Heat-resistant flexible transparent conductive film and preparation method thereof

A transparent conductive film, flexible technology, applied in the direction of conductive coating, cable/conductor manufacturing, conductive layer on the insulating carrier, etc., can solve the complex preparation process of flexible transparent conductive film, poor heat resistance of flexible transparent conductive film, harsh production conditions and other problems, to achieve the effect of short time-consuming, improved electrical conductivity, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the heat-resistant flexible conductive film comprises the following steps:

[0021] Step 1): Take silver nitrate, glycerol, ammonium chloride or ammonium fluoride, and polyvinylpyrrolidone by weighing respectively according to the above formula to form a mixed solution;

[0022] Step 2): stirring and heating the obtained mixed solution at 200° C. for 20-30 minutes to obtain a nano-silver wire suspension;

[0023] Step 3): Pass the suspension of silver nanowires through a 400-mesh filter to separate the silver nanowires;

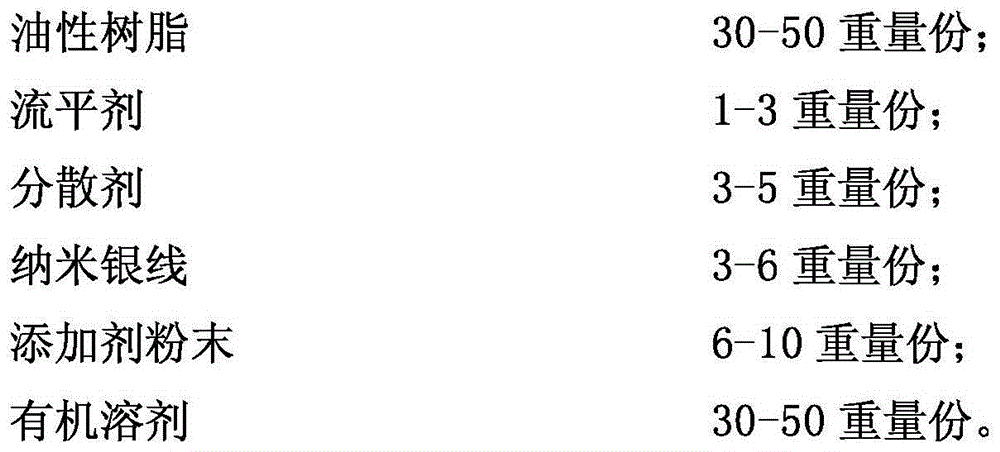

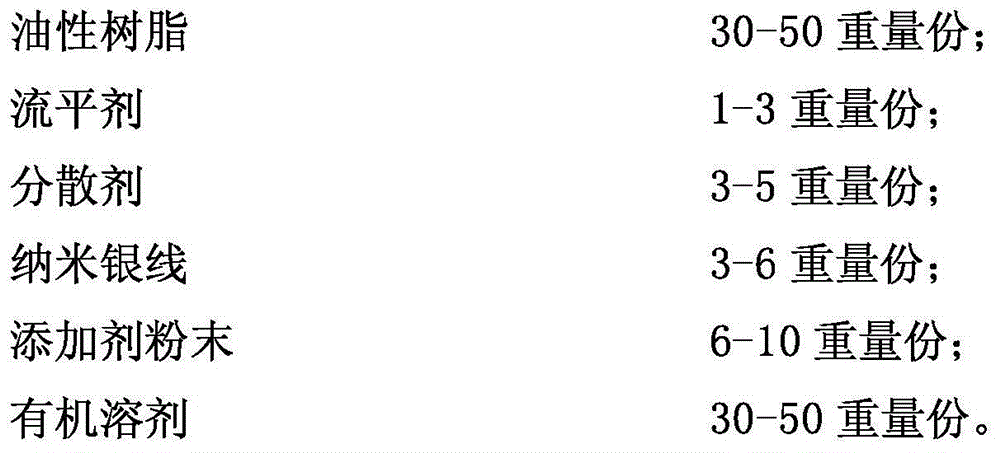

[0024] Step 4): Weigh the oleoresin, leveling agent, dispersant, nano-silver wire, additive powder and an appropriate amount of organic solvent according to the above formula. And they were put into the reaction vessel and stirred for 30min to obtain the coating of the novel heat-resistant flexible transparent conductive film;

[0025] Step 5): uniformly coating the coating on the PET film, and adjusting its thickness to 0.5...

Embodiment 1

[0028] Weigh 10g of silver nitrate, 100g of glycerol, 10g of ammonium chloride, and 20g of polyvinylpyrrolidone to make a mixed solution, and stir and heat the mixed solution at 200°C for 30min. Pass the suspension of the prepared silver nanowires through a 400-mesh filter screen to separate the silver nanowires.

[0029] Weigh 50g oleoresin, 3g leveling agent, 5g dispersant, 6g nano-silver wire, 10g additive powder, 50g ethyl acetate and stir for 30min, then evenly spread on PET film, and adjust its thickness to 0.8μm, at 120 Bake and shape in an oven at ℃ for 5-10 minutes to obtain a heat-resistant flexible transparent conductive film.

[0030] After testing, the prepared film has a surface resistance of 45Ω, a light transmittance of 80%, and a haze of 2.5%. Compared with a film prepared without adding additive powder, its deformation temperature is increased by 25°C through a comparison test.

Embodiment 2

[0032] The preparation of silver nanowires is as in Example 1.

[0033] Weigh 30g oleoresin, 1g leveling agent, 3g dispersant, 3g nano-silver wire, 6g additive powder, 30g toluene and stir for 30min, then evenly coat on the PET film, and adjust its thickness to 0.5μm. Bake and shape in an oven for 5-10 minutes to obtain a heat-resistant flexible transparent conductive film.

[0034] After testing, the surface resistance of the prepared film is 45Ω, the light transmittance is 85%, and the haze is 2.5%. Compared with the film prepared without adding additive powder, its deformation temperature is increased by 25°C through a comparison test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com