Patents

Literature

955results about How to "Lower activation energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

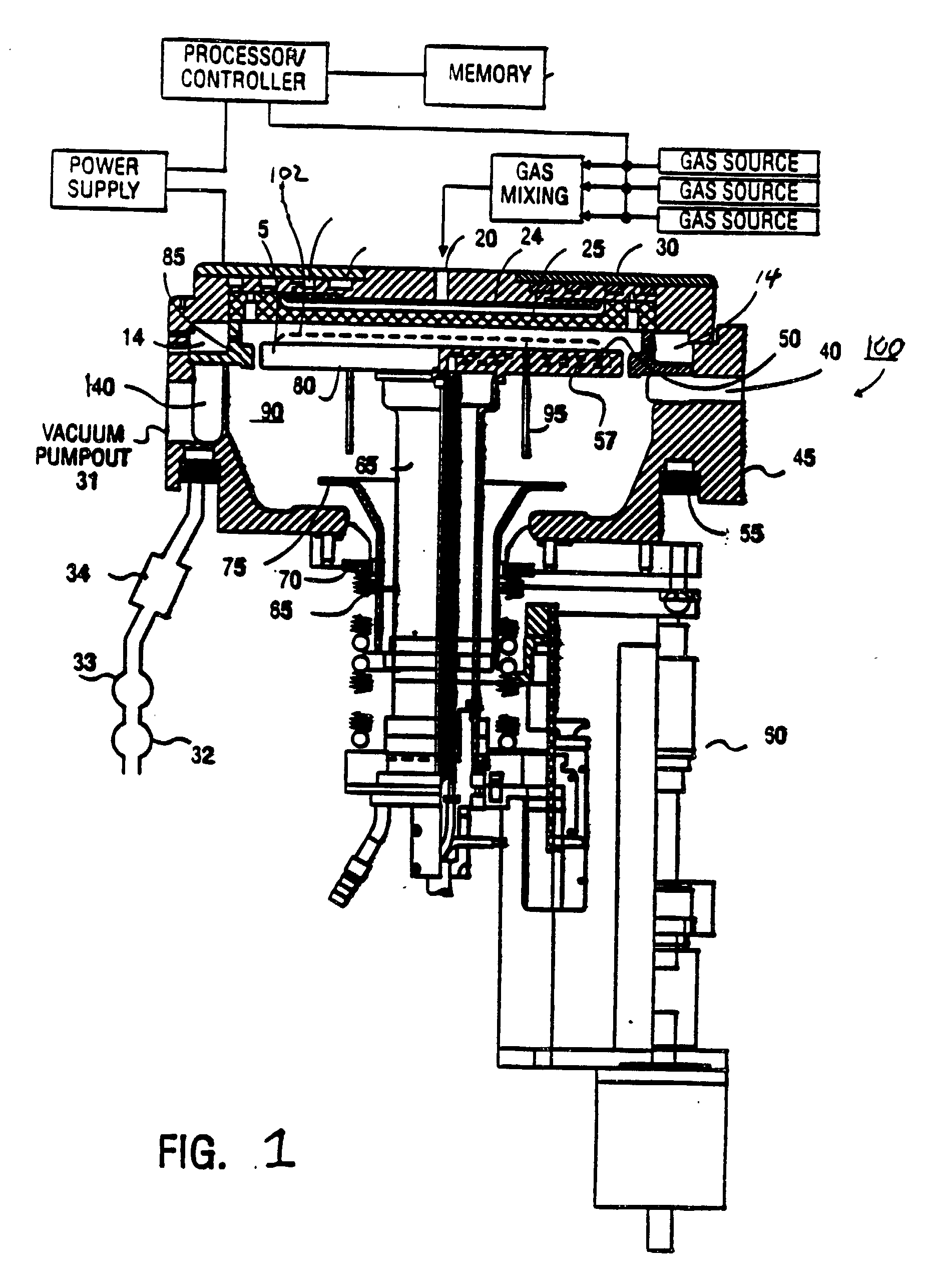

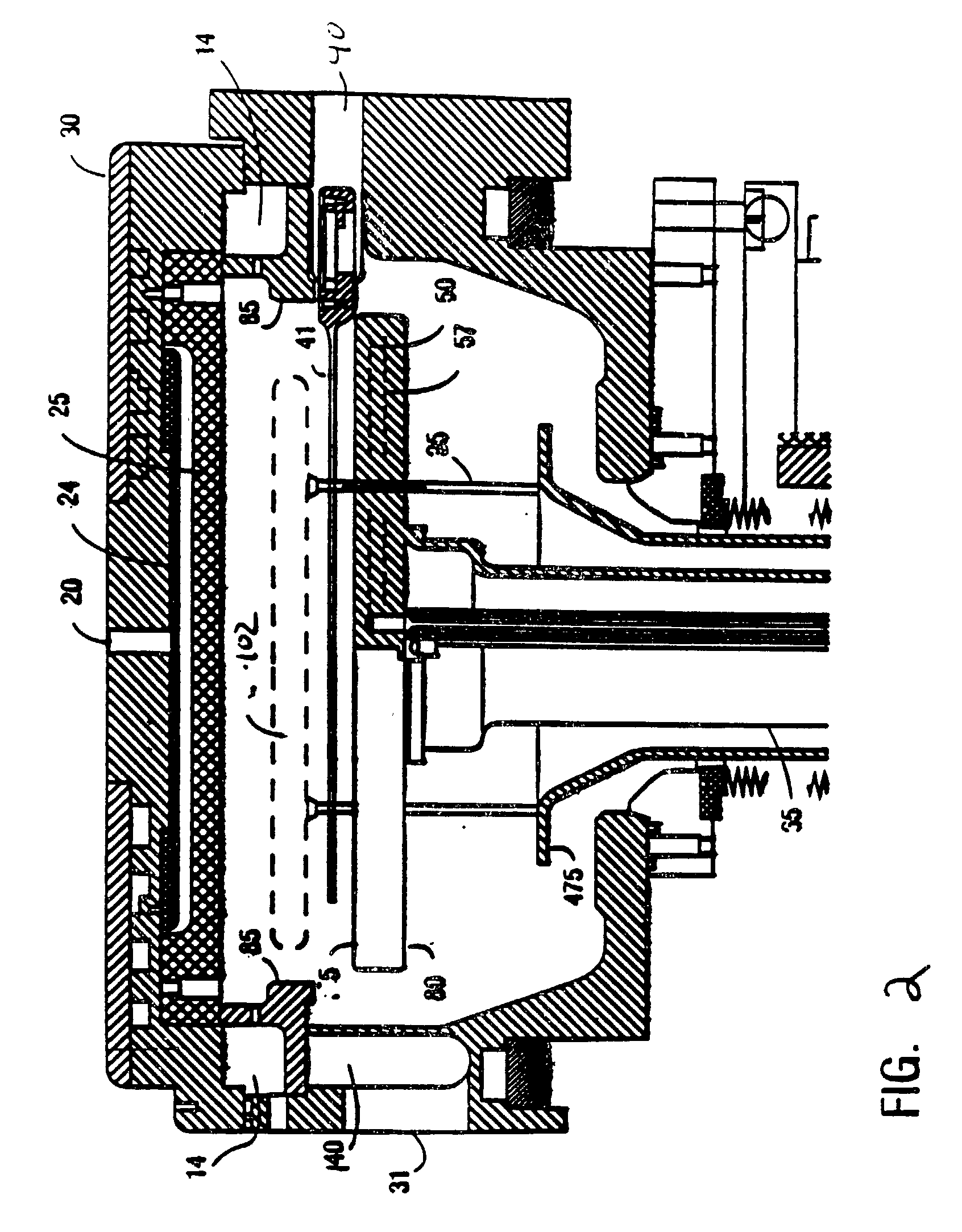

Method and apparatus for forming silicon containing films

InactiveUS20030124818A1Lower activation energyDecomposes faster and more efficientlyFrom solid stateSemiconductor/solid-state device manufacturingElectrical resistance and conductanceActivation energy

The present invention describes a method and apparatus for forming a uniform silicon containing film in a single wafer reactor. According to the present invention, a silicon containing film is deposited in a resistively heated single wafer chamber utilizing a process gas having a silicon source gas and which provides an activation energy less than 0.5 eV at a temperature between 750° C.-550° C.

Owner:APPLIED MATERIALS INC

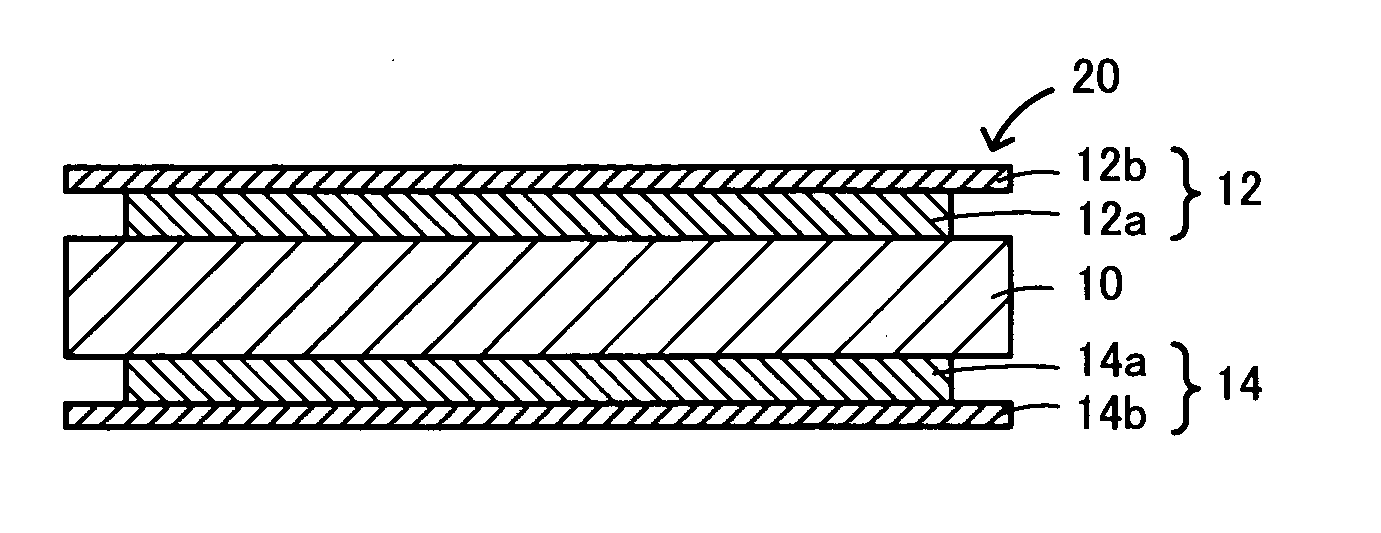

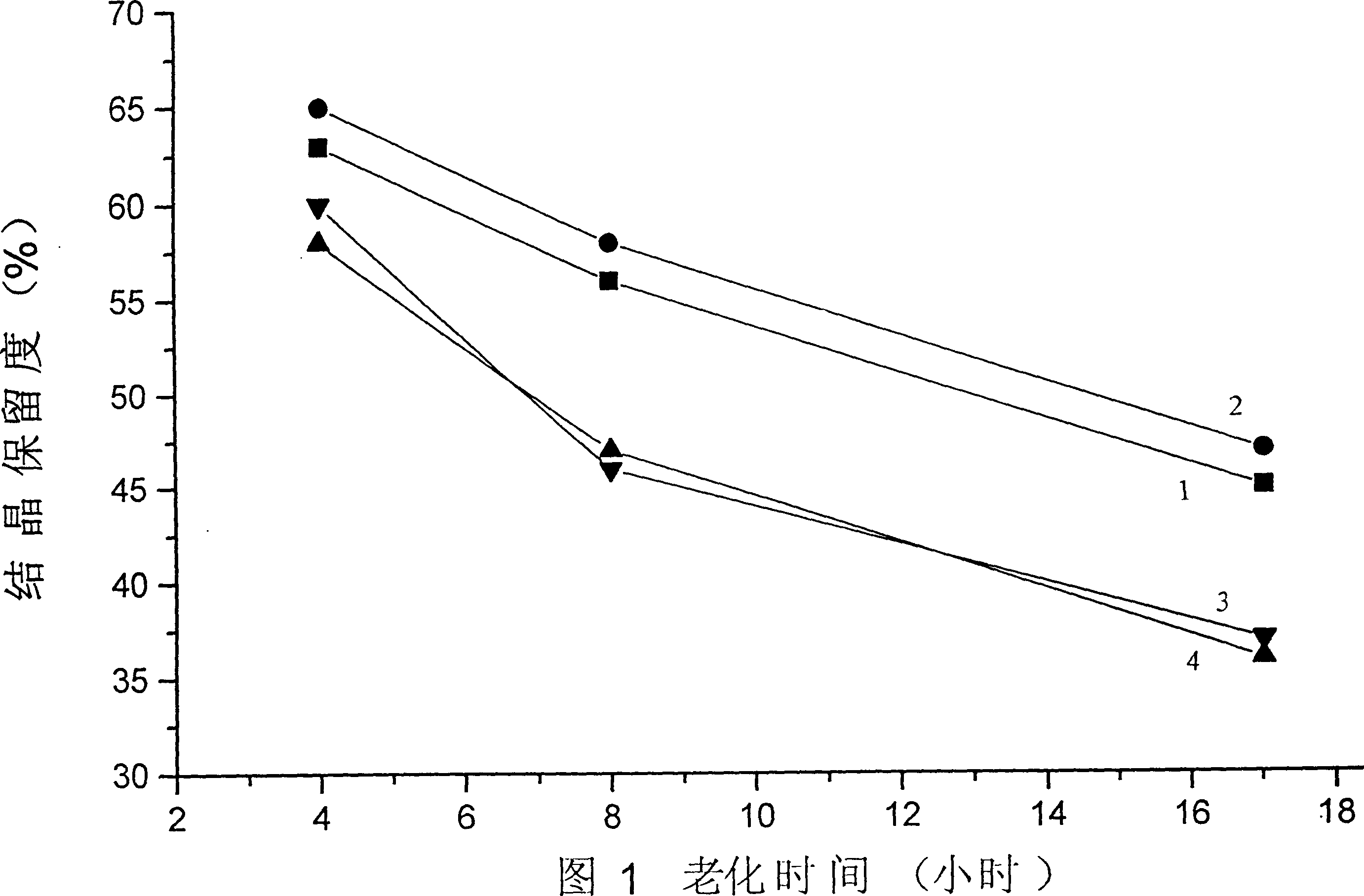

Garnet-type lithium ion-conducting oxide and all-solid-state lithium ion secondary battery containing the same

ActiveUS20110244337A1Improve lithium ion conductivitySmall rate of changeSolid electrolyte cellsElectrolytesAll solid stateIntensity normalization

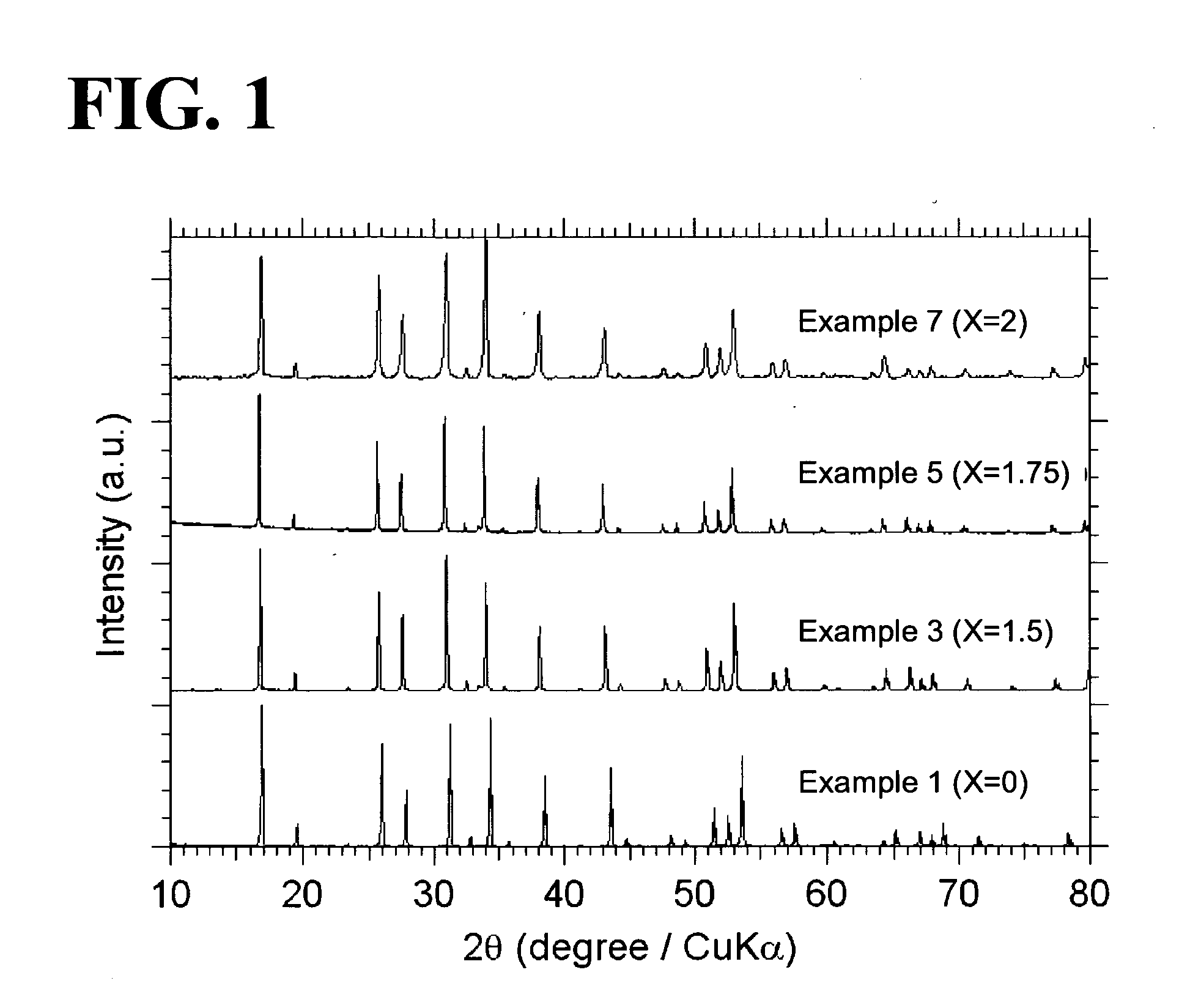

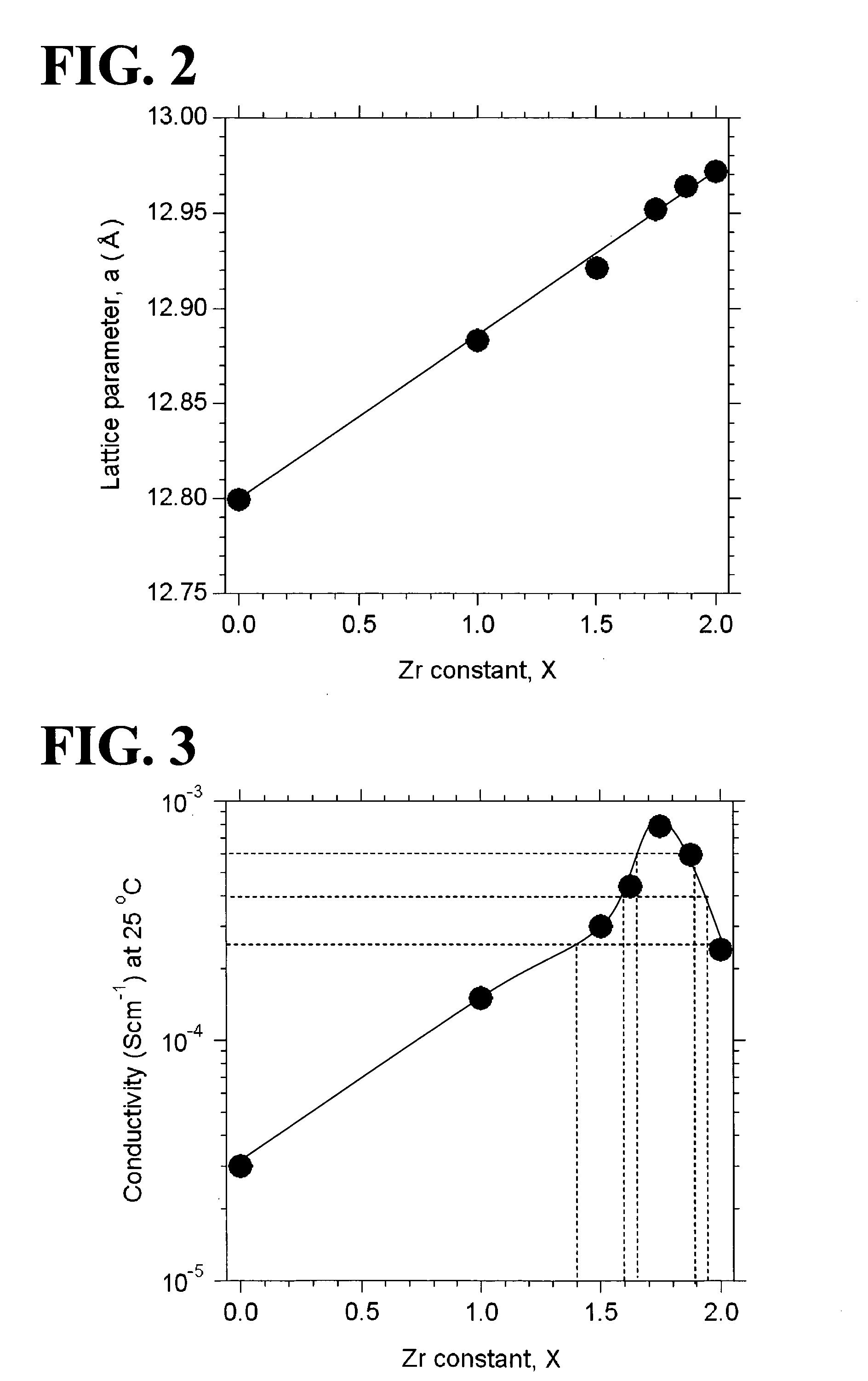

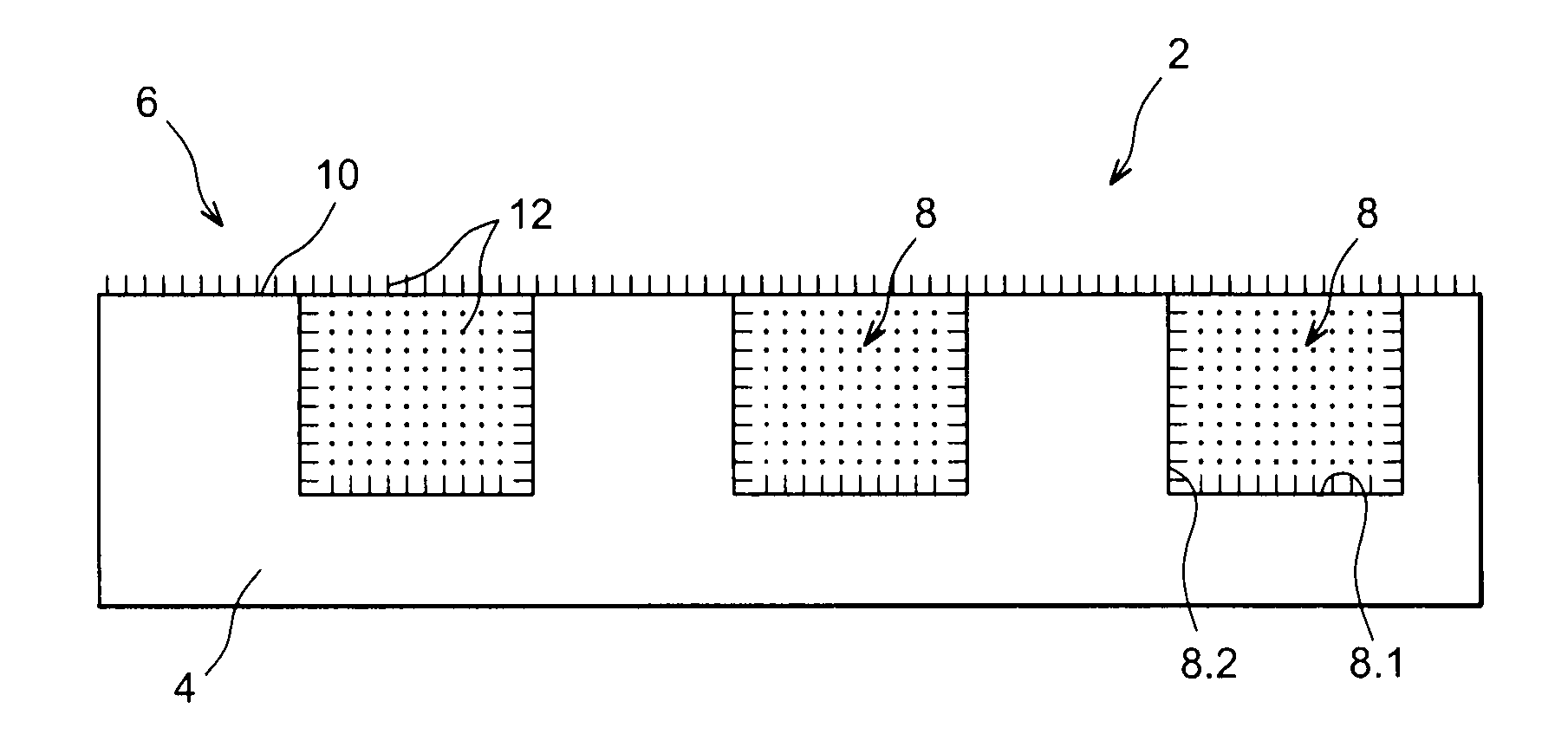

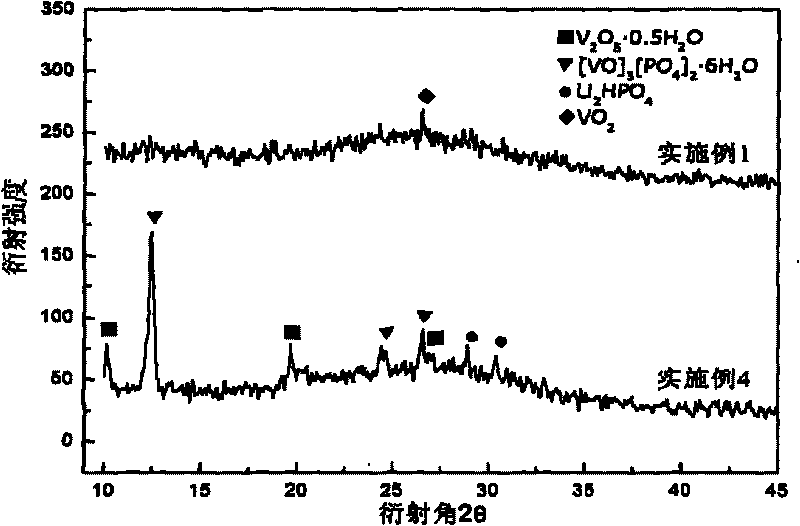

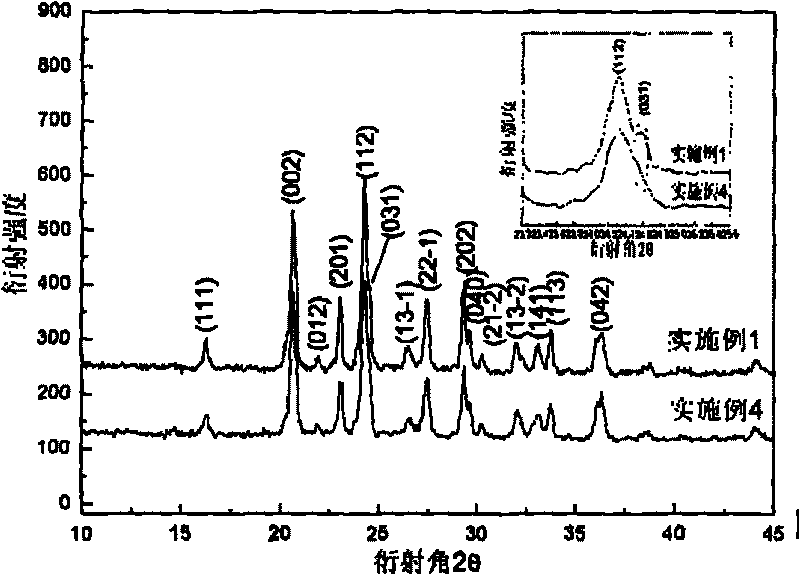

An all-solid-state lithium ion secondary battery containing a novel garnet-type oxide serving as a solid electrolyte. The garnet-type lithium ion-conducting oxide is one represented by the formula Li5+XLa3(ZrX, A2-X)O12, wherein A is at least one selected from the group consisting of Sc, Ti, V, Y, Nb, Hf, Ta, Al, Si, Ga, Ge, and Sn and X satisfies the inequality 1.4≦X<2, or is one obtained by substituting an element having an ionic radius different from that of Zr for Zr sites in an garnet-type lithium ion-conducting oxide represented by the formula Li7La3Zr2O12, wherein the normalized intensity of an X-ray diffraction (XRD) pattern with a diffraction peak, as normalized on the basis of the intensity of a diffraction peak, is 9.2 or more.

Owner:TOYOTA CENT RES & DEV LAB INC

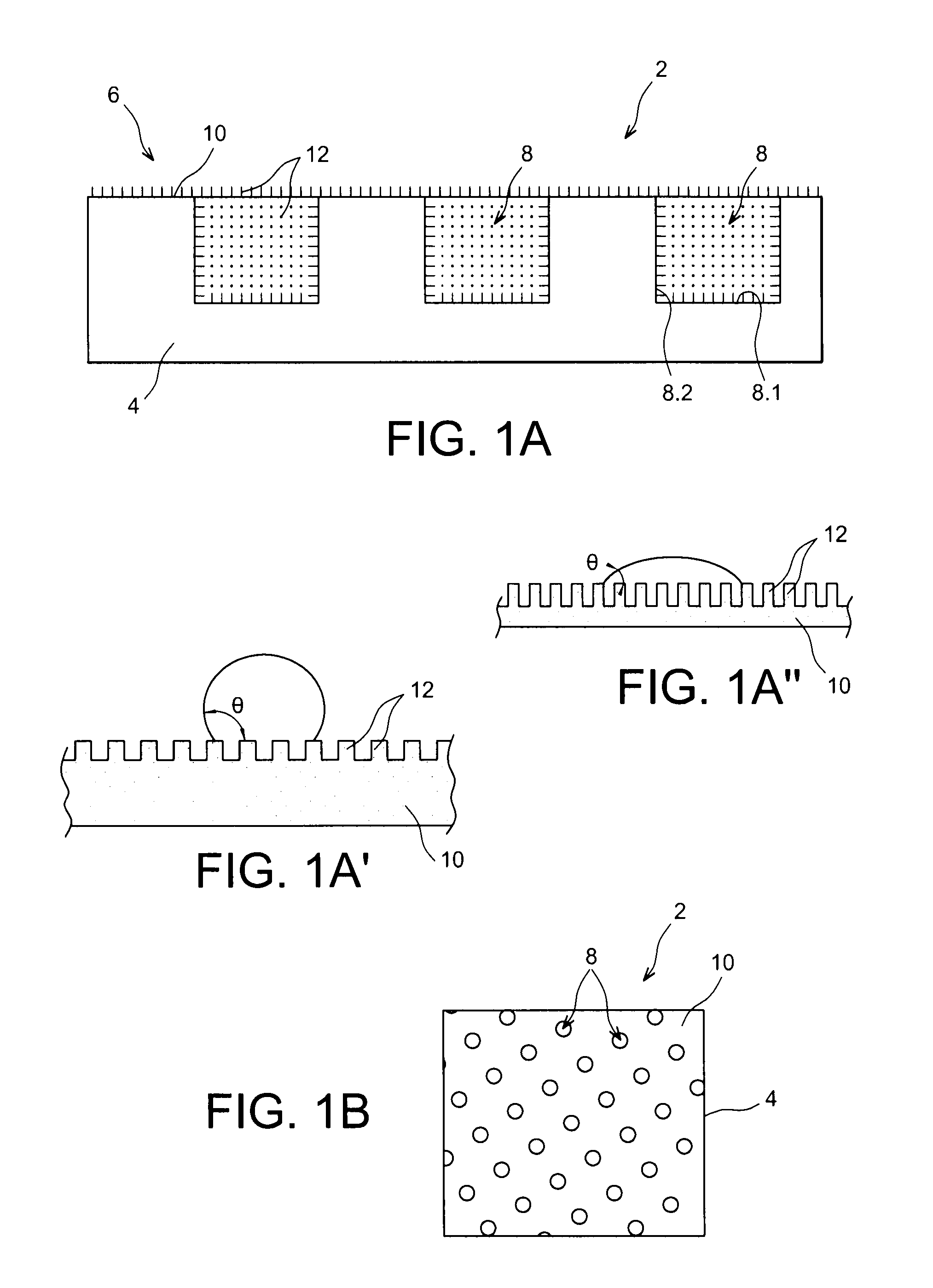

Heat exchange structure and cooling device comprising such a structure

ActiveUS20110198059A1Improve performanceImprove efficiencyMaterial nanotechnologyDecorative surface effectsNanoparticleEngineering

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

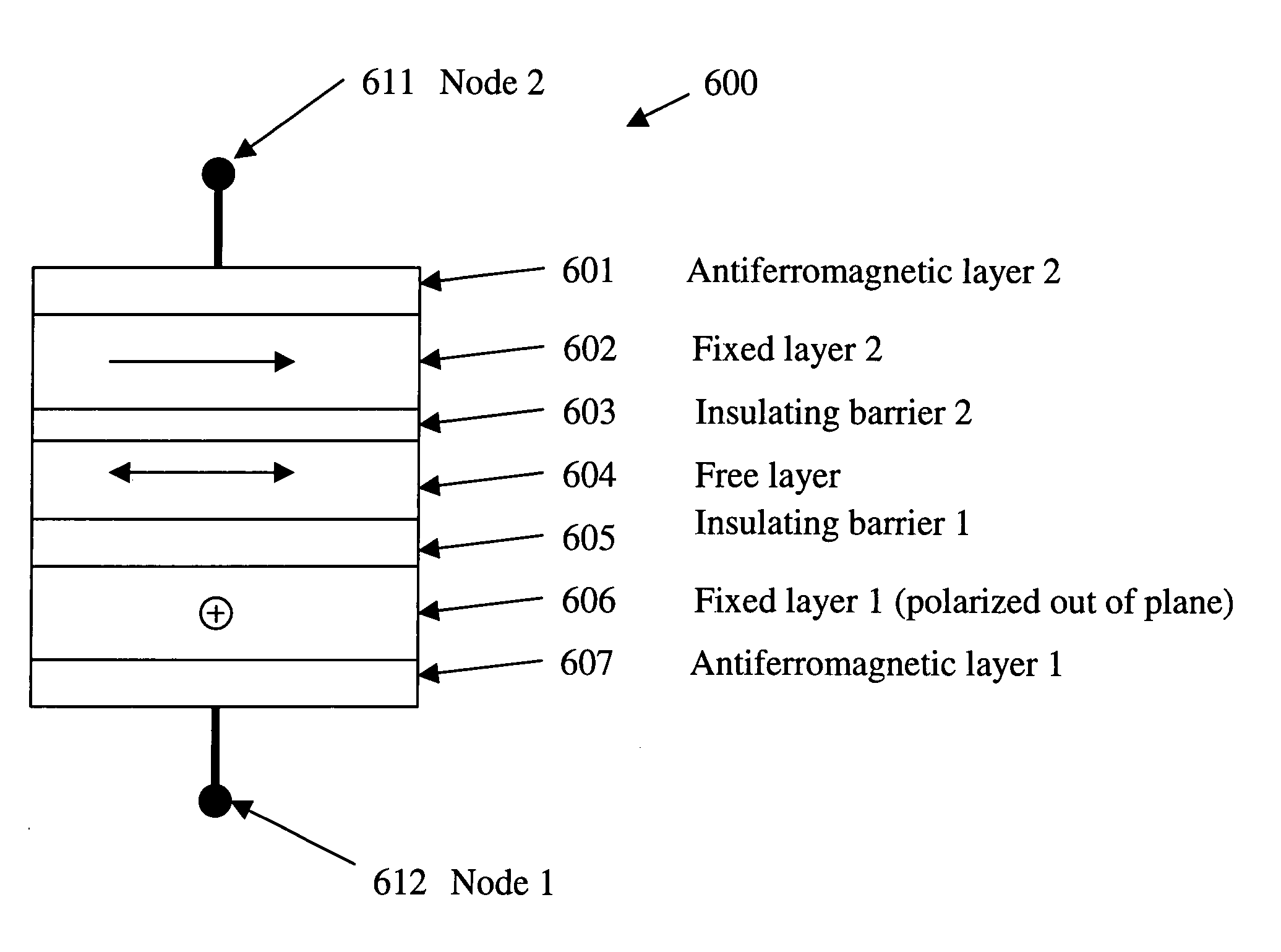

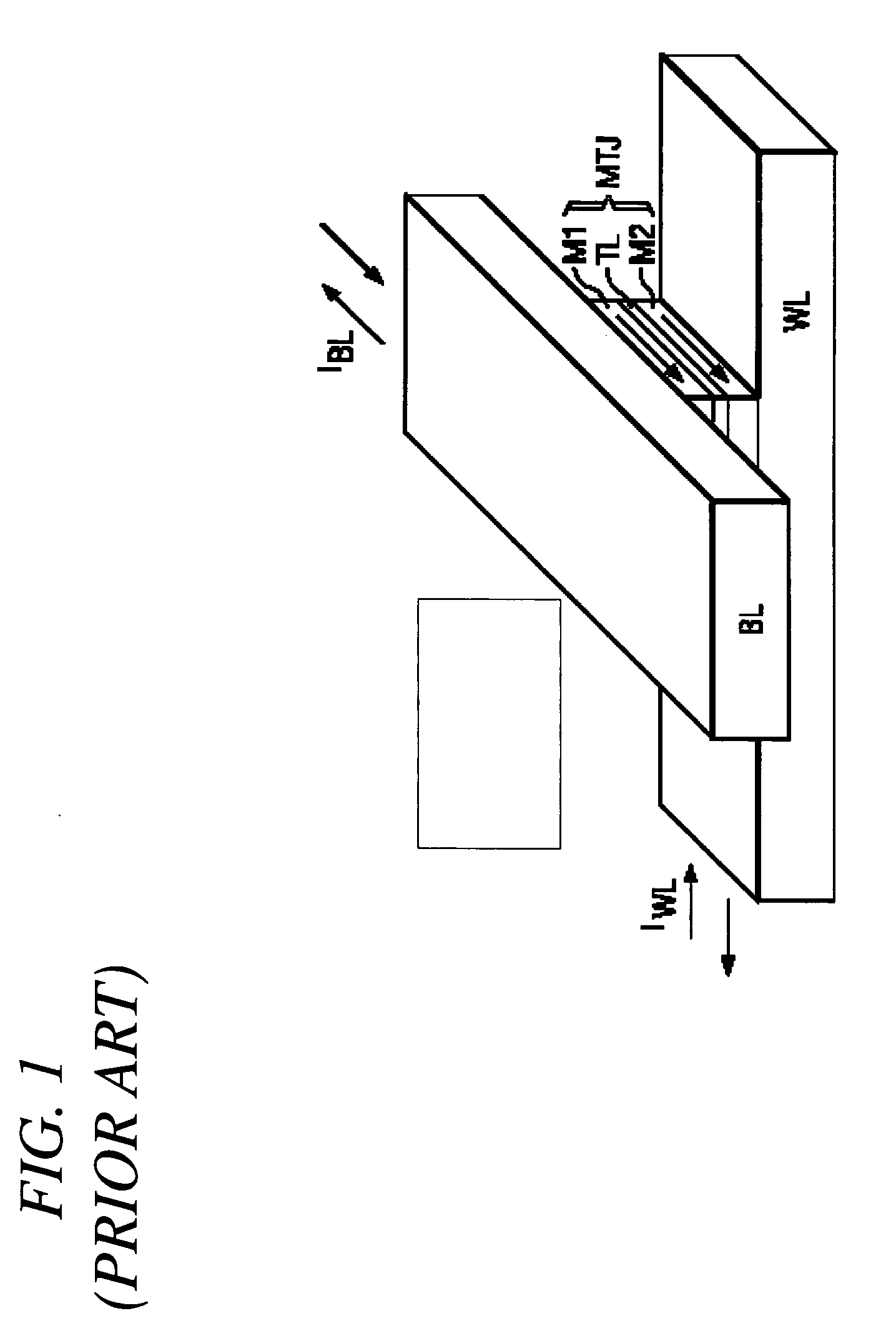

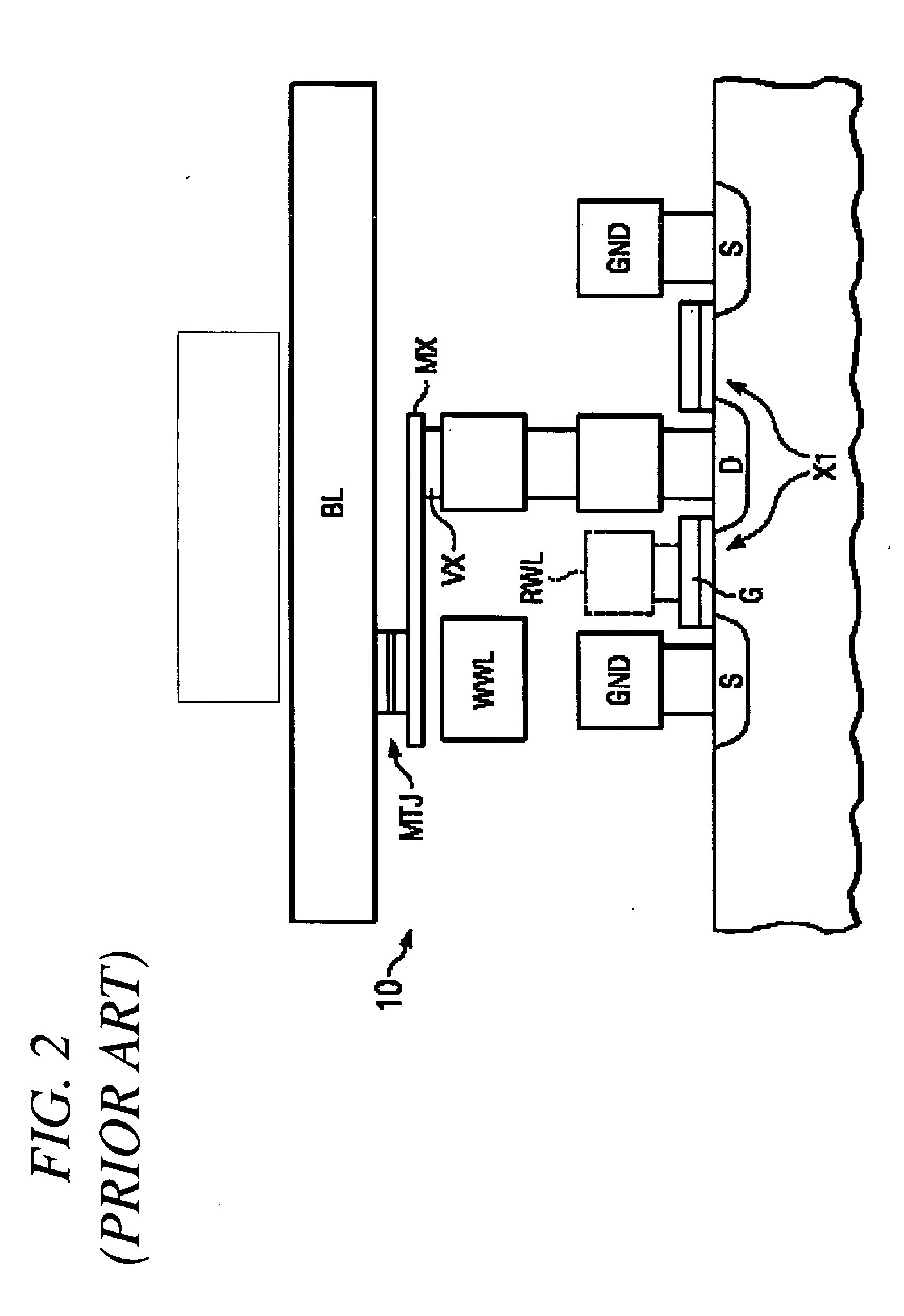

Read out scheme for several bits in a single MRAM soft layer

InactiveUS20060013039A1Increase memory densityReduce manufacturing costSemiconductor/solid-state device manufacturingDigital storageSoft layerElectrical resistance and conductance

A magnetic tunnel junction (MTJ) device is configured to store at least two bits of data in a single cell utilizing the variable resistance characteristic of a MTJ. The MTJ includes a soft and two fixed magnetic layers with fixed field directions oriented in perpendicular directions. The soft magnetic layer is separated from the fixed layers by insulating layers preferably with different thicknesses, or with different material compositions. The resulting junction resistance can exhibit at least four distinct resistance values dependent on the magnetic orientation of the free magnetic layer. The cell is configured using a pattern with four lobes to store two bits, and eight lobes to store three bits. The resulting cell can be used to provide a fast, non-volatile magnetic random access memory (MRAM) with high density and no need to rewrite stored data after they are read, or as a fast galvanic isolator.

Owner:INFINEON TECH AG

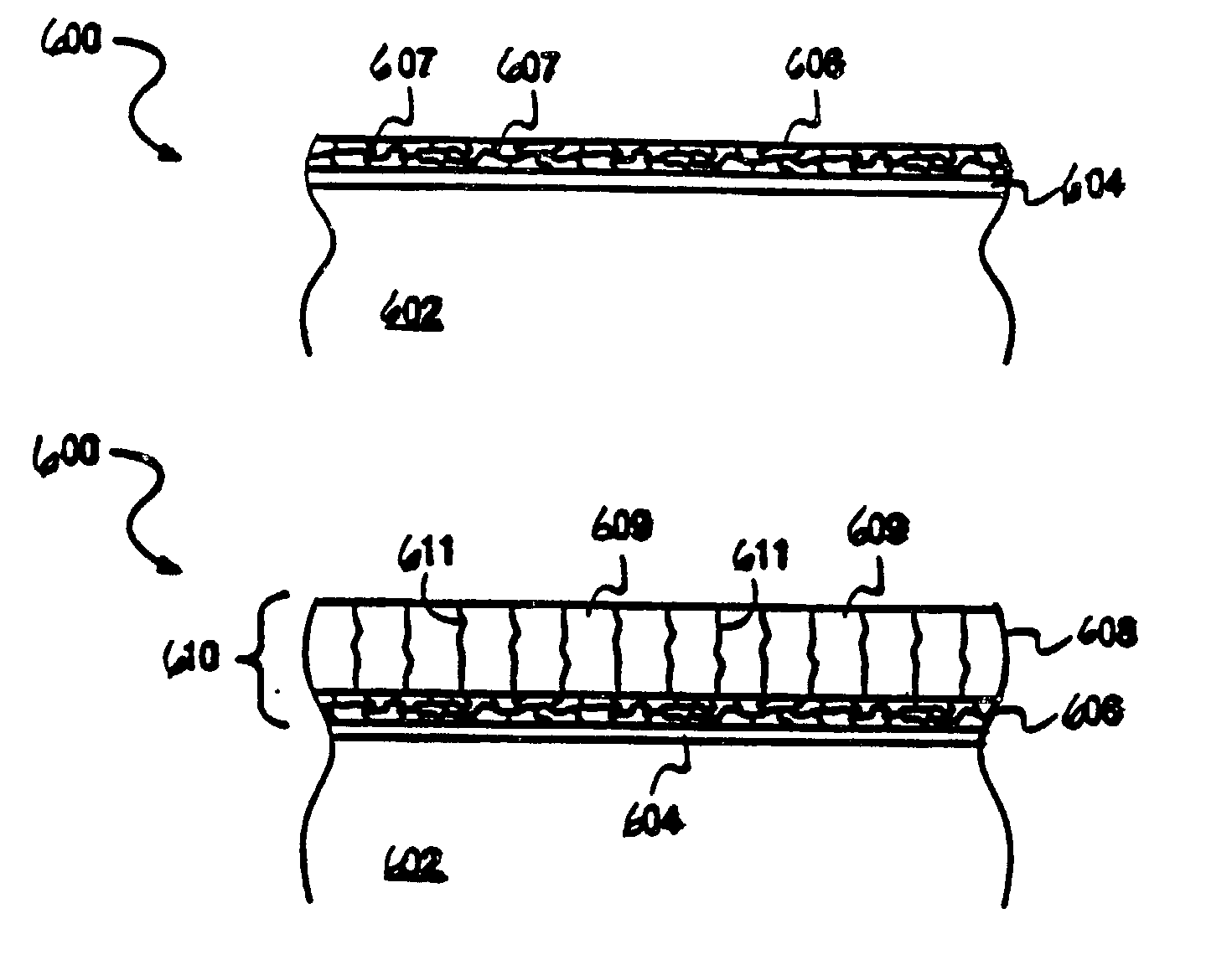

Composite proton exchange membrane and preparation method thereof

InactiveCN102427141AGood chemical stabilitySimple preparation processFilament/thread formingSolid electrolyte fuel cellsFiberWater insoluble

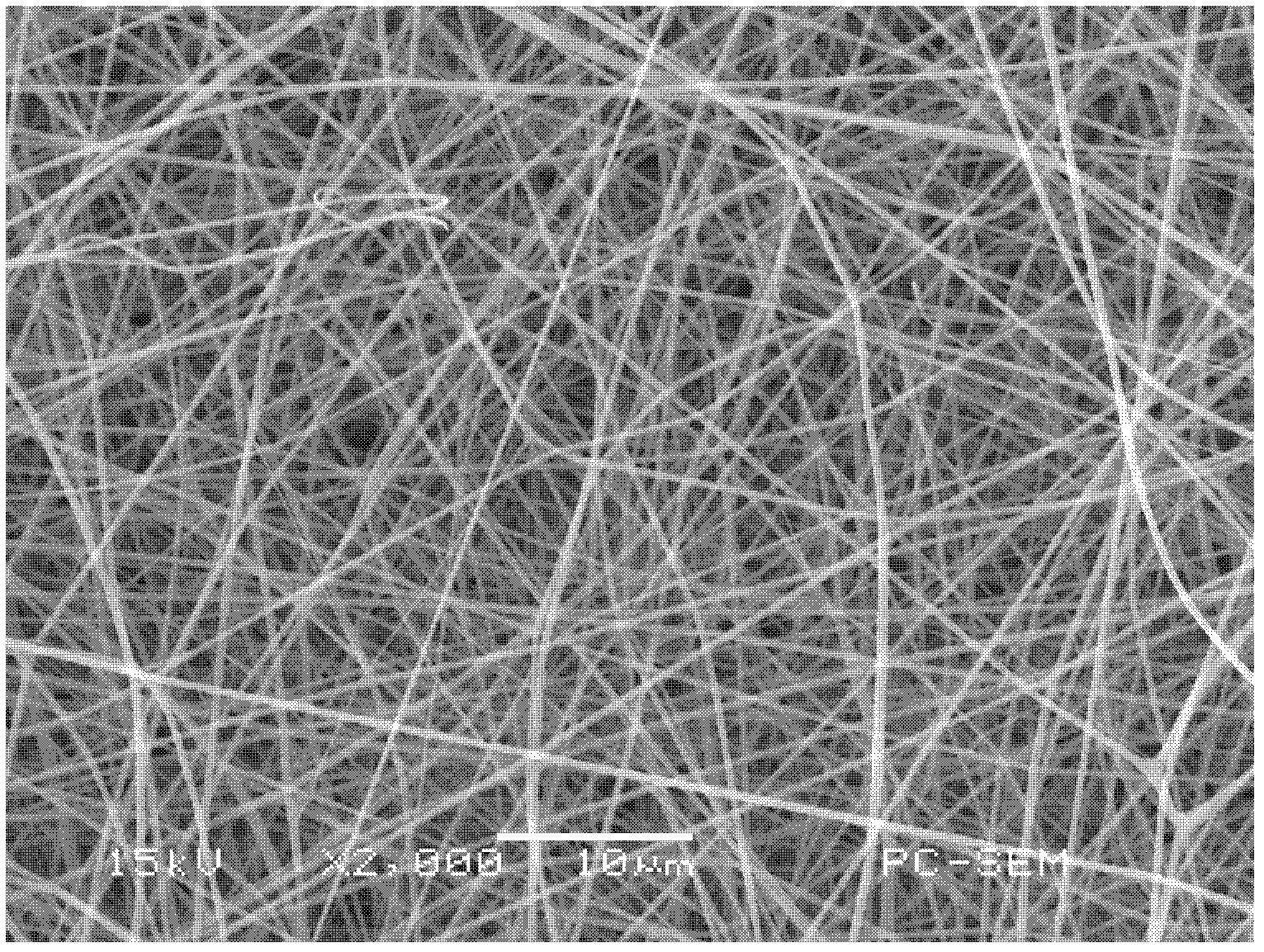

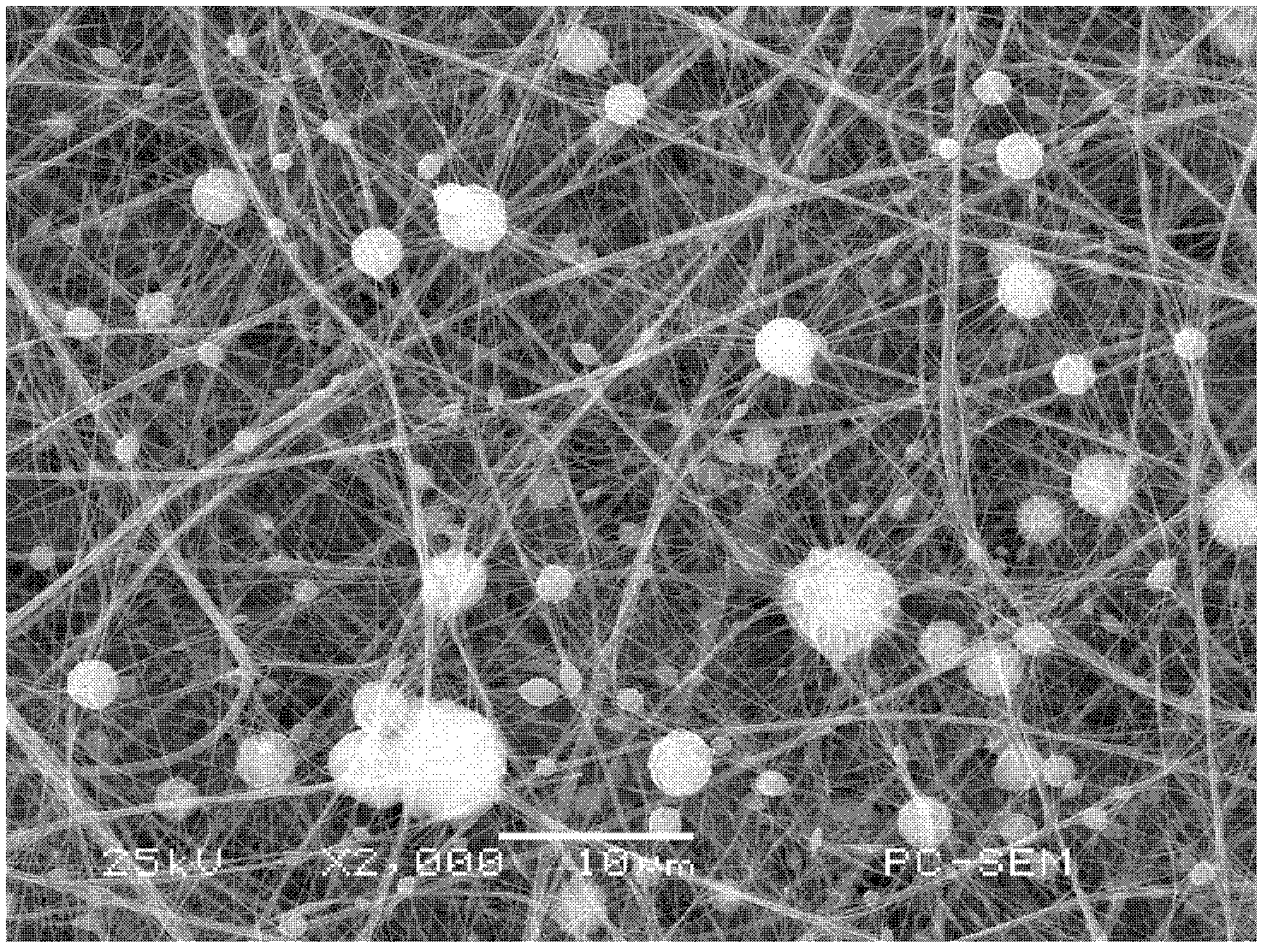

The invention discloses a composite proton exchange membrane and a preparation method thereof. The preparation method for the composite proton exchange membrane comprises the following steps of: dissolving a soluble proton exchange resin A and a water insoluble high molecular polymer B to obtain solutions for electrostatic spinning; adding the solutions for the electrostatic spinning into two injectors of an electrostatic spinning device respectively, and performing the electrostatic spinning under electrostatic high pressure to obtain chemically-heterogeneous electrostatic spinning fiber membranes; modifying the chemically-heterogeneous electrostatic spinning fiber membranes by using an electrostatic self-assembly method to obtain a modified chemically-heterogeneous electrostatic spinning fiber membrane; dissolving the water insoluble high molecular polymer B in the modified chemically-heterogeneous electrostatic spinning fiber membrane by using a solvent, and dispersing and filling the dissolved water insoluble high molecular polymer B into gaps of the chemically-heterogeneous electrostatic spinning fiber membrane; and heating and drying the solvent to obtain the composite proton exchange membrane. The composite proton exchange membrane has high chemical stability, high proton conductivity and low proton conduction activation energy. The preparation method for the composite proton exchange membrane is simple and low in preparation cost.

Owner:SUN YAT SEN UNIV

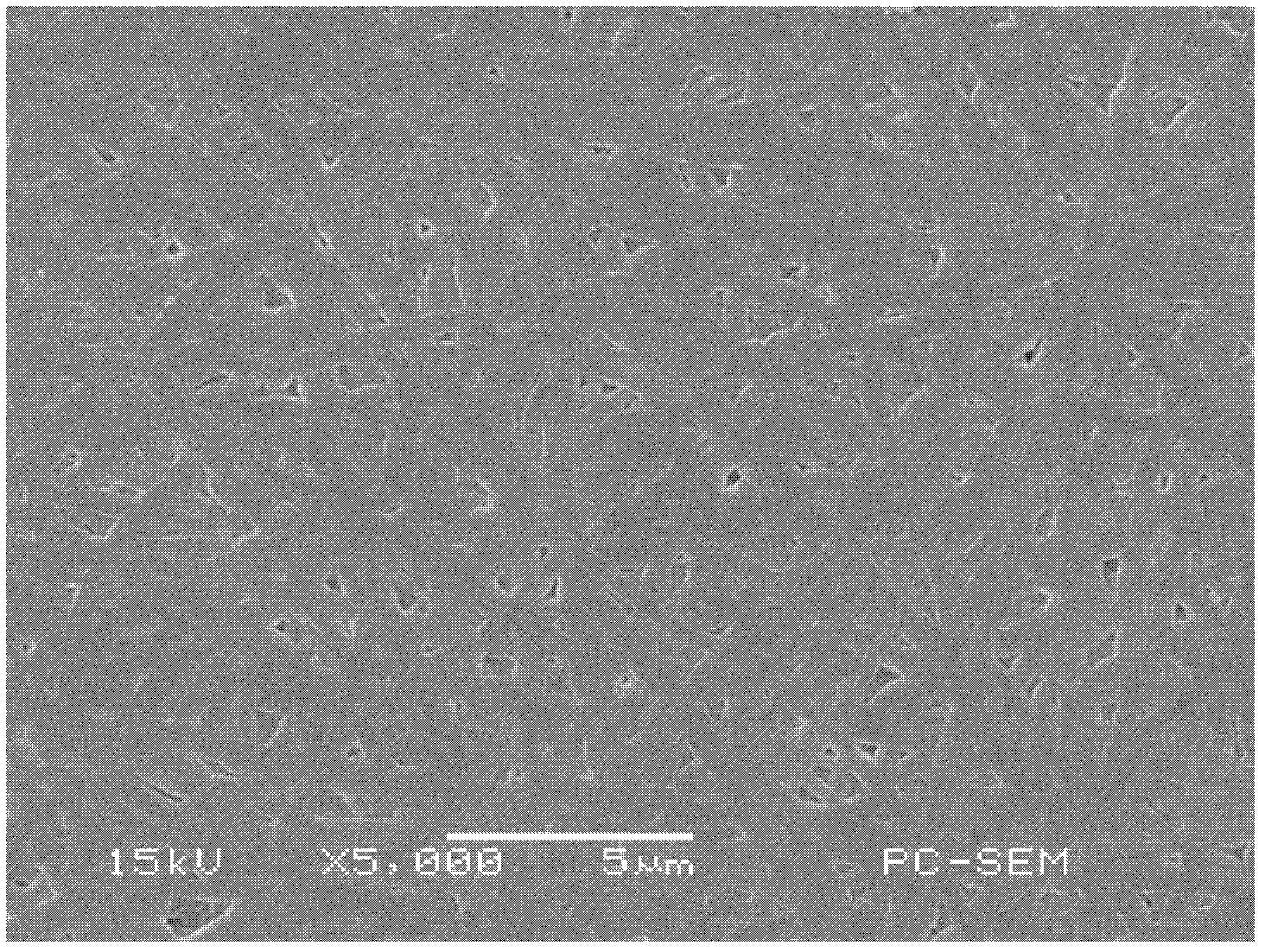

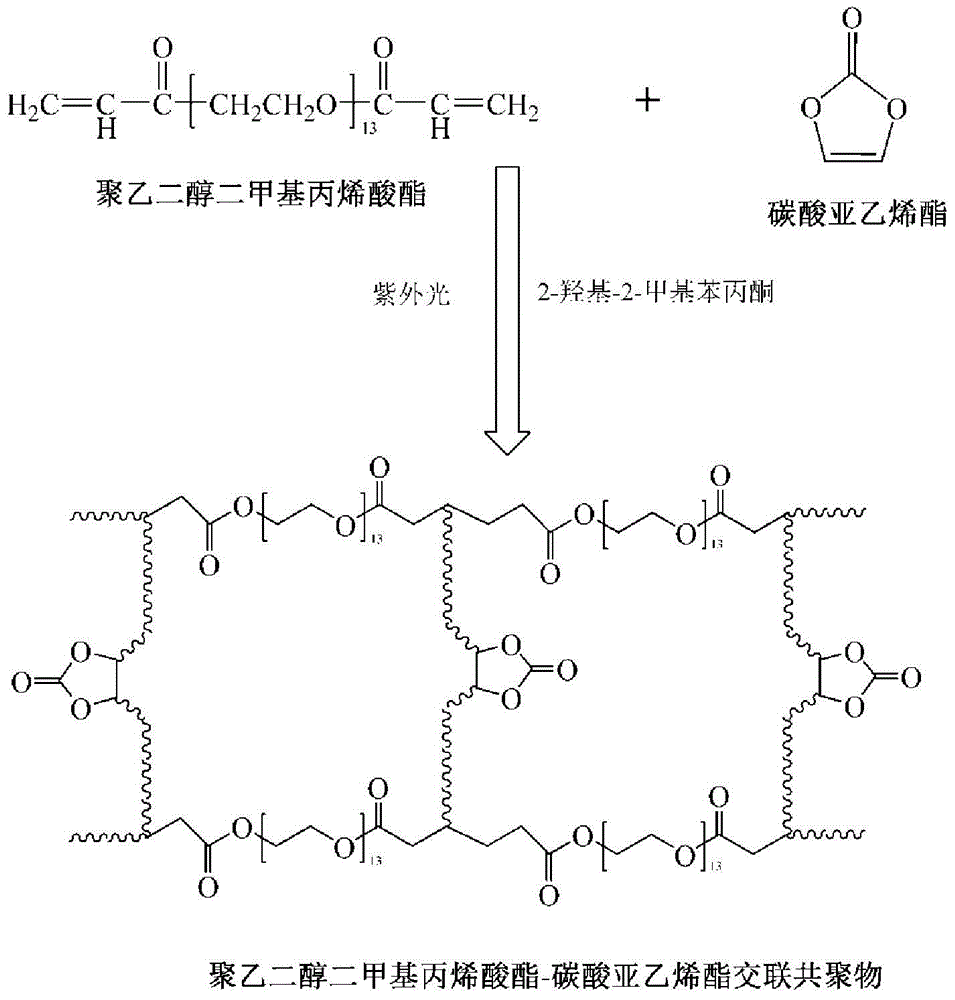

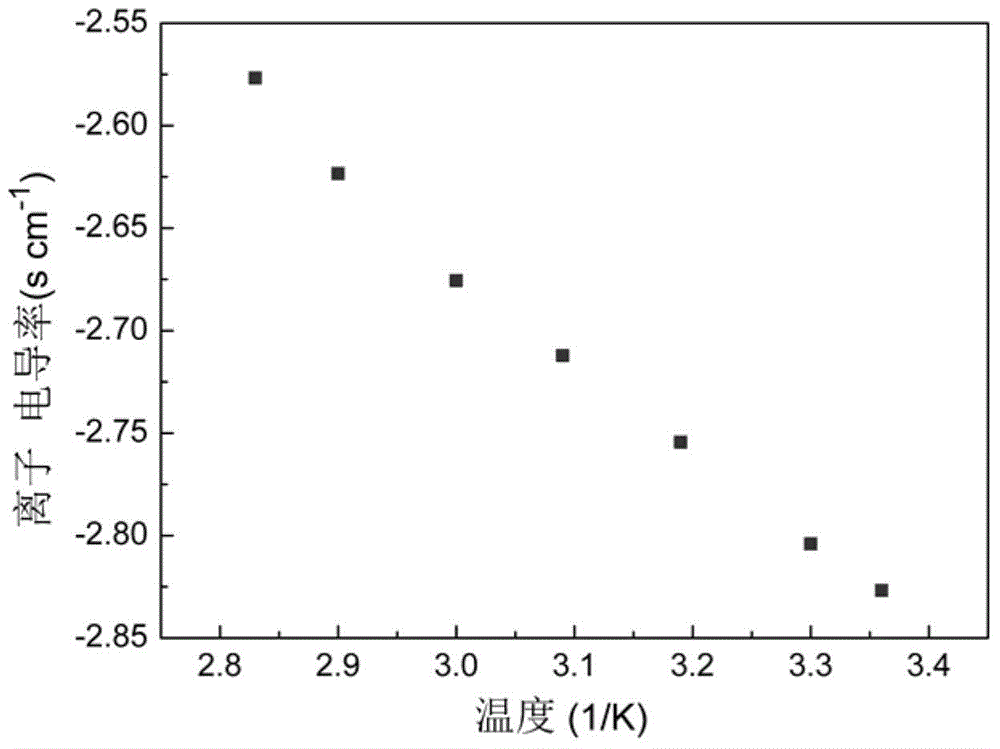

Preparation method of semi-interpenetrating network polymer gel electrolyte membrane

The invention provides a preparation method of a semi-interpenetrating network polymer gel electrolyte membrane. The method comprises the following steps: (A) adding a linear polymer and a solvent to a sample bottle, stirring and dissolving the linear polymer and the solvent, adding polyethylene glycol dimethyl acrylic ester, vinylene carbonate and a photoinitiator, and mixing the polyethylene glycol dimethyl acrylic ester, the vinylene carbonate and the photoinitiator evenly to form a solution; (B) coating a glass plate with the solution, covering a layer of glass plate to form a sandwich structure, and curing the sandwich structure to obtain an ultraviolet-cured semi-interpenetrating network polymer membrane; and (C) immersing the ultraviolet-cured semi-interpenetrating network polymer membrane into liquid electrolyte. According to the gel electrolyte provided by the invention, the balance between the ionic conductivity and the mechanical property is relatively well realized; the ionic conductivity at room temperature can be up to 1.49*10<-3>S cm<-1>; the mechanical property is good; the heat stability is good; the electrolyte can be prevented from leaking; the interface stability is good; and a lithium iron phosphate / metal lithium battery assembled by the gel polymer electrolyte membrane has excellent cycle performance and rate performance.

Owner:SHANGHAI JIAO TONG UNIV

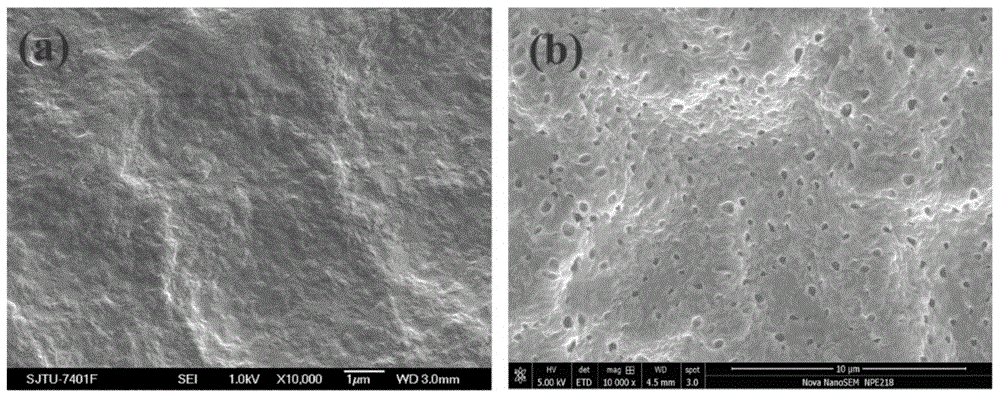

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

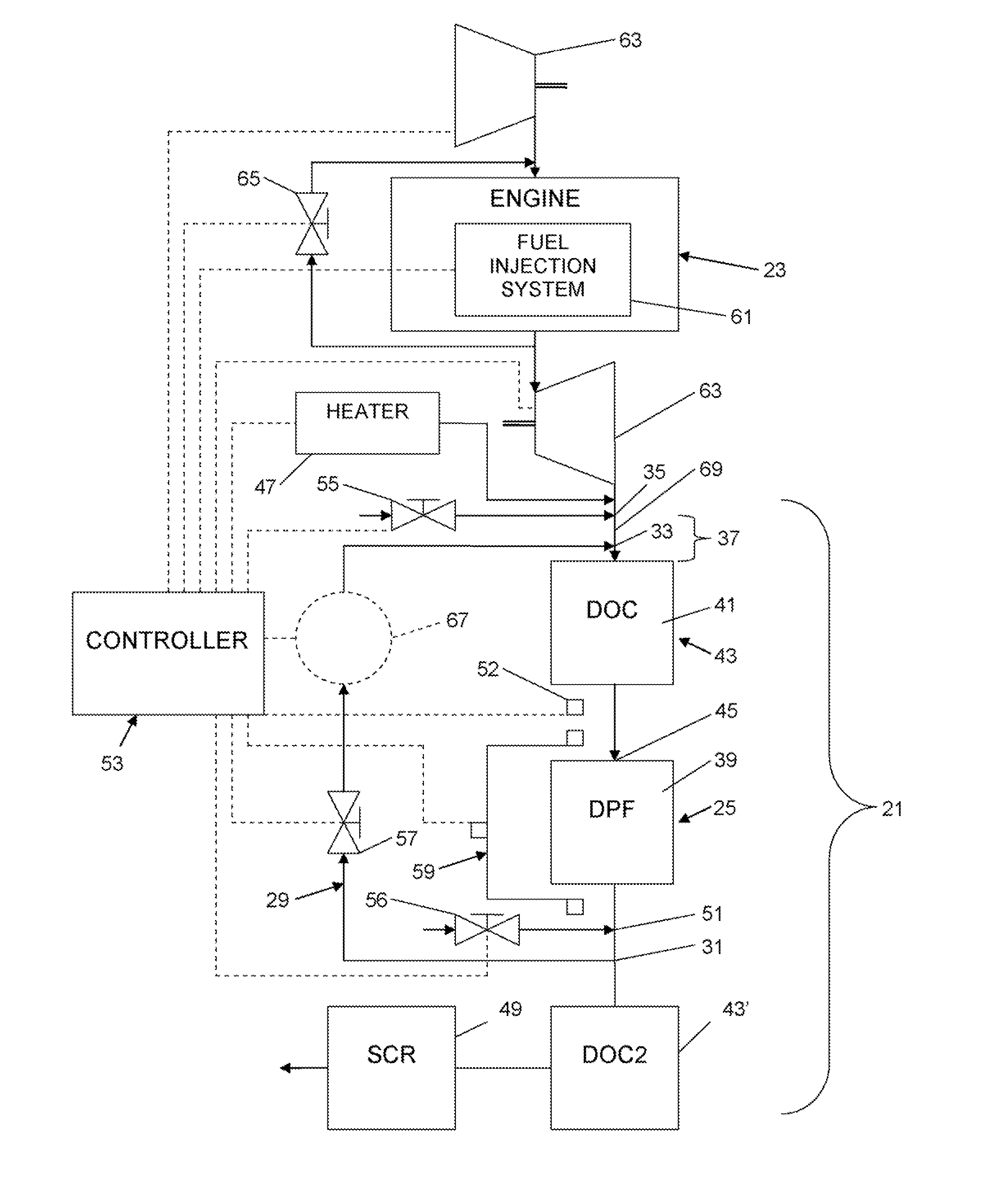

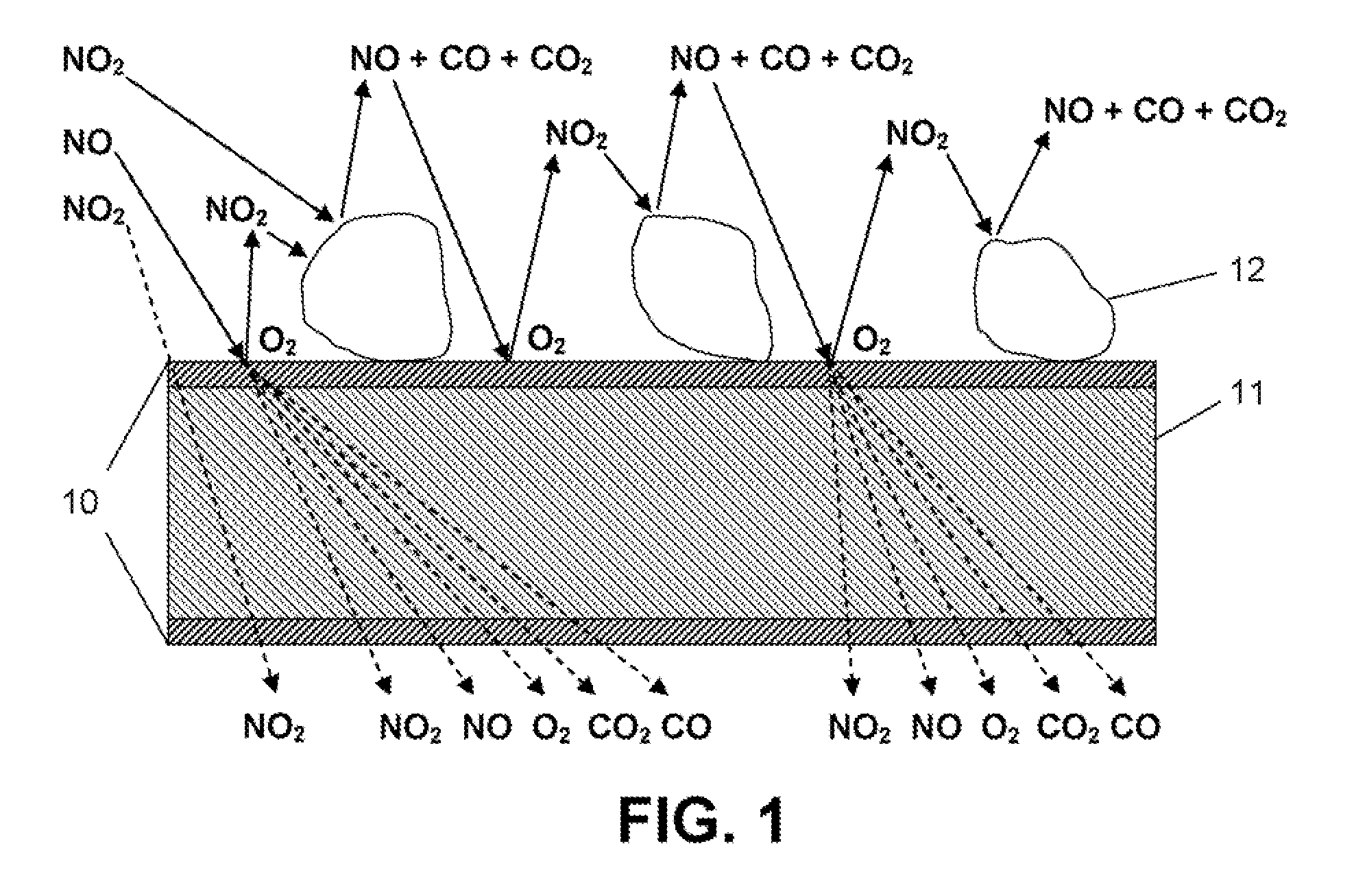

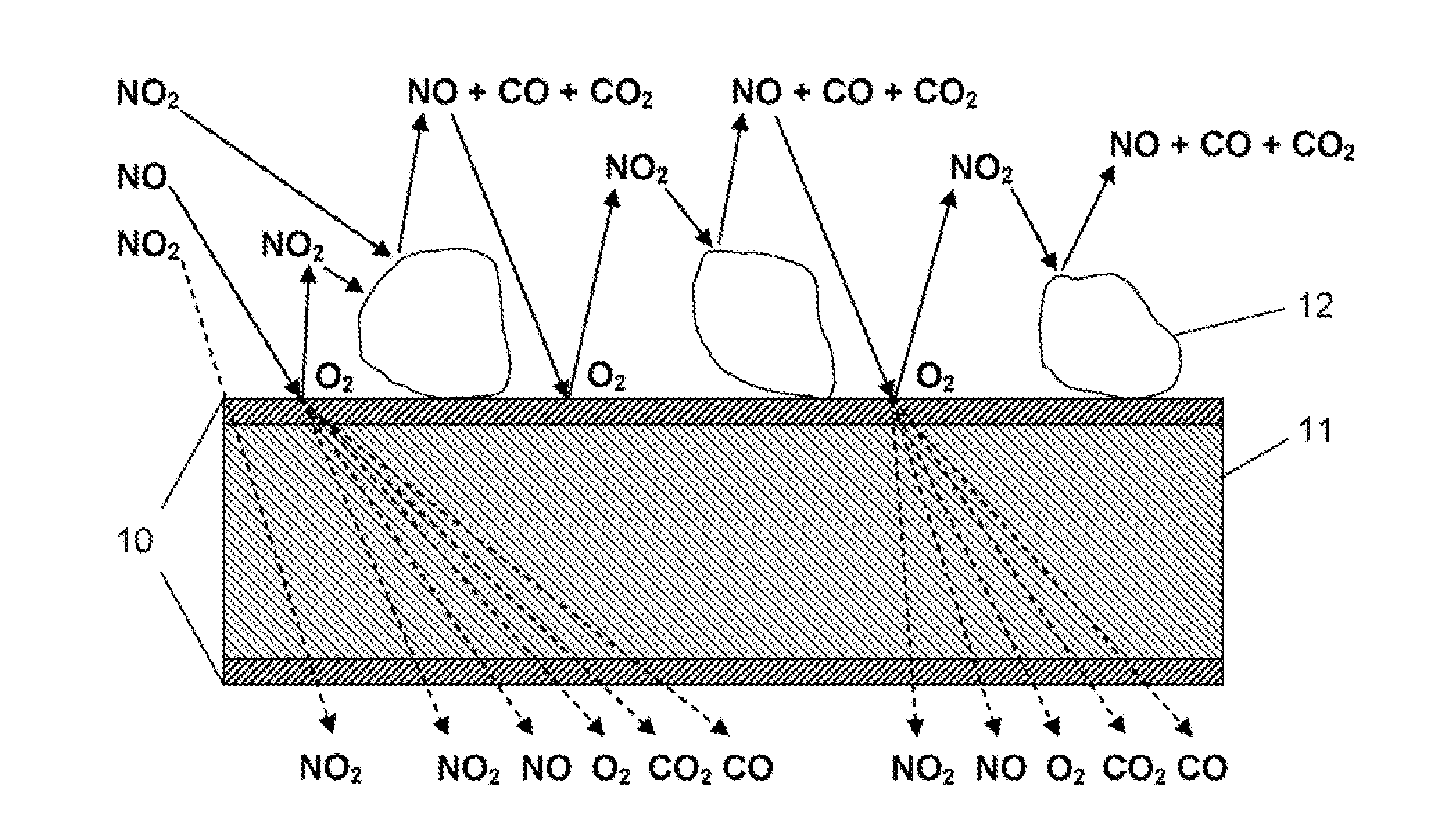

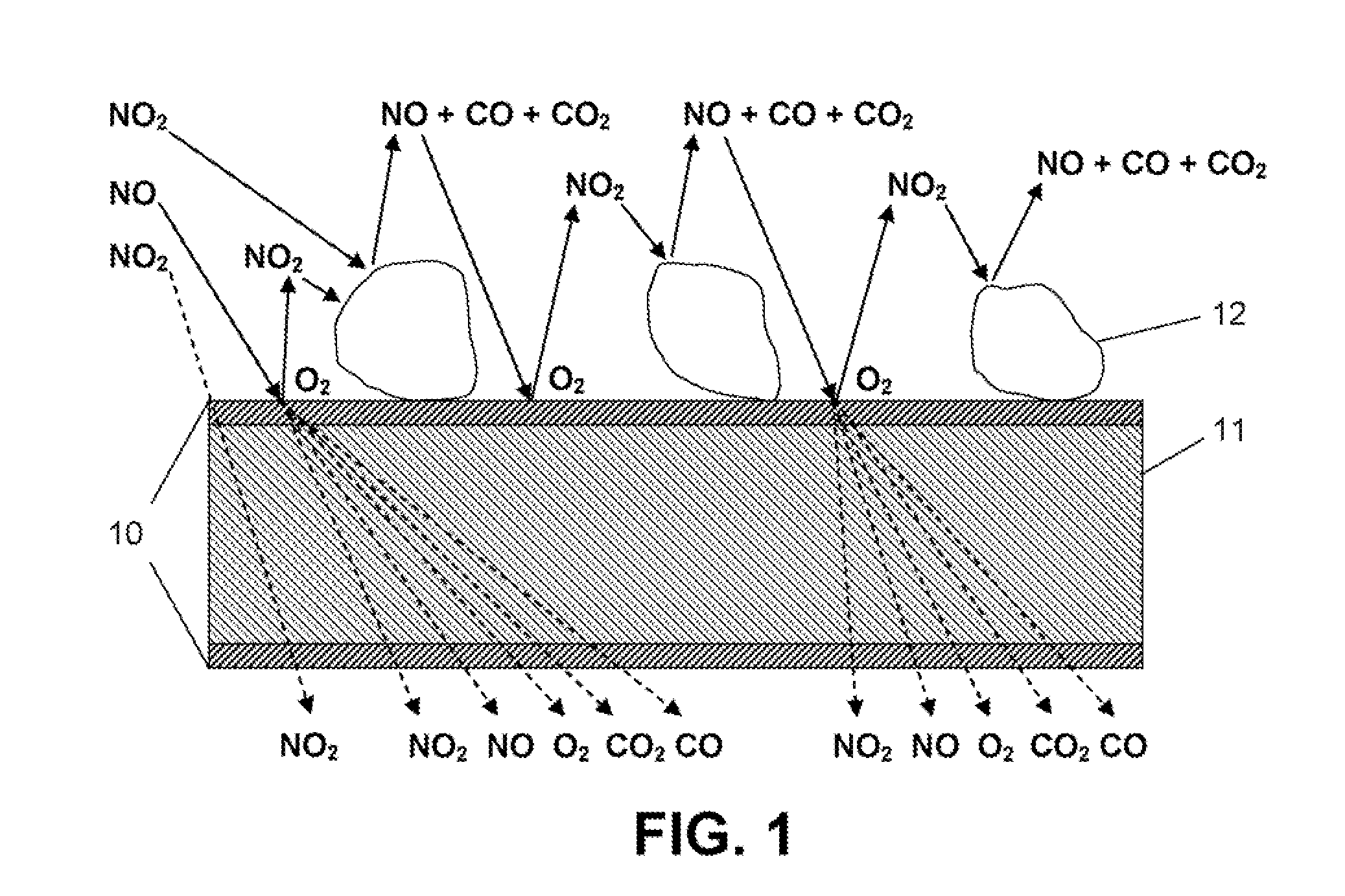

Method and apparatus for no2-based regeneration of diesel particulate filters using recirculated NOX

InactiveUS20110000190A1Lower activation energyElectrical controlExhaust apparatusDiesel particulate filterSoot

In a method for performing NO2-based regeneration of a diese! particulate filter (DPF) using recirculated NOx, the DPF is regenerated by oxidizing soot in the DPF with NO2 so that CO, CO2, and NO are formed, at least some NOx is recirculated from a takeoff point to a point upstream of the takeoff point. NO2 can be formed by reacting the recirculated NO with 02. During regeneration of the DPF, at least some of the NO2 that oxidizes soot in the DPF is recirculated ISI 02 or formed from recirculated NO that is reacted with 02 to form NO2. An exhaust aftertreatment system for performing NO2-based regeneration of a diesel particulate filter (DPF) using recirculated NOx is also disclosed.

Owner:MACK TRUCKS

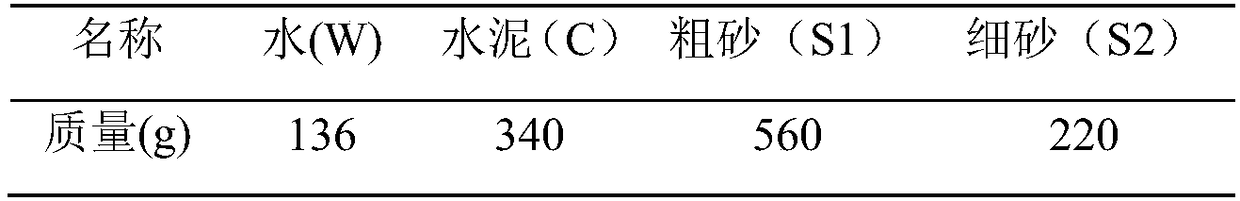

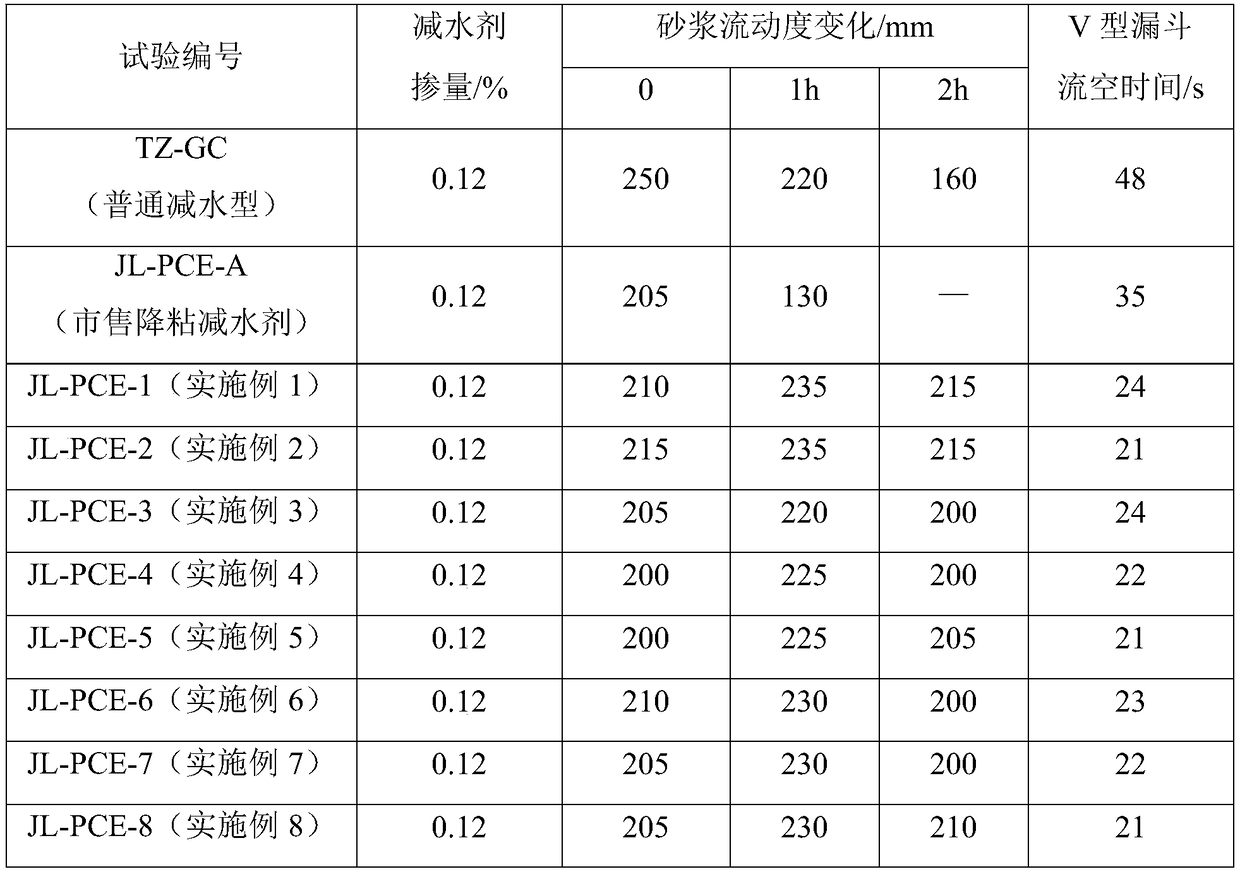

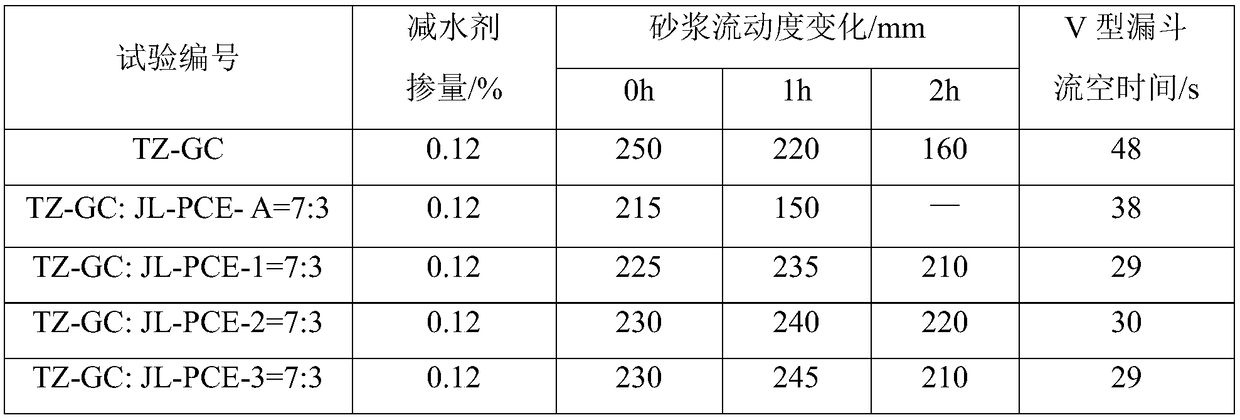

A kind of preparation method of high performance water reducer

InactiveCN102286134AHigh priming activityIncrease the rate of polymerizationHigh strength concreteChemistry

A preparation method of a polycarboxylate high-performance water reducer, under the protection of an inert gas and under the action of an oxidation-reduction initiation system and a chain transfer agent, the active macromonomer A (methallyl poly Oxyethylene ether), small molecule monomer B (methacrylic acid or acrylic acid) and small molecule monomer C (sodium methacrylate, sodium propylene sulfonate or sodium styrene sulfonate) are prepared by copolymerization in water. The invention adopts a highly active oxidation-reduction initiation system, which can increase the polymerization reaction rate, lower the polymerization temperature and shorten the reaction time, and the polymer has an ideal molecular structure. The water reducing agent prepared by the invention has excellent properties such as high water reducing rate, good dispersibility, no loss of slump over time, and high concrete strength; at the same time, the method of the invention adopts copolymerization reaction in water, the preparation process is simple, and it also has green Environmental protection, low energy consumption, low cost and other characteristics.

Owner:江苏天音化工有限公司 +1

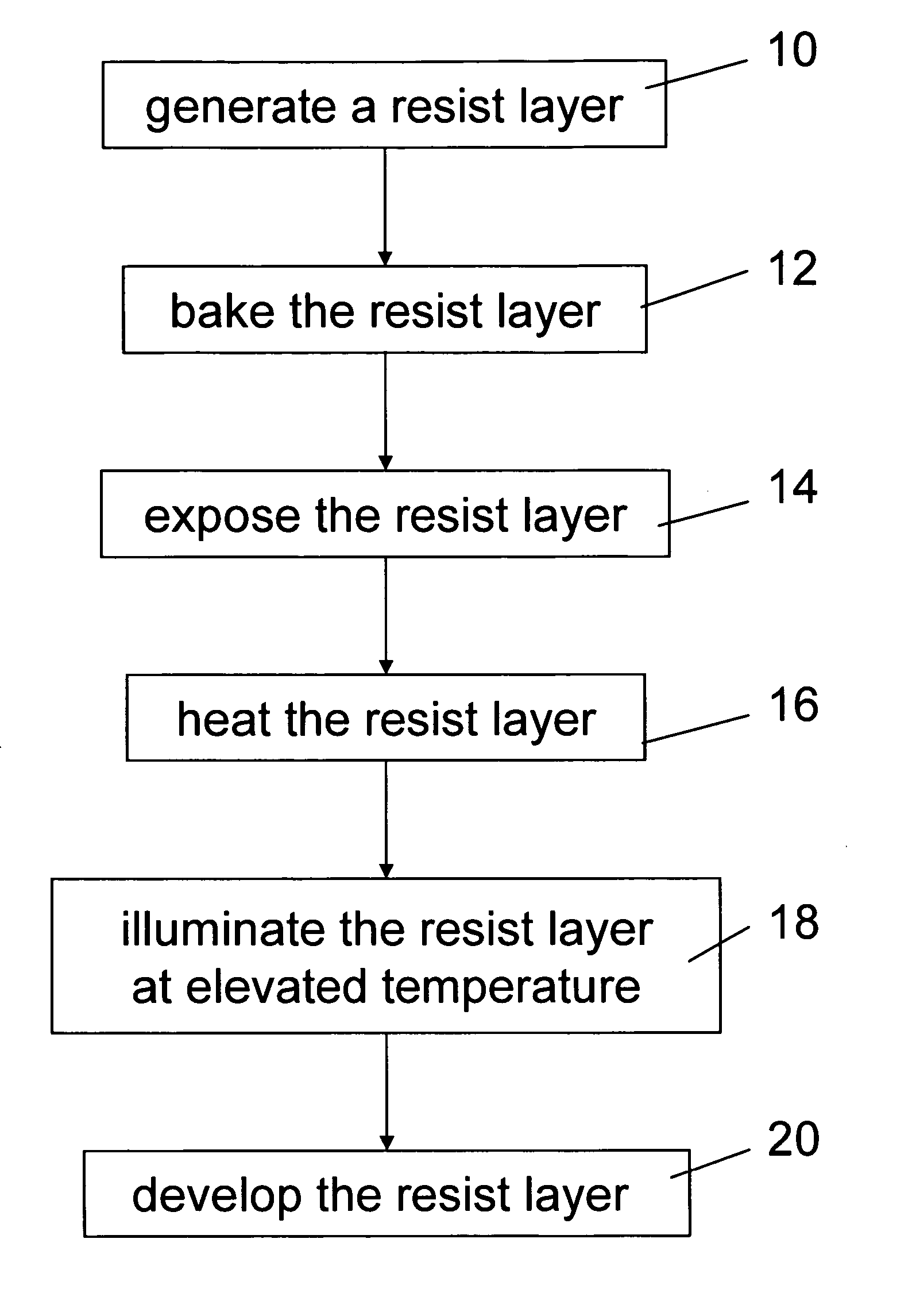

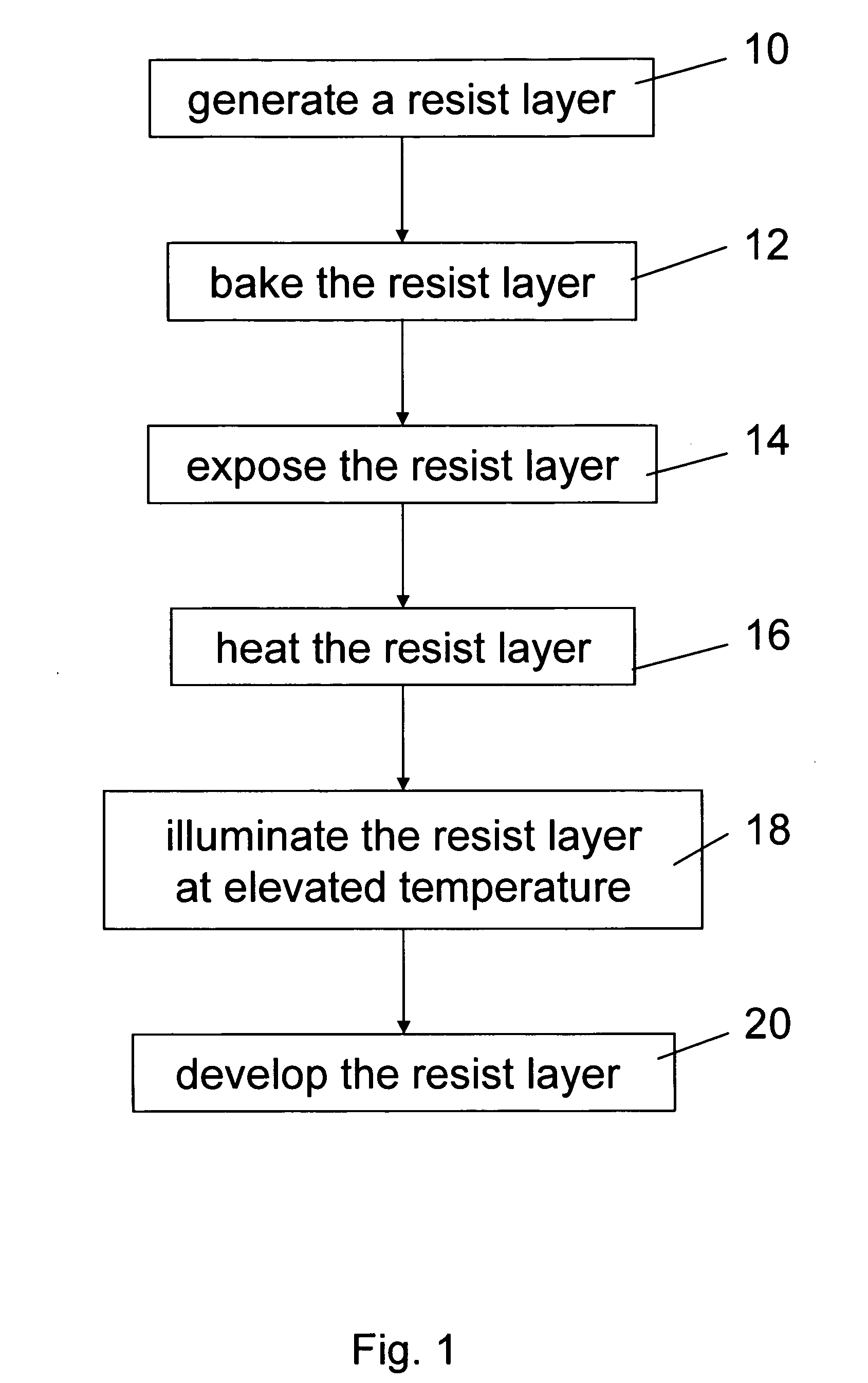

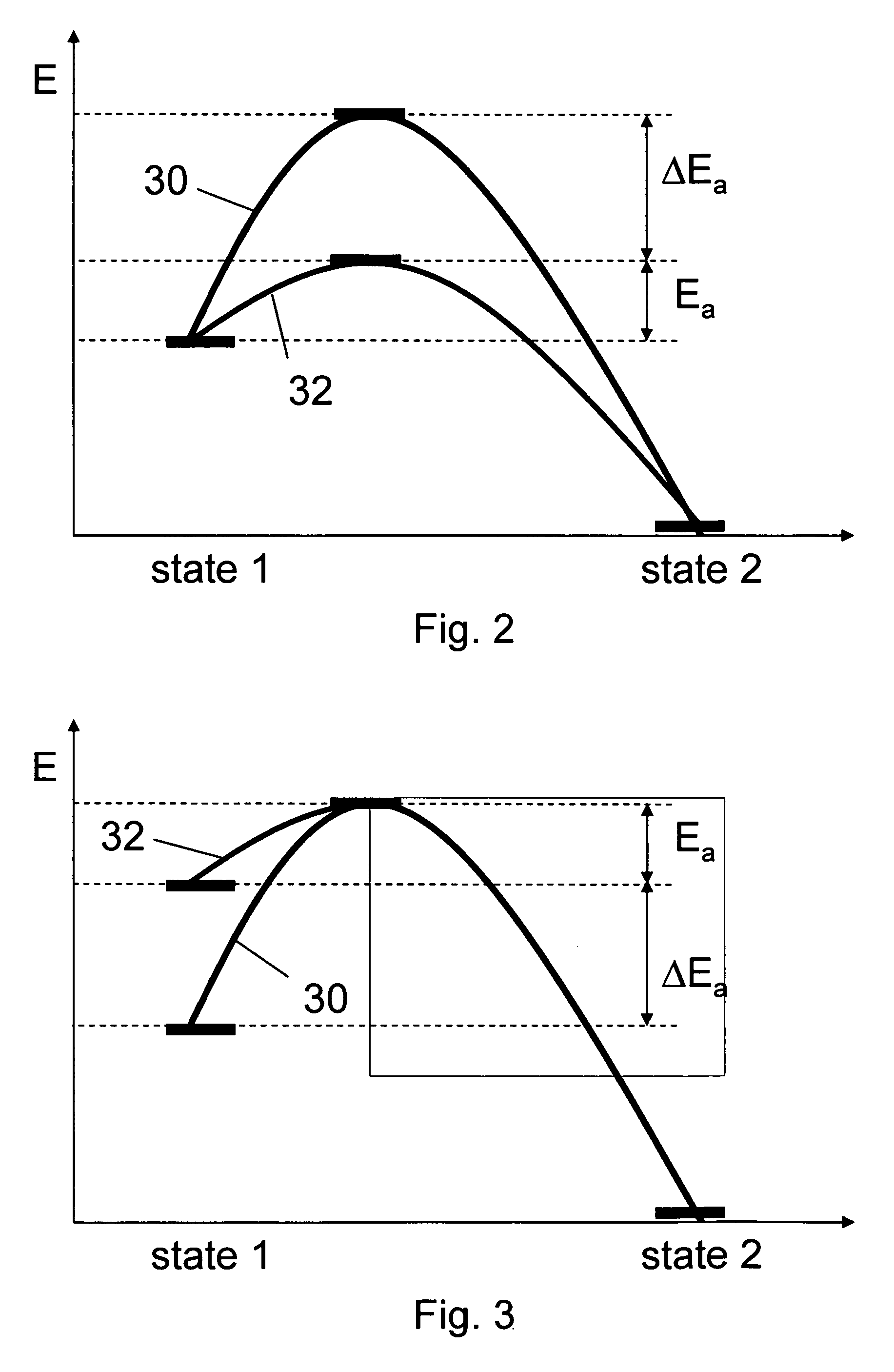

Method and apparatus for a post exposure bake of a resist

InactiveUS20060269879A1Reduce blurReduce diffusePhotomechanical exposure apparatusPhotosensitive material processingResistSolubility

Method and Apparatus for A Post Exposure Bake Of A Resist In a Method for patterning a chemically amplified resist layer, the resist layer is provided on a substrate, the resist layer comprising resist molecules in a first state with a first solubility. Predetermined regions of the resist layer are exposed to a first radiation to generate a catalytic species in the exposed predetermined regions of the resist layer. The resist layer is exposed to a second radiation and resist molecules in the predetermined regions of the resist layer are converted from the first state into a second state with a second solubility, the conversion of a resist molecule being catalyzed by the catalytic species, and the activation energy of the catalyzed conversion of the resist molecule being lowered by the absorption of the second radiation in the resist molecule. The resist layer is developed with a predetermined developer.

Owner:INFINEON TECH AG

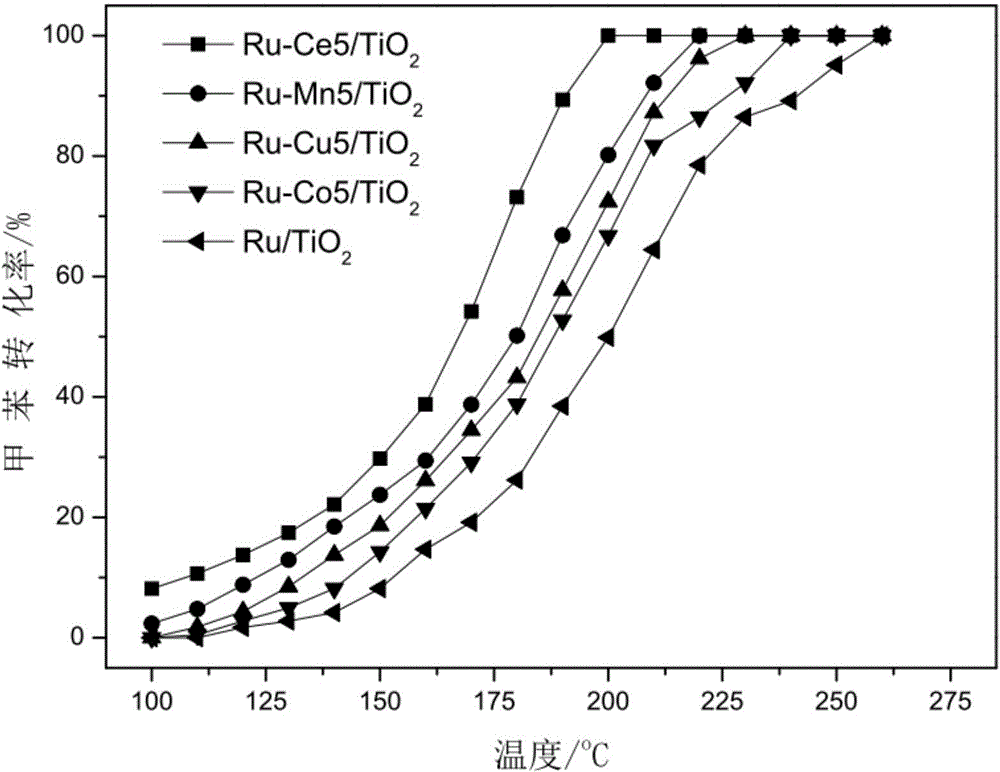

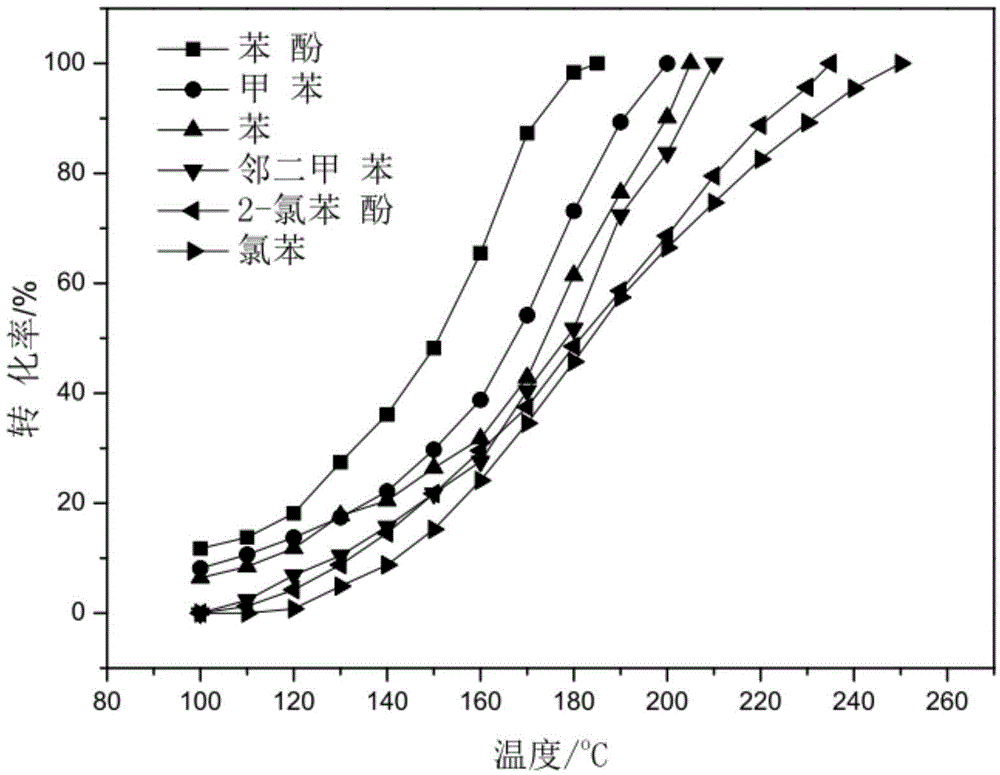

Supported bimetallic catalyst for catalytic oxidation of VOCs and preparation method and application thereof

ActiveCN104353459ALower activation energyPromote degradationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationCopper oxide

The invention relates to a supported bimetallic catalyst for the catalytic oxidation of VOCs and a preparation method and application thereof. The supported bimetallic catalyst takes titanium dioxide as a carrier, a first active component as ruthenium dioxide, a second active component as any one of magnesium oxide, cobalt oxide, copper oxide or cerium oxide and is capable of accelerating the catalytic oxidation efficiency on the VOCs through the concerted catalysis effect between the two active components. Compared with a commercial supported palladium-platinum catalyst, the supported bimetallic catalyst disclosed by the invention is lower in cost and higher in universality, achieves the complete oxidation temperature of multiple VOCs between 170 DEG C and 250 DEG C, is superior to the commercial supported palladium-platinum catalyst in integral property and very high in final reaction product CO2 selectivity and has preferable application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

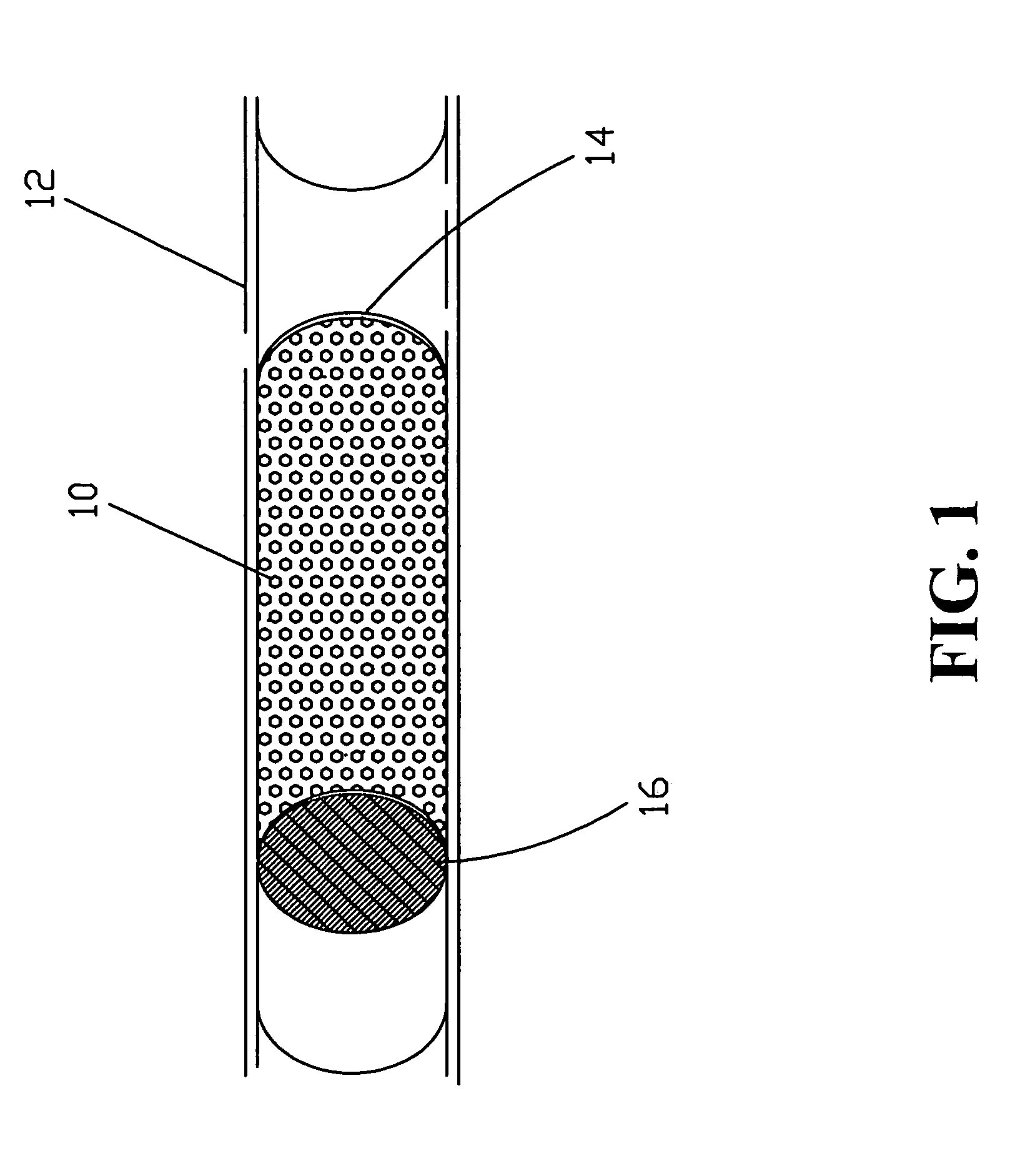

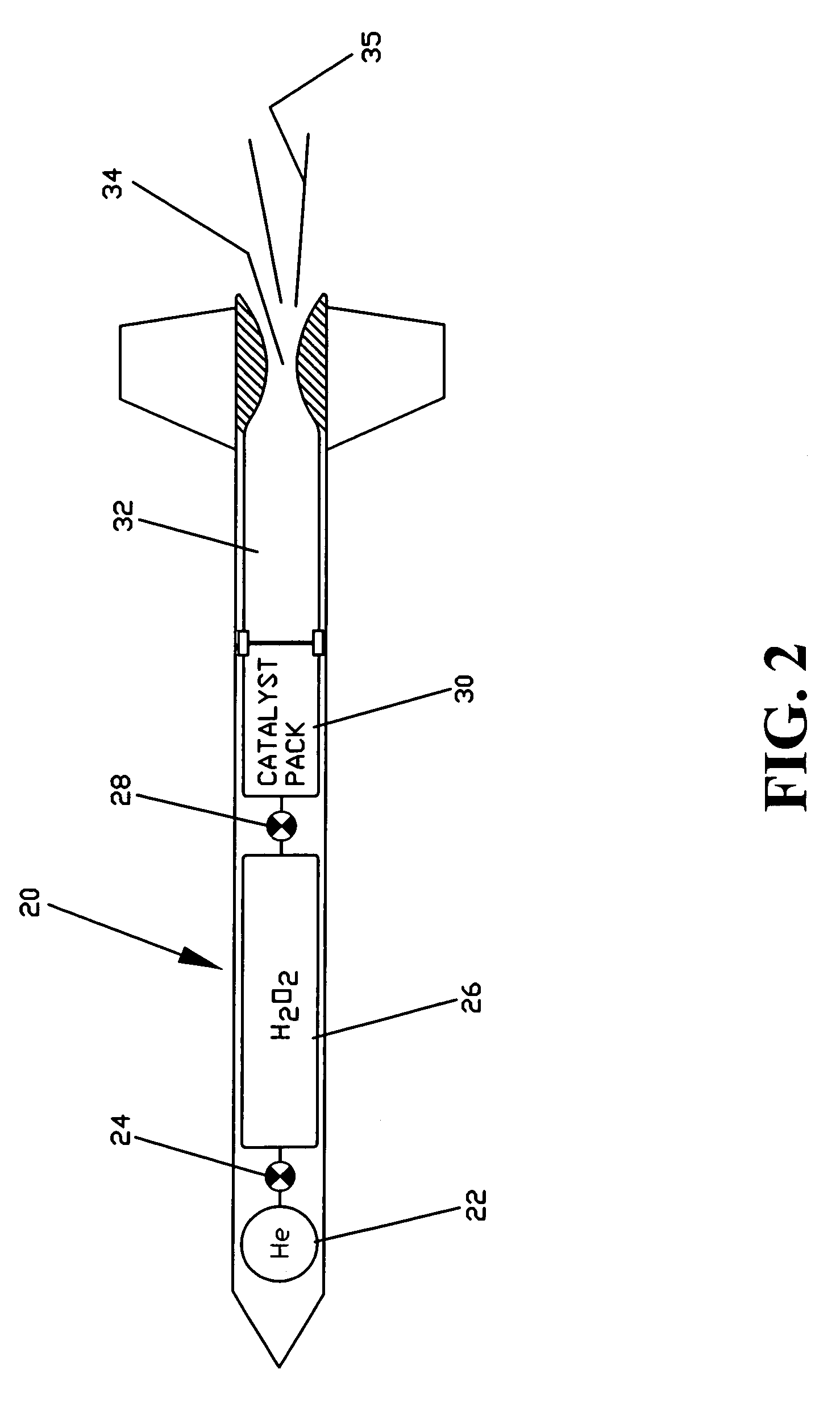

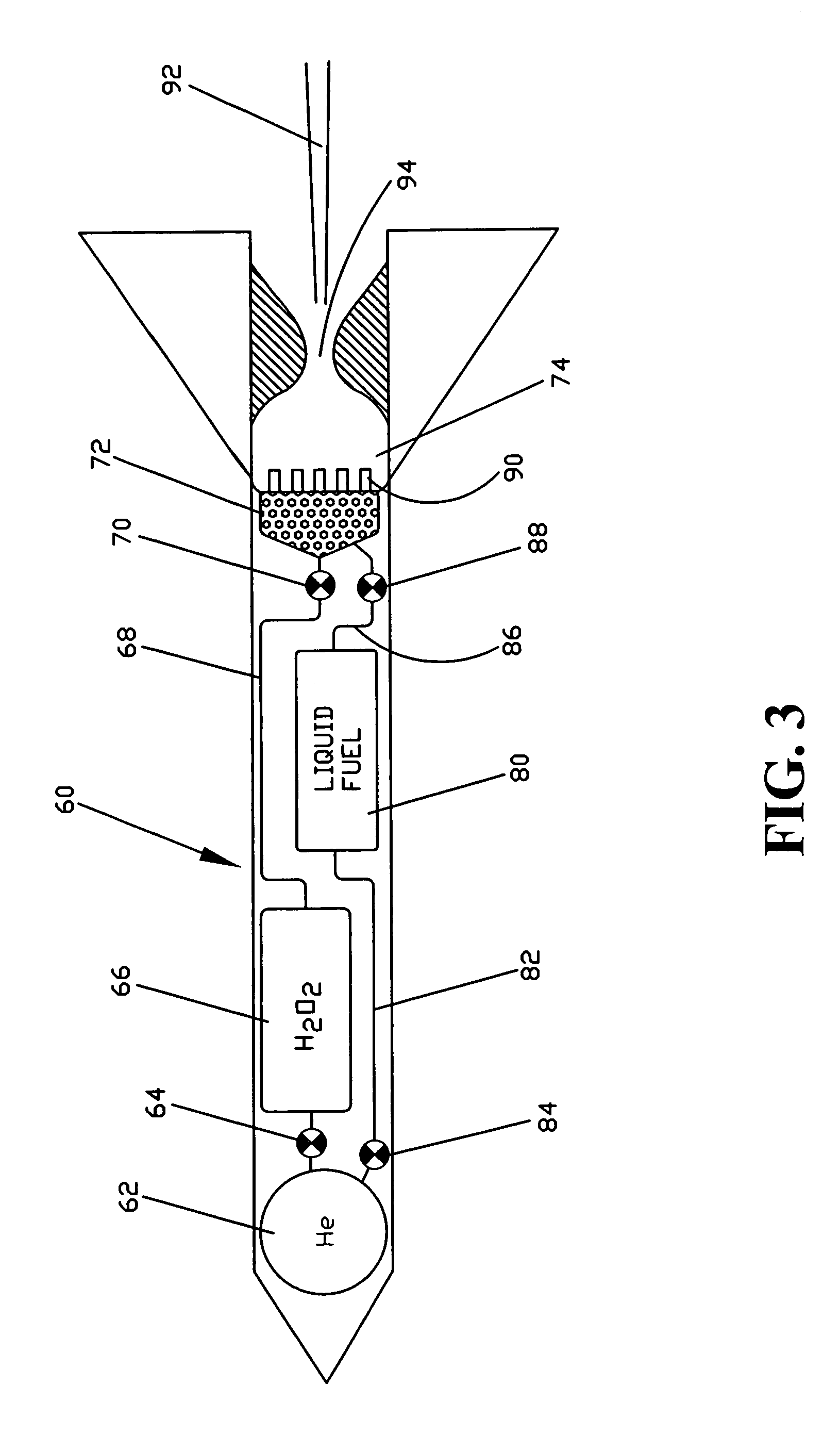

H2O2 decomposition catalyst

InactiveUS6991772B1Promote decompositionLower activation energyOxygen/ozone/oxide/hydroxideMolecular sieve catalystsCombustion chamberDecomposition

An activated catalyst for the rapid decomposition of H2O2 is provided wherein a porous high surface area catalyst base, e.g. a zeolite molecular sieve (ZMS) is impregnated or doped with a solution of metal cation salts and an ionic promoter, dried and calcined to form an activated catalyst. Such activated catalyst, in the form of a porous monolith or chunks, extrudate, pieces, pellets, or spheres, can be poured into and confined, in a tight pack, in a cavity of a rocket housing, downstream of a pressurized H2O2 tank. The H2O2 is flowed through the catalyst and undergoes rapid decomposition into steam and O2 and flows out the propellant nozzle of such rocket. Advantages of such activated catalyst are that it can be employed to rapidly decompose H2O2 to propel a) a mono-propellant rocket, b) a bipropellant rocket (having fuel and a combustion chamber) and c) a hybrid rocket (powered by H2O2 and fuel grain) and can also be used for a starter cartridge decomposition catalyst, a gas generator decomposition catalyst and the like. Another benefit of the activated catalyst of the invention is its low weight which is highly suitable in small flightweight rocket systems.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

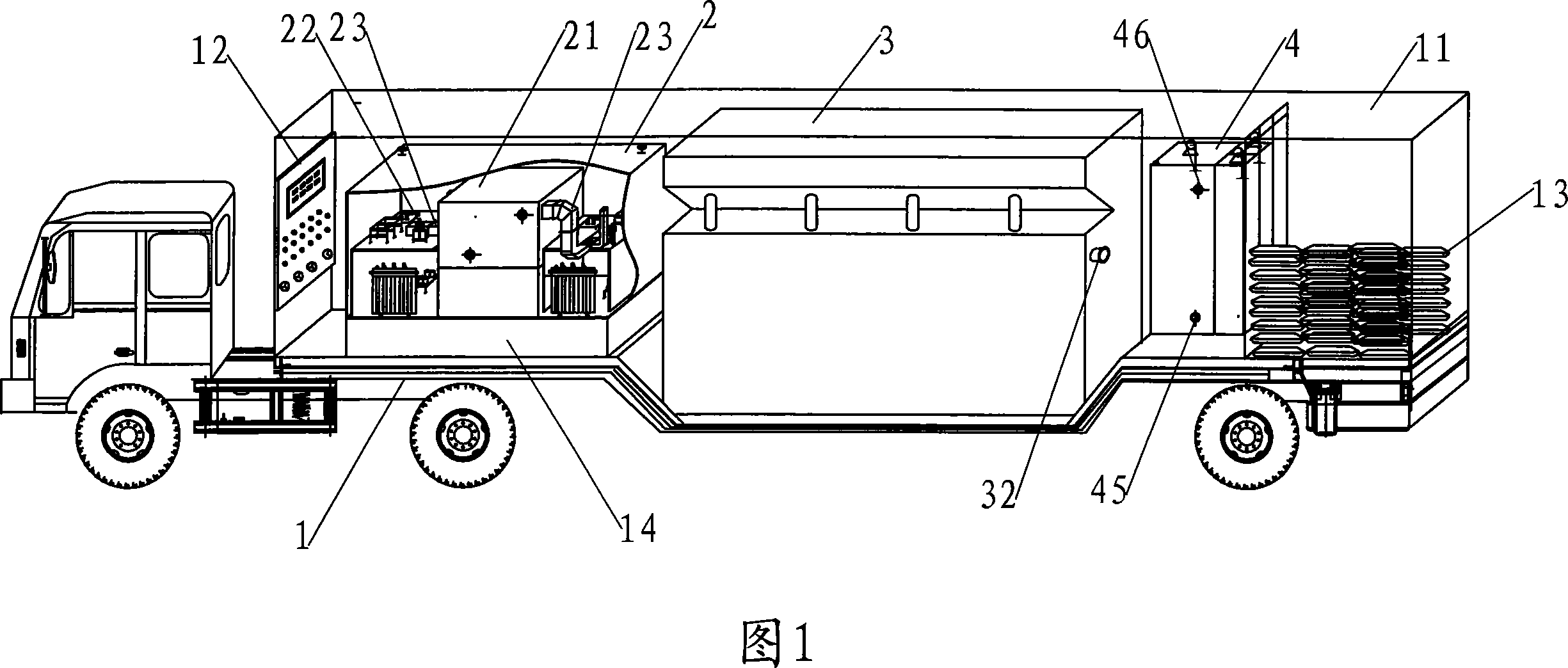

Mobile sewage treatment apparatus

ActiveCN101234794AImprove passabilityImprove processing efficiencyWater/sewage treatment by irradiationMicrowaveWater treatment system

The invention relates to a movable microwave emergency device for treating sewage, which comprises a carrier and a microwave sewage treatment system arranged on the carrier. The microwave sewage treatment system comprises a microwave reactor (2), a sedimentation filtering reactor (3) arranged on the lower part of the microwave reactor (2) and connected with the sewage outlet of the microwave reactor (2) through pipes, and a sensitizer arranged on the upper pipes of the microwave reactor (2) as well as an adding set (4) of other water treating agent. The movable microwave emergency device solves the technical issues that the current microwave sewage treatment system can not meet the requirement in terms of size for the vehicle and the utilization efficiency of the microwave is low. Particularly, the movable microwave emergency device is applicable to continuously treat the sewage generated by unexpected events and produced by enterprises with a little sewage producing quantity.

Owner:孙宪彬

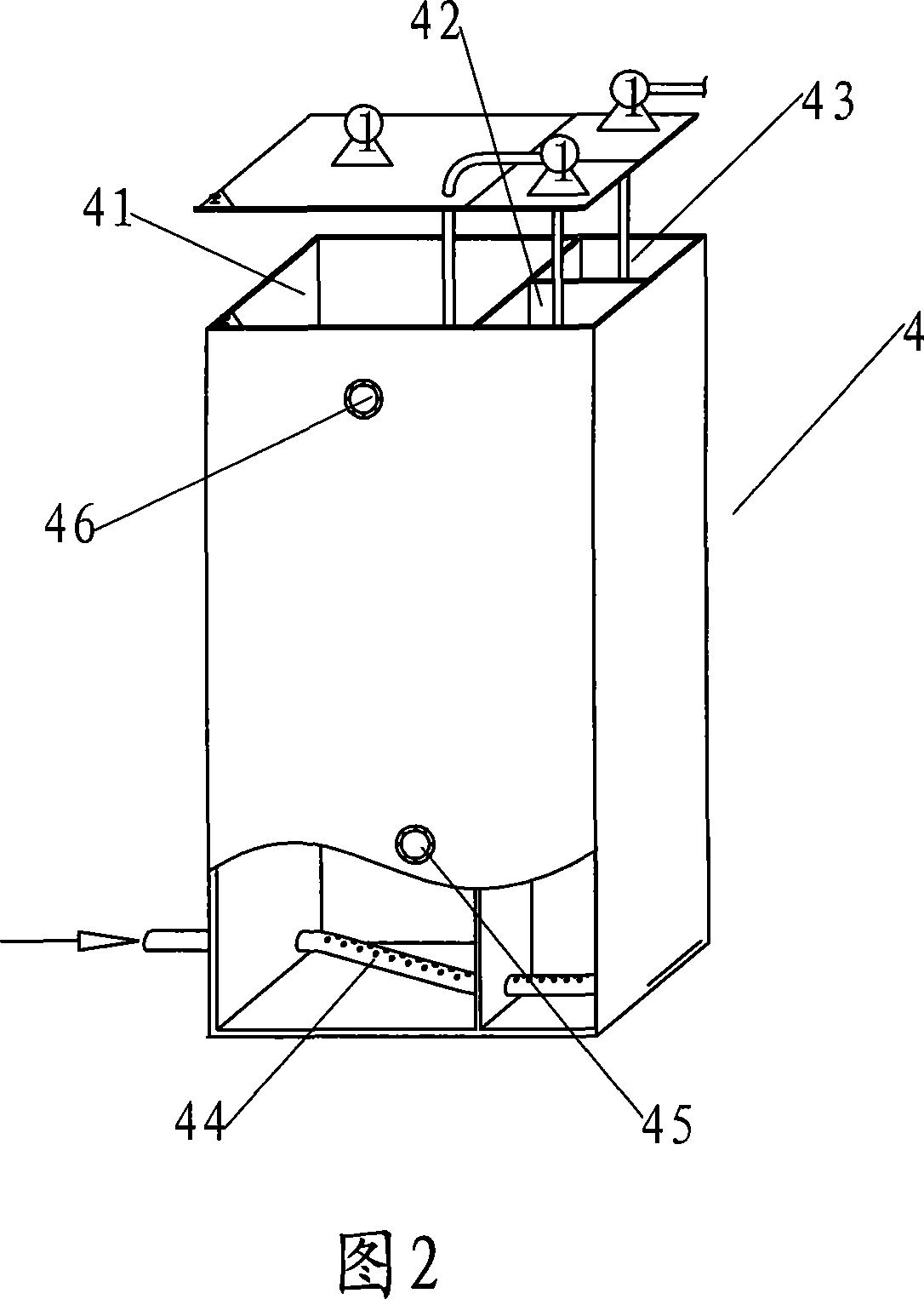

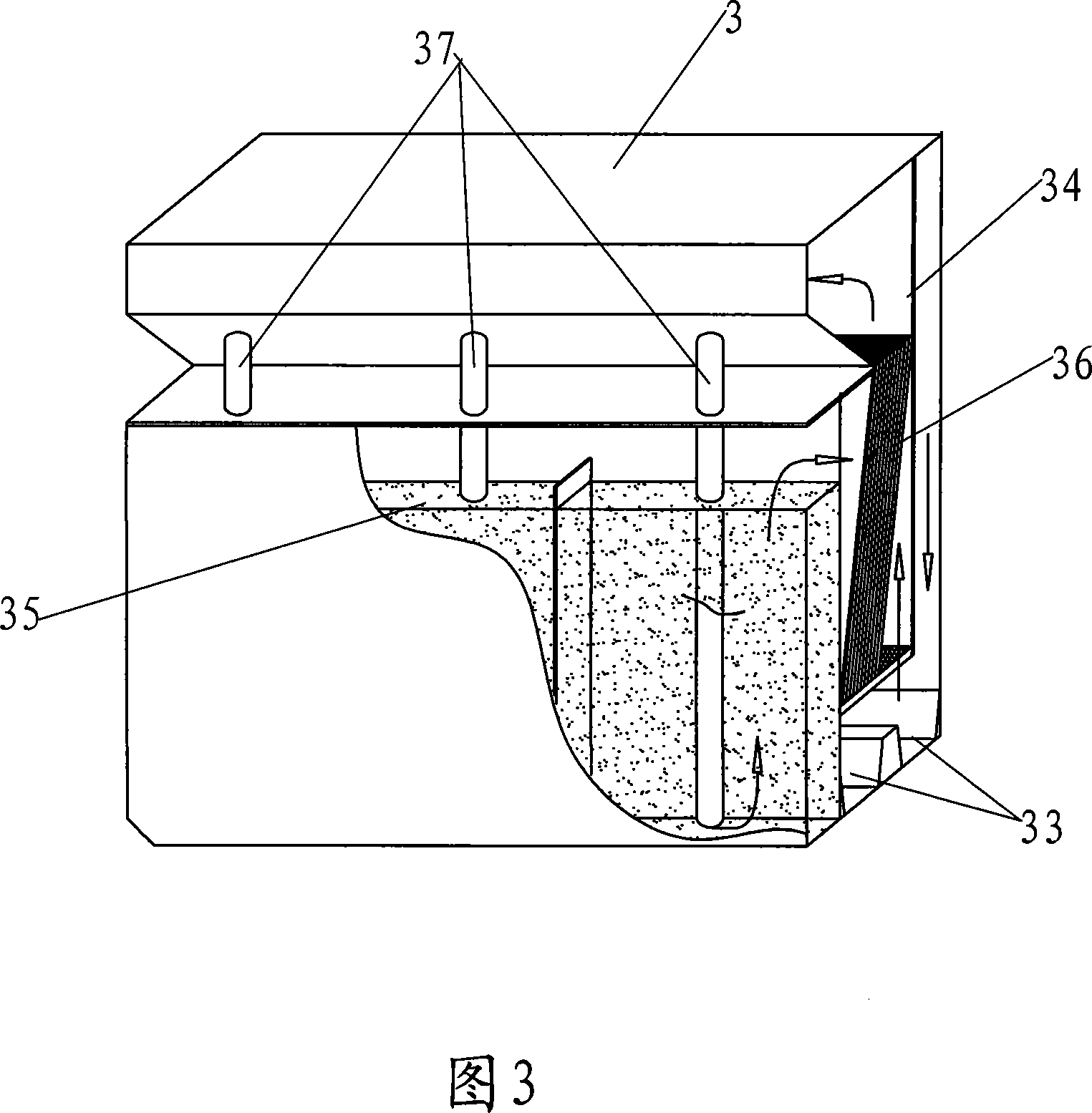

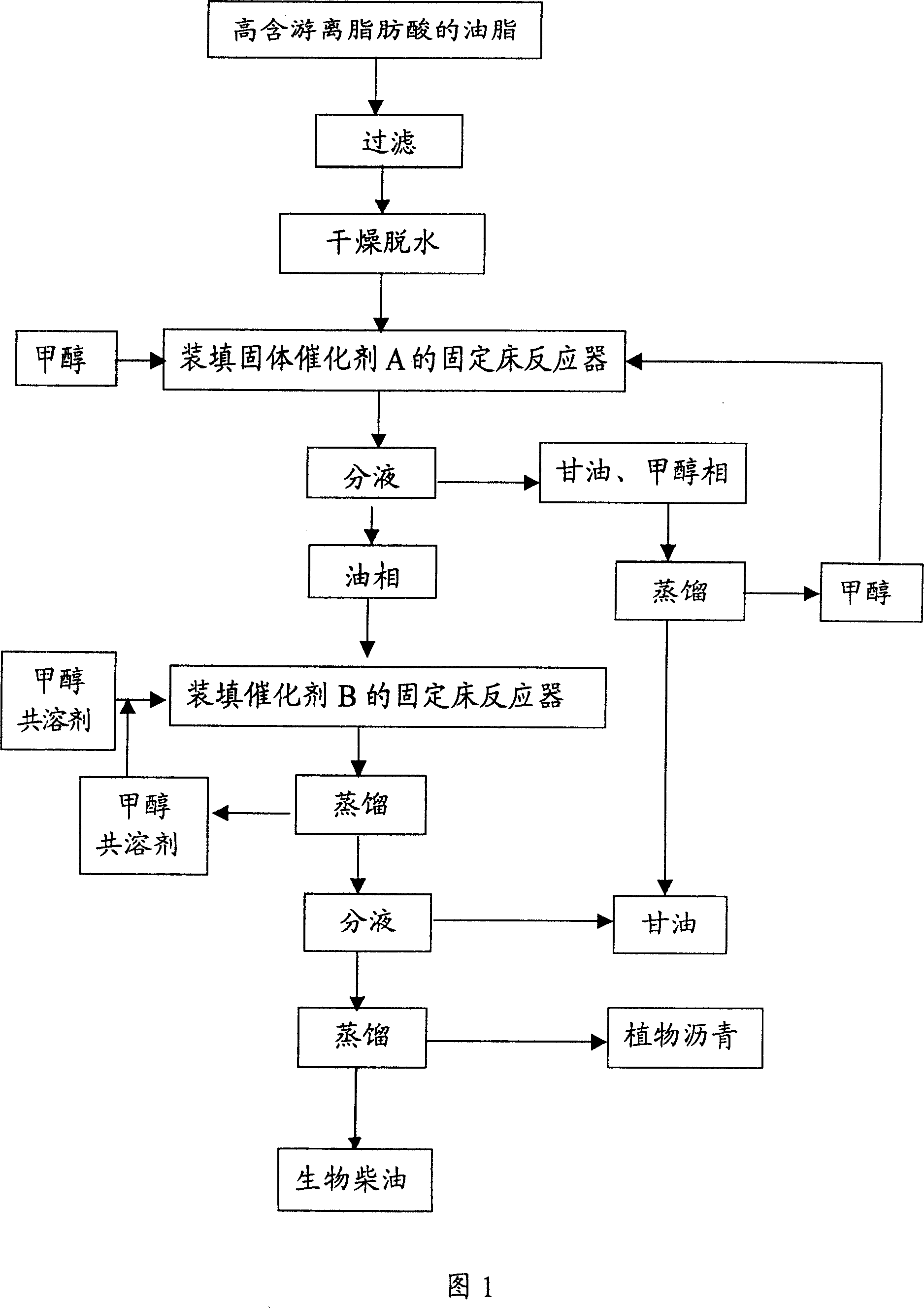

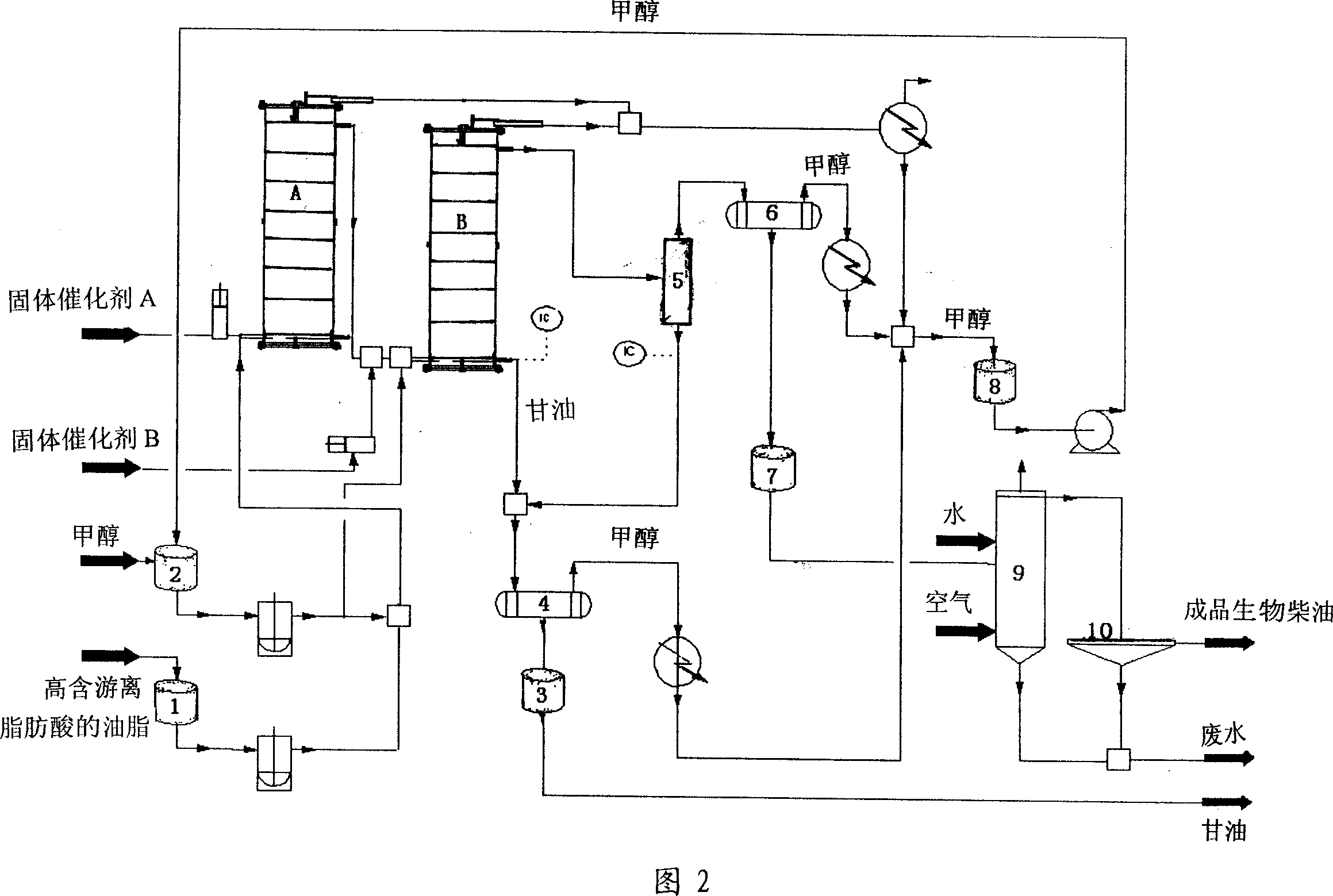

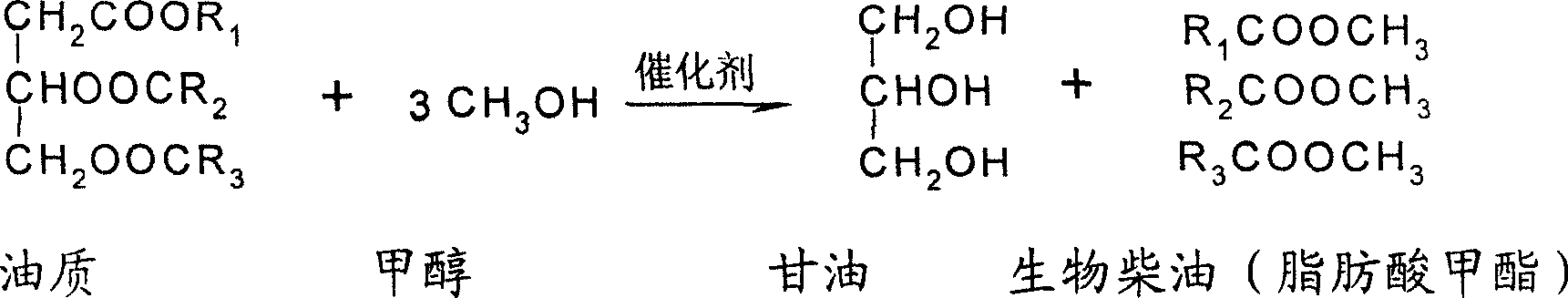

Preparation method of biological diesel oil

InactiveCN1928016AHigh catalytic activityLower activation energyBiofuelsLiquid hydrocarbon mixture productionSolventGlycerol

The present invention relates to biodiesel oil preparing process, and provides one biodiesel oil preparing process with solid acid and solid alkali as catalyst to lower the activating energy and raise the reaction speed. The biodiesel oil preparing process includes the following steps: reacting dried grease with high free fatty acid content, methanol or ethanol, and cosolvent in the molar ratio of 1 to 6-1 to 6.05 in the first fixed bed reactor with solid catalyst A at 60-65 deg.c for about 3 hr; separating the oil phase from others; reacting the oil phase in the second fixed bed reactor with solid catalyst B with methanol or ethanol and cosolvent at 60-65 deg.c for about 3 hr; distilling out methanol or ethanol and cosolvent; separating the biodiesel oil from glycerin phase; and distilling the biodiesel oil phase to obtain biodiesel oil product. The catalyst of the present invention has high catalytic activity and can lower the activating energy and raise the reaction speed.

Owner:张海军

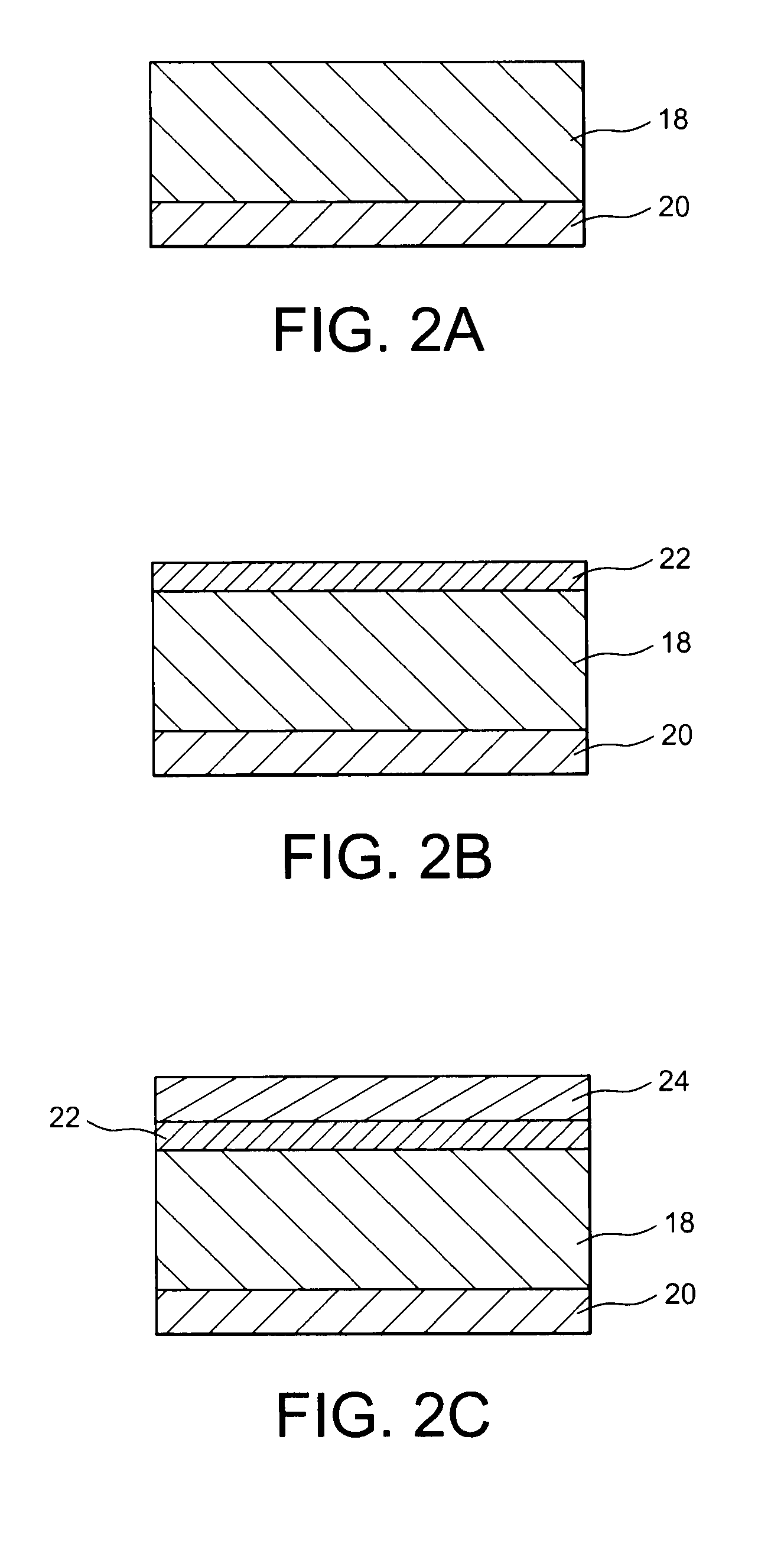

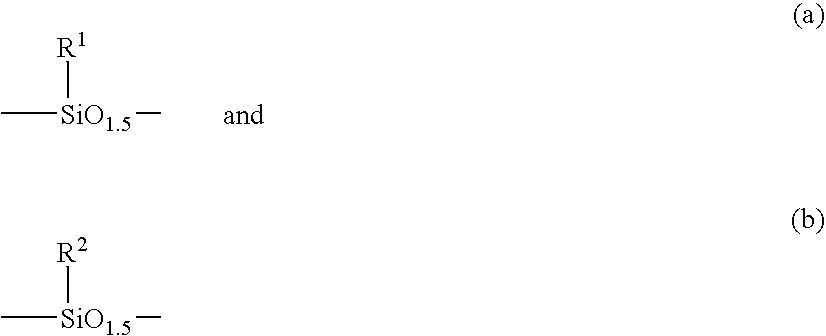

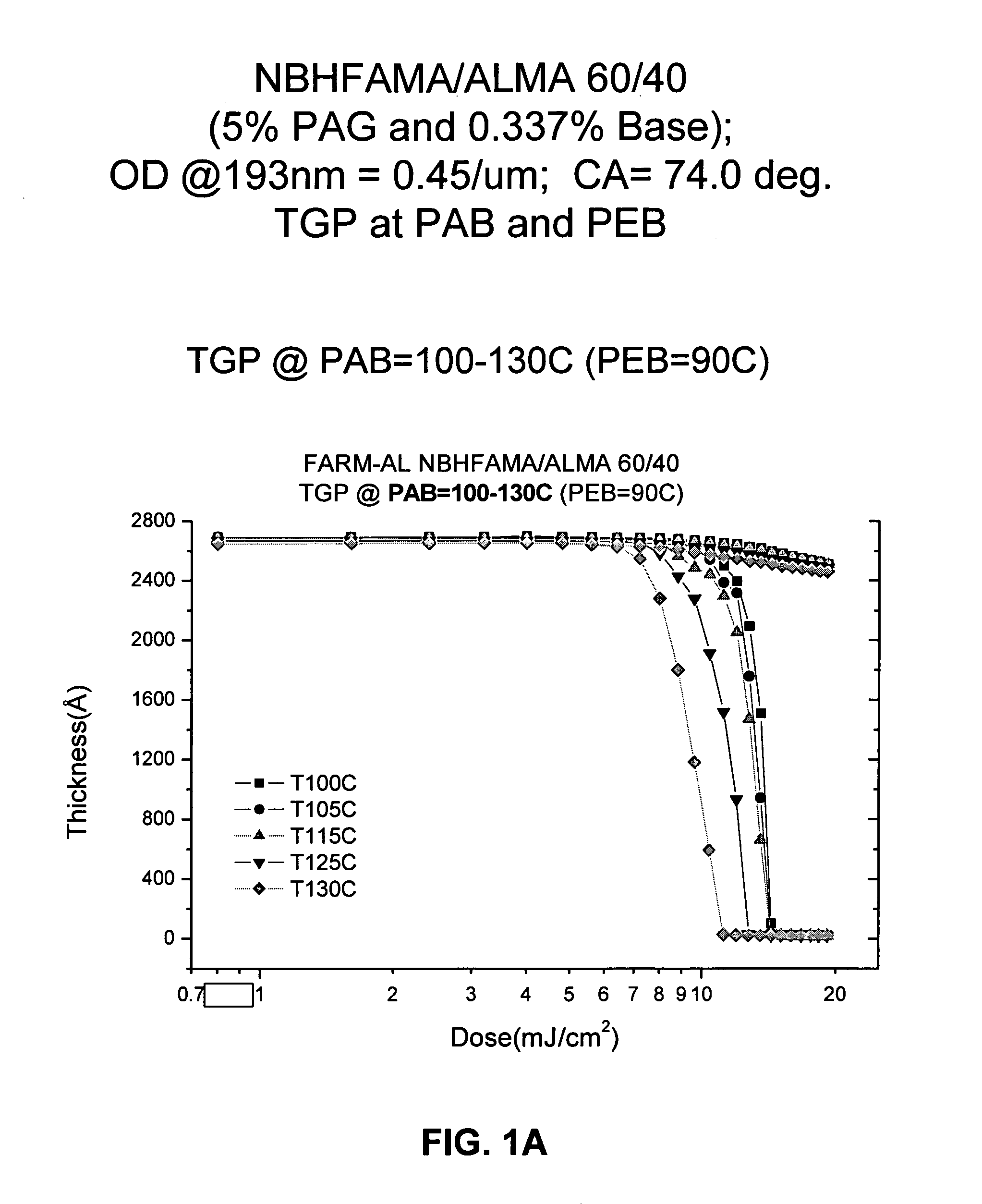

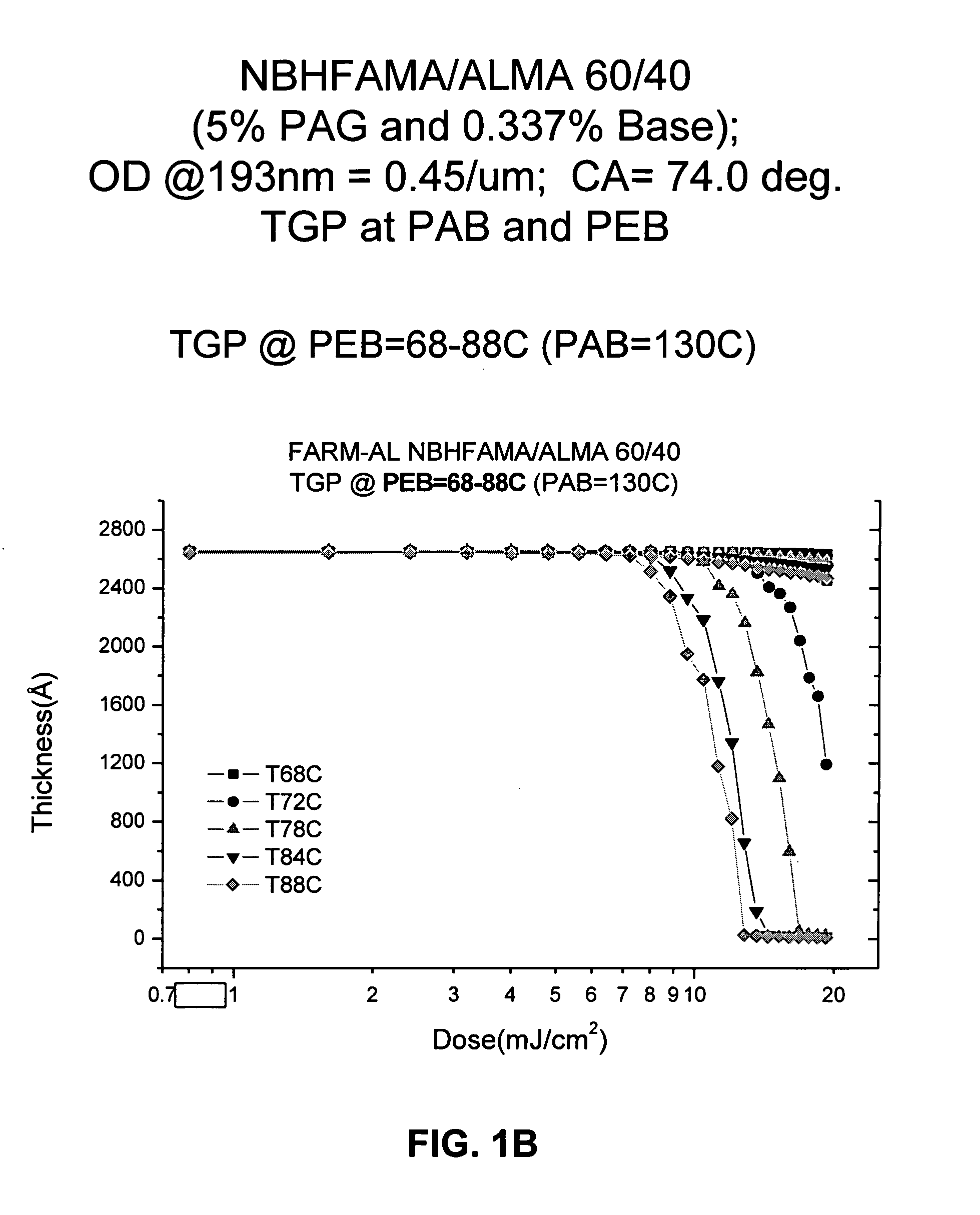

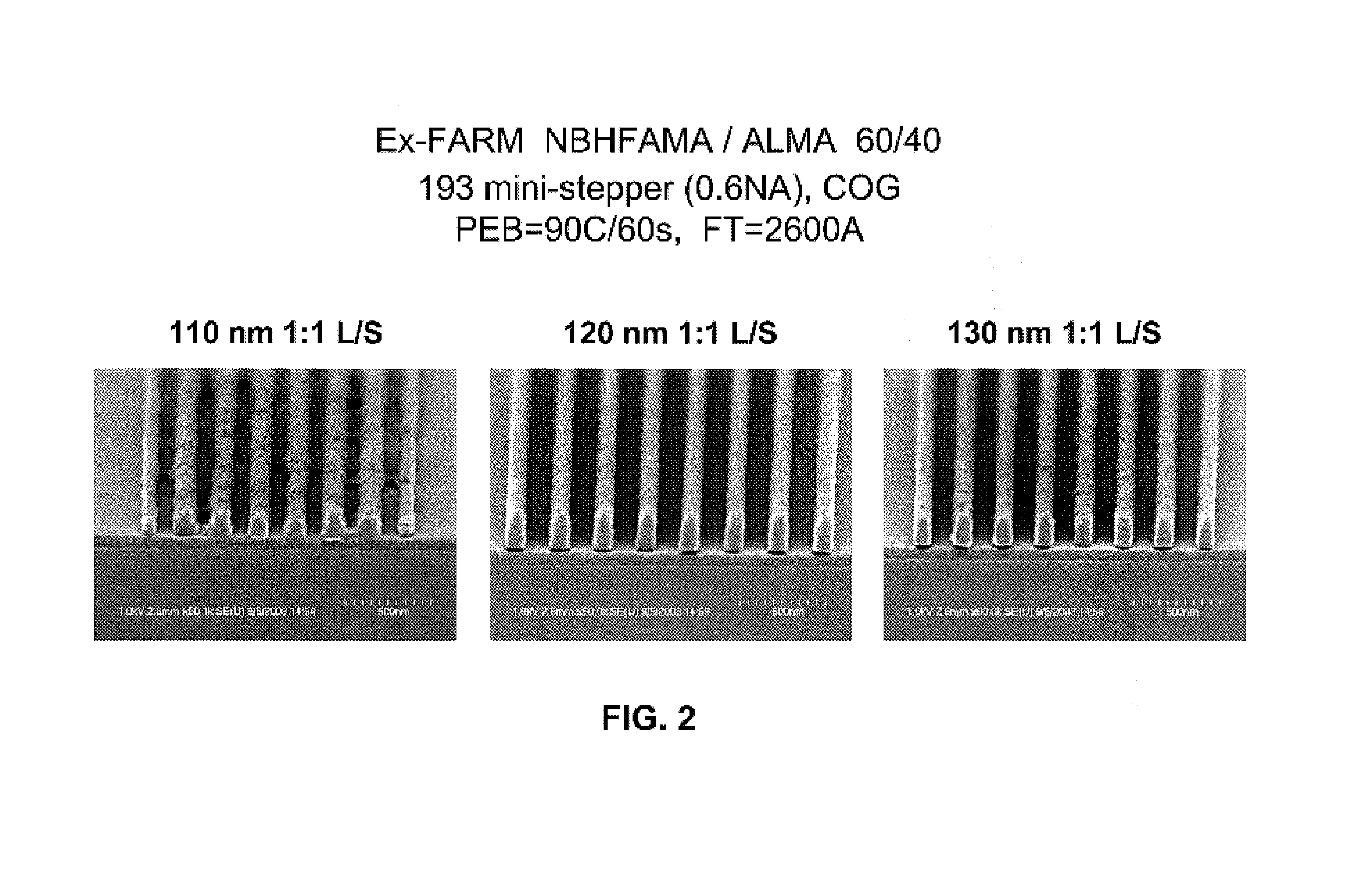

Low-activation energy silicon-containing resist system

InactiveUS6939664B2Lower activation energyHigh optical densitySemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersPolymer scienceAcid catalysis

Inventive silsesquioxane polymers are provided, and resist compositions that contain such silsesquioxane polymers are provided in which at least a portion of the silsesquioxane polymer contains fluorinated moieties, and at least a portion of the silisesquioxane polymer contains pendant solubility inhibiting acid-labile moieties that have low activation energy for acid-catalyzed cleaving, and the presence of high optical density moieties are minimized or avoided. The inventive polymer also contains pendant polar moieties that promote alkaline solubility of the resist in aqueous alkaline solutions. The inventive polymers are particularly useful in positive resist compositions. The invention encompasses methods of using such resist compositions in forming a patterned structure on a substrate, and particularly multilayer (e.g. bilayer) photolithographic methods, which methods are capable of producing high resolution images at wavelengths such as 193 nm and 157 nm.

Owner:GLOBALFOUNDRIES INC

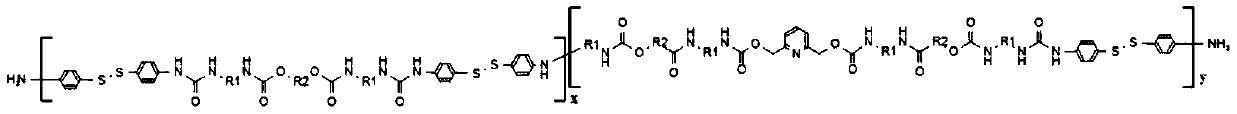

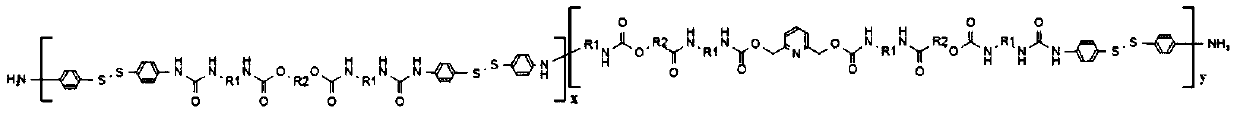

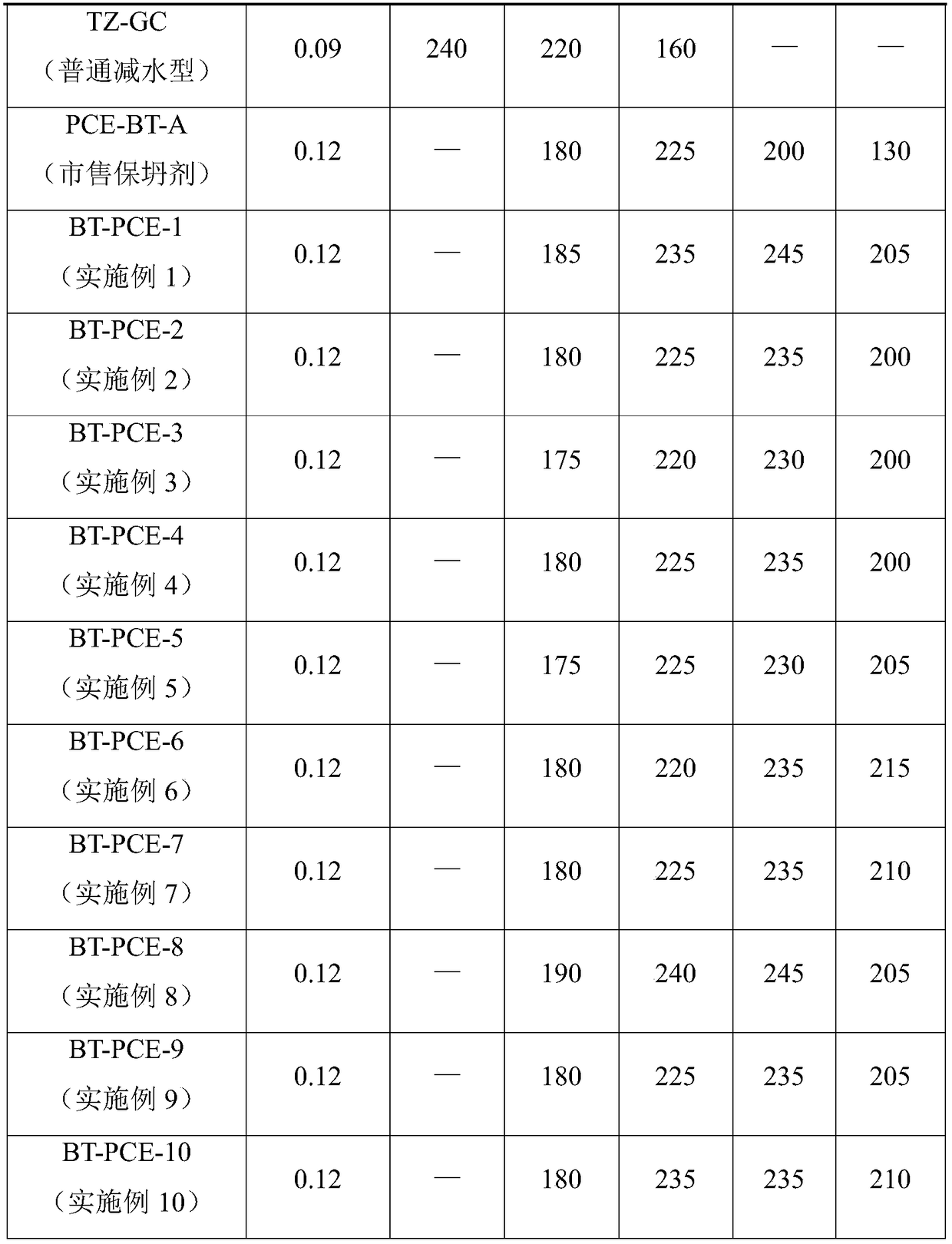

Polycarboxylic water reducer with viscosity reducing and slump retaining functions, and preparation method thereof

InactiveCN109021181AReduce the hydrophilic-lipophilic balanceReduce generationHigh strength concreteWork performance

The invention discloses a polycarboxylic water reducer with viscosity reducing and slump retaining functions, and a preparation method thereof, and belongs to the technical field of building materials. The polycarboxylic water reducer is prepared through the following steps: free radical polymerization of an unsaturated polyether monomer I, an unsaturated block modified polyether monomer II, an unsaturated carboxylic acid monomer, an unsaturated carboxylic acid alkyl ester, an unsaturated phosphate ester monomer, a chain transfer agent, an oxidant, a reducing agent and deionized water in an aqueous solution at 15-30 DEG C, addition of an alkali solution to adjust the pH value, and water supplementation. The water reducer can meet the requirements of the water-reducing and slump-retaining performances of high-strength concrete, and also can greatly reduce the viscosity of the concrete and significantly improve the working performances of the high-strength concrete, so the problems of fast slump loss and excessive viscosity of existing polycarboxylic water reducers are solved. The preparation method can be carried out at normal temperature without a heat source, so the preparation method has the advantages of simple production device, reasonable process, simplicity in operation, high production efficiency, and suitableness for industrial production and promotion.

Owner:SICHUAN TONGZHOU CHEM TECH

Process of compounding and roasting desulfurized cinder and potash ore to produce composite K-Ca-Si-S fertilizer

InactiveCN1974494AEmbody the scientific conceptLower activation energyCalcareous fertilisersPotassium fertilisersTrace elementCinder

The present invention discloses process of compounding and roasting desulfurized cinder and potash ore to produce composite K-Ca-Si-S fertilizer. The composite K-Ca-Si-S fertilizer is produced with potash ore 25-55 wt%, desulfurized cinder 15-50 wt%, limestone 5-55 wt% and additive 2-5 wt%, and through mixing, milling, roasting at 1000-1050 deg.c for 2-3 hr, cooling and ball milling. The production process has desulfurized cinder as one kind of solid waste utilized and potash ore heat decomposed to produce the fertilizer with soluble potassium oxide, soluble Ca, Si and S compounds and trace elements. The additive can lower the potash ore decomposing temperature from 1100-1150 deg.c to 1000-1050 deg.c.

Owner:广州康沣农业科技有限公司

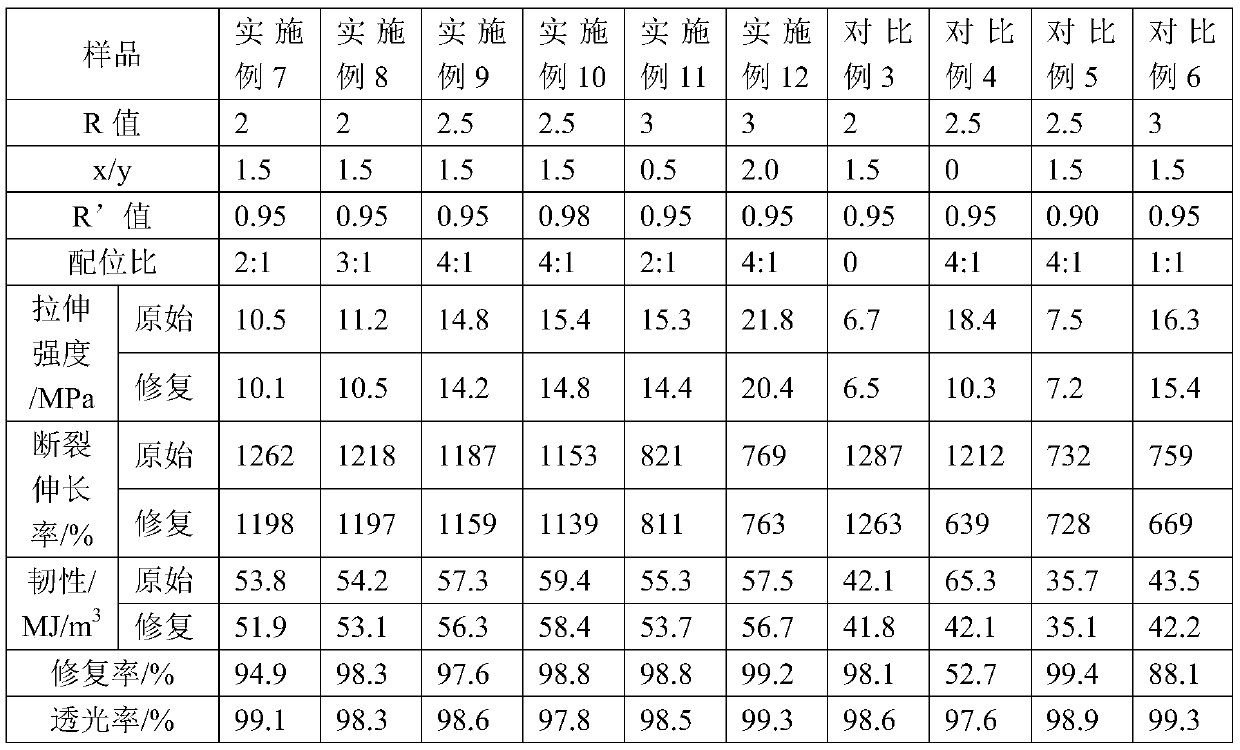

Transparent high strength and high toughness room temperature self-repairing thermoplastic polyurethane urea elastomer and preparation method

The invention discloses a transparent high strength and high toughness room temperature self-repairing thermoplastic polyurethane urea elastomer and a preparation method. The elastomer is synthesizedby: conducting chain extension twice on a prepolymer generated from diisocyanate and polyether diol with 2, 6-pyridine dimethanol and 4, 4'-diaminodiphenyl disulfide respectively. The pyridine ring onthe main chain can coordinate with polyvalent metal ions to form coordinate bonds between macromolecular chains, thus inducing self-repairing capability and also limiting molecular chain slip so as to improve the tensile strength and toughness. The aromatic disulfide on the main chain has low activation energy, and can produce reversible exchange reaction under room temperature condition to realize efficient self-repairing ability. By controlling the R value and the relative ratio of the two chain extenders, the tensile strength of the polyurethane urea elastomer can reach 8MPa or above, thetoughness can reach 45MJ / m<3> or above, the 6h self-repairing efficiency at 25DEG C can reach 90% or above, and the light transmittance can reach 95% or above. The transparent high strength and high toughness room temperature self-repairing thermoplastic polyurethane urea elastomer provided by the invention has excellent mechanical properties, self-repairing capability and light transmittance, canmeet the use requirements of flexible intelligent electronic equipment, and has great application potential.

Owner:ZHENGZHOU UNIV

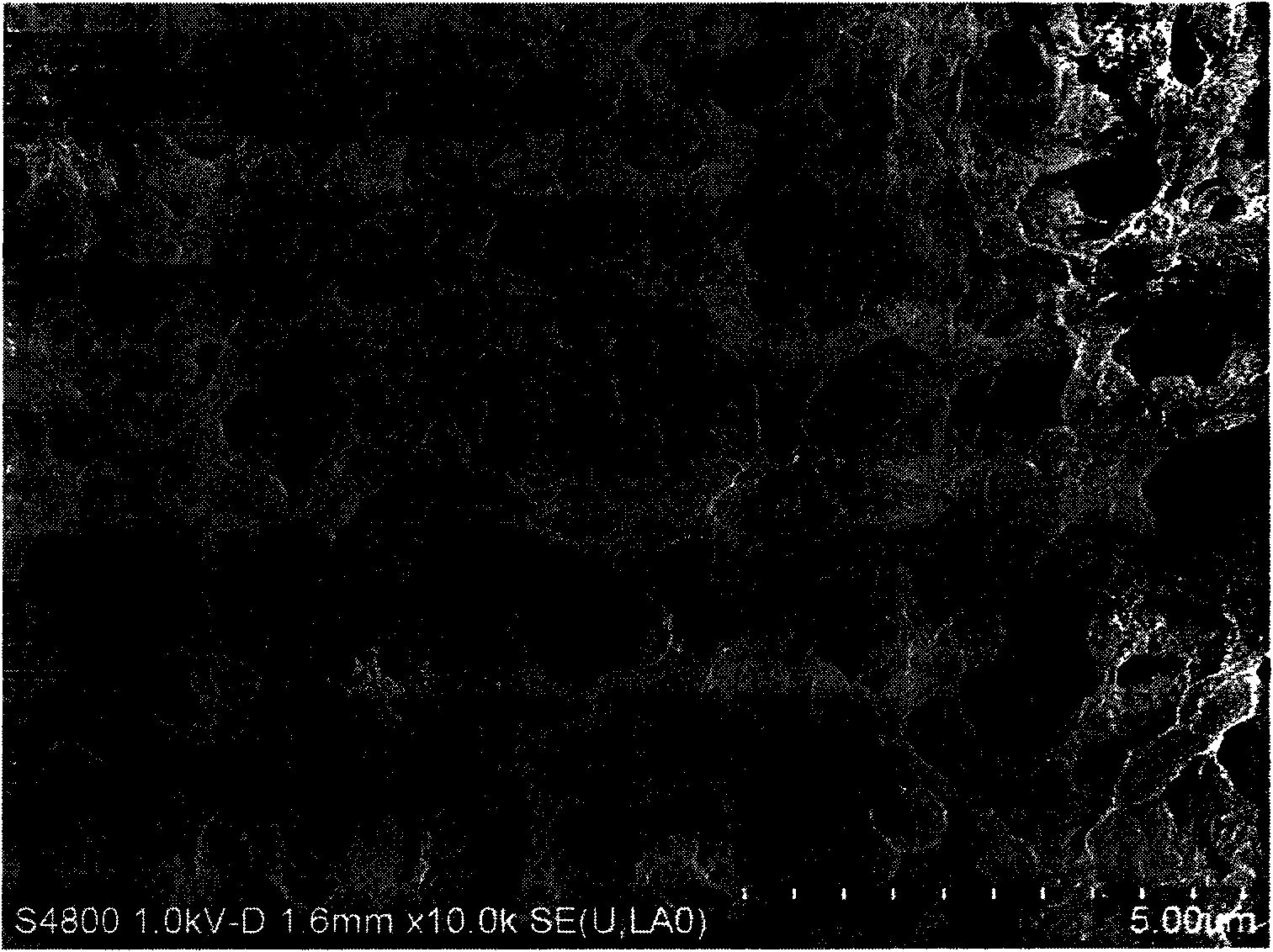

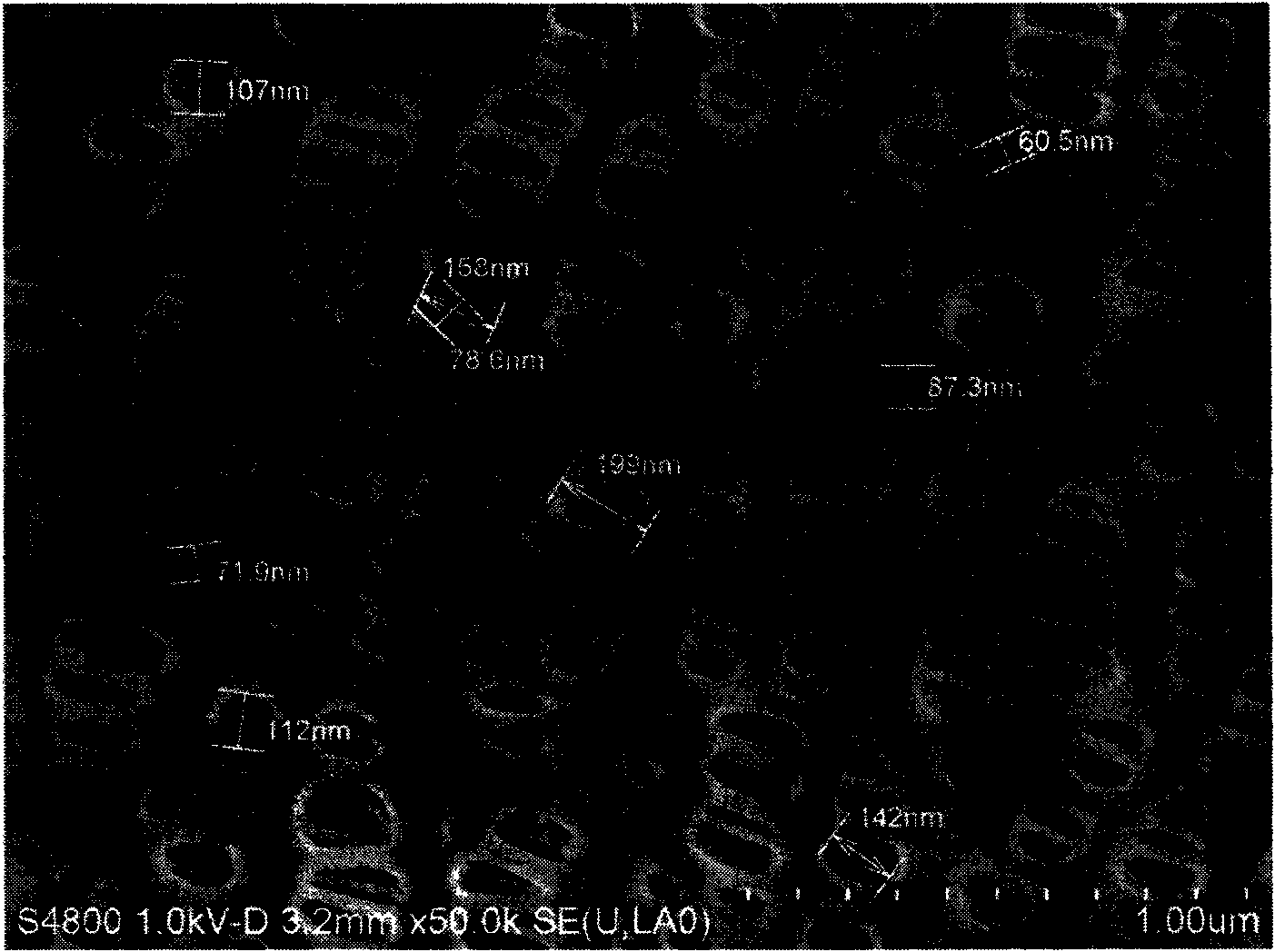

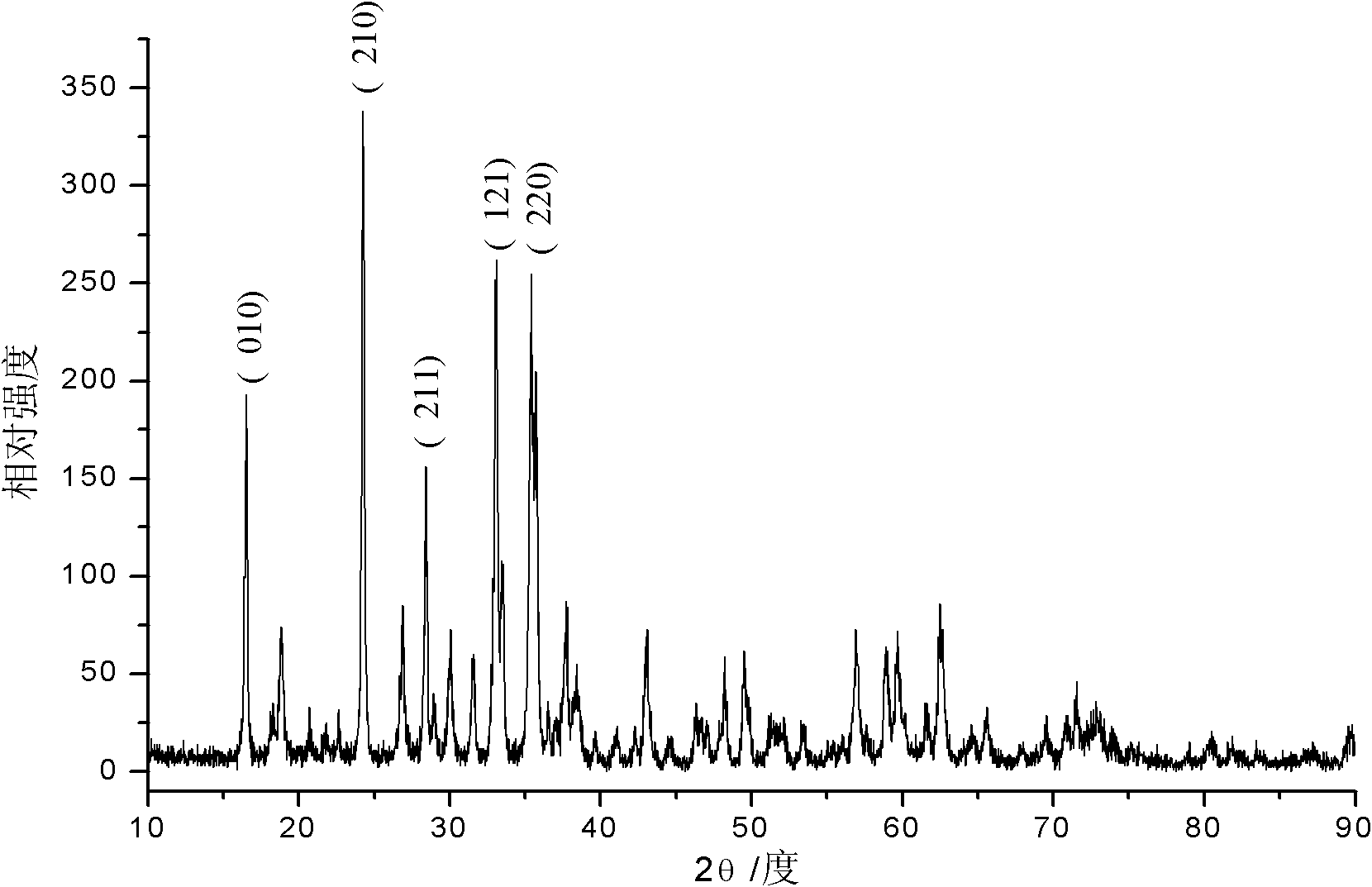

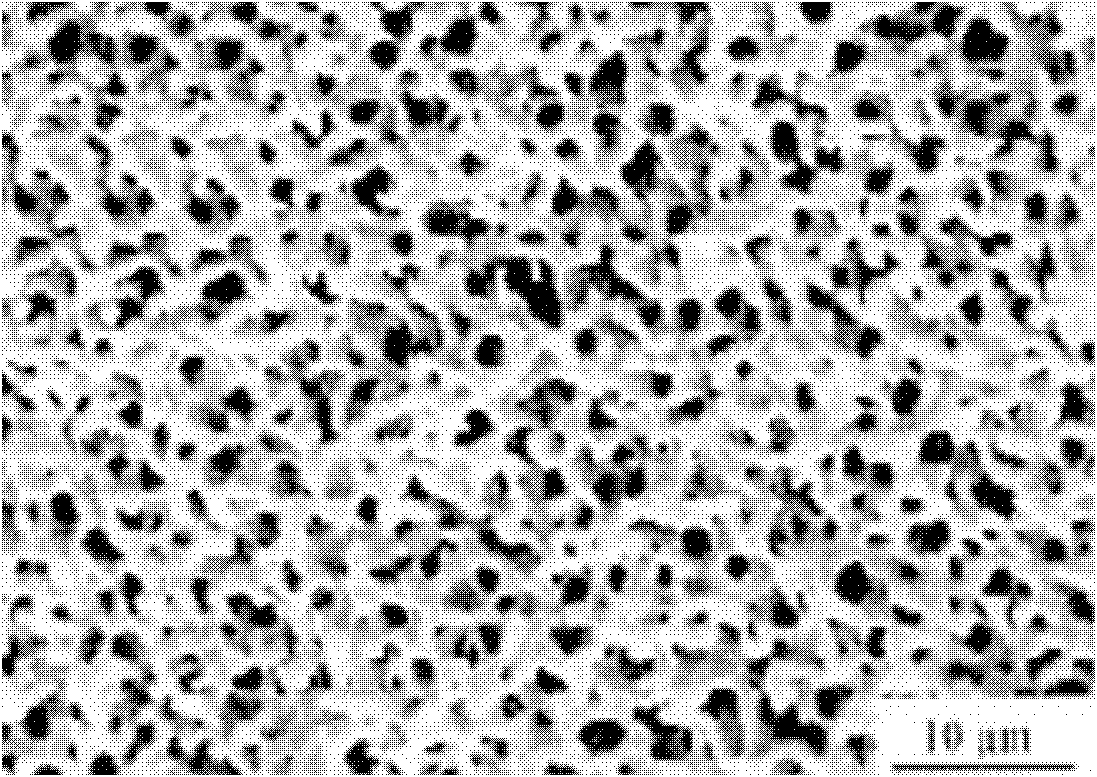

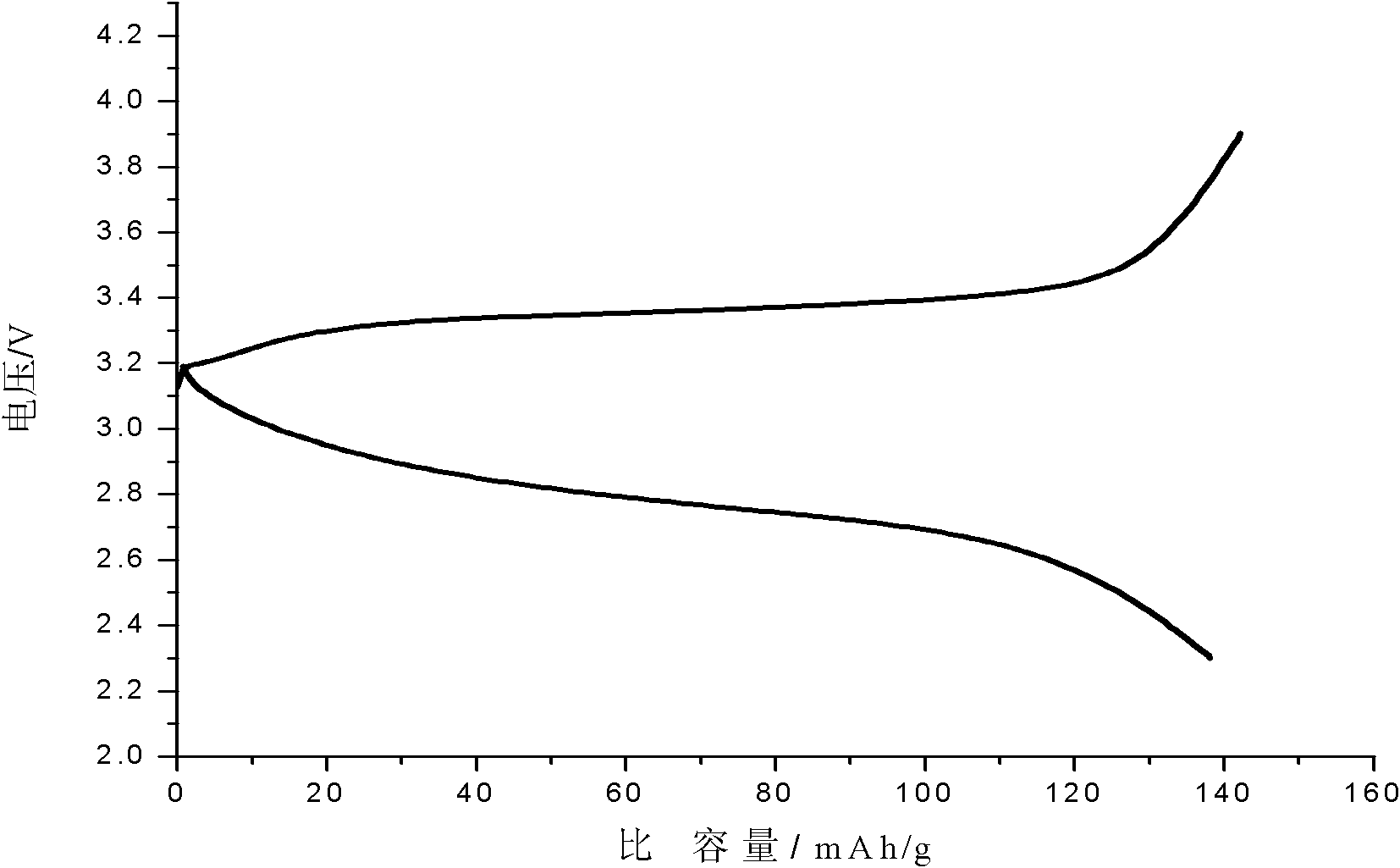

Porous carbon coated ferrous silicate lithium anode material and preparation method thereof

The invention relates to a porous carbon coated ferrous silicate lithium anode material and a preparation method thereof. Polyethylene glycol is adopted as a pore forming agent, gel is formed by the hydrolytic condensation of tetraethoxysilane, and the polyethylene glycol is pyrolyzed to form continuous frames and penetrated macropore / mesoporous port channels in the calcining process of a precursor, wherein the average pore size of the macropore is within 0.5 to 3.9mu m, the average pore size of the mesopore is within 18 to 40nm, and the average porosity is within 57.2 to 71.9 percent. A three-dimensional network structure is formed by the hydrolytic condensation of the tetraethoxysilane, thereby reducing the migration distance in the crystal lattice recombination process and the activation energy required by migration, being beneficial to reducing the reaction temperature and shortening the reaction time and producing the product which has high phase purity and accords with the stoichiometric ratio. The porous structure increases the specific surface area of the material, not only is beneficial to the infiltration of electrolyte in particles, improves the deintercalation probability of lithium ions inside crystals and the utilization ratio of the lithium ions, but also prevents the crystal grains from growing in the calcining process and aggregating in the charging and discharging process and improves the electrochemical property of the anode material.

Owner:TIANJIN UNIV

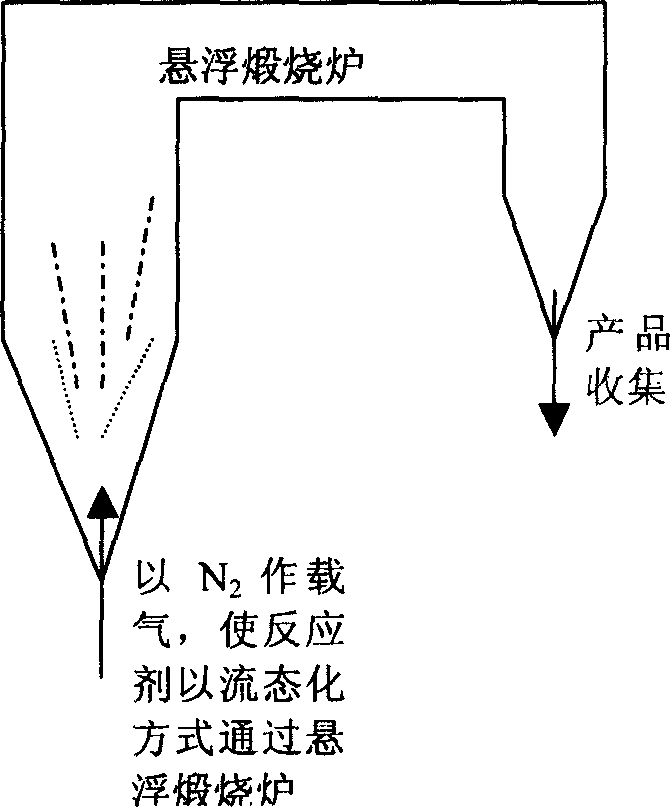

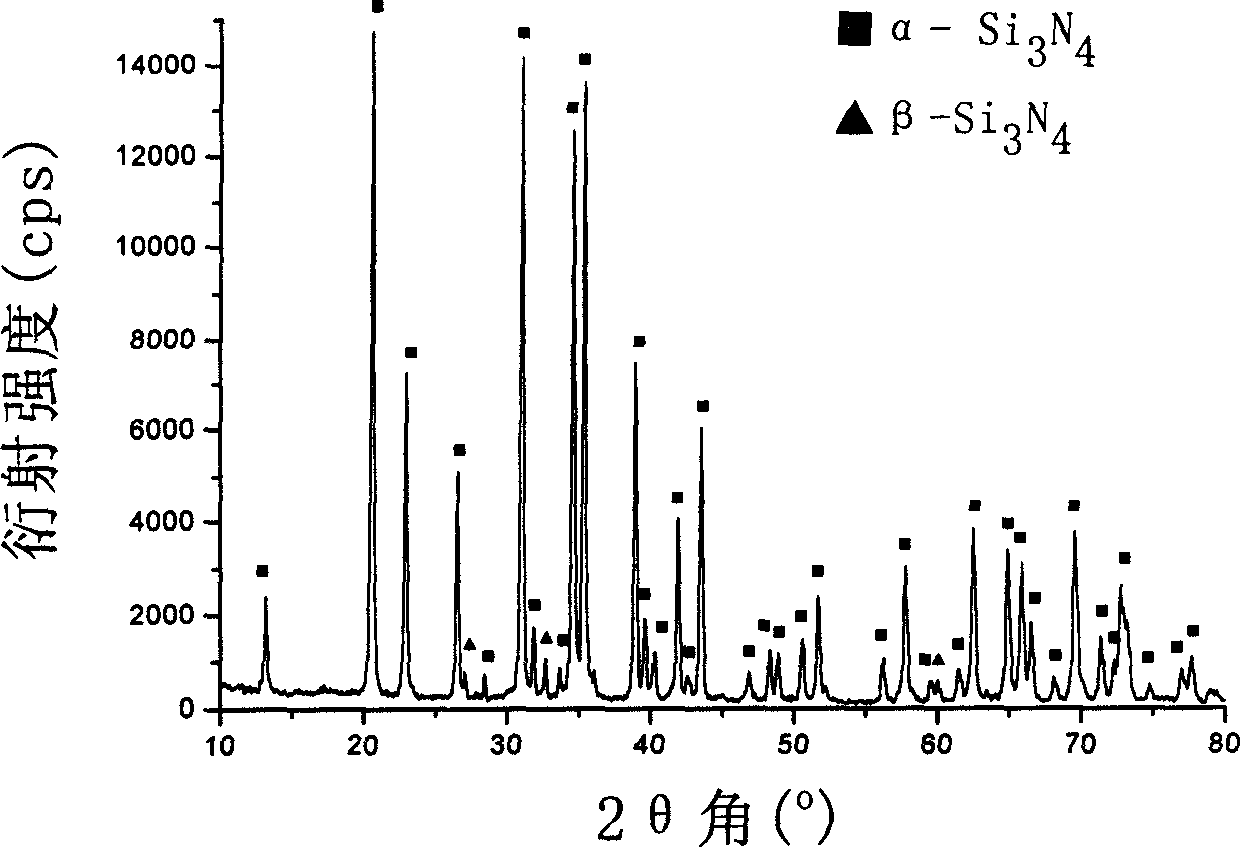

Method for synthesizing silicon nitride powder by atmospheric pressure combustion

A process for synthesizing silicon nitride powder by atmospheric pressure combustion includes such steps as proportionally mixing Si powder with catalyst, adding silicon nitride for activating and combustion reaction. Its main product is Si3N4.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Process for solid-phase microwave synthesis of polypeptide

InactiveCN1699404AIncrease reaction rateLower activation energyPeptide preparation methodsBulk chemical productionCombinatorial chemistrySolvent

Disclosed is a process for solid-phase microwave synthesis of polypeptide comprising, (1) preparing amino acid and resin compound, (2) removing amino protecting group through microwave radiation, (3) condensating amino acid through microwave radiation, (4) replacing amino acids, repeating step (2) and (3) to synthesize the needed polypeptides, (5) preparing the polypeptides crude product.

Owner:NANJING UNIV OF TECH

Process for preparing super-stable Y zeolite containing rare-earth elements

InactiveCN1159101CAchieve the purpose of exchangeLower activation energyCatalytic crackingMolecular sieve catalystsHigh resistanceRare-earth element

A rare-earth contained super-stable Y zeolite is prepared from the super-stable Y zeolite containing sodium oxide (3-5 wt.%), rare-earth compound and water in wt ratio of 1:(0.001-0.5):(1-10) through preparing solution of rare-earth compound, mixing and the said Y zeolite, and grinding with shearing stress of at least 10 kg / cm2 for at least 1 min. Its advantages are higher hydrothermal stability, high stability of activity, and high resistance to sodium and heavy metal pollutions.

Owner:CHINA PETROLEUM & CHEM CORP +1

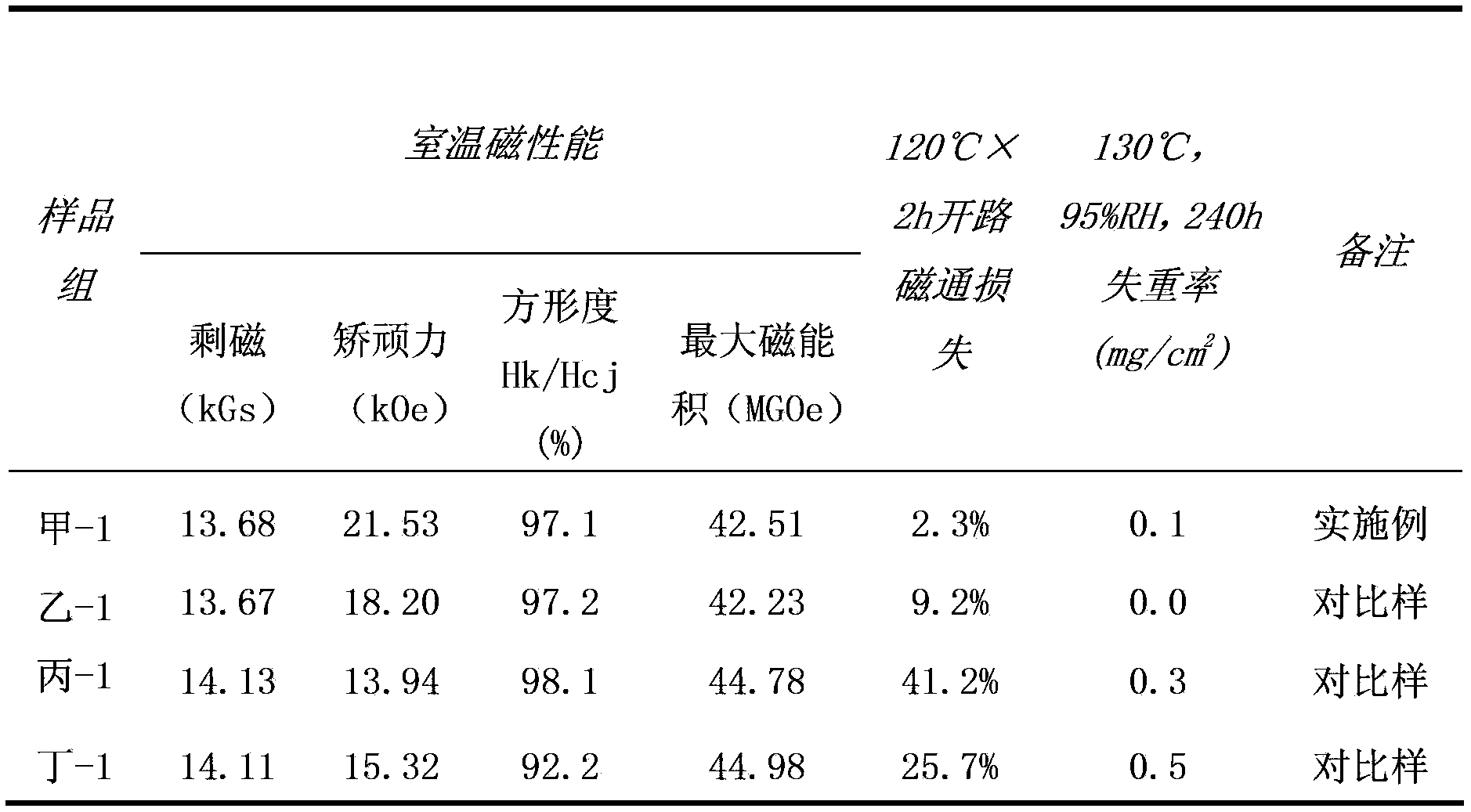

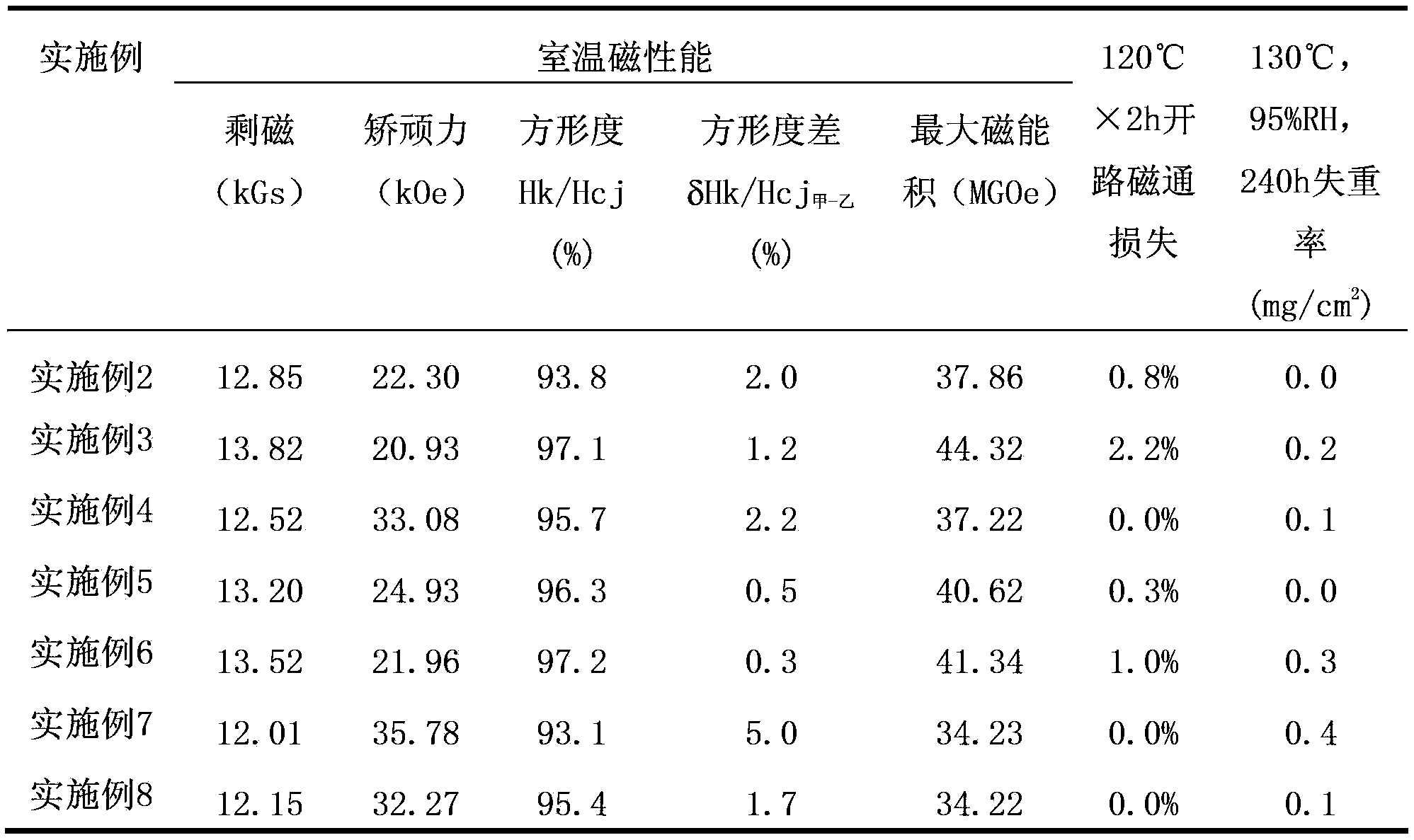

Rare-earth permanent magnet and preparation method thereof

ActiveCN104051101ALower activation energyEasy to spreadPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementPowder method

The invention discloses a rare-earth permanent magnet. The rare-earth permanent magnet mainly comprises the following components in percentage by atom: 12.1-16.2 percent of R, 0-3.4 percent of M1, 0-7.2 percent of M2, 5.1-7.4 percent of B and the balance of T, wherein the R is at least one of rear-earth elements including Y and Sc, and at least contains Nd; the M1 is at least one of Nb, Ti, Zr, V, Cr, Mo and Mn; the M2 is at least one of Al, Cu, Zn, Ga, In, Ge and Sn; the T is Fe or Fe and Co. A preparation method of the rare-earth permanent magnet comprises the processes of preparation of a magnet blank, coating, thermal treatment, and ageing, wherein the magnet blank is prepared by using a double-alloy method or a composite powder method. According to the magnet prepared by using the method, the coercive force, the temperature resistance and the corrosion resistance of a larger-size magnet can be improved, and the residual magnetism and the squareness of the magnet are not reduced.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Preparation method of anode material vanadium-lithium phosphate powder for lithium ion battery

InactiveCN101734637AGuaranteed ultra-close contactOvercome the deficiency of not being fully exposedCell electrodesPhosphorus compoundsMolecular levelLithium-ion battery

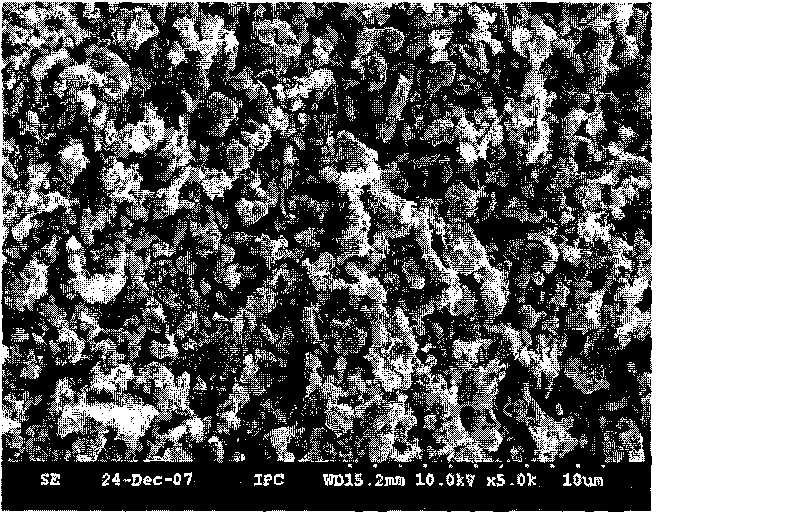

The invention relates to a preparation method of anode material vanadium-lithium phosphate powder for lithium ion battery, belonging to the technical field of battery material. The preparation method provided in the invention is implemented by homogenizing raw materials followed by secondary drying to obtain a precursor, heating at 550-1000 DEG C in non-oxide atmosphere to prepare vanadium-lithium phosphate powder. In the method, the precursor homogenized on micro-scale is prepared by secondary drying, raw materials can be mixed on molecular level of the solution, all the elements are uniformly mixed, thus avoiding composition segregation, ensuring super close contact among raw materials, overcoming the defect of incomplete contract of raw materials in solid phase technique and greatly reducing reaction activation energy; the whole process dispenses with procedures of grinding, pre-treating, crushing and the like, the prepared material has higher specific discharge capacity and capacity retention rate, and the method is simple in technique, continuous in operation and easy for industrial production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

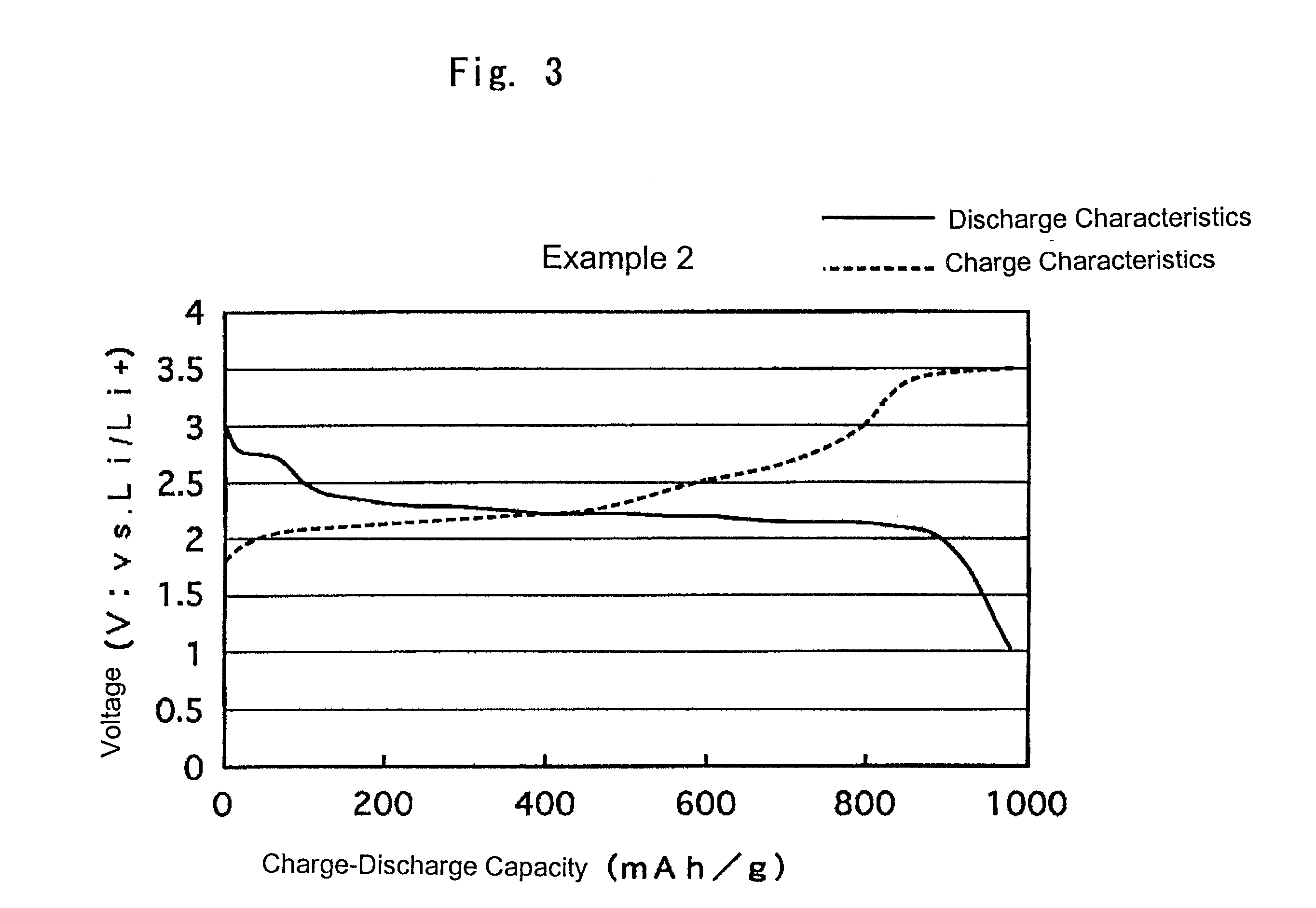

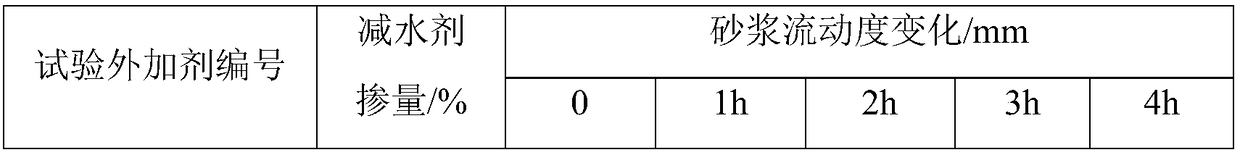

Electrode active material and lithium secondary battery

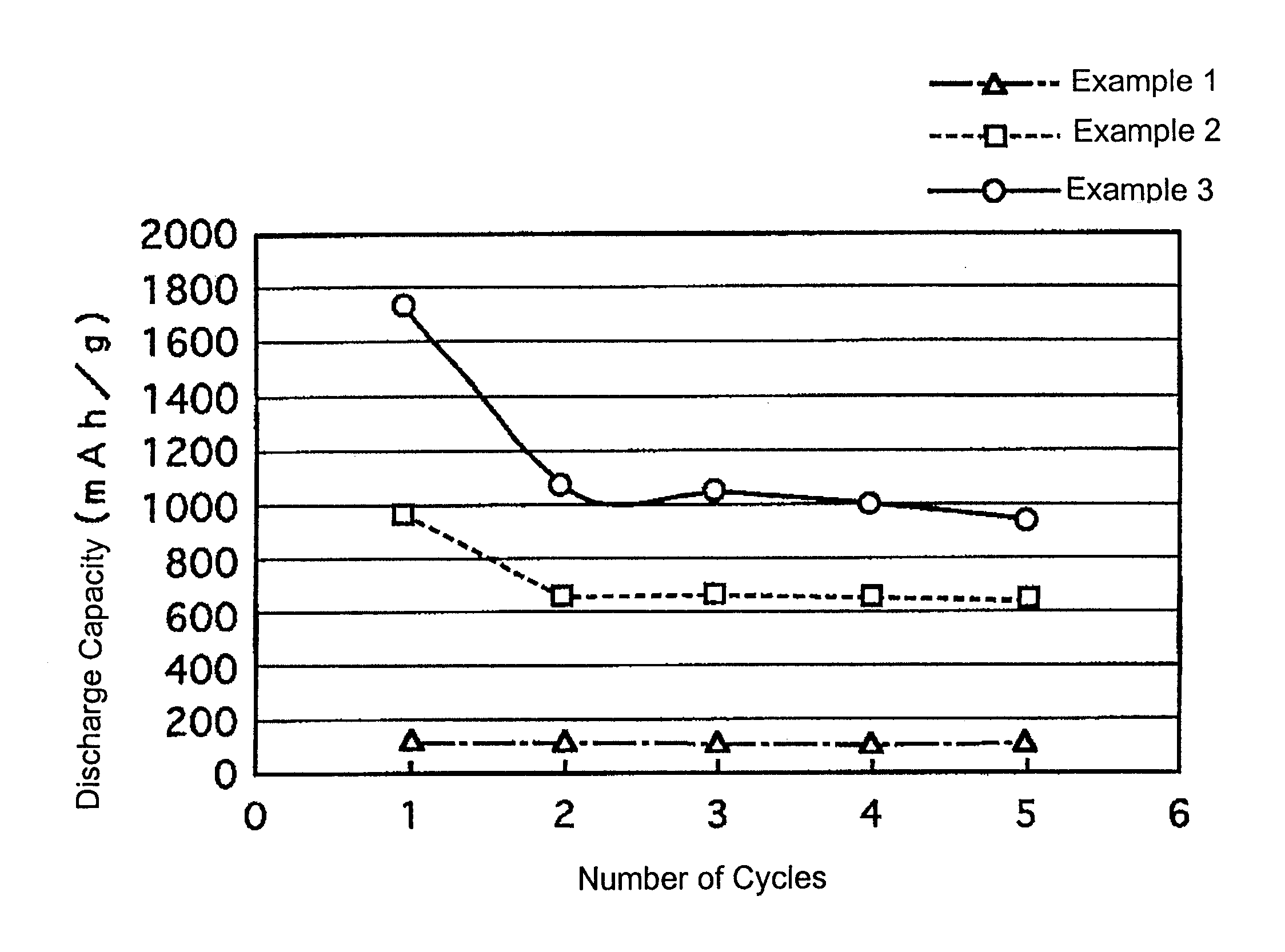

InactiveUS6692870B2Light weightIncrease energy densityPhysical/chemical process catalystsNon-aqueous electrolyte accumulatorsActivated carbonHigh energy

Owner:SANYO ELECTRIC CO LTD

Highly adaptive ultralong-slow release slump-retaining agent and normal and low temperature preparation method thereof

The invention discloses a highly adaptive ultralong-slow release slump-retaining agent and a normal and low temperature preparation method thereof. Mainly, polyether macromonomer, unsaturated carboxylic acid monomer, unsaturated carboxylic ester monomer, unsaturated phosphate ester monomer, unsaturated amide monomer, oxidant, reducing agent, chain transfer agent and deionized water carry out freeradical polymerization by aqueous solution at the temperature of 5-25 DEG C, after sodium hydroxide solution is then added to regulate pH value, water is then replenished, and thereby the slump-retaining agent is prepared. The preparation method does not need a heat source, reaction is carried out under normal and low temperatures, equipment is simple, the operability is high, the production efficiency is high, the prepared slump-retaining agent has ultralong slow release capability, slump can be retained for a long time, the adaptability is high, and the performance is excellent.

Owner:SICHUAN TONGZHOU CHEM TECH

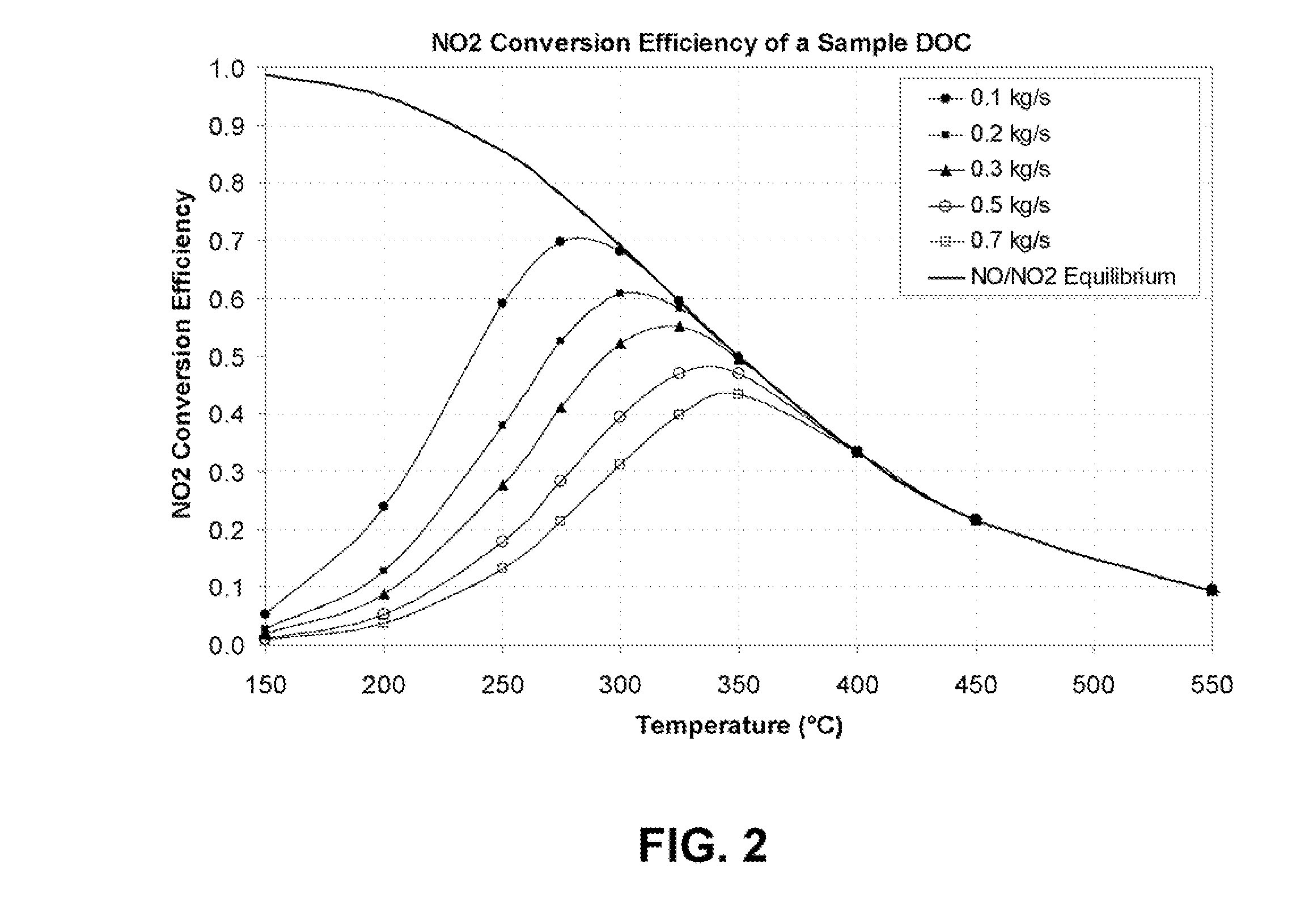

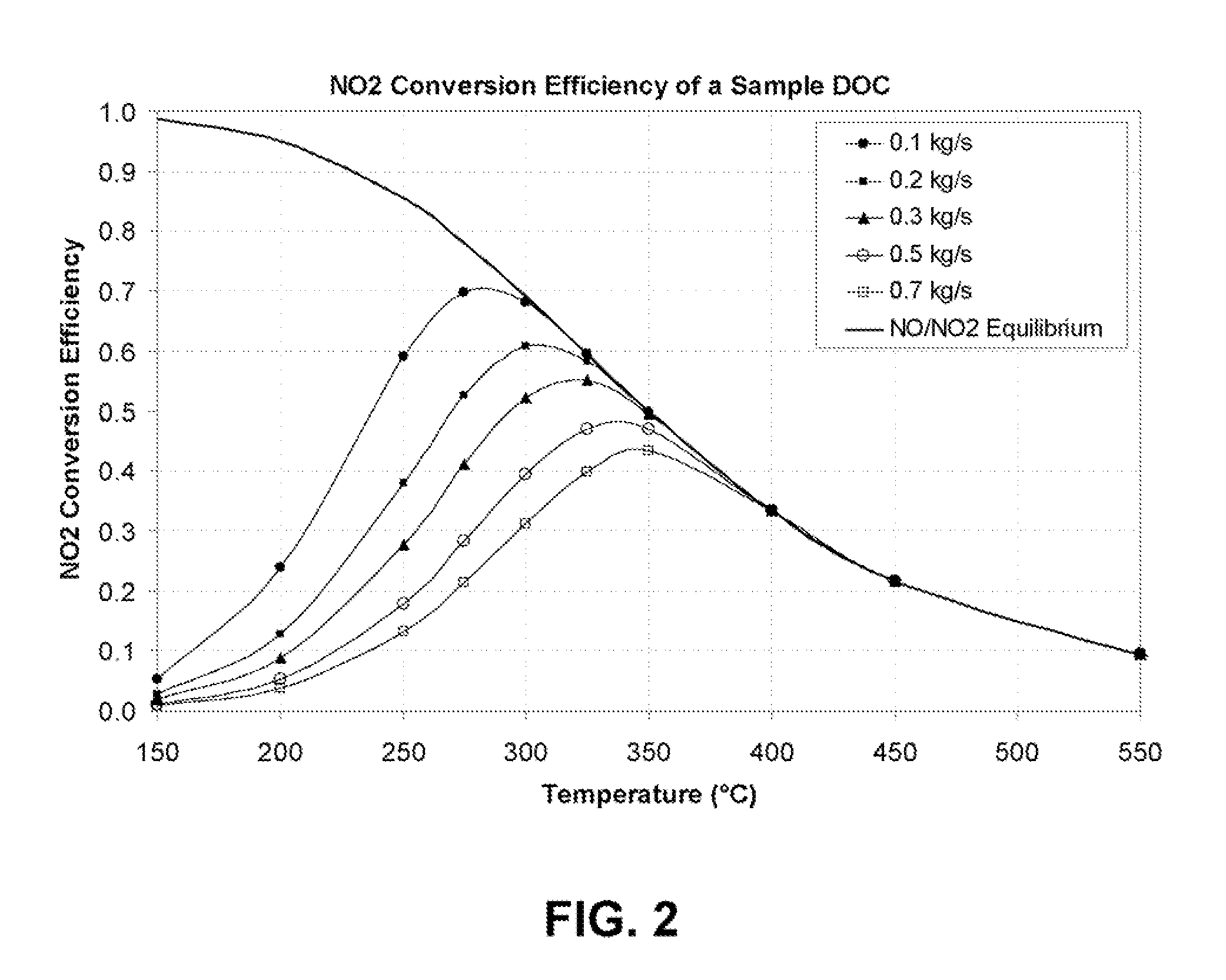

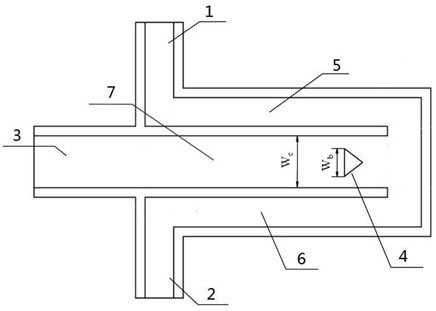

Method and apparatus for regenerating a catalyzed diesel particulate filter (DPF) via active no2-based regeneration with enhanced effective no2 supply

ActiveUS20100326055A1Enhanced effective NO supplyLower activation energyElectrical controlExhaust apparatusSoot particlesDiesel particulate filter

In a method for regenerating s catalyzed diesel particulate filter (DPF) via active NO2-based regeneration with enhanced effective NO2 supply, a NOx containing gas is introduced into the DPF, and a temperature of at least one of the DPF, the NOx containing gas, and soot in the DPF is controlled while control Sing NOx levels at an inlet of the DflF so that the NOx containing gas reacts with the catalyst to form N 02 molecules that thereafter react with soot particles to form CO, CO2, and NO molecules and a N02 efficiency is greater than 0.52 gC / gNO2 and so that less than two thirds of the soot mass that is removed from the DPF is oxidized by 02 molecules in the gas to form CO and CO2 molecules.

Owner:VOLVO LASTVAGNAR AB

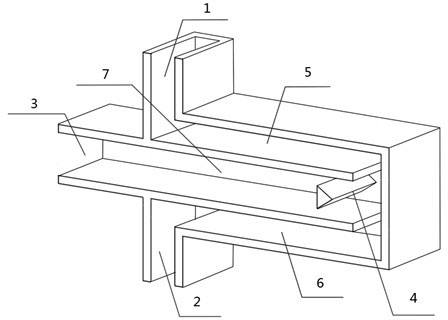

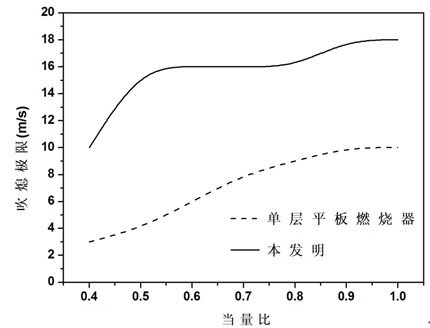

Micro-combustor

InactiveCN102183019AReduce heat lossSave energyIndirect carbon-dioxide mitigationGaseous fuel burnerAutomotive engineeringCombustion chamber

The invention discloses a micro-combustor, which comprises a bluff body, two preheating channels and a combustion chamber, wherein the preheating channels and the combustion chamber are all plate-shaped; the cross section of the bluff body is triangular or circular; the bluff body is arranged at an inlet of the combustion chamber; the ratio of the width of the bluff body to the width of the combustion chamber is 0.3-0.6; the two preheating channels are both L-shaped and are respectively arranged at upper and lower sides of the combustion chamber; and outlets of the preheating channels are both communicated with the inlet of the combustion chamber. By using the micro-combustor, the defect of the prior art is overcome. By preheating and catalyzing fuels and air (when a non-pre-mixing combustion mode is adopted) or the pre-mixture of the fuels and air (when a pre-mixing combustion mode is adopted), the energy used for igniting is lowered, the igniting delay time is shortened and the exhaust heat loss is reduced. Besides, a low-speed high-temperature recirculation region formed behind the bluff body is utilized to fully mix the fuels and air, prolong the gas retention time and stabilize the flame. The micro-combustor can be used for efficiently expanding the stable combustion limit and increasing the combustion efficiency and can be widely applied to various micro-power systems.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for treating heavy-metal-containing wastewater by external electric field reinforced micro-electrolysis technology

InactiveCN102432087APromote migrationLower activation energyWater contaminantsWater/sewage treatmentElectrolysisEmission standard

The invention discloses a method for treating heavy-metal-containing wastewater by an external electric field reinforced micro-electrolysis technology, and belongs to the fields of water treatment technologies and recycling. In the method, the heavy-metal-containing wastewater is pretreated or not pretreated and then introduced into an external electric field reinforced micro-electrolysis reactor to be treated, a micro-electrolysis filler is filled in the reactor and is put in an external electric field with certain intensity, and micro-electrolysis reaction is promoted and reinforced through the reinforcing effect of the external electric field, so that metal ions in the wastewater are reduced into metal simple substances on the surface of the filler, and effluent can meet the requirement of the wastewater emission standard or can be directly recycled in the production process. The method has the advantages of high reaction speed, removal rate, recycling efficiency and environment compatibility and the like.

Owner:KUNMING UNIV OF SCI & TECH

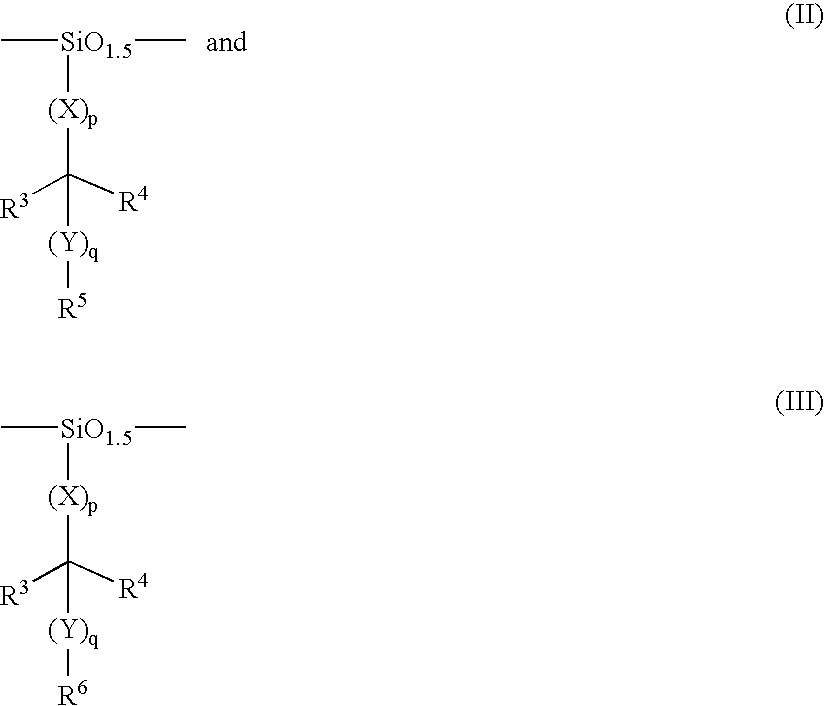

Low activation energy photoresists

ActiveUS7193023B2Lower activation energyMinimizing conditionPhotosensitive materialsPhotosensitive materials for photomechanical apparatusPolymer scienceCarboxylic acid

Polymers containing an acetal or ketal linkage and their use in lithographic photoresist compositions, particularly in chemical amplification photoresists, are provided. The polymer is prepared from at least one first olefinic monomer containing an acetal or ketal linkage, the acid-catalyzed cleavage of which renders the polymer soluble in aqueous base; and at least one second olefinic monomer selected from (i) an olefinic monomer containing a pendant fluorinated hydroxyalkyl group RH, (ii) an olefinic monomer containing a pendant fluorinated alkylsulfonamide group RS, and (iii) combinations thereof. The acetal or ketal linkage may be contained within an acid-cleavable substituent RCL in the first olefinic monomer. A method for using the photoresist compositions containing these polymers in preparing a patterned substrate is also provided in which the polymer is rendered soluble in aqueous base at a temperature of less than about 100° C. by acid-catalyzed deprotection of pendent acetal- or ketal-protected carboxylic acid groups.

Owner:INT BUSINESS MASCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com