Method for preparing porous polymer micro needle by using template method and application thereof

A technology of porous polymer and template method, which is applied in the direction of microneedles, medical devices, needles, etc., can solve the problems of complex preparation process of porous polymer microneedles, difficulties in large-scale production and application, and difficult to control the size. The effect of uniform size distribution, adjustable porosity and regular pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

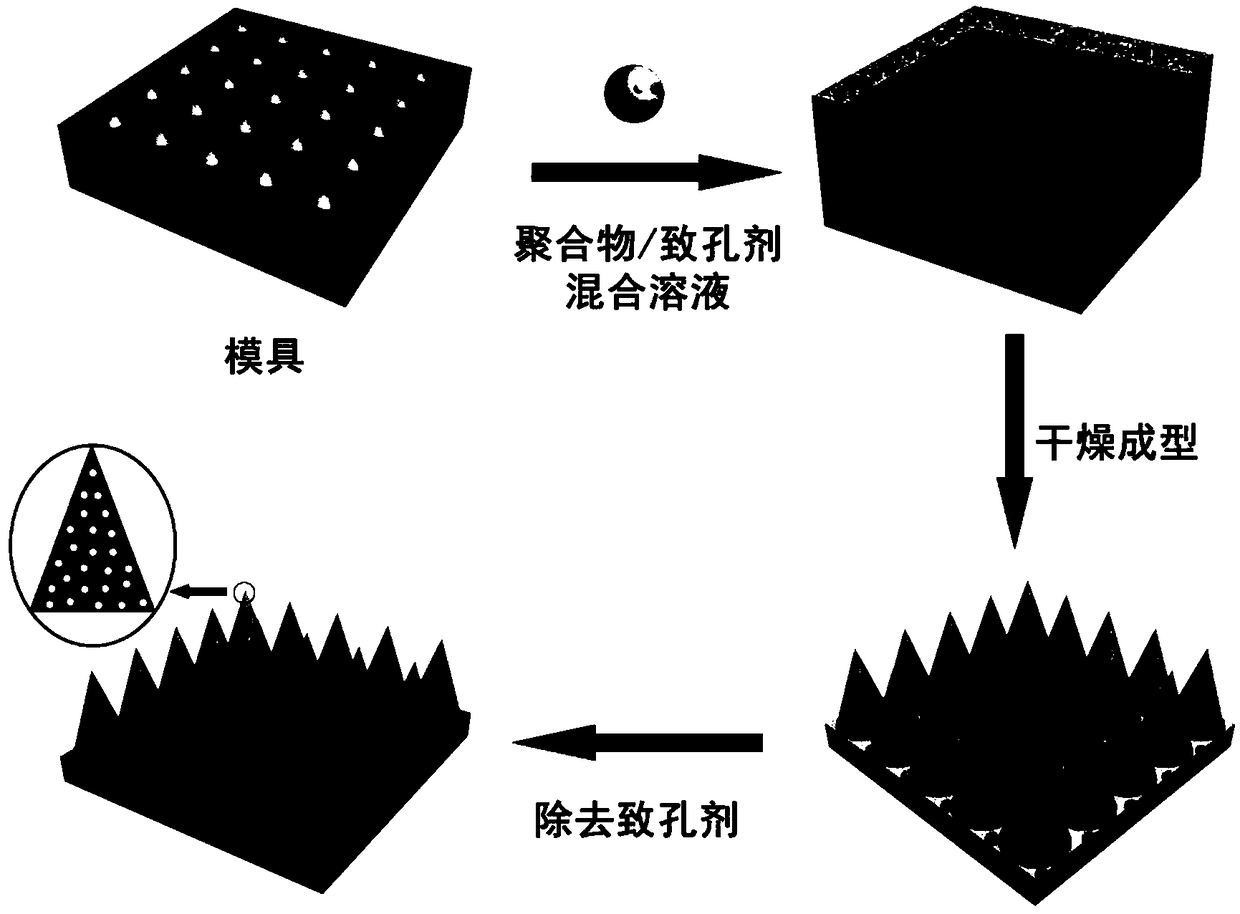

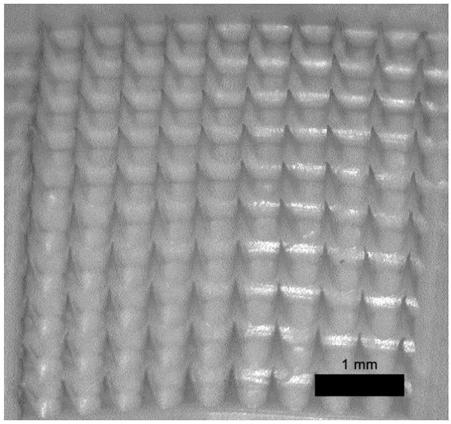

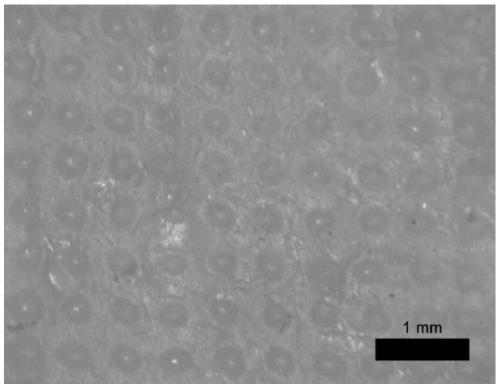

[0051] A porous polymer microneedle array prepared by a template method is prepared as follows: first, a polytetrafluoroethylene negative mold is prepared by laser etching; then, polyvinylidene fluoride and calcium carbonate with a size of 500nm A mass ratio of 7 is added to dimethyl sulfoxide to be configured into a solution, and the above solution is added dropwise to the polytetrafluoroethylene negative mold, and vacuuming promotes the solution to enter the mould; heating and drying dimethyl sulfoxide, peeling off to obtain Solid polyvinylidene fluoride microneedles containing calcium carbonate; the obtained solid microneedles are placed in 2mol / L dilute nitric acid solution to remove calcium carbonate nanoparticles to obtain porous polyvinylidene fluoride microneedles.

Embodiment 2

[0053] A porous polymer microneedle array prepared by a template method is prepared according to the following method: first, a PDMS negative mold is prepared by a microtemplate method; then, polysulfone and calcium carbonate with a size of 2 μm are added in a mass ratio of 3:7 Prepare a solution in dimethyl sulfoxide, drop the above solution onto the PDMS negative mold, and ultrasonically promote the solution to enter the mold; dry the dimethyl sulfoxide, and peel off to obtain solid polysulfone microneedles containing calcium carbonate; The obtained solid microneedles are placed in 2mol / L dilute nitric acid solution, and the calcium carbonate nanoparticles are removed to obtain porous polysulfone microneedles.

Embodiment 3

[0055] A porous polymer microneedle array prepared by a template method is prepared as follows: first, a stainless steel negative mold is prepared by micro-electromechanical processing technology; then, polysulfone and sodium chloride with a size of 50 μm are mixed in a mass ratio of 3:7 Add the solution to N-methylpyrrolidone to form a solution, add the above solution dropwise to the stainless steel female mold, and vacuumize to promote the solution into the mold; heat and dry N-methylpyrrolidone, and peel off to obtain a solid polymer containing sodium chloride. Sulfone microneedles; the obtained solid microneedles are placed in pure water to remove sodium chloride to obtain porous polysulfone microneedles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com