Highly adaptive ultralong-slow release slump-retaining agent and normal and low temperature preparation method thereof

An adaptable, slump-preserving agent technology, applied in the field of high-adaptability ultra-long slow-release slump-preventing agent and its normal and low temperature preparation, can solve the problem that the slow-release time can only reach 1-2 hours, and the slump-retaining agent has poor slump-preserving performance , harsh reaction conditions and other problems, to achieve the effect of prolonging the slump retention time, increasing the strength and toughness, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

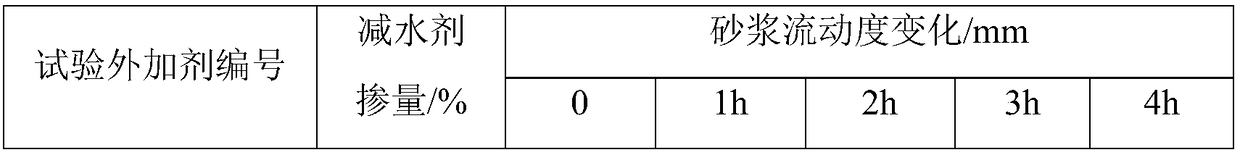

Examples

Embodiment 1

[0027] A highly adaptable ultra-long slow-release slump-retaining agent, including the following raw materials in parts by weight: 390 parts of comonomers, 4.0 parts of oxidizing agents, 0.66 parts of reducing agents, 1.75 parts of chain transfer agents, and 505 parts of deionized water; Monomers include unsaturated polyether macromonomers, unsaturated carboxylic acid monomers, unsaturated carboxylic acid ester monomers, unsaturated phosphate ester monomers and unsaturated amide monomers, and the ratio of their substances is : 1.0:2.28:2.69:1.12:0.21; the consumption of chain transfer agent is preferably 0.58% of unsaturated polyether macromonomer quality, the consumption of oxidizing agent is preferably 1.3% of unsaturated polyether macromonomer quality, the reducing agent The dosage is preferably 0.22% of the mass of the unsaturated polyether macromonomer.

[0028] The normal and low temperature preparation method of the above-mentioned highly adaptable ultra-long slow-relea...

Embodiment 2

[0035] A highly adaptable ultra-long slow-release slump-retaining agent, including the following raw materials in parts by weight: 395 parts of comonomers, 3.6 parts of oxidizing agents, 0.65 parts of reducing agents, 1.85 parts of chain transfer agents, and 505 parts of deionized water; Monomers include unsaturated polyether macromonomers, unsaturated carboxylic acid monomers, unsaturated carboxylic acid ester monomers, unsaturated phosphate ester monomers and unsaturated amide monomers, and the ratio of their substances is : 1.0:2.26:2.60:1.26:0.43; the consumption of chain transfer agent is preferably 0.62% of unsaturated polyether macromonomer quality, the consumption of oxidant is preferably 1.2% of unsaturated polyether macromonomer quality, and the amount of reducing agent The dosage is preferably 0.22% of the mass of the unsaturated polyether macromonomer.

[0036] The normal and low temperature preparation method of the above-mentioned highly adaptable ultra-long slow...

Embodiment 3

[0043] A highly adaptable ultra-long slow-release slump-retaining agent, including the following raw materials in parts by weight: 394 parts of comonomer, 3.6 parts of oxidizing agent, 1.25 parts of reducing agent, 1.75 parts of chain transfer agent, 525 parts of deionized water; Monomers include unsaturated polyether macromonomers, unsaturated carboxylic acid monomers, unsaturated carboxylic acid ester monomers, unsaturated phosphate ester monomers and unsaturated amide monomers, and the ratio of their substances is : 1.0:2.39:2.53:1.04:0.28; the consumption of chain transfer agent is preferably 0.58% of unsaturated polyether macromonomer quality, the consumption of oxidizing agent is preferably 1.2% of unsaturated polyether macromonomer quality, the reducing agent The dosage is preferably 0.42% of the mass of the unsaturated polyether macromonomer.

[0044] The normal and low temperature preparation method of the above-mentioned highly adaptable ultra-long slow-release slump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com