NaBH4 hydrogen production catalyst Co-CoOx@C-rGO and preparation method thereof

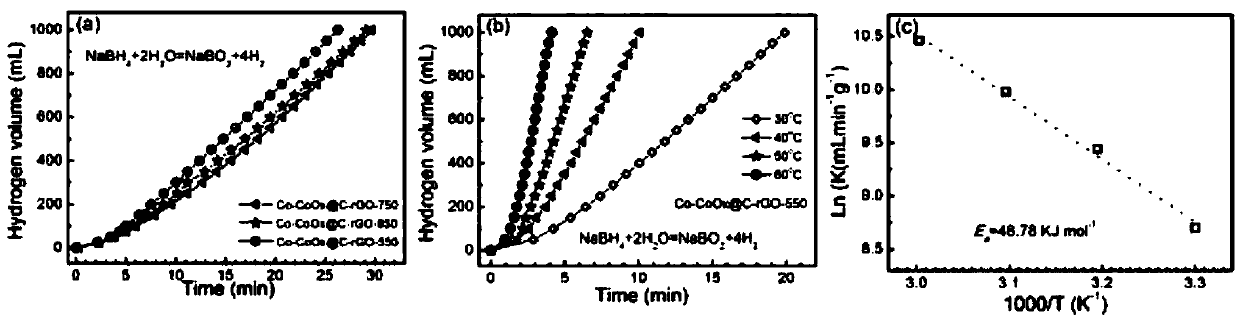

A catalyst and ethanol dispersion technology, which is applied in the field of NaBH4 hydrogen production catalyst Co-CoOx@C-rGO and its preparation, can solve the problems of high cost, affecting large-scale use, and low reserves, so as to reduce activation energy and improve Catalytic activity, the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The NaBH 4 The preparation method of the catalyst of hydrogen production, the steps are as follows:

[0028] (1), GO is put into ethanol, and stirring and ultrasonic are carried out alternately, obtain the ethanol dispersion liquid of GO;

[0029] (2), metal salt C 4 h 6 CoO 4 The aqueous solution of GO was added to the ethanol dispersion of GO, and then placed in a water bath at 80 °C and stirred for 10 h;

[0030] (3) Add the aqueous solution of glucose and continue to stir for 30 minutes, then transfer to a 500mL reaction kettle, and heat at 170°C for 12 hours;

[0031] (4), suction filtration, washing with water and ethanol, then freeze-drying for 24 hours;

[0032] (5) After grinding and freeze-drying, the solid is put into a tube furnace, and heated at 10°C min under a nitrogen atmosphere. -1 Raise the temperature, bake at 550-750°C for 1 hour, and collect the product to obtain the catalyst.

[0033] Preferably, in step (1), the concentration of the ethanol...

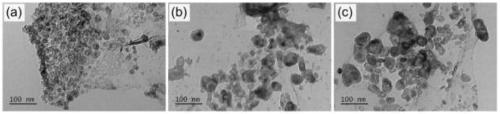

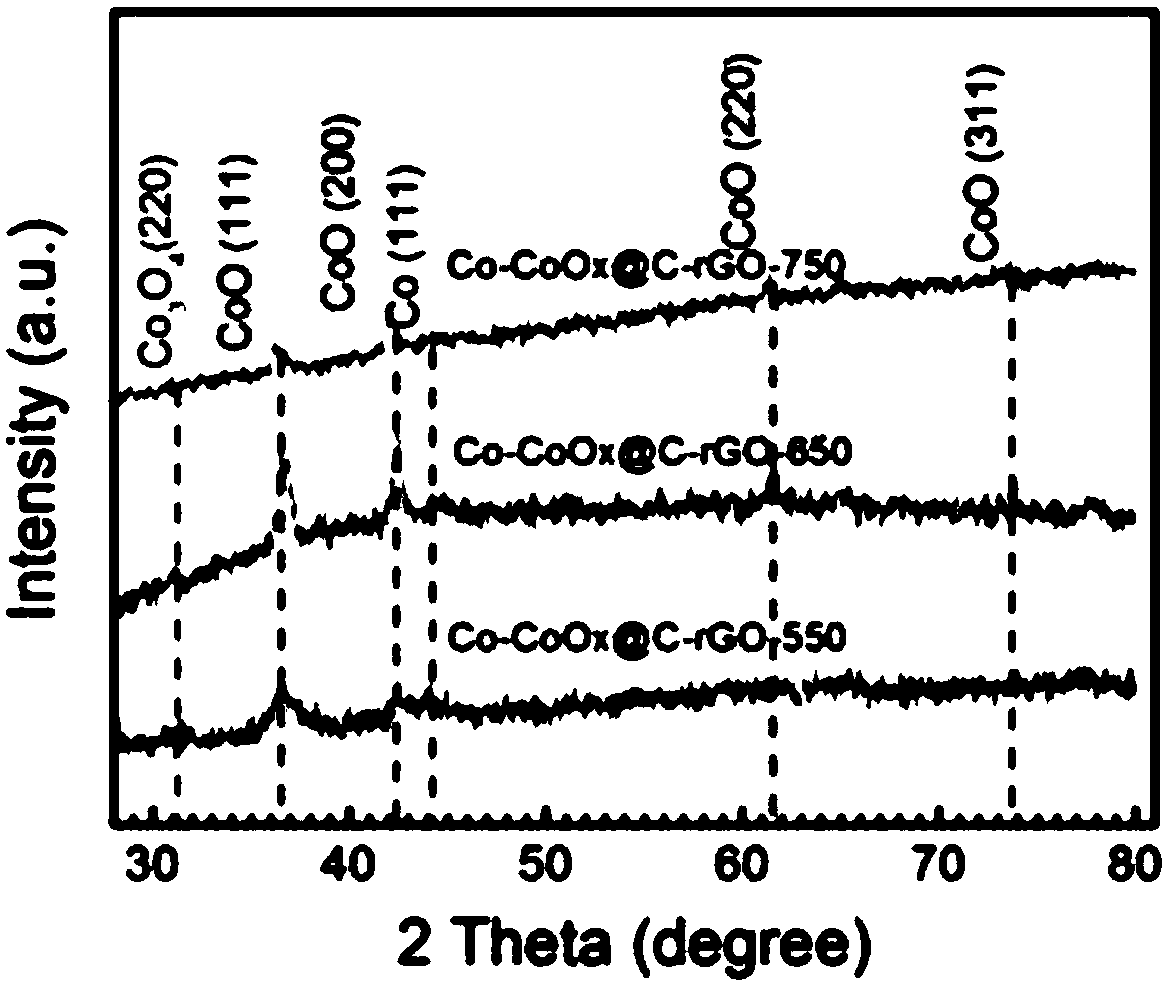

Embodiment 1

[0039] Catalyst Co-CoO x The preparation method of @C-rGO-550, the steps are as follows:

[0040] (1) Add GO (300mg) into ethanol (300mL), stir and ultrasonically carry out alternately for 2h to ensure uniform dispersion, and obtain the ethanol dispersion of GO, which is transferred to a three-necked flask (500mL);

[0041] (2), metal salt C 4 h 6 CoO 4 Aqueous solution (0.2M, 60mL) was added to the ethanol dispersion of GO, then placed in a water bath at 80°C and stirred for 10h;

[0042] (3) Add an aqueous solution (10 mL) of glucose (800 mg) to the above liquid, continue to stir for 30 minutes, then transfer to a 500 mL reaction kettle, and heat at 170°C for 12 hours;

[0043] (4), suction filtration, washing with water and ethanol, then freeze-drying for 24 hours;

[0044] (5) After grinding and freeze-drying, the solid is put into a tube furnace, and heated at 10°C min under a nitrogen atmosphere. -1 Raise the temperature, bake at 550°C for 1 hour, collect the produ...

Embodiment 2

[0046] The difference from Example 1 is that in step (5), the firing temperature is 650° C., and the others are the same as in Example 1.

[0047] The resulting target product number is Co-CoO x @C-rGO-650.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com