Patents

Literature

706 results about "Ammonium citrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

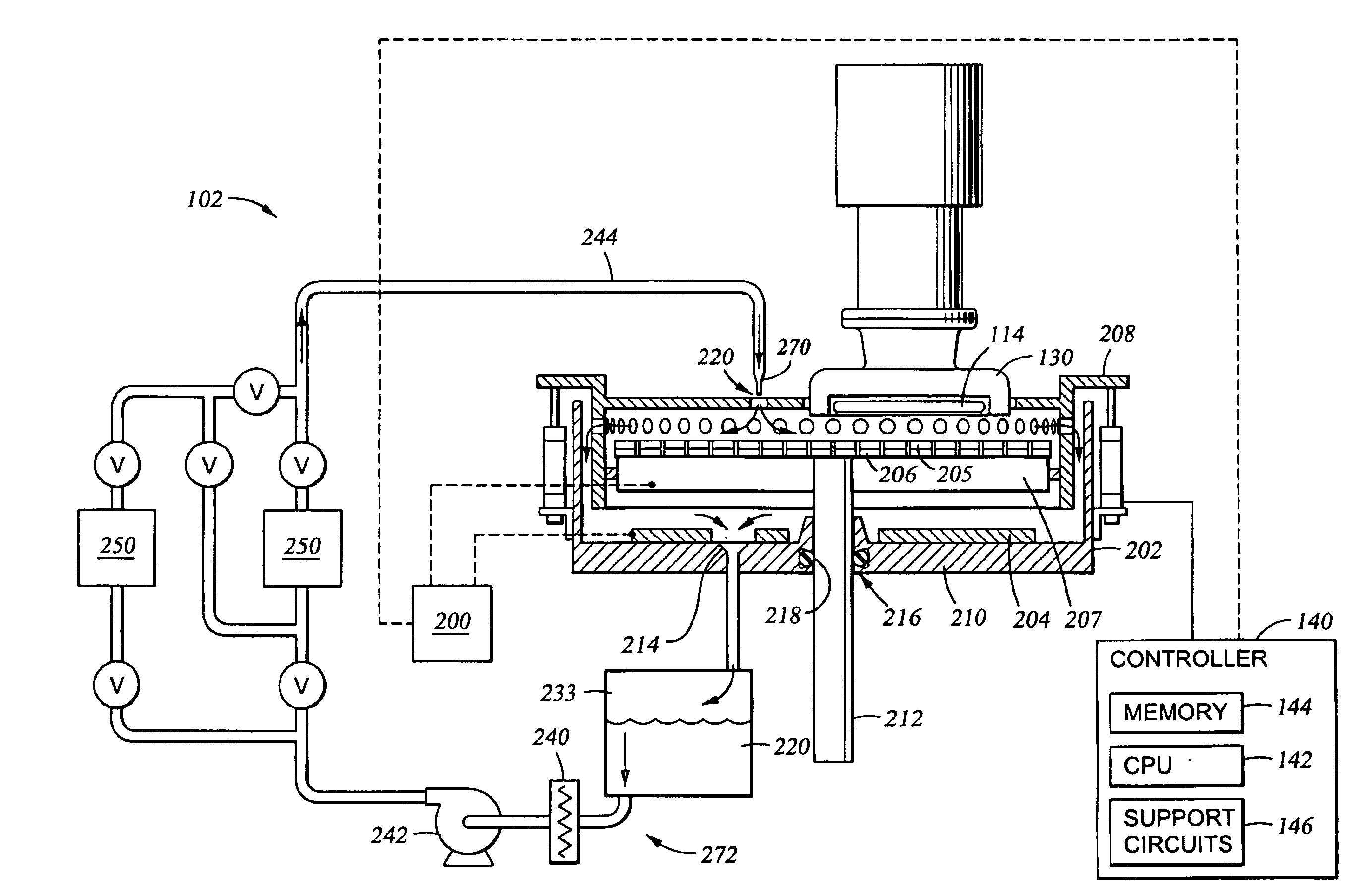

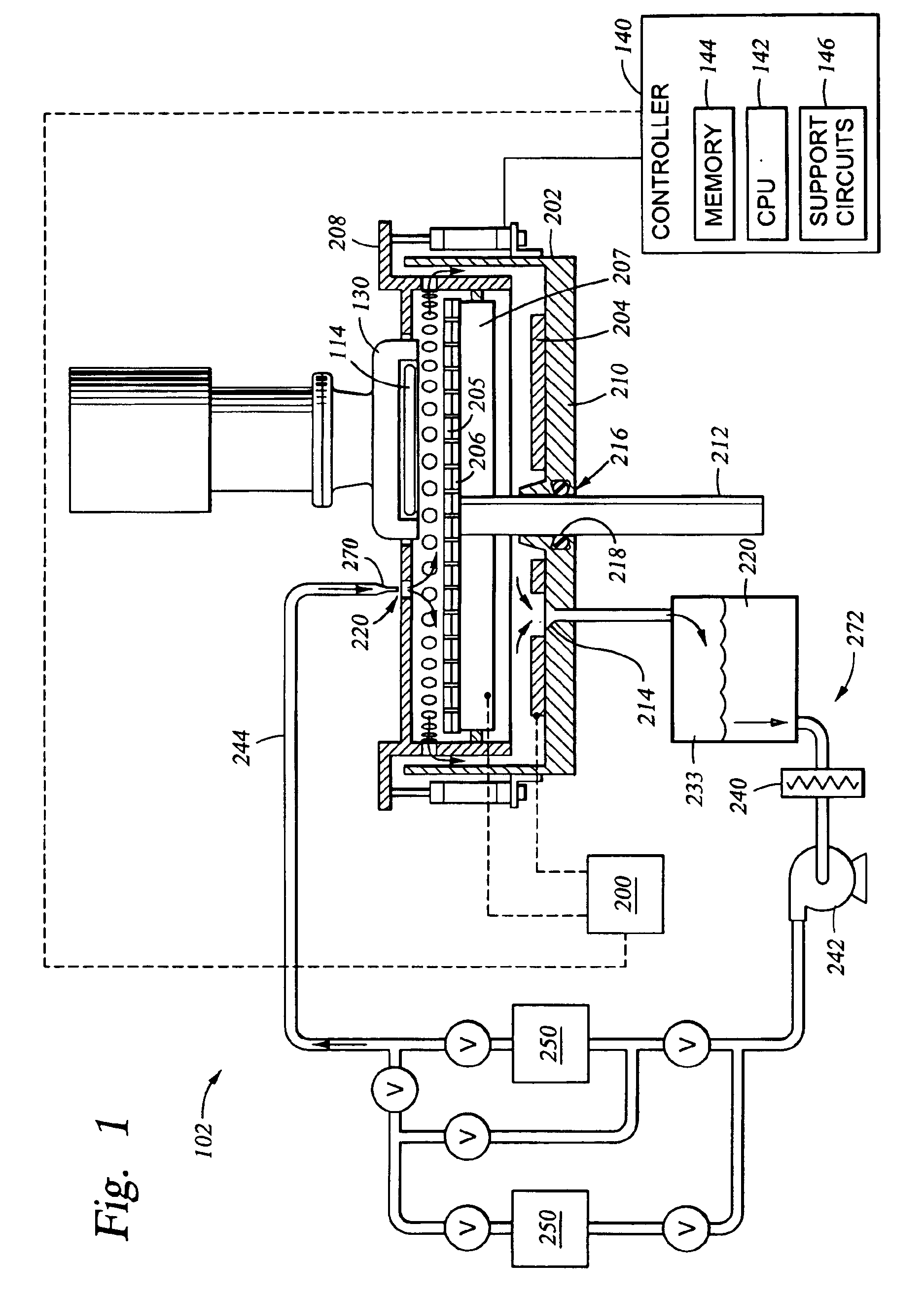

Electrolyte composition and treatment for electrolytic chemical mechanical polishing

Owner:APPLIED MATERIALS INC

Fountain solution and preparation method thereof

InactiveCN101870213AEasy to keep hydrophilicAdequate dampening capacityPrinting pre-treatmentGermabenPropylene glycol

The invention discloses a fountain solution, which is characterized in that: the fountain solution comprises the following raw materials in percentage by weight: 1 to 15 percent of glycerin, 0.1 to 10 percent of ammonium citrate, 0.1 to 10 percent of malic acid, 0.1 to 5 percent of defoaming agent, 0.1 to 10 percent of wetting agent, 0.1 to 5 percent of bactericide, 1 to 15 percent of L-PCA-Na, 1 to 15 percent of propylene glycol and 1 to 15 percent of sorbierite; and the preparation method comprises the following steps: adding the ammonium citrate, the malic acid, the wetting agent, the L-PCA-Na in a weight percentage ratio, then adding 50 to 80 percent of water, uniformly mixing the materials and the water; and adding the propylene glycol, the sorbierite, the glycerin, the defoaming agent and the bactericide into the obtained mixture and then uniformly stirring the mixture so as to obtain the fountain solution. The fountain solution has the advantages of environmental protection, strong fountain capability, wet non-verbal-visual part, sufficient pH-value buffering, difficult ink emulsification, large electric conductivity, large surface-tension buffering range and easy operating control.

Owner:杜广清

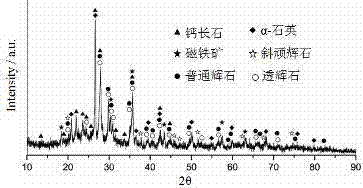

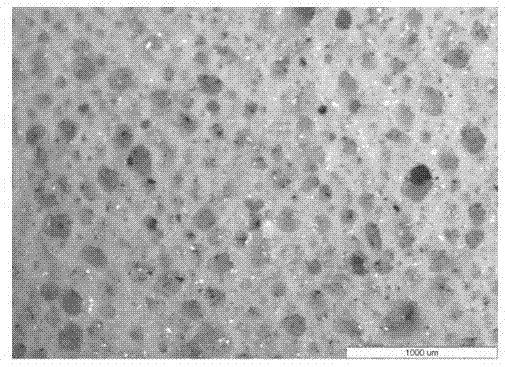

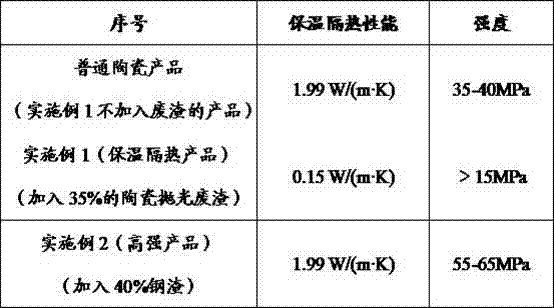

Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

ActiveCN103570340AReduce the cost of degummingSave the drying processCeramic materials productionClaywaresFluidized bed dryingThermal insulation

The invention discloses architectural ceramic prepared from industrial solid waste through a dry method and a process for preparing the architectural ceramic. The architectural ceramic comprises the following components in percentage by mass: 30-60% of solid waste, 40-70% of ceramic raw material and 1-3% of ceramic additive, wherein the ceramic raw material is selected from one or a composition of multiple of clay raw material, feldspar raw material or talc, and the ceramic additive is one or a combination of multiple of sodium tripolyphosphate, sodium silicate, ammonium chloride, ammonium citrate, sodium humate, sodium lignin sulfonate sodium, ethylenediamine tetraacetic acid disodium and edetic acid. After being pretreated, the granules of the solid waste are fine and are mixed evenly in a dry mixing manner and a spray drying manner and are directly used for pressing of green bricks or stored in a bin for standby, so that the ball milling energy consumption and the peptization cost are reduced, the humidification pelleting and fluidized bed drying procedures are omitted, the formula can be quickly adjusted according to the functional characteristics of the architectural ceramic, the process is simple and convenient to control, and the architectural ceramic has such good properties as heat preservation, thermal insulation and high strength.

Owner:FOSHAN OCEANO CERAMICS +1

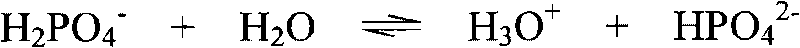

Offset printing fountain solution composition containing composite buffer system

InactiveCN101758680AAdapt to the needs of actual printingGood buffer tolerancePrinting pre-treatmentSodium citrateCitric acid

The invention relates to an offset printing fountain solution composition containing composite buffer system, which contains two buffer systems, wherein one of the buffer systems comprises citric acid and M2(I)HPO4, and in the molecular formula M2(I)HPO4, M is K plus, Na plus or NH4 plus ion; and the other buffer system comprises citric acid and potassium citrate, sodium citrate or ammonium citrate, components are as follows in percentage by weight: 1.0-10 percent of the citric acid, 1.0-10 percent of K2HPO4, Na2HPO4 or (NH4)2HPO4, 1.0-10 percent of the potassium citrate, the sodium citrate or the ammonium citrate, and the balance water. When 1 percent to 5 percent by weight of working solution prepared with the diluted fountain solution is used for printing, the change of pH value is less than 0.35, and when 1 percent to 2 percent of working solution is prepared, the change of pH value is less than 0.25. The ultrahigh buffering property of the fountain solution can significantly help to improve adaptability and tolerance during high-speed printing operation.

Owner:HUNAN NORMAL UNIVERSITY

Fire retardant compositions with reduced aluminum corrosivity

InactiveUS6905639B2Reduced-tendency to corrode various metalBroaden applicationFireproof paintsAntifouling/underwater paintsBiopolymerFerrous Gluconate

Corrosion-inhibited fire retardant compositions and methods of making and using the same are provided. The corrosion-inhibited fire retardant compositions are comprised of at least one fire retardant component, at least one biopolymer having a particle size diameter of less than about 100 microns, and a corrosion inhibiting system. The corrosion inhibiting system is comprised of at least one corrosion inhibiting compound selected from a group of compounds including azoles, insoluble ferric pyrophosphate, soluble ferric pyrophosphate, ferrous oxalate, ferric citrate, ferrous sulfate, ferric ammonium citrate, soluble ferric orthophosphate, insoluble ferric orthophosphate, ferric ammonium oxalate, ferric ammonium sulfate, ferric bromide, ferric sodium oxalate, ferric stearate, ferric sulfate, ferrous acetate, ferrous ammonium sulfate, ferrous bromide, ferrous gluconate, ferrous iodide, ferric acetate, ferric fluoroborate, ferric hydroxide, ferric oleate, ferrous fumarate, ferrous oxide, ferric lactate, ferric resinate and any combination thereof. In a specific embodiment, the corrosion-inhibited fire retardant composition includes a xanthan biopolymer.

Owner:PERIMETER SOLUTIONS LP

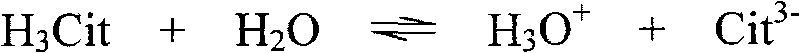

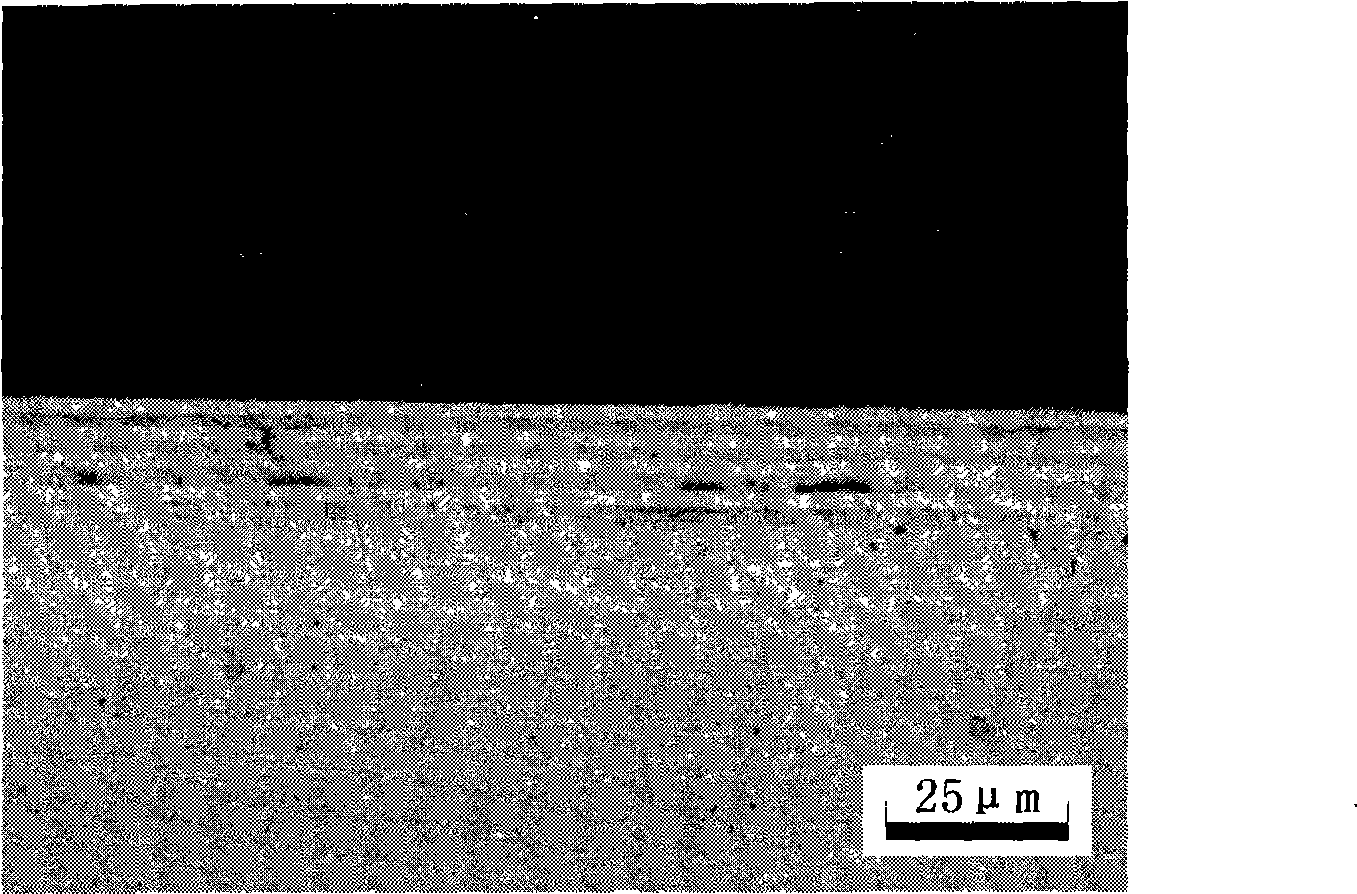

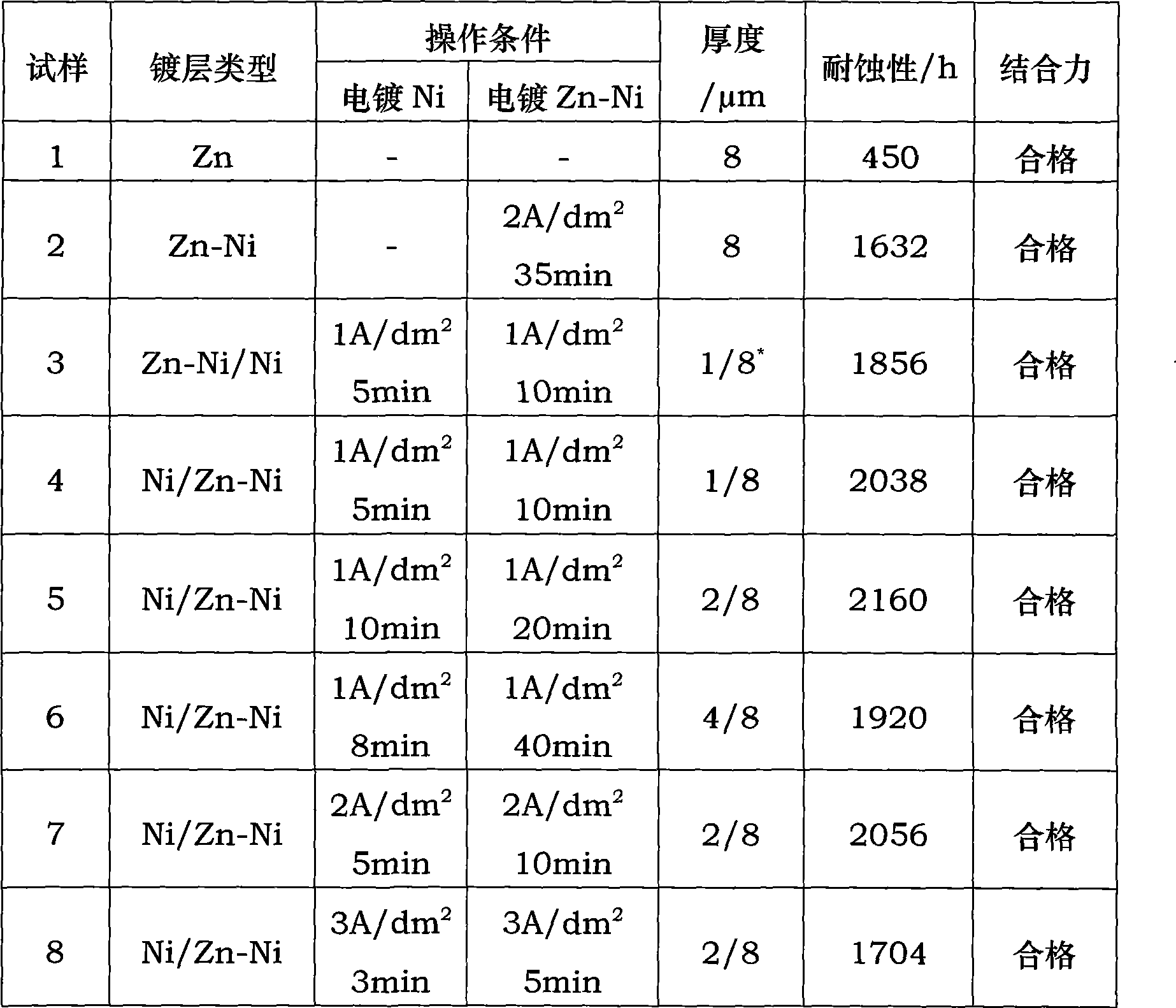

Method for modulating zinc-nickel alloy and nickel combined multi-layer membranous by electrochemical deposition component

InactiveCN101487134ASolve the problem of large compositional changesImprove current efficiencyPyrophosphateElectrochemistry

The invention provides a method for modulating a multilayer film consisting of Zn-Ni alloy and Ni by electro-chemically depositing compositions, comprising five steps as follows: preparing alkaline liquor, pickling liquor and electroplating solution, mechanical grinding and cleaning plating articles, alkaline washing, pickling and electroplating, wherein, the electroplating solution comprises alkaline electroplating solution with electroplated Zn-Ni alloy and neutral and alkaline electroplating solution with electroplated Ni; the electroplating solution of Ni consists essentially of a main salt and a complexing agent; the main salt is one or two compositions out of NiSO4 and NiCl2; and the complexing agent consists of two or more substances as follows: ammonium citrate, sodium citrate, citric acid, ammonia, sodium pyrophosphate, potassium pyrophosphate and triethanolamine. The Zn-Ni / Ni or Ni / Zn-Ni multilayer film electroplated by the method has smooth plating layer surface, better corrosion resistance and higher current efficiency and plating layer adhesion.

Owner:BEIHANG UNIV

Process for preparing active aluminium oxide

InactiveCN1425612AUniform temperatureUniform concentrationAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

The present invention relates to the preparation process of active gamma-Al2O3. The mixed water solution of materials including aluminum chloride, ammonia water, pore expander ammonium oxalate or ammonium citrate, etc. is heated and concentrated to produce aluminum hydroxide precipitate; the precipitate is dried and heated to obtain solid powder and to decompose its NH4Cl, which is recovered from hot gas flow through cooling and crystallization; and the solid powder is roasted at 400-800 deg.c for 3-6 hr to convert into gamma-Al2O3. The present invention produces aluminum hydroxide through evaporation and concentration, rather than neutralization, and aluminium hydroxide is precipitated and separated in a stable and balanced solid-liquid state, and this is favorable to producing aluminium hydroxide grains with homogeneous size.

Owner:XIAMEN UNIV

High solid phase drilling fluid filter cake removal treating fluid

ActiveCN101597488AGood lifting effectHigh corrosion rateCleaning apparatusDrilling compositionPotassiumDissolution

Owner:PETROCHINA CO LTD

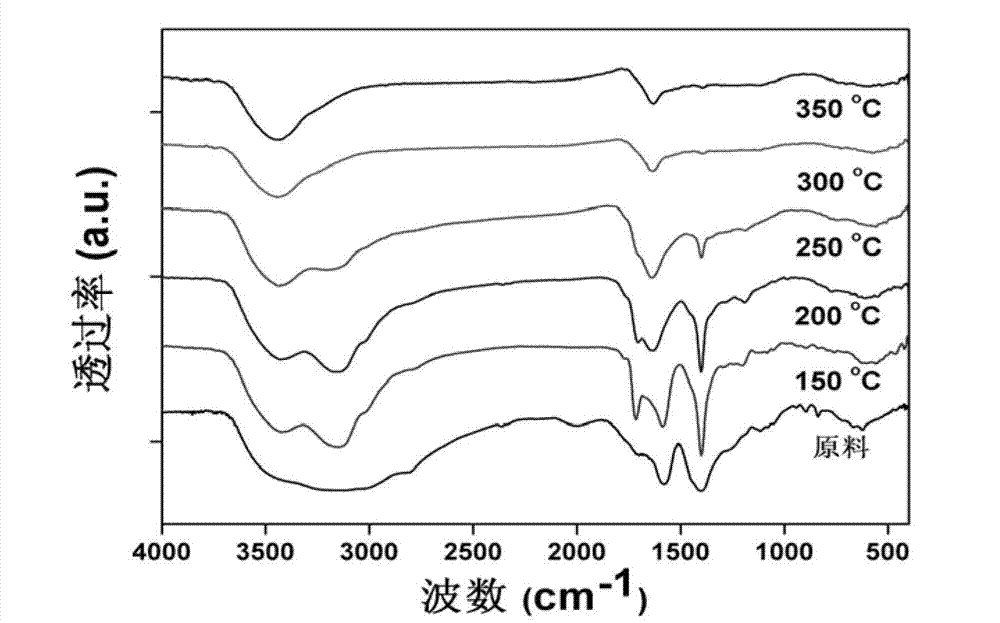

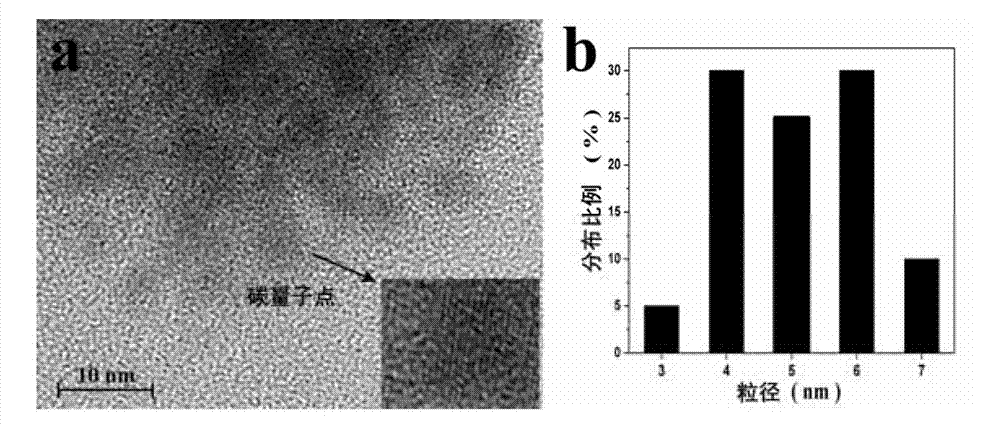

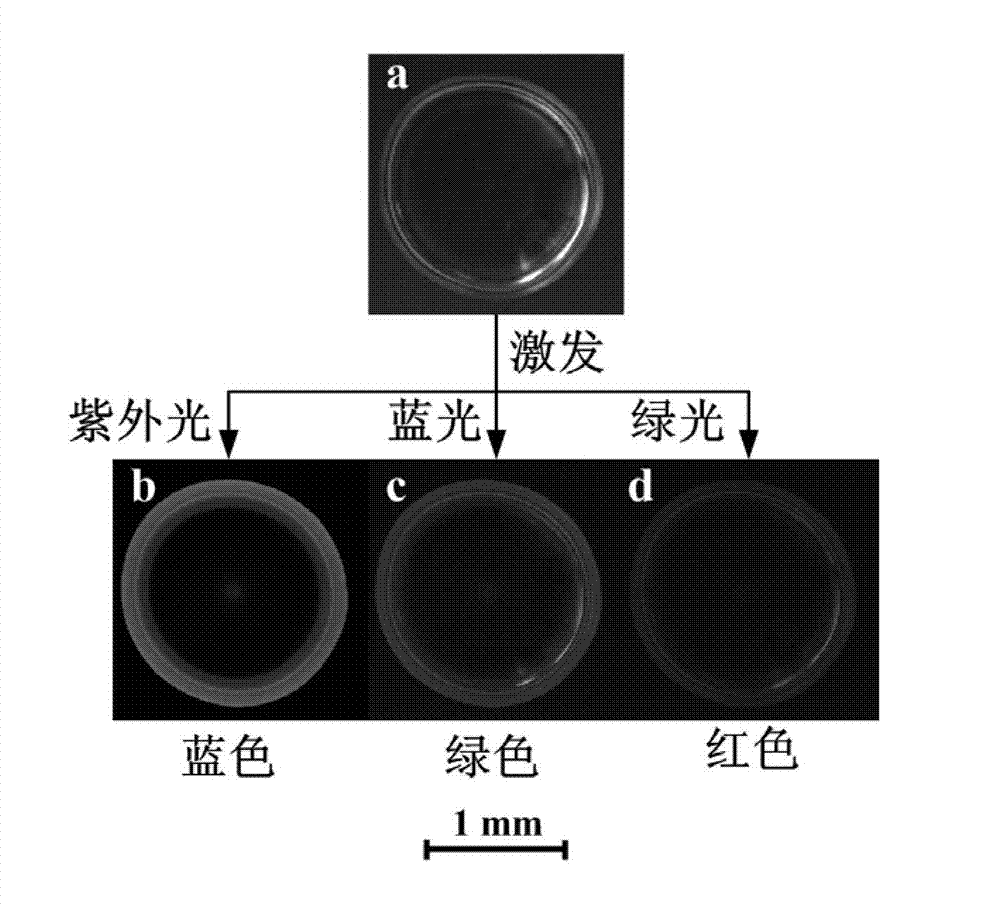

Method for preparing high-yield carbon quantum dots

InactiveCN102816567AEasy to operateWide variety of sourcesLuminescent compositionsQuantum yieldPhysical chemistry

The invention discloses a method for preparing high-yield carbon quantum dots, which comprises the following steps that: (1) ammonium citrate is put into an electric heating furnace, the temperature rises at a heating rate of 5 to 50 DEG C / min, and the reaction is carried out for 2-4h at a temperature of 150 to 250 DEG C to obtain a pyrolysis product; (2) the pyrolysis product is milled into powder and added with ethanol to be stirred and centrifuged to remove insolubles to obtain a brown ethanol solution containing carbon quantum dots; and (3) the drying is carried out to obtain the carbon quantum dots. The process is simple to operate, the source of raw materials is wide, the cost of raw materials is low, the preparation conditions has low requirements and are relatively mild, the yield of obtained carbon quantum dots and the quantum yield are higher, the problems that the carbon quantum dots can not be produced on the scale and the fluorescence quantum yield of the obtained carbon quantum dots is low due to the limit of the process and the raw materials in the traditional preparation method of the carbon quantum dots can be solved, and the method can be applied to the fields such as biomarker, bio-imaging, a photovoltaic device, and a biosensor.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

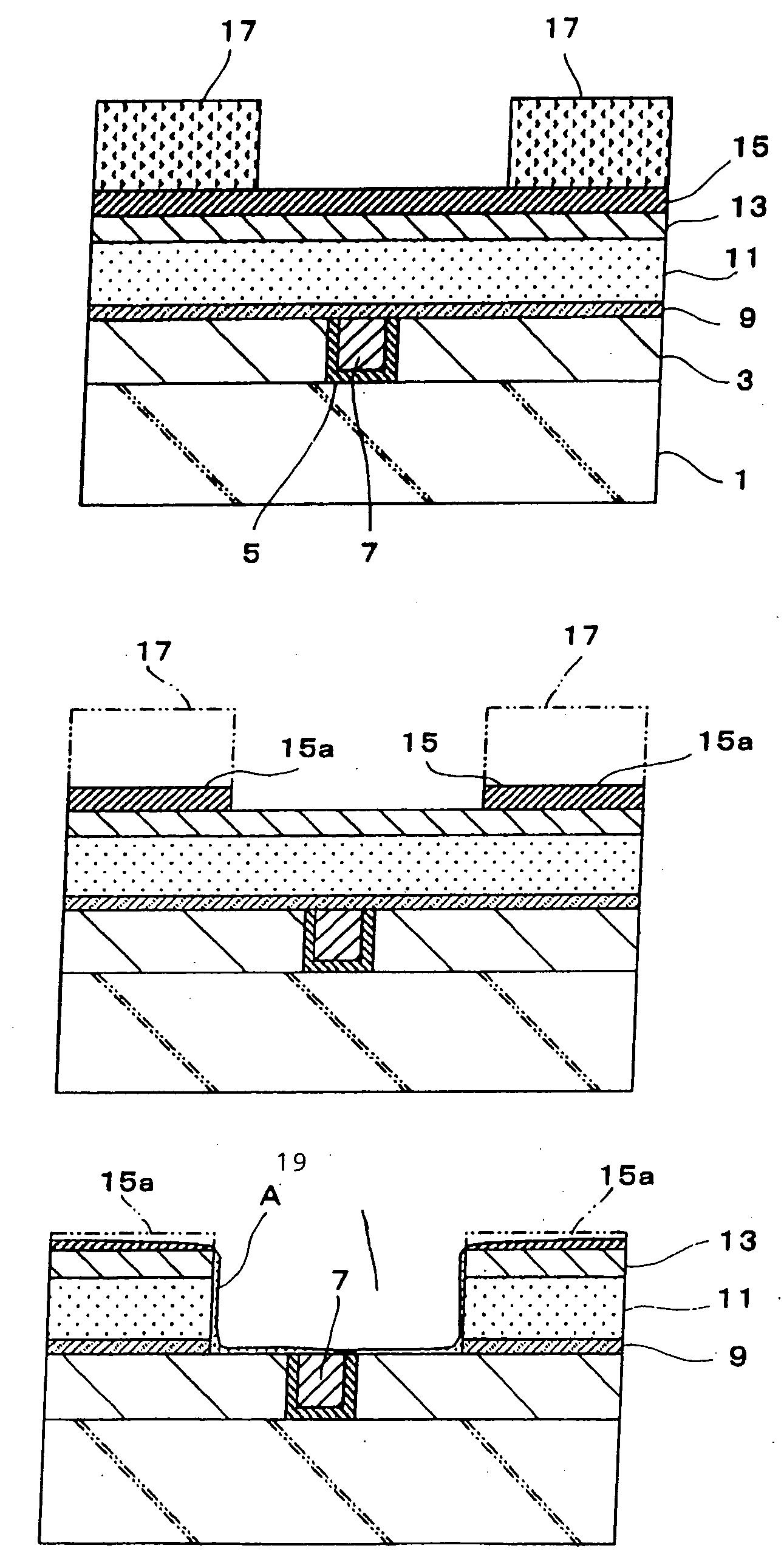

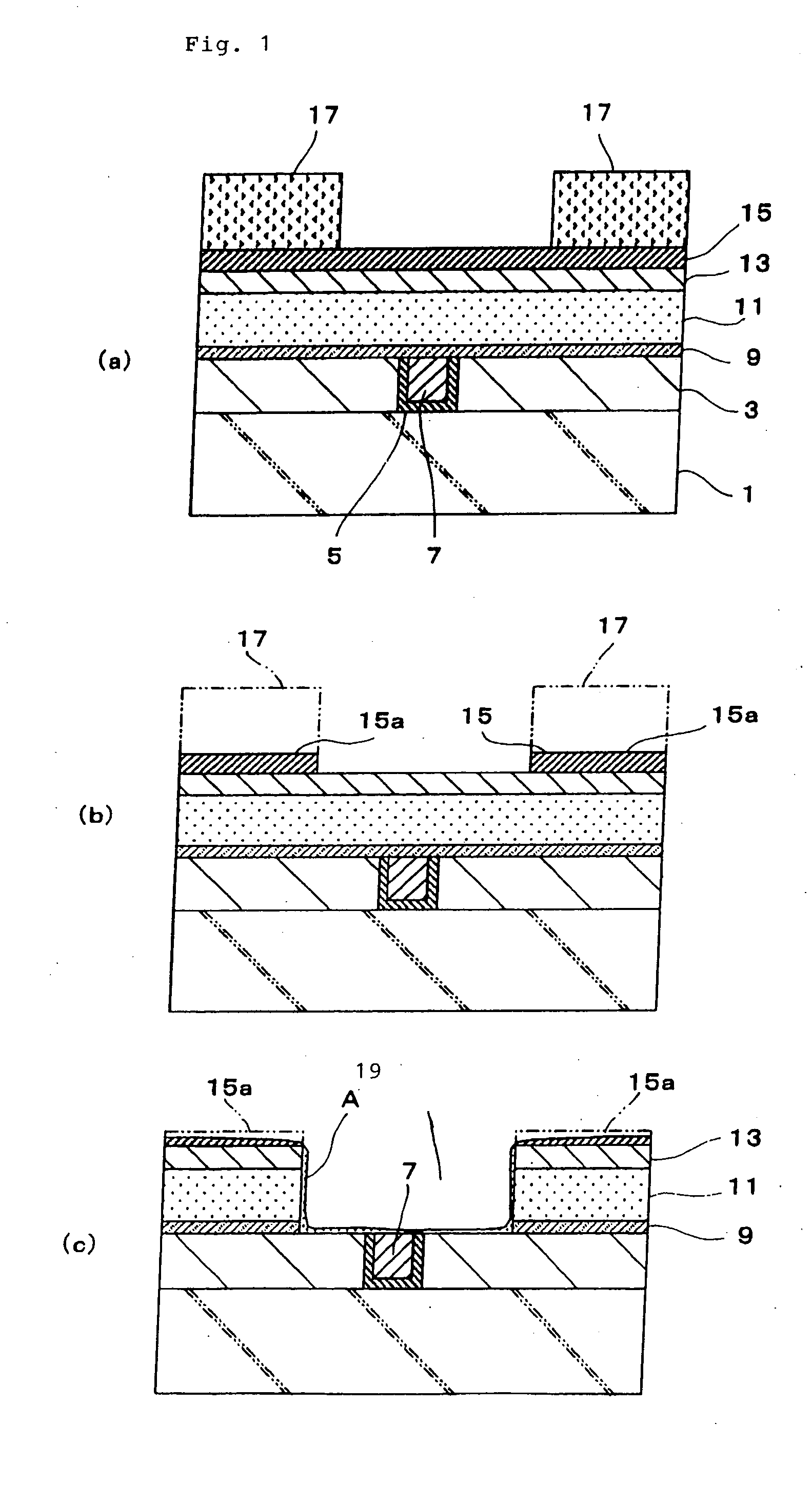

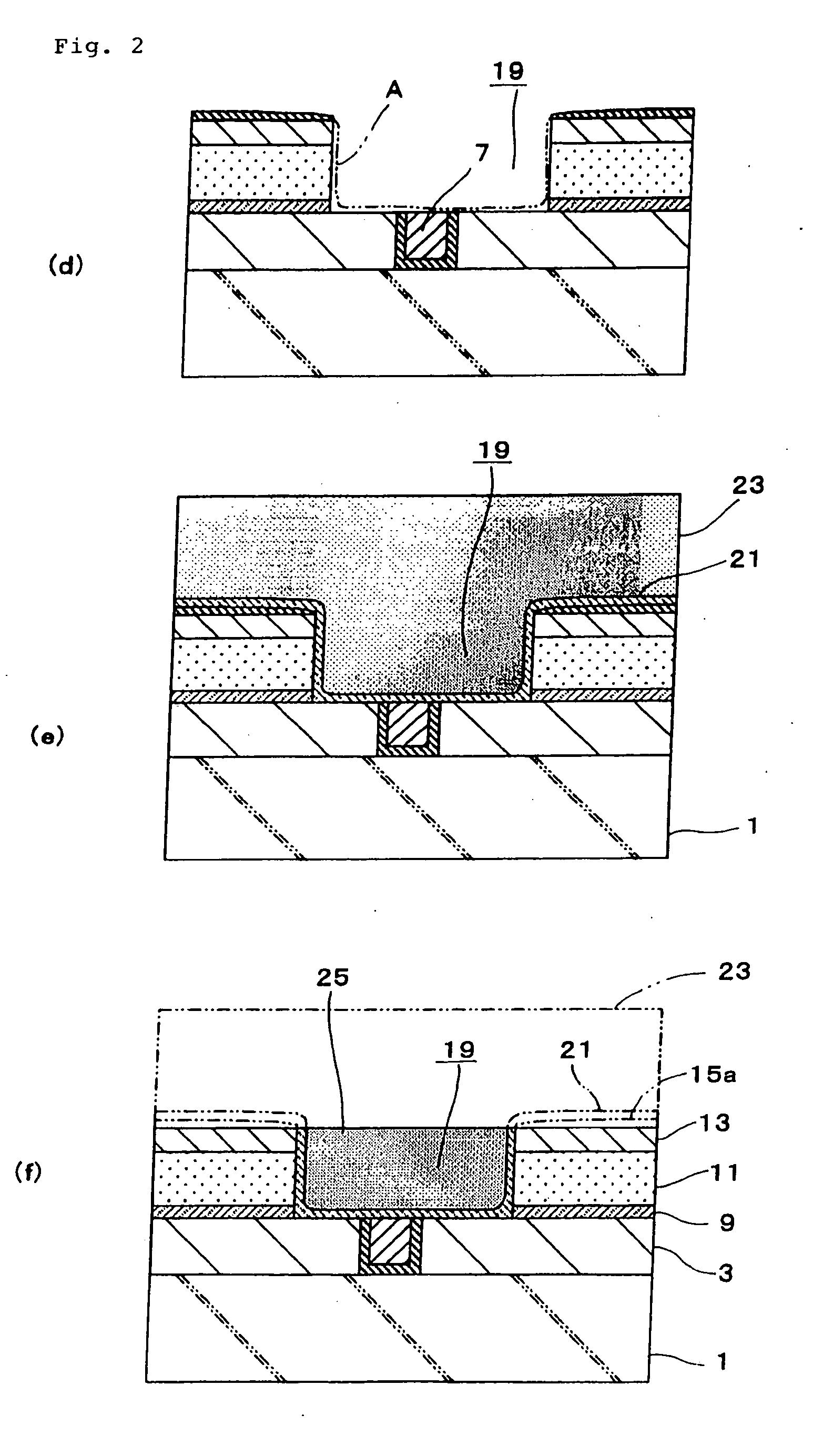

Post-dry etching cleaning liquid composition and process for fabricating semiconductor device

InactiveUS20060019201A1Avoid corrosionReduce the burden onInorganic/elemental detergent compounding agentsSemiconductor/solid-state device detailsDevice materialAmmonium oxalate

A post-dry etching cleaning liquid composition for cleaning a substrate after dry etching is provided, the cleaning liquid composition containing at least one type of fluorine compound, glyoxylic acid, at least one type of organic acid salt, and water. With regard to the fluorine compound, ammonium fluoride may be used. With regard to the organic acid salt, at least one of ammonium oxalate, ammonium tartarate, ammonium citrate, and ammonium acetate may be used.

Owner:SONY CORP +2

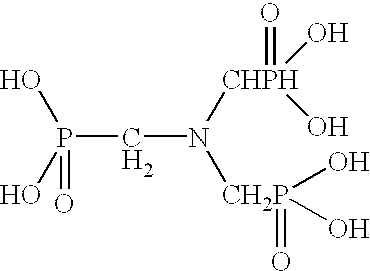

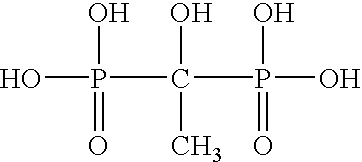

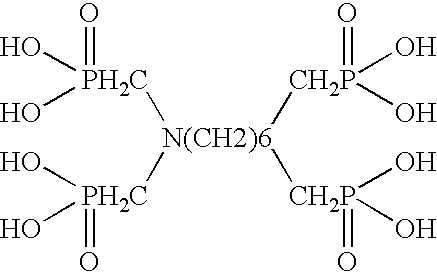

Ammonium polyphosphate solutions containing multi-functional phosphonate corrosion inhibitors

InactiveUS6846437B2Reduce corrosionOther chemical processesLiquid fertilisersSuspending AgentsFerrous Gluconate

A corrosion-inhibited fire retardant composition is provided that comprises at least one ammonium polyphosphate, at least one suspending agent, at least one phosphonate selected from a group consisting of aminotri(methylenephosphonic acid), 1-hydroxyethylidene-1,1-diphosphonic acid, hexamethylenediaminetetra(methylenephosphonic acid), diethylenetriaminepenta(methylenephosphonic acid), salts thereof, and mixtures thereof and a corrosion inhibiting system. The corrosion inhibiting system is comprised of at least one corrosion inhibiting compound selected from a group consisting of azoles, insoluble ferric pyrophosphate, soluble ferric pyrophosphate, ferrous oxalate, ferric citrate, ferrous sulfate, ferric ammonium citrate, insoluble ferric orthophosphate, soluble ferric orthophosphate, ferric ammonium oxalate, ferric ammonium sulfate, ferric bromide, ferric sodium oxalate, ferric stearate, ferric sulfate, ferrous acetate, ferrous ammonium sulfate, ferrous bromide, ferrous gluconate, ferrous iodide, ferric acetate, ferric fluoroborate, ferric hydroxide, ferric oleate, ferrous fumarate, ferrous oxalate, ferrous oxide, ferric lactate, ferric resinate, and any combination thereof. Methods of making and using the same are also described. In addition, agricultural plant nutrients comprising the same are provided.

Owner:PERIMETER SOLUTIONS LP

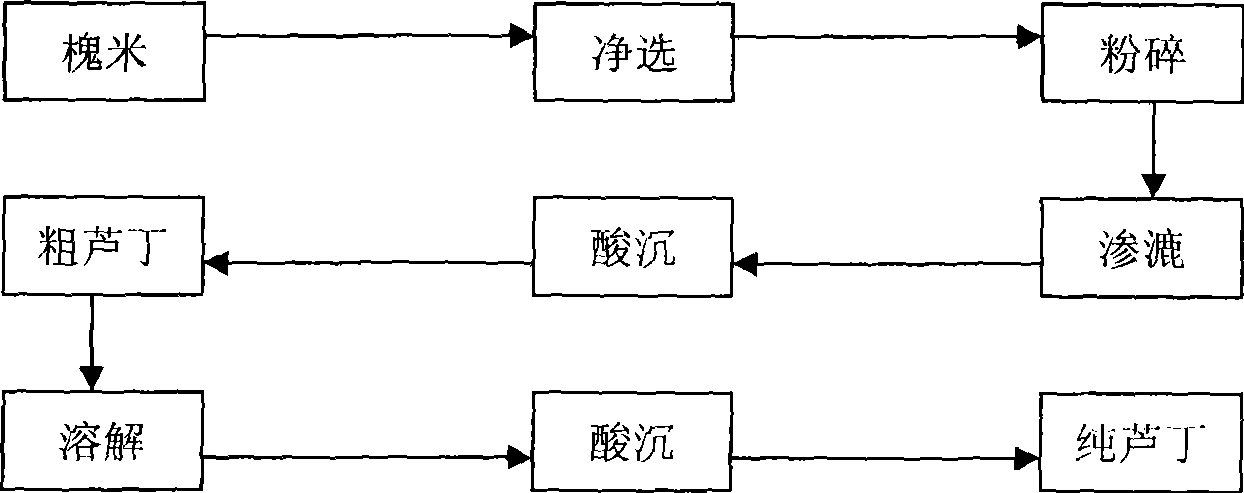

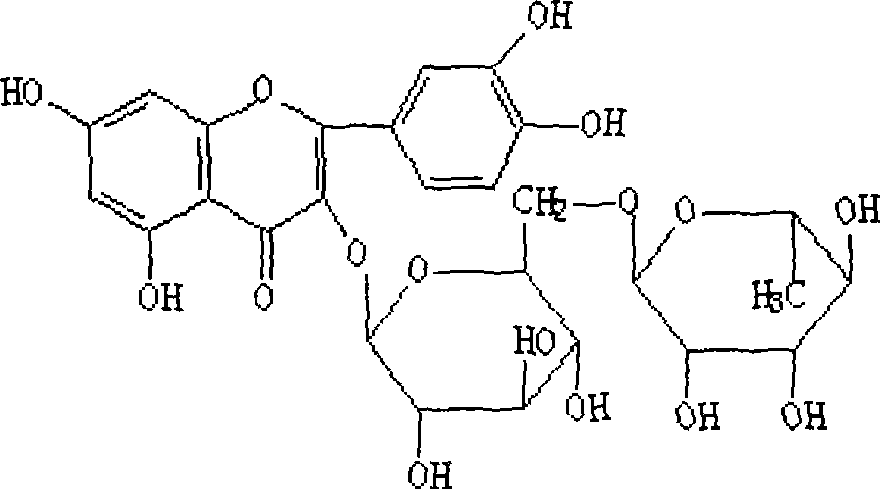

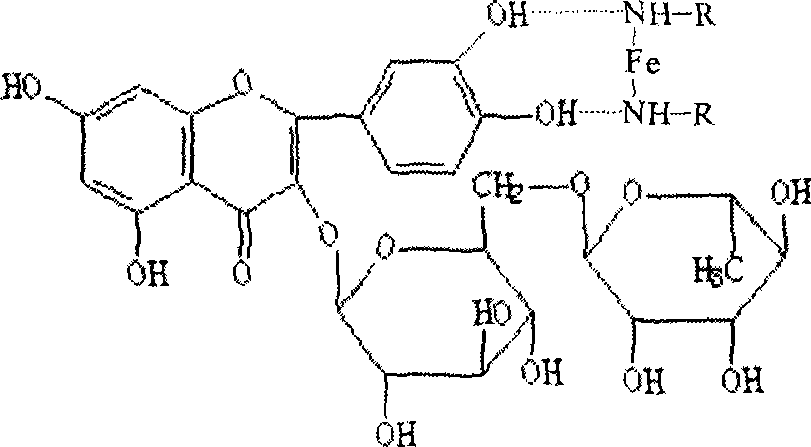

Production process for extracting high-purity birutan from flos sophora

ActiveCN101423538AImprove solubilityThe chance of mutual aggregation is reducedSugar derivativesSugar derivatives preparationSolubilityFlos

The invention discloses a production process for extracting high-purity rutin from bud of Chinese scholartree. The process mainly comprises the following steps: selecting clean bud of Chinese scholartree, crushing the bud of Chinese scholartree, percolating the bud of Chinese scholartree through a dissolvent, carrying out the acid precipitation of the filtrate, and drying the filtrate, so as to obtain crude rutin; dissolving the crude rutin in saturated ferric ammonium citrate solution, putting the solution in water bath at a temperature between 40 and 50 DEG C; and stirring the solution for 30 minutes, filtrating, cooling down the solution through standing, then carrying out acid precipitation and suction filtration, cleaning the filter residue through purified water to reach neutrality, and drying the filter residue, so as to obtain the refined rutin. The production process has the advantages that ferric ammonium citrate is taken as the flux of rutin, thereby polymerizing the ferric ammonium citrate molecule and the ortho-phenolic hydroxyl in the rutin molecule, ensuring that the planar structure of the rutin molecule is polymerized into a heterocycle-shaped complex steric structure, reducing the mutual polymerization of the rutin molecules, and greatly improving the solubility of the rutin in water; the production process not only has high yield and purity, but also has simple technology and low manufacturing cost.

Owner:GUANGXI CHANFANG PHARMACEUTICAL CO LTD

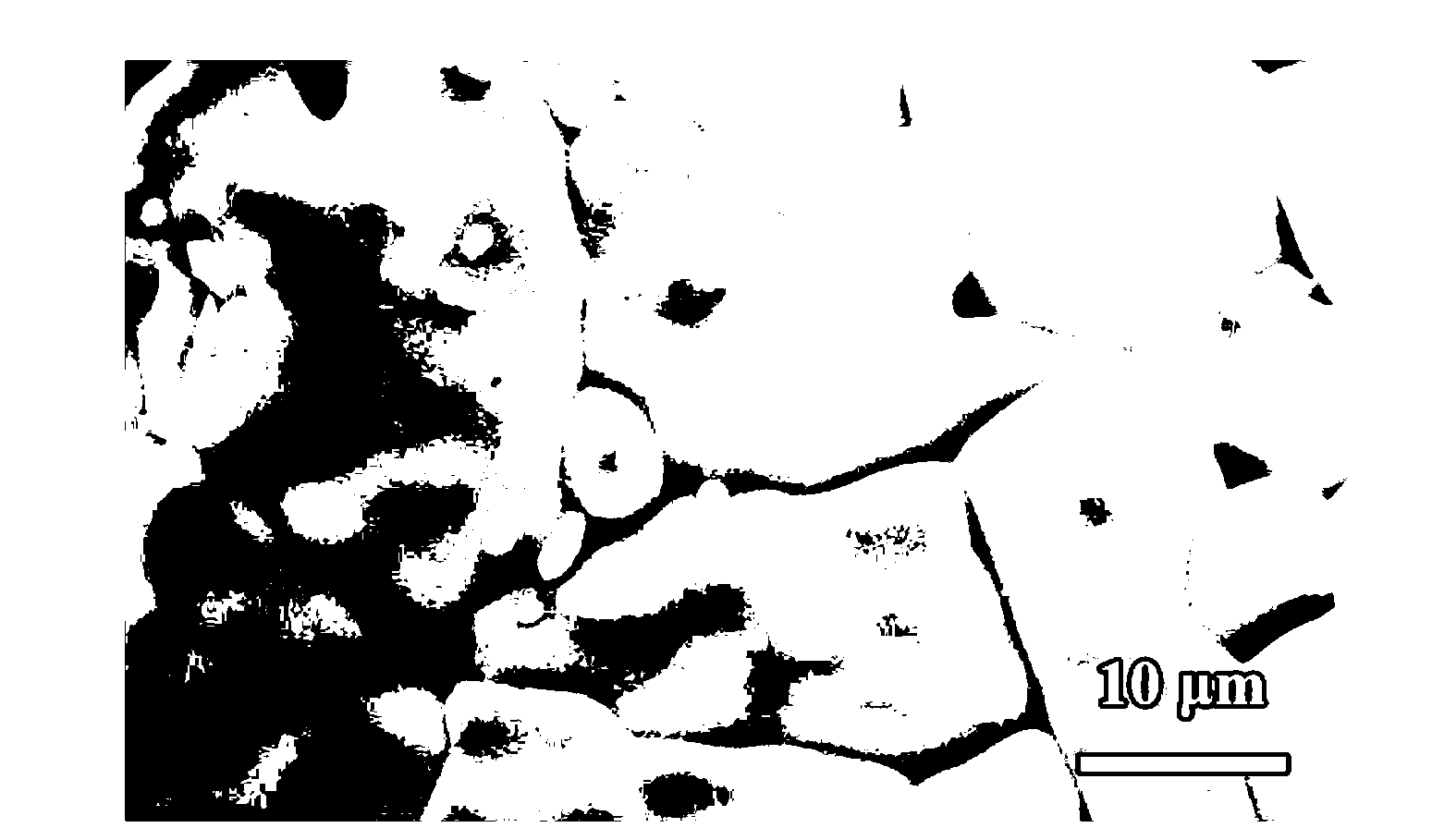

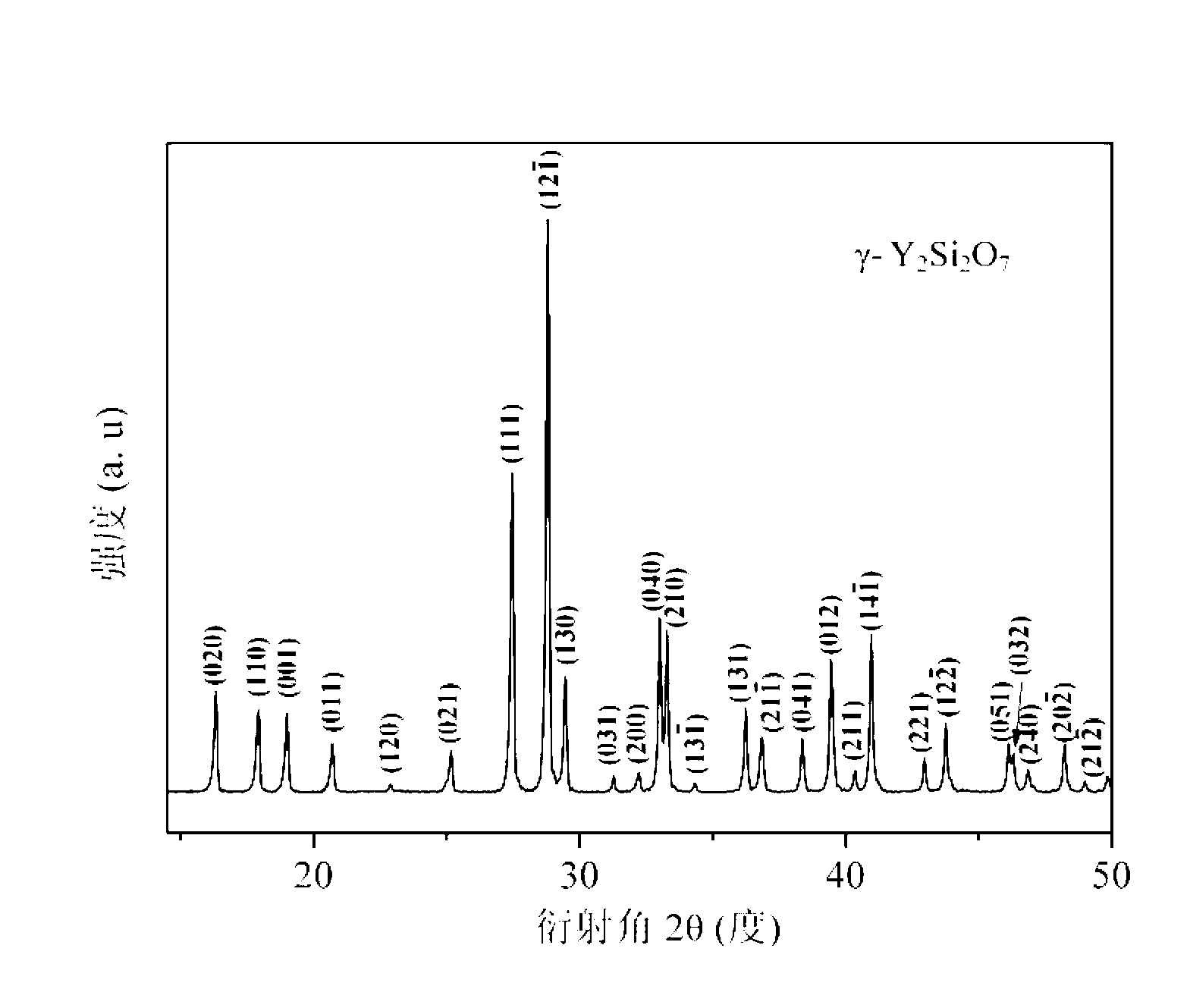

Preparation method of yttrium-silicon-oxygen porous high-temperature ceramic material

ActiveCN103011817AOptimal Control StructureImprove stabilityCeramicwareSilicon oxygenPolyethylene glycol

The invention relates to the field of porous high-temperature ceramic materials, in particular to a method for preparing a yttrium-silicon-oxygen porous high-temperature ceramic material by an organic foam impregnating technology. The method comprises the following steps: with organic polyurethane foam as a template, after alkali corrosion and soaking pretreatment by a CMC (carboxyl methyl cellulose) solution, impregnating and slurrying in a Y2SiO5 slurry (prepared by mixing Y2SiO5 powder, the CMC solution, silica sol, kaolin, and polyethylene glycol or ammonium citrate); centrifuging and drying to remove excessive slurry in the template; performing thermal treatment at 700-900 DEG C to remove the organic foam template, and presintering; performing high-temperature reaction and sintering for 1.5-2.5 hours at 1,500-1,550 DEG C; and preparing the Y2Si2O7 porous high-temperature ceramic. The preparation method is simple and convenient and low in cost, and is applicable to preparation of the Y2Si2O7 porous ceramic material with a controllable pore structure and a relatively compact skeleton; and by the preparation method, the synthesis efficiency of such materials can be greatly improved and the application range of the materials in the technical field can be widened.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

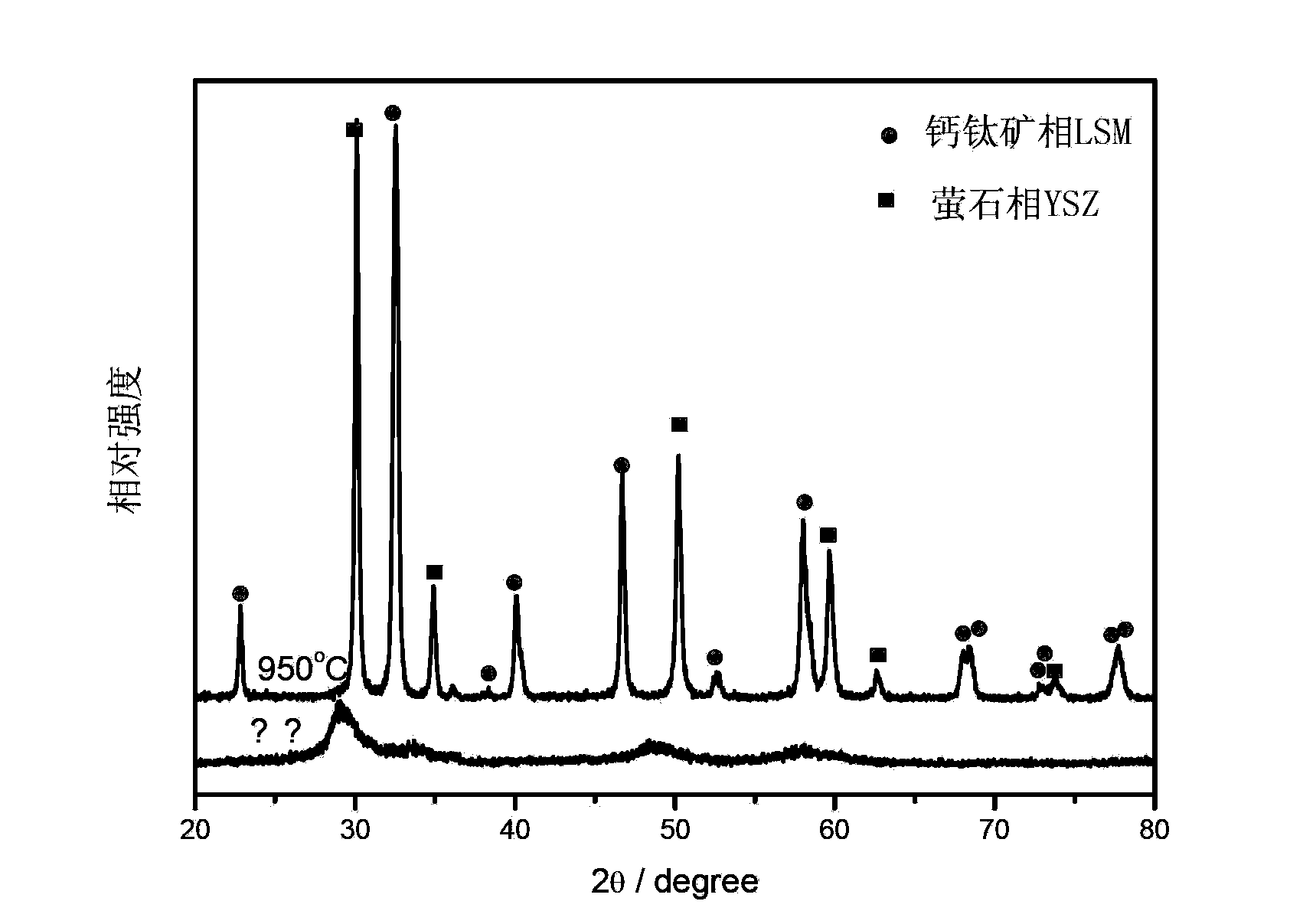

Method for preparing solid oxide fuel cell composite cathode through low-temperature sintering

The invention provides a method for preparing a solid oxide fuel cell composite cathode through low-temperature sintering. The method comprises: employing a composite cathode material primary powder synthesized by employing an ammonium citrate process to prepare a slurry, coating an anode electrolyte two-in-one assembly, and sintering at a low temperature of 900-1000 DEG C for preparing the cell cathode. The composite cathode possesses perovskite phase and cubic fluorite phase at the same time, and is a mixed ionic electronic conductor. Particle size is uniform, specific surface area is large, many three-phase interfaces as electrochemical active sites exists and are uniformly distributed in the whole cathode body, cell performances are higher than those of a conventional mechanically mixed cathode, and a cell can stably run.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Pyrophosphate copper plating used as grounding electroplate liquid for cyanogen-free copper plating

The invention discloses a strike bath solution with pyrophosphate plating copper as the cyanide-free copper, which contains a make-up agent and rehydration salt; the make-up agent contains the following raw materials: potassium pyrophosphate, copper pyrophosphate, ammonium citrate, sorbol, sulfosalt, phenyl carboxylate, dextrin, alkyl thiourea and nitrogen heterocyclic; the rehydration salt is as supplementation of all raw materials in the make-up agent during the plating process; the invention does not contain harmful substances, such as cyanidum, heavey metal, etc and is in compliance with EU RoHS Directive (2002 / 95 / EC) with stable bath solution and wide cathode current density range, and the plating layer prepared by the invention is fine, even and in a semi-bright state; and the make-up is conducted with original solution, supplementation is conducted with single rehydration salt, which is convenient in operation and simple in management; the plating layer is well adhesive to the matrix, with good straggling capability and covering capability. The invention is applicable in pre-plating of iron materials, zinc alloys, aluminum alloys and copper alloys, as well as barrel plating and suspension plating, with the waste water easy to dispose, which will not bring the secondary pollution.

Owner:江门市瑞期精细化学工程有限公司

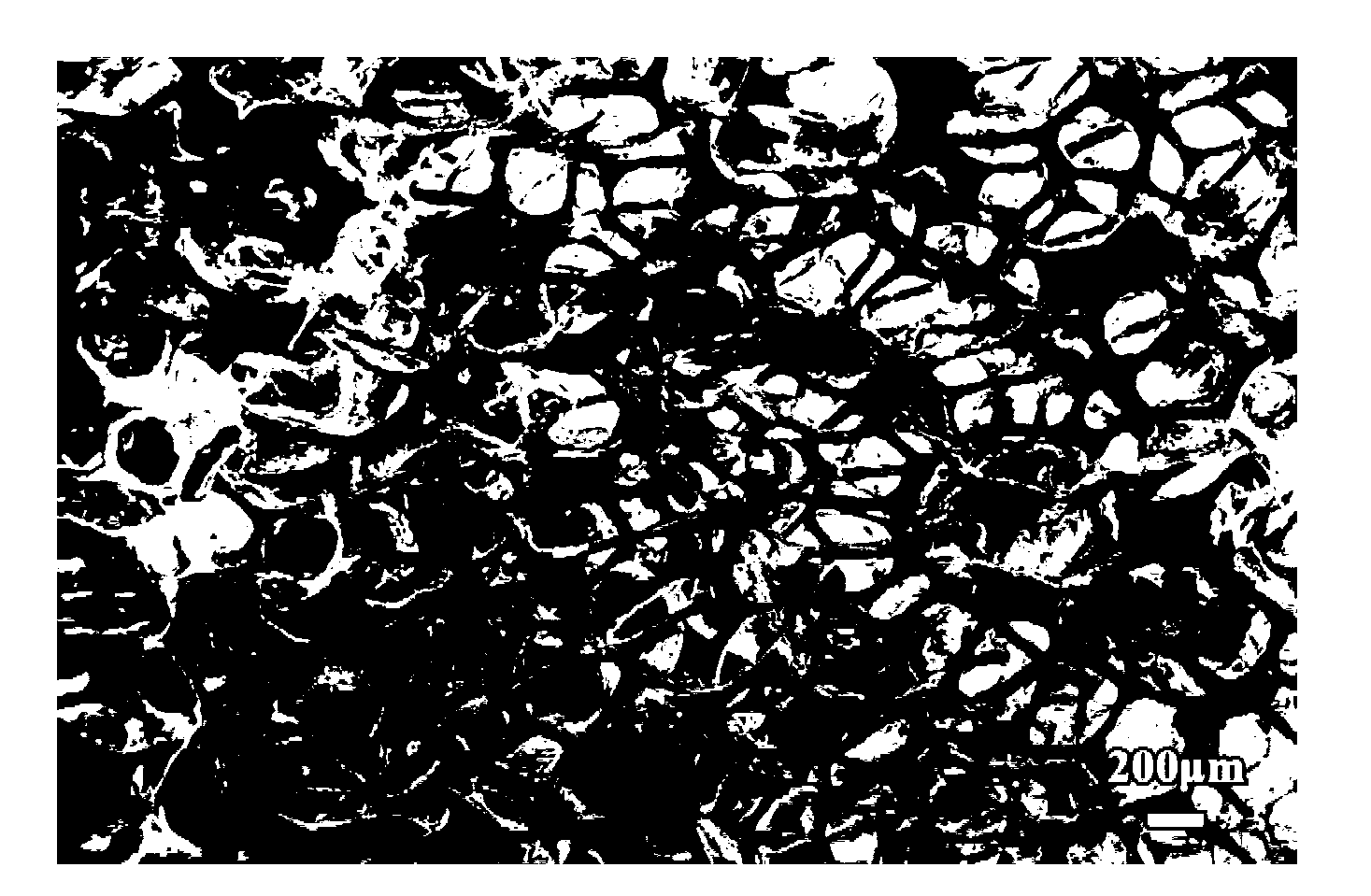

Manufacture method of high porosity and high strength yttrium-silicon-oxygen porous ceramics

The invention relates to the porous ceramics material field, and concretely relates to a method for manufacturing high porosity and high strength yttrium-silicon-oxygen porous ceramics material through a foaming injection coagution process. According to the method, yttrium oxide and silicon oxide mixed power can be taken as a raw material, water is taken as a disperse medium, polyethyleneimine or ammonium citrate is selected as a dispersant, acrylamide or N-methylolacrylamide is taken as a monomer, a cross-linking agent N,N'-methylene bisacrylamide is added, a foaming agent sodium dodecyl sulfate, a peeling inhibitor polyoxyethylene, a catalyst N, N, N',N'-tetramethyl ethylenediamine and an initiator ammonium persulfate are added after stirring, and then injection mold solidification is carried out, drying is carried out for 24-48 hours at room temperature after demoulding, and then drying is carried out for 24-36 hours under the temperature of 60-90 DEG C, high temperature reaction sintering is carried out for 1.5-2.5 hours under the temperature of 1500-1550 DEG C finally, and the gamma-Y2Si2O7 porous ceramics can be finally manufactured. The manufactured gamma-Y2Si2O7 porous ceramics material having a multi-layer pore structure has controllable porosity with high porosity (75-85%) and high strength (3-8MPa).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

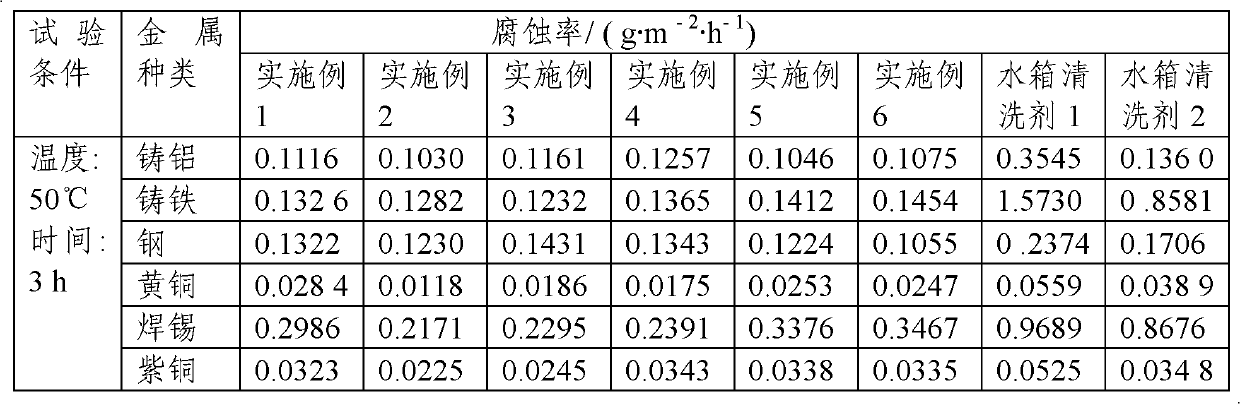

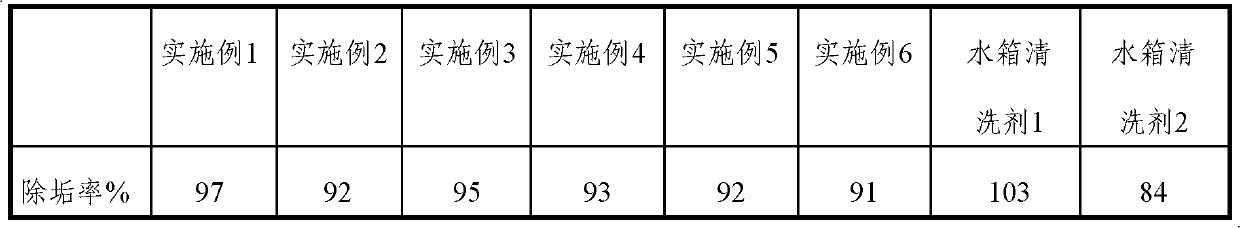

Cleaning agent for automobile cooling system

The invention provides a cleaning agent for an automobile cooling system. The cleaning agent comprises, by weight, 3 to 20% of glycolic acid, 2 to 9% of citric acid, 2 to 10% of methanesulfonic acid, 1 to 10% of ammonium citrate, 0.5 to 7% of a corrosion inhibitor and 0.01 to 2% of a surfactant, with the balance being deionized water. The cleaning agent for the automobile cooling system in the invention can effectively remove calcium scale, magnesium scale and iron rust in the cooling system, is applicable to cleaning of a variety of materials like carbon steel, iron, copper and aluminum in a cooling system of an engine and has the advantages of high efficiency, mildness and a low corrosion rate. The cleaning agent is applicable to general repair and maintenance of an automobile and is used for removing dirt generated due to usage of water as a cooling medium so as to increase the efficiency of heat transfer between the engine and the cooling medium and enable operation of the engine to be smoother.

Owner:CHINA PETROLEUM & CHEM CORP

Formula for culture medium of cordyceps militaris liquid strains and method for culturing same

InactiveCN101513161AAvoid cakingRemove in timeHorticultureFertilizer mixturesMonopotassium phosphateBottle

The invention discloses a formula for the culture medium of cordyceps militaris liquid strains and a method for culturing the same. The invention is characterized in that the method comprises the following steps: preparing a culture solution with the pH value being 7.5 from the following components by percentage: 0.8% of peptone, 2% of glucose, 0.1% of ammonium citrate, 0.1% of magnesium sulfate, 0.1% of monopotassium phosphate, 0.002% of vitamin B1 and 92.9% of water; filling containers, such as erlenmeyer flasks, saline bottles or preserving jars, with the culture solution; carrying out regular autoclaving on the culture solution; then, grafting the slant mother culture of cordyceps militaris onto the culture solution; and carrying out standing and culturing for 7 to 10 days in a light-blocking and airtight culture room with the temperature being 18 to 22 DEG C to obtain the cordyceps militaris liquid strains. The invention dispenses with fermentation tanks, shaking tables and other devices, therefore, the investment is small; no sterile air is introduced, therefore, the operation is convenient; and no energy is consumed, as a result, the invention is energy-saving and environment-friendly.

Owner:镇江市食用菌研究所

Methods for conditioning surfaces of polishing pads after chemical-mechanical polishing

Owner:MICRON TECH INC

Special culture medium for culturing yew plant cells to produce taxol

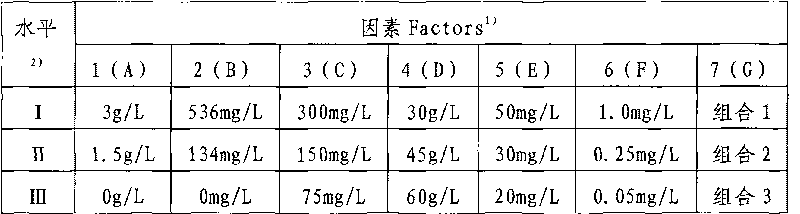

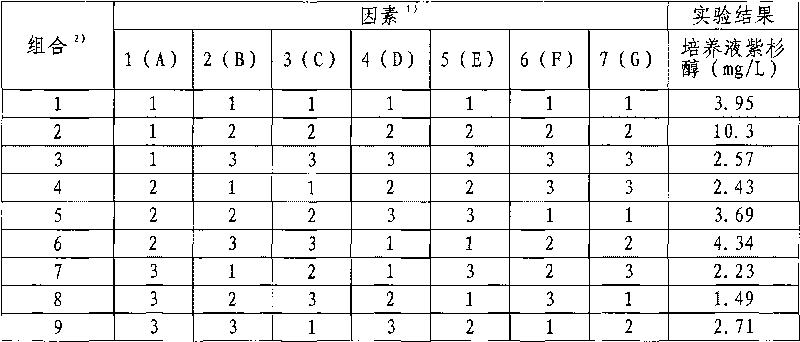

The invention discloses a special culture medium for culturing yew plant cells to produce taxol, which is obtained by taking B5 culture medium as a basic formula and utilizing an orthogonal optimization test. When the basic component comparison production is carried out on the special culture medium and the B5 culture medium, the content of the taxol in the special culture medium is 4.2 times that of the B5 culture medium; when high-density of yew plant cells are planted, a combined test is carried out by adding silver nitrate, salicylic acid, chitosan, methyl jasmonic acid, tribasic ammonium citrate, lanthanum sulfate, phenylalanine, glycine, tryptophan and lysine in the culturing process, which can further improve the content of the taxol and shorten the production period of cells; and when the cells are cultured at the thirty-first day, the highest content of the taxol in the special culture medium is 285.15 mg / L which is 81 times the highest content of the taxol in the B5 culture medium, thus the taxol can be effectively produced by using the special culture medium for culturing yew plant cells to produce taxol.

Owner:GUANGDONG KELUN PHARMACEUTICAL CO LTD

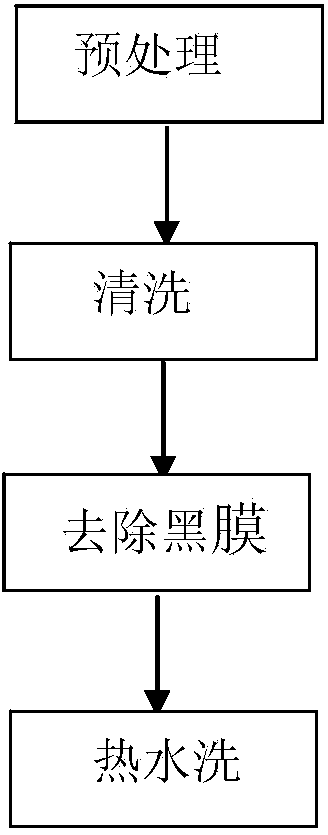

Cleaning liquor and treatment method for removing residual magnesium alloys in die

The invention provides cleaning liquor for removing residual magnesium alloys in a die. The cleaning liquor comprises the following components in percentage by weight: 60-240g of hydrochloric acid, 1-10g of ammonium citrate, 0.5-2g of EDTA (Ethylene Diamine Tetraacetic Acid), 5-55g of a corrosion inhibitor and 750-950g of water. Meanwhile, the invention provides a treatment method for cleaning the residual magnesium alloys by using the cleaning liquor according to the following four steps: pretreatment, cleaning, removing black films and washing by hot water. The cleaning liquor and treatment method have the benefits that damages cannot caused to the die and no influence is made on dimensional precision of the die, and configuration and operating method are simple and feasible, so that the surface roughness Ra1.0-1.5 of the die is effectively guaranteed. Referring to standards of GB8923-1988 Rusting Grade on Surface of Steel Products and Derusting Grade before Coating, according to the method, the surface rusting condition of the die is improved from grade D to grade A, and the grade Sa 3 of compressed-air blast cleaning is realized, so that one grade is raised relative to that of existing die cleaning liquor in the existing market.

Owner:TIANJIN DONGYI MAGNESIUM PROD +1

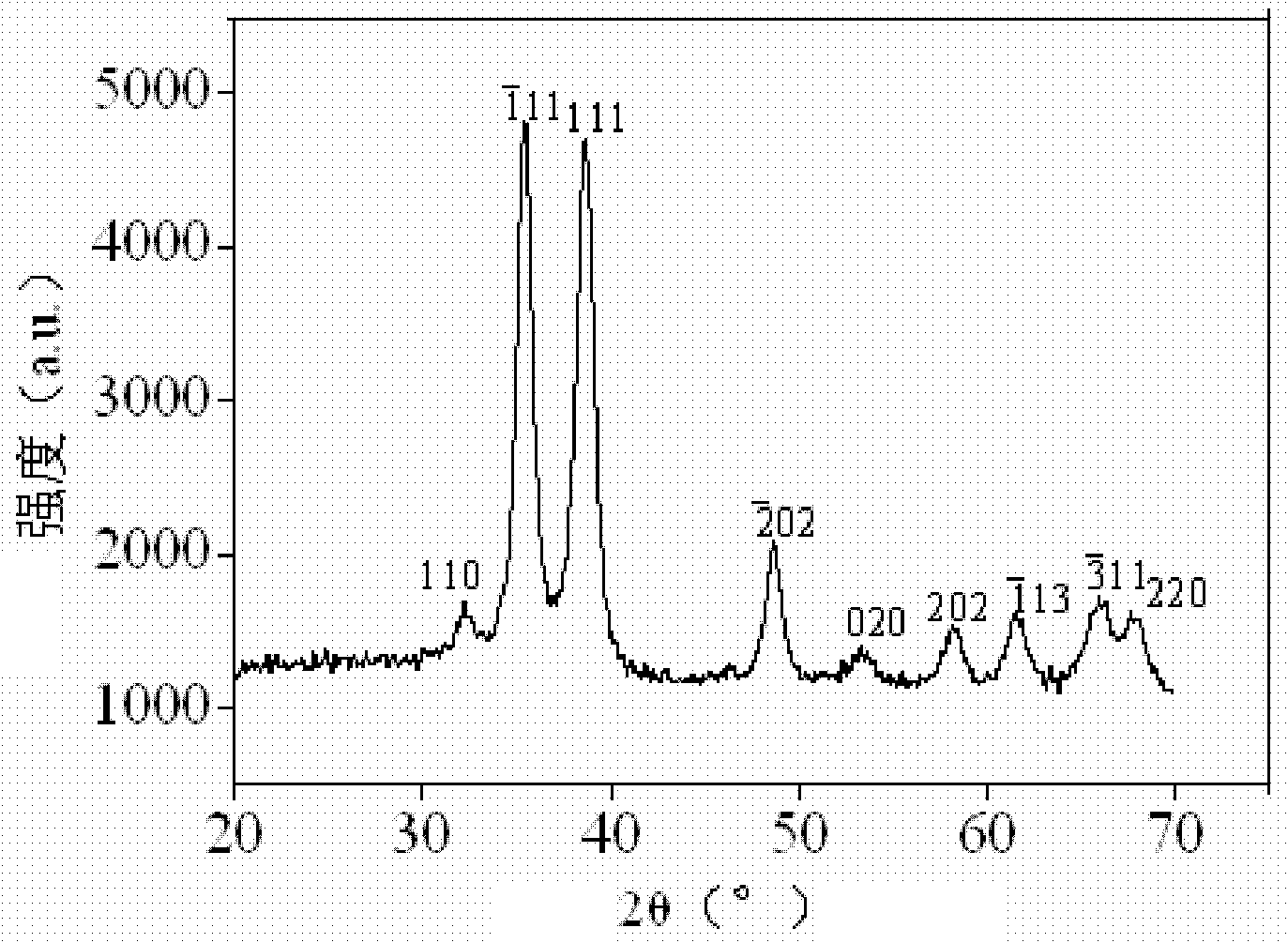

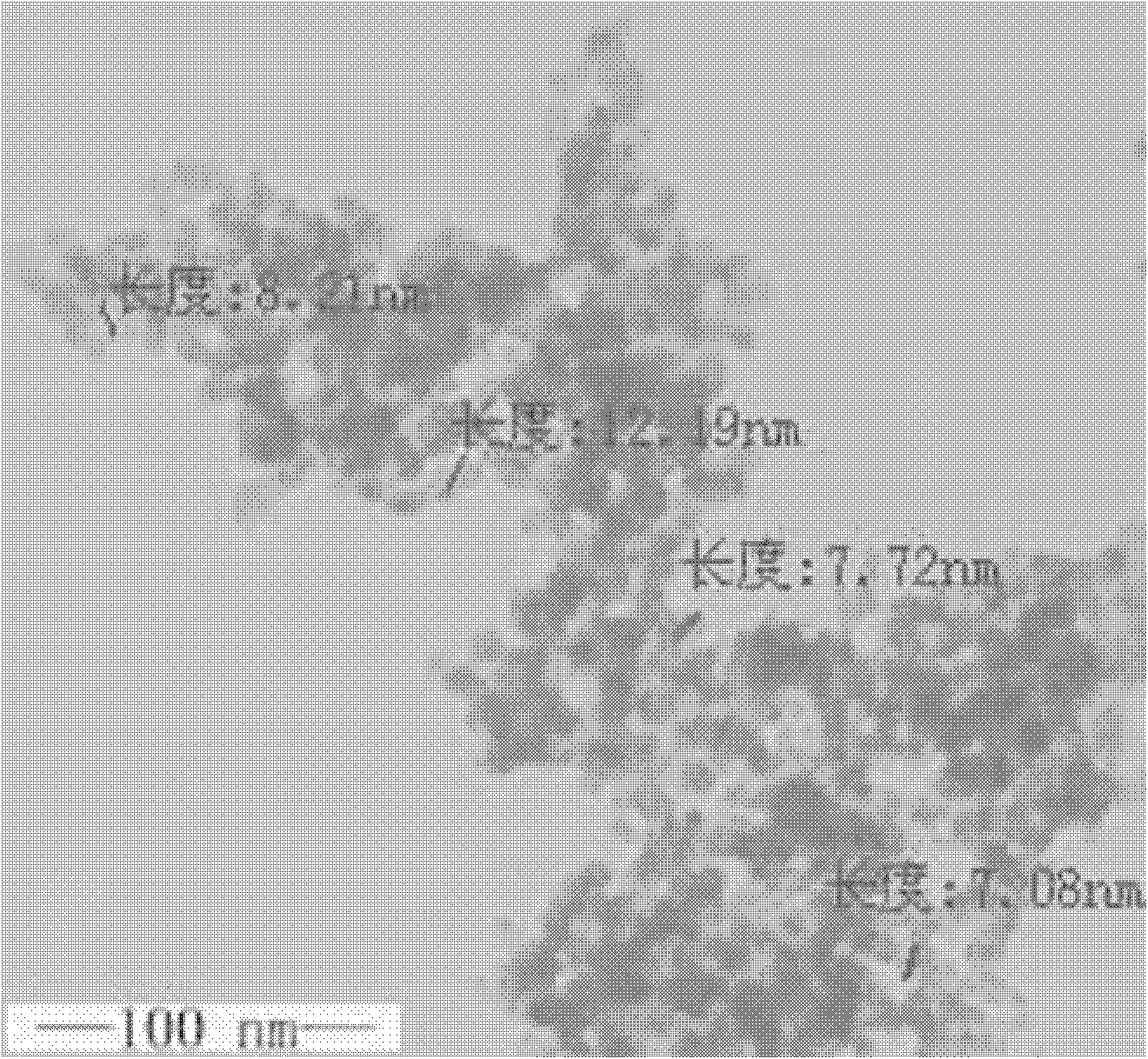

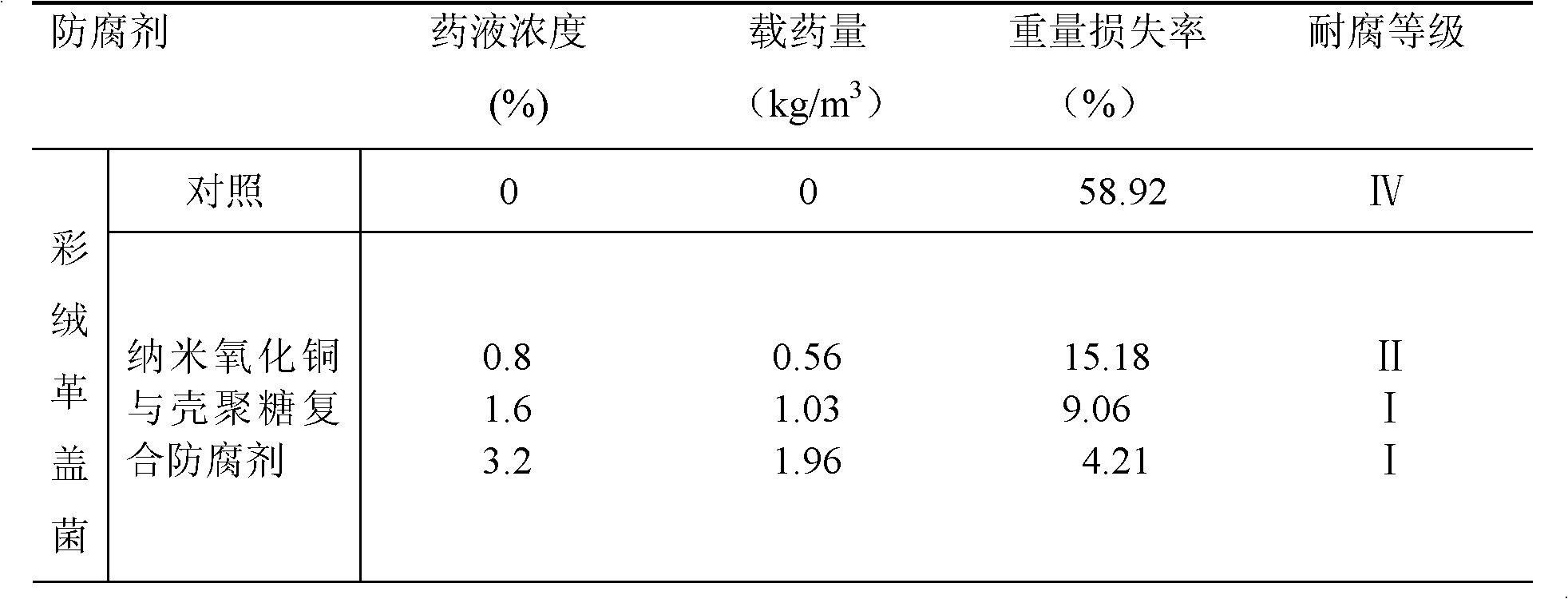

Wood preservative and preparation method thereof

ActiveCN102275192AGood fixation rateImprove permeabilityWood impregnation detailsViscous liquidGloeophyllum trabeum

The invention discloses a wood preservative and a preparation method thereof and belongs to the field of preservatives. The invention aims to solve the technical problem that a wood preservative has severe environmental harm, low permeability and low erosion resistance in the prior art. The wood preservative is prepared from nano copper oxide, ammonium citrate, distilled water, chitosan and a solution of acetic acid. The preparation method comprises the following steps of: 1, mixing the nano copper oxide and the ammonium citrate, adding the distilled water, and stirring to obtain nano copper oxid dispersion; and 2, adding the chitosan into the solution of acetic acid, adding the nano copper oxid dispersion, and stirring to obtain the wood preservative. The wood preservative is black brown viscous liquid and has an obvious bacteriostatic effect on wood decomposing fungi, such as monilinia fructicola, namely Gloeophyllum trabeum, and white rot fungi, namely Coriolus versicolor.

Owner:NORTHEAST FORESTRY UNIVERSITY

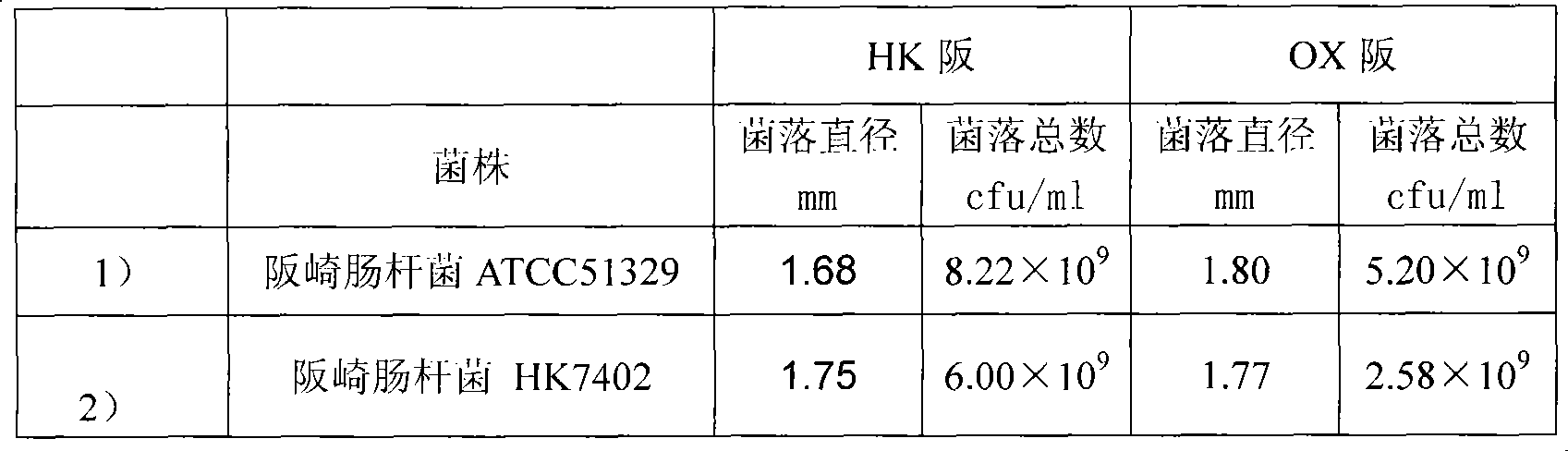

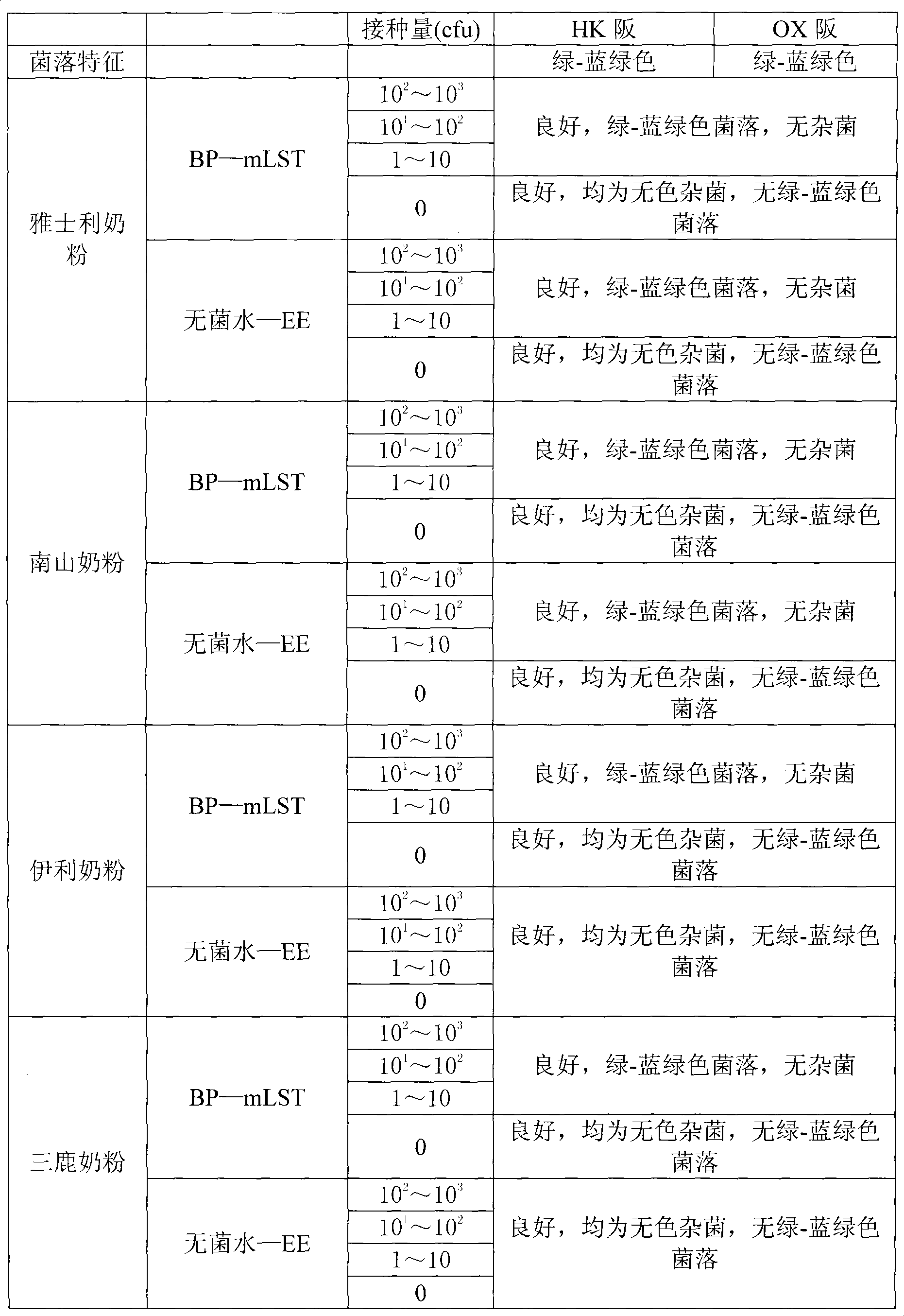

Enterobacter sakazaii colour development culture medium, detection kit and detection method

InactiveCN101423862ASave testing costSave testing timeMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementMicroorganismGram

The invention provides a fluorogenic culture medium of Enterobacter sakazakii, a test kit and a test method thereof, and relates to a method for testing microbe and a composition used by the method. The fluorogenic culture medium comprises the compositions as follows: 8 to 20 grams of peptone, 4 to 7 grams of beef extract powder, 4 to 7 grams of sodium chloride, 1.0 to 2.0 grams of cholate, 12 to 20 grams of agar, 0.05 to 0.5 grams of X-a-glucopyranoside, 0.01 to 0.04 grams of Na2CO3, 0.3 to 2.0 grams of ferric ammonium citrate, and 0.3 to 2.0 grams of sodium thiosulfate. The test kit consists of the fluorogenic culture medium of Enterobacter sakazakii, an enriched liquid A ,namely buffer peptone water culture medium, and an enriched liquid B, namely modified lauryl sulfate pancreas peptone broth. The test kit is configured simply, and the test method has high sensitivity in detection, so the method is suitable for treating large flux samples.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

Preparation method of zirconium oxide structural ceramics

The invention relates to a preparation method of zirconium oxide structural ceramics, which comprises the following steps: mixing yttrium-oxide-dope zirconium oxide ceramic powder and a binding agent, wherein the binding agent accounts for 10-25 wt% of the mixture; blending the mixture; and carrying out CIM injection molding and vacuum hot-pressed sintering to obtain the zirconium oxide structural ceramics of which the density is up to 6.05-6.1g / cm<3>, the hardness is up to 1050-1400HV and the heat conductivity coefficient is up to 2.3-3W / (m.k). The yttrium-oxide-dope zirconium oxide ceramic powder is prepared by the following steps: carrying out a chemical coprecipitation method to obtain a precipitate, wherein zirconium oxychloride and yttrium nitrate are used as the raw materials, sodium hydroxide is used as a precipitant, and ammonium citrate is used as a dispersant; and washing the precipitate, drying, and presintering to obtain the yttrium-oxide-dope zirconium oxide ceramic powder.

Owner:JIANGXI UNIV OF SCI & TECH

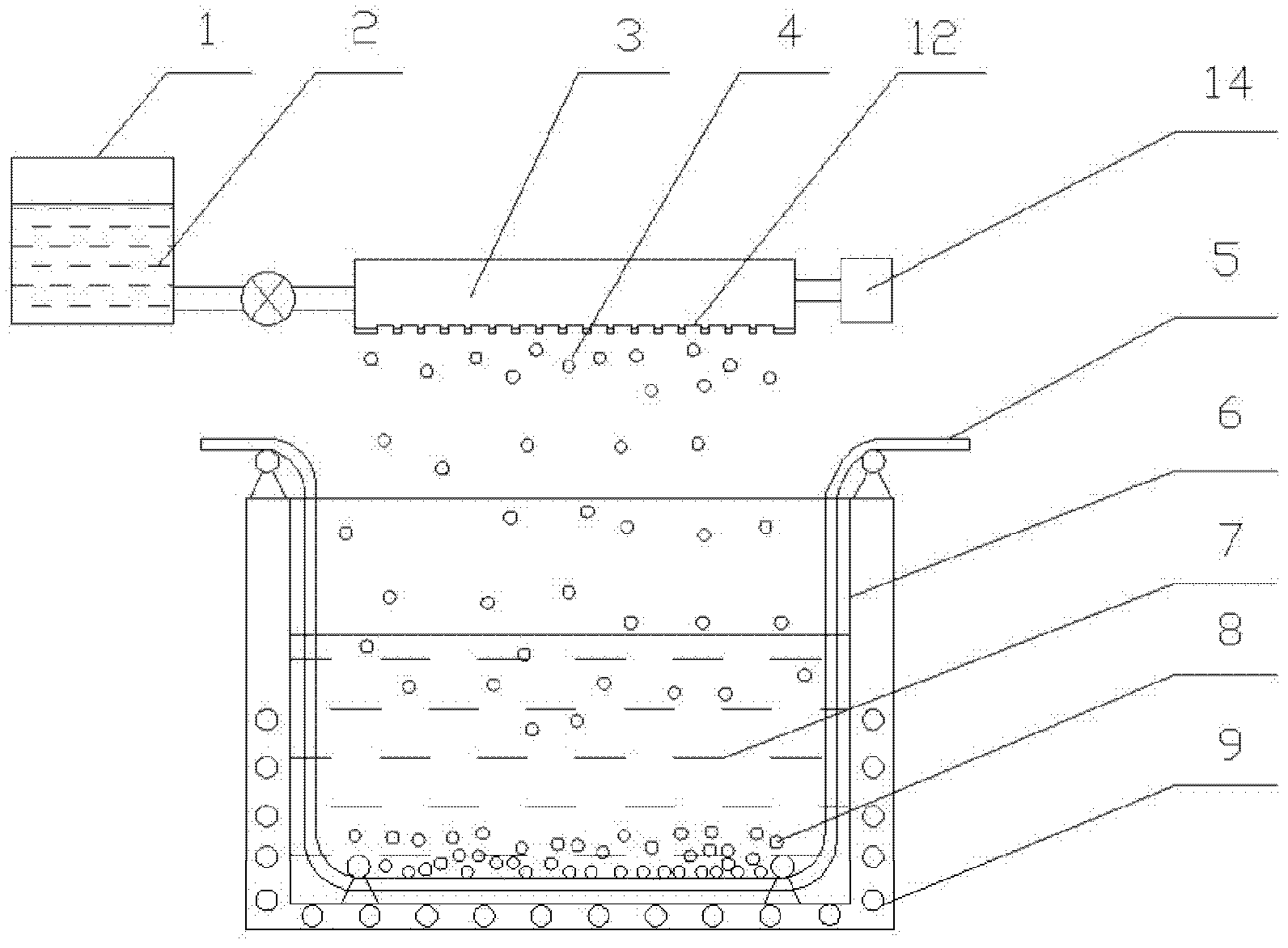

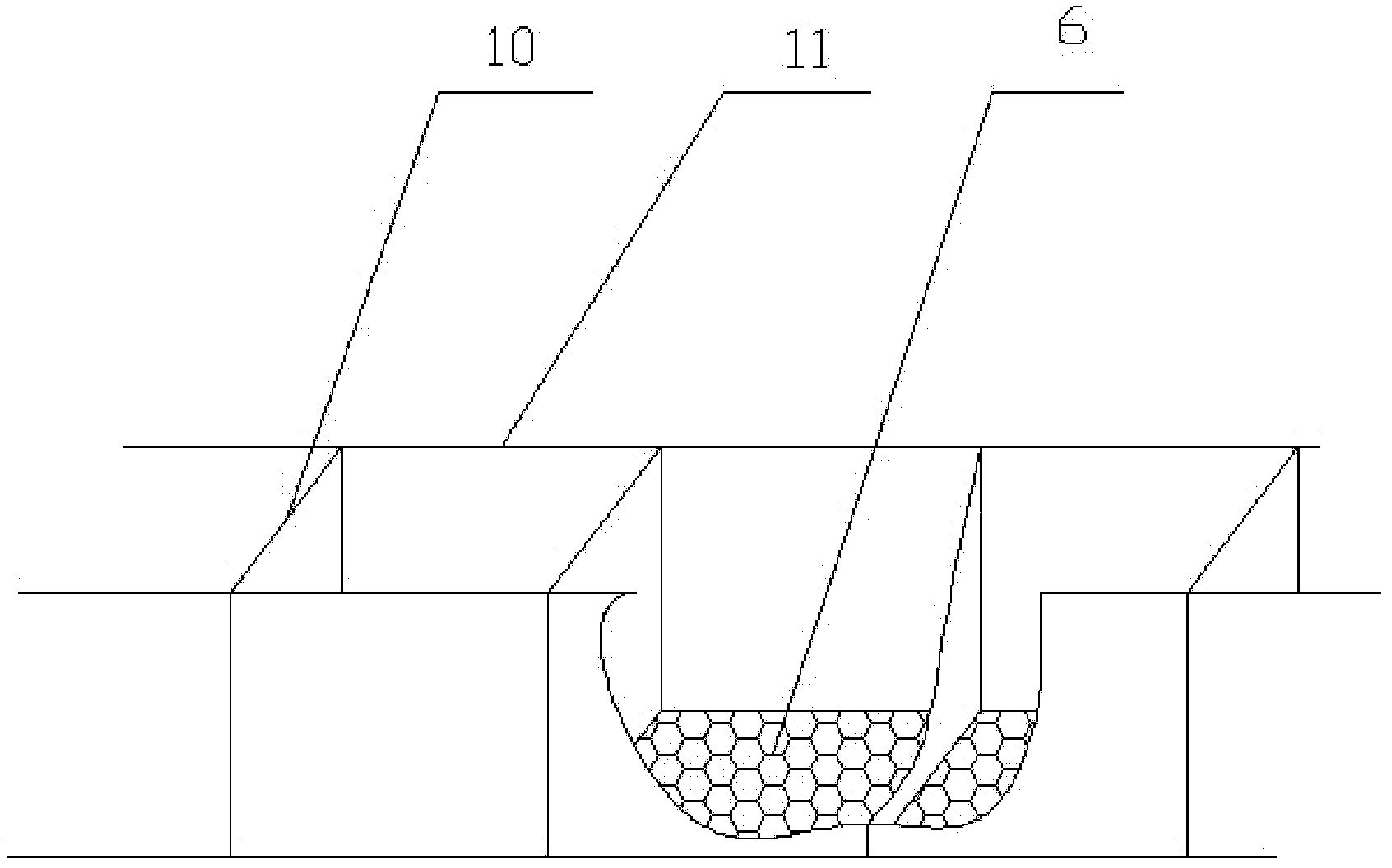

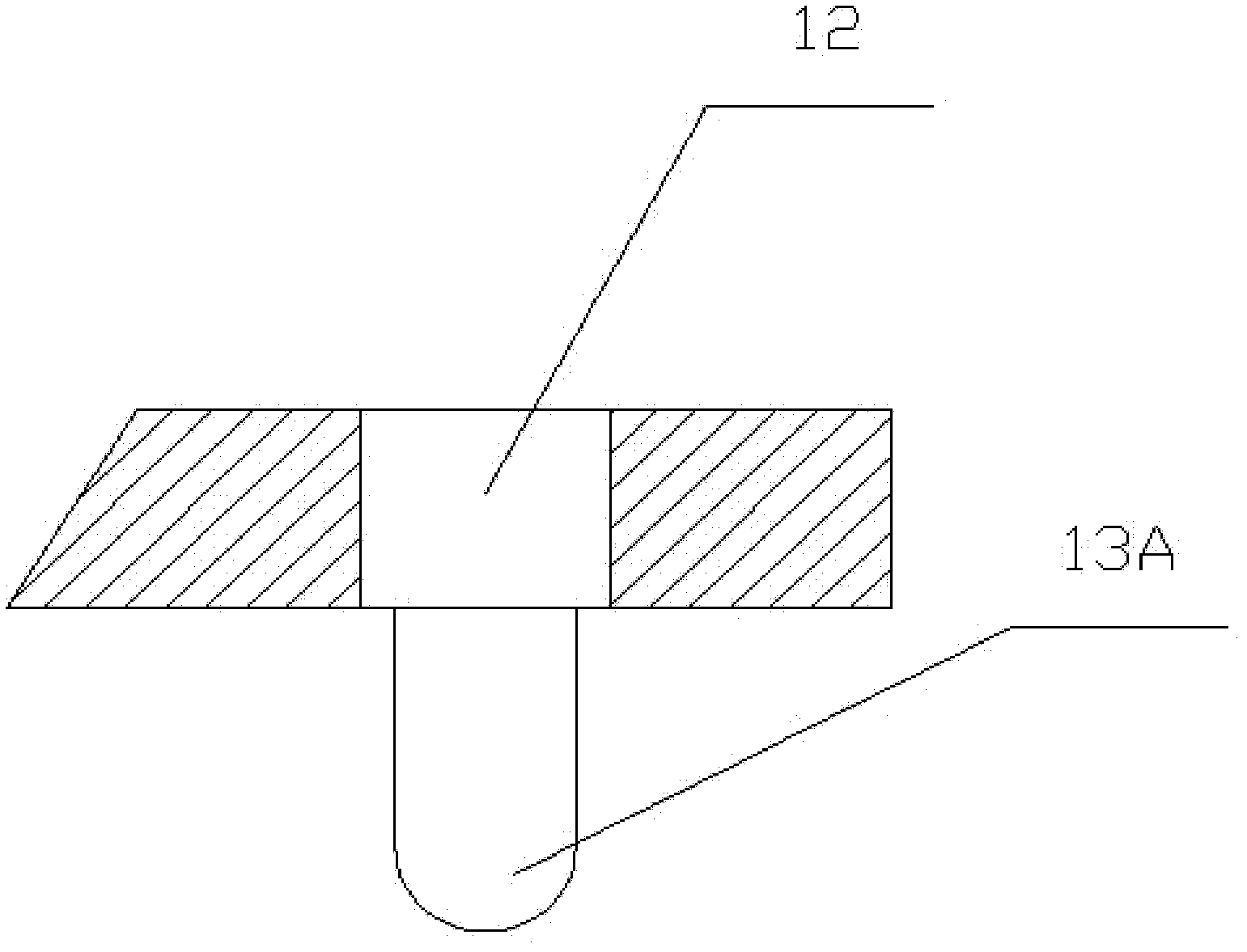

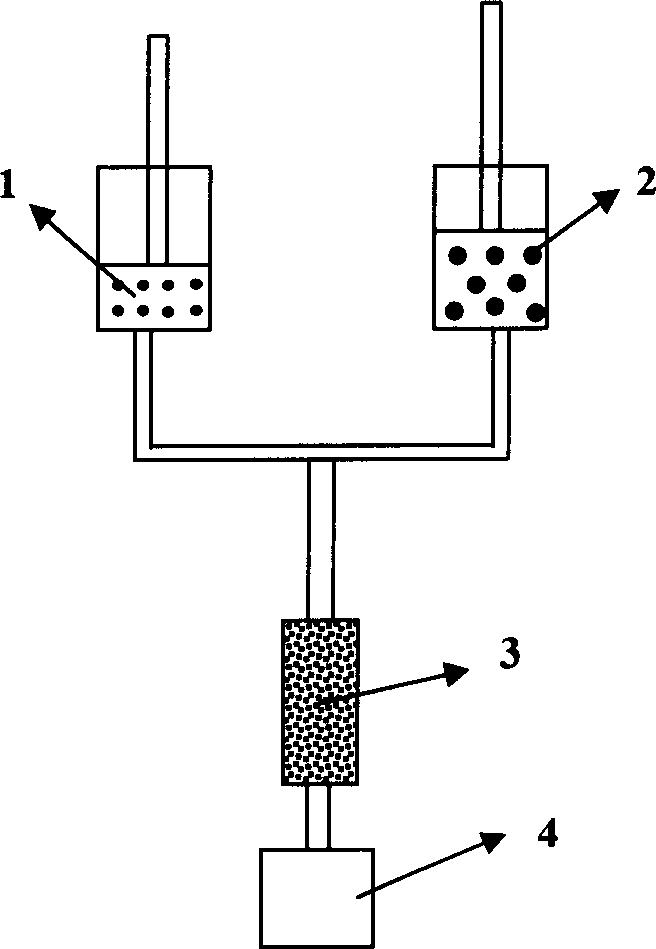

Forming method and device of ceramic micro-bead green body

The invention relates to a forming method and device of a ceramic micro-bead green body, belonging to the technical field of structural ceramics. The forming method of the ceramic micro-bead green body comprises the following steps of: preparing suspended slurry by adopting ammonium citrate and polyacrylic acid, forming liquid beads via a titrator, enabling the liquid beads to drip into hot glycerin in a collecting tank for forming beads, and solidifying to form the micro-bead green body. The forming device of the ceramic micro-bead green body is as follows: a slurry storage tank is connected with the titrator, a titration hole is arranged at the bottom of the titrator, the collecting tank containing the glycerin is arranged below the titrator, the collecting tank is provided with a heating device, and a screen mesh is arranged in the collecting tank. According to the forming method disclosed by the invention, slurry prepared by safe and non-toxic raw and auxiliary materials, and the beads are formed in the hot glycerin and solidified. The forming method and device has the advantages of simple equipment, convenience in operation, good quality of the formed beads, high efficiency and capability of realizing continuous production. The forming method and device which has the benefits of safety, environmental protection, simplicity in operation and high efficiency is provided for forming the ceramic micro-bead green body.

Owner:GANZHOU KOIN STRUCTURE CERAMICS

On-line treatment method of acidic etching solution

InactiveCN102839379AReduce volumeImprove antioxidant capacityProcess efficiency improvementSodium phosphatesOxidation resistant

The invention discloses an on-line treatment method of an acidic etching solution, which is characterized by comprising the following steps: using a pyridine carboxylic ester extracting agent Mextral CLX-50 to directly extract copper in the acidic etching solution; performing back extraction on the copper-carrying pyridine carboxylic ester extracting agent with water, a sodium citrate water solution, an ammonium citrate water solution, sodium phosphate and an ammonium phosphate water solution; performing oil removal treatment on the etching solution; and distributing for recycling. According to the invention, the acidic etching solution is directly extracted, and the oxidation resistance is high. The acidic etching solution does not need to be subjected to pretreatment (e.g. regulation of pH value and removal of oxidizer), and the service life is long. Besides, the operating cost is lowered, and simultaneously, the volume of the waste solution is reduced.

Owner:CHONGQING KOOPPER CHEM IND

Method for producing ceramics through granite powder waste

InactiveCN106242508ALower firing temperatureReduce dosageCeramic materials productionClaywaresPyrophylliteZircon

The invention discloses a method for producing ceramics through purified granite powder waste. 10-35 parts by weight of zircon sand, 5-30 parts by weight of high-whiteness potassium-sodium feldspar powder, 3-25 parts of kaolin, 5-25 parts of pyrophyllite, 3-25 parts of gypsum, 3-20 parts of nutshell powder, 2-20 parts of iron mine milltailings, 1-15 parts of zinc oxide, 1-15 parts of magnesium oxide, 1-15 parts of barium oxide, 1-10 parts of pentalyn, 1-10 parts of ammonium citrate and 1-10 parts of calcium hypophosphite are weighed; kaolin, pyrophyllite and gypsum are taken to be mixed and crushed, and wet ball milling, drying, calcining, water quenching, drying and crushing are carried out; zircon sand, high-whiteness potassium-sodium feldspar powder and iron mine milltailings are taken to be mixed and crushed, and size mixing, microwave treatment, size mixing, ultrasonic treatment and drying are carried out; the prepared powder and the remaining raw materials are stirred, mixed, subjected to compression moulding and sintered, and the ceramics are obtained. The ceramics have the very prominent mechanical property, the production cost is reduced, the service life is prolonged, and the method is widely applied to producing whiteware, domestic ceramics and craft ceramics.

Owner:吴海屏

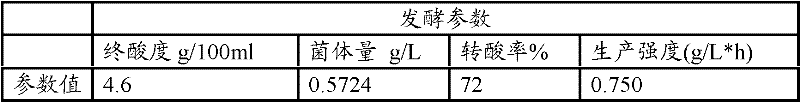

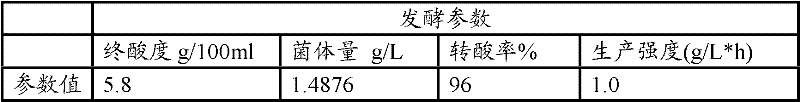

Acetic acid bacterium fermentation nutritive salt and use method thereof

InactiveCN102443549AQuality improvementIncrease productionBacteriaMicroorganism based processesYeastAcetic acid

The invention relates to acetic acid bacterium fermentation nutritive salt, which comprises the following ingredients in percentage by weight: 26 percent to 27 percent of hydrolyzed yeast powder, 15 percent to 16 percent of ammonium citrate, 44 percent to 45 percent of glucose, 4 percent to 5 percent of dipotassium phosphate, 3 percent to 4 percent of disodium hydrogen phosphate and 5 percent to 6 percent of magnesium sulfate, perfectly, the hydrolyzed yeast powder accounts for 26.5 percent, the ammonium citrate accounts for 15.5 percent, the glucose accounts for 44.8 percent, the dipotassium phosphate accounts for 4.2 percent, the disodium hydrogen phosphate accounts for 3.7 percent, and the magnesium sulfate accounts for 5.3 percent. The invention also relates to a use method of the acetic acid bacterium fermentation nutritive salt. The acetic acid bacterium fermentation nutritive salt has the advantages that the design is unique, the nutritive requirement of the acetic acid bacterium fermentation process is completely met, the fermentation period can be shortened, the acetic acid quality can be improved, the acetic acid yield can be improved, the production cost can be reduced, and the acetic acid bacterium fermentation nutritive salt is suitable for large-scale popularization and application.

Owner:JIANGNAN UNIV

Method for preparing ceramic with pore gradient

InactiveCN1830902AImprove performanceEasy to operateCeramicwareClaywaresTetramethylammonium hydroxidePorosity

A process for preparing the porosity-gradient ceramic includes such steps as adding deionized water to ceramic powder and disperser, ball grinding to obtain slurry A, adding deionized water to solidifying organic substance (starch or modified starch), ultrasonic dispersing or ball grinding to obtain slurry B, vacuum mixing, fast filling the mixture in mould, solidifying, drying and sintering. Said ceramic powder is chosen from alumina powder, SiC powder and Si3N4 powder. Said disperser is chosen from ammonium citrate and ammonium tetramethyl hydroxide.

Owner:TSINGHUA UNIV

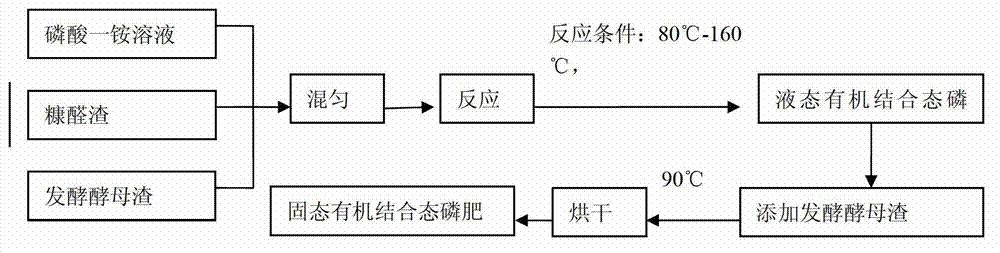

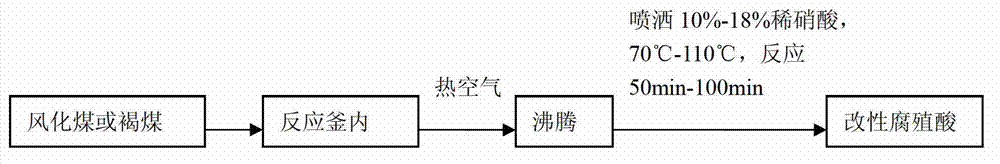

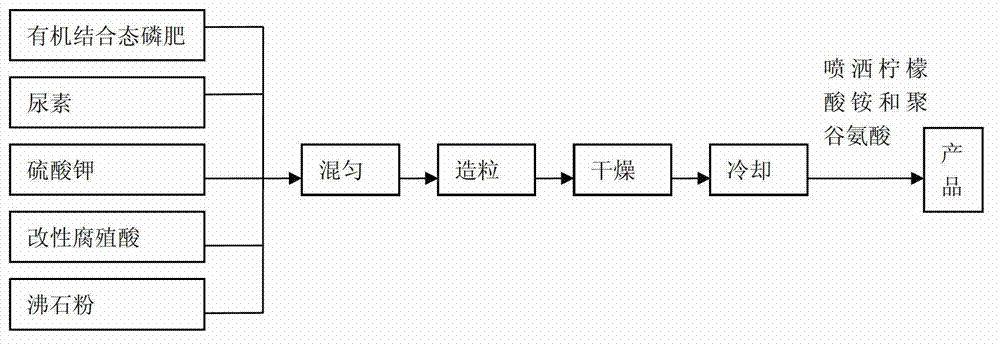

Organic/inorganic compound fertilizer for improving phosphorus use efficiency and preparation method thereof

ActiveCN103204748AEasy to fixIncrease the number ofFertilizer mixturesPhosphate ionInorganic compound

The invention provides an organic / inorganic compound fertilizer for improving phosphorus use efficiency. The compound fertilizer consists of the following components according to parts by weight: 4.0-5.0 parts of organic combined phosphatic fertilizer, 2.0-3.0 parts of urine, 1.8-2.5 parts of potassium sulfate, 0.6-0.8 part of modified humic acid, 0.4-0.5 part of zeolite powder, 0.08-0.15 part of an ammonium citrate solution, and 0.03-0.07 part of a polyglutamic acid solution. According to the compound fertilizer provided by the invention, the inorganic phosphorus is combined onto an organic molecular structure in the form of a phosphate ion, so that the immobilization of the phosphate ion in the soil is reduced; through modifying the humic acid, the quantity of active functional groups of the humic acid is increased, and by adding two phosphorus activating agents of zeolite powder and ammonium citrate, the phosphorus activating effect is enhanced; and through the addition of water-retaining agent polyglutamic acid, the fertilizer can improve water retaining performance, water permeability and air permeability of the soil, enhances mobility of the phosphorus in the soil, and improves granular structure of the soil.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com