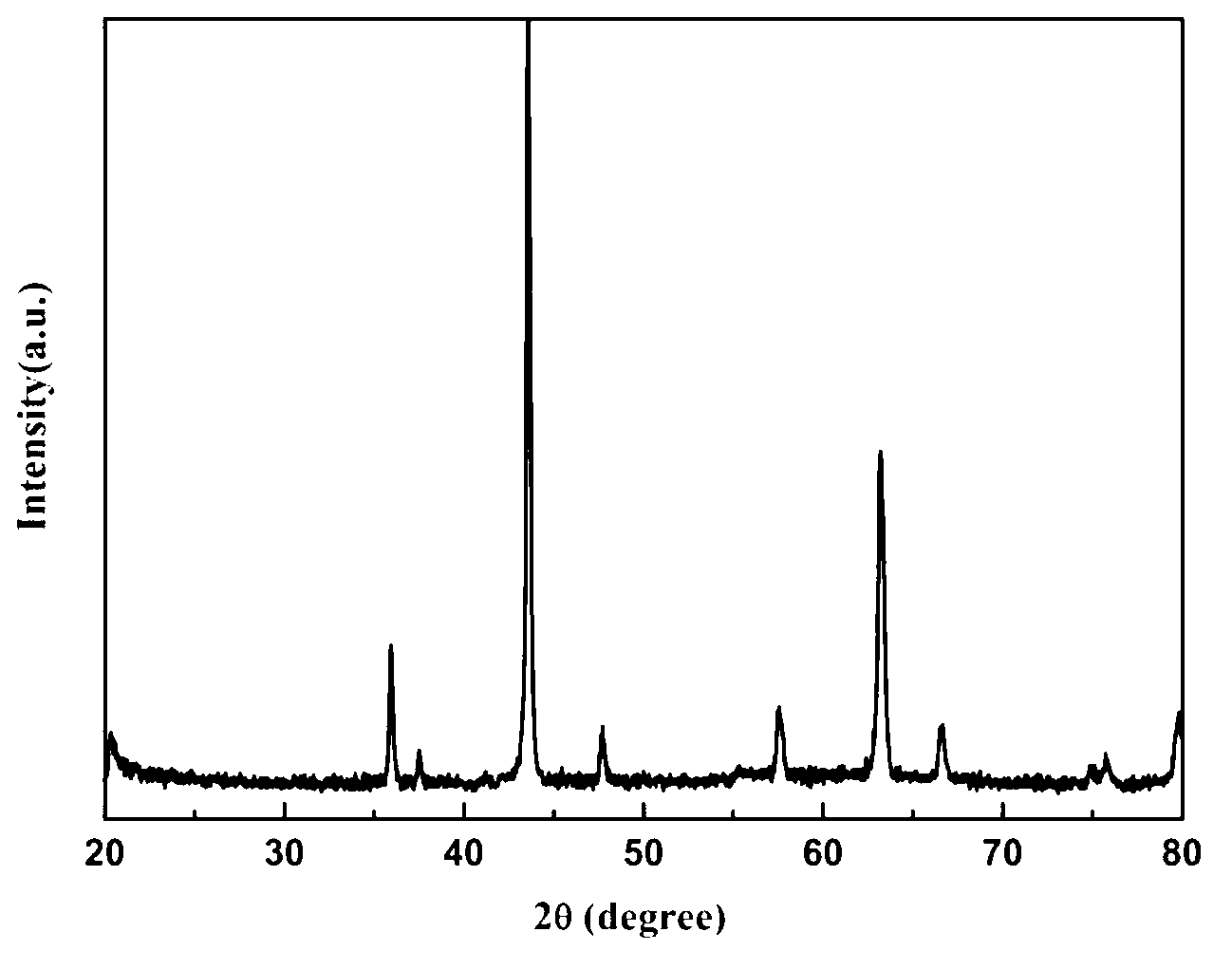

Boron carbide micro powder and preparation method thereof

InactiveCN101804980AEasy to manufactureSuitable for large-scale productionRoom temperatureBoron carbide

The invention discloses a preparation method of a boron carbide micro powder, which comprises the following steps: 1) mixing boron trioxide with bamboo carbon micro powder in the molar ratio of 2 to 7 at room temperature; and then mechanically grinding and crushing the mixture so as to obtain a homogeneous composite precursor; and 2) heating the homogeneous composite precursor in a vacuum sintering furnace for 1 to 4 hours at the temperature of 2,000 to 2,200 DEG C; and cooling the sintered product and taking the cooled product out so as to obtain boron carbide micro powder. The invention also provides the boron carbide micro powder prepared by the method. The boron carbide micro powder prepared by the method has the characteristics of high purity and controllable particle size distribution.

Owner:ZHEJIANG UNIV

Enamel material for 1Cr18Ni9Ti stainless steel surface and preparation method thereof

The invention provides an enamel material for 1Cr18Ni9Ti stainless steel surface and a preparation method thereof. The enamel material is prepared by sintering a raw material comprising the following ingredients: 39-42 parts by weight of silicon dioxide, 12-14 parts by weight of aluminum oxide, 6-9 parts by weight of titanium dioxide, 0.5-1 parts by weight of magnesium oxide, 5-7 parts by weight of zinc oxide, 3-5 parts by weight of calcium oxide, 0.5-3.5 parts by weight of nickel oxide, 5-7 parts by weight of boron trioxide and 18-20 parts by weight of sodium oxide. The enamel material provided by the invention has high temperature tolerance, the heat resistance temperature of the enamel material can be higher than 600 DEG C, the acid and alkali corrosion resistance is relatively excellent, the enamel material is guaranteed to be well matched with a 1Cr18Ni9Ti stainless steel base material under a high temperature, and the enamel material can be effectively prevented from dropping.

Owner:DATANG INT CHEM TECH RESINST +1

Lead-free solder glass

InactiveCN102010127AMeet environmental protection requirementsApplicable sealingBoron trioxideSilicon dioxide

The invention relates to lead-free solder glass, which comprises the following raw materials in percentage by weight: 35-55% of bismuth oxide, 15-25% of boron trioxide, 15-35% of zinc oxide, 0.1-10% of barium oxide, 0.1-10% of cuprous oxide, 0.1-10% of magnesium oxide, 0.1-10% of silicon dioxide, 0.1-10% of aluminum oxide, 0.1-3% of manganese dioxide, and 0.1-3% of titanium dioxide. The solder glass is lead-free, can realize lead-free electronic products under the condition of keeping a lower glass softening temperature, has the characteristics of low softening temperature, excellent chemical stability, large resistivity, and good mobility, is powerfully competitive in the aspects of lead free and excellent performance, and has high cost performance and wide market development prospect.

Owner:上海歌灵新材料科技有限公司

High-saturation iron-series pigment and production method thereof

ActiveCN102492312AEasy to get materialsLess materialInorganic pigment treatmentTin dioxideRefractive index

Owner:河北欧克新型材料股份有限公司

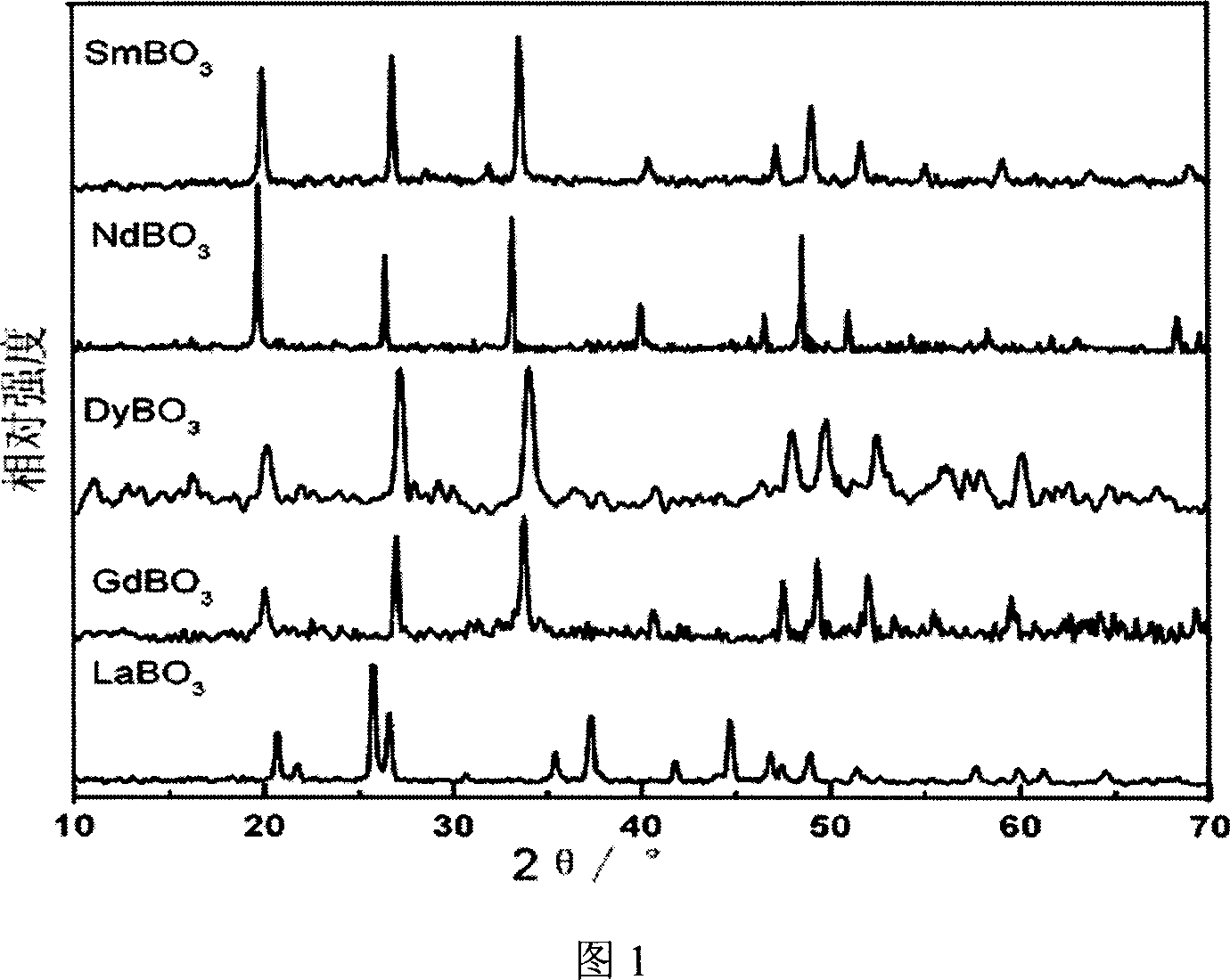

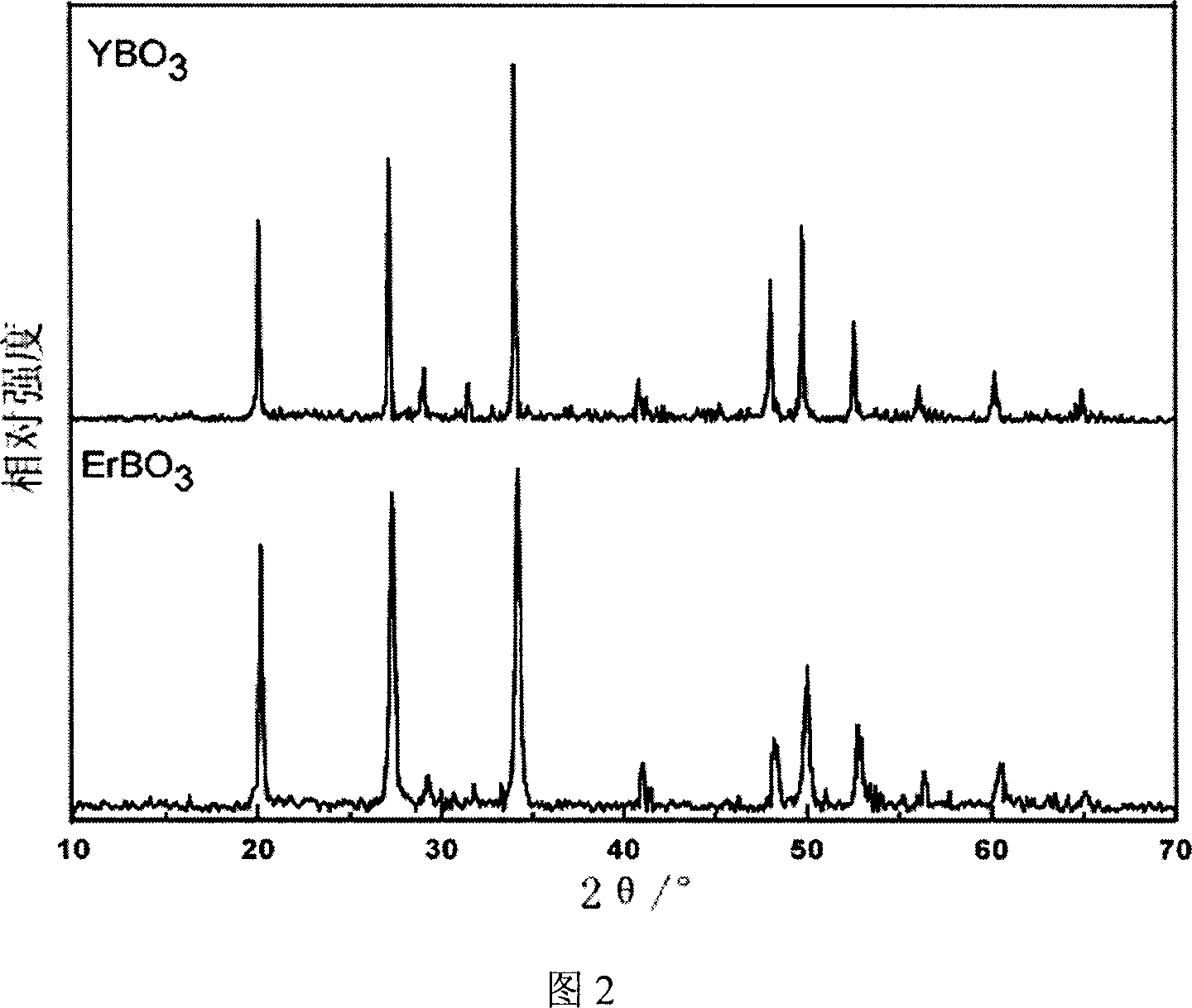

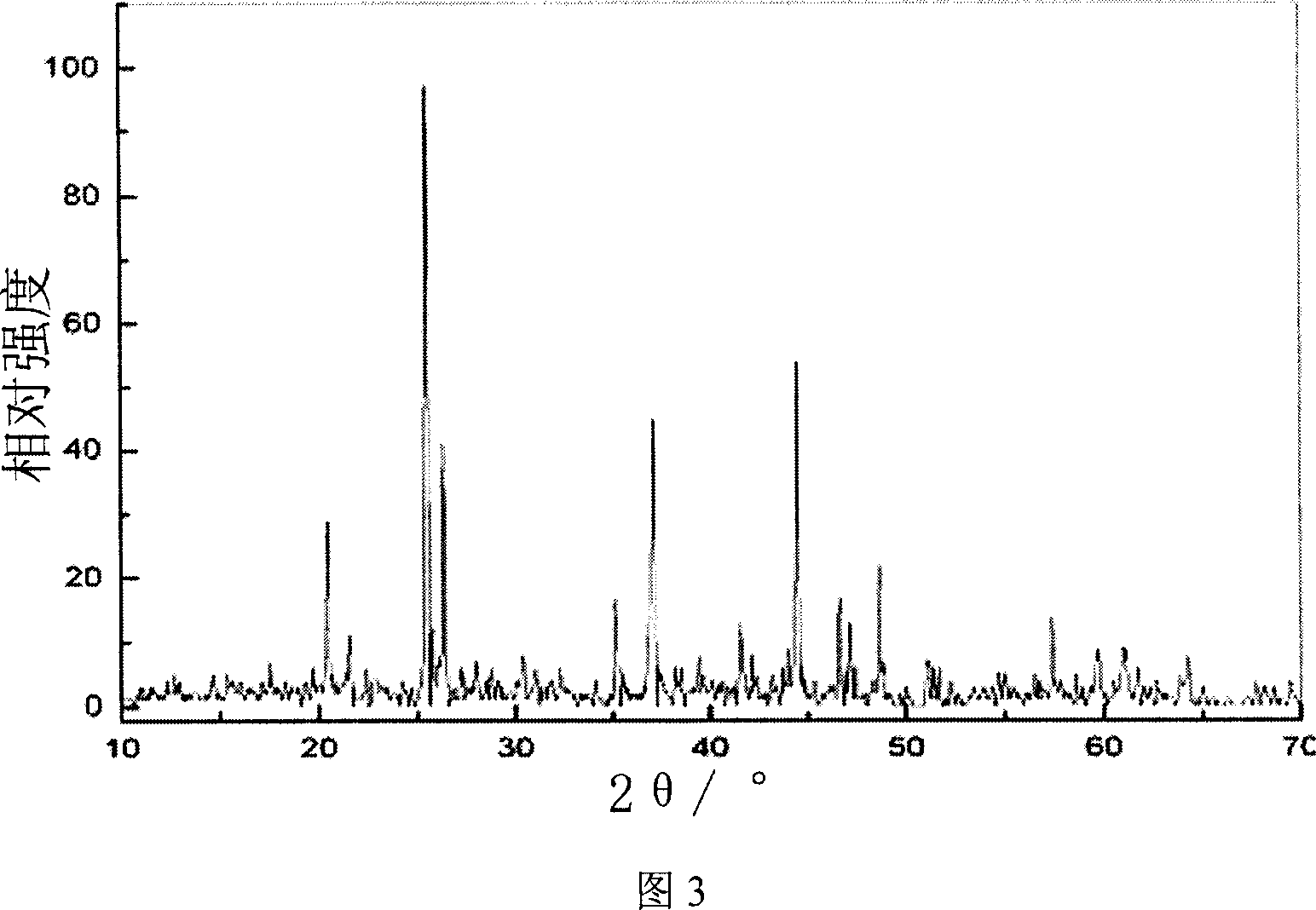

Low temperature process of preparing RE borate crystal with oxide as precursor

InactiveCN1974885AMeet the requirements of sustainable developmentEasy to operatePolycrystalline material growthFrom normal temperature solutionsRare earthHydrothermal synthesis

The present invention belongs to the field of micron / nanometer material preparing technology and hydrothermal synthesis technology, and is especially low temperature process of preparing RE borate crystal with oxide as precursor. In the hydrothermal system, insoluble RE oxide and hydrated boron trioxide or boron trioxide as the boron source and precursor are reacted at 190-280 deg.c for 12-48 hr, and through further washing, the required RE borate crystal is obtained. The present invention provides one inorganic synthesis way, and the production process has no any pollution. The present invention has simple technological process, easy-to-constitute reaction system, high product purity and other advantages, and is suitable for industrial production.

Owner:TONGJI UNIV

High-temperature anti-oxidation coating of high-temperature graphite electrode

The invention relates to a graphite electrode coating, and particularly relates to a high-temperature anti-oxidation coating of a high-temperature graphite electrode coated with a high-temperature anti-oxidation ceramic coating, belonging to the technical field of electrode production. The high-temperature anti-oxidation coating is prepared from the following raw materials in parts by weight: 15-50 parts of aluminum oxide, 5-30 parts of diboron trioxide, 1-5 parts of magnesium oxide, 0-5 parts of dispersing agent and 20-70 parts of soluble phosphate solution. By adopting the coating disclosed by the invention, the graphite electrode can be effectively prevented from being oxidized, so that the consumption and production cost of the graphite electrode are reduced.

Owner:JIANGXI HENGDA HI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com