Patents

Literature

353results about How to "Reduced post-processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

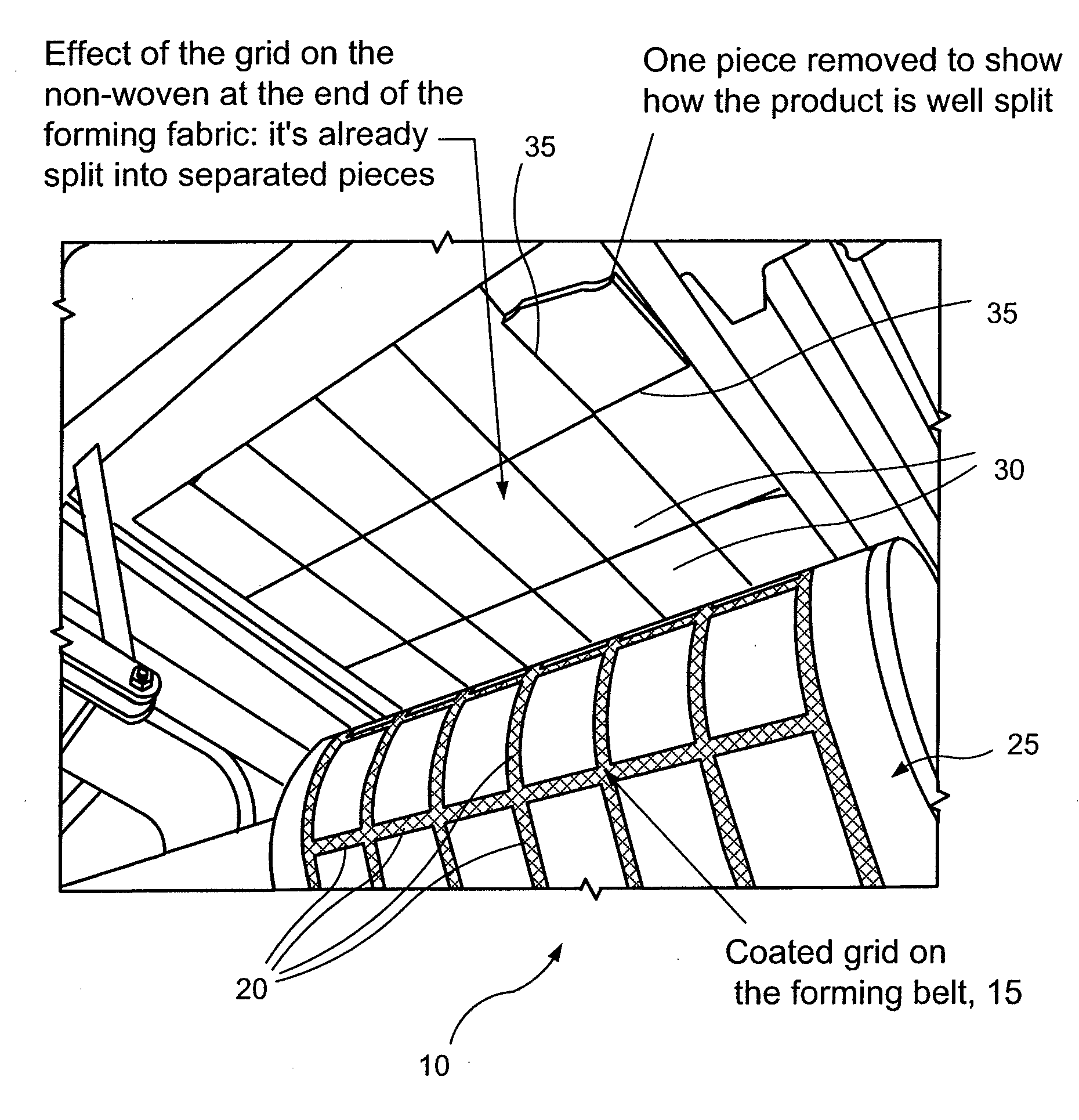

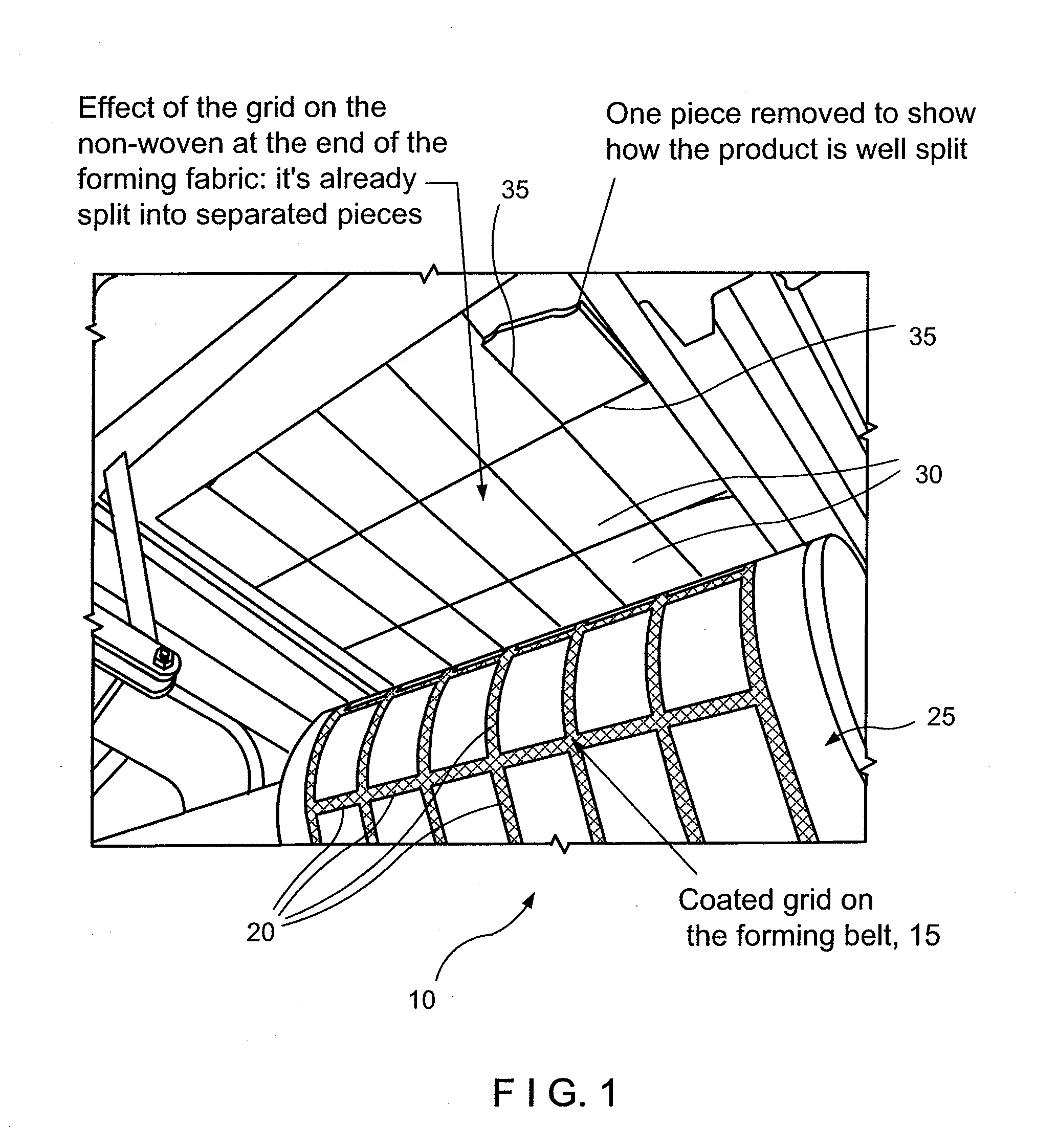

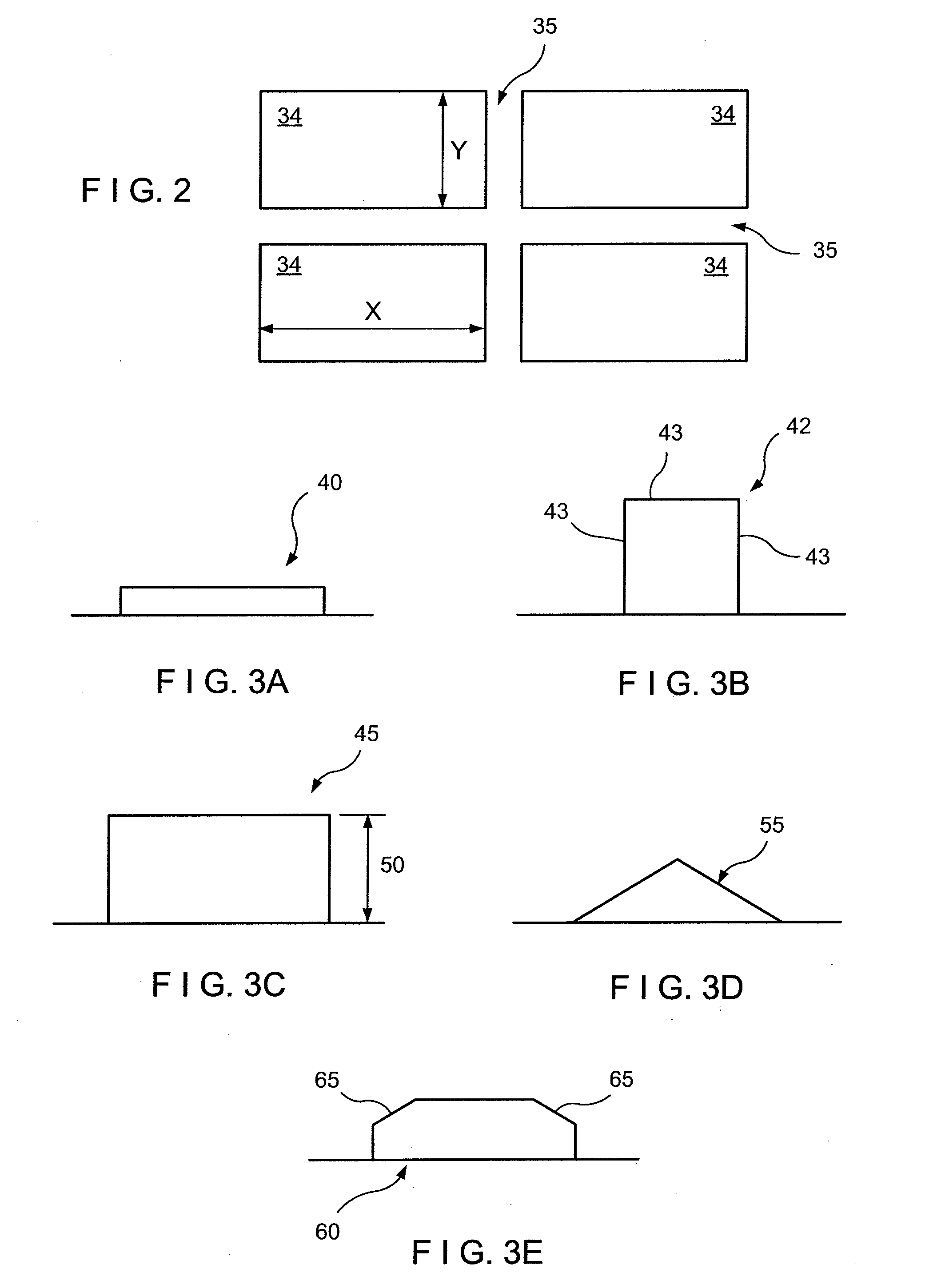

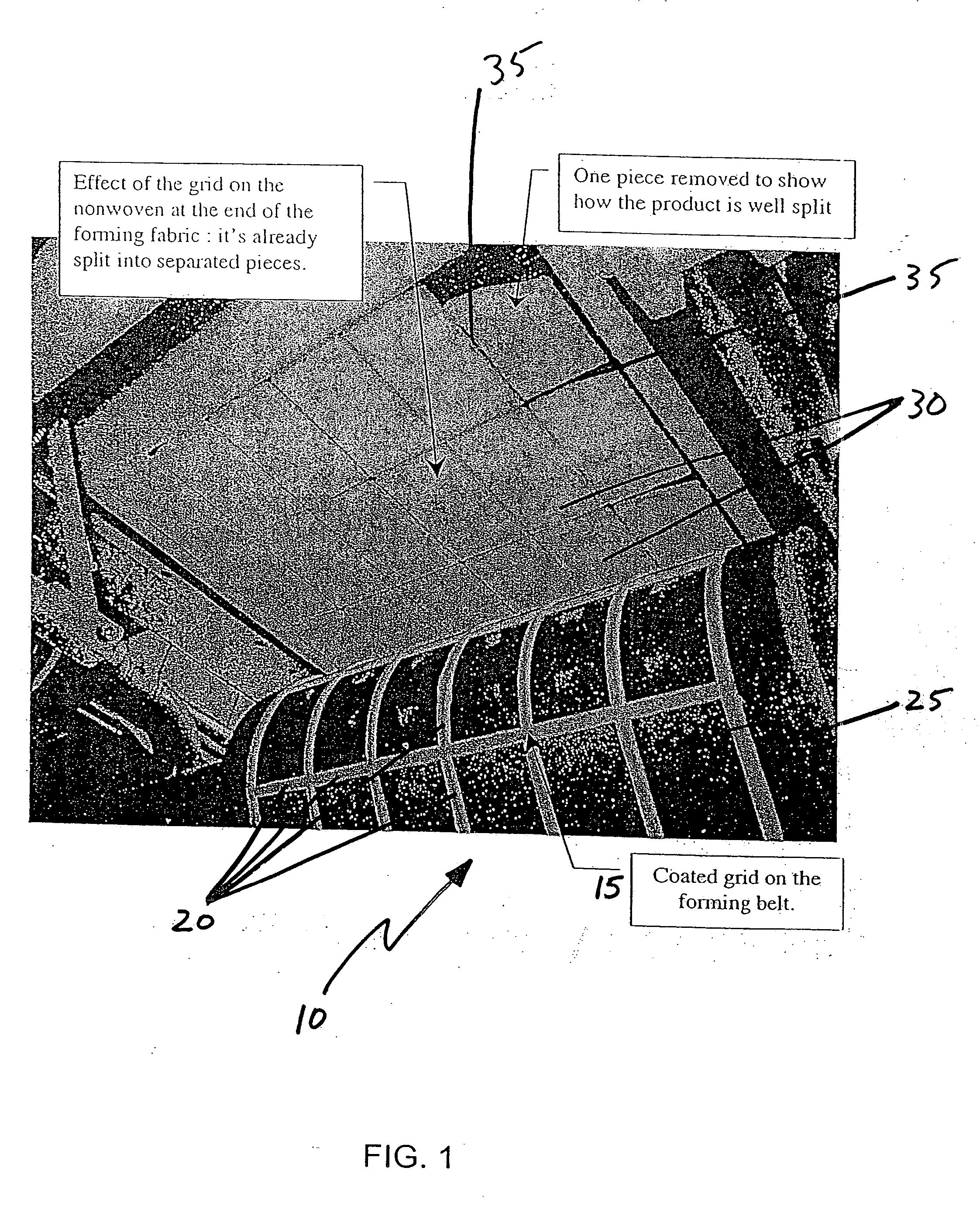

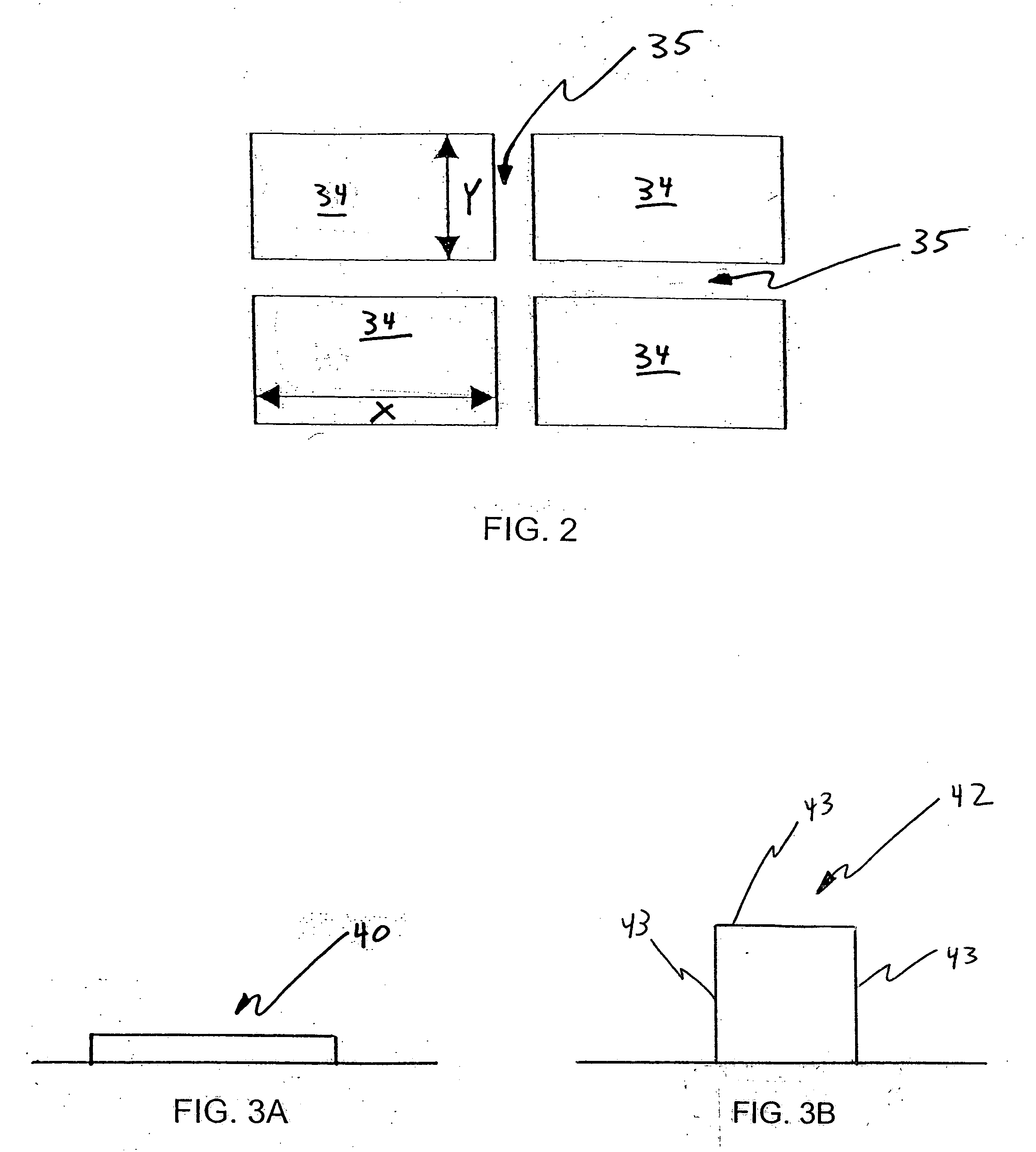

Sheet Slitting Forming Belt for Nonwoven Products

Owner:MONNERIE JEAN LOUIS +1

Micro-emulsification stainless steel cutting liquid

The invention disclose a micro-emulsification type stainless steel cutting fluid belonging to metal-cutting lubricant technical field to solve the problems that the existing cutting fluid can not be commendably used in cutting process of stainless steel and can endanger the health of the workers. The micro-emulsification type stainless steel cutting fluid comprises 20-40 wt% water, 5-20 wt% paraffin base mineral oil or naphthenic base mineral oil, 1-15 wt% non-ionic surfactant of alkyl phenol polyoxyethylene ether or fatty alcohol polyoxyethylene ether, 5-10 wt% chloroparaffin, 1-10 wt% petroleum sodium sulphonate and hardship or alkenyl succinic acid rust preventive, 5-25 wt% mixing alkyol amine of mono ethanolamine and trieanolamine, 5-15 wt% oleic acid, 2-10 wt% polyatomic alcohol lauric acid ester or polyatomic alcohol oleic acid ester, 0.1-0.5 wt%.benzotriazole, and 0.1-0.5 wt% methyl silicone oil anti-foam agent. The micro-emulsification type stainless steel cutting fluid is specially used in the cutting process of the stainless steel.

Owner:CHINA PETROCHEMICAL CORP +1

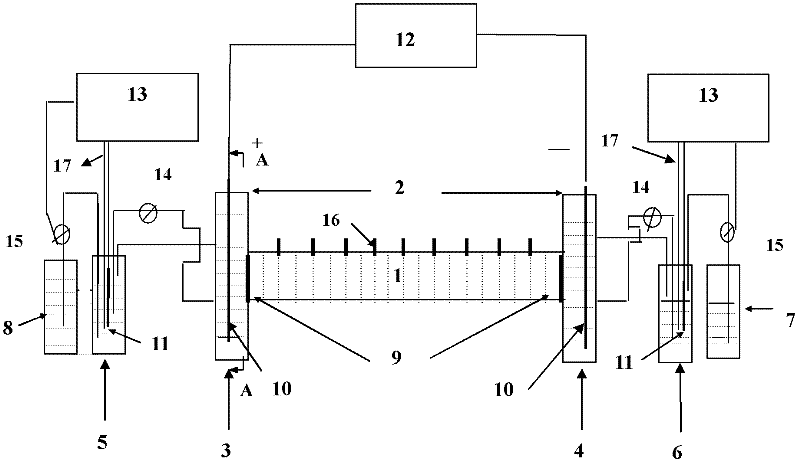

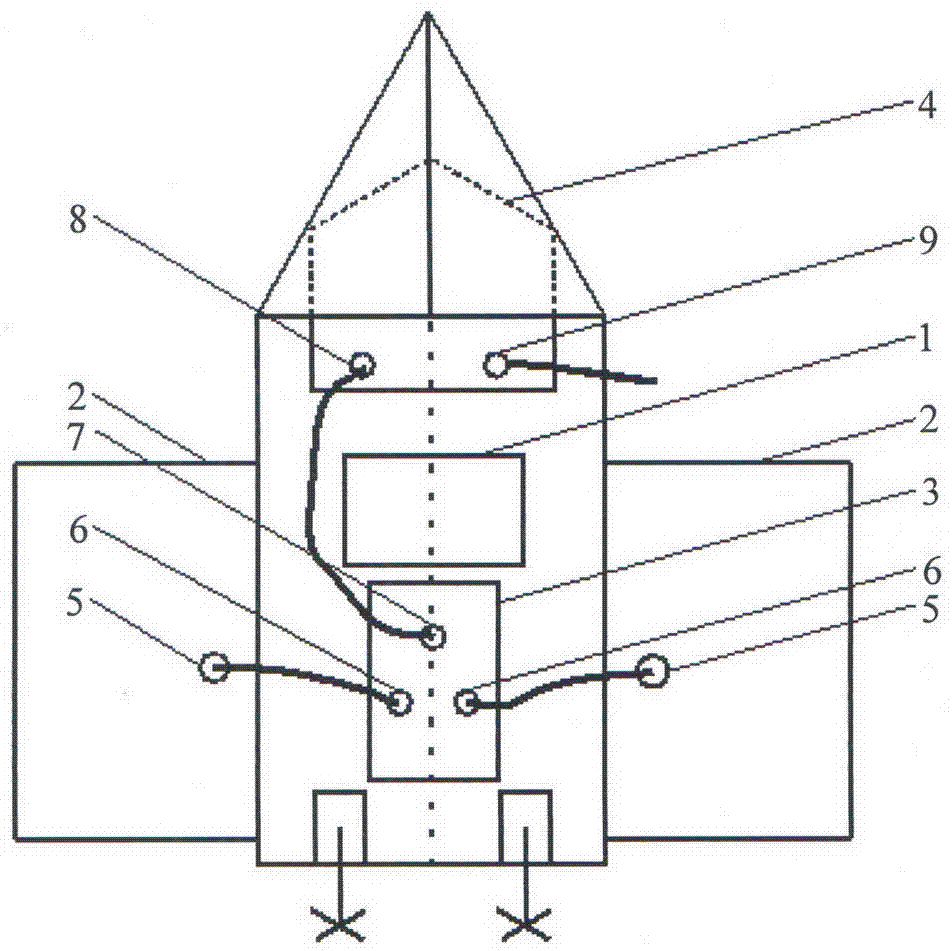

Electric complex-strengthening repairing method and device of heavy metal-organic co-contaminated soil

InactiveCN102513348APromote migrationImprove removal efficiencyContaminated soil reclamationHypochloritePersulfate

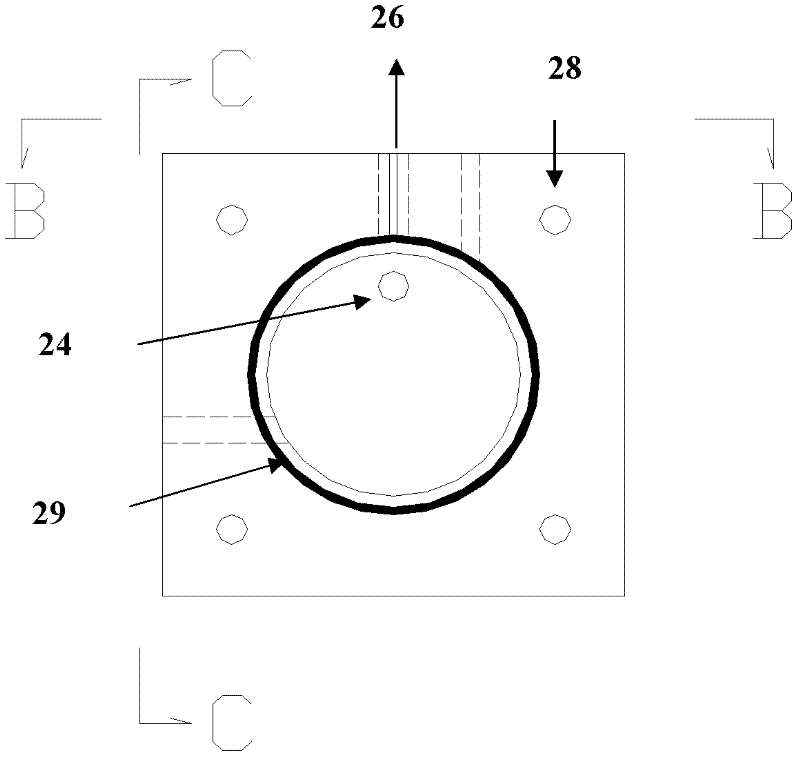

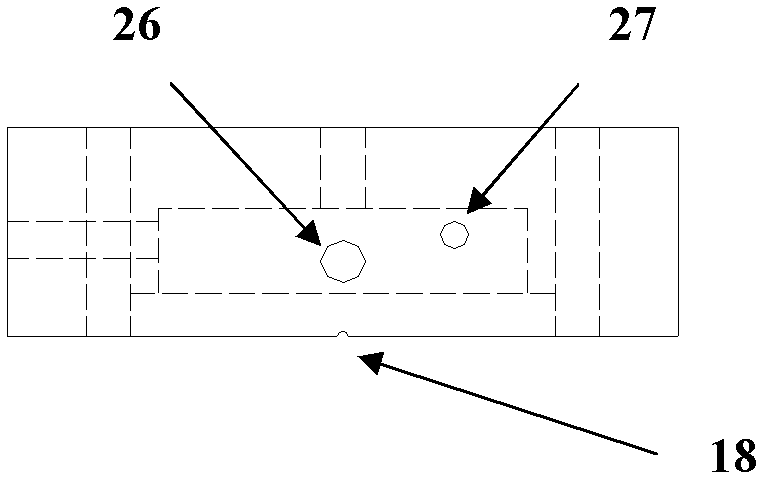

The invention provides an electric complex-strengthening repairing method and device of heavy metal-organic co-contaminated soil. The method provided by the invention comprises the following steps of: filling contaminated soil into an electric repairing device, and then adding an oxidant into a cathode electrolyte and an anode electrolyte or directly spraying the oxidant on the contaminated soil, wherein the oxidant comprises hydrogen peroxide, pypocholoride and persulfate; applying a direct-current electric field on a cathode and an anode, wherein the strength of the electric field is 0.5-2 V / cm; and controlling the pH values of the cathode electrolyte and the anode electrolyte to be 3-11. By selecting the suitable for oxidant and controlling the pH value of the electrolyte, the migration of the heavy metal can be effectively increased and the removing efficiency is improved; and meanwhile, the oxidant is used for effectively degrading organic pollutants when the pollutants are migrated, thereby relieving the post-treatment and simultaneously removing the heavy metal and the organic pollutants.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Preparation method of p-aramid nanofiber

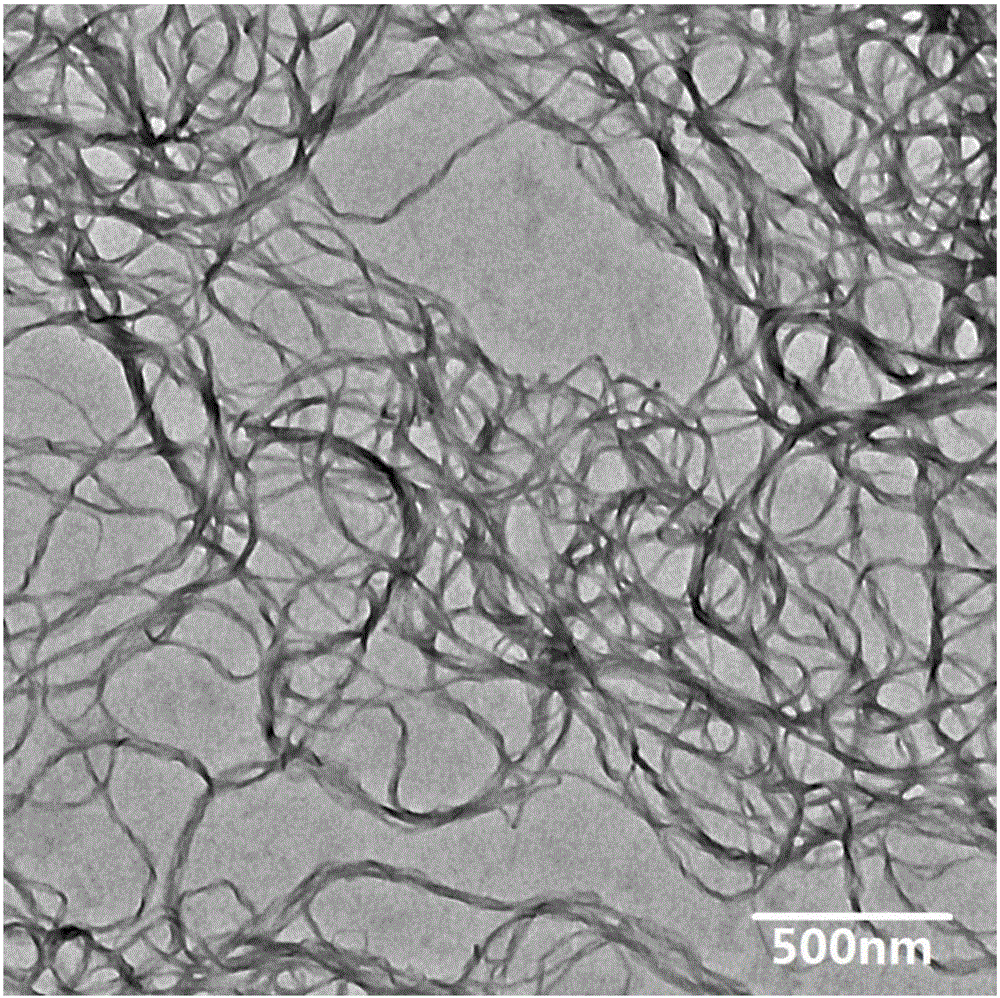

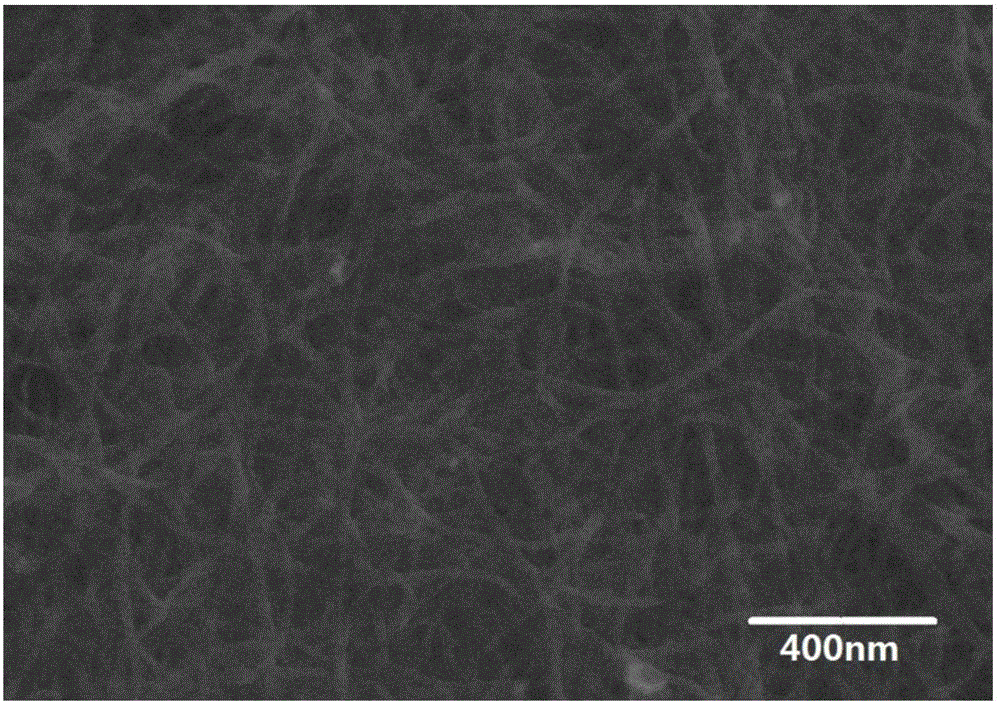

ActiveCN105153413AReduce usageSimple processArtificial filament recoveryArtificial filament washing/dryingMicrometerNanofiber

The invention relates to a preparation method of p-aramid nanofiber, and belongs to the technical field of polymer new materials. The diameter of the prepared p-aramid nanofiber ranges from tens of nanometers to hundreds of nanometers, and the length of the prepared p-aramid nanofiber ranges from hundreds of nanometers to tens of micrometers. According to the preparation method, a certain amount of surface active agents are added in the PPTA low-temperature polymerization process, aggregation of PPTA molecules is controlled while PPTA molecule chains are lengthened, and the p-aramid nanofiber which is uniform in size and has the diameter capable of being regulated within the range between nanometer and submicron can be prepared under the auxiliary effect of other means (for example, precipitator and high-speed shearing and dispersing). The preparation method is short in production flow, devices are simple, batched and stable production can be achieved, and therefore the requirement for industrially producing the p-aramid nanofiber on a large scale is met; the preparation method has wide application prospects and can be used for preparing lithium-ion battery separators and high-performance composites.

Owner:SHANDONG JUFANG NEW MATERIAL CO LTD

Method for preparing biodiesel by using supported solid acid combining cosolvent

InactiveCN101418225AReduced post-processingReaction is easy to controlMolecular sieve catalystsBiofuelsBiodieselAlcohol

The invention discloses a method for producing biodiesel in the presence of a supported solid acid catalyst and a solubilizing agent. The method is characterized in that: (1) a hydrophobic solid acid catalyst which is high in catalytic efficiency, recyclable, easily separable and simple in post treatment process is adopted; (2) a cosolvent is introduced during a reaction process to improve reaction conditions and reduce reaction temperature and pressure; (3) the cosolvent and lower alcohols used in the reaction can be recycled; and (4) equipment corrosion and environmental pollution are avoided and advantages of low requirements on equipment corrosion, short technical process, environmental-friendly production, low investment in equipment and low operation cost are achieved.

Owner:BEIJING UNIV OF CHEM TECH

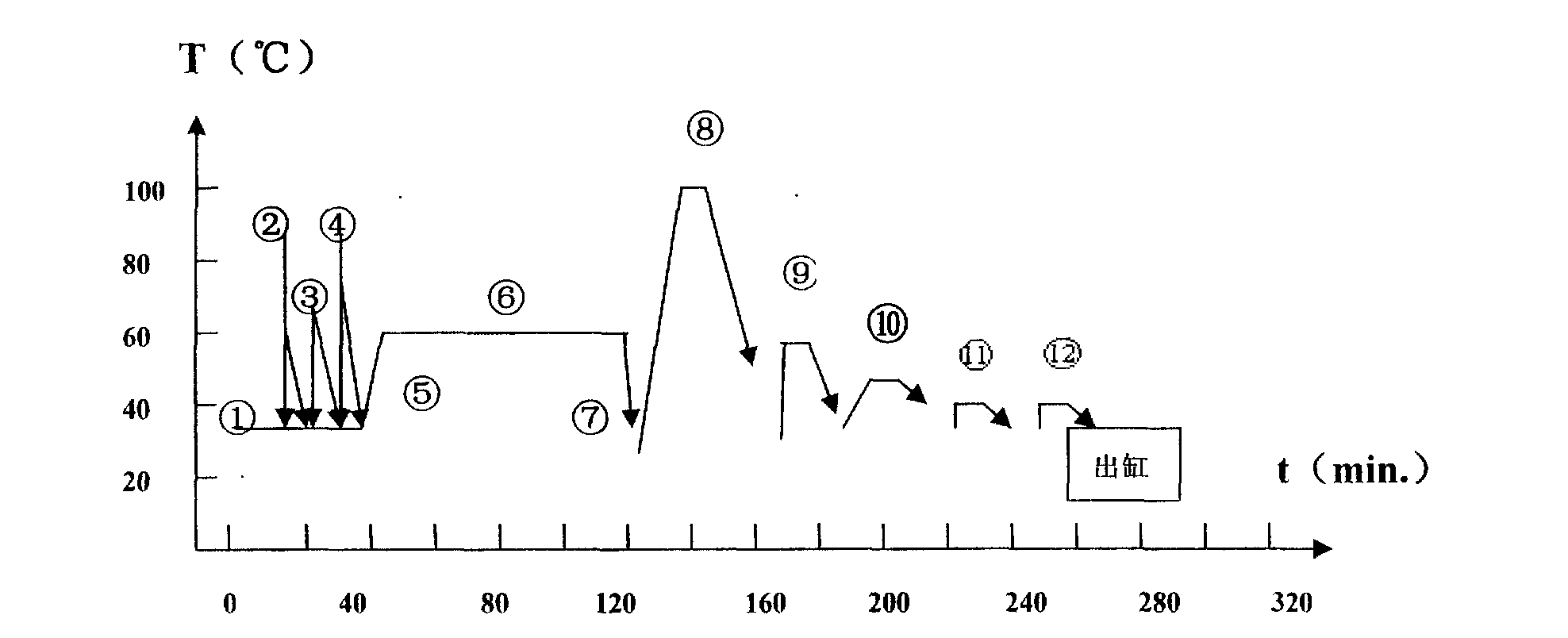

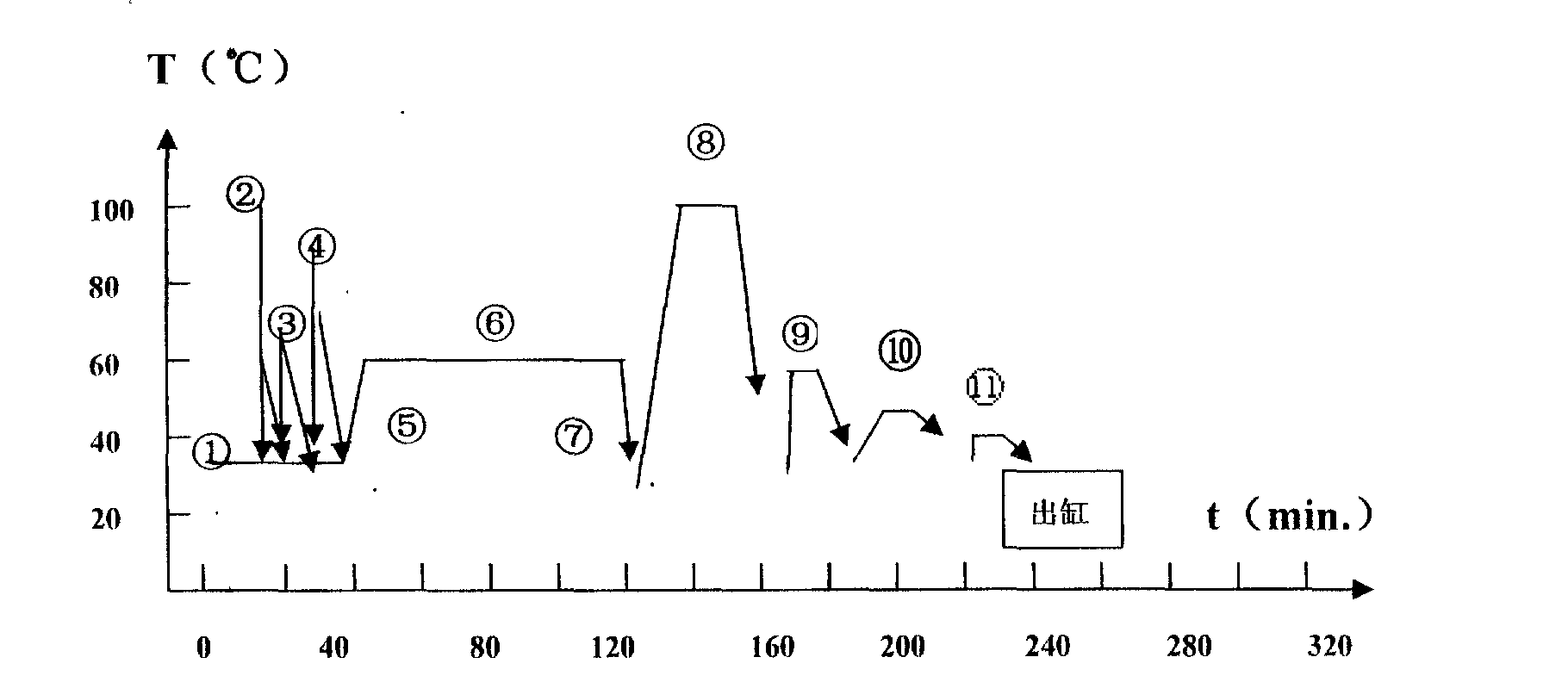

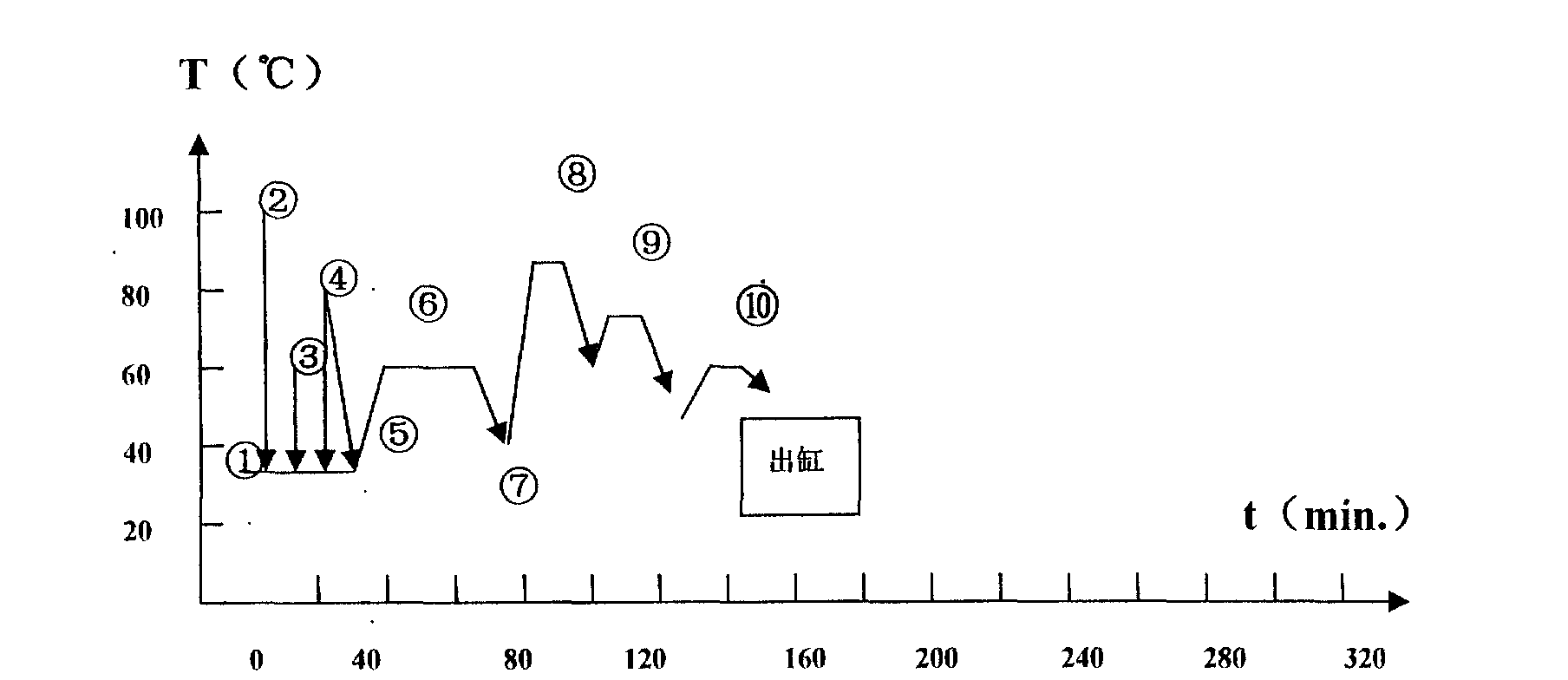

Reactive dye ultra-short rapid dyeing and fixation technology method

The invention relates to a reactive dye ultra-short rapid dyeing and fixation technology method. The method is realized by effectively minimizing auxiliary time such as feeding, shortening and optimizing post-processing processes, especially carrying soap boiling (one bath color mending) only once in advance to the greatest extend, merging washing, using less hot water and controlling the use of water aiming at various substances to be dyed according to dyeing requirements and the conditions of normal or abnormal and with the help of various accessory ingredients, thereby the reactive dye normal or abnormal dyeing conditions (especially mediate high color with a dye usage higher than 1percent of o. W. f) by the single one bath process, the multifunction composite one bath process, or the like, comprising pre-processing, dyeing, polishing with enzyme, and color mending, and even the pre-processing and the whole dyeing procedure in conventional equipment in an ultra-low bath ratio limit state can be completed well within 2.5-8h. The effects of thorough energy saving and emission reduction, efficiency increasing and consumption reduction, cleaner production and environmental protection are achieved.

Owner:罗海航 +1

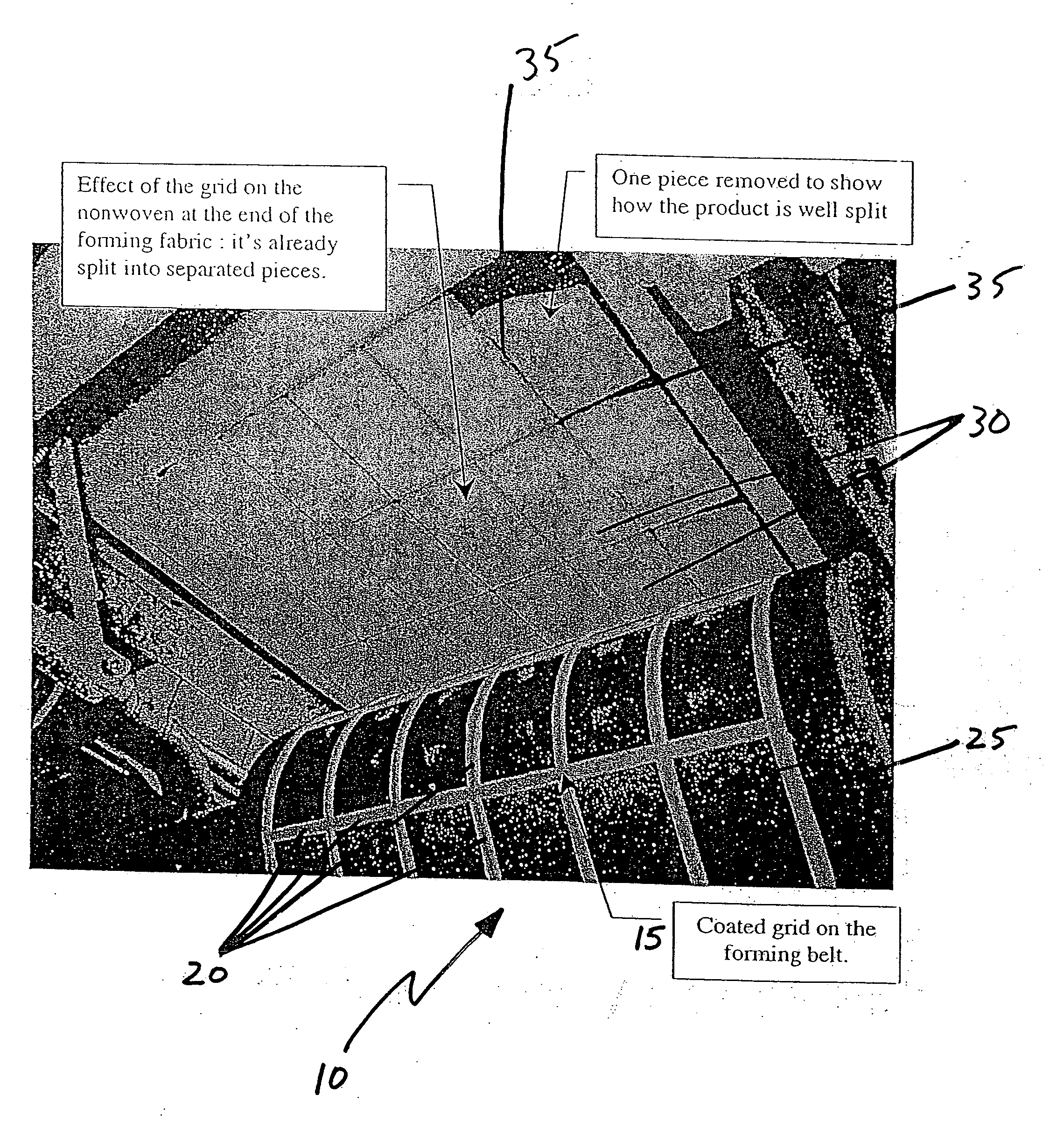

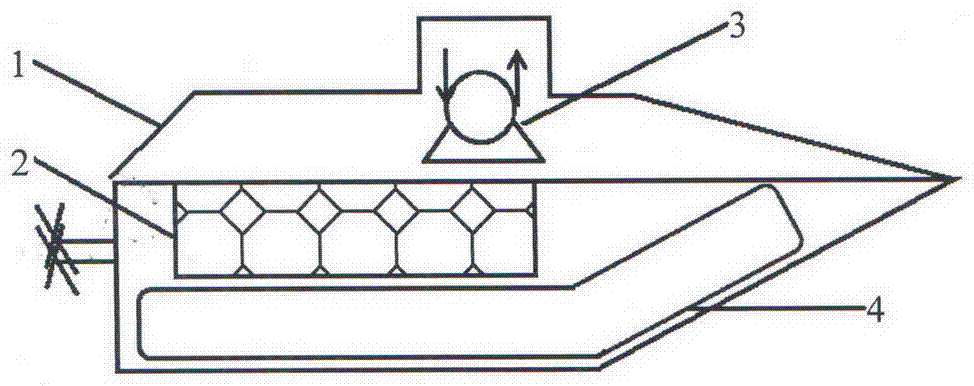

Sheet slitting forming belt for nonwoven products

InactiveUS20070116928A1Reduce post-processingReduced post-processingSynthetic resin layered productsPretreated surfacesBiomedical engineeringSheet material

Owner:ALBANY INT CORP

Abrasion resistant ink used for ink-ejecting direct plate-making technology and preparation method thereof

The invention discloses a hard-wearing ink for ink-ejecting direct plate-making technique in ink domain, which comprises the following steps: mixing 10%-30% cross linkable resin, 2%-10% silica dioxide or titanium oxide inorganic nanometer particle, 10%-30% fast-drying solvent, 1%-10% humectant and 20%-77% main body dissolvent; grinding; filtering; removing insoluble matter, impurity, silica dioxide with grain diameter more than 100nm or titanium oxide inorganic nanometer particle in balling liquid; getting the ink. This ink can increases abradability of paint and can get high quality ink-ejecting CTP plate, which possesses good abradability and image resolution.

Owner:INST OF CHEM CHINESE ACAD OF SCI

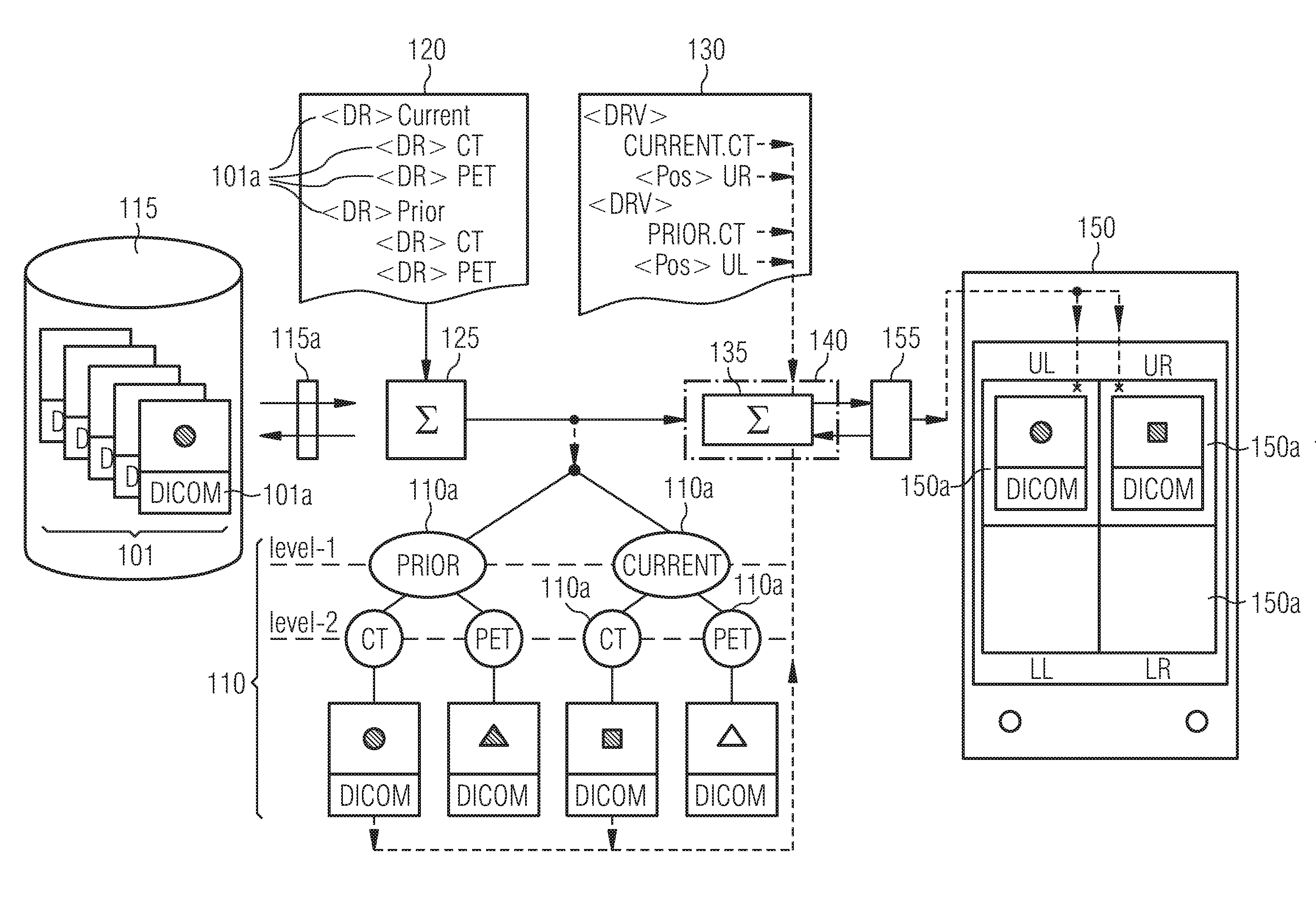

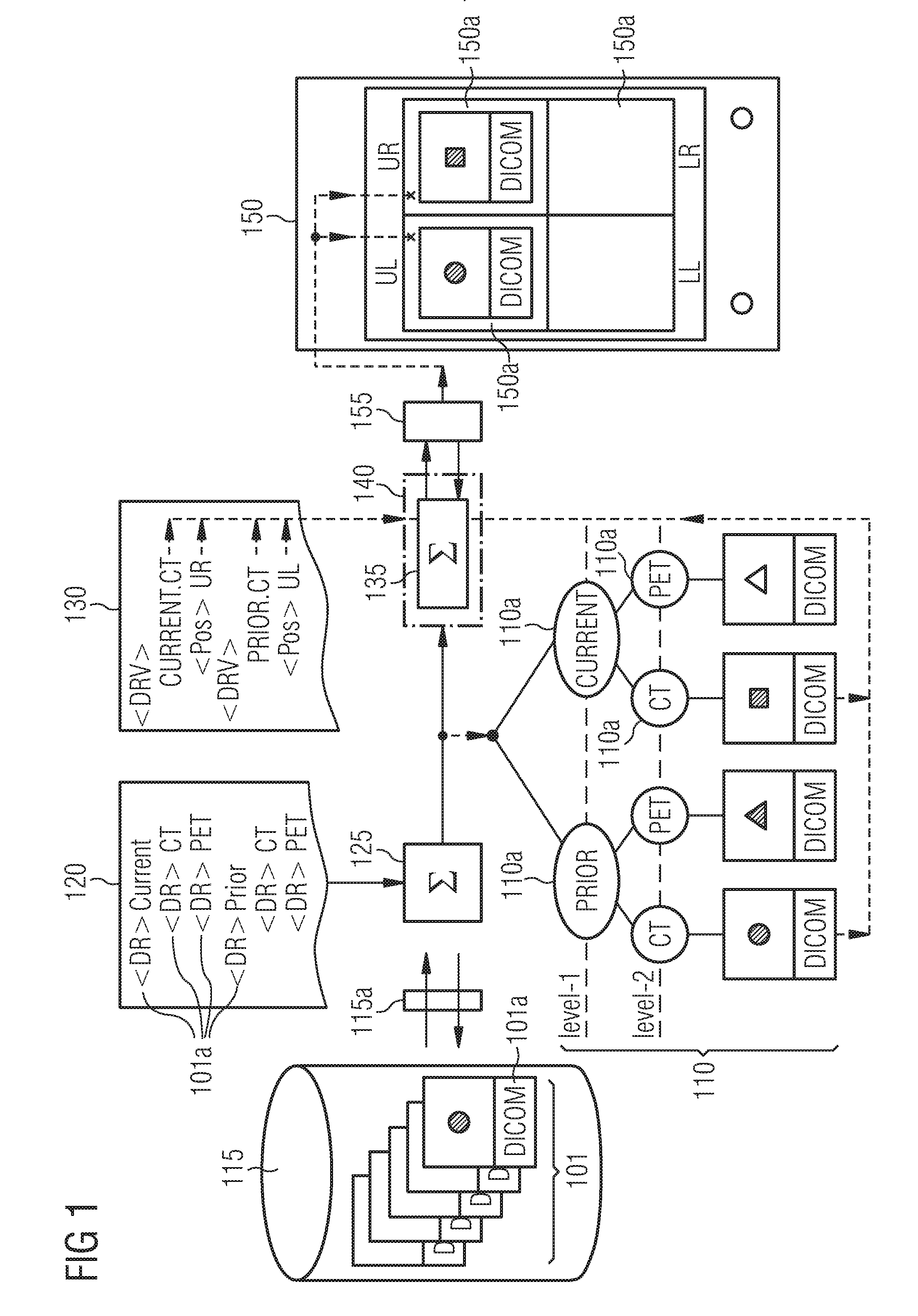

Data and Display Protocols

InactiveUS20090164247A1Easy post-processingReduced post-processingOffice automationMedical imagesOperating systemMedical treatment

The invention is related to a method and system for structuring a plurality of items of medical data in electrical form. The plurality of items of medical data is structured by a data protocol into a plurality of medical data clusters having cluster tags based on attributes of the plurality of items of medical data and the data protocol. The clustered plurality of items of medical data is used for the purpose of post processing by a plurality of post-processing modules.

Owner:SIEMENS AG

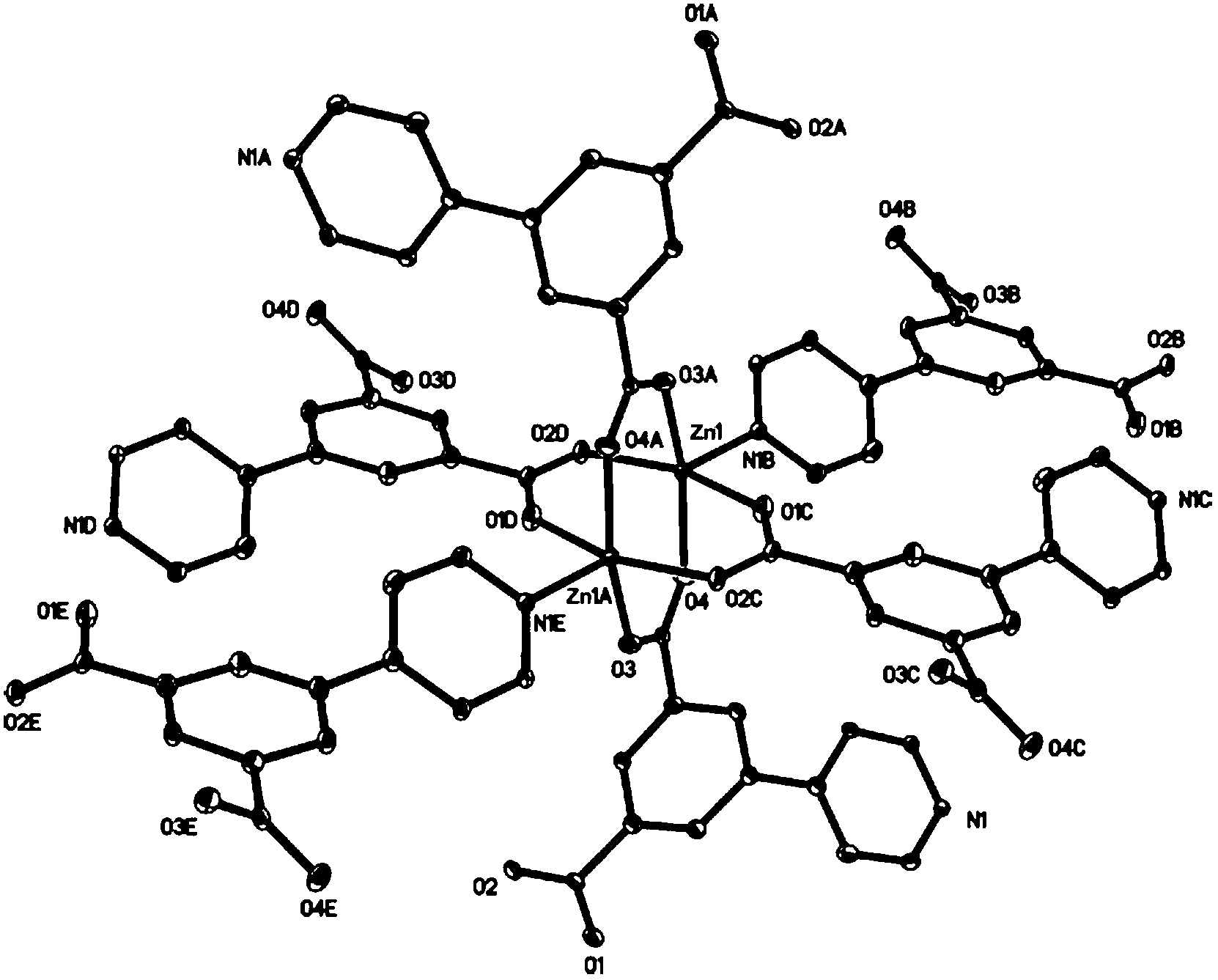

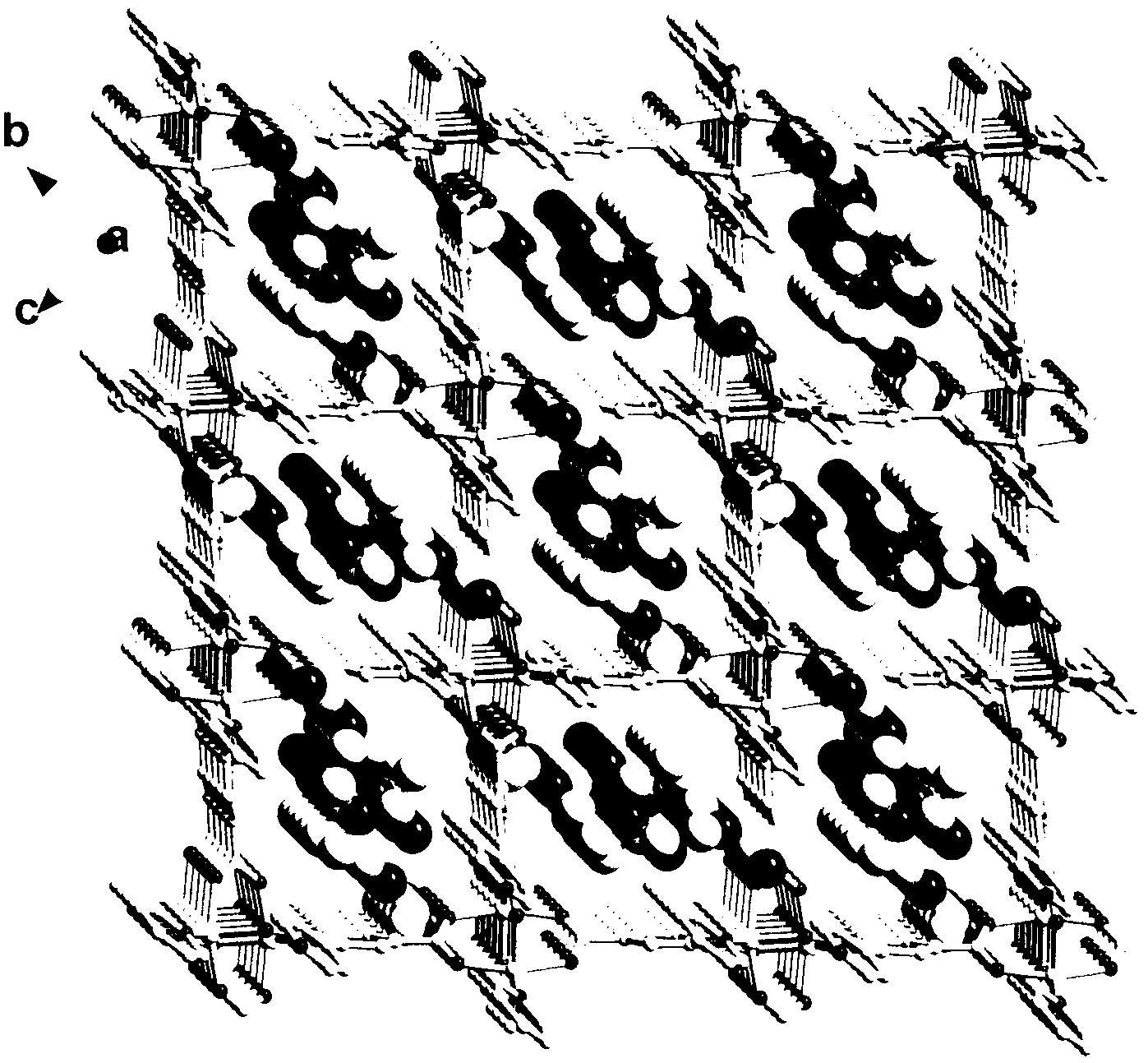

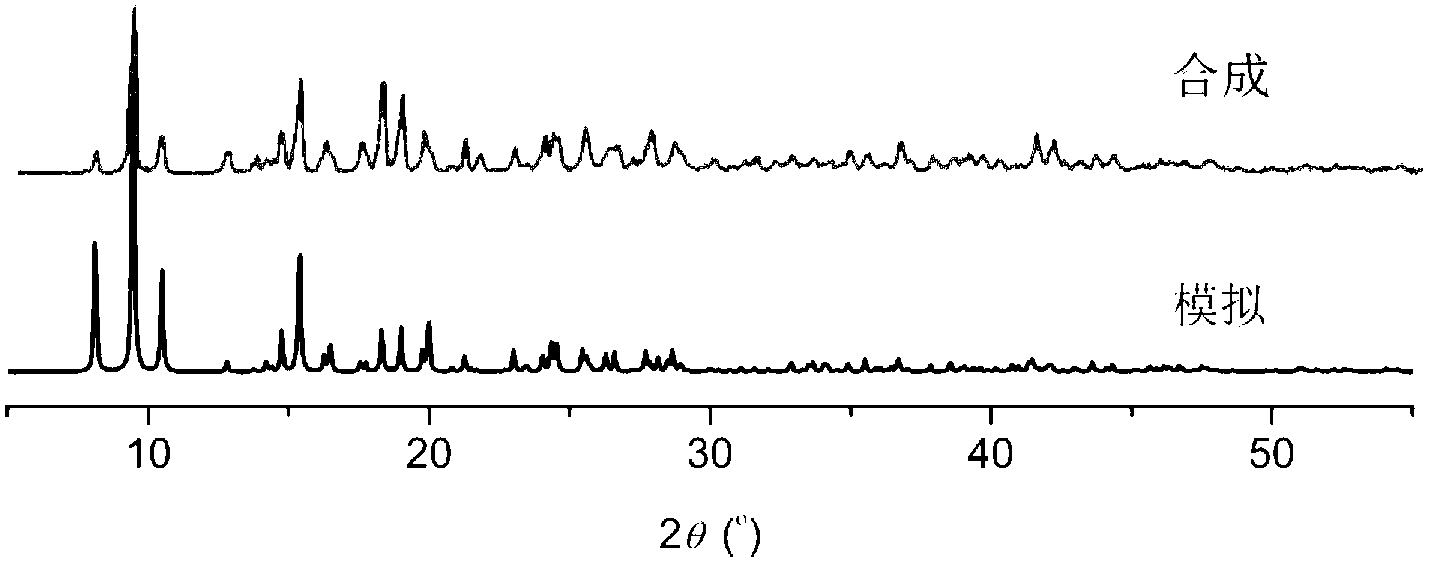

Luminous metal-organic framework material with chemical sensing function as well as preparation method and application thereof

InactiveCN103242352AHigh purityImprove stabilityChemiluminescene/bioluminescenceFluorescence/phosphorescenceOrganic solventMetal-organic framework

The invention relates to a luminous metal-organic framework material with a chemical sensing function, a preparation method of the luminous metal-organic framework material, and an application of the material in detection of nitrobenzene organic matters. The preparation method comprises the following steps of: dissolving 5-(4-pyridyl)-1, 3-phthalic acid and zinc salt into an organic solvent in a certain proportion; and then synthesizing in a solvothermal way so as to obtain the luminous metal-organic framework material. The preparation method is simple in preparation process, high in material purity and excellent in stability. The synthesized metal organic framework material has the maximum emission wavelength of 381nm in water, and the fluorescence intensity of the synthesized metal organic framework material is gradually reduced as the unceasing increase of the concentration of the nitrobenzene organic matters, therefore, the material can be well applied to the detection of the nitrobenzene organic matters, and has the advantages of being fast in speed, simple, convenient, great in selectivity, high in sensitivity, etc.

Owner:LIAOCHENG UNIV

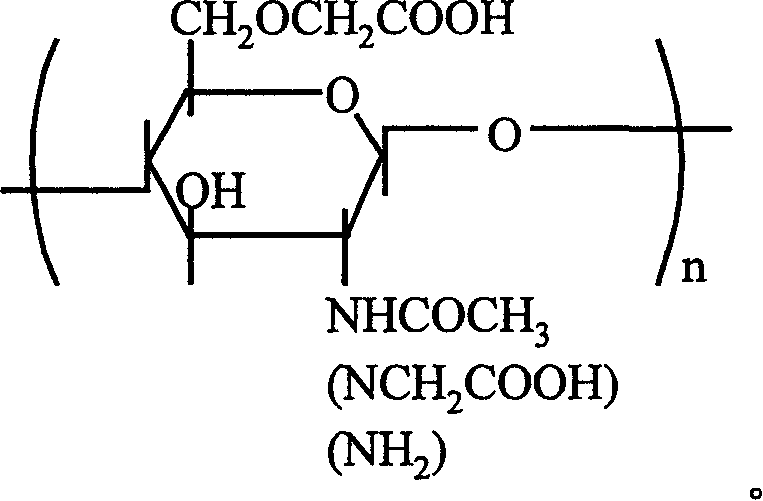

Carboxymerhyl chitosan sponge with water-absorbent dilatability and its preparation method and use thereof

The invention relates to a method for producing a water-absorbing swellable carboxymethyl chitosan sponge and its application, which comprises: adding a little chitosan powder or chitosan powder into the carboxymethyl chitosan solution with a quantitation of glycerin as the elasticizer, making every 100 ml solution with carboxymethyl chitosan of 1-5 g, chitosan powder or chitosan powder of 0.5-2 g and glycer of 1-5 g, stirring to foam and adding the environment-friendly ion-cross linker to cross-linking completely, cooling and drying to get the production. In the invention, using water-soluble materials as raw materials to avoid contamination, and using non-aldehyde group ion-cross linker to avoid residual toxicity of aldehyde group.

Owner:上海美宝生命科技有限公司

Thermosetting plastic

The invention discloses a thermosetting plastic. The thermosetting plastic is characterized by comprising the following components in parts by weight: 60-95 parts of thermosetting resin, 5-40 parts of low-shrink additive, 150-300 parts of an inorganic mineral filler, 2-4 parts of an initiator, 0.6-1 part of calcium hydroxide micro powder, 2-6 parts of zinc stearate micro powder and 30-60 parts of glass fiber. In comparison with a conventional thermosetting plastic, the thermosetting plastic can be solidified more rapidly, high strength can be maintained within a wide temperature range, and the flame-retardant effect is good.

Owner:宁波华缘复合新材料有限公司

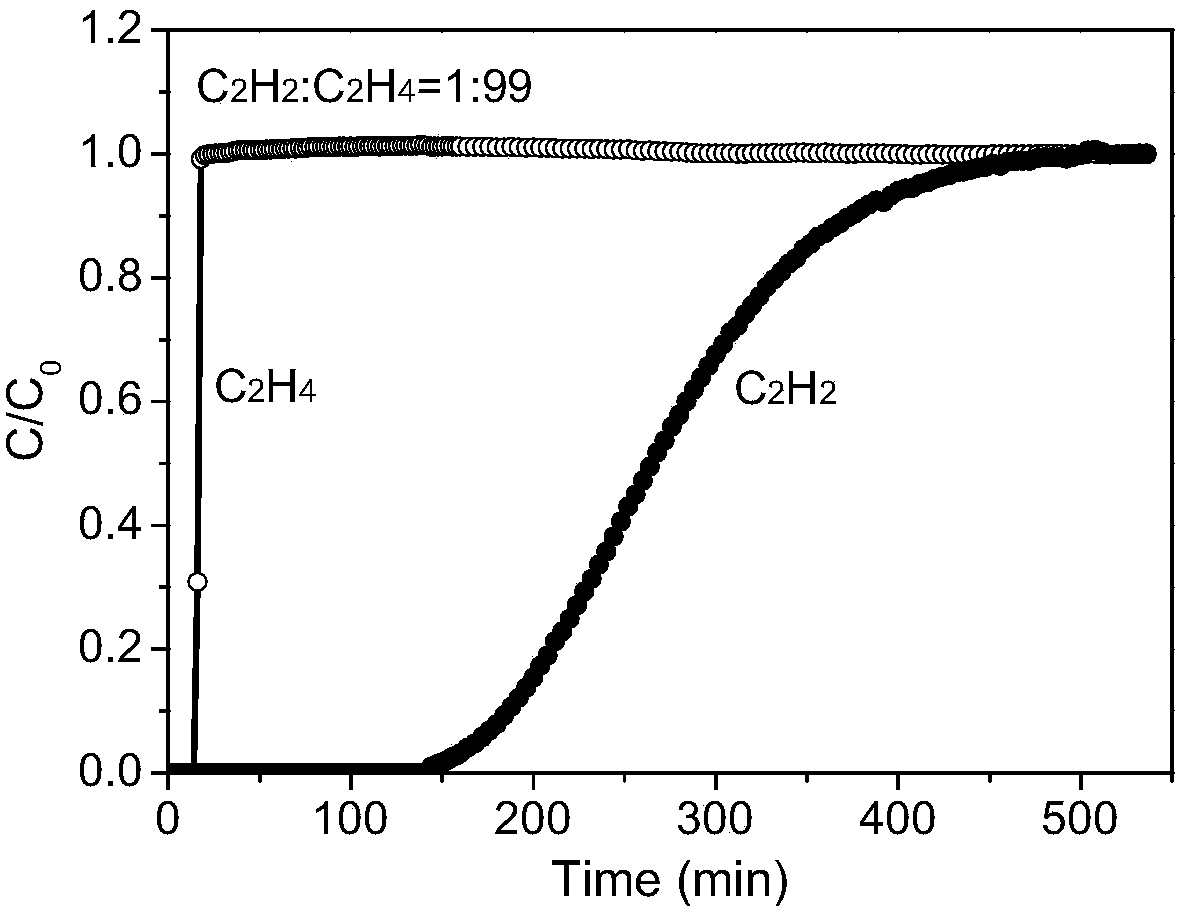

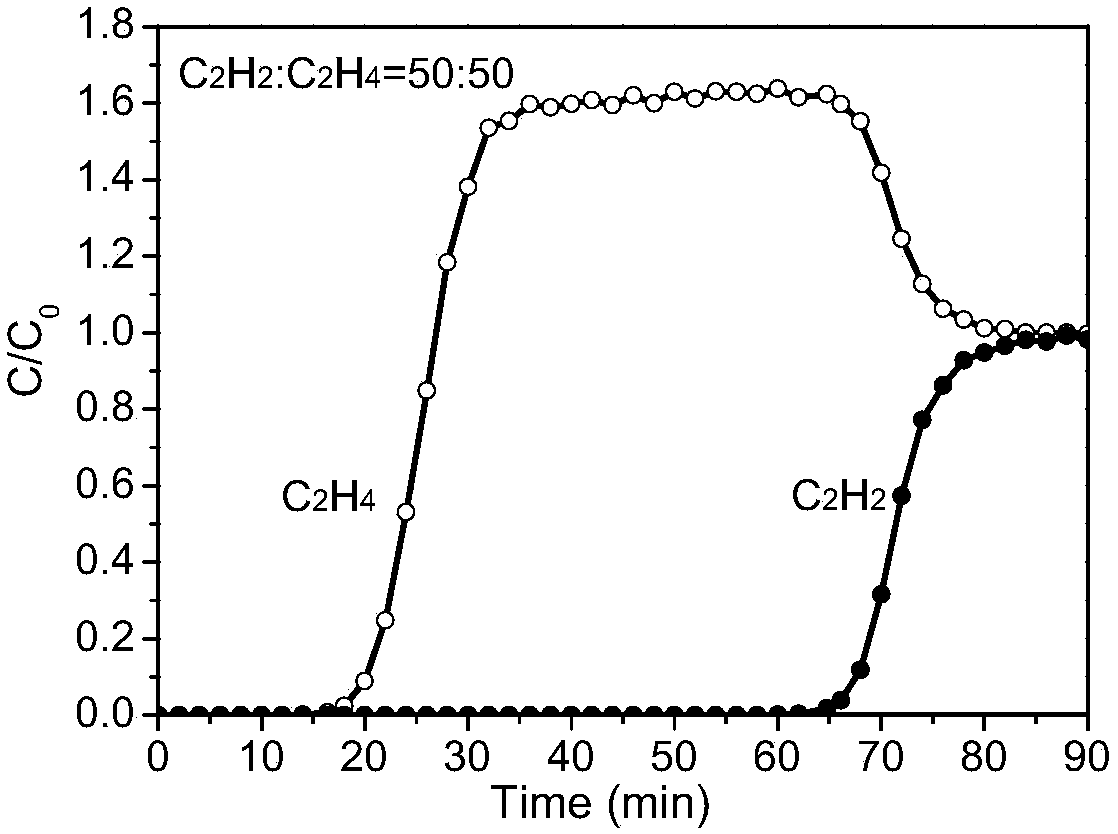

Method for separating ethylene and acetylene from mixed gas

ActiveCN108014751AEasy synthesis costLower synthesis costOther chemical processesAdsorption purification/separationAlkaline earth metalGallic acid ester

The invention discloses a method for separating ethylene and acetylene from a mixed gas. The method comprises the step of using a metal organic frame material as an adsorbent for separating the ethylene and the acetylene from the mixed gas containing the ethylene and the acetylene; the metal organic frame material has a structural formula of M(C7O5H4).2H2O, wherein M is a metal ion, and the metalorganic frame material is a three-dimensional network structure formed by coordination bonds or intermolecular forces from a transition metal ion or alkaline earth metal ion and gallic acid. The metalorganic frame material has a large adsorption capacity for the acetylene and an excellent selectivity for adsorption and separation of ethylene / acetylene. The materials for the synthesis of the material is cheap and easy to obtain, the material preparation process is simple, and the cost is low; and the material has good regeneration and repetition performance, can still maintain the original adsorption effect after vacuum or heating regeneration, and has broad industrial application prospects.

Owner:ZHEJIANG UNIV

Synthesis of polylactate in supercrilical fluid of CO2

InactiveCN1583819AWill not polluteAchieve separationBulk chemical productionReaction temperatureSolvent

A synthesis of polylactic acid in super-critical CO2 fluids iscarried out by: adjusting mono-lactide' concentration in a reaction kettle, catalyst and cosolving reagent and its concentration, adjusting reaction temperature, CO2 pressure, reaction time, CO2 purity etc. conditions, to obtain polylactic acid with different molecular weights, and extracting and removing the non-reacted monomers, catalysts and cosolving reagents etc. low molecular weight substances with super-critical CO2 after reaction. The polylactic acid is obtained without post treatment and direct post processing. This invention has advantages of without pollution for products and environment, saving post treatment works, only through depressing operation to realize separating for products and CO2 solvent. It meets demands of current green world environmental protection and saves resources.

Owner:DONGHUA UNIV

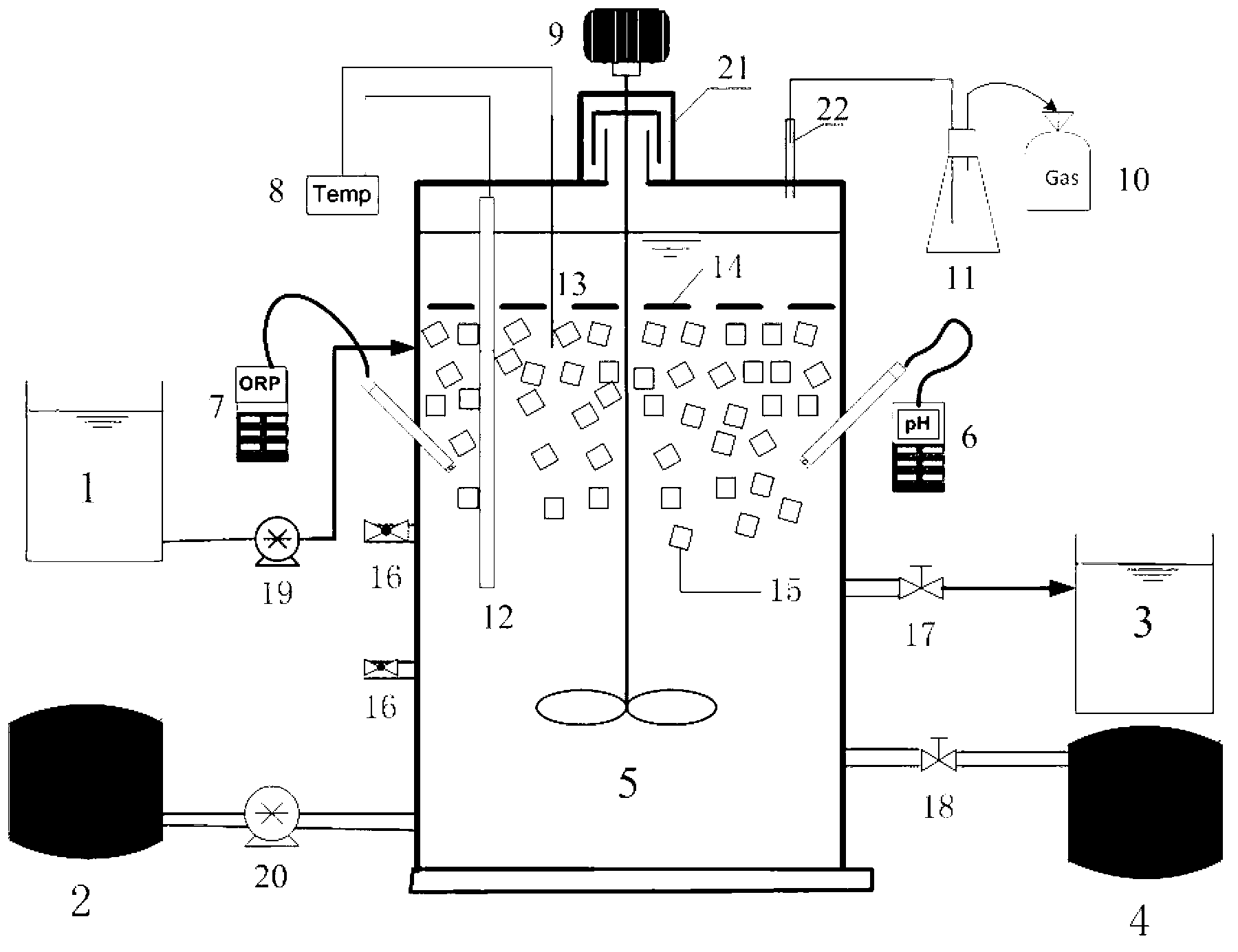

Method for treating high-content ammonia and nitrogen for shortcut nitrification to discharge effluent by coupling simultaneous denitrification of sludge fermentation with autotrophic nitrogen removal

ActiveCN103058374ALow costImprove dehydration effectTreatment with aerobic and anaerobic processesBiological sludge treatmentDenitrifying bacteriaTotal nitrogen

The invention discloses a method for treating high-content ammonia and nitrogen for shortcut nitrification to discharge effluent by coupling simultaneous denitrification of sludge fermentation with autotrophic nitrogen removal, belonging to the technical field of biochemical process sewage treatment. The high-efficiency removal of total nitrogen in wastewater and the reduction of sludge are realized in the same space by combined action of hydrolysis acidifying bacteria, denitrifying bacteria and anaerobic ammonium oxidation bacteria. The method is characterized in that part of NO2--N in effluent is reduced by short-chain fatty acid generated by hydrolytic acidification of residual sludge under the action of the denitrifying bacteria; and the other part of NO2--N and ammonia nitrogen released in the hydrolytic acidification process are removed by an anaerobic ammonia oxidation reaction, thereby greatly reducing the concentration of total nitrogen in the effluent and finishing the reduction of the residual sludge simultaneously. The technology is suitable for advanced treatment of high-content ammonia and nitrogen for shortcut nitrification to discharge the effluent.

Owner:TIANJIN HUANCHUANG TECH DEV CO LTD

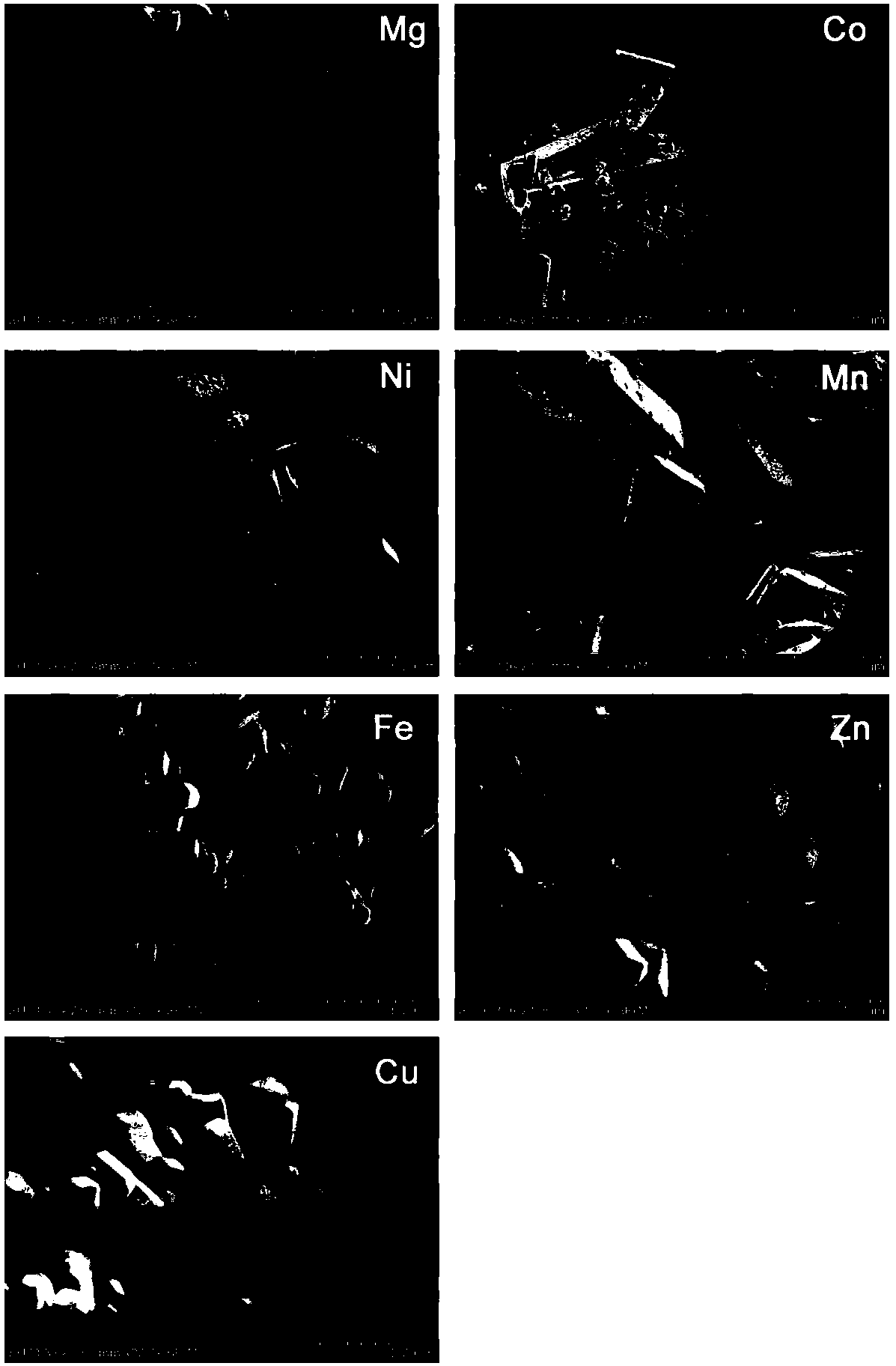

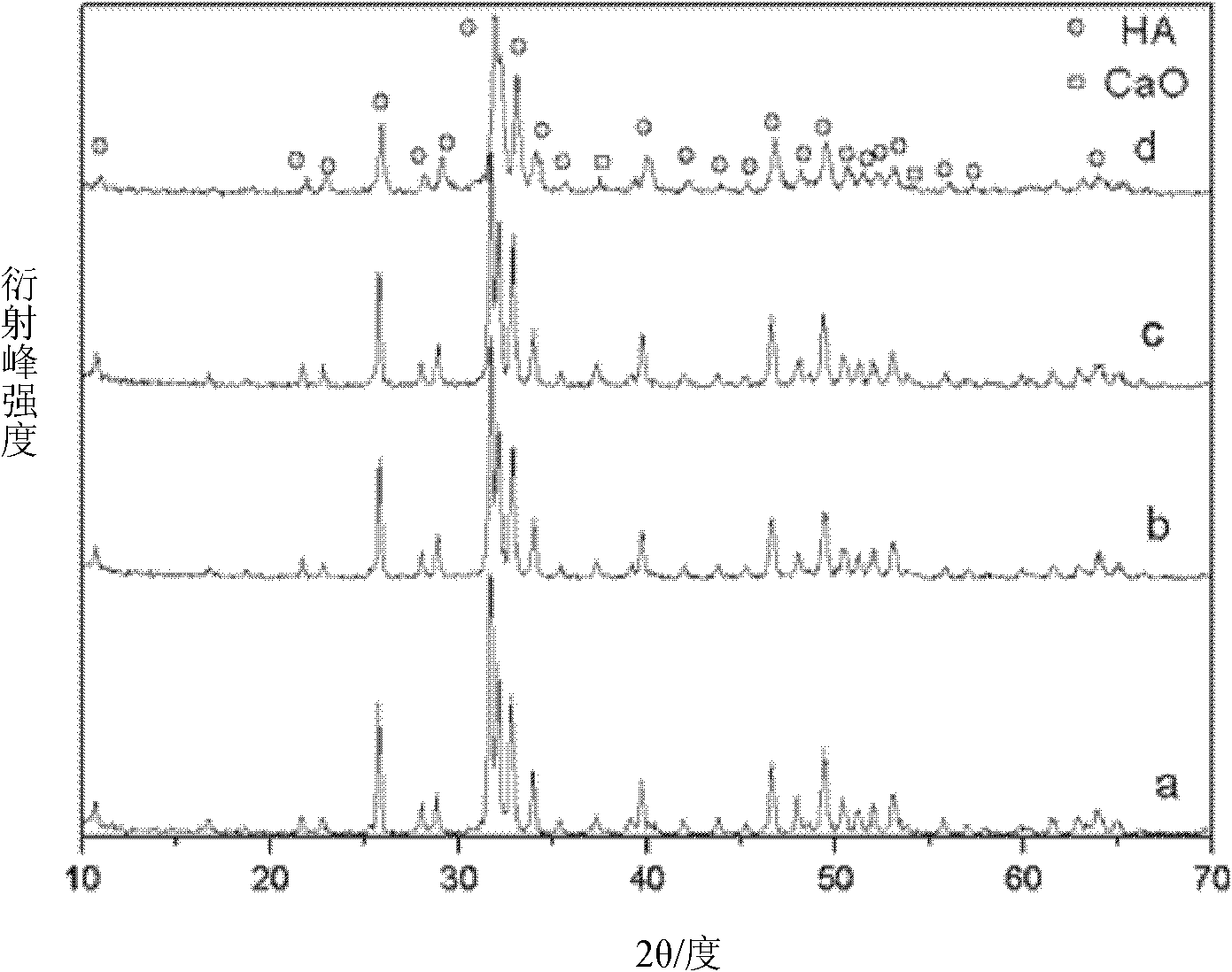

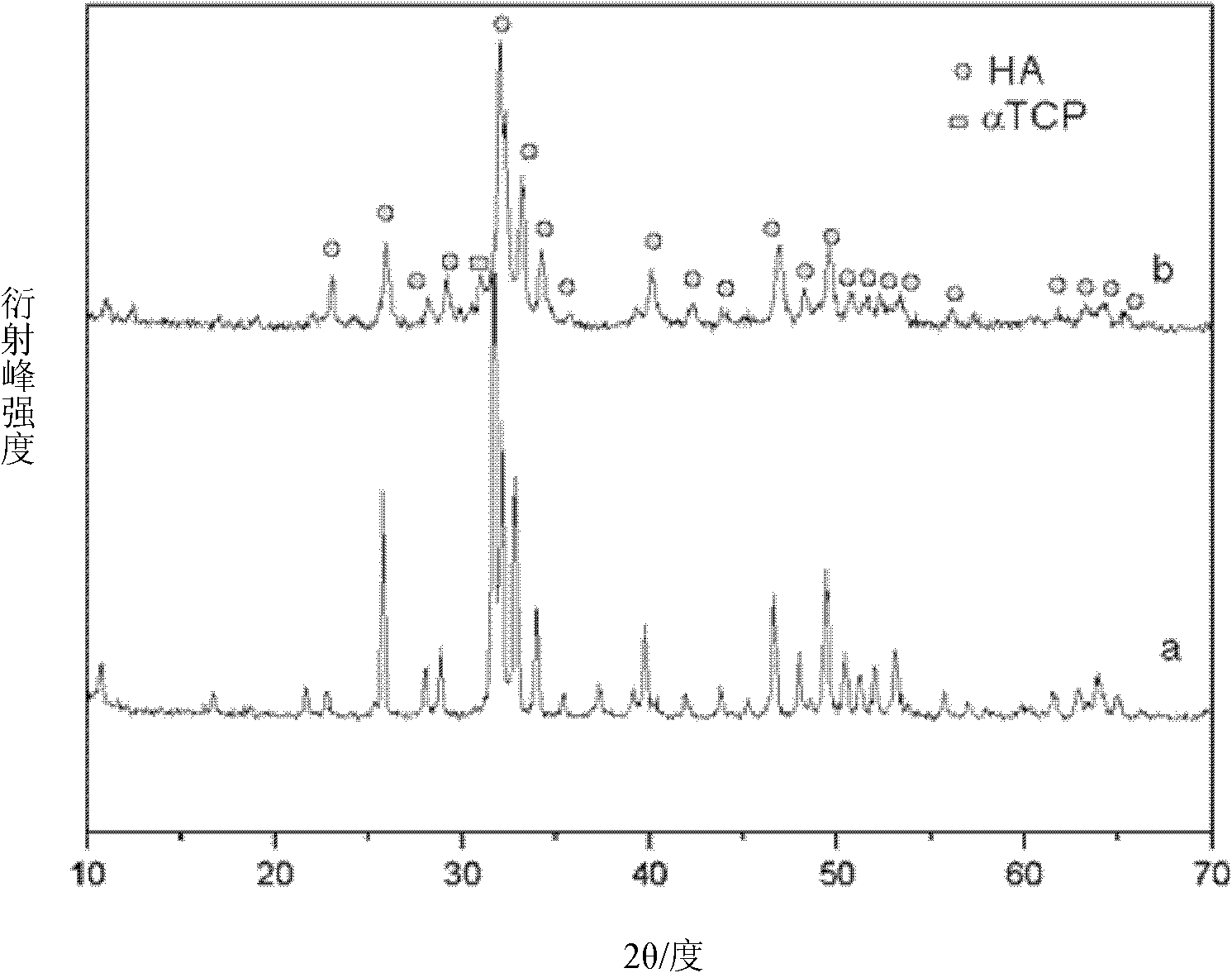

Preparation method of hydroxyapatite bioactive coating doped with trace elements

The invention belongs to the technical field of biomedical composite materials, in particular to a preparation method of a hydroxyapatite bioactive bionic coating containing trace elements. The method comprises the following steps of: firstly, reacting raw materials for preparing hydroxyapatite containing the trace elements according to the proportion at a certain temperature to obtain a suspension; and then transmitting the suspension as a precursor liquid to a high-temperature area of plasma flame and directly spraying the suspension on a biomedical metal substrate to form the hydroxyapatite coating containing the trace elements. The invention has simple process and low production cost; and the obtained hydroxyapatite coating contains the trace elements such as silicon, magnesium and the like closer to human bony bionic components and has better osteogenesis capability and important application value.

Owner:SICHUAN UNIV

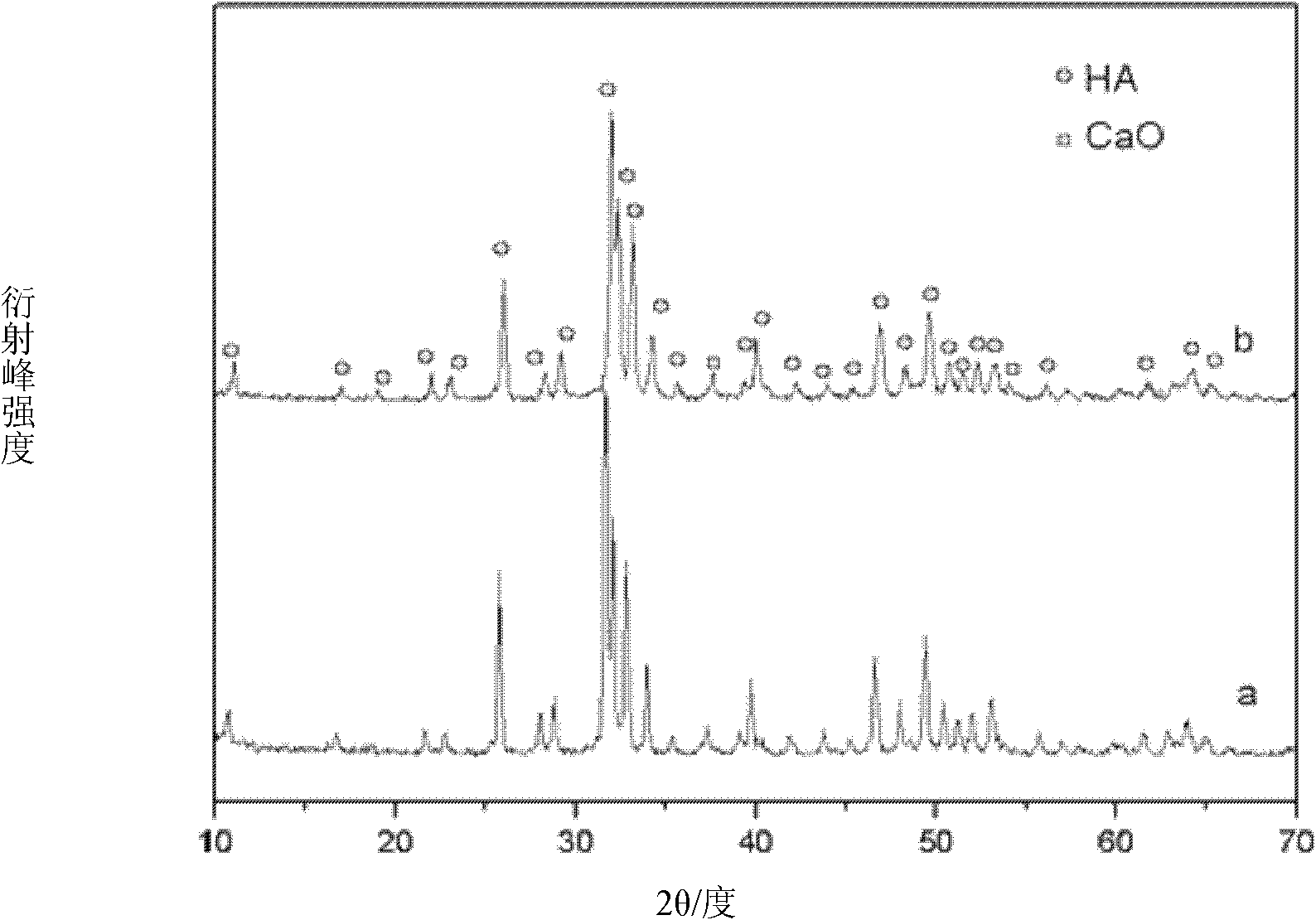

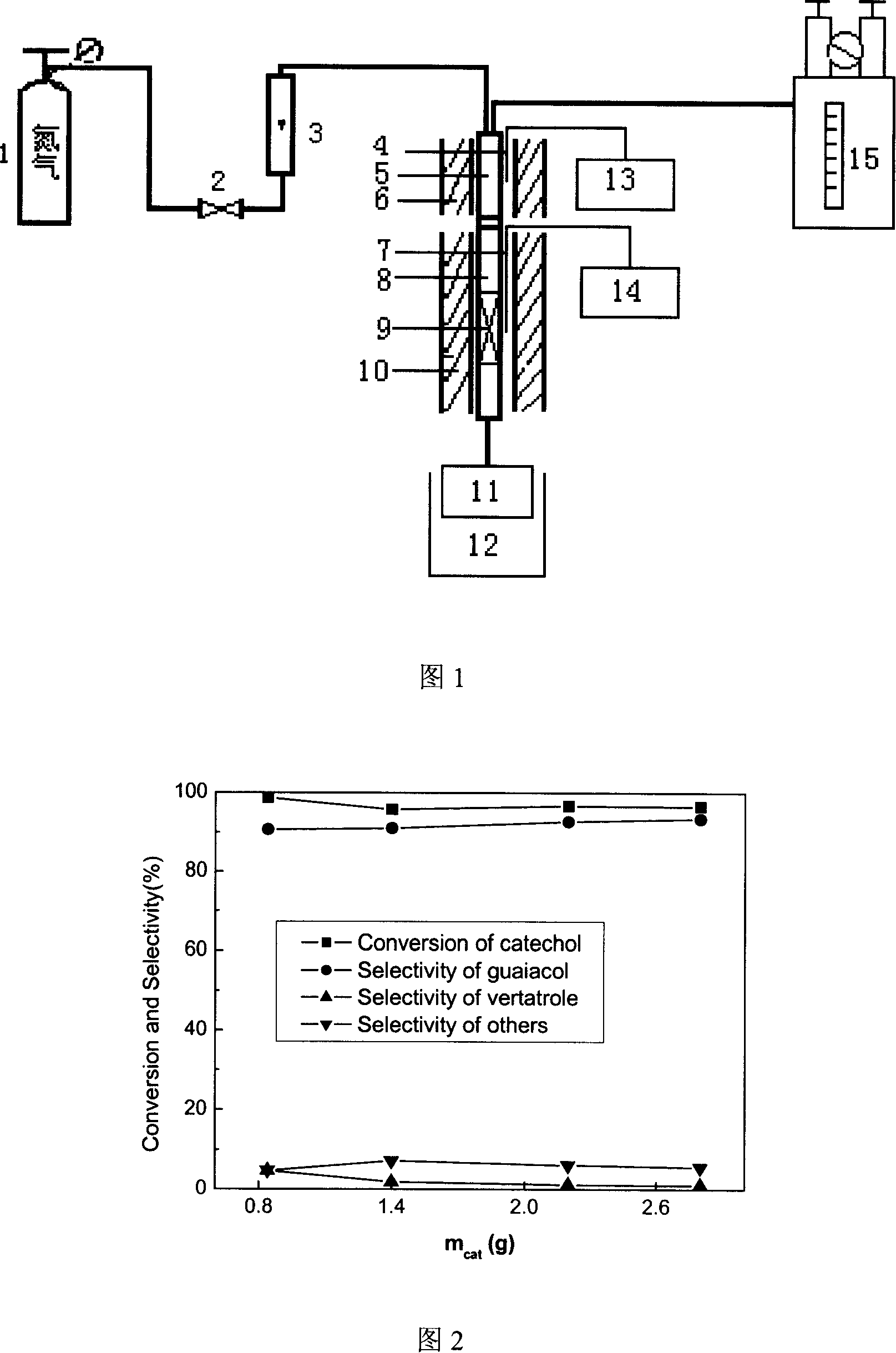

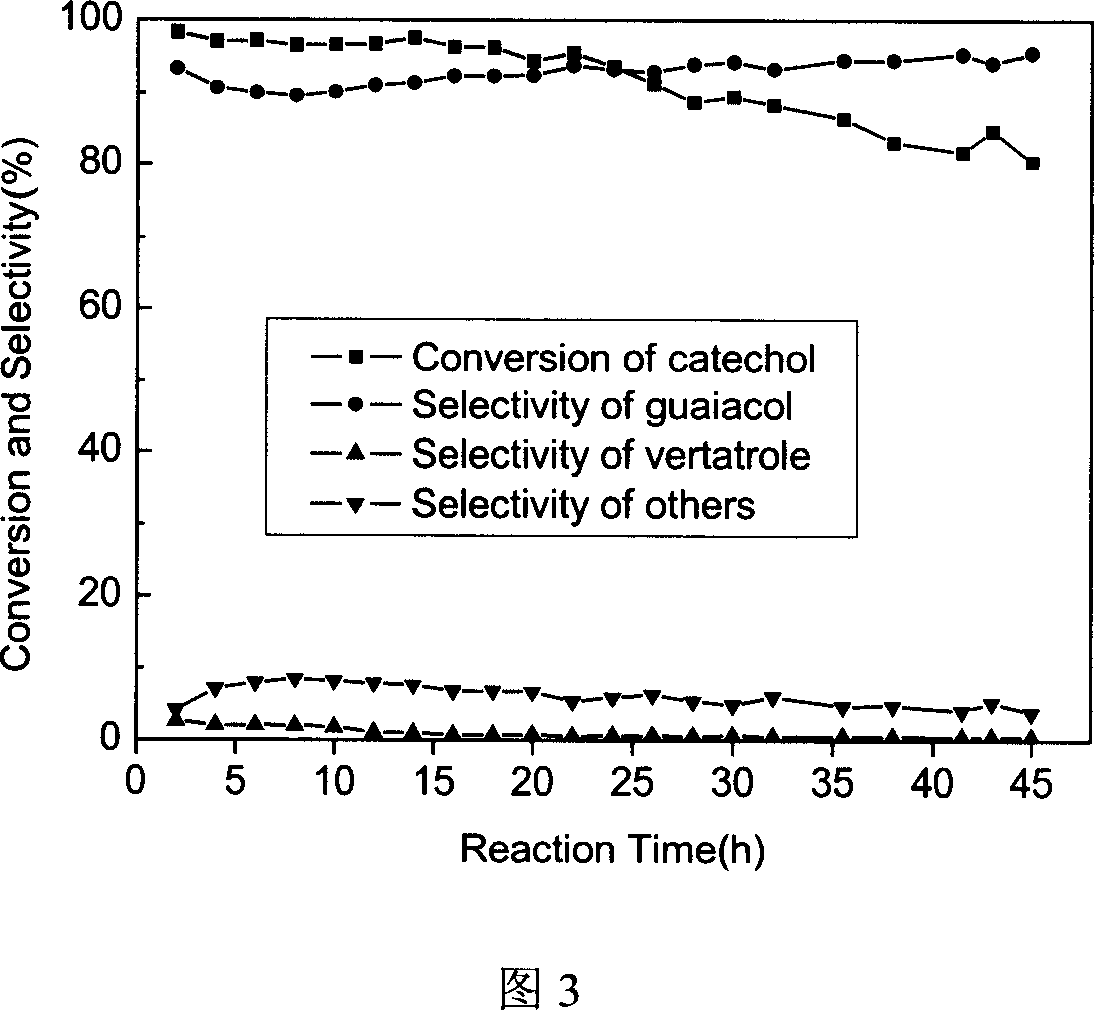

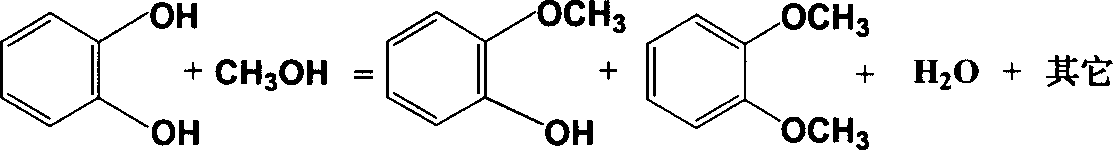

Method for synthesizing guaiacol

ActiveCN101081805AHigh activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsEther preparation by compound dehydrationReaction temperatureGuaiacol

The present invention is process of synthesizing guaiacol, and relates to the application of catalyst in catalytically synthesizing guaiacol through the solid phase alkylation reaction between catechol and methanol. The catalyst has active component of ammonium metatungstate, sodium tungstate, ammonium molybdenum, ammonium biphosphate, ammonium phosphate, ammonium chromate or silicotungstic acid; and carrier of active carbon, SiO2, ZnO, Al2O3, TiO2, BaCO3 or CaO; and active component supporting amount of 2.1-30.2 wt%. The process of synthesizing guaiacol has catalytic reaction temperature of 533-573 K, the molar ratio between catechol and methanol of 1 / 7-1 / 2.5, and catalyst amount of 0.84-2.8 weight portions. During the process, the mixed solution of catechol and methanol is fed to the pre-heater in the flow rate of 0.3-2ml / hr, gasified and reacted catalytically at the temperature of 533-573 K.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

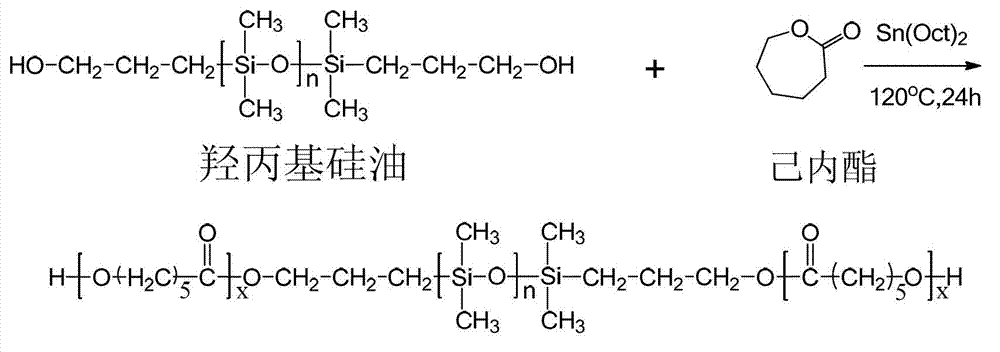

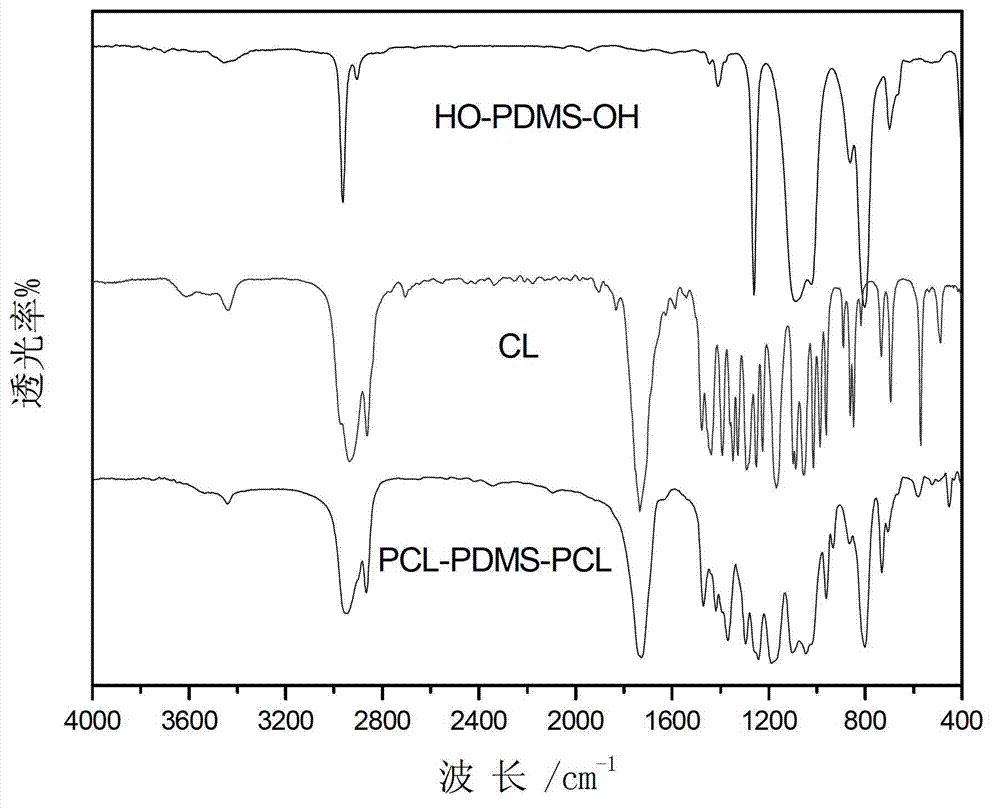

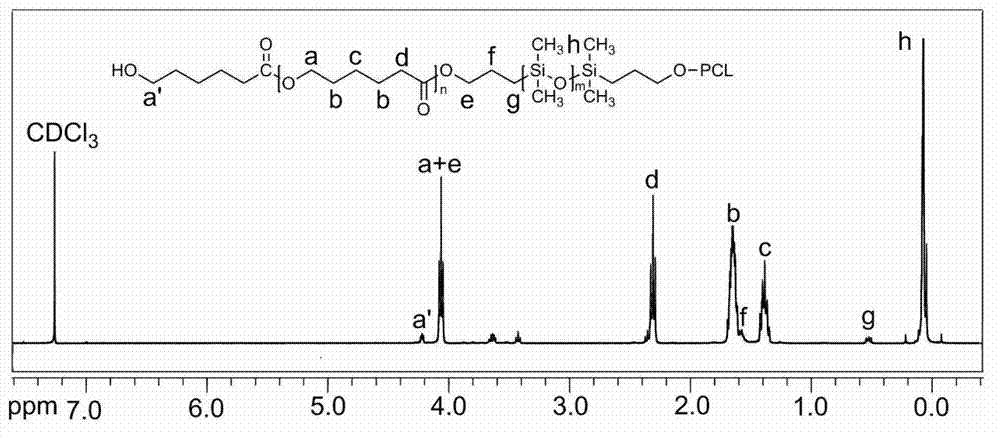

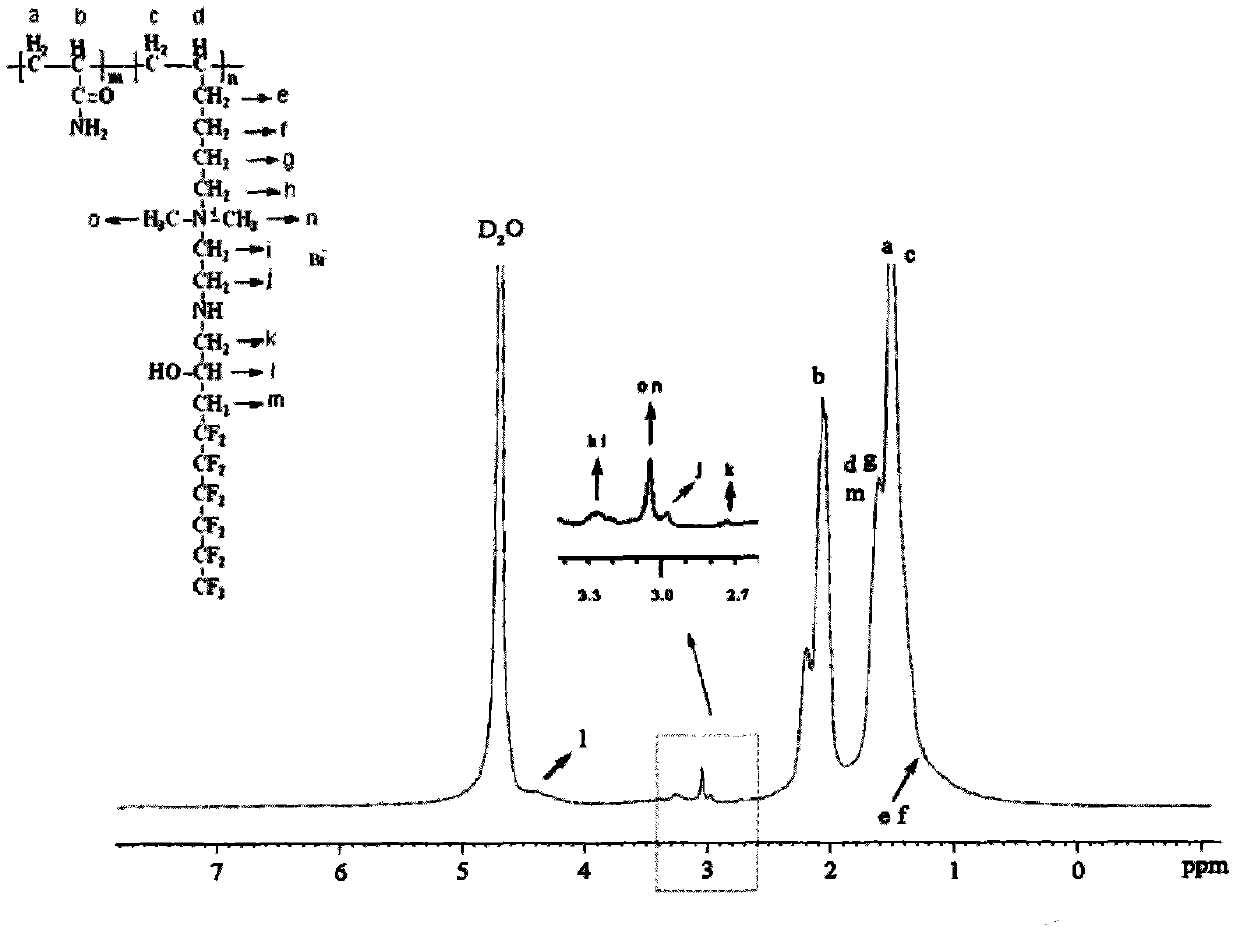

Supercritical carbon dioxide dispersion polymerization stabilizer as well as preparation method and using method thereof

InactiveCN103193963ALow costReduced post-processingBulk chemical productionPoly l lactic acidStabilizing Agents

The invention discloses a supercritical carbon dioxide dispersion polymerization stabilizer with a structure as polycaprolactone-b-polydimethylsiloxane-polycaprolactone. The stabilizer can be used for the synthesis of PLLA (Poly L Lactic Acid) at the reaction conditions of the reaction pressure of 19 MPA and the reaction temperature of 90 DEG C; the dosage of the stabilizer is 10%-3% of the weight of the polymerization reaction monomer; and the prepared product can be directly used for a drug sustained release system. The invention further discloses a method for preparing the stabilizer, wherein an ABA ternary segmented copolymer is prepared by using hydroxypropyl silicone oil and caprolactone as main materials through catalytic ring-opening of catalyst stannous octoate, wherein the weight ratio of the hydroxypropyl silicone oil to the caprolactone is (2:1) to (1:1). The stabilizer can be used for dispersion polymerization reaction of aliphatic polyesters including polyethyllactide, polycaprolactone and the like in a supercritical carbon dioxide. The preparation method is simple in process and environment-friendly, wherein the carbon dioxide can be recycled, so that the cost is low and the application prospect is good.

Owner:DALIAN UNIVERSITY

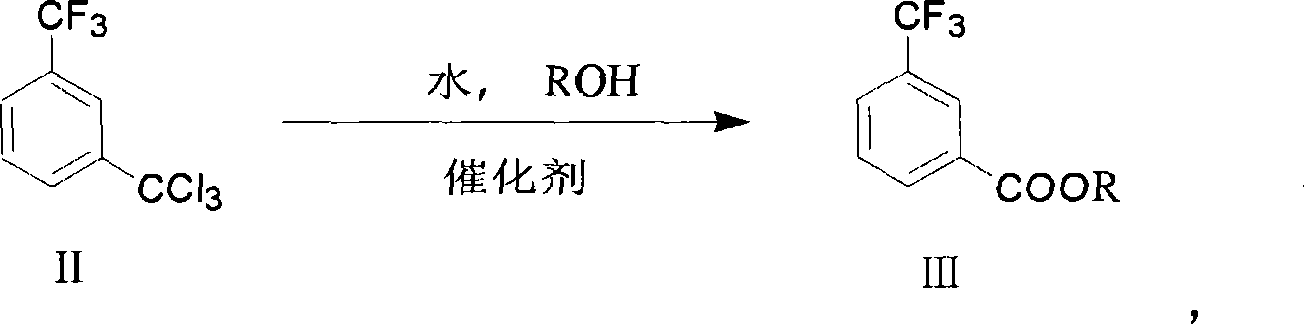

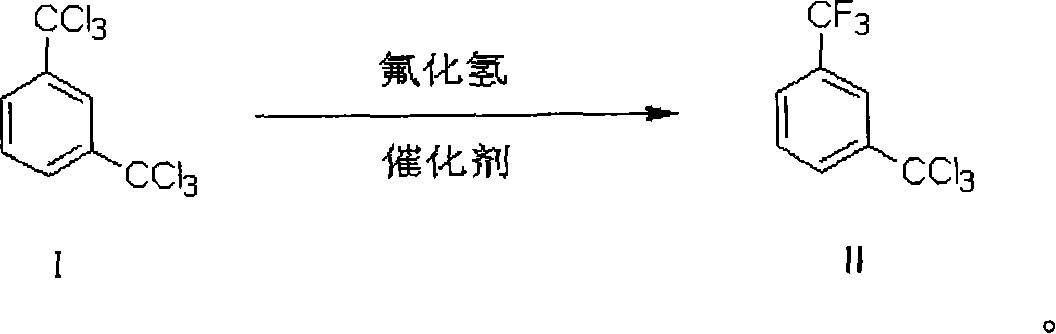

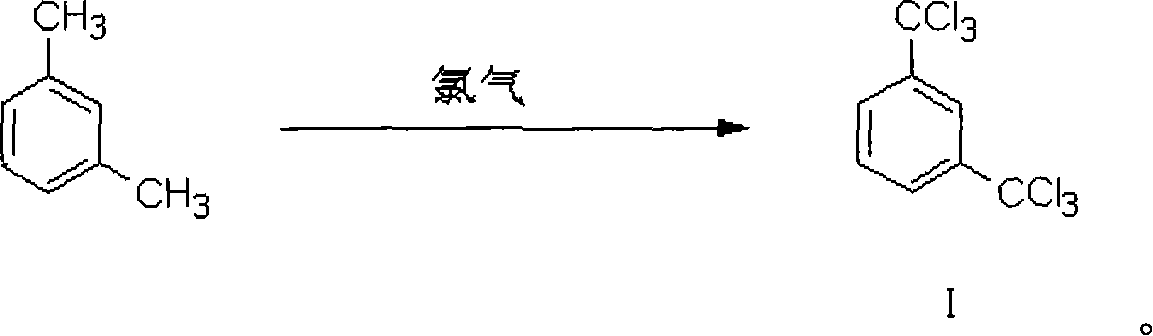

Prepn process of 3-trifluoro methyl benzoate

InactiveCN101066926AHigh purityQuality improvementOrganic compound preparationCarboxylic acid esters preparationSolventTrifluoromethyl

The preparation process of 3-trifluoromethyl benzoate includes the following steps: adding water into m-trichloromethyl trifloromethyl benzene for hydrolysis in the presence of zinc-containing catalyst, and the subsequent adding hydroxyl compound ROH for esterification to produce 3-trifluoromethyl benzoate, where R is alkyl radical, aryl radical, alkaryl radical or aralkyl radical. The m-trichloromethyl trifloromethyl benzene is prepared through the fluoridation of meta-bis(trichloro methylbenzene) and hydrogen fluoride in the presence of catalyst; and meta-bis(trichloro methylbenzene) is prepared through the reaction of metaxylene and chlorine in meta-bis(trichloro methylbenzene) solvent under the action of initiator or photoinitiator.

Owner:SHANGHAI CHEMSPEC CORP

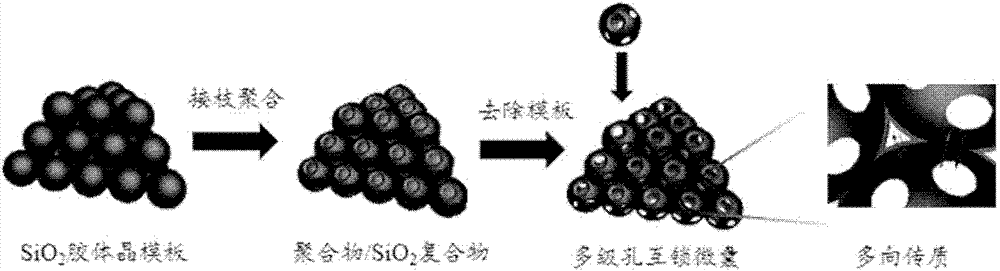

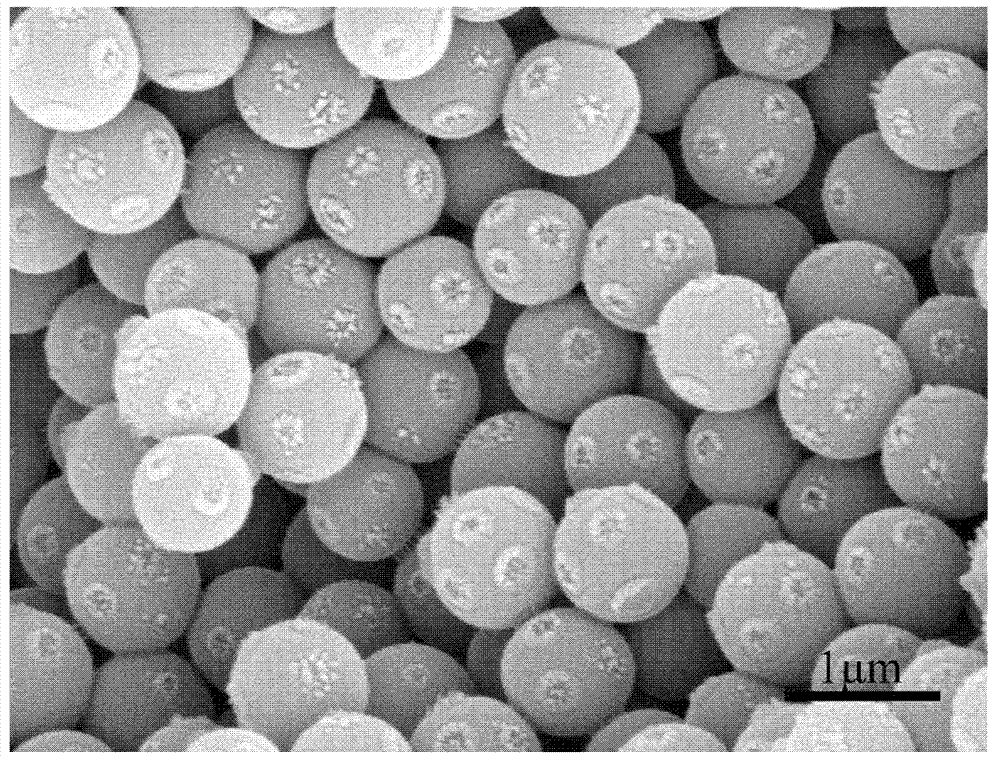

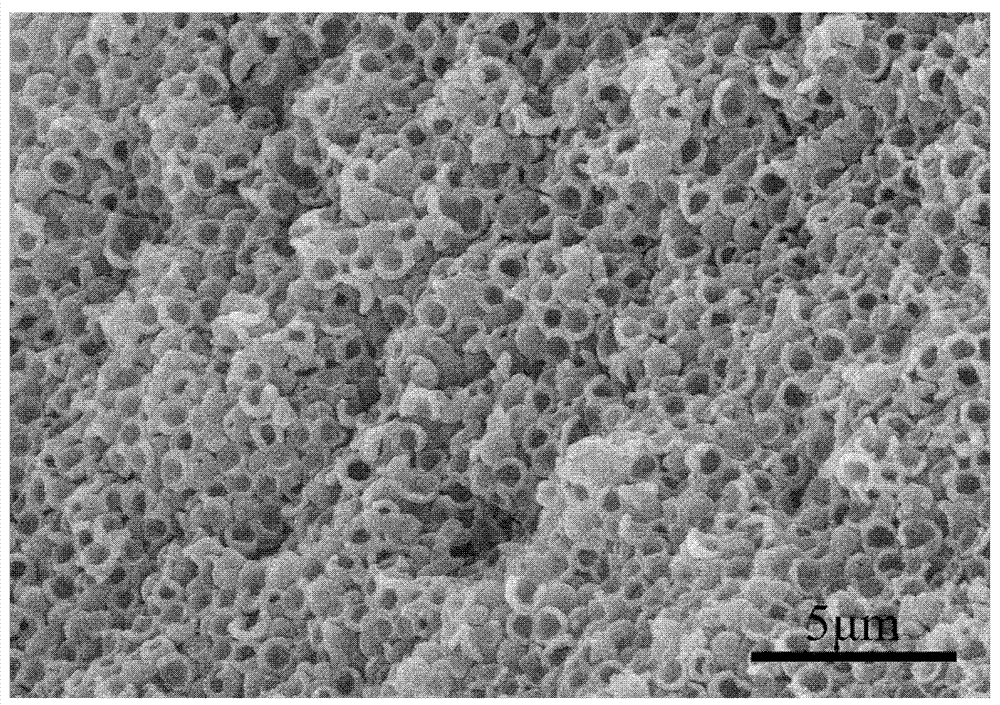

Preparation method for polymer-based hierarchical porous structure interlocking microcapsule

ActiveCN103933911ALarge specific surface areaGood application effectMicroballoon preparationMicrocapsule preparationDouble bondRadical polymerization

The invention discloses a preparation method for a polymer-based hierarchical porous structure interlocking microcapsule. The method comprises the steps of modifying a silicon dioxide colloid crystal template, controllably grafting a polymer by a surface triggering atom transferring free radical polymerization method and a double-bond free radical polymerization method, crosslinking a linear polymer chain section by an Friedel-Crafts crosslinking method for an external crosslinking agent, removing the silicon dioxide colloid crystal template to prepare the polymer-based hierarchical porous structure interlocking microcapsule. Due to the controllably grafted polymer layer, a certain slit is reserved between every two adjacent microcapsules, so that the mass is reduced, and more mass transfer ways are formed; by the adoption of the Friedel-Crafts crosslinking method for the external crosslinking agent, micropores and mesoporous are formed by crosslinking capsule walls made of polymer materials; the apertures of the formed holes and the crosslinking degree are adjusted according to the type of the crosslinking agent; a foundation is laid for the application; communicating windows formed among the micropores, the mesoporous and the interlocking microcapsules in the capsule walls and the slits between the microcapsules adopt classified hole interlocking structures in the mass.

Owner:HEBEI UNIV OF TECH

Method for recovering nickel in chemical nickel-plating ageing liquid

ActiveCN102212842AImprove wettabilityConvenient and quick escapePhotography auxillary processesThioureaPolyethylene glycol

The invention discloses a method for recovering nickel in a chemical nickel-plating ageing liquid, and the method comprises the following steps: (1) adding 1100-1300 parts by weight of the chemical nickel-plating ageing liquid into an electrolytic cell, and regulating the pH value of the ageing liquid to 8-10 by use of solid sodium hydroxide; (2) dissolving 0.01-0.03 part by weight of polyethylene glycol, 0.01-0.02 part by weight of 2-mercapto benzimidazole, 0.03-0.06 part by weight of thiourea, 0.005-0.03 part by weight of hide glue and 0.3-0.5 part by weight of sodium hypophosphite into 40-70 parts by weight of water, adding the mixture into the electrolytic cell, and adding 1-3 parts by weight of 5mol / L hydrochloric acid solution; (3) at normal temperature, on the basis of taking a stainless steel plate as a cathode and a reticular plate plated with iridium oxide titanium alloy as an anode, reacting for 8-10 hours at constant reaction current of 0.6-1.0A, thus obtaining a recoveredmetal nickel on the cathode. The method has the advantages of high recovery rate, simple equipment, low cost and the like, works at normal temperature and is easy to realize.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

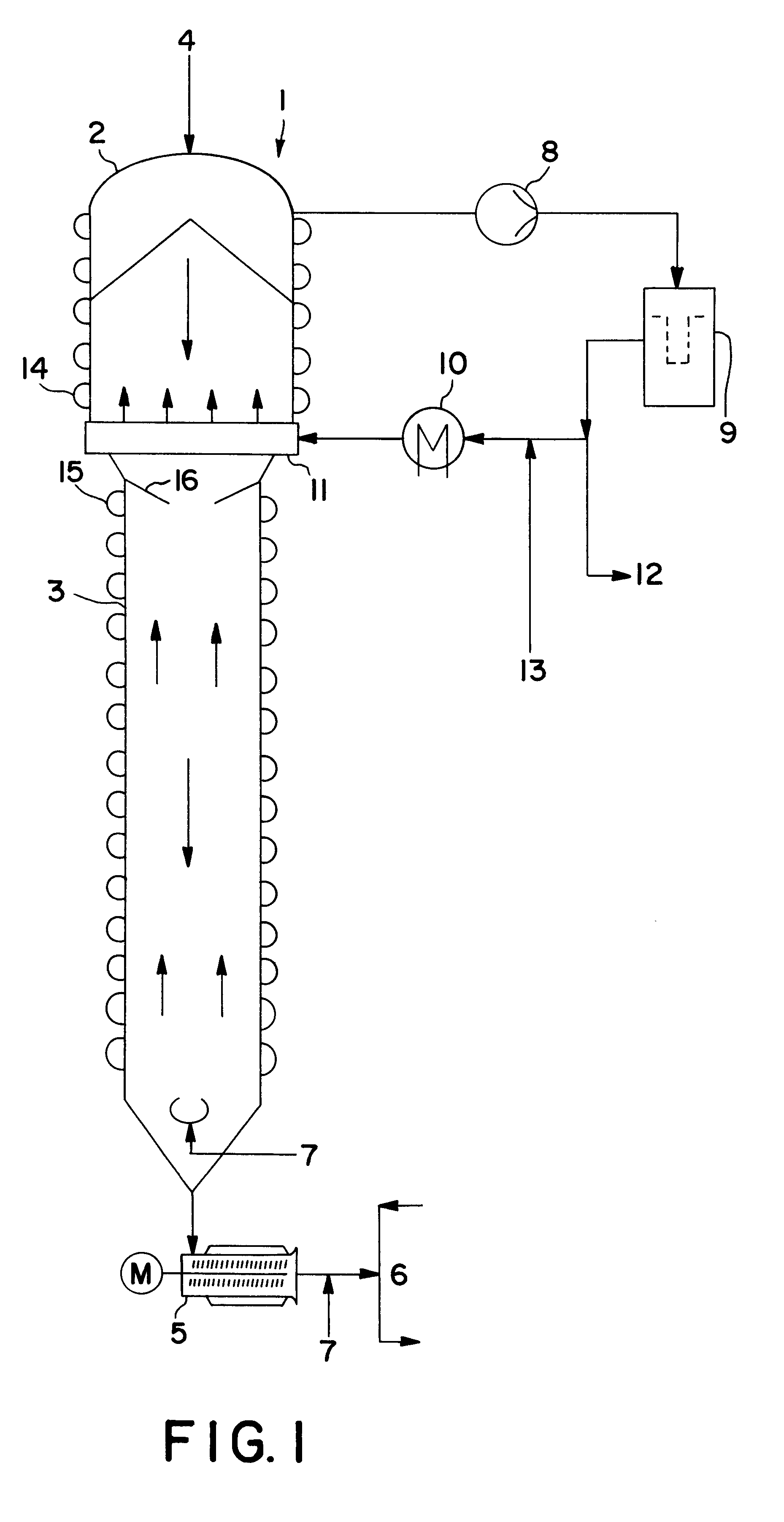

Continuous polyamide extraction process

A process for continuous extraction of polyamide particles in an essentially vertical extraction column using an aqueous extractant comprises using an extraction column that is divided into two zones and performing an extraction with a recirculating 15-40% strength by weight aqueous epsi-caprolactam solution in the first zone and then with countercurrent water at a from 5 to 40° C. lower temperature in the second zone. The process provides for economical extraction of polyamides with a low level of monomers and oligomers.

Owner:BASF AG

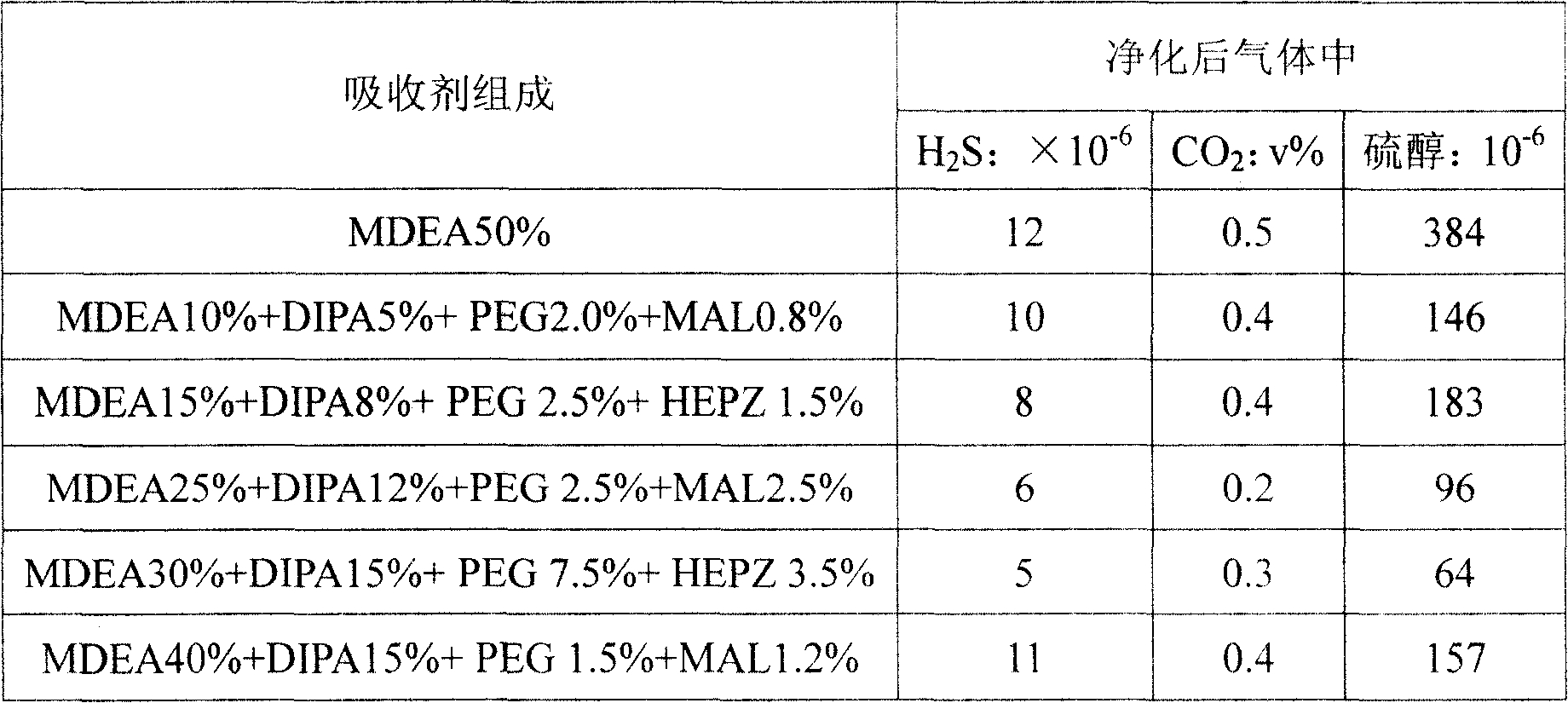

Absorbent removing thiol from acidic airflow and method therefor

The invention relates to the field of gas purification technology and provides an absorbent and a method for adding the adequate activating agent as absorbent into the compound amine solution. The absorbent and method can get rid of almost all H2S and most of mercaptan. The compound amine consists of MDEA and DIPA, and the activating agent consists of PEG400 and HEPZ or MAL. The invention reduces post treatment process, is economical and has high efficiency.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

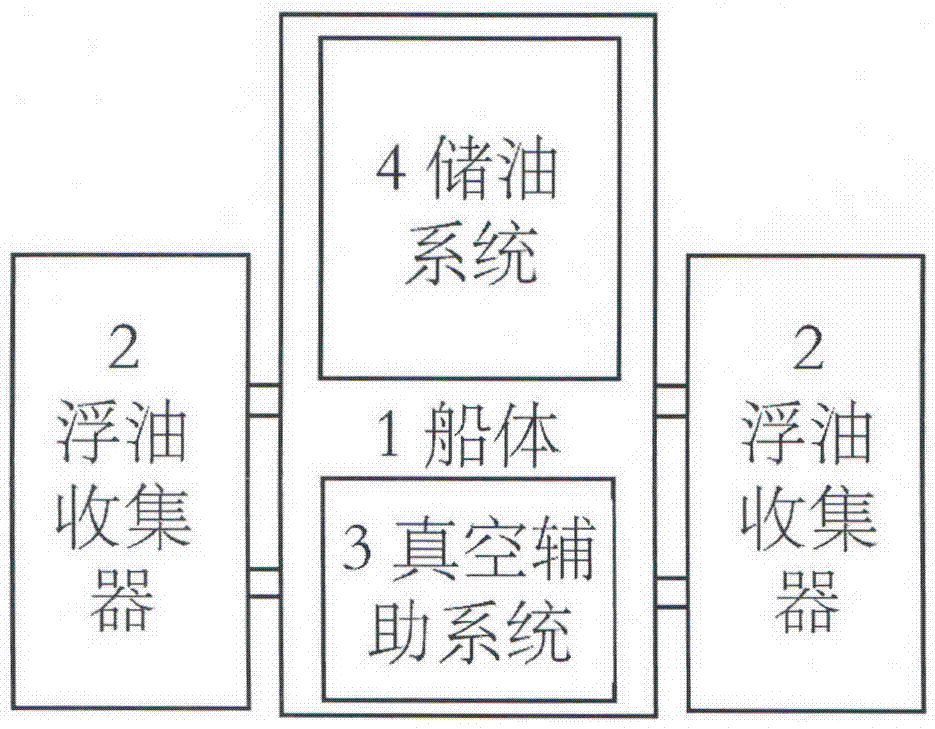

Oil slick collection method

InactiveCN105442514AContinuous collectionEfficient collectionWater cleaningGeneral water supply conservationOrganic chemical solventRemote control

The invention relates to the fields of oil and water separation and environmental pollutant treatment, in particular to an oil slick collection method. According to the method, a ship body, oil slick collectors, an auxiliary vacuum system and an oil storage system are involved; oil slick can be recycled continuously and efficiently through an oil-water separation material and the auxiliary vacuum system, and meanwhile in combination with the maneuvering flexibility due to remote control over a water surface ship, a guarantee is provided for the health and safety of operators. The oil slick collectors involved in the method can be used in water areas of rivers, lakes, the ocean and the like and has wide application prospects in the fields of organic chemical solution diffusion prevention, crude oil and petrochemical product leakage treatment and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI +2

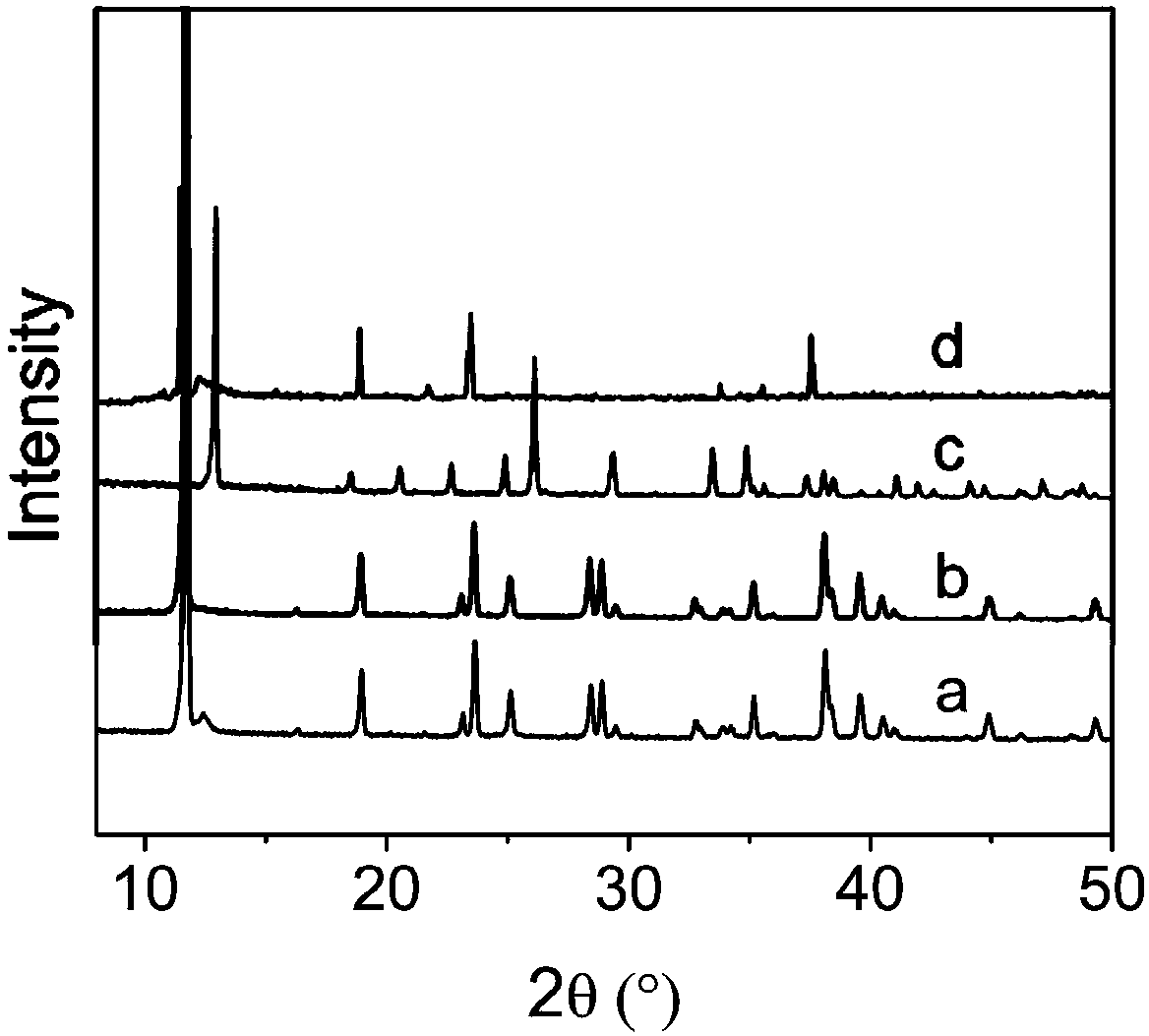

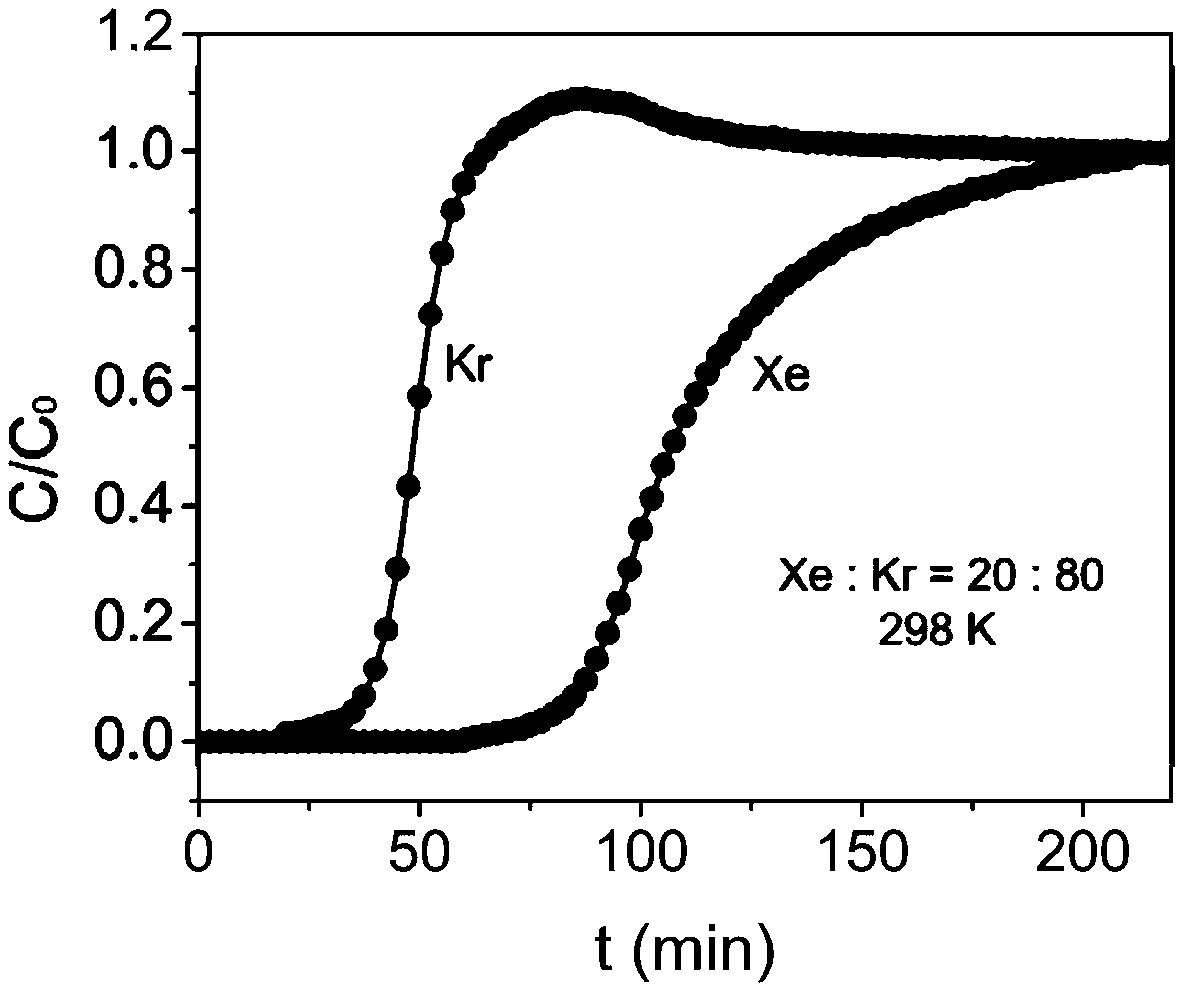

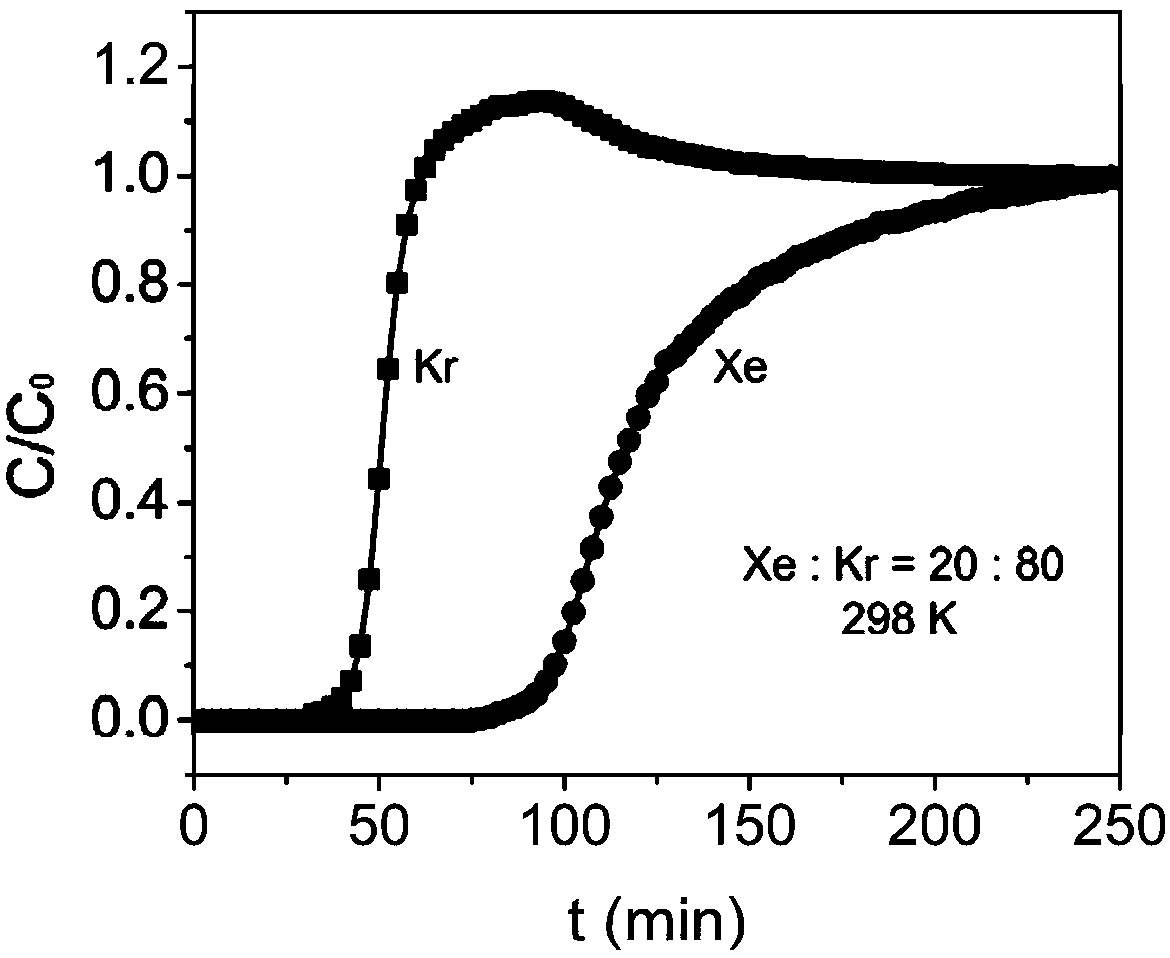

Metal-organic framework material for separating xenon and krypton and method for separating xenon and krypton

ActiveCN108727607ALower synthesis costStable structureOther chemical processesDispersed particle separationKryptonAlkaline earth metal

The invention discloses a metal-organic framework material for separating xenon and krypton and a method for separating xenon and krypton. The metal-organic framework material is good in stability andhigh in adsorptive separation selectivity, the preparation method is simple, and the preparation cost is low. The general structural formula of the metal-organic framework material is [M(C4O4(OH)2).3H2O or [M(C4O4)].2.5H2O, wherein M is metal ions, and transition metal ions or alkaline earth metal ions and squaric acid form a 3D network structure through coordinate bonds or intermolecular actingforce. A preparation method comprises the steps as follows: (1) inorganic salt, squaric acid, alkali and deionized water are mixed in proportion, and the obtained mixture is put in a reactor for a hydrothermal reaction after being stirred to be dissolved, wherein the inorganic salt comprises chlorate, nitrate, acetate, carbonate, sulfate or perchlorate of metal ions; (2) after the hydrothermal reaction, a product is washed with deionized water multiple times, vacuum drying is performed, and the metal-organic framework material is obtained. The metal-organic framework material is used as an adsorbent to perform adsorptive separation on mixed gas containing xenon and krypton.

Owner:ZHEJIANG UNIV

3D printing process method of high-strength aluminum-magnesium alloy

ActiveCN111872386ALow costImprove qualityAdditive manufacturing apparatusTransportation and packaging3D modelingMaterials science

The invention relates to a 3D printing process method of a high-strength aluminum-magnesium alloy, and belongs to the technical field of 3D printing. Firstly, high-strength aluminum-magnesium alloy raw materials are mixed evenly through heating and melting; then high-quality aluminum-magnesium alloy powder is prepared from the high-strength aluminum-magnesium alloy in a molten state through a gasatomization technology, and aluminum-magnesium alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is carried out according to 3D model data of parts in printing equipment with inert gas introduced, and a 3D printing product with the high-strength aluminum-magnesium alloy as a raw material is obtained. Compared with the prior art, as for the product printed through the process method, the relative density can reach 99% or above, the Vickers hardness can reach 110 HV or above, the tensile strength can reach 430 MPa or above, the elongation can reach 21%, through proper heat treatment, the Vickers hardness of a sample can reach 150 HV or above, the tensile strength can be further increased to 520 MPa or above, and the elongation is maintained at 17% or above.

Owner:TONGJI UNIV

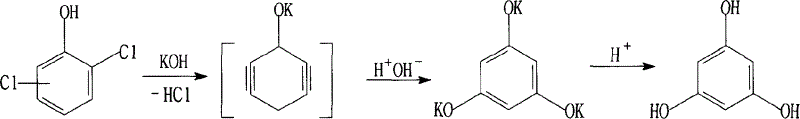

Improved preparation technology of phloroglucinol

InactiveCN1785948AReduce dosageLow costOrganic chemistryOrganic compound preparationBoiling pointPotassium hydroxide

The present invention relates to an improved preparation method for synthesizing phloroglucin. Said invention uses 2.4-dichlorophenol or 2.6-dichlorophenol as original raw material, and utilizes potassium hydroxide and inert solvent with high boiling point to make reaction of first-elimination after-addition to prepare phloroglucin by means of one-step process. Its yield is 56.6%-65.2%.

Owner:NAN JING RHINE PHARM TECH

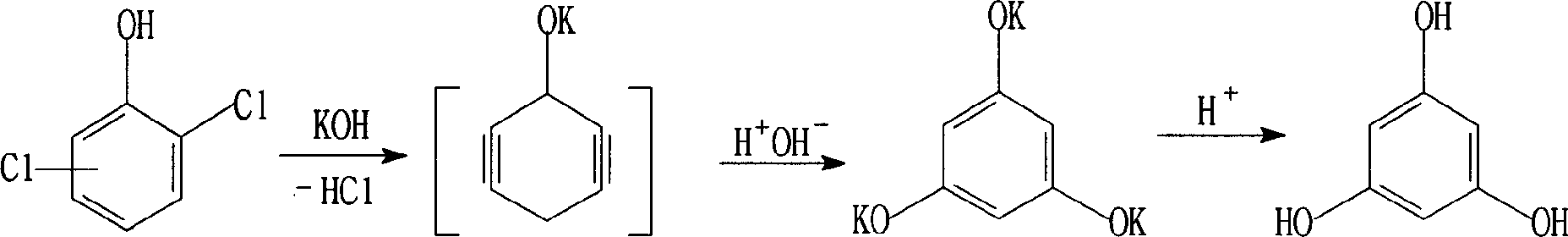

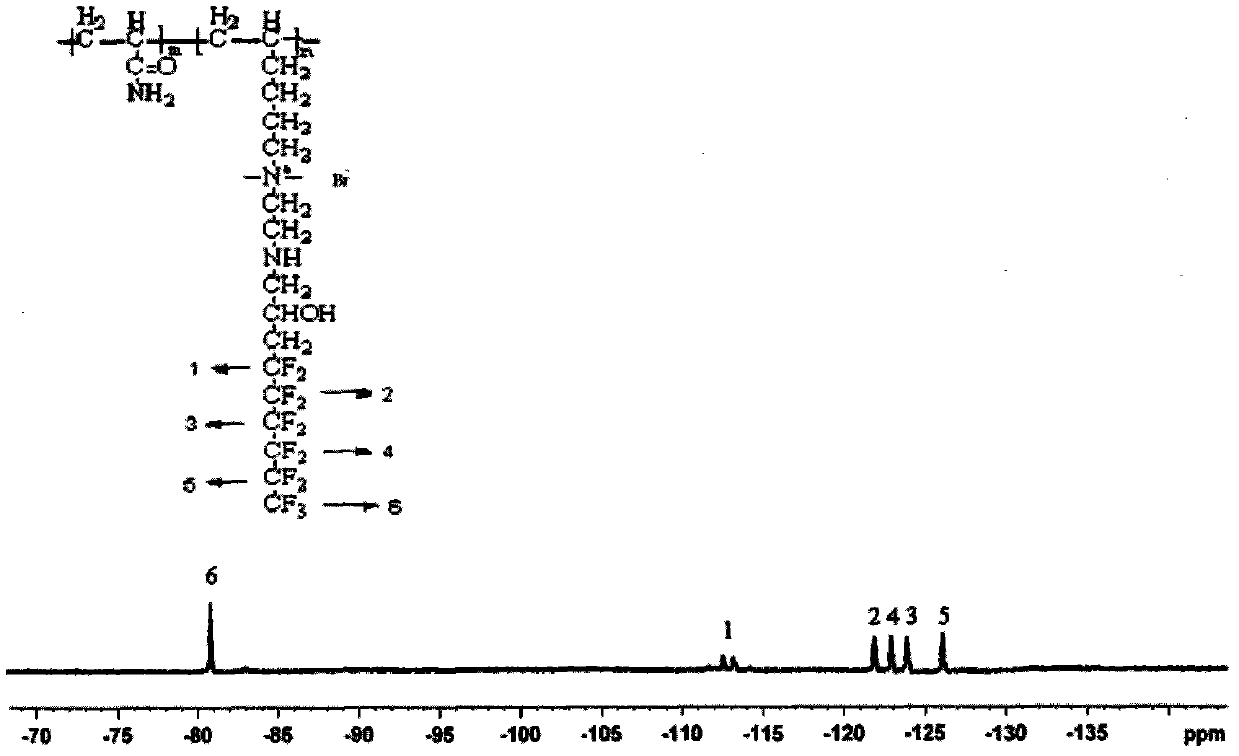

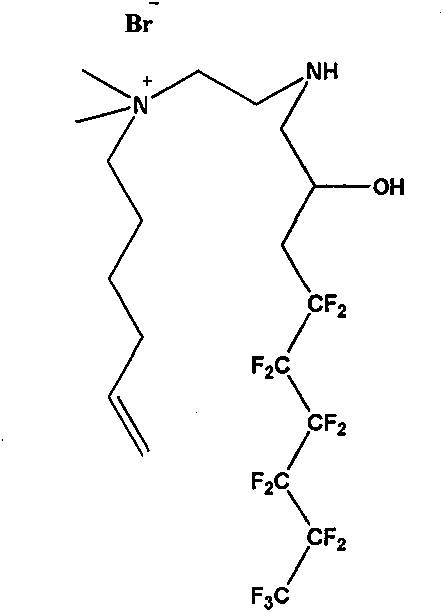

Method for preparing fluorocarbon-modified polyacrylamide by using soap-free emulsion method

The invention discloses a method for preparing fluorocarbon-modified cationic polyacrylamide by a soap-free emulsion polymerization method and belongs to the technical field of water-soluble polymer synthesis. The method comprises the following steps of: adopting a free radical polymerization method, taking pure water as a solvent, and taking potassium persulphate (KPS) as an initiator; dispersing a novel fluorocarbon / hydrocarbon mixed cationic surface active monomer with surface activity in the system in the form of a micelle; copolymerizing the novel fluorocarbon / hydrocarbon mixed cationic surface active monomer with acrylamide (AM) in the absence of an emulsifier and in the presence of a single solvent, namely pure water, thus successfully synthesising a perfluorocarbon-modified amphoteric hydrophobic associated polymer with temperature-resistant, viscosity-increasing and anti-shearing performances; and carrying out simple treatments to obtain the powder product. The prepared fluorocarbon-modified hydrophobic associated polymer can be widely applied to the fields of oilfield development, coating, fire-fighting, printing, electroplating, daily-use chemical industry, medicine, and the like.

Owner:山东大学(威海)

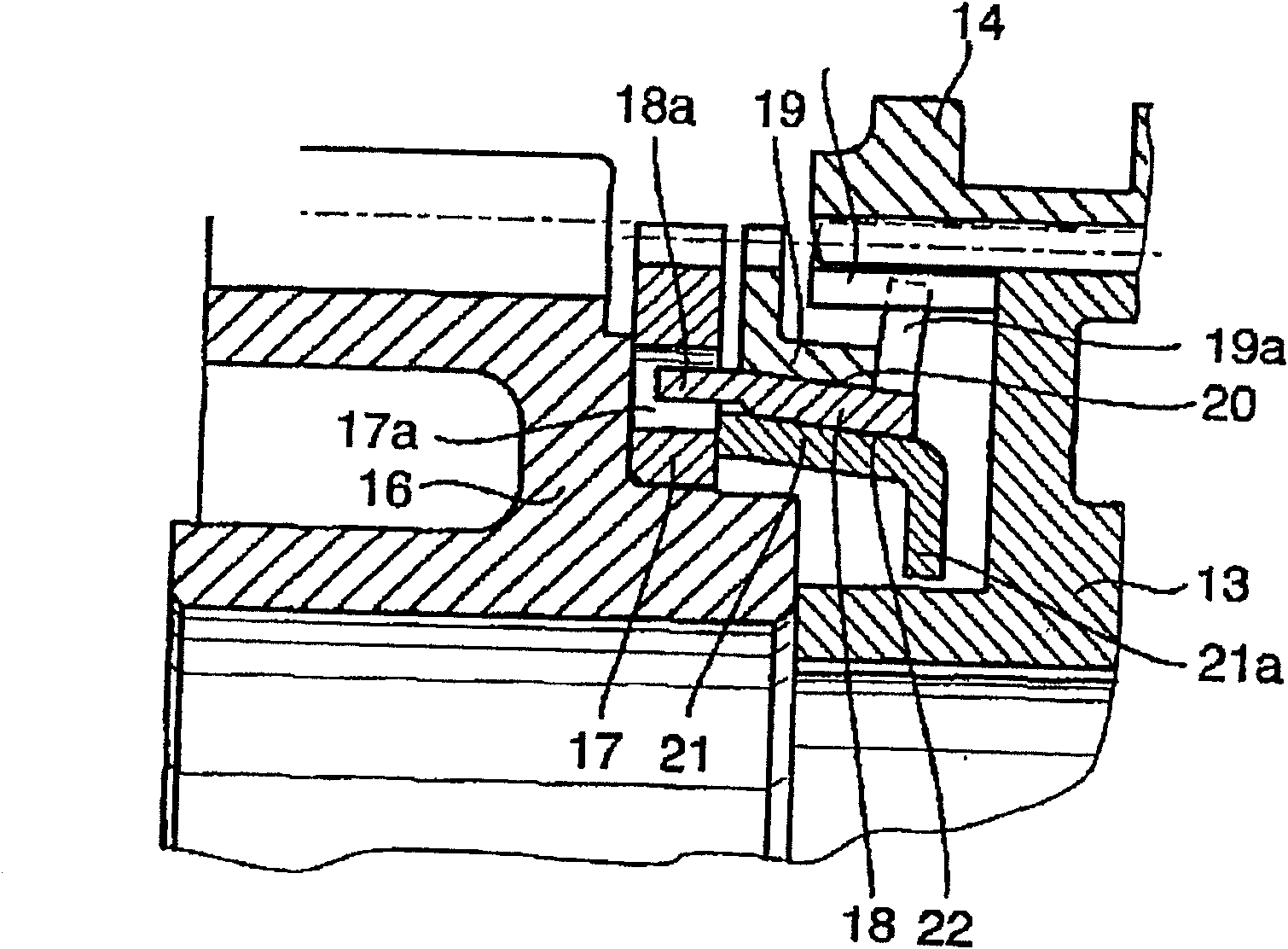

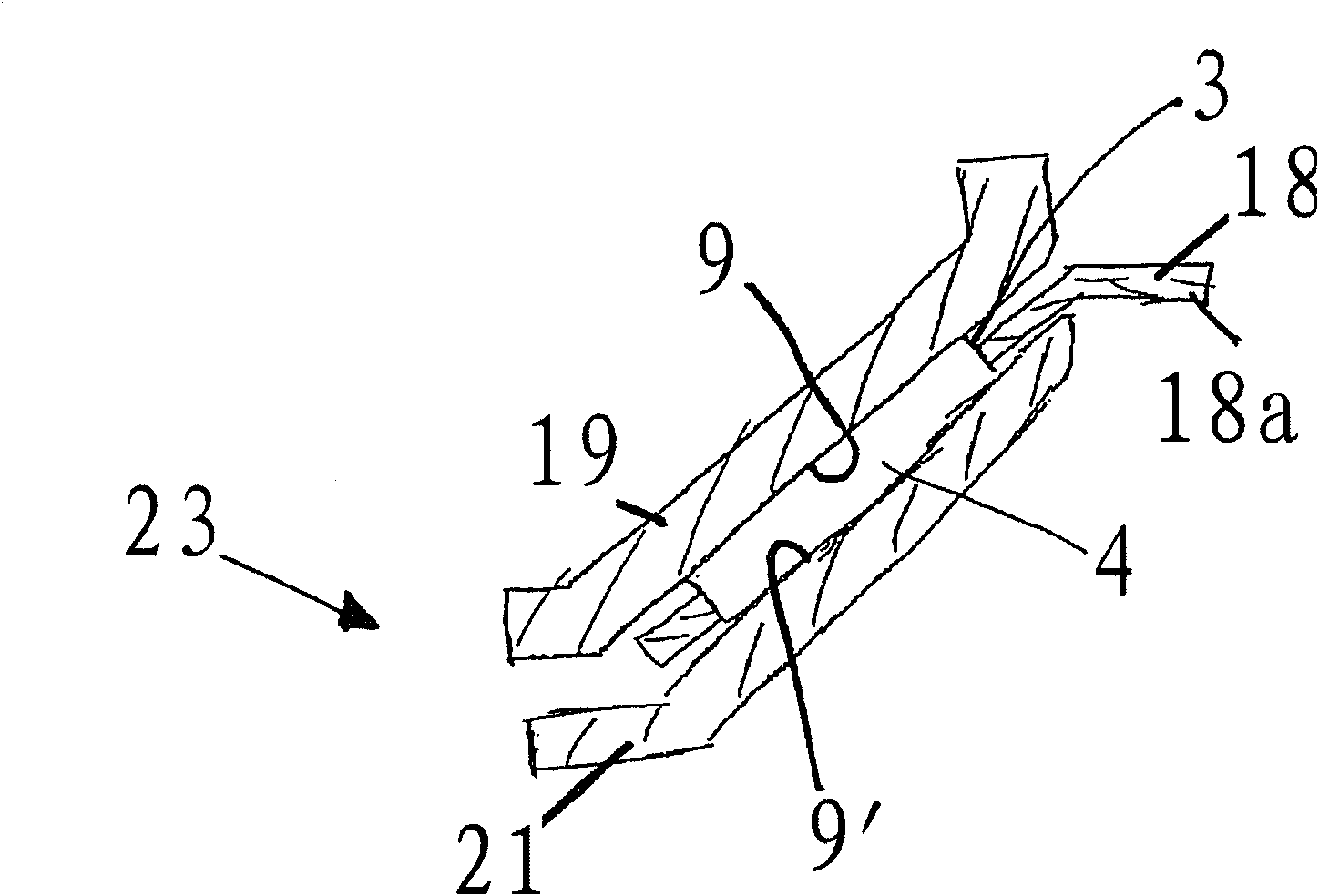

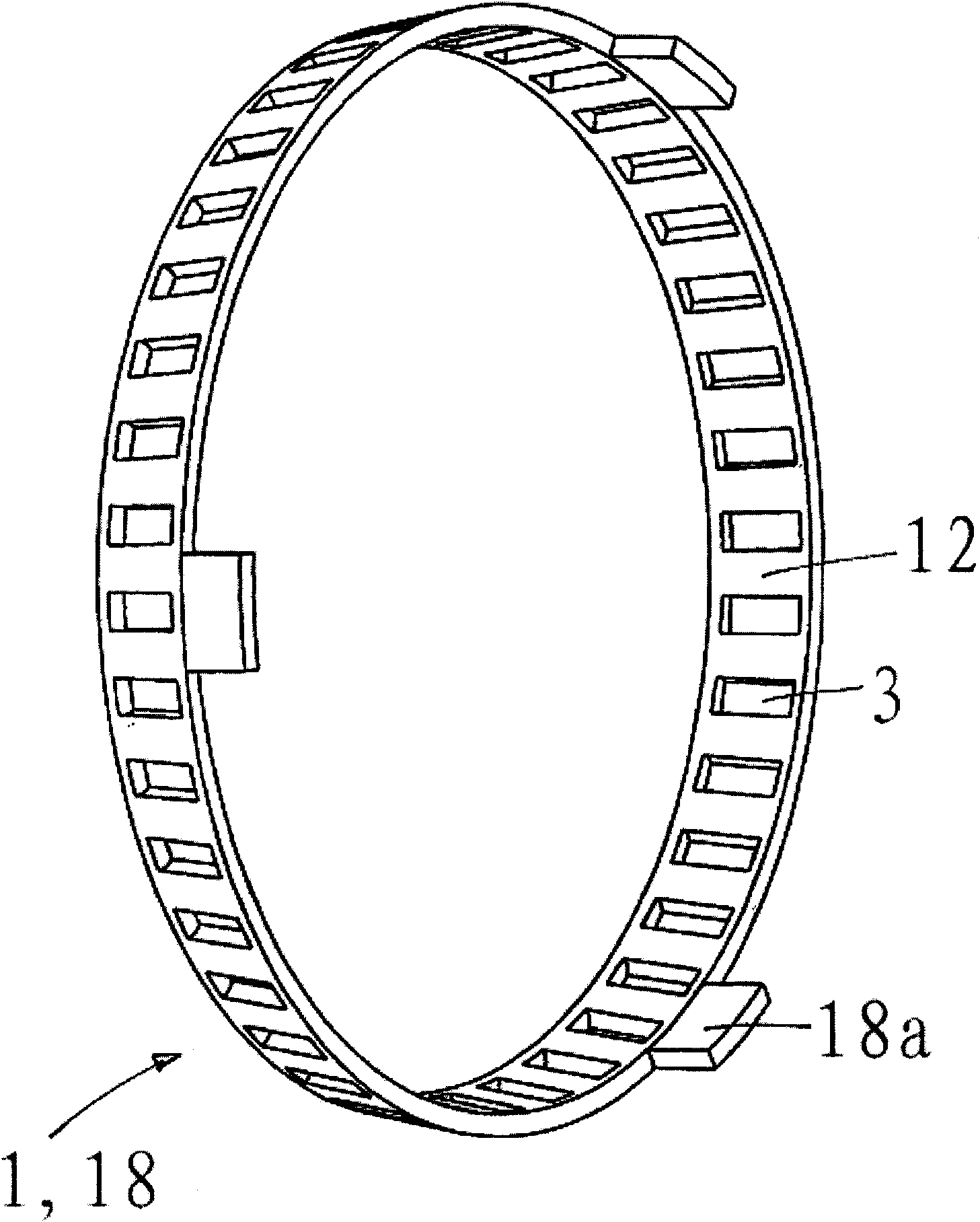

Synchronizing ring of a synchronizing device

InactiveCN101589244AReduced post-processingEasy to manufactureMechanical actuated clutchesFriction liningComputer science

A synchronizing ring (1) for a synchronizing device of a motor vehicle gearing, with a ring body (2), wherein the ring body (2) has a plurality of recesses (3), and frictional elements (4) are arranged in the recesses (3).

Owner:SCHAEFFLER TECH AG & CO KG

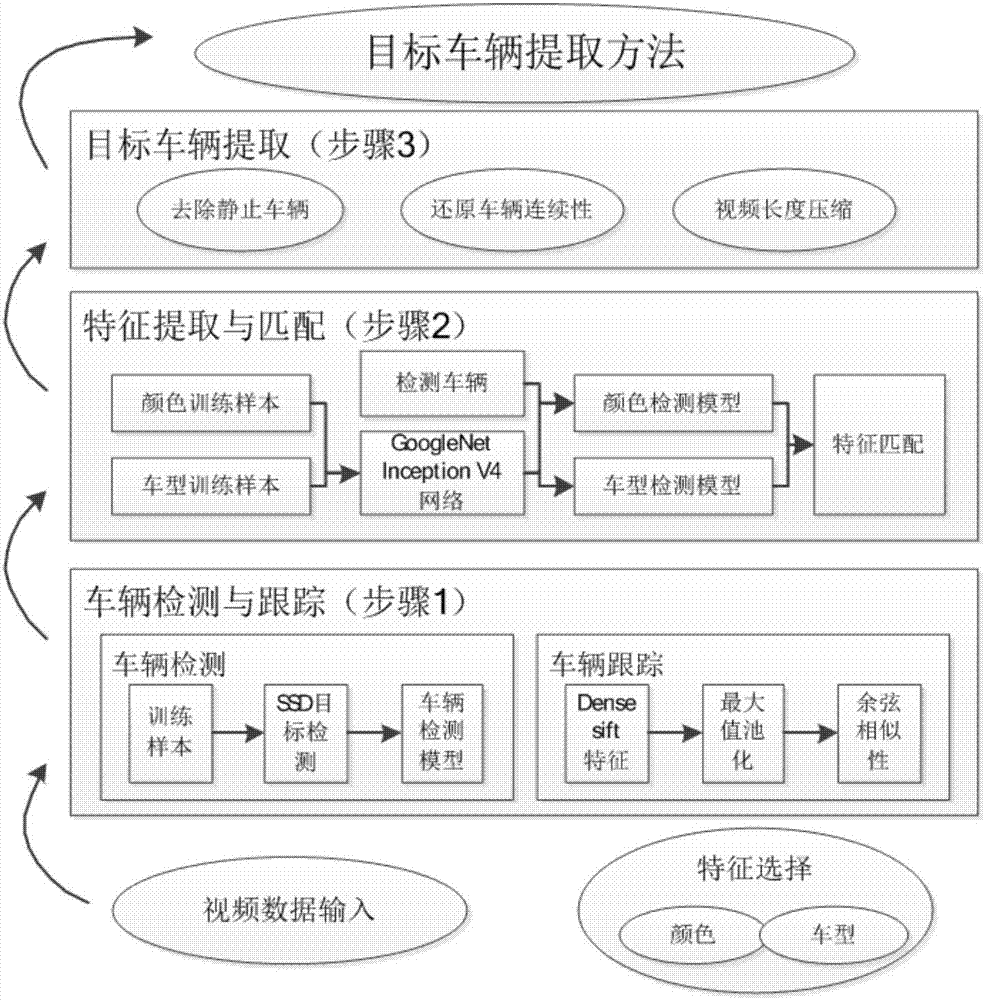

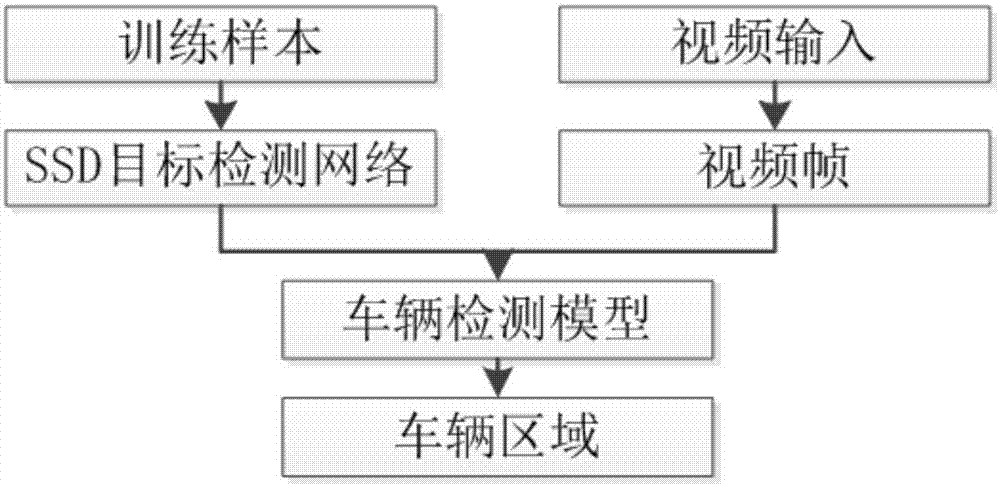

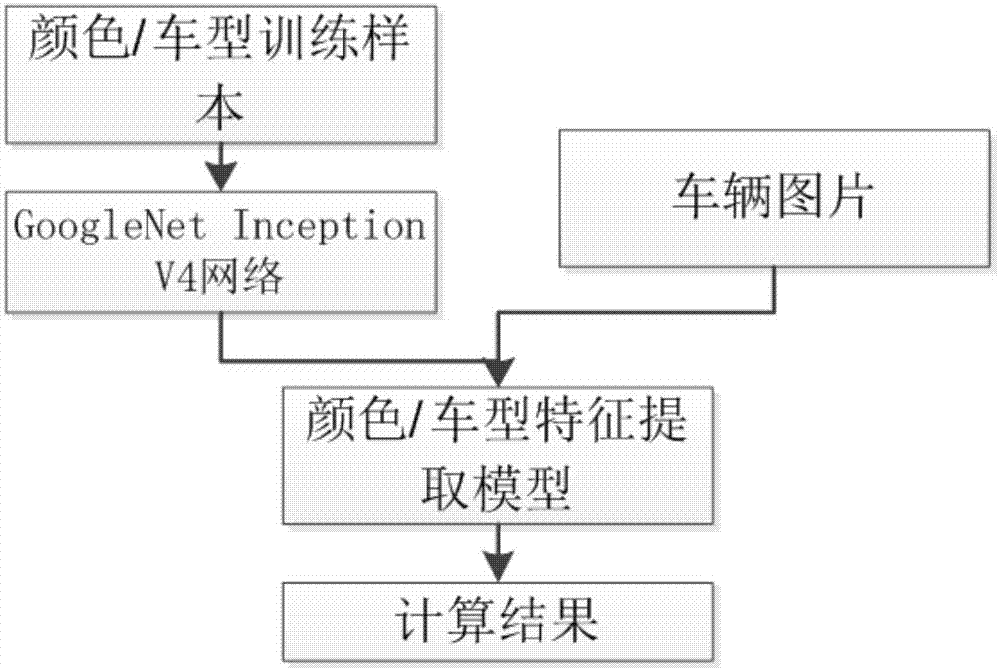

Target vehicle extraction method based on video

ActiveCN107491748AImprove accuracyGuaranteed Compression IntegrityImage enhancementImage analysisFeature extractionVideo image

The invention discloses a target vehicle extraction method based on a video, and aims to solve the problem that result video compression accuracy is low since parts of frames of target vehicle fails in being extracted since a target vehicle extraction process ignores a problem that the feature information of the same vehicle has differences in different frames in the prior art. Through first-time feature extraction, a target vehicle is screened, a static vehicle is removed, then, a subsequent video frame and the target vehicle are subjected to similarity matching, feature extraction and matching does not need to be carried out if the similarity matching is successful, and the problem that feature information reflected by the same vehicle in different video frames has certain differences to cause feature extraction errors so as to affect compression accuracy is avoided. By use of the method disclosed by the invention, result video compression accuracy is improved, and meanwhile, the technical barrier that the prior art considers that the video frame needs to carry out feature extraction frame by frame is overcome. The method is suitable for the field of video image processing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com