Preparation method of metal silver nanowires with adjustable length and diameter

A technology for silver nanowires and metallic silver, which is applied in the field of preparing silver nanowires by polyhydroxy reduction method, can solve the problems of cumbersome post-processing process and complicated operation, and achieves the effects of being suitable for industrial production, low reaction temperature and controllable diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1.1 Heat and stir 5 ml of ethylene glycol at 120°C for 3 h to obtain solution A.

[0036] 1.2 Add 0.085 g AgNO 3 Dissolve in 3 ml ethylene glycol to obtain solution B. At the same time, 0.05 g polyvinylpyrrolidone (K 30 ) and 0.0018 g of sodium chloride were dissolved in another 3 ml of ethylene glycol to obtain solution C. Mix the two solutions and continue stirring for 200 min to obtain solution D.

[0037]1.3 Add solution D dropwise to solution A at a rate of 120 ml / min, stir while adding, and heat and stir the reaction solution at 120°C for 23 h.

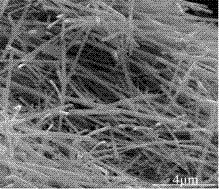

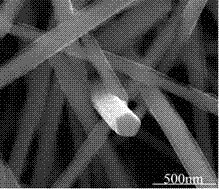

[0038] 1.4 After the reaction is completed, the above reaction solution was centrifuged and washed 3 to 4 times with distilled water and absolute ethanol (centrifugal speed 13000 rpm) to remove unreacted polyvinylpyrrolidone (K 30 ) and other impurities. Finally, the washed samples were dispersed in absolute ethanol. figure 1 , figure 2 It is the SEM picture of the silver nanowires synthesized in this example. It ...

Embodiment 2

[0040] 2.1 Heat and stir 5 ml of ethylene glycol at 120°C for 3 h to obtain solution A.

[0041] 2.2 Add 0.085 g AgNO 3 Dissolve in 3 ml ethylene glycol to obtain solution B. 0.1 g polyvinylpyrrolidone (K 30 ) and 0.0018 g of sodium chloride were dissolved in another 3 ml of ethylene glycol to obtain solution C. Mix the two solutions and continue stirring for 140 min to obtain solution D.

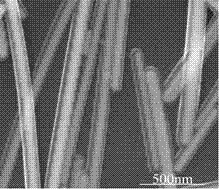

[0042] 2.3 The preparation and washing process of the samples are the same as those in Examples 1.3 and 1.4 above, the average diameter of the silver nanowires is 90 nm, and the average length is 1 μm to 10 μm, such as image 3 shown.

Embodiment 3

[0044] 3.1 Heat and stir 5 ml of ethylene glycol at 120°C for 3 h to obtain solution A.

[0045] 3.2 Add 0.085 g AgNO 3 Dissolve in 3 ml ethylene glycol to obtain solution B. 0.15 g polyvinylpyrrolidone (K 30 ) and 0.0018 g of sodium chloride were dissolved in another 3 ml of ethylene glycol to obtain solution C. Mix the two solutions and continue stirring for 80 min to obtain solution D.

[0046] 3.3 The preparation and washing process of the sample is the same as in the above examples 1.3 and 1.4, the average diameter of the silver nanowires is 50 nm, and the average length is 50 μm ~ 60 μm, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com