Preparation method of high-heat explosive containing cerium hydride

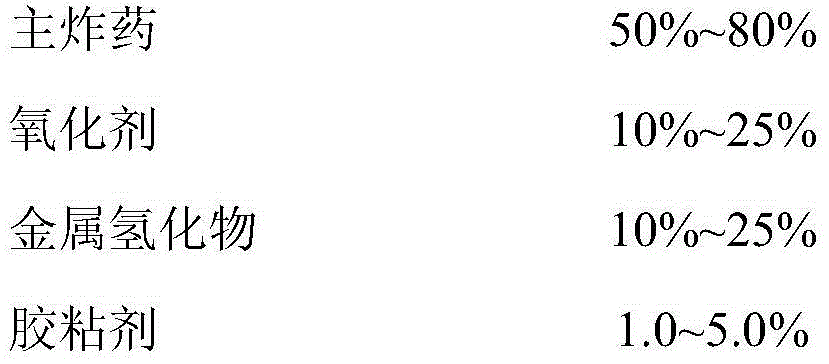

A high-calorie, explosive technology, used in nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, ammonium perchlorate compositions, nitroalkane compositions, etc. Energy requirements and other issues, to achieve the effect of easy control, simple production process, low production cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dry granulation process to prepare high-calorie explosives, the formula ratio is RDX:AP:CeH 3 : polyazide glycidyl ether = 50: 25: 22: 3, the steps are as follows: weigh RDX, coated AP, and coated CeH according to the formula ratio 3 , polyazidoglycidyl ether; the mixture in (1) is added in the capacious vessel; Add 2.5% adhesive to the vessel containing the mixture, make it moist, knead evenly by dry method, and make a medicine group; ( 3) Squeeze and granulate the drug group on a 10-mesh sieve. When the drug particles under the sieve volatilize a large amount of solvent, loosen them with copper chopsticks so that the inner layer solvent can volatilize; (4) Put the drug particles with dry surface into In a special aluminum or copper vessel, dry at 80°C for 8 hours under vacuum, with a vacuum degree of 0.06; (5) Mix the dried powder with 20-mesh undersize and 80-mesh oversize to obtain a mixed explosive. The density is 1.92g / cm 3 , the detonation velocity is 9960m / s, ...

Embodiment 2

[0028] Dry granulation process to prepare high-calorie explosives, the formula ratio is RDX:AP:CeH 3 : silicone rubber = 65:18:15:2, the steps are as follows: weigh RDX, coated AP, coated CeH according to the formula ratio 3 , silicone rubber; (2) add the mixture in (1) to a spacious container; add 2% adhesive to the container containing the mixture to make it moist, knead it evenly by dry method, and make a drug group; (3 ) Squeeze and granulate the drug group on a 10-mesh sieve. When the drug particles under the sieve volatilize a large amount of solvent, loosen it with copper chopsticks so that the inner layer solvent can volatilize; (4) put the drug particles with dry surface into special In an aluminum or copper vessel, dry at 40°C for 6 hours under vacuum, with a vacuum degree of 0.02; (5) Mix the dried pellets with 20-mesh undersize and 80-mesh oversize to obtain a mixed explosive. The density is 2.42g / cm 3 , the detonation velocity Dv=10080m / s, the highest detonation...

Embodiment 3

[0030] Dry granulation process to prepare high-calorie explosives, the formula ratio is HMX: acetone peroxide tetramer: CeH 3 : silicone rubber=65:18:15:2, the steps are as follows: weigh HMX, coated acetone peroxide tetramer, coated CeH 3 , silicone rubber; (2) add the mixture in (1) to a spacious container; add 2.3% adhesive to the container containing the mixture to make it moist, knead it evenly by dry method, and make a medicine group; (3 ) Squeeze and granulate the drug group on a 10-mesh sieve. When the drug particles under the sieve volatilize a large amount of solvent, loosen it with copper chopsticks so that the inner layer solvent can volatilize; (4) put the drug particles with dry surface into special In an aluminum or copper vessel, dry at 80°C for 8 hours under vacuum, with a vacuum degree of 0.08; (5) Mix the dried powder with 20-mesh undersize and 80-mesh oversize to obtain a mixed explosive. The density is 2.51g / cm 3 , the detonation velocity Dv=11100m / s, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com