Patents

Literature

911results about How to "Ensure production safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for supplementing lithium for negative electrode of lithium ion battery

ActiveCN102916165AAvoid LithiumAvoid deformationElectrode manufacturing processesElectrolyte/reactants regenerationMetallic lithiumElectrical battery

The invention belongs to the technical field of lithium ion batteries, in particular to a method for supplementing lithium for a negative electrode of a lithium ion battery. The method comprises the following steps: spraying or dripping an organic lithium solution on a surface of a negative electrode in an inert atmosphere, so that lithium ions in the organic lithium solution are reverted to metal lithium which is embedded into the negative electrode; and drying the negative electrode. Compared with the prior art, in the method, the organic lithium solution is sprayed or dipped on the surface of the negative electrode evenly so as to realize lithium supplementation in a wet process, thereby effectively avoiding metallic lithium powders floating in the air in a dry process to ensure safe production; and the whole process is simple, the cost is lower, the amount of the lithium supplementation can be controlled accurately through the amount and the time by spraying or dripping the organic lithium solution so as to supplement the lithium evenly, thereby preventing lithium precipitation and deformation of the negative electrode and improving the initial efficiency of the battery. Therefore, the the energy density of the battery is improved. Additionally, the invention further discloses another method for supplementing the lithium for the negative electrode of the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH +1

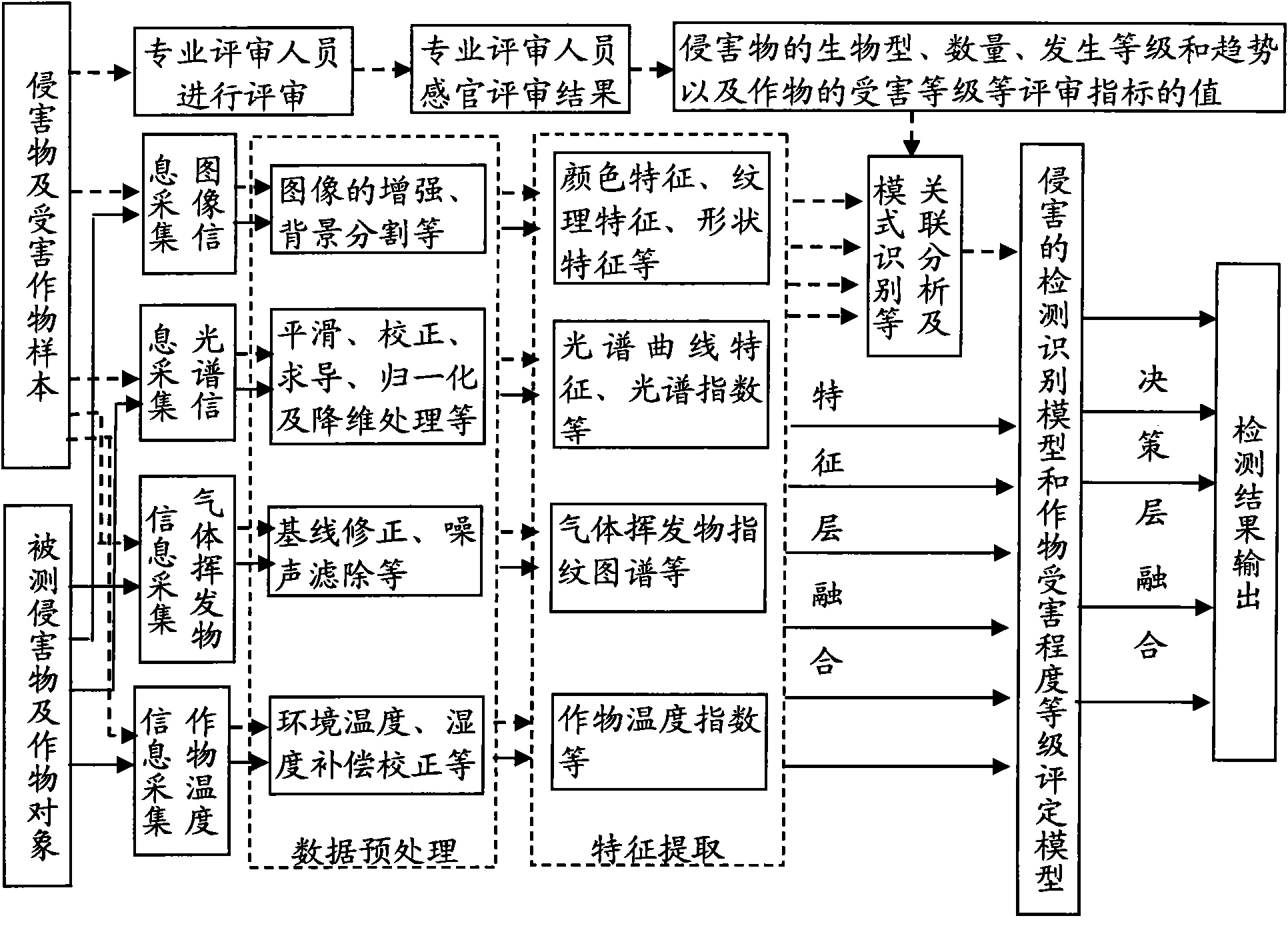

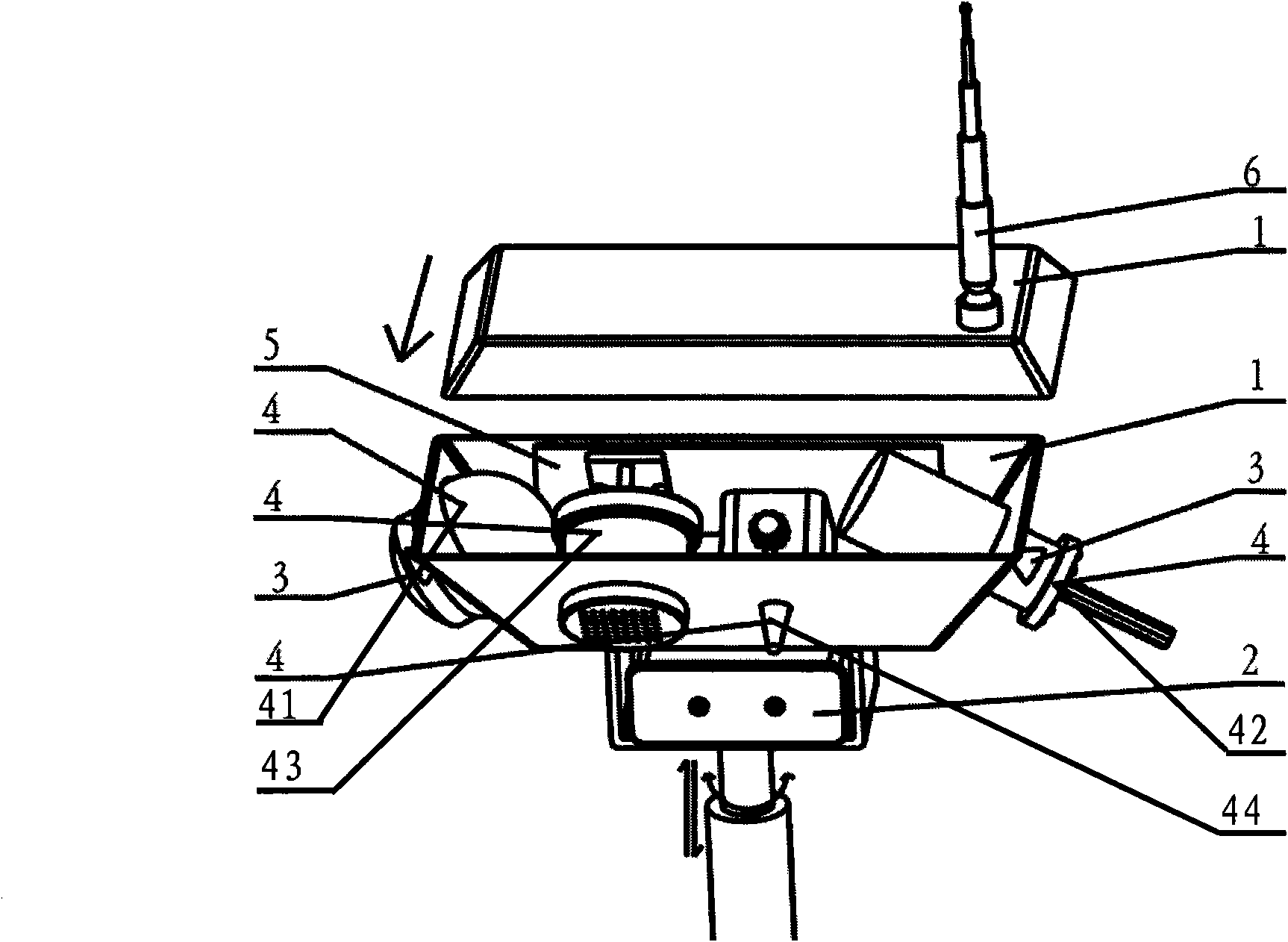

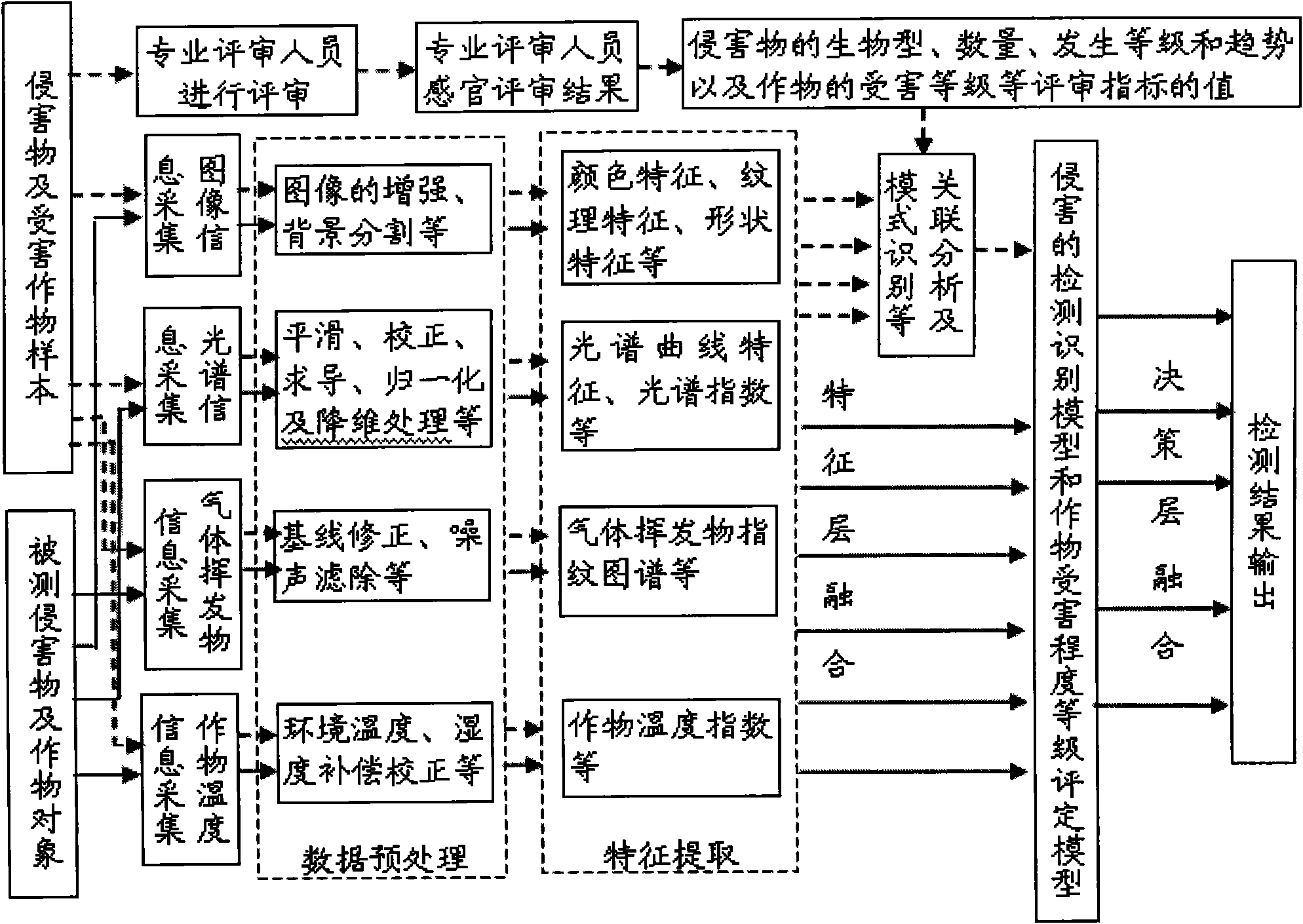

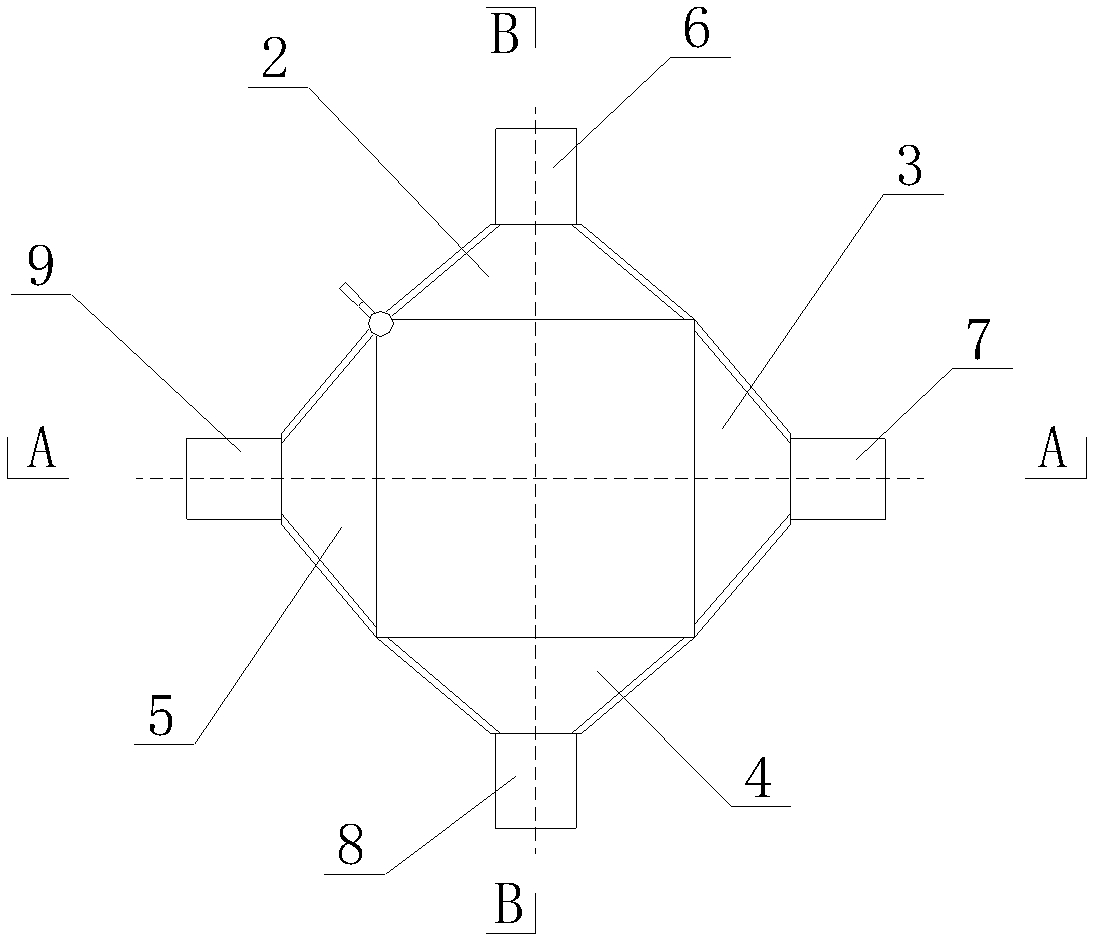

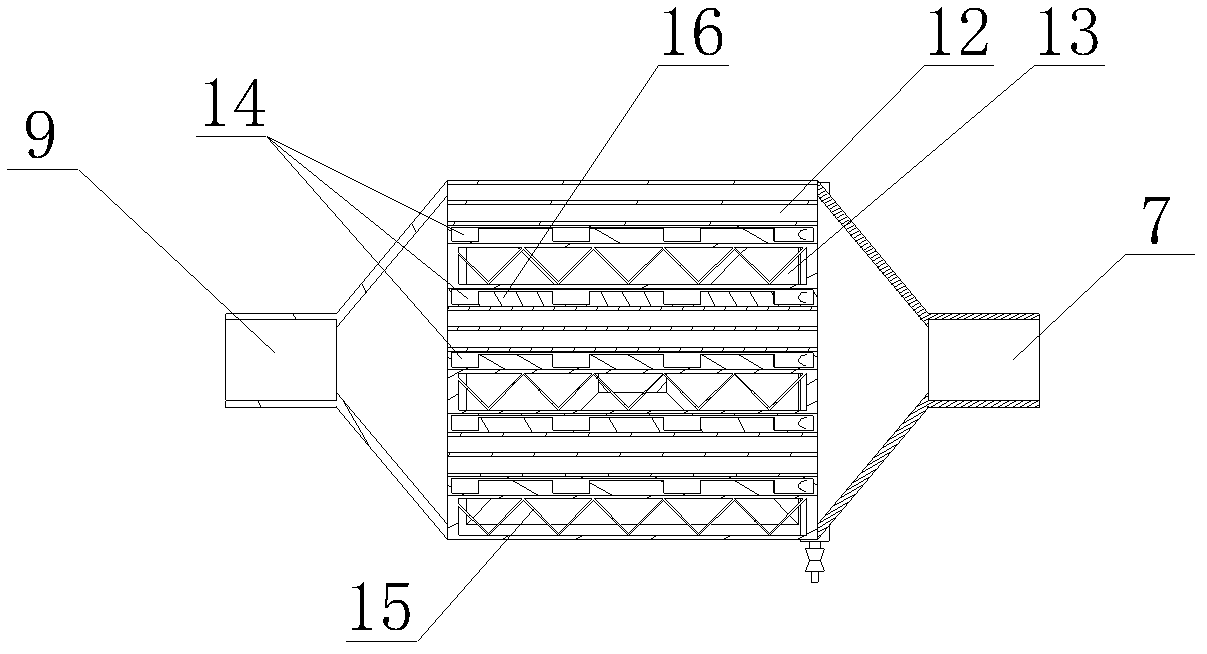

Method and device for early detecting crop pests based on multisensor information fusion

InactiveCN102084794AHigh precisionImprove efficiencyColor/spectral properties measurementsPlant protectionRelevant informationCrop pest

The invention relates to the technical field of plant protection, and discloses a method and device for early detecting crop pests based on multisensor information fusion. The method disclosed by the invention is used for detecting a crop pest condition through a model building stage, an information collecting stage, a characteristic quantity drawing stage and an information fusion and detection distinguishing stage. By using the method and the device, the shortage of purely depending on a single machine checking and monitoring method is overcome, relevant information of specific pests can beobtained from multiple aspects, multiple kinds of information can be fused for intelligent detection; and multiple kinds of information are subjected to demonstration check for mutual compensation byusing complementarity and redundancy of the information, and further the detecting and monitoring accuracy and efficiency of a field crop pest robot are improved.

Owner:SOUTH CHINA AGRI UNIV

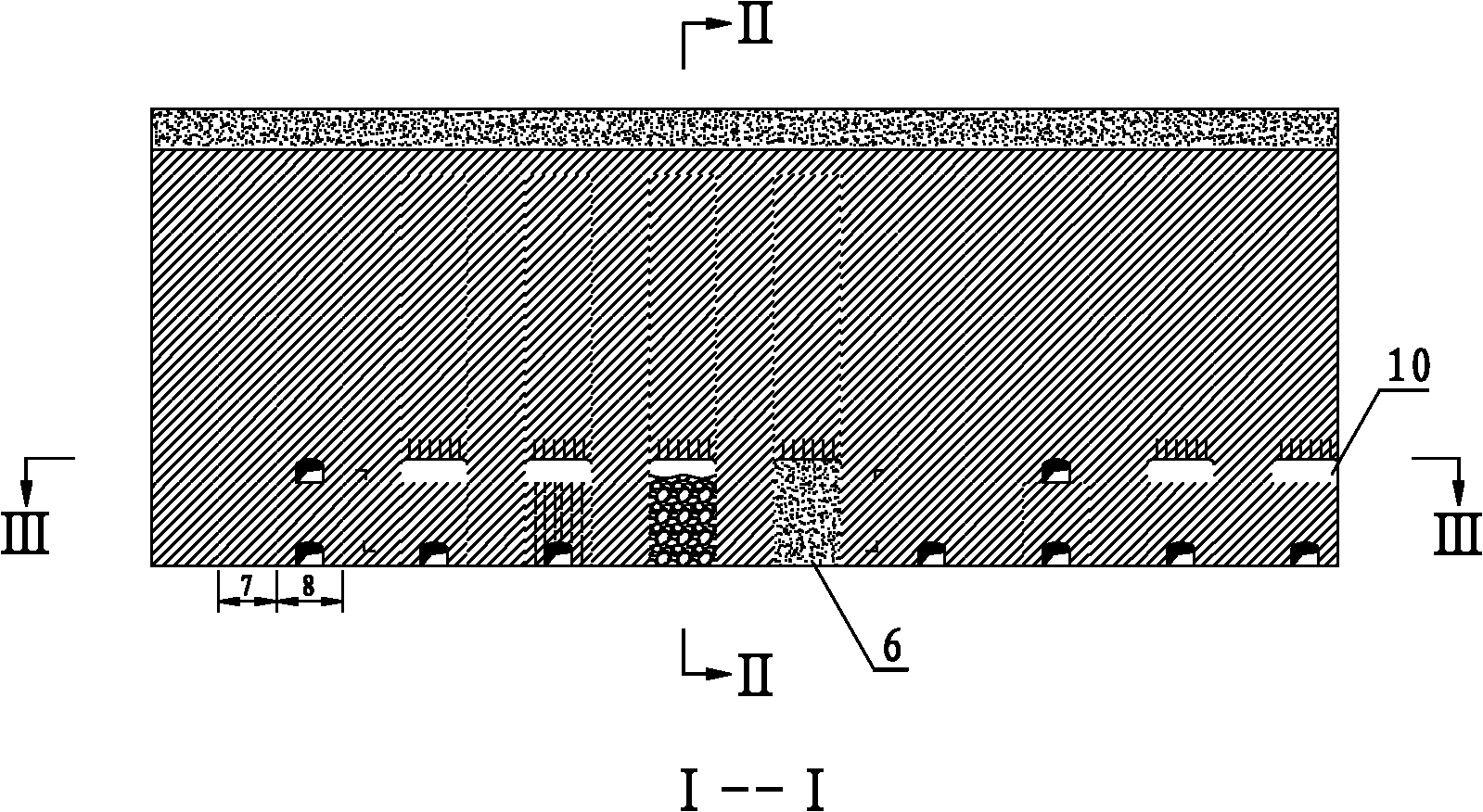

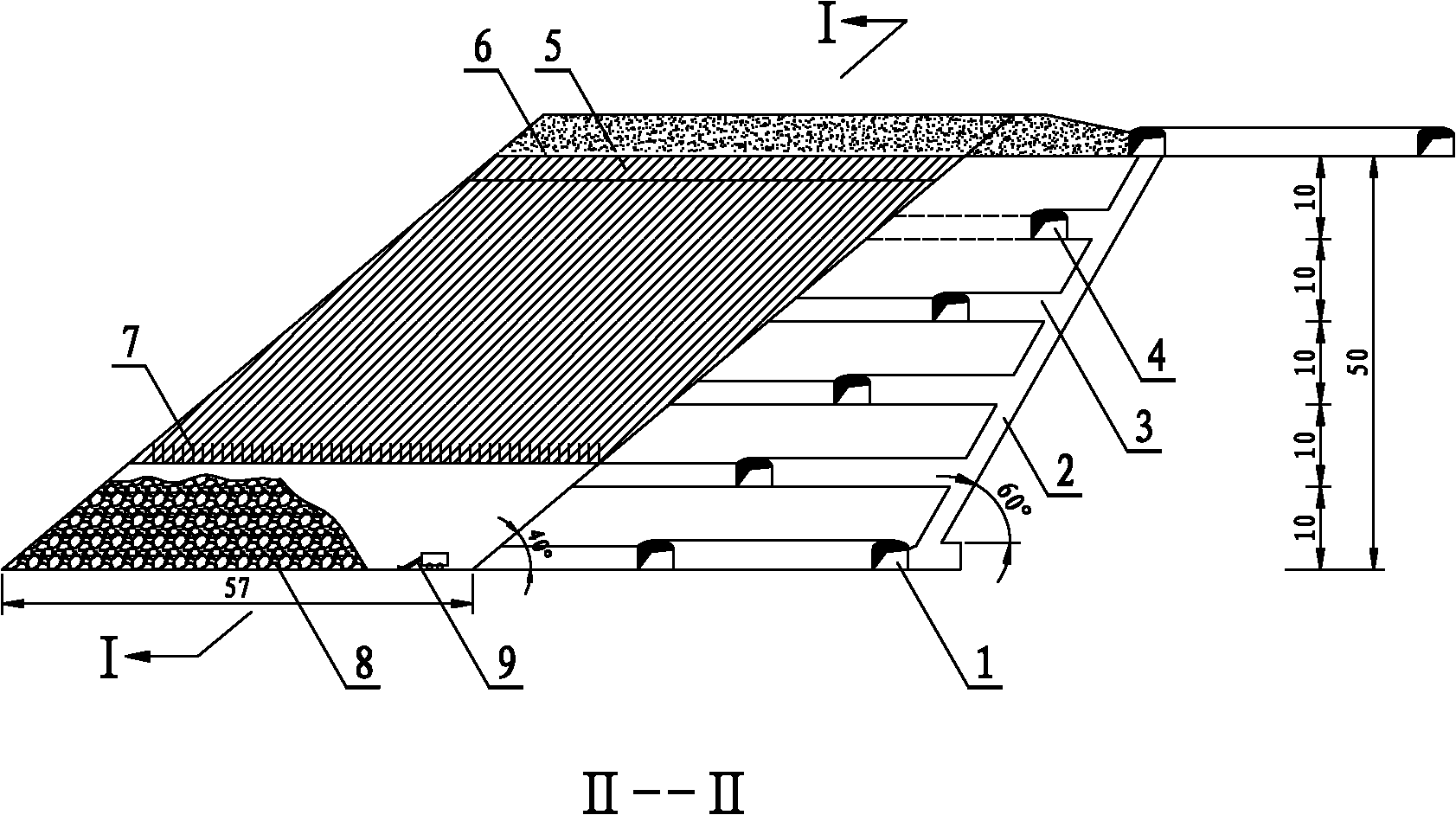

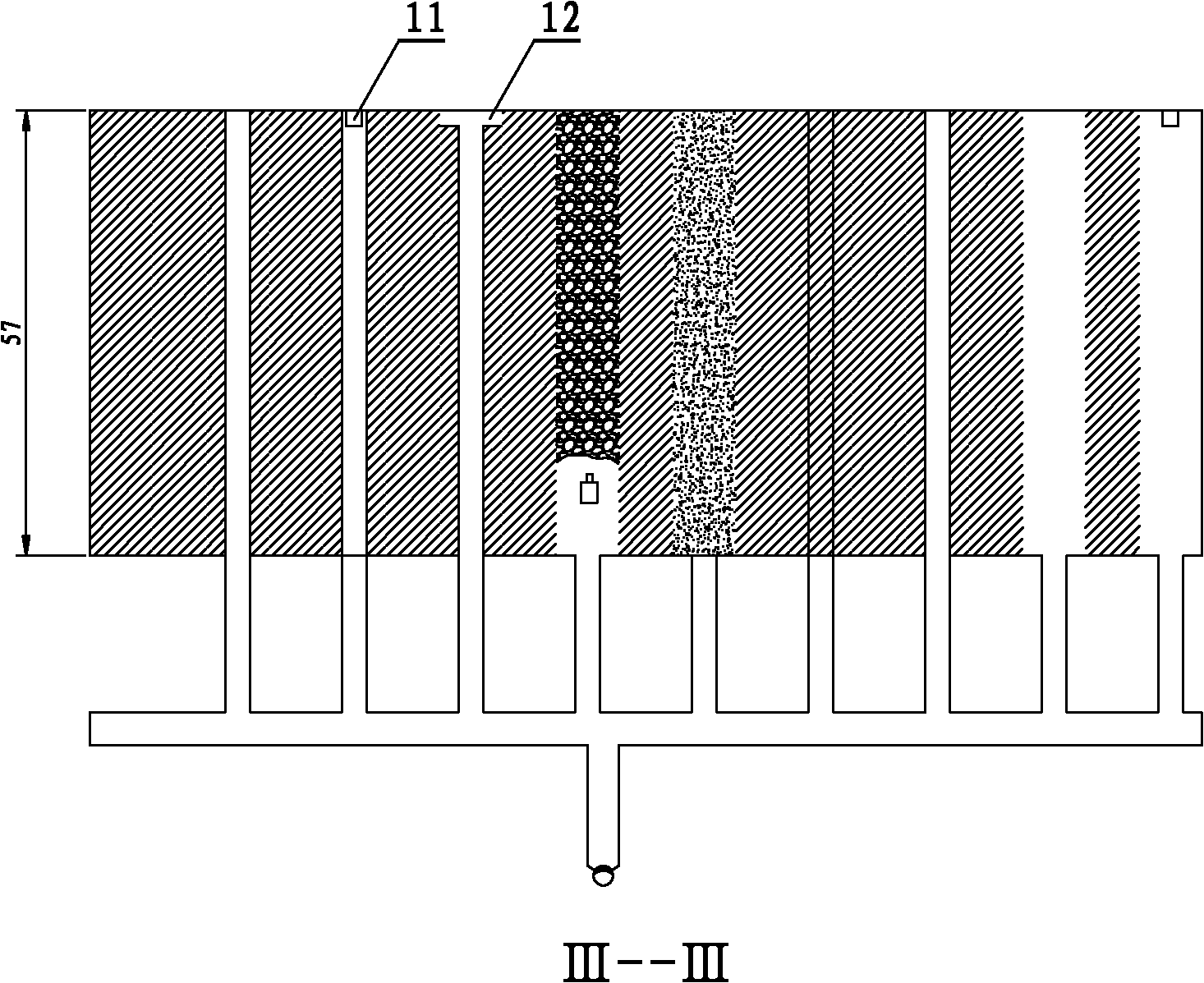

Fully-segmented presplitting squeezing primary-blasting mining method

InactiveCN102155228AHigh mining intensityImprove efficiencyUnderground miningBlastingMineralogyUltimate tensile strength

The invention discloses a fully-segmented presplitting squeezing primary-blasting mining method. The method comprises the following steps of: 1, performing sublevel mining on slowly inclined thick and large crushed ore bodies; 2, arranging a stope free with a bottom structure along a direction vertical to the direction of the ore bodies; 3, using a trackless development mode of a lower plate outside-vein sublevel tunnel and an outside-vein concentrated winze; 4, constructing a full-section pre-control top tunnel serving as a shoring tunnel and a drilling tunnel; 5, performing presplit blasting so as to form the outline of the stope, squeezing and blasting so as to form a mine, and performing presplitting, squeezing and primary-blasting on the fully-segmented ore bodies to form the mine; 6, concentratively removing the ore by trackless equipment under a fully-segmented open stope; and 7, concentratively filling in a large scale after full segmentation. The method has the remarkable characteristics of high mining safety, simple process, low loss and depletion, high mechanical degree and mining strength, high production capability of the stope, high efficiency, low cost, low labor intensity and the like.

Owner:CENT SOUTH UNIV

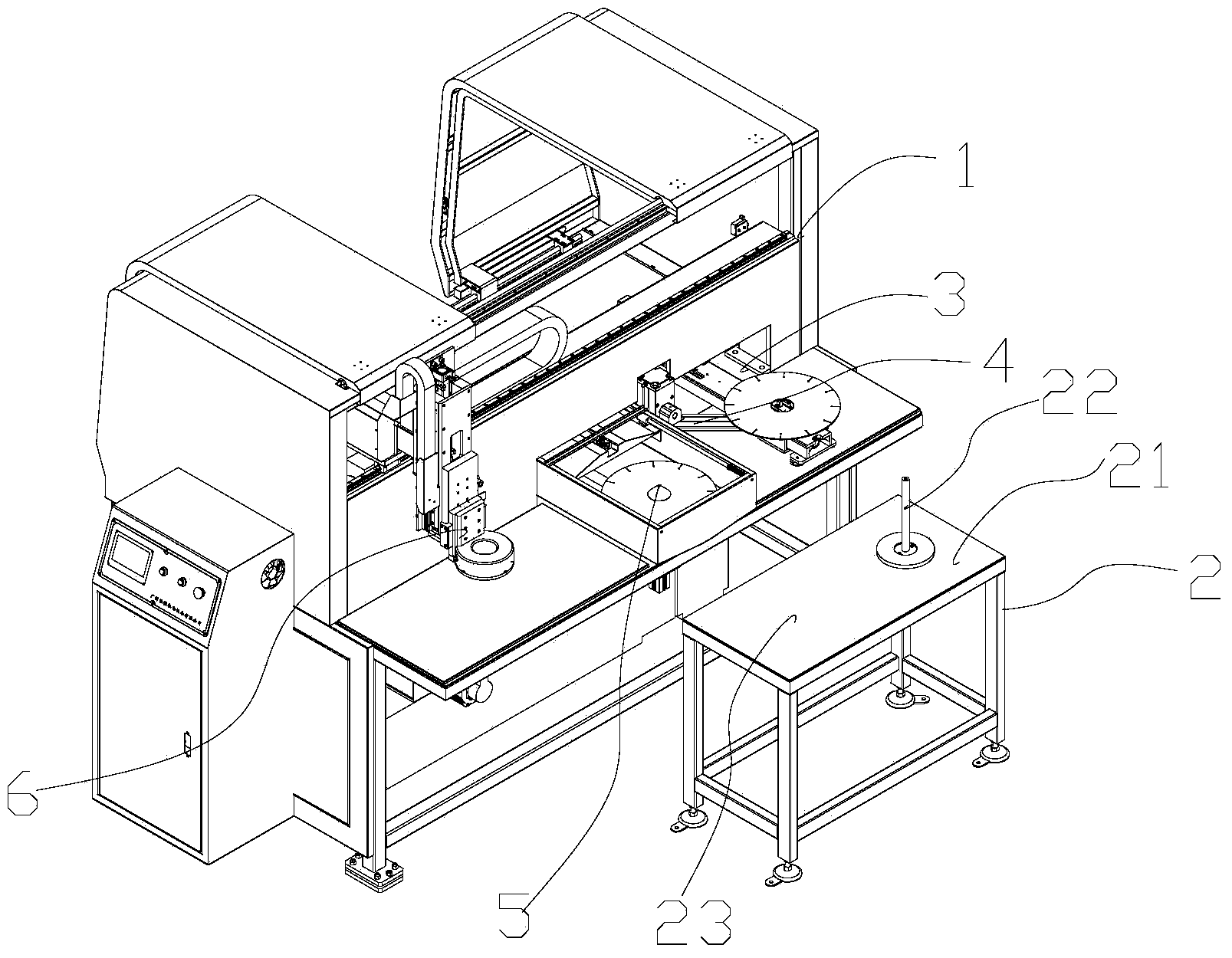

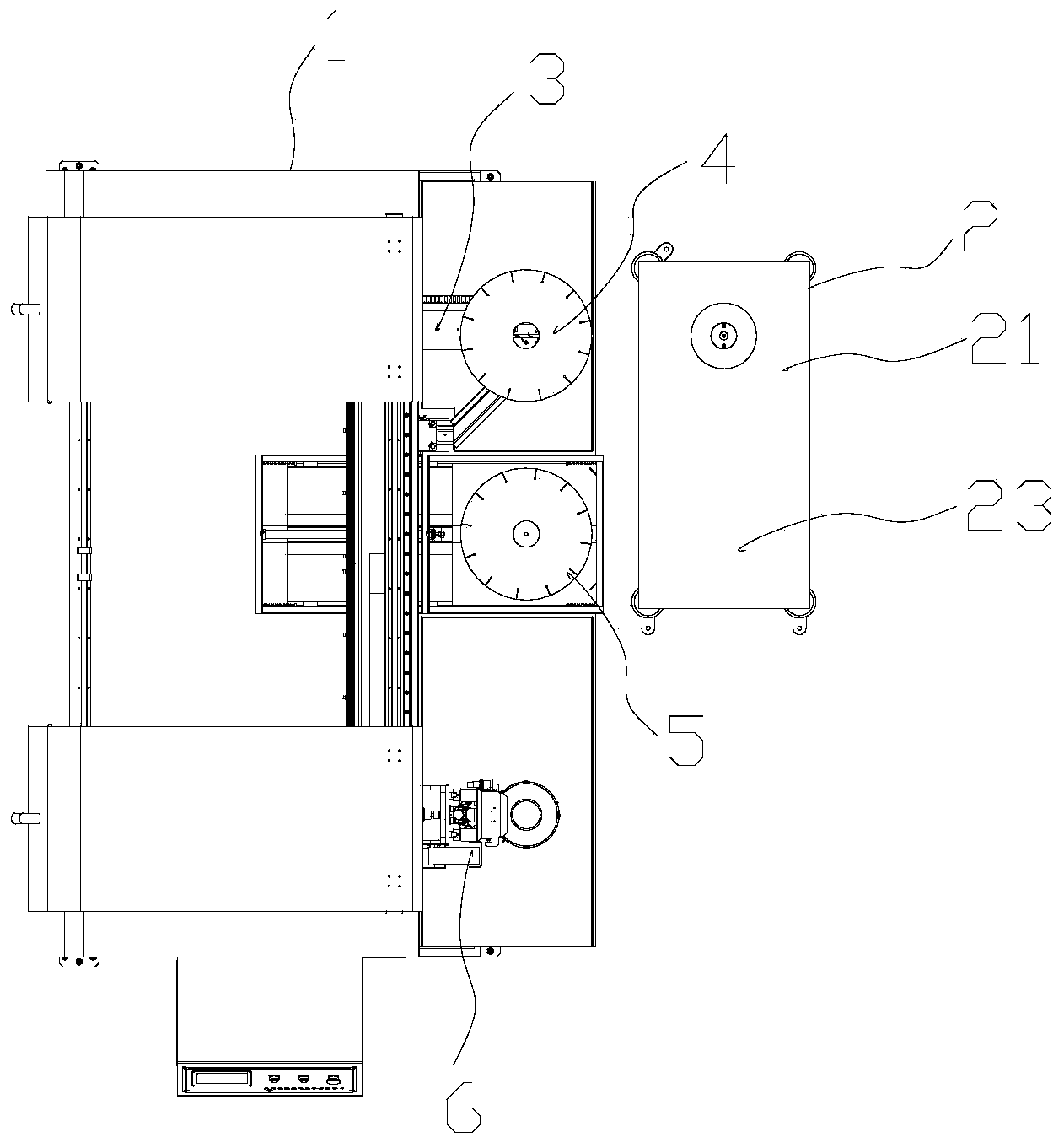

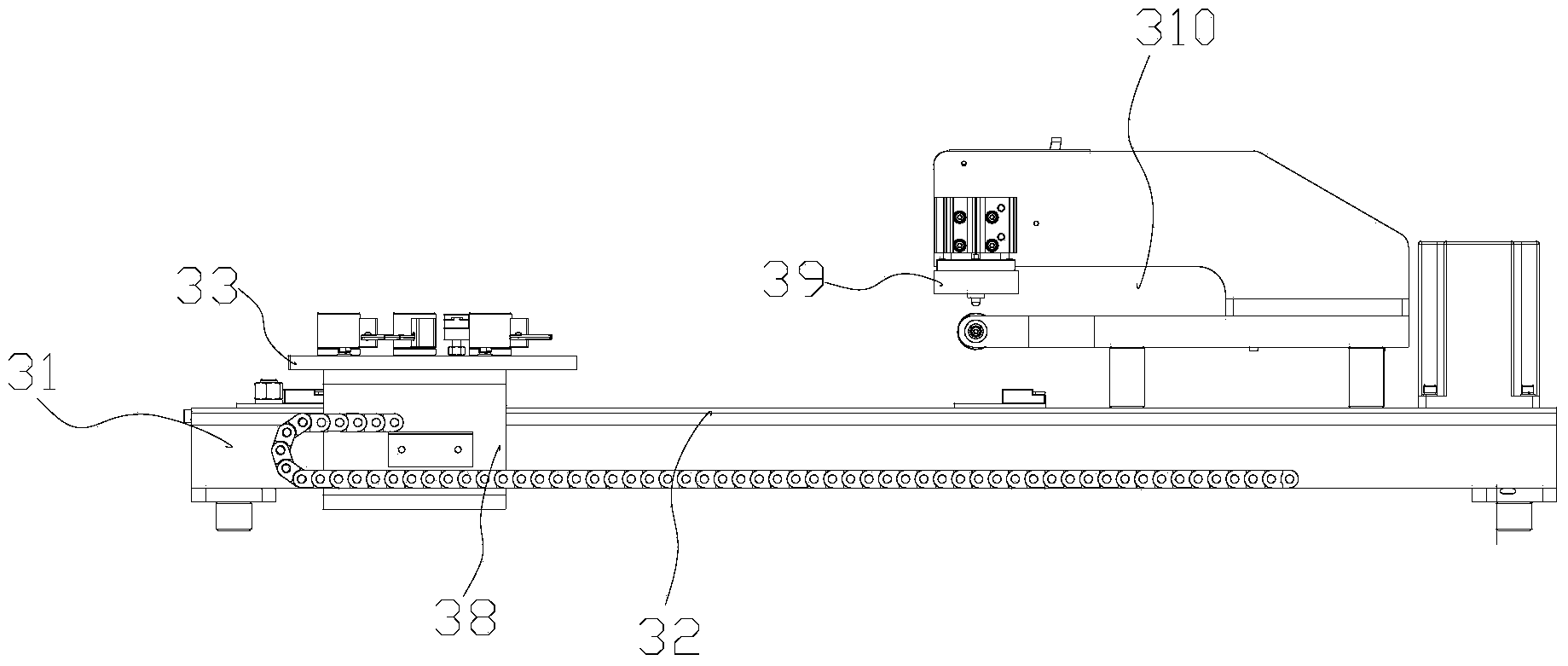

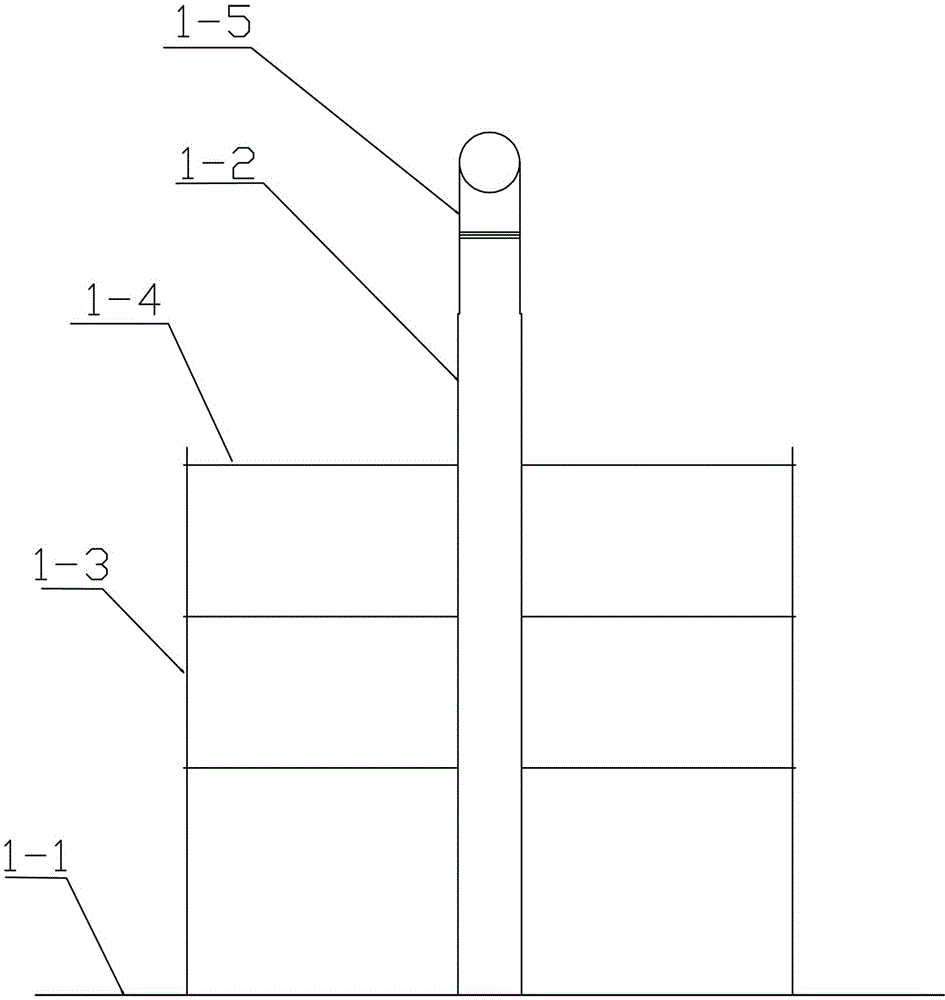

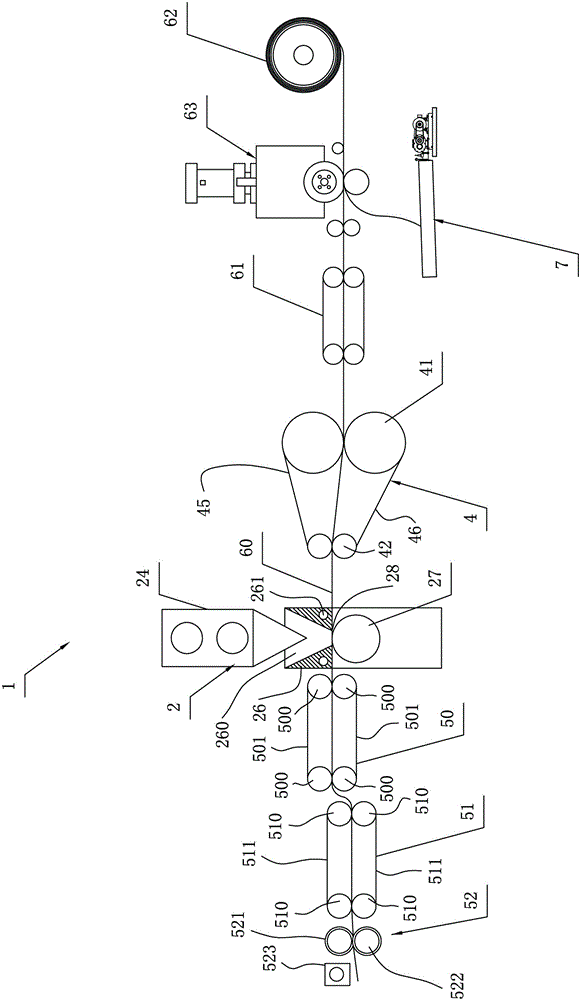

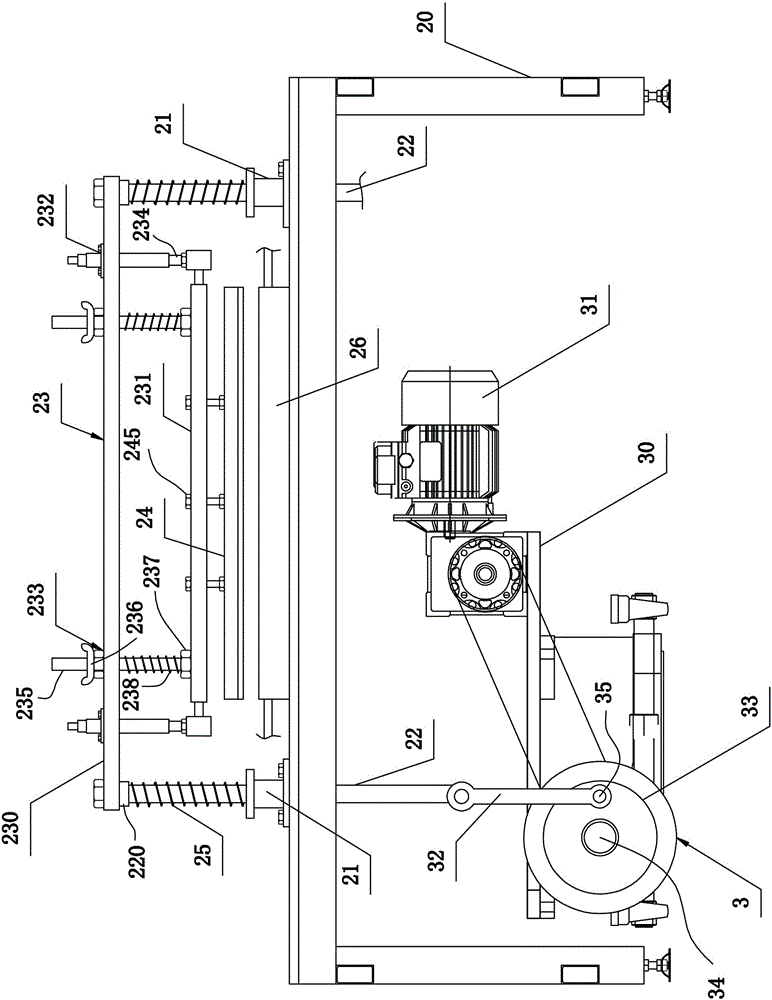

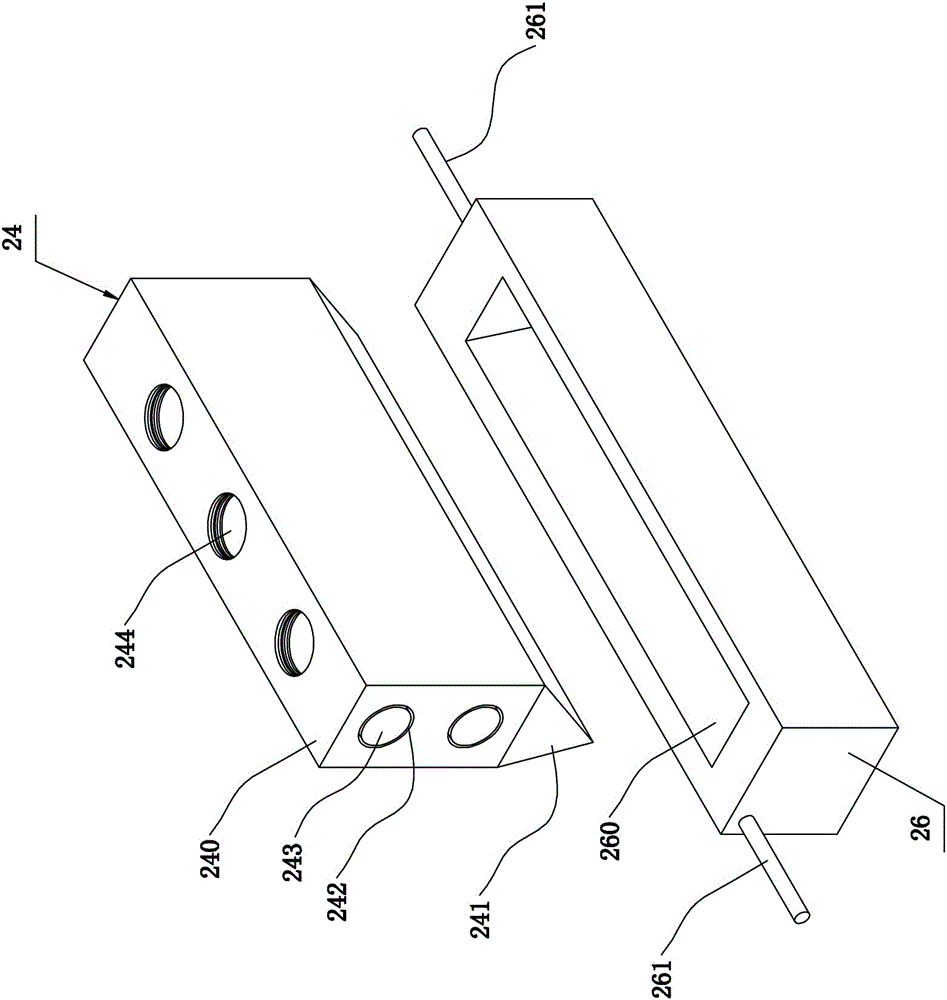

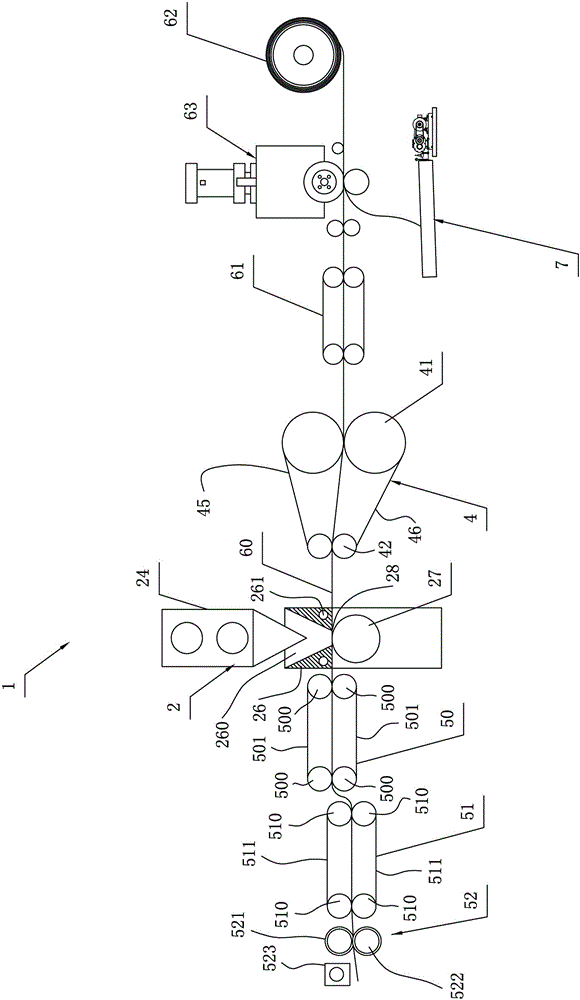

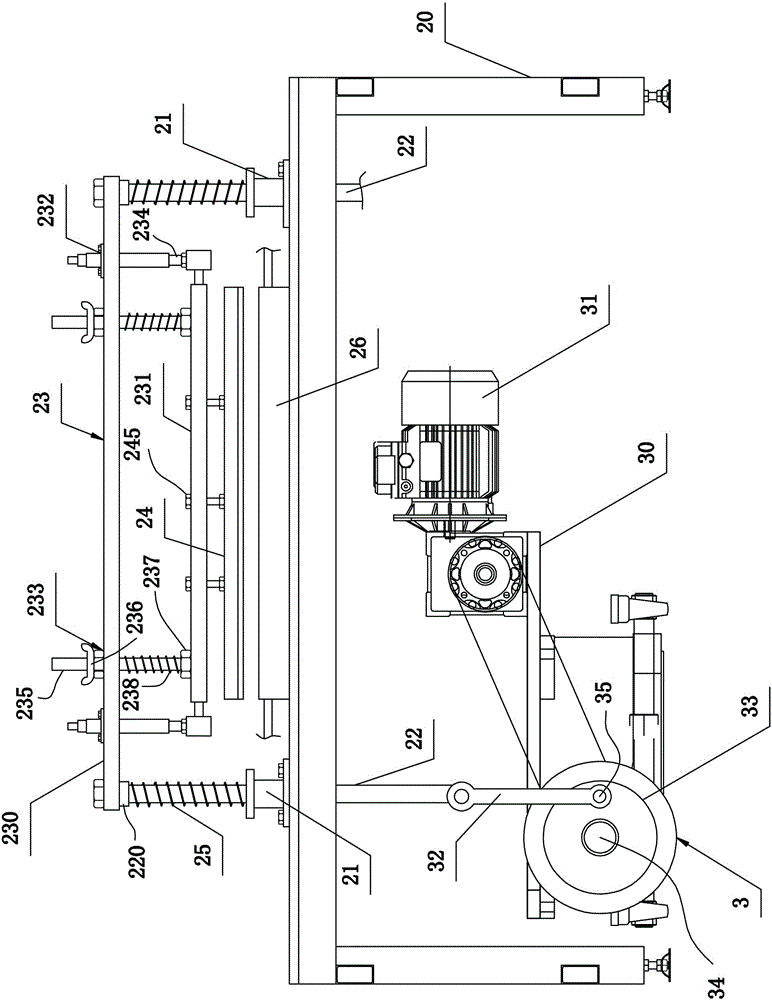

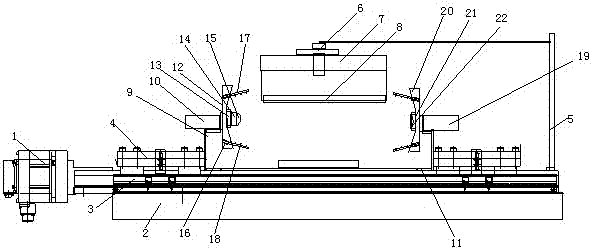

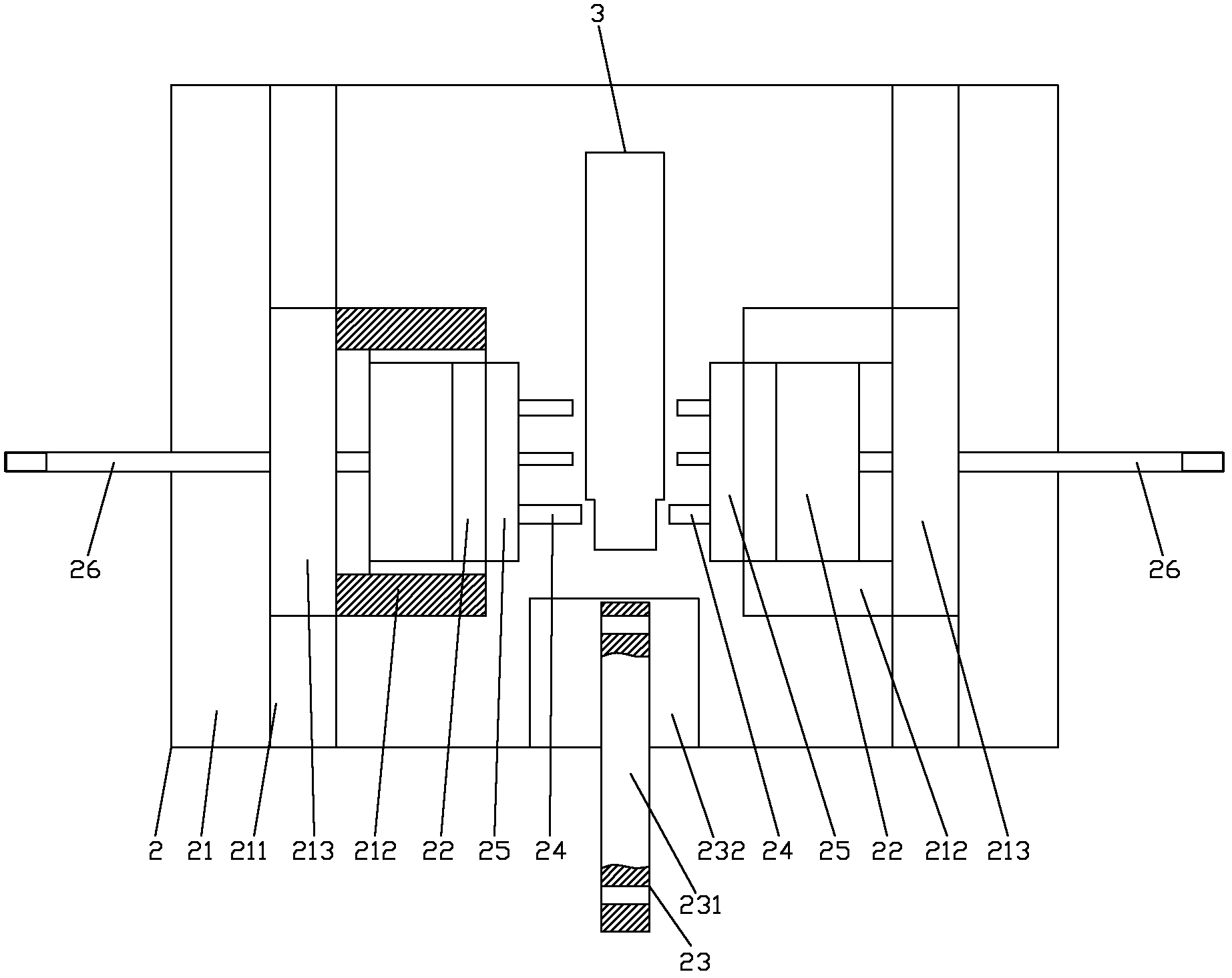

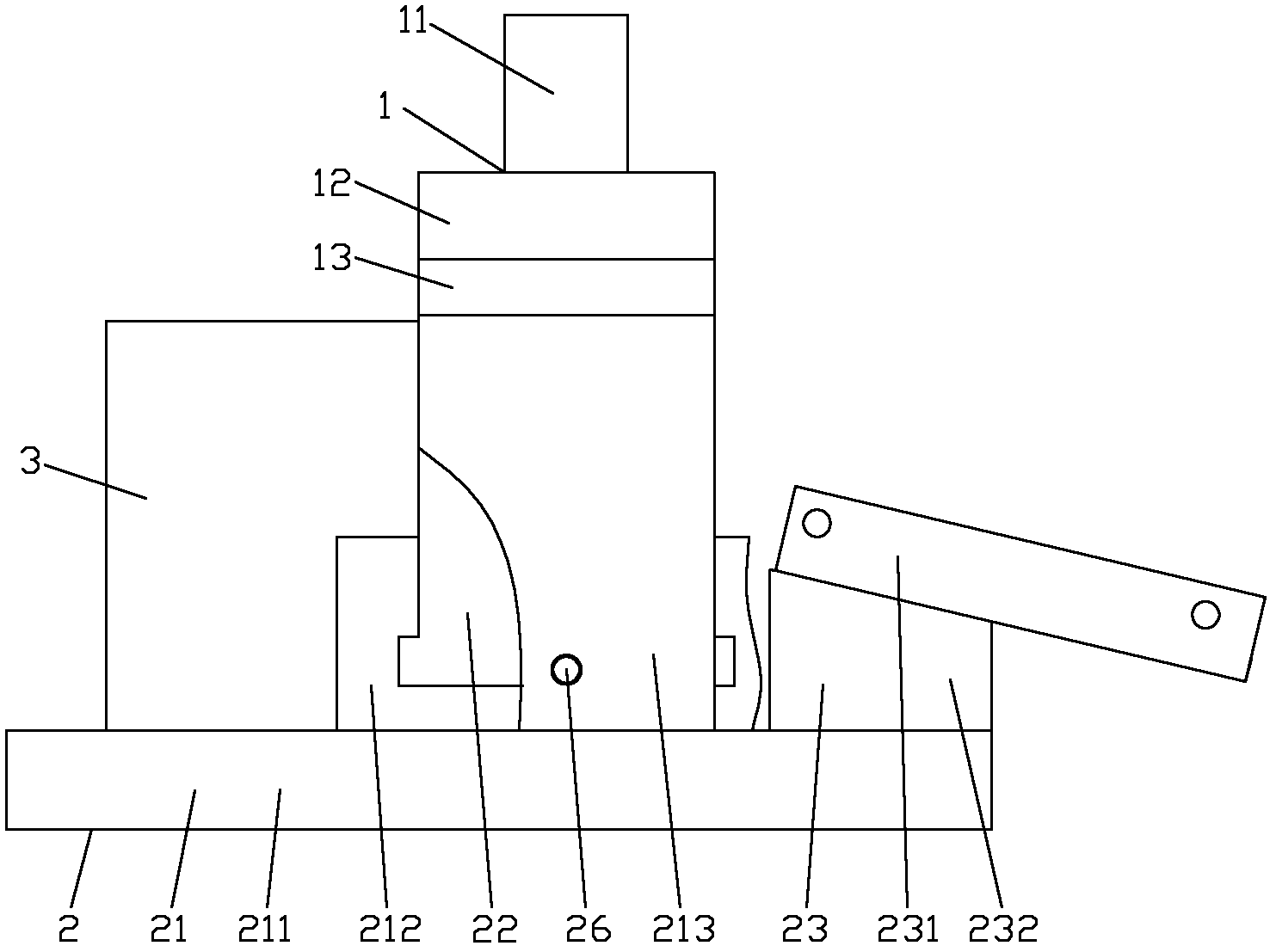

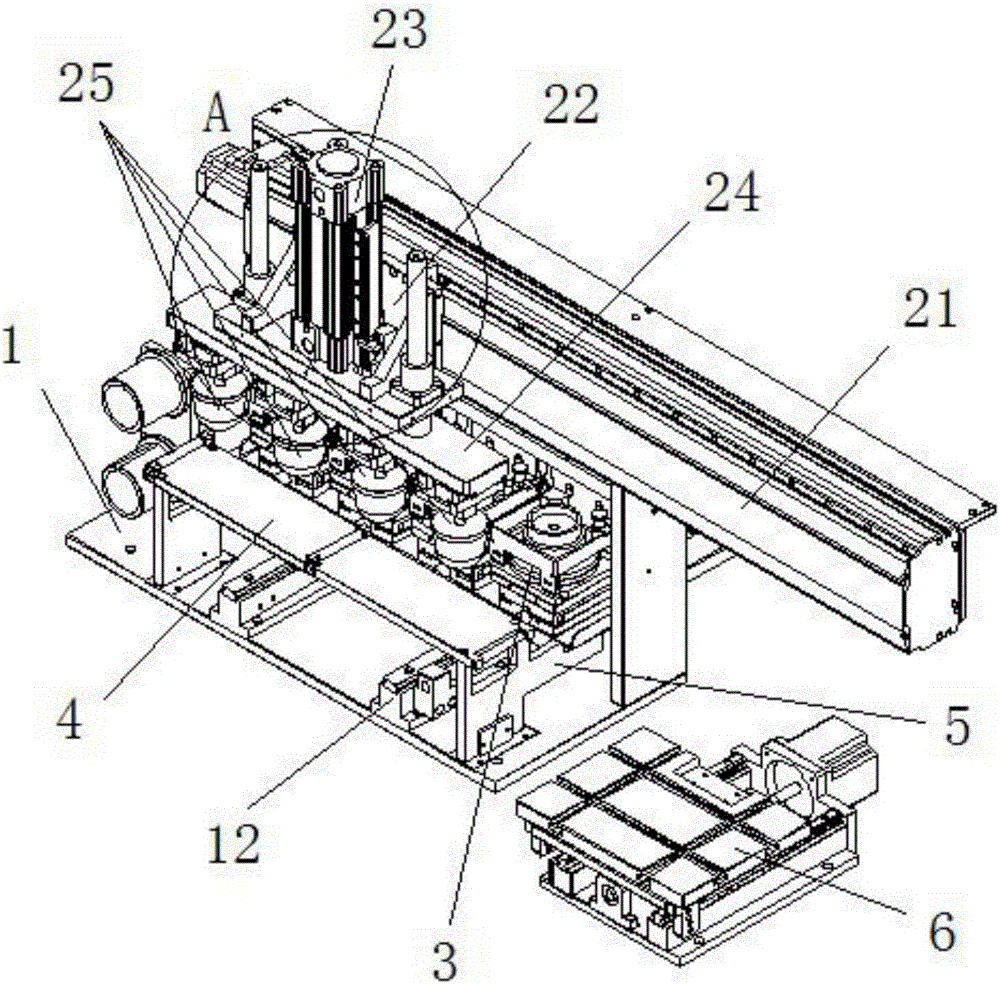

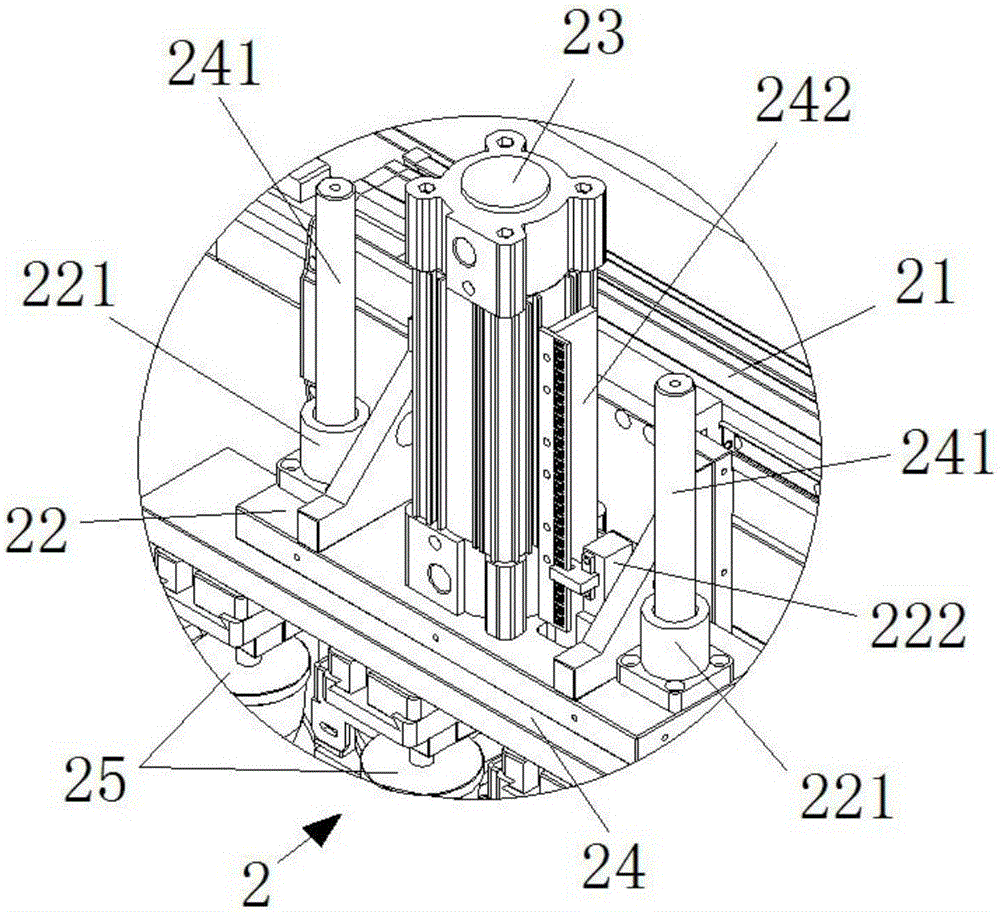

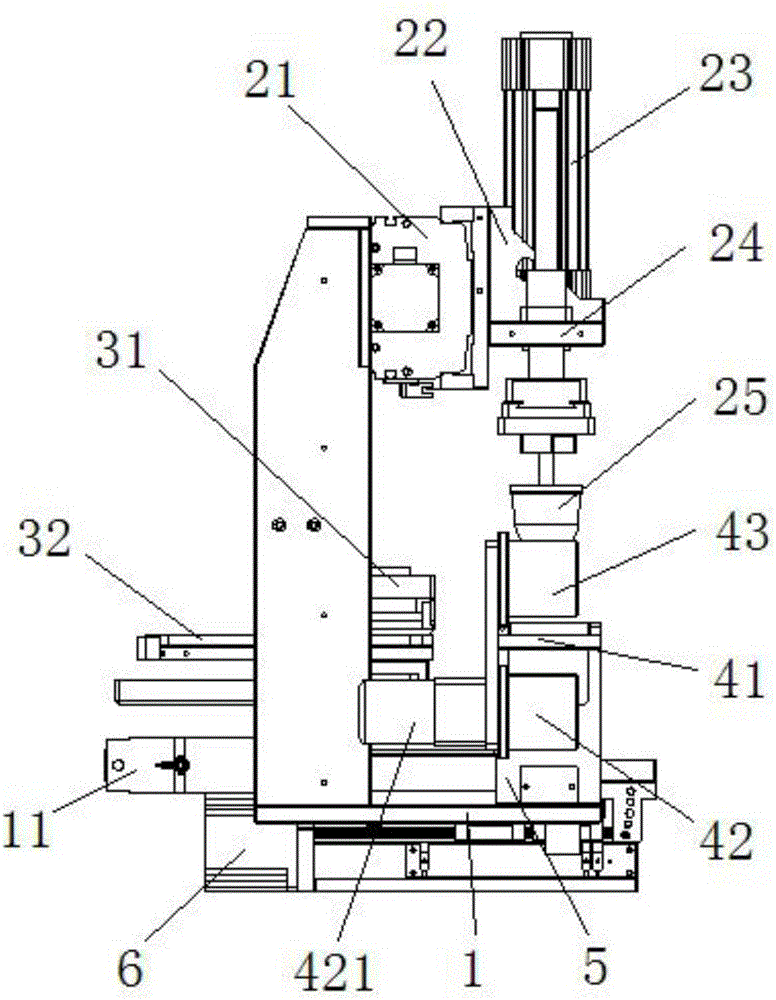

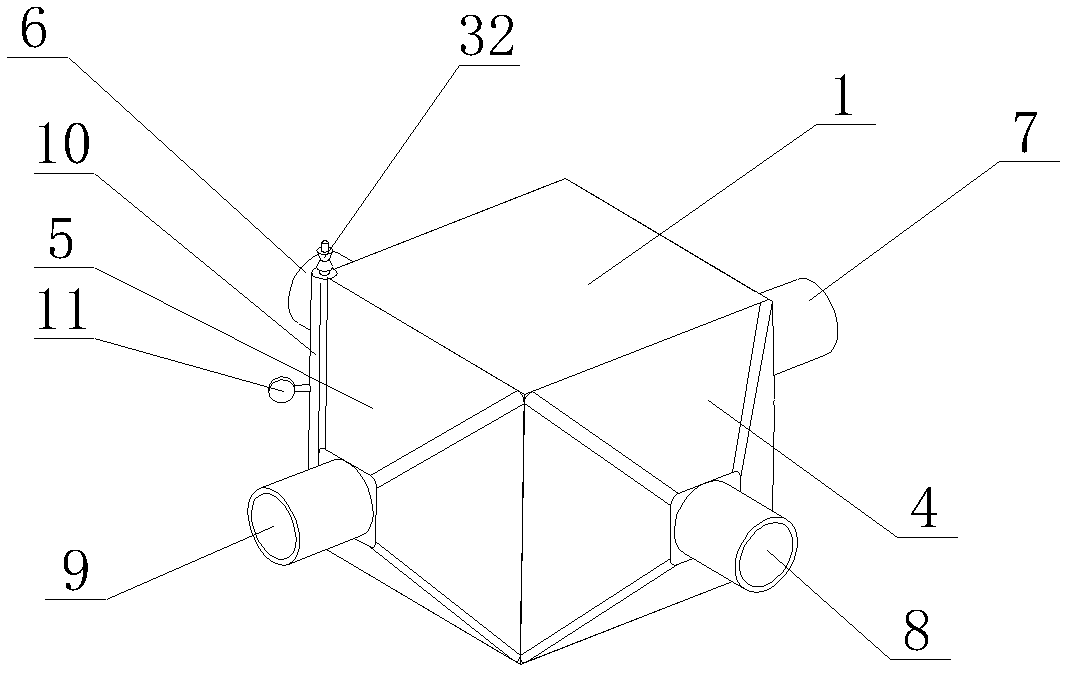

Full-automatic horizontal surface grinding machine mechanical arm

ActiveCN103831680AReduce labor costsImprove pass rateProgramme-controlled manipulatorGripping headsWork periodNumerical control

The invention discloses a full-automatic horizontal surface grinding machine mechanical arm which comprises a machine table and a product containing table. An automatic detection device, a turning device, a cleaning device and a grabbing mechanical arm body are arranged on the machine table. The product containing table and the machine table are arranged side by side. The automatic detection device, the turning device, the cleaning device and the grabbing mechanical arm body are all installed on the machine table, and an automatic grinding machine device is connected with the machine table. By means of the automatic detection device, the turning device, the cleaning device, the grabbing mechanical arm body and the automatic grinding machine device, saw blades are fed, discharged, detected, cleaned and ground in a full-automatic mode, full-automatic operation of the whole process is achieved, and labor cost of an enterprise is greatly reduced; by means of accurate numerical control operation, cost is reduced, the yield is improved, and the production loss rate is reduced; production efficiency is improved, and working time is shortened; by means of full-automatic production, guarantees can be provided for workers on the aspects of mechanical contusion, tiny dust and exhaust gas inhalation and metal dirty water corrosion to human bodies.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

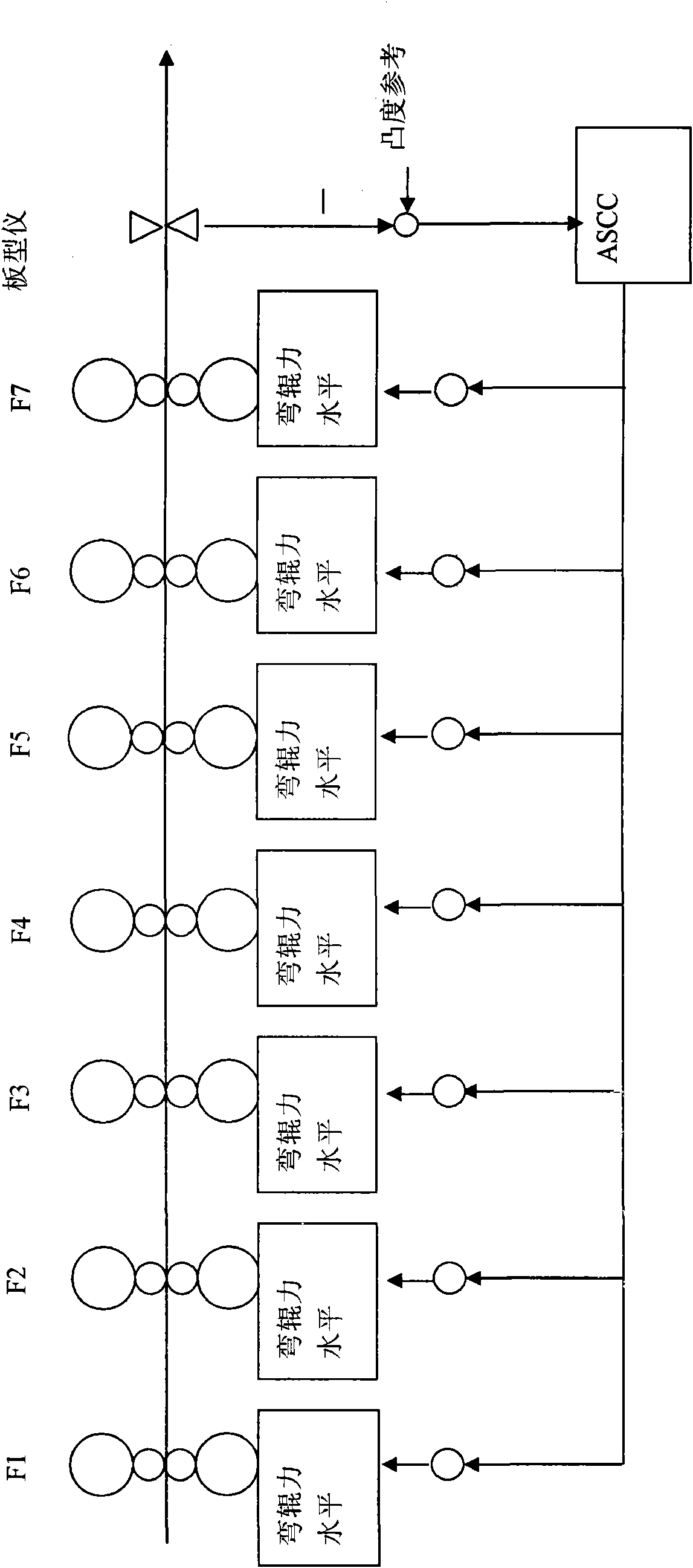

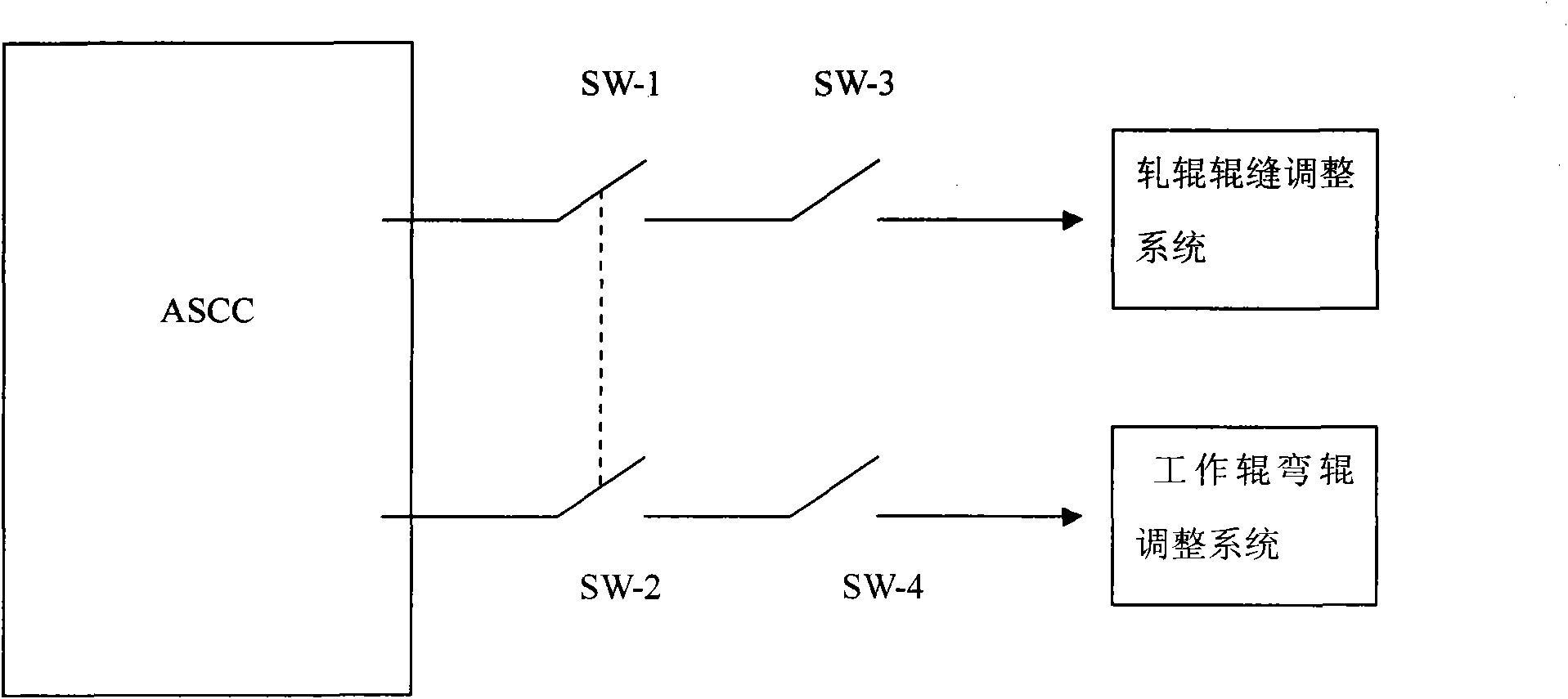

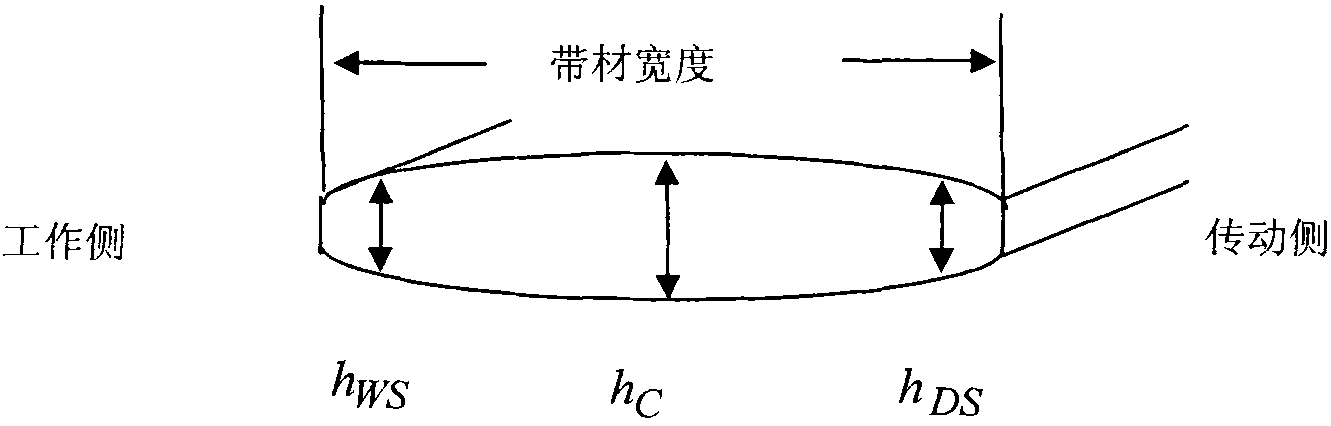

Method for automatically controlling convexity and/or wedge of hot rolled in series type rolling machine and system thereof

ActiveCN101890435AAvoid snaking motionEliminate single disadvantagesProfile control deviceAutomatic controlEconomic benefits

The invention relates to a method for automatically controlling the convexity and / or wedge of a hot rolled in series type rolling machine and a system (ASCC) thereof. The method comprises the following steps of: building feedback control for the bending of a working roll and the flattening of a roll gap from a first finishing mill stander to a final finishing mill stander in the hot rolled in series type rolling machine to automatically control the convexity (wedge) of strip steel, i.e. comparing the strip steel wedge which is detected by an ASCC model with the object wedge during rolling to obtain the difference; and correcting the difference through the comprehensive computation and the control method of the system to build a step type adjusting method. Therefore, the invention maximizes the response of the feedback control to correct the wedge and the convexity of the strip steel, guarantees the good flatness of products, prevents the strip steel to have snake-like motion in each stander, overcomes the defect that the existing convexity controlling method is single, and comprehensively balances the relationship between the convexity and the wedge. The invention can guarantee the convexity precision of the wedge along the long axis direction of the strip steel, improves the flatness, guarantees the product quality and the production safety, and can effectively improve the economic benefit of steel rolling factories.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

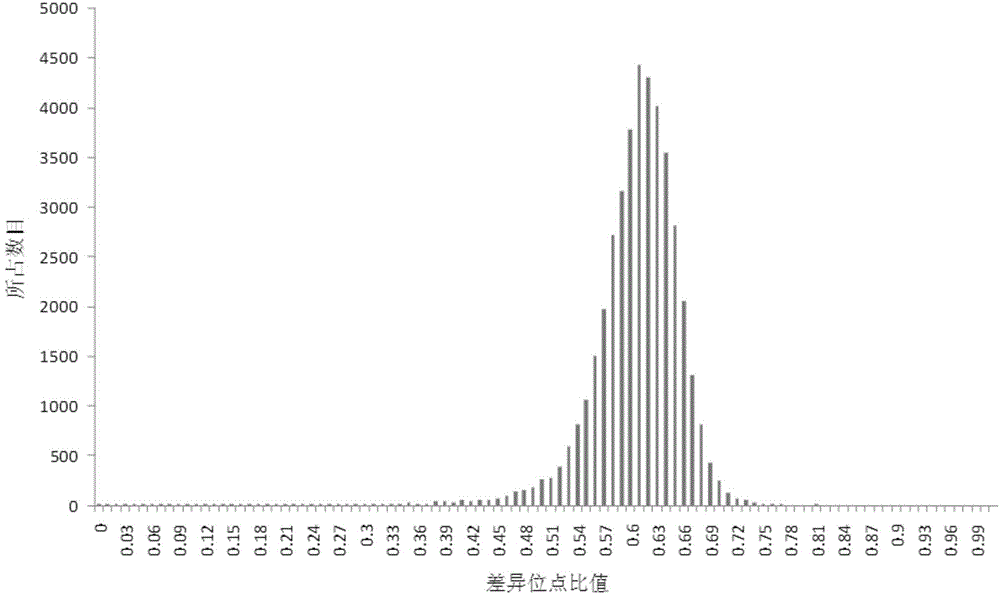

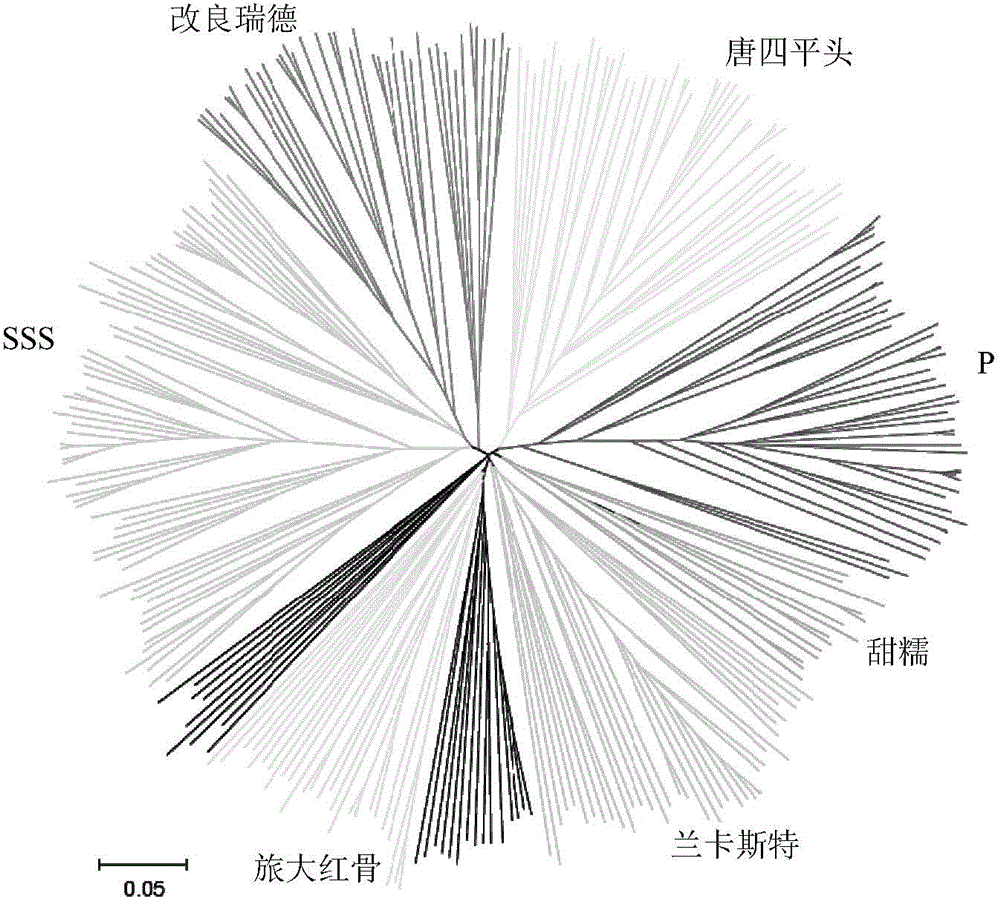

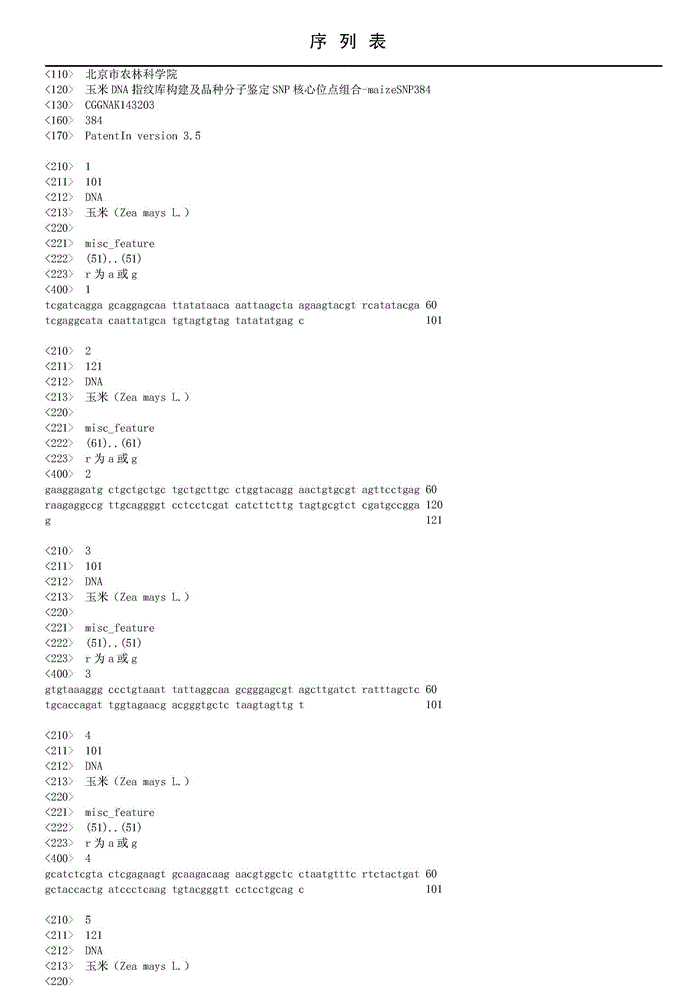

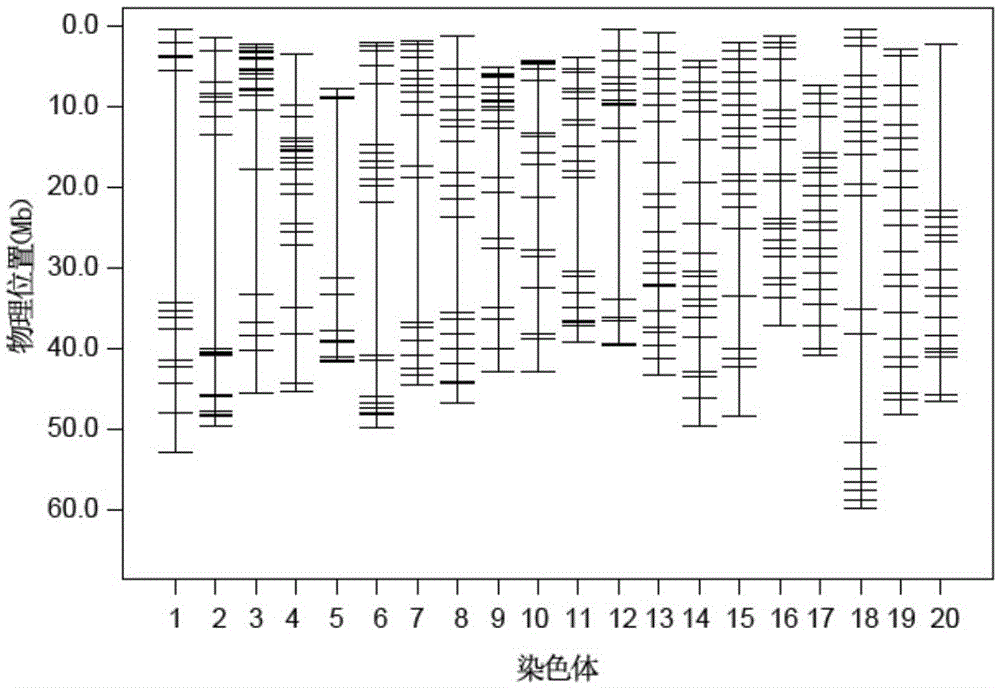

Core SNP sites combination maizeSNP384 for building of maize DNA fingerprint database and molecular identification of varieties

ActiveCN104532359AImprove stabilityGood repeatabilityNucleotide librariesMicrobiological testing/measurementMolecular identificationAgricultural science

The invention discloses a core SNP sites combination maizeSNP384 for building of a maize DNA fingerprint database and molecular identification of varieties, and an application of the core SNP sites combination. The invention provides applications of 384 SNP sites in any one of the following conditions: (1) building of the maize DNA fingerprint database; (2) detecting of the authenticity of maize varieties; (3) genetic analysis of corn germplasm resources; and (4) molecular breeding of maize, wherein the physical positions of the 384 SNP sites are determined by comparison on the basis of a whole genome sequence of the maize variety B73; the version number of the whole genome sequence of the maize variety B73 is B73 RefGen V1; and the 384 SNP sites are MG001-MG384. An experiment proves that the 384 SNP sites can be applied to building of the maize variety DNA fingerprint database, identification of the variety authenticity, dividing of germplasm resource groups, and other related researches.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

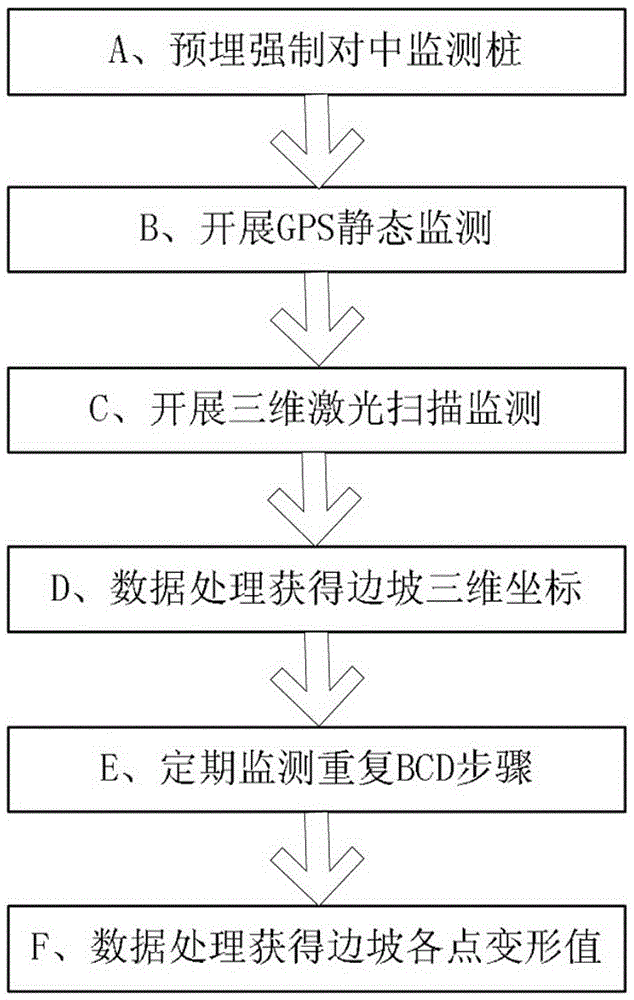

Three dimensional laser scanning-GPS-combined side slope monitoring method

ActiveCN105526908AImprove personnel safetyReduce construction workloadActive open surveying meansHeight/levelling measurementGeomorphologyLaser scanning

The invention relates to a three dimensional laser scanning-GPS-combined side slope monitoring method. The monitoring method is characterized in that a three dimensional laser scanner system and a GPS monitoring positioning system are combined and are used for accurate monitoring of side slope geologic hazard. The method can accurately detect and forecast mine side slope geologic hazard, improve side slope monitoring intelligence and prediction effects, realize real-time monitoring of side slope deformation, accurate prediction of side slope deformation trend and precaution of geologic hazards such as side slope displacement and falling and guarantee mine production safety.

Owner:ANSTEEL GRP MINING CO LTD

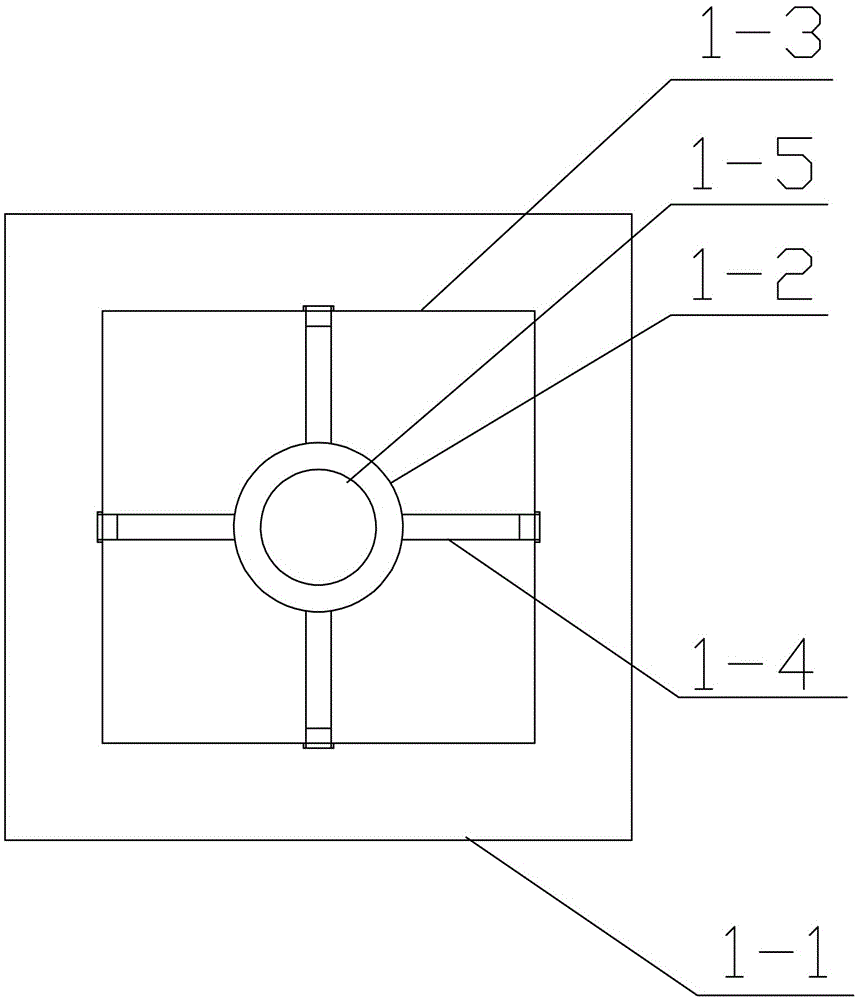

Image processing and recognizing method for real-time monitoring power high voltage circuit breaker switch state

InactiveCN1845605AAchieving identifiabilityRealize fault alarmCharacter and pattern recognitionClosed circuit television systemsDigital videoPattern recognition

The disclosed image processing and recognition method for real-time monitor on power high-voltage circuit breaker comprises: with camera, decoder and video server, sending acquired signal to monitor center for remote video monitor; extracting target picture to recognize the ON / OFF state by sorting match with color and character structure features for fault analysis with accuracy ratio more than 98%. This invention can improve information level for power system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

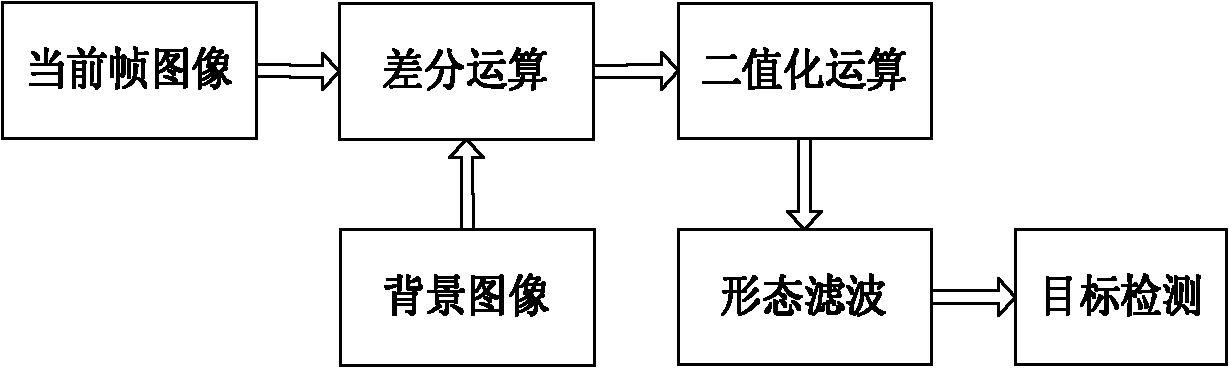

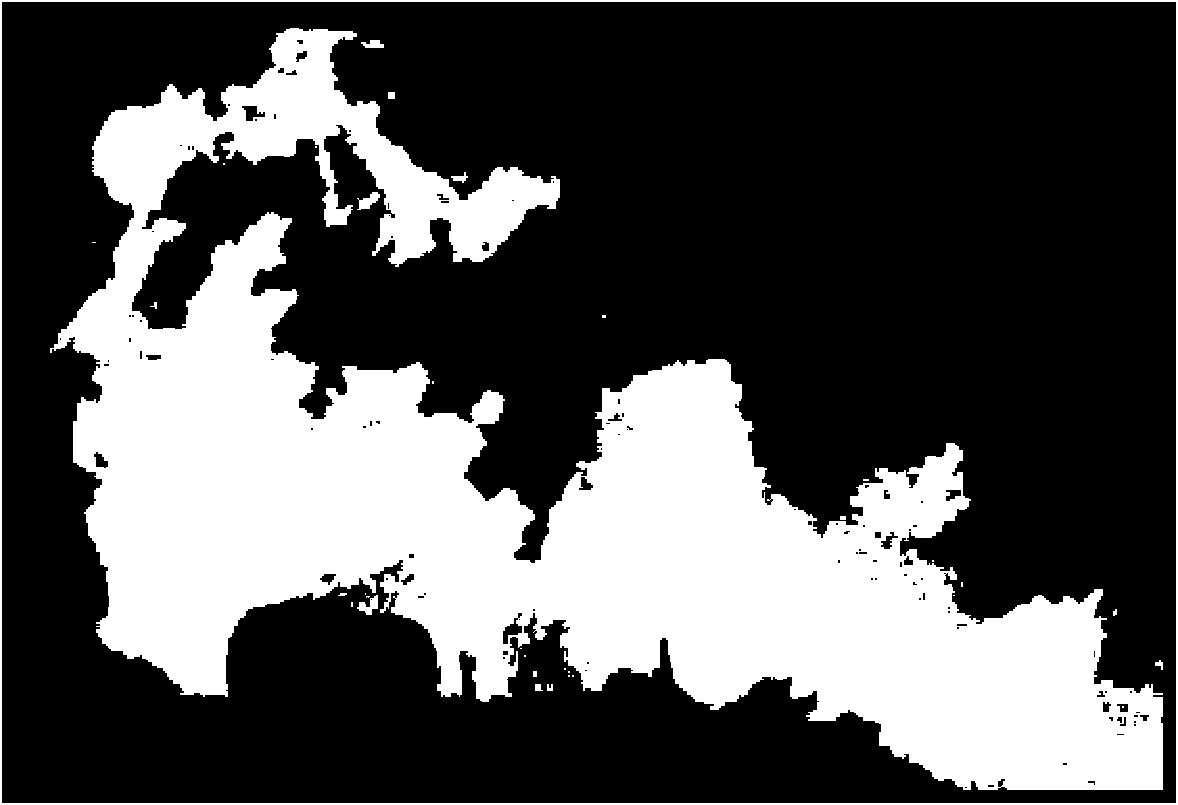

Method for recognizing fire disaster of power transmission line based on video variance analysis

InactiveCN102208018AEnsure production safetyImage analysisBiological neural network modelsNerve networkElectric power

The invention discloses a method for recognizing a fire disaster of a power transmission line based on video variance analysis. According to the method, a camera collects video signals of the power transmission line, and transmits the collected signals back to a monitoring center in a mode of video streaming through a video server; the monitoring center intercepts digital images of the power transmission line required to be monitored from the video streaming to obtain monitored target images; a background difference distribution method is used to detect whether the target images are abnormal after pretreatment; the flame feature detection is carried out on a suspected region; and a fire disaster can be recognized accurately by an artificial nerve network. The method for recognizing a fire disaster provided by the invention provides a novel, intuitive and accurate means to ensure the production safety of electric power enterprises, and has very important realistic significance; and the equipment is simple and economic.

Owner:XI'AN POLYTECHNIC UNIVERSITY

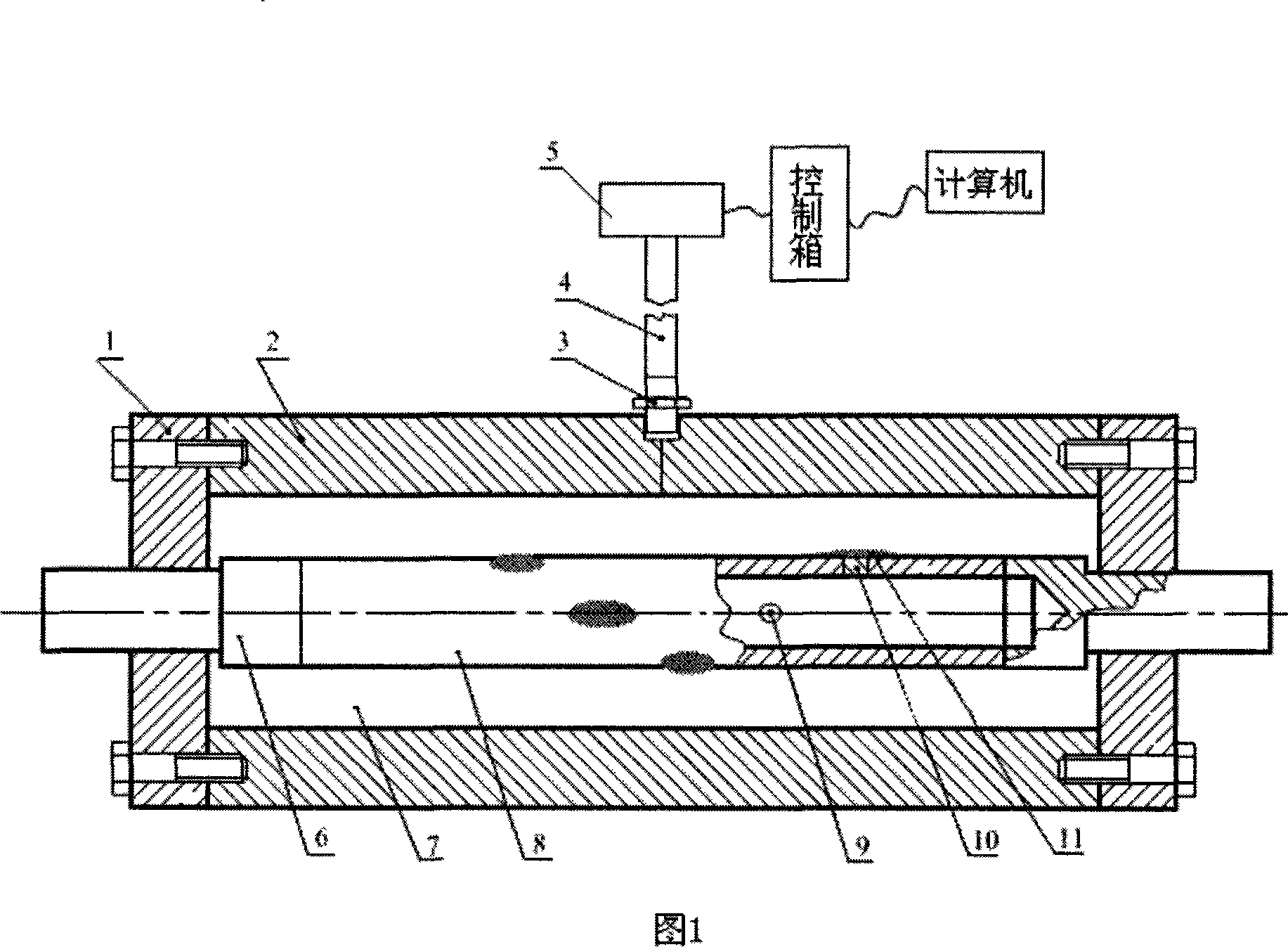

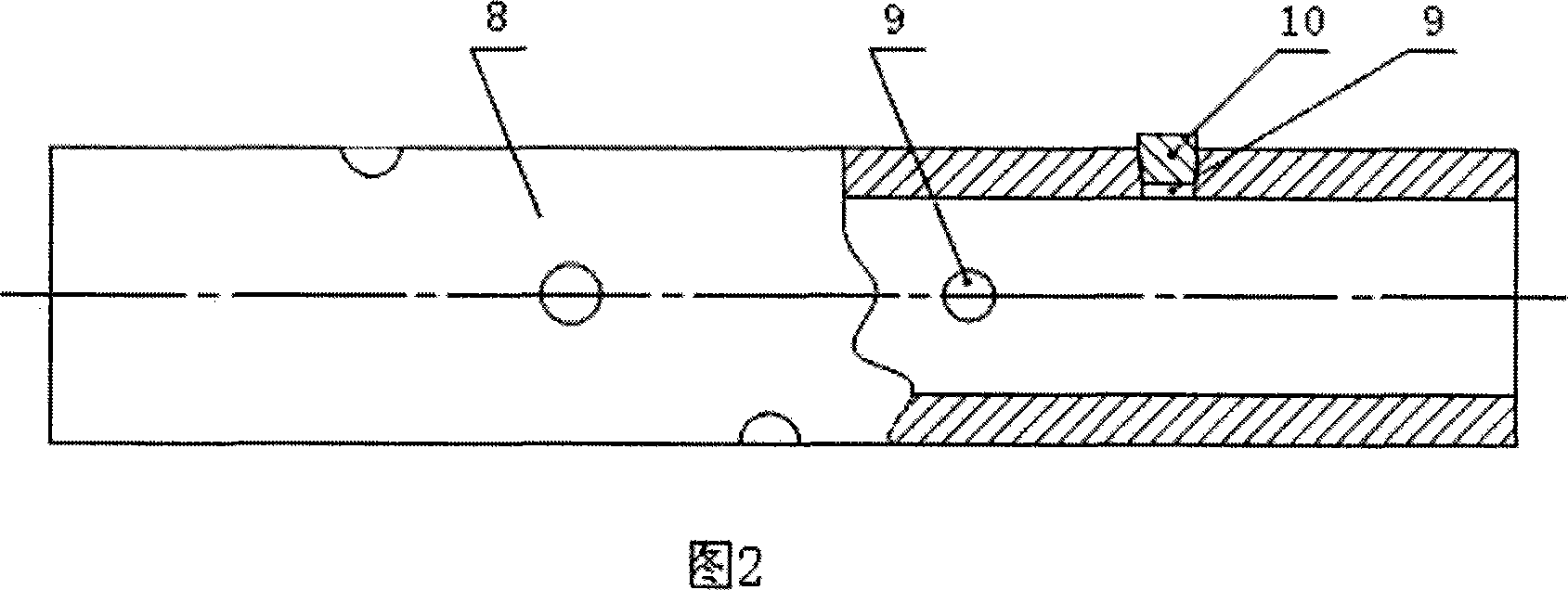

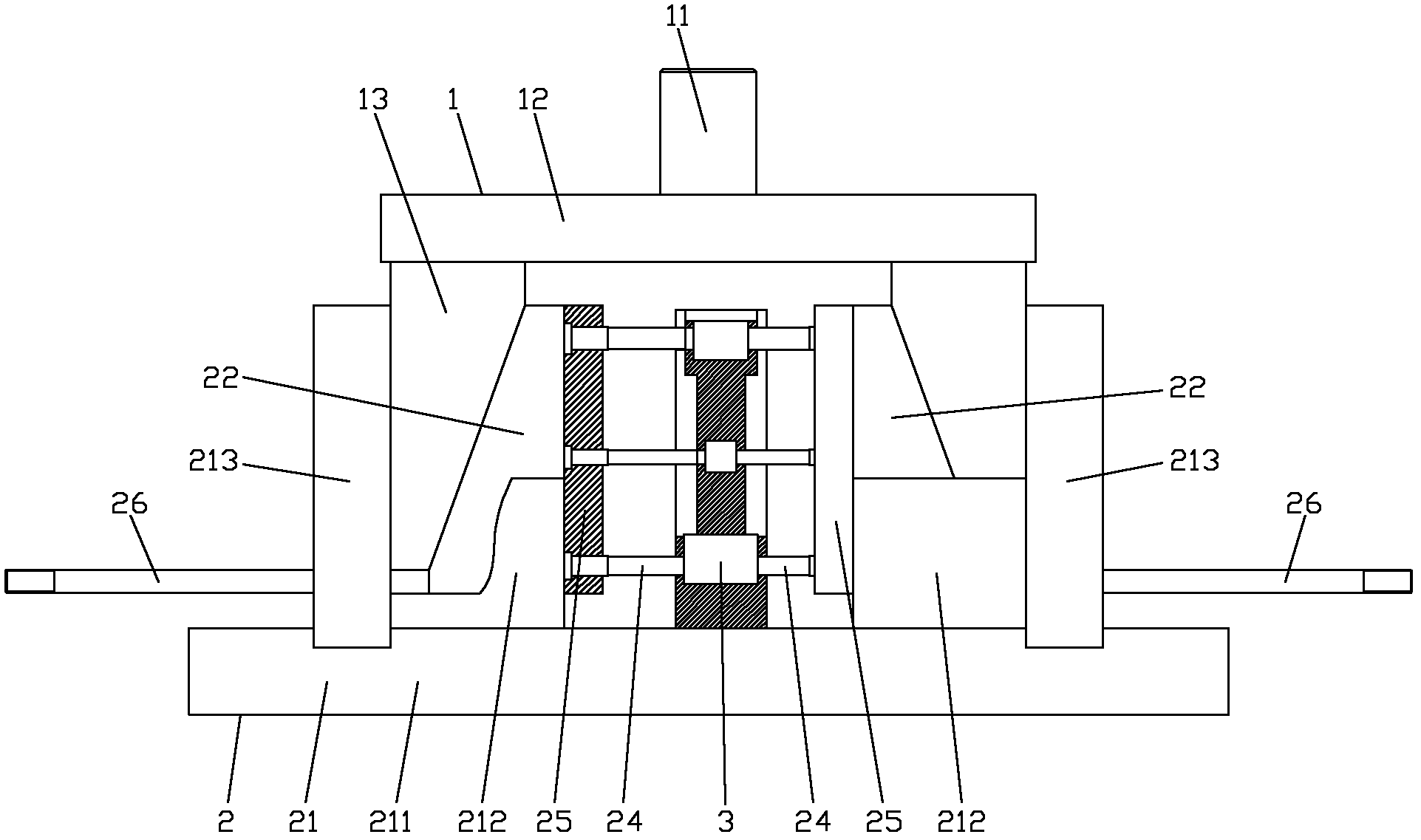

Reservoir casing perforation anti-crushing simulation test method and simulation test machine

ActiveCN101122552AOptimize job parametersEnsure safetyMaterial strength using tensile/compressive forcesStructural/machines measurementTest performanceHigh pressure

The perforation anti-collapse simulation test method and the simulation test machine of the oil layer casing are applied to the ground test of the anti-collapse performance of the oil layer casing after perforation in the oil well. The characteristics of the simulation testing machine are: the pressure cylinder is cylindrical, a hydraulic sensor and a high-pressure conduit are fixed on the pressure cylinder wall, and sealing flanges are respectively fixed at both ends of the pressure cylinder. A plug is fixed in the center hole of the plugging flange. The process of the test method: preparation of the oil layer casing for the test; metal plugging of the simulated hole; sealing of both ends of the oil layer casing for the test; installation; pressure test to complete the whole process of the test. The effect is: adopting the invention can complete the anti-collapse test of the casing casing in the oil layer after simulating perforation on the ground. It can obtain the anti-collapse ability of oil layer casing after perforation, optimize the operation parameters of oil and gas fields, and ensure the safety of pipe string structure and production safety of oil well. Suitable for indoor installation, computer control, easy to obtain the anti-collapse ability of oil layer casing after perforation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

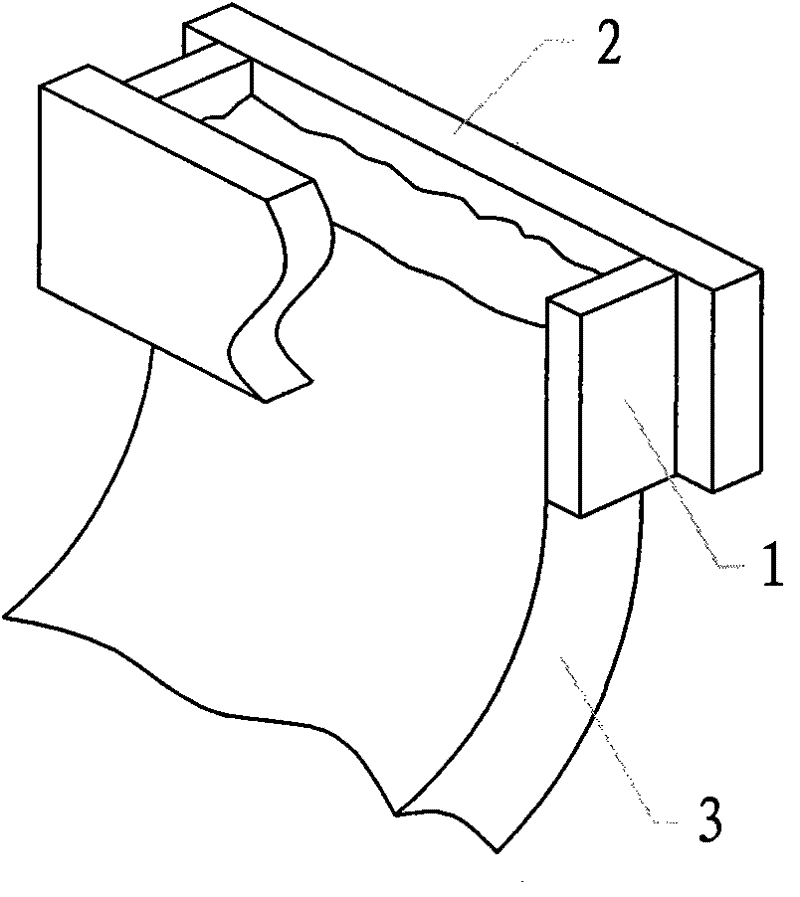

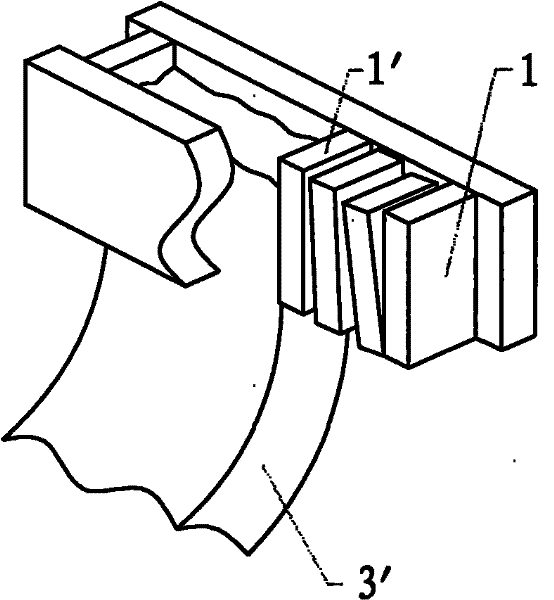

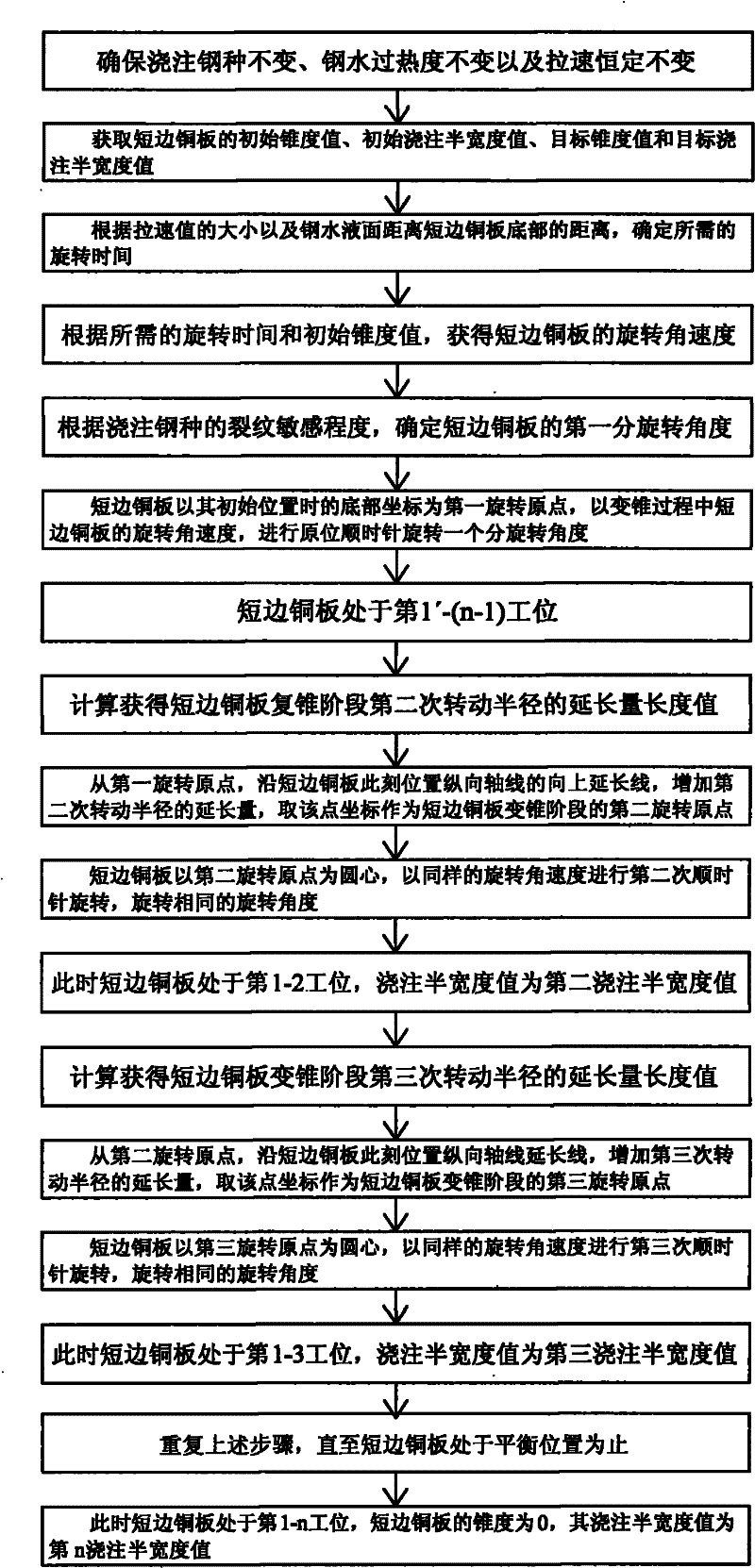

A high-speed short-side width adjustment method for continuous casting of slab continuous casting machine mold

The invention relates to a non-stopped pouring high-speed short-edge width regulating method of a slab continuous casting machine crystallizer, belonging to the field of metal casting. The method comprises the following steps of: driving a short edge copper plate at one side of a crystallizer to move, wherein a poured steel type, molten steel overheating degree and casting speed are guaranteed tobe constant; acquiring an initial conical degree value, an initial pouring half width value, a target conical degree value and a target pouring half width value of the short edge copper plate of the crystallizer; and realizing thermal width adjustment on a casting in a moving state by adopting the swinging track of the discrete variable rotating radius short edge copper plate and utilizing a dynamic change rule of amount of contraction of a cross section during the period that the cross section is changed at a certain casting speed. By applying the method provided by the invention, high-speedshort edge width adjustment can be carried out under the condition that the slab continuous casting machine does not stop pouring, specification switching is carried out under the condition that the capacity of the casting machine is not influenced, the production capabilities changeable in specification and flexibly switchable of the casting machine can be fully played; and the probability that defects such as breakout owning to switching, overhigh cutting amount of transition billet and the like are caused is reduced while the slab specification switching efficiency is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of carboxylated graphene

The invention belongs to the technical field of graphene preparation, and relates to an improvement of a preparation method of carboxylated graphene. The improvement of the preparation method is characterized by comprising the following preparation steps: preparing a graphene oxide suspension liquid; preparing a graphene turbid liquid; preparing a precursor turbid liquid of carboxylated graphene; preparing an acidic carboxylated graphene turbid liquid; preparing water-containing carboxylated graphene; and preparing carboxylated graphene powder. By adopting the improved preparation method of carboxylated graphene disclosed by the invention, the pure and fluffy carboxylated graphene powder can be prepared by virtue of the simplest steps. Prepared carboxylated graphene disclosed by the invention has excellent characteristics of graphene, can also be used for solving the agglomeration problem of graphene in solvents, and has good dispersibility.

Owner:北京石墨烯技术研究院有限公司

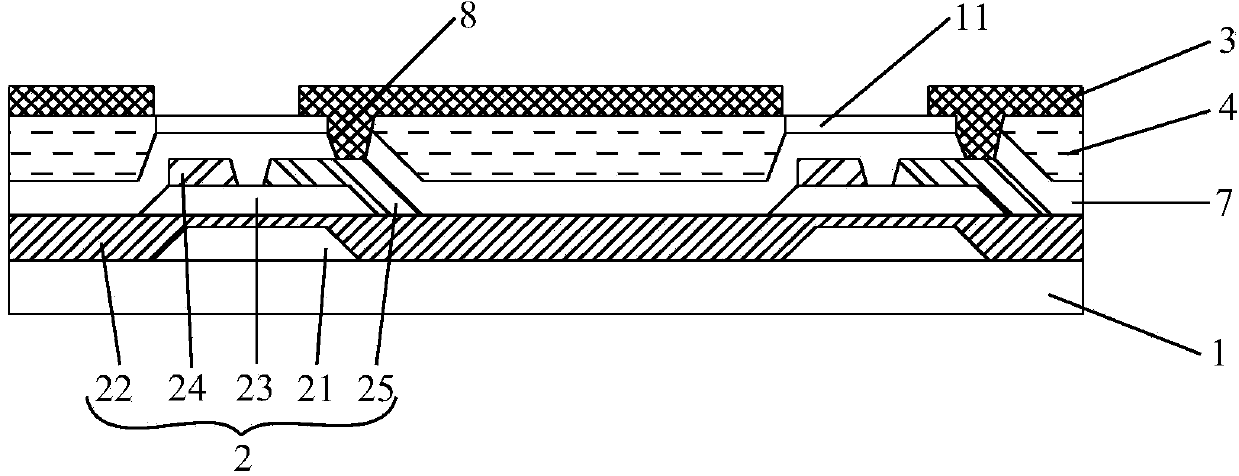

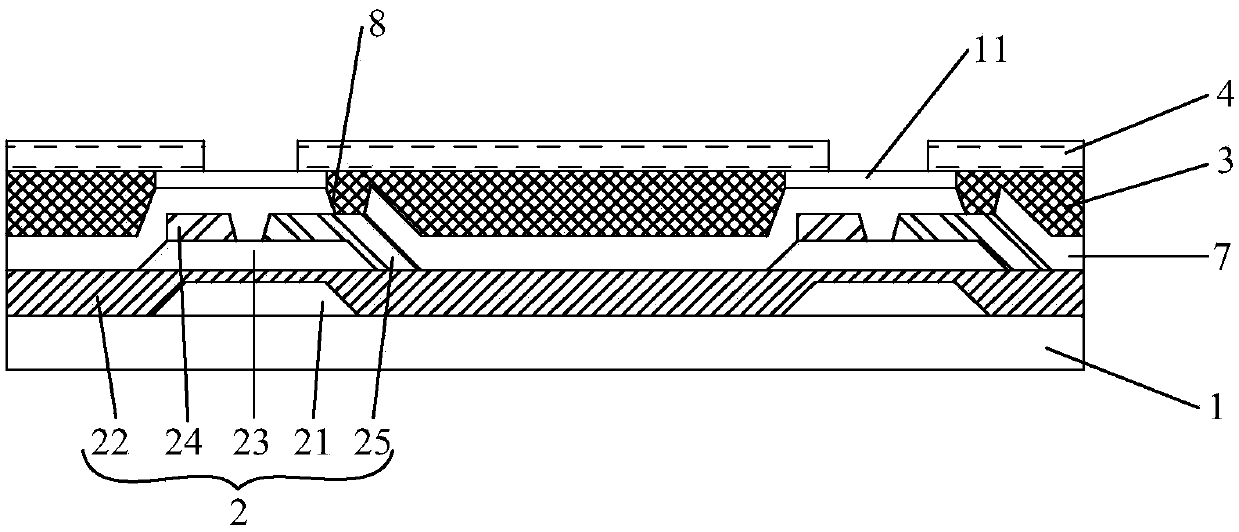

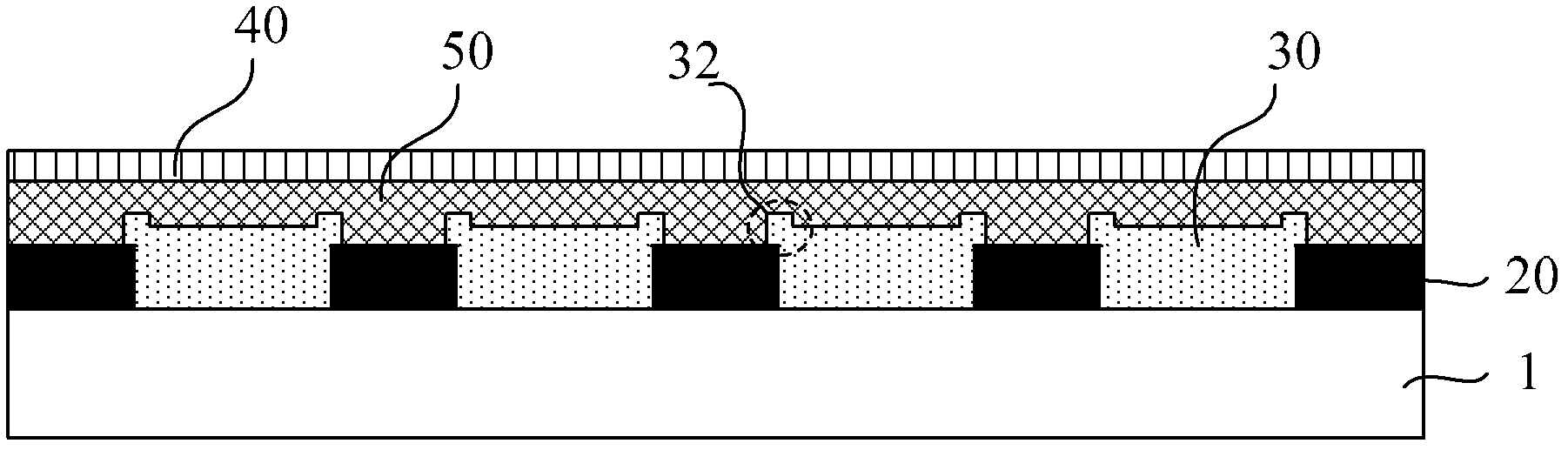

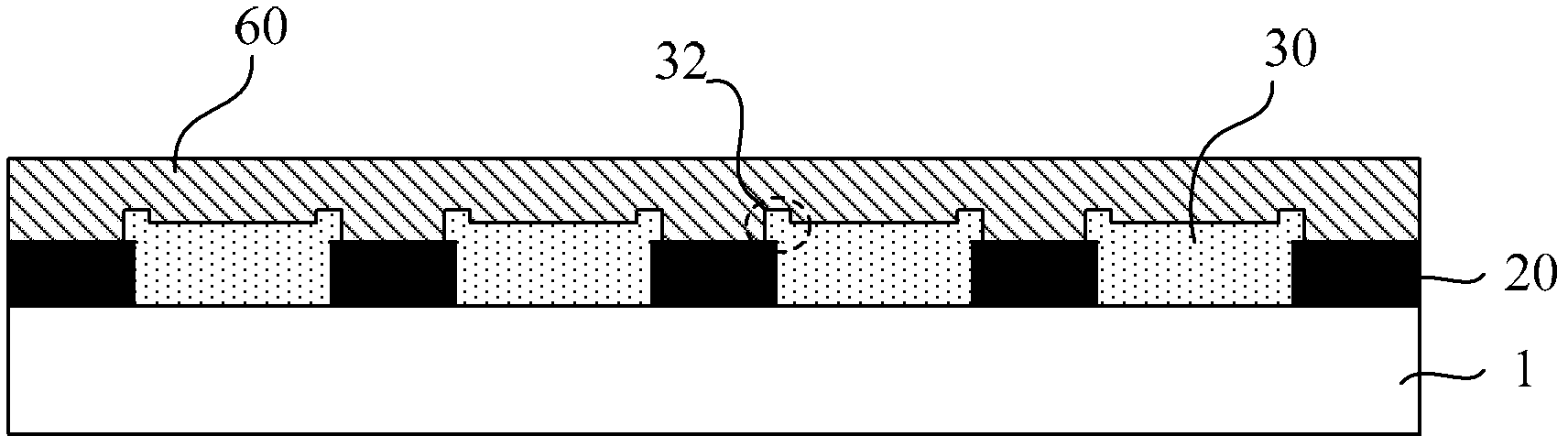

Array substrate, preparation method thereof and display device

ActiveCN103700674AEnsure production safetyGuaranteed production efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceProtection layer

The embodiment of the invention discloses an array substrate, a preparation method thereof and a display device, and relates to the technical field of display. According to the array substrate, the preparation method and the display device, disclosed by the invention, the layer structure of the array substrate can be simplified, the preparation difficulty of the array substrate can be reduced, and thus the production yield of the array substrate can be increased. The array substrate comprises a liner substrate, a TFT (Thin Film Transistor) unit, a colorful film and a flat protection layer, wherein the TFT unit is positioned above the liner substrate, the flat protection layer is electrically connected with a drain electrode of the TFT unit, and the flat protection layer is conductive.

Owner:BOE TECH GRP CO LTD

Coal additive and method for raising coke output and performance

InactiveCN101020831AFully carryFast and Efficient CarryCoke ovensSolid fuelsEngineeringProcess engineering

The present invention relates to coal additive and method for raising coke output and performance. The coal additive contains surface activating catalyst, co-solvent, permeation assistant and solvent. When the coal additive is used, the surface activating catalyst is dissolved in the solvent, added into coal through a specific mode, and distributed on the surface of coal and inside coal under the action of the permeation assistant. During producing coke, the coal additive is heated and the volatile component is separated out, to raise the output and performance of the produced coke. The high performance coke may be used in coal burning, dry distilling, gasifying, liquefying and other fields. The present invention can reach the aims of raising the utilization rate of coal, saving coal resource, reducing pollutant, etc.

Owner:北京金源化学集团有限公司

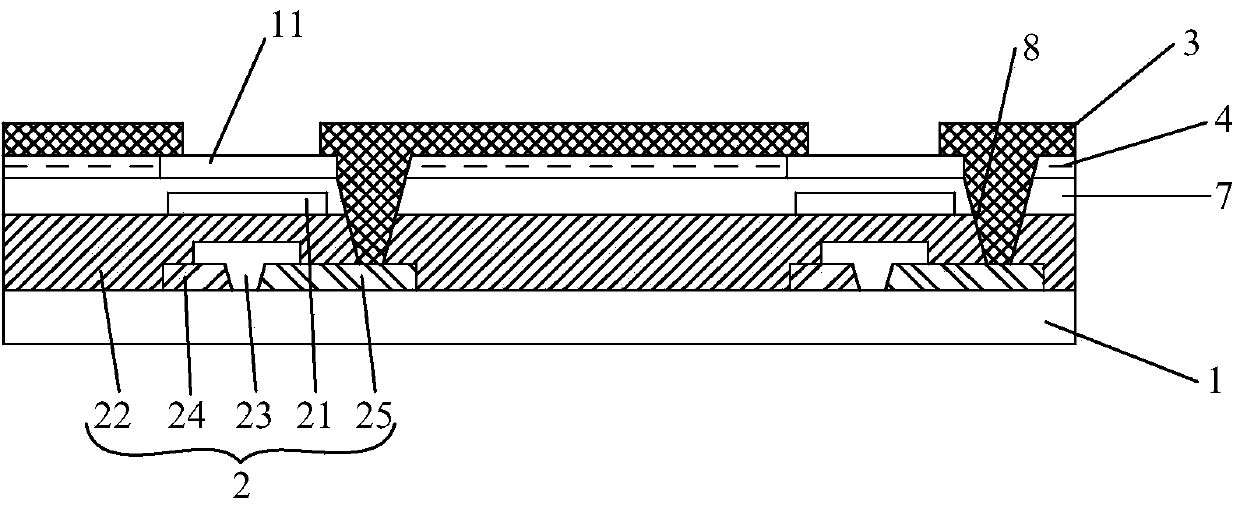

Mine side slope deformation monitoring and early warning system and early warning method thereof

InactiveCN103578229AEnsure production safetyAccurate detectionAlarmsDeformation monitoringEngineering

The invention relates to the technical field of geological disaster monitoring, in particular to a mine side slope deformation monitoring and early warning system and an early warning method thereof. The early warning system is composed of a ground control subsystem, a space wireless communication network and a communication auxiliary subsystem of monitoring workers, wherein the ground control subsystem, the space wireless communication network and the communication auxiliary subsystem are used for carrying out communication connection. The ground control subsystem is composed of a GPS mine side slope monitoring subsystem and a GPS monitoring data processing subsystem. The GPS monitoring mine side slope subsystem comprises a set of displacement measuring robots, a receiving antenna, a data transmission module, a GPS receiver and a power supply system, wherein the GPS receiver is used for receiving mine side slope deformation data collected by the displacement measuring robots. Various data are collected in real time, the monitoring data are processed, and the uploaded data are fast and automatically stored, transmitted, updated, counted and managed. The mine side slope deformation monitoring and early warning system has the advantages that the mine side slope displacement is dynamically monitored in real time, and safety production of a mine is guaranteed.

Owner:ANSTEEL GRP MINING CO LTD

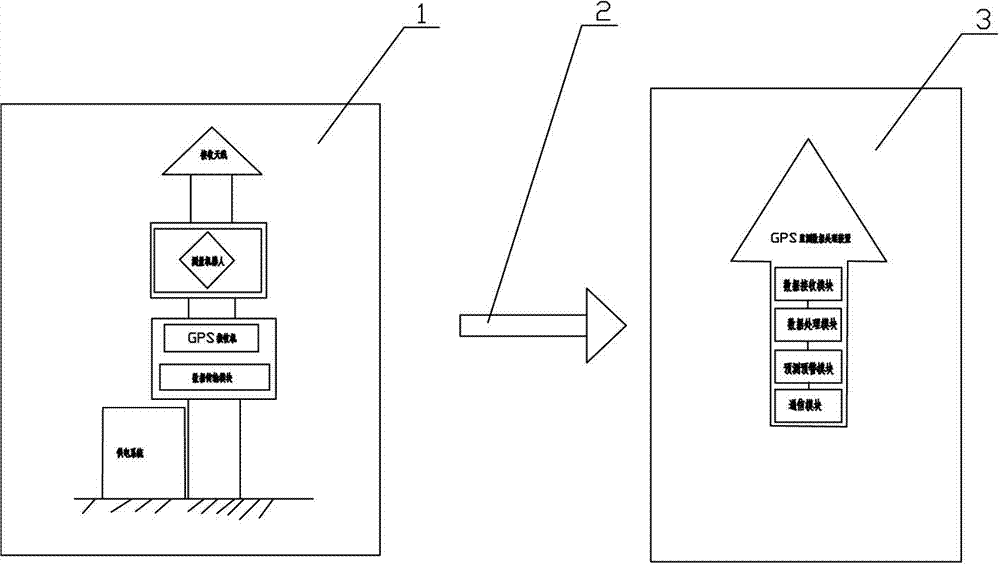

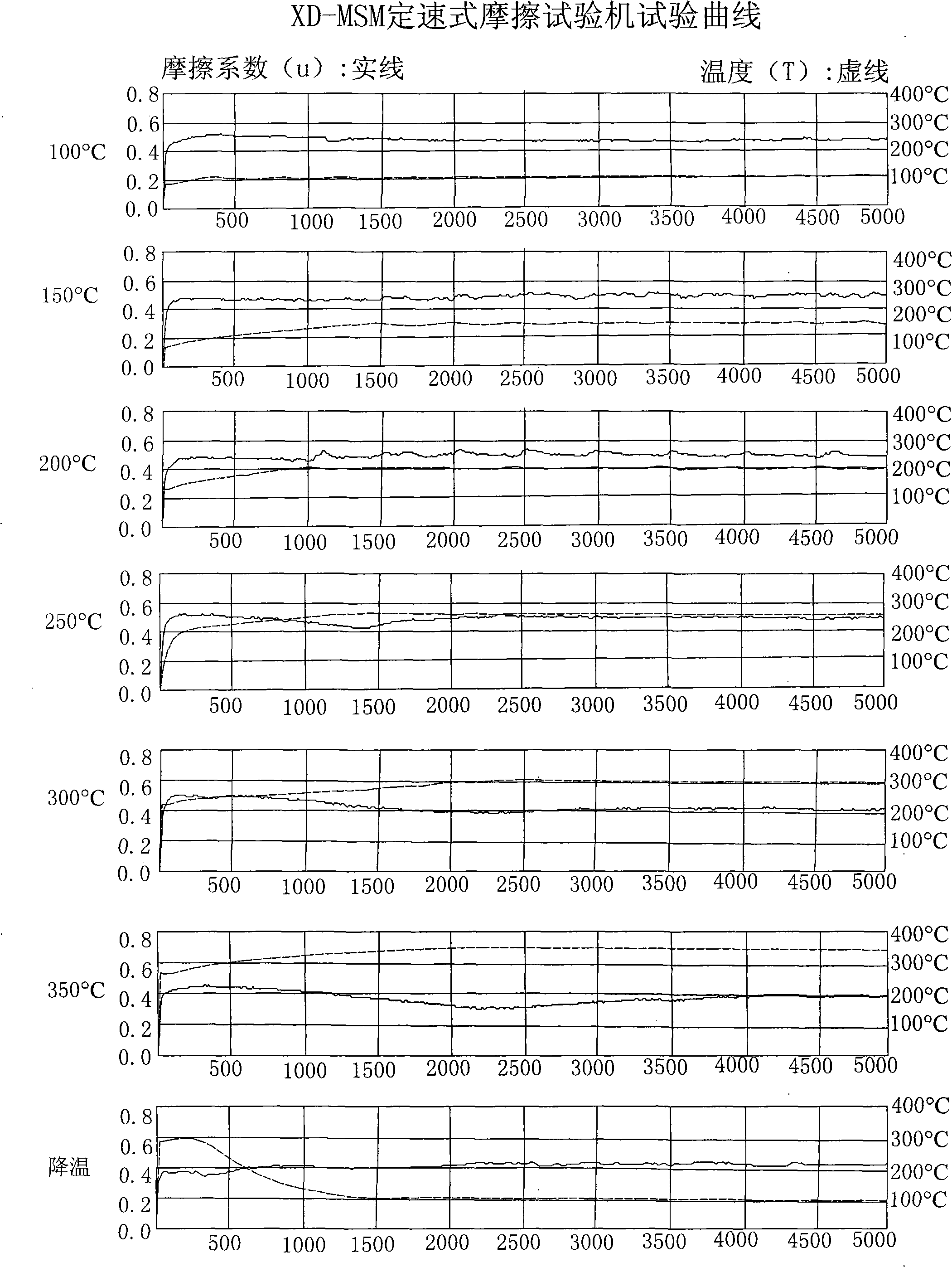

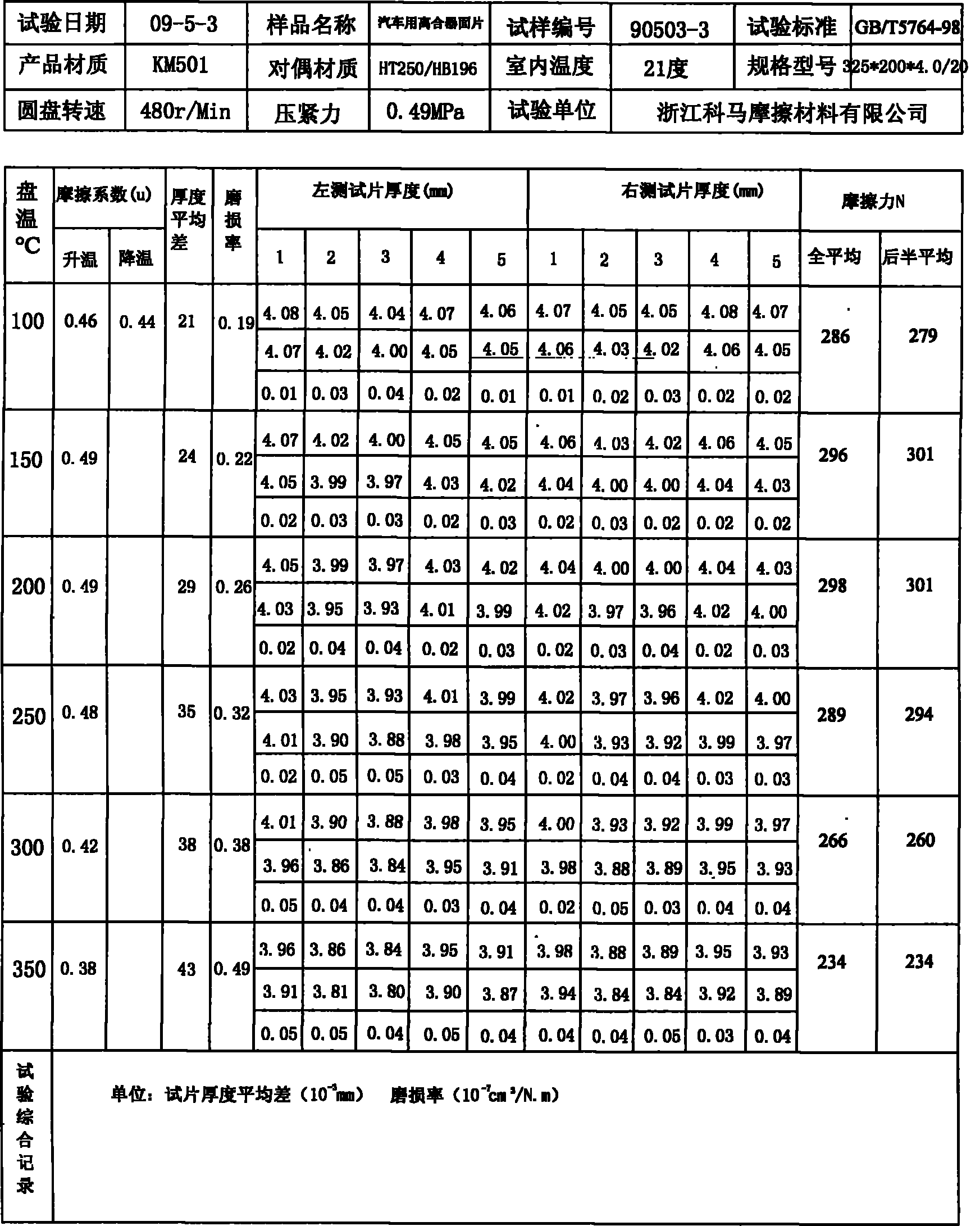

Novel non-rubber winding clutch facing

InactiveCN101792571AReduce coefficient of frictionIncrease coefficient of frictionFriction clutchesFriction liningThermal expansionConductor Coil

The invention provides a novel non-rubber winding clutch facing, which adopts a water soluble phenolic resin as a binding material. The water soluble phenolic resin is prepared by using 100 parts by weight of phenol and 105 to 115 parts by weight of formaldehyde as the raw materials through the condensation reaction under the action of 0.1 to 0.2 part by weight of basic catalyst. The content of solid product obtained after the water soluble phenolic resin is dried accounts for 50 to 55 percent of the weight of the original phenolic resin. The invention uses the water soluble phenolic resin as the novel binder to produce the vehicle clutch facing. The water soluble phenolic resin binder has the advantages of small heat fading, small thermal expansion, higher safety factor and the like, thus, the prepared clutch facing has the advantages of good heat resistance which can reach over 350 DEG C, higher and stable friction coefficient, small heat fading, good wearing resistance and the like, also has the characteristics of stable clutch, particularly smaller thermal expansion and the like, eliminates the flammable and combustible hidden troubles and guarantees the production safety.

Owner:浙江科马摩擦材料股份有限公司

Transparent electroconductive resin, color film substrate and its manufacturing method, liquid crystal display device

ActiveCN102627823AGood light transmissionImprove conductivityNon-conductive material with dispersed conductive materialNon-linear opticsLiquid-crystal displayManufacturing technology

The invention discloses a transparent electroconductive resin, a color film substrate and its manufacturing method and a liquid crystal display device, relates to the technical field of liquid crystal display, and aims to raise properties of the liquid crystal display device and simultaneously simplify the manufacturing technology of the liquid crystal display device. The transparent electroconductive resin disclosed by the invention contains a transparent matrix resin, organic acid-doped polyaniline and toluene. The color film substrate disclosed by the invention contains a substrate, on which a common electrode formed by the transparent electroconductive resin is disposed. The invention can be applied to the manufacturing field of the liquid crystal display panel.

Owner:BOE TECH GRP CO LTD

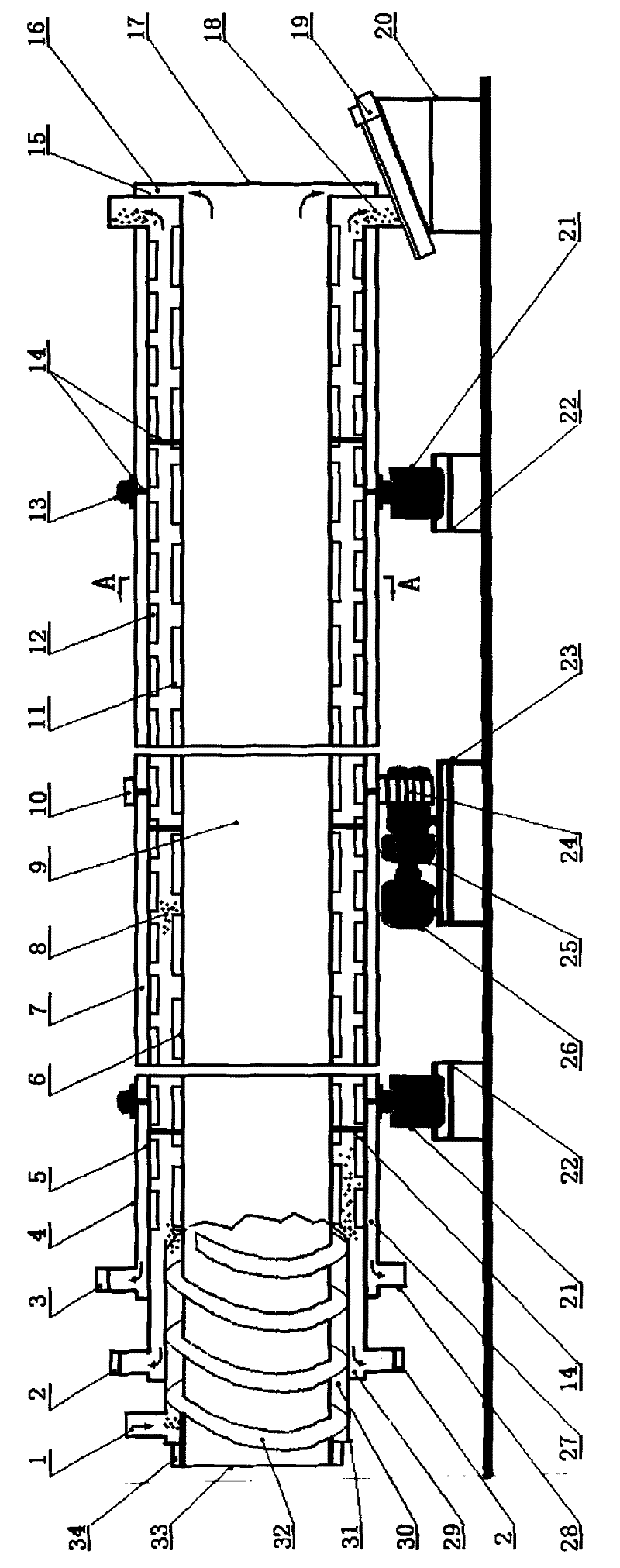

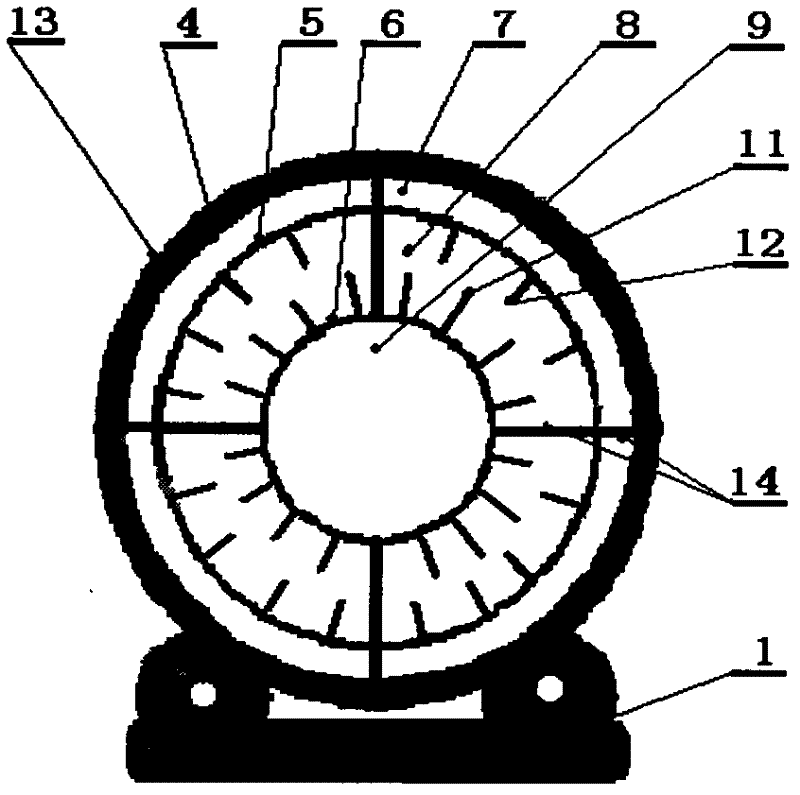

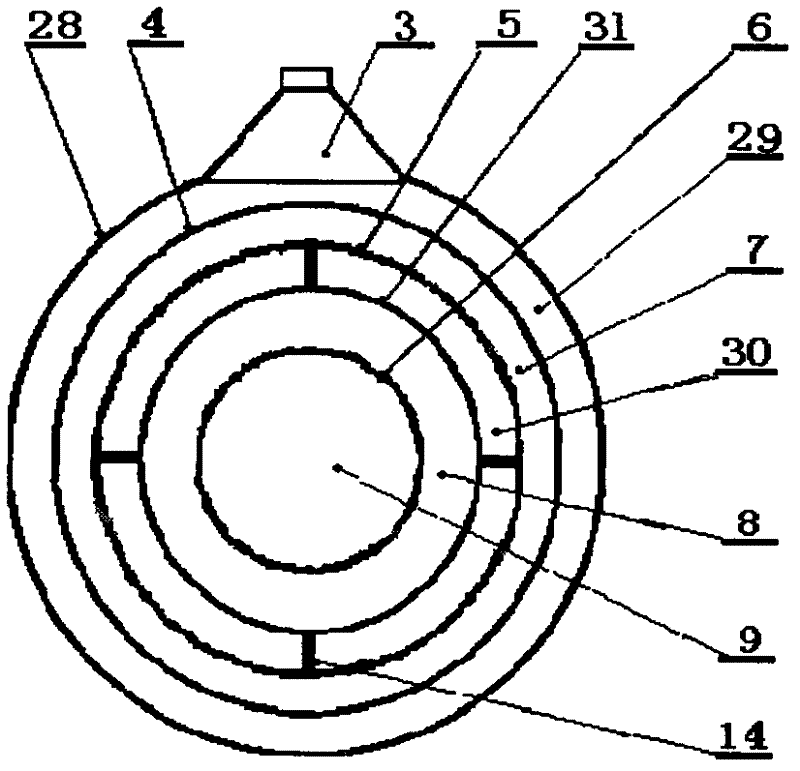

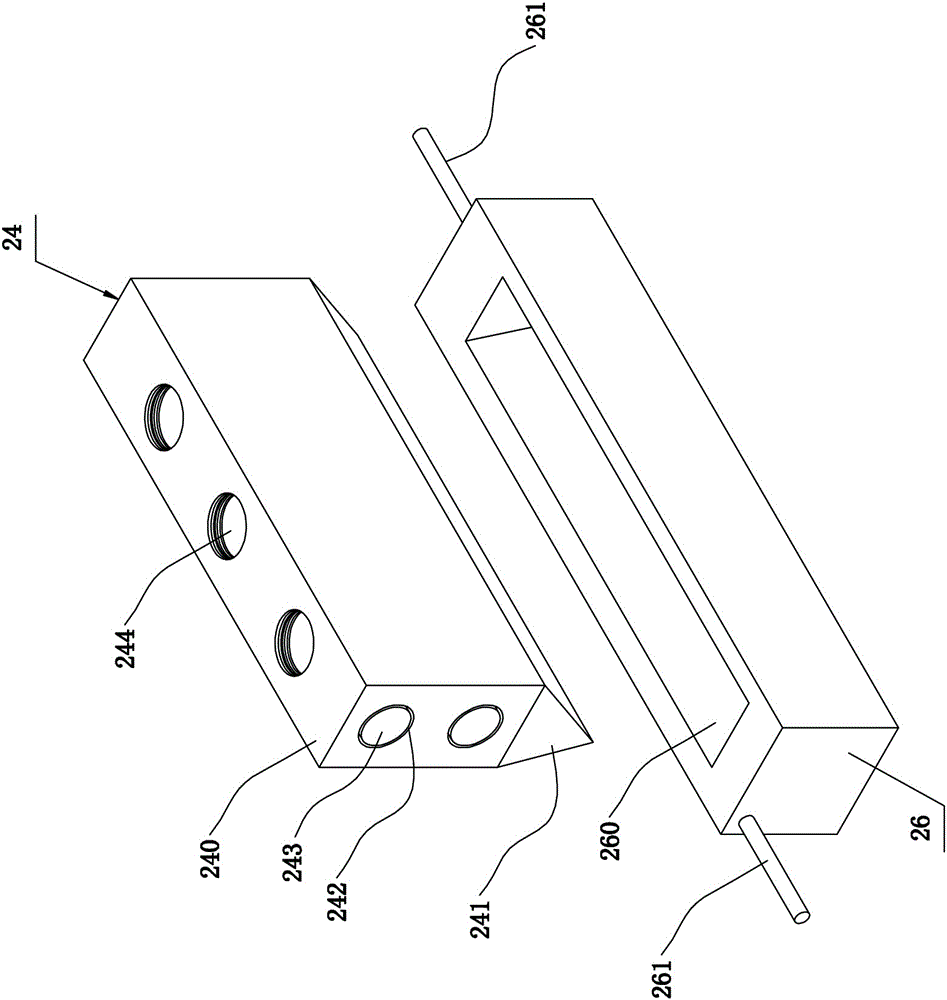

Countercurrent double-loop cylinder dryer

InactiveCN102445059AAvoid contactQuality improvementDrying gas arrangementsDrying chambers/containersFlue gasDrum drying

The invention relates to a countercurrent double-loop cylinder dryer, which comprises a support, an inner cylinder, an outer cylinder, a driving device, a feeding device and a discharging device, and is characterized in that: a middle cylinder is arranged between the inner cylinder and the outer cylinder, and one end of the inner cylinder and one end of the middle cylinder are respectively provided with an annular seal plate; one end of the outer cylinder is provided with a seal plate, and the three cylinders constitutes a material layer and two flue gas heating units, i.e., an inner-layer flue and an outer-layer flue; and a plurality of reinforcing supporting columns are arranged among the three cylinders for connecting and positioning, and frying plates are uniformly arranged on the outer wall plate of the inner cylinder and the inner wall plate of the middle cylinder. The problems that the material and the flue gas flow from the same pipeline, and are fully mixed, so that the dried material is mixed with impurities and the production safety is possibly generated by ineffectively controlling sparks in the flue gas to be contacted with the material and the like in the traditional drum drying machine can be solved, the structural design is reasonable, the performance is stable, the process flow is smooth, the overheating time of a dry area is long, the thermal efficiency is high, the energy is saved and the consumption is reduced, the quality of the dried material is high, and the range of application is wide.

Owner:NANNING ZHONGXIU ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

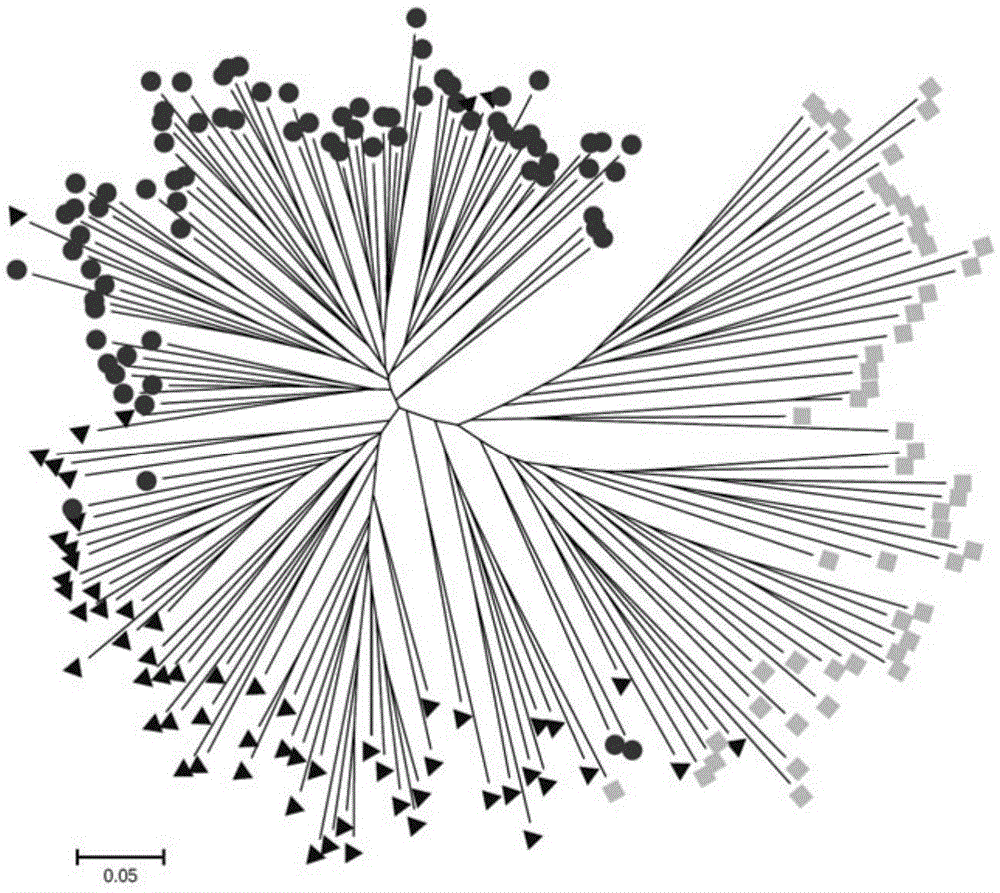

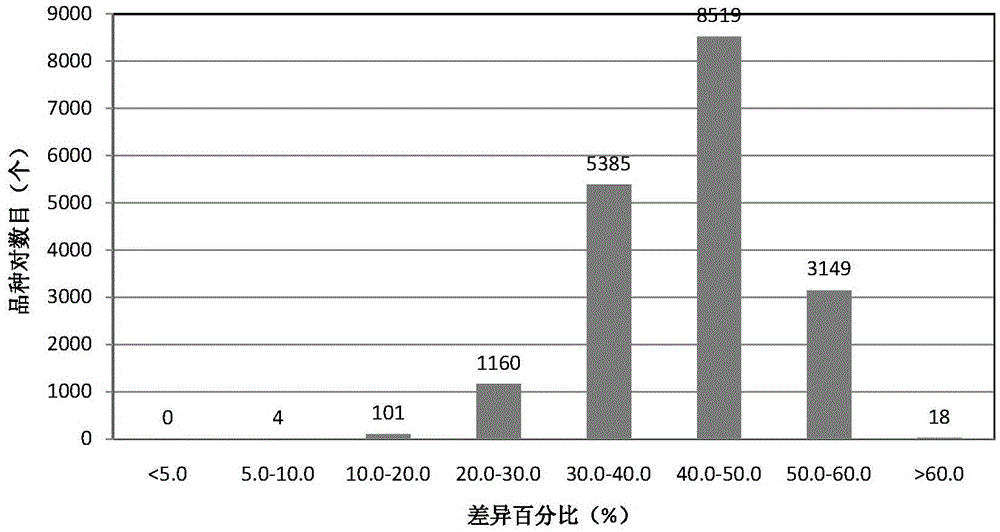

384 SNP loci and application thereof in soybean variety resource identification

ActiveCN105567857AProtection of rights and interestsSpeed up the breeding processMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceGenome

The invention discloses 384 SNP loci and application thereof in soybean variety resource identification. In the application disclosed by the invention, the physical locations of the 384 SNP loci are determined on the basis of whole genome sequence alignment of the soybean variety of Williams 82, and the version number of a whole genome sequence of the soybean variety of Williams 82 is Glyma.Wm82.al(Gmax1.01); the 384 SNP loci are SMK001-SMK384. An SNP chip based on the 384 SNP loci can be applied to identifying a soybean variety resource; the application of the combination of the 384 SNP loci can greatly improve the detection accuracy, shorten the detection time and improve the detection level, which provides a strong technical support for soybean variety popularization and seed market testing, and accelerates the seed selection process of an excellent new soybean variety.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

Bag making machine hot-sealing and hot-pressing mechanism capable of working stably

The invention discloses a bag making machine hot-sealing and hot-pressing mechanism capable of working stably. The mechanism comprises a fixing frame body, two guide sleeves, pull rods, a cutter fixing frame and a hot-sealing cutter. The upper ends of the pull rods are fixedly connected to the two ends of the cutter fixing frame respectively and each provided with an upper end abutting portion. The side wall of the upper portion of each pull rod is sleeved with a compression spring. The upper end and the lower end of each compression spring are connected to the corresponding upper end abutting portion and the top of the corresponding sleeve respectively in an abutting mode. At least one pull rod penetrates through the corresponding guide sleeve and then is in transmission connection with an intermittent motion mechanism. According to the bag making machine hot-sealing and hot-pressing mechanism, it can be ensured that the hot-sealing and hot-pressing positions and motion strengths of the hot-sealing cutter for air bubble films or pearl wool films under the hot-sealing and hot-pressing cutter are consistent all the time, and the hot-sealing cutter will not shift even if hot-sealing and hot-pressing are frequently and constantly carried out; accordingly, the working efficiency of the bag making machine hot-sealing and hot-pressing mechanism is greatly improved, and the service life of the bag making machine hot-sealing and hot-pressing mechanism is greatly prolonged.

Owner:洪东坡

Bag machine with improved structure

ActiveCN104985864AThere will be no offsetSimple structureBox making operationsPaper-makingEngineeringMechanical engineering

A bag machine with an improved structure comprises a convey assembly, a feed assembly, and a hot-sealing hot-pressing mechanism; the hot-sealing hot-pressing mechanism comprises a fixed rack, two guide sleeves, pull rods, a cutter fixing rack and a hot-sealing cutter; tops of each pull rod are respectively fixed on two ends of the cutter fixing rack; each pull rod is provided with a top abut portion; an upper side wall of each pull rod is sleeved by a compression spring; at least one pull rod penetrates the corresponding guide sleeve and is in transmission connection with an intermittence motion mechanism, wherein the intermittence motion mechanism is used for controlling the cutter fixing rack to complete up-down mobile motions in cycle in a fixed time. The bag machine can ensure the hot-sealing cutter to carry out hot-sealing hot-pressing for right blow bubble films or pearl cotton films with consistent positions and motion forces in each time; even under frequent continuously hot-sealing hot-pressing, no hot-sealing cutter offset condition is generated, thus greatly improving work efficiency and life of the bag machine.

Owner:洪东坡

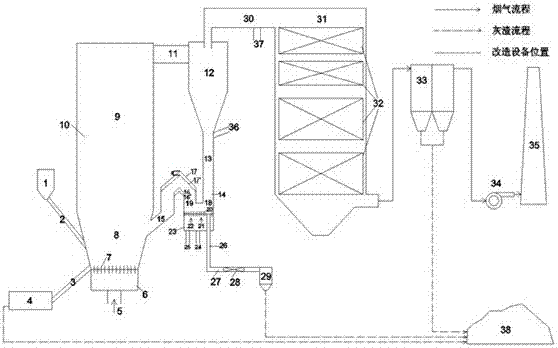

Circulating fluidized bed boiler and material return abnormity adjusting method thereof

InactiveCN107191925AKeep clearAir chamber air pressure is normalFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

A circulating fluidized bed boiler and an adjustment method for abnormal material return, comprising a furnace, a separator, a material return standpipe, a material return valve and a tail flue to form a circulating fluidized bed boiler. The furnace, the separator, the material return standpipe and the material return valve form an external circulation loop. The adjustment method for the abnormal return of circulating fluidized bed boiler: lower the height of the rising section of the return valve by 300mm, add a return sealing air duct at the bottom of the separator and the upper part of the return standpipe, set up a purge device in the horizontal flue, The ash discharge pipe is installed in the hole on the air distribution plate of the return valve, and the ash discharge pipe is installed at the lowest part of the return air chamber. After cleaning out the debris of the return valve, start it again. Stop the furnace to check the condition of the wind cap and repair the wind cap in good condition. The above measures can solve the problem of abnormal material return caused by different reasons. The invention is simple in operation, easy to popularize, easy to carry out equipment transformation and low in cost, and is widely applicable to large-scale circulating fluidized bed boilers.

Owner:大同煤炭职业技术学院

Automatic packaging equipment for fruit with prickly shell

InactiveCN106927075ASimple structureEasy to useWrapping with article rotationPackaging fruits/vegetablesDrive motorEngineering

An automatic wrapping device for fruits with thorns in the shell, which is characterized in that it includes a driving motor, a connecting seat on one side, a screw rod connected to the motor is arranged in the connecting seat, and a set of relatively movable sliding parts is arranged on the setting screw rod. seat, an object clamping structure is provided on the inner side of the sliding seat, and a plastic film wrapping device is provided on the upper part of the connecting seat. A connection plate is provided at the output end of the rotating electrical machine, and the top block structure is connected at the center position inside the connection plate, and a group of inclined grooves are arranged at the end position of the inner side of the connection plate, and claws are provided in each inclined groove. There are locking teeth on the bottom, and a concave block structure at the center position on the inner side of the opposite connection plate. The automatic wrapping device with this structure is simple in structure and easy to use, and can effectively pack durians well. The labor force is reduced, the production efficiency is improved, and at the same time, it is not easy to injure the operator's fingers, thus ensuring production safety.

Owner:滁州昭阳电信通讯设备科技有限公司

Engine base punching die

InactiveCN102366774AReasonable structureImprove surface qualityShaping toolsPerforating toolsPunchingEngineering

The invention discloses an engine base punching die which comprises an upper die, a lower die and a female die, wherein the upper die comprises a fixing plate connected with a die shank and wedge-shaped blocks fixed on the lower surface of the fixing plate, and inclined planes are formed on the two wedge-shaped blocks; the lower die comprises a base provided with a horizontal slide rail, slide blocks in sliding connection with the slide rail and a workpiece positioning device fixed on the base, inclined planes corresponding to the inclined planes on the wedge-shaped blocks are formed on the slide blocks, a punching head is fixedly arranged at one side of the punching motion direction of each slide block, and the workpiece positioning device is used for positioning a workpiece in a bolt fastening mode; and the female die is positioned between the two slide blocks and is fixed on the base, and a guide hole is formed on the female die in the position corresponding to the punching head. The hole processed by using the engine base punching die disclosed by the invention has better surface quality, no need of grinding and high production efficiency; the female die can not generate collision with the motion of the punching head; the structure of the die is reasonable; each component has good stress effect; and the production safety can be effectively ensured.

Owner:CHONGQING BEIBEI DISTRICT FENGHUO MACHINERY MFG

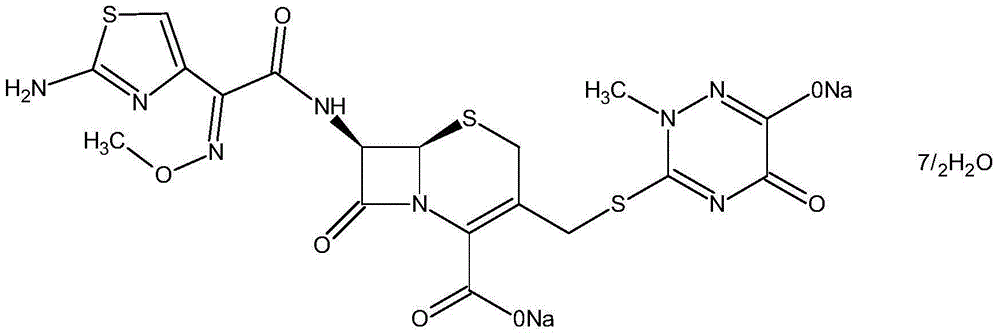

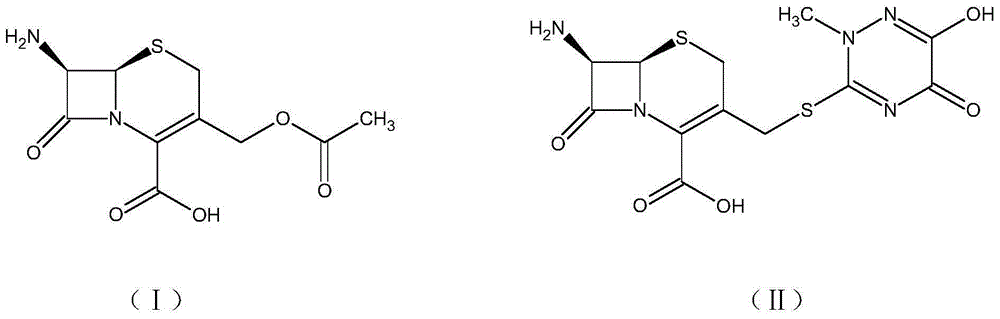

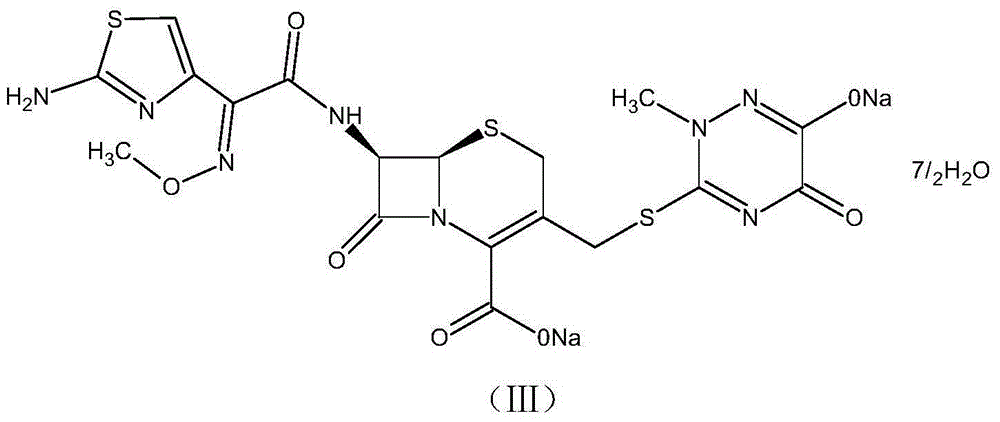

One-pot synthesis method of ceftriaxone sodium

InactiveCN105061472AEnsure production safetyAvoid Potential ContaminationOrganic chemistryOne-pot synthesisOrganic base

The invention relates to a one-pot synthesis method of ceftriaxone sodium. The adopted one-pot synthesis method comprises the following steps: directly adopting an organic solution of 7-ACT as the intermediate 7-ACT is not separated in a solid manner, adding an organic solvent B, an antioxidant and water into the organic solution of the 7-ACT, then, adding AE active ester, performing further reaction under the action of organic base, adding a salt forming agent for salt formation, performing standing, extraction, water phase decolorization and filtering, and adding water-soluble organic solvent C crystal, so as to obtain the ceftriaxone sodium. According to the method for synthesizing the ceftriaxone sodium, the whole-process non-artificial direct contact to materials can be realized, the whole-process whole-solvent flow-state closed operation can be implemented, the control on the interaction effect of personnel and materials during the production process is facilitated, the shortening of the production period is facilitated, the production operation is simplified, the discharge of waste liquid is reduced, the energy consumption during the intermediate drying process is reduced, and the effect of reducing the cost to a certain degree is achieved.

Owner:山东安弘制药有限公司

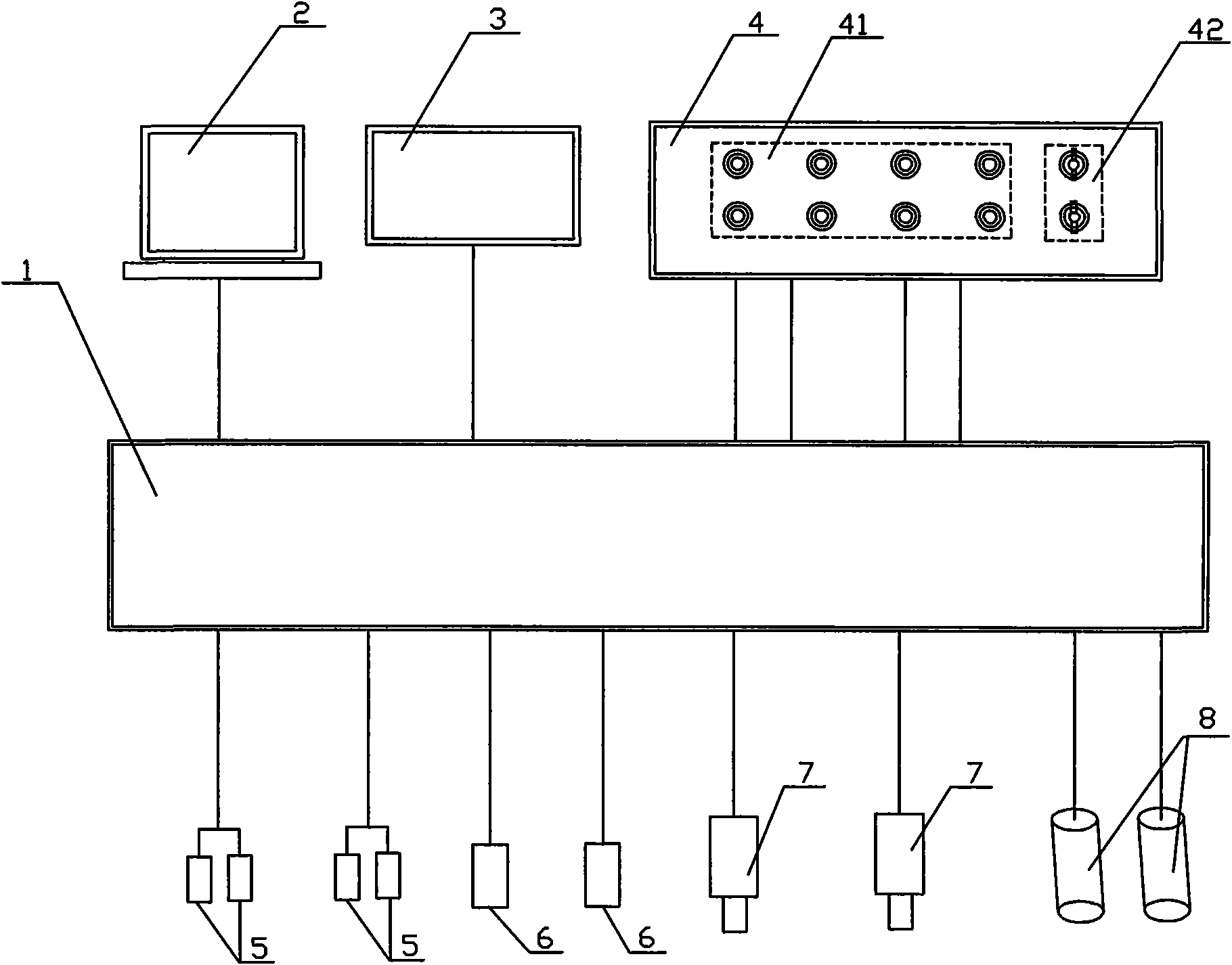

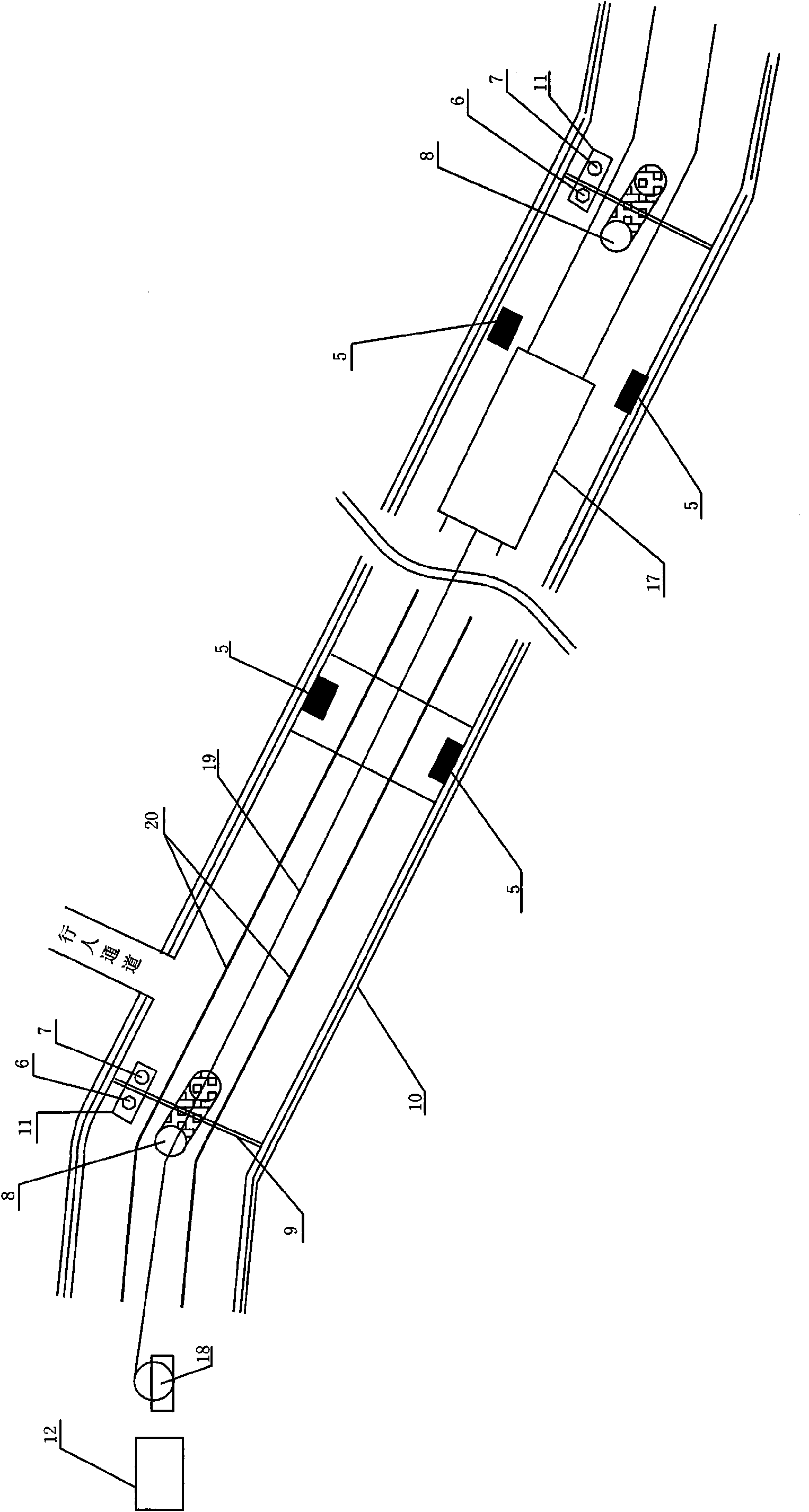

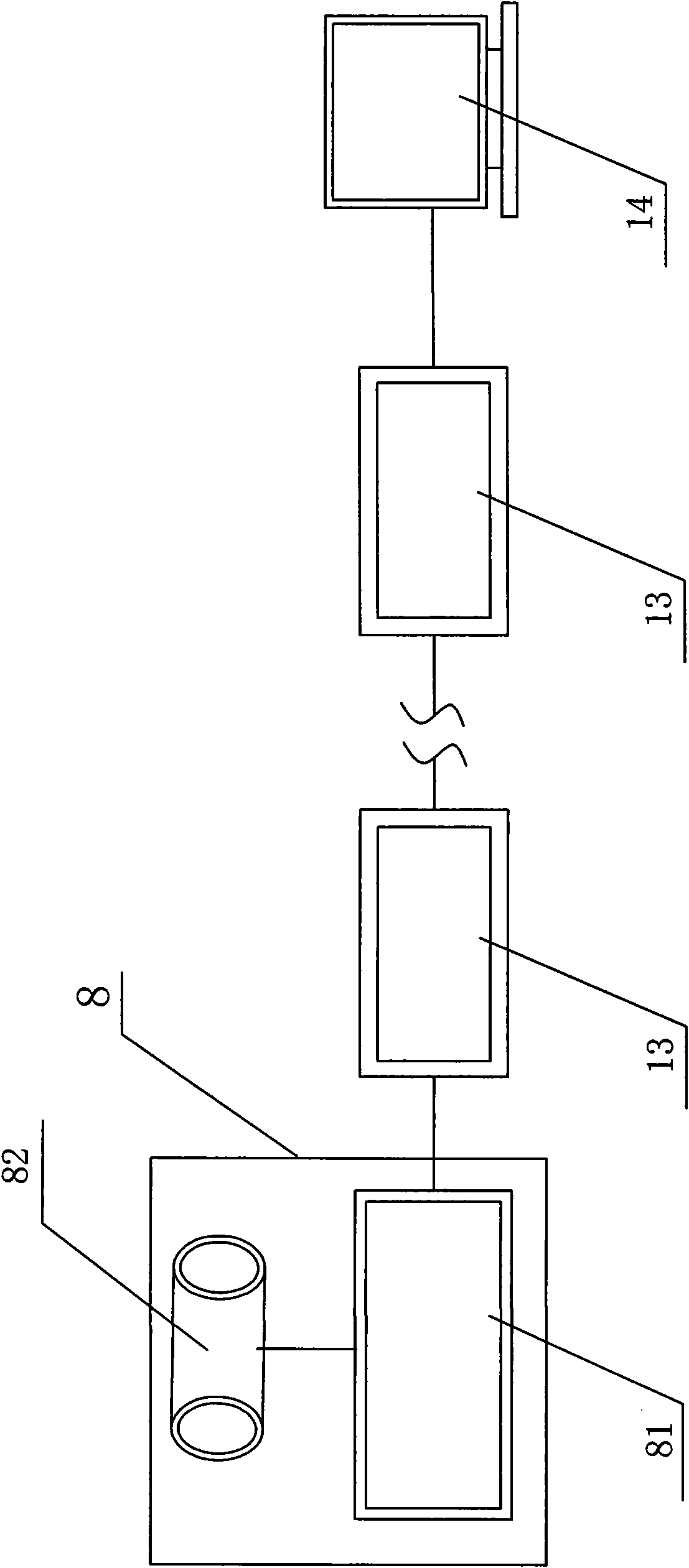

Personnel monitoring system for transport inclined shaft

InactiveCN101592039ASimple structureLow calorific valueMining devicesUnderground transportAutomatic controlElectromagnetic lock

The invention discloses a personnel monitoring system for a transport inclined shaft, which comprises a system main control box, wherein the system main control box is connected with an optically controlled sensor, a door in-place sensor and a vision sensor, and analyzes and processes data acquired by the optically controlled sensor, the door in-place sensor and the vision sensor; and the system main control box is connected with and controls an explosion-proof electromagnetic lock, realizes the interlocking of driving vehicle and pedestrians in the transport inclined shaft, and ensures that people and vehicles cannot synchronously walk. The system main control box is connected with and controls a monitor, an alarm voice box and a console, the vision sensor comprises a vision server, and the vision server is connected with an explosion-proof camera, and uploads data acquired by the explosion-proof camera to a host computer which is connected with a network switch and is arranged in a ground dispatch room. The system achieves the aims of monitoring the pedestrians in the transport inclined shaft by a winch driver and monitoring personnel of the dispatch room and realizing the automatic control by analyzing and processing signals acquired by the sensors, realizes closed inclined shaft transportation, and ensures that no people walk when the vehicles are driven and no vehicle is driven when people walk.

Owner:闫云龙

Multi-color and multi-position pad printing machine

The invention belongs to the technical field of pad printing and discloses a multi-color and multi-position pad printing machine. The multi-color and multi-position pad printing machine comprises a base, a pad printing assembly arranged on the base in a straddling manner, a plurality of ink feeding assemblies located below the pad printing assembly, a cleaning assembly located in front of the ink feeding assemblies and a material supporting assembly located beside the ink feeding assemblies; the pad printing assembly comprises a horizontally-arranged servo module which is provided with an X movement module capable of moving in the X direction; the X movement module is provided with a first cylinder which drives an adhesive head assembly to move up and down in the Z direction; the adhesive head assembly is provided with pad printing adhesive heads side by side in the X direction, and the number of the pad printing adhesive heads corresponds to that of the ink feeding assemblies; and the material supporting assembly comprises a base, a carrying table located above the base and a third cylinder fixed to the base and driving the carrying table to move in the X direction. The multi-color and multi-position pad printing machine can print colorful patterns formed by combining different color blocks on products, cost is saved compared with a common multi-color pad printing machine, and besides, debugging is easy and fast.

Owner:YINGTUO ELECTRONICS APP KUSN

Safety heat exchanger capable of monitoring leakage in real time

InactiveCN102620582AGuaranteed vacuumImprove heat transfer efficiencyMeasurement of fluid loss/gain rateStationary plate conduit assembliesHeat transfer efficiencyEngineering

The invention relates to a safety heat exchanger capable of monitoring leakage in real time. The safety heat exchanger comprises a cross-flow type shell and a heat exchanger core which is arranged in the cross-flow type shell, wherein a first fluid inlet, a second fluid inlet, a first fluid outlet and a second fluid outlet are respectively formed on a first sealing head, a second sealing head, a third sealing head and a fourth sealing head; a first vacuum layer sealing head is arranged at a joint of the first sealing head and the fourth sealing head; a vacuumizing device and a pressure detector or a material component detector are arranged on the first vacuum layer sealing head; a first vacuum layer is communicated with the first vacuum layer sealing head; a first fluid flow channel is respectively communicated with the first fluid inlet and the first fluid outlet; and a second fluid flow channel is respectively communicated with the second fluid inlet and the second fluid outlet. The safety heat exchanger capable of monitoring the leakage in real time is high in heat transfer efficiency, high in performance and high in equipment safety and can monitor the leakage situation in real time, and production safety and production quality are ensured.

Owner:刘猛

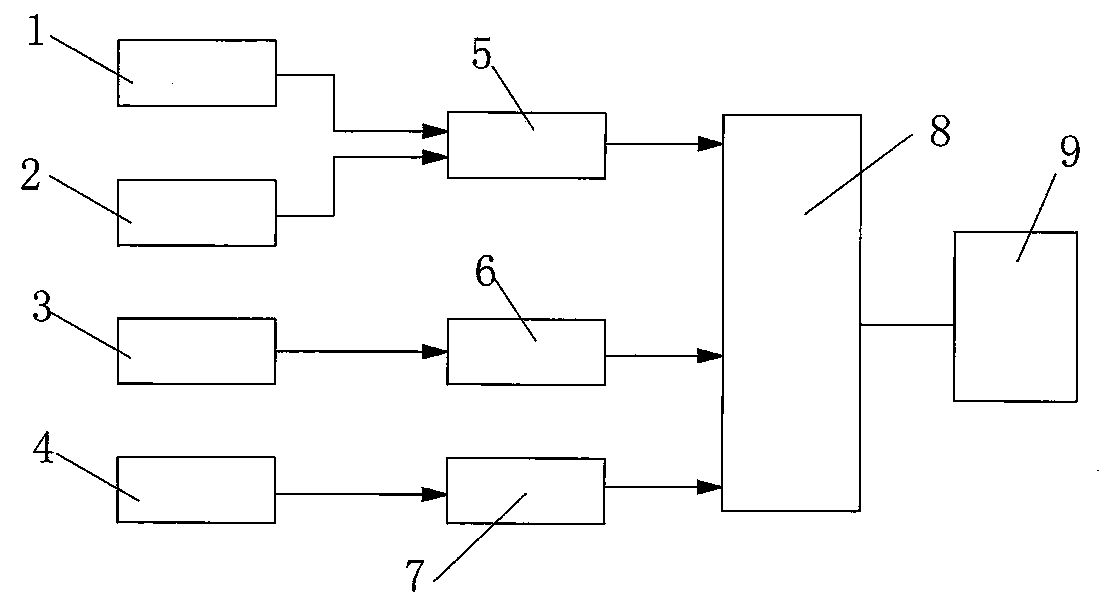

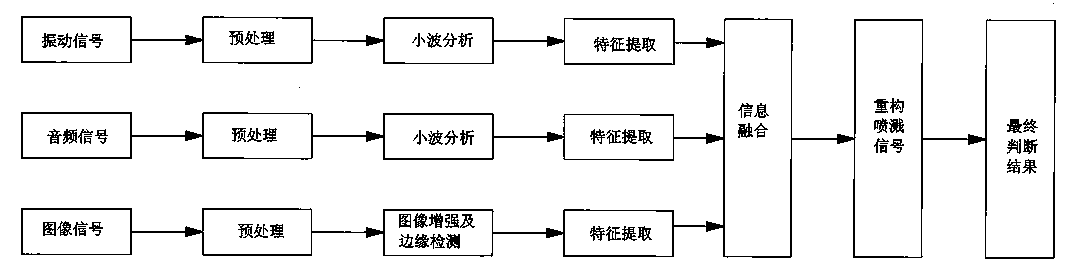

Method for forecasting splashing in argon oxygen refined low-carbon ferrochromium production process

InactiveCN103468876AIncrease uncertaintyImproving the Accuracy of Splash ForecastingResearch ObjectSmelting process

The invention discloses a method for forecasting splashing in the argon oxygen refined low-carbon ferrochromium production process. Regarding the argon oxygen refined low-carbon ferrochromium production process, splashing generated in the smelting process is used as a research object, on the basis of deeply analyzing the occurrence mechanism of splashing in the smelting process, vibration signals, audio signals and flame image signals inside a furnace in the splashing process are used as characteristic signals for representing splashing, a multi-sensor information fusion technology is utilized to conduct fusion processing on the vibration signals, the audio signals and the flame image signals inside the furnace, and then splashing signals are reconstructed. According to the method, the occurrence of splashing in the argon oxygen refined low-carbon ferrochromium production process is accurately forecasted, the yield of alloy is improved, and production safety is guaranteed.

Owner:CHANGCHUN UNIV OF TECH

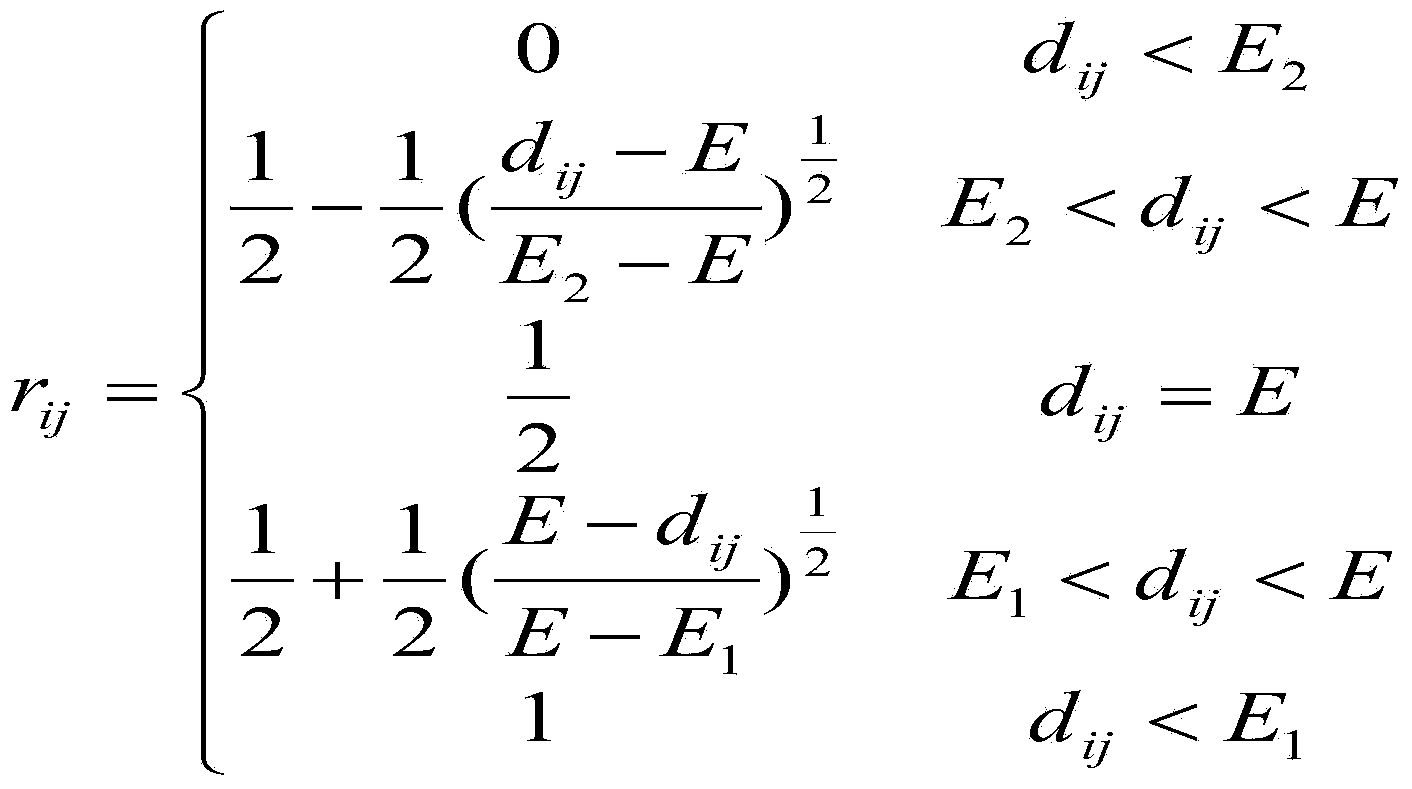

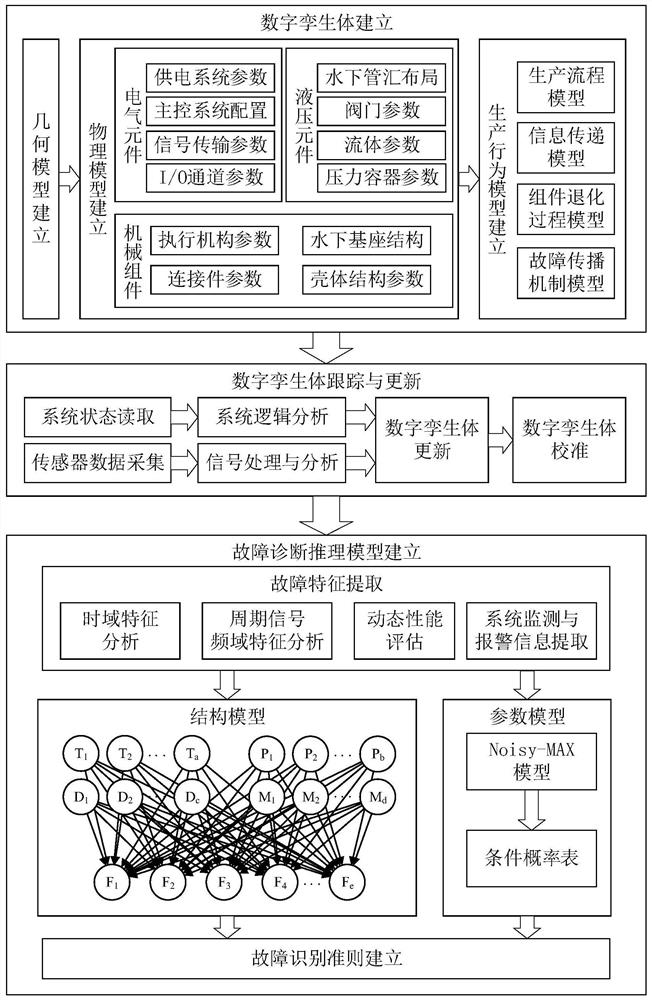

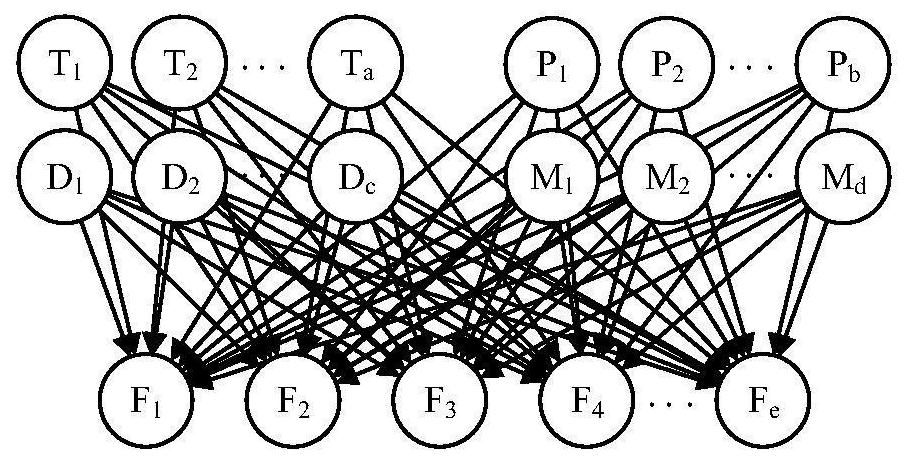

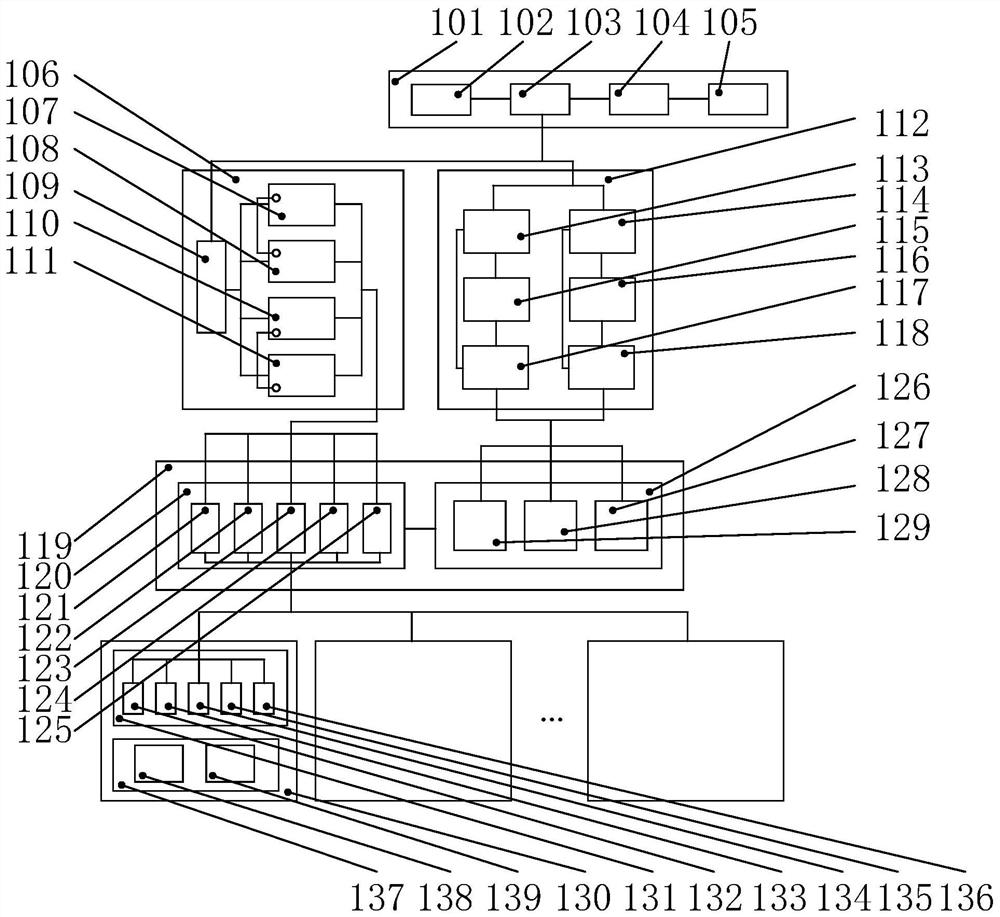

Fault diagnosis method and system for digital twin-driven offshore oil underwater production system

ActiveCN111967189AEnsure production safetyHigh fault diagnosis accuracyMathematical modelsDatabase updatingProcess engineeringPower unit

The invention belongs to the field of petroleum engineering, and particularly relates to a fault diagnosis method and system for a digital twin-driven offshore oil underwater production system. The fault diagnosis method for the digital twin-driven offshore oil underwater production system comprises three steps of digital twin body establishment, digital twin body tracking and updating and fault diagnosis reasoning model establishment. The fault diagnosis system for the digital twin-driven offshore oil underwater production system comprises seven parts: a data collection and analysis subsystem, a water control module data acquisition and processing subsystem, a hydraulic power unit data acquisition and processing subsystem, an electric power unit data acquisition and processing subsystem,an underwater control module data acquisition and processing subsystem, an underwater control module electronic module group data acquisition and processing subsystem and an underwater Christmas treedata acquisition and processing subsystem.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com