Preparation method of yttrium-silicon-oxygen porous high-temperature ceramic material

A technology of high-temperature ceramics and porous ceramics, which is applied in the field of preparation of yttrium-silicon-oxygen porous high-temperature ceramic materials to achieve the effects of improving synthesis efficiency, broadening application range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

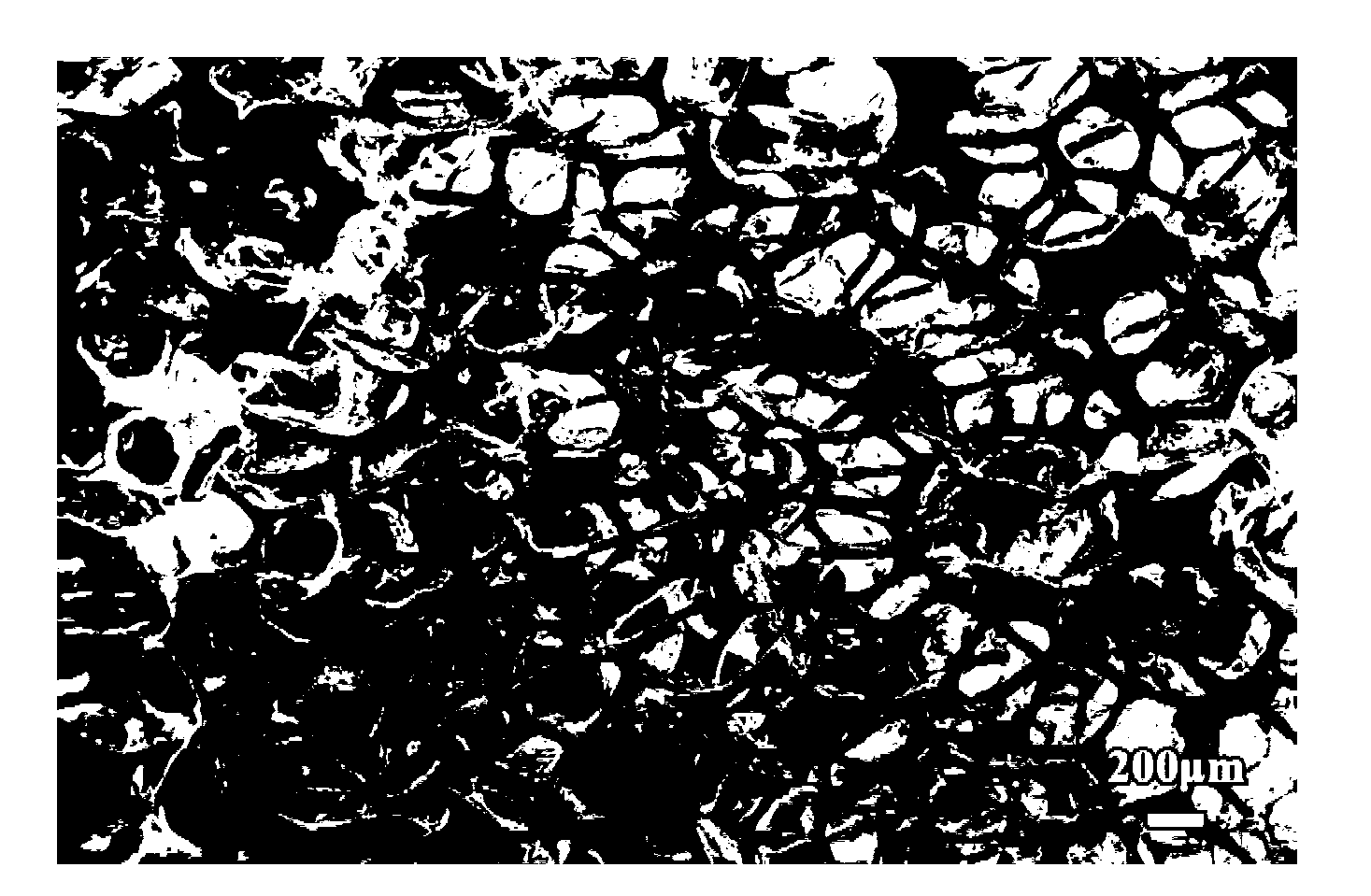

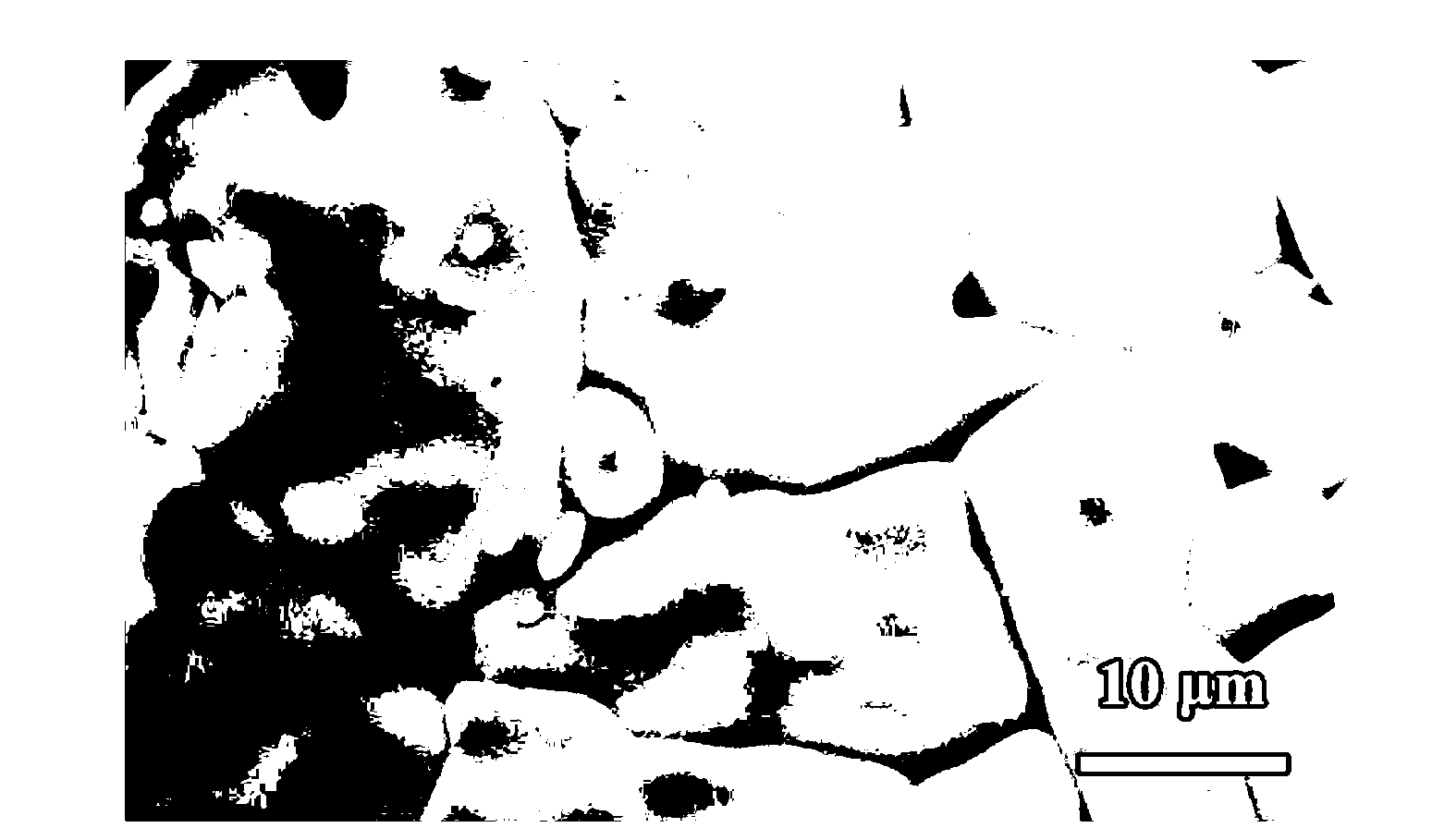

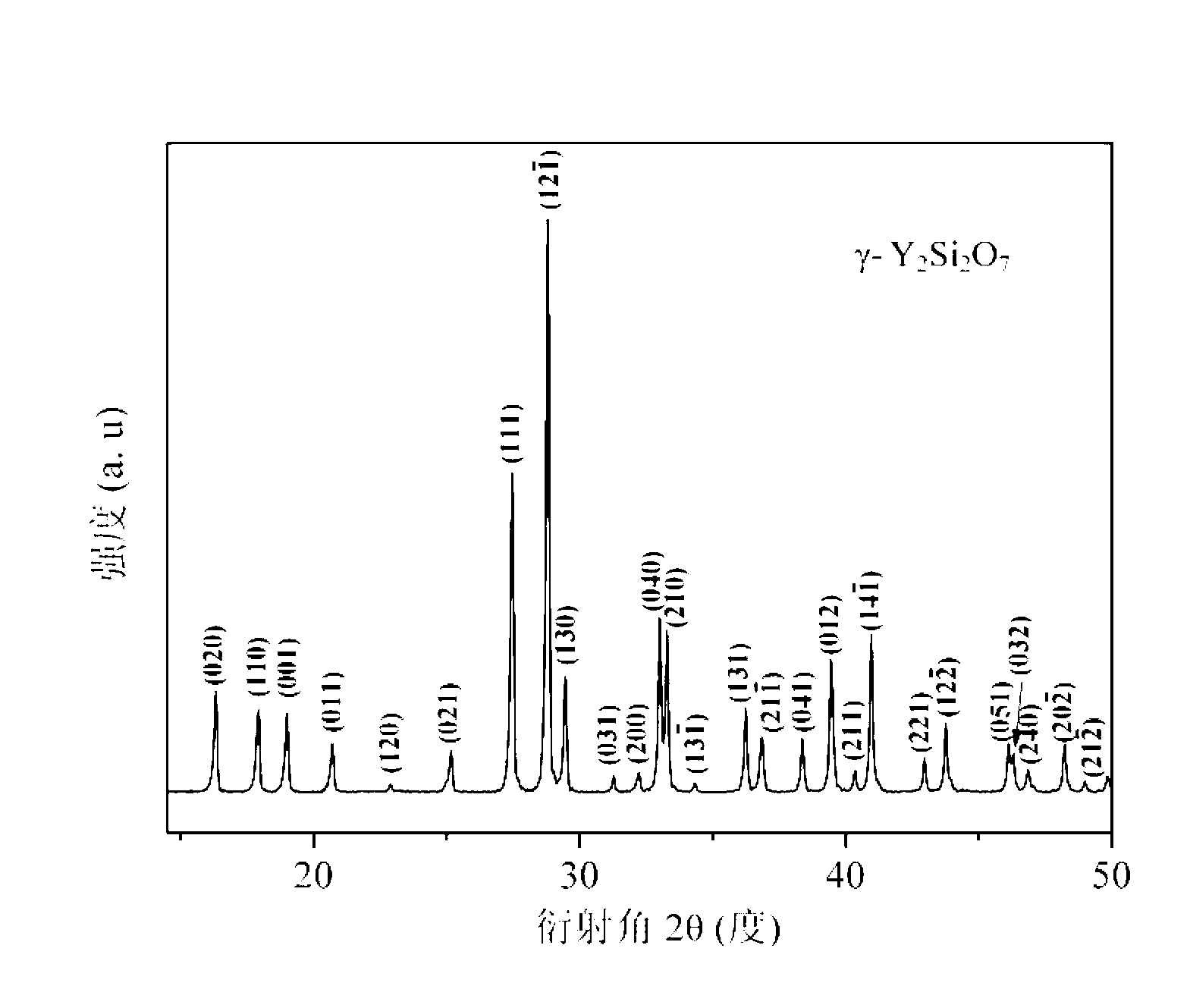

[0020] First, clean the surface of the polyurethane foam template with a porosity of 60ppi (pores per inch) with deionized water, take it out and dry it; then soak it in a NaOH solution with a mass fraction of 20% at 50°C for 3 hours, and then clean it with deionized water and drying; then soaked in a 1% CMC (sodium carboxymethylcellulose) solution for 2 hours and then dried.

[0021] Will Y 2 SiO 5 Powder 52g, deionized water 5g, CMC solution (mass fraction 1%) 10g, silica sol (mass fraction 30%) 30g, kaolin 0.5g and polyethylene glycol (molecular weight 20000) 0.2g were mixed to prepare slurry , and adjust the pH value of the slurry to 9. The treated foam formwork is dipped in the slurry and hangs the slurry twice, each dipping is 30s, and the excess slurry in the formwork is removed by centrifugation and dried to obtain a prefabricated body.

[0022] Next, the preform is heated to 700°C in the air for pretreatment, the heating rate is 0.5°C / min, and the holding time is 1...

Embodiment 2

[0024] First clean the surface of the polyurethane foam template with a porosity of 60ppi (pores per inch) with deionized water, take it out and dry it; then soak it in a NaOH solution with a mass fraction of 15% at 60°C for 2 hours, and then clean it with deionized water and drying; then soaked in a 2% CMC (sodium carboxymethylcellulose) solution for 3 hours and then dried.

[0025] Will Y 2 SiO 5 60g of powder, 7.5g of deionized water, 6.5g of CMC solution (2% by mass fraction), 35g of silica sol (25% by mass fraction), 0.8g of kaolin and 0.5g of polyethylene glycol (molecular weight of 6000) were mixed and prepared slurry, and adjust the pH value of the slurry to 10. The treated foam formwork was dipped in the slurry and slurryed 4 times for 30s each time, and the excess slurry in the formwork was removed by centrifugation and dried to obtain a prefabricated body.

[0026] Next, the preform is heated to 900°C in the air for pretreatment, the heating rate is 1°C / min, and ...

Embodiment 3

[0028] Use deionized water to clean the surface of the polyurethane foam template with a porosity of 60ppi (pores per inch), take it out and dry it; then soak it in a NaOH solution with a mass fraction of 20% at 55°C for 2.5h, then wash it with deionized water Washing and drying; then soaking in 1% CMC (sodium carboxymethylcellulose) solution for 3 hours and then drying.

[0029] Will Y 2 SiO 5Powder 50g, deionized water 6g, CMC solution (mass fraction is 2%) 5g, silica sol (mass fraction is 30%) 35g, kaolin 0.7g and ammonium citrate 0.4g mix and prepare slurry, and slurry pH Adjust the value to 11. The treated foam formwork was dipped in the slurry, and the slurry was hung for 3 times, each dipping was 30s, and the excess slurry in the formwork was removed by centrifugation and dried to obtain a prefabricated body.

[0030] Next, the preform is heated to 800°C in the air for pretreatment, the heating rate is 0.5°C / min, and the holding time is 1.5h, and the organic foam ske...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com