Hydrogen evolution reaction catalyst and preparation method thereof

A technology for hydrogen evolution reaction and catalyst, applied in chemical instruments and methods, physical/chemical process catalyst, chemical/physical process, etc., can solve problems such as unfavorable large-scale preparation and commercial application, harsh reaction conditions, etc., and achieve broad industrial application Prospects, low production cost, strong universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 1g of molybdenum diselenide powder and place it in 100mL of isopropanol, add 2wt% hydrogen peroxide and sonicate for 5 hours, pour off the supernatant after standing still, add 100mL of isopropanol and then sonicate for 5 hours, take the upper nanometer Lamellar dispersion at 50 o C vacuum drying in a vacuum oven for 3 days to remove residual solvents to obtain nanosheet composites.

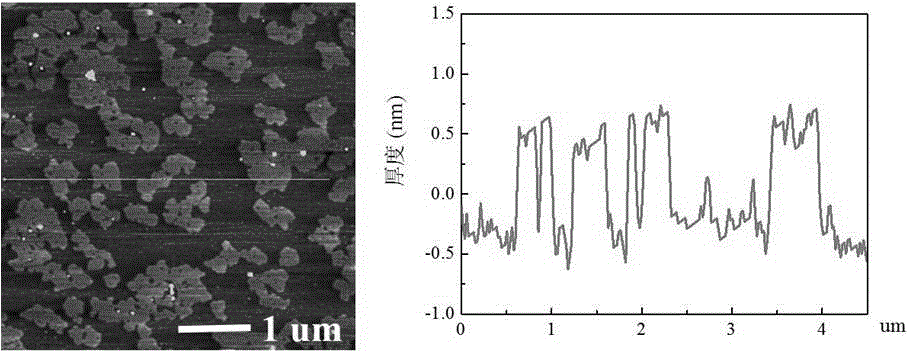

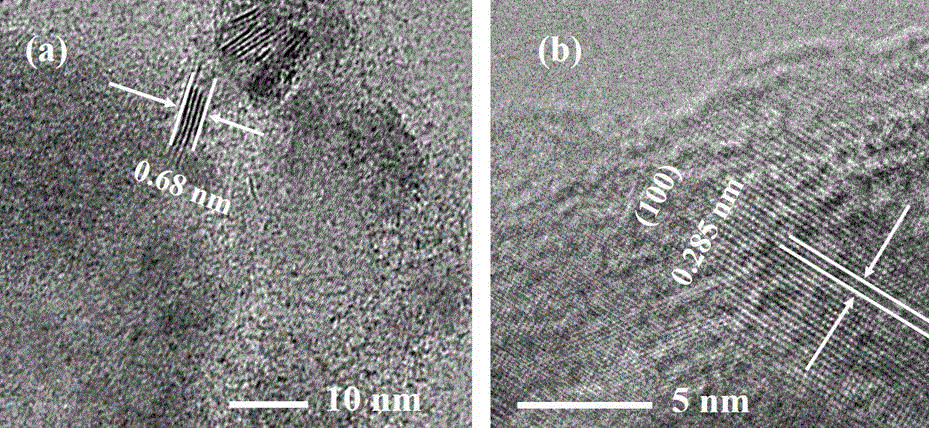

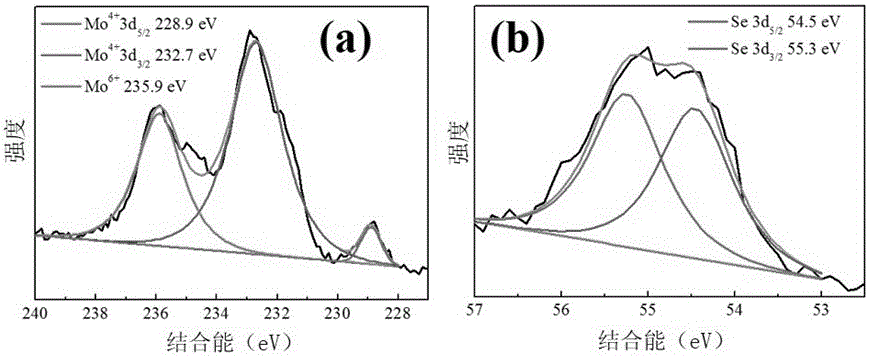

[0023] from figure 1 It can be seen from the figure that the sheet thickness of the prepared molybdenum diselenide and its oxide nanosheet composites is very small, and the edges are irregular and have some hole structures, indicating that there are many defects in it that may be partially oxidized, and compared with Larger surface area. from figure 2 It can be seen that the prepared nanosheets still retain the crystal structure of molybdenum diselenide, in which figure 2 In a, it can be observed that the interplanar spacing of the nanosheets is 0.68 nm, which corresponds to the...

Embodiment 2

[0025] Take 1g of molybdenum disulfide powder and place it in 120mL isopropanol, add 2wt% hydrogen peroxide and sonicate for 4 hours, pour off the supernatant after standing still, add 120mL isopropanol and then sonicate for 4 hours, take the upper nanosheet after standing still layer dispersion at 50 o C Vacuum drying in a vacuum oven for 4 days to remove residual solvents to obtain nanosheet composites.

[0026] from Figure 5 It can be seen that the catalytic performance of molybdenum disulfide and its oxide nanosheet composites is also greatly improved compared with the molybdenum disulfide nanosheet itself, indicating that this is a kind of hydrogen evolution that can be used to improve the transition metal dichalcogenides. A general approach to catalytic performance.

[0027] Therefore, the catalyst prepared by our method has very good catalytic performance for hydrogen evolution reaction, and its performance is comparable to that of traditional metallic platinum catal...

Embodiment 3

[0029] Take 1g of molybdenum diselenide powder and place it in 150mL N-methylpyrrolidone, add 5wt% hydrogen peroxide and sonicate for 3 hours, pour off the supernatant after standing still, add 150mLN-methylpyrrolidone and then sonicate for 3 hours, take it after standing still The dispersion of the upper nanosheet layer was placed in water and dialyzed for 5 days to remove solvents and other water-soluble impurities. Finally, the product is freeze-dried with a freeze dryer to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com