Preparation method of polymer conversion ceramic-based wave-absorbing material loaded with nitrogen-doped graphene in situ

A nitrogen-doped graphene and wave-absorbing material technology, applied in the field of wave-absorbing materials, can solve the problems of easy-structure agglomeration wave-absorbing properties, cumbersome preparation methods, insufficiencies, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) First disperse 6g of urea into 15ml of xylene solution, then transfer it to a Schlenk device, add 6.6ml of liquid polysilazane, stir and react at 80°C for 2h, and then remove the organic solvent under vacuum. Solvent, you can get a single-source precursor;

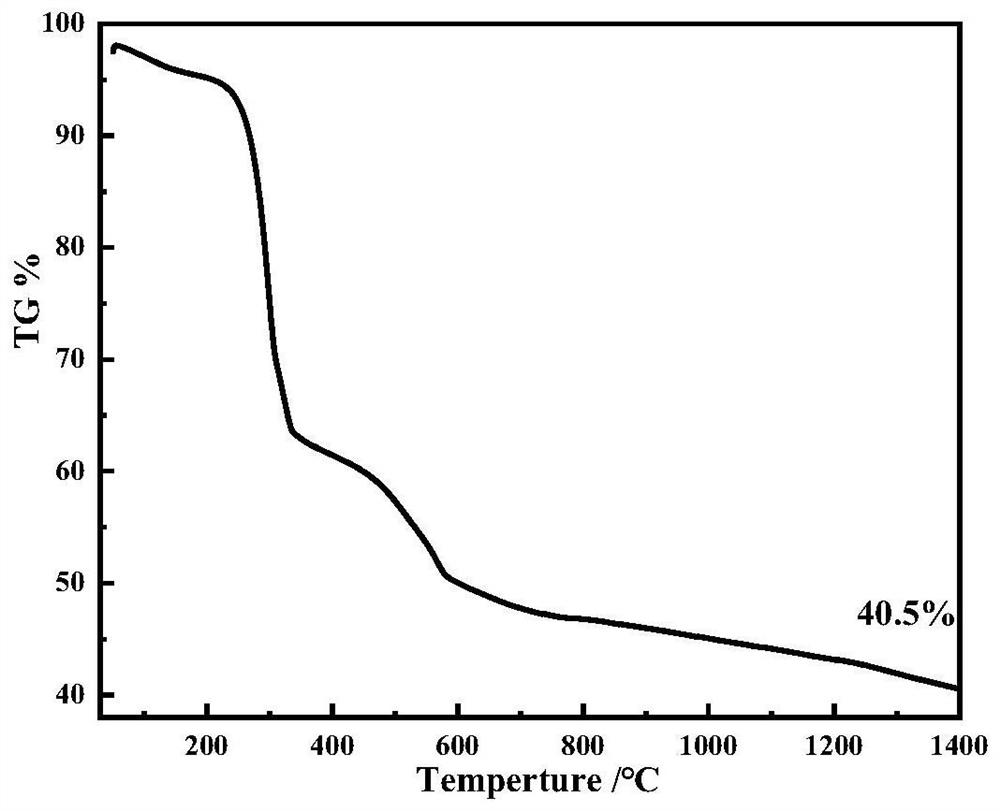

[0033] (2) Put the obtained single-source precursor into a tube furnace, use nitrogen as a protective gas, and raise the temperature of the furnace to 300°C at a heating rate of 5°C / min, so that the precursor is fully cross-linked and solidified at this temperature 2h, after the heat preservation is completed, turn off the heating power supply and naturally cool down with the furnace. Fully grind and sieve the cured powder to obtain a 200-mesh precursor powder;

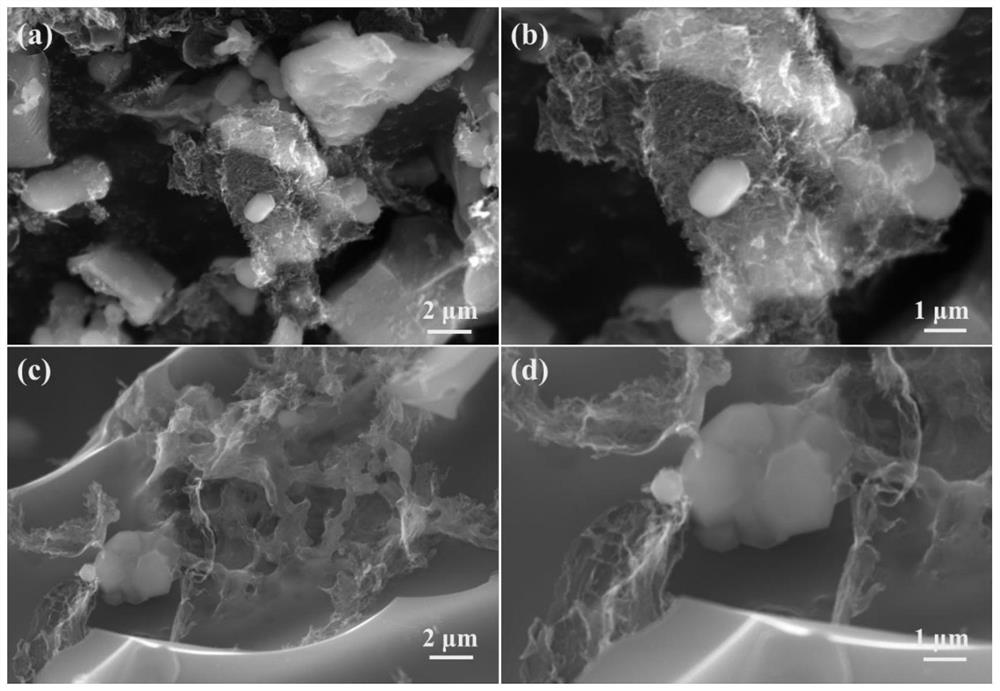

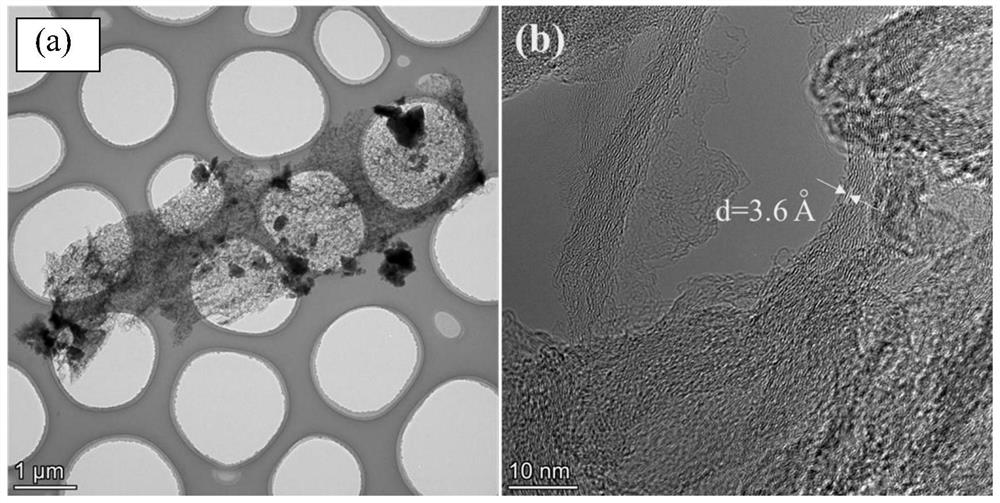

[0034] (3) Put the sieved precursor powder into a graphite crucible, then put the crucible into a high-temperature tube furnace, use nitrogen as a protective gas, and raise the furnace temperature to 900 °C at a heating rate of 5 °C / min. At this tempe...

Embodiment 2

[0036] (1) First disperse 3g of melamine into 15ml of xylene solution, then transfer it to a Schlenk device, add 6ml of liquid polysiloxane, stir and react at 80°C for 2h, and then remove the organic solvent under vacuum , the single-source precursor can be obtained;

[0037](2) Put the obtained single-source precursor into a tube furnace, use nitrogen as a protective gas, and raise the temperature of the furnace to 180°C at a heating rate of 5°C / min, so that the precursor is fully cross-linked and solidified at this temperature 5h, after the heat preservation is completed, turn off the heating power supply and naturally cool down with the furnace. Fully grind and sieve the cured powder to obtain a 300-mesh precursor powder;

[0038] (3) Put the sieved precursor powder into a graphite crucible, then put the crucible into a high-temperature tube furnace, use nitrogen as a protective gas, and raise the furnace temperature to 1000 °C at a heating rate of 5 °C / min. At this tempe...

Embodiment 3

[0040] (1) First disperse 10g of N,N'-methylenebisacrylamide into 30ml of xylene solution, then transfer it to a Schlenk device, add 5ml of liquid polysilazane, and stir at 100°C React for 3 hours, and then remove the organic solvent under vacuum to obtain a single-source precursor;

[0041] (2) Put the obtained single-source precursor into a tube furnace, use nitrogen as a protective gas, and raise the temperature of the furnace to 220°C at a heating rate of 5°C / min, so that the precursor is fully cross-linked and solidified at this temperature 2h, after the heat preservation is completed, turn off the heating power supply and naturally cool down with the furnace. Fully grind and sieve the cured powder to obtain a 300-mesh precursor powder;

[0042] (3) Put the sieved precursor powder into a graphite crucible, then put the crucible into a high-temperature tube furnace, use nitrogen as a protective gas, and raise the furnace temperature to 1100 °C at a heating rate of 8 °C / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com