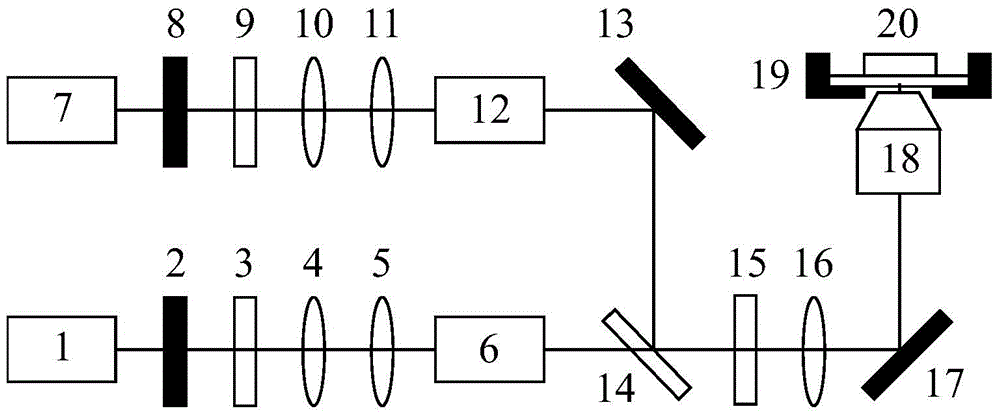

System and method for preparing micro-nano array structure by means of laser light

A technology of array structure and micro-lens array, which is used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of uneven plane distribution of energy beam spots, inability to process hundreds of micro-nano structures in parallel, and high spot center energy. Problems such as low edge energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

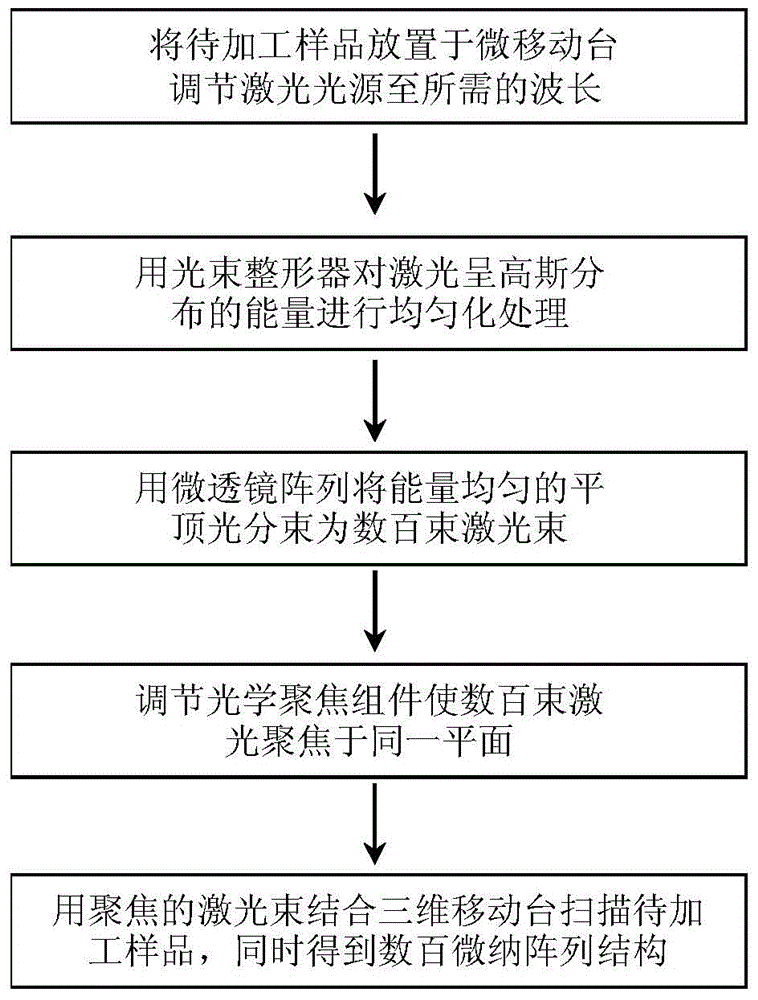

[0121] The following combination Figure 7 with Figure 8 The present invention will be described in detail by taking the preparation of a silver nano-dot array with a single beam on a glass substrate as an example.

[0122] First, the shutters 2 and 8 of the first light path and the second light path are closed, and the sample carrying the silver ion solution is placed on the micro moving stage.

[0123] The sample carrying the silver ion solution includes a glass substrate to be processed, a silver ion solution applied on the substrate, and a transparent auxiliary substrate. The concentration of silver ions in the silver ion solution is 0.01M-0.5M, and the concentration of the surfactant n-decylphthalein sarcosine sodium salt is 0.01M-0.2M. In order to prevent the evaporation of the solution during the manufacturing process of the metal micro / nano structure, a sandwich structure consisting of a glass substrate to be processed, a silver ion solution and a transparent auxiliary sub...

Embodiment 2

[0136] The following combination Figure 7 with Picture 9 The present invention will be described in detail by taking the preparation of a silver nanowire array on a glass substrate with a single beam as an example.

[0137] Keep the other conditions the same as in Example 1. Adjust the total power of the femtosecond pulsed laser beam generated by the laser to 0.1-2.8W by adjusting the first optical attenuator located on the optical path. The moving speed of the three-dimensional micro moving stage is 20nm / ms-1nm / ms, and silver nanowire arrays with a diameter of 100-500nm can be obtained on a glass substrate.

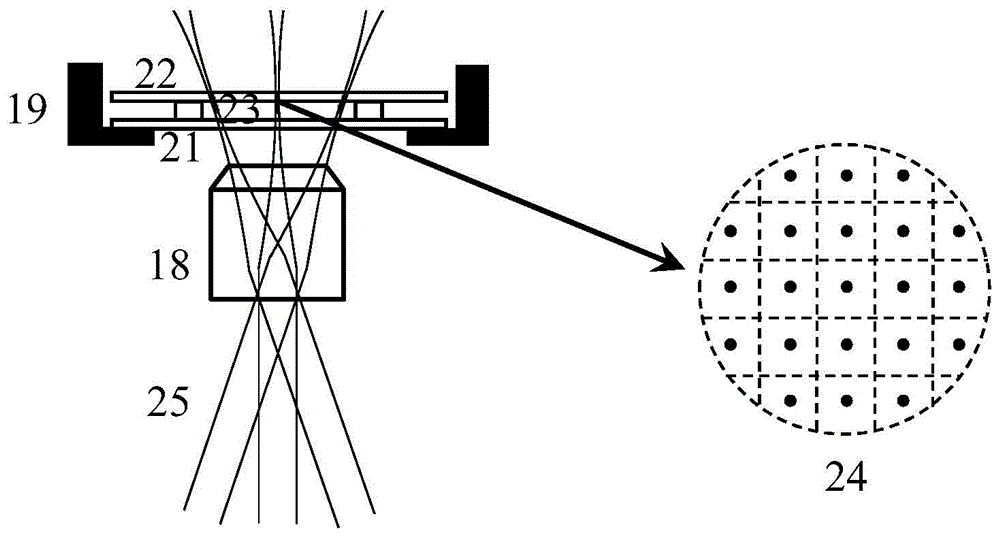

[0138] Picture 10 In order to use the method of producing metal nanowires using laser light of the present invention, a microlens array with a period of 600 microns splits the flat-top light into approximately 70 beams. Under the laser light source 780nm femtosecond laser and a 100x objective lens, the total power is 193mW, adjust 70 laser beams to focus on the interface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com