Patents

Literature

43results about How to "Overcoming associativity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

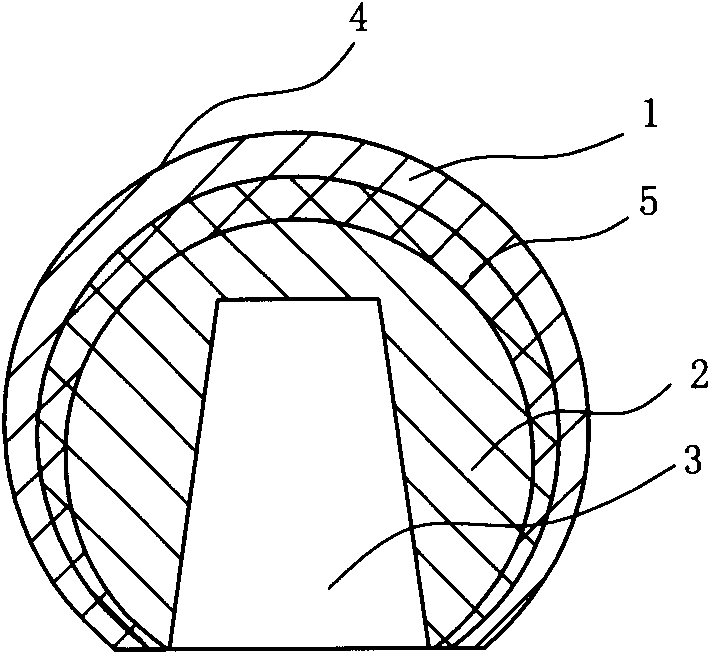

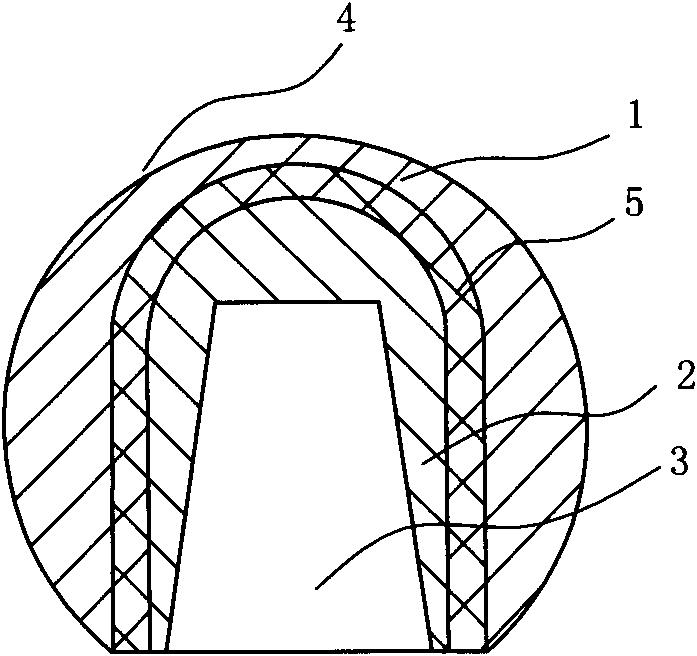

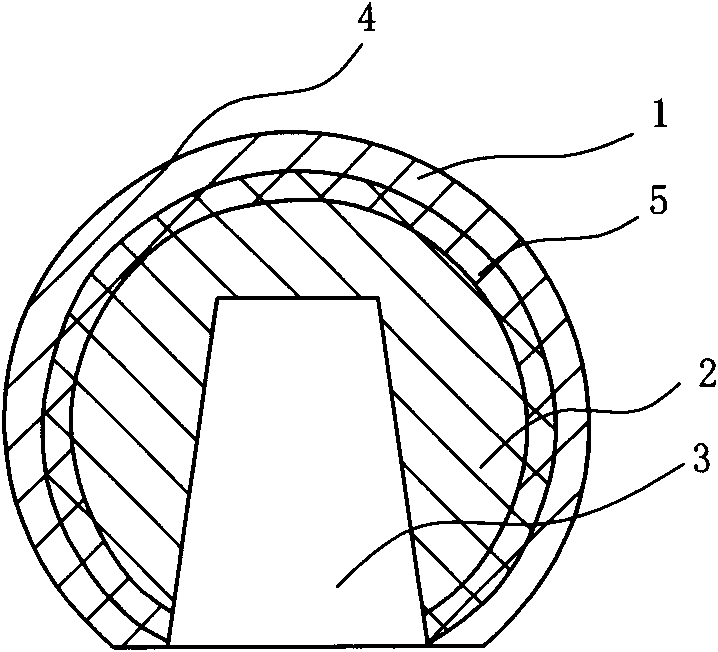

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

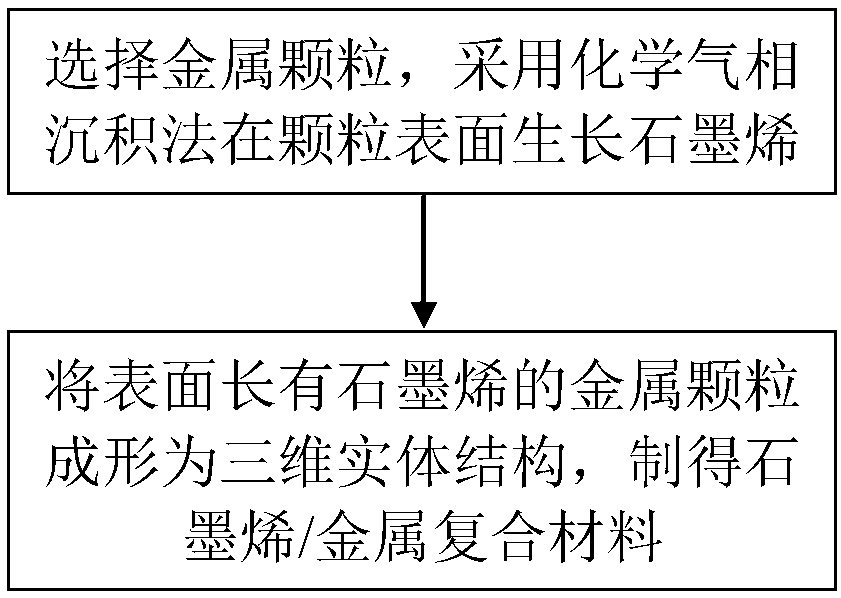

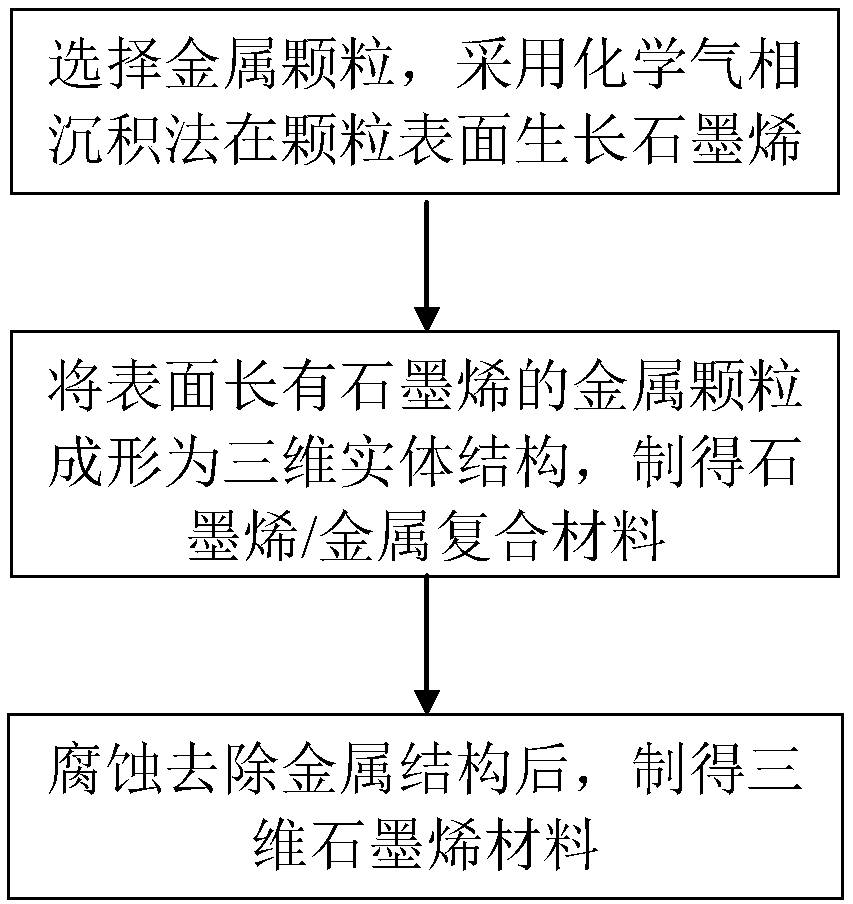

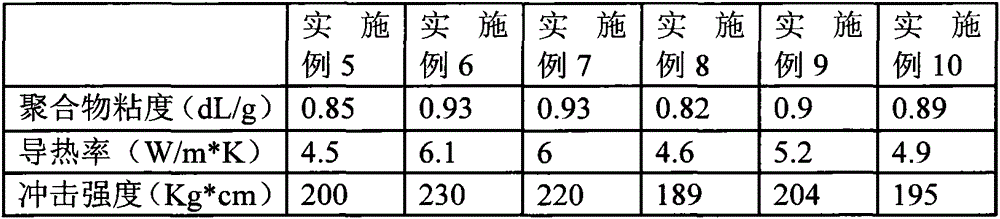

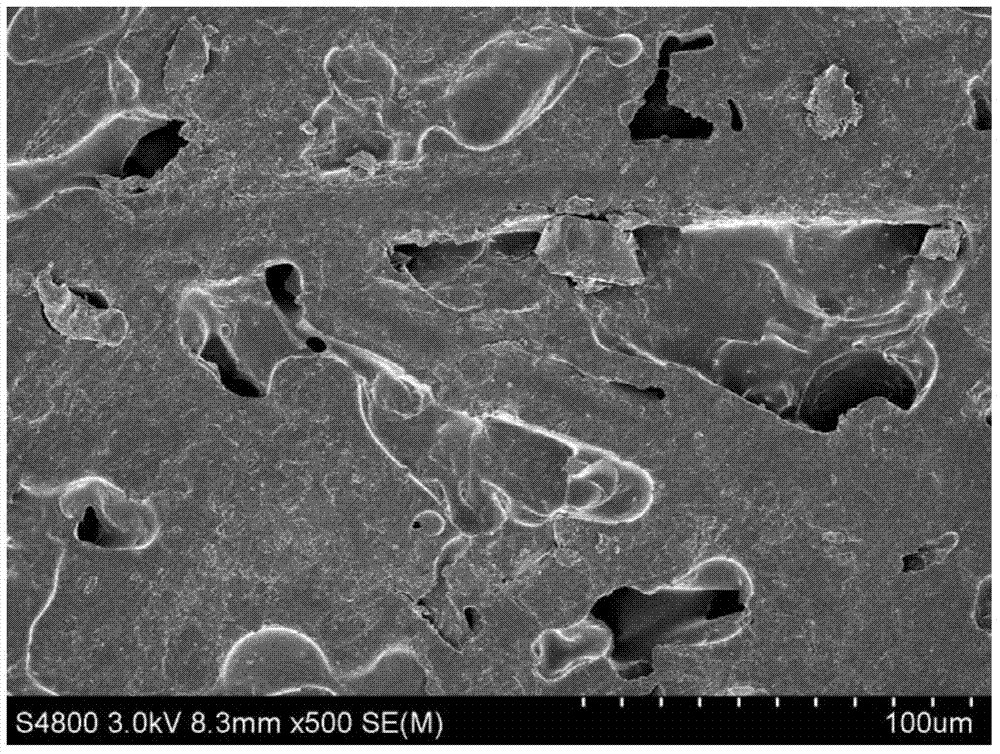

Method for preparing graphene/metal composite material and three-dimensional graphene

InactiveCN108034930AEvenly dispersedOvercoming dispersionAdditive manufacturing apparatusTransportation and packagingMetal particleCvd graphene

The invention belongs to the preparation field of graphene and a composite material of the graphene, and particularly discloses a method for preparing a graphene / metal composite material and three-dimensional graphene. The method for preparing the graphene / metal composite material includes the following steps that a chemical vapor deposition method is adopted for growing the graphene on the surfaces of metal particles; and the metal particles with the graphene being grown on the surfaces are molded to be of a three-dimensional entity structure, and accordingly the graphene / metal composite material is prepared. The method for preparing the three-dimensional graphene includes the specific steps that metal components in the prepared graphene / metal composite material are removed through corrosion with corrosive liquid, and accordingly the three-dimensional graphene can be prepared. By adoption of the method, a graphene / metal composite material product and a three-dimensional graphene material with excellent performance can be prepared; and the method has the advantages of being easy and convenient to operate, short in preparation period, wide in applied range and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

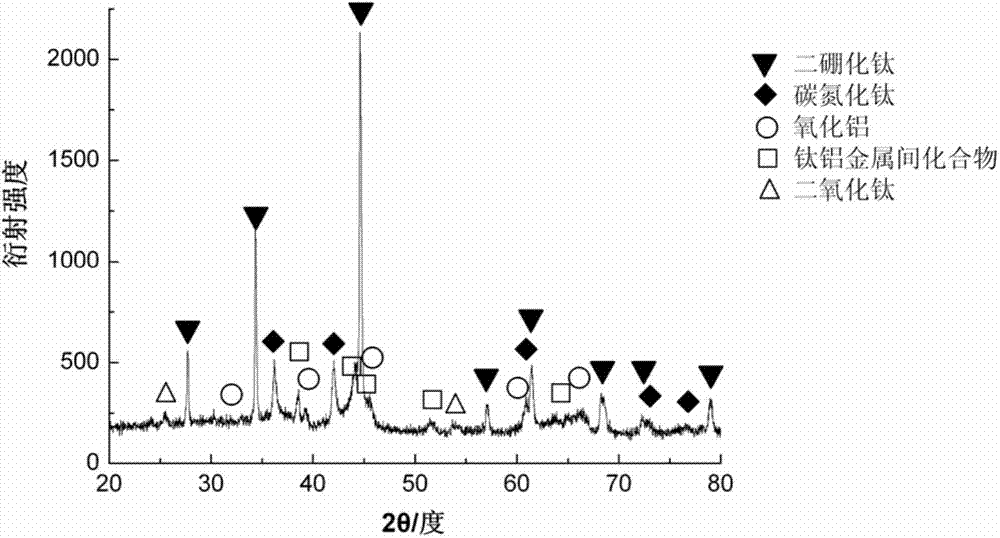

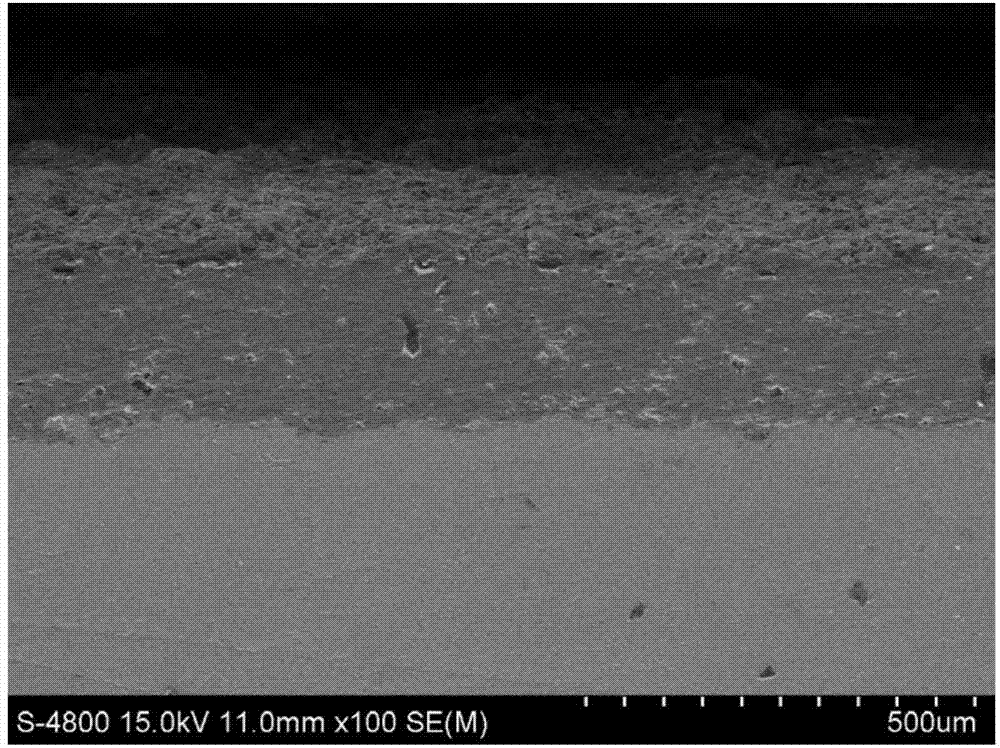

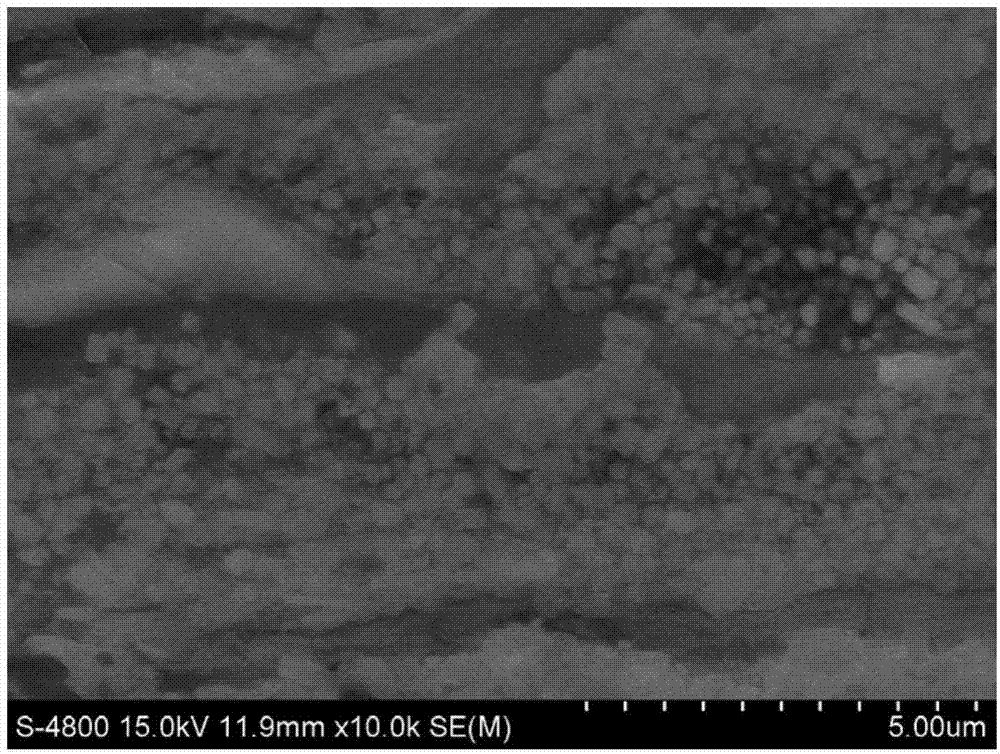

Preparation method of titanium boride based inorganic composite coating

Relating to plating of metal materials, the invention provides a preparation method of a titanium boride based inorganic composite coating. The mixed powder of micron-sized metal Al powder, micron-sized, submicron-sized or nano-sized TiO2 powder, and micron-sized, submicron-sized or nano-sized B4C powder is taken as a raw material, the mixed powder is sprayed on the alloy underlayer surface of a metal or alloy workpiece surface by thermal spraying. During thermal spraying, the Al, TiO2 and B4C in the mixed powder react with nitrogen in a powder feeding gas to synthesize the titanium boride based inorganic composite coating in situ. The method provided in the invention overcomes the defects of high raw material cost, complicated preparation process, high energy consumption, low efficiency, difficult control of coating processing precision, low coating density, poor coating uniformity, weak binding force between the coating and a substrate, low coating toughness, easy coating cracking, and unsuitability for application in large-scale industrial production existing in the prior art for preparation of titanium boride based composite coatings.

Owner:HEBEI UNIV OF TECH

Preparation method of carbon-carbon composite material/hydroxyapatite/polylactic acid biological material

InactiveCN101991879AOvercoming associativityOvercome practicalityElectrolytic inorganic material coatingProsthesisCarbon compositesCalcium phosphate coating

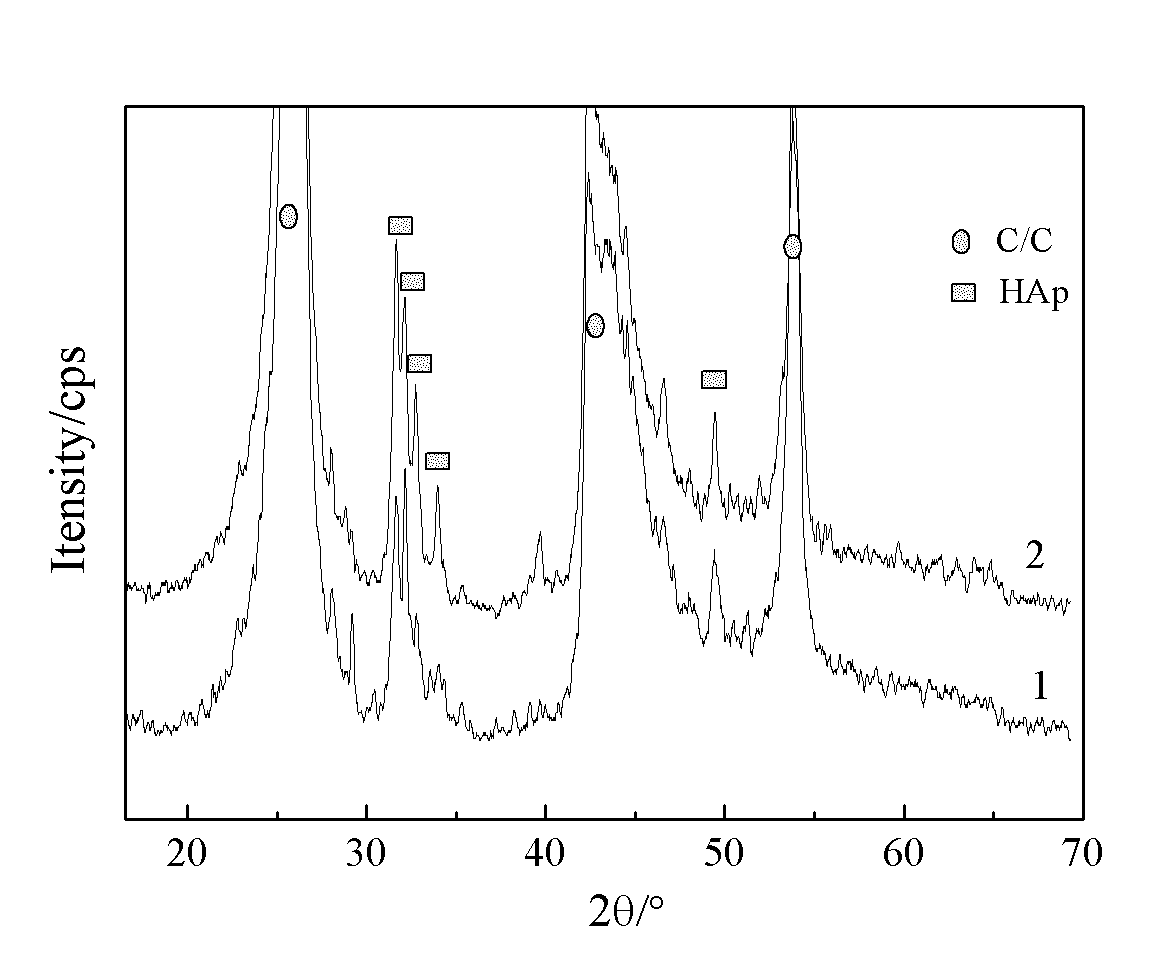

The invention discloses a preparation method of a carbon-carbon composite material / hydroxyapatite / polylactic acid biological material. The method comprises a pretreatment procedure of a carbon-carbon composite material, a preparation procedure of a calcium phosphate coating and a preparation procedure of a polylactic acid coating, wherein the preparation procedure of the calcium phosphate coating comprises the following steps of: (a) preparing an electro-deposition solution; and (b) carrying out electrochemical deposition. Compared with the prior art, on the basis of the traditional electrochemical deposition method, an ultrasonic process is introduced, and by utilizing the oscillation cavitation effect of ultrasonic waves, coatings which are deposited on the surface of a substrate but insufficiently bonded fall off and are renewedly deposited, thereby the defect that the electrochemical deposition coatings are impractical due to insufficient bonding force is overcome; and meanwhile, the method has the advantage of simple process and is easy for application.

Owner:CHERY AUTOMOBILE CO LTD

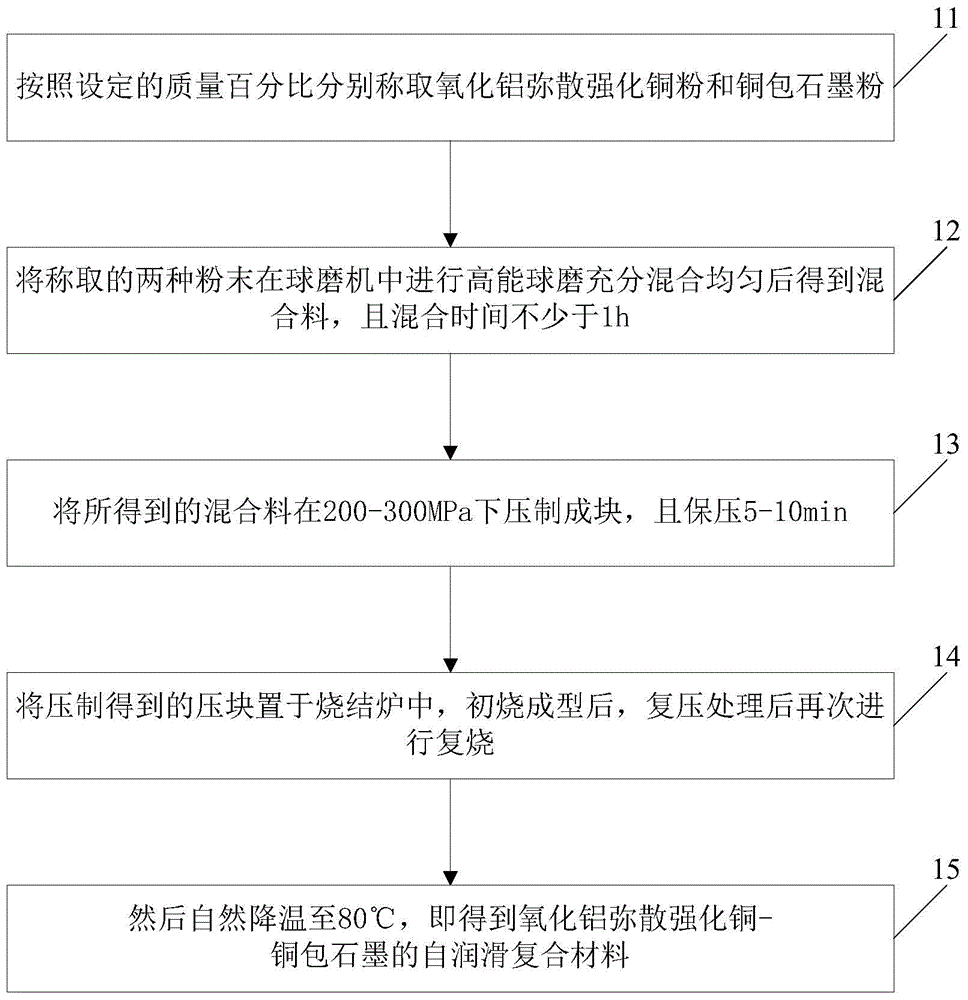

Preparation method of self-lubricating composite material

The invention discloses a preparation method of a self-lubricating composite material. The preparation method comprises the following steps: respectively weighing aluminum oxide dispersion strengthened copper powder and copper-coated graphite powder according to a set mass percentage ratio; performing high-energy ball milling on two weighed powders in a ball mill, and fully and uniformly mixing to obtain a mixed material under the condition that the mixing time is not less than 1 hour; pressing the obtained mixed material into blocks at 200-300MPa, and maintaining pressure for 5-10 minutes; putting briquettes obtained by virtue of pressing into a sintering furnace, performing initial sintering and molding, then performing re-pressing treatment, and then performing re-sintering again; and then naturally cooling to 80 DEG C to obtain the self-lubricating composite material. By adopting the preparation method disclosed by the invention, the problems that a copper-based graphite composite material is poor in interface bonding force, and graphite and copper are poor in wettability can be solved, and the high-temperature strength, heat conduction performance and tribological performance of the copper-based graphite composite material can be improved.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

DTPA modified material and preparation method for rapid-full-dissociation type DGT (Diffusive gradients in thin films) coupling phase prepared therefrom

ActiveCN105148846AGuaranteed in-situ applicationExpand application spaceOther chemical processesColloidal chemistry detailsCouplingAmmonia

The invention relates to a DTPA modified material and a preparation method for a rapid-full-dissociation type DGT (Diffusive gradients in thin films) coupling phase prepared therefrom. DTPA reacts with Mg<2+> and Al<3+> under alkaline conditions. The method comprises the steps: (1) adding 24.4ml of ammonia water (NH4(OH)) and methanol into 73.20ml of water, uniformly mixing the ammonia water, the methanol and the water, then, adding 32.78g of DTPA into the mixture, and thoroughly dissolving DTPA; (2) fetching another beaker, adding 593.34ml of water and 197.78ml of ammonia water into the beaker, uniformly mixing the water and the ammonia water thoroughly; and (3) simultaneously adding solutions obtained in the step (1) and the step (2) into a solution containing MgCl2.6H2O and AlCl3.6H2O so as to prepare the DTPA modified material, carrying out spray drying, then, sieving the dried DTPA modified material by a sieve with the pore size of 200 meshes (75 microns) so as to form a heavy-metal adsorption material for a DGT coupled film, then, adding the heavy-metal adsorption material into a polyacrylamide gel solution, and carrying out reaction at a certain temperature, thereby preparing the DGT coupled film. The gel film prepared by the method disclosed by the invention has the effects of heavy-metal adsorption and short-time full dissociation, and the disadvantage that the dissociation of the former heavy-metal coupling phase is slow and incomplete is overcome. The materials used are cheap and are easily prepared, and no secondary pollution is caused, so that the popularization and application of a DGT technology are facilitated.

Owner:TIANJIN TIANRUN YIKANG ENVIRONMENTAL PROTECTION TECH CO LTD

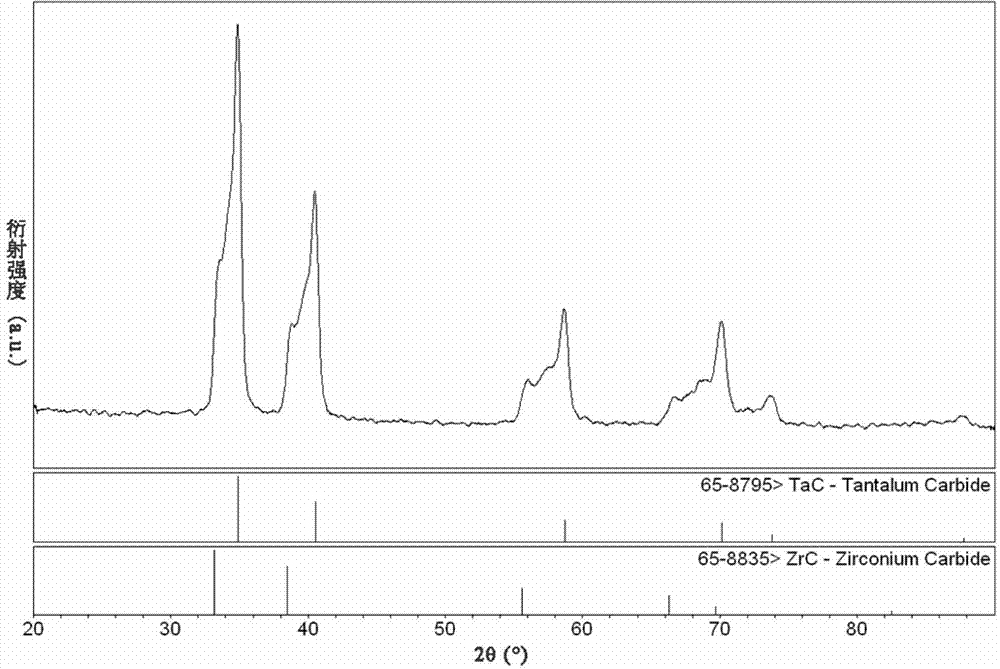

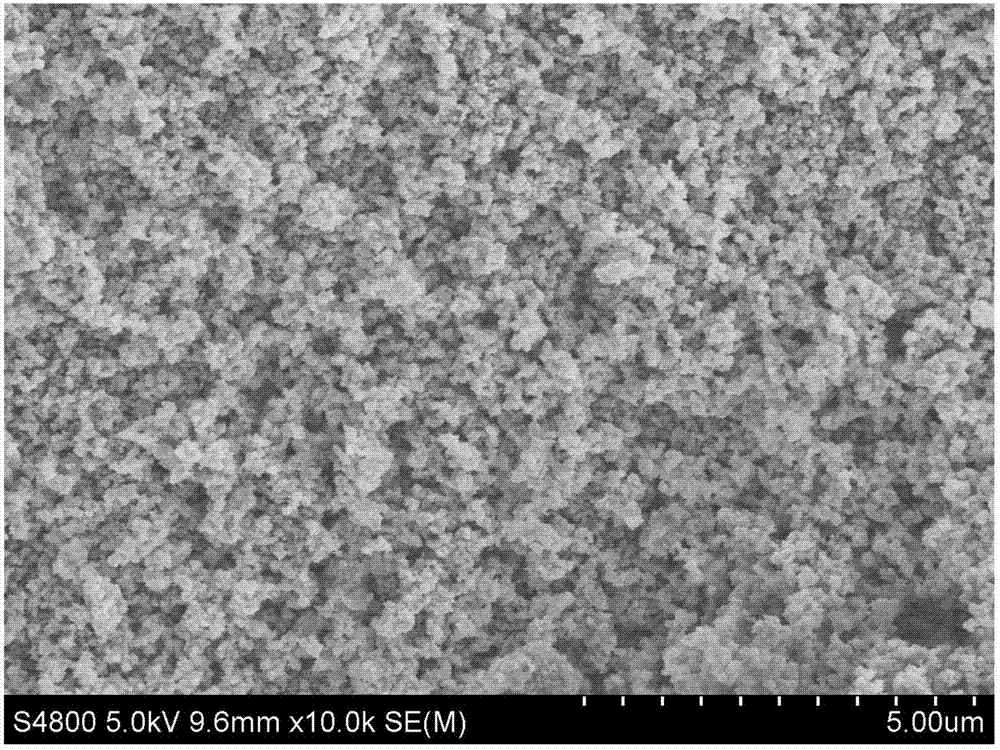

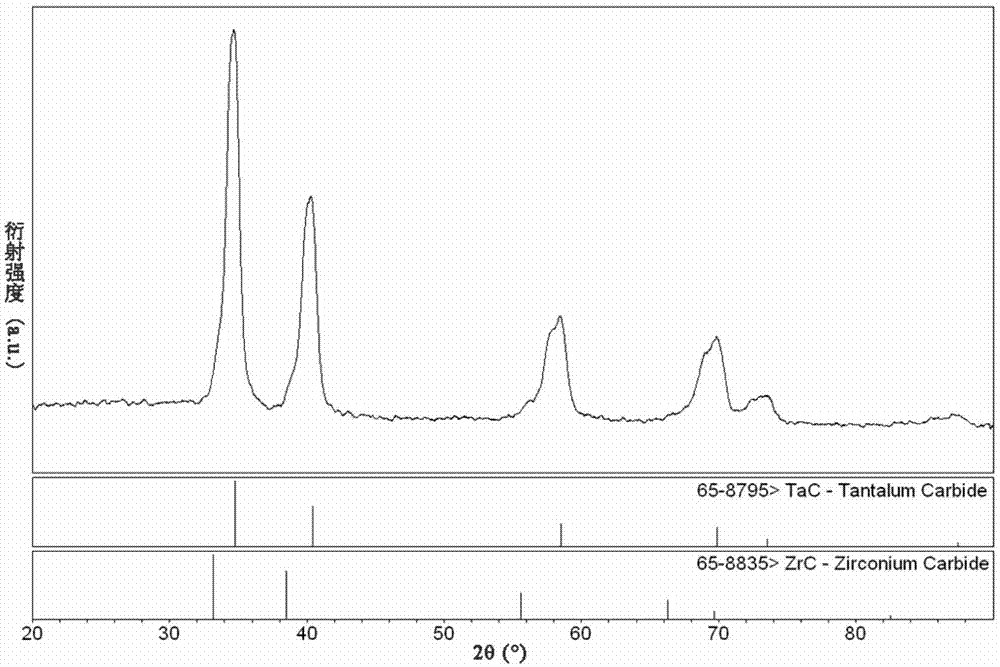

Ta-Zr-C ternary ceramic and preparation method thereof

The invention discloses a Ta-Zr-C ternary ceramic and a preparation method thereof. The Ta-Zr-C ternary ceramic provided by the invention is of Ta-Zr-C continuous single-phase solid solution ceramic powder. The preparation method comprising the following steps of (1) proportioning precursor solution; (2) preparing sol; (3) aging; (4) drying; and (5) calcining the dried material at a high temperature and in steps. The Ta-Zr-C ternary ceramic provided by the invention has the characteristics that the grain size is small, the components are uniform, the purity is high and the like, and the preparation method provided by the invention has the excellent advantages that the requirement of the process equipment is simple, the temperature requirement is low, the cost is low and the like.

Owner:NAT UNIV OF DEFENSE TECH

Nano compound anticorrosive paint and preparation method thereof

InactiveCN102786873AOvercome easy reunion,Overcoming associativityAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceOrganoclay

The invention discloses a preparation method of nano compound anticorrosive paint. The paint is characterized by comprising the following steps of: taking polyurethane, polystyrene and organic clay as structural units, adopting a method of combining an interpenetrating network technology and an in-situ intercalation polymerization, and obtaining organic clay-polyurethane and polystyrene ternary nano compound anticorrosive paint. The preparation method provided by the invention has the characteristics of simplicity and convenience in technology, environmental protection, excellent paint performance and low cost, so that a novel paint product with high performance is provided and can be extensively applied to anticorrosion in the fields of automobile painting, buried steel pipes, chemical and mechanical equipments and the like.

Owner:KUNMING UNIV OF SCI & TECH

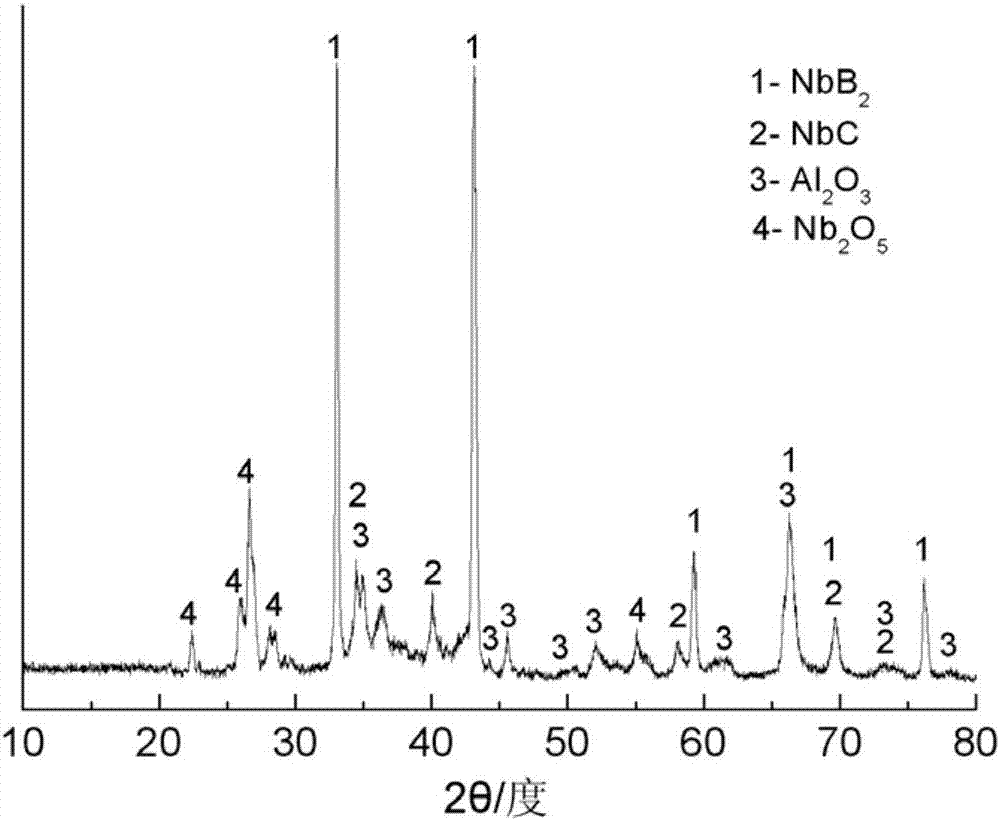

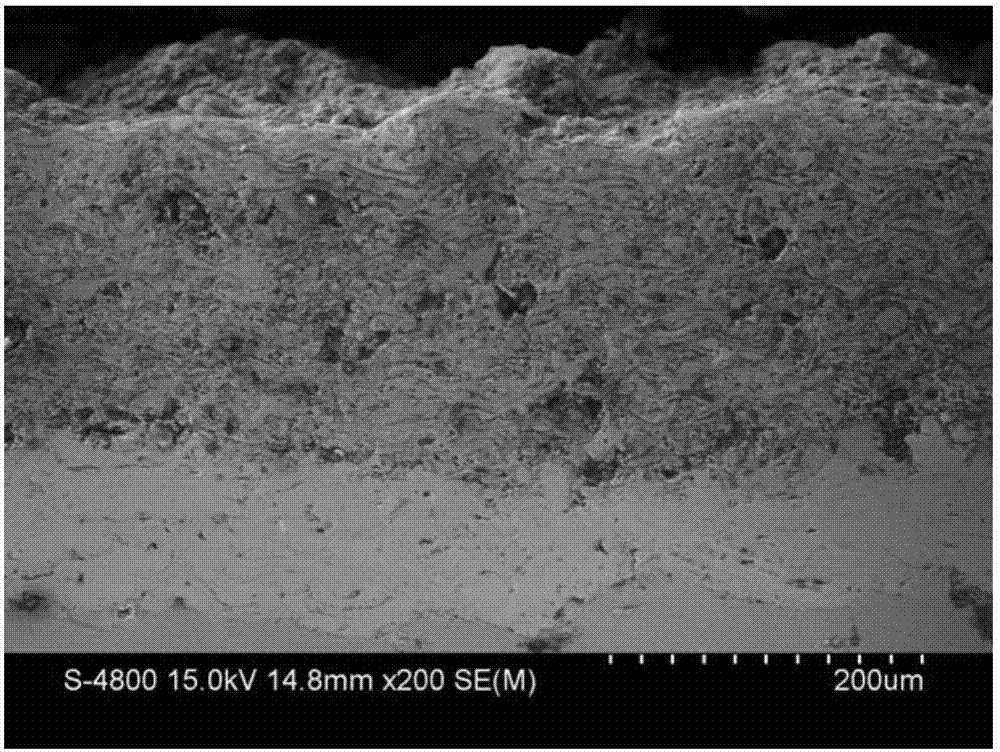

Preparation method of niobium boride base coating

The invention provides a preparation method of a niobium boride base coating, and relates to the field of plating of materials by use of boride. A niobium boride base multi-phase ceramic coating is formed in a composite mode through a thermal spraying in-situ reaction. The preparation method of the niobium boride base coating comprises the steps that niobium oxide / boron carbide / aluminum composite powder for thermal spraying is prepared; pretreatment of a metal matrix material is conducted; and preparation of the niobium boride base coating is conducted. The preparation method of the niobium boride base coating overcomes the defects that in the process of preparation of a niobium boride coating in the prior art, the technology is complex, the energy consumption is high, the pollution is serious, the efficiency is low, the coating thickness is small, the coating porosity is high, the force of combination between the coating and a matrix is low, and power preparation is difficult.

Owner:HEBEI UNIV OF TECH

Method for preparing lithium hexafluorophosphate by using composite solvent

InactiveCN102491305ALow boiling pointResidue reductionSecondary cellsPhosphorus compoundsDistillationEvaporation

The invention relates to a safe and reliable method for preparing lithium hexafluorophosphate by using a composite solvent. The technical steps of the method are simple. The method comprises steps that: anhydrous phosphoric acid, calcium fluoride and sulfur oxide are subject to a reaction, such that PF5 gas is obtained by evaporation; the evaporated PF5 gas is dehydrated, such that a high-purity anhydrous PF5 product is obtained; diethyl ether and anhydrous methyl cyanide are respectively dehydrated, such that high-purity diethyl ether and anhydrous methyl cyanide are obtained; high-purity lithium fluoride is added to the diethyl ether solution; methyl cyanide is added to the obtained solution; the PF5 gas is slowly delivered into the solution while stirring; when a reaction is finished, high-purity nitrogen is delivered into the solution, such that displacement is carried out until no PF5 gas is remained in a vessel; a dry product Li(CH3CN)4PF6 obtained through distillation is heatedand decomposed, such that LiPF6 is prepared; LiPF6 is dissolved under room temperature, such that a solution with a concentration of 1M is obtained; the solution is filtered by using a precise filterwith a specification of 0.2mum, such that a clarified solution is obtained; the solution is dried, such that a pure LiPF6 product is obtained.

Owner:山东省智能光电新能源研究院

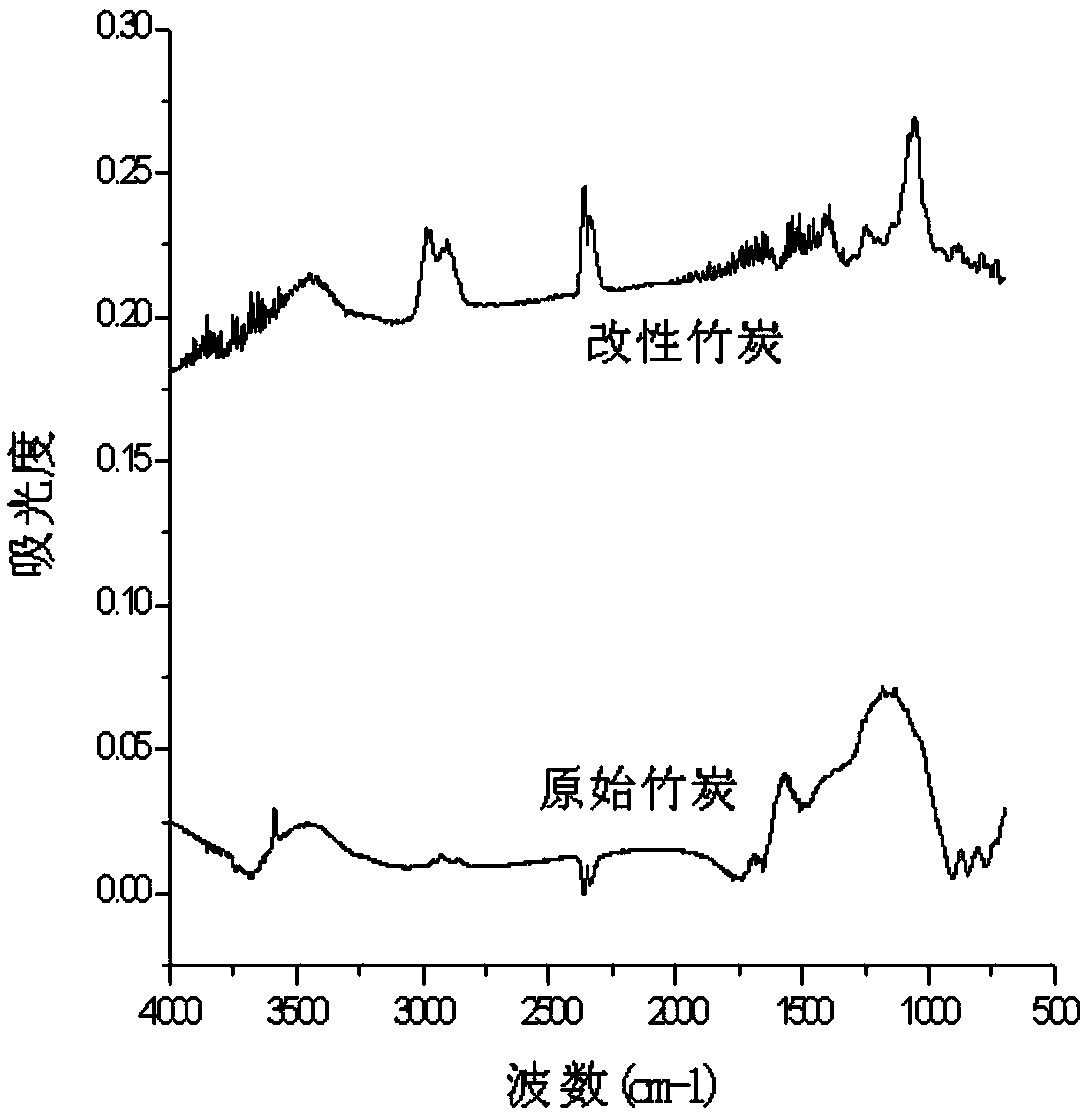

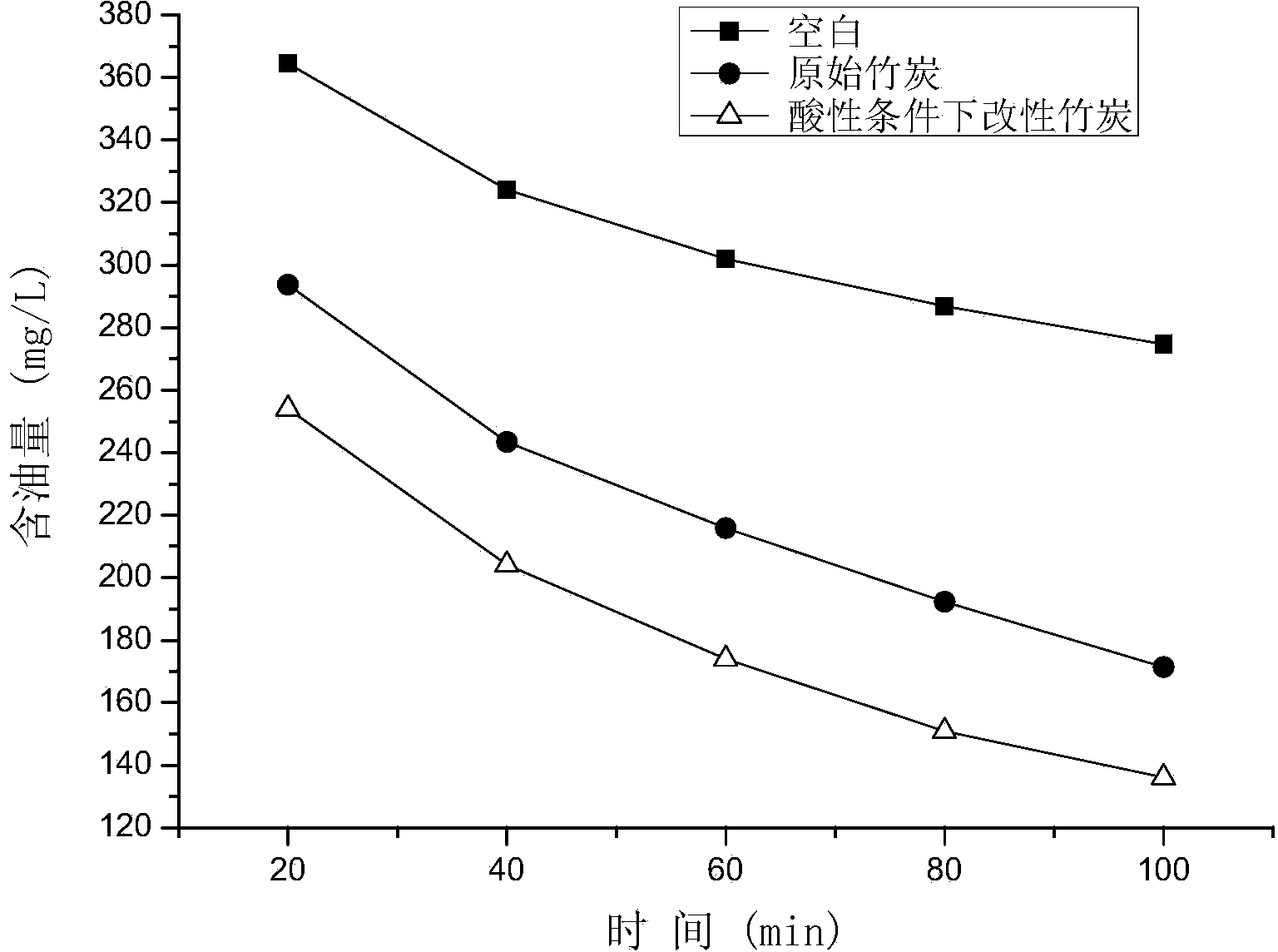

Bamboo charcoal modification method applicable to oily wastewater treatment

InactiveCN103706332AOvercoming Hydrophobic SubstancesOvercoming associativityFatty/oily/floating substances removal devicesOther chemical processesHydroxy compoundBamboo charcoal

The invention relates to a bamboo charcoal modification method applicable to oily wastewater treatment. The bamboo charcoal modification method comprises the steps: adding bamboo charcoal into a silane coupling agent ethanol solution so as to enable a silane coupling agent and hydroxyl groups on the surface of the bamboo charcoal to generate conjugation reaction, then separating, washing and drying the reacted bamboo charcoal, thus obtaining modified bamboo charcoal. Compared with the prior art, the bamboo charcoal modification method overcomes the defects that an existing commonly used coarse-grained filler modification method is infirm for the conjugation between hydrophobic substances and materials and has a great limit on the materials and the like; through contact angle tests and oil removal tests, the hydrophobicity of the modified bamboo charcoal is enhanced, the oil removal rate can be increased by 13%, and a resource approach can be provided for bamboo processing wastes.

Owner:TONGJI UNIV

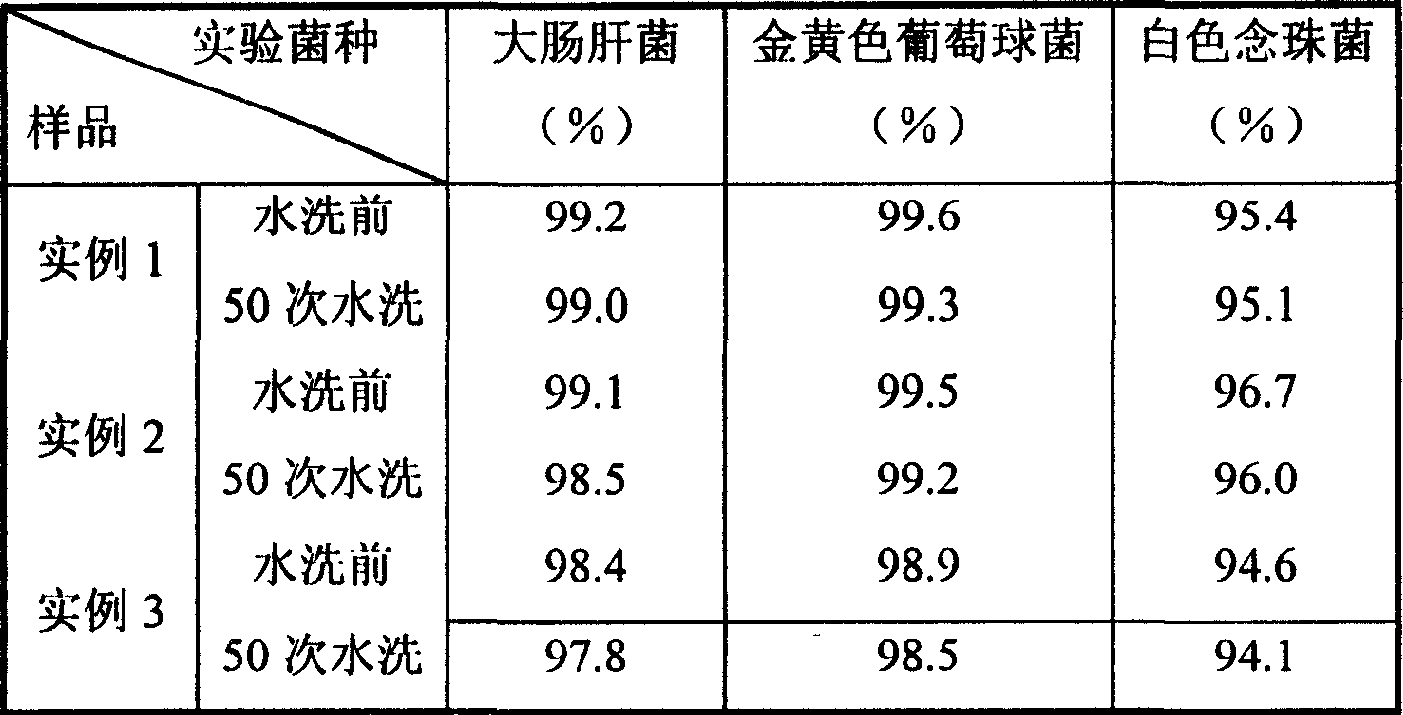

Gel-sol antibacterial agent and its preparation and application

By means of sol-gel technology, the present invention prepares titanium-containing sol with tetrabutyl titanium as precursor. The sol is used in finishing cotton fabric through rolling-stoving-roasting process, and sol treated cotton fabric has excellent lasting antibiotic performance and negative ion releasing effect. The treating process has no side effect on the hand feeling and strength of the fabric.

Owner:DONGHUA UNIV

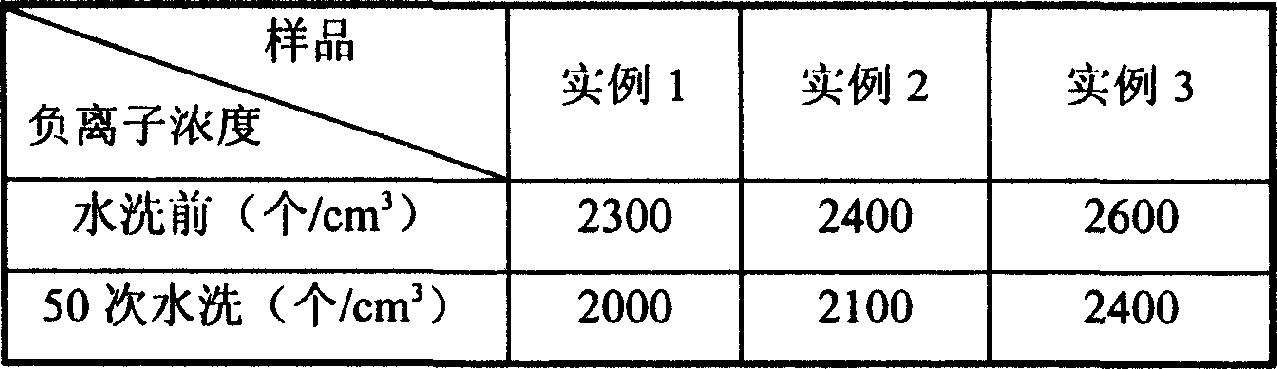

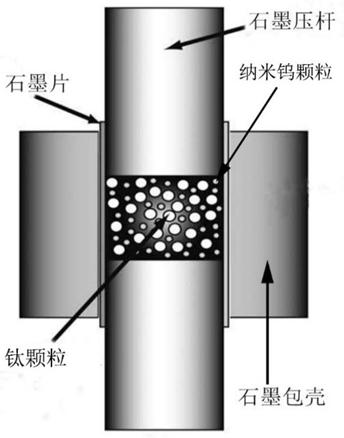

Tungsten nanoparticle-based enhanced light metal-based composite material and preparation method thereof

The invention discloses a tungsten nanoparticle-based enhanced light metal-based composite material and a preparation method thereof. The tungsten nanoparticle-based enhanced light metal-based composite material and the preparation method solve the problems of poor interface bonding between a metal matrix of a composite material and particles and non-uniform particle dispersion in the prior art. According to the preparation method, tungsten nano powder and light metal powder are subjected to high-energy ball milling to form a solid solution, then the solid solution is sintered after compression molding, nano tungsten particles are separated out and evenly distributed in the light metal matrix, and the tungsten nanoparticle-based enhanced light metal-based composite material is obtained. Bymeans of the tungsten nanoparticle-based enhanced light metal-based composite material and the preparation method, design is scientific, the method is simple, and operation is facilitated; and a high-energy ball milling method and powder sintering are creatively combined, and solid solution-precipitation of tungsten nanoparticles is achieved, so that the tungsten nanoparticles in the size being 50 nm or below are introduced into a light metal-based material, the strength, toughness and high-temperature mechanical property of the light metal-based composite material are greatly improved, and requirements of aerospace and other fields for low density and high performance of structural materials are better met.

Owner:北京理工大学重庆创新中心 +1

Tough road surface base layer material solidifying agent and preparation method thereof

The invention relates to a tough road surface base layer material solidifying agent and a preparation method thereof. The tough road surface base layer material solidifying agent is characterized by being formed by mixing the following components in percentage by weight: 5 to 40 percent of polymer emulsion, 2 to 20 percent of viscosity increaser, 1 to 30 percent of inorganic adhesive, 0.1 to 5 percent of auxiliary agent and 5 to 91.9 percent of water; the polymer emulsion is one or mixture of phenyl propyl emulsion and polyacrylic acid emulsion; the viscosity increaser is one of emulsified petroleum resin, emulsified asphalt and asphalt resin extract emulsion and one or mixture of emulsified abietic resin and acrylate; the inorganic adhesive is water-soluble silicate; and the auxiliary agent is one or two of preservative, wetting and dispersing agent and defoaming agent. The tough road surface base layer material solidifying agent used in the construction of a tough road surface base layer has the advantages of high solidifying strength, good water stability and low cost.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

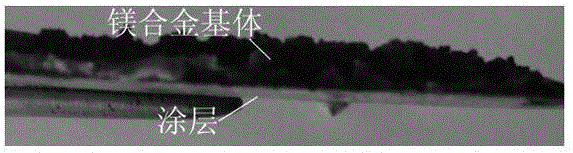

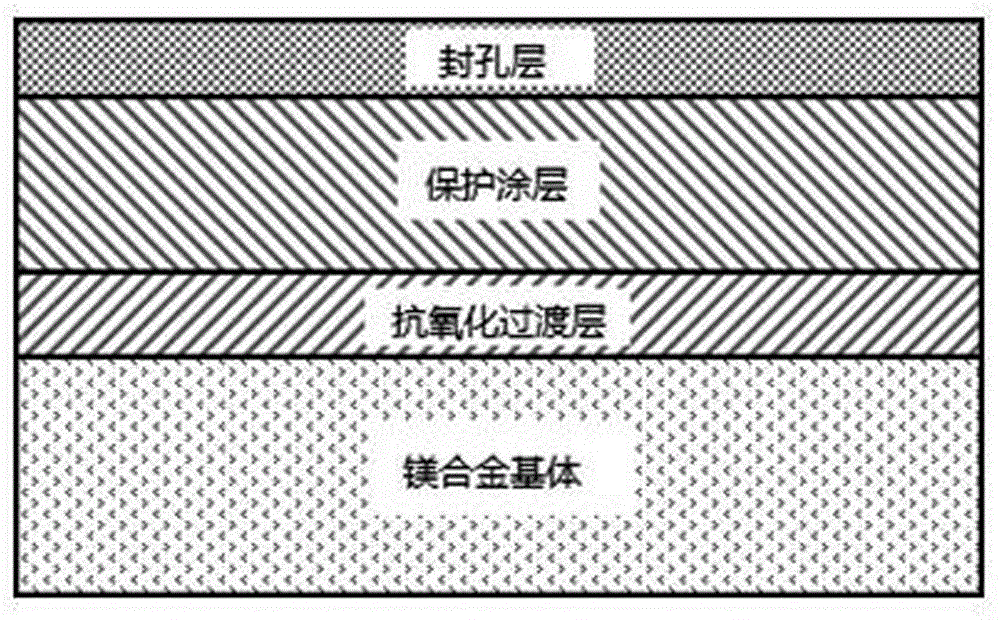

Magnesium alloy surface treatment method utilizing combination of laser beams and coated layer

InactiveCN106835129ACutting defectImprove corrosion resistanceMolten spray coatingSuperimposed coating processThermal sprayingOxidation resistant

The invention discloses a magnesium alloy surface treatment method utilizing combination of laser beams and a coated layer. The surface treatment method comprises the following steps that (1) a laser cladding method is adopted, and an oxidation resistance transition layer is prepared on the surface of a magnesium alloy; (2) a thermal spraying method is adopted, and a protective coating is prepared on the oxidation resistance transition layer; and (3) a laser re-melting method is adopted, and the protective coating is subjected to hole sealing treatment. The magnesium alloy surface treatment method is universally suitable for preparation of a magnesium alloy corrosion resistance layer, through the oxidation resistance transition layer, the protective coating and hole sealing of the protective coating, a magnesium alloy base material is subjected to multi-way protection, penetrability passageway corrosion defects existing in a single corrosion resistance layer can be effectively cut off, and corrosion resistance of a magnesium alloy material is greatly improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

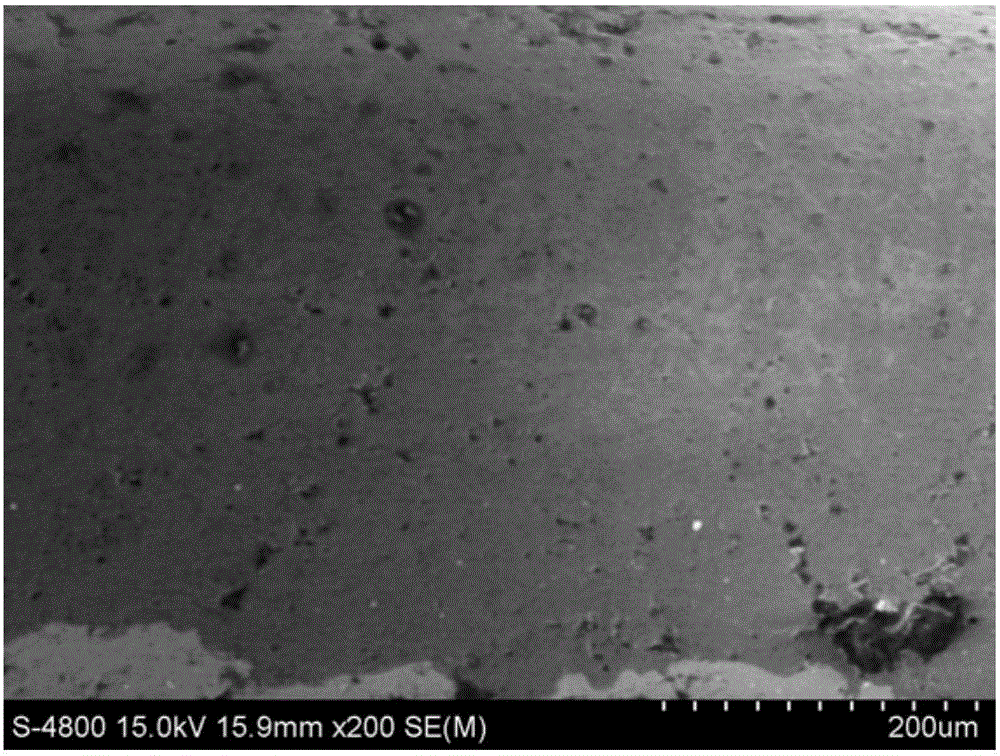

Preparation method of tungsten boride composite coating

InactiveCN107523777AHighlight substantive featuresHigh densityMolten spray coatingThermal sprayingMetallic materials

The invention discloses a preparation method of a tungsten boride composite coating, and relates to coating of boride on metal materials. The tungsten boride composite coating is synthesized through a thermal spraying in-situ reaction. The preparation method comprises the steps that tungsten oxide / boron carbide / aluminum composite powder used for thermal spraying is prepared; the base material surface needing the coating is pretreated; and the tungsten boride composite coating is prepared. The defects that the existing technology for preparing the tungsten boride composite coating is complex, high in cost, large in pollution and low in deposition efficiency, and the coating is small in thickness, low in compactness, poor in uniformity, low in toughness, poor in binding force with a base body, likely to be cracked and not suitable for being applied in large-scale industrial production are overcome.

Owner:HEBEI UNIV OF TECH

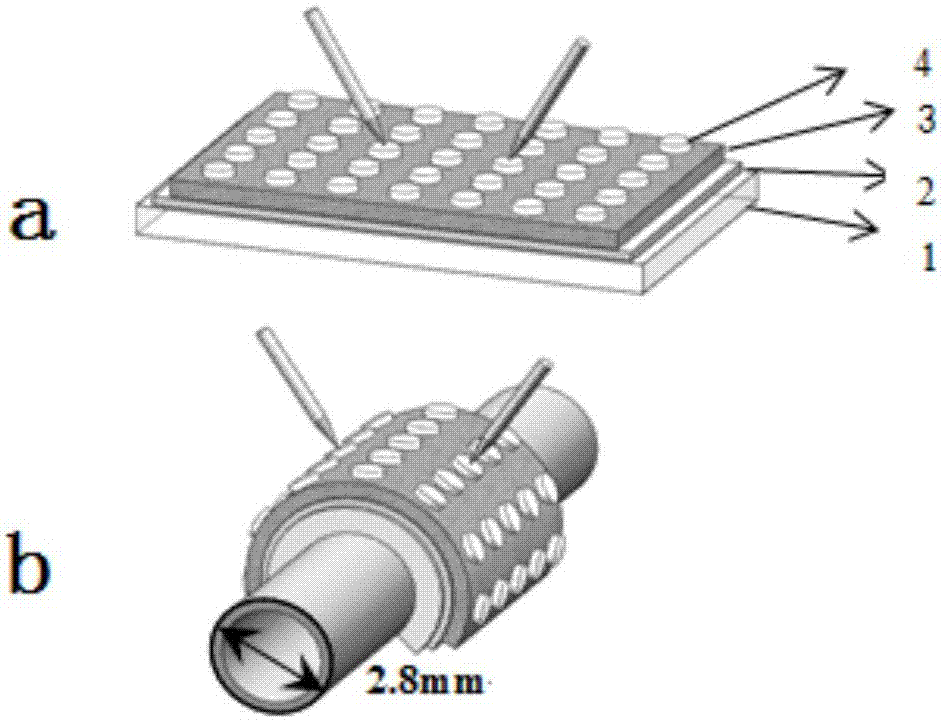

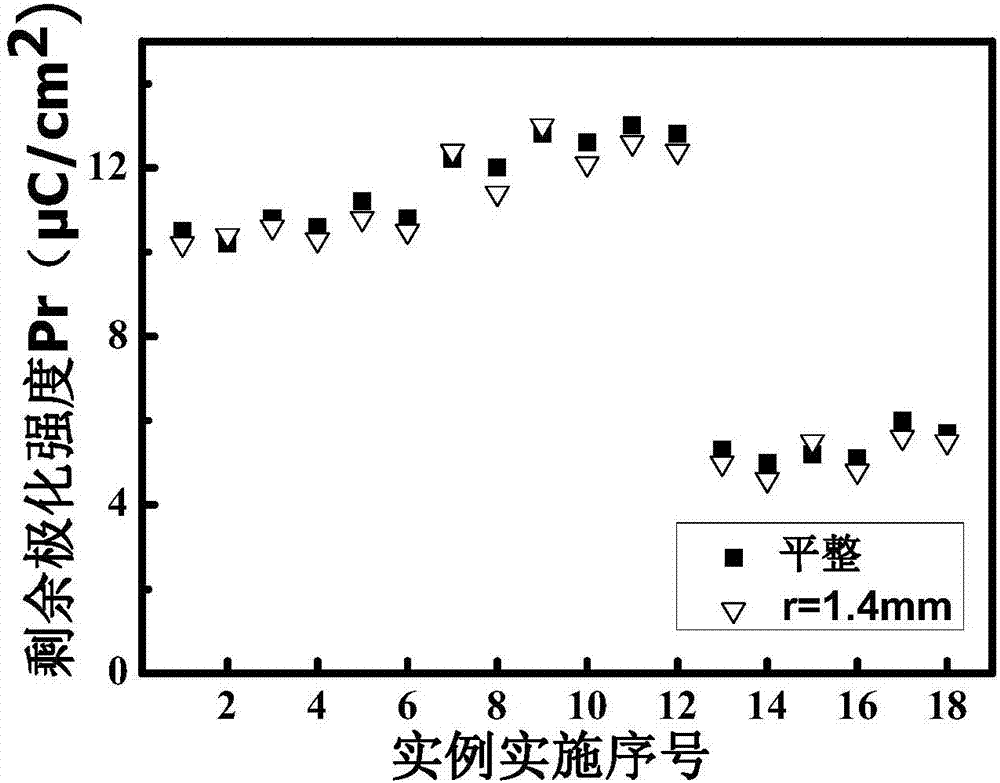

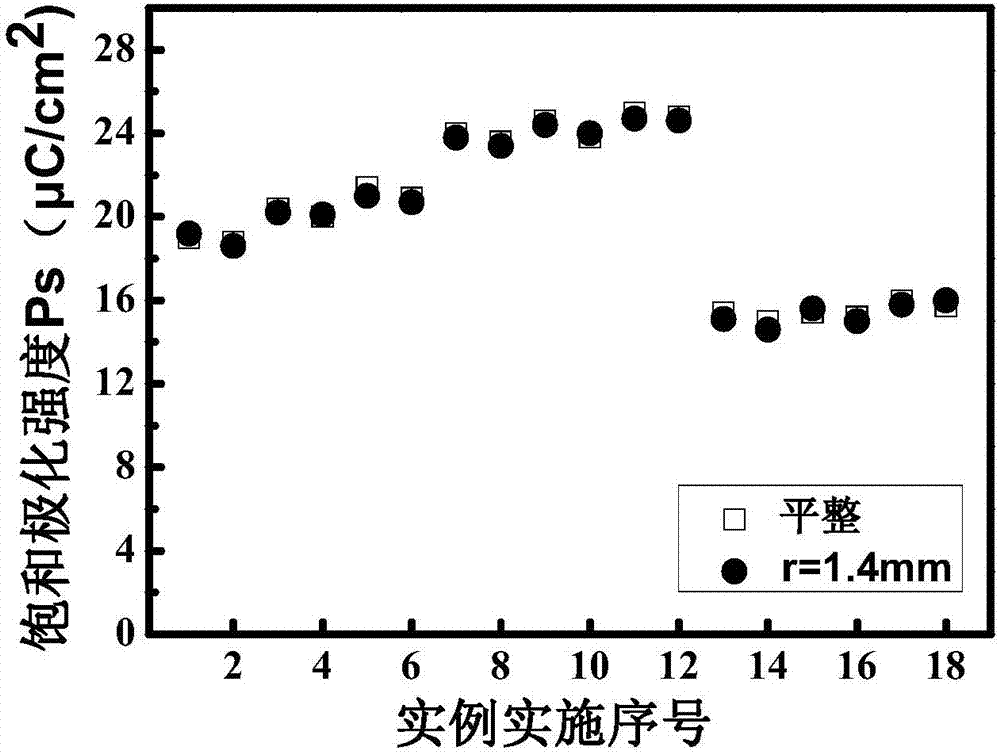

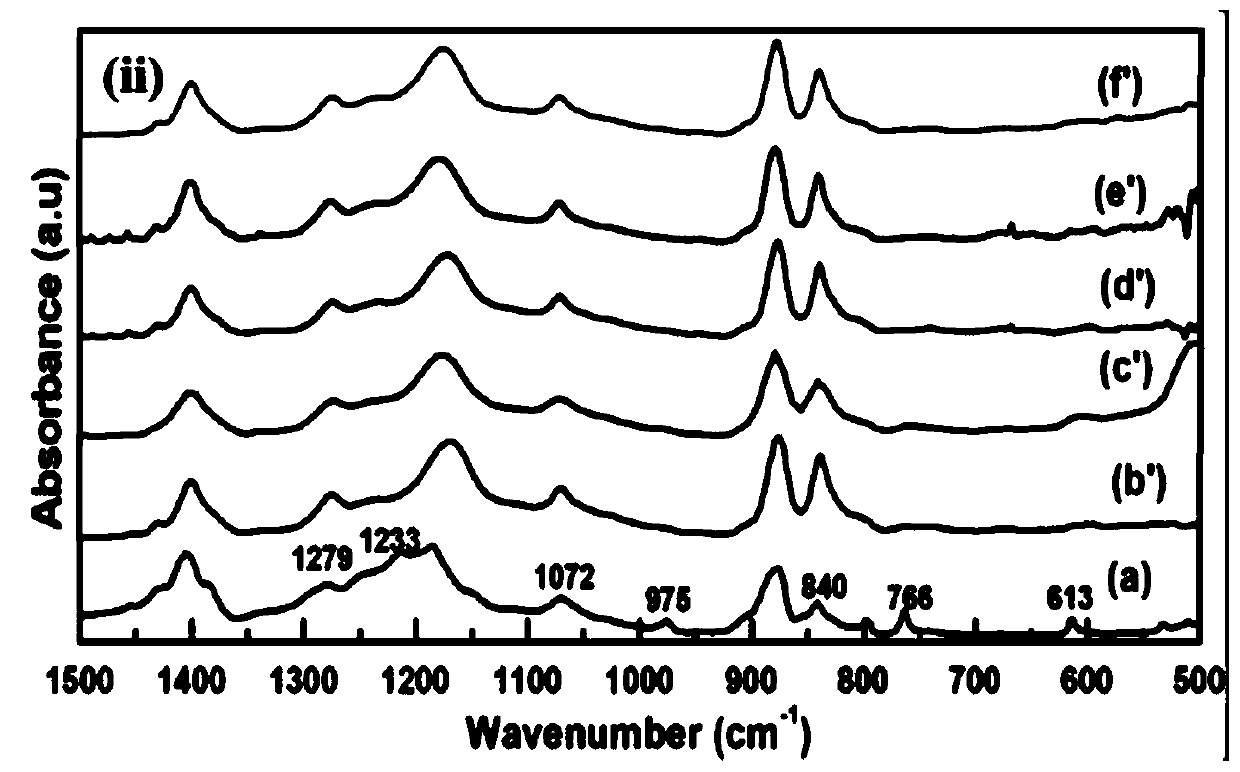

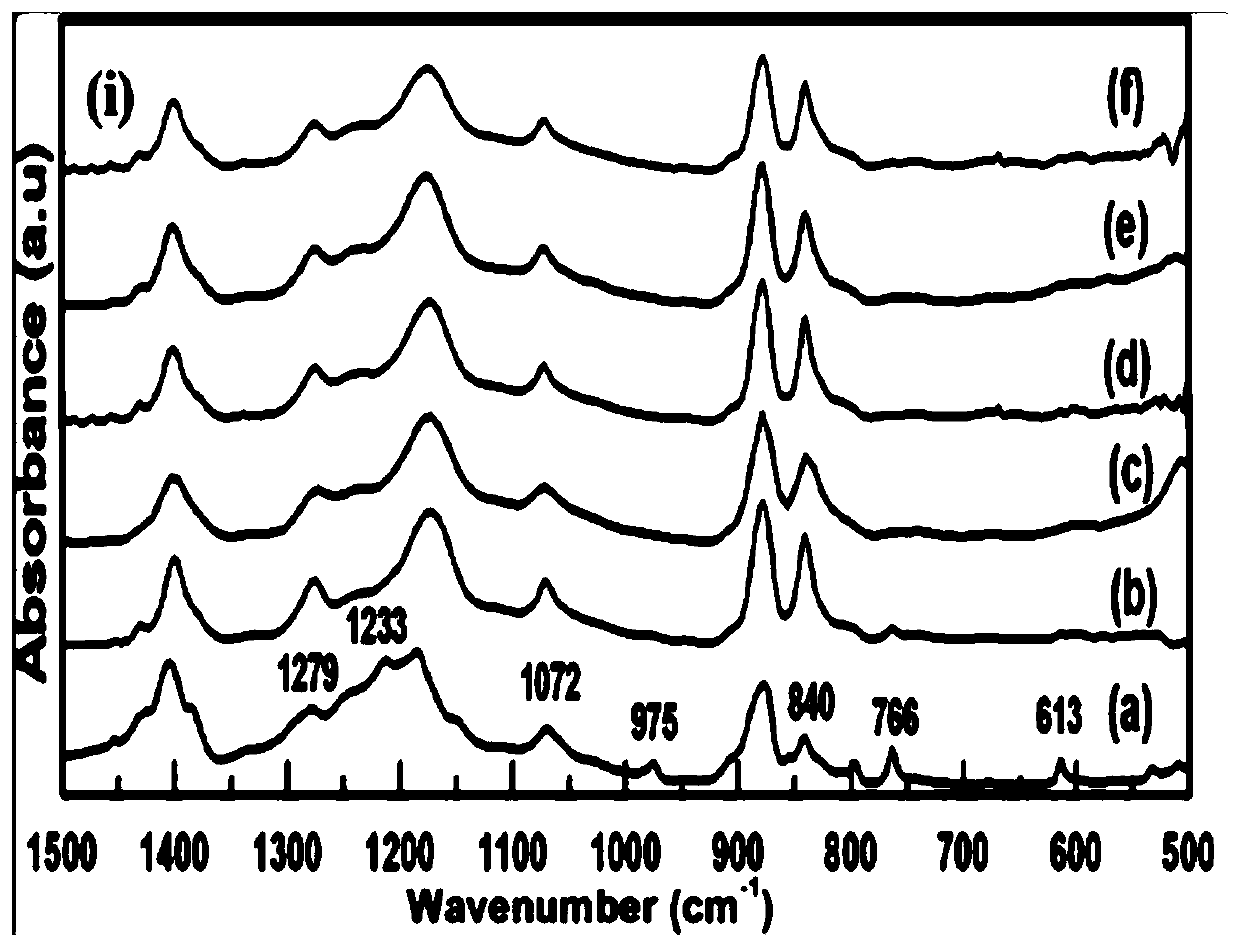

Transparent flexible oxide ferroelectric memory

ActiveCN107221532AHigh light transmittanceImprove high temperature resistanceSolid-state devicesSemiconductor devicesTransmittanceTemperature resistance

The invention discloses a transparent flexible oxide ferroelectric memory. The transparent flexible oxide ferroelectric memory consists of a mica substrate, a ZnO-doped transparent electrode, an oxide ferroelectric film and an ITO transparent electrode which are connected in sequence. According to the ferroelectric memory disclosed by the invention, the stratified perovskite oxide ferroelectric film serves as a ferroelectric functional layer; the light-admitting quality of the ferroelectric memory is high, and the light transmittance of visual light with the wavelength of over 400 nm is more than 80%; the ferroelectric memory is flexible and resistant to bending, and when the bending radius is 1.4 mm, the saturated polarization intensity and remaining polarization intensity approach to numeral values in a smooth state; the high temperature resistance is high, and after 450-degree annealing, the saturated polarization intensity and remaining polarization intensity are free of obvious change; and the transparent flexible oxide ferroelectric memory has wide application prospects.

Owner:NANJING UNIV OF SCI & TECH

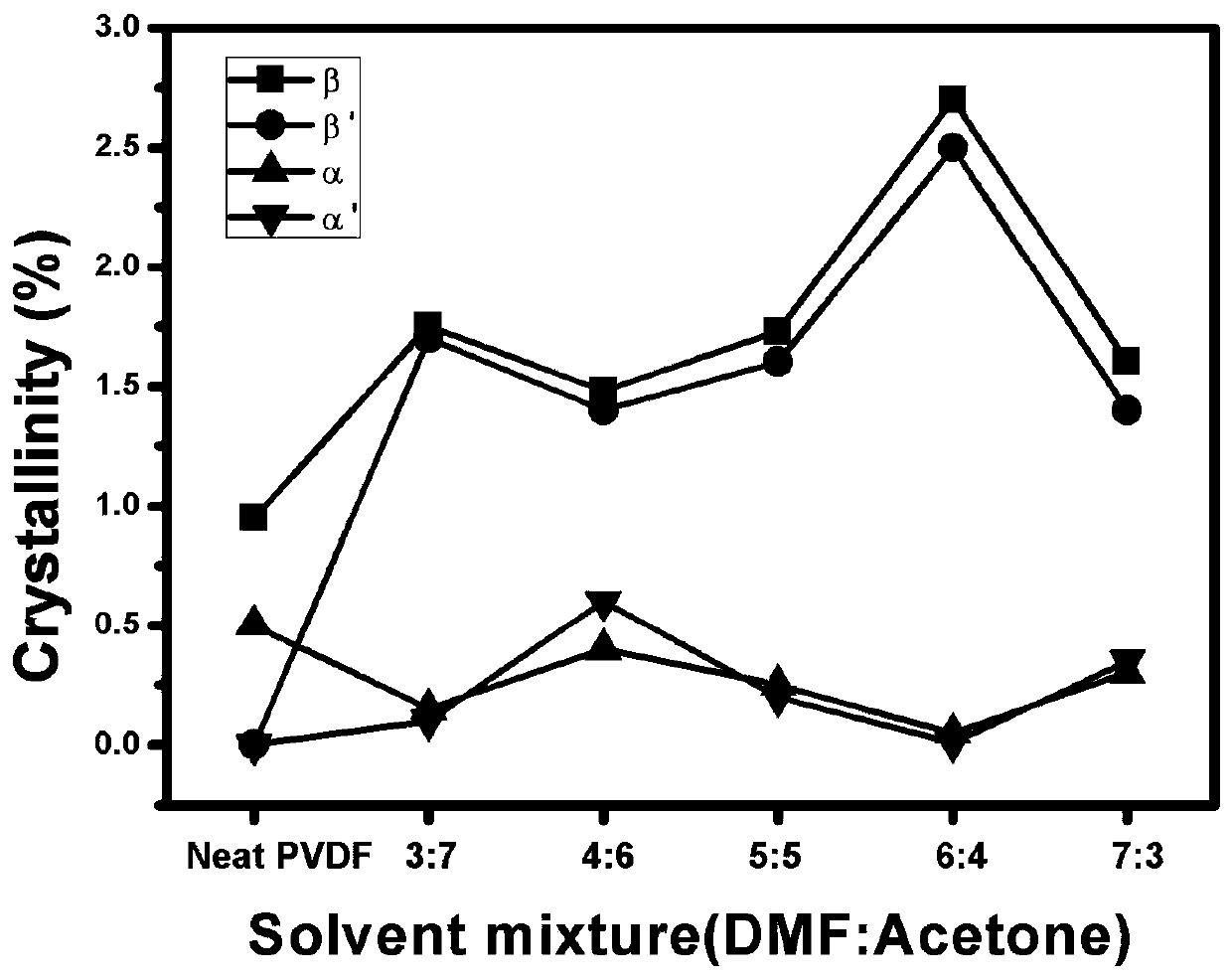

Composite piezoelectric film and preparation method and application thereof

PendingCN111063794AUniform distribution of piezoelectric effectLarge output piezo voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionFiberSpinning

The invention belongs to the technical field of piezoelectric materials, and particularly relates to a composite piezoelectric film and a preparation method and application thereof. The preparation method comprises the following steps: adding inorganic piezoelectric powder into a polymer solution to obtain a precursor solution; and carrying out electrostatic spinning on the precursor solution andperforming collection in a water medium to obtain the composite piezoelectric film. The composite piezoelectric film is a porous structure fiber film and is filled with inorganic piezoelectric powder,and a polymer piezoelectric material and a rigid piezoelectric material are well compounded. Moreover, the composite piezoelectric film is a beta-phase enhanced flexible composite film, can generatea relatively large output piezoelectric voltage, has a relatively high piezoelectric constant, is uniform in piezoelectric effect distribution, and can solve the problem that an existing polymer piezoelectric film cannot be effectively combined with an inorganic piezoelectric material to form a flexible device with high piezoelectric performance. In addition, the preparation method is simple in preparation process and beneficial to large-scale production.

Owner:GUANGDONG UNIV OF TECH

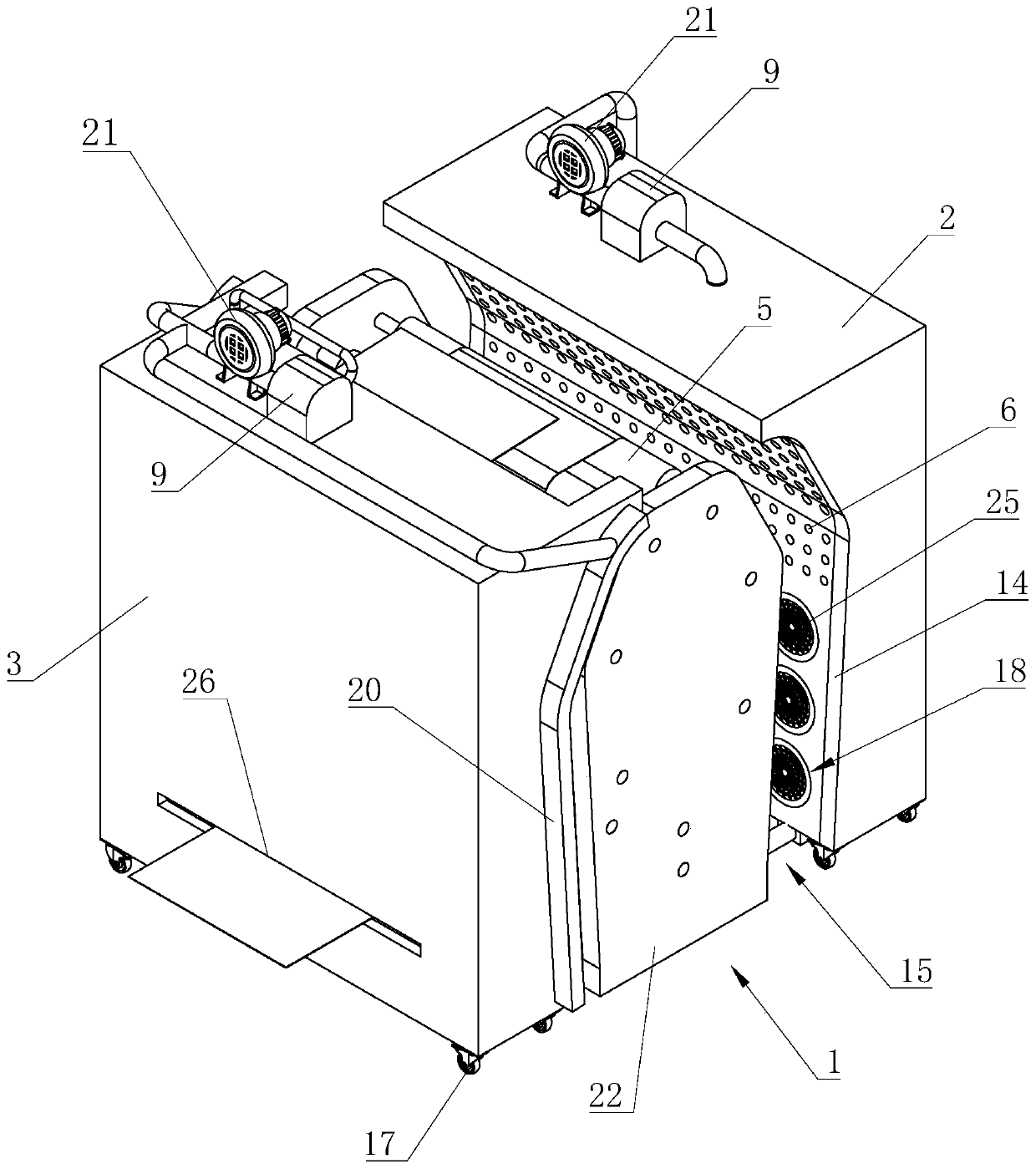

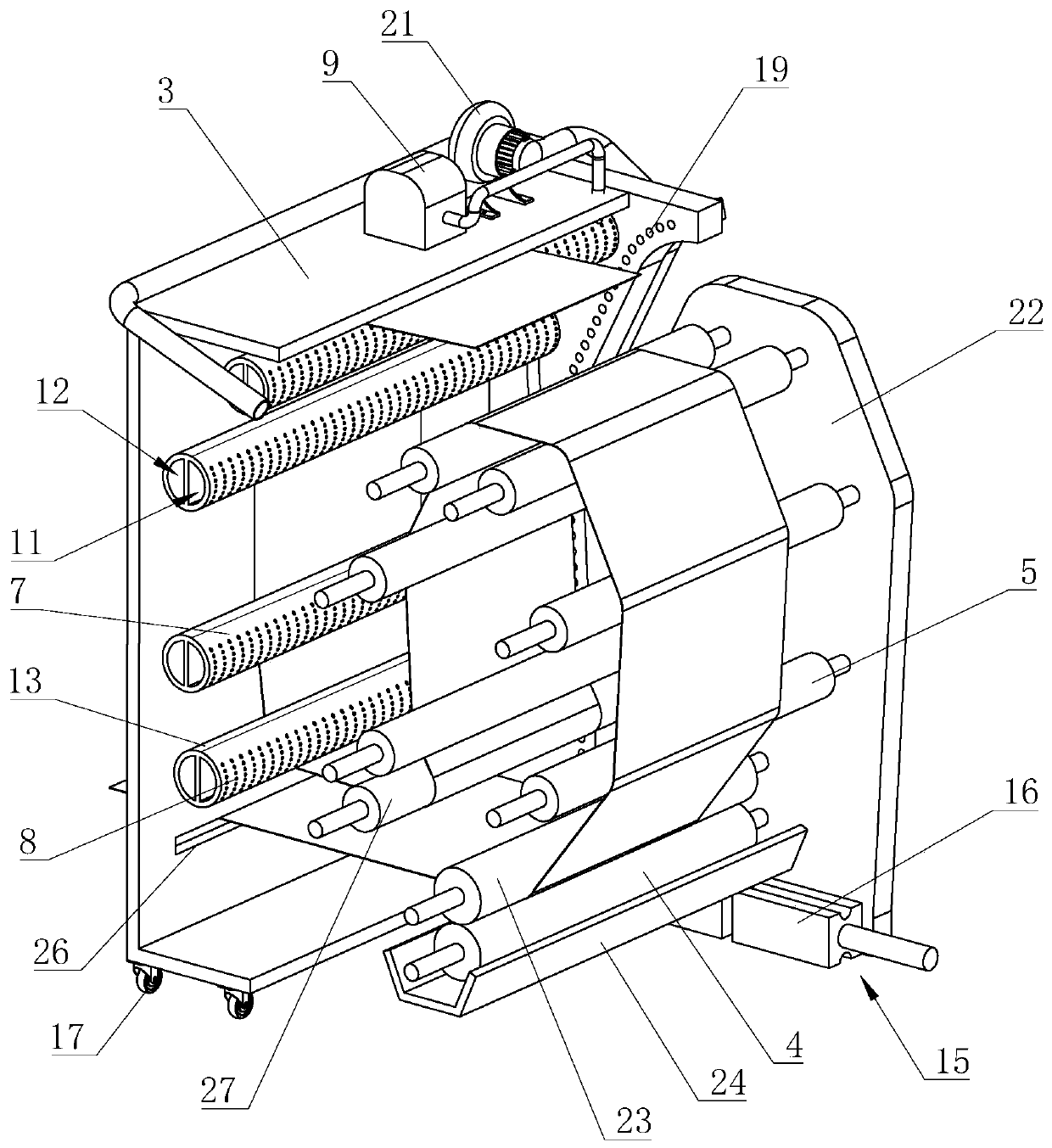

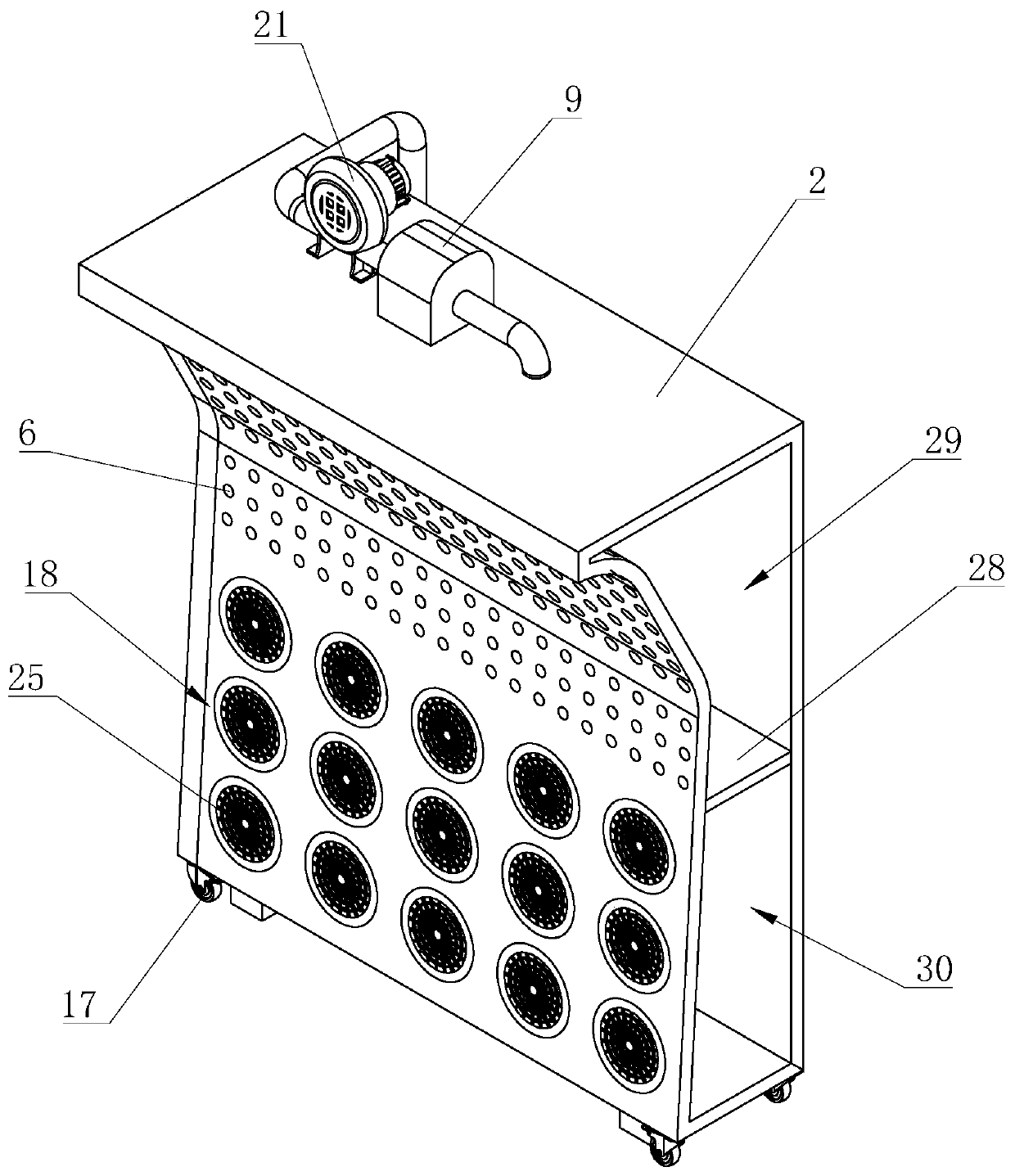

Drying device of film printing machine

ActiveCN110406251AOvercoming associativityOvercoming AdhesionPrinting press partsPrinting inkPulp and paper industry

The invention discloses a drying device of a film printing machine. The drying device comprises a machine frame, a first-stage drying oven and a second-stage drying oven, wherein the first-stage drying oven and the second-stage drying oven are arranged on the two sides of the machine frame, a printing roller is installed at the bottom end of the machine frame, a plurality of first-stage air supplyholes are formed in one side face, facing the material conveying roller, of the first-stage drying oven, a plurality of drying rollers which are hollow are fixed to one side, facing the material conveying roller, of the second-stage drying oven, a plurality of second-stage air supply holes are formed in one side, facing the material conveying roller, of the drying rollers, and electric heating air boxes which communicate with the first-stage air supply holes and the second-stage air supply holes are correspondingly arranged on the first-stage drying oven and the second-stage drying oven. Thedrying device has the technical effects of being high in printing ink drying efficiency and good in drying quality.

Owner:武汉天利包装有限公司

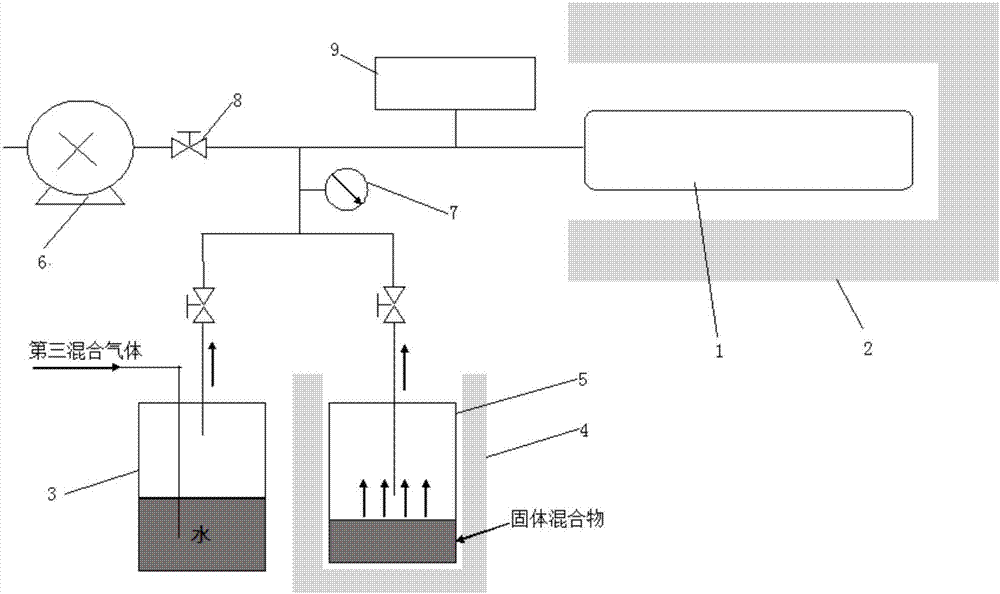

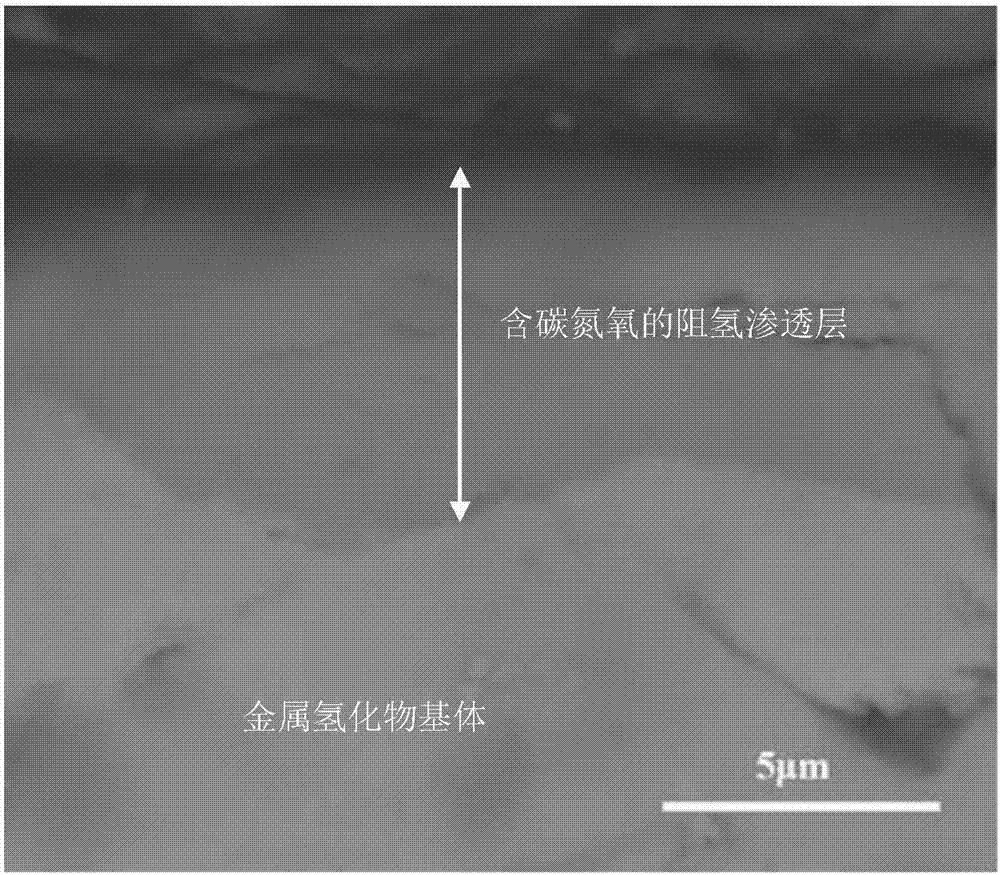

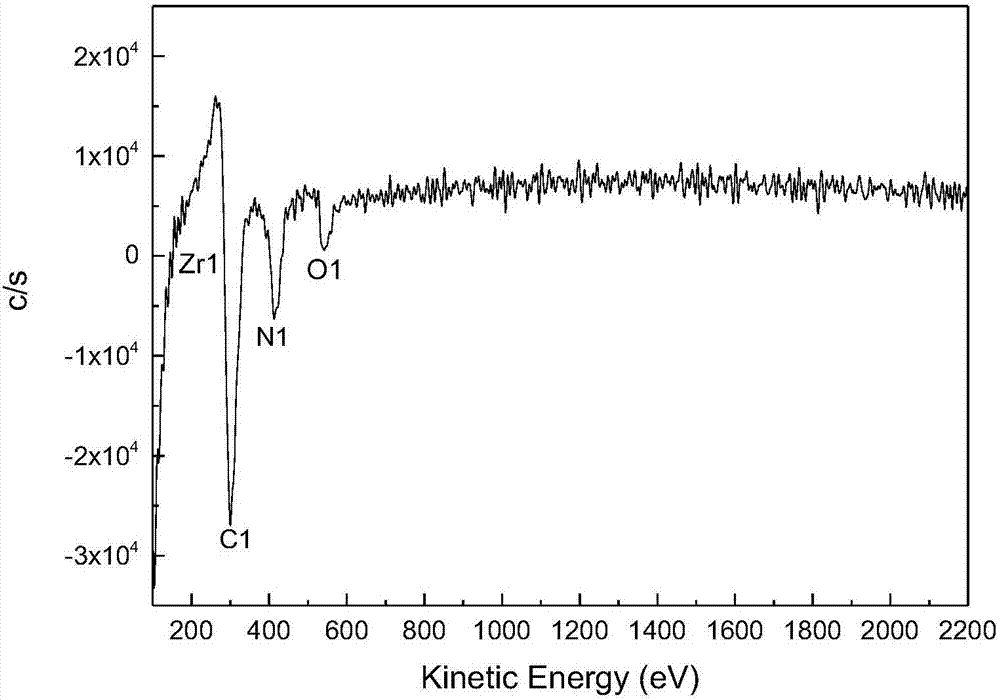

Preparation method for hydrogen-resistance permeation layer on surface of metal hydride

ActiveCN107043906AExcellent resistance to hydrogen permeationPrevent hydrogen releaseSolid state diffusion coatingCarbideOxygen

The invention relates to a preparation method for a hydrogen-resistance permeation layer on the surface of metal hydride. According to the preparation method, a metal hydride matrix subjected to surface treatment is sealed in a vacuum reaction vessel; gas containing carbon oxygen or nitrogen oxygen or carbon-nitrogen oxygen is injected into the reaction vessel at constant flow; an in-situ reaction is conducted between the gas containing the carbon oxygen or the nitrogen oxygen or the carbon-nitrogen oxygen and metal elements of the matrix at the temperature of 400-900 DEG C; and the dense and complete hydrogen-resistance permeation layer containing the carbon oxygen or the nitrogen oxygen or the carbon-nitrogen oxygen is obtained after cooling. The preparation method for the hydrogen-resistance permeation layer on the surface of the metal hydride solves the problems of interlayer defects and untight interlayer combination of a carbide film overlaying with an oxide film, a nitride film overlaying with the oxide film, and the nitride film overlaying with the carbide film and the oxide film, restrains / retards precipitation of hydrogen from the metal hydride matrix effectively, and has a high hydrogen-resistance permeation capacity.

Owner:有研资源环境技术研究院(北京)有限公司

Method for roll-to-roll continuous printing of OLED flexible display panel

ActiveCN110635068AGood effectOvercome uniformity issuesSolid-state devicesSemiconductor/solid-state device manufacturingAlloyPolyimide membrane

The invention provides a method for roll-to-roll continuous printing of an OLED flexible display panel. The method comprises the following steps of coating on anode coating solution containing graphene on a surface of a polyimide film in a roll-to-roll continuous printing device in a blade coating manner; carrying out ink-jet printing on a hole transport material and a hole injection layer material which are alternately distributed on an anode surface; then, carrying out ink-jet printing on a luminescent material, and carrying out ink-jet printing on an electron transport material and an electron injection layer material which are alternately distributed; further laminating with a film deposited with an alloy to form a cathode; and finally carrying out heat setting, packaging and reeling.By using the method of the invention, defects of non-uniform printing, easy formation of a coffee effect and untight combination in direct ink-jet printing are overcome, transmission efficiency is improved, and a controllable thickness and controllable precision are realized. The method is suitable for large-area, large-scale, continuous and stable preparation of the OLED flexible display panel.

Owner:山西穿越光电科技有限责任公司

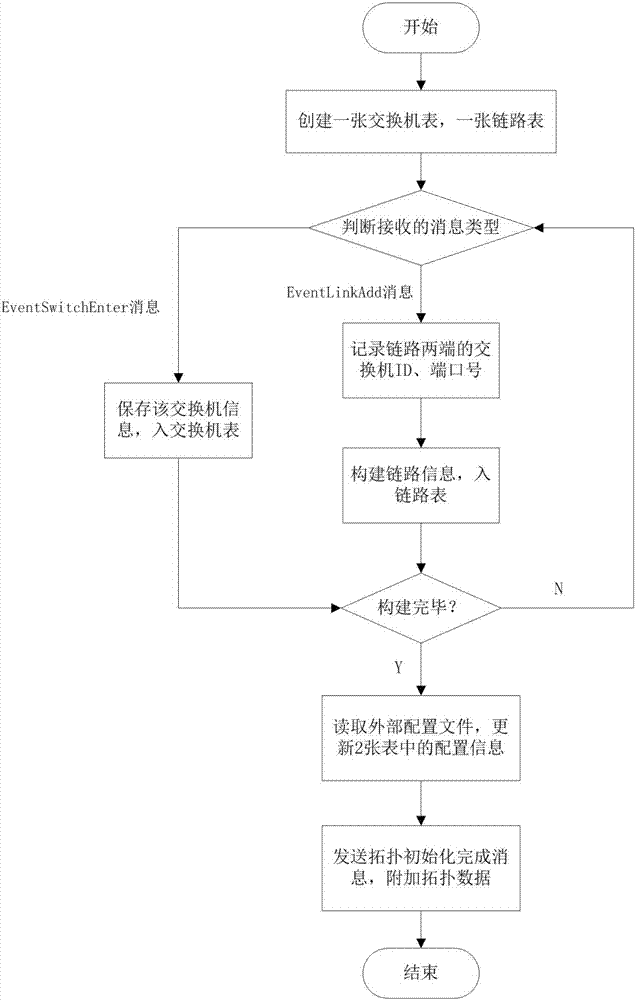

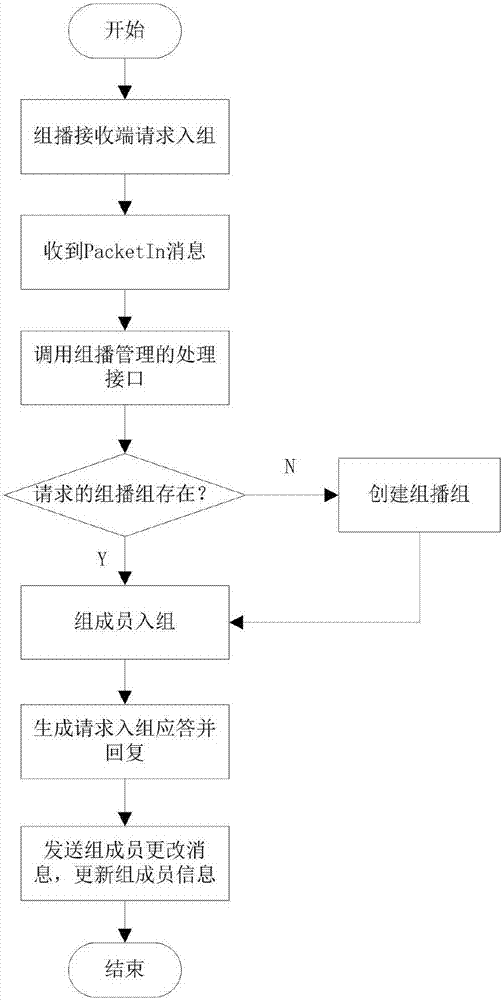

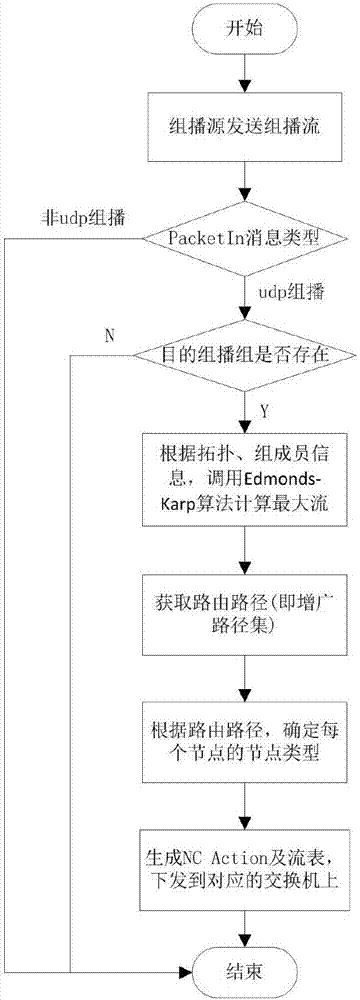

Multicast transmission method of network coding in SDN network

ActiveCN107196860AOvercoming the inability to apply network codingOvercoming associativitySpecial service provision for substationChannel coding adaptationControl layerService implementation

The invention provides a multicast transmission method of network coding in an SDN network. An Openvswitch switch has an OpenFlow protocol supporting the network coding, and the Openvswitch switch is a switch that supports the OpenFlow protocol and can perform coding and decoding. The core technology, the OpenFlow protocol, of the SDN network is to separate a data layer and a control layer of a network device, the control layer provides service implementation and logic control, and the data layer executes data forwarding so as to realize flexible control and intelligent management of the network, and the network is convenient to expand. The network coding is a major breakthrough in the processing and transmission of information in the network, it allows an intermediate node of the network to perform coding processing on transmitted information and to perform decoding and restoration on a receiving node, thereby improving the network throughput, and the reliability and security of data transmission. By adoption of the multicast transmission method provided by the invention, the network coding is effectively applied to the SDN network, the problem that the network coding application cannot be organically combined with the SDN network in the prior art is overcome, and the advantages of the both are combined, thereby having an important research value on the network development in the future.

Owner:SOUTHWEST JIAOTONG UNIV

Production method of environment-friendly cigarette packet material

ActiveCN107119494AImproved rheological propertiesGood molding effectFlexible coversWrappersLaser patterningPolypropylene

The invention relates to a manufacturing method of a packaging material, in particular to a production method of an environment-friendly cigarette packet material. The production method mainly comprises the steps of: A, performing laser die pressing on a BOPP (biaxially-oriented polypropylene) film to form a laser pattern on the BOPP film, B, coating a first layer on the front surface of raw paper, performing flattening treatment on the front surface of the raw paper, coating a second layer on the front surface of the raw paper in a high-temperature pressed environment, performing rolling compounding on the raw paper and the BOPP film, and C, coating a first layer on the back surface of the raw paper and performing flattening treatment on the back surface of the raw paper. The method does not use non-renewable metal aluminum as a raw material any longer, saves non-renewable mineral resources and energy sources, makes full use of a high technology and a new technology to effectively avoid generation of environmental pollutants, raises an environment-friendly grade of a product, saves the resources to the greatest extent, protects an environment, achieves a zero utilization standard of the aluminum, and avoids the generation of three industrial wastes, the product with the higher environment-friendly grade has higher market competitiveness, and the method has wider market prospects.

Owner:SHANTOU XINDA COLOR PRINTING PACKAGING MATERIALS

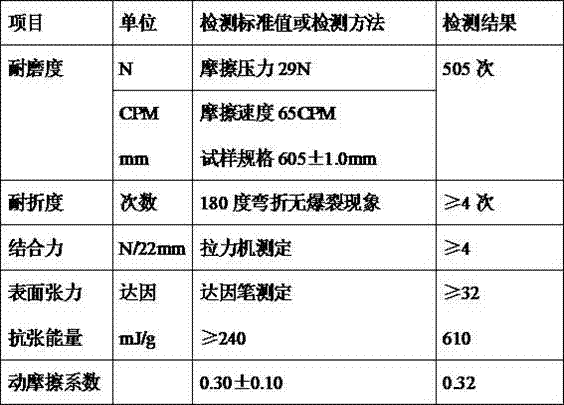

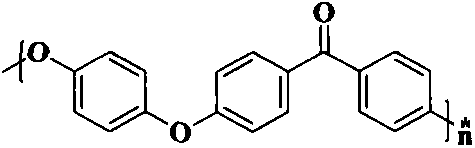

Preparation method of polyetheretherketone nonstick coating material

ActiveCN105001384AOvercoming dispersionOvercoming associativityCoatingsPoly ether ether ketoneIce water

The invention relates to a preparation method of polyetheretherketone nonstick coating material. The method is characterized by comprising the following steps: adding multiwalled carbon nanotubes into concentrated nitric acid and concentrated sulfuric acid, and stirring at 60-120 DEG C; adding reactants drop by drop into ice water, allowing to stand for layering, washing with distilled water, drying and grinding for obtaining a first reaction product; carrying out a reaction of the first reaction product and thionyl chloride and dimethyl formamide for obtaining a second reaction product; after dissolving the second reaction products with acetone, adding the second reaction product drop by drop into a mixed solution of hydroquinone, triethylamine and acetone, performing a reaction for 1.8-2.2 hours at 55-65 DEG C, carrying out a pumping filtration, washing, drying for obtaining a third reaction product; under the protection of nitrogen, adding the third reaction product, hydroquinone, 4,4'-difluorobenzophenone and sulfobenzide in order into a reactor, carrying out heating to 140-160 DEG C, adding alkali carbonate, and reacting for 5 hours; after grinding, washing and drying, obtaining a polyetheretherketone nonstick coating.

Owner:NINGBO GRAMMY KITCHENWARE

Preparation method of tara modified zirconium complex tanning agent and tanning agent prepared by preparation method

ActiveCN106755632ATanningGood shrinkage temperatureTanning treatmentEvaporation PurificationAqueous sodium hydroxide

The invention relates to a preparation method of a tara modified zirconium complex tanning agent. The preparation method of the tara modified zirconium complex tanning agent comprises the following processing steps: one, a tanning extract is dissolved in water and tara initial mixed liquor is obtained; two, the tara initial mixed liquor obtained in the step one is centrifuged, and supernatant is obtained; three, the supernatant in the step two is subjected to rotary evaporation purification; four, a solution in the step three is transferred to a reaction kettle, a sodium hydroxide aqueous solution is added, a pH value of the solution is adjusted to be greater than 7, heat preservation is carried out for half an hour, then a hydrogen peroxide solution is added, and the solution is kept in an alkaline environment; five, under ordinary pressure, temperature reaction happens, then cooling to room temperature is carried out; and six, a pH value of the solution is adjusted with dilute sulphuric acid, a tetravalent zirconium salt aqueous solution is added, heating-up is carried out, then cooling and discharge are carried out, and a required product is obtained. With the adoption of the technical scheme, the prepared tara modified zirconium complex tanning agent is good in comprehensive performance, is environmental-friendly, and has the advantages of retaining the tanning property of a zirconium metal tanning agent and the selective filling property of a tanning extract degraded product simultaneously, and the like, so that the problem that a chromium type tanning agent has pollution to the environment is solved.

Owner:WENZHOU UNIVERSITY

Environment-friendly artificial carbonized wood production method

InactiveCN105479570AImprove adhesionHigh strengthFlat articlesDomestic articlesCarbonizationSODIUM SILICATE SOLN

The invention discloses an environment-friendly artificial carbonized wood production method. The method includes four steps of raw material treatment, hot press molding, carbonization treatment and surface treatment. In raw material treatment, a mixture composed of pure fine pine powder, a sodium silicate solution, silica sol, nanometer titania powder, sodium lignin sulfonate and talcum powder according to the weight part ratio of 5-8:2-5:0.4-0.6:0.1-0.3:0.04-0.08:0.02-0.04 is stirred evenly in a heated state, so that a blank material with the moisture content ranging from 8% to 12% is obtained, the stirring speed ranges from 230 r / min to 250 r / min, and stirring time ranges from 15 min to 25 min. Artificial carbonized wood produced through the method has the characteristics of being good in flame resistance, good in waterproof performance, environmentally friendly, suitable for multiple fields and particularly suitable for the working environment making contact with water for a long time.

Owner:黄万忠

Preparation method of rare earth-modified paper base friction material

ActiveCN103541267AIncrease frictionImprove interfacial bond strengthPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperRare-earth elementFiber

The invention discloses a preparation method of a rare earth-modified paper base friction material. The preparation method comprises the following steps of dissolving a cashew nut shell oil-modified phenolic resin in anhydrous ethanol to obtain a solution A, dispersing multi-walled carbon nanotubes in a sodium dodecyl sulfate aqueous solution to obtain a suspension liquid B, adding a nitrate solution of a rare earth element into the suspension liquid B to obtain a suspension liquid C, dispersing chopped carbon fibers, bamboo fibers and diatomite in water and adding the suspension liquid C into the mixed solution to obtain a solution D, carrying out defibering on the solution D, carrying out sheet-making and drying to obtain a sample sheet, soaking the sample sheet in the solution A, taking out the sample sheet, carrying out drying in air, and carrying out hot press molding to obtain the rare earth-modified paper base friction material. The preparation method realizes full combination of the rare earth element and the carbon nanotubes, utilizes their synergism, realizes preparation of the single-layer paper base friction material, has simple and easily controllable processes, solves the problem that the friction material obtained by the prior art has the uneven surface, unfirmly-bonded interfaces and unstable friction performances, greatly improves friction performances of the rare earth-modified paper base friction material and effectively reduces a wear rate.

Owner:盐城抱璞文化传媒有限公司

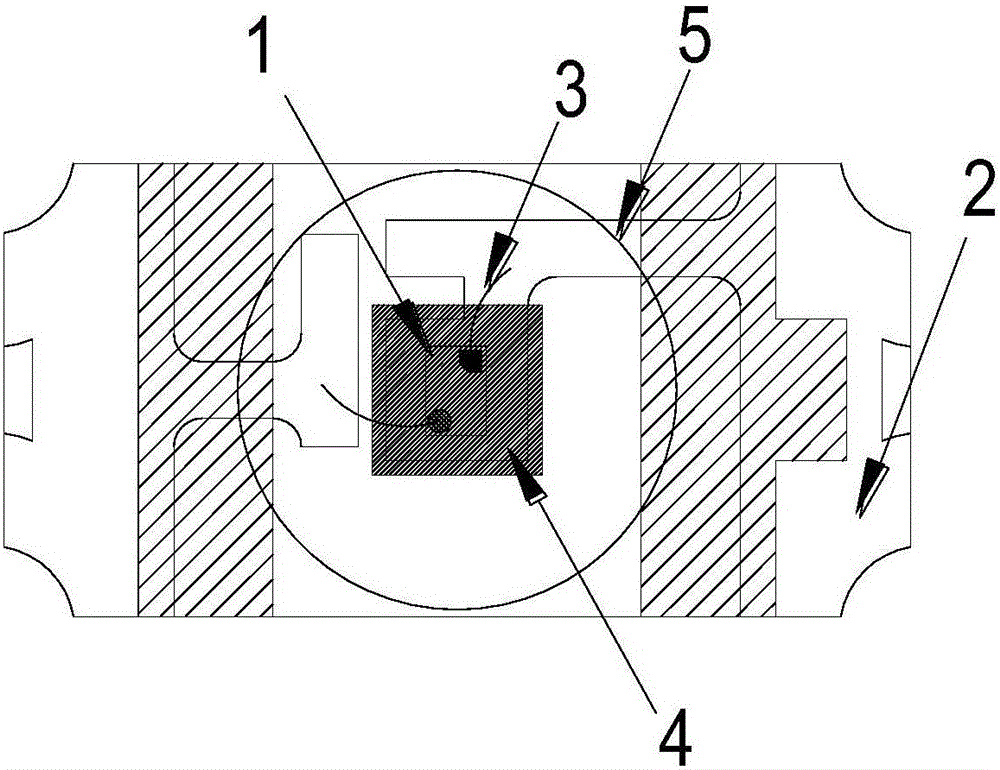

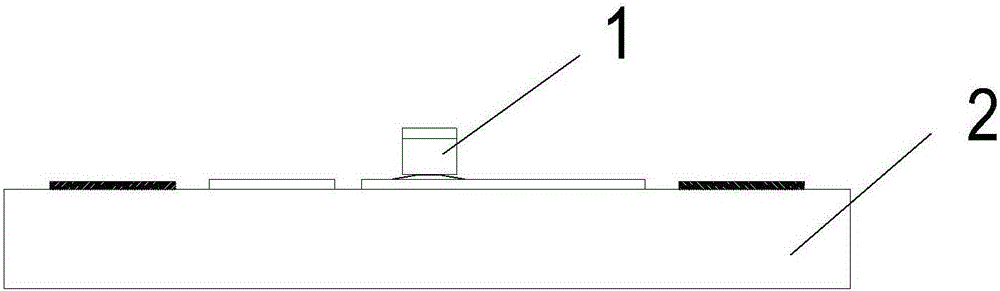

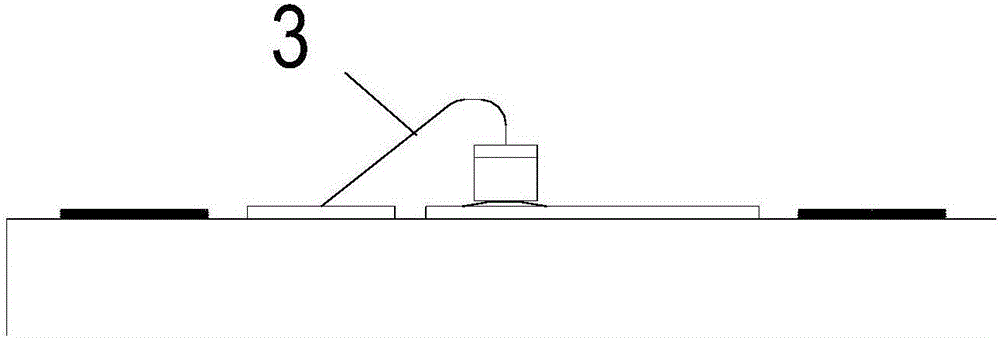

Round Lens and Chip LED light-emitting component and production technology

The invention discloses a round Lens and Chip LED light-emitting component and a production technology thereof. The light-emitting component comprises a PCB substrate, a blue LED chip and a lampshade, wherein the front surface of the blue LED chip is fixedly connected to the PCB substrate; the surface, connected with the blue LED chip, of the PCB substrate is provided with a conductive layer; the blue LED chip is connected to the conductive layer through a guide wire; silica gel is sprayed on an upper layer of the blue LED chip and is packaged on the PCB substrate through transparent gel; the lampshade is fixed on the PCB substrate; and the blue LED chip and the sprayed silica gel are located in the lampshade. A round Lens chip LED white-light product is innovated by a small area spraying technique; and meanwhile, the problem of the binding property, short lifetime and the like of an existing general chip LED white-light / blue-light product are solved.

Owner:AMICC OPTO ELECTRONICS TECH

PH responsive plant fiber functional material as well as preparation method and application thereof

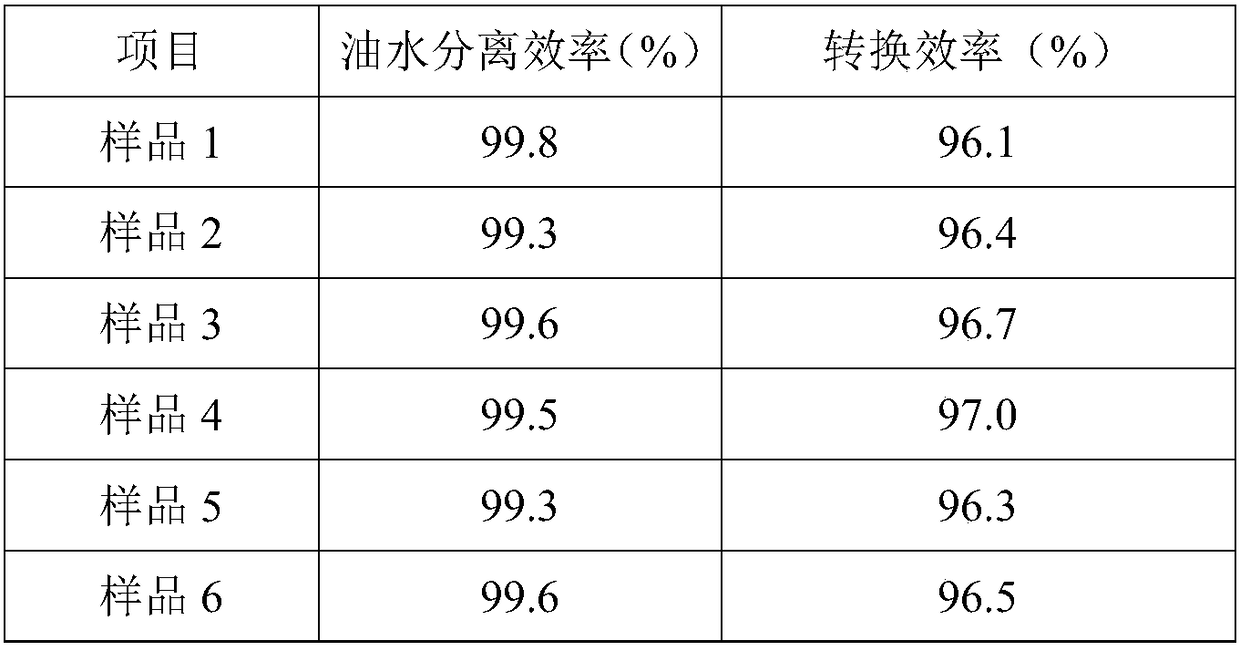

ActiveCN108530585AHigh pH Responsive SensitivityRealize two-way intelligent conversionNon-miscible liquid separationFiberOil water

The invention discloses a pH responsive plant fiber functional material as well as a preparation method and application thereof. With a plant fiber as a matrix, the grafting of a negative pH responsive group and a positive pH responsive group is initiated on the surface of the plant fiber by a free radical; the concentration of negative pH responsive monomers and positive pH responsive monomers ina reaction system are maintained at 0.138-0.552 mol / L and 0.14-0.56 mol / L, respectively, and the sequence of adding the monomers is also controlled, so as to enable the mass ratio of the negative pHresponsive group and the positive pH responsive group grafted on the surface of the plant fiber to be 1:(2-4) or (2-4):1 and the total grafting ratio of the groups on the surface of the plant fiber tobe 50%-80%. Therefore, the material has higher pH responsive sensitivity in a narrower pH range, and two-way intelligent conversion between hydrophilic oleophobicity and lipophilic hydrophobicity ofthe material is achieved. The material is of high oil-water separation efficiency, good regeneration stability and good environmental suitability.

Owner:GUANGXI UNIV

Method for producing wood-based artificial carbonized wood

InactiveCN105269652AImprove adhesionHigh strengthFlat articlesDomestic articlesCompression moldingSulfonate

The invention discloses a method for producing a wood-based artificial carbonized wood. The method comprises the following four steps: processing raw materials; carrying out hot compression molding; carbonizing; performing surface treatment. The raw materials are processed by mixing and stirring, namely, a mixture, comprising pure fine pine powder, a sodium silicate solution, silica sol, nano-titania powder, sodium lignin sulfonate, talcum powder and sodium montmorillonite based on the weight part ratio of (4-8): (2-4): (0.3-0.5): (0.1-0.3): (0.03-0.07): (0.02-0.04): (0.01-0.03), is uniformly stirred for 20 to 25min at the speed of 230-250r / min under a heating state, so as to obtain a blank with water content of 8 to 12%. The wood-based carbonized wood has the characteristics of being outstanding in flame retardant property, outstanding in waterproofing performance, and being environmental friendly; the wood-based carbonized wood is applicable to a plurality of fields, and is particularly applicable to working environments being in contact with water for a long term.

Owner:黄万忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com