Supported bimetallic catalyst for catalytic oxidation of VOCs and preparation method and application thereof

A catalytic oxidation and catalyst technology, applied in the field of resources and the environment, can solve problems such as chlorine poisoning, poor activity, and poor universality, and achieve the effects of high selectivity, good stability, and increased reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

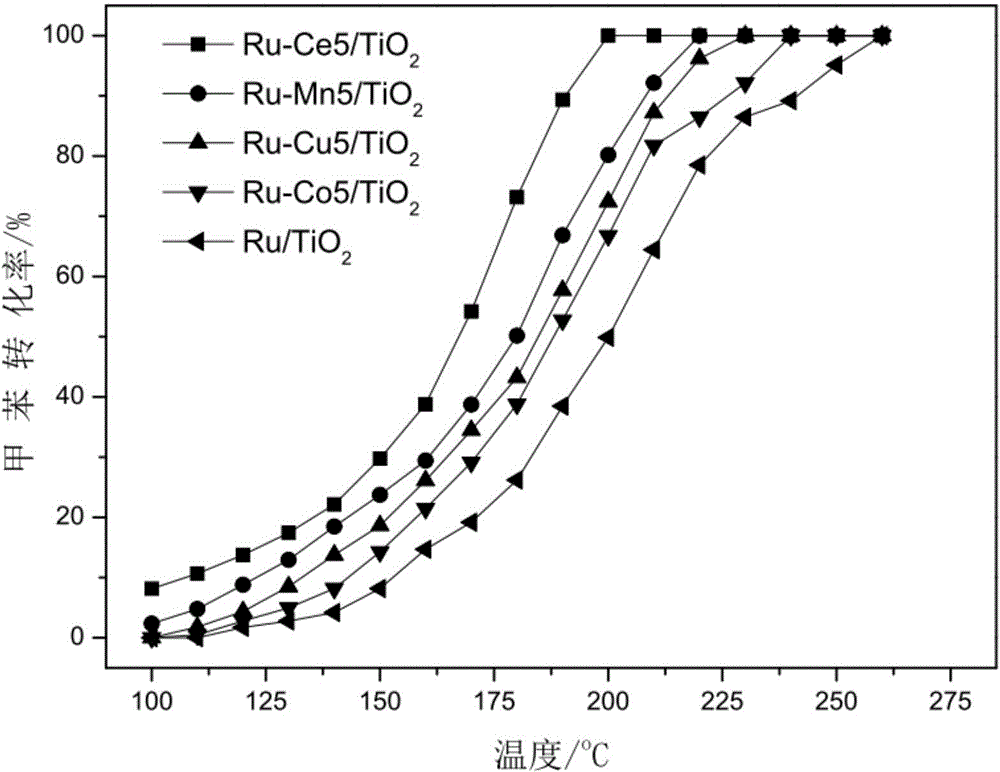

[0032] A catalyst for catalytic oxidation of VOCs, comprising a carrier, a first active component and a second active component, the carrier is titanium dioxide, the first active component is ruthenium dioxide, the second active component is manganese oxide, and the catalyst The mass of ruthenium is 100wt%, the mass percent of ruthenium in the catalyst in the first active component is 0.2wt%, and the atomic molar ratio of ruthenium and manganese is 1:1.

[0033] Above-mentioned catalyst adopts impregnation preparation, and it comprises the steps:

[0034] (1) Manganese nitrate and ruthenium trichloride are dissolved in water together to obtain a mixed metal salt solution;

[0035] (2) After calcining the carrier at 350°C for 1 hour, add water to obtain a titanium dioxide slurry, add the mixed solution obtained in step (1) into the titanium dioxide slurry, and stir at the same time, then let it stand for 1 hour, and then fully impregnate , placed in an oven at 80°C and heated ...

Embodiment 2

[0038] The rest is the same as that of Example 1 except that the pretreatment of the carrier is calcination at 350°C for 3 hours, the first drying treatment is drying at 130°C for 10 hours, and the first calcination treatment is calcination at 600°C for 6 hours.

[0039] At a space velocity of 60000mL / (g h), when the simulated flue gas containing 1000ppm toluene is catalytically oxidized, the complete oxidation temperature of toluene is 325°C, CO 2 The selectivity is 90%.

Embodiment 3

[0041] Except that the mass percentage of ruthenium element in the catalyst is 2wt%, and the atomic molar ratio of ruthenium and manganese is 1:10, the rest is the same as that of Example 2.

[0042] At a space velocity of 60000mL / (g h), when the simulated flue gas containing 1000ppm toluene is catalytically oxidized, the complete oxidation temperature of toluene is 250°C, CO 2 Selectivity ≥ 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com