Patents

Literature

4023results about How to "Improve firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

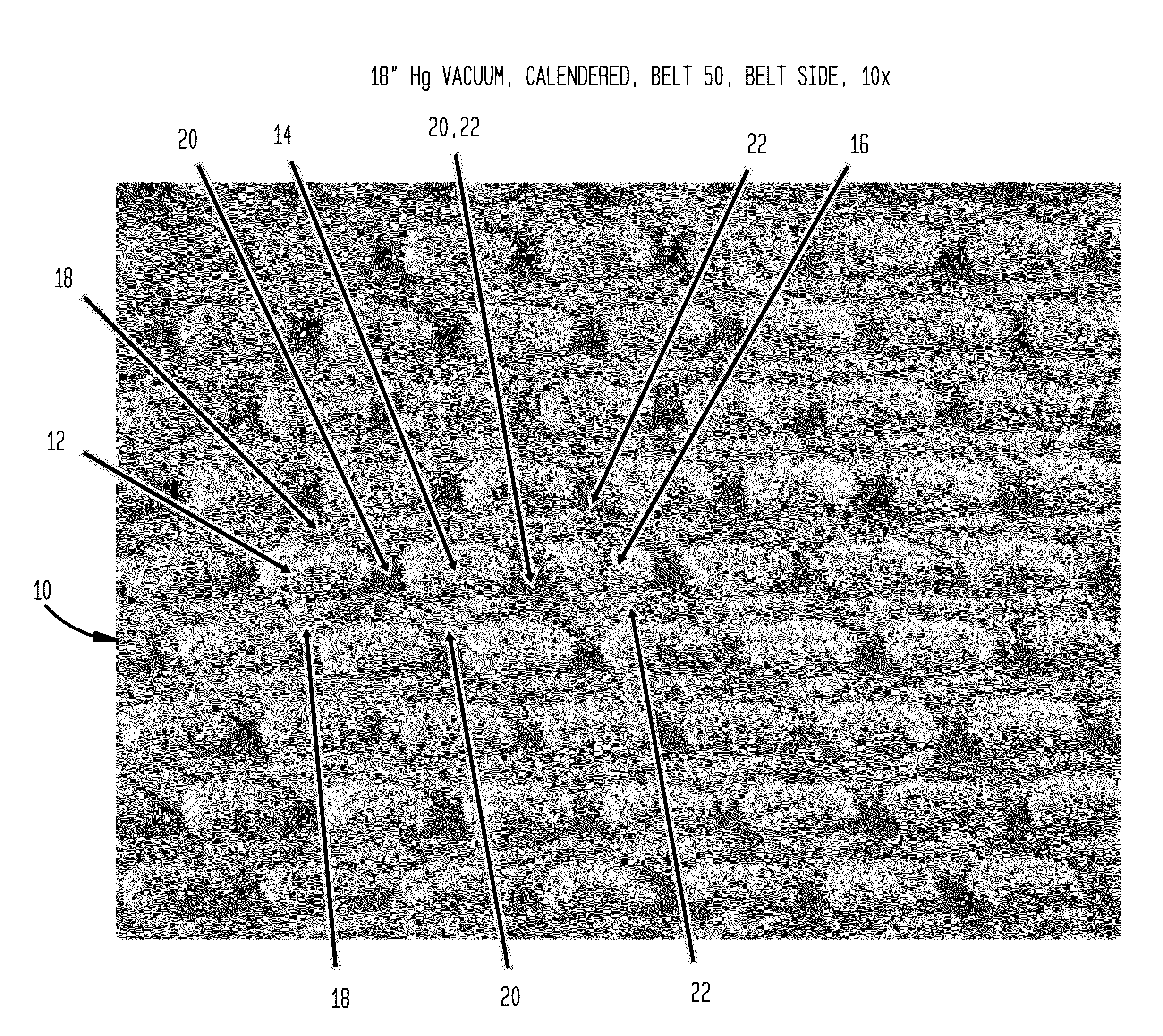

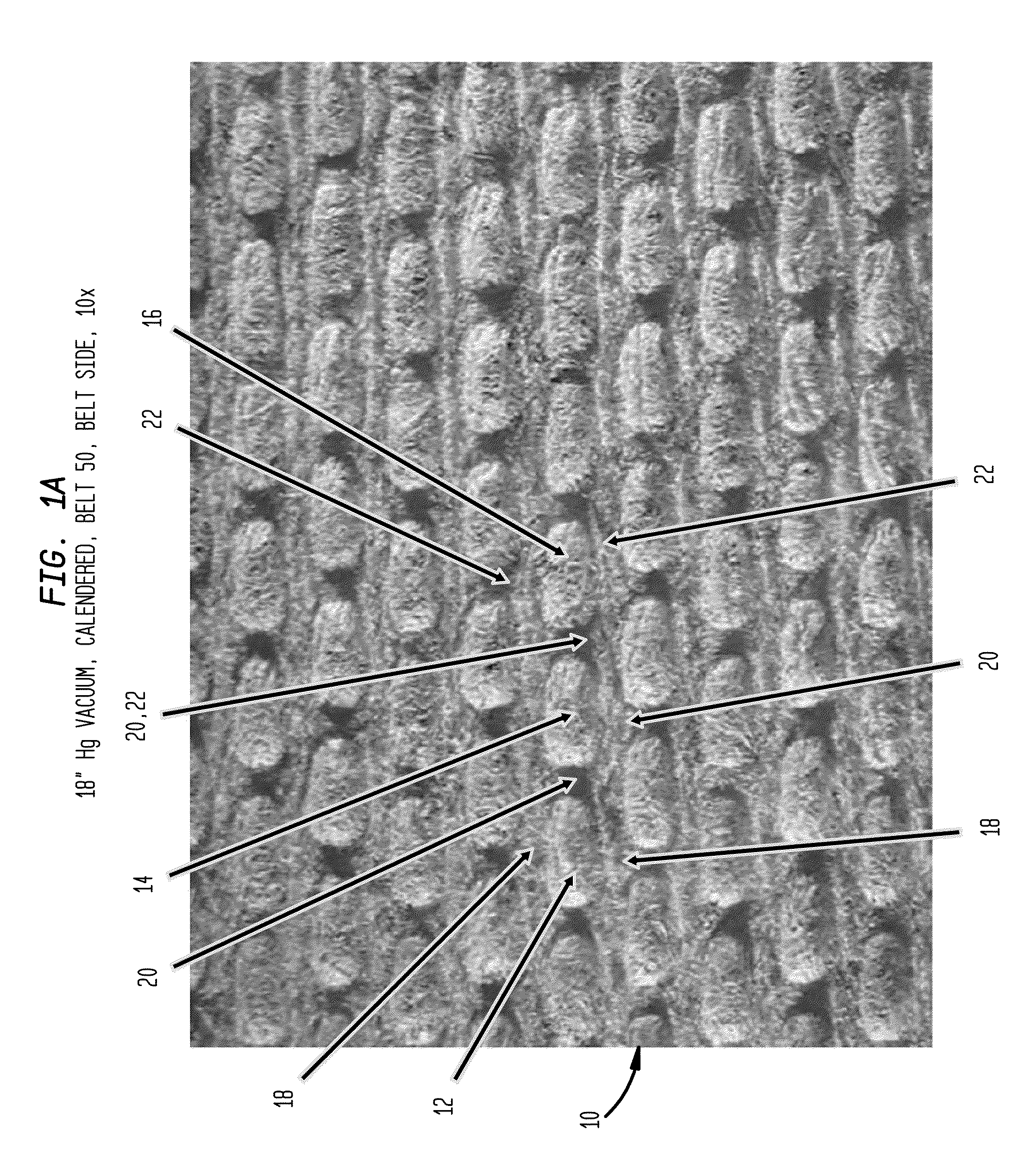

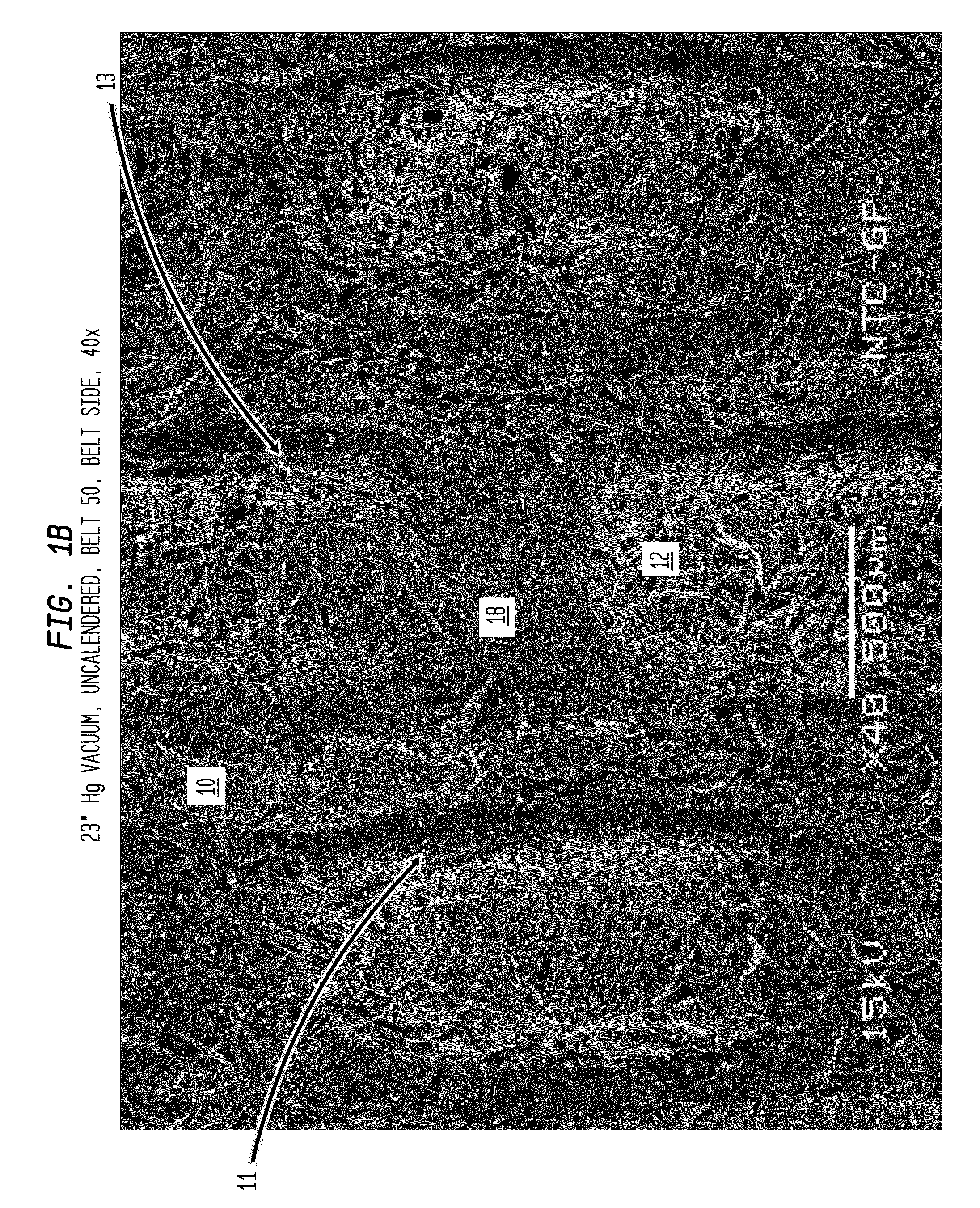

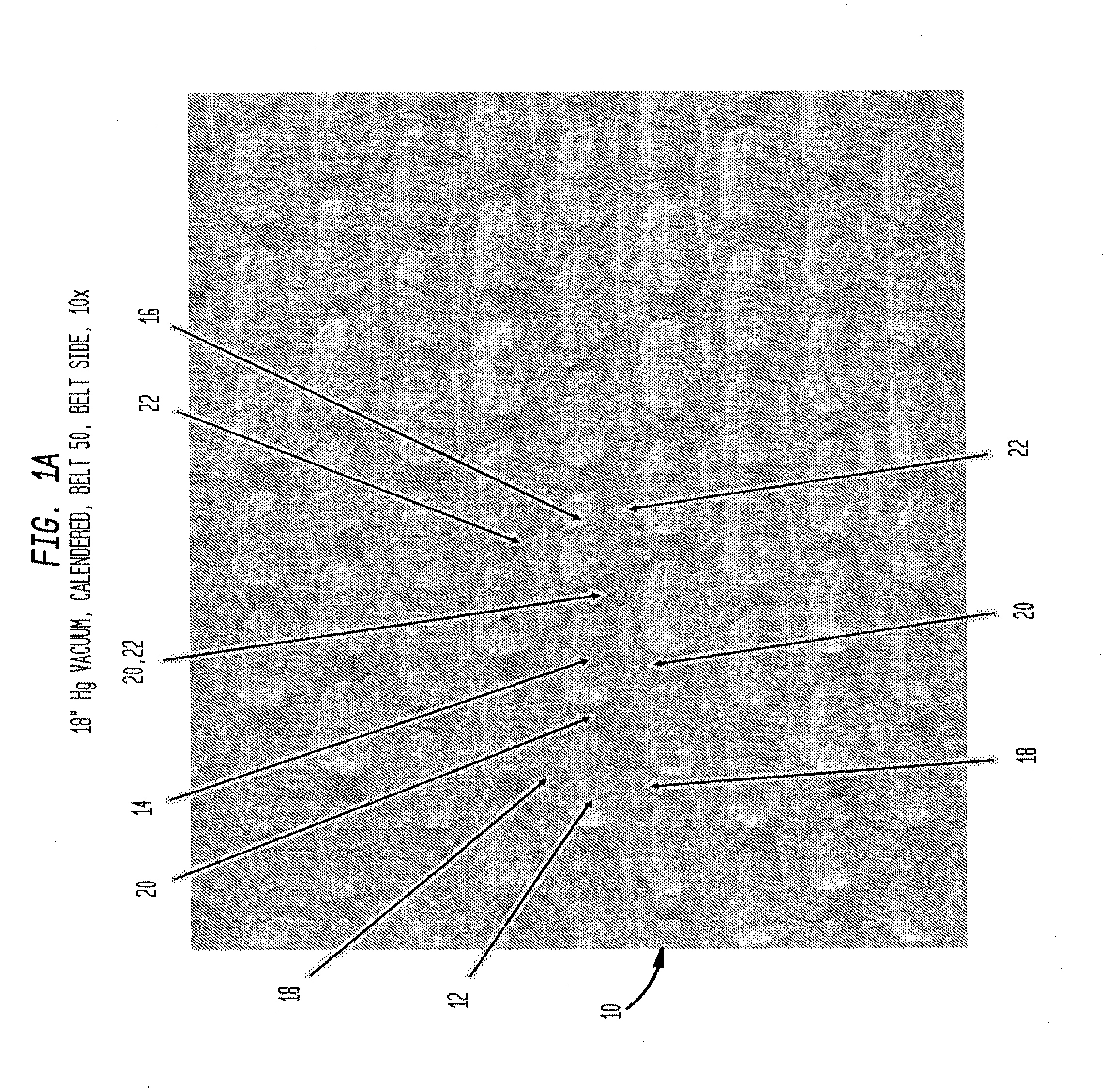

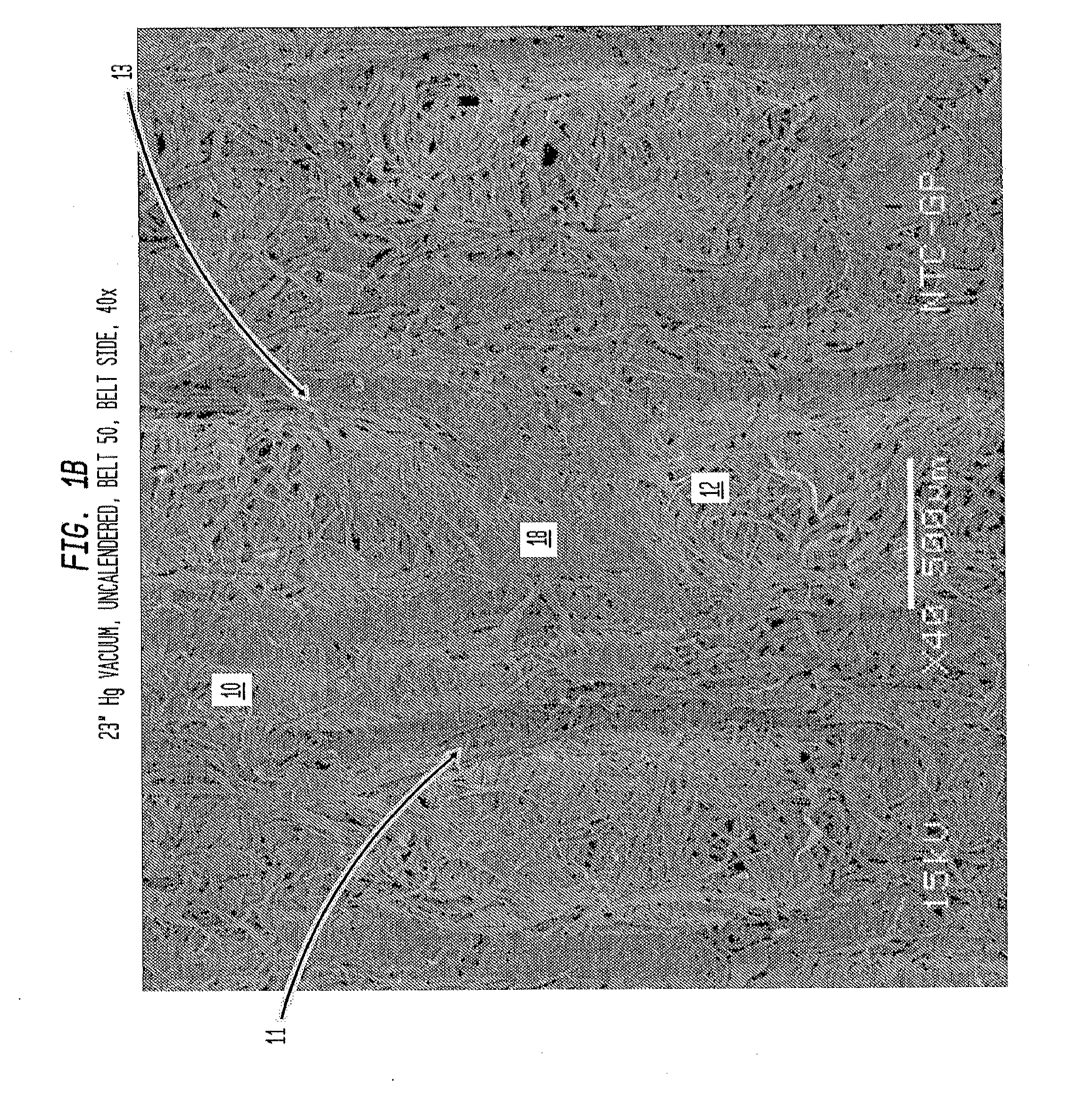

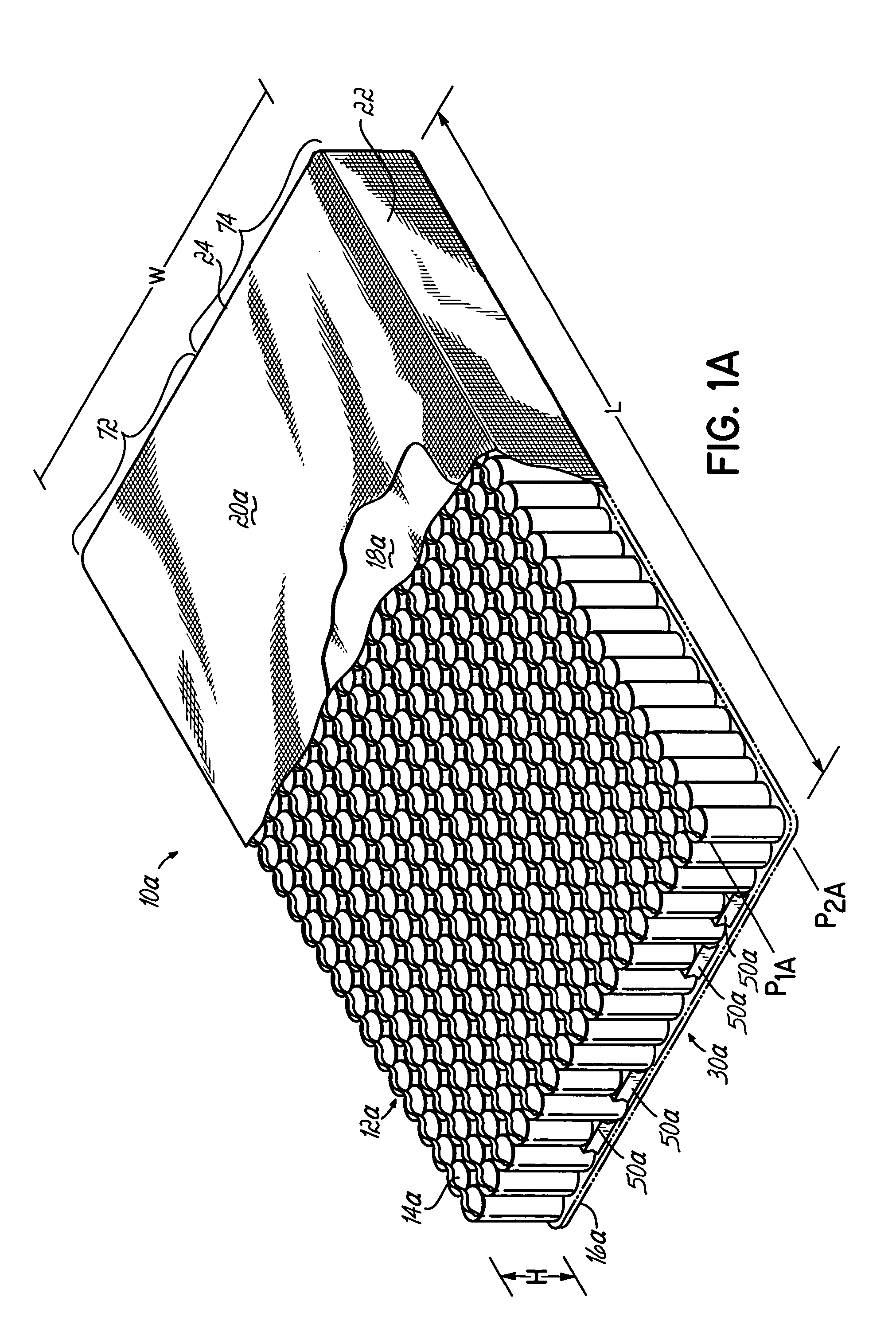

Belt-Creped, Variable Local Basis Weight Absorbent Sheet Prepared With Perforated Polymeric Belt

ActiveUS20100186913A1High local basis weightHigh roll firmnessNon-fibrous pulp additionNatural cellulose pulp/paperChemistryCellulose

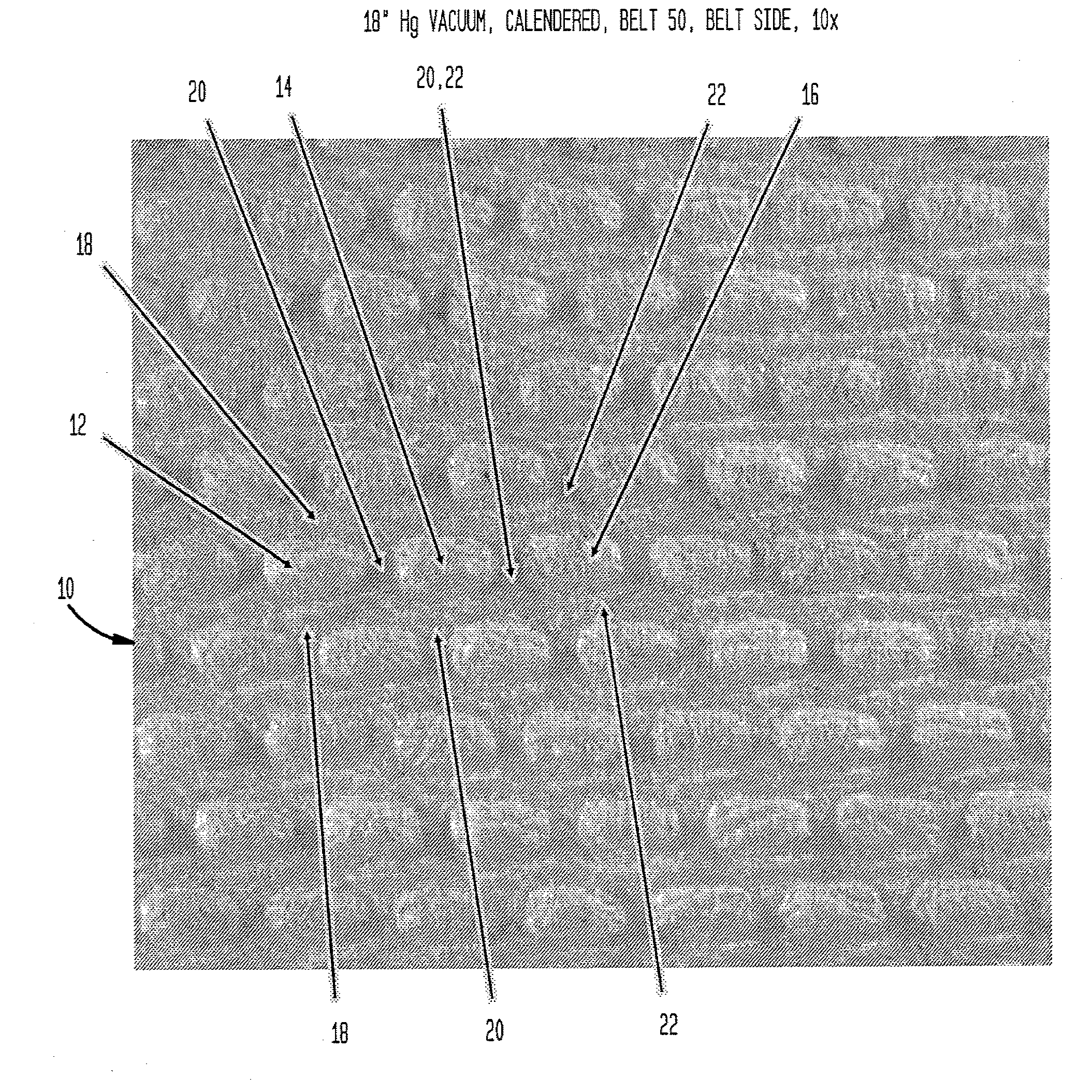

An absorbent cellulosic sheet is formed by belt creping a nascent web at a consistency of 30% to 60% utilizing a generally planar perforated polymeric creping belt to form a sheet with fiber-enriched higher basis weight hollow domed regions on one side of the sheet joined by a network of lower local basis weight connecting regions forming a network where upwardly and inwardly inflected consolidated fibrous regions exhibiting CD fiber orientation bias form transition areas between the connecting regions and the domed regions. When formed into roll products, the cellulosic sheets exhibit a surprising combination of bulk, roll firmness, absorbency and softness. The consolidated fibrous regions are preferably saddle shaped and exhibit a matted structure on both their outer and inner surfaces.

Owner:GPCP IP HLDG LLC

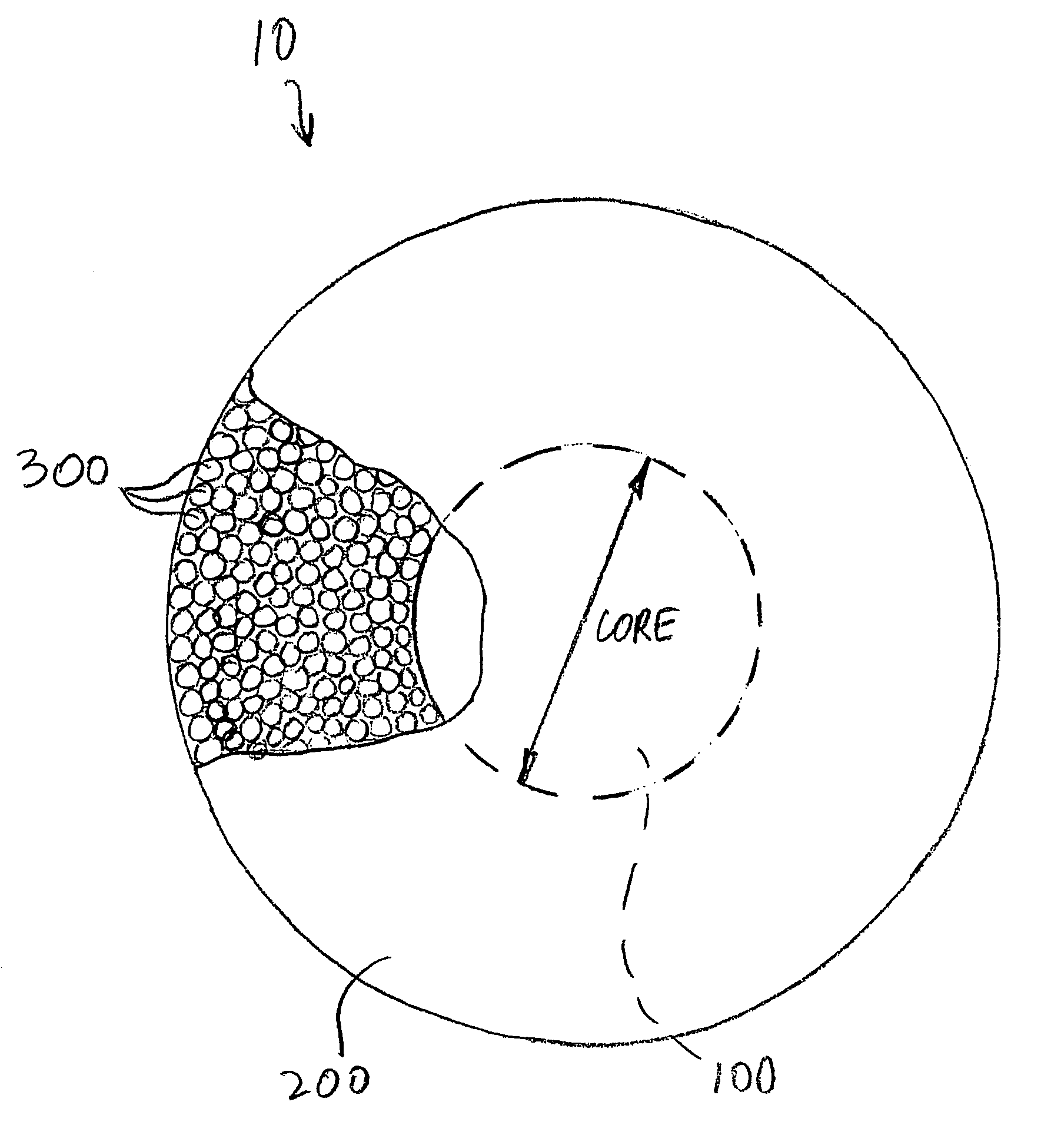

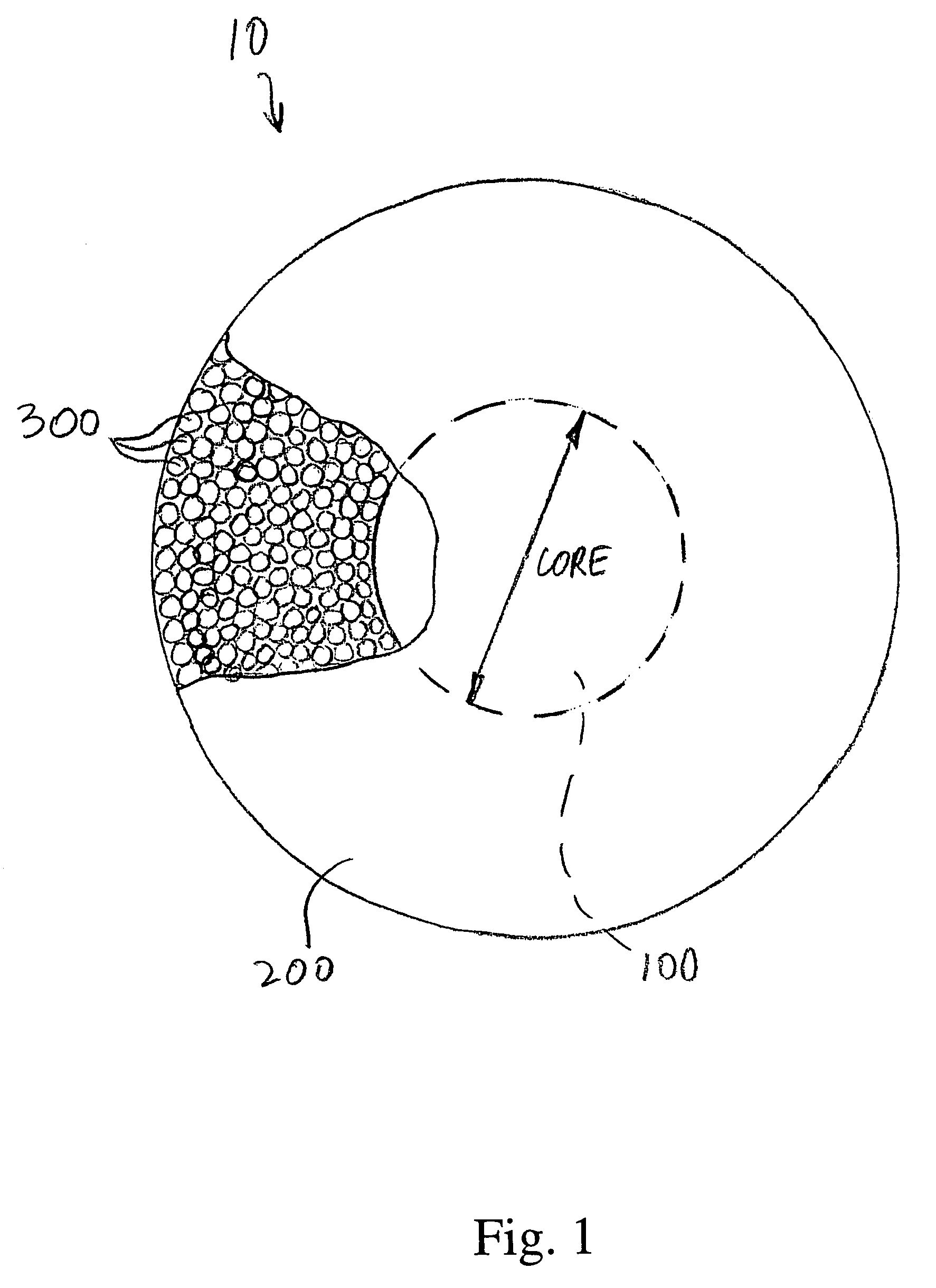

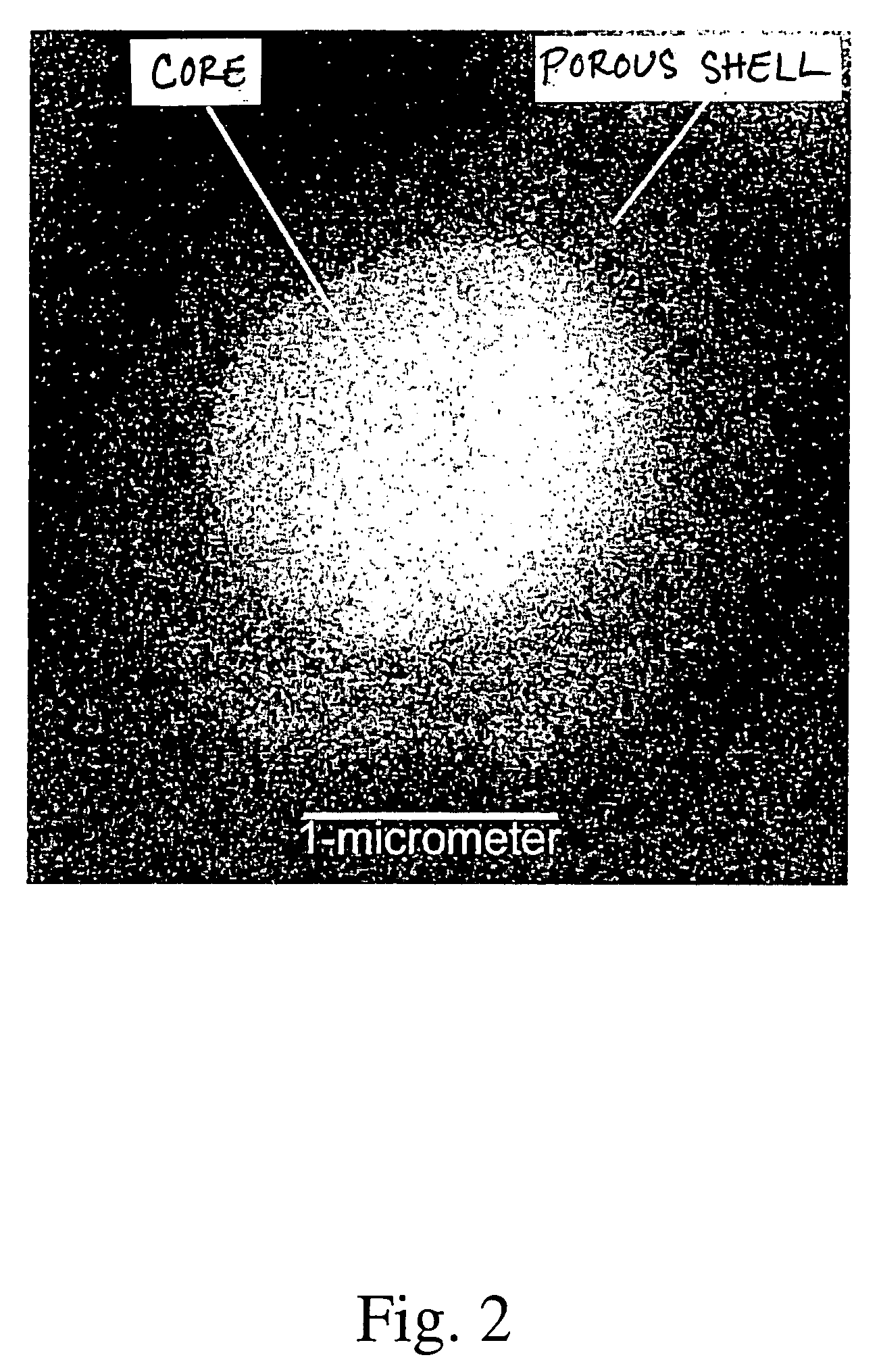

Porous microparticles with solid cores

InactiveUS20070189944A1Narrow size distributionHighly ruggedIon-exchange process apparatusMaterial nanotechnologyChromatography columnNanometre

The present invention relates to microparticles, particularly spherical silica microparticles, which may be useful in liquid chromatography. Specifically, the microparticles include a solid core and an outer porous shell surrounding and irreversibly joined to the core. The shell is composed of a plurality of colloidal nanoparticles, which are applied using an electrostatic multi-multilayering method. The resulting microparticles have a small particle diameter, such as about 1 μm to 3.5 μm, a high particle density, such as about 1.2 g / cc to 1.9 g / cc, and a high surface area, such as about 50 m2 / g to 165 m2 / g. These microparticles can be used to form packed beds and liquid chromatographic columns, which are more efficient and rugged than conventional liquid chromatographic columns.

Owner:ADVANCED MATERIALS TECHNOLOGIES

Method of using skin compositions including tensioning polymers

InactiveUS20060210513A1Improving skin functionReduce appearance problemsCosmetic preparationsToilet preparationsWrinkle skinThird generation

The invention features a method of treating at least one sign of aging on the skin selected from the group consisting of (i) thickening the skin, (ii) enhancing the barrier function of skin, and / or (iii) treating at least one sign of aging on the skin selected from the group consisting of enhancing the elasticity of said skin, enhancing the firmness of said skin, smoothing the surface of the skin, and reducing the appearance of wrinkles on the skin, wherein the method includes applying to skin in need of such treatment a skin care composition including a tensioning polymer, wherein the tensioning polymer has a contractile force greater than about 3 g / mg and a water resistance index from about 0.9 to about 1.9.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Agents for controlling biological fluids and methods of use thereof

InactiveUS20070059350A1Good hemostasisHigh viscosityOrganic active ingredientsBiocideMedicineIncision Site

Therapeutic formulations adapted for positive-pressure application for controlling biological fluid at a desired site in a subject, absorbent articles comprising therapeutic formulations, and anti-infective devices coated with therapeutic formulations, said formulations comprising about 25% to about 99% by weight liquid-crystal forming compound and 0% to about 75% by weight solvent. In addition, methods of using said formulations including methods for controlling biological fluid at a desired site in a subject, methods for controlling blood loss, and methods for facilitating effective closure of a vascular wound or incision site at a desired site in a subject are disclosed, the methods comprising administering particular formulations comprising liquid-crystal forming compounds and solvents that are described herein.

Owner:SOUTHEASTERN MEDICAL TECH

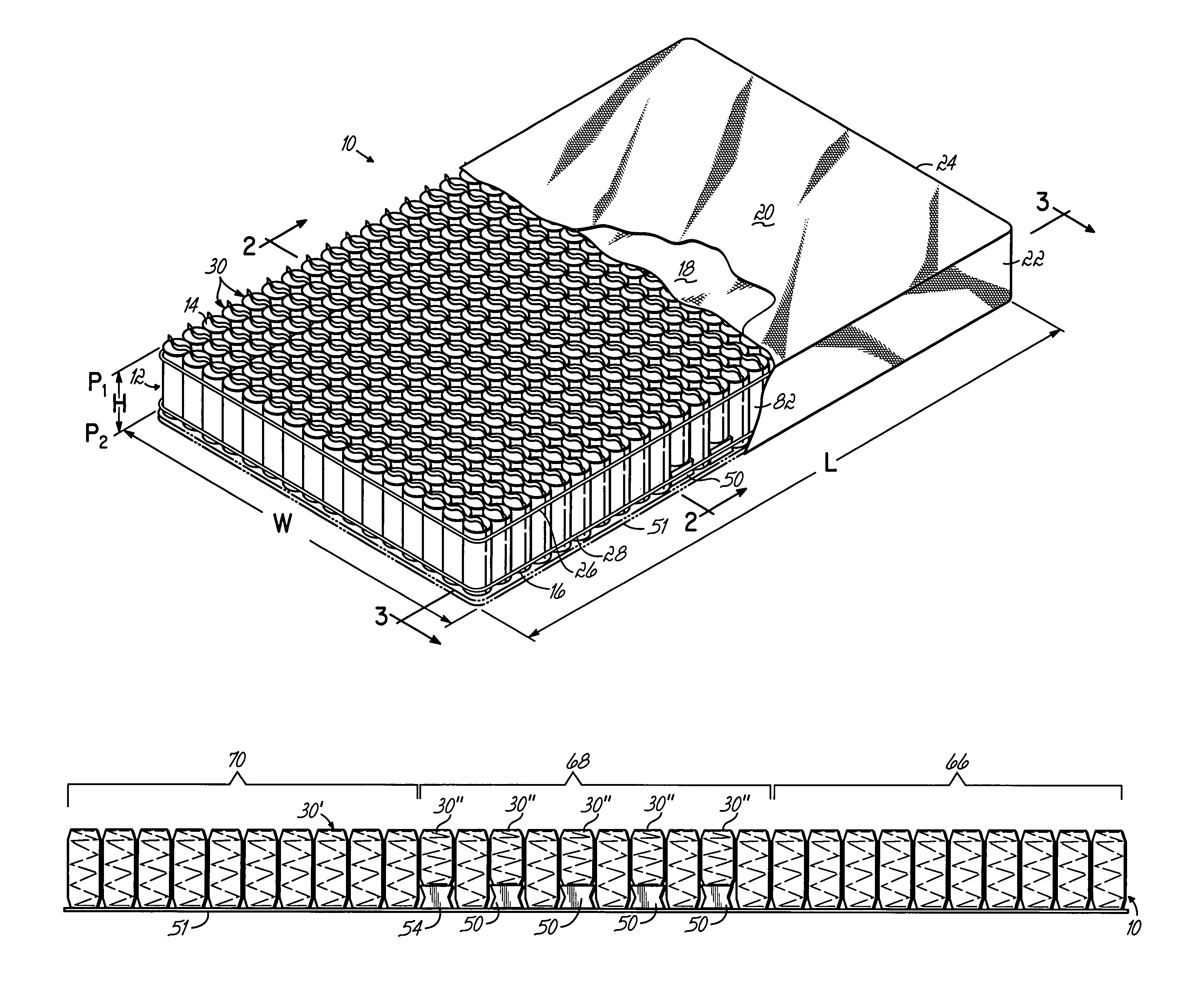

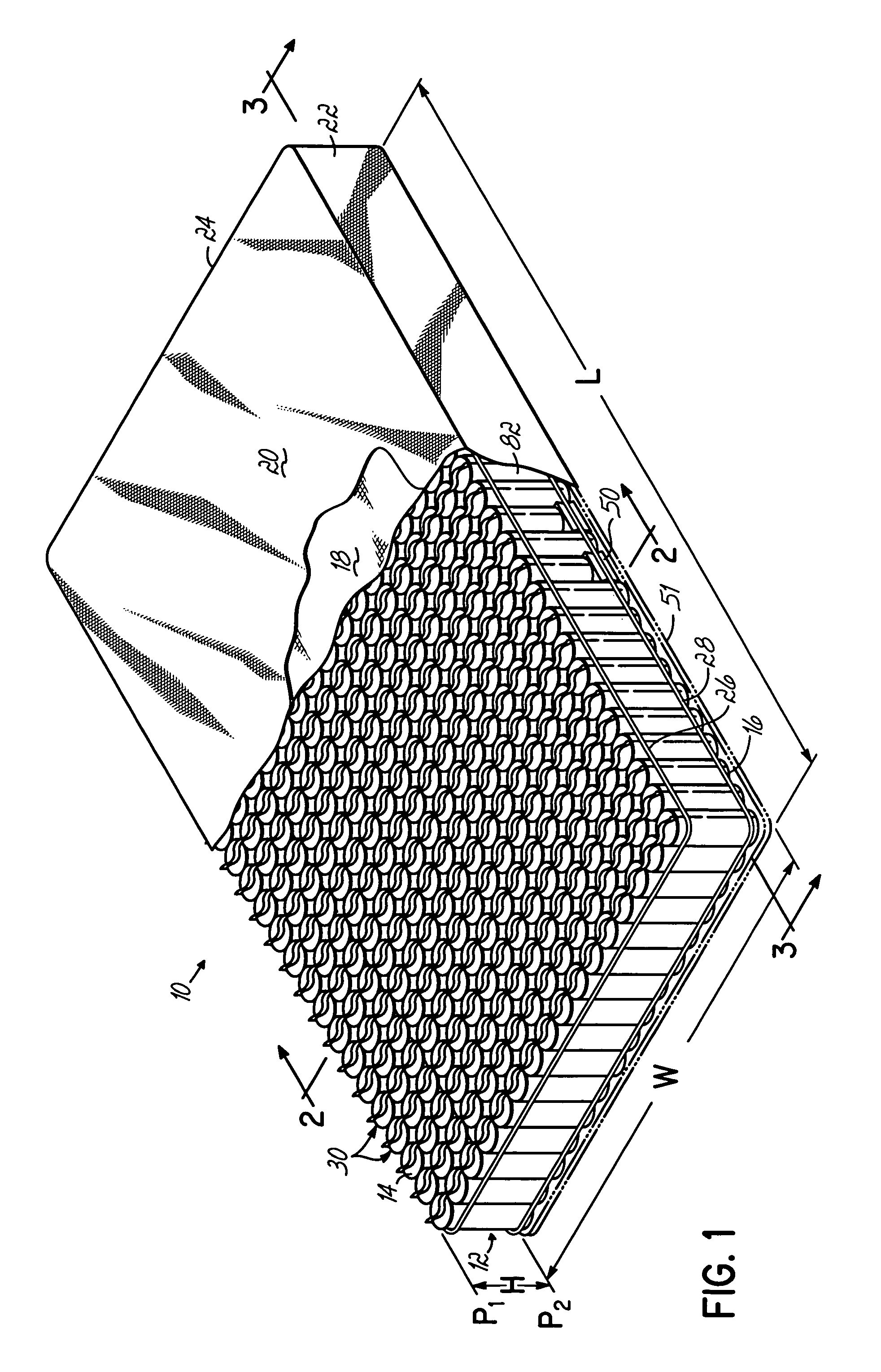

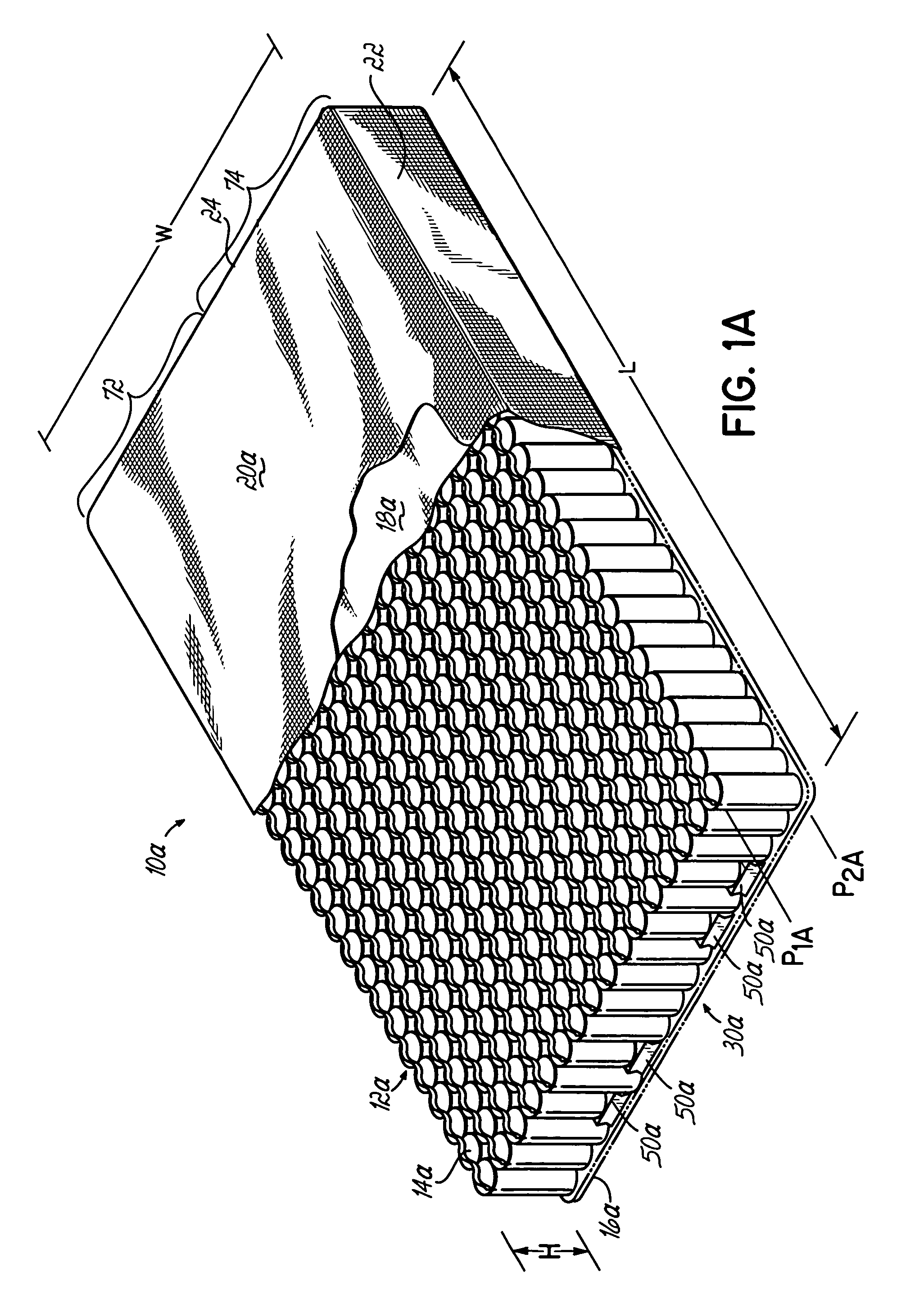

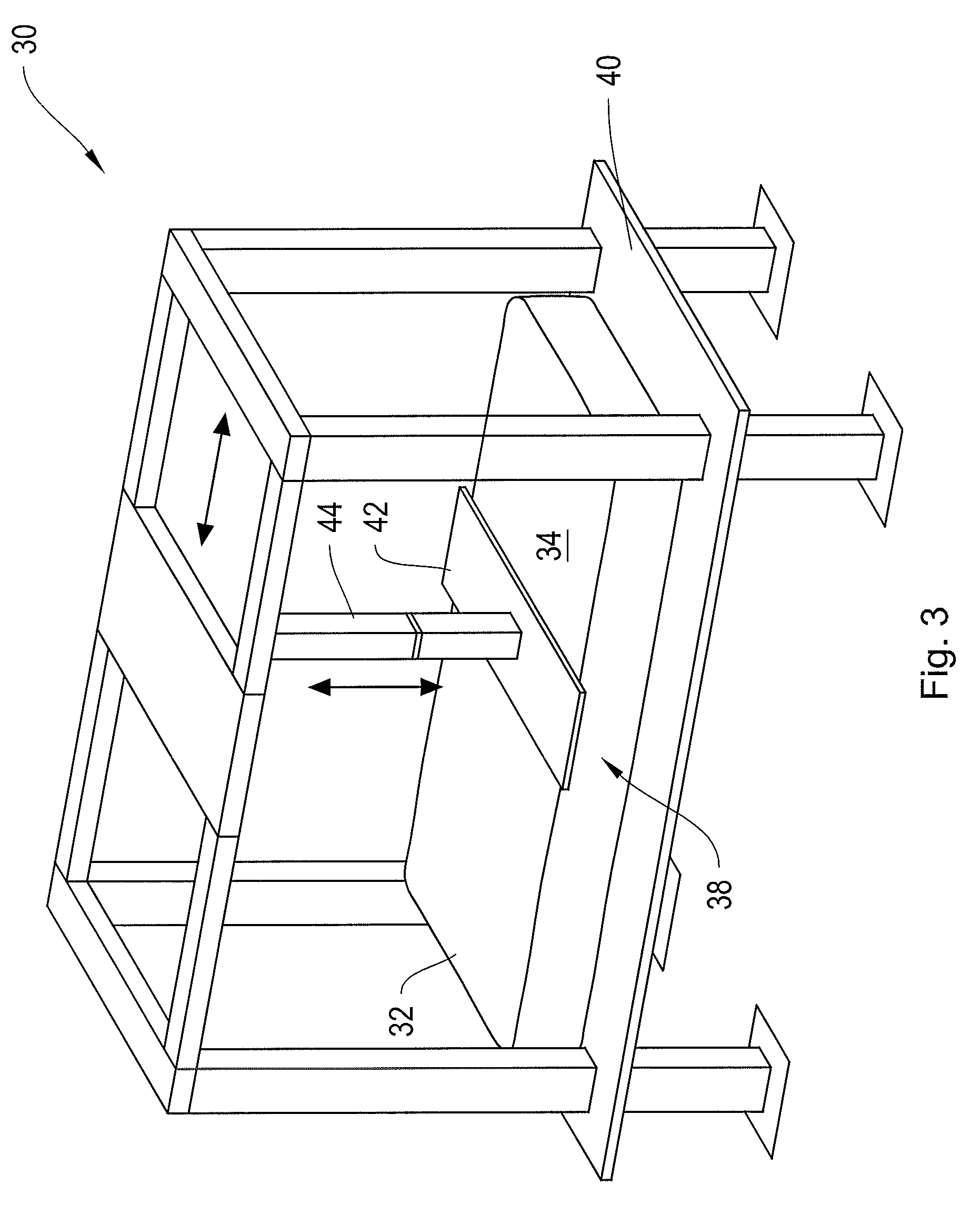

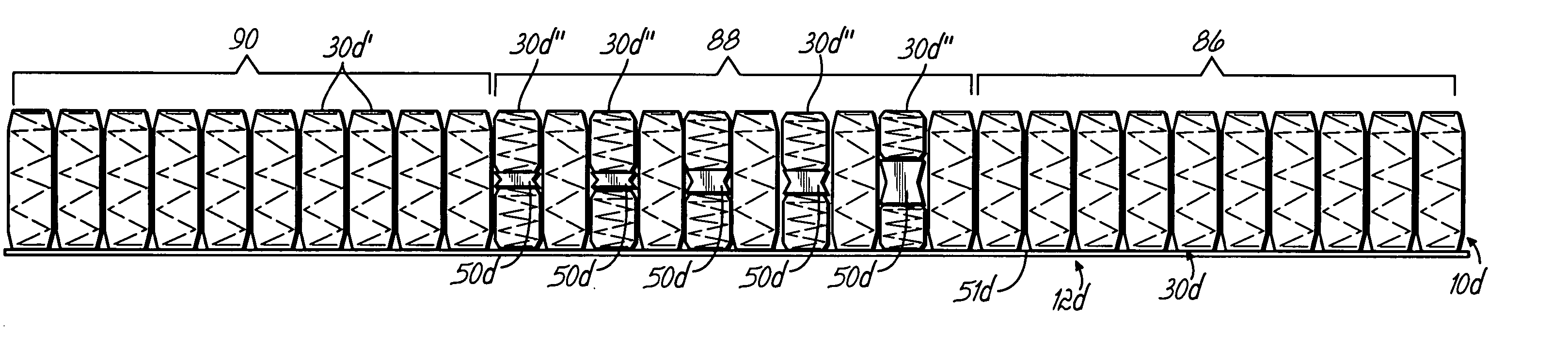

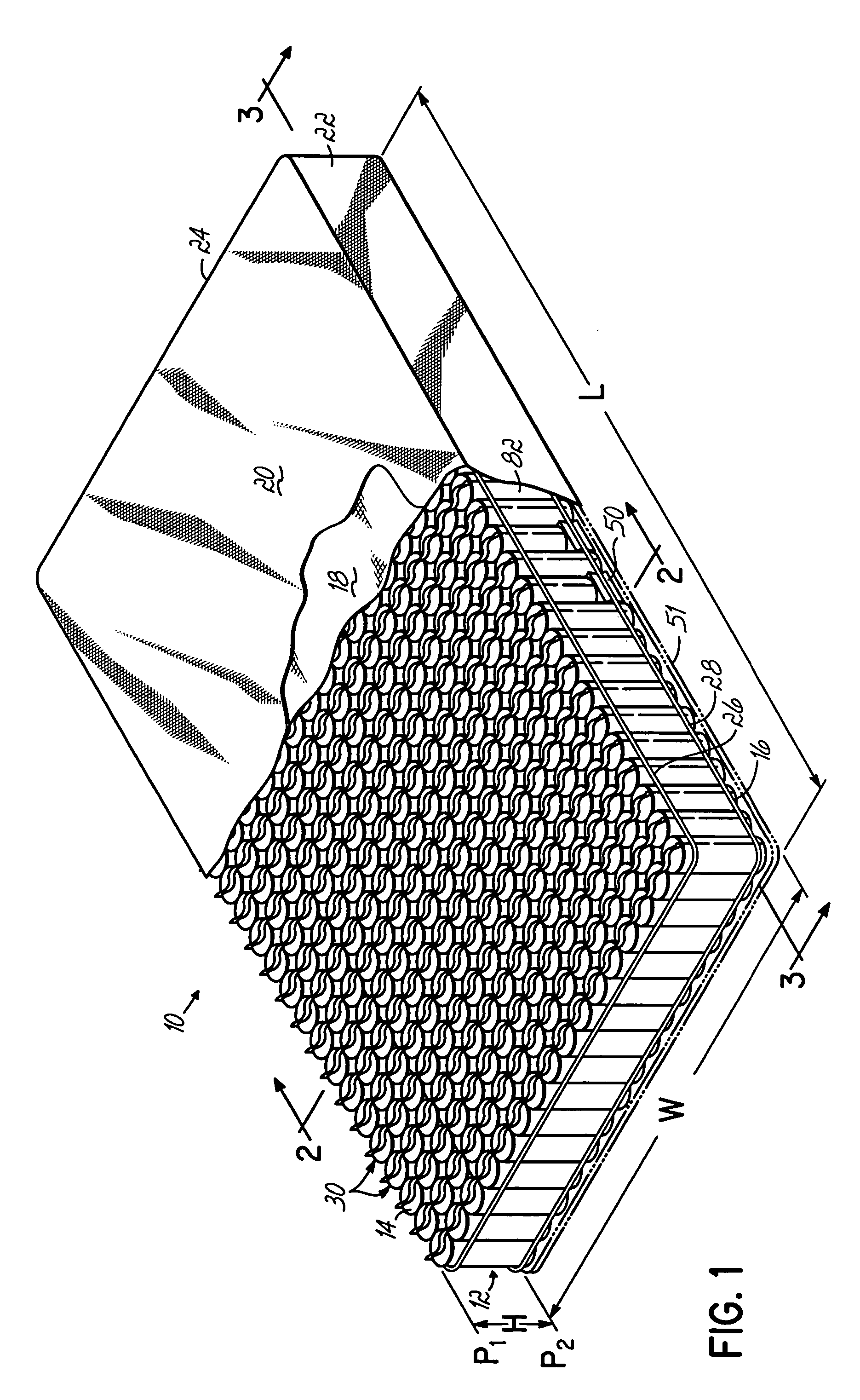

Pocketed bedding or seating product having inflatable members

ActiveUS6986182B2Improve firmnessStuffed mattressesMultiple spring combinationsEngineeringMechanical engineering

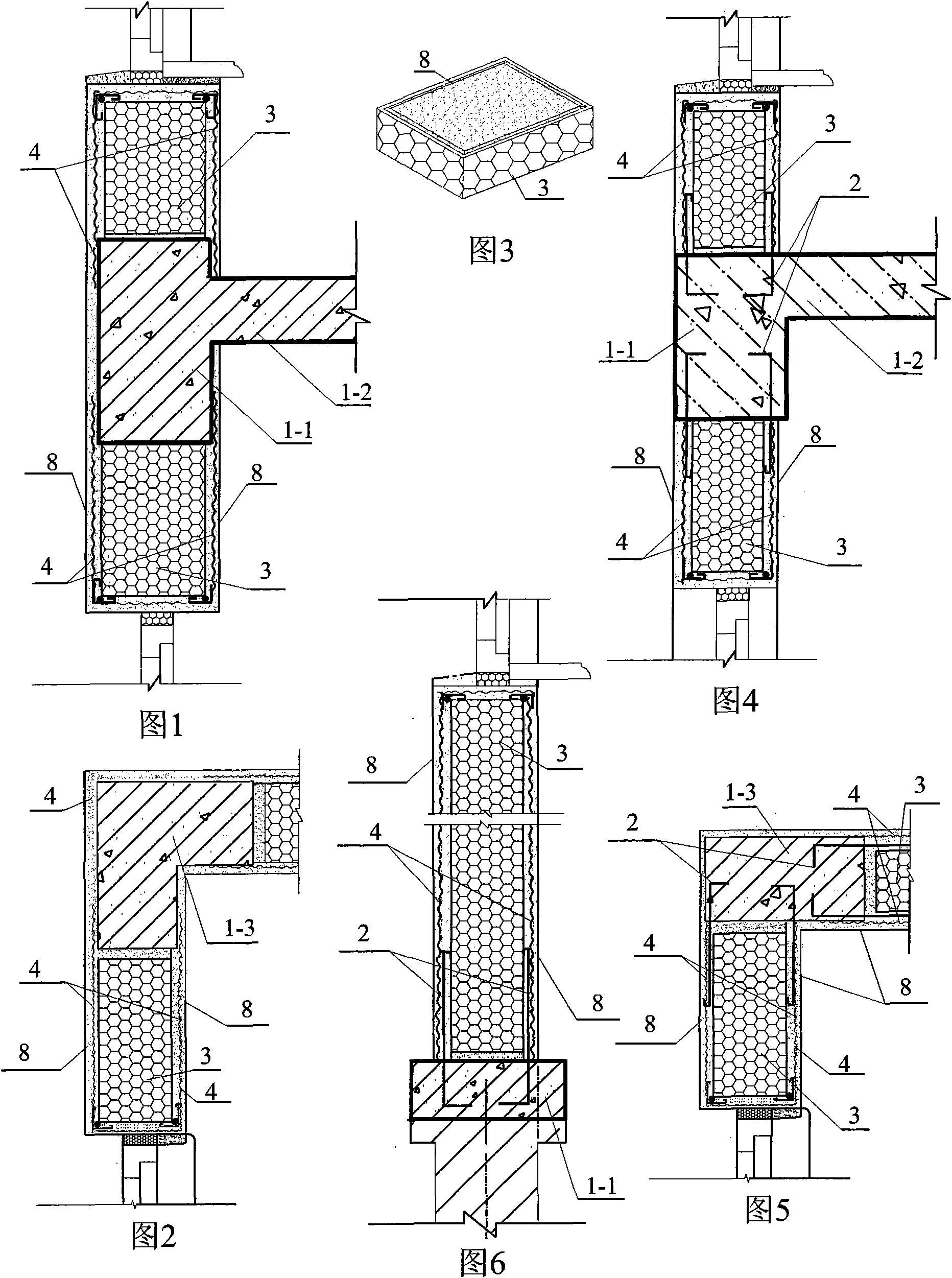

A bedding or seating product comprises a pocketed spring assembly having a plurality of parallel strings of springs joined to each other. Each of said strings of springs comprises a row of interconnected pockets, each of the pockets containing at least one spring encased in a fabric pocket. An inflatable member is sandwiched between a lower scrim sheet and some strings of springs. When inflated, the inflatable member preloads select areas of the product.

Owner:L & P PROPERTY MANAGEMENT CO

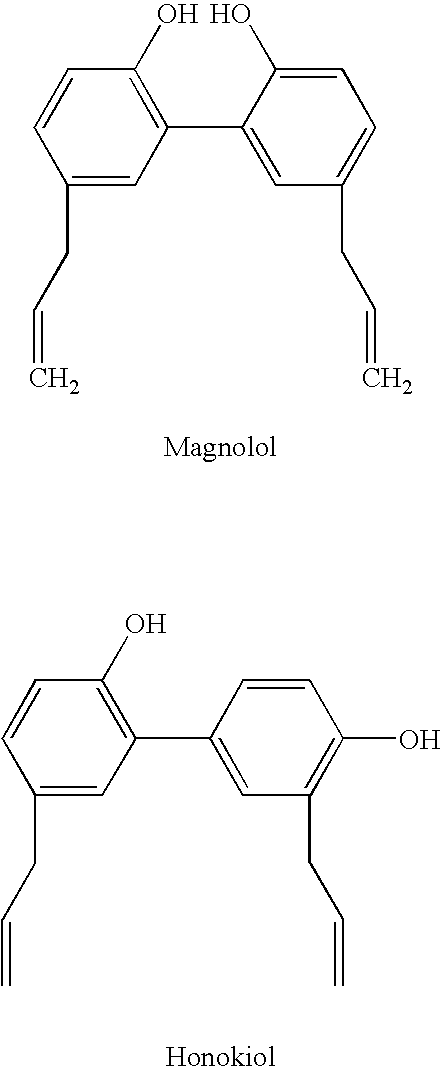

Magnolia extract containing compositions

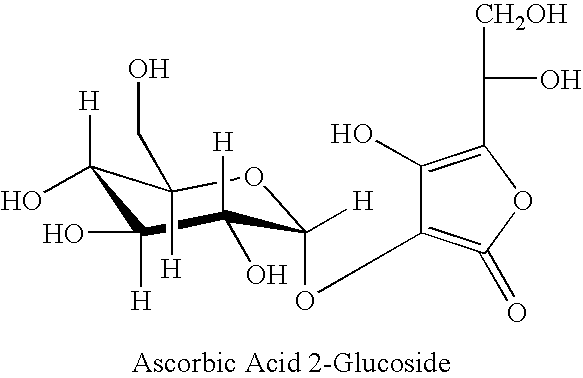

ActiveUS20080260869A1Increase of collagen synthesisIncrease productionCosmetic preparationsBiocideCentella asiatica extractDipeptide

Disclosed is a composition comprising at least two of the following ingredients: Magnolia extract, honokiol, humulus lupulus extract, hesperidin methyl chalcone, gotu kola, dipeptide valyl-tryptophane, palmitoyl tetrapeptide-3, corylus avellana bud extract, centella asiatica extract, cucumis sativa extract, morus alba extract, hibiscus sabdariffa flower extract, vitis vinifera extract, ascorbyl glucoside, citrus medica limonum extract, avena sativa kernel extract, hydrolyzed soy protein, aniseed myrtle extract, tasmania lanceolata leaf extract, artemisia abrotanum extract, or citrus grandis fruit extract or any combination thereof. Also disclosed are methods of treating skin conditions by topically applying the composition to skin.

Owner:MARY KAY INC

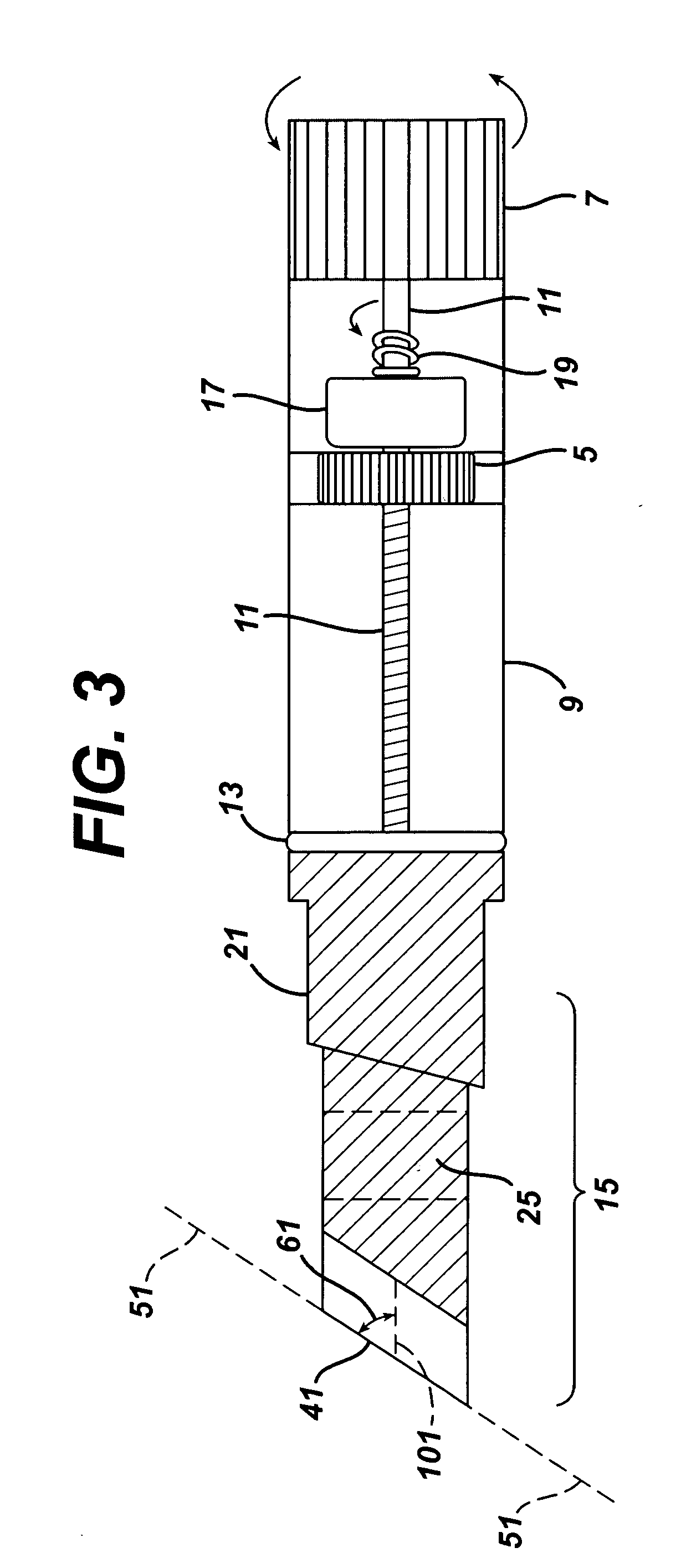

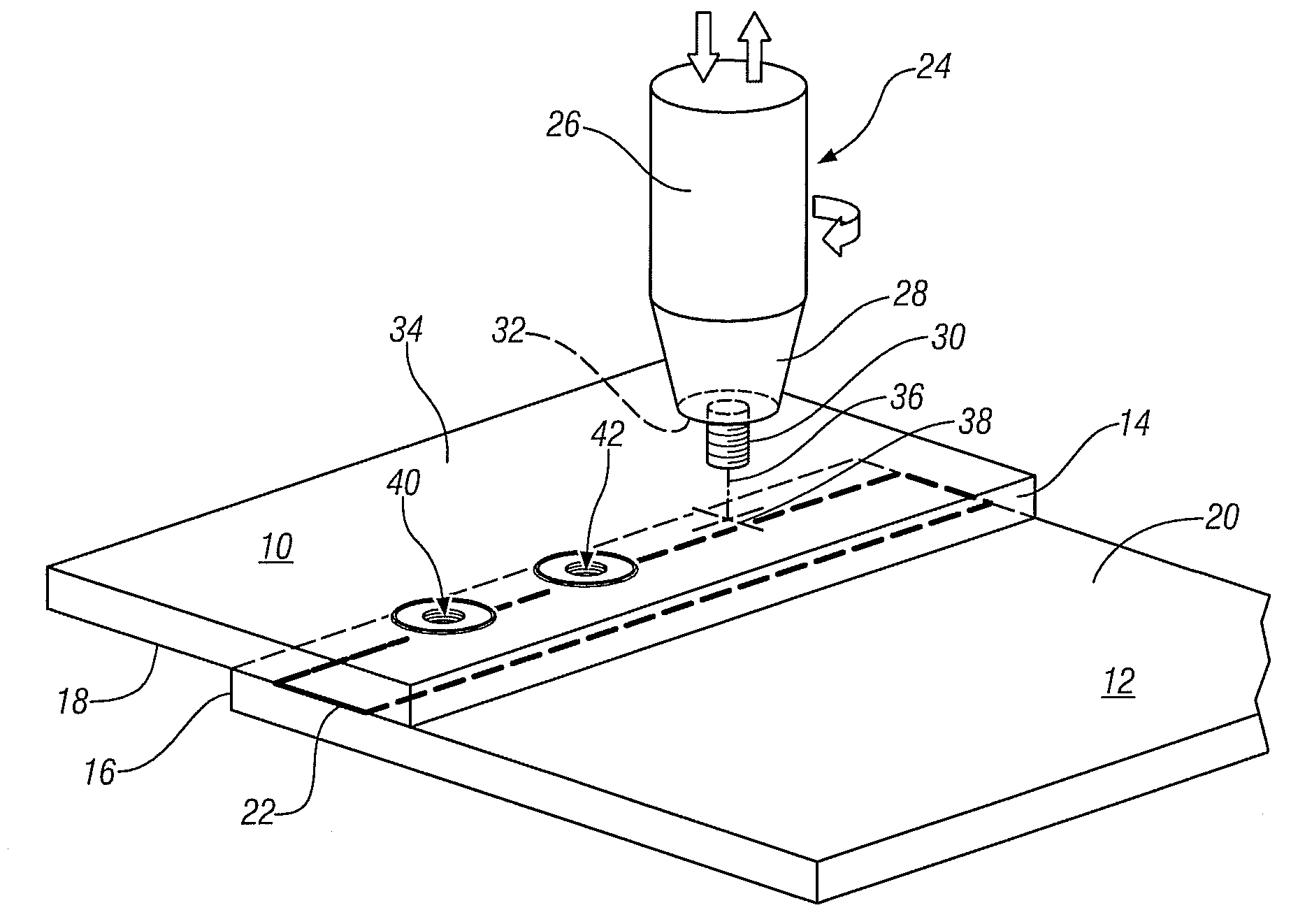

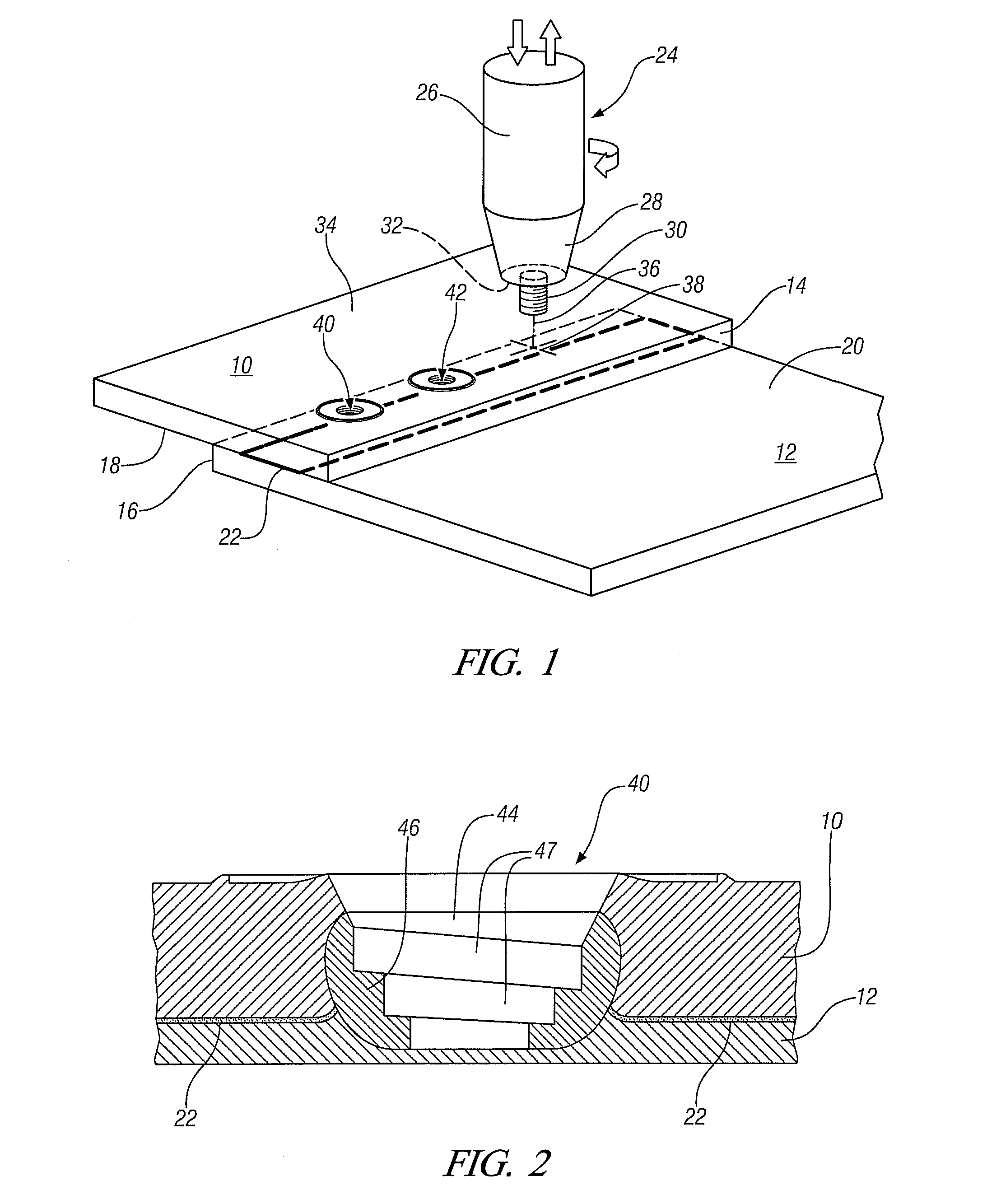

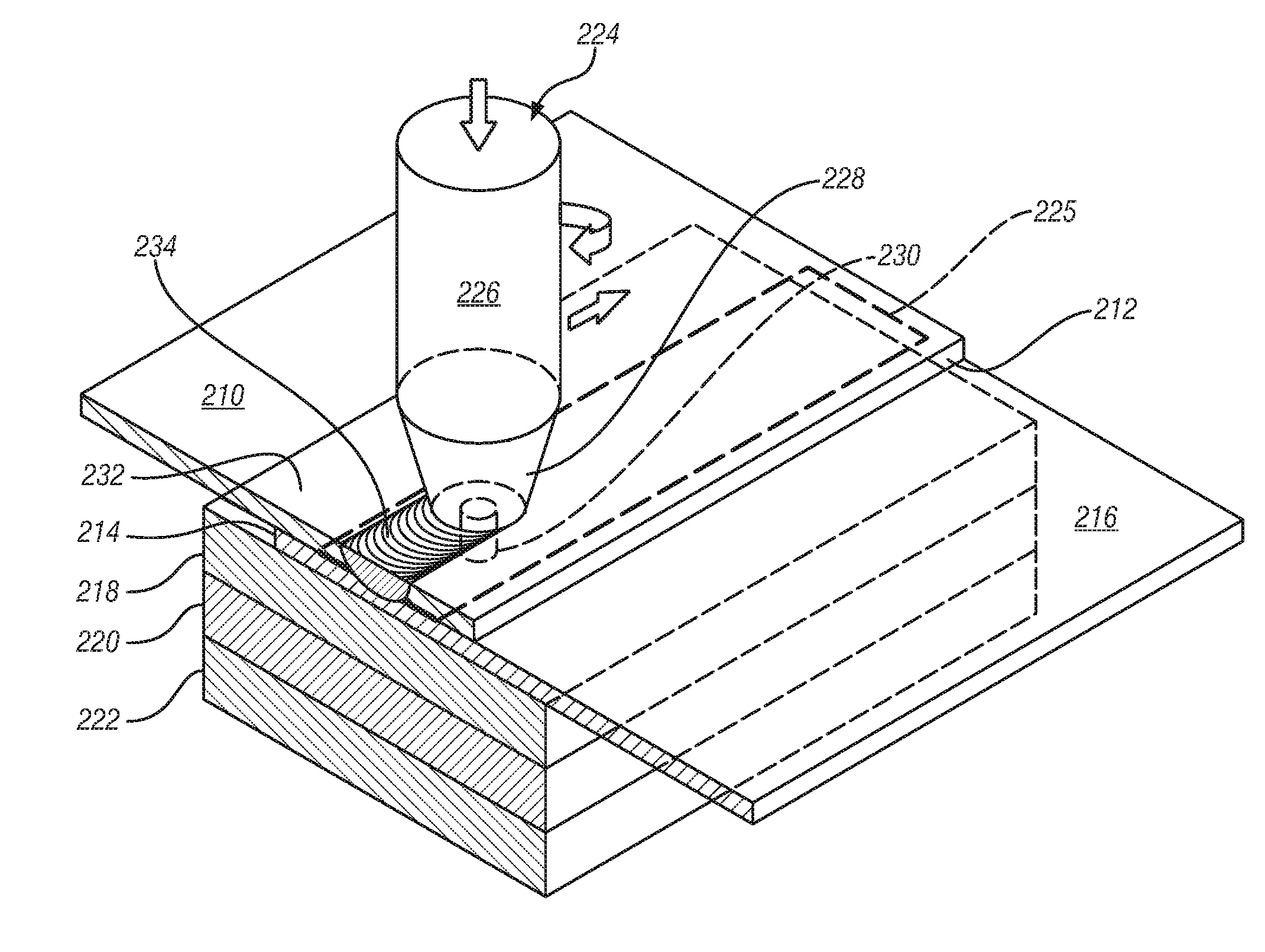

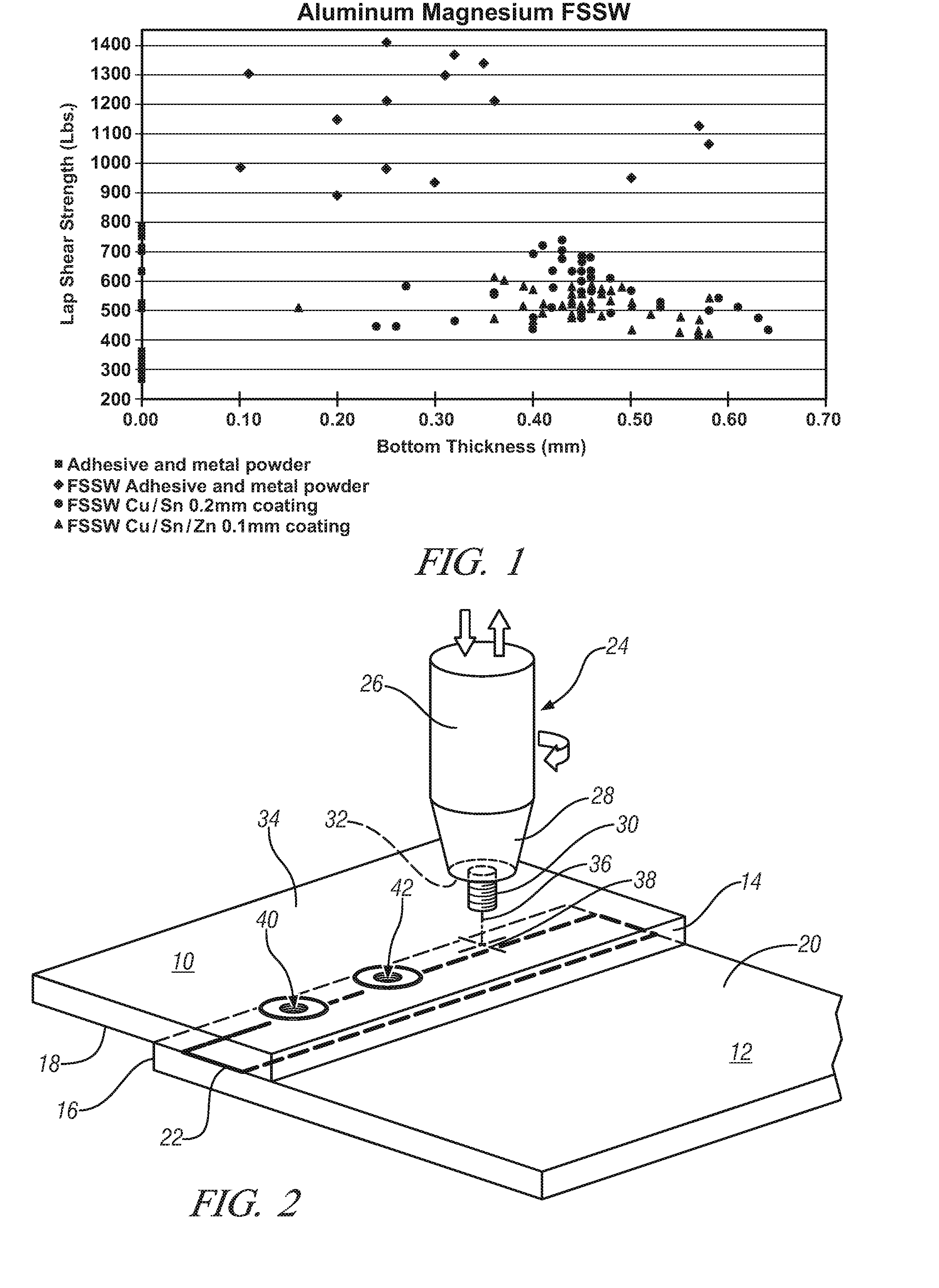

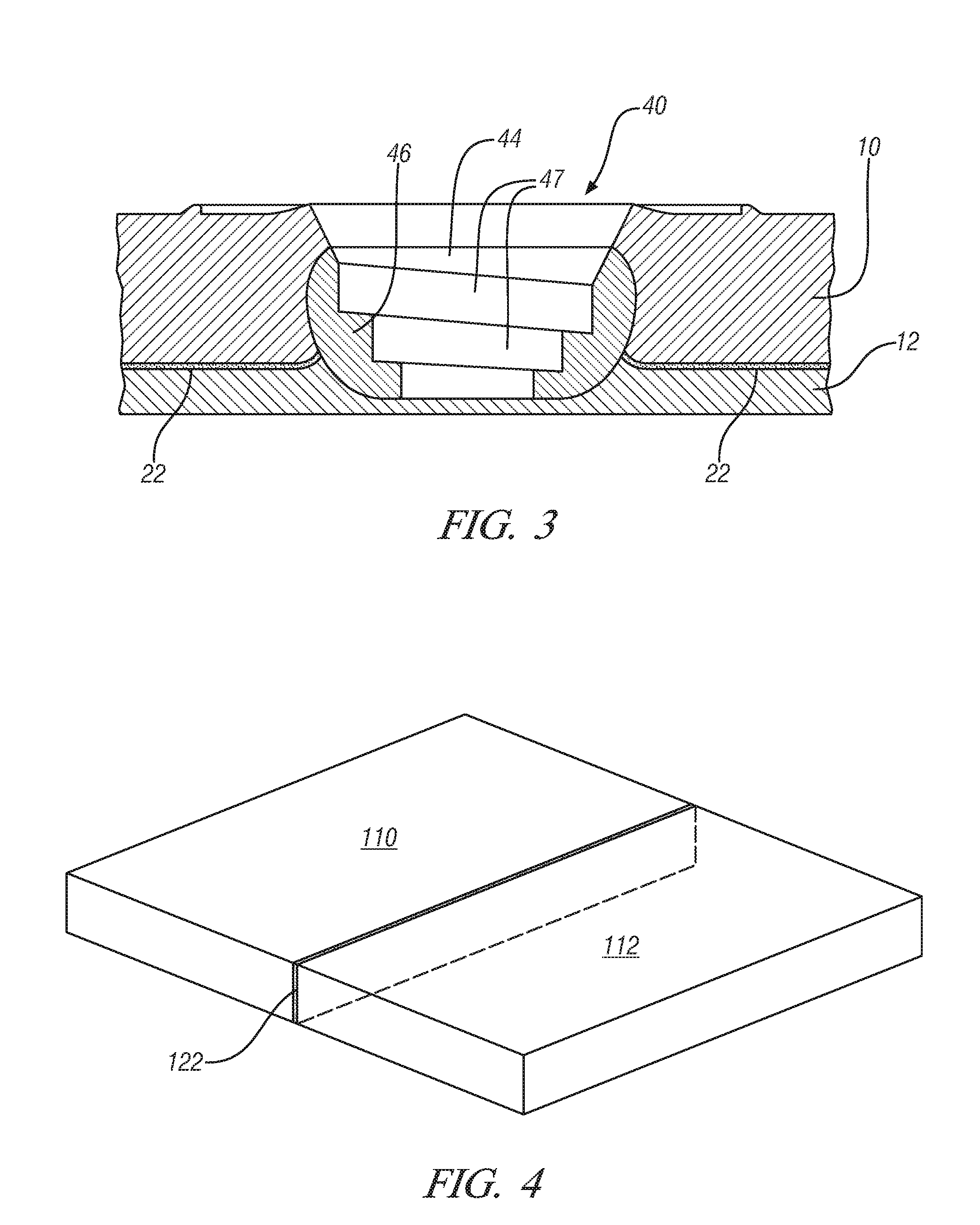

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

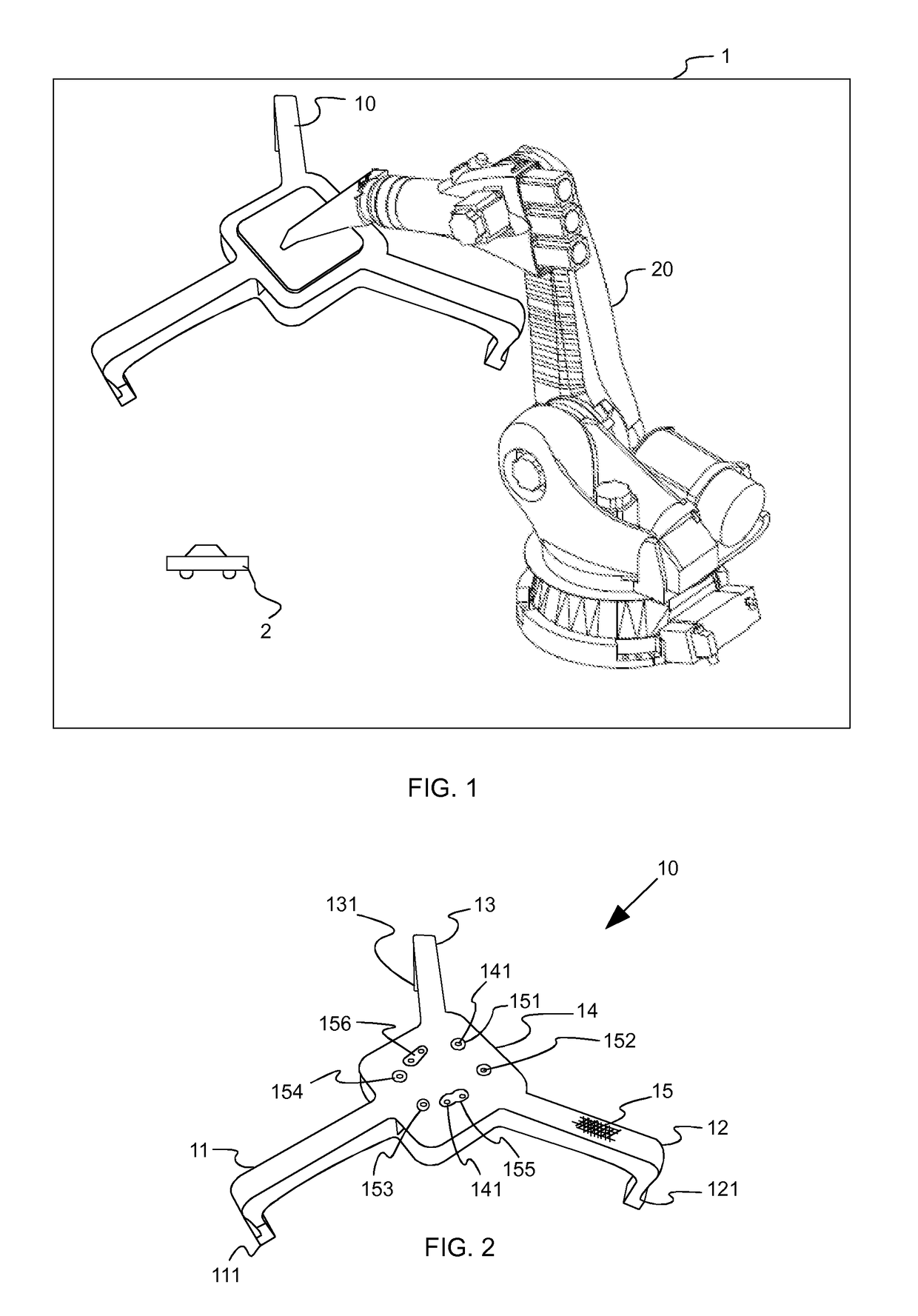

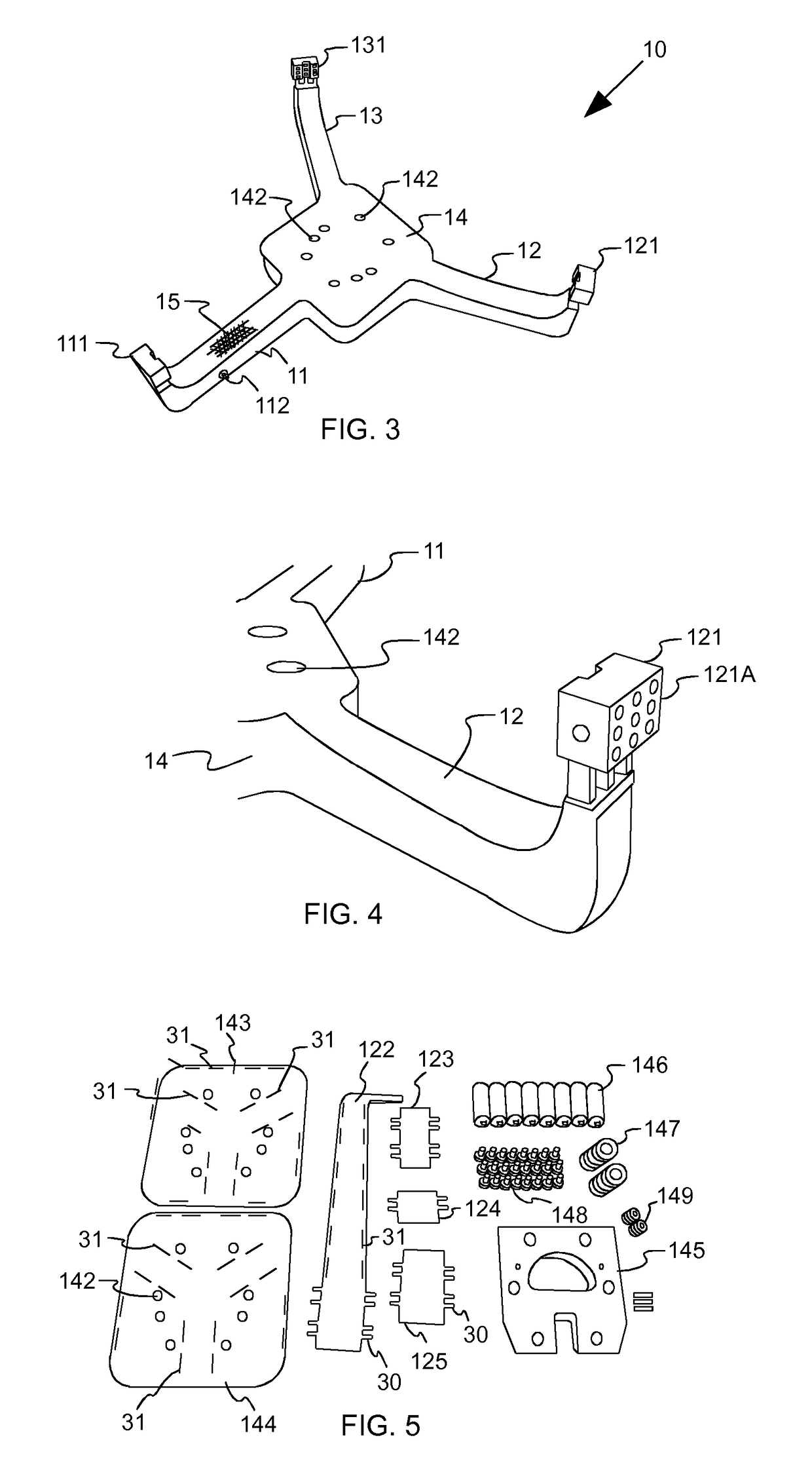

Device for use in the handling of a load and method for producing such a device

ActiveUS10173327B2Reduce weightAdapted flexiblyProgramme-controlled manipulatorGripping headsFiberEngineering

A device for use in handling a load and a method for producing the device are provided. The device comprises a three-dimensional framework that comprises a plurality of single parts, a cover made of a fiber-reinforced plastics with which the framework is covered, and at least one mounting unit for a handling unit for handling a part that is useable in the production of an object and that forms the load.

Owner:FFT PRODIONSSYST

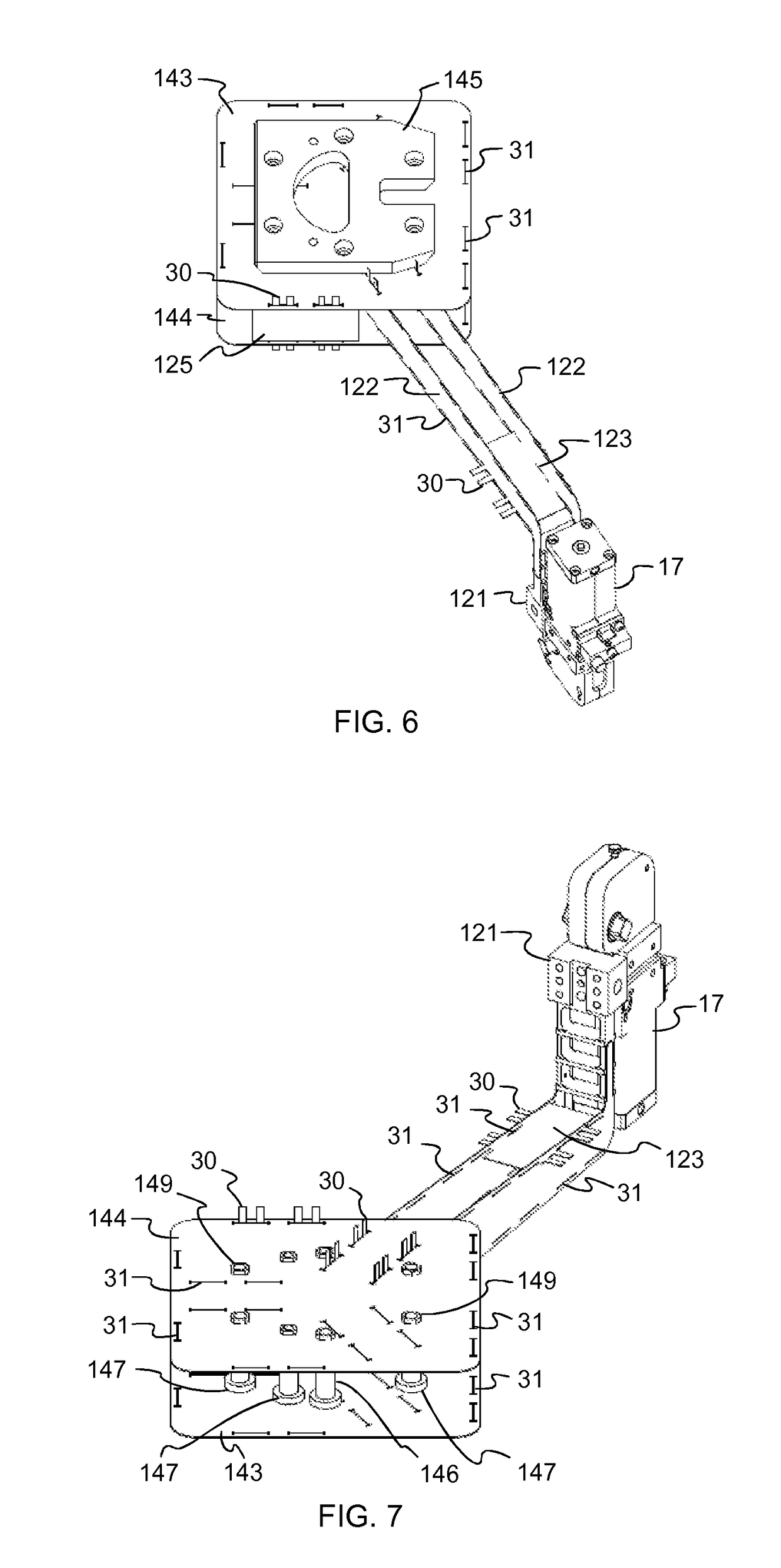

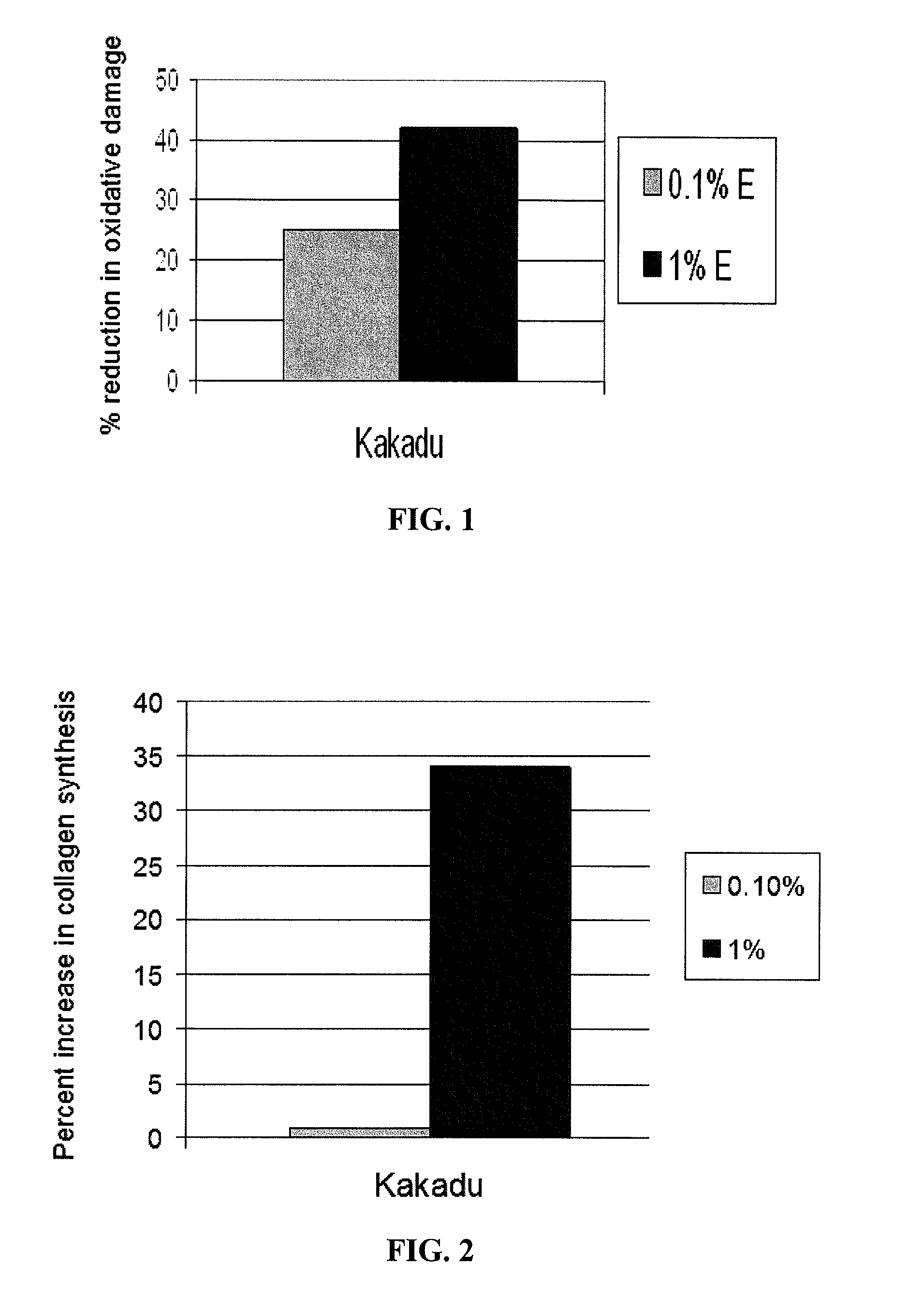

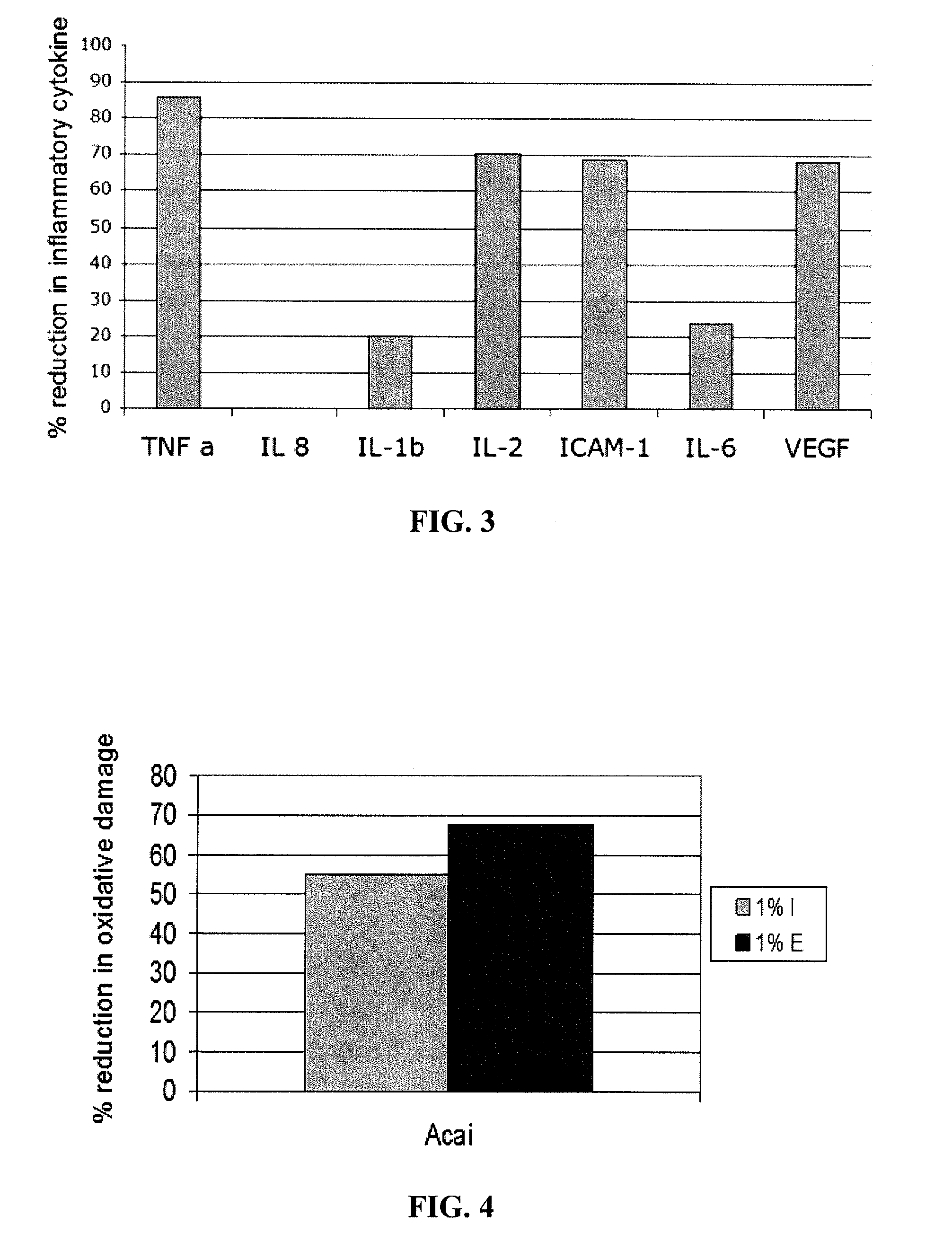

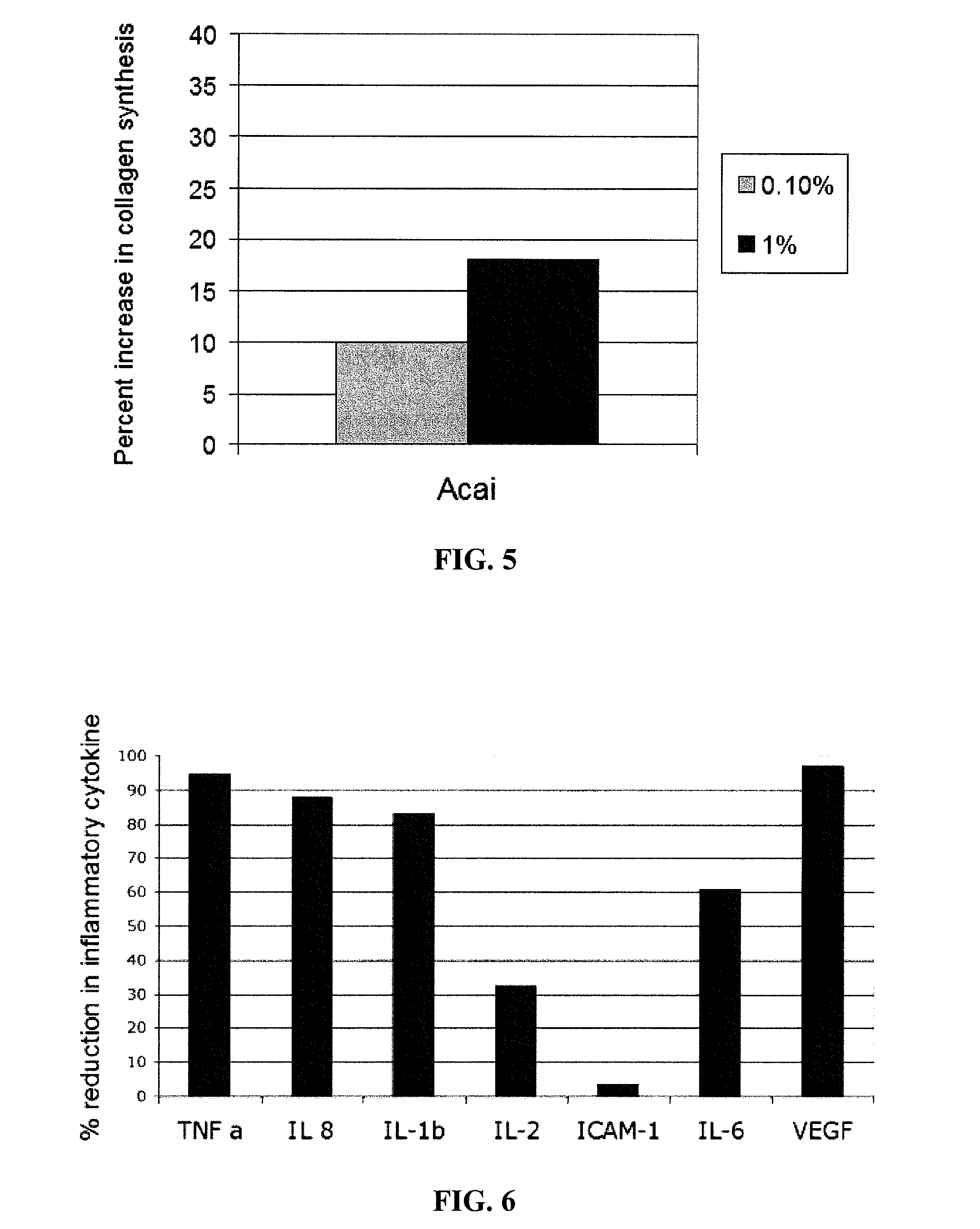

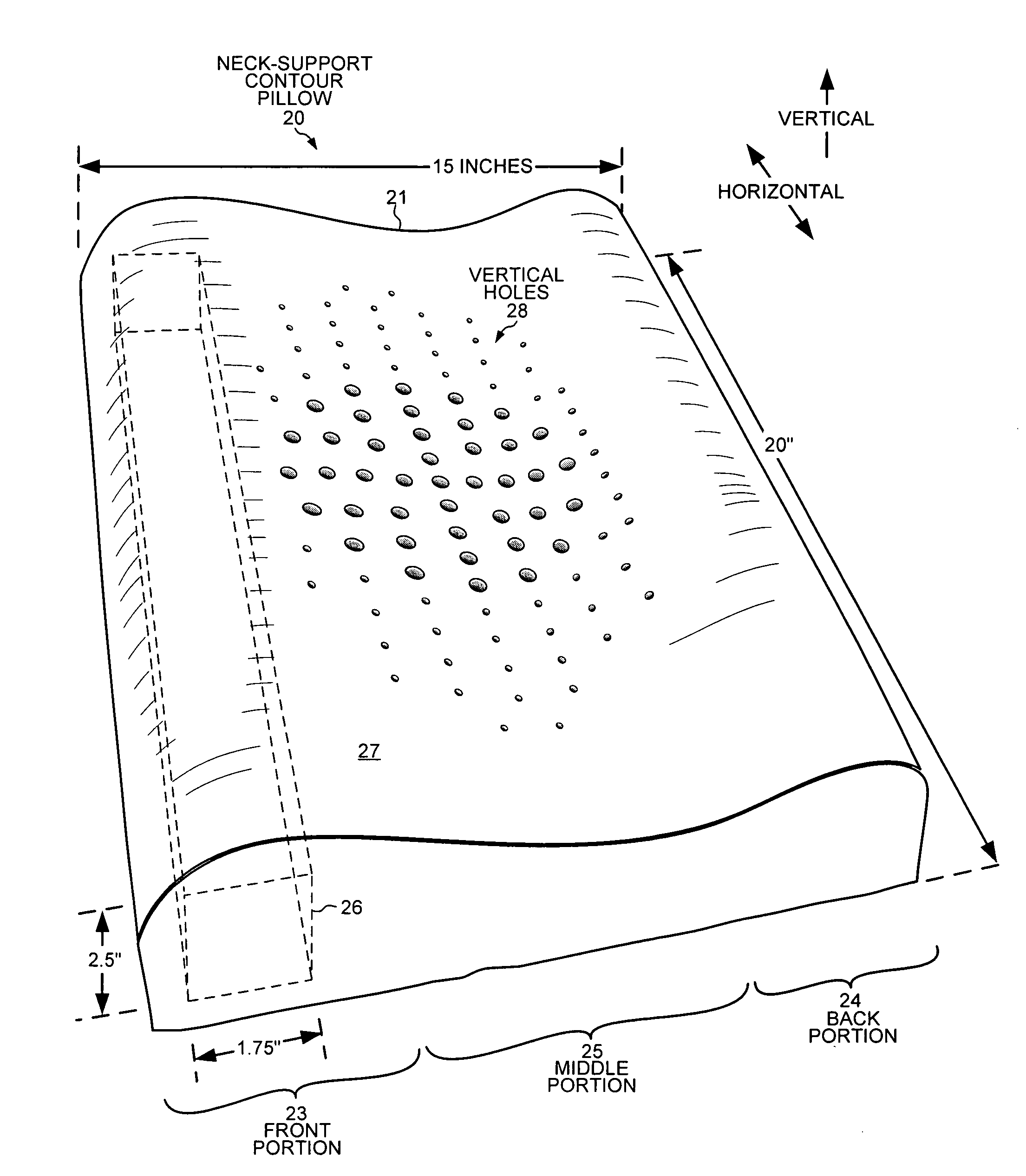

Compositions comprising kakadu plum extract or acai berry extract

InactiveUS20070166275A1Increase stratum corneum turnover rateIncrease collagen synthesisCosmetic preparationsBiocideMedicineAcai Berries

A topical skin care composition comprising kakadu plum extract or acai berry extract, or a combination of both, is disclosed. The composition can include a high oxygen radical absorbance capacity (ORAC) value. The composition can improve the skin's visual appearance, physiological functions, clinical properties, and / or biophysical properties.

Owner:MARY KAY INC

Topical skin care formulations

InactiveUS20110044920A1Improve visual appearanceExtended maintenance periodCosmetic preparationsBiocideCaprylyl GlycolStearic acid

Disclosed is a topical skin care composition that includes water, silymarin, hydrolyzed algin, palmitoyl tripeptide 8, ceramide 2, pomegranate extract comprising pomegranate sterols, glycerin, disodium EDTA, caprylic / capric triglyceride, shea butter, C12-15 alcohols benzoate, dimethicone, glyceryl stearate and PEG 100 stearate, cetyl alcohol, stearyl alcohol, stearic acid, butylene glycol, caprylyl glycol, and (s) a mixture of acrylamide / sodium acryloyldimethyl taurate copolymer, isohexadecane, and polysorbate 80.

Owner:MARY KAY INC

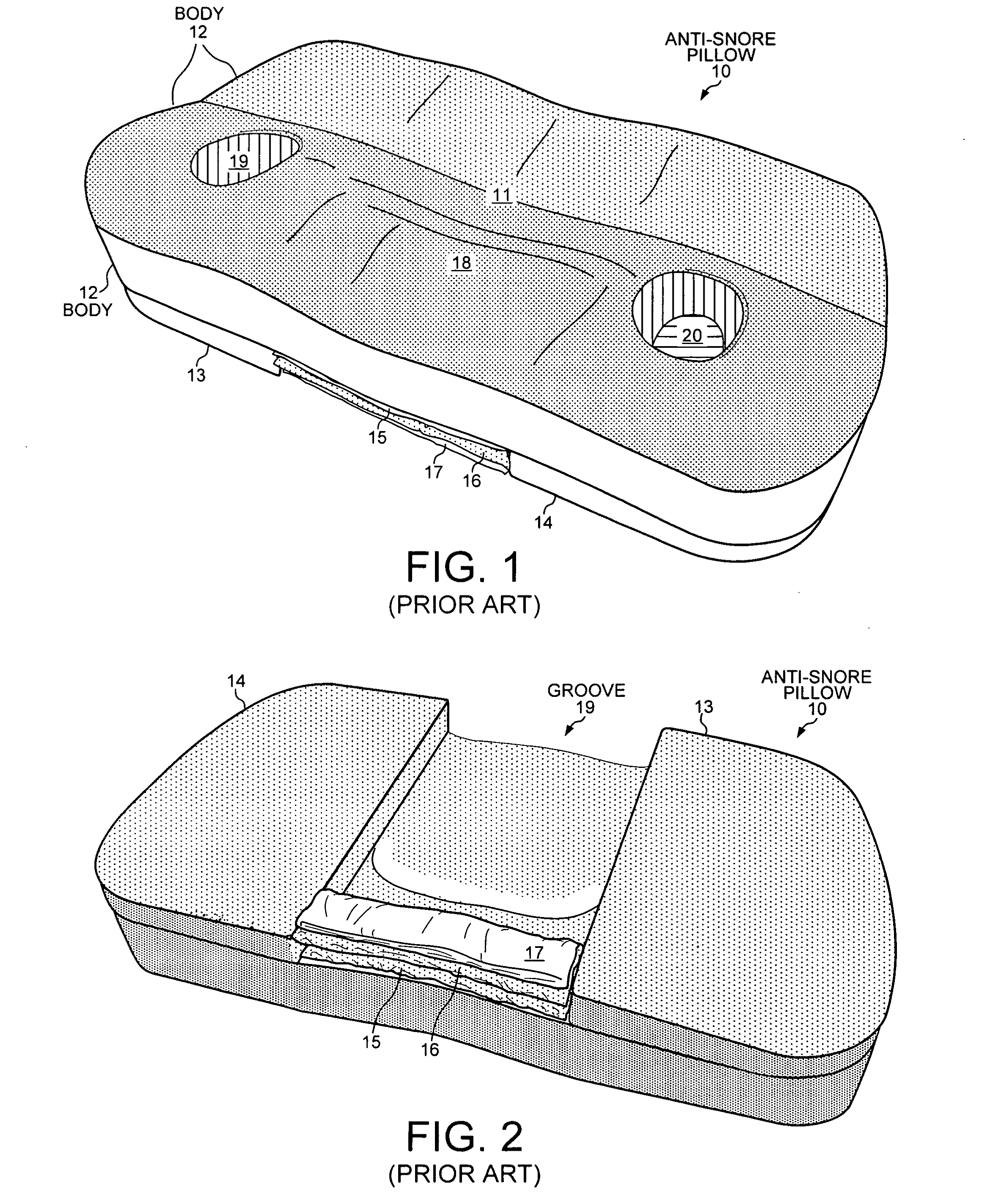

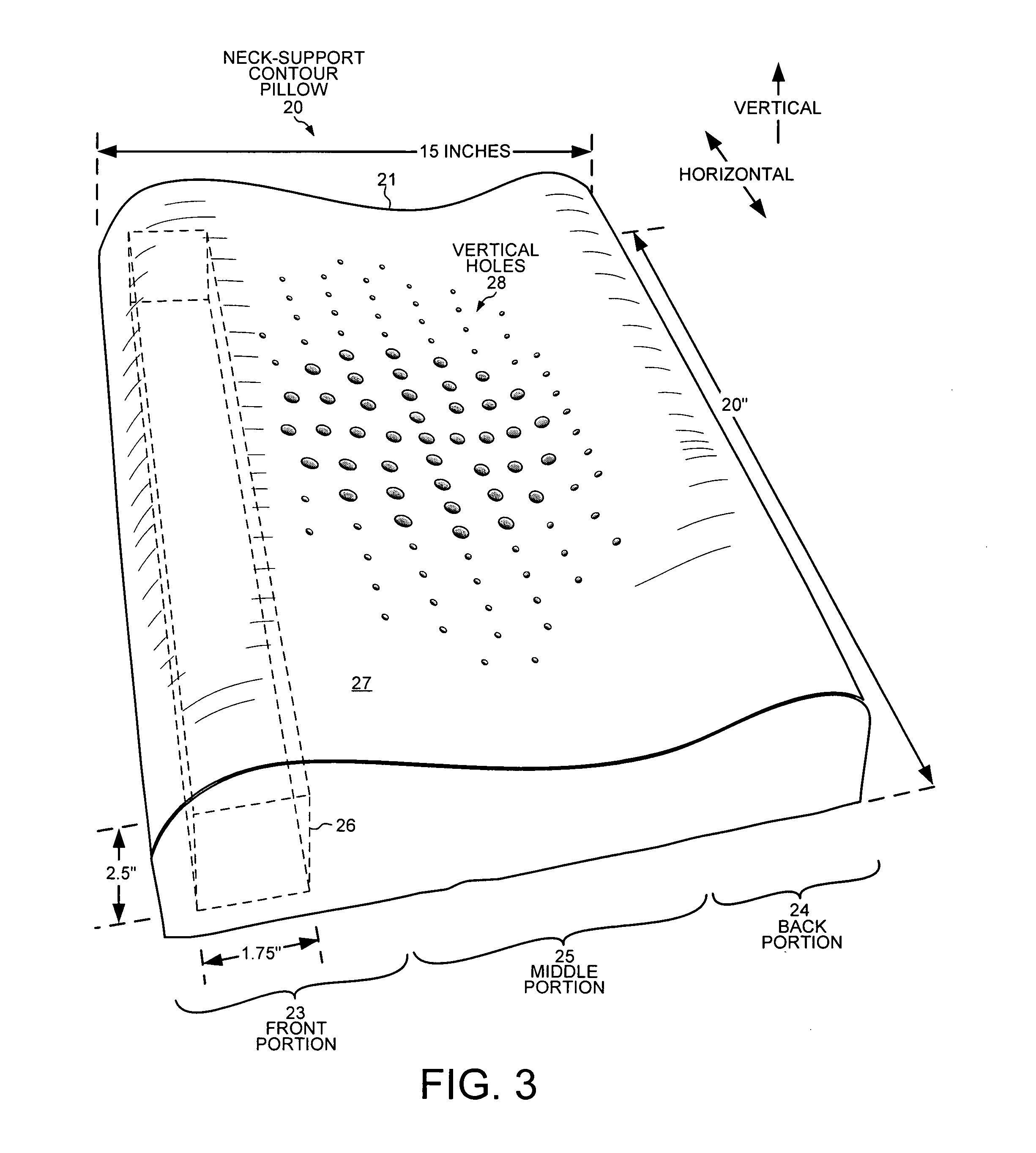

Anti-snore neck-support contour pillow

Owner:ZINUS

Mask liquid with multiple skin care effects and preparation method thereof

InactiveCN106074315AImprove moisturizing abilityAdjust water and oil balanceCosmetic preparationsToilet preparationsLong lastingWrinkle

The invention discloses mask liquid with multiple skin care effects and a preparation method thereof, aims at providing mask liquid which has effects of skin whitening, speckle removing, wrinkle smoothing, inflammation relieving and diminishing, long-lasting moisturizing and grease balancing, and belongs to the technical field of cosmetics. According to the technical scheme, the mask liquid is prepared from, by weight, 0.5%-3% of sericin, 3.011%-14.02% of a plant extract, 1.11%-8.35% of a moisturizer, 8%-15% of polyalcohol, 0.1%-1.5% of active peptides, 0.08%-0.15% of Carbomer, 0.08%-0.15% of triethanolamine, 0.02%-0.06% of disodium EDTA, 0.3%-0.5% of a preservative and the balance deionized water.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Friction stir welding of dissimilar metals

InactiveUS20100089976A1Improve adhesionImprove joint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesAdhesiveMaterials science

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions including an adhesive placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of an adhesive with copper, tin, zinc, and / or other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

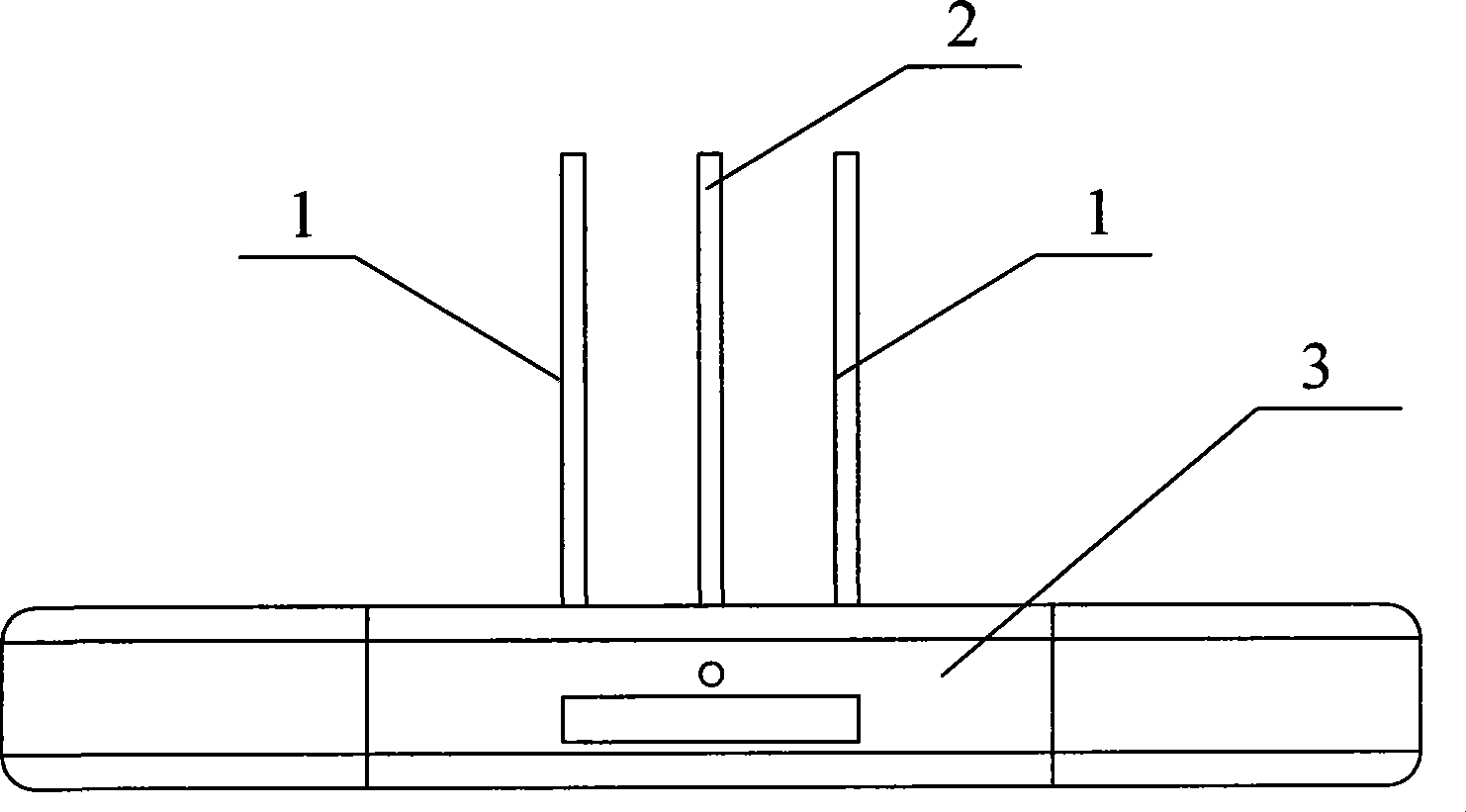

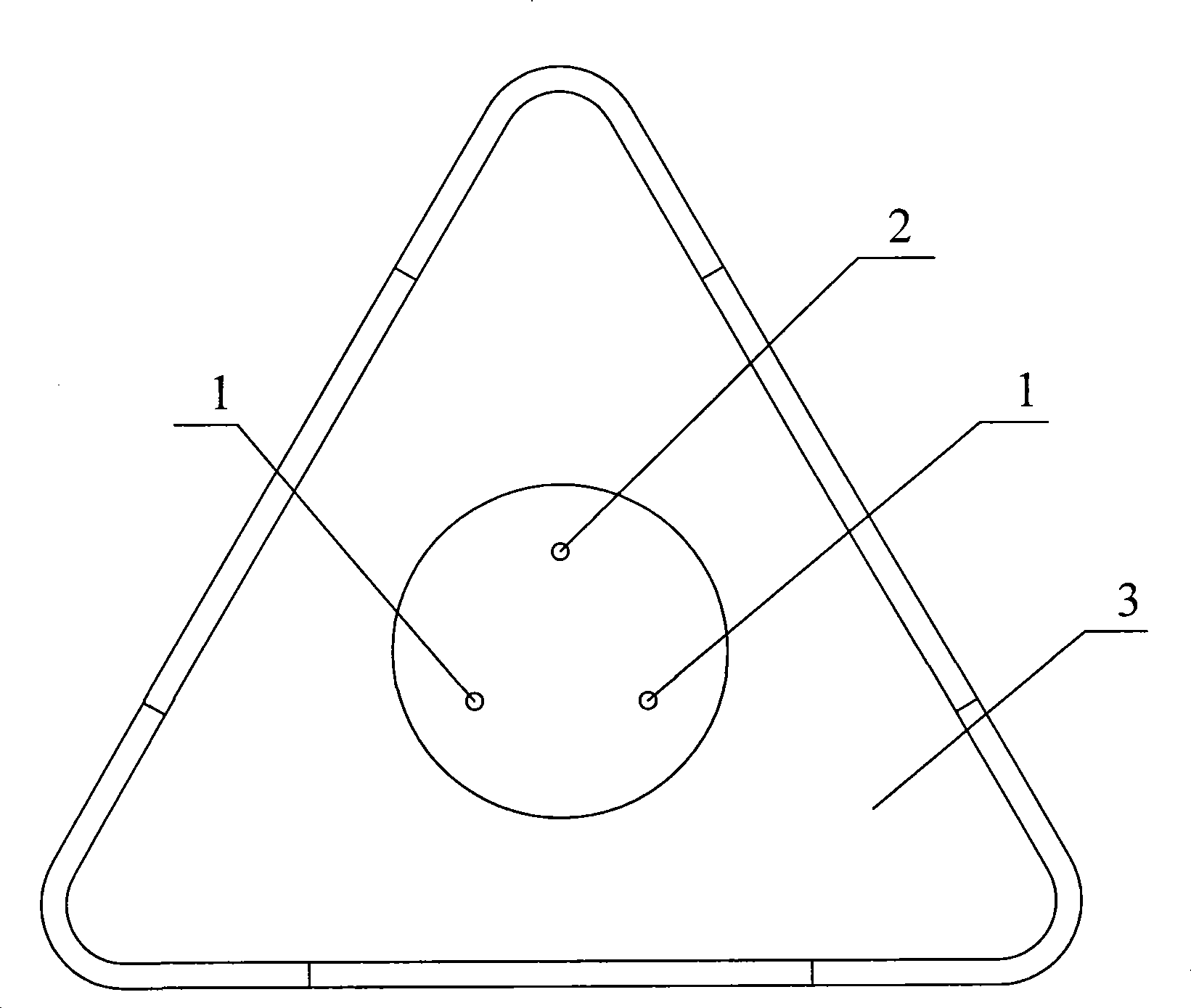

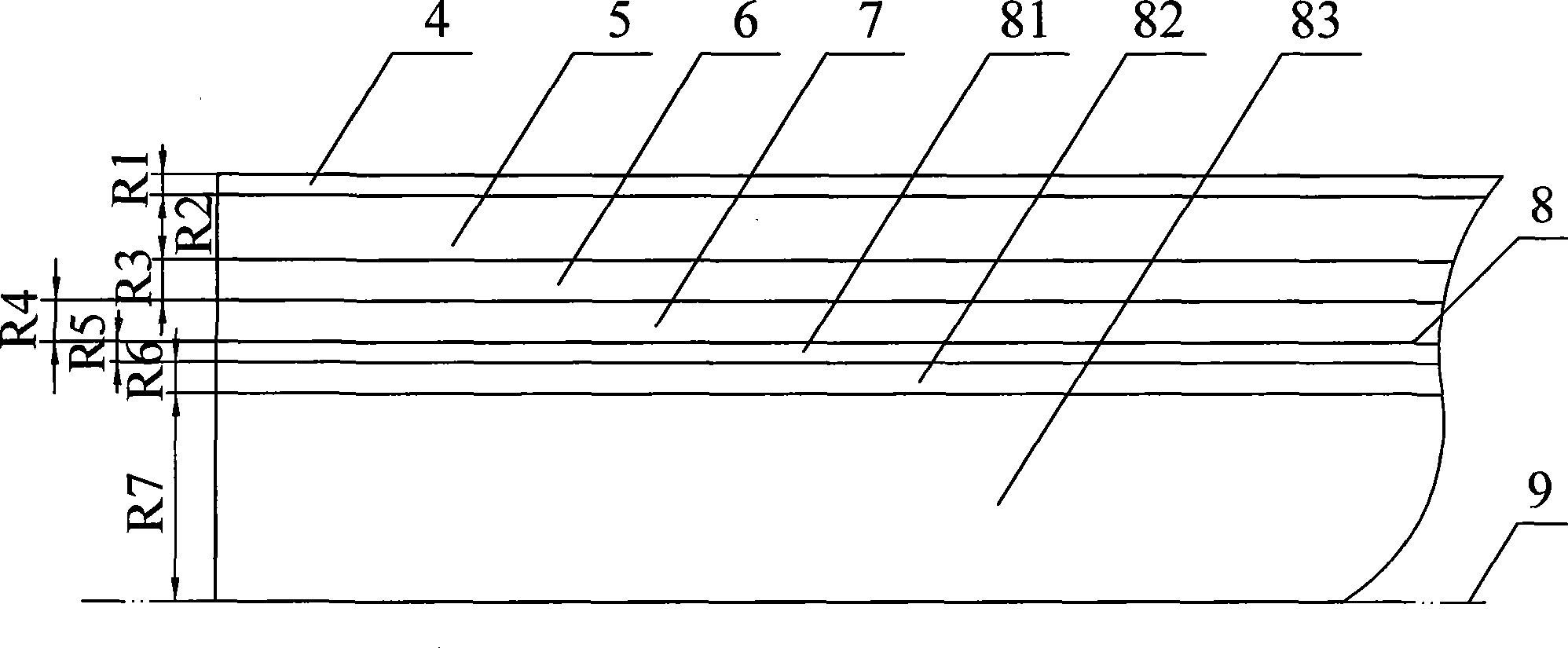

Needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof

ActiveCN101530327AShort response timeStable jobDiagnostic recording/measuringSensorsGlucose sensorsConcentrations glucose

The invention discloses a needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof. The sensor comprises a needle reference electrode (2) and at least one needle working electrode (1) including a conducting layer (8) and an enzyme membrane layer (6), and is characterized in that the working electrode (1) further comprises a polymer material inner membrane layer (7) and a polymer material control diffusion layer (5), and the conducting layer (8), the polymer material inner membrane layer (7), the enzyme membrane layer (6) and the polymer material control diffusion layer (5) are coated in turn from inner to outside. According to the manufacturing method in the invention, the glucose sensor has good stability, high flexibility, wide linear range of output current and glucose concentration, short response time, continuous real-time monitoring, good fastness and stability of enzyme bonding, high flexibility, selectivity and repeatability.

Owner:HUZHOU MEIQI MEDICAL EQUIP CO LTD

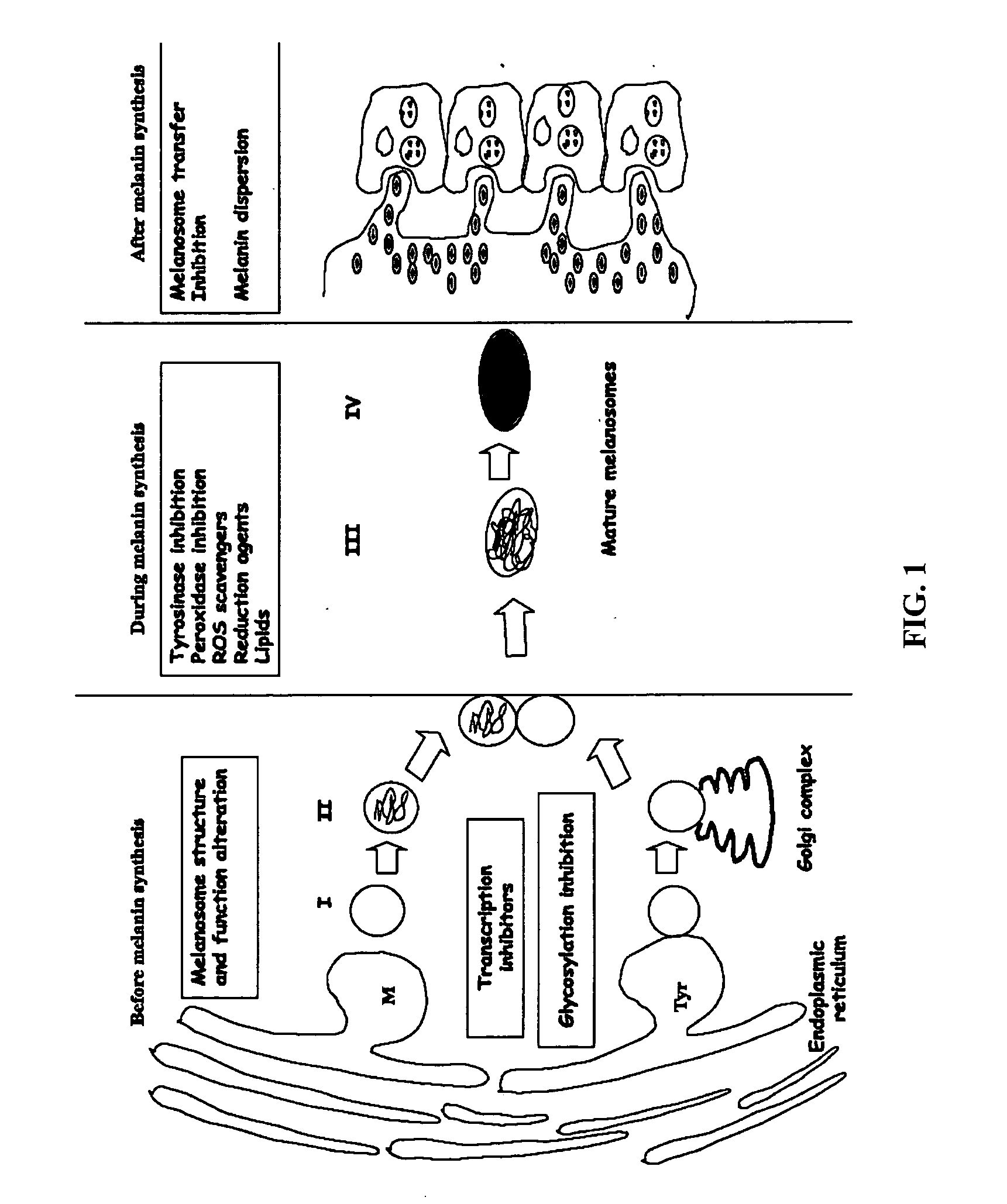

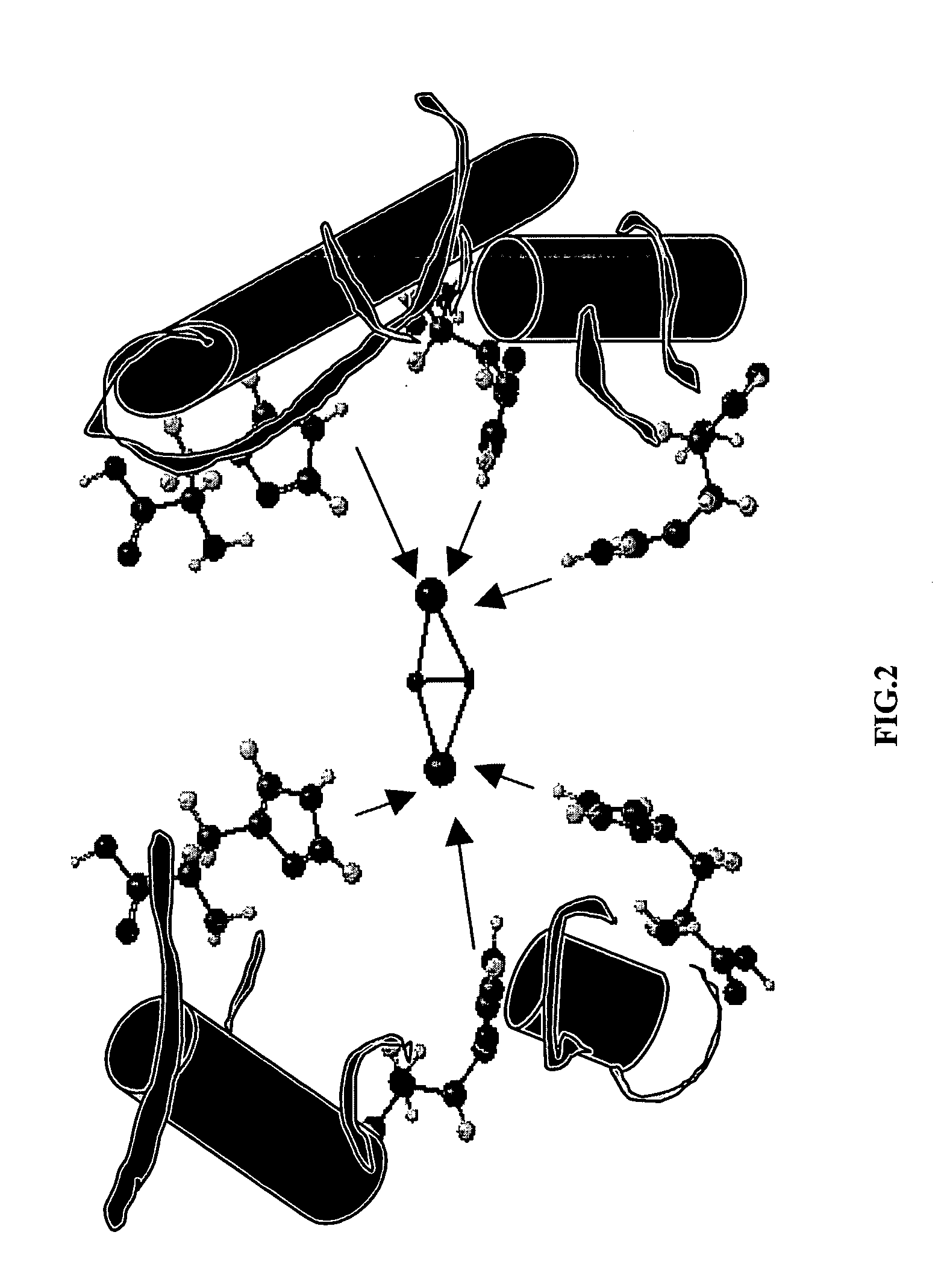

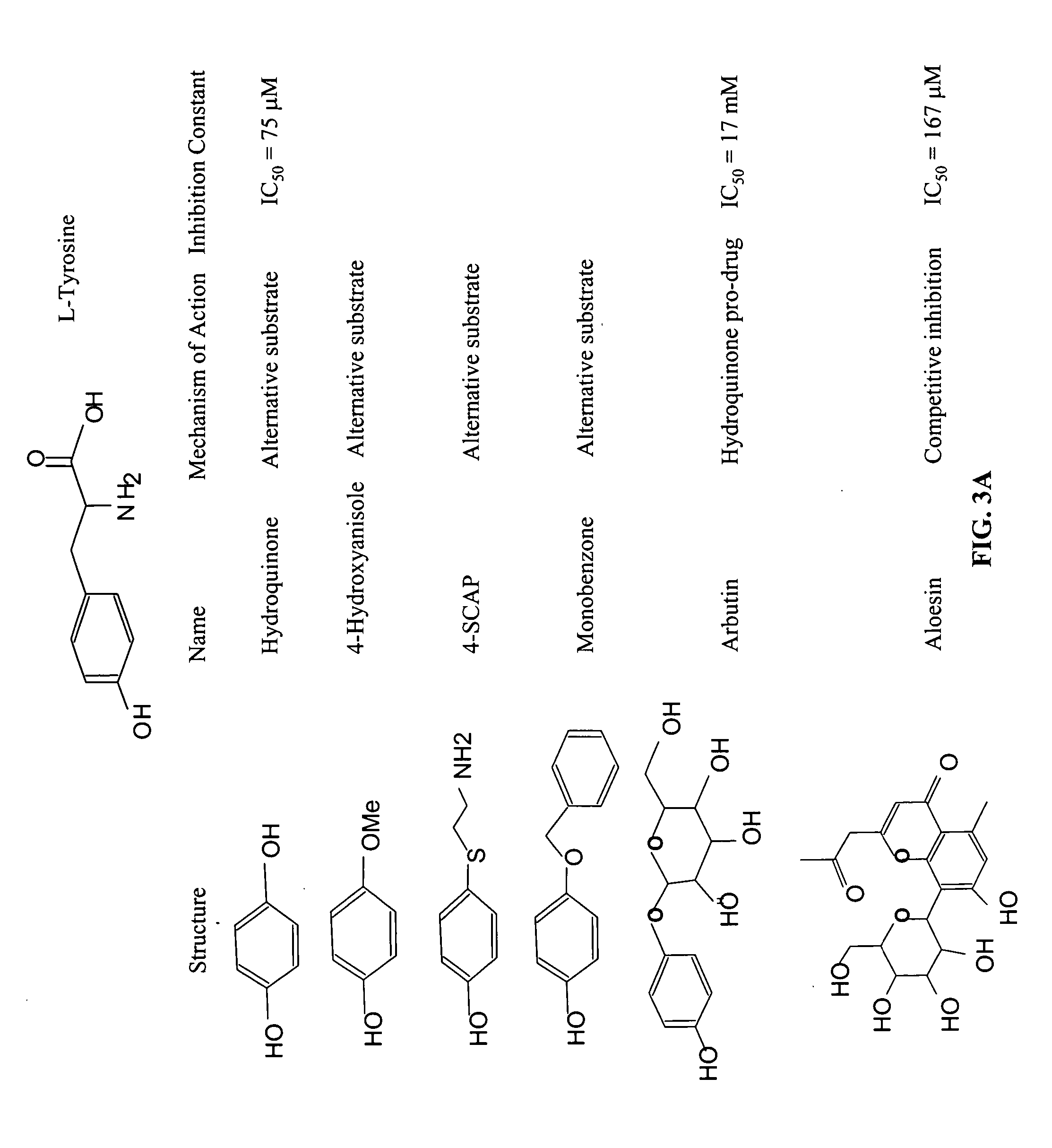

Diarylalkanes as potent inhibitors of binuclear enzymes

InactiveUS20050267047A1Prevent browning and color changeAvoid damageAntibacterial agentsOrganic active ingredientsChemistryOverproduction

The present invention implements a strategy that combines an enzyme inhibition assay with a chemical dereplication process to identify active plant extracts and the particular compounds—diarylalkanes and / or diarylalkanols within those extracts that specifically inhibit binuclear enzyme function. Included in the present invention are compositions of matter comprised of one or more of diarylalkanes and / or diarylalkanols, which inhibit the activity of binuclear enzymes, particularly tyrosinase and which prevent melanin overproduction. The present invention also provides a method for inhibiting the activity of a binuclear enzyme, particularly tyrosinase and a method for preventing and treating diseases and conditions related to binuclear enzyme function. The present invention further includes a method for preventing and treating melanin overproduction and diseases and conditions of the skin related thereto. The method for preventing and treating diseases and conditions related to binuclear enzyme function and melanin overproduction is comprised of administering to a host in need thereof an effective amount of a composition comprising one or more diarylalkanes and / or diarylalkanols synthesized and / or isolated from one or more plants together with a pharmaceutically acceptable carrier.

Owner:UNIGEN PHARM INC

Topical skin care formulation

Disclosed is a multi-beneficial topical skin care composition, and methods for its use, that can hydrate skin, increase the firmness of skin, reduce the appearance of fine lines or wrinkles on skin, and reduce the appearance of age spots on skin. The composition can include a combination of skin active ingredients comprising euterpe oleracea fruit extract, punica granatum sterols, caprooyl tetrapeptide-3, tocopherol or tocopherol acetate, and niacinamide, a combination of skin moisturizing agents comprising glycerin and butyrospermum parkii, a photo stable combination of sunscreen agents providing the composition with a sun protection factor (SPF) of at least about 15, and a dermatologically acceptable vehicle which imparts a non-greasy feel when applied to skin.

Owner:MARY KAY INC

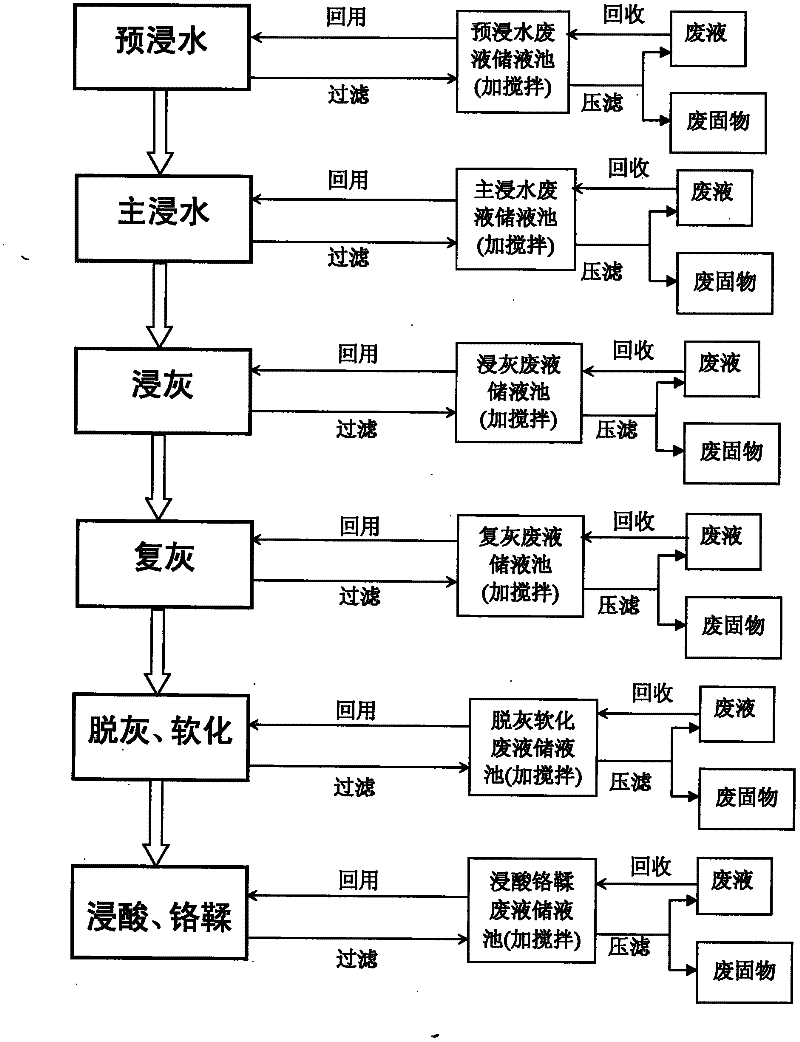

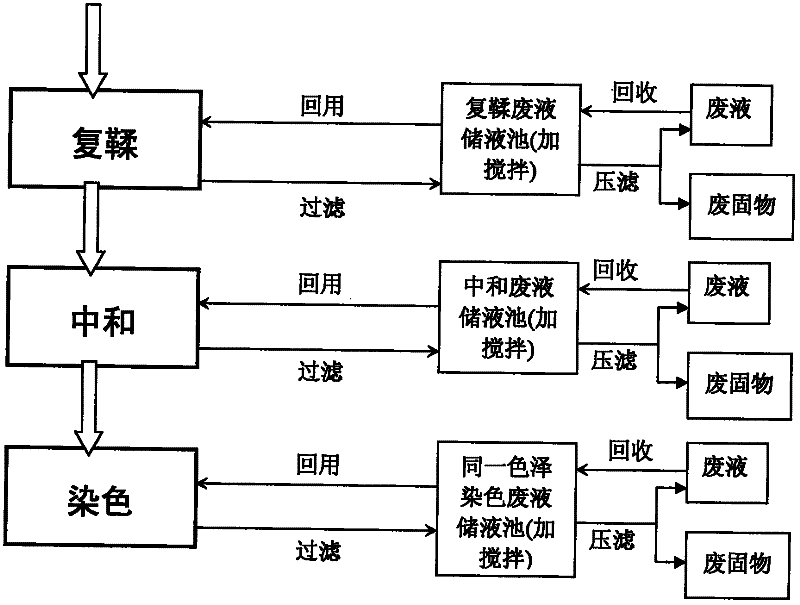

Tanning production process capable of recycling waste water repeatedly from soaking to dyeing

ActiveCN102534056AImprove firmnessHigh fullnessTanning treatmentPre-tanning chemical treatmentWastewaterSewage

The invention provides a tanning production process capable of recycling waste water repeatedly from soaking to dyeing, which is characterized in that waste liquid recycling is conducted in procedures of pre-soaking, main-soaking, liming, deliming and softening, pickling and chrome tanning, retanning, neutralizing and dyeing step by step, and waste liquid in all the procedures achieves full-closed circulation recycling. The technology is tested and verified in actual production in a tanning workshop of BIOSK (sq) Chemicals Co. Limited. The process achieves recycling of waste water from the pre-soaking to the dyeing, sewage discharging is greatly reduced, a problem of tanning pollution is solved thoroughly, quality of finished leather can be guaranteed simultaneously, loose side rate of the finished leather is effectively reduced, degree of compacting and fullness of the finished leather is improved, chemical materials can be saved by 15% to 55%, for example, chromium powder is saved by 35% to 65%, partial chemical materials can be saved by more than 90%, and exceptional chemical materials such as salt can be saved by 100%.

Owner:宝斯卡(商丘)化工有限公司

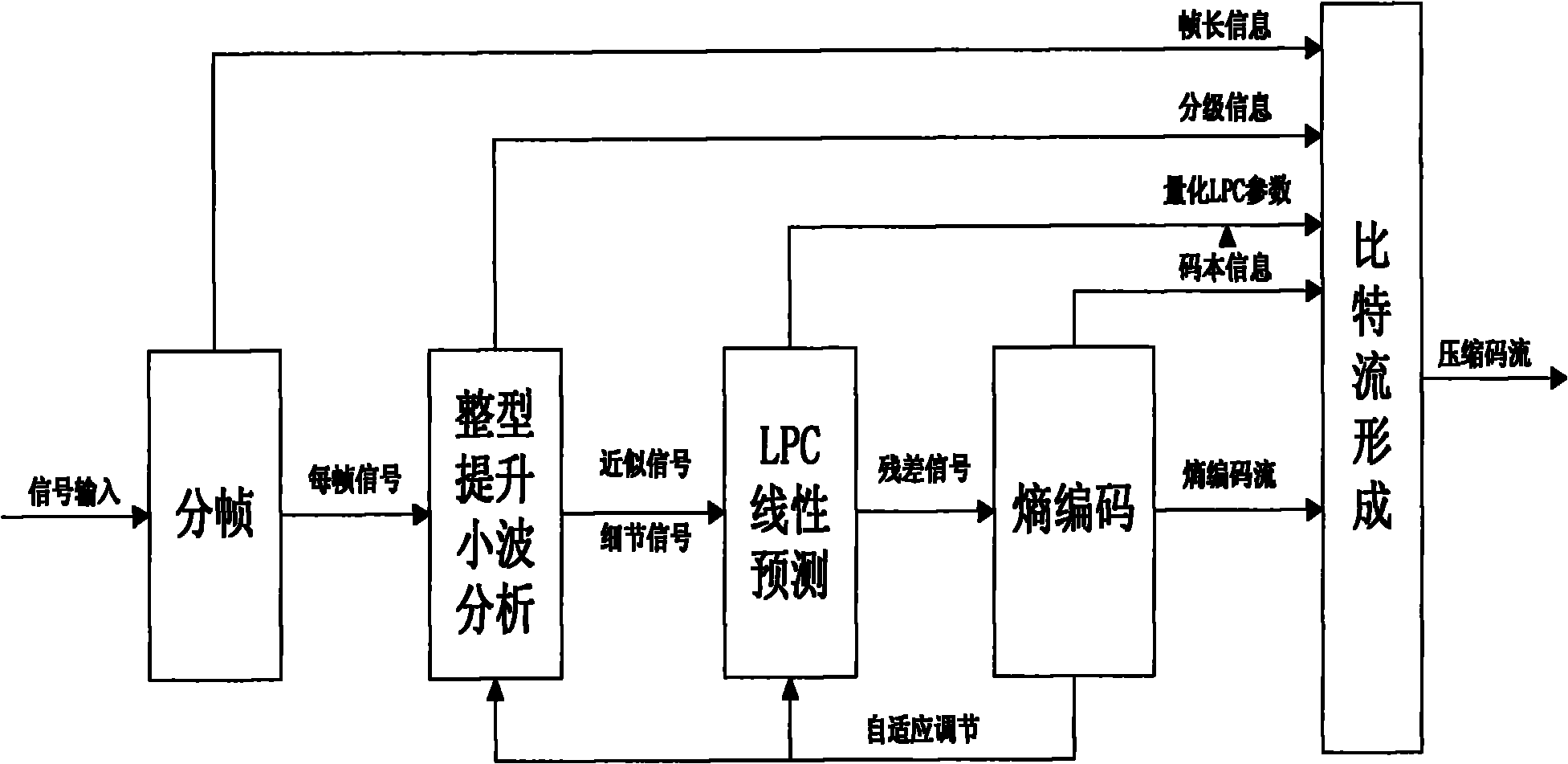

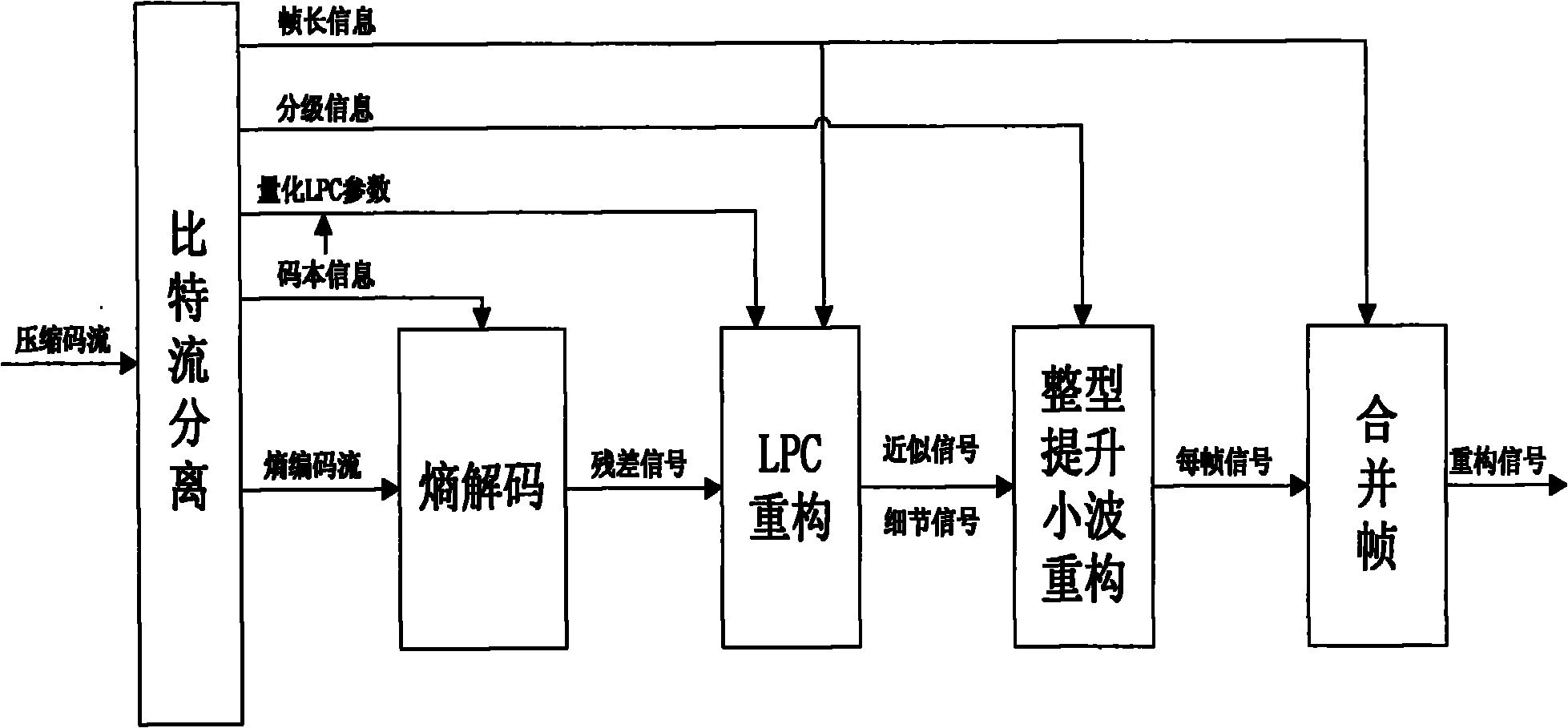

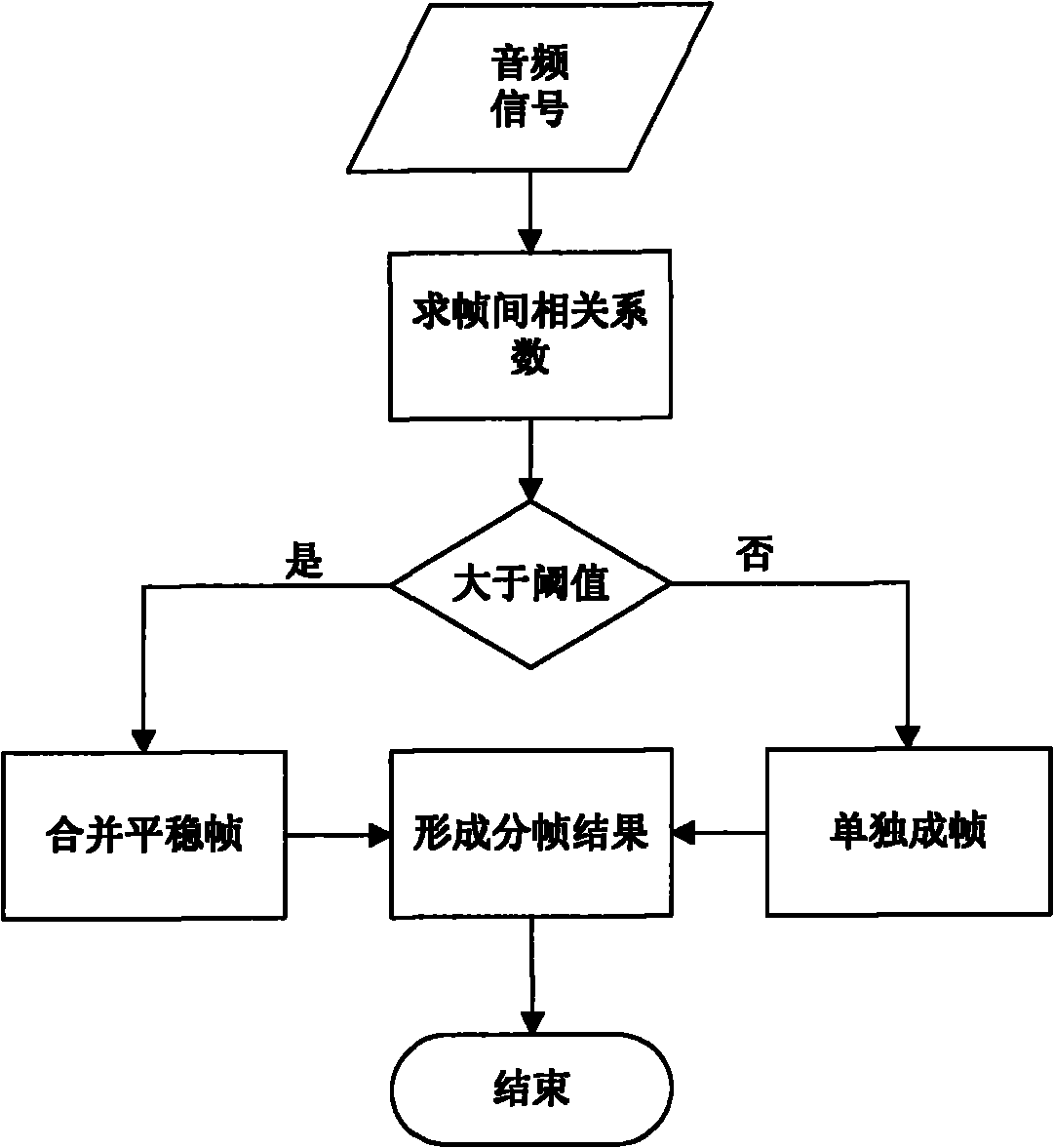

Integer wavelet transform-based audio lossless compression encoding and decoding method

ActiveCN101944362AStrong correlationAvoid errorsSpeech analysisSource encodingComputation complexity

The invention discloses an audio lossless compression encoding and decoding method and belongs to the field of information source encoding and decoding. In the method, a signal is framed adaptively according to related conditions of the former frame and the later frame of the signal, wherein a frame signal after framing is a combination of signals with similar signal characteristics, so that an encoder can achieve higher compression efficiency and is good for later integer wavelet transform and linear predictive encoding. For lossless compression encoding, a signal can be completely reconstructed, and the complete reconstructed characteristic of the signal is guaranteed by adopting integer lifting wavelet transform. Compared with the prior art, after a related adaptive framing-based module and an integer lifting wavelet-based de-correlation module are introduced, redundant information in an original signal can be well de-correlated, and the generated compressed data contains less redundant information. Therefore, the audio lossless compression encoding and decoding method can greatly improve the compression ratio by low computation complexity.

Owner:PEKING UNIV

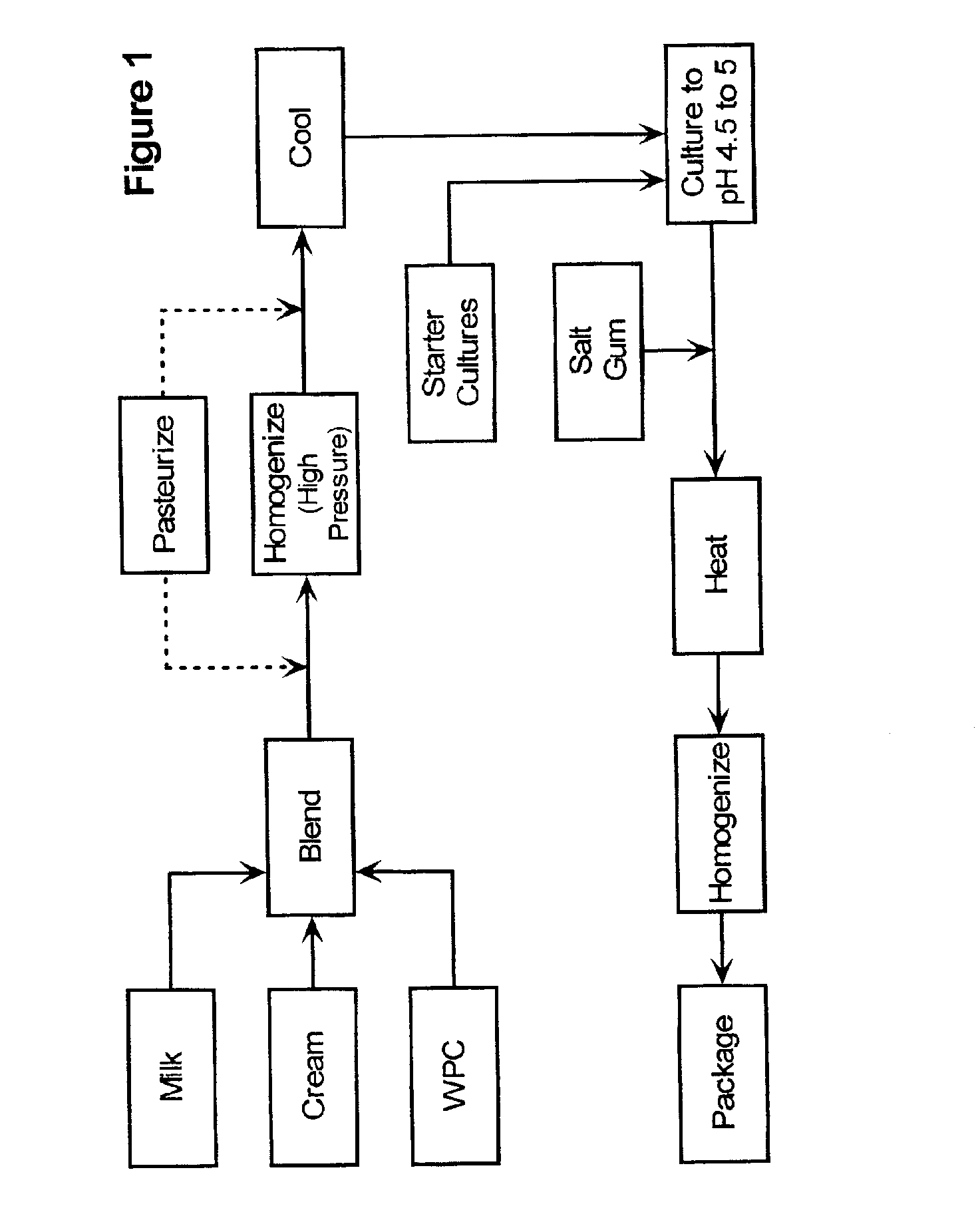

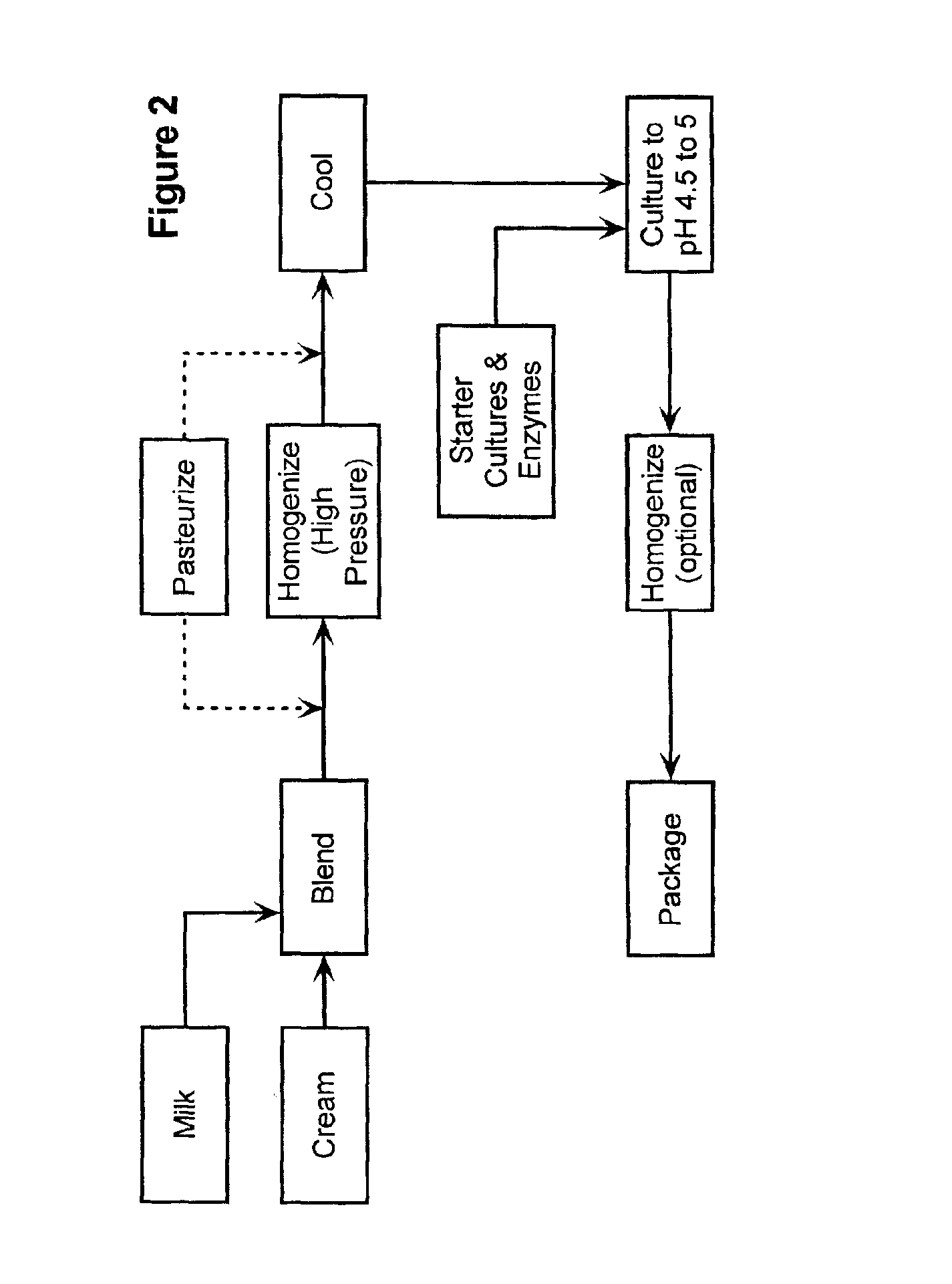

Dairy products with reduced average particle size

InactiveUS6861080B2Improve the immunityIncrease pressureMilk preparationCheese manufactureCream cheeseMilk products

The present invention relates to superior dairy products which have firmness qualities and textural qualities not observed in conventional dairy products. The dairy products of this invention have average fat particle sizes of less than about 0.8 microns, preferably of about 0.1 to about 0.8 microns, and more preferably about 0.2 to about 0.6 microns. The dairy products which may be manufactured using this process are cream cheese, sour cream, and dairy products containing at least 4 percent fat. The present invention also provides a process for making a cream cheese product without the removal of whey and having average fat particle sizes of less than about 0.8 microns, preferably of about 0.1 to about 0.8 microns, and more preferably about 0.2 to about 0.6 microns.

Owner:KRAFT FOODS GRP BRANDS LLC

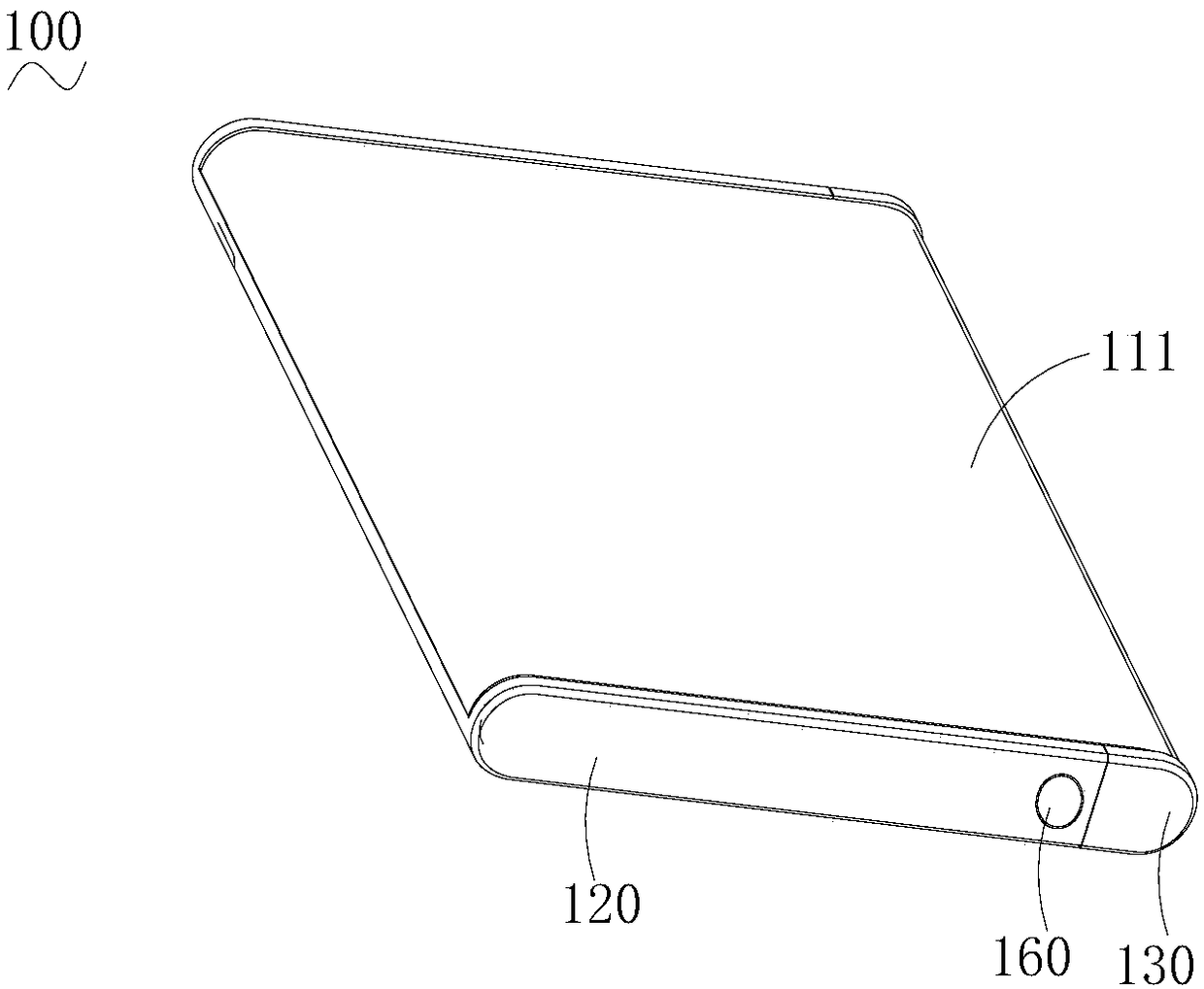

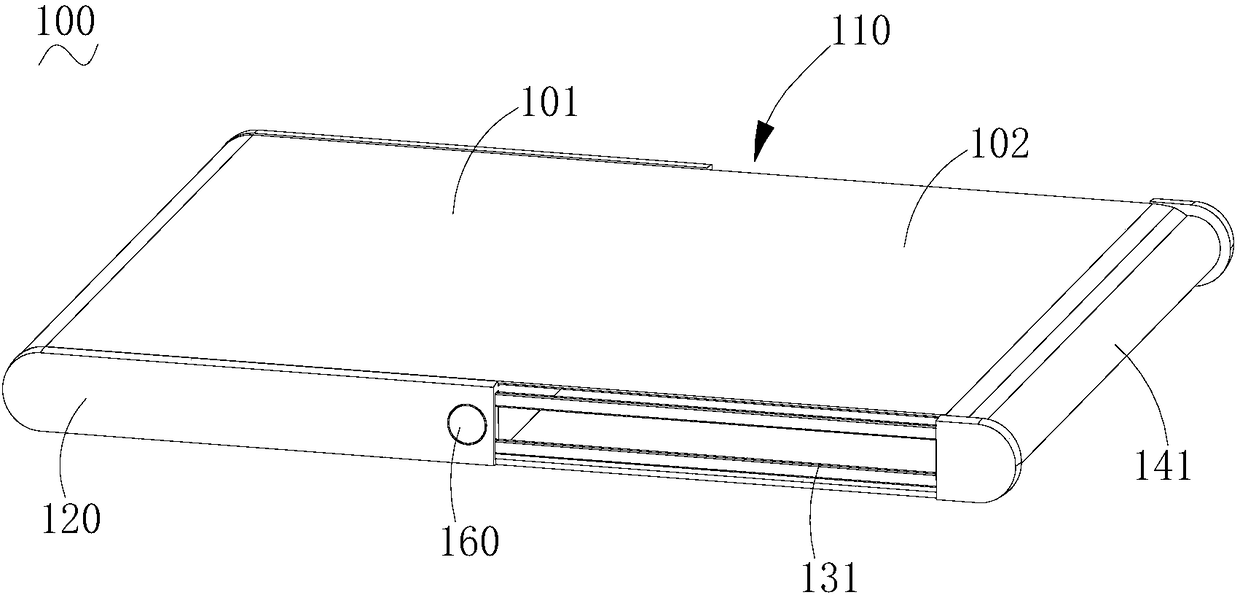

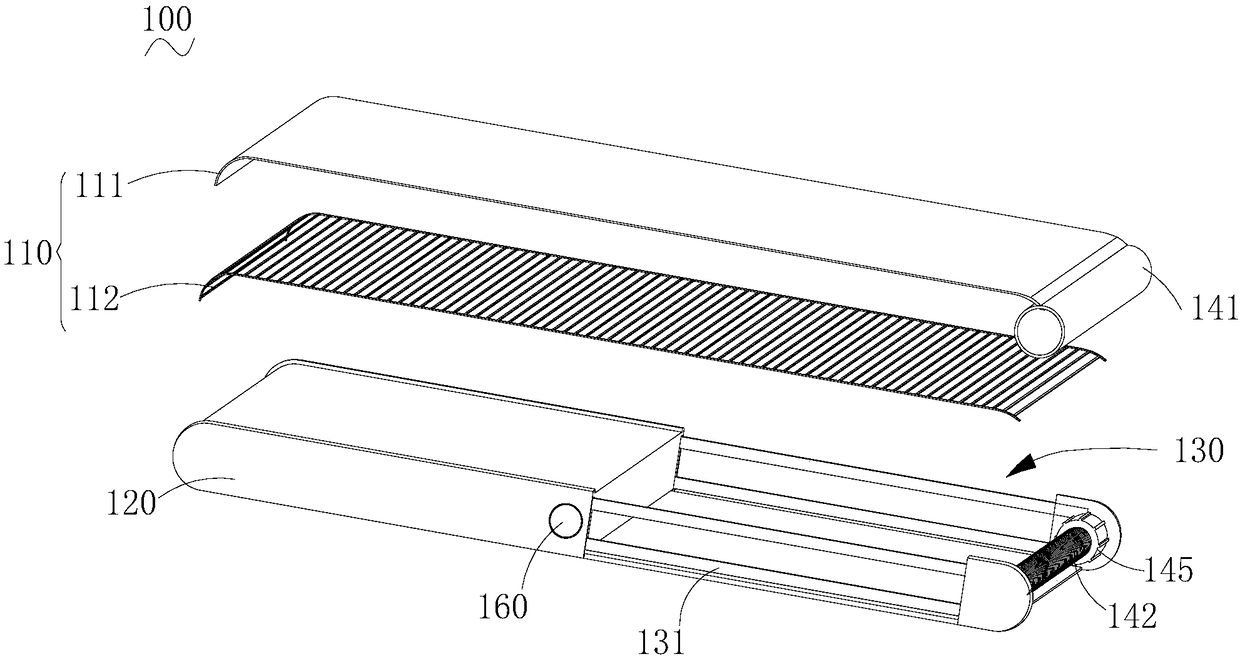

Display device and electronic product

ActiveCN108520702ASatisfy the big screen and big field of viewEasy to carryDigital data processing detailsIdentification meansTorsion springEngineering

The invention relates to a display device. The device comprises a wound sheet having a first portion and a second portion, a fixed support, a movable support and a reel mechanism, and the wound sheetcomprises a flexible display screen and a curtain support layer; the fixed support is used for supporting the first portion; the movable support is used for supporting the second portion; the movablesupport slides relative to the fixed support; the reel mechanism is used for winding the second portion; the reel mechanism is mounted at one end of the movable support; the winding mechanism includesa reel sleeve, a torsion spring for driving the reel sleeve to rotate and retract through pretightening force and a support shaft for supporting the torsion spring; the support shaft is fixed to themovable support. According to the above display device, when the wound sheet is unfolded, the flexible display screen can all be displayed, good rigidity can be maintained, and the requirements of touch control or other operations are met; when the second portion of the wound sheet is wound, the entire display device is reduced in size and easy to carry. The invention also discloses an electronicproduct.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

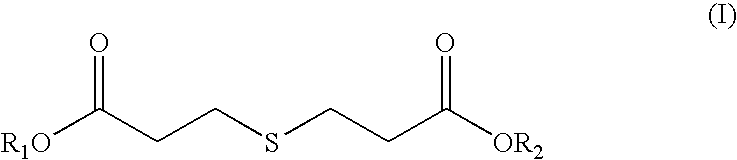

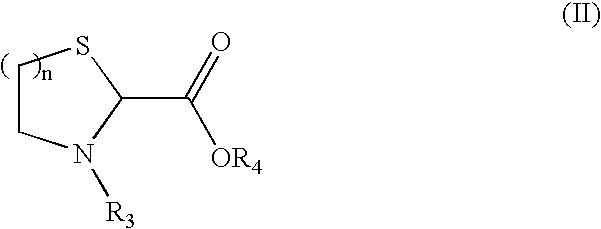

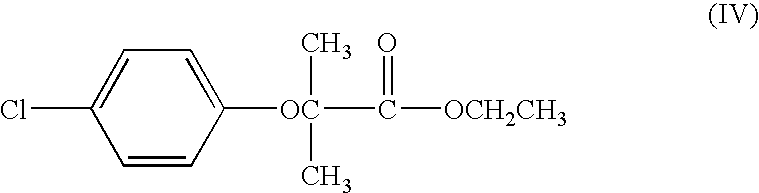

Cosmetic compositions and methods for using same to improve the aesthetic appearance of skin

InactiveUS20040067245A1Treating and preventing and ameliorating sign of dermatological agingImprove aestheticsCosmetic preparationsSalicyclic acid active ingredientsPerilla oilCarboxylic acid

The present invention relates to compositions useful in treating hyperpigmentation and the various signs of dermatological aging in human skin. The present invention also relates to cosmetic compositions and methods of using such compositions that improve the aesthetic appearance of skin. Further, the present invention relates to methods of applying the compositions to the skin to effect treatment and to improve the aesthetic appearance of skin, particularly, by providing anti-aging benefits to the skin. These and other objects of the present invention are achieved by a method and composition that comprises (a) a de-pigmenting agent or anti-aging agent in an amount effective to prevent, treat and / or ameliorate pigmentation or the various signs of aging at an area of skin to which it is applied, and (b) a cosmetically or pharmaceutically acceptable vehicle. Suitable de-pigmenting agents include 3,3'-thiodipropionic acid, thiazolidine-2-carboxylic acid, Kaempferol-7-glucoside, perilla oil, and clofibrate and clofibrate analogs and / or derivatives, as well as those set forth below. Suitable anti-aging agents include 3,3'-thiodipropionic acid and / or its derivatives.

Owner:AVON PROD INC

Method of manufacturing an aged mattress assembly

ActiveUS7690096B1Improve firmnessHigh hardnessUpholstery manufactureStuffed mattressesPre-conditionPre conditioning

Owner:DREAMWELL +1

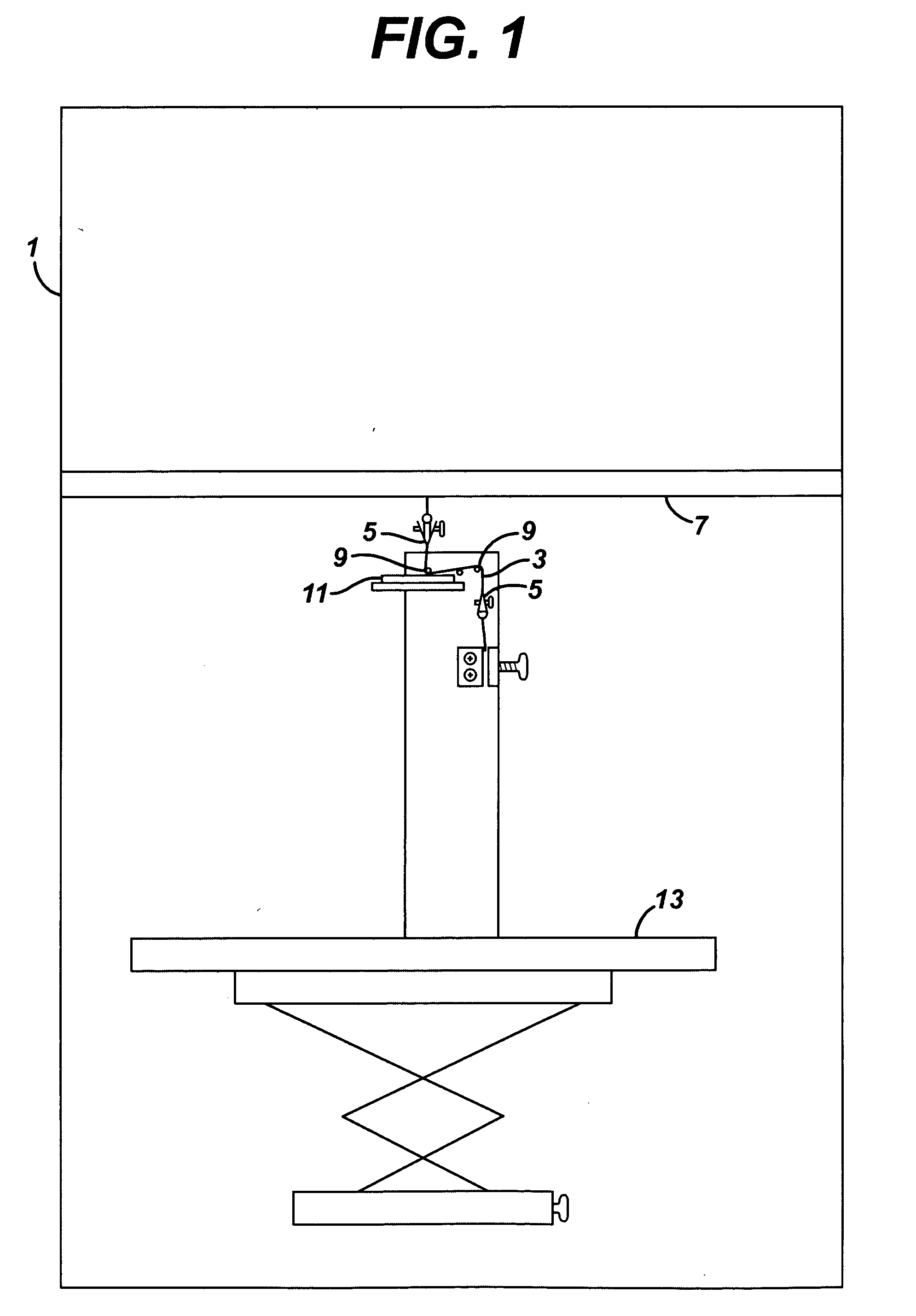

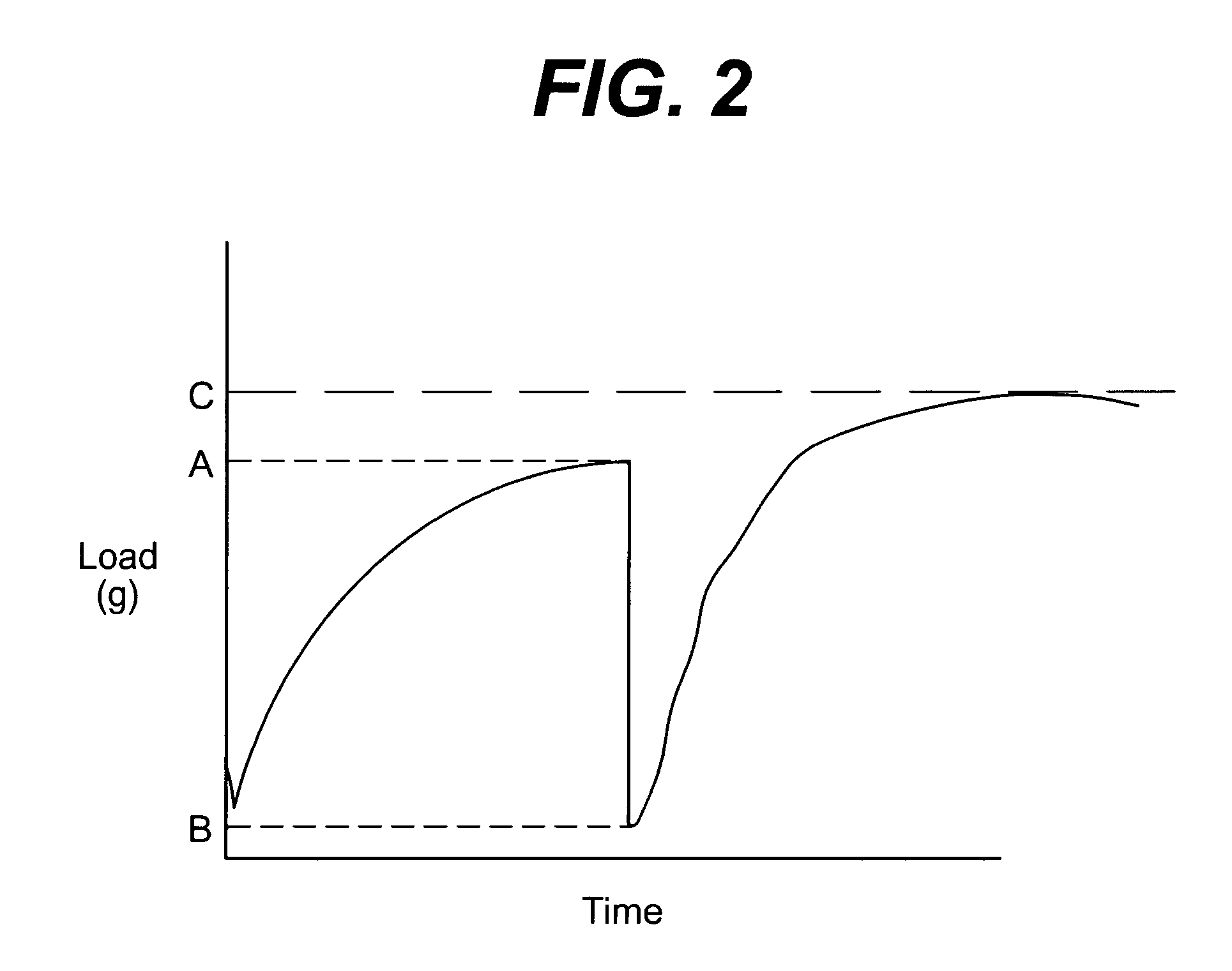

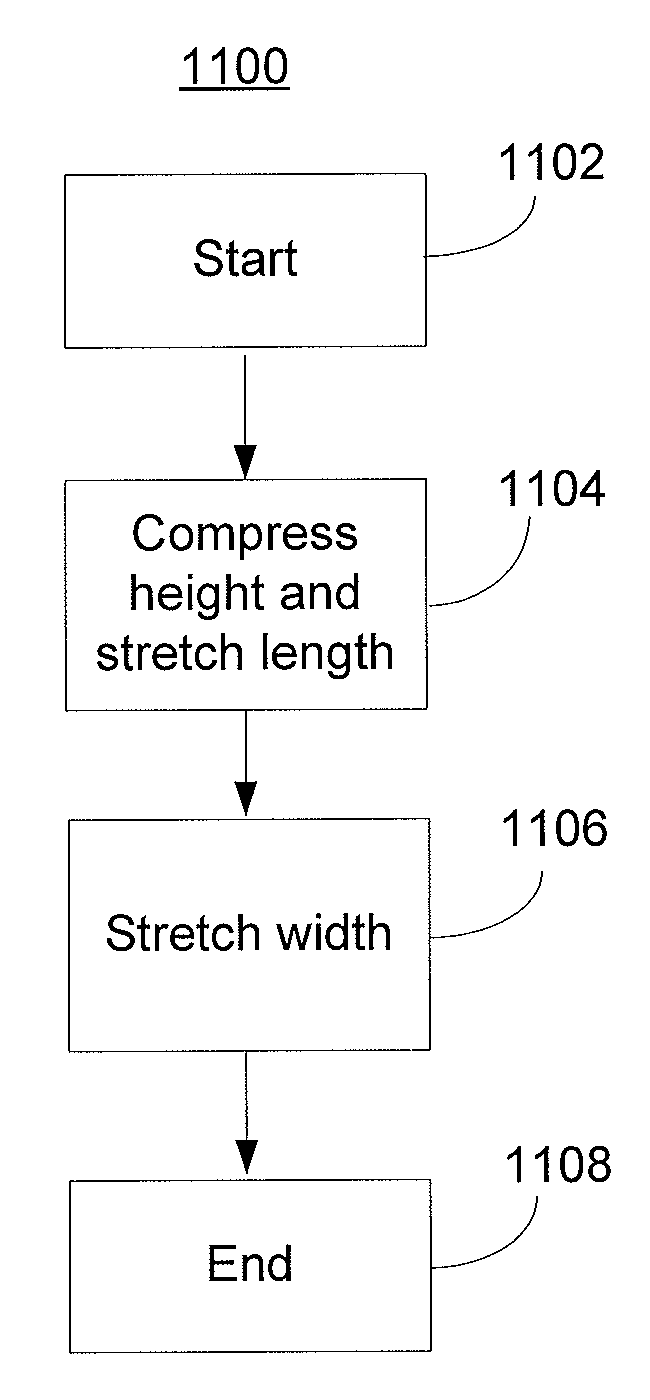

Pre-conditioned foam pad

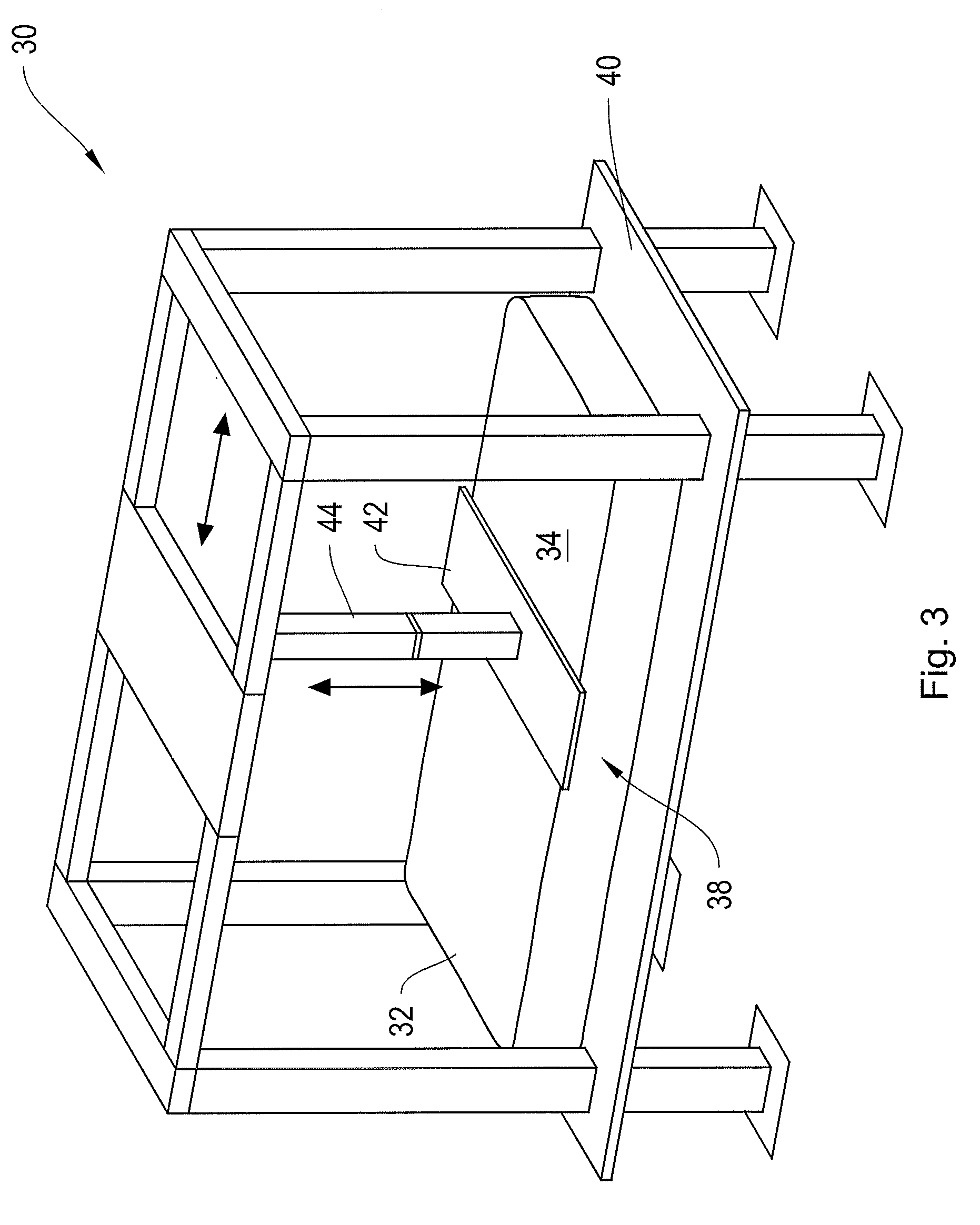

ActiveUS20100072676A1Improve firmnessHigh hardnessUpholstery manufactureStuffed mattressesPre-conditionPre conditioning

Mattresses and methods for processing a flexible foam material for use in a mattress to provide a mattress foam material that has more consistent firmness over time and area. The methods include pre-conditioning the foam pad or mattress by applying a force across a substantial portion of a major surface of the mattress to compress or stretch the height of the foam, the length of the foam, and / or the width of the foam to break or open closed cells. In certain embodiments, the force is applied by repeatedly pressing a platen against the foam pad or placing the foam pad between one or more rollers.

Owner:DREAMWELL +1

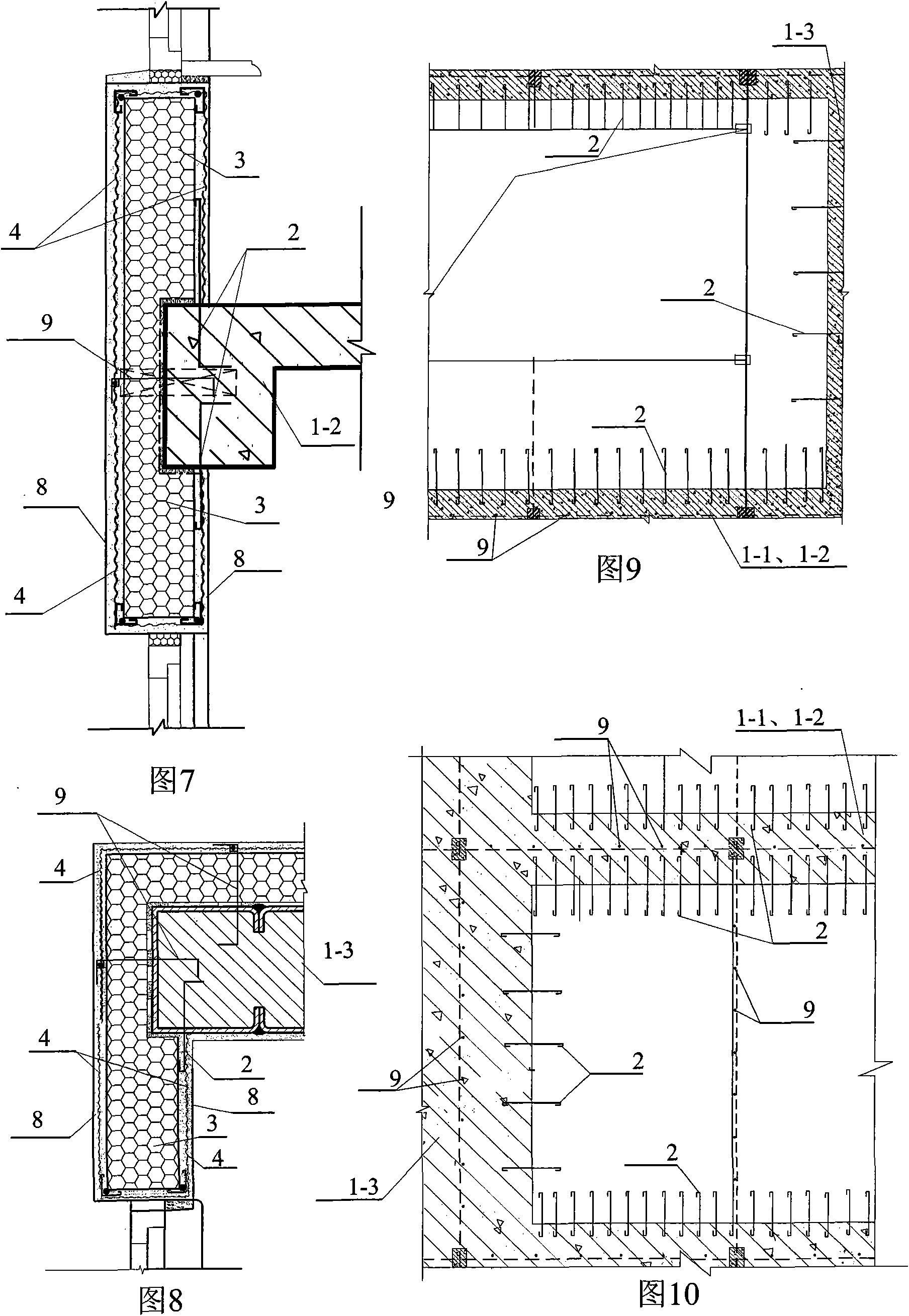

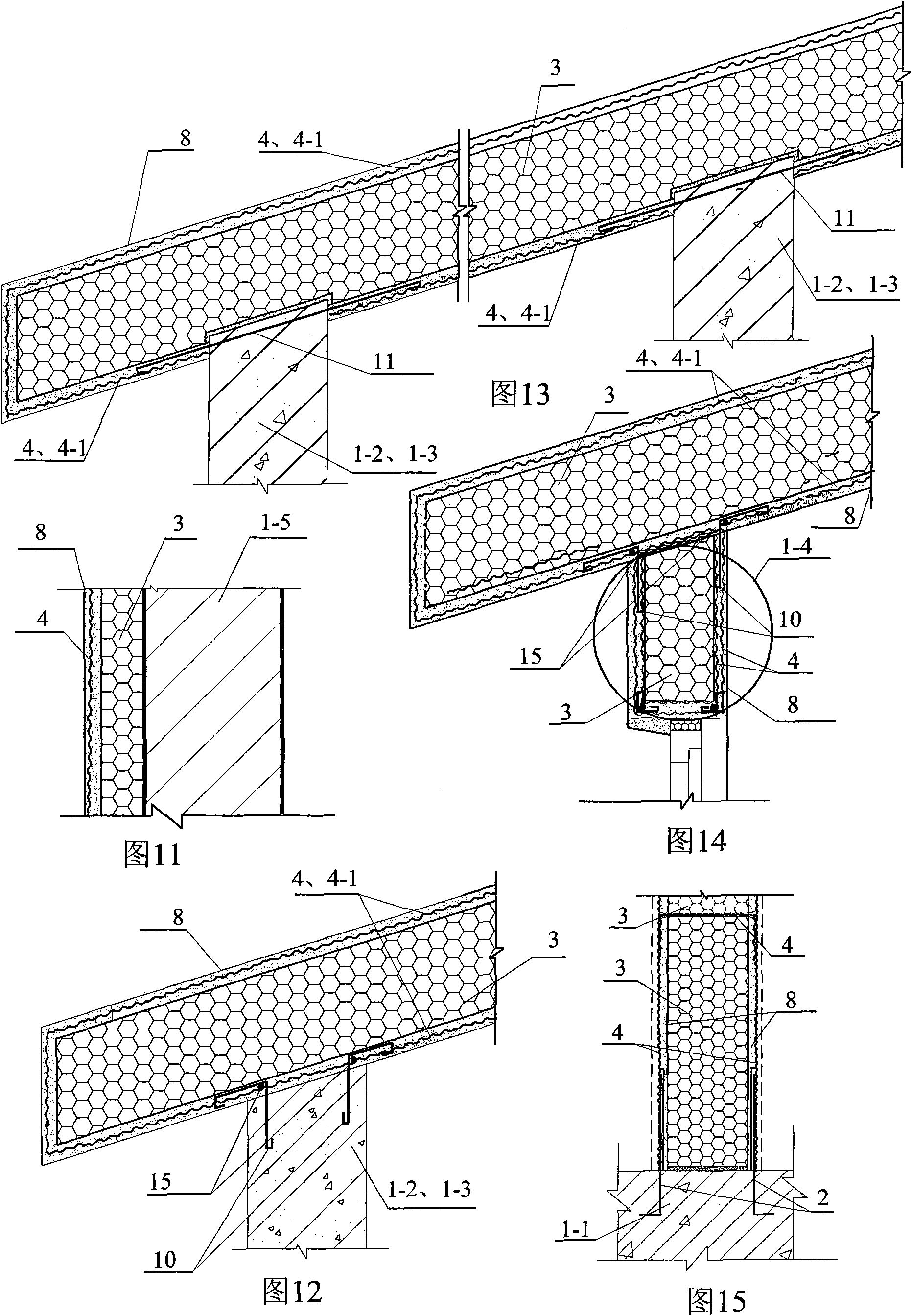

Composite component of alkaline-resisting mesh cloth plastering

InactiveCN101570981AReduce weightGood wind and shock resistanceRoof covering using slabs/sheetsStrutsMoisture barrierProtection layer

The invention relates to a composite component of alkaline-resisting mesh cloth plastering, relating to a building composite component and aiming at the problems of high construction cost, inconvenient construction and the like of the current energy-saving wall body. The structure one is as follows: a sandwich layer 3 is struck to the interior of a beam column frame of a load-carrying member 1; the interior and the exterior the sandwich layer 3 have cement mortar protective courses 8; an alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8 and is connected with the load-carrying member 1 in a sticking way. The structure two is as follows: the sandwich layer 3 is struck to a basic unit wall 1-5; the exterior of the sandwich layer 3 has the cement mortar protective courses 8; the alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8. The structure three is as follows: the sandwich layer 3 is positioned between the upper and lower cement mortar protective courses 8; the lower cement mortar protective course 8 is positioned on a building major structure 1; the upper protective course 8 covers the sandwich layer 3; the alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8. The method of construction is as follows: an interface agent is painted on the sandwich layer or cement mortar to stick the alkaline-resisting mesh cloth 4; when the interface agent is damp, the cement mortar ash is carried out; the glass is used as a waterproof and dampproof moisture barrier; a caking agent is struck to the surface of a structural cement to serve as the waterproof and dampproof moisture barrier. The method has the advantages of low construction cost, convenient construction, etc.

Owner:吴淑环

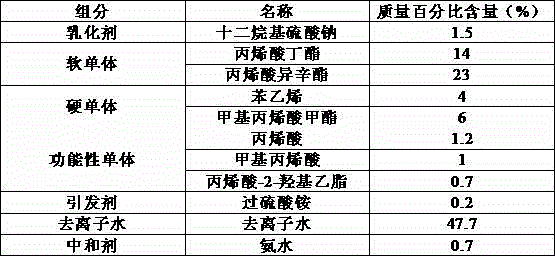

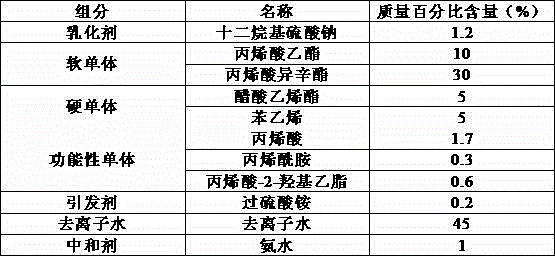

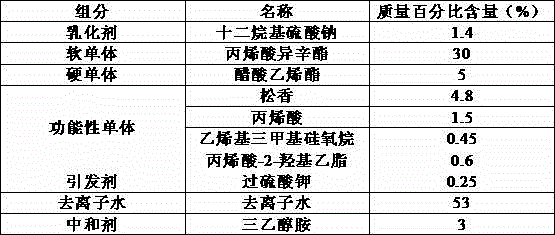

Adhesive emulsion for environment-friendly textile gilding printing paste and preparation method thereof

The invention discloses adhesive emulsion for environment-friendly textile gilding printing paste and a preparation method thereof. The emulsion consists of the following components in percentage by weight: 0.5-3% of emulsifier, 30-50% of soft monomer, 6-15% of hard monomer, 2-5% of functional monomer, 0.1-0.3% of initiator, 40-60% of deionized water and 0.5-2% of neutralizer. The adhesive is prepared into gilding paste and is used for bonding textile gilding foil; and the shortcomings of the products on the market of low net operability, hard handfeel, unsatisfactory firmness, easy color losing after washing, environmental pollution and the like are overcome. Through the invention, the prepared adhesive has excellent initial viscosity and sustained viscosity and good water resistance, and can realize good adhesive force against different textile fabrics; and meanwhile, the adhesive has good cohesion permanent viscosity, is environment-friendly without releasing toxic substances such as formaldehyde and the like, and does not contain the alkylphenol additives. The adhesive emulsion disclosed by the invention is suitable for the cold and hot gilding technology of manual or mechanical printing, is easy to operate, and has soft handfeel, no sand hole and high yield.

Owner:BAILIHE CHEM ZHONGSHAN

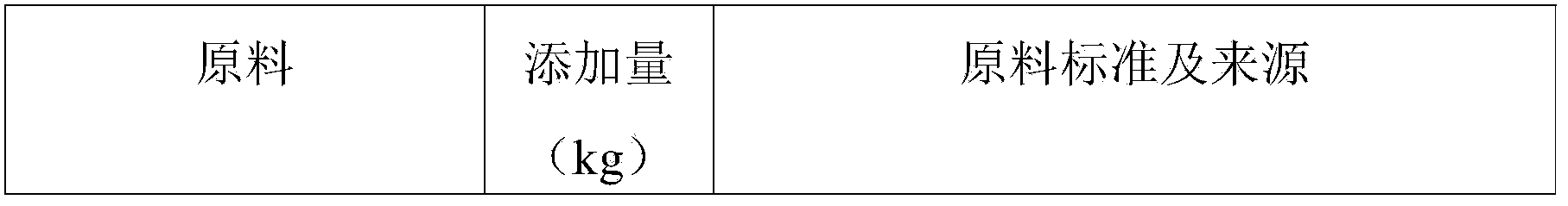

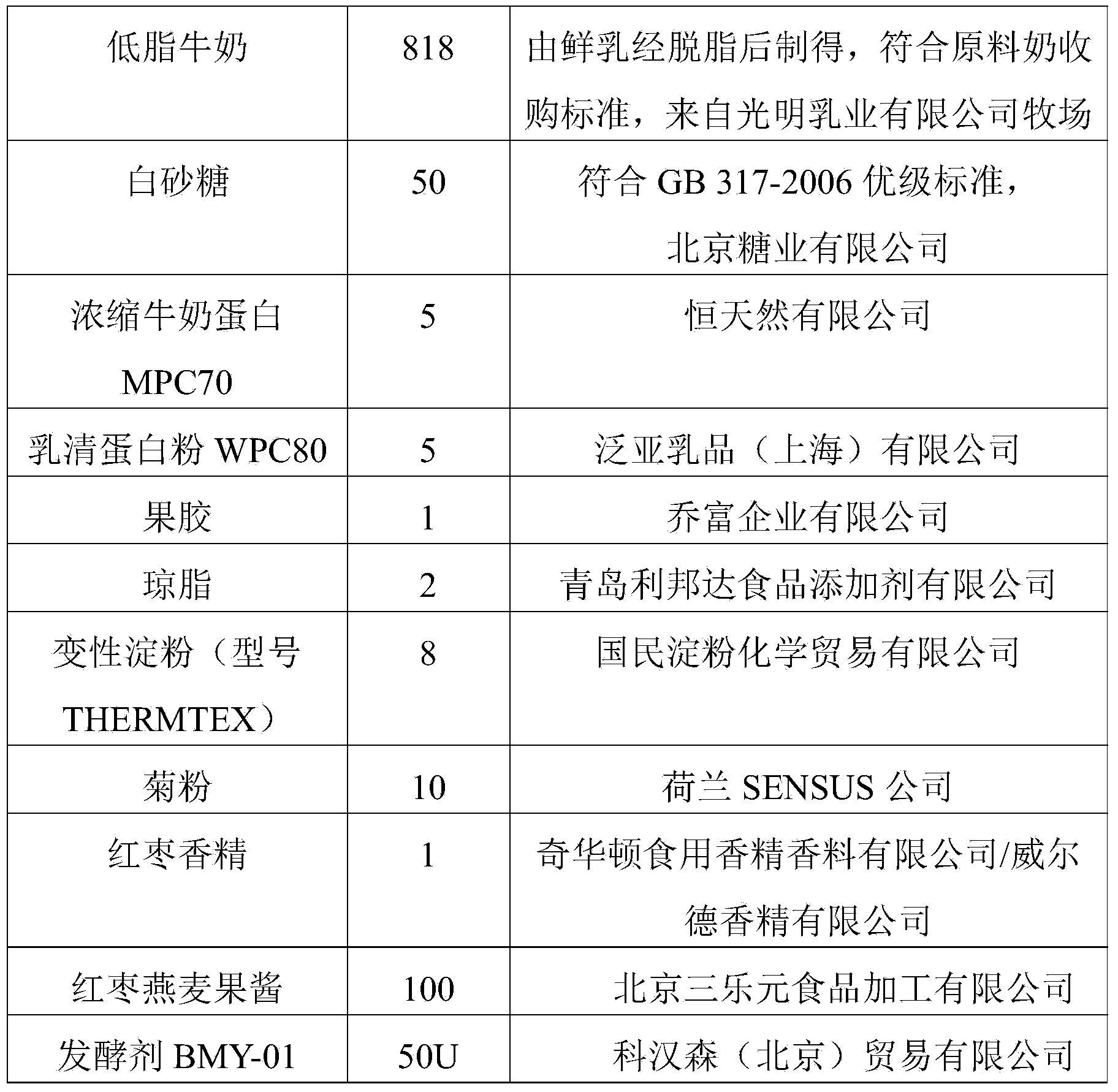

Low-fat and high-protein jam yogurt and preparation method of low-fat and high-protein jam yogurt

ActiveCN104041589APreparation for industrializationLarge scale preparationMilk preparationFlavorWhey protein

The invention discloses low-fat and high-protein jam yogurt and a preparation method of the low-fat and high-protein jam yogurt. The low-fat and high-protein jam yogurt is prepared from the following raw materials based on 1000 parts by weight: 800-860 parts of low-fat milk, 1-10 parts of concentrated milk protein, 3-15 parts of whey protein powder, 80-120 parts of jam, 0.2-60 parts of a sweetening agent, 1-30 parts of inulin, 8-20 parts of a thickening agent and 0-1 part of edible essence; the low-fat and high-protein jam yogurt also comprises a leavening agent, and the dosage of the leavening agent is 50-200U in every 1000kg of raw materials. The low-fat and high-protein jam yogurt is prepared by the conventional yoghourt preparation method in the field. The low-fat and high-protein jam yogurt has the advantages of being good in texture, good in flavor, complete in nutrition and good in product stability, and being capable of realizing diversification of varieties.

Owner:BRIGHT DAIRY & FOOD

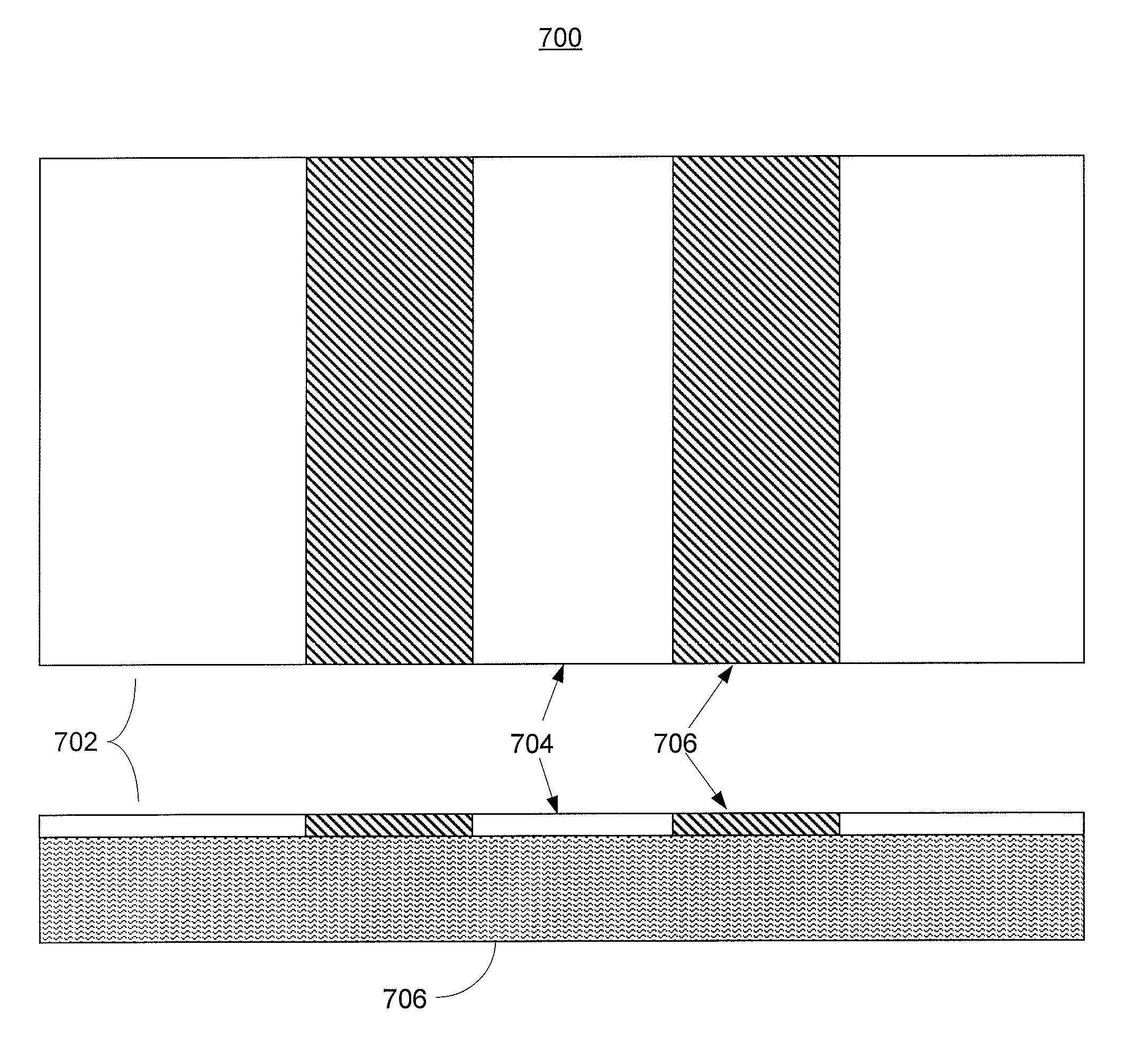

Methods of Making a Belt-Creped Absorbent Cellulosic Sheet Prepared with a Perforated Polymeric Belt

InactiveUS20120241113A1High local basis weightImprove firmnessNon-fibrous pulp additionNatural cellulose pulp/paperCellulosePolymer science

A method of making a belt-creped absorbent cellulosic sheet. A paper making furnish is compactively dewatered to form a dewatered web having an apparently random distribution of papermaking fiber orientation. The dewatered web is applied to a translating transfer surface that is moving at a transfer surface speed. The web is belt-creped from the transfer surface at a consistency of from about 30% to about 60% utilizing a generally planar polymeric creping belt having a plurality of perforations, under pressure, in a belt creping nip defined between the transfer surface and the creping belt. The belt travels at a belt speed that is slower than the speed of the transfer surface. The web is creped from the transfer surface and redistributed on the creping belt to form a web having a plurality of interconnected regions of different local basis weights. The web is then dried.

Owner:GPCP IP HLDG LLC

Pocketed bedding or seating product having inflatable members

ActiveUS20050273939A1Improve firmnessStuffed mattressesMultiple spring combinationsEngineeringMechanical engineering

A bedding or seating product comprises a pocketed spring assembly having a plurality of parallel strings of springs joined to each other. Each of said strings of springs comprises a row of interconnected pockets, each of the pockets containing at least one spring encased in a fabric pocket. An inflatable member is sandwiched between a lower scrim sheet and some strings of springs. When inflated, the inflatable member preloads select areas of the product.

Owner:L & P PROPERTY MANAGEMENT CO

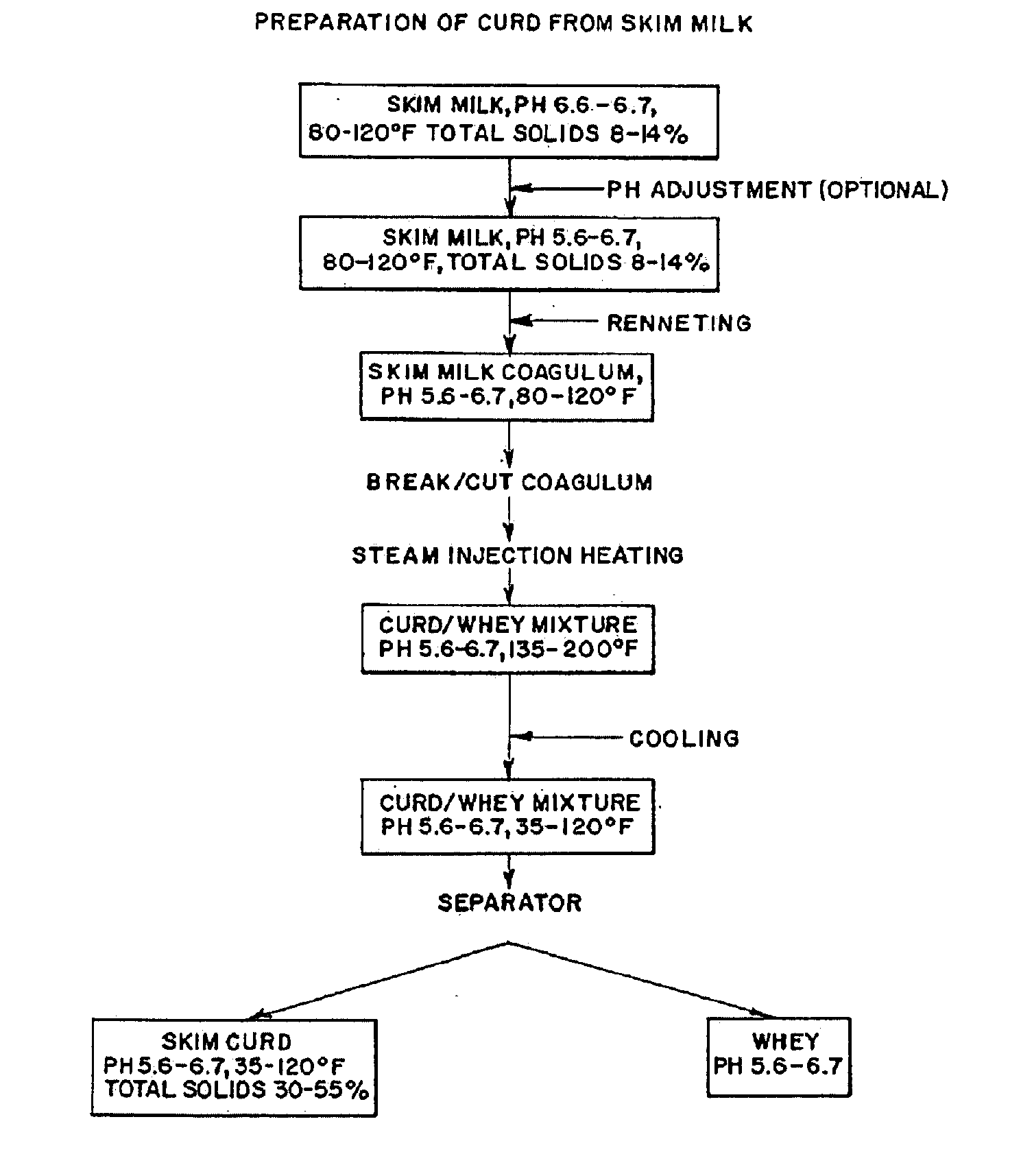

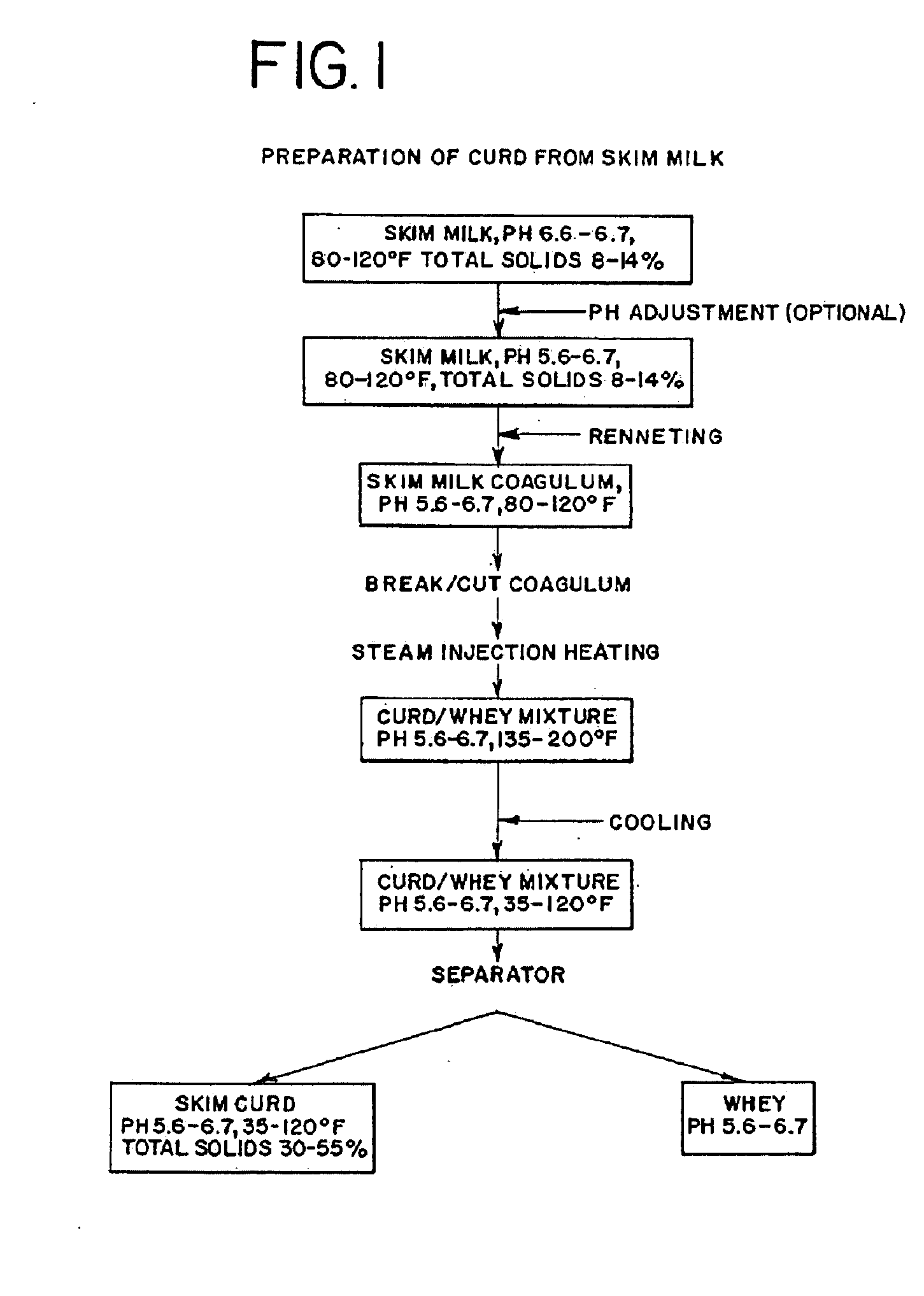

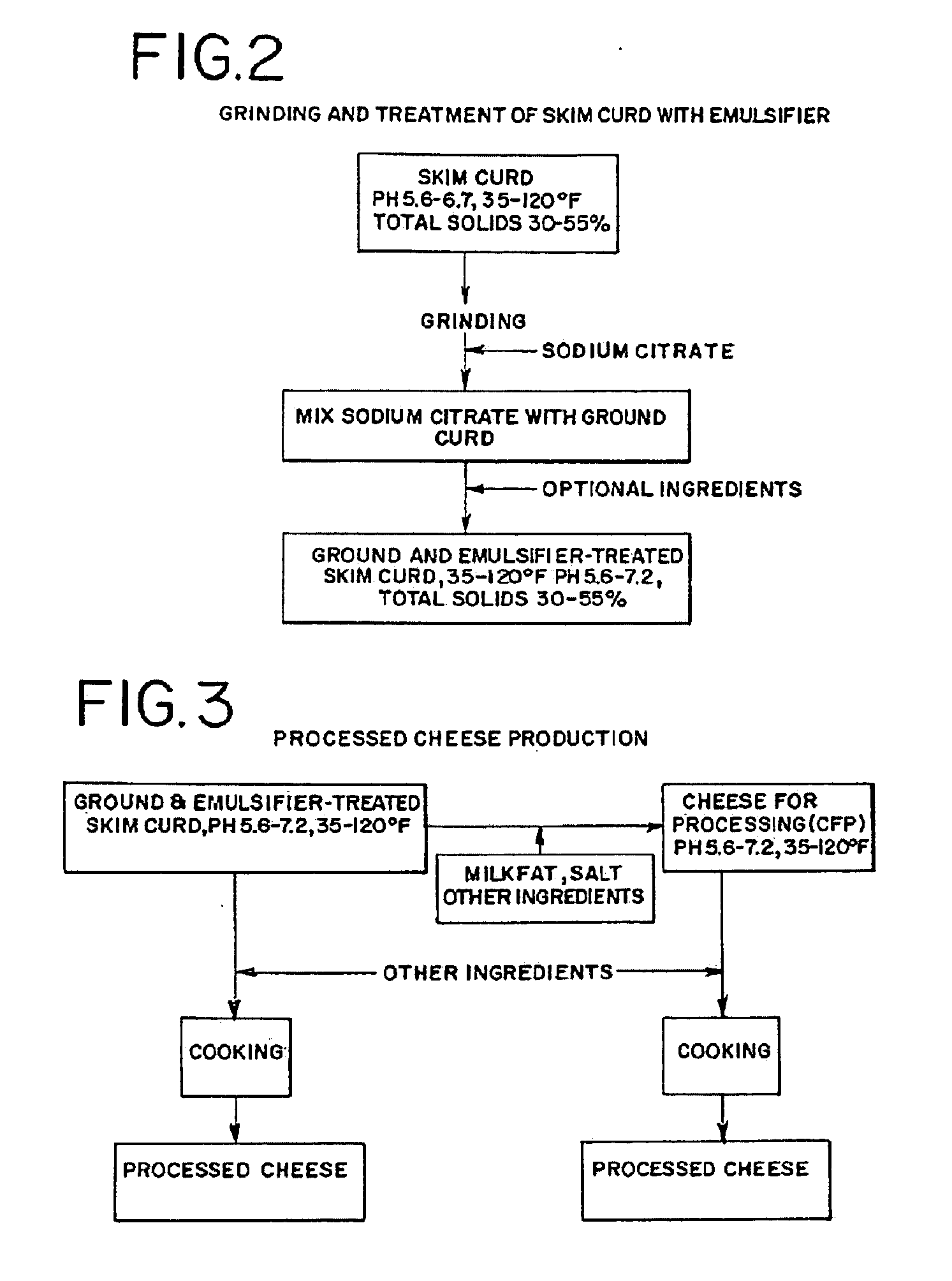

Curds for processed and imitation cheese, cheese products produced therefrom, novel intermediate products and methods of making same

InactiveUS20060062873A1High activityRapid and economical productionMilk preparationCheese manufactureAdditive ingredientEnzyme

Methods of making novel cheese curds and cheese products comprise the steps of providing a fluid milk protein source containing casein; mixing a milk coagulating enzyme into the fluid milk protein source; allowing the milk coagulating enzyme to react with the casein for a time sufficient for the fluid milk protein source to form coagulum while at a pH of 5.6 or above; heating the coagulum containing the enzyme treated casein to a temperature of at least 135° F., more preferably at least 150° F., while the fluid milk protein source is at a pH of 5.6 or above, for a time sufficient to cause syneresis of the coagulum and to form curds; and separating the curds from liquid remaining from the curd formation. In another embodiment, the milk coagulating enzyme is allowed to react with the casein for at least three hours while at a temperature at which a coagulum does not form; after which the fluid milk protein source containing the enzyme treated casein is heated to at least 135° F., for a time sufficient to cause the casein to form curds. The curds from either embodiment may be mixed with additional ingredients to make the cheese products, including processed and imitation cheese. A composition consisting essentially of a fluid milk protein source containing casein and milk coagulating enzyme in the form of a coagulum at a temperature of at least about 160° F., as well as ground curds having a weight average particle size of about 1.5 mm or less, are novel.

Owner:SCHREIBER FOODS

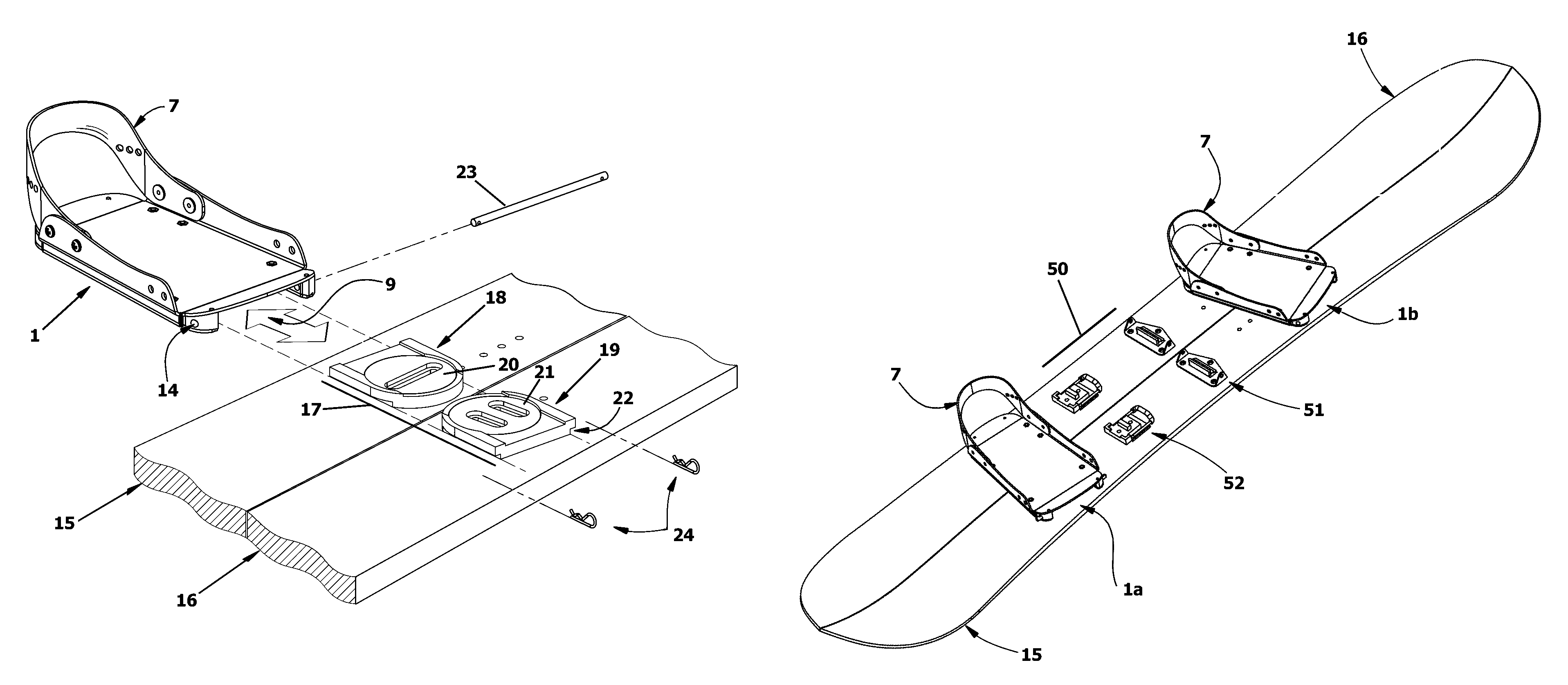

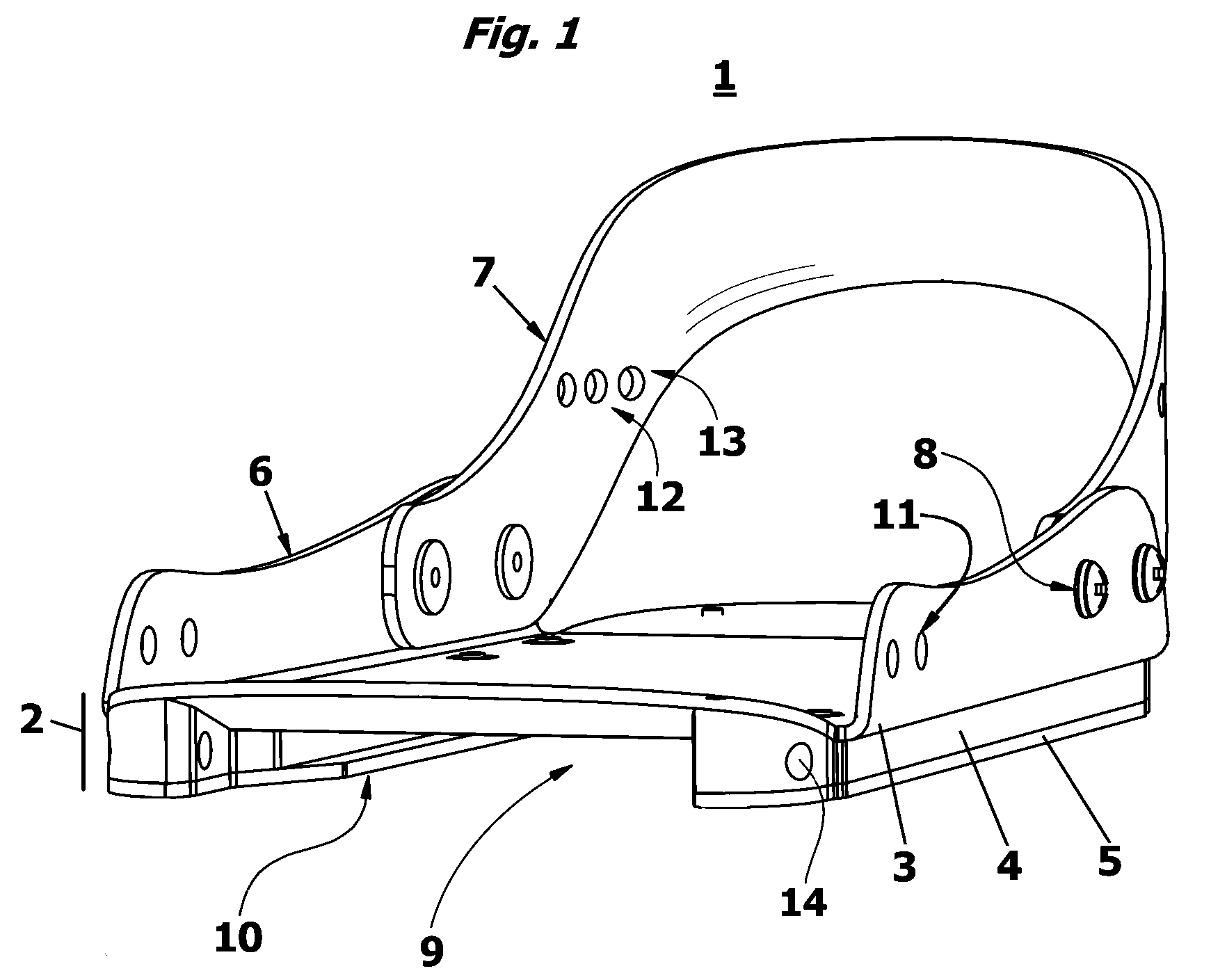

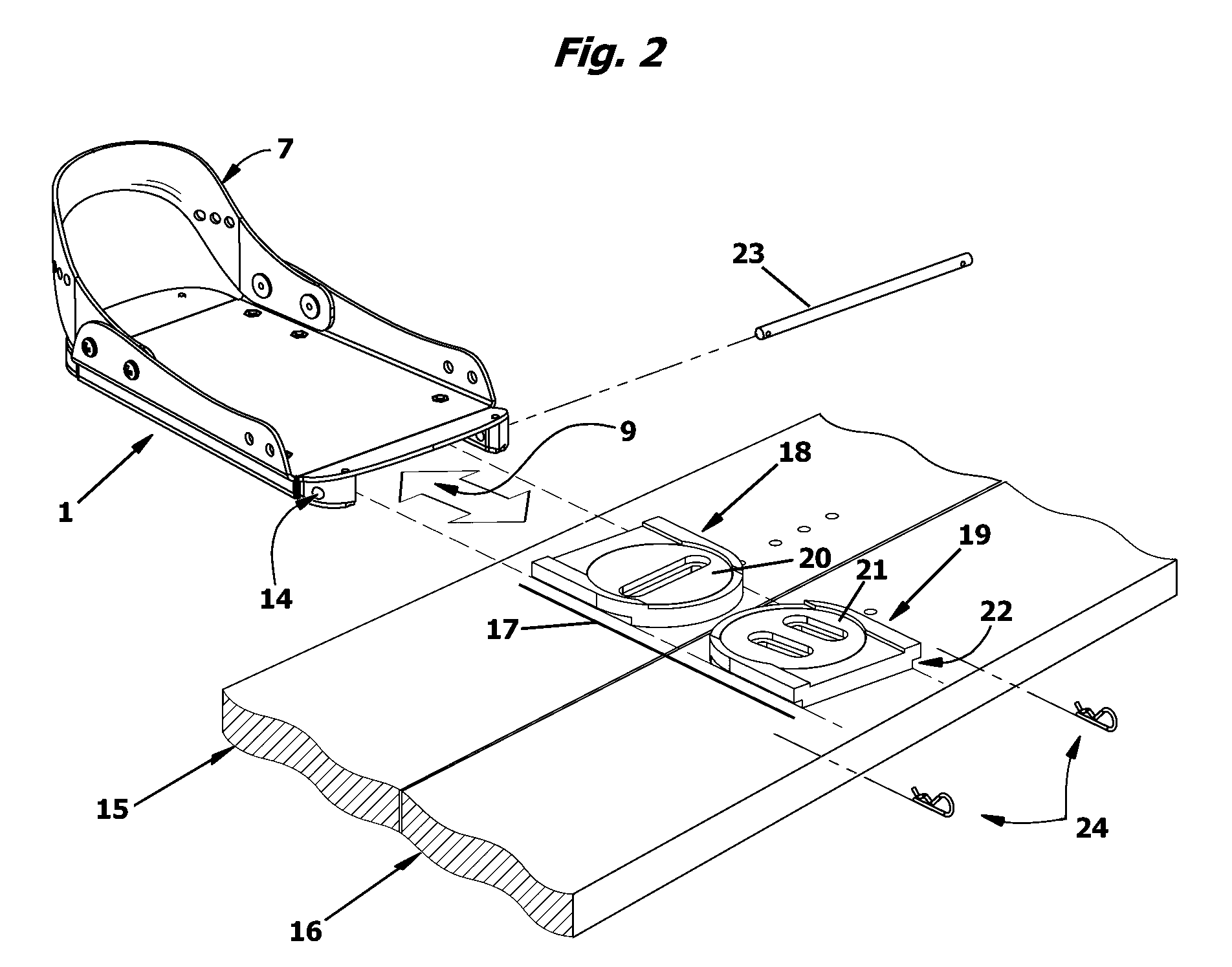

Splitboard bindings

ActiveUS8226109B2Improved boot bindingReduced torsional stiffnessCarriage/perambulator accessoriesSki bindingsEngineeringRigid structure

Splitboard boot bindings for backcountry splitboarding. Each of a pair of soft-boot bindings is provided with an integral boot binding lower that conjoins the two halves of a splitboard without the additional weight or height of an adaptor mounting plate, upper binding baseplate or “tray”, and extra fasteners of the prior art. The boot binding lower is formed as a modified sandwich box girder or modified monolithic box girder and provides improved torsional stiffness for splitboard riding. When subjected to a torque applied by the rider, the bottom mediolateral flanges of the box girders are configured to contactingly engage the top face of the splitboard, thereby dynamically coupling the rider's boot sole and the board via a single rigid structure. In a preferred embodiment, the web or “spacer” members are characterized by an aspect ratio or contour height that is varied from heel to toe.

Owner:SPARK R&D IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com