Preparation method of polyaniline/carbon foam composite material with controllable absorbing properties

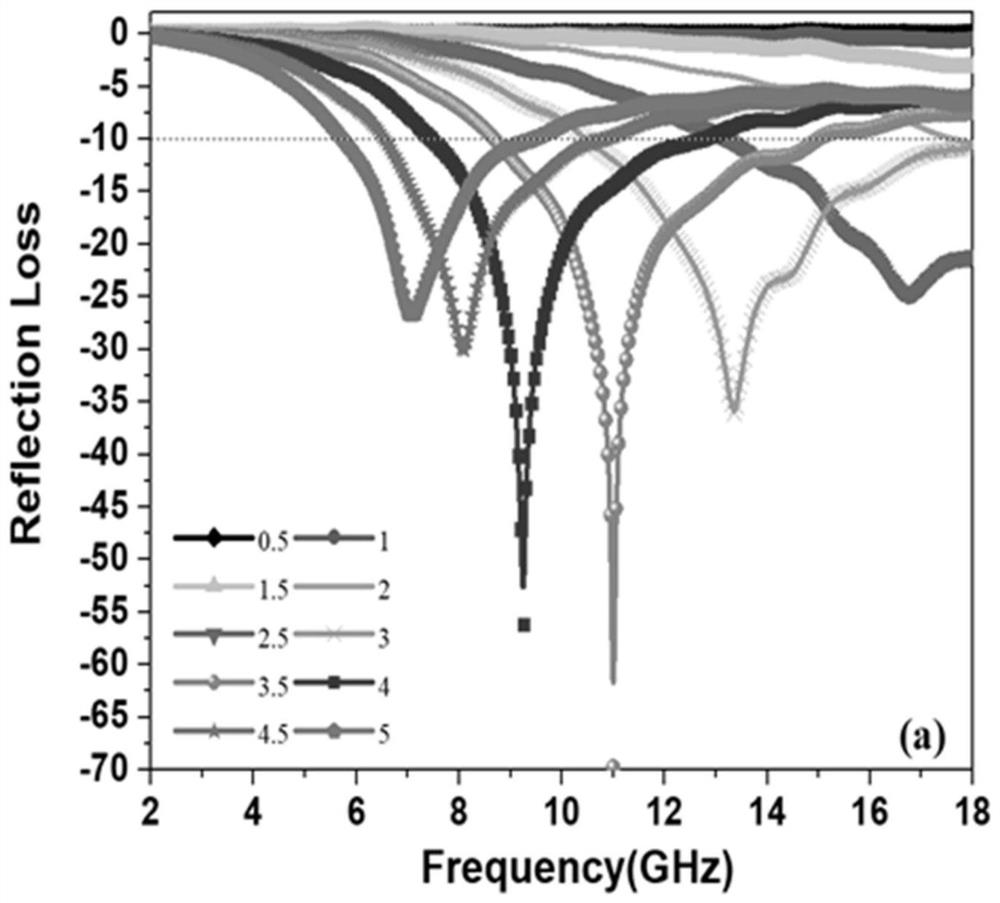

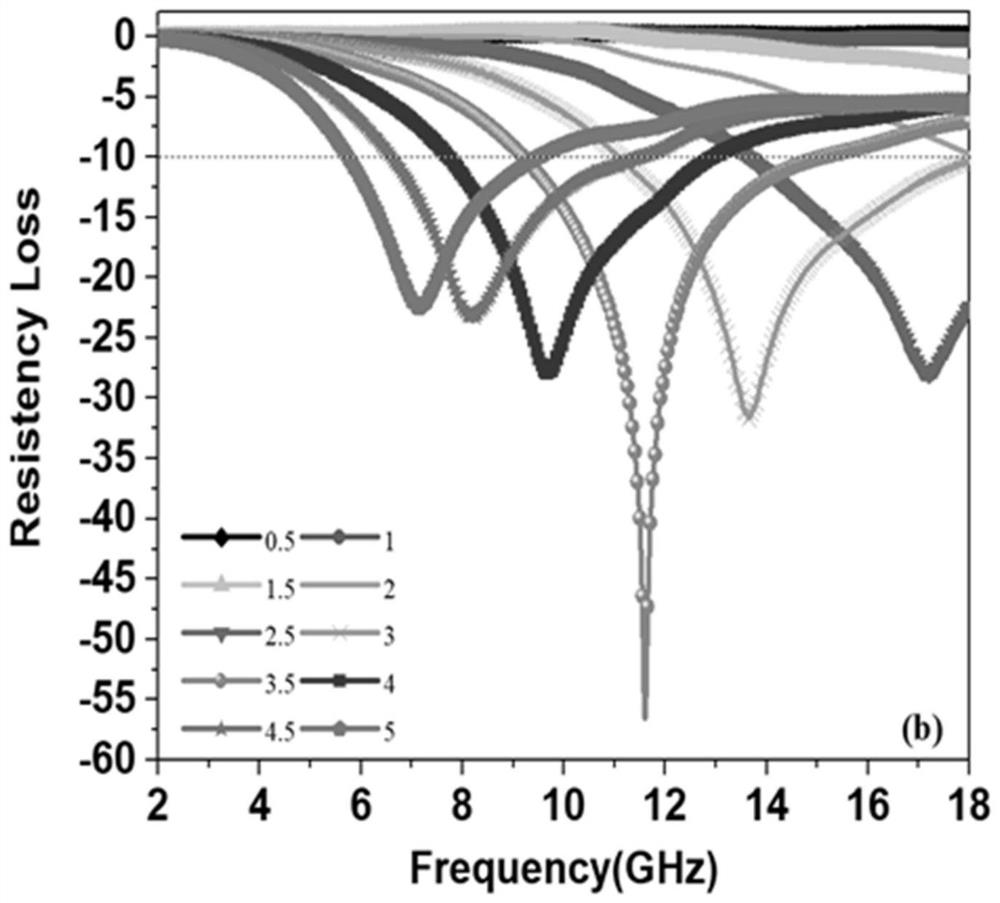

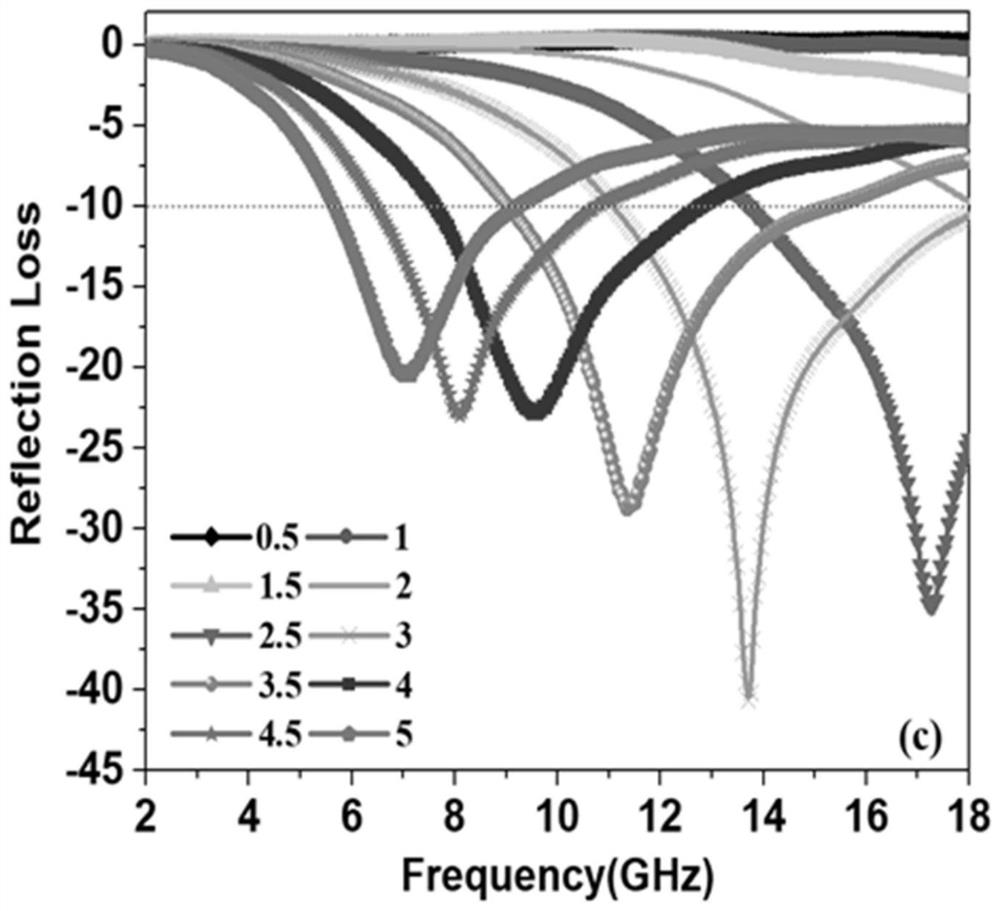

A technology of composite materials and microwave-absorbing performance, which is applied in the field of preparation of microwave-absorbing materials, can solve problems such as low microwave-absorbing strength and complicated preparation methods, achieve light-weight microwave-absorbing performance, improve dielectric loss capability, and reduce surface resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of the polyaniline / carbon foam composite material with controllable wave-absorbing performance that the present invention proposes, concrete steps are as follows:

[0029] (1) Preparation of carbon foam: calcining clean melamine foam in a resistance furnace: calcining at a constant temperature of 500-950° C. for 1-5 hours, then gradually cooling to room temperature. The whole process was carried out under nitrogen protection. After the foam is cooled to room temperature, take it out and soak it in concentrated sulfuric acid for 1-50 minutes, then wash it repeatedly with deionized water until neutral, and dry it in a vacuum oven at 20-50°C for 1-12 hours;

[0030] (2) Preparation of dispersion A: Weigh 0.01mol-0.8mol of protonic acid, add 0.02-0.1mol of oxidizing agent into 50-360ml water; under 500W power, ultrasonically disperse for 10-45min, so that protonic acid and oxidizing agent are fully dispersed in water, The protonic acid used is ...

Embodiment 1

[0035] This embodiment is a preparation method of a polyaniline / carbon foam composite material with controllable wave-absorbing performance, which is carried out according to the following steps:

[0036] (1) Preparation of carbon foam: calcining clean melamine foam in a resistance furnace: calcining at a constant temperature of 950° C. for 2.5 hours, then gradually cooling to room temperature. The whole process was carried out under nitrogen protection. After the foam is cooled to room temperature, take it out and soak it in concentrated sulfuric acid for 15 minutes, then wash it repeatedly with deionized water until neutral, and dry it in a vacuum oven at 50°C for 12 hours;

[0037] (2) Preparation of dispersion liquid A: weigh 0.02 mol of p-toluenesulfonic acid, add 0.02 mol of ammonium persulfate into 360 ml of water; under 500W power, ultrasonically disperse for 45 minutes, so that the protonic acid and oxidant are fully dispersed in the water;

[0038] (3) Preparation o...

Embodiment 2

[0044] This embodiment is a preparation method of a polyaniline / carbon foam composite material with controllable wave-absorbing performance, which is carried out according to the following steps:

[0045] (1) Preparation of carbon foam: calcining clean melamine foam in a resistance furnace: calcining at a constant temperature of 950° C. for 2.5 hours, then gradually cooling to room temperature. The whole process was carried out under nitrogen protection. After the foam is cooled to room temperature, take it out and soak it in concentrated sulfuric acid for 15 minutes, then wash it repeatedly with deionized water until neutral, and dry it in a vacuum oven at 50°C for 12 hours;

[0046] (2) Preparation of dispersion A: Weigh 0.3 mol of hydrochloric acid, add 0.02 mol of ammonium persulfate into 360 ml of water; under 500W power, ultrasonically disperse for 45 minutes, so that protonic acid and oxidant are fully dispersed in water;

[0047] (3) Preparation of dispersion B: ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com