Patents

Literature

277results about How to "The process is simple and controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

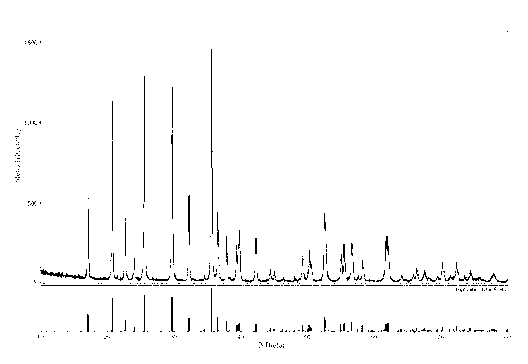

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

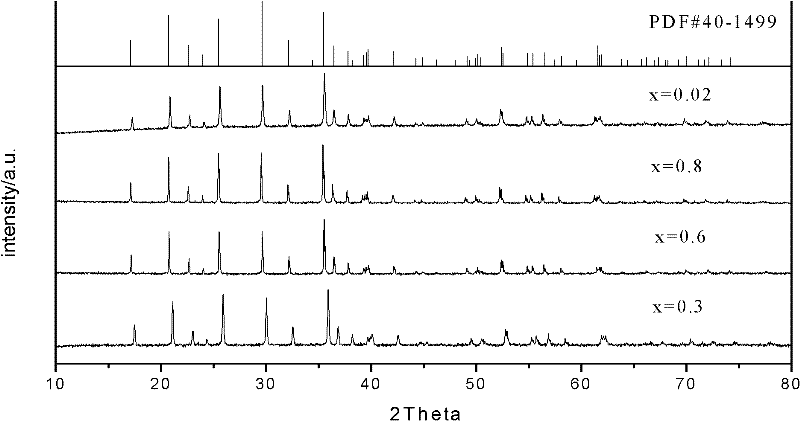

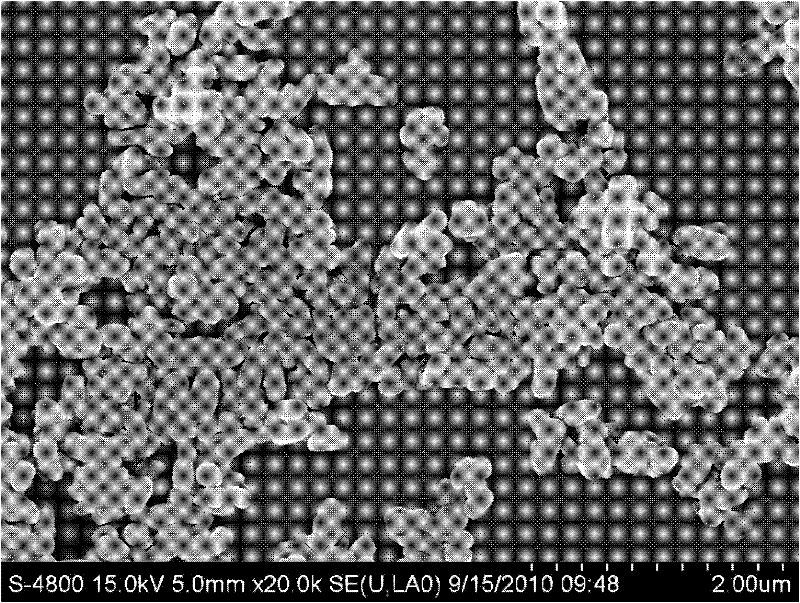

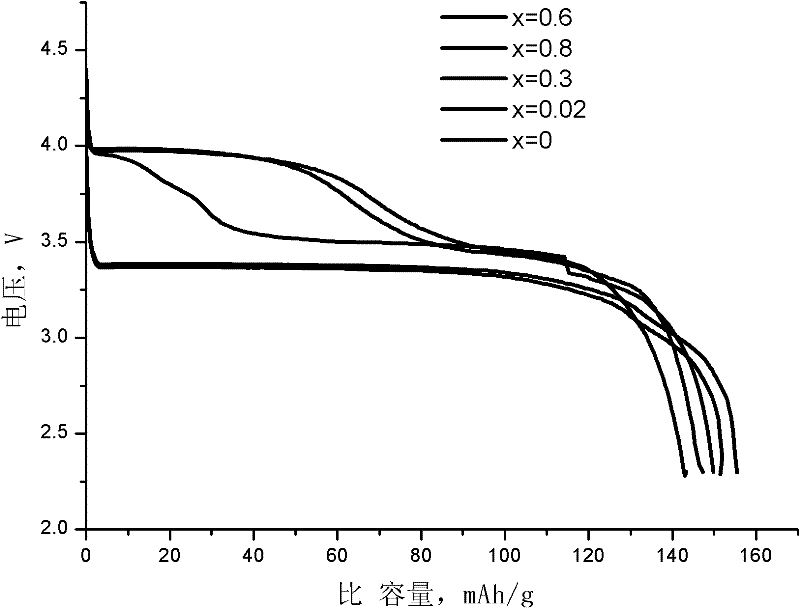

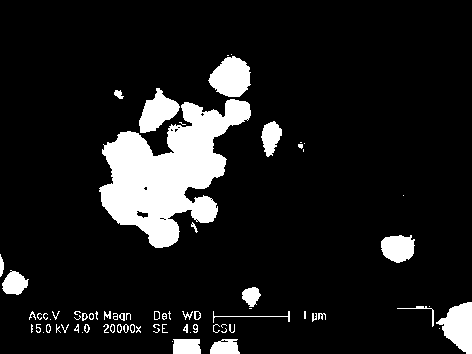

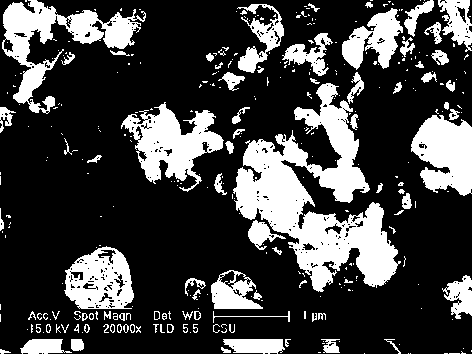

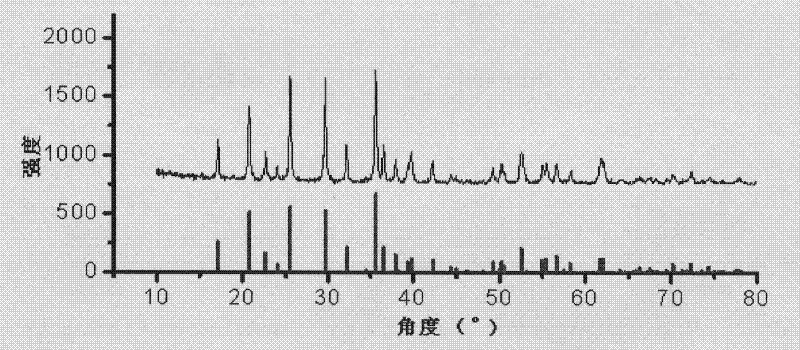

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

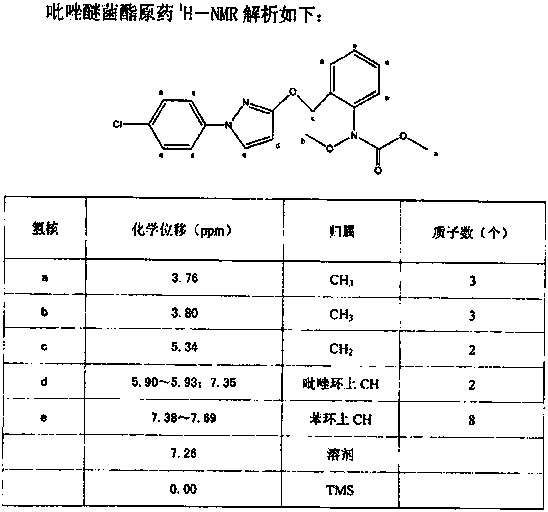

Synthetic technology for pyraclostrobin

ActiveCN104211641AFormation reaction is easy to controlSmooth responseOrganic chemistryMethylanilineChlorobenzene

The invention concretely relates to a synthetic technology for pyraclostrobin. The synthetic technology comprises: firstly performing cyclization to obtain 1-(4-chlorophenyl)-pyrazol-3-one, oxidizing the pyrazol ring under the effect of an oxidant to generate 1-(4-chlorophenyl)-3-hydroxypyrazole, then using 2-nitrobenzyl bromide to performing etherification to generate 1-(4-chlorophenyl)-3-[2-(nitrophenyl)methoxy]-1H-pyrazole, then using a reducing agent to perform nitro reducing, so as to generate N-hydroxyl-2-[N'-(4-chlorophenyl)pyrazol-3'-yloxymethyl]aniline, then using ClCO2CH3 to perform N-acylation reaction to generate methyl N-hydroxyl-N-2-{[N'-(4-chlorophenyl)pyrazol-3'-yloxymethyl]phenyl}formate, and finally performing hydroxyl methylation under an alkaline condition to generate pyraclostrobin. The technology enables all operations in the pyraclostrobin preparation process to be relatively controllable, helps to improve the stability of the preparation process and improve the product yield, successfully employs low-cost reagents and substantially reduces production cost, and also the employed reagents are relatively small in toxicity, is relatively beneficial for environment protection, and has no corrosivity on plastic pipes, so that the production safety is improved.

Owner:SHANDONG KANGQIAO BIO TECH CO LTD

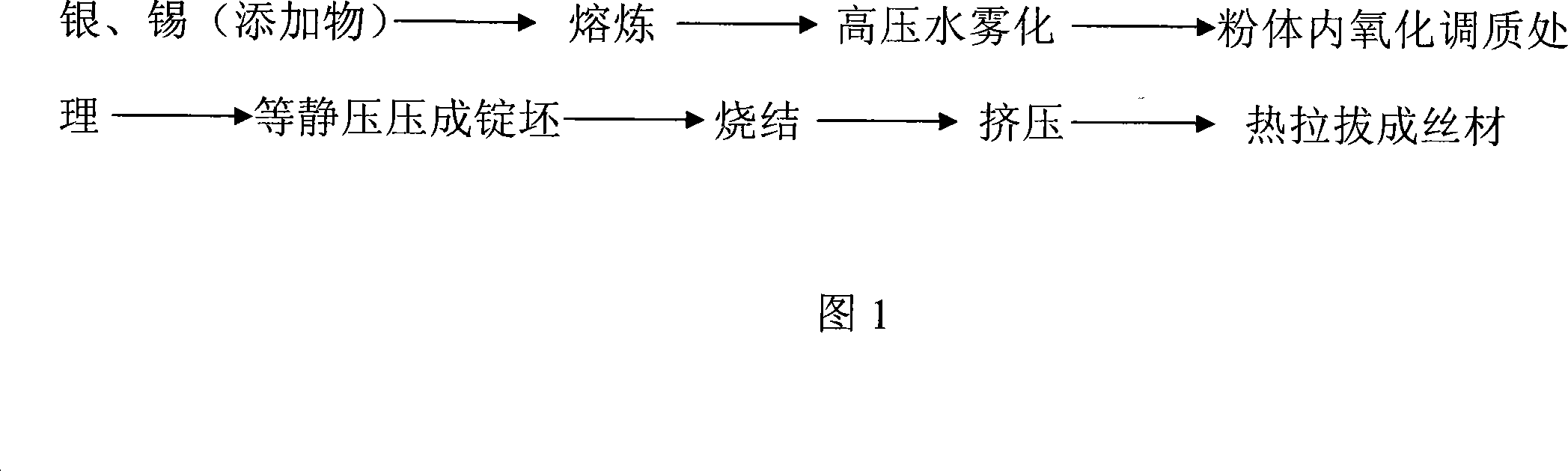

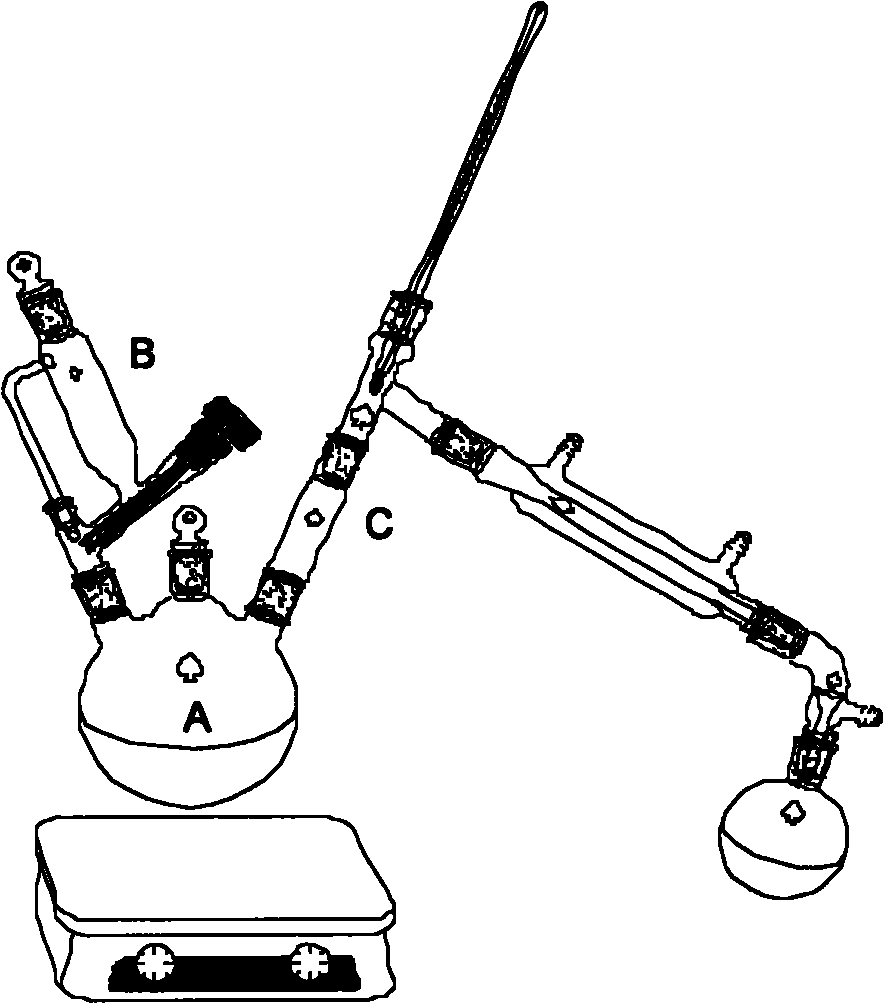

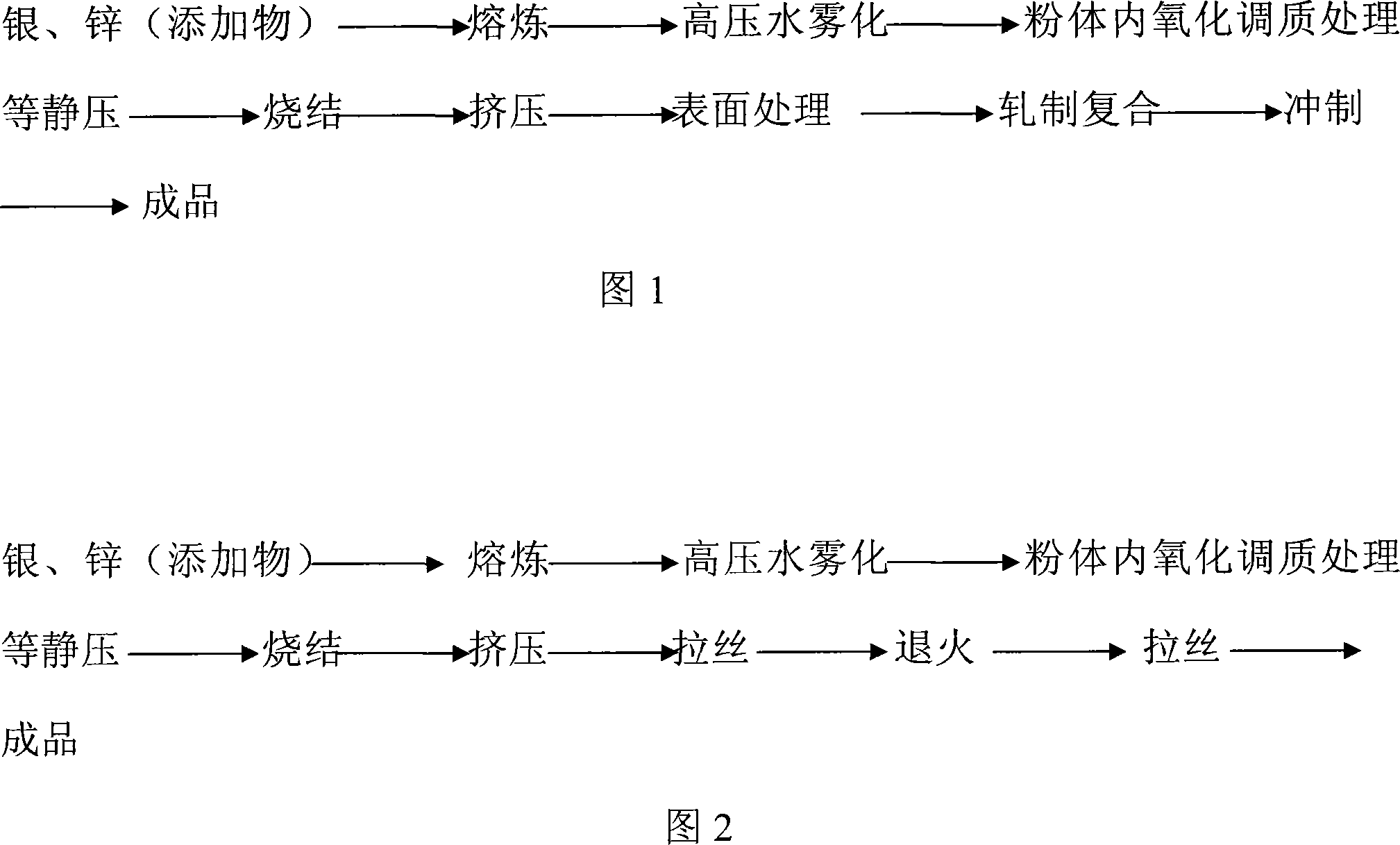

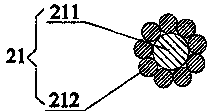

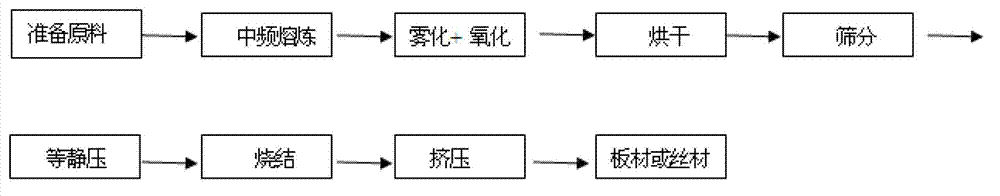

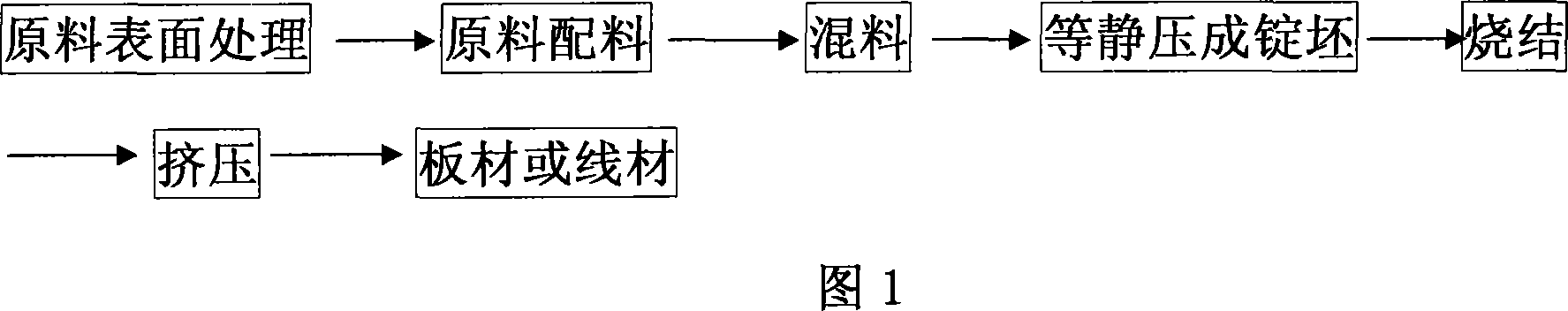

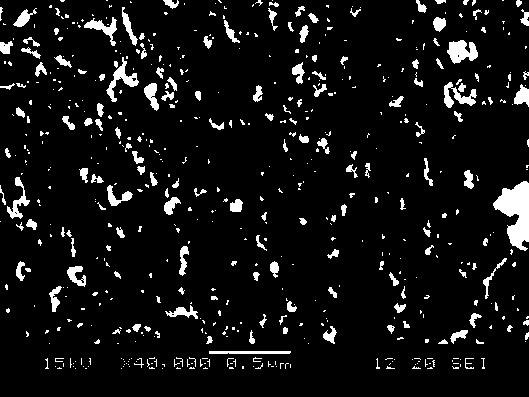

Method of preparing novel silver tin oxide silk electrical contact material

InactiveCN101202169AGranularity is easy to controlImprove surface activityContactsIntermediate frequencyElectric properties

The invention relates to a novel preparing method of a material used for a silver tin oxide wire electric contact. The invention has a process that the material prepared by silver, tin and additives according to a certain proportion is put into an intermediate frequency smelter for melting; a high pressure water atomizing device is adopted for high pressure alloy atomization; atomized alloy powder is dried and oxidated for modification; an isostatic pressing ingot is formed after isostatic pressing treatment; the ingot is agglomerated in a heating furnace; the agglomerated ingot is delivered into an extruding machine to extrude wires; the extruded wire is pulled and annealed to get a finished wire. The material property and electric property of the silver tin oxide wire electric contact material manufactured by the method can satisfy the use condition with high requirement.

Owner:FUDA ALLOY MATERIALS

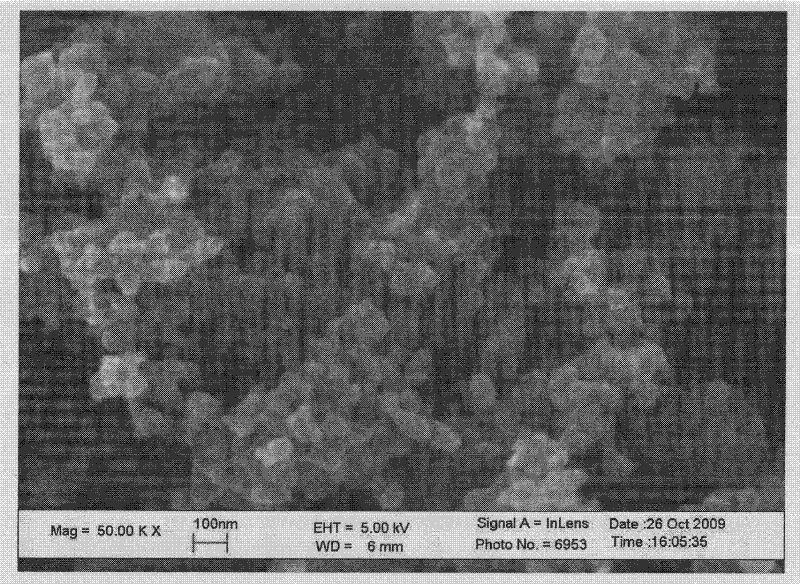

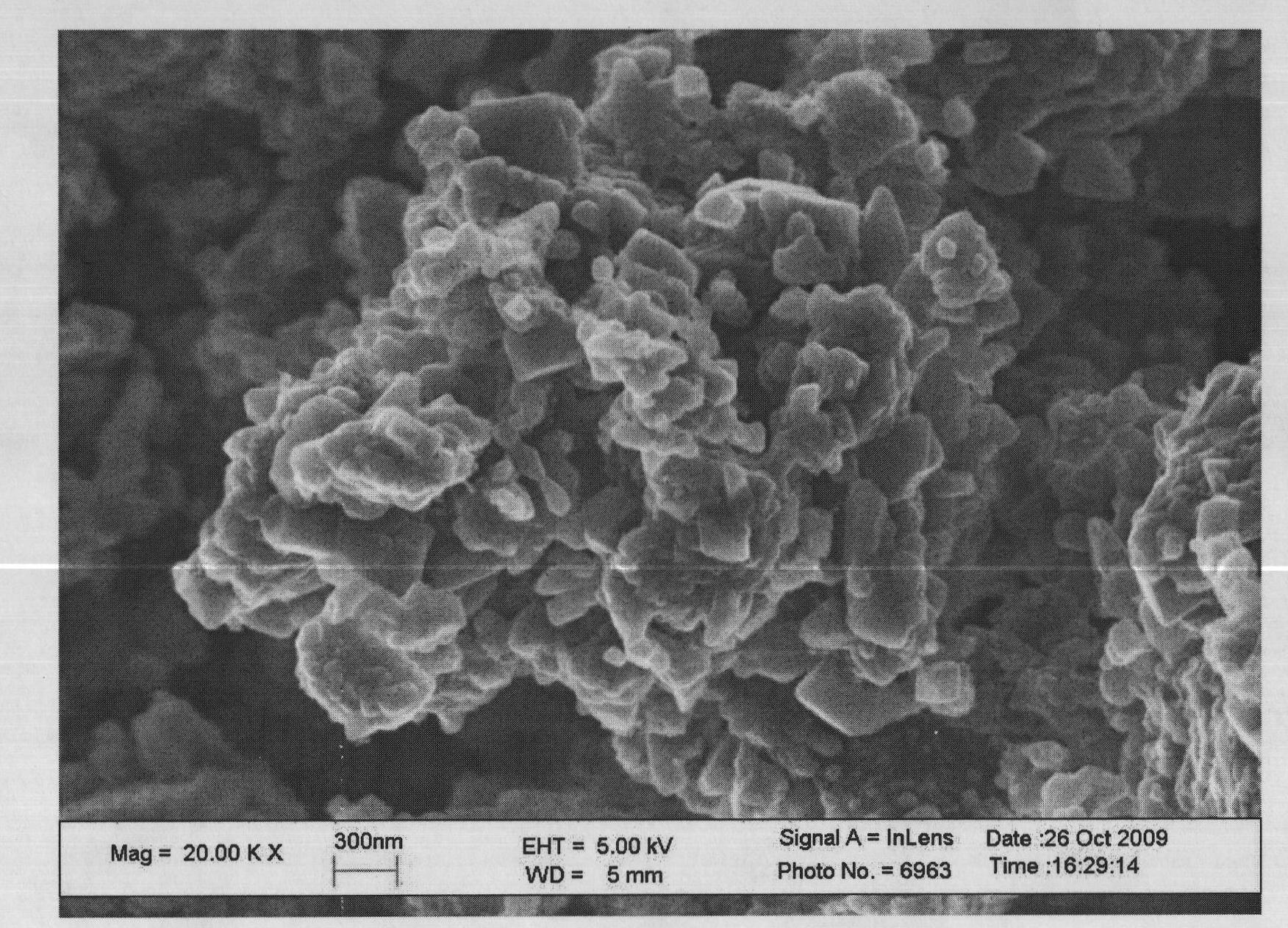

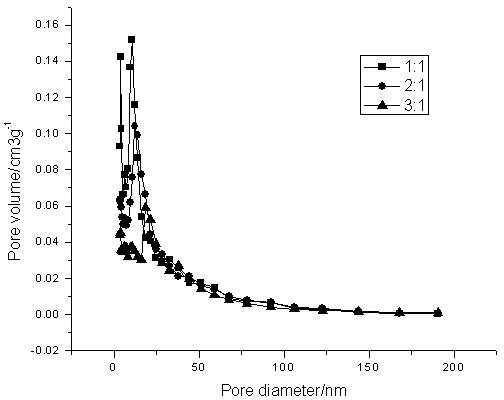

Preparation method of echinoid titanium dioxide microspheres in single/double layer cavity structure

InactiveCN101941736ALarge specific surface areaEasy to shapeTitanium dioxideMicrosphereSilicon dioxide

The invention relates to a preparation method of echinoid titanium dioxide microspheres in single / double layer cavity structure, belonging to the field of nano composite materials. The method comprises the following steps: (1) preparing monodisperse silicon dioxide microspheres with uniform particle size; (2) by using silicon dioxide as a template, coating a titanium dioxide layer on the surface of the silicon dioxide microspheres by using a sol-gel method to obtain core-shell type silicon dioxide / titanium dioxide composite microspheres; (3) regulating the concentration of sodium hydroxide solution, the hydrothermal reaction time and other conditions, and preparing echinoid titanium-base microspheres in the single / double layer cavity structure in a controllable way; and (4) treating the echinoid titanium-base microspheres in the single / double layer cavity structure with hydrochloric acid with a certain concentration, and calcining at high temperature to obtain anatase-type echinoid titanium dioxide microspheres in the single / double layer cavity structure. The material prepared by the method has the high-activity pure-phase titanium dioxide crystal structure, and has the advantages of large specific area, complete appearance and high yield; the technical process is controllable and easy to operate; and the invention also has the advantages of low preparation cost, no pollution and low energy consumption.

Owner:UNIV OF SCI & TECH BEIJING

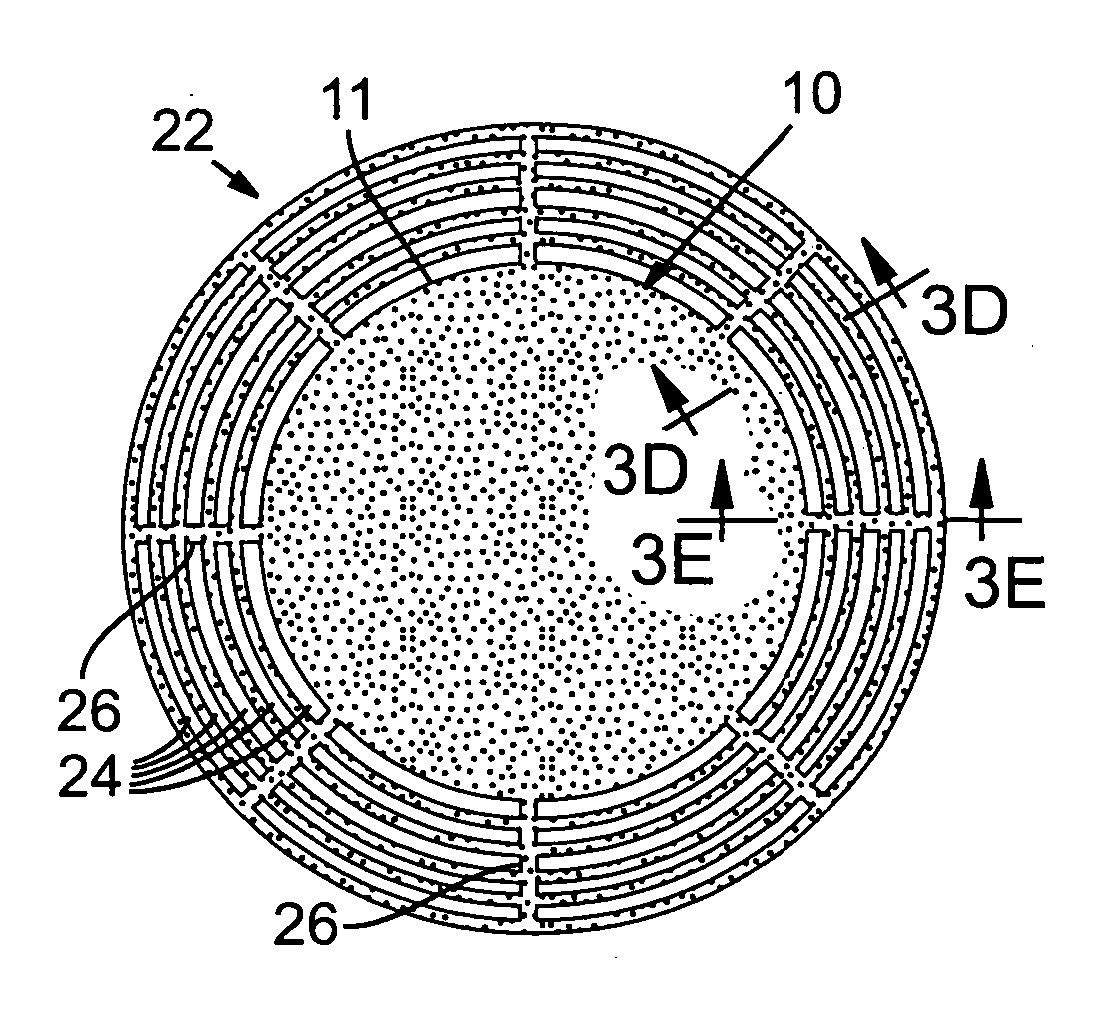

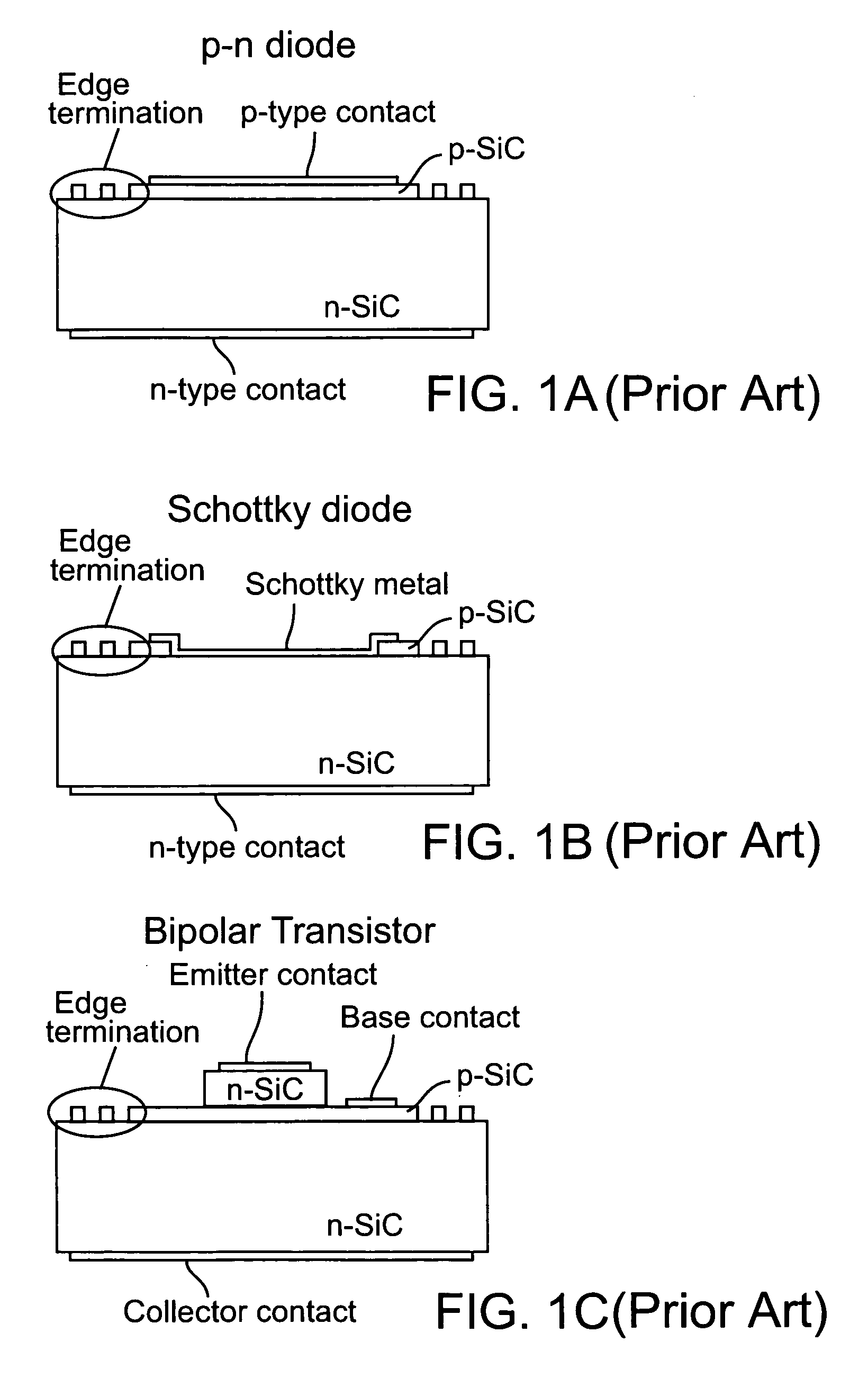

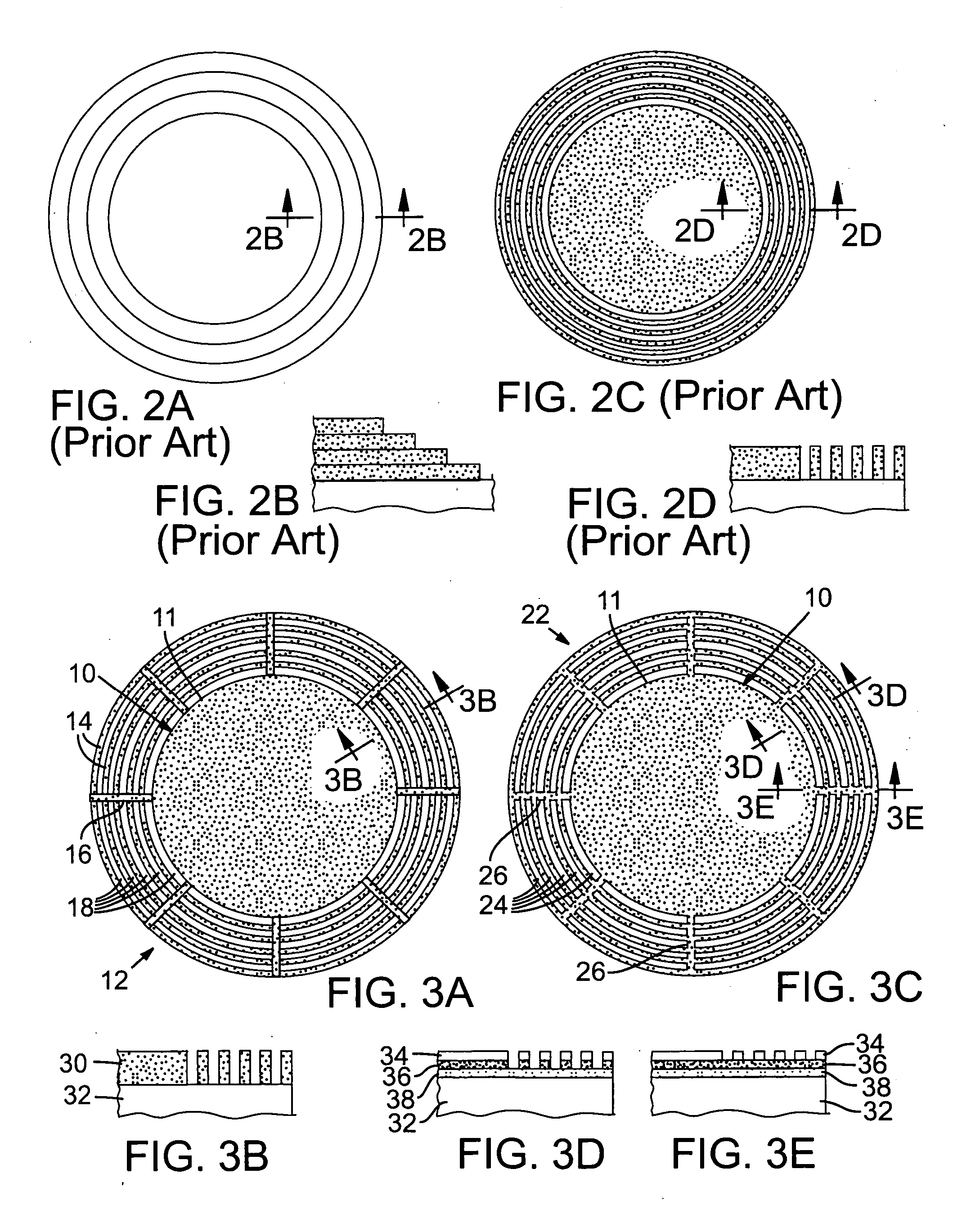

Junction termination structures for wide-bandgap power devices

InactiveUS20060118900A1High blocking voltageSimple and controllable processTransistorRadial gradientElectrical resistivity and conductivity

Disclosed are a variety of junction termination structures for high voltage semiconductor power devices. The structures are specifically aimed at providing a high breakdown voltage while being constructed with a minimal number of process steps. The combination of an RIE etch and / or implantation and anneal process with a finely patterned mesh provides the desired radial gradient for maximum breakdown voltage. The structures provide control of both the conductivity and charge density within the region. These structures can beneficially be applied to all high voltage semiconductor device structures, but are of particular interest for wide bandgap devices as they tend to have very high breakdown fields and scaled dimensions of the depletion layer width.

Owner:MICROSEMI

Silver zinc oxide electric contact material and preparation method thereof

InactiveCN101944441AEasy to oxidizeUniform metallographic structureFinal product manufactureContactsPunchingZinc alloys

The invention discloses a silver zinc oxide electric contact material and a preparation method thereof, and belongs to the technical field of electrical materials. The method comprises the following steps of: melting and ingoting silver, zinc and additives in a smelter according to a certain weight ratio, sintering and extruding into strips, and drawing to form a silver-zinc alloy wire material; oxidizing the silver-zinc alloy wire material to obtain a silver zinc oxide wire material; cutting the wire material into pieces by an open-back inclinable press, pressing the cut pieces in a steel die to manufacture an extruded stock, and sintering and extruding the cut pieces to manufacture a plate or a wire material; polishing the surface of the extruded plate, performing hot rolling on silver, rolling, punching and molding; and drawing, annealing and drawing the extruded wire material to a finished product wire material with phi of between 0.5 and 3.0mm to produce the rivet electric contact. In the method, the silver-zinc wire material is used for oxidation, so the alloy is easily oxidized without special oxidizing equipment; the metallographic phase of the material has uniform tissue without an oxidation zinc lean region or oxidation aggregation, and the consistency of the material performance, high compactness and good processing performance can be ensured; the method can realize mass production and has low production cost; and the production process and the material per se have no pollution to the environment.

Owner:YANGZHOU LEYIN ALLOY TECH

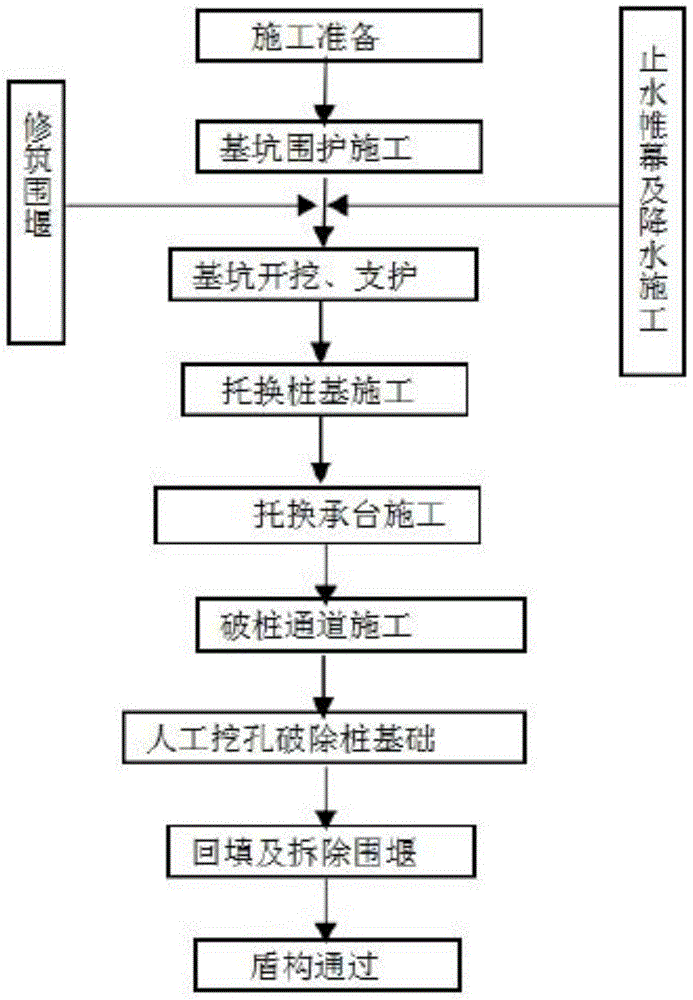

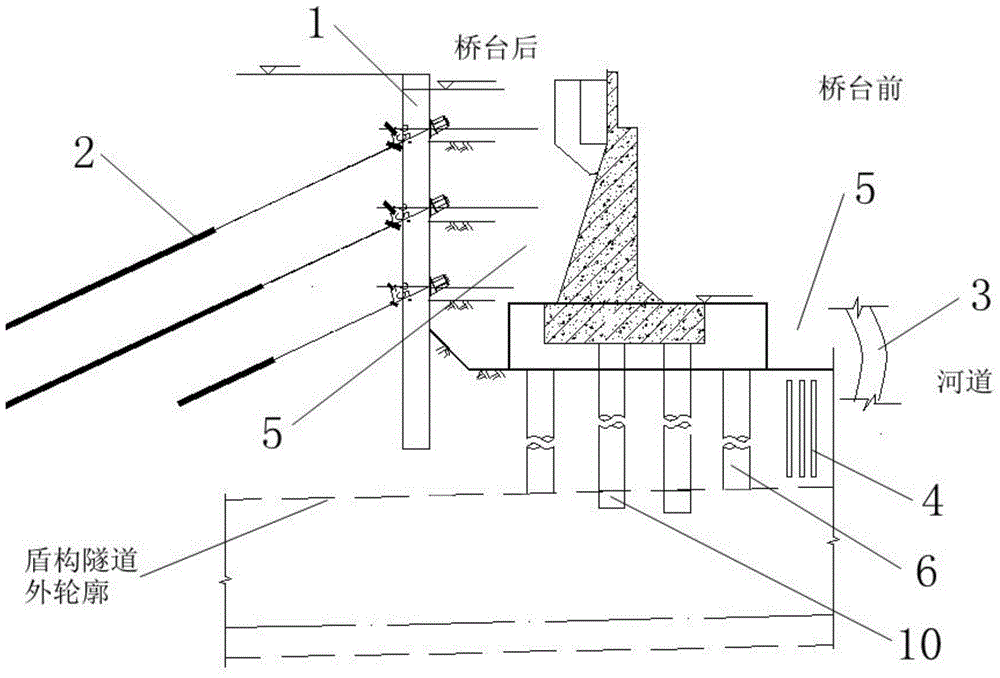

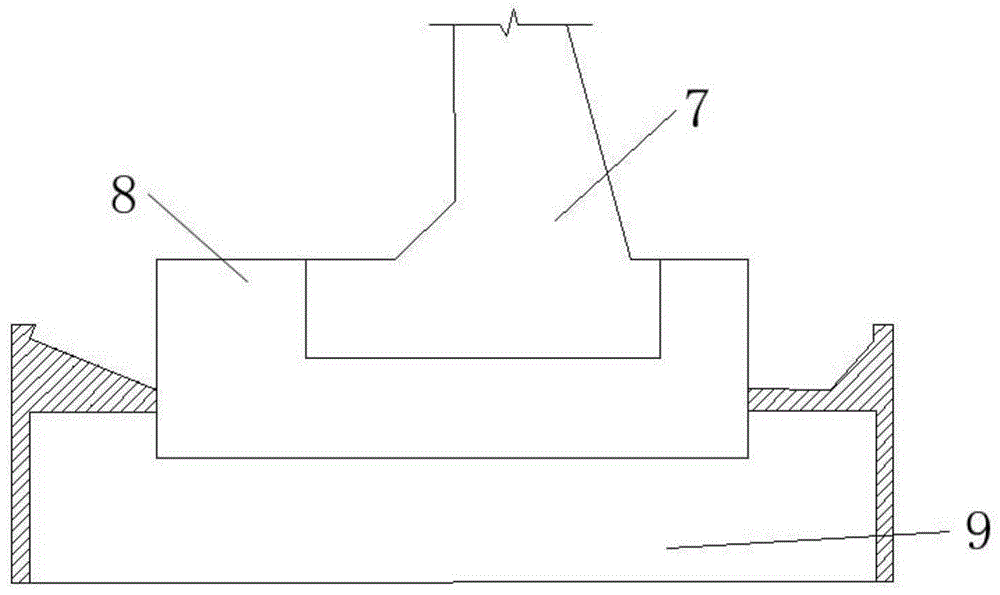

Construction method for cropping bridge pile foundation at sandy gravel stratum of abyssal region

InactiveCN105672348ALow costConstruction quality is easy to controlBulkheads/pilesSocial benefitsCofferdam

The invention discloses a construction method for cropping a bridge pile foundation at a sandy gravel stratum of an abyssal region. A passive underpinning principle is adopted; firstly, an enclosing structure is constructed behind an existing bridge abutment by a certain distance, and a temporary cofferdam is constructed in a river, so that operation space is provided; an underpinning pile foundation and an underpinning bearing table are constructed in the enclosing structure, and dead loads of an existing bridge is transferred to an underpinning pile and the underpinning bearing table; and a pile breaking channel is dug below the underpinning bearing table, and the pile is finally removed with a manual hole digging method. According to the method, on the premise that the construction quality is guaranteed, the construction schedule can be quickened, the manufacturing cost is reduced, and influences of underpinning construction on existing buildings, pipes and ground transportation are reduced; and the construction method has the technical advancement and has social benefits and economic benefits.

Owner:CHONGQING UNIV

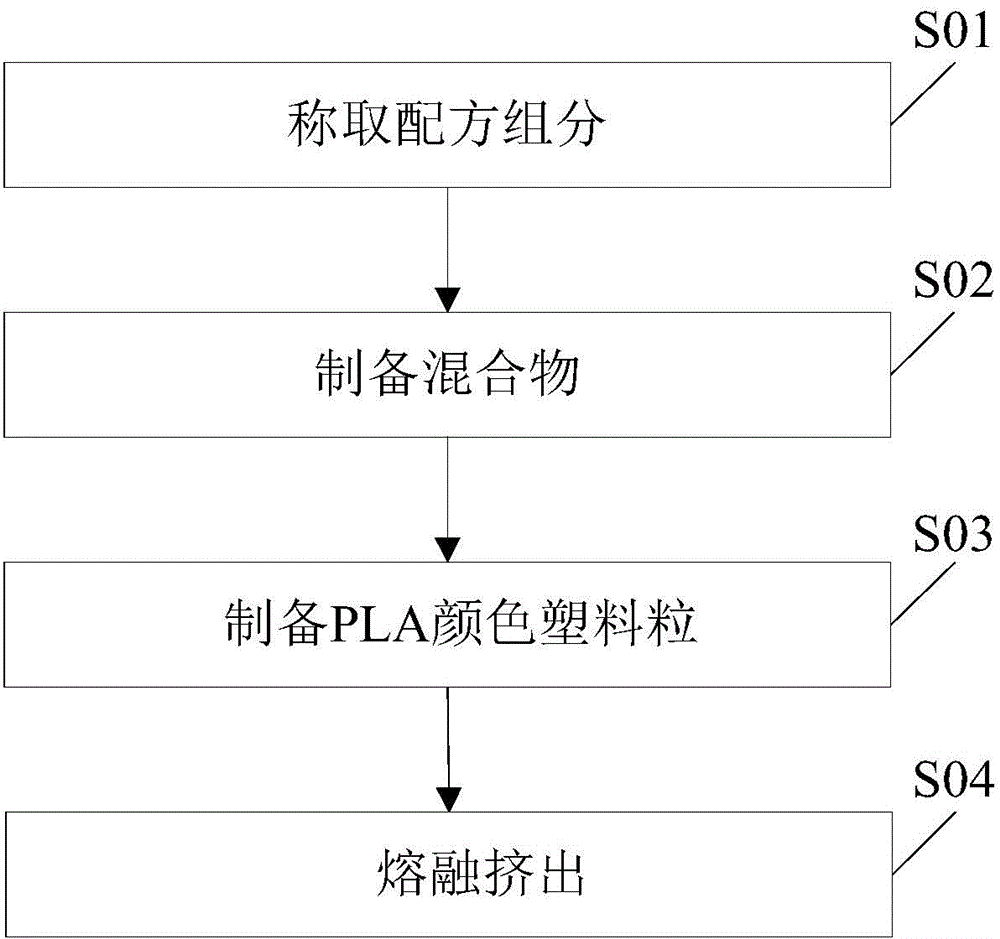

3D printed PLA consumable and preparation method thereof

InactiveCN104672826ABiodegradableQuality improvementAdditive manufacturing apparatusPolymer science3d printer

The invention belongs to the field of 3D printers and provides a 3D printed PLA consumable and a preparation method thereof. The 3D printed PLA consumable is prepared from the following raw materials in percentage by weight: 99.3-99.7% of PLA plastic, 0.1-0.3% of pigments and 0.2-0.4% of auxiliaries. The preparation method comprises the following steps: weighing the components in percentage by weight; uniformly mixing the weighed components to obtain a mixture; adding the obtained mixture into a double screw extruder; coupling and extruding to obtain PLA colored plastic particles; and then adding the PLA colored plastic particles into a 3D twine machine to prepare the 3D printed PLA consumable. According to the 3D printed PLA consumable, a high-quality, environment-friendly and naturally degradable PLA product is manufactured by utilizing PLA plastic on the premise that the environment-friendly degrading advantage of the PLA plastic is not changed, and the preparation method is simple in step, easy to control and low in cost.

Owner:LIFENG NEW MATERIAL TECH SHENZHEN

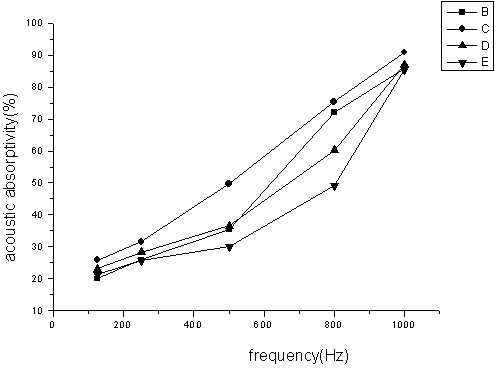

Lightweight inorganic insulation board containing silica aerogel and preparation method thereof

The invention discloses a lightweight inorganic insulation board containing silica aerogel and a preparation method thereof. The preparation method comprises the following steps: a. preparing surfactant liquid: fully stirring a surfactant and water to prepare a uniform surfactant liquid for standby use; b. preparing powder: fully mixing cement, ash calcium, aerogel, light aggregate fillers, fibers and latex powder and stirring uniformly to prepare powder for standby use; c. preparing the inorganic insulation board: adding the uniformly mixed powder to the surfactant liquid within 5-10 minutes through stirring, then filling the slurry into a die for forming and curing at normal temperature, thus obtaining the final product. Compared with the traditional inorganic insulation boards and insulation boards containing non-silica aerogel, the prepared inorganic insulation board containing silica aerogel has the characteristics of short production cycle, simple and controllable process and low price, has good heat insulation property and effectively solves the problems of high heat conductivity coefficients and higher water absorption of conventional inorganic insulation boards, and the heat conductivity coefficient of the inorganic insulation board can be reduced by 10-30%.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

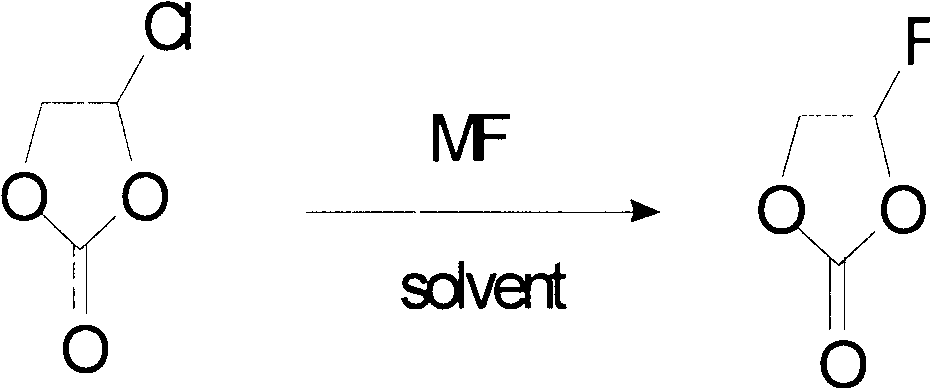

Method for preparing fluoroethylene carbonate

The invention discloses a method for preparing fluoroethylene carbonate, which comprises the following steps: providing a mixture of a fluorating agent and a solvent; providing a chloroethylene carbonate raw material; heating the mixture, and dripping the chloroethylene carbonate into the mixture under a constant pressure when the mixture is heated to a required temperature; and performing distillation under reduced pressure on a reaction system during dripping or after dripping to obtain a coarse fluoroethylene carbonate product. When the preparation method of the invention is used, high-purity and low-moisture content product can be obtained in a shorter period.

Owner:ZHEJIANG HUAJING FLUORINE CHEM TECH

Technique for preparation of novel silver zinc oxide contact material

InactiveCN101202168AParticle surface activity is highEasy to processContactsHigh densityIntermediate frequency

The invention relates to a novel preparing process of a material used for a silver zinc oxide contact. The invention has a process that a material prepared by silver, zinc and additives according to a certain proportion is put into an intermediate frequency smelter for melting; a high pressure water atomizing device is adopted for high pressure alloy atomization; atomized alloy powder is dried and oxidated for modification; an equal static ingot is formed after equal static treatment; the ingot is agglomerated in a heating furnace; the agglomerated ingot is delivered into an extruding machine to extrude plates or wires; the extruded plate is rolled and punched for shaping after surface treatment and silver restoring; the extruded wire is pulled and annealed to get a finished wire which is used for making rivets or different shape materials. The silver zinc oxide contact material prepared by the process has uniform metallographic structure, high density and good machining performance.

Owner:FUDA ALLOY MATERIALS

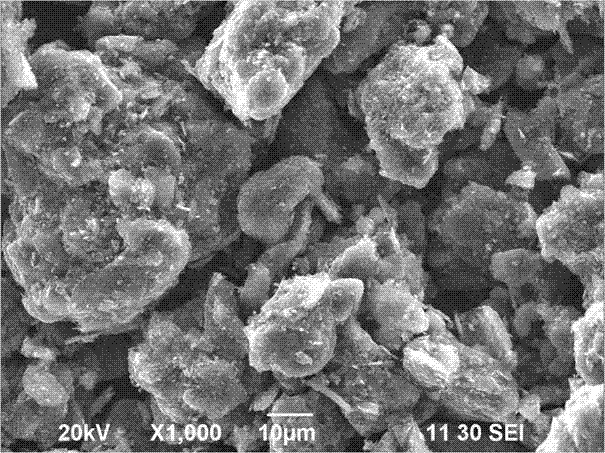

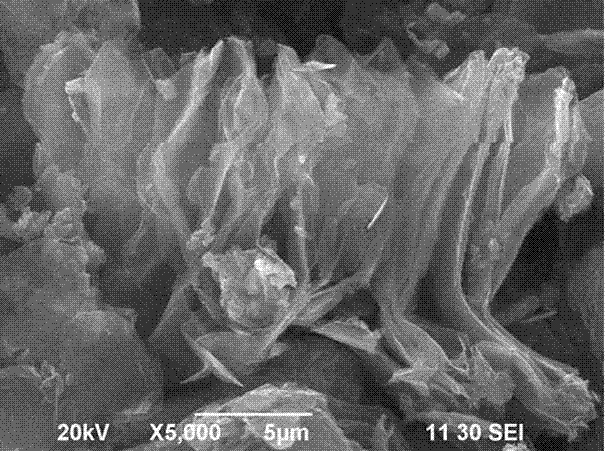

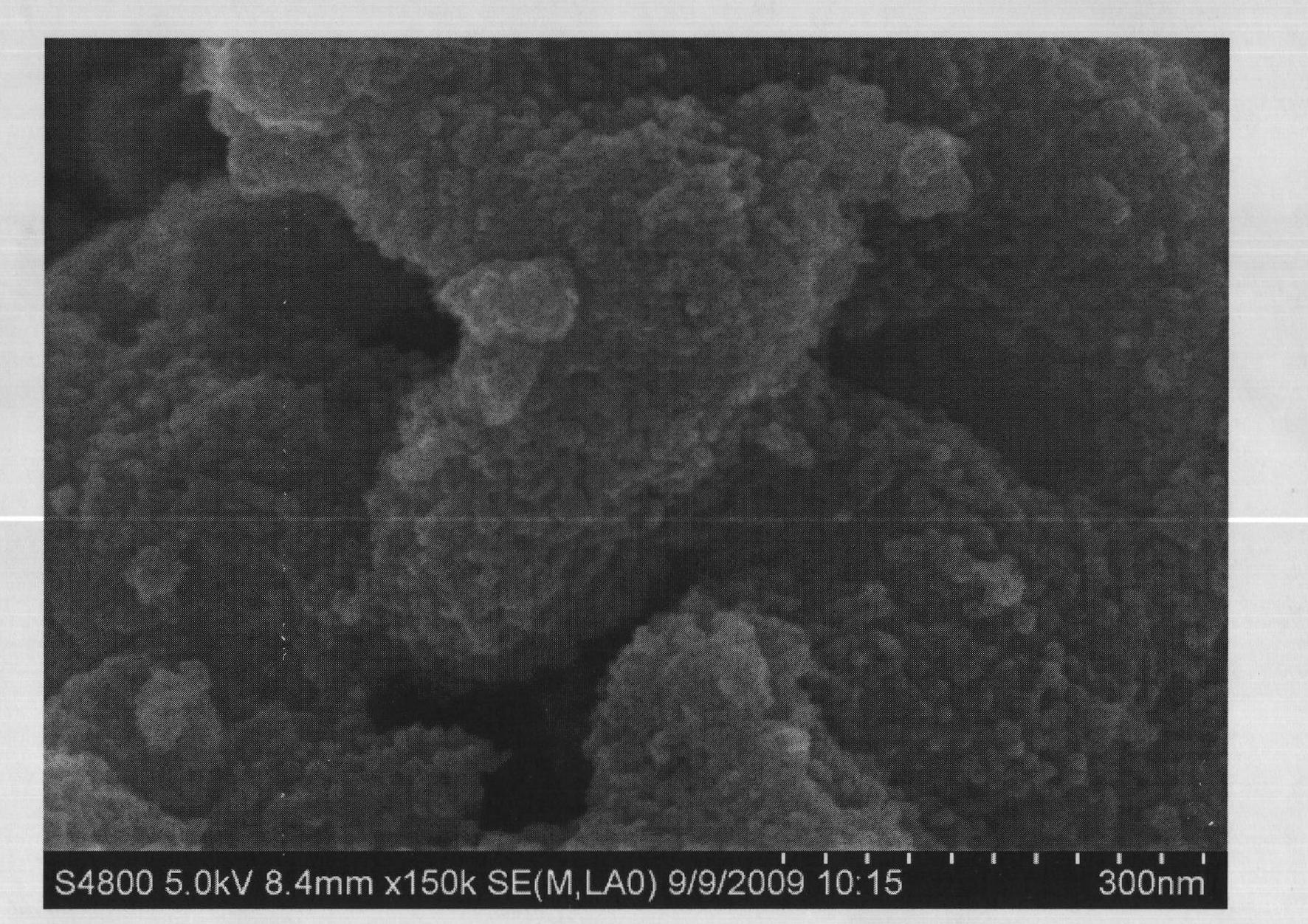

Method for preparing lithium iron phosphate/carbon composite material by thickener doping modification

InactiveCN103165896AUniform particle sizeSmall granularityCell electrodesCarbon compositesCarbon coating

The invention relates to a method for preparing a lithium ion battery positive electrode material, specifically a lithium iron phosphate / carbon composite material by thickener doping modification, and provides an improvement method for the problems that lithium iron phosphate particles are not uniform, strength of a surface carbon coating layer is unstable, and the like in the prior art. The method has the technical characteristics that a water-soluble organic carbon resource or a conductive carbon black is added in a prepared water solution of the thickener with a certain concentration under mechanical stirring; then precursor powder is added with stirring; and finally the obtained slurry is dried and heat-treated at a high temperature to obtain doped high-performance Li1-xMxFePO4 / C powder with consistent particle morphologies. The method is simple in process, convenient for operations and easy for industrialized production and has relatively wide application prospects.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

Preparation method of silicon-based/graphene composite

ActiveCN103094573AEvenly distributedDoes not pose a health and safety riskCell electrodesLithium-ion batteryElectric field

The invention belongs to the technical field of new materials for a lithium ion battery, and particularly relates to a preparation method of a silicon-based / graphene composite. The preparation method comprises the following steps of: taking a pole of the silicon-based / graphene composite as a working electrode and the pole of a lithium source-containing material as a counter electrode, assembling a battery together with propylene carbonate and lithium salt-containing electrolyte and a diaphragm; charging and discharging the battery to co-embed lithium ions and carbonate propylene ester into graphite layers under the action of electric field, so as to enable the graphite layers to be stripped; dismantling the battery, placing a lithium-embedded silicon-based / graphene composite precursor into dimethyl carbonate solution for soaking, and vaccumizing and drying; and conducting ultrasonic cleaning and lithium removal in diluted hydrochloric acid, vacuumizing and filtering, drying, and burning under inert gas atmosphere. Compared with the prior art, the preparation method is simple and controllable in procedures, low in cost, safe and environment-friendly and incapable of causing environment and health security risk; and a great deal of hydrogen can also be collected in the preparation process of the composite, so that economic benefits are obvious.

Owner:DONGGUAN AMPEREX TECH

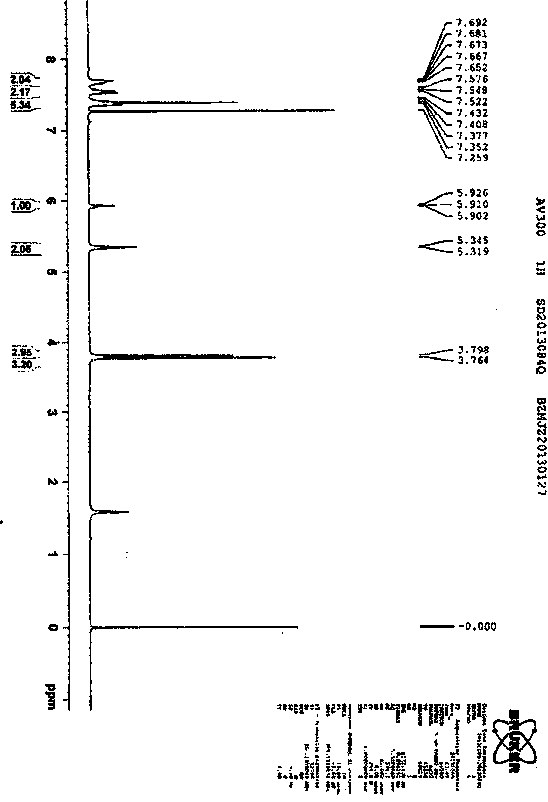

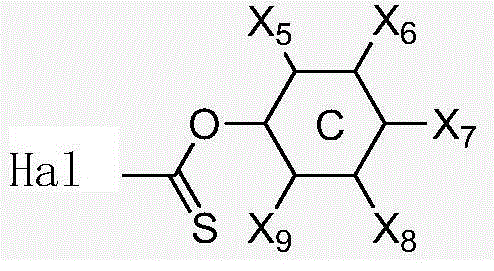

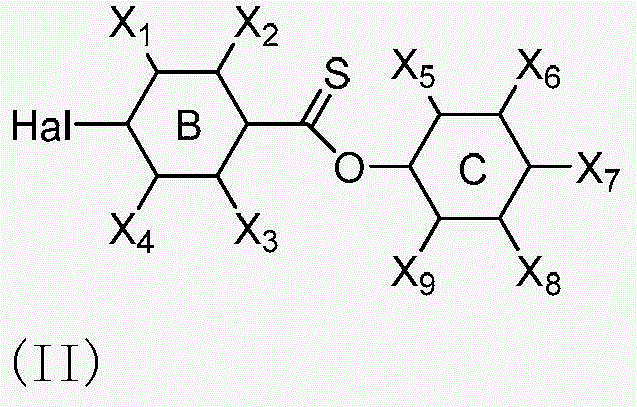

Preparation method of CF2O-contained monomer liquid crystal compound

ActiveCN103980098AHigh purityQuality improvementLiquid crystal compositionsOrganic compound preparationSolventCopper salt

The invention provides a preparation method of a CF2O-contained monomer liquid crystal compound. The preparation method comprises the following steps of (1) with a compound with a structure as shown in the formula I as a raw material, reacting under the catalytic action of a zinc reagent and copper salt and in the existence of a solvent to generate a compound with a structure as shown in the formula II; (2) enabling the compound with the structure as shown in the formula II and a fluorinated reagent to be subjected to fluoridation in the existence of the solvent to generate a compound with a structure as shown in the formula III; (3) enabling the compound with the structure as shown in the formula III and boric acid as shown in the formula IV to be subjected to SUZUKI coupled reaction in the existence of the solvent to obtain the CF2O-contained monomer liquid crystal compound with a structure as shown in the formula V, wherein the CF2O-contained monomer liquid crystal compound with a structure as shown in the formula V is as shown in the specification.

Owner:SHANGHAI CHEMSPEC CORP +1

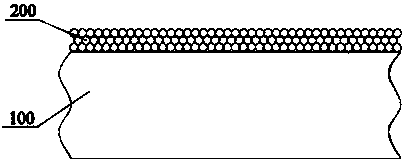

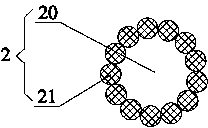

Self-cleaning hydrophilic composite material and preparation method thereof

ActiveCN103787586AEffective time extensionThe process is simple and controllableFilm structureMicrostructure

The invention provides a self-cleaning hydrophilic composite material and a preparation method thereof, wherein the self-cleaning hydrophilic composite material comprises a transparent substrate and a composite film positioned on the transparent substrate surface; the composite film comprises hollow microspheres with cavities therein, a spherical shell material of the hollow microspheres is a composite particle; the composite particle is a core-shell coating structure, a core material is SiO2 nano particle, a shell material is TiO2, the particle size of the shell material TiO2 is less than that of the core material SiO2. By improving a film structure on the basis of a microscopic structure, the self-cleaning hydrophilic composite material simultaneously has ultra-hydrophilic antifogging, anti-microbial and dustproof effects, and the time of the ultra-hydrophilic effectiveness is prolonged.

Owner:BYD CO LTD

Method for preparing silver tin oxide material

The invention provides a method for preparing a silver tin oxide material. The method comprises the following steps: (1) preparing raw materials, wherein the raw materials are base stocks or mixture of the base stocks and additives; (2) performing intermediate frequency smelting on the raw materials, and performing oxidation treatment while water atomization is performed to obtain alloy powder; (3) drying and sieving the alloy powder, and enabling the alloy powder to form an isostatic pressing ingot blank after isostatic pressing; and (4) burning the isostatic pressing ingot blank in a hydrogen heating furnace, performing thermal extrusion on the burnt ingot blank, and extruding panels or wire stocks made of silver tin oxide materials. By means of the method for preparing the silver tin oxide material, oxidization is finished in an atomization process, the oxidization of the powder is full, the tissue is even, and processing performance of the material is improved; the content of oxide in a material system can be improved to 20%, and using requirements of large-current electrical equipment are met; and the preparation method of the material is free of environment pollution, the technological process is easy to control, the production period is short, and stable large-volume production can be achieved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

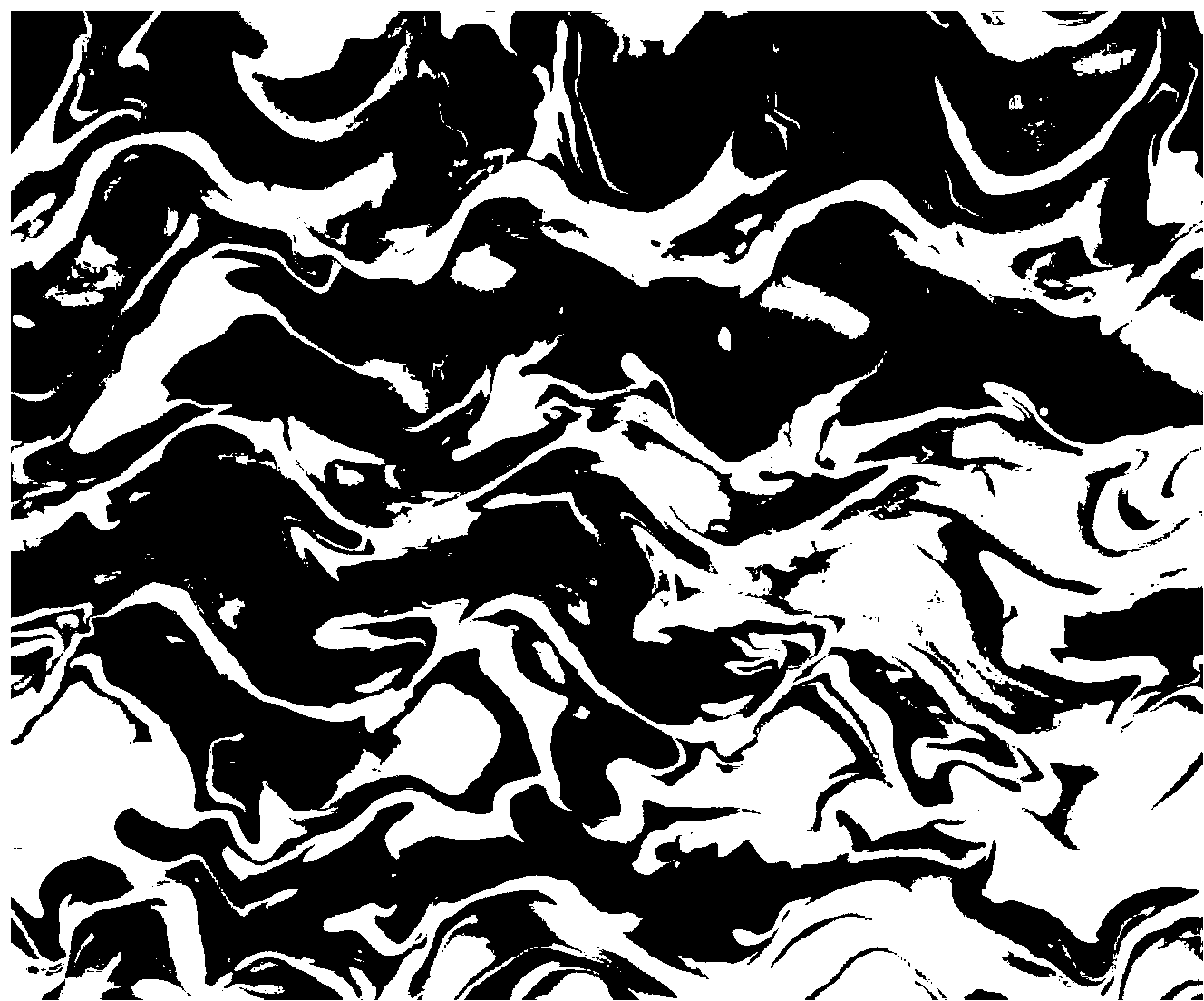

Production method of imitative natural stone texture porcelain tile

ActiveCN103213192AEase of Controlled RecyclingNatural and smooth textureCeramic shaping apparatusBrickSlurry

The invention discloses a production method of an imitative natural stone texture porcelain tile. By adjusting the caliber size and the shape of a slurry outlet of a distributing pipeline, and the arrangement position and swinging of the pipeline, different colors of slurry is sprayed onto the surface of a green brick under certain pressure to form different color gradients which are similar to patterns and lines formed by flowing, impact and extrusion of lava, the texture is natural and smooth, the effect is lifelike, the decorative effect is comparable to the decorative effect of natural stone, the working procedure is easy to control, and the mass production is stable. Meanwhile, by adopting the method provided by the invention, the slurry is easily recycled, and the overall production cost is effectively controlled.

Owner:GUANGDONG DOWSTONE TECH

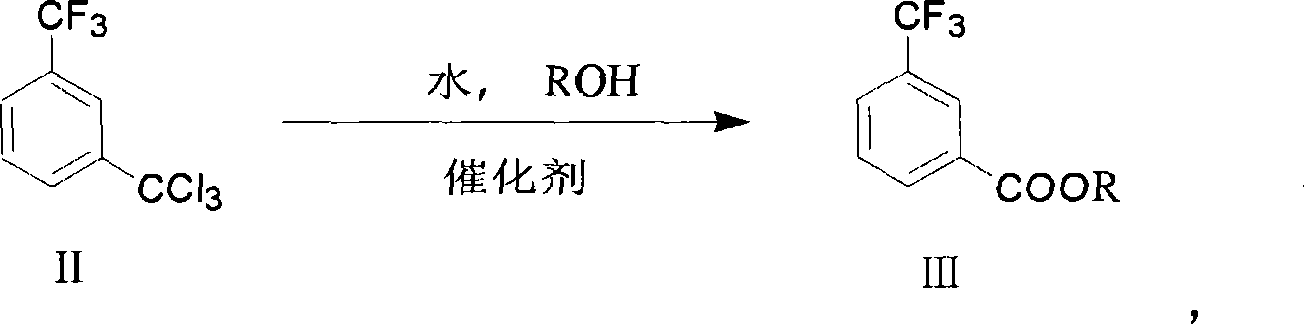

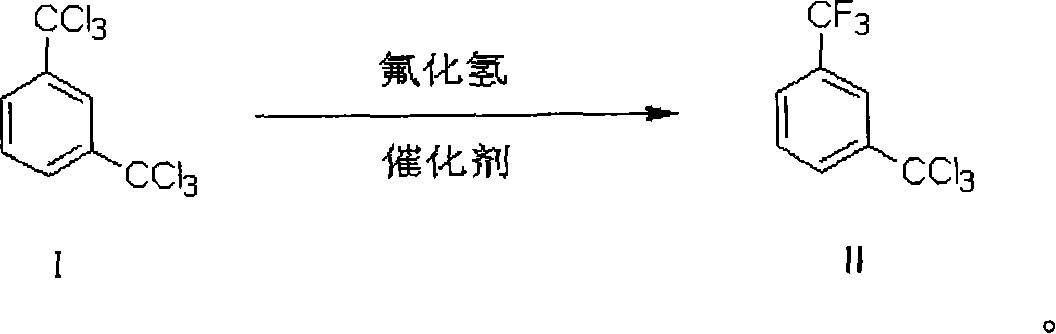

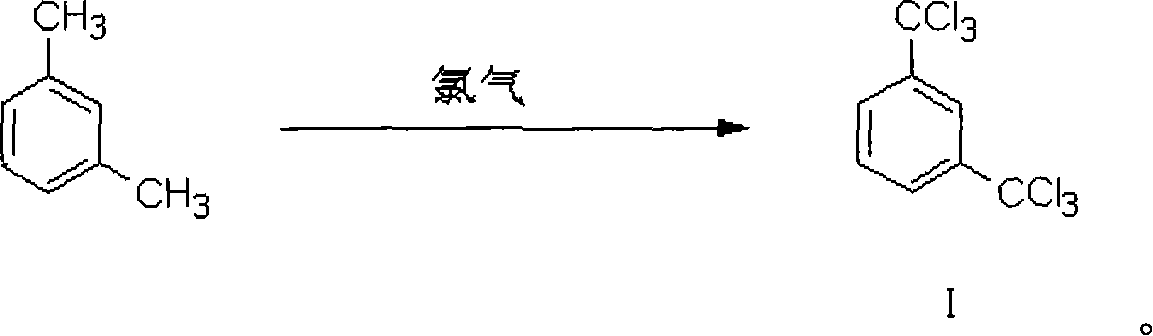

Prepn process of 3-trifluoro methyl benzoate

InactiveCN101066926AHigh purityQuality improvementOrganic compound preparationCarboxylic acid esters preparationSolventTrifluoromethyl

The preparation process of 3-trifluoromethyl benzoate includes the following steps: adding water into m-trichloromethyl trifloromethyl benzene for hydrolysis in the presence of zinc-containing catalyst, and the subsequent adding hydroxyl compound ROH for esterification to produce 3-trifluoromethyl benzoate, where R is alkyl radical, aryl radical, alkaryl radical or aralkyl radical. The m-trichloromethyl trifloromethyl benzene is prepared through the fluoridation of meta-bis(trichloro methylbenzene) and hydrogen fluoride in the presence of catalyst; and meta-bis(trichloro methylbenzene) is prepared through the reaction of metaxylene and chlorine in meta-bis(trichloro methylbenzene) solvent under the action of initiator or photoinitiator.

Owner:SHANGHAI CHEMSPEC CORP

Preparation method of lithium ion phosphate used as positive electrode active material

InactiveCN102208618AUniform particle size distributionImprove conductivityCell electrodesPhosphorus compoundsPyrrolePhosphate

The invention provides a preparation method of lithium ion phosphate, which is used as a positive electrode active material. The preparation method comprises the steps that: a. a phosphorus source, an iron source and an organic monomer solution are mixed under a controlled pH value of 4 to 6, such that a phosphate precursor is prepared; b. the phosphate precursor obtained from the step a is mixed with a lithium source, and the mixture is subject to a ball milling process; c. the resulting material obtained from the step b is baked under an inert atmosphere. The organic monomer is one or more selected from aniline, thiophene or pyrrole. The prepared lithium ion phosphate positive electrode active material is nano-sized, and has well-distributed particle sizes. The lithium ion phosphate particles can be uniformly coated with carbon with a thickness of a few nanometers, such that the conductivity of the material can be improved. With the material provided by the present invention, the electrode polarization degrees of the batteries during high rate charging / discharging are reduced, the reversible capacities of the batteries are improved, and the cycle lives of the batteries are prolonged. Also, the method provided by the present invention has advantages of low cost, high yield, stable product performance, and simple and controllable processes. With the method, large-scale clean industrial production of the material can be realized.

Owner:BYD CO LTD

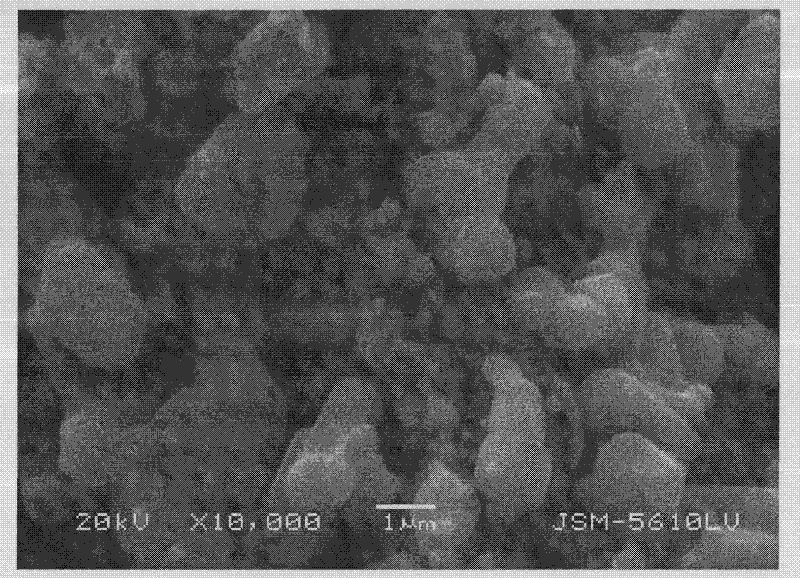

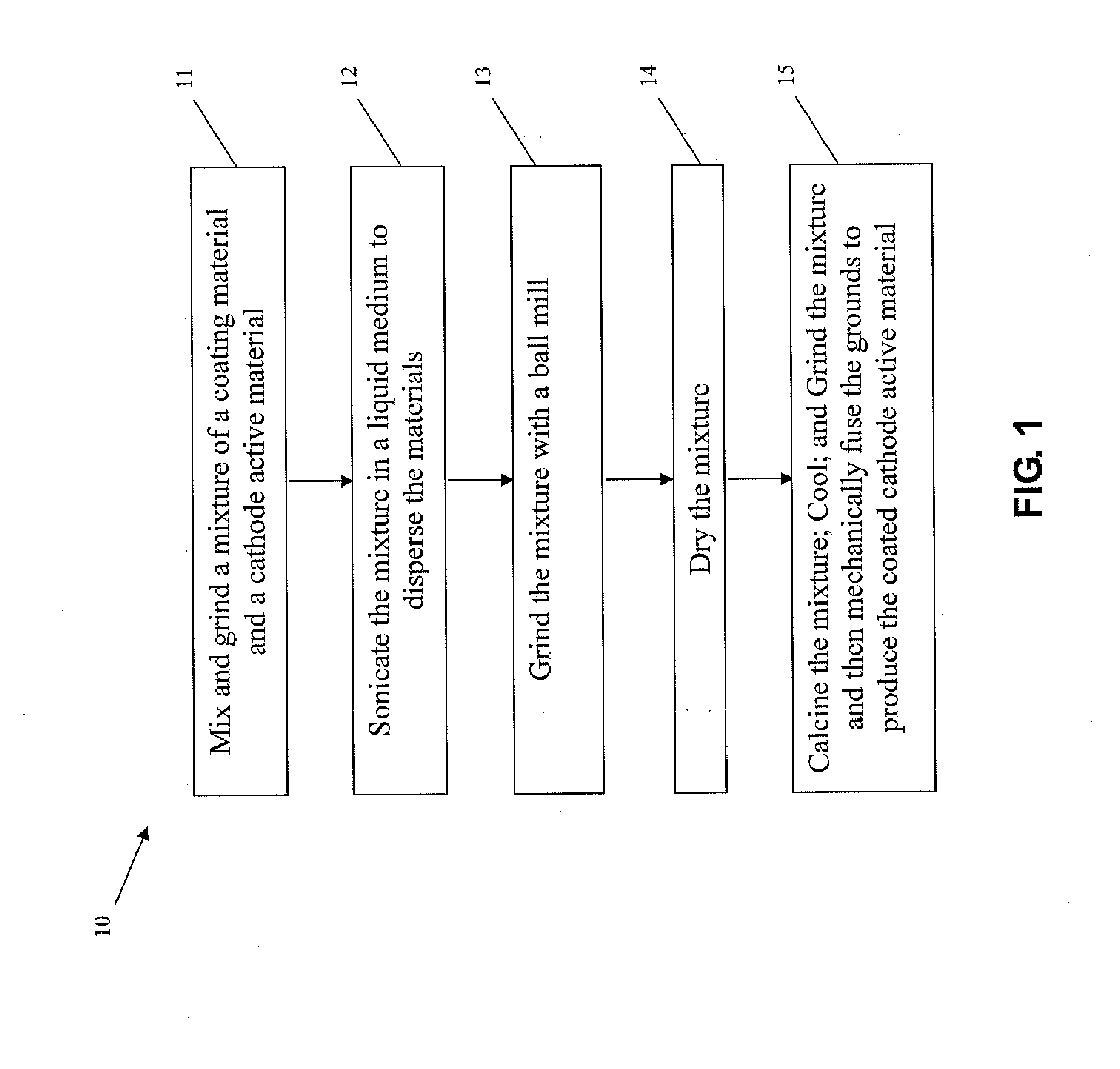

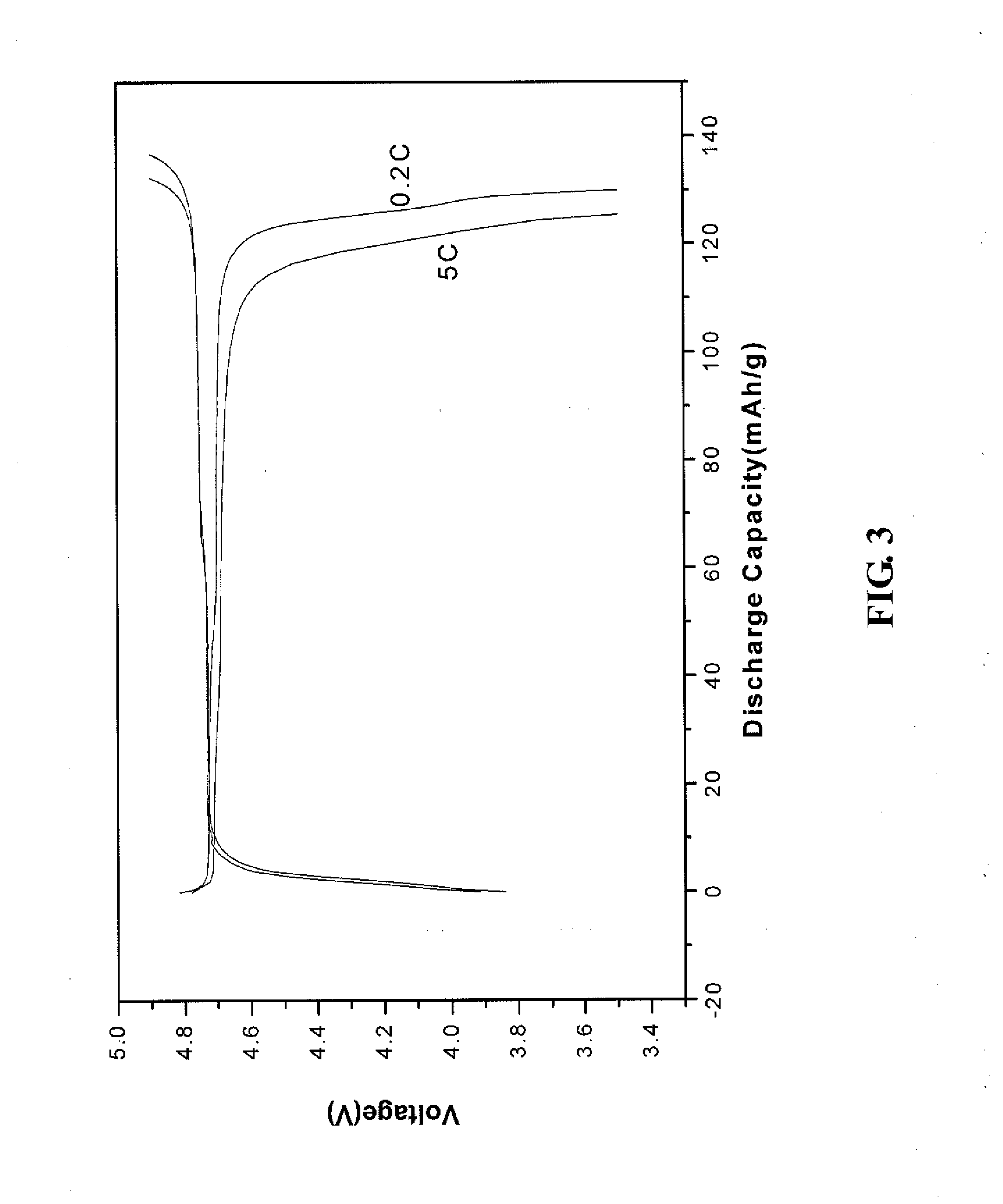

METHODS FOR SURFACE COATING OF CATHODE MATERIAL LiNi0.5-XMn1.5MXO4 FOR LITHIUM-ION BATTERIES

InactiveUS20140106223A1Easy to adaptHigh rateElectrode thermal treatmentNon-aqueous electrolyte accumulator electrodesCarbon coatingSucrose

A high-voltage lithium-ion battery cathode material includes LiNi0.5-xMn1.5MxO4 (0≦x≦0.2, M═Mg, Zn, Co. Cu, Fe, Ti, Zr, Ru, and Cr), which is coated with a coating material, which may be a carbon coating material, a metal phosphate coating material, or a combination thereof. The carbon coating material may be acetylene black, graphene oxide, conductive graphite, glucose, sucrose, starch, lactose, maltose, phenolic resins, polyvinyl alcohol, or a combination thereof, and the metal phosphate coating material may be FePO4, LiFePO4, CoPO4, Mn3(PO4)2, LnPO4. The coating material may account for 1 to 10% (wt %). Products of the present invention have high reversible capacities. Synthesis methods are disclosed that are simple and controllable, can produce uniform coating, and are suitable for industrial scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of recycling method of silicon wafer cutting waste mortar

The invention provides a method for recycling waste mortar for cutting silicon wafers, comprising the following steps: a. solid-liquid separation of waste mortar for cutting silicon wafers to obtain solid sand and liquid parts; b. adding decolorization to the liquid parts obtained in step a agent, ion adsorbent and filter aid, and solid-liquid separation to obtain polyethylene glycol cutting recovery liquid; c. the solid sand material obtained in step a is separated and removed by magnetic separation to obtain a mixture of silicon and silicon carbide; d. Heat the mixture of silicon and silicon carbide obtained in step c under vacuum at 1425-1550°C; cool to room temperature and filter through a sieve, collect the material under the sieve to obtain silicon carbide micropowder, collect the material on the sieve to obtain silicon block; pulverize silicon block to obtain silica fume. The recovery method provided by the invention is very environment-friendly, and the separation of silicon and silicon carbide is more thorough, and the recovered polyethylene glycol, silicon carbide and silicon powder have higher purity.

Owner:BYD CO LTD

Recycling process of sintering neodymium iron boron discard black wafer

InactiveCN104801718AImprove recycling ratesThe process is simple and controllableInorganic material magnetismRecycling and recovery technologiesStrong acidsWaste material

The invention discloses a recycling process of a sintering neodymium iron boron discard black wafer. The recycling process comprises the following steps of pretreatment of waste material, multi-stage crushing, hydrogen decrepition, powder preparation by jet milling, blending of main alloy and auxiliary alloy, forming of a magnetic field, and sintering, so as to prepare a neodymium iron boron magnet which has satisfactory requirement; the auxiliary alloy is an alloy fine powder containing one or multiple of praseodymium neodymium, holmium iron, gadolinium iron and dysprosium iron, and the percentage of auxiliary alloy is 1% to 50%. The recycling process has the advantages that the utilizing rate of waste material of the black wafer is high, the flow process is simple and controllable, the operability is strong, and the manufacturing cost is saved; strong acid and strong alkaline with higher pollution property are not contained, the environment-friendly effect is realized, and the economic and social benefits are higher.

Owner:安徽万磁电子有限公司

Method for preparing silver copper oxide electric contacting material

A method of preparing silver copper oxide electrical contact material is disclosed. The raw material composition, particle size, weight percentage are in that: base metal: silver powder and copper oxide powder have powder particle size of 1.5 mu m -50 mu m, copper oxide powder takes the quantity of more than 2%-25%, based on total weight, the rest is silver; additive: bismuth oxide does not exceed 0.9% of the total weight, nickel oxide does not exceed 1% of total weight. Raw material is surface treated, after batching, the raw material is mixed uniformly in a powder mixing machine to form an isostatic pressing ingot after isostatic pressed; The isostatic pressing ingot is sintered in a heating furnace to obtain a sintered ingot; then the sintered ingot is transported into a extruder to extrude into a plate or wire material. The produced silver copper oxide electrical contact material can satisfy the operation requirement of high-performance low-voltage electrical apparatus, thus is applicable to a DC contactor especially.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Preparation method of anode active material

The invention provides a preparation method of an anode active material, which comprises the steps of: a, adding a titanium source and an organic carbon source in an organic solution with the pH value of 0-6 to prepare a mixture solution; b, adding an oxidizing agent in the mixture solution, reacting for 1-24h at a temperature of 20-80 DEG C, then separating and settling, washing with water, drying to obtain a titanium-containing precursor; and c, carrying out mixing and ball-milling on the titanium-containing precursor obtained in the step b and a lithium source, and then roasting in an inert gas. A lithium titanate composite material prepared by adopting the method disclosed by the invention has less impurity phases; the prepared nanometer lithium titanate particles are attractive in appearance; and the preparation method has the advantages of short time, low energy consumption, low cost, high yield, uniform particles of the prepared material, stable performance of the prepared material, simple and controllable process, and capability of realizing massive industrialized clean production.

Owner:BYD CO LTD

Preparation method of low-density SiO2 aerogel/sponge composite material

InactiveCN103665422AEasy to operateThe process is simple and controllableSupercritical dryingAlcohol

The invention discloses a preparation method of a low-density SiO2 aerogel / sponge composite material. The preparation method is characterized by comprising the following steps: (a) mixing a silicon source, absolute ethyl alcohol, deionized water and formamide according to the molar ratio of 1:(10-20):(2-7):(1-3), and then adding an acid catalyst of which the molar ratio to the silicon source is (0.001-0.01):1; adding alkali liquor to adjust the pH value after fully stirring and hydrolyzing at 0-60 DEG C; (b) taking a mixed solution in the step (a) into a mold containing sponge, standing to obtain wet gel; (c) replacing a solvent of the wet gel for 3-8 times by adopting absolute ethyl alcohol, wherein each replacement time is 8-24 hours, and carrying out supercritical drying under the environment of CO2 after replacement is finished, so as to prepare the low-density SiO2 aerogel / sponge composite material.

Owner:NANJING TIANYIN ADVANCED MATERIAL TECH

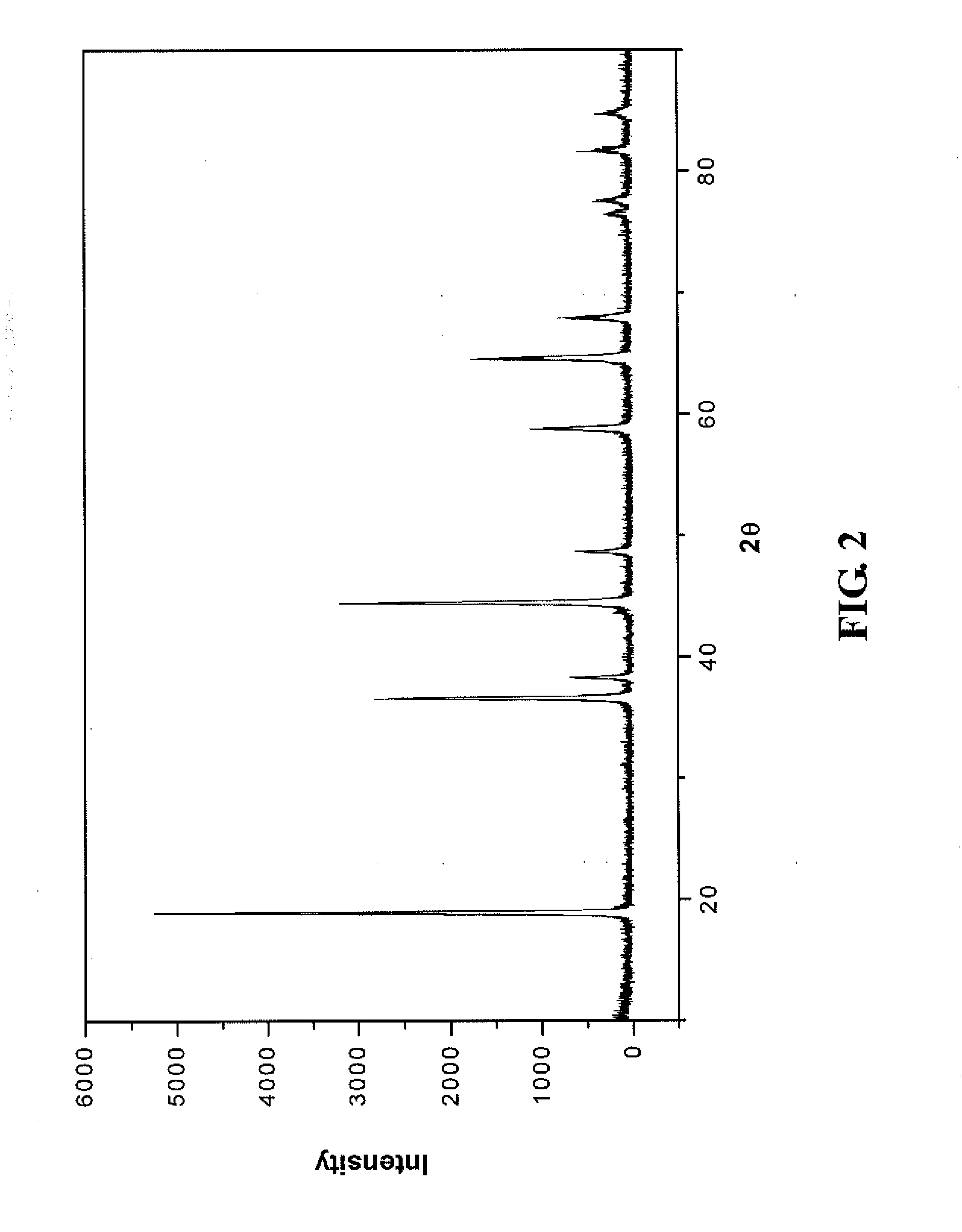

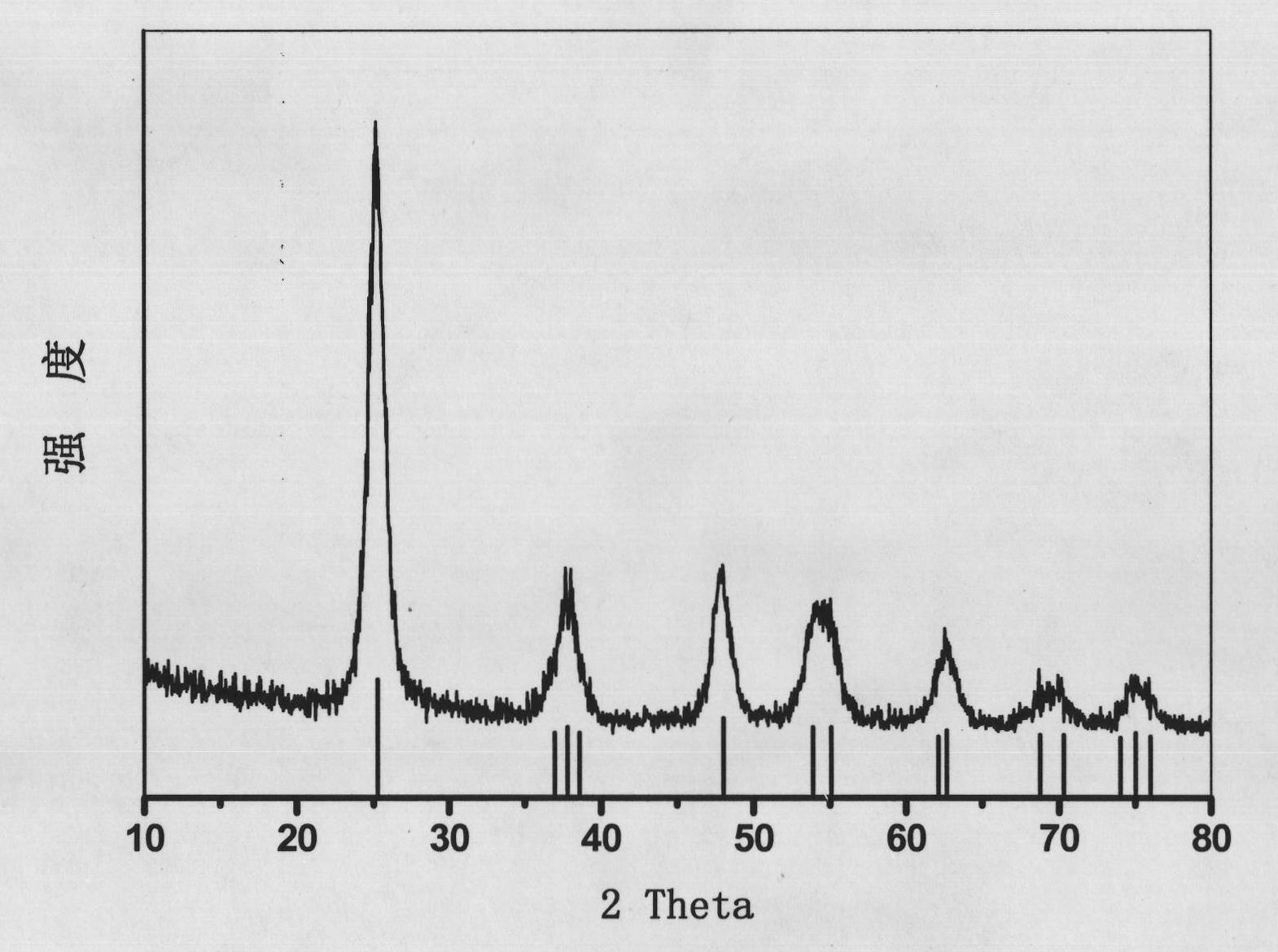

LiMnxFe1-xPO4 positive electrode active material and preparation method thereof

ActiveCN104752718AAvoid the defect of uneven mixingStable structurePositive electrodesPhosphorus compoundsHigh cellElectrical battery

The invention provides a preparation method of a LiMnxFe1-xPO4 positive electrode active material. The method comprises the following steps that a soluble trivalent manganese salt solution, a soluble ferric iron salt solution and a soluble phosphate radical-containing substance solution are blended to form a mixed solution, the mixed solution undergoes a reaction to produce a MnxFe1-xPO4.2H2O precursor, and LiMnxFe1-xPO4 is prepared from the MnxFe1-xPO4.2H2O precursor. The invention also provides the LiMnxFe1-xPO4 positive electrode active material obtained by the preparation method. The LiMnxFe1-xPO4 positive electrode active material has the advantages of uniform particle size distribution, perfect morphology, no agglomeration, small particle size and material electroconductivity improvement. A cell prepared from the LiMnxFe1-xPO4 positive electrode active material has excellent rate discharge performance, especially has high-rate discharge performance, has a high cell charging-discharging capacity, stable cell charging-discharging performances and good cycle performances, lays the foundation in excellent positive electrode active material development and is conducive to material application and cell development.

Owner:BYD CO LTD

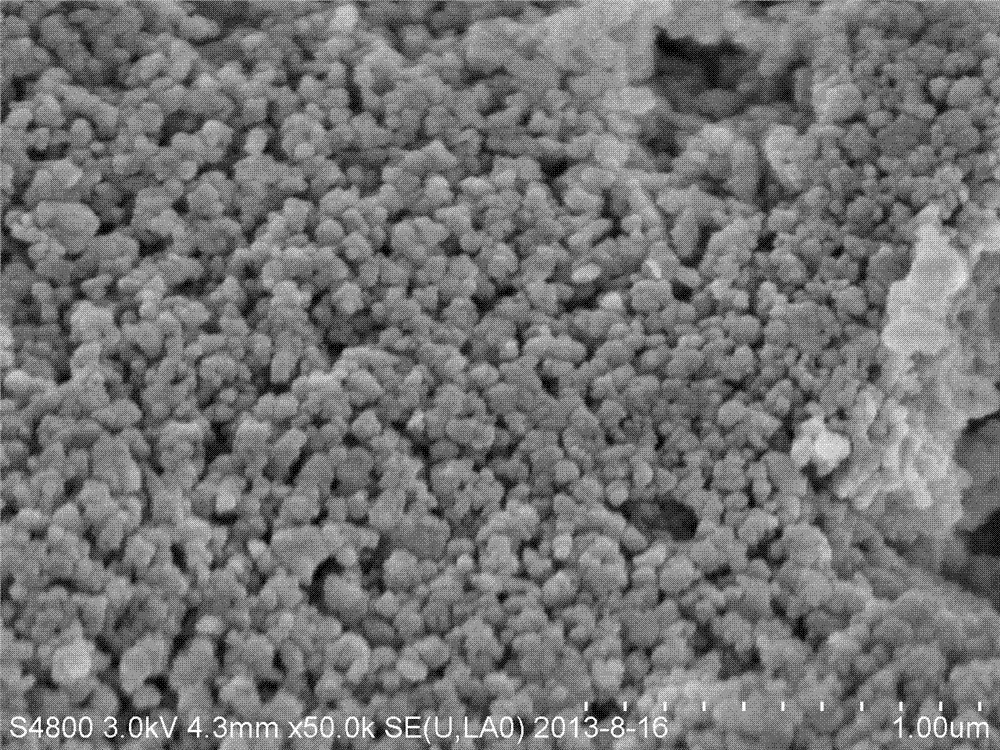

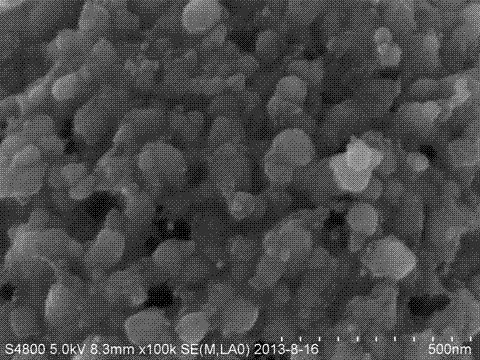

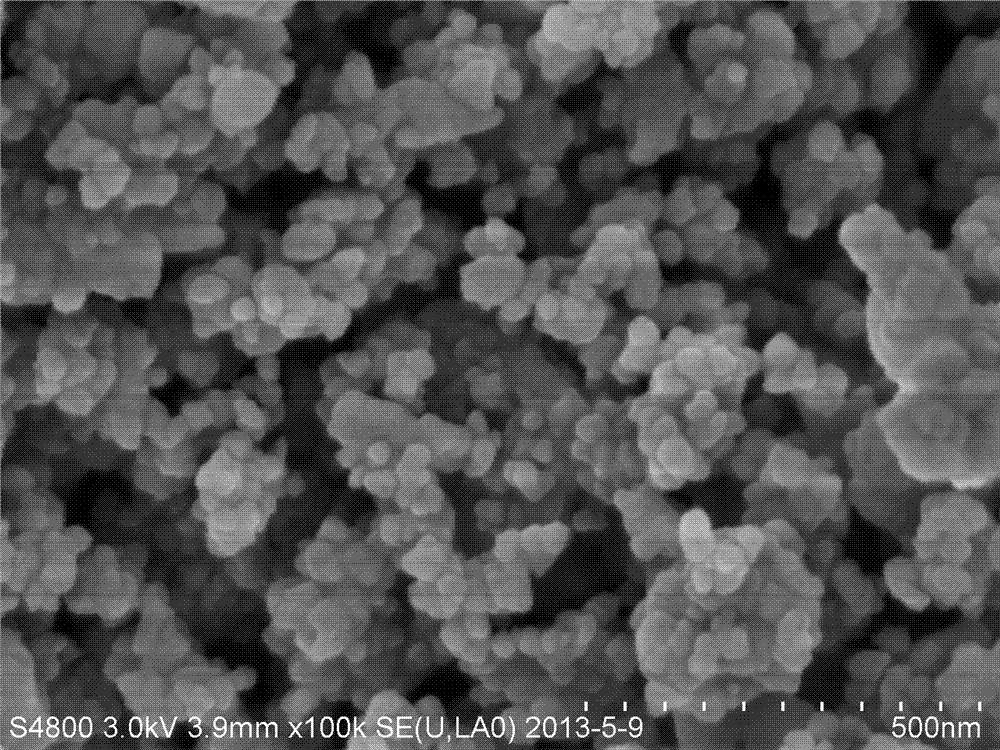

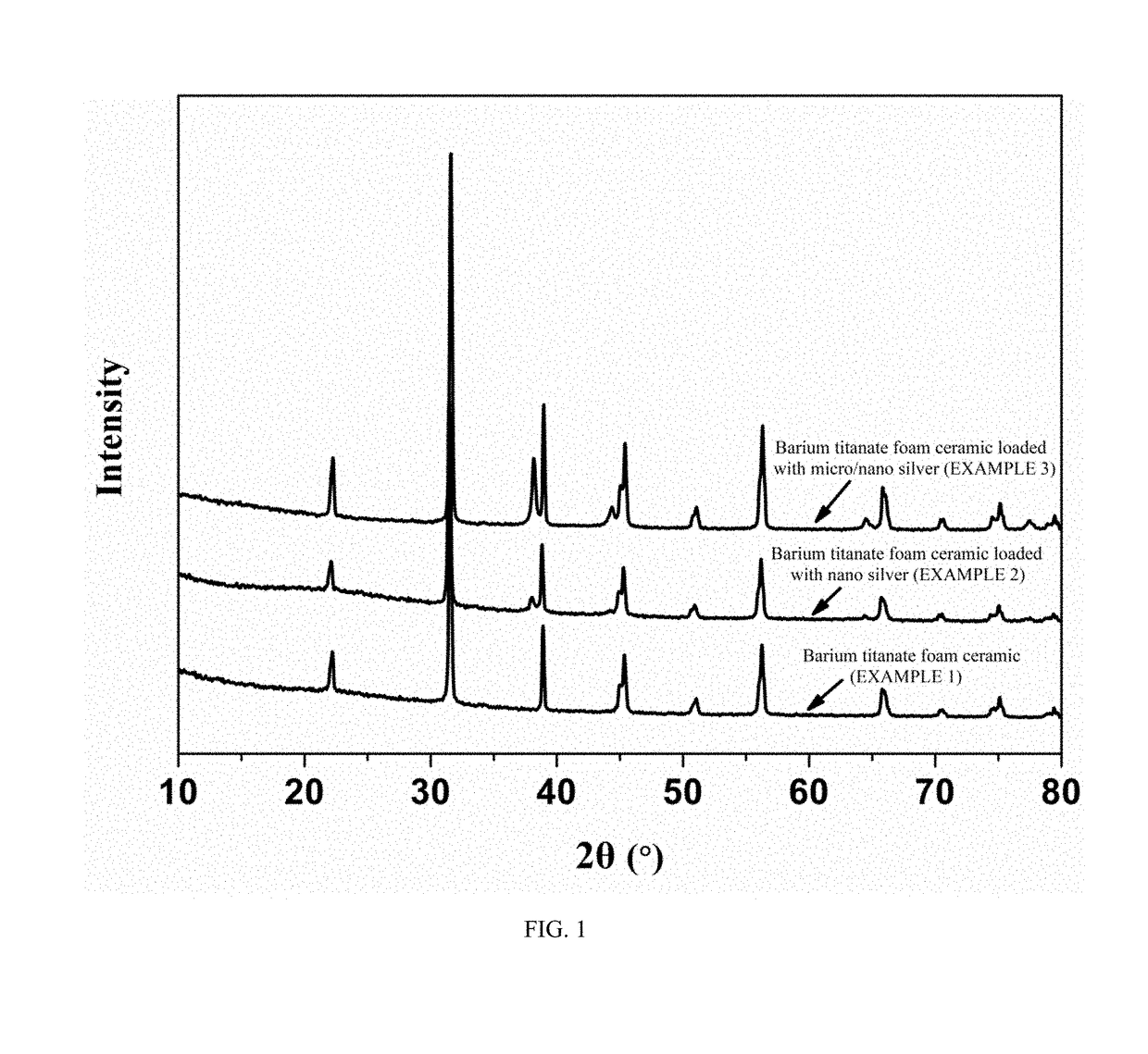

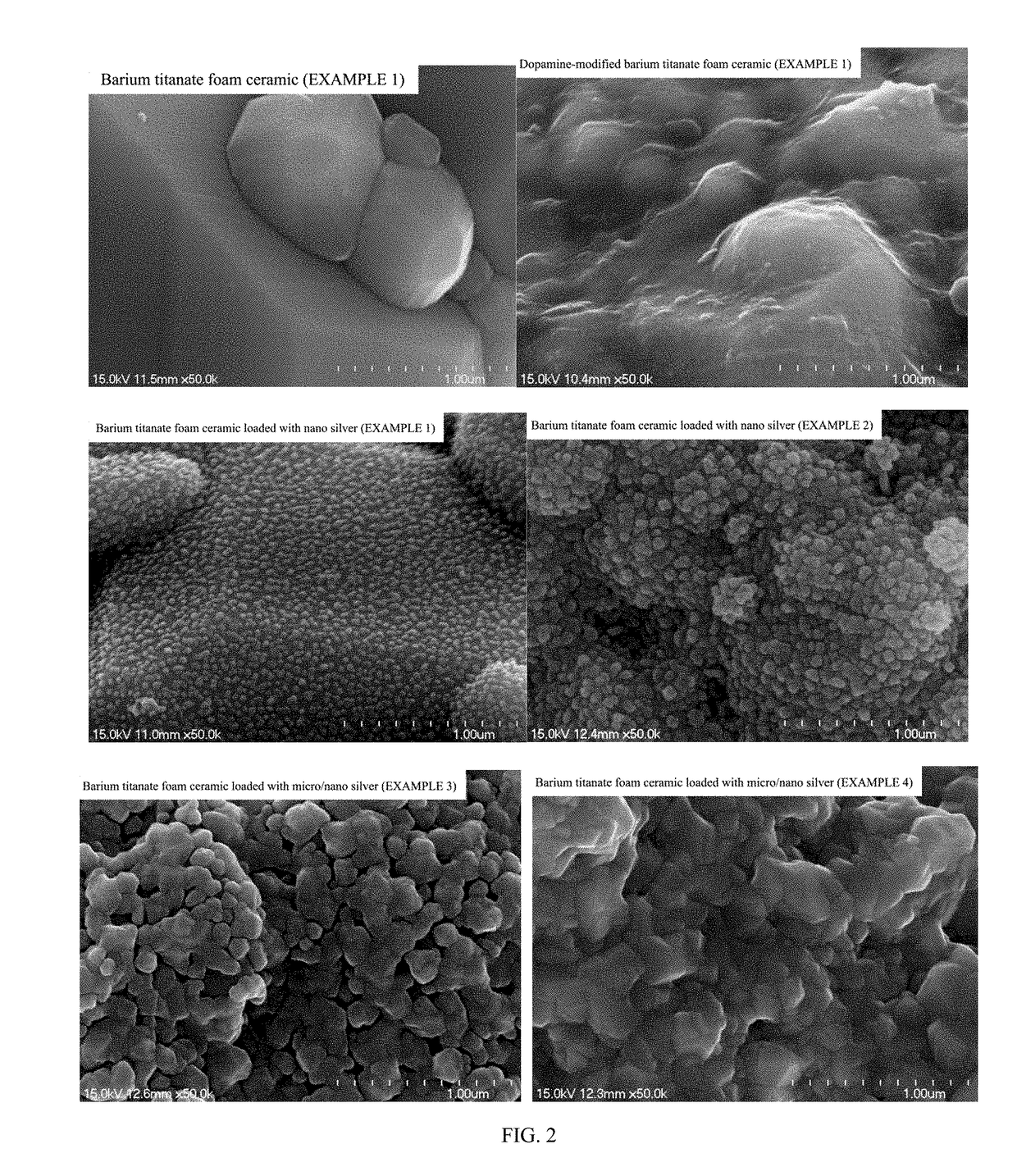

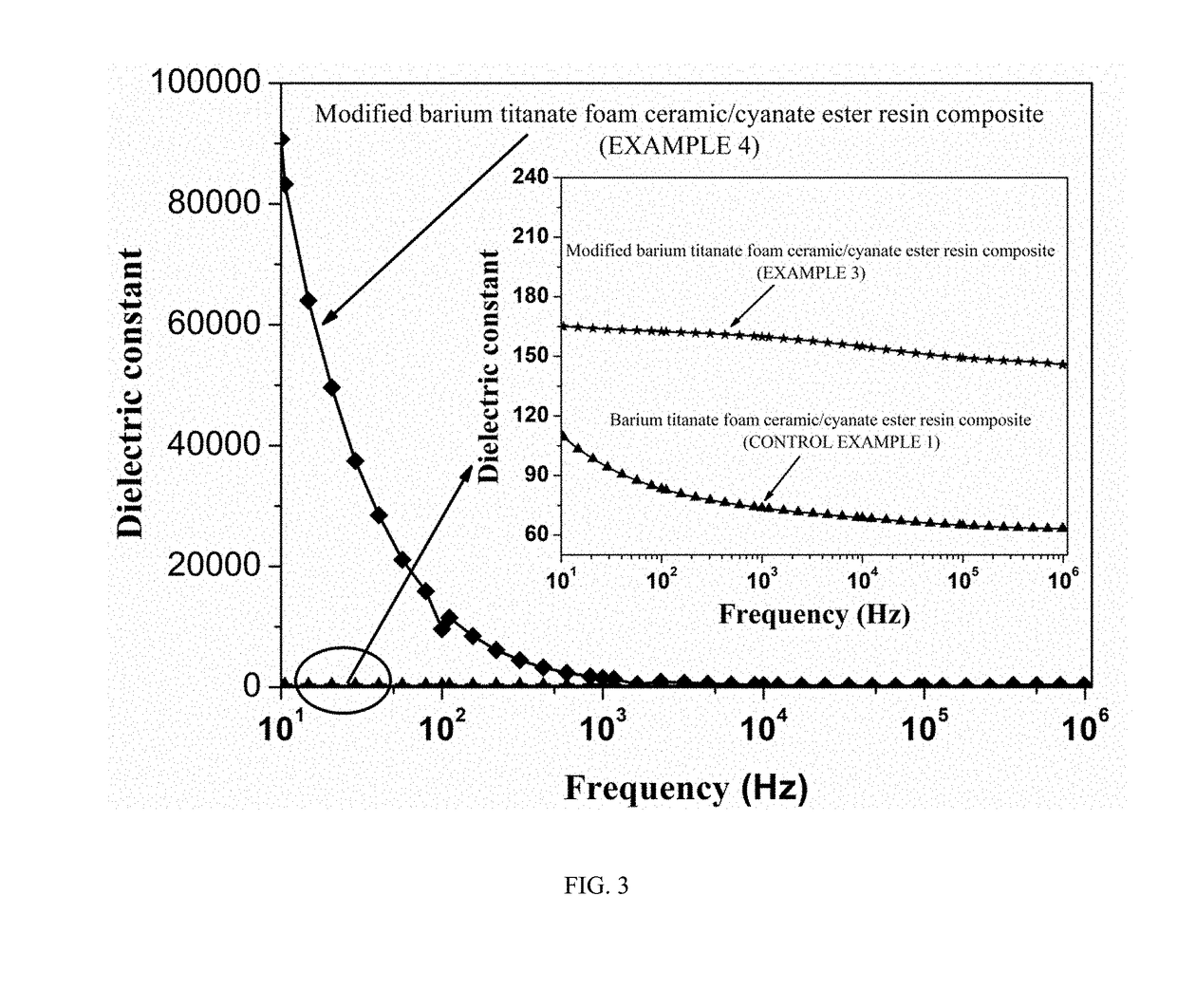

Modified barium titanate foam ceramic/thermosetting resin composites and preparation method thereof

ActiveUS20190016644A1Excellent dielectric propertiesHigh dielectric constantCeramicwareMolten stateBarium titanate

Disclosed are a modified barium titanate foam ceramic / thermosetting resin composite material and a preparation method therefor. An organic additive is used as an auxiliary; deionized water is used as a solvent; nanometer barium titanate is used as a ceramic raw material; and same are mixed and ground so as to form a slurry. A pre-treated polymer sponge is impregnated in the slurry for slurry coating treatment and a barium titanate foam ceramic is obtained after drying and sintering. Then, through dopamine modification, micrometer / nanometer silver is in-situ deposited on a skeleton surface. A resin, which is in the molten state and is thermosettable, is immersed into pores of the modified barium titanate foam ceramic, and a modified barium titanate foam ceramic / thermosetting resin composite material is obtained after a thermosetting treatment.

Owner:SUZHOU UNIV

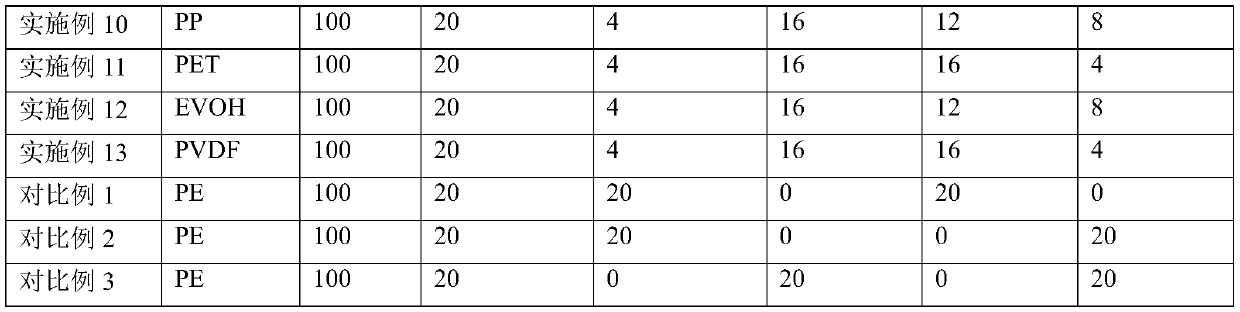

Preparation method of hydrophobic polymer film material

ActiveCN110218347AShort production processThe process is simple and controllableFlat articlesRolling angleFilm material

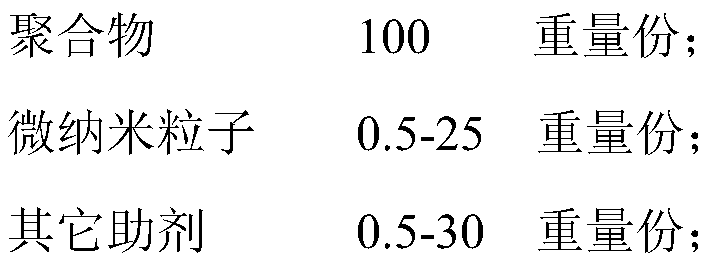

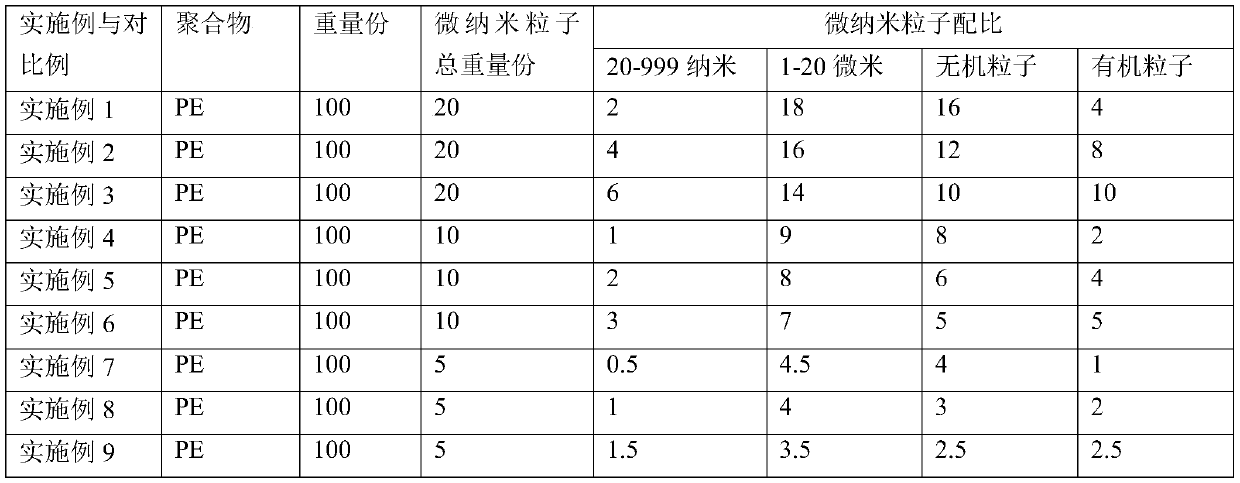

The invention provides a preparation method of a hydrophobic polymer film material. The material comprises the following components in parts by weight: 100 parts of a polymer; 0.5-25 parts of micro-nano particles; and 0.5-30 parts of other auxiliary agents. The preparation step comprises: melt-mixing the polymer, the micro-nano particles and the other auxiliary agents, performing extrusion, calendering or tape casting to form a film blank, and then performing stretching; and forming micro-nano protrusions and cavity rough surface structures after stretching to obtain the hydrophobic polymer film material. The water contact angle of the material is 120 degrees or more, and the rolling angle is 15 degrees or less.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing large-sized ceramic grinding balls

The invention discloses a method for large-sized ceramic grinding balls, which belongs to the technical field of grinding media. The method comprises: firstly, preparing monomer solution for gelcasting; secondly, adding ceramic powder into the monomer solution, stirring the solution uniformly to obtain stable slurry, adding a catalyst and an initiator into the slurry, stirring the slurry under vacuum to exhaust air; and finally, pouring the slurry into a mold, keeping the temperature of the slurry till the monomer reacts with a crosslinker completely to obtain a ceramic grinding ball biscuit, and drying and sintering the biscuit to obtain the ceramic grinding ball. The ceramic grinding ball manufactured by the method has high strength, hardness, wear resistance, corrosion resistance and high-temperature stability; meanwhile, the size of the ball can be controlled by the size of the ball mold cavity of the mold; and the method is particularly suitable for forming large-sized ceramic grinding balls, is low in cost and makes industrial production easy.

Owner:SHANGHAI JIAO TONG UNIV

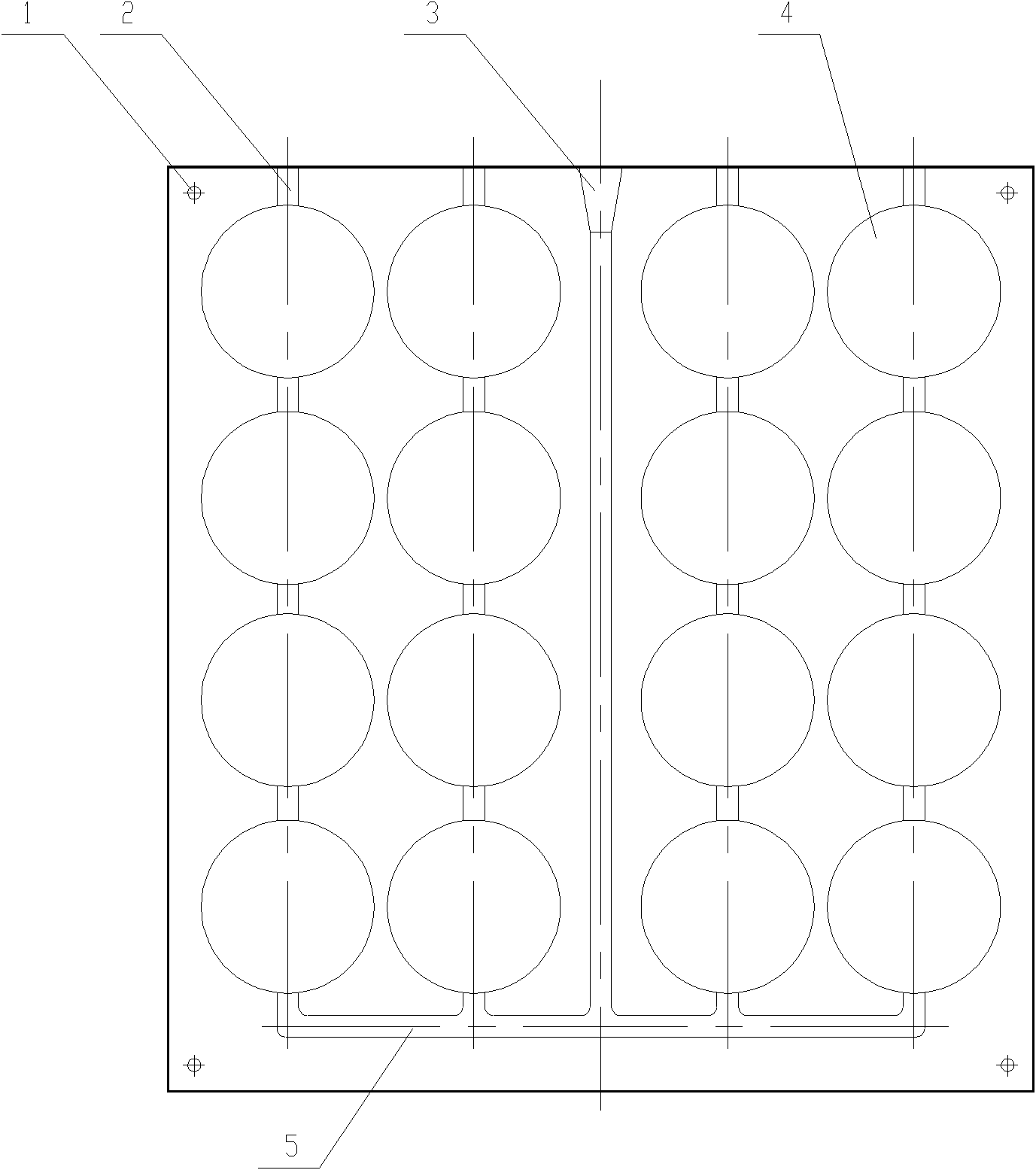

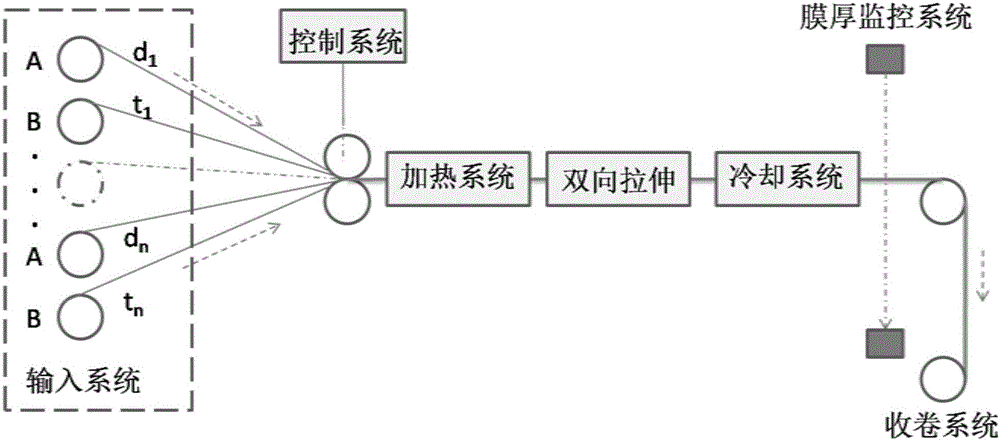

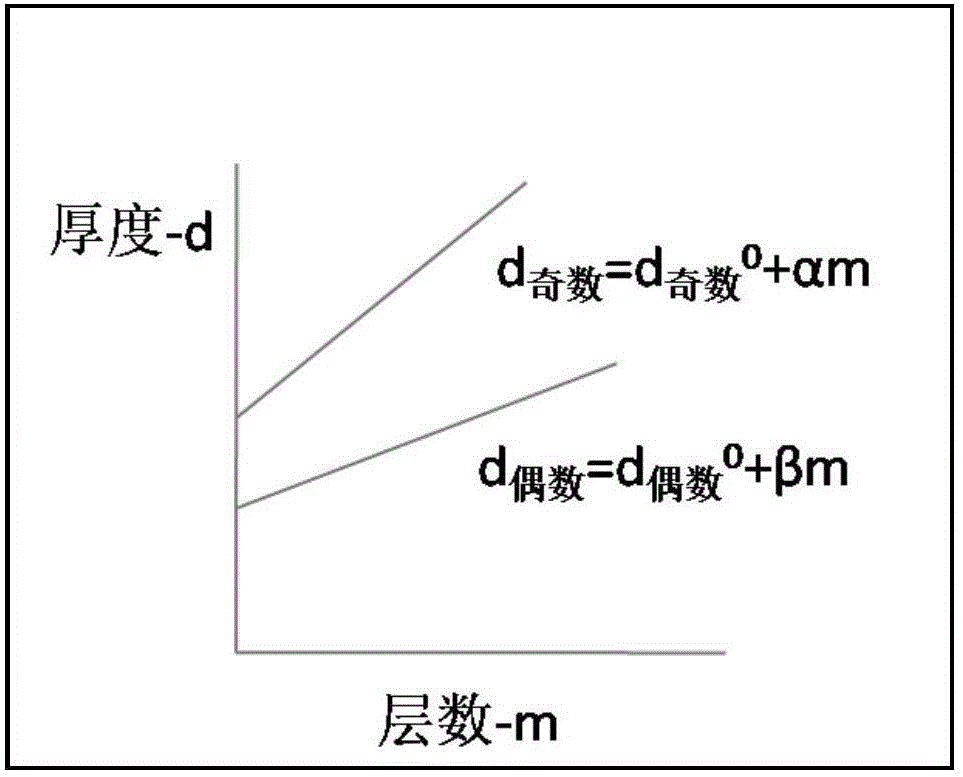

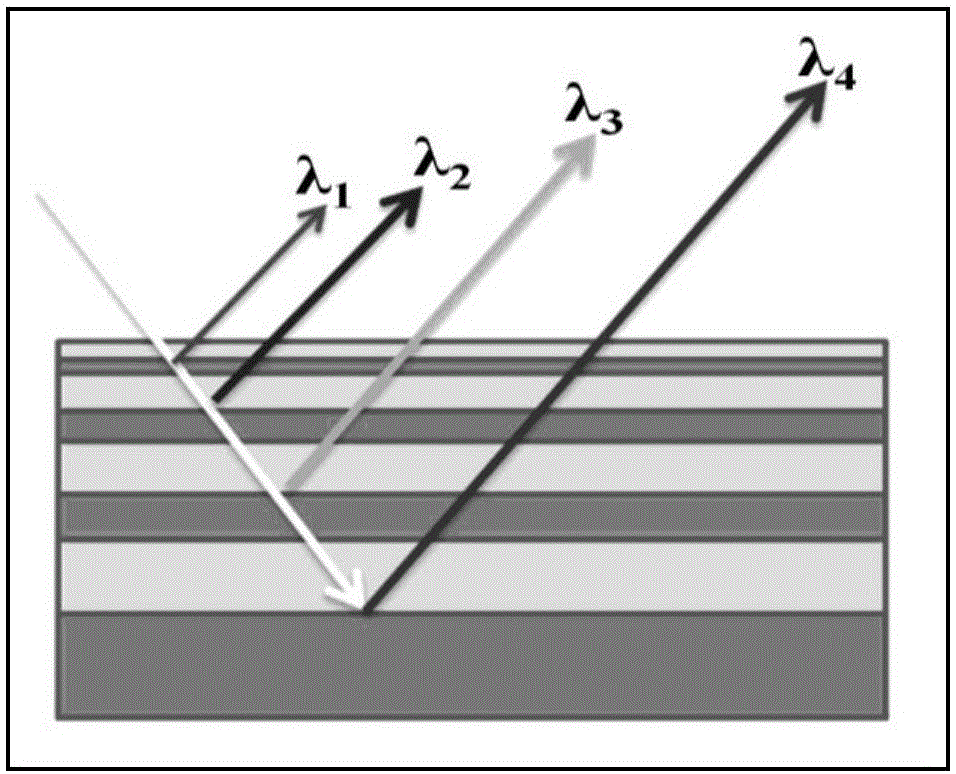

Polymer multilayer optical film with linear trapezoidal thickness structure and manufacturing method thereof

InactiveCN106772708AThe process is simple and controllableReduce manufacturing costOptical elementsBroadbandChemistry

The invention discloses a polymer multiplayer optical film with a linear trapezoidal thickness structure and a manufacturing method thereof. The polymer multilayer optical film comprises n first optical film layers and m second optical film layers, wherein the first optical film layers are made of a polymer A; the second optical film layers are made of a polymer B; the polymer A and the polymer B have different refractive indexes; the n first optical film layers and the m second optical film layers are laminated alternately layer by layer; the thicknesses of the n first optical film layers increase layer by layer in a linear gradient way along an overlapping direction; the thicknesses of the m second optical film layers increase layer by layer in a linear gradient way along an overlapping direction; the polymer multilayer optical film is obtained by adopting a bidirectional extension technology. By adopting the polymer multilayer optical film with the linear trapezoidal thickness structure, bandwidth reflection can be performed selectively; for example, infrared light of a certain bandwidth is reflected, ultraviolet light is reflected fully, and visible light is reflected fully. The polymer multilayer optical film is simple in manufacturing process, is low in cost, and can be widely applied in the fields of agricultural plastic tents, automobile window films, building window films and liquid crystal display brightening films.

Owner:安徽昂科丰光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com