Patents

Literature

646results about "Nitrated acyclic/alicyclic/heterocyclic amine explosive compositions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-toxic, heavy-metal free sensitized explosive percussion primers and methods of preparing the same

ActiveUS8206522B2Metal azide explosive compositionsMetal fulminate explosive compositionsEngineeringOxidizing agent

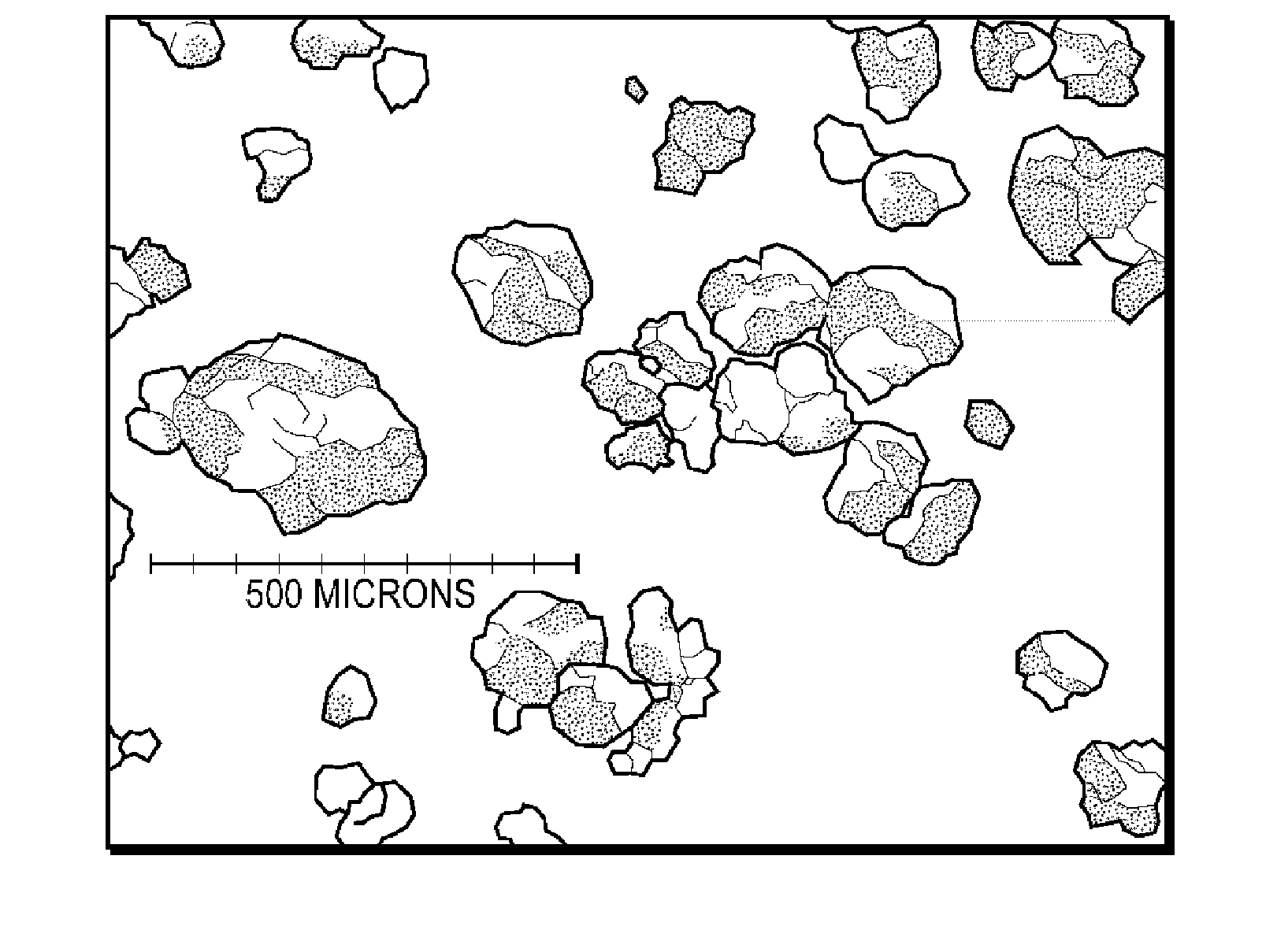

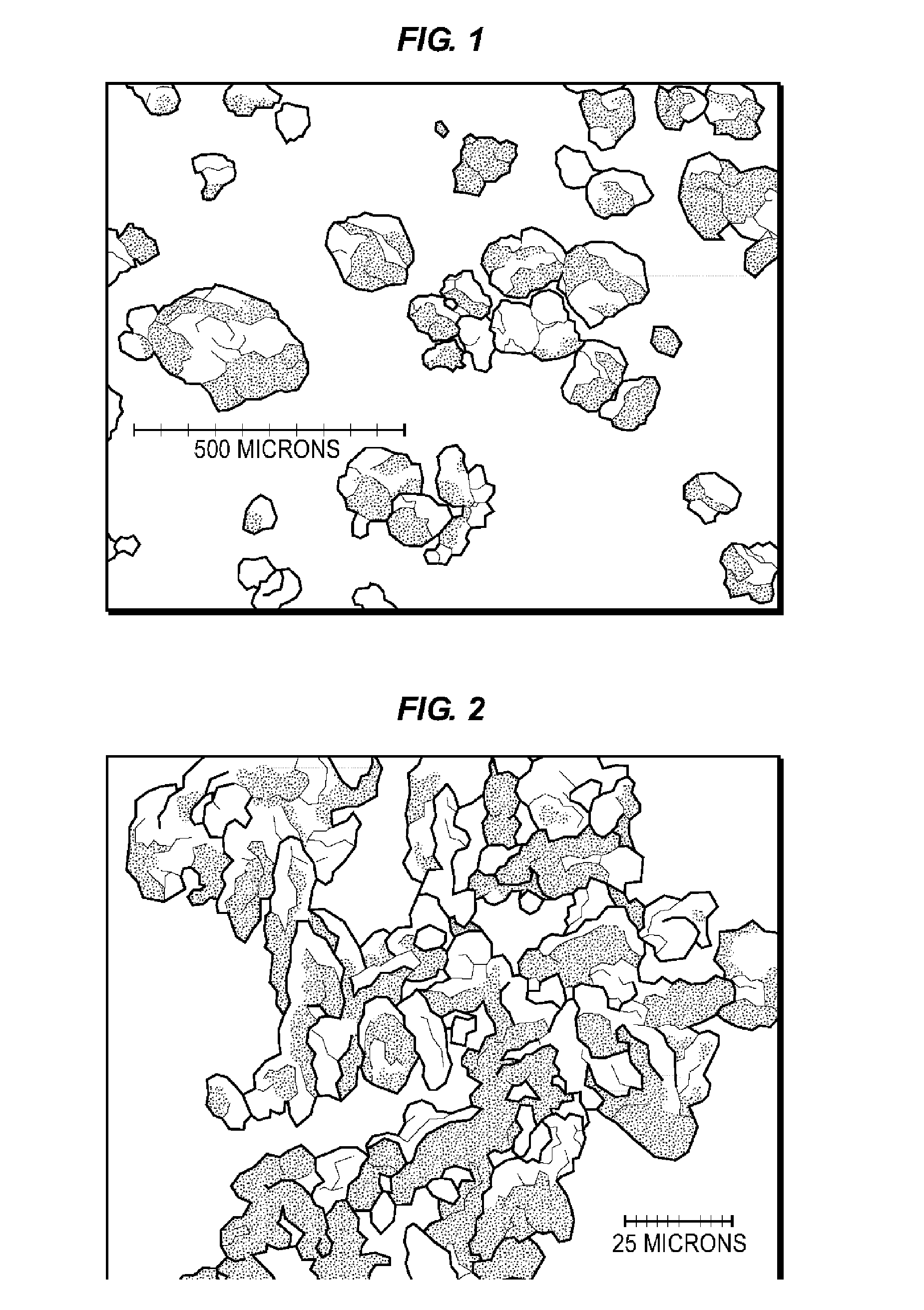

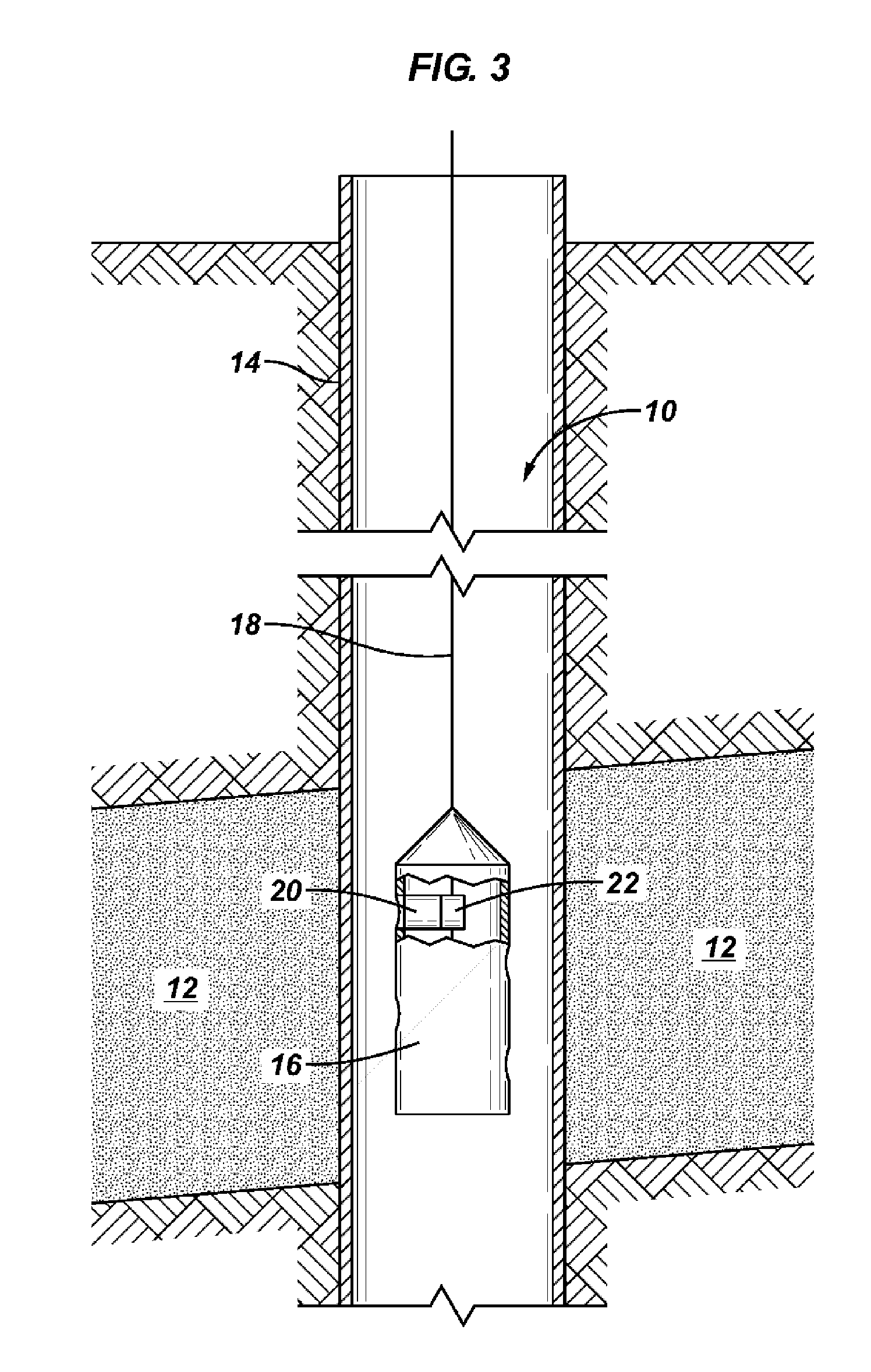

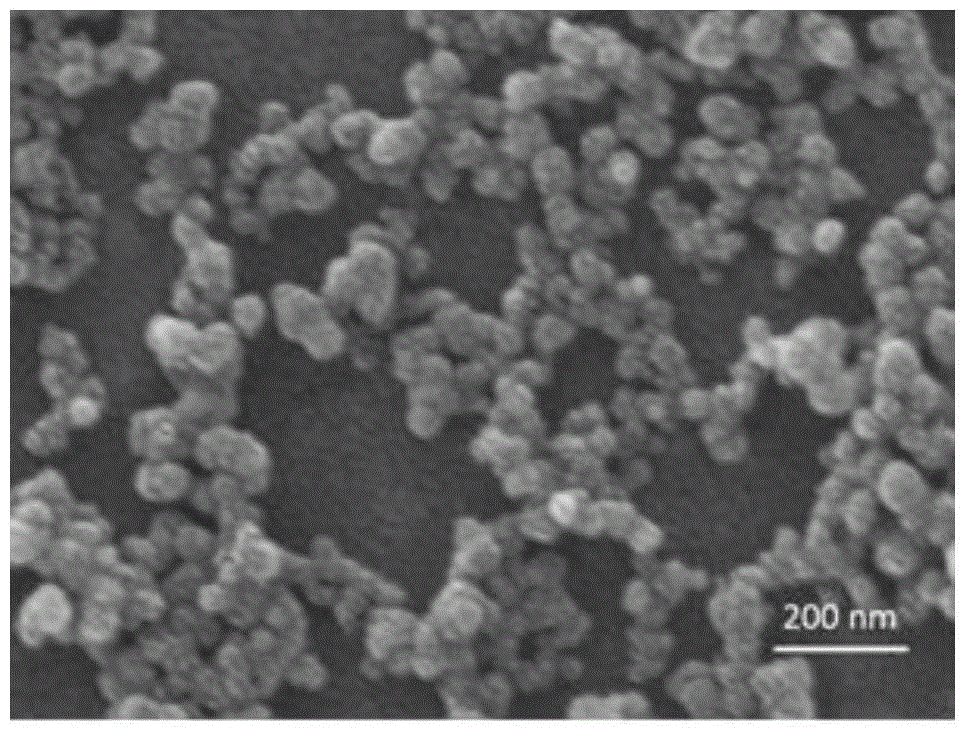

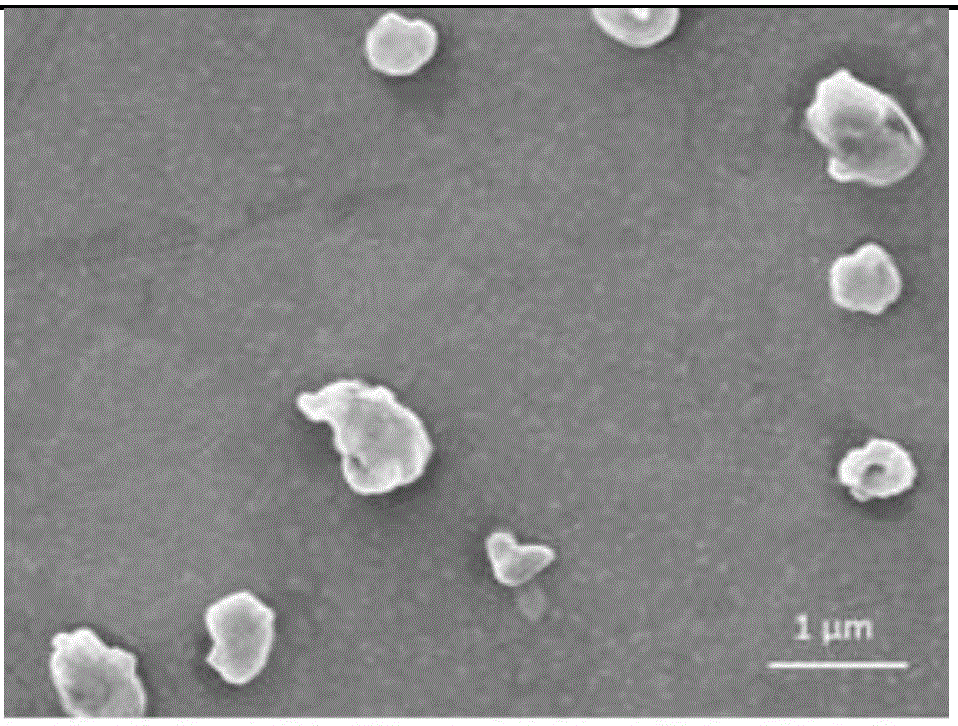

A non-toxic, non-hydroscopic percussion primer composition and methods of preparing the same, including at least one explosive component that has been traditionally considered a moderately insensitive explosive or secondary explosive, and at least fuel particle component having a particle size of about 1.5 microns to about 12 microns, which allows the use of moderately active metal oxidizers. The sensitivity of the primer composition is created by the interaction between the moderately insensitive explosive and the fuel agent such that traditional primary explosives such as lead styphnate or DDNP are not needed. The primer composition also eliminates the risks and dangers associated with traditional nano-sized fuel particles.

Owner:FEDERAL CARTRIDGE

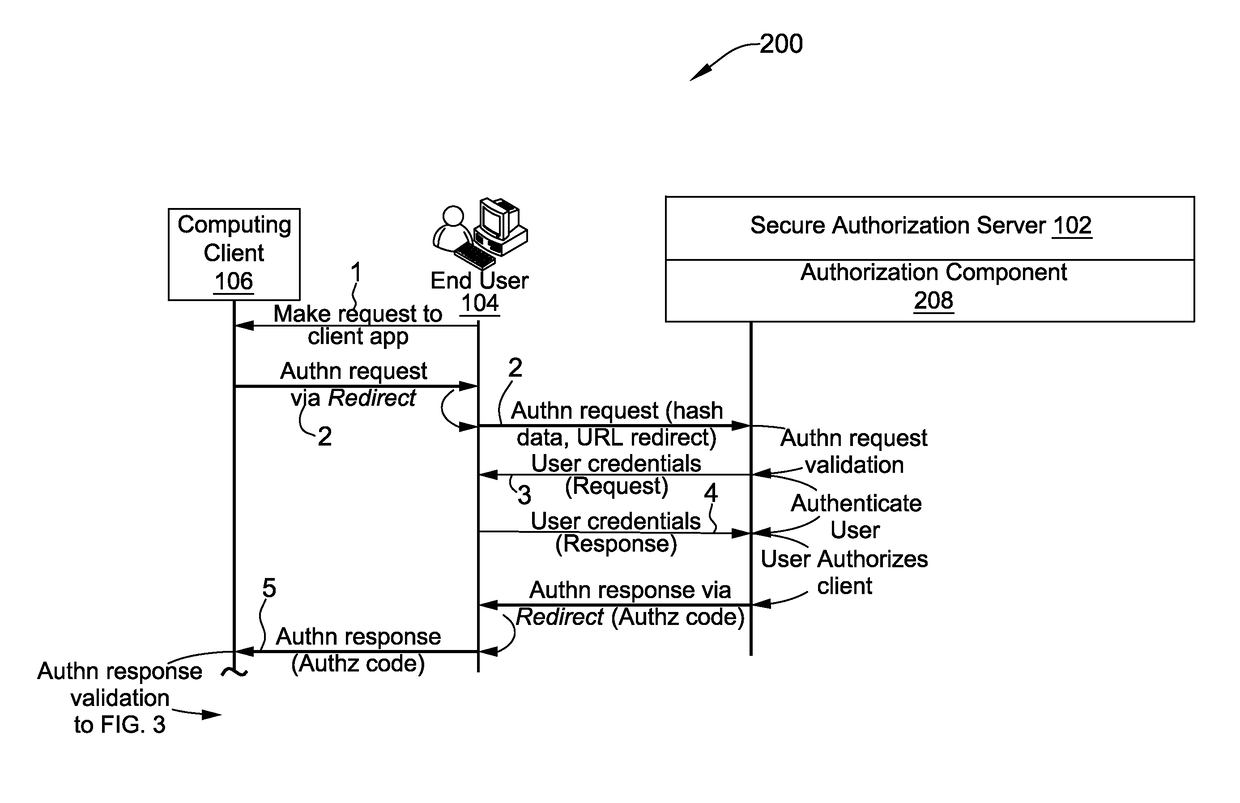

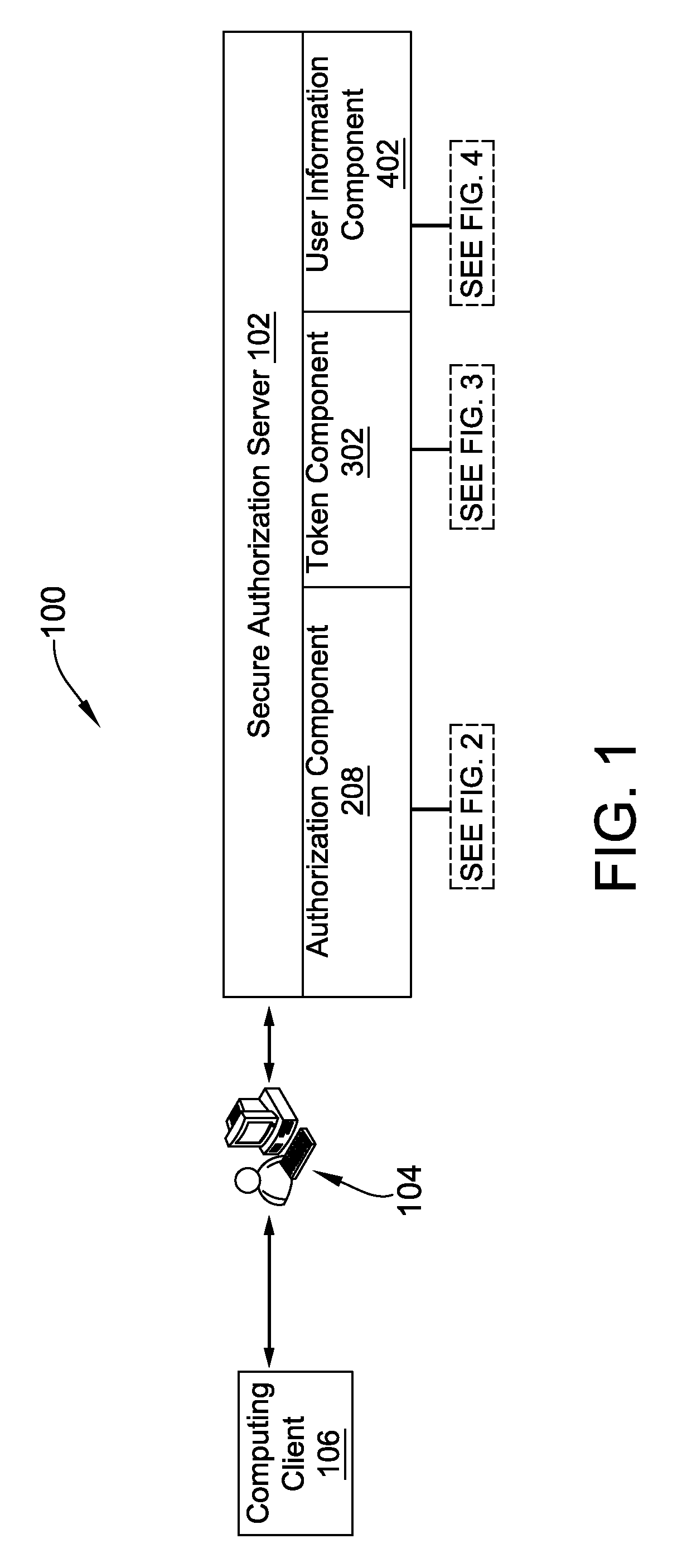

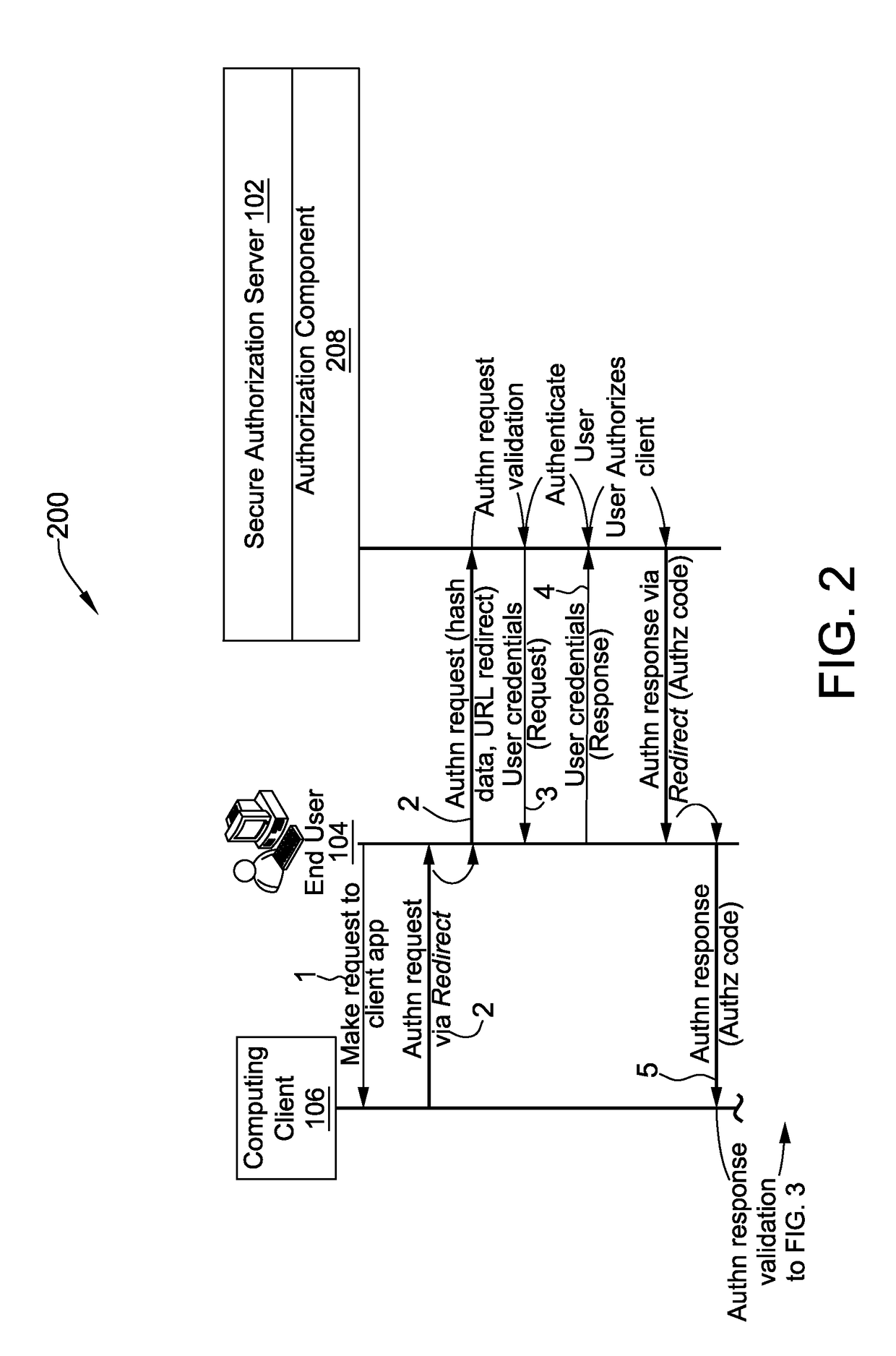

Systems and Methods for Authenticating an Online User Using a Secure Authorization Server

ActiveUS20170142108A1Computer security arrangementsNitrated aromatic explosive compositionsComputerized systemClient-side

A secure authorization server computer system for verifying an identity of an end-user is provided. The computer system is programmed to receive, from a computing client, an authentication request at an authorization component. The authentication request includes a secure authentication request identifier. The computer system is also programmed to validate the authentication request at the authorization component by validating the secure authentication request identifier. The computer system is further programmed to transmit an authentication response from the authorization component to the computing client. The authentication response includes an authorization code. The authorization code represents a validation of the authentication request.

Owner:MASTERCARD INT INC

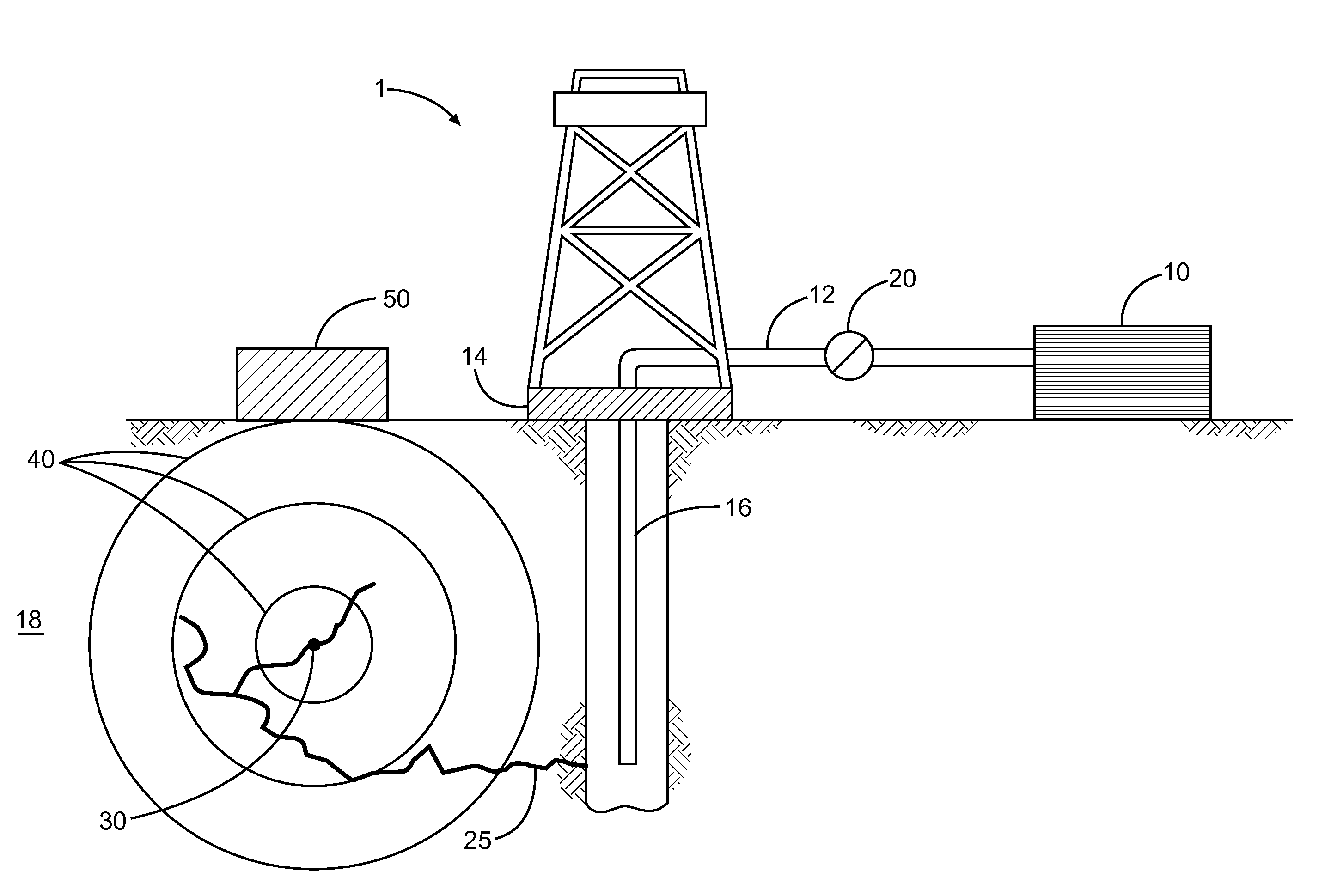

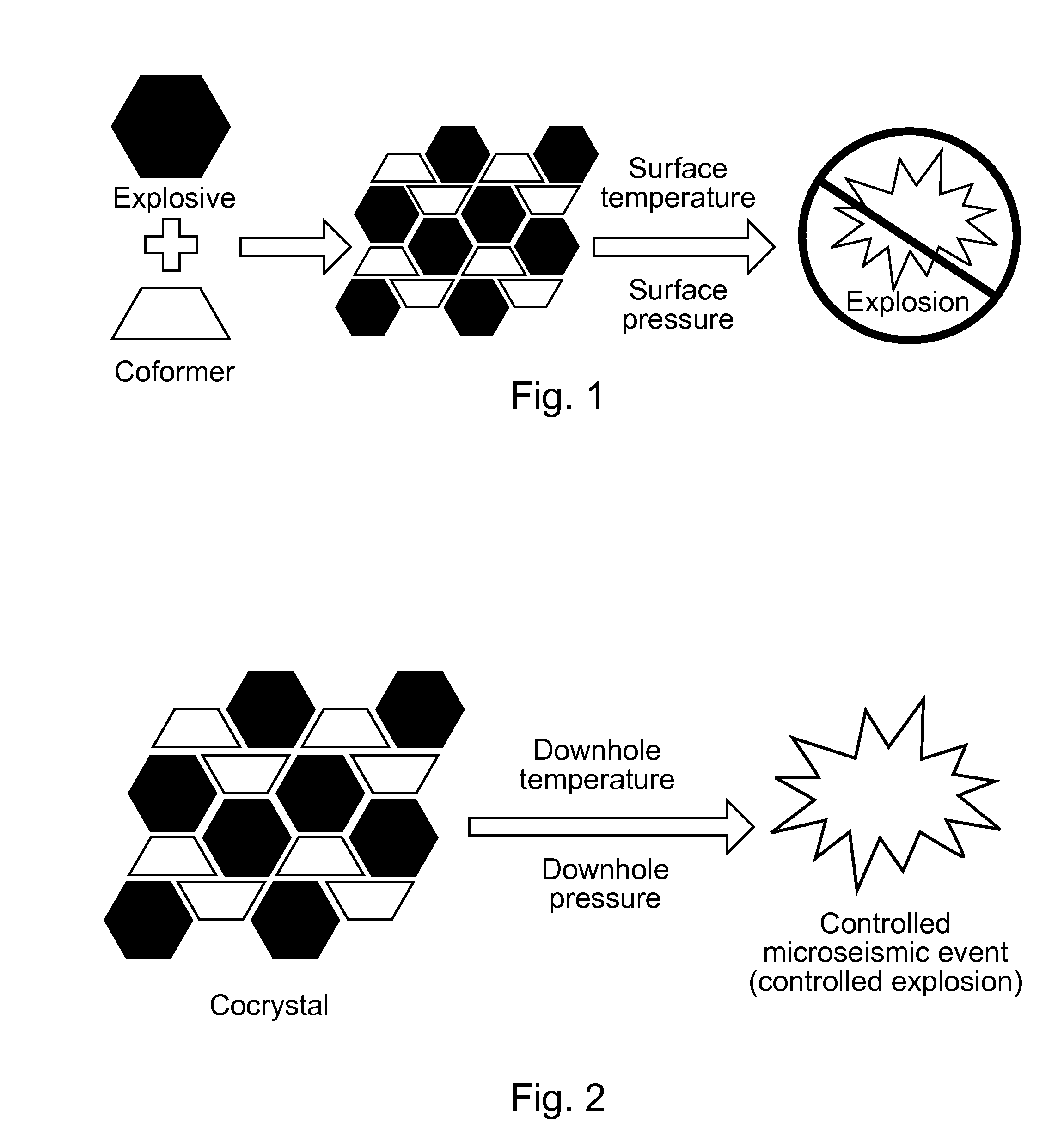

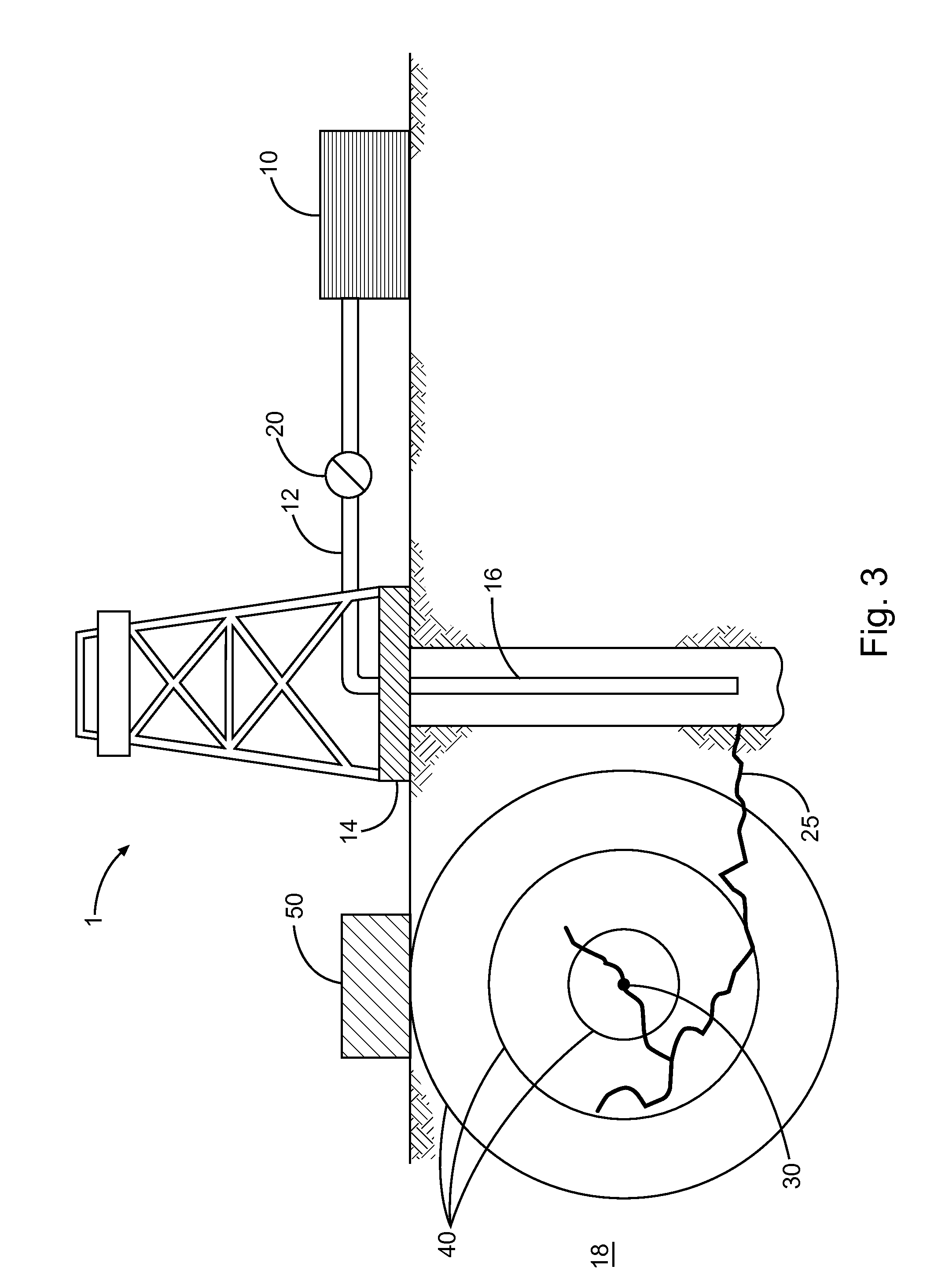

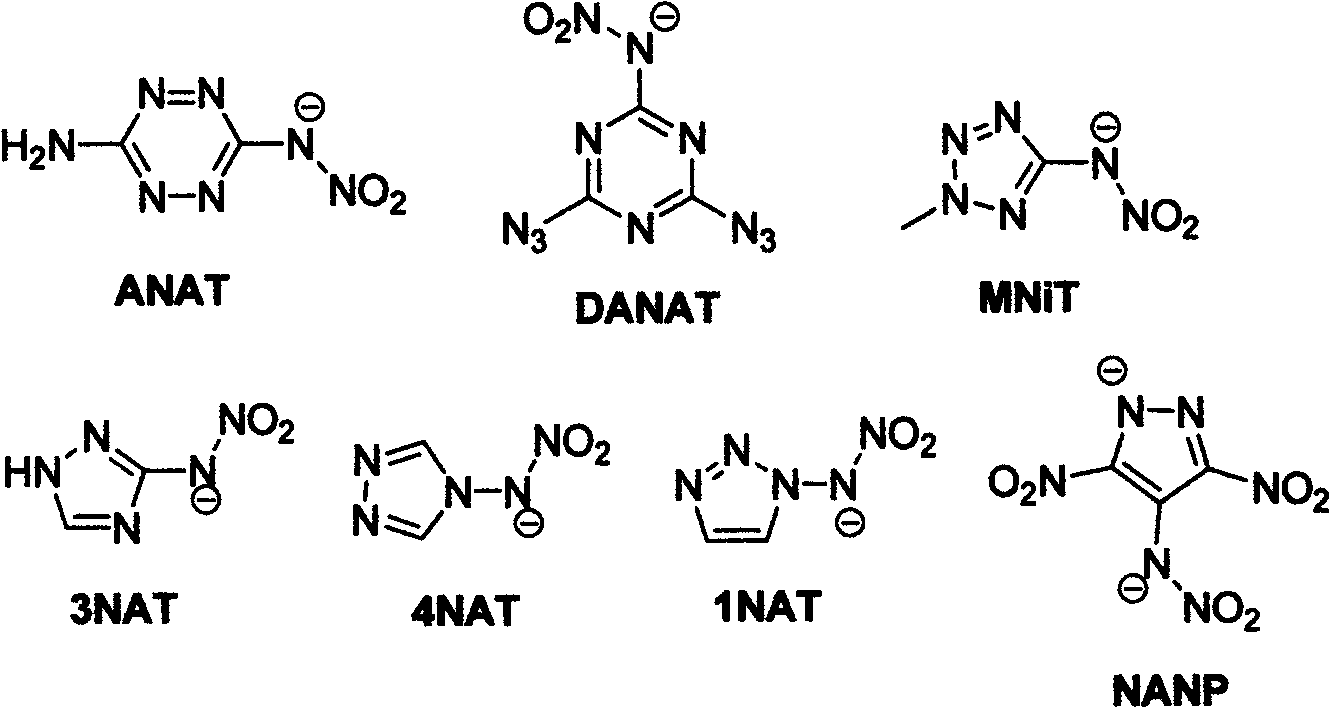

Energetic cocrystals for treatment of a subterranean formation

InactiveUS20160177698A1Well as to enableSafe handlingSurveyFluid removalChemistryHigh energy compound

The present invention relates to energetic cocrystals, and to methods for using the same for treatment of a subterranean formation. In various embodiments, the present invention provides a method of treating a subterranean formation, the method including obtaining or providing a composition including energetic cocrystals. Each energetic cocrystal independently includes an energetic compound and a secondary material. The method also includes placing the composition in a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

High energy insensitive press-fitting high polymer bonded explosive

ActiveCN107879867AHigh energyImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityAdhesive

The invention relates to a high energy insensitive press-fitting high polymer bonded explosive which is prepared from the following components in percentages by weight: 45-75% of main body explosive,5-20% of auxiliary explosive, 15-30% of metal fuel, 1-5% of an adhesive and 1-3% of an insensitive agent, wherein the main body explosive is TKX-50. In order to solve the existing problem that press-fitting PBX is not compatible in power properties and low vulnerability, a high energy insensitive explosive system is introduced. By adding the high energy insensitive main body explosive, the PBX formula has good power properties and low vulnerability. The detonation velocity of the explosive formula is greater than 7500m / s, the explosion heat is greater than 7500J / g, the power is greater than 1.85TNT (2,4,6-trinitrotoluene), and meanwhile, the friction sensitivity of the explosive formula is smaller than 20%, the impact sense is 0, and the explosive can pass examinations of low vulnerabilitytest items such as quick cook-off, slow cook-off and bullet impact.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

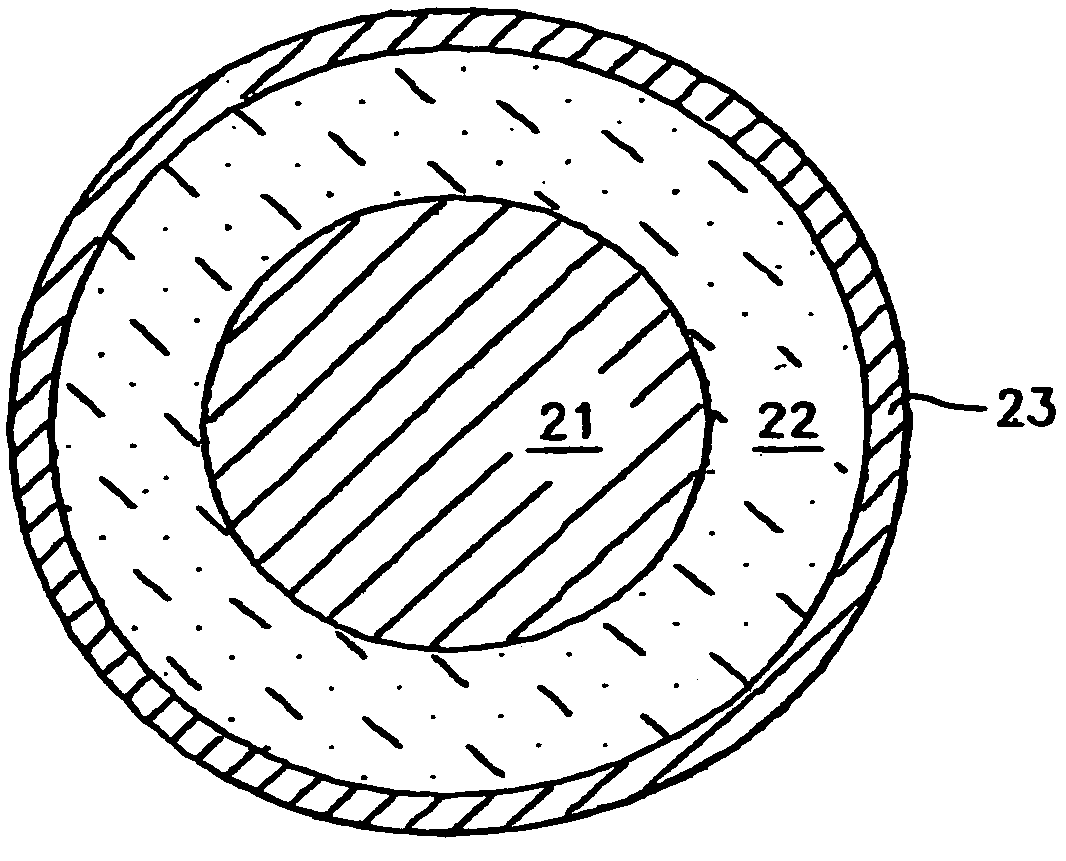

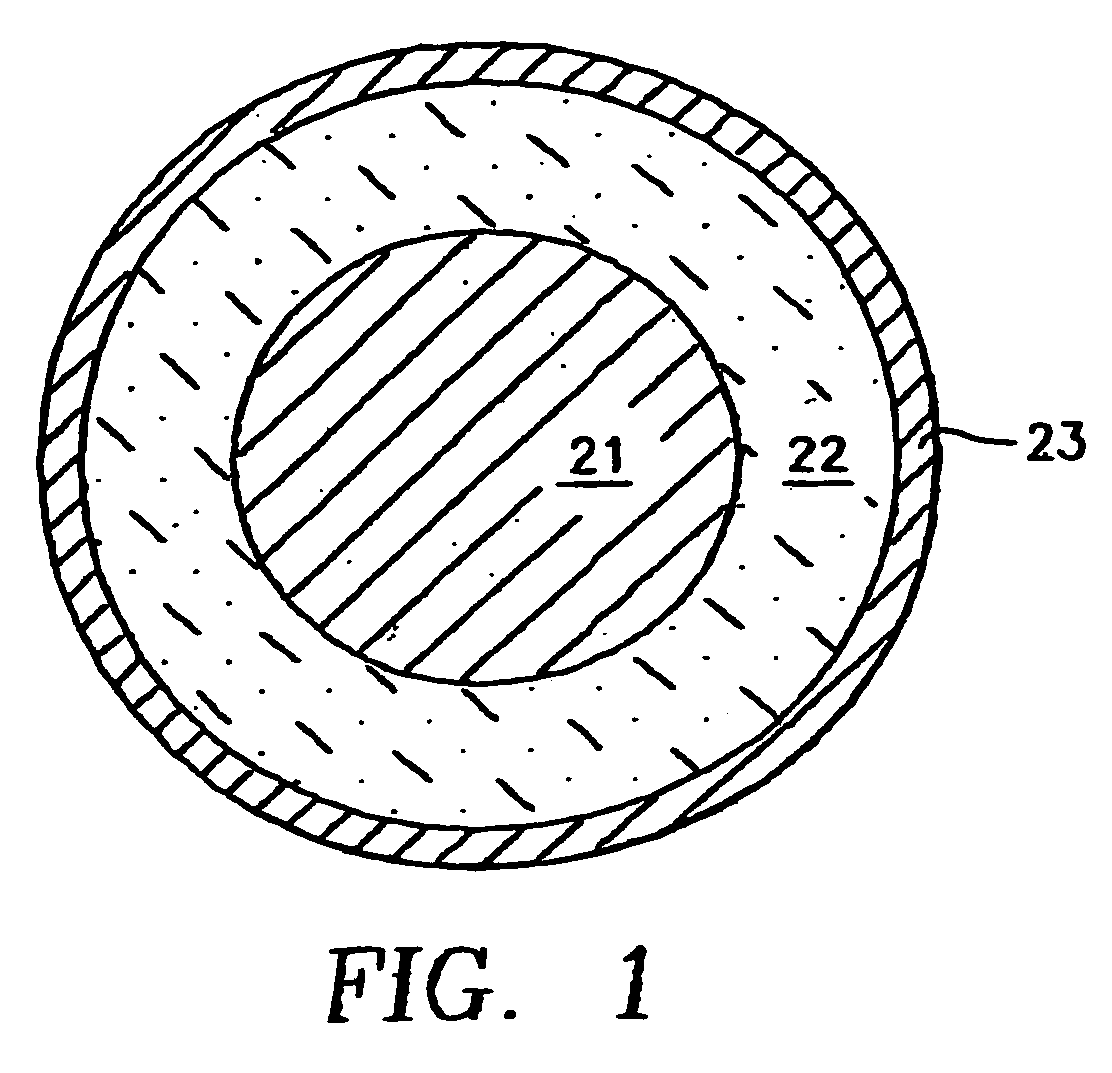

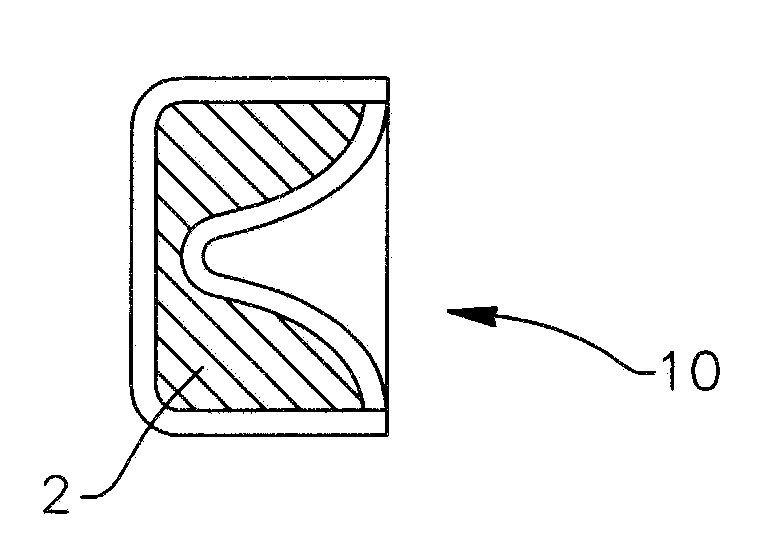

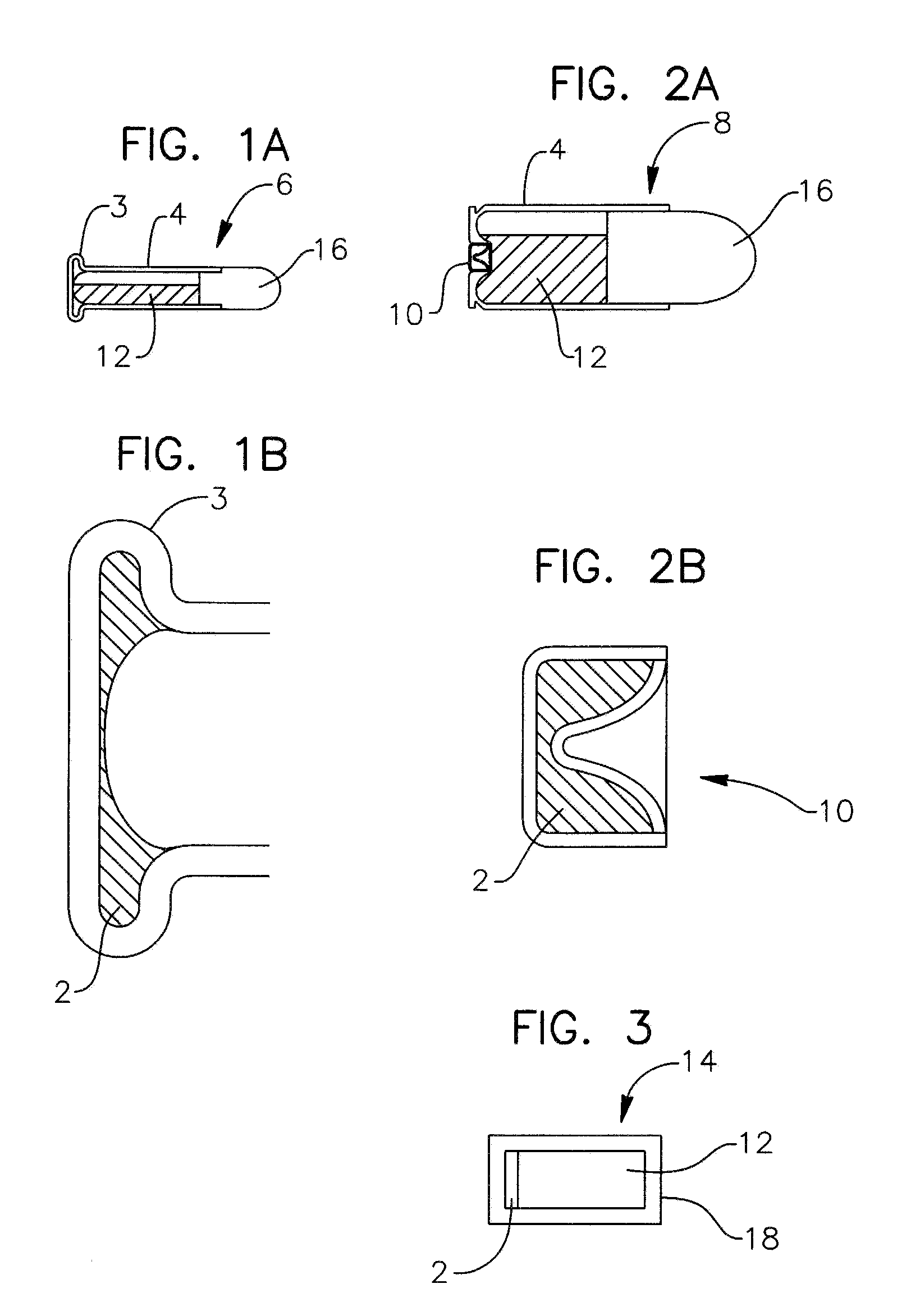

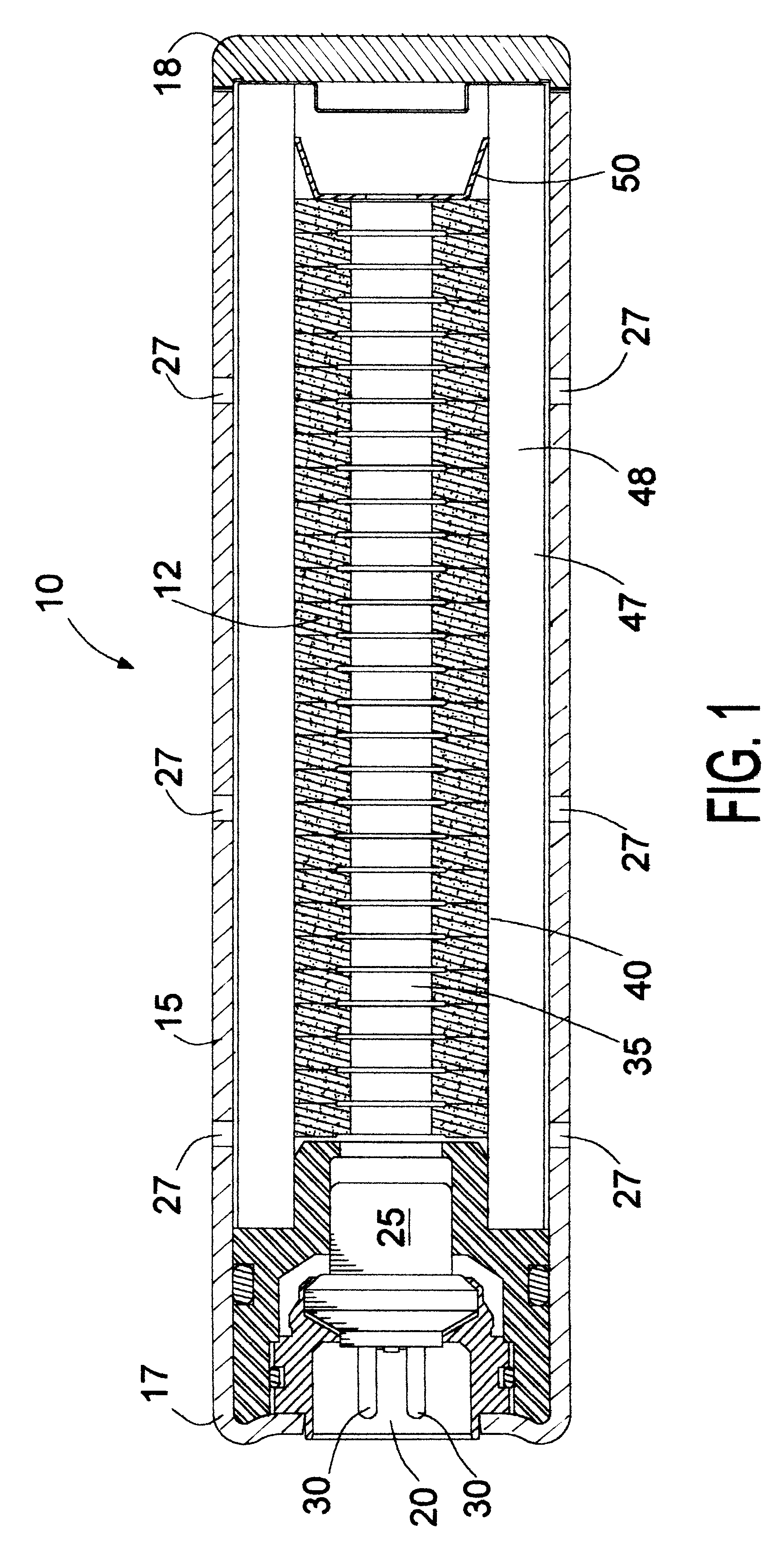

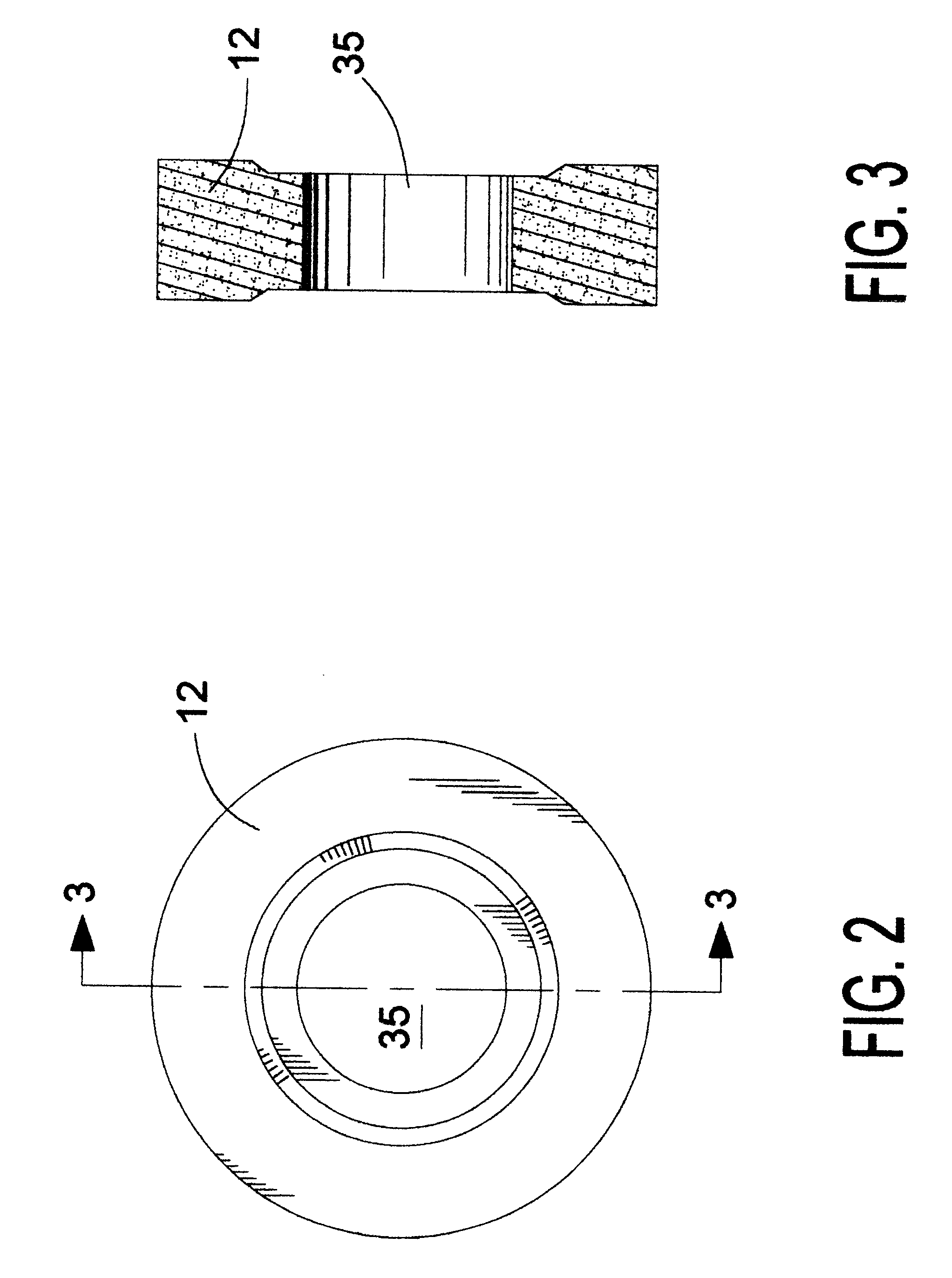

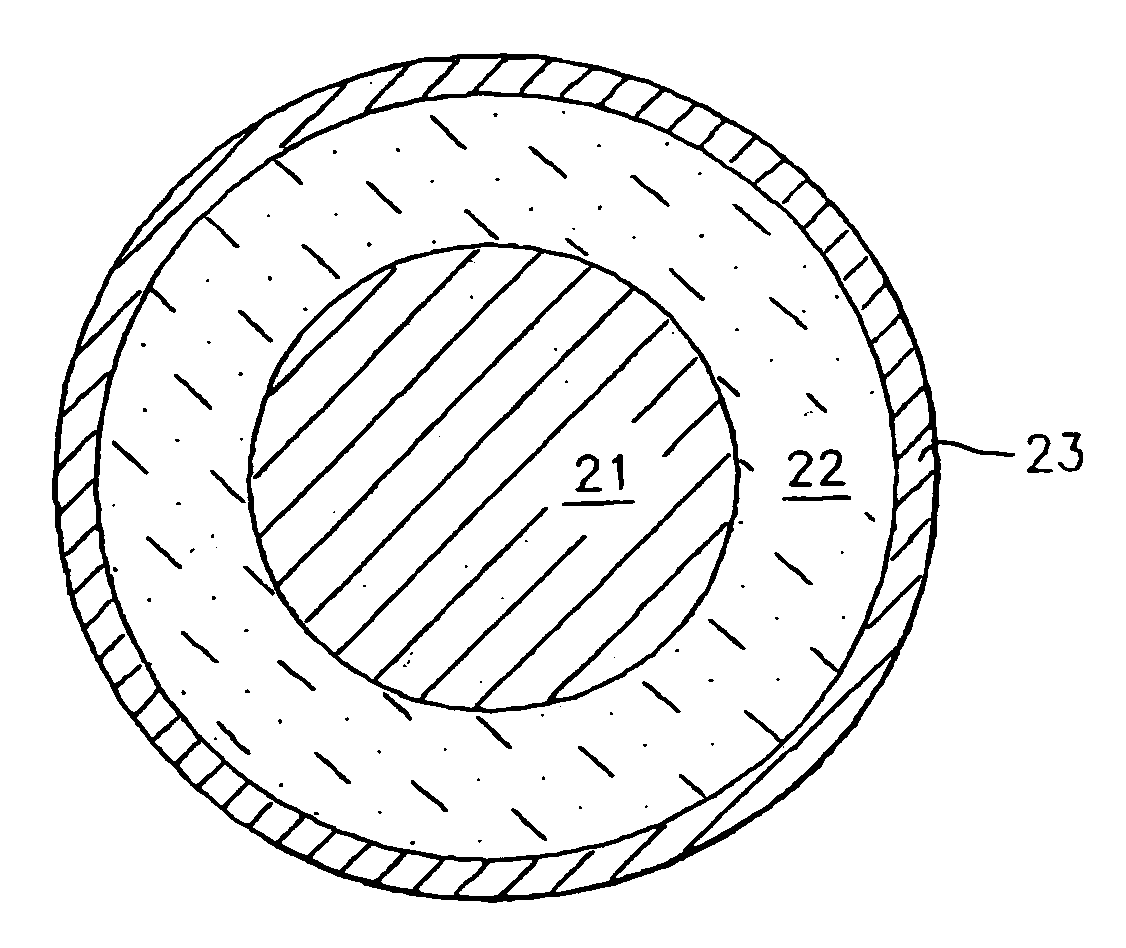

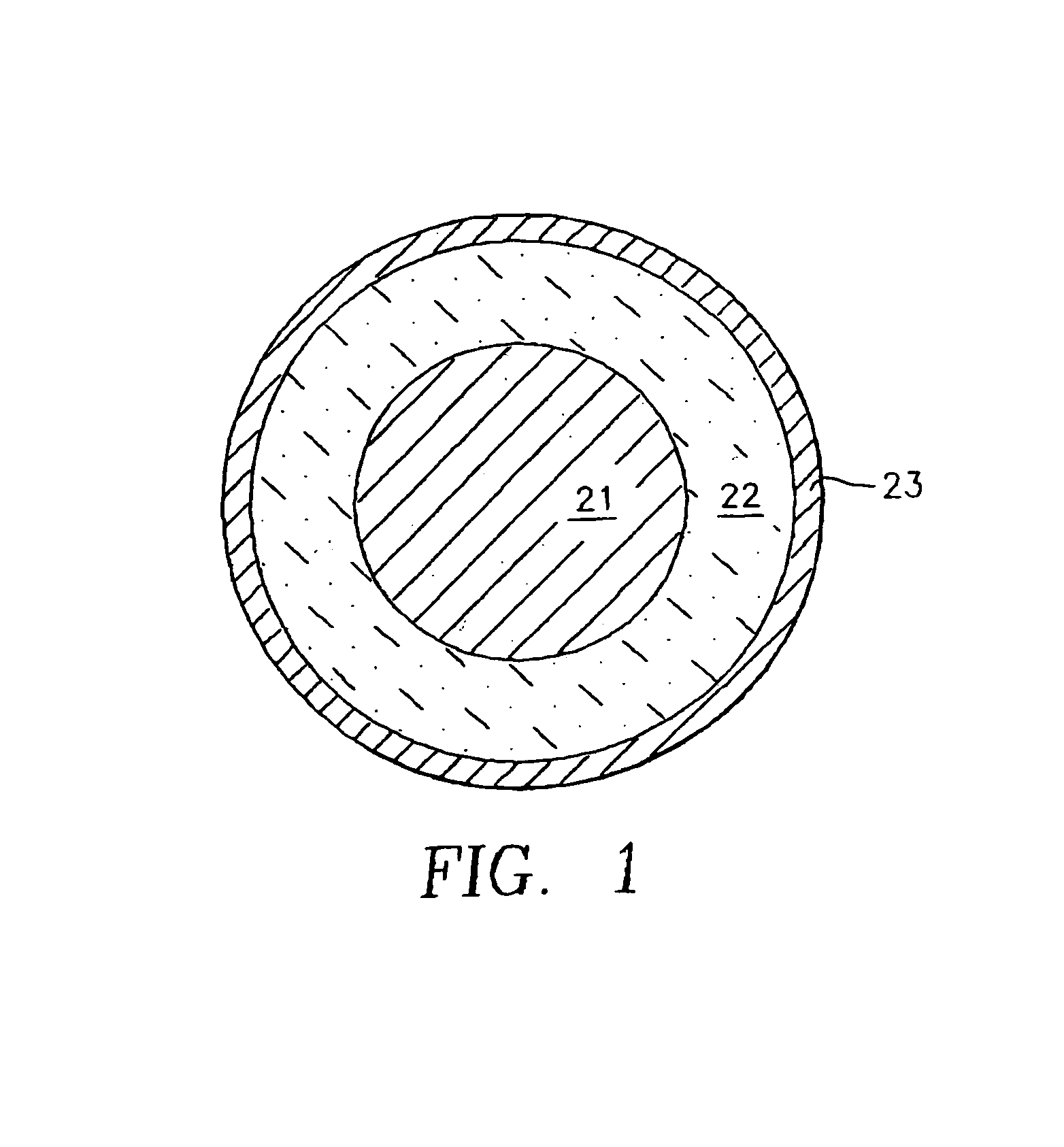

Advanced thermobaric explosive compositions

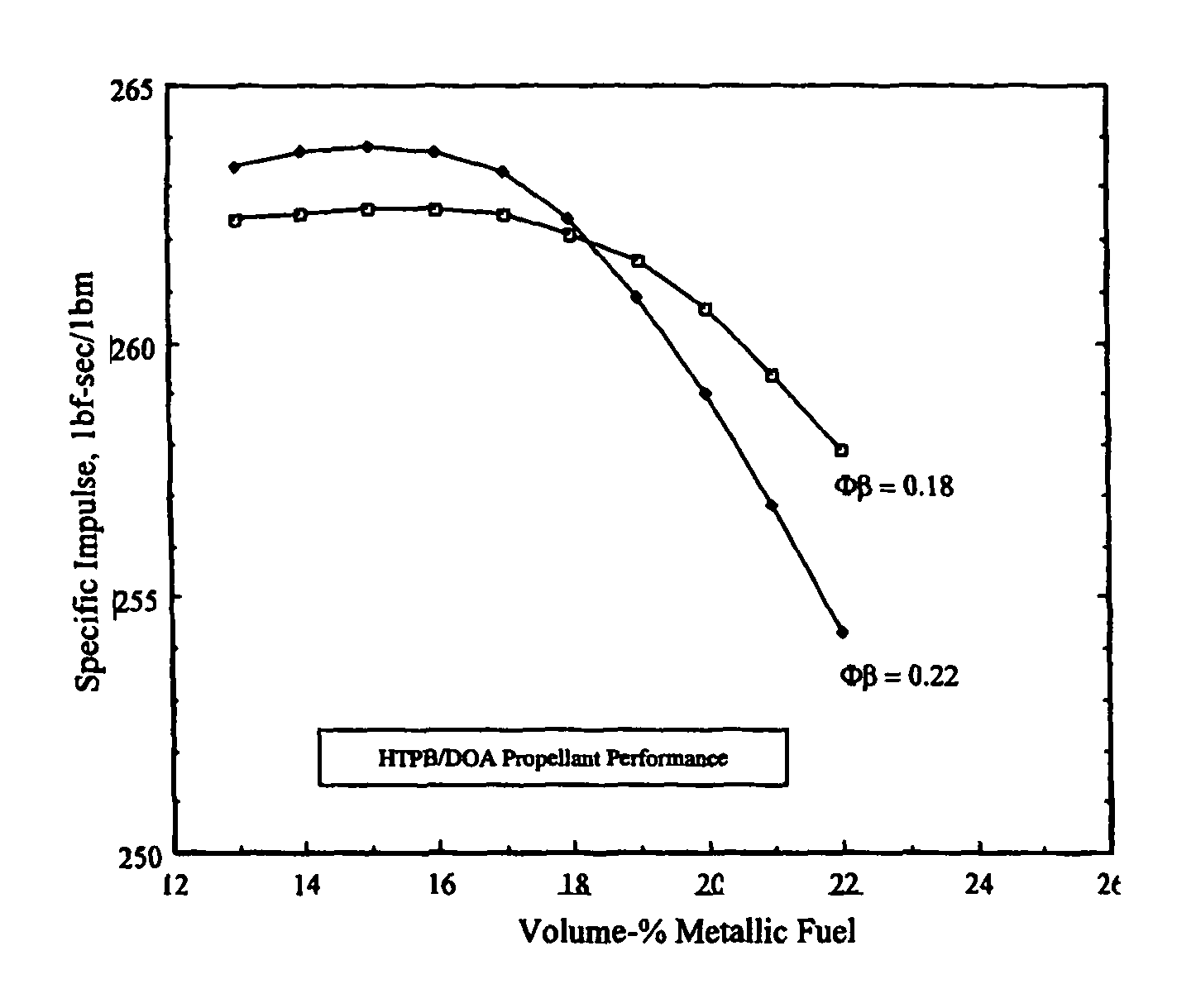

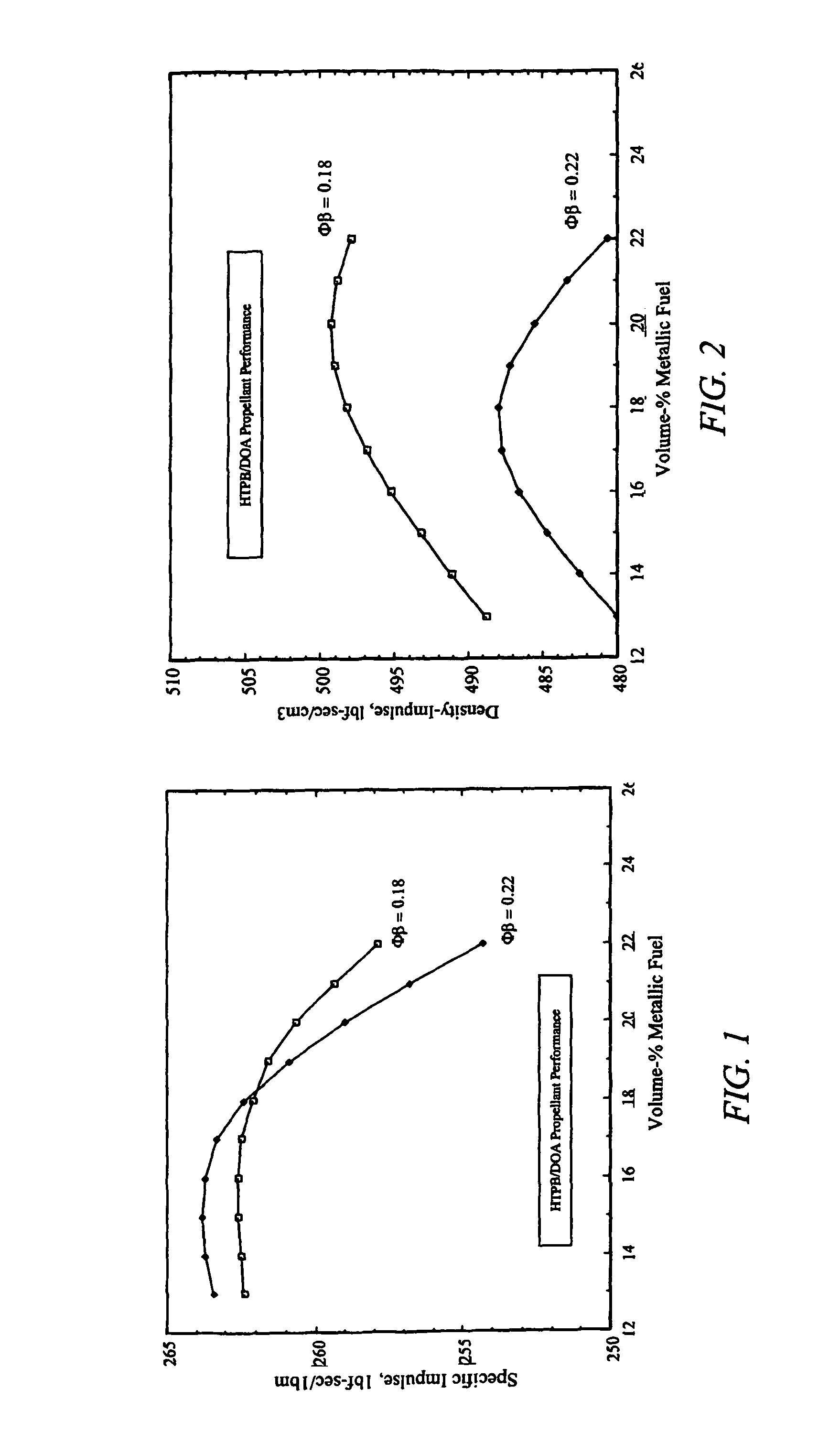

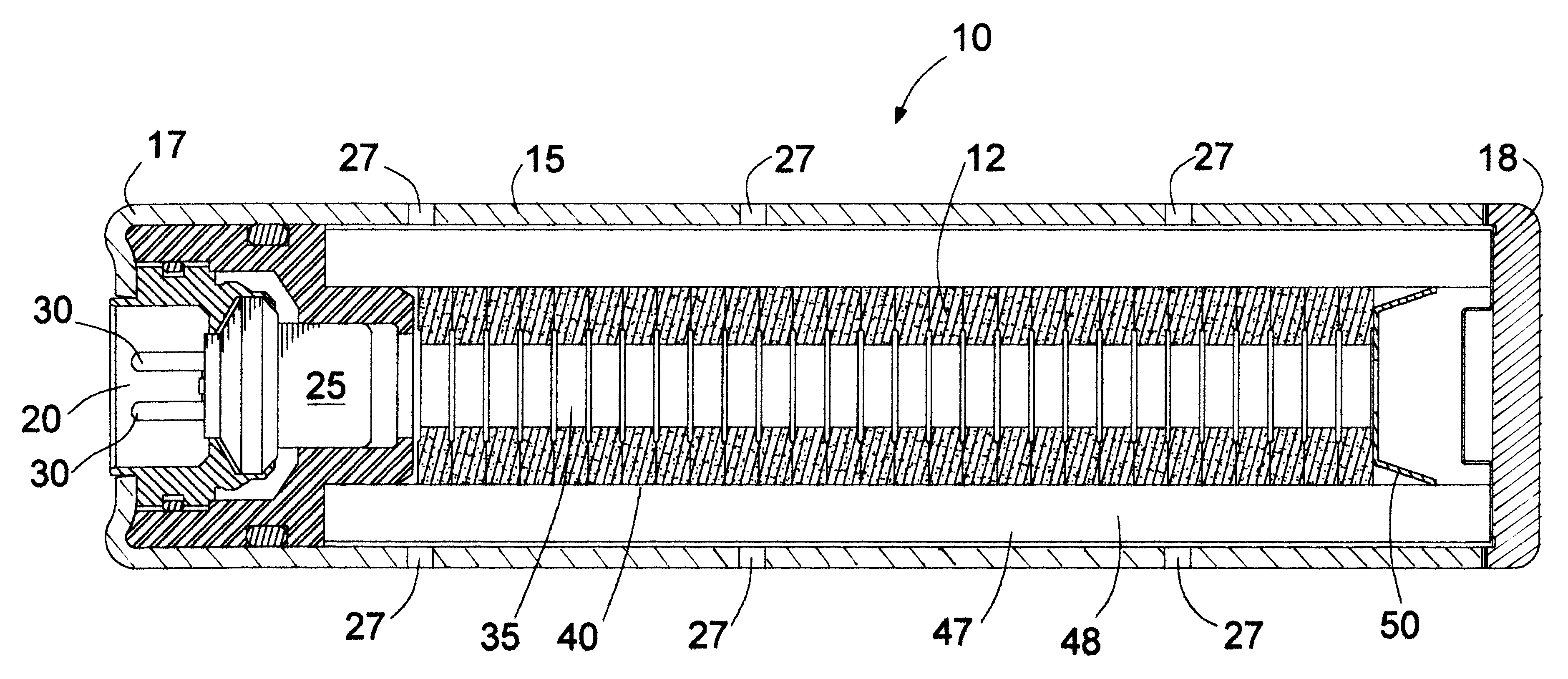

InactiveUS6955732B1Promote combustionIncrease pressureNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPlasticizerSolid fuel

The invention disclosed herein relates to an explosive capable of enhanced combustion efficiently capable of sustaining a high pressure over a period of time in a confined environment, such as an air tight room or a cave, where oxygen may be in limited supply. An embodiment of the present invention is a metal composite that combines a binder, a reactive metal and an oxidizer. In another embodiment, a plasticizer and a catalyst are added. In another embodiment of the present invention, a solid fuel-air explosive (SFAE) having an annular construction is used. In a typical annular construction, a cylindrical shell of SFAE surrounds the cylindrically shaped high explosive. The SFAE includes at least one of reactive metal and metal composite. In addition, the metal composite is formed from at least one reactive metal, at least one binder and an oxidizer.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

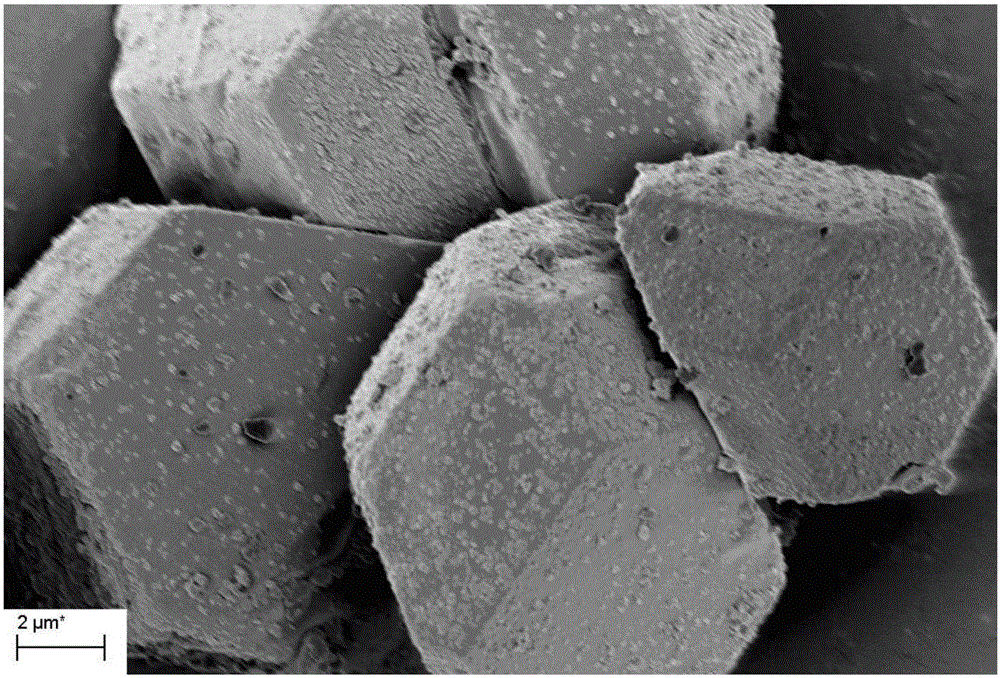

Method for coating energetic crystal surfaces

ActiveCN105777457AEfficient coatingExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFiltrationVacuum drying

The invention discloses a method for coating energetic crystal surfaces. Coating of the energetic crystal surfaces is achieved through oxidation-self-polymerization of dopamine under the condition of a weakly alkaline aqueous solution and formation of poly-dopamine coatings powerfully adhering to material surfaces. The method comprises the following steps: dissolving Tris in a mixed solution of water and ethanol in a volume ratio of 9 to 1 and then dropwise adding hydrochloric acid to prepare a buffer solution with the pH value of 8.0-10.0; then dissolving dopamine in the buffer solution to prepare a dopamine solution with the concentration of 1-5g / L; then adding a proper amount of energetic crystal to the dopamine solution and stirring the materials at a stirring rate of 200-900rpm to form uniform suspension; and continuously stirring the suspension for a period of time and then carrying out suction filtration and vacuum drying. The method has the beneficial effects that coating of the energetic crystal surfaces is completed in the aqueous phase, so the method is green and safe; and especially, the method can achieve efficient coating aiming at the energetic crystal surfaces with different characteristics.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

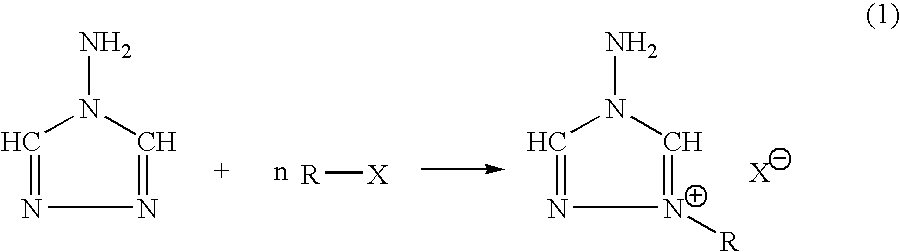

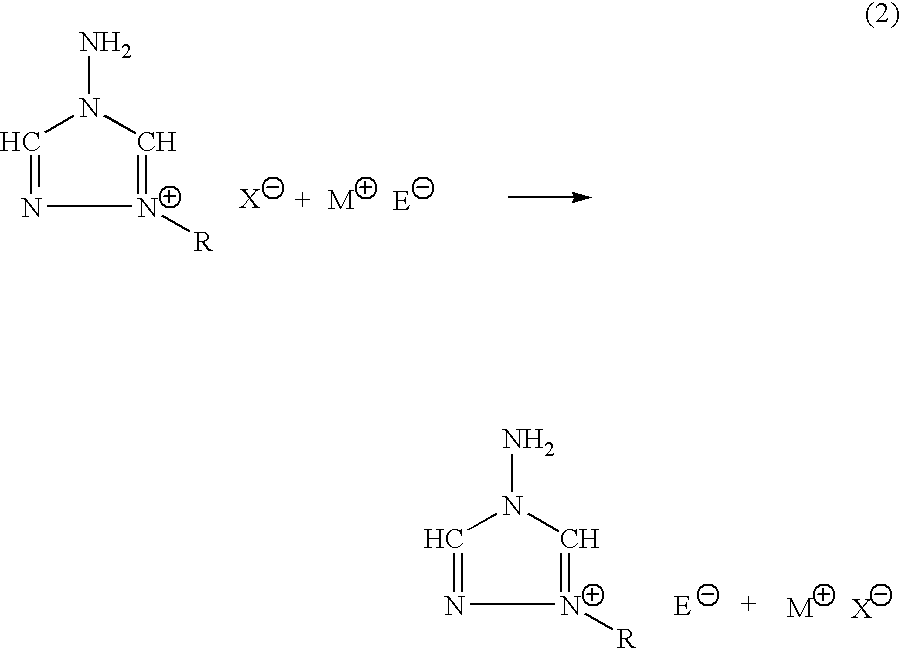

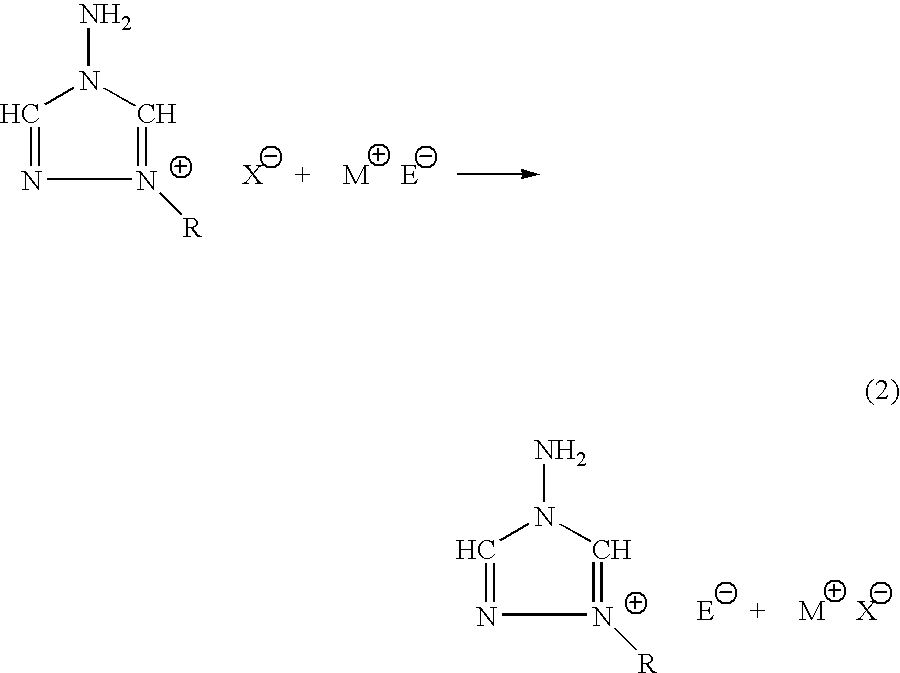

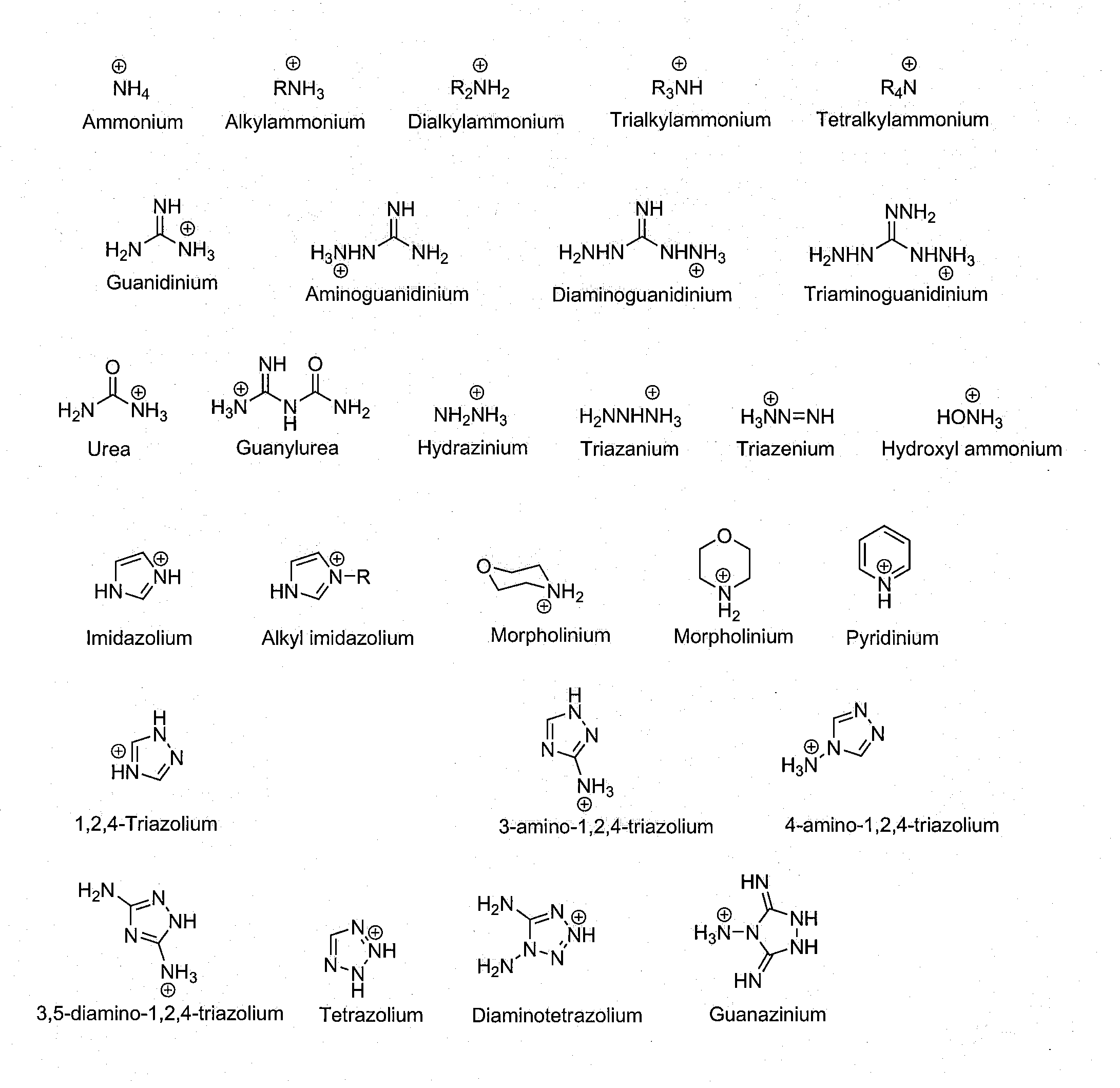

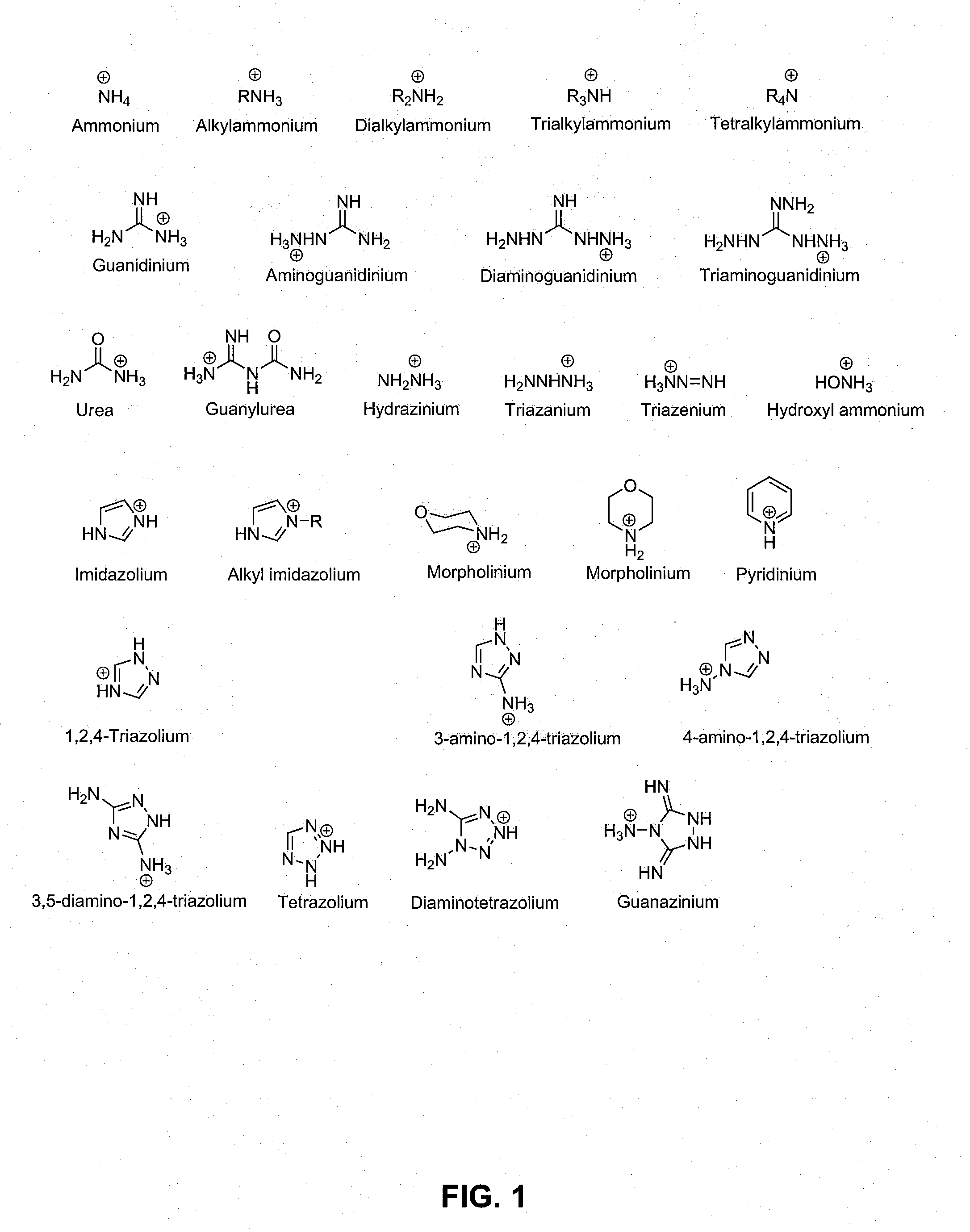

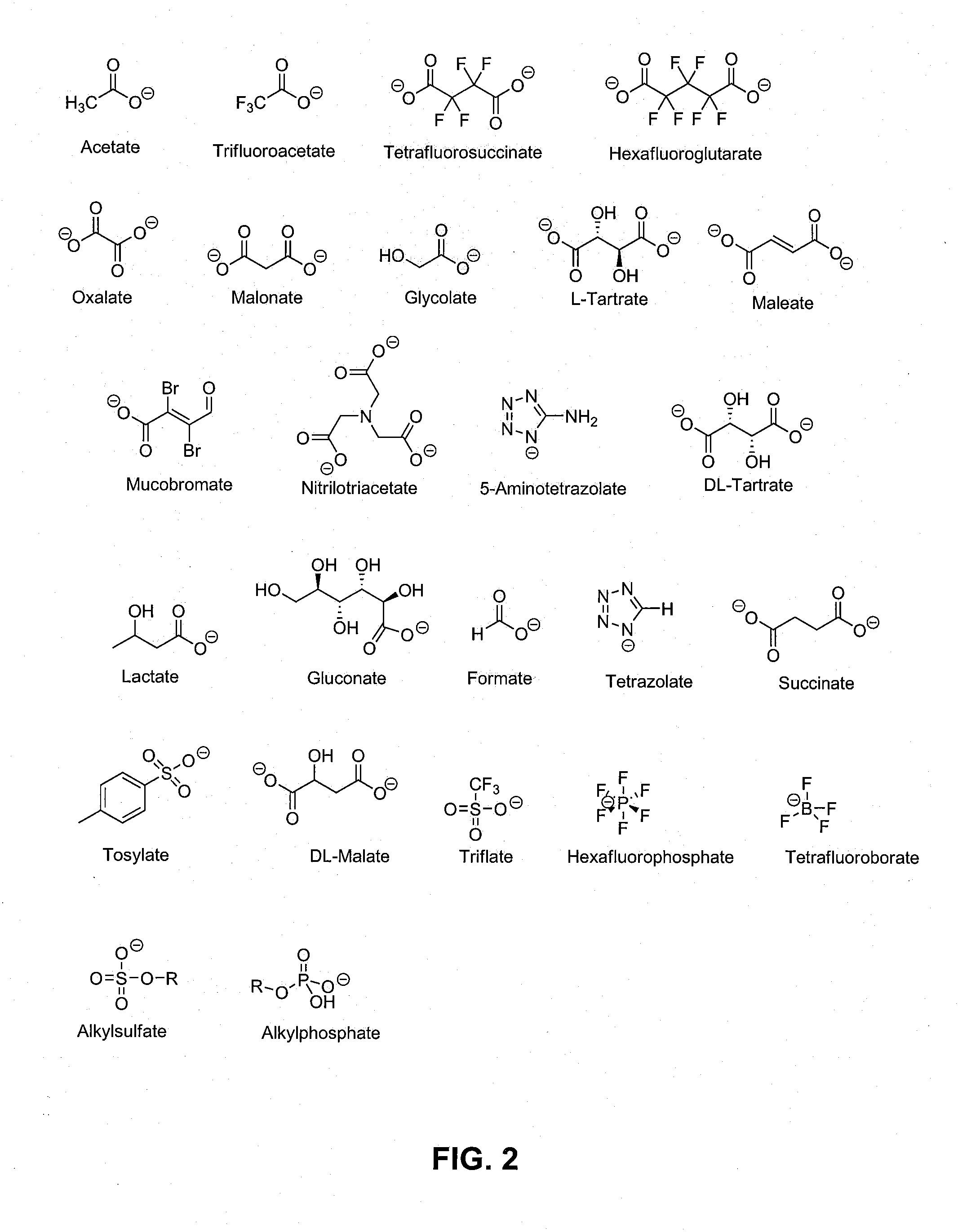

Energetic ionic liquids

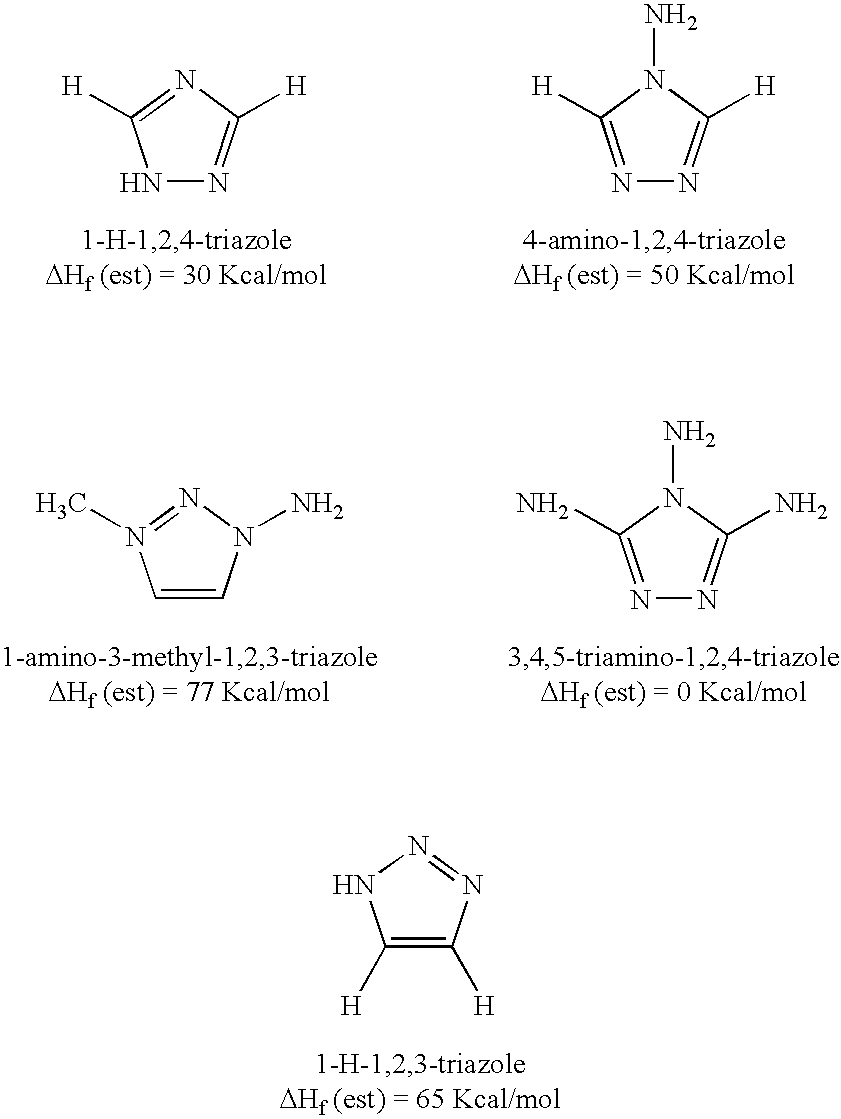

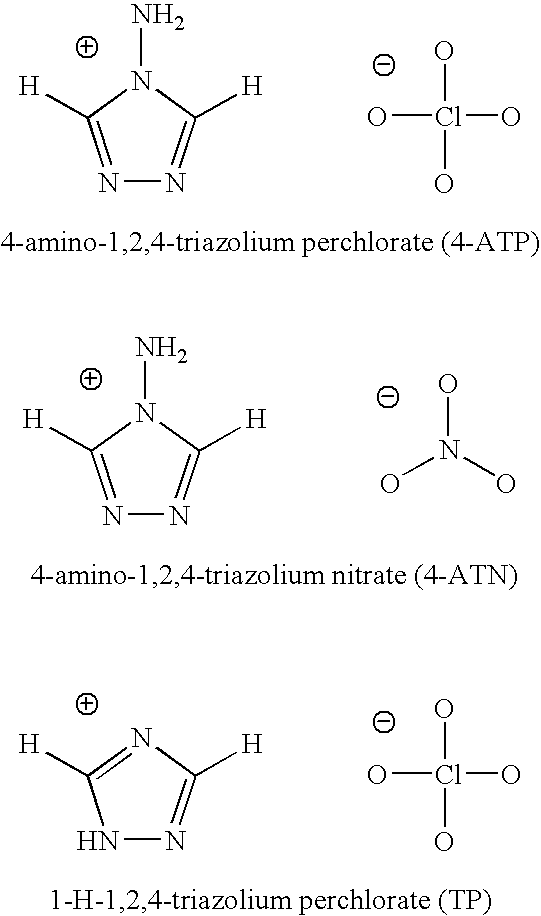

InactiveUS7645883B1Safer processing techniqueEfficient replacementOrganic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsIonic liquidIon

Owner:AIR FORCE THE US SEC THE

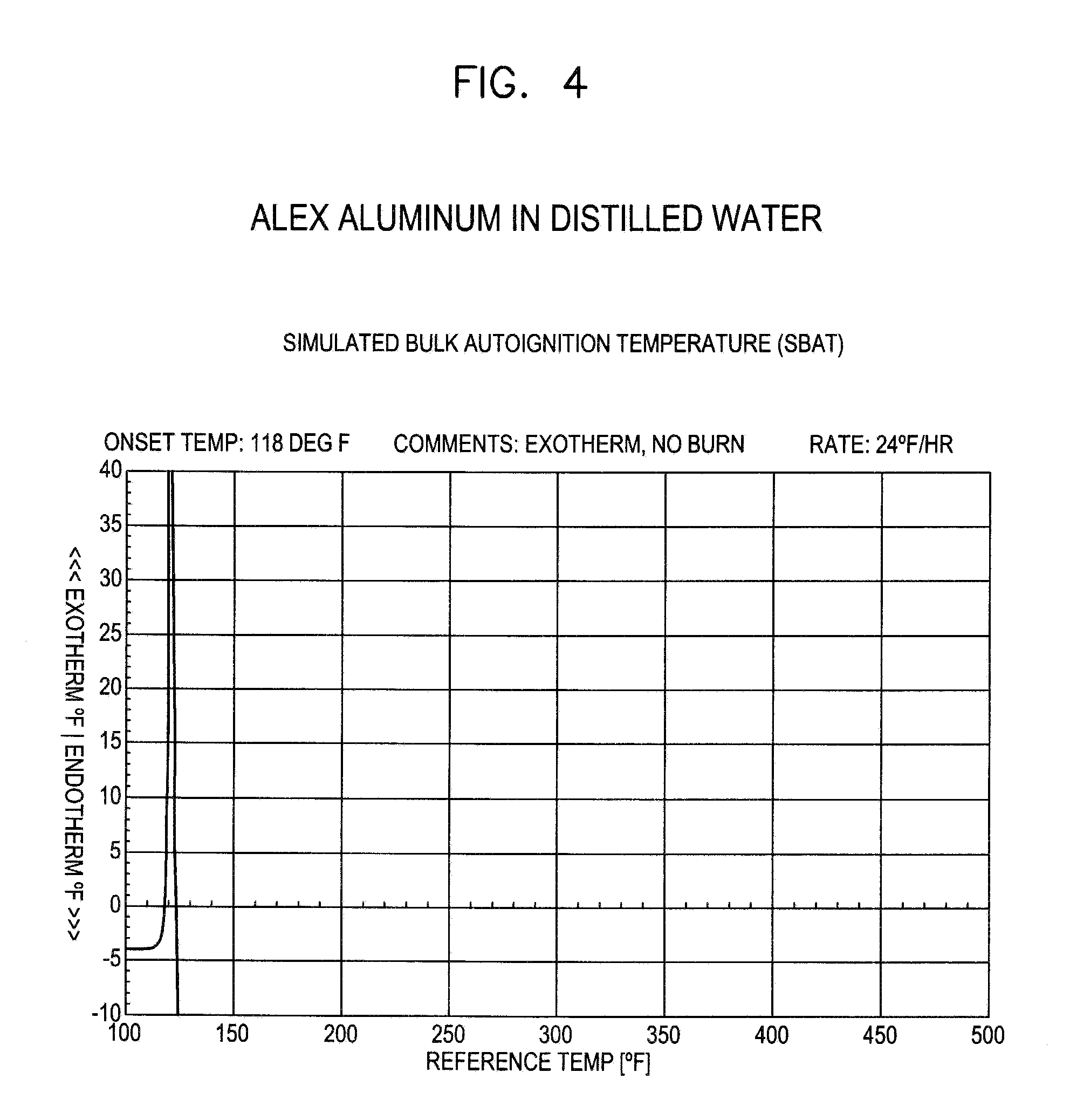

Pressable explosive composition

InactiveUS20060060273A1Requirement is often presentNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsSlurryMaterials science

The present invention relates to low-sensitivity, pressable, aluminum-containing explosive compositions and a method of producing them. The compositions comprise between 45 and 95% by weight explosive crystals, between 5 and 55% by weight passivated aluminum and a binder that is chosen such that the composition satisfies the requirements for low-sensitivity explosives (IM requirements). Due to the fact that the aluminum is passivated, the composition can be produced by the use of a well-known water slurry process.

Owner:DYNO NOBEL INC

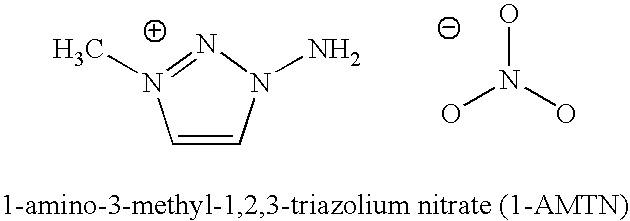

Energetic ionic salts

InactiveUS7745635B1High yieldHigh purityOrganic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNitrateIodide

The invention provides a) a method for making improved ionic halide salts, e.g., 1-methyl-4-amino-1,2,4-triazolium iodide and b) a method for making energetic ionic salts, e.g., 1-methyl-4-amino-1,2,4-triazolium nitrate, in high yield and purity from triazolium precursors. Also provided are the resulting novel salts from the above methods.

Owner:THE GOVERNMENT OF THE US SEC THE AIR FORCE +1

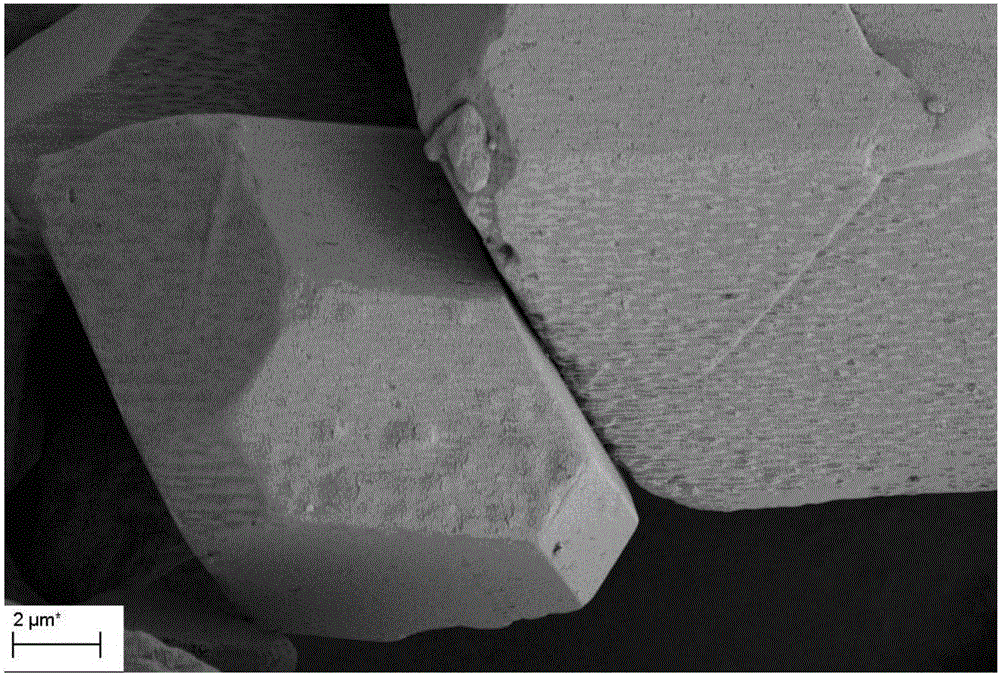

RDX Composition and Process for Its Manufacture

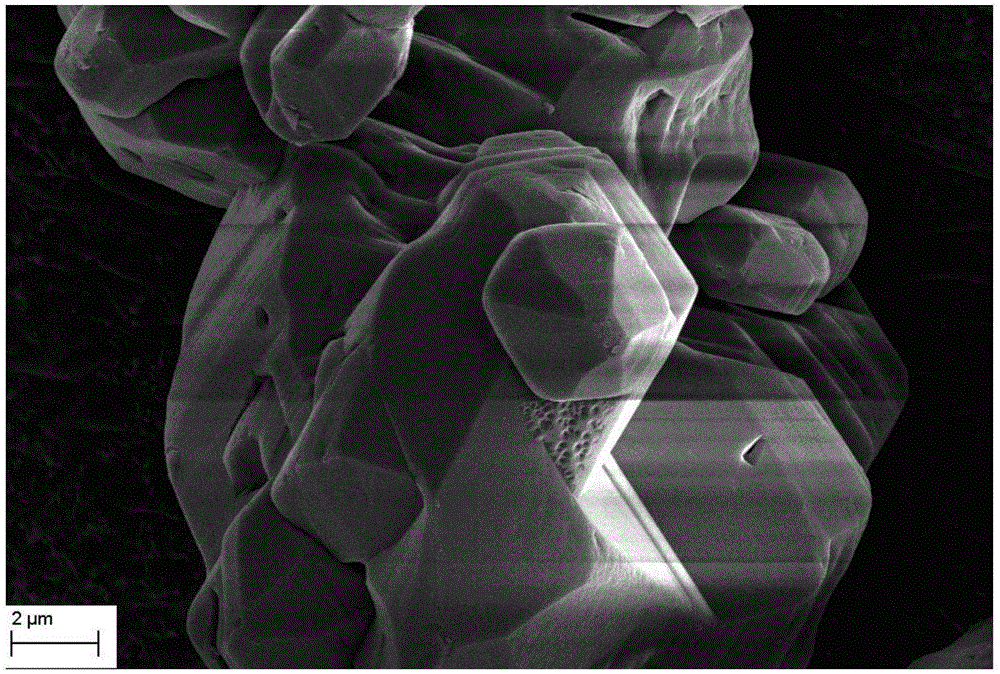

InactiveUS20060272756A1Explosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsSolventCrystal density

An explosive composition can be produced by dissolving RDX in a volume of a first solvent to form a first solution, and adding a second solvent to the first solution. The second solvent is miscible with the first solvent, but RDX is soluble in the second solvent to an extent no greater than 1 g RDX / 100 g of the second solvent. Precipitated RDX crystals can be recovered. The RDX crystals can have a crystal density of less than 1.80 g / cm3.

Owner:SCHLUMBERGER TECH CORP

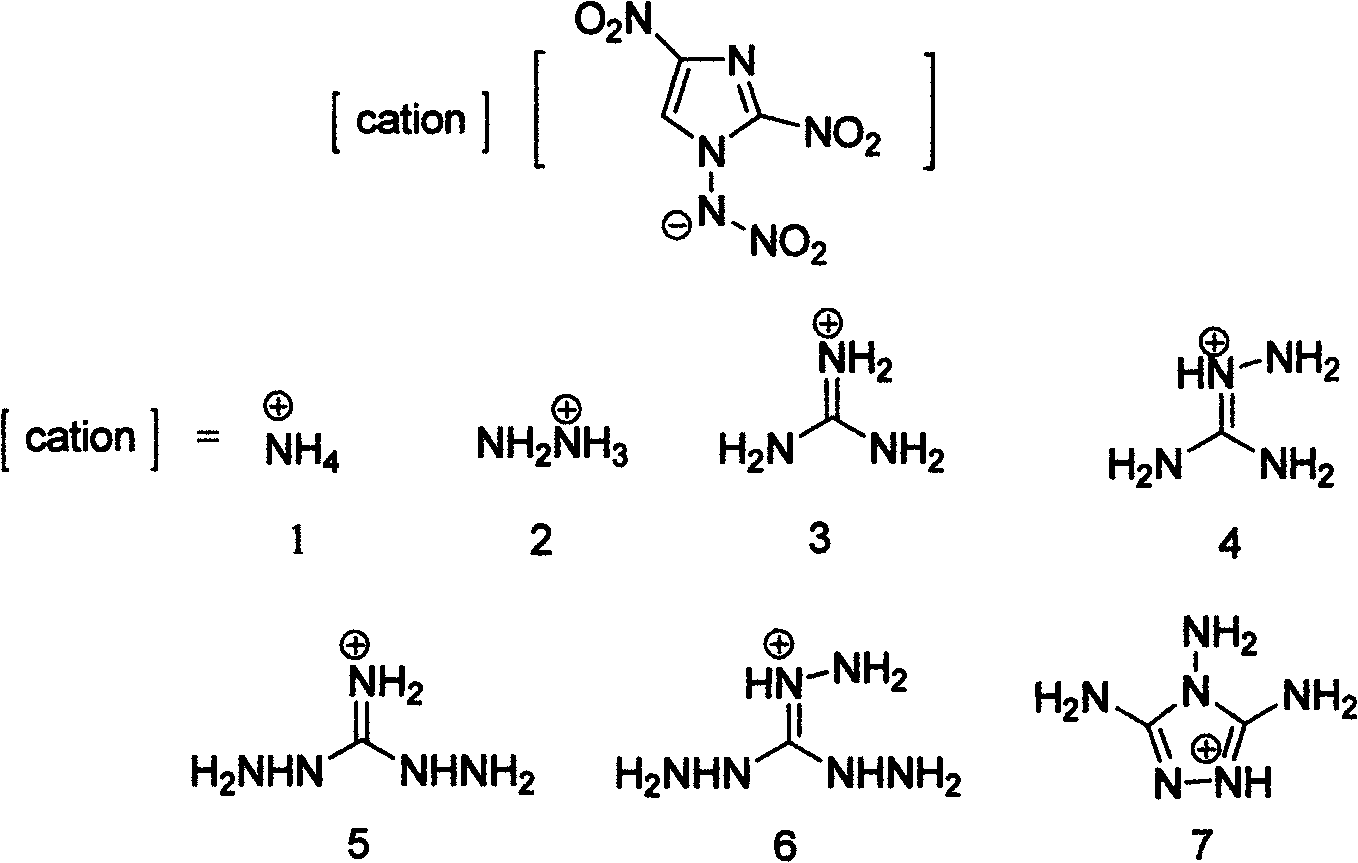

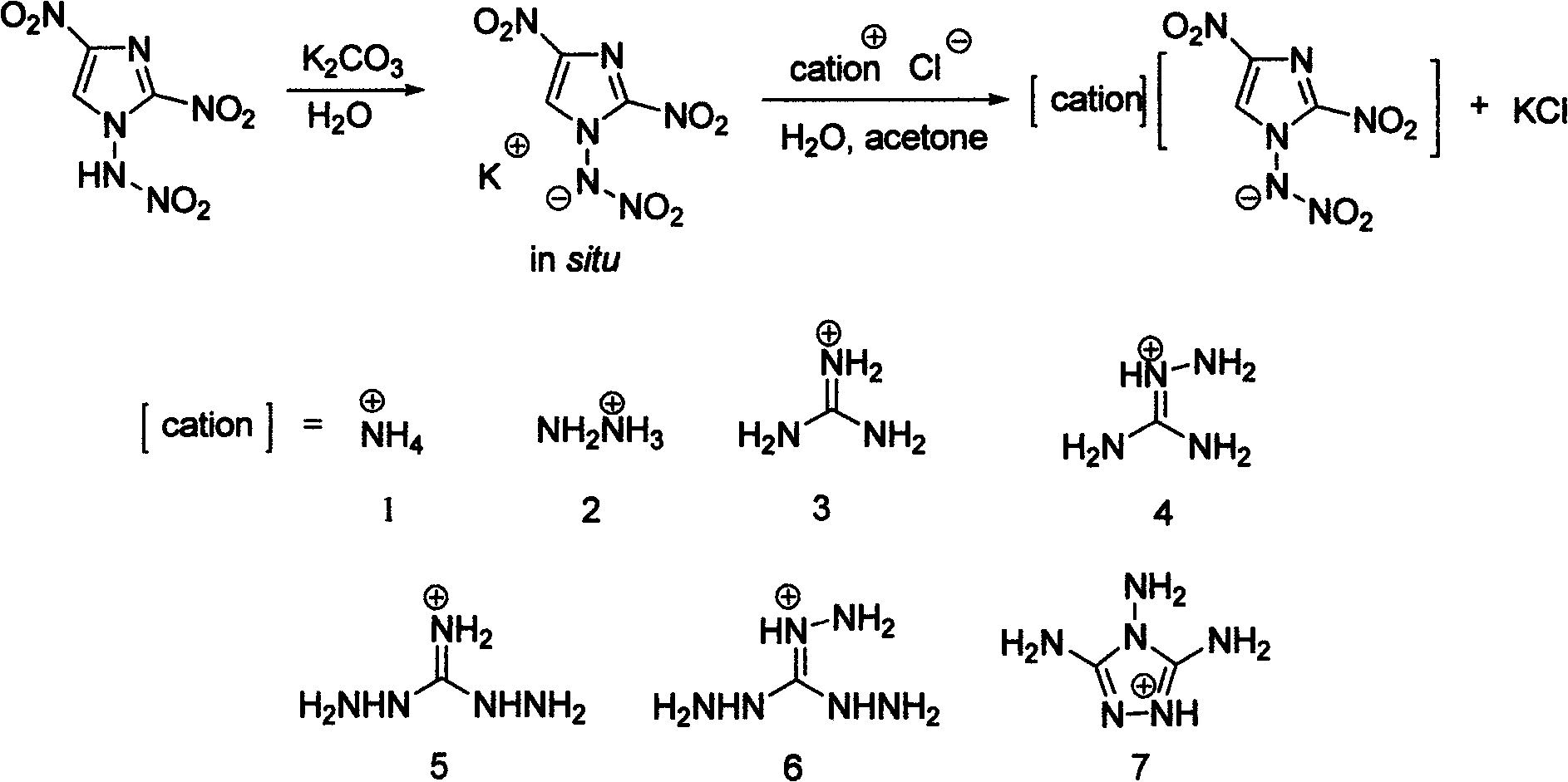

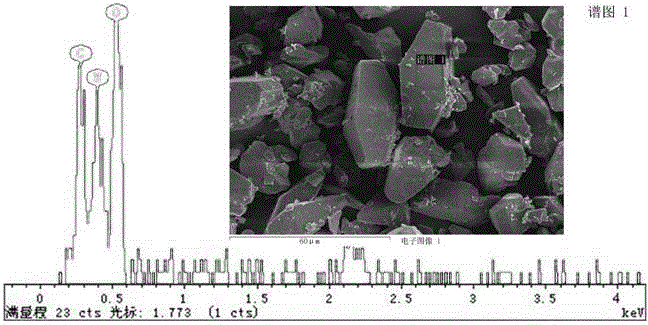

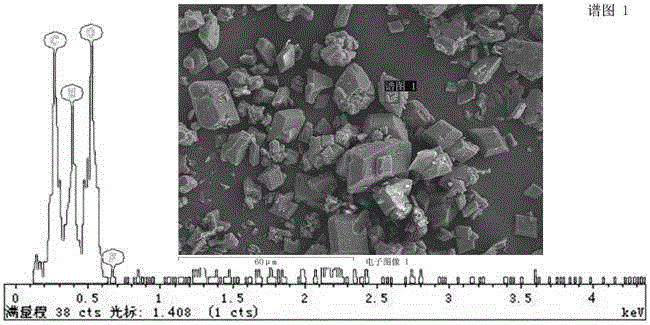

Energetic ion salts of 1-nitramine-2, 4-dimetridazloe and preparation method thereof

InactiveCN103483264AExcellent detonation speed and pressure performanceThe synthesis method is simpleOrganic chemistryOrganic compound preparationNitroimidazoleHydrazine compound

The invention discloses energetic ion salts of 1-nitramine-2, 4-dimetridazloe and a preparation method thereof, and belongs to the technical field of energetic materials. The synthetic method is as follows: dissolving the 1-nitramine-2, 4-dimetridazloe in deionized water to obtain a pale yellow clear liquid, adding with stirring 0.5 time molar equivalent of potassium carbonate at room temperature for in-situ generation of 1-nitramine-2, 4-dimetridazloe potassium salt, then adding one time molar equivalent of ammonium chloride, hydrazine hydrochloride, guanidine hydrochloride, monoaminoguanidine hydrochloride, diaminoguanidine hydrochloride, triaminoguanidine hydrochloride and 3, 4, 5-triamino-1, 2, 4-triazole hydrochloride, stirring to precipitate a pale yellow solid precipitate, after about 1 hour of reaction, filtering the pale yellow precipitate, further recrystallizing a coarse product by use of an acetone and diethyl ether mixed solvent to obtain a pure product. The synthetic method of the invention is simple, mild in condition and high in yield, and is environmental friendly due to using of the deionized water as a solvent. The density of involved seven salts is 1.70-1.93g cm<-3>, the detonation velocity calculated by EXPLO software is between 8370 and 9209 m s<-1>, the detonation pressure is between 29.3 and 40.5 GPa, the actually measured impact sensitivity is 4-40J, the detonation performance is excellent, and the energetic ion salts are potential energetic materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for cladding energetic materials

InactiveCN104591932AImprove solubilityCoated evenlyNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNon solventAnti solvent

The invention relates to a method for cladding energetic materials and particularly relates to a method for coating energetic materials by taking liquid CO2 as an anti-solvent, a dispersion agent and a drying medium. The method provided by the invention is mainly used for solving the technical problems of the existing method for coating energetic material that the coating is not uniform, the operation is complicated, some special energetic materials cannot be coated by a wet process, the solvent cannot be mutually soluble with a non-solvent to limit the application of the water (or solution) suspension method and cause the environment pollution. The invention provides a method for coating energetic materials by taking liquid CO2 as an anti-solvent, a dispersion agent and a drying medium. The method provided by the invention has the advantages of uniform coating, simple operation, wide application range and no environmental pollution.

Owner:ZHONGBEI UNIV

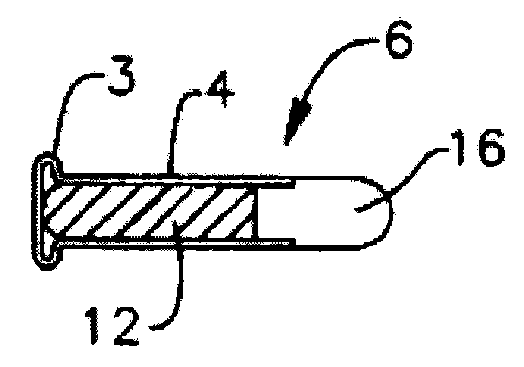

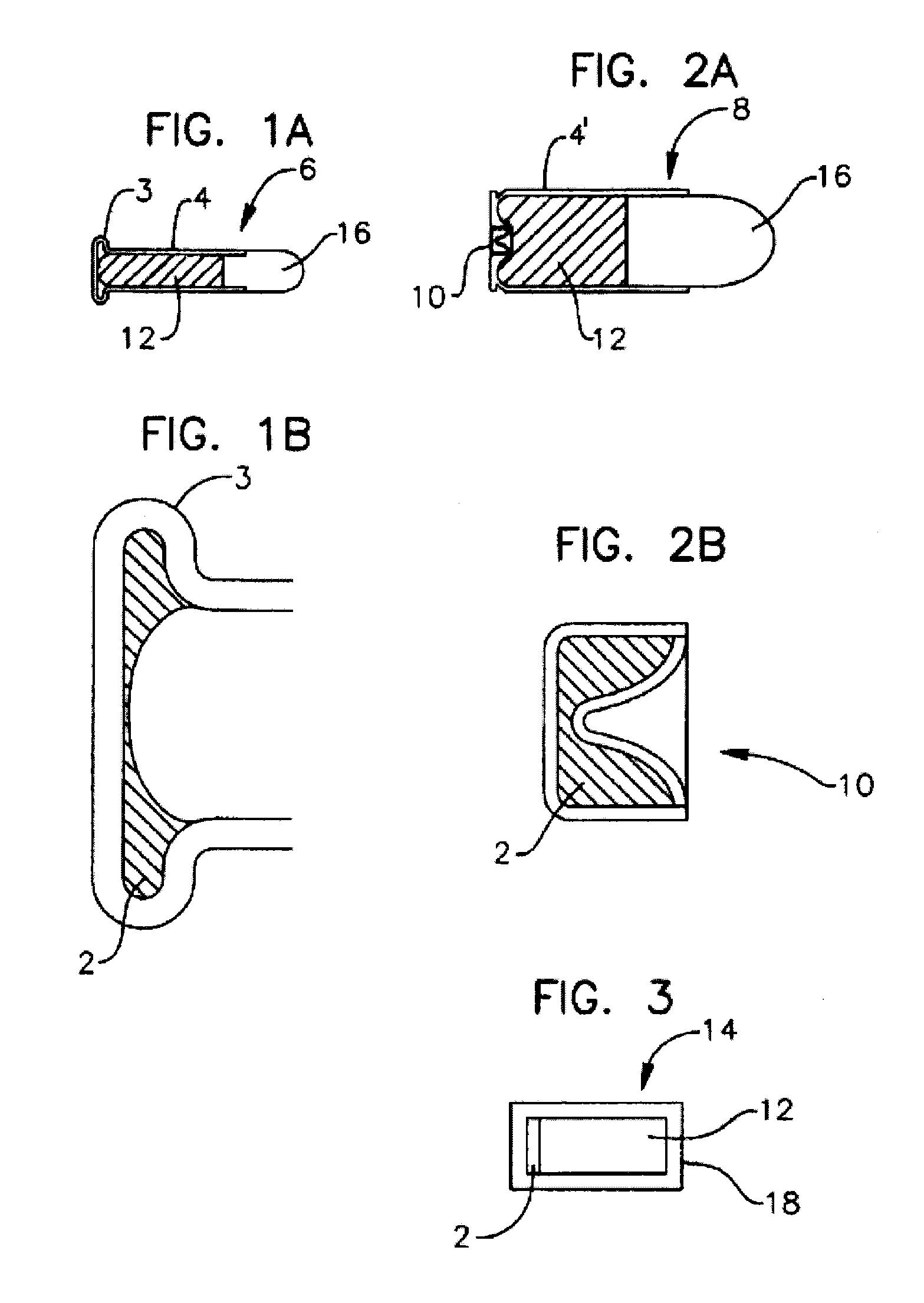

Non-toxic percussion primers and methods of preparing the same

Owner:FEDERAL CARTRIDGE

High-gurney-energy low-vulnerability PBX explosive and preparation method thereof

ActiveCN103145512AEfficient damageMeet needsExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsMedicinePlasticizer

The invention discloses a high-gurney-energy low-vulnerability PBX explosive and a preparation method thereof. The PBX explosive comprises ingredients in parts by weight: 90 parts of HMX, 4-4.5 parts of bonding agent, 2-3 parts of insensitiveness agent, 2-2.5 parts of plasticizer, and 0.4-0.5 parts of curing agent. The preparation method of the PBX explosive comprises the following steps: preparing materials; material mixing: performing material mixing by adopting batch-feeding and kneading mode; performing vacuum processing and vacuum pouring; and heating and curing. The PBX explosive has more than 90% of solid content, and is excellent in cast rheological property; the gurney coefficient of the explosive, tested by the standard cylinder experiments, can achieve 2.83km / s, and the explosive has high safety.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

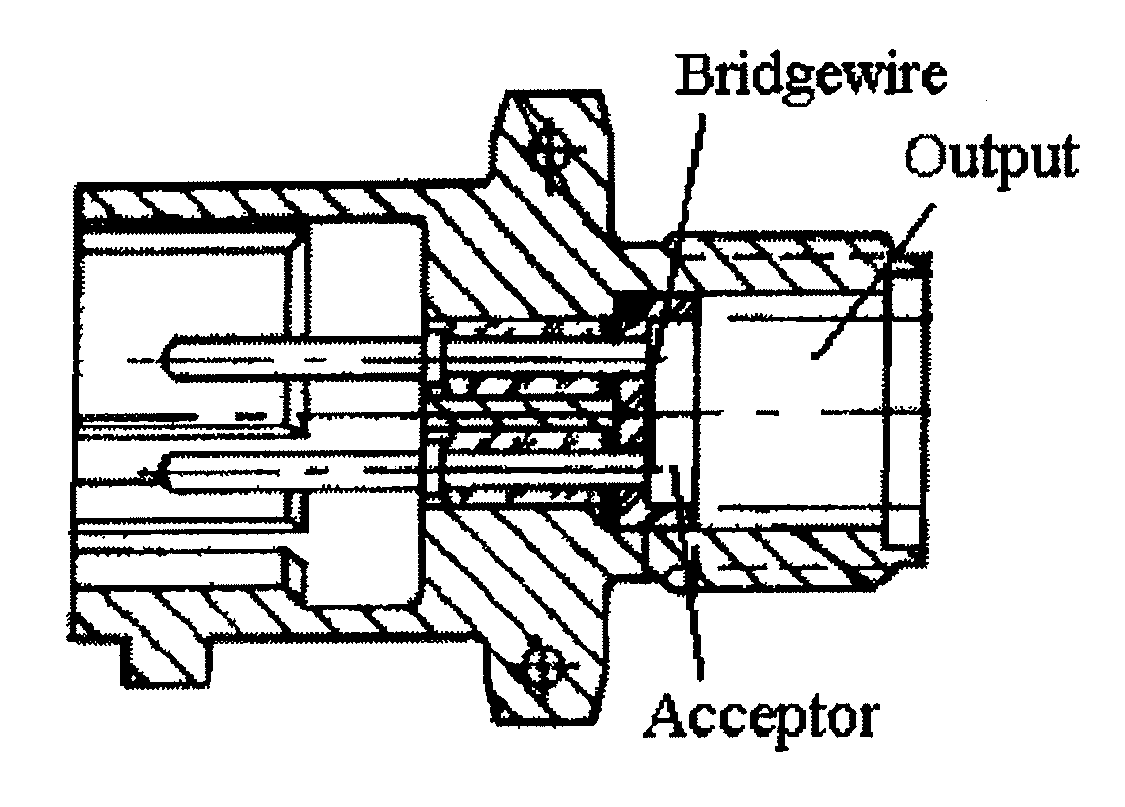

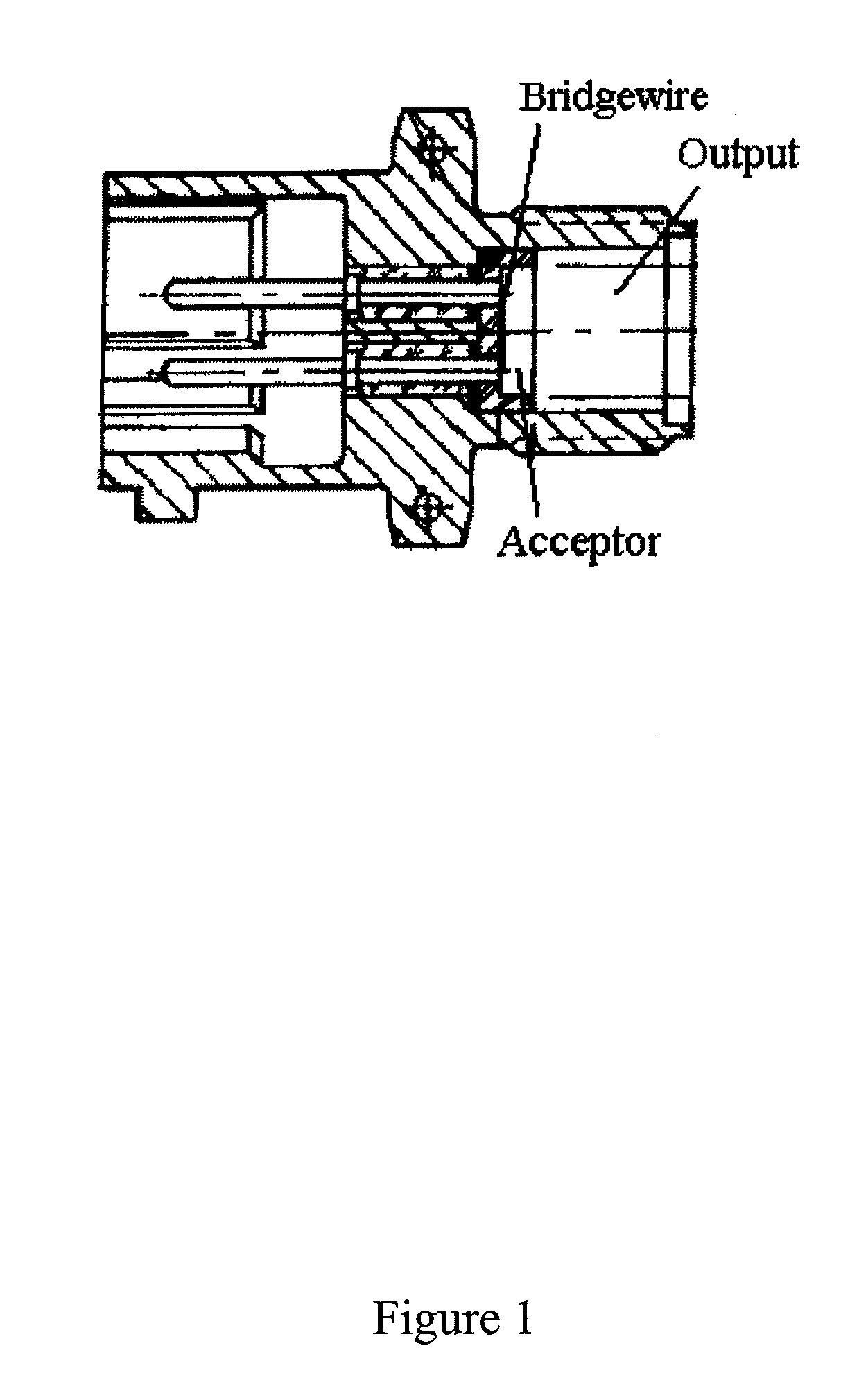

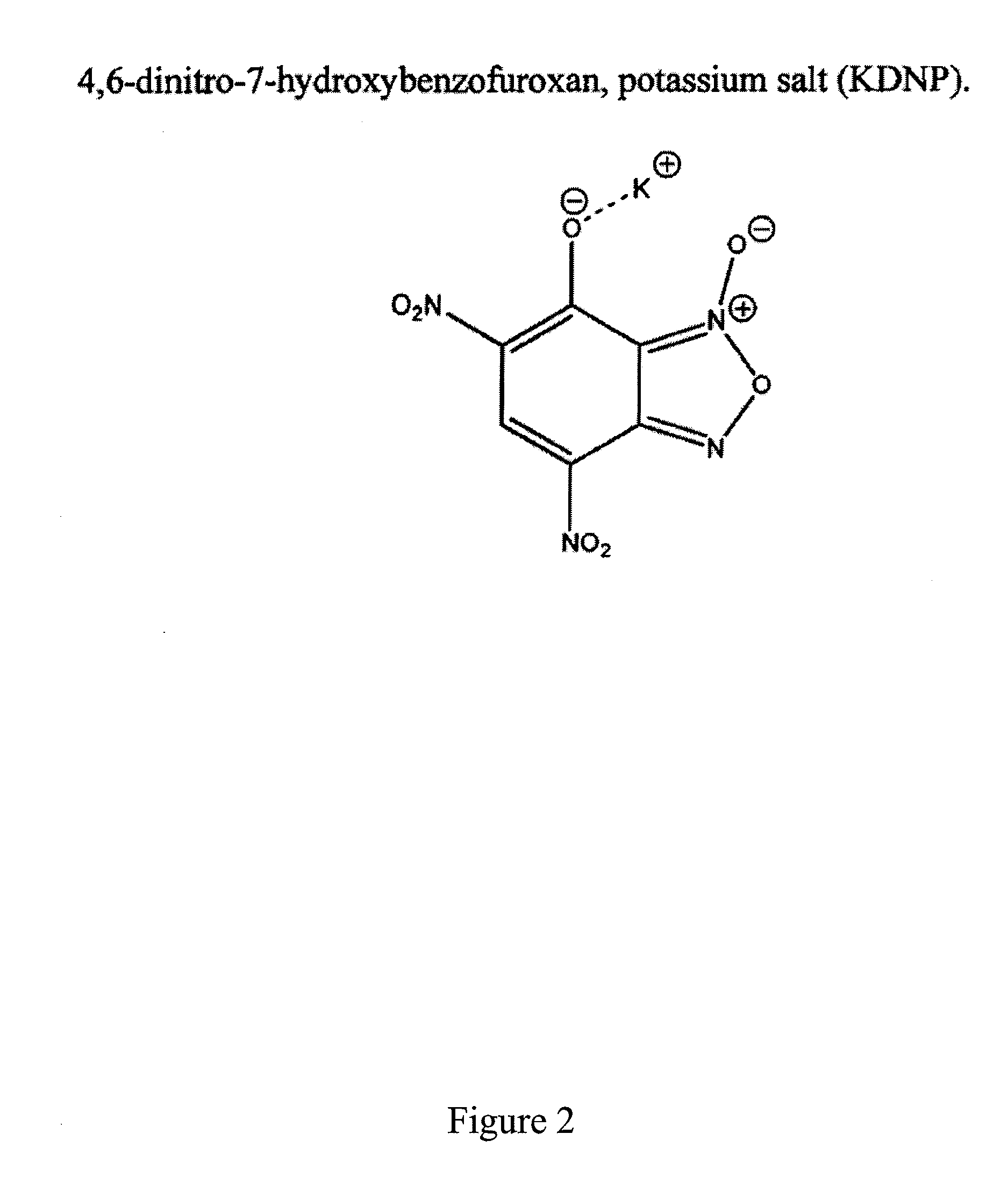

Lead-free primers

Embodiments of the present subject matter provide an improved percussion primer composition and improved hot-wire igniter acceptor, wherein lead styphnate is replaced with a lead-free material, 4,6-dinitro-7-hydroxybenzofuroxan, potassium salt (KDNP). Embodiments of the percussion primer composition include KDNP, a sensitizer, an oxidizer, calcium silicide, a fuel, and a binder. Sensitizers may include tetracene. Oxidizers may include alkali or alkaline earth nitrates, oxides, or peroxides (such as barium nitrate). Fuel materials may include metals, metal sulfides, or other non-metallic materials. Common binders may include nitrocellulose based shellacs, gum arabic / poly vinyl alcohol mixtures, and guar gum / poly vinyl alcohol mixtures. Embodiments of the hot-wire igniter device include a bridgewire, an acceptor, and an output, where KDNP is the acceptor. Power supply may be in the form of constant current / voltage or current flow from a capacitor discharge. Certain embodiments utilize a variety of output formulations, such as BKNO3, black powder, and Red Dot double base propellant.

Owner:PACIFIC SCI ENERGETIC MATERIALS +1

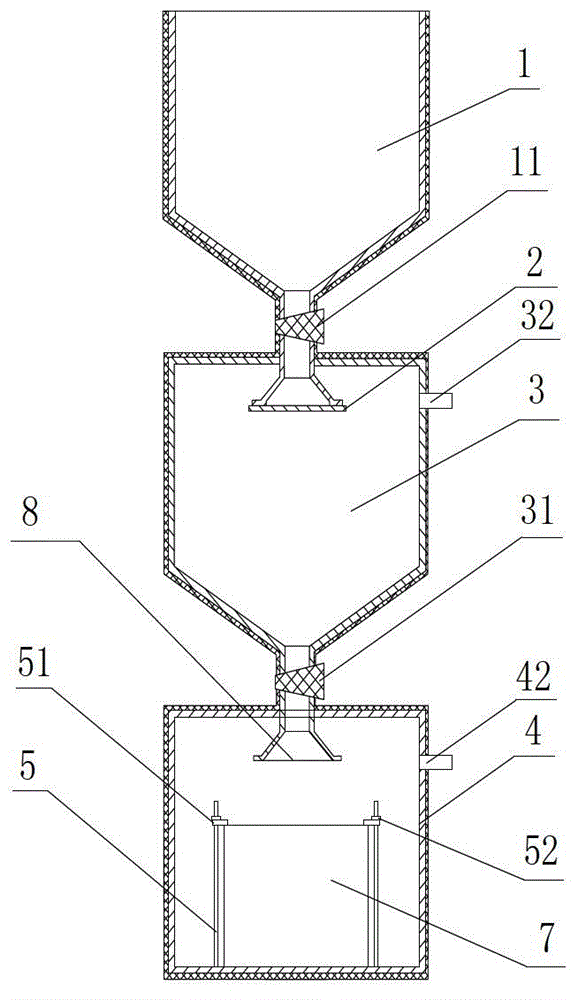

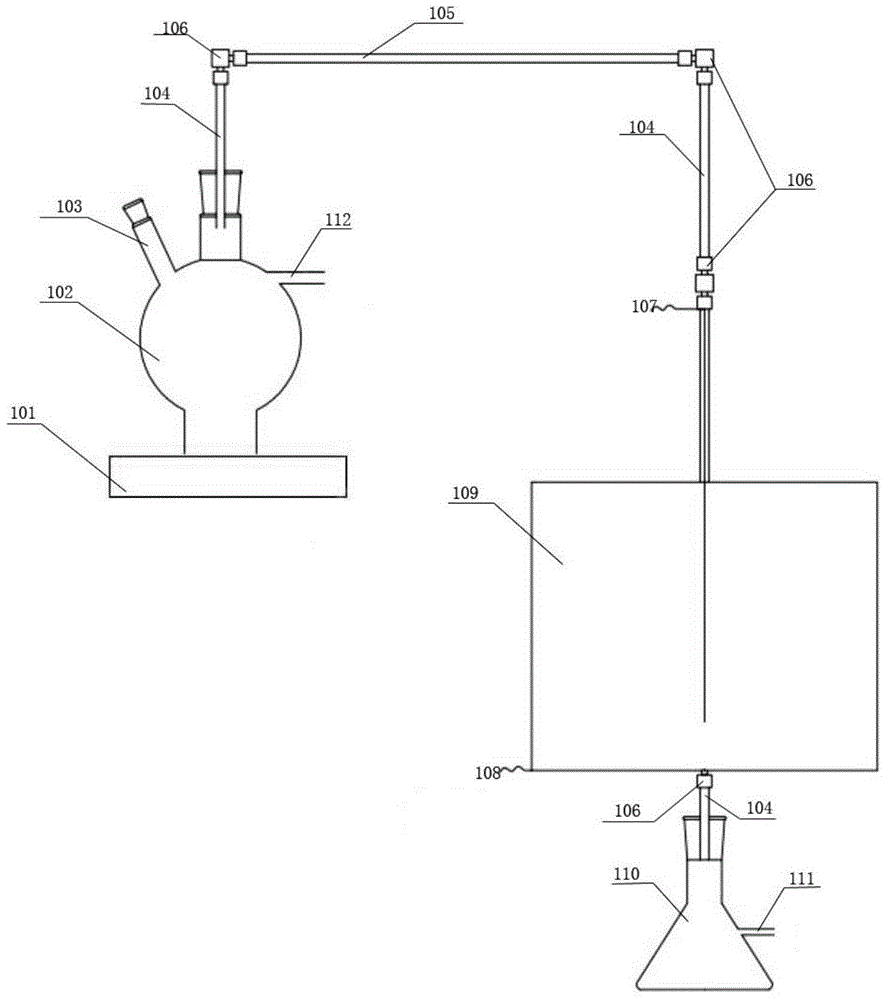

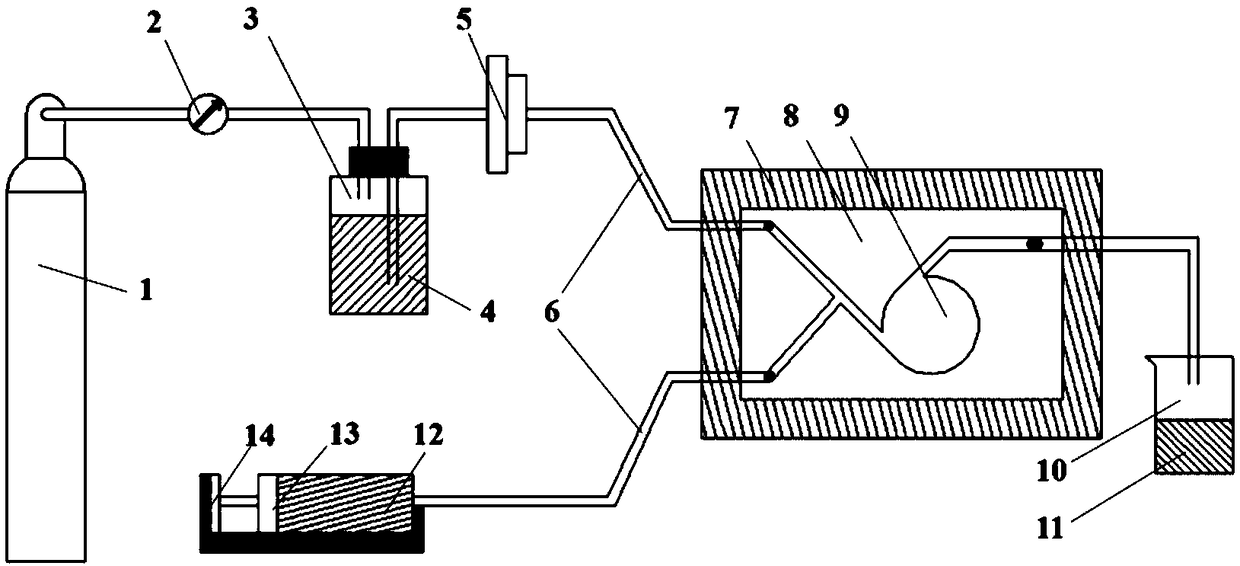

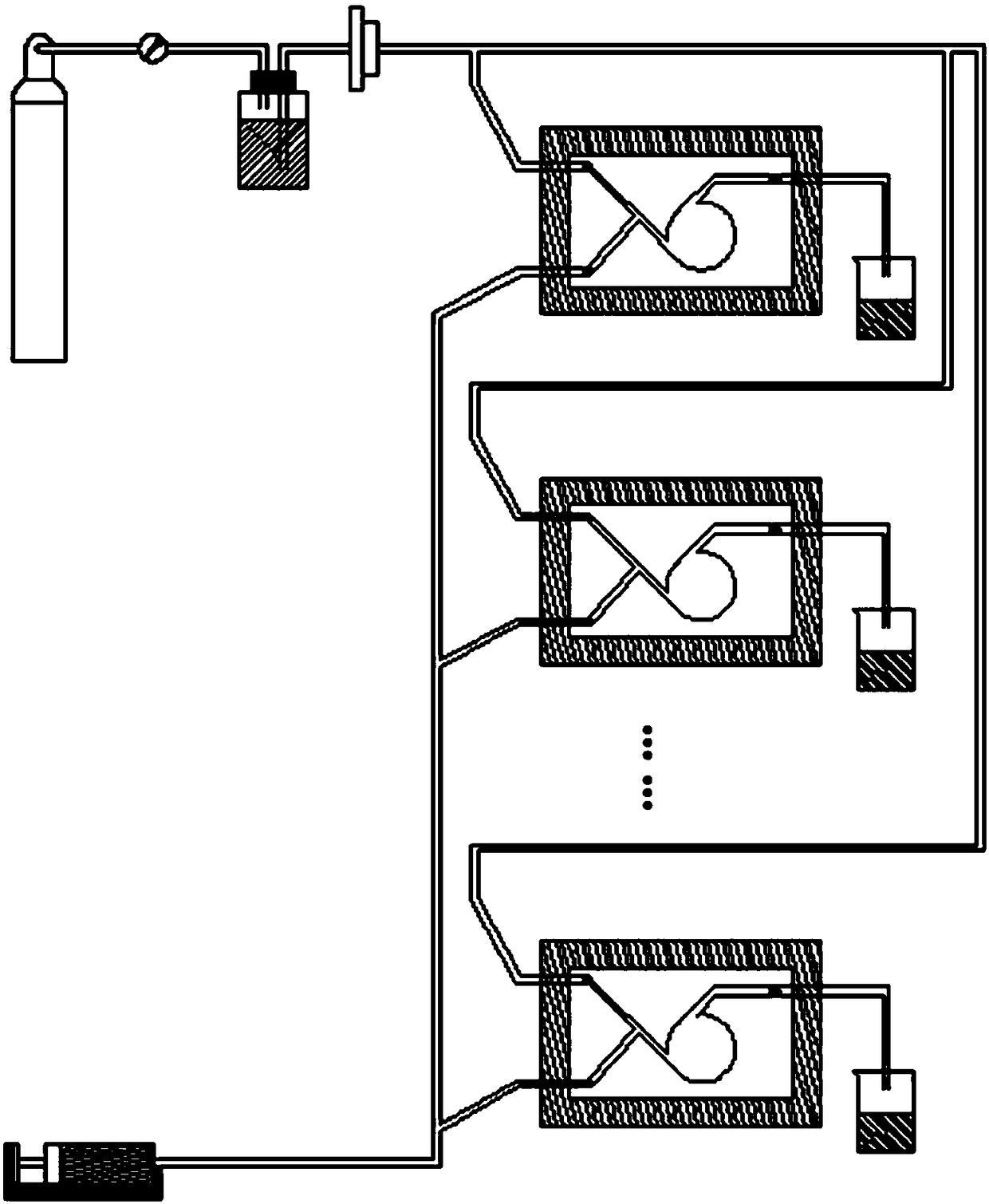

Method and device for preparing nanometer-eutectic energetic material

InactiveCN103977593AFine granularityUniform grainNitrated aromatic explosive compositionsSolution crystallizationSolventHigh pressure

The invention discloses a method and a device for preparing a nanometer-eutectic energetic material. The method comprises the following steps that an energetic material is dissolved in a good solvent and then is transported into a temperature gradient heating furnace through inert gases in an ultrasonic spray manner, and then nanometer-eutectic energetic material crystals are collected through a high-voltage electrostatic field and the good solvent and the inert gases are cooled and recovered. The device used in the method is formed by sequentially communicating an ultrasonic device, the temperature gradient heating furnace, the high-voltage electrostatic field and a receiving device in a sealing manner. The method can prepare the energetic material crystals with the crystal size being 20-1000nm, is wide in preparation range, and can realize continuous operation. The preparation method is simple in procedures and is easy to operate, reaction conditions are mild and are easily controlled, and the method can be applied to various kinds of eutectic explosives. The crystal grains of the prepared nanometer-eutectic energetic explosives are uniform, and the purity is larger than 99.9 percent. Waste liquid in the preparation procedures is recovered, and the minimum pollution to the environment is realized.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

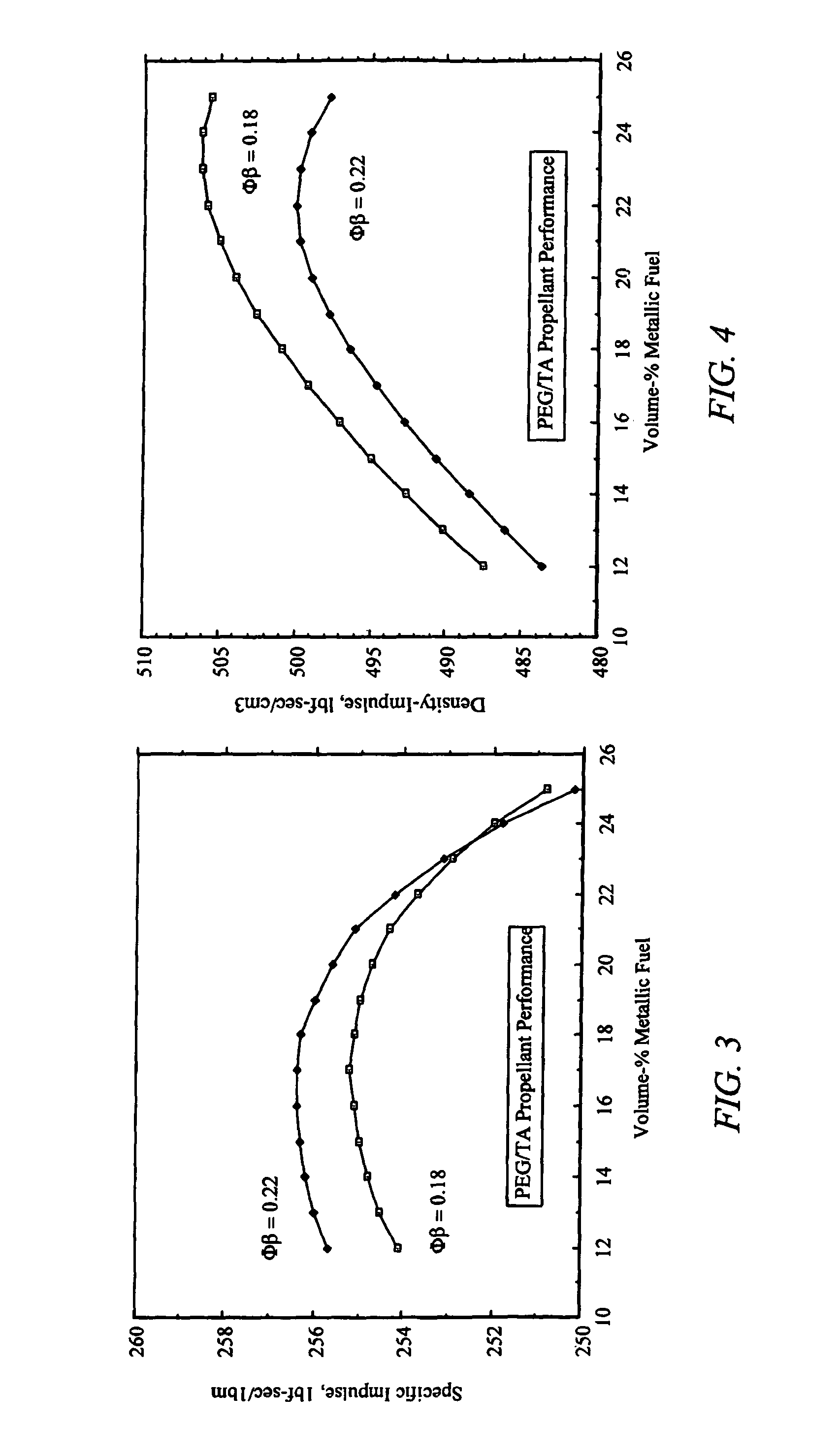

High burning rate tactical solid rocket propellant, and related method

InactiveUS8986473B1Improve solubilityNon-explosive fillers/gelling/thickening agentsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsCombustionHeat conducting

The invention is a composition for a high burning-rate solid rocket propellant, where the composition includes a binder compounded with a soluble energetic additive; a metallic fuel; and an oxidative fuel. The resulting composition has a tactical Class 1.3 hazard rating, and a linear regression rate that is substantially equivalent to a tactical Class 1.1 hazard rating obtainable using solid rocket propellants. The composition may include a heat-conducting element, a plasticizer, a curing component, a combustion catalyst, and curing catalyst.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Non-toxic, heavy-metal free sensitized explosive percussion primers and methods of preparing the same

A non-toxic, non-hydroscopic percussion primer composition and methods of preparing the same, including at least one explosive component that has been traditionally considered a moderately insensitive explosive or secondary explosive, and at least fuel particle component having a particle size of about 1.5 microns to about 12 microns, which allows the use of moderately active metal oxidizers. The sensitivity of the primer composition is created by the interaction between the moderately insensitive explosive and the fuel agent such that traditional primary explosives such as lead styphnate or DDNP are not needed. The primer composition also eliminates the risks and dangers associated with traditional nano-sized fuel particles.

Owner:FEDERAL CARTRIDGE

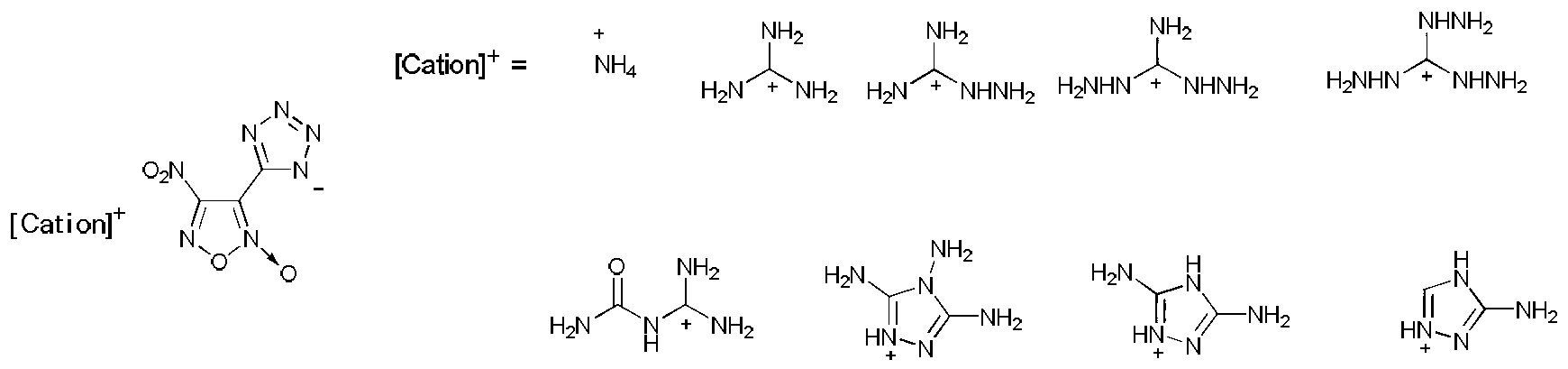

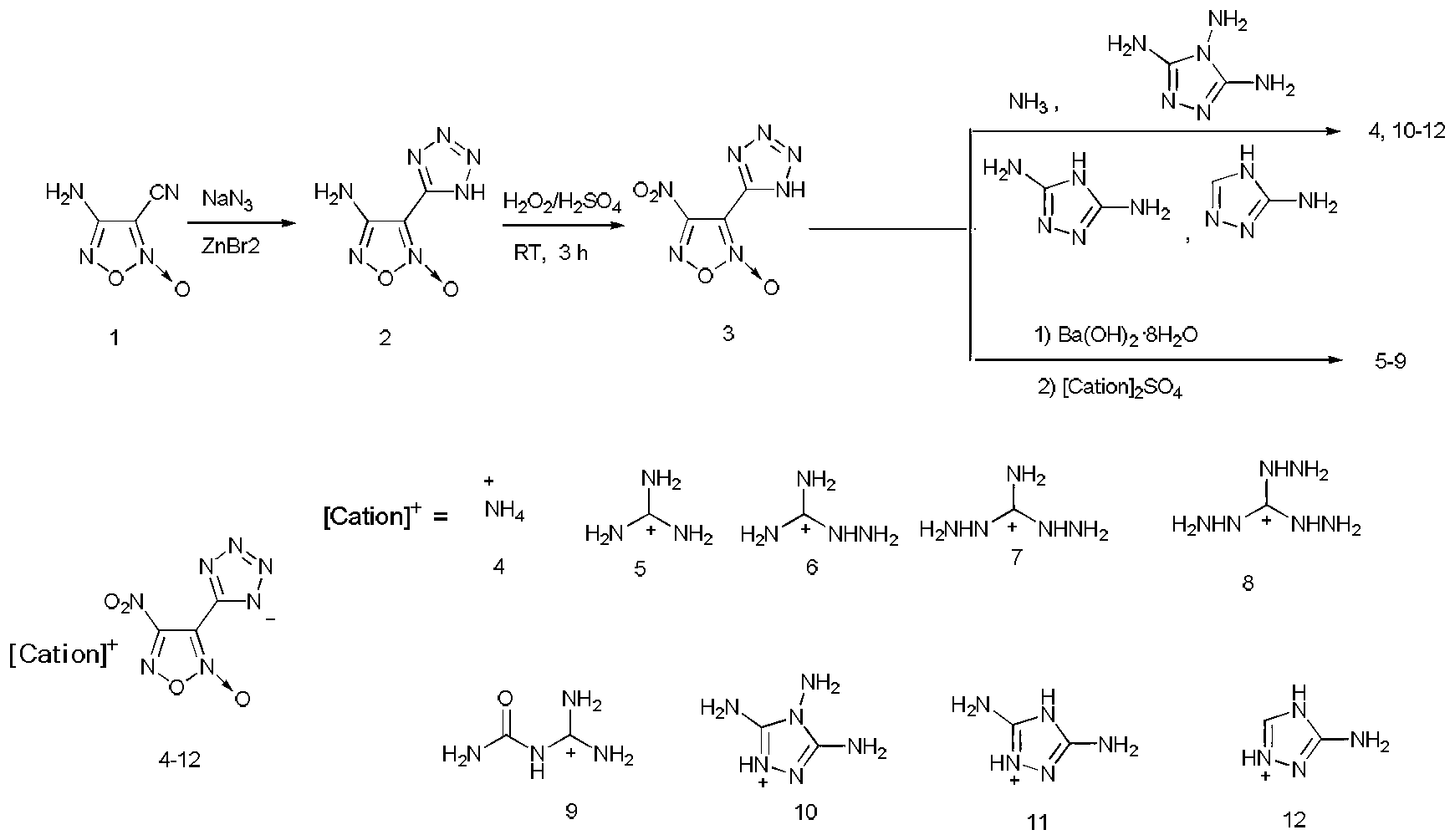

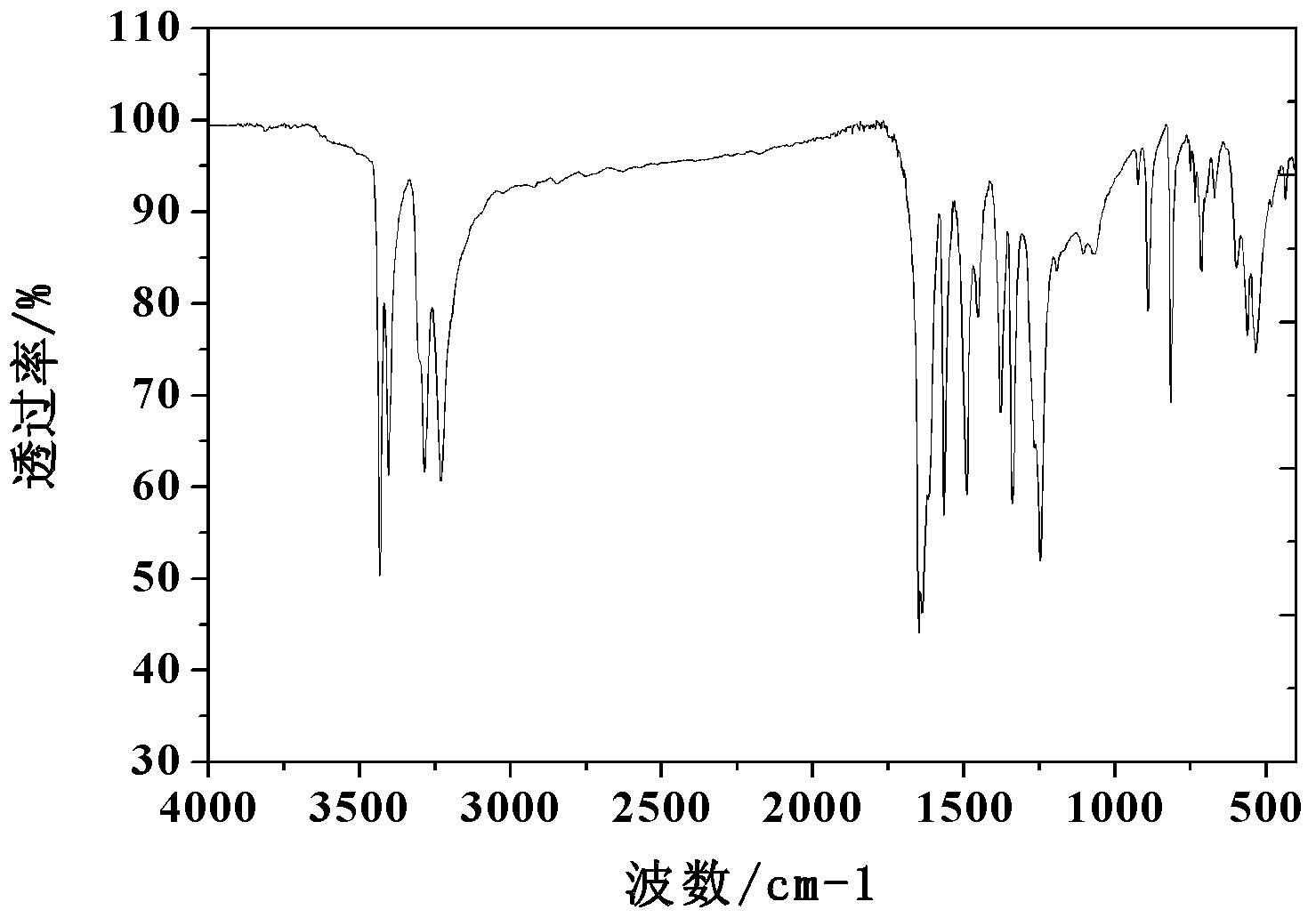

4-nitro-3-(5-tetrazole) furoxan energetic ionic salt and preparation method thereof

InactiveCN103059009AThe synthesis method is simpleMild conditionsOrganic chemistryOrganic compound preparationDetonationHigh density

The invention discloses a 4-nitro-3-(5-tetrazole) furoxan energetic ionic salt and a preparation method thereof, belongs to the technical field of energetic materials. A synthesis method of the 4-nitro-3-(5-tetrazole) furoxan energetic ionic salt is as follows: directly reacting the 4-nitro-3-(5-tetrazole) furoxan with a corresponding cation, and steaming for eliminating a solvent so as to obtain a target product; reacting the 4-nitro-3-(5-tetrazole) furoxan with the sulfate of the equimolar corresponding cation after mixing the 4-nitro-3-(5-tetrazole) furoxan with equimolar Ba(OH)2.8H2O, filtering and precipitating, steaming and eliminating the solvent in the filtrate to obtain the target product. The synthesis method provided by the invention is simple and easy to industrialize. The referred 9 energetic ionic salt has high density (rho: 1.55-1.84g / cm3), wherein the degree of percussion sensitivity of two compounds is more than 40J, and the energetic ionic salt belongs to insensitive explosive. The energetic ionic salt has excellent calculation detonation property and is a potential energetic material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High energy thermoplastic elastomer propellant

InactiveUS6997996B1Eliminate needHigh energyLoomsExplosive working-up apparatusHigh energyPlasticizer

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Preparation method of cubic short rod-like 1-oxygen-diamido-3,5-dinitro pyrazine explosive

ActiveCN103467217AEliminate Luanite defectsImprove subsequent processing and forming performanceNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNon solventCrystal morphology

The invention discloses a preparation method of a cubic short rod-like 1-oxygen-diamido-3,5-dinitro pyrazine (or 2,6-diamido-3,5-dinitro pyrazine-1-oxide with a code being LLM-105) explosive. According to the method, a solvent-non-solvent impinging jet crystallization mode is adopted; nitric acid (HNO3) is taken as a good solvent of LLM-105; the LLM-105 crystal is rapidly crystallized and separated out in a non-solvent containing a surfactant. By adopting the method disclosed by the invention, the cubic short rod-like LLM-105 crystal with regular crystal morphology can be obtained; the rod length of the LLM-105 crystal is 2-3 microns. The thermal performance of the LLM-105 crystal prepared by the method disclosed by the invention is obviously changed; thermal decomposition peak temperature is reduced to 343 DEG C from 350 DEG C; the LLM-105 crystal prepared by the method disclosed by the invention can be applied to a booster explosive.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

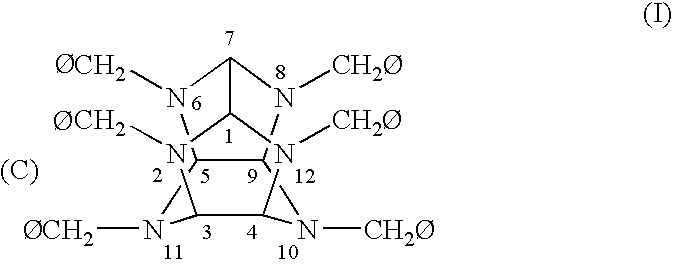

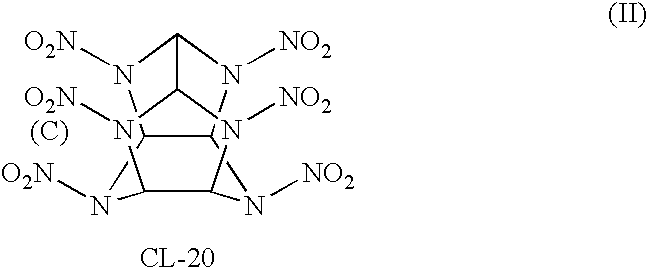

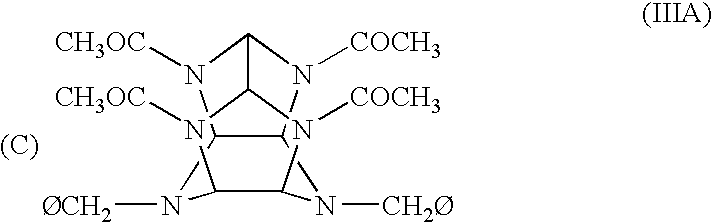

Polycyclic, polyamides as precursors for energetic polycyclic polynitramine oxidizers

ActiveUS7129348B1Organic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsHydrogenNitrogen

Hexabenzylhexaazaisowurtzitane is converted to tetracetyl, dibenzyl azaisowurtzitane. The benzyl groups are removed by catalytic transfer hydrogenolysis leaving a pair of available nitrogens. The available nitrogens are acetylated, and the resulting intermediate is converted to CL-20 with a strong nitrating agent.

Owner:NORTHROP GRUMMAN SYST CORP

Ammonium nitrate and paraffinic material based gas generating propellants

InactiveUS6176950B1Minimizes ballistic variabilityProcess environmental protectionExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsParaffin waxNitric oxide

An ammonium nitrate and paraffinic material based gas generating composition is provided. The gas generating composition includes ammonium nitrate as a oxidizer, mixed with a paraffinic material as a fuel. Examples of paraffinic material include paraffin wax, and broadly includes polyolefins. Polyolefins include polyethylene, polypropylene and polybutylene. Additionally, as alternatives, the gas generating composition of the present invention can also include a small quantity of magnesium stearate, potassium perchlorate or alternatively, RDX. The ammonium nitrate oxidizer, the paraffinic material fuel and the additional alternative components are combined and mixed in a predetermined stoichiometric ratio. The gas generating composition is devoid of metal oxides and produces virtually no particulate and slag upon ignition. It also produces an acceptable, low level of undesirable trace effluents such as carbon monoxide, and nitric oxide, both of which are inherently present in nonazide gas generating compositions. The gas generating composition is environmentally friendly after the deployment of the gas generant and abrasive damage to the tooling used in the manufacture of the gas generating composition is minimized.

Owner:ADVANCED INFLATOR TECH L L C

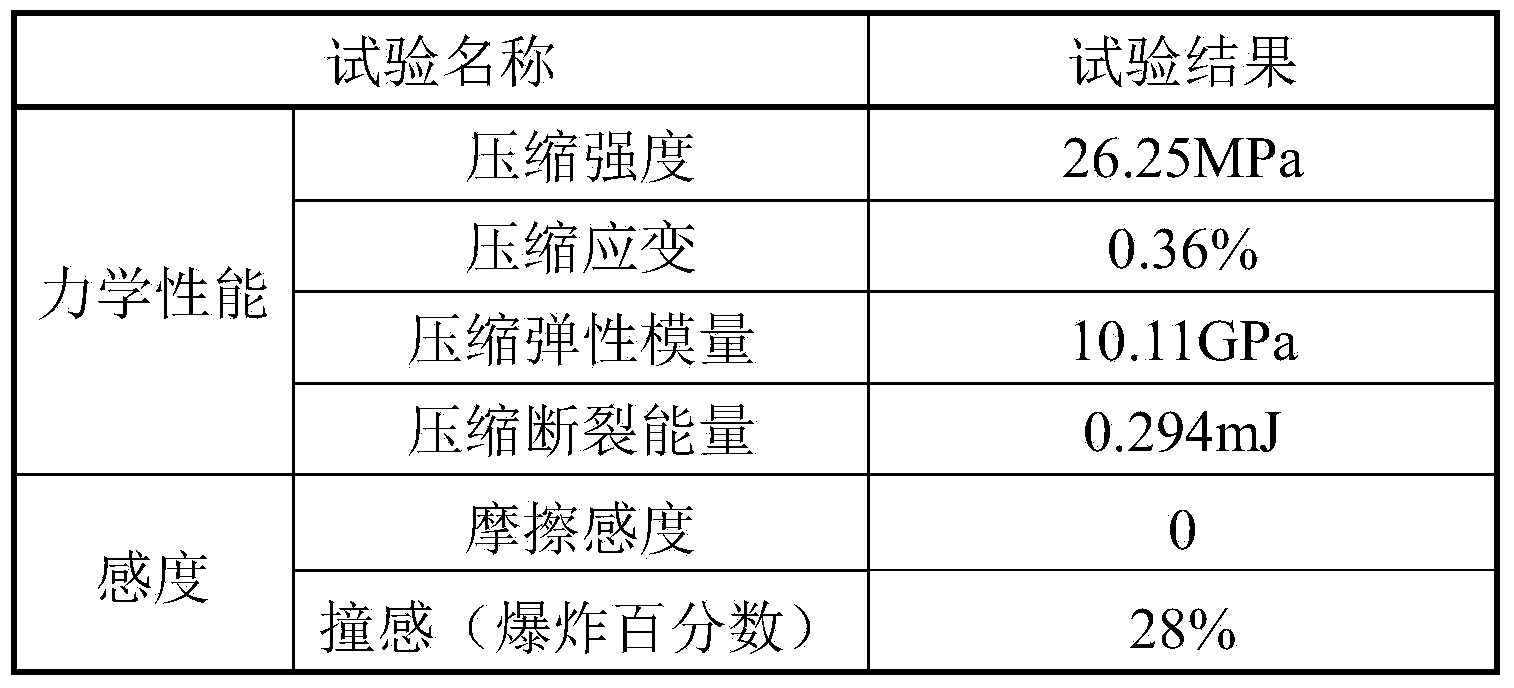

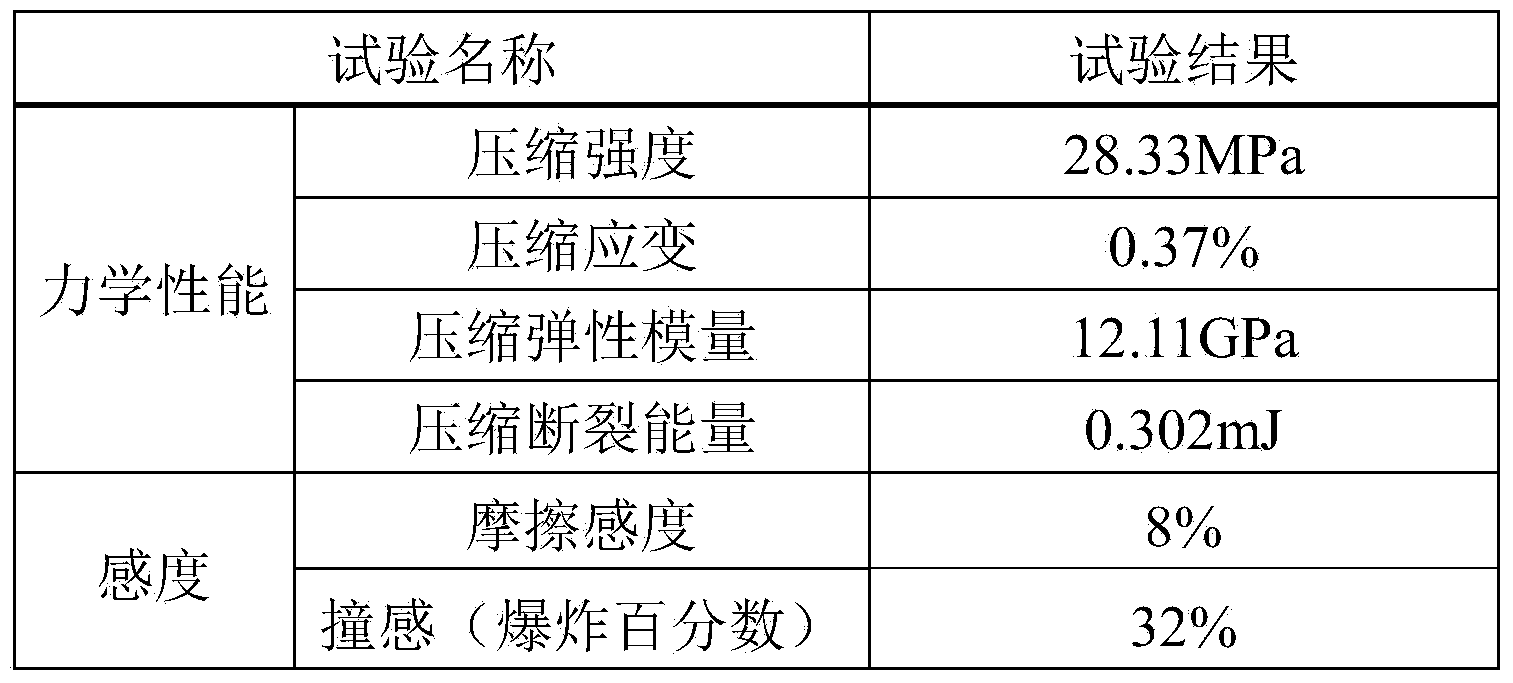

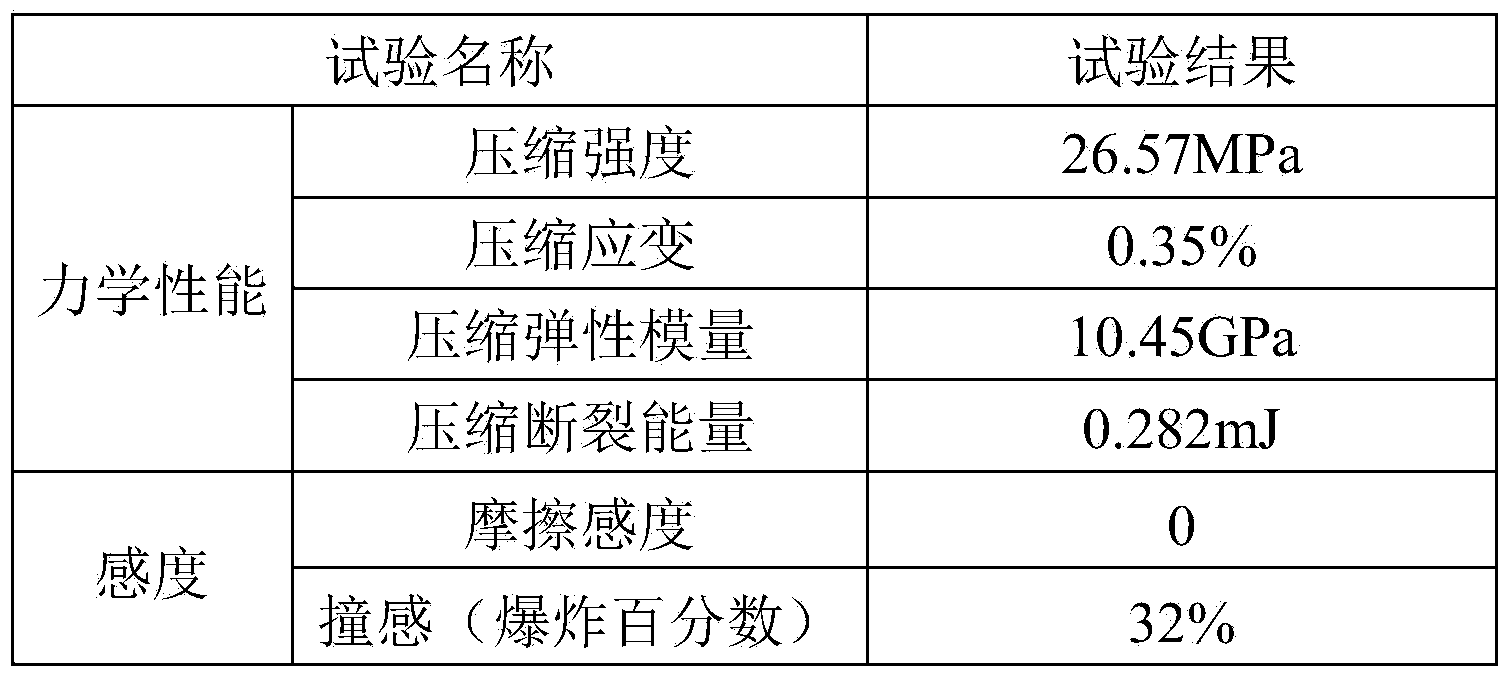

Metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and preparation method thereof

ActiveCN103588595AHigh strengthImprove toughnessNitroglycerine explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsMetal fiberFriction sensitivity

The invention discloses metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and a preparation method thereof. The melt-cast explosive comprises components in parts by weight as follows: 30-40 parts of TNT, 60-70 parts of hexogen or octogen, 0-3 parts of metal fiber and 0-2 parts of paraffin. The preparation method comprises the steps as follows: a surfactant solution is used for treating the metal fiber; materials are compounded; the materials are placed in an explosive melting machine for mixing; and casting is performed under atmospheric pressure. The TNT-based melt-cast explosive has the mechanical properties as follows: the compressive strength is larger than or equal to 24 MPa, the compressive strain is larger than or equal to 0.33%, the compressive modulus of elasticity is larger than or equal to 9 GPa, lower mechanical sensitivity is provided, the friction sensitivity is 0%-10%, and the impact sensitivity is 20%-40%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Preparation of explosive and explosion lamination method of texture interface

ActiveCN104227221AReduce critical diameterHigh densityNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDetonationEngineering

The invention discloses preparation of skin explosive and an explosion lamination method of a texture interface. A base plate with a certain texture structure is arranged on the surface; an outwards-protruding or flat covering plate is pressed into a concave part of the base plate under the action of the skin explosive or other explosion energy; a convex part of a base plate material is sunk into a concave part of the covering plate, so that the tight combination is realized. The skin explosive has the characteristics of stable detonation performance and good viscoelasticity, stability, storage performance and the like, and can be prepared into rolls in advance to be stored, so that explosive distribution time is shortened and the continuous production of compounding metal boards is convenient to realize; the skin explosive can be compounded with metal materials, namely plates, rods, pipes and the like. A texture interface composite plate is subjected to the explosion lamination by adopting a manner of combining physical extruding deformation with a metallurgical bonding phase, and the physical and chemical properties of sheet materials on the two sides of a combining interface are not changed; the explosive amount of a unit area is small and the energy utilization rate is high. The explosion lamination method of the texture interface can be applied to the production of metal plates and thin plates, which have greater physical property difference, such as melting points.

Owner:UNIV OF SCI & TECH OF CHINA

Precursor of an explosive composition including at least one ionic liquid and a method of desensitizing an explosive composition

An ionic liquid is disclosed. A precursor composition that comprises at least one ionic liquid and at least one energetic material is also disclosed, as is a method of synthesizing an ionic liquid and a method of desensitizing an explosive composition.

Owner:NORTHROP GRUMMAN SYST CORP

Gas generating composition

InactiveUS6779464B1Nitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAmmonium perchlorate explosive compositionsNitroguanidinePerchlorate

A gas generating composition is obtained in which an amount of a combustion residue based on a unit amount of a gas generated is reduced.A gas generating composition comprising nitroguanidine, guanidine nitrate or a mixture thereof as a fuel and further an oxidizing agent. The oxidizing agent is a perchloric acid salt, a nitric acid salt or a mixture thereof, and when the oxidizing agent is ammonium perchlorate, a chlorine neutralizer is further incorporated.

Owner:DAICEL CHEM IND LTD

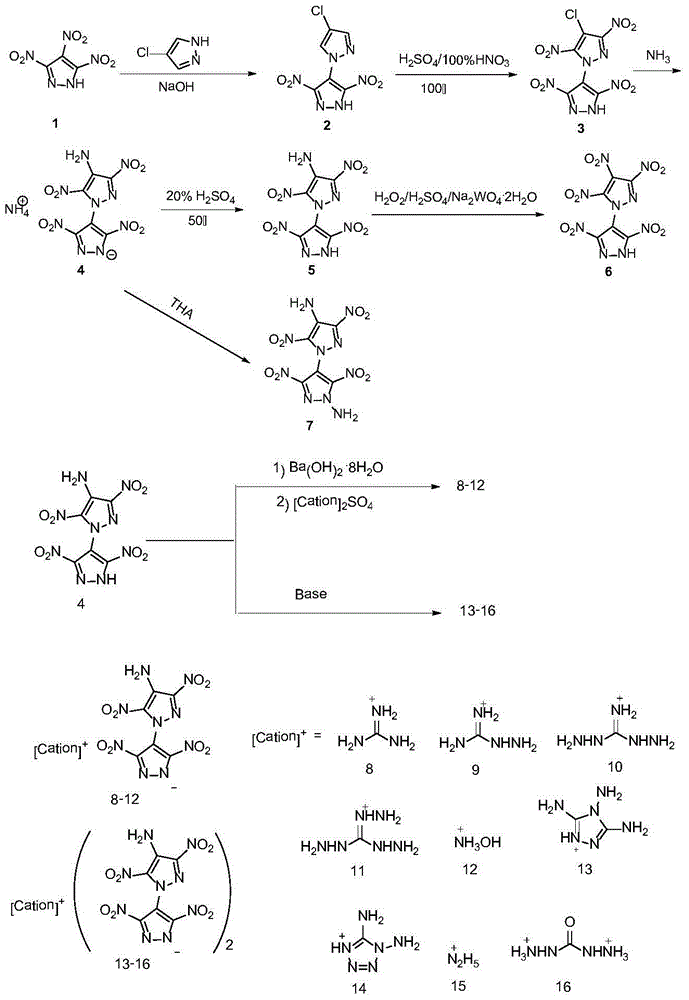

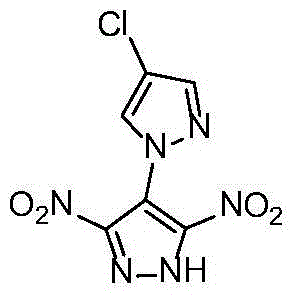

Bispyrazolyl energetic compounds and preparation method thereof

InactiveCN103601680AThe measured impact is greater than 60JImprove detonation performanceOrganic chemistryOrganic compound preparationHigh densityDetonation

The invention relates to bispyrazolyl energetic compounds and a preparation method thereof, and belongs to the technical field of energetic materials. The synthesis method of the compounds comprises the following steps: 1, reacting 3,4,5-trinitropyrazole with 4-chloropyrazole to obtain a compound (2), nitrating the compound (2) to obtain a compound (3), aminating to obtain a compound (4), and acidifying and aminating to obtain a neutral maternal (5) and a compound (7) respectively; 2, oxidizing the neutral maternal to obtain a compound (6); 4, mixing the neutral maternal (5) with Ba(OH)2.8H2O, reacting the obtained mixture with sulfate of a corresponding cation, filtering, and evaporating the obtained filtrate to remove a solvent in order to obtain target products (8-12); and 4, directly reacting the neutral maternal (5) with the corresponding cation, and evaporating the obtained material to remove a solvent in order to obtain target products (13-16). The referred fourteen energetic compounds have the characteristics of good thermal stability, high density, low impact sensitivity, and excellent calculated detonation performance, and are potential insensitive high explosives.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Castable thermobaric explosive formulations

InactiveUS6969434B1Promote combustionIncrease pressureNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPlasticizerSolid fuel

The invention disclosed herein relates to an explosive capable of enhanced combustion efficiently capable of sustaining a high pressure over a period of time in a confined environment, such as an air tight room or a cave, where oxygen may be in limited supply. An embodiment of the present invention is a metal composite that combines a binder, a reactive metal and an oxidizer. In another embodiment, a plasticizer and a catalyst may be added. In a preferred embodiment of the present invention, a solid fuel-air explosive (SFAE) having an annular design is used. In a typical annular design, a cylindrical shell of SFAE surrounds the cylindrically shaped high explosive. The SFAE may be selected from the group consisting of reactive metal and metal composite. In addition, the metal composite is formed from at least one reactive metal, at least one binder and an oxidizer.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

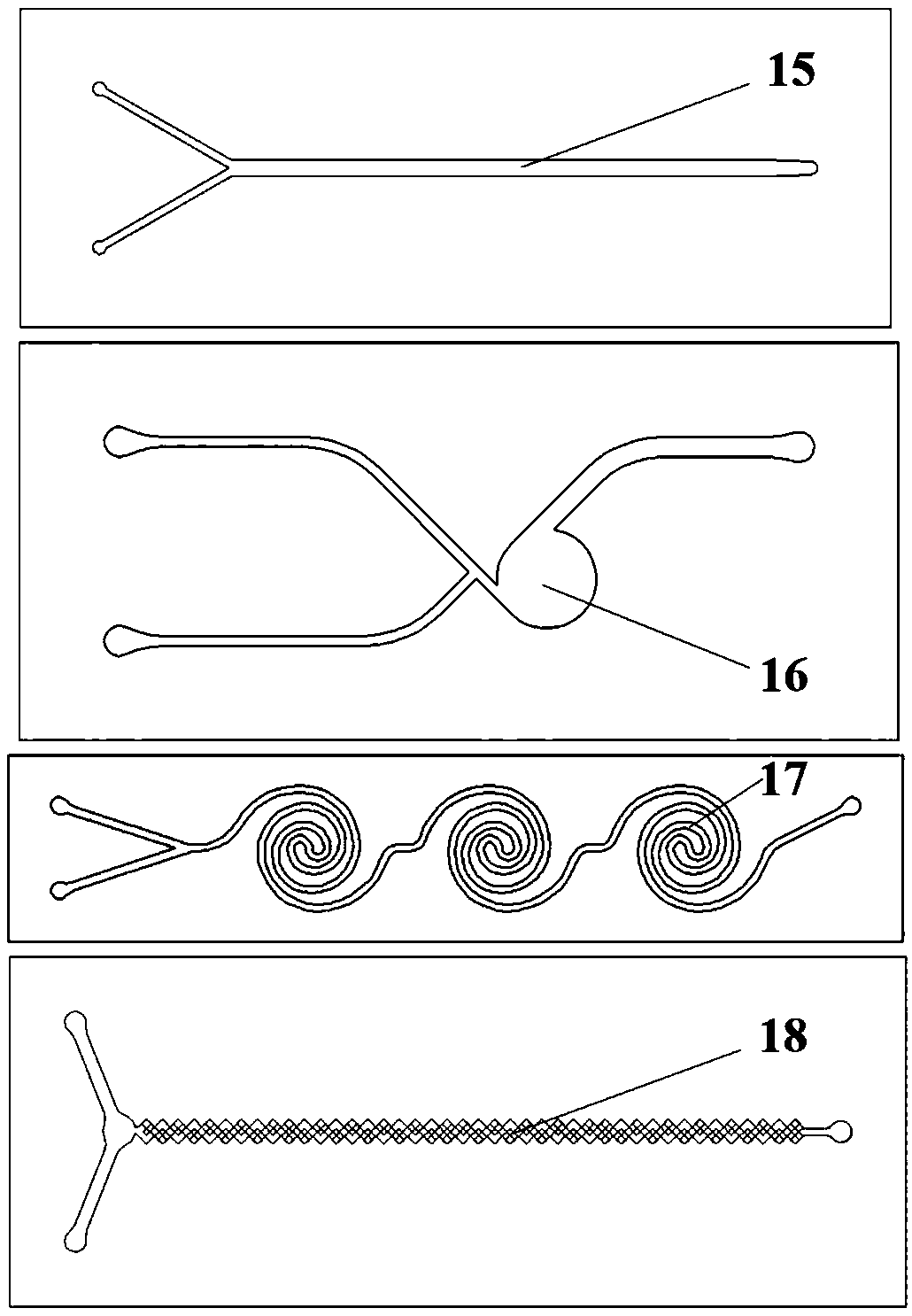

Nano-explosive preparation system and nano-explosive preparation method based on microfluidic technology.

ActiveCN108863687AQuick mixShort residence timeMaterial nanotechnologyExplosive working-up apparatusTemperature controlNon solvent

The invention relates to the field of initiating explosive devices, in particular to a nano-explosive preparation system and a nano-explosive preparation method based on the microfluidic technology. The system comprises a fluid driving unit, a recrystallization unit, a sample collection unit and a connection component; the fluid driving unit is used for driving solvents and non-solvent solutions;the recrystallization unit comprises a temperature control device and a microchip; the microchip comprises a micro-mixing structure; after the fluid driving unit drives the solvents and the non-solvent solutions to contact with the microchip, rapid mixing can be realized at a recrystallization temperature under the action of the micro-mixing structure to form suspensions; the sample collection unit is used for collecting the suspensions flowing out from the microchip; the connection component is sequentially connected with the fluid driving unit, the recrystallization unit and the sample collection unit. The nano-explosive preparation system and the nano-explosive preparation method have the advantages that the solvents and the non-solvent solutions are rapidly mixed to react to generate the suspensions through the temperature control device and the micro-mixing structure of the recrystallization unit, and the suspensions are washed, filtered and dried to obtain nano-explosives with uniform crystal forms, good crystal appearance and concentrated particle size distribution.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com