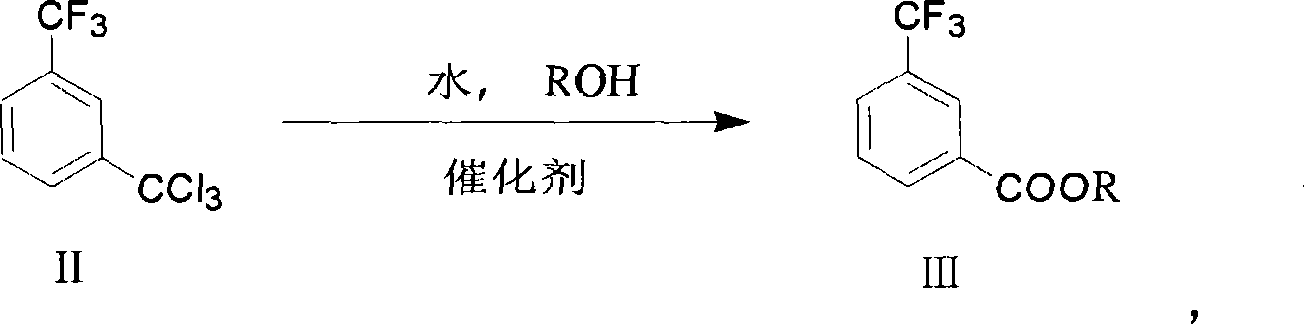

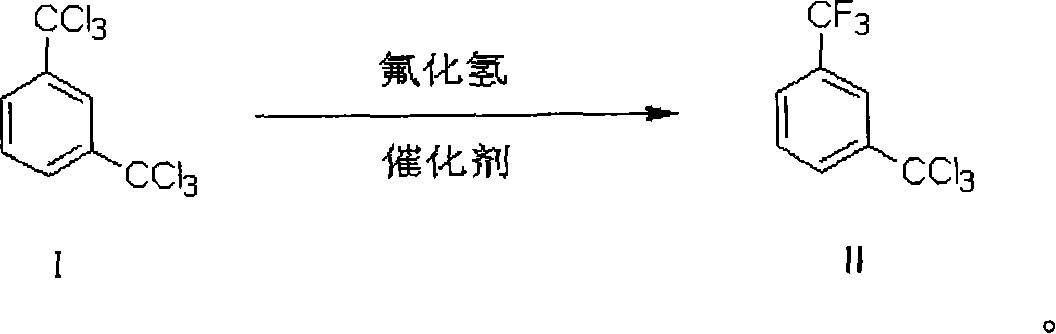

Prepn process of 3-trifluoro methyl benzoate

A kind of technology of trifluoromethyl benzoate and trichloromethyl trifluoromethyl benzene, applied in the field of preparation of 3-trifluoromethyl benzoate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

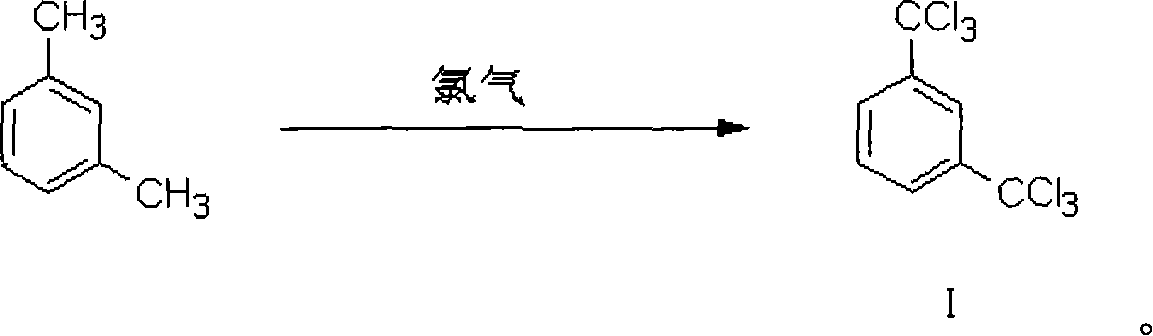

[0073] Preparation of m-ditrichloromethylbenzene

[0074] After mixing 563 mole parts of m-ditrichloromethylbenzene and 1689 mole parts of m-xylene, the temperature inside the reactor was raised to 120°C, then the ultraviolet lamp was turned on, chlorine gas was introduced, and the temperature inside the reactor was kept at 120-140°C. The reaction was carried out for 30 hours. According to gas chromatography analysis, the content of m-dichloromethyltrichloromethylbenzene, an intermediate of the chlorination reaction, is lower than 0.5%. Measured by GC-MS method, the reaction product is m-ditrichloromethylbenzene.

[0075] Degassing under reduced pressure, distilling the reaction solution under reduced pressure, collecting fractions at 154-158°C / 10mmHg to obtain 2068 parts of m-ditrichloromethylbenzene, the yield of chlorination reaction was 89.3%, m-ditrichloromethyl The purity of benzene is 97.2%.

Embodiment 2-9

[0077] Preparation of m-ditrichloromethylbenzene

[0078] Proceed in the same manner as in Example 1, except that the reaction temperature, raw material ratio and reaction time are as shown in Table 1. Table 1 also shows the yield, the purity and the high boiler content of the obtained product of m-bistrichloromethylbenzene.

[0079] In addition, Example 8 uses 2% by weight of azobisisobutyronitrile (based on the weight of m-xylene) as an initiator instead of UV initiation.

Embodiment 9

[0080] Example 9 uses 2% by weight of benzoyl peroxide (based on the weight of m-xylene) as the initiator instead of UV initiation.

[0081] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com