Patents

Literature

171results about How to "Simple preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

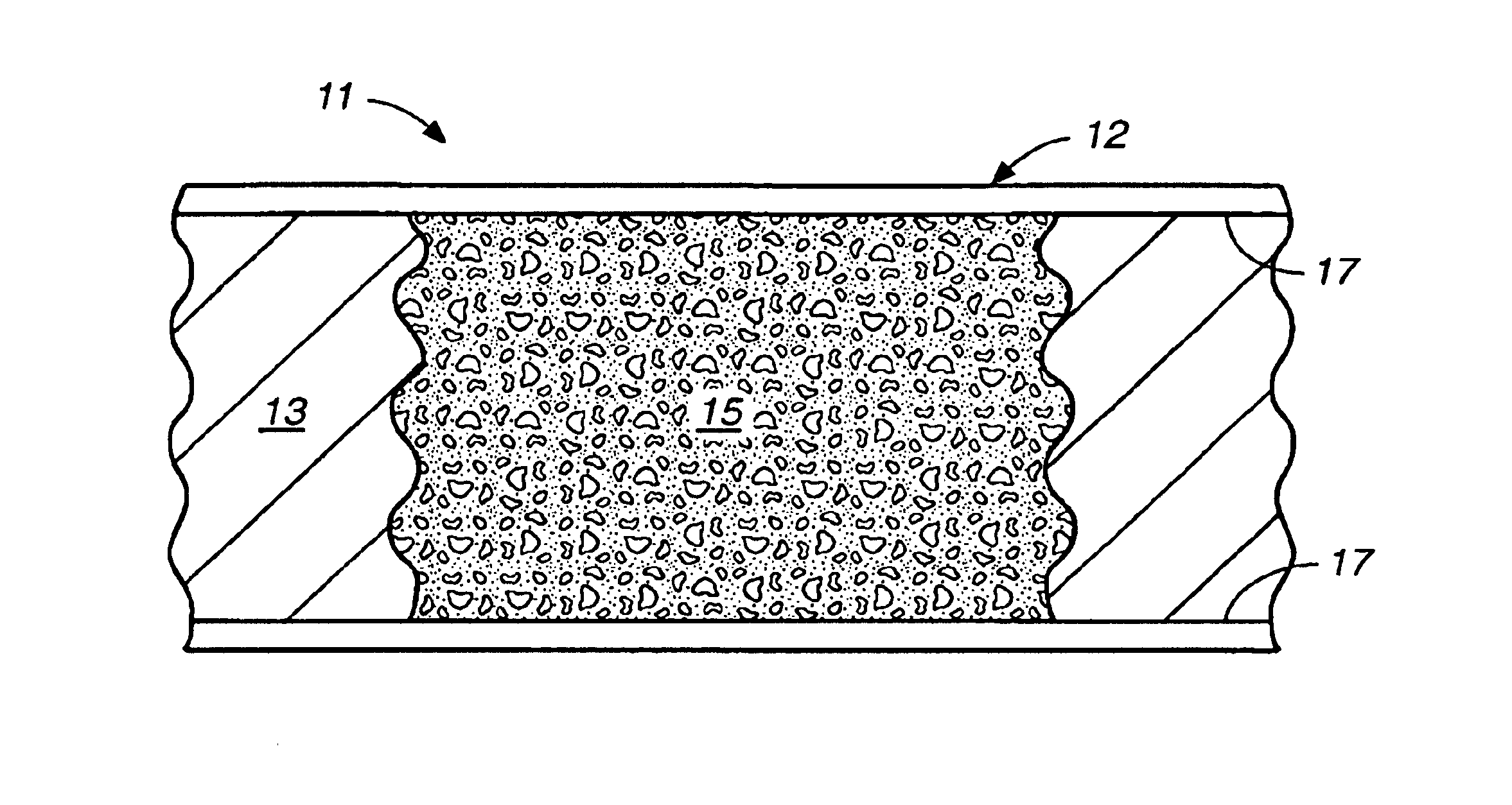

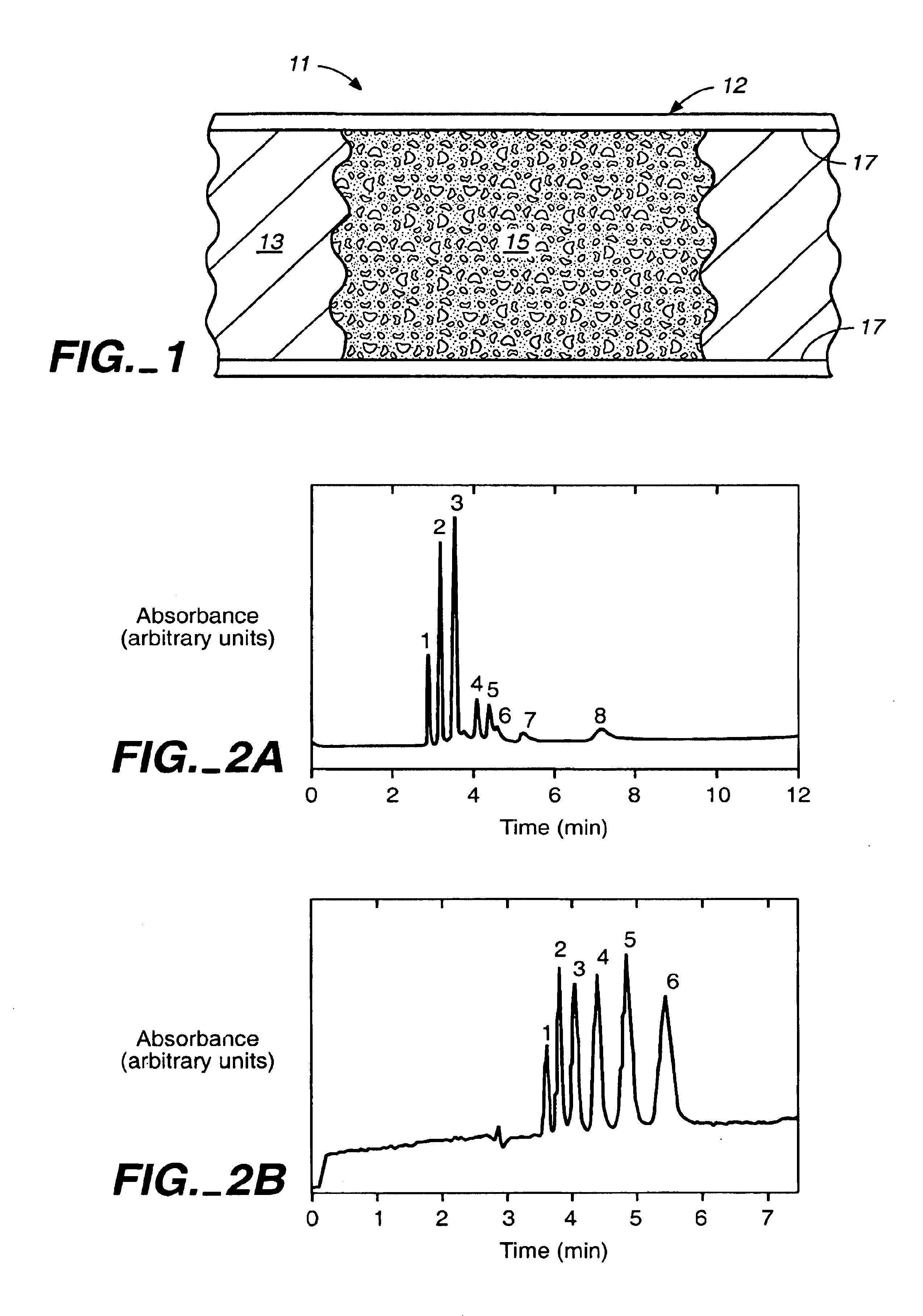

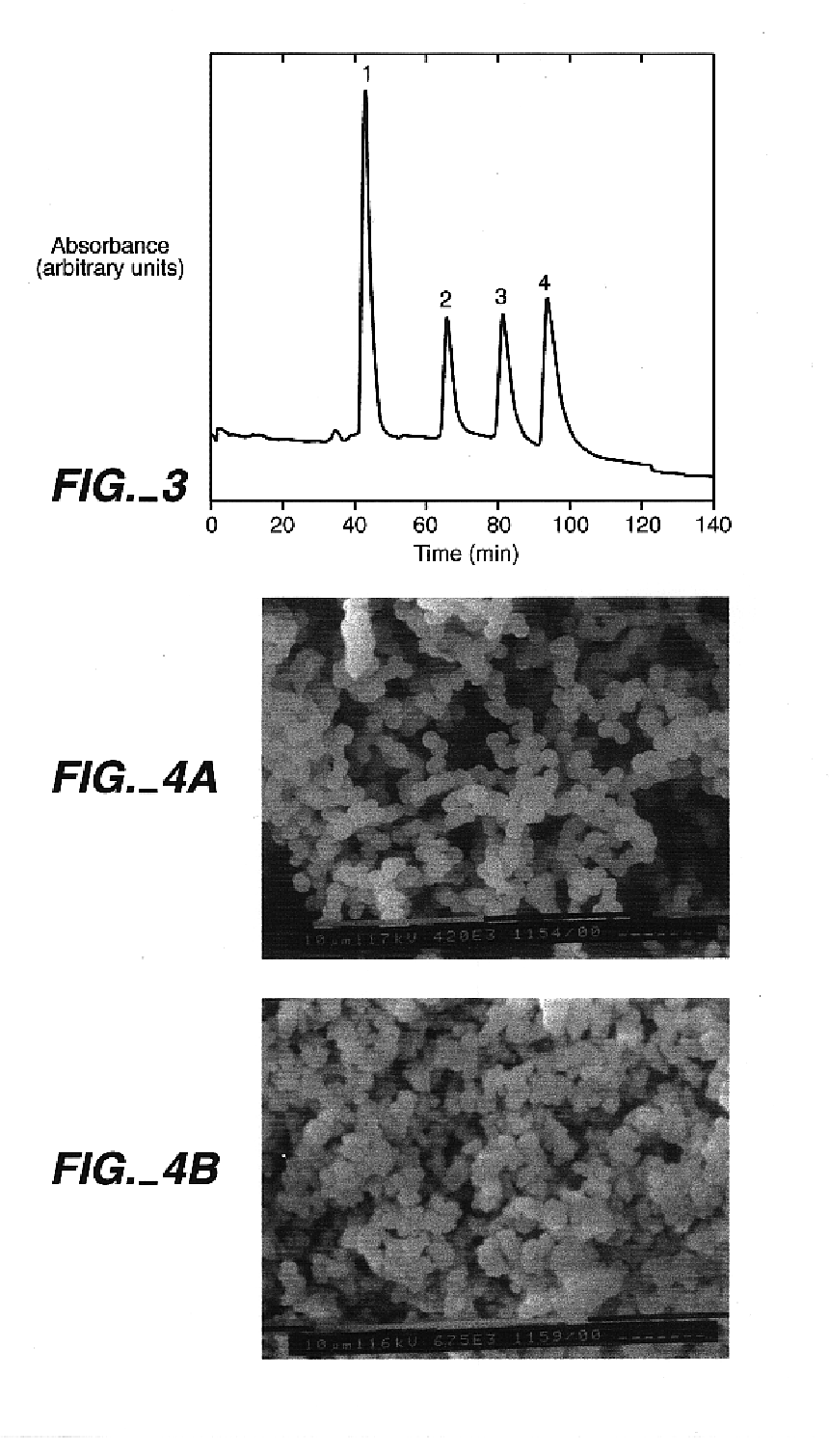

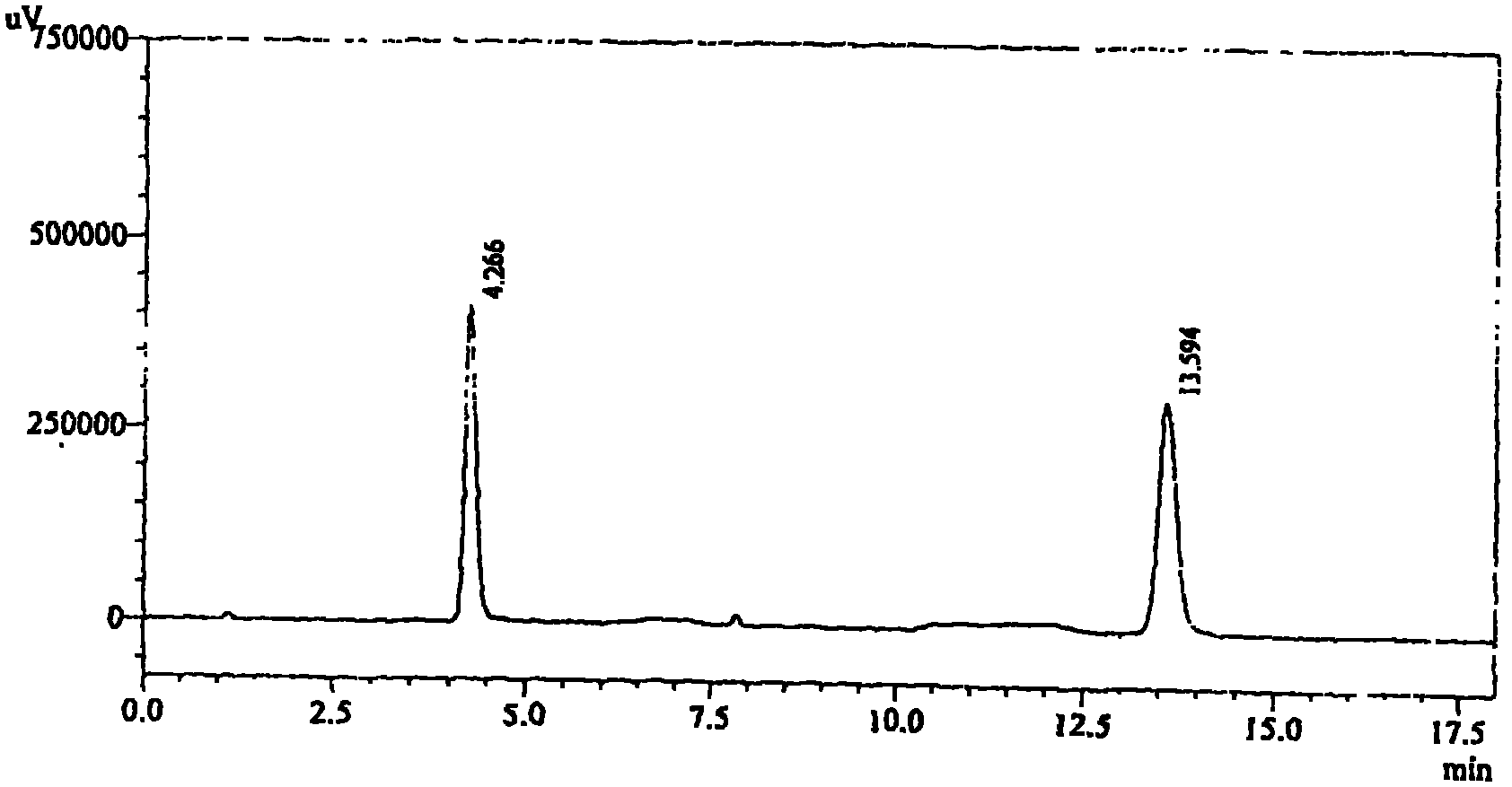

Photopolymerized sol-gel column and associated methods

InactiveUS6866785B2Simple preparationShort preparation timeIon-exchange process apparatusComponent separationChemistrySol-gel

A separation column and a method of making the separation column are provided. The separation column includes a separation channel and fritless separation medium in the channel. The separation medium includes a porous matrix, and the porous matrix includes a metal organic polymer, such as a photopolymer. The separation medium can be used to separate a sample of analytes.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

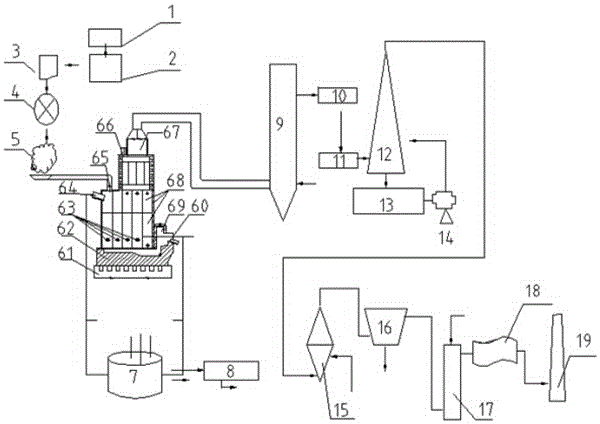

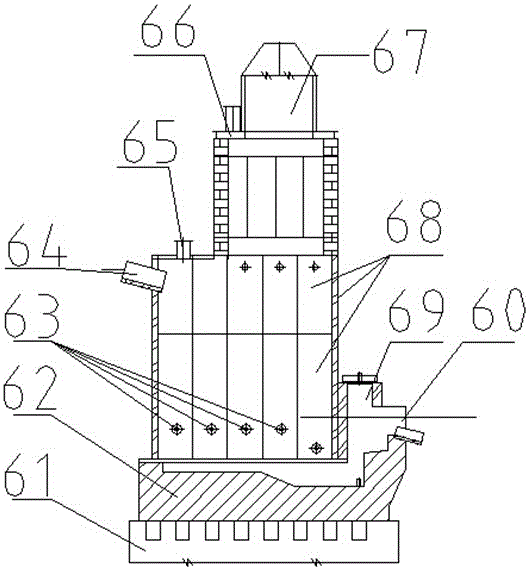

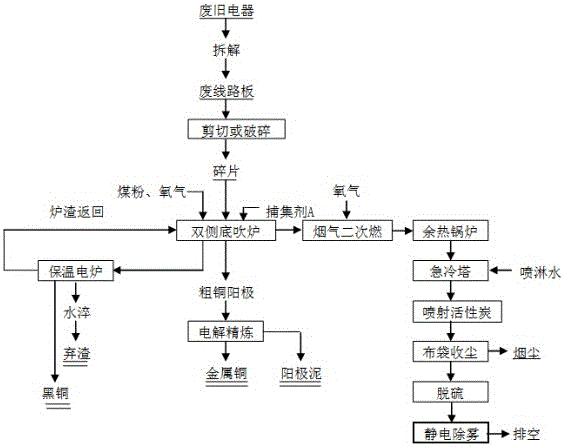

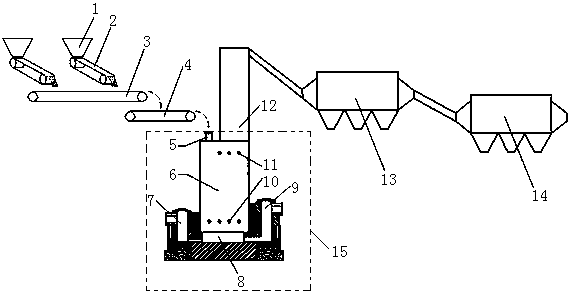

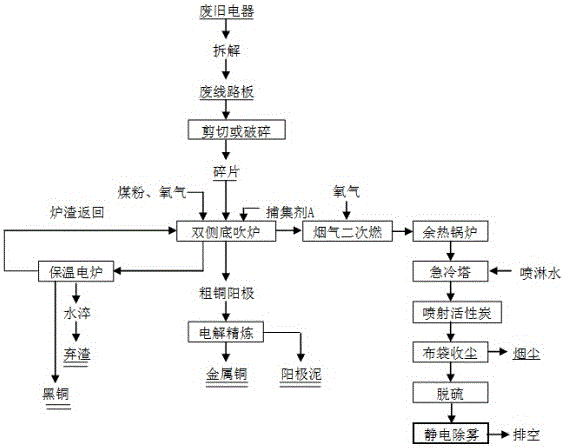

Complete equipment and method for extracting and purifying precious metals from waste circuit boards

ActiveCN106086415AComponent adaptabilitySimple preparationProcess efficiency improvementPrinted circuit boardQuenching

The invention discloses complete equipment and a method for extracting and purifying precious metals from waste circuit boards. The complete equipment comprises a bottom-blowing furnace, a secondary smoke combustion furnace, an absorption tower, a pulsed jet cloth filter, a wet desulfurization device and an electrostatic precipitation defogging device, and is characterized in that smoke generated by the bottom-blowing furnace is discharged through a flue arranged on the top of the bottom-blowing furnace; the flue communicates with an inlet of the secondary smoke combustion furnace; the secondary smoke combustion furnace communicates with a spraying quenching tower through a smoke waste heat boiler; an outlet of the spraying quenching tower communicates with the pulsed jet cloth filter through the absorption tower; an activated carbon spraying device is arranged inside the absorption tower; the pulsed jet cloth filter communicates with the wet desulfurization device; and the wet desulfurization device communicated with a chimney through the electrostatic precipitation defogging device. Effective separation and respective enrichment and recycle of various metals are achieved, organic substances are used as fuel, and no secondary pollution is generated for the environment. The process procedure is short, and the remarkable economic, environment-friendly and social benefits are achieved.

Owner:江西自立环保科技有限公司

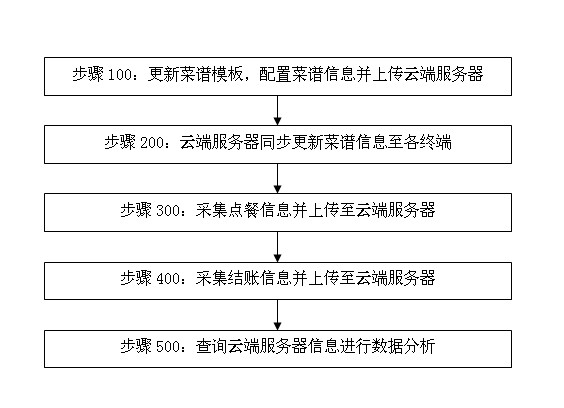

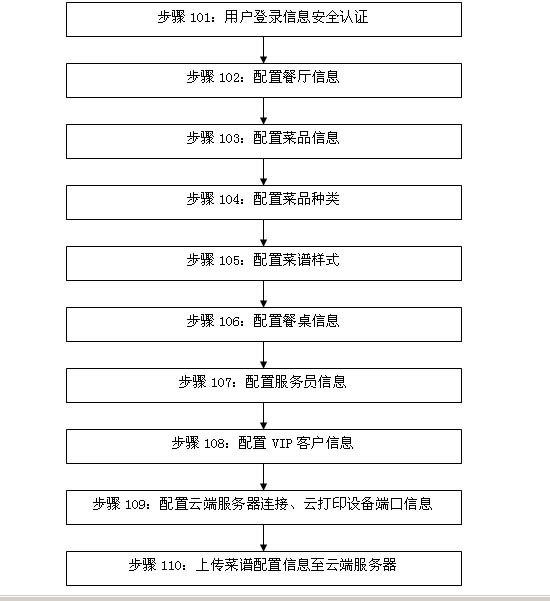

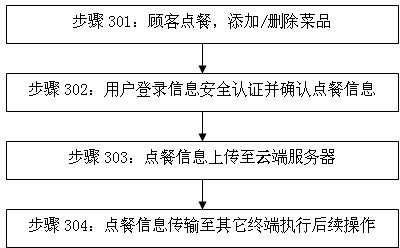

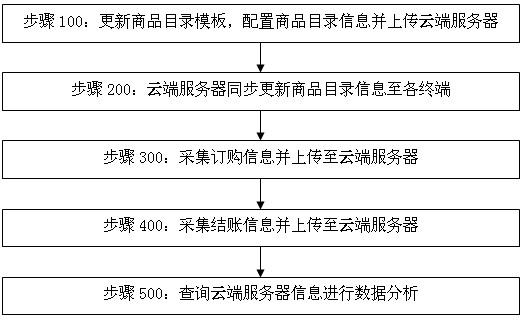

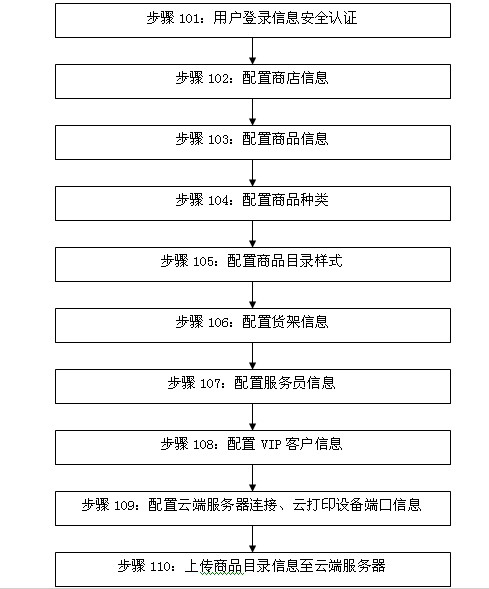

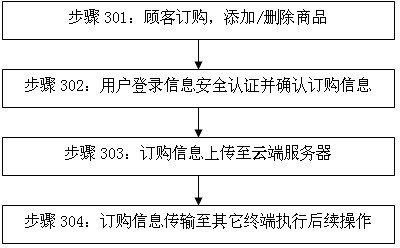

Intelligent terminal electronic ordering method and system based on 3G and cloud technology

InactiveCN102663656ASave resourcesSave moneyData processing applicationsTransmissionRelevant informationStatistical analysis

The invention relates to an intelligent terminal electronic ordering method and a system based on 3G and cloud technology, uses a 3G or WiFi wireless network and internet for data exchange, configures a menu on the computer terminal or intelligent terminal and uploads the menu information to the cloud server, after synchronous update of other terminal device, the intelligent terminal can be used for ordering operation, and the ordering information is uploaded to the cloud server and connected terminal thereof for execution of subsequent operation; The intelligent terminal can also be used for billing operation, billing information is uploaded to the cloud server and a connected cloud printing device for execution of bill printing. Restaurant operation conditions can be queried on both the computer terminal and the intelligent terminal. The method not only makes the menu configuration easy, improves ordering experience, but also improves service quality and efficiency, relevant information is stored on the cloud server, and the consumption data can be used for statistic analysis at any moment.

Owner:CHENGDU BOYUE CHUANGXIN TECH

Method and device for producing crude antimony trioxide by smelting of rich oxygen side-blown volatile molten pool

The invention discloses a method and a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The method comprises the following steps: by taking an antimonial material as a raw material, blind coal or coke or a natural gas or a coal gas and the like as supplement fuel, and iron ore and lime as fluxes, blowing oxygen-enriched air, entering a furnace to react after metering a charging material, so as to produce high-temperature smoke and melt; condensing and dedusting the high-temperature smoke, and then feeding the smoke to an acid making system to prepare an acid, wherein the condensed powder is a crude antimony trioxide product to feed to the next procedure to process; respectively discharging the high-temperature melt after settling and layering in a hearth; quenching the slag to be directly used as a waste slag, and returning a little of produced antimony matte and crude antimony; and feeding noble antimony to the next procedure to process and extract gold. The invention also comprises a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The device has the advantages of being strong in raw material adaptability, low in energy consumption, high in smoke SO2 concentration, high in direct recovery rate and recovery rate of antimony and noble metal, clean and environment-friendly to produce, low in production cost and the like, and the acid can be directly prepared.

Owner:锡矿山闪星锑业有限责任公司 +3

Waste circuit board material disposal and utilization technology

ActiveCN106086416AComponent adaptabilitySimple preparationPhotography auxillary processesProcess efficiency improvementMelting tankElectrolysis

The invention discloses a waste circuit board material disposal and utilization technology. Waste circuit board materials serve as raw materials, and are subjected to mechanical crushing and smelting in an oxygen enrichment side-blowing molten pool at the temperature of 1100-1400 DEG C to produce crude copper rich in rare and noble metals; then metallic copper and anode mud rich in rare and noble metals are obtained through electrolytic refining; smelting gas restrains resynthesis of dioxin after being subjected to secondary combustion and quick cooling; and a bag collector recycles oxides of volatile metals such as tin, lead and zinc, and the dust content of the drained gas is 0-15 mg / Nm<3>. A trapping agent can make the copper content of slag be lower than 0.2%, recycling of all rare and noble metals is achieved, and the slag is waste slag containing silicate and can be used as cement raw materials or road foundation laying materials. The waste circuit board materials and the like are recycled and utilized, effective separation and respective enrichment and recycle of various metals are achieved, organic substances are used as fuel, and no secondary pollution is generated for the environment. The process procedure is short, and the remarkable economic, environment-friendly and social benefits are achieved.

Owner:江西自立环保科技有限公司

Chinese medicinal composition for treating gout and preparation method thereof

InactiveCN103920117ASimple preparationEasy to takeAnthropod material medical ingredientsInorganic active ingredientsPOLYGONUM CUSPIDATUMHoneysuckle

The invention discloses a Chinese medicinal composition for treating gout and a preparation method thereof. The Chinese medicinal composition comprises more than forty Chinese medicinal components such as angelica, gentiana macrophylla, peach seeds, ground beetle, earthworm, poria cocos, glabrous greenbrier rhizome, yam rhizome, clematis root, white atractylodes rhizome, atractylodes, cortex phellodendri, raw coix seeds, eupatorium lindleyanum, polygonum cuspidatum, cyathula root, rhizoma alismatis, honeysuckle stem, astragalus root, loosestrife herb and red peony root. The Chinese medicinal composition facilitates pharmacy and administration, is specially used for treating the gout, is safe in clinical application, and treats both symptoms and root causes. Through reasonable compatibility of each component, the treatment effect is improved, the medicinal properties are changed or alleviated, and the toxicity and side effects of medicaments are eliminated. The medicaments with strong properties and flavors are alleviated, the treatment effect is significant, many active ingredients are absorbed, and the composition has a good effect of treating or relieving the symptoms of the gout.

Owner:韩世昌

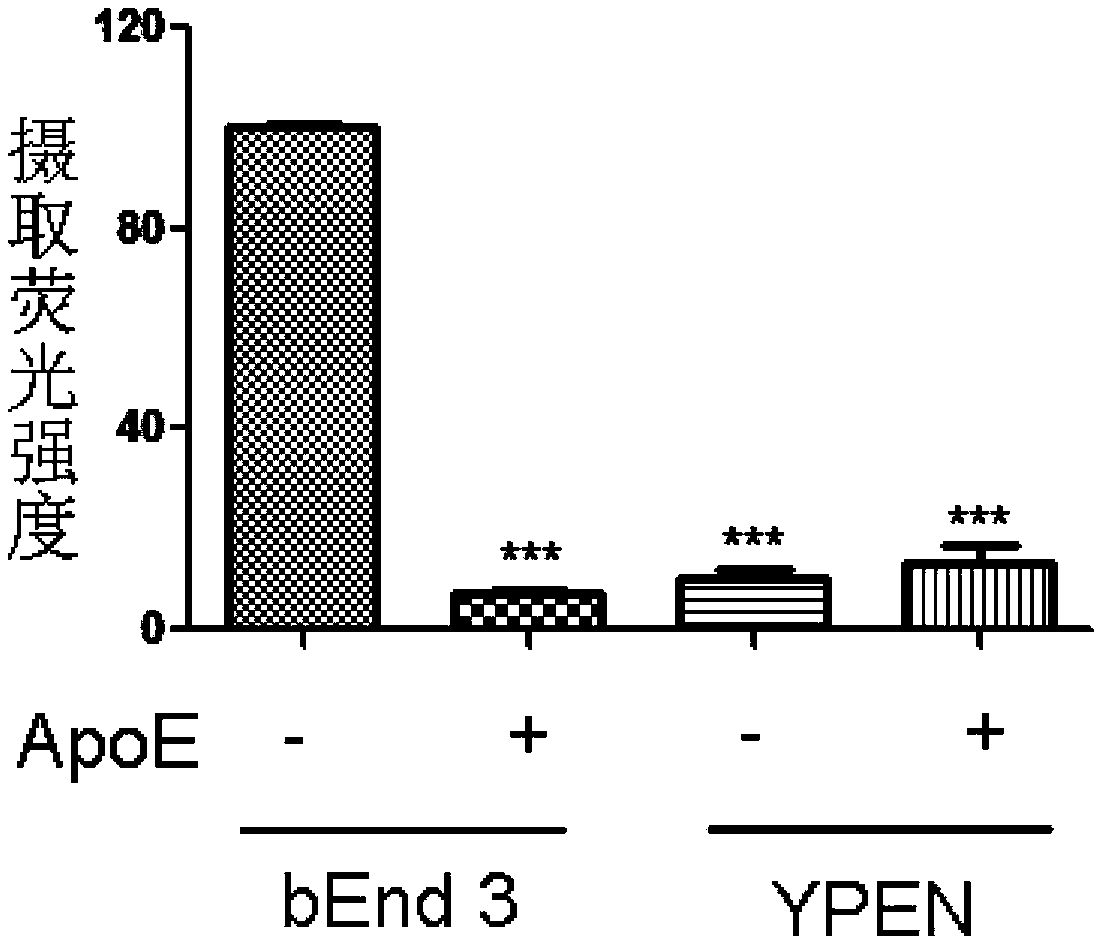

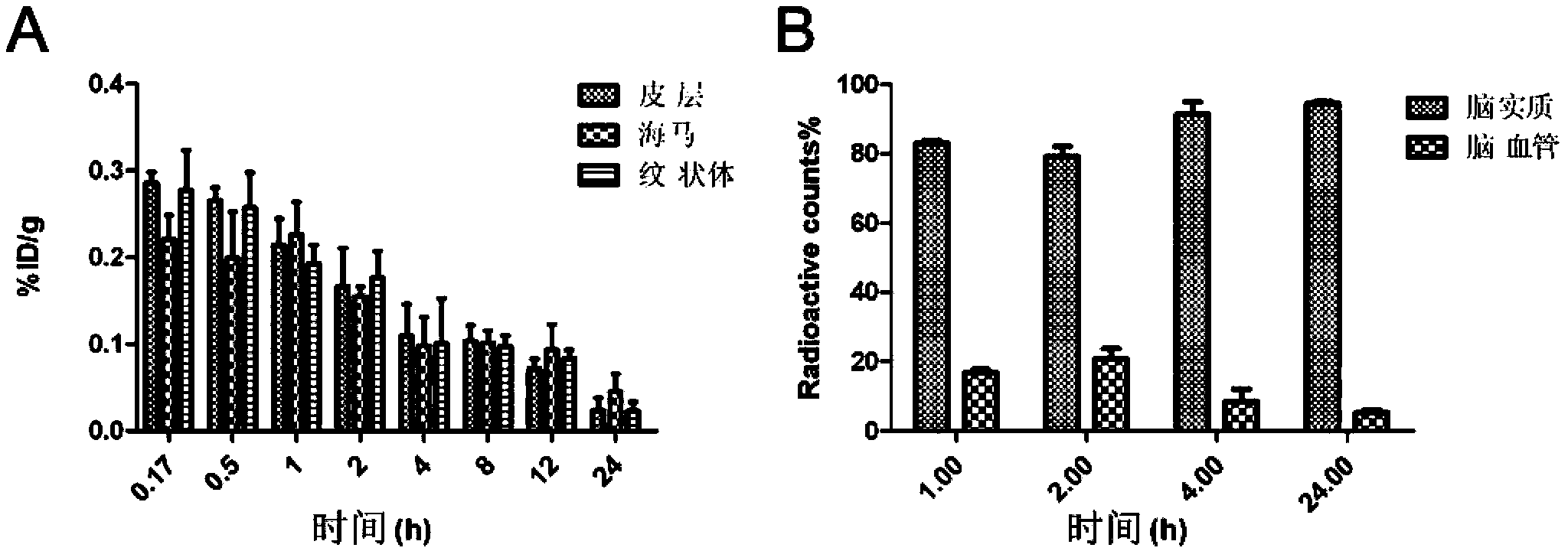

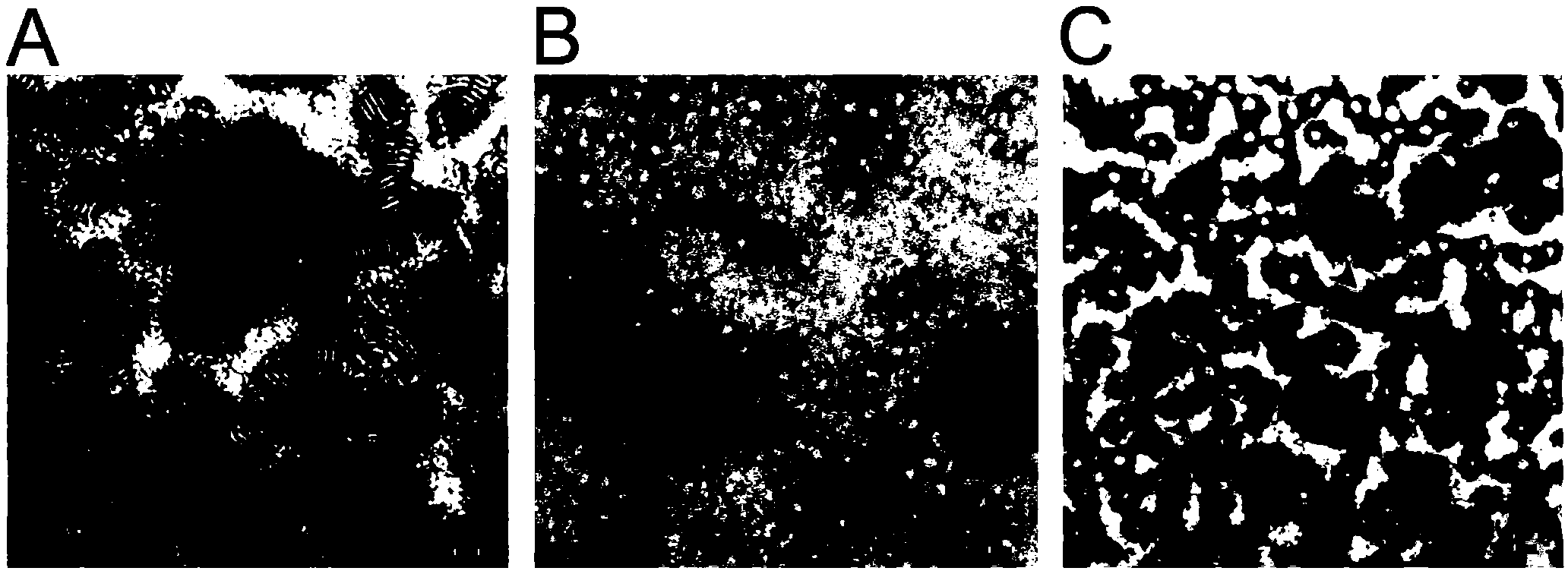

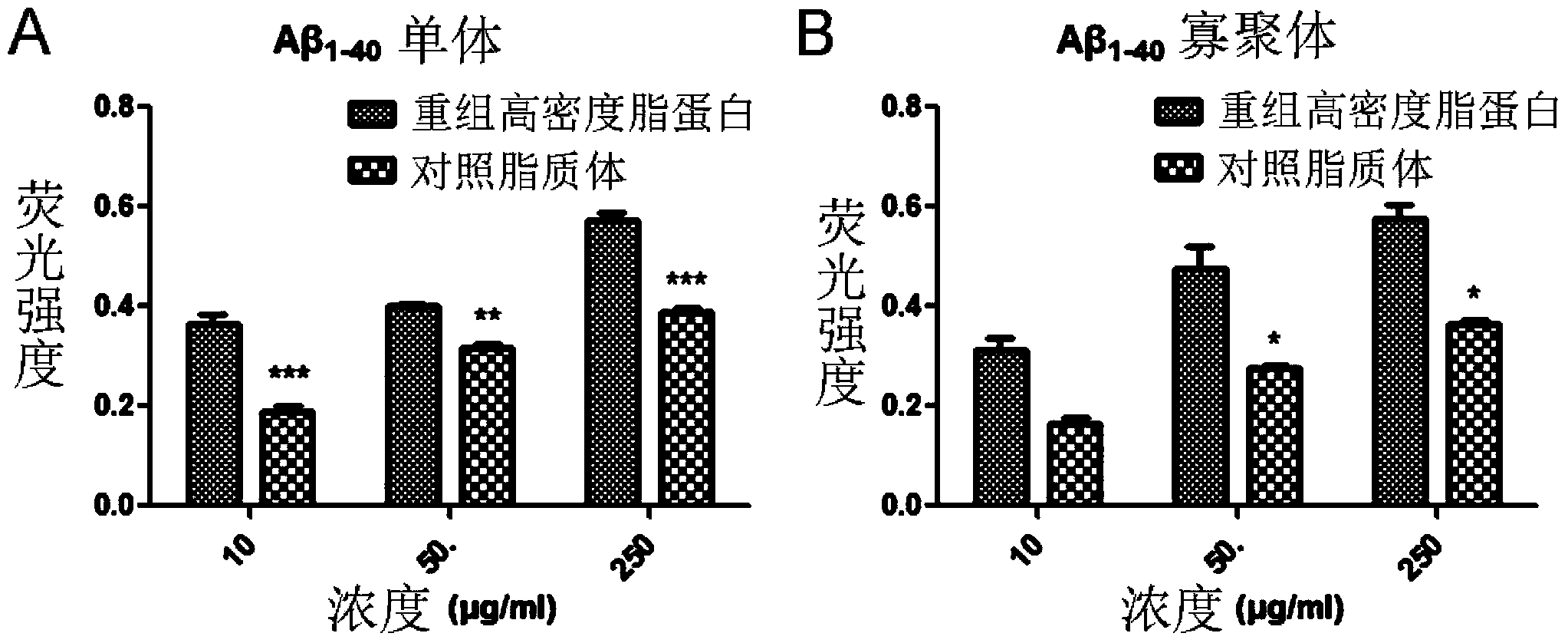

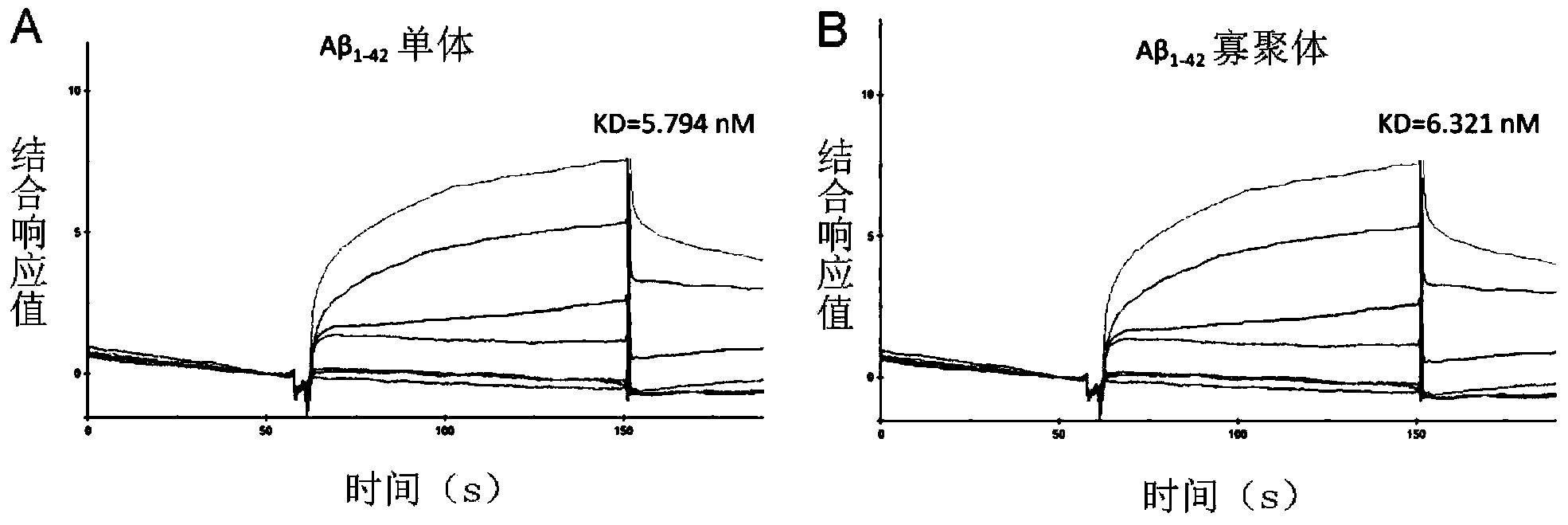

A beta targeted recombinant lipoprotein nano drug carrier and preparation method and application thereof

InactiveCN104138600AAddressing Scarcity of SourcesSimple preparationNervous disorderGenetic material ingredientsDiseaseLipid formation

The invention discloses an A beta targeted recombinant lipoprotein nano drug carrier and a preparation method and application thereof. The A beta targeted recombinant lipoprotein nano drug carrier comprises lipid, apolipoprotein and a drug, the drug is an alzheimer disease targeting therapeutic or diagnostic drug, and comprises one or a plurality of small molecule chemical therapeutic drugs and large molecule polypeptide, protein, gene therapeutic and diagnostic drugs. By construction of the drug carrier, the defects of scarce sources, cumbersome preparation, low quality controllability and the like of natural lipoprotein can be solved, and the drug carrier provides a new and more effective and safe solution for delivery of the alzheimer disease targeting therapeutic or diagnostic drug, and has the important research value and clinical application prospects.

Owner:SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

Commodity sales management method on basis of 3G (3rd generation telecommunication) and cloud technology and by aid of intelligent terminal and system

InactiveCN102637276AEasy for daily maintenanceSimple preparationMarketingRelevant informationStatistical analysis

The invention relates to a commodity sales management method on the basis of 3G (the 3rd generation telecommunication) and the cloud technology and by the aid of an intelligent terminal and a system. The commodity sales management method includes exchanging data by the aid of a 3G or WiFi (wireless fidelity) wireless network and the internet; configuring a catalog on a computer terminal or the intelligent terminal and uploading the catalog to a cloud server; allowing ordering operation by the aid of the intelligent terminal after other terminal equipment is synchronously updated; uploading ordering information to the cloud server and other terminals connected with the cloud server to actuate follow-up operation; or allowing billing operation by the aid of the intelligent terminal, and uploading billing information to the cloud server and cloud printing equipment connected with the cloud server to actuate bill printing. Operation conditions of a shop can be inquired via both the computer terminal and the intelligent terminal. By the aid of the commodity sales management method and the system, configuration of the catalog is facilitated, shopping experiences are improved, the service quality and efficiency are also enhanced, and relevant information is stored in the cloud server so that statistic analysis of consumption data can be carried out at any time.

Owner:CHENGDU BOYUE CHUANGXIN TECH

Oxo anion-adsorbing ion exchangers

InactiveUS20070241057A1Simple preparationImprove arsenic adsorptionIon-exchanger regenerationOrganic anion exchangersIron oxyhydroxideBrown iron oxide

The present invention relates to a process for the preparation of iron oxide / iron oxyhydroxide-containing weakly basic anion exchangers prepared according to the phthalimide process and their use for removing oxo anions and their thio analogues, preferably of arsenic, from water and aqueous solutions and to a regeneration process.

Owner:LANXESS DEUTDCHLAND GMBH

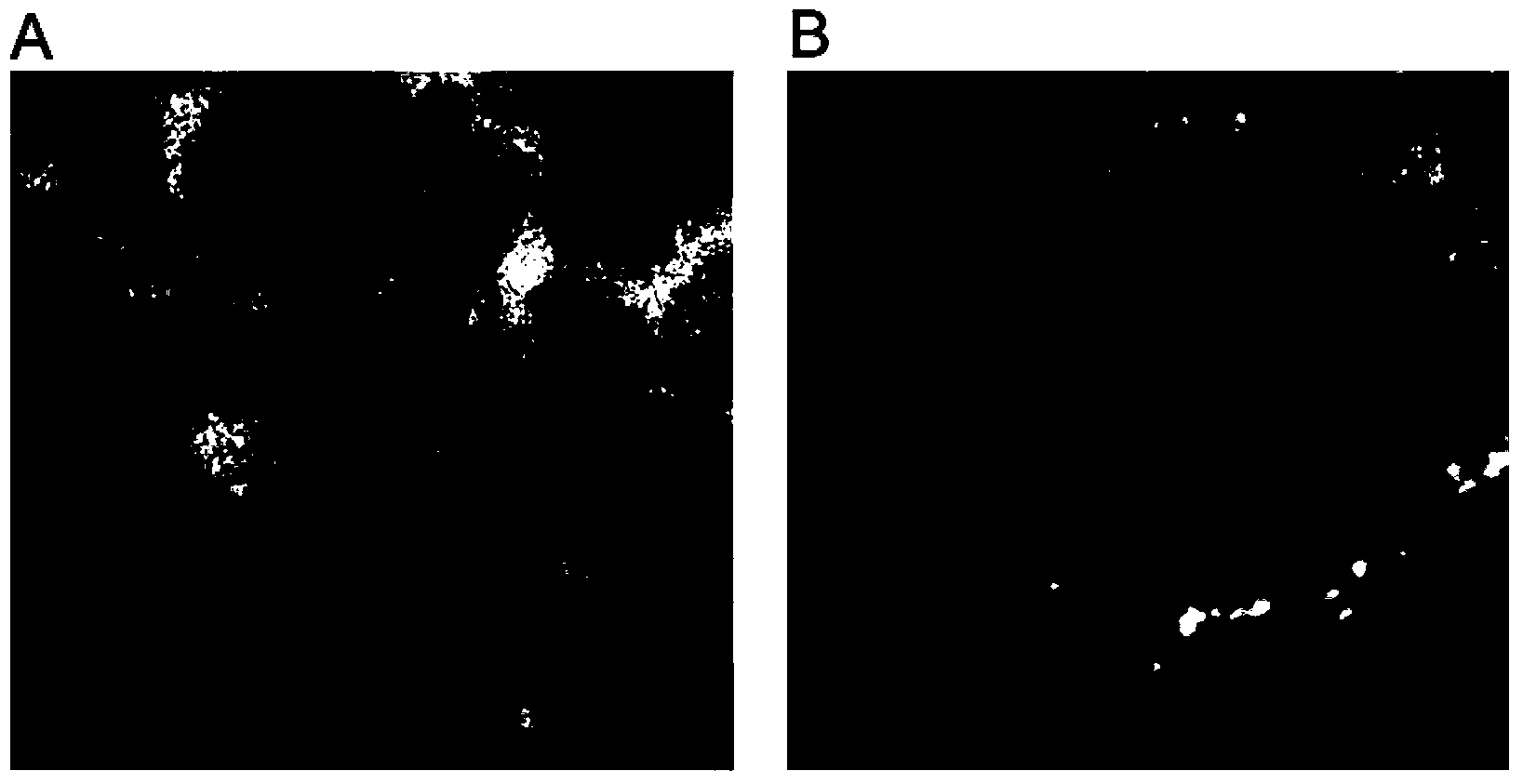

Application of bionic reconstituted high-density lipoprotein in preparation of drugs for prevention and treatment of Alzheimer disease

InactiveCN104138595AAddressing Scarcity of SourcesSimple preparationNervous disorderApolipeptidesDrugPeptide

Disclosed is a use of bionic recombinant high density lipoprotein (HDL) in the preparation of drugs for preventing and treating Alzheimer's disease. The bionic recombinant HDL consists of lipid and apoprotein. The apoprotein is one or more of ApoE and mimetic peptide thereof, ApoA-I and mimetic peptide thereof, and Apo-II and mimetic peptide thereof, Apoc and mimetic peptide thereof. Preferably, the apoprotein is one or more of ApoE3 and mimetic peptide thereof.

Owner:SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

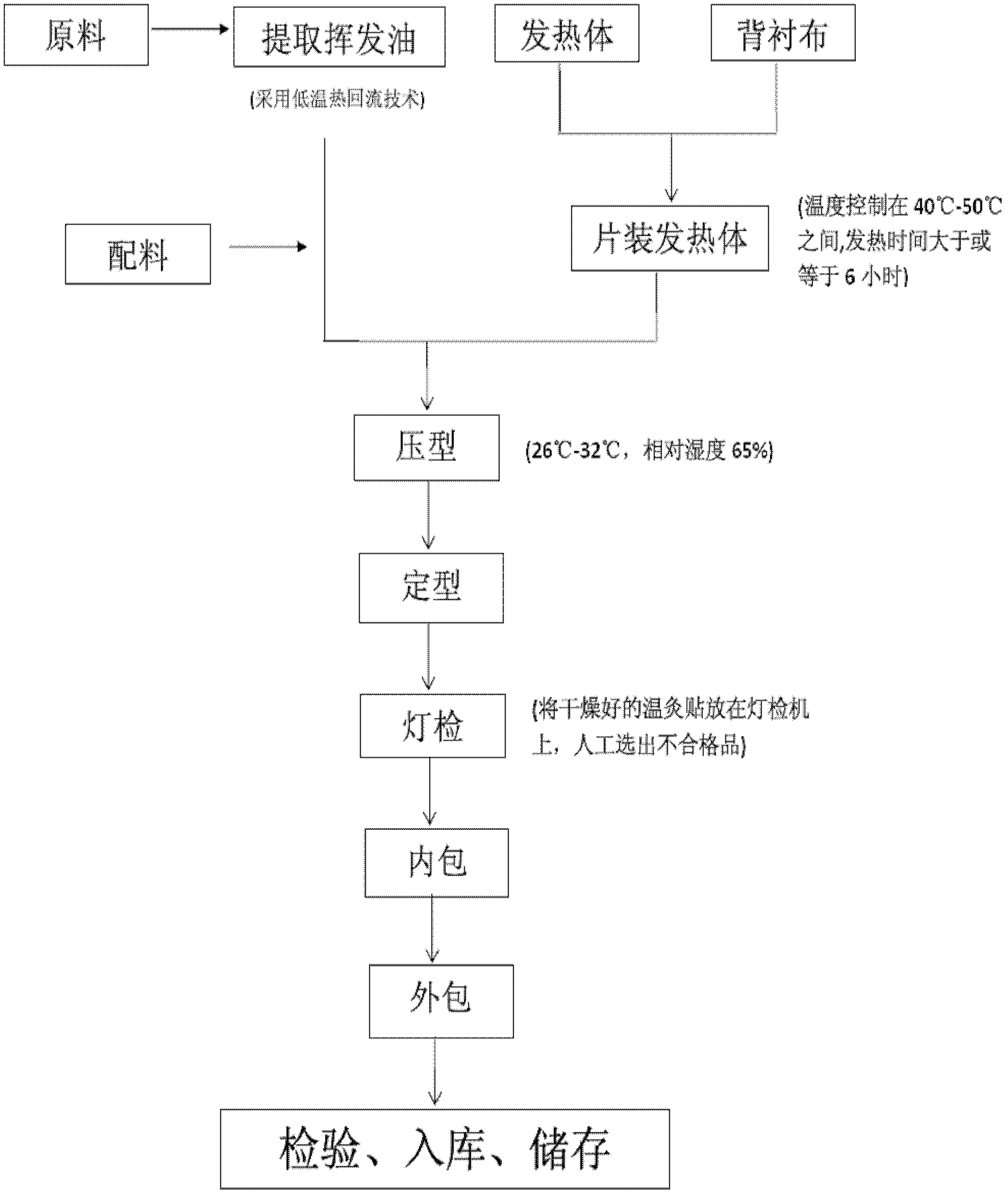

Mild moxibustion plaster added with heating element and application thereof

ActiveCN102357111AHas an expectorant effectCounter cardiotonicDevices for heating/cooling reflex pointsOrganic active ingredientsIndometacinSaline water

The invention belongs to the medicine category, and in particular discloses a mild moxibustion plaster. The mild moxibustion plaster comprises the following components in parts by weight: 40-50 parts of blumea oil, 20-30 parts of indometacin, 30-45 parts of heating element, 5-10 parts of medical rubber and 2-5 parts of back lining cloth, wherein the heating element comprises reduced iron powder, active carbon, saline water and far infrared ceramic powder on a ratio by weight of reduced iron powder to active carbon to saline water to far infrared ceramic powder as (8-14):(3-6):1:(5-8). According to the mild moxibustion plaster disclosed by the invention, the moxibustion method is combined with plasters, so that a mild moxibustion plaster is developed; and the mild moxibustion plaster is used for moxibustion treatment, therefore the disadvantages of inconsistent moxibustion time, less human body absorption and large raw material waste and the like in the conventional moxibustion method are completely overcome.

Owner:HUNAN JINLIUGU PHARMA

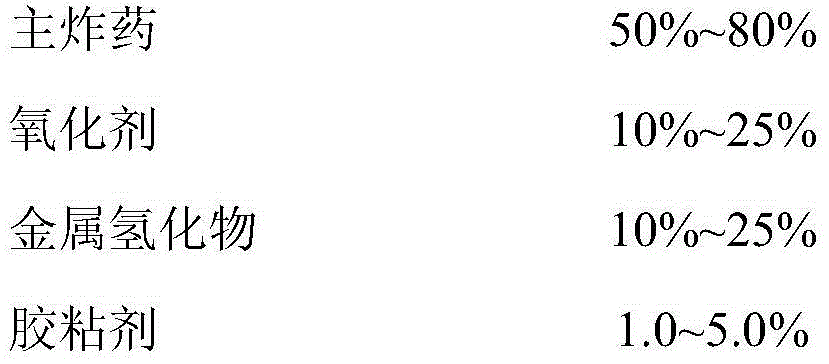

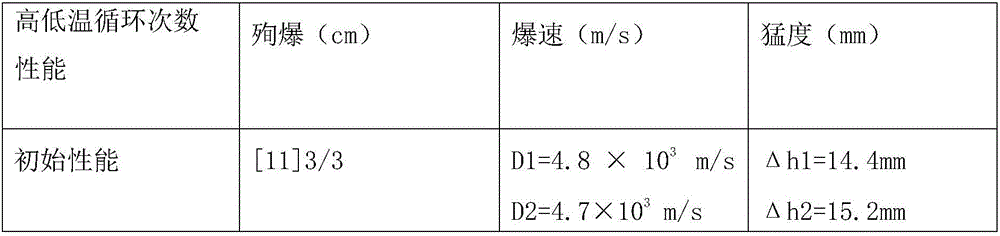

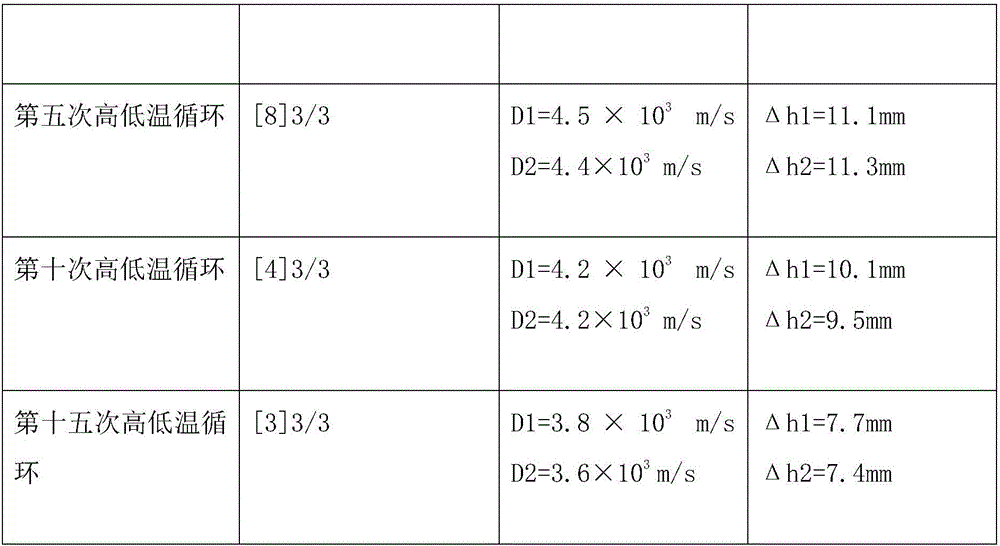

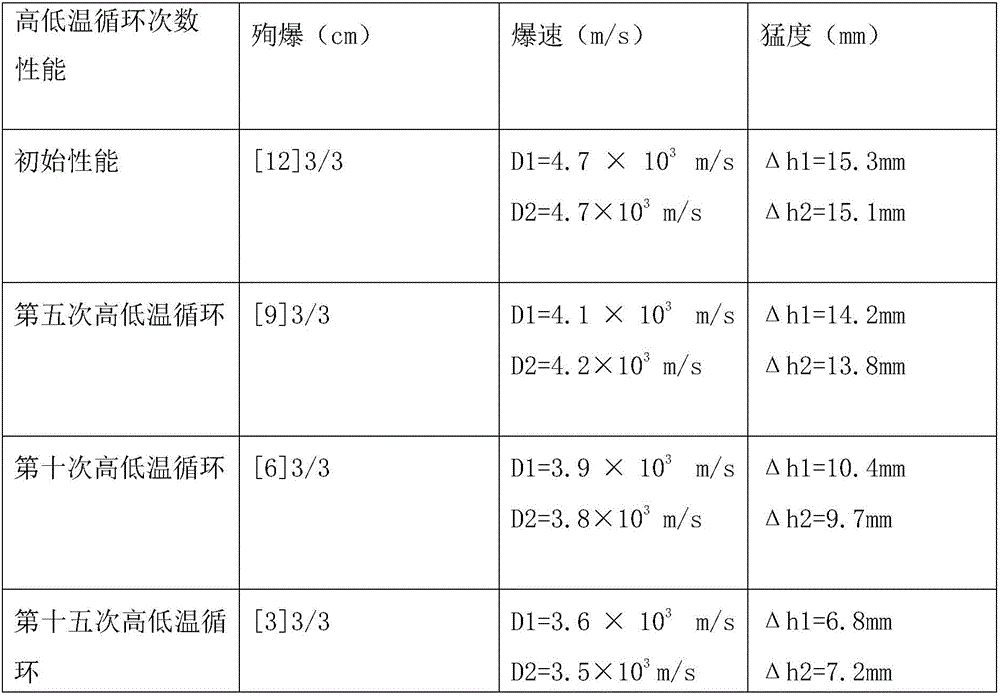

Preparation method of high-heat explosive containing cerium hydride

ActiveCN103980073ASimple production processSimple preparationNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAdhesiveCerium

According to the invention, metal hydride and an oxidizing agent are mixed, and under the action of an adhesive, the mixture is granulated to prepare a high-heat mixed explosive. The explosive contains the following components, by mass, 50-80% of cyclonite (RDX) and octogen (HMX) or hexanitrohexaazaisowurtzitane (CL-20), 10-25% of an oxidizing agent, 10-25% of metal hydride and 1.0-5% of a binder. According to the invention, metal hydride is added into the explosive for the first time so as to obtain the high-heat high-power explosive with the value of explosion heat being 14000-22000kJ / kg. The explosive has excellent sensitivity, and storage life of the explosive reaches 30 years. The explosive is suitable for charge by using press-fitting technology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Xiao Jin dispensible tablet and preparation method thereof

InactiveCN102764311AEasy to takeSimple preparationAntibacterial agentsAntipyreticLumbricusSkin color

The invention relates to a Xiao Jin dispensible tablet and a preparation method thereof. The preparation method is as follows: muskone, semen momordicae, prepared kusnezoff monkshood root, resina liquidamberis, frankincense, myrrh, trogopterus dung, alcohol processed radix angelica sinensis, lumbricus and fragrance ink are taken as raw materials to prepare raw medicine material fine powder and extract fine powder, and a proper amount of auxiliary material is added, so that a Xiao Jin dispensible tablet capable of being disintegrated within three minutes fully and achieveing a uniform dispensible state is prepared. The Xiao Jin dispensible tablet has efficacies of removing stasis and decreasing swellinging, is used for curing crewels, goiter and tumor, lump in breast which are caused by nitrogen stagnation and have the symptoms that part or a plurality of parts of skin or part or a plurality of parts of masses under the skin can be pushed to move, or the bone or bone joints are swelled, are not changed in skin color, has sclerema and is painful; and the Xiao Jin dispensible tablet has the characteristics that the Xiao Jin dispensible tablet can be disintegrated and dispersed uniformly, is easier to accept and take by patients, and is more convenient to carry and use.

Owner:JIANGXI HERBFINE HI TECH +1

Composition containing candesartan and amlodipine, preparation process, testing process and application thereof

ActiveCN102670604AUnique formulaReduce manufacturing costOrganic active ingredientsComponent separationCandesartanAngina

The invention relates to a composition and a preparation process, a testing process and an application thereof. The composition comprises a therapeutically effective amount of candesartan or pharmaceutically acceptable ester or salt, a therapeutically effective amount of amlodipine or other pharmaceutically acceptable salt, 70-150 parts of mannitol or lactose, 2-5 parts of croscarmellose sodium or cross-calcium carboxymethyl cellulose and 5-40 parts of microcrystalline cellulose or corn starch. The composition is easy to prepare, low in production cost, utilizes accessories of unique prescription, and the like, can be prepared into oral preparation in forms of tablets, capsules, granules and the like by means of pharmaceutics, can be checked by different checking processes, has high quality, has functions of treating hypertension, angina pectoris and kidney diseases and has effect of myocardial protection.

Owner:SICHUAN SUNNYHOPE PHARM CO LTD

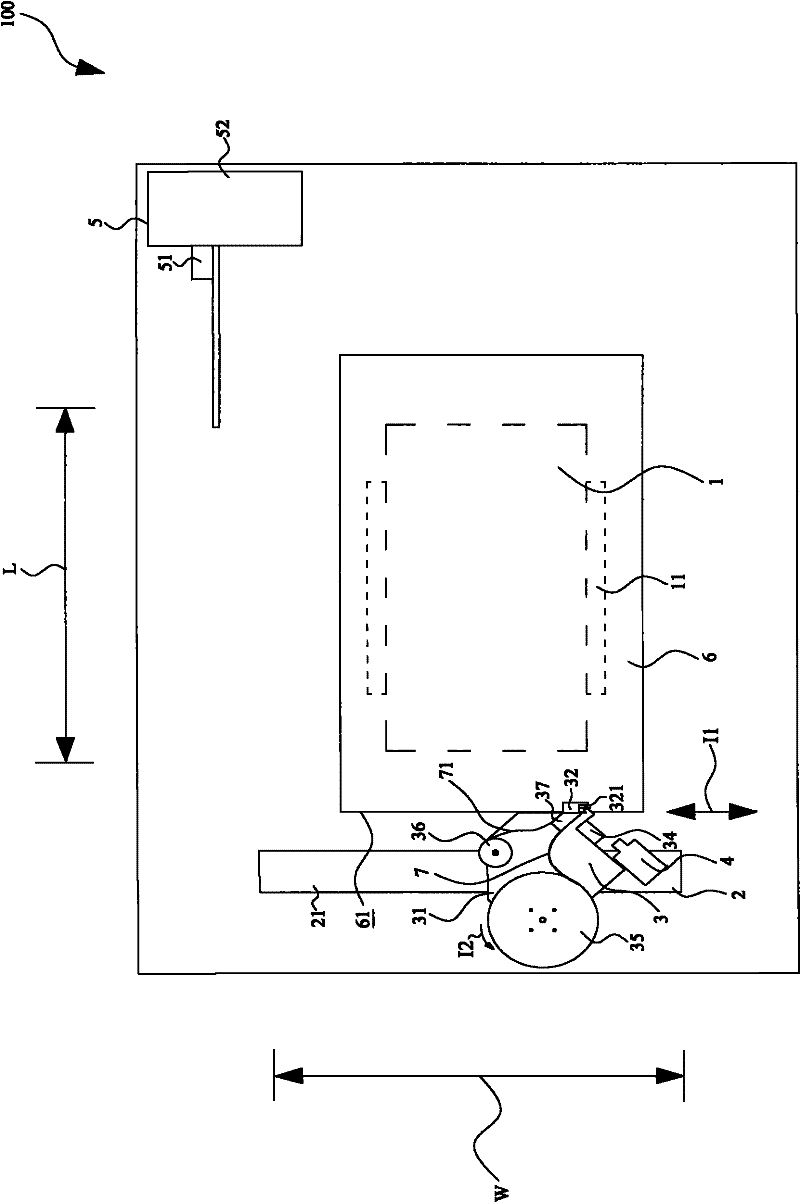

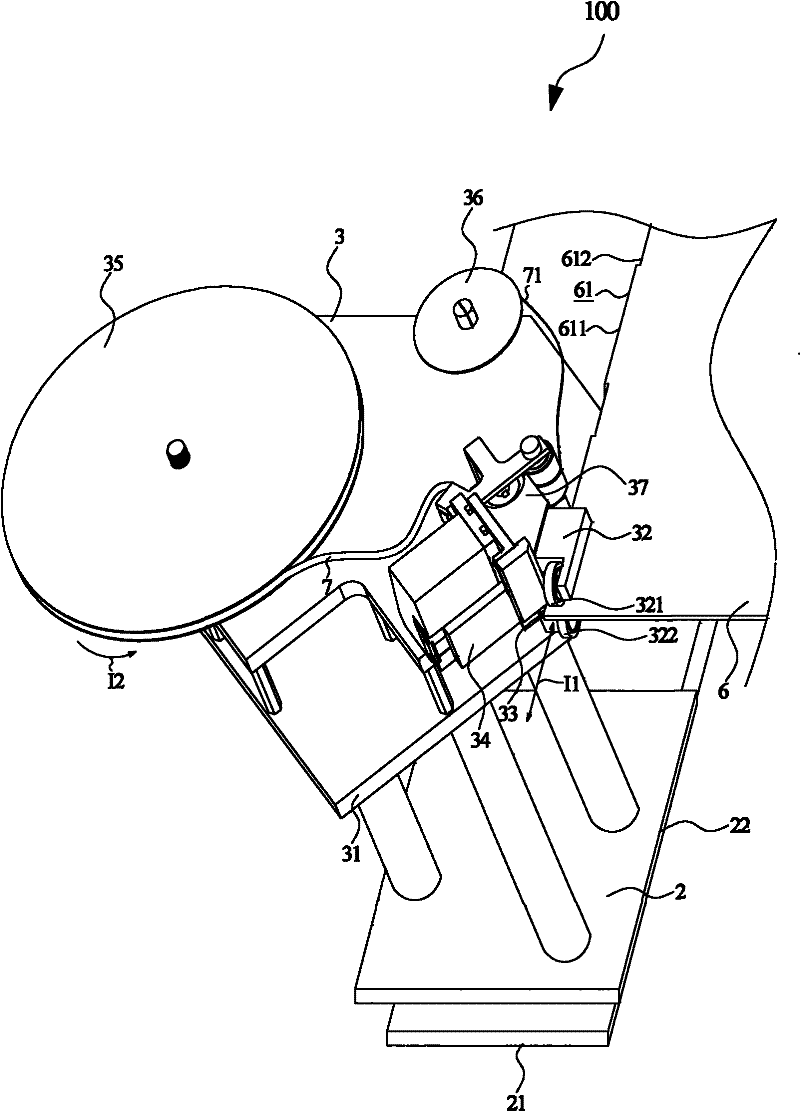

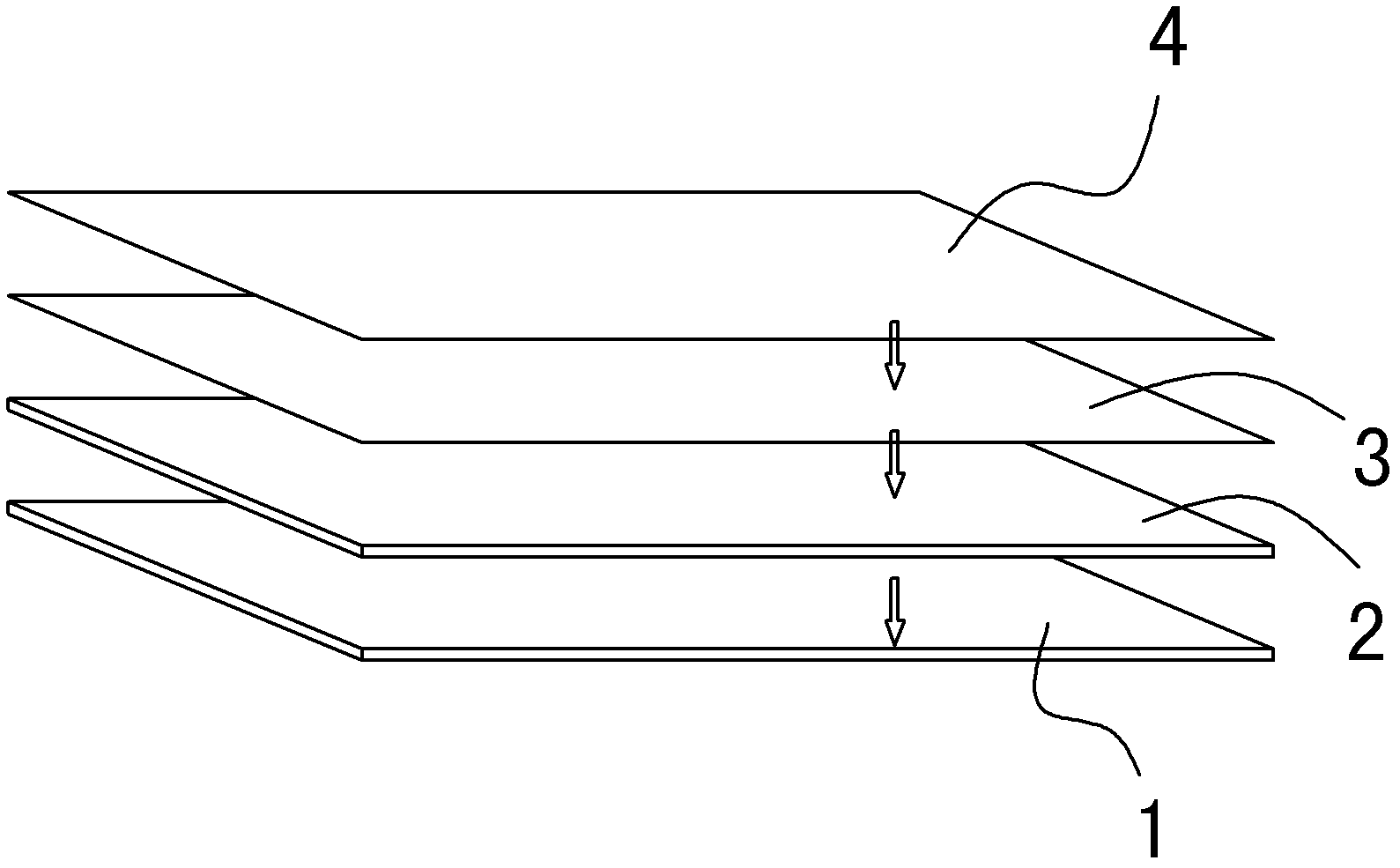

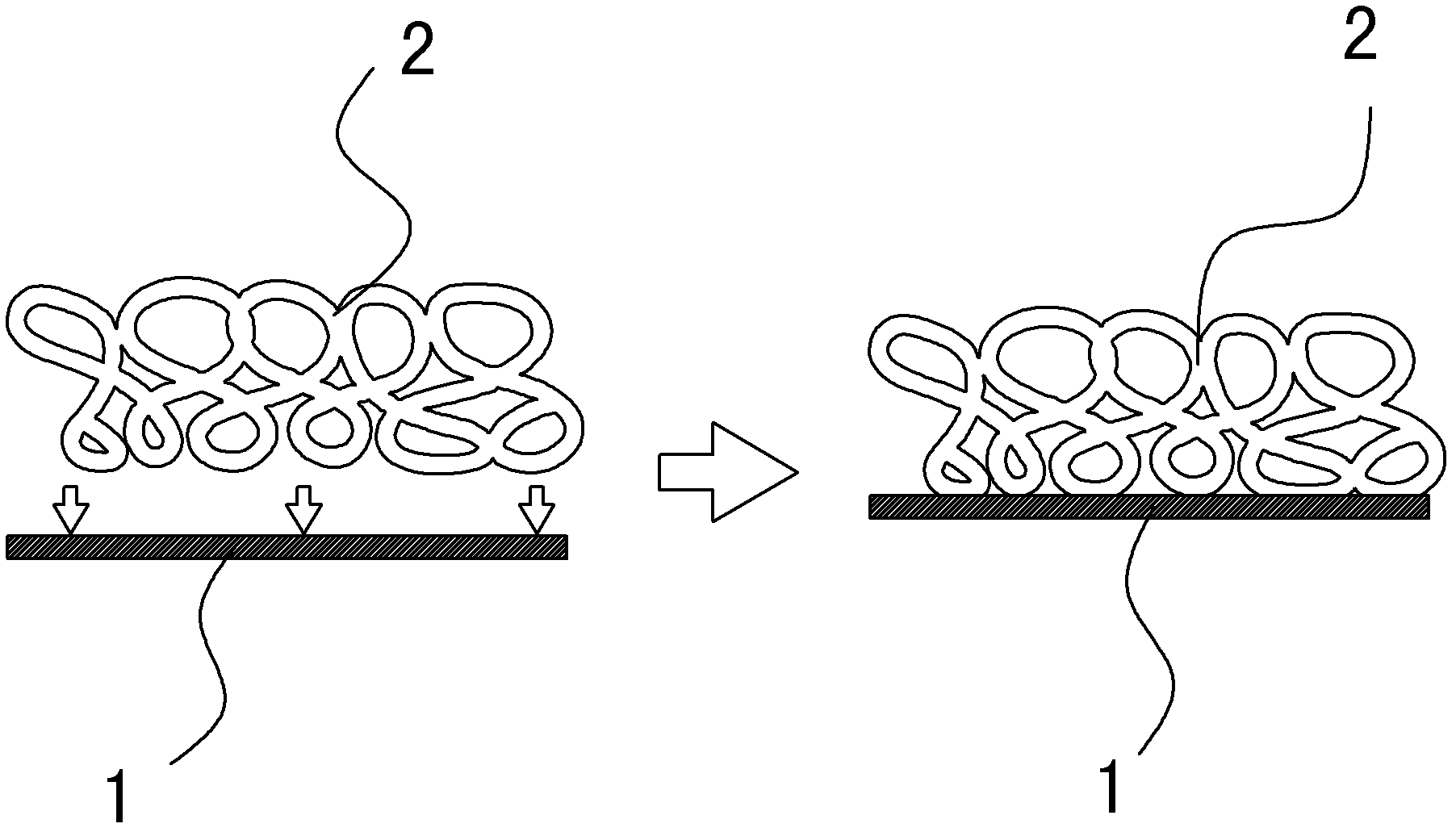

Film attachment method of light guide plate

InactiveCN102289023AMembrane Material No. SimpleSimple preparationLamination ancillary operationsLaminationEngineeringLight guide

The invention discloses a method for attaching a film material of a light guide plate, comprising: placing the light guide plate on a supporting mechanism, moving the film material attaching mechanism to the film material attaching surface corresponding to one side of the light guide plate, and pressing the upper part of the moving member The pressing part and the lower pressing part press the light guide plate in the thickness direction of the light guide plate, the separation member separates the film material on the supply path of the film material from the profile, and the attachment member passes along the path of the light guide plate with a narrow surface or a The film that has been separated from the profile is moved and pressed flat on the film attachment surface of the light guide plate in the way of positive contact of the narrow line, and then the film that has not been separated from the profile is cut by the cutting member And it will not cut off the profile. Adopting the technical scheme of the invention can simplify the inventory management of membrane materials and solve various disadvantages caused by manual pasting.

Owner:DYNACOLOR

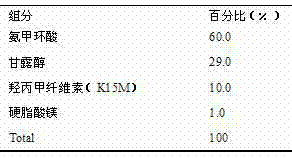

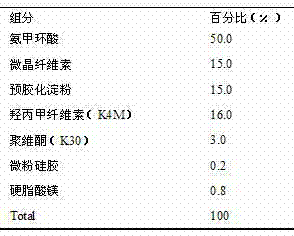

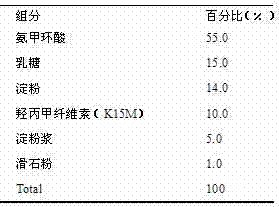

Tranexamic acid sustained-release solid composition and preparation method thereof

InactiveCN102525878ASolve the problem of too fast dissolution in waterMaintain blood levelsPeptide/protein ingredientsPharmaceutical non-active ingredientsBlood concentrationTranexamic acid

The invention discloses a tranexamic acid sustained-release solid composition and a preparation method thereof. The sustained-release solid composition is prepared by taking tranexamic acid as a raw material and adding a sustained-release framework material in a proper proportion. The prepared preparation is capable of achieving zero-order release within 3 h to keep blood concentration steady and is used for treating women suffering from menorrhagia clinically.

Owner:BEIJING WANQUAN SUNSHINE MEDICAL TECH CO LTD

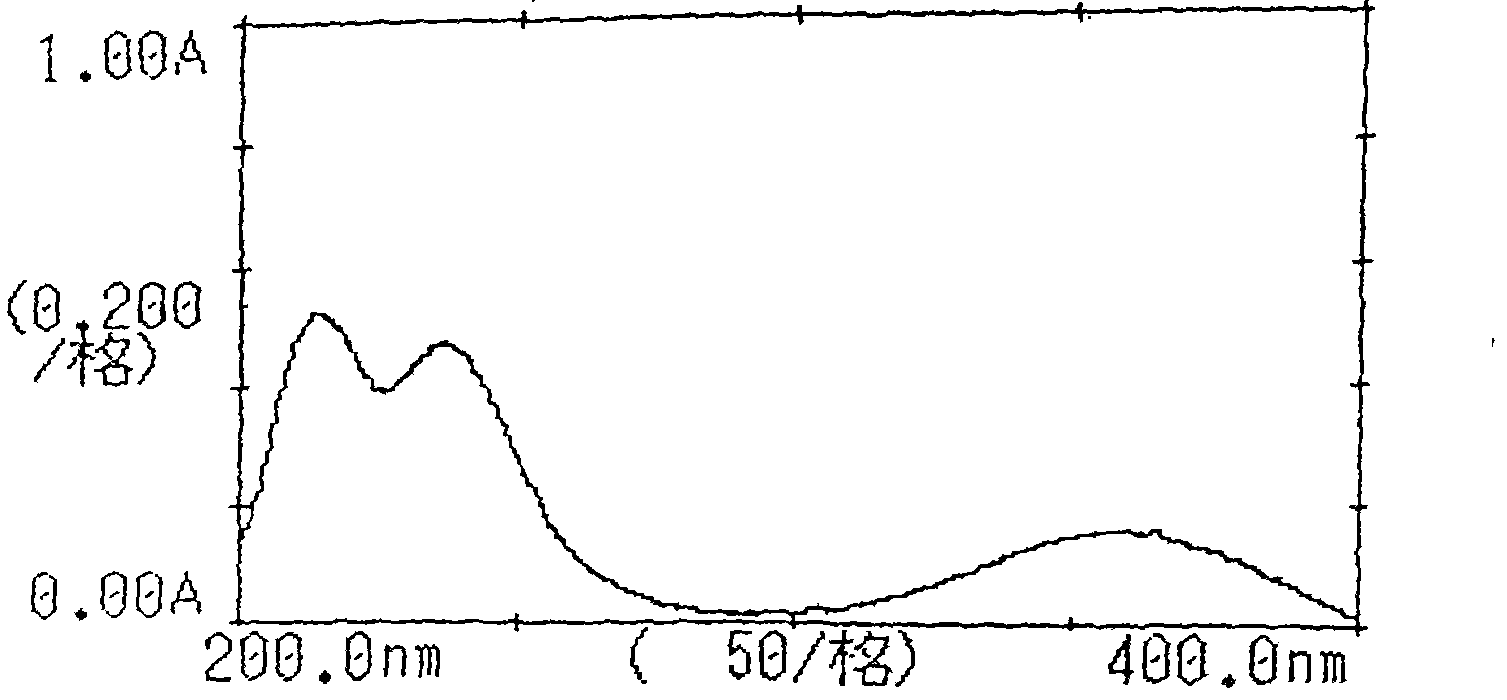

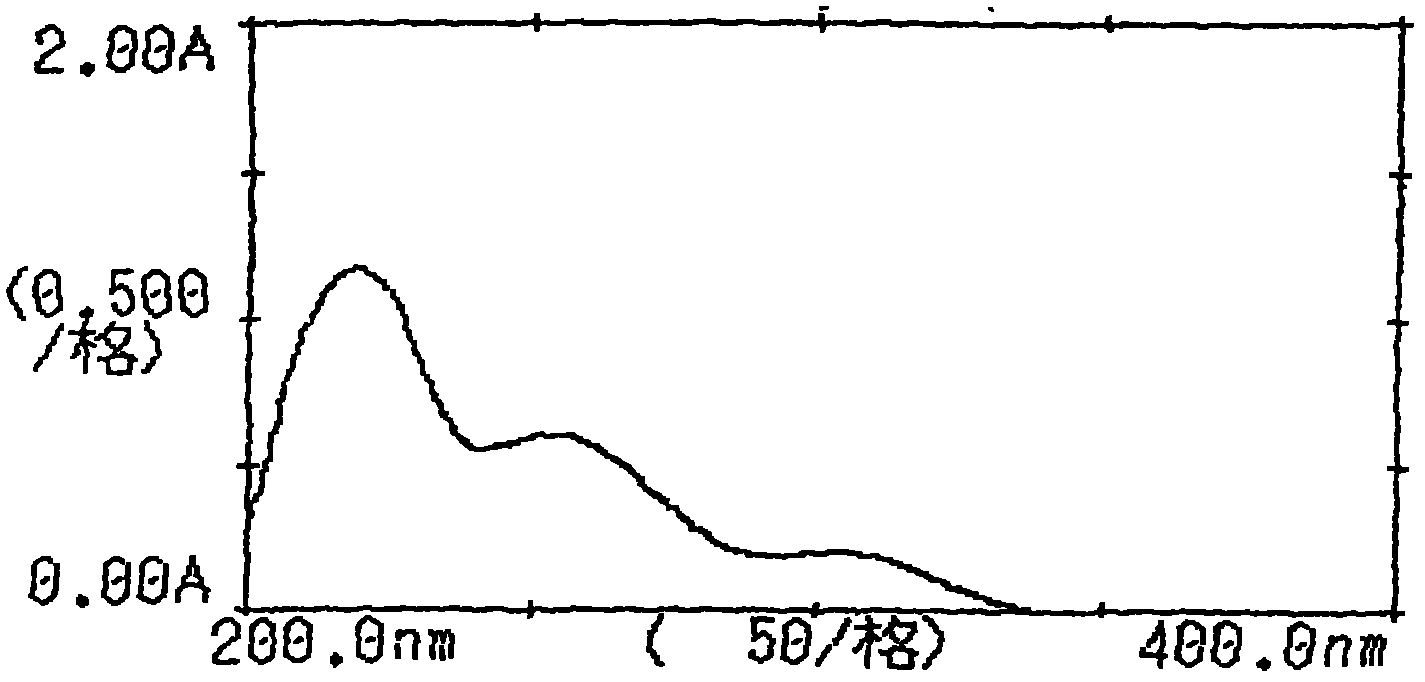

Formula of compound oil phase for emulsion explosive emulsified in static state and sensitized at medium temperature and low temperature

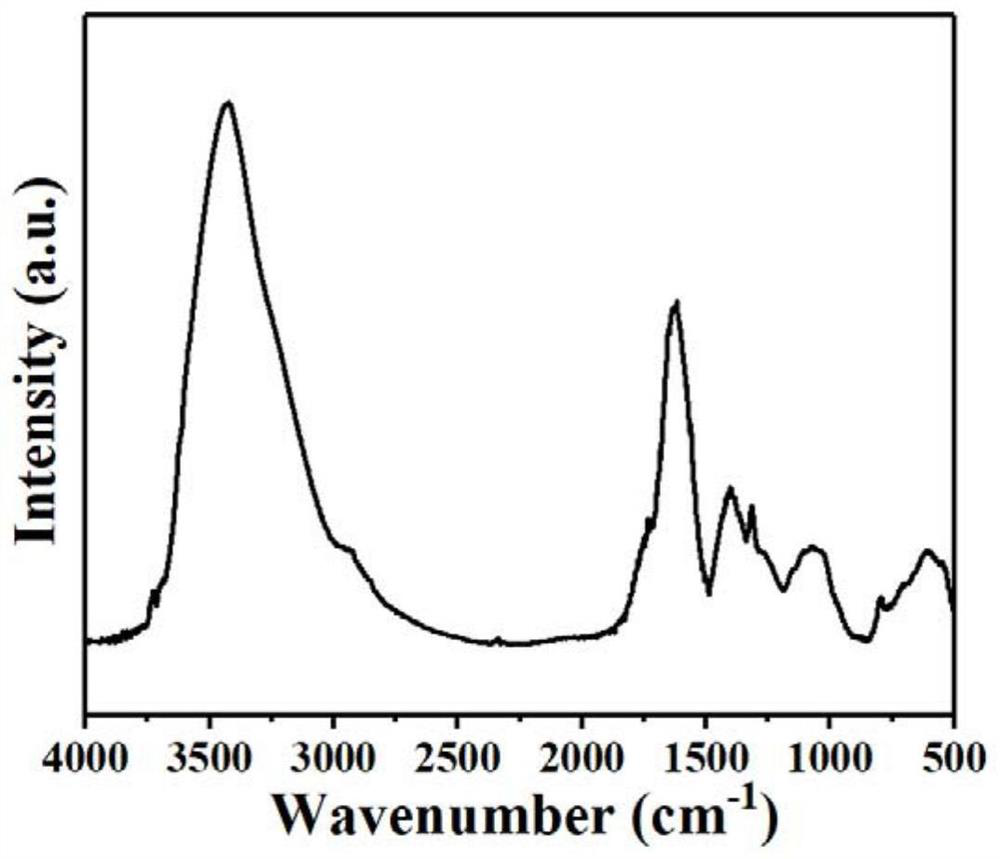

InactiveCN105949016AHigh calorific valueSimple recipeNon-explosive/non-thermic compositionsMass ratioEmulsion explosive

A formula of a compound oil phase for an emulsion explosive emulsified in a static state and sensitized at the medium-low temperature comprises wax substances, a compound emulsifier and an additive in the mass ratio being (61%-65%): (38.5%-34%): (0.5%-1%), and the compound oil phase is generated by mixing the wax substances, the compound emulsifier and the additive; the wax substances are mainly petroleum by-products and have the indexes as follows: the kinematic viscosity is 6-10 mm<2> / s (at the temperature of 100 DEG C), the oil content is 20%-35%, the drip melting point is 50-70 DEG C, and the flash point is higher than or equal to 170 DEG C; the compound emulsifier is prepared after a polymeric surfactant meeting the standard infrared spectrogram curve is added to an sp-80 emulsifier, the content of glycan in the sp-80 emulsifier is smaller than or equal to 0.1%, the dynamic viscosity is 1,050-1,150 mpa.s (at the temperature of 40 DEG C), the hydroxyl value ranges from 240 mg KOH / g to 270 mg KOH / g, and the acid value is smaller than or equal to 4.0 mg KOH / g; the kinematic viscosity of the compound oil phase is 12.5-17 mm<2> / s (at the temperature of 100 DEG C), the oil content is 50%-65%, the drip melting point is 50-65 DEG C, the flash point is higher than or equal to 200 DEG C, and the HLB (hydrophile-lipophile balance) value is 3-6; the additive is a cosurfactant. The formula has the advantages as follows: no oil phase materials are required to be added, and all performance indexes of the produced emulsion explosive can completely meet the national standard.

Owner:GEZHOUBA YIPULI HUBEI CHANGTAI CIVIL EXPLOSIVE

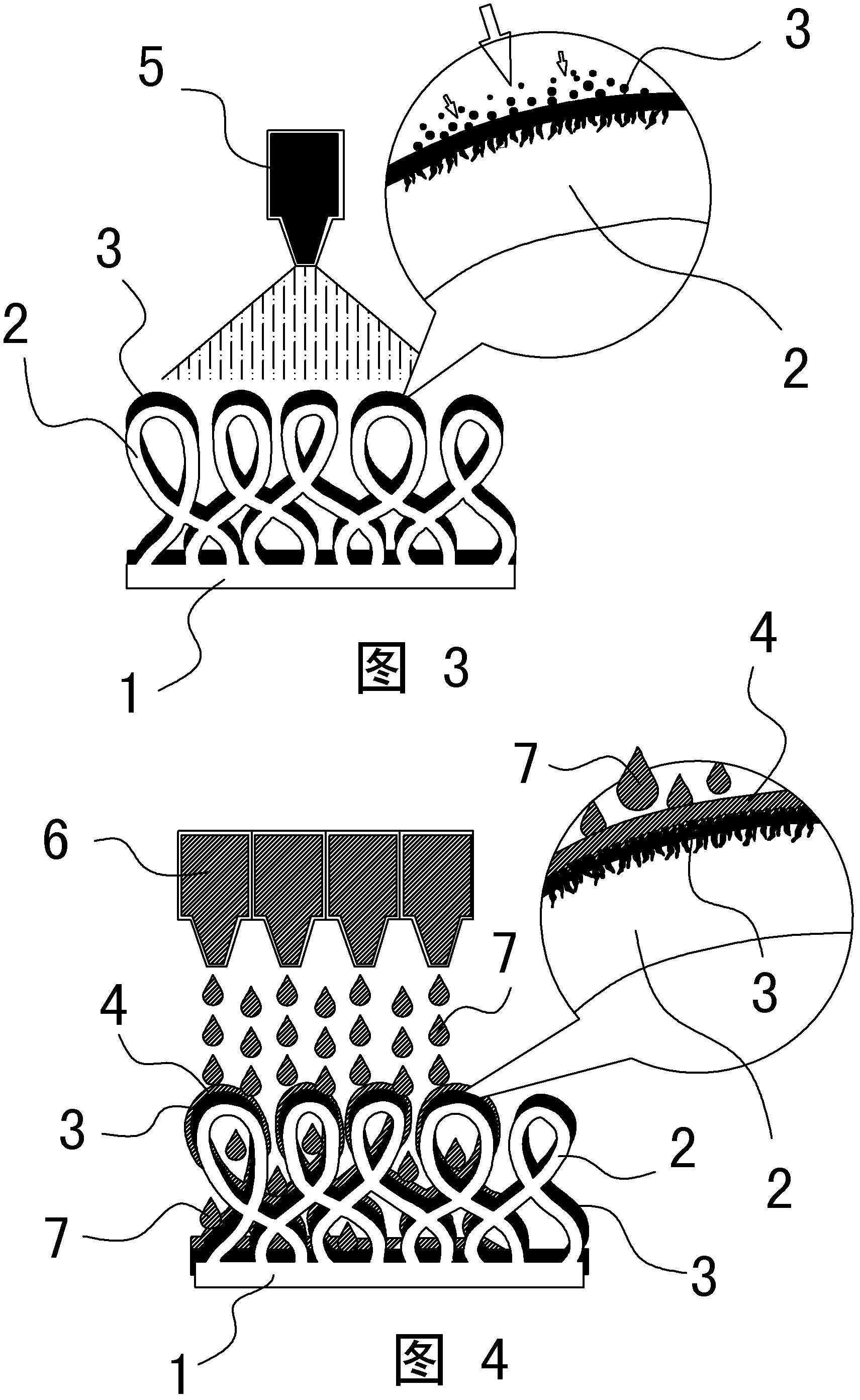

Pattern color spraying method for plastic yarn-loop floor mat

The invention relates to a pattern color spraying method for a plastic yarn-loop floor mat, which is characterized by using the white or light-colored plastic yarn-loop floor mat as a color spraying object and being operated according to the following steps: firstly, spraying a pre-press processing liquid coating on the front side of the plastic yarn-loop floor mat in a uniform vaporific mode by utilizing spraying equipment; secondly, using color eco-solvent ink as a spraying raw material and performing spraying to the front side of the plastic yarn-loop floor mat in a mode of scanning line by line by utilizing a color spraying machine according to a preset pattern until the pattern is formed by spraying; and thirdly, heating and curing to enable the sprayed color pattern to be firmly attached to the surface layer of the plastic yarn-loop floor mat. According to the invention, for the non-planar and hollow-out yarn-loop layer, the color pattern is subjected to spraying by adopting a mode of increasing the ink quantity or increasing the ink jetting times, however, pattern layers on yarn loops with different heights can be converged to form the complete pattern; the complete pattern can be seen from any overhead view angle at a certain height; and the defect that the plastic yarn-loop structure cannot be printed with color or develop color is broken through.

Owner:无锡市维一方家居用品有限公司

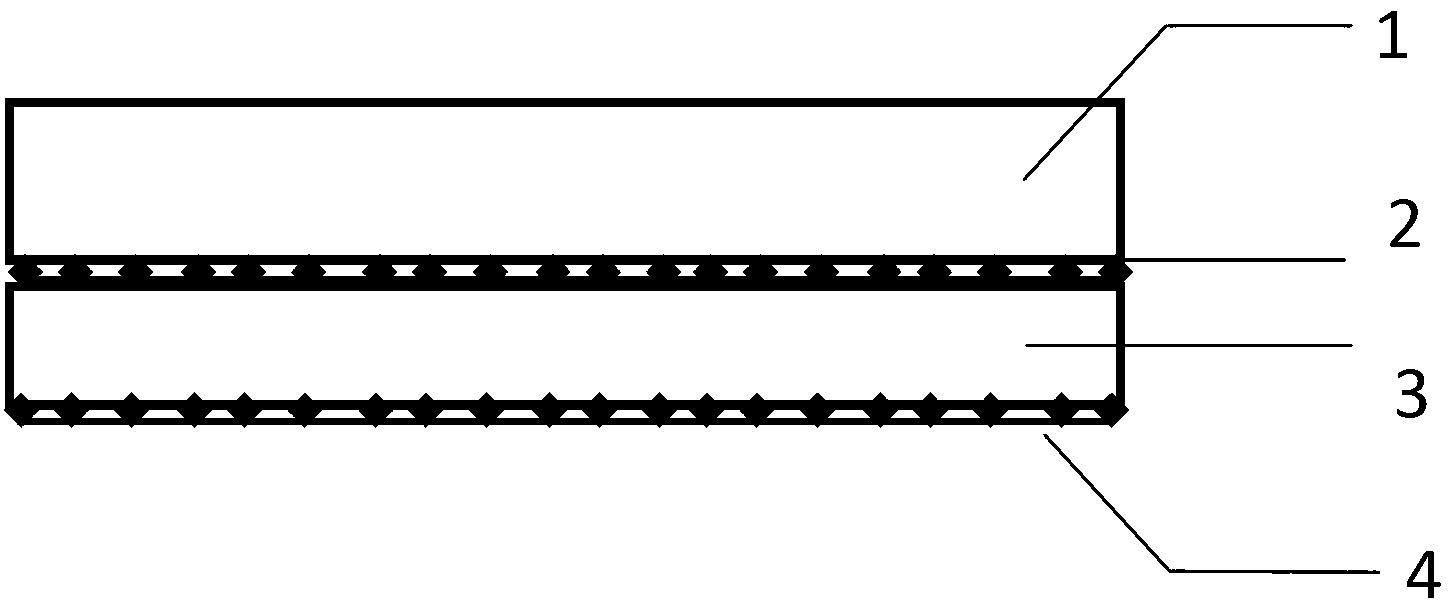

Composite rubber asphalt concrete steel bridge surface pavement structure

ActiveCN103225264AReduce thicknessReduce dead loadBridge structural detailsSurface layerCrack resistance

The invention relates to a composite rubber asphalt concrete steel bridge surface pavement structure which sequentially consists of the following structure layers from a steel bridge to a surface layer: an adhesive waterproof layer and fine particle type dense composite rubber asphalt concrete, wherein the total pavement thickness of the adhesive waterproof layer and the fine particle type dense composite rubber asphalt concrete is 6-7cm. According to the optimized design of structure combination, the balance of sliding resistance, bending resistance and high-temperature shearing resistance are mainly considered on the surface layer, the surface layer is made of a medium particle type material, the compaction, the high-temperature shearing resistance and deformation compliance are mainly considered on a lower layer, and the lower layer is made of a fine particle type material. According to the technical scheme, the composite rubber asphalt concrete steel bridge surface pavement structure has a high high-temperature property, high crack resistance and the compaction, the adhesive waterproof layer has high pull strength, and the shear translation damage to a asphalt concrete layer under the action of the vehicle load can be effectively avoided.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

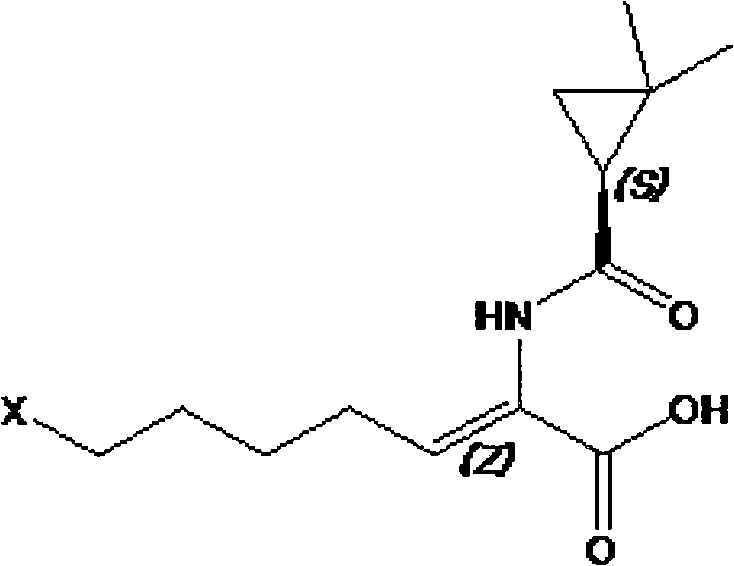

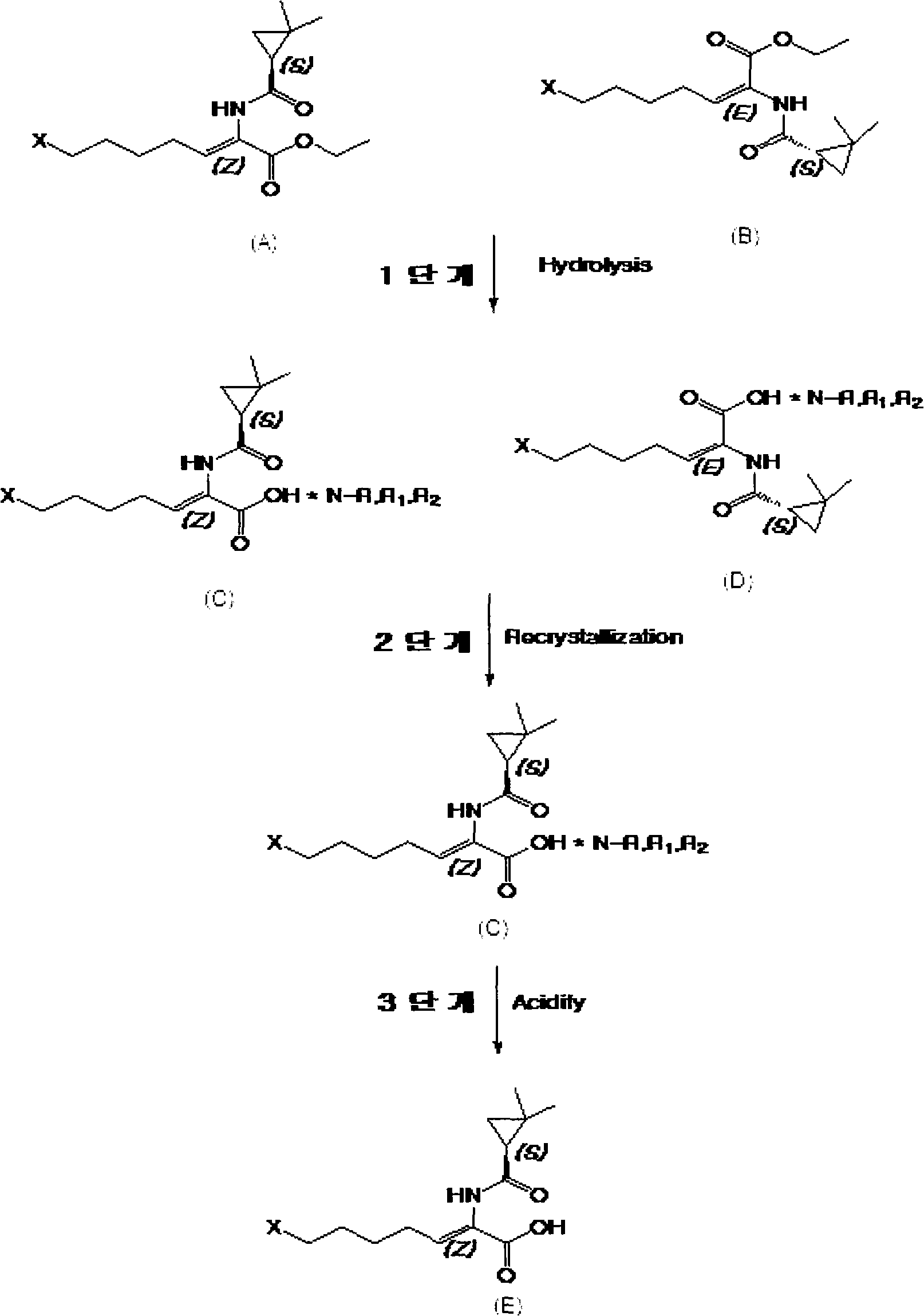

Method for preparing intermediate of cilastatin

InactiveCN102030674AHigh yieldSimple preparationAmino preparation from aminesOrganic compound preparationMethylcyclopropaneSolvent

A producing method of a cilastatin intermediate is provided to obtain (Z)-7-hollow-2-((s)-2,2'-dimethylcyclopropane carboxamido)-2-heptenoic acid and its salt with high purity. A producing method of a cilastatin intermediate comprises the following steps: obtaining an (E,Z)-7-hollow-2-((s)-2,2'-dimethylcyclopropane carboxamido)-2-heptenoic acid alkali salt solution using a hydrolyzation after adding an alkali solution; extracting a first organic solvent layer from the reactant after adding a first organic solvent and acid to perform a layer separation; obtaining a mixed crystal of the (E,Z)-7-hollow-2-((s)-2,2'-dimethylcyclopropane carboxamido)-2-heptenoic acid alkali salt; and obtaining (Z)-7-hollow-2-((s)-2,2'-dimethylcyclopropane carboxamido)-2-heptenoic acid amine salt.

Owner:DHC CORP +2

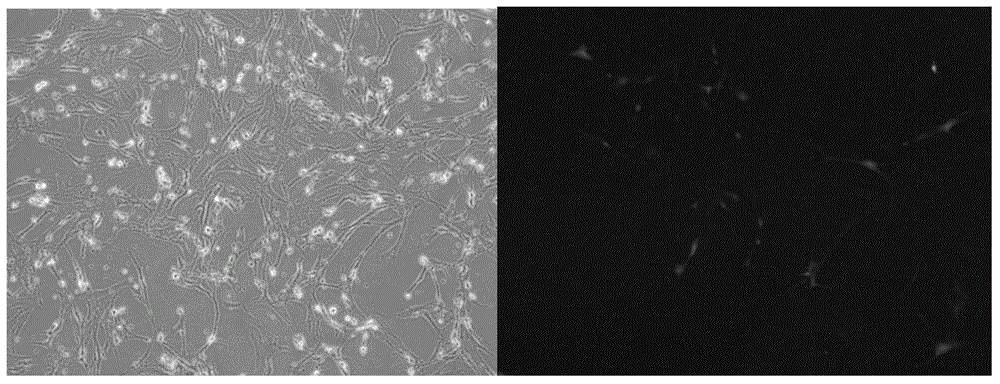

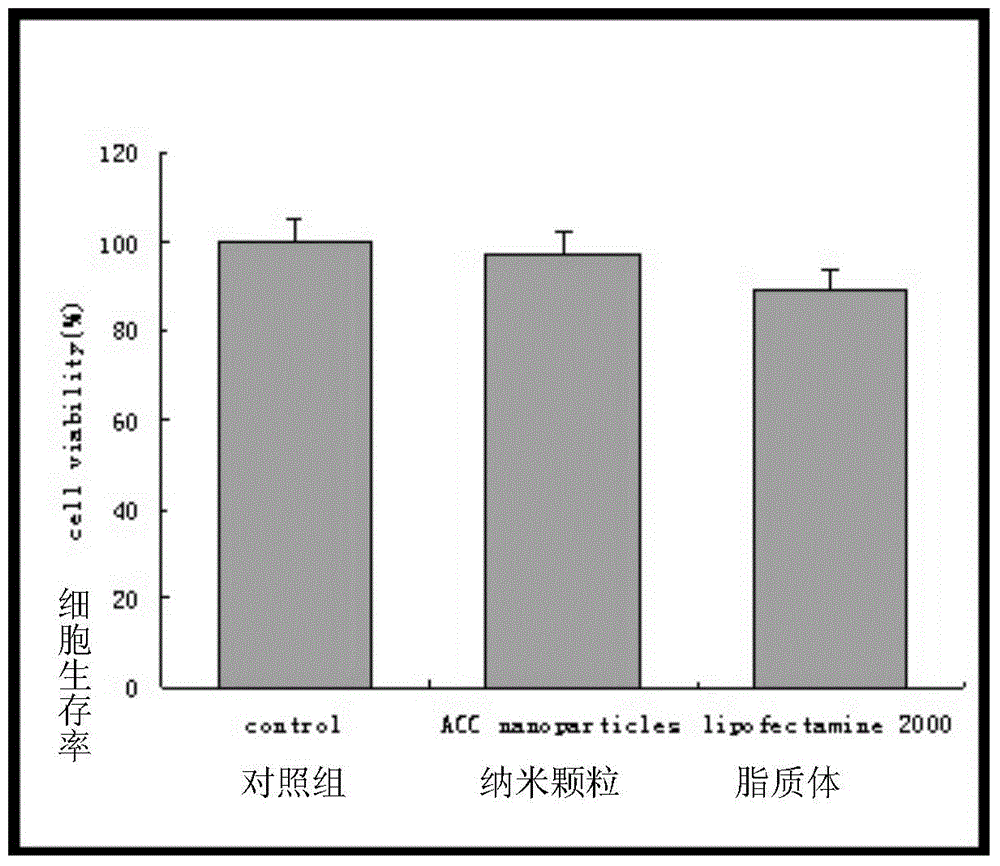

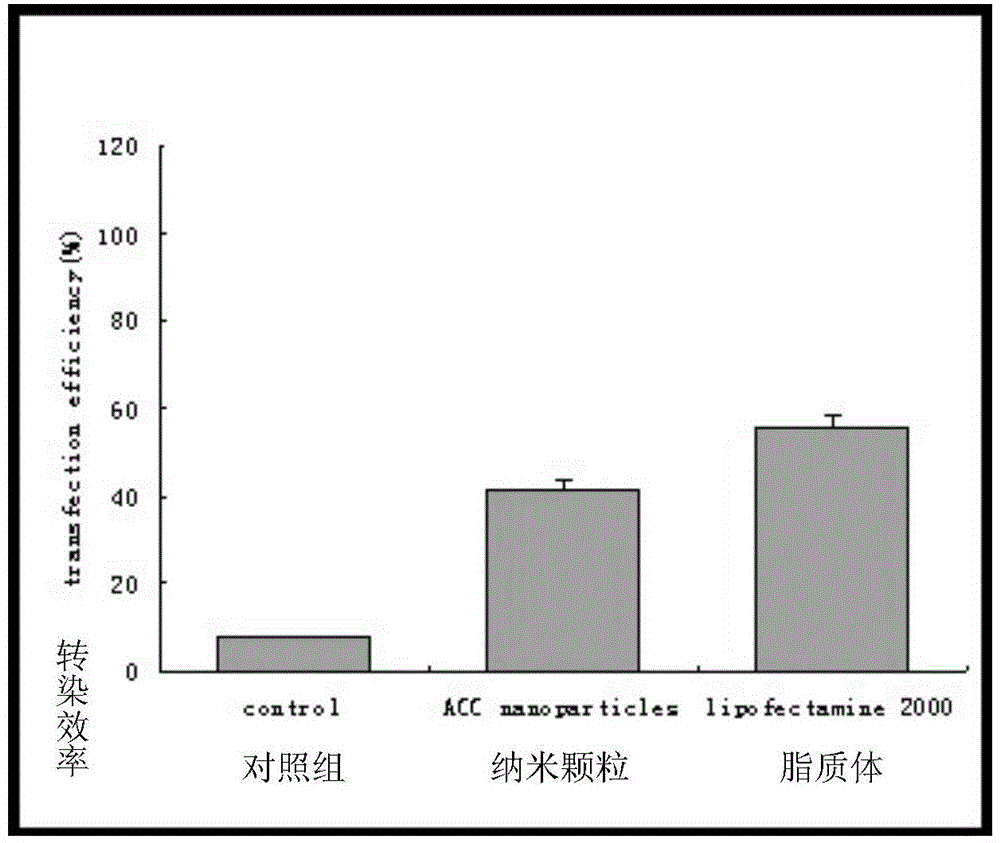

Functional nano catechin gene-introduction material and preparation method thereof

InactiveCN103820492AHigh transfection efficiencyGood biocompatibilityVector-based foreign material introductionDispersityBiocompatibility Testing

The invention discloses a functional nano catechin gene-introduction material. Catechin and ferrous sulfate are combined into a catechin-Fe<2+> nanometer spherical material of which the average diameter is about 100 nm, the catechin content is 0.94 g / g, and the ferrous ion content is 0.06 g / g. The invention further discloses a preparation method of the functional nano catechin gene-introduction material. The functional nano catechin gene-introduction material has relatively high transfection efficiency which can reach about 40 percent in human breast carcinoma cells. The toxicity is low, the catechin is high in biocompatibility, and thus the cell survival rate is very high. The dispersity of the material is high and the material conforms to the requirements of transfection; the cost is extremely low; the catechin is a main active ingredient extracted from tea leaves, namely a polyphenolic compound, the price of the catechin is low, and ferrous sulfate is also a common cheap reagent which is easy to get. For the material preparation, the reaction is simple and easy in operation, and the repeatability is high.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

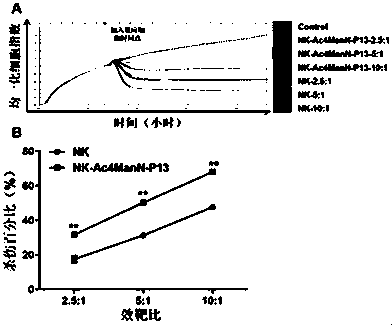

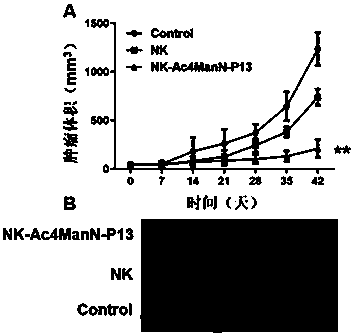

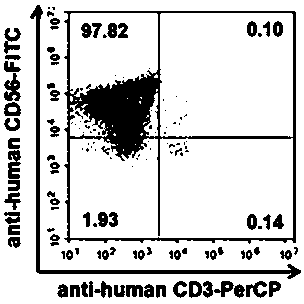

Preparation method for membrane surface engineered NK cell, pharmaceutical composition and application

PendingCN110205291AImprove targetingEnhance tumor invasive abilityMammal material medical ingredientsBlood/immune system cellsAbnormal tissue growthChemical reaction

The invention relates to the construction of targeted NK cells used for tumor immunotherapy, and specifically relates to a preparation method for a membrane surface engineered NK cell, a pharmaceutical composition and an application. A targeting vector is adopted to introduce an azide group or DBCO on the surface of a NK cell, and polypeptide targeting PD-L1 can be coupled to the surface of the NKcell through copper-free click chemical reaction, so that a membrane surface engineered NK cell can be constructed. An application of the membrane surface engineered NK cell in treating PD-L1 positive tumor including head and neck squamous cell carcinoma, non-small cell lung cancer and triple negative breast cancer is also disclosed. Compared with the prior art, the preparation method has the following advantages: the targeting of the NK cell can be strengthened, so that potential hazards caused by viral vector transfection can be eliminated; the problems of CAR-T cell individualization and complex manufacturing processes can be solved; and the tumor infiltration capabilities and targeted killing activity of the NK cell can be enhanced, and immune escape mediated by a PD-1 / PD-L1 pathway can be effectively blocked, so that the membrane surface engineered NK cell has potential clinical application prospets.

Owner:THE FIRST AFFILIATED HOSPITAL OF BENGBU MEDICAL COLLEGE

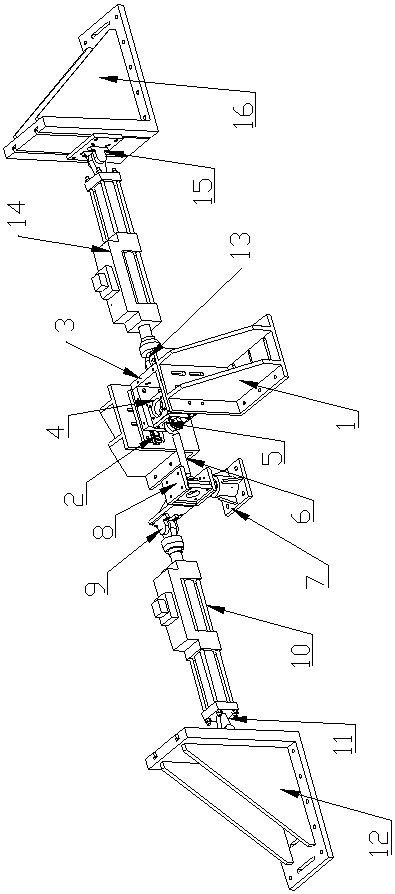

Radial and defection combined loading bench test tool for traction bar

InactiveCN108120595AGuaranteed to workGuaranteed versatilityVehicle testingMachine part testingFixed frameBench test

The invention relates to a radial and deflection combined loading bench test tool for a traction bar. The radial and deflection combined loading bench test tool comprises a slide rail counterforce support, wherein the slide rail counterforce support is connected with a linear slide rail; the linear slide rail is connected with a fixed frame; a fixed block is connected to the interior of the fixedframe and connected with a spherical hinge connection block; the spherical hinge connection block is hinged to the traction bar; the traction bar is hinged to a rotary base; a defection tool is connected to the upper part of the rotary base; a deflection actuator spherical hinge B is connected to the left side surface of the deflection tool and hinged to a deflection actuator; the deflection actuator is hinged to a deflection actuator spherical hinge A; the deflection actuator spherical hinge A is connected with an actuator counterforce support A; a radial actuator spherical hinge B is hingedto the right side surface of the fixed frame; the right end of the radial actuator spherical hinge B is connected with a radial actuator; the right end of the radial actuator is hinged to a radial actuator spherical hinge A; and the right side surface of the radial actuator spherical hinge A is connected with an actuator counterforce support B. The radial and deflection combined loading bench testtool for the traction bar has the advantages of reasonable structure, accurate test, high safety and reliability, excellent adaptability and low manufacture cost.

Owner:HENAN VOCATIONAL & TECHN COLLEGE OF COMM

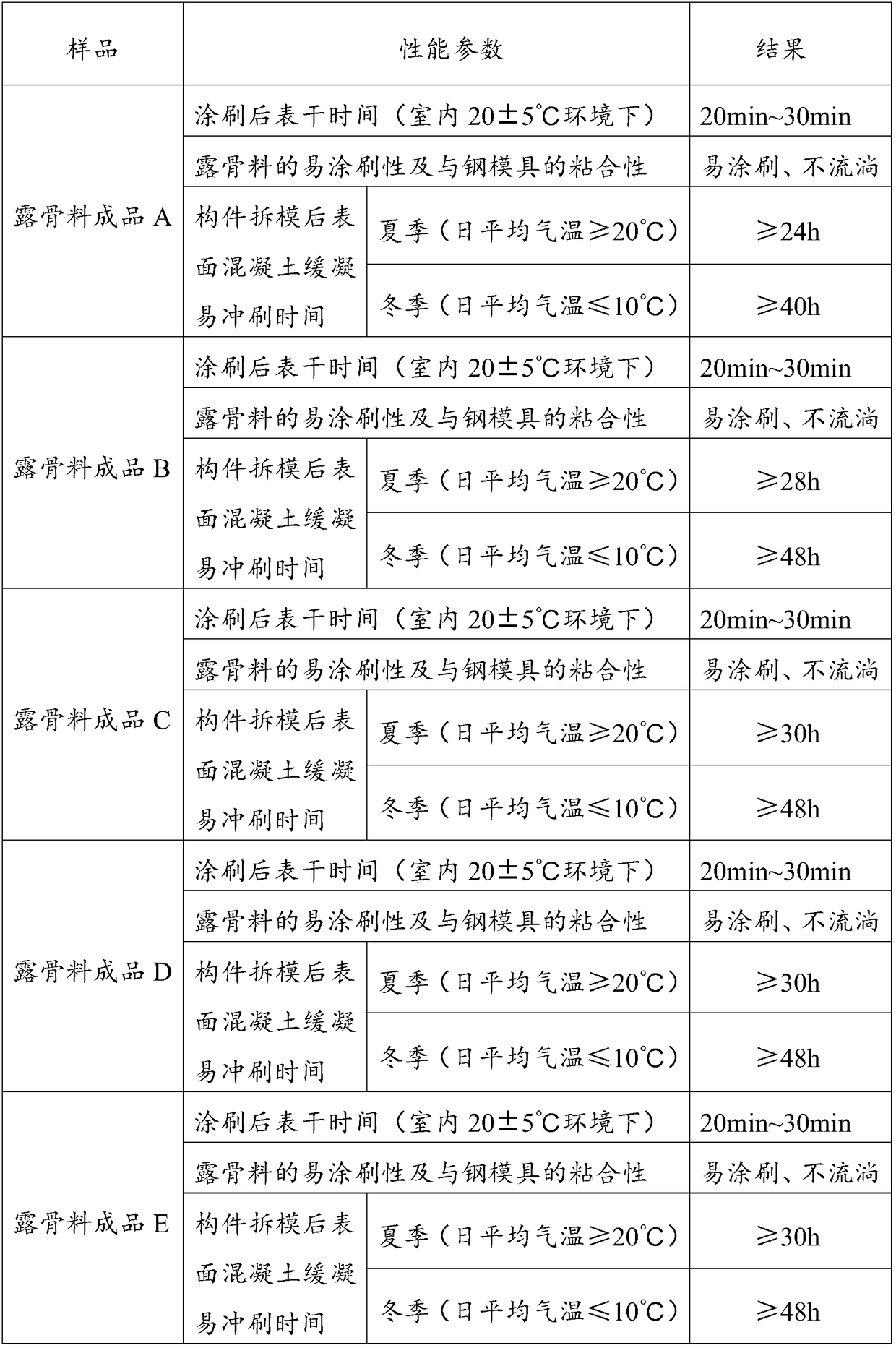

Precast concrete component exposed aggregate and preparation method thereof

The invention relates to the technical field of precast concrete components, discloses precast concrete component exposed aggregate and solves the problems that exposed aggregate in the prior art hascomplex ingredients, high production cost and high selling price. The precast concrete component exposed aggregate is prepared from the following raw materials in mass percent: 7.5% to 10% of sodium gluconate, 0.8% to 1.2% of thickening agent, 0.1% to 0.5% of preservative and 88.3% to 91.6% of water, wherein the raw materials are evenly mixed to prepare the precast concrete component exposed aggregate. The precast concrete component exposed aggregate has the advantages of simple ingredients, low cost, easiness in being painted, no fluidity and good use effect. The invention further discloses apreparation method of the exposed aggregate. All the ingredients are mixed according to steps to obtain a finished product of the exposed aggregate, and the preparation method is simple.

Owner:西安建工绿色建筑集团有限公司

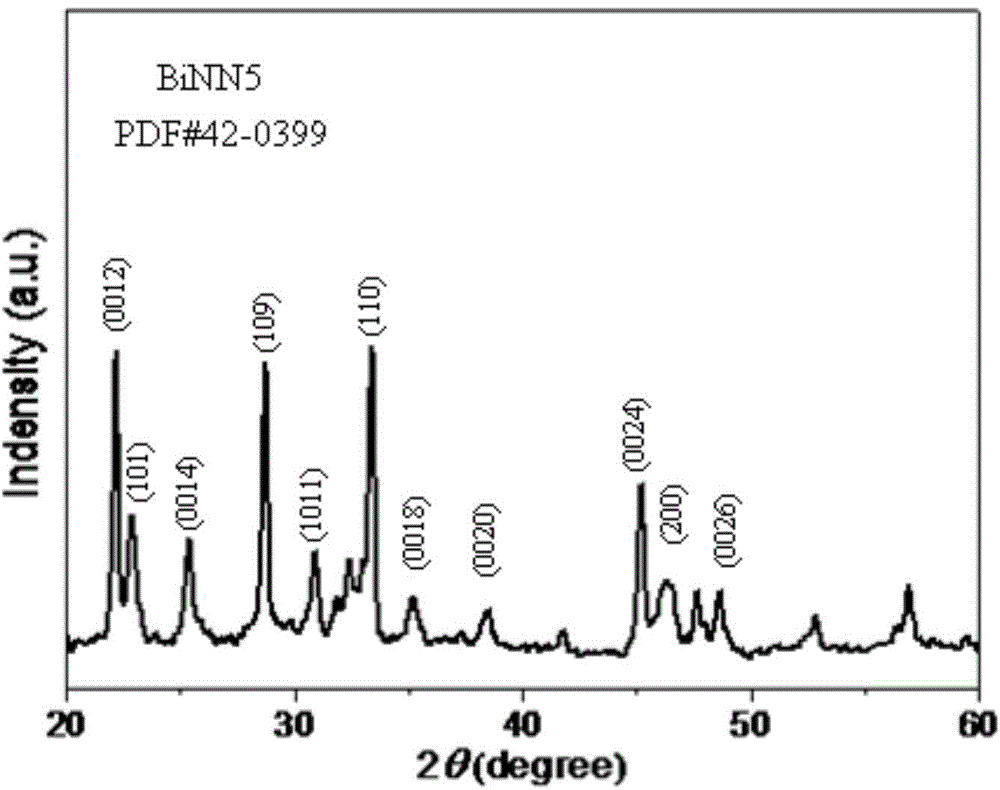

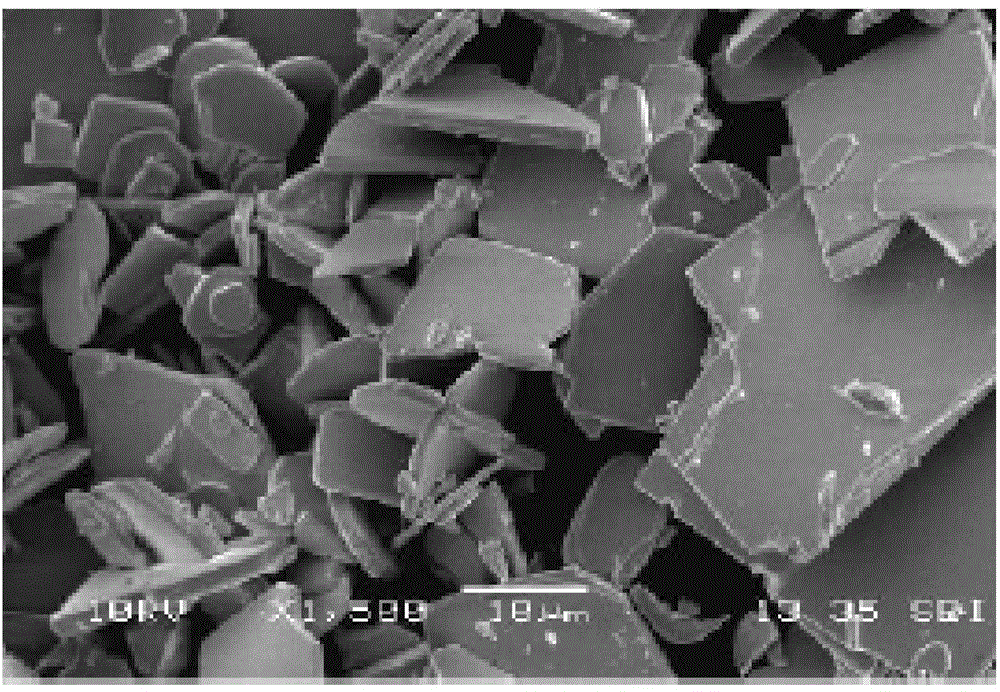

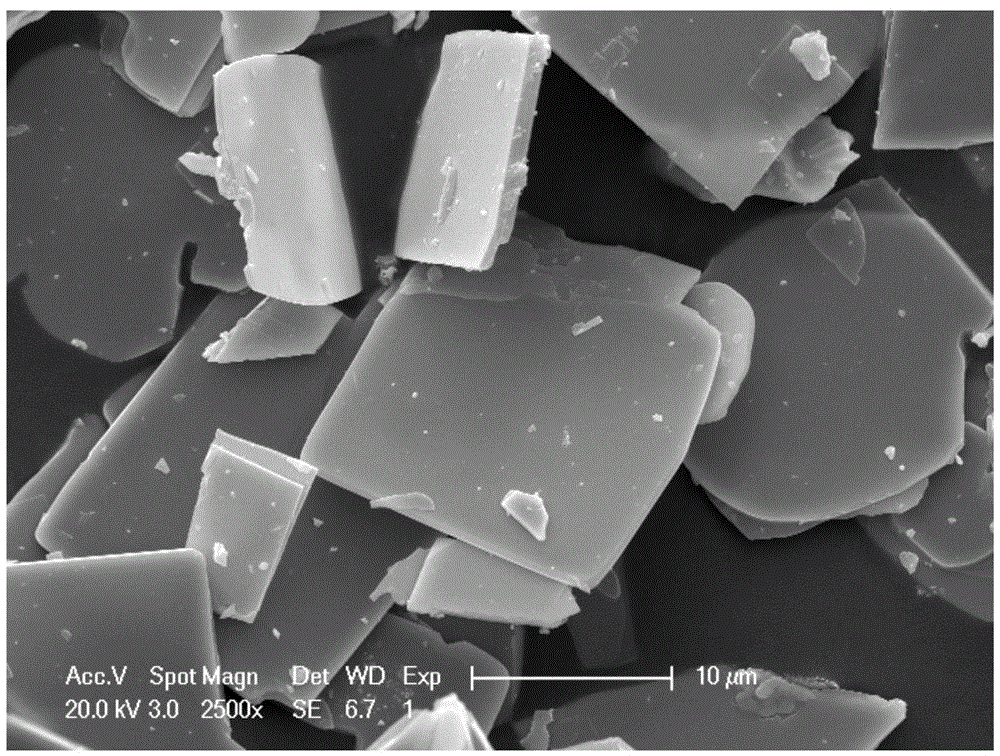

Method for synthesizing flaky sodium niobate powder with large length-diameter ratio

The present invention relates to a method for synthesizing flaky sodium niobate powder with a large length-diameter ratio. The method comprises the following steps of preparing flaky Bi2.5Na3.5Nb5O18 powder from Bi2O3, alkali metal carbonate and Nb2O5 as raw materials in the presence of NaCl as molten salt by virtue of a molten-salt growth method, then placing flaky Bi2.5Na3.5Nb5O18 powder into a nylon barreling pot, adding zirconium oxide balls and anhydrous ethanol, barreling and then pre-sintering with NaCl molten salt, raising the temperature to the synthesis temperature, maintaining the temperature and cooling to obtain a powder mixture containing NaNbO3; finally cleaning the powder mixture containing NaNbO3 to obtain flaky sodium niobate powder with the large length-diameter ratio. Compared with a template prepared from Na2CO3 as a raw material, the template prepared from flaky sodium niobate powder disclosed by the invention is more uniform, larger in size and smaller in thickness and mainly used for preparing a lead-free piezoelectric textured ceramic, and the template with a large length-diameter ratio is more conductive to improving the texture degree and piezoelectric properties of the ceramic and is important significance of promoting the research on the lead-free piezoelectric ceramic.

Owner:TONGJI UNIV

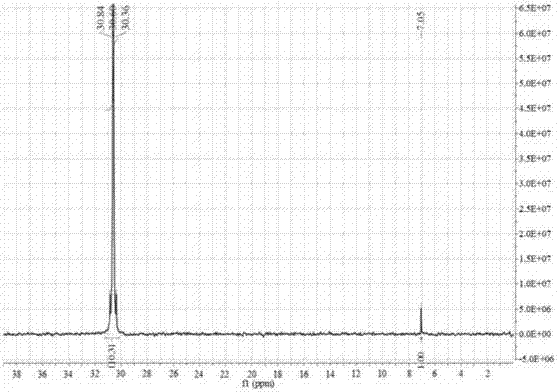

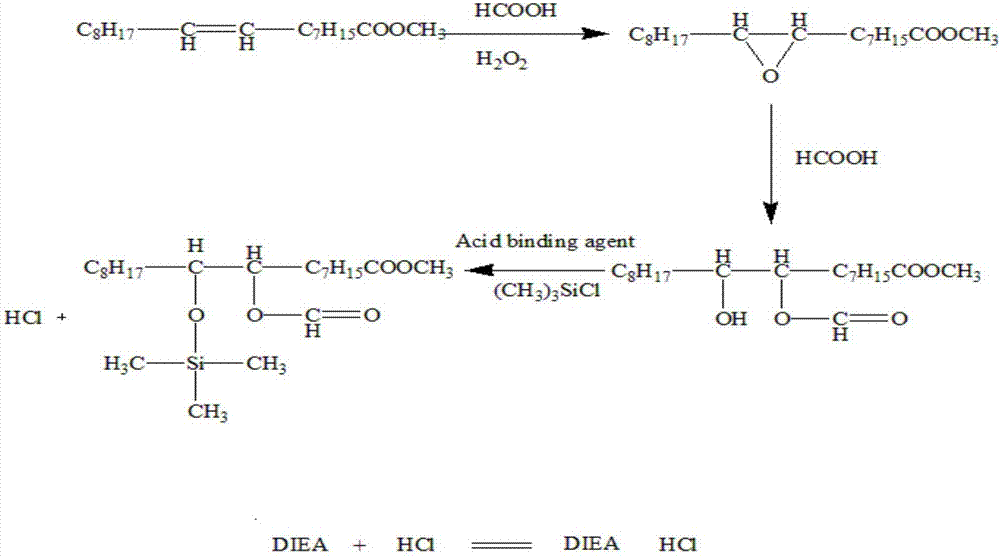

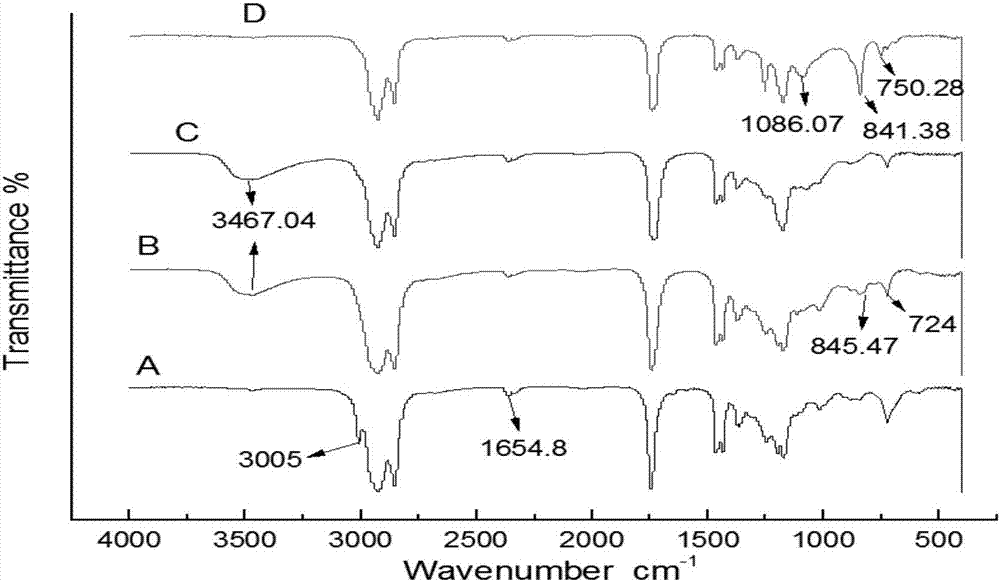

Method for preparing silicon-based biolubricant base oil from organosilicon modified fatty acid ester

The invention provides a method for preparing silicon-based biolubricant base oil from organosilicon modified fatty acid ester. The method comprises the following specific steps: mixing fatty acid ester with organic acid and a catalyst and adding the mixture into an epoxidation reaction kettle, dropwise slowly adding an oxidizing agent, reacting, standing for layering, fetching a supernatant liquid and distilling to obtain epoxidized aliphatic ester; carrying out a ring-opening reaction between epoxidized aliphatic ester and organic acid, washing to neutral level after the reaction and carrying out reduced pressure distillation to obtain a ring-opening product; stirring the ring-opening product and heating to reaction temperature, dropwise adding organosilicon and an acid binding agent according to requirements and carrying out a silylation reaction, directly carrying out reduced pressure distillation after the reaction, and separating a solid to obtain the silicon-based biolubricant base oil. By the above method, the disadvantage that biolubricant base oil produced by existing technologies has poor oxidation stability and poor viscosity-temperature characteristic is overcome. The production process is environment-friendly, and energy consumption is low. The industrial acid binding agent used in the method is low-cost such that cost of the product is reduced.

Owner:NANJING UNIV OF TECH

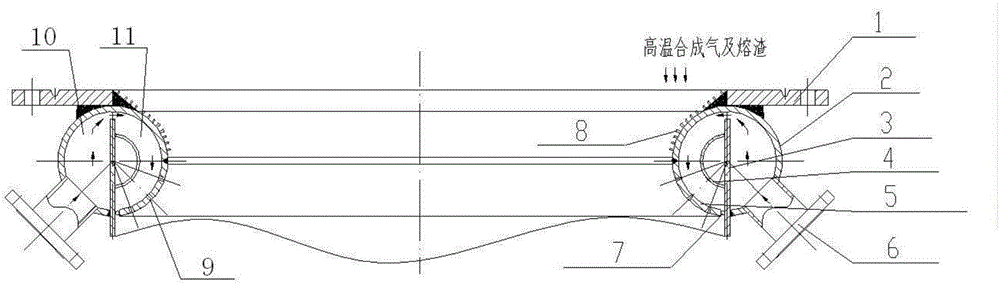

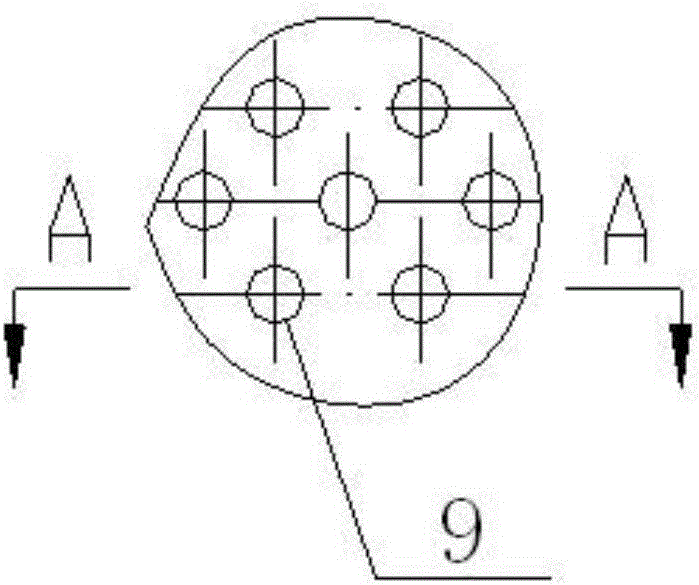

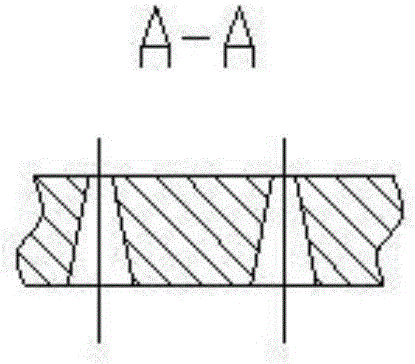

Gasification furnace chilling ring

ActiveCN106635182ALow costSimple preparationCombined combustion mitigationCombustible gas productionWater channelSlag

The invention discloses a gasification furnace chilling ring, comprising an annular fixing plate, a channel ring, a distance ring, an inner ring, a distribution ring and a plurality of chilling water inlet pipes, wherein the channel ring is fixed at the bottom of the annular fixing plate, the distribution ring is provided with a plurality of spraying holes arrayed in a staggered way; the distance ring is arranged in the middle of the channel ring and divides the channel ring into a channel chamber on the outer side and a distribution chamber on the inner side, the bottom of the distance ring is in butt joint with a downcomer of a gasification furnace, the height of the distance ring is adjustable, a chilling water channel is formed between the top of the distance ring and the inner wall of the top of the channel ring, and a plurality of fixed-distance steel balls for controlling an annular space between the distribution ring and the distance ring are arranged between the distribution ring and the distance ring; the inner ring has a semi-pipe structure and is fixed on the distance ring, the inner ring is located in the distribution chamber, and the inner ring is provided with a plurality of holes for liquid passing and ventilating; the plurality of chilling water inlet pipes are arranged on the lower outer side of the channel ring and are communicated with the channel chamber; the upper surface of the inner side of the channel ring is evenly provided with a plurality of slag nails, and a refractory material is applied among the slag nails.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

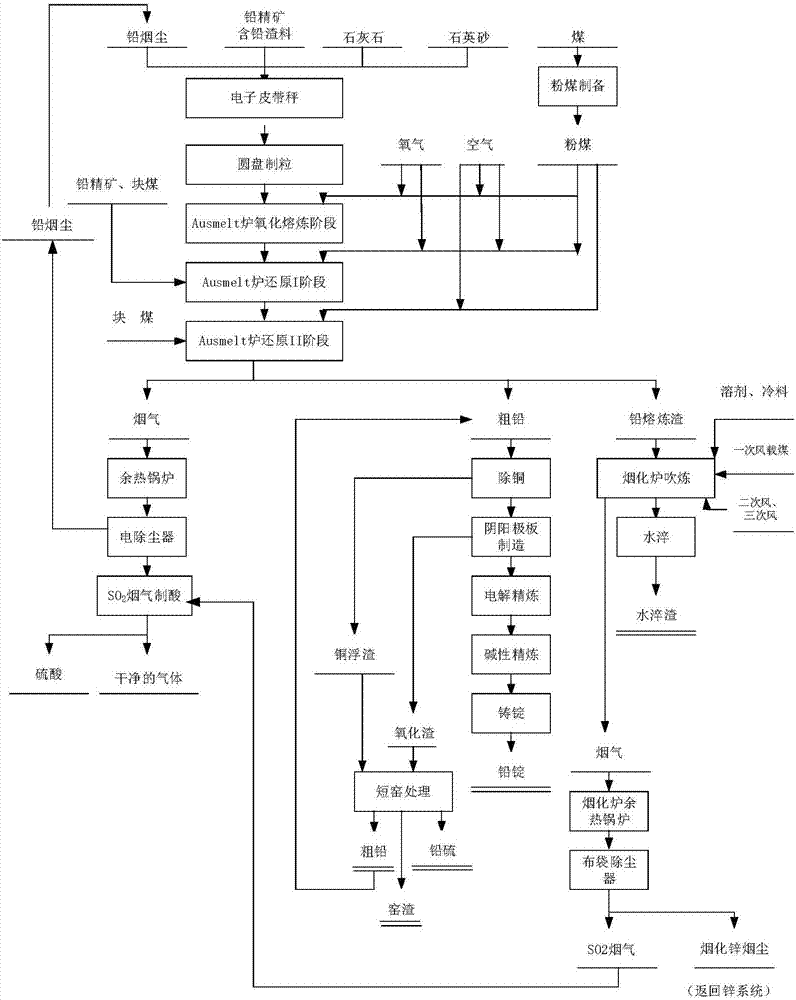

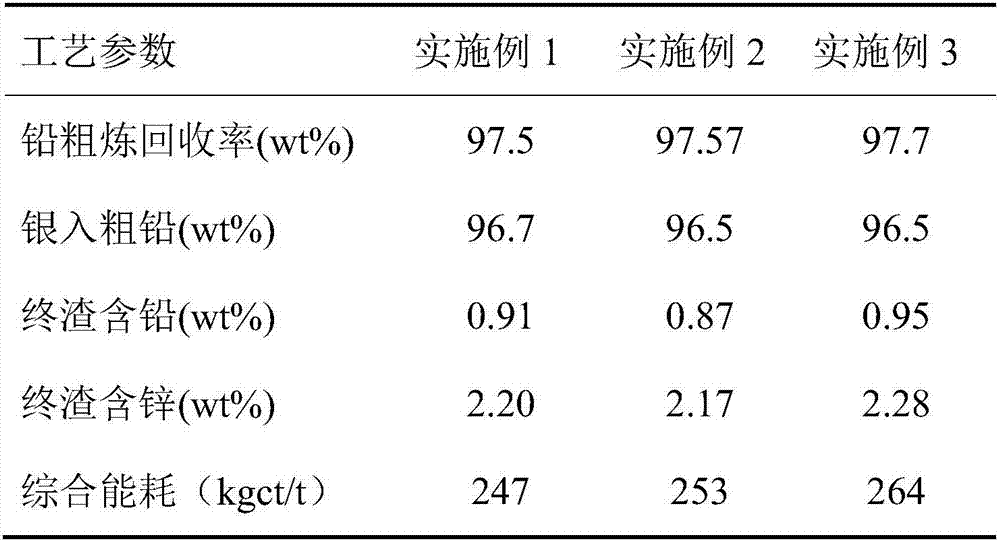

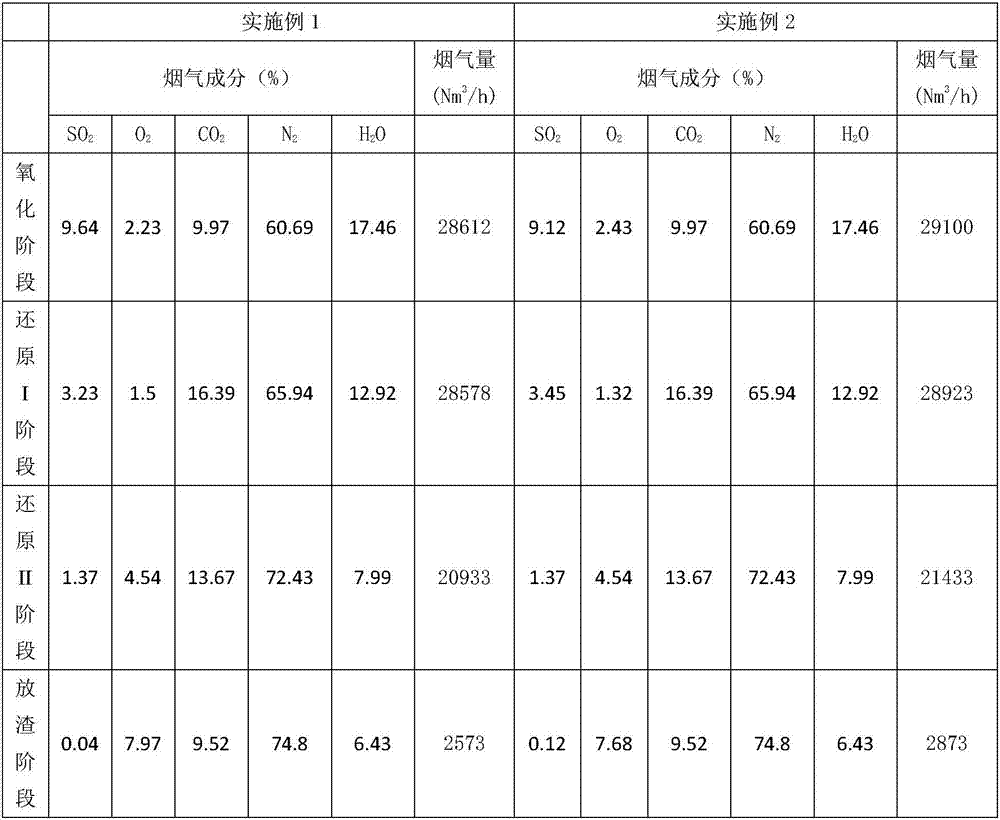

Lead concentrate processing technology

ActiveCN106893871AAdaptableSimple preparationProcess efficiency improvementMaterials preparationLead smelting

The invention discloses a lead concentrate processing technology. The lead concentrate processing technology comprises an oxidization smelting step carried out in an Ausmelt furnace, a reduction smelting step I, a reduction smelting section II, and a fuming step carried out in a fuming furnace. The lead concentrate processing technology is high in raw material adaptability, and simple in material preparation process; after the mixture is pelletized and fed into the furnace, the quantity of powder dust taken away by the fume discharged from the furnace can be obviously decreased, and as a result, the fume dust rate can be reduced; a traditional lead sintering process is removed, so that the low-level pollution caused by powder dust and SO2 fume can be removed, and as a result, the operation environment can be effectively improved; the Ausmelt furnace used for lead smelting and fuming furnace for fuming are combined, so that the technological processes are reduced; the equipment investment is saved; the energy consumption is low; and the lead recovery rate is high; in addition, furnace bodies used in the technology are sealed, so that the fume leakage is small, and as a result, the working environment is optimized; the fume produced in the smelting step and the fuming step can be effectively separated; as the fume in the Ausmelt furnace and the fume in the fuming furnace are mixed, and the SO2 content can reach the acid making requirement, and thus a good condition is provided to the acid making technology.

Owner:呼伦贝尔驰宏矿业有限公司

Chinese patent medicine for treating astenia wind-heat syndrome and preparing method

ActiveCN1850225AShort course of treatmentQuick resultsUrinary disorderAluminium/calcium/magnesium active ingredientsForsythiaNephritis

The present invention relates to a Chinese patent medicine for effectively curing nephritis. It is made up by using 14 Chinese medicinal materials of imperata root, forsythia fruit, schizonepeta, apricot kernel, areca husk, poria and others through a certain preparation process.

Owner:LIAONING HUANREN PHARMA

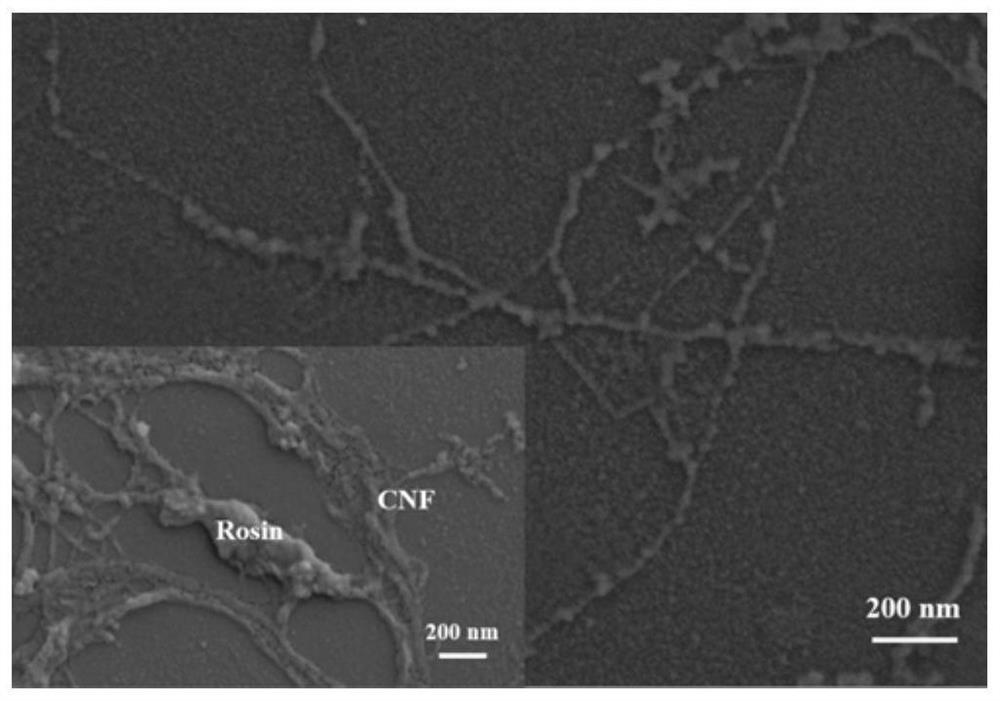

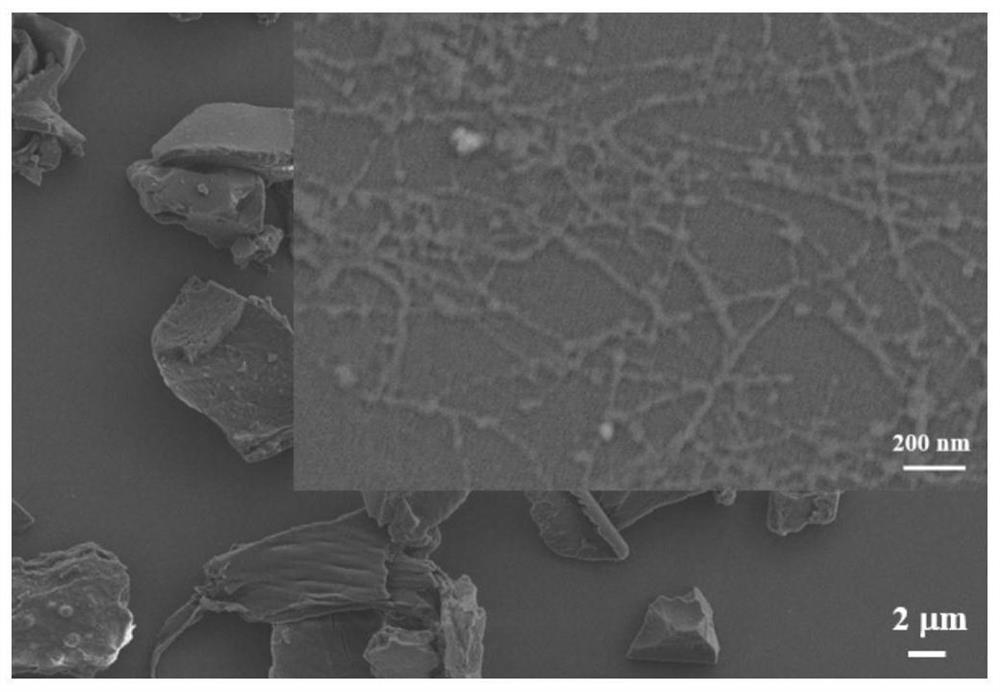

Preparation method of nano cellulose with antibacterial property

The invention provides a preparation method of nano cellulose with antibacterial property. According to the method, impurities such as lignin and hemicellulose pectin in natural biomass are removed by utilizing a hydrogen peroxide thermal oxidation treatment technology, and meanwhile, 1->4 glucosidic bonds among amorphous beta-d-glucose rings in cellulose molecular beams are broken, so that the nanocellulose with the diameter within a nano range is prepared. Meanwhile, part of hydroxyl in the cellulose is oxidized into carboxyl. Due to the fact that the surface of the cellulose has a large number of functional groups, antibacterial components contained in the biomass can be grafted to the surface of the nanocellulose through intermolecular force, hydrogen bonds or covalent bonds, and the nanocellulose is endowed with antibacterial performance. The nano cellulose prepared by the method has excellent antibacterial performance and good organic solvent dispersion stability; and the preparation process is simple, green, pollution-free, low in cost and beneficial to industrialization. The material has a wide application prospect in the field of antibacterial composite materials.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com