Method for preparing graphene/metal composite material and three-dimensional graphene

A technology of metal composite materials and graphene, which is applied in the direction of metal material coating technology, metal processing equipment, additive manufacturing, etc., can solve the problems of poor dispersion and interface bonding performance, and achieve simple operation, wide adaptability, and short preparation cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

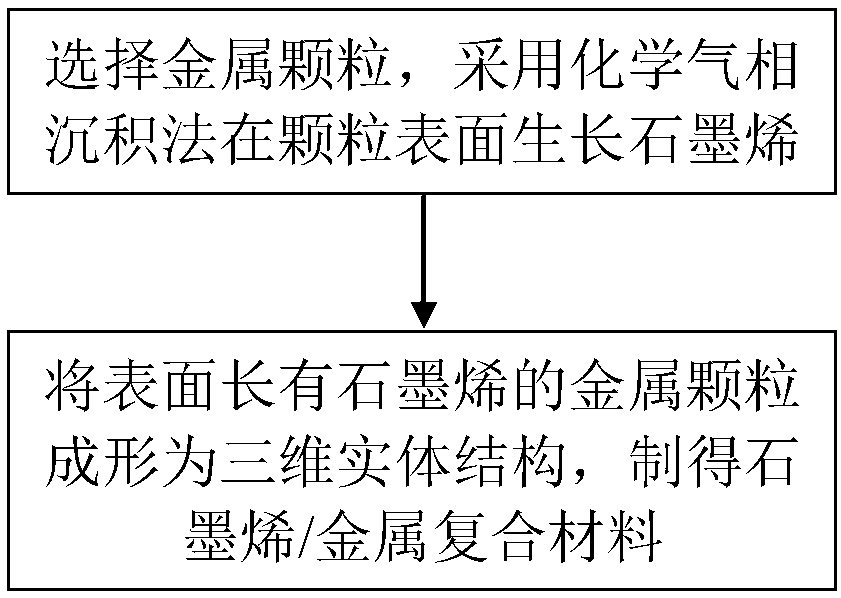

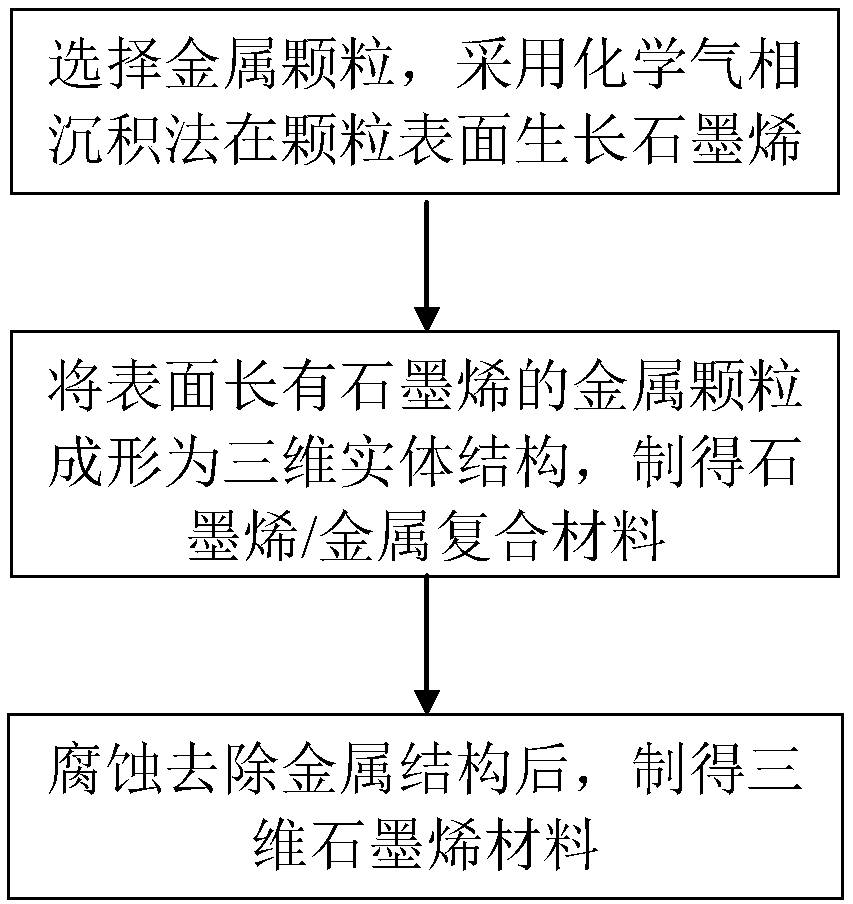

Method used

Image

Examples

Embodiment 1

[0037] (1) Select Ni particles with an average particle size of 30 μm, put them into a CVD tube furnace, and feed argon as a protective gas; under the conditions of an argon flow of 500 sccm and a hydrogen flow of 100 sccm, the sample is heated to 1000° C. in 50 minutes; Under the conditions of argon flow rate of 500sccm and hydrogen flow rate of 100sccm, the reduction was carried out at 1000 °C for 30 minutes; Graphene is grown, and the growth time is 5 minutes. After the growth, 100 sccm of gaseous hydrogen and 500 sccm of argon gas are continuously introduced, and the temperature is rapidly cooled to room temperature at a rate of 100 ° C per minute, thereby obtaining metal Ni particles with graphene grown on the surface. The number of graphene layers is 3;

[0038] (2) the Ni metal particles with graphene on the surface obtained in the step (1) are loaded into a graphite mold with a diameter of 30 mm, then spark plasma sintering is carried out at 800° C. / 60 MPa, and the tem...

Embodiment 2

[0041] (1) Select Cu particles with an average particle size of 50 μm, put them into a CVD tube furnace, and feed argon as a protective gas; under the conditions of an argon flow of 300 sccm and a hydrogen flow of 50 sccm, the sample is heated to 850° C. in 30 minutes; Under the conditions of argon flow rate of 300sccm and hydrogen flow rate of 50sccm, the reduction was carried out at 850 ° C for 30 minutes; after the insulation was completed, a mixed gas of acetylene, hydrogen and argon was introduced (the gas flow rates were acetylene 10sccm, hydrogen 50sccm and argon 300sccm respectively), and the Graphene is grown, and the growth time is 10 minutes. After the growth, 50 sccm of hydrogen gas and 300 sccm of argon gas are continuously introduced, and the temperature is rapidly cooled to room temperature at a rate of 100 ° C per minute, thereby obtaining the metal Cu particles with graphene grown on the surface. The number of graphene layers is 1;

[0042] (2) The Cu metal pa...

Embodiment 3

[0045] (1) Select Fe particles with an average particle size of 10 μm, put them into a CVD tube furnace, and feed argon as a protective gas; under the conditions of an argon flow of 500 sccm and a hydrogen flow of 100 sccm, the sample is heated to 1000° C. in 50 minutes; Incubate at 1000 ℃ for 10 minutes under the conditions of argon flow rate of 500 sccm and hydrogen flow rate of 100 sccm; after the insulation is completed, a mixed gas of methane, hydrogen and argon (gas flow rates are respectively 30 sccm for methane, 100 sccm for hydrogen and 500 sccm for argon) are introduced to start growth. Graphene, the growth time is 10 minutes, and after the growth, 100 sccm of gaseous hydrogen and 500 sccm of argon gas are continuously introduced, and rapidly cooled to room temperature at a rate of 100 ° C per minute, thereby obtaining the metal Fe particles with graphene grown on the surface, graphite The number of alkene layers is 6;

[0046] (2) the Fe metal particles with graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com