Bag making machine hot-sealing and hot-pressing mechanism capable of working stably

A heat-pressing mechanism and bag-making machine technology, applied in container manufacturing machinery, rigid/semi-rigid container manufacturing, box making operations, etc., can solve the problems of easy deviation of heat-sealing knives, high rejection rate, heat-sealing and heat-pressing The strength and position deviation are large, and the structure is simple, the practicability is strong, and the firmness is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

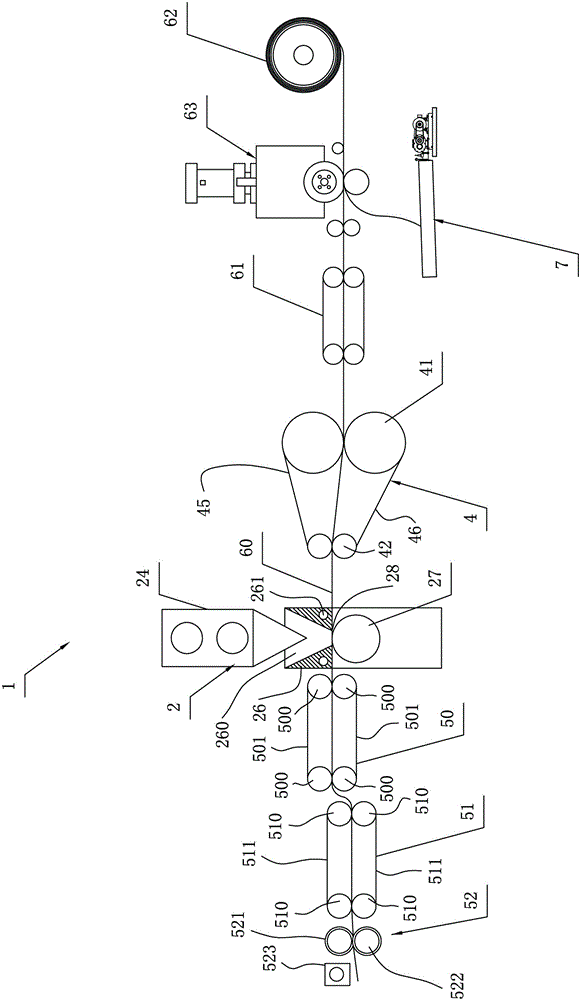

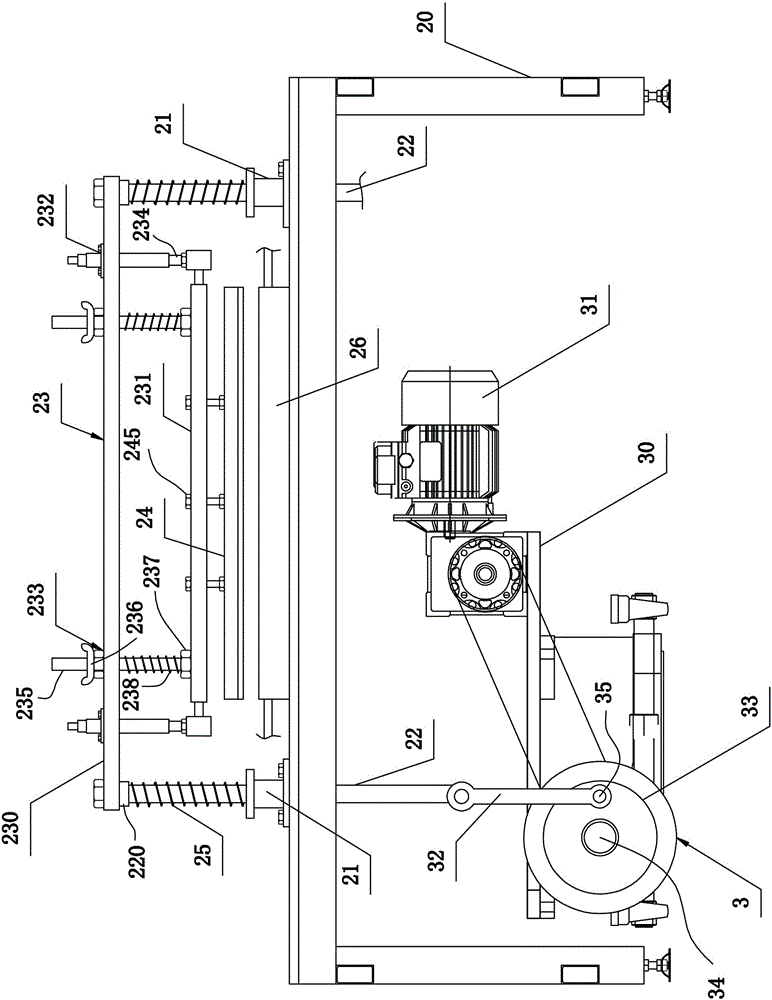

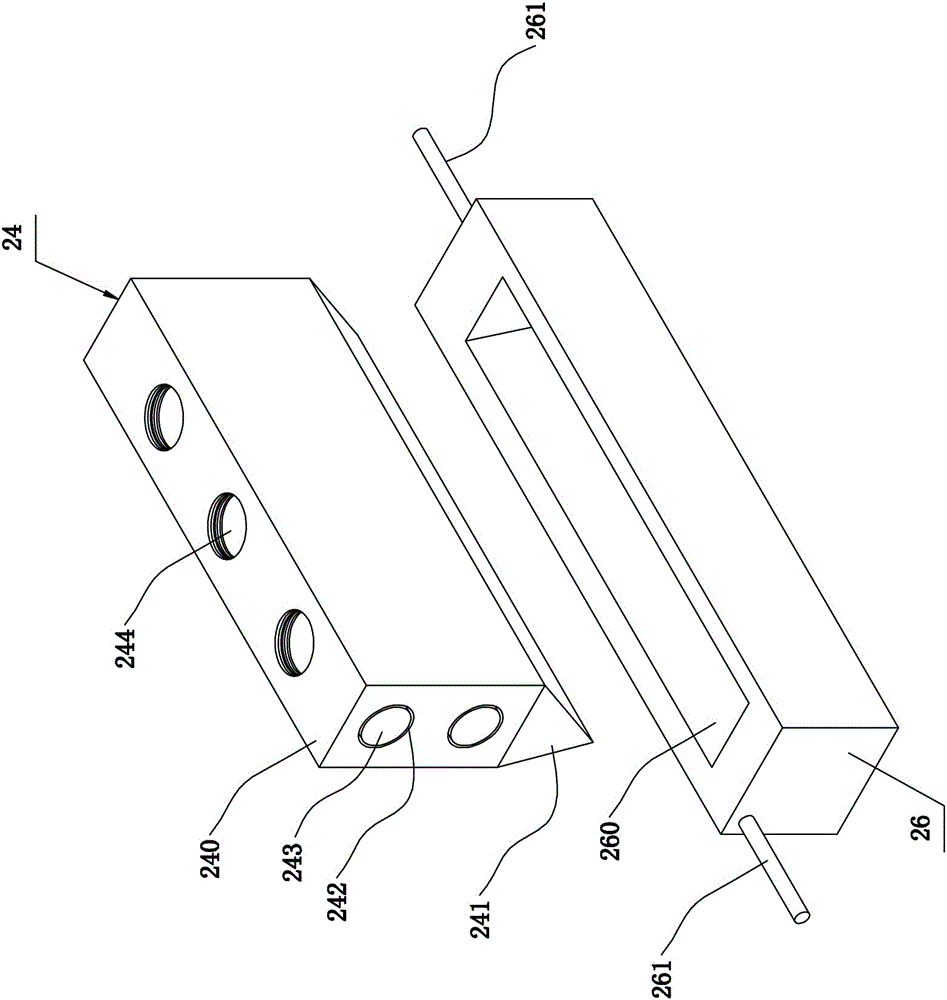

[0038] refer to Figure 1-Figure 10. A bag-making machine 1 with improved structure includes a conveying assembly 61 for dragging the pearl cotton film or air bubble film, a feeding assembly 62 for placing the pearl cotton film or air bubble film 60, and a feeding assembly 62 for placing the pearl cotton film or air bubble film The air bubble film 60 is cut into block-shaped heat-sealing and hot-pressing mechanism 2, and the heat-sealing and hot-pressing mechanism 2 includes a fixed frame body 20, two guide sleeves 21 installed on both sides of the fixed frame body 20, which can be slidably installed up and down. The pull rod 22 in each guide sleeve 21, the cutter holder 23 and the heat-sealing cutter 24 installed on the cutter holder 23, the upper ends of each of the pull rods 22 are respectively fixedly connected to the cutter holder 23 Each of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com