Patents

Literature

751results about How to "Easy to cast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

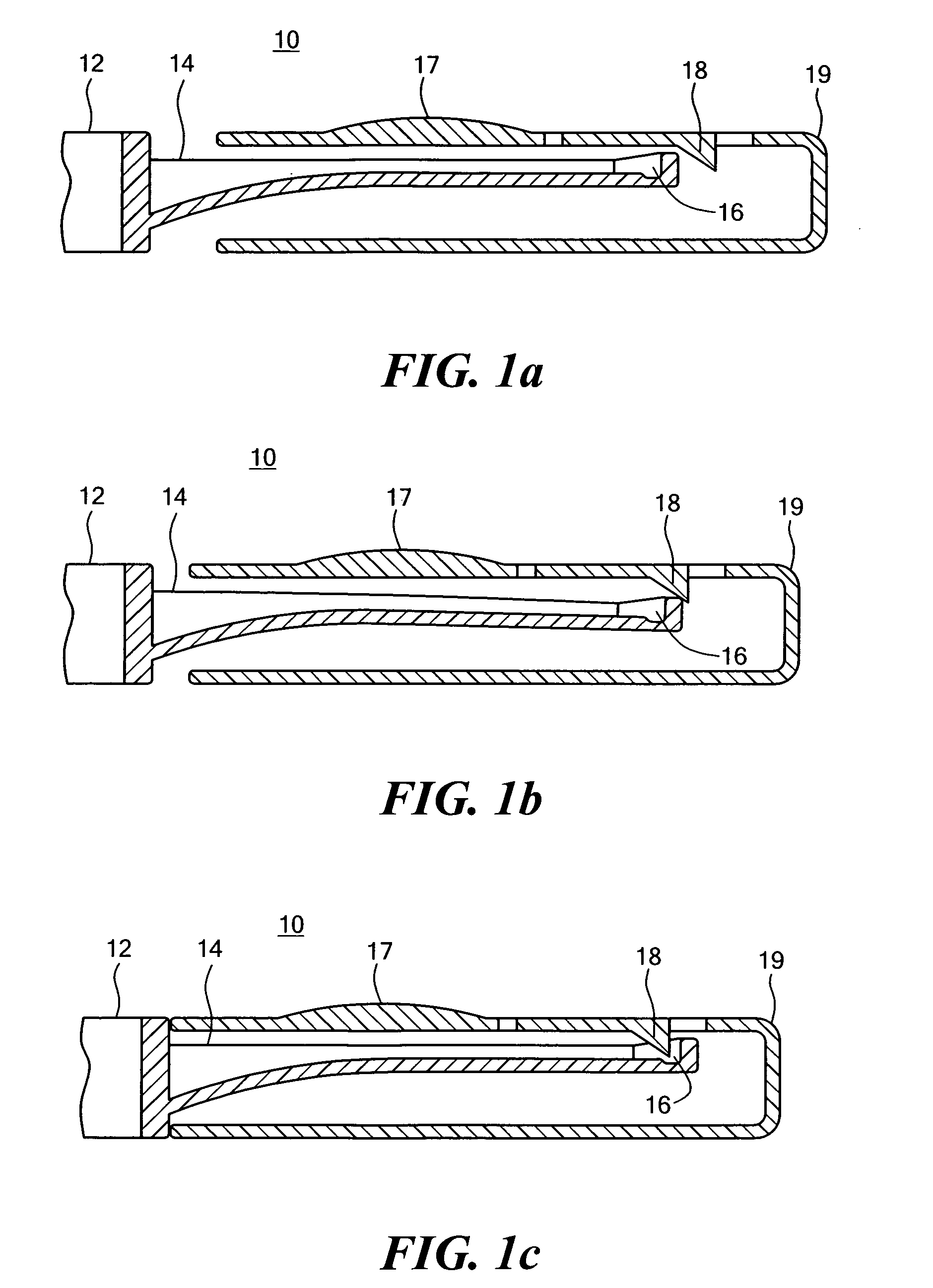

Image projecting device and method

InactiveUS20060018025A1Easy to castImprove efficiencyPicture reproducers using projection devicesOptical elementsProjection opticsSpatial light modulator

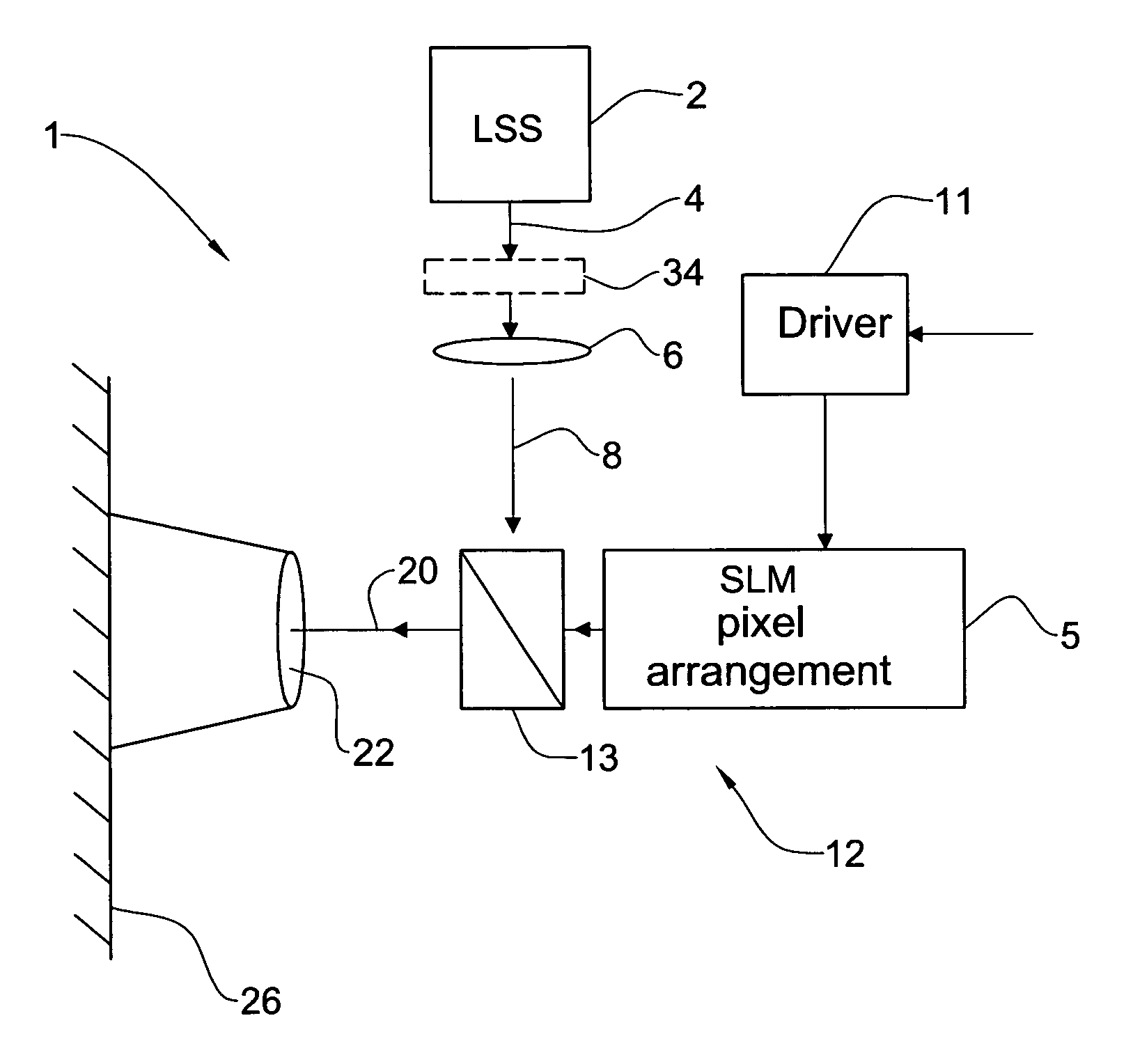

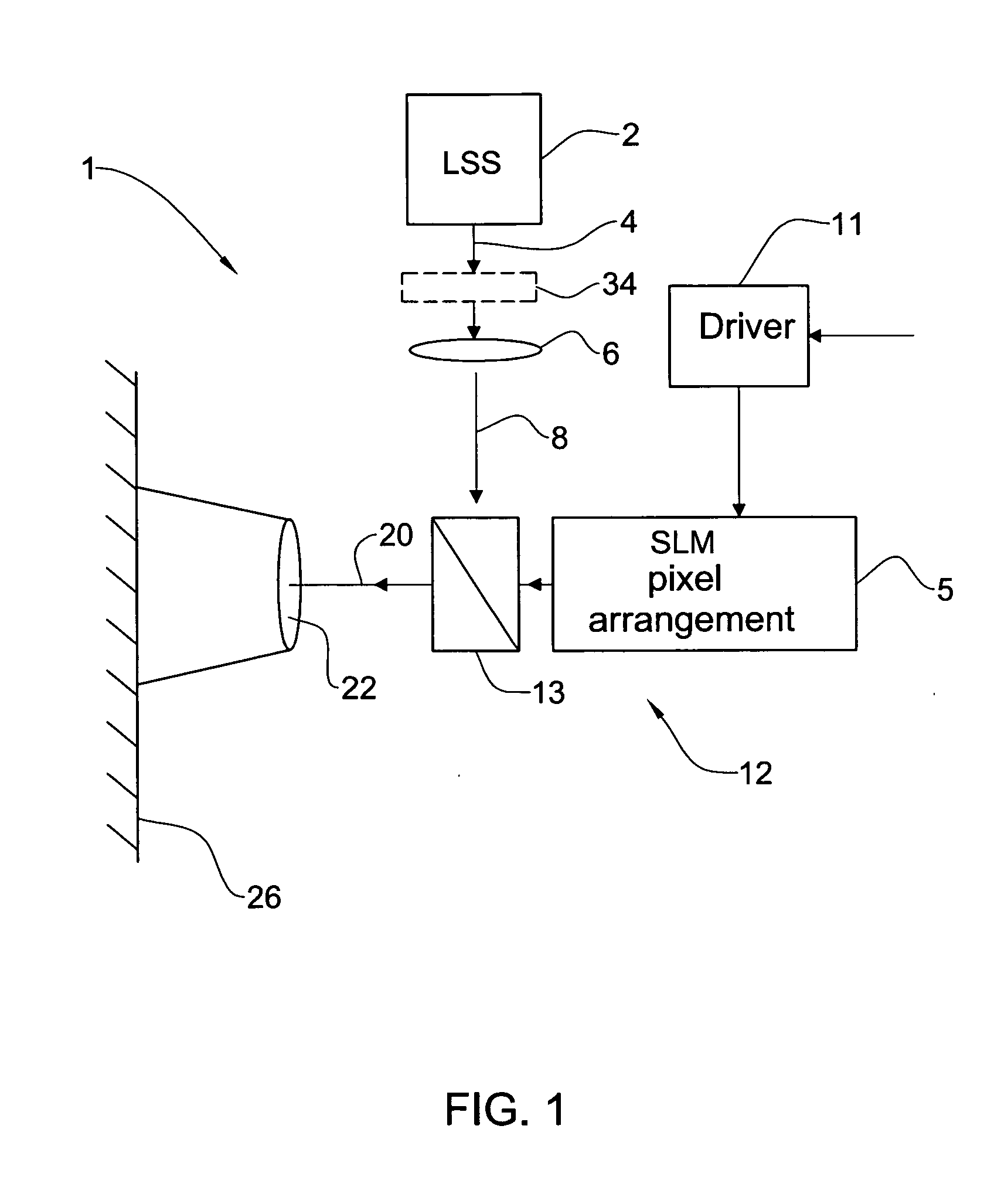

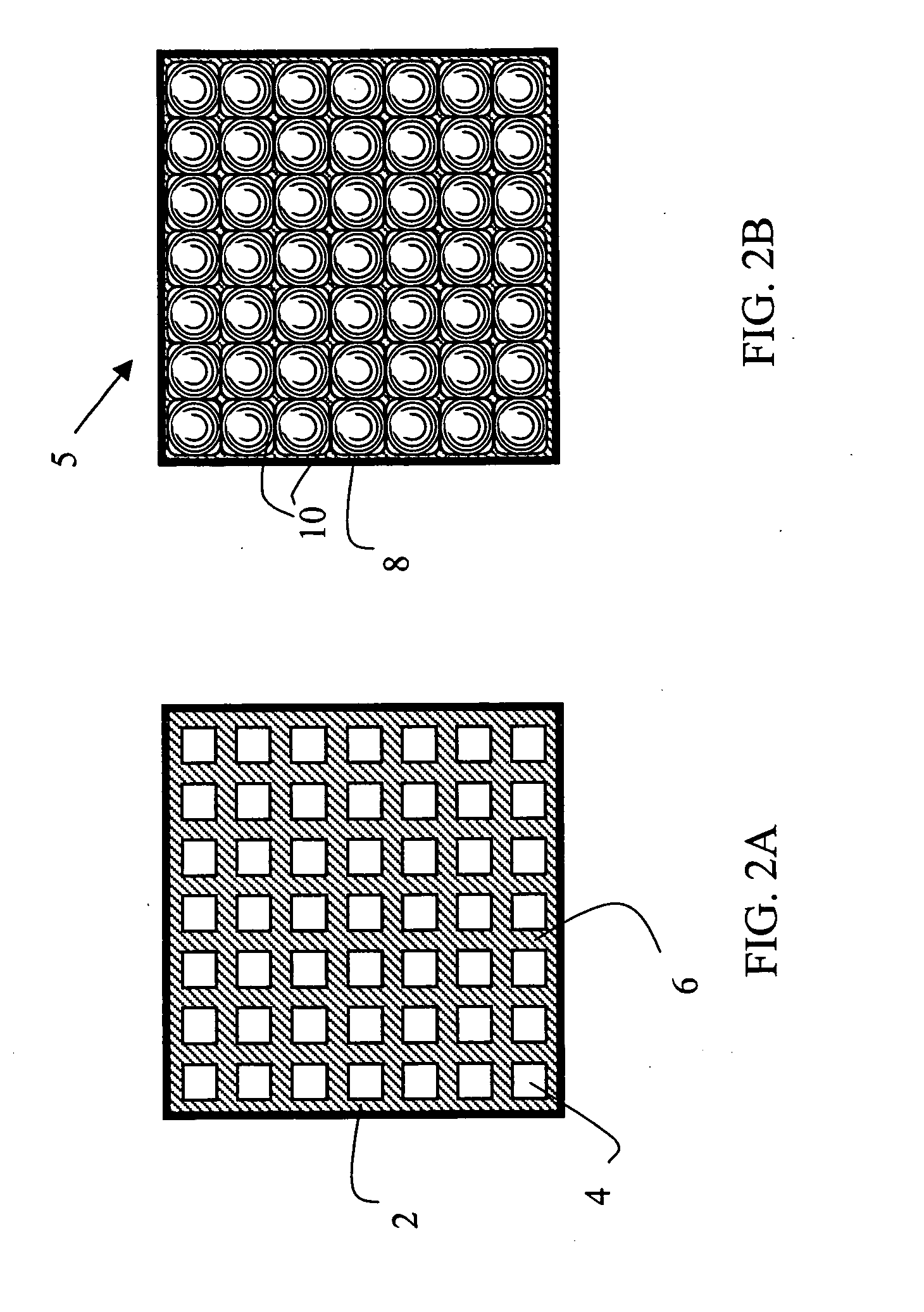

An image projecting device and method are presented. The device comprises a light source system, a spatial light modulator (SLM) unit, and an image projection optics accommodated at the output side of the SLM unit. The SLM unit may be reflective or transmissive. The SLM unit comprises an SLM pixel arrangement enclosed between two glass substrates. The pixel array arrangement is formed by a pixel array assembly and at least one microlens assembly. The microlens assembly includes at least one microlens array accommodated proximate of the pixel array assembly. The light source system may comprise n light sources and a light converting means in optical path of light generated by the n light sources, to thereby produce m light beams of different wavelength ranges, wherein m>n. The light source system may comprise a multi-mode laser, thereby reducing a speckle effect in an integrated speckle pattern produced by the multiple modes, as compared to that of a single mode.

Owner:EXPLAY

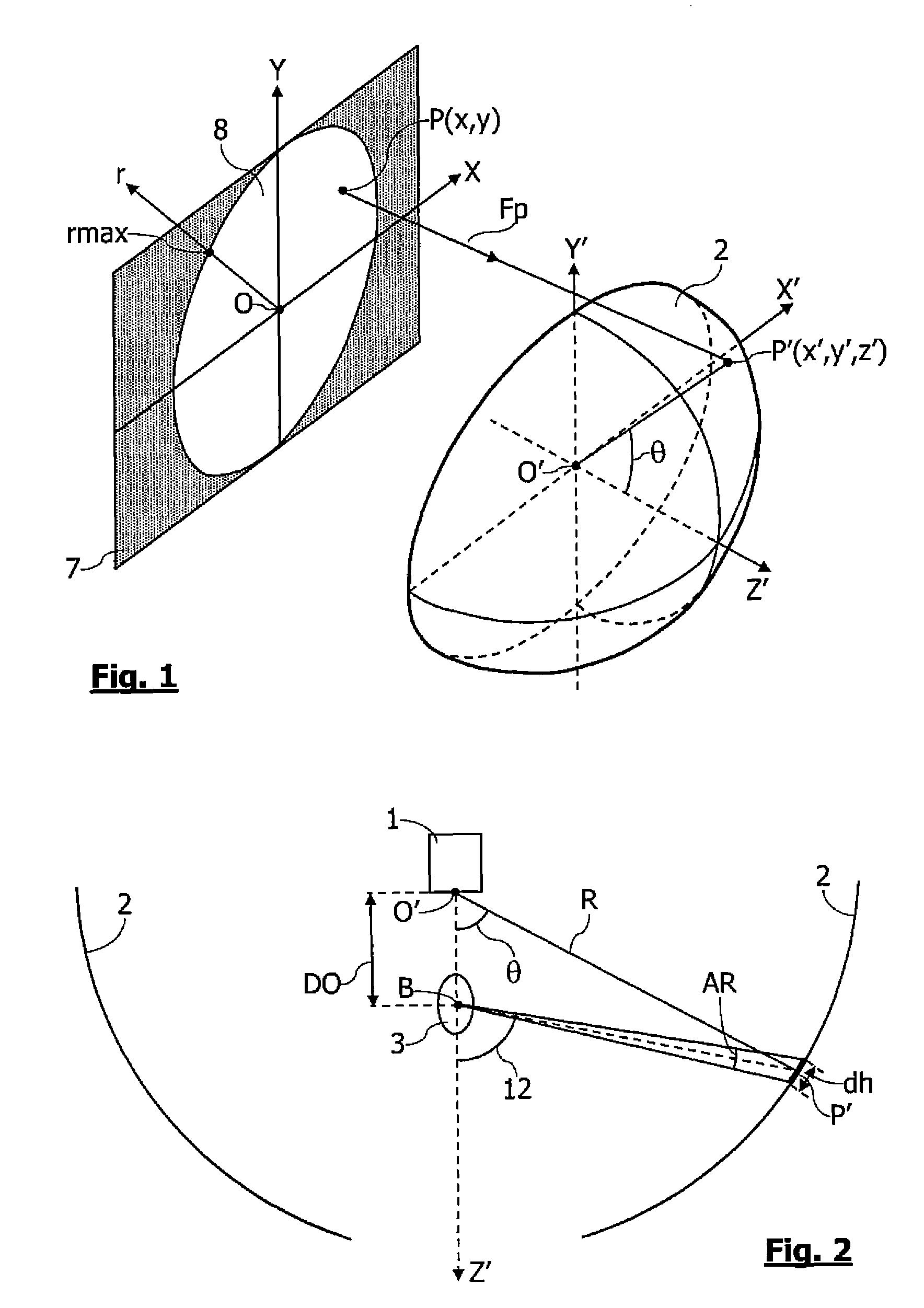

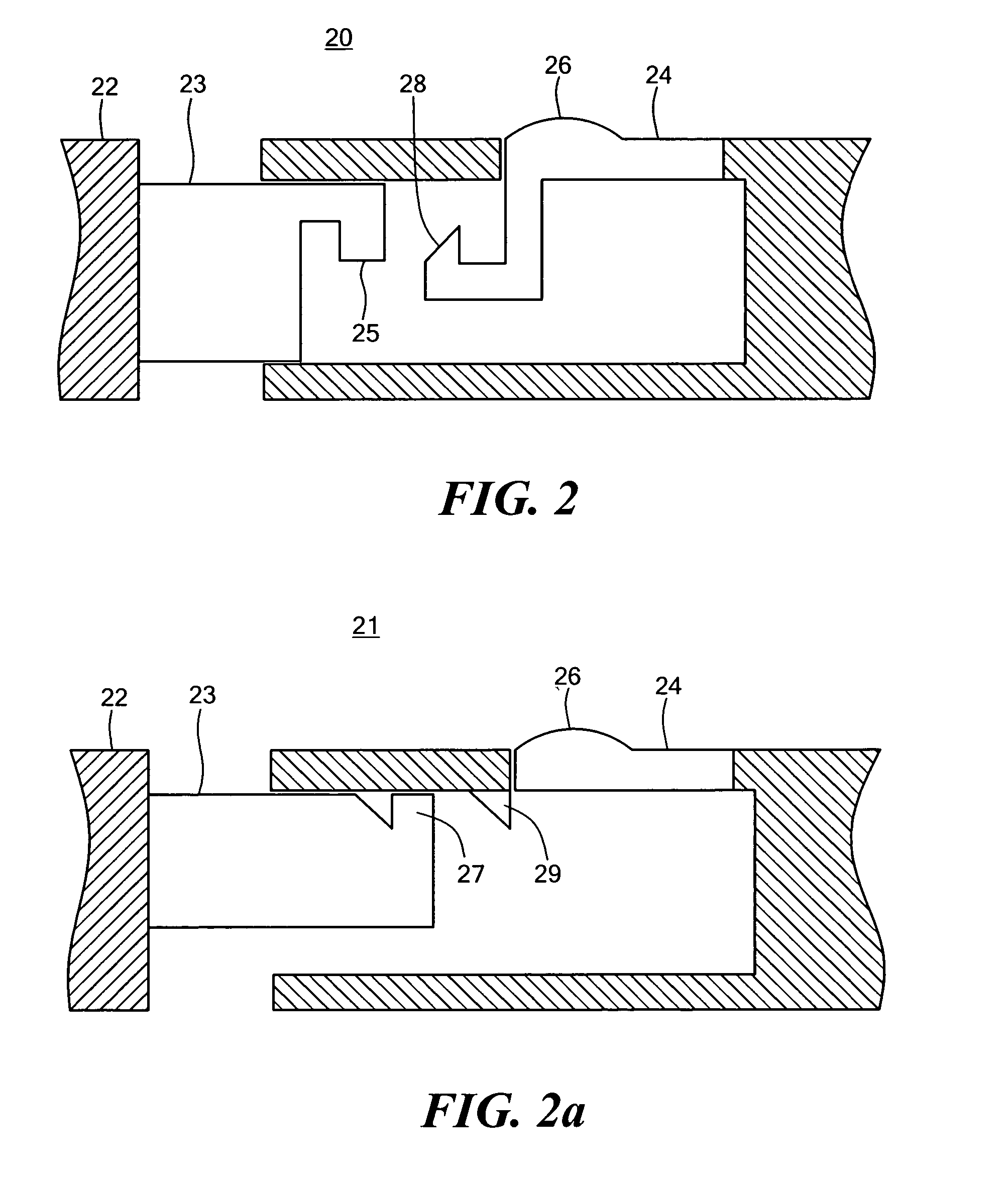

Method and device for projecting a panoramic image with a variable resolution

ActiveUS8016426B2Constant resolutionEasy to castProjectorsPanoramic photographyObservation pointProjection image

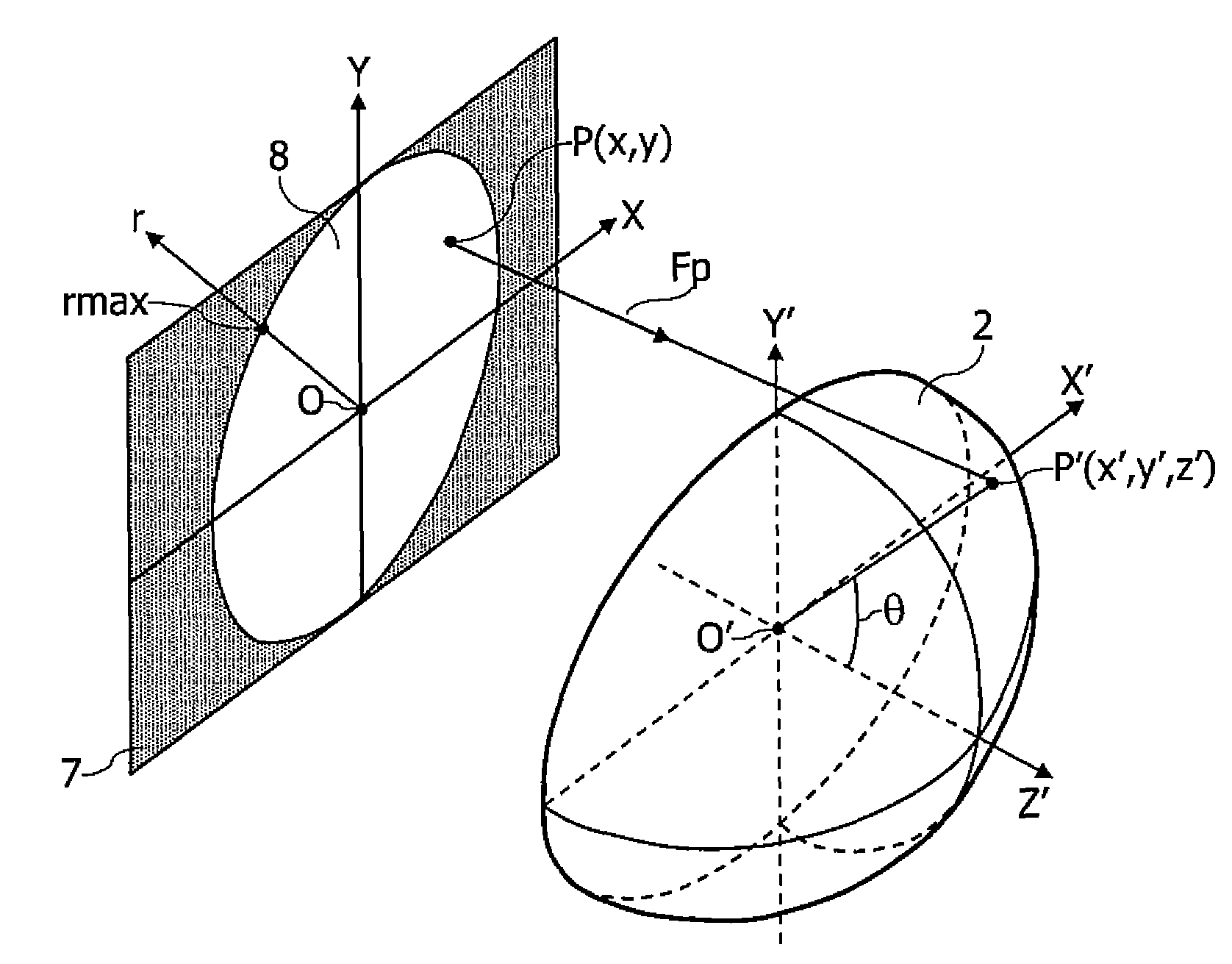

Embodiments include a method and apparatus for projecting a panoramic image, the method including steps of generating an image on an image generation surface, and then projecting the generated image on a projection surface to obtain a panoramic projected image, the points of the generated image being projected on the projection surface according to a non uniform distribution determined as a function of at least one parameter of a set comprising the shape of the generated image, the shape of the projection surface, and the position of an observation point of the projected image, in relation to the projection surface.

Owner:IMMERVISION INC

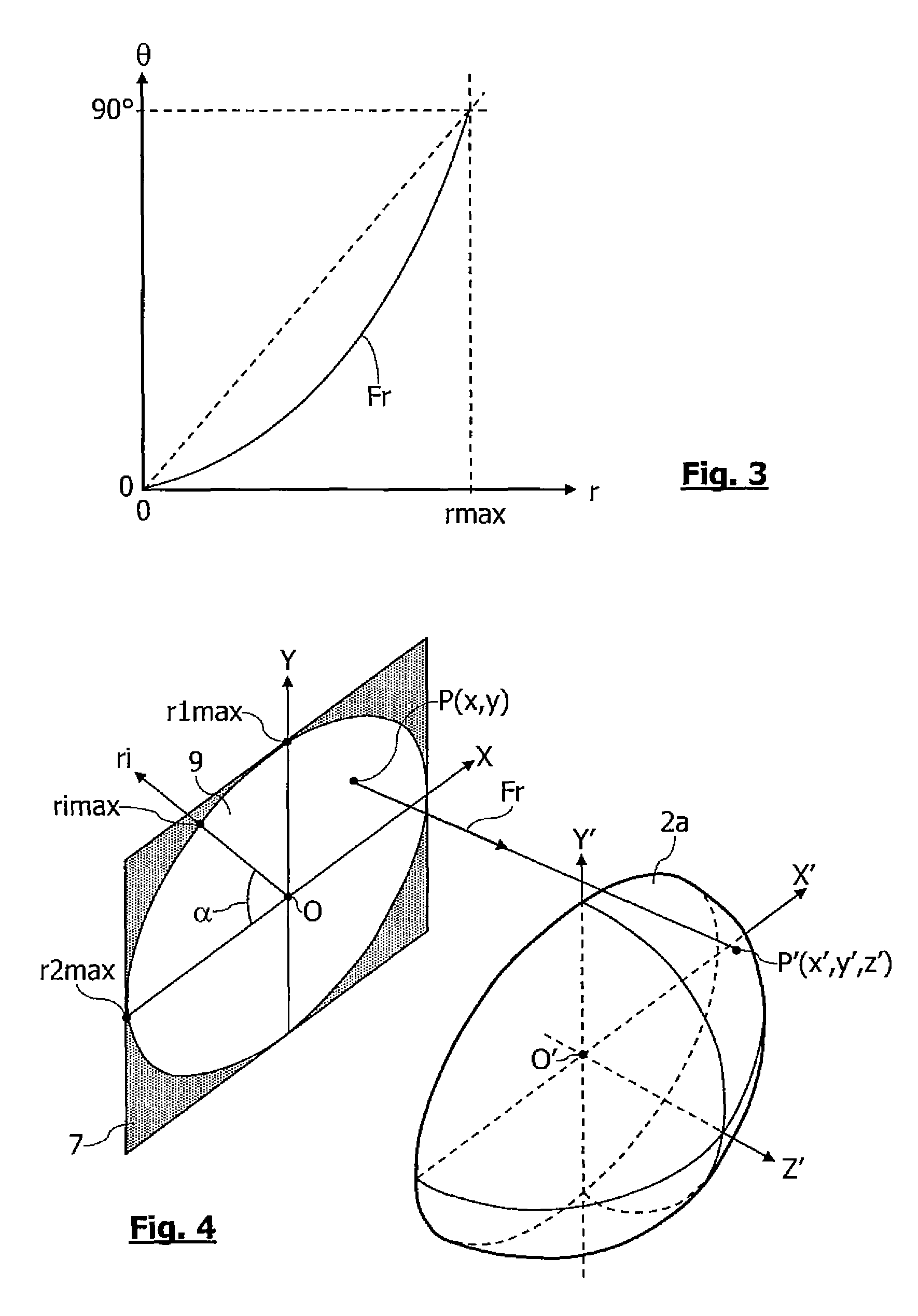

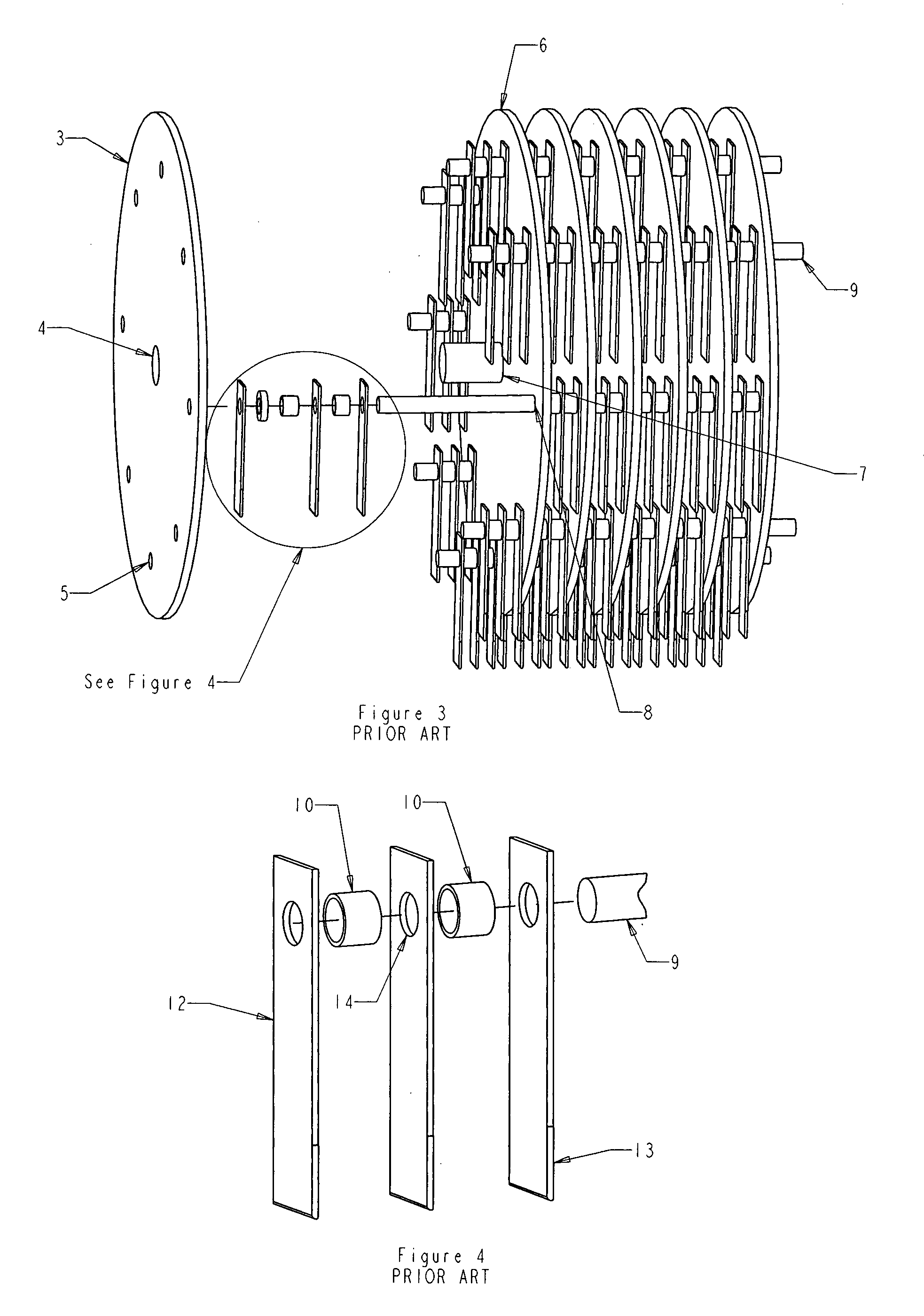

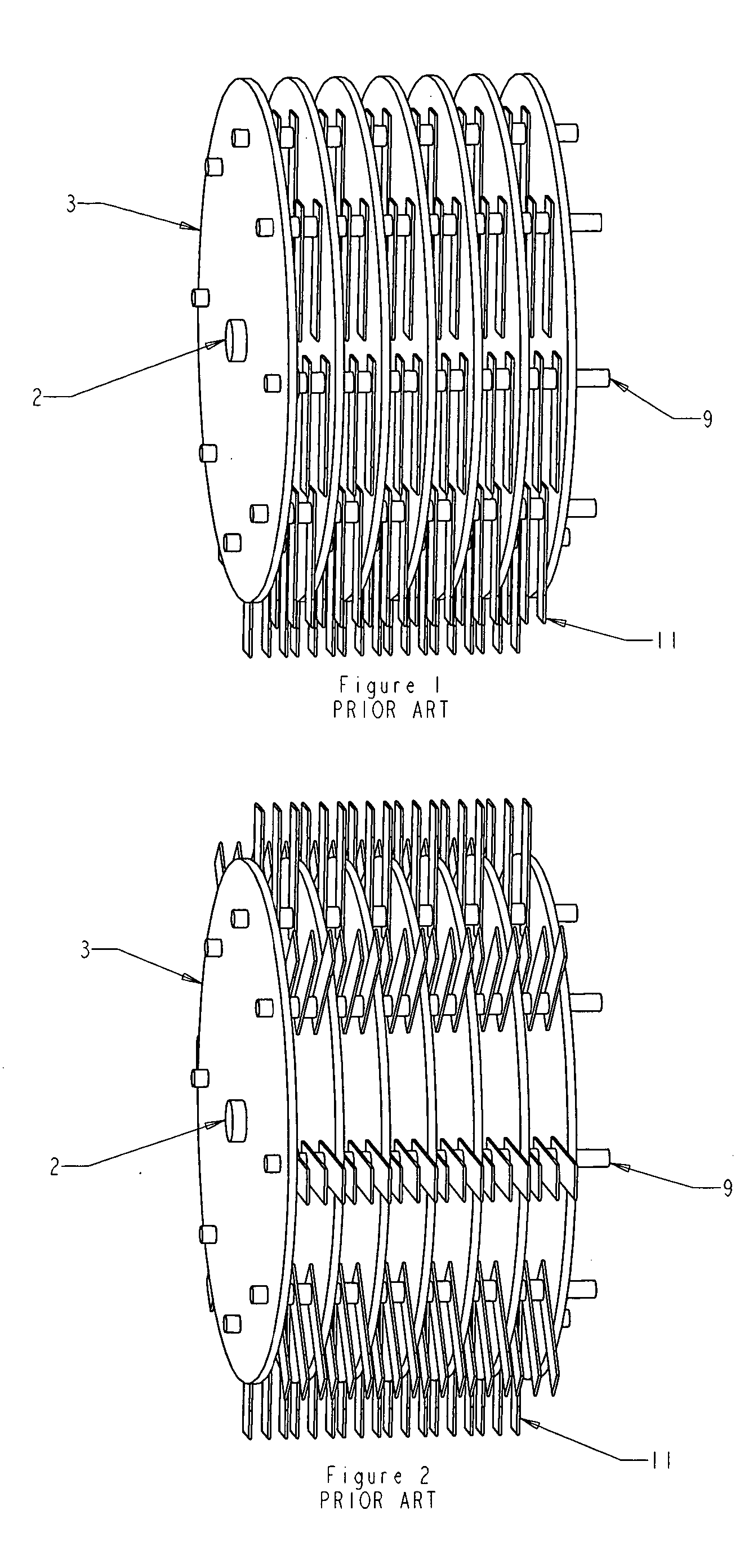

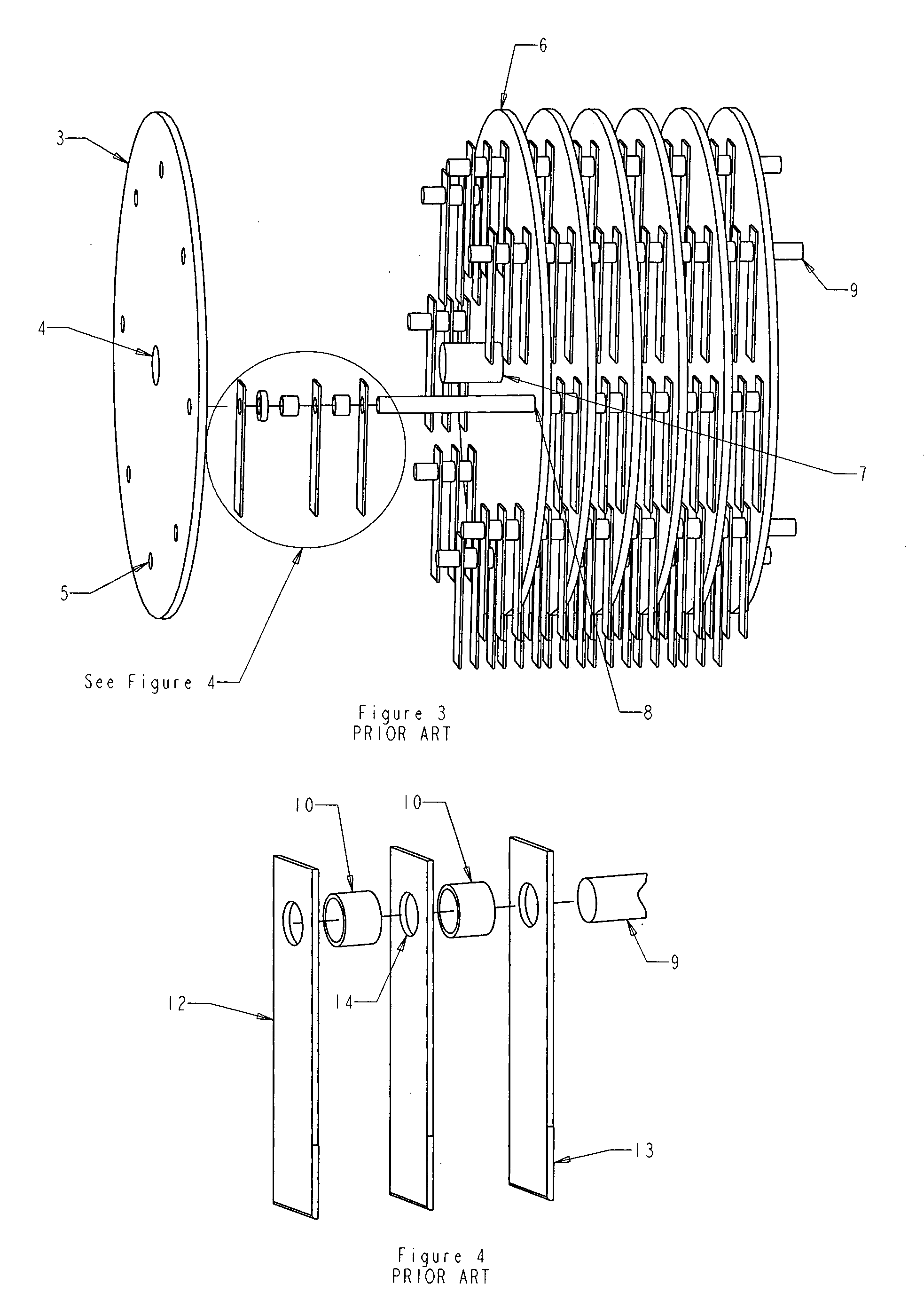

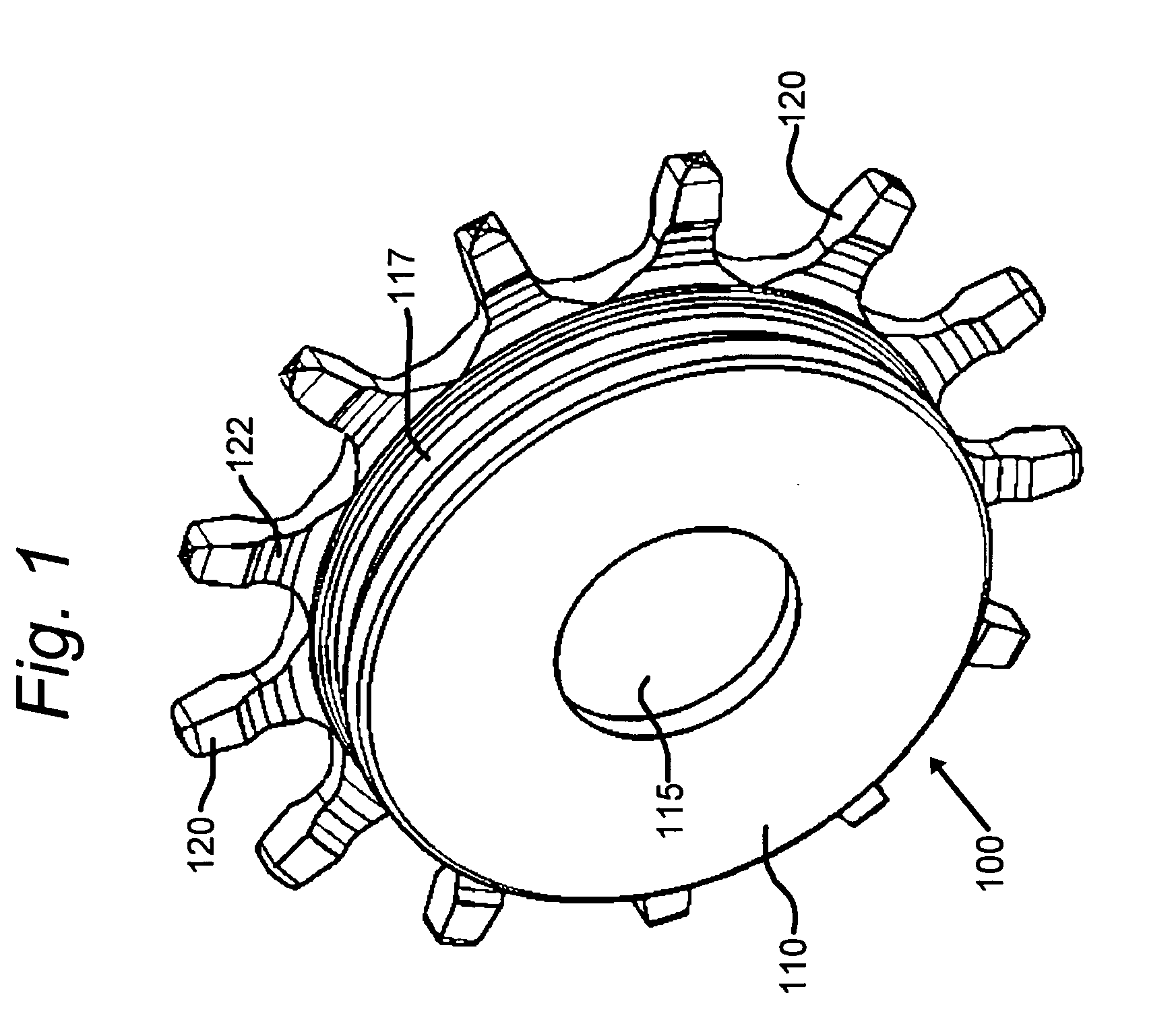

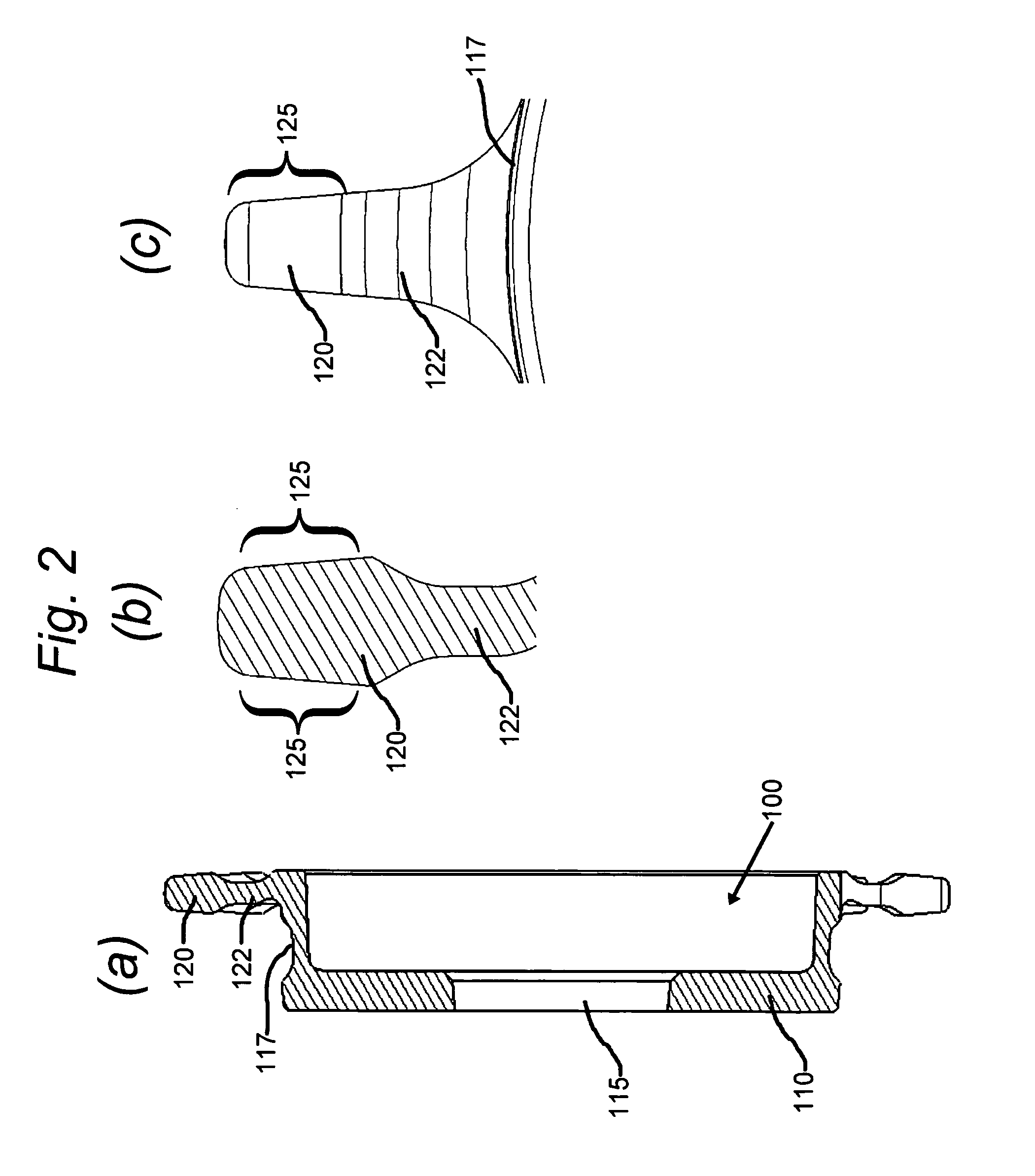

Forged hammermill hammer

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The design as disclosed and claimed is forged increasing the strength of the hammer. The shape of hammer as disclosed and claimed uses this improved strength to reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design incorporates comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

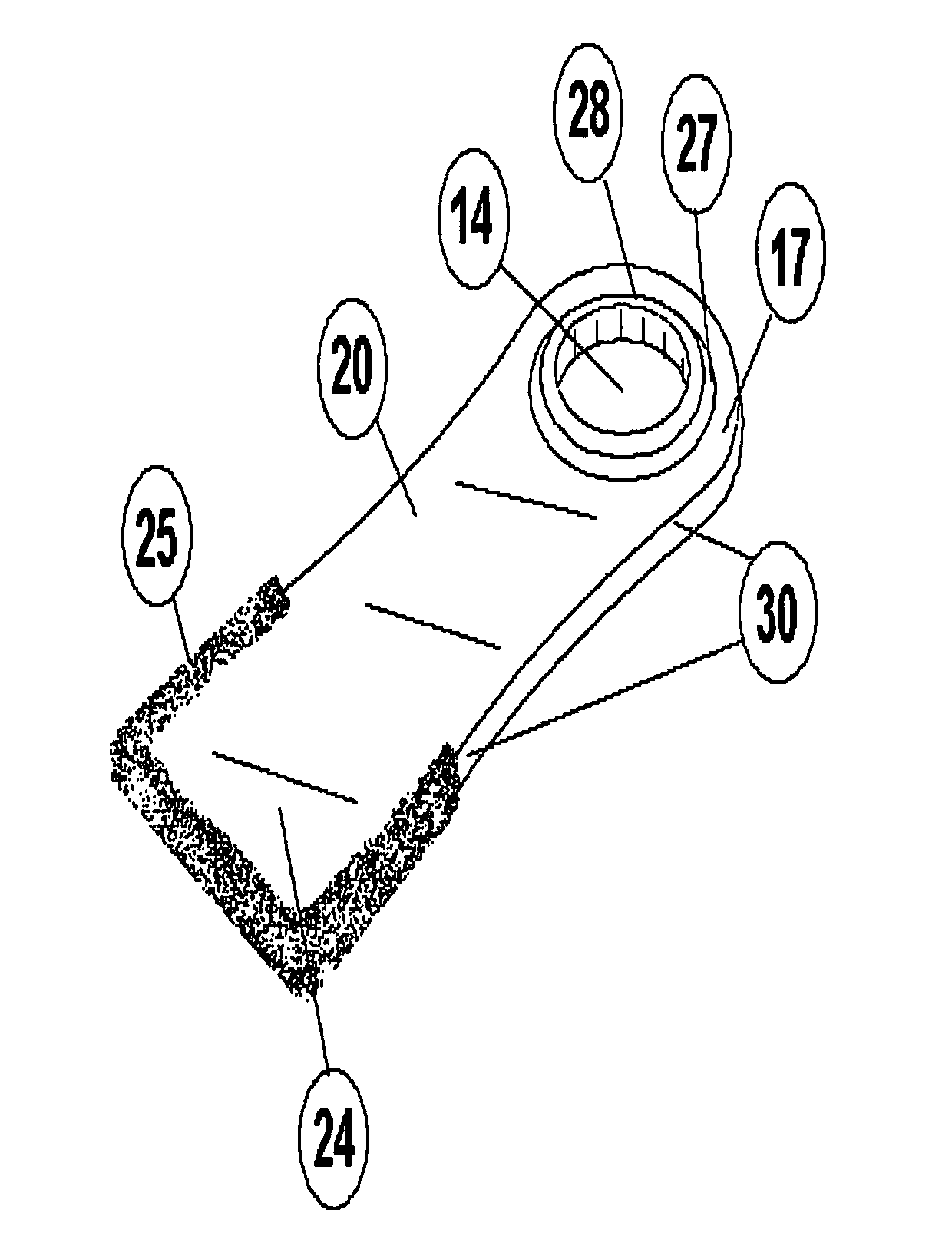

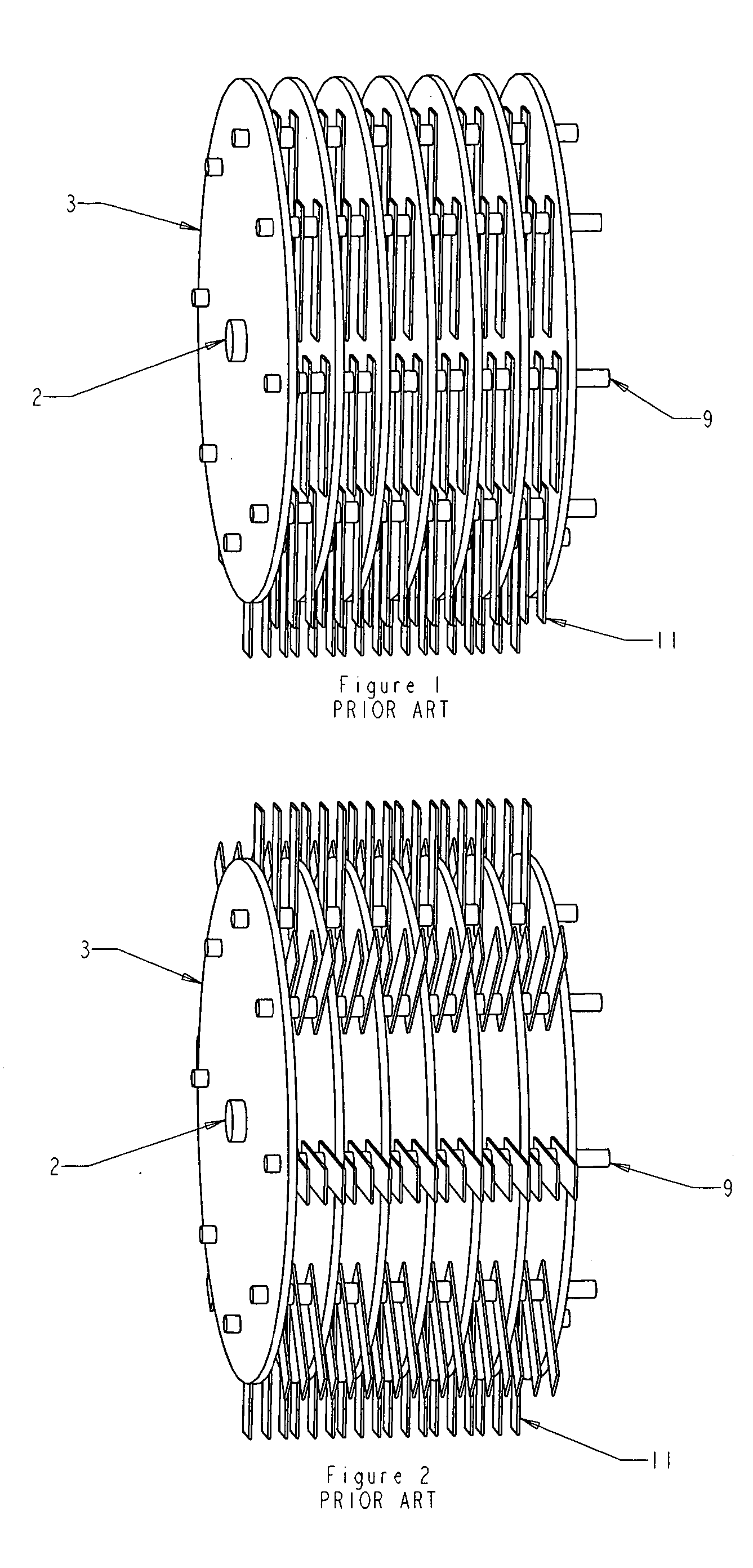

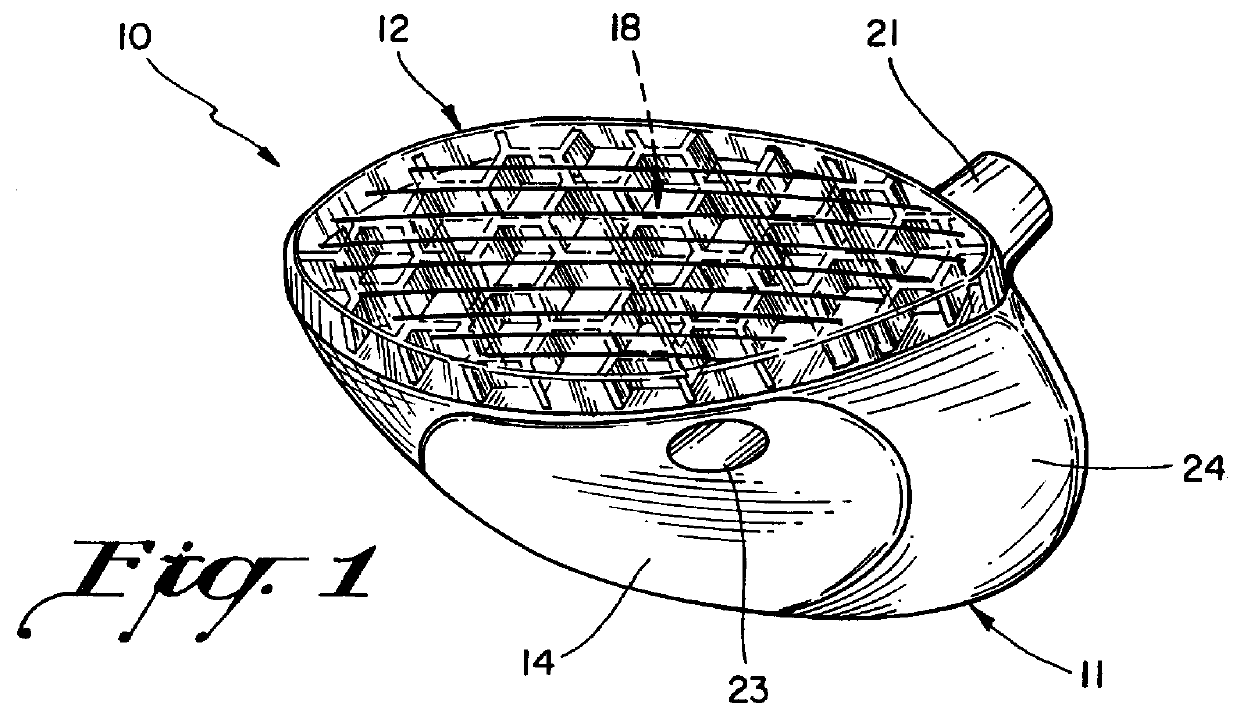

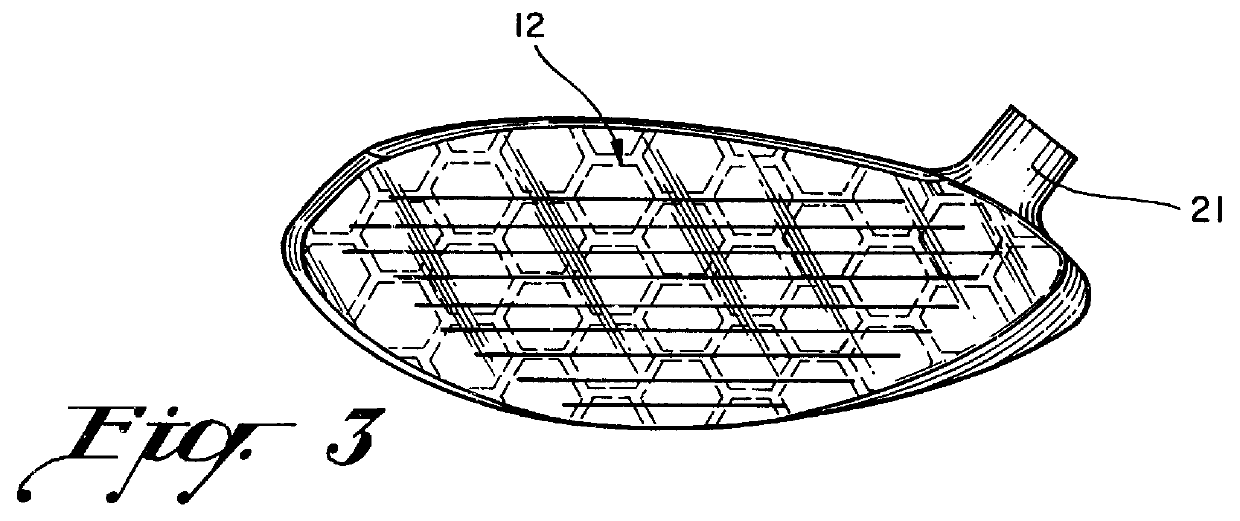

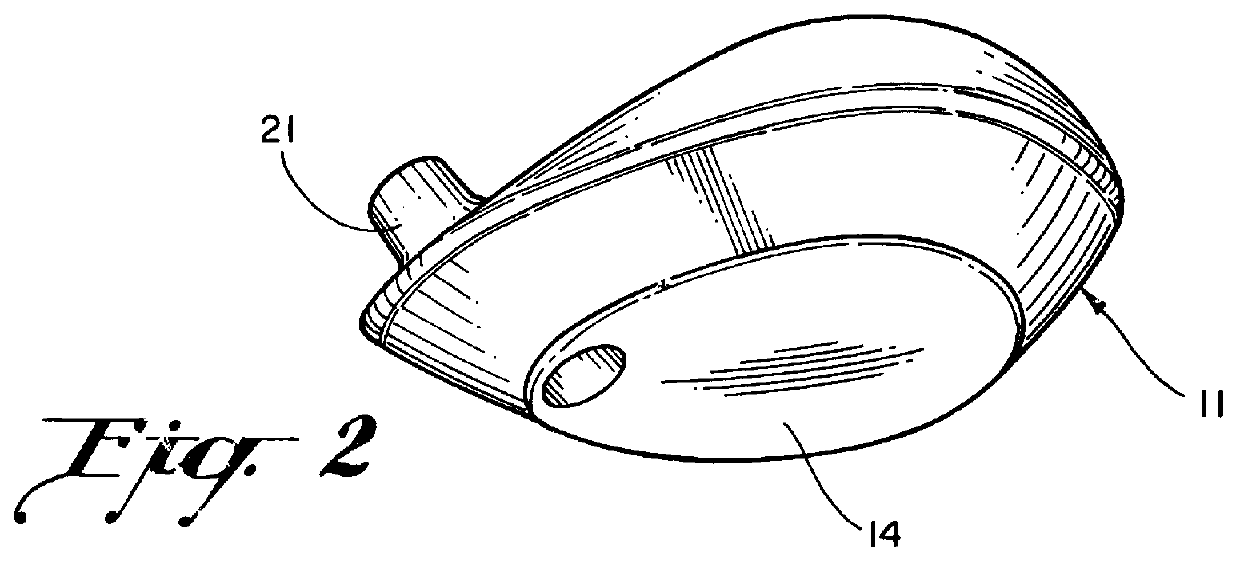

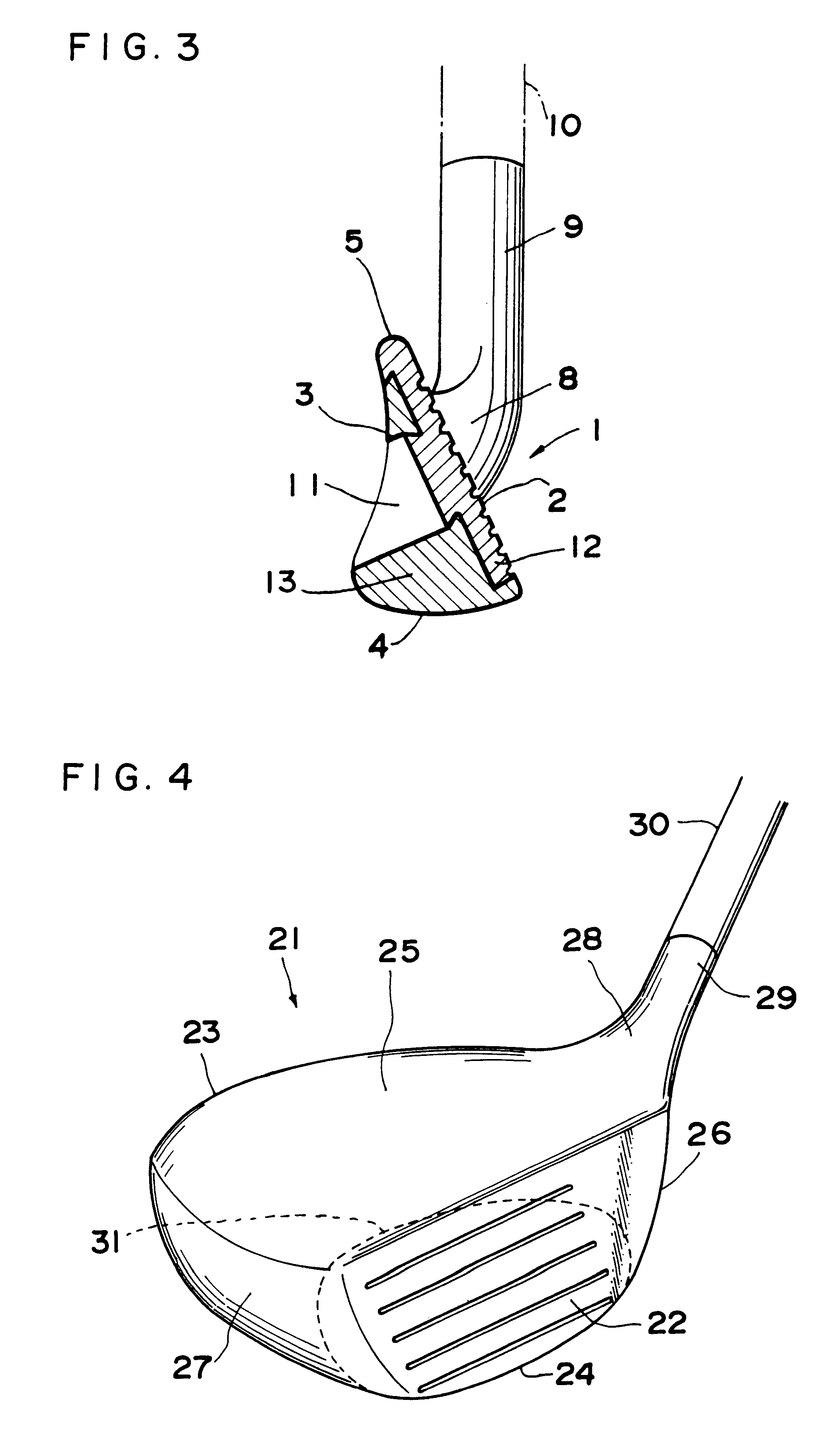

Golf club head with increased radius of gyration and face reinforcement

InactiveUSRE36950E1Increased radius of gyrationImprove impact performanceFoundry mouldsFoundry coresHeel-and-toeVertical plane

An improved high impact metal clubhead with a unique reinforced composite face wall, increased radius of gyration, and a positive lift air foil surface contour. The composite face wall includes an impact supporting wall rigidified by a pattern of integrally cast reinforcing bars that extend forwardly, rather than rearwardly, from the supporting wall. The reinforced supporting wall is covered by a very hard plastic ball striking insert that is cast in situ over the supporting wall. The increase in radius of gyration is accomplished by extending the heel and toe portions of the clubhead along the face wall further from the geometric center of the head, beyond present day parameters for high impact clubheads. And the positive lift is effected by contouring the top wall of the clubhead downwardly and rearwardly from the base wall more severely almost to the plane of the sole plate, and flattening the rear wall so it is almost co-planar with the sole plate. This configuration results in the top wall being equal to or greater in length than the combined length of the sole plate and rear wall in a vertical plane extending through the clubhead along the target line. The laws of continuity of matter and the air foil shape of the top wall eliminate the negative lift or drag in today's "woods" and offer the possibility of some positive lift to increase ball overspin.

Owner:KARSTEN MFG CORP

Underwater sensor apparatus

ActiveUS20110214500A1Small sizeEasily tied to fishing lineElectric signal transmission systemsSamplingGraphical user interfaceMarine engineering

An underwater sensor device comprises a submersible housing including one or more housing components, one or more sensors for monitoring and collecting water characteristics, a controller for controlling operations of the one or more sensors and an graphical user interface mounted to the housing that displays the water environmental data. The housing defines a channel that extends through one of the housing components, and at least one of the sensors is mounted to the housing and extends into the channel. The controller is disposed within the housing and is operatively connected to the one or more sensors.

Owner:YSI INC

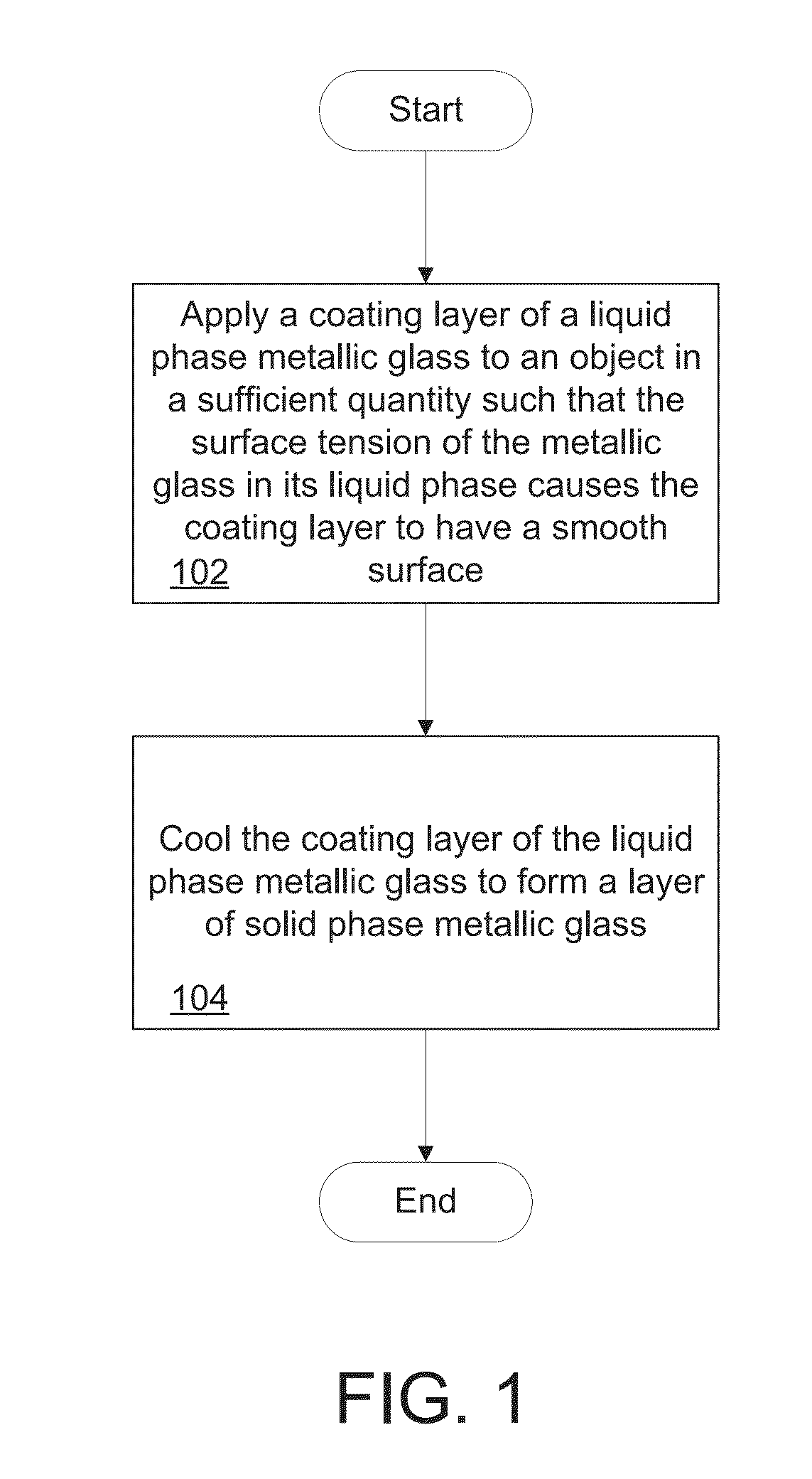

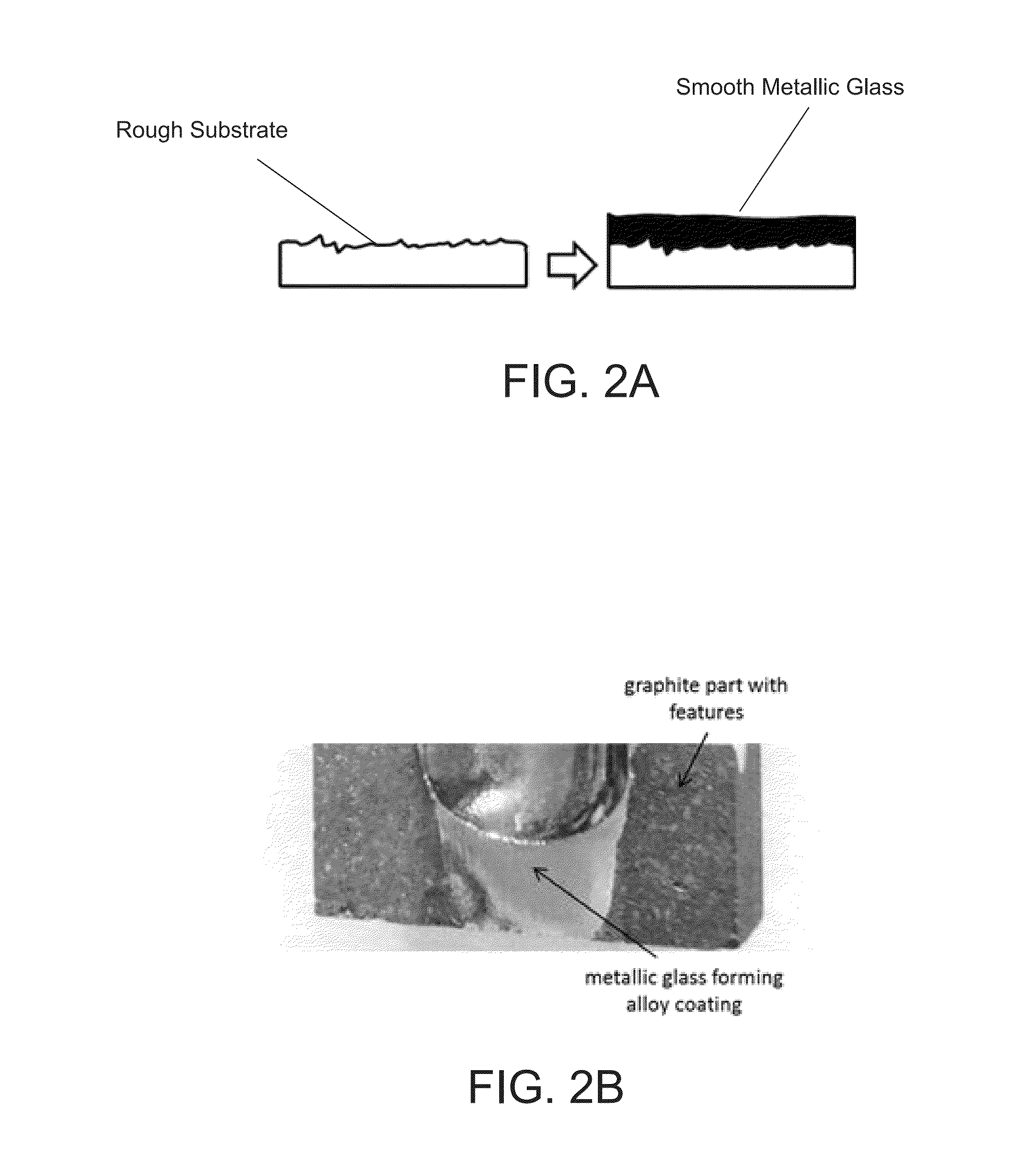

Systems and Methods Implementing Layers of Metallic Glass-Based Materials

ActiveUS20140141164A1Eliminate excessLower melting temperatureHot-dipping/immersion processesMolten spray coatingMetalMaterial system

Systems and methods in accordance with embodiments of the invention implement layers of metallic glass-based materials. In one embodiment, a method of fabricating a layer of metallic glass includes: applying a coating layer of liquid phase metallic glass to an object, the coating layer being applied in a sufficient quantity such that the surface tension of the liquid phase metallic glass causes the coating layer to have a smooth surface; where the metallic glass has a critical cooling rate less than 1000 K / s; and cooling the coating layer of liquid phase metallic glass to form a layer of solid phase metallic glass.

Owner:CALIFORNIA INST OF TECH

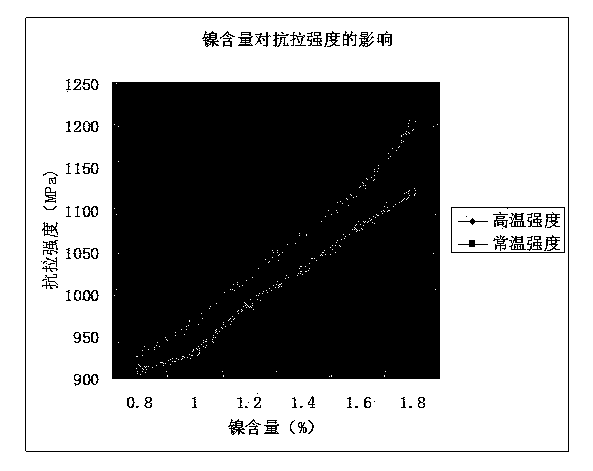

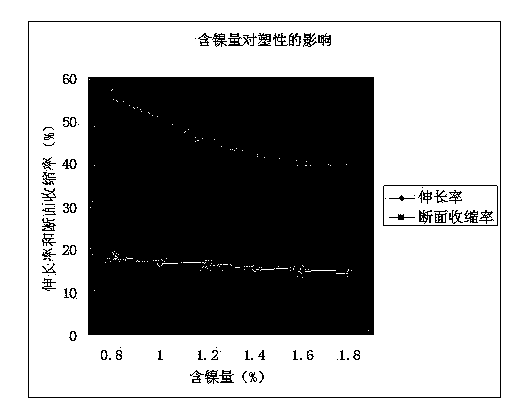

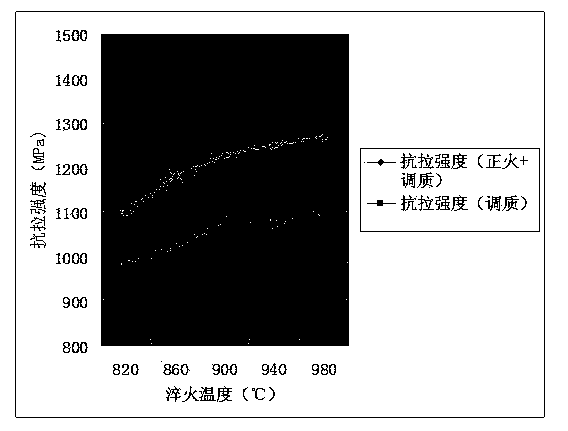

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

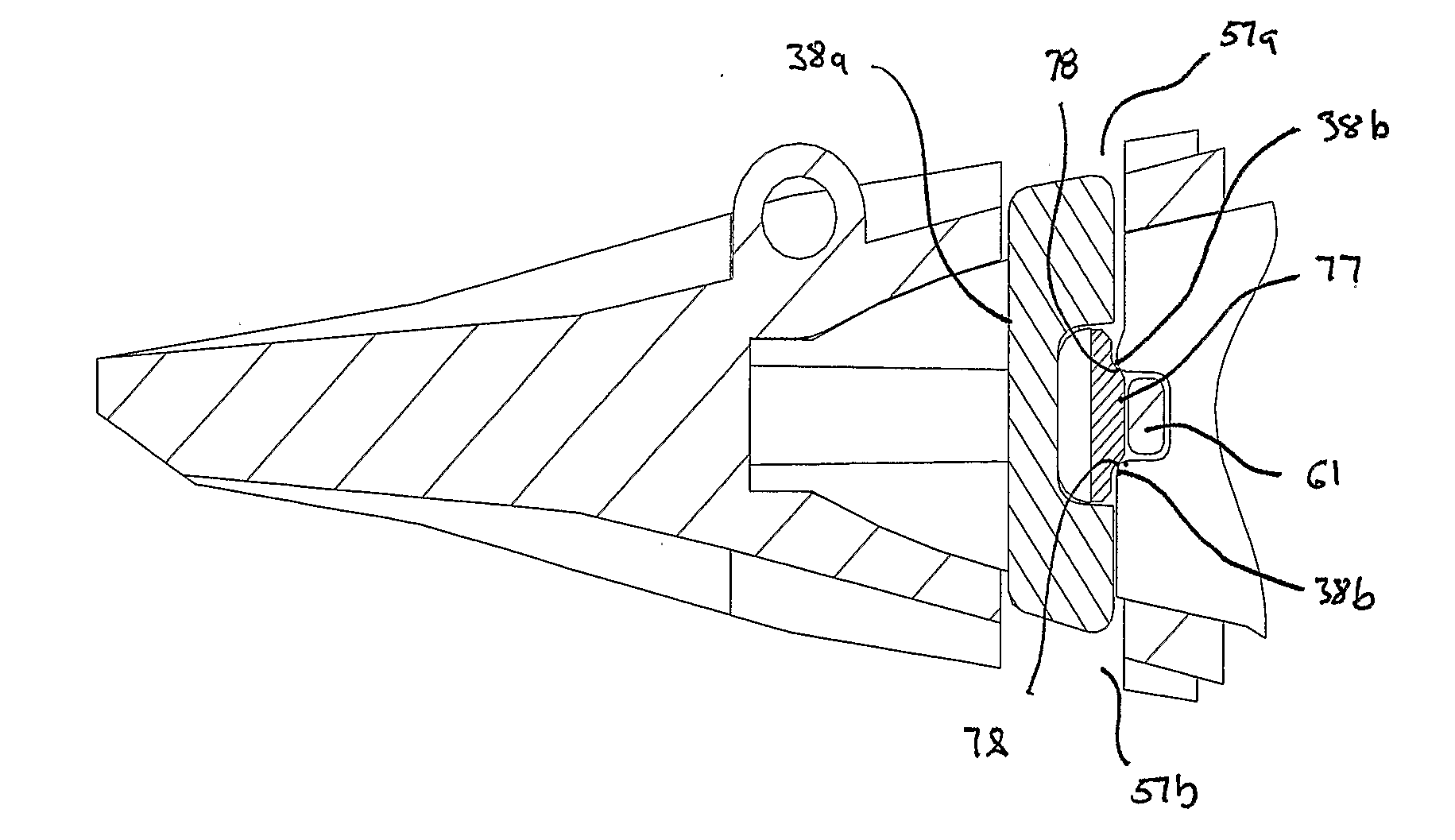

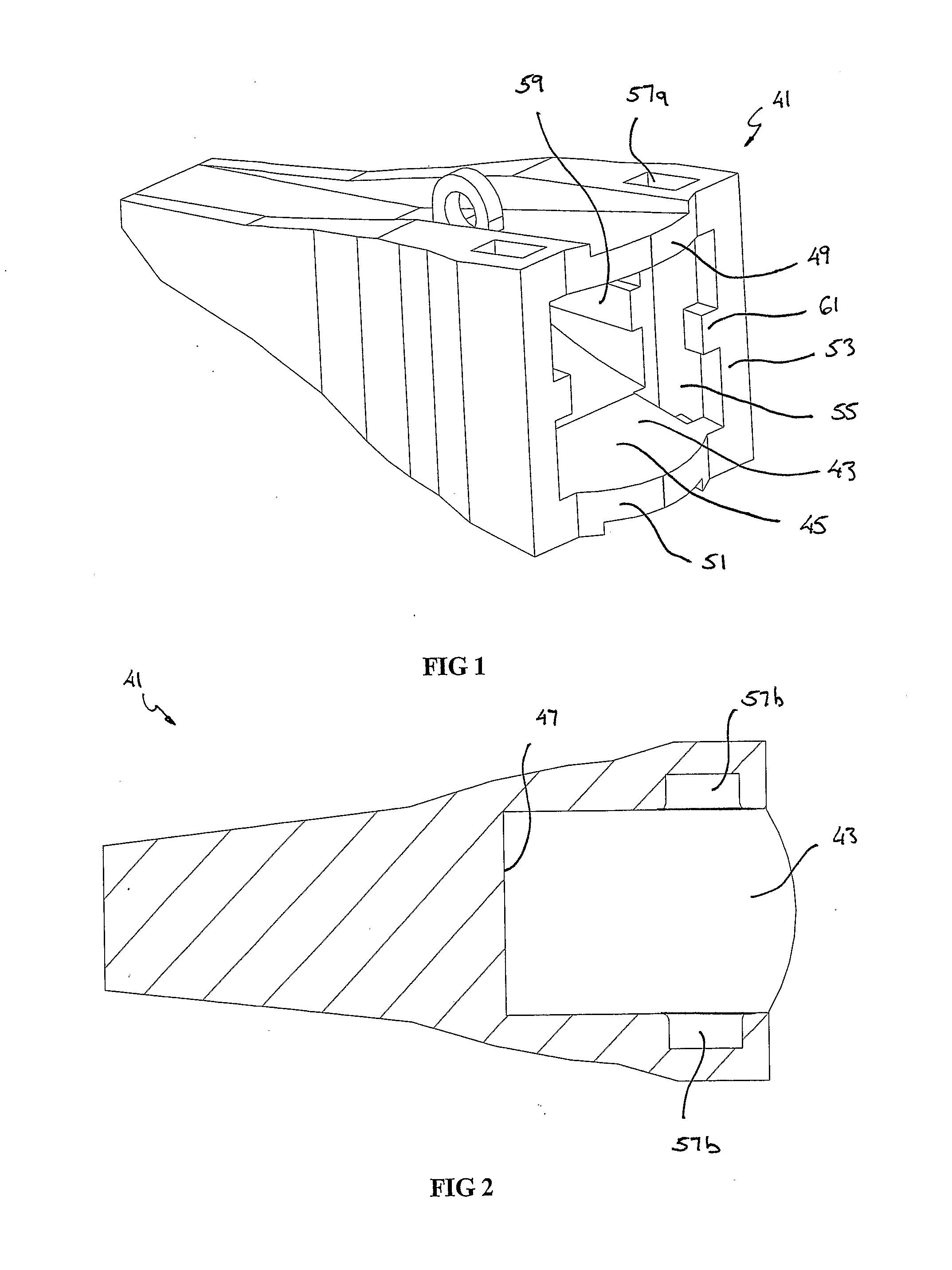

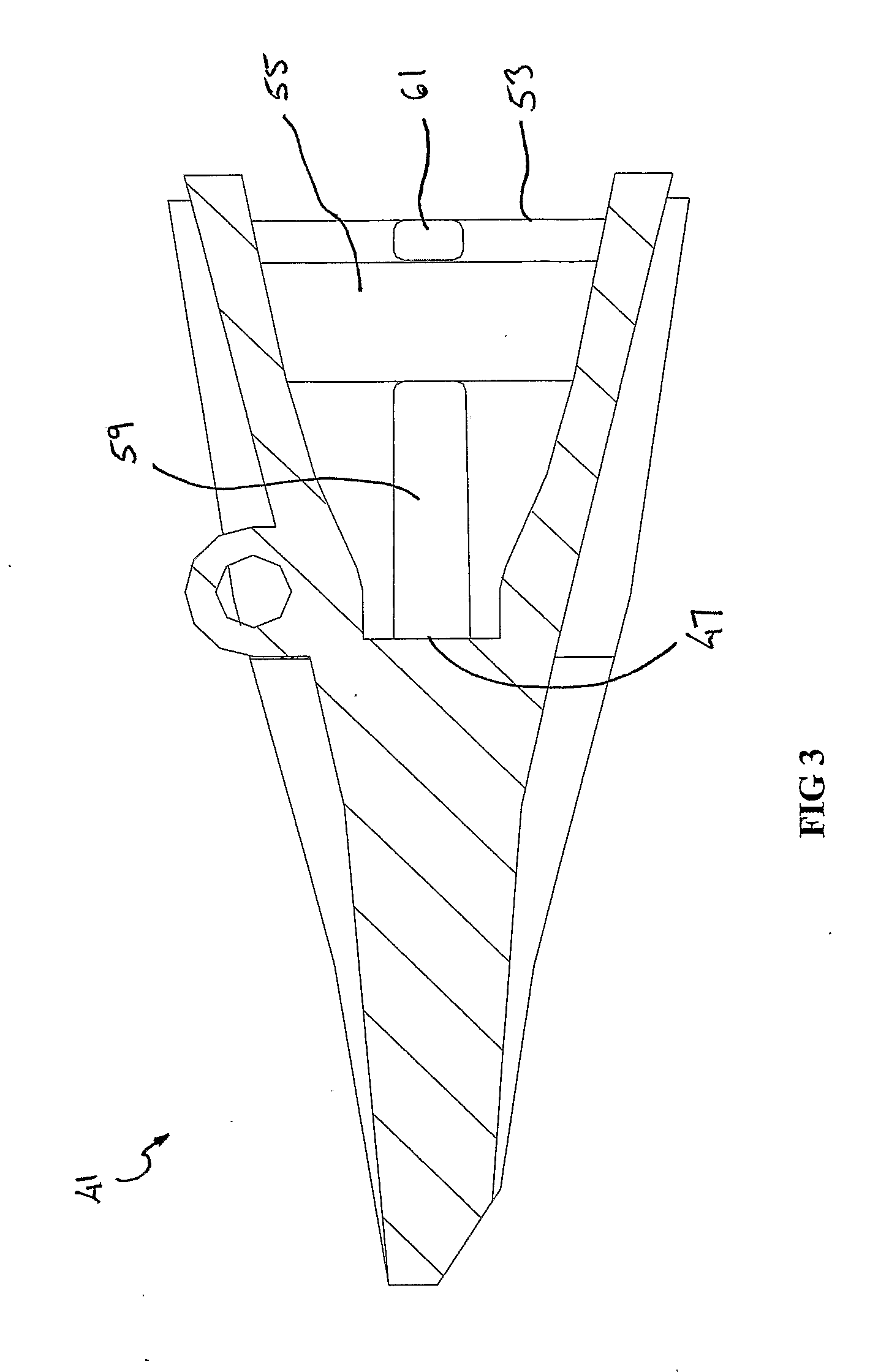

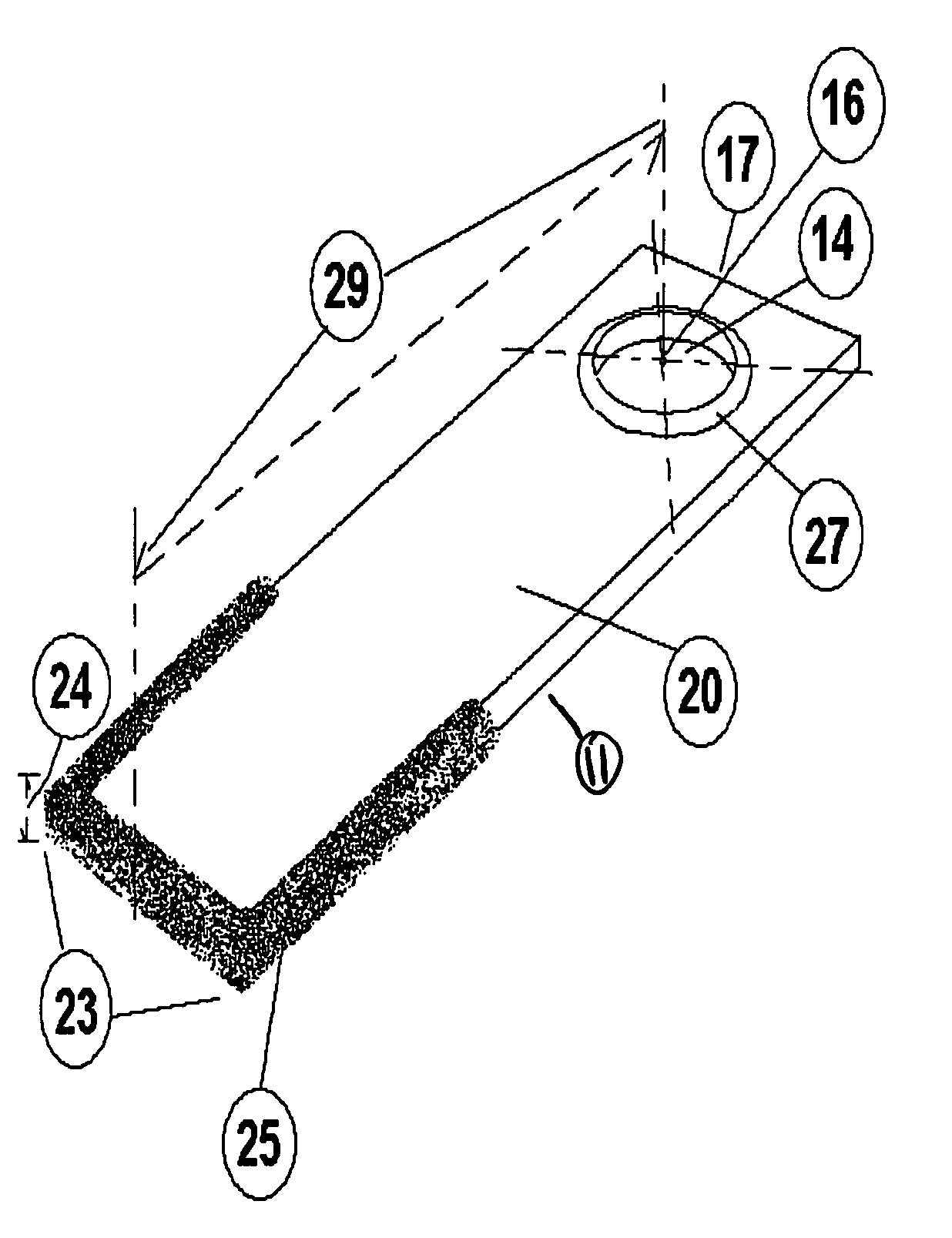

Tooth and Adaptor Assembly

Abstract A tooth and adaptor assembly (11) for use on earthmoving machinery, the assembly comprising an adaptor (21) adapted to be secured to a bucket or like component on the earthmoving machinery. The adaptor (21) comprising a nose (27) having an at least one sidewall (35) incorporating a first channel (37) and a second channel (39) angled relative to each other. The assembly (11) also a tooth (41) adapted to be received on the adaptor (41) and releasably secured thereto. The tooth comprises a socket (43) having sidewalls (53). At least one sidewall (53) incorporates a third channel (55) at an angle complementary to the second channel (39), such that when assembled the two channels (39, 55) co-operate to define an enclosure (91). An upper wall (49 of the socket (43) has at least one aperture (57) therethrough, and which is aligned with the third channel (55). The assembly (11) further comprises at least one locking mechanism (71) for locking the tooth (41) to the adaptor (21). The locking mechanism (71) having at least one projection (77) and adapted to be received through the aperture (57). During assembly the projection (77) moves inwardly with respect to the locking mechanism (71) as it enters the enclosure, the locking mechanism (71) moving towards its normal extended position when the projection (77) aligns with the first channel (37) wherein the assembly (11) is in its locked condition.

Owner:BRADKEN OPERATIONS

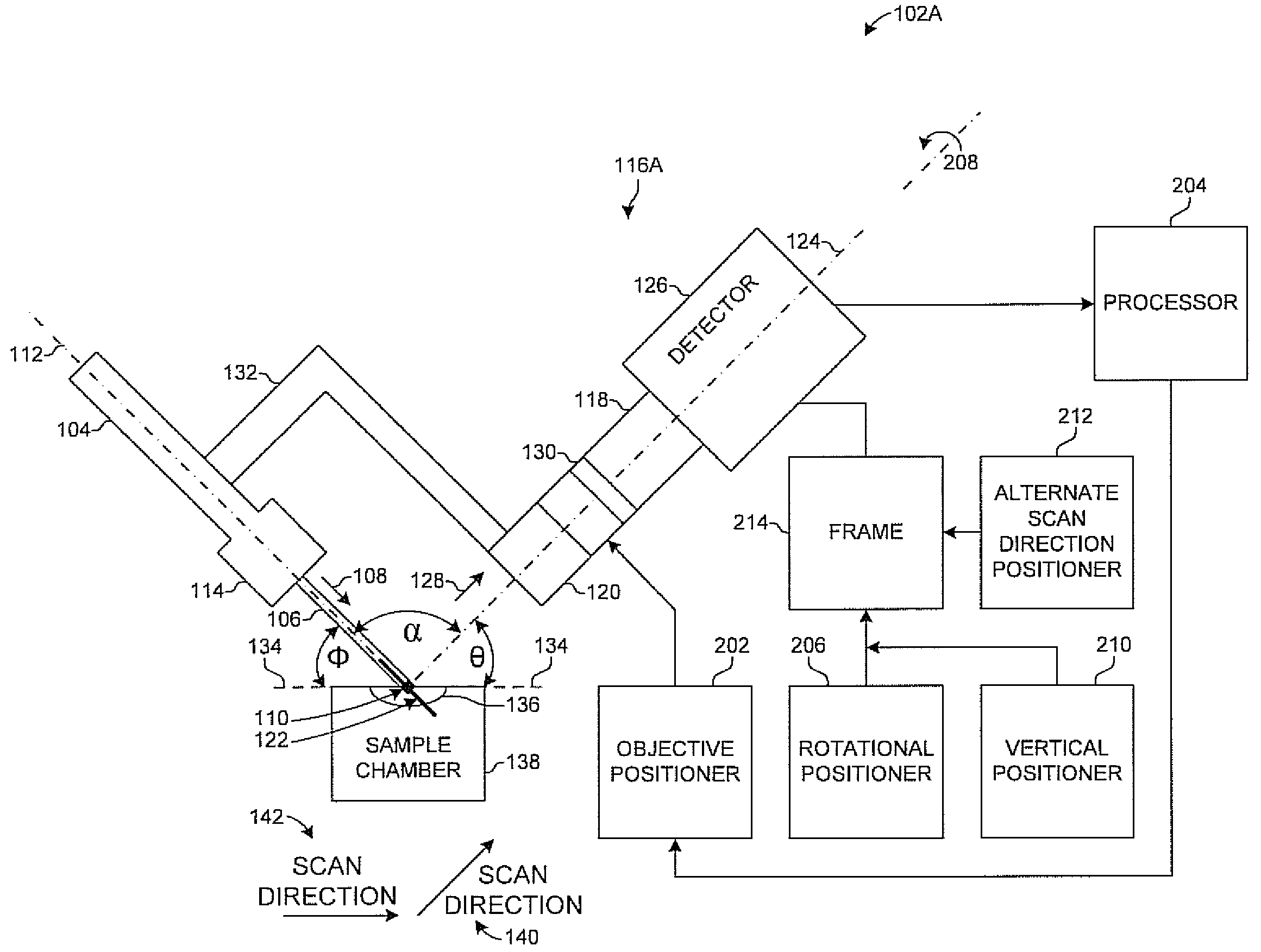

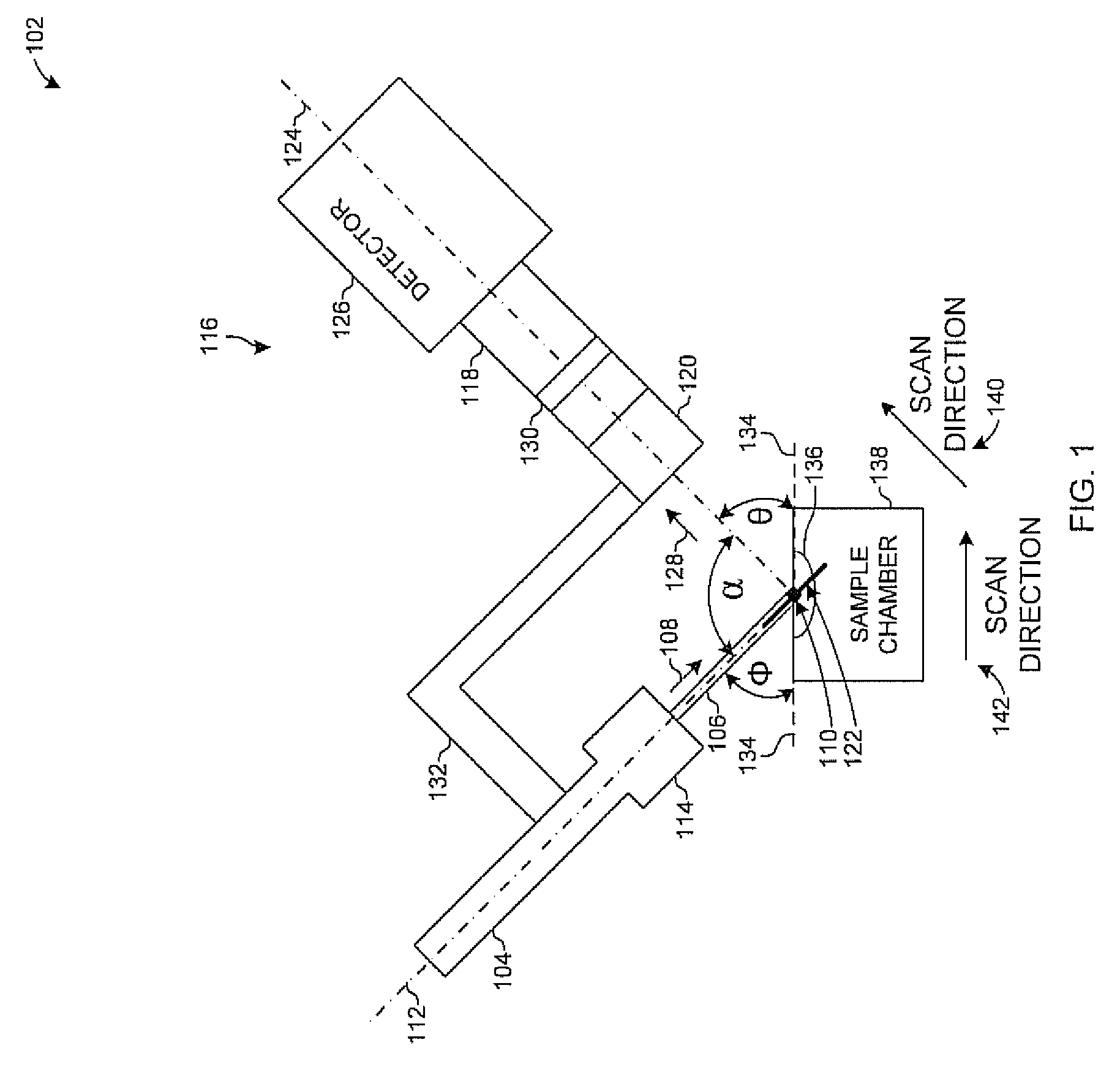

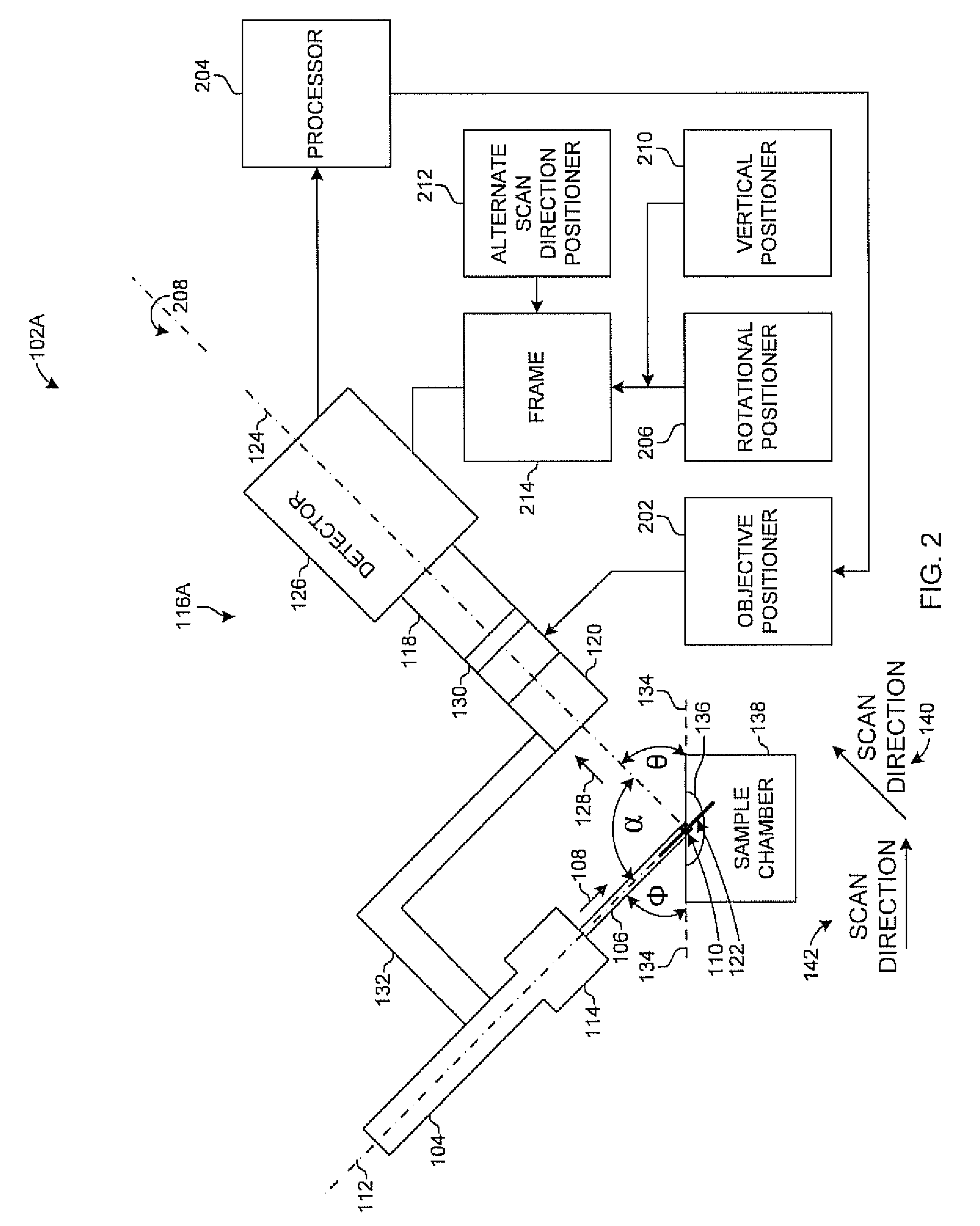

Objective-coupled selective plane illumination microscopy

A microscope assembly (102) includes an illumination source (104) coupled to an optical assembly by a coupler (132). The optical assembly includes an objective with optics that move along an optic axis. The illumination source (104) generates a light blade (106) that illuminates a portion of a sample (136) at an illumination plane (110). The light blade (106) induces a fluorescent emission from the sample (136) that is projected through the objective optics to a detector (126). The focal plane (122) of the objective optics is fixed with respect to the illumination source (104) by the coupler (132) so that the illumination plane (110) is coincident with the focal plane (122) as the objective optics move along the optic axis (124). The objective and illumination may be rapidly scanned along the optic axis to provide rapid three-dimensional imaging while the objective and illumination may also be rapidly scanned along the optic axis (124) to provide rapid three-dimensional imaging.

Owner:WASHINGTON UNIV IN SAINT LOUIS

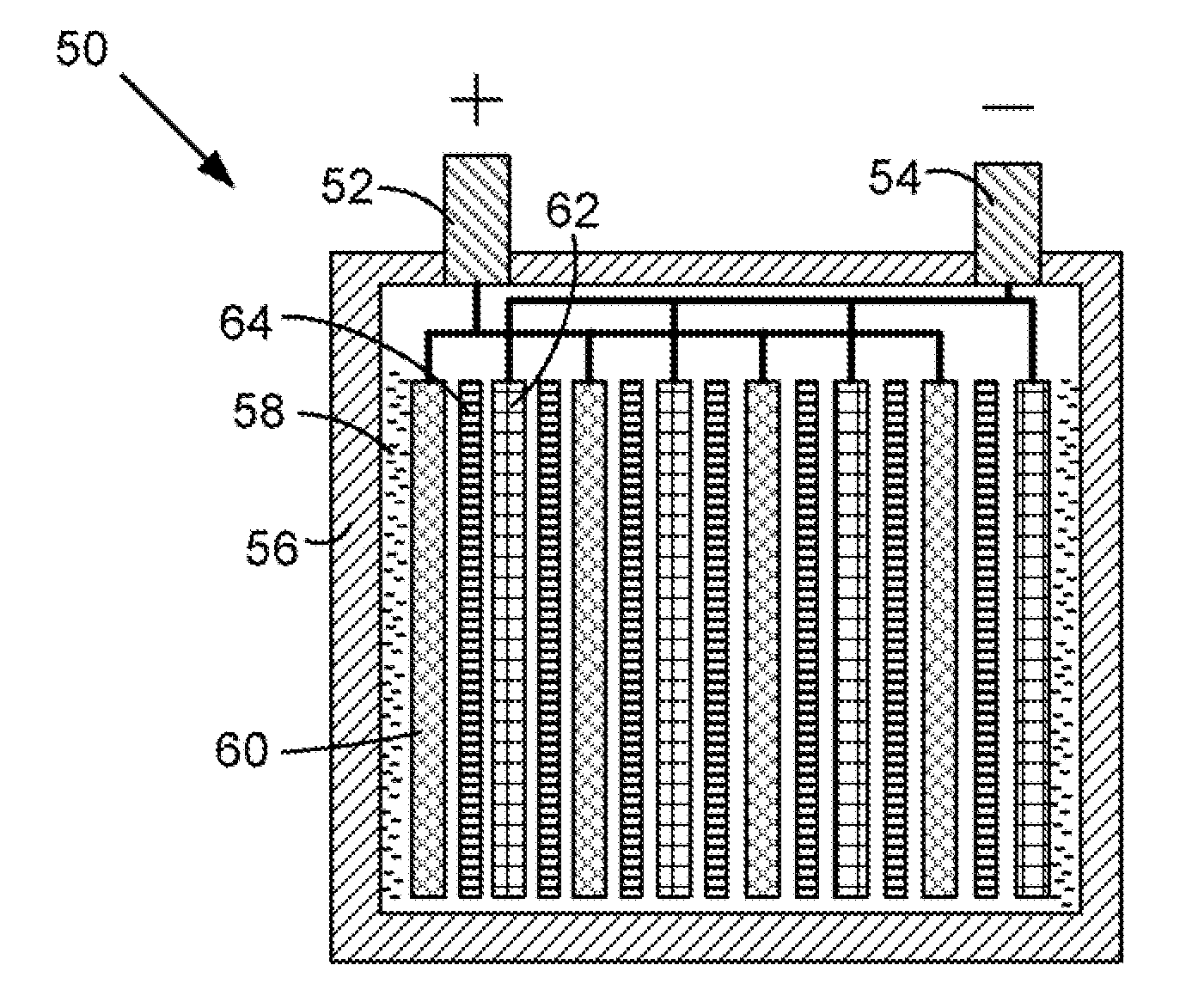

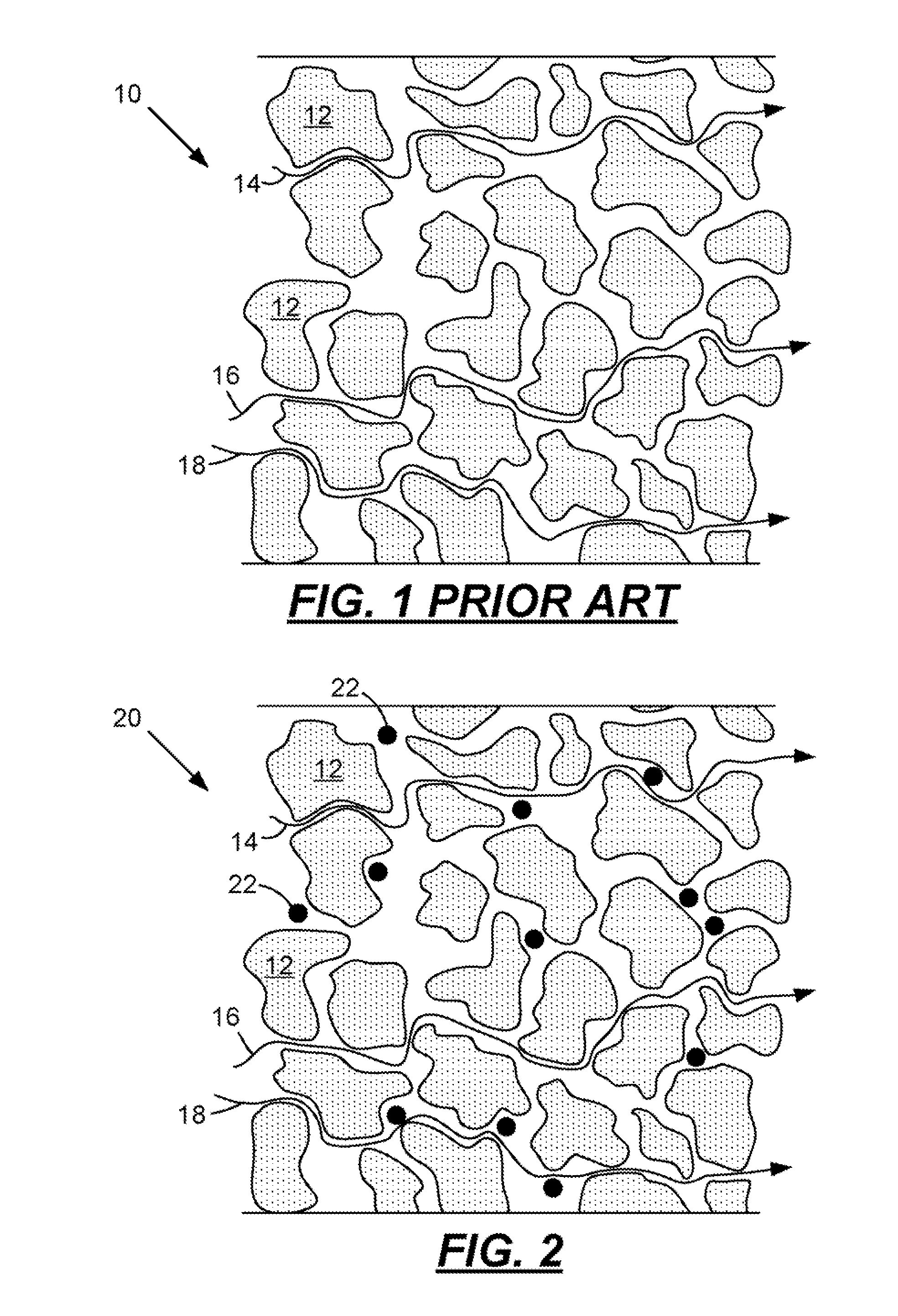

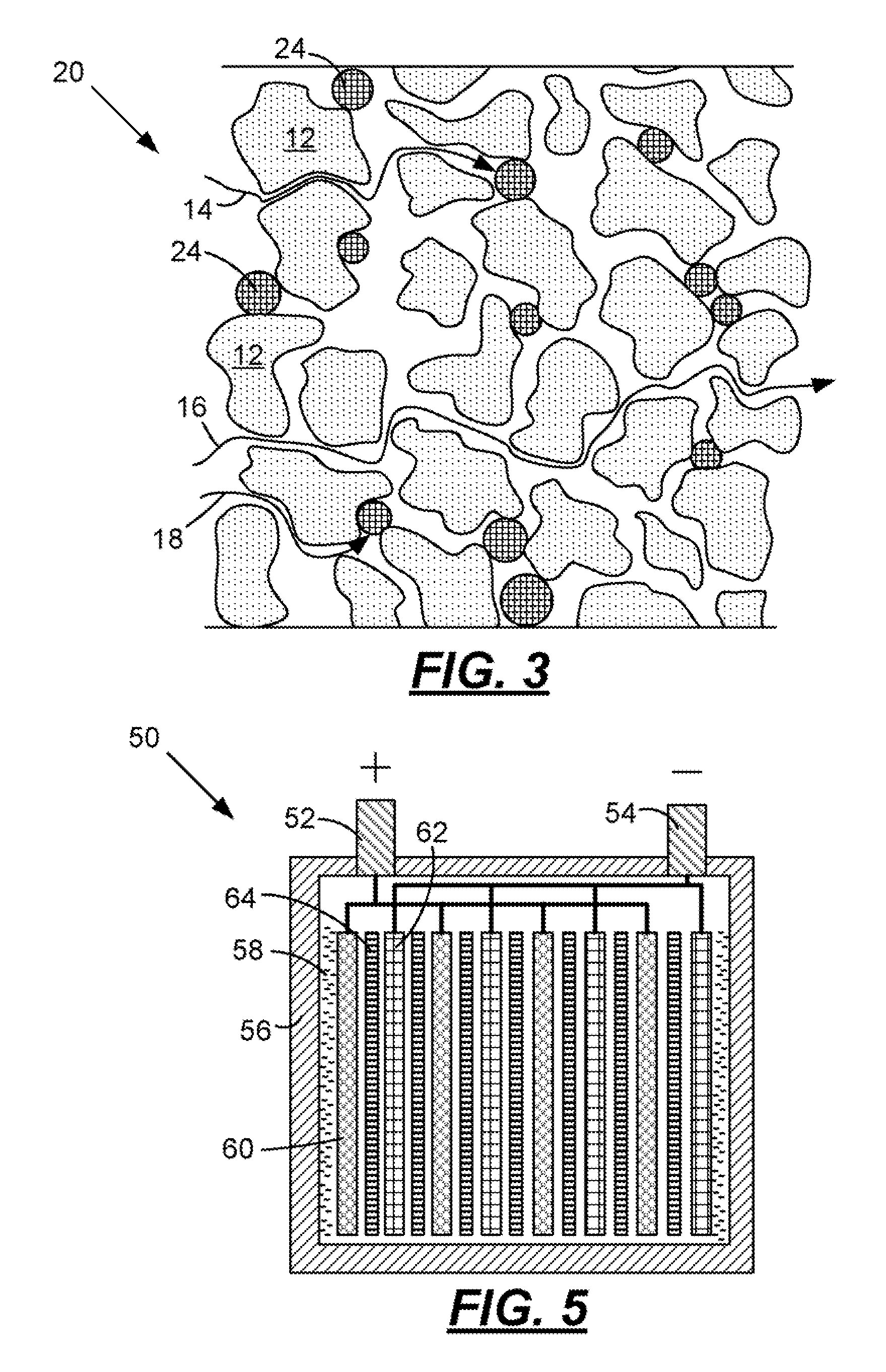

Smart battery separators

InactiveUS20080113259A1Improve energy performanceElectrical resistance increasePrimary cellsSecondary cells charging/dischargingElectrolyteEnergy storage

A separator for an energy storage cell having a microporous matrix including a reversible porosity-controlling agent. The porosity-controlling agent is selected from the group consisting of agents that change size as a function of temperature, agents that change size as a function of electrolyte concentration, and agents that change size as a function of temperature and electrolyte concentration to provide a change in an overall porosity of the separator.

Owner:MP ASSETAB CORP

Low-temperature co-fired ceramic tape casting material and preparing method and application thereof

The invention relates to a low-temperature co-fired ceramic tape casting material and a preparing method and application of the low-temperature co-fired ceramic tape casting material. The low-temperature co-fired ceramic tape casting material comprises, by weight, 35-50% of inorganic-phase components and 50-65% of organic-phase components. The inorganic-phase components include borosilicate glass powder and aluminum oxide ceramic powder, wherein the weight ratio of the borosilicate glass powder to the aluminum oxide ceramic powder is 2:3-3:2, and the borosilicate glass powder includes CuO which accounts for less than 3% of the power in weight. The organic-phase components include a solvent, an adhesion agent, a plasticizing agent and a dispersing agent, wherein the solvent is an alcohol-ester mixed solvent, and alcohol accounts for 20-70% in the mixed solvent in weight.

Owner:ZHEJIANG SIRAMIC TECH CO LTD

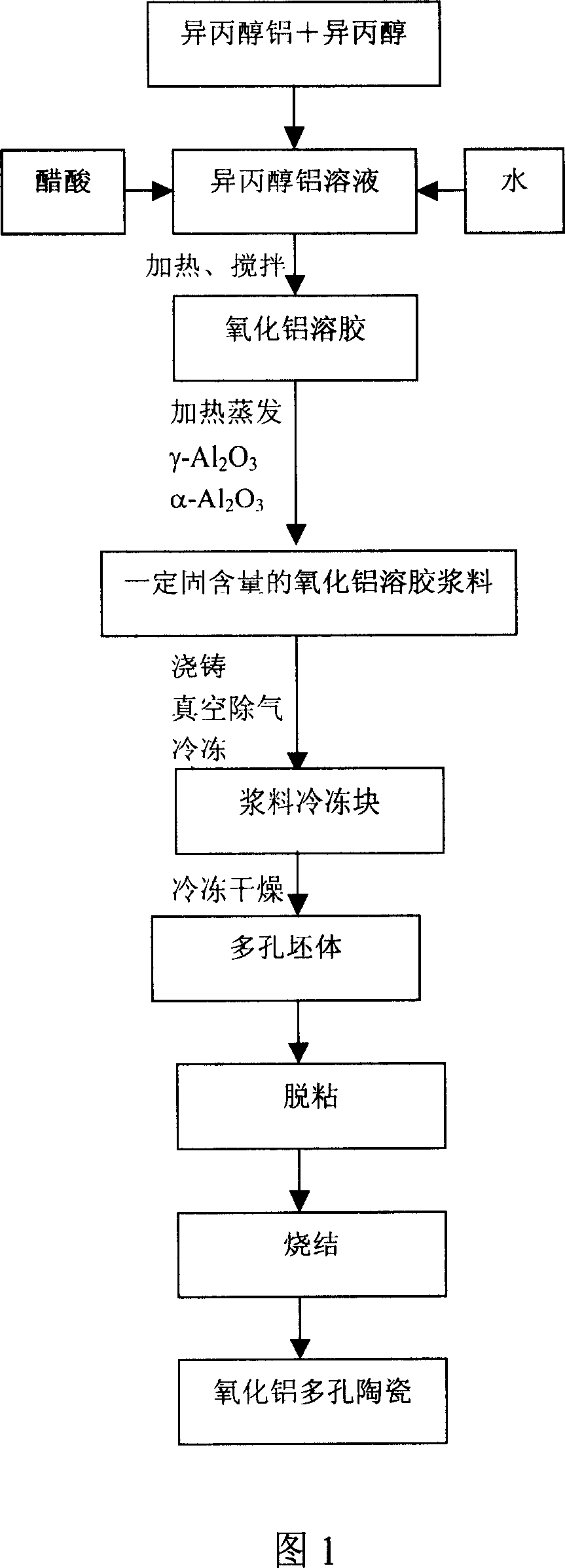

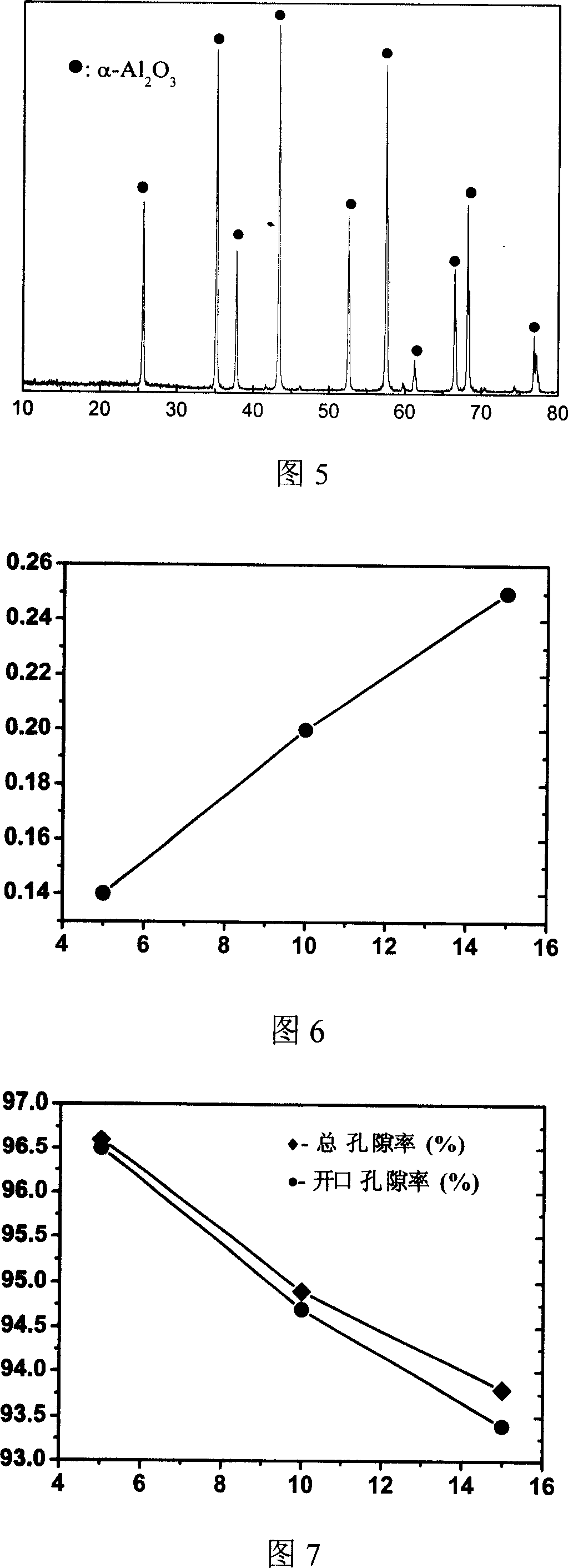

Method for preparing alumina porous ceramic using gelatin wrapping-freeze drying process

The invention discloses a preparing method of porous alumina ceramic through sol-gel freezing drying technique, which comprises the following steps: adopting aluminium isopropoxide as former; hydrolyzing under high temperature to obtain alumina sol; controlling the solid content of sol; adding moulding agent; blending evenly; casting; moulding; removing air to form vacuum; freezing at low temperature; drying and moulding the frozen sample; detackifying moulded sample under low temperature; placing in the high-temperature furnace; sintering; obtaining the porous alumina ceramic with bending-proof strength reaching 65Mpa and bulk density at 0.14-2.4g / cm3. The adjustable aperture is 1-100um, which can be filter, catalyst carrier and heat insulating material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

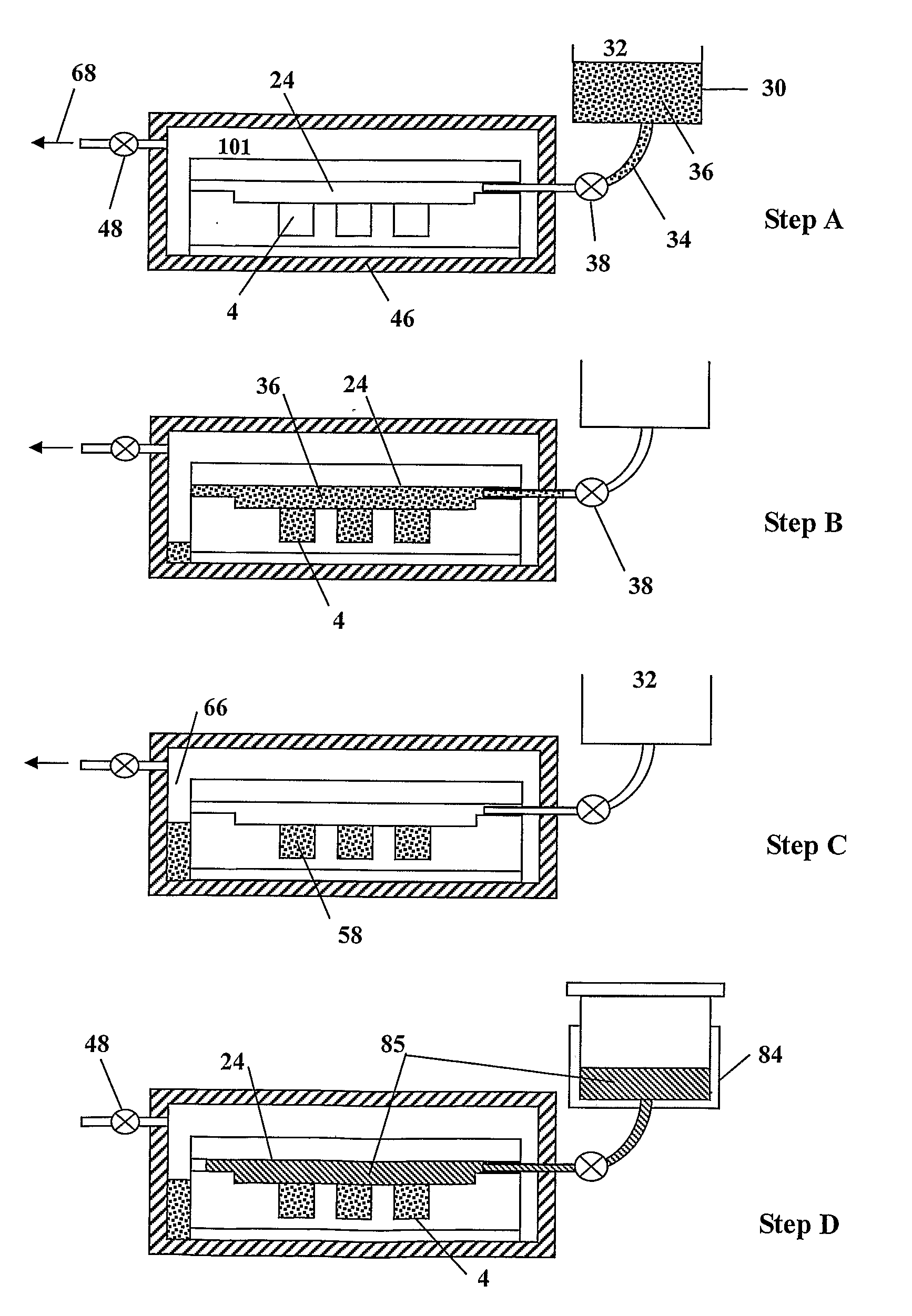

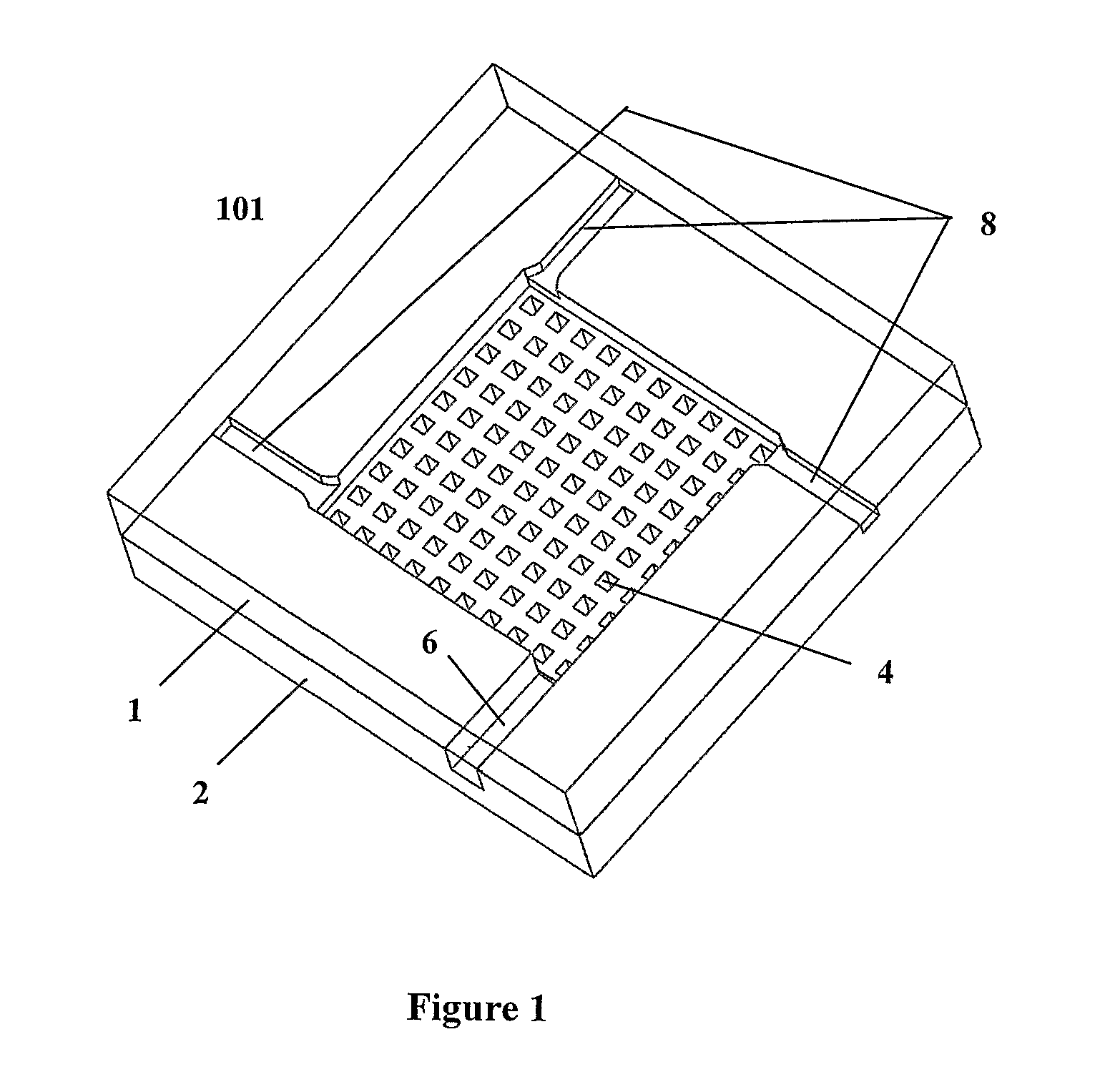

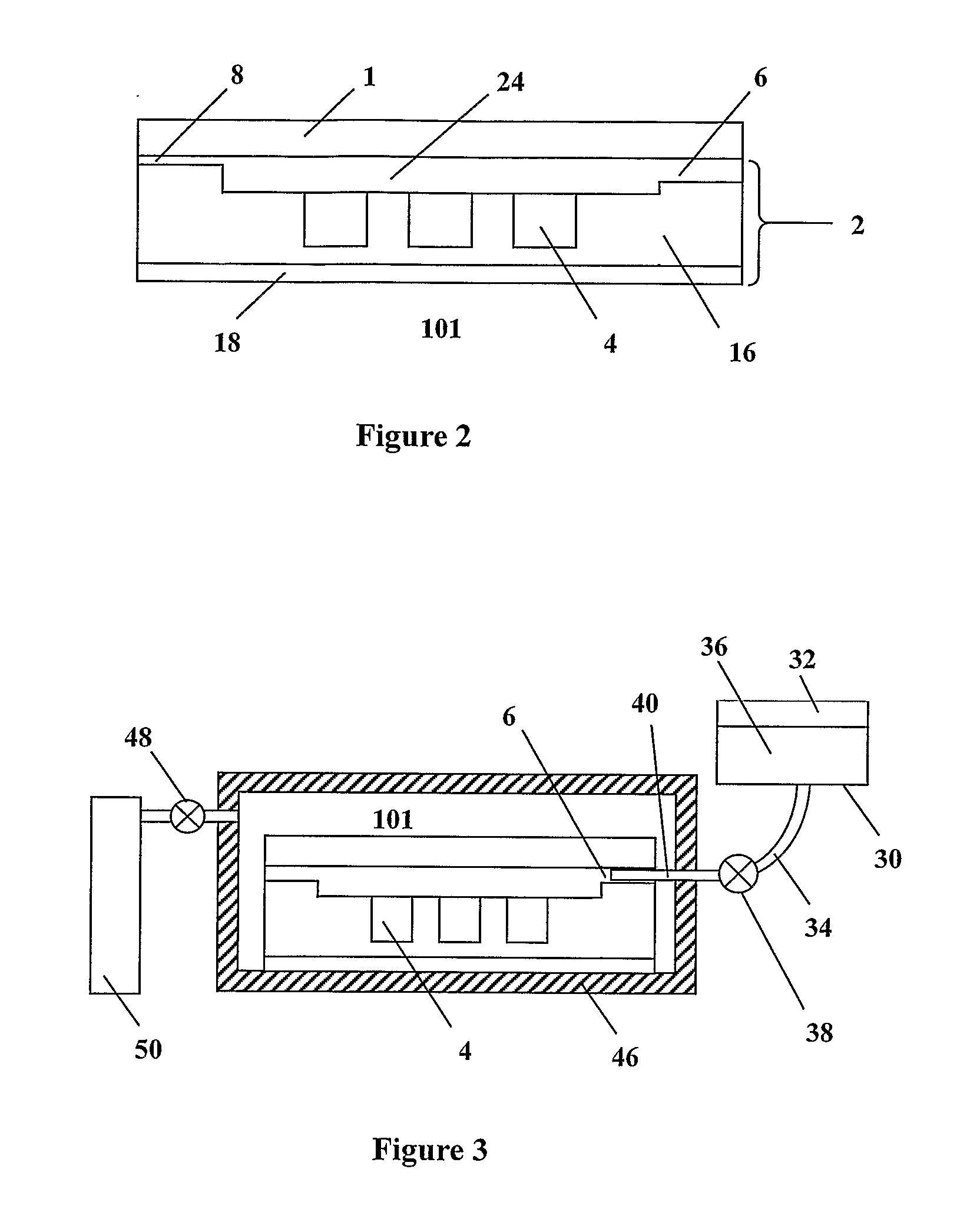

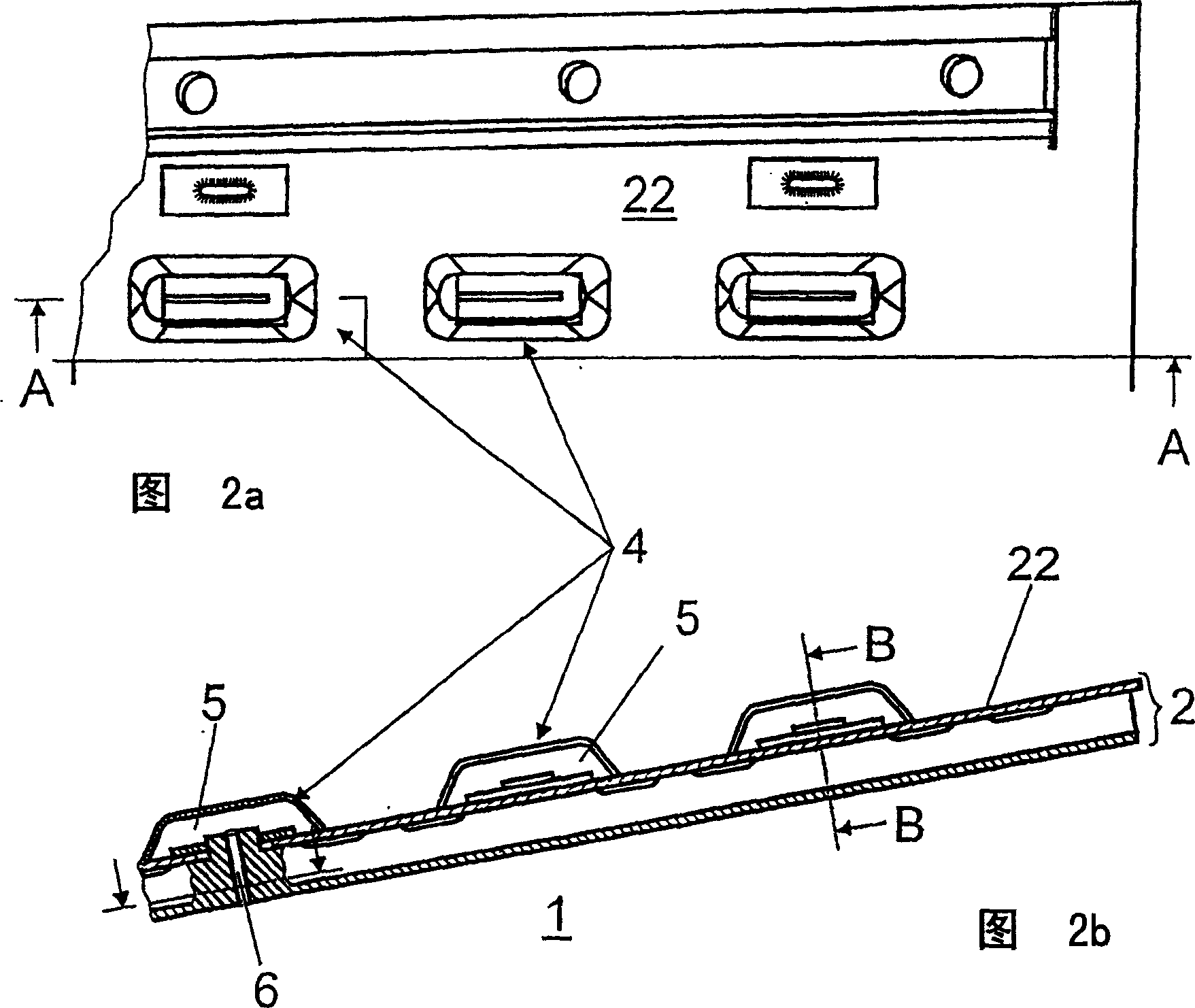

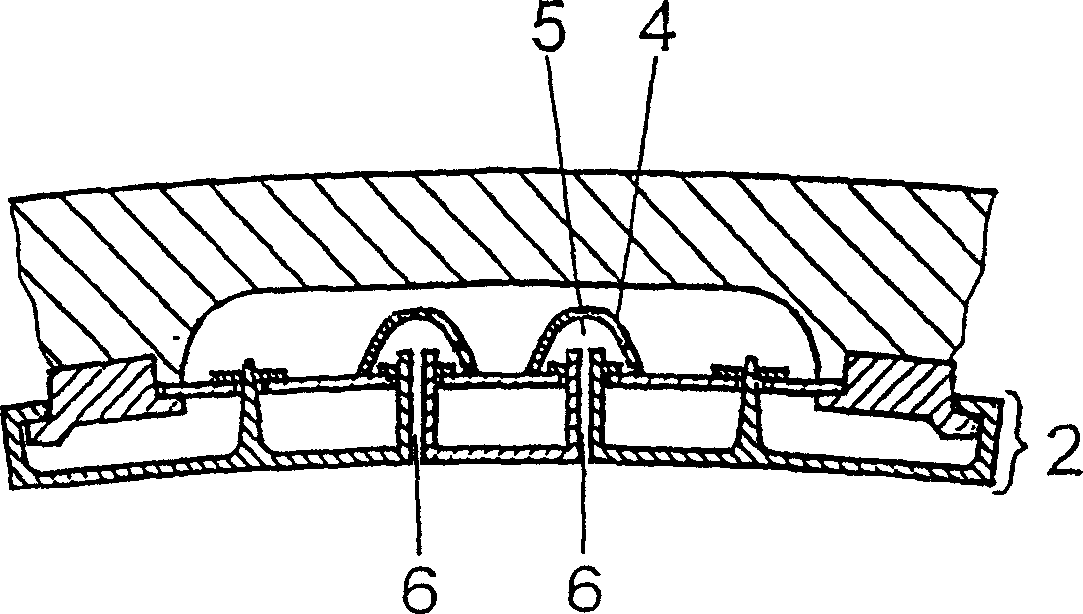

Microfluidic device

InactiveUS20100252128A1Avoid cross-contaminationPrevent sample evaporationLaboratory glasswaresBranching pipesInlet channelEvaporation

The present invention provides a microfluidic device comprising a plurality of wells, each of which may be substantially filled with a liquid without either the need for expensive individual sample loading or the requirement to isolate individual wells to prevent cross contamination and sample evaporation. A base member (2) comprises a plurality of wells (4) in the form of an array, an inlet channel (6) and three outlets (8).

Owner:GONG HAI QING +2

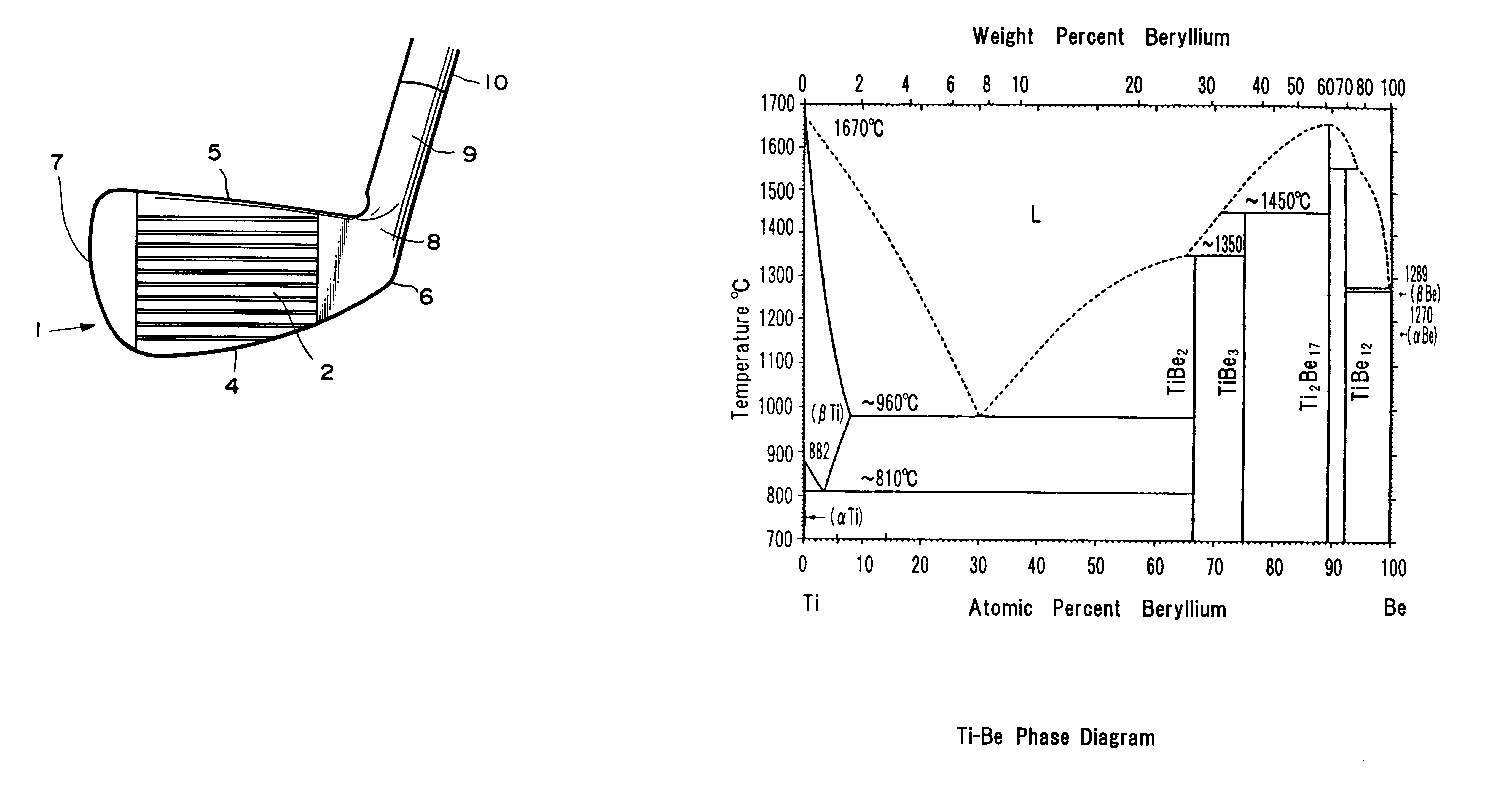

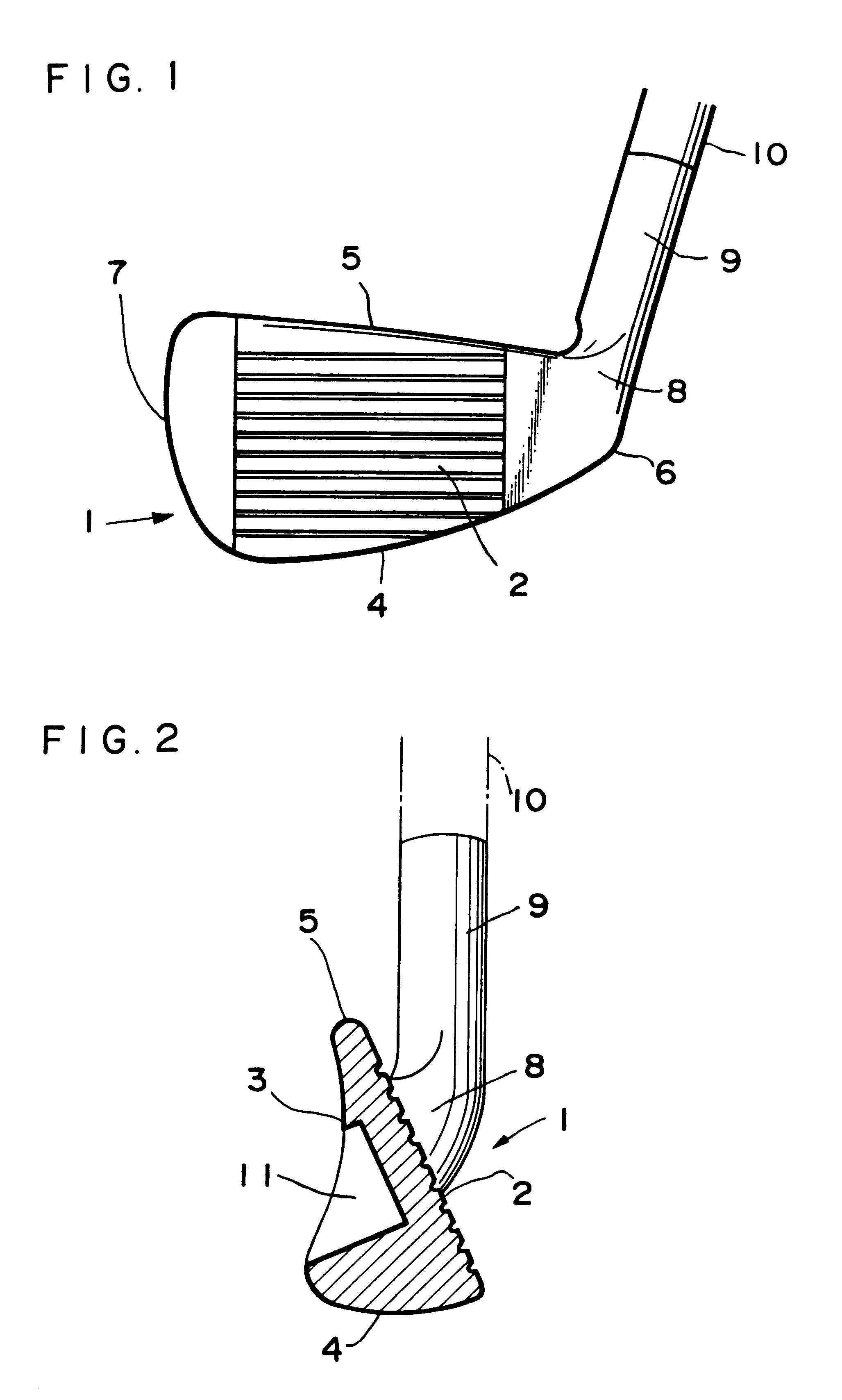

Golf club

A golf club which is so light as to be large-sized, with an improved durability, suited for easy casting. Ti-Be alloy is used for the material of a head 1. Be is present in Ti as a TiBe and / or TiBe2 in a proportion of about 20 mol %. The use of such Ti-Be alloy will result in the lightening of the head 1 as well as the enhanced Young's modulus thereof, thus improving the durability thereof. The Ti-Be alloy has such a lower melting point of 1000 degrees centigrade or below as compared to pure titanium, that the casting thereof is easy.

Owner:ENDO MFG COMPANY

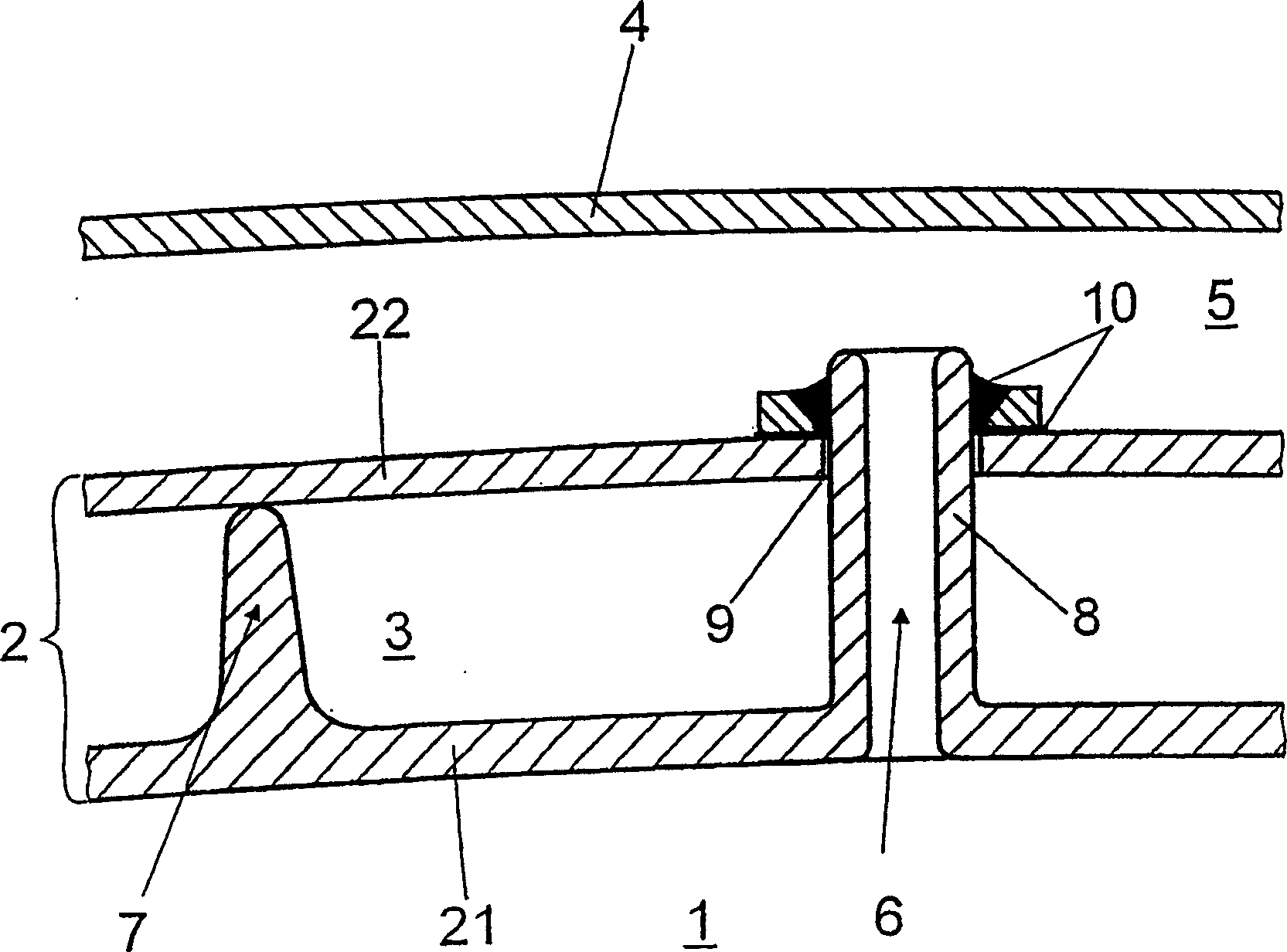

Damping arrangement for reducing combustion chamber pulsations in a gas turbine system

InactiveCN1551965AAvoid complicationsEasy to castContinuous combustion chamberCold airCombustion chamber

A description is given of a damping arrangement for reducing resonant vibrations in a combustion chamber (1), with a combustion-chamber wall (2), which is of double-walled design and, with an outer wall-surface part (22) and an inner wall-surface part (21) facing the combustion chamber (1), gastightly encloses an intermediate space (3), into which cooling air can be fed for purposes of convective cooling of the combustion-chamber wall (2). The invention is distinguished by the fact that at least one third wall-surface part (4) is provided, which, with the outer wall-surface part (22), encloses a gastight volume (5), and that the gastight volume (5) is connected gastightly to the combustion chamber (1) by at least one connecting line (6).

Owner:ANSALDO ENERGIA SWITZERLAND AG

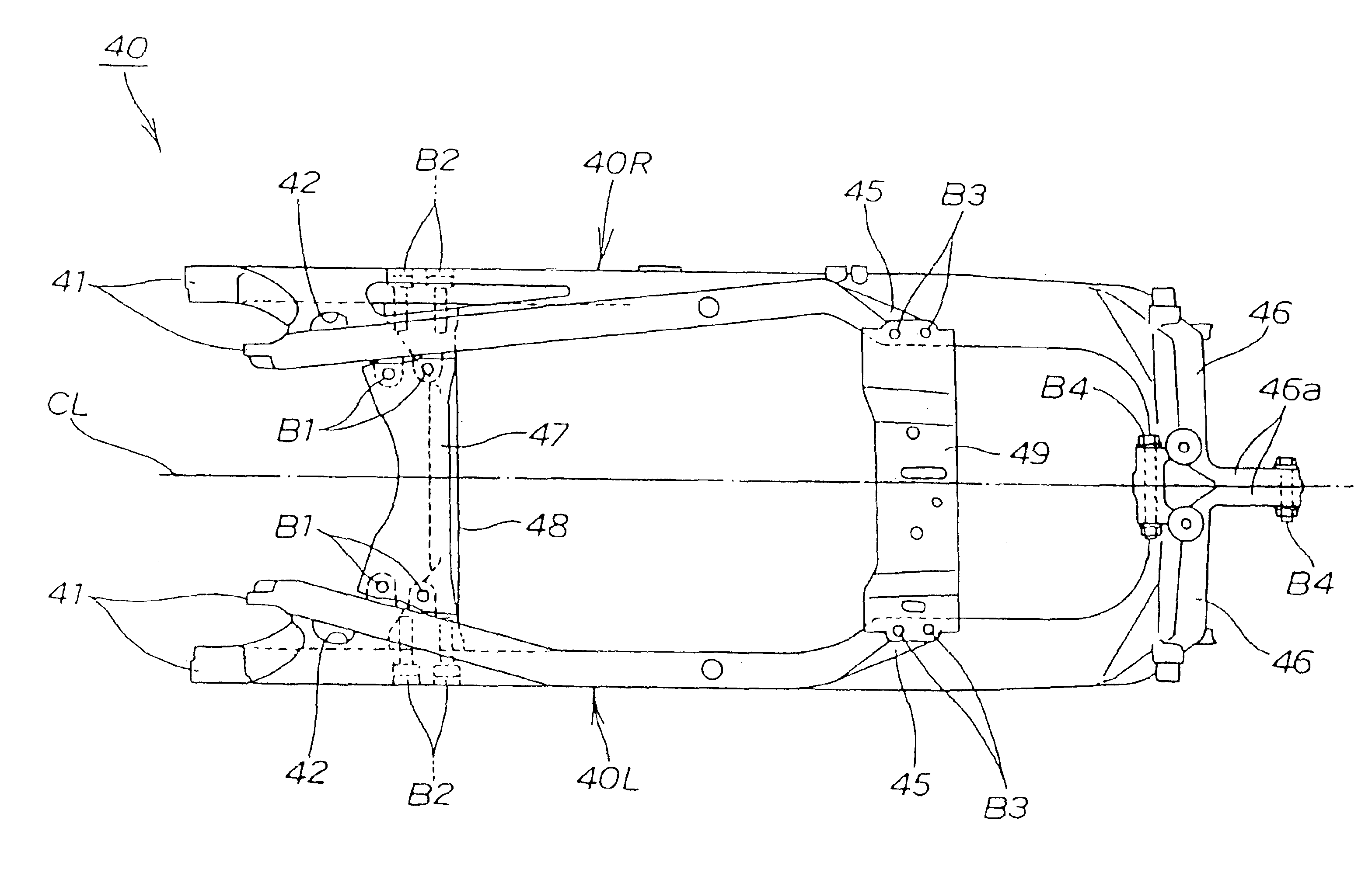

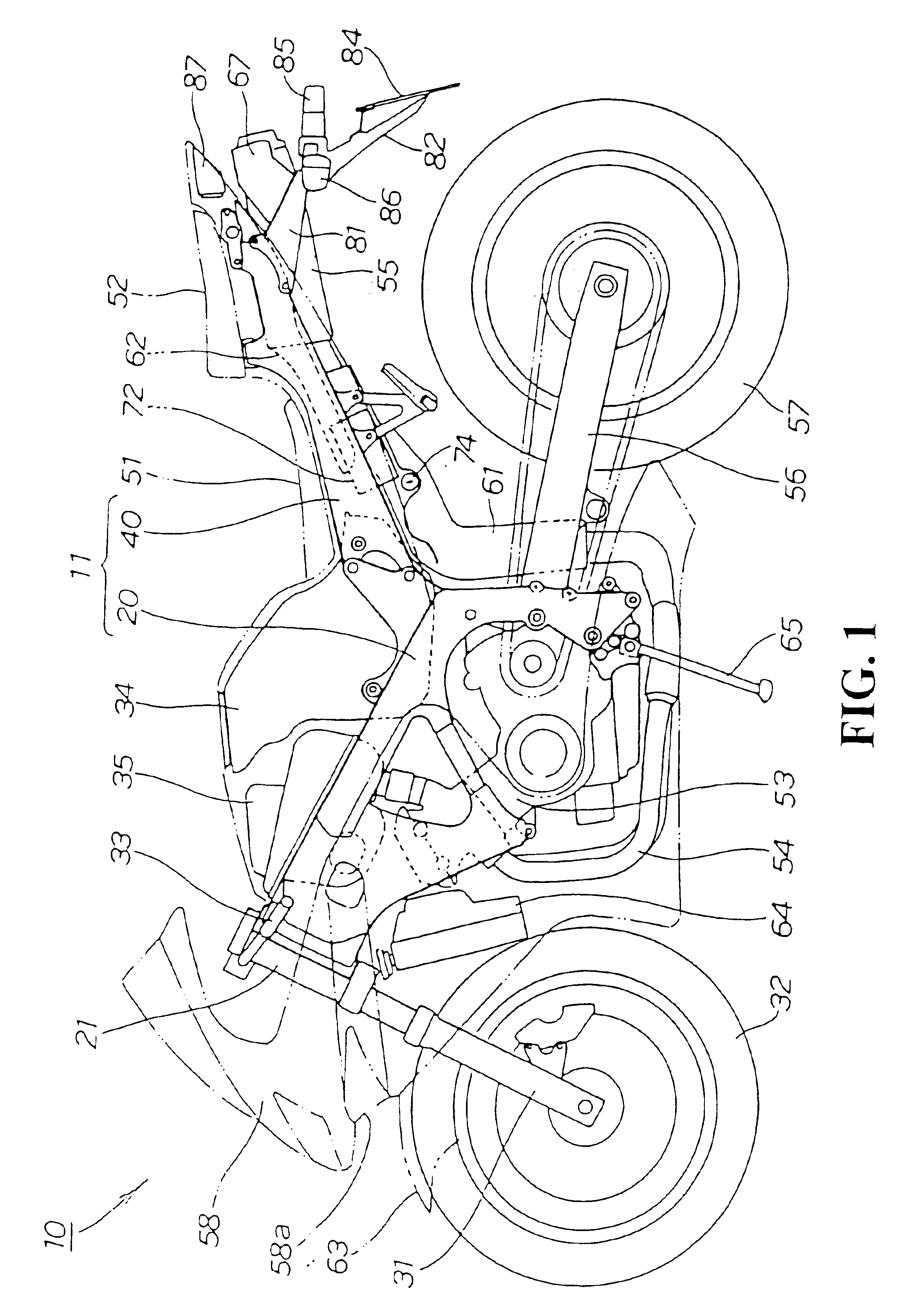

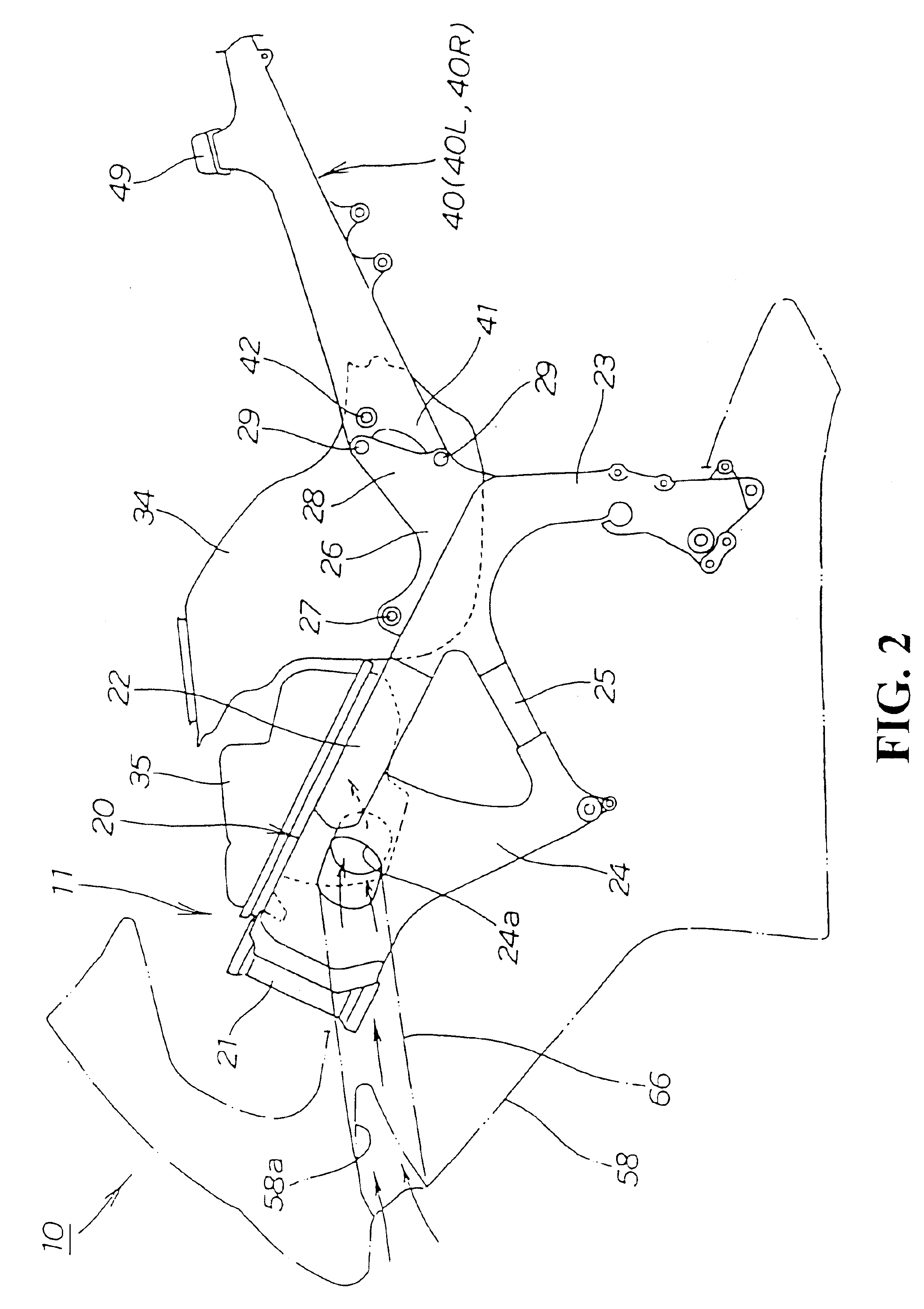

Seat rail structure

A seat rail extending rearwardly from a vehicle body frame to support a seat. The seat rail is formed of a left-and-right two-split cast product having a substantially flat upper surface and, at the same time, includes cross members. These cross members can be mounted later using bolts. The seat can be arranged above the seat rail and the cross members and, at the same time, a seat engaging member which engages the seat with the cross member can be formed on the cross member. The seat rail is constituted of the left and right seat rails which are divided with respect to a vehicle width center. This seat rail structure provides for simple manufacture and assembly.

Owner:HONDA MOTOR CO LTD

Method for preparing nutrition soft sweets

ActiveCN101268797ASufficient liquidityStable quantityConfectionerySweetmeatsOxygenHigh water content

The invention provides a preparation method of nutritious soft sweets. The method overcomes the problems that the nutrient content is easy to be damaged and is lost overmuch, etc. in the preparation process by the existing preparation technique of the nutritious soft sweets. For the preparation technique of the invention, feed liquid containing high water content is cast and molded firstly, then is dried and dehydrated under the vacuum condition, when the feed liquid is added with a nutritious hardening agent, as well as dried and dehydrated at high temperature, the hot nutritious hardening agent with unstable oxygen is damaged or lost, thereby ensuring the quantity of the nutritious hardening agent added in the feed liquid keeps stable in the preparation process. The nutritious soft sweets obtained by the preparation method of the invention not only are excellent in color, smell and taste, but also have less loss of the nutritious hardening agent, and finally the quantity of the nutritious content contained by the product is also stable.

Owner:广东富味健康科技有限公司

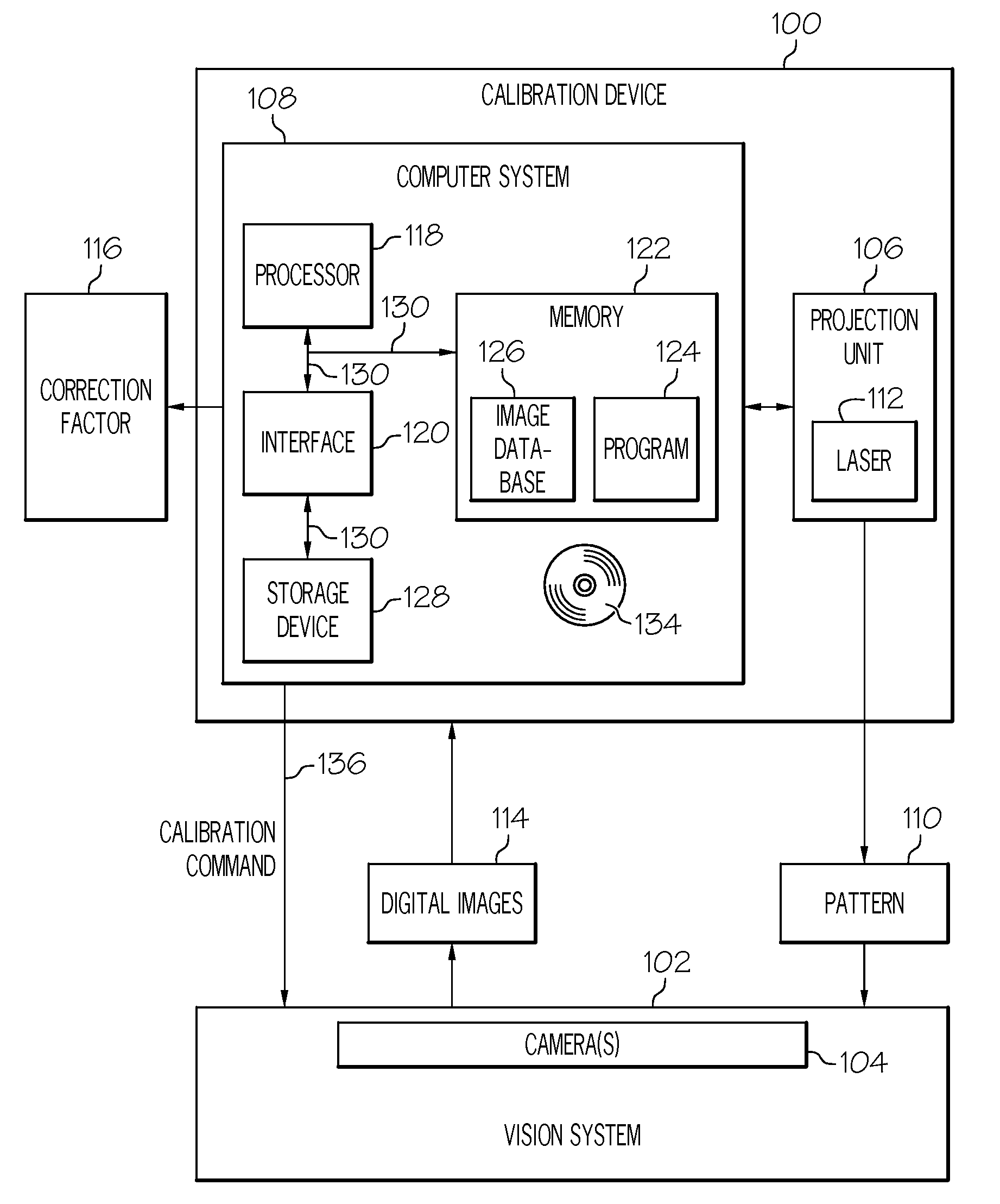

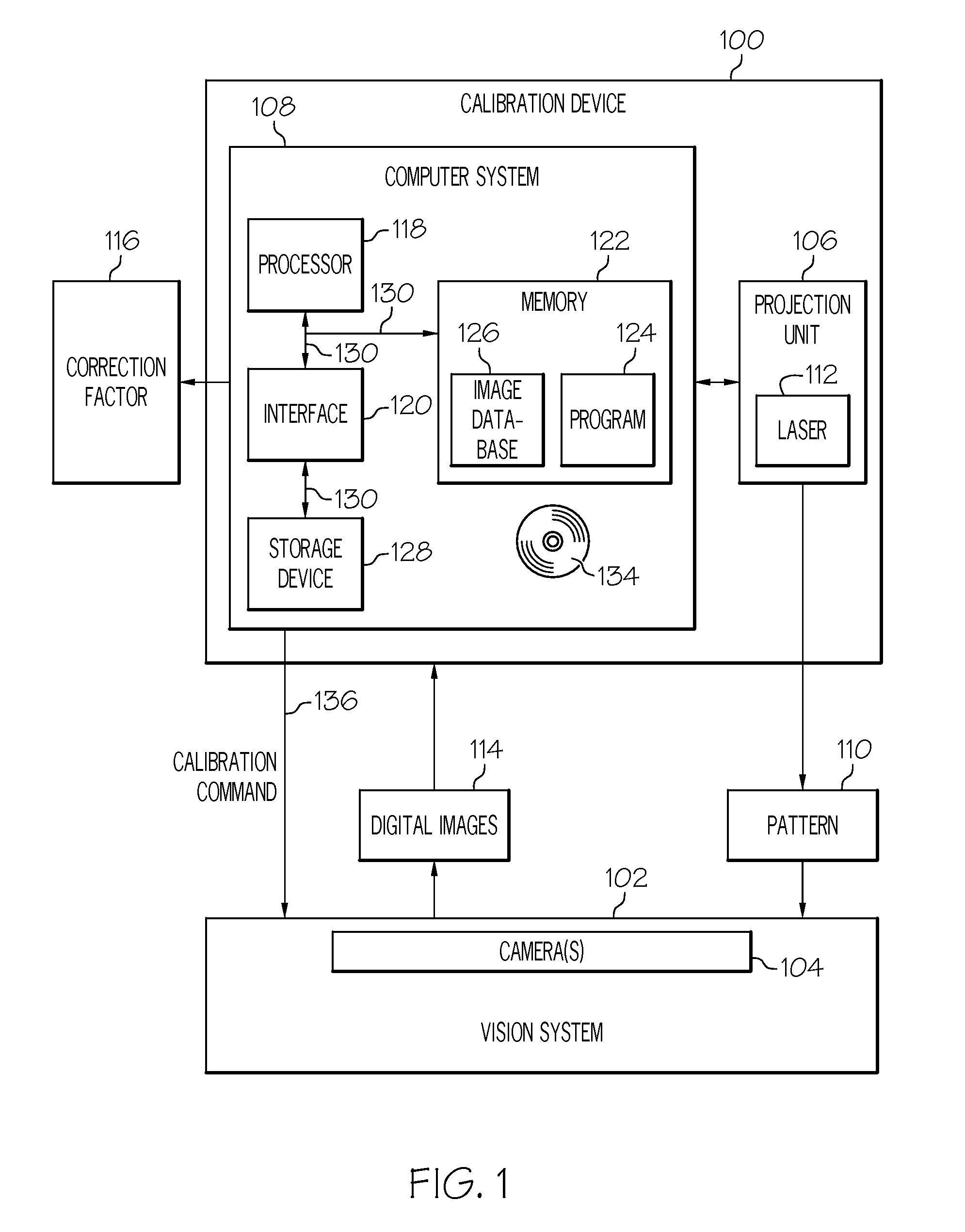

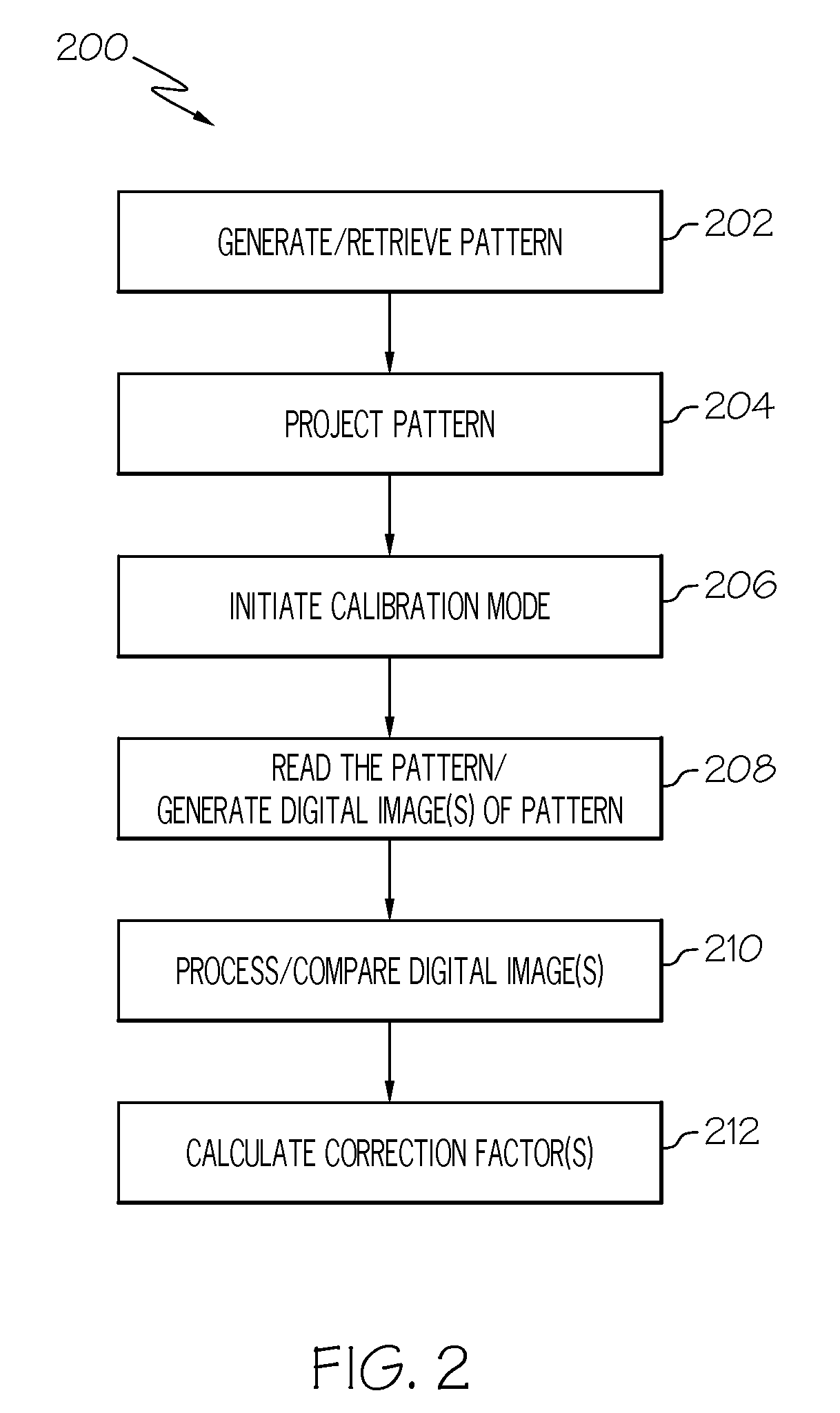

Methods and systems for calibrating vehicle vision systems

InactiveUS20100179781A1Easy CalibrationEasy to castImage analysisCharacter and pattern recognitionComputer visionVisual perception

Owner:GM GLOBAL TECH OPERATIONS LLC

Forged hammermill hammer

ActiveUS20060032958A1High strengthDecrease susceptibility to rod hole elongationGrain treatmentsEngineeringHardness

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The design as disclosed and claimed is forged increasing the strength of the hammer. The shape of hammer as disclosed and claimed uses this improved strength to reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design incorporates comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

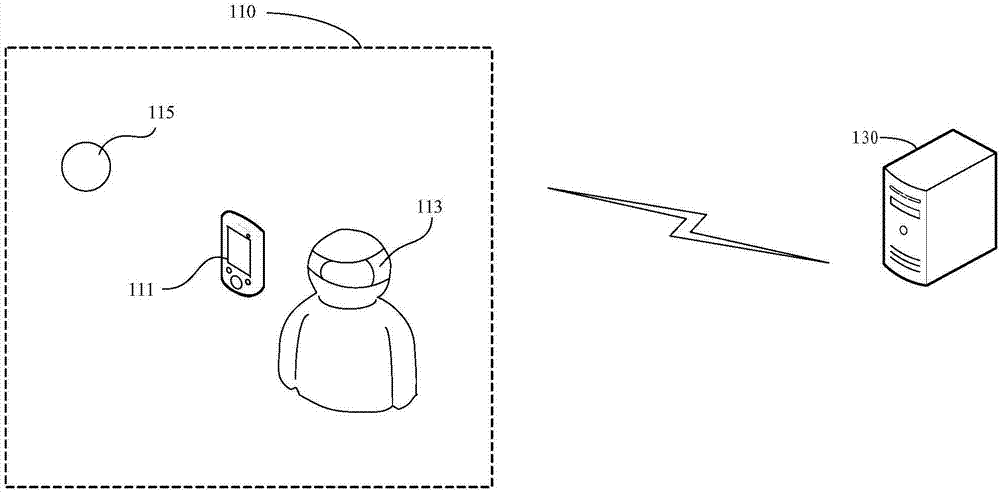

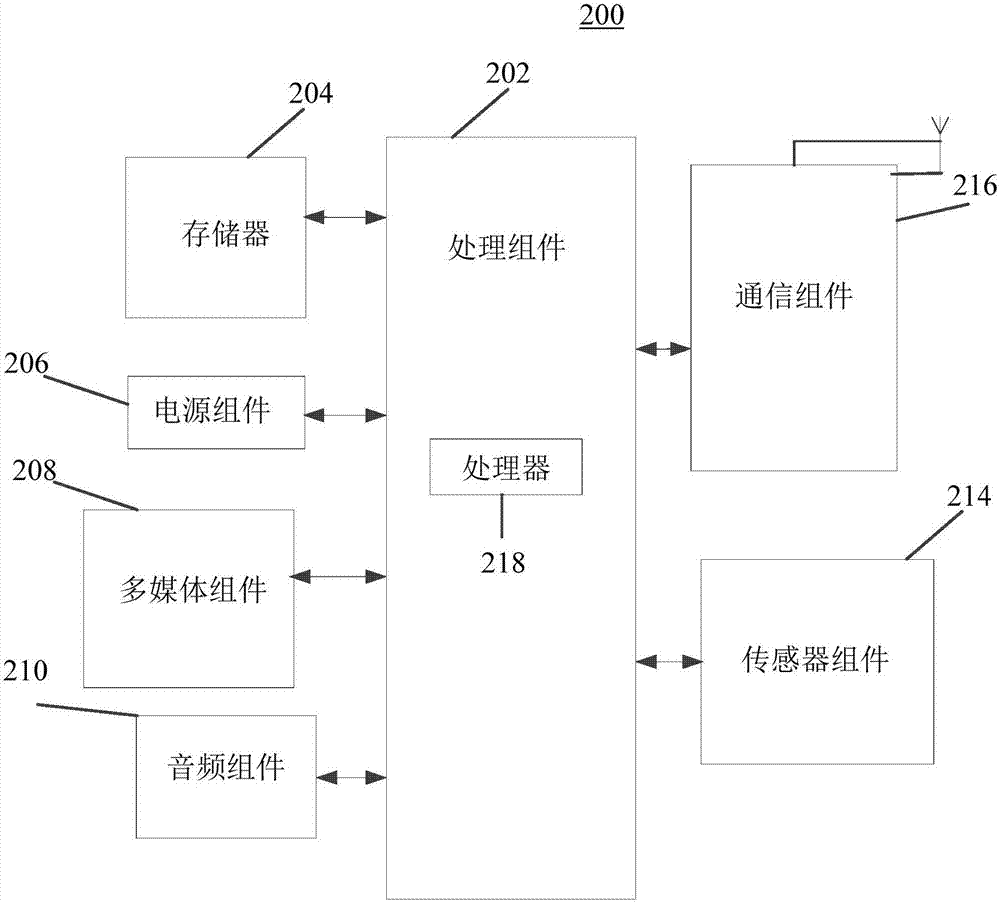

Method and device for controlling intelligent home system and readable computer storage medium

ActiveCN107358007AEasy to controlEnsure safetyGeometric CADInput/output for user-computer interactionData acquisitionVirtual reality

The invention discloses a method and device for controlling an intelligent home system and a readable computer storage medium. The method includes the steps of requesting model data to a server; rendering through the model data to obtain a virtual scene related to the intelligent home system; performing the display of the virtual scene through accessed virtual reality equipment; controlling the action video data collection of triggering actions generated by a performing user in the virtual scene, and therefore triggering the server to obtain the action information; according to the action feedback process performed in the virtual scene, controlling the intelligent home system by the action feedback process. Through the projection from the user to the virtual scene and the action feedback process performed in the virtual scene, the user can use the virtual reality equipment to know the controlled situation of the intelligent home system after the operation of the intelligent home system is triggered, and therefore the security and precision of the control of the intelligent home system are ensured.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Spectral standard sample of Al-Li alloy and its prepn

InactiveCN1403613AAvoid burnsPrevent surface oxidationPreparing sample for investigationAnalysis by material excitationIngotLi element

The present invention is a spectral standard sample of Al-Li alloy and its preparation process. The present invention features the alloy contains the following chemical elements dispersed homogeneously in aluminum: Si 0.025-0.223 wt%, FE 0.044-0.264 wt%, Cu 0.0019-1.61 wt%, Mg 0.193-6.000 wt%, Li 0.930-2.530 wt%, Zr 0.042-0.168 wt%, Zn 0.023-0.205 wt%, Ti 0.0026-0.134 wt% and Mn 0.015-0.139 wt%. The present invention can avoid the burn loss and surface oxidation of Li element to ensure the correct ratio of Li element in the standard sample. The intermittent semi-continuous casting process prevents the cracking of the alloy ingot.

Owner:SOUTHWEST ALUMINUM GRP

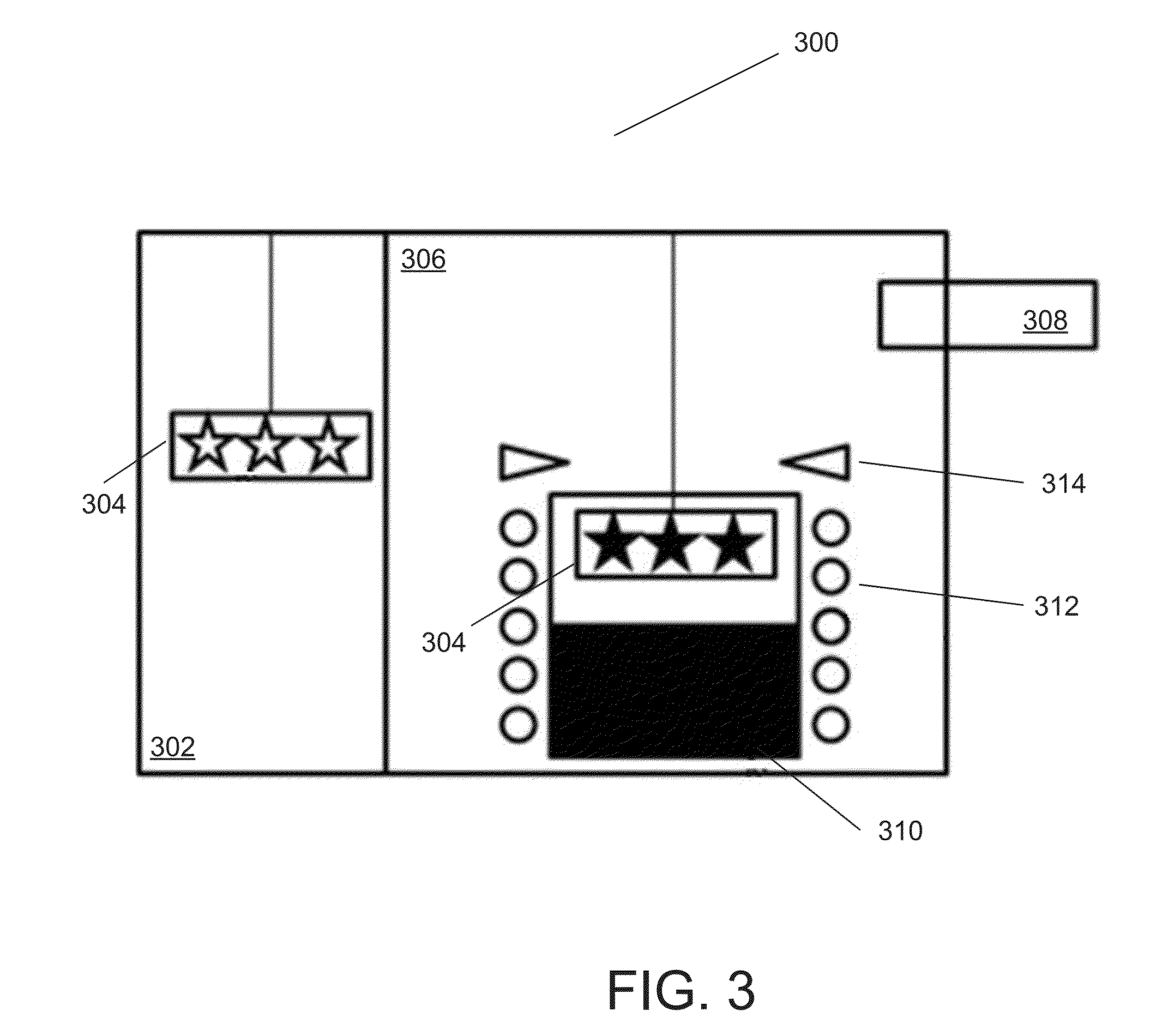

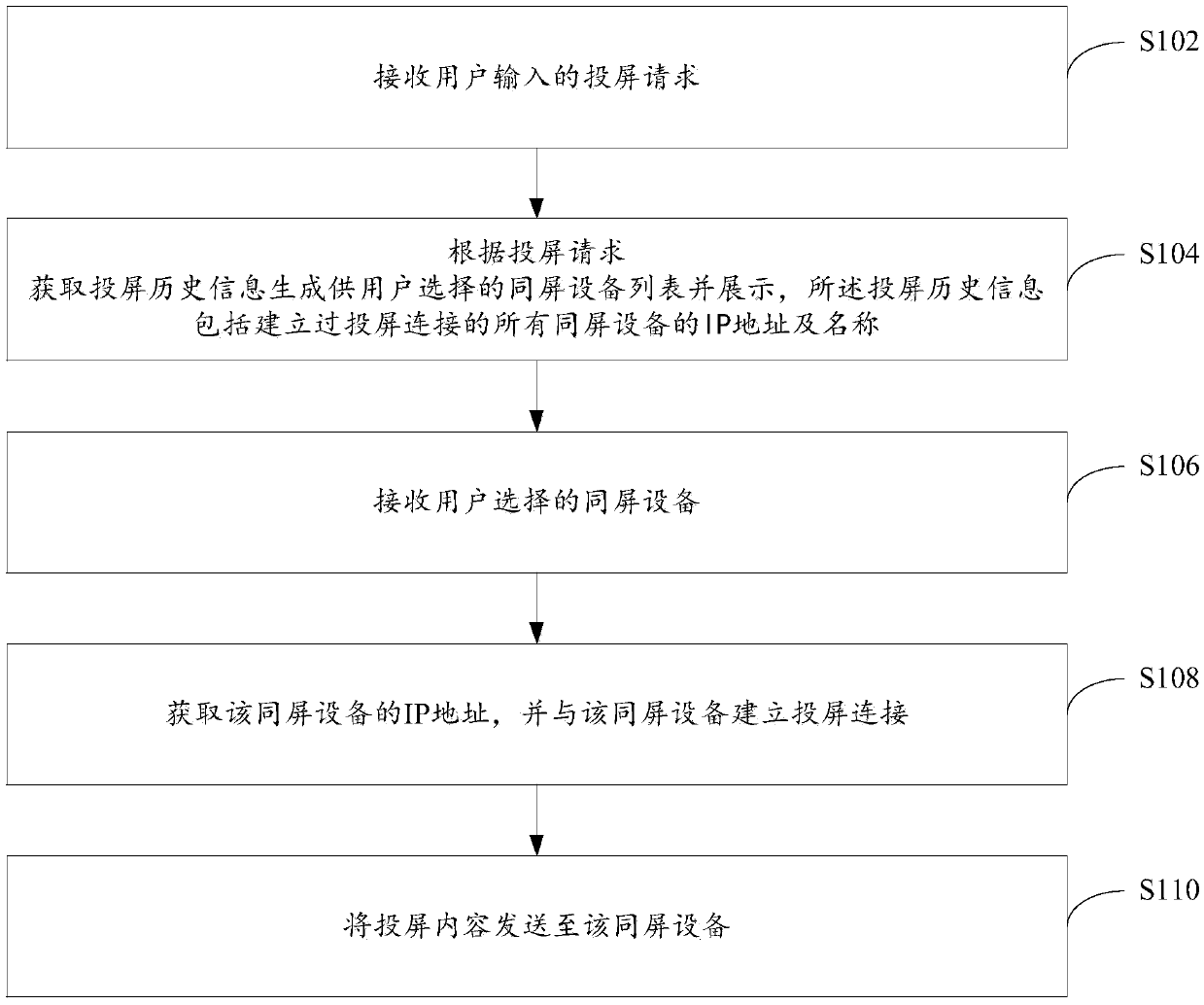

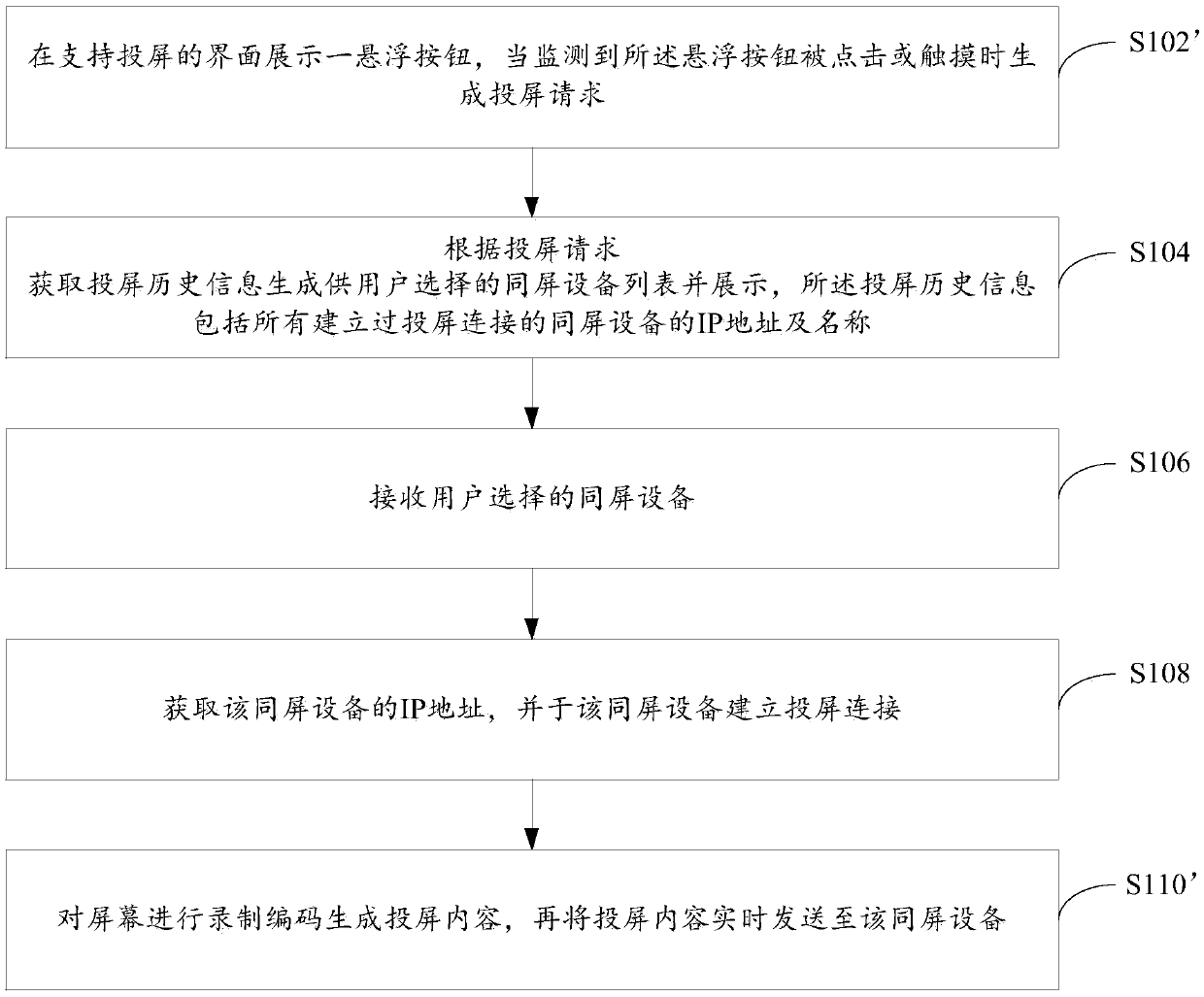

Method, device and system for screening, intelligent terminal, and storage medium

InactiveCN109525889AEasy to castFree from burdenSelective content distributionIp addressComputer science

The invention discloses a method, a device and a system for screening, an intelligent terminal, and a storage medium. The method for screening comprises of: receiving a screening request input by a user; obtaining the screening history information to generate and display a list of the screening device selected by the user, where the screening history information comprises IP addresses and names ofall the screening devices that have established the screening connection; receiving the screening device selected by the user; obtaining the IP address of the screening device, and establishing a screening connection with the screening device; and sending the screened content to the screening device. The technical solution of the method, the device and the system for screening, the intelligent terminal, and the storage medium, reduces the difficulty of screening for the user, and improves the user experience.

Owner:SHENZHEN EAGLESOUL TECH CO LTD

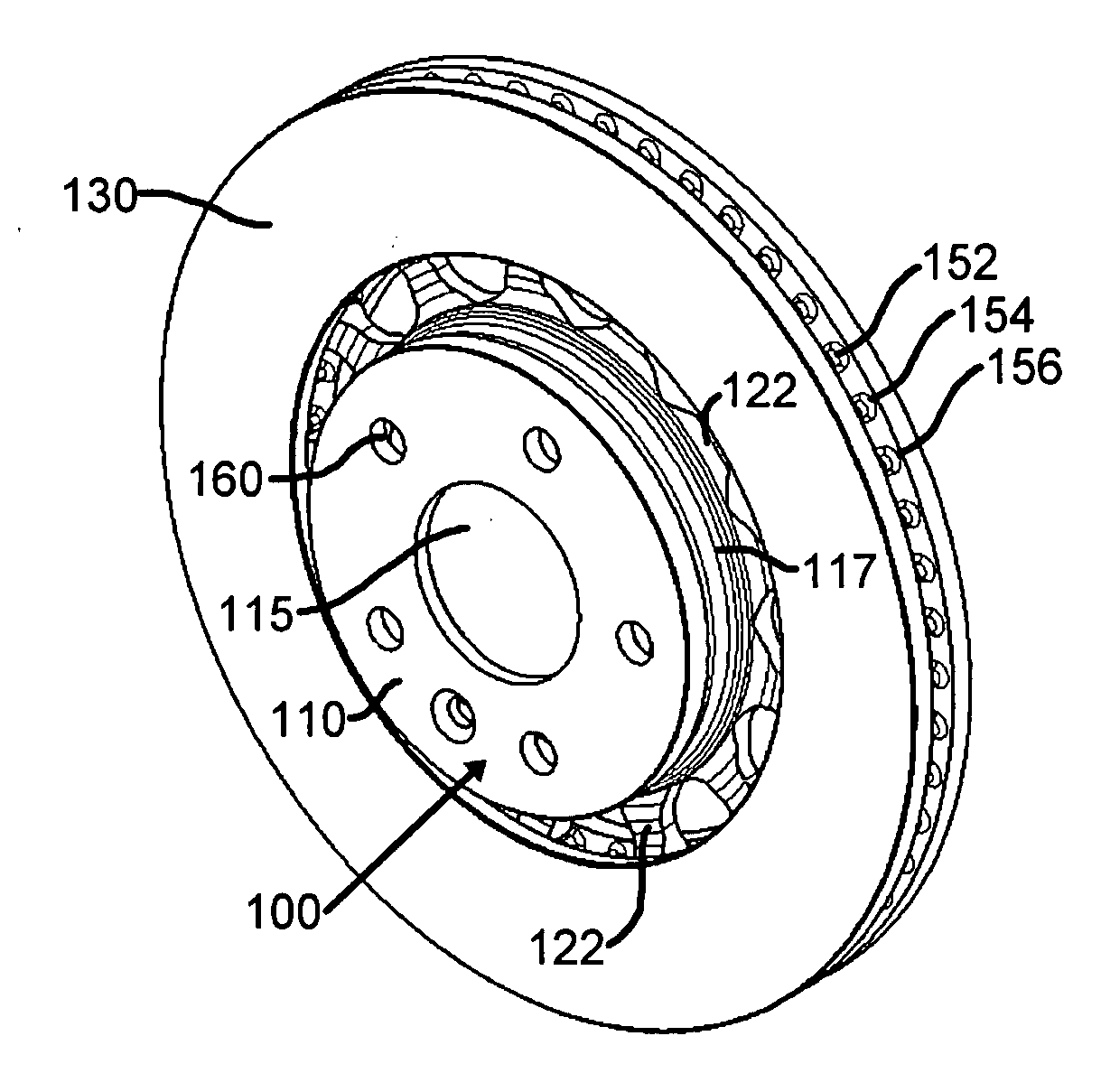

Composite brake disc

InactiveUS20110061980A1Reduce massReduce propensityFoundry mouldsBraking discsCeramic coatingMicrostructure

A brake disc arrangement has a mounting portion formed of a metal, with a plurality of radial protuberances extending radially outward therefrom. The radial protuberances each have a radially distal tip portion, and a ceramic coating is applied to the radially distal tip portion of the radial protuberances. The brake plate portion is cast so as to surround the radially distal tip portions. However, it is isolated therefrom by the ceramic coating. At least some of the radially distal tip portions are formed of metal having a microstructure created by electrical discharge machining to increase dampening. A sand core within a core box holds the mounting portion in a predetermined fixed orientation. The molten metal is poured into the core box mold, and the metal brake plate portion is prevented by the ceramic coating from welding to any of the plurality of radial protuberances.

Owner:RASSINI FRENOS S A DE

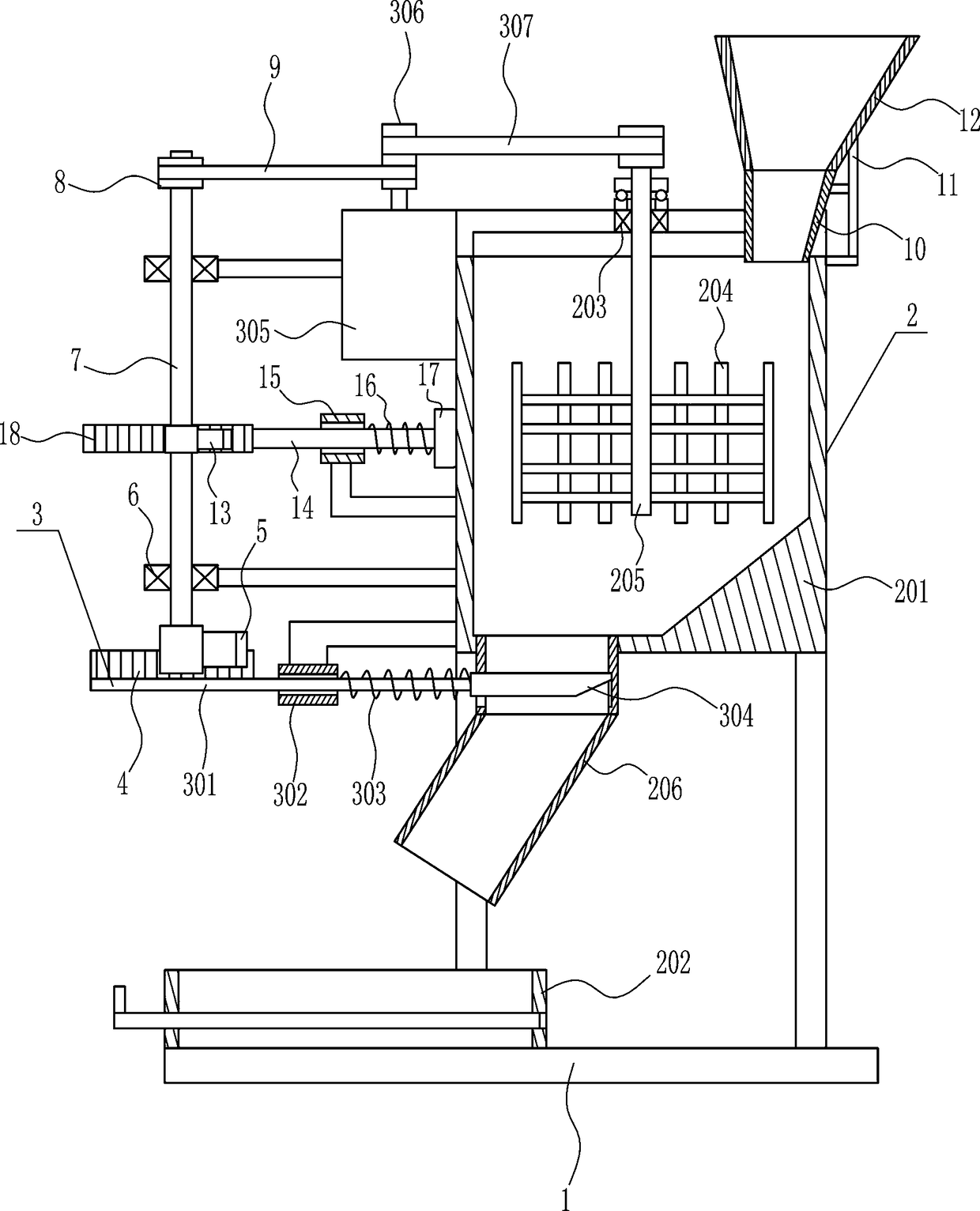

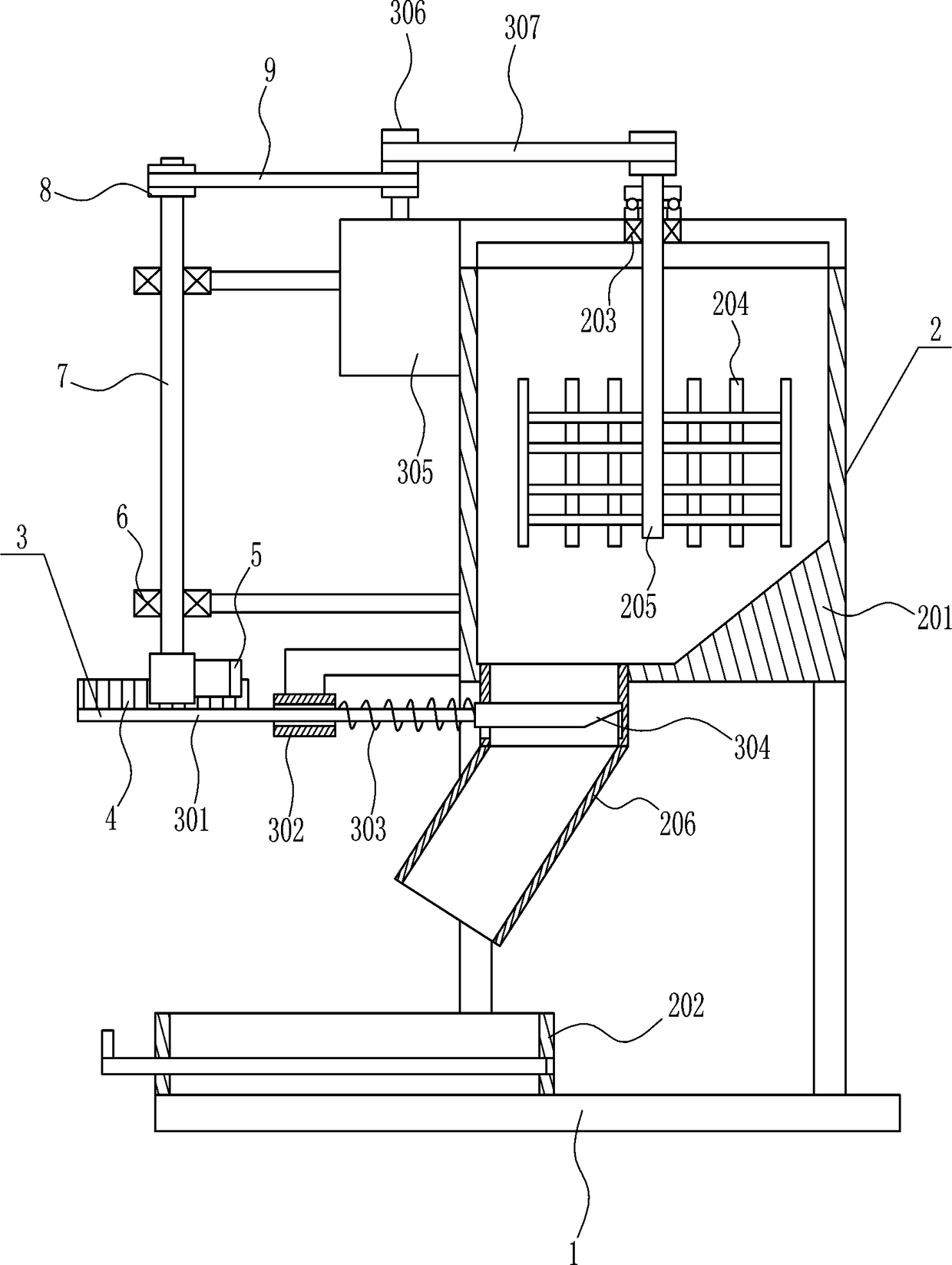

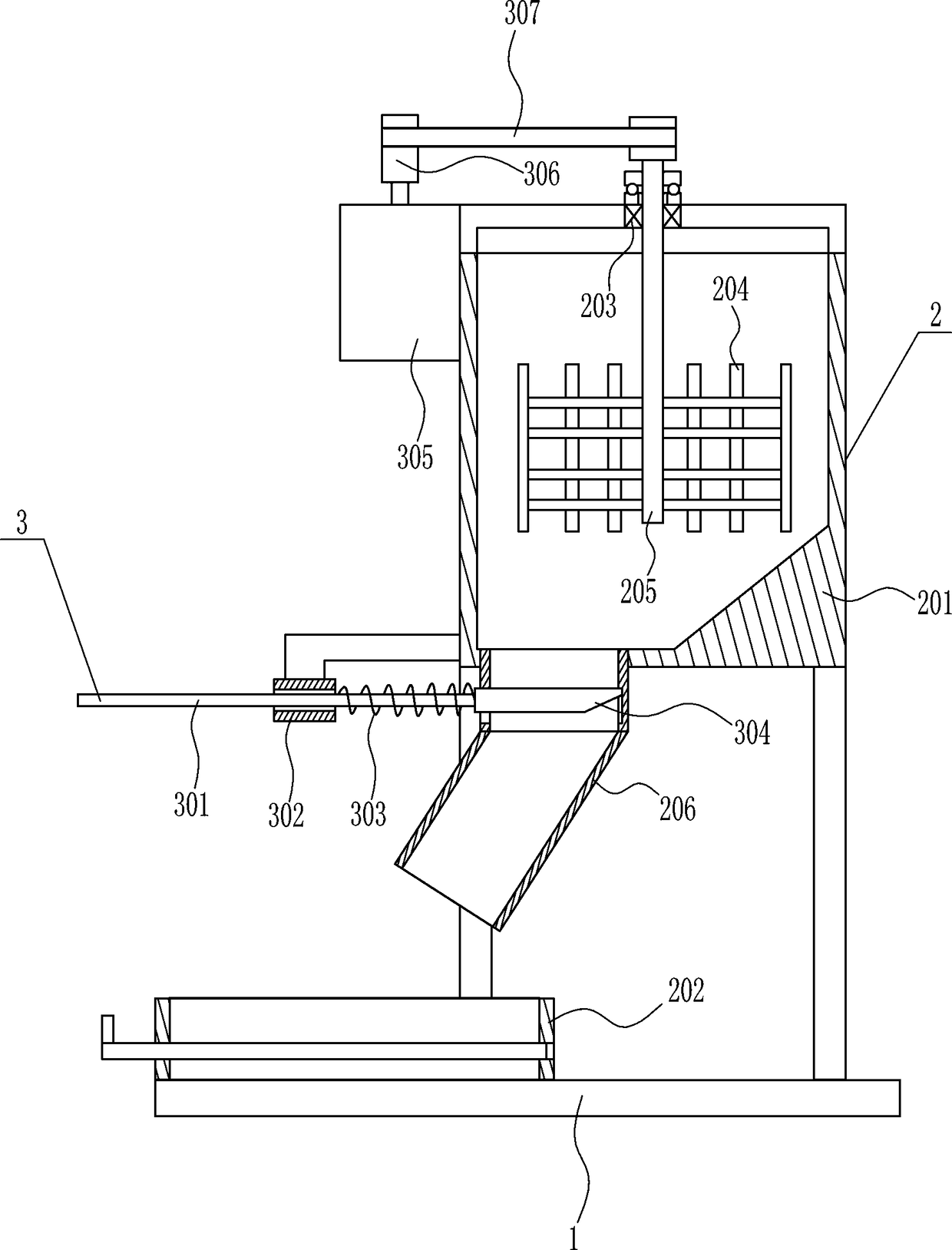

Building cement slab casting device

ActiveCN108789836AEasy to castPlay a cleaning roleFeeding arrangmentsCement mixing apparatusCement boardMaterials science

The invention relates to a casting device, in particular to a building cement slab casting device. The building cement slab casting device is aims to fully stir the mixing material of a cement slab and be capable of controlling the continuous intermittent outflow of the stirred cement. According to the technical scheme, the building concrete slab casting device includes a bottom plate and the like; and the top of the bottom plate is connected with a stirring mechanism, and the upper side of the stirring mechanism is connected with a driving mechanism. By means of the building cement slab casting device, the effects that the mixing material of the concrete slab can be fully stirred, and the continuous intermittent outflow of the stirred cement can be controlled are achieved, an arranged stirring rod can effectively and fully stirred the material in a stirring box, the uniformity of the amount of the cement and sand in the cast concrete slab is facilitated, and an arranged manual pullingfirst sliding rod move leftwards to control the outflow amount of a discharging hopper, in this way, the cement slab is casted more conveniently.

Owner:浙江大春科技股份有限公司

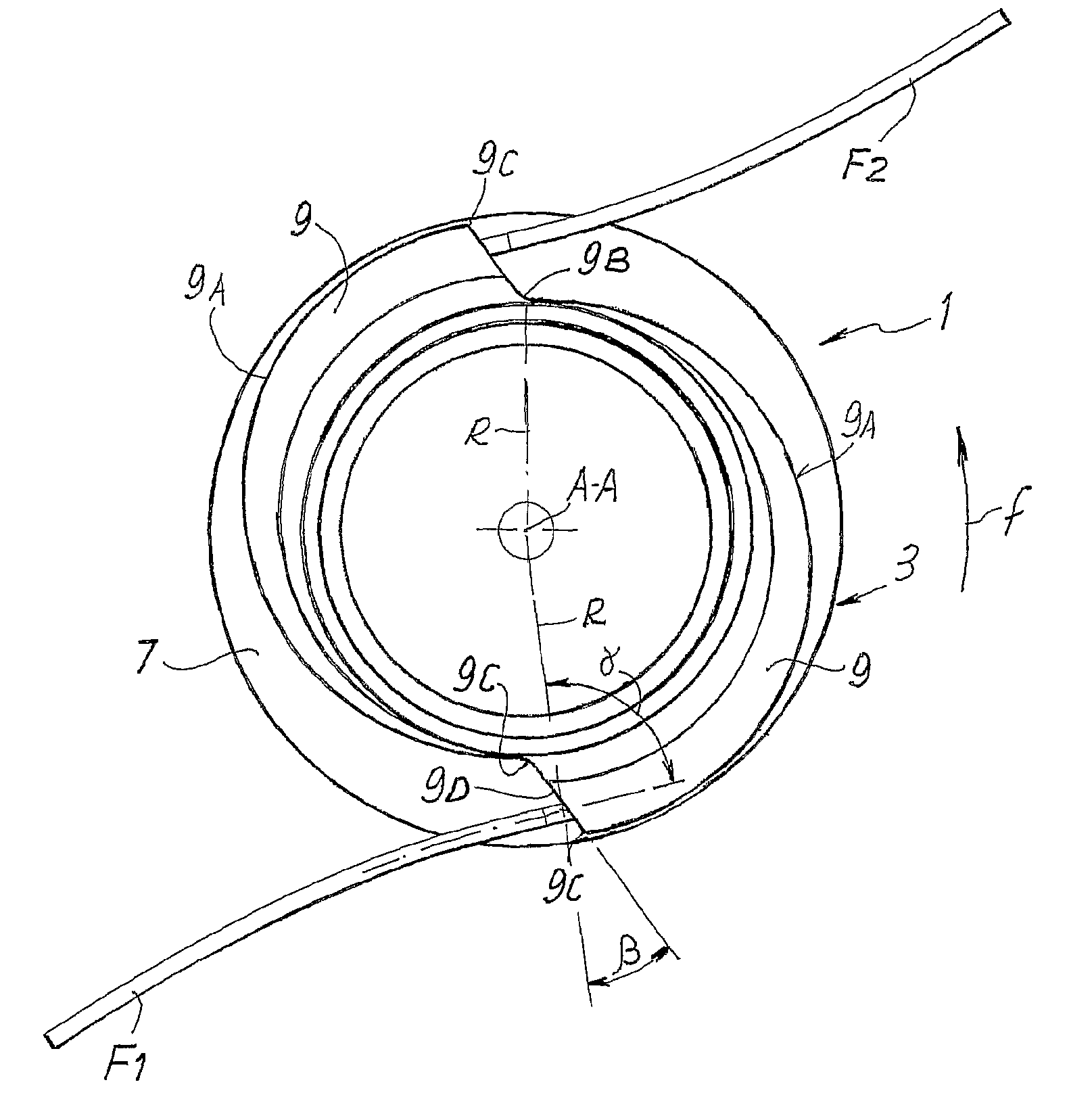

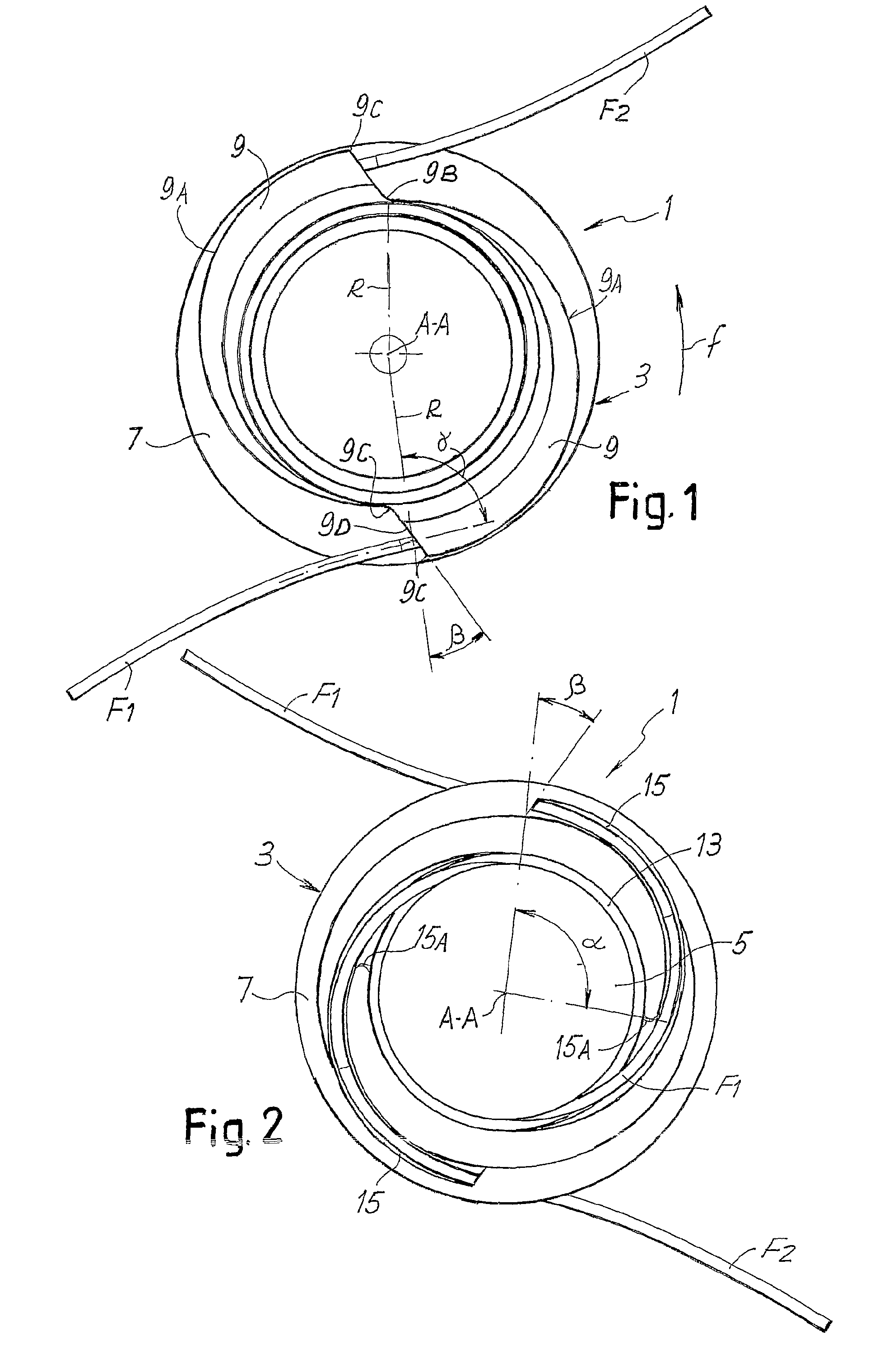

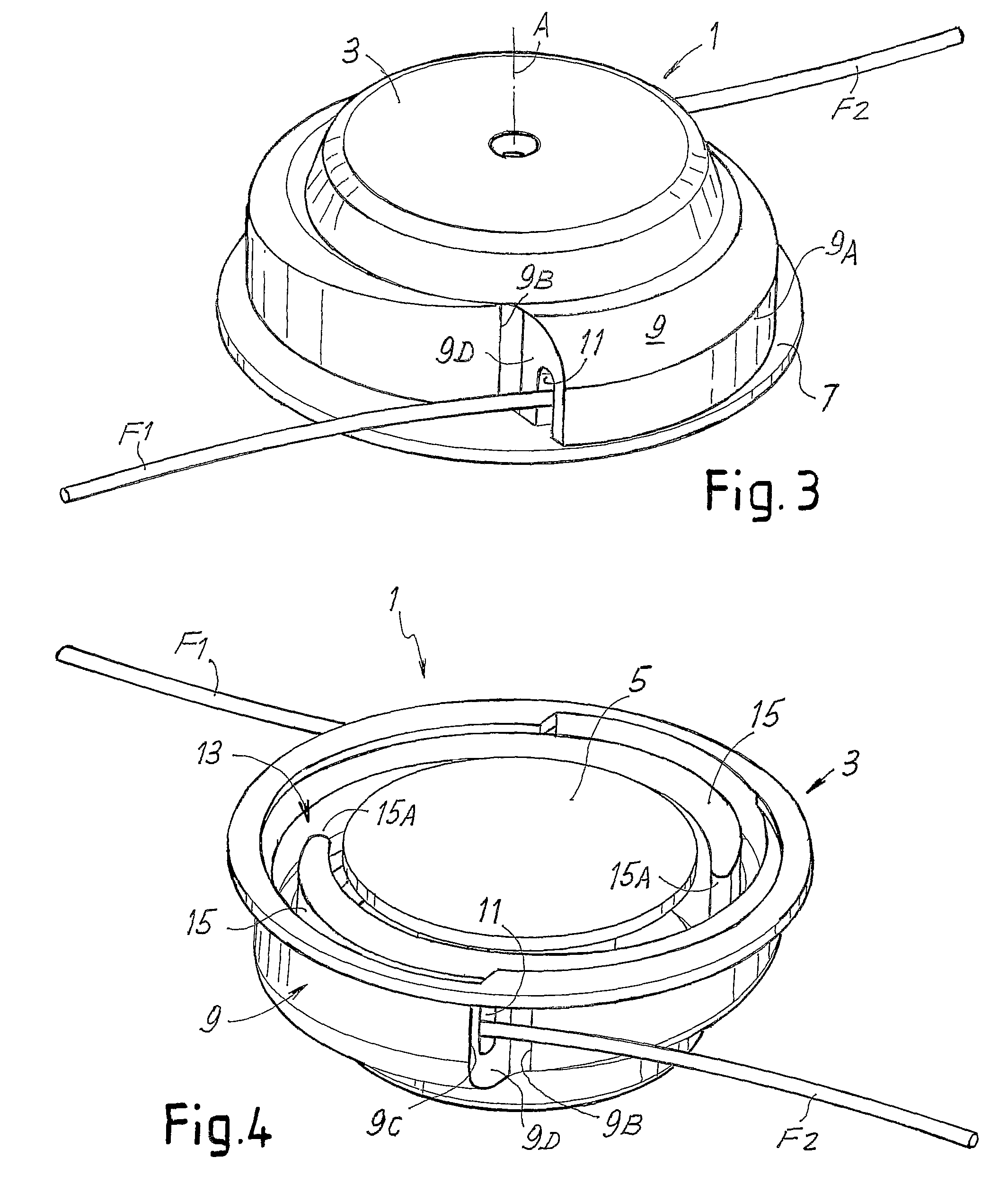

Grass-cutting head with spiral guide channels for the cutting line

The grass-cutting head (101) has a body (103) forming a housing for at least one spool of cutting line (F1; F2), provided with at least one outlet hole (111) of an end of the cutting line wound on said spool positioned inside the head. For each outlet hole, a guide channel for the cutting line is also provided, extending from the inside of the housing towards the hole and having an inclined trend, gradually moving away from said axis of rotation.

Owner:ARNETOLI MOTOR

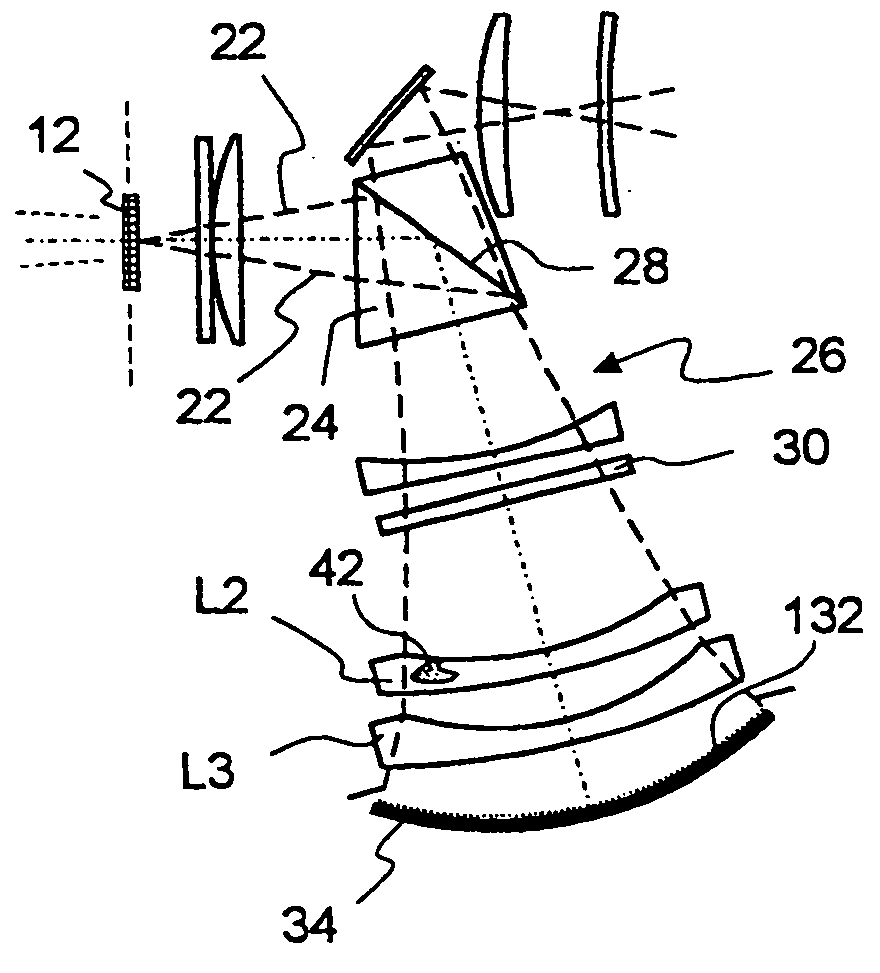

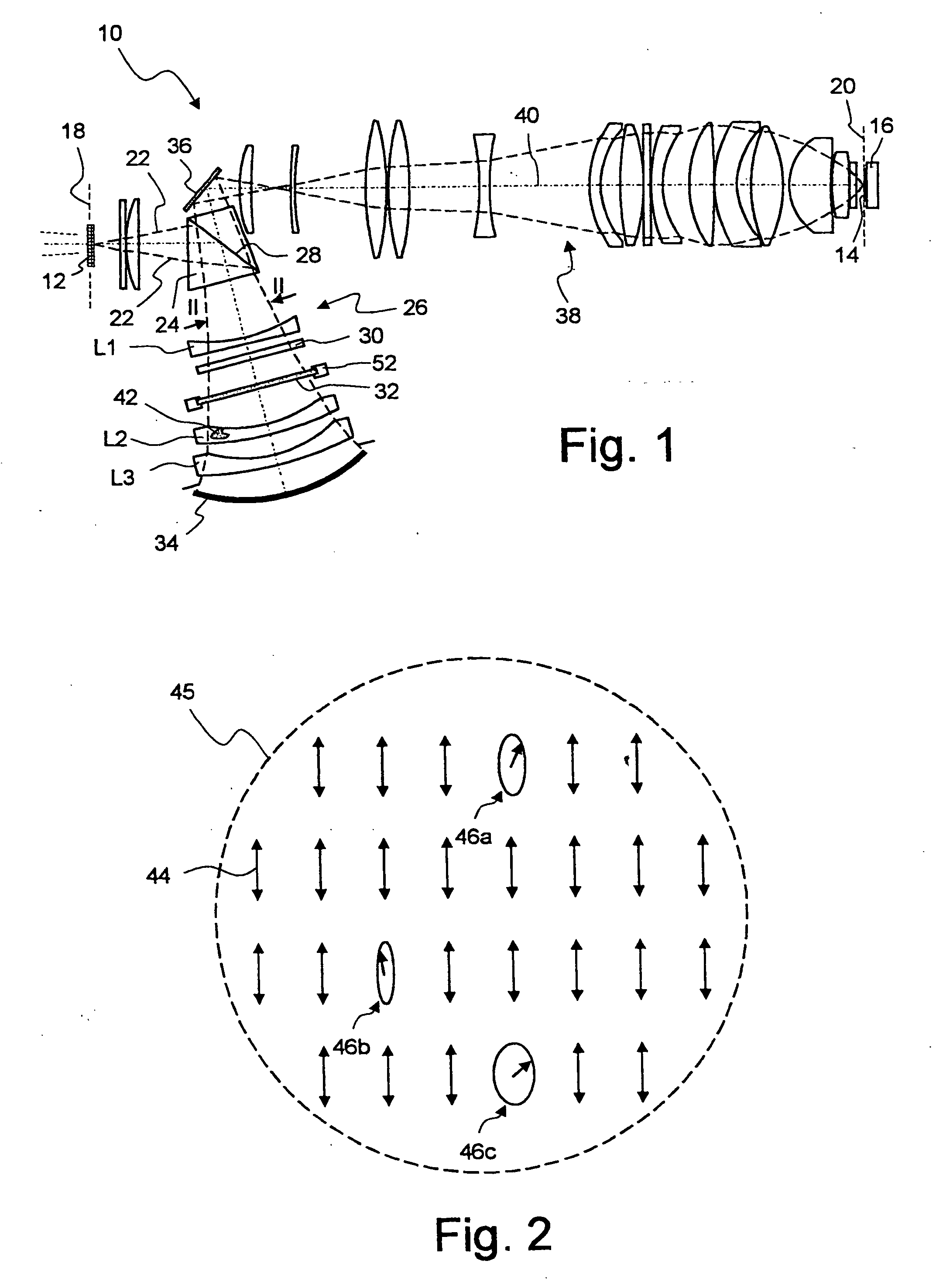

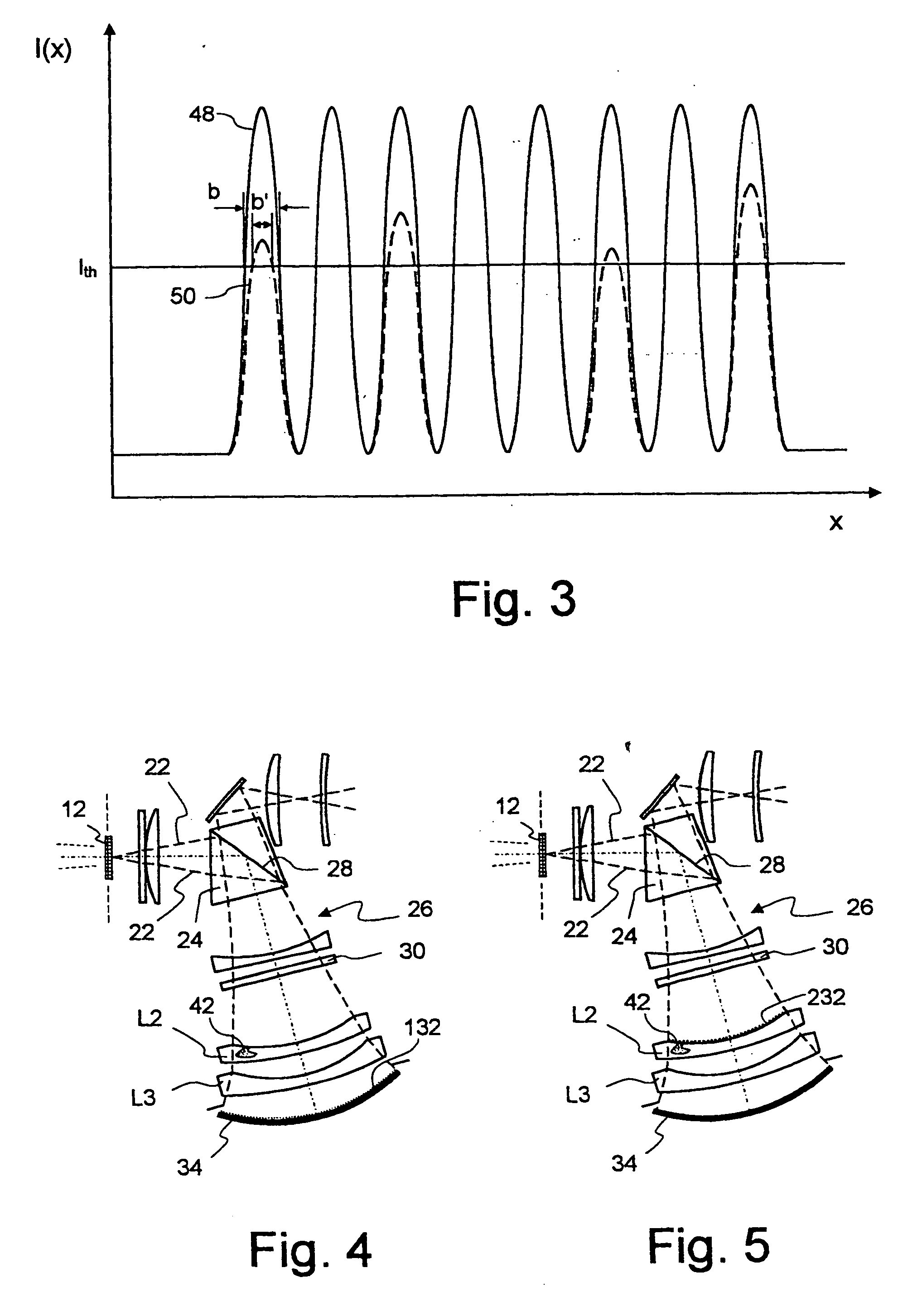

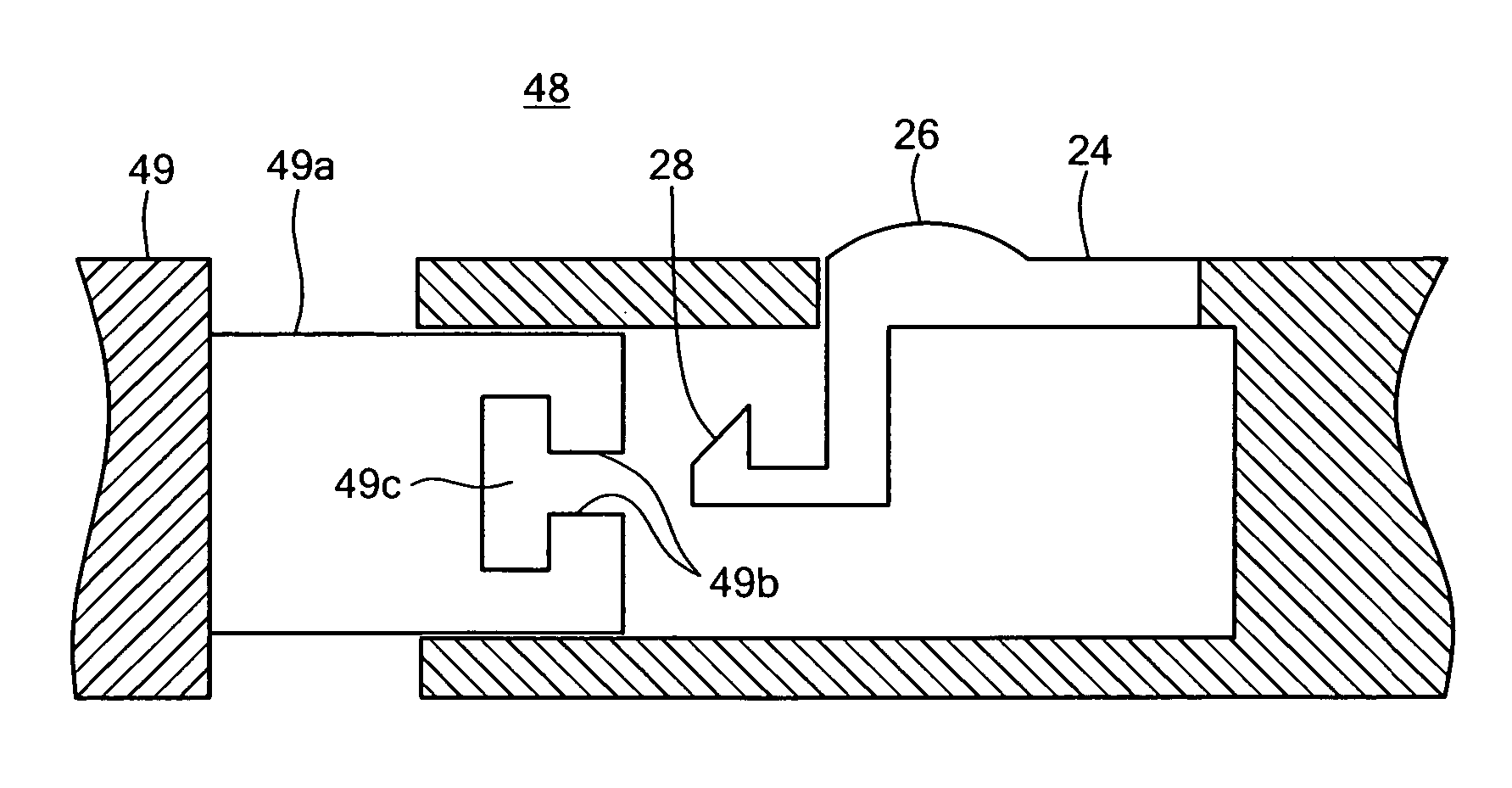

Projection lens for a microlithographic projection exposure apparatus

A projection lens (10) for a microlithographic projection exposure apparatus has a first optical element, for example a birefringent lens (L2), that has polarization dependent properties causing intensity fluctuations in an image plane of the projection lens. These fluctuation may be produced by a second optical element (24), for example a polarization selective beam splitting layer (28), that is arranged downstream of the first optical element. A gray filter (32; 132; 232) disposed in the beam path reduces the intensity fluctuations.

Owner:CARL ZEISS SMT GMBH

High-strength copper-titanium alloy and preparation method thereof

The invention discloses a high-strength copper-titanium alloy, which consists of the following components in percentage by mass: 0.2 to 5.0 percent of titanium, 0 to 3 percent of third alloy elements and the balance of copper, wherein the third alloy elements are Al, Sn and Zn. A preparation method comprises the following steps: adding Cu into a vacuum induction electric furnace for smelting, sequentially adding titanium and the third alloy elements, and performing casting to obtain a copper-titanium alloy ingot; performing surface milling and hot rolling to obtain a copper-titanium alloy plate; performing solid solution treatment, cold rolling and aging treatment to obtain the high-strength copper-titanium alloy. The high-strength copper-titanium alloy and the preparation method thereof have the advantages that a TiAl intermetallic compound is taken as a synergistically enhanced precipitated phase, so that the enhancement effects of a second precipitated phase of the copper-titanium alloy are improved; the prepared copper-titanium alloy has tensile strength of 550 to 800 Mpa and plastic elongation of 2 to 10 percent, and can be used for preparing various elastic spring pieces, explosion-proof tools and plug connectors.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

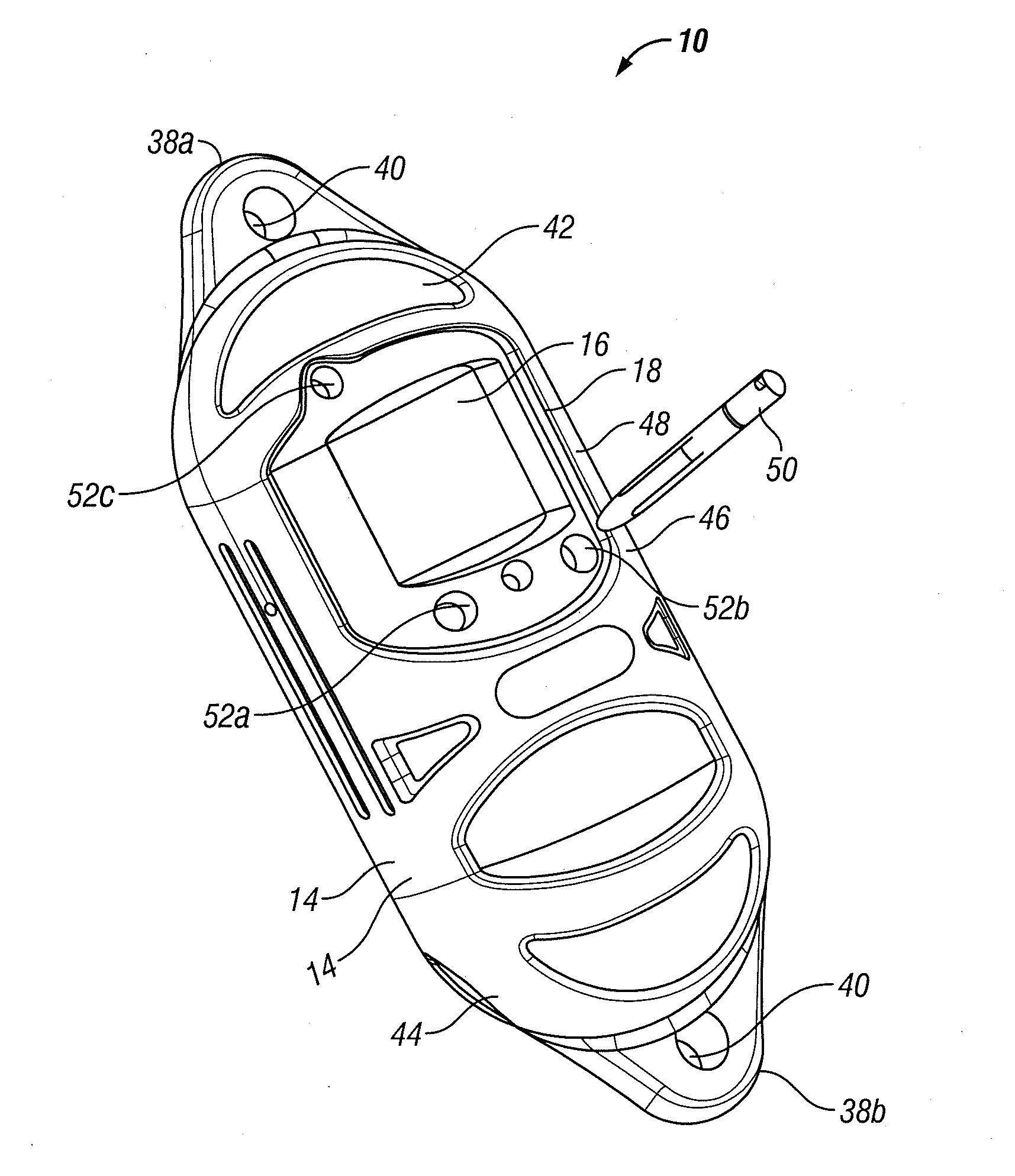

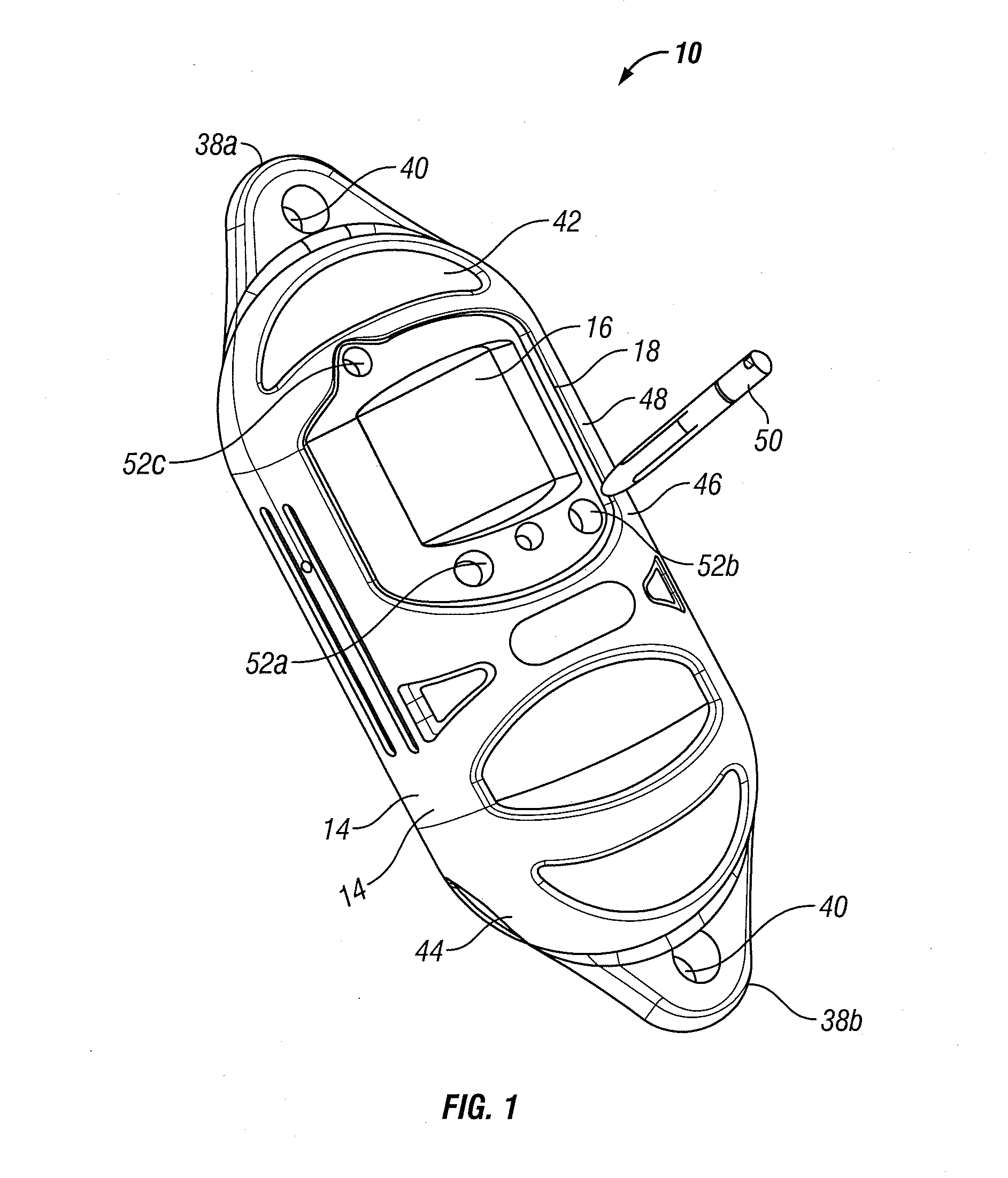

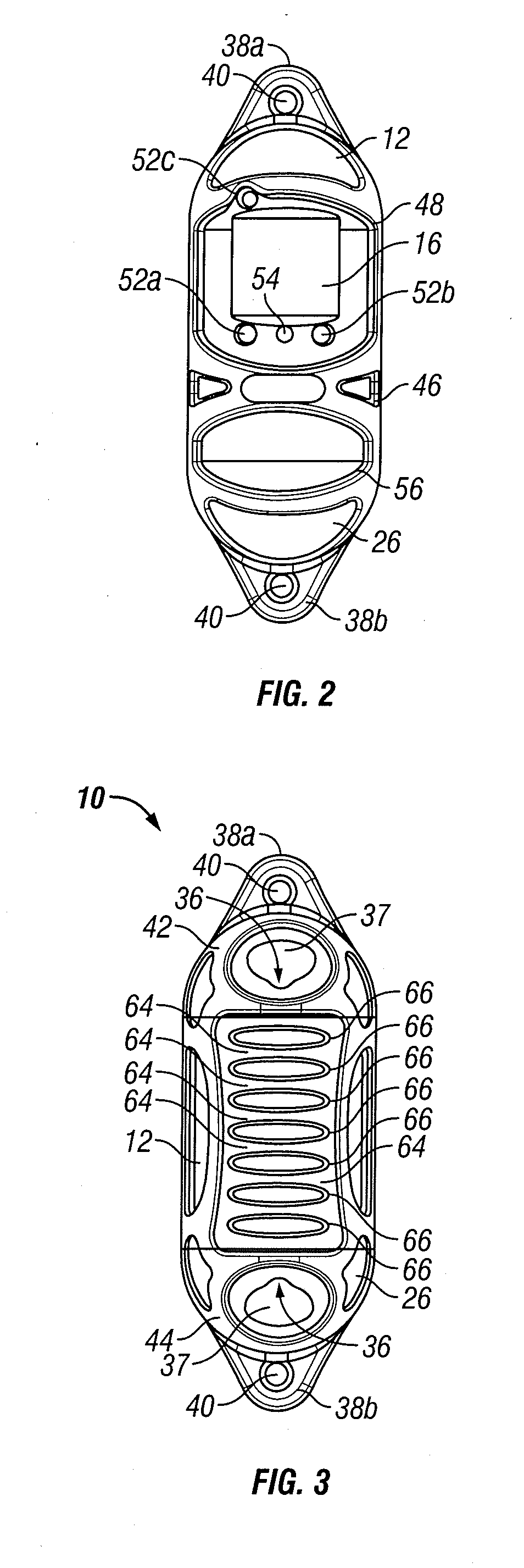

Safety buckle with multiple orientation clasp

ActiveUS20050210641A1Secure child resistant featureSufficient clearanceSnap fastenersClothes buttonsEngineering

Owner:SAFE STRAP

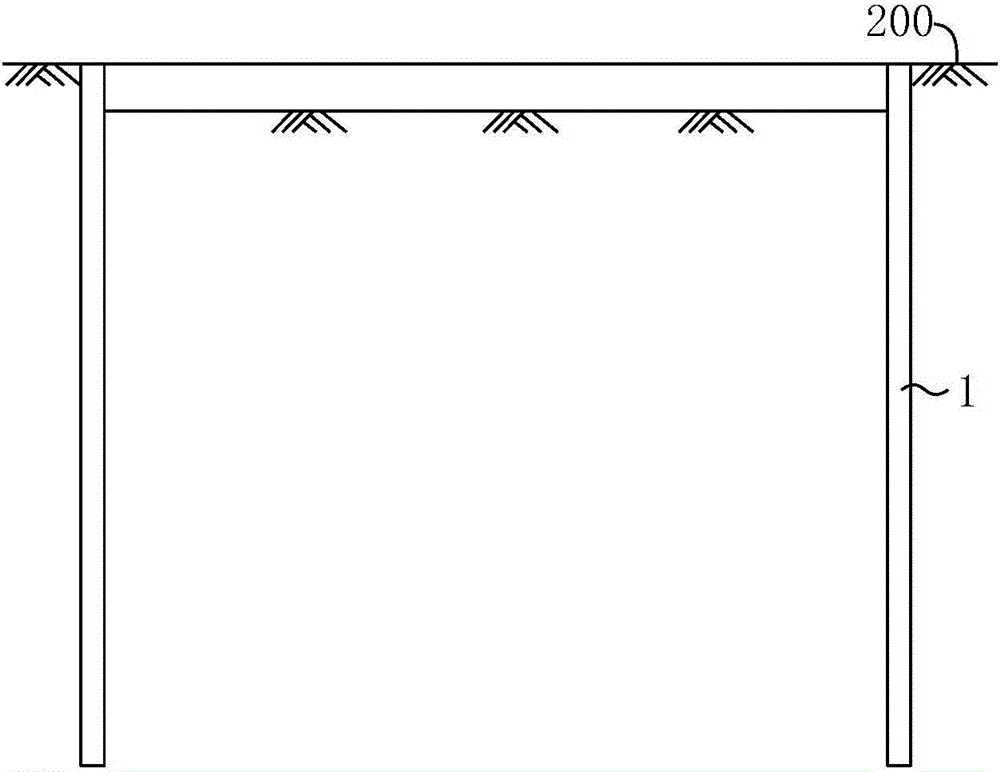

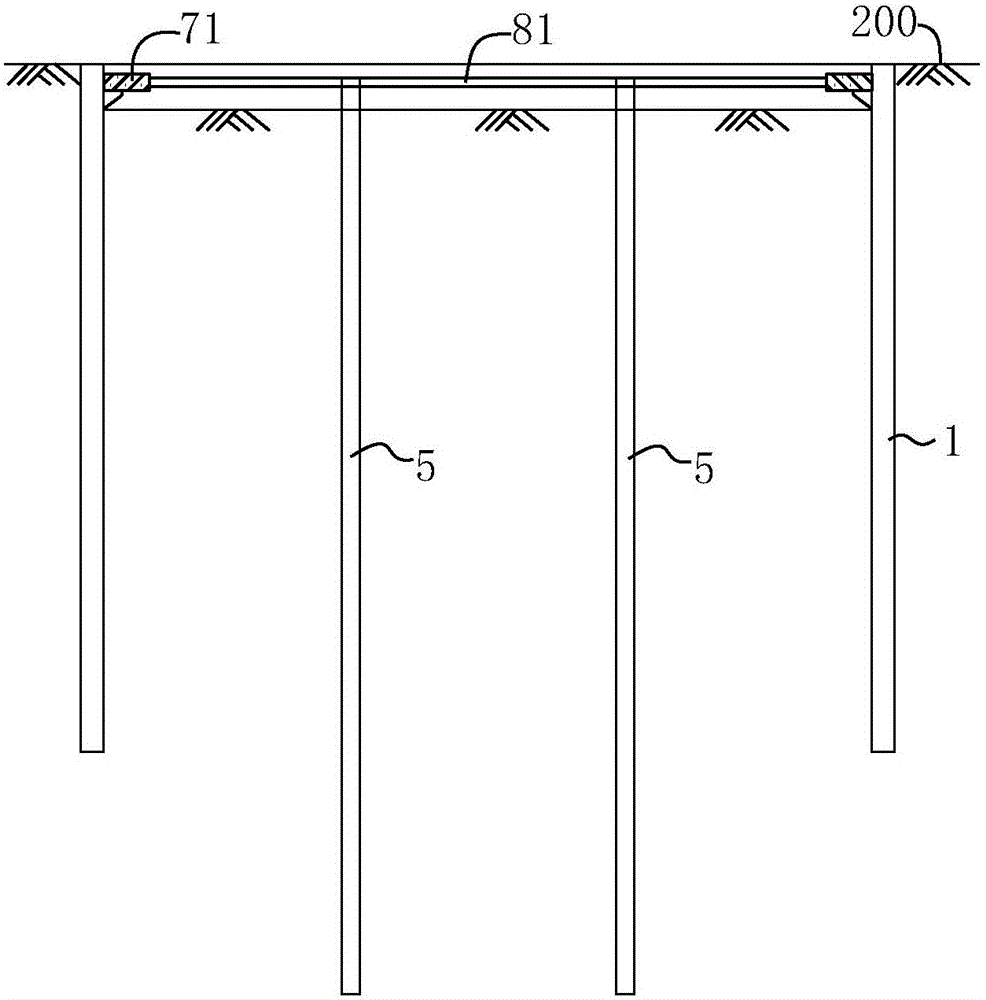

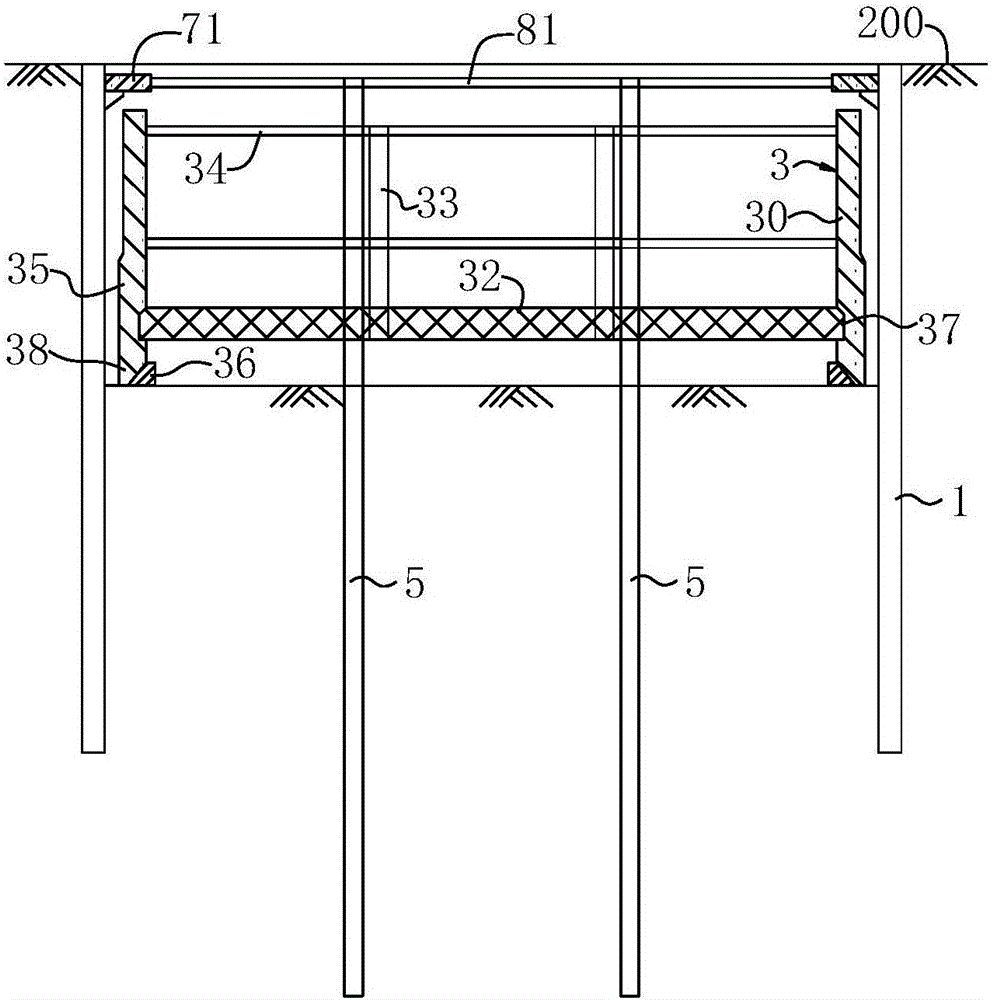

Steel sheet pile and open caisson combined underground garage and construction method thereof

ActiveCN106013052AHigh strengthTightly boundArtificial islandsExcavationsReinforced concreteEngineering

The invention discloses a steel sheet pile and open caisson combined underground garage. A body structure of the underground garage comprises an external wall and an external wall supporting structure; the external wall is composed of an upper external wall body and a lower external wall body which are connected in an up-down manner; the upper external wall body is a steel plate pile wall formed by connecting steel plate piles with one another; the lower external wall body is a reinforced concrete well wall of an open caisson; and the external wall supporting structure serves as a supporting structure of a parking platform of the underground garage at the same time. The external wall of the underground garage adopts a compounded external wall composed of the steel plate pile wall and the well wall of the open caisson, and the beneficial effects of the steel plate pile wall and the well wall of the open caisson are combined. The invention further discloses a construction method of the underground garage. According to the construction method, firstly, the steel plate piles sink to form the steel plate pile wall; and then the open caisson is poured in the steel plate pile wall and sinks. By means of the construction method, the building cost of the underground garage is successfully reduced, and the building time of the underground garage is successfully shortened.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

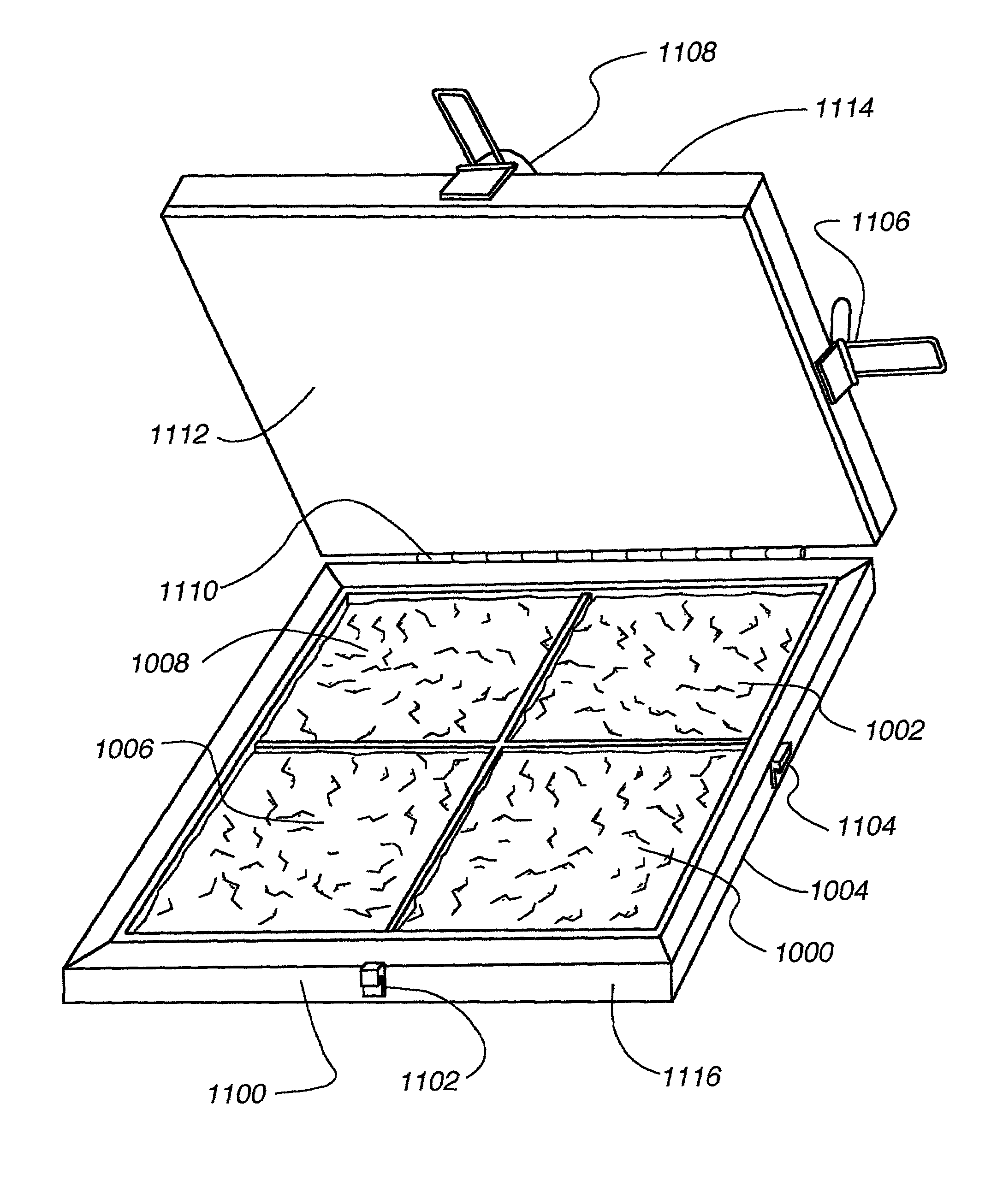

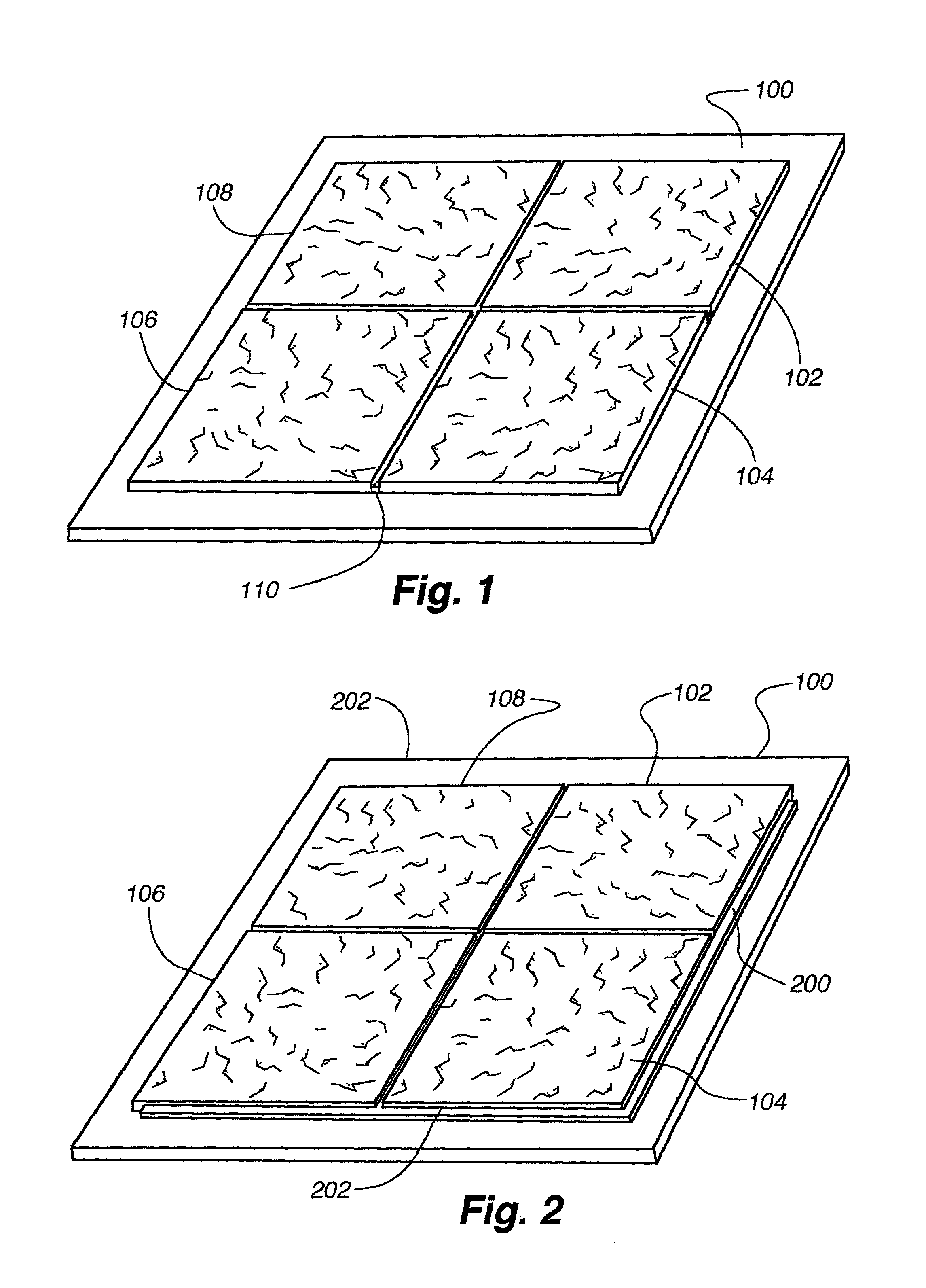

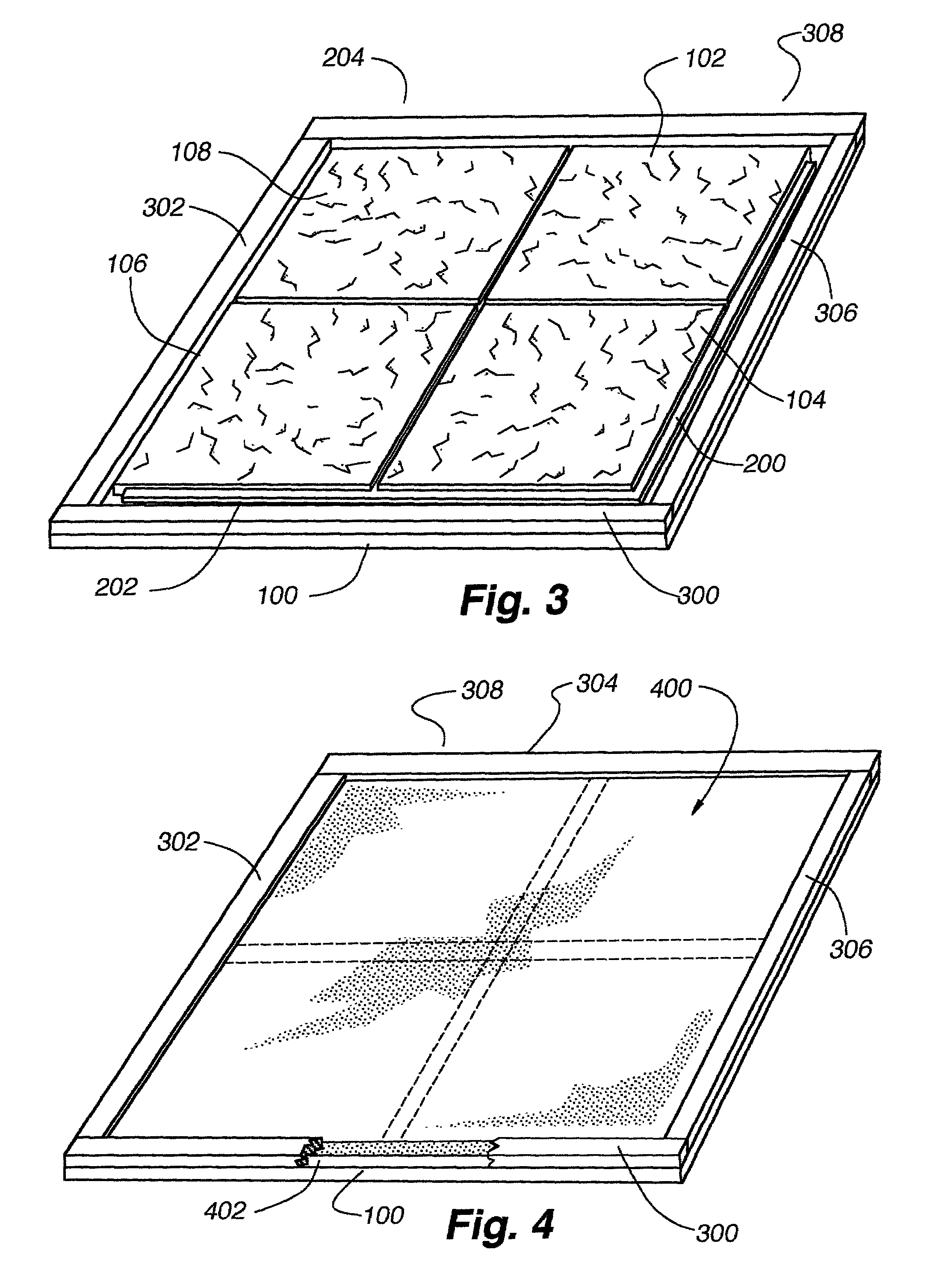

Methods and apparatus for producing manufactured articles having natural characteristics

ActiveUS7235204B2Easy to castAvoid stickingCeramic shaping apparatusDomestic articlesPolymer scienceThermosetting polymer

A method for making a thermosetting polymer reproduction of an object preferably comprises the steps of modifying an original object such as an object found in nature (e.g., a stone or array of stones) or a manmade article (e.g., a carved decorative object) to a predetermined configuration, making a first mold of at least part of the surface of the original object, filling the first mold with a first thermosetting polymer material to produce a reproduction of at least part of the surface of the original object, modifying the reproduction to a predetermined configuration, making a second mold from the modified reproduction and filling this second mold with a thermosetting polymer material to produce a reproduction of at least part of the surface of the original object. The second mold can be used repeatedly to produce reproductions in commercial quantities.

Owner:SD4 PANEL TECH L L C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com