Patents

Literature

59results about How to "Sufficient liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

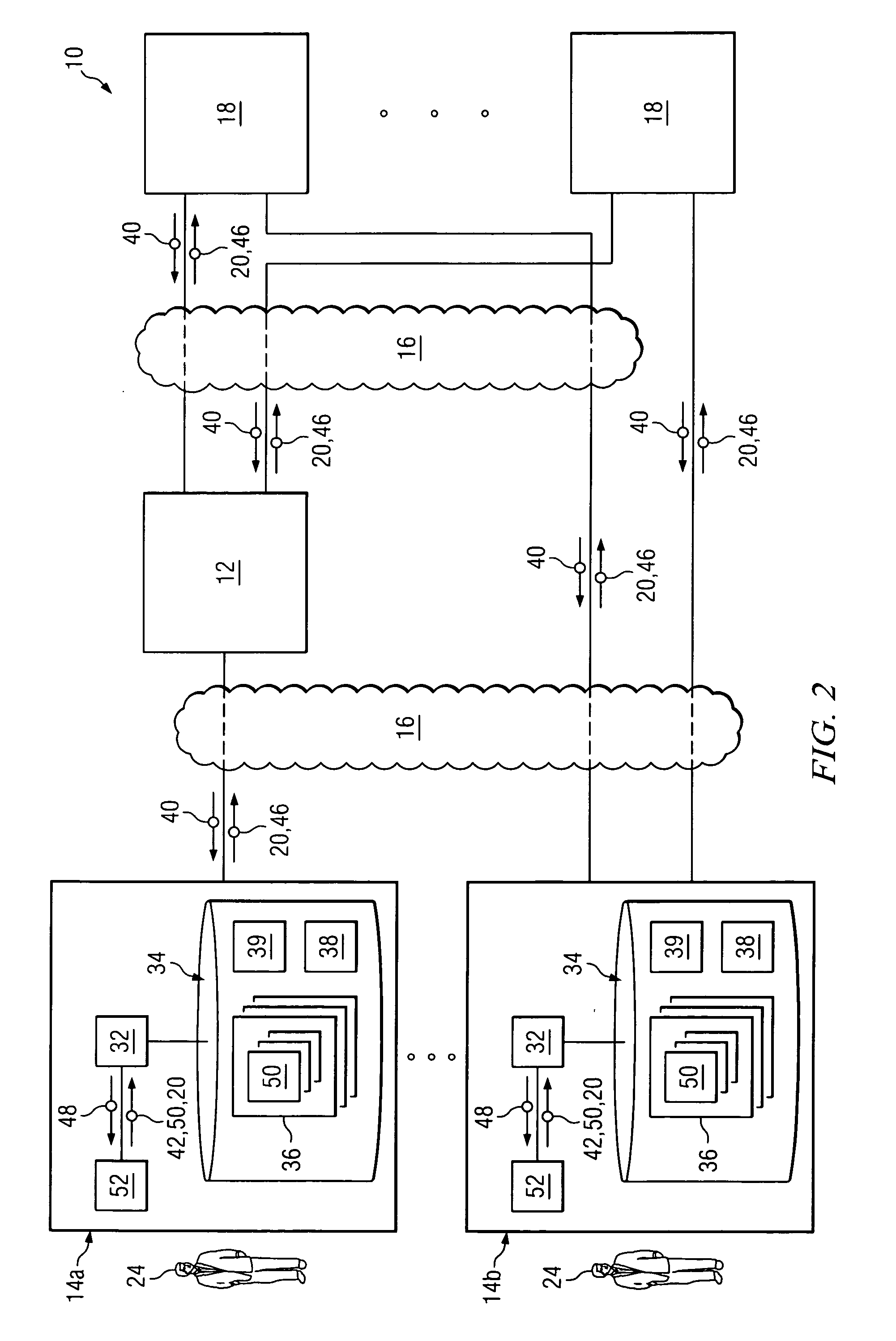

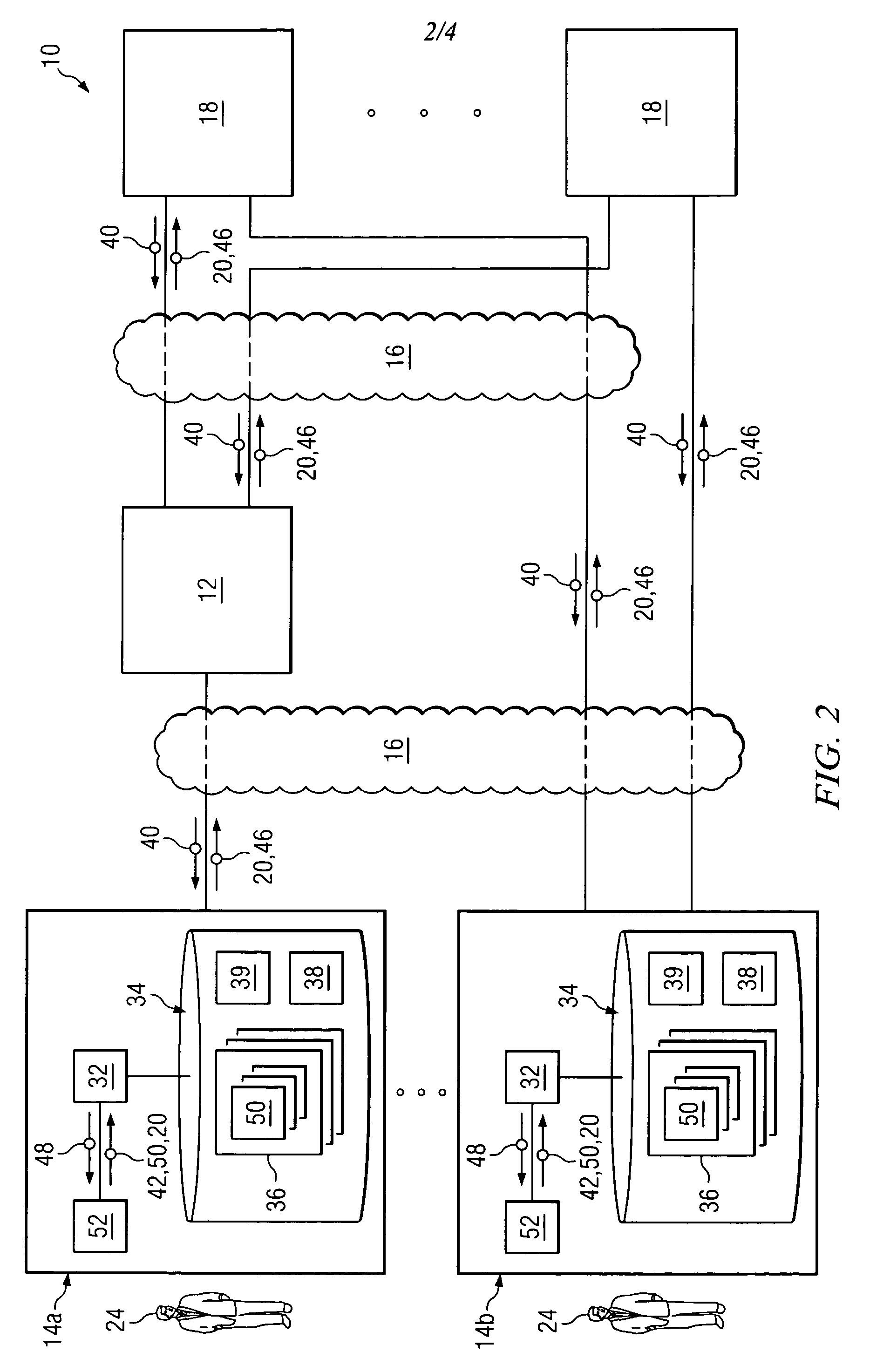

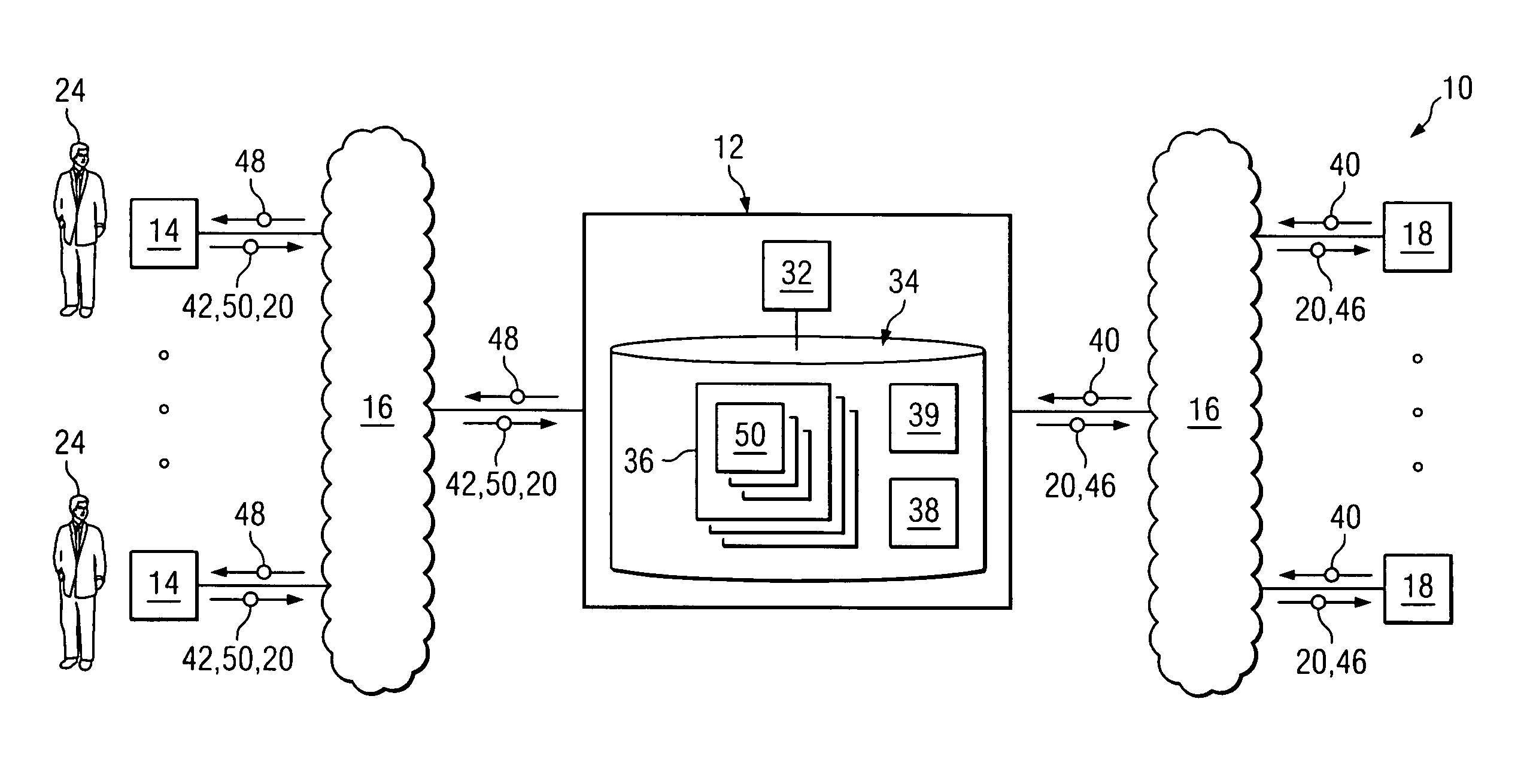

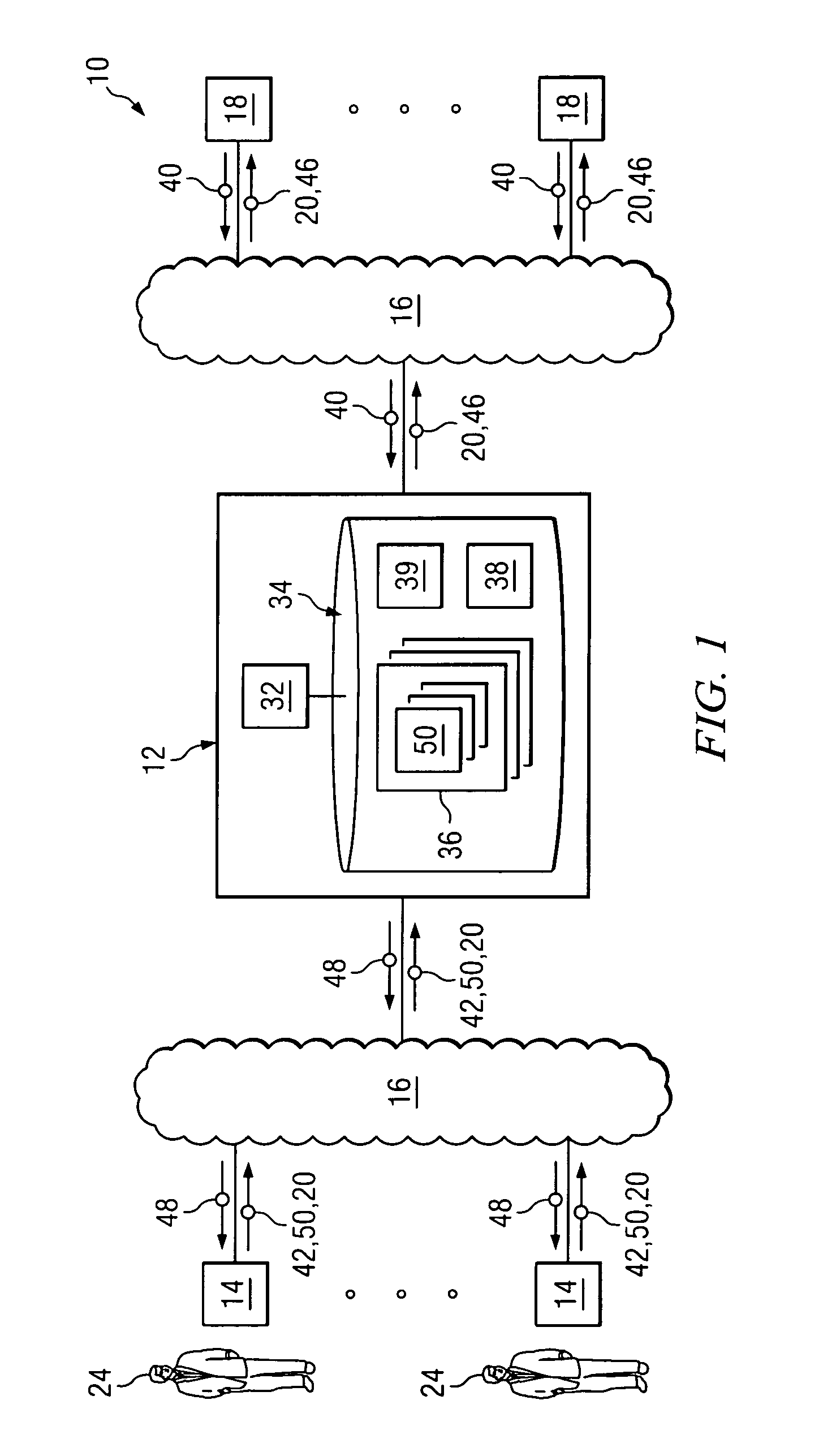

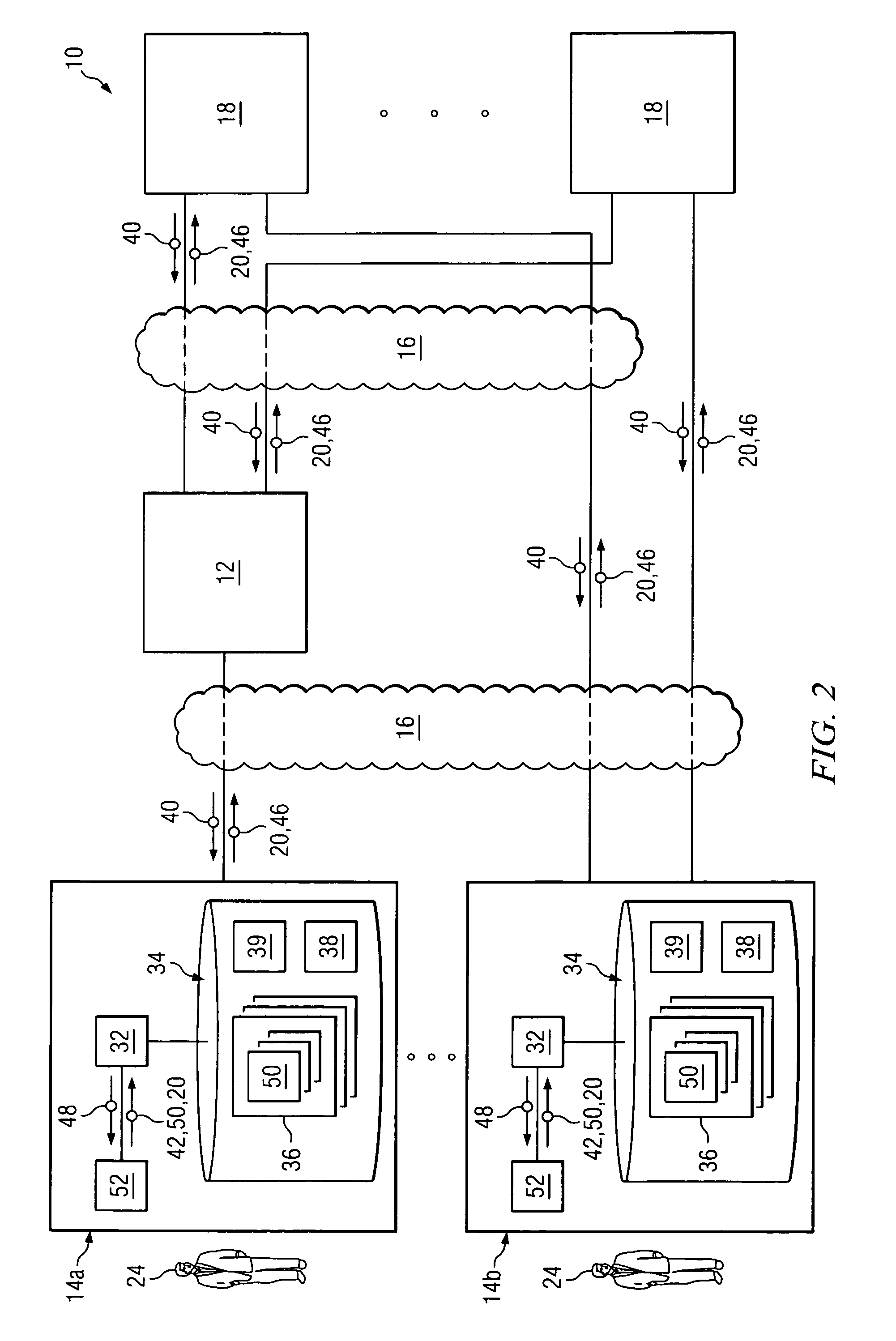

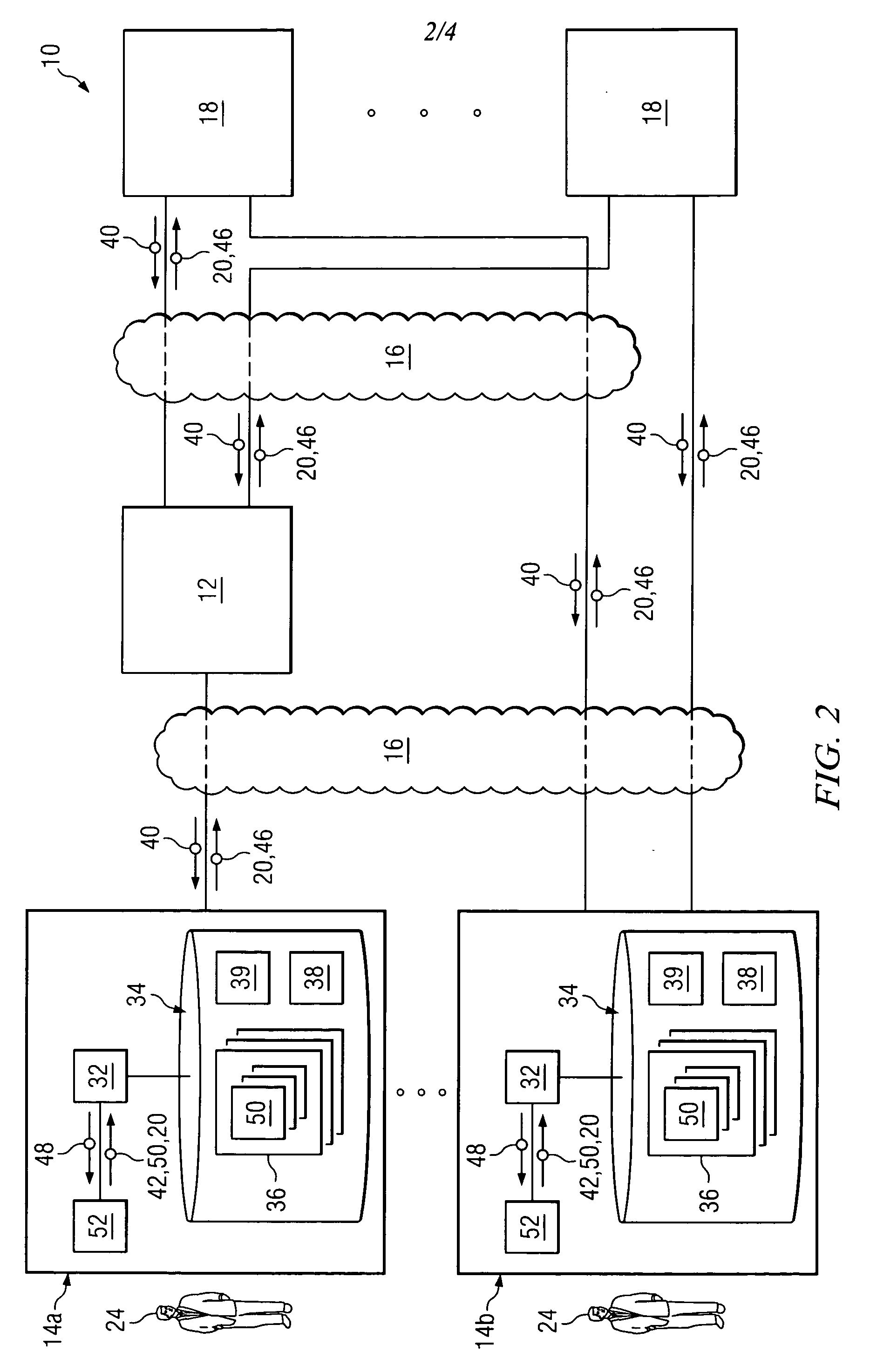

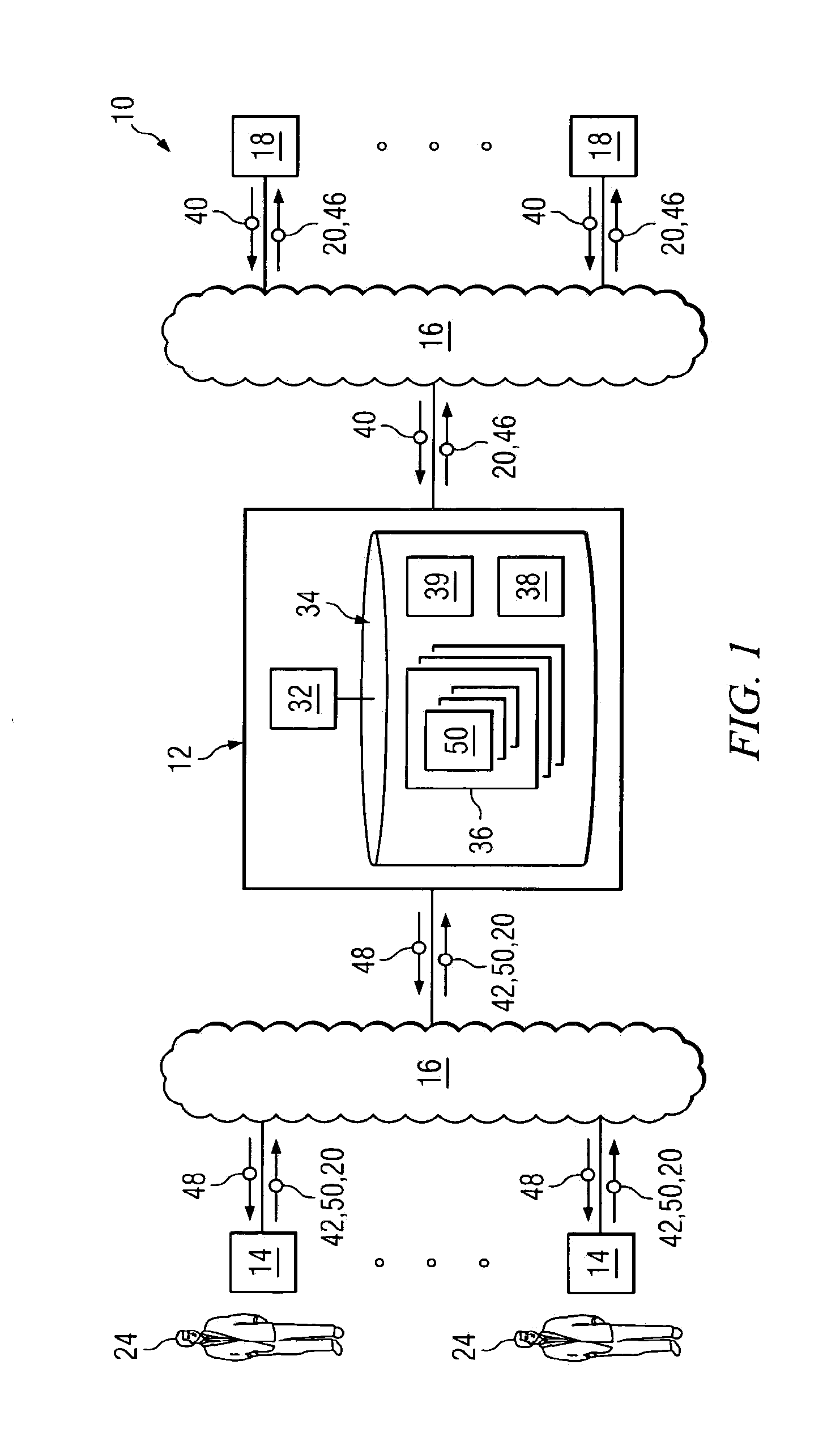

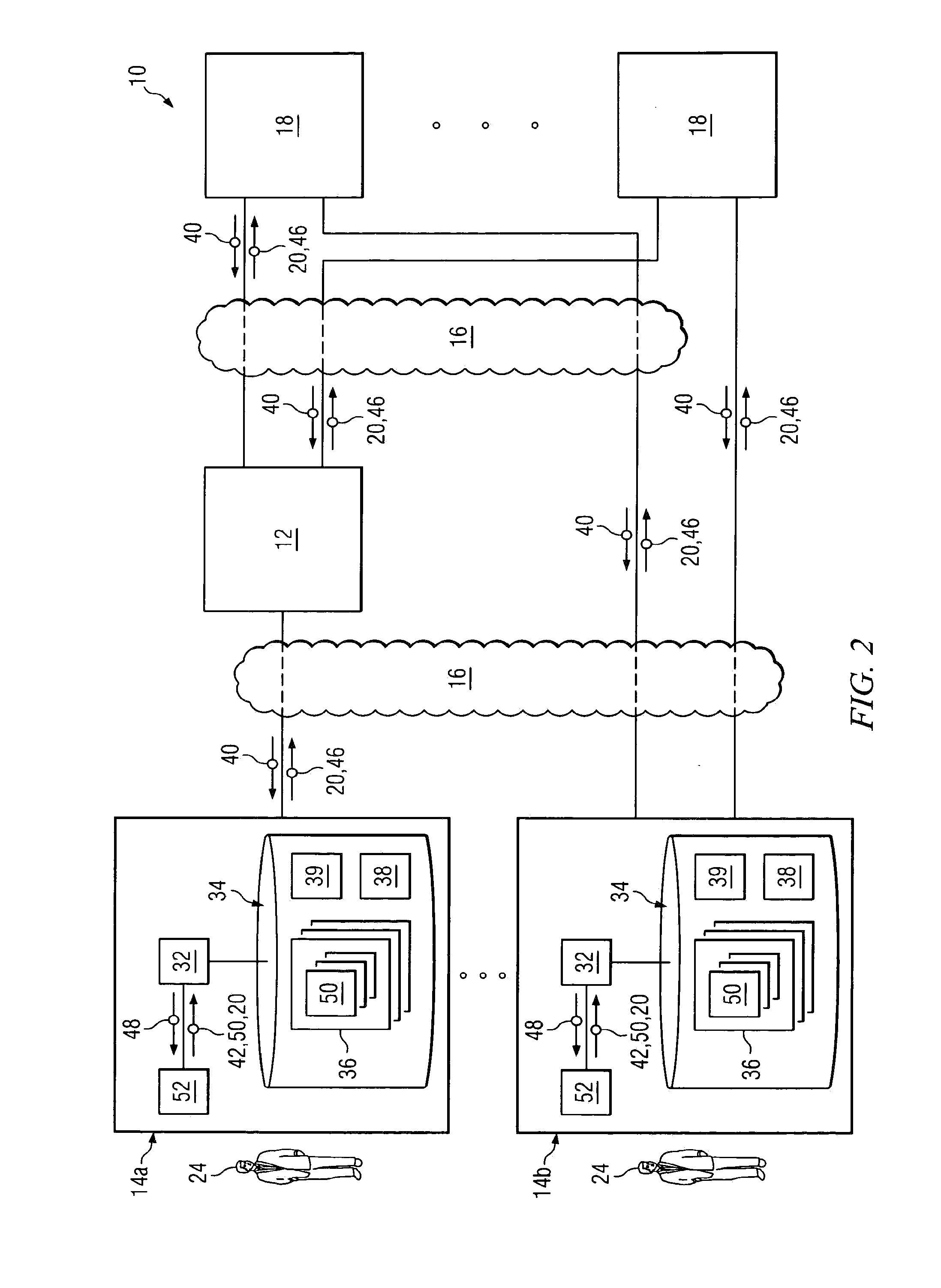

System and method for processing composite trading orders at a client

ActiveUS20070143204A1Save calculationShorten the timeFinancePayment architectureOrder formData mining

An apparatus for processing a composite trading order comprises an interface operable to display a composite value representing a weighted quantity of a plurality of trading products. The apparatus further comprises a processor operable to receive at least one input representing a composite trading order, wherein the at least one input comprises a quantity that is equal to at least a portion of the weighted quantity. The at least one input is usable to generate one or more constituent trading orders that, when filled, combine to satisfy the composite trading order.

Owner:BGC PARTNERS LP

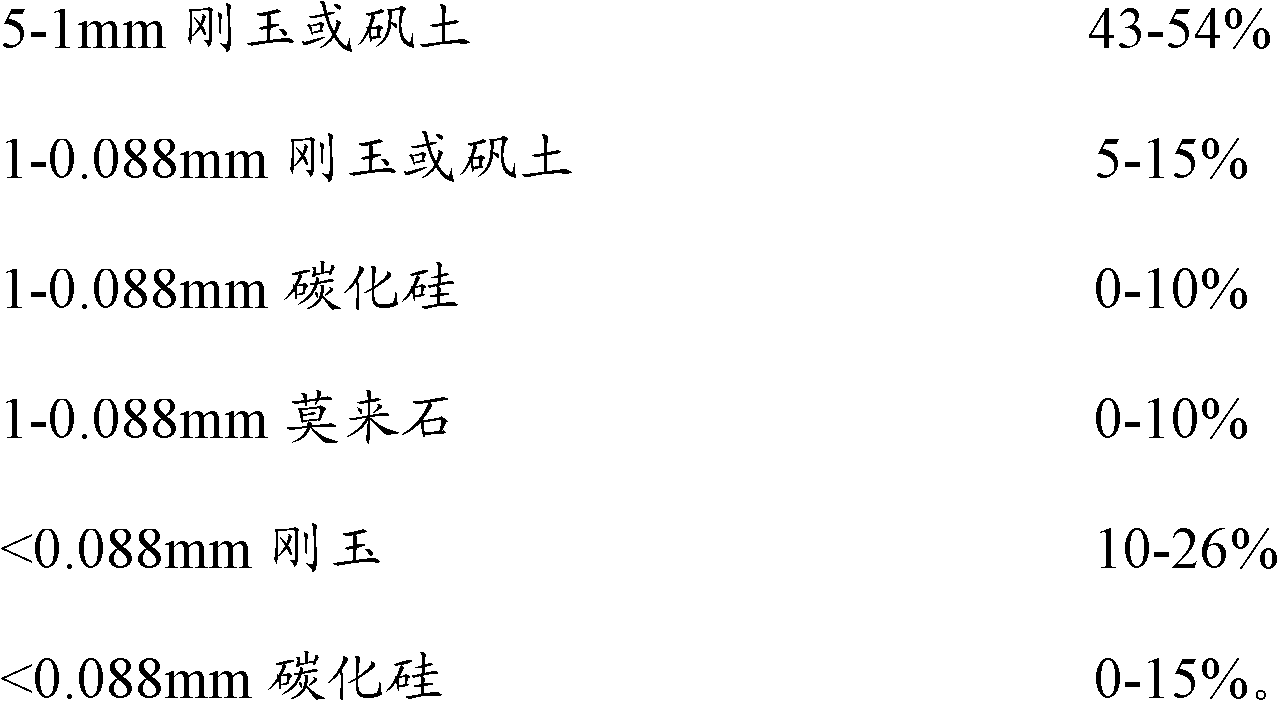

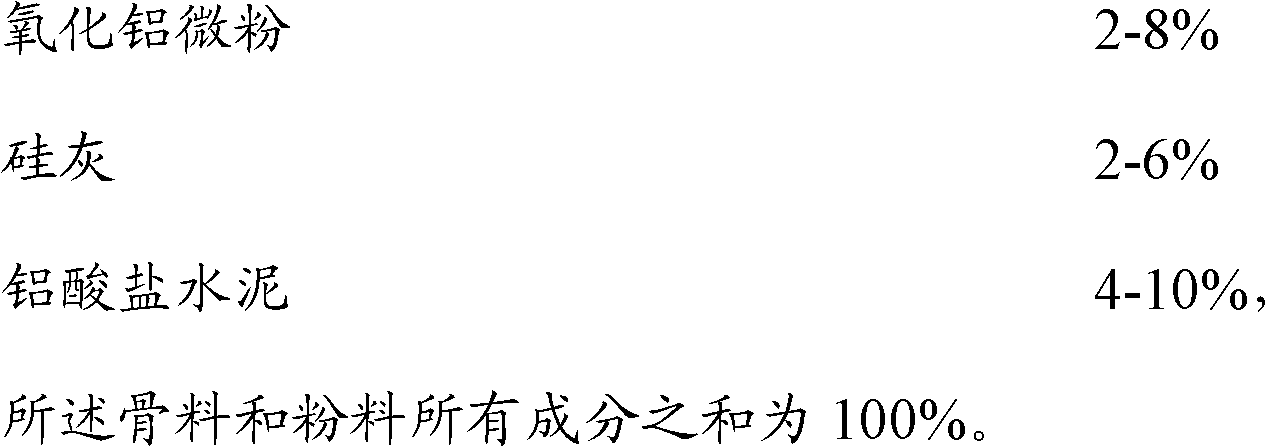

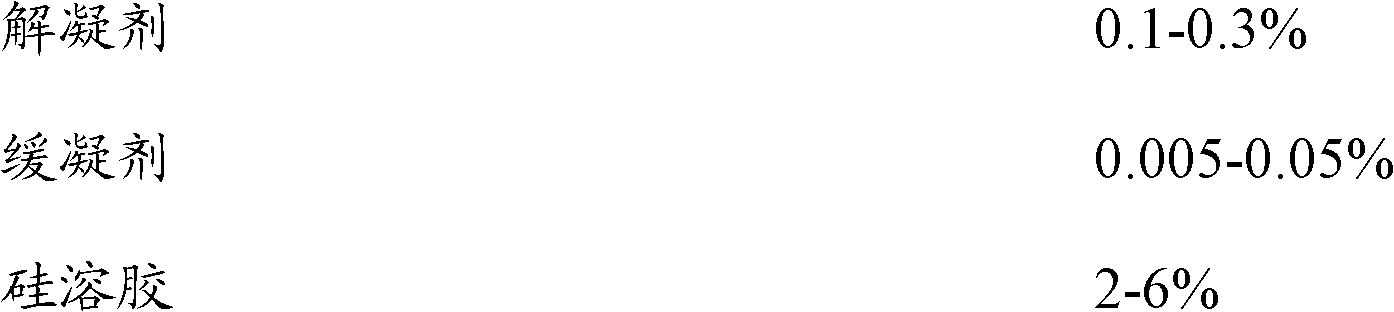

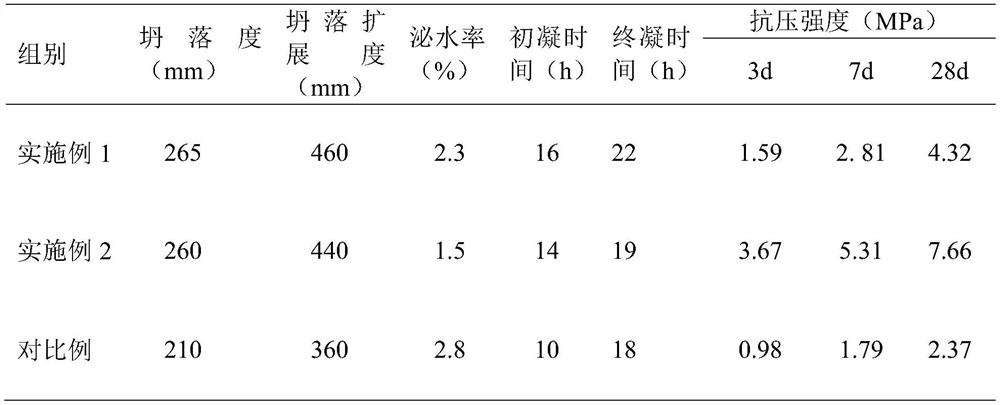

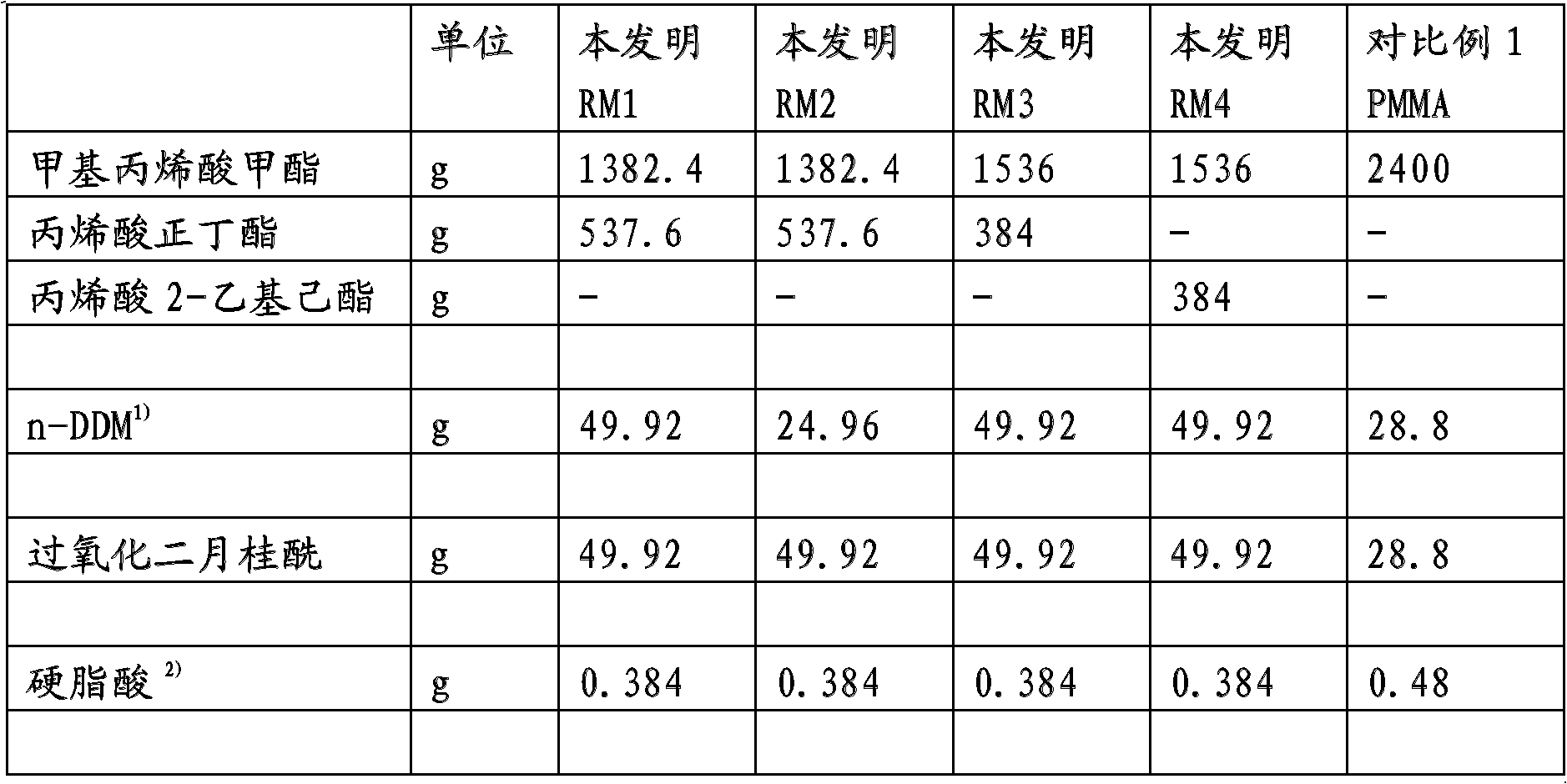

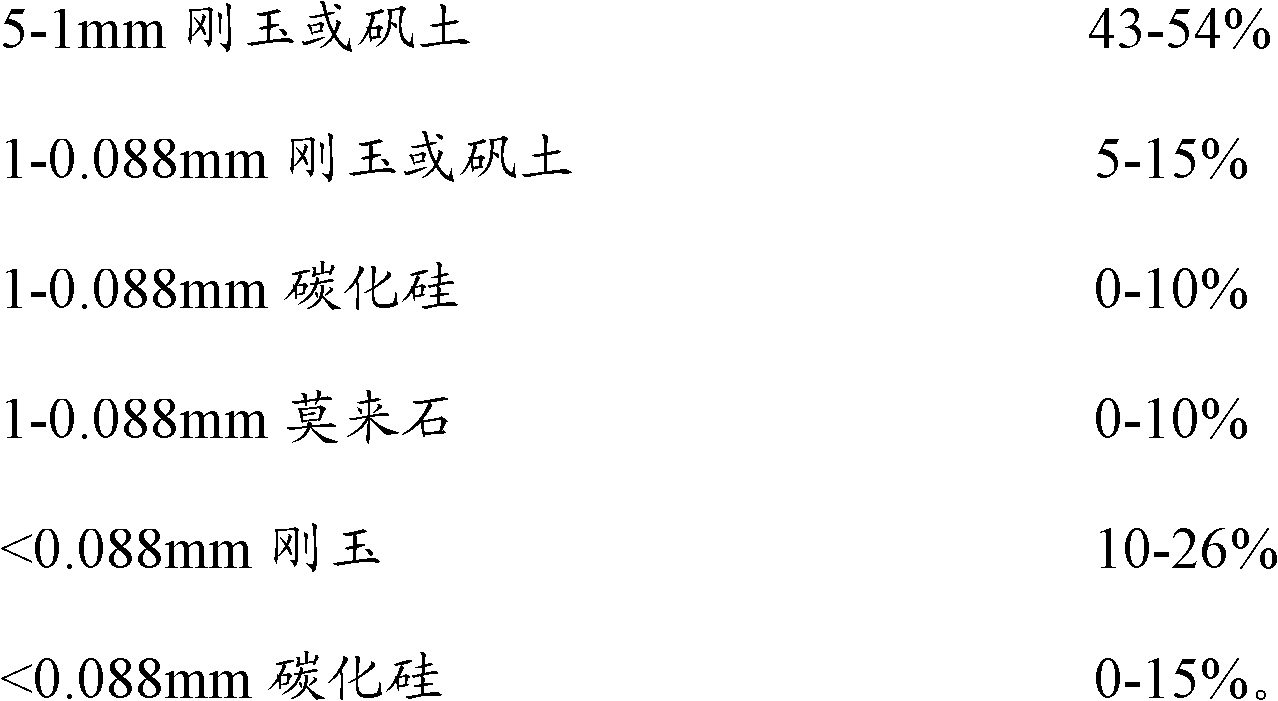

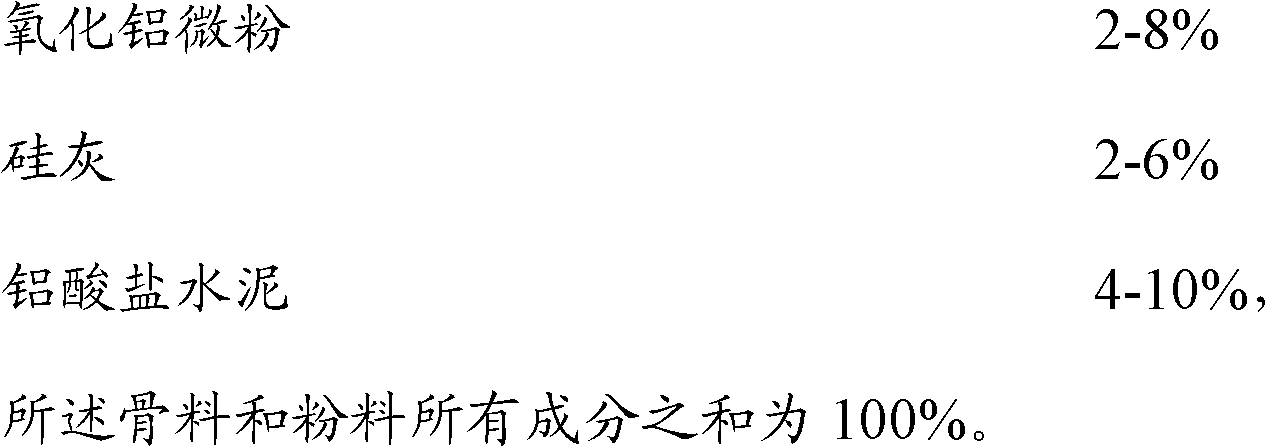

Composite bonding low-temperature constructional castable refractory

The invention relates to a composite bonding low-temperature constructional castable refractory, which can be used for high-temperature kiln engineering. According to the castable refractory, corundum, alumina, mullite and silicon carbide are used as an aggregate, silica sol is used as a bonding agent, aluminate cement is used as a curing agent and a bonding aid, and alumina micro powder, wollastonite, a deflocculant, a retarder, water and the like are added. The composite bonding low-temperature constructional castable refractory has high low-temperature constructional performance, high performance of high-temperature resistance, erosion resistance, thermal shock resistance and high mechanical performance, and meets the requirements of overhauling in winter on the premise that the service life of the castable refractory is not influenced.

Owner:ANHUI RUITAI NEW MATERIALS TECH

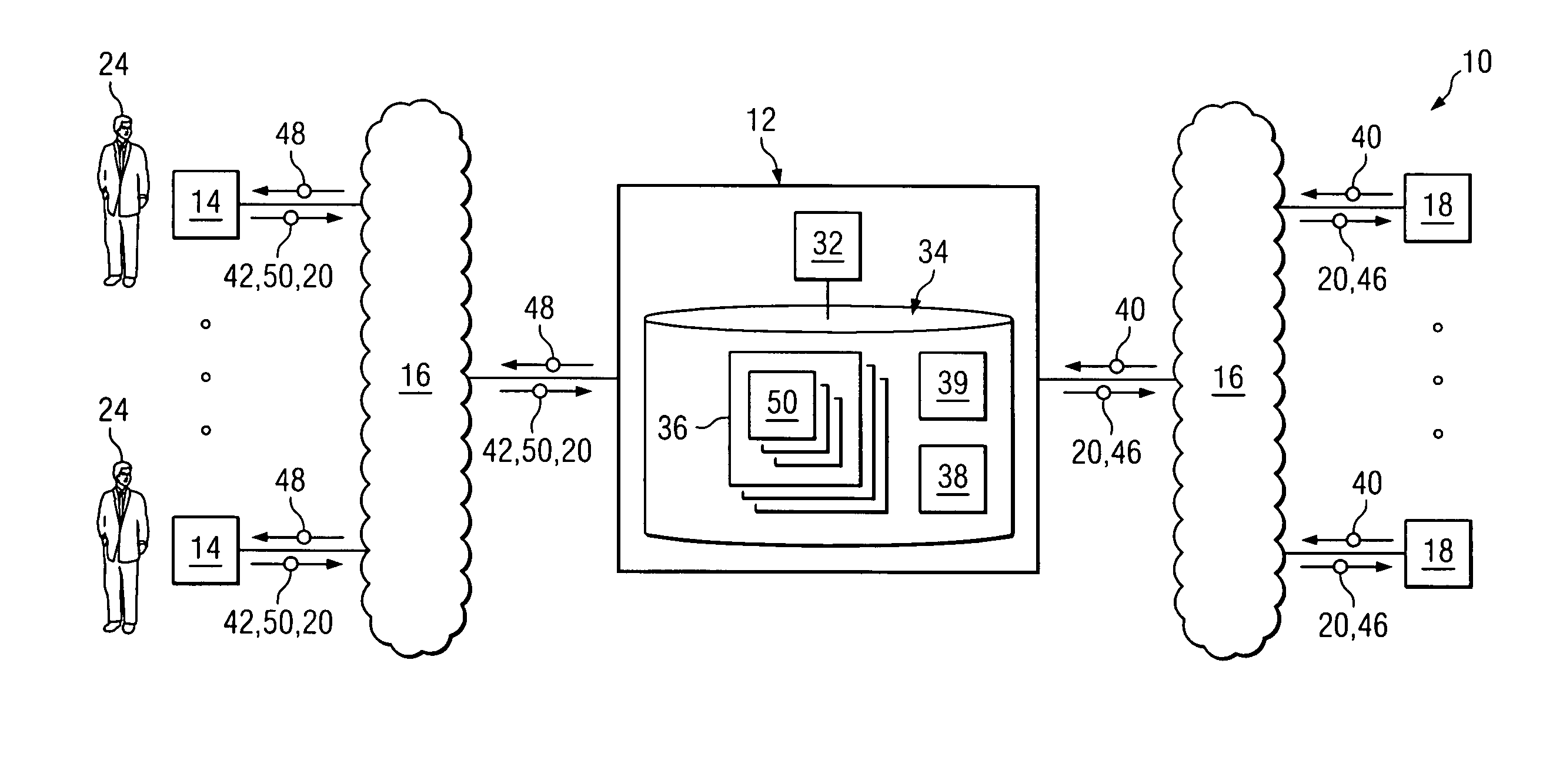

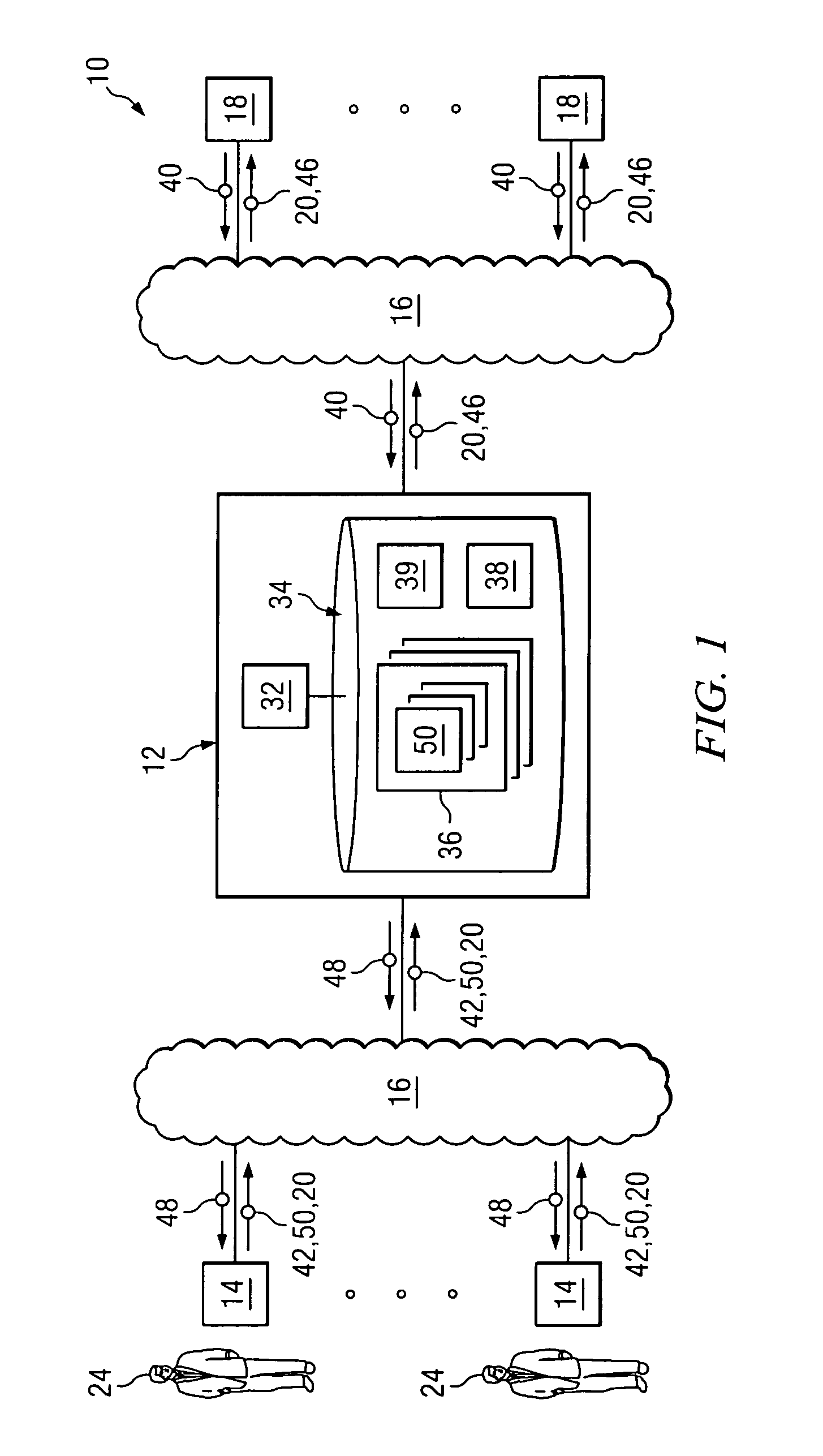

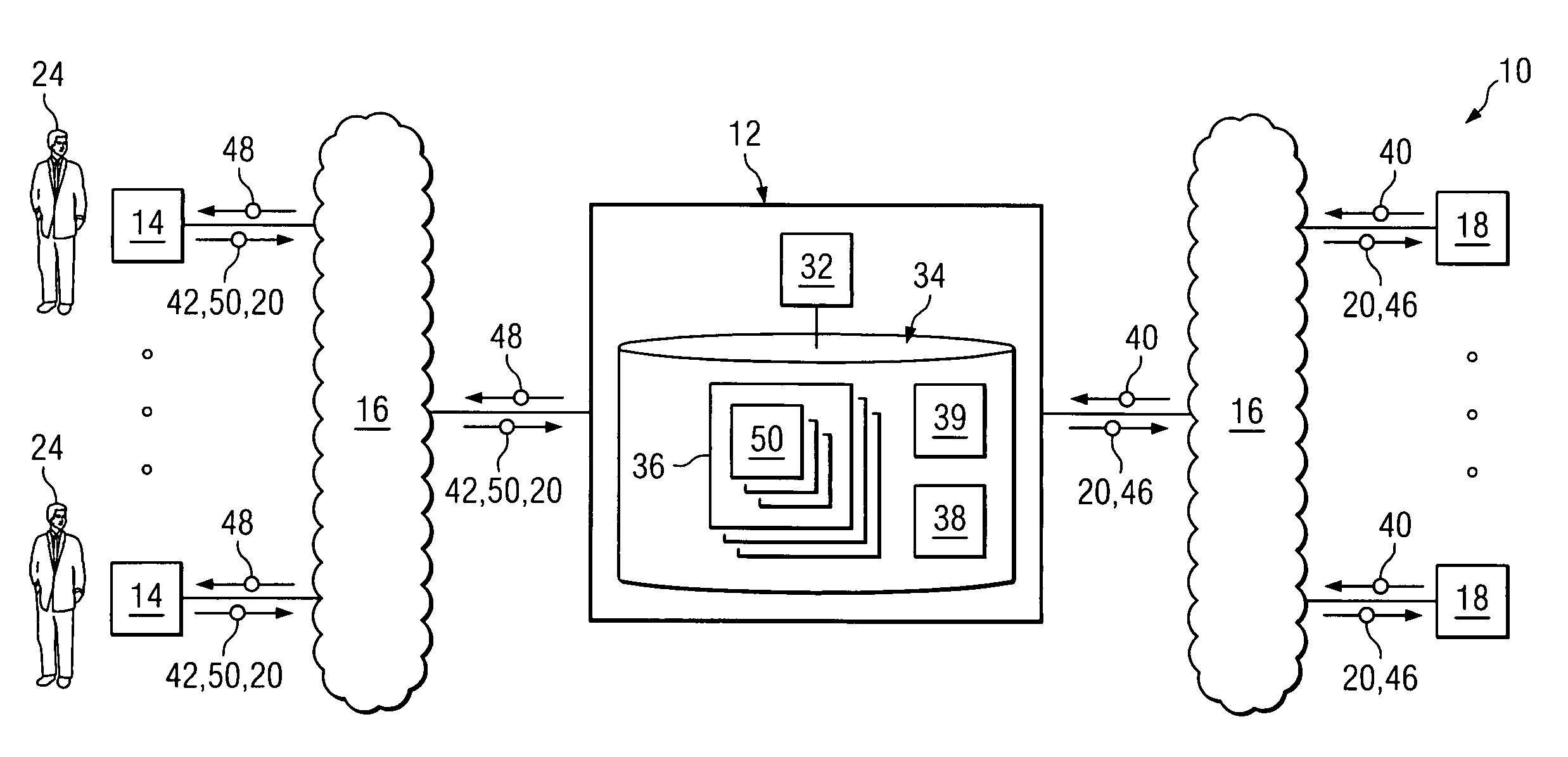

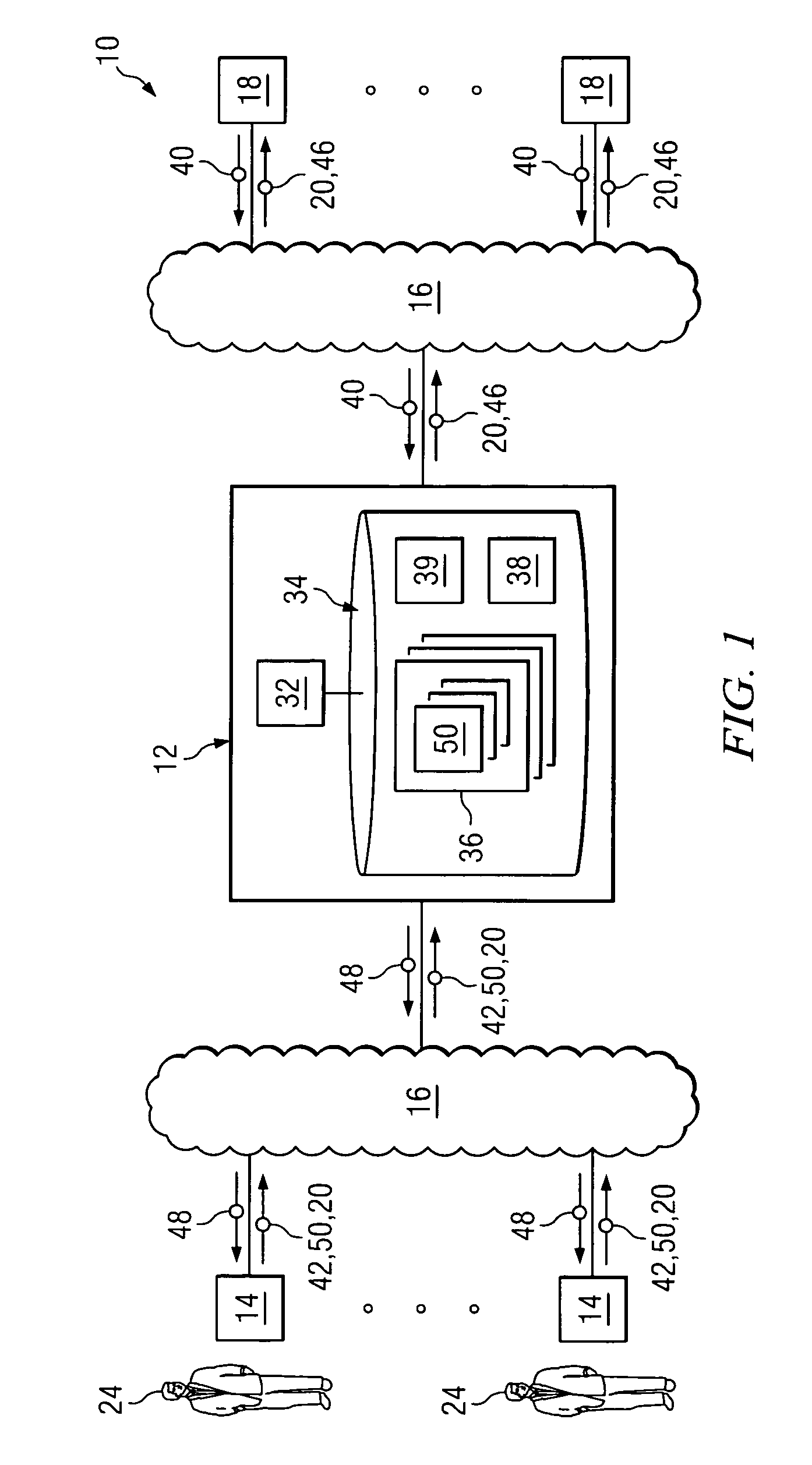

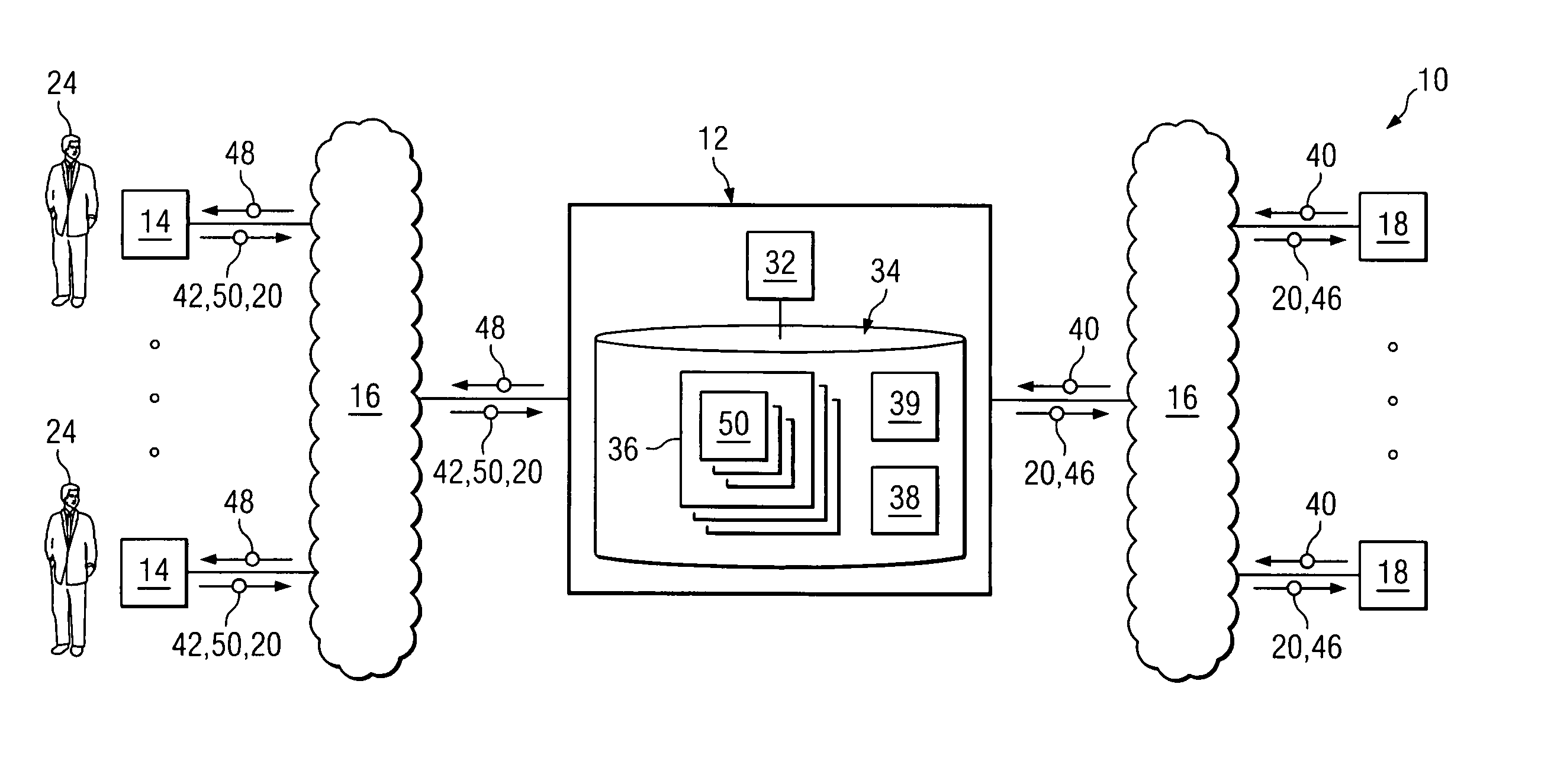

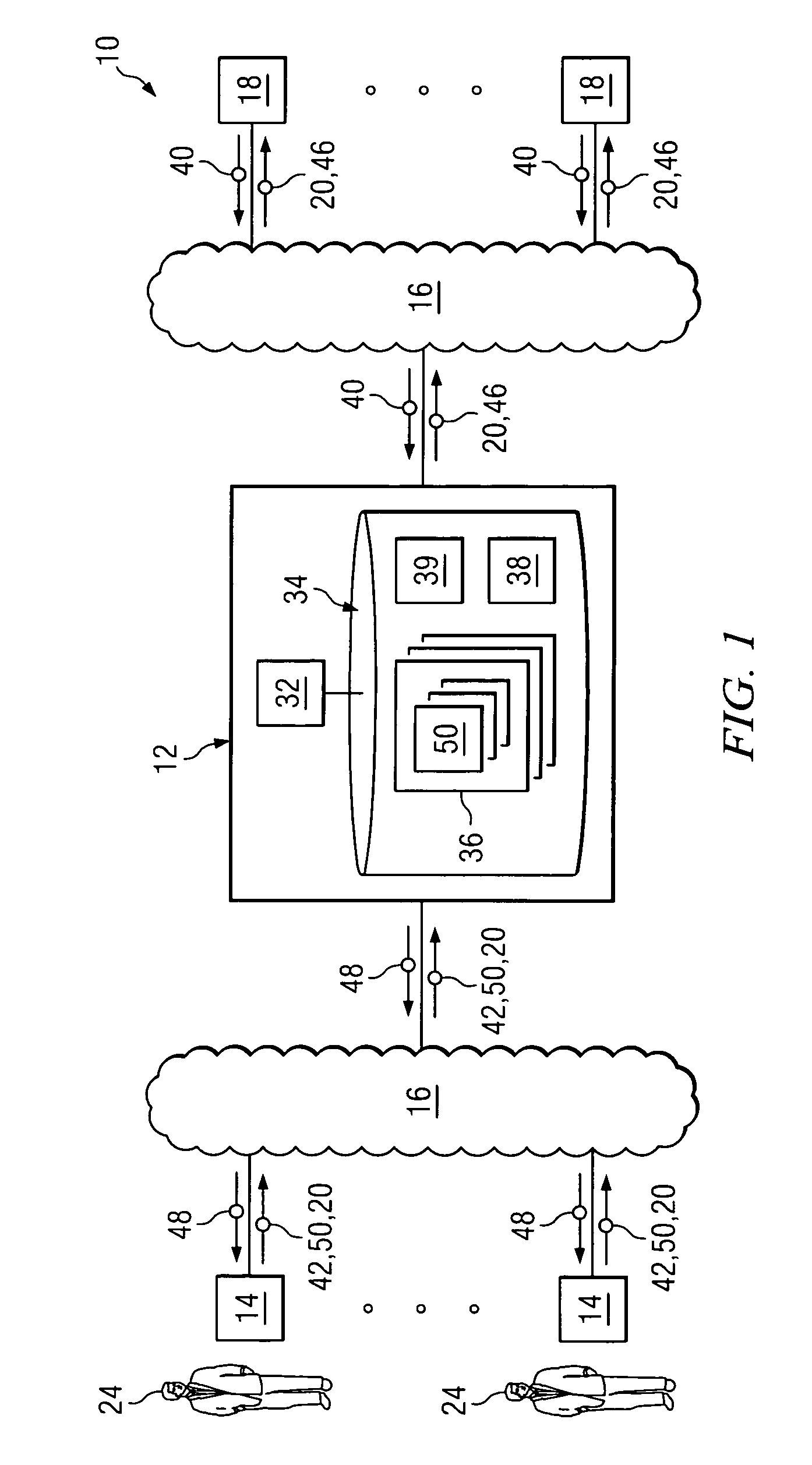

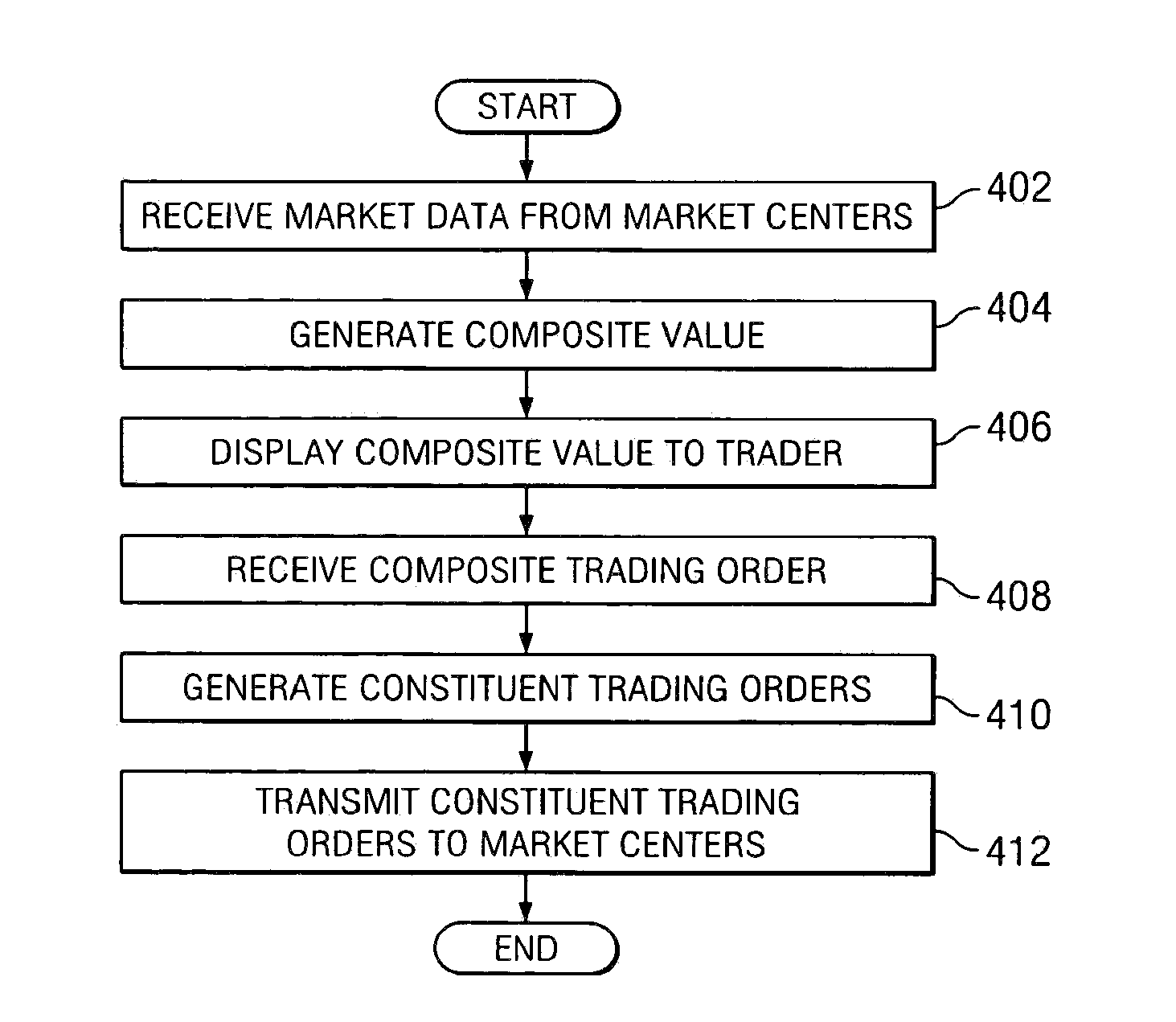

Apparatus and methods for processing composite trading orders

ActiveUS7711644B2Save calculationShorten the timeFinancePayment architectureComputer scienceDatabase

A system for processing a composite trading order comprises a memory operable to store market data received from one or more market centers. The system further comprises a processor operable to generate a composite value based at least in part on the market data. The processor is further operable to receive a composite trading order associated with at least a portion of the composite value. The processor is further operable to generate a plurality of constituent trading orders that, when filled, combine to satisfy the composite trading order.

Owner:BGC PARTNERS LP

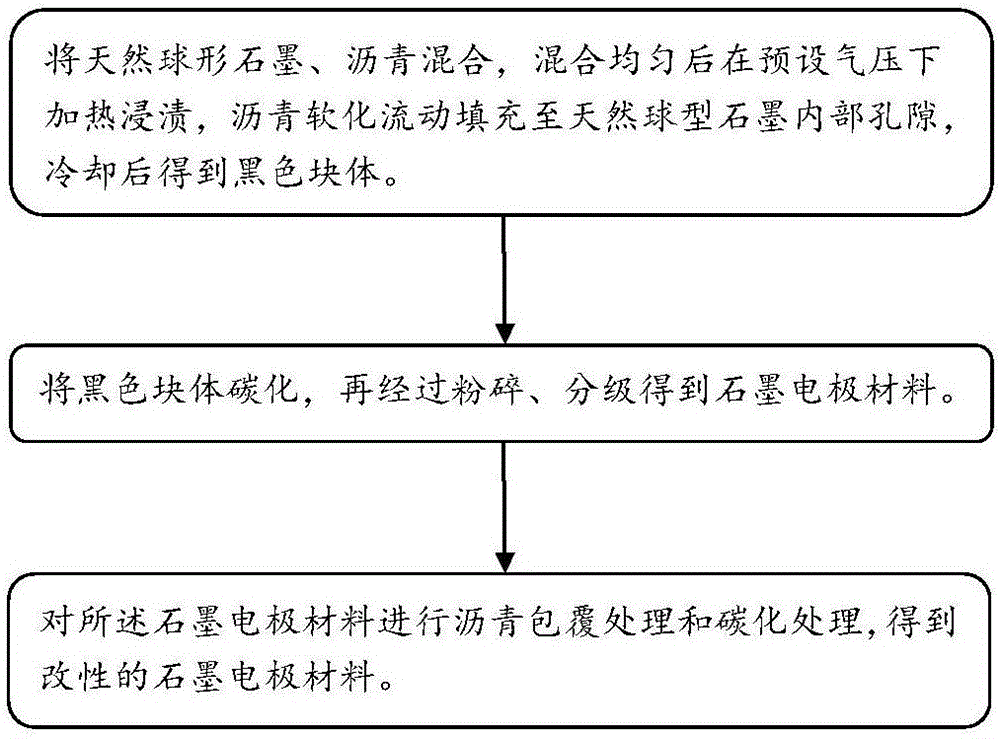

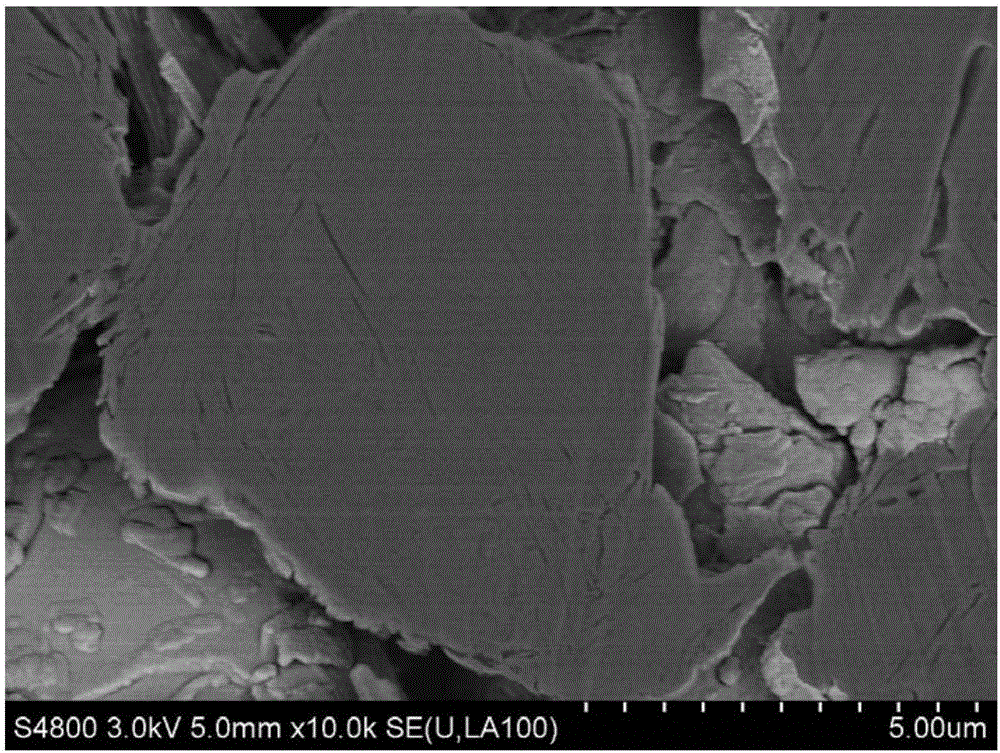

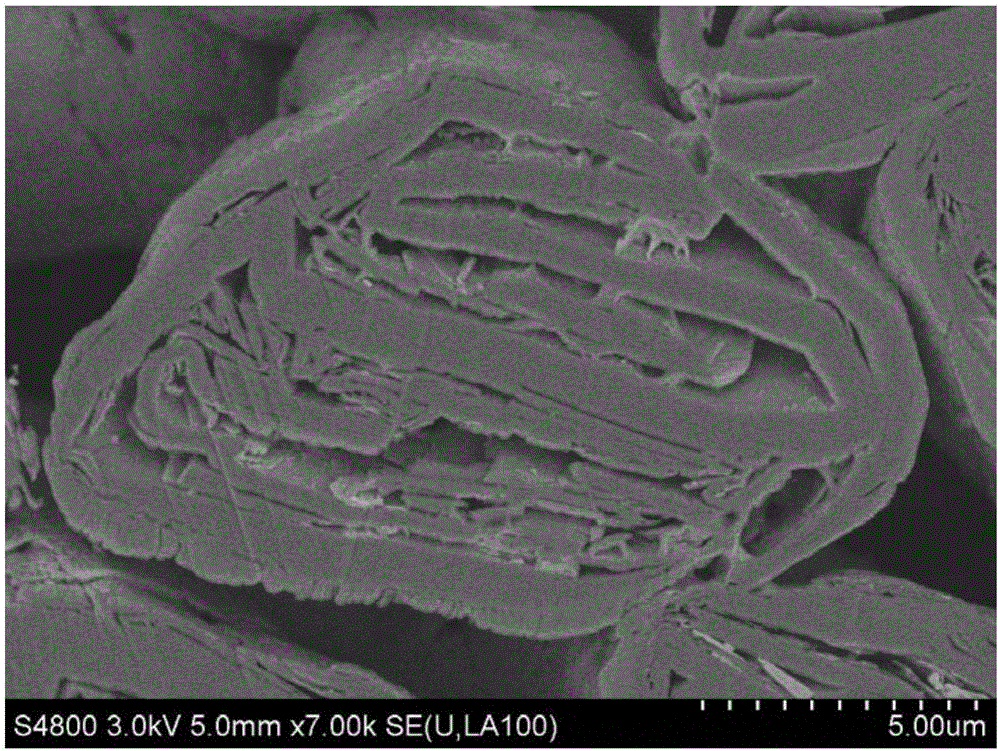

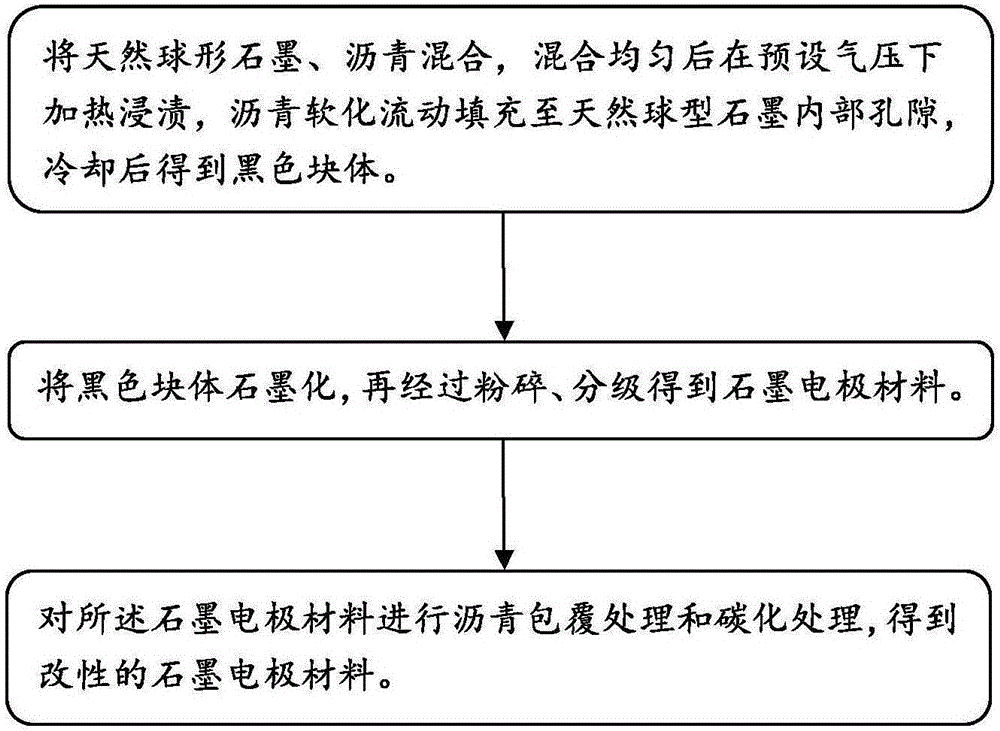

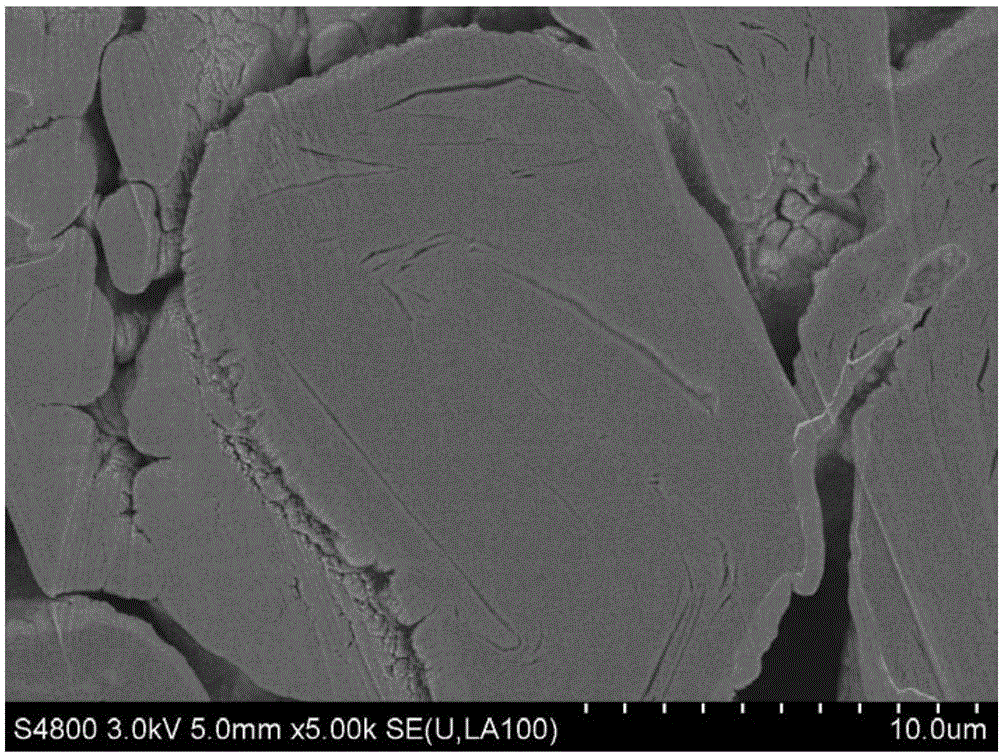

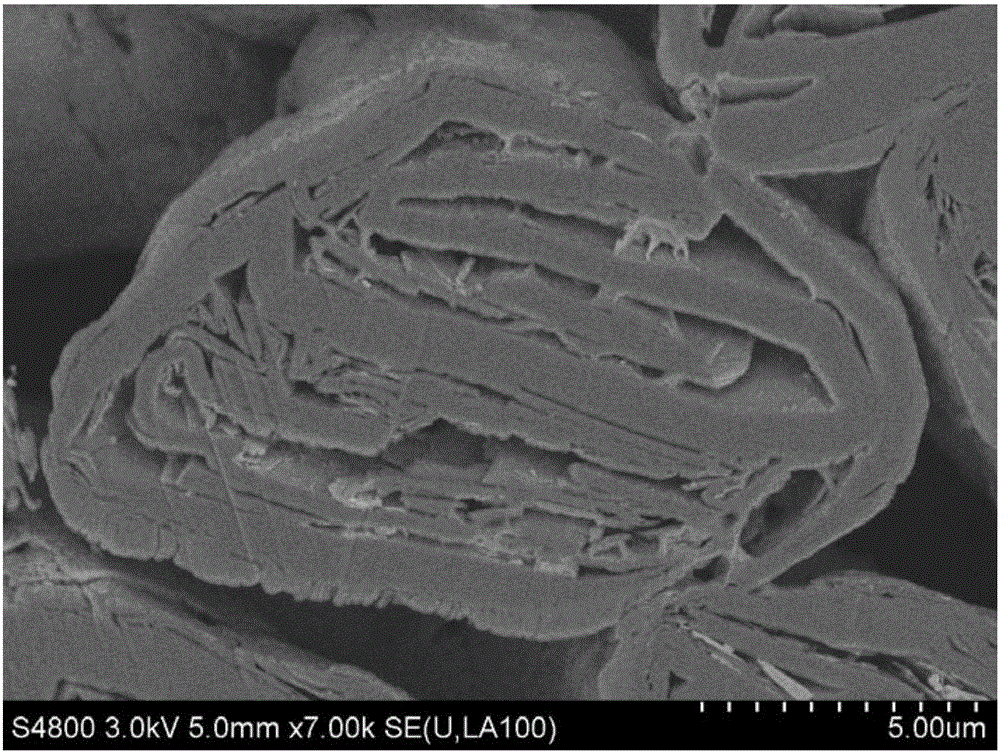

A soft carbon graphite composite anode material, a preparing method and a lithium ion battery

ActiveCN106252596APromote circulationSufficient liquidityCell electrodesSecondary cellsCarbonizationCarbon graphite

A preparing method of a soft carbon graphite composite anode material is provided. The method includes S1) a step of mixing natural spherical graphite and asphalt, heating and dipping under a preset pressure after fully mixing to allow the asphalt to be softened and to flow into and fill inner pores of the natural spherical graphite, and cooling to obtain an intermediate, and S2) a step of carbonizing the intermediate, crushing and grading to obtain the composite anode material. According to the method, the asphalt is softened at a high temperature, flows into and fills the inner pores of the graphite particles and then carbonization is performed to obtain the composite anode material with excellent cyclic performance. The method is simple in process, low in cost and high in practicality. The soft carbon graphite composite anode material prepared by the method and a lithium ion battery applying the soft carbon graphite composite anode material are also provided.

Owner:BTR NEW MATERIAL GRP CO LTD

Method for preparing nutrition soft sweets

ActiveCN101268797ASufficient liquidityStable quantityConfectionerySweetmeatsOxygenHigh water content

The invention provides a preparation method of nutritious soft sweets. The method overcomes the problems that the nutrient content is easy to be damaged and is lost overmuch, etc. in the preparation process by the existing preparation technique of the nutritious soft sweets. For the preparation technique of the invention, feed liquid containing high water content is cast and molded firstly, then is dried and dehydrated under the vacuum condition, when the feed liquid is added with a nutritious hardening agent, as well as dried and dehydrated at high temperature, the hot nutritious hardening agent with unstable oxygen is damaged or lost, thereby ensuring the quantity of the nutritious hardening agent added in the feed liquid keeps stable in the preparation process. The nutritious soft sweets obtained by the preparation method of the invention not only are excellent in color, smell and taste, but also have less loss of the nutritious hardening agent, and finally the quantity of the nutritious content contained by the product is also stable.

Owner:广东富味健康科技有限公司

Graphite negative electrode material, preparation method and lithium ion battery

ActiveCN106169584APromote circulationSufficient liquidityCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

The invention provides a preparation method of a graphite negative electrode material. The method comprises the following steps: S1: after natural spherical graphite and asphalt are mixed evenly, carrying out heating dipping under preset pressure intensity, carrying out asphalt softening, and causing the asphalt to flow and fill the internal pore of the natural spherical graphite, and cooling to obtain an intermediate product; and S2: carrying out graphitization on the intermediate product, and carrying out smashing and grading to obtain the graphite negative electrode material. By use of the preparation method of the graphite negative electrode material, the asphalt is softened at a high temperature, the softened asphalt flows and fills the internal pore of a graphite particle, and the graphite negative electrode material with excellent circulation performance is obtained through the graphitization. The preparation method has the advantages of being simple in technology, low in cost and high in practicality. The invention also provides the graphite negative electrode material prepared from the preparation method, and a lithium ion battery which applies the graphite negative electrode material.

Owner:BTR NEW MATERIAL GRP CO LTD

Methods and apparatus for composite trading order processing

ActiveUS7711640B2Save calculationShorten the timeFinancePayment architectureOrder formOrder processing

Owner:BGC PARTNERS LP

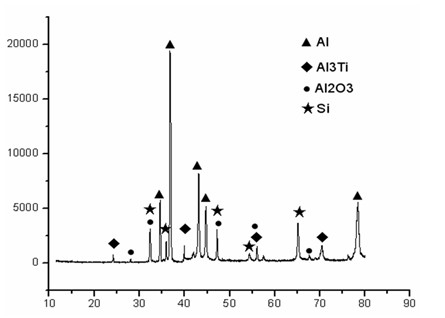

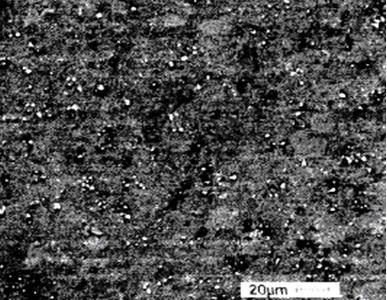

A cross-scale in-situ particle reinforced aluminum matrix composite material and its preparation method

ActiveCN102296196AStrong designabilityAchieving Cross-Scale Composite StrengtheningNanoparticleMicroparticle

The invention relates to an in-situ particle reinforced aluminum matrix composite material, in particular to a cross-scale in-situ particle reinforced aluminum matrix composite material and a preparation method thereof. The method comprises the following steps of: melting Al-Si alloy; adding 10-25 percent by weight of SiO2 for melting according to proportioning requirement of volume fraction of reinforcing particles of different scales in the composite material; heating to 800-850 DEG C, preserving the heat for 5-10 minutes and then refining; subsequently performing ultrasonic treatment; adding 1-2 percent by weight of titanium powder and 0.3-0.5 percent by weight of rare earth during ultrasonic treatment; standing for 5-10 minutes; slagging off; adjusting temperature for pouring; and finally forming (Si+Al3Ti) microparticle and Al2O3 nanoparticle reinforced aluminum matrix composite material. The method has the advantages of simple preparation process, low cost, low overall reaction temperature and less aluminum burnt loss.

Owner:JIANGSU UNIV

System and method for processing composite trading orders

A system for processing a composite trading order comprises a memory operable to store market data received from one or more market centers. The system further comprises a processor operable to generate a composite value based at least in part on the market data. The processor is further operable to receive a composite trading order associated with at least a portion of the composite value. The processor is further operable to generate a plurality of constituent trading orders that, when filled, combine to satisfy the composite trading order.

Owner:BGC PARTNERS LP

Feed for metal injection molding and preparation method of feed

InactiveCN106270522AEvenly distributedImprove liquidityTransportation and packagingMetal-working apparatusMetal formingMicrometer

The invention provides feed for metal injection molding and belongs to the field of metal molding. The feed is prepared by mixing 9.2-10.5 wt% of binder with 89.5-90.8 wt% of metal powder. The metal powder laser grain size distribution D90 ranges from 18 micrometers to 30 micrometers. The binder comprises polyformaldehyde, a high-molecular polymer, a plasticizer, a surfactant, a compatilizer and lubricant. A preparation method of the feed includes the steps that the binder is obtained after polyformaldehyde, the high-molecular polymer, the compatilizer, the plasticizer, the surfactant and the lubricant are mixed to be uniform at the temperature of 150-200 DEG C; the feed is prepared after the binder and the metal powder are mixed. The feed is high in fluidity, the binder is easy to remove, and the obtained product is high in dimensional precision and small in impurity content. The preparation method of the feed is easy and convenient to operate, the uniform feed can be efficiently obtained, various ingredients in the feed are not damaged, and the use effect of the feed is well guaranteed.

Owner:JIANGXI YUEAN SUPERFINE METAL

Degreasant composition

ActiveCN103469232AAvoid residual silicon effectsGuaranteed adhesionHot-dipping/immersion processesMetallic materialsMaterials science

The invention discloses a degreasant composition for a hot-dip galvanized wire. The degreasant composition is used for surface treatment in steel rolling. The high-efficiency degreasant composition for the hot-dip galvanized wire comprises the following chemical components by mass: 20 to 35% of an alkali metal hydroxide, 1 to 5% of a second alkali source, 1 to 10% of an inorganic degreasing auxiliary agent, 1 to 10% of an organic degreasing auxiliary agent, 1 to 5% of a surfactant and 0.5 to 5% of an de-foaming agent, with the balance being water. The degreasant composition provided by the invention does not contain silicate, allows a hot dip galvanizing coating to have good adhesion and is applicable to degreasing of the hot-dip galvanized wire; the GPES de-foaming agent used in the degreasant composition can more effectively improve a degreasing effect under the condition of no inclusion of silicate and does not generate foam in use. The degreasant composition has the advantages of simple composition, usage of cheap and easily available raw materials, good stability, no corrosion to a metal material, high degreasing efficiency, friendliness to the environment, applicability to a low temperature environment, capacity of guaranteeing subsequent galvanizing quality in steel rolling, etc.

Owner:UNIV OF SCI & TECH LIAONING

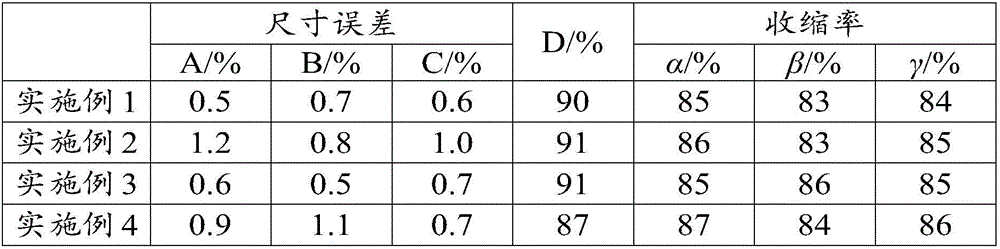

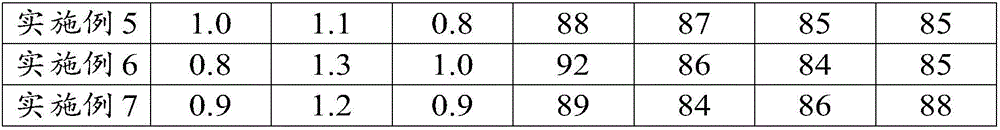

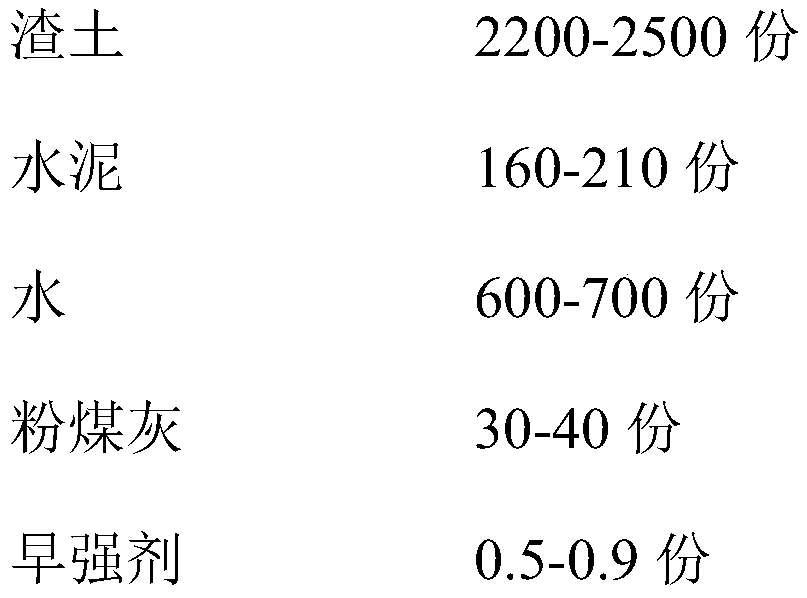

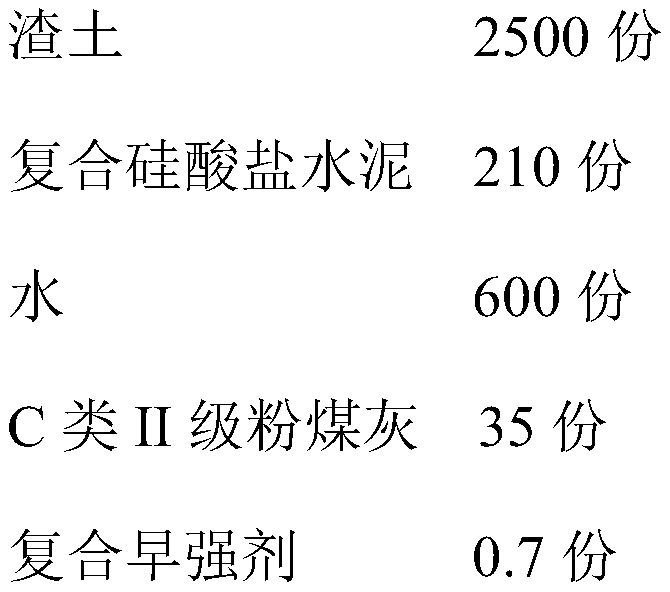

Improved residue soil regeneration backfill material and preparation method thereof

The invention provides an improved residue soil regeneration backfill material and a preparation method thereof, wherein residue soil is used as a main component and is doped with a proper amount of cement, water, fly ash and an early strength agent, and mixing stirring is performed to prepare the improved residue soil regeneration backfill material. The preparation method comprises: removing foreign matters and contaminated and deteriorated parts, respectively weighing various components according to the formula, and mixing and stirring the weighed components until the texture is uniform so as to obtain the finished product. According to the invention, with the method, the reutilization of residue soil is achieved, the environment pollution caused by pipeline excavation operation is reduced, the engineering cost of backfill operation is reduced, and the later strength of the backfill material is improved while the backfill material has enough fluidity.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

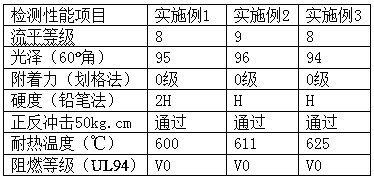

High-temperature-resistant flame-retardant powder paint and production method thereof

InactiveCN110643280AImprove stabilityImprove insulation performanceFireproof paintsPowdery paintsEpoxyPowder coating

The invention discloses high-temperature-resistant flame-retardant powder paint and a production method thereof. The powder paint is produced from the following raw materials in parts by weight: 30-60parts of organic silicon resin, 30-60 parts of epoxy resin, 3.4-6.8 parts of modified dicyandiamide, 0.2-0.4 part of dimethylimidazole, 10-20 parts of silica powder, 10-20 parts of mica powder, 0.3-0.6 part of a sand textured agent, 30-60 parts of a flame retardant and 1.2-2.4 parts of carbon black. A film, which is formed after the produced powder paint is subjected to spraying and curing, has excellent high-temperature-resistant performance, fireproof performance and flame-retardant performance in the premise that the mechanical performance, including the levelling performance and the anti-impact performance, of the film is not affected; and according to the powder paint, the production method is simple, and industrial production can be conducted.

Owner:广西南宁维一防腐科技有限公司

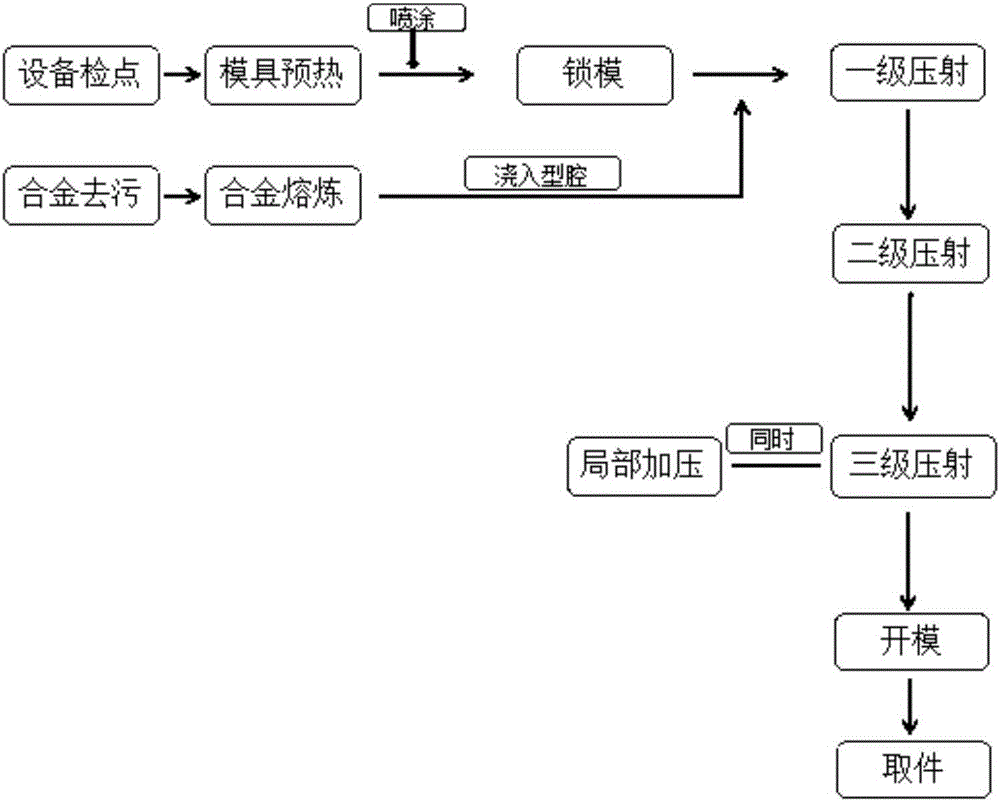

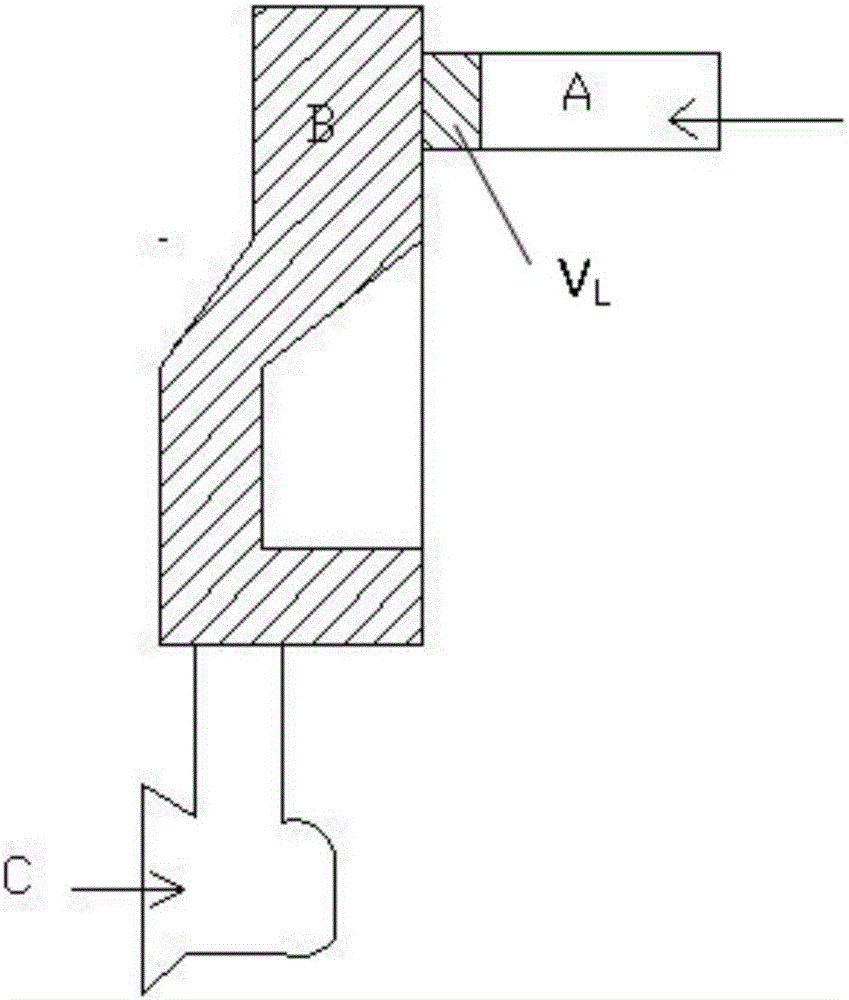

Die-casting forming method free from shrinkage cavity and shrinkage porosity defects for thick wall die-casting fitting

InactiveCN106270441ASolve the shrinkage porosity that is easy to appearSolve defects such as poresMold fillingDie casting

The invention discloses a die-casting forming method free from shrinkage cavity and shrinkage porosity defects for a thick wall die-casting fitting. By the adoption of the method, the problems of shrinkage cavity, shrinkage porosity and air hole defects which are likely to happen to a thick wall aluminum alloy die-casting fitting frequently can be solved effectively. The die-casting forming method includes the main contents that a specific pouring method with the low superheat degree is adopted, large fullness pouring with the pressure chamber fullness being 60%-70% is used, the high-pressure mold filling die-casting technique is utilized, and the internal compactness zero-defect performance of the die-casting fitting is achieved. The local pressurization structure is added in mold design, and pressurization feeding at the thick wall position far away from the position of an inner casting gate is realized. By the adoption of the method, the casting defects of the thick wall die-casting fitting can be reduced, the rejection rate of products is lowered, material wasting is avoided, cost is reduced and benefits are increased.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD +1

Preparing method for embedded expanding piece of car

Am embedded expandable plate for car is prepared through prepairng the foaming mother particles from resin, foaming agent, foaming assistant and disperser, proportionally mixing then with polyolefin resin and cross-linking agent, and injection moulding.

Owner:HENKEL CORP

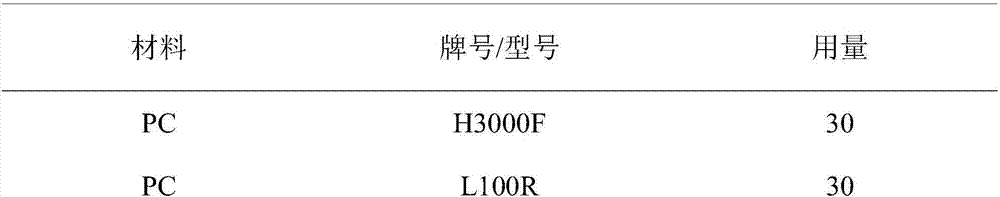

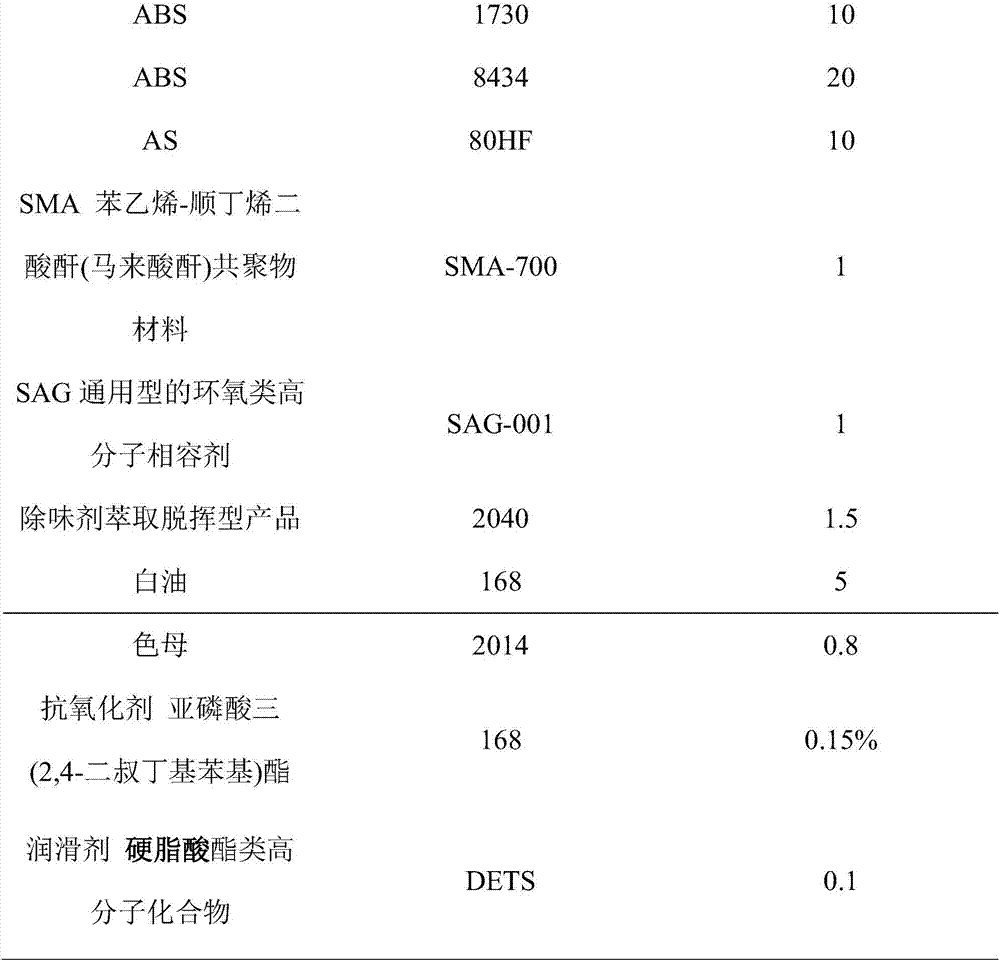

Low-odor spray-coating-free PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

The invention discloses a low-odor spray-coating-free PC / ABS (polycarbonate / acrylonitrile butadiene styrene) material and a preparation method thereof. The material is prepared from the following ingredients including 40 to 80phr of PC, 20 to 60phr of ABS, 5 to 10phr of AS, 0 to 1phr of lubricating agents, 1 to 1.5phr of deodorants, 0.5 to 1phr of heat stabilizers, 0.5 to 1phr of color masterbatch, 0 to 10phr of compatibilizers, 0 to 5phr of processing auxiliary agents, 0.1 to 0.5phr of antioxidants and 0 to 5phr of ultraviolet light absorbers. The material has the low odor and spray-coating-free appearance requirements; the odor grade is lower than or equal to 3.0; the appearance luster is good; the blackness is high; the thermal stability is high; the defects of flowing marks, melting and connecting wires, silver silks and the like cannot be easily generated; the spraying work procedure is omitted; the good spray-coating-free effect is achieved; through the creative selection on raw materials and auxiliary agents and the process innovation, a low-odor spray-coating-free PC / ABS material is produced, and is obviously superior to similar products in the market.

Owner:太仓市华鼎塑料有限公司

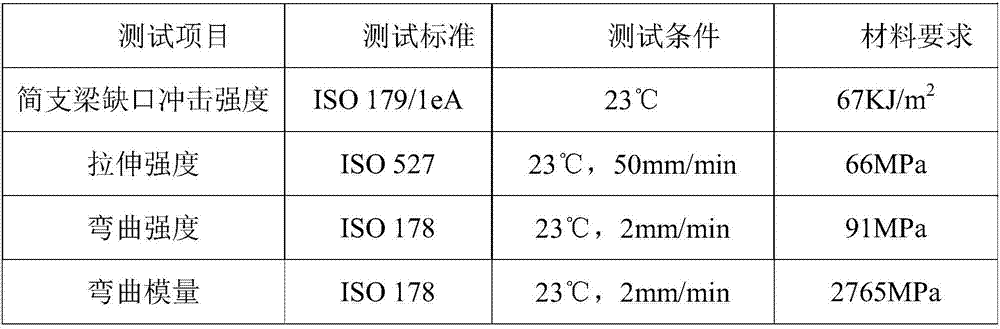

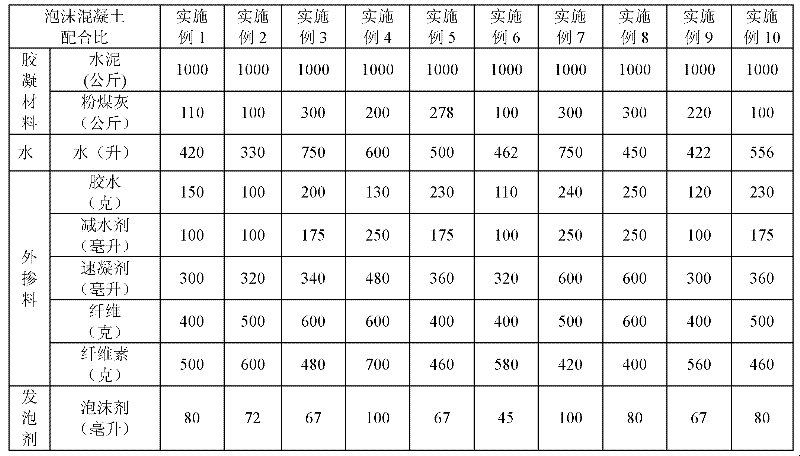

Foam concrete for wet-spraying support of coal mine and preparation method thereof

The invention relates to foam concrete for wet-spraying support of a coal mine and a preparation method. The foam concrete comprises a cementing material, water, an admixture and a foaming agent, wherein the cementing material is prepared from cement and fly ash, and the admixture comprises glue, a water reducing agent, an accelerating agent, fiber and cellulose. The invention can produce the foam concrete which not only has light weight and the functions of fire resistance, crack resistance, dynamic pressure resistance and the like, but also has great viscosity, and is particularly suitable for concrete spraying support operation of the coal mines and underground works. The formula can overcome the shortcomings of high rebound degree, large dust, incapability of ensuring spraying strength and the like during construction of a dry spraying method; and the problems of too fast solidification, pipe blockage and the like of an existing wet spraying method are also solved.

Owner:SHANDONG UNIV +2

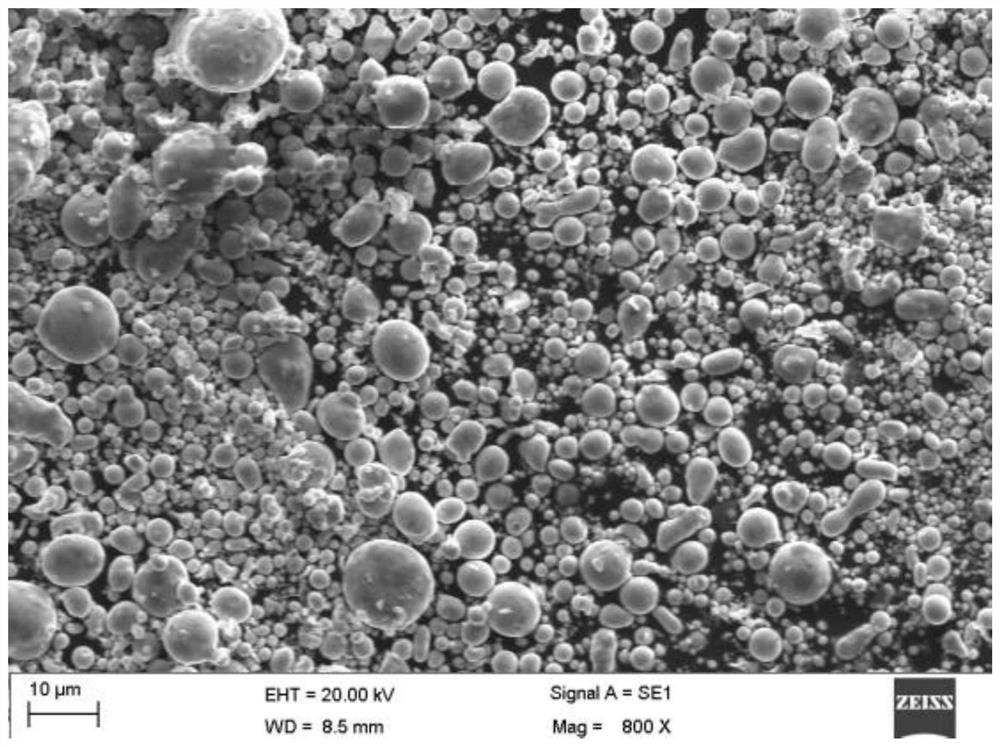

420 stainless steel powder for MIM and water-gas combined atomization pulverizing method thereof

ActiveCN112111693AGood sphericityFully filledTransportation and packagingMetal-working apparatusSS - Stainless steelHigh pressure water

The invention discloses 420 stainless steel powder for MIM and a water-gas combined atomization pulverizing method thereof, and belongs to the field of alloy materials. The 420 stainless steel powdercomprises the following elements in percentage by weight: 0.5-0.6% of C, less than or equal to 1.0% of Si, 0.7-1.5% of Mn, 0.1-0.7% of N, 12.0-14.0% of Cr, 1.0-3.0% of Ni, 0.5-1.5% of Mo, 0.1-0.5% ofCo, 0.5-1.5% of Nb and the allowance Fe and impurities. The method comprises the steps of adopting a medium-frequency induction furnace for smelting, dumping the medium-frequency induction furnace, and enabling molten steel to flow into a tundish and flow out of a leakage hole; enabling high-pressure water to be sprayed out from a nozzle of the spraying disc and focused on the molten steel flow tocrush the molten steel into fine particles, and cooling the fine particles into metal particles in the flying process; and conducting filtering, vacuum drying and screening, and thus obtaining fine powder of which the particle size is less than 400 meshes. The method has the beneficial effect that the alloy powder prepared by the process has good degree of sphericity. Due to the good degree of sphericity, the powder can obtain enough flowability in the process of being injected into a mold cavity in the MIM process, the mold cavity can be fully filled with the powder, an injection blank withhigh density is obtained, and size fluctuation is small.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

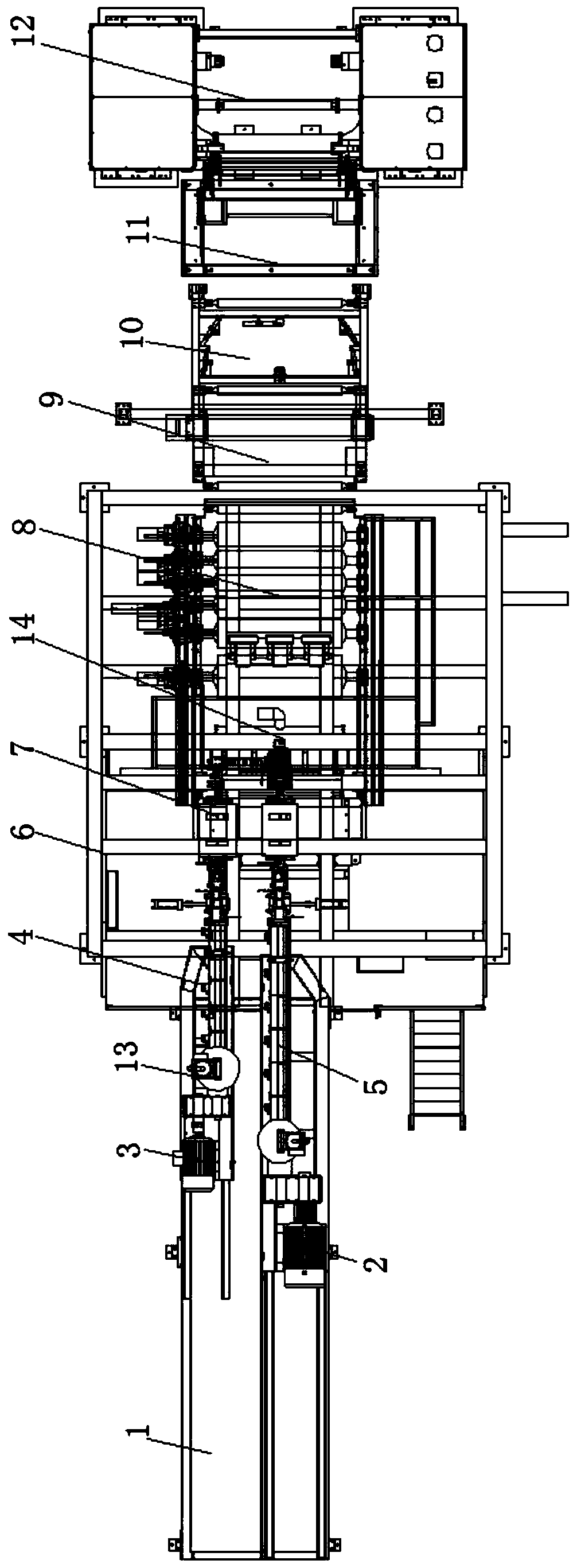

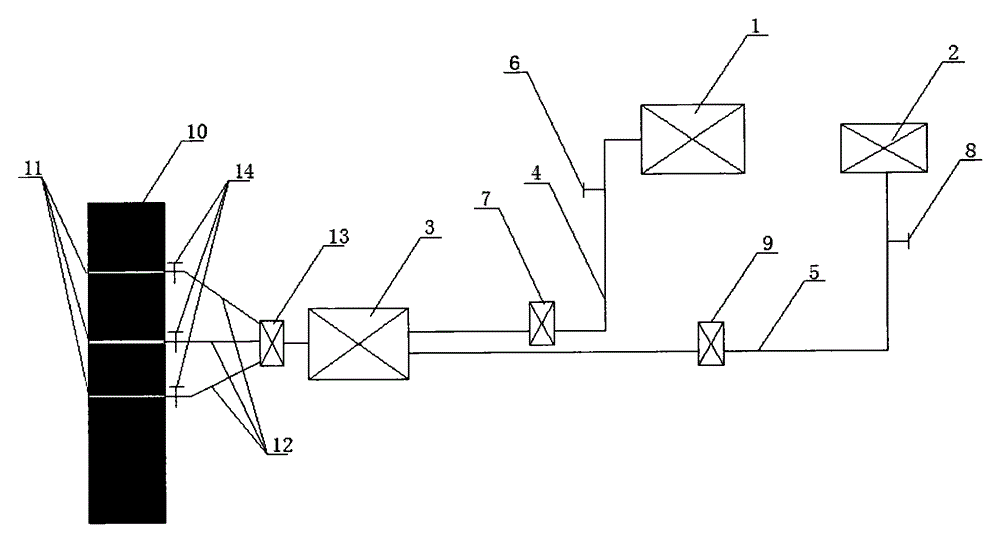

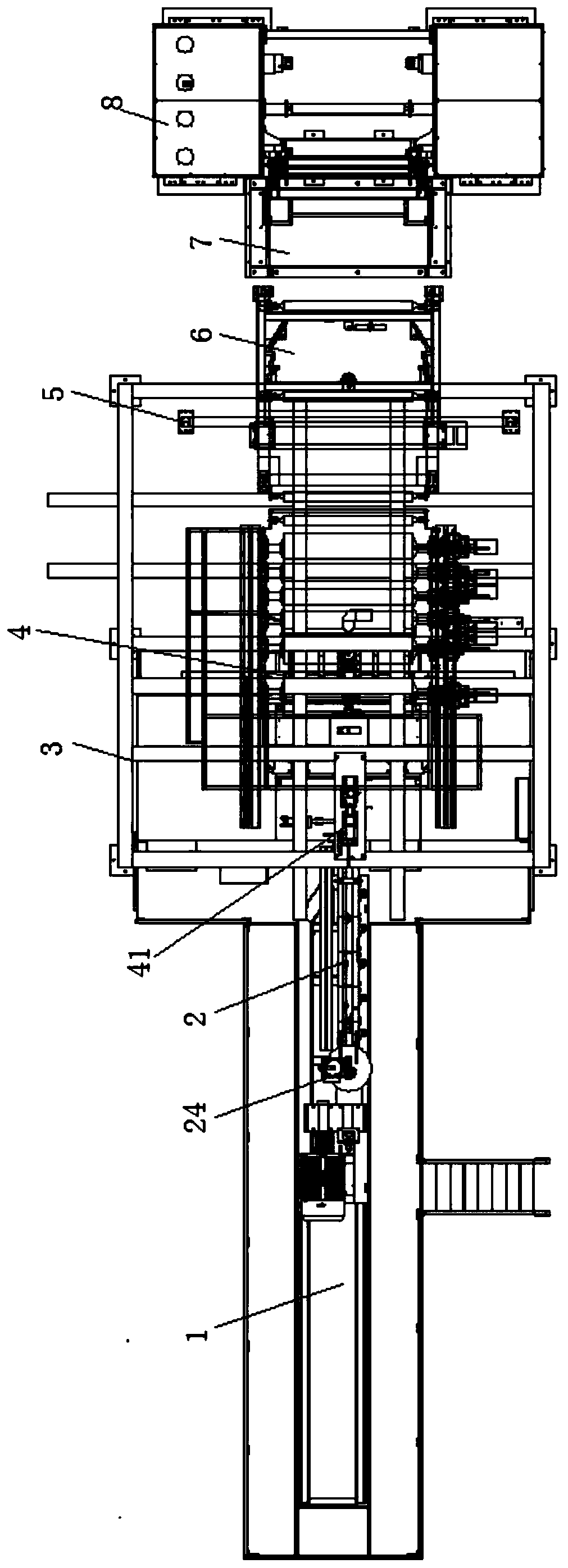

Production equipment for three-layer co-extrusion membrane of lithium battery

InactiveCN110355976ASolve the problem of prone to layer channelingEvenly distributedElectric machineryEngineering

The invention relates to the technical field of production of lithium battery membranes and discloses production equipment for a three-layer co-extrusion membrane of a lithium battery. The equipment comprises an extrusion platform, a first power motor, a second power motor, a first screw extruder, a second screw extruder, a curtain coating platform, a melt pump, a curtain coating machine, a swingdevice, a pulling device, a rolling device, a metal separator and a three-cavity mold. The bottoms of the first power motor, the second power motor, the first screw extruder and the second screw extruder are fixedly connected to the top of the extrusion platform separately, and the output ends of the first power motor and the second power motor are in transmission connection with the input ends ofthe first screw extruder and the second screw extruder respectively. According to the production equipment, the problem is solved that after being extruded, the raw materials are easily moved in different layers. The raw materials are evenly distributed after being extruded by the extruders, the overall raw materials are homogenized, the fluidity of the extruded raw materials can be improved, andthe effect of plastifying the raw materials is improved.

Owner:广东宝路盛精密机械有限公司

Underground coal mine fire preventing and extinguishing material and using method thereof

InactiveCN105126289AImprove liquidityImprove water retentionDust removalFire preventionEngineeringCoal

The invention discloses an underground coal mine fire preventing and extinguishing material and method. The underground coal mine fire preventing and extinguishing material comprises, by weight, 2 parts to 3.5 parts of water glass, 1.5 parts to 2.5 parts of sodium metaaluminate and 95 parts to 96 parts of water. Under the condition that it is ensured that the fire preventing and extinguishing material has the enough fluidity, the water-retaining property of the material can be effectively improved, the underground coal mine fire preventing and extinguishing work effect can be greatly improved, and the coal mine production safety can be forcefully ensured.

Owner:CCTEG CHINA COAL RES INST

Composite trading order processing

ActiveUS20100262528A1Save calculationShorten the timeFinancePayment architectureOrder processingData mining

A system for processing a composite trading order comprises a memory operable to store market data received from one or more market centers. The system further comprises a processor operable to generate a composite value based at least in part on the market data. The processor is further operable to receive a composite trading order associated with at least a portion of the composite value. The processor is further operable to generate a plurality of constituent trading orders that, when filled, combine to satisfy the composite trading order.

Owner:BGC PARTENRS INC

Tire sidewall rubber without mold release agent

InactiveCN105646954AGood viscosity and processabilityExcellent flex resistanceSpecial tyresCarbon blackRaw rubber

The invention relates to a tire sidewall rubber without a mold release agent and a processing technology thereof. According to a design scheme provided by the invention, the formula mainly comprises the following components: natural rubber with a grade of SMR20, butadiene rubber BR9000, stearic acid, active zinc oxide, an anti-aging agent 4020, an anti-aging agent 3100, an anti-aging agent TMQ, rubber protective wax, carbon black N339, an internal releasing agent with a grade of AT-16, environment-friendly aromatic hydrocarbon oil with a grade of Vivatec 500, an accelerant CBS, insoluble sulfur IS-6005, and an anti-scorching agent CTP. The formula employs a natural rubber and butadiene rubber coexistent raw rubber system, uses the new materials, i.e. the internal releasing agent with a grade of AT-16, the active zinc oxide and environment-friendly aromatic hydrocarbon oil with a grade of Vivatec 500. By applying the formula to rubber production, the operation is simple and convenient, the production cost is low, and the rubber processing properties are good. The invention provides a tire sidewall rubber without a mold release agent for tire production.

Owner:SICHUAN TYRE & RUBBER CO LTD

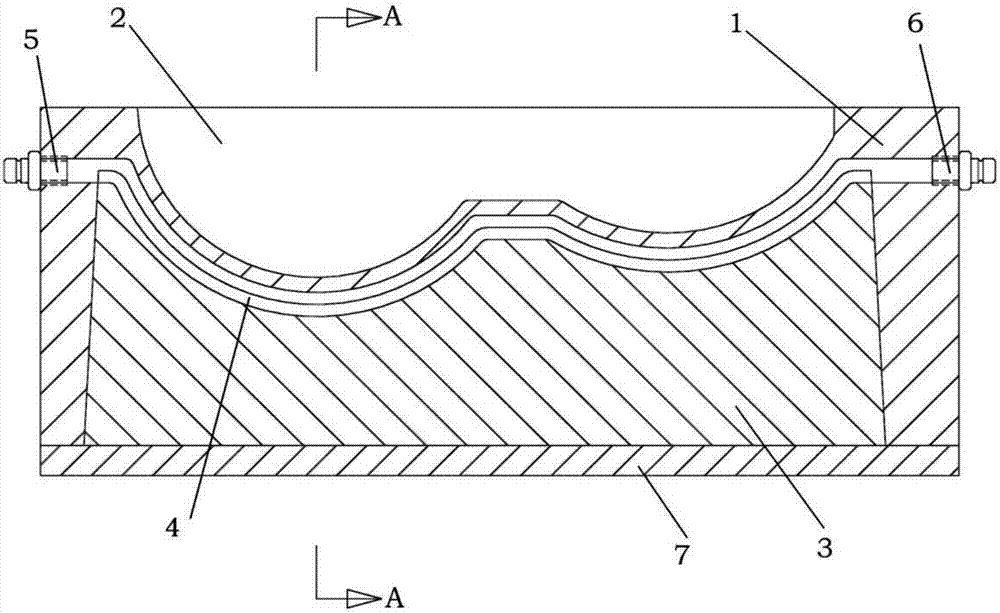

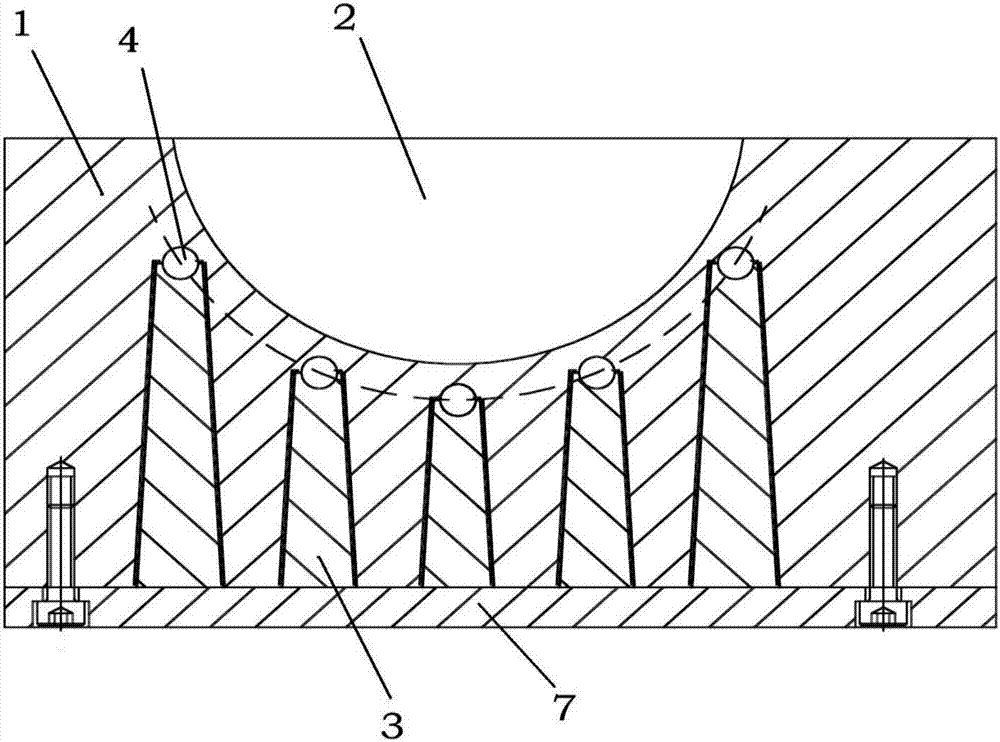

Shape tending heating cooling die and machining and usage method thereof

InactiveCN106862491ASufficient liquidityUniform solidificationFoundry mouldsFoundry coresEngineeringMachining

A shape heating and cooling mold, comprising a die, a cavity is formed on the die, the bottom of the die is provided with an additional block insertion groove, and the top of the additional block insertion groove is processed with an upper groove, the upper groove The arrangement is consistent with the outline of the bottom of the cavity; the additional block inserts an additional water channel block into the groove, the shape of the additional water channel block is consistent with the insertion groove at the bottom of the die, and the heat-resistant Spray sealing material to fill; the top of the waterway additional block is formed with a lower groove, and the lower groove cooperates with the upper groove to form a waterway; the waterway runs through the die, and the two ends of the waterway respectively form a water inlet and an outlet on the side wall of the die Nozzle; the mating surfaces of the additional block of the water channel and the insertion groove of the additional block are all inclined inward, and the inclination angle is 85 to 88 degrees. There is a pressing block under the die, which is fixed on the die by bolts, The tight block is against the additional block of the water channel, so that the additional block of the water channel is fixed.

Owner:FUJIAN UNIV OF TECH

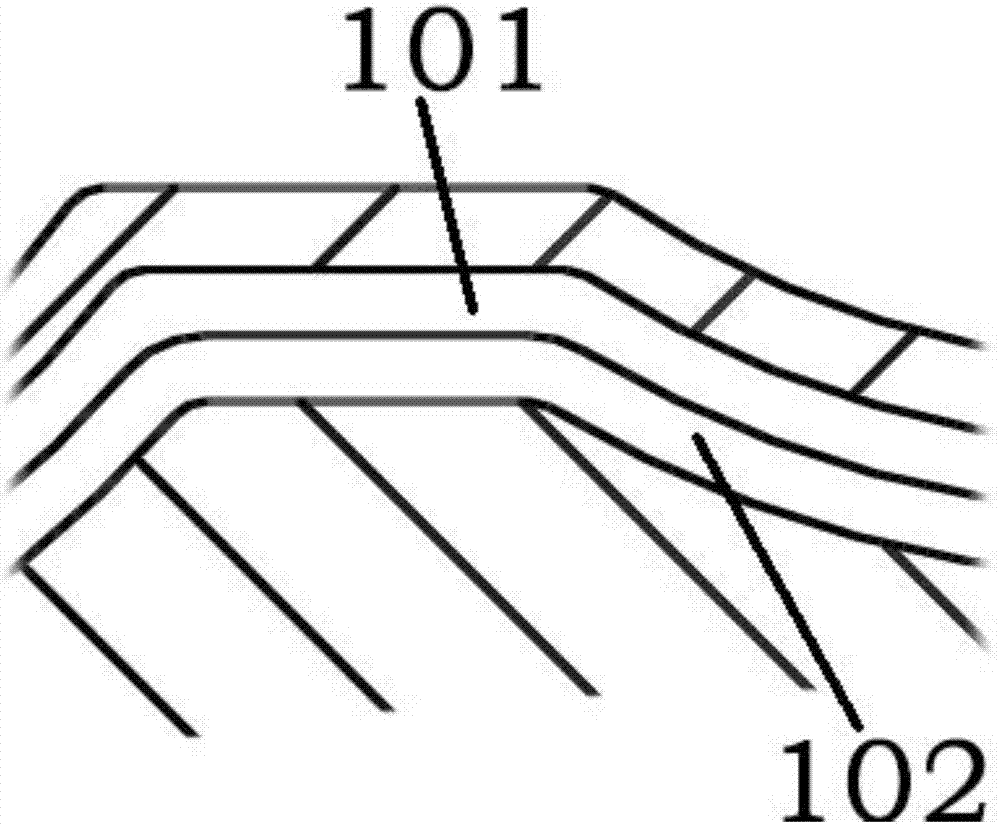

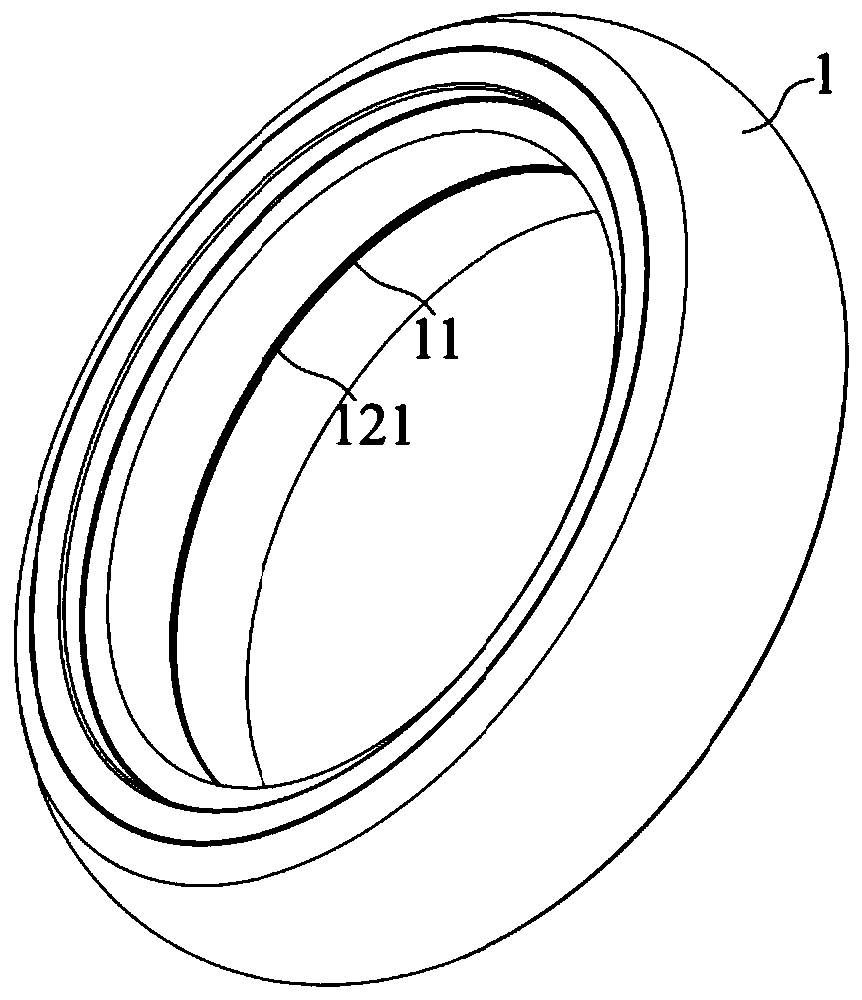

One-time formed inflatable hollow tire and manufacturing method thereof

InactiveCN110509584ABroaden applicationImprove shock absorptionNon-inflatable tyresTyresAtmospheric pressureTire manufacturing

The invention discloses a one-time formed inflatable hollow tire and a manufacturing method thereof and belongs to the field of tire manufacturing. The tire comprises a cavity structure, an opening structure, an air impervious liner and an inflating valve installing hole, wherein the cavity structure is formed in a tire body in the periphery direction, a hollow cavity is formed in the tire body, the opening structure is arranged in a groove in an inner ring face of the tire body in the periphery direction, the opening structure enables the cavity structure and the outside to communicate, the air impervious liner is formed by a first air impervious liner body formed on the surface of the cavity structure and a second air impervious liner body for opening and closing the opening structure, and the inflating valve installing hole is formed in one side of the tire body and enables the cavity structure and the tire body to communicate. According to the tire, by means of cooperation of the opening structure and the cavity structure, the hollow tire body can be formed at a time, the air impervious liner can also be coated conveniently, the manufacturing technology of the tire is simplified, an inflating valve is installed through the inflating valve installing hole to inflate the hollow structure, by means of cooperation with the air impervious liner, a vibration reducing cavity for stabilizing air pressure is formed, and the vibration reducing performance is improved greatly.

Owner:安徽世界村智能装备有限公司

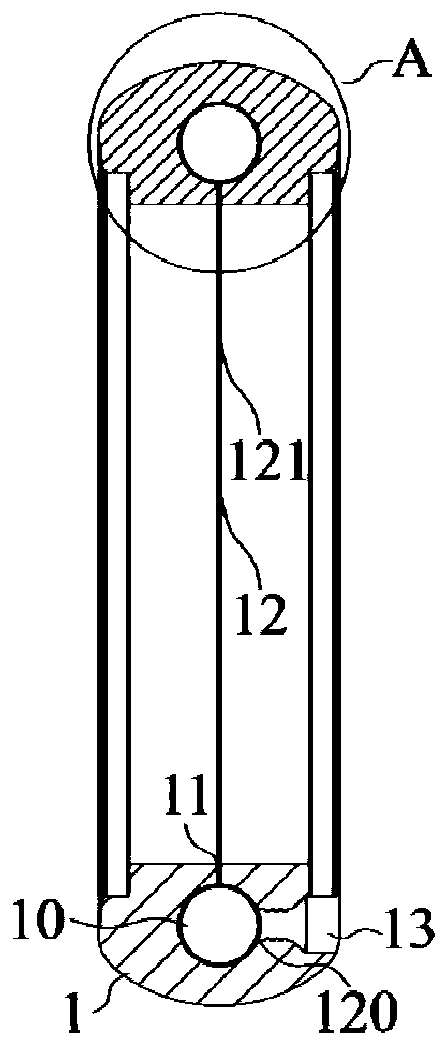

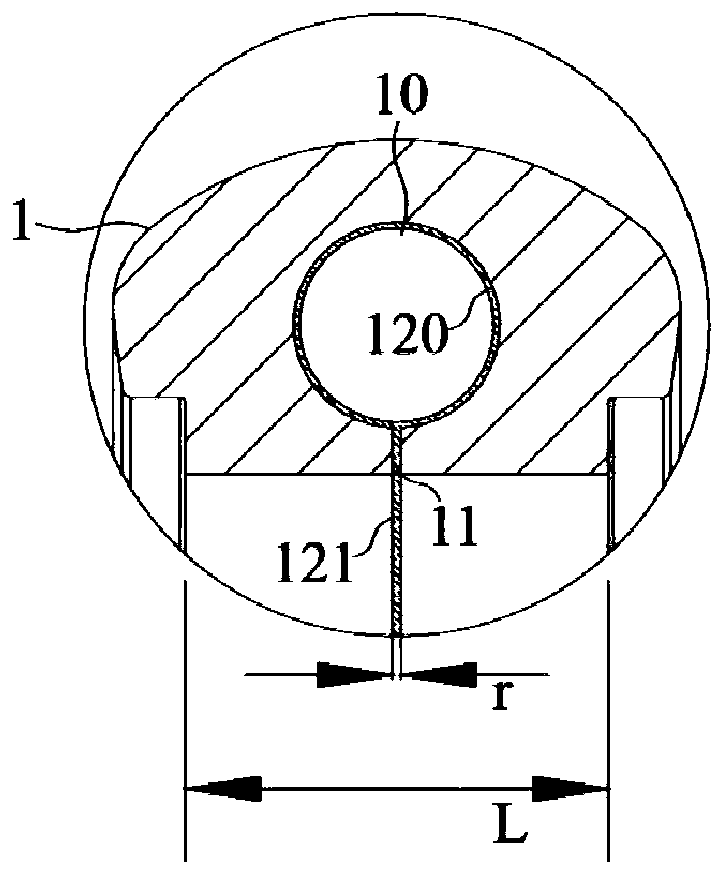

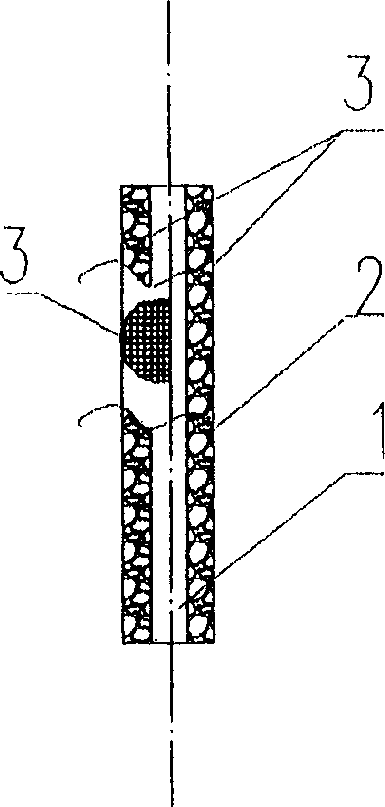

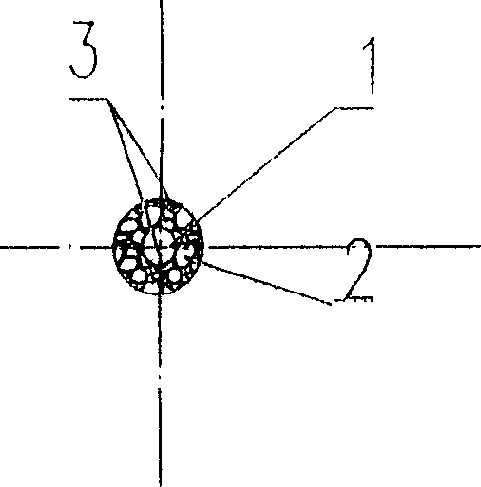

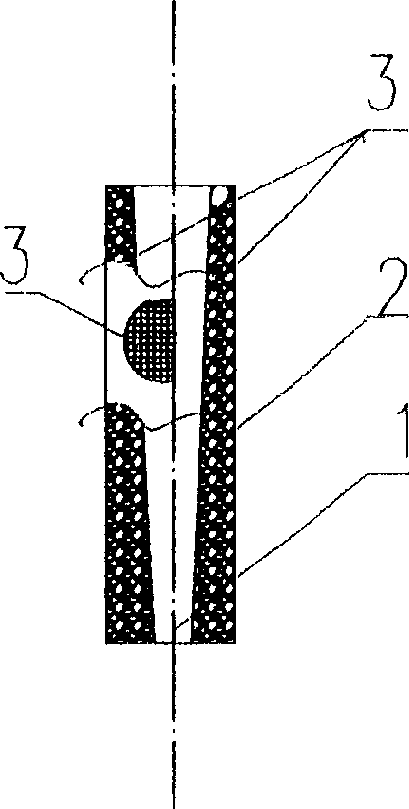

Diphase separating element, and separator, reactor and adsorption equipment of containing the element

InactiveCN1695769ASufficient liquidityEasy to replaceDispersed particle filtrationLoose filtering material filtersFixed bedSolid particle

A two-phase separating unit and the two-phase separator, the fixed-bed reactor for catalytic reaction and the gas adsorbing apparatus, all of which contains said two-phase separating, are disclosed. Said two-phase separating unit is composed of two or more perforated barrels to form one or more annular cavities, in which the solid particles are filled to form the inrregular gap channels.

Owner:董安城

Coal gangue activity exciting agent and high-fluidity and high-solid-content cemented filling slurry

The invention discloses a coal gangue active activator and high-fluidity high-solid-content cemented filling slurry, and the coal gangue active activator is composed of the following components: 2.5-15 parts by weight of calcined dolomite or calcined limestone, 3-9 parts by weight of silicate, 35-80 parts by weight of caustic soda, 3-22 parts by weight of gypsum and 0.025-1.4 parts by weight of a water reducing agent. The high-fluidity and high-solid-content cemented filling slurry is composed of water and a cemented filling material. The cemented filling material is composed of 65-95 parts by weight of coal gangue and 5-35 parts by weight of a coal gangue activity exciting agent; the mass fraction of water in the high-fluidity and high-solid-content cemented filling slurry is 7.2-9.8 wt%. The coal gangue can be hydrated and hardened to generate enough strength without using cementitious materials such as cement, and the cemented filling slurry is low in water content and good in fluidity, does not shrink after being hardened, and can be well topped due to micro-expansion.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

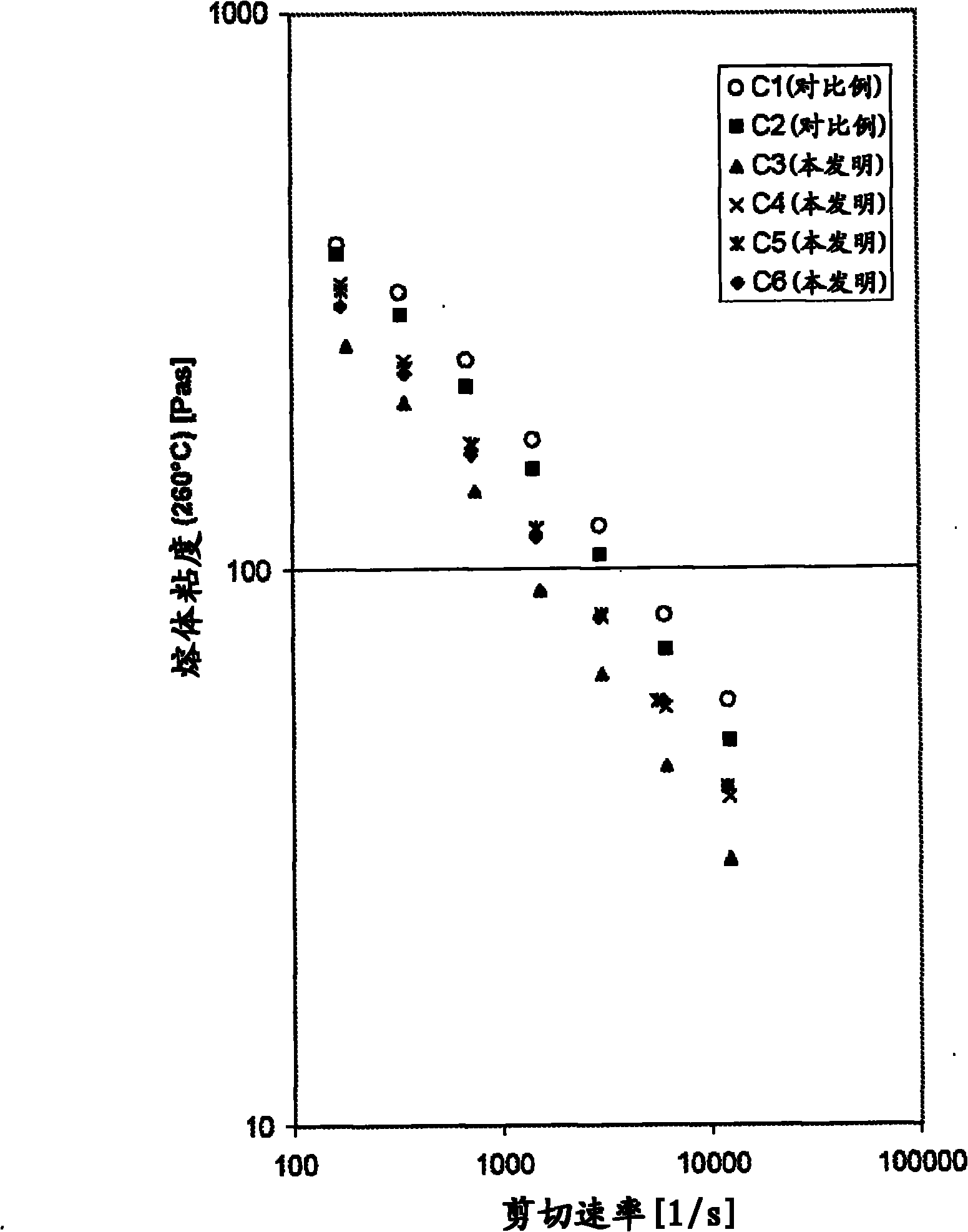

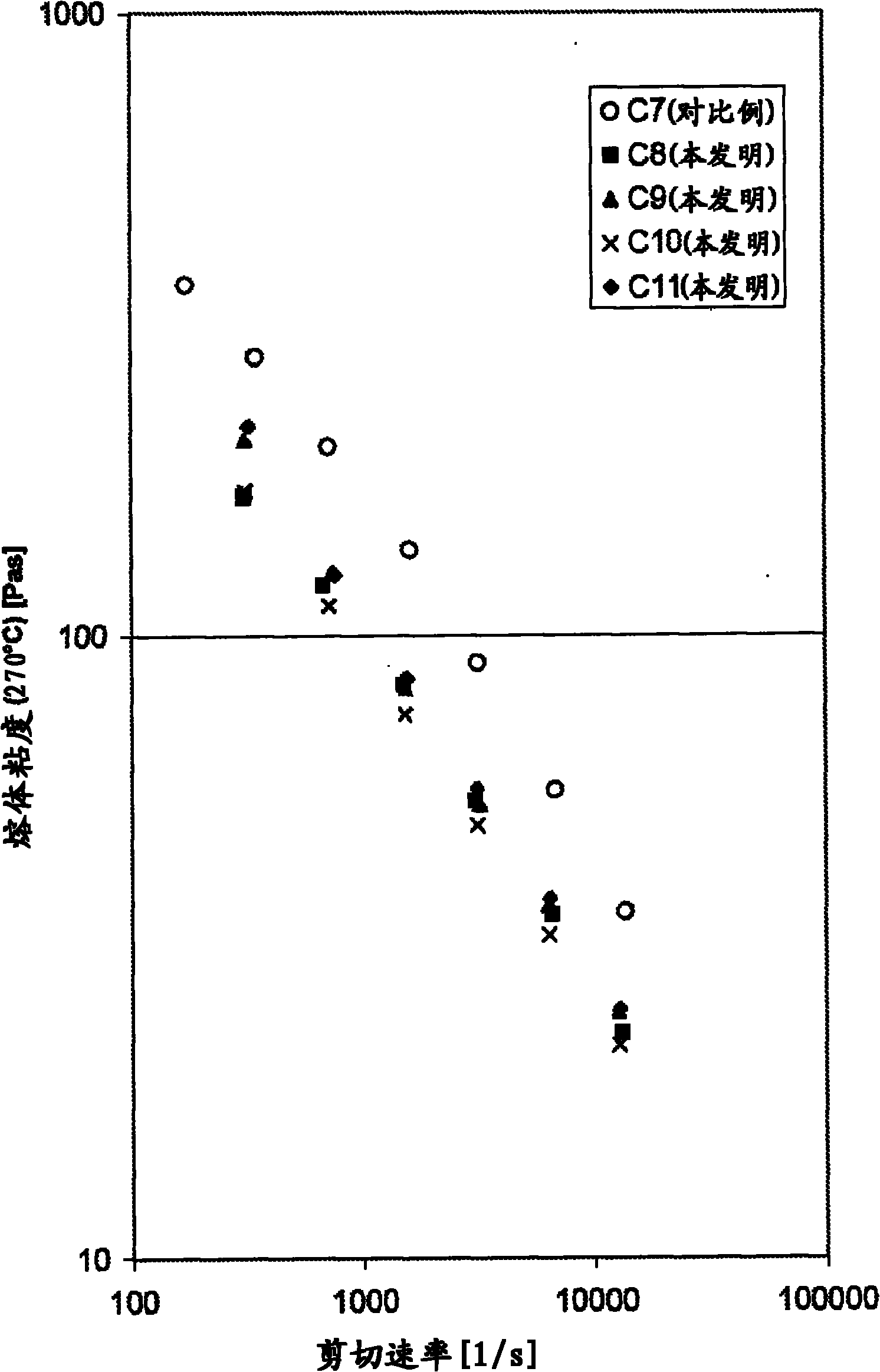

Rheology modifier

The invention relates to a rheology modifier for improving the flowability of technical plastics, which drastically improves the thermoplastic processing behavior of the plastics without impairing the usage properties of the manufactured molded bodies.

Owner:TH GOLDSCHMIDT AG

Composite bonding low-temperature constructional castable refractory

ActiveCN102491769BSufficiently resistant to erosionService life is not affectedRefractoryWollastonite

The invention relates to a composite bonding low-temperature constructional castable refractory, which can be used for high-temperature kiln engineering. According to the castable refractory, corundum, alumina, mullite and silicon carbide are used as an aggregate, silica sol is used as a bonding agent, aluminate cement is used as a curing agent and a bonding aid, and alumina micro powder, wollastonite, a deflocculant, a retarder, water and the like are added. The composite bonding low-temperature constructional castable refractory has high low-temperature constructional performance, high performance of high-temperature resistance, erosion resistance, thermal shock resistance and high mechanical performance, and meets the requirements of overhauling in winter on the premise that the service life of the castable refractory is not influenced.

Owner:ANHUI RUITAI NEW MATERIALS TECH

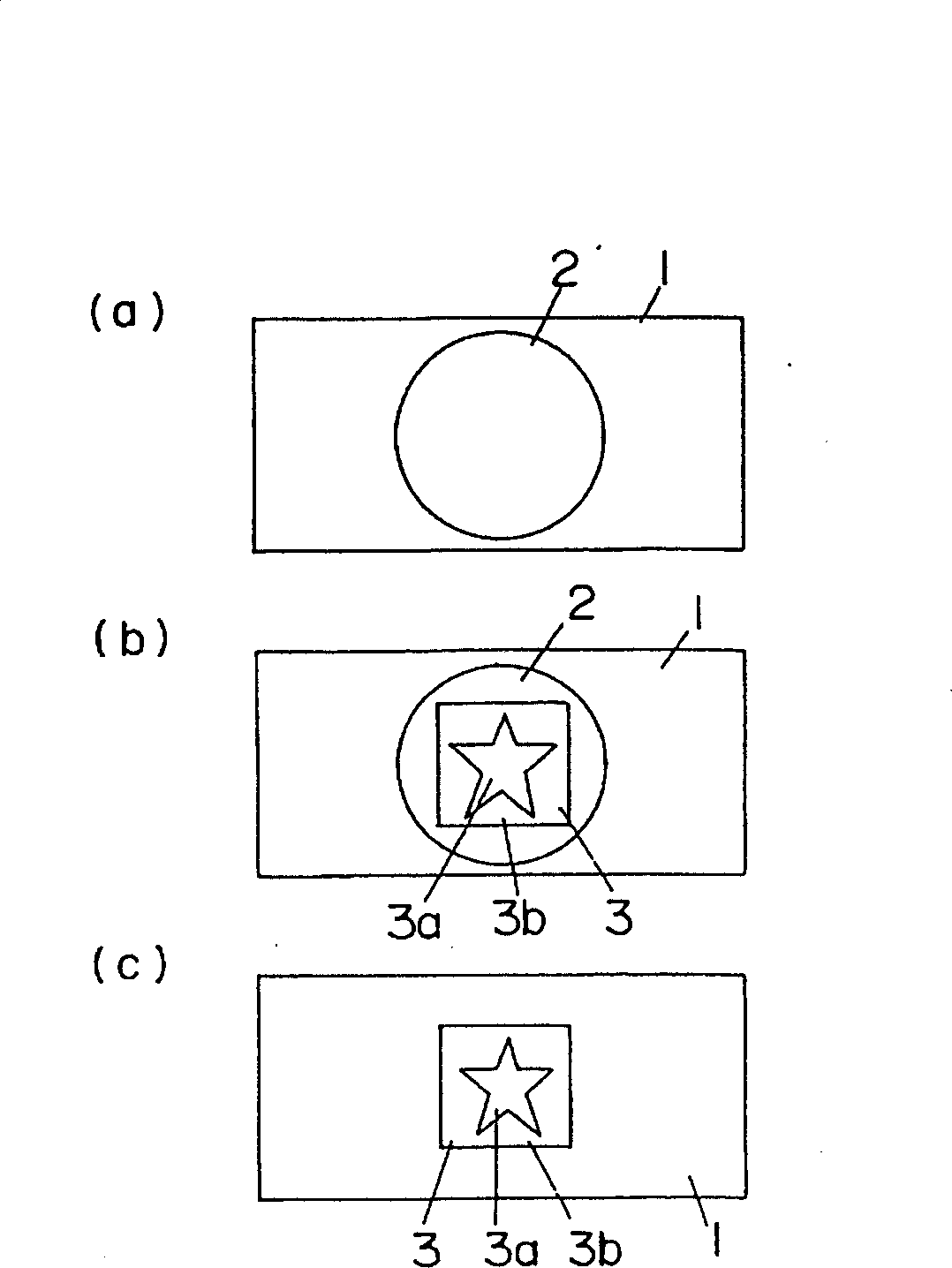

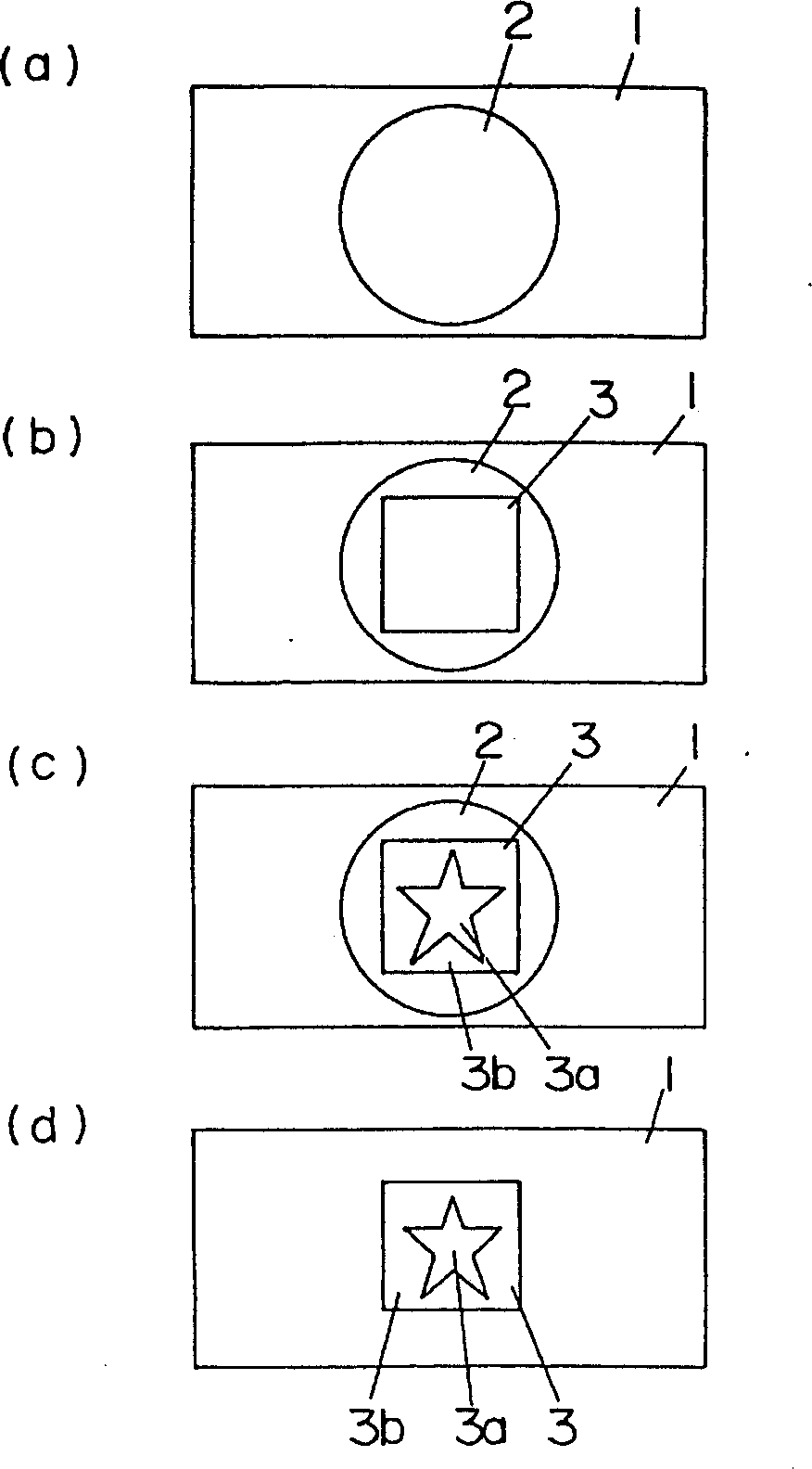

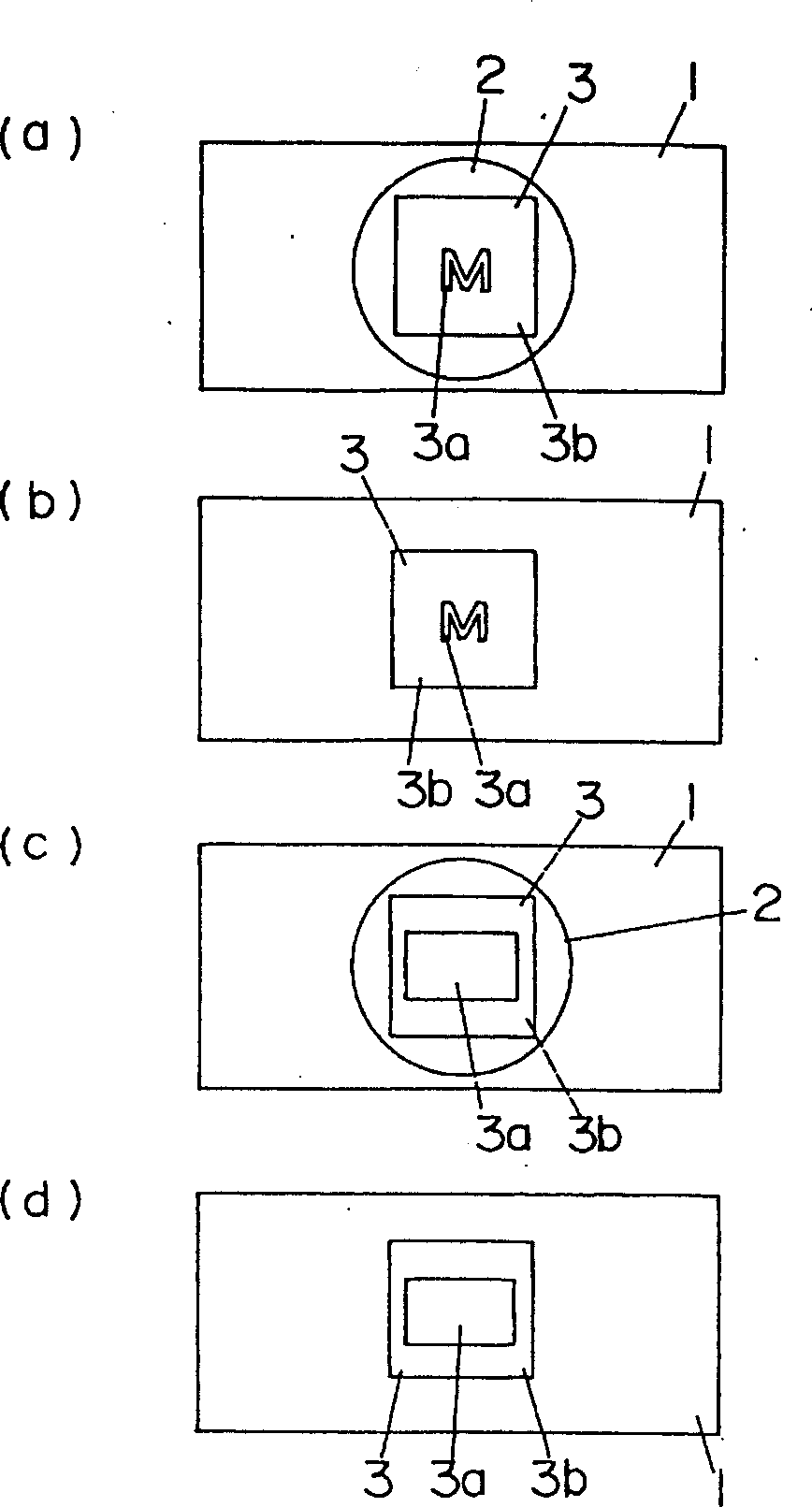

Decorative method for forming body

InactiveCN1361014AAvoid damageLong-term decorationSpecial ornamental structuresArtistic surface treatmentIrradiationAtomic physics

A coating film 2 of an uncured resin composition which is curable in response to irradiation with an energy beam is formed on the surface of a molding. A desirable portion of the coating film 2 is irradiated with the energy beam. Thus, the portion of the coating film 2 irradiated with the energy beam is cured to form a surface decorative layer 3.

Owner:MATSUSHITA ELECTRIC WORKS LTD

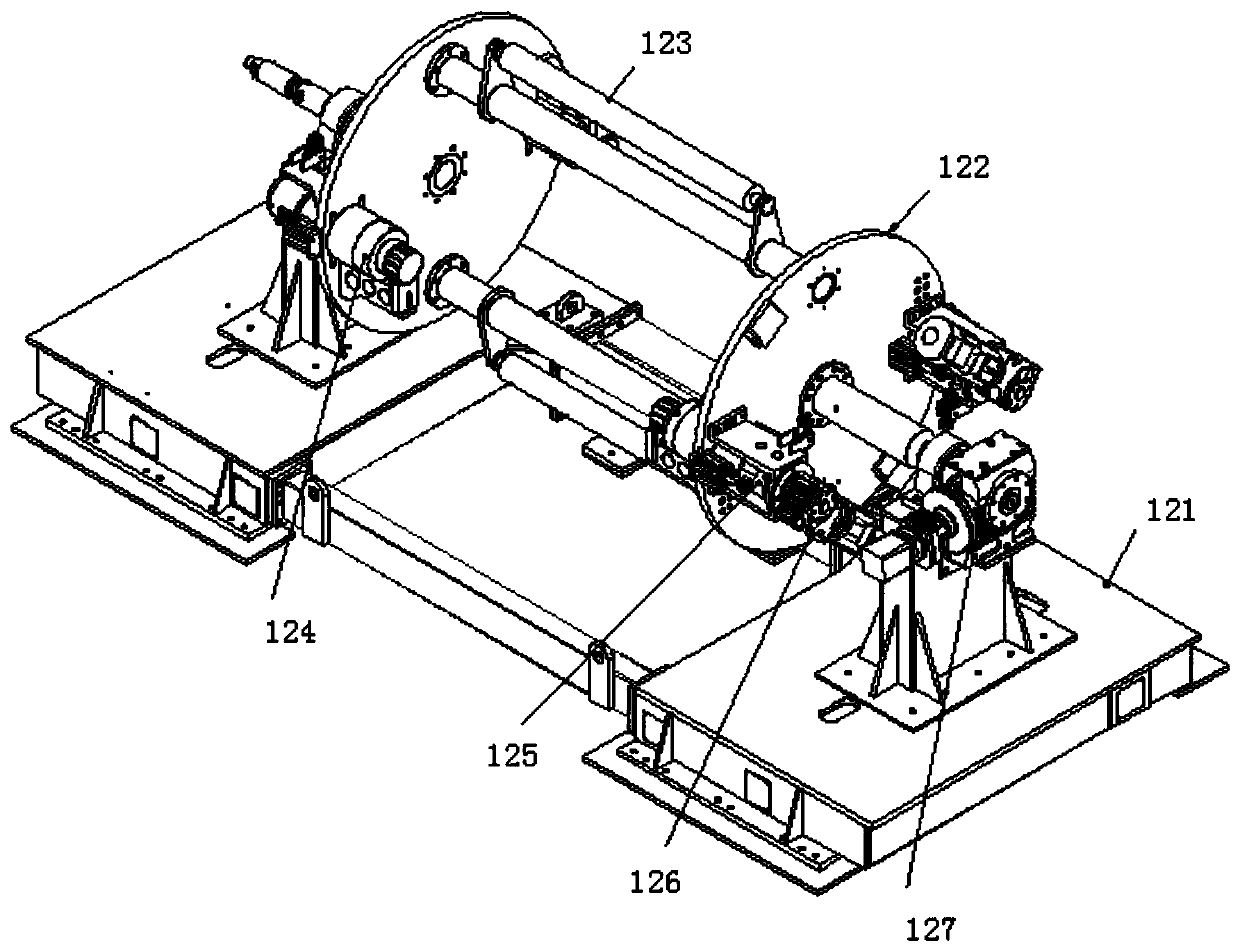

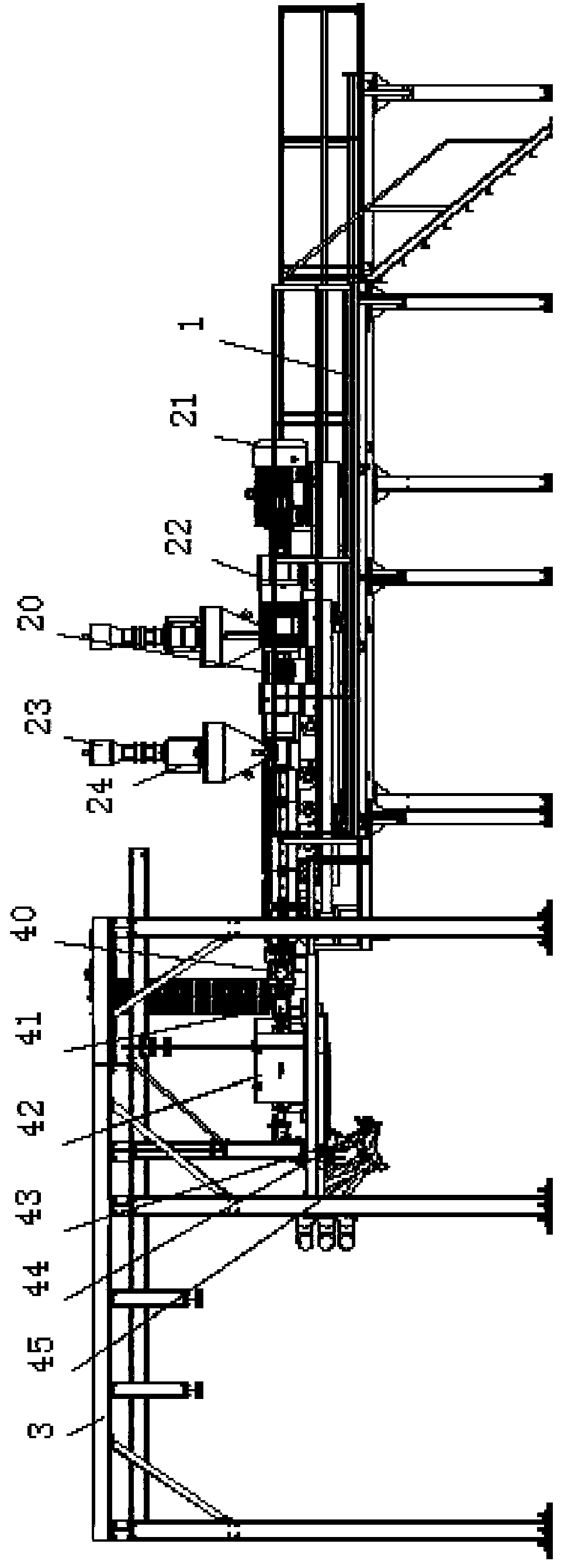

Lithium battery single-layer diaphragm production line

InactiveCN110311080AGuaranteed liquidityImprove plasticizing effectCell component detailsPower batteryProduction line

The invention relates to the technical field of lithium battery diaphragm production, and discloses a lithium battery single-layer diaphragm production line. The lithium battery single-layer diaphragmproduction line comprises a mounting frame, a screw extrusion mechanism, a platform frame, a casting mechanism, a thickness gauge, a swinging machine, a tractor and a winding machine, wherein the screw extrusion mechanism is positioned on the right side of the top of the mounting frame, the right side of the mounting frame is fixedly connected with the left side of the platform frame, the castingmechanism is positioned on the top of the platform frame, the thickness gauge is positioned on the right side of the top of the platform frame, the thickness gauge is positioned on the right side ofthe casting mechanism, the left side of the swinging mechanism is fixedly connected with the middle position of the right side of the platform frame, the tractor is positioned on the right side of theswinging machine, and the winding machine is positioned on the right side of the tractor. The production line solves the problems of poor plasticizing effect and poor flowability of the extruded rawmaterials, can meet the technical requirements of power battery production, improves the separation effect between positive and negative electrodes of the lithium battery and can improve the overall quality of the lithium battery.

Owner:广东宝路盛精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com