Patents

Literature

305results about How to "Good controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

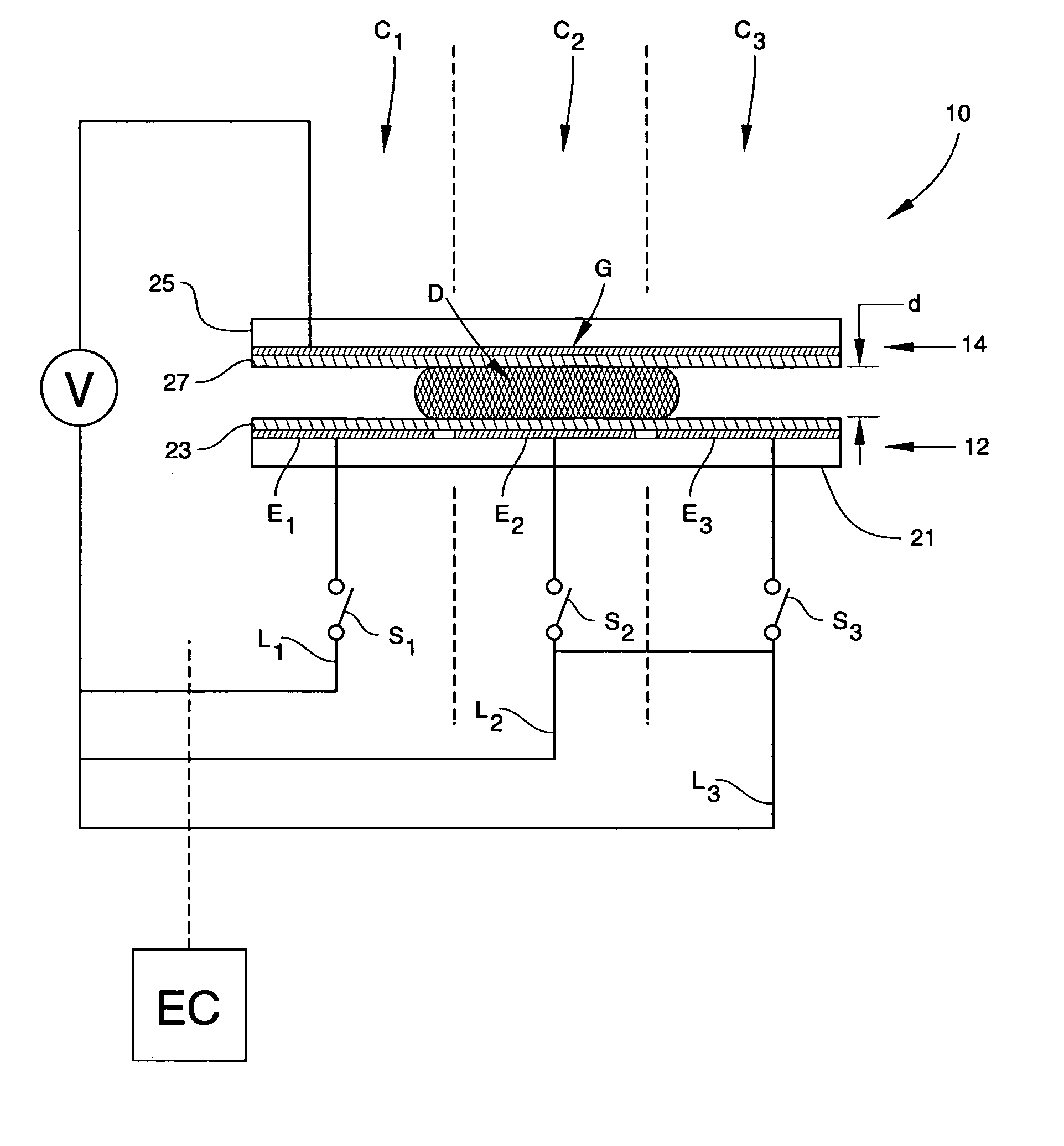

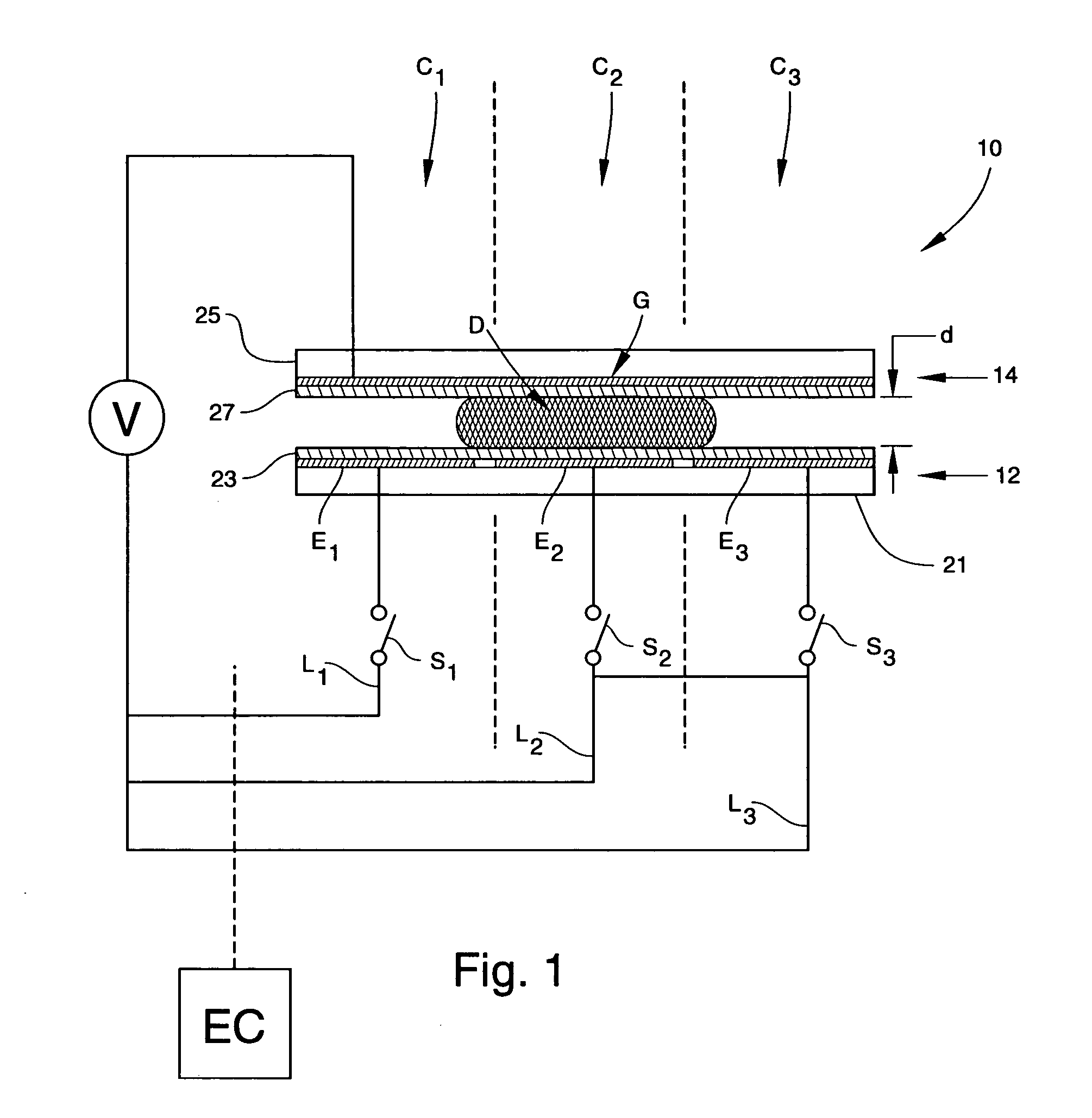

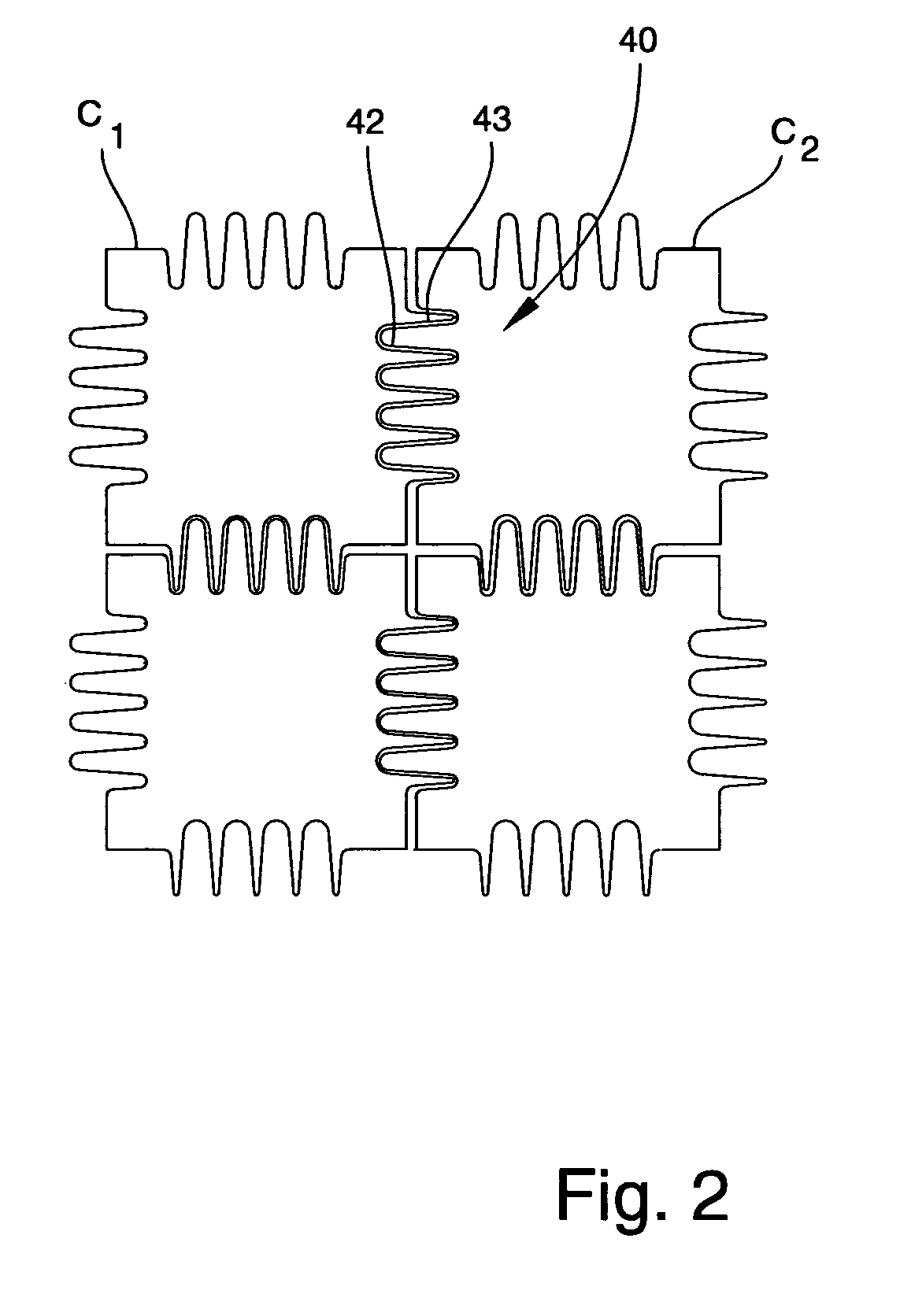

Methods for performing microfluidic sampling

InactiveUS20070037294A1Good controllabilityHigh accuracyLiquid separation by electricityElectrostatic separationBiomedical engineeringVoltage

Methods for performing microfluidic sampling are provided. The method includes providing a substrate including an arrangement of first, second and third electrodes, wherein the second electrode is interposed between the first and third electrodes. The method additionally includes causing a fluid input to continuously flow to the first electrode and biasing the first, second and third electrodes to a first voltage to cause a portion of the fluid input to spread across the second and third electrodes. The method further includes biasing the second electrode to a second voltage different from the first voltage to form a droplet on the third electrode, the droplet being separate from the fluid input.

Owner:DUKE UNIV

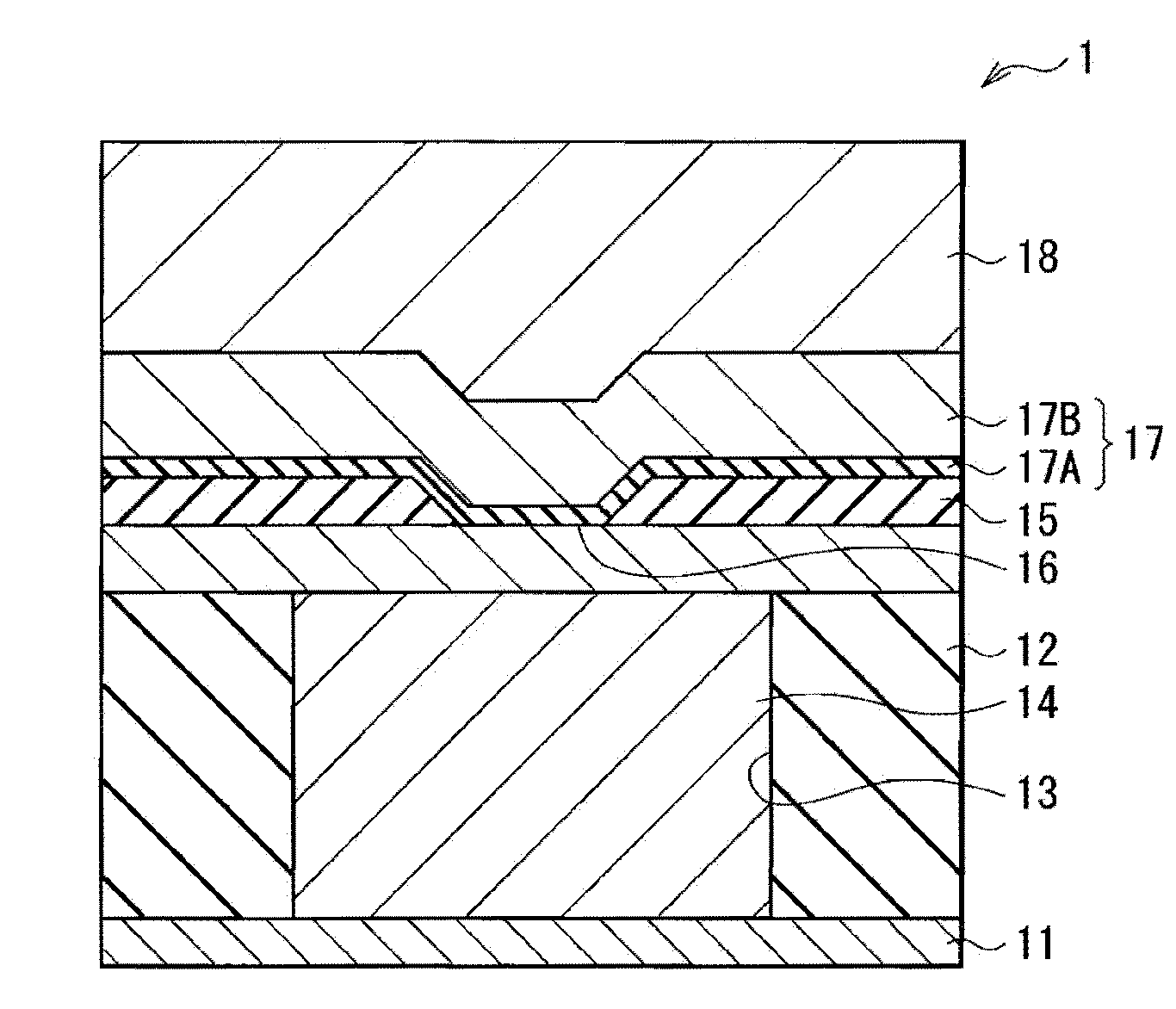

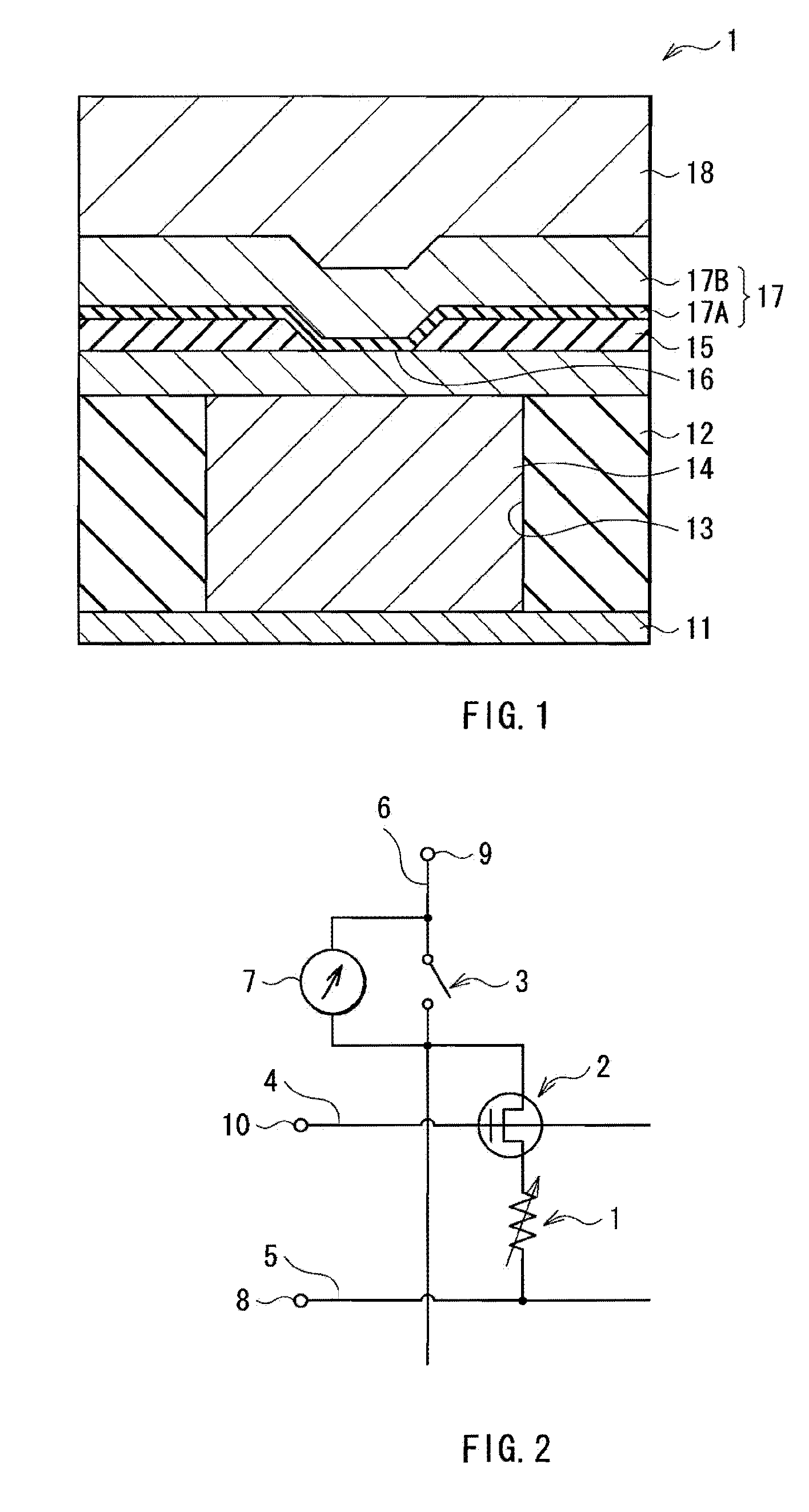

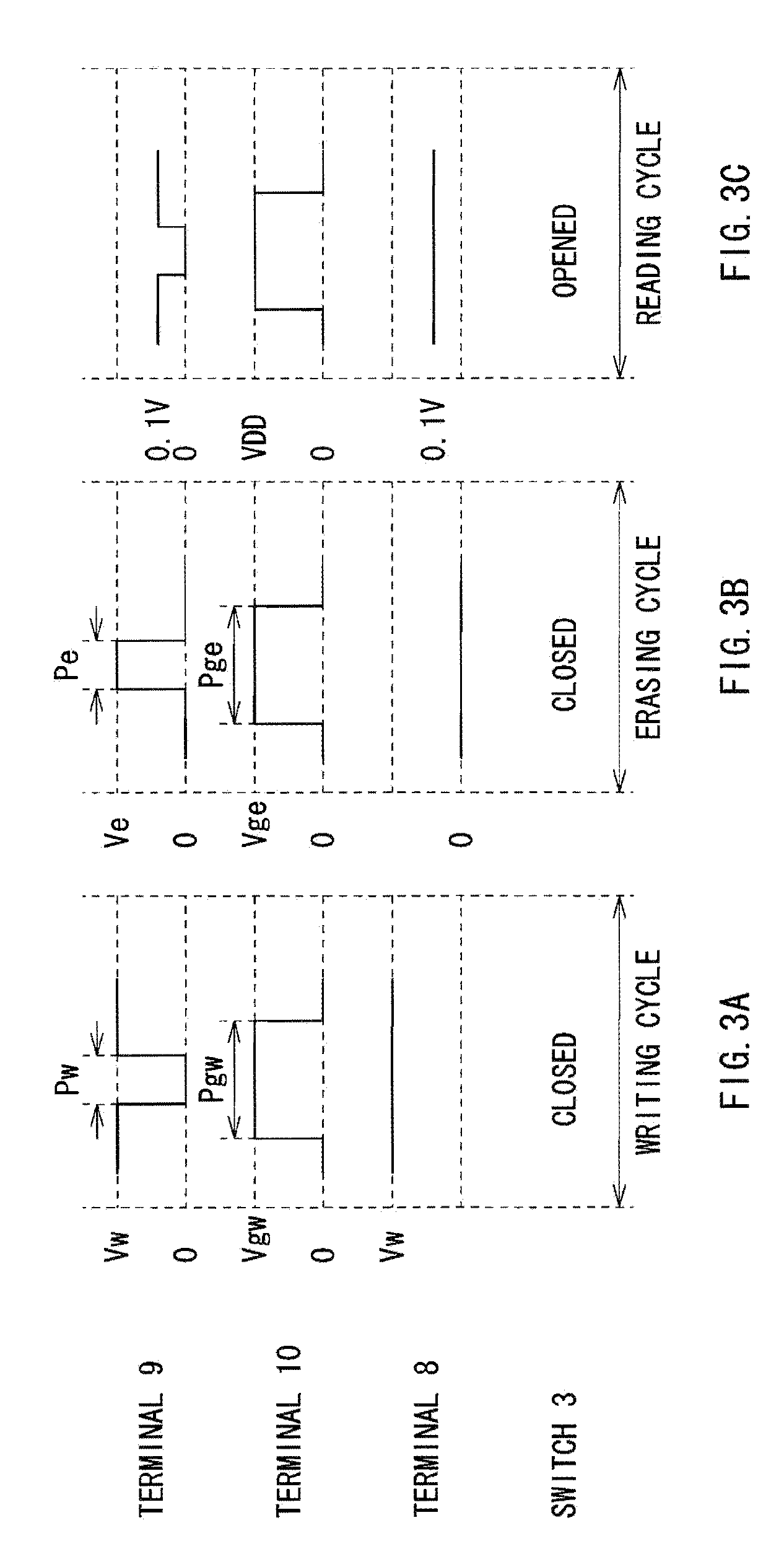

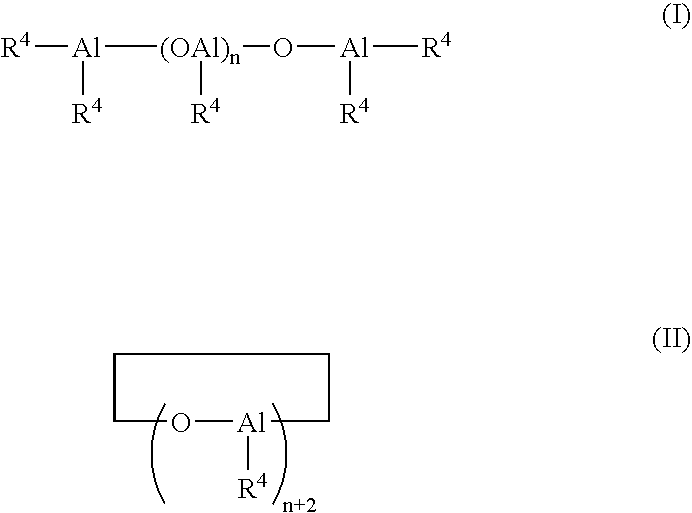

Memory element and memory device

ActiveUS20090173930A1Low resistance stateGood controllabilitySolid-state devicesDigital storageVoltage pulsePhysics

A memory device of a resistance variation type, in which data retaining characteristic at the time of writing is improved, is provided. The memory device includes: a plurality of memory elements in which a memory layer is provided between a first electrode and a second electrode so that data is written or erased in accordance with a variation in electrical characteristics of the memory layer; and pulse applying means applying a voltage pulse or a current pulse selectively to the plurality of memory elements. The memory layer includes an ion source layer including an ionic-conduction material and at least one kind of metallic element, and the ion source layer further contains oxygen.

Owner:SONY SEMICON SOLUTIONS CORP

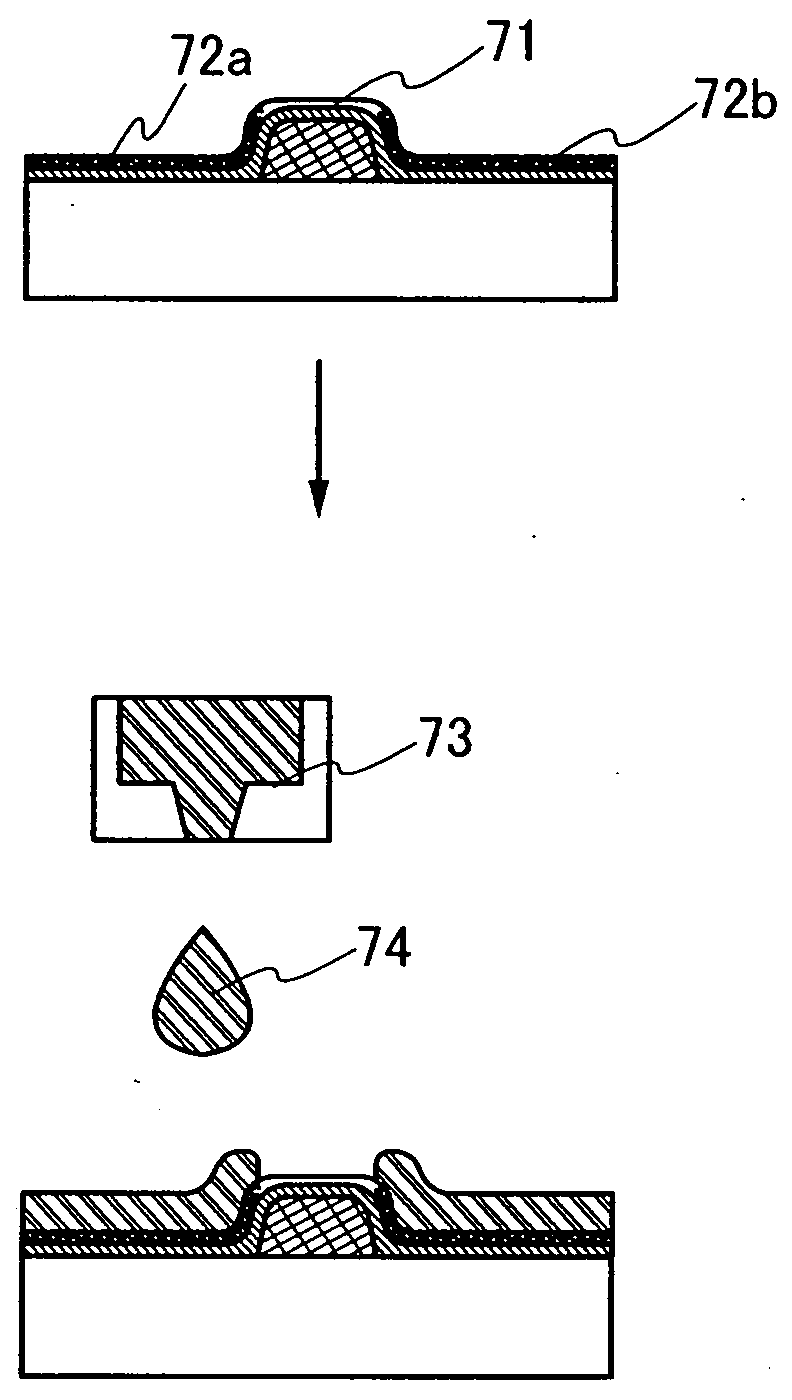

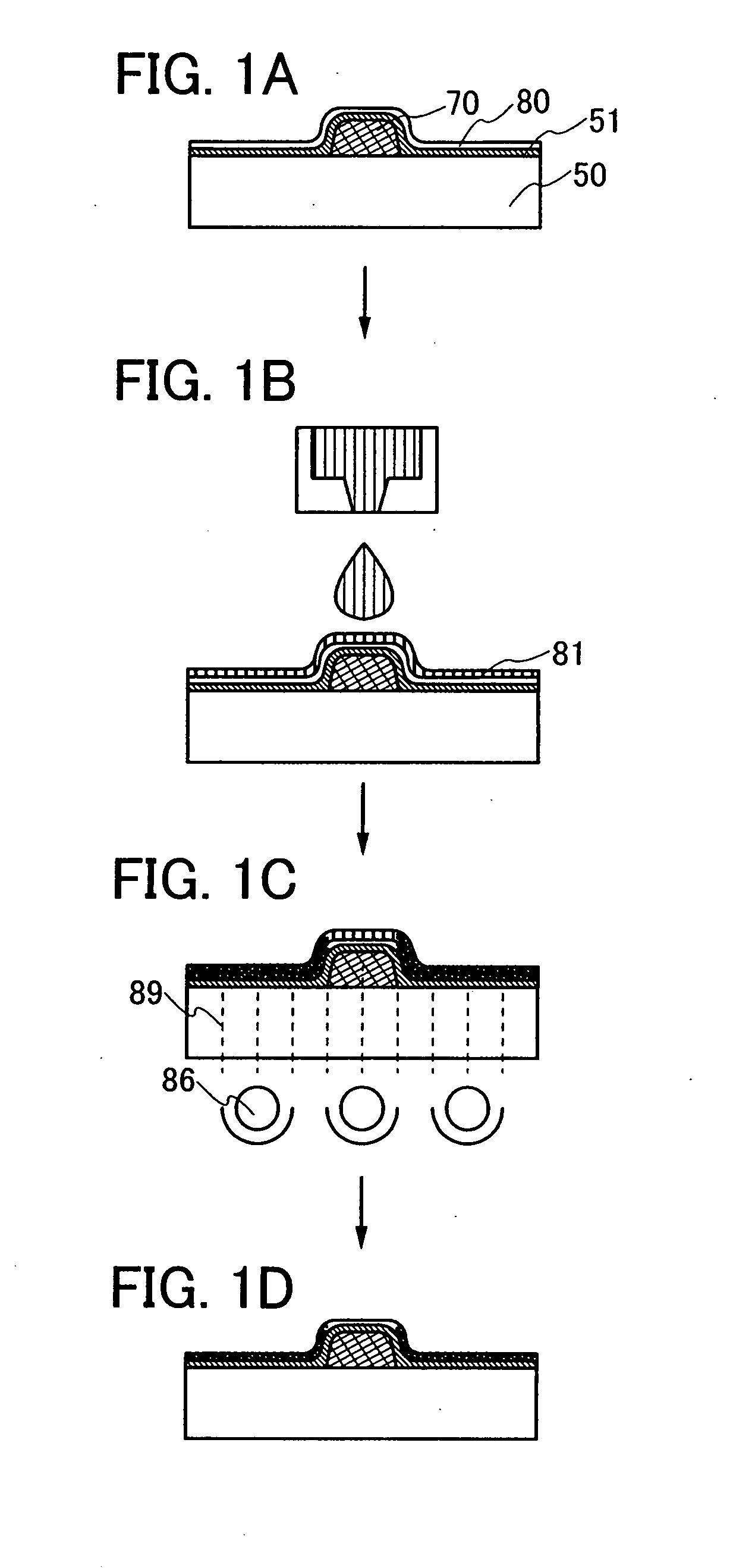

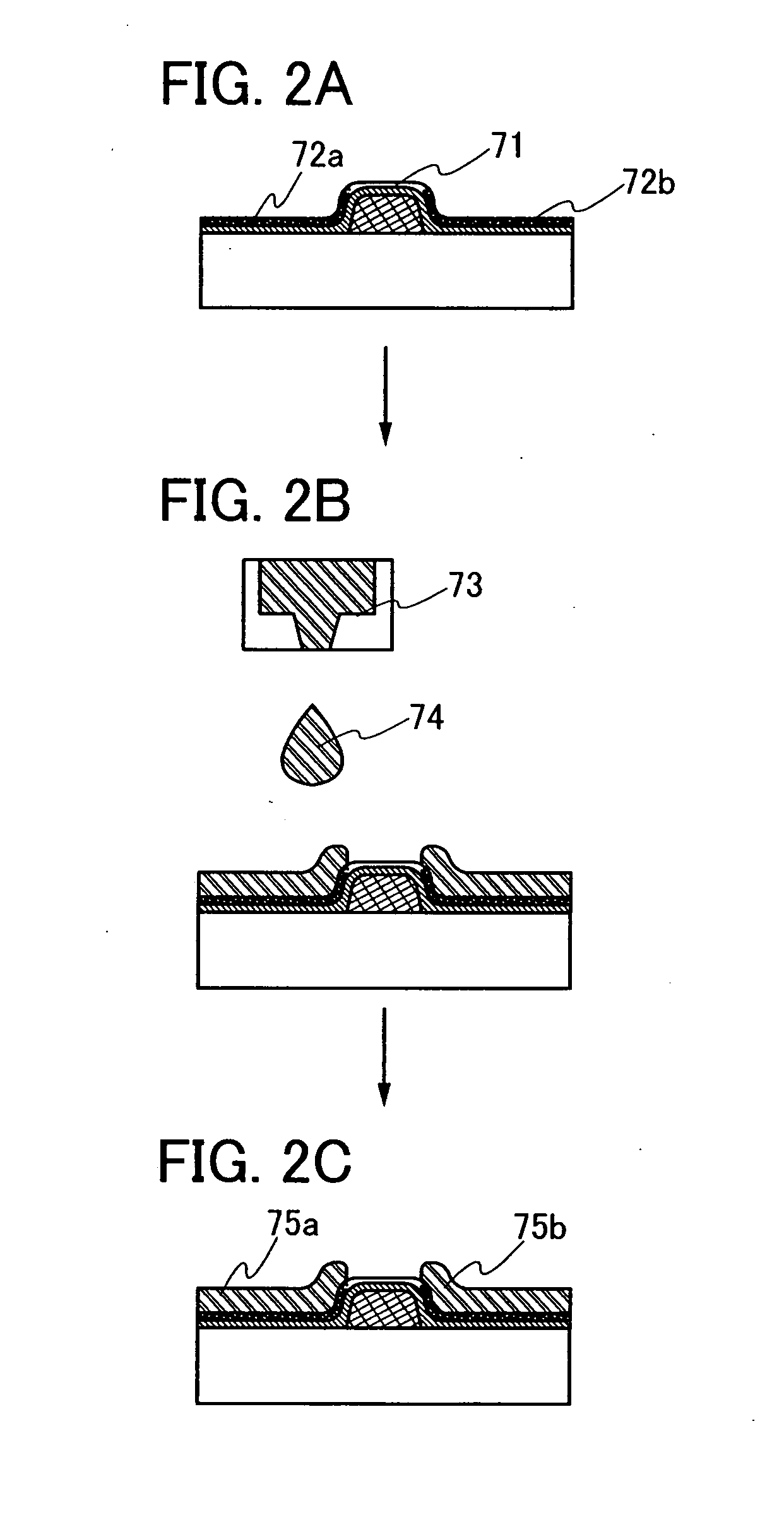

Manufacturing method for a circuit pattern, a thin film transistor and an electronic appliance

InactiveUS20070207274A1Good controllabilityFavorable electrical characteristicMolten spray coatingSolid-state devicesElectrical and Electronics engineeringElectronic equipment

A circuit pattern is formed by following steps: forming a light-blocking mask over a major surface of a light-transmitting substrate, forming a first film in a first region over the substrate and the mask, forming a photocatalytic film in at least a part of the first region over the first film, changing wettability of the first film in a second region which is in the first region, being in contact with the photocatalytic film, and not overlapping the mask, by light irradiation from a back surface opposite to the major surface of the substrate, removing the photocatalytic film, and forming a composition including a pattern forming material in the second region.

Owner:SEMICON ENERGY LAB CO LTD

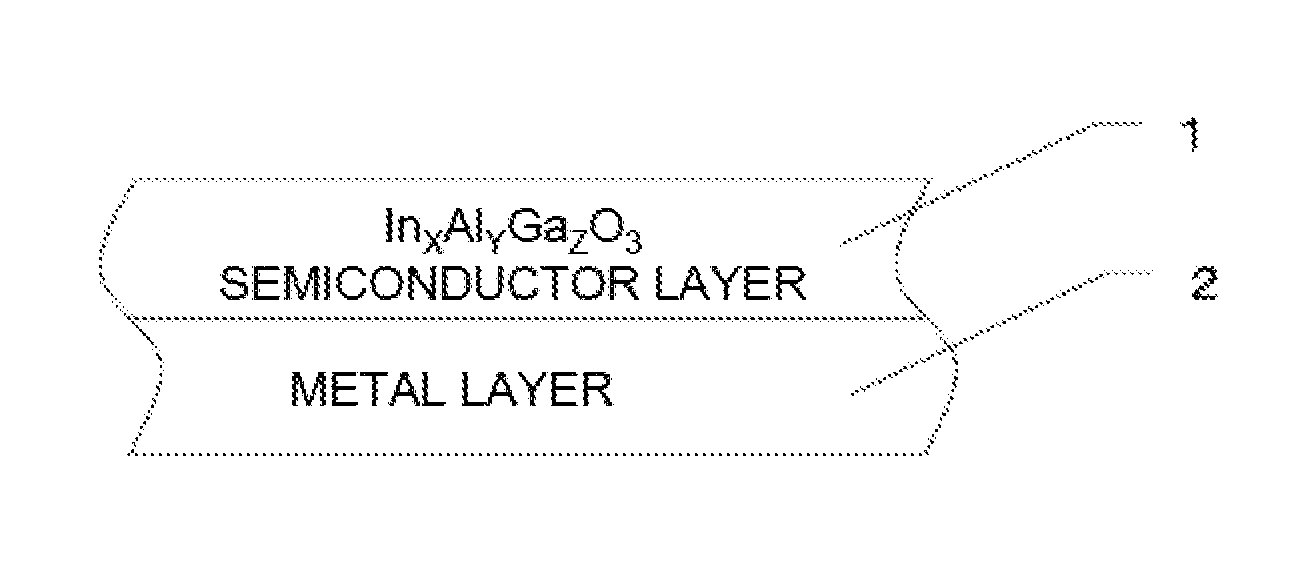

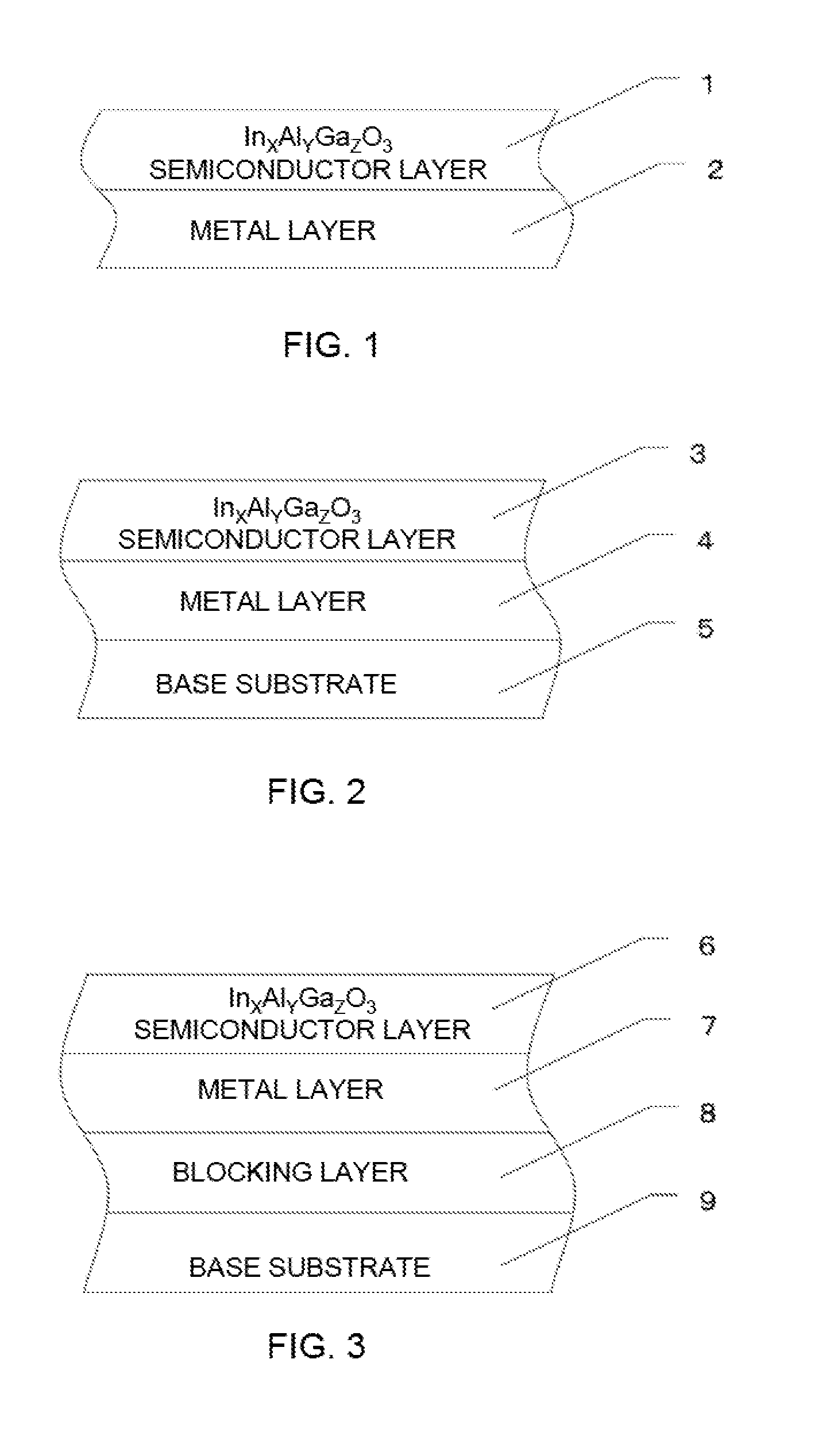

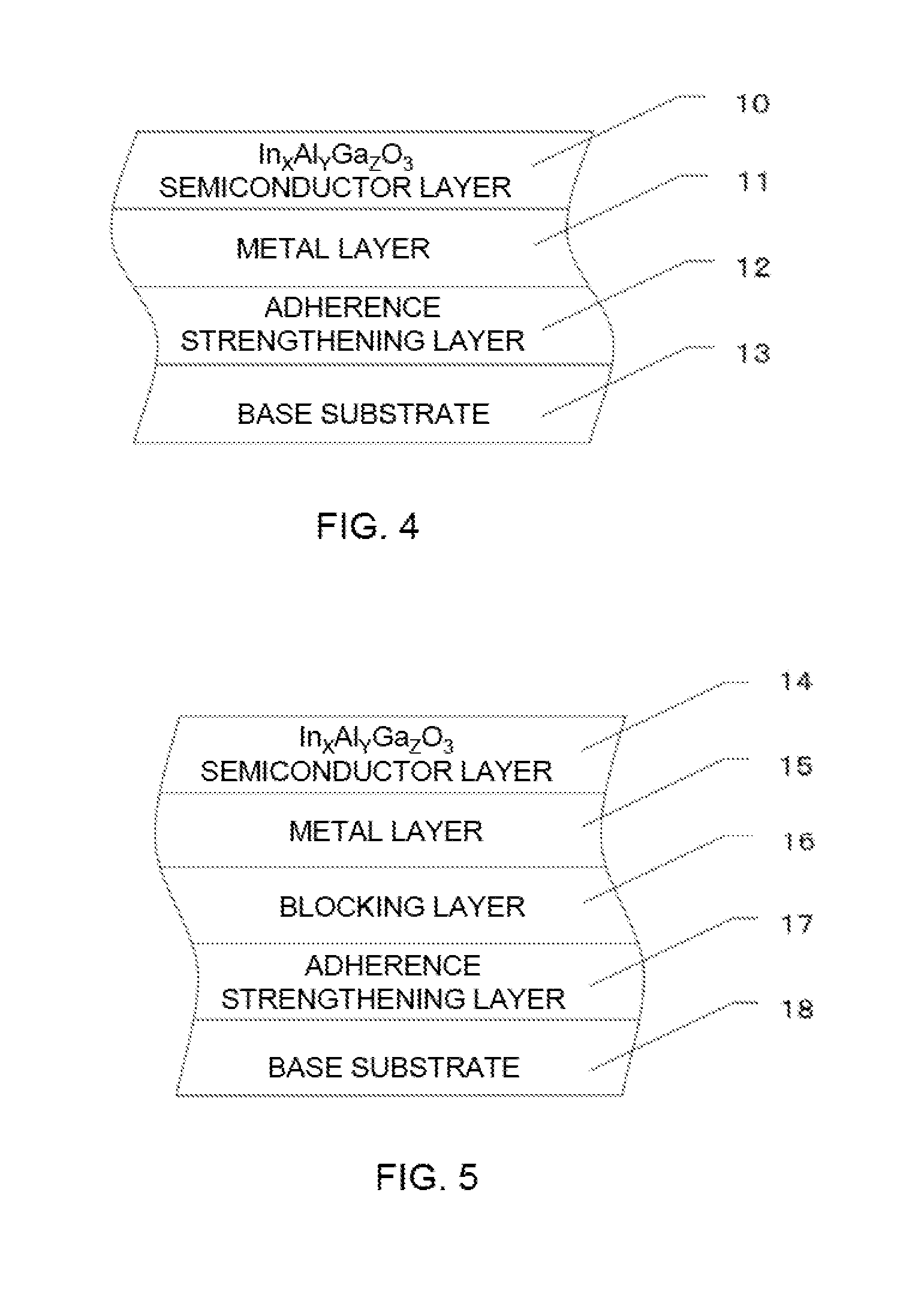

Crystalline multilayer structure and semiconductor device

ActiveUS20150325660A1Good propertyGood controllabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor propertiesIndium

Provided is a crystalline multilayer structure having good semiconductor properties. In particular, the crystalline multilayer structure has good electrical properties as follows: the controllability of conductivity is good; and vertical conduction is possible. A crystalline multilayer structure includes a metal layer containing a uniaxially oriented metal as a major component and a semiconductor layer disposed directly on the metal layer or with another layer therebetween and containing a crystalline oxide semiconductor as a major component. The crystalline oxide semiconductor contains one or more metals selected from gallium, indium, and aluminum and is uniaxially oriented.

Owner:FLOSFIA

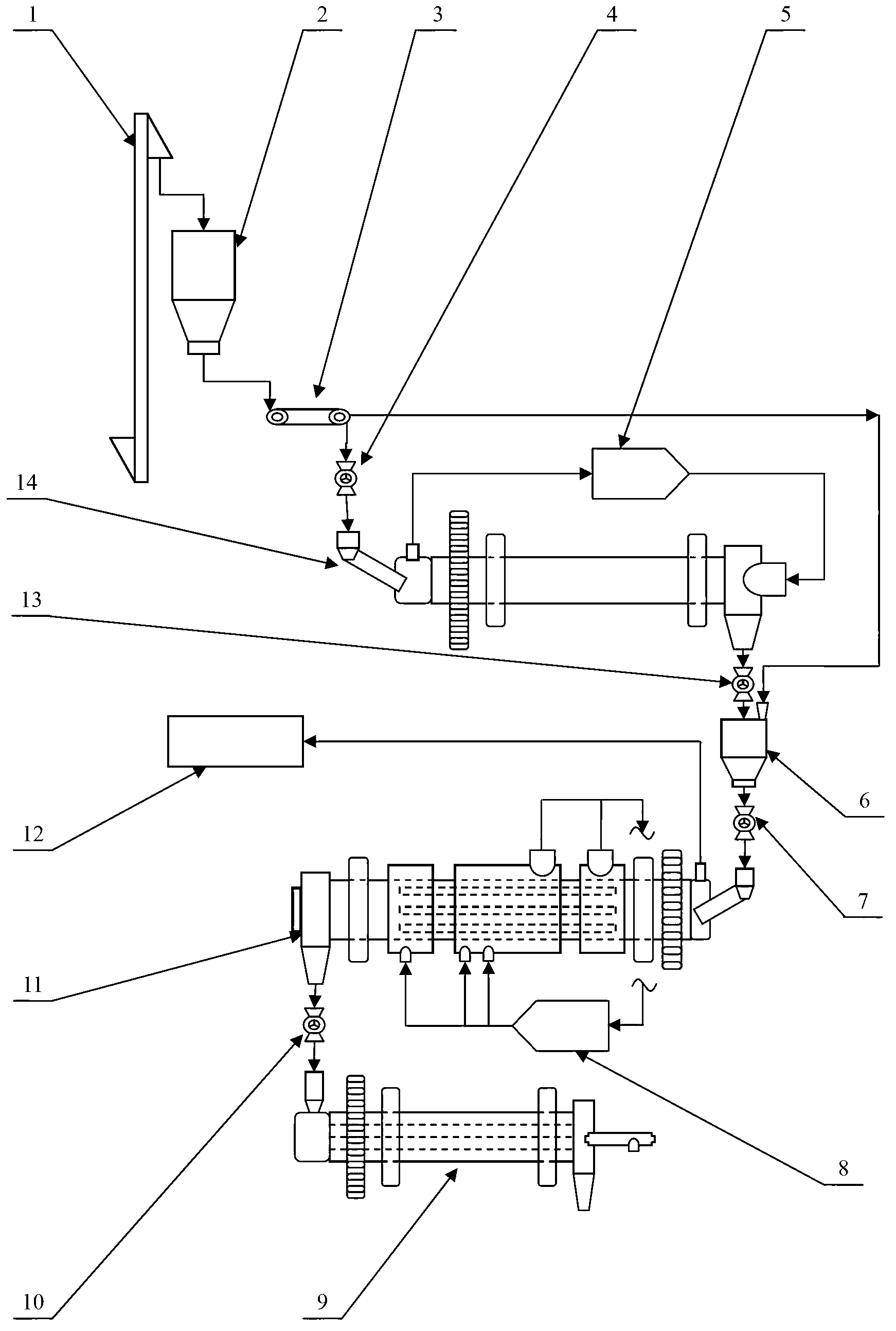

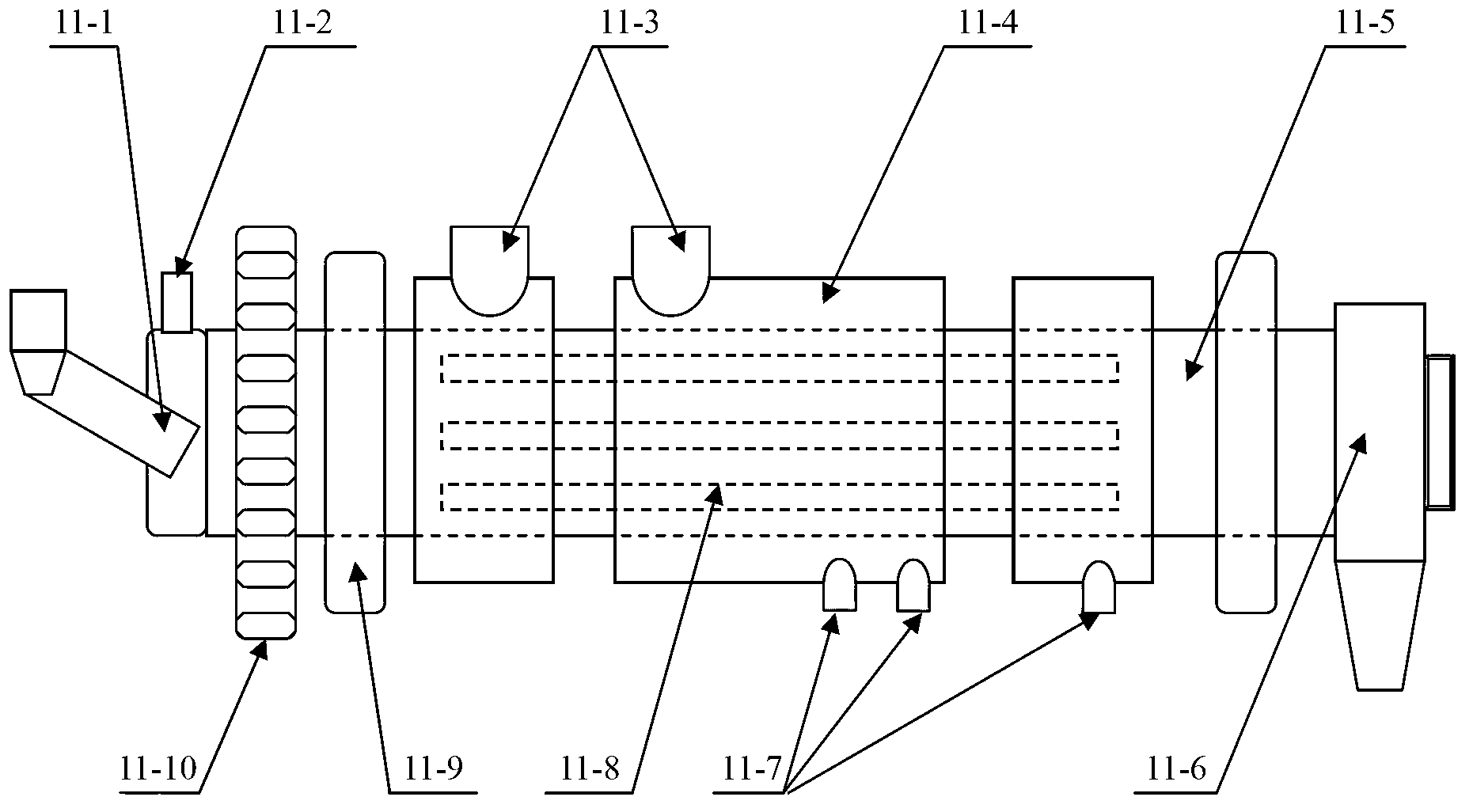

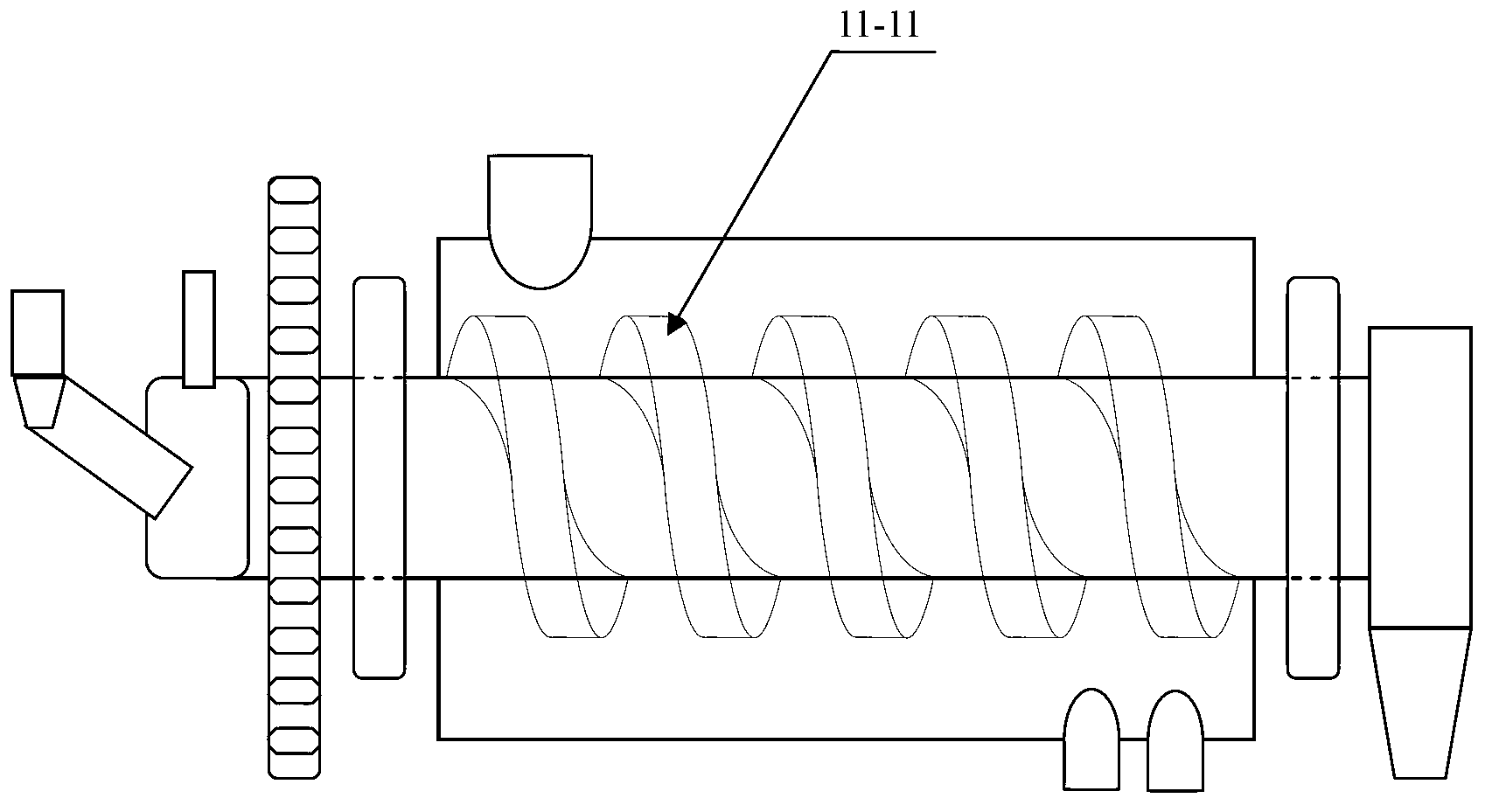

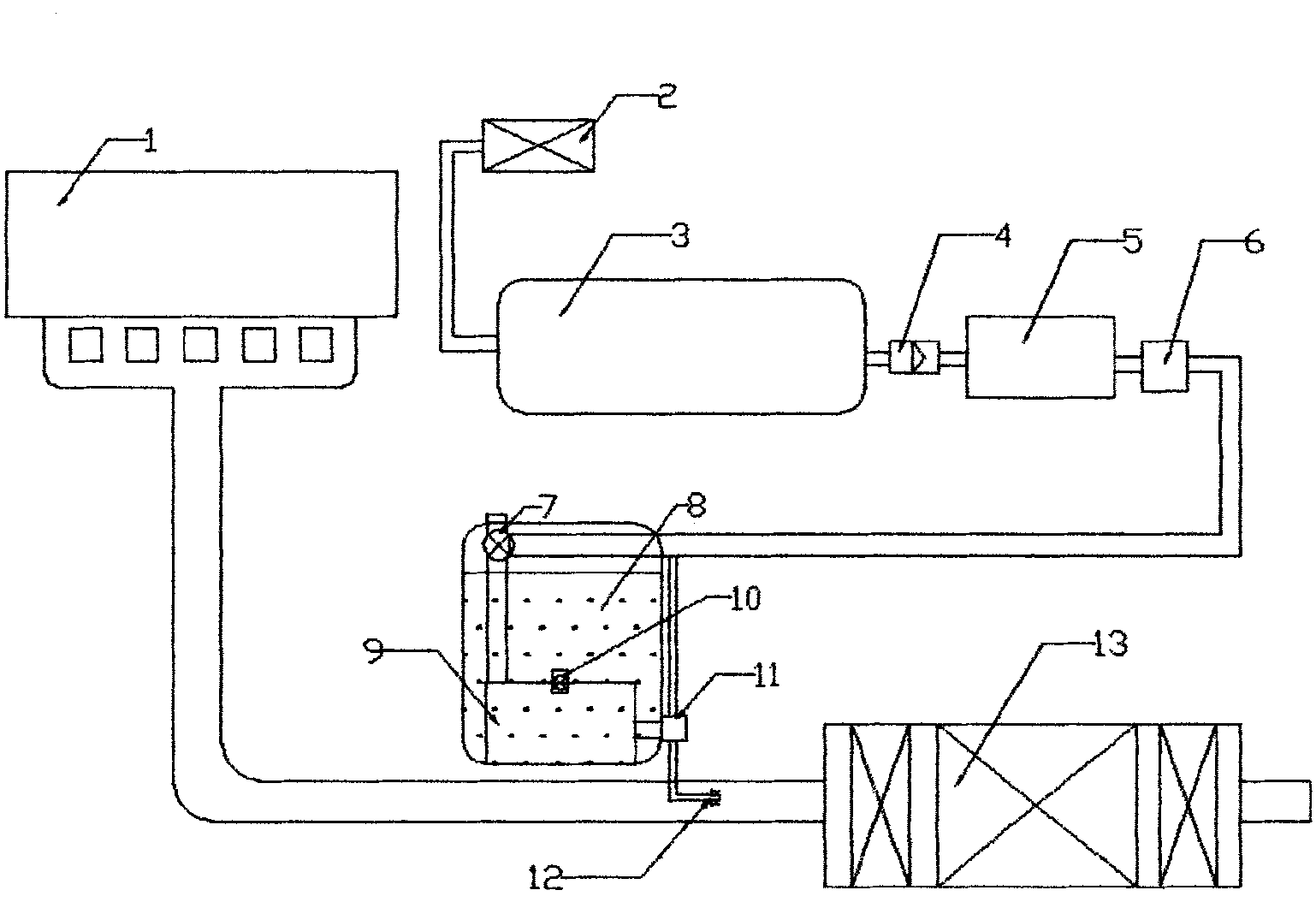

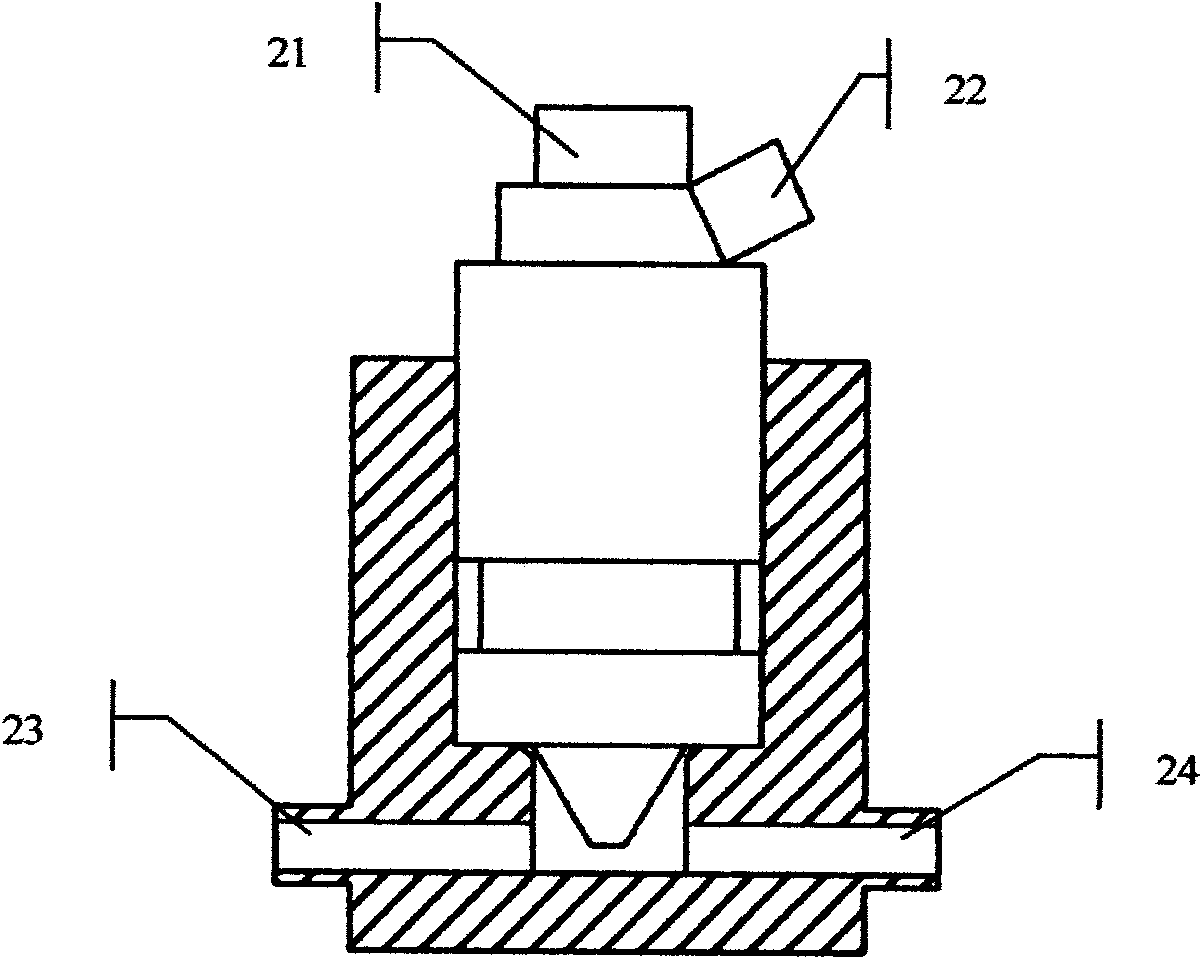

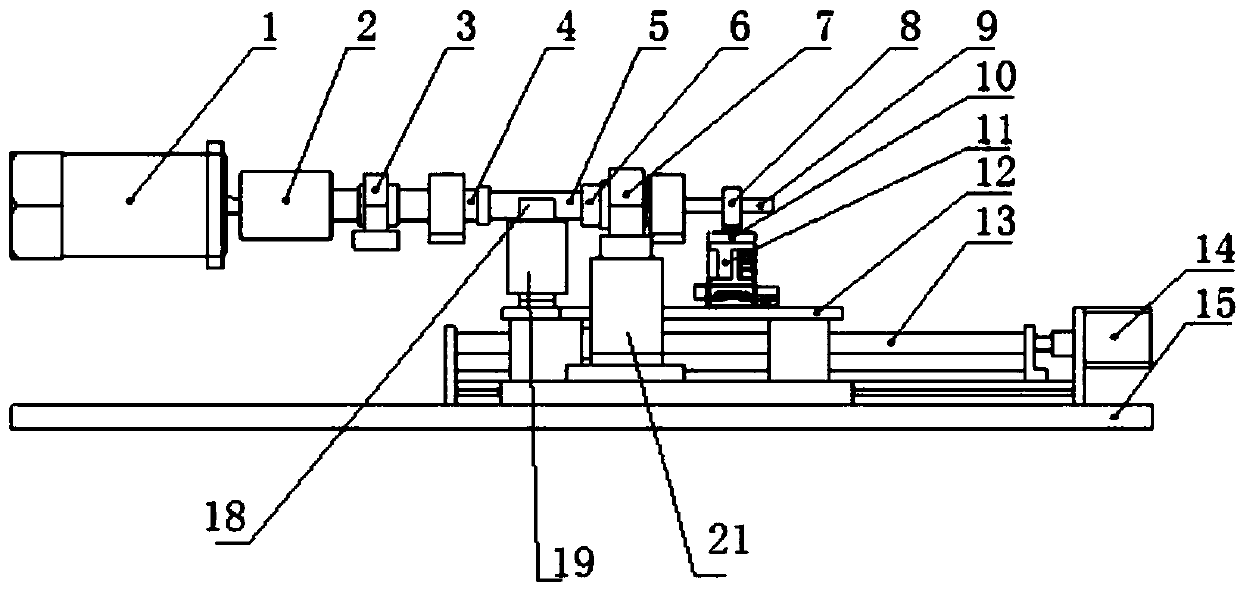

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

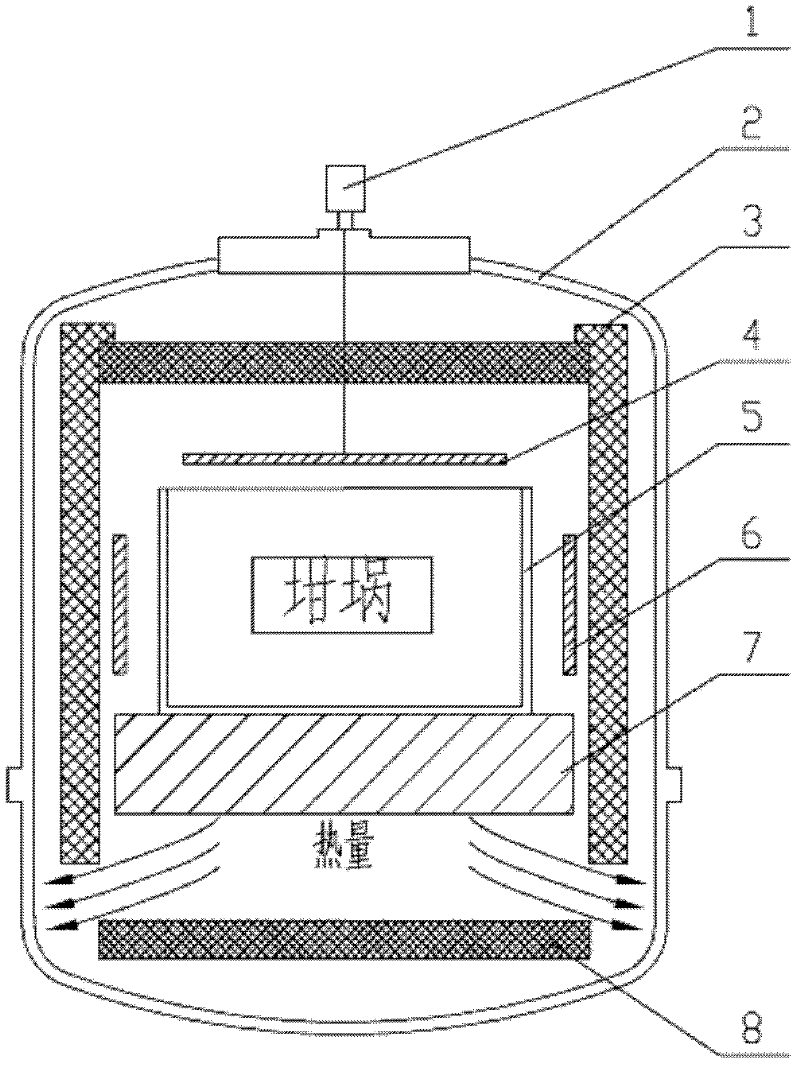

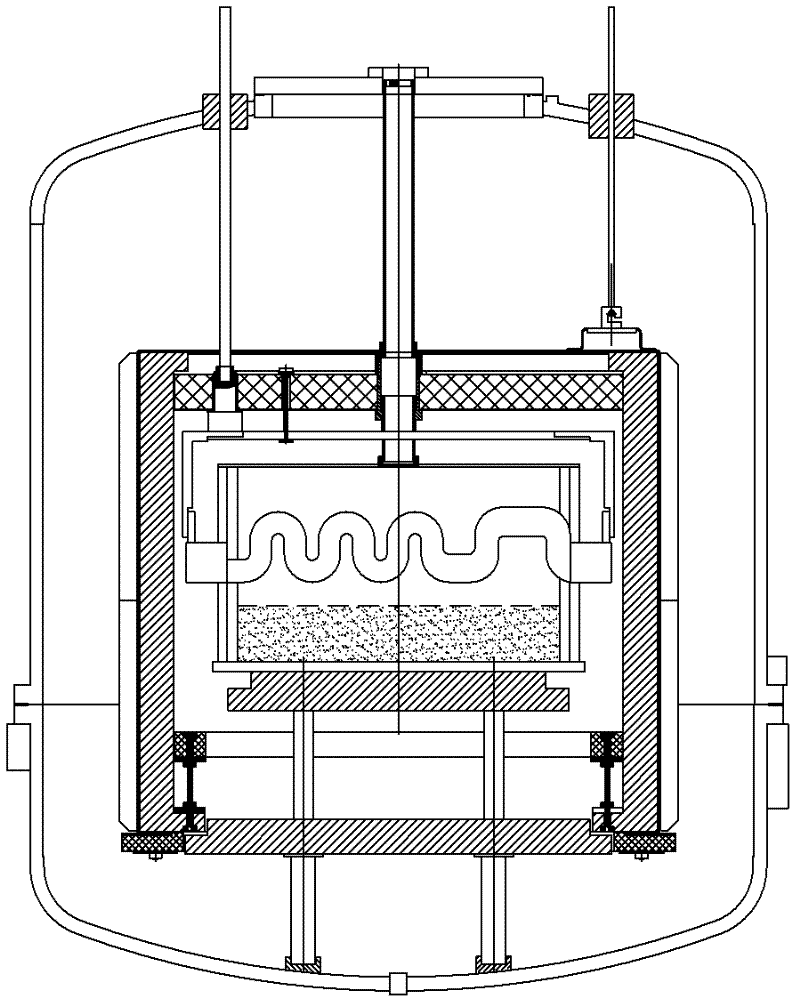

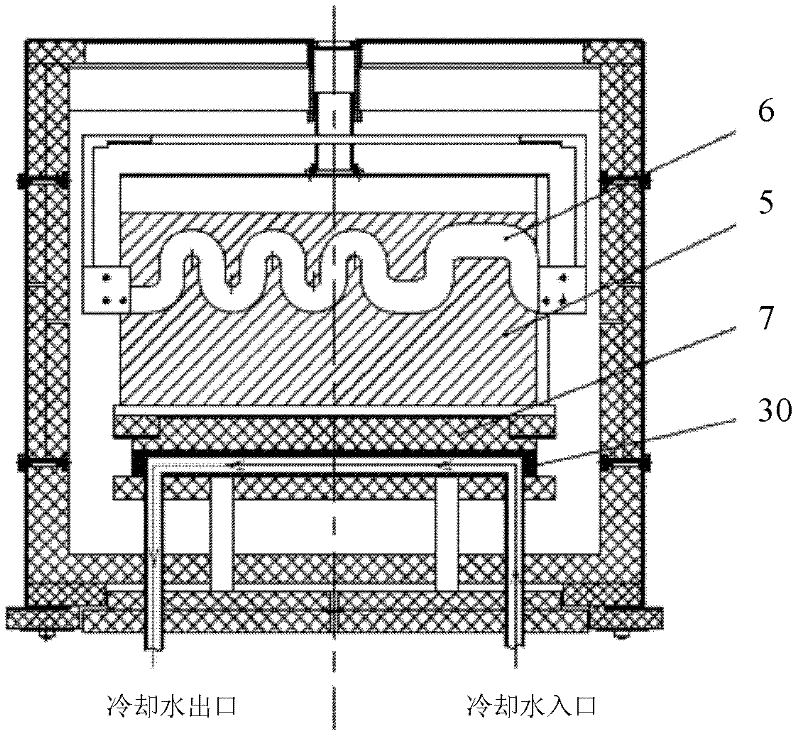

Closed cooling system of gas cooled polysilicon ingot furnace

ActiveCN102234837APrecise temperature controlEasy to controlPolycrystalline material growthSingle crystal growth detailsNuclear engineeringCrucible

The invention relates to the manufacture technical field of polysilicon ingot furnaces, and aims to provide a closed cooling system of a gas cooled polysilicon ingot furnace. The system comprises a heat exchange platform positioned on a supporting column and used for placing a crucible, wherein a cooling gas channel is arranged in the heat exchange platform; a gas inlet and a gas outlet at two ends of the cooling gas channel are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline; and the heat exchange platform, the cooling gas inlet pipeline, the cooling gas outlet pipeline, a cooling gas power pump group and a cooler form a closed circulation loop of the cooling gas. Compared with the cooling method of radiation cooling and water cooling, the system related by the invention has strong gas cooling control capacity and high industrial controllability; the gas is fed into the heat exchange platform evenly, so that the whole temperature of the heatexchange platform is even, which is in favor of even nucleation of a silicon melt at the bottom of the crucible; and the reducing speed of the temperature at the bottom of the crucible can be precisely controlled during the crystal growth.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL +1

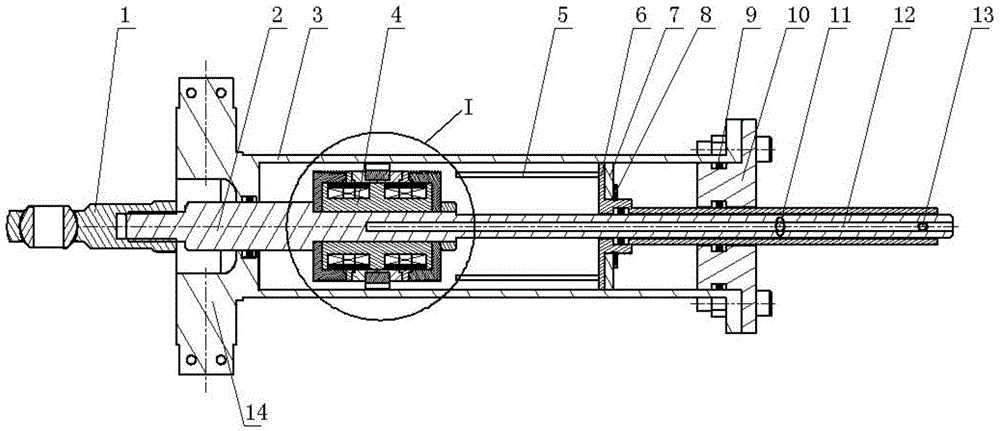

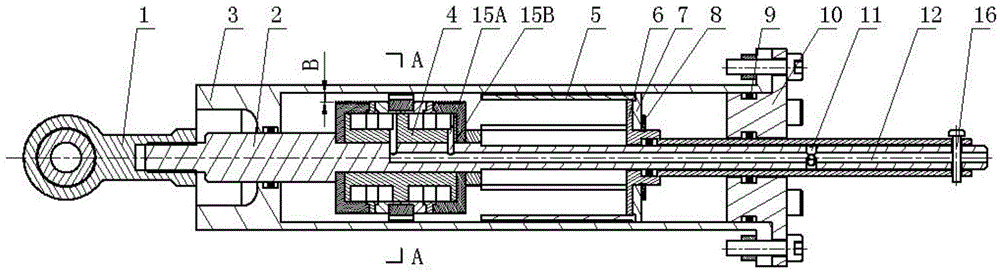

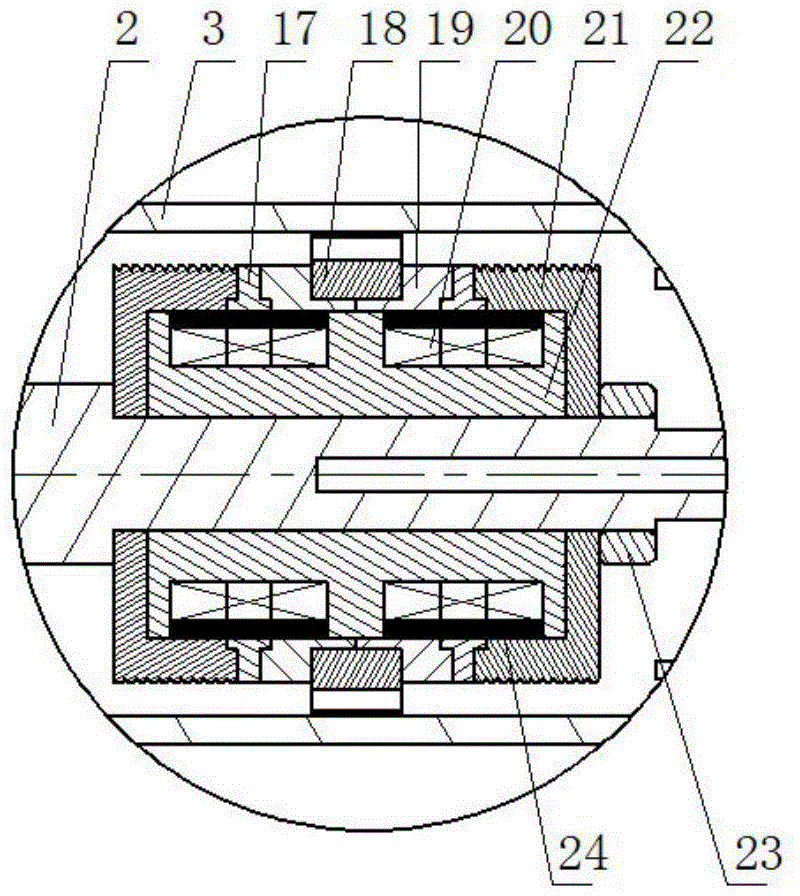

Damping-adjustable magneto-rheological lag damper

ActiveCN104455178AAchieve regulationTake full advantage of mobilitySpringsNon-rotating vibration suppressionLagControl theory

The invention relates to a damping-adjustable magneto-rheological lag damper. The damping-adjustable magneto-rheological lag damper comprises a cylinder barrel, a piston rod, a piston component and a damping adjusting mechanism. Stub shafts are integrally produced at the outer edge of the left end of the cylinder barrel symmetrically and radially, and an end cover is mounted at the right end of the cylinder barrel hermetically and coaxially. The piston rod is penetratingly mounted in the cylinder barrel coaxially, and two ends of the piston rod are positioned outside the cylinder barrel. The piston component is mounted at the position, on the inner left side of the cylinder barrel, of the piston rod coaxially. The damping adjusting mechanism is slidably mounted at the position, corresponding to the piston component and positioned on the inner right side of the cylinder barrel, of the piston rod coaxially and rotates around an axial center by a certain angle prior to being fittingly mounted together with the piston component, and the left end, positioned outside the cylinder barrel, of the piston rod is in coaxial threaded connection with a rod-end joint bearing. The damping-adjustable magneto-rheological lag damper has the advantages of simple structure, low energy consumption, small size, rapidity in response, continuous forward and reverse adjustability in damping force within a wide range, good temperature stability, easiness in combination with a computer to achieve intelligent control and the like, thereby being quite promising in application prospect.

Owner:CIVIL AVIATION UNIV OF CHINA

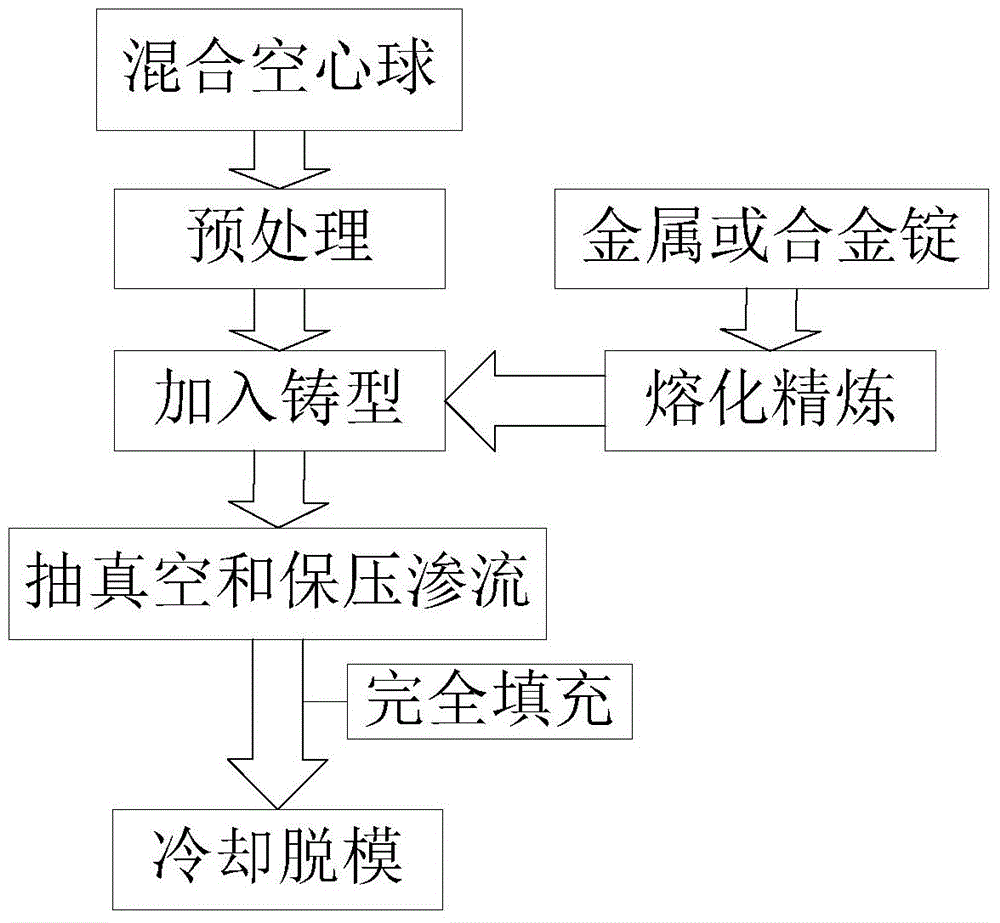

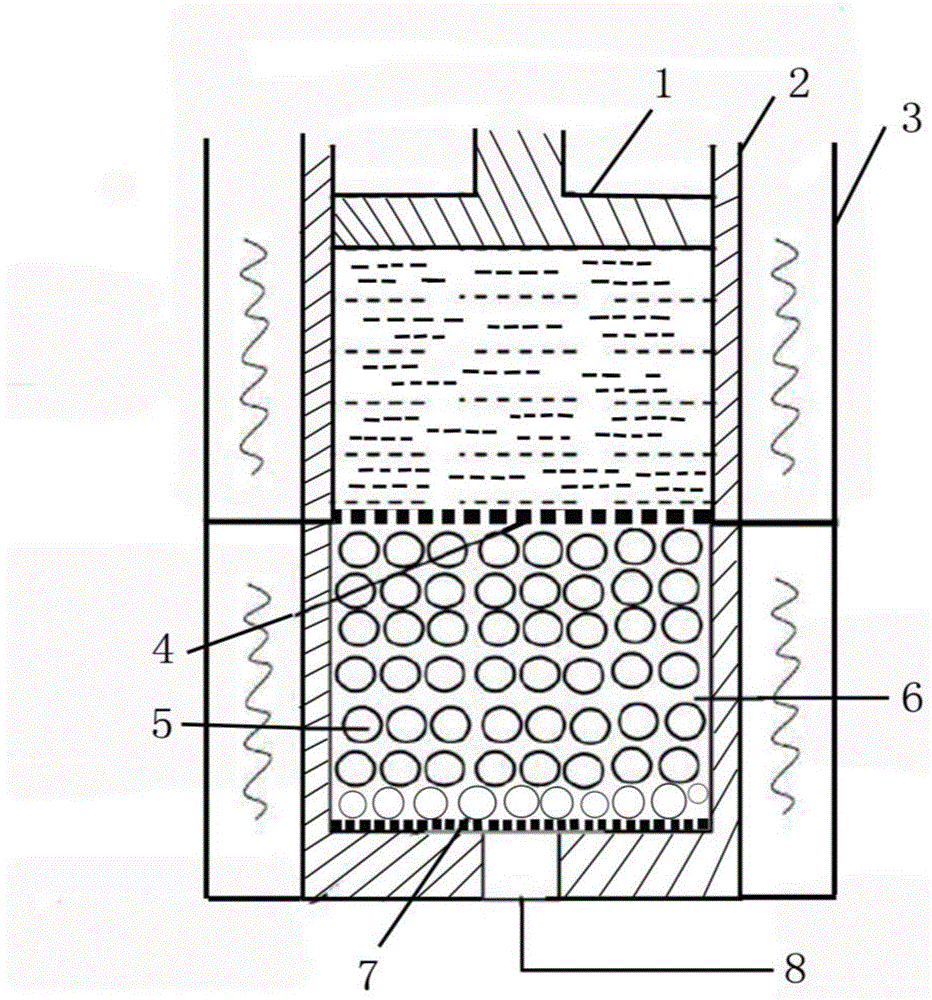

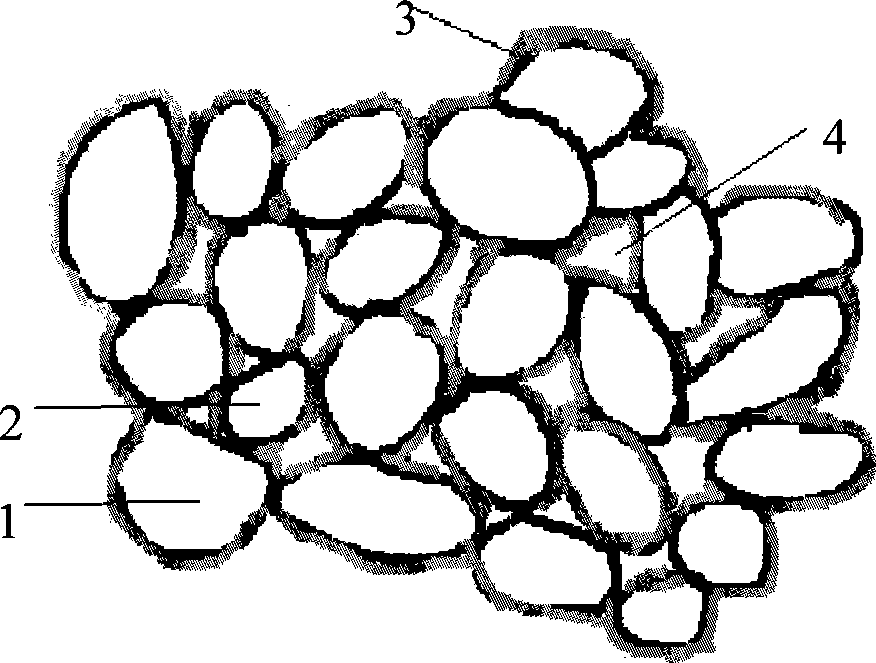

One-stage method for preparing metal matrix light-weighted composite material

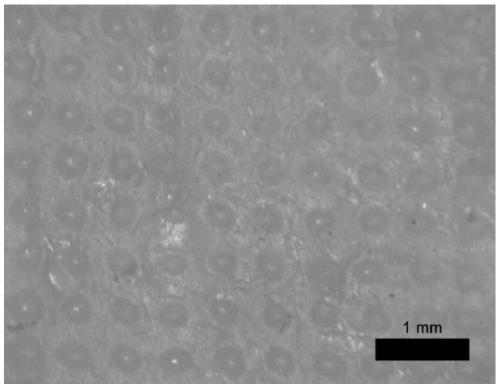

InactiveCN104588617AWell-proportioned holesGood controllabilityMetal matrix compositeEnergy absorption

The invention relates to a one-stage method for preparing a metal matrix light-weighted composite material. The invention uses the method of pressure maintaining percolation and vacuum suction casting to make molten metal immerse into the gaps among hollow spheres by penetrating through a porous ceramic plate or a graphite plate under the function of negative pressure, after the molten metal is cooled down after totally infiltration, and finally, the molten metal is demoulded and taken out, then a foamed metal matrix composite material including closed bubbles can be obtained. The hollow spheres are mixed hollow spheres of two or more than two kinds of Al2O3 hollow spheres, SiC hollow spheres, C hollow spheres or glazed hollow beads of different or same sizes. The porosity of the metal matrix composite material prepared by the method of the invention can reach more than 60% and the density can be obviously reduced, besides, the compression strength can be improved by 20-50% compared with the similar product, so that the high-strength and light-weighted matrix light-weighted composite material with various functions like damp shock absorption, sound insulation and noise reduction, energy absorption can be obtained. According to the one-stage method for preparing the metal matrix light-weighted composite material disclosed by the invention, the process is simple, the procedure is less and the applicable range to the varieties and sizes of the hollow sphere particles is wide, and nearly no selection to the matrix metal, the foam metal products of different densities can be prepared.

Owner:TONGJI UNIV

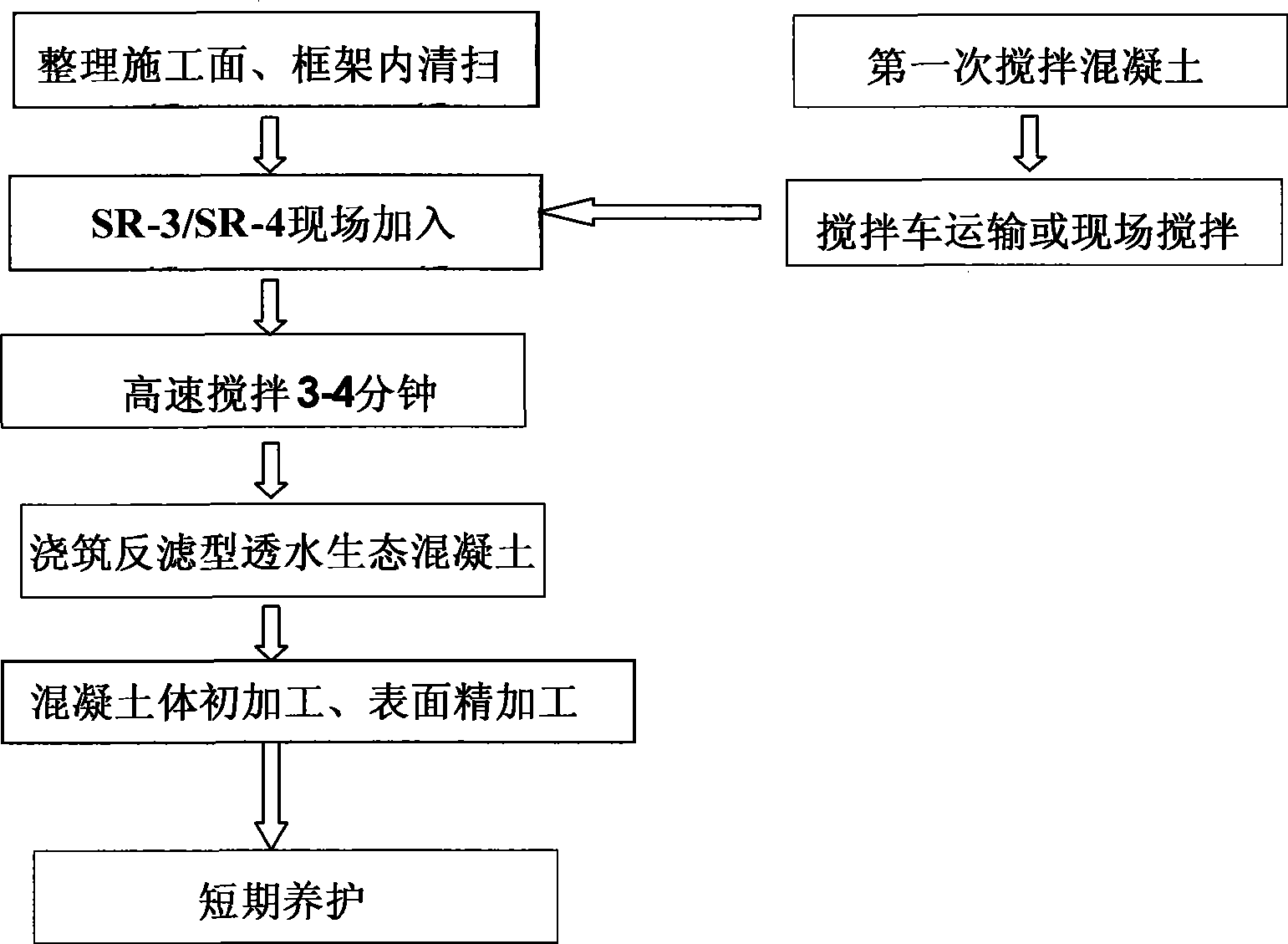

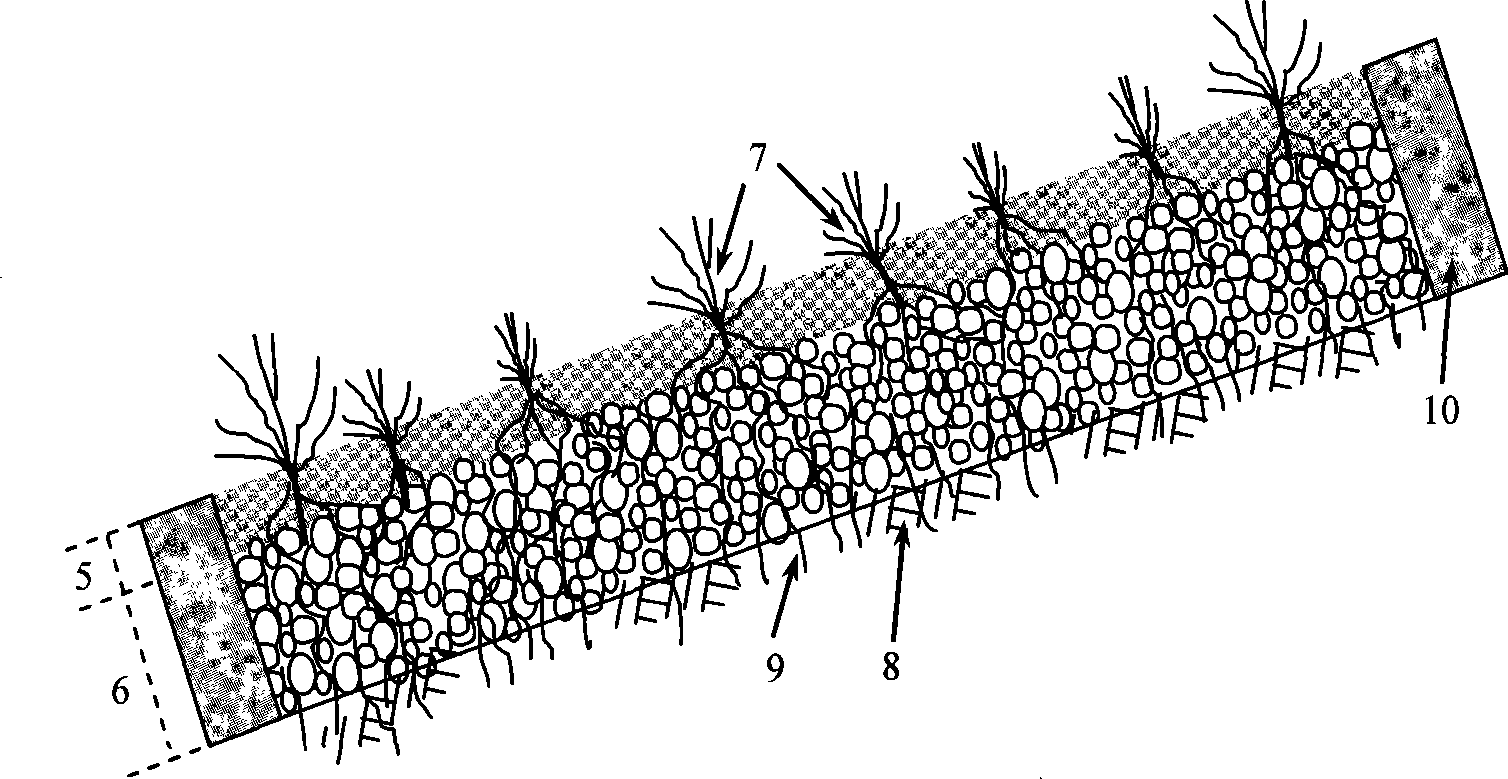

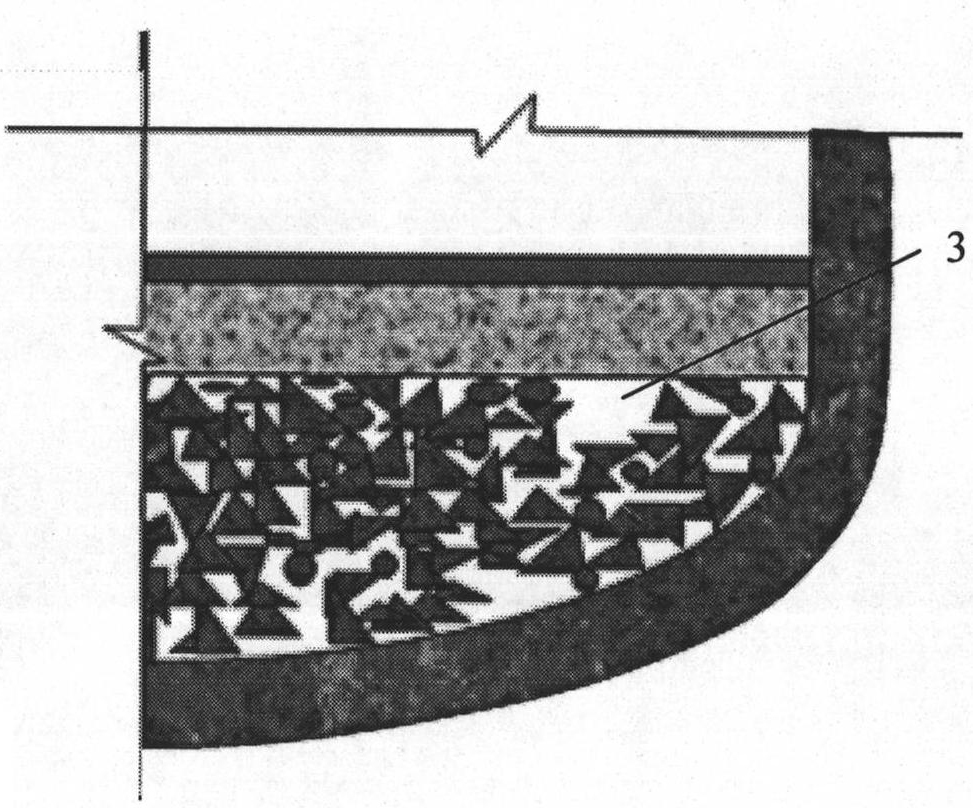

Cast-in-situ invert filter type pervious ecological concrete and method for constructing slope protection thereof

The invention discloses cast-in-situ reversed filtering type non-watertight eco-concrete and a construction method for a revetment thereof. The eco-concrete is the composition of grain aggregates and a cement hydrate; the grain aggregates comprise coarse aggregates and thin aggregates, which account for 70 to 85 percent of the total weight of the composition; the cement hydrate is the mixture of Portland cement, water and additive; the doping amount of the cement and the water accounts for 14.5 to 29.5 percent of the total weight of the composition; the additive comprises calcium salt, silicon powder, functional inorganic salt as well as lignosulphonate question mark hydroxycarboxylic acid; and the doping amount of the additive accounts for 0.1 to 0.5 percent of the total weight of the composition. The eco-concrete of the invention can realize cast-in-situ construct, and has higher anti-pressing intensity; moreover, the poriness size and the aperture distribution range can be designed and the controllability is good; the cast-in-situ reversed filtering type non-watertight eco-concrete applied to the fields of revetment protecting and controlling can improve the anti-pressing intensity, the permeable performance and the reversed filtering performance of the concrete revetment and simultaneously has the function of greening vegetation.

Owner:JCK +1

Biomedical polysaccharide hemostatic and healing sponge and preparation method thereof

ActiveCN103480033ASimple technical operationGood controllabilityAbsorbent padsBandagesChemistrySodium carboxymethylcellulose

The invention discloses biomedical polysaccharide hemostatic and healing sponge and a preparation method thereof, and belongs to the technical field of medical materials. The preparation method comprises the following steps: firstly, dissolving a polysaccharide material carboxymethyl cellulose, hyaluronic acid or a mixture thereof into an alkaline solution, stirring sufficiently, and swelling into colloid; secondly, adding a crosslinking agent into the colloid, stirring sufficiently, incubating into uniform gel, and dialyzing and purifying the obtained gel; thirdly, adding glycerin into the purified product, stirring at a high speed for bubbling, and pouring into a lyophilizing disk; and finally, performing freeze drying at a low temperature to obtain dehydrated sponge. The hemostatic and healing sponge prepared with the method is good in flexibility, do not drop crumbs, is strong in liquid absorption, can provide a wet environment to a wound, is non-stick to the wound, is good in biocompatibility, is qualified in heavy metal detection and endotoxin detection, is non-cytotoxic in a bio-safety test, is free of intradermal irritation and sensitization response, and has the functions of stopping bleeding rapidly, absorbing exudate and promoting wound healing.

Owner:JIANGSU CHANGJIYONG BIOTECH CO LTD

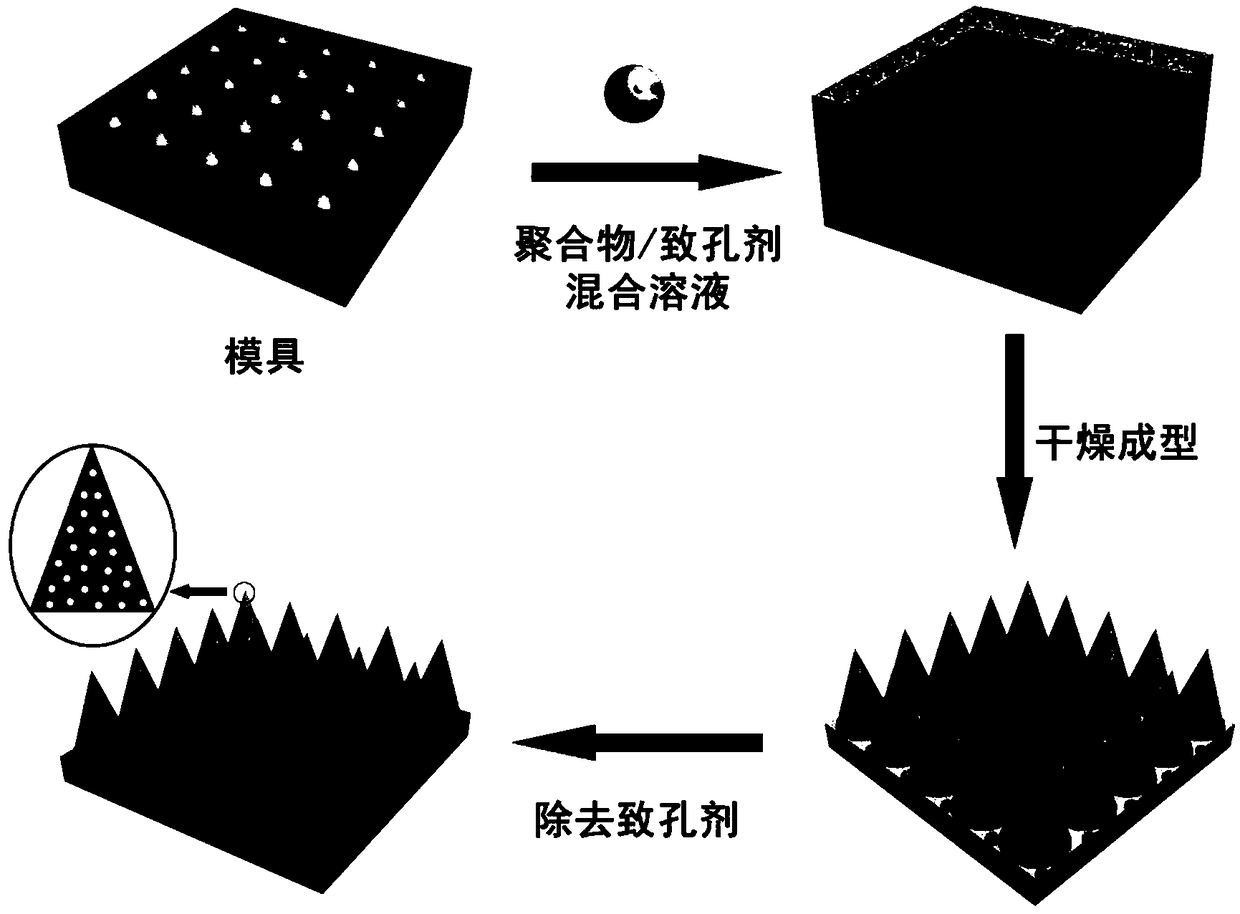

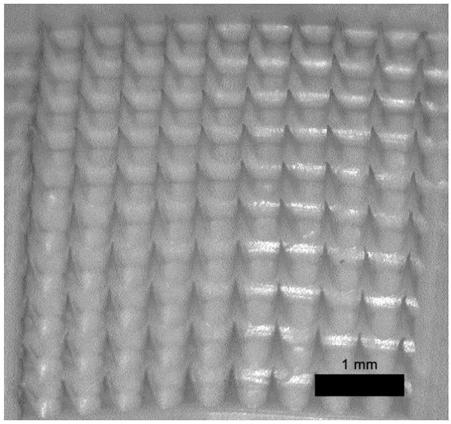

Method for preparing porous polymer micro needle by using template method and application thereof

InactiveCN109364366AOvercome the cumbersome preparation processOvercome the conditionsMicroneedlesPharmaceutical delivery mechanismTissue fluidHair growth

The invention discloses a method for preparing a porous polymer micro needle by using a template method and an application thereof. The method comprises the following steps of: (1) dissolving a polymer and a template agent in a solvent to prepare a polymer solution; (2) filling the polymer solution into a micro needle mould; (3) removing the solvent in the obtained micro needle mould to obtain a solid micro needle; (4) removing the template agent in the obtained solid micro needle to obtain the porous polymer micro needle. By improving the overall process flow design of the preparation method,the method can solve the technical problems of a complex preparation process, harsh conditions, a complicated process, high price, difficult control of the pore structure and size, difficult large-scale production and application and the like of the porous polymer micro needle, the obtained porous polymer micro needle can be used for tissue fluid extraction and transdermal administration, such asskin tissue fluid and blood extraction and transdermal administration of proteins, polypeptides and small molecular drugs in cosmetic, hair growth, immunity, treatment and other applications.

Owner:HUAZHONG UNIV OF SCI & TECH +1

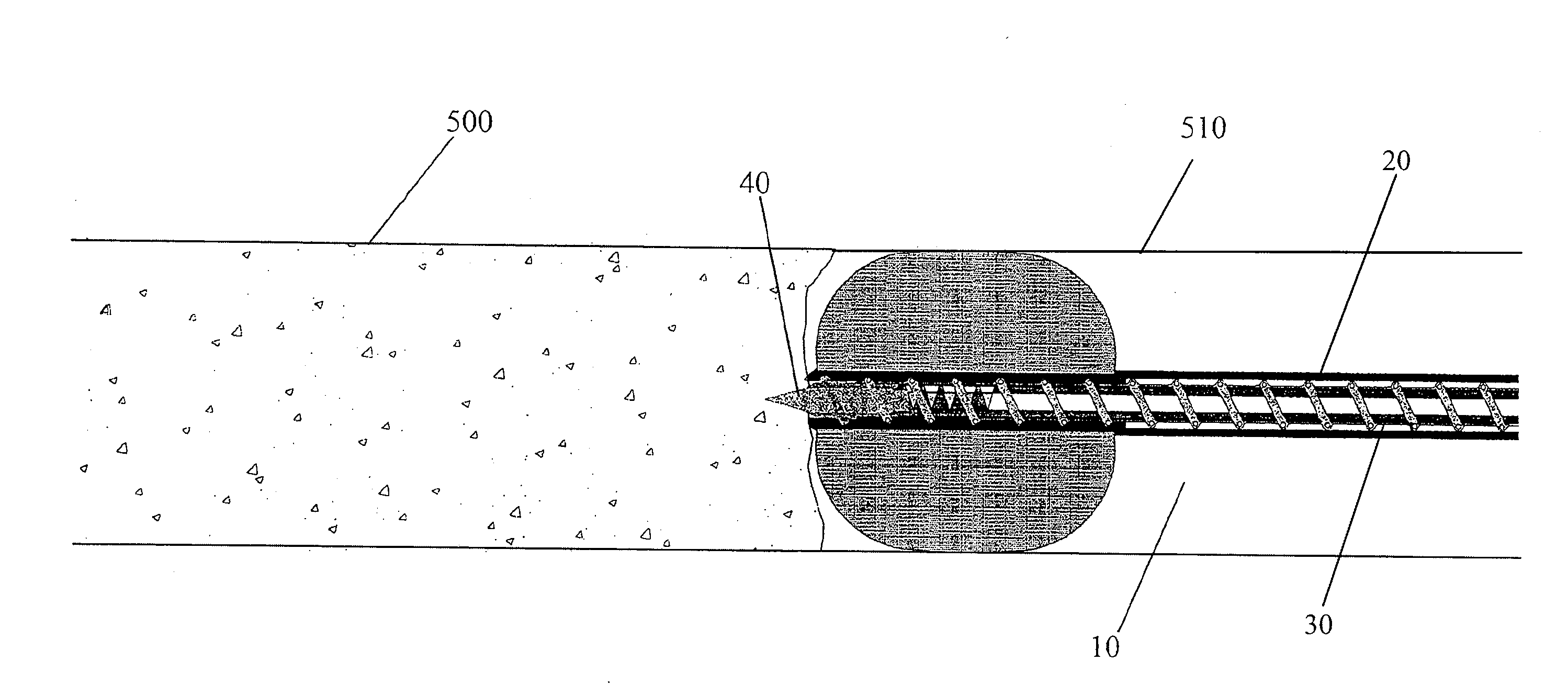

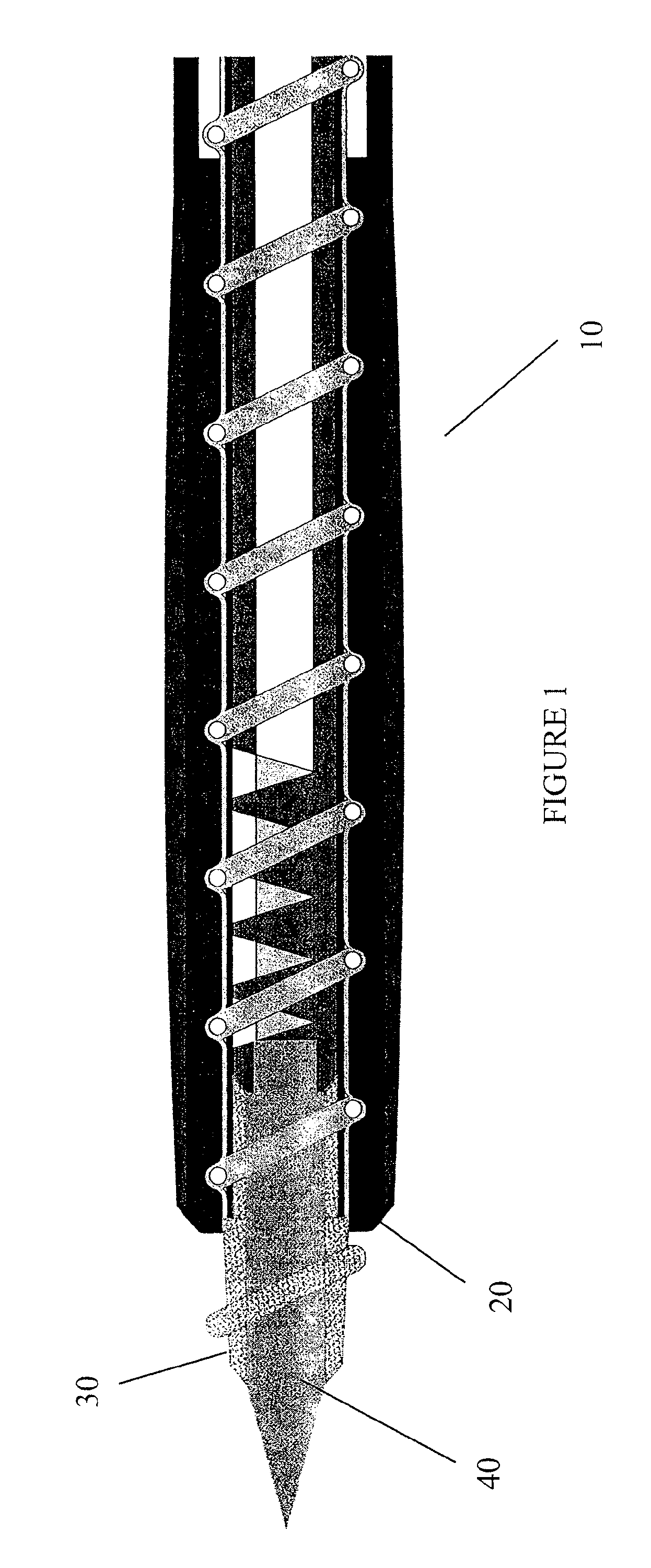

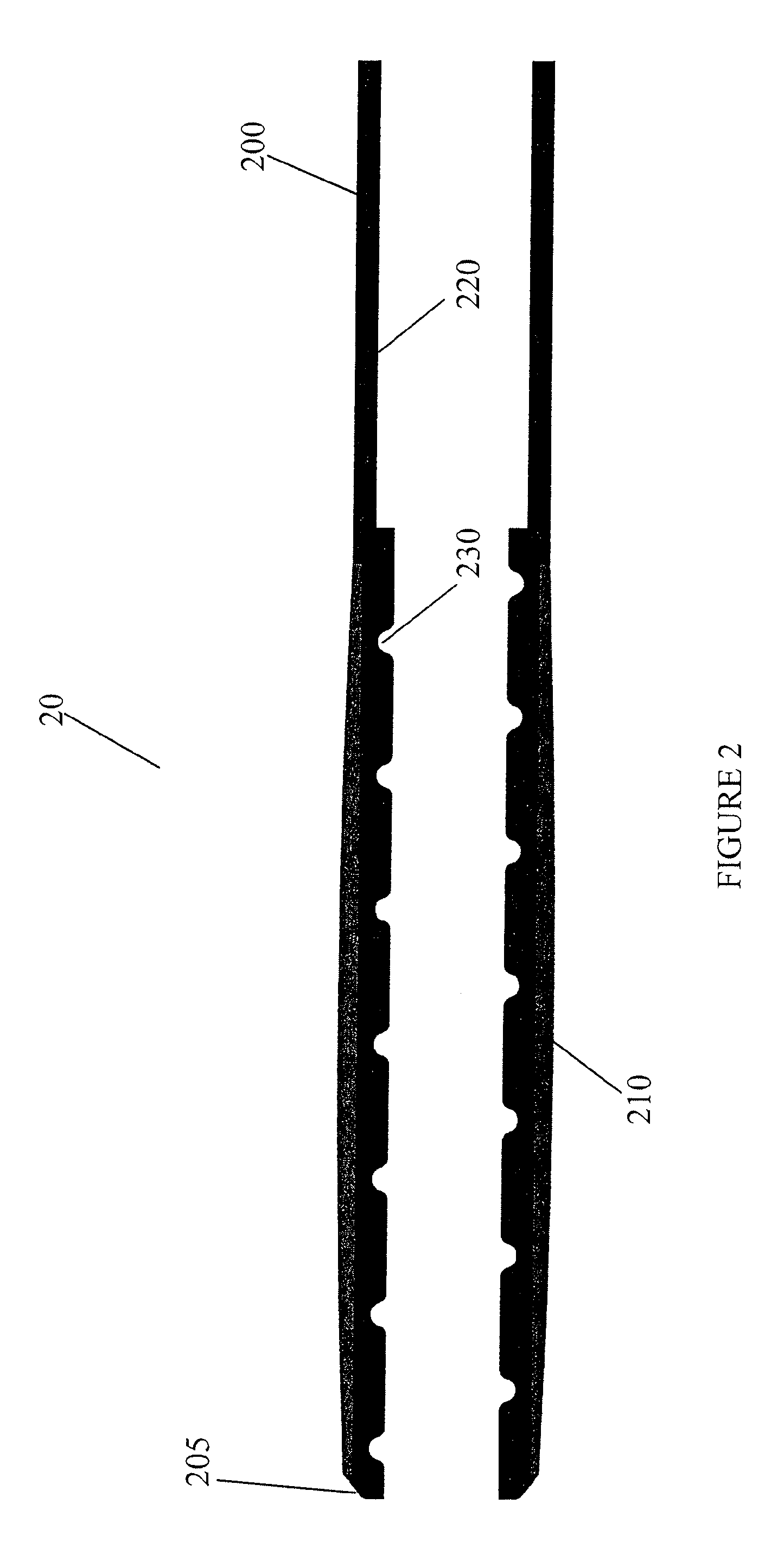

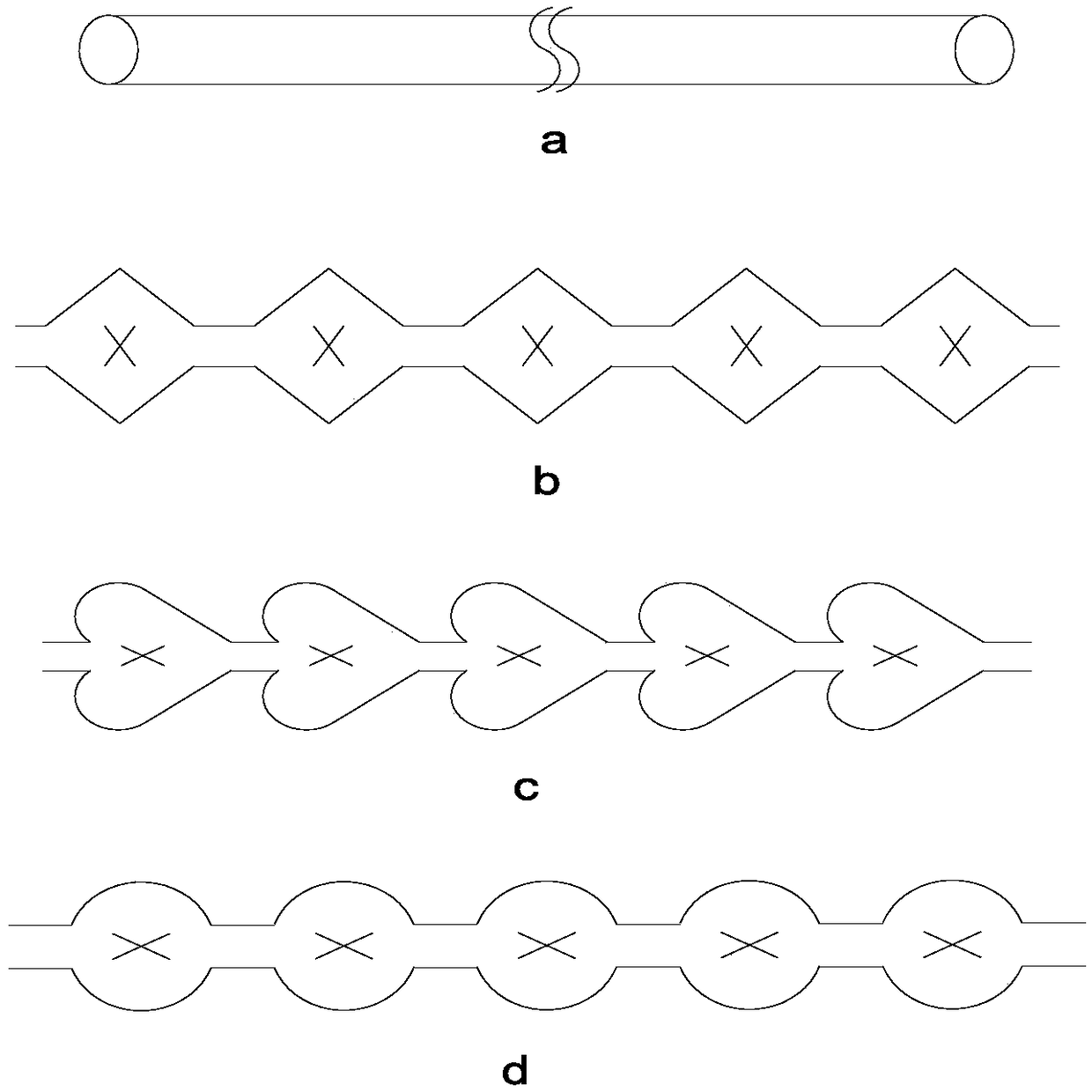

Vascular occlusion drill

InactiveUS20100082051A1Good controllabilitySimple to manufactureBalloon catheterCannulasVessel occlusionMedical treatment

The invention provides a medical device for treatment of an obstructed vessel, the apparatus comprising: (a) an external conduit comprising a proximal end, a distal end, a cylindrical outer surface sized for passage through a blood vessel, and an internal lumen, the conduit lumen being threaded within at least a portion of the length of the conduit at the distal end, and (b) a shaft comprising a proximal end, a distal end, an internal lumen, and a cylindrical outer surface fitted inside the conduit lumen and having external threading over at least a portion of the length of the shaft at the distal end; where the shaft threading engages the external conduit threading allowing the shaft to be advanced through the lumen by rotation of the shaft.

Owner:THORPE PATRICIA E +2

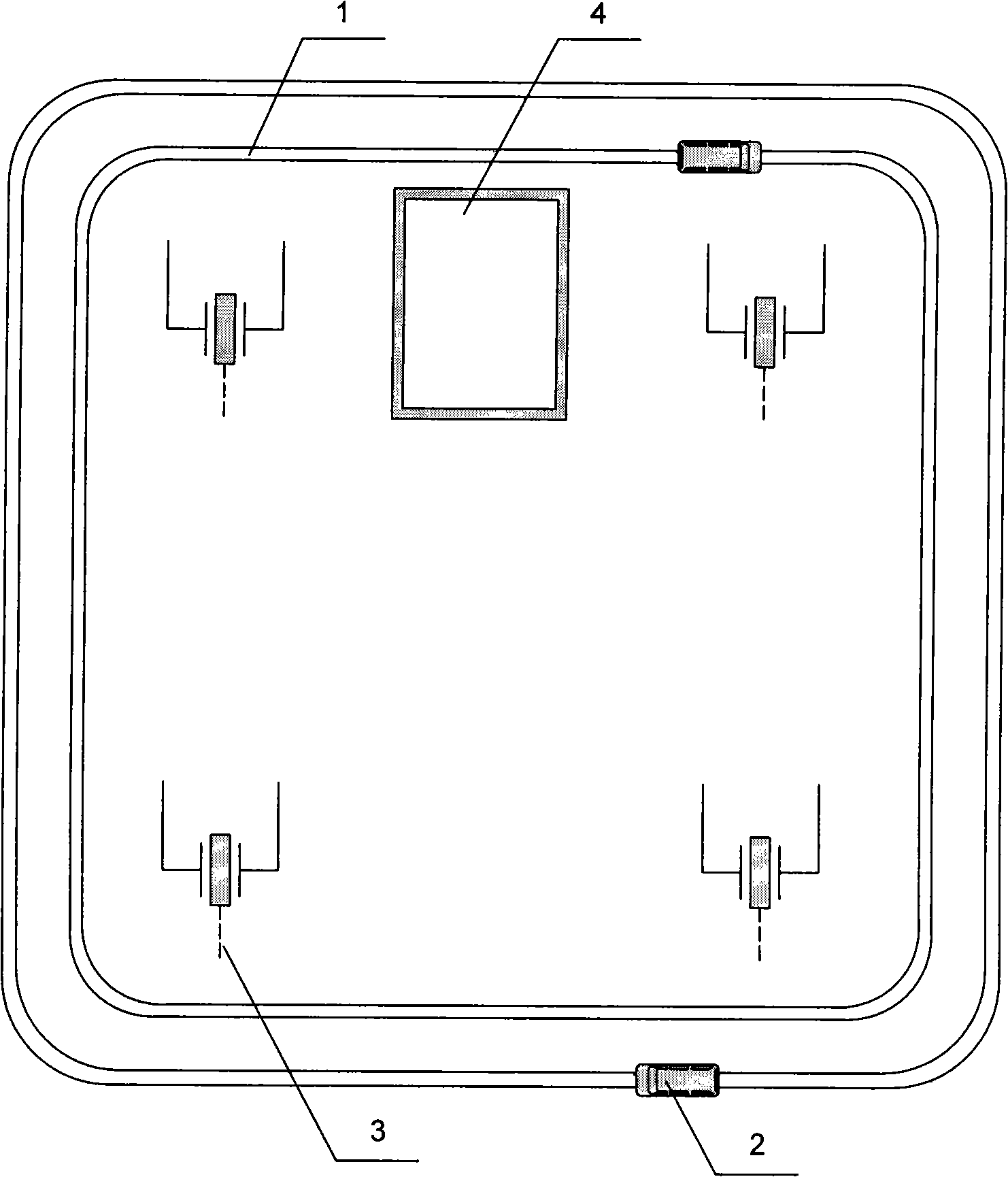

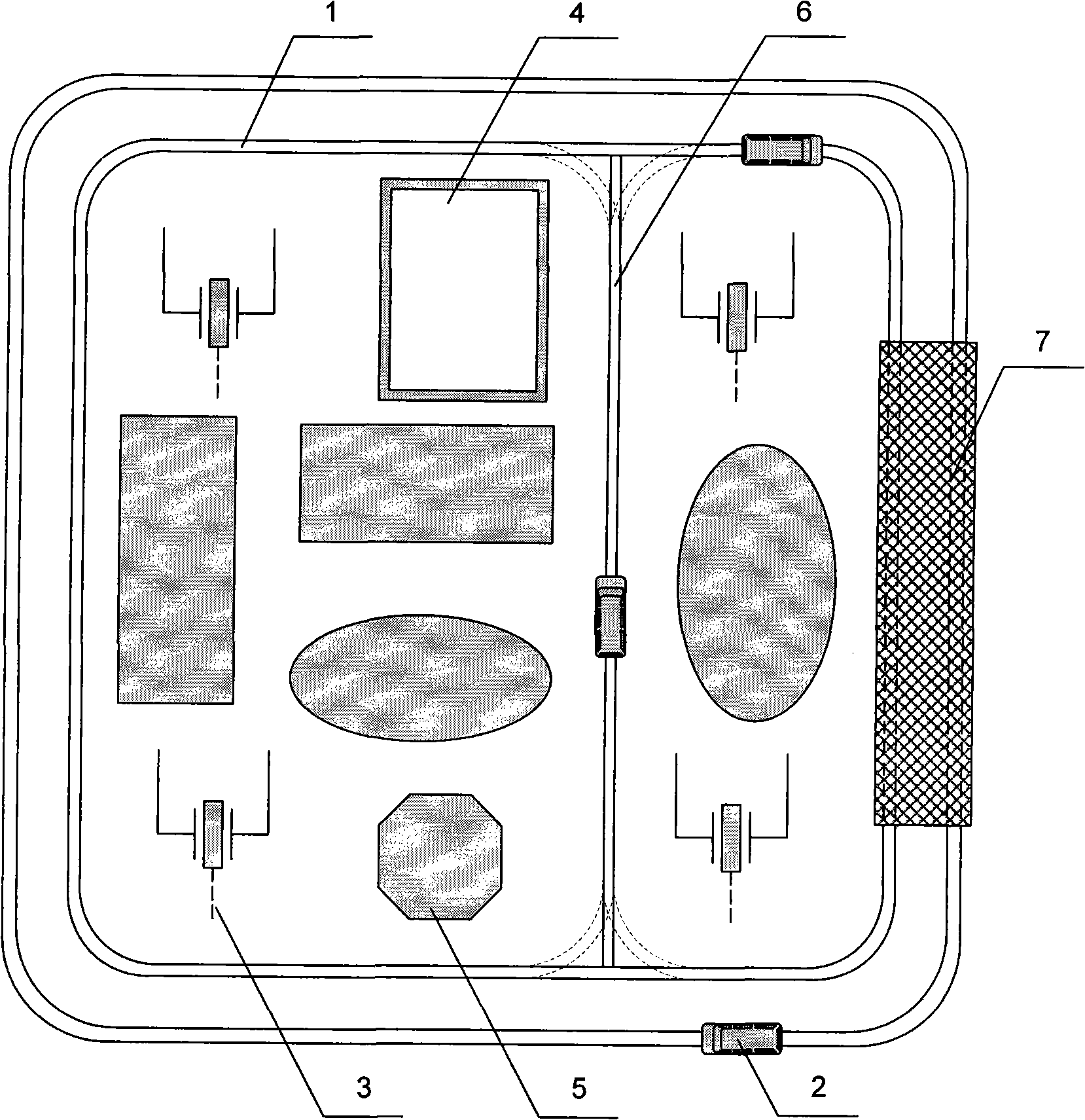

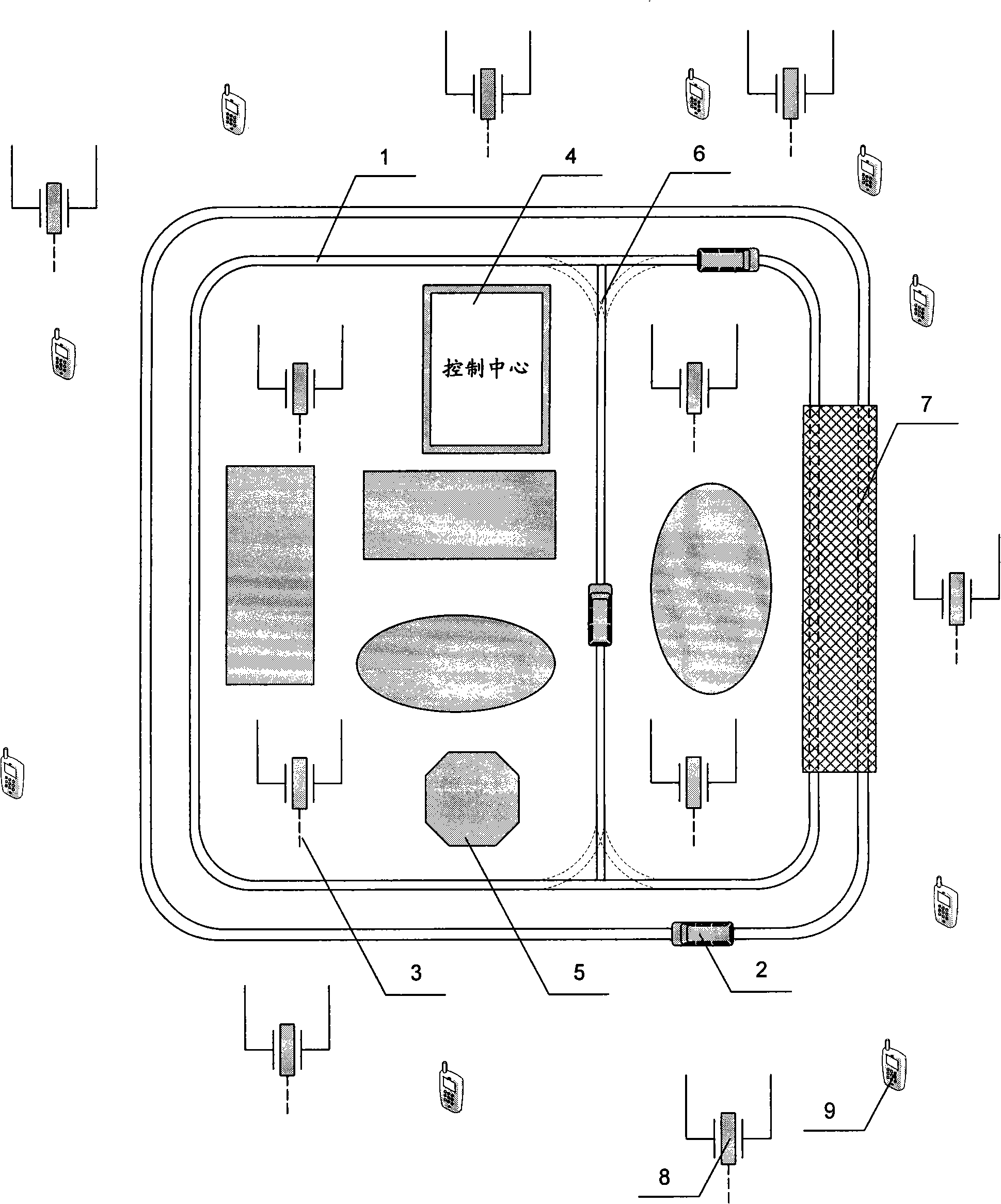

Universal external field wireless test system

ActiveCN101351011AFlexible layoutRealize simulationRadio/inductive link selection arrangementsEngineeringEnvironmental simulation

The invention relates to a general external field wireless test system, including a track, a test carriage for carrying a test terminal and running on the track, an antenna for providing at least one wireless network environment of wireless system and forming at least one track coverage cell on the track, and a control center for controlling the running mode of the test carriage and the work mode of the antenna. The invention can realize various external field wireless environmental simulations, high speed wireless test environmental simulation, various switch tests, test environmental simulation in which various wireless systems coexist, wireless advanced research, wireless arithmetic research, wireless equipment test, terminal test environmental simulation, network performance test of free bearing mobile terminal in order to analyze special wireless network performance, locate special wireless network exception and provide convenient wireless test environment for new technology experiment and frontier study of wireless network.

Owner:CHINA MOBILE COMM GRP CO LTD

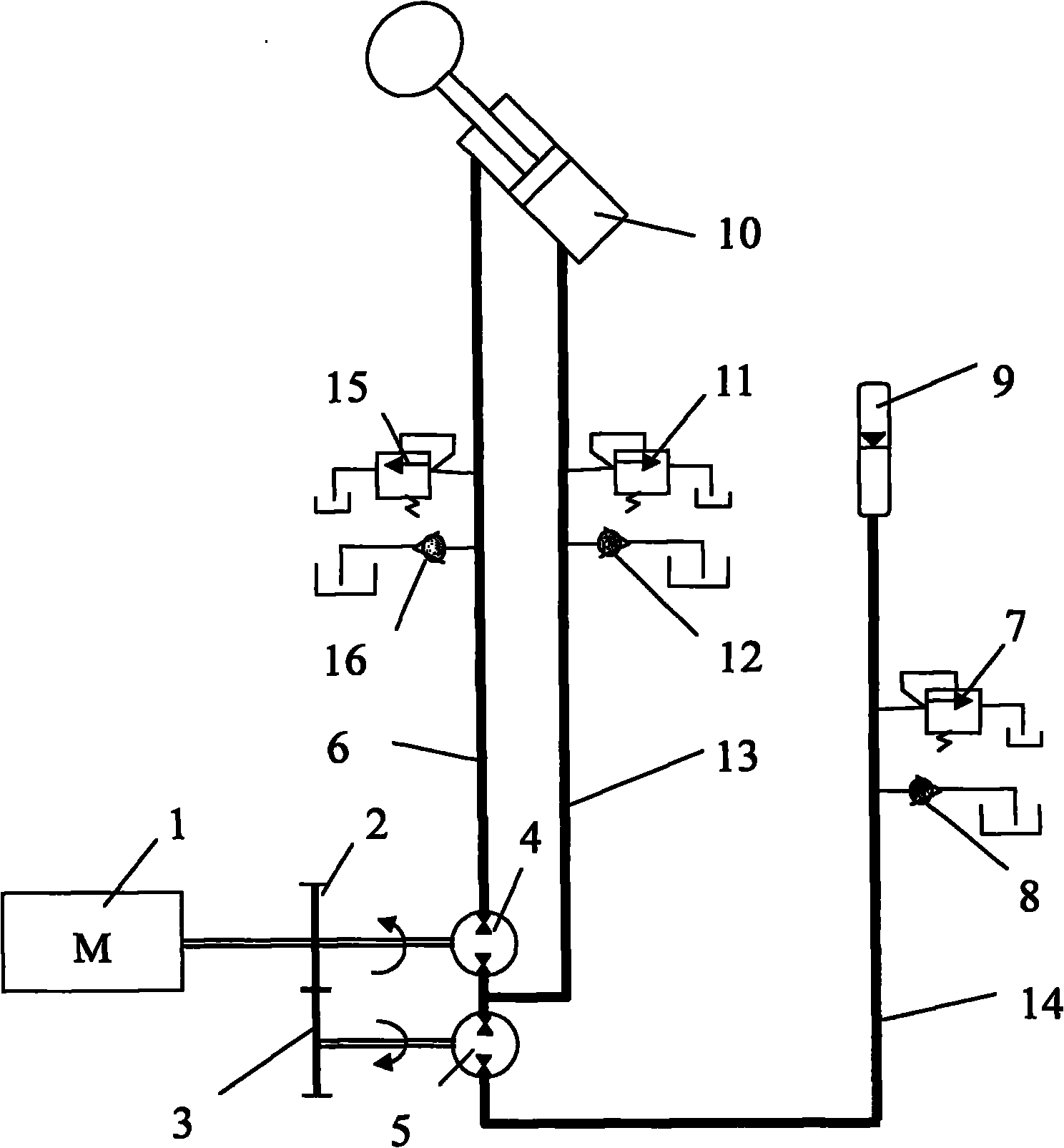

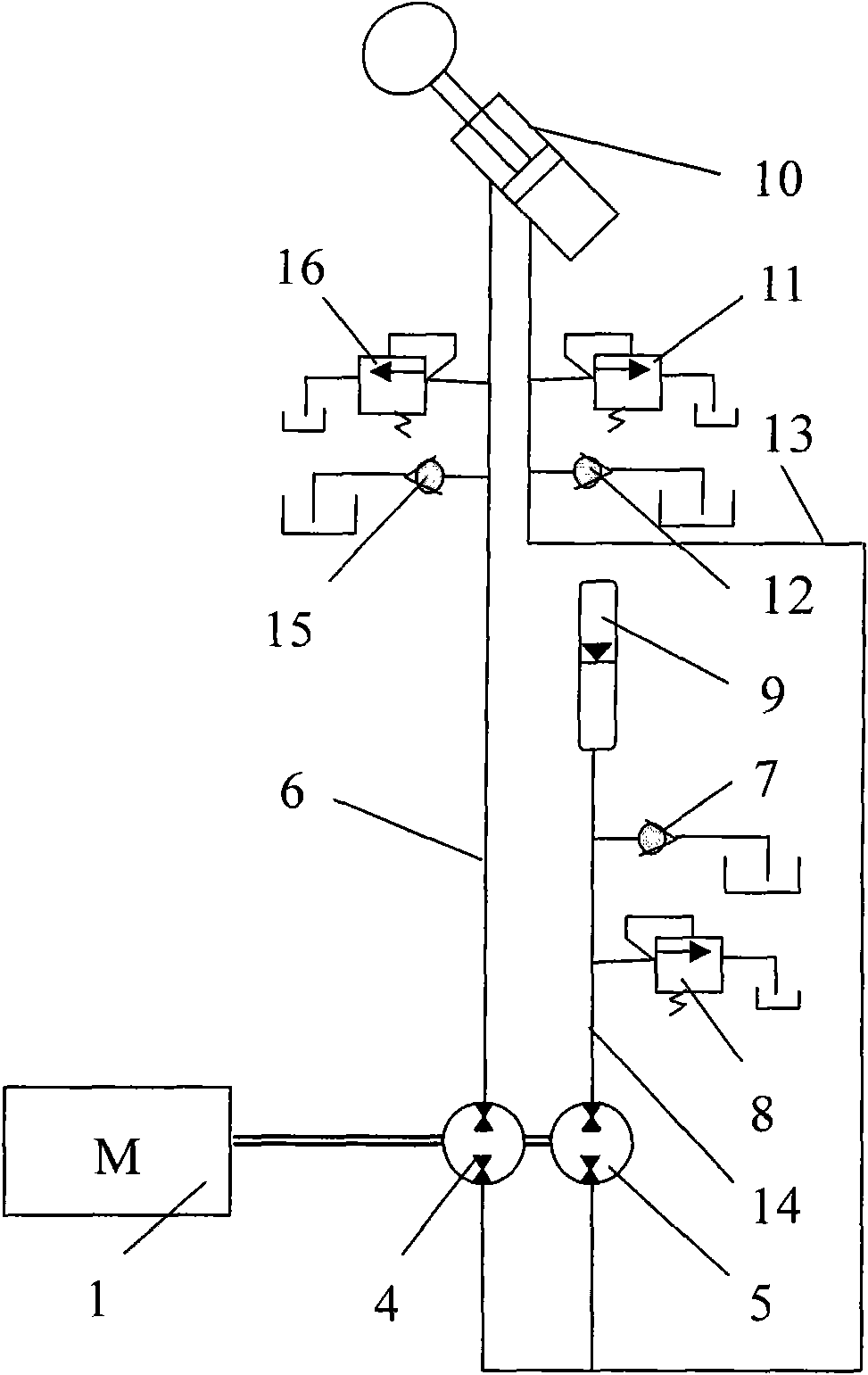

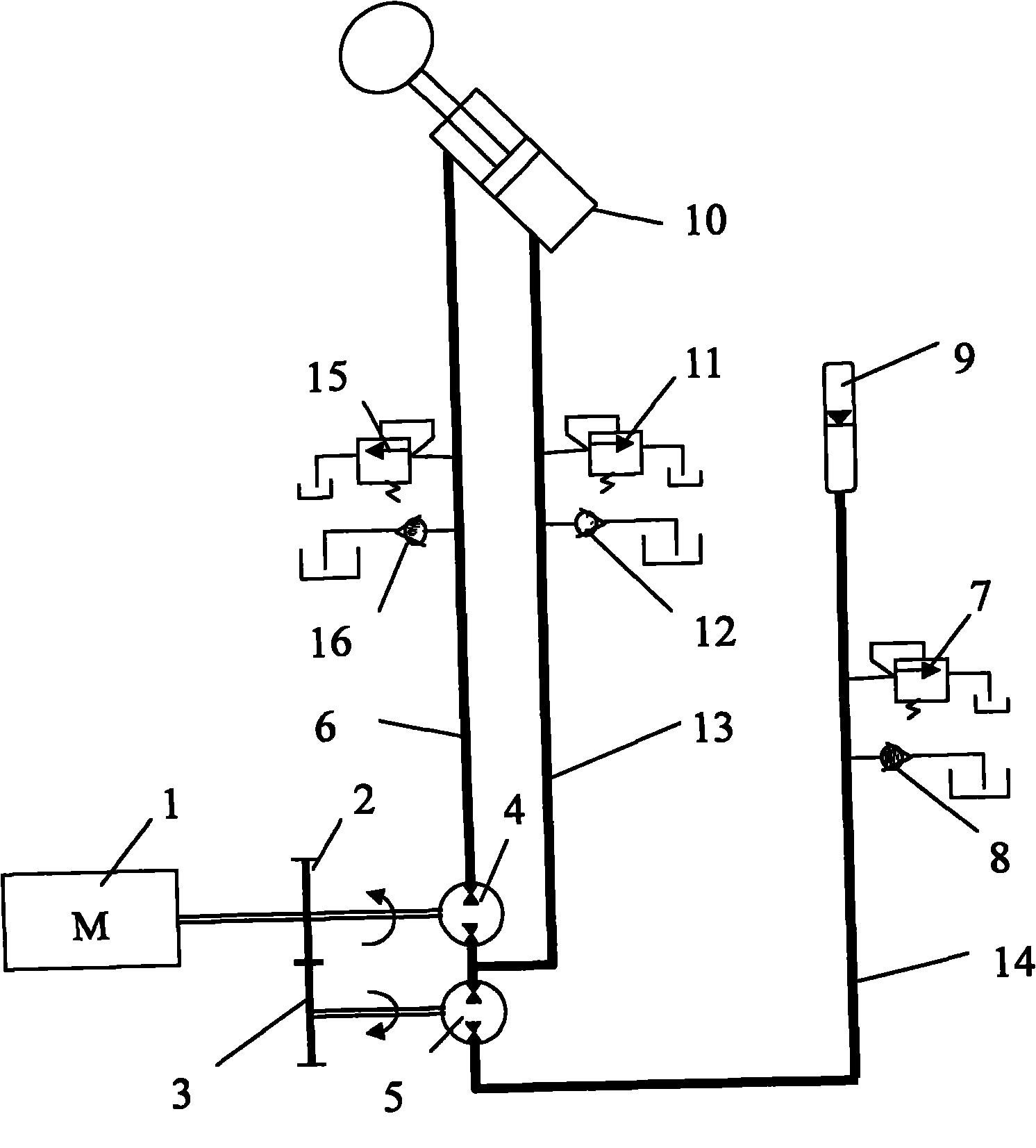

Gravitational potential energy recovery device during descending of engineering machinery movable arm

InactiveCN101956405ALess energy conversionGood controllabilityMechanical machines/dredgersFluid-pressure actuator componentsSystem safetyCheck valve

The invention relates to a gravitational potential energy recovery device during descending of an engineering machinery movable arm, comprising three parts, i.e. a hydraulic device for driving the movable arm to work, an accumulator device and a hydraulic system safety protection device, wherein the hydraulic device adopts two bidirectional quantitative hydraulic pumps-motors, an oil port thereof is respectively connected with a rod cavity of a movable arm cylinder (10) and an accumulator (9) by a connecting pipeline, and another oil port thereof is connected with a rodless cavity of the movable arm cylinder (10) by a connecting pipeline; the two bidirectional quantitative hydraulic pumps-motors are driven by mechanical transmission or driven coaxially; the flow ratio of the two bidirectional quantitative hydraulic pumps-motors is 1:(K-1), wherein K is the area ratio of the rodless cavity and the rod cavity of the movable arm cylinder; and the hydraulic system safety protection device mainly comprises three groups of overflowing valves and three groups of check valves which are respectively arranged on connecting pipelines.

Owner:JILIN UNIV

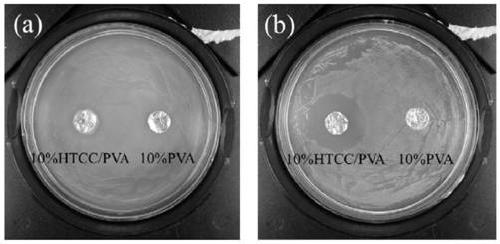

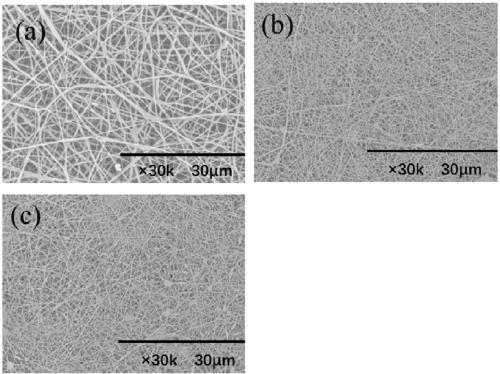

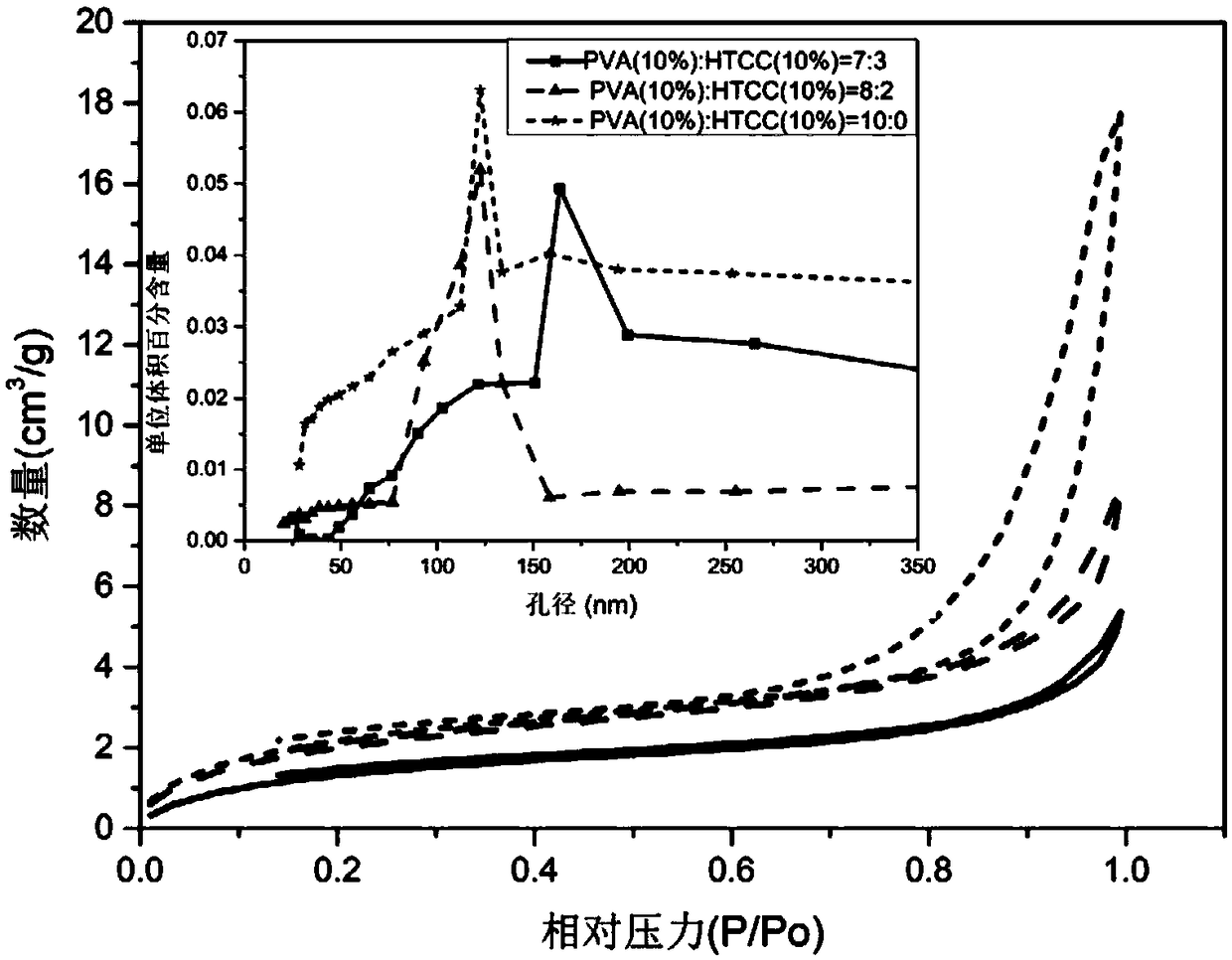

Method for preparing quaternary ammonium salt chitosan and polyvinyl alcohol antibacterial filter composite material

InactiveCN109316824ASimple methodMild conditionsMembrane filtersConjugated synthetic polymer artificial filamentsWater bathsQuaternary ammonium cation

The invention discloses a method for preparing a quaternary ammonium salt chitosan and polyvinyl alcohol antibacterial filter composite material. The method is characterized by comprising the following steps: mixing and stirring chitosan powder, acetic acid and deionized water to form a chitosan acetic acid solution; adding isopropyl alcohol, stirring and standing; heating a container through a water bath, and dropwise adding a certain amount of 2,3-epoxypropyltrimethylammonium chloride at set intervals to react; at the end of the reaction, adding absolute ethanol to the container, precipitating, performing suction filtration, and then soaking with acetone, washing, performing suction filtration, and drying to obtain modified quaternary ammonium salt chitosan; preparing a spinning solutionfrom the modified quaternary ammonium salt chitosan, and adding the spinning solution into a polyvinyl alcohol spinning solution to be mixed and stirred to obtain a mixed spinning solution, and obtaining the composite material by an electro-spinning method. The method disclosed by the invention satisfies the development requirements that the material is light and thin, and has good filterabilityand excellent antibacterial performance and the like in practical application, and can be used for preparing biomedical antibacterial protective materials such as biofiltration membranes, protective masks, wound dressings and the like.

Owner:DONGHUA UNIV

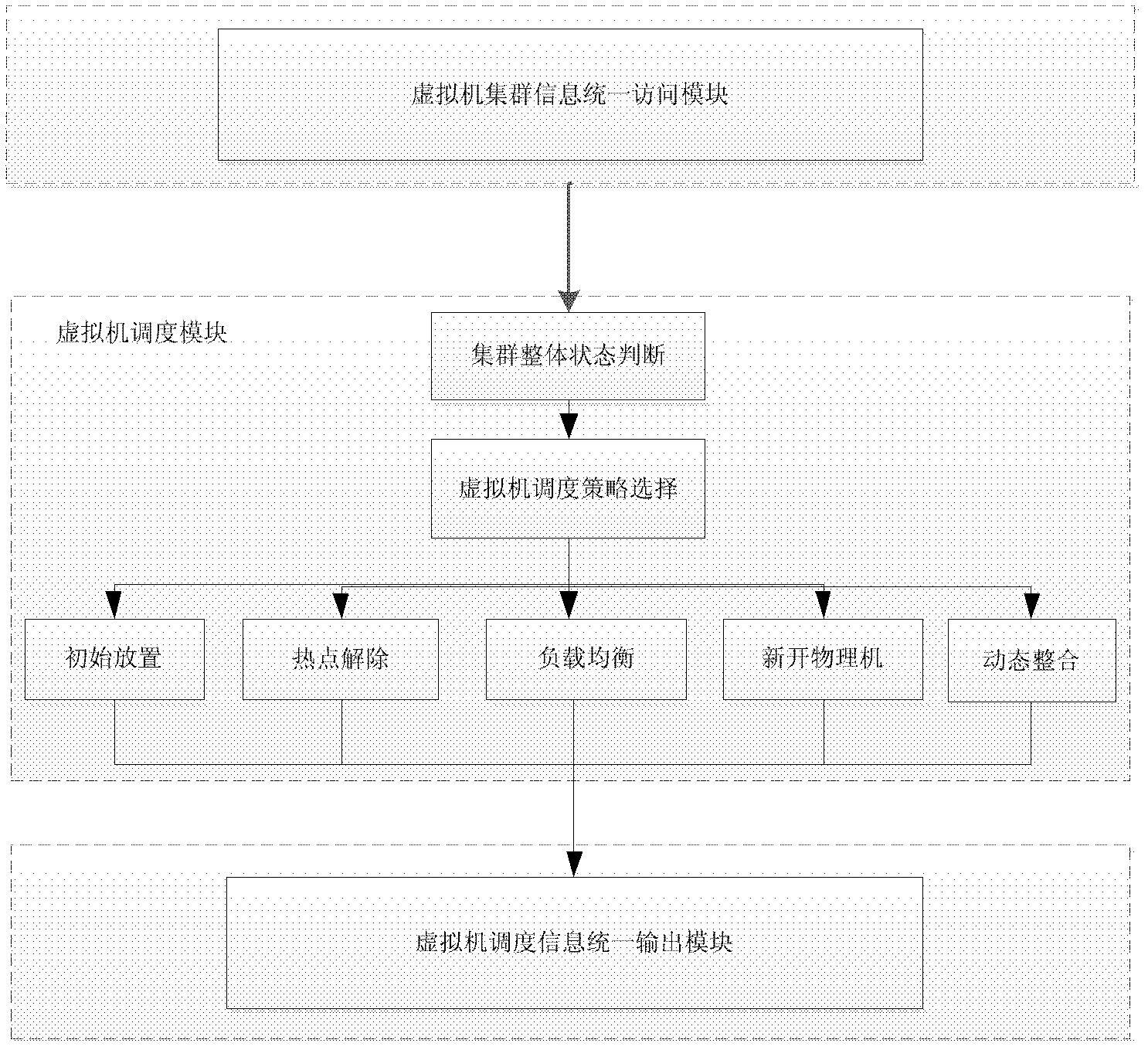

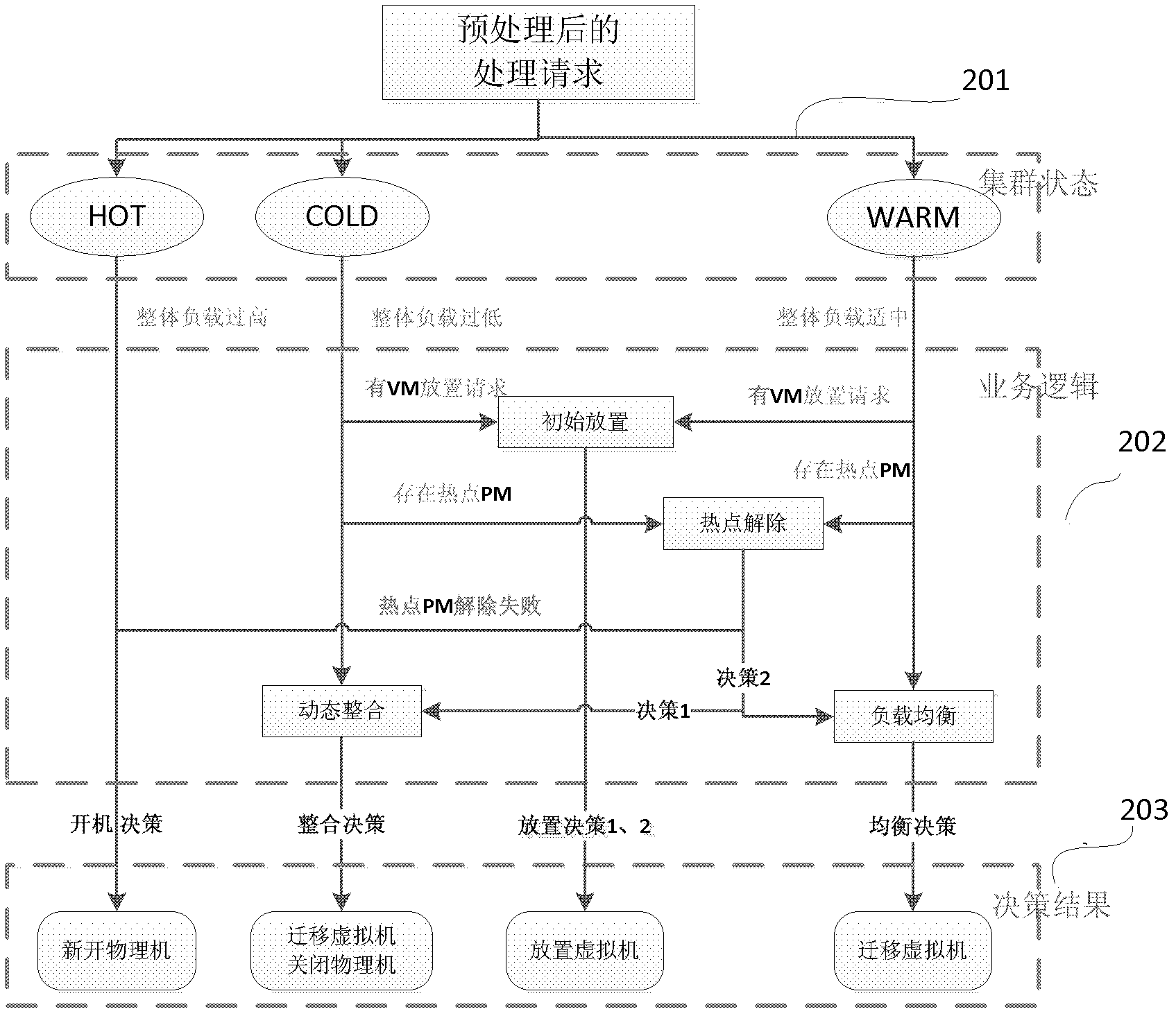

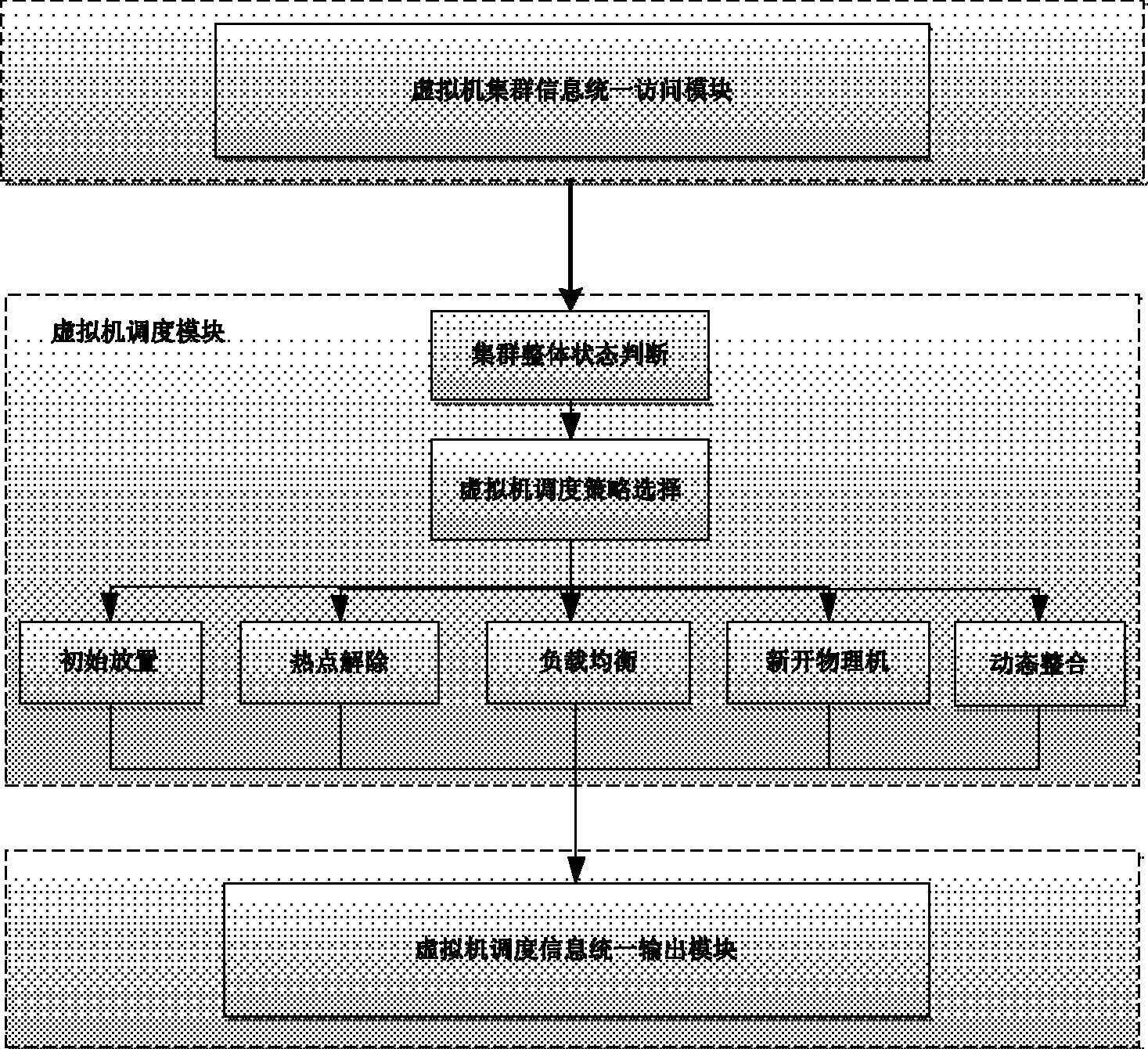

Multi-field supportable virtual machine dispatching device and multi-field supportable virtual machine dispatching method

InactiveCN102662754AScheduling supportHigh transparencyProgram initiation/switchingSoftware simulation/interpretation/emulationMulti fieldModularity

The invention discloses a multi-field supportable virtual machine dispatching device and a multi-field supportable virtual machine dispatching method. The multi-field supportable virtual machine dispatching device comprises a virtual machine cluster information central access module, a virtual machine dispatching module and a virtual machine dispatching information central output module, wherein the virtual machine cluster information central access module is used for receiving input cluster information, the virtual machine dispatching module is used for analyzing cluster information and generating dispatching policy required by fields, and the virtual machine dispatching information central output module is used for centrally outputting policy information. The virtual machine cluster information central access module receives processing requests of a virtualization cluster system and preprocesses the same into a uniform input information format. The virtual dispatching module classifies states of the virtualization cluster system according to input information, generates corresponding dispatching policy for processing the requests according to classifications and outputs dispatching commands through the information central output module. Dispatching virtualization clusters under multiple fields can be realized well, and the purpose of dispatching under different fields is achieved. By modular design, uniform interfaces are used among modules, transparency in design of dispatching algorithm is improved, and application range is wide.

Owner:ZHEJIANG UNIV

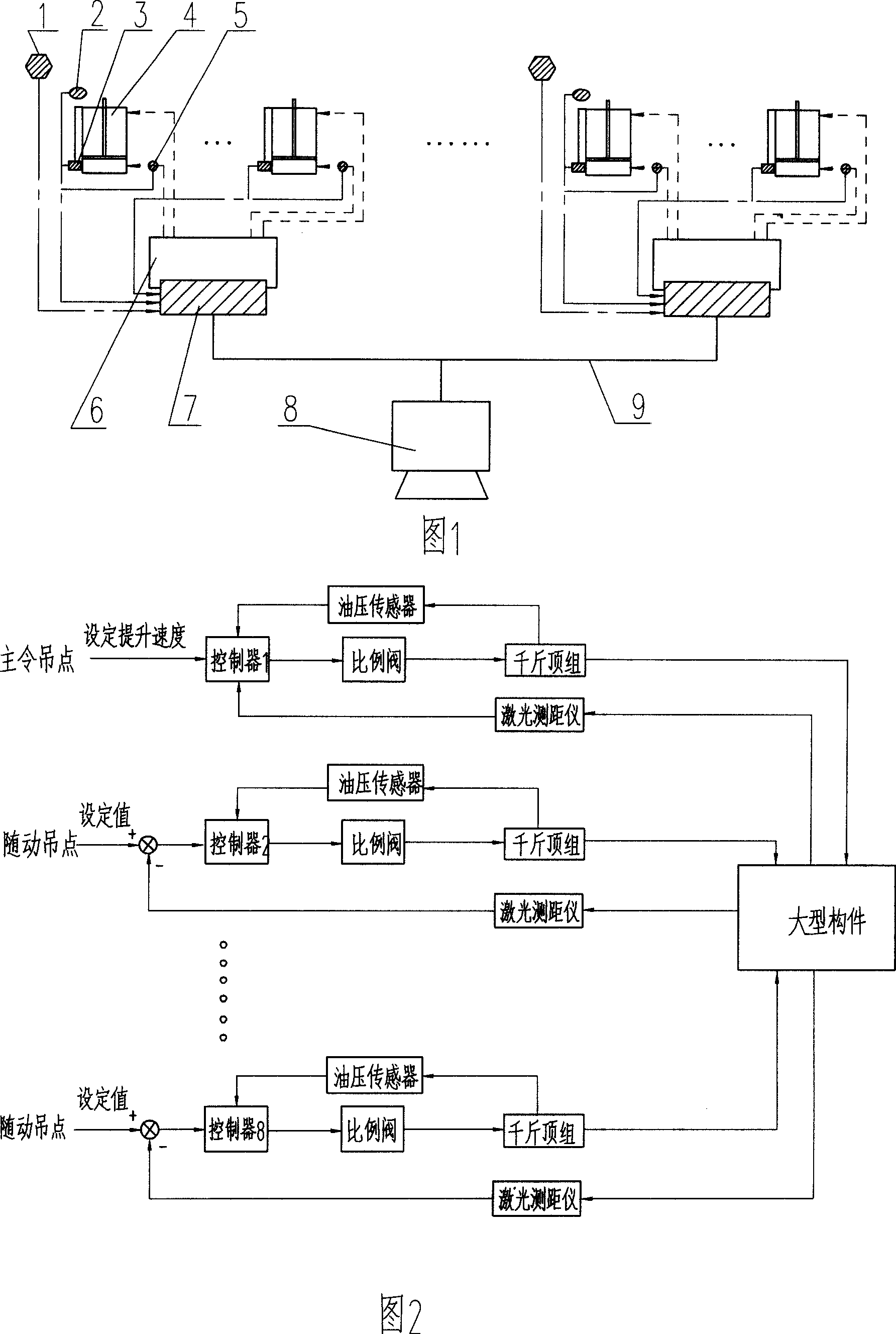

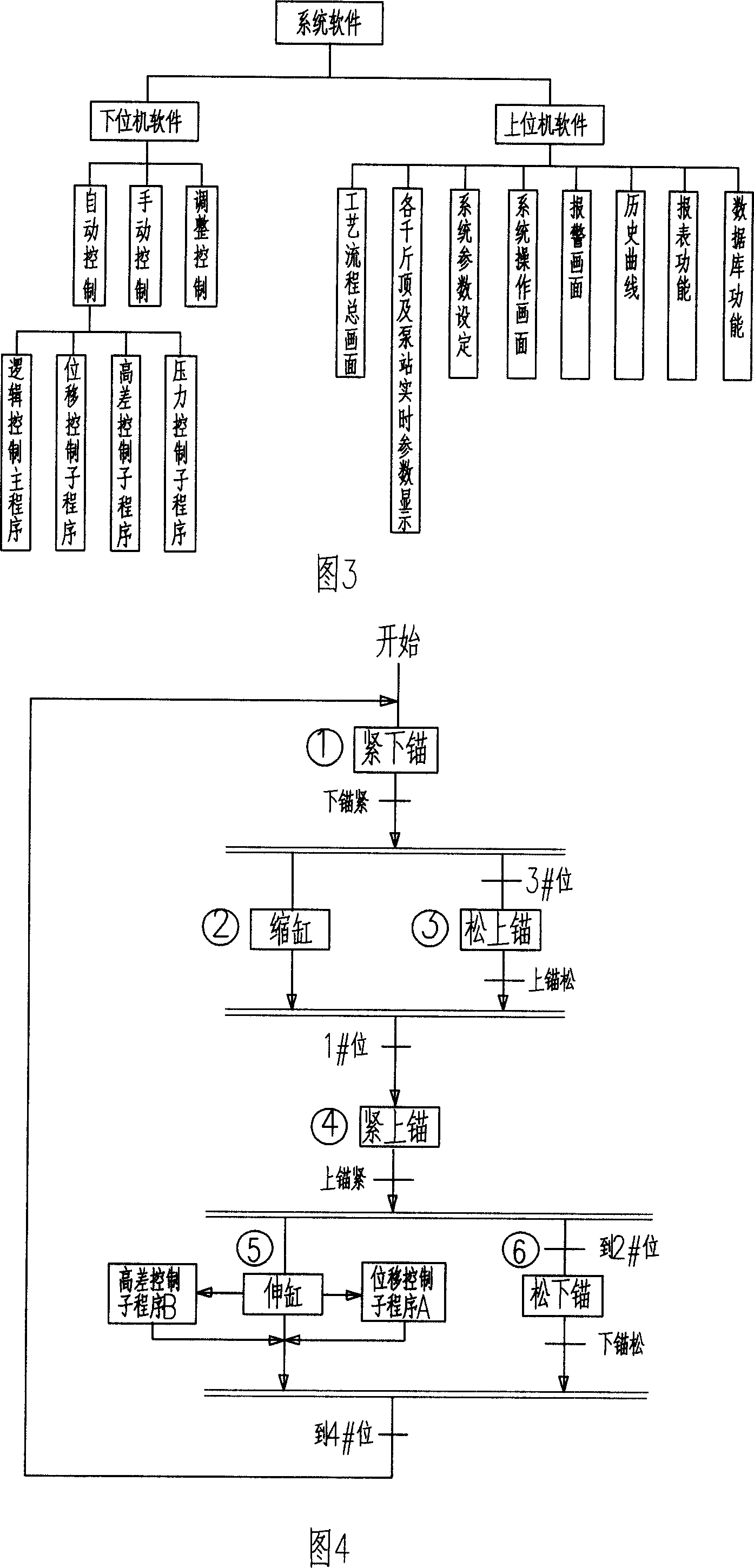

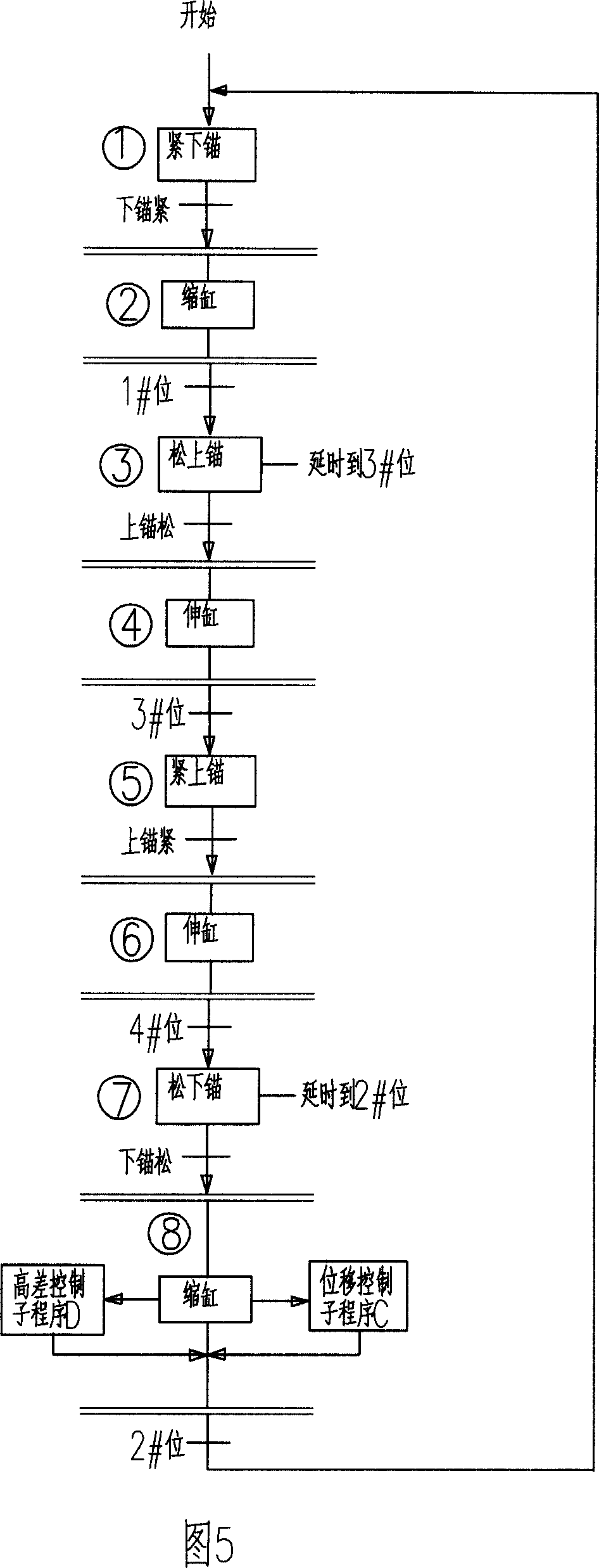

Hydraulic hoisting monitor system and its use in hydraulic hoisting control

ActiveCN1987700AReasonable configurationStrong fault toleranceSafety devices for lifting equipmentsComputer controlData acquisitionEngineering

The monitored control (MC) system is composed of up device, low device and data acquisition system. The up device is a MC computer with monitored control software in use for monitored controlling system and data management. The low device includes n pieces of site controller composed of n pieces of programmable controller with logic control main program and synchronous adjustment sub program being written into. Being installed on y pieces of hydraulic power unit, the n pieces of site controller through real time network is connected to MC computer. The method includes remote control mode, and local control mode. No mater how large the system is, direct selecting mode for jacks is adopted in the system. Features are: simple system circuit, intuitive operations, and accurate measurement. Configuration software is in use for monitoring system and querying historical data. The invention is in use for lifting control of large-scale component.

Owner:LIUZHOU OVM MASCH CO LTD

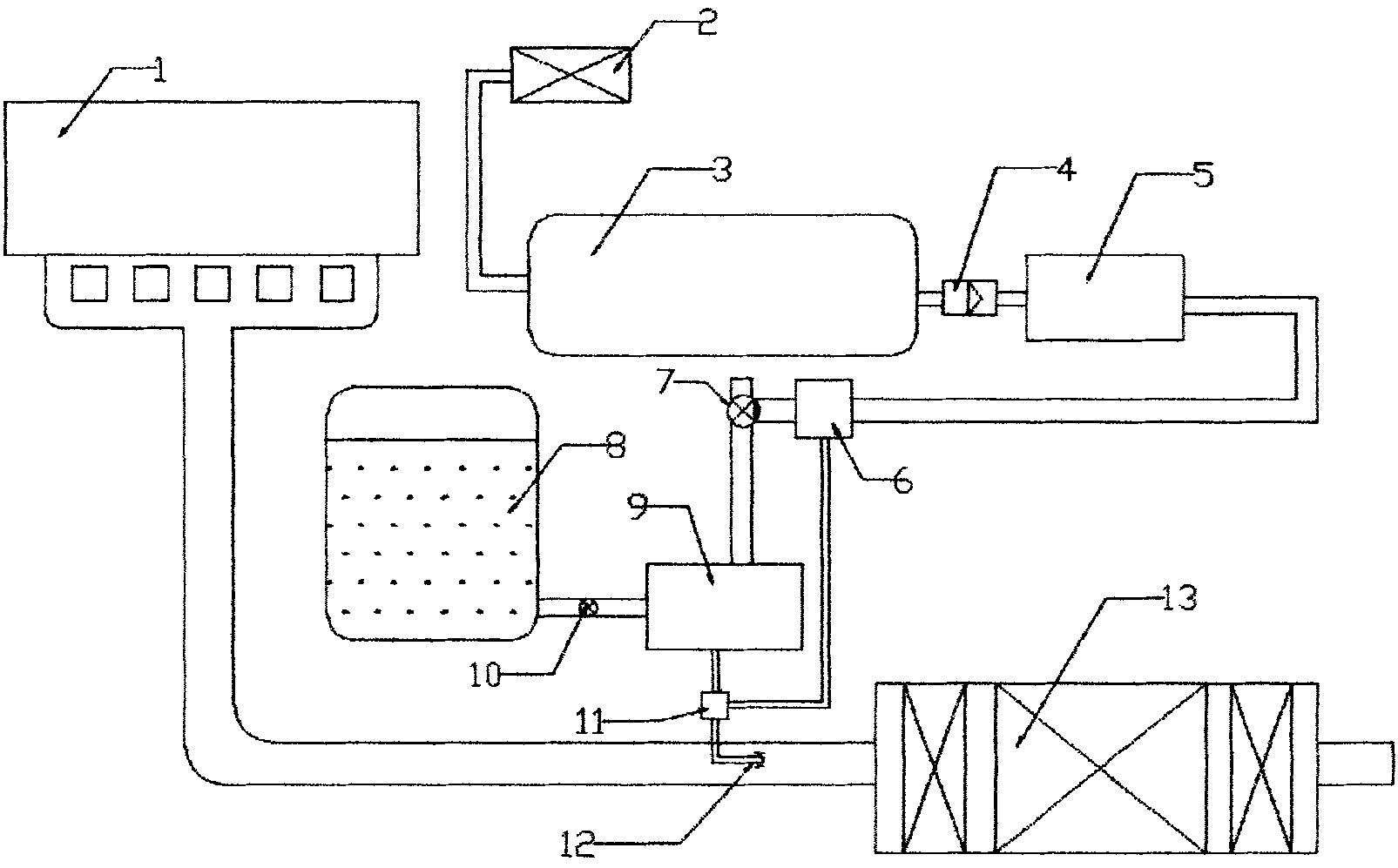

Device and method for adding diesel urea solution

InactiveCN101798946AGood controllabilityImprove reliabilityInternal combustion piston enginesExhaust apparatusEngineeringEnergy consumption

The invention relates to a device and a method for adding diesel urea solution and belongs to the technical field of engine exhaust-gas disposal. The device comprises a urea box, N pressure chambers connected with the urea box, a switch valve for realizing control, air inlet / outlet pipes positioned at the top of the pressure chambers, three-way valves positioned at the top of the air inlet / outletpipes, urea solution outlet pipes positioned at the bottom of the pressure chambers, control units connected with the three-way valves, the switch valves, and urea solution flow rate controllers, wherein the other ends of the outlet pipes are connected in series with the urea solution flow rate controllers and urea solution nozzles in turn. The invention provides a pumpless urea solution adding device, a system and a method, which have the advantages of low energy consumption, simple structure, low cost of devices, reliable operation and excellent atomization effect.

Owner:MILITARY TRANSPORTATION UNIV PLA

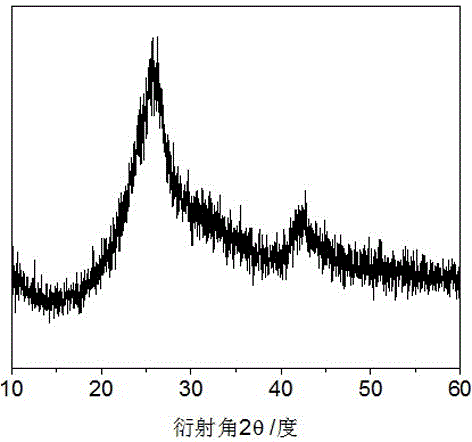

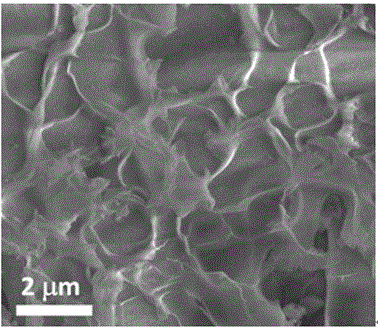

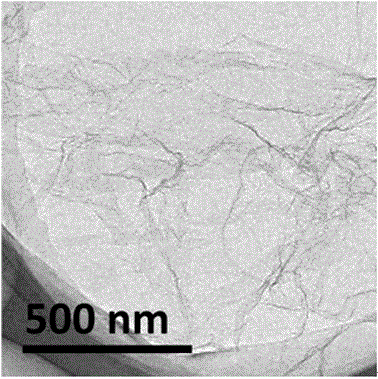

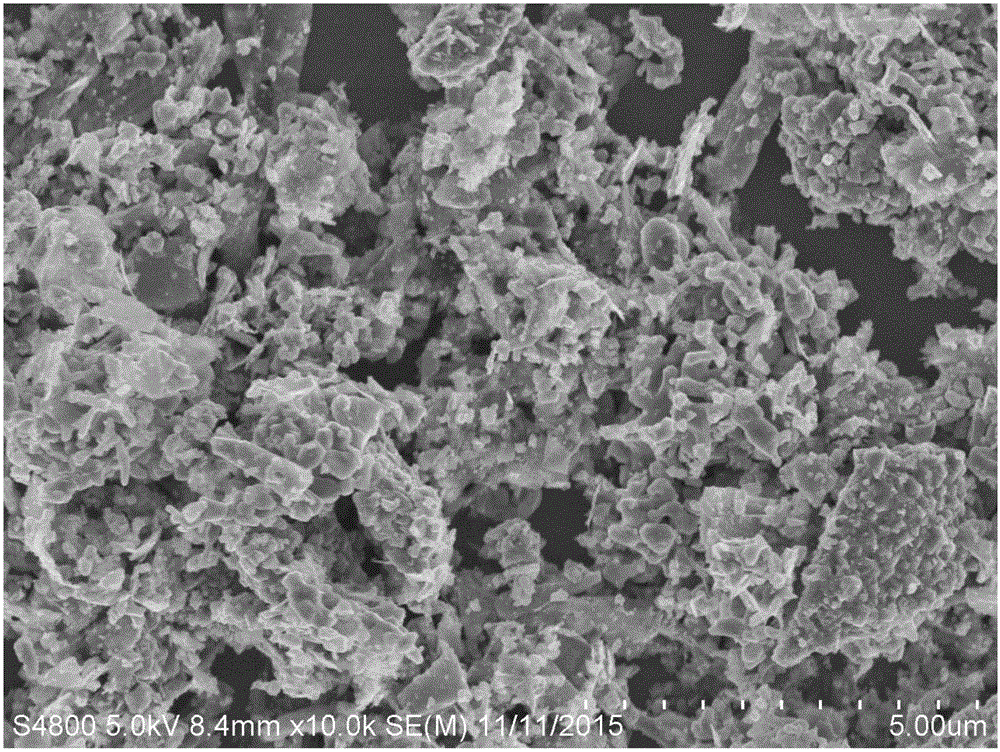

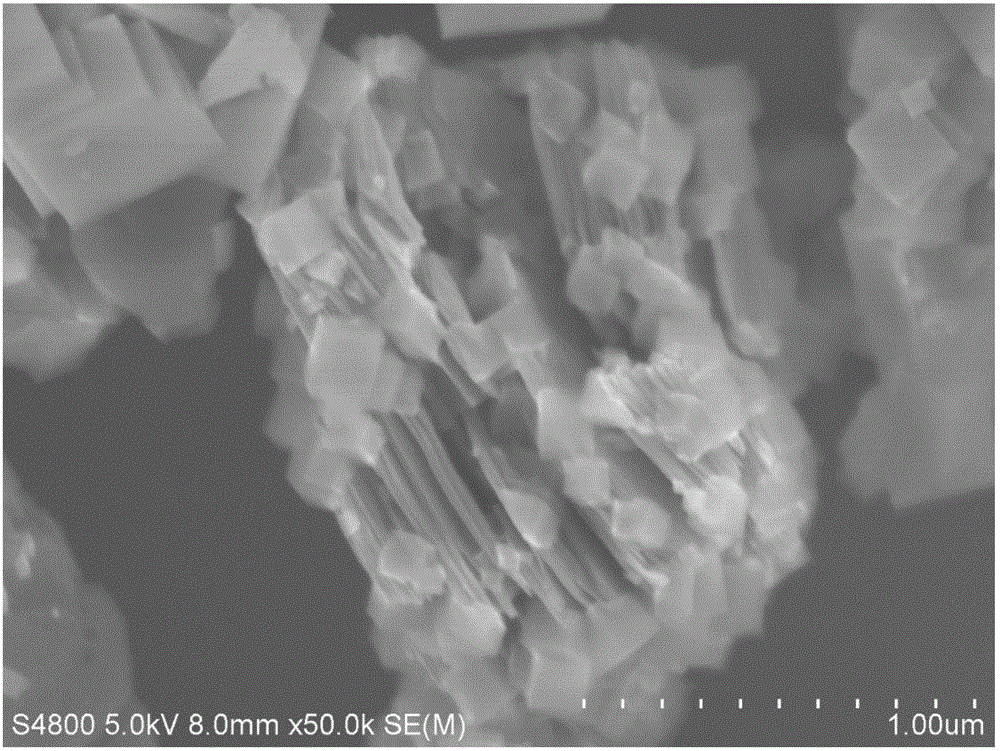

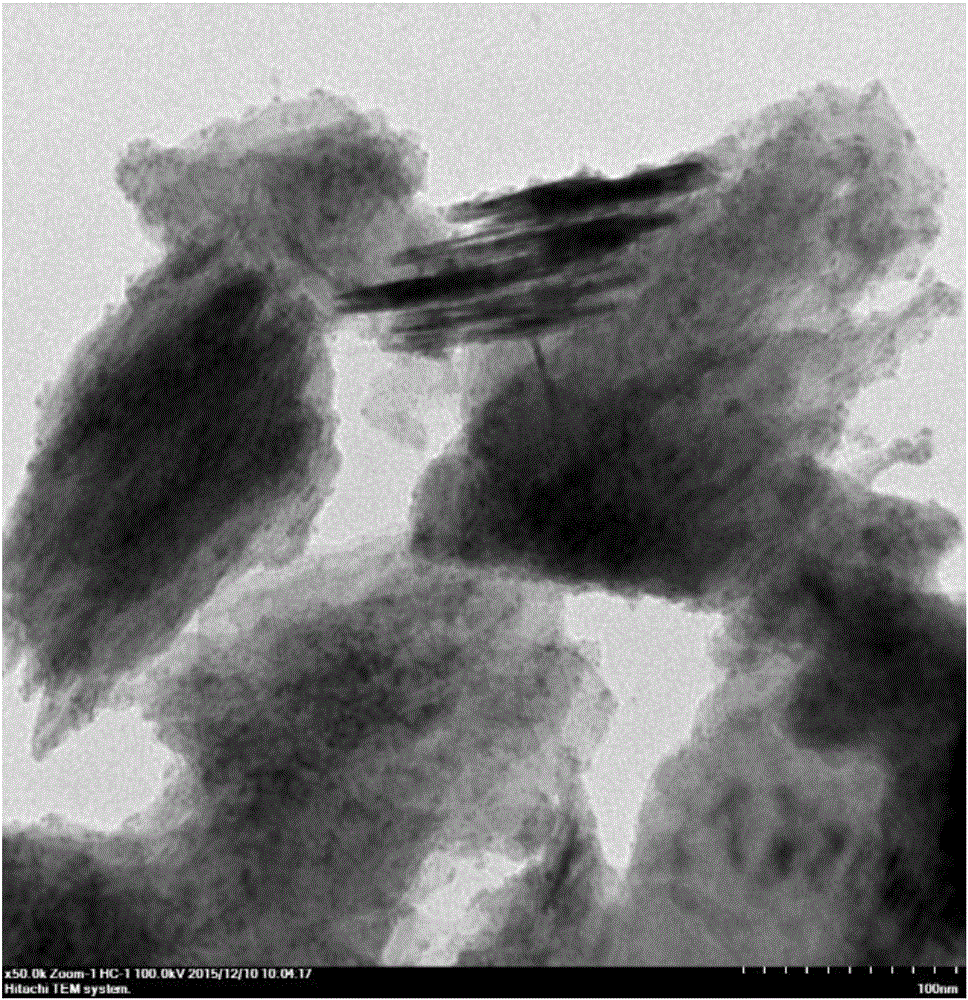

Compounding method for nanometer ultrathin boron carbon nitrogen sheet

ActiveCN106430128AThe synthesis process is simpleGood controllabilityNitrogen and non-metal compoundsOrganocatalysisBoron trioxide

The invention discloses a compounding method for a nanometer ultrathin boron carbon nitrogen sheet and belongs to the technical field of material preparation. The method comprises the following steps: mixing diboron trioxide, melamine, glucose and the mixed salt of NaCl and KCL, then grinding, and performing heat treatment on the acquired powder under the atmosphere of ammonia gas, thereby acquiring the nanometer ultrathin boron carbon nitrogen sheet. According to the invention, the low-cost mixed salt and the boron carbon nitrogen precursor have a heating reaction under the atmosphere of ammonia gas, and the fused mixed salt is utilized as a template of the boron carbon nitrogen sheet, is evaporated at high temperature and is peeled, so that the nanometer ultrathin boron carbon nitrogen sheet characterized by having a graphite like phase crystal structure, the thickness of an atom-level ultrathin sheet, a huge size and a high specific area can be prepared. The compounding method disclosed by the invention is simple in operation; complex and expensive instruments and equipment are not required; the adopted raw materials are low in cost and are easily acquired; the environmental pollution is little; the method is suitable for large-scale production; and the compounding method has significance in boosting the application of the nanometer ultrathin boron carbon nitrogen sheet in the fields of photoelectric materials, organic catalysis, hydrogen storage carriers, detection analysis, and the like.

Owner:FUZHOU UNIV

Compound film enhanced by inclusion complex of ring molecule and polymer and preparation method thereof

InactiveCN101462388AStrong specificityGood controllabilitySynthetic resin layered productsSolventSelf assemble

The invention discloses a composite membrane reinforced by an inclusion complex of ring molecules and a polymer. The composite membrane is mainly formed by a polymer layer consisting of a linear polymer or a branch polymer and an inclusion complex layer formed by serially sleeving the ring molecules on partial chain links of the polymer which are compounded and accumulated layer by layer. The preparation of the composite membrane mainly comprises the following steps: a polymer component and a ring molecule component are dissolved into a solvent respectively to be prepared into a solution; and a substrate material is alternately immersed into the solution prepared by the polymer component and the ring molecule component, is kept stand for a period of time, and is taken out to remove excessive adhesive substances, and a multi-layer membrane system can be obtained by circulating the process. Compared with the prior art, a supermolecular multi-layer membrane greatly strengthens the mechanical property and the friction-resistant performance of the multi-layer membrane by introducing a self-assembling inclusion component of the polymer and the ring molecules, and has broad varieties of selectable polymers and broad application prospect.

Owner:SICHUAN UNIV

Preparation method of methyl phenyl vinyl silicone resin

The invention discloses a preparation method of methyl phenyl vinyl silicone resin. The preparation method comprises the following steps: firstly mixing and agitating organic solvent, deionized water and strong acid, then dropwise adding a mixture for hydrolysis reaction, and increasing temperature and reflowing to obtain mixed solution, wherein the mixture consists of difunctional alkoxy silane, trifunctional alkoxy silane, monofunctional alkoxy silane and tetraethoxysilane; standing the mixed solution, cooling to room temperature, separating out an organic layer, washing the organic layer with deionized water till the organic layer becomes neutral, then adding an alkaline catalyst into the organic layer, increasing the temperature for azeotropic reflowing for a certain time to obtain azeotropic reflowing solution; cooling the azeotropic reflowing solution to 50 DEG C below, then adding solid acidic neutralizer, stirring for neutralizing, filtering, and conducting vacuum purification to obtain the methyl phenyl vinyl silicone resin. According to the preparation method, the process is easy to control, the labor intensity is low, the whole process has small toxicity, and the preparation method has the advantages that monomer sources are wide, cost is low, and the prepared methyl phenyl vinyl silicone resin has stable storage performance.

Owner:中山市卫宝婴儿用品有限公司

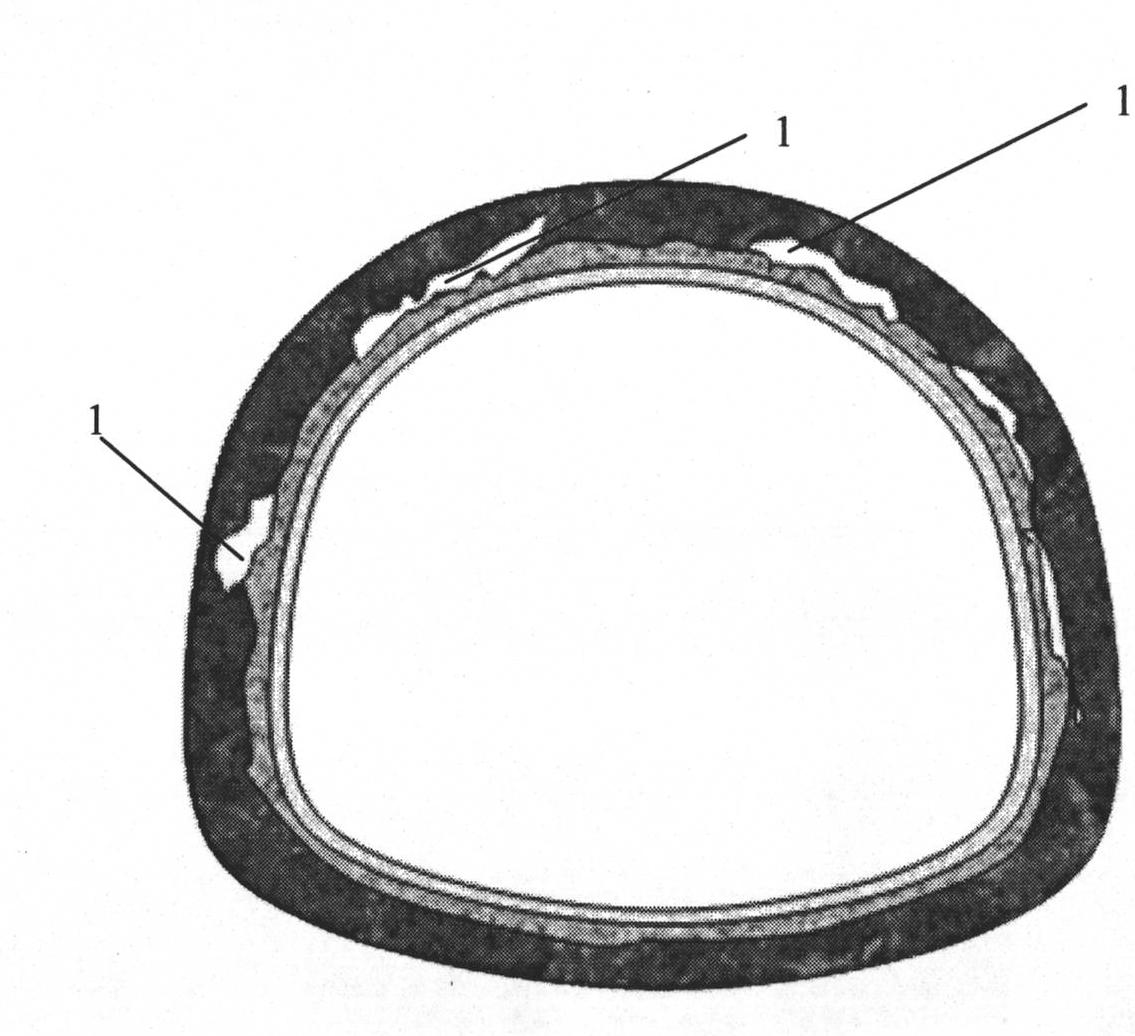

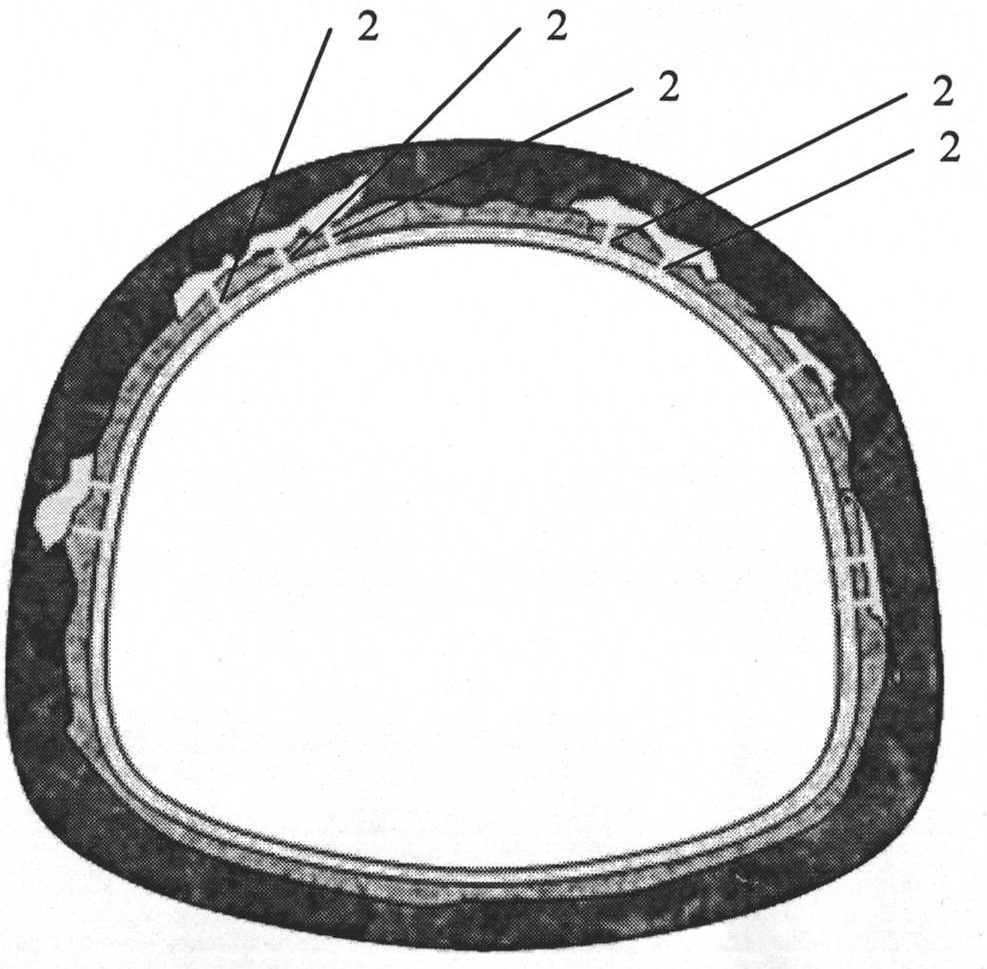

High polymer grouting technology for treating tunnel void and construction method thereof

InactiveCN102052081AIncreased durabilityIncrease elasticityUnderground chambersTunnel liningFast fillingTherapeutic effect

The invention discloses high polymer grouting technology for treating a tunnel void and a construction method thereof. The technology comprises the following steps of: detecting the tunnel void on the basis of a ground penetrating radar (GPR) or a falling weight deflectometer (FWD); and injecting a high polymer material to a void part according to the condition of the tunnel void, wherein after the material reacts, the volume is expanded quickly and the material is cured to quickly fill the void. The technology has the characteristics of good treatment effect, quick construction, no requirement on curing, obvious target, high controllability, cost conservation and the like. Compared with the traditional tunnel void treating method, the technology is innovative obviously in the aspects of technical principle and construction method and develops a new, quick, economical and practical way for maintaining a tunnel and enabling the tunnel to be durable.

Owner:ZHENGZHOU URETEK TECH

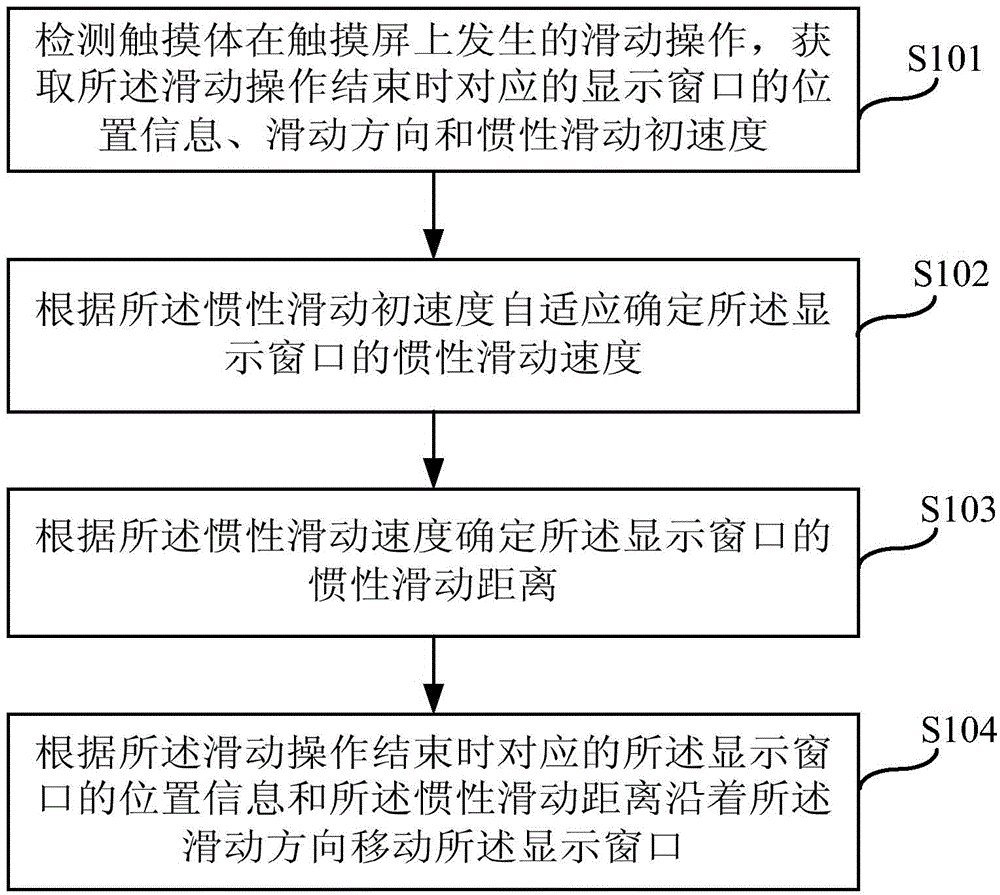

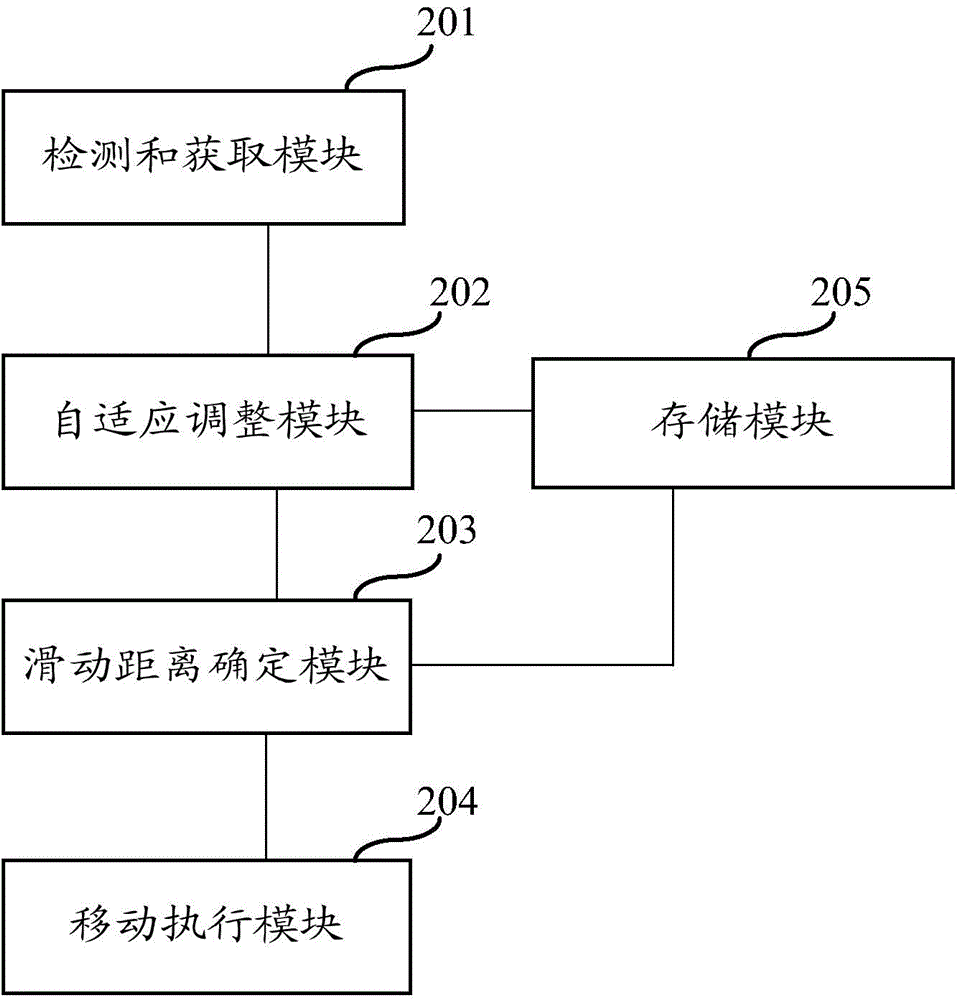

Sliding control method and device for touch screen as well as electronic equipment

ActiveCN105760067AGood controllabilityProcessing speedInput/output processes for data processingSelf adaptiveControllability

The invention provides a sliding control method and device for a touch screen as well as electronic equipment. The sliding control method for the touch screen comprises steps as follows: sliding operation performed by a touch body on the touch screen is detected, and corresponding location information, sliding direction and inertial sliding initial speed of a display window when the sliding operation is ended are acquired; an inertial sliding speed of the display window is self-adaptively determined according to the inertial sliding initial speed; an inertial sliding distance of the display window is determined according to the inertial sliding speed; the display window is moved in the sliding direction according to the corresponding location information and the inertial sliding distance of the display window when the sliding operation is ended. The technical scheme has the beneficial effects as follows: the inertial sliding speed of the display window can be self-adaptively adjusted, and the controllability is good; the processing speed is high, and the compatibility is good.

Owner:ALIBABA (CHINA) CO LTD

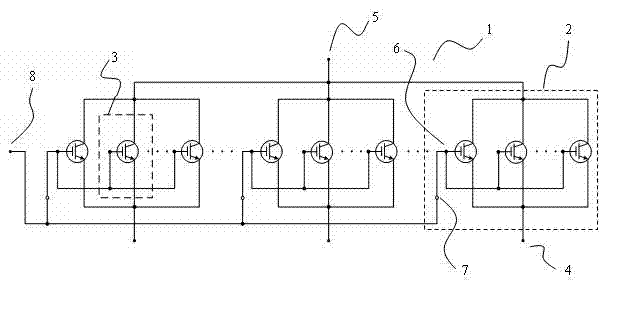

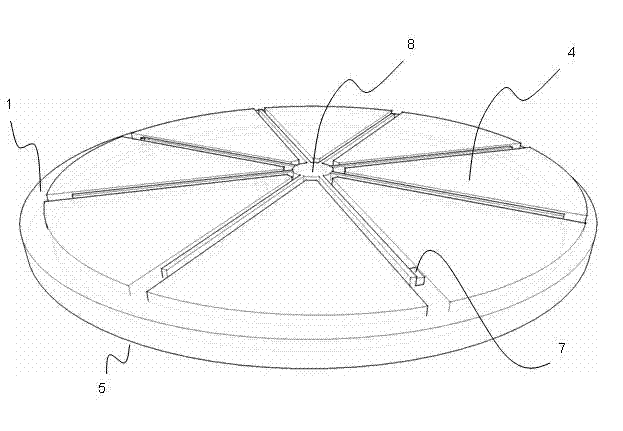

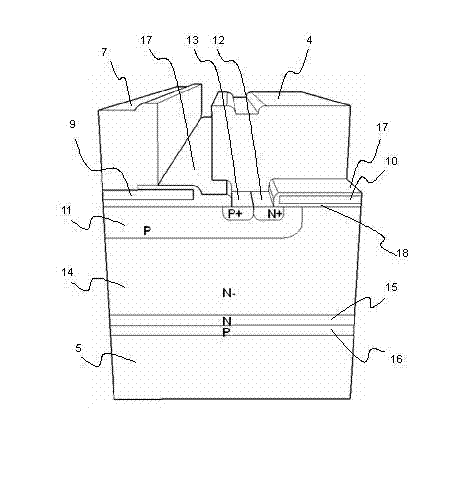

High-current full-wafer full-crimp flat-pack IGBT and manufacturing method thereof

ActiveCN102270640AIncrease working voltageReduce Switching Power ConsumptionTransistorSemiconductor/solid-state device manufacturingEngineeringMetal electrodes

The invention discloses a heavy-current whole-wafer total-pressure-contact flat-plate encapsulated IGBT (Insulated Gate Bipolar Transistor) and a manufacturing method thereof. The heavy-current whole-wafer total-pressure-contact flat-plate encapsulated IGBT comprises an IGBT whole wafer and a total-pressure-contact flat-plate encapsulation, the whole wafer comprises multiple independent IGBT device regions, each IGBT device region is composed of multiple IGBT units which are connected in parallel, collectors of all the IGBT device regions are connected in parallel to form a total collector, atransmitter is led from each IGBT device region independently, gate poles of all the IGBT device regions in a normal operating state are connected to a total gate pole arranged in the center of the wafer by using an interconnecting line, and the transmitter of each IGBT device region is connected with a metal electrode plate of a total transmitter in parallel by virtue of a metal gasket of the transmitter. According to the invention, a heavy-current IGBT whole wafer device is realized, the advantages of high working voltage, low switching power consumption and simple voltage control of the gate pole are maintained, current carrying capacity, heat-conducting property, heat shock resistance and long-term reliability of the device are improved, and the problem of property matching between IGBT units is solved.

Owner:HUNAN UNIV

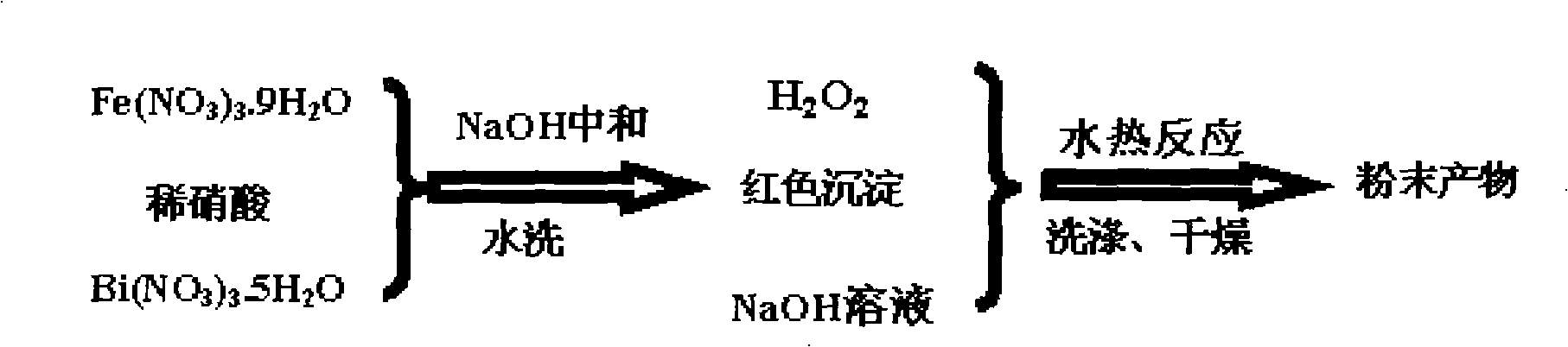

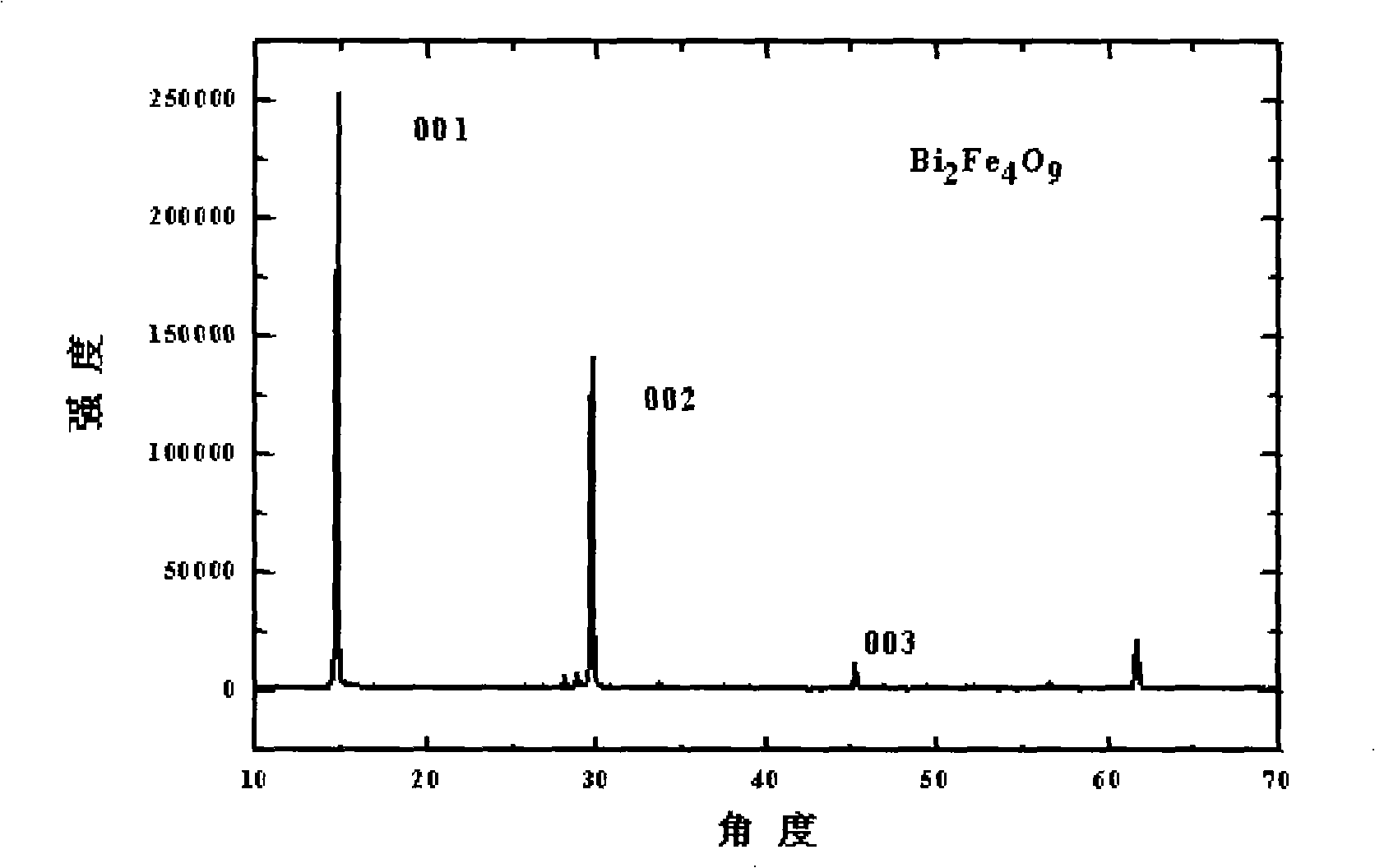

Low temperature condition preparation of orientated growth nanometer flaky Bi2Fe4O9

ActiveCN101319381AImprove performanceChange performancePolycrystalline material growthFrom normal temperature solutionsAlcoholAqueous solution

The invention discloses a method for synthesizing a highly directional nano flake Bi2Fe4O9 crystal at a low temperature. The method mainly adopts the hydrothermal preparation method and comprises the following steps that: Bi(NO3)3.5H2O and Fe(NO3)3.9H2O with the same mol ration are dissolved in a dilute nitric acid, a sodium hydrate aqueous solution is titrated into the mixed solution until the precipitation is complete, and the mixture is filtered and washed by water until the solution is neutral. The method is characterized in that the obtained precipitation is dissolved in a sodium hydrate aqueous solution with a concentration of between 8 and 20 mol per liter, 2 milliliters of H2O2 solution against 40 milliliters of the H2O2 solution are added, the mixture is put in a reaction kettle and reacts for 12 to 72 hours at a temperature of between 160 and 200 DEG C, the product is washed by de-ionized water and alcohol and is dried in an oven, and the obtained final product is the directionally growing nano flake Bi2Fe4O9.

Owner:山东产研陶瓷研究院有限公司

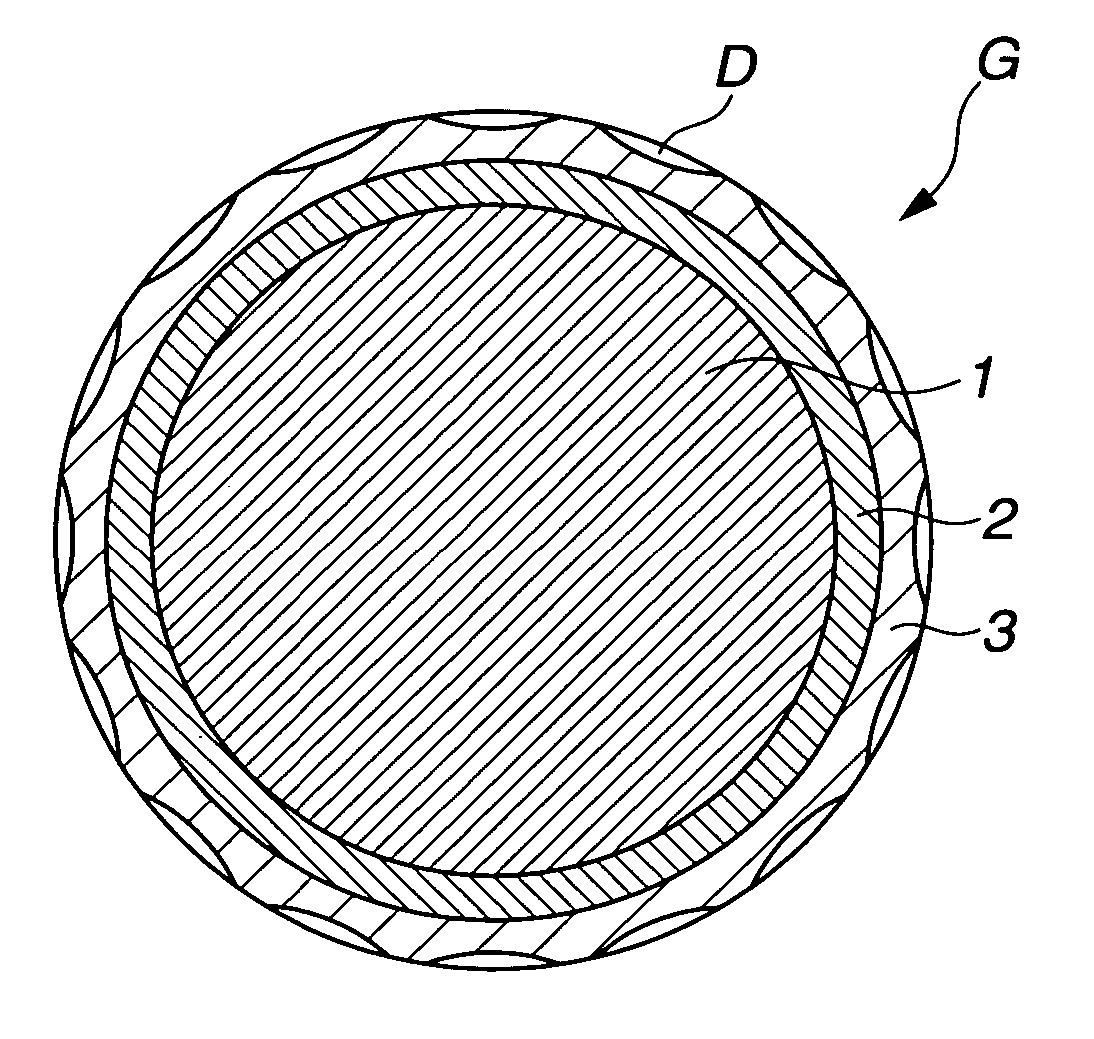

Three-piece solid golf ball

Owner:KURARAY CO LTD

Novel MOF composite material and preparation method and application thereof

ActiveCN106611653ASimple and safe operationShorten the production cycleMaterial nanotechnologyHybrid capacitor electrodesCapacitanceStored energy

The invention belongs to the technical field of composite materials and provides a novel MOF composite material and a preparation method and application thereof. The composite material comprises an MXene layered structure and an MOF crystal structure penetrating the MXene layered structure. According to the material, metal A ions generated by etching an MAX material is directly taken as a metal ion source to react with an added organic ligand to generate MOF crystal through a ''one-step method'', and the final MOF composite material is directly obtained through one-step reaction. The material can be used for the field of lithium batteries and super-capacitors. The method provided by the invention is simple and safe in operation in preparation, short in production period, low in production cost and high in yield, is free of a by-product basically, and can be used for the lithium batteries, the super-capacitors and the like to improve the stored energy and the utilization efficiency.

Owner:NANJING UNIV OF POSTS & TELECOMM

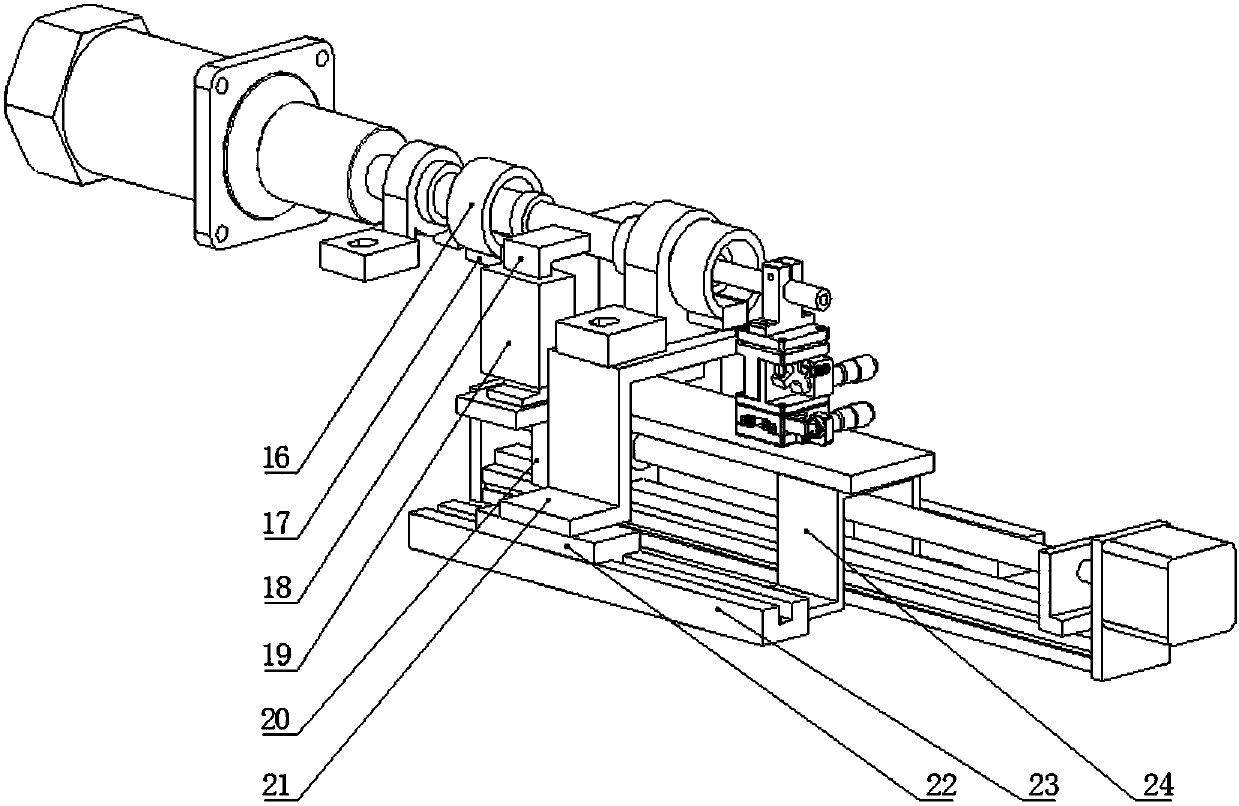

Titanium alloy pipe inner wall magneto-rheological polishing method and device

ActiveCN107791107AGood controllabilityImprove material removal ratePolishing machinesGrinding work supportsApparent viscosityMagnetic current

The invention provides a titanium alloy pipe inner wall magneto-rheological polishing method and device. Magneto-rheological liquid is pumped into a polishing head inner cavity along the inner surfaceof a transmission rod under the effect of a creepage pump, and flows over through rectangular holes around the middle of a polishing head, the liquid flows to the polishing area from the left side and the right side, under the effect of a magnetic field, the apparent viscosity and the shear yield stress of the magneto-rheological liquid are rapidly increased, a Bingham medium with certain viscousplasticity is formed, along with relative motion of the polishing head and the pipe wall, the Bingham medium carries out shear removal on the pipe wall material, the magneto-rheological liquid obtained after polishing is collected through magneto-rheological liquid collecting mechanisms on the two sides of a pipe fitting, through filtering and stirring, the polishing process is continuously carried out, and circular utilization of the magneto-rheological liquid is achieved; in the magneto-rheological liquid circulation process, heat generated in the polishing area is brought away. The inner wall of the titanium alloy pipe can be automatically polished, the beneficial effects of being easy to control, good in polishing uniformity, high in work efficiency and the like are achieved, and themethod and device are particularly suitable for polishing treatment of the inner wall surface of the fine and long titanium alloy pipe.

Owner:NORTHEASTERN UNIV

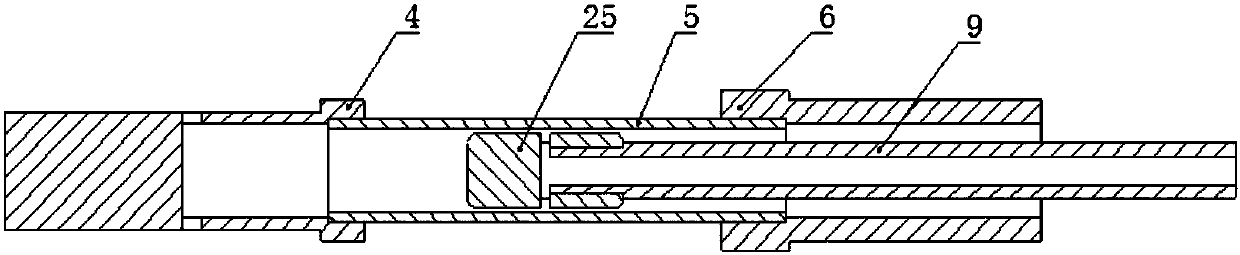

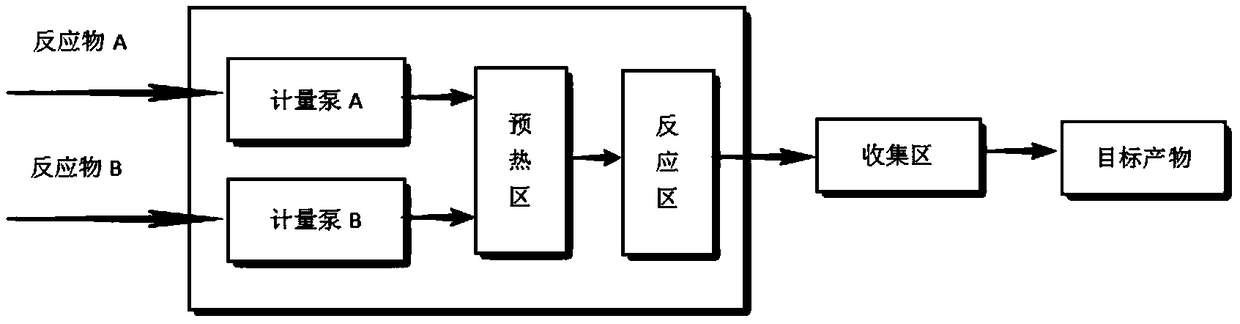

Method for continuous synthesis of dialkyl phosphite in micro-channel reactor

InactiveCN108840884AShort reaction timeIncrease temperatureGroup 5/15 element organic compoundsChemical industryAlcoholDolichyl phosphate

The invention discloses a method for continuous synthesis of dialkyl phosphite in a micro-channel reactor and belongs to the technical field of organic synthesis technologies. The method is used for generating the dialkyl phosphite through continuous reaction in the micro-channel continuous-flow reactor by using alcohol and phosphorus trichloride as substrates. Phosphorus trichloride is used as the material A, an alcohol solution is used as the material B, and the material A and the material B enter a micro-channel simultaneously through a metering pump for the continuous esterification reaction. According to the technological method, the high mass and heat transfer efficiency of the micro-channel reactor is utilized, the mass transfer rate between the two phase materials is effectively increased, and the safety and the operability of a test are greatly improved.

Owner:CHANGZHOU UNIV

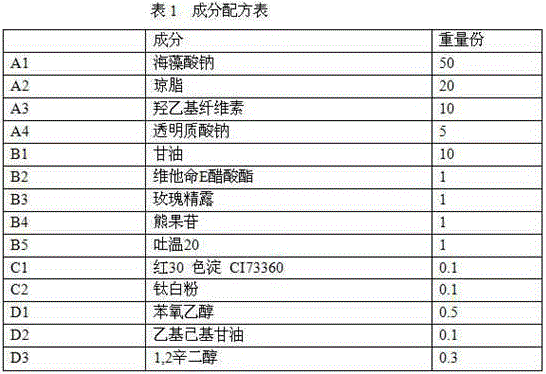

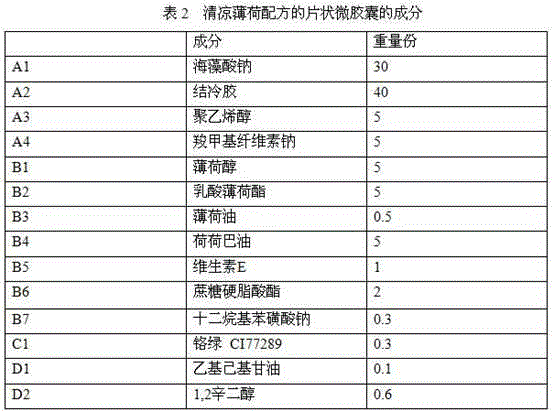

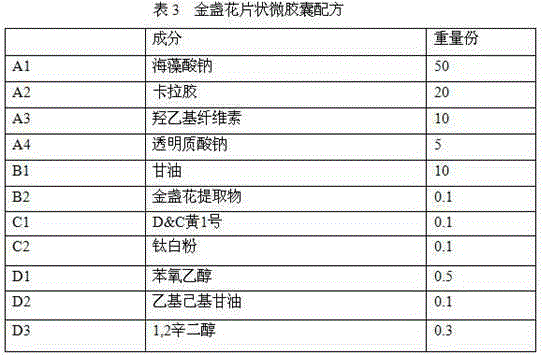

Flake microcapsule

ActiveCN105395373AReduce surface tensionGood natureCosmetic preparationsToilet preparationsPolymer sciencePreservative

The invention discloses a flake microcapsule, which belongs to the technical field of microcapsules, and comprises components with parts by weight: alginate or alginate 30-50 parts, hot melt gel 20-40 parts, water-soluble film-forming materials 5-10 parts and preservatives 0.1-1 part. The flake microcapsule enables surface tension of raw materials after being compounded to be lower than salt solutions such as calcium chloride and the like through a collaborative compatibility effect between various components of the raw materials, and gel extends on the surface of salt water to be unfolded and form a film, thereby forming a flake microcapsule. The flake microcapsule has steady property, is easy to smear, and has excellent quality.

Owner:CHONGQING PELLETS TECHN & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com