Metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and preparation method thereof

A technology of metal fiber and melting and casting explosives, which is applied in the directions of explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, nitroglycerin compositions, etc. Processing steps and other issues to achieve the effect of enhancing strength and toughness, good material rheology, and conducive to casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

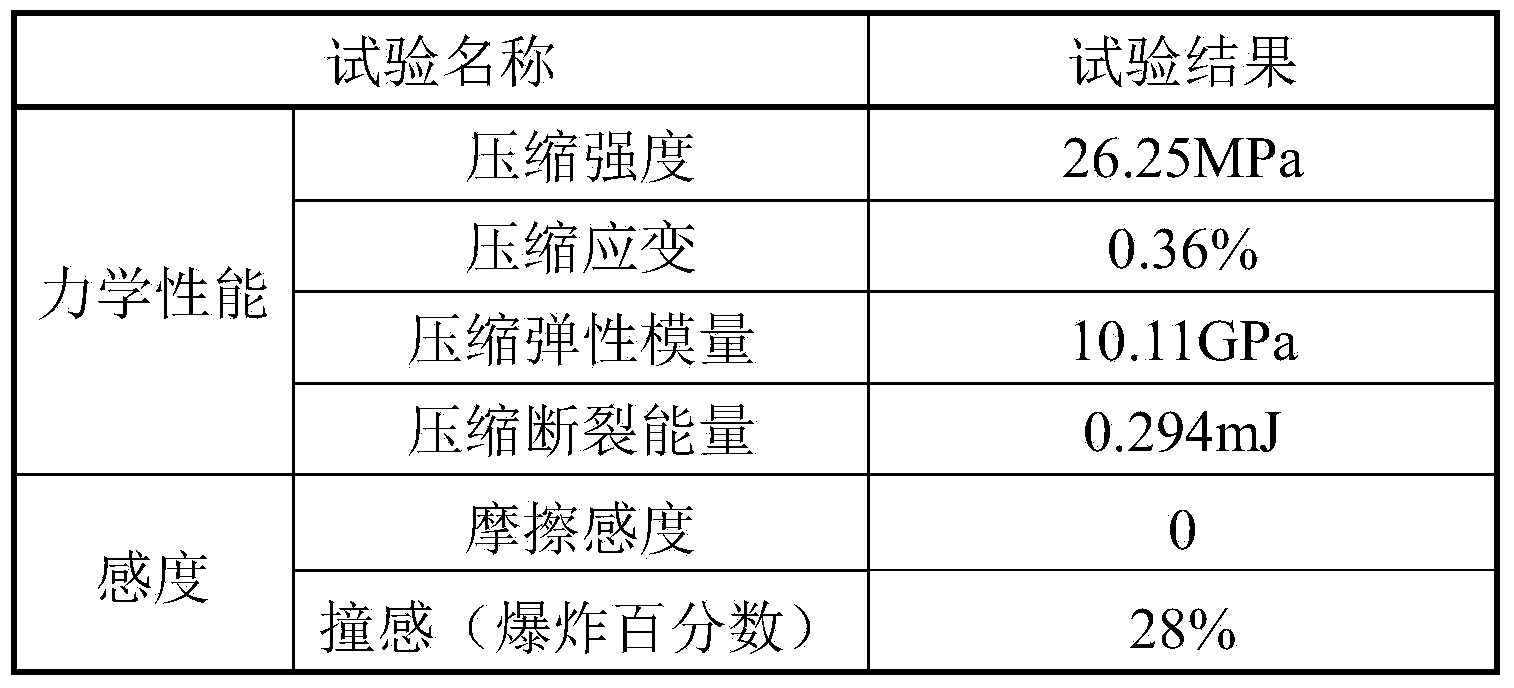

Embodiment 1

[0022] Example 1: Aluminum fiber toughened and reinforced TNT-based fused-cast explosive and its preparation method

[0023] The formula composition (percentage by weight) of aluminum fiber toughening reinforced TNT-based fused-cast explosive is as follows:

[0024] TNT, 35%;

[0025] RDX, 62.5%; RDX coarse and fine particles comply with GJB296A-1995 Class 3 and Class 5 particle size standards, of which 22.5% are coarse and 40% are fine;

[0026] Aluminum fiber, 1.0%; the length of the aluminum fiber is 3 mm, and the diameter is 70 μm;

[0027] Paraffin, 1.5%.

[0028] The preparation method of TNT-based melting and casting explosive is as follows:

[0029] Step 1: Aluminum fiber pretreatment: put the aluminum fiber in an ethanol solution with a mass fraction of 2% sodium dodecylbenzenesulfonate, stir for 30 minutes at a speed of 200-500 rpm, ultrasonically disperse for 10 minutes with an ultrasonic oscillator, filter and dry .

[0030] Step 2: Ingredients: Weigh the comp...

Embodiment 2

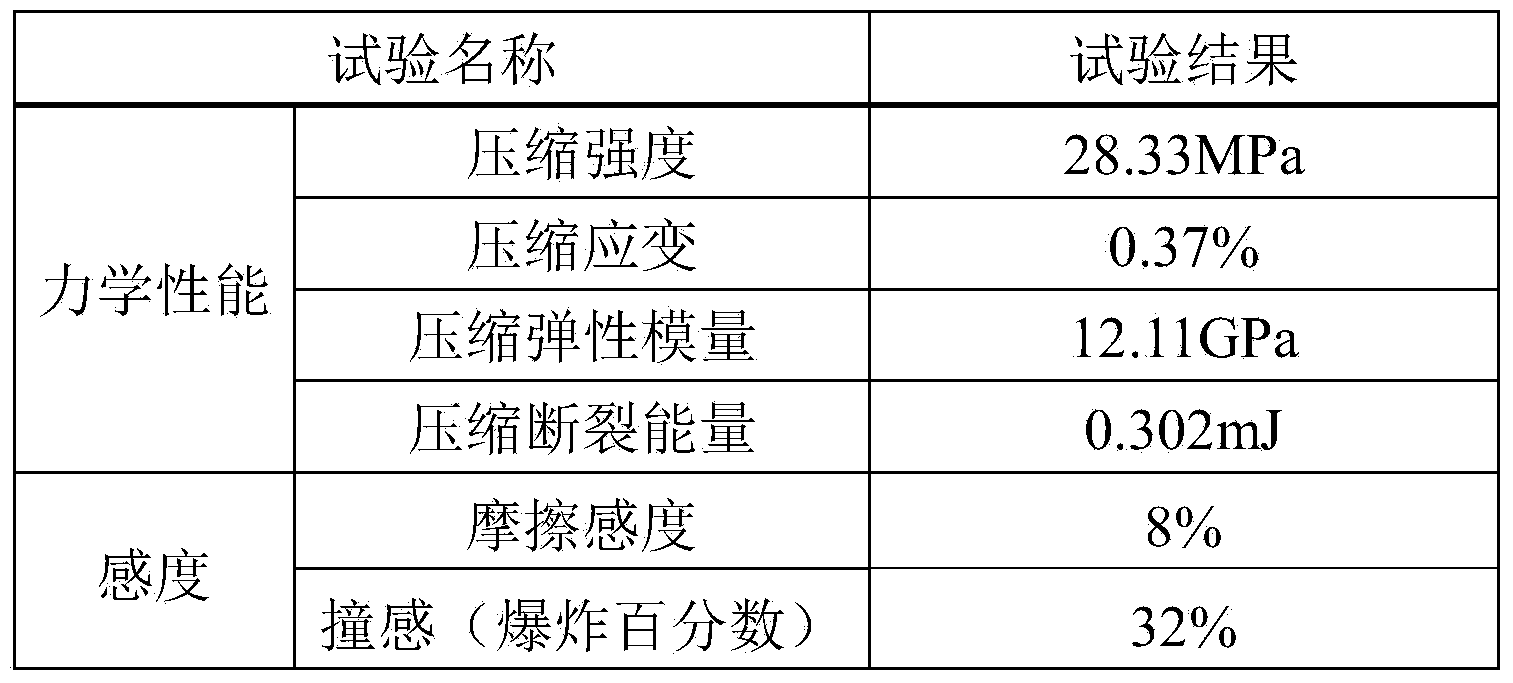

[0036] Embodiment 2: Stainless steel fiber toughened and reinforced TNT-based fused-cast explosives

[0037] The formula composition (percentage by weight) of stainless steel fiber toughened and strengthened TNT-based melt-cast explosive is as follows:

[0038] TNT, 35%;

[0039] RDX, 62.5%; RDX coarse and fine particles comply with GJB296A-1995 Class 3 and Class 5 particle size standards, of which 32.5% are coarse and 30% are fine;

[0040] Stainless steel fiber, 1.0%; the diameter of stainless steel fiber is 15μm, and the length is 6mm;

[0041] Paraffin, 1.5%;

[0042] The preparation method of the stainless steel fiber toughened and reinforced TNT-based fused-cast explosive in Example 2 is the same as that in Example 1.

[0043] The properties of the prepared stainless steel fiber toughened and reinforced TNT-based fused-cast explosives are shown in Table 2.

[0044] Table 2: Properties of TNT-based fused-cast explosives reinforced by stainless steel fibers

[0045] ...

Embodiment 3

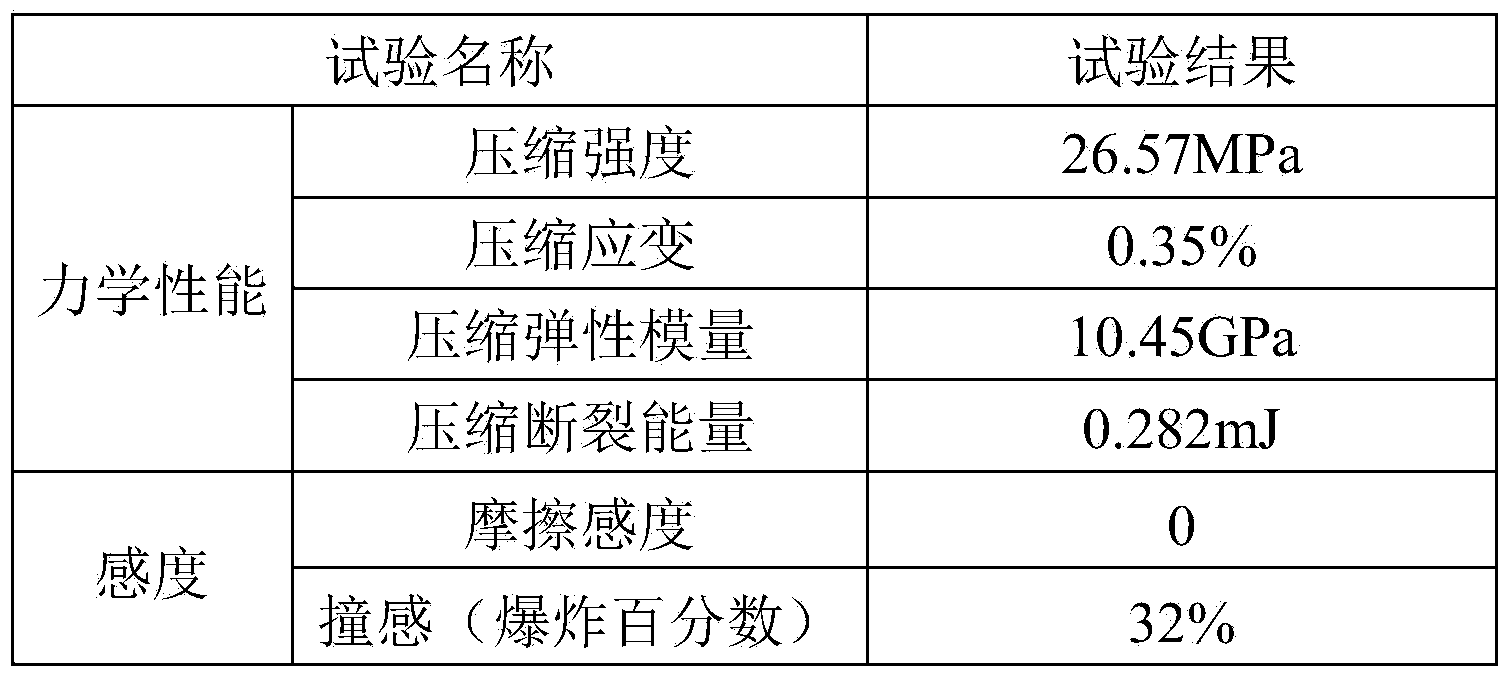

[0046] Embodiment 3: Copper fiber toughened and reinforced TNT-based fused-cast explosives

[0047] The formula composition (percentage by weight) of copper fiber toughening reinforced TNT-based fused-cast explosive is as follows:

[0048] TNT, 32.5%;

[0049] HMX, 65%; the coarse and fine particles of HMX meet the 3rd and 5th standards of GJB2335-1995 respectively, of which 40% are coarse particles and 25% are fine particles;

[0050] Copper fiber, 1.0%; the diameter of the copper fiber is 30μm, and the length is 3mm;

[0051] Paraffin, 1.5%;

[0052] The preparation method of copper fiber toughened and reinforced TNT-based fused-cast explosive in Example 3 is the same as that in Example 1.

[0053] The properties of the prepared copper fiber toughened and reinforced TNT-based fused-cast explosives are shown in Table 3.

[0054] Table 3: Properties of TNT-based fused-cast explosives reinforced by copper fiber toughening

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com