Underground coal mine fire preventing and extinguishing material and using method thereof

A fire prevention and coal mine technology, applied in fire prevention equipment, fire prevention, dust prevention, etc., can solve problems such as unsatisfactory application effect of ammonium bicarbonate gel, affect fire prevention effect, pollute underground environment, etc., and improve fire prevention operation effect , the effect of extinguishing is ideal, and the effect of ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The coal mine underground fire-proofing material contains water glass, sodium metaaluminate and water, water glass accounts for 2-3.5 parts (weight), sodium metaaluminate accounts for 1.5-2.5 parts, water accounts for 95-96 parts (weight) .

[0032] The method for preventing and extinguishing fires in underground coal mines uses the above-mentioned anti-fire-extinguishing materials in underground coal mines to prevent and extinguish fires, comprising the steps of:

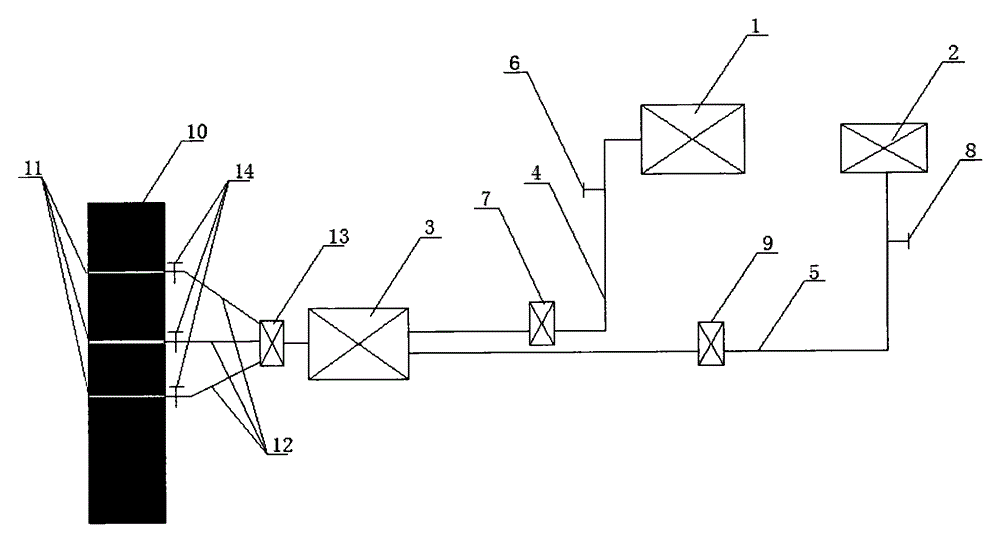

[0033] (a) On the ground of the mine, set up water glass solution preparation station 1 and sodium metaaluminate solution preparation station 2, and install sodium metaaluminate gel preparation station 3 in the mine where spontaneous combustion has occurred or there is a potential spontaneous combustion area near the roadway , the water glass solution preparation station 1 and the sodium metaaluminate solution preparation station 2 are connected to the sodium metaaluminate gel preparation station 3 through t...

Embodiment 2

[0040] In the described coal mine underground fire extinguishing material, water glass accounts for 2.5-3.5 parts (weight), sodium metaaluminate accounts for 1.5-2.5 parts (weight), and water accounts for 95-96 parts (weight).

[0041] The method for preventing and extinguishing fires in underground coal mines uses the above-mentioned anti-fire-extinguishing materials in underground coal mines to prevent and extinguish fires. The steps are basically the same as in Embodiment 1, except for the following two points:

[0042] In step (c), the water glass solution is prepared by the water glass solution preparation station 1, water glass accounts for 2.5-3.5 parts (weight), water accounts for 68 parts (weight), and is passed through the sodium metaaluminate solution preparation station (2) prepare sodium metaaluminate solution, wherein, sodium metaaluminate accounts for 1.5-2.5 parts (weight), water accounts for 27-28 parts (weight);

[0043] In the sodium metaaluminate gel formed...

Embodiment 3

[0045] In the described coal mine underground fire prevention material, water glass accounts for 2.7 parts (weight), sodium metaaluminate accounts for 1.5-2.3 parts (weight), and water accounts for 95-95.8 parts (weight).

[0046] The method for preventing and extinguishing fires in underground coal mines uses the above-mentioned anti-fire-extinguishing materials in underground coal mines to prevent and extinguish fires. The steps are basically the same as in Embodiment 1, except for the following two points:

[0047] In step (c), the water glass solution is prepared by the water glass solution preparation station 1, water glass accounts for 2.7 parts (weight), water accounts for 68 parts (weight), and is prepared by the sodium metaaluminate solution preparation station 2 Go out sodium metaaluminate solution, wherein, sodium metaaluminate accounts for 1.5-2.3 parts (weight), and water accounts for 27-27.8 parts (weight);

[0048] In the sodium metaaluminate gel formed in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com