Patents

Literature

158 results about "Two dimensional crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-dimensional crystals can grow on a surface within minutes. What they will look like depends on the solute and its concentration, the solvent, the temperature, the humidity, and many other factors. The result is often a surprise.

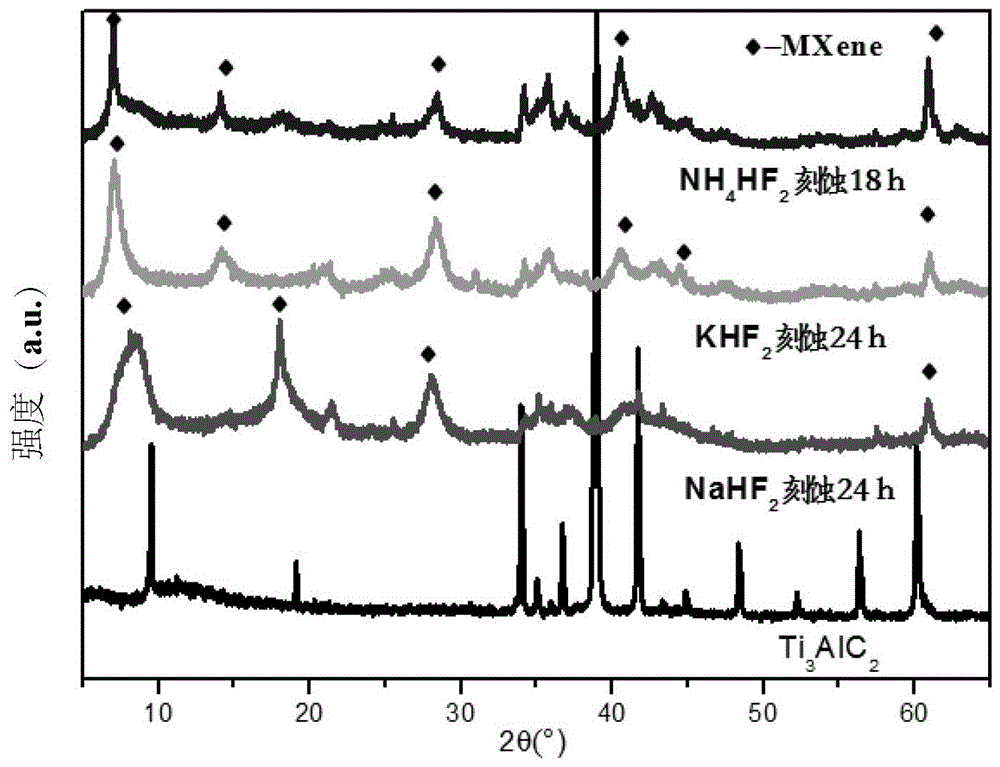

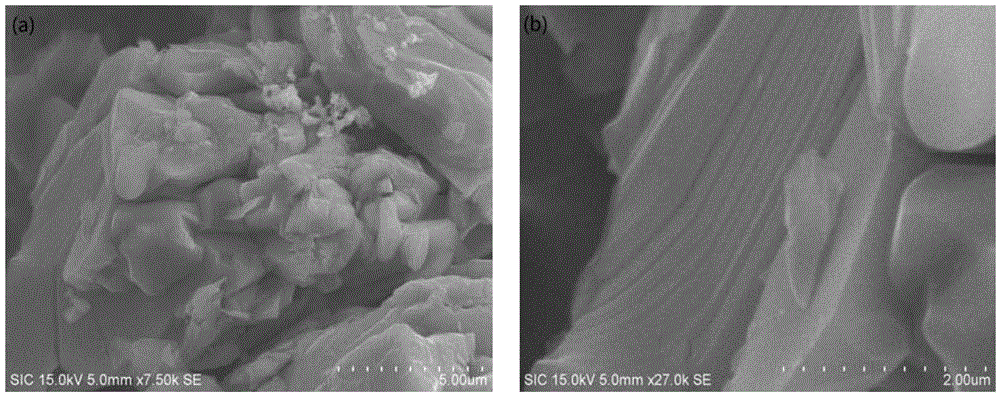

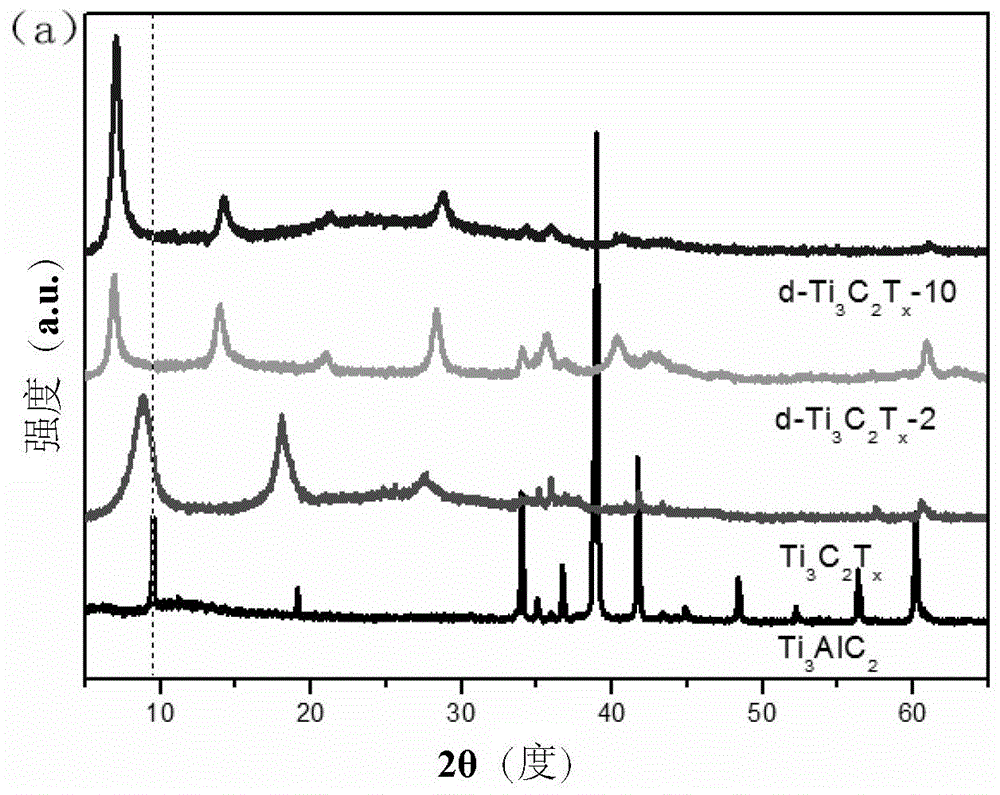

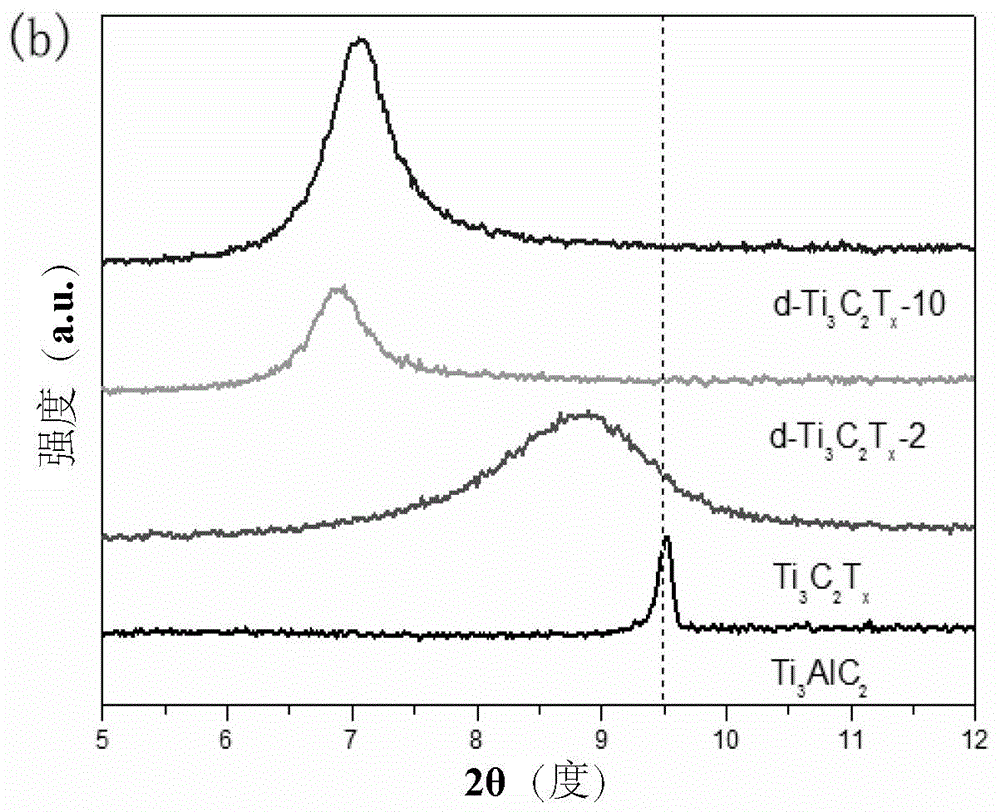

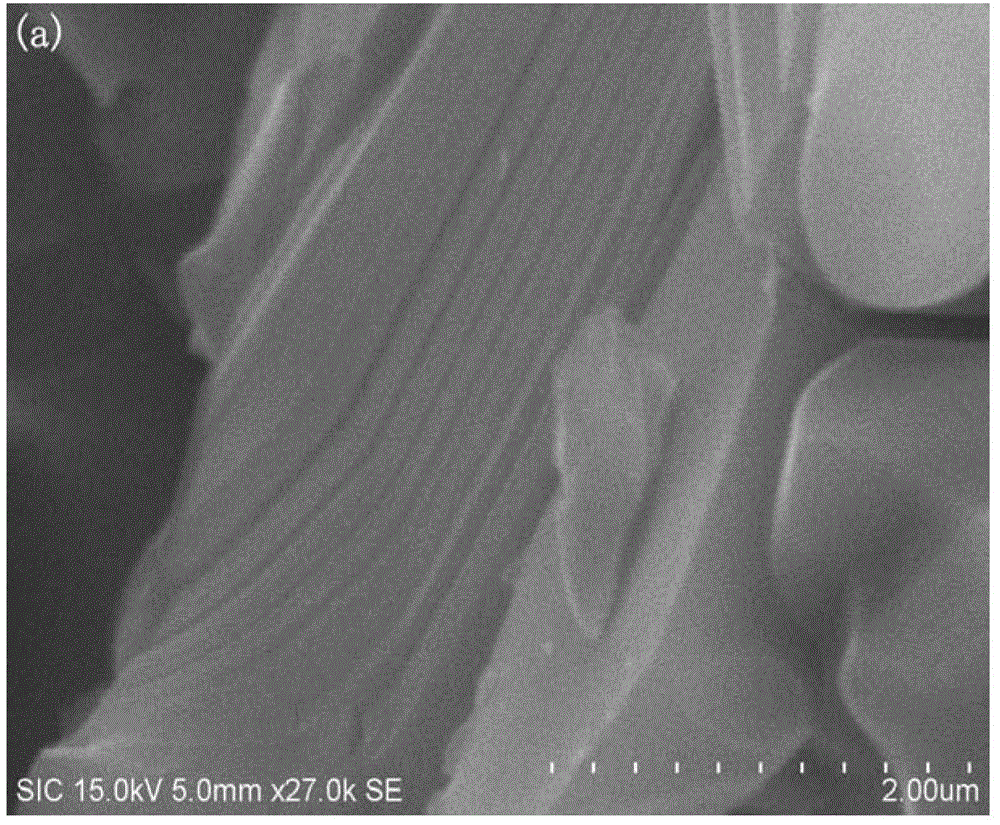

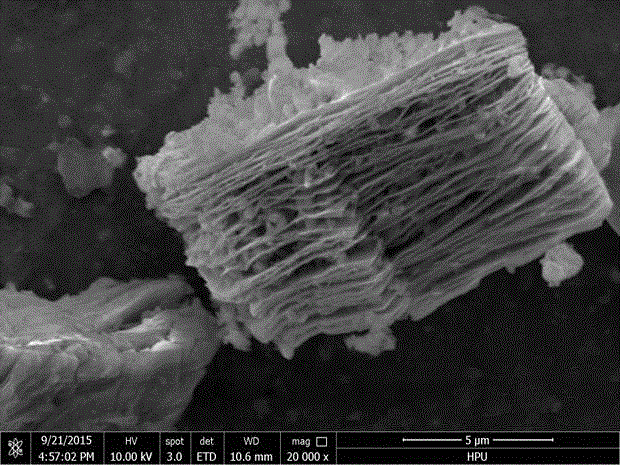

Preparing method for two-dimensional crystal MXene nanometer material

InactiveCN106220180AObvious two-dimensional layered structureSimple methodSupercapacitorTwo dimensional crystal

The invention relates to a preparing method for a two-dimensional crystal MXene nanometer material. The preparing method comprises the steps that a high-purity ternary lamellar MAX-phase ceramic block material is ground and then screened, and MAX-phase ceramic powder is obtained; the MAX-phase ceramic powder and HF acid salt crystals are weighed in the mass ratio of 2:(5-15) and then added into deionized water, an etching reaction is carried out at 30-85 DEG C, washing and drying are carried out, and the two-dimensional crystal MXene nanometer material is obtained. The MXene nanometer material prepared through the method has an obvious graphene-like two-dimensional lamellar structure and is expected to be applied to the fields such as supercapacitors, lithium ion batteries and adsorption; the MAX phase is subjected to etching treatment with acid salt, the method is simple and easy to implement, safe and reliable, and large-scale industrialized popularization is easy.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

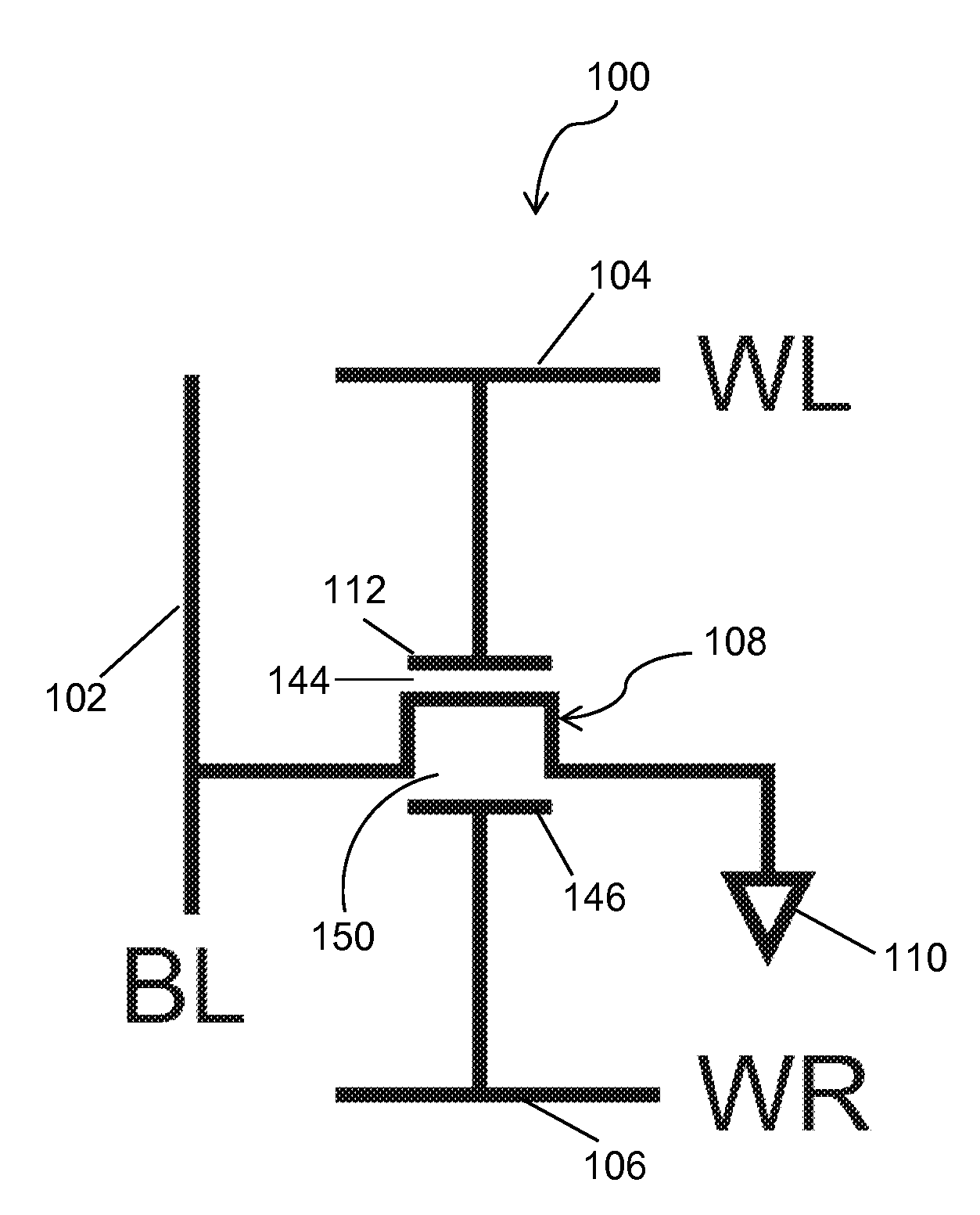

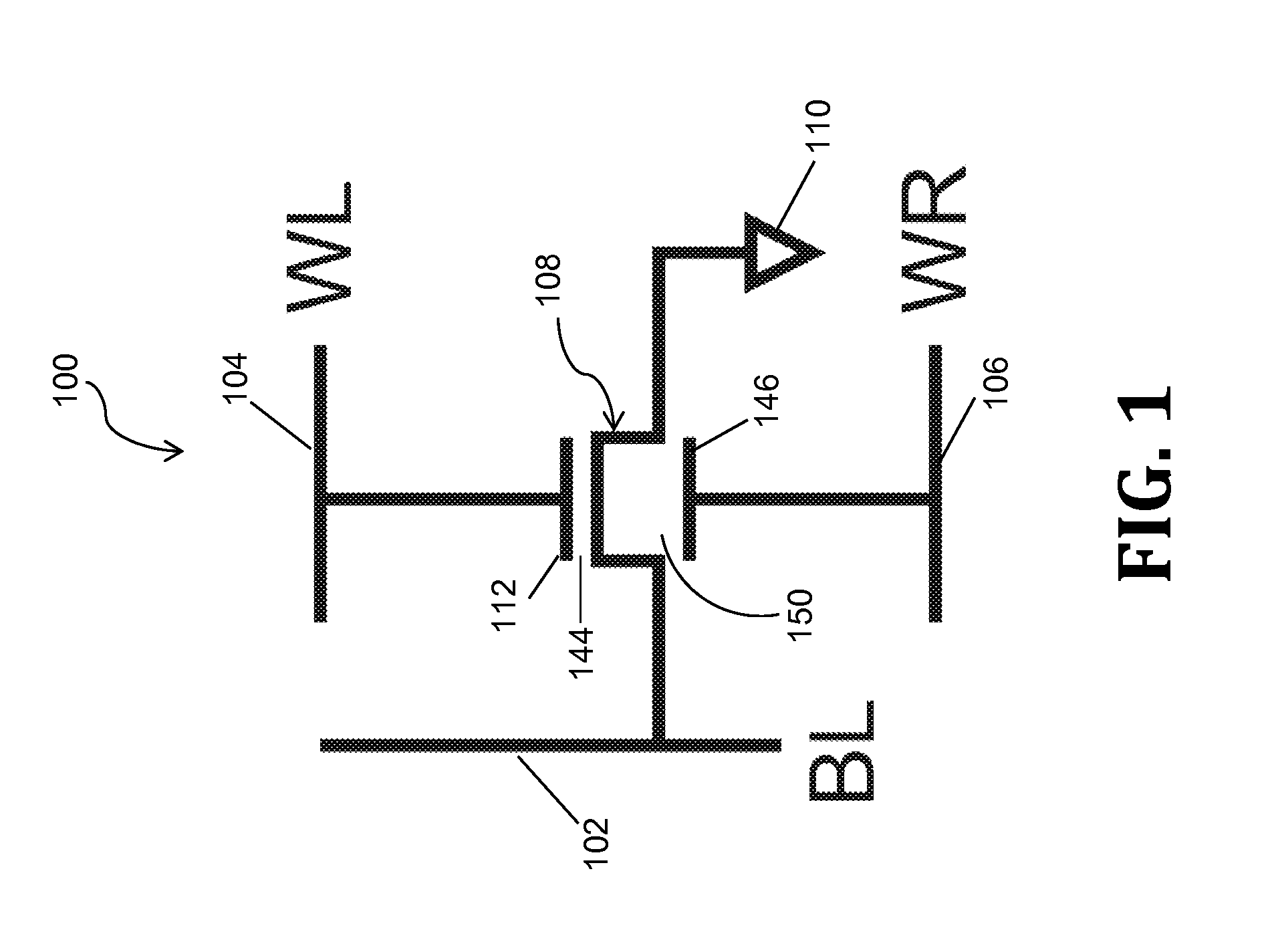

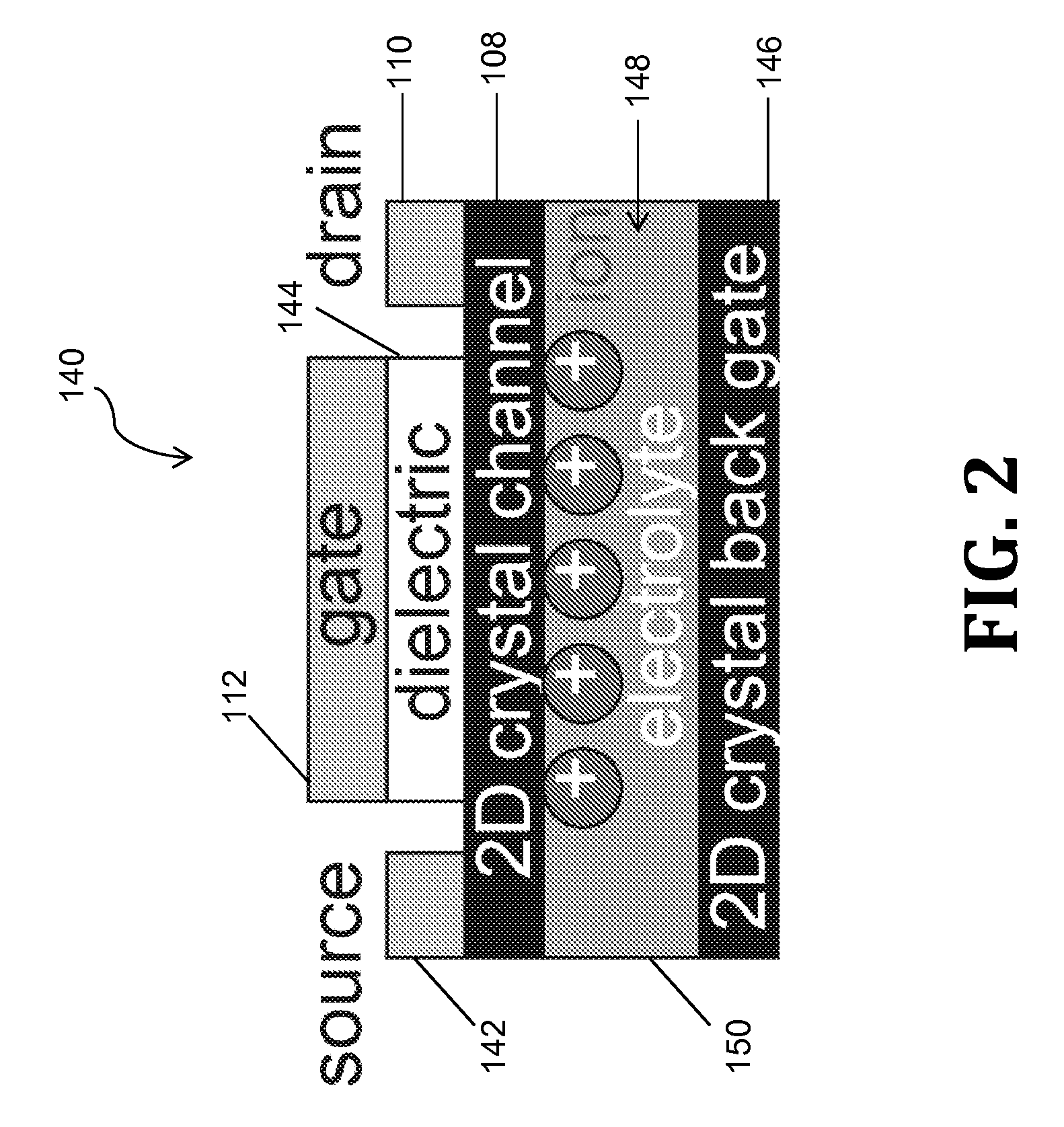

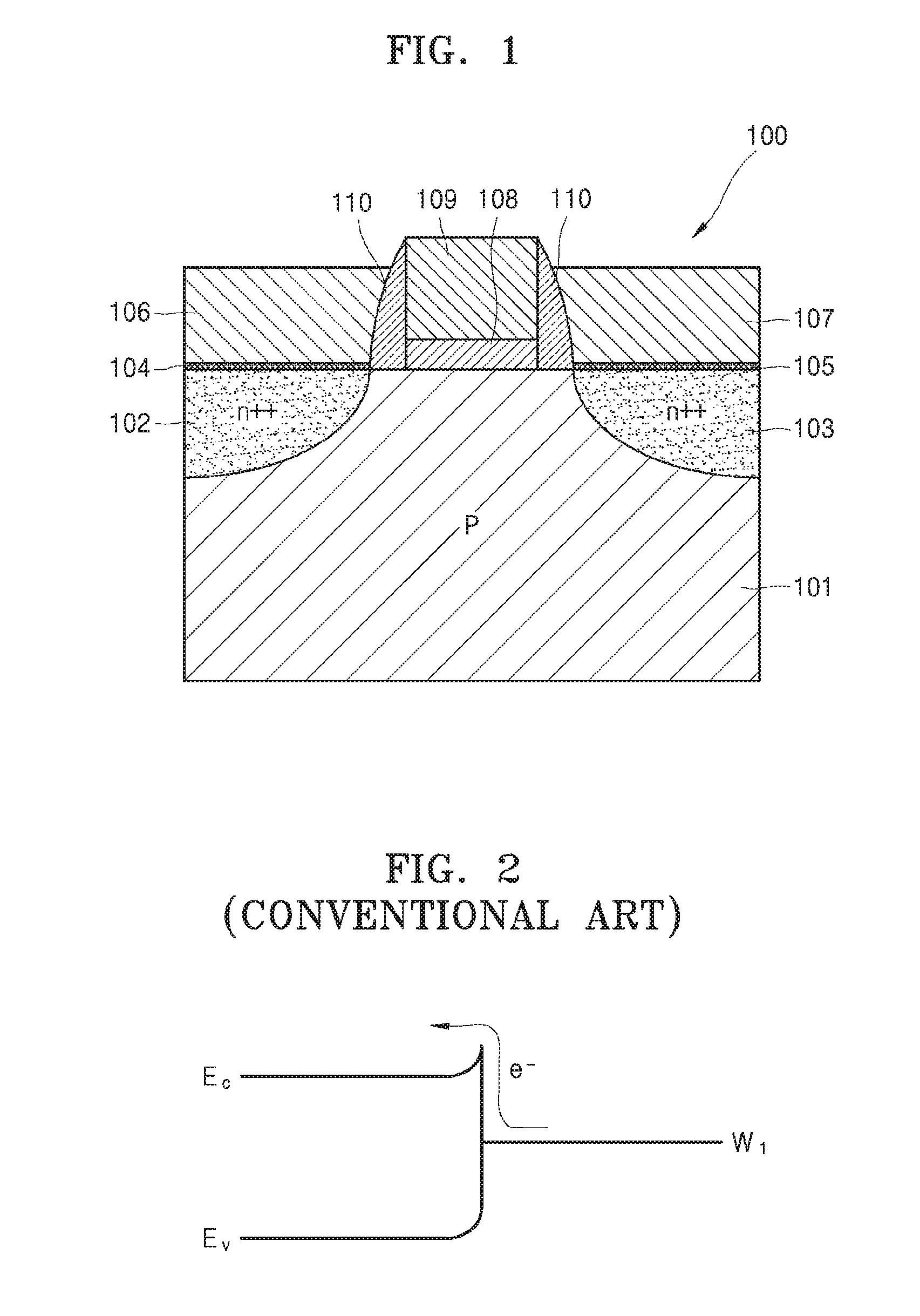

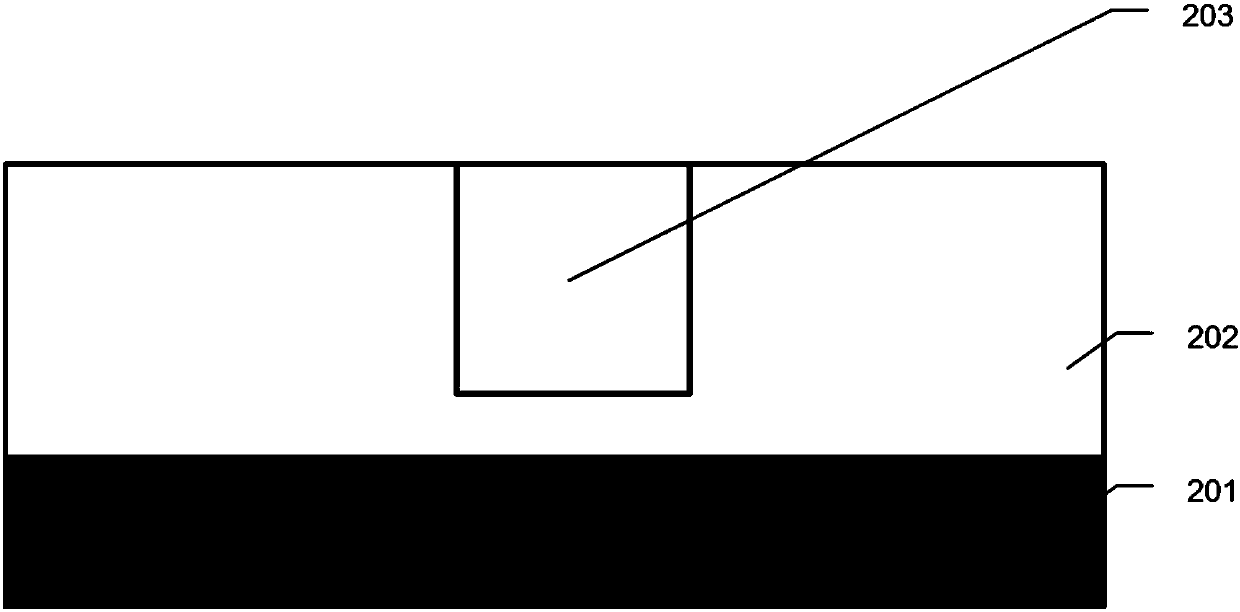

Single transistor random access memory using ion storage in two-dimensional crystals

A single-transistor random access memory (RAM) cell may be used as universal memory. The single-transistor RAM cell generally includes a first gate, a 2D-crystal channel, a source, a drain, an ion conductor, and a second (back) gate. The single-transistor RAM cell is capable of drifting ions towards the graphene channel. The ions in turn induce charge carriers from the source into the graphene channel. The closer the ions are to the graphene channel, the higher the conductivity of the graphene channel. As the ions are spaced from the graphene channel, the conductivity of the graphene channel is reduced. Thus the presence of the charged ions adjacent to the channel is used to modify the channel's conductivity, which is sensed to indicate the state of the memory.

Owner:UNIV OF NOTRE DAME DU LAC

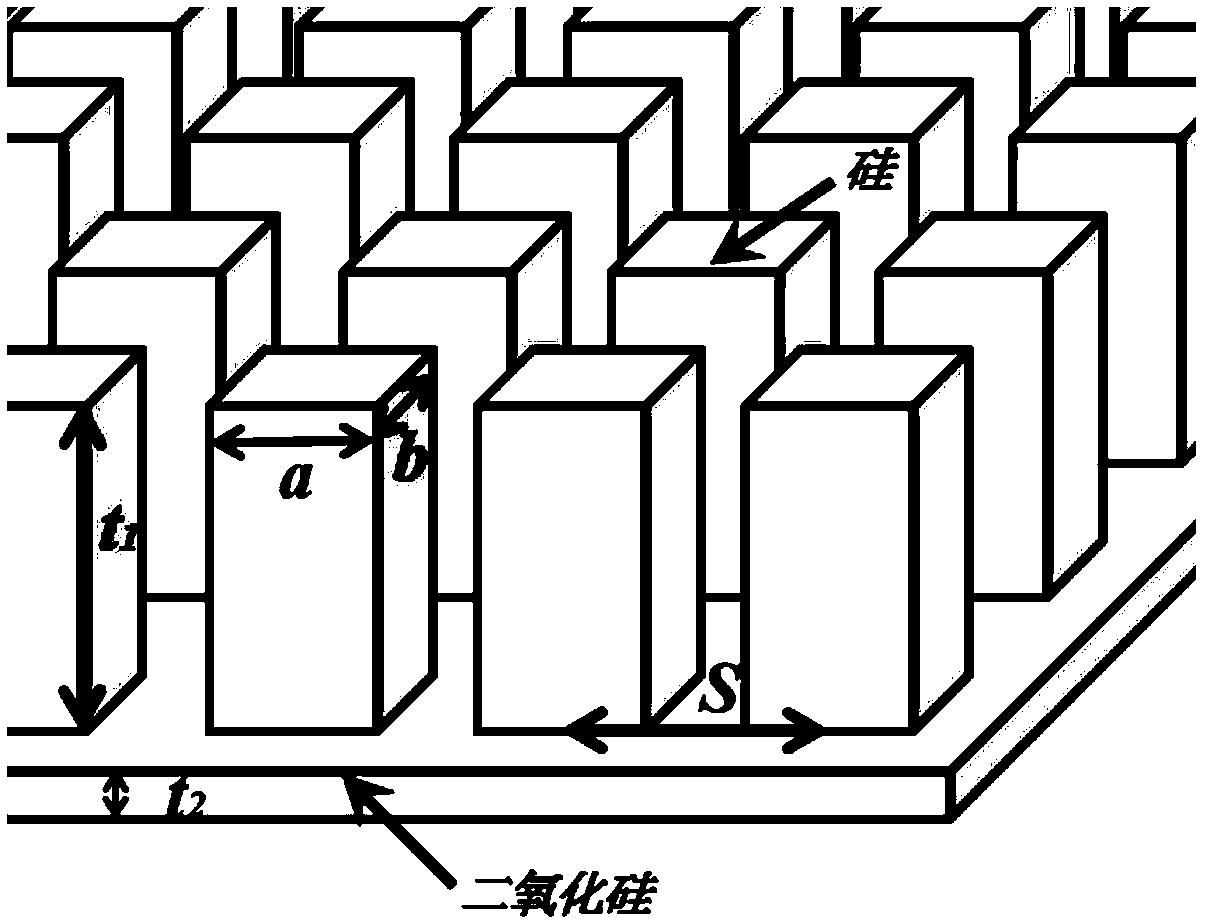

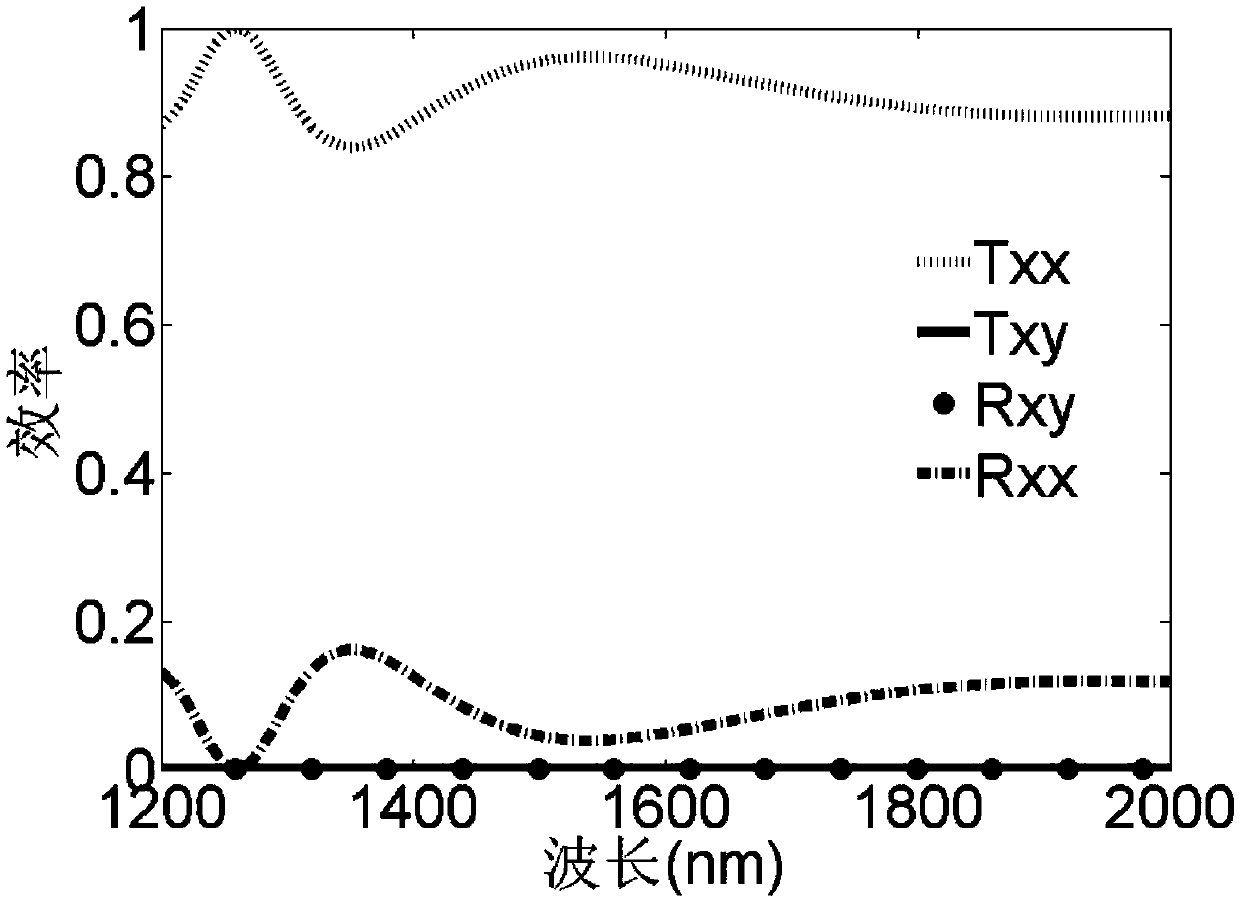

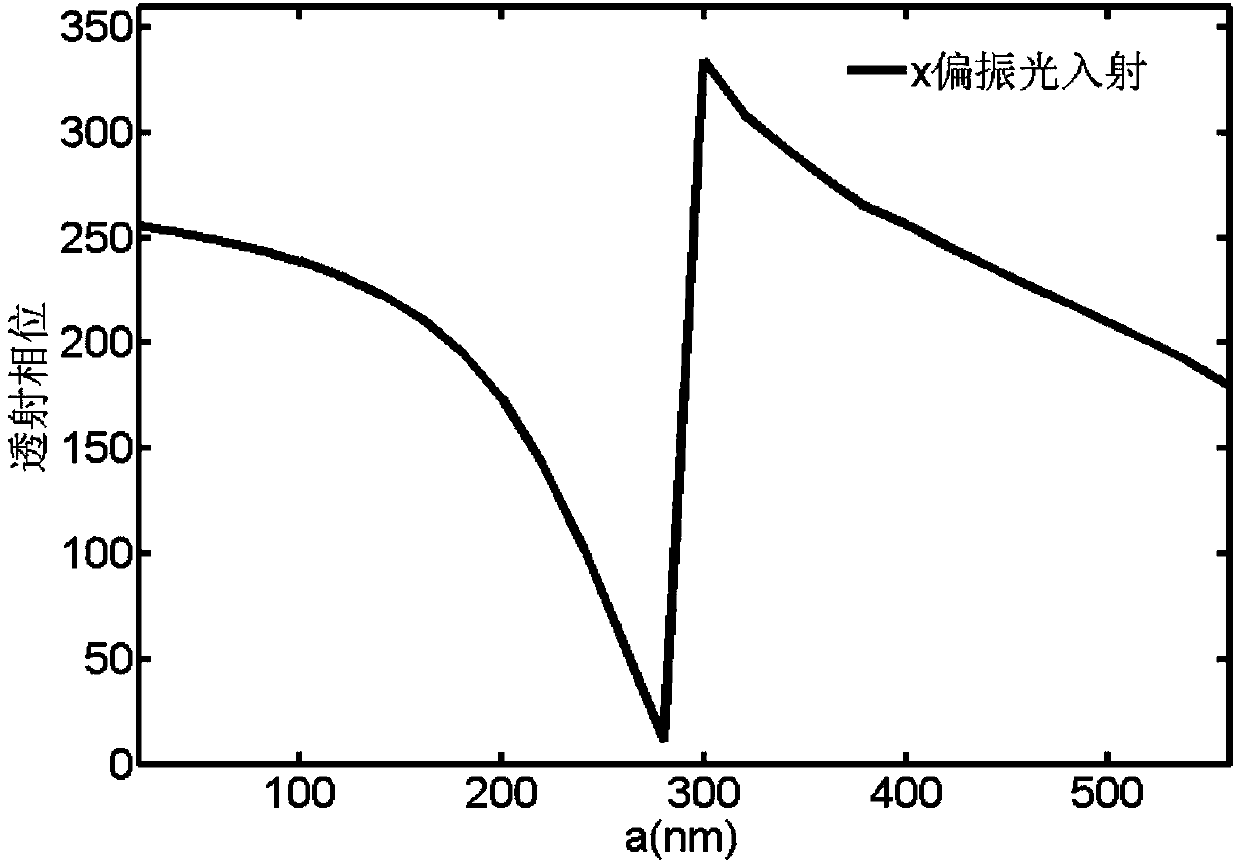

Difunctional device integrating wave plate based on medium meta-surface and optical device

The invention discloses a wave plate based on a medium meta-surface, a beam deflector and a difunctional device integrating the wave plate and a focusing lens. The devices work in a communication waveband, silicon is adopted as a dielectric material, and a substrate is made from silicon dioxide. The devices are characterized in that the brick shape of the silicon material serves as the design ofa unit structure, and a plurality of brick-shaped structures conforming to required phase gradient are arranged according to two-dimensional crystal lattice periodicity to form a rectangular array; the thickness of silicon nano-bricks of the unit structures with medium meta-surfaces is 0.9 microns. The transmitted phase difference of an x-line deflection light component and a y-line deflection light component of incident light is controlled by adjusting the length and width of the unit structures while the deflector or the focusing lens is achieved before phase wave control, and accordingly functions of the wave plate are achieved. Compared with existing devices, the devices are simple in structure, and the deflection efficiency is improved to 80%. Compared with existing wave plates and optical devices which are used in a stacked way, processing and manufacturing inconvenience is overcome, and integration and miniaturization of the optical devices are facilitated.

Owner:DONGGUAN UNIV OF TECH

Stripping method of stratified materials

The invention discloses a stripping method of stratified materials. The stripping method comprises the following steps of: weighing 30-70% of stratified materials, 0.2-5% of an organic intercalation agent, and the balance of a solvent, and mixing and stirring the weighed stratified materials, the weighed organic intercalation agent and the weighed solvent so as to obtain paste; placing the paste in a closed container, and performing static steeping; heating the steeped paste under the condition of continuously stirring, filtering the paste, washing the filtered paste, drying the washed paste so as to obtain a filter cake; placing 10-50% of filter cake, 0.5-30% of an inorganic intercalation agent, and the balance of a solvent into a closed container, uniformly mixing the filter cake, the inorganic intercalation agent and the solvent so as to obtain paste; performing static steeping; heating the closed container with the paste under the condition of 50-200 DEG C for 2-8h; cooling the heated closed container with the paste to room temperature; performing repeated heating and cooling; performing filtering; performing cleaning so as to obtain a secondary filter cake and a filtrate agent; adding the secondary filter cake and the filtrate agent in the solvent for ultrasonic stripping so as to obtain a dispersion liquid; filtering the dispersion liquid; washing the filtered dispersion liquid with deionized water; and performing vacuum drying so as to obtain the stratified materials. The stripping method disclosed by the invention solves the problems that the prior art for preparing the two dimensional crystal materials is low in efficiency, small in yield, high in environmental pollution, and the like. Defects and impurities are not led in the two-dimensional crystal materials.

Owner:HUNAN UNIV

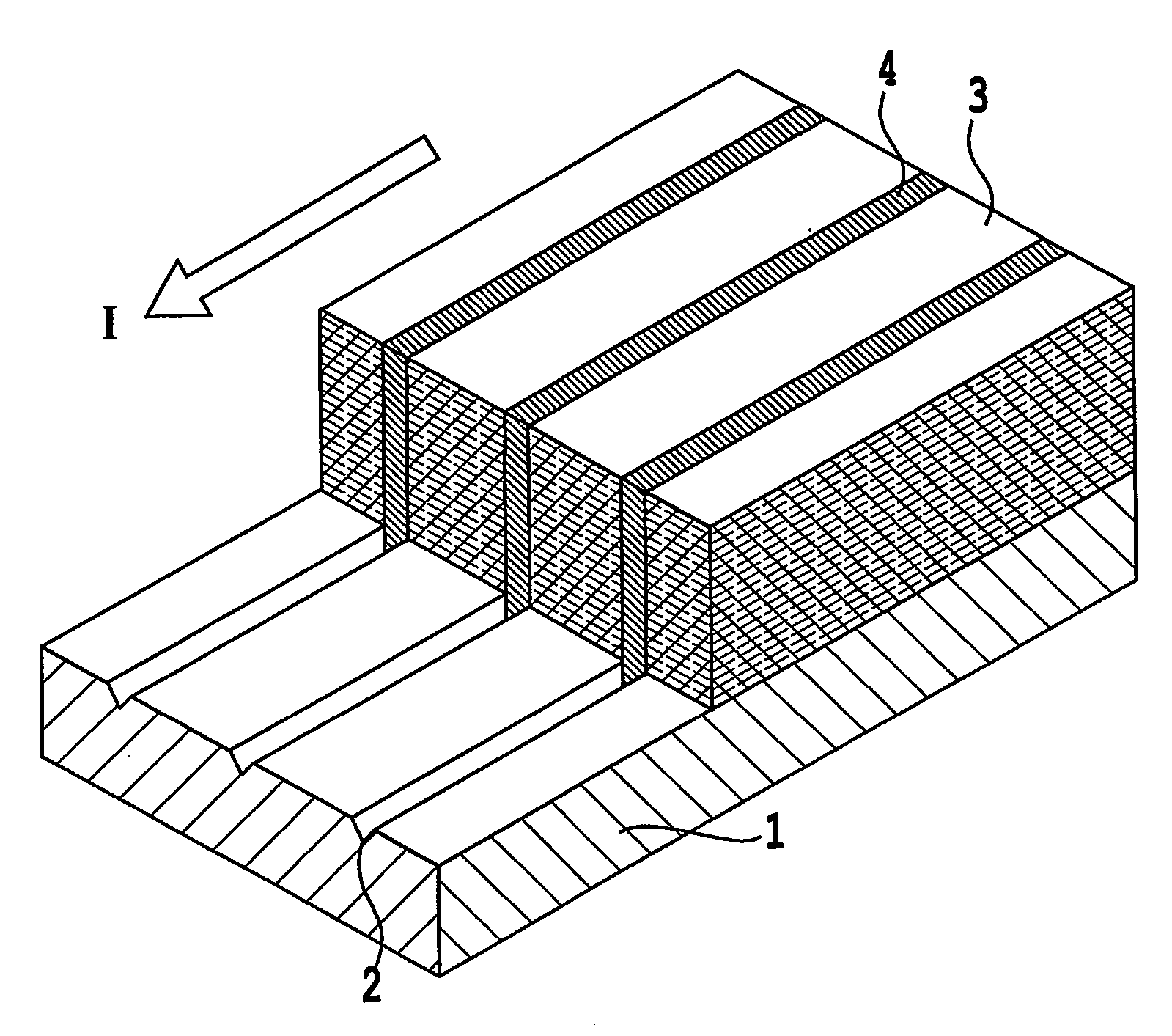

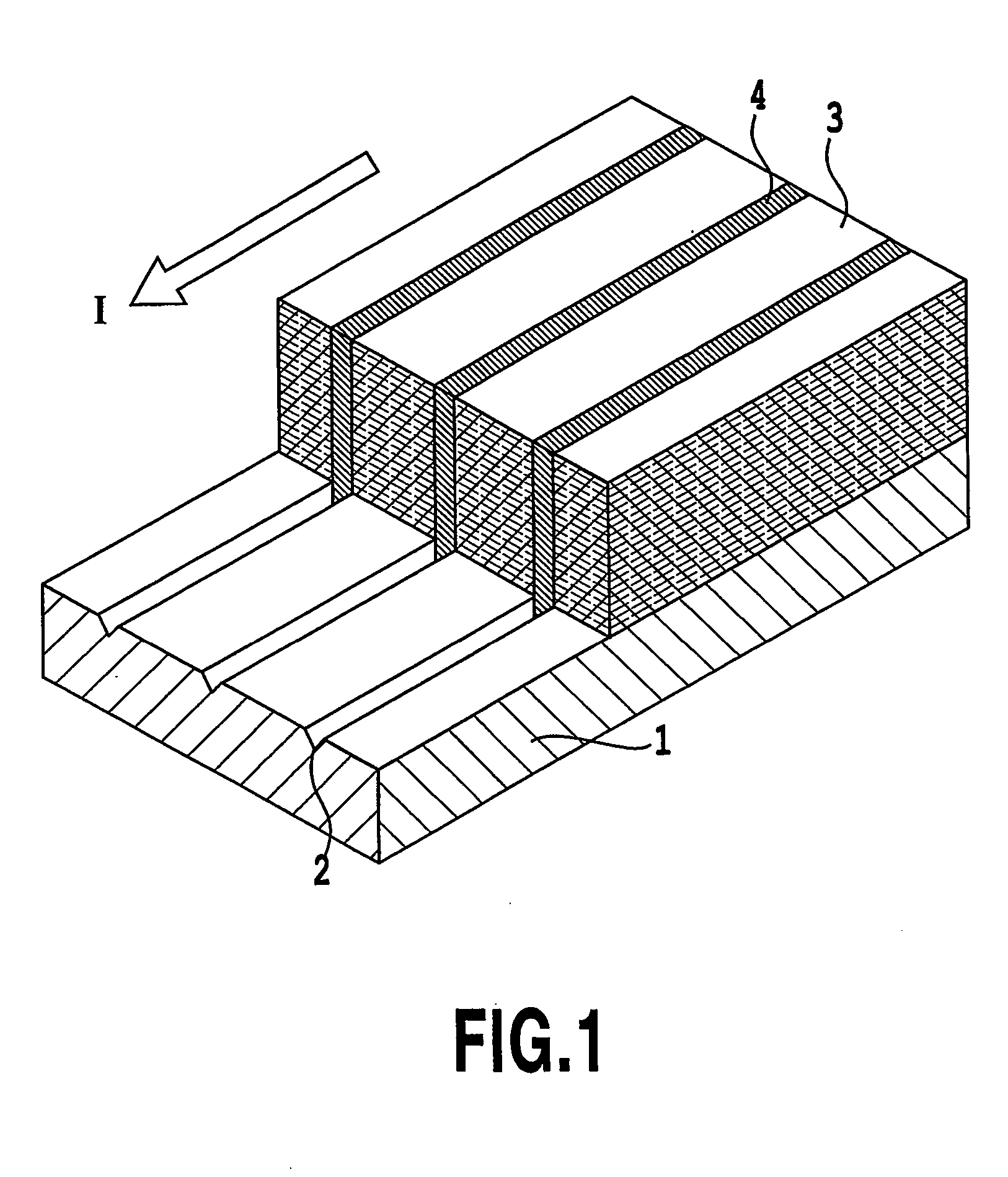

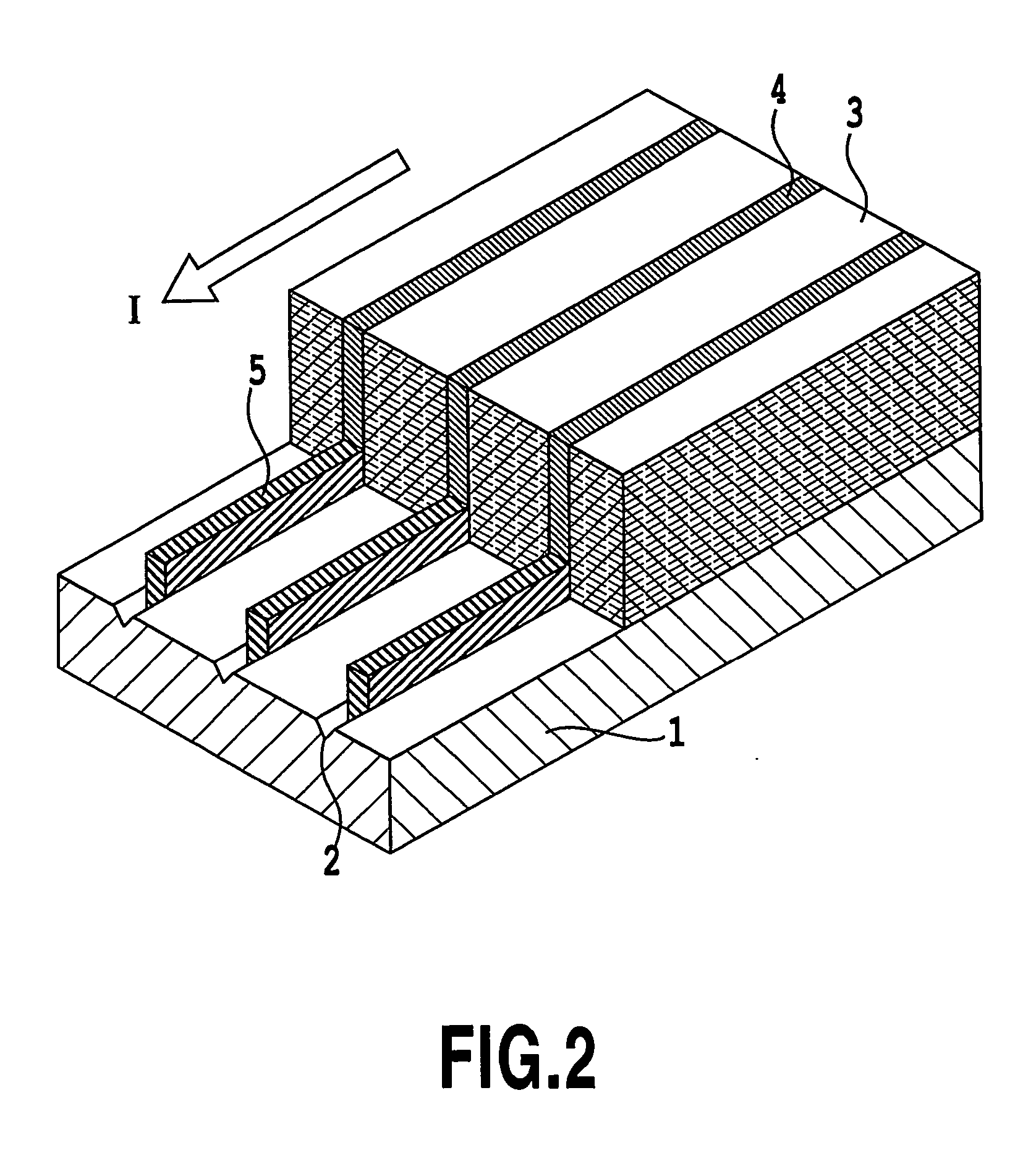

Superconducting film and method of manufacturing the same

InactiveUS20060258539A1Low costHigh JcSuperconductors/hyperconductorsVacuum evaporation coatingMicrowaveCurrent limiting

The present invention relates to a superconducting film having a substrate and a superconductor layer formed on the substrate, in which nano grooves are formed parallel to a current flowing direction on a substrate surface on which the superconductor layer is formed and two-dimensional crystal defects are introduced in the superconductor layer on the nano grooves, and a method of manufacturing this superconducting film. A superconducting film of the invention, which is obtained at low cost and has very high Jc, is useful in applications such as cables, magnets, shields, current limiters, microwave devices, and semifinished products of these articles.

Owner:JAPAN SCI & TECH CORP +1

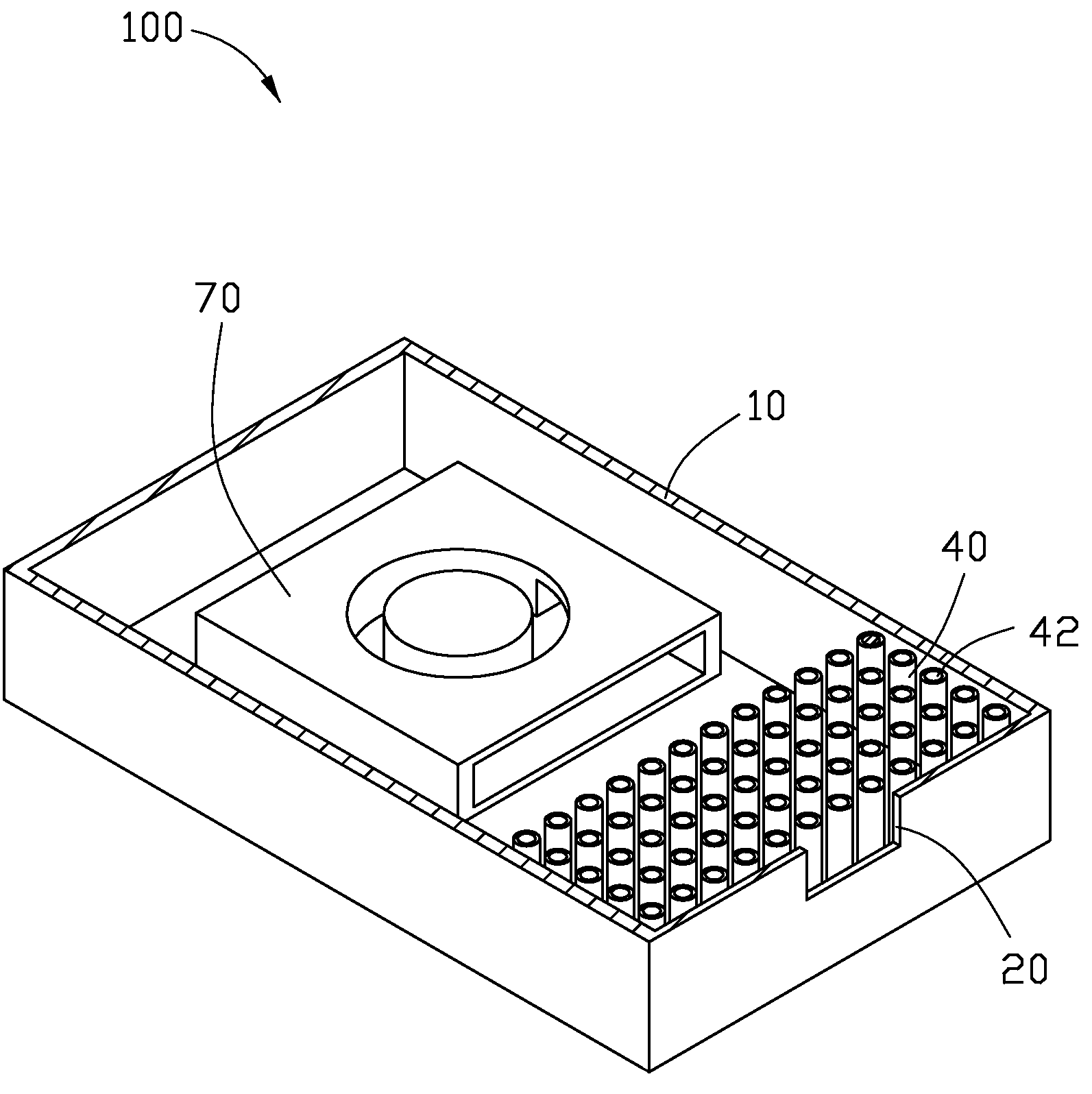

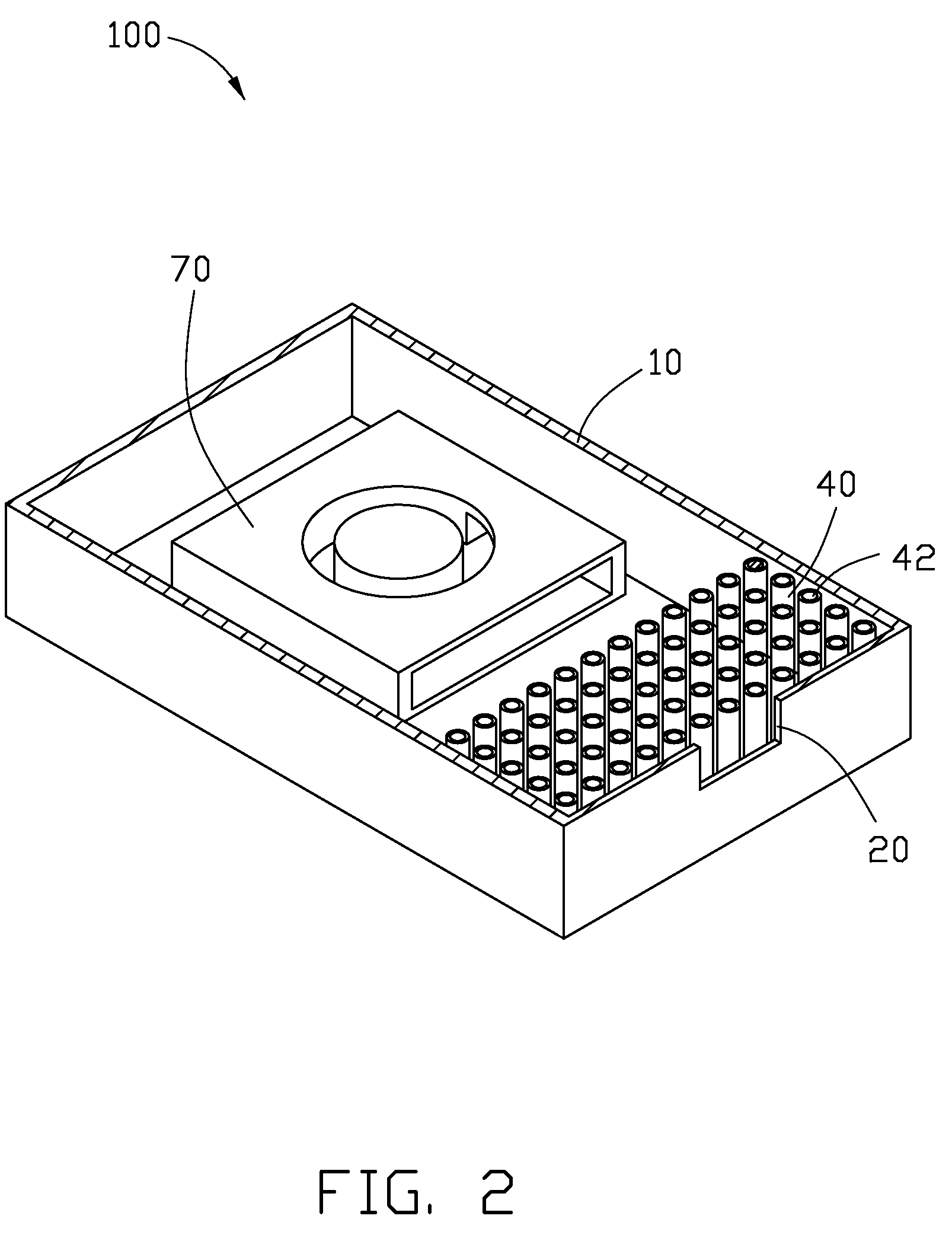

Electronic device with phononic crystal structure

InactiveUS20090284918A1Digital data processing detailsCooling/ventilation/heating modificationsCrystal structureTwo dimensional crystal

An exemplary electronic device includes a housing and a plurality of parallel bars. The housing defines a chamber therein and a heat-dissipating opening at one side thereof. The bars are configured for abating noises, and are received in the chamber and adjacent to the heat-dissipating opening. The bars are arranged in a two-dimensional crystal lattice.

Owner:HON HAI PRECISION IND CO LTD

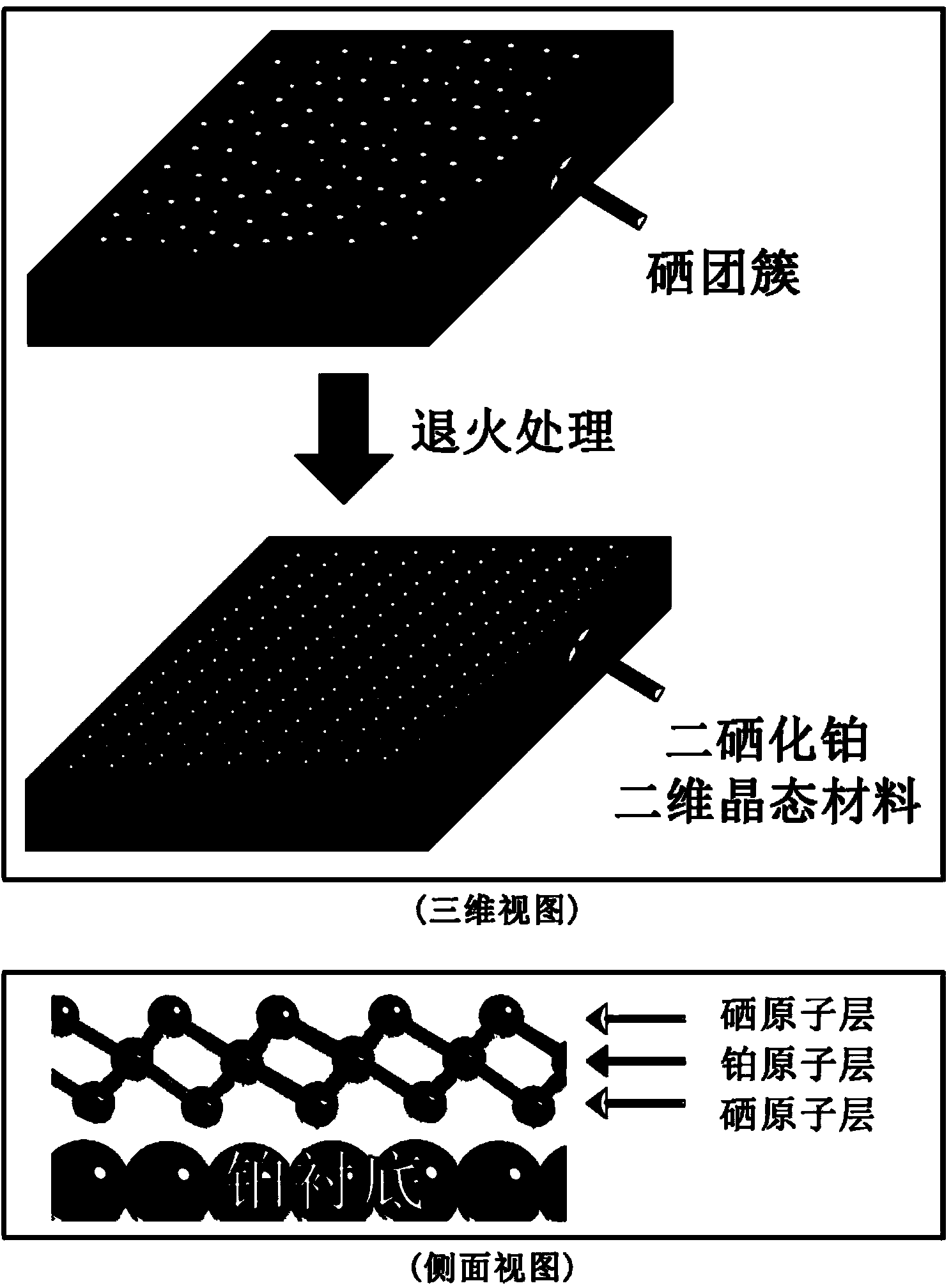

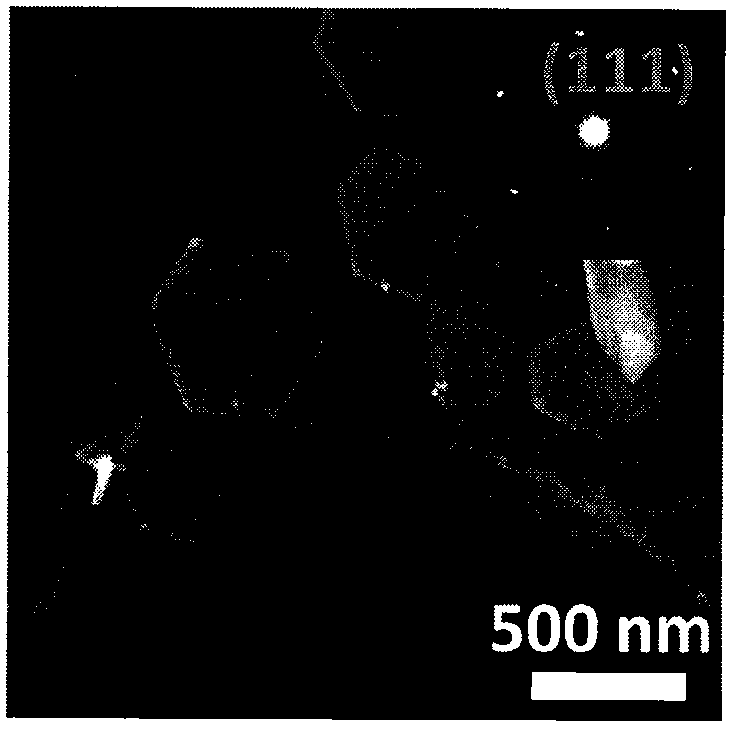

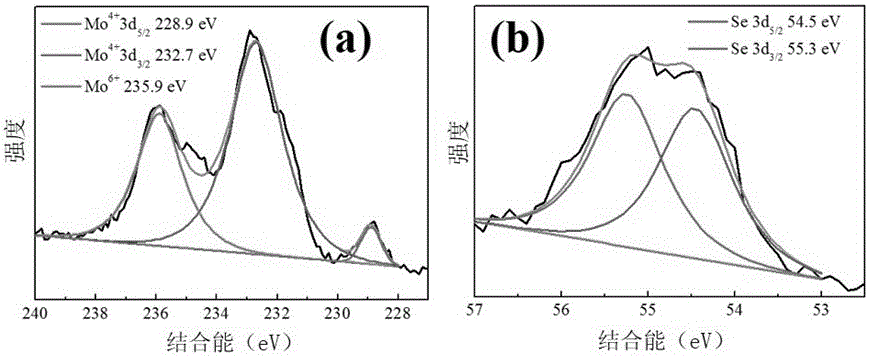

Platinum diselenide crystal material and preparation method thereof

ActiveCN104233214ABroaden the field of studyImprove electronic propertiesVacuum evaporation coatingSputtering coatingTitanium diselenideSe element

The invention discloses a platinum diselenide crystal material and a preparation method thereof. The preparation method comprises the following steps: 1) under a vacuum environment, evaporating and depositing a proper amount of high purity selenium on a metal platinum substrate; and 2) carrying out an annealing treatment, so that selenium atoms covering the surface of the substrate and platinum atoms on the substrate interact to form a two-dimensional ordered crystalline state membrane structure in a sandwich arrangement of selenium-platinum-selenium so as to obtain the platinum diselenide crystal material. The inorganic two-dimensional crystalline state material is a new member of a transitional metal disulfide compound family, expands the field of research on non-carbon based two-dimensional crystal materials, and has a wide application potential in future information electronics and apparatus development and research. According to the method disclosed by the invention, the platinum diselenide two-dimensional crystalline state material with a big area and a high quality is grown on a molecular beam epitaxial method, so that the electronic properties of the platinum diselenide crystalline state material and related applications and development are favorably researched.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

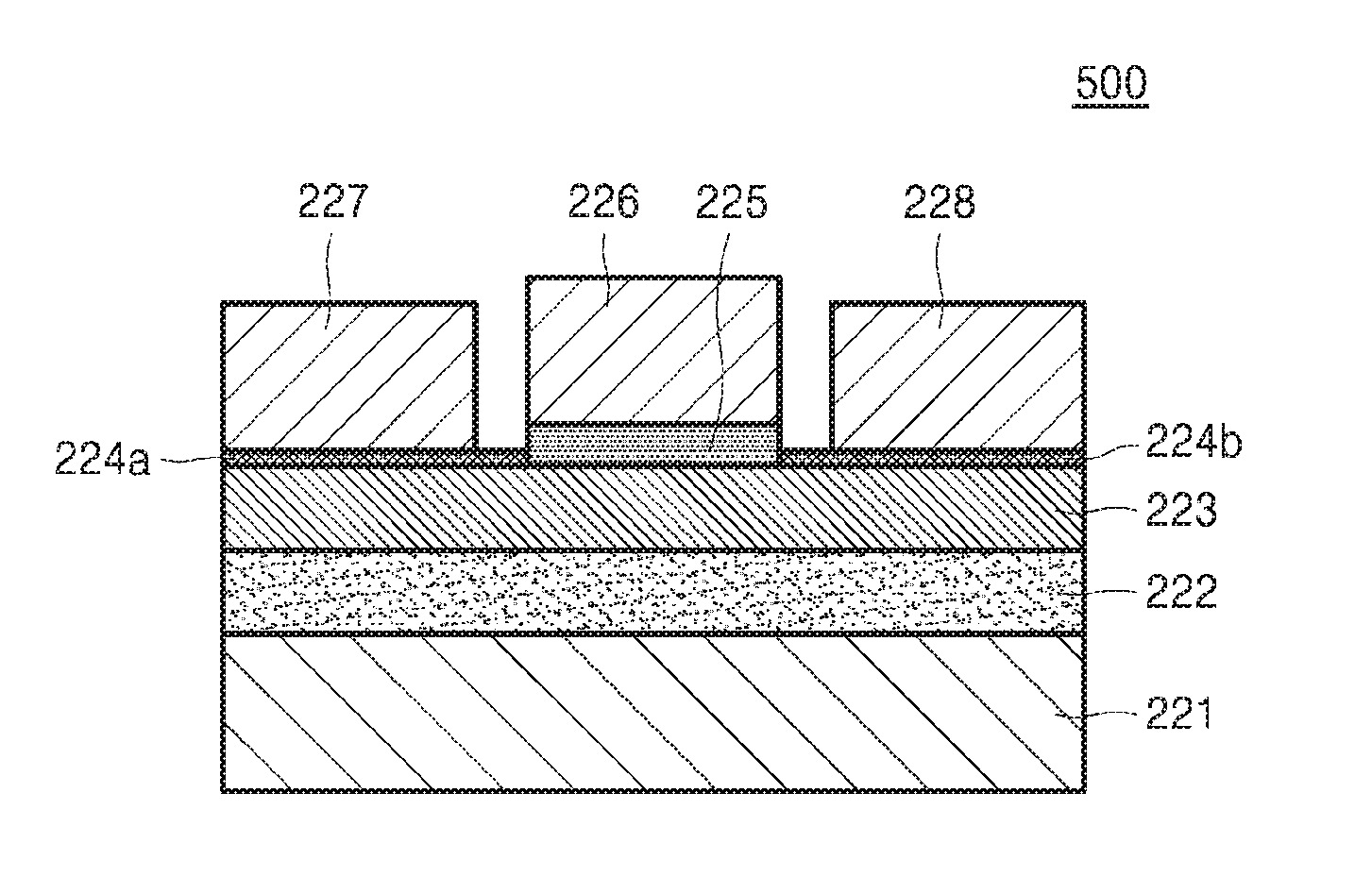

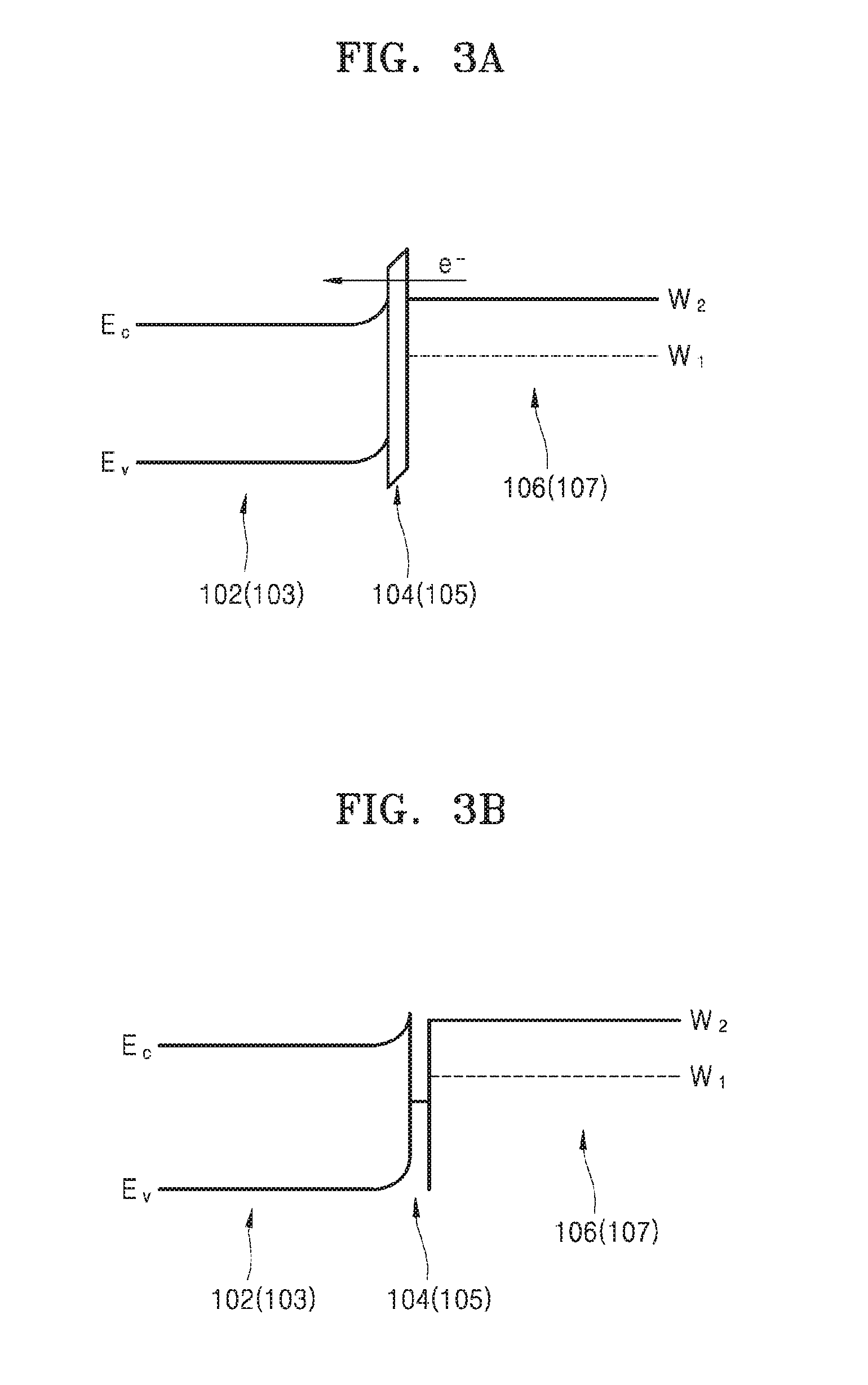

Semiconductor device including metal-2 dimensional material-semiconductor contact

ActiveUS20160343805A1Semiconductor/solid-state device manufacturingSemiconductor devicesDevice materialTwo dimensional crystal

A semiconductor device includes a semiconductor layer, a metal layer electrically contacting the semiconductor layer, and a two-dimensional material layer between the semiconductor layer and the metal layer and having a two-dimensional crystal structure.

Owner:SAMSUNG ELECTRONICS CO LTD

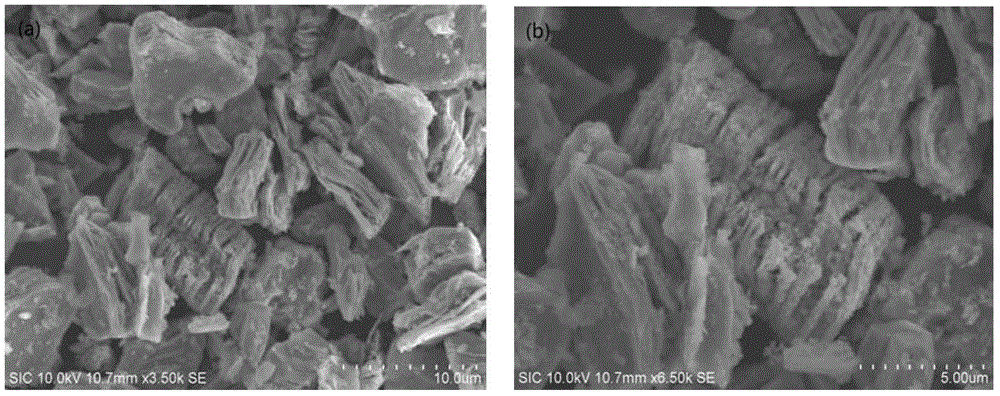

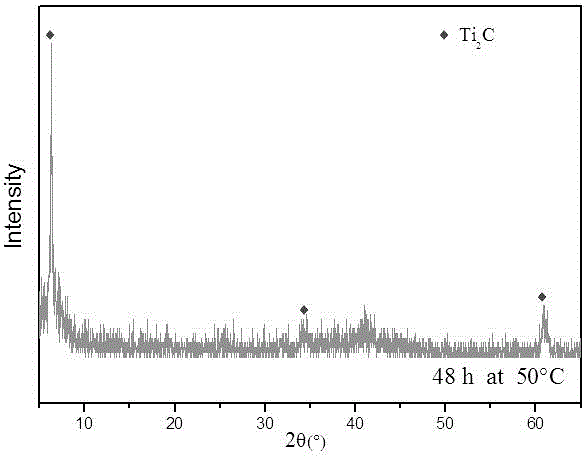

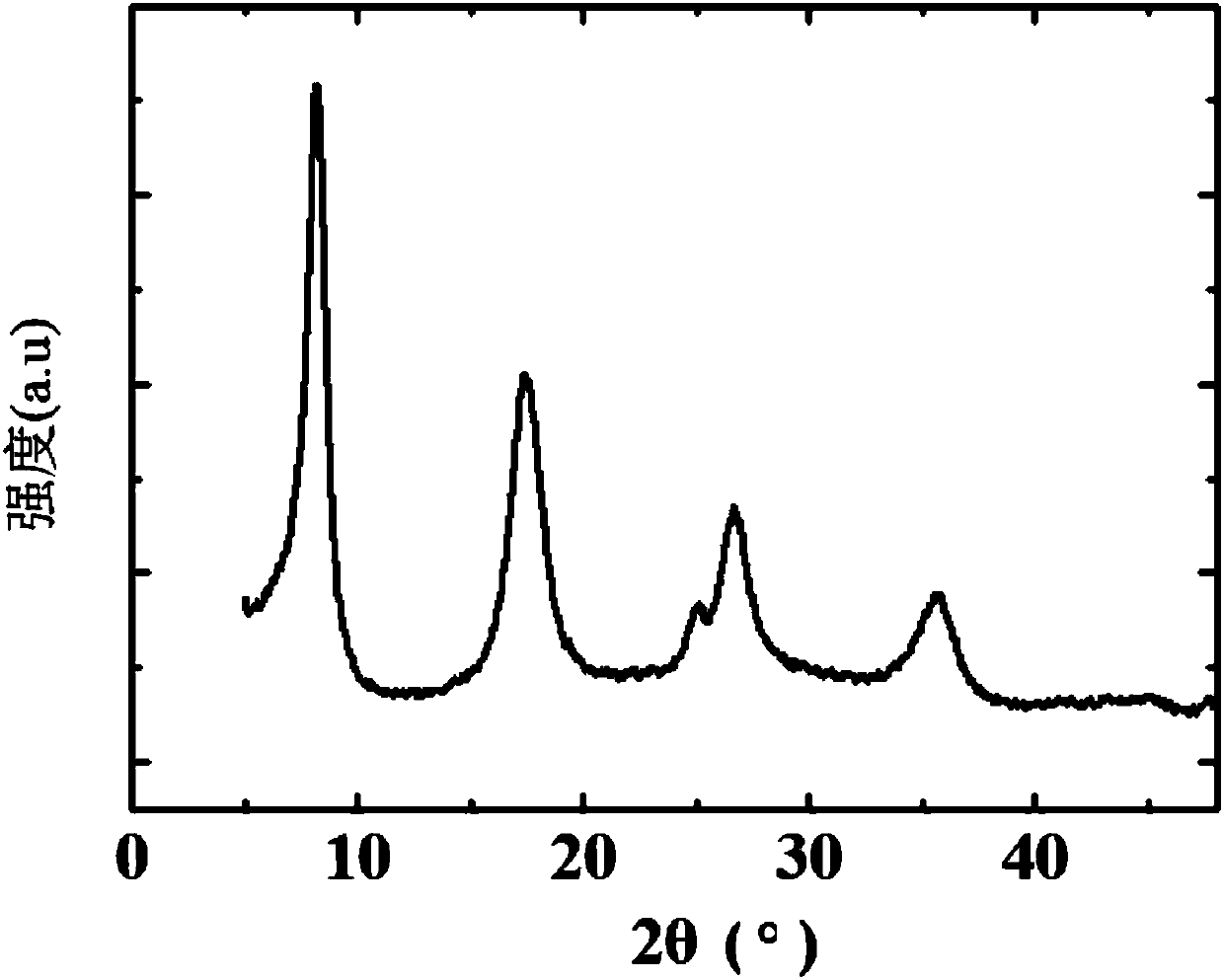

Method for intercalating and stripping two-dimensional crystal titanium carbide nano material by using ammonia water

InactiveCN106185936AAvoid reunion effectLarge specific surface areaNanotechnologyMetallurgySupercapacitor

The invention relates to a method for intercalating and stripping a two-dimensional crystal titanium carbide nano material by using ammonia water. The method comprises the following steps: putting a two-dimensional crystal titanium carbide material into ammonia water, performing intercalation and stripping by using a high-speed shearing machine, and performing washing and vacuum drying, thereby obtaining the two-dimensional crystal titanium carbide nano material of which the interlayer spacing is increased. The two-dimensional crystal titanium carbide nano material provided by the invention is relatively large in interlayer spacing, the aggregation effect of titanium carbide can be overcome to a certain extent, the specific surface area of the two-dimensional crystal titanium carbide nano material can be increased, and the properties of the material in fields of supercapacitors, lithium ion batteries, adsorption and the like can be improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

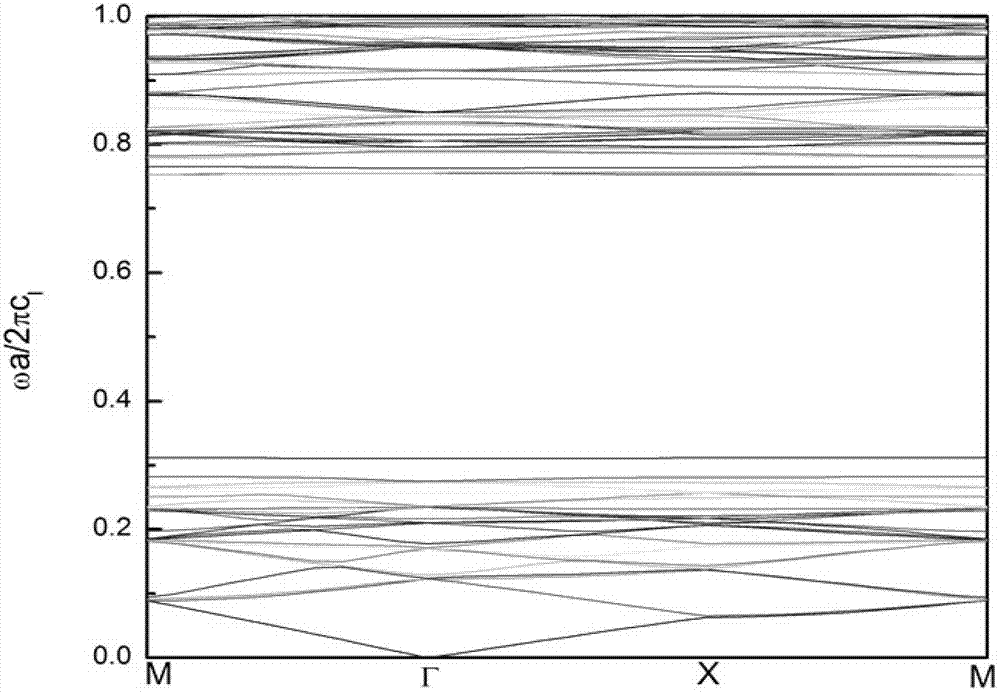

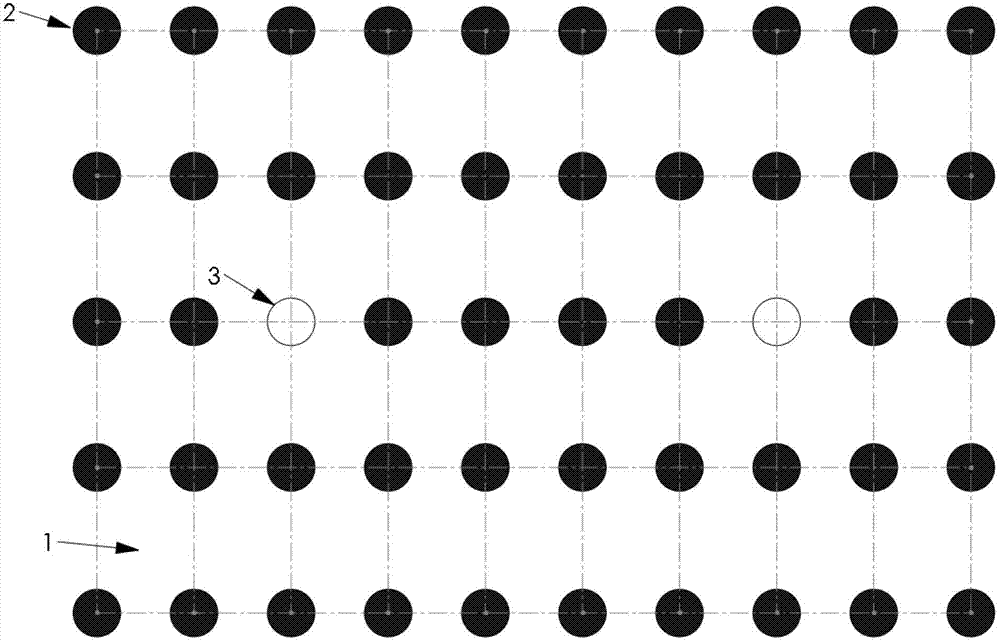

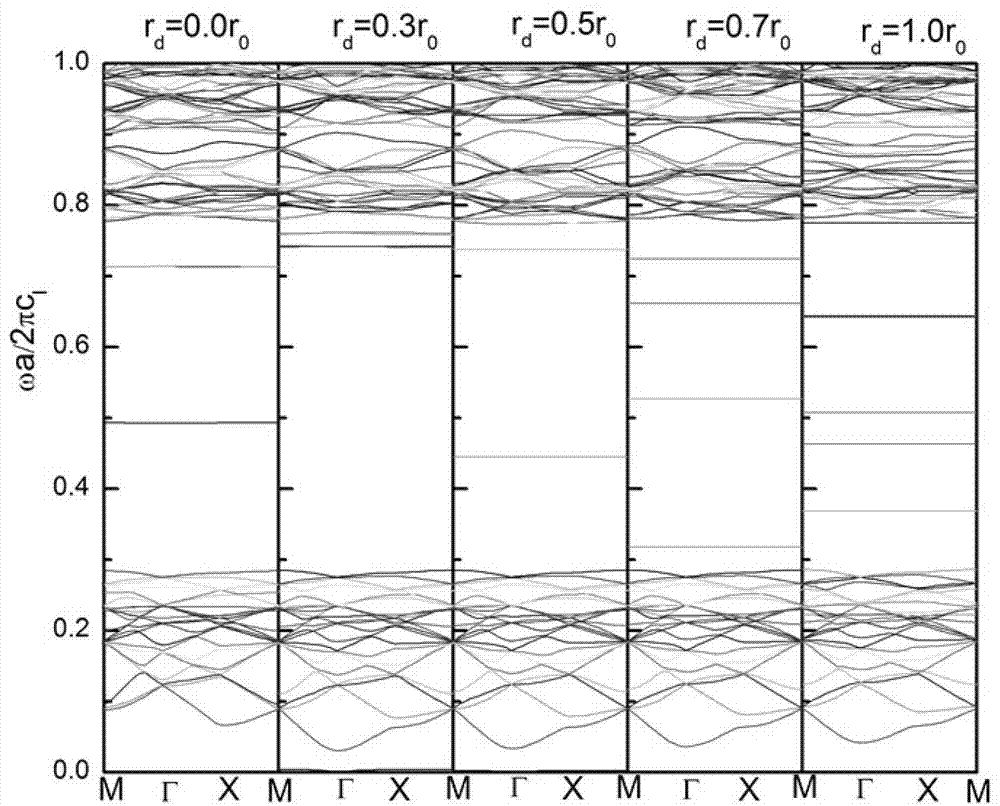

Sound energy capturing system based on photonic crystal defect

InactiveCN103198824ANovel sound energy capture methodManufacturing technology requirements are lowSound producing devicesSound energyPhotonic crystal

The invention discloses a sound energy capturing system based on a photonic crystal defect. The system is composed of a plurality of two-dimensional crystal lattice units in a periodic arrangement mode, and each two-dimensional lattice unit is formed by the fact that water cylinders parallel to one another and a central defect air cylinder are arrayed in mercury according to a two-dimensional crystal lattice. The radius r0 of each water cylinder is equal to 0.31a, the radius rd of the defect air cylinder is equal to 1.0r0 or 0.7r0 or 0.5r0 or 0.3r0 or 0, wherein a is a crystal lattice constant, and r0 and rd are respectively the radius of the water cylinder and the radius of each defect air cylinder. The water cylinder of the two-dimensional crystal lattice unit has at least five layers, and the crystal lattice constant a is 1-10cm. According to the sound energy capturing system based on the photonic crystal defect, different defect modes can be produced through changing of size of the radius of each defect air cylinder, and sound energy in different frequency ranges is captured. Requirements to a preparative technique are relatively low, a manufacturing process is simple, and designability is strong.

Owner:GUANGDONG UNIV OF TECH

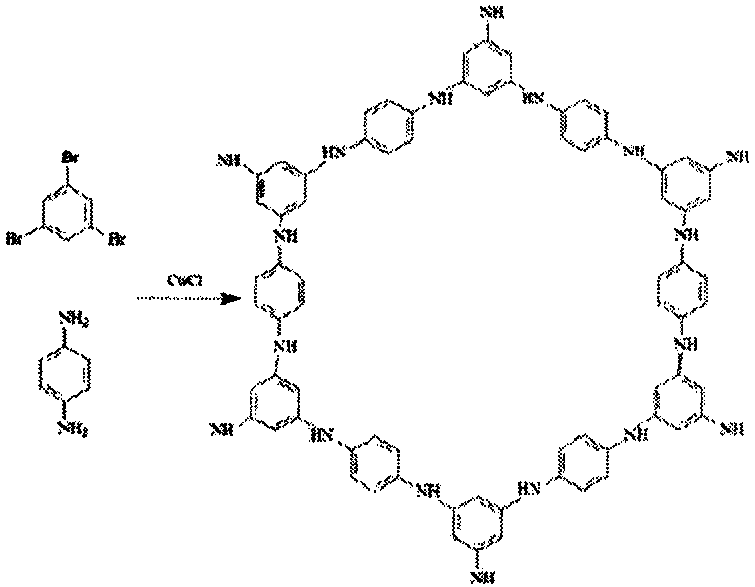

Novel growth method of two-dimensional organic polymer through two-dimensional crystal surface catalysis

ActiveCN107936261AUniform thicknessShape is easy to controlCopper chloridesCopper foilTwo dimensional crystal

The invention provides a novel growth method of a two-dimensional organic polymer through two-dimensional crystal surface catalysis. A solid-liquid interface rapid preparation method is adopted to directly prepare a two-dimensional cuprous chloride nano-crystal material which has template and catalysis effects on a copper foil substrate; 1,3,5-tribromobenzene and p-phenylenediamine are used as monomer molecules; polymerization reaction is directly carried out on the surface of a two-dimensional cuprous chloride nano-crystal which is used as a catalyst, so as to obtain the two-dimensional organic polymer. According to the method disclosed by the invention, the two-dimensional organic polymer is prepared from specific monomers by utilizing surface-catalyzed reaction and two-dimensional organic polymerization reaction types are widened.

Owner:射阳县新港污水处理有限公司

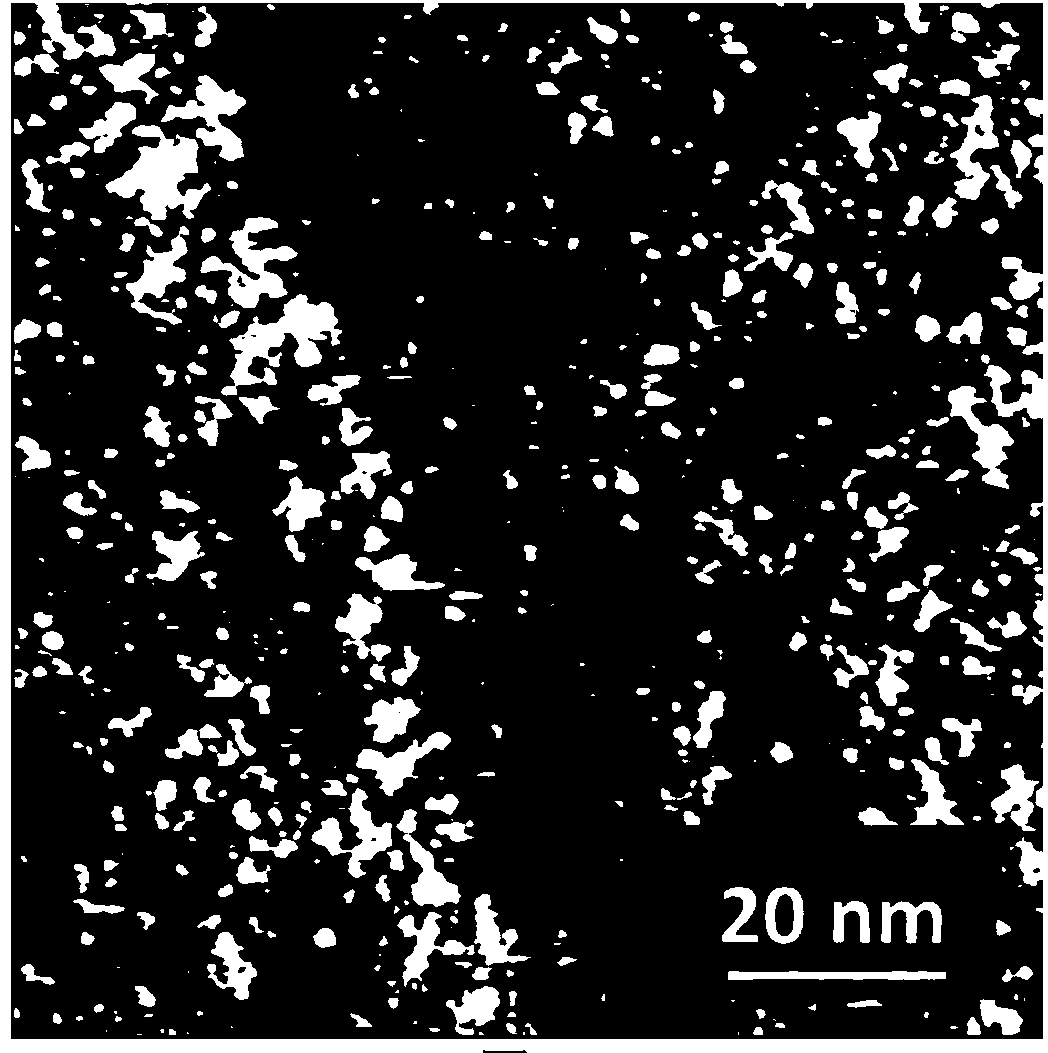

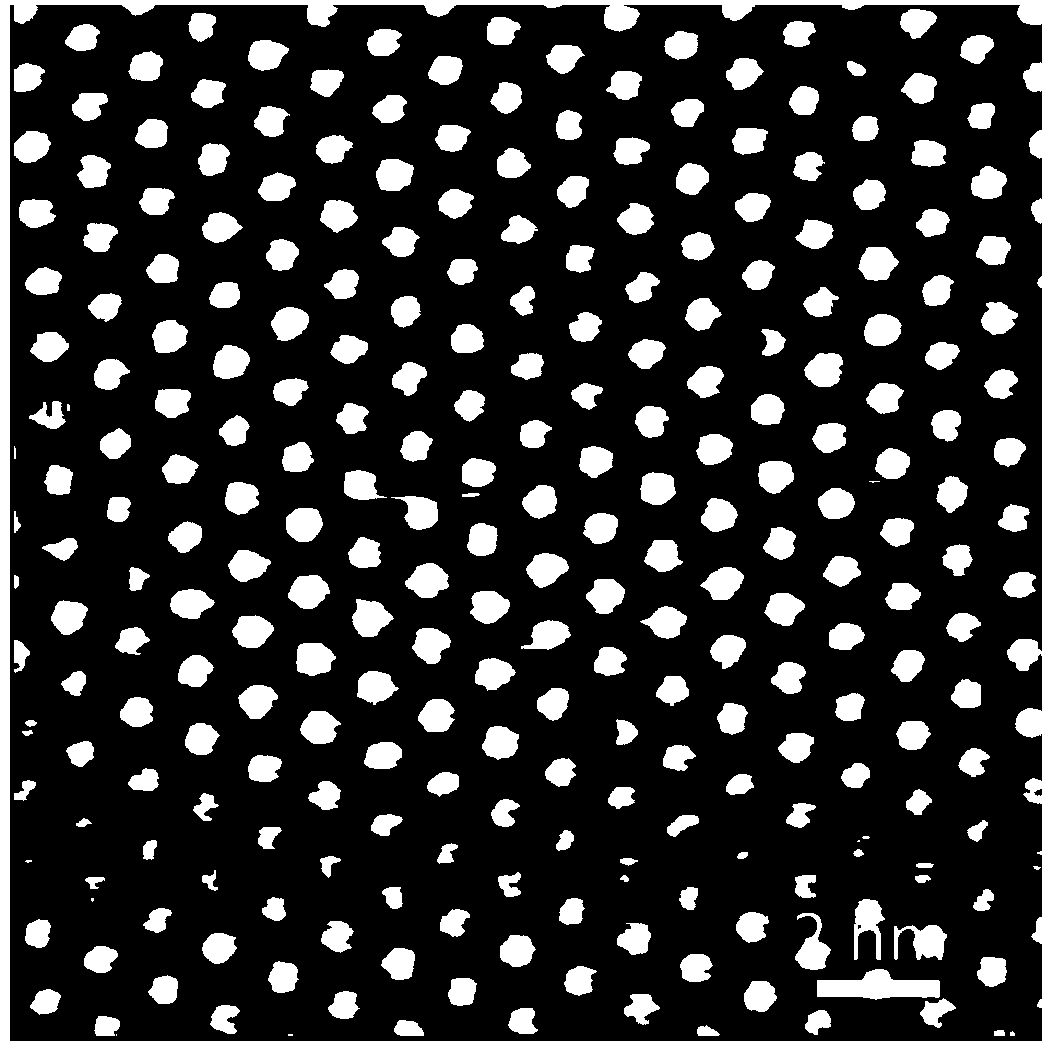

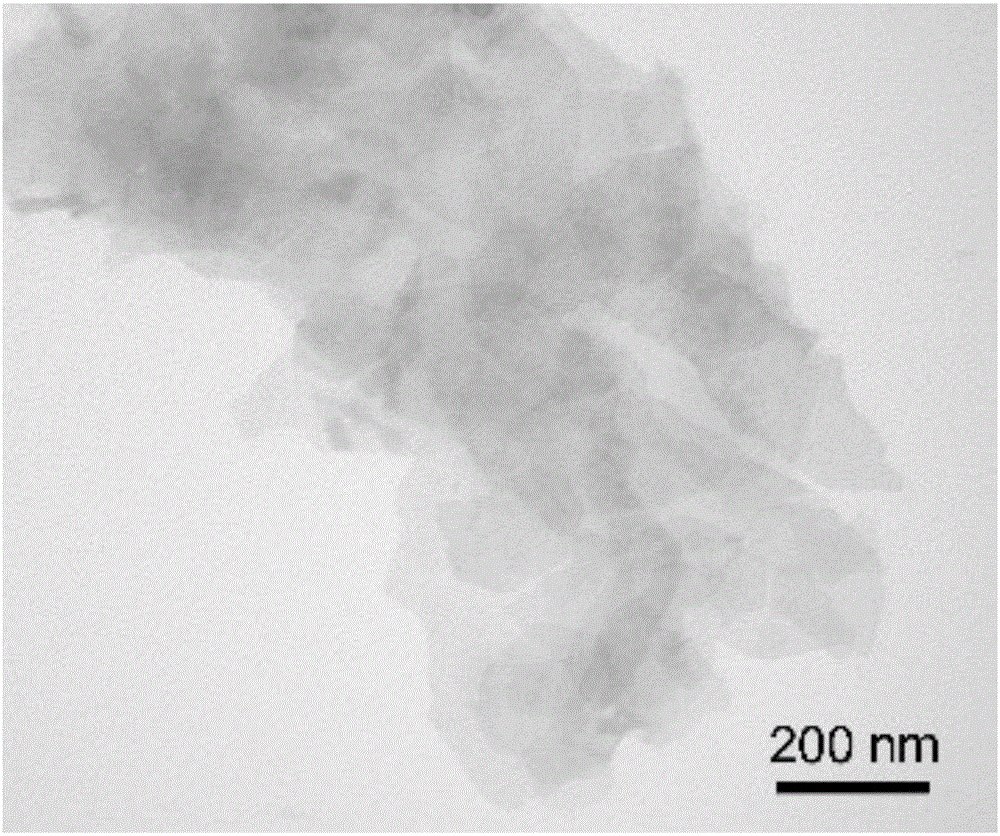

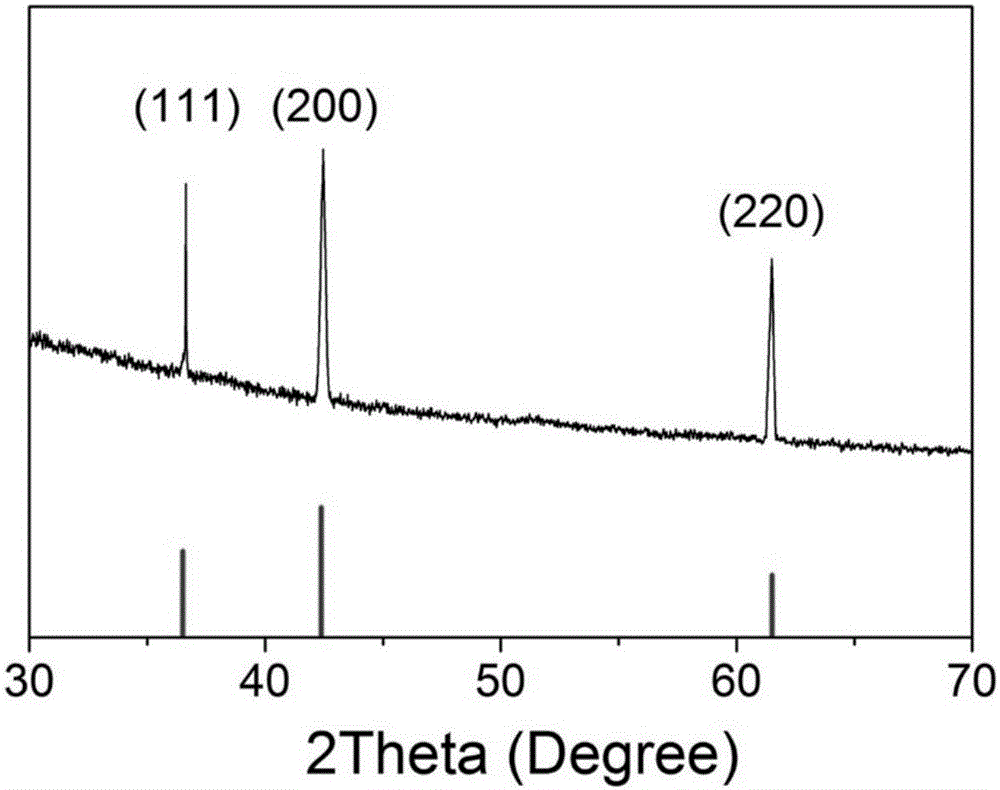

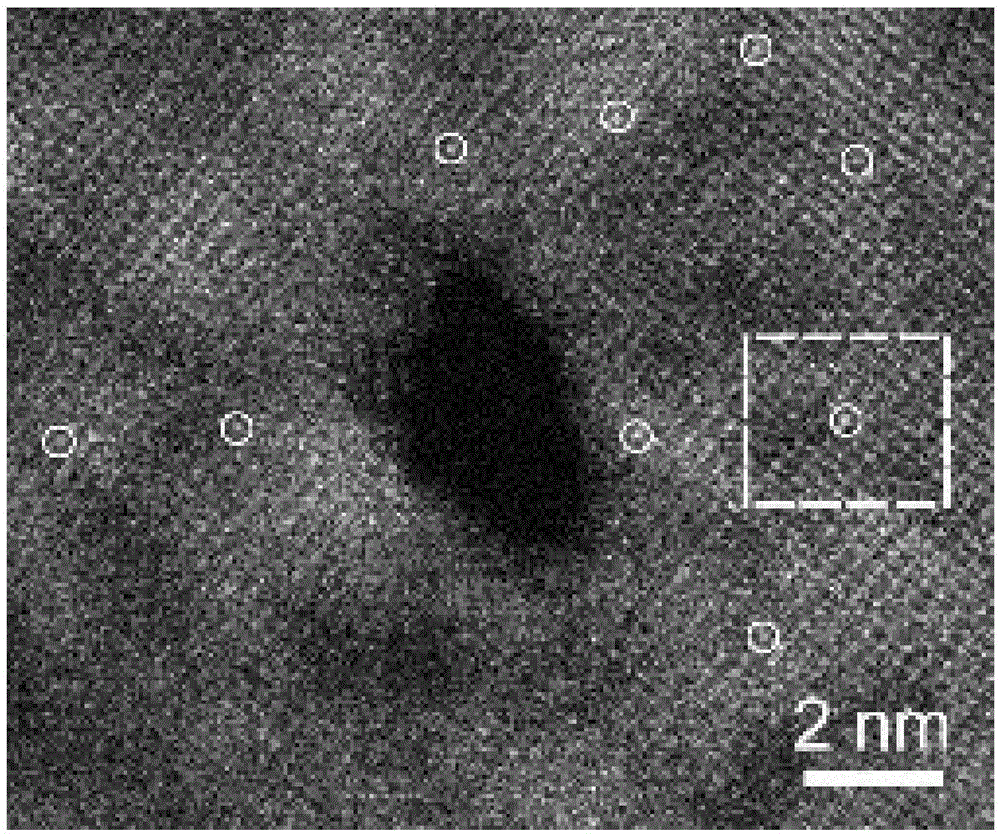

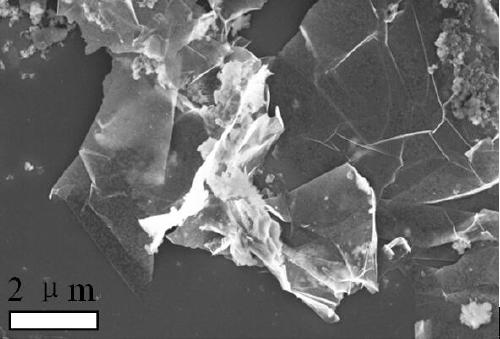

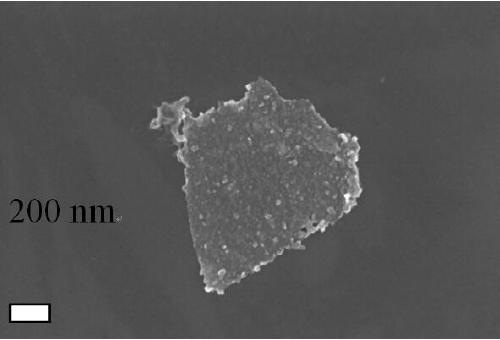

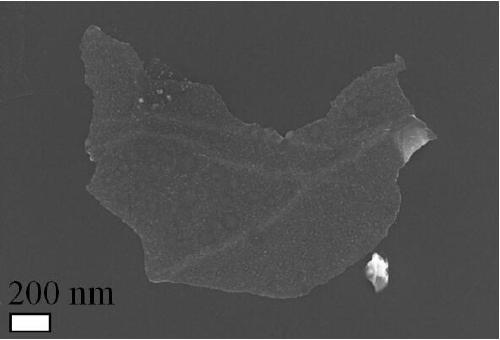

Rh/CoO nanometer catalyst, and preparation method and application thereof

ActiveCN106362766AImprove activity stabilityImprove catalytic stabilityPreparation by carbon monoxide reactionMetal/metal-oxides/metal-hydroxide catalystsDispersityHigh activity

The invention discloses a Rh / CoO nanometer catalyst. Rh atoms are independently and uniformly loaded on the surface of a CoO flake with a two-dimensional crystal structure. The invention also discloses a preparation method for the Rh / CoO nanometer catalyst. The preparation method comprises the following steps: mixing the CoO flake with the two-dimensional crystal structure with deionized water so as to obtain a mixed solution A; adding a sodium hexachlororhodate solution into the mixed solution A and carrying out uniform mixing so as to obtain a mixed solution B; and subjecting the mixed solution B to stirring and cleaning at room temperature and to vacuum drying so as to obtain the Rh / CoO nanometer catalyst. The invention also discloses application of the Rh / CoO nanometer catalyst to hydroformylation of propylene. According to the invention, through high dispersity of single atoms and strong interaction between substrates, the Rh / CoO nanometer catalyst has high activity, high selectivity and high stability in hydroformylation of propylene, and the heterogeneous structure of the catalyst facilitates separation and collection of the catalyst from a reaction system; so the catalytic advantages of the catalyst in hydroformylation of propylene are given to full play.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

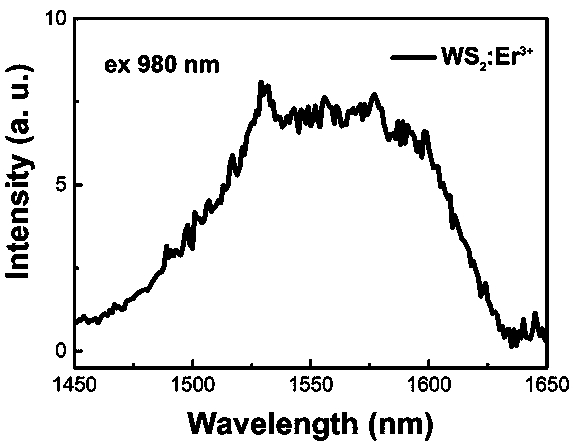

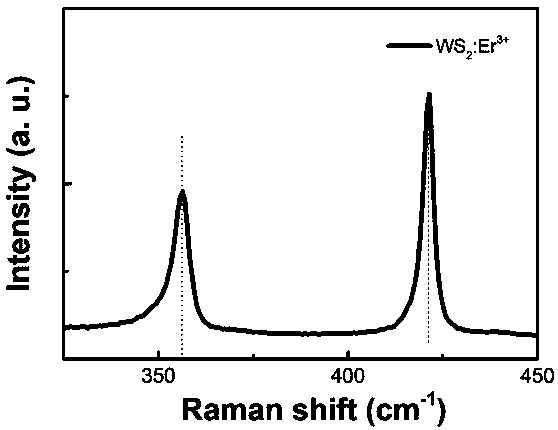

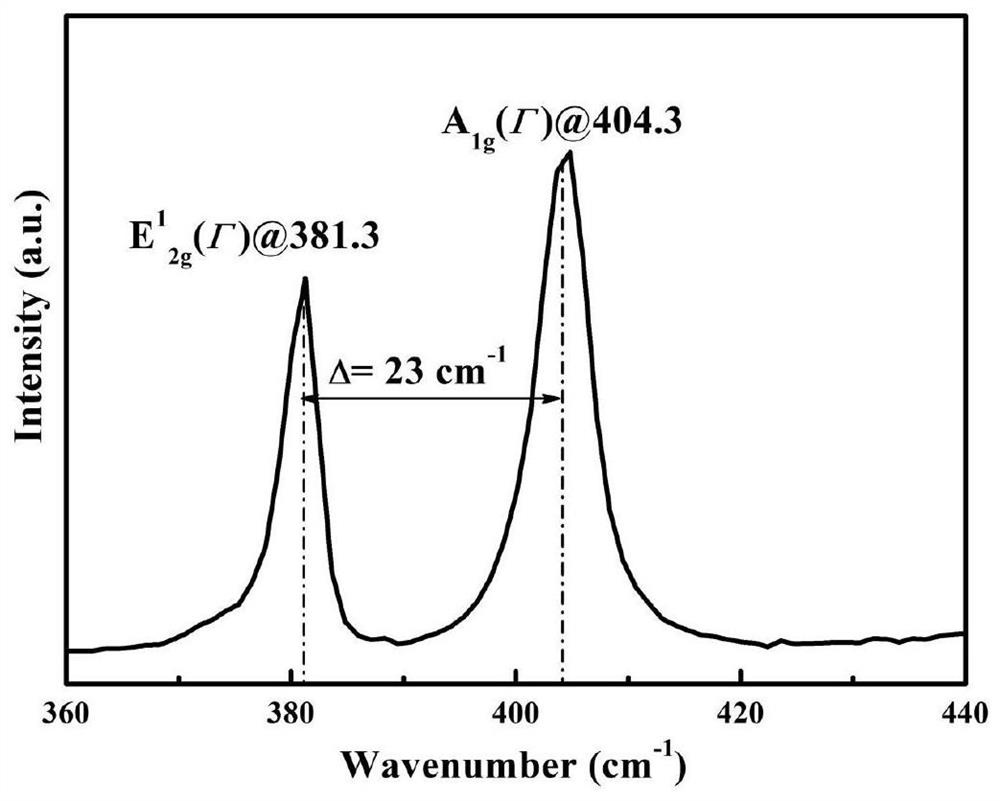

Preparation method of rare earth erbium doped tungsten disulfide thin film material with controllable layers

The invention relates to a preparation method of rare earth erbium doped two-dimensional layered tungsten disulfide thin film material with controllable layers. The method comprises the following steps that firstly, a substrate is washed, an alloy film of erbium and tungsten is prepared by magnetron sputtering a high purity metal target material, then the sulfur powder is placed in a first temperature zone, the deposited alloy film is placed in a second temperature zone, and a vacuum tube furnace is vacuumized; the carrier gas is fed into the vacuum tube furnace for washing, then gas is continuously fed, the first temperature zone is heated to 120-200 DEG C, the second temperature zone is heated to 700-900 DEG C, and growing is conducted for more than 10 minutes; and finally, the temperature of the first temperature zone and the second temperature zone is reduced to the room temperature, and the erbium doped two-dimensional layered tungsten disulfide thin film material is obtained. According to the preparation method, the sputtering power and time are adjusted, the two-dimensional thin films with different thickness, morphology and doping concentration can be obtained, the two-dimensional crystal thin films with wafer grade and even morphology can be obtained, the photoelectric properties are high, and the preparation method can be used for the preparation of ultra-thin opticalelectronic devices of atomic grade and used in the fields such as luminescent devices and photoelectric detectors.

Owner:CHINA JILIANG UNIV

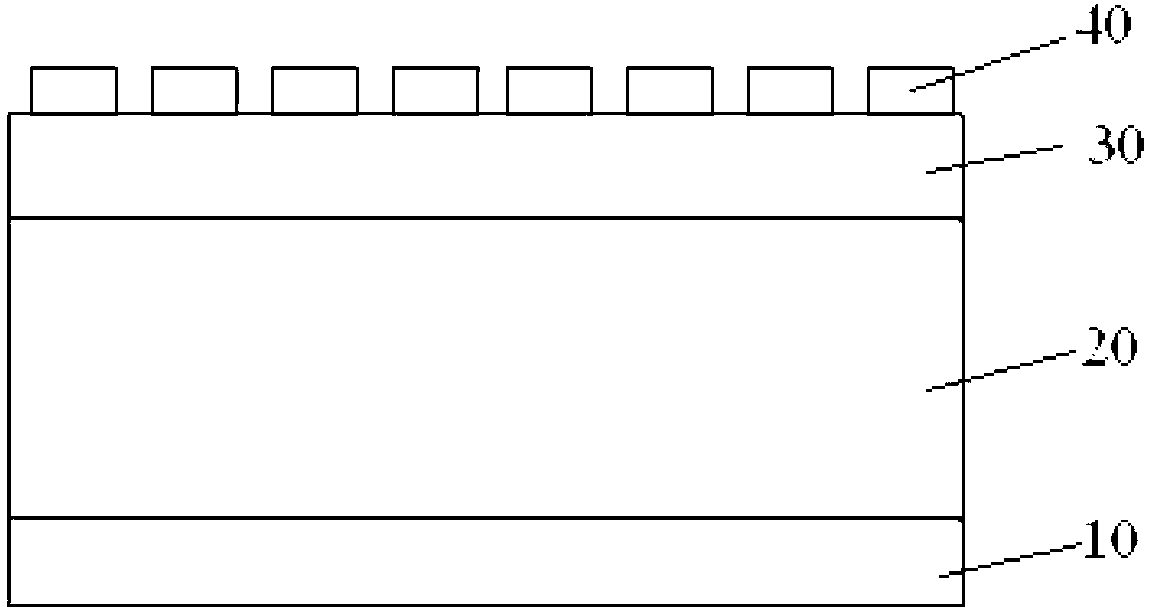

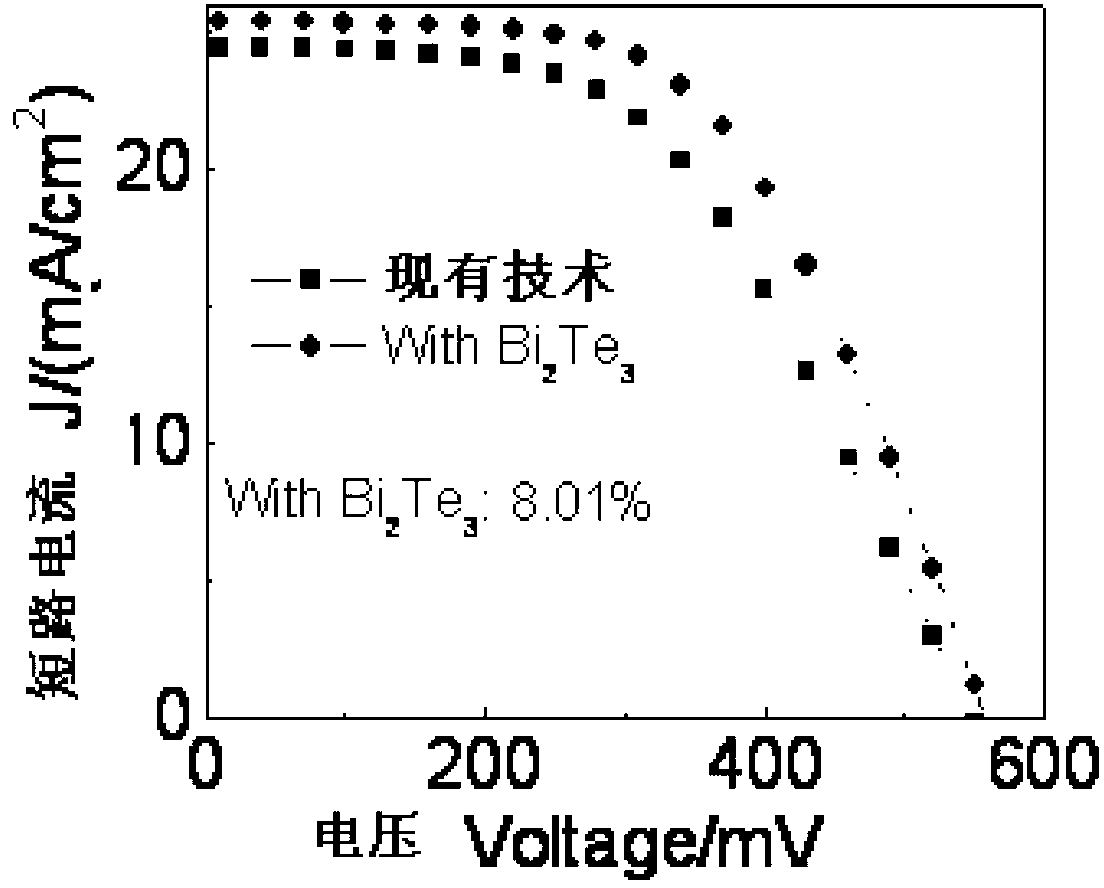

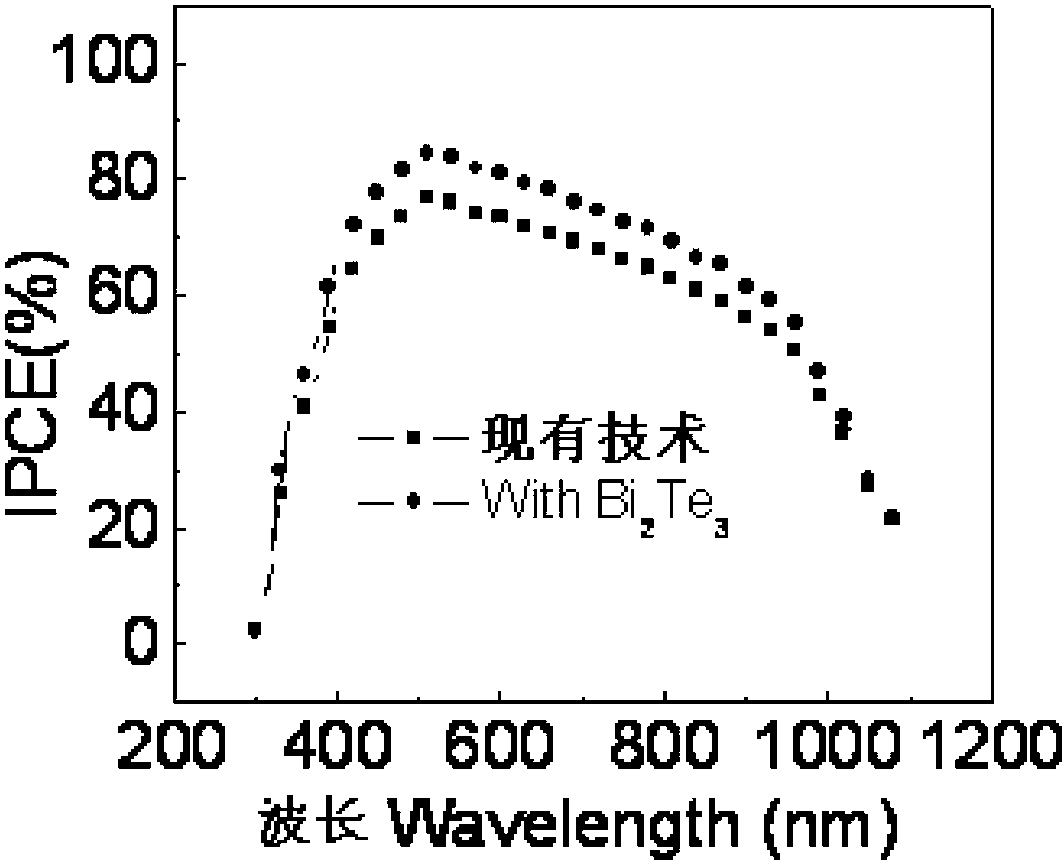

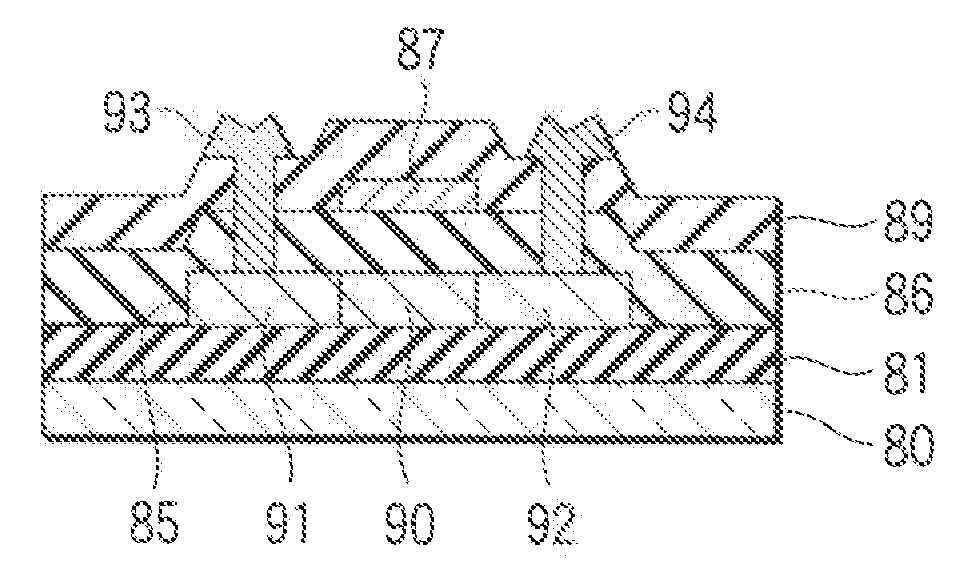

Organic-two-dimensional crystal-inorganic hybrid heterojunction solar cell device and preparation method thereof

ActiveCN103296211AEnhanced charge transport capabilityImprove stabilityFinal product manufactureSolid-state devicesHeterojunctionHole transport layer

The invention discloses an organic-two-dimensional crystal-inorganic hybrid heterojunction solar cell device and a preparation method thereof. The solar cell device comprises a metal back electrode, an n-type silicon-based substrate, an organic conjugated film uniformly mixed by conjugated organic matters and two-dimensional laminar nanocrystalline materials and metal gate electrodes sequentially from bottom to top. The surface of the silicon-based substrate is coated with mixed solution of the two-dimensional laminar nanocrystalline materials and the conjugated organic matters in a spin manner, or the two-dimensional laminar nanocrystalline materials and the conjugated organic matters of different concentrations are coated on the surface of the silicon-based substrate directly and sequentially in a spin manner to serve as a hole transport layer; stability of cells are improved by modification of an organic-inorganic matter hybrid heterojunction, charge transport capability of the solar cells is enhanced, surface state density defects are overcome effectively, and the solar cell device is simple to operate and easy for industrial production.

Owner:SUZHOU INAINK ELECTRONICS MATERIALS CO LTD

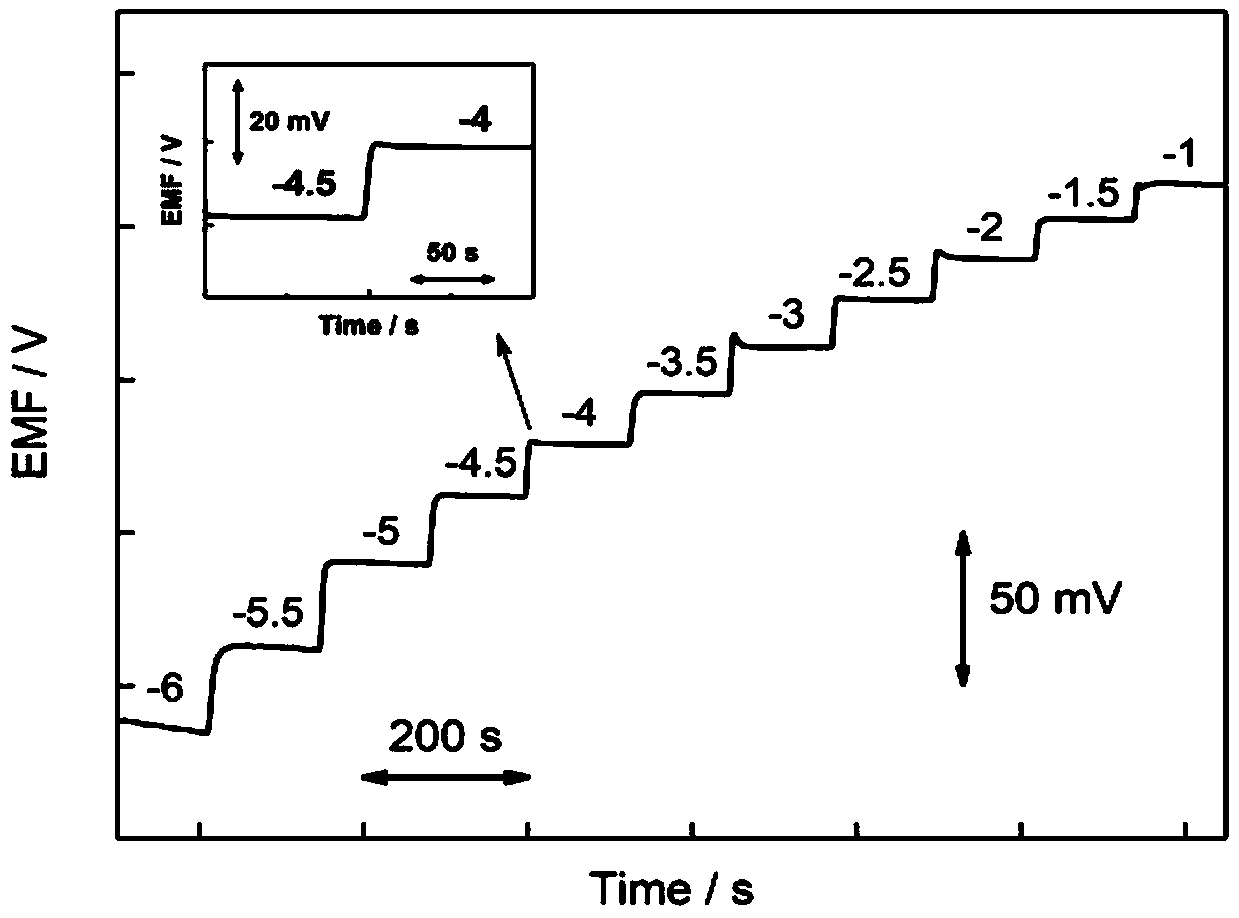

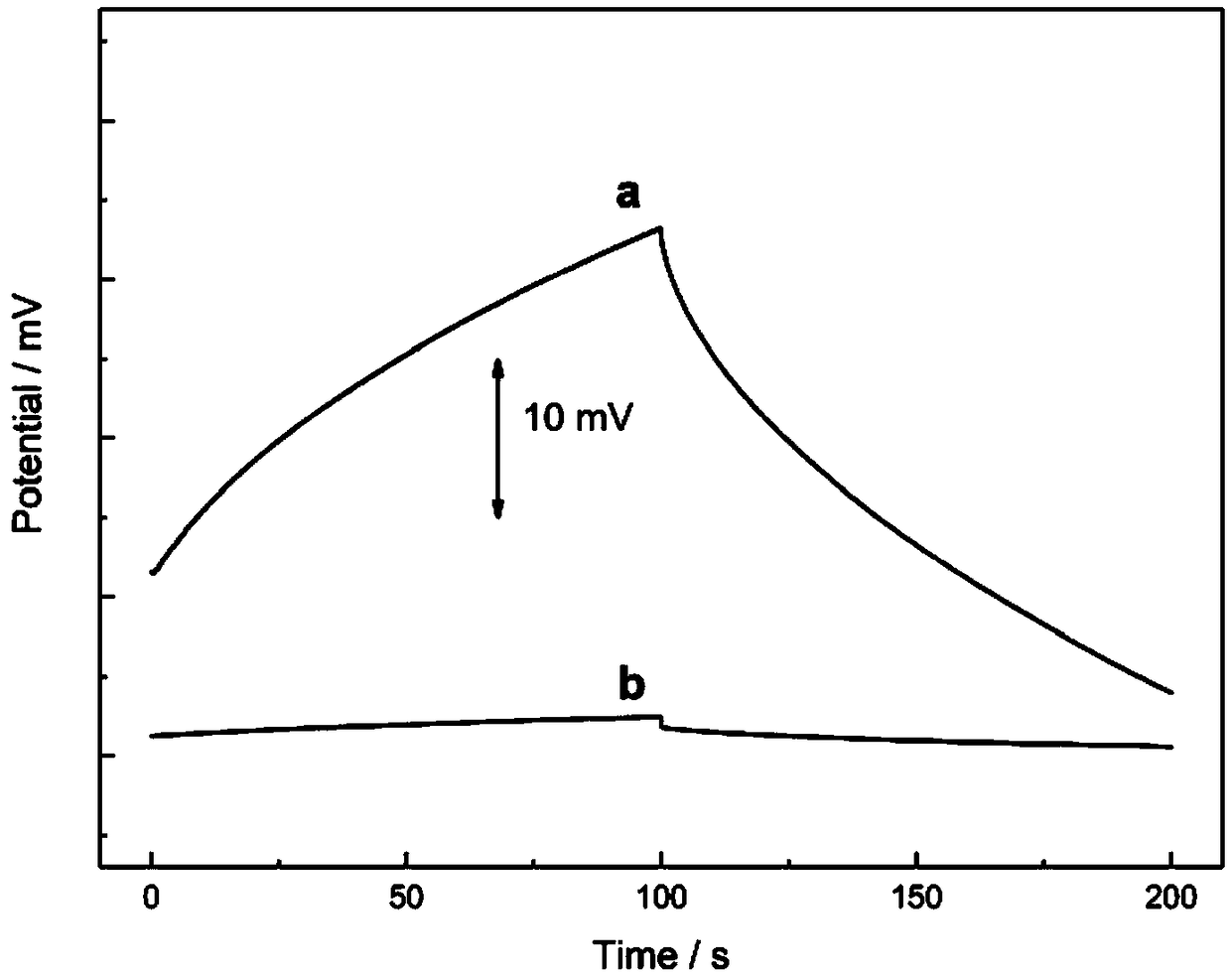

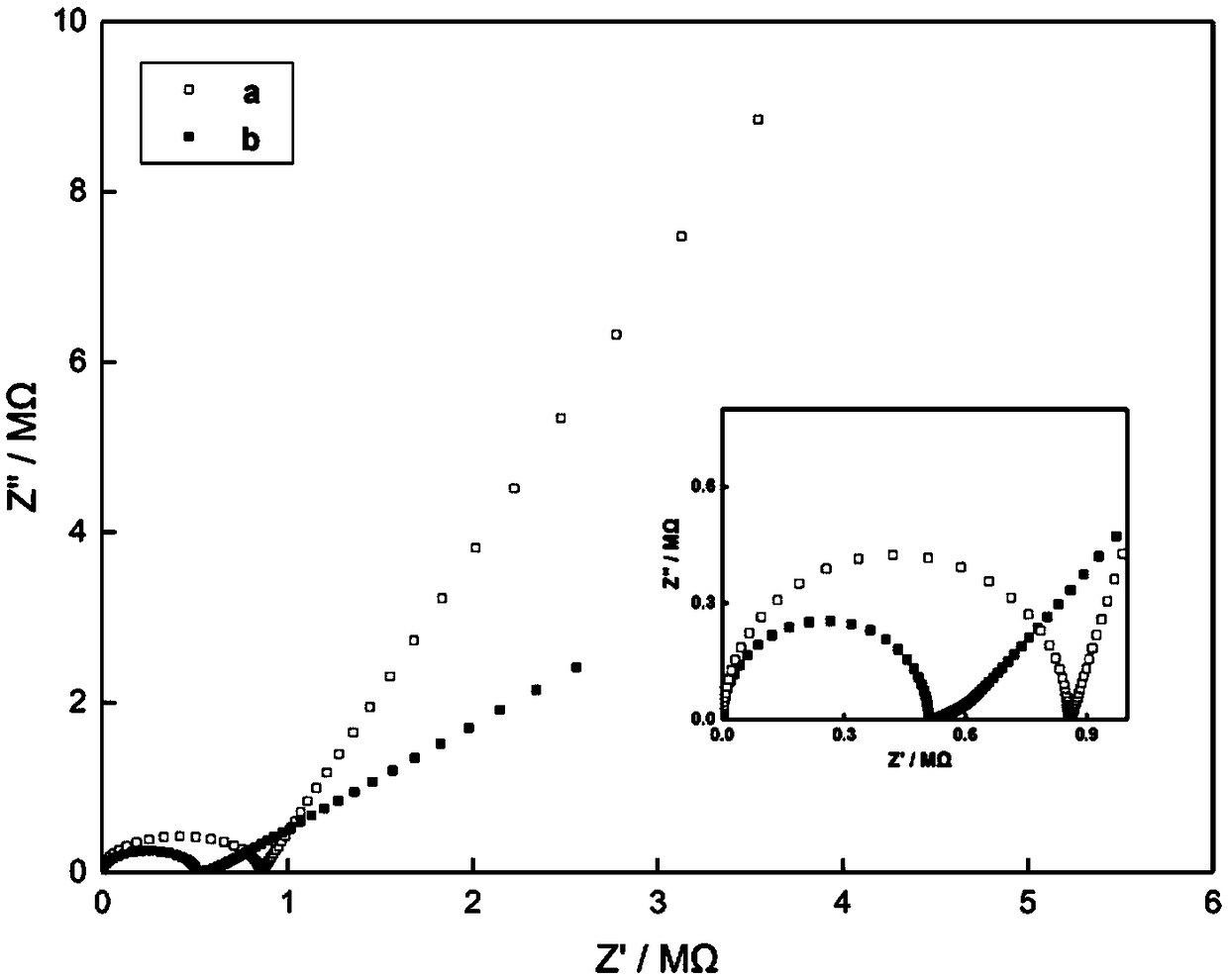

MXene nanosheet modification-based all-solid-state ion-selective electrode and preparation method thereof

ActiveCN109374711AIncrease the rate of electron transferReduce distractionsMaterial electrochemical variablesTransition metal carbidesAll solid state

The invention discloses an MXene nanosheet modification-based all-solid-state ion-selective electrode. The MXene nanosheet modification-based all-solid-state ion-selective electrode comprises an electrode matrix, an MXene nanosheet modification layer and an ion-selective polymer membrane, wherein the MXene nanosheet modification layer and the ion-selective polymer membrane are sequentially wrappedonto the electrode matrix; applied MXene is a transition metal carbide or carbonitride two-dimensional crystal with a chemical formula of M1+1Xn, wherein n=1, 2 or 3, M is a transition metal element,and X is carbon and / or nitrogen elements. The invention also discloses a preparation method of the MXene nanosheet modification-based all-solid-state ion-selective electrode. The MXene nanosheet modification layer can greatly improve the electron transfer velocity between the electrode matrix and the ion-selective polymer membrane and meanwhile reduce external influence on electrode performance.Therefore, compared with traditional coated ion-selective electrodes, the MXene nanosheet modification-based all-solid-state ion-selective electrode not only has the advantages of stable potential, good repeatability and the like, but also is low in cost and simple in preparation.

Owner:ZHEJIANG UNIV

Preparing method for two-dimensional material-transition metal heterojunction sheet

The invention provides a method for simply and rapidly preparing a two-dimensional material-transition metal heterojunction nano sheet. In the electric field, a blocky two-dimensional crystal containing a laminar structure is converted into a few-layer sheet, and transition metal heterojunction modification is conducted on the sheet. According to the method, the blocky two-dimensional crystal serves as a work electrode, additional inert materials serve as other electrodes, all the electrodes are connected with a wire and immersed in an electrolyte, continuous electrification is conducted, andblocky two-dimensional materials are layered in a solvent containing an intercalation agent. After a period of time, transition metal positive ions are added in the same device, continuous electrification continues, the two-dimensional material-transition metal heterojunction nano sheet is obtained, an obtained product is collected, cleaned and subjected to ultrasonic treatment, and the two-dimensional material-transition metal heterojunction is obtained. Electrochemistry is utilized in the method, and a transition metal modified thin-layer two-dimensional sheet is obtained. According to the method, conditions are simple, cost is low, repeatability is good, and environment friendliness is achieved.

Owner:深圳市中科墨磷科技有限公司

Method for preparing two-dimensional material with atmospheric-pressure plasmas

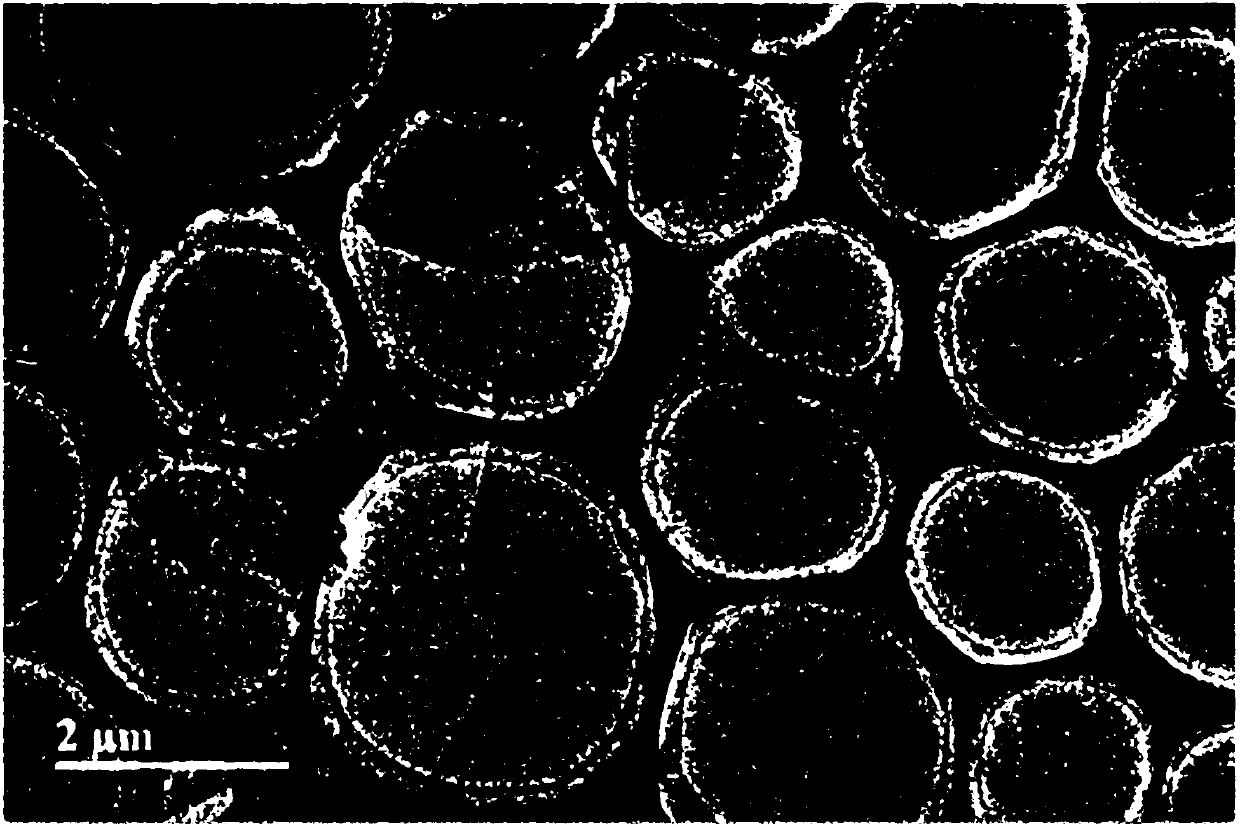

ActiveCN107777674AReduce yieldControl rateGrapheneNanotechnologyBlack phosphorusTwo dimensional crystal

The invention relates to a method for preparing two-dimensional material with atmospheric-pressure plasmas. According to the method, a stripping device with a negative electrode being material crystalis constructed on the basis of an atmospheric-pressure plasma technique, and a two-dimensional crystal wafer is obtained by stripping of the material crystal. Compared with other stripping methods, the method has advantages of simple steps, convenience in operation, short time, high efficiency, freeness of utilization of complex expensive equipment and extra chemical agents and freeness of environmental pollution and material surface contamination and is especially applicable to preparation of two-dimensional black phosphorus materials. In addition, the method can be implemented under normal-temperature normal-pressure conditions, the process is easier to control, and industrial application is benefited.

Owner:SHENZHEN INST OF ADVANCED TECH

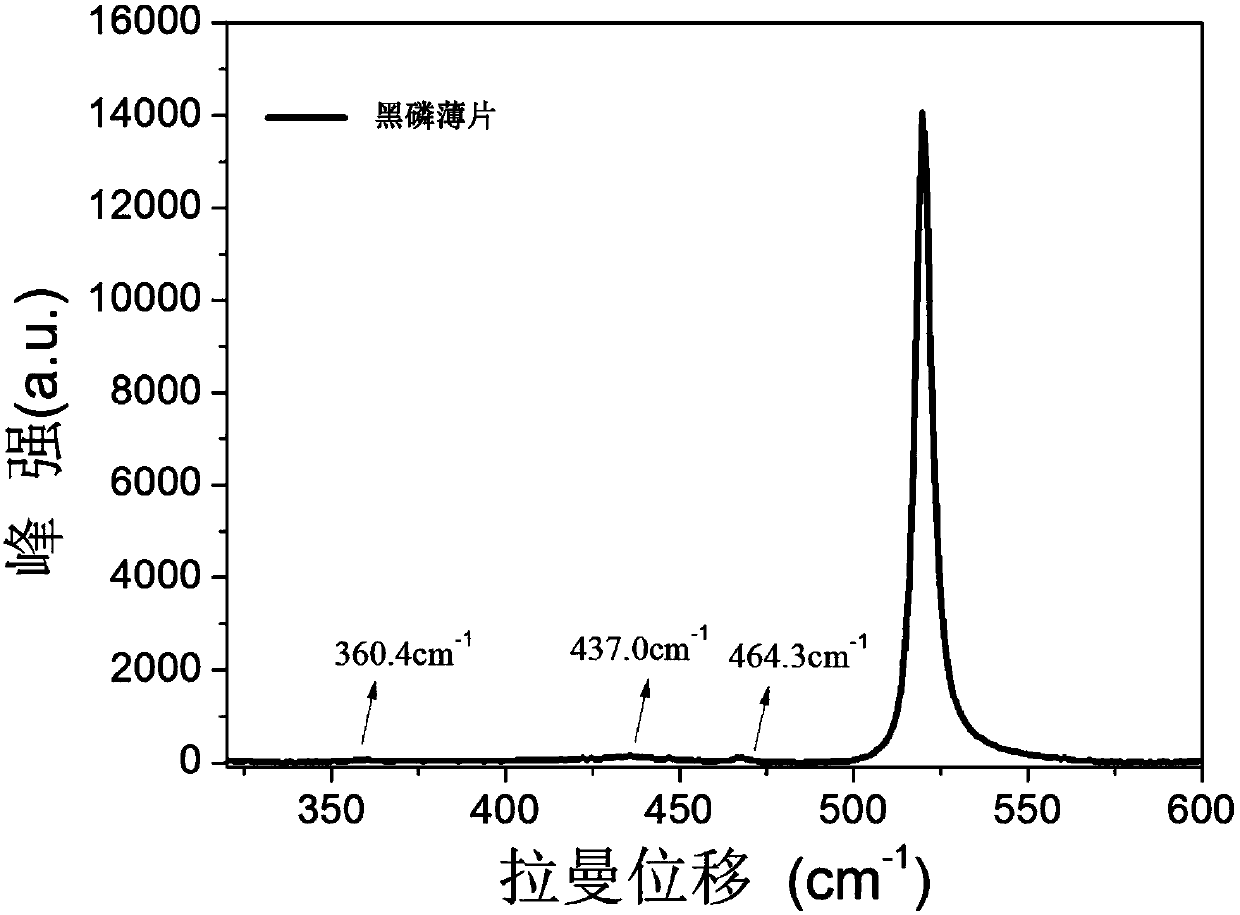

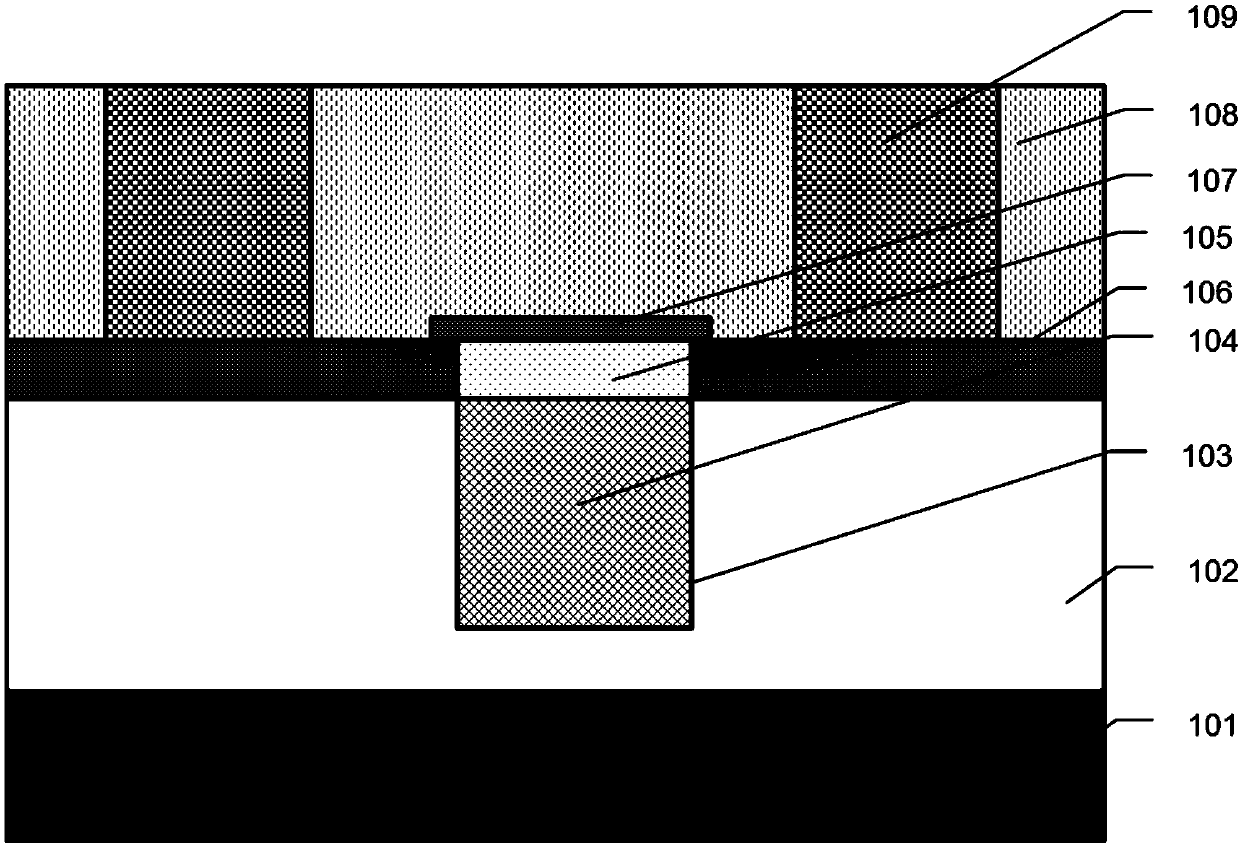

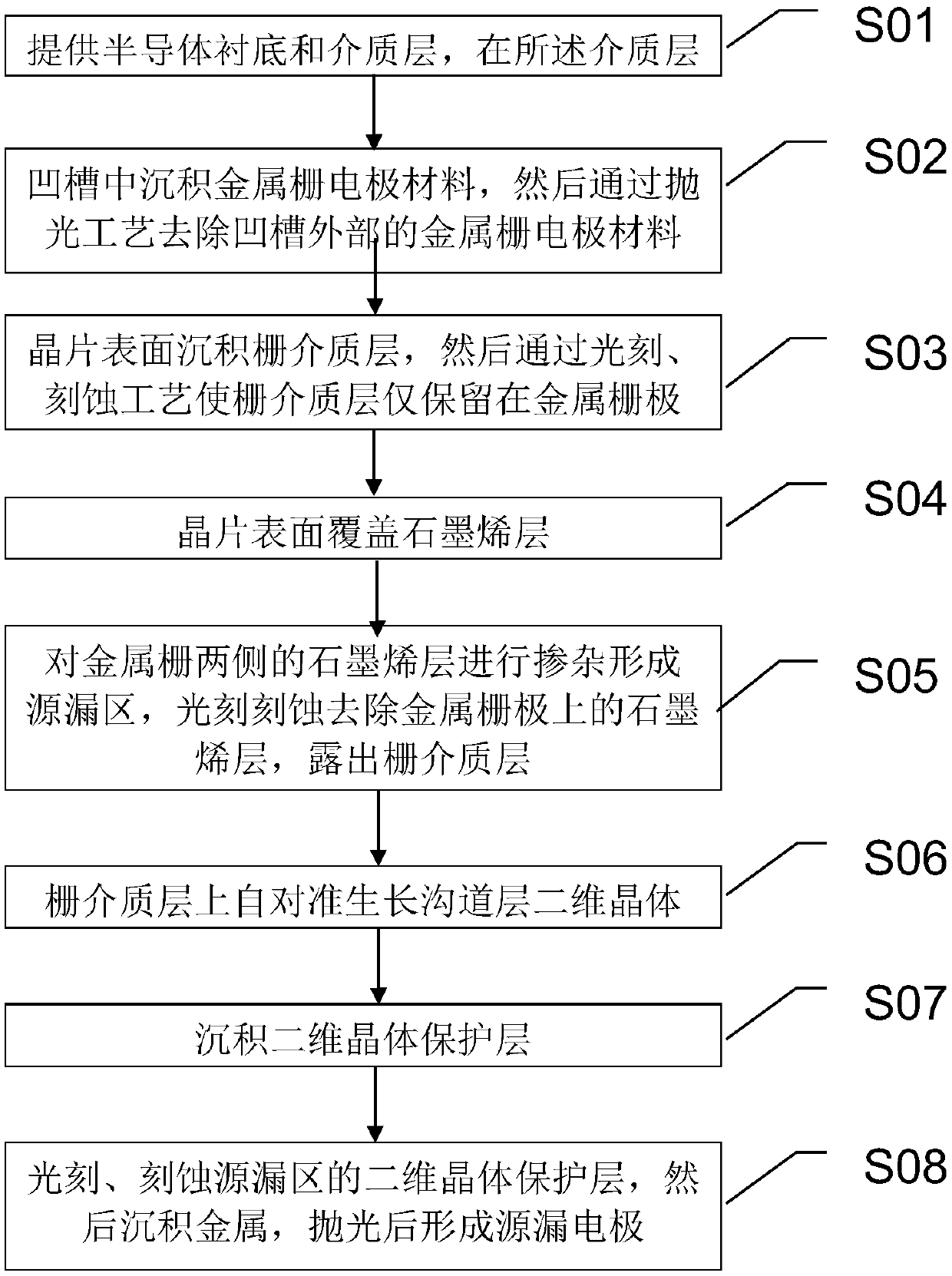

Two-dimensional crystal material field effect transistor and preparation method thereof

ActiveCN107634099AAvoid exposureSmall sizeMaterial nanotechnologySemiconductor/solid-state device manufacturingCMOSDoped graphene

The invention discloses a two-dimensional crystal material field effect transistor, which comprises a semiconductor substrate, a dielectric layer, a metal gate, a gate dielectric layer, a channel layer, a graphene layer, a two-dimensional crystal protection layer, a source electrode and a drain electrode. The invention further discloses a method for preparing the two-dimensional crystal material field effect transistor. A two-dimensional crystal material directly grows on the gate dielectric layer in a self-aligned manner, and doped graphene is adopted as a source and a drain and connected with metal as the source electrode and the drain electrode to prepare the field effect transistor. According to the two-dimensional crystal material field effect transistor and the preparation method thereof, the field effect transistor with stable two-dimensional crystal material film property can be manufactured by adopting a conventional CMOS manufacture procedure; and the ultimate target of preparing a small-size and large-scale two-dimensional crystal field effect transistor array is achieved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

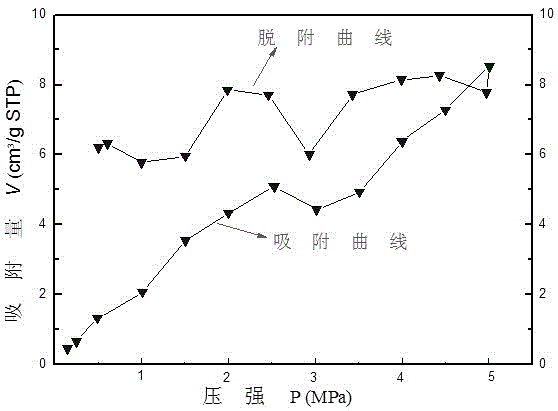

Application of two-dimensional crystal compound Ti2C in adsorption and decomposition of methane in low-concentration gas as adsorbent

InactiveCN105582806AReduce pressurePhysical/chemical process catalystsOther chemical processesSorbentDecomposition

The invention discloses application of two-dimensional crystal compound Ti2C in adsorption and decomposition of methane in low-concentration gas as adsorbent. The two-dimensional crystal compound Ti2C has a two-dimensional layered structure similar to that of graphene and is composed of titanium atoms on the upper surface and the lower surface and a carbon atom layer in the middle. The material has a high specific surface area and high optical catalytic performance. Methane molecules in low-concentration gas can be adsorbed, and adsorbed methane molecules can not enter the environment again when the pressure intensity of methane is decreased. By means of the optical catalytic performance of the material, harmful methane can be decomposed into harmless carbon dioxide and water. The novel adsorption and decomposition material provides a new effective path for harmless processing of low-concentration gas.

Owner:HENAN POLYTECHNIC UNIV

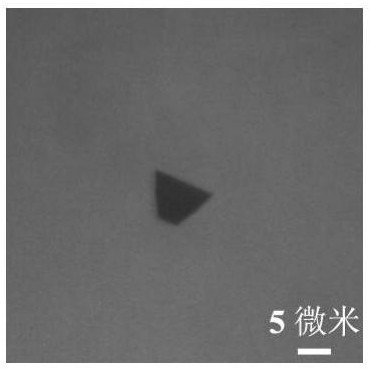

Preparation method of two-dimensional molybdenum sulfide crystal material with special morphology

ActiveCN112663139AAchieve preparationPolycrystalline material growthFrom chemically reactive gasesSulfidationTwo dimensional crystal

The invention discloses a preparation method of a two-dimensional molybdenum sulfide crystal material with a special morphology. The preparation method of the MoS2 crystal material with different special morphologies comprises the following steps of adopting a chemical vapor deposition method, taking Si / SiO2 as a substrate and nanoscale MoO3 powder as a Mo source, inversely buckling the substrate above the powder to construct a narrow confinement space, reacting with sulfur vapor, and preparing the MoS2 crystal materials with different special morphologies on the substrate, namely trapezoids, parallelograms and irregular parallelograms. The obtained MoS2 crystal materials with different morphologies can be used as channel materials of transistors to be applied to the field of ultrathin electronic devices. According to the preparation method disclosed by the invention, a narrow confinement space is constructed between the substrate and the material source, and the growth of two-dimensional MoS2 crystal materials with different special morphologies is successfully realized, so that the growth theory of the two-dimensional material is further researched.

Owner:HANGZHOU DIANZI UNIV

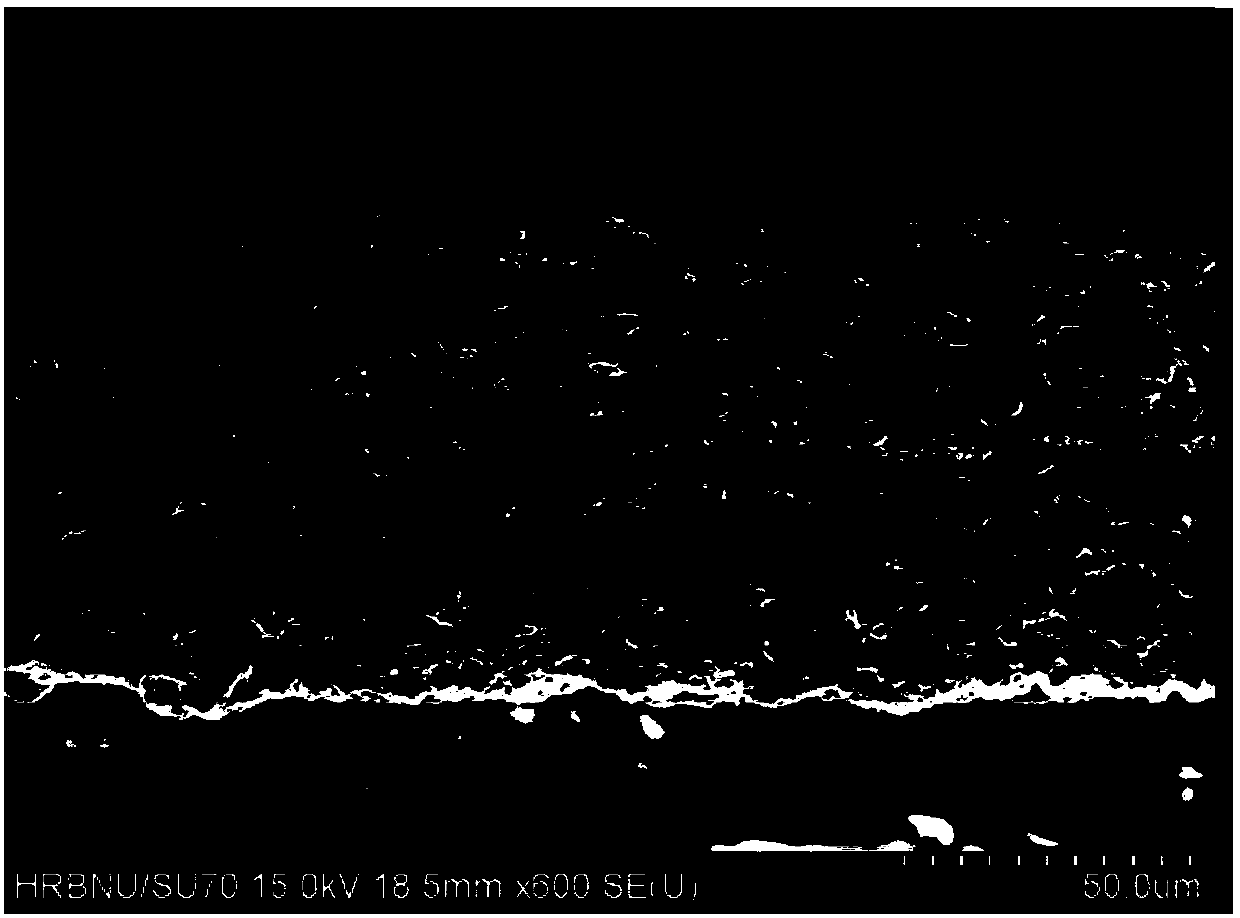

Preparation method and application of three-dimensional multi-dimension porous crystal titanium carbide

ActiveCN107640772AHighly corrosiveImprove uniformityHybrid capacitor electrodesCell electrodesCapacitanceTwo dimensional crystal

The invention discloses a preparation method and application of three-dimensional multi-dimension porous crystal titanium carbide, relates to a preparation method and application of crystal titanium carbide, and aims to solve the problem that existing two-dimensional crystal titanium carbide is liable to stack, and especially has low mass specific capacitance when the mass is relatively large. Themethod comprises the following steps: I, preparing a two-dimensional layered titanium carbide nanosheet; II, calcining to obtain the three-dimensional multi-dimension porous crystal titanium carbide.The mass specific capacitance of the three-dimensional multi-dimension porous crystal titanium carbide prepared by the method is about 129F / g when the mass is 10mg. By adopting the preparation method, the three-dimensional multi-dimension porous crystal titanium carbide can be obtained.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

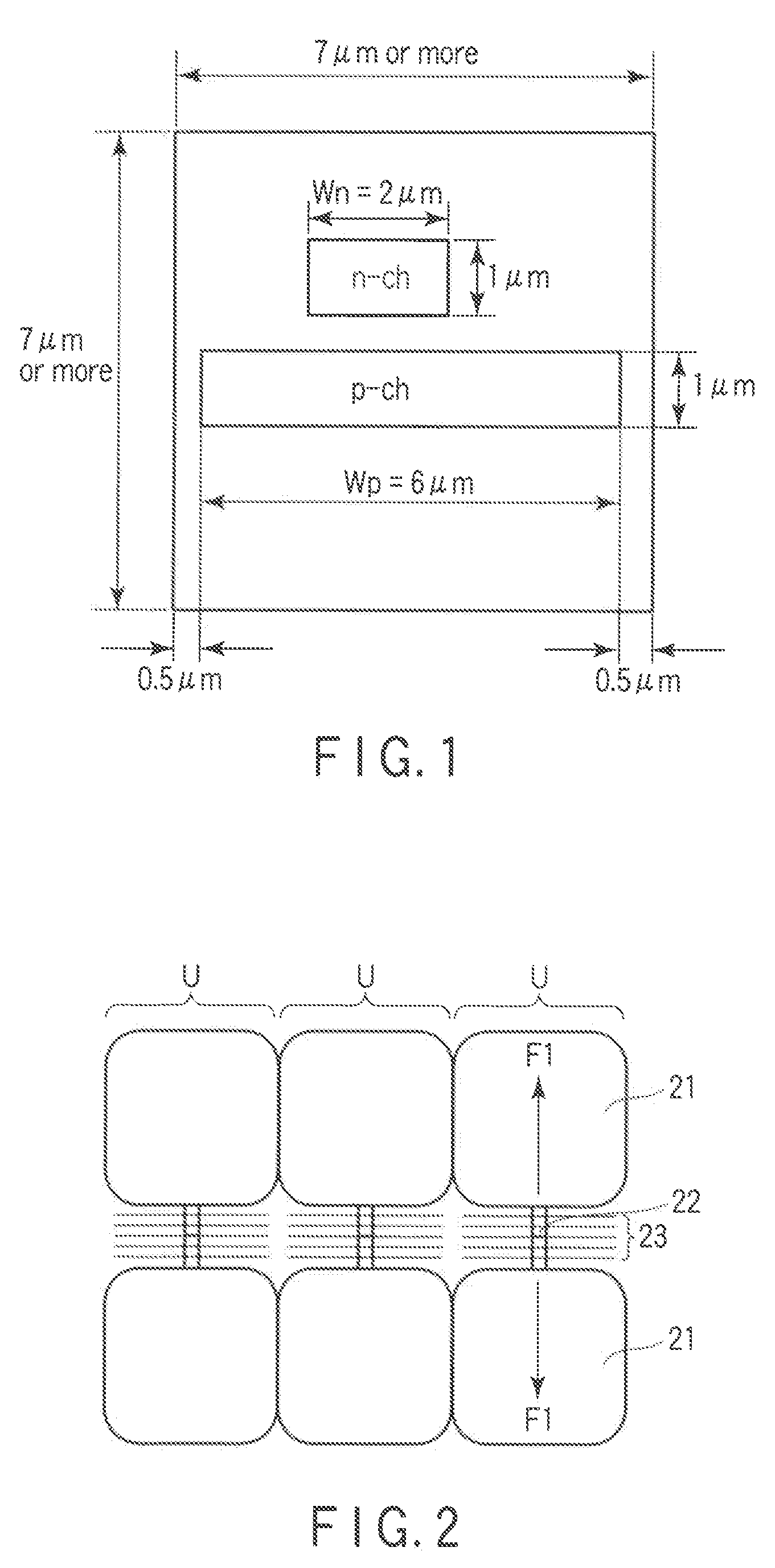

Crystal silicon array, and manufacturing method of thin film transistor

InactiveUS20090134394A1Large particle sizeTransistorSolid-state devicesSingle crystalTwo dimensional crystal

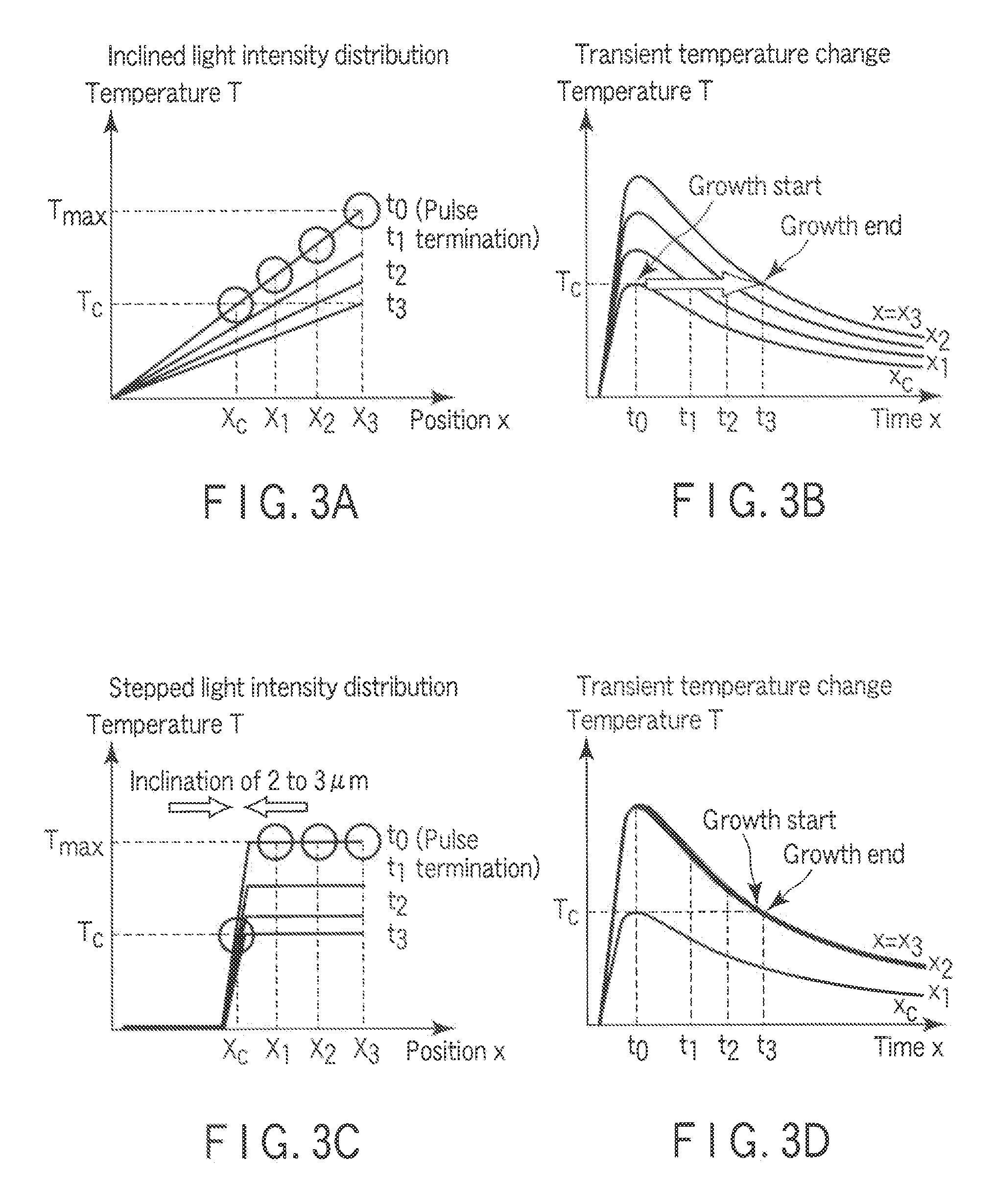

A crystal silicon array includes a crystallized unit region obtained by crystallizing at least a part of a non-single crystal semiconductor film. The crystallized unit region includes at least one square two-dimensional crystal portion having a size of 7 μm square or more, and at least one needle crystal portion having a grain length of 3.5 μm or more.

Owner:ADVANCED LCD TECH DEVMENT CENT

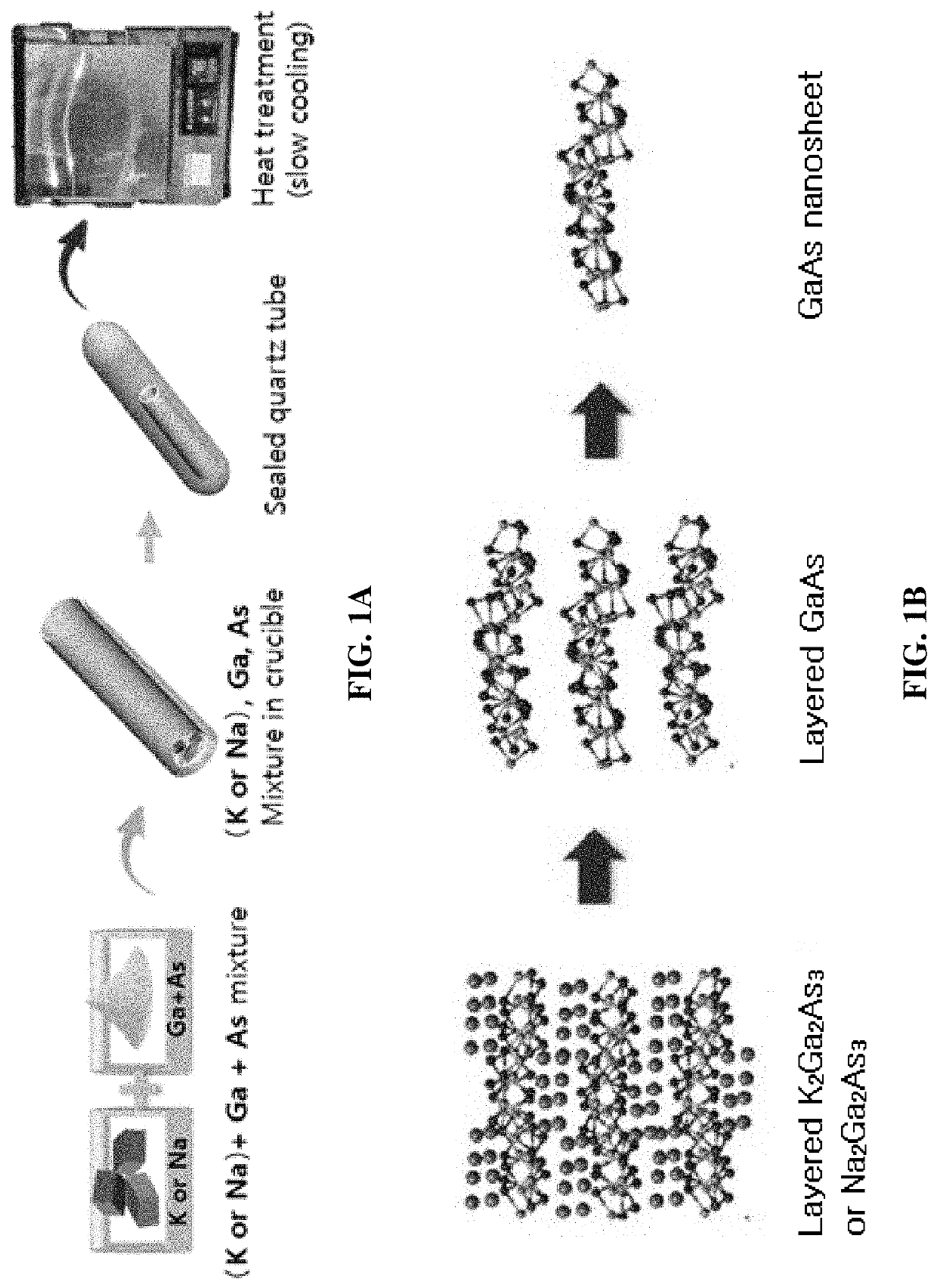

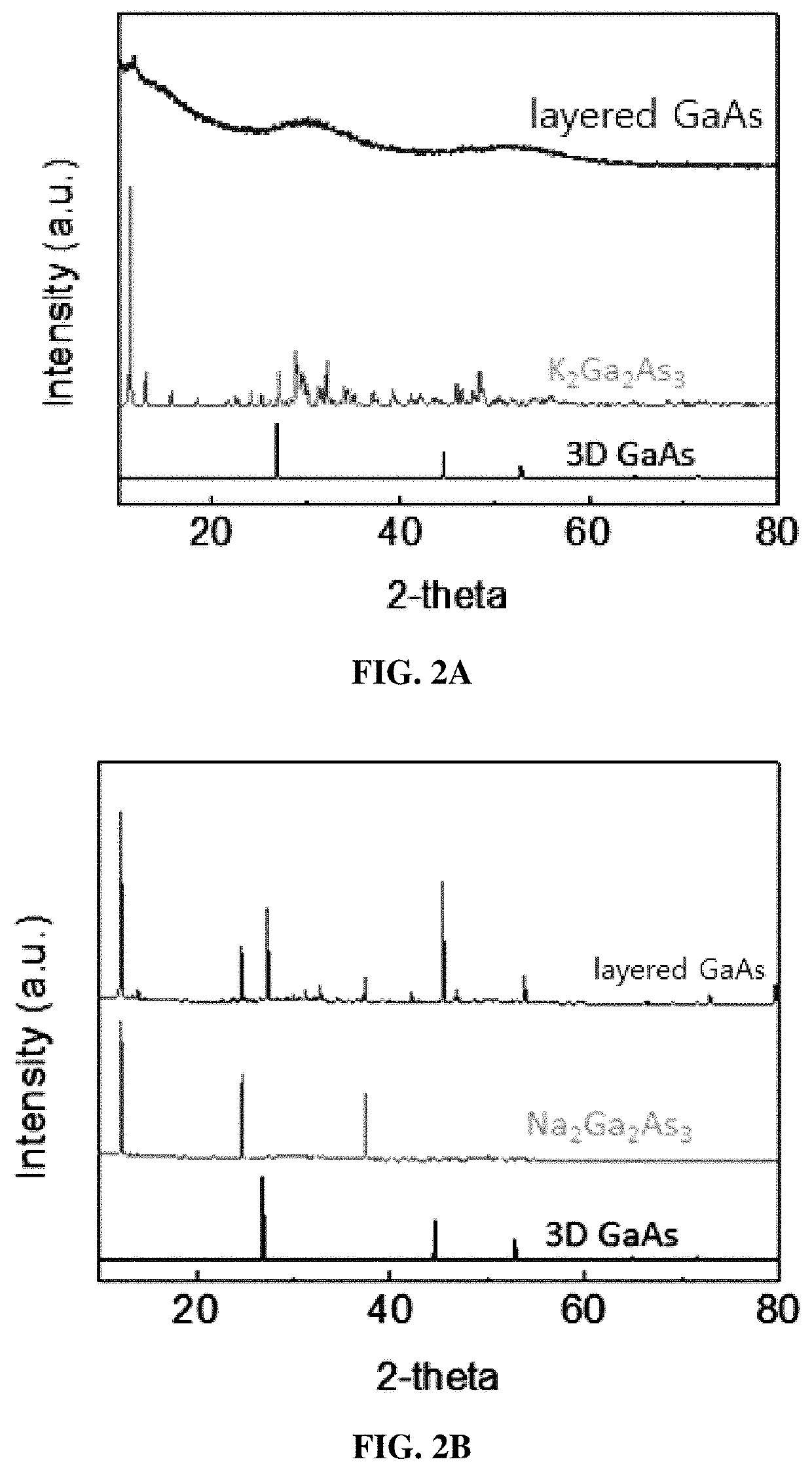

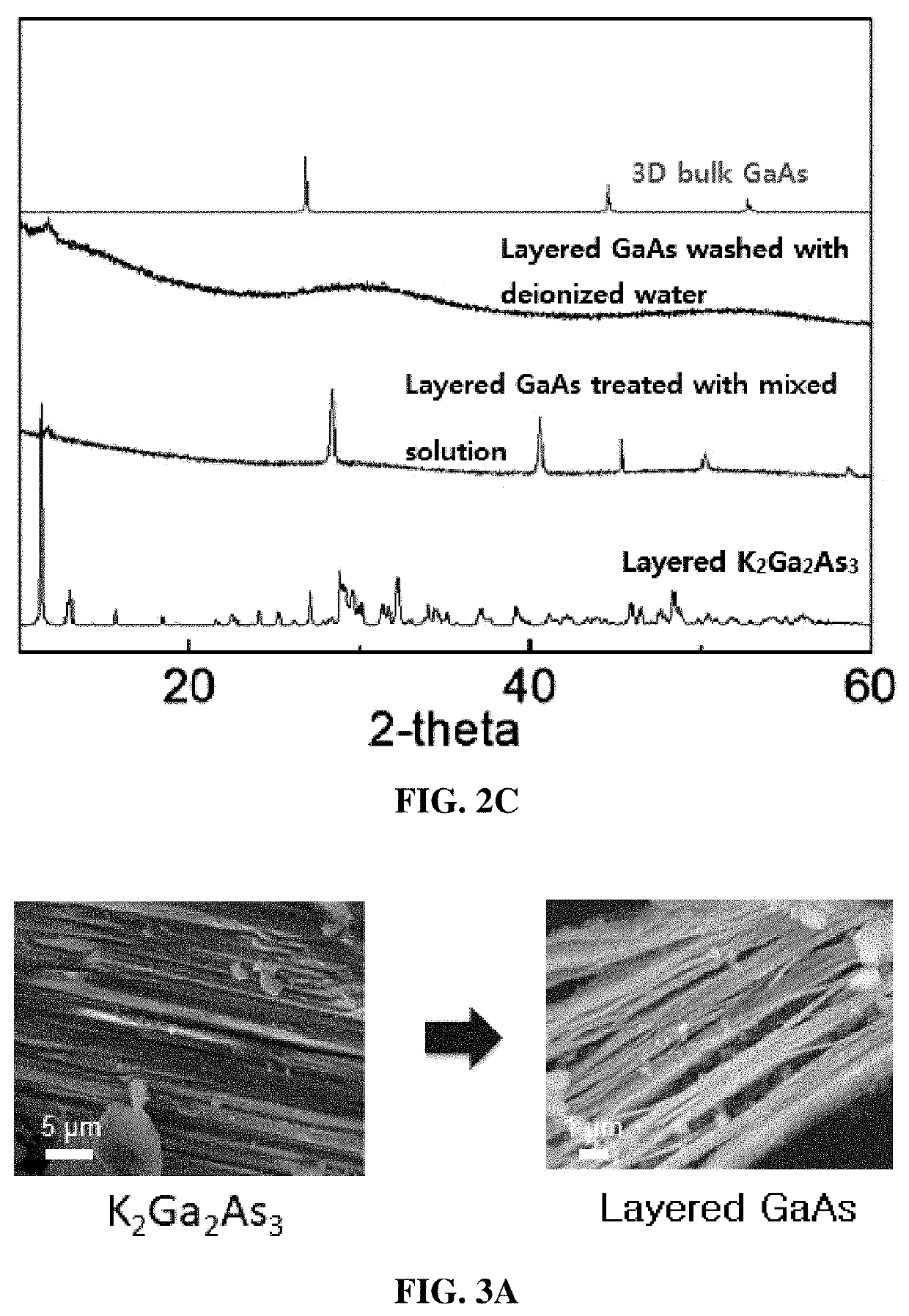

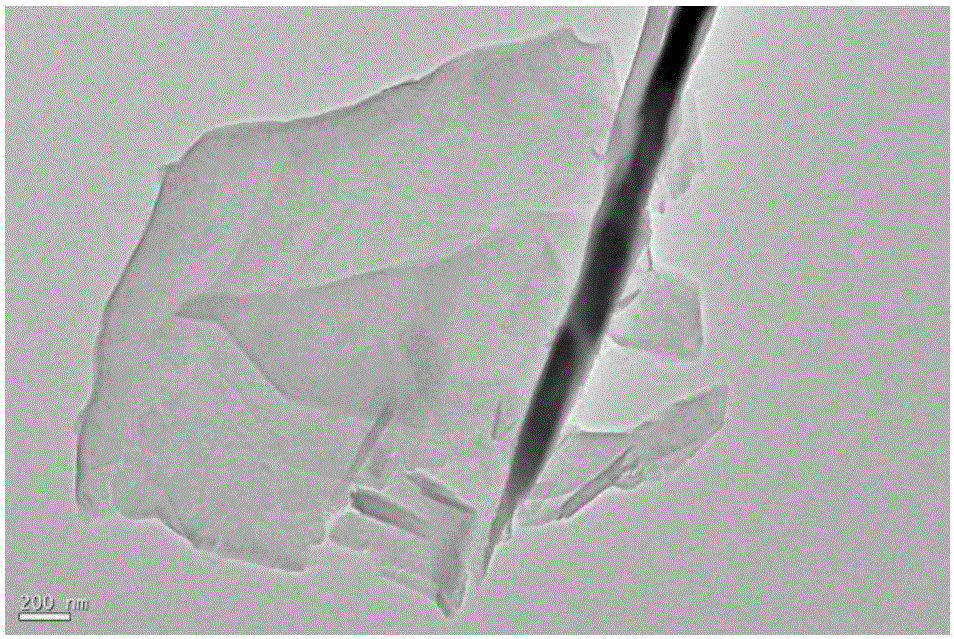

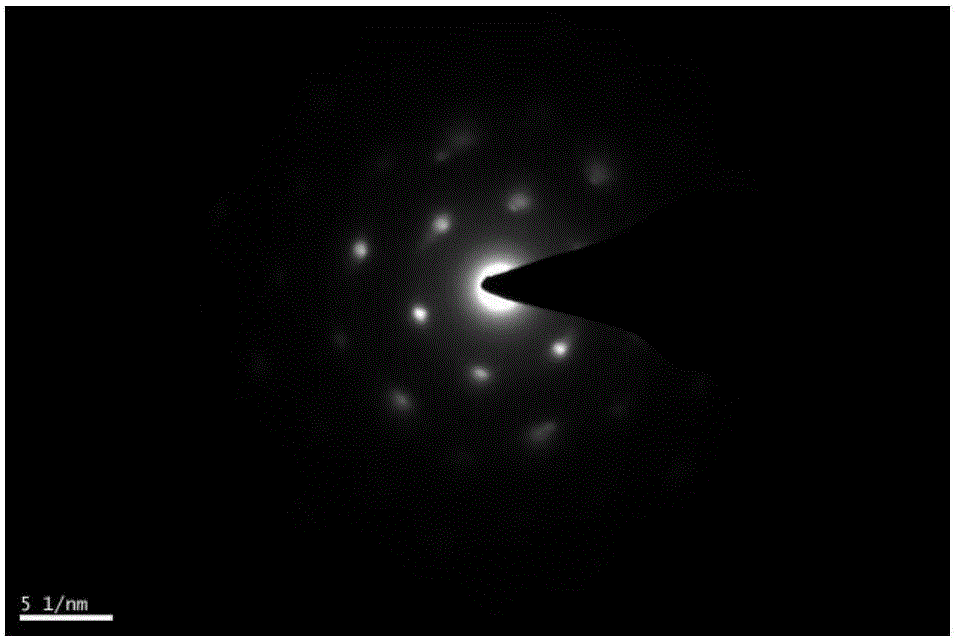

LAYERED GaAs, METHOD OF PREPARING SAME, AND GaAs NANOSHEET EXFOLIATED FROM SAME

InactiveUS20190352799A1Improve electrical performanceAbility to readilyMaterial nanotechnologyPolycrystalline material growthIn planeCrystallography

The present invention relates to: layered gallium arsenide (GaAs), which is more particularly layered GaAs, which, unlike the conventional bulk GaAs, has a two-dimensional crystal structure, has the ability to be easily exfoliated into nanosheets, and exhibits excellent electrical properties by having a structure that enables easy charge transport in the in-plane direction; a method of preparing the same; and a GaAs nanosheet exfoliated from the same.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

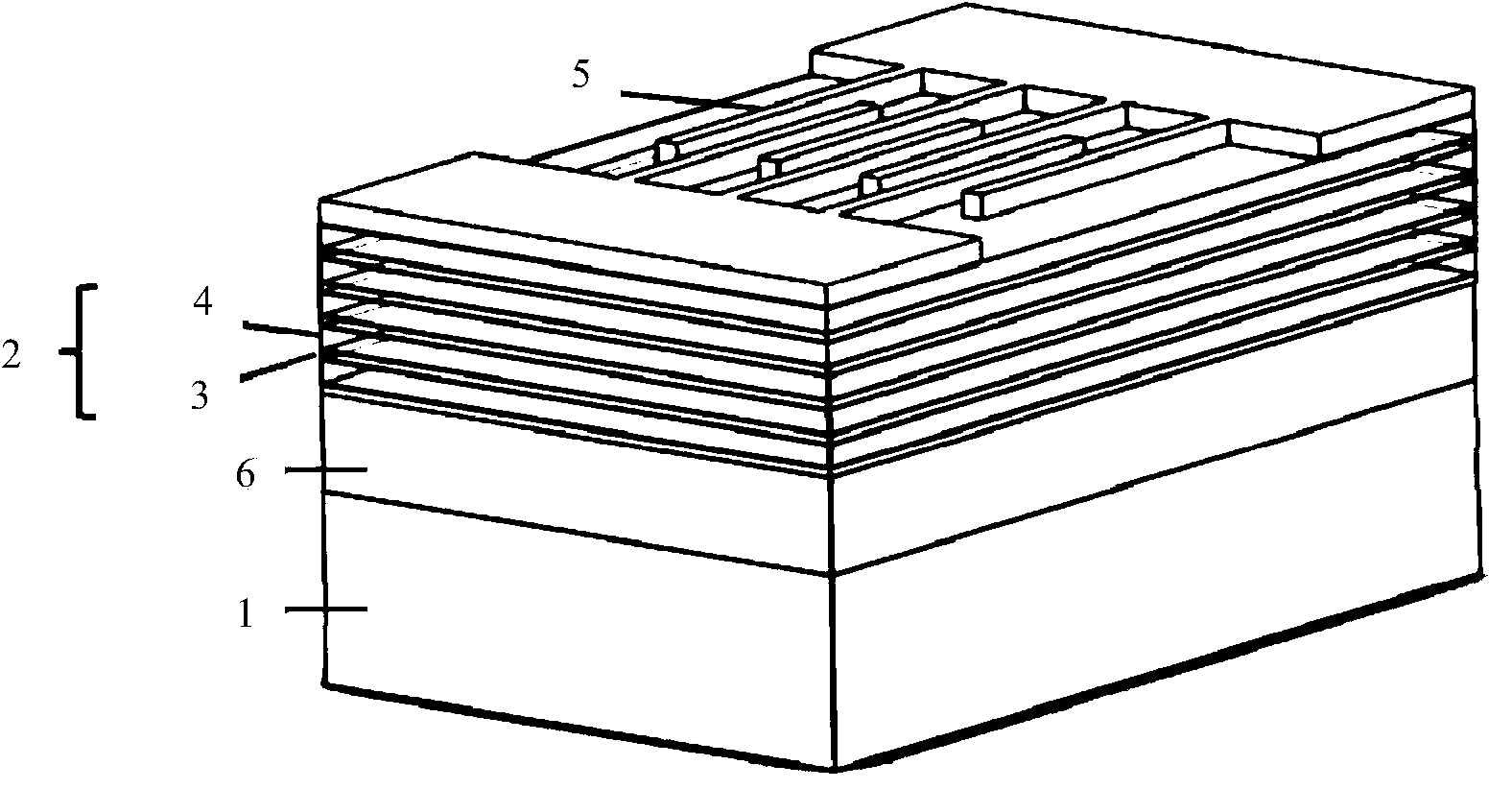

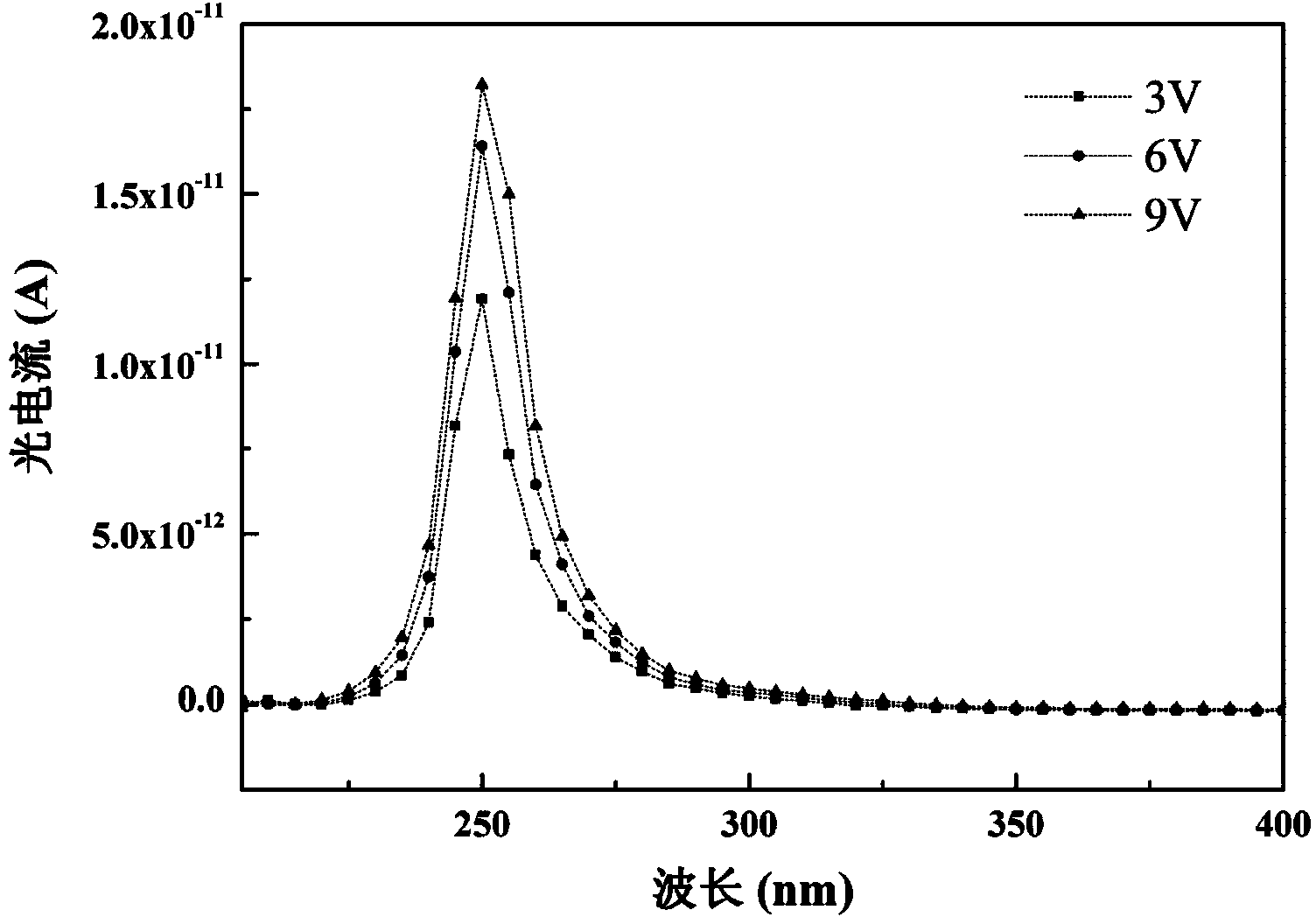

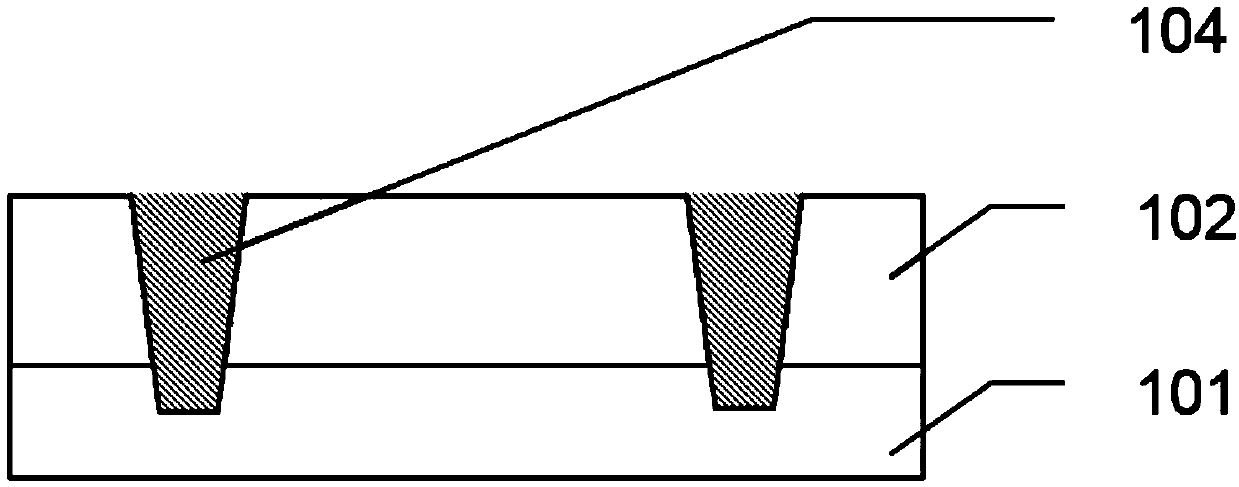

Ultraviolet single-wavelength MSM photoelectric detector based on two-dimensional crystal lattices

ActiveCN103474503AImplement detectionEasy to transportSemiconductor devicesPotential wellTwo dimensional crystal

The invention discloses an ultraviolet single-wavelength MSM photoelectric detector, and belongs to the technical field of semiconductor photoelectric devices. The ultraviolet single-wavelength MSM photoelectric detector based on two-dimensional crystal lattices uses the quantum restriction effect to achieve the adjustable single wavelength and can develop the advantage of high quantum level state density more easily. The ultraviolet single-wavelength MSM photoelectric detector comprises a substrate, the two-dimensional crystal lattices with the quantum level and a metal interdigital electrode. The two-dimensional crystal lattices grow on the substrate alternatively, and the number of the alternative growth periods is at least 20. Each two-dimensional crystal lattice in each alternative growth period is composed of a first dielectric film layer and a second dielectric film layer, wherein the forbidden band of the first dielectric film layer is arranged in the forbidden band of the second dielectric film layer and forms a semiconductor I-class superlattice, the first dielectric film is used as a potential well, and the second dielectric film is used as a potential barrier; the Schottky contact is formed between the metal interdigital electrode and the two-dimensional crystal lattices.

Owner:XIAMEN UNIV

Preparation method of graphene

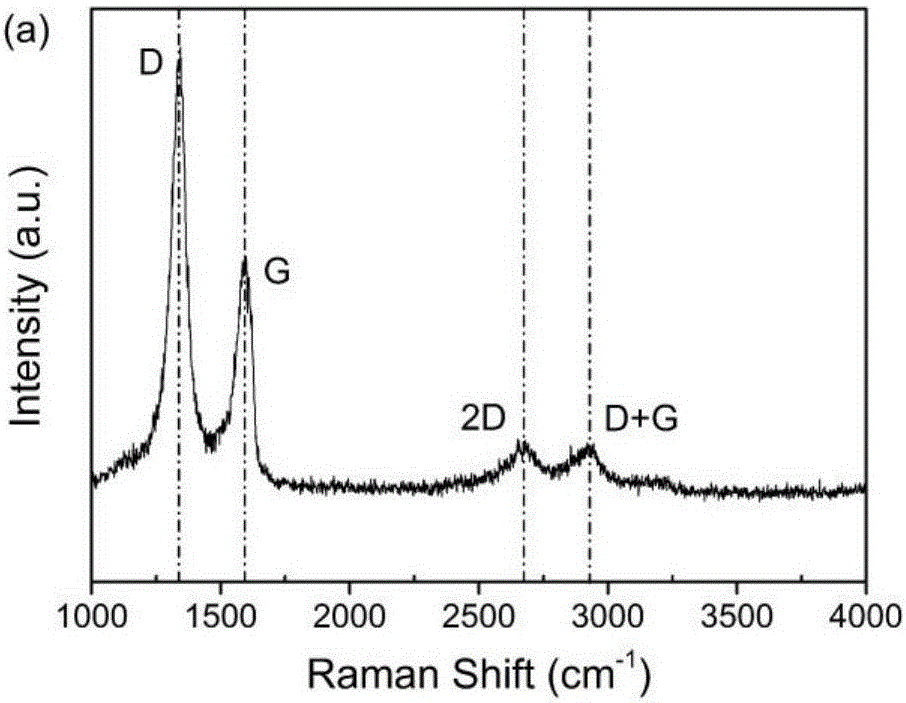

InactiveCN105883783ARestoring the 2D crystal structureGood electrical propertiesChemical reactionElectrical performance

The invention provides a preparation method of graphene. The method comprises the specific steps that graphite fluoride and hydrazine hydrate are subjected to a reduction reaction in a liquid phase reaction system to obtain graphene. According to the scheme, the graphite fluoride is used as a raw material, and peeling and reduction of the graphite fluoride can be completed only through one-step reaction. The involved reaction is a liquid phase chemical reaction. The uniformity and high yield of the product are ensured, the two-dimensional crystal structure of graphene can be recovered to the maximum limit, and therefore the excellent electrical performance of the graphene is reserved. Experiment results show that the conductivity of the obtained graphene is 2670 S / m and is much higher than that of graphene obtained through a chemical oxidation reduction method in the prior art.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

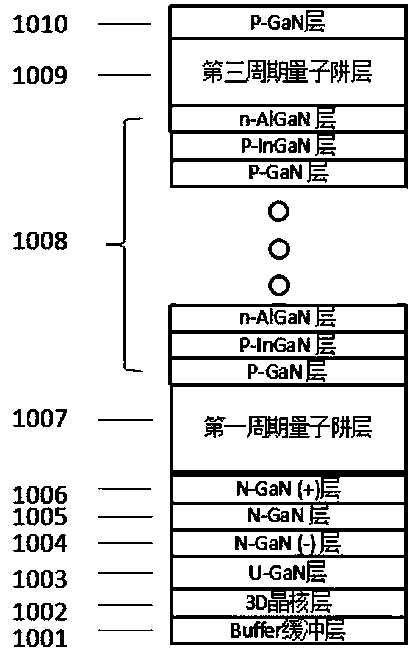

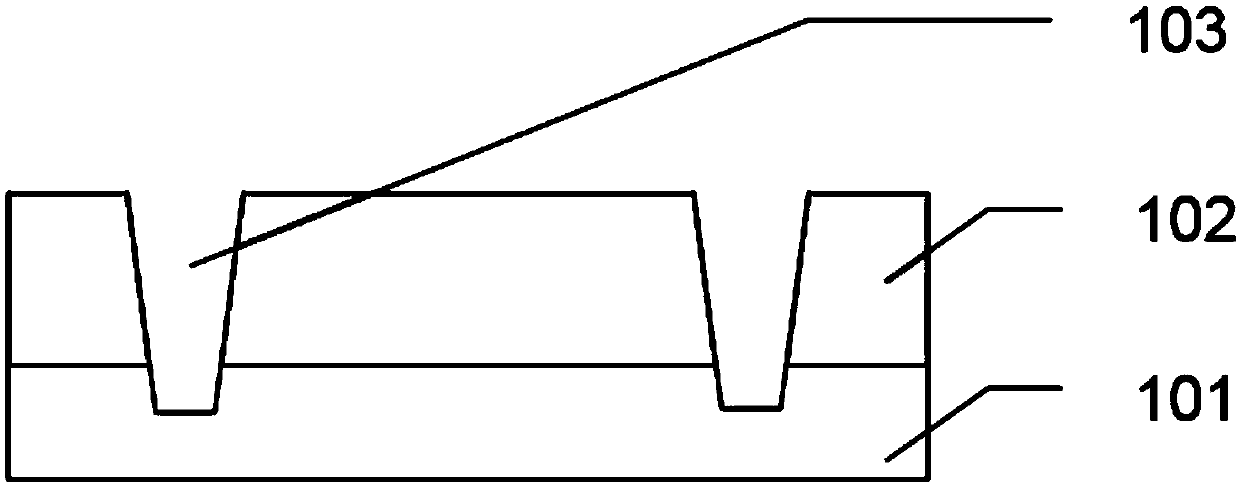

Epitaxial preparation method of gallium nitride LED

The invention discloses an epitaxial preparation method of a gallium nitride LED. The method comprises the following steps of growing a gallium nitride buffer layer on a sapphire substrate; annealingthe gallium nitride buffer layer shape to form at least one crystal nucleus island-buffer layer; and transversely growing the gallium nitride layer on the basis of the crystal nuclear island until allthe crystal nuclear islands are connected with each other, so as to form an integral two-dimensional crystal layer-3D crystal nucleus layer. According to the preparation method, a buffer insertion layer is grown in the middle of an active region. The buffer insertion layer is formed by alternately laminating a first sub-layer, a second sub-layer and a third sub-layer. The first sub-layer is madeof P-type gallium nitride, the second sub-layer is made of P-type indium gallium nitrogen, and the third sub-layer is made of N-type aluminum gallium nitrogen. According to the technical scheme, the functions of electronic deceleration and uniform expansion are achieved through consumption, blocking and emission effects. The problem of leakage current of positive conduction is solved, and the problem that the light emitting efficiency of the conventional gallium nitride LED epitaxial structure is lowered along with the increasing of the current density is solved.

Owner:贵州杰芯光电科技有限公司

Phase change memory and preparation method thereof

InactiveCN109560104AReduced series resistanceImprove driving abilitySolid-state devicesSemiconductor devicesUnit sizePhase-change memory

The invention discloses a phase change memory, which comprises a substrate, a doping layer, a diode and a phase change resistor from bottom to top, wherein the doping layer is arranged on the top of the substrate; the doping layer and the substrate independently comprise at least two pieces of shallow trench isolation; the diode is positioned between two pieces of shallow trench isolation and comprises a first two-dimensional crystal film and a second two-dimensional crystal film; the second two-dimensional crystal film is positioned above the first two-dimensional crystal film; and the phasechange resistor comprises a lower electrode, sulfide with a phase change ability, and an upper electrode, wherein the lower electrode, the sulfide and the upper electrode are positioned above the second two-dimensional crystal film in sequence. By use of the phase change memory and the preparation method thereof, the unit size of a 1D1R structure phase change memory device unit prepared from the diode prepared from the two-dimensional crystal and the phase change resistor is small, the storage density of the phase change memory can be improved, and meanwhile, graphene is adopted as a lower electrode to lower device power consumption.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

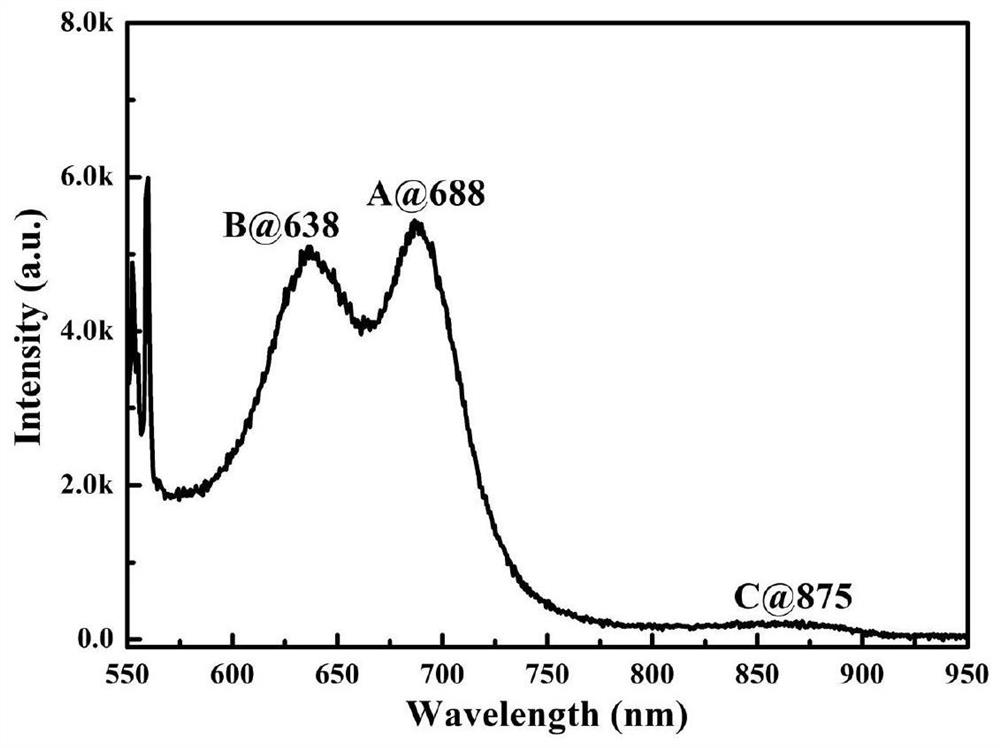

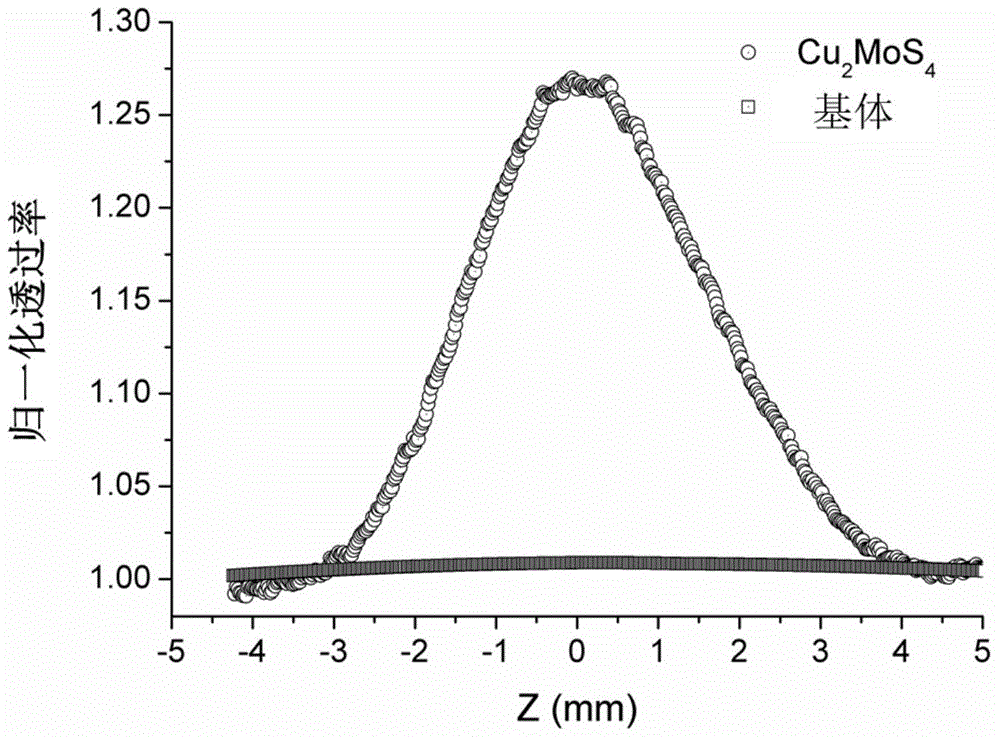

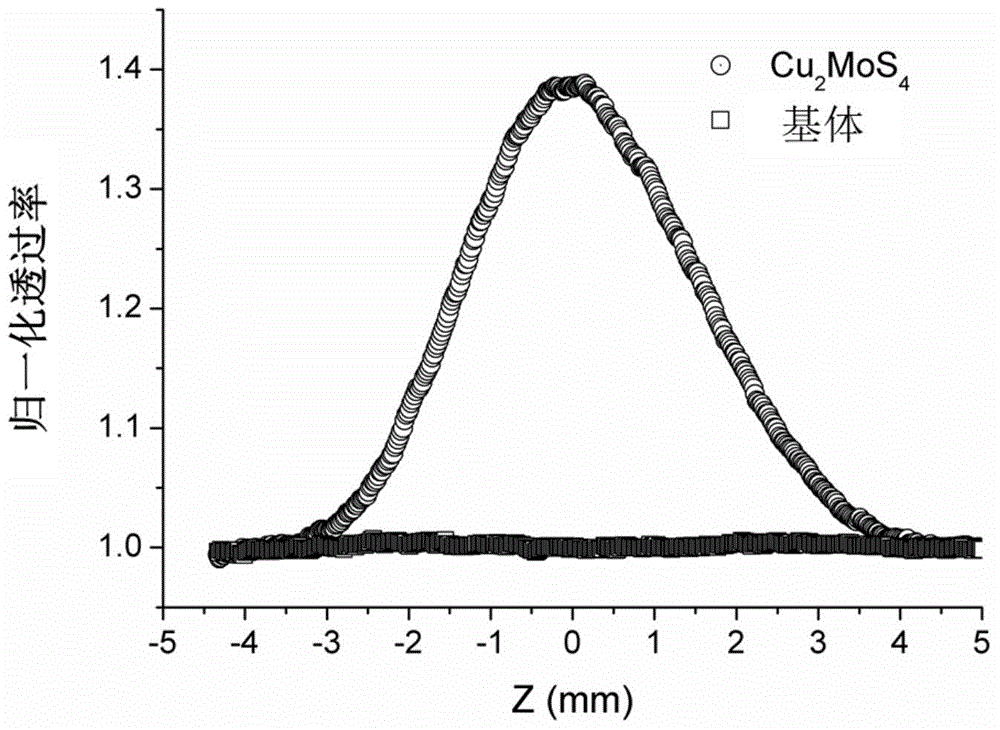

Application of Cu2MoS4 two-dimensional crystal and saturable absorber device comprising same

InactiveCN105098576ALarge scale preparationLow costActive medium materialActive medium shape and constructionMode-lockingTwo dimensional crystal

The invention discloses an application of a Cu2MoS4 two-dimensional crystal and a saturable absorber device comprising the same. The saturable absorber device comprises a two-dimensional crystal packaged in a transparent container and used as a saturable absorber, and a substrate bearing the saturable absorber. The saturable absorber is a Cu2MoS4 two-dimensional layered crystal. A new material system with an excellent saturated absorption characteristic is discovered, and provides more opportunities for development of new saturable absorbers. The saturable absorber device has the advantages of being low in cost, being prepared in a large scale, having a small volume, and being capable of forming various types of mode locking devices, and can be applied to fields like pulse fiber lasers and so on.

Owner:ZHEJIANG UNIV

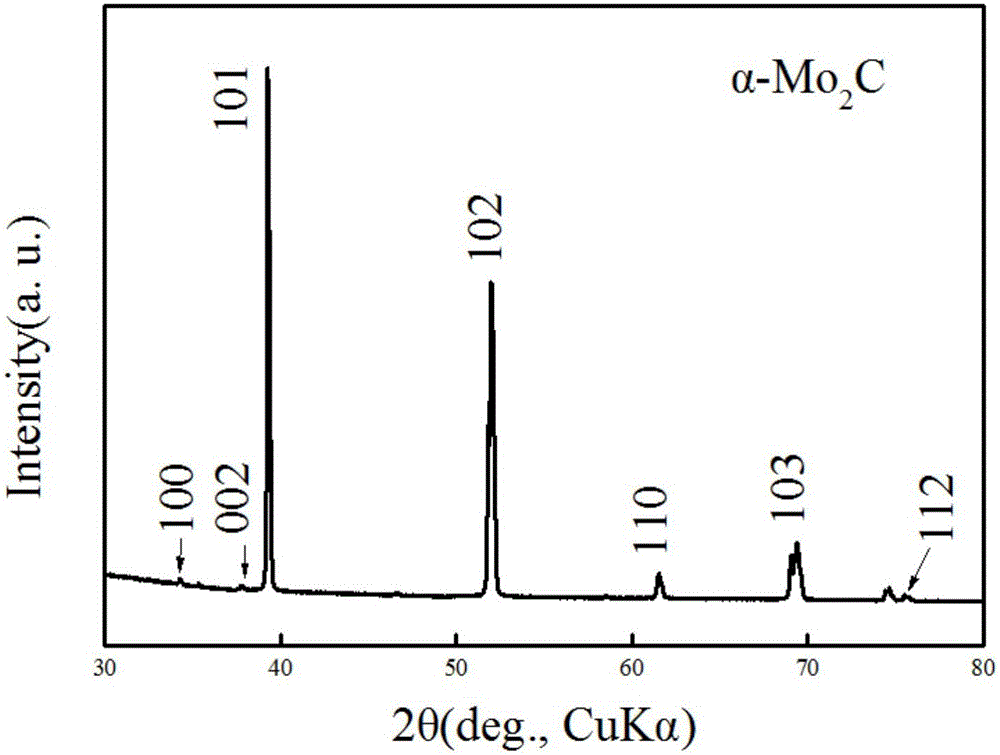

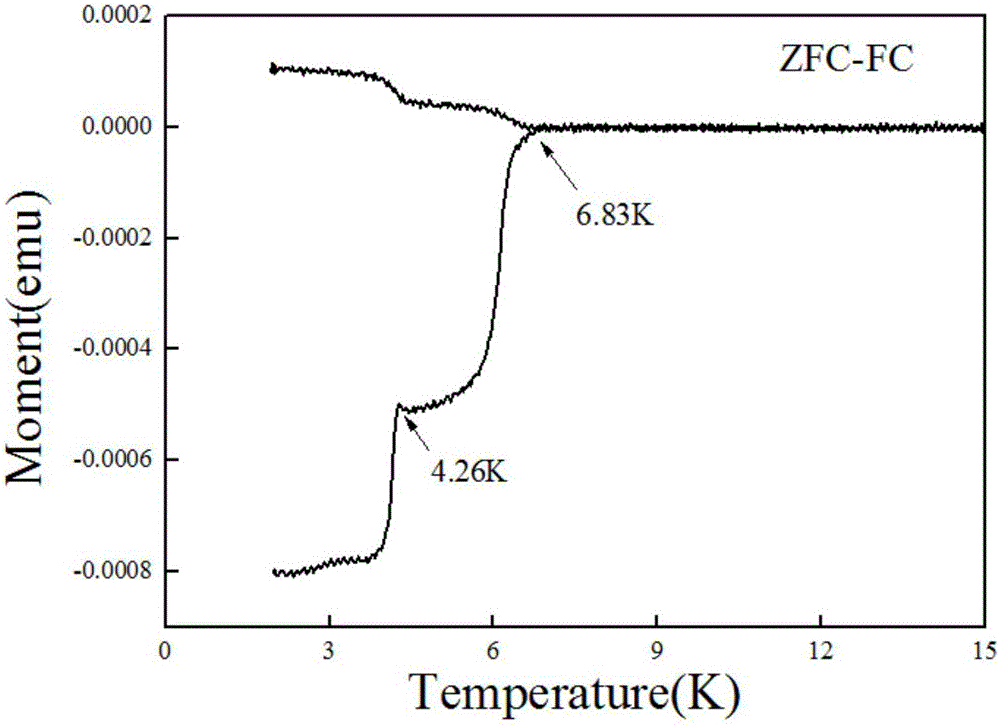

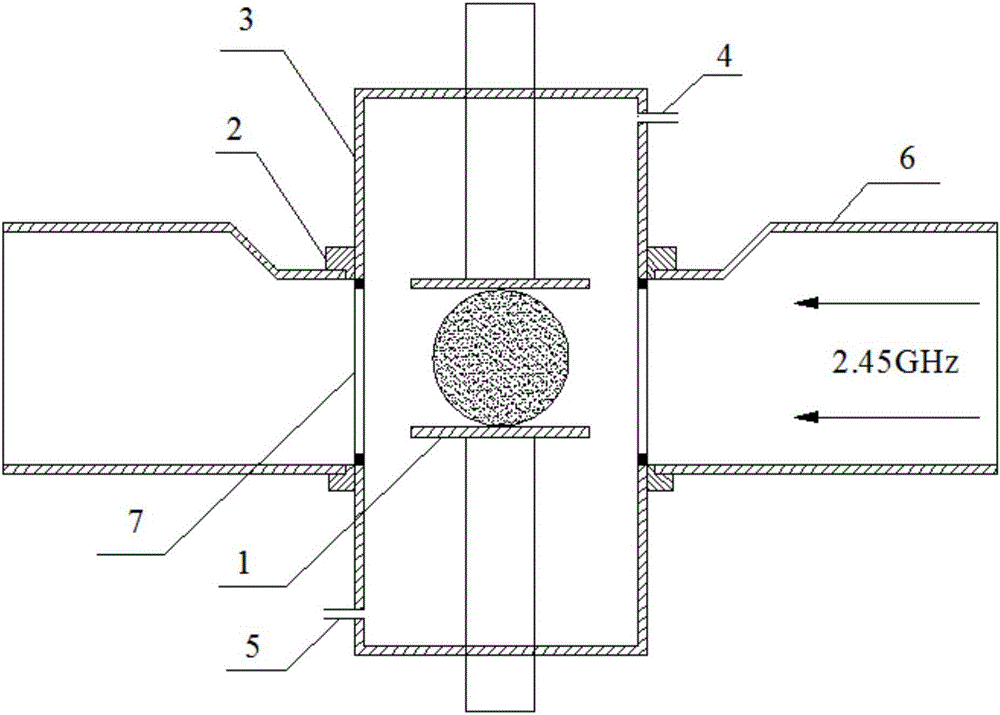

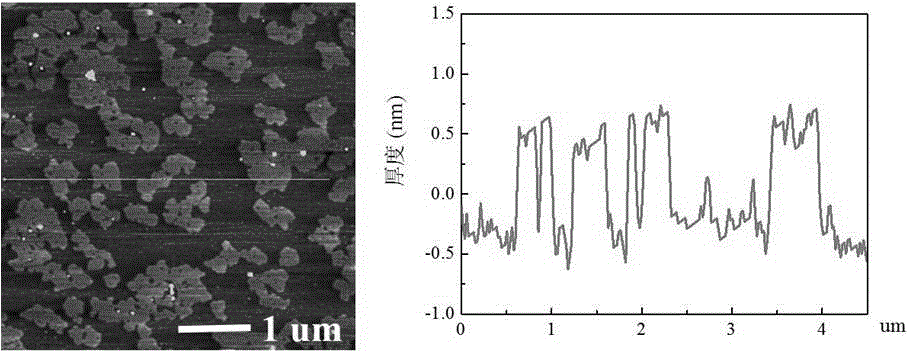

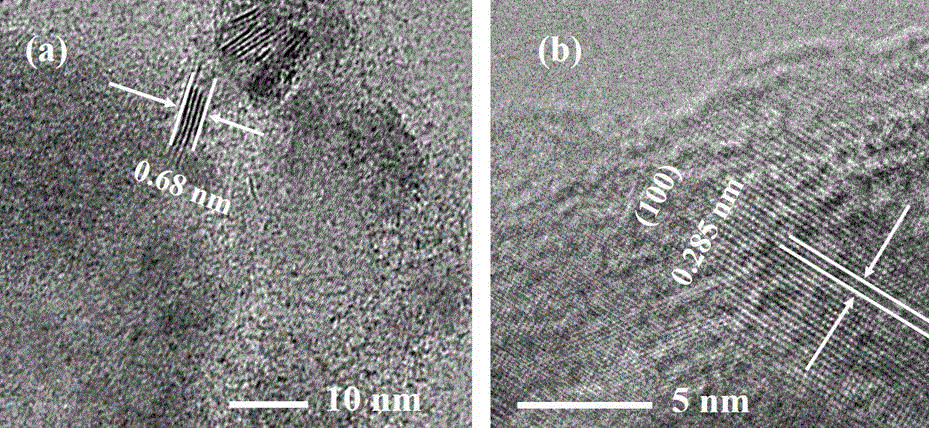

Method for preparing alpha-phase molybdenum carbide crystals through microwave plasma enhanced chemical vapor deposition

InactiveCN106011784AHigh activityFacilitate depositionChemical vapor deposition coatingThermal chemical vapor depositionTwo dimensional crystal

The invention belongs to the field of two-dimensional crystal preparation and discloses a method for preparing alpha-phase molybdenum carbide crystals through microwave plasma enhanced chemical vapor deposition. The method is characterized by comprising the steps of 1, placing cleaned silicon wafers into a cavity of a device for preparing the molybdenum carbide crystals and vacuumizing the cavity; 2, guiding hydrogen gas into the cavity, adjusting the microwave power, the hydrogen flow and the air pressure and stimulating generation of plasmas after gas inside the cavity absorbs the microwave energy; 3, covering the silicon wafers with the plasmas, heating the silicon wafers, adjusting a vacuum micrometering valve and enabling the air pressure inside the cavity to be kept within a certain range; and 4, sequentially guiding methane and molybdenum hexafluoride into the cavity after the state of the plasmas becomes stable, adjusting the gas flow and the proportion, turning off a microwave source after reaction is completed, taking out samples after the cavity is cooled and finally obtaining the alpha-phase molybdenum carbide crystals. The purity of the molybdenum carbide crystals prepared through the method is high, research on the characteristics such as the electric property and the superconductivity of the molybdenum carbide crystals is convenient, and the obtained samples have low-temperature superconductivity.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com