Method for preparing large-sized ceramic grinding balls

A large-size, grinding ball technology, applied in the field of grinding media, to achieve the effect of low one-time investment, simple and controllable process flow, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Zirconia ceramic grinding ball

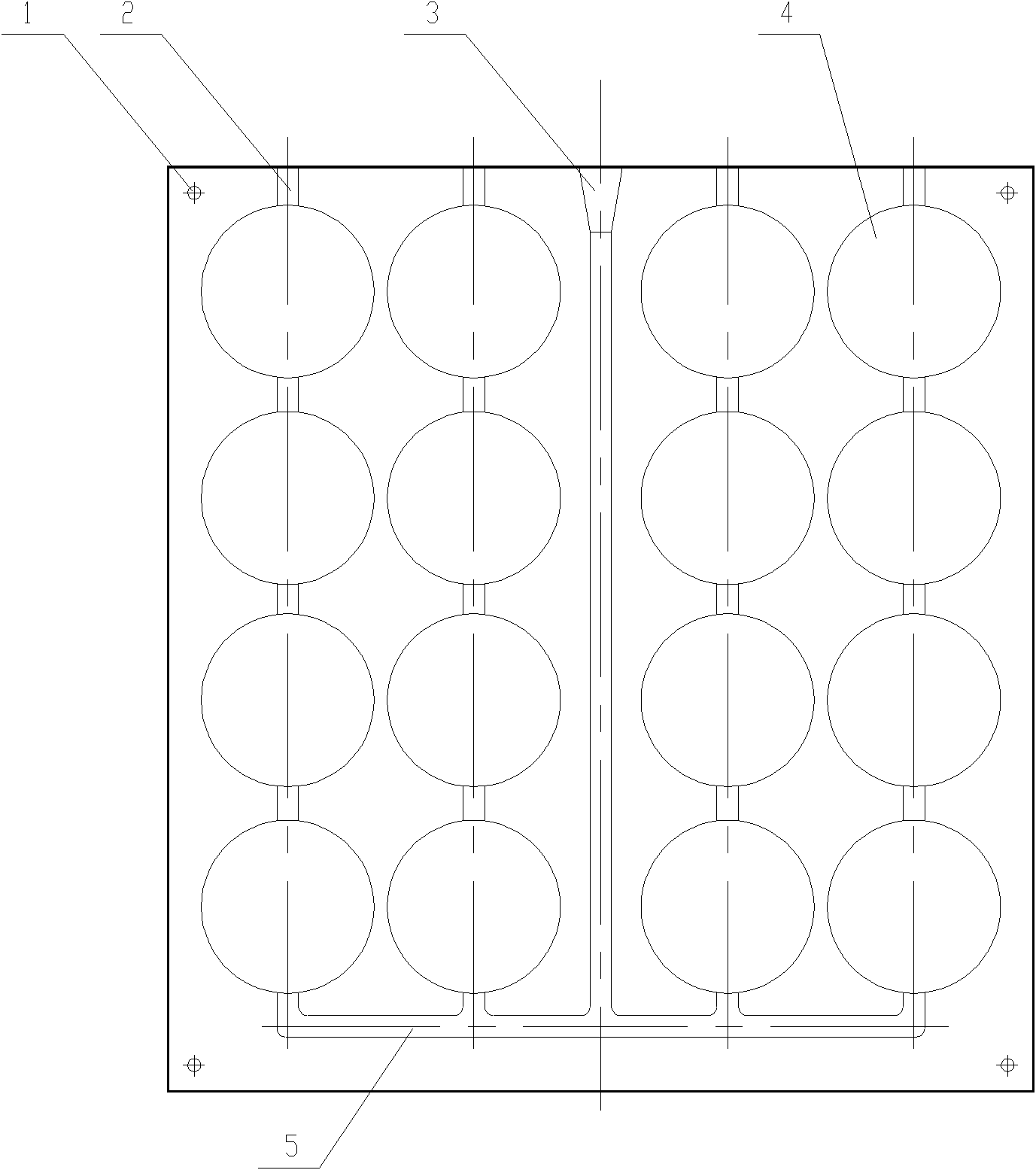

[0034] In the present embodiment, the mold that adopts is graphite mold, and its structure is as follows figure 1 As shown in , each mold has 16 spherical cavities.

[0035] The raw material is commercially available 8% yttria-stabilized zirconia powder (purity>99%), with an average particle size of 0.5 microns. Prepare 1000ml premixed solution, the mass ratio is: 10% acrylamide; 1% N,N'-methylenebisacrylamide; 2% ammonium polyacrylate; 87% deionized water.

[0036] Prepare a slurry with a mass solid content of 80%, and ball mill and mix for 2 hours.

[0037]Add the catalyst tetramethylethylenediamine and the initiator ammonium persulfate respectively, the addition amount is 0.2% of the mass of the above slurry, and after vacuum stirring and degassing for 15 minutes, inject the slurry from the gate of the mold, when the slurry Until it comes out of the riser, the mold is then transferred to an oven preheated to 80°C and ...

Embodiment 2

[0040] Embodiment 2: alumina ceramic grinding ball

[0041] In this embodiment, the mold used is a plastic mold, and its structure is as follows figure 1 As shown in , each mold has 16 spherical cavities.

[0042] The raw material is commercially available α-alumina (purity>99.5%) with an average particle size of 1 micron. Prepare 1000ml premixed solution, the mass ratio is: 9% acrylamide; 0.45% N,N'-methylenebisacrylamide; 0.55% ammonium polyacrylate; 90% deionized water.

[0043] Prepare a slurry with a mass solid content of 70%, and ball mill and mix for 5 hours.

[0044] Add the catalyst tetramethylethylenediamine and the initiator ammonium persulfate respectively, the addition amount is 0.15% of the above-mentioned slurry mass, and after vacuum stirring and degassing for 20 minutes, inject the slurry from the gate of the mold, when the slurry Until it emerges from the riser, the mold is then transferred to an oven preheated to 70°C for 20 minutes. The mold is placed a...

Embodiment 3

[0047] Embodiment 3: silicon nitride ceramic grinding ball

[0048] In this embodiment, the mold used is an aluminum alloy mold, and its structure is as follows figure 1 As shown in , each mold has 16 spherical cavities.

[0049] The raw material is commercially available silicon powder (purity > 99%), the particle size distribution is 1-30 micron, and the average particle size is 10 micron, with 4% aluminum oxide and 1% yttrium oxide as sintering aid (the ratio of sintering aid is the mass ratio relative to the silicon powder). Prepare 1000ml premixed solution, the mass ratio is: 12% acrylamide; 0.6% N,N'-methylenebisacrylamide; 1% ammonium citrate; 86.4% deionized water.

[0050] Prepare a slurry with a mass solid content of 60%, and ball mill and mix for 3 hours.

[0051] Add the catalyst tetramethylethylenediamine and the initiator ammonium persulfate respectively, and the addition amount is 0.1% of the above-mentioned slurry mass, and after vacuum stirring and degassin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com