Patents

Literature

1692 results about "Silver nanowires" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

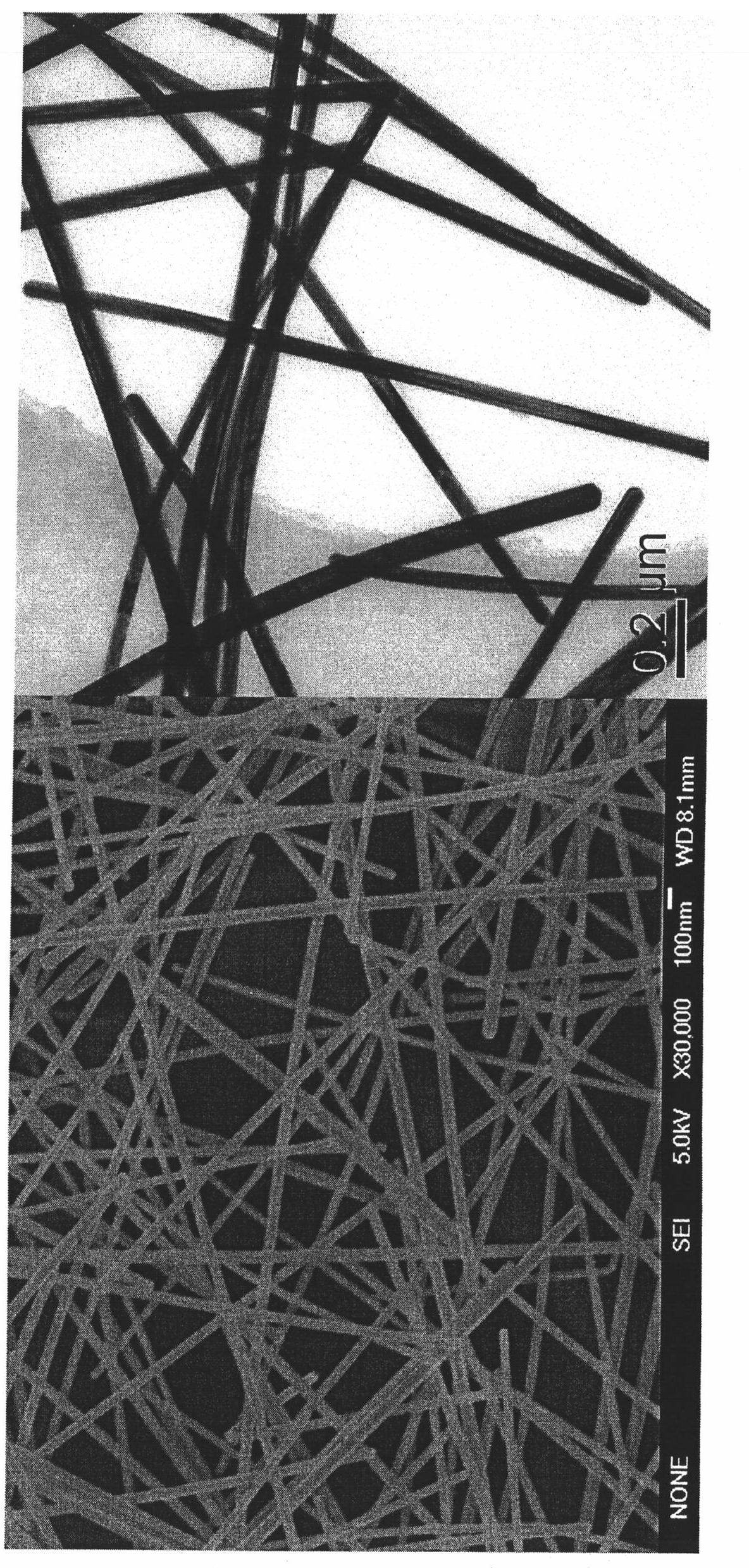

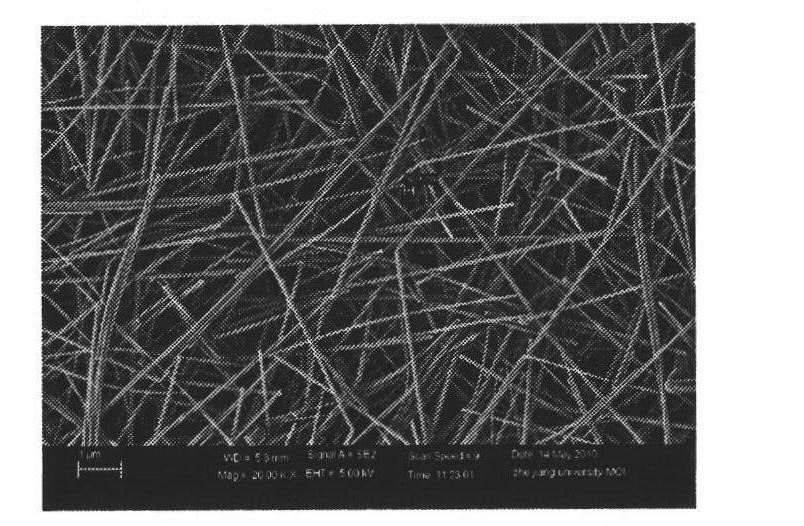

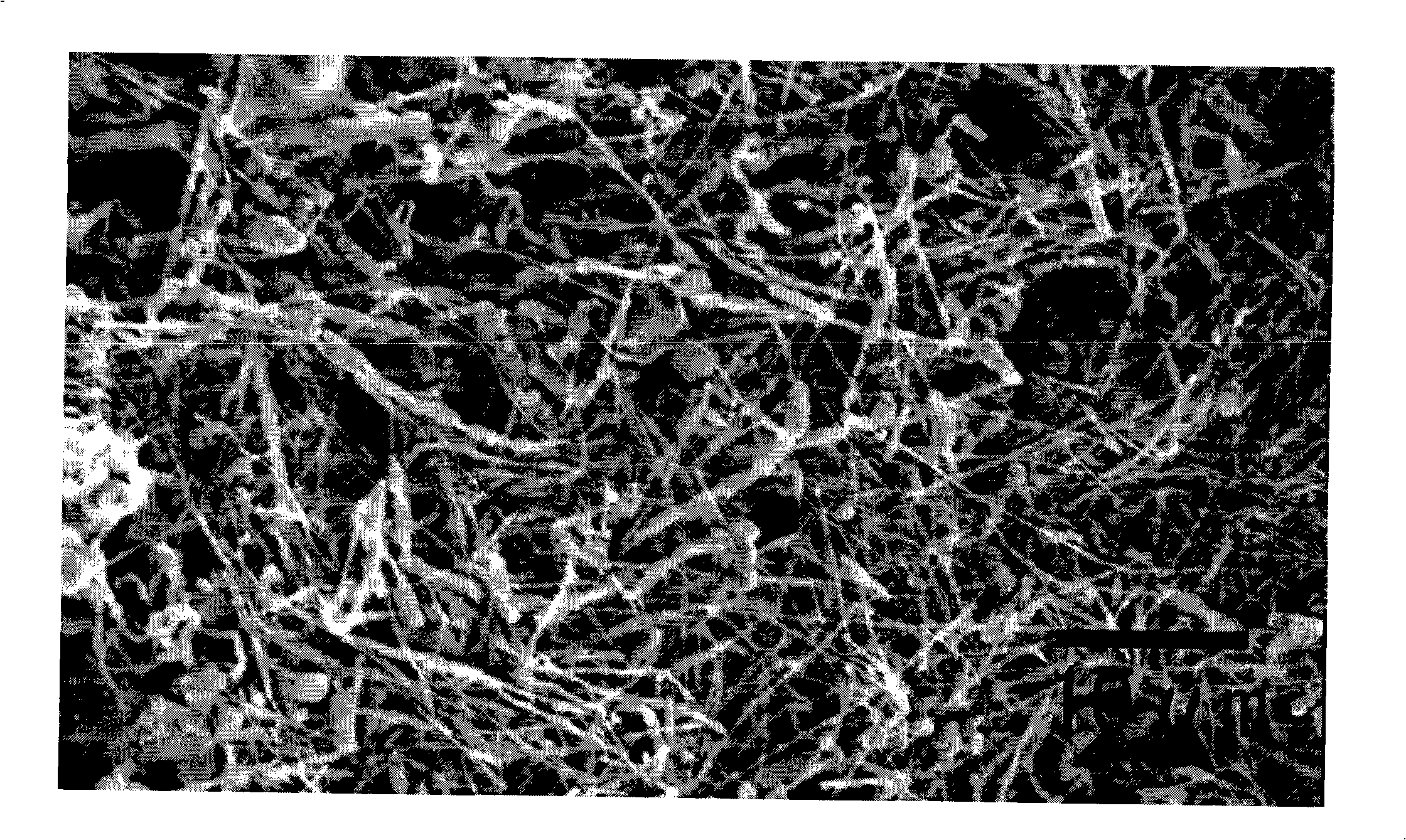

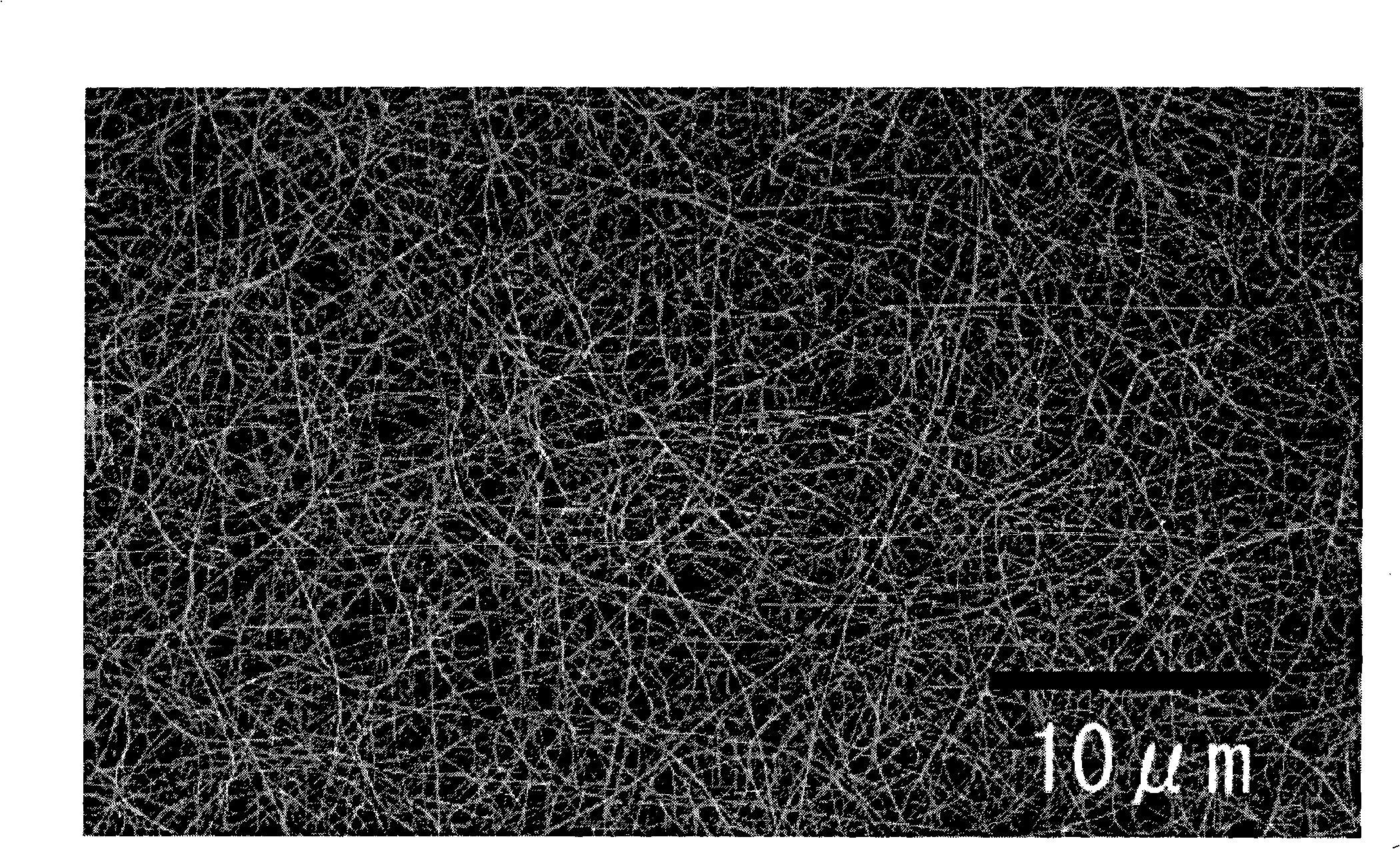

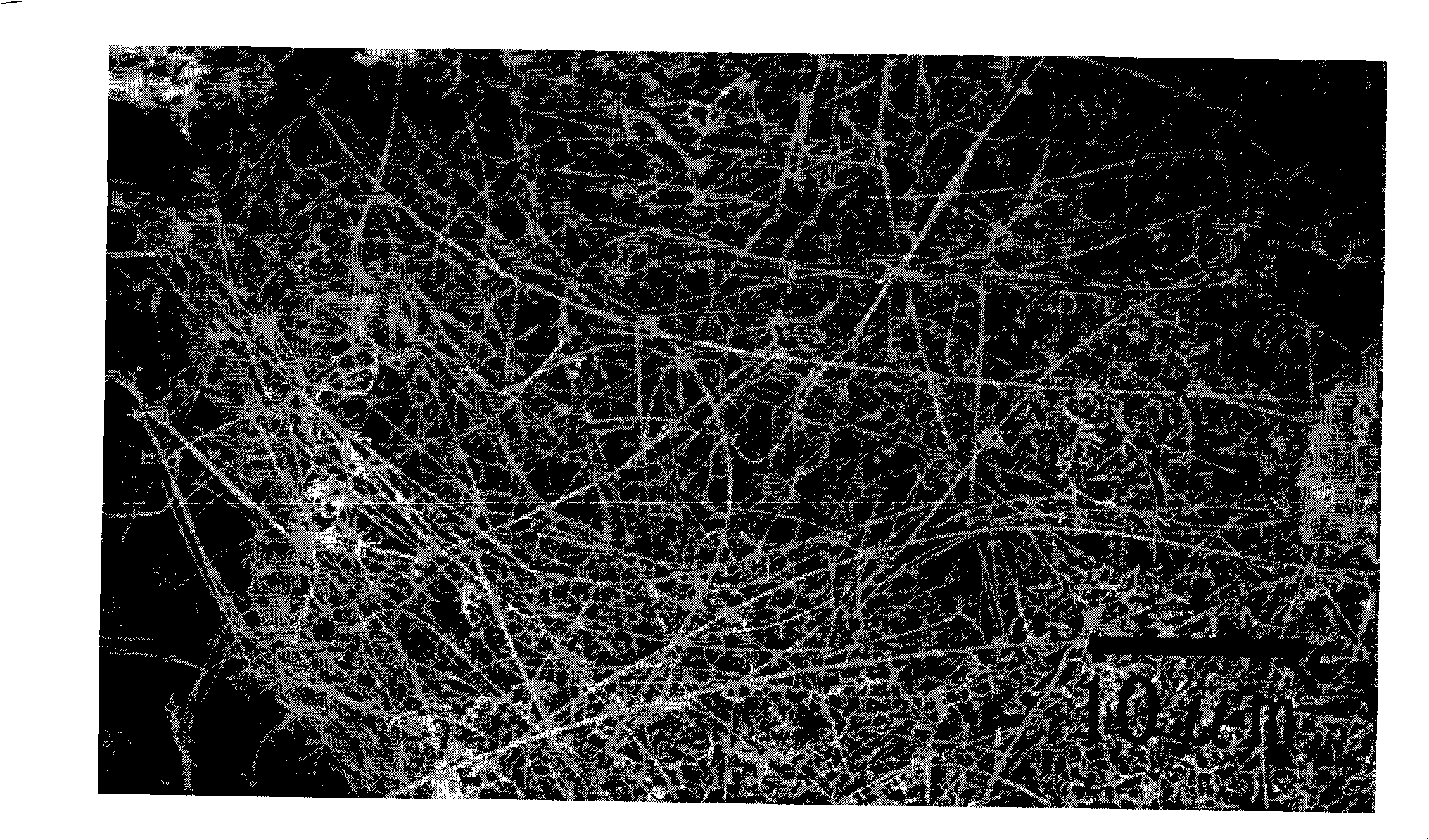

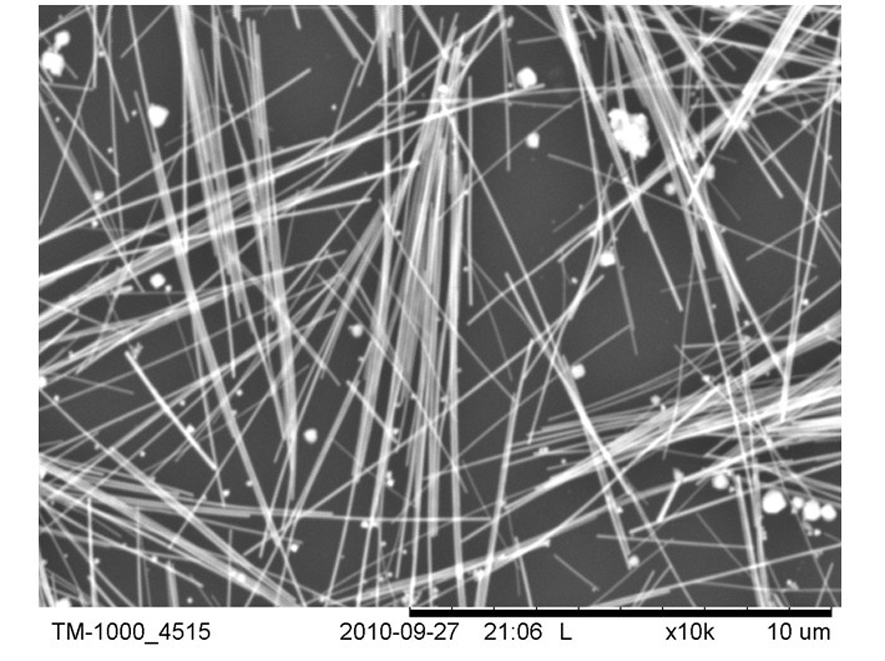

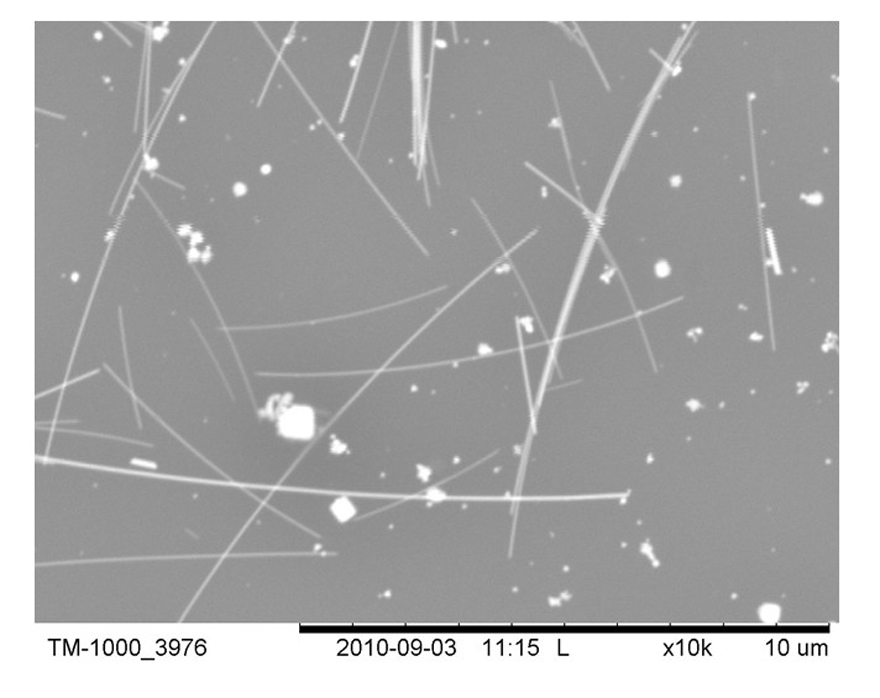

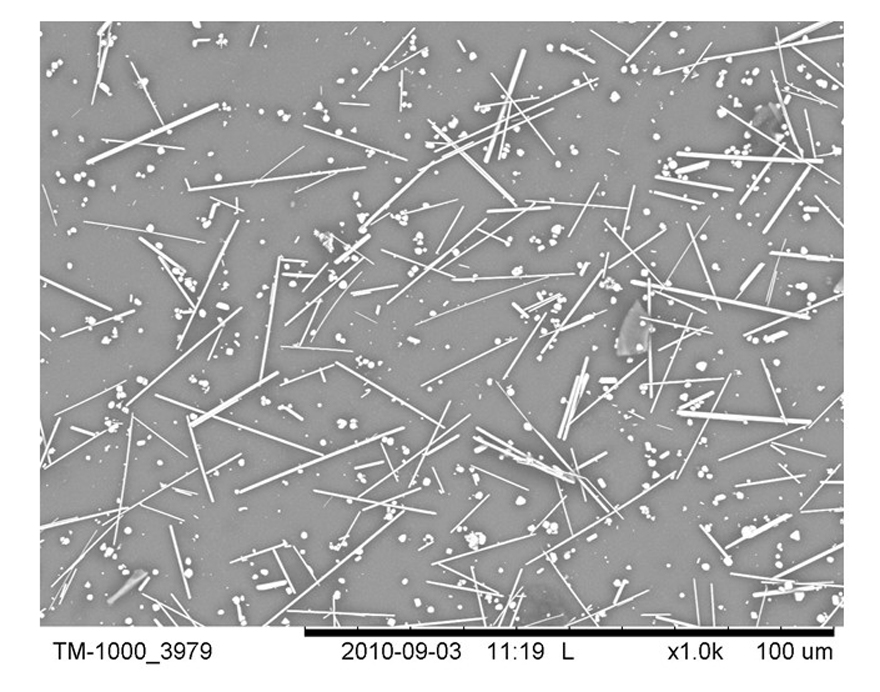

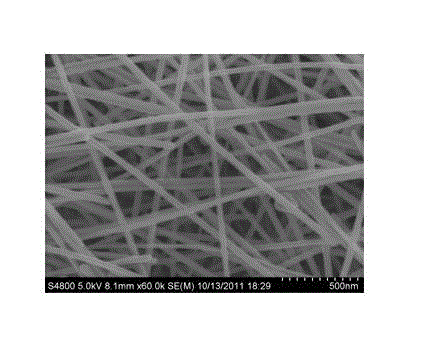

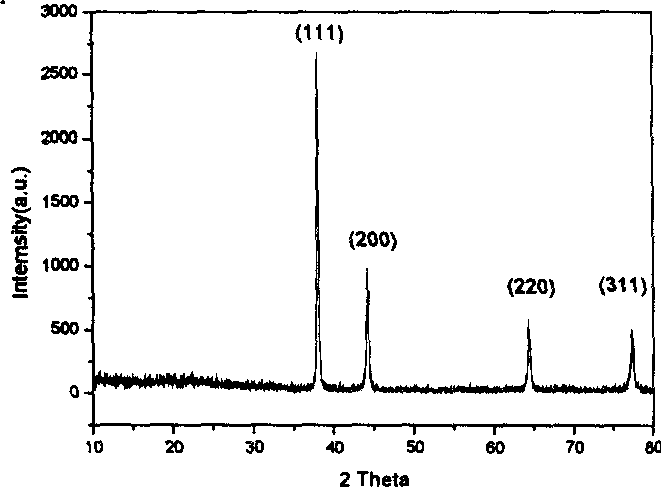

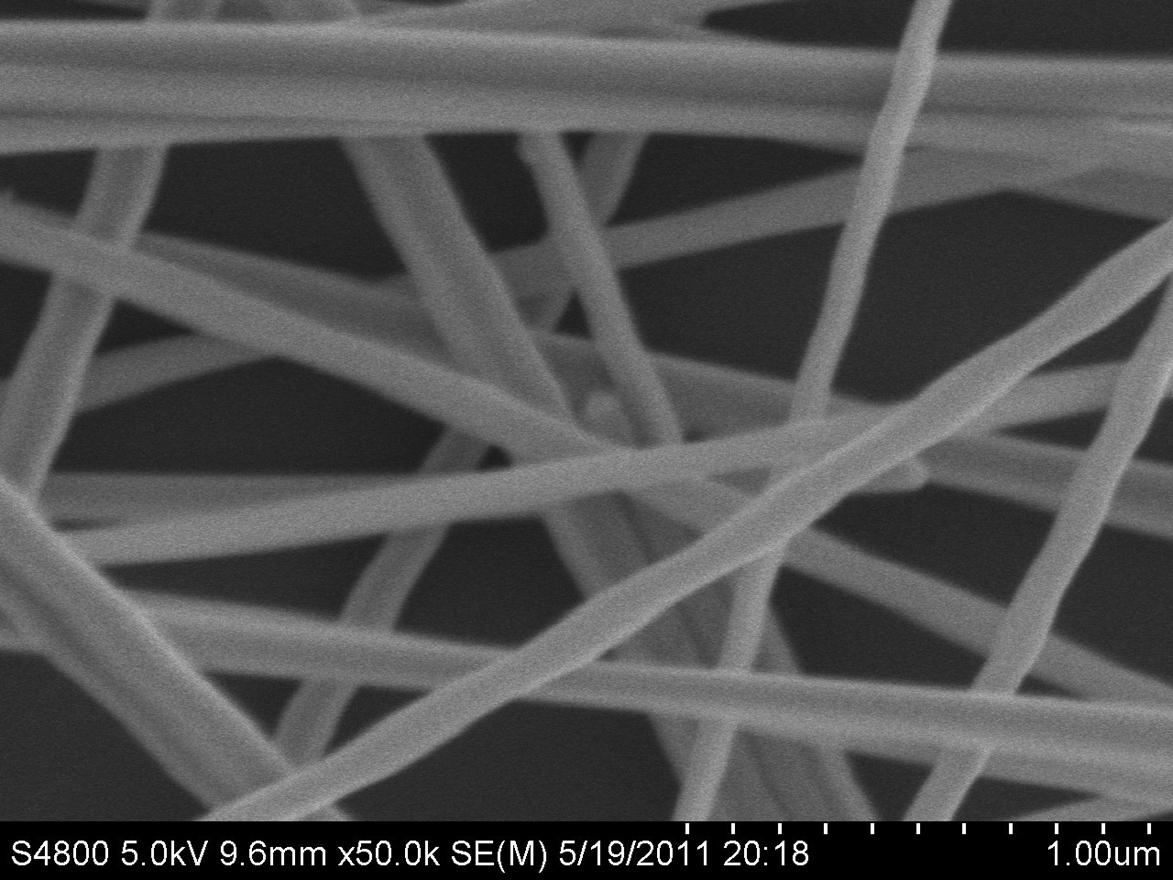

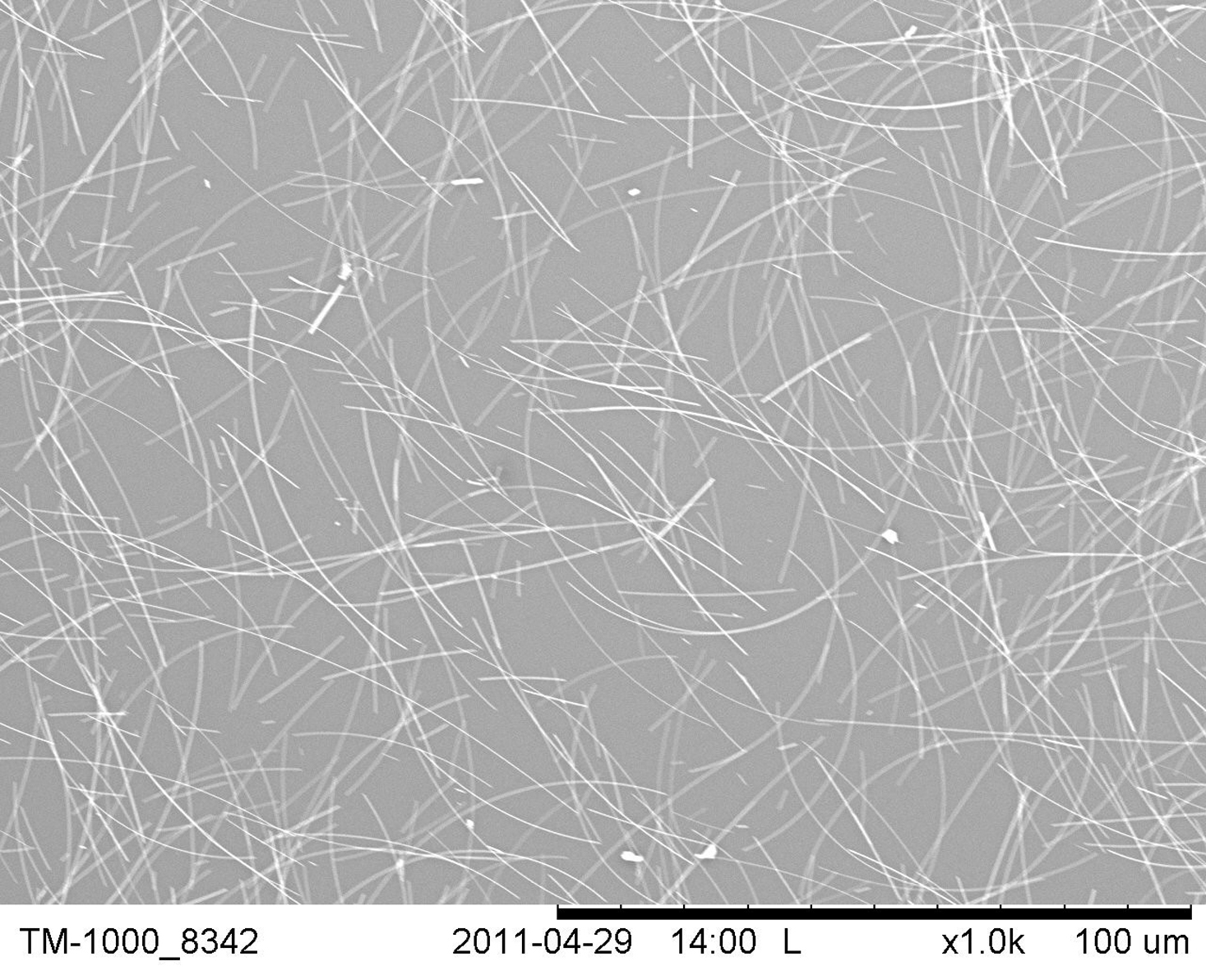

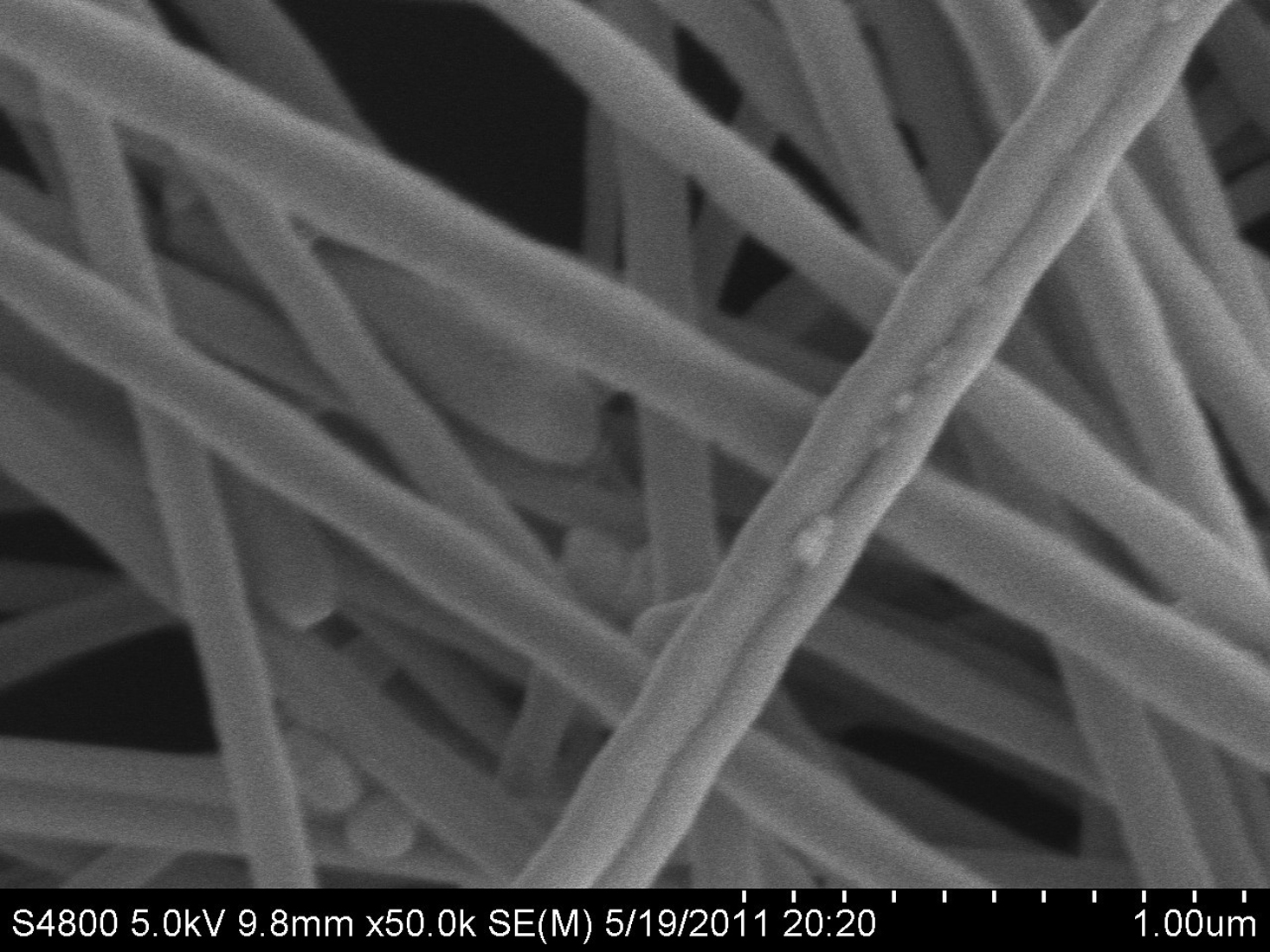

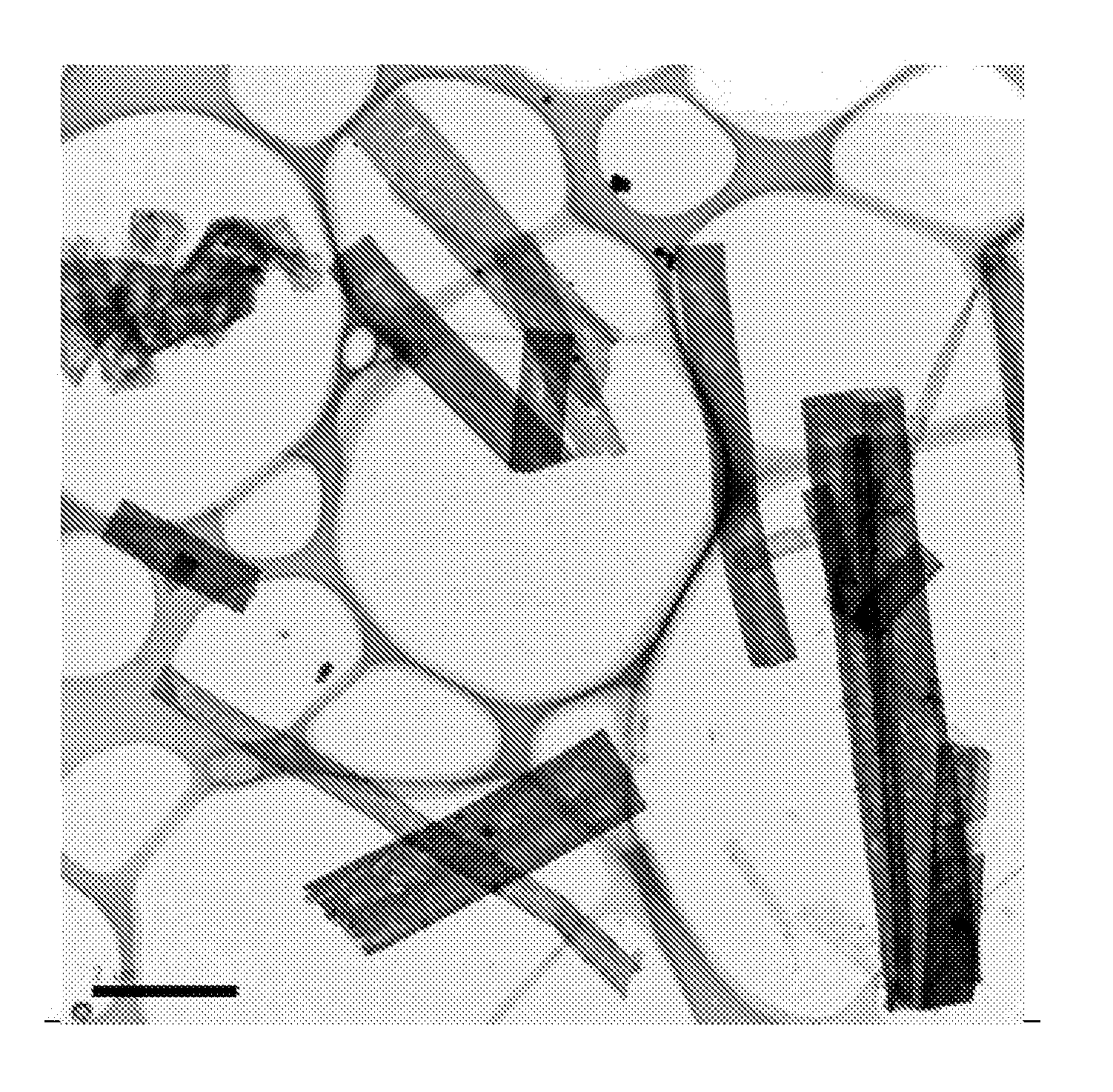

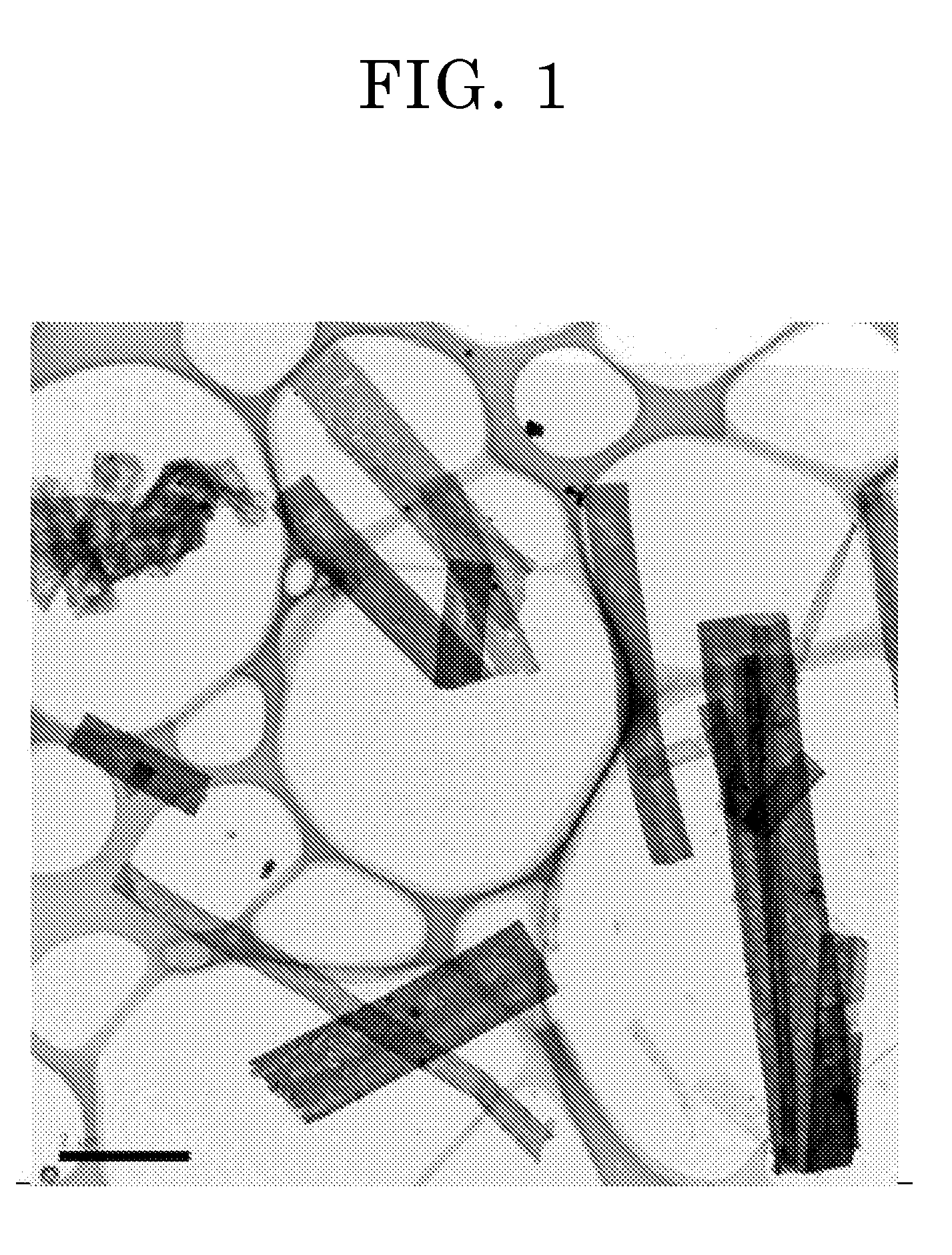

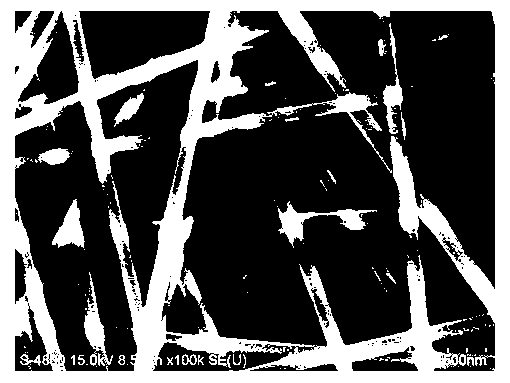

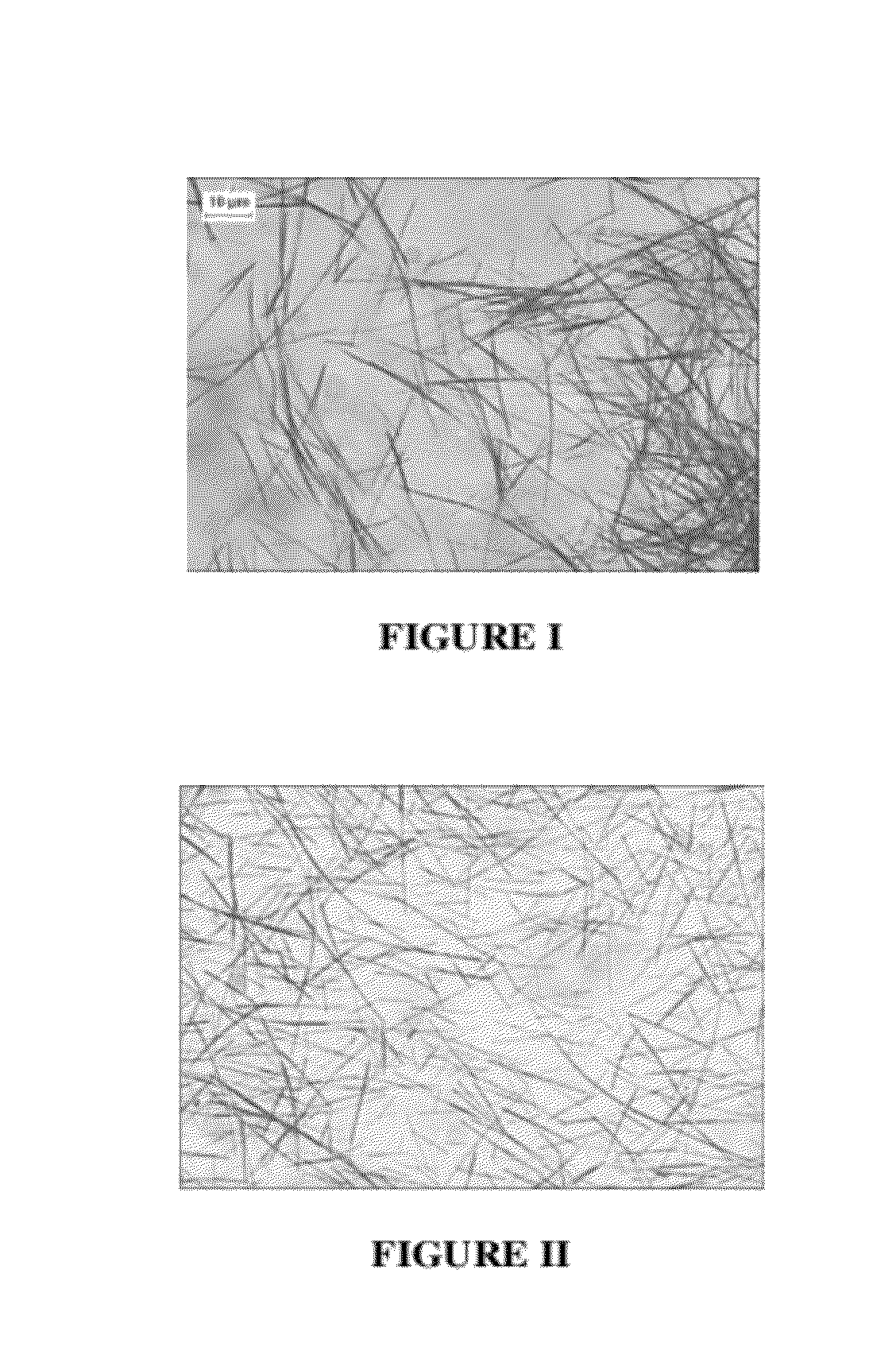

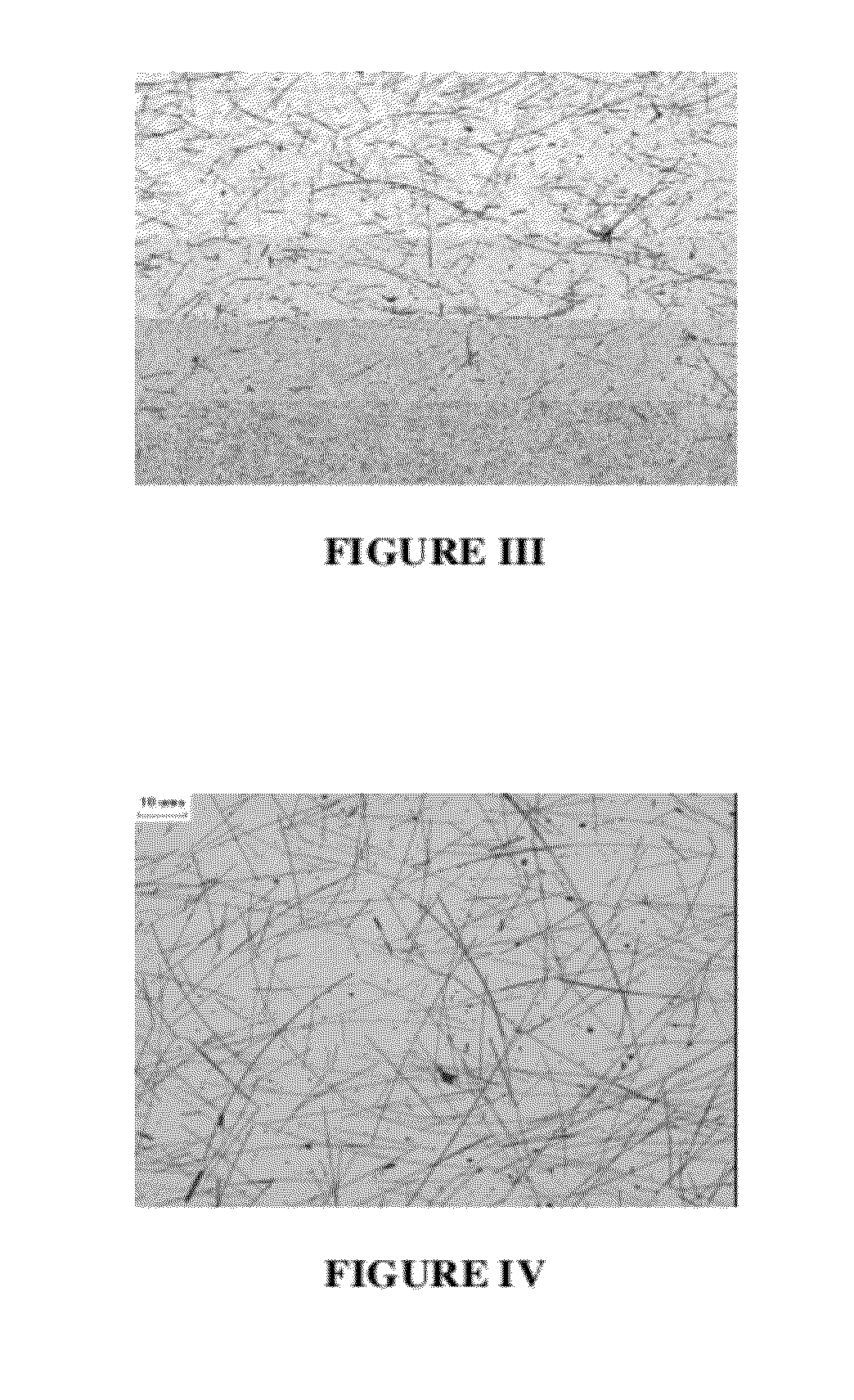

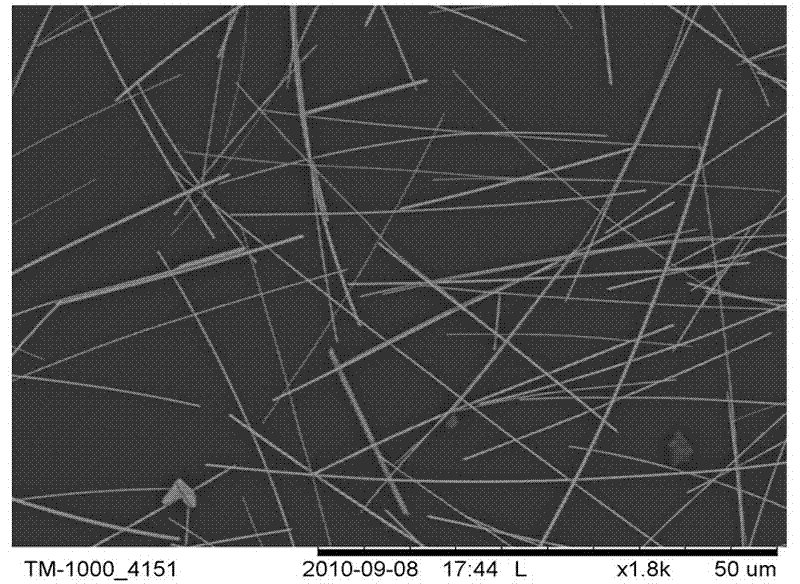

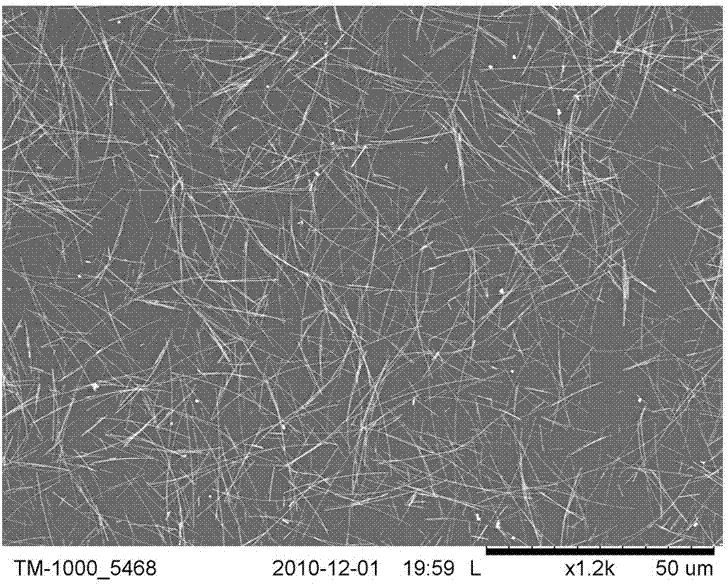

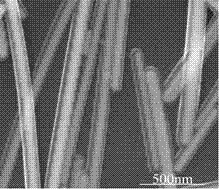

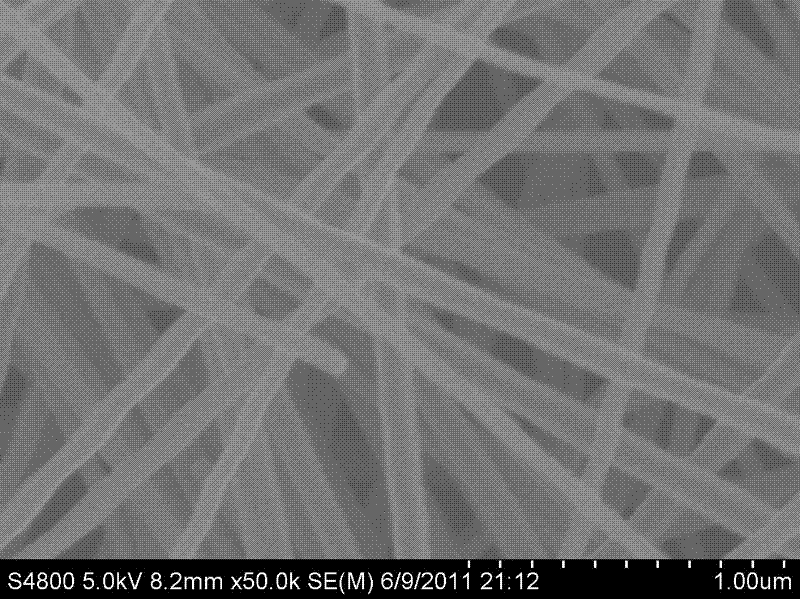

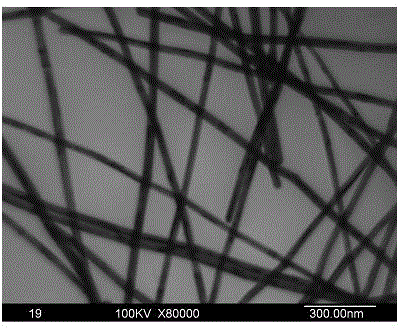

Silver nanowires are a class of silver nanoparticles which have been widely studied for their possible use in several advanced technology applications, thanks to their exciting optical, thermal and electrical properties.

Metal nanowire networks and transparent conductive material

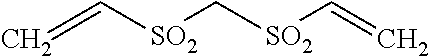

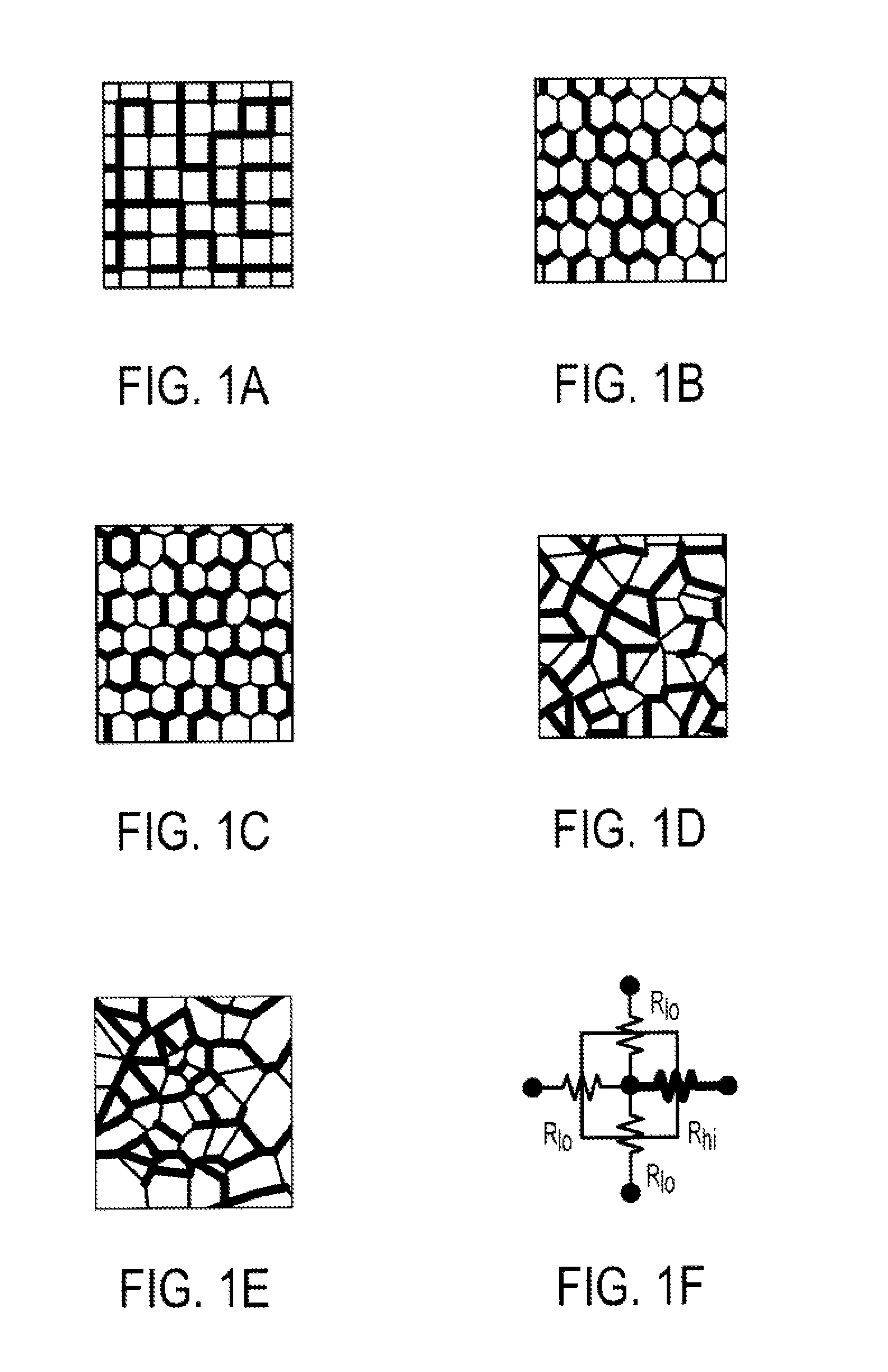

ActiveUS20130341074A1Material nanotechnologyTransparent dielectricsElectrical resistance and conductanceOptical transparency

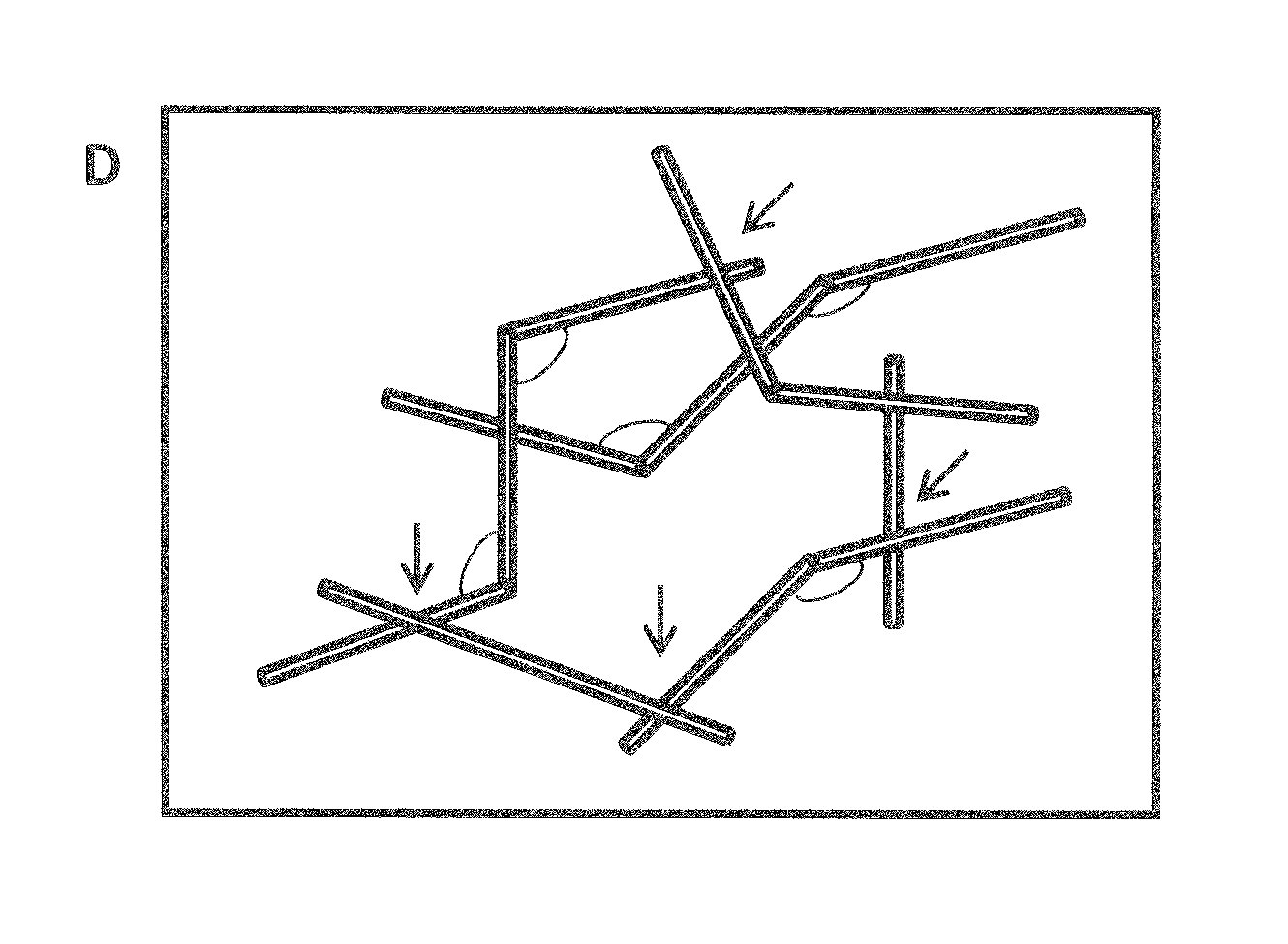

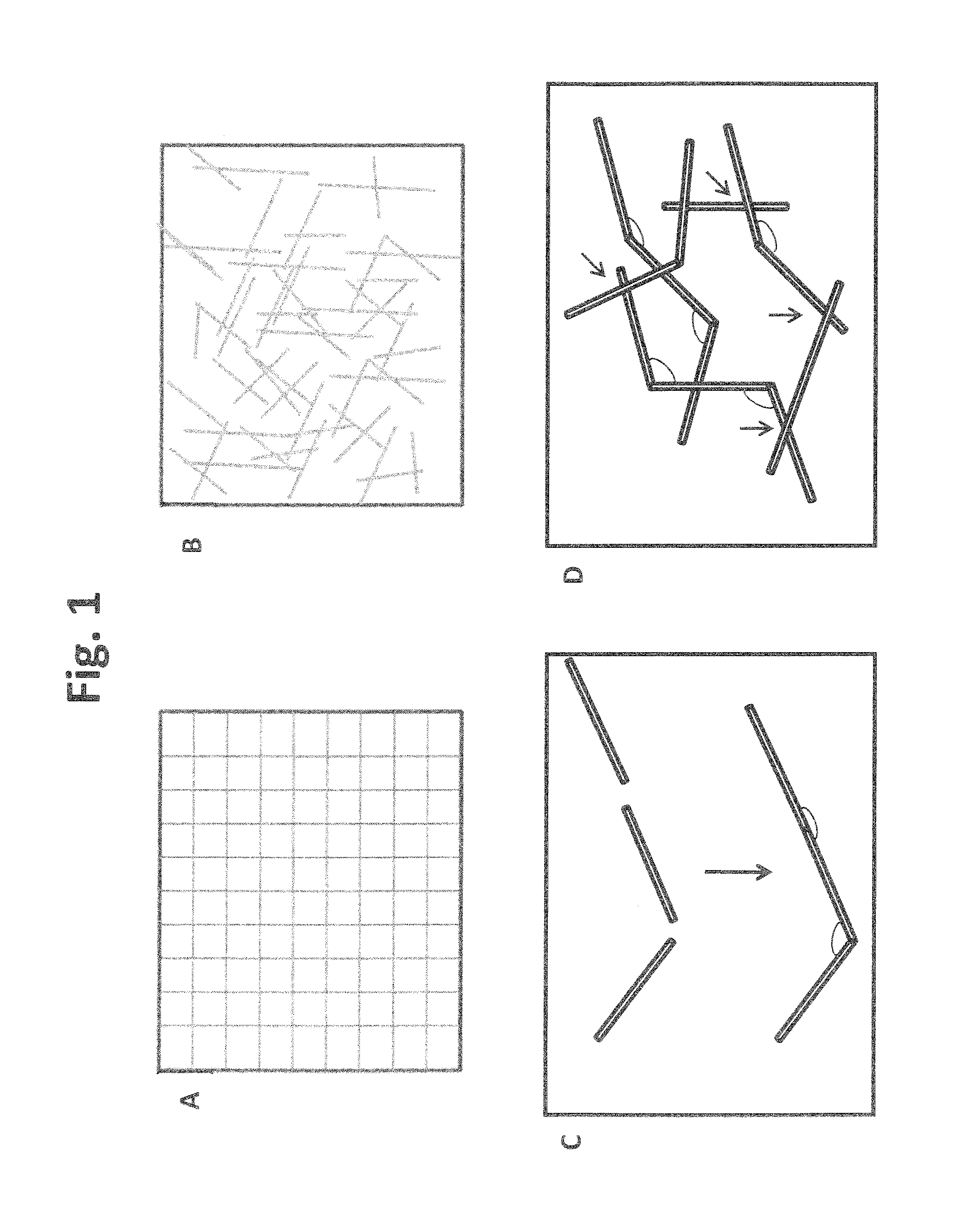

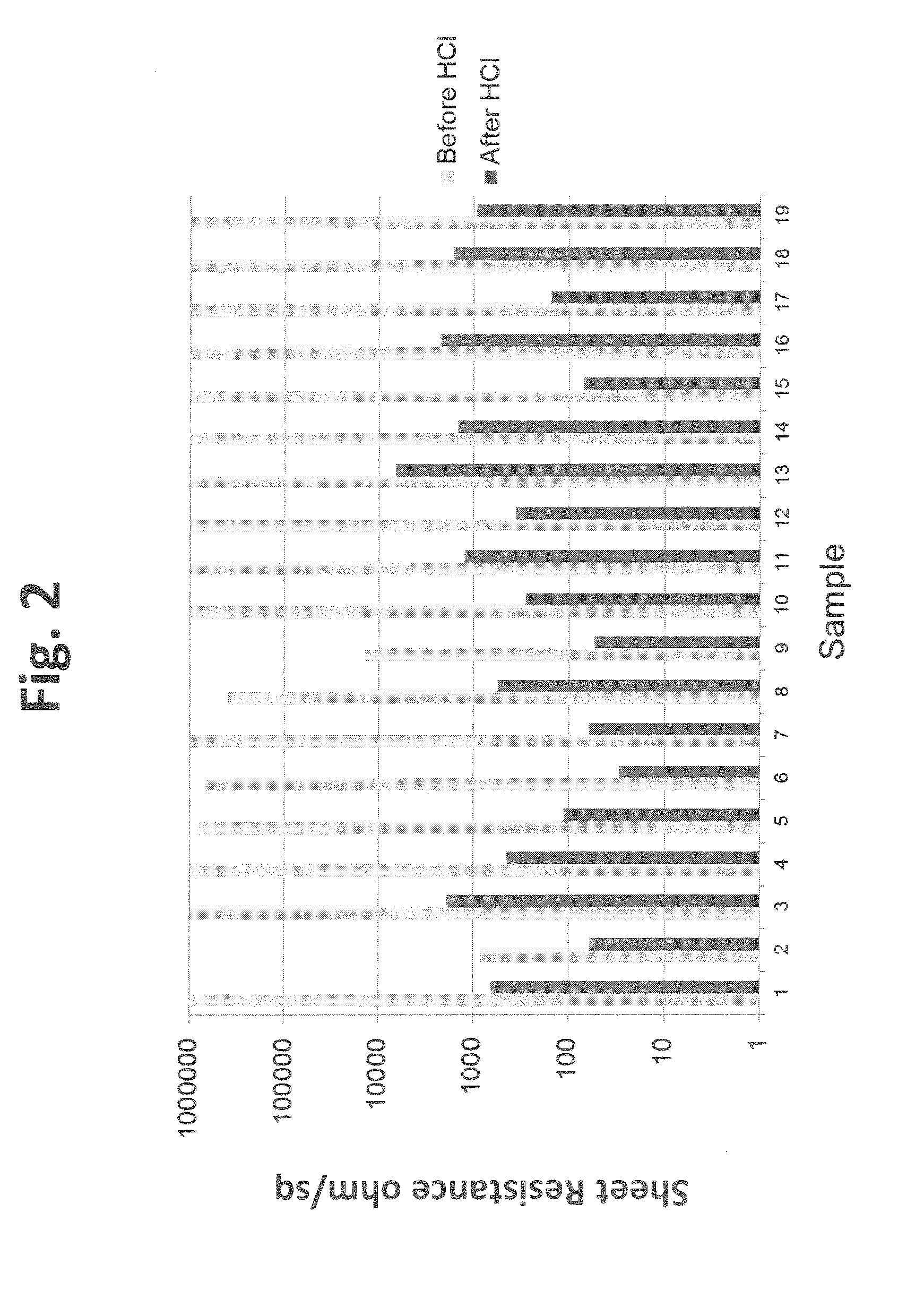

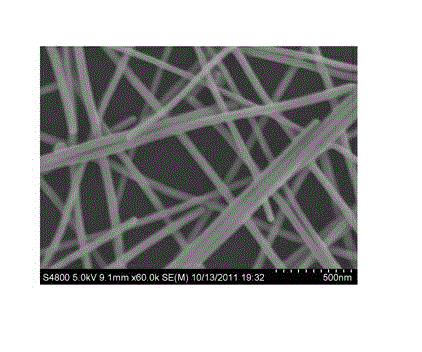

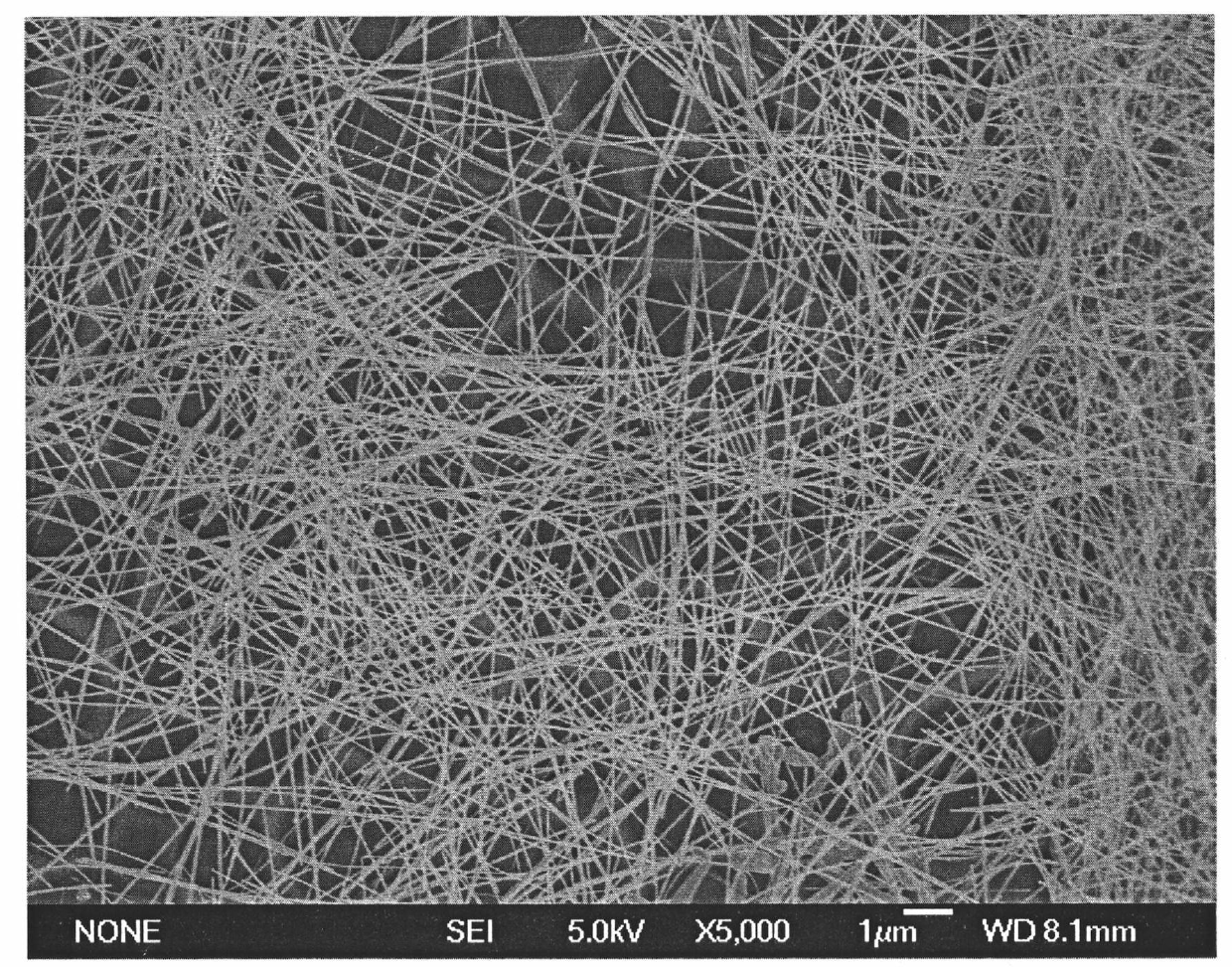

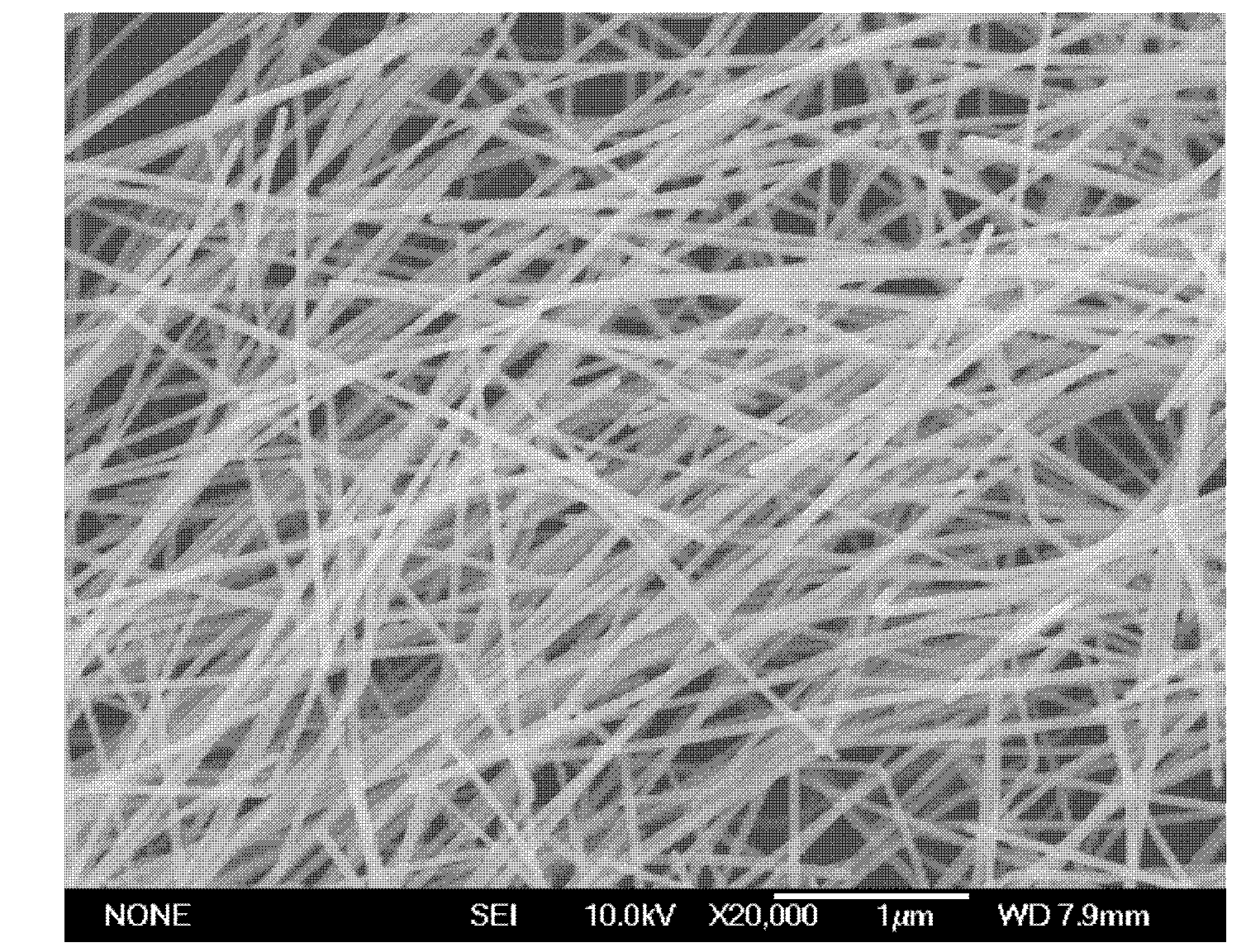

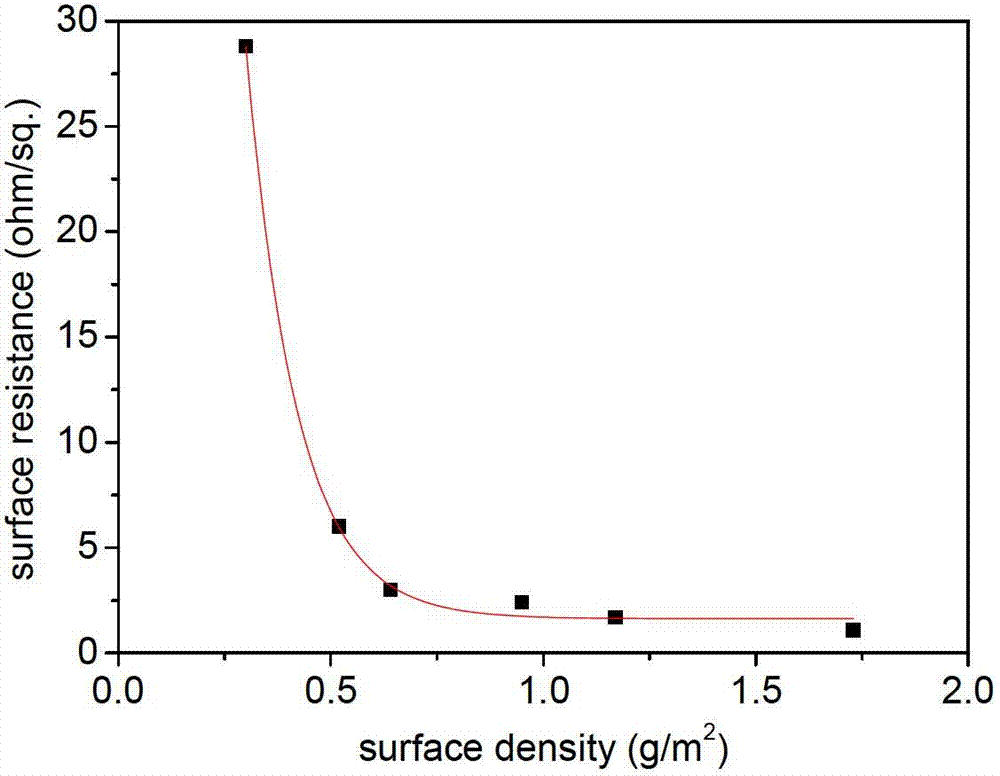

Metal nanowires, such as silver nanowires coated on a substrate were fused together to form fused metal nanowire networks that have greatly improved conductivity while maintaining good transparency. Materials formed form the fused metal nanowire networks described herein can have a transparency to visible light of at least about 85% and a sheet resistance of no more than about 100 Ohms / square or a transparency to visible light of at least about 90% and a sheet resistance of no more than about 250 Ohms / square. The method of forming such a fused metal nanowire networks are disclosed that involves exposure of metal nanowires to various fusing agents on a short timescale. When formed into a film, materials comprising the metal nanowire network demonstrate low sheet resistance while maintaining desirably high levels of optical transparency, making them suitable for transparent electrode formation.

Owner:C3 NANO INC

Silver nanowire-based transparent conductive thin film and preparation method thereof

InactiveCN102087886AReduce roughnessReduce transmittanceConductive layers on insulating-supportsIndividual molecule manipulationPolyvinyl alcoholPolymethyl methacrylate

The invention provides a silver nanowire-based transparent conductive thin film and a preparation method thereof. The preparation method is characterized by comprising the following steps of: forming a uniform adhesive layer on a substrate by organic polymer fluid; and forming a silver nanowire conductive layer on the adhesive layer, wherein silver nanowires can be firmly adhered to the adhesive layer. Through the adhesive layer, the firmness and the reliability of the silver nanowire transparent conductive thin film are greatly improved, the problem of easiness of falling of the silver nanowires is solved, and the selection range of the substrate is expanded. If the adhesive layer is formed by polyvinyl alcohol on a polymethyl methacrylate (PMMA) substrate, the visible light transmittance reaches 84 percent when square resistance is 130.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Quick and efficient synthesis method for silver nanowires

InactiveCN101934377AImprove production efficiencyReduce reaction preparation timeHigh concentrationSynthesis methods

The invention discloses a quick and efficient synthesis method for silver nanowires. The method comprises the following steps of: 1) introducing inert gas into a reactor, adding 2 volume parts of glycol into the reactor, and stirring, heating, condensing and refluxing the glycol; quickly adding 1 volume part of glycol solution of silver nitrate at molar concentration of between 0.1 and 0.5m into the reactor; slowly dropwise adding 1 to 2 volume parts of PVP at molar concentration of between 0.15 and 0.75m and 4 to 32 mu m of glycol solution of MnCl2 at the same time; and reacting and cooling the mixture to the room temperature to obtain reaction mother liquor of the silver nanowires; and 2) transferring the reaction mother liquor of the silver nanowires into a centrifugal tube; adding acetone into the centrifugal tube and performing centrifugal separation to remove supernatant and retain precipitate; adding de-ionized water or ethanol into the centrifugal tube and performing centrifugal separation to remove the supernatant and retain precipitate, and repeating the operation for 1 to 3 times; and extracting and dispersing the precipitate with ethanol to obtain the silver nanowires. The method shortens the reaction time and also has high selectivity for the synthesis of the silver nanowires under conditions of high concentration.

Owner:ZHEJIANG UNIV

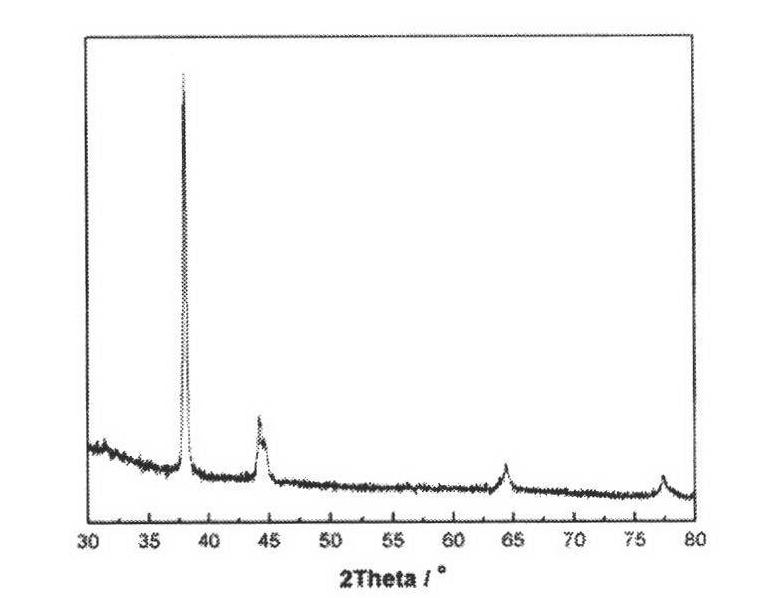

Silver nanowire, production method thereof, and aqueous dispersion

InactiveUS20090242231A1Good storage stabilityMaterial nanotechnologyPolycrystalline material growthBoiling pointSolvent

A method for producing a silver nanowire including heating a silver complex in a water solvent at a temperature equal to or below the boiling point of the water solvent, and the silver nanowire produced by the method.

Owner:FUJIFILM CORP

Method for preparing silver nano-wire in large batch

ActiveCN101310899AUniform sizeReduce manufacturing costPolycrystalline material growthSingle crystal growth detailsReducerSolvent

The invention discloses a method for preparing nanometer silver lines in large batch. anhydrous silver nitrate AgNO3 with the concentration of 99.9percent, anhydrous glycol (C2H6O2) of 99.8percent and polyvinylpyrrolidone (PVP, with the molecular weight of 55,000) of 98percent are selected as the raw materials; in a microwave-assisting environment, the method of adopting the glycol to reduce the silver nitrate is adopted to prepare nanometer silver lines in large batch. By replacing the original solvent heating method with the high-heat environment created by microwave, the method not only greatly saves the reaction time but also reduces the preparing costs for the nanometer silver lines. The glycol, a moderate reducer, can slow the reaction, thus providing the time for the growth of nanometer silver lines. The method of the invention is the optimal method for preparing the nanometer silver line according to testing results by comparing the influence of micro strength, precursor concentration and microwave processing time on the appearance and size of the prepared nanometer lines. The method of the invention has low cost, is simple method and easily controlled and has high practical value in the application to the industrial production developing nanometer silver lines.

Owner:溧阳常大技术转移中心有限公司

Method for preparing silver nanometer wire with controllable wire diameter by cation control microwave method

ActiveCN102029400APolycrystalline material growthSingle crystal growth detailsMicrowave methodDiameter ratio

The invention provides a method for preparing silver nanometer wire with controllable wire diameter by a cation control microwave method, aiming at solving the problems of rough wire diameter, low diameter ratio and the like during preparation of the silver nanometer wire by the traditional microwave method. The method comprises the following steps of: (1) adding a mixture of silver nitrate powder and a dispersing agent into ethylene glycol and preparing a solution reaction system containing silver ions; (2) adding a cation control agent in the solution reaction system containing silver ions and evenly stirring to obtain a reaction precursor; and (3) irradiating the reaction precursor under microwave, centrifuging, ultrasonically washing and drying the solution prepared through microwave irradiation to obtain the silver nanometer wire powder with controllable wire diameter. The invention has the advantages of simple preparation method, high efficiency and low cost and ensures that the high-quality silver nanometer wire can be prepared repeatedly within wide range of reaction condition. By using a soft template method, the size of the wire diameter is controlled by using the cation control agent without introducing any impurity.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

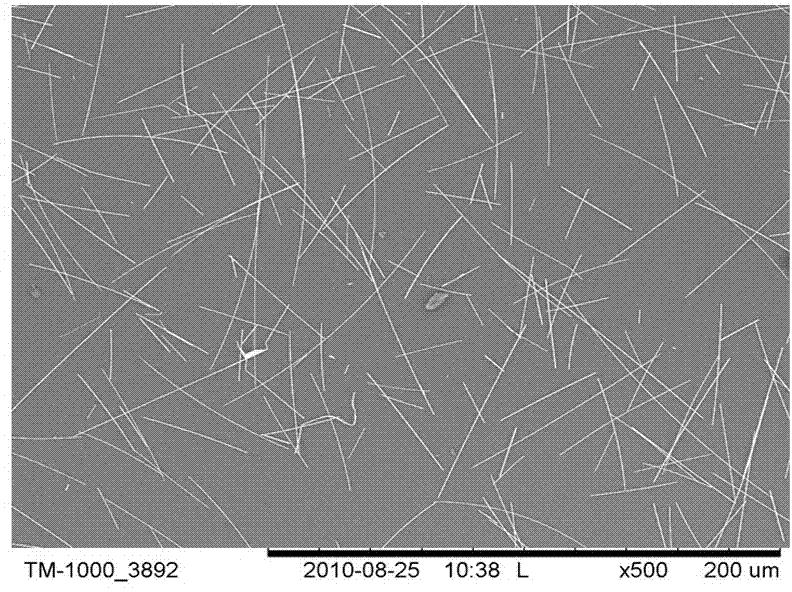

Method for preparing nano-silver wire with high length-diameter ratio

ActiveCN102744417AQuality improvementSimple preparation processPolycrystalline material growthFrom normal temperature solutionsHydrogen NitrateMicrowave method

The invention provides a method for preparing a nano-silver wire with high length-diameter ratio. At least one polyhydroxy liquid organic (1), silver nitrate (2), polyvinylpyrrolidone (PVP) with a K value equal to or larger than 30 (3), at least one hydrogen nitrate compound or one hydrogen-containing compound (4) and at least one chloride for a reaction solution, wherein the chloride can be dissolved in the polyhydroxy liquid organic and can produce chloride ions after dissolved. Reaction is perform for more than 10 minutes under the condition that the reaction temperature is lower than the boiling temperature of the polyhydroxy liquid organic or a part of ingredients is subjected to chemical reaction to form a nano-silver wire solution containing length-diameter ratio exceeding 200, and solid-liquid separation is performed to obtain the nano-silver wire or nano-silver wire dispersing liquid. The nano-silver wire prepared by means of the method is high in length-diameter ratio and yield, few in impurities and good in thickness and length uniformity, and the shortcomings including complicated preparing technology process by means of a traditional polyol method, many impurities and non-uniformity by means of a microwave method and the like are overcome.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

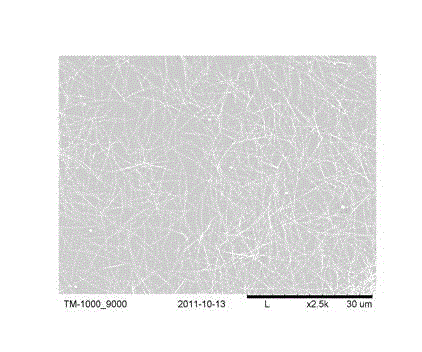

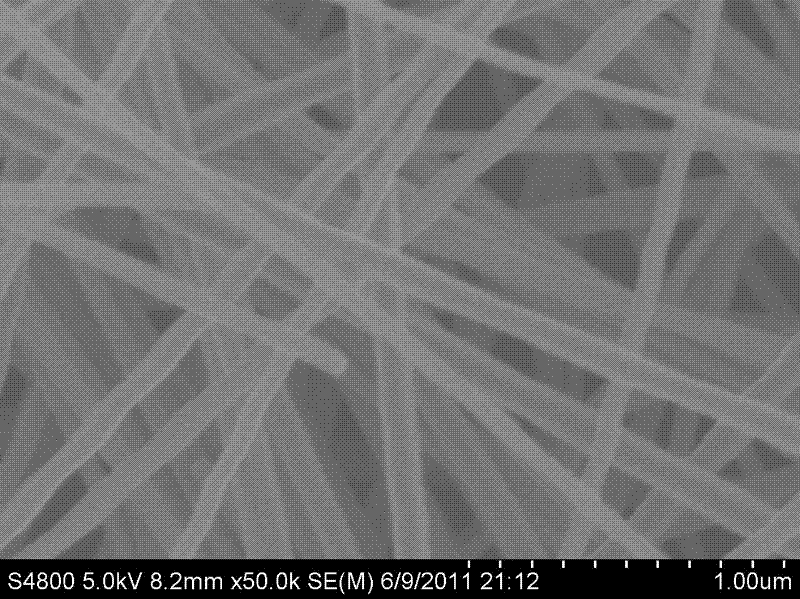

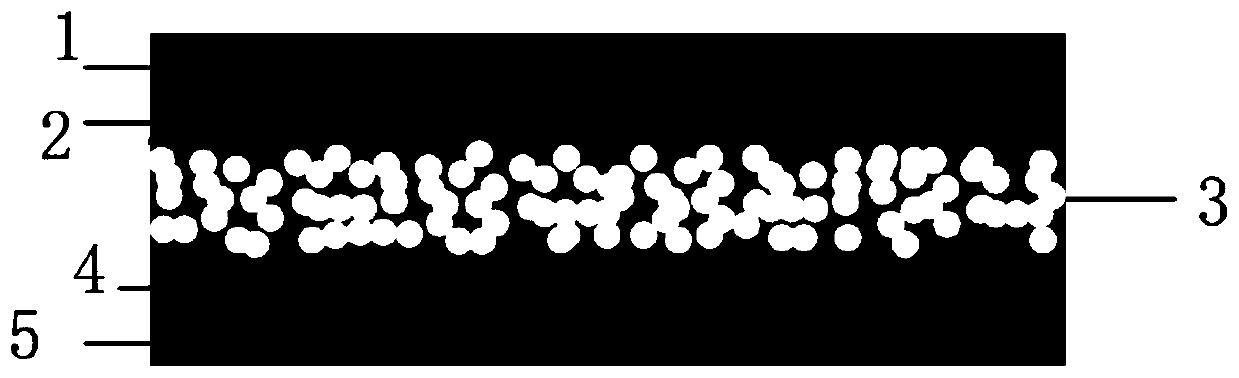

Planar silver nanowire transparent conductive thin film and preparation method thereof

InactiveCN102087885AImprove the firmness of the bondImprove bindingConductive layers on insulating-supportsIndividual molecule manipulationPolyethylene terephthalate glycolPolyethylene terephthalate

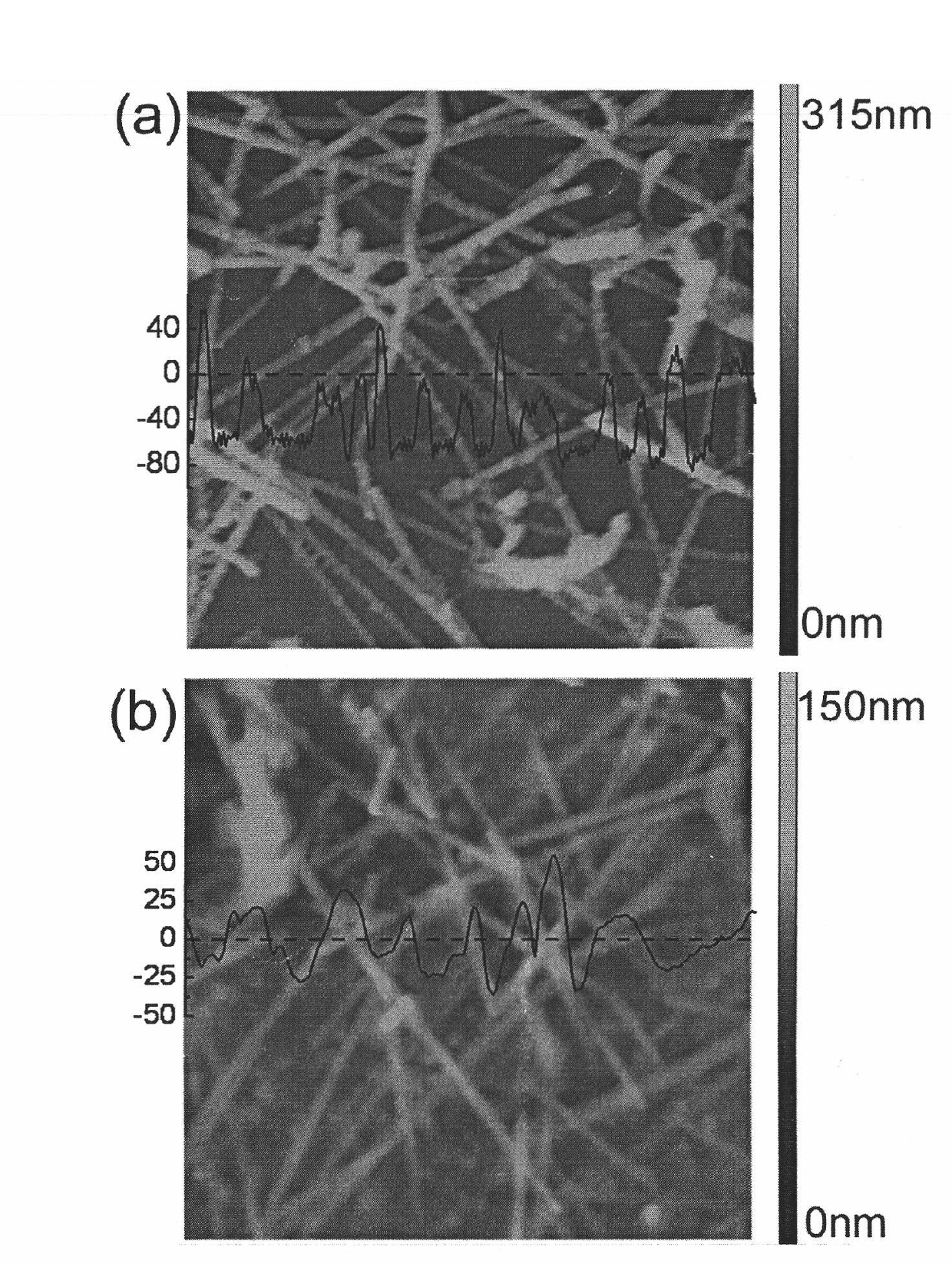

The invention provides a planar silver nanowire transparent conductive thin film and a preparation method thereof. The transparent conductive thin film is characterized in that: a silver nanowire conductive layer which is arranged on a substrate is covered by a planar conductive polymer layer; the silver nanowire conductive layer realizes a conduction function; and the planar polymer layer fills holes in the silver nanowire conductive layer, so that the surface roughness is reduced and the firmness of the bonding of the silver nanowires and the substrate is improved. For example, the roughness of the silver nanowire transparent conductive thin film on the polyethylene terephthalate (PET) substrate is reduced to 25nm from 67nm when the conductive layer is not covered by using a poly(3,4-dioxy ethyl thiophene) / poly(styrene sulfonic acid) planar layer, the visible light transmittance reaches 77 percent when square resistance is 158, and good bonding force is guaranteed.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Silver nanowire transparent conductive film based on thermoplastic transparent polymer and preparation method thereof

InactiveCN102270524ASolve the problem of easy falling offGood chemical stabilityMaterial nanotechnologyConductive layers on insulating-supportsPolymer scienceFilm base

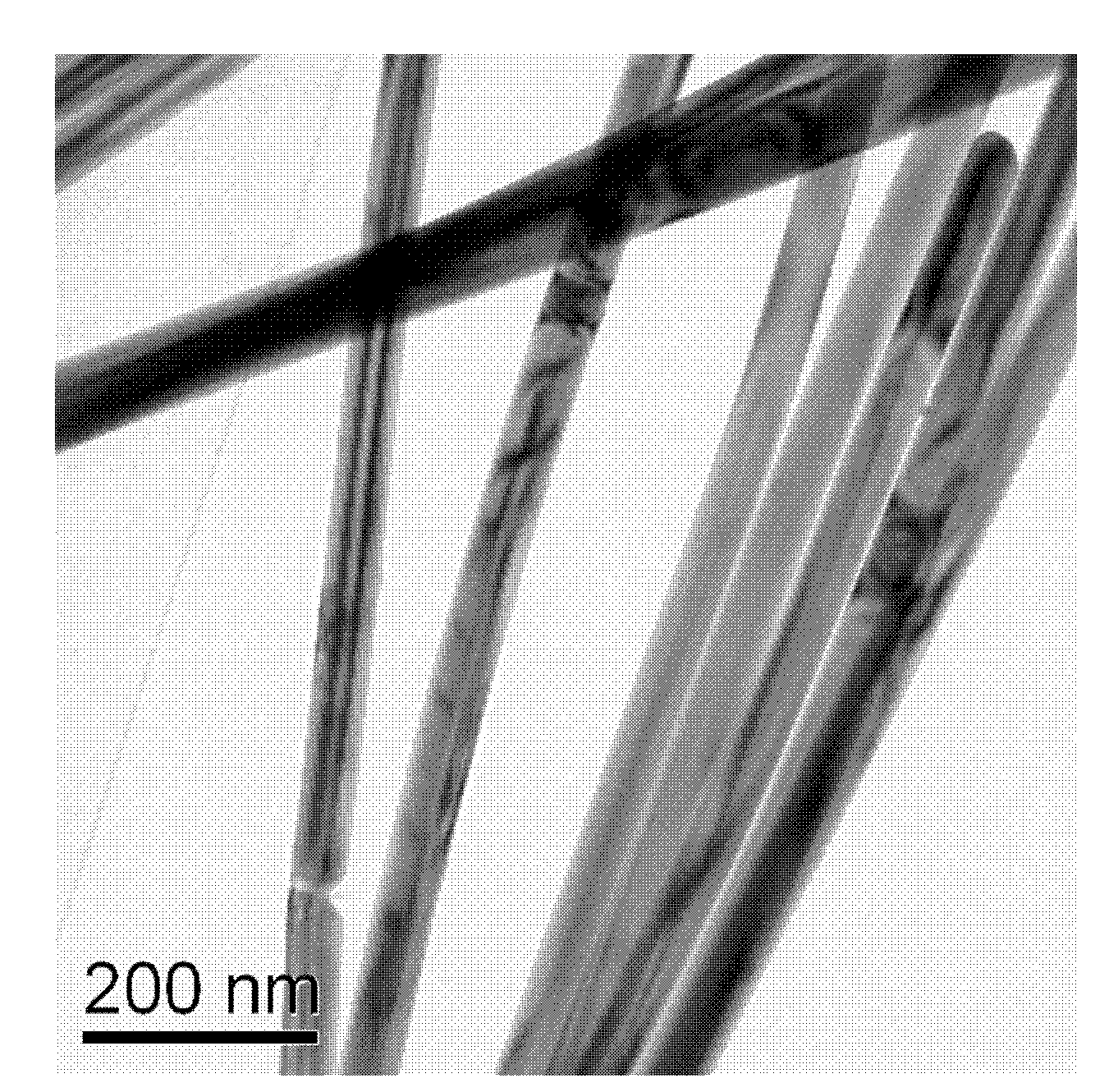

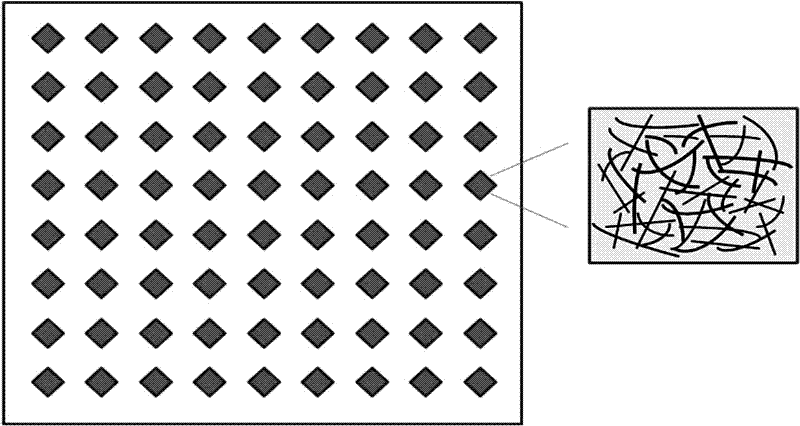

The invention provides a structure and a preparation method of a silver nanowire transparent conductive film based on a thermoplastic transparent polymer, which is characterized in that the silver nanowire conductive network is uniformly spread on a hard substrate, and then the The method makes a continuous silver nanowire conductive network embedded on the surface of a thermoplastic transparent polymer, and part of the surface of the silver nanowire is exposed to the air to form a silver nanowire conductive film based on the thermoplastic transparent polymer.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Silver nanometer wire synthesizing process

InactiveCN1740405ARaw materials are easy to getSimple processFrom melt solutionsHigh concentrationPolymer solution

The present invention belongs to the field of nanometer material preparing technology, and provides a two-step silver nanometer wire synthesizing process with high form selectivity and high efficiency. Under the protection of inert gas, very dilute ethylene glycol solution of silver nitrate is first added into ethylene glycol to prepare silver crystal seed; ethylene glycol solution of silver nitrate in relatively high concentration and ethylene glycol polymer solution in the corresponding concentration and volume are then added into the reaction system with crystal seed; and through crystal growth, silver nanometer wire is obtained. By means of regulating reaction condition, the size and form of the silver nanometer wire may be controlled. The present invention has low reaction cost and high silver nanometer wire yield, and the obtained silver nanometer wire has high purity, good structure and high mechanical performance.

Owner:ZHEJIANG UNIV

Method for preparing length-diameter-ratio nano-silver wire by pH-value regulation solvothermal method

The invention relates to a method for preparing a length-diameter-ratio nano-silver wire by a pH-value regulation solvothermal method. The method comprises the following steps of: preparing the following ethylene glycol solution, namely an ethylene glycol solution A of silver nitrate or silver acetate, an ethylene glycol solution B of polyvinyl pyrrolidone (PVP), an ethylene glycol solution C of water-soluble chloride and concentrated acid D; mixing the components according to a certain amount and fully stirring to form a final mixed solution; moving the final mixed solution into a reaction kettle; placing in an oven for reaction for a certain time; taking the reaction kettle out and cooling to room temperature to obtain mother liquid of the nano-silver wire; adding alcohol into the mother liquid for diluting, and removing supernatant liquor to obtain a precipitate; and repeatedly performing centrifugal separation, and thus obtaining nano-silver wire dispersion liquid uniformly dispersed in the alcohol. The method is simple, high in efficiency and low in cost, and can prepare high-quality nano-silver wires within a wider range of reaction condition; and prepared products are high in length-diameter ratio, good in length uniformity and low in impurity content.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

Metal oxide microparticles, transparent conductive film, and dispersion

InactiveUS20090233086A1High transparencyImprove conductivityIndividual molecule manipulationSynthetic resin layered productsMicroparticleMaterials science

The present invention provides a transparent conductive film including metal oxide microparticles having a mean particle diameter of 2 nm to 1,000 nm and silver nanowires having a minor axis diameter of 2 nm to 100 nm and an aspect ratio of 10 to 200.

Owner:FUJIFILM CORP

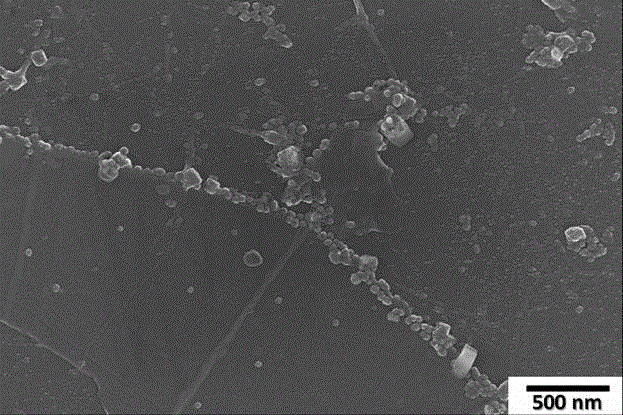

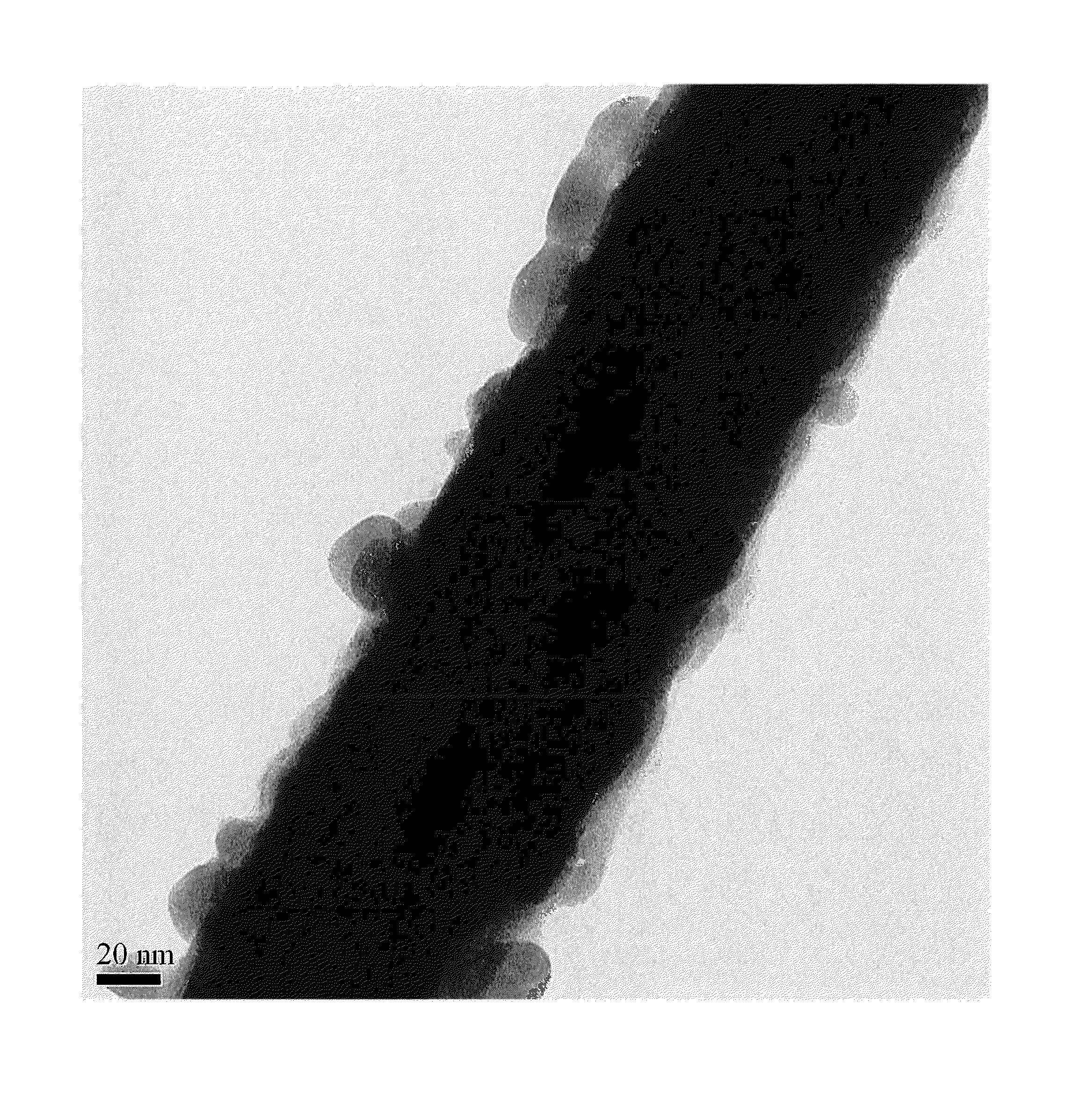

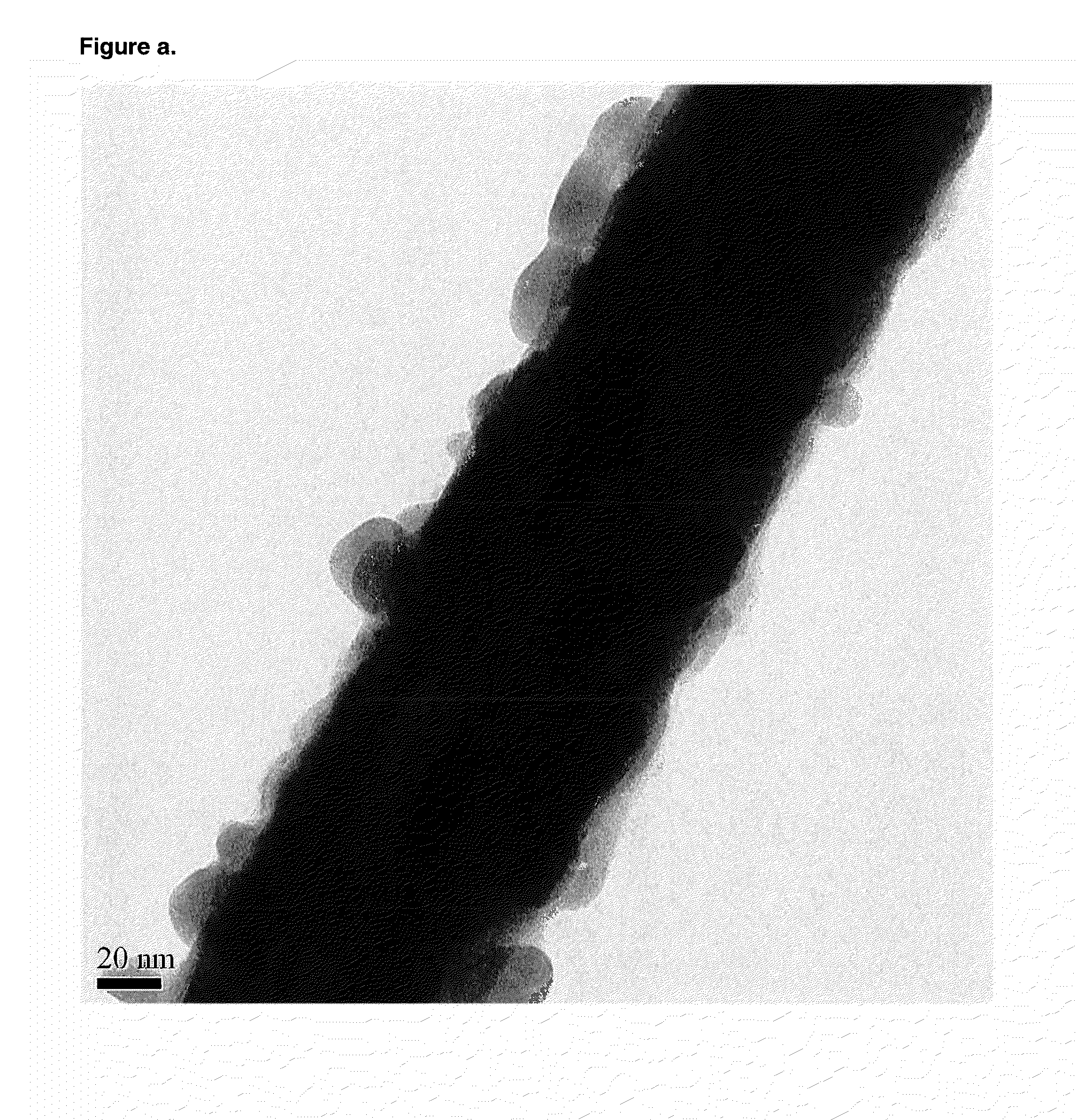

Metallic nanowire-graphene bridge structural composite material and preparation method thereof

InactiveCN104934108AImprove technical performance indicatorsMeet industrial application requirementsMaterial nanotechnologyConductive layers on insulating-supportsElectronMultiple layer

The present invention discloses a metallic nanowire-graphene bridge structural composite material which comprises multiple layers of grapheme and metallic nanowires and is characterized in that the metallic nanowires are arranged at one side or two sides of the surface of a grapheme sheet layer, the metallic nanowires are welded to the metallic nanoparticles at the surface of the grapheme, and a metallic nanowire-graphene bridge structural composite material is formed. According to the composite material, the transmittance is larger than 85% to 92%, the surface resistance is smaller than 1 Omega at the same time, in an optimal embodiment, a transparent conductive film with the transmittance larger than 90% and the surface resistance smaller than 1 Omega is realized, and the current and future industrial application requirements are fully satisfied. Through growing the metallic nanoparticles with proper density at the surface of the single-layer or few-layer grapheme and assembling and welding the metallic nanowires (such as silver nanowires and copper nanowires) on the metallic nanoparticles, grapheme-metallic nanowires are formed and are assembled and processed to form a grapheme-metallic nanowires bridge structure, a transport path is provided for electrons, and thus the surface resistance of a grapheme assembly film is greatly reduced.

Owner:CHONGQING YUANSHI GRAPHENE TECH DEVCO LTD

Carbon nano material/metal nano material composite nano ink

InactiveCN102993820AReduce manufacturing costLow costConductive layers on insulating-supportsInksCyclohexanoneKetone

The invention provides a carbon nano material / metal nano material composite nano ink which comprises solvent, an additive, a carbon nano material and a metal nano material. The carbon nano material / metal nano material composite nano ink is characterized in that the solvent can comprise water, alcohol organic solvent (ethanol(alcohol), isopropanol, n-butanol and the like), ester organic solvent (ethyl acetate, butyl acetate, ethylene-propylene acetate and the like), benzene organic solvent (methylbenzene, dimethylbenzene and the like) and ketone organic solvent (cyclohexanone, acetone, methylethylketone, butanone and the like); the additive comprises surfactant, pH value stabilizer, defoaming agent, diluter, reinforcer and the like; the carbon nano material comprises a single-layer carbon nanotube, a double-layer carbon nanotube, a multi-layer carbon nanotube and graphene; the metal (copper, silver, gold, platinum, nickel and the like, also including an alloy nano material, an ITO metal composite nano material and the like) nano material further comprises a metal nanoparticle, a metal nanowire or a metal nanotube; the components of the nano ink must include one carbon nano component and one metal nano component, such as a single-layer carbon nanotube and copper nanowire composite ink, a double-layer carbon nanotube and silver nanowire composite ink, a single-layer carbon nanotube and silver nanoparticle composite ink or any other possible combination; the components can be regulated according to specific applications; and a composite nano conductive film can be formed on different bases through different electronic printing processes. The ink can be used in the printing of a flexible base material and can be conveniently prepared into a flexible conductive film.

Owner:杨阳

Method for manufacturing silver nanowire

The invention discloses a method for manfuacturing a silver nanowire, and the method comprises the following steps of: (a) providing a mixed solution, wherein the mixed solution at least contains a protective agent and an additive, and the additive is a halide or a compound capable of generating an insoluble salt with silver ions; (b) providing a silver precursor solution containing silver compounds, and adding the precursor solution in the mixed solution at least in twice; and (c) separating to obtain the silver nanowire. The method for manufacturing a silver nanowire has the beneficial effects that the protective agent is adopted at first, and then the silver precursor solution is added at least in twice rather than one time, the silver nanowire with high wire diameter ratio and suitability for production in a large scale can be obtained.

Owner:NUOVO FILM SUZHOU CHINA INC

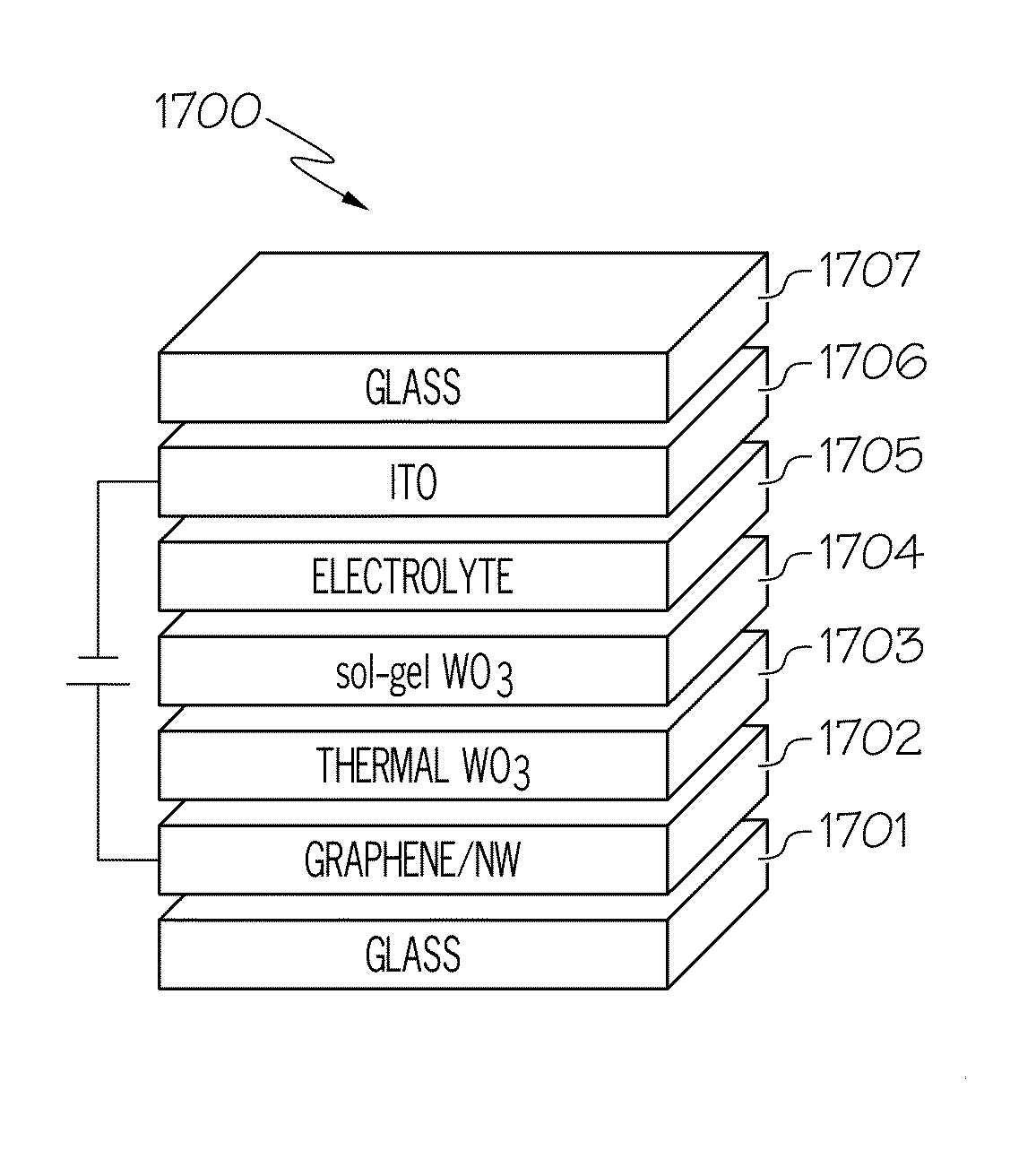

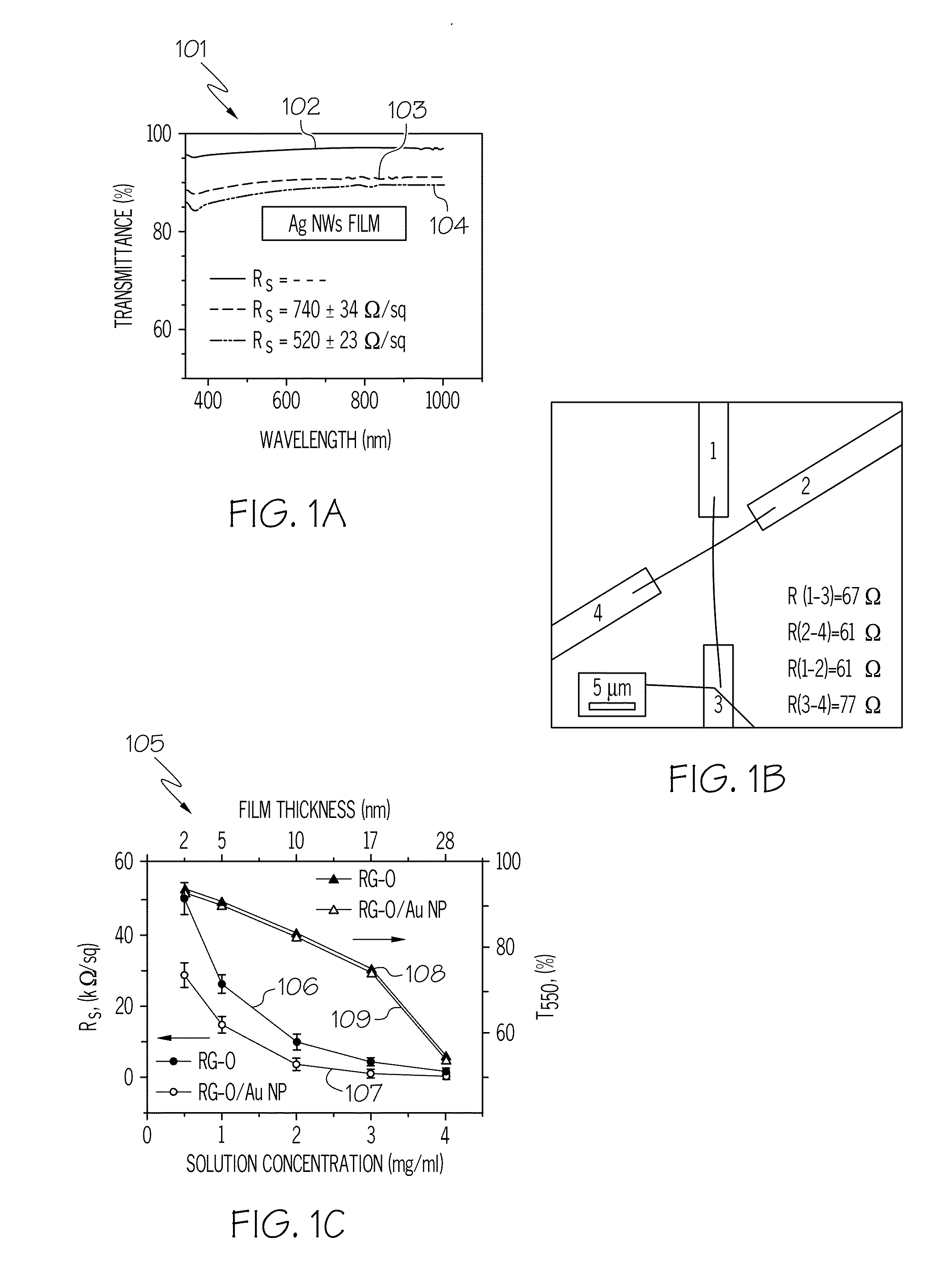

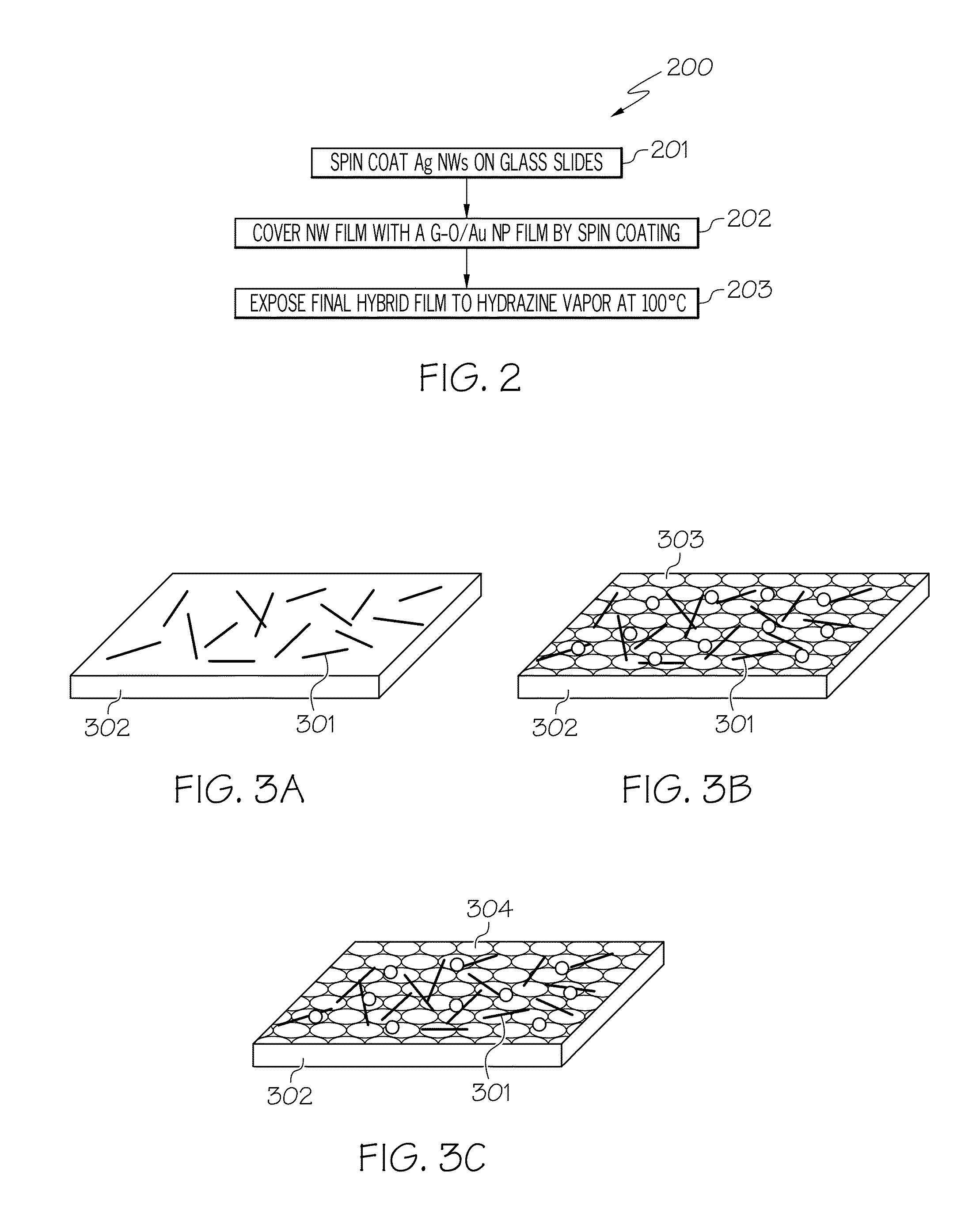

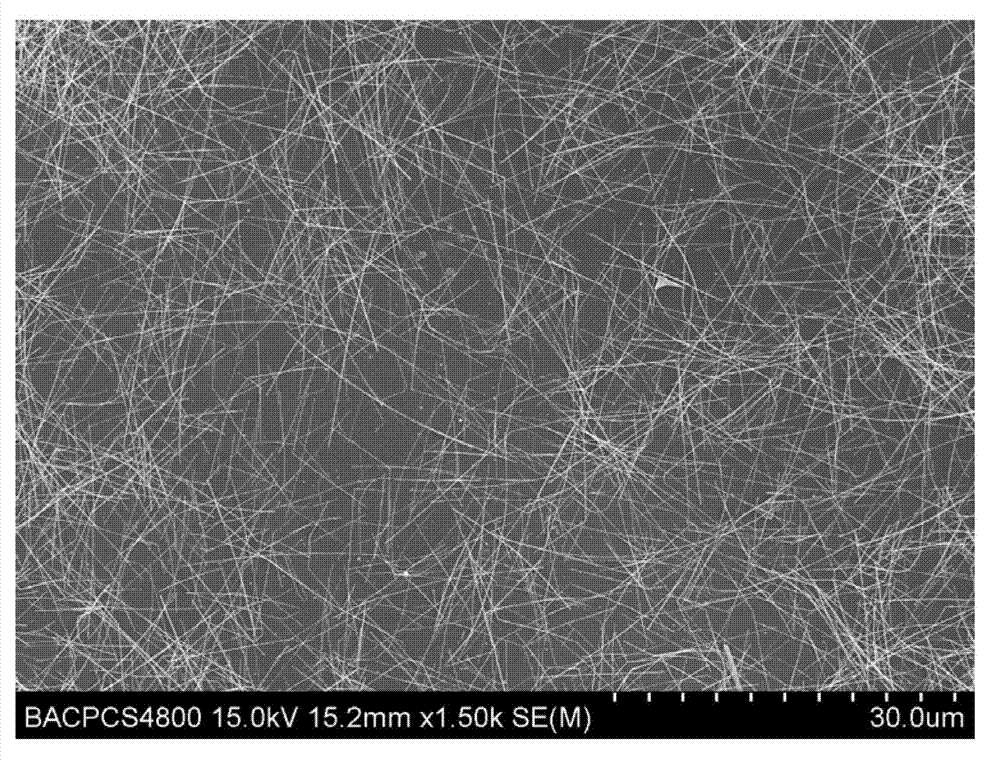

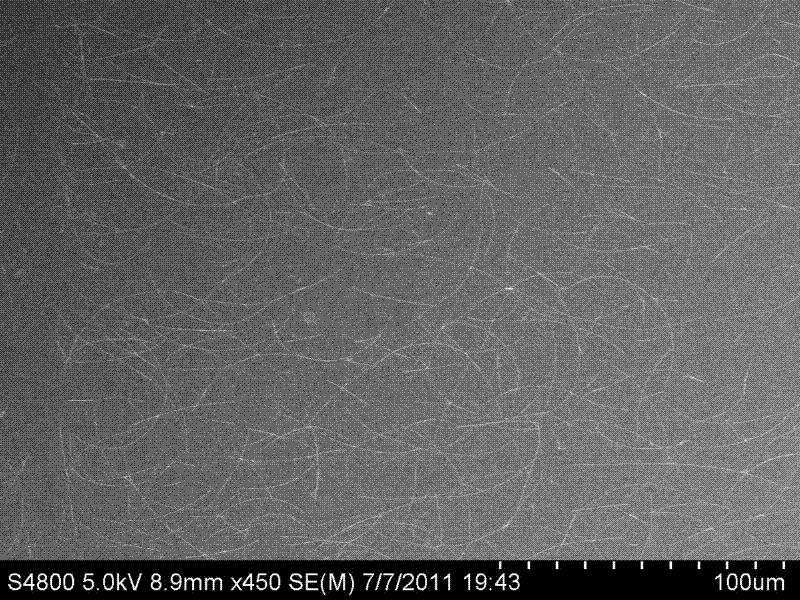

Graphene/metal nanowire hybrid transparent conductive films

A hybrid transparent conductive film, and methods for fabricating such hybrid transparent conductive films, involving the assembly of two-dimensional graphene-based materials with one-dimensional silver and / or copper nanowires with high optical transmittance and good electrical conductivity. The hybrid films are characterized by a good degree of control of the architecture at the nanoscale level, where the weakness(es) of each component are offset by the strengths of the other components. By rational design of the structure and using simple and locate-cost fabrication methods, hybrid films with sheet resistance of 26 ohm / sq and optical transmittance (at λ=550 nm) of 83% for reduced graphene oxide / silver nanowire films, and 64 ohm / sq and optical transmittance of 93.6% for monolayer graphene / silver nanowire films have been fabricated. These values are comparable to transparent conductive films based on indium tin oxide but are now able to be used in flexible electronics due to their good mechanical properties.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

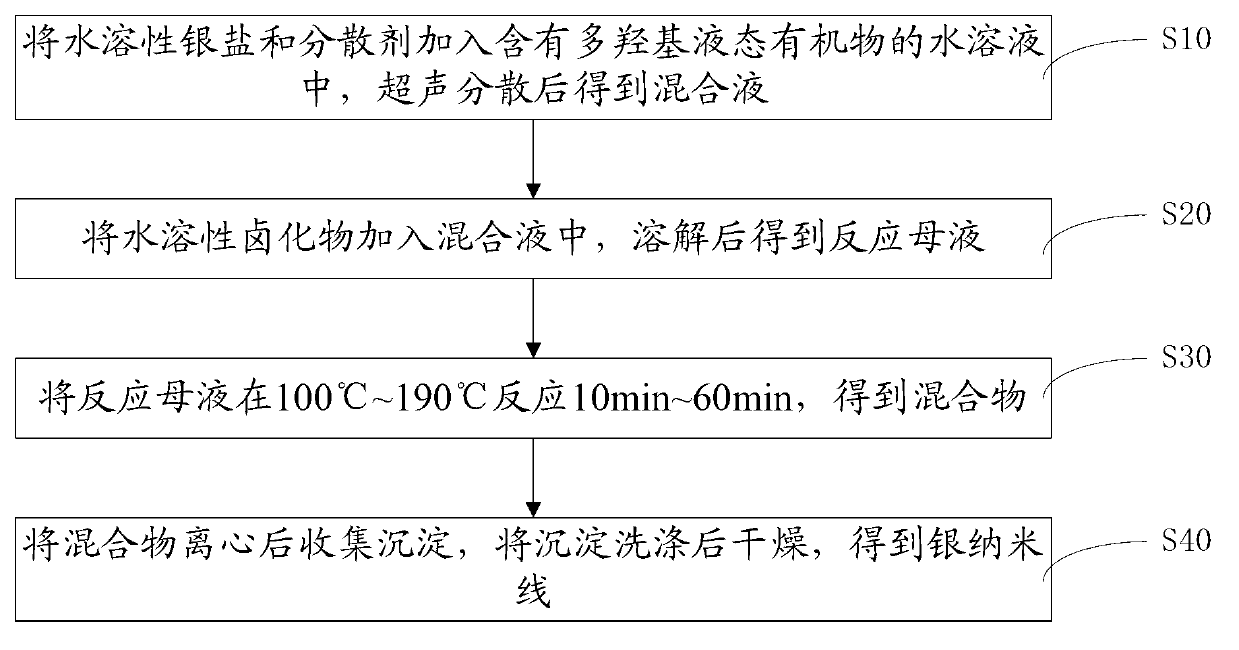

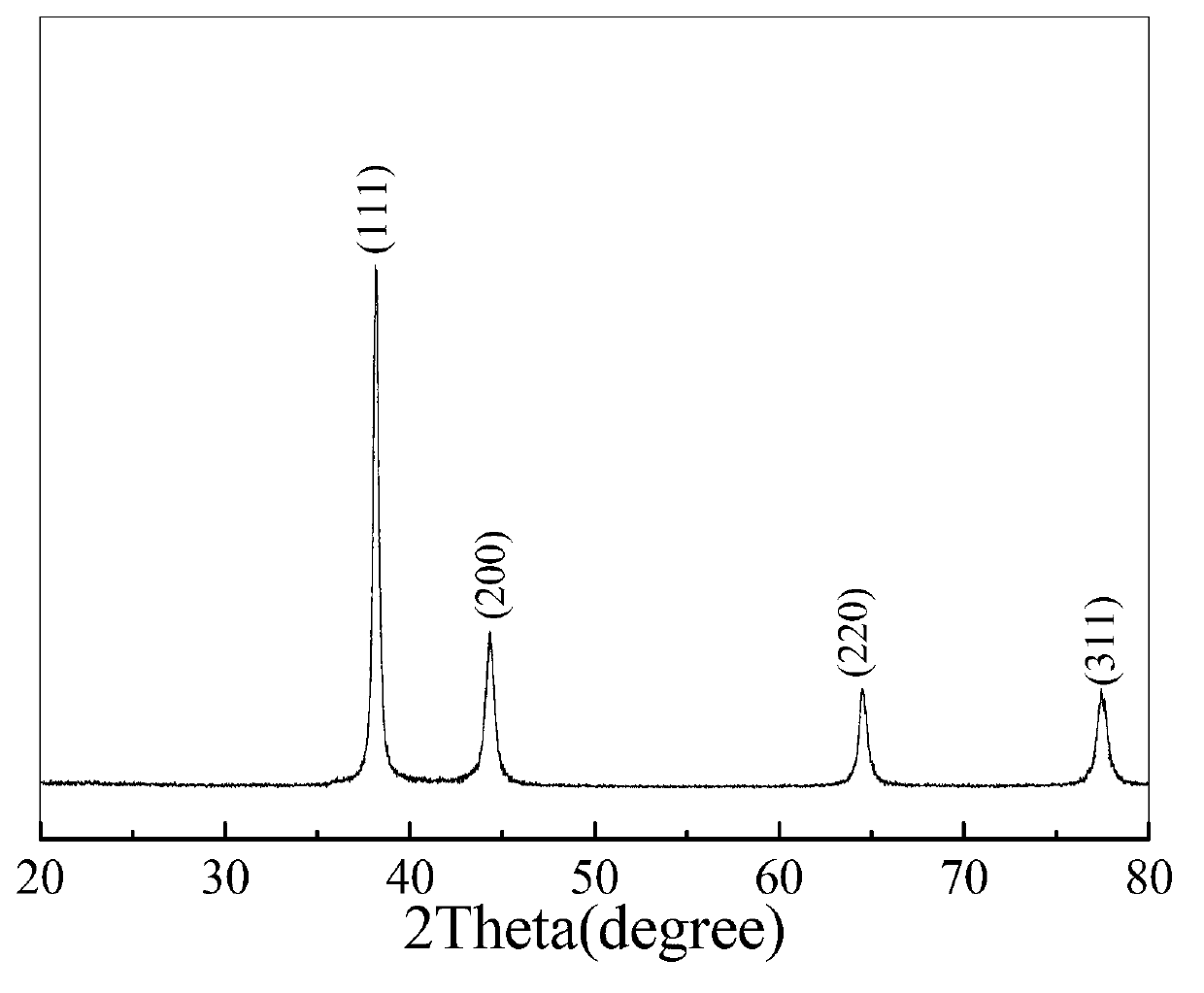

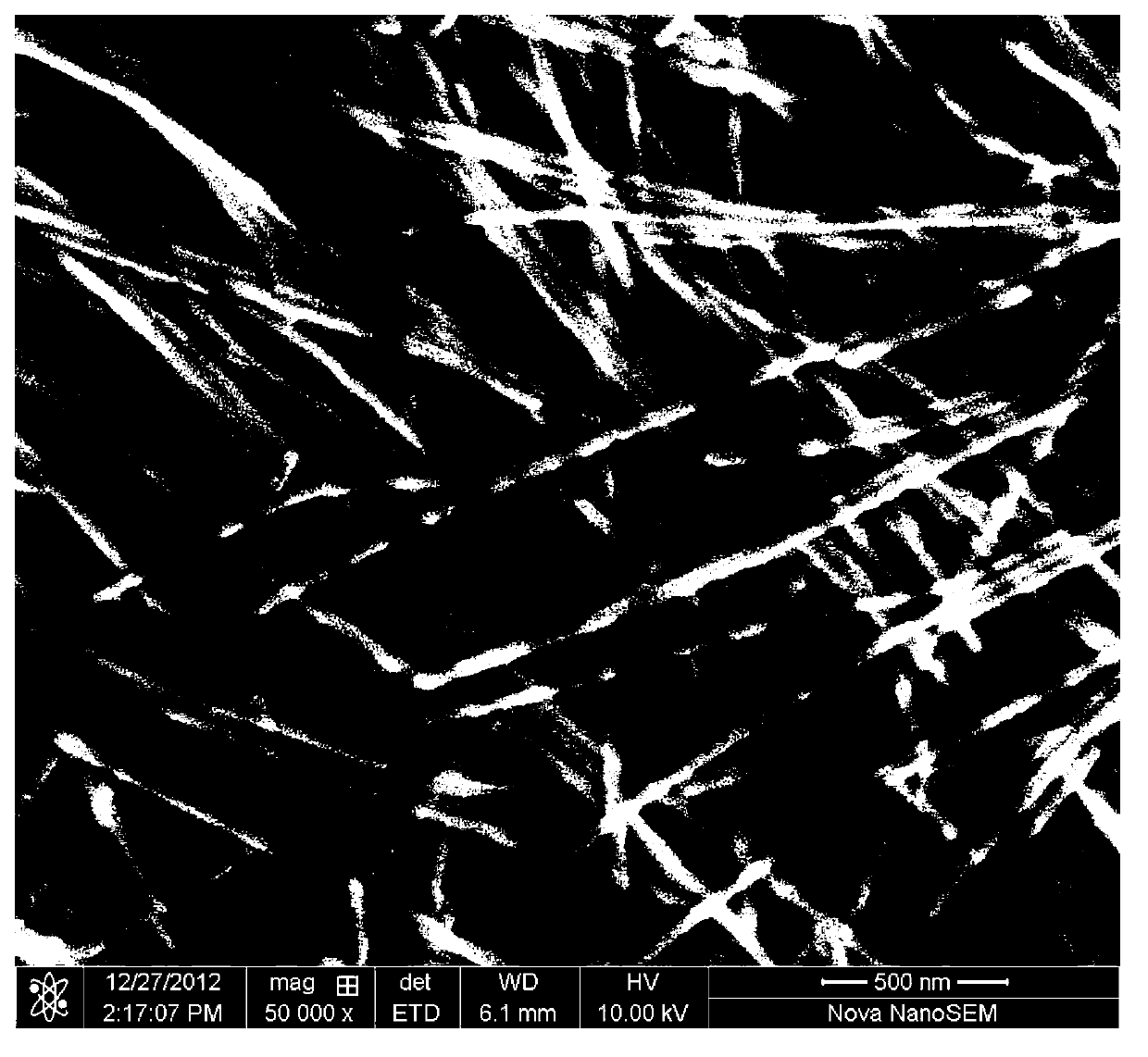

Preparation method of silver nanowires

Provided is a preparation method of silver nanowires. The preparation method of the silver nanowires includes the following steps: adding water-solubility silver salt and dispersing agents into aqueous solution comprising polyhydroxy liquid organic matters, and obtaining mixed liquor after ultrasonic dispersion; adding water-solubility halide into the mixed liquor, and obtaining reaction mother liquor after dissolving; reacting the mother liquor under 100-190 DEG C for 10-60 minutes, and obtaining mixtures; and collecting sediment after centrifugation of the mixtures, drying the sediment after washing of the sediment and obtaining the silver nanowires. The preparation method of the silver nanowires is short in preparation time.

Owner:SHENZHEN INST OF ADVANCED TECH

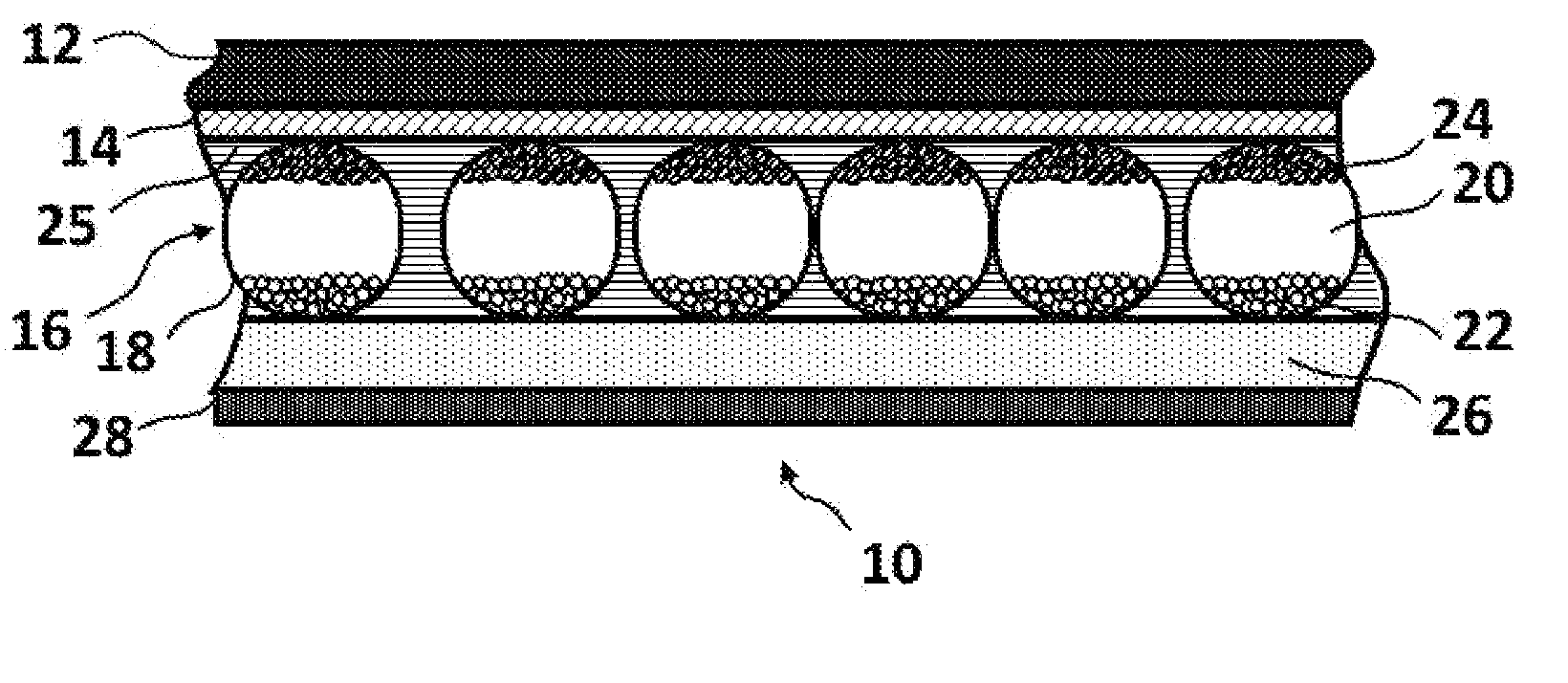

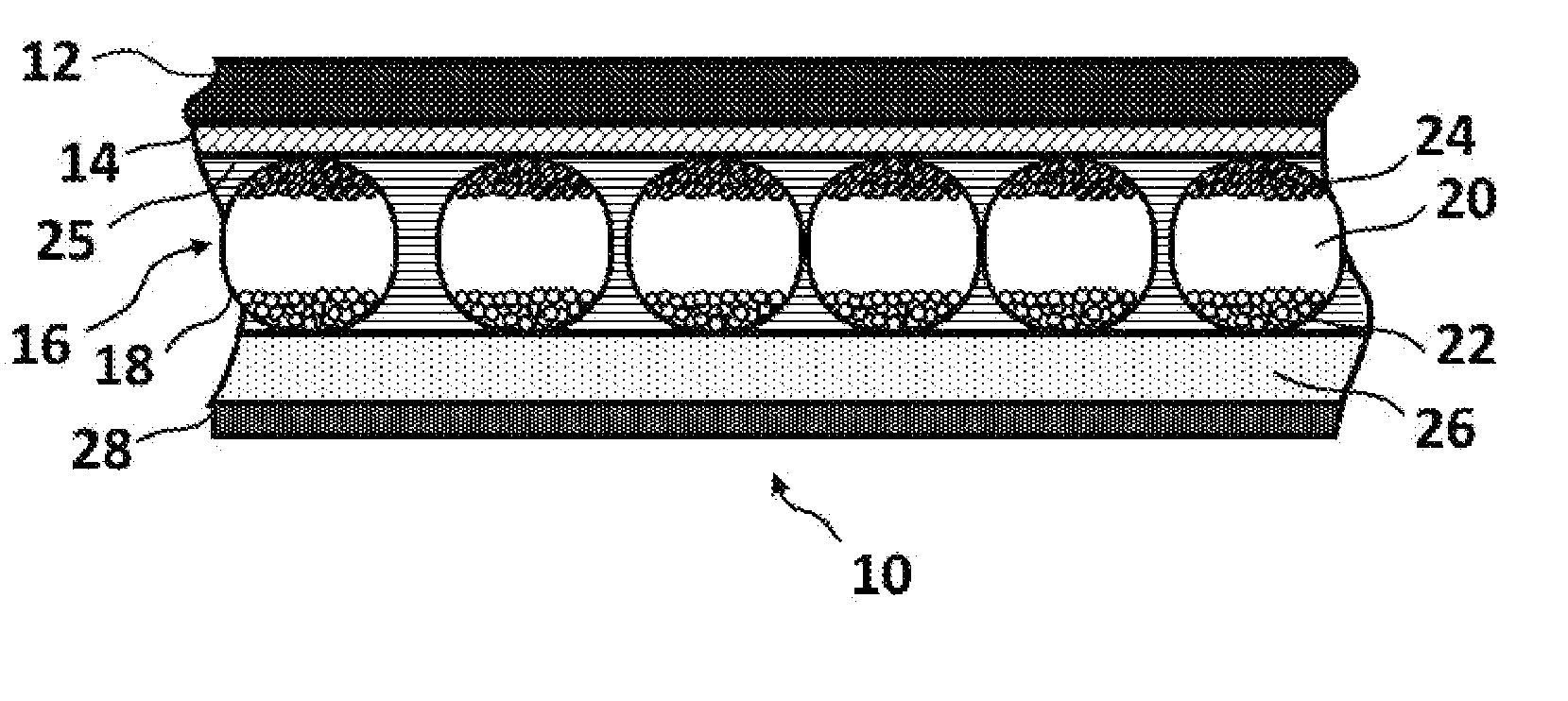

Controlled polymeric material conductivity for use in a two-phase electrode layer

ActiveUS20150205178A1Solve the excessive conductivityStatic indicating devicesPolyureas/polyurethane adhesivesPolymer electrolytesPolyelectrolyte

An electro-optic display containing a two-phase, light-transmissive electrically-conductive layer comprising a first phase made of a highly electronically-conductive matrix and a second phase made of a polymeric material composition having a controlled volume resistivity. The matrix of the first phase may be formed from carbon nanotubes, silver nanowires, a metal coated open foam structure, or a printed mesh of wires. The polymeric material composition of the second phase may be a conductive polymer, or a polymer and an additive such as a salt, a polyelectrolyte, a polymer electrolyte, or a solid electrolyte, or combinations thereof.

Owner:E INK CORPORATION

Method of producing silver nanowires

A method for the production of silver nanowire comprising the steps of: heating a first solution comprising a polyol and a salt; adding a second solution comprising a polyol and a silver nitrate; adding a third solution comprising a polyol and an organic polymer as a template carrier creating a combined solution; stirring the combined solution at an elevated temperature for a time period followed by cooling the combined solution; and washing the combined solution and isolating the silver nanowires.

Owner:BLUE NANO

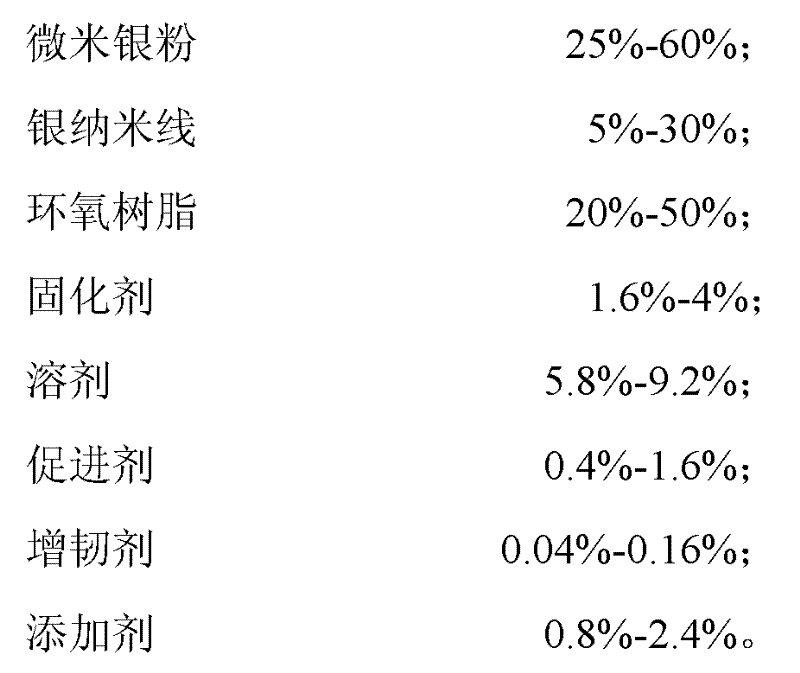

Silver nanowire doped conductive silver colloid and preparation method thereof

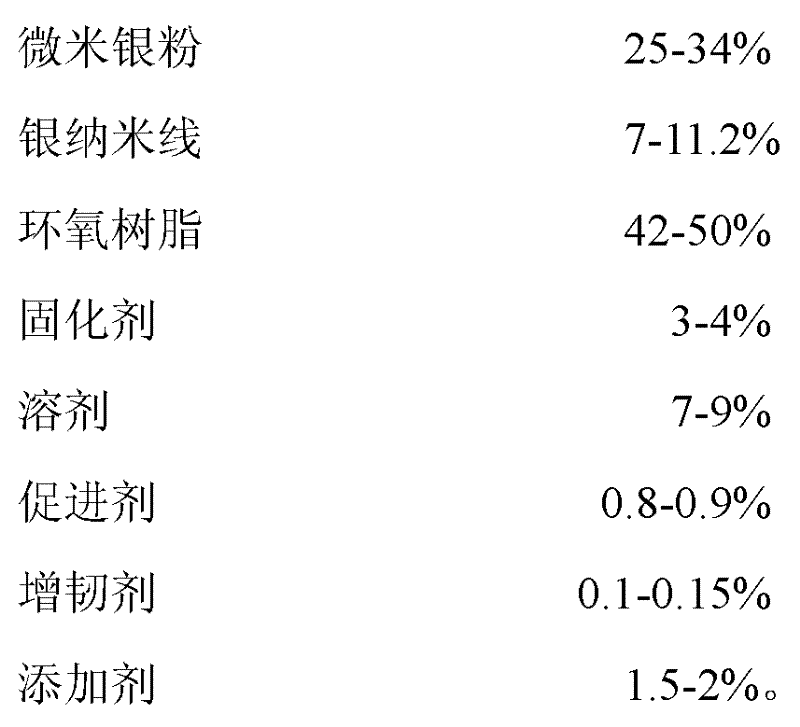

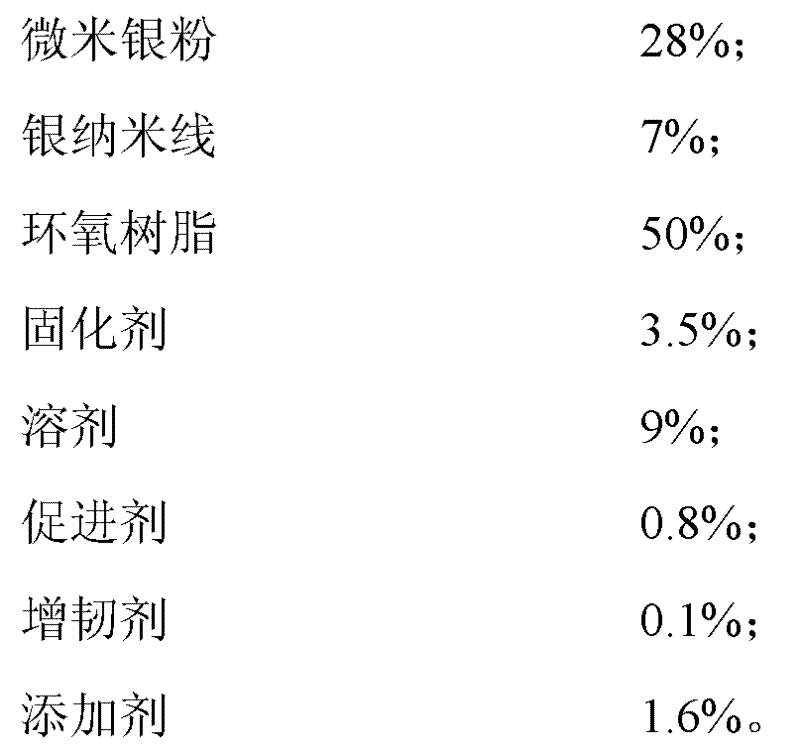

InactiveCN102676102AImprove electrical performanceReduce silver contentNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to the field of semiconductor electronic materials, and in particular relates to a silver nanowire doped conductive silver colloid and a preparation method thereof. The raw materials of the silver nanowire doped conductive silver colloid provided by the invention comprise the following components in percentage by weight: 25-60% of micrometer silver powder, 5-30% of silver nanowires, 20-50% of epoxy resin, 1.6-4% of curing agent, 5.8-9.2% of dissolvent, 0.4-1.6% of accelerant, 0.04-0.16% of toughening agent and 0.8-2.4% of additive. The conductive silver colloid is prepared by mixing and doping single-crystal silver nanowires and silver granules, thus, the total silver doping amount is reduced to 35-45%, and the conductive silver colloid has a favorable conductive effect, high shear strength, low working temperature and good ageing-resistant performance, and the cost of the conductive silver colloid is reduced. The silver nanowire doped conductive silver colloid can be widely applied to the fields of solar cell (film, crystal silicon) conductive colloids, conductive colloid LED (Light-Emitting Diode) package and the like.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

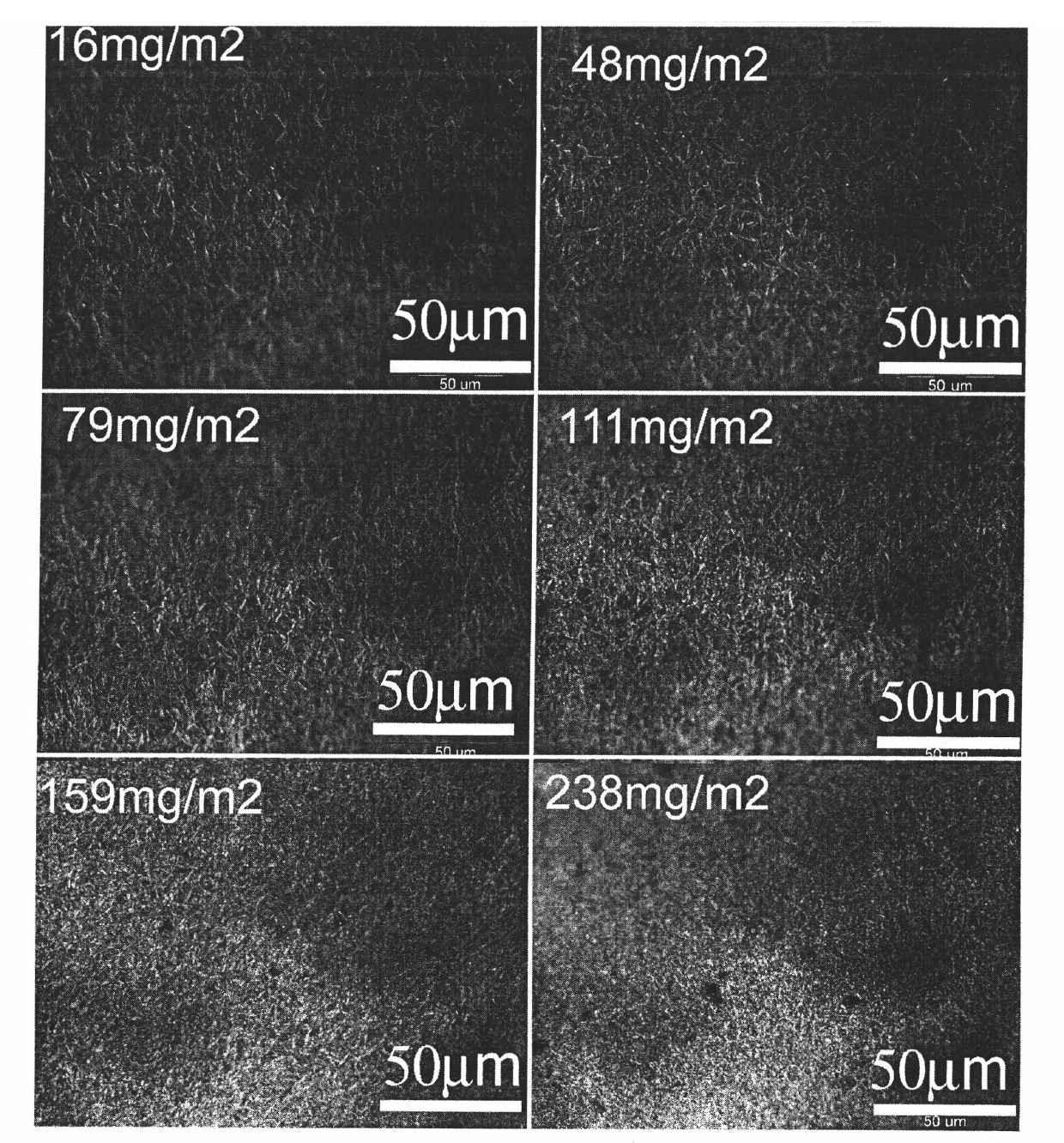

Transparent conductive film comprising water soluble binders

InactiveUS20120107598A1NanotechSynthetic resin layered productsPolyvinyl alcoholTransparent conducting film

Transparent conductive films comprising silver nanowires dispersed in polyvinyl alcohol or gelatin can be prepared by coating from aqueous solvent using common aqueous solvent coating techniques. These films have good transparency, conductivity, and stability. Coating on a flexible support allows the manufacture of flexible conductive materials.

Owner:CARESTREAM HEALTH INC

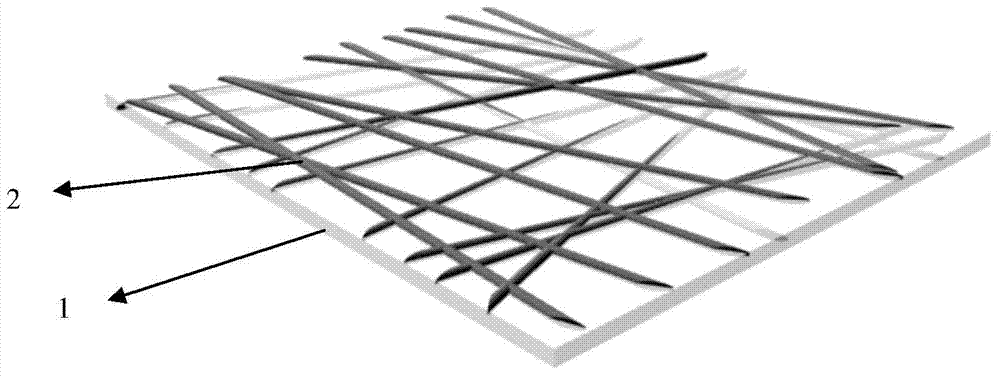

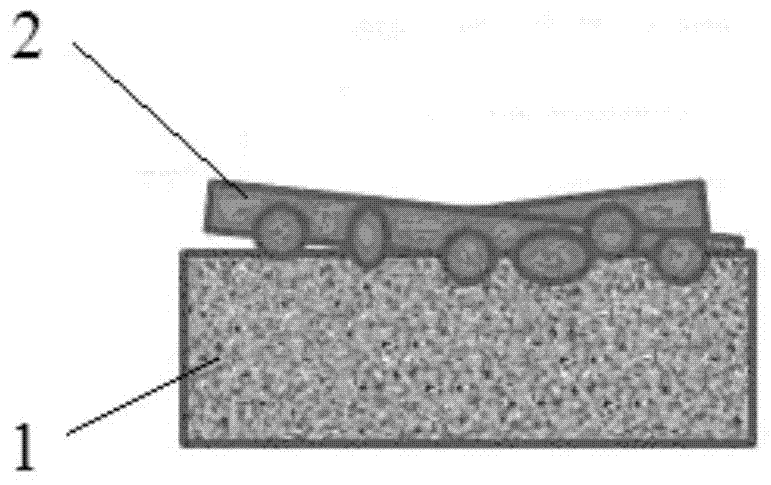

Flexible and transparent electrode film based on silk fibroin and manufacturing method and application thereof

InactiveCN103762014AGood biocompatibilityPromote degradationConductive layers on insulating-supportsIndividual molecule manipulationIrritationBiocompatibility Testing

The invention discloses a flexible and transparent electrode film based on silk fibroin which comprises a flexible supporting layer and a conducting layer and is characterized in that the conducting layer is a silver nanowire film formed by silver nanowire interwoven networks. The flexible supporting layer is a silk fibroin film, wherein silk fibroin solution is dried and solidified to adhere to the silver nanowire film through Van der Waals force to form the silk fibroin film. The electrode film has good light transmittance and conductivity at the same time and is high in flatness and binding force and good in affinity with the human body. Particularly, the silk fibroin is adopted as the supporting layer, so that the supporting layer is good in biocompatibility, biological degradability and optical performance and free of poison and irritation, the degradation process is also controllable, and the electrode film can be used in the aspects of electronic products, conductive film substrates, screens and others making intimate contact with the human body. The invention further provides a manufacturing method and application of the electrode film.

Owner:SUZHOU UNIV

Composite conductive film, its preparation method and its application

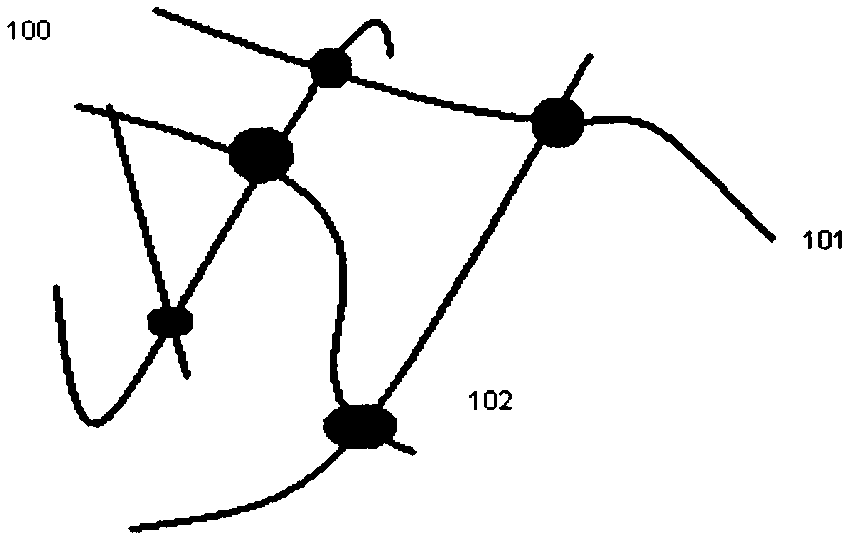

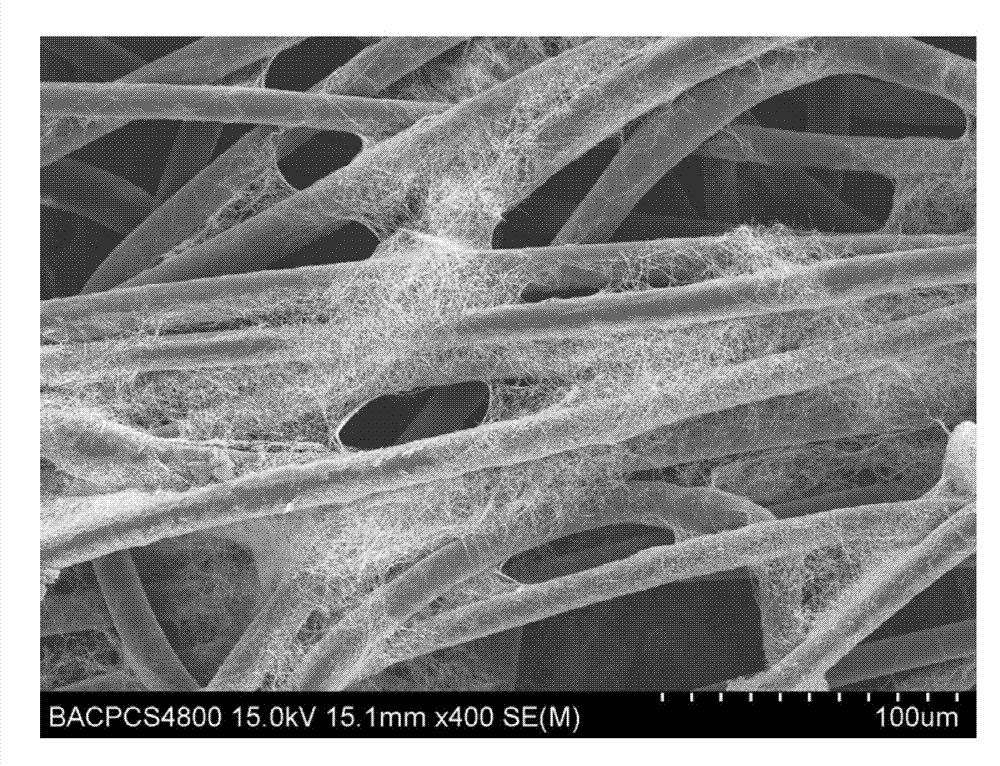

ActiveCN102785437AImprove toughnessHigh impact damage toleranceSynthetic resin layered productsMetal layered productsFiberCarbon fibers

The invention relates to a design and a preparation method of a continuous carbon laminated fiber reinforced resin matrix structure composite material taking account of the conductivity and the high toughness, a corresponding intermediate composite conductive film and a final composite material product. The composite conductive film having a high conductivity and a toughness potential is prepared through utilizing a low-surface-density non-woven fabric having a network structure, a porous film or a fabric as a functional carrier, and loading highly-conductive nano-micro scale silver nanowires and other auxiliary conductive components, such as carbon nanotubes, graphene and the like; and the composite conductive film is disposed between layers of a routine carbon laminated fiber composite material through an intercalation technology, and is molded and cured to prepare the high-conductivity and high-toughness structure composite material. The method is simple to operate, the toughness of the obtained composite material is greatly improved, the resistivity in the layers and the resistivity between the layers are greatly decreased, the caused weight gain of the composite material is extremely small, and the high conductivity and the high toughness of the whole composite material are realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

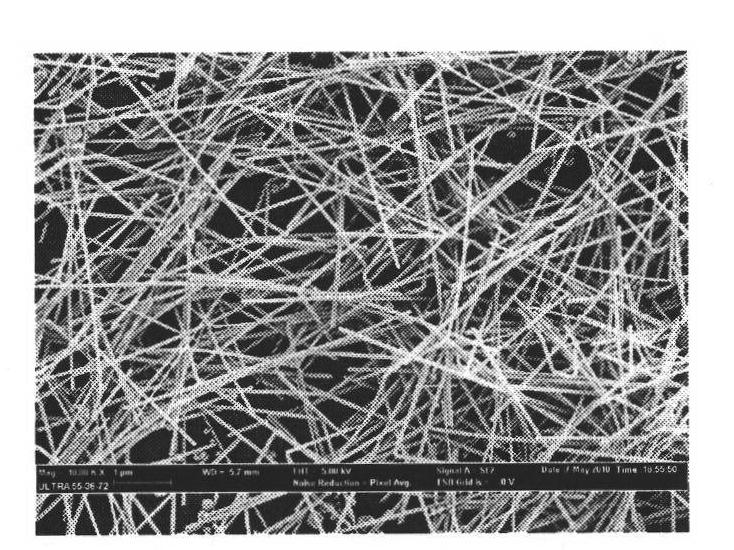

A method for rapid and large-scale preparation of silver nanowires with high aspect ratio

InactiveCN102259190AQuality improvementEasy to prepareMaterial nanotechnologyPolycrystalline material growthWater solubleMaterials science

Disclosed is a method suitable for efficiently producing silver nanowires with high aspect ratio. In this method, silver nanowires with aspect ratio of more than 300 and purity of more than 80% are produced through an acid compound mediated microwave-assisted wet chemistry method. Such silver nanowires are especially suitable for the application in the flexible transparent electrodes, as they can simultaneously improve the electrical conductivity and transparency.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

Preparation method of metal silver nanowires with adjustable length and diameter

InactiveCN102328095ALow reaction temperatureLow costPolycrystalline material growthSingle crystal growth detailsAlcoholReaction temperature

The invention discloses a preparation method of metal silver nanowires with adjustable length and diameter. The method comprises the following steps: dissolving silver nitrate in polyhydric alcohol for preparing solution; dissolving an alkali metal halide and a reducing compound in the polyhydric alcohol for preparing the solution; mixing the two types of the solution, and fully reacting under stirring to get the mixed solution; heating the polyhydric alcohol to 120-160 DEG C, dripping into the mixed solution, keeping the temperature and reacting for 15-44 hours; and performing centrifugal separation on reaction solution after the reaction, and washing lower-layer precipitate to get the silver nanowires. According to the preparation method, inert gas does not need to be introduced for protection, the reaction temperature is low, the preparation process is simple, the yield is high, the cost is low, and the insufficiencies of complex preparation procedure, low yield, high cost and the like in the template plate, the seeding method, the traditional polyhydroxy reduction method and the like can be overcome, thereby having important significance for large-batch industrial production and actual application thereof of the silver nanowires.

Owner:UNIV OF JINAN

UV curing silver nanowire ink and its preparation method and application method

InactiveCN102311681ASimple processEasy to prepareInksPhotosensitive materials for photomechanical apparatusEpoxyUV curing

The invention provides a UV curing silver nanowire ink, a preparation method and an application method thereof, namely a transparent conductive film with certain patterns is prepared by the application of one-step method. According to the invention, a silver nanowire ink containing a UV curing epoxy resin mixture; then, the ink forms a film on a transparent substrate by one-step method; the film undergoes selective UV irradiation and uncured ink is removed so as to form the transparent conductive film with specific patterns. Selective curing of the UV curing epoxy resin mixture can be accomplished according to pattern requirements; in addition, the production technology of the silver nanowire transparent conductive film is greatly simplified by one-step method. Therefore, the invention has a great practical application value.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

Water-solubility silver nanowire writing ink and preparation method thereof as well as using method thereof

ActiveCN102391737AInksNon-conductive material with dispersed conductive materialOrganic solventThin membrane

The invention provides water-solubility silver nanowire writing ink and a using method of the water-solubility silver nanowire writing ink for preparing a transparent conductive thin film. The water-solubility silver nanowire writing ink is characterized in that the silver nanowire writing ink containing a water-solubility polymer is prepared, and then the writing ink forms the conductive thin film on a transparent substrate by a one-step method. The water-solubility polymer can realize the firm adhesive bonding between the silver nanomwire and the substrate and solves the difficult problem of poor adhesive bonding performance between the silver nanowire and the substrate; the one-step method greatly simplifies the productive technology of the silver nanowire transparent conductive thin film; an organic solvent is not used in the whole production process; and therefore, the water-solubility silver nanowire writing ink is environment-friendly and pollution-free and has very good practical application value.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

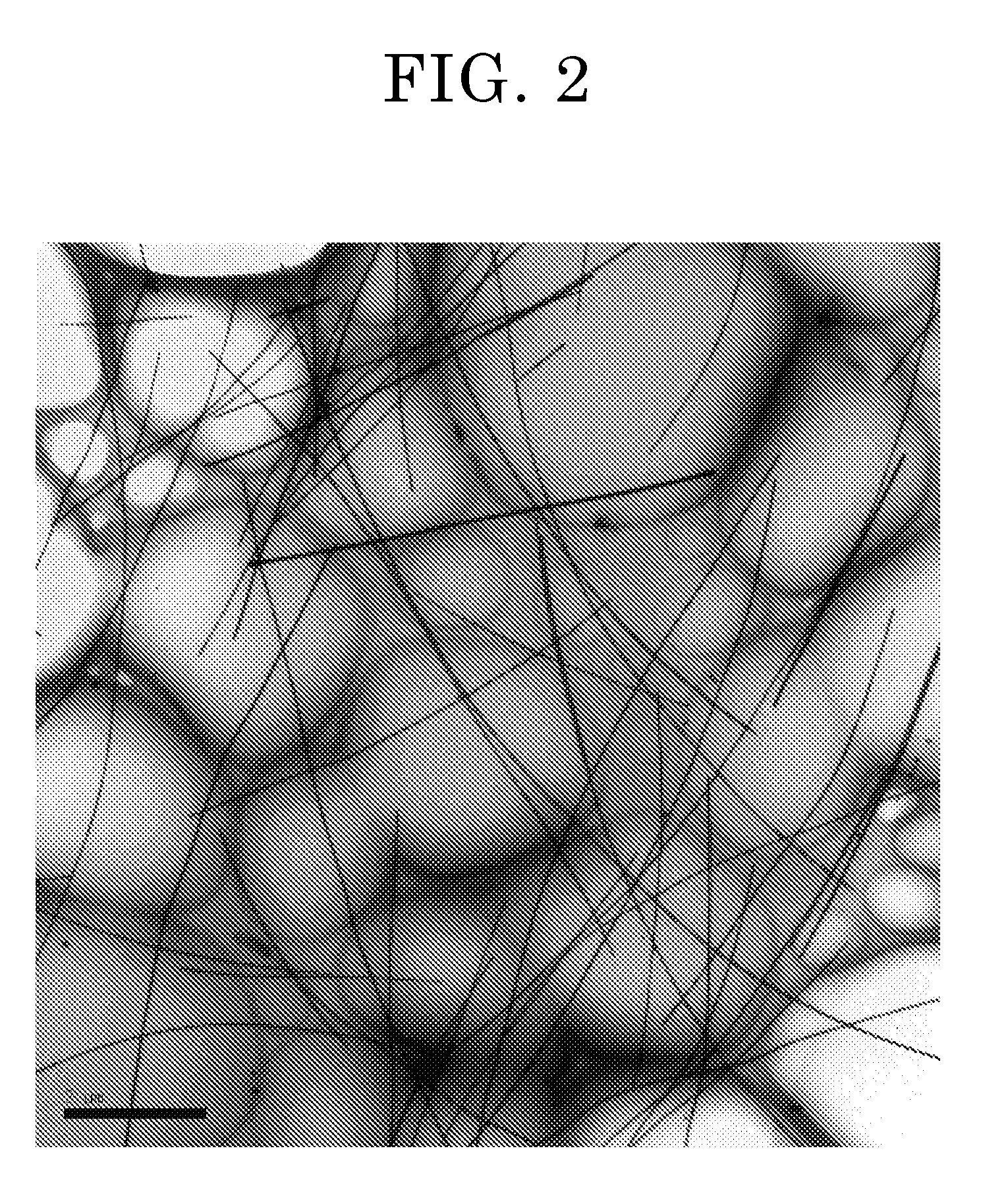

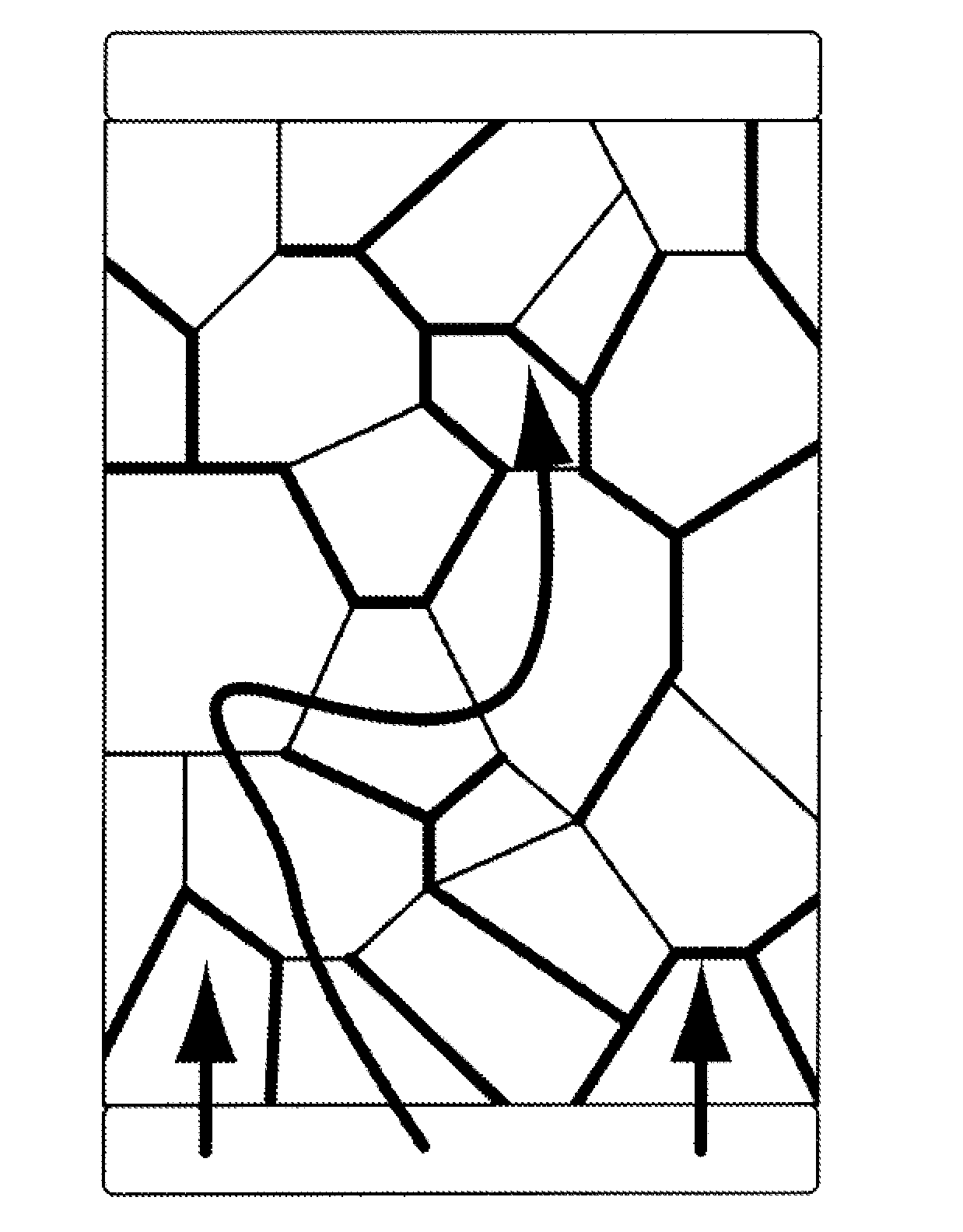

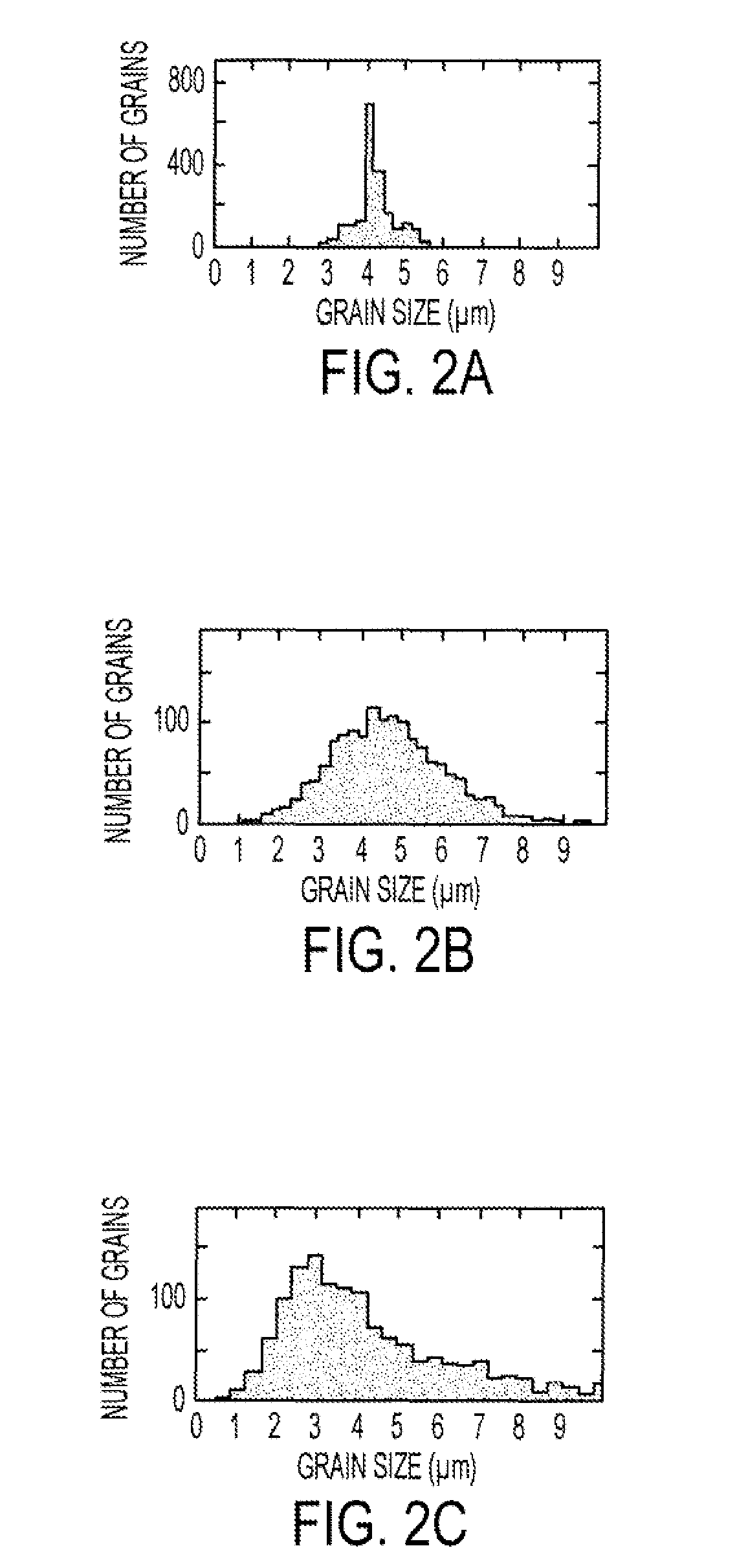

High optical transparent two-dimensional electronic conducting system and process for generating same

InactiveUS20140014171A1Easy to transportLow densityRoof covering using sealantsFinal product manufactureConductive materialsSingle crystal

Hybrid transparent conducting materials are disclosed with combine a polycrystalline film and conductive nanostructures, in which the polycrystalline film is “percolation doped” with the conductive nanostructures. The polycrystalline film preferably is a single atomic layer thickness of polycrystalline graphene, and conductive nanostructures preferably are silver nanowires.

Owner:PURDUE RES FOUND INC

Flexible capacitive sensor fabricated by employing silver nanowire flexible electrode and fabrication method of flexible capacitive sensor

InactiveCN110455443AGood flexibilityHigh sensitivityMaterial nanotechnologyForce measurementSignal responseThin layer

The invention relates to a flexible capacitive sensor fabricated by employing a silver nanowire flexible electrode. The flexible capacitive sensor comprises an upper-layer flexible electrode plate, alower-layer flexible electrode plate and an intermediate flexible dielectric layer, wherein each flexible electrode comprises a flexible substrate, a silver nanowire electrode thin film layer, and thesilver nanowire electrode thin film layer is arranged in the flexible substrate. A fabrication method of the electrode employs a transfer printing method, the silver nanowire electrode thin film layer is fabricated in an electrode template, a flexible polymer is injected for curing, so that the silver nanowire conductive thin film layer is transferred to the flexible substrate. The flexible dielectric layer is divided into two types comprising a thin film structure and a porous structure, the thin film structure is fabricated by uniformly coating a flexible polymer prepolymer on a silicon wafer to form a thin layer, the porous structure is fabricated by a template method, the flexible polymer prepolymer is uniformly mixed with salt, a film formation structure is fabricated and cured, andthe porous dielectric layer structure is obtained after salt removal. The flexible capacitive sensor is simple in fabrication method and has favorable signal response.

Owner:BEIHANG UNIV

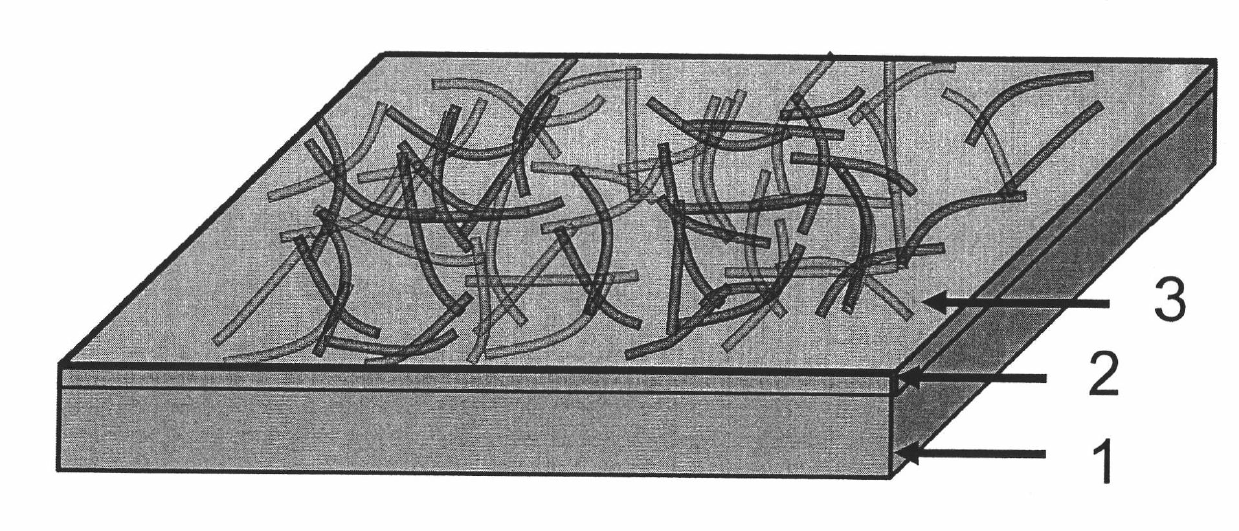

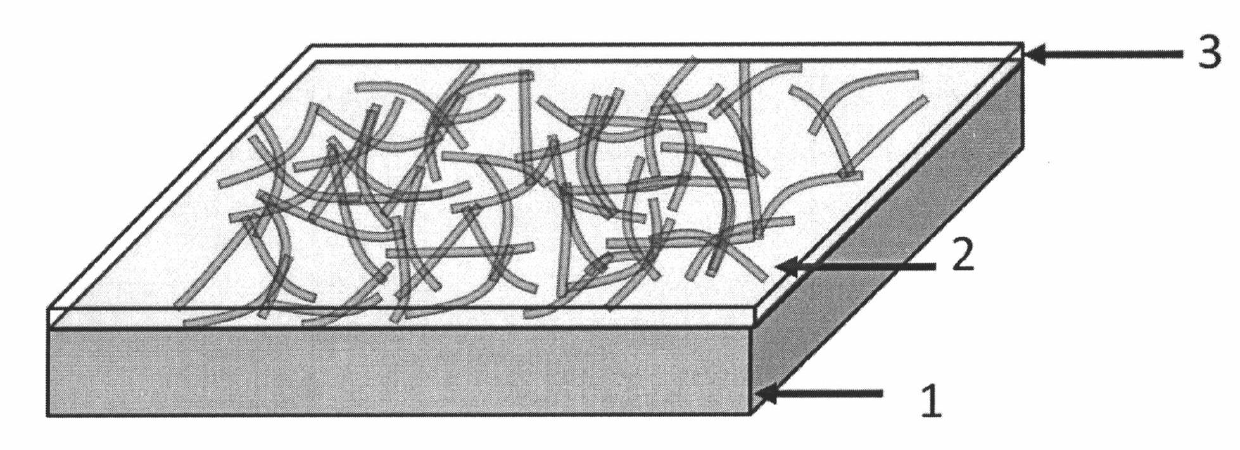

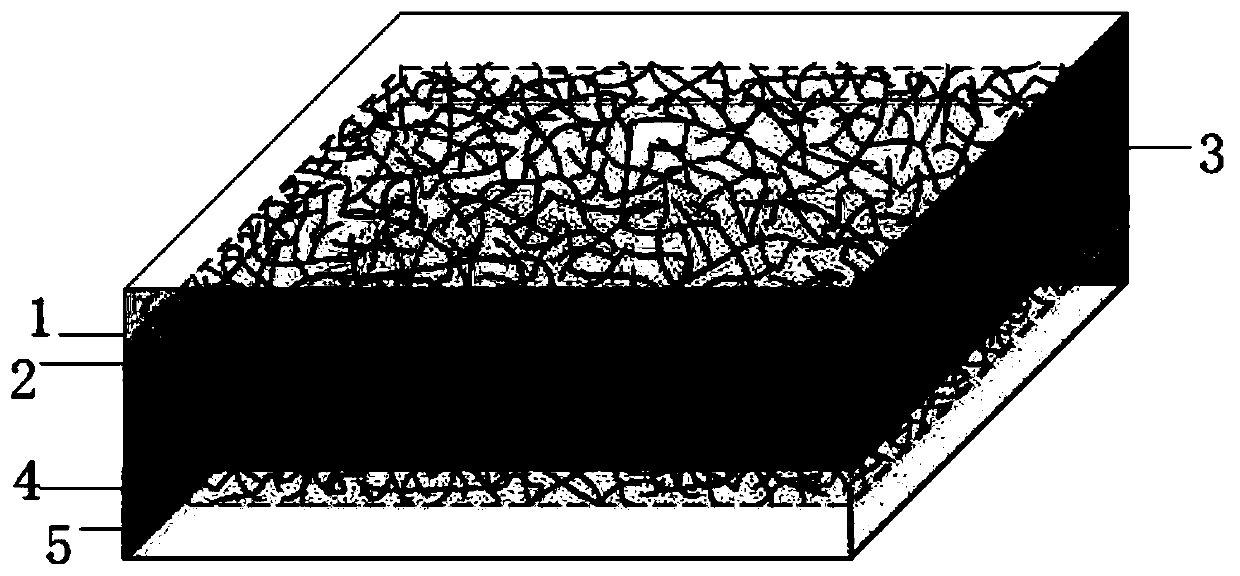

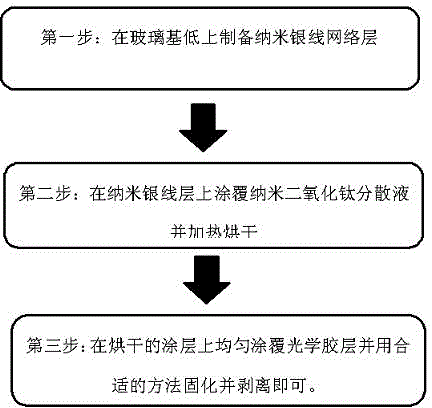

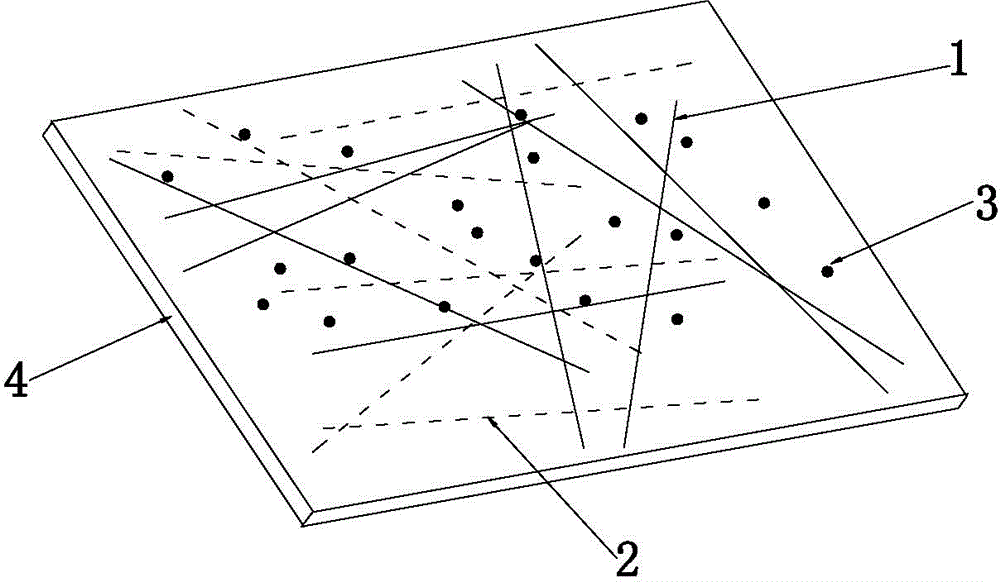

Flexible transparent conductive film based on silver nanowires and preparation method

ActiveCN104134484AImprove flexibilityImprove transmittanceConductive layers on insulating-supportsCable/conductor manufactureFilm baseAdhesive

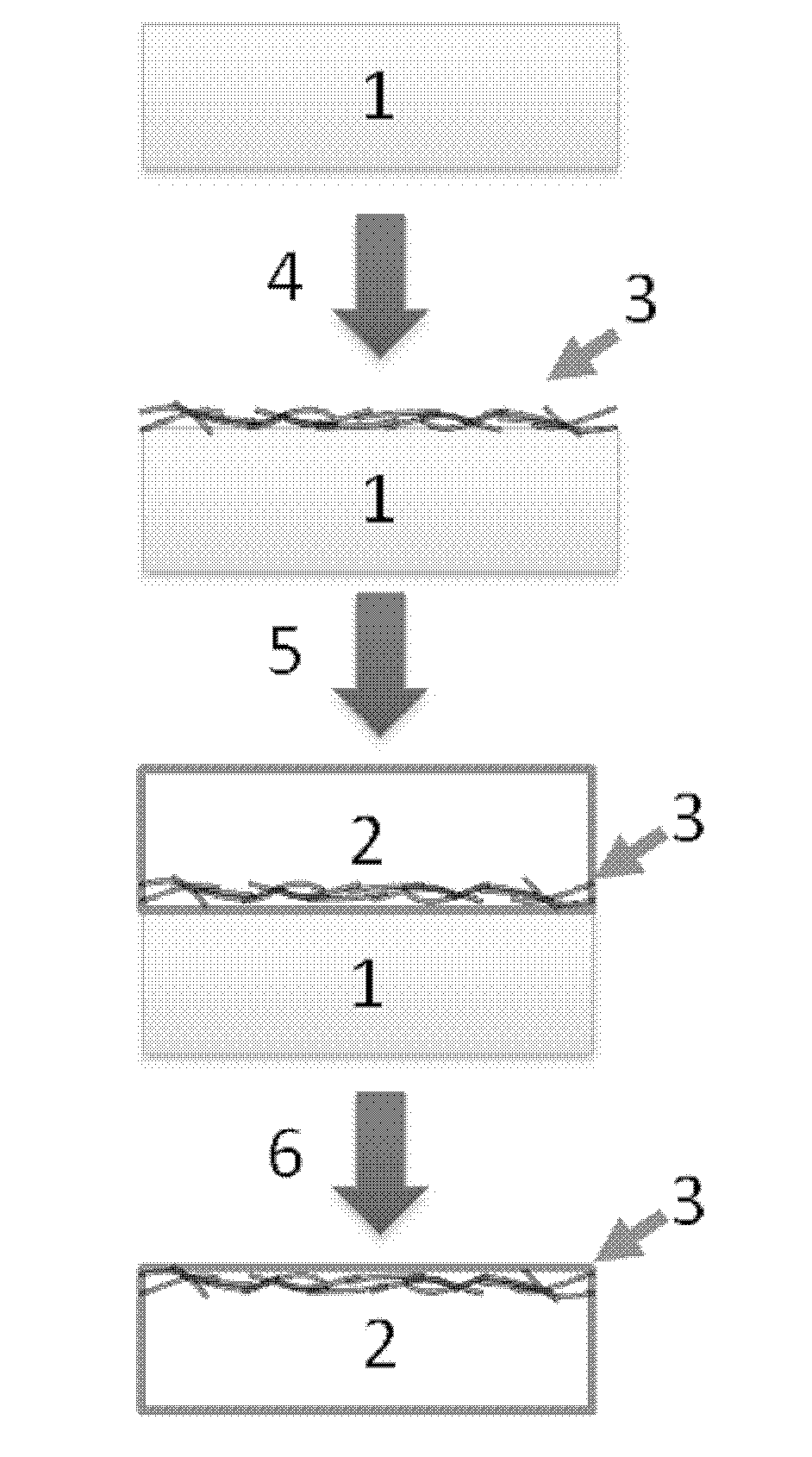

The invention provides a flexible transparent conductive film based on silver nanowires and a preparation method. The transparent conductive film comprises a silver nanowire network layer (1), a nano particle filled layer (2) and an optical adhesive layer (3). The prepared transparent conductive film based on the silver nanowires is low in resistance, high in transmittance and surface evenness and simple in structure and preparation process, operation is simple and convenient, no high-temperature and high-pressure process is needed, safety is guaranteed, energy consumption is low, and a cumbersome process of film transferring is not needed. Meanwhile, the flexible transparent conductive film is low in cost and suitable for large-scale application.

Owner:NANJING GUOZHAO OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

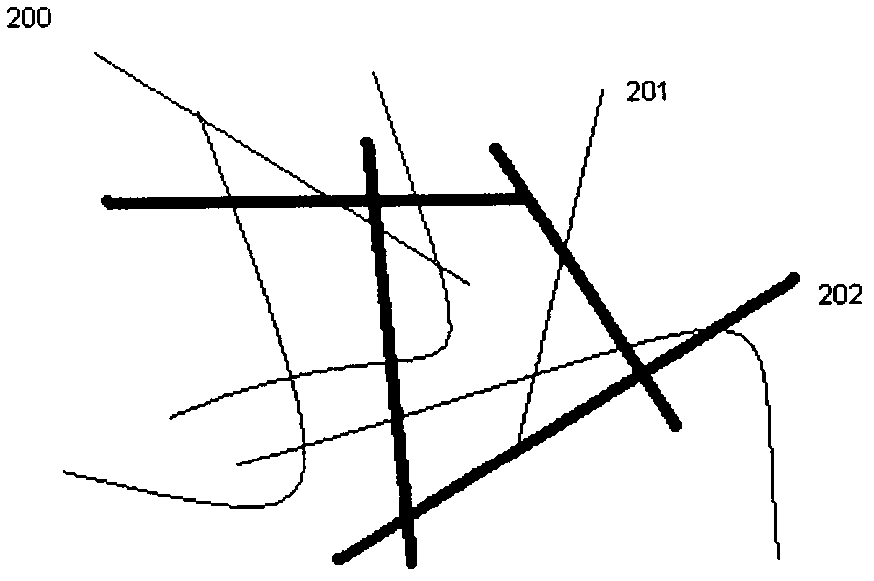

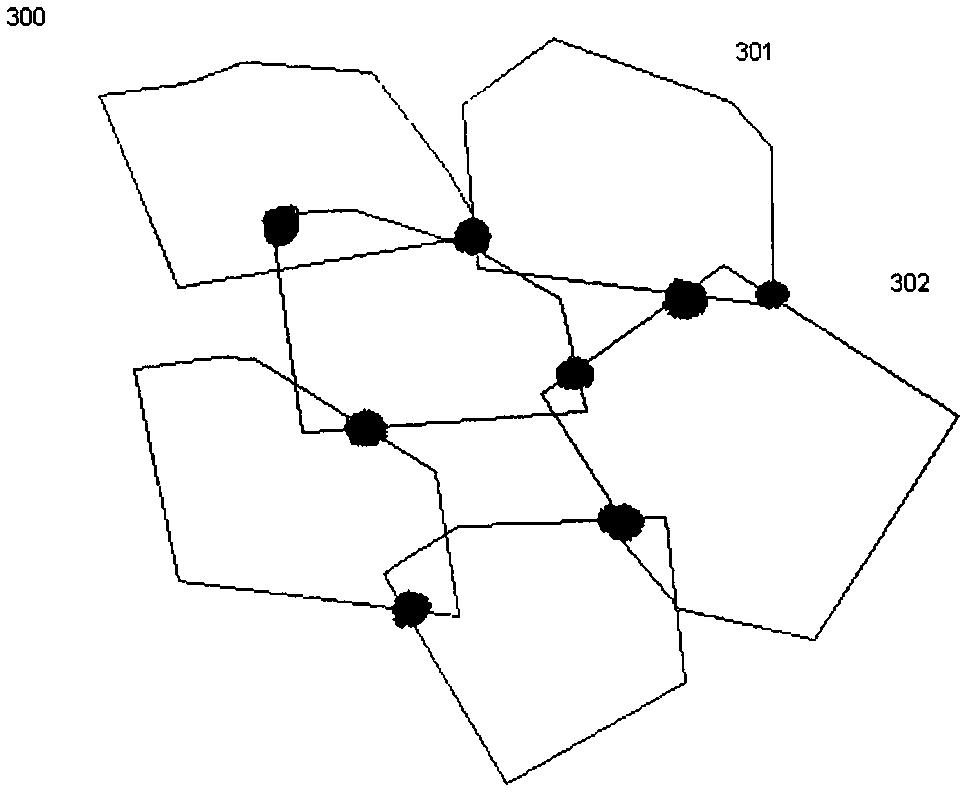

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com