Patents

Literature

150results about How to "Large scale preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-frequency patch resistor and manufacturing method thereof

InactiveCN101923928ALarge resistance rangeLarge scale preparationResistor trimmingResistor detailsMicrowaveCharacteristic impedance

The embodiment of the invention discloses a high-frequency patch resistor which comprises a substrate, a back electrode, a surface electrode, a resistor body and a first lateral conducting electrode, wherein in order to enable characteristic impedance to be matched with anticipatory target impedance, the resistor body is provided with an external cutting notch, i.e. cutting is started from the edge of the resistor body, the partial area of the resistor body is directly cut off from the resistor body, and the cross-sectional area of the resistor body can be decreased to a greater degree, so that the high-frequency patch resistor has a larger resistance-adjusting range and is beneficial to the matching of the characteristic impedance of the characteristic impedance resistor and the anticipatory target impedance. The invention also provides a manufacturing method of the high-frequency patch resistor to manufacture the high-frequency patch resistor with the larger resistance-adjusting range. The high-frequency patch resistor provided by the invention is suitable for microwave radio-frequency structures and chipping, and meanwhile, the high-frequency patch resistor can be manufactured in large scales and with high efficiency by utilizing the manufacturing method of the high-frequency patch resistor provided by the invention.

Owner:四平市吉华高新技术有限公司

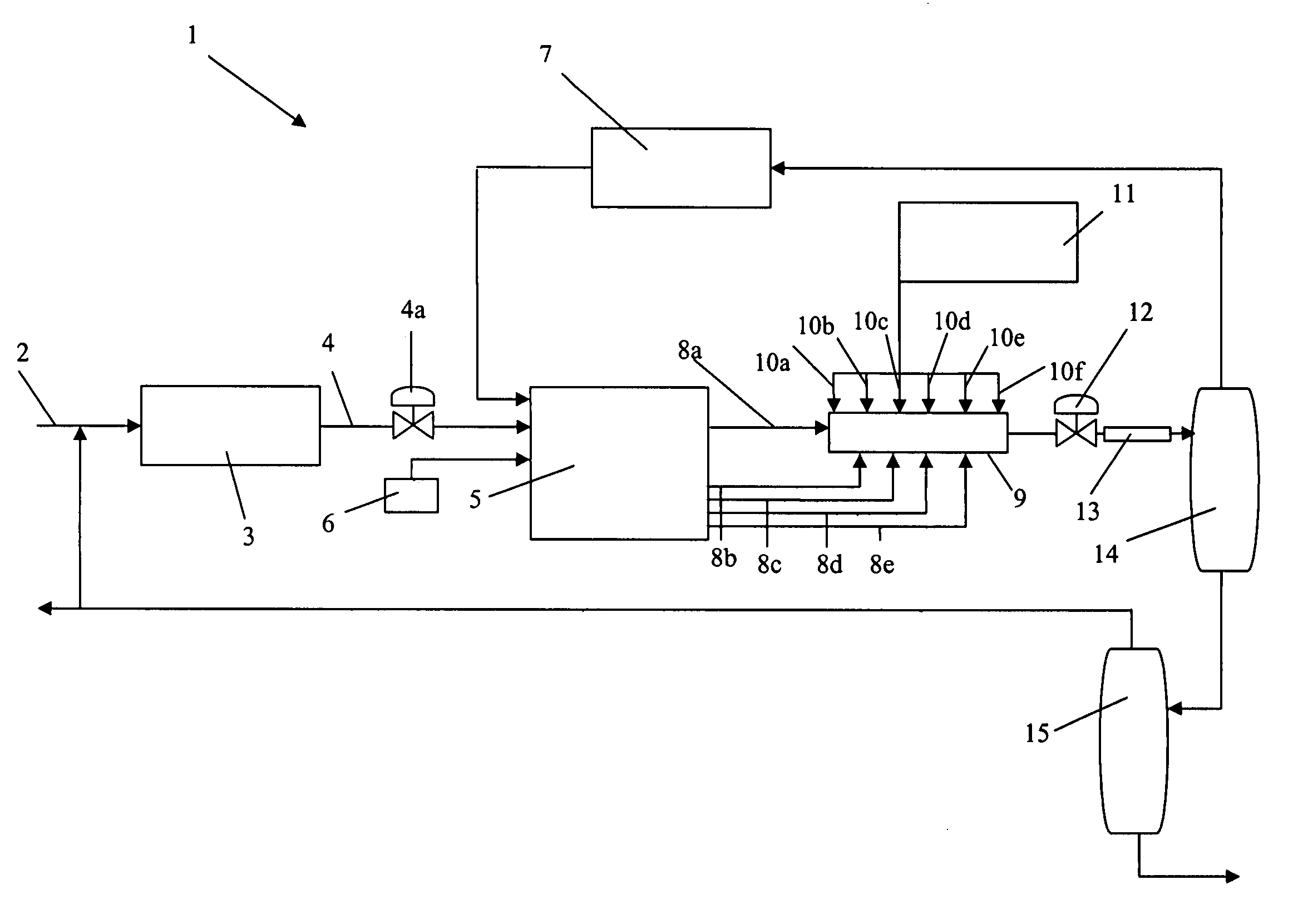

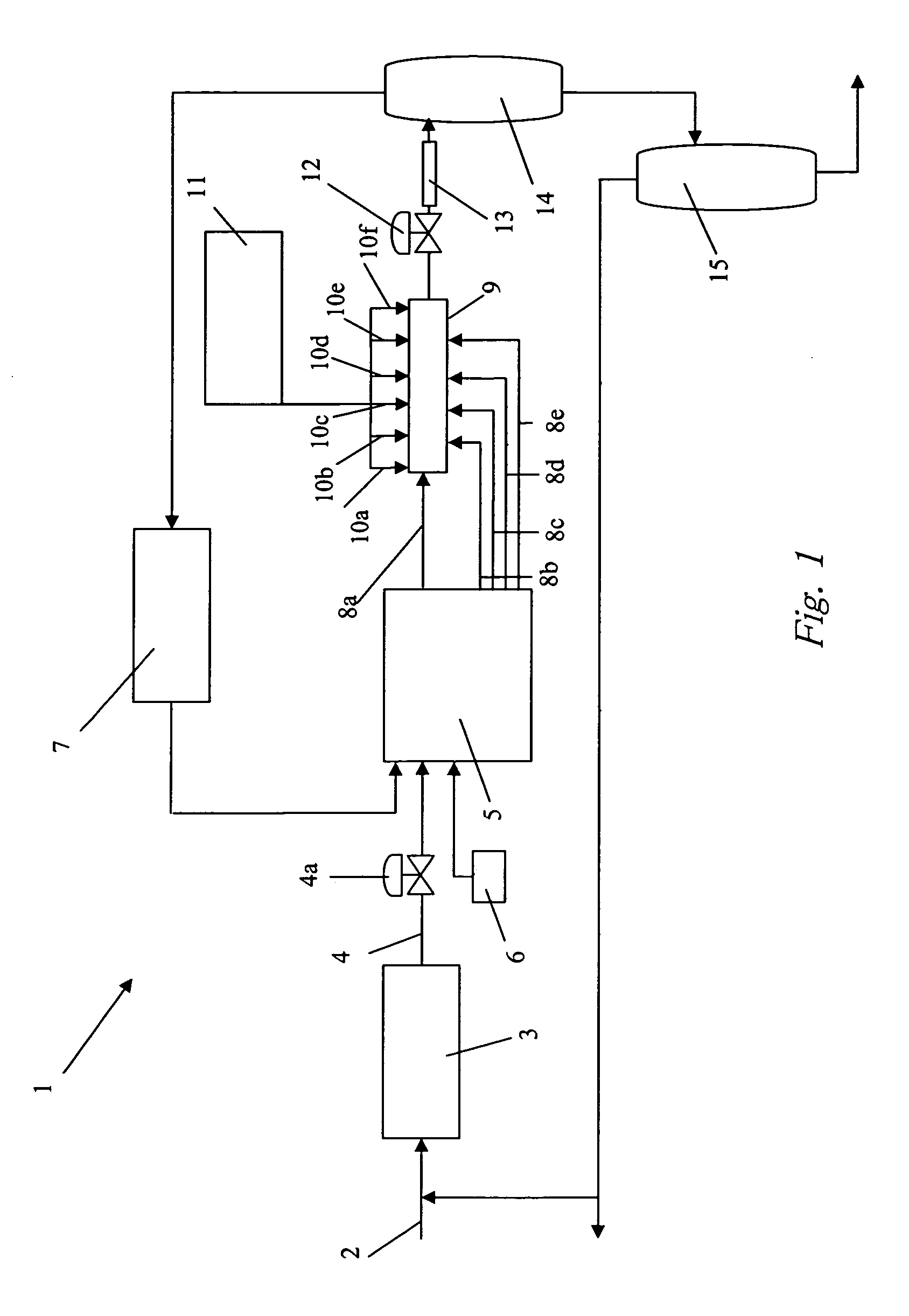

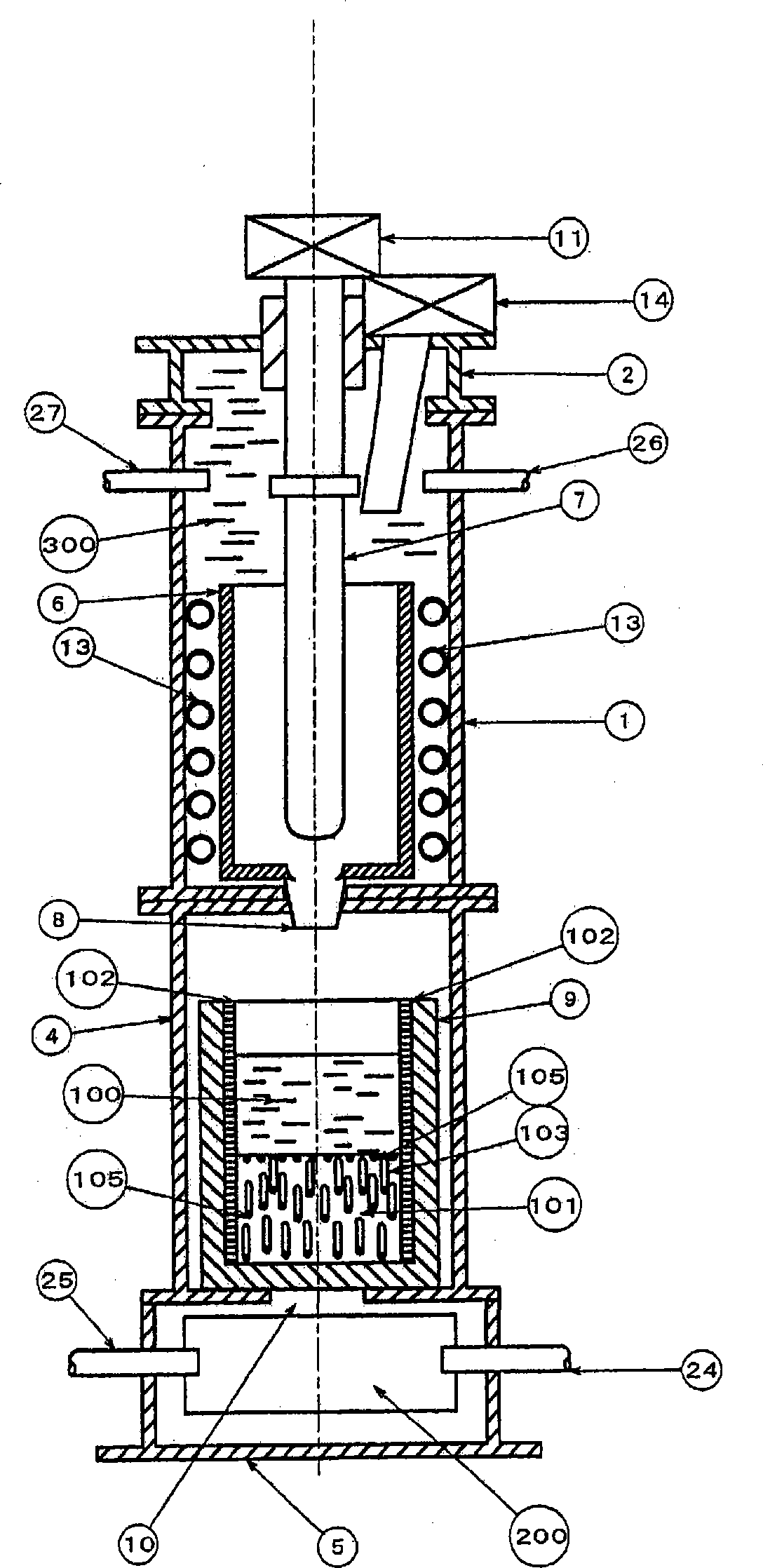

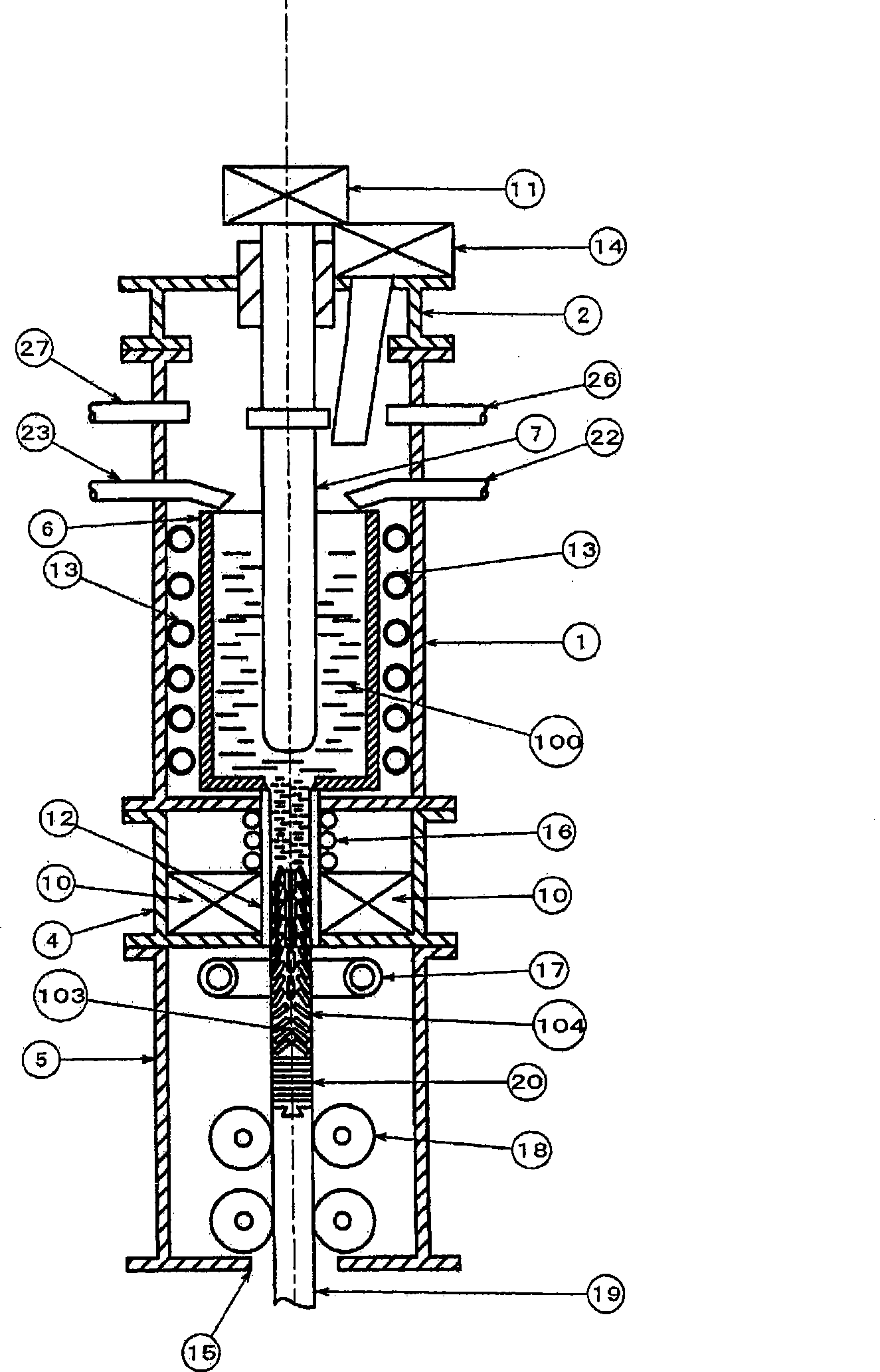

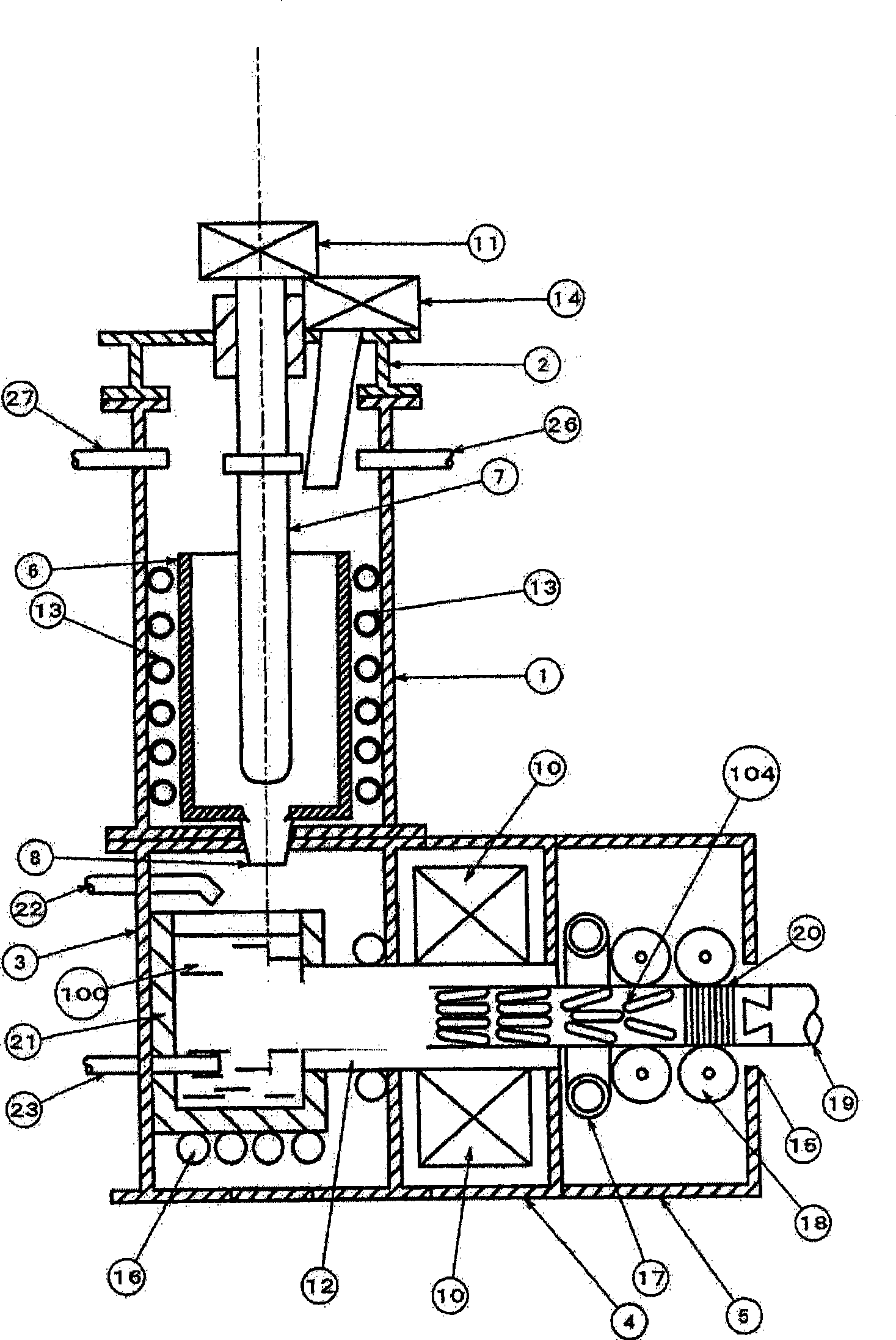

Process and apparatus for manufacturing ethylene polymers and copolymers

InactiveUS7582709B2Reliable and efficient method of manufactureEfficient heat dissipationEthylene productionChemical/physical/physico-chemical stationary reactorsPolymer scienceReaction zone

The invention relates to a process for the manufacture of ethylene polymers and copolymers in which ethylene is compressed in a primary compressor at a throughput of at least 55 tonnes / hour, mixed with recycled ethylene and further compressed in a two-stage reciprocating secondary compressor having at least 14 cylinders to a pressure of at least 2300 bar at a throughput of at least 120 tonnes / hour, heating at least a portion of that ethylene to a temperature of at least 95° C. and introducing it into a tubular reactor of diameter at least 65 mm and a length of at least 1500 m, introducing initiator in at least three reaction zones to give a conversion of at least 28% and maintaining a pressure drop over the reactor to maintain a flow velocity of at least 6 m / s.

Owner:EXXONMOBIL CHEM PAT INC

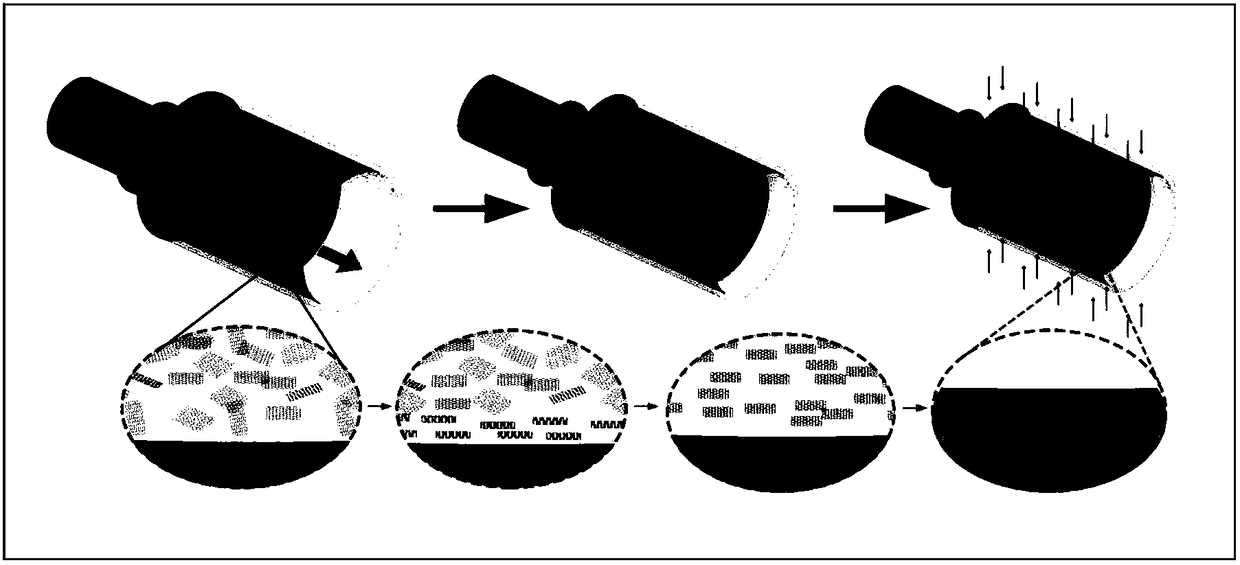

Method for effectively preparing high-orientation and high-compactness two-dimensional material thin film

ActiveCN108568926ASolution coatingUniform coatingFlat articlesCoatingsComposite filmMechanical property

The invention relates to the field of preparation and application of two-dimensional materials, in particular to a method for effectively preparing a high-orientation and high-compactness two-dimensional material thin film. The method comprises the following steps: taking a circular tube with a smooth inner surface as a casting die; pouring a solution which contains a two-dimensional material intothe die when the die rotates in the peripheral direction at high speed; uniformly coating the inner surface of the die with the solution by using centrifugal force; forming shear force which drives the two-dimensional material to be regularly arranged layer by layer in an oriented manner in the peripheral direction in the solution in a centrifugal rotating process; and meanwhile, driving the two-dimensional material to be accumulated at high compactness by the centrifugal force so as to obtain the two-dimensional material thin film with high orientation and high compactness. The method is suitable for preparing various two-dimensional materials such as graphene, and composite thin films and laminated heterostructure thin films of the two-dimensional materials; electric property, heat property, mechanical property and the like of the thin film are greatly improved; and the method is used in the field of high-performance electric conduction / heat-conduction thin films, heat management materials, high-strength thin films, electronic / optoelectronic devices, compact energy storage, gas / ion separating films, proton transmitting films and the like.

Owner:深圳烯材科技有限公司

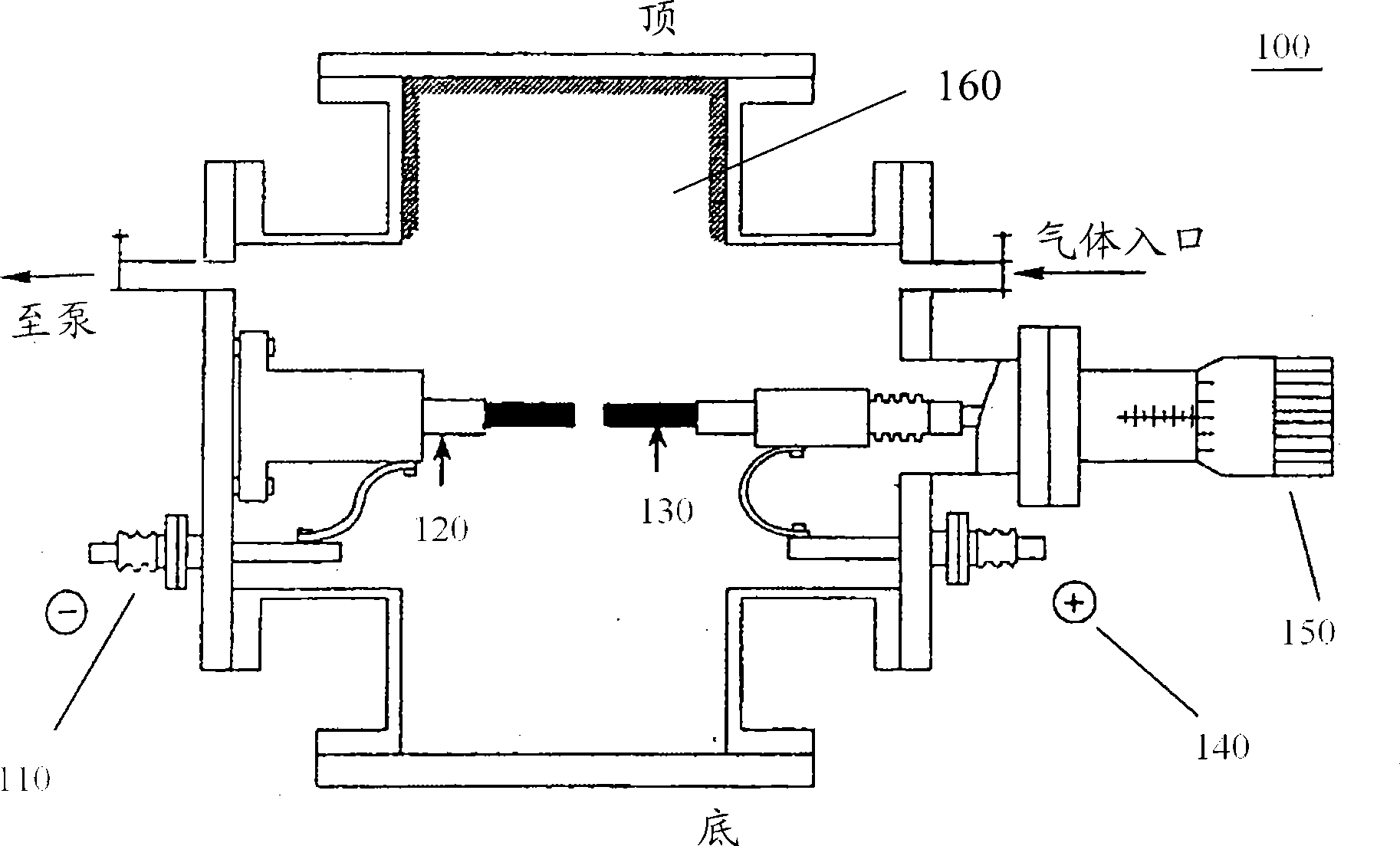

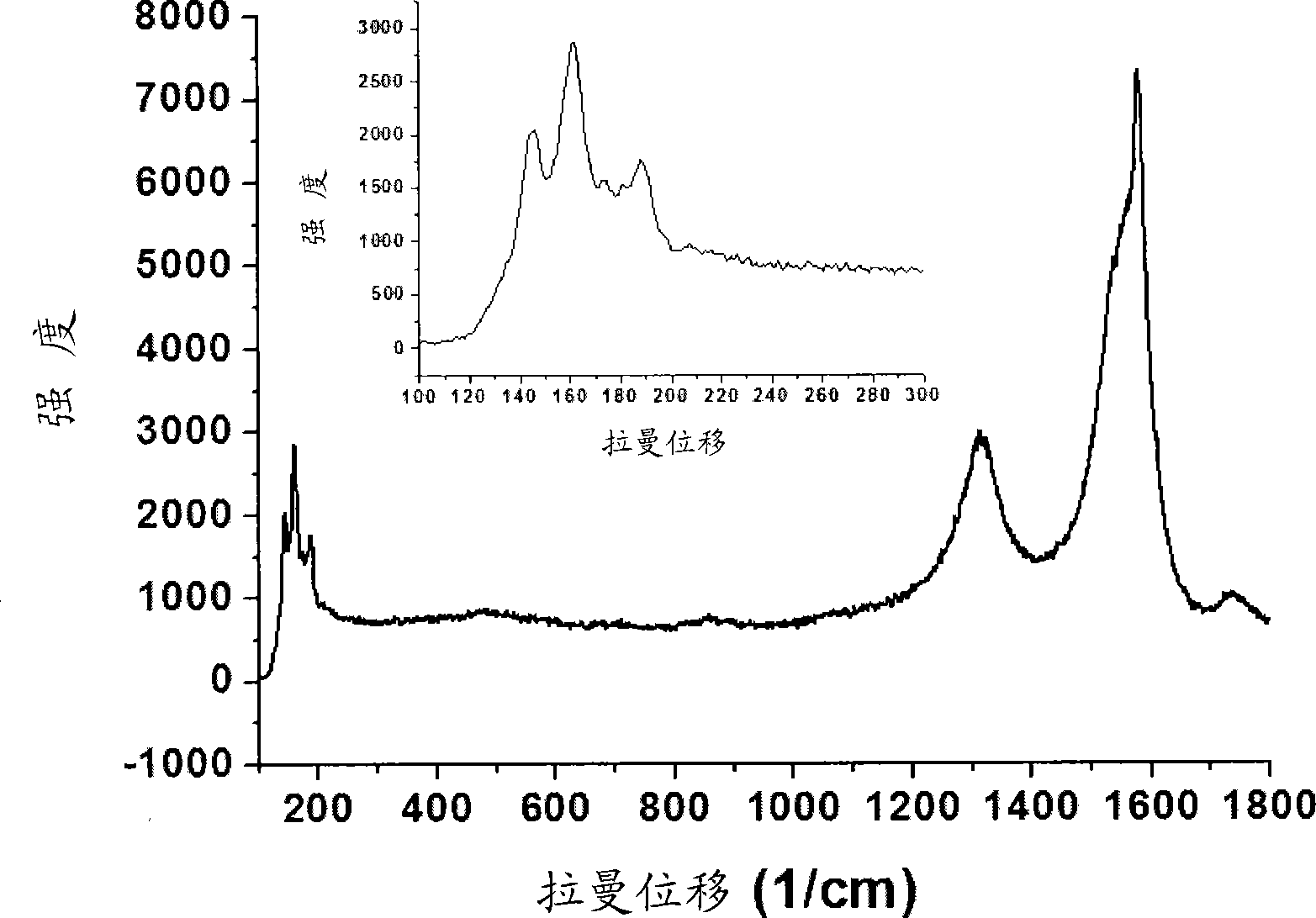

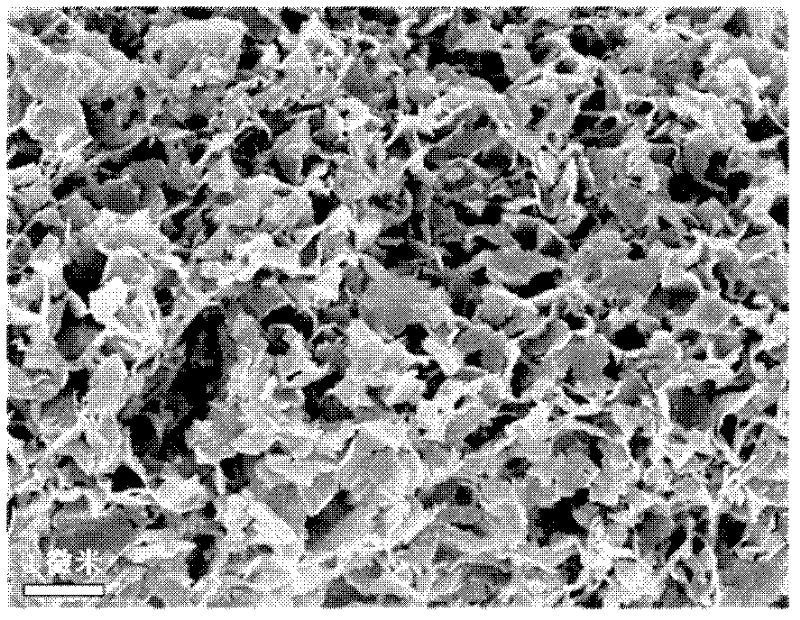

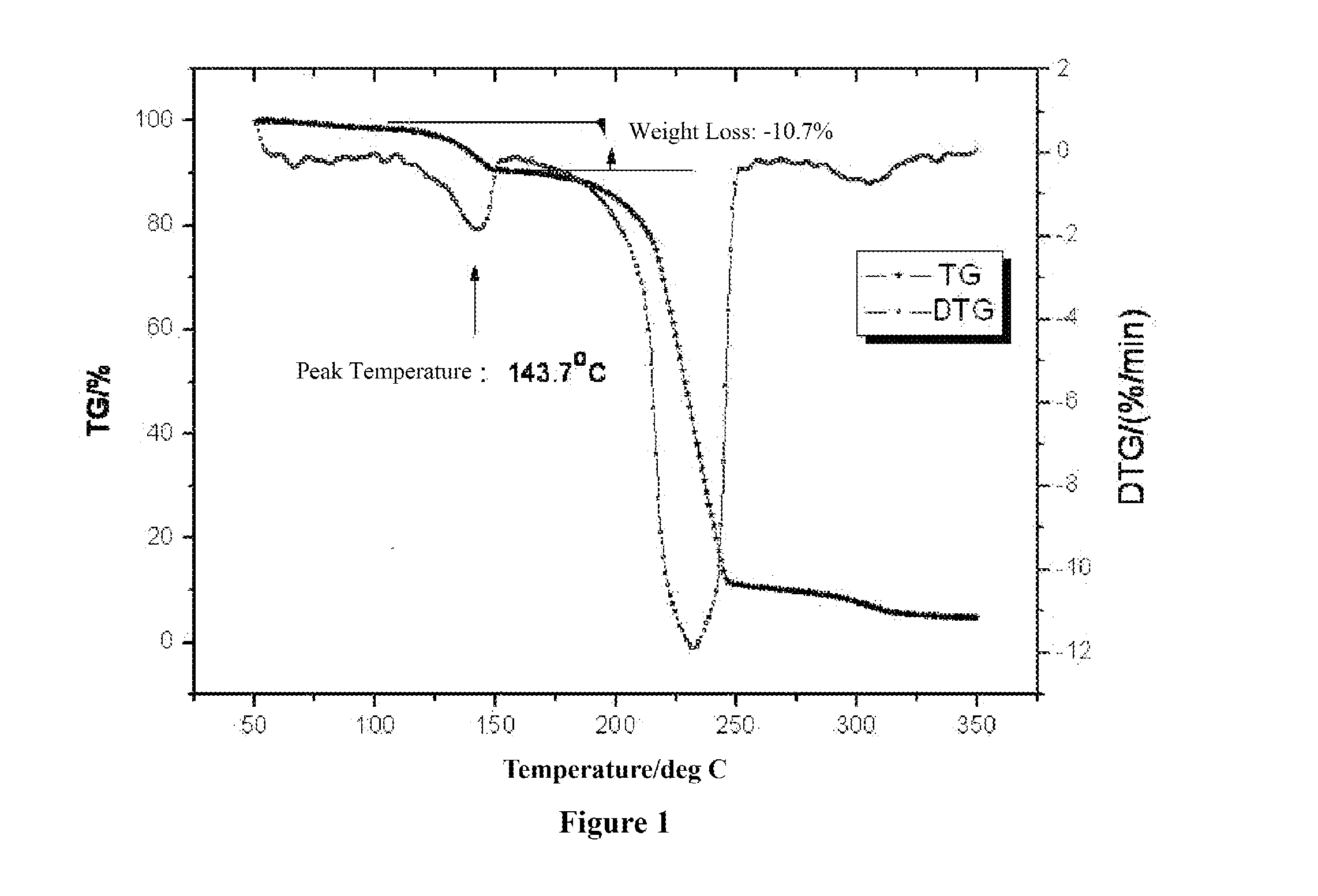

Nitrogen doped carbon nanotube and preparation method thereof, and carbon nanotube element

InactiveCN101450799AEasy to manufactureLarge scale preparationPolycrystalline material growthSingle crystal growth detailsNitrogen sourceGraphite

The invention discloses a graphite electric arc discharge method for preparing a nitrogen-doped carbon nano-tube, the nitrogen-doped carbon nano-tube, and a carbon nano-tube element using the nitrogen-doped carbon nano-tube. In the electric arc discharge method for preparing the nitrogen-doped carbon nano-tube, a mixture comprising graphite, a catalyst and a nitrogenous organic compound used as a nitrogen source is used to prepare an anode, and the anode and a cathode are used for electric arc discharge to prepare the nitrogen-doped carbon nano-tube.

Owner:SONY CORP

Method for preparing salt-tolerant microbial agent

InactiveCN103540555ARapid industrialization startSimple stepsFungiBacteriaInorganic saltsMixed culture

The invention discloses a method for preparing a salt-tolerant microbial agent. The method comprises the following steps of in an open culture device, directly carrying out mixed culture on a salt-tolerant microbial flora in a high-salt environment sample under the condition that total salt concentration is 1%-30%; and adding an organic carbon source, nutrient elements and trace elements according to the needs in a culture process, controlling and keeping proper pH, temperature and dissolved oxygen relatively stable. The salt-tolerant microbial agent prepared by adopting the method has good salt tolerance and salinity impact resistance, can degrade organic substances in water without being restrained by high-concentration inorganic salt under the condition that total salt concentration is 1%-30%, and can be directly used for purifying high-salt-content wastewater with salt concentration of 1%-30%. The method disclosed by the invention is simple to operate, short in implementation period and capable of quickly carrying out industrial application.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

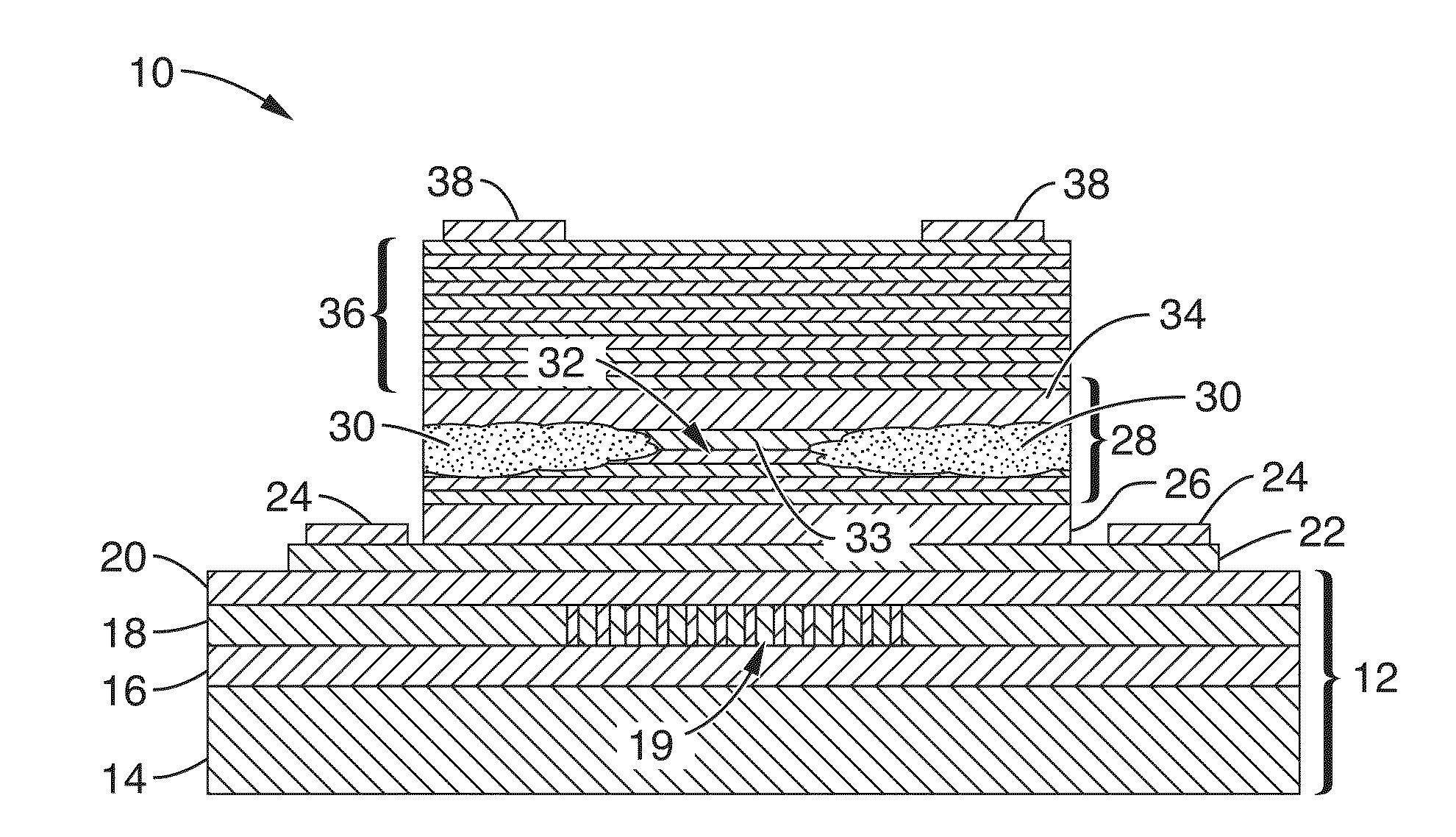

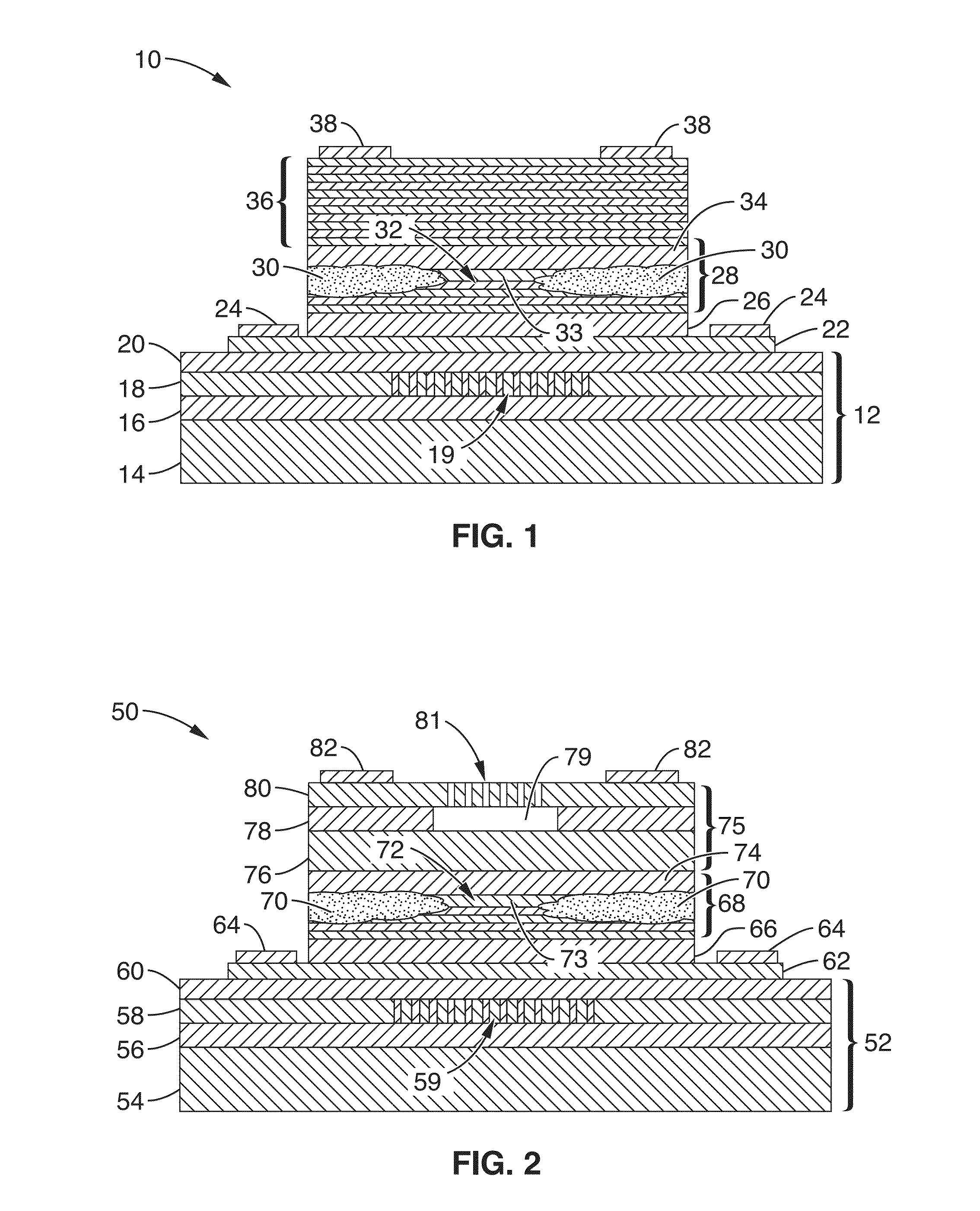

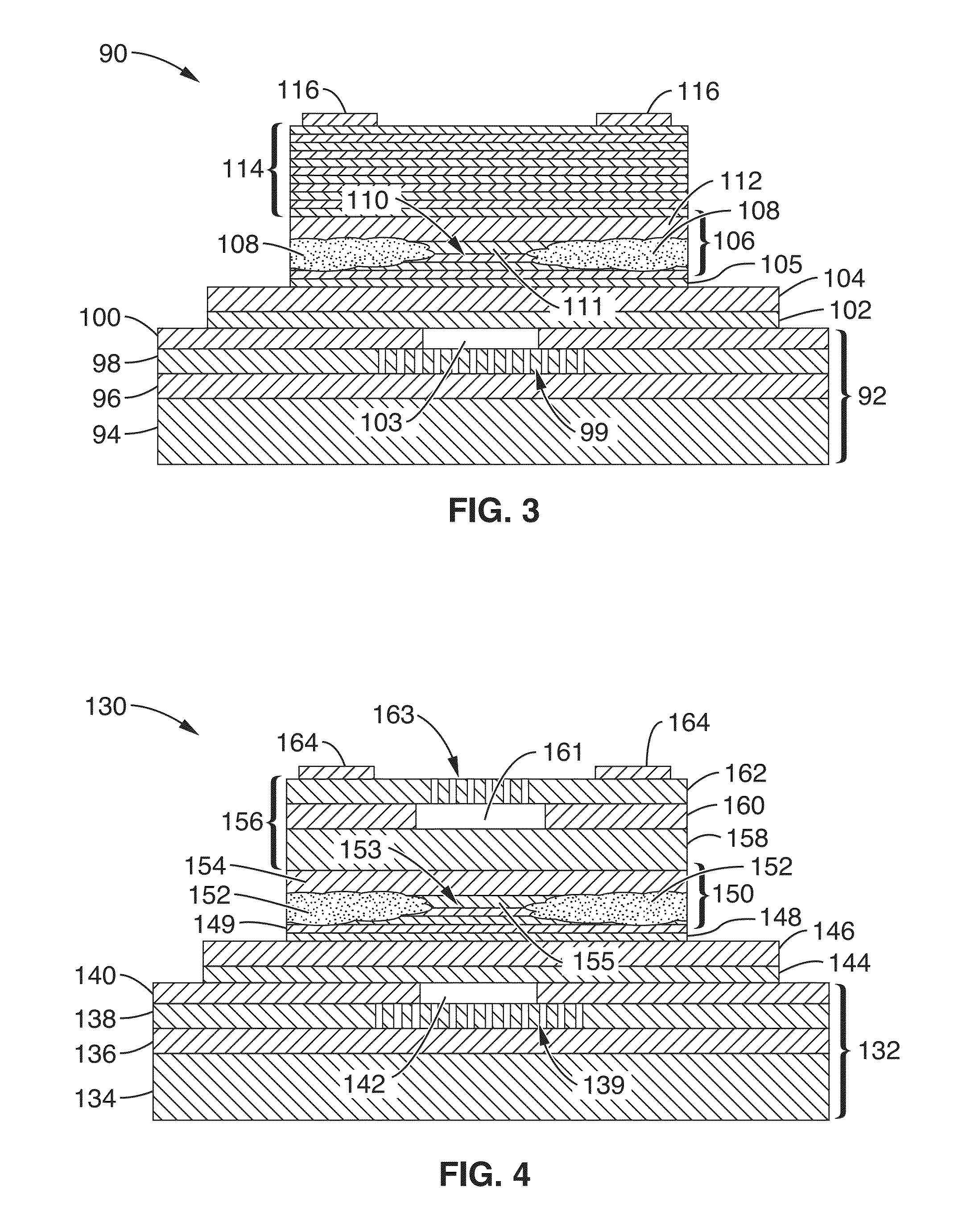

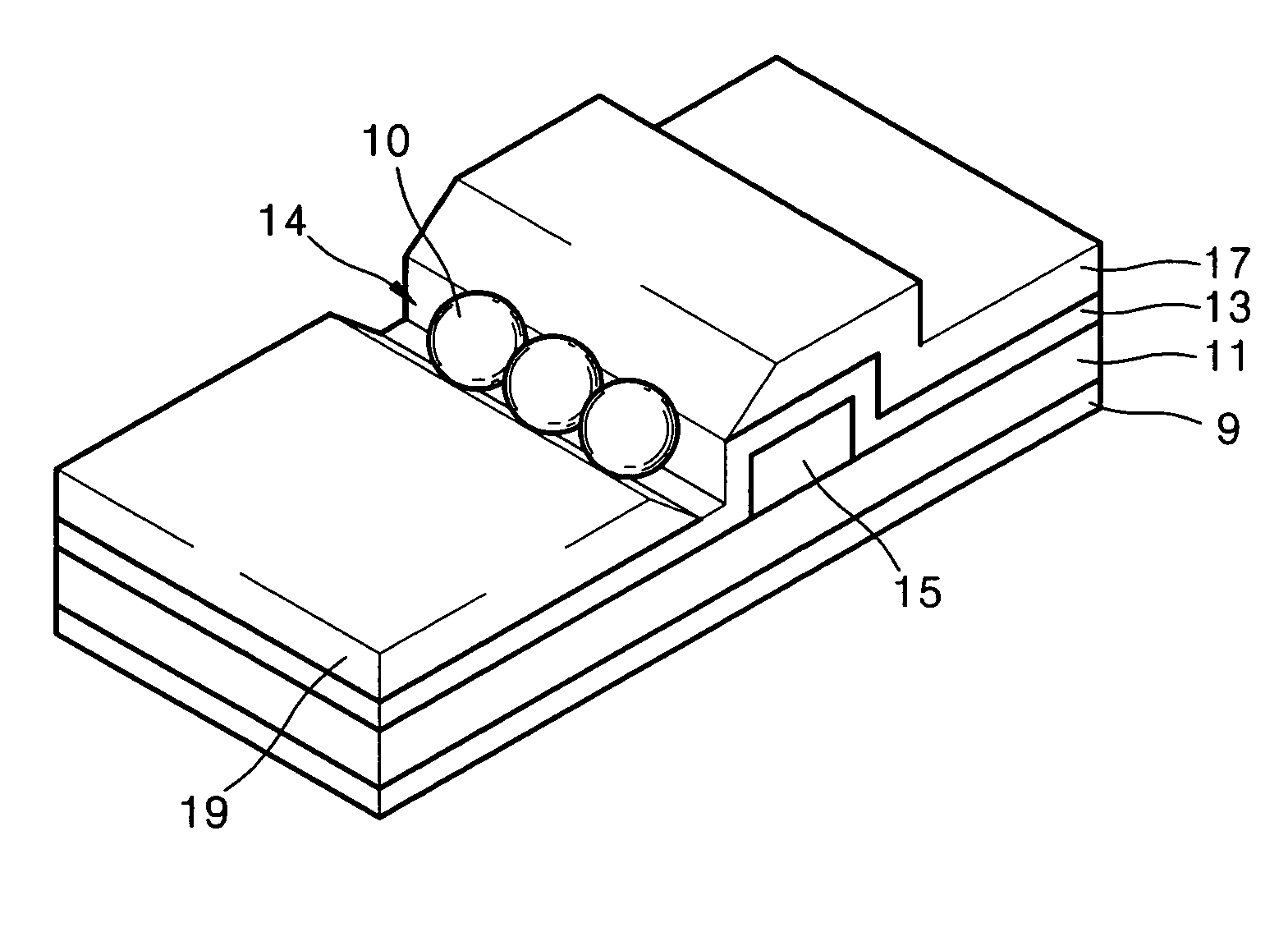

Vertical cavity surface emitting lasers with silicon-on-insulator high contrast grating

InactiveUS20150288146A1Reduce manufacturing costLarge scale preparationOptical wave guidanceSemiconductor laser arrangementsGratingLength wave

A surface emitting laser apparatus is formed using a patterned silicon-on-insulator (SOI)-like substrate which is patterned with a buried sub-wavelength high contrast grating and adapted for bonding of a half-VCSEL device containing at least an active region and an upper mirror, to create a VCSEL. The wavelength of the VCSEL, or any individual VCSEL within an array of VCSEL devices, can be set in response to changing HCG characteristics of the lower mirror in the SOI-like substrate, or in the region above the lower mirror within the half-VCSEL. The inventive VCSEL device and fabrication method are beneficial for a number of application and devices.

Owner:RGT UNIV OF CALIFORNIA

Method for manufacturing porous body

InactiveCN101473055AEasy to prepareSimple control principleMelt-holding vesselsSiliconMolten stateAtmospheric pressure

Provided is a method for manufacturing a porous body characterized in that after dispersing a gas generating compound in a molten-state material for forming the porous body, the molten material is solidified. The high quality and highly uniform porous body can be manufactured even at an atmospheric pressure, without requiring high pressure ambience.

Owner:LOTUS ALLOY

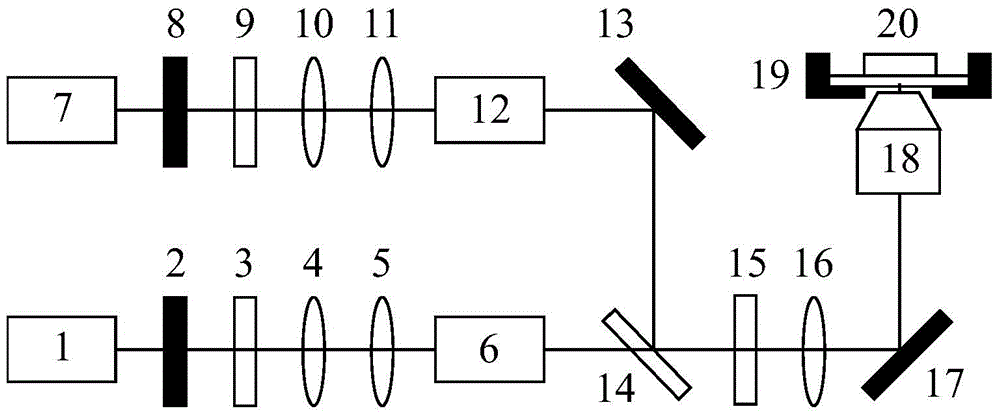

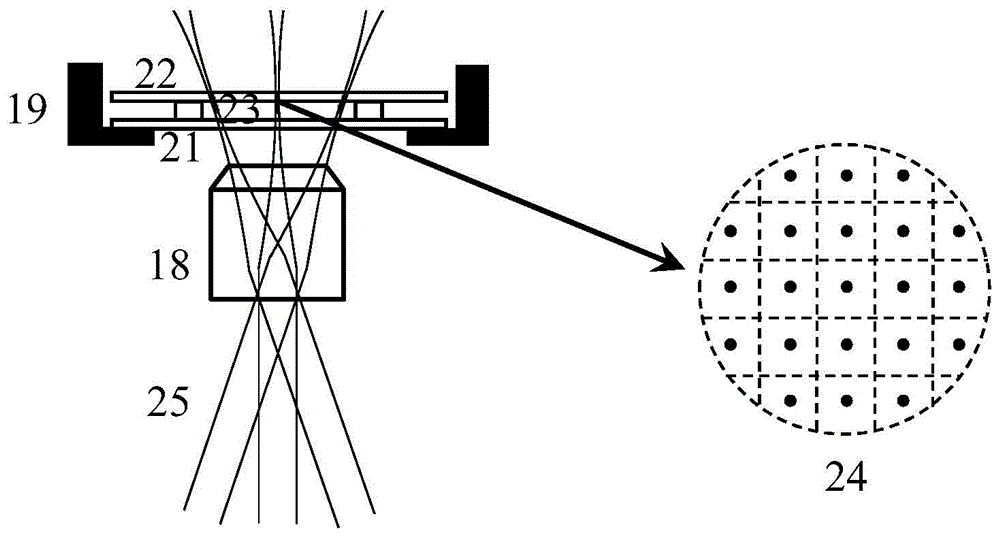

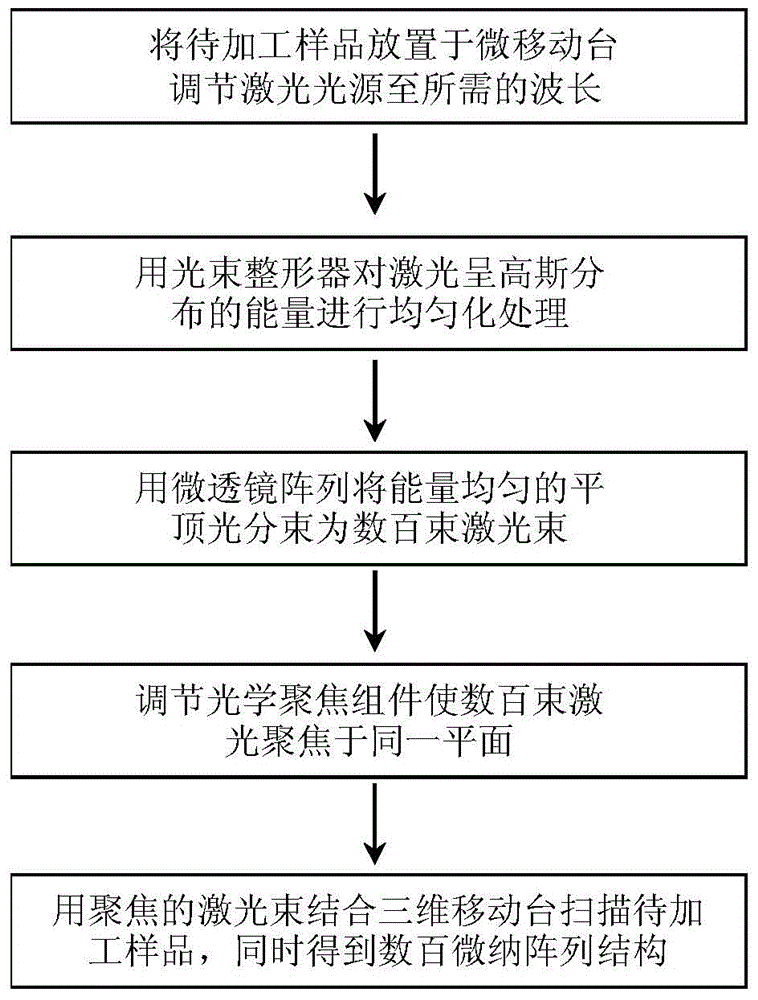

System and method for preparing micro-nano array structure by means of laser light

ActiveCN104439699AImprove consistencyFast preparationLaser beam welding apparatusMicro nanoLight beam

The invention discloses a system and method for preparing a micro-nano array structure by means of laser light. The method for preparing the micro-nano array structure by means of laser light comprises the steps that a first laser beam with the wavelength enabling a material to be processed to generate the multiphoton absorption effect is provided; homogenization treatment is conducted on the first laser beam in Gaussian distribution, so that a first flat beam with energy evenly distributed is obtained; the first flat beam is split into multiple laser beams arranged in an array mode by means of a microlens array component; the multiple laser beams arranged in the array mode are focused to beam focusing components located on the same plane respectively; a metal ion solution placed on a minitype movable table controlled by a computer is scanned, so that hundreds of micro-nano periodical array structures are obtained, wherein the beam spot area of the first flat beam is equal to or smaller than the effective array area of the microlens array component. According to the method for preparing the micro-nano array structure by means of laser light, the micro-nano array structures of the same structure and in controllable dimensions can be prepared in a large-scale mode rapidly.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

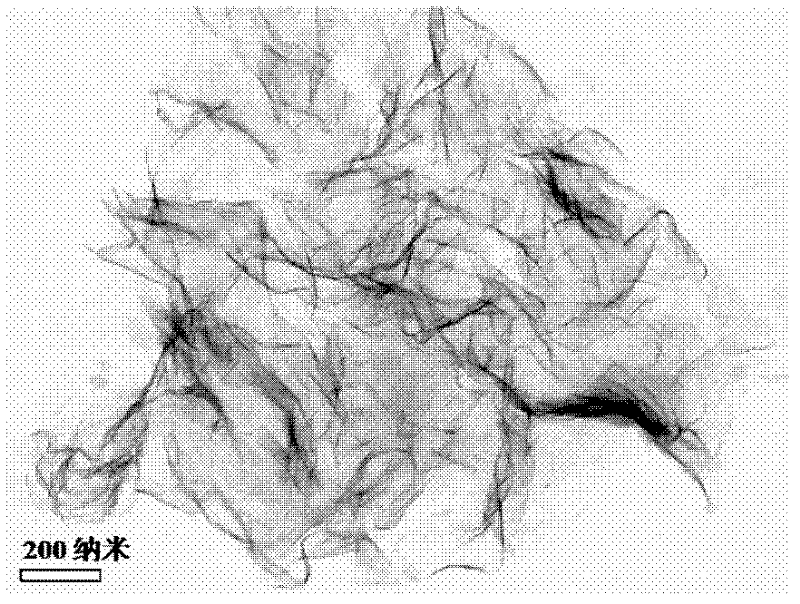

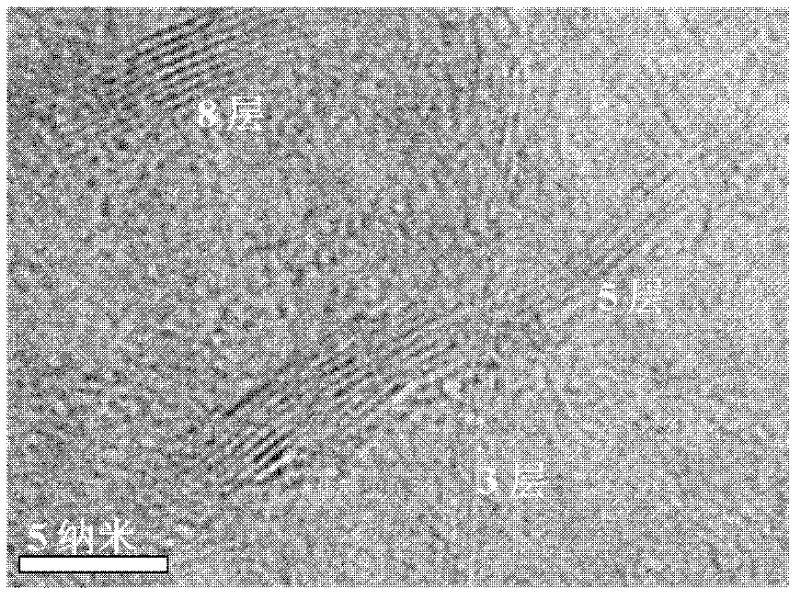

Method for preparing multilayer graphene

ActiveCN102351172AAbundant sources of raw materialsThe reaction process is mild and controllableCvd grapheneBulk polymerization

The invention discloses a method for preparing multilayer graphene. The method is characterized in that: a compound of a vinyl polymer is prepared through carrying out bulk polymerization or in situ polymerization on raw materials consisting of 85-98.5 wt% of a vinyl monomer, 1-10 wt% of a layered compound and 0.5-5 wt% of an aromatization catalyst, a mixture containing the multilayer graphene isprepared through heating the compound of the vinyl polymer for 1min-10h at 700-1500DEG C in an inert atmosphere, and the purified multilayer graphene with the thickness of 0.35-15nm is prepared through immersing the mixture containing the multilayer graphene in a solution containing 10-30% by mass of hydrofluoric acid for 1-48h, separating to obtain a solid, and immersing the separated solid in amixed solution which comprises concentrated sulfuric acid and concentrated nitric acid according to a volume ratio of 1:1 for 1-48h, and separating. The method of the invention has the following advantages: the vinyl polymer is used as a carbon source, so the raw material source is abundant; the aromatization catalyst used in the invention can be directly obtained from the market; reaction processes are mild and controllable, and operations are convenient; and the low cost and large scale preparation of graphene can be realized.

Owner:UNIV OF SCI & TECH OF CHINA

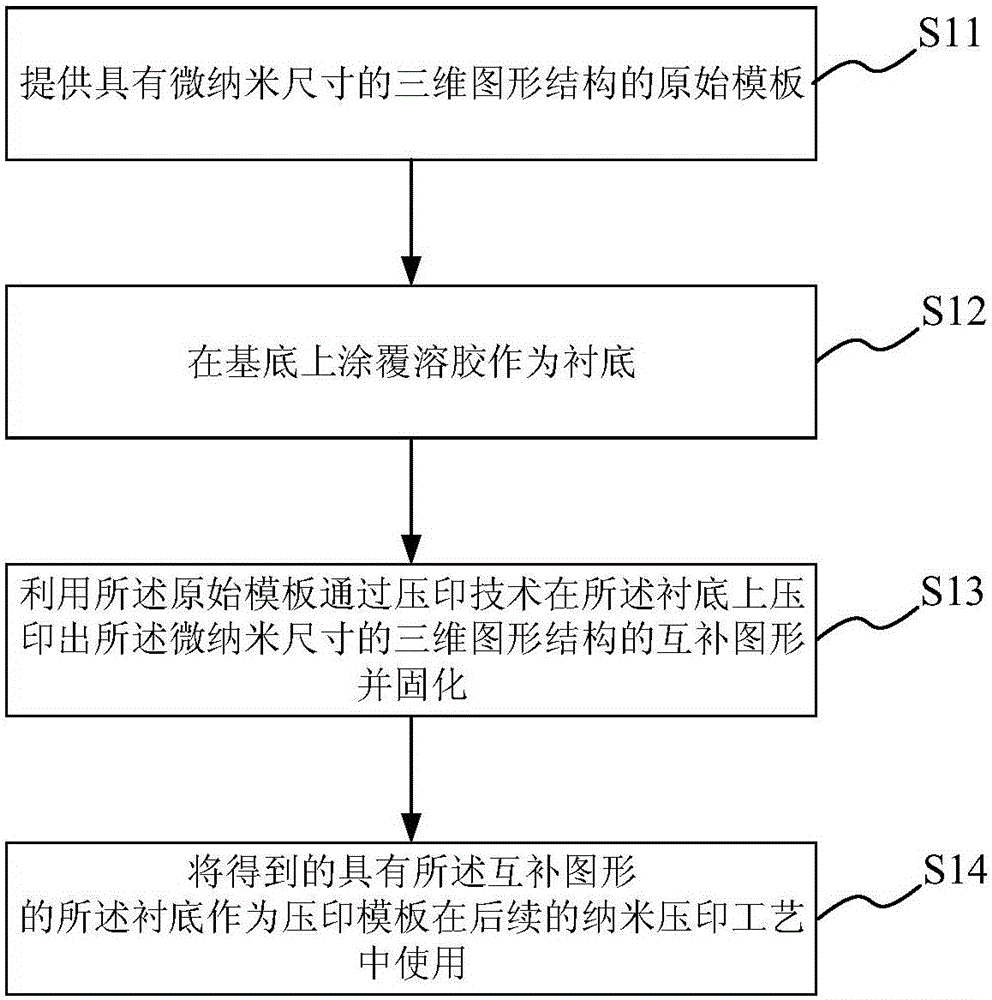

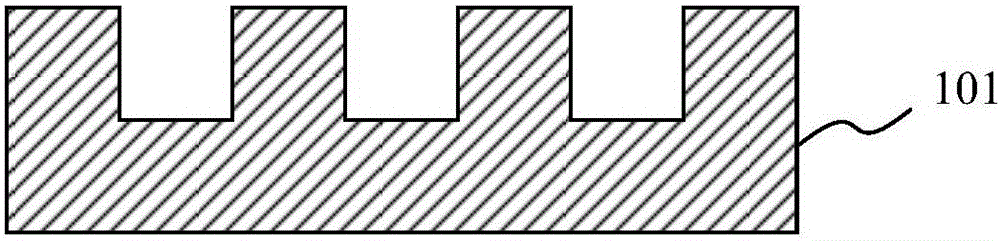

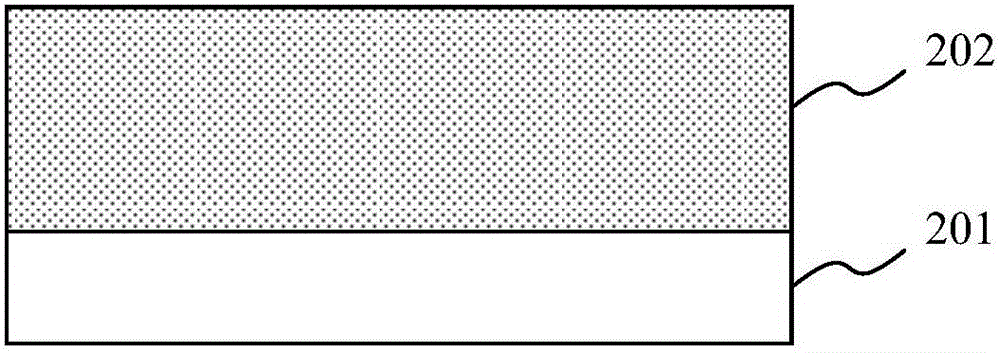

Preparing method for nanoimprint template

InactiveCN105824190AGood repeatabilityFast preparationPhotomechanical apparatusMicro nanoRepeatability

The invention provides a preparing method for a nanoimprint template .The method includes the following steps that a micro-nano original template of a three-dimensional graph structure is provided; a base is coated with sol to serve as a substrate; a complementary graph of the micro-nano three-dimensional graph structure is imprinted on the substrate with the original template through an imprinting technology; the obtained substrate with the complementary graph is used as the template in the follow-up nanoimprint process .The preparing method for the nanoimprint template is high in repeatability, capable of preparing the inorganic template fast at low cost on a large scale and capable of being used in the processes of ultraviolet imprinting and thermal imprinting, the prepared template is high in mechanical strength and reutilization, conformality in the follow-up imprinting process is good, a base material with a higher depth ratio can be obtained by using the template as a mask plate after etching, and the problem that the structure is shallow after etching when photoresist serves as the mask plate can be solved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Liquid metal microparticles with core-shell structures and preparation method and application thereof

InactiveCN109570515AAvoid corrosionWide range of application scenariosTransportation and packagingMetal-working apparatusMicro nanoNanometre

The invention relates to liquid metal microparticles with core-shell structures and a preparation method and application thereof. Each liquid metal microparticle comprises a core formed by liquid metal and a shell completely wrapping the outer layer of the core, wherein the shell is prepared from an organic high-molecular polymer. The preparation method comprises the steps that the organic high-molecular polymers are dissolved in an organic solvent to form a polymer solution; liquid metal is dropwise added into the polymer solution to disperse the polymer solution into micro-nano particles; and the micro-nano particles are extruded into water through a micropore structure, and thus the liquid metal microparticles with the core-shell structures are obtained after standing. The preparation method of the liquid metal microparticles is convenient and rapid, the sizes of the prepared microparticles can reach the nanometer grade and are uniform and stable, and the problem that the liquid metal microparticles can coagulate again is completely solved. The liquid metal microparticles with the core-shell structures can be quickly prepared in a large scale, and the liquid metal microparticleswith the core-shell structures can be applied to the fields of phase-change microcapsules, nanometer fluids, drug-carrying robots and the like and have excellent application prospects at the industrialization aspect.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

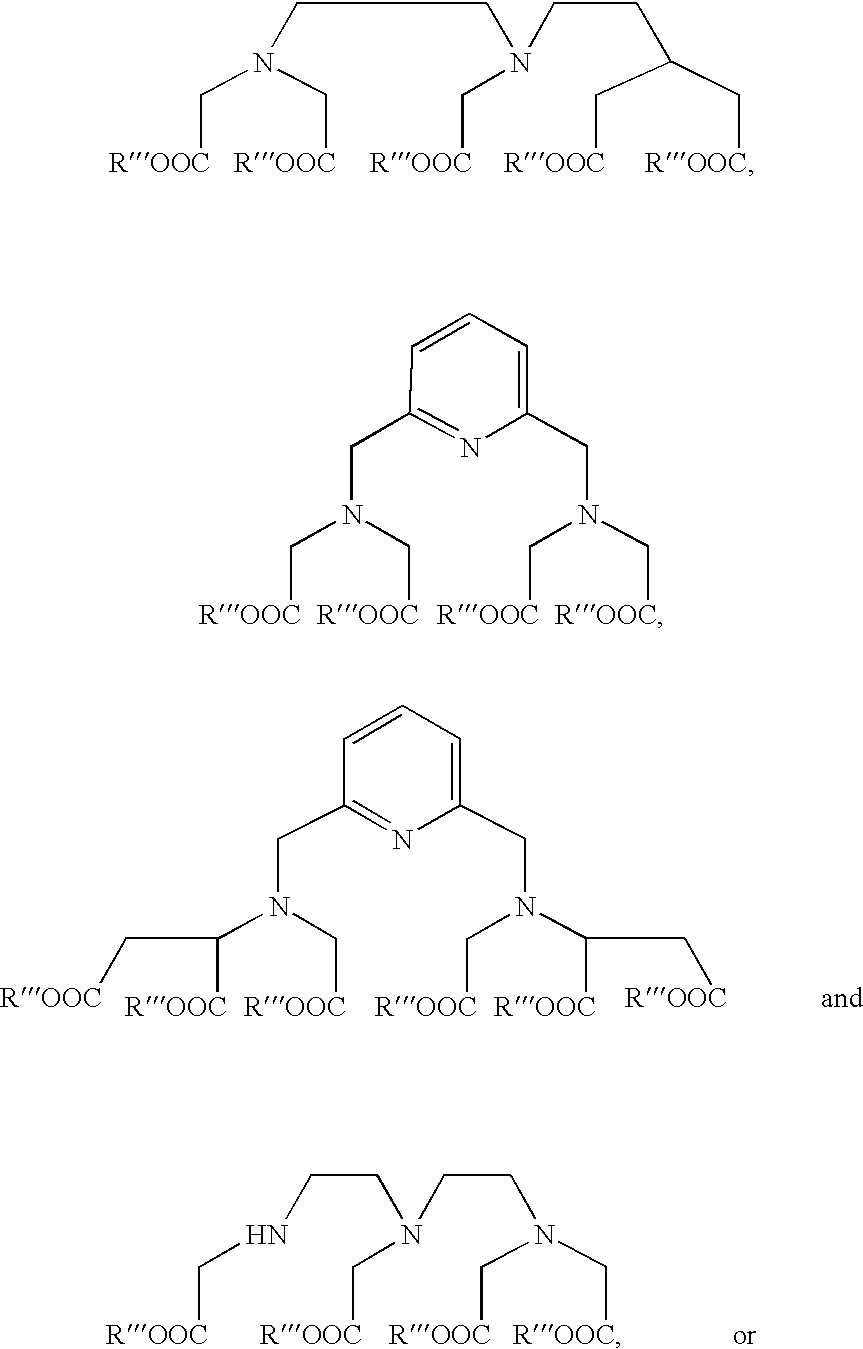

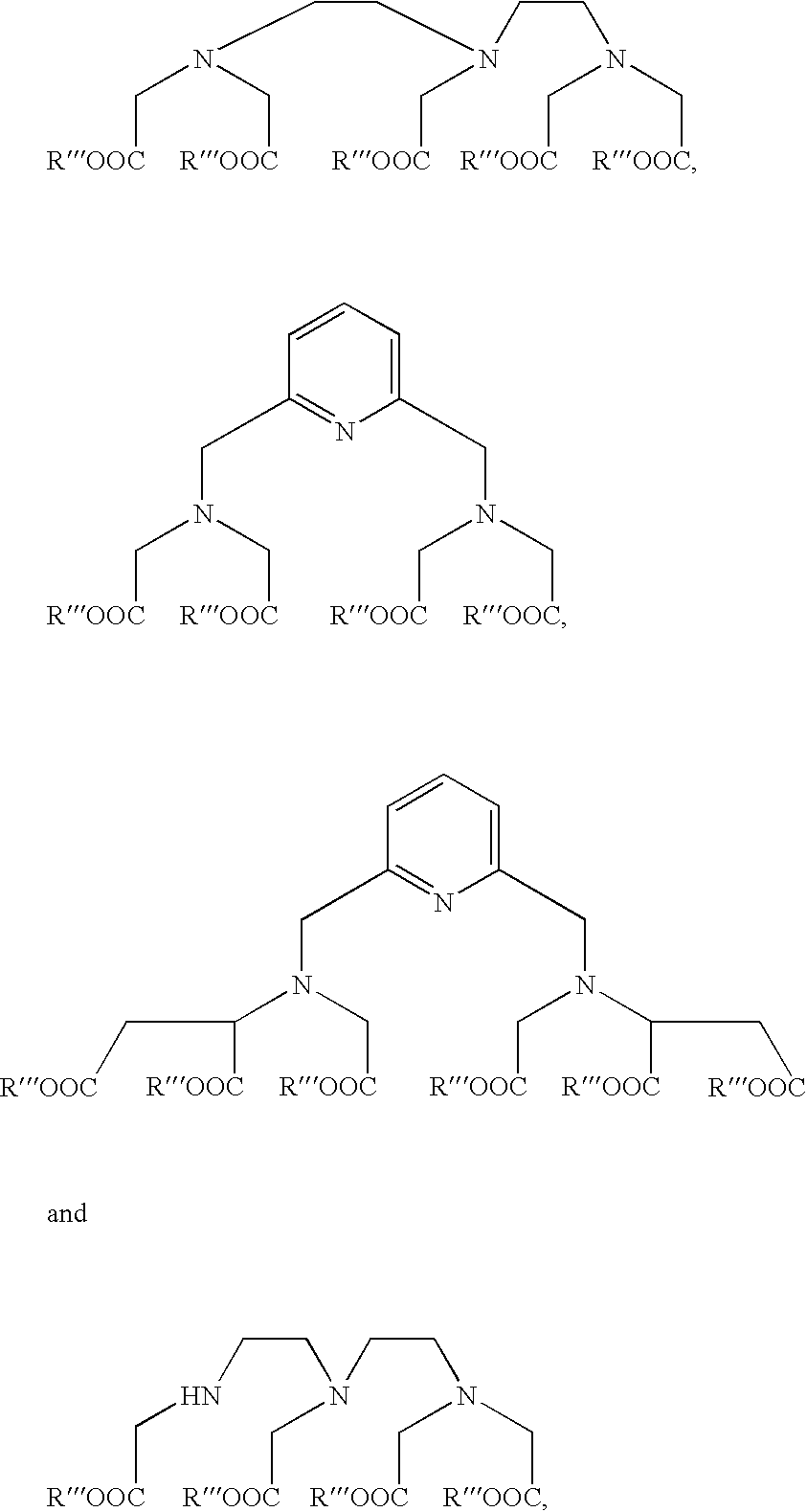

Oligonucleotide labeling reactants and their use

InactiveUS6949639B1Highly simplifiedSimple methodSugar derivativesGroup 5/15 element organic compoundsAlkyl transferIminodiacetic acid

Owner:WALLAC

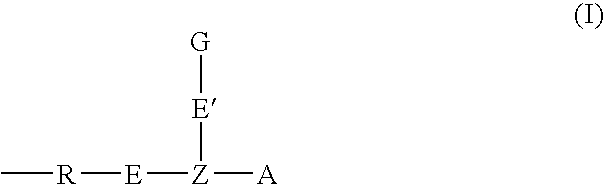

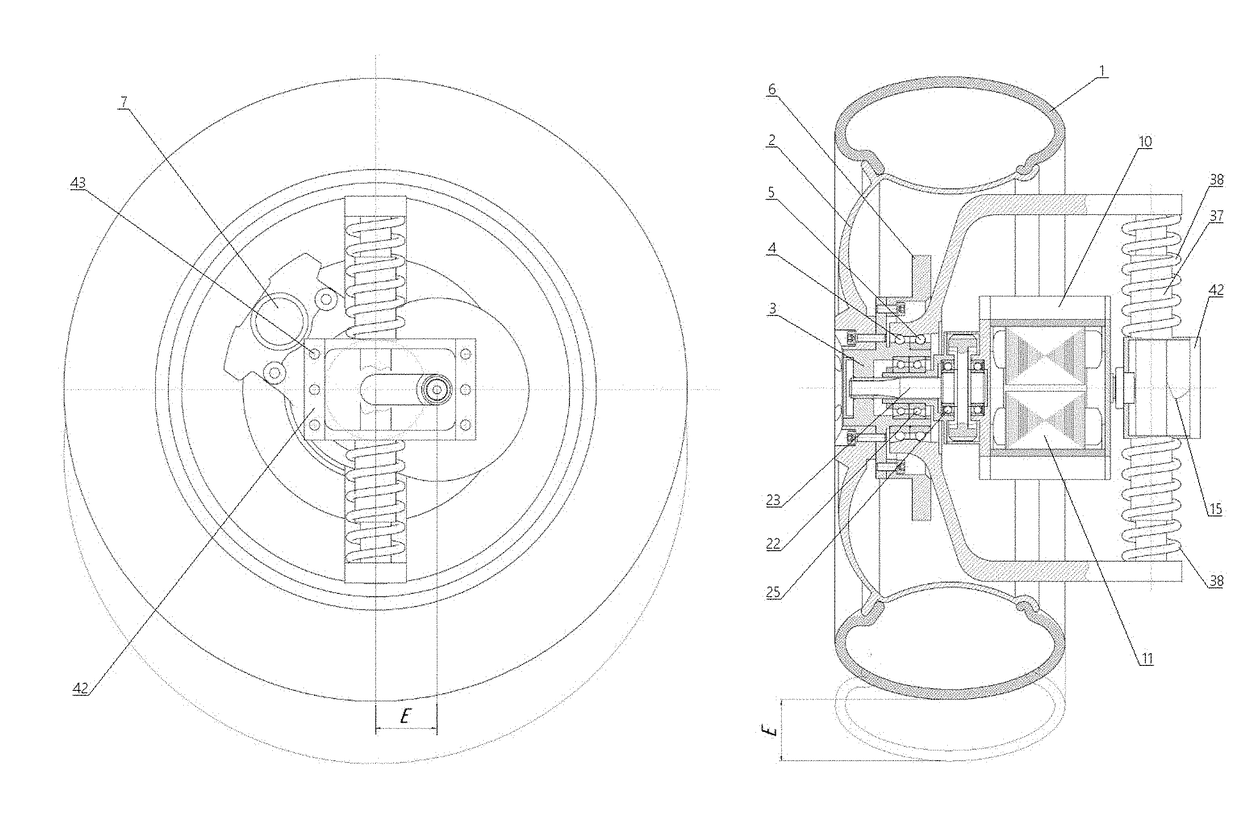

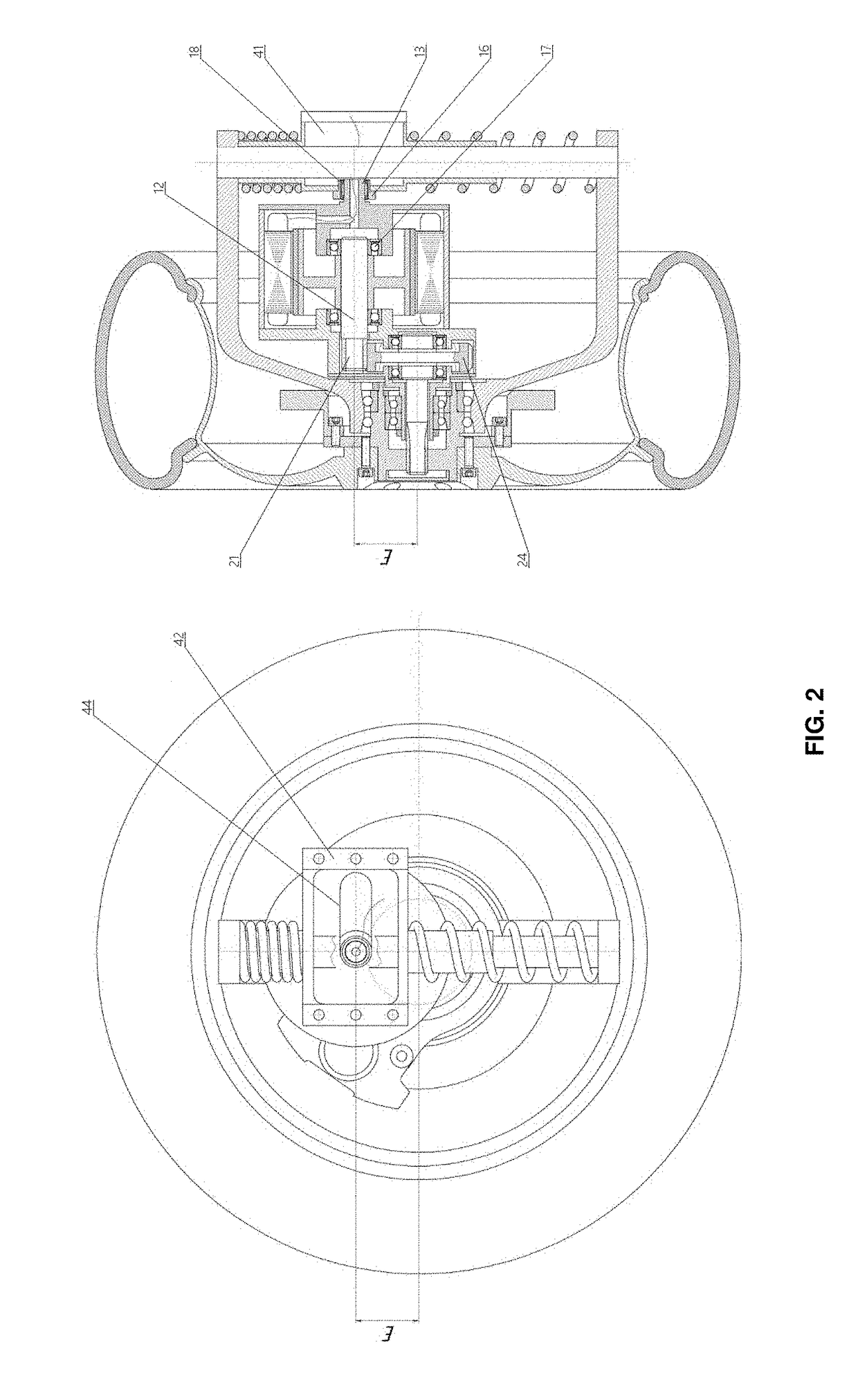

In-wheel motor for a vehicle and a vehicle comprising the motor

ActiveUS20180056767A1Comfortable to useIncrease motivationElectric propulsion mountingMotor depositionGear wheelElectric motor

The present invention relates to a motor wheel for a vehicle and a vehicle comprising the motor wheel. The motor wheel comprises a wheel, an electric motor, a reduction gear transmitting rotation from the electric motor to the wheel, and a dampening structure connecting the wheel to a vehicle bearing member. The electric motor comprises an electric motor case. The reduction gear comprises a reduction gear case coupled to the electric motor case and rotatably mounted within the wheel hub. The electric motor case is connected to the bearing member of the vehicle and is displaceable relative to the bearing member. The invention improves dynamic properties to the vehicle, reduces vibrations transmitted to the vehicle body, and provides a more comfortable drive.

Owner:OBSHCHESTVO S OGRANICHENNOI OTVETSTVENNOSTIU AMT

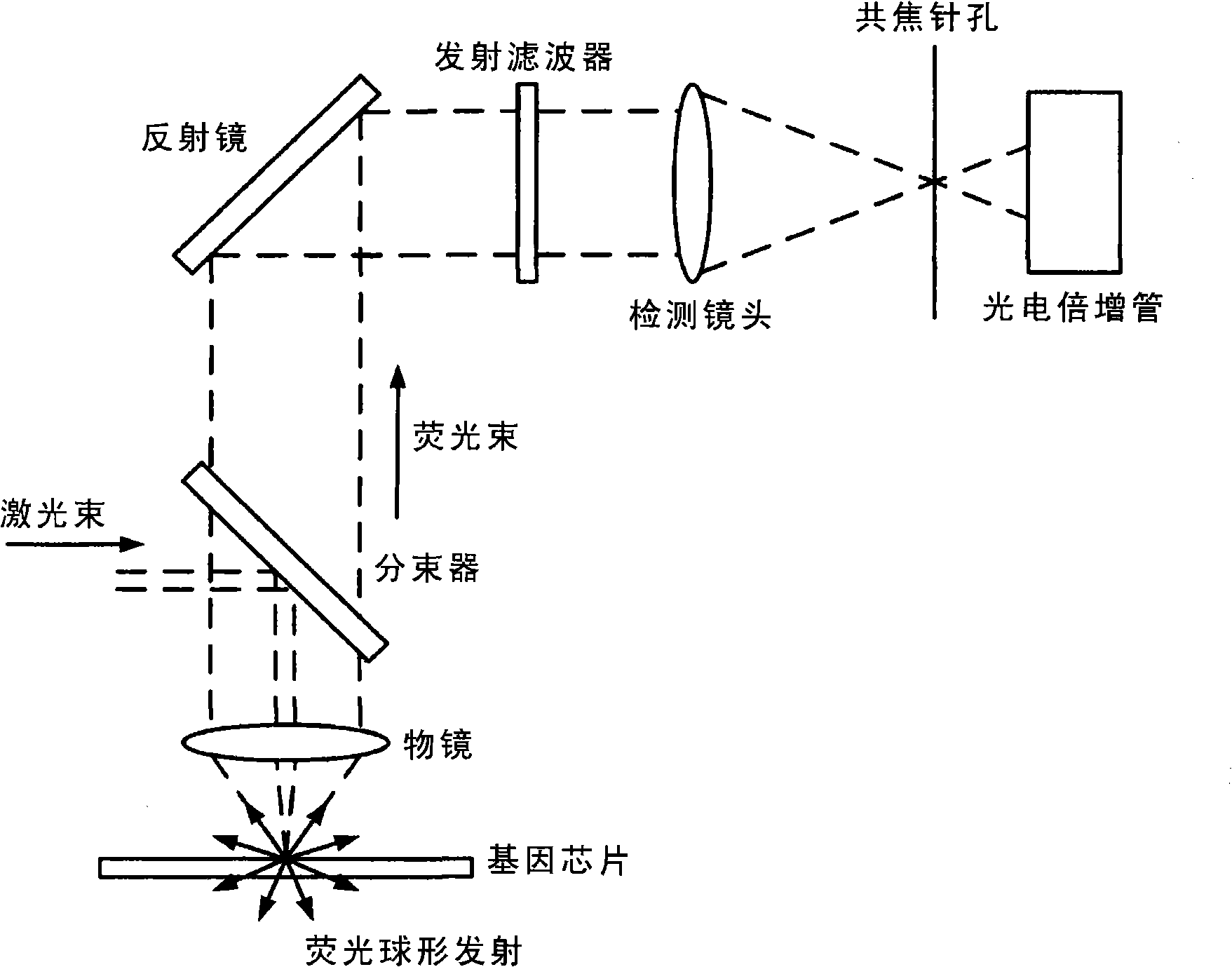

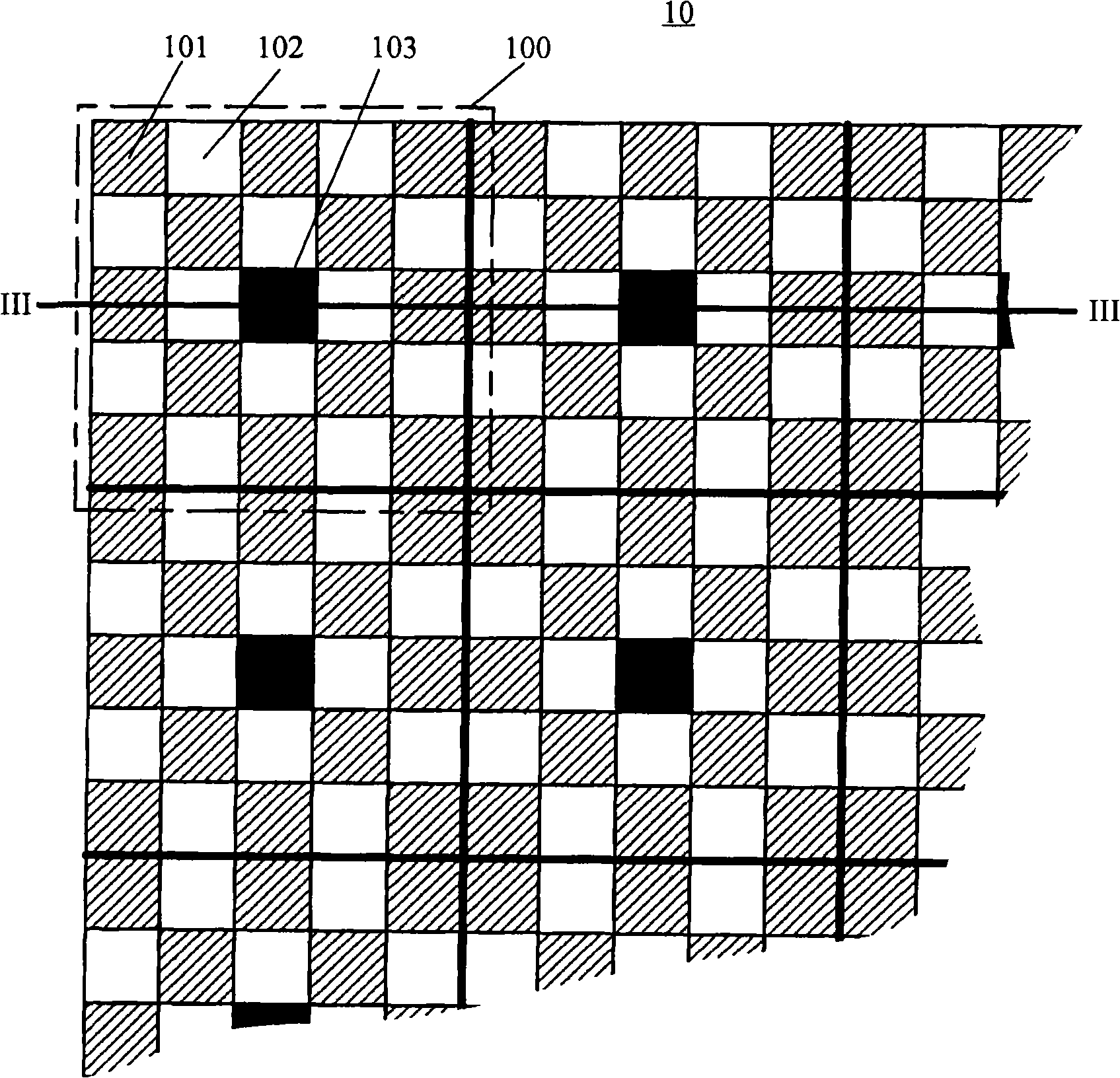

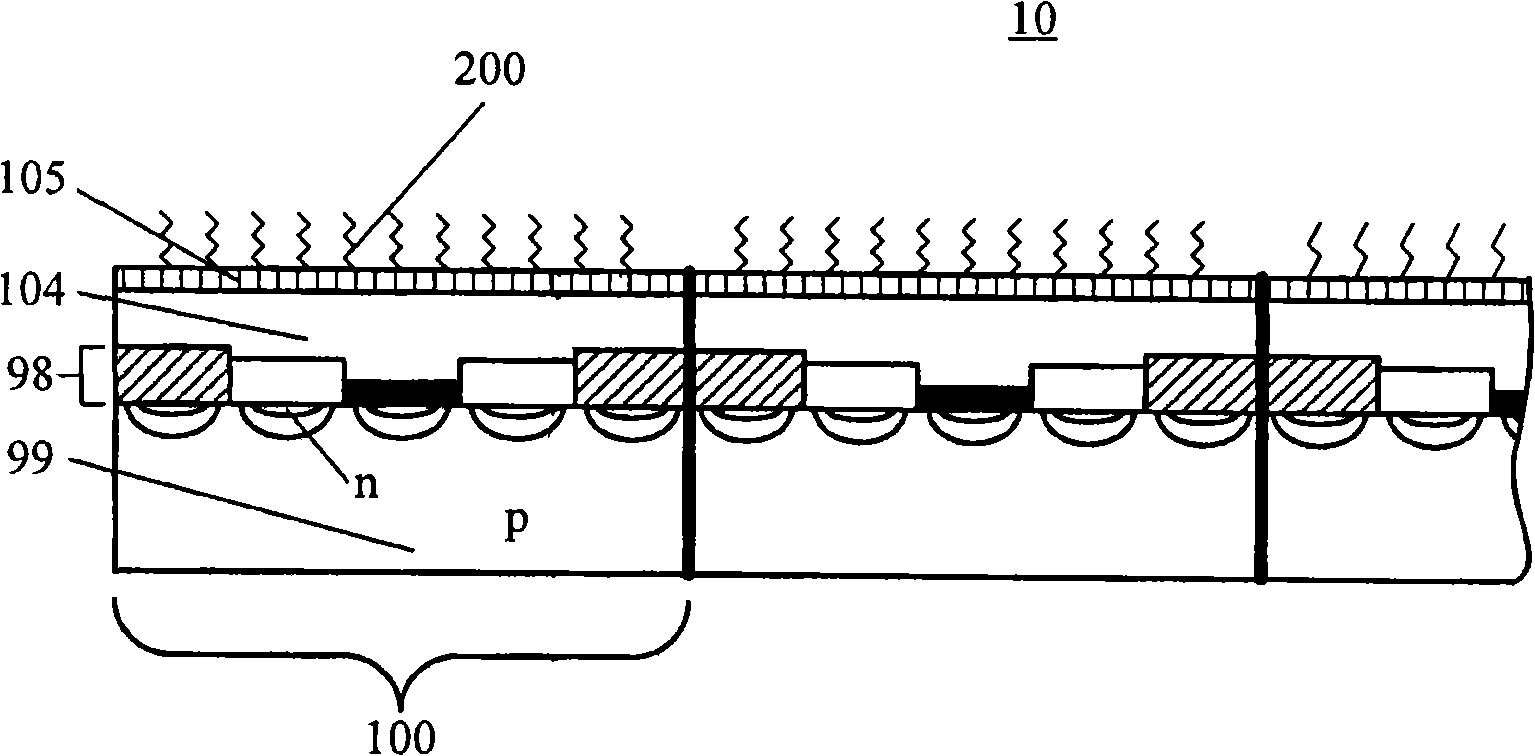

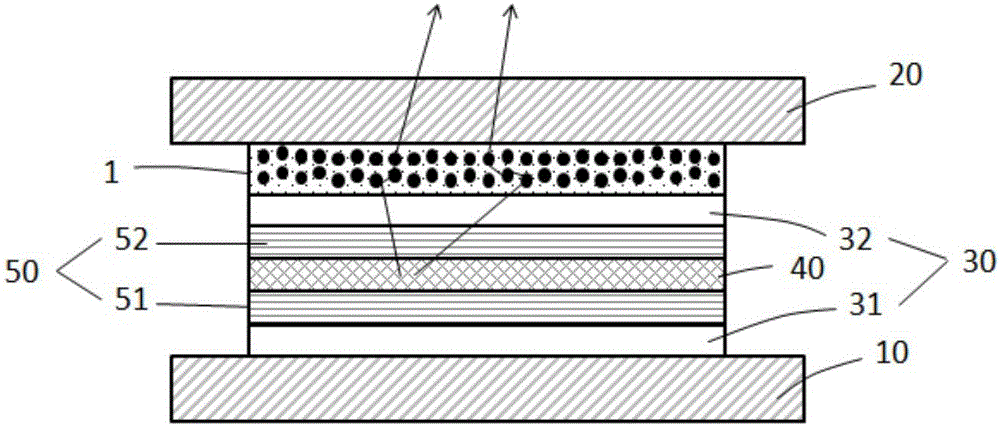

Biochip, method for making same, and apparatus applying the biochip

InactiveCN101493411ALow costHigh detection sensitivityMicrobiological testing/measurementBiological testingLength waveLight filter

The invention discloses a biochip and a preparation method thereof, and a device using the biochip. The biochip comprises at least one detection unit and at least a group of biomolecule probes, and each detection unit comprises at least one detection pixel and at least one reference pixel, and responds to a group of identical biomolecule probes; each detection pixel comprises a semiconductor optical sensor in an arrayed semiconductor optical sensor and an optical filter in an arrayed optical filter, the optical filter totally covers the surface of the semiconductor optical sensor; each reference pixel comprises a semiconductor optical sensor in the arrayed semiconductor optical sensor; each optical filter is provided with a characteristic wavelength so that the wavelength in a predetermined width range with the characteristic wavelength as a center can be transmitted through the optical filter, but the wavelength out of the range can not be transmitted.

Owner:邵剑心 +1

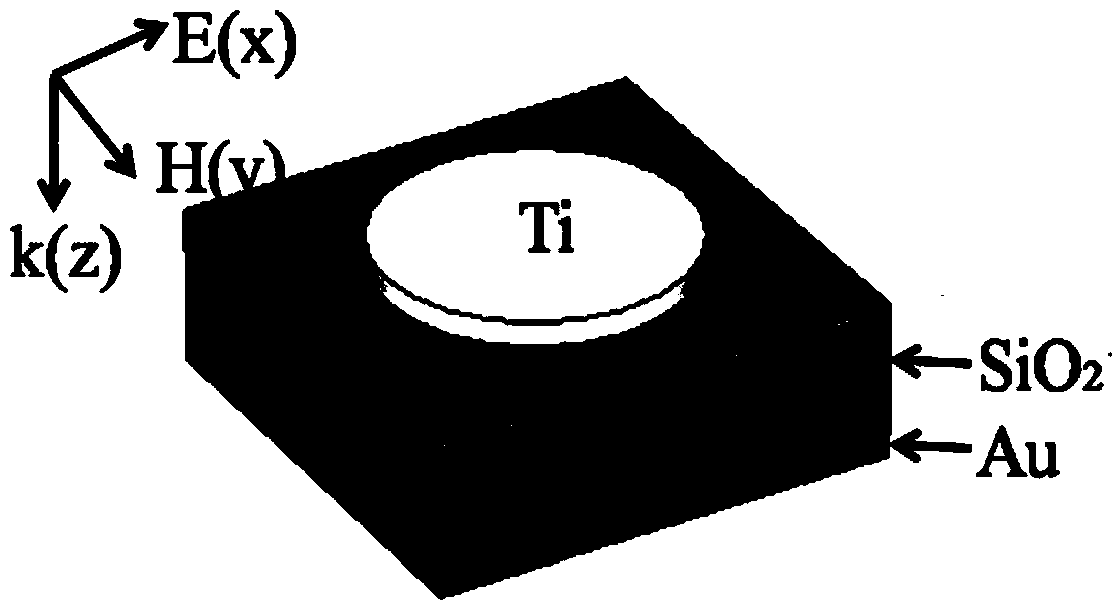

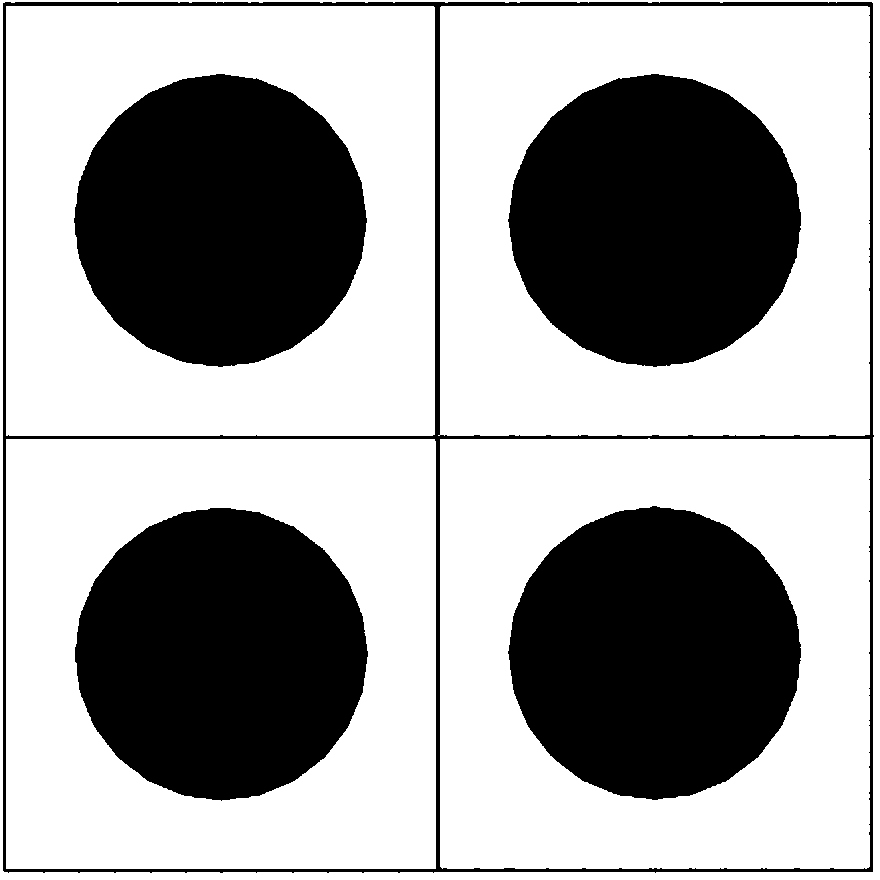

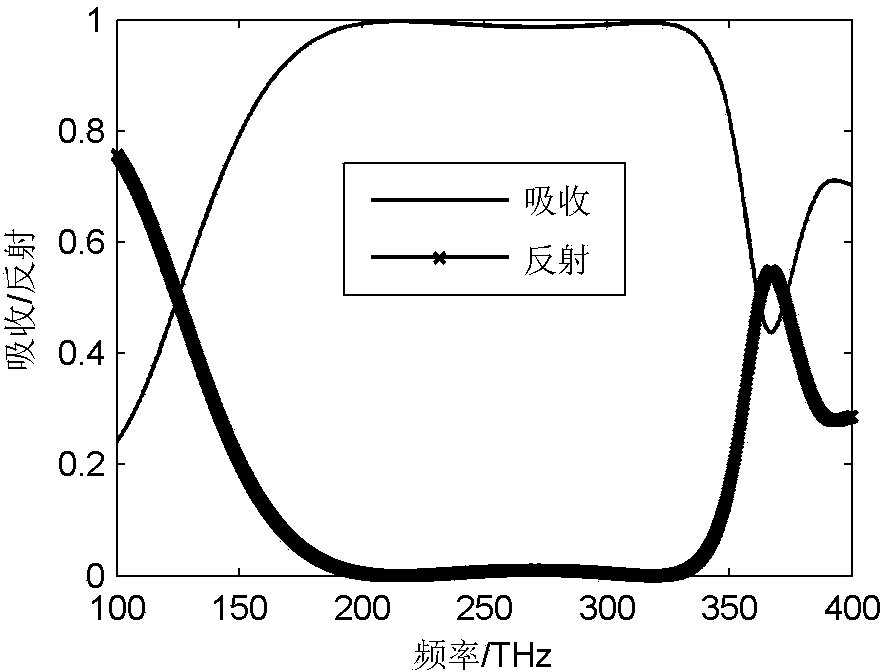

Design method for large-bandwidth strong-absorption metamaterial near-infrared wave-absorbing material

InactiveCN104181622AAbsorption BandwidthImprove conversion efficiencyOptical elementsCircular discUnit structure

The invention discloses a design method for a large-bandwidth strong-absorption metamaterial near-infrared wave-absorbing material. The method includes the following steps: 1. according to an effective medium theory and through simulation of a CST microwave studio, S parameters are obtained, wherein a frequency domain calculation mode is adopted during the simulation; periodic unit structures are periodically distributed in x and y directions and the periodic distribution is set as a periodic boundary condition; and according to parameters S11 (Omega) and S21(Omega) obtained through scanning, a resistance value is calculated. 2. through change of the period of the unit structures and the sizes of titanium resonant plates, corresponding absorption frequencies are adjusted and then the plurality of resonant plates of different sizes are horizontally placed in one unit so that absorption spectral lines corresponding to the different resonant plates are overlapped. The method adopts a high-loss metal so that a wideband wave-absorbing effect can be achieved through a simple structure. Resonant units of one size are replaced by the resonant units of different sizes so that a resonance mode of adjacent frequencies can be triggered and an absorption bandwidth can be further expanded.

Owner:ZHEJIANG UNIV

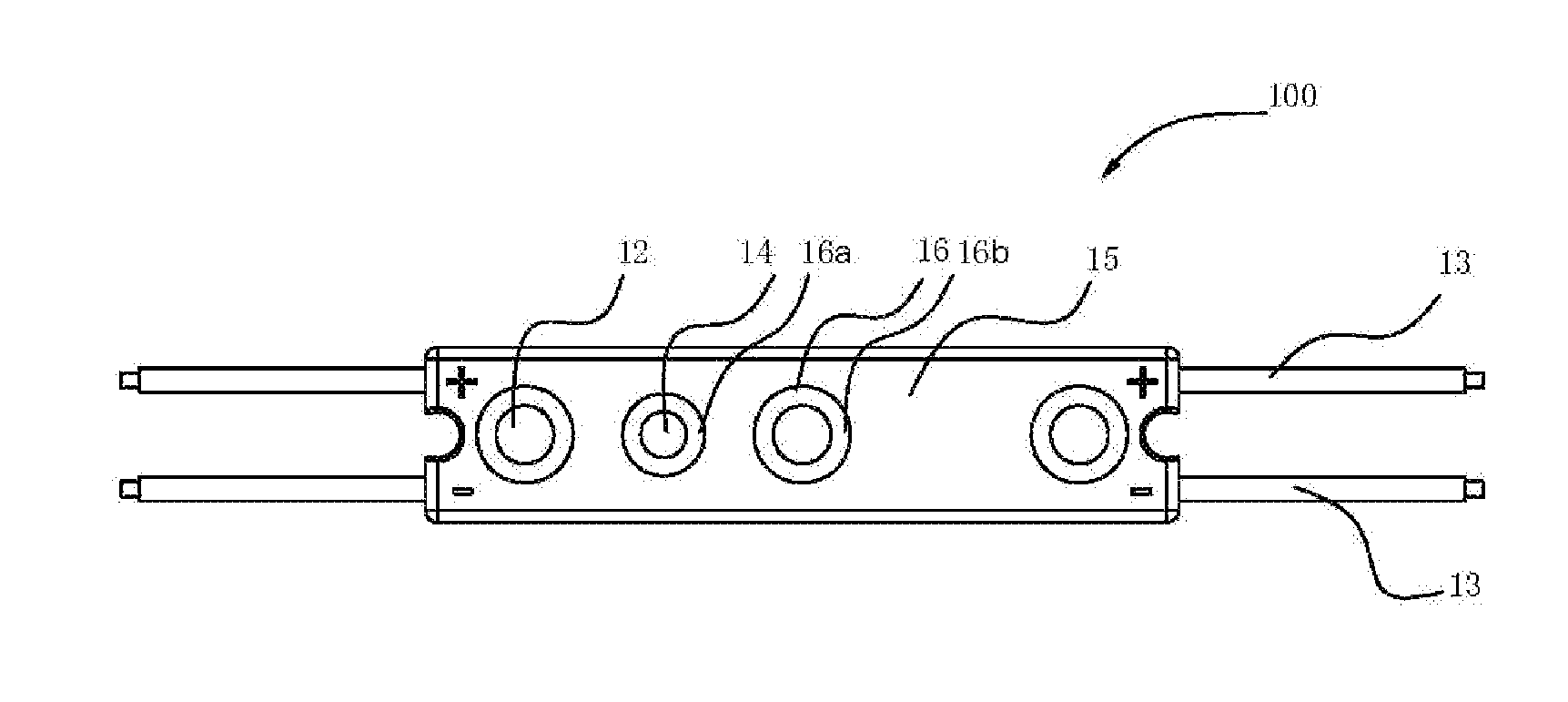

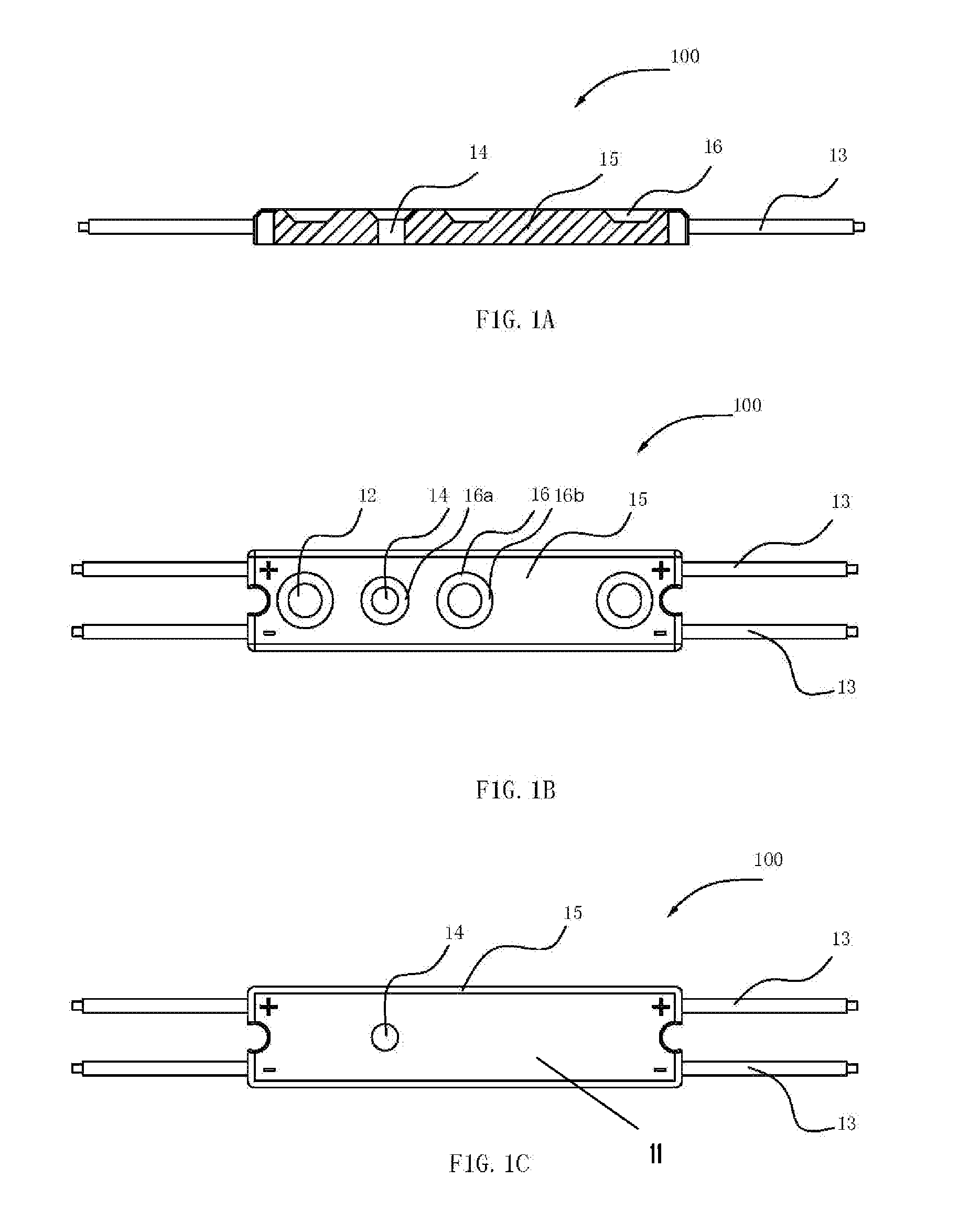

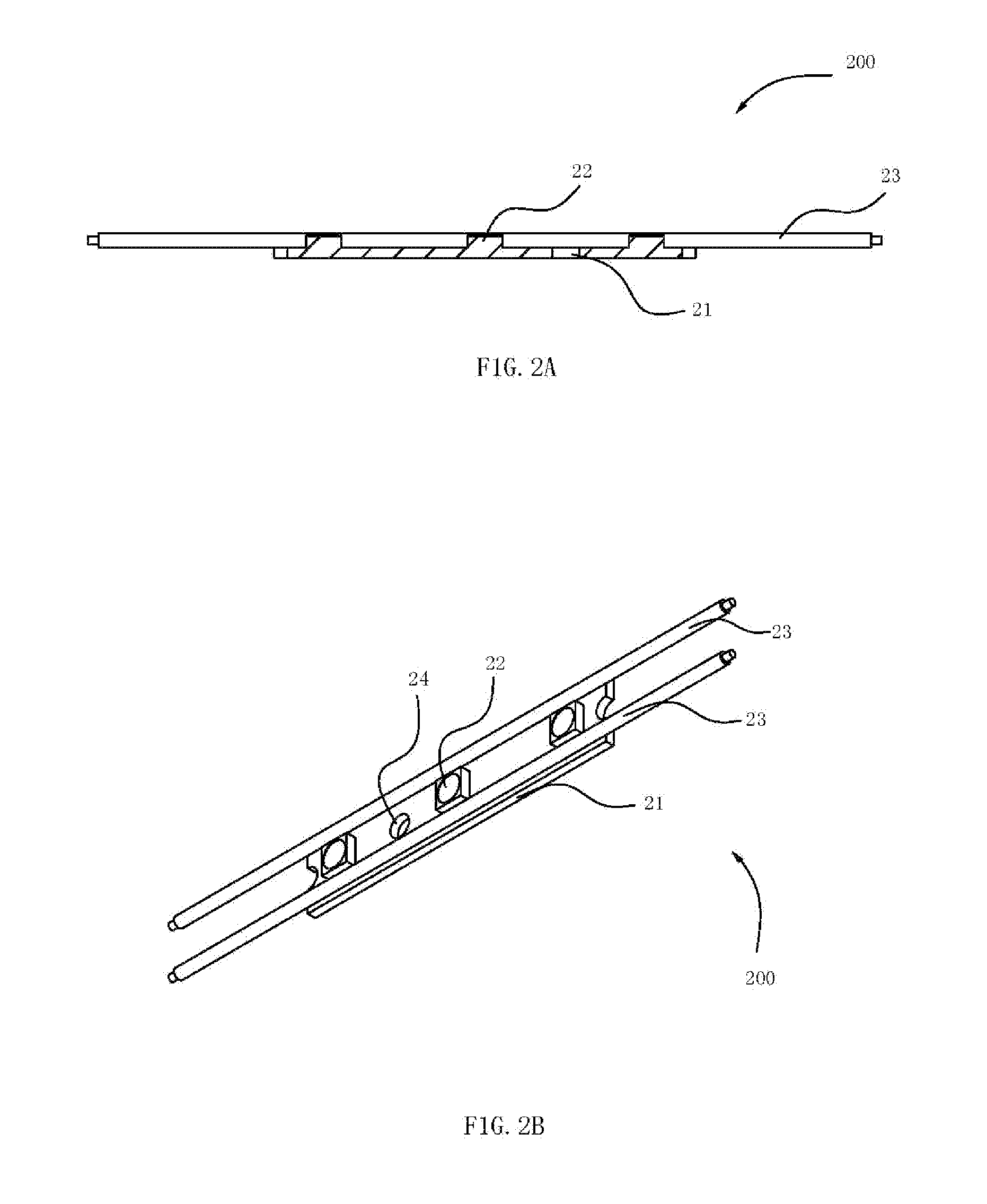

Light emitting diode light source modules

InactiveUS20120002407A1Increase usageLow manufacturing costPoint-like light sourceVehicle interior lightingMetal substrateEngineering

The present invention provides a highly-protective, heat dissipating LED light source module that may be waterproof or non-waterproof. In an embodiment, the present invention provides an LED light source module comprising: a waterproof housing comprising a metal substrate and a plastic cover integrally disposed on one or more surfaces of the metal substrate; and at least one light emitting diode, electronic component, and power line disposed on and operably connected with the metal substrate and encapsulated thereon by the plastic cover. In other embodiments are provided LED light source modules comprising: a circuit board with at least two through holes disposed at selected positions; at least one light emitting diode, electronic component, and power line disposed on the circuit board and operably connected therewith; and a plastic cover comprising at least two pins disposed and shaped for interconnection with corresponding through holes of the circuit board. The simple LED light source models disclosed may be efficiently and inexpensively produced and are capable of withstanding the harsh environments in which they are sometimes used.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD +1

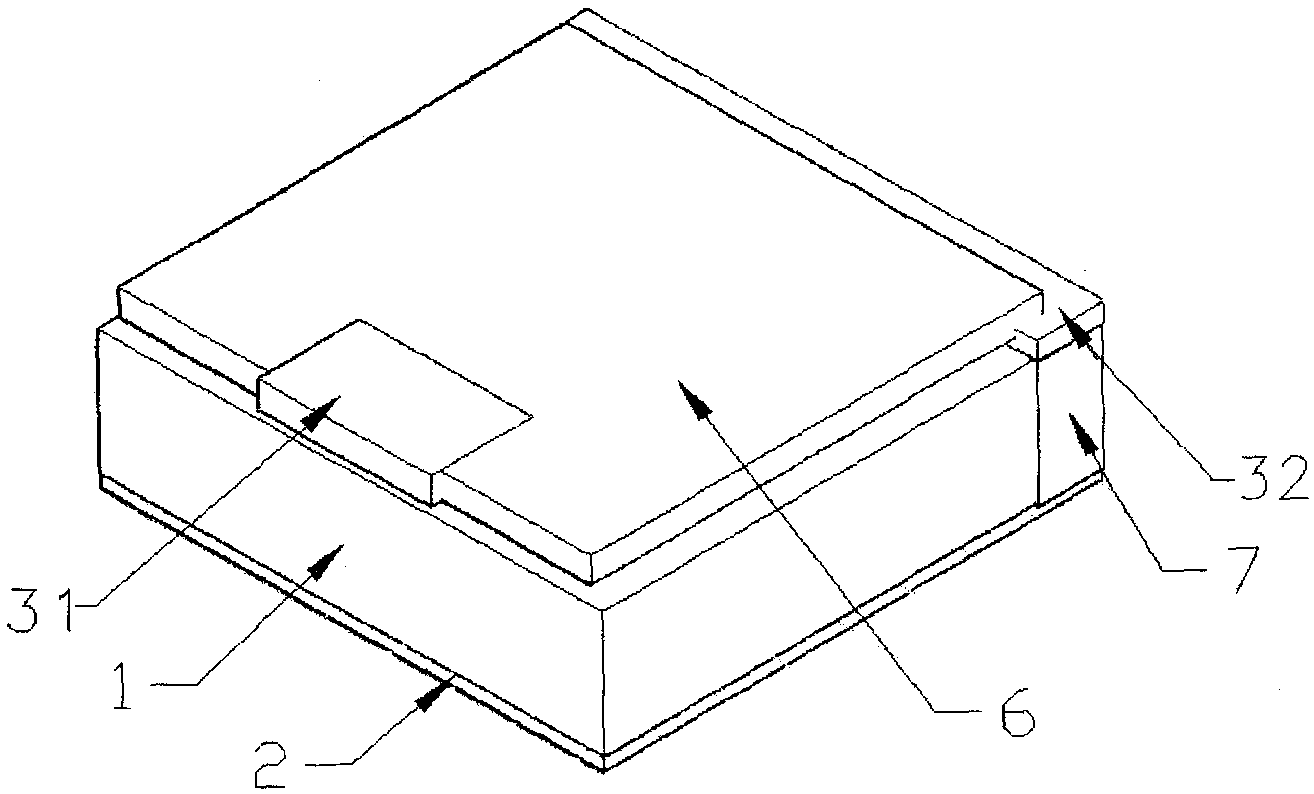

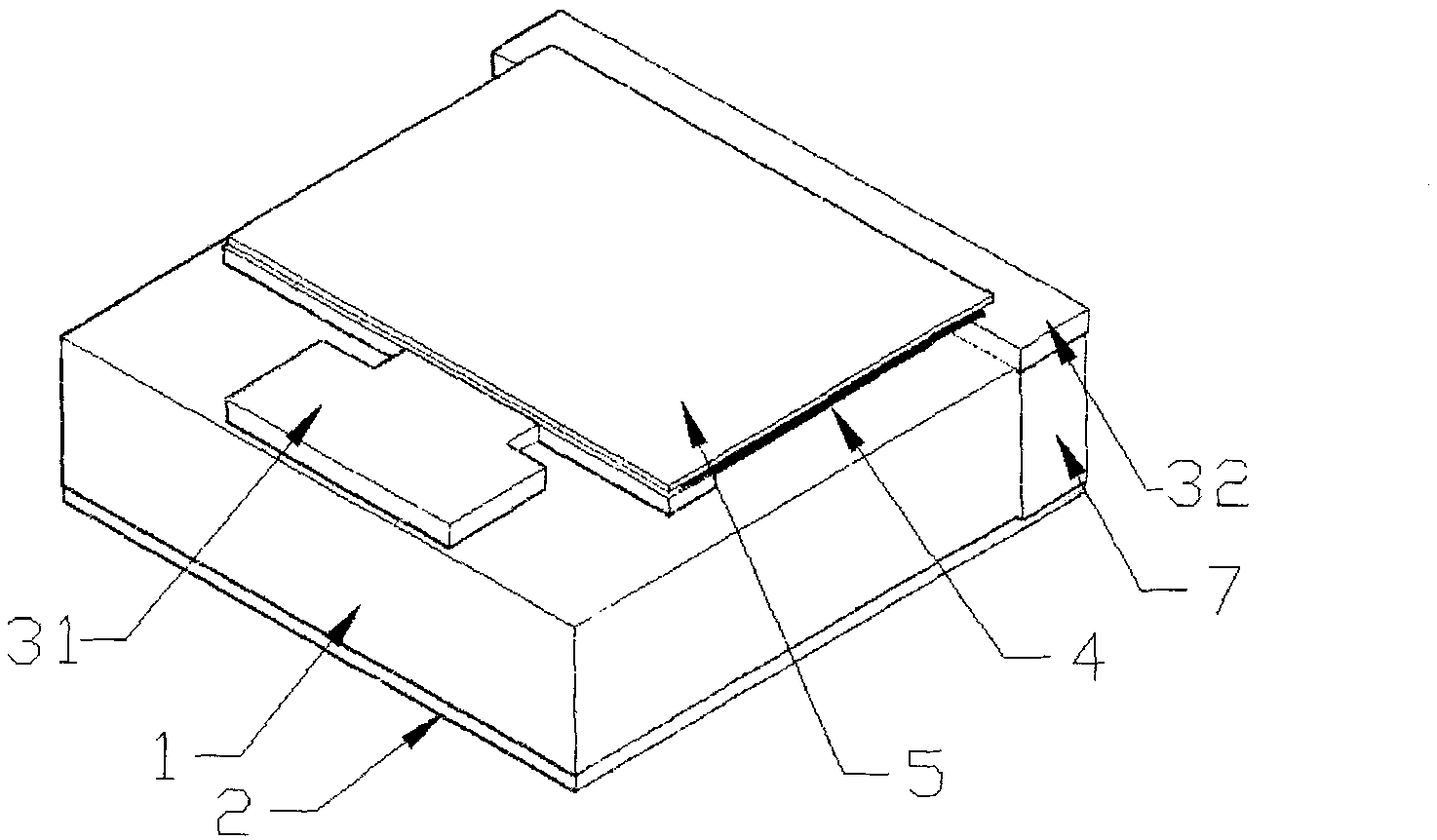

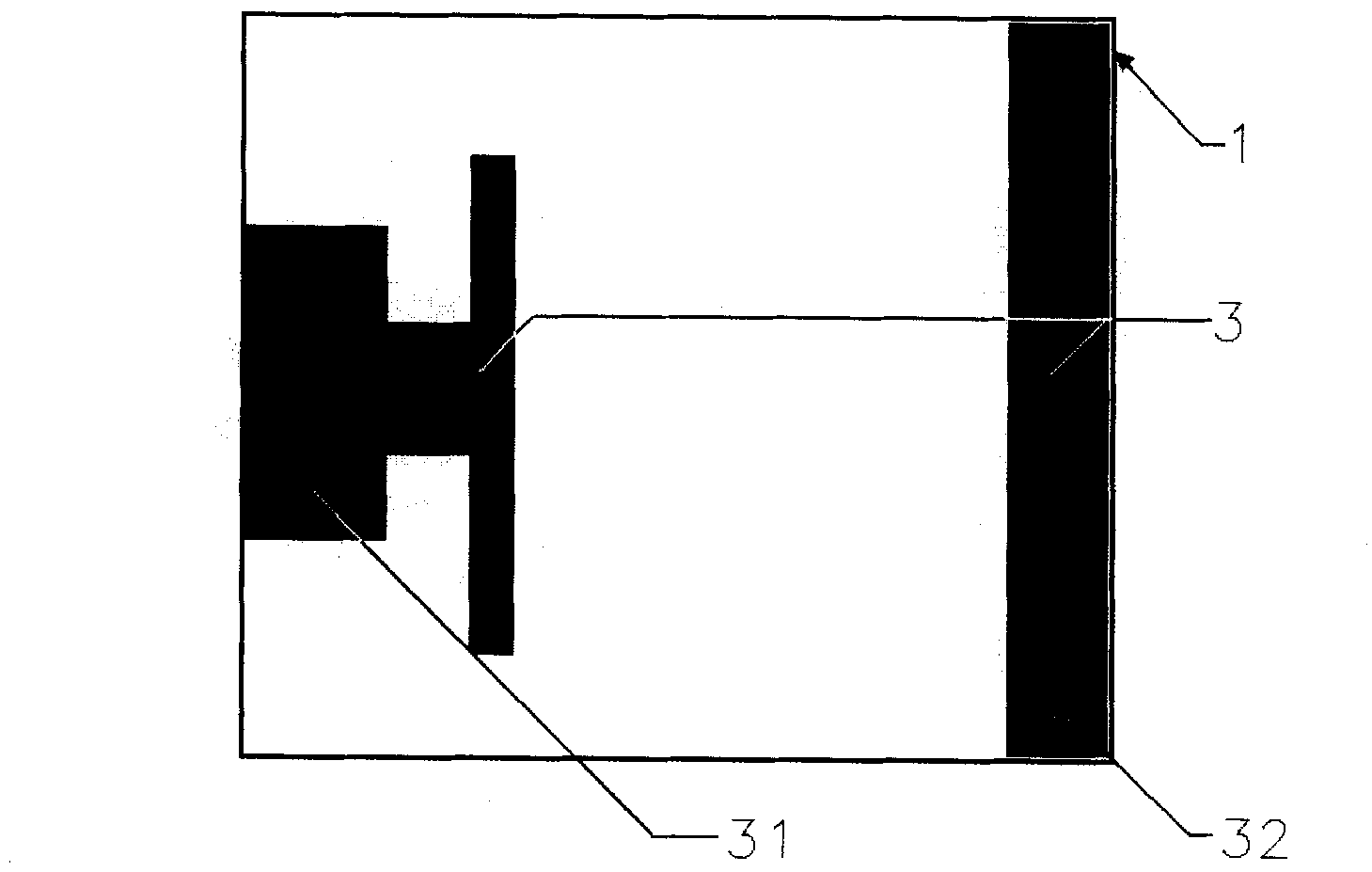

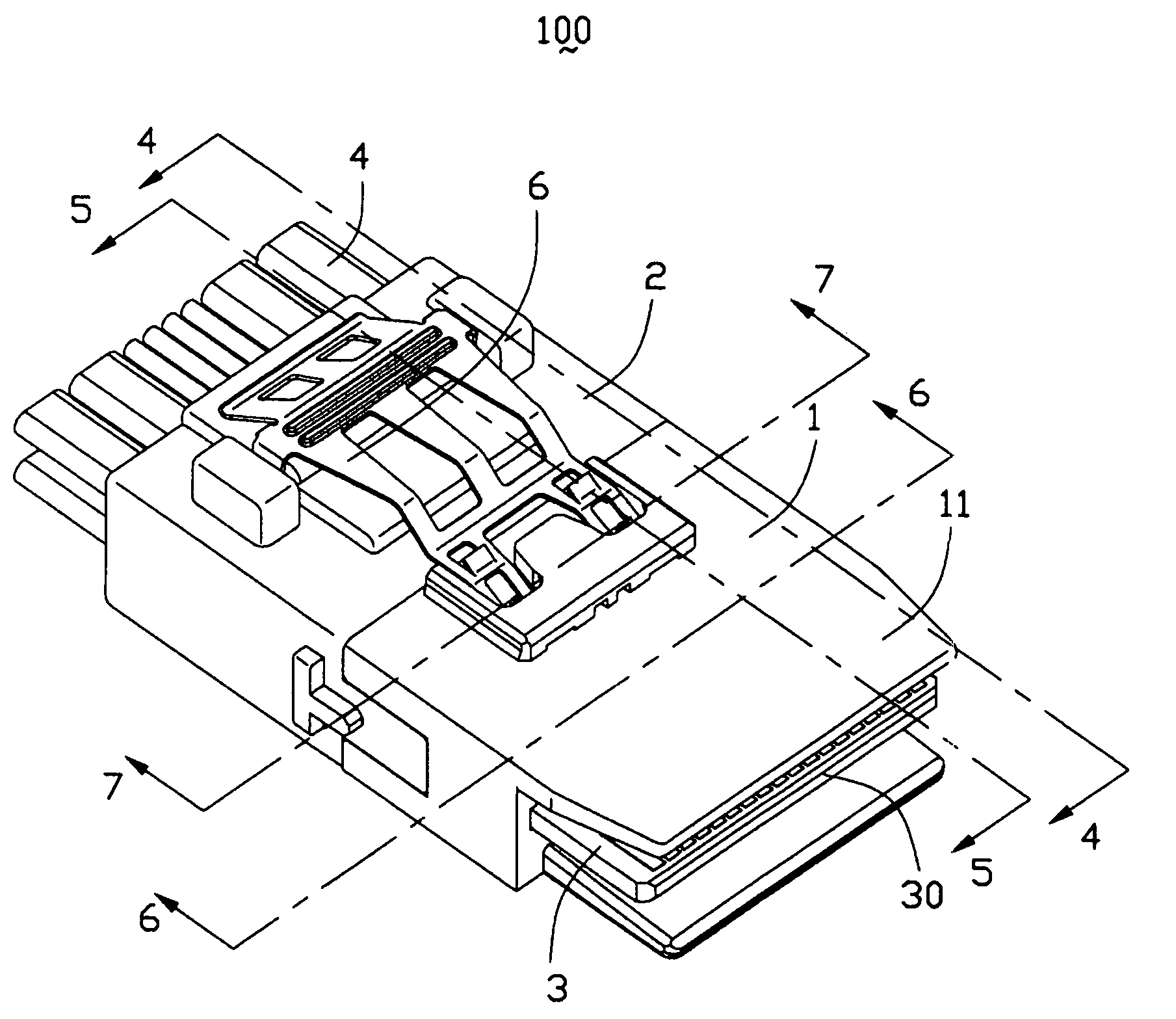

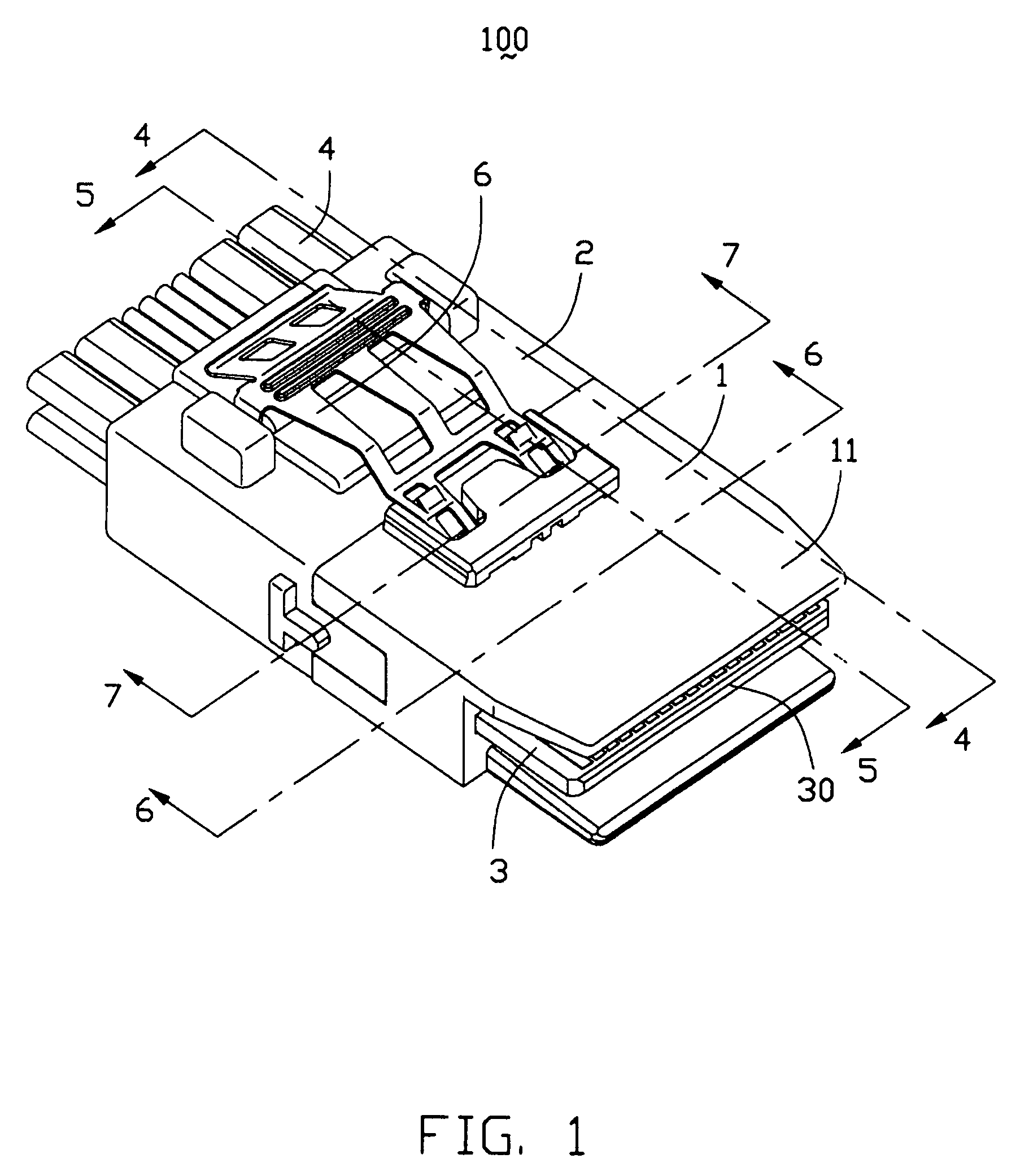

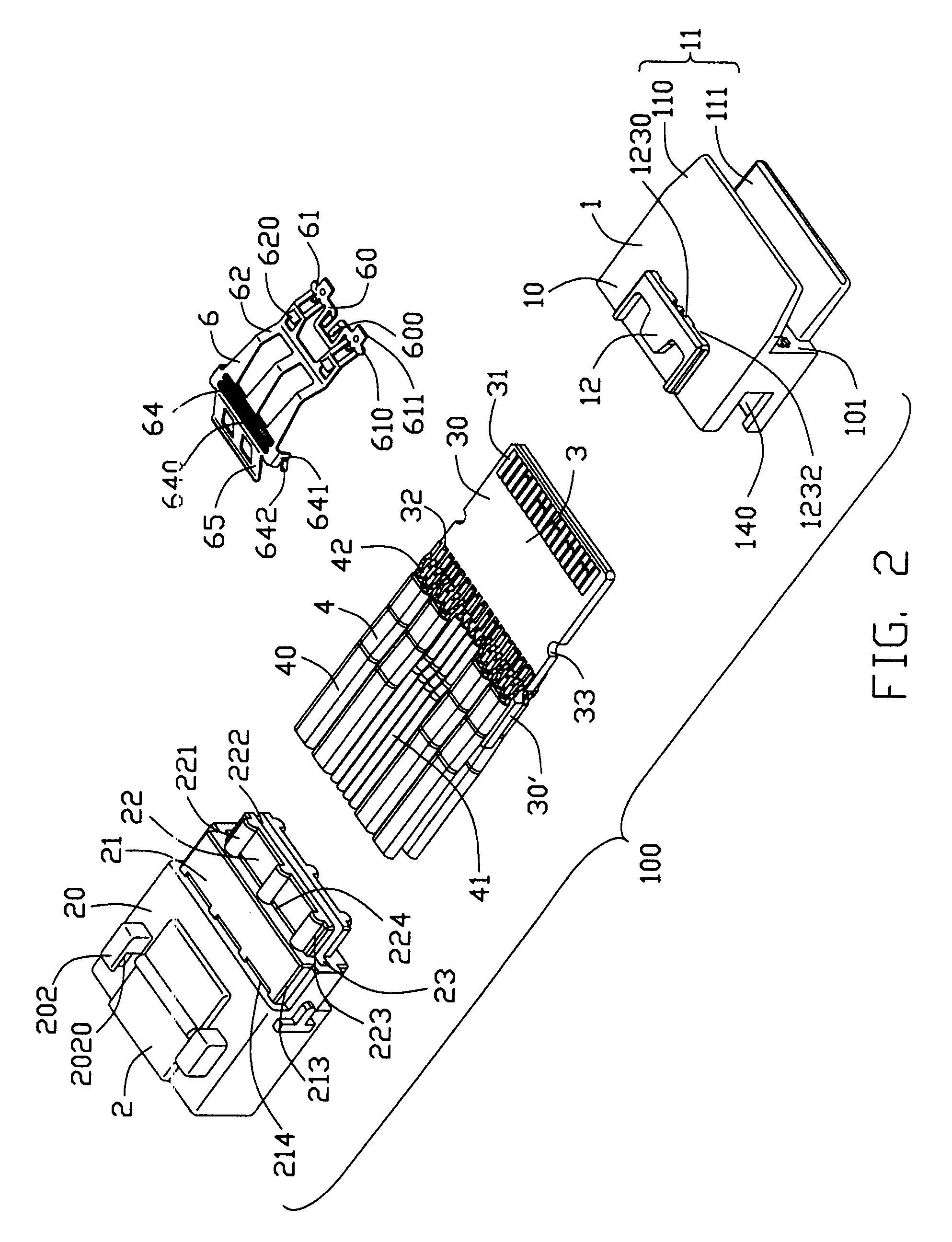

Cable connector assembly and method of manufacturing the same

InactiveUS7189098B1Firmly connectedLarge scale preparationEngagement/disengagement of coupling partsContact member assembly/disassemblyEngineeringPrinted circuit board

A cable connector assembly (100) includes a housing defining a mating direction, a first housing piece (1) with a mating interface (11) formed thereon and a second housing piece (2) attached to the first housing piece (1) along the mating direction, a printed circuit board (3) received in the housing, and defining a mating portion (30) accessible from the mating interface (11) of the first housing piece (1), a cable (4) attached to the printed circuit board (3), and a latch (6) attached with the housing for locking the cable connector assembly (100) with a complementary connector.

Owner:HON HAI PRECISION IND CO LTD

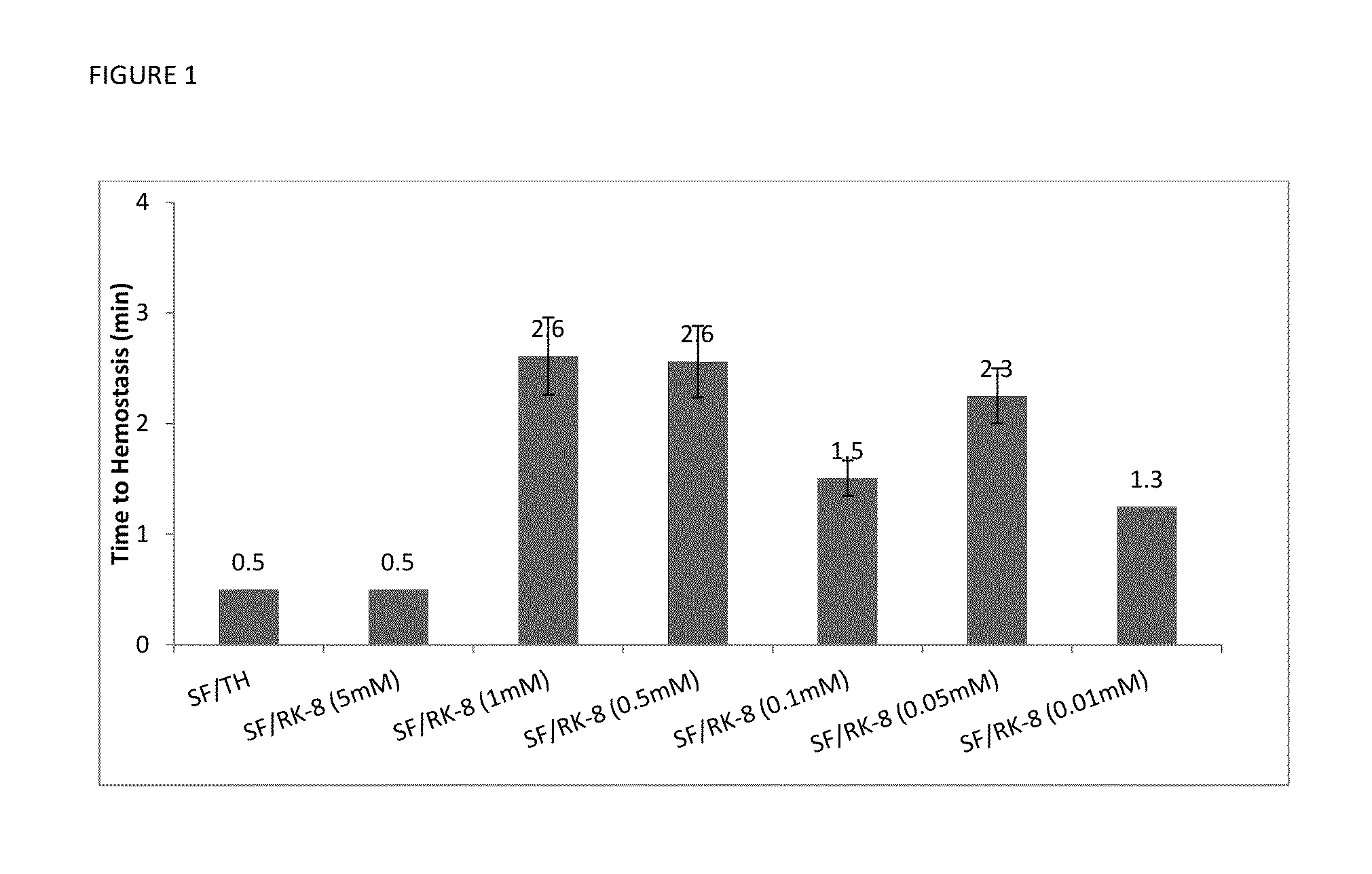

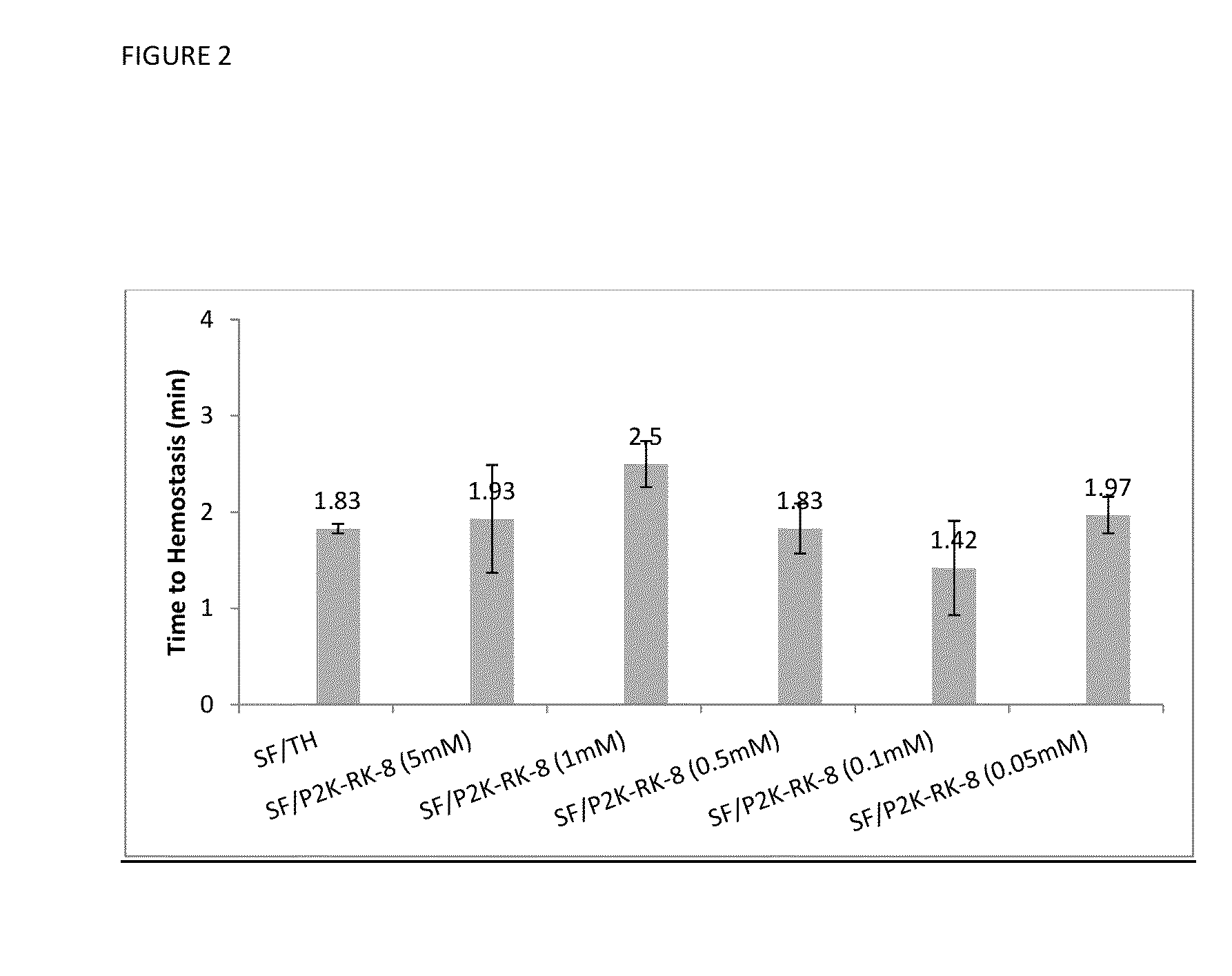

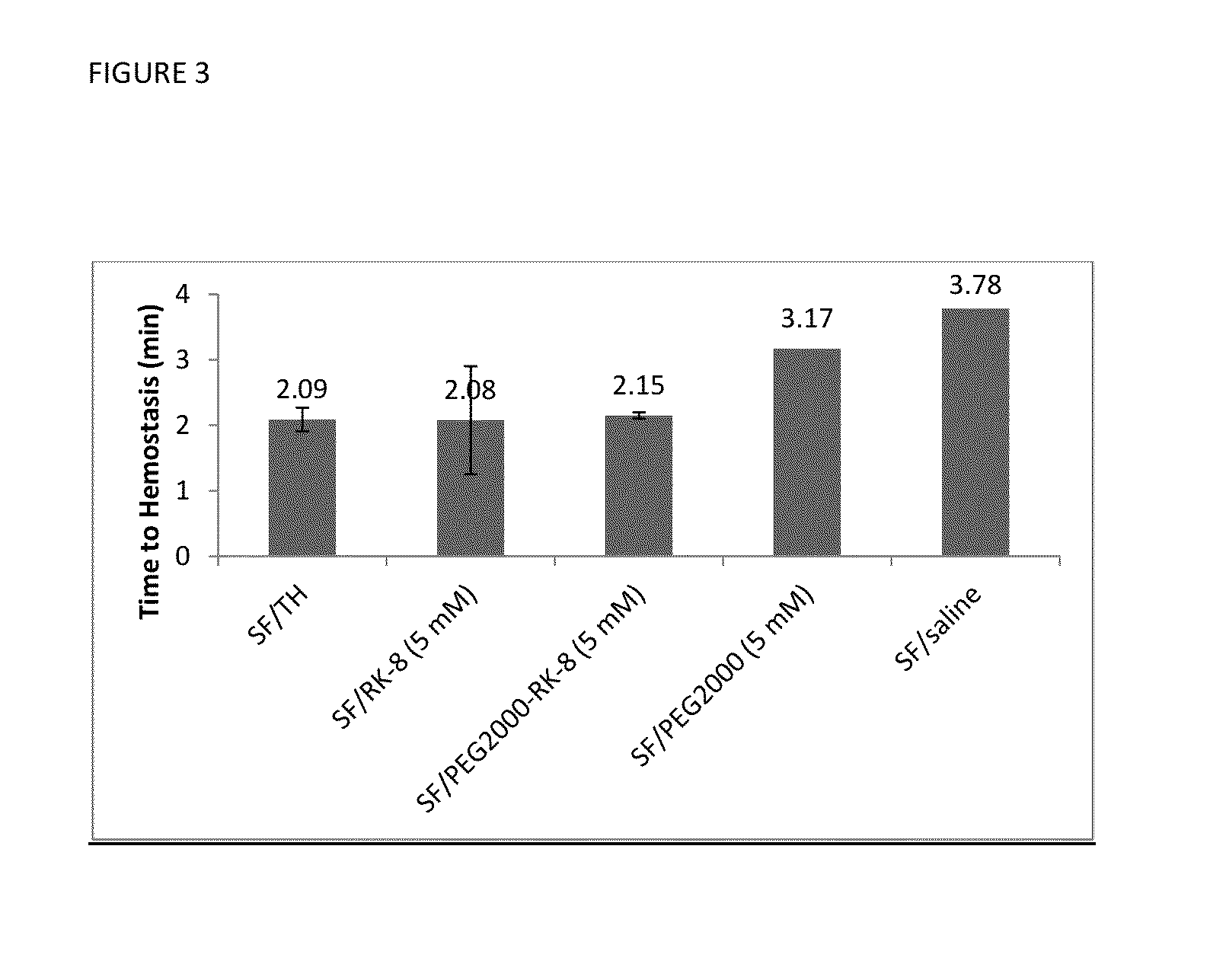

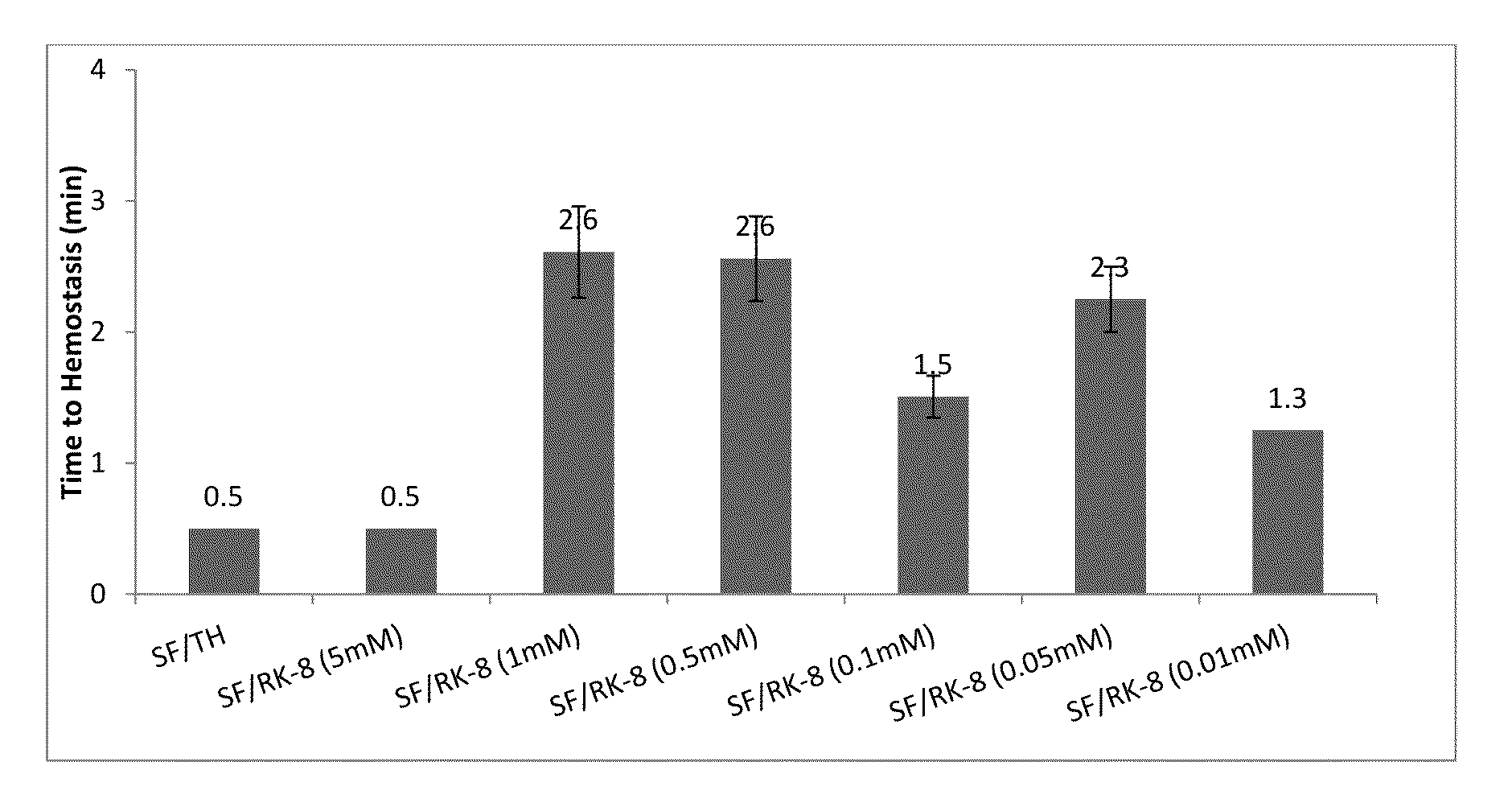

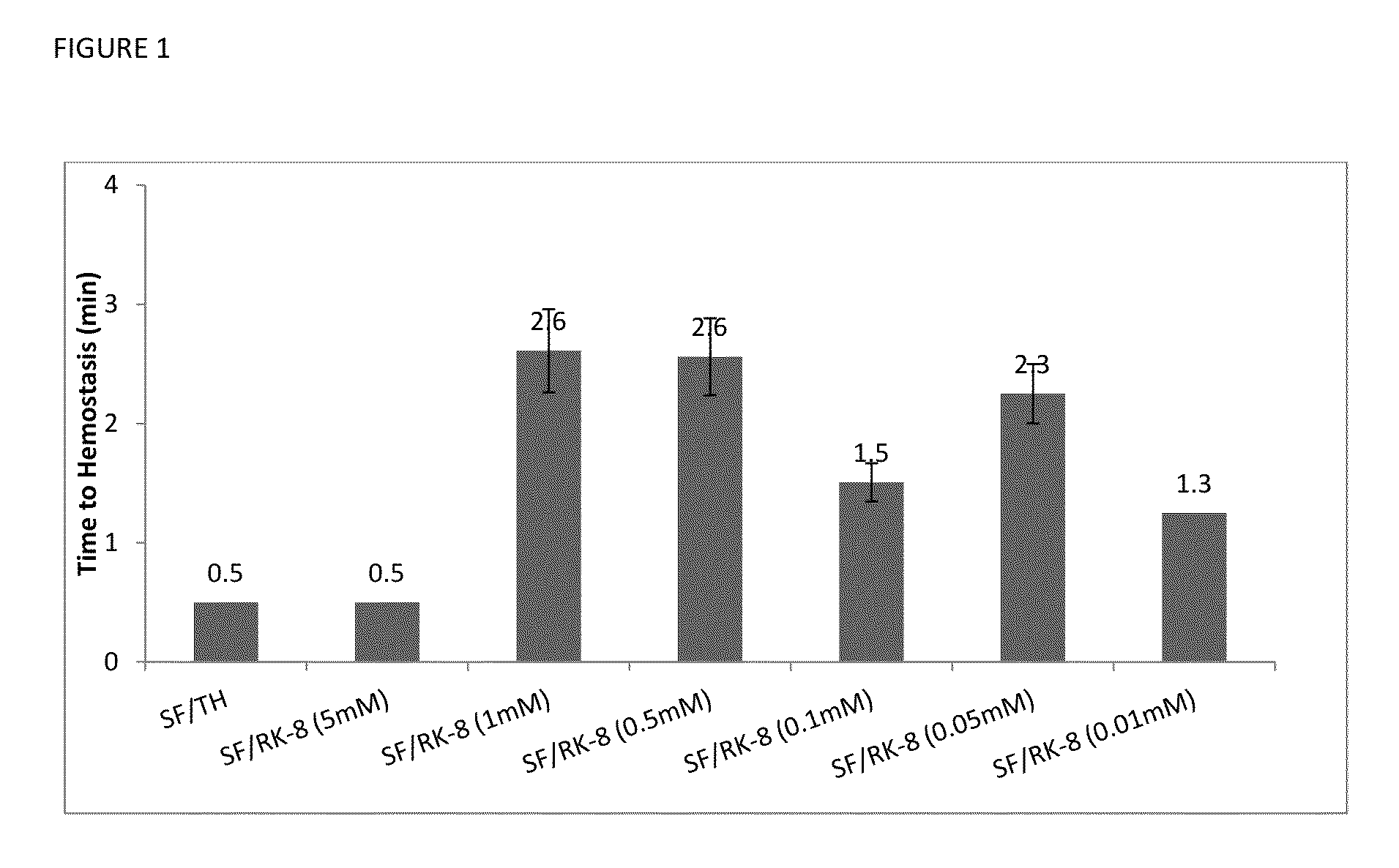

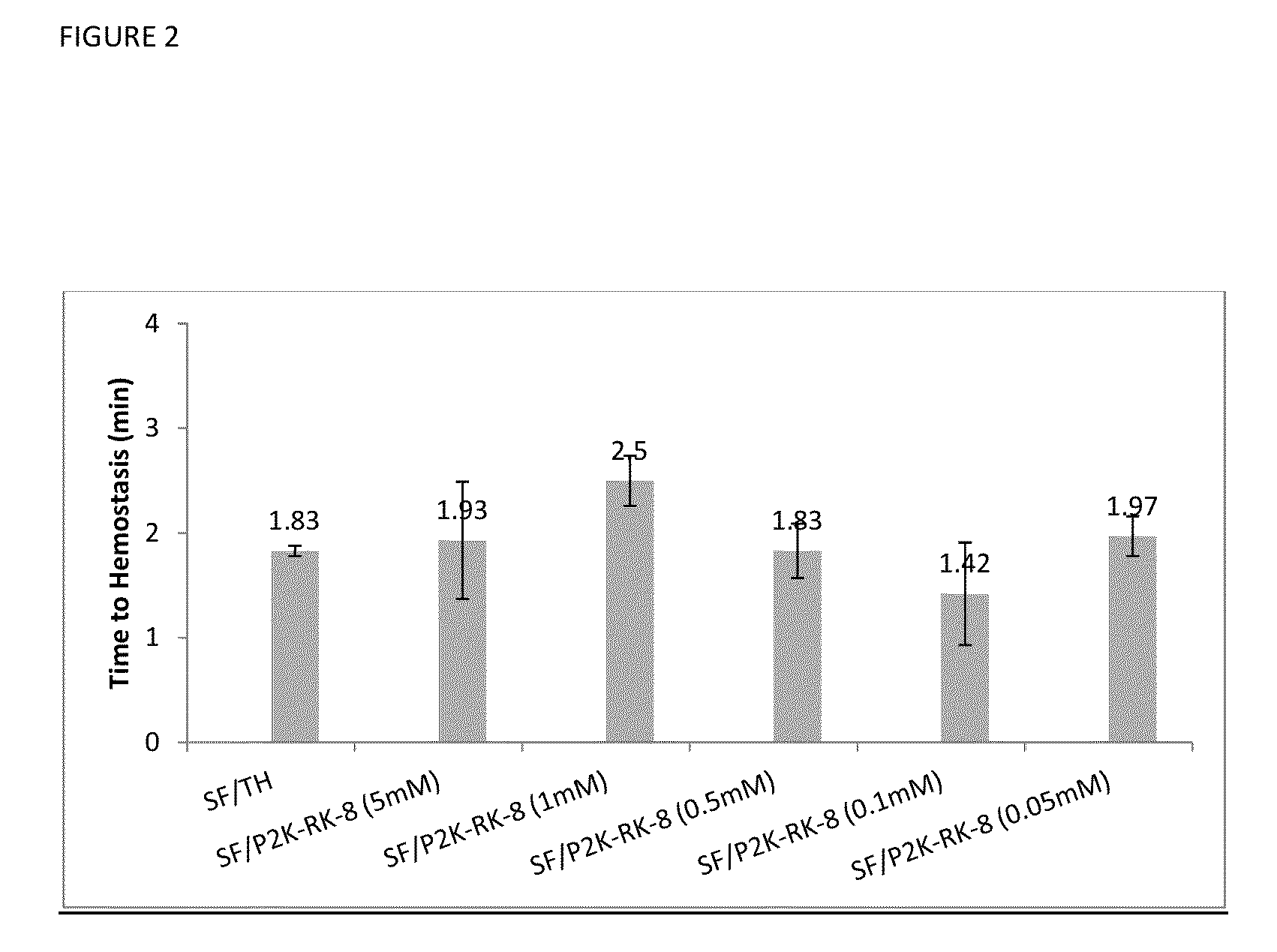

Procoagulant Peptides and Their Derivatives and Uses Therefor

ActiveUS20130004478A1Improve solubilityCost effectiveFibrinogenSurgical adhesivesAbsorbable polymersGenetically engineered

The present invention is directed to a hemostatic or tissue sealing material having (a) a peptide having a sequence SEQ ID NO: 1 or an amino acid analog sequence thereof, and (b) a scaffold for said peptide or amino acid analogue sequence. The scaffold is preferably hemostatic, such as a natural or genetically engineered absorbable polymer, a synthetic absorbable polymer, or combinations thereof. The natural or genetically engineered absorbable polymers can be selected from the group consisting of a protein, a polysaccharide, or combinations thereof.

Owner:ETHICON INC

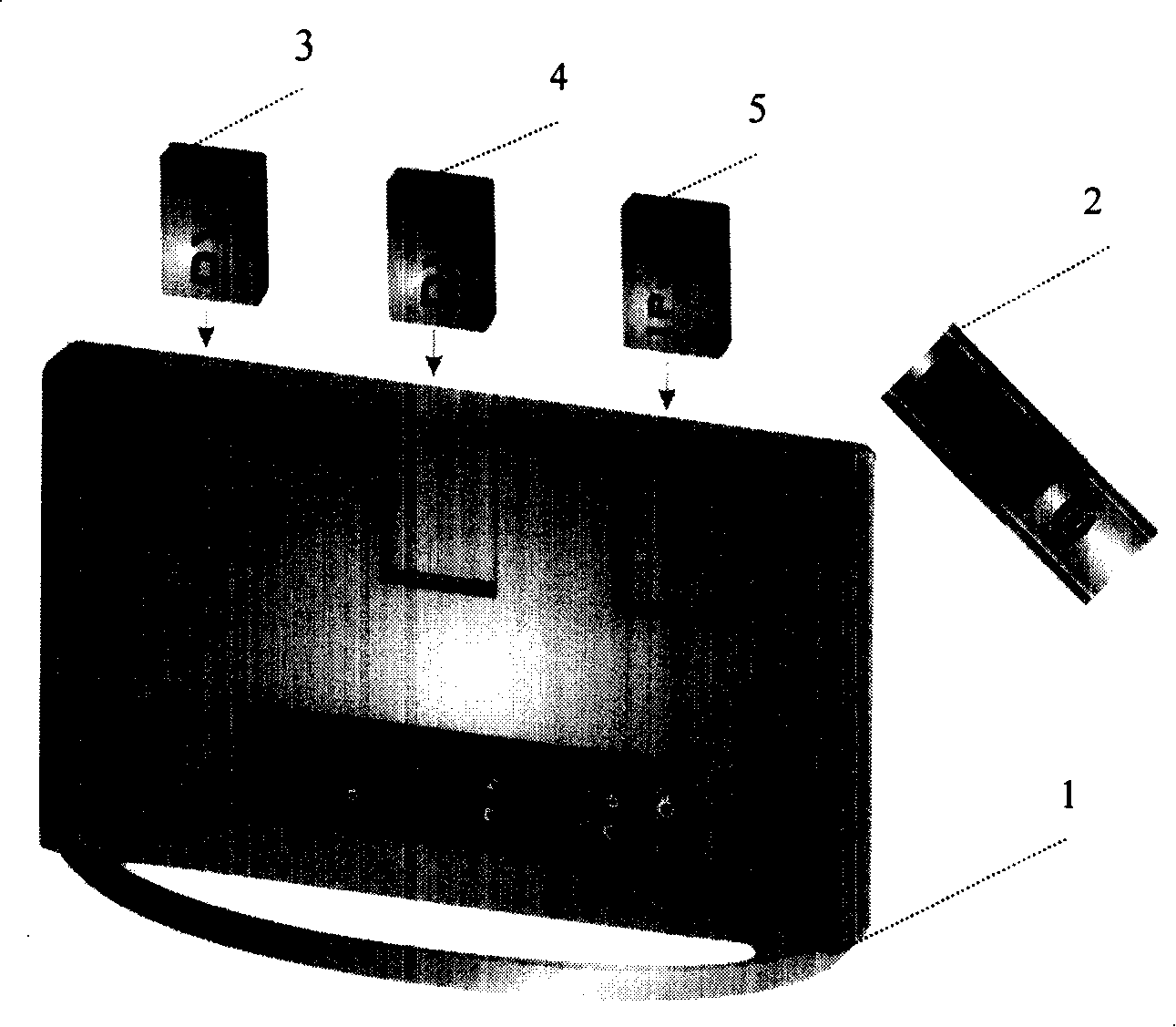

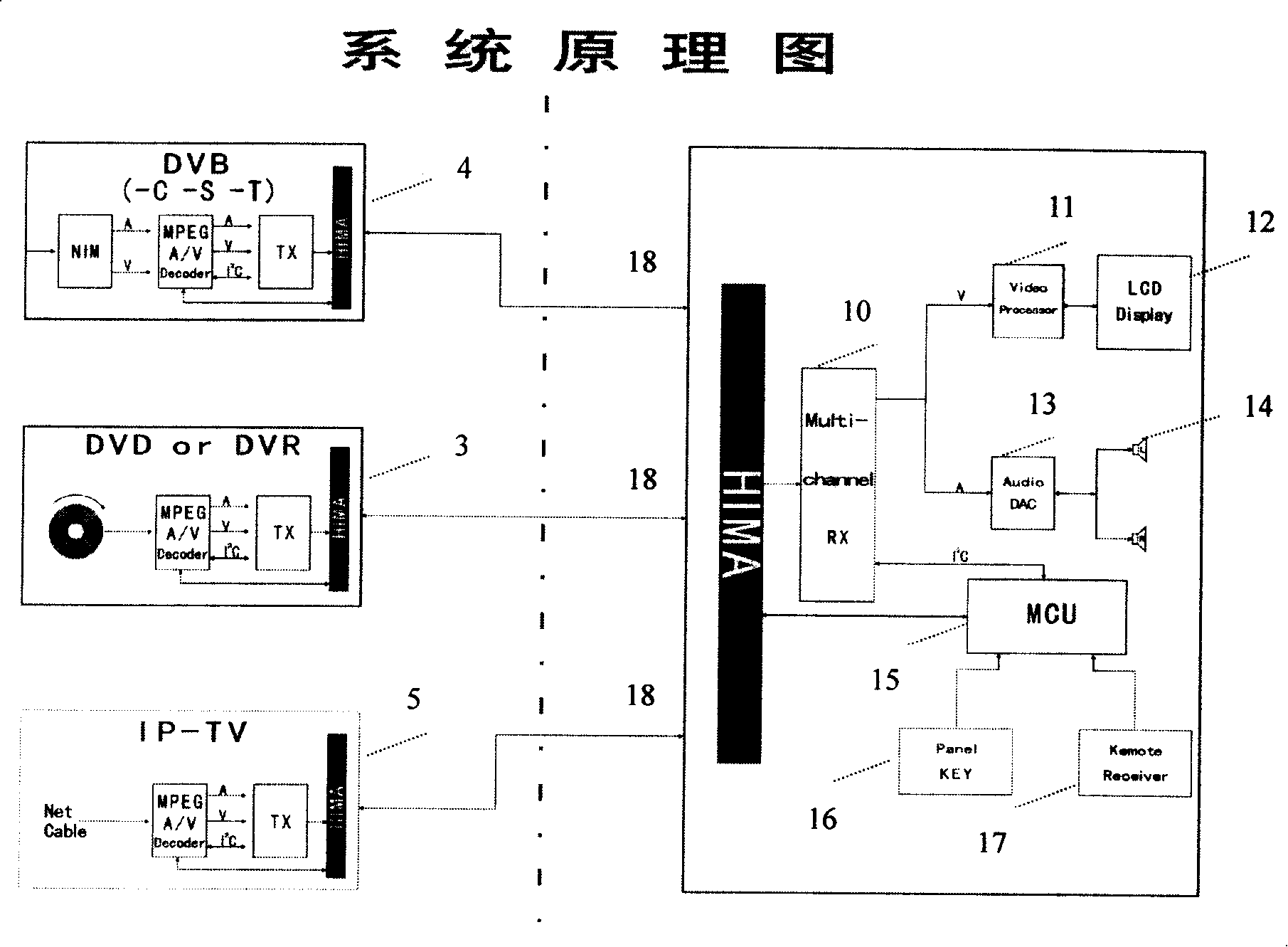

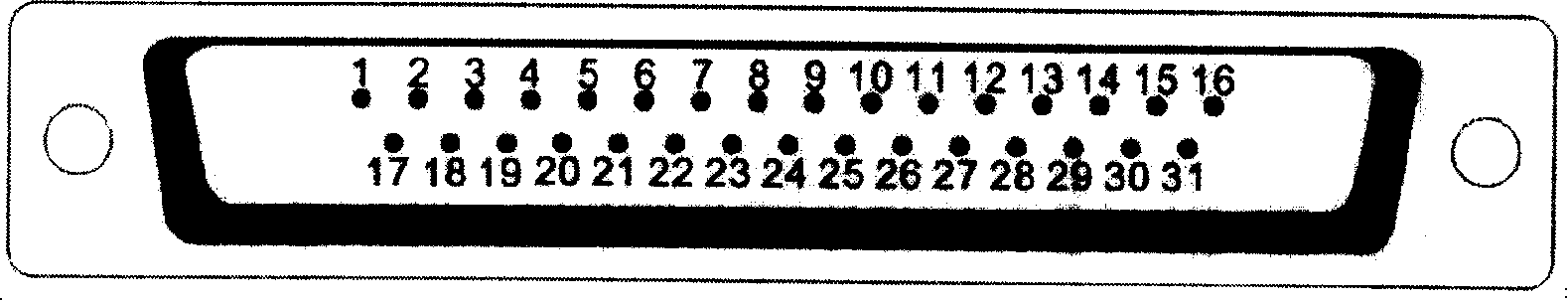

Touch panel type multifunctional remote controller and its control method

InactiveCN101192338ALarge scale preparationSmooth connectionNon-electrical signal transmission systemsInput/output processes for data processingKey pressingRemote control

The invention relates to a method for controlling a touch-screen-style multifunctional remote controller. the controlling method comprises the following steps provided that the remote controller is in the working status: the controller seeks corresponding controlling information for a signal source in a controlling device according to the signal source selected by a user on a touch display screen; content of a function menu exchanged is automatically displayed on the touch display screen according to remote controlling information; according to the key selection made by the user on the content of the function menu, the device outputs an infrared signal to control and splay the corresponding signal source in the device. The invention also discloses a touch-screen-style multifunctional remote controller at the same time. By adopting the touch-screen-style multifunctional remote controller and the controlling method thereof provided by the invention, the utilization of one remote controller can control play of a plurality of signal sources and realize the connection and disconnection of power supply for the signal source.

Owner:幸琳

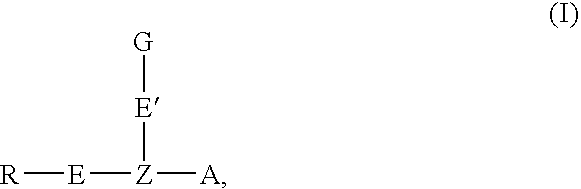

Oligonucleotide labeling reactants and their use

InactiveUS20040260080A1Highly simplifiedSimple methodSugar derivativesGroup 5/15 element organic compoundsAlkyl transferIminodiacetic acid

The invention relates to a novel labeling reactant of formula (I) suitable for labeling an oligonucleotide wherein: R is a temporary protecting group. A is either a phosphorylating moiety or a solid support tethered to a bridge point Z via a linker arm E. E' is a linker arm between G and Z. G is a bivalent aromatic structure, tethered to two iminodiacetic acid ester groups N(COOR''')2 or G is a structure selected from a group consisting of or G is a protected functional group. The invention further concerns a method for direct attachment of a conjugate group to an oligonucleotide structure enabling the attachment of a desired number of these groups during chain assembly. The method comprises a Mitsonobu alkylation.

Owner:HOVINEN JARI +1

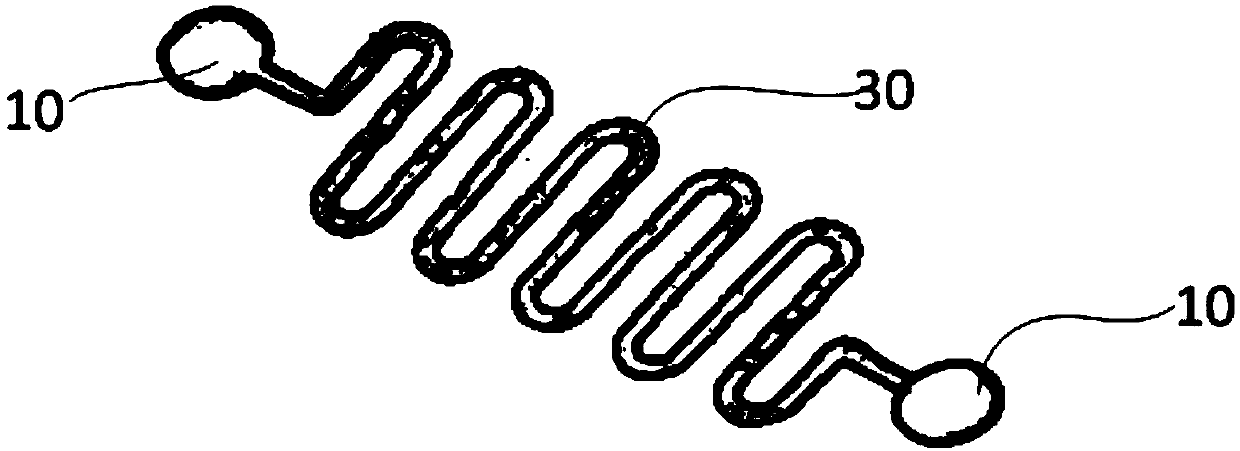

Flexible lead, preparation method of flexible electronic device and flexible wireless energy supply device

ActiveCN109545450AHigh precisionLarge scale preparationConductive layers on insulating-supportsParticular array feeding systemsPre strainResource utilization

The invention provides a flexible lead, a preparation method of a flexible electronic device and a flexible wireless energy supply device. The method comprises steps that a base material formed through combining a rigid substrate, a sacrificial layer and a functional film is provided; a femtosecond laser is utilized to cut the functional film of the base material such that the functional film is formed with a planar wire structure; the sacrificial layer is removed, and the planar wire structure is separated from the rigid substrate; a two-dimensional flexible wire is formed on the planar wirestructure; or the planar wire structure is assembled to a pre-stretched flexible substrate, pre-strain of the flexible substrate is released, and the planar wire structure is bent to form a three-dimensional flexible wire . The method is advantaged in that the flexible wire with high precision, large scale and no pattern limitation can be prepared, unique advantages of fast property, environmentalprotection, low cost, high resource utilization rate and insensitivity to the external environment can be further realized, and the method is suitable for preparing 2D and 3D flexible wires.

Owner:TSINGHUA UNIV

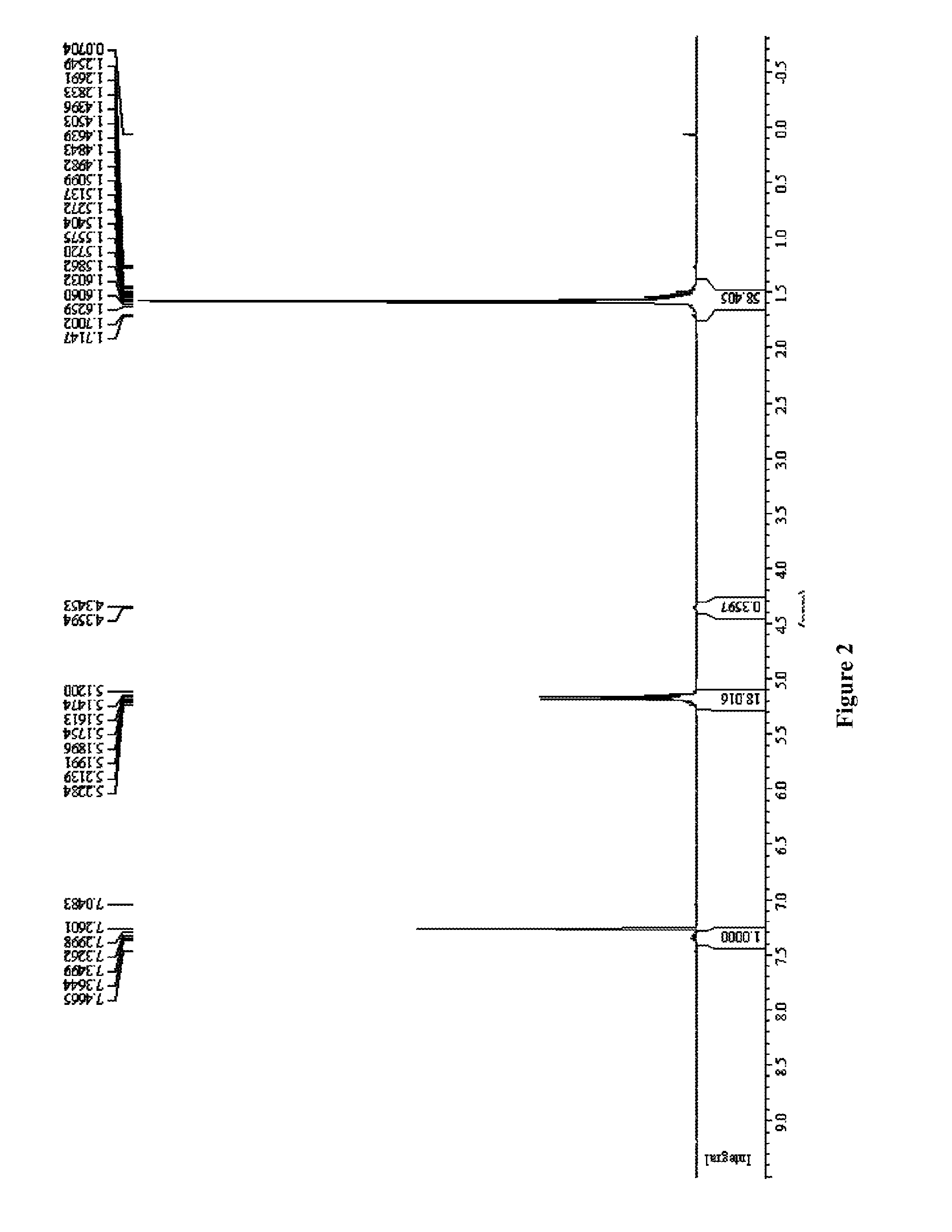

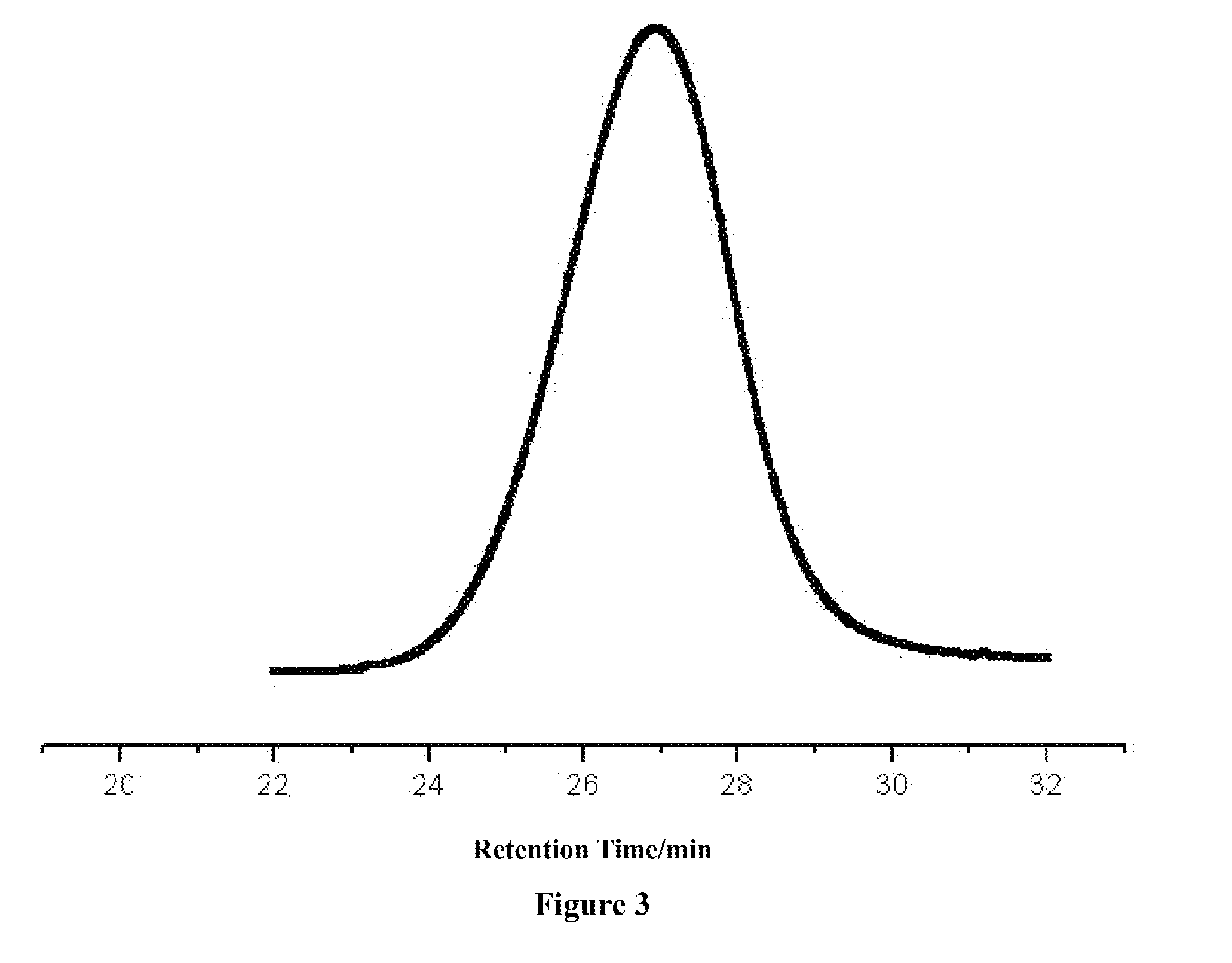

Ring-opening polymerization of cyclic compounds catalyzed by carbene derivatives

ActiveUS20110144296A1High molecular weightEfficient executionOrganic-compounds/hydrides/coordination-complexes catalystsCarbeneCyclic compound

This disclosure provides methods of controlled polymerization of cyclic compounds catalyzed by carbene derivatives having a general formula as shown below, and to obtain a biodegradable polymeric material having a large molecular weight, a narrow dispersity, and no metallic impurity.

Owner:NANJING UNIV OF TECH

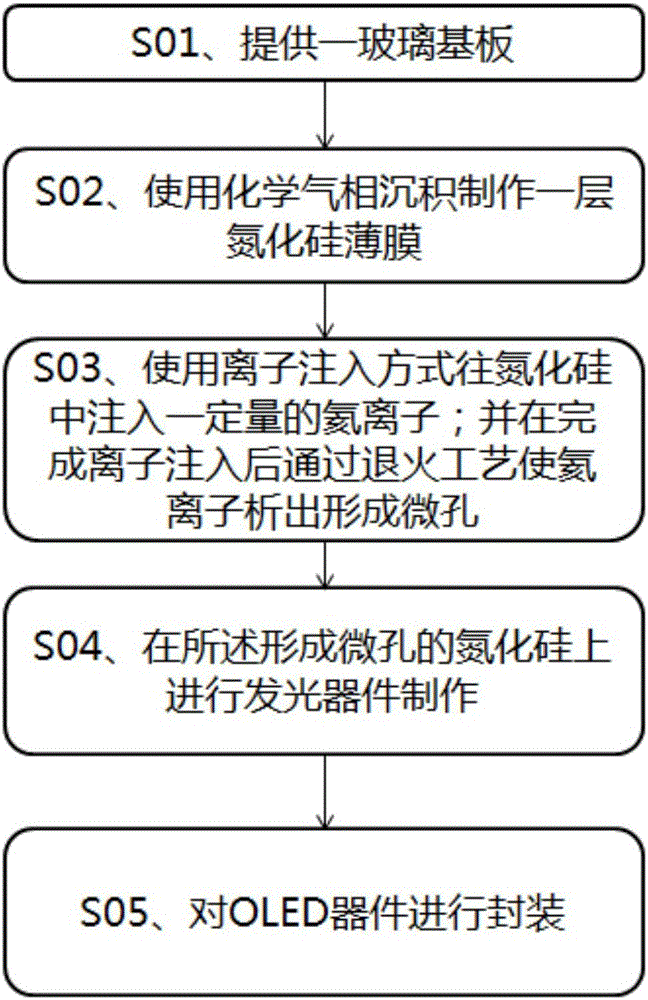

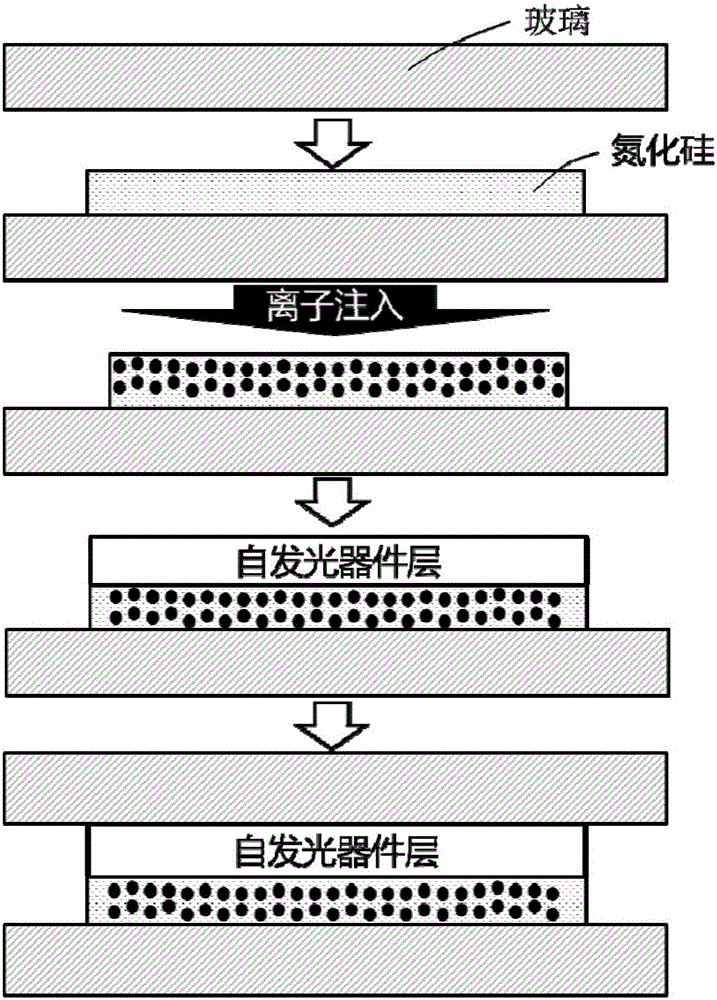

Organic light-emitting display device and manufacturing method thereof

InactiveCN106328819AReduce internal reflectionsImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight extraction in LEDs

The invention discloses an organic light-emitting display device, which comprises a lower substrate, a packaging layer, at least one light extraction layer, an electrode layer, a light-emitting layer and a functional layer, wherein the electrode layer, the light-emitting layer and the functional layer are arranged between the lower substrate and the packaging layer, and a micropore structure is formed in the light extraction layer. The invention further discloses a manufacturing method of the organic light-emitting display device. The organic light-emitting display device is provided with the light extraction layer with the micropore structure, and enables light to be scattered repeatedly by micropores when getting into the light extraction layer through reasonably setting the position of the light extraction layer, thereby reducing internal reflection at the light extraction layer on the whole, and enabling more light to be extracted and emitted from the light-emitting device. Therefore, the light-emitting efficiency of the device can be substantially improved. In addition, the organic light-emitting display device can be manufactured in a large scale, is low in cost and has important practical application values.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid (METH)acrylic syrup for impregnating a fibrous substrate, method for impregnating a fibrous substrate, and composite material produced after polymerisation of said pre-impregnated substrate

The invention relates to a liquid (meth)acrylic syrup for impregnating a fibrous substrate. The invention especially relates to a viscous liquid syrup mainly containing methacrylic or acrylic components. The invention also relates to a method for producing such a syrup. The invention relates further to a method for impregnating a fibrous substrate or long fibers with said viscous liquid syrup. The invention also relates to a fibrous substrate pre impregnated with said syrup, which is useful for the production of mechanical or structured parts or products. The invention also relates to a production method for producing mechanical or structured parts or items and to three-dimensional mechanical or structured parts produced by said method. The invention allows significant reduction of the exothermic peak during the polymerization of the syrup, reduction of the residual monomer content at the end of the polymerization, and production of parts in a composite material without defects or with few defects.

Owner:ARKEMA FRANCE SA

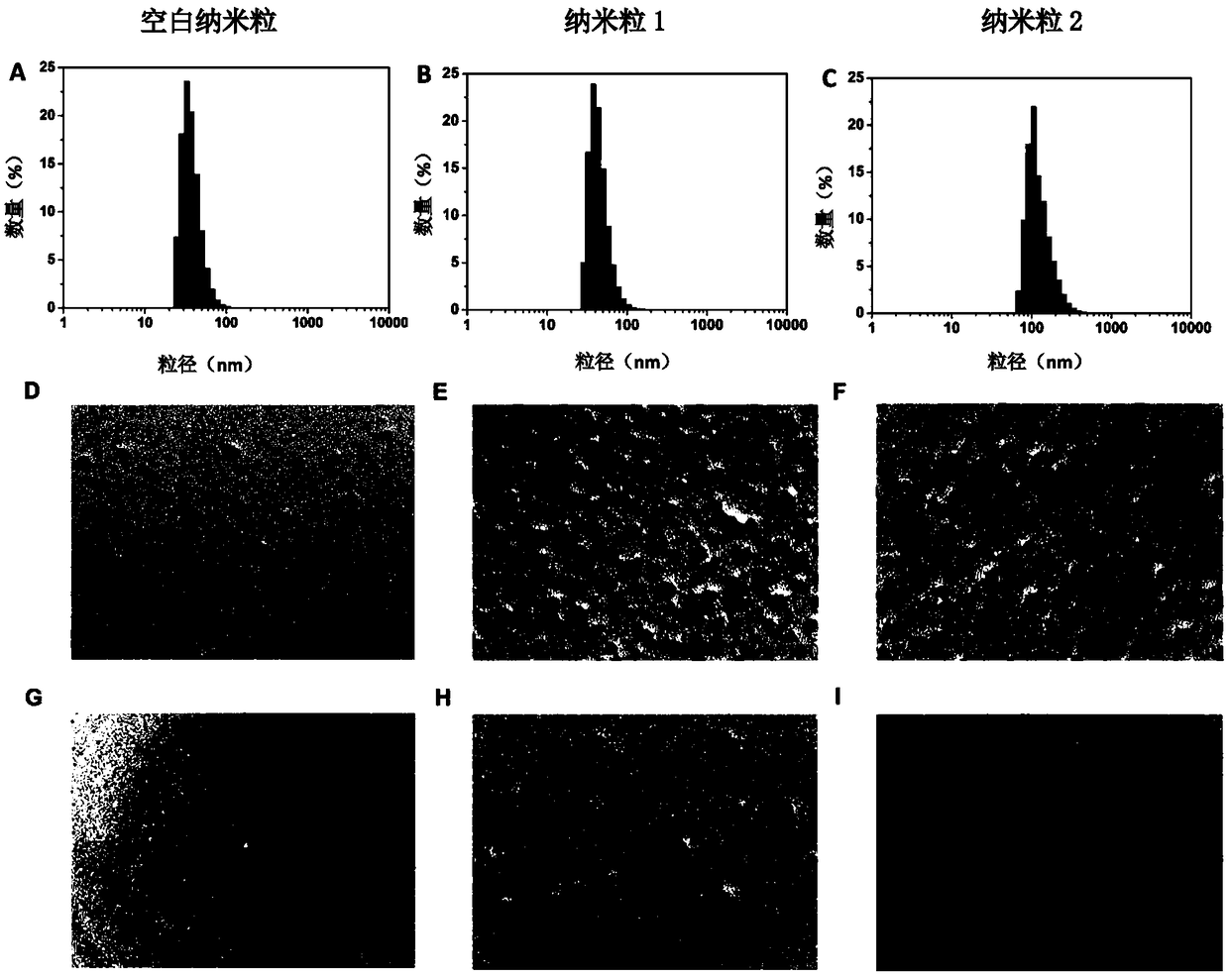

Therapeutic protein-loaded nanoparticle and method for preparing the same

ActiveCN108778257ASustainable preparationLarge-scale preparationPeptide/protein ingredientsMetabolism disorderDiseaseTherapeutic protein

The present invention belongs to the technical field of nanomedicine, and relates to a method for preparing a therapeutic protein-loaded nanoparticle, as well as a therapeutic protein-loaded nanoparticle, a suspension and a pharmaceutical composition comprising the nanoparticle, and a pharmaceutical preparation comprising the nanoparticle, the suspension or the pharmaceutical composition. The present invention further relates to a use of the nanoparticle in manufacture of a pharmaceutical composition, wherein the pharmaceutical composition is useful in prevention or treatment of a disease thatcan be prevented or treated by the therapeutic protein comprised in the nanoparticle.

Owner:SUN YAT SEN UNIV +1

Perovskite material and preparation method and application thereof

InactiveCN109957394ALarge scale preparationHigh purityOrganic compound preparationSolid-state devicesHigh absorptionHalogen

The present application discloses a perovskite material having the chemical formula AxMyXz; wherein A comprises at least one of organic ammonium ions; the organic ammonium ion is selected from at least one of organic ammonium ions of the formula: Y1, Y2, Y3 are independently selected from H or halogen elements, and at least one of Y1, Y2, Y3 is a halogen element; M is selected from at least one ofGe, Sn, Pb, Sb, Bi, Cu, Mn, Sr, In, Tl, Ag; X is at least one selected from the group consisting of halogen elements. The perovskite system in the present application has good stability, good ultraviolet anti-aging effect, high absorption coefficient and good film-forming property, and the preparation method thereof can be used for large-scale preparation and application.

Owner:ZHIJING NANOTECH CO LTD

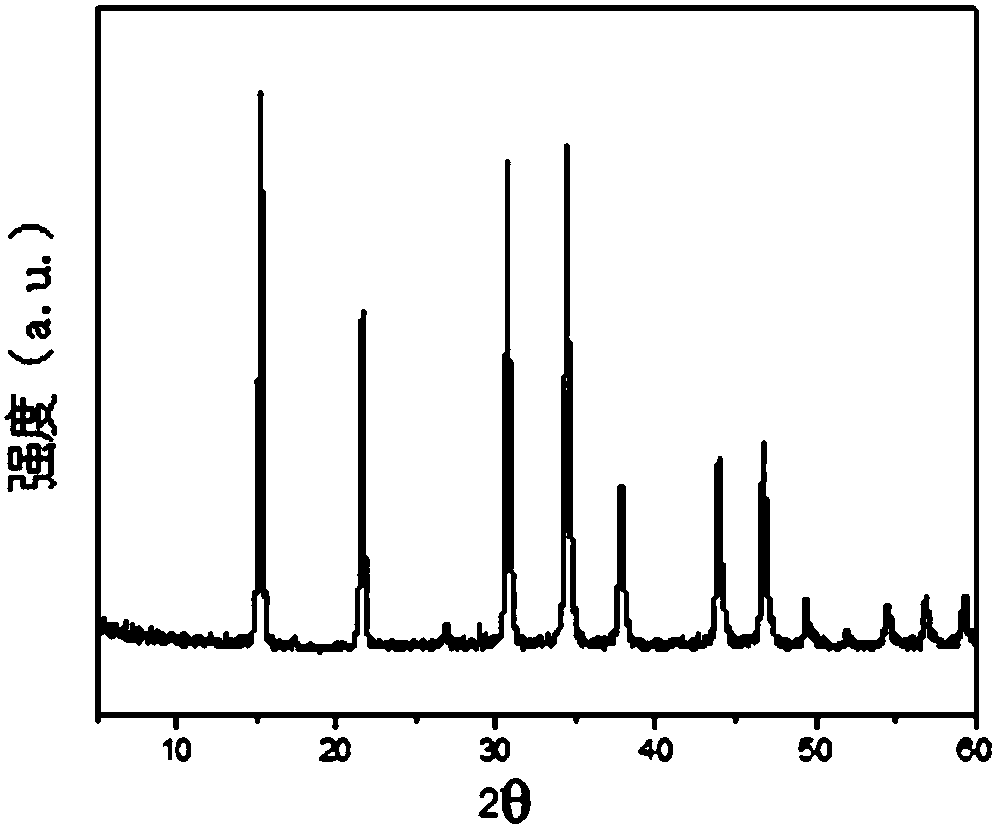

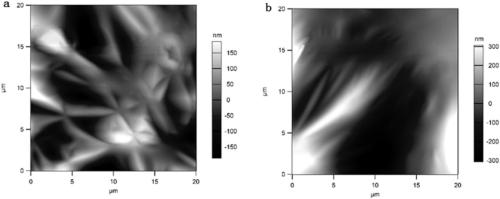

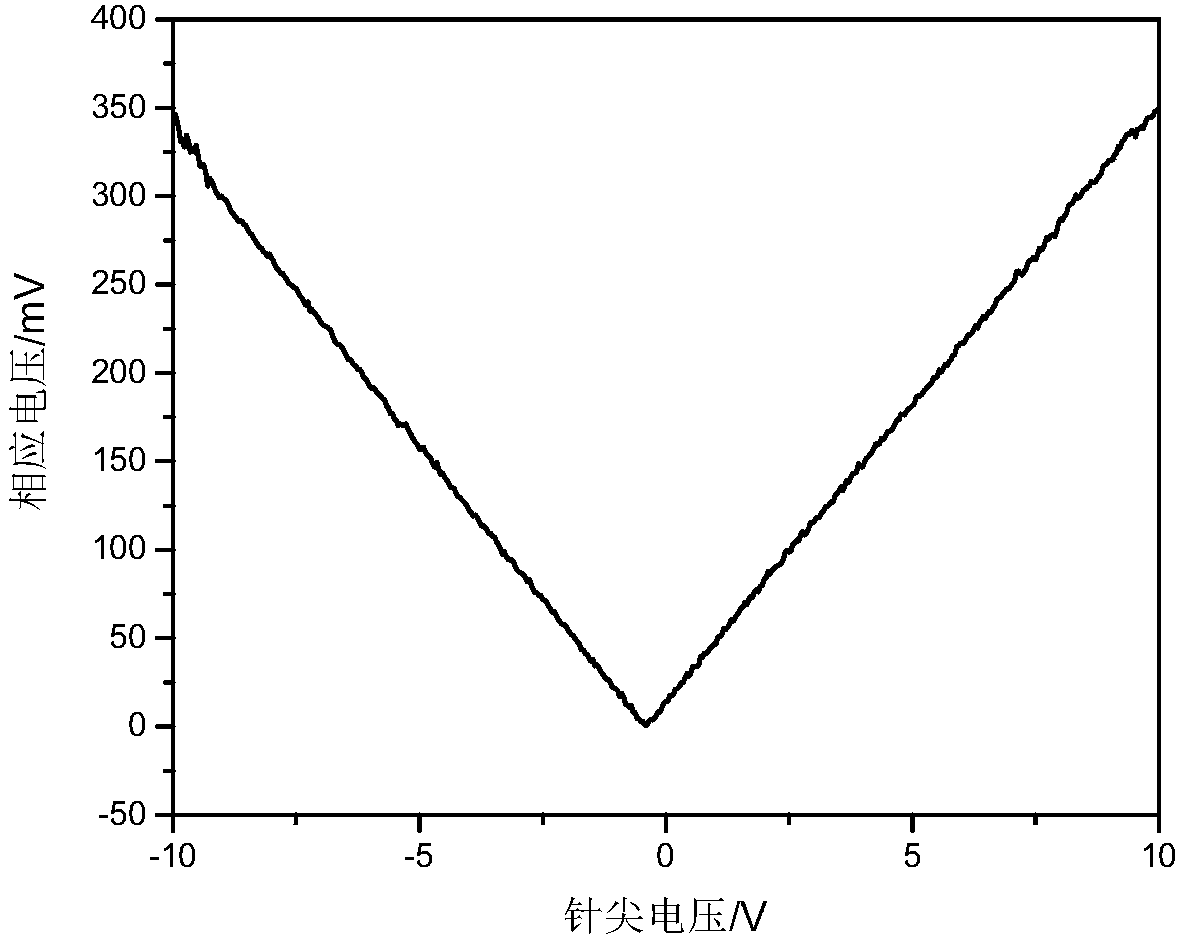

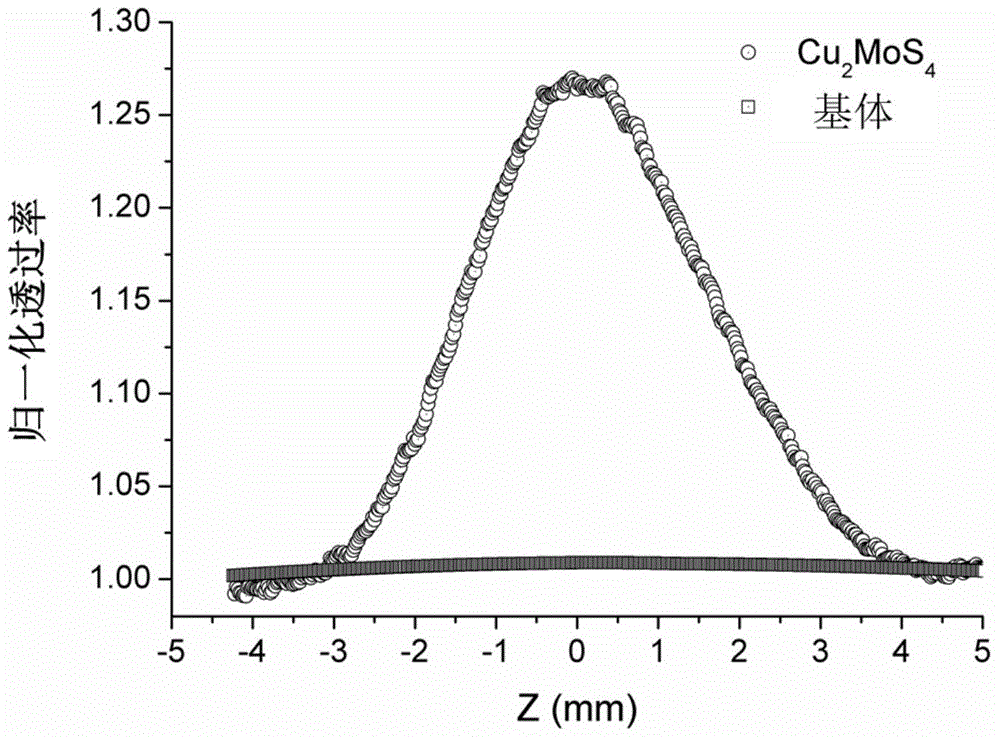

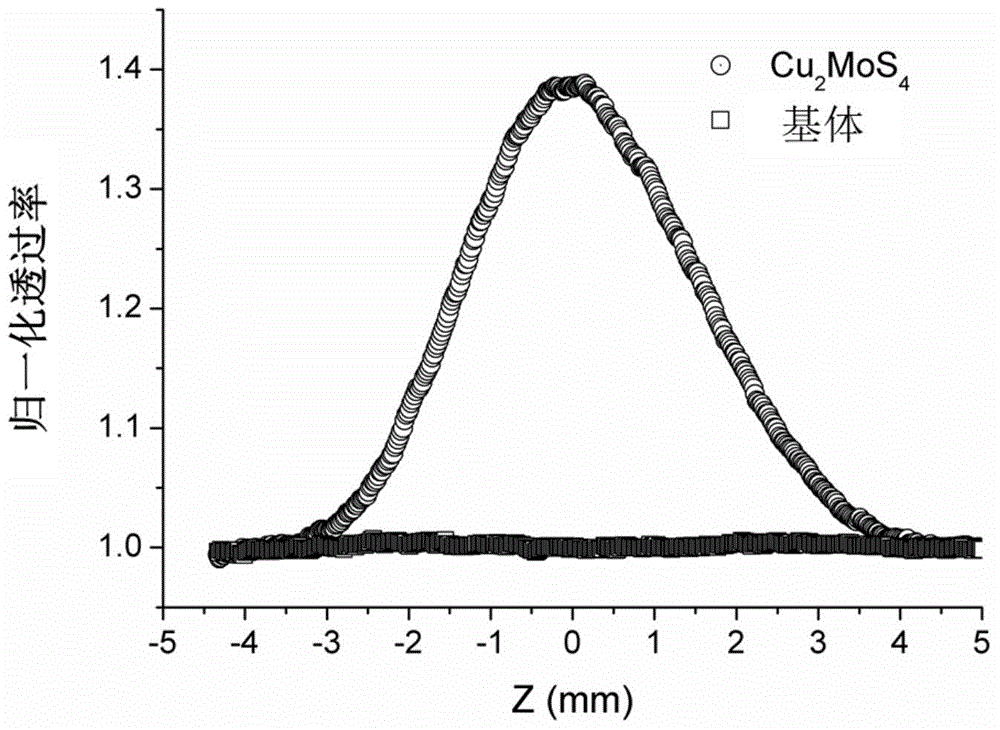

Application of Cu2MoS4 two-dimensional crystal and saturable absorber device comprising same

InactiveCN105098576ALarge scale preparationLow costActive medium materialActive medium shape and constructionMode-lockingTwo dimensional crystal

The invention discloses an application of a Cu2MoS4 two-dimensional crystal and a saturable absorber device comprising the same. The saturable absorber device comprises a two-dimensional crystal packaged in a transparent container and used as a saturable absorber, and a substrate bearing the saturable absorber. The saturable absorber is a Cu2MoS4 two-dimensional layered crystal. A new material system with an excellent saturated absorption characteristic is discovered, and provides more opportunities for development of new saturable absorbers. The saturable absorber device has the advantages of being low in cost, being prepared in a large scale, having a small volume, and being capable of forming various types of mode locking devices, and can be applied to fields like pulse fiber lasers and so on.

Owner:ZHEJIANG UNIV

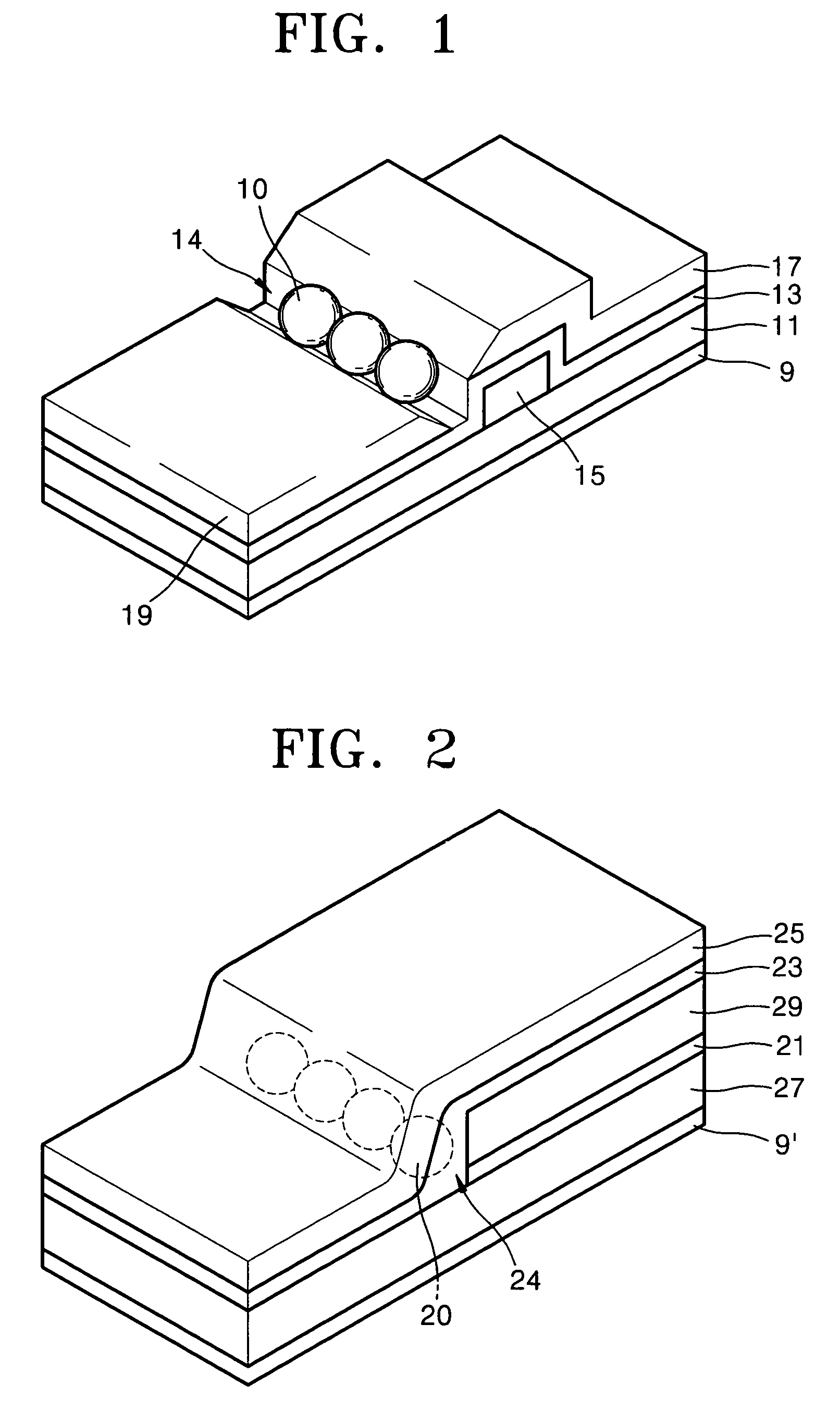

Single-electron transistor using nanoparticles

InactiveUS6984845B2Large scaleLarge scale preparationNanoinformaticsSemiconductor/solid-state device manufacturingSingle electronNanoparticle

A single-electron transistor using nanoparticles is provided. The single-electron transistor includes a first insulating film, a gate electrode patterned in a stripe form on the first insulating film, a second insulating film formed on exposed surfaces of the first insulating film and the gate electrode in such a way that a stepped portion is formed at a boundary between the gate electrode and the first insulating film, first and second electrodes formed on the second insulating film in such a way that a groove is formed at the stepped portion to expose a surface of the second insulating film, the first and second electrodes being separated from each other by the groove, and nanoparticles positioned at the groove and contacting with the first and second electrodes, the nanoparticles being channels for electron transfer. The single-electron transistor is manufactured using previously prepared nanoparticles and a general semiconductor process, thereby enabling low cost, mass production and operation at room temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

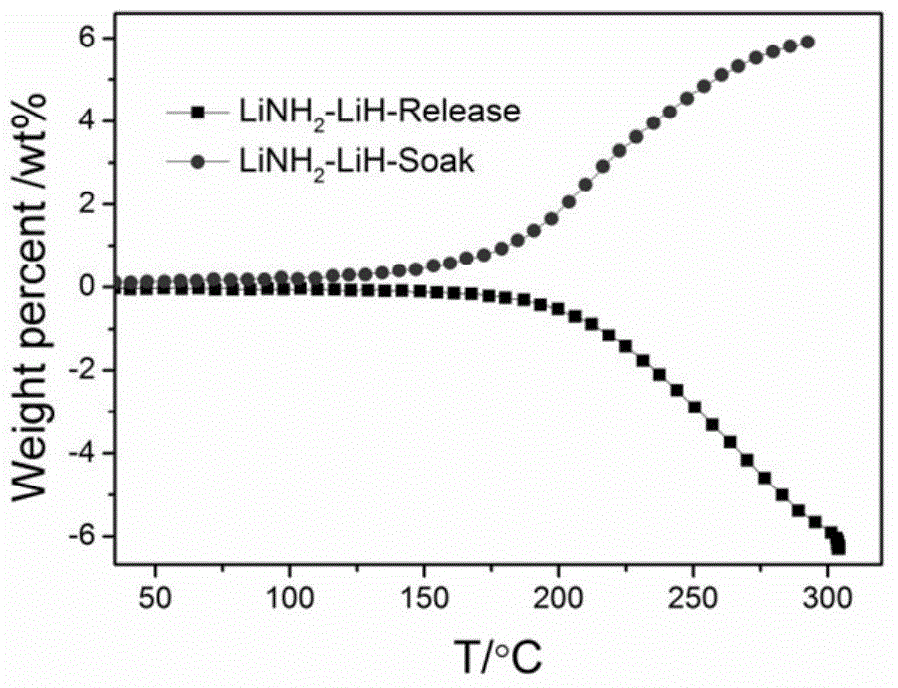

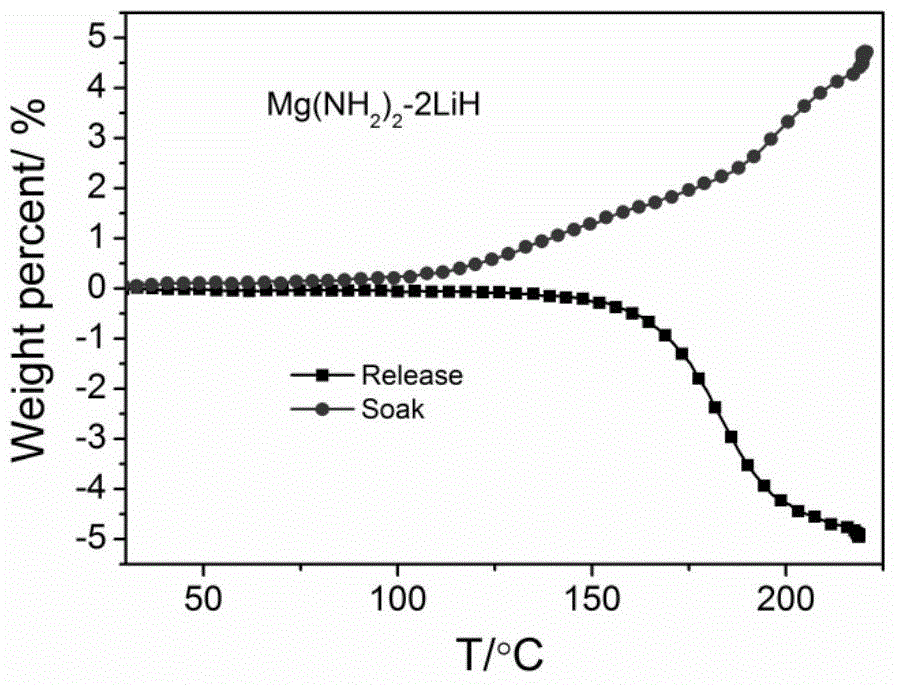

Method for cheaply and extensively preparing nitrogen-based metal compound hydrogen storage material

ActiveCN105776132ASafe and cheap to prepareStrong safety and operabilityHydrogen productionHost materialNitrogen

The invention discloses a method for extensively preparing a nitrogen-based metal compound hydrogen storage material. The nitrogen-based metal compound hydrogen storage material is obtained through uniform mixing, calcining, deamination and hydrogenation with one or two or more of a metallic element, a metal hydride and a metal nitrogen-based compound as a host material and other compounds as an assistant. The metal nitrogen-based compounds can be one or two or more of a metal amino compound, a metal imino compound and a metal nitrogen compound. The metal element can be a group I-III metal or an early transition metal. The nitrogen-based metal compound hydrogen storage material can be safety, cheaply and extensively prepared through the method, so the preparation cost of the nitrogen-based metal compound hydrogen storage material is greatly reduced. The cheap hydrogen storage material provides extremely important guidance for civilianization and practicalization of hydrogen storage systems.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Procoagulant peptides and their derivatives and uses therefor

ActiveUS9149511B2Improve solubilityCost effectiveFibrinogenSurgical adhesivesAbsorbable polymersGenetically engineered

The present invention is directed to a hemostatic or tissue sealing material having (a) a peptide having a sequence SEQ ID NO: 1 or an amino acid analog sequence thereof, and (b) a scaffold for said peptide or amino acid analog sequence. The scaffold is preferably hemostatic, such as a natural or genetically engineered absorbable polymer, a synthetic absorbable polymer, or combinations thereof. The natural or genetically engineered absorbable polymers can be selected from the group consisting of a protein, a polysaccharide, or combinations thereof.

Owner:ETHICON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com