Patents

Literature

64 results about "Short lifetime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

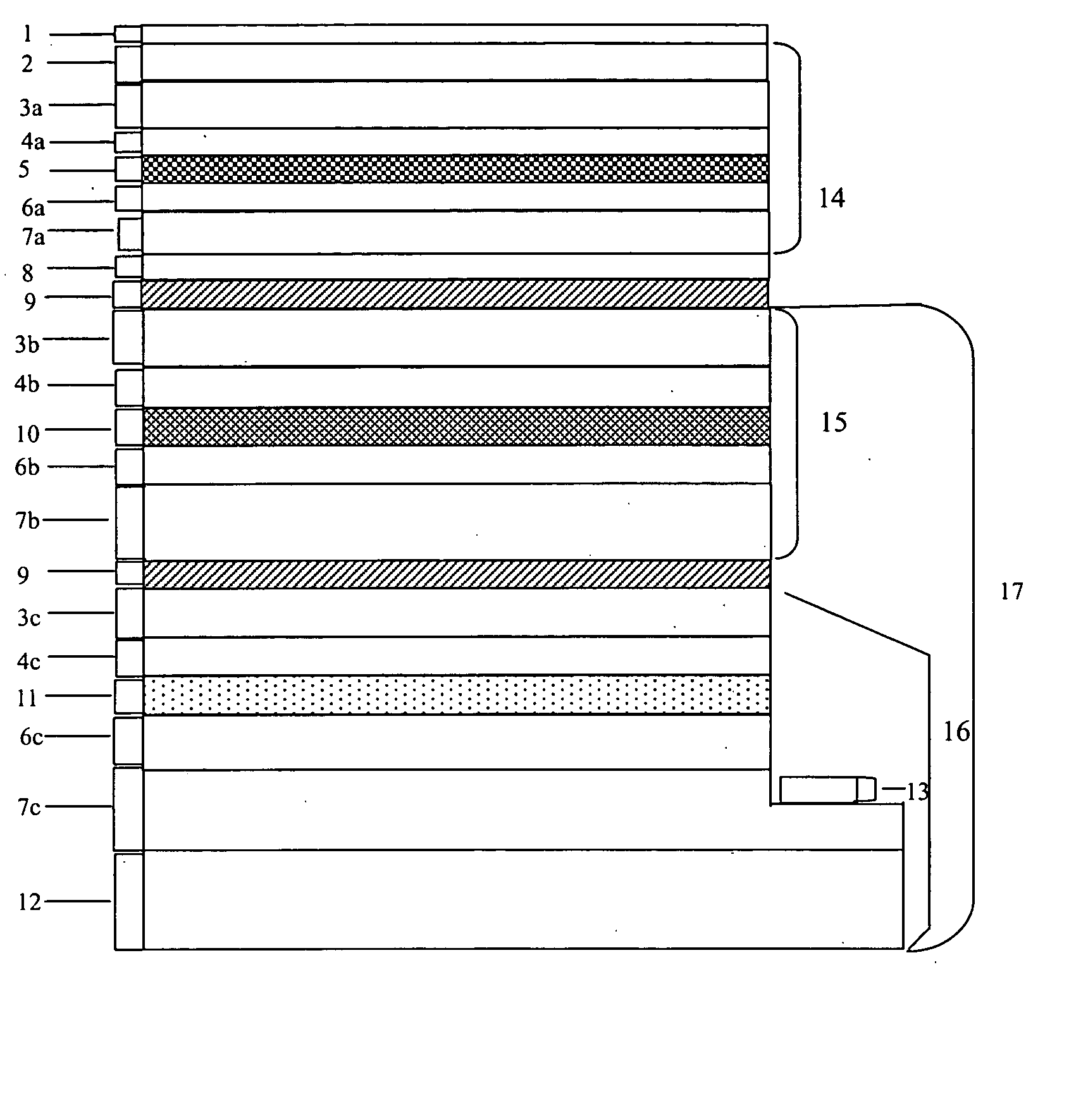

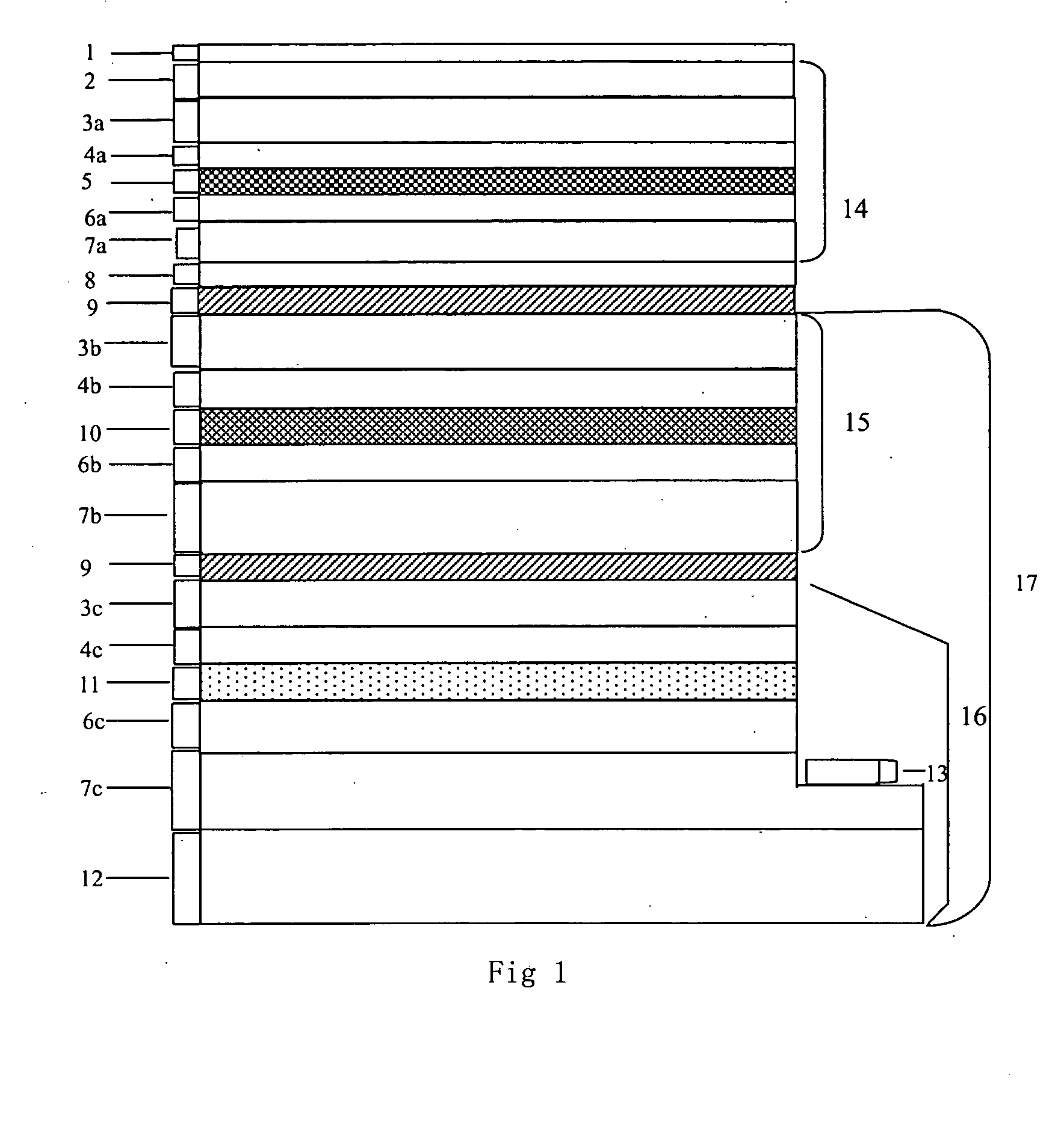

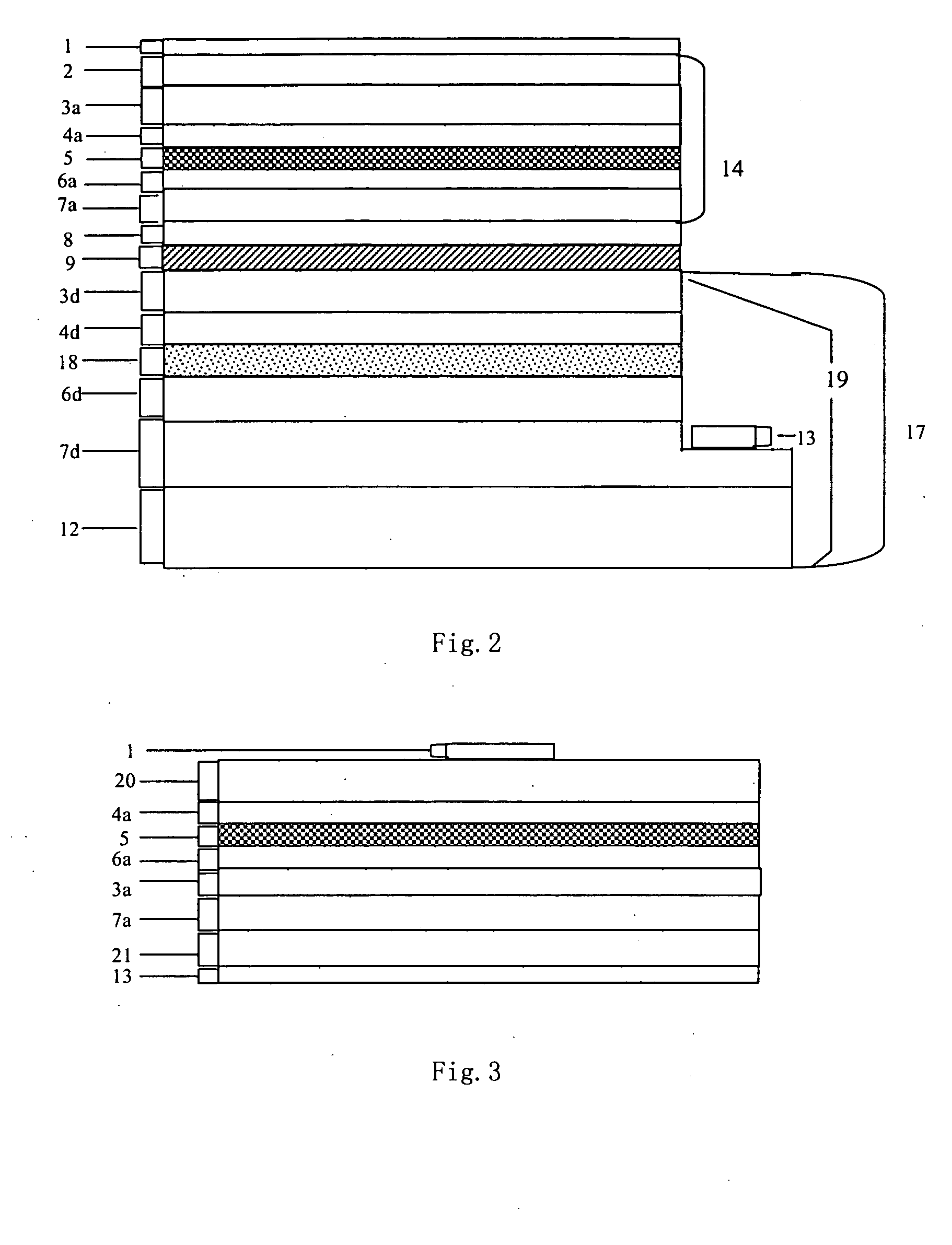

High efficiency multi-active layer tunnel regenerated white light emitting diode

InactiveUS20050067627A1Improved current spreadingEasy to spreadSemiconductor devicesGreen cellSemiconductor materials

A high efficiency and high brightness multi-active layer tunneling regenerated white color semiconductor light emitting diode having a p type electrode 1, a monolithic red light cell 14, a tunnel junction 9, a monolithic green light 15 and blue light cell 16 (or a monolithic cyan light cell 19), wherein each of said cells are electrically connected by tunnel junctions 9, and the red cell physically connected with blue and green cell (or cyan cell) by wafer bonding layer 8. The lights from each cell synthesize white color light. The white light emitting diode only has one time optical-electrical conversion, so the quantum efficiency is high. Moreover, the white LED totally made from semiconductor materials, the lifetime of the white LED lamp is not limited by the relatively short lifetime of fluorescent material.

Owner:BEIJING UNIV OF TECH

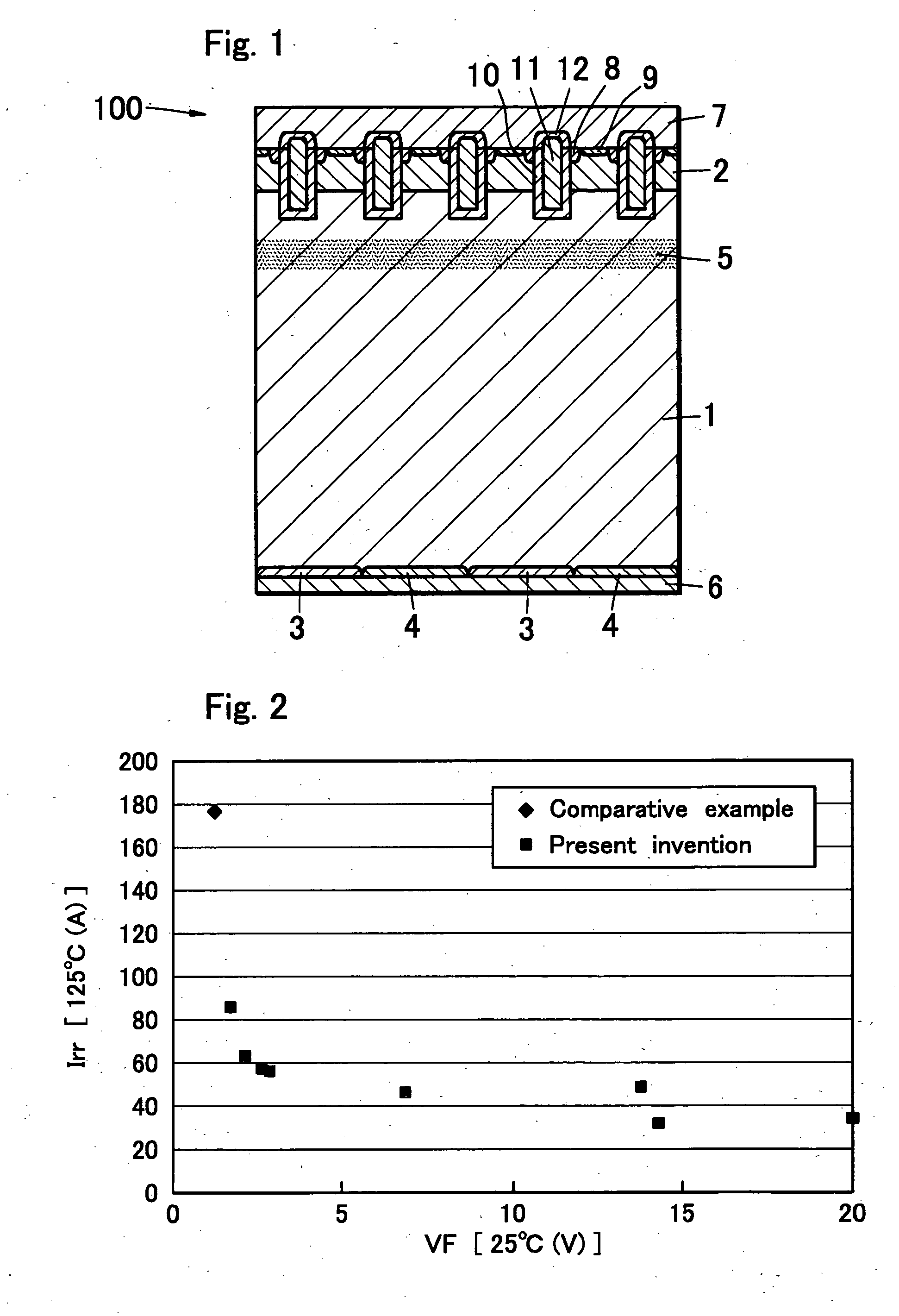

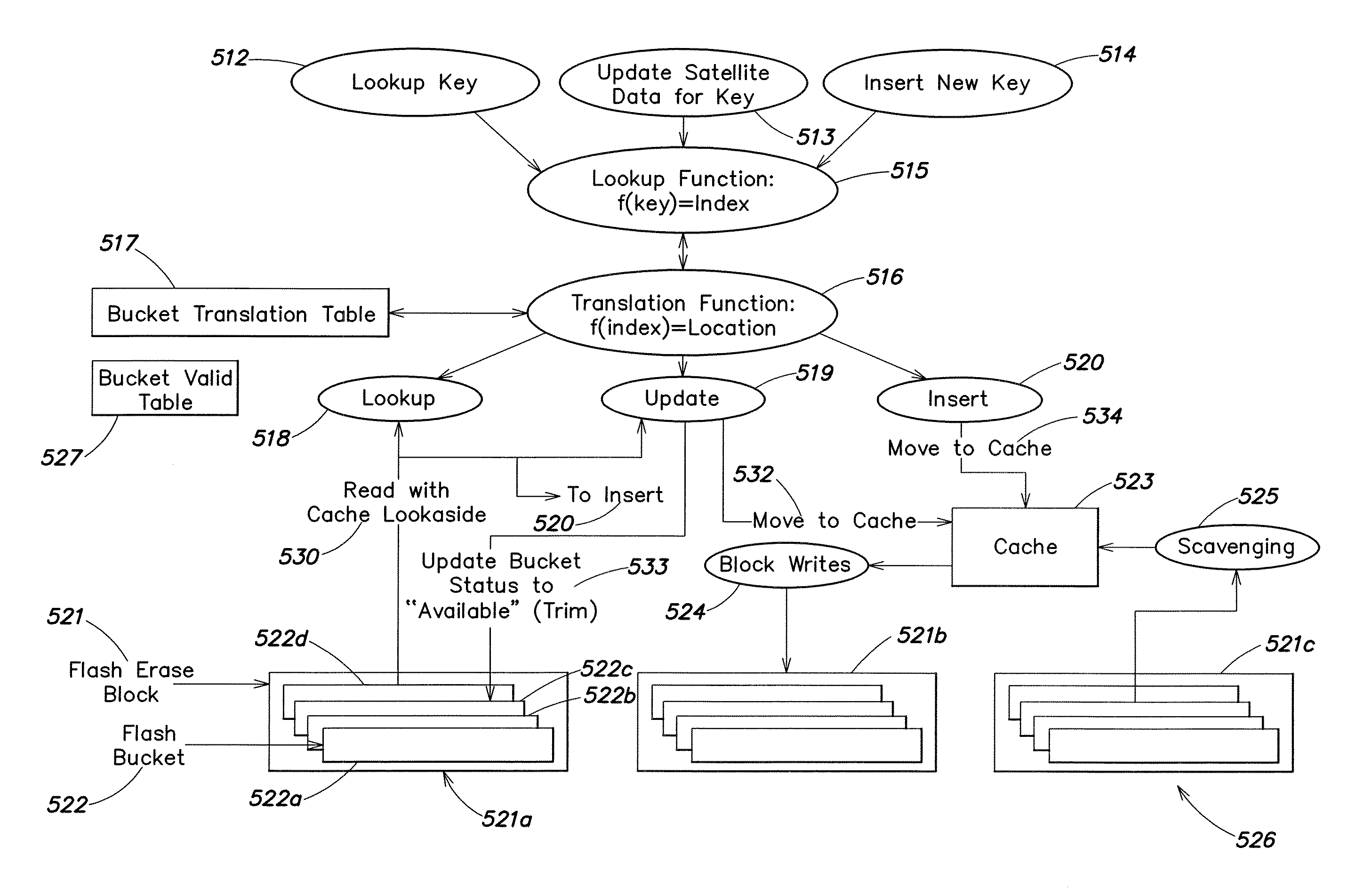

Reverse conducting semiconductor device and a fabrication method thereof

ActiveUS20050258493A1Reverse recovery is improvedAvoid large quantitiesTransistorSolid-state devicesDevice materialEngineering

To provide a reverse conducting semiconductor device in which an insulated gate bipolar transistor and a free wheeling diode excellent in recovery characteristic are monolithically formed on a substrate, the free wheeling diode including; a second conductive type base layer to constitute the insulated gate bipolar transistor; a first conductive type base layer for constituting the insulated gate bipolar transistor, an anode electrode which is an emitter electrode covering a first conductive type emitter layer and the second conductive type base layer, a cathode electrode which is a collector electrode covering the first conductive type base layer and a second conductive type collector layer formed on the part of the first conductive type base layer, wherein a short lifetime region is formed on a part of the first conductive type base layer.

Owner:MITSUBISHI ELECTRIC CORP

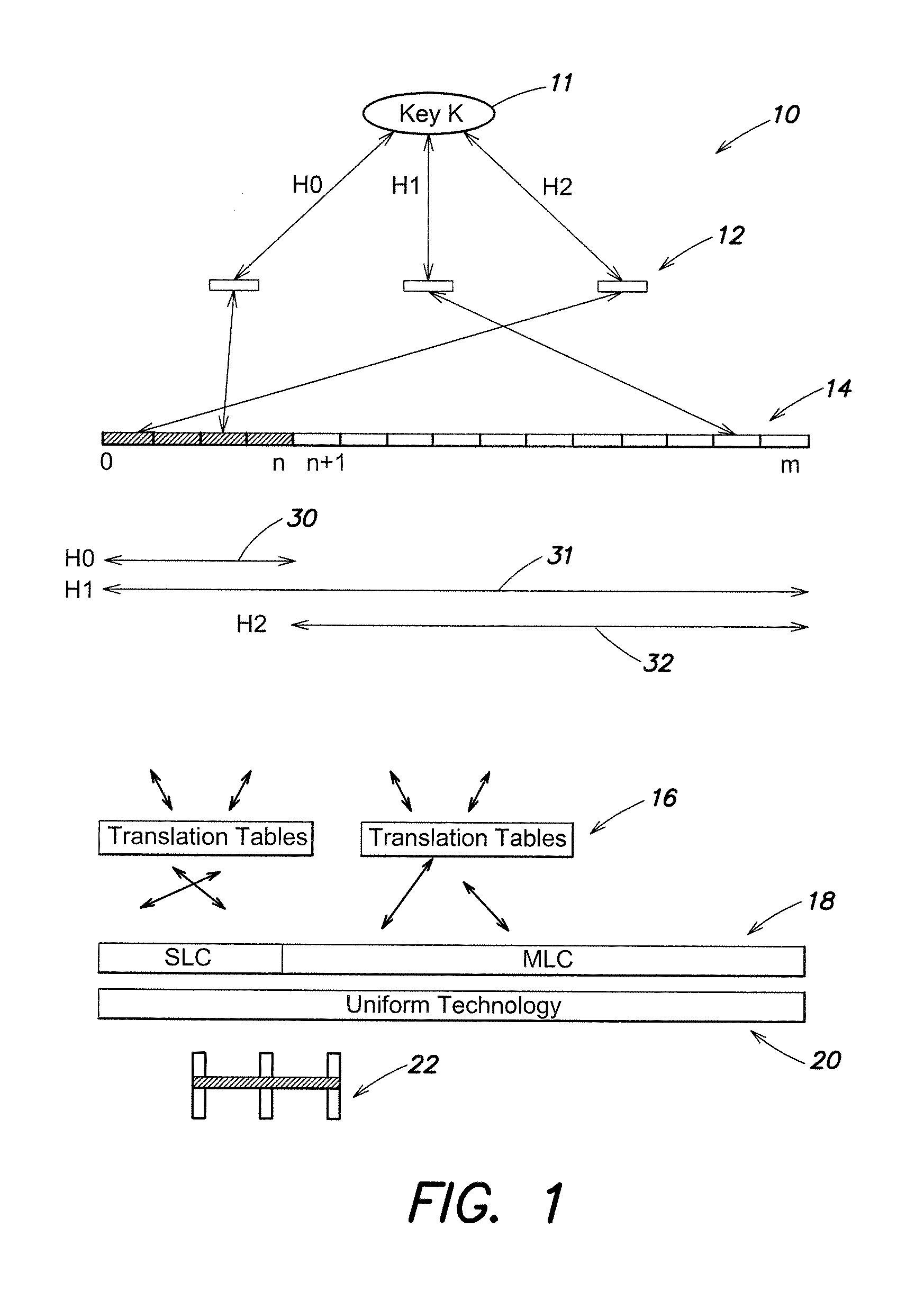

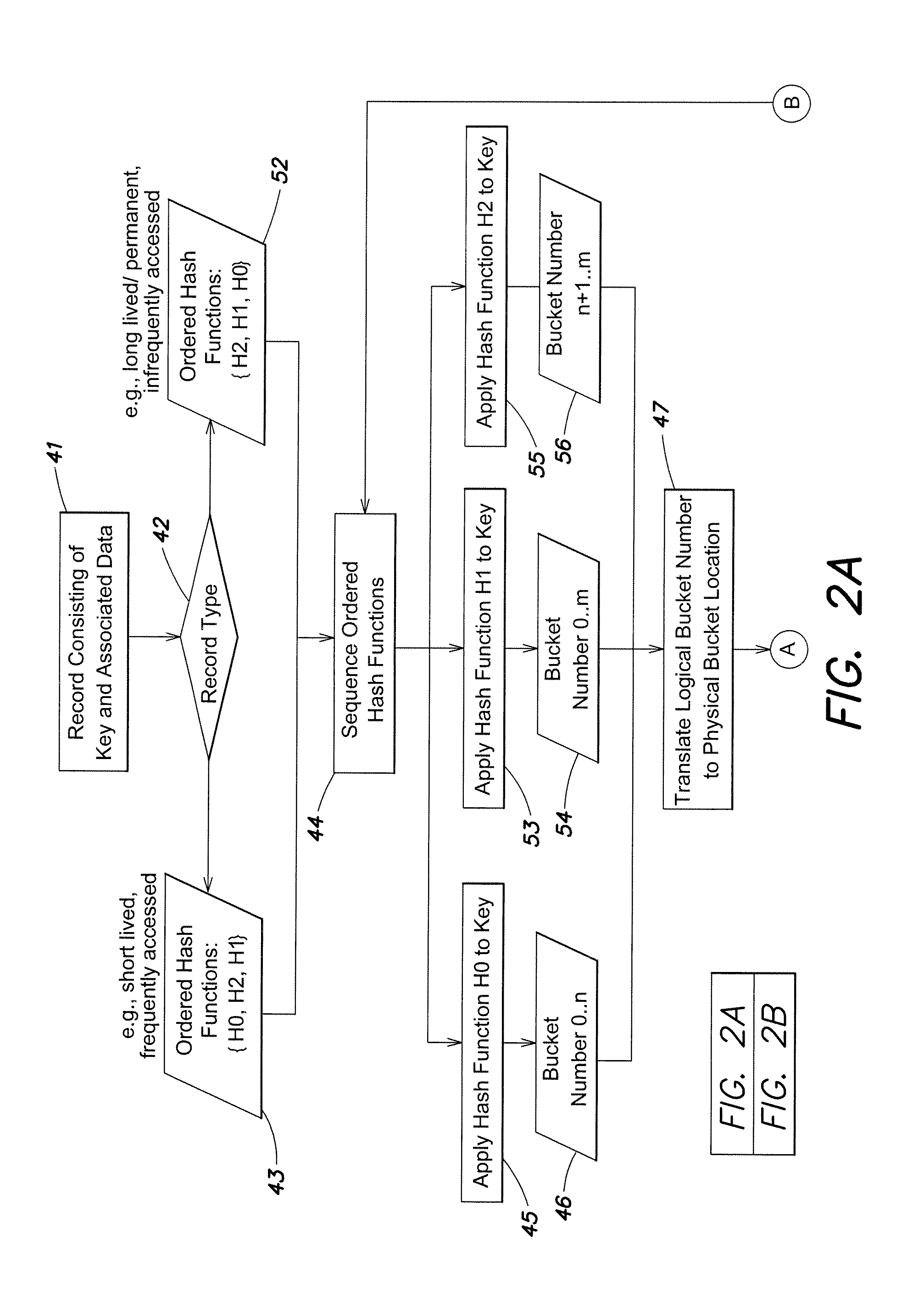

Method and apparatus utilizing non-uniform hash functions for placing records in non-uniform access memory

ActiveUS20130227195A1Easy accessShort lifeMemory architecture accessing/allocationDigital data information retrievalHash functionRandom access memory

Method and apparatus for storing records in non-uniform access memory. In various embodiments, the placement of records is localized in one or more regions of the memory. This can be accomplished utilizing different ordered lists of hash functions to preferentially map records to different regions of the memory to achieve one or more performance characteristics or to account for differences in the underlying memory technologies. For example, one ordered list of hash functions may localize the data for more rapid access. Another list of hash functions may localize the data that is expected to have a relatively short lifetime. Localizing such data may significantly improve the erasure performance and / or memory lifetime, e.g., by concentrating the obsolete data elements in one location. Thus, the two or more lists of ordered hash functions may improve one or more of access latency, memory lifetime, and / or operation rate.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

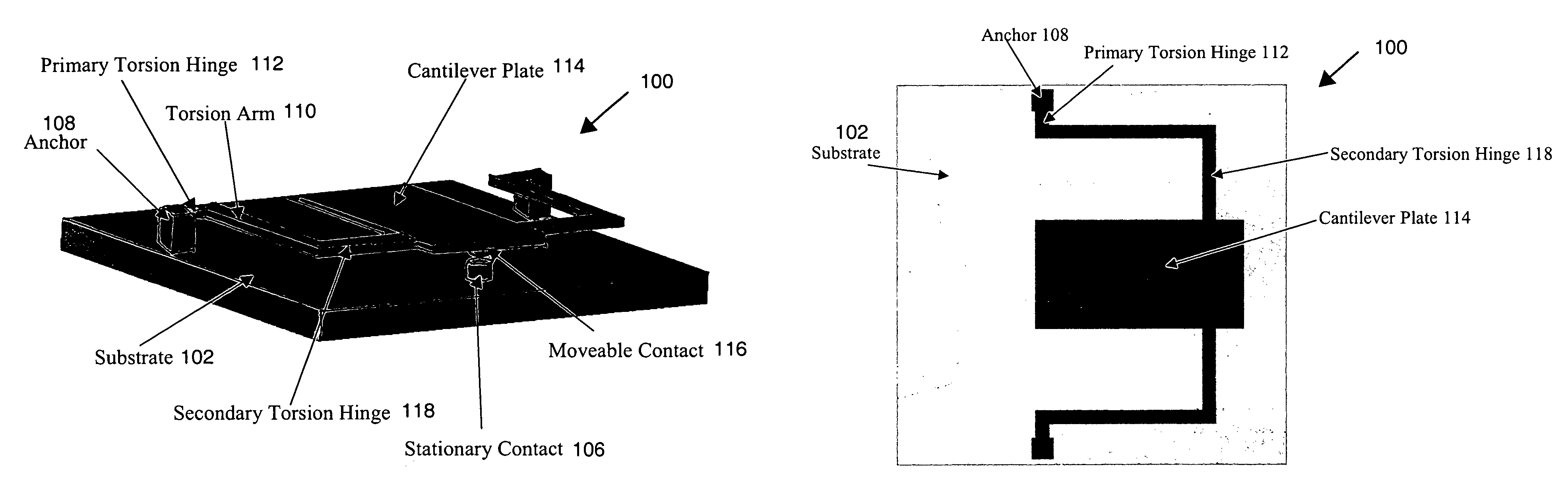

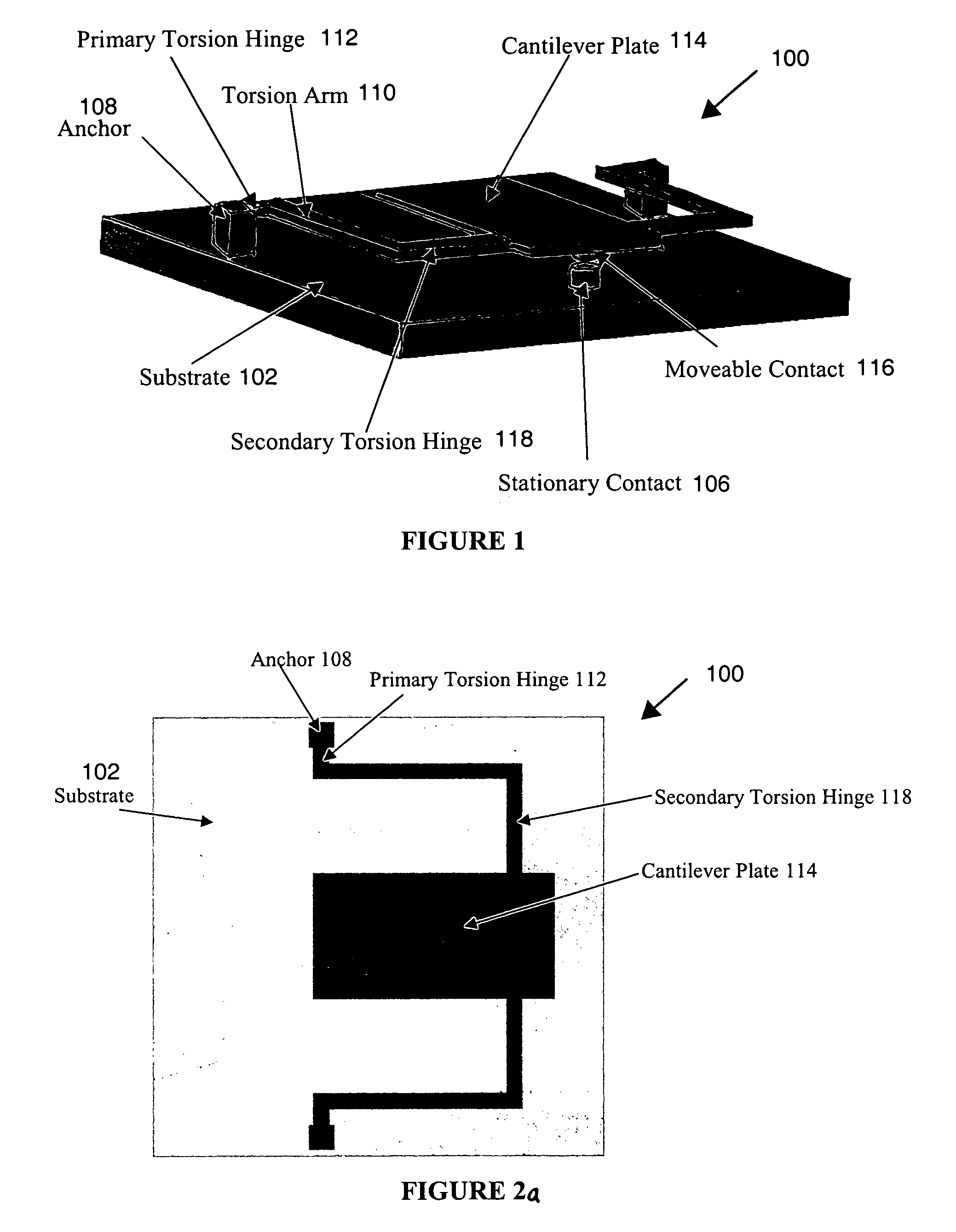

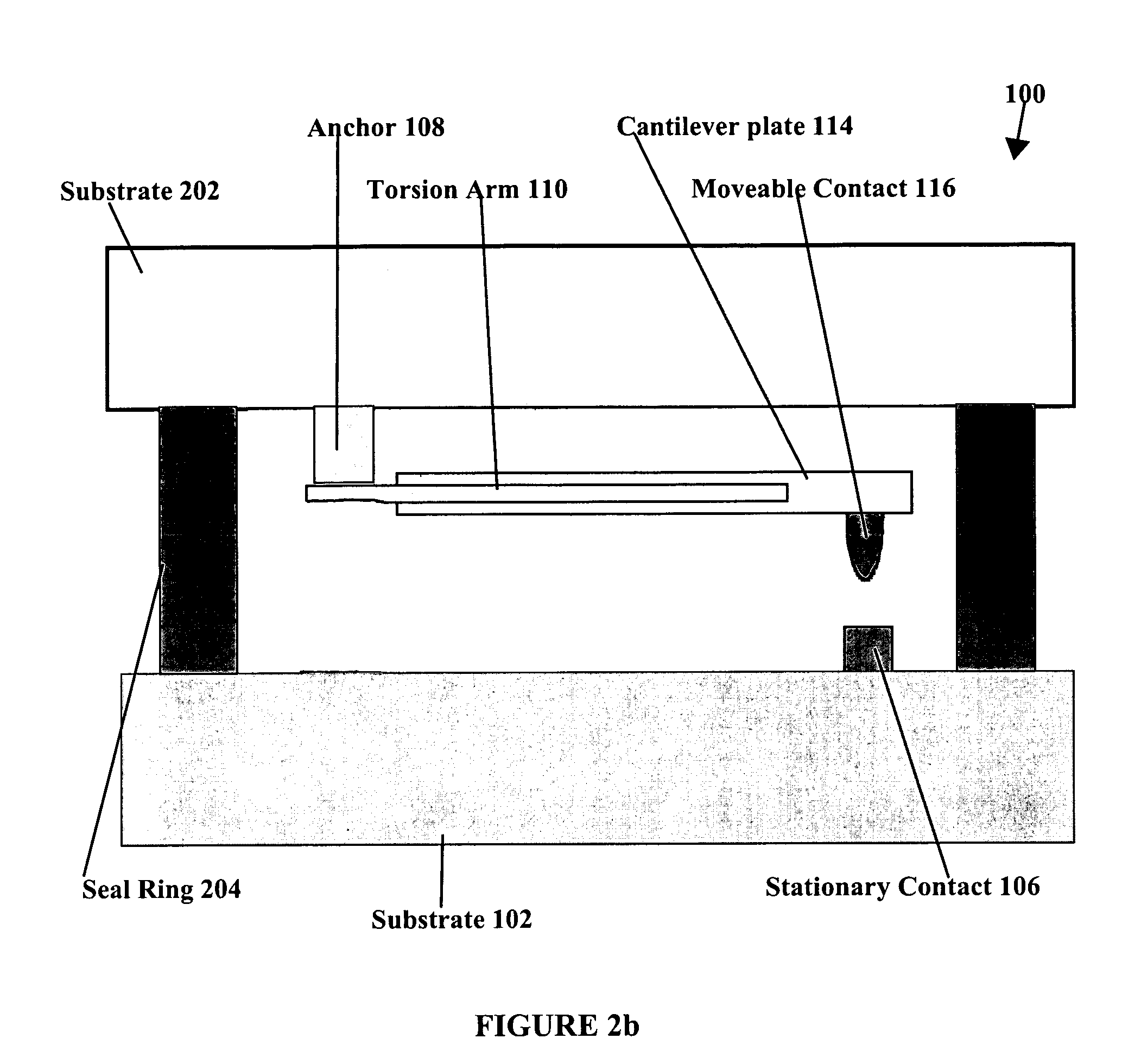

High force MEMS device

InactiveUS7692521B1Reduce impactReducing damage and stictionElectrostatic/electro-adhesion relaysElectrostrictive/piezoelectric relaysCantileverQ-switching

Problems with the short lifetime of MEMS devices, low actuation forces, contaminant build-up on contacts, etc. are minimized by a MEMS device with an improved cantilever design that enables high force while maintaining large gaps. The improved cantilever design both allows for high force and fast switching while minimizing damage to contacts. The improved design can be fabricated on one or two substrates, which are bonded together with a seal ring to provide a packaged MEMS device.

Owner:MICROASSEMBLY TECH

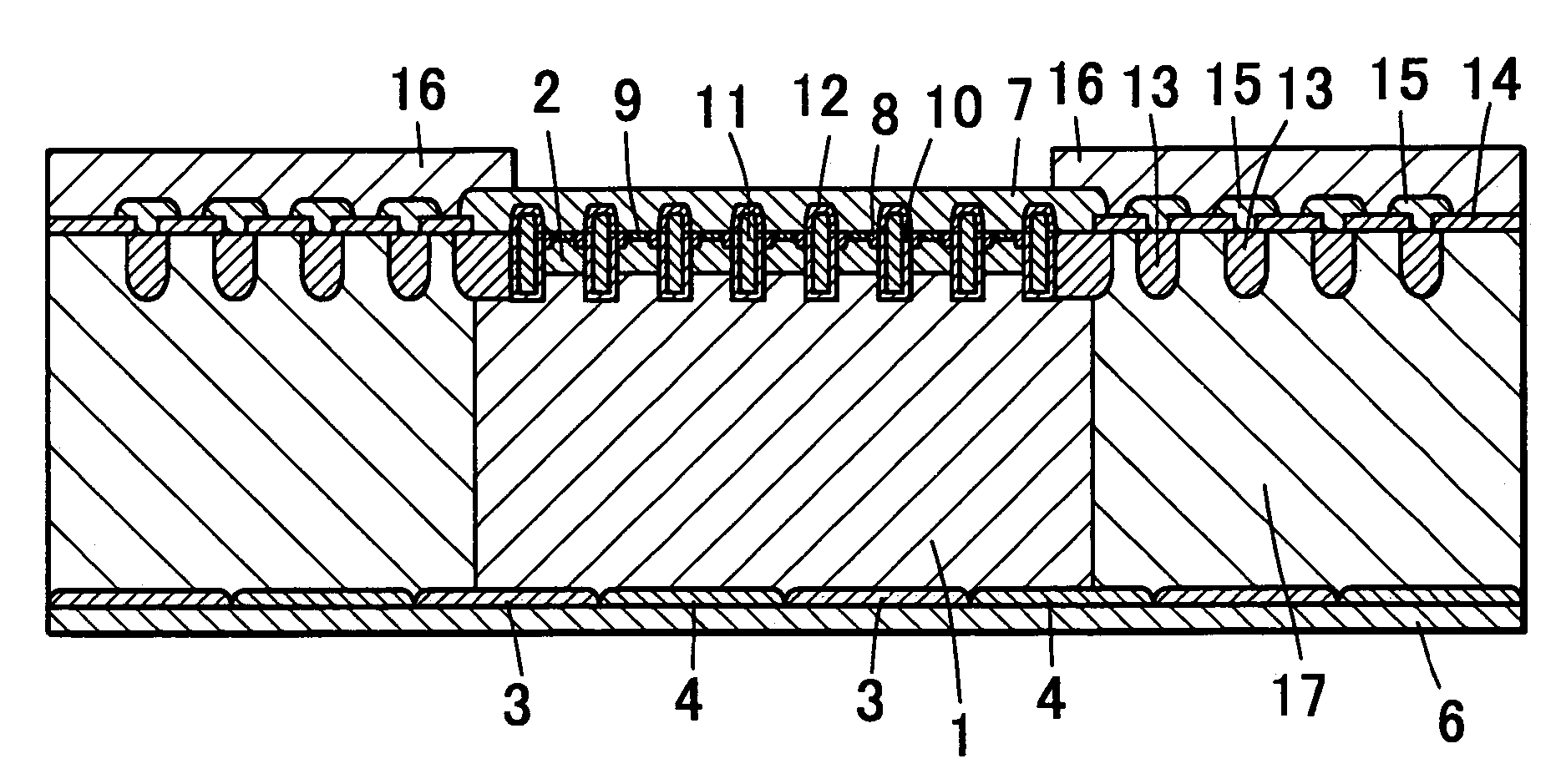

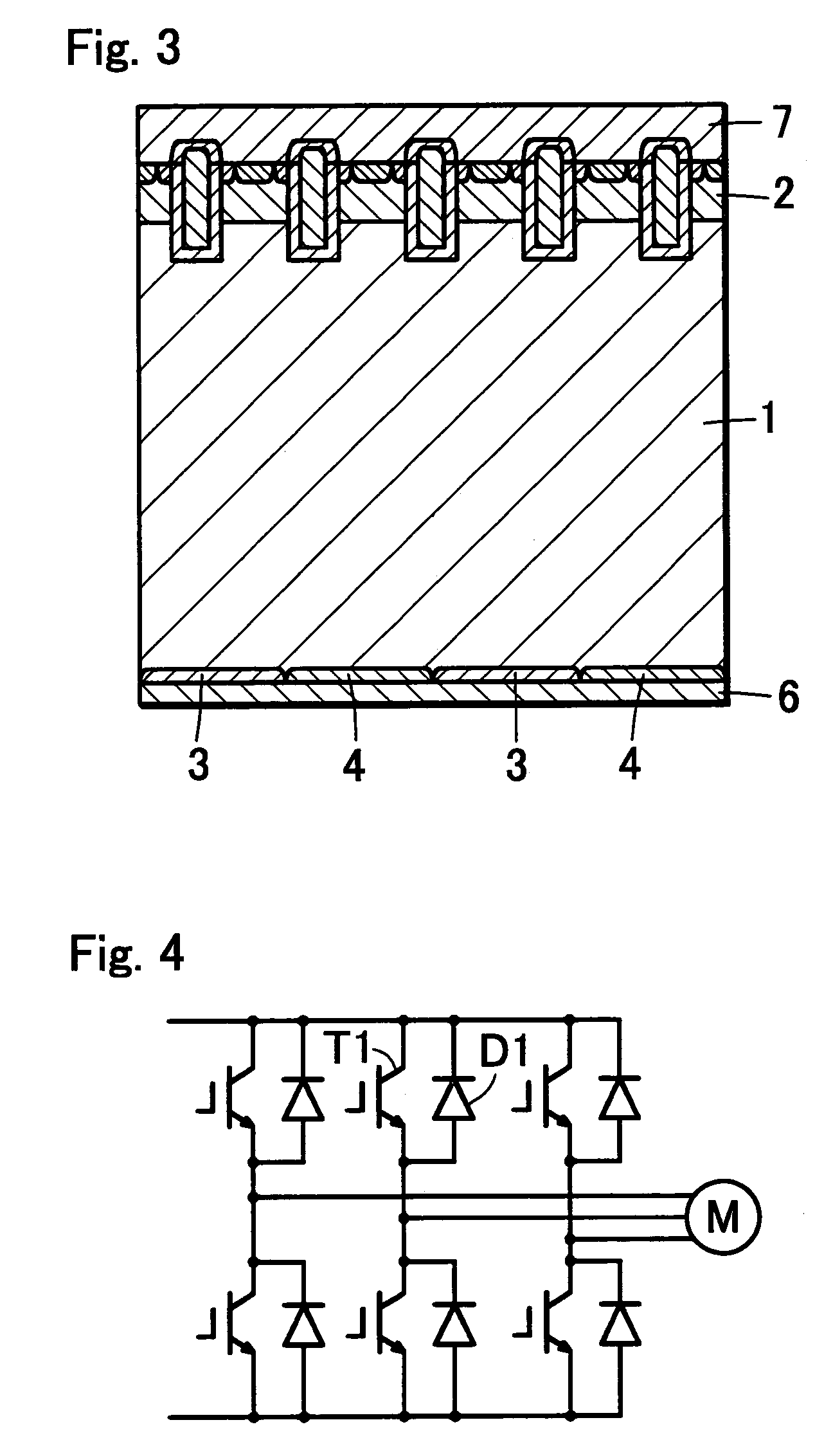

Reverse conducting semiconductor device and a fabrication method thereof

ActiveUS7400017B2Promote recoveryAvoid large quantitiesTransistorSolid-state devicesFlyback diodeEngineering

To provide a reverse conducting semiconductor device in which an insulated gate bipolar transistor and a free wheeling diode excellent in recovery characteristic are monolithically formed on a substrate, the free wheeling diode including; a second conductive type base layer to constitute the insulated gate bipolar transistor; a first conductive type base layer for constituting the insulated gate bipolar transistor, an anode electrode which is an emitter electrode covering a first conductive type emitter layer and the second conductive type base layer, a cathode electrode which is a collector electrode covering the first conductive type base layer and a second conductive type collector layer formed on the part of the first conductive type base layer, wherein a short lifetime region is formed on a part of the first conductive type base layer.

Owner:MITSUBISHI ELECTRIC CORP

Layered silicate catalysts pillared with metal oxide

InactiveUS6703501B1Speed up the conversion processHigh selectivityLactams preparationMolecular sieve catalystsPorous catalystCyclohexanone oxime

The present invention relates to porous catalysts comprising layered silicate and metal oxides, and a method of preparing epsilon-caprolactam from cyclohexanone oxime using the catalyst. This new catalyst can resolve the environmental and safety problems arising from conventional liquid acid process. Also the present catalyst solves the problem of short lifetime of current solid acid catalysts. Moreover, the present catalyst provides higher selectivity and yield.

Owner:KOREA INST OF SCI & TECH

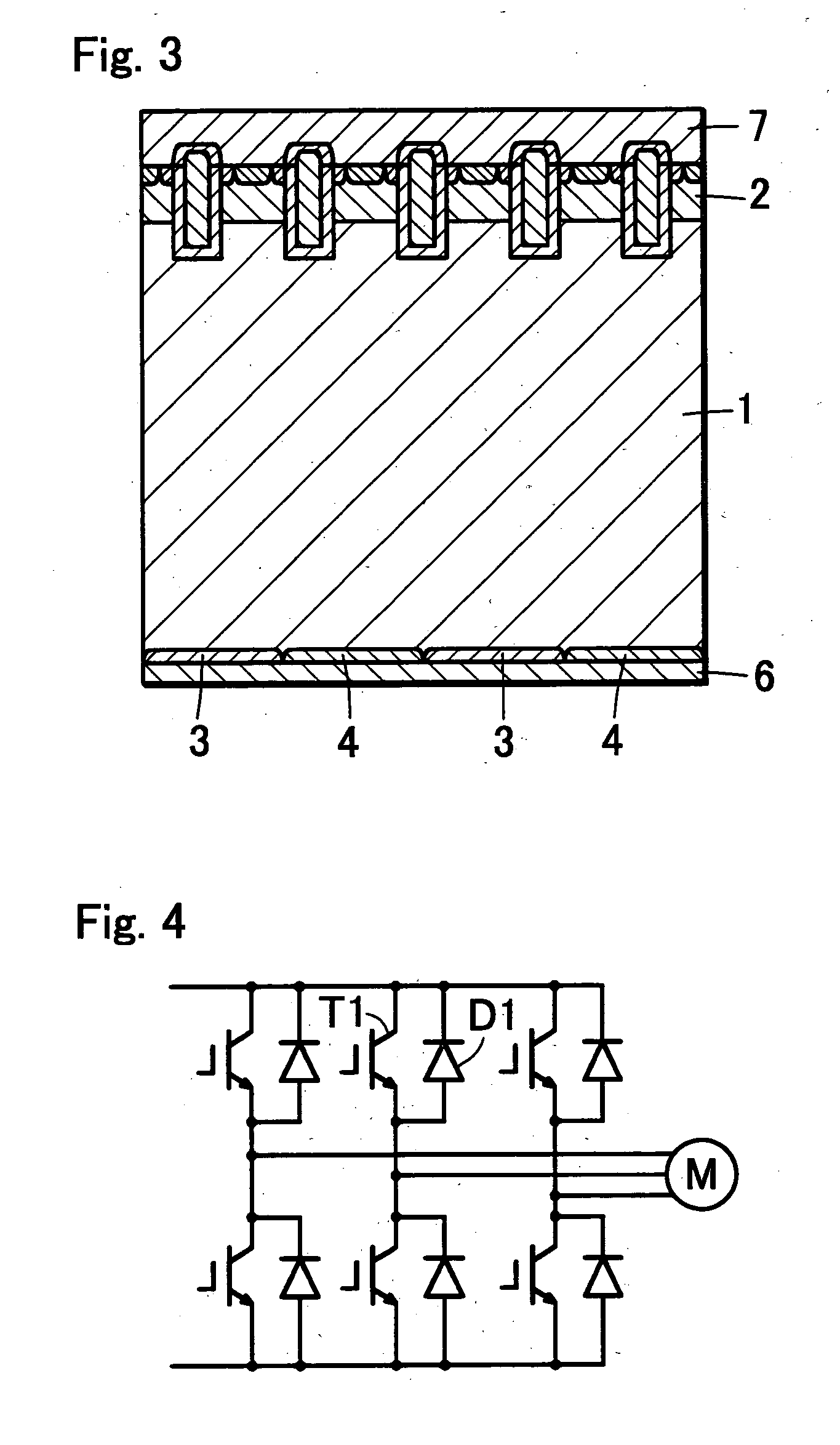

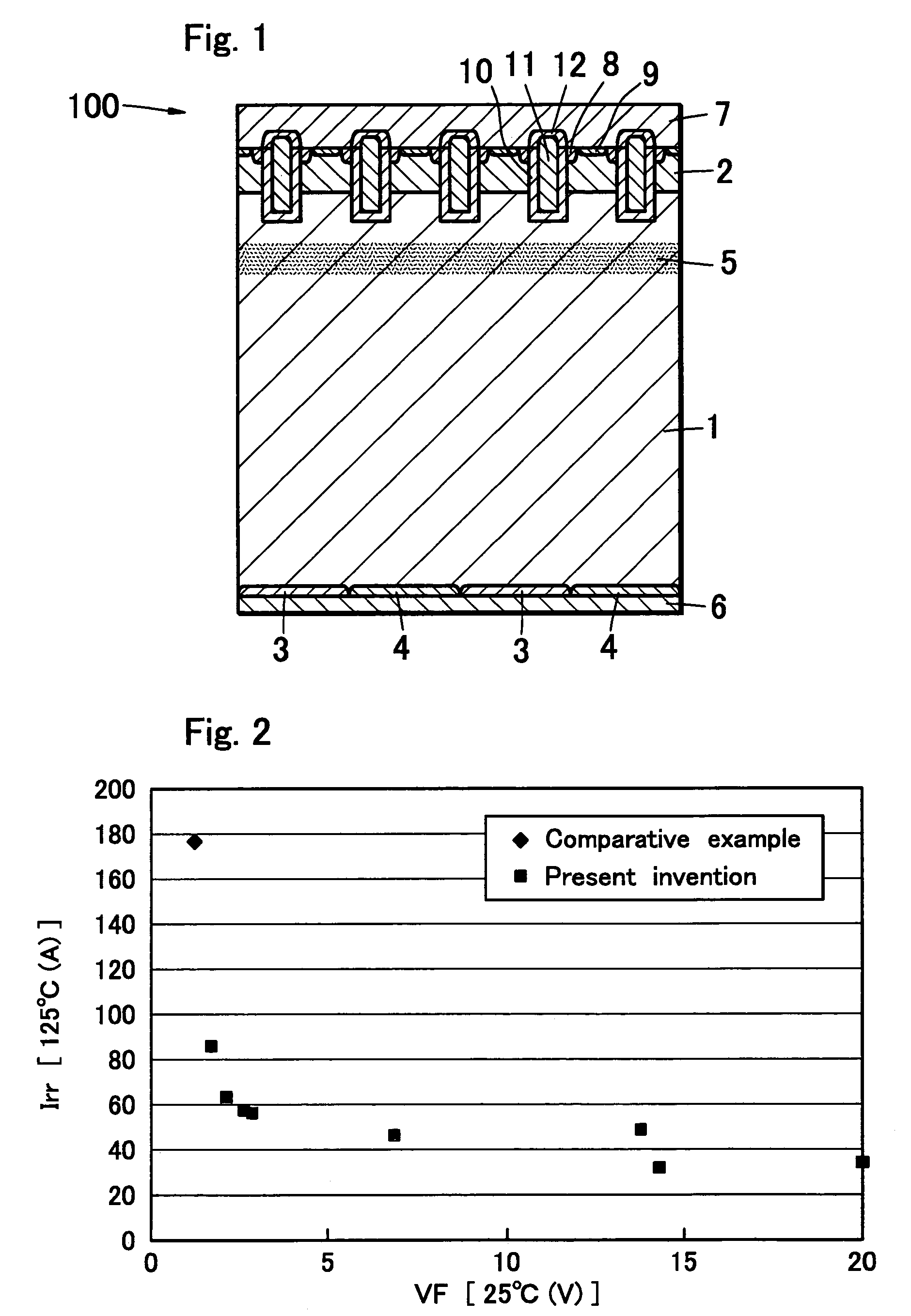

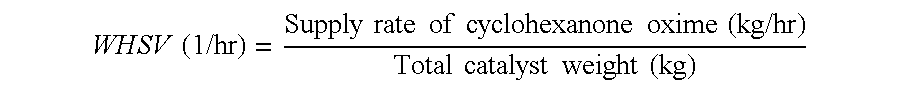

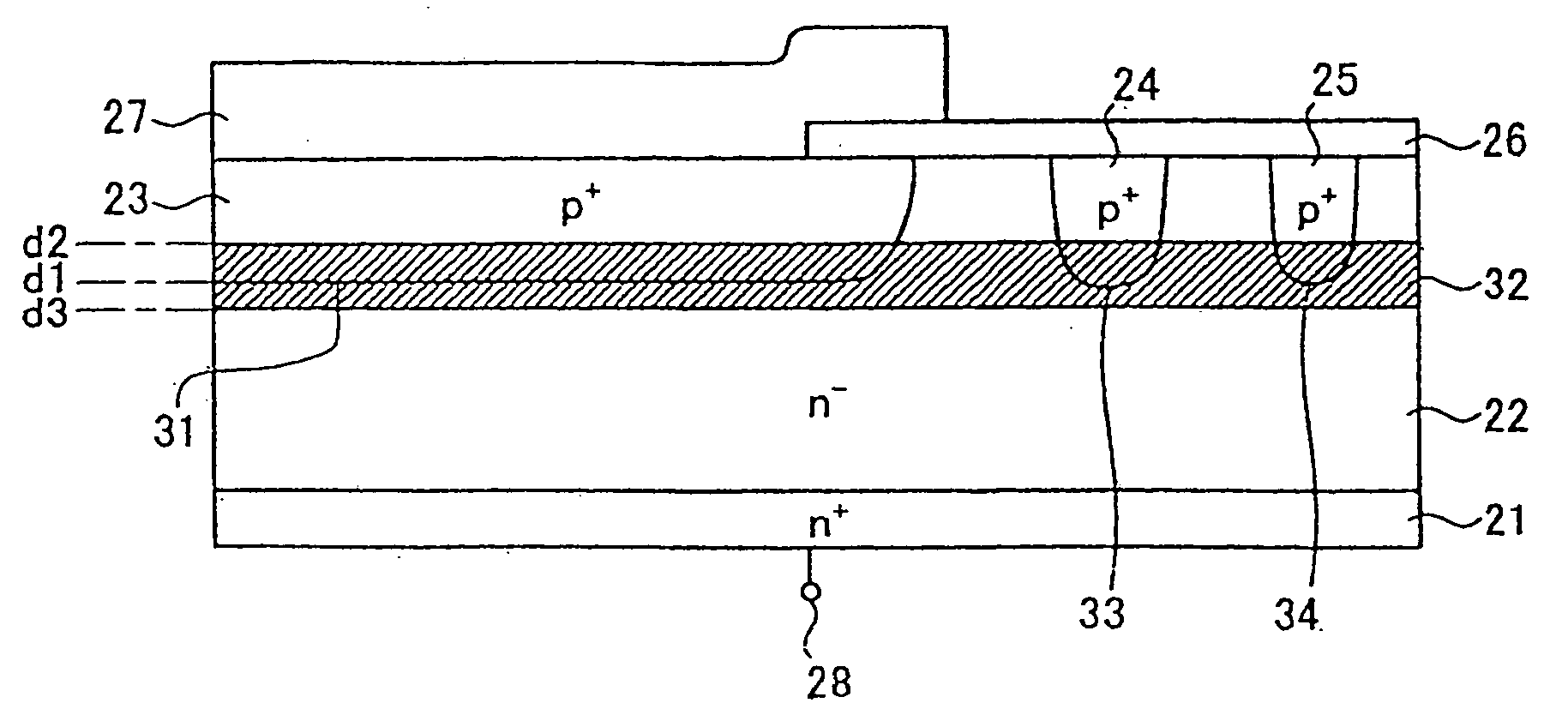

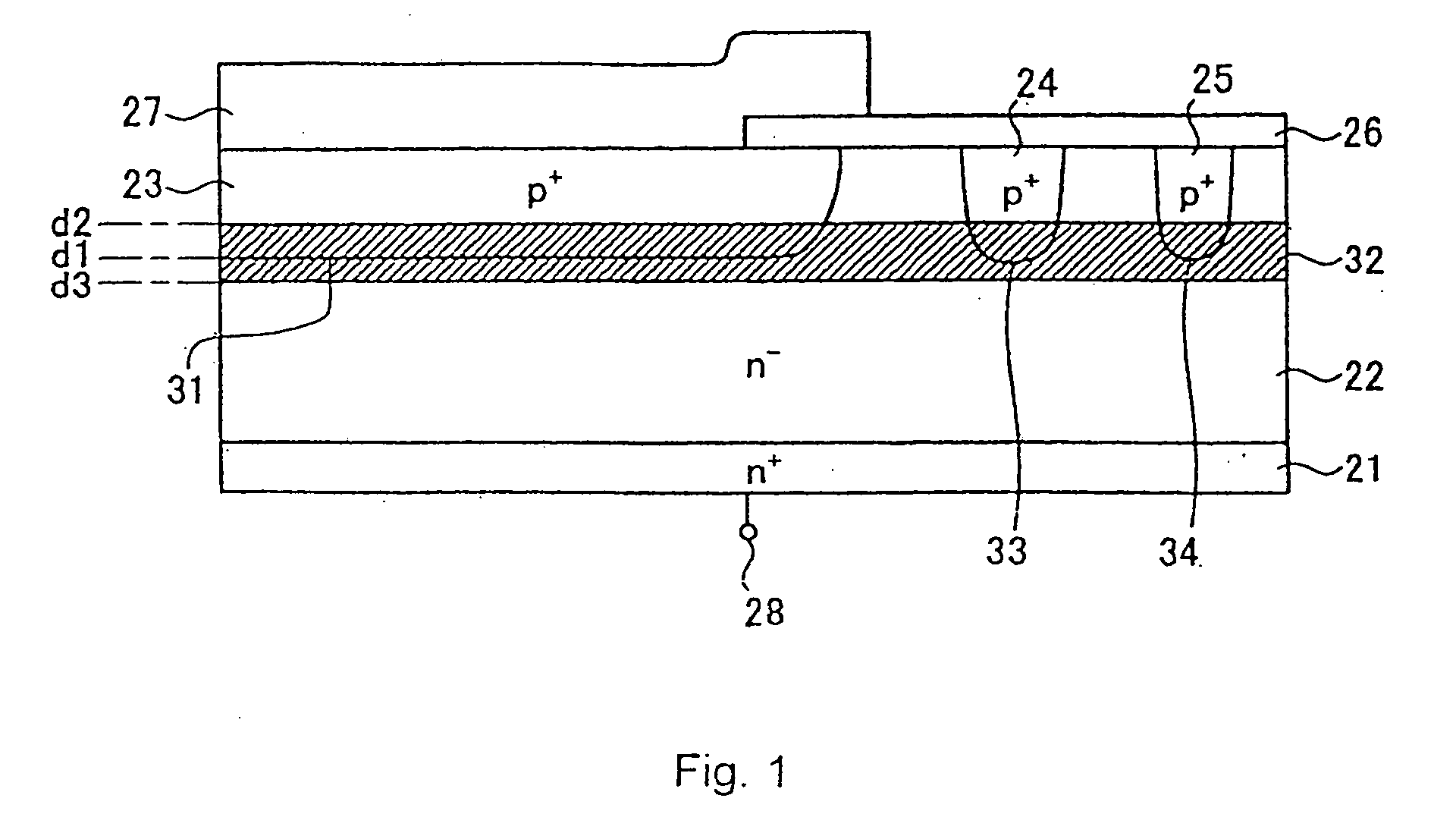

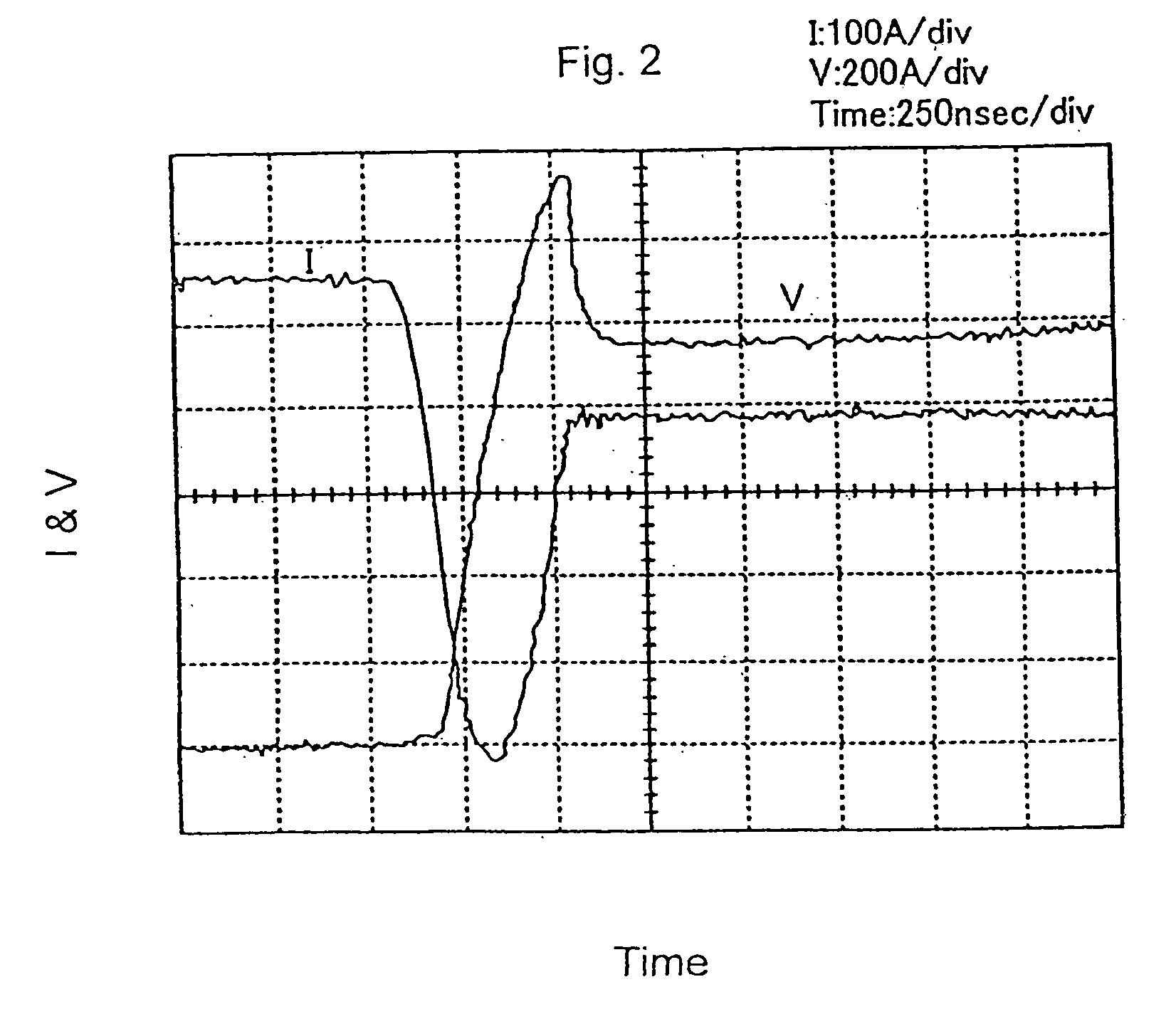

Semiconductor device with a short-lifetime region and manufacturing method thereof

ActiveUS20050263842A1High di/dt capabilityIncreasing forward voltageFinal product manufactureSemiconductor/solid-state device manufacturingDevice materialReverse recovery

A semiconductor device has an n−-semiconductor layer and p+-diffusion regions each having a depth of 14 to 20 μm (design value) selectively formed in the n− semiconductor layer. With the entire surface of the chip irradiated with light ions, such as He ions, a lifetime killer is introduced from a position d2 shallower than a position d1 of a p-n junction surface, formed from the n−-semiconductor layer and the p+-diffusion regions, to a position d3 deeper than the position d1 to form a short-lifetime region over the entire chip. The irradiation is carried out so that the light ion irradiation half width is not more than the depth of the p+-diffusion regions and a position of a peak of the light ions becomes deeper than the light ion irradiation half width and within the range between 80% and 120% of the depth of the p+-diffusion regions. Thus, in a semiconductor device such as a converter diode, a capability for a high decay rate of a reverse recovery current di / dt can be brought sufficiently high to such an extent that the device can withstand a lightening surge with a low forward voltage VF being kept low.

Owner:FUJI ELECTRIC CO LTD

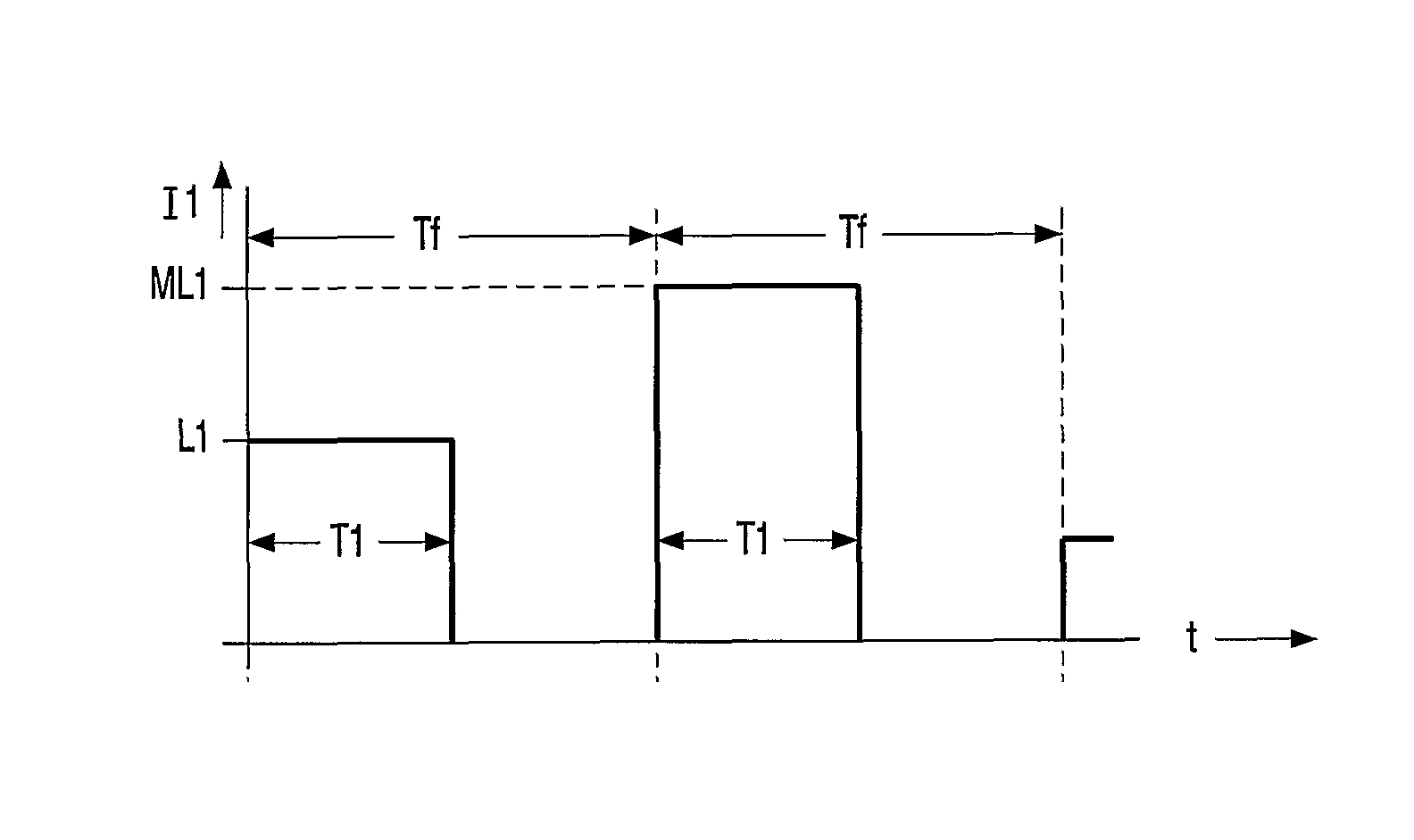

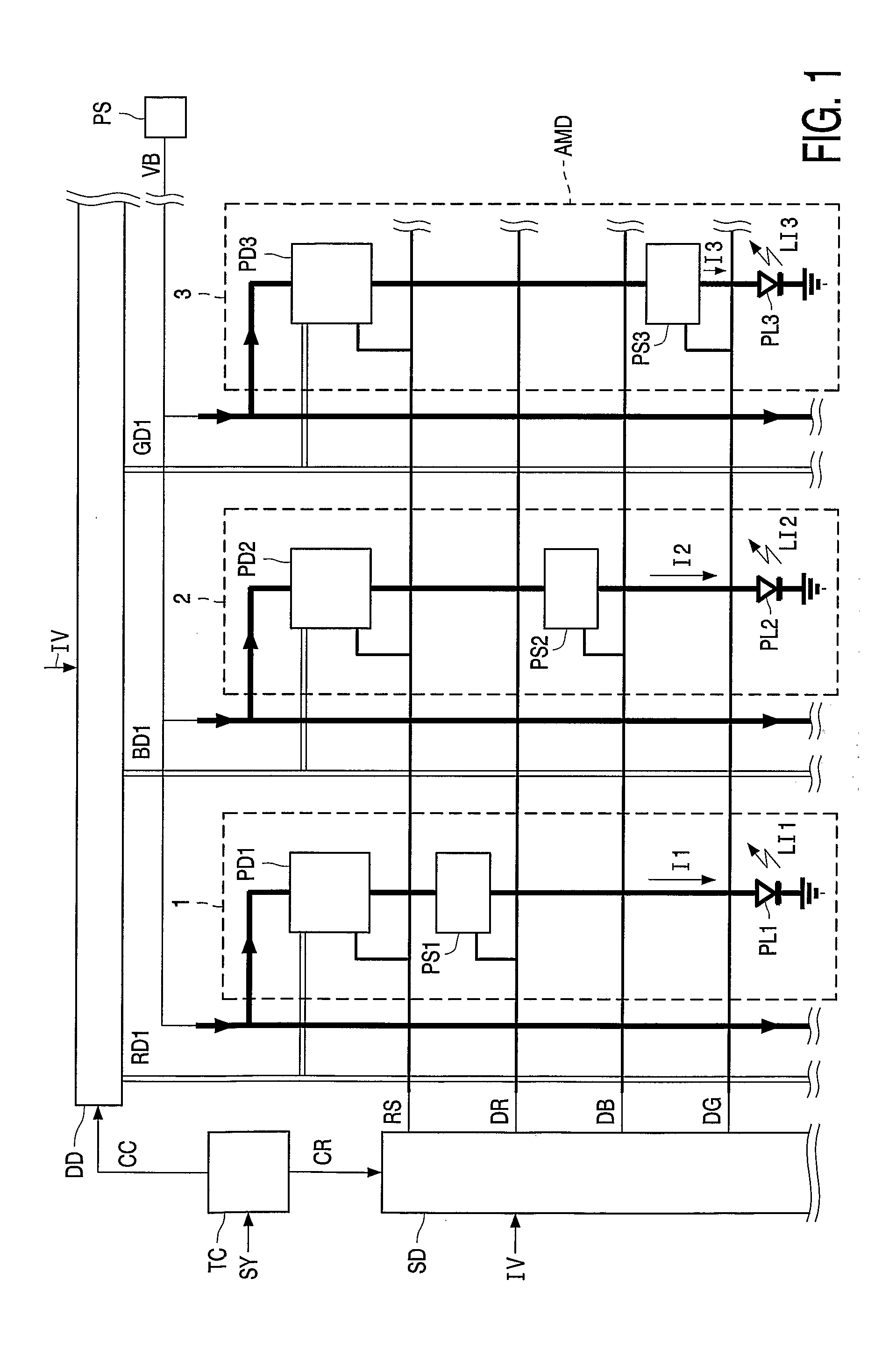

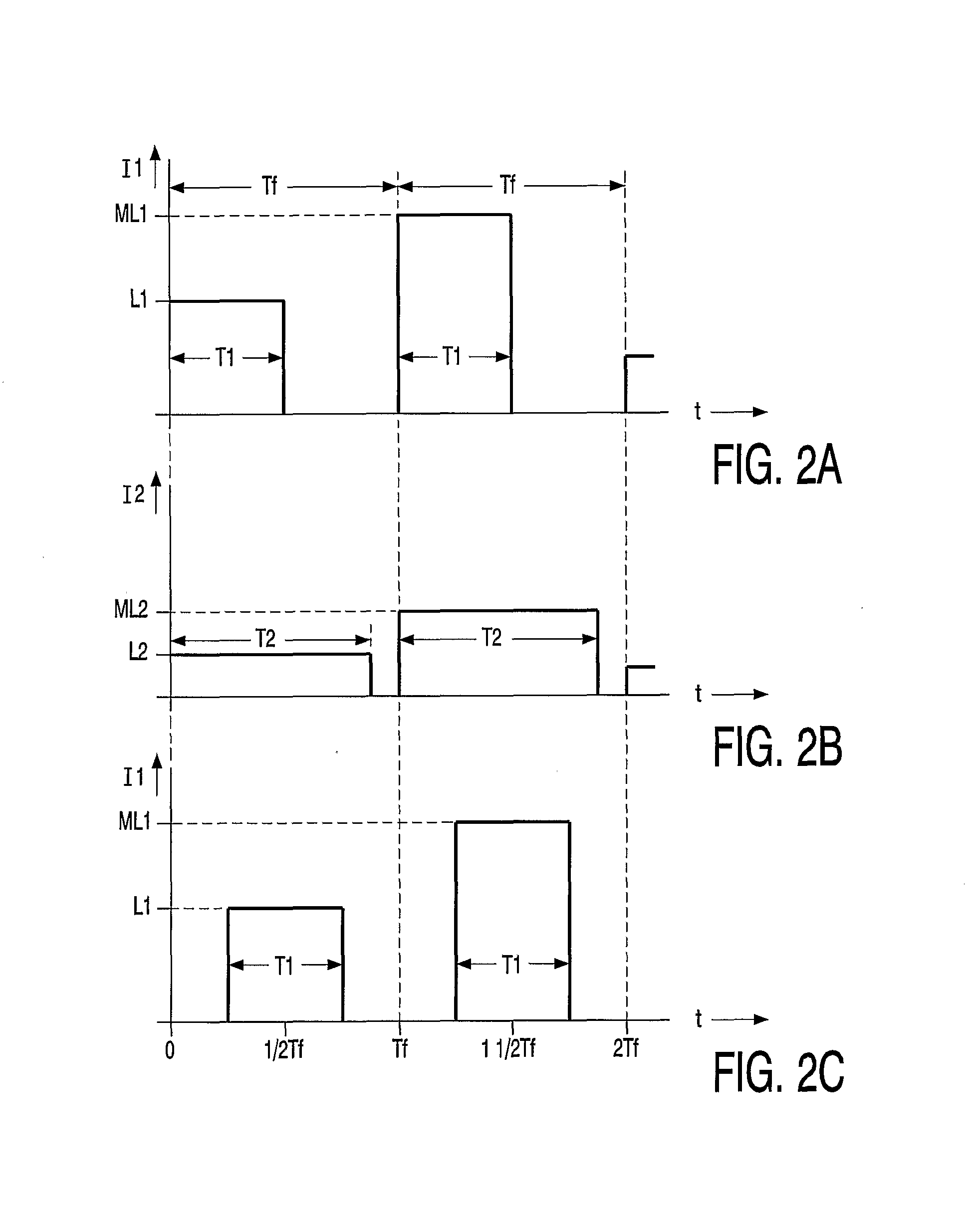

Driving To Reduce Aging In An Active Matrix Led Display

InactiveUS20080018632A1Reduce brightnessReduce motion blurElectrical apparatusElectroluminescent light sourcesLED displayActive matrix

A driver (DD, SD, PD1, PS1, PD2, PS2) supplies, at a frame rate, a first current (I1) with a first duty cycle being smaller than one to a first light emitting element (PL1) of an active matrix display (AMD) and a second current (I2) to a second light emitting element (PL2) of the active matrix display (AMD). The second light emitting element (PL2) has a shorter lifetime than the first light emitting element (PL1). The driver (DD, SD, PD1, PS1, PD2, PS2) limits controls the second duty cycle to be larger than the first duty cycle.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

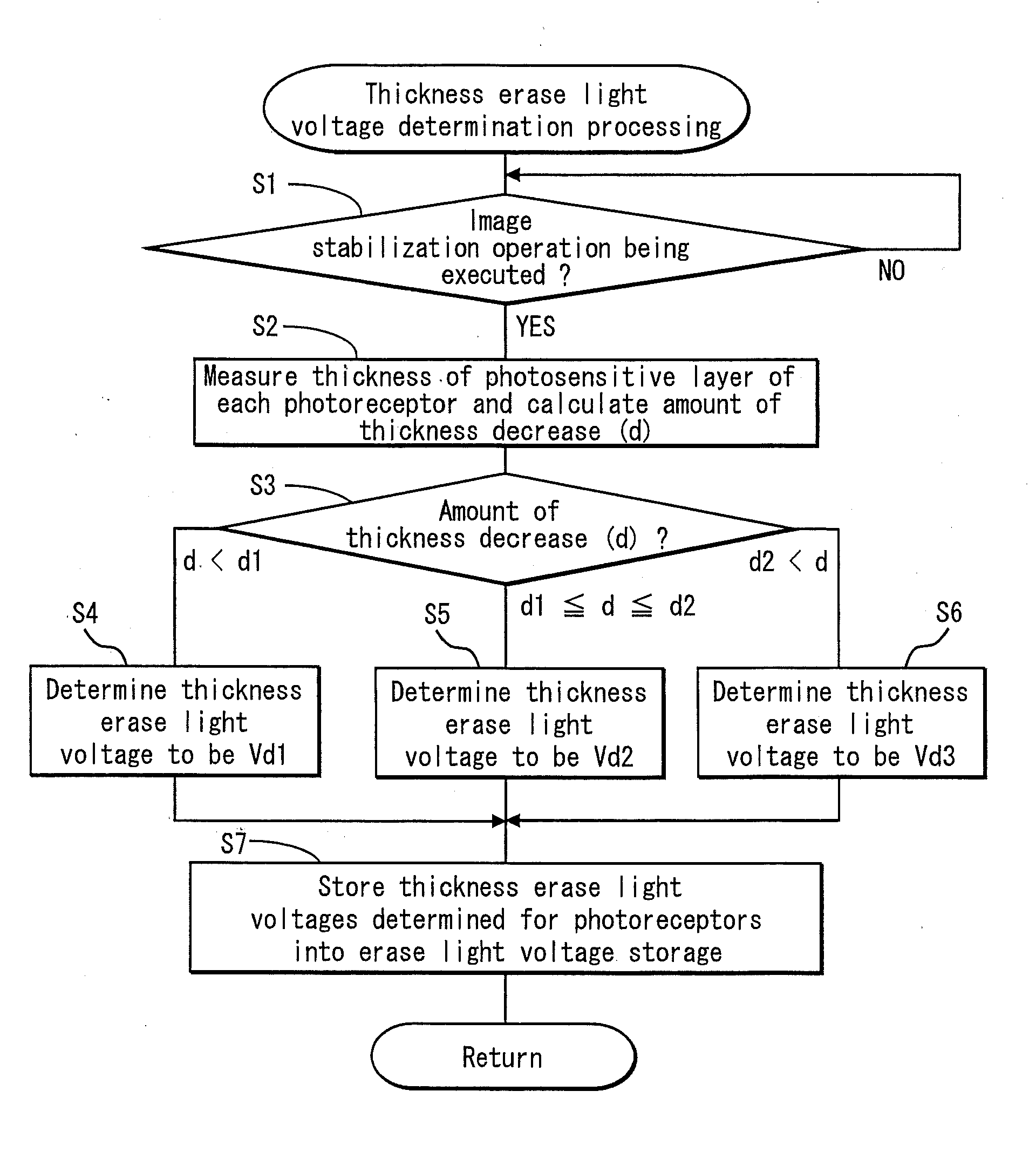

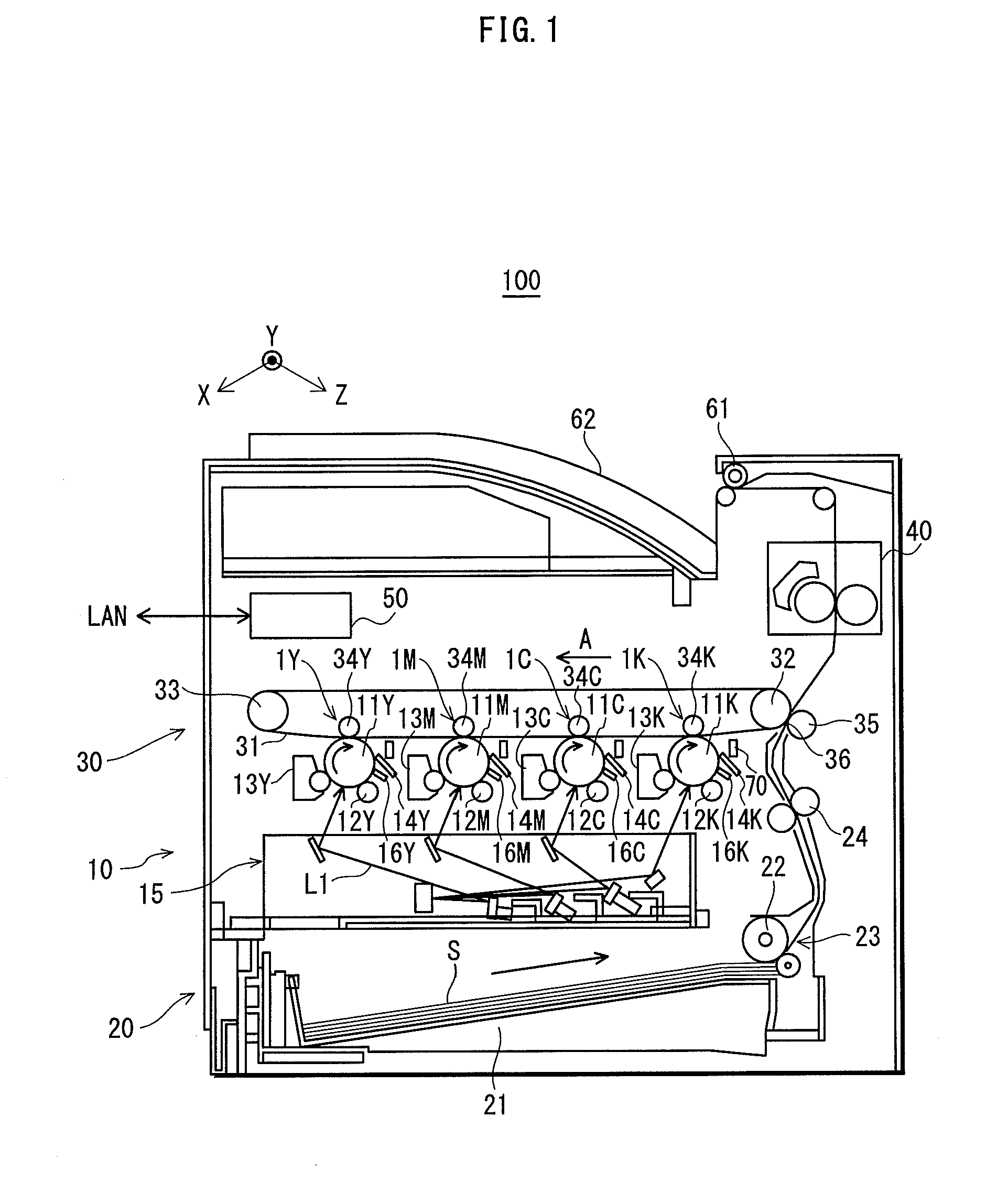

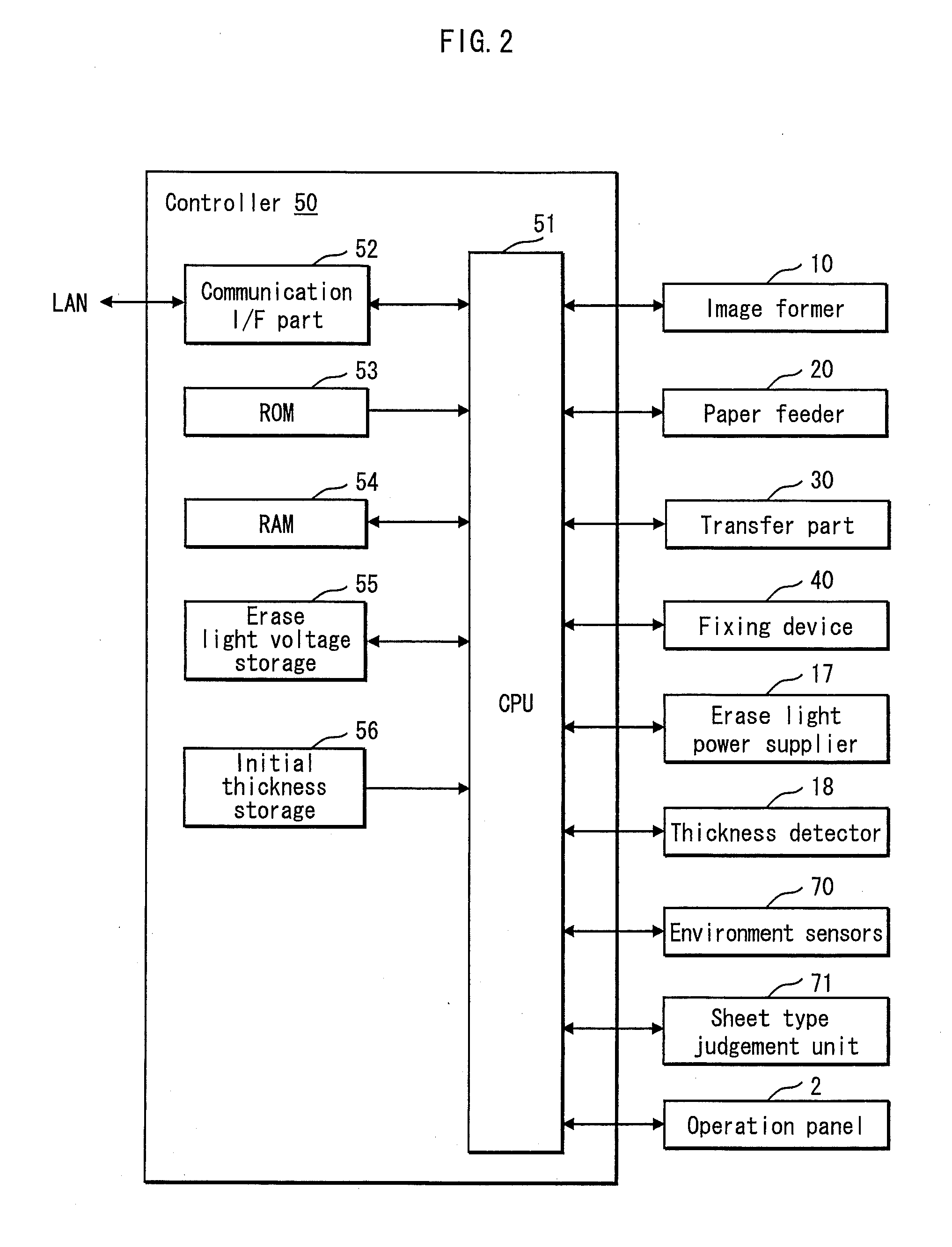

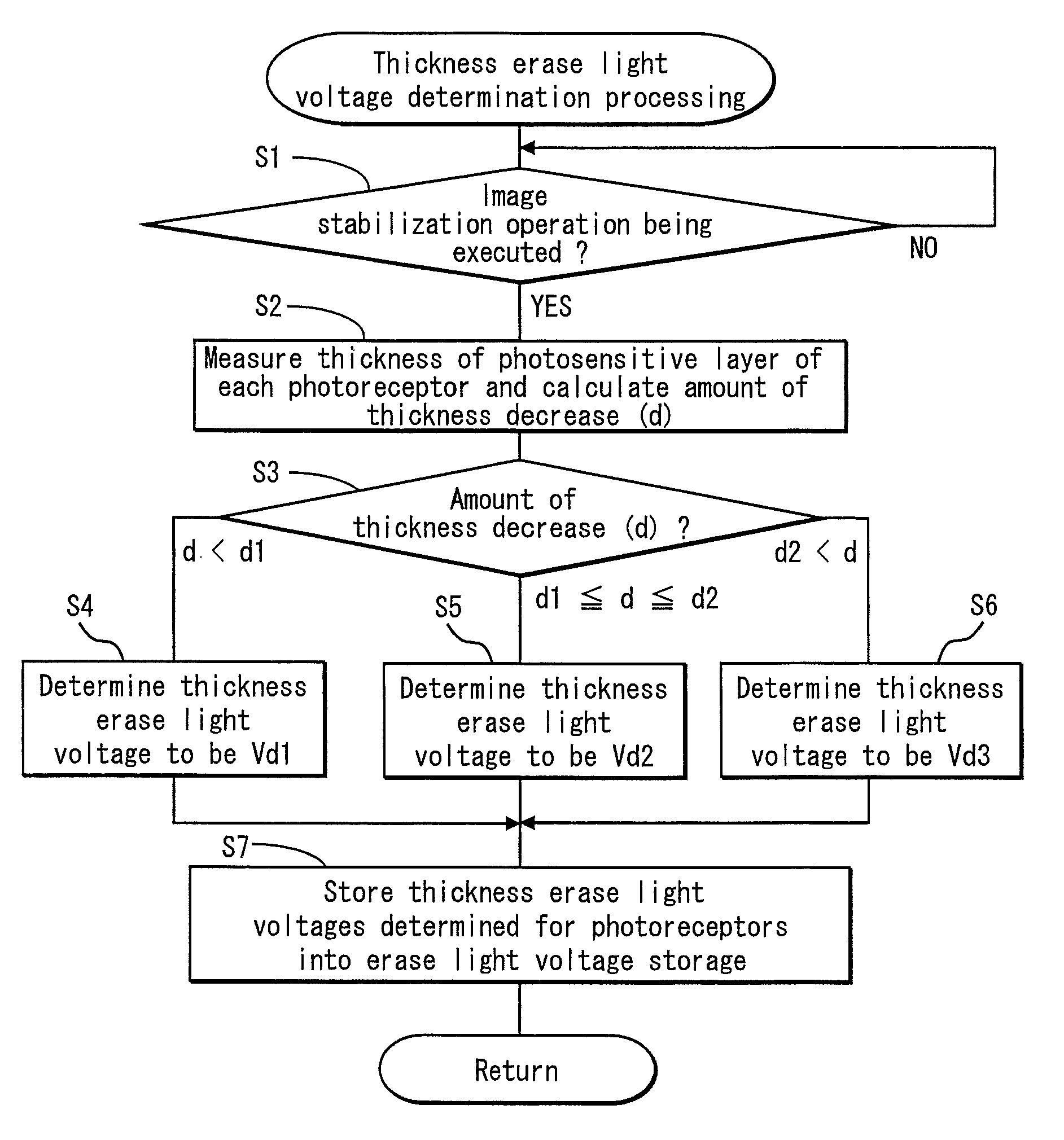

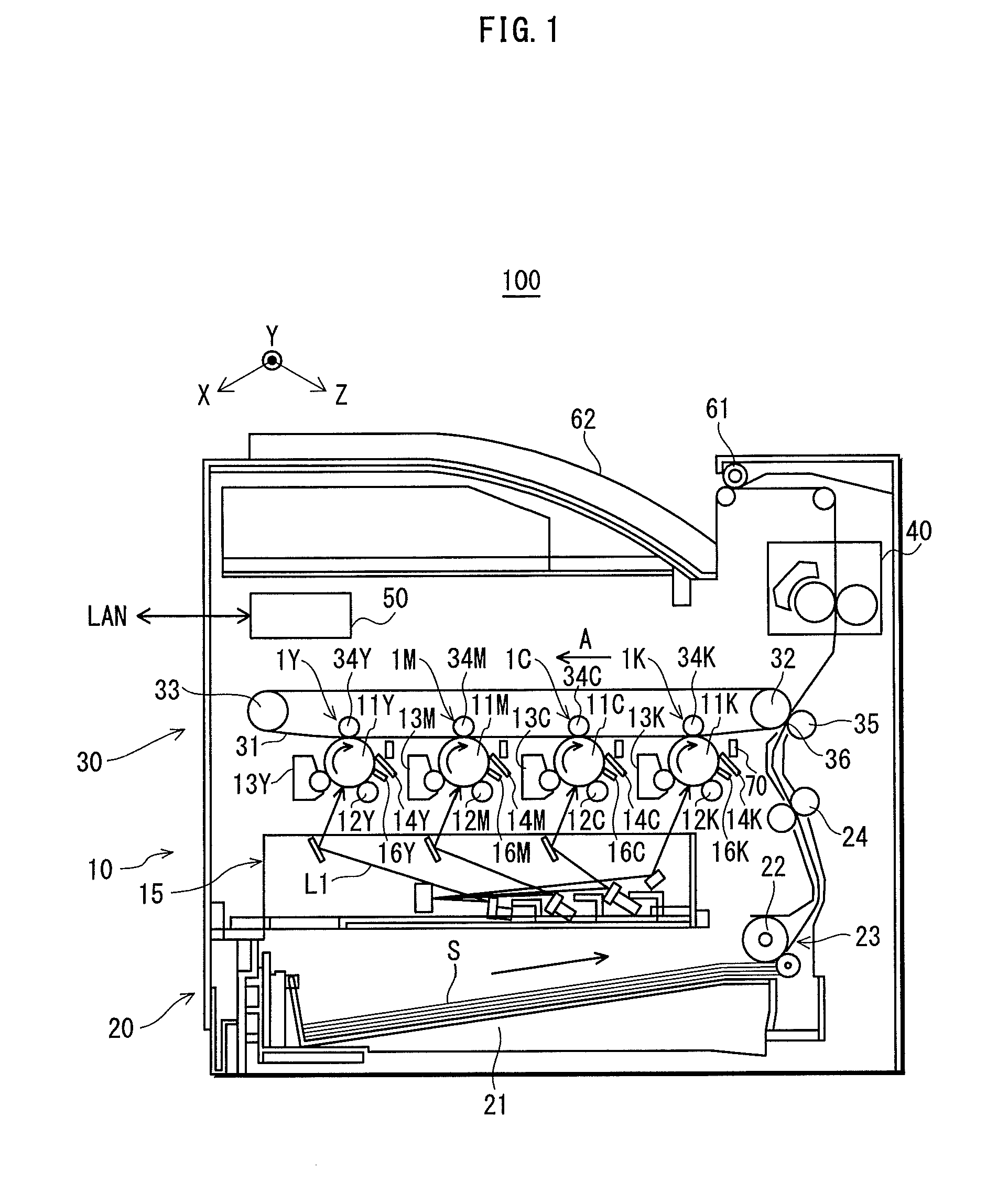

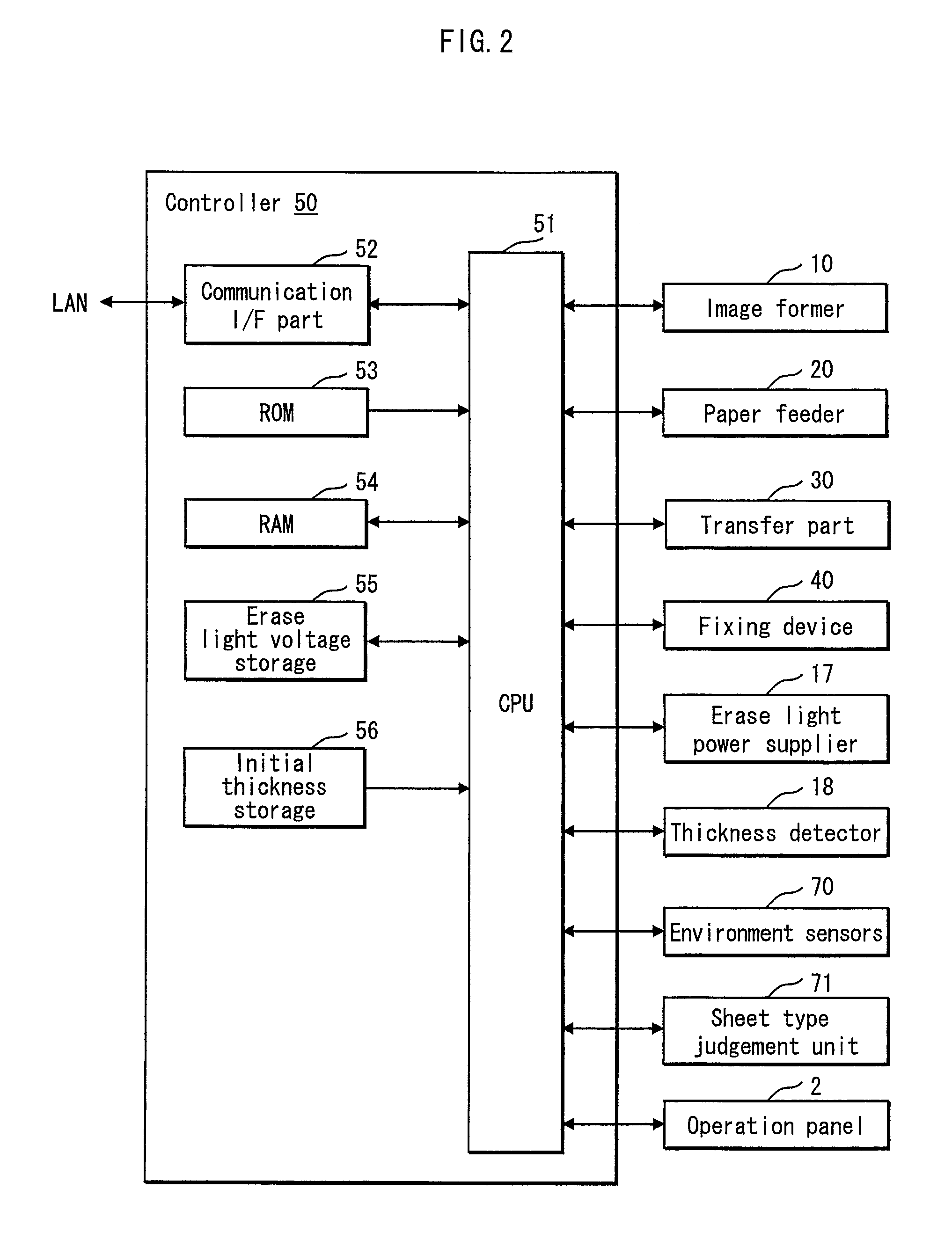

Image forming apparatus, image forming unit, and erase light control method

InactiveUS20100239280A1Suppression of image deteriorationEfficiently extending lifetimeElectrographic process apparatusImage formationComputer science

Electric charge remaining on a photoreceptor after transfer causes image deterioration. According to one conventional method widely used in view of this problem, erase light is emitted onto a photoreceptor after the transfer to remove the electric charge remaining on the photoreceptor. However, such a method poses the following problem: emission of erase light leads to light-induced fatigue of the photoreceptor, and as a result, the photoreceptor which has deteriorated from the light-induced fatigue wears down due to abrasion and the like with a cleaner blade, resulting in a shorter lifetime of the photoreceptor. Thus, the thickness of the photosensitive layer is detected to acquire the amount of thickness decrease, and the amount of the erase light is reduced according to the acquired amount of thickness decrease.

Owner:KONICA MINOLTA BUSINESS TECH INC

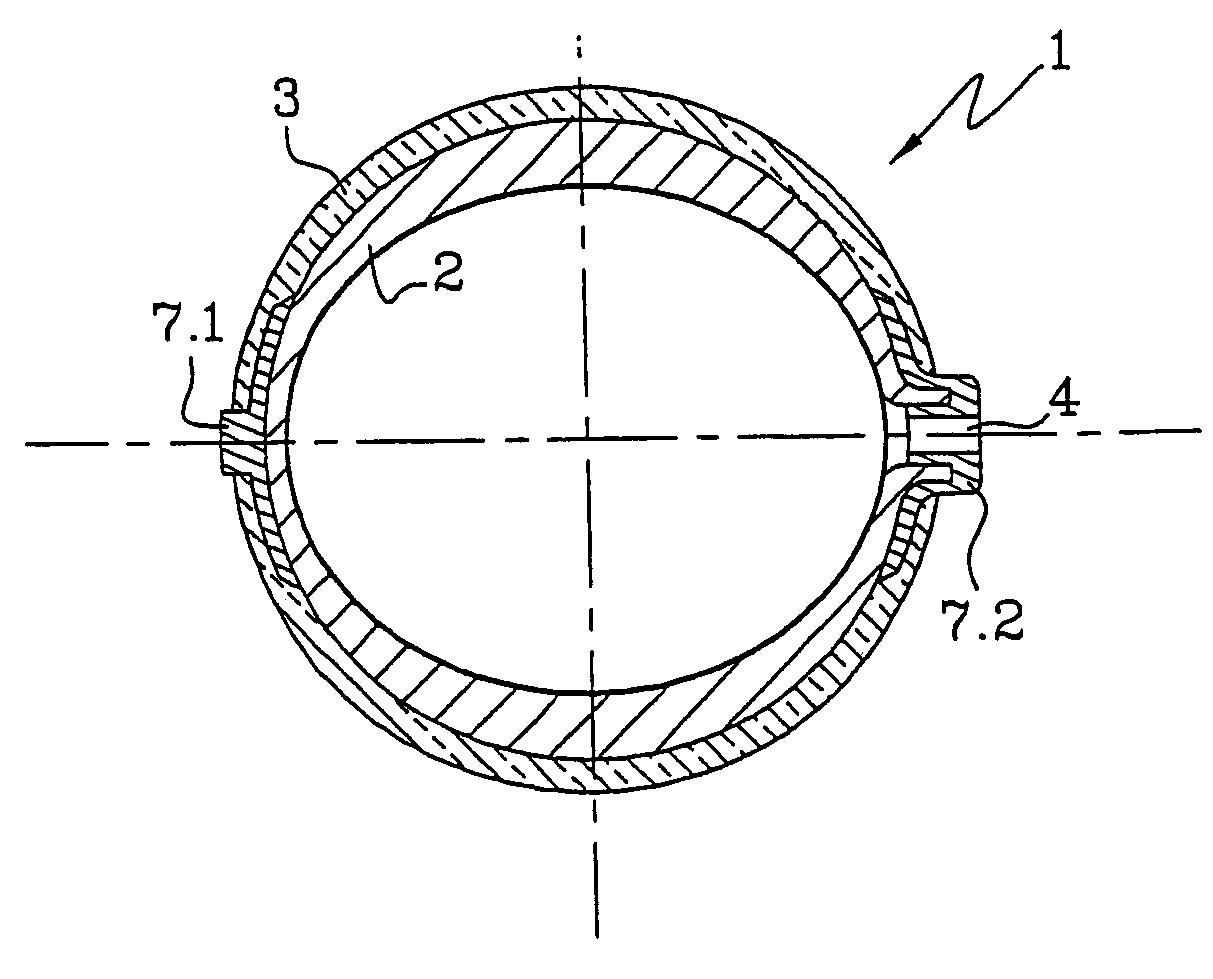

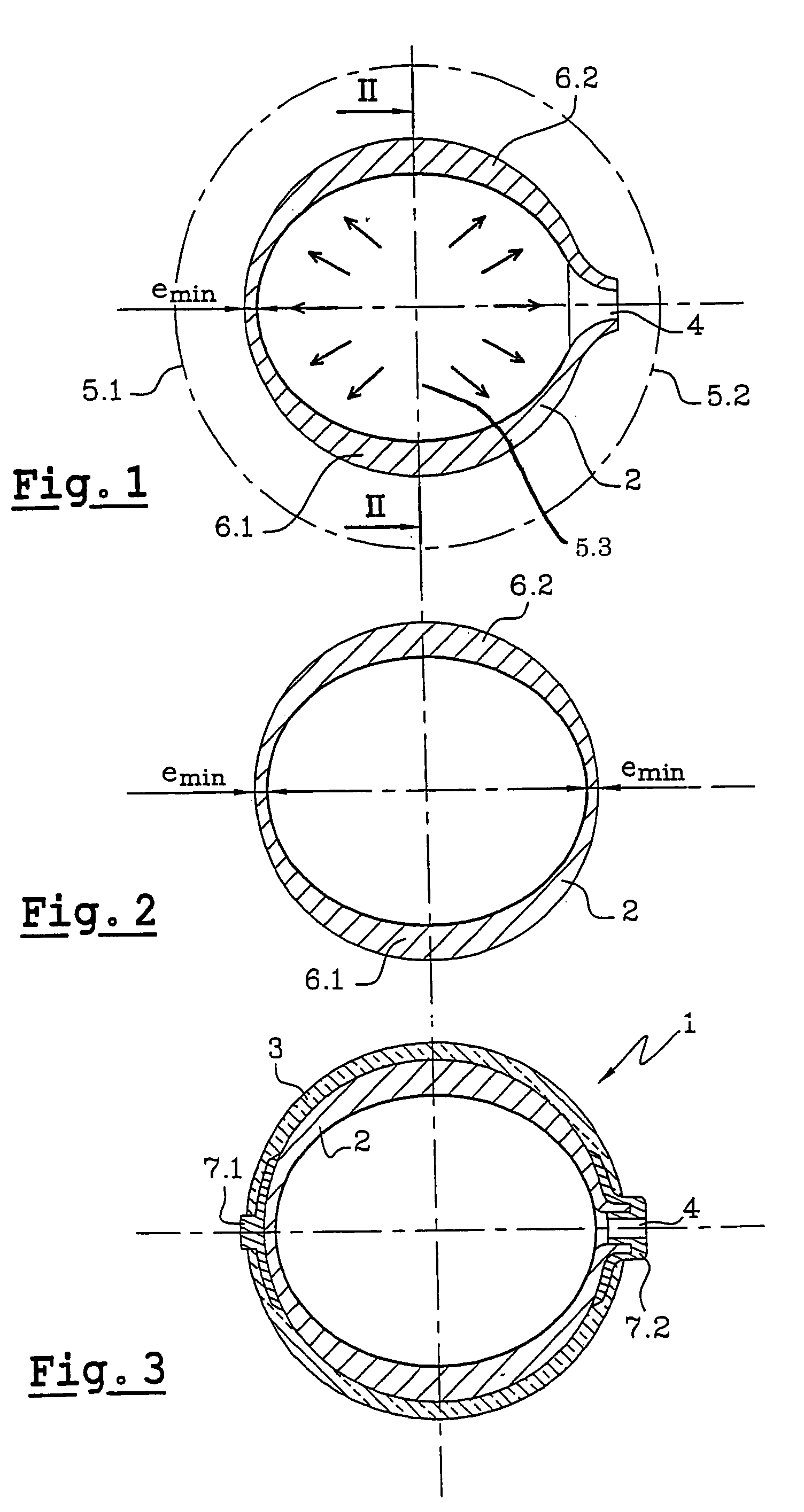

Process for the production of a high pressure vessel particularly for a space engine and vessel obtained therby

InactiveUS6962672B2Reduce internal porosityContainer filling methodsGas handling applicationsPolyamideShort lifetime

A process for the production of a vessel for high pressure gas, particularly helium, for a space launcher or for a satellite with a short lifetime, includes the steps of: a production of an internal skin of a plastic material selected from polyethylene and crystallized polyamide, a winding a reinforcement of fibers and resins, and a providing the obtained vessel with the necessary conduits and control valves.

Owner:EADS LAUNCH VEHICLE

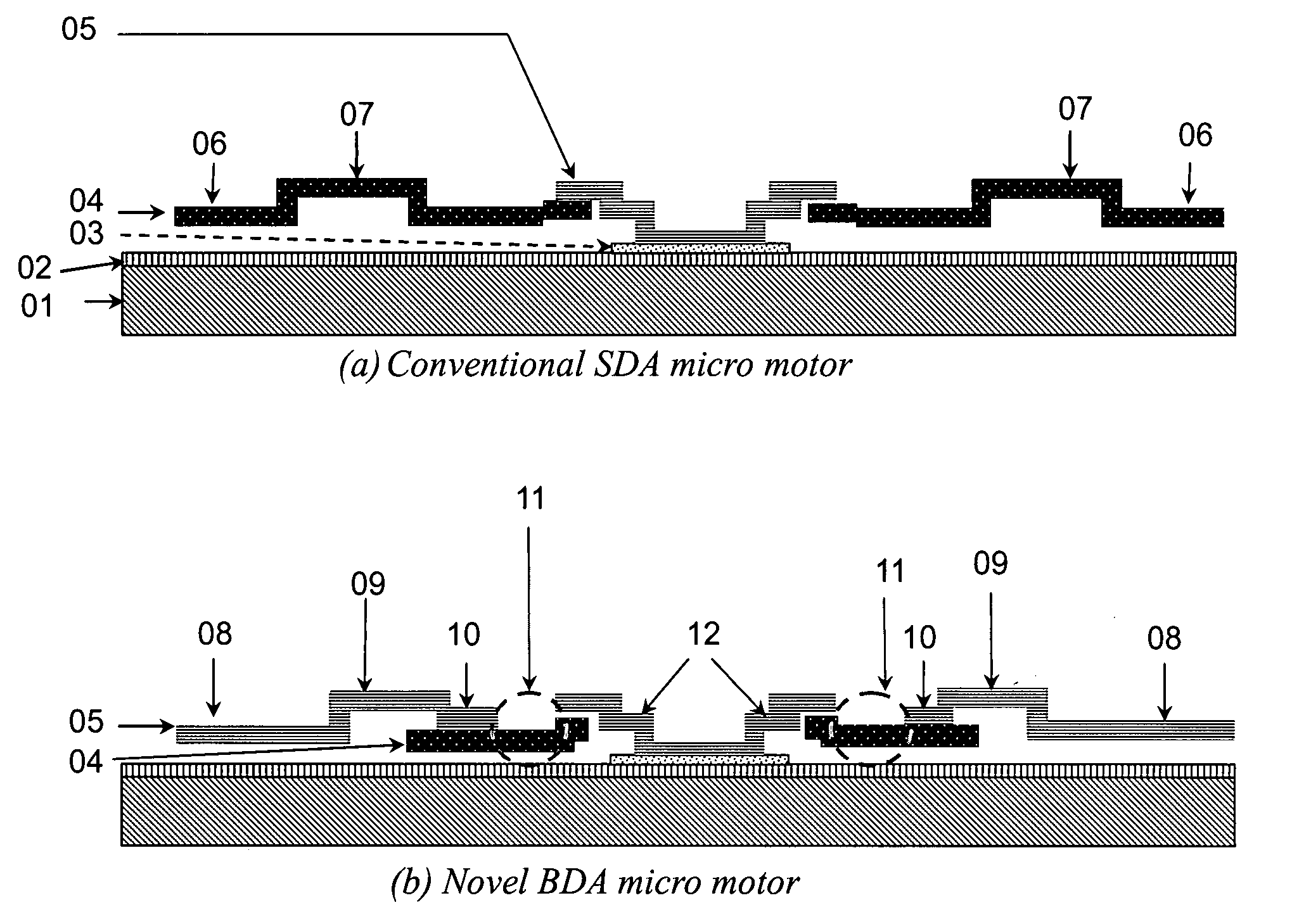

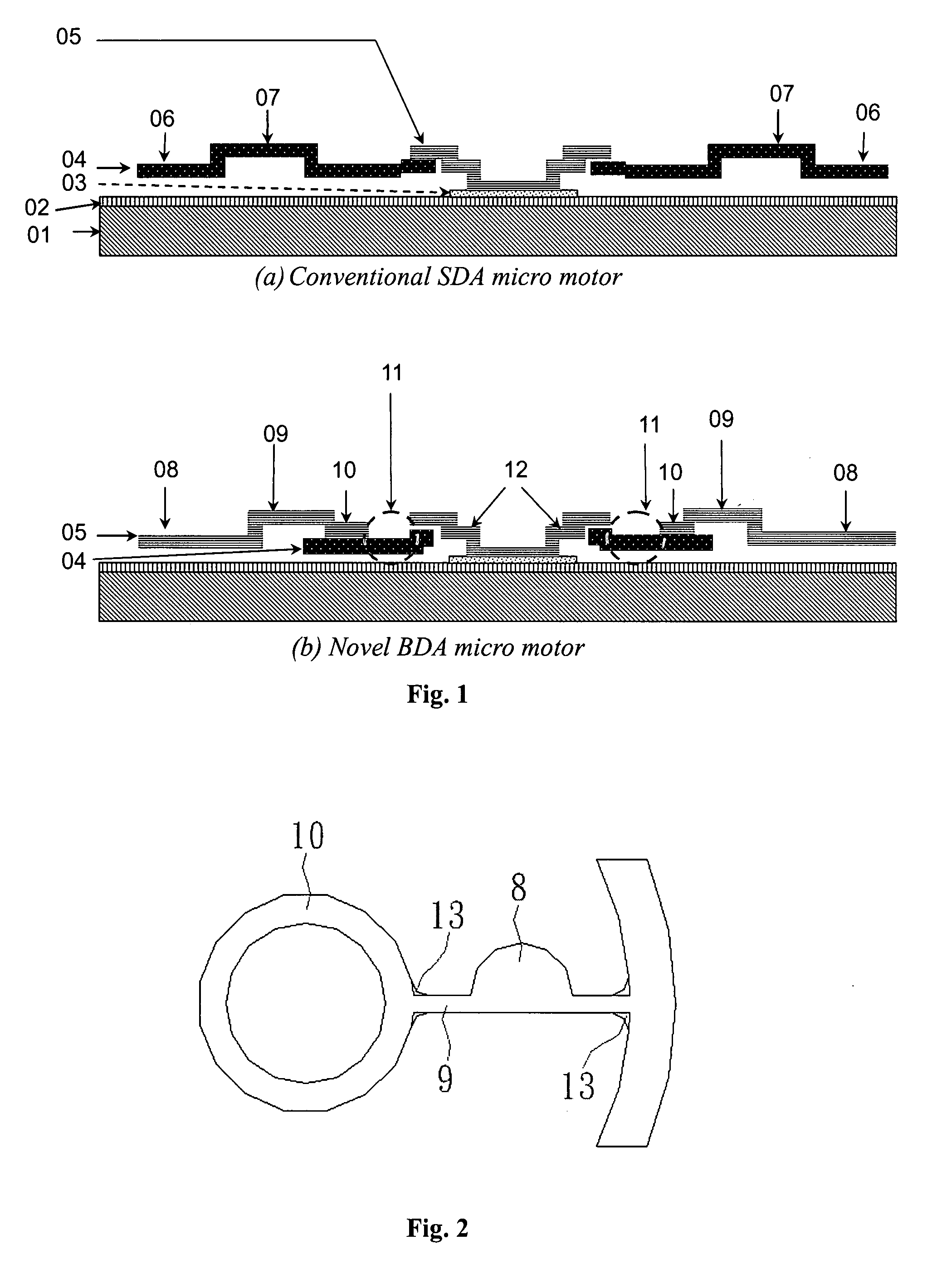

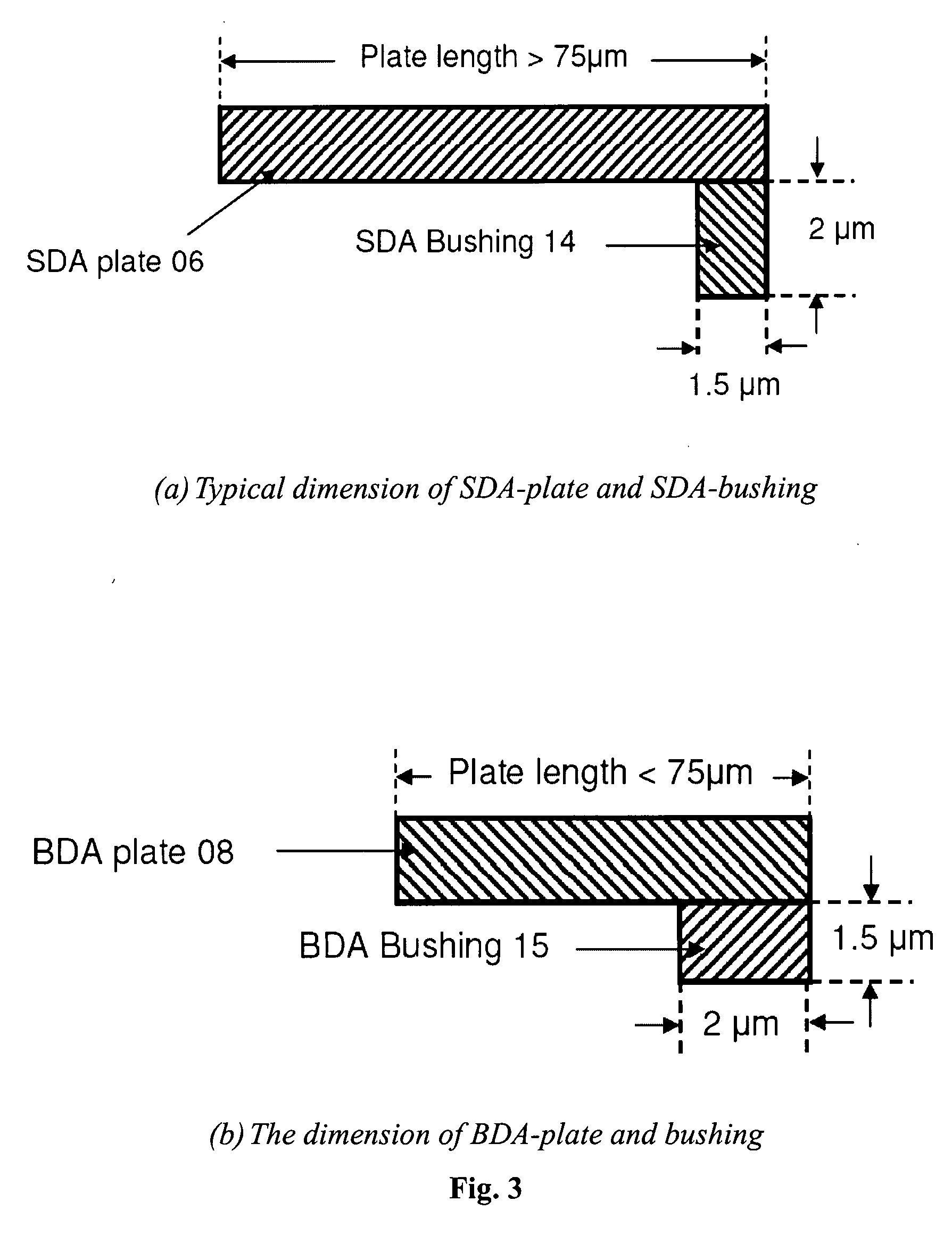

Bounce drive actuator and micromotor

InactiveUS20080280231A1Increased flexural rigidityReduce exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusActuatorScratch drive actuator

Provided is the design and fabrication of the novel bounce drive actuator (BDA) for the development of a new-type micro rotary motor. Although the scratch drive actuator (SDA) micro motor has been developed more than one decade, such device has limited commercial applications due to its shorter lifetime, high power consumption and sudden reverse rotation. In contrast, present invention proposes an innovative BDA micro rotary motor with different actuating mechanism and improved performance. Several significant investigations shown in this research present that the length of the SDA-plate is longer than 75 μm and the plate length of the BDA is less than 75 μm. Under the same driving power and frequency with SDA-based micro motor, the BDA-based micro rotary motor exhibited a consistent “reverse” rotation and a higher speed. BDA has higher flexural rigidity due to its shorter length of plate; thus, the contact area of the bending BDA-plate and the insulator substrate will substantially be reduced even under the same applied voltage as the priming value of SDA-plate. Furthermore, a novel rib and flange structure design for the improvement of lifetime (>100 hrs) and rotational speed (>30 rpm) of BDA micro motor was also demonstrated in this invention.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

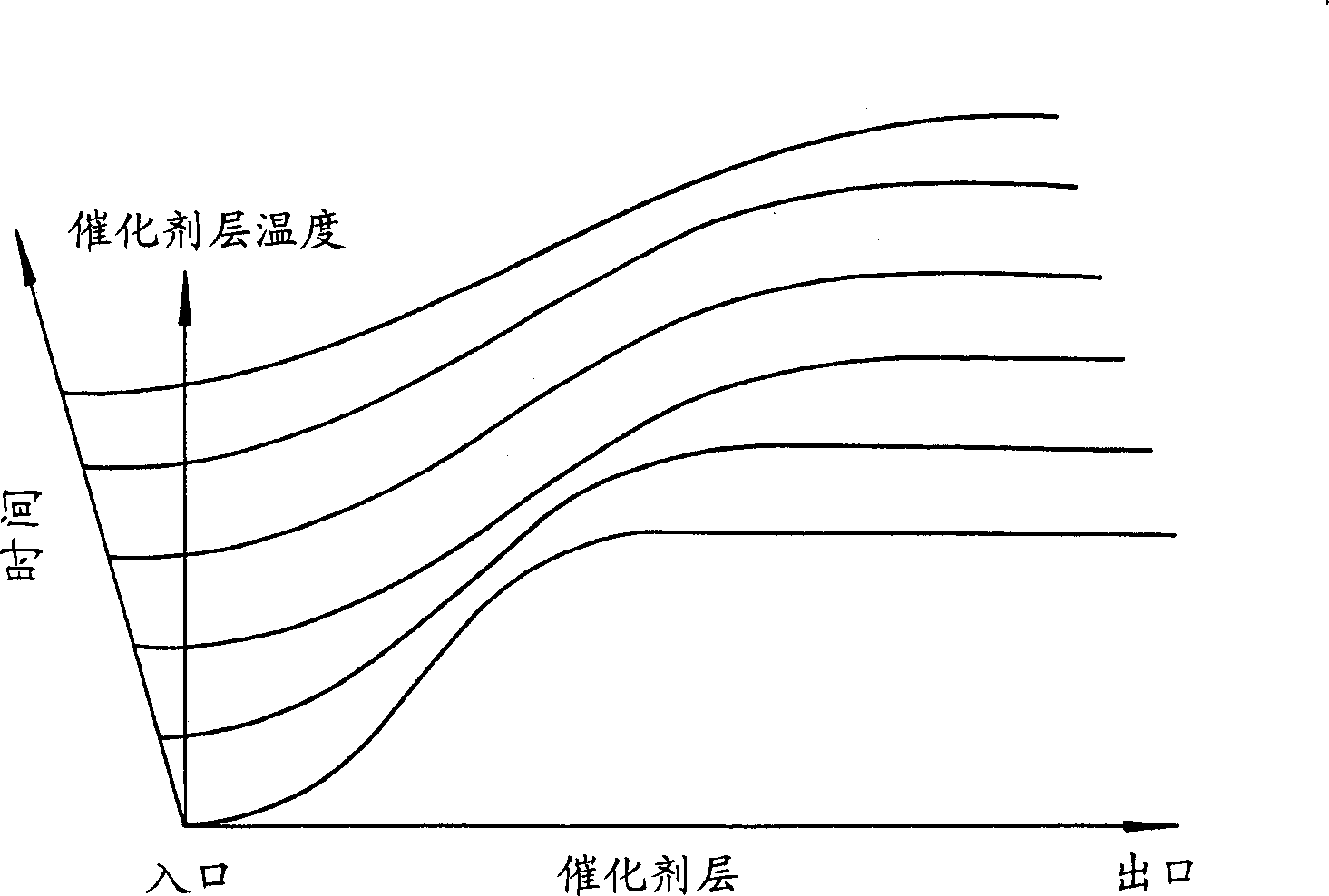

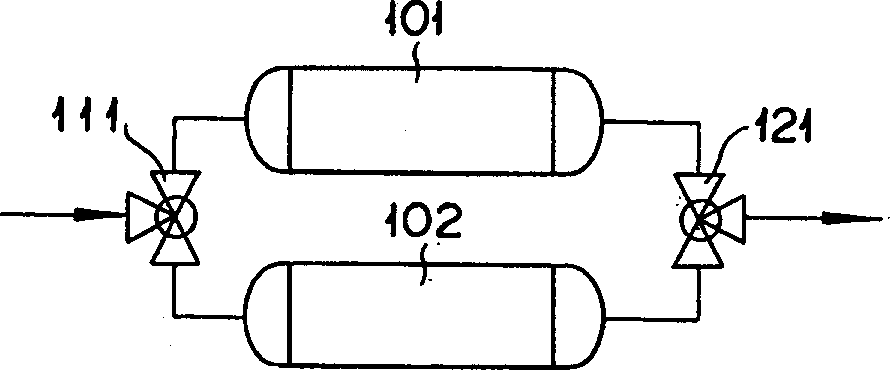

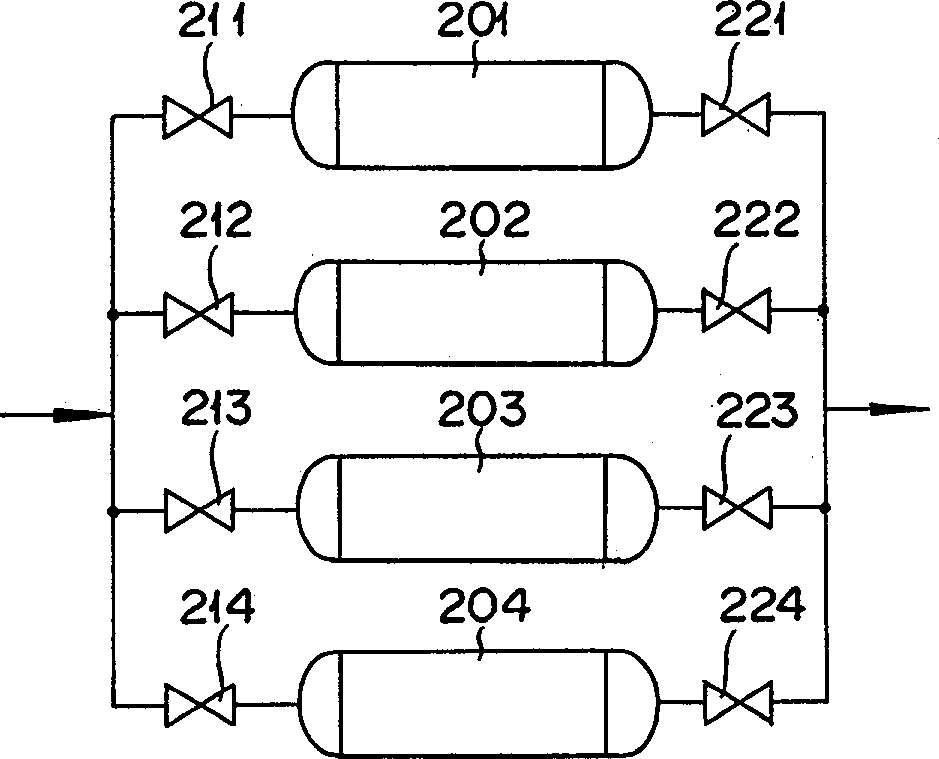

Process and apparatus for producing alkane hydramine

InactiveCN1297884AHigh yieldMolecular sieve catalystsOrganic compound preparationAlkaneOrganic matter

In producing alkanolamines by use of a microporous material as a catalyst, the difficulty in industrially performing the production because of the short lifetime of the catalyst is resolved. A process of regenerating the catalyst by removing an organic substance deposited on the catalyst by means of decomposing and / or extracting the substance is introduced, and thereby steady production is carried out substantially over the long term by switching the reaction and the regenerating processes.

Owner:NIPPON SHOKUBAI CO LTD

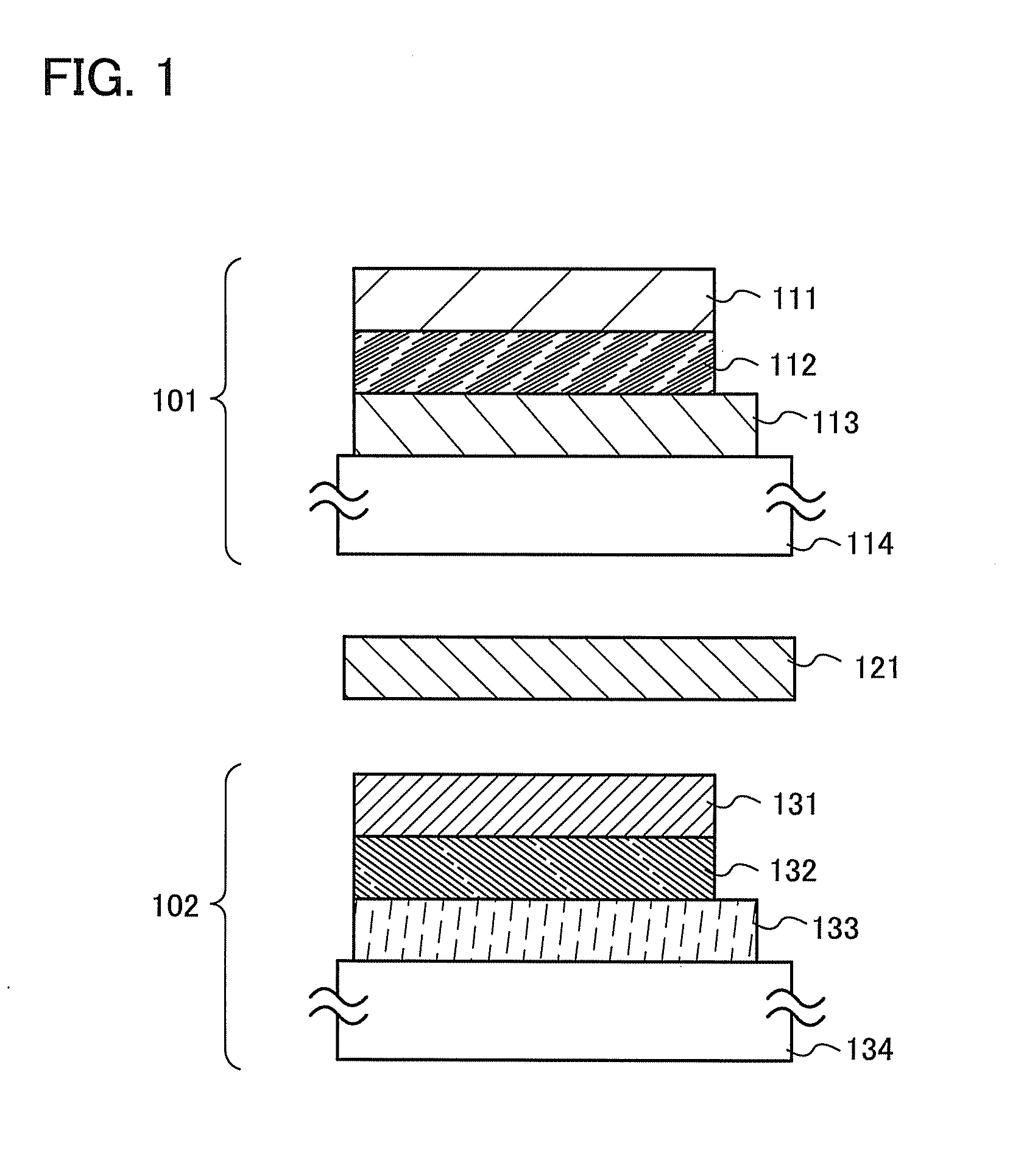

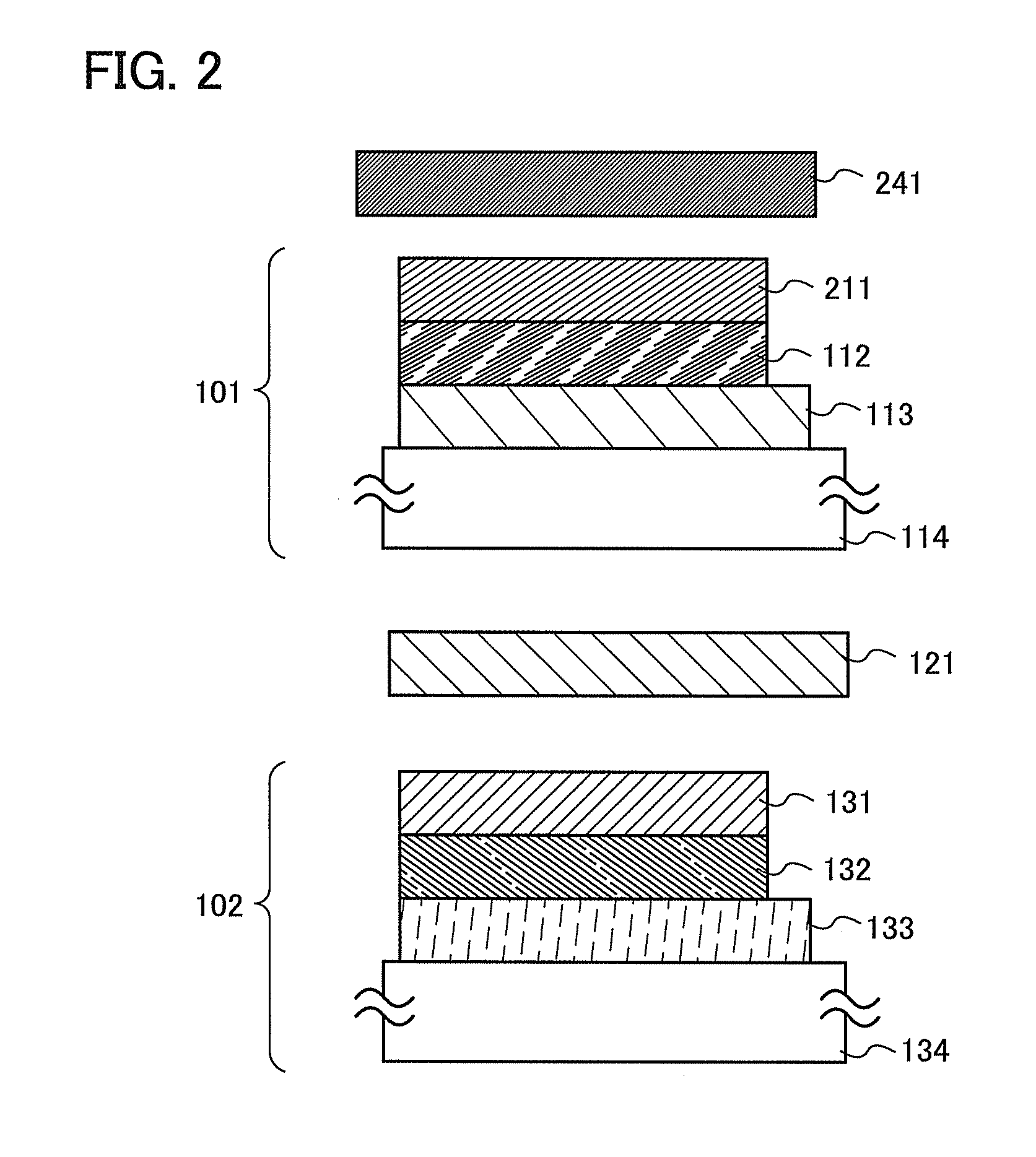

Light-Emitting Device

InactiveUS20110260190A1Improve efficiencyCapability of modulating lightElectroluminescent light sourcesSolid-state devicesUltrasound attenuationLength wave

Blue organic EL elements, which have a shorter lifetime and lower luminance characteristics than green and red ones, have had a problem: particularly when blue elements are used in a light-emitting device capable of modulating light emission colors, light significantly attenuates and characteristics further deteriorates. A dielectric mirror which is selective in wavelength is provided between organic EL elements, and the number of times especially blue light emission from an organic EL element is transmitted through an electrode having a light-transmitting property is reduced as much as possible, so that attenuation of light is suppressed. Thus, a light-emitting device capable of modulation of light emission colors which has a high luminance and a long lifetime can be provided. In the light-emitting device, voltages applied to the organic EL elements, which deteriorate individually, are separately controlled, whereby the color tone can be kept constant for a long period.

Owner:SEMICON ENERGY LAB CO LTD

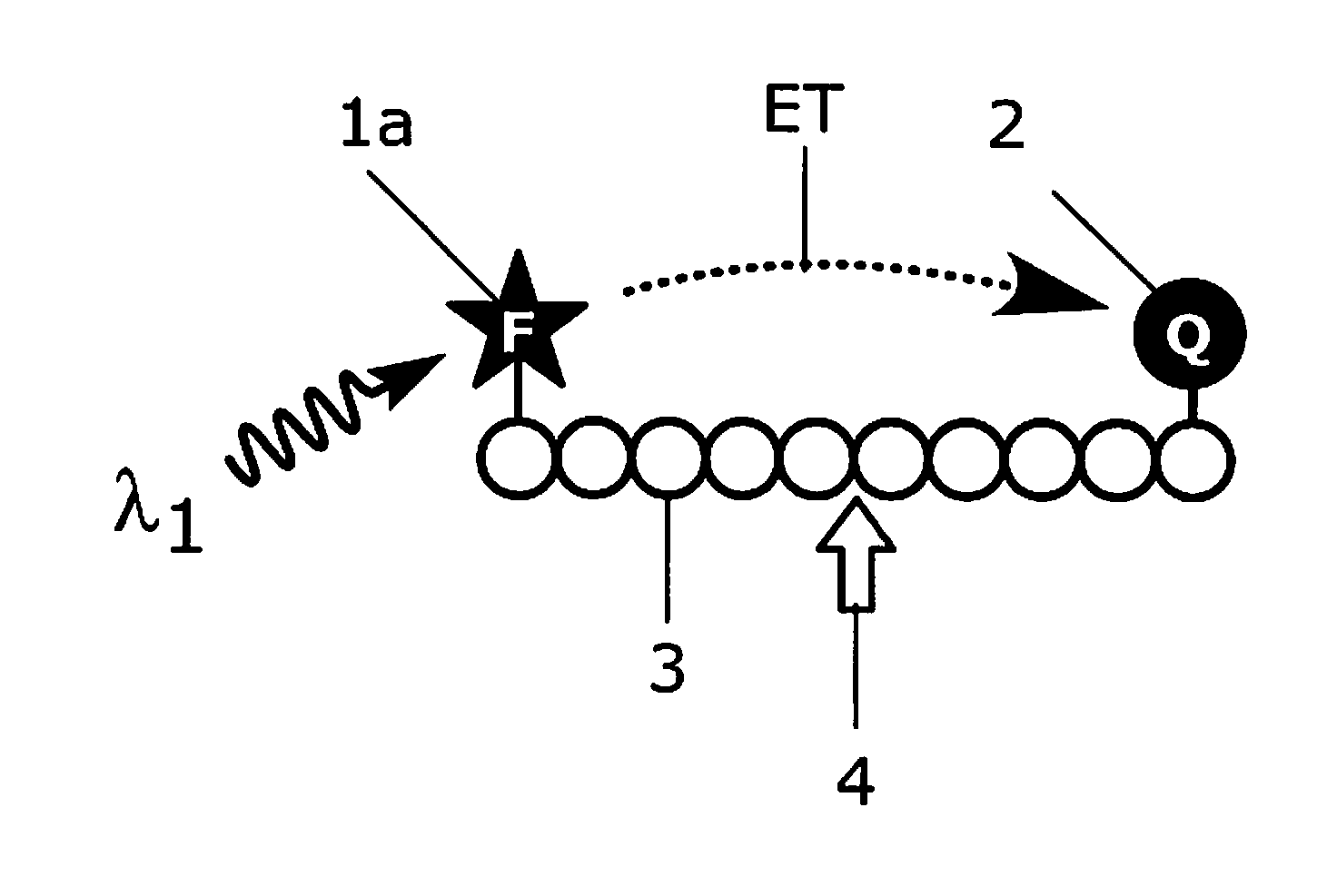

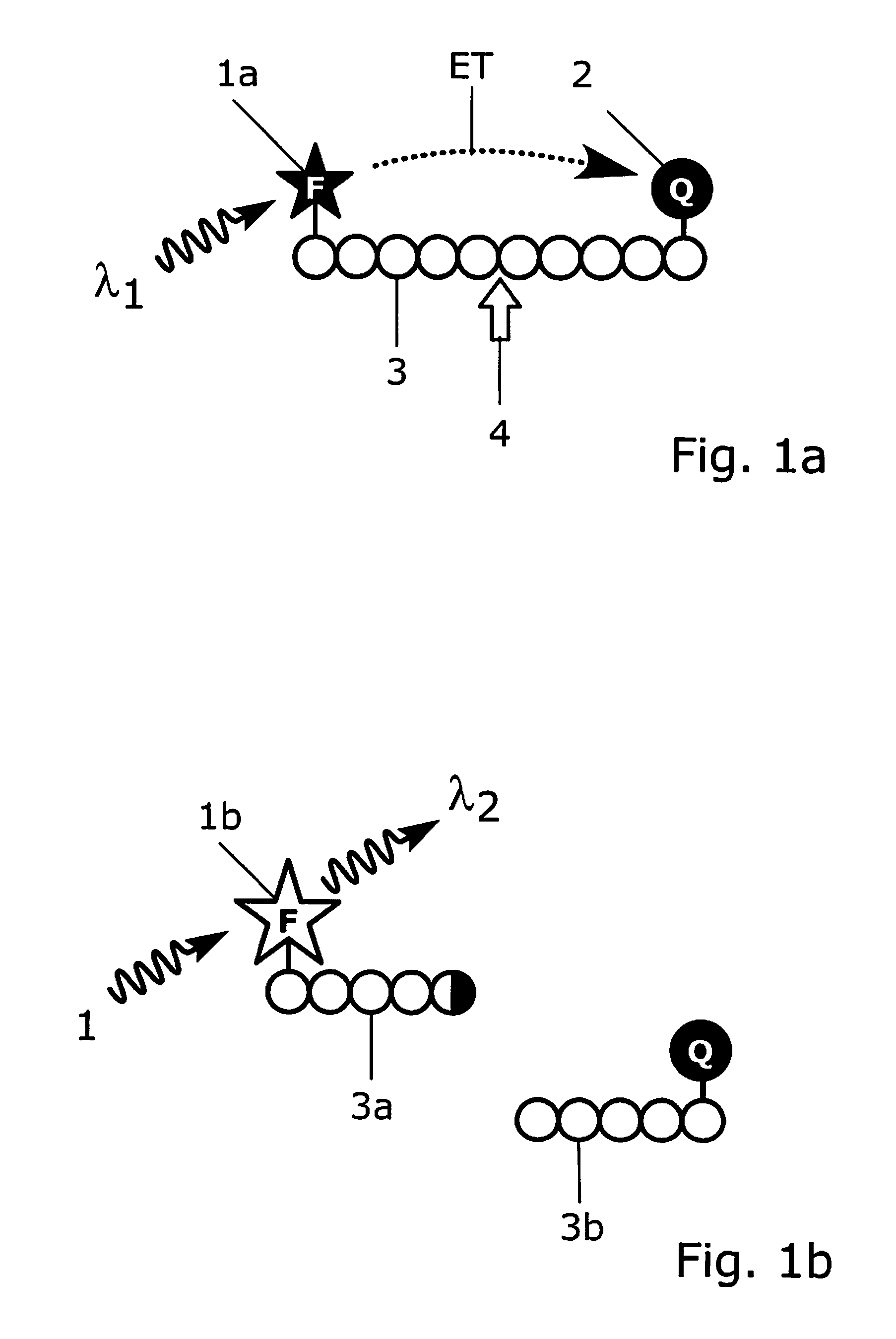

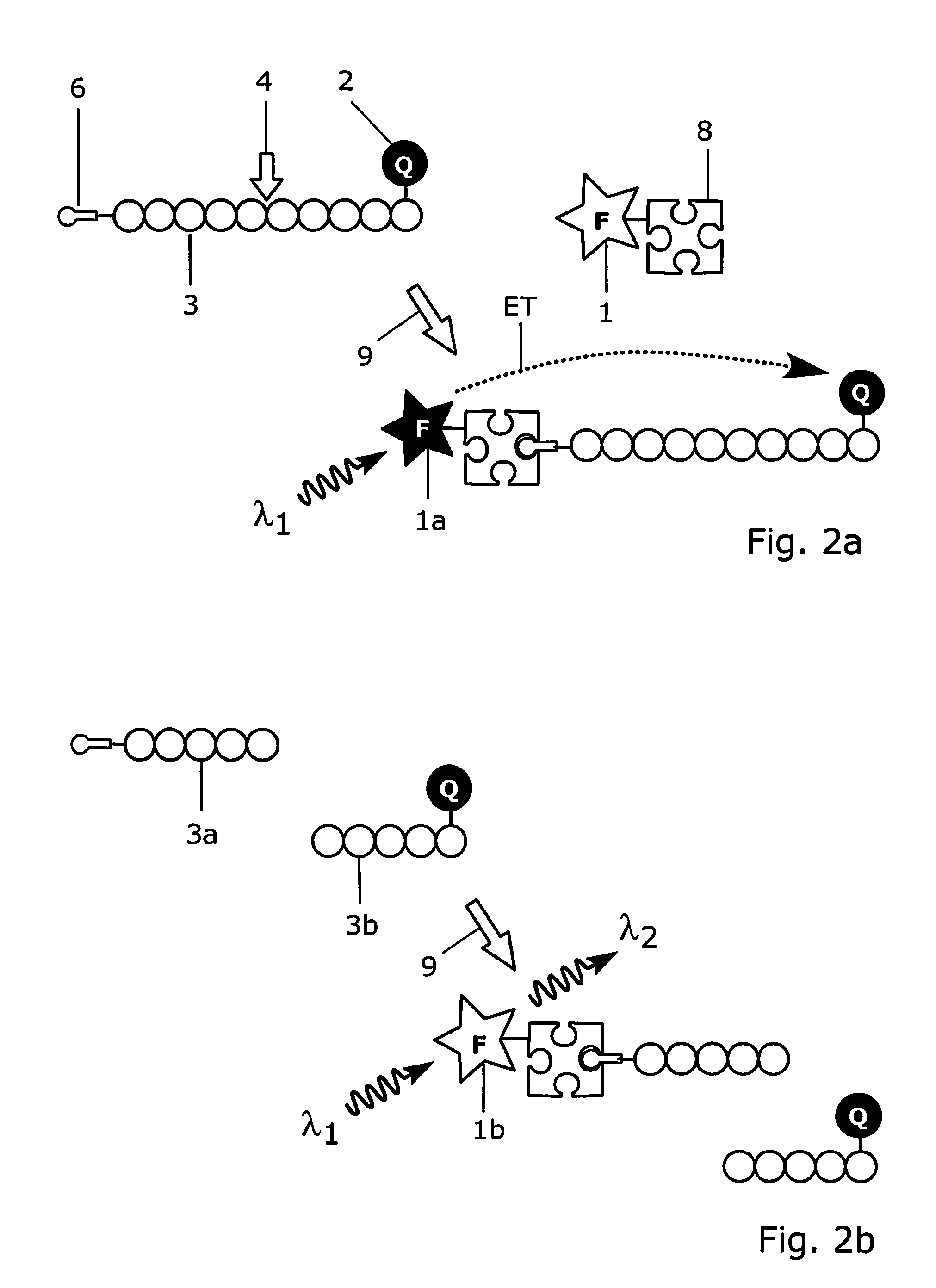

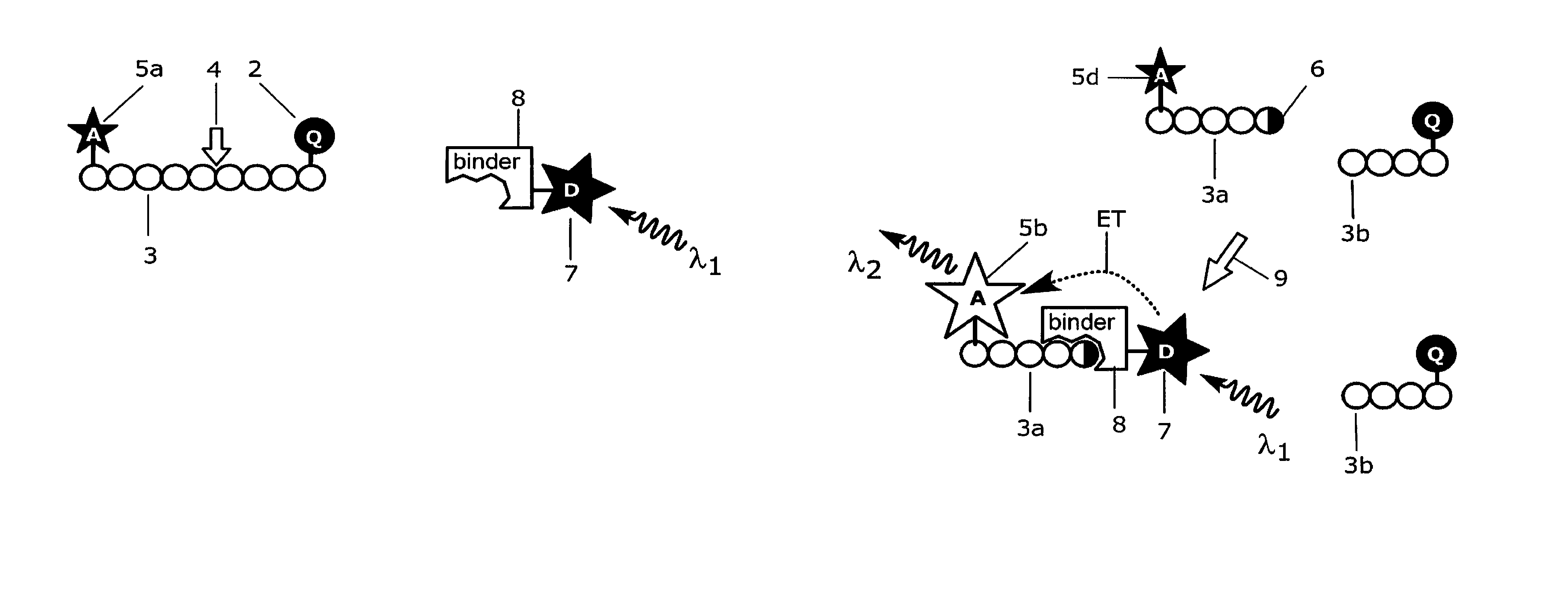

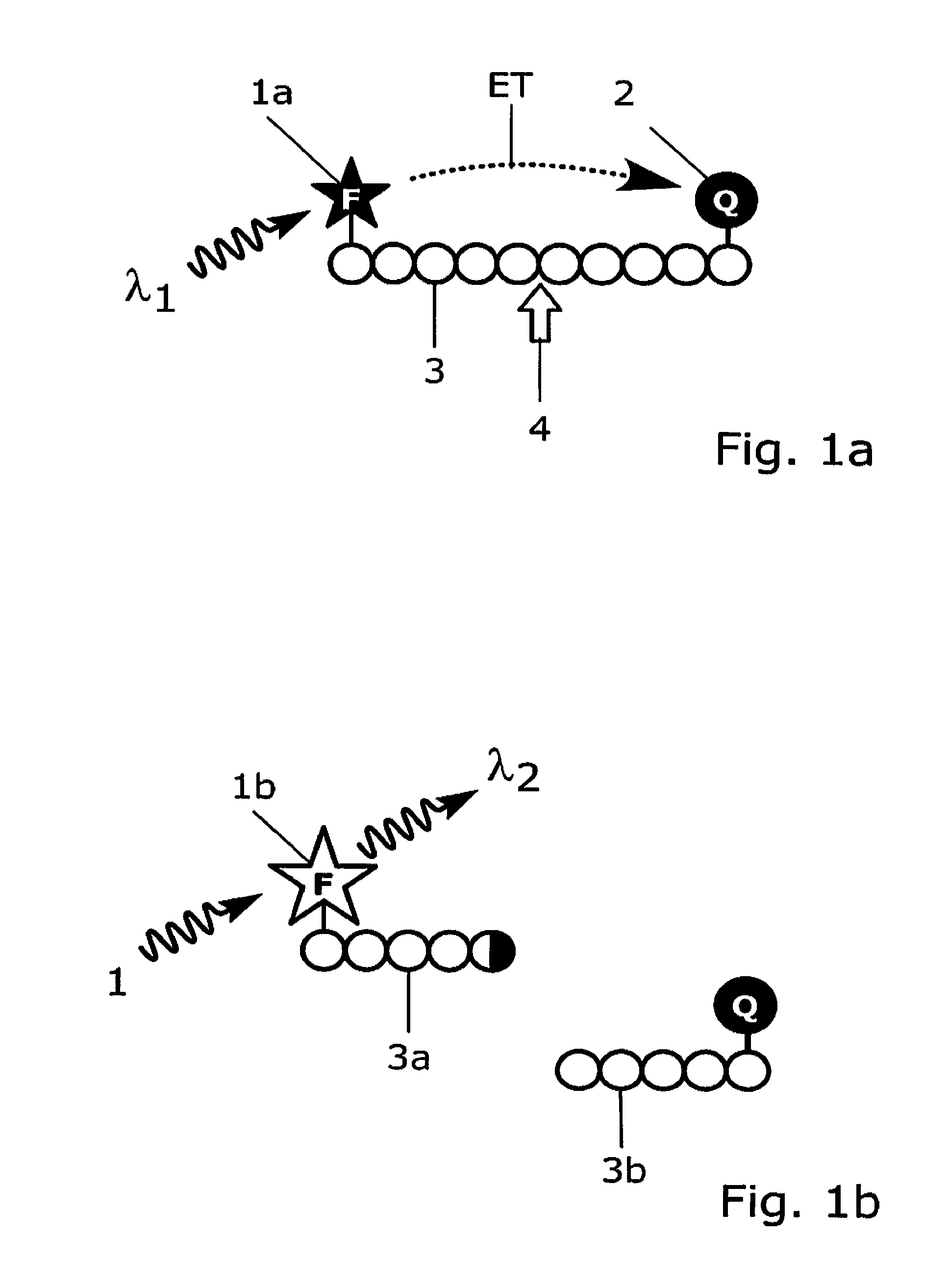

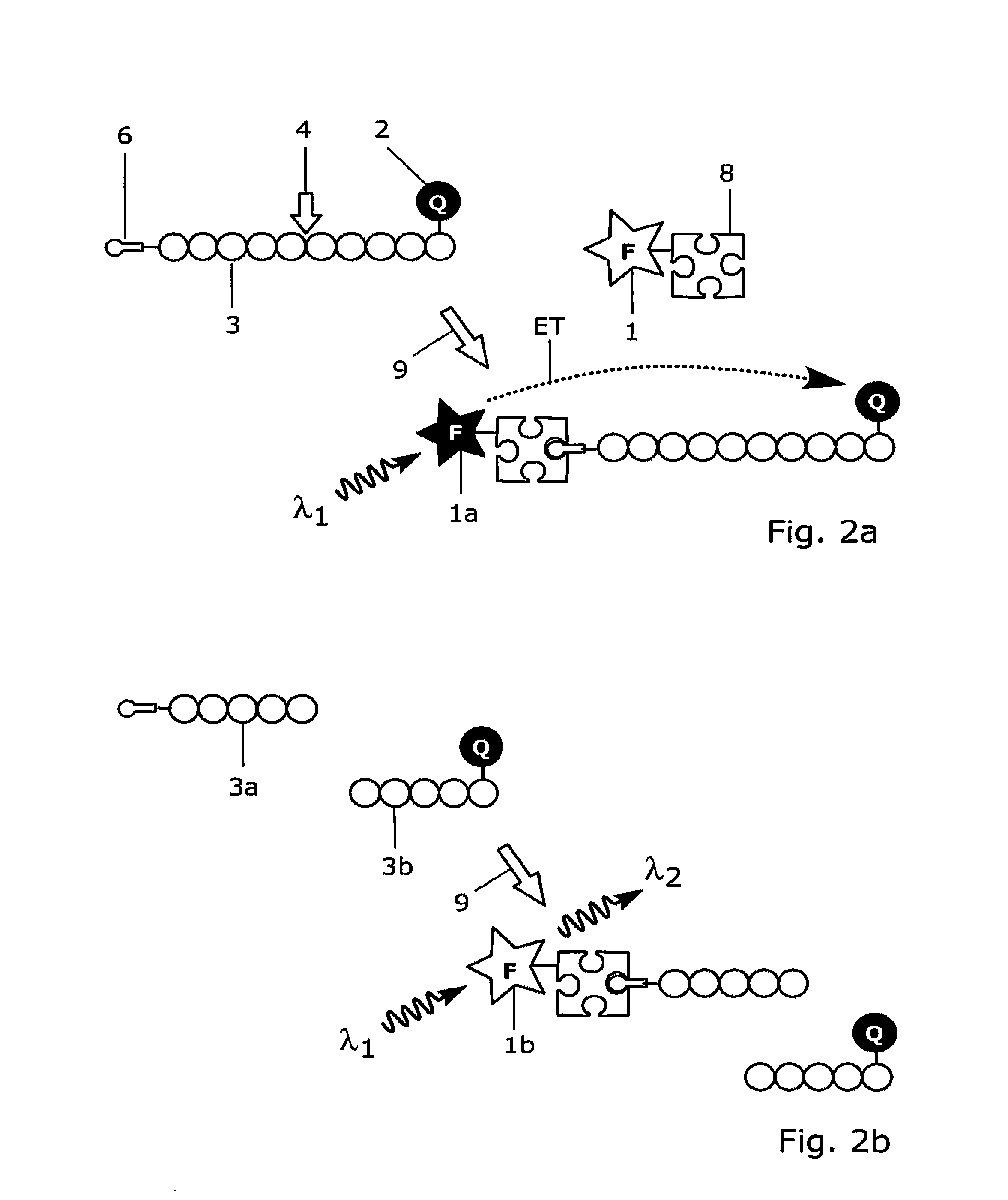

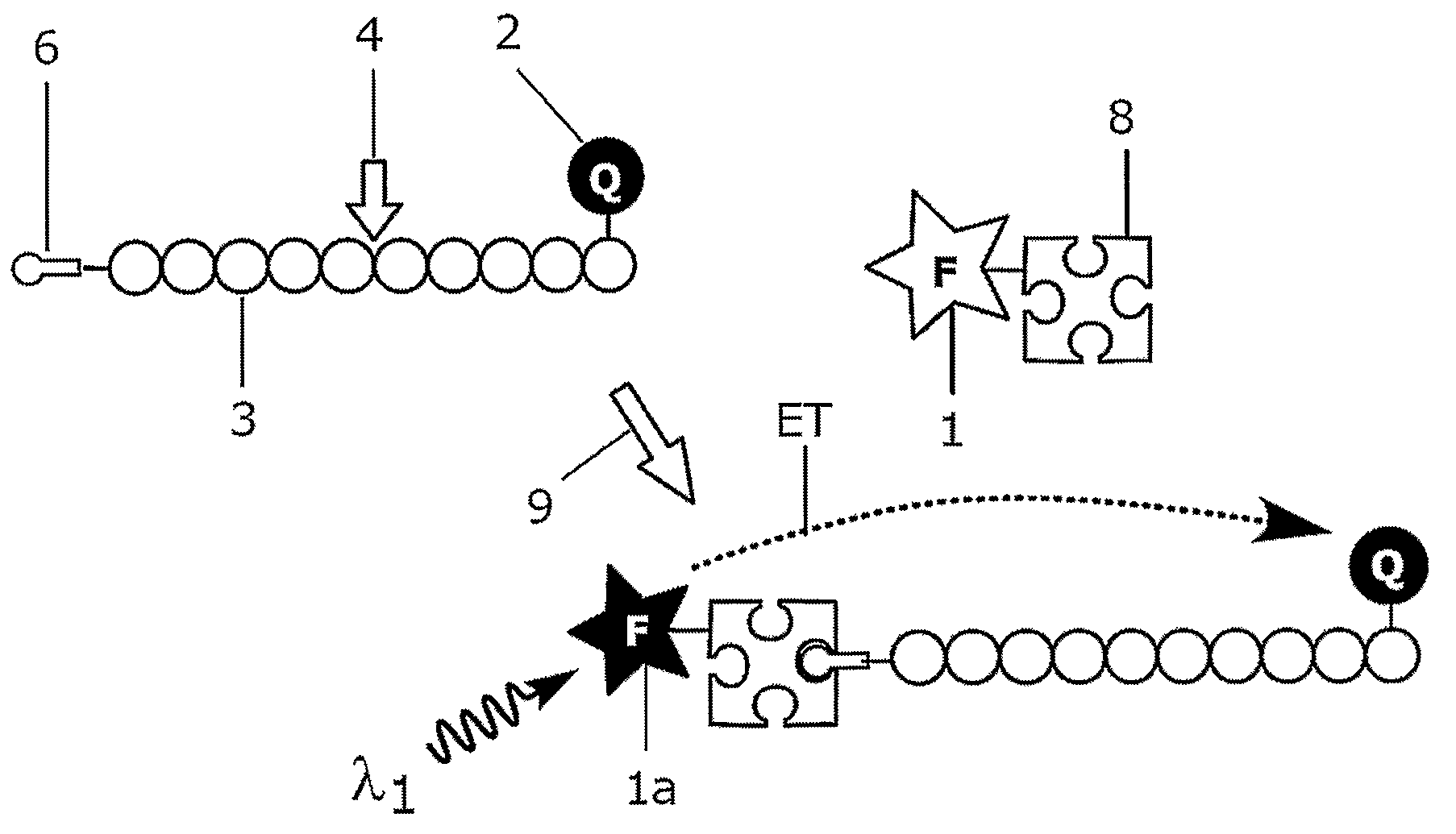

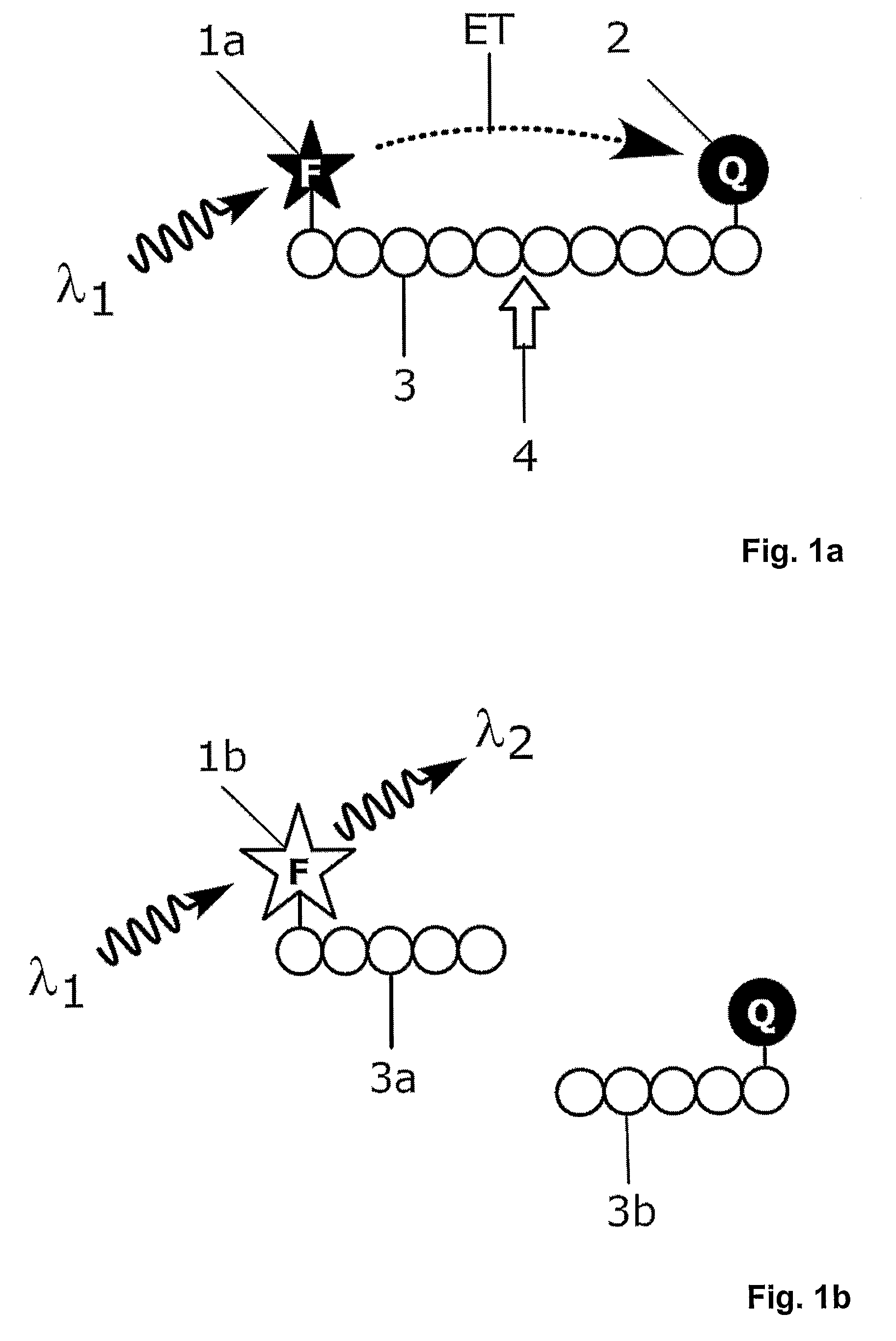

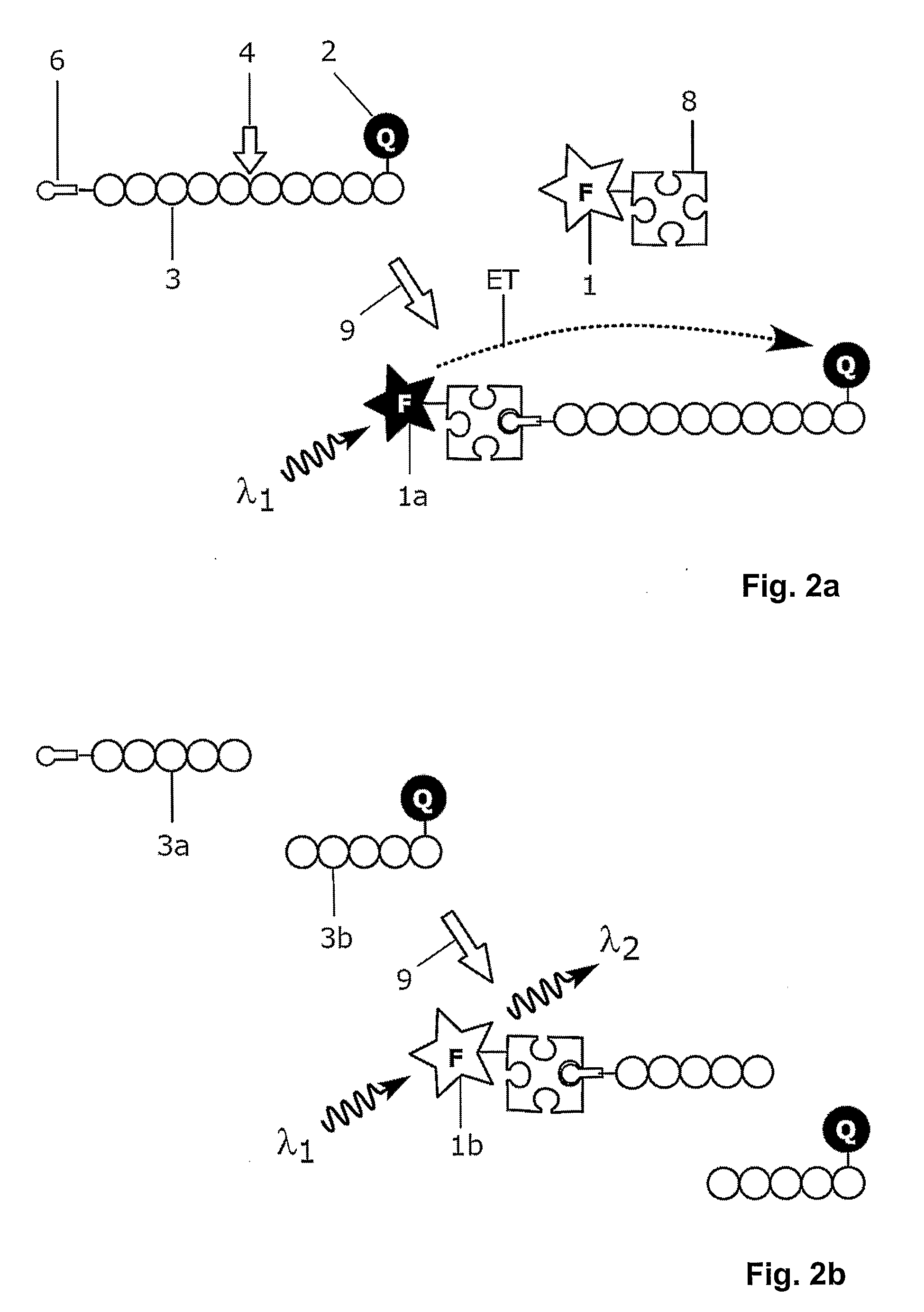

Improved homogeneous luminescence bioassay

A homogenous bioassay including i) a first group containing a short lifetime fluorescent acceptor capable of energy transfer, and ii) a second group containing a quencher capable of energy transfer from an acceptor, with the first and second groups linked by at least a first linkage. The bioassay measures the acceptor's fluorescence increase resulting from cleavage of the first linkage. The bioassay also includes iii) a third group containing a donor for energy transfer to the acceptor, where the donor is an up-conversion fluorescent compound, a long-lifetime fluorescent compound or an electrogenerated luminescent compound. A conformational or terminal epitope is created on the first group through cleavage of the linkage, and the third group includes a binder with affinity for this conformational or terminal epitope. The acceptor's fluorescence is brought about by exciting the donor. Also disclosed are kits for homogenous bioassays according to the method of the invention.

Owner:HIDEX

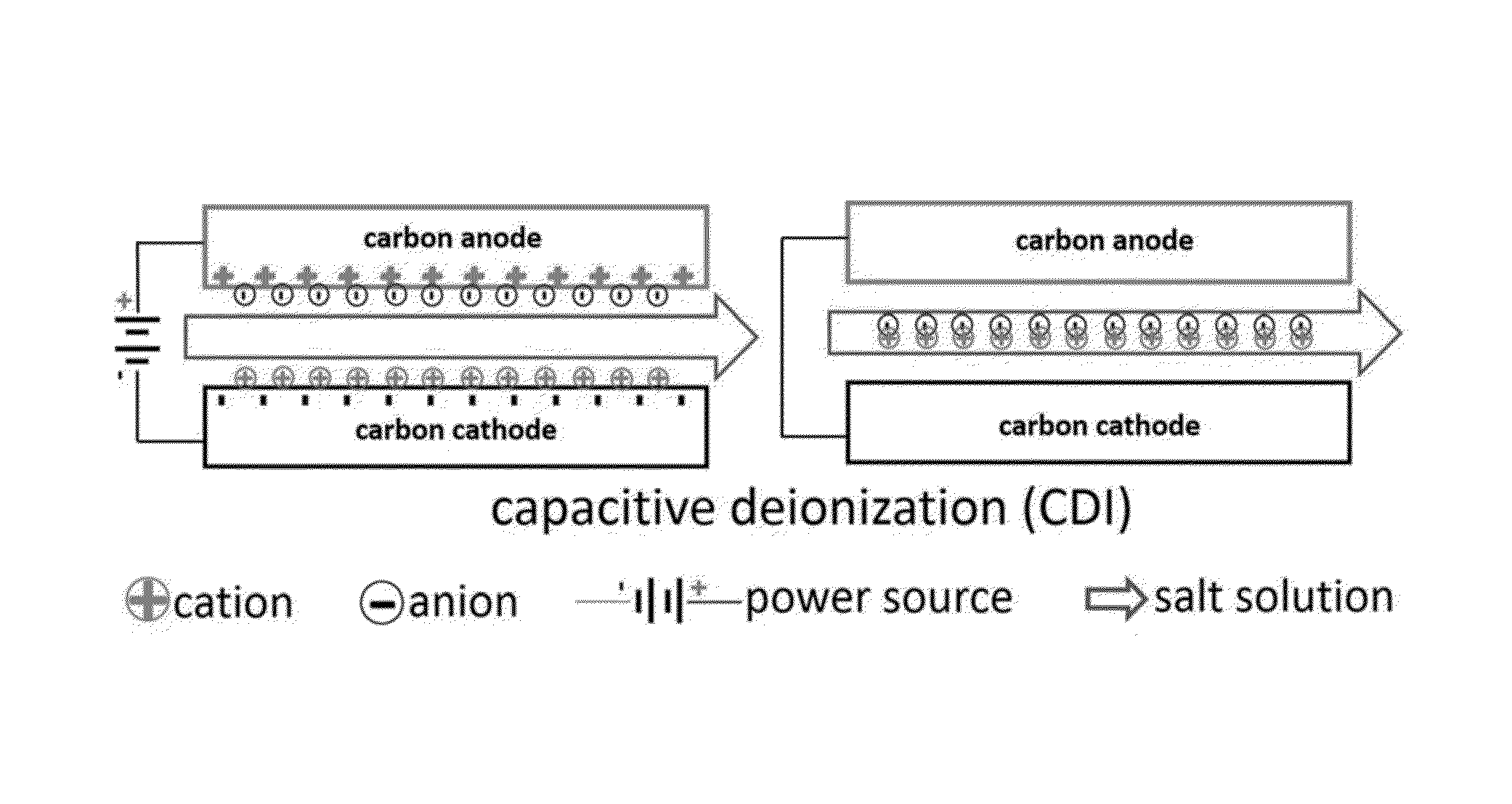

Potential of Zero charge-Based Capacitive Deionization

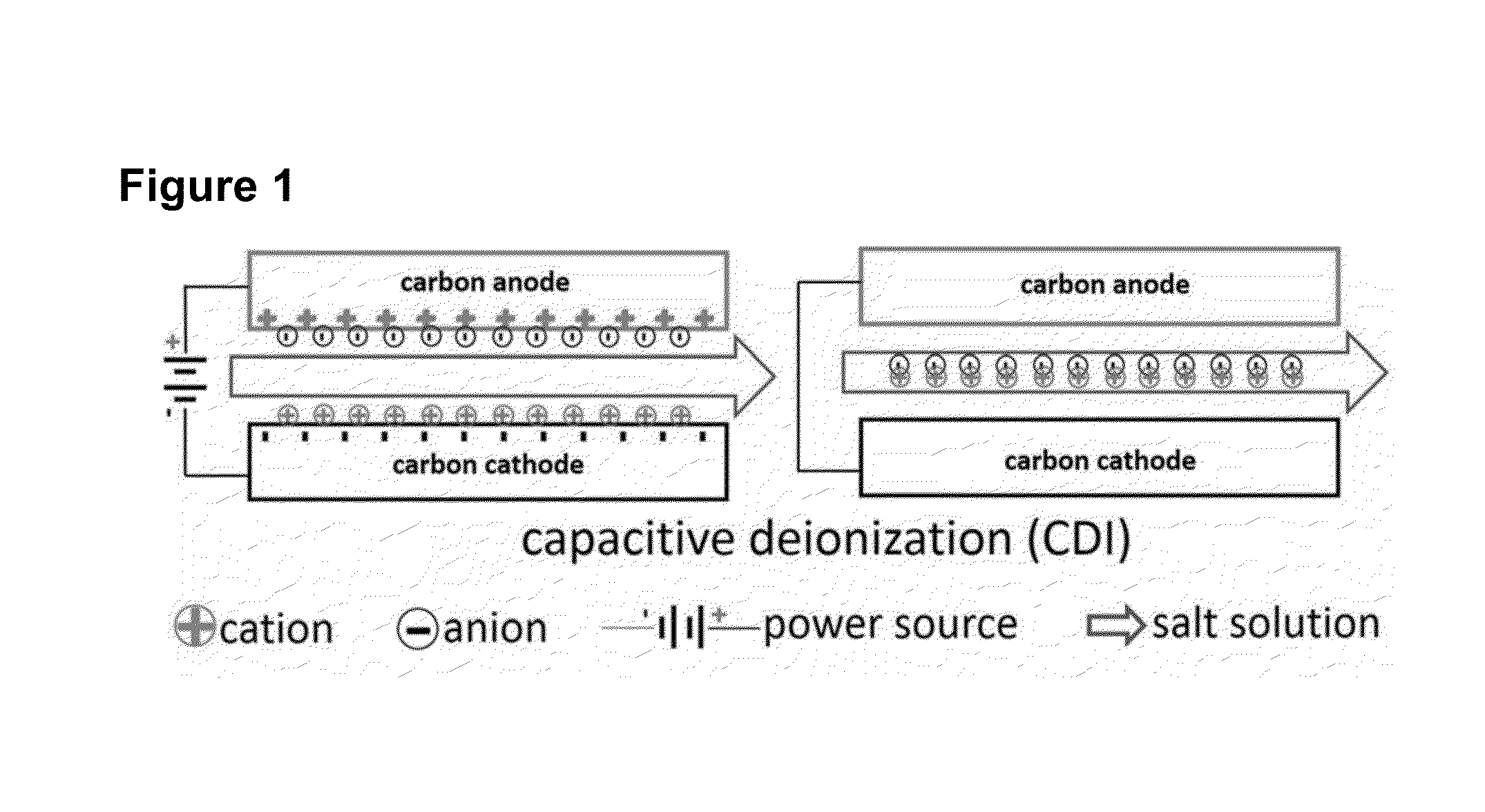

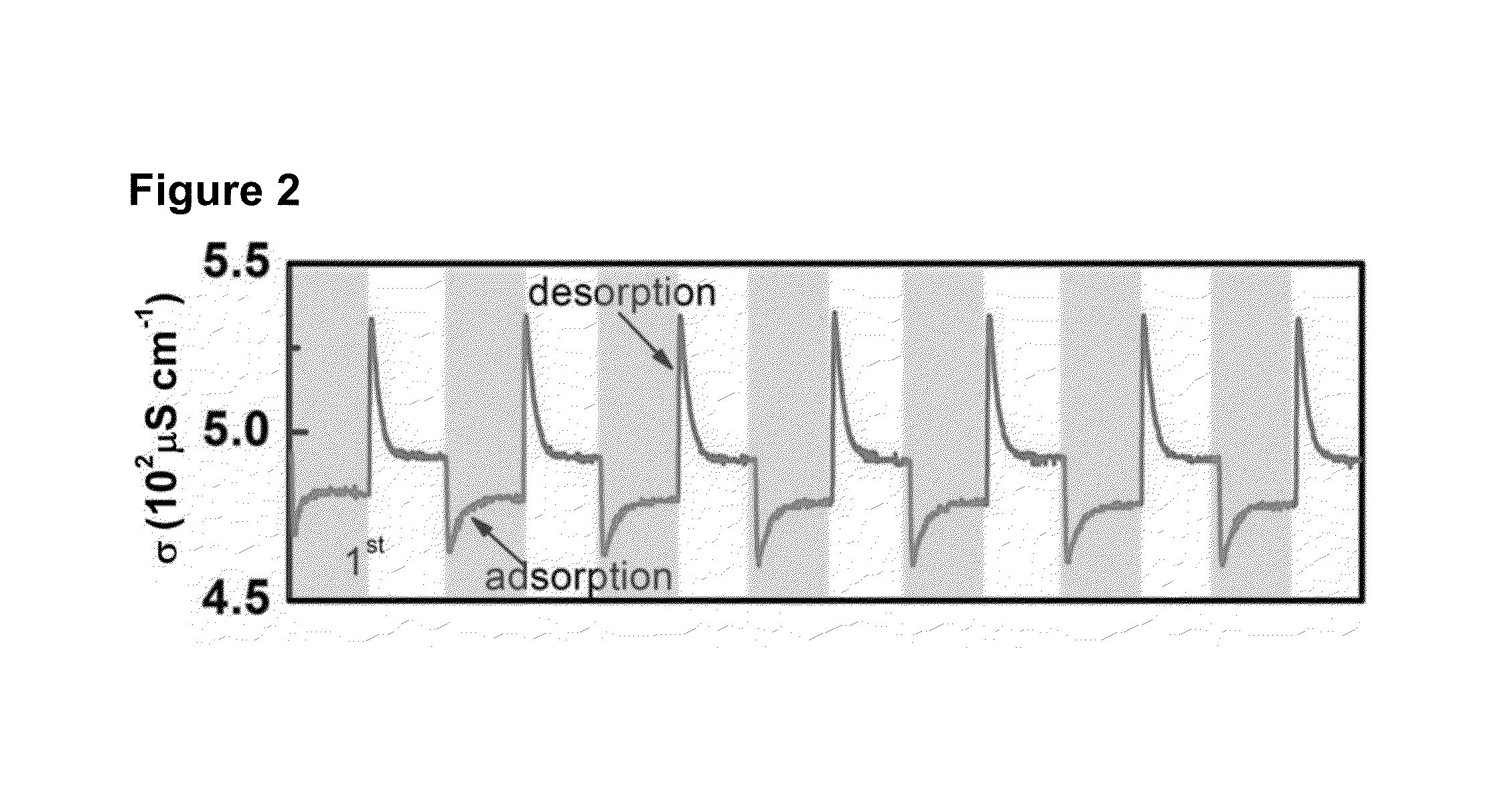

ActiveUS20160167984A1Prevent penetrationEasy to adjustWater treatment parameter controlFatty/oily/floating substances removal devicesCapacitanceCapacitive deionization

The invention is a capacitive, aka electrostatic, deionization apparatus and method that solves the problem of short lifetime of conventional capacitive deionization (CDI) and of membrane capacitive deionization (MCDI) devices and methods by shifting the Potential of Zero Charge of electrode surfaces through surface modifications. Such electrode surface modifications provide very long lifetime capacitive deionization devices and methods.

Owner:UNIV OF KENTUCKY RES FOUND

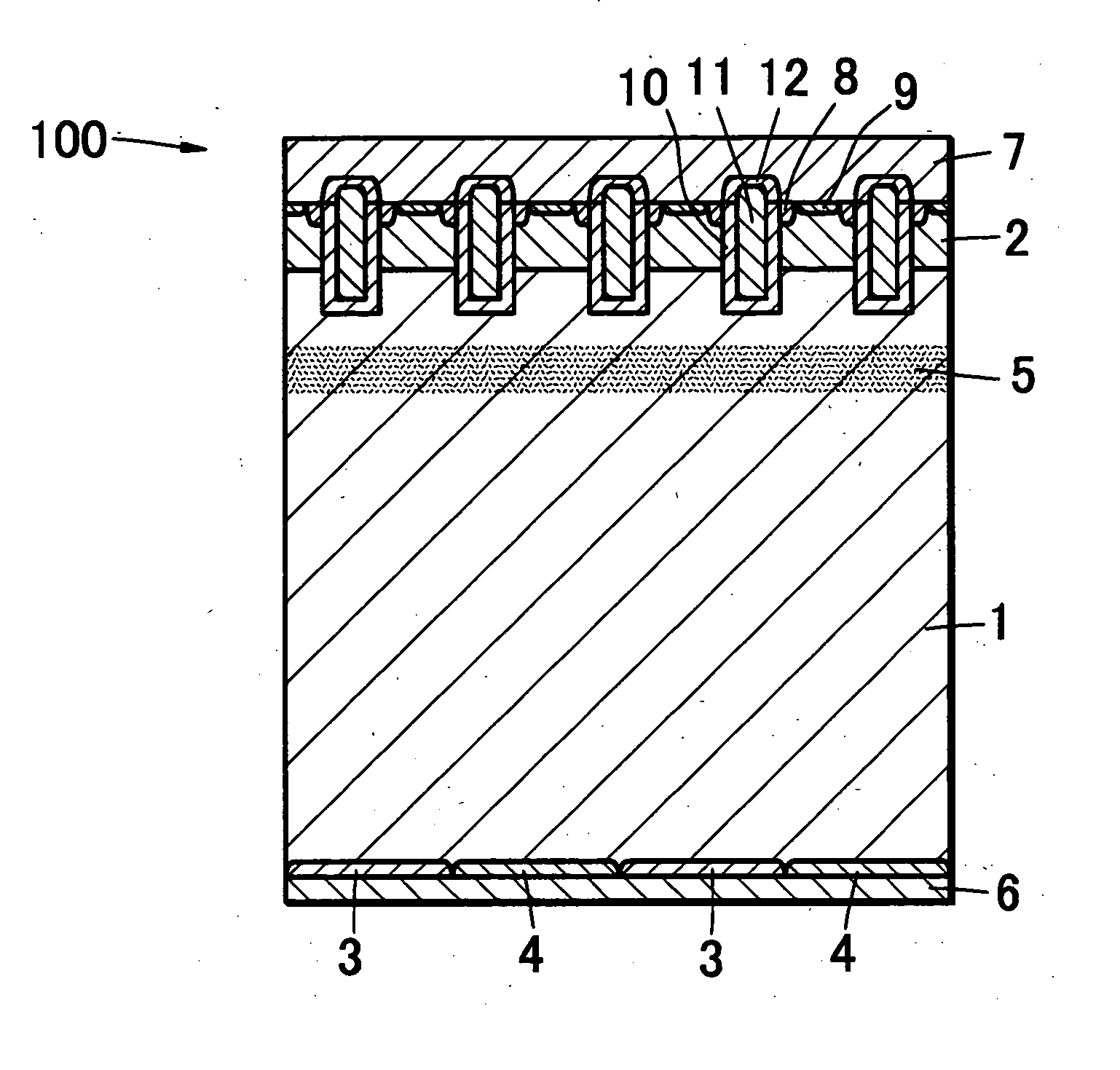

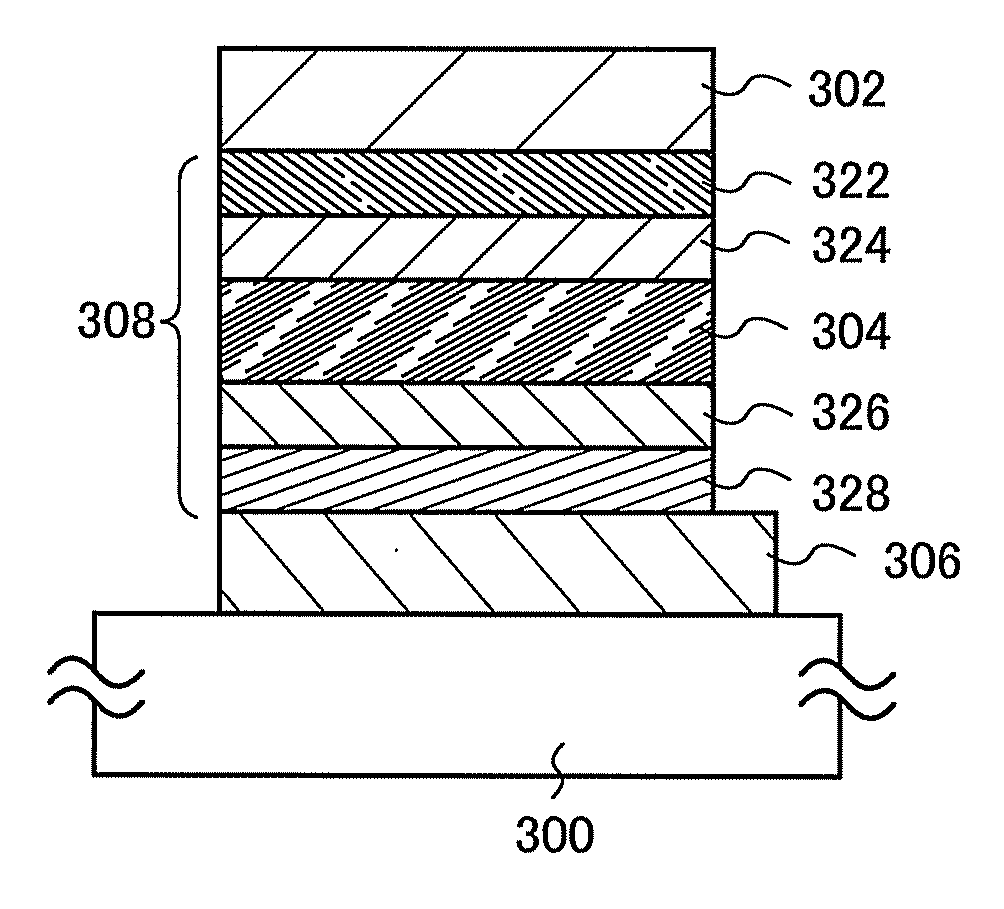

Semiconductor device

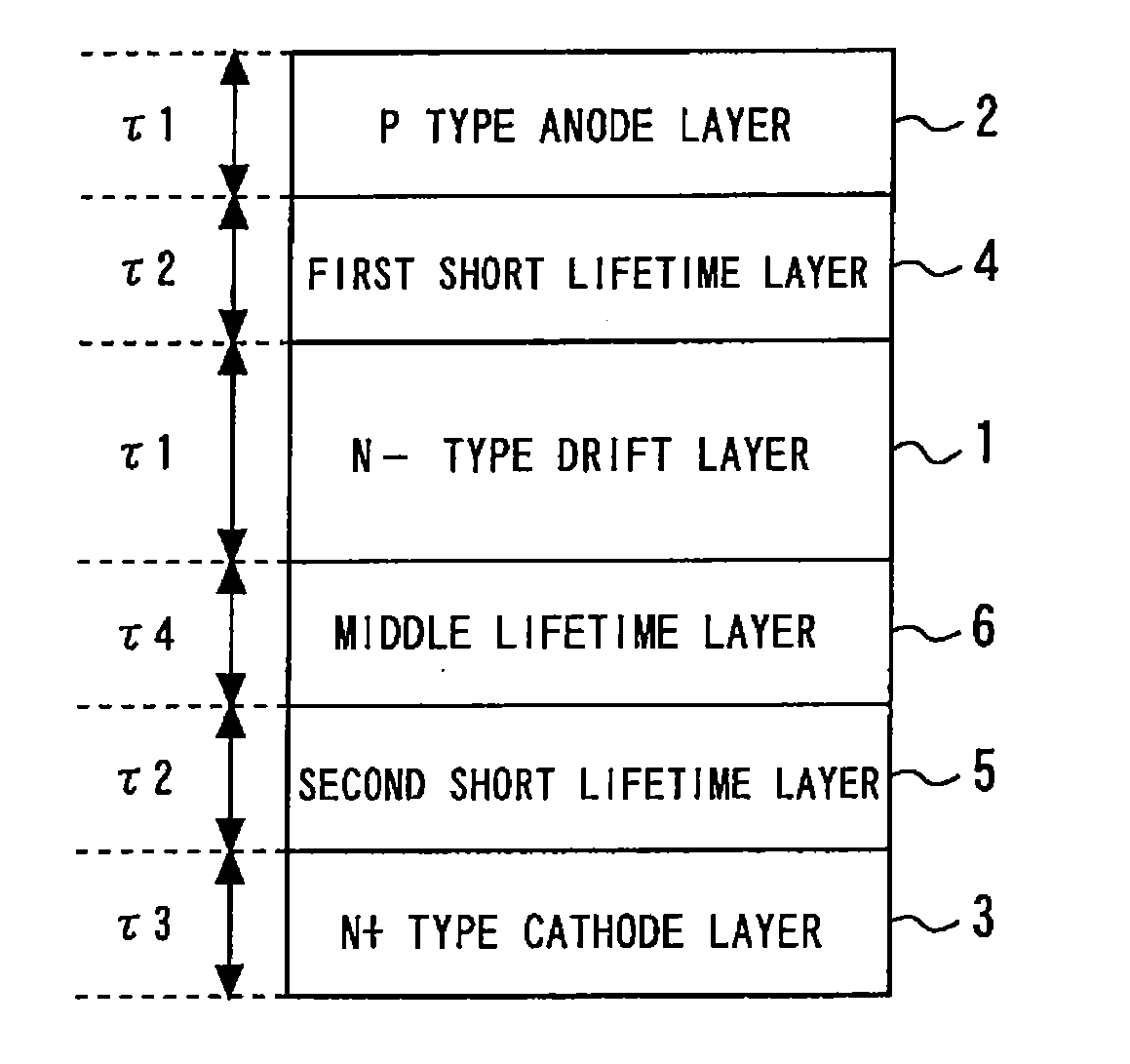

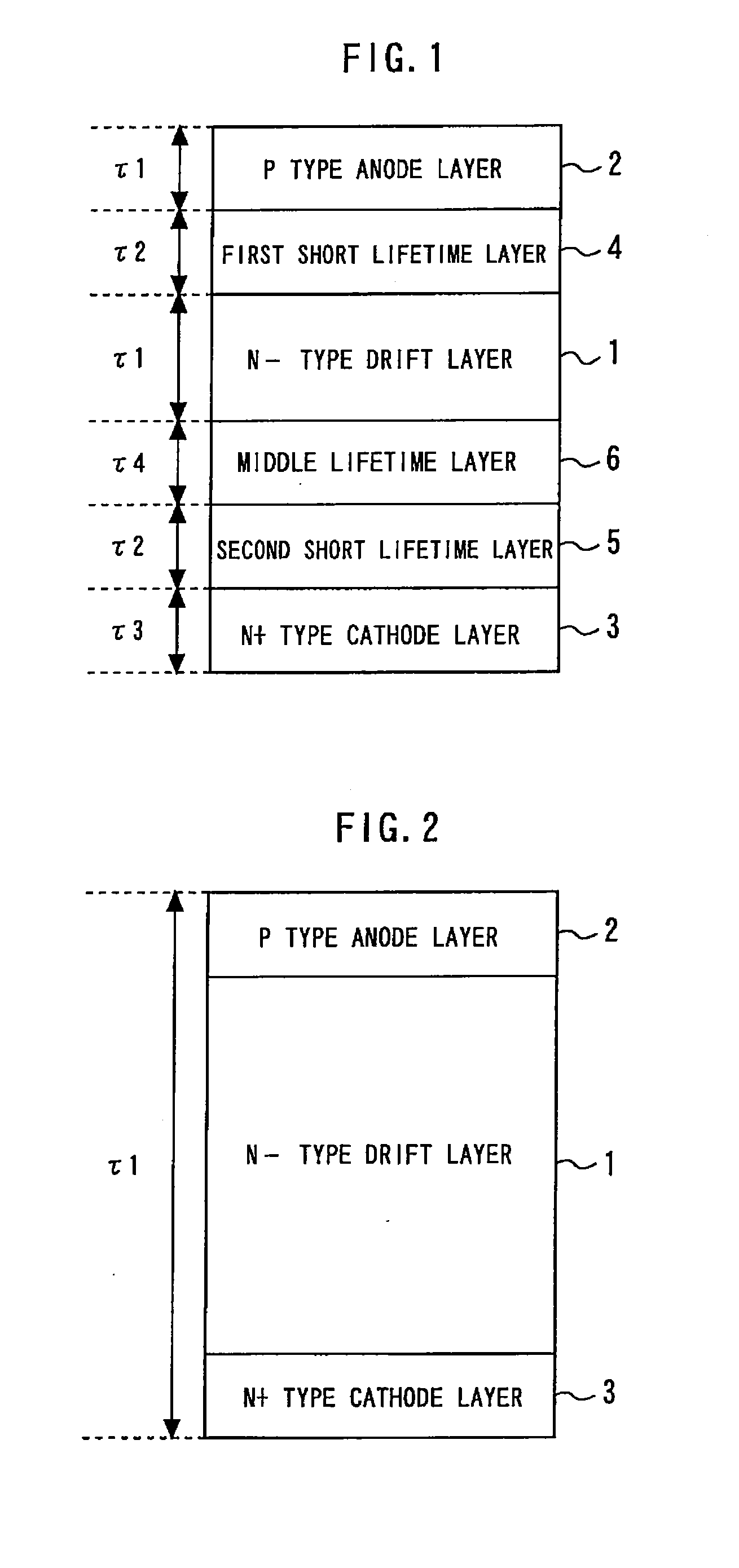

ActiveUS20130093065A1Reduce recoveryReduce withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceCharge carrier

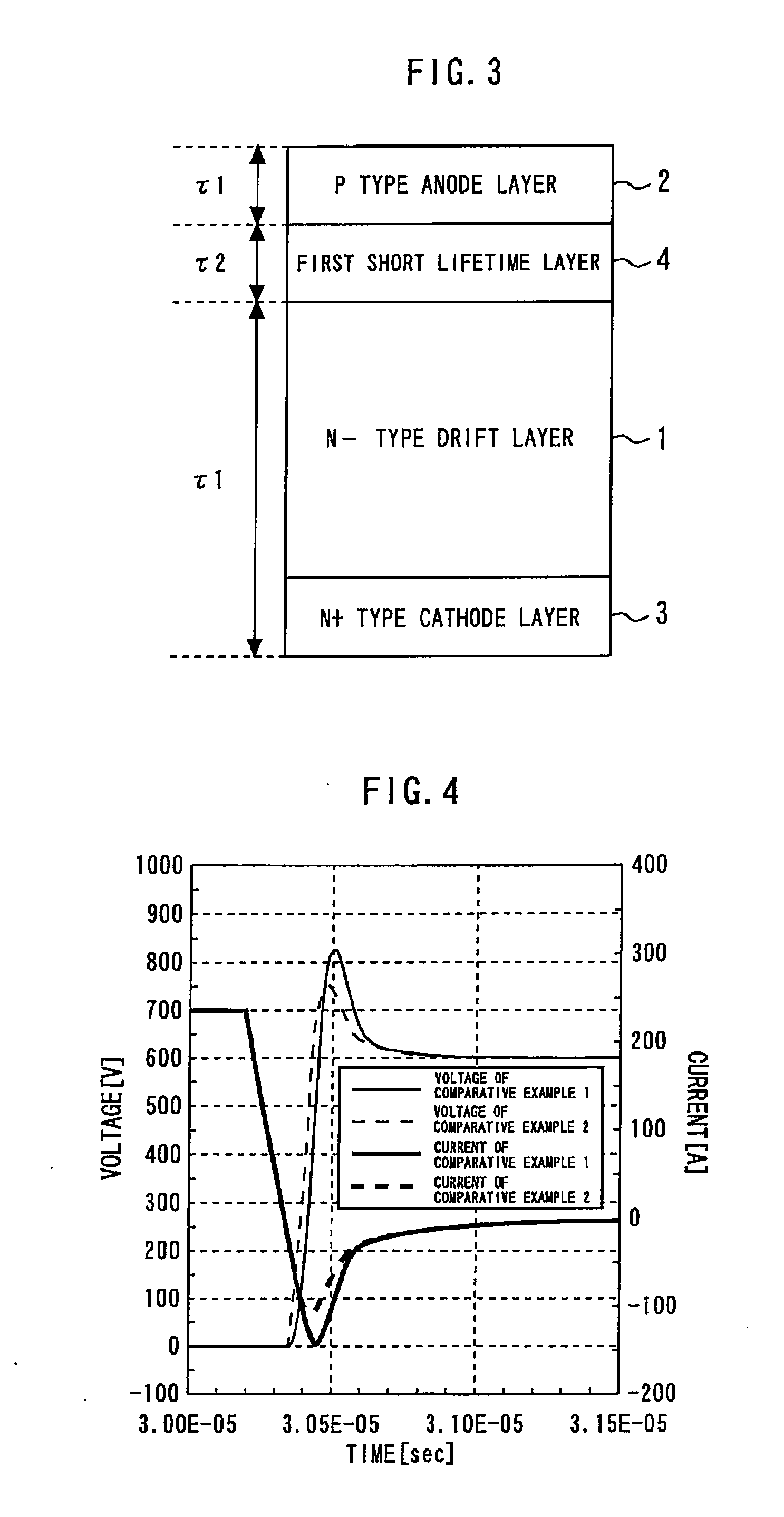

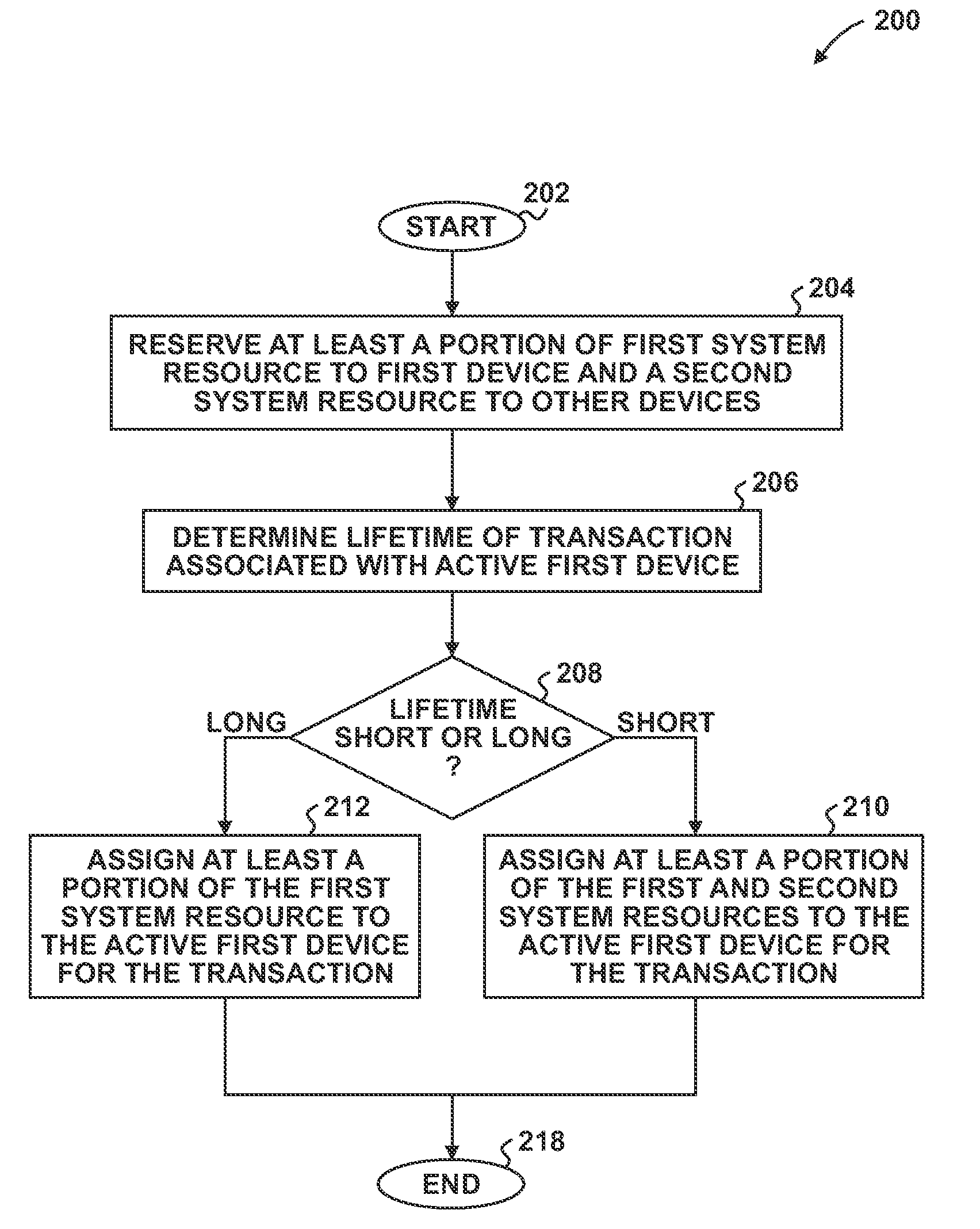

A semiconductor device includes: an N-type drift layer; a P-type anode layer above the N-type drift layer; an N-type cathode layer below the N-type drift layer; a first short lifetime layer between the N-type drift layer and the P-type anode layer; and a second short lifetime layer between the N-type drift layer and the N-type cathode layer. A carrier lifetime in the first and second short lifetime layers is shorter than a carrier lifetime in the N-type drift layer. A carrier lifetime in the N-type cathode layer is longer than the carrier lifetime in the N-type drift layer.

Owner:MITSUBISHI ELECTRIC CORP

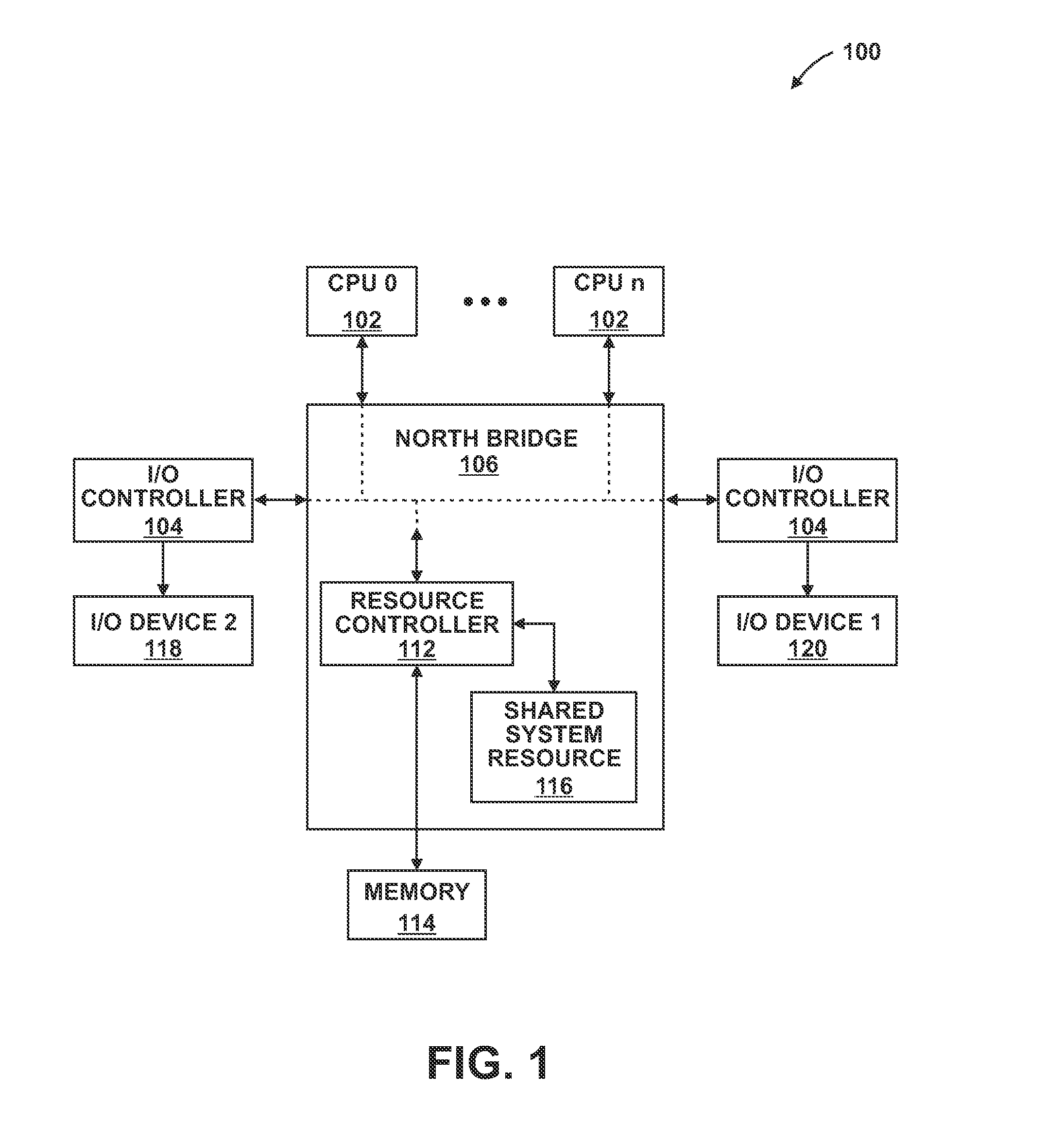

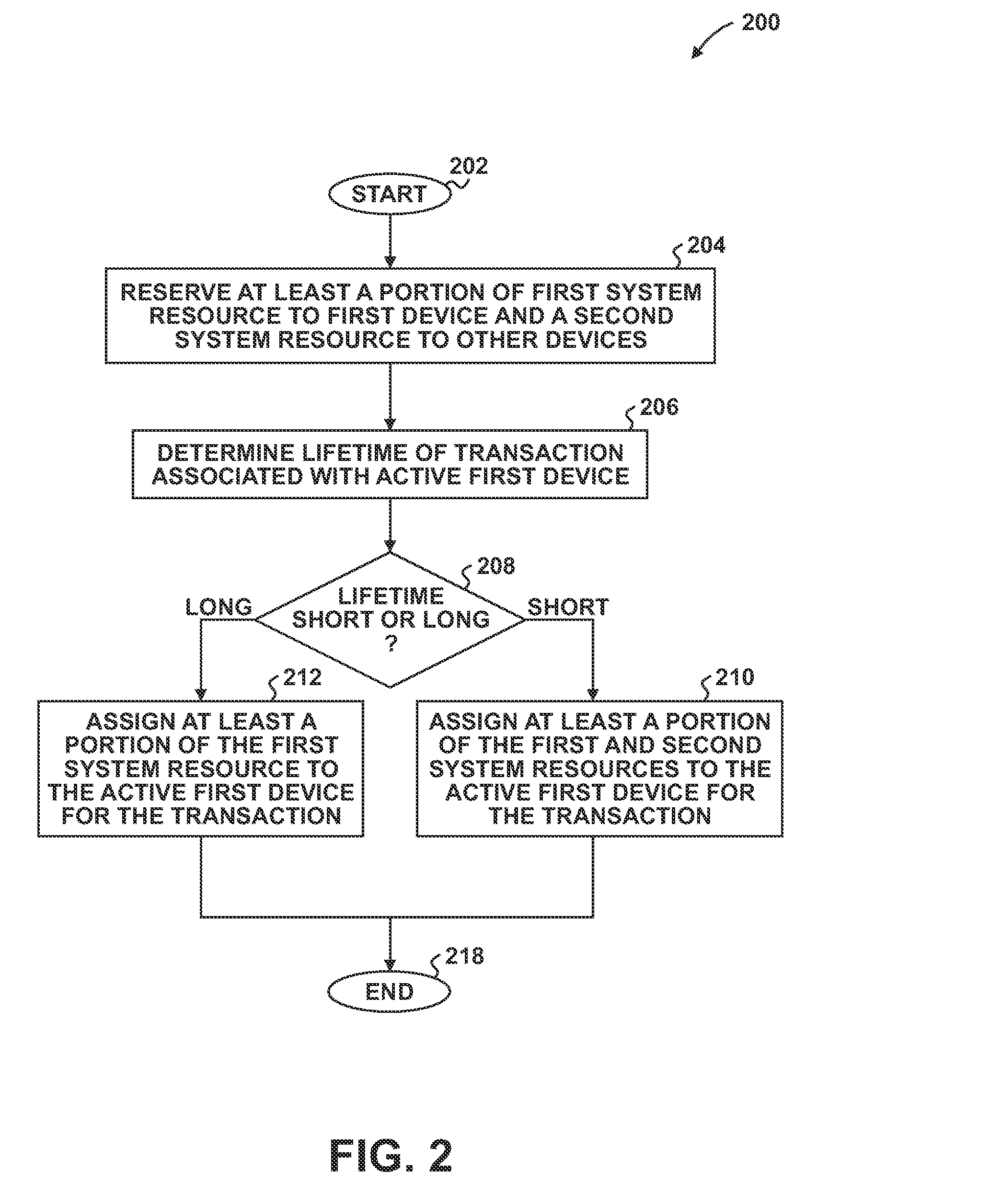

Techniques for sharing resources among multiple devices in a processor system

InactiveUS20080295097A1Multiprogramming arrangementsMemory systemsShared resourceDistributed computing

A technique of shared resource handling for multiple devices includes determining a first lifetime of a first transaction associated with an active first device, included within the multiple devices. The technique also includes assigning at least a portion of a first system resource to the active first device for use in the first transaction, when the first lifetime corresponds to a long-lifetime. Finally, the technique includes assigning at least a portion of a second system resource to the active first device for use in the first transaction, when the first lifetime corresponds to a short-lifetime. In this case, the second system resource was previously reserved to one or more inactive second devices, included within the multiple devices.

Owner:GLOBALFOUNDRIES INC

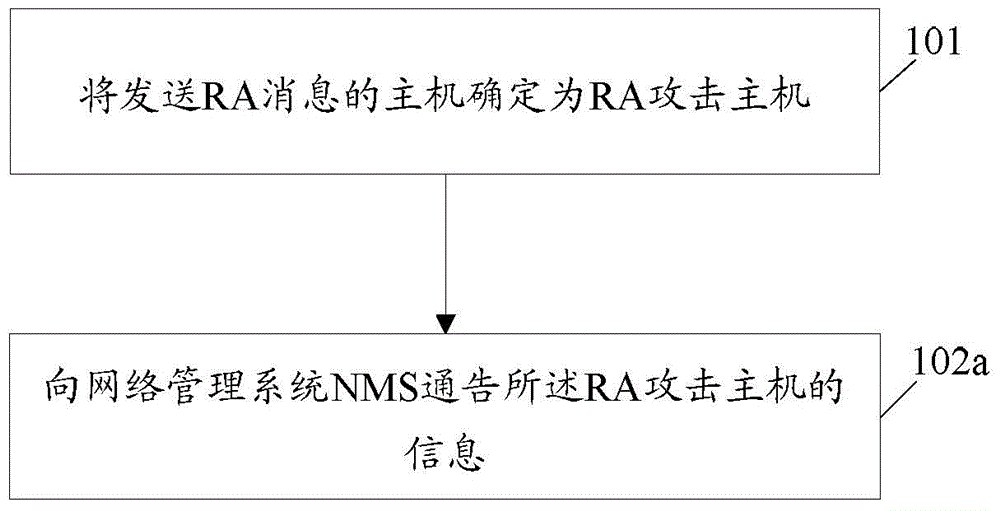

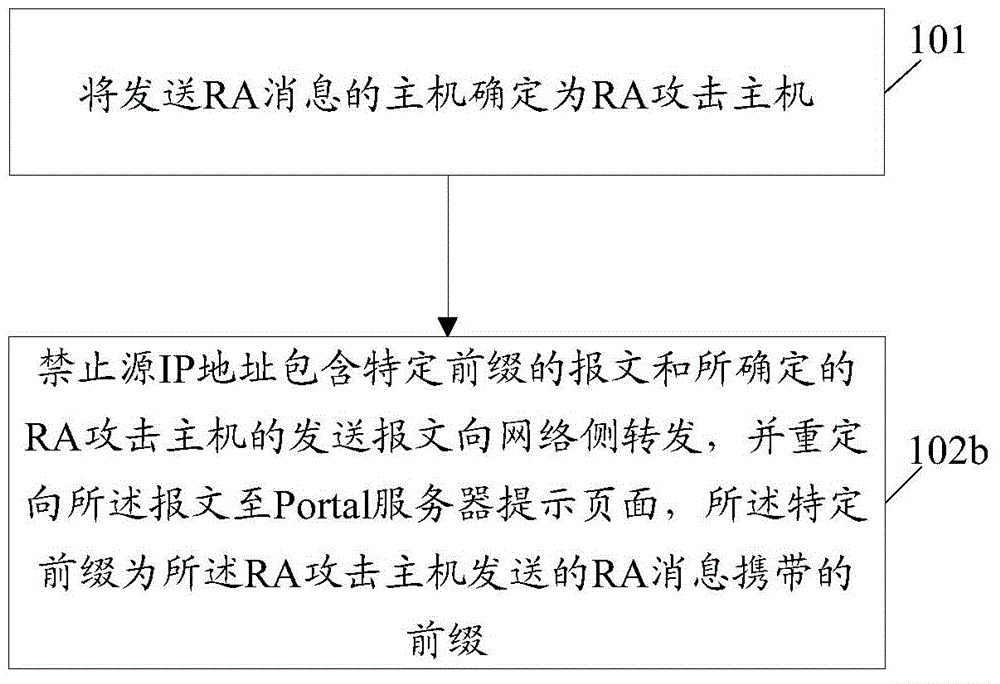

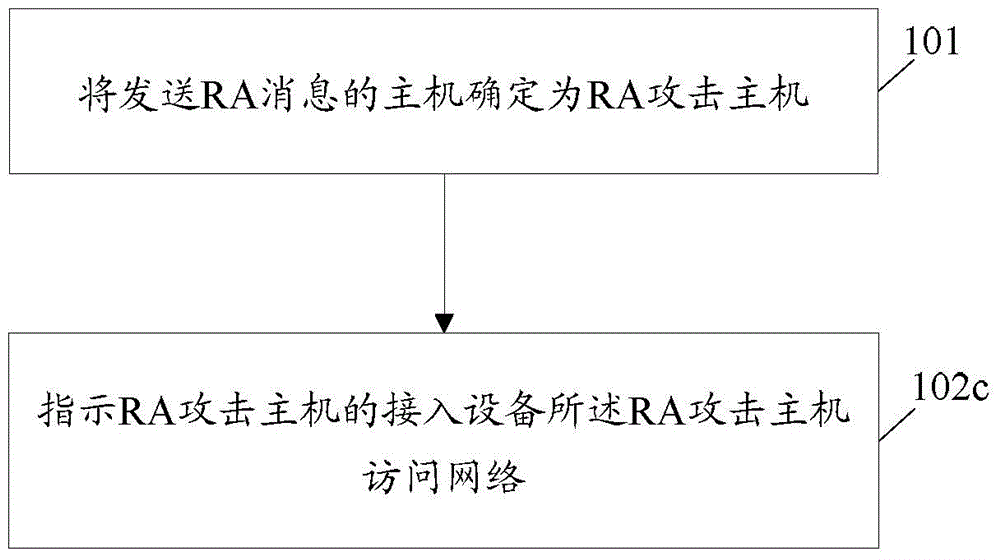

Router advertisement attack prevention method, apparatus and device

InactiveCN104426839APrecise positioningPrevent leakageTransmissionNetwork managementRouter advertisement

Disclosed is a router advertisement (RA) attack prevention method, a device, equipment and a computer storage medium, said method comprising: in accordance with a received RA message, determining an RA attack host; executing at least one of the following operations: notifying a network management system of RA attack host information; prohibiting a source Internet Protocol (IP) address from including a packet having a specific prefix and a sending packet of said determined RA attack host being forwarded to a network side, and redirecting said packet to an entrance server prompt page, said specific prefix being the prefix carried by the RA message sent by said RA attack host; instructing the access equipment of said RA attack host to prohibit the RA attack host from gaining network access; simulating said RA attack host attacker in sending a new RA message, said new RA message carrying a prefix which has a shorter lifetime than the lifetime of the prefix carried in the RA message sent by said RA attack host.

Owner:ZTE CORP

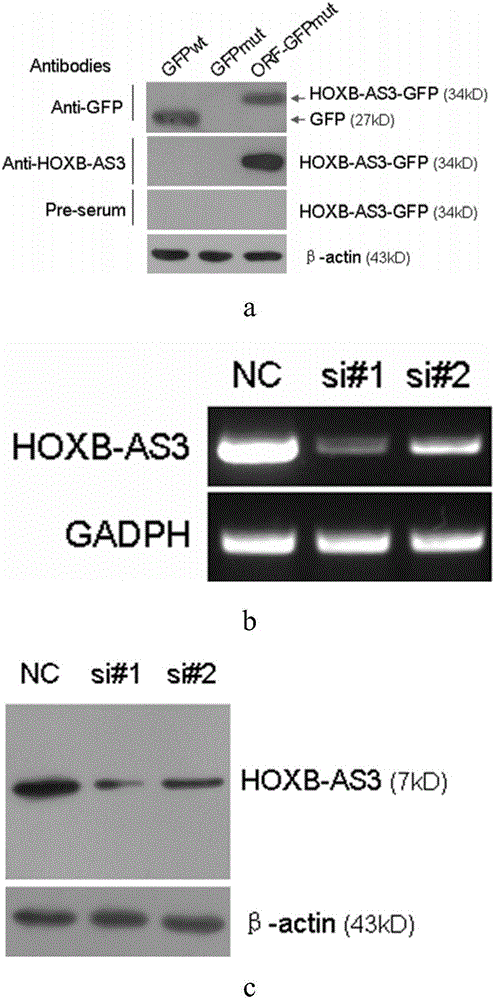

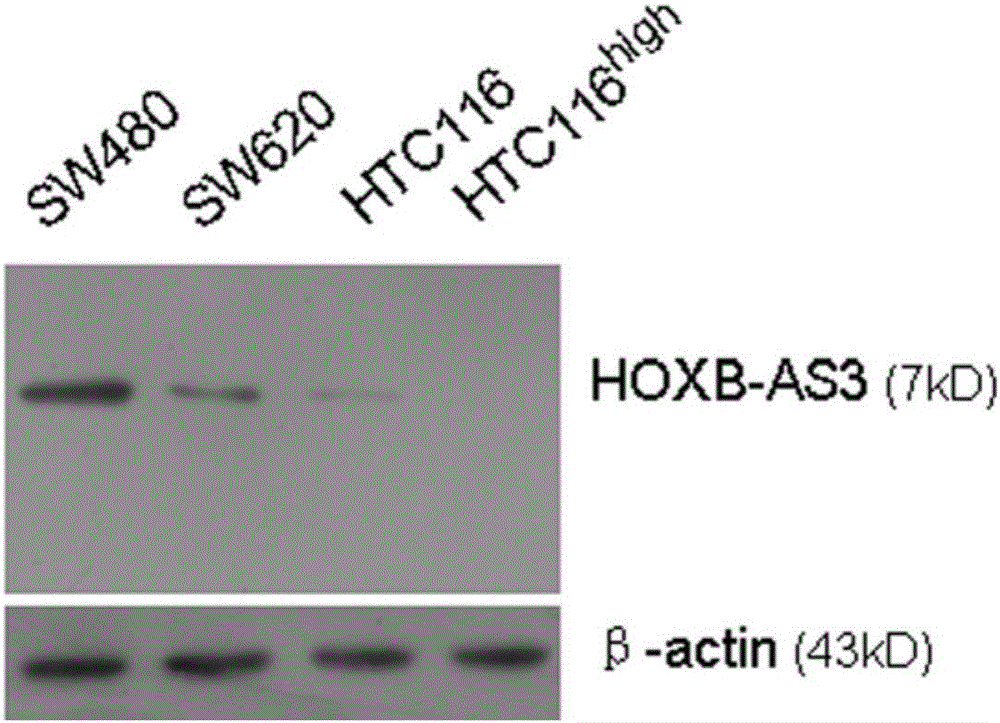

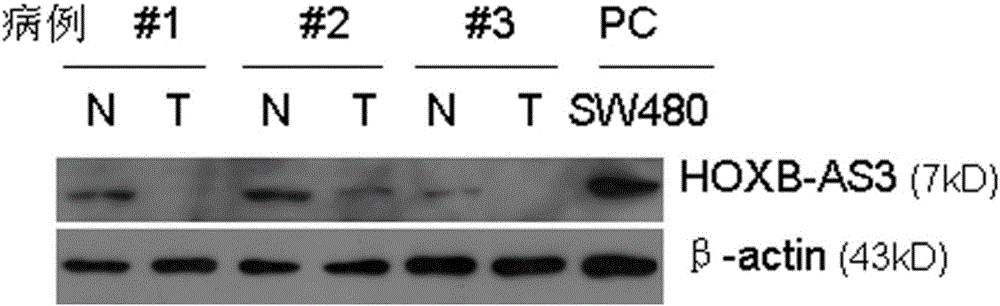

Method and kit for prognosis judgment of colon cancer

ActiveCN106053837AIncreased mortalityShort lifespanDisease diagnosisBiological testingMortality rateClinical study

The invention provides a method for prognosis judgment of colon cancer. The method comprises the step of detecting the amino acid sequence of a polypeptide, wherein the amino acid sequence is the sequence shown in SEQ NO.1 or a sequence with 99% of display content identical with the display content of the sequence shown in SEQ NO.1. A novel marker, namely HOXB-AS3 polypeptide, for prognosis evaluation and judgment of colon cancer is also provided. Clinical study proves that low expression or expression failure of the HOXB-AS3 polypeptide in colon cancer tissue is positively related to poor prognosis of colon cancer patients, and patients with low HOXB-AS3 polypeptide level in colon cancer tissue have higher death rate and shorter lifetime. Therefore, by using the HOXB-AS3 polypeptide as the biomarker, the positive coincidence rate is effectively increased when the kit is clinically applied to prognosis judgment of colon cancer. Furthermore, by detecting the level of the HOXB-AS3 polypeptide in a biological sample tissue slice, generation, malignancy grade and metastatic potential of colon cancer can be judged easily.

Owner:THE THIRD AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIVERSITY

Homogeneous luminescence bioassay

Owner:HIDEX

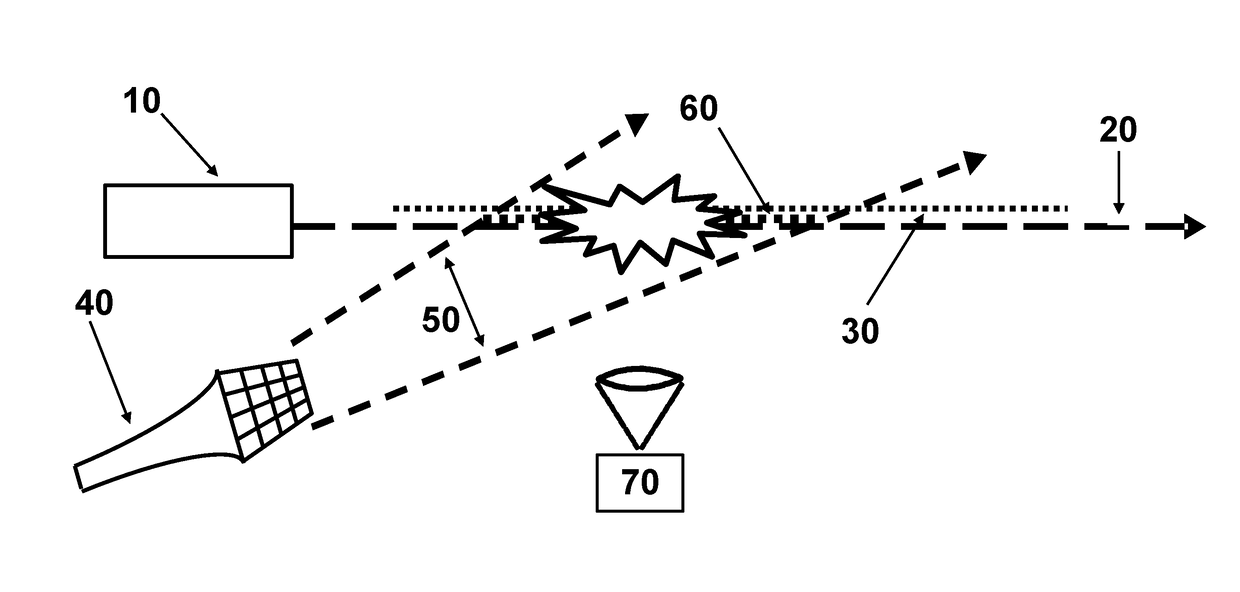

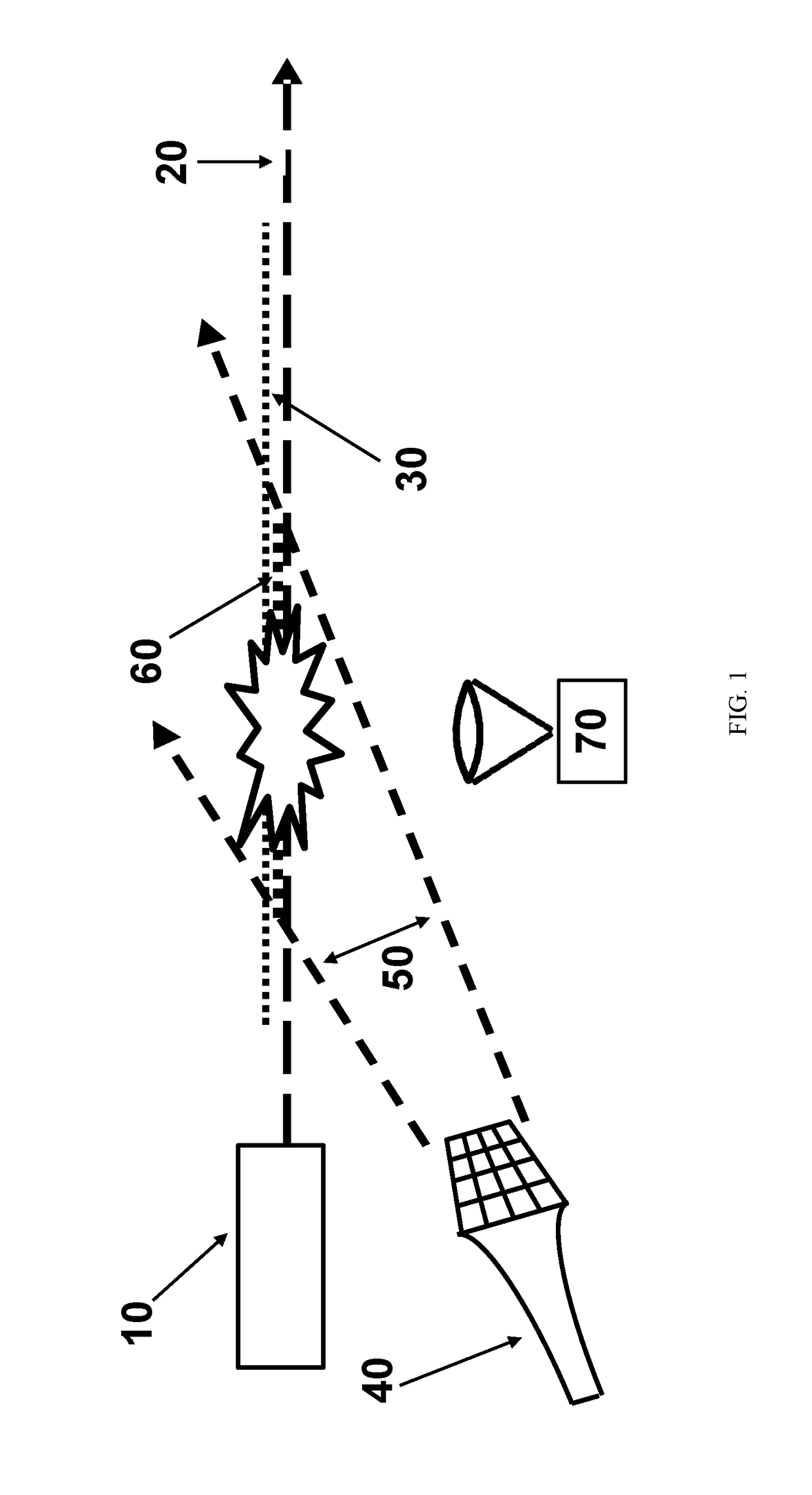

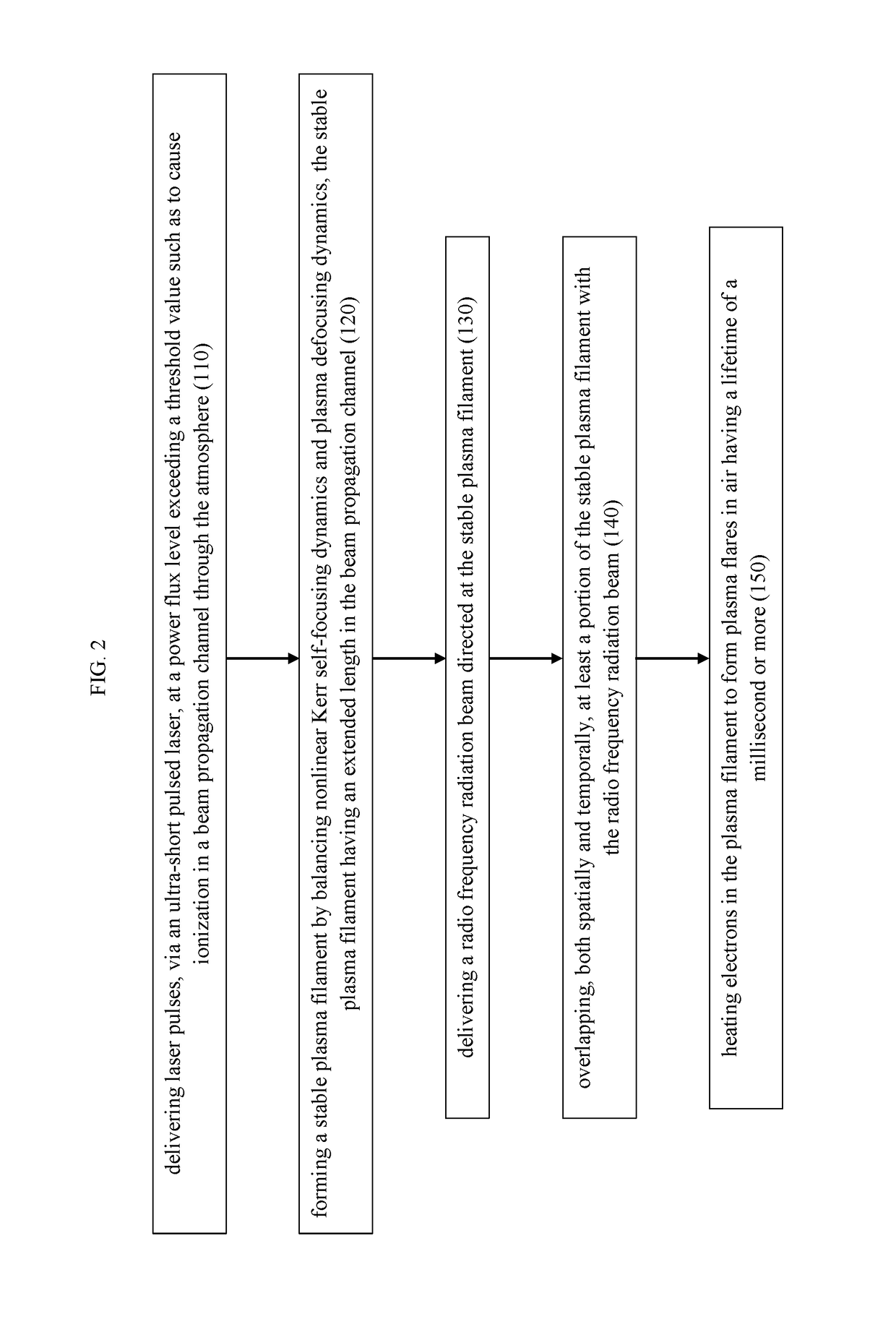

Long lifetime plasma flares by laser breakdown of air with intense RF heating

ActiveUS10104756B1Increase the lengthActive medium materialNon-linear opticsMicrowaveUltra short pulse

The system and method for creating plasma flares in air by using an ultra-short pulse laser (USPL) that generates plasma filaments with a short lifetime (in nanoseconds), and by heating these plasma filaments with intense microwave (RF) radiation to induce robust air breakdown, resulting in long lifetime (up to milliseconds) plasma flares in the atmosphere.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

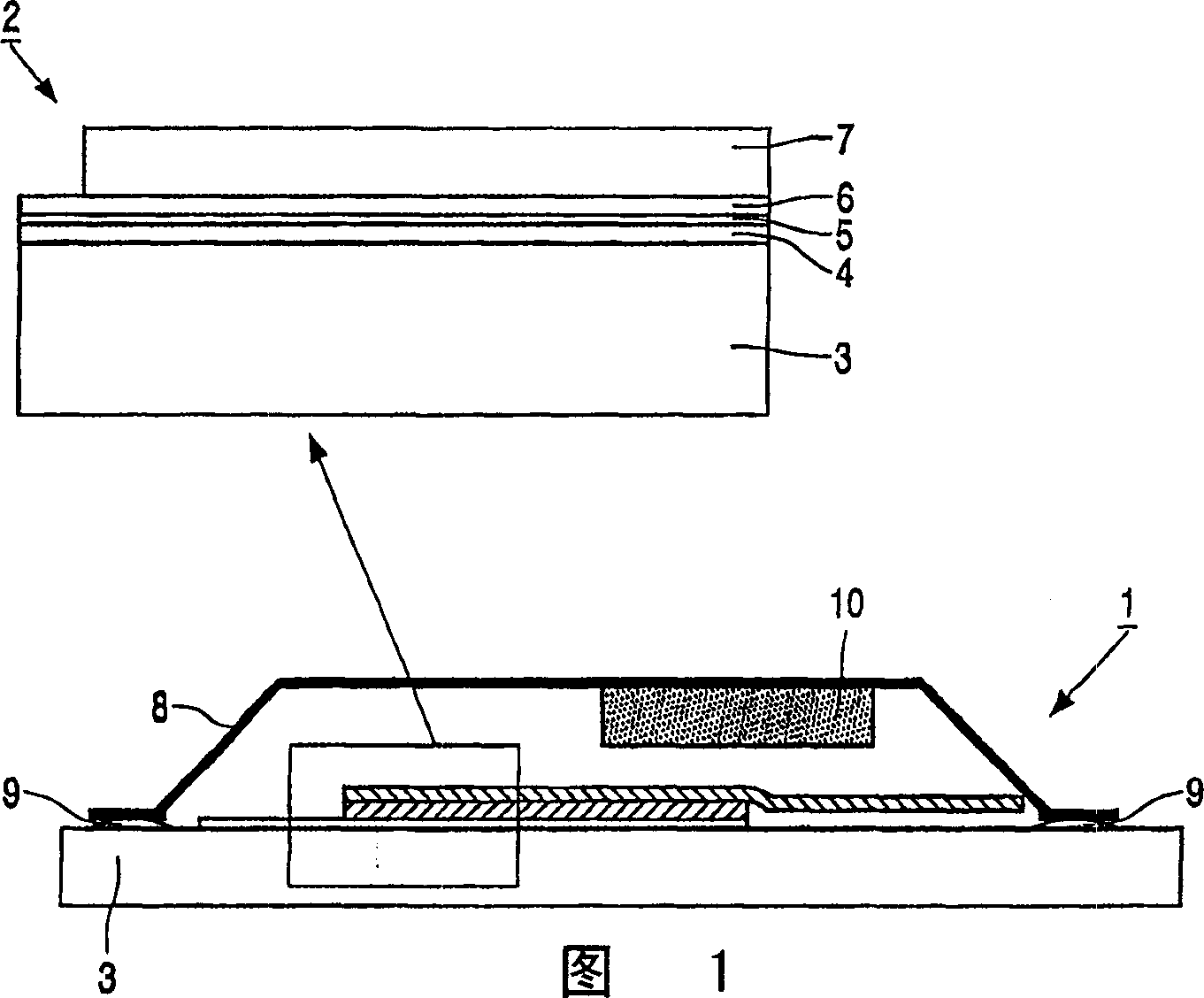

Method for encapsulation of light emitting polymer devices

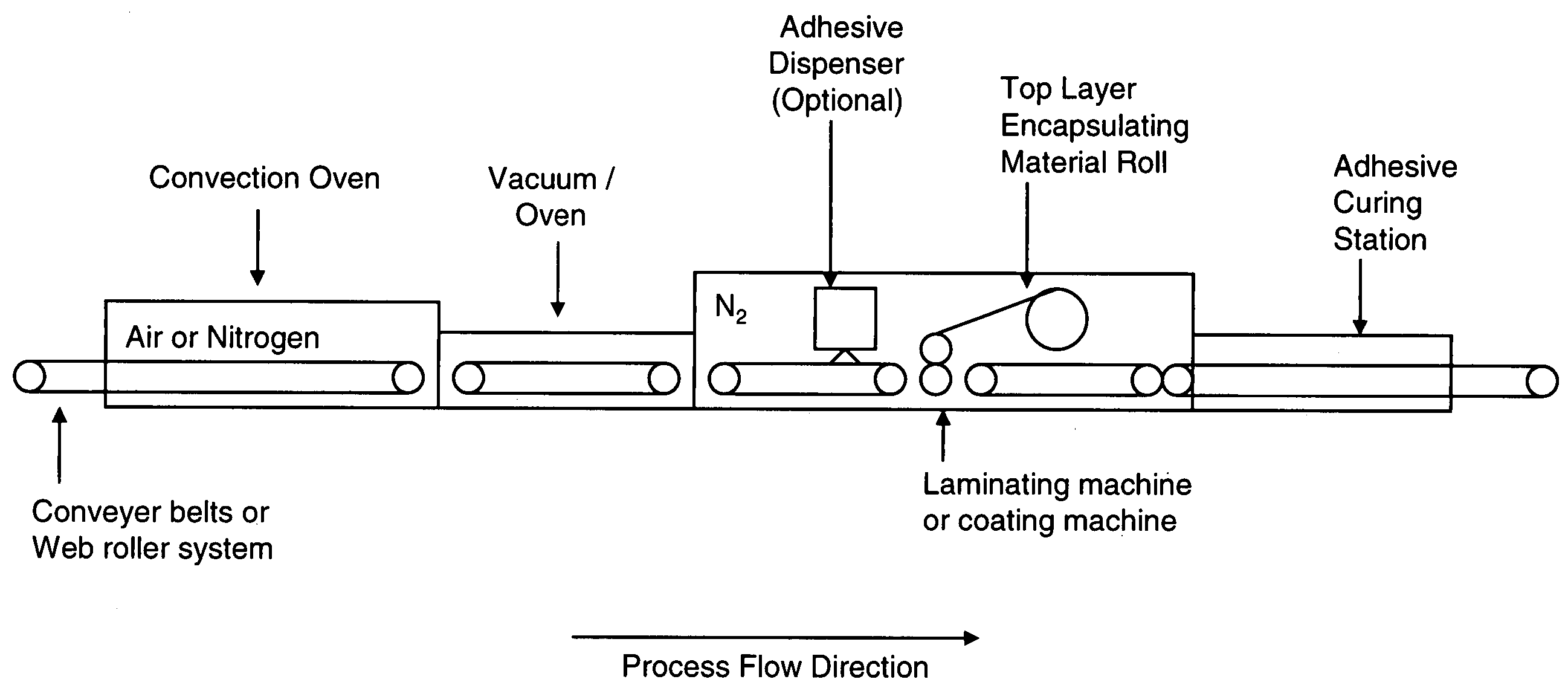

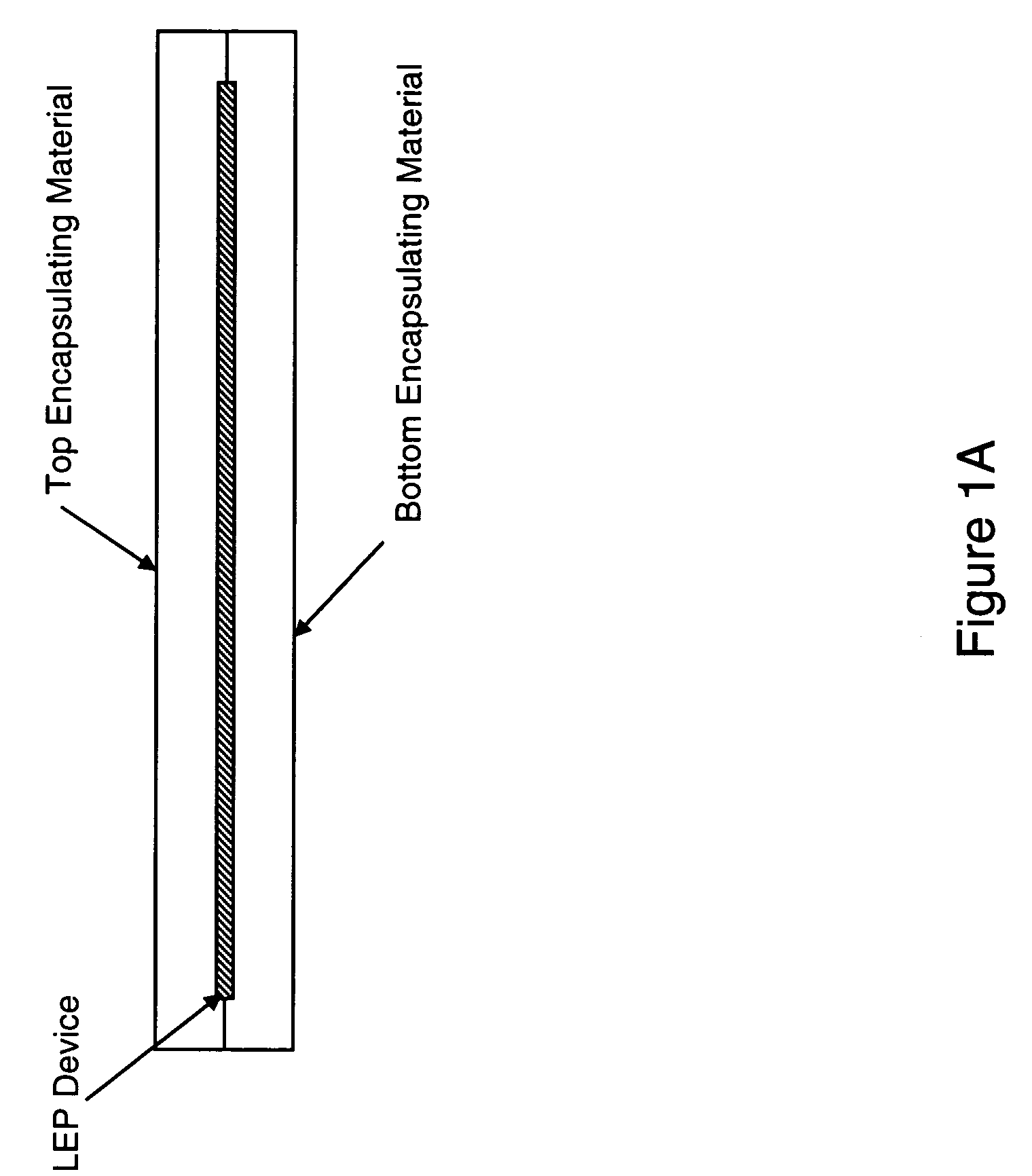

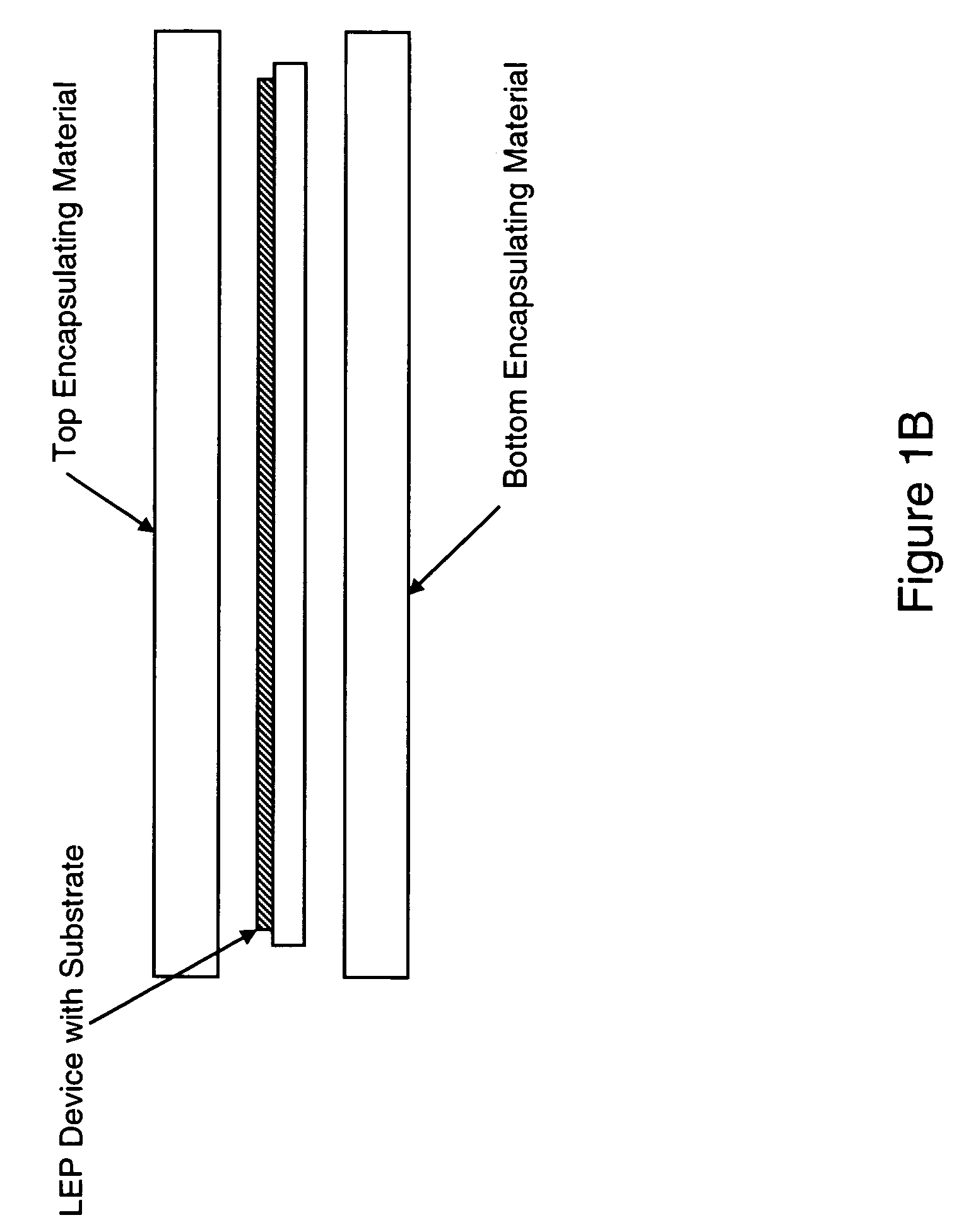

ActiveUS7261795B2Low rateLow dielectric constantDischarge tube luminescnet screensLamination ancillary operationsEpoxyAdhesive

A cost effective manufacturing process encapsulates a light emitting polymer (LEP) device between two flexible sheet materials, where one sheet may act as the substrate for the LEP device and the other sheet may act as a cover for the LEP device, and at least one of the sheets is transparent. Both encapsulating sheets and, as required, an adhesive system binding the sheets together provide sufficient environmental barriers with low moisture vapor transmission rates (MVTR) and oxygen transmission rates (OTR). The encapsulating sheets may, for example, be laminated together, sandwiching the LEP device in a vacuum, or oxygen / moisture free, and inert gas environment. Prior to encapsulation the LEP device may be heated and placed in a vacuum to remove moisture, air and residual solvents. The process may also be designed for roll to roll, sometimes called web based processing, where the LEP device and / or encapsulating sheet material are in a continuous roll format with an adhesive with low air permittivity, such as some UV or thermal curable epoxies, or a melt lamination process used to attach the encapsulating sheets. For LEP devices with short lifetime requirements, the encapsulating material may be in liquid form and applied by spraying, dipping, doctor balding, and the like, or printing, such as screen printing, roller coating or lithographic application in single or multiple layers. Such material may also contain desiccants to further remove water and / or oxygen.

Owner:SUMITOMO CHEM CO LTD

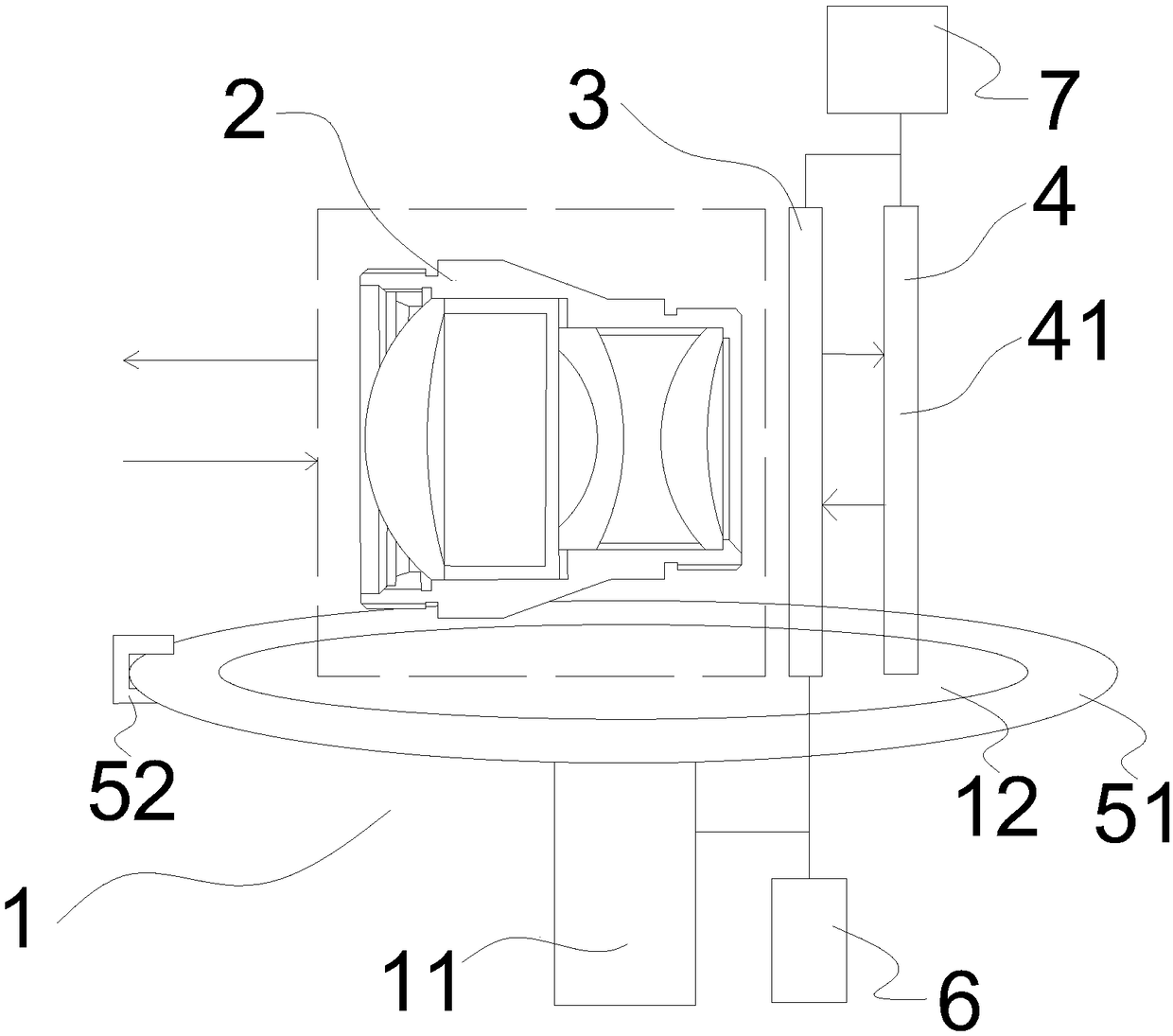

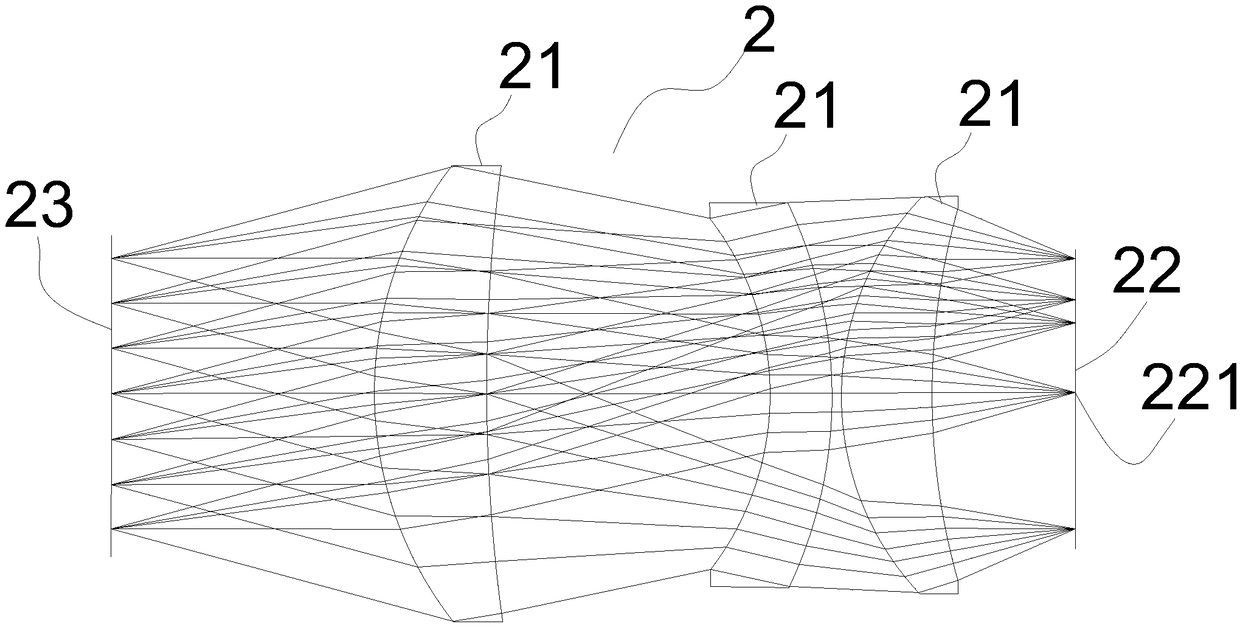

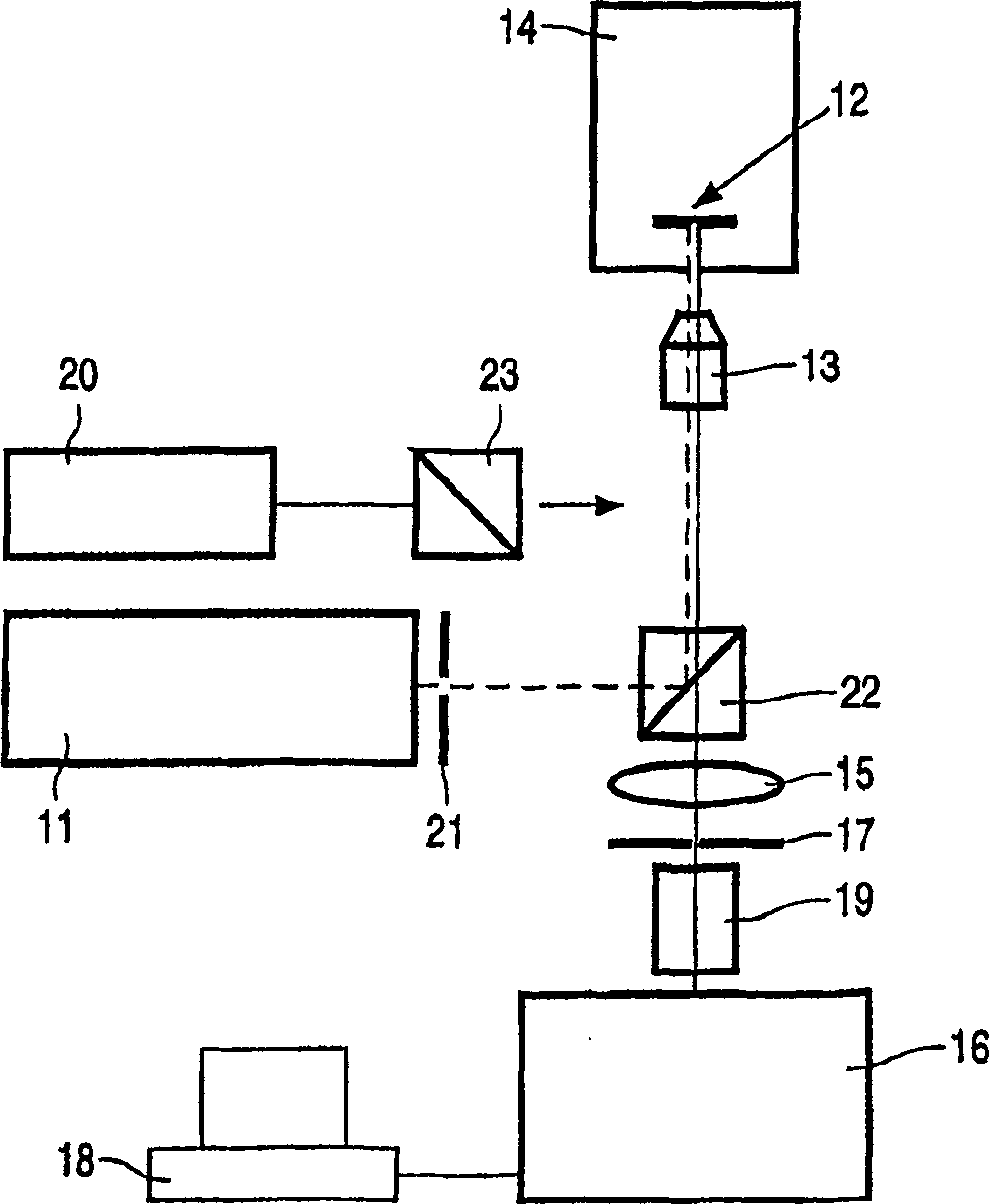

Transmitting and receiving integrated telecentric optical system applied to three-dimensional scanning fiber laser radar

PendingCN109031242ASmall sizeReduce the difficulty of assembly and adjustmentWave based measurement systemsThree dimensional measurementOptoelectronics

The invention discloses a transmitting and receiving integrated telecentric optical system applied to a three-dimensional scanning fiber laser radar and mainly solves the technical problems of low measurement density, low measurement accuracy, large size, poor reliability and short lifetime in the prior art employing a two-dimensional galvanometer to achieve three-dimensional measurement. The transmitting and receiving integrated telecentric optical system applied to the three-dimensional scanning fiber laser radar comprises a driving assembly, a fiber laser assembly, a telecentric lens and areceiving sensor assembly, wherein the fiber laser assembly is used for emitting and receiving laser, the telecentric lens is used for achieving emission laser collimation and receiving laser convergence, the receiving sensor assembly is used for receiving the laser, the telecentric lens, the fiber laser assembly and the receiving sensor assembly are sequentially arranged, and the driving assemblyis used for simultaneously driving the telecentric lens, the fiber laser assembly and the receiving sensor assembly to rotate. With the transmitting and receiving integrated telecentric optical system disclosed by the technical scheme, the problem is solved very well, and the transmitting and receiving integrated telecentric optical system can be applied to the three-dimensional laser radar.

Owner:SUZHOU UNION INTELLIGENT TECH CO LTD

Homogeneous Luminescence Bioassay

This invention relates to a homogenous bioassay for use in measurement of biological activity, its modulation or analyte concentration of a sample, said bioassay comprising a first group comprising an acceptor, which acceptor is a short lifetime fluorescent compound capable of energy transfer, and a second group comprising a quencher, which quencher is capable of energy transfer from an acceptor. The increase or decrease, respectively, of fluorescence of said acceptor due to the decrease or increase, respectively, of energy transfer from said acceptor to said quencher resulting from lengthening or shortening, respectively, of the distance between said acceptor and quencher is measured. Characteristic for the invention is that the bioassay comprises a further third group comprising a donor for energy transfer to said acceptor, which donor is an up-conversion fluorescent compound, a long-lifetime fluorescent compound or an electrogenerated luminescent compound; and said first group comprises a tag, said third group comprises a binder, and said binder has a high affinity for binding to said tag. The fluorescence of said acceptor is brought about by exciting the donor resulting in energy being transferred from the donor to the acceptor.

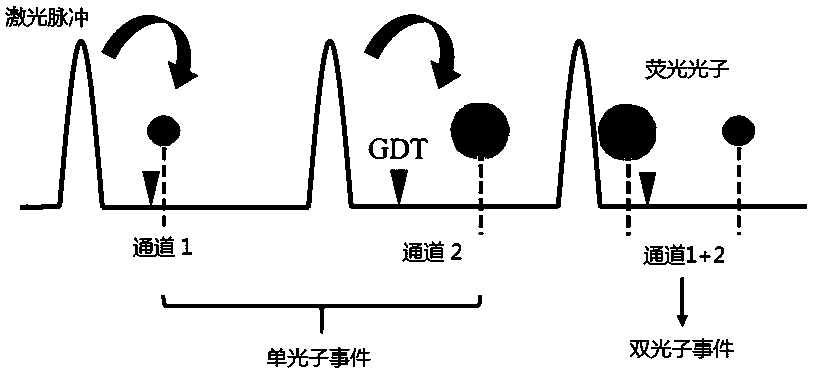

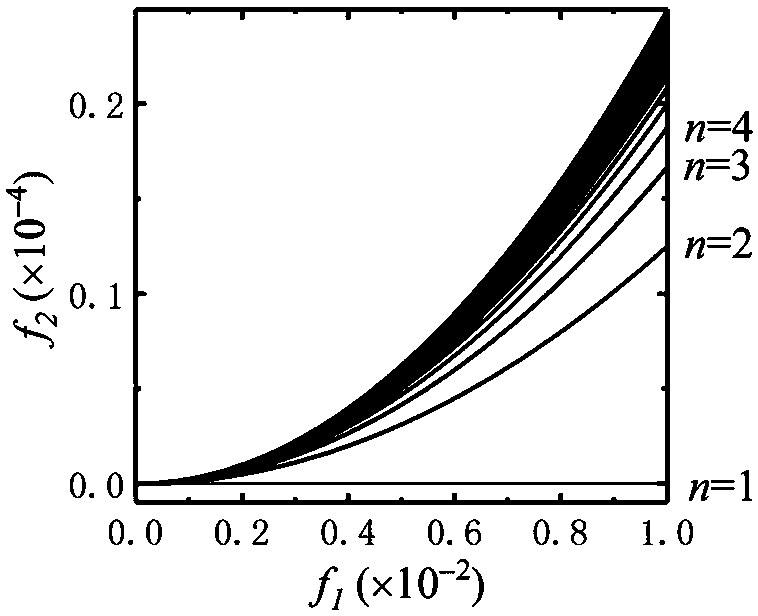

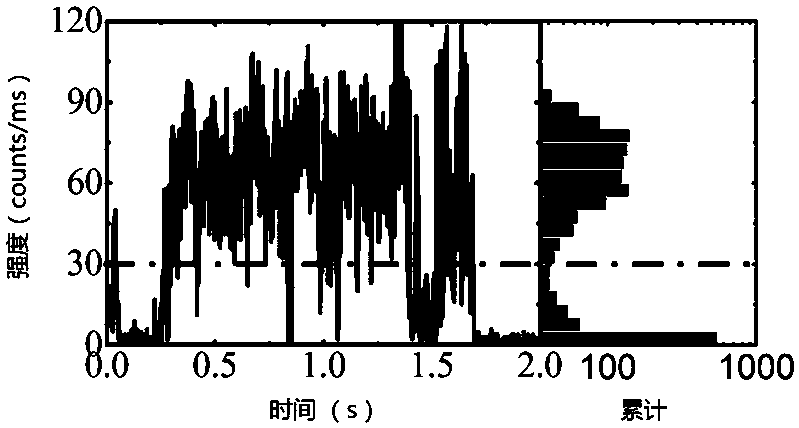

Fast identification method for single quantum dot

ActiveCN108387558AEfficient identificationEfficient manufacturingFluorescence/phosphorescenceQuantum yieldQuantum entanglement

The invention relates to the quantum information field, in particular to a fast identification method for single quantum dot. Directed at quantum dots with high biexciton quantum yield and fluorescence blinking, the fast identification method for single quantum dot effectively eliminates biexciton photon generated by biexciton state based on the characteristic that biexciton state has shorter lifetime than single exciton state. The novel quantum dots with high biexciton quantum yield can be used for preparation of correlated photon pair sources effectively, and can be used in quantum key distribution, quantum entanglement and other quantum information fields, wherein the fast identification of single quantum dot is crucial for preparation of correlated photon pair sources.

Owner:SHANXI UNIV

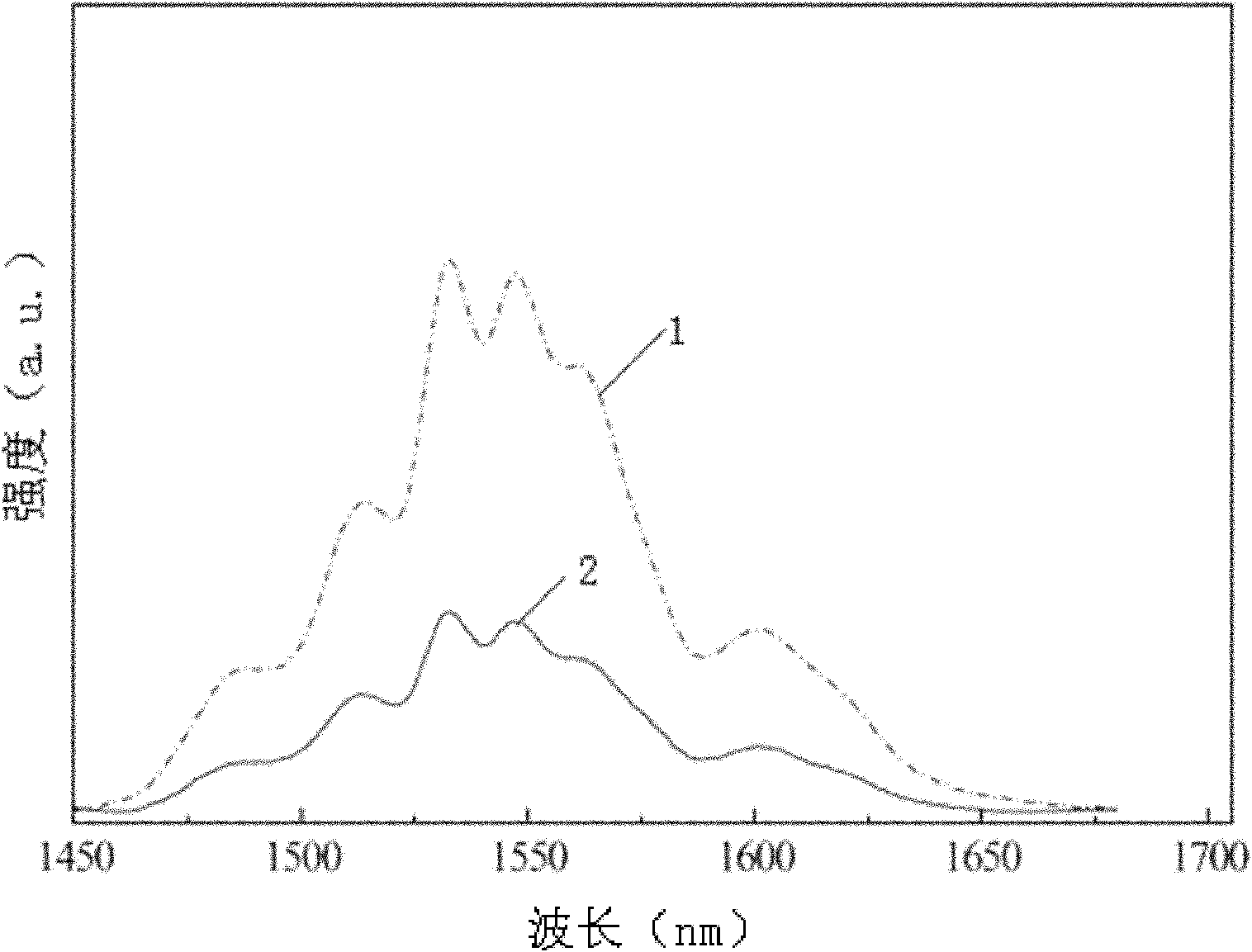

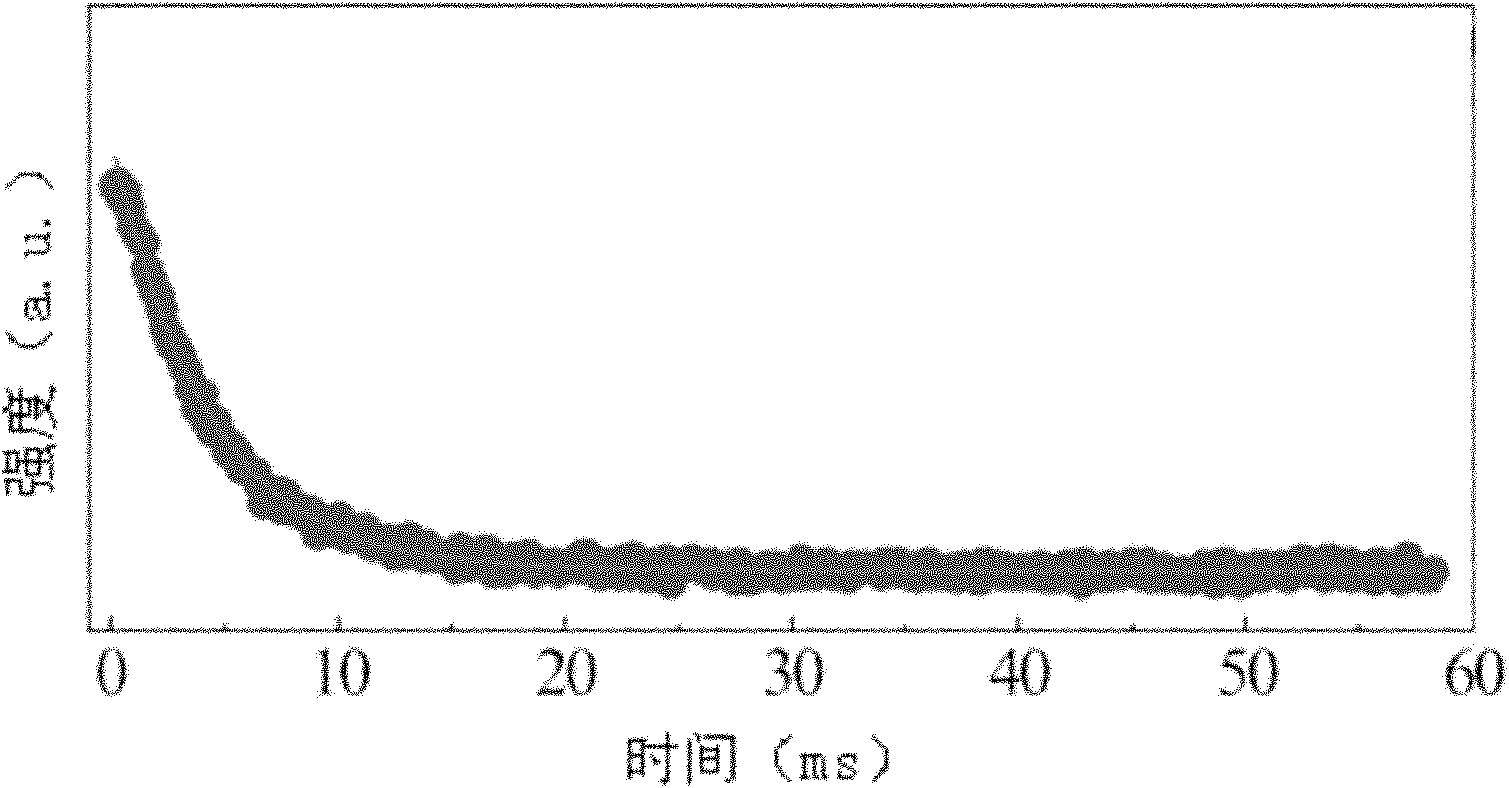

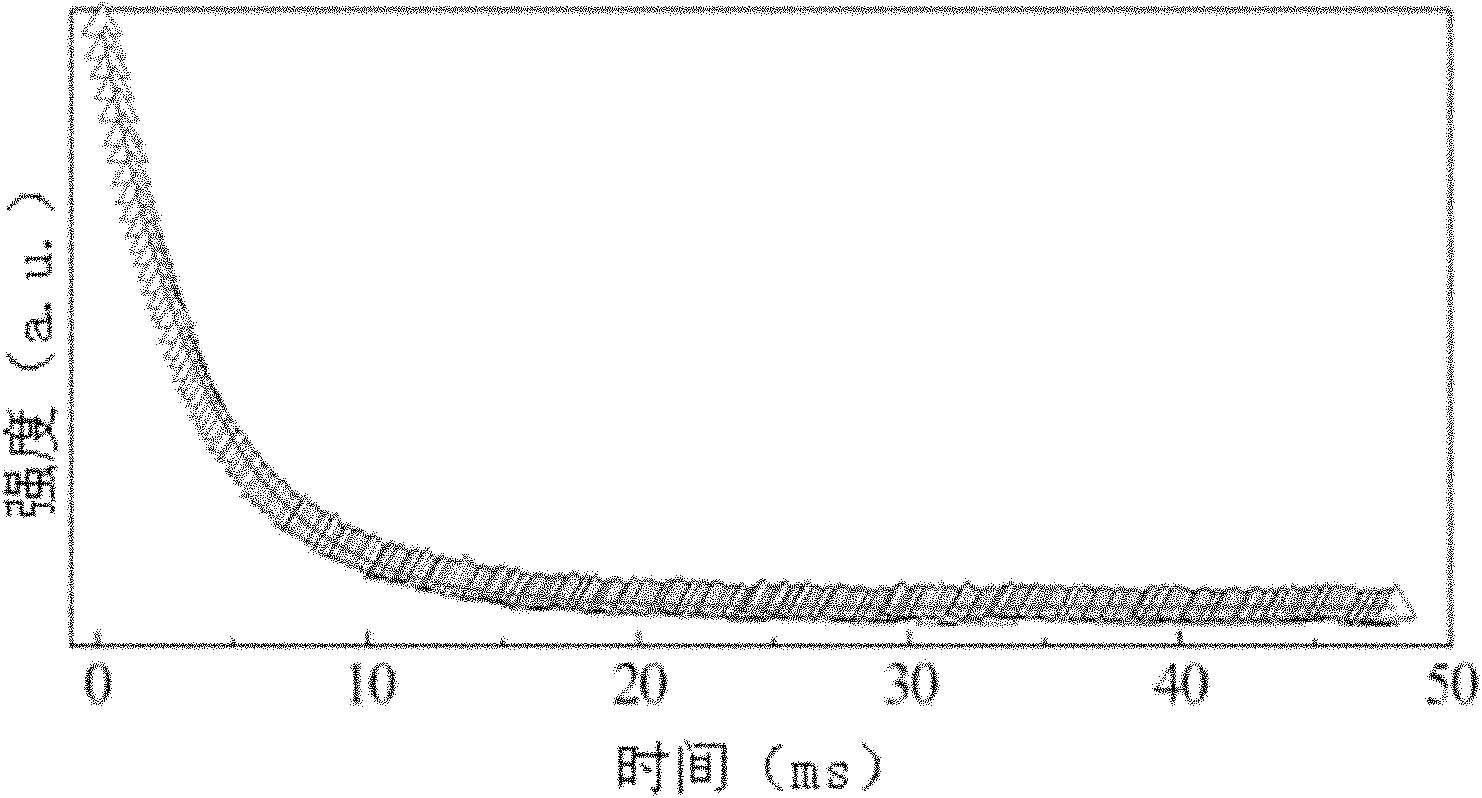

Zirconium, erbium and ytterbium-doped lithium niobate crystal and preparation method thereof

InactiveCN102162133AIncreased light emission intensityHigh luminous intensityPolycrystalline material growthBy pulling from meltYTTERBIUM OXIDELuminous intensity

The invention discloses zirconium, erbium and ytterbium-doped lithium niobate crystal and a preparation method thereof, and relates to three-doped LiNbO3 crystal and a preparation method thereof. The problems of low luminous intensity and short lifetime of the conventional erbium-doped lithium niobate crystal are solved. The zirconium, erbium and ytterbium-doped lithium niobate crystal is prepared from five raw materials, namely zirconium oxide, erbium oxide, ytterbium oxide, niobium pentaoxide and lithium carbonate. The method comprises the following steps of: weighing the raw materials, melting the raw materials to obtain a melt, performing crystal growth by adopting a pulling method, annealing, and performing polarization treatment. Compared with an un-doped sample, the emission intensity of the crystal under 1,550nm band light is improved by about 3 times. The 4I13 / 2 energy level life tau of Er<3+> ions of the crystal reaches 4.23ms, is prolonged by 8.18 percent compared with the erbium and ytterbium-doped lithium niobate crystal, and is prolonged by nearly two times compared with the life (2.3ms) of the single Er (1mol%)-doped LiNbO3 crystal. The crystal has good application prospect on the aspects of optical waveguide laser devices and amplifiers.

Owner:HARBIN INST OF TECH

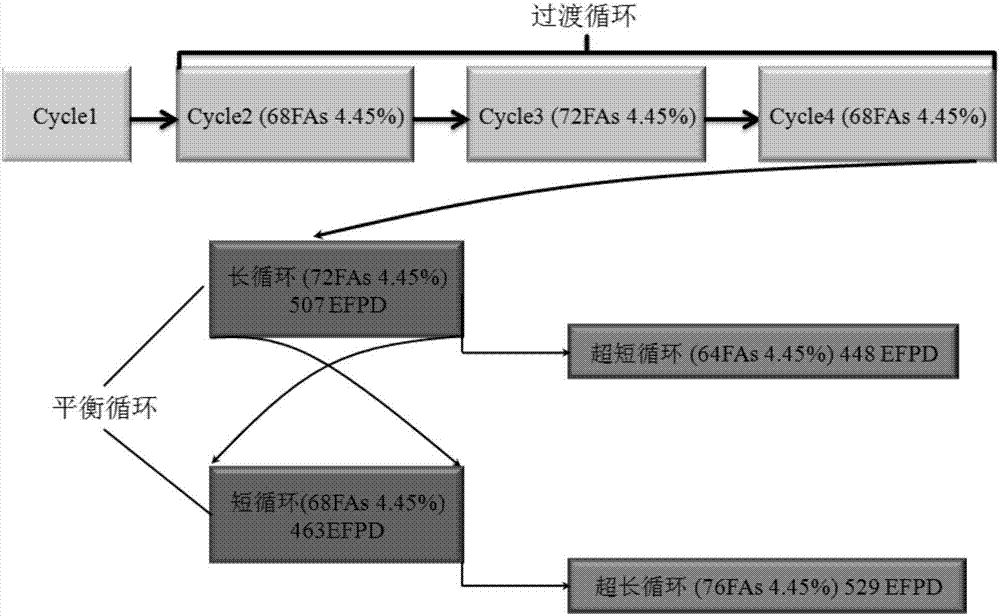

Refueling and loading method of pressurized water reactor core with alternative lifetime length

InactiveCN107093480AAdapt to grid requirementsPossess engineering practical valueNuclear energy generationReactor fuel elementsPressurized water reactorReactor design

The invention belongs to the technical field of reactor design, and relates to a refueling and loading method of a pressurized water reactor core with alternative lifetime length. According to the refueling and loading method, in order to achieve long lifetime circulation, when refueling is conducted, 72-80 groups of fuel assemblies which have the longest burning time in 170-180 groups of fuel assemblies of the reactor core are replaced with new fuel assemblies; in order to achieve short lifetime circulation, when refueling is conducted, 60-68 groups of fuel assemblies which have the longest burning time in 170-180 groups of fuel assemblies of the reactor core are replaced with new fuel assemblies, when the fuel assemblies are replaced, the new fuel assemblies are placed at a secondarily outer circle of the reactor core and at the position close to the center of the reactor core, and burned fuel assemblies are placed at other positions of the reactor core. By the adoption of the refueling and loading method of the pressurized water reactor core with the alternative lifetime length, the purpose can be achieved that the lifetime length of the pressurized water reactor core is alternative and / or adjustable, and on the basis of the alternative and / or adjustable lifetime length of the pressurized water reactor core, overlong lifetime circulation and ultrashort lifetime circulation can be further achieved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Image forming apparatus, image forming unit, and erase light control method

InactiveUS8391749B2Efficiently extending lifetimeSuppression of image deteriorationElectrographic process apparatusImage formationComputer science

Electric charge remaining on a photoreceptor after transfer causes image deterioration. According to one conventional method widely used in view of this problem, erase light is emitted onto a photoreceptor after the transfer to remove the electric charge remaining on the photoreceptor. However, such a method poses the following problem: emission of erase light leads to light-induced fatigue of the photoreceptor, and as a result, the photoreceptor which has deteriorated from the light-induced fatigue wears down due to abrasion and the like with a cleaner blade, resulting in a shorter lifetime of the photoreceptor. Thus, the thickness of the photosensitive layer is detected to acquire the amount of thickness decrease, and the amount of the erase light is reduced according to the acquired amount of thickness decrease.

Owner:KONICA MINOLTA BUSINESS TECH INC

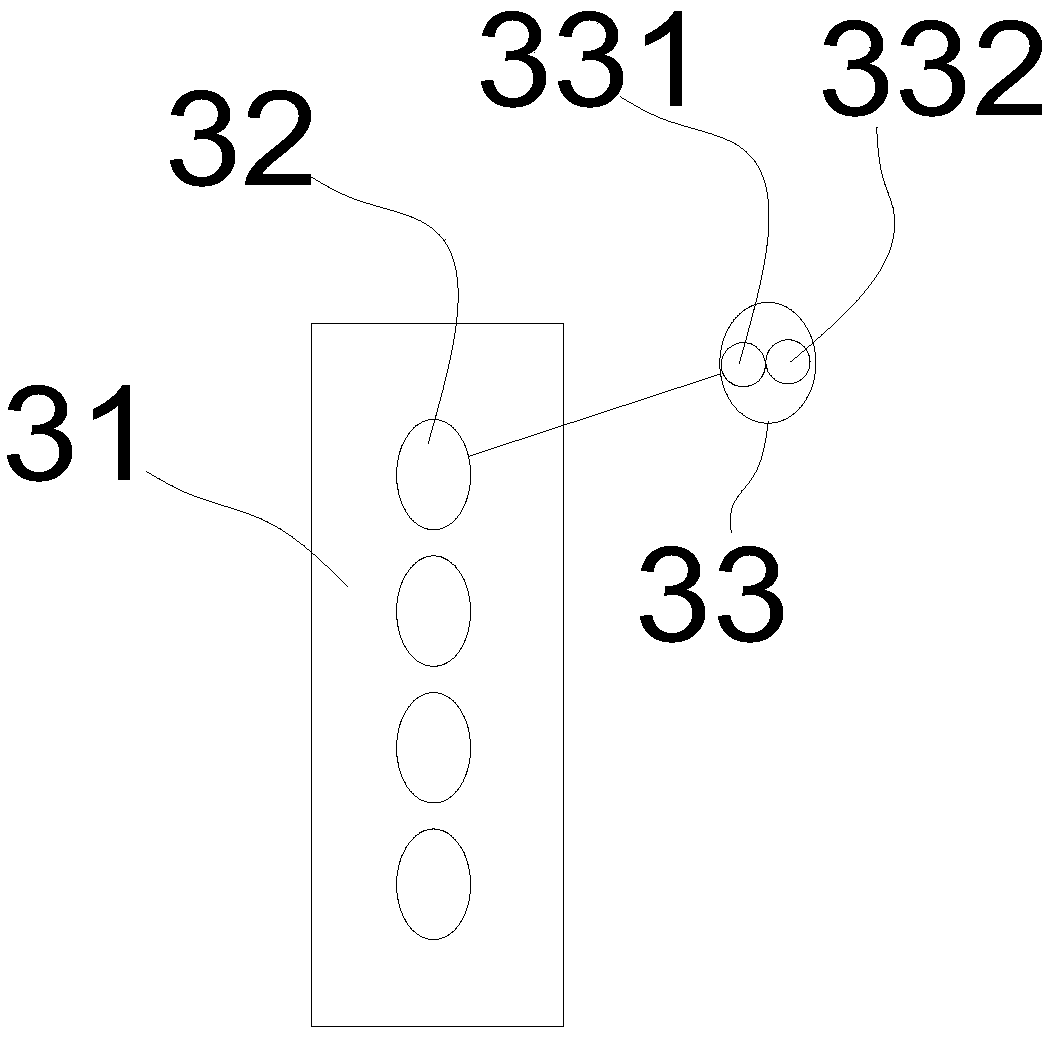

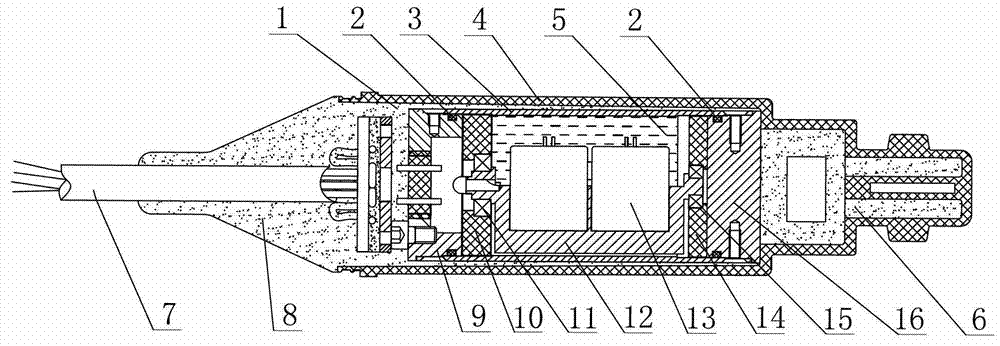

Whole sealing double check detector

InactiveCN102879810AAvoid enteringImprove the ability to receive vibration signalsSeismic signal receiversAnti jammingSilicone oil

The invention provides a whole sealing double check detector which solves the technical problems of poor sealing performance caused by unsteady quality and burn-in of an O-shaped sealing ring and reduced anti-jamming capability and short lifetime both caused by silicone oil leakage of the existing double check detector. The whole sealing double check detector is provided with an outer shell; the outer shell is internally provided with a main rotating hull; the main rotating hull is provided with a detector core; one side of the outer shell is provided with an outgoing cable and a sealing plug, and the other side of the outer shell is provided with a hydrophone probe; the outer shell and the hydrophone probe are externally provided with an outer protecting shell; and the outer protecting shell is connected with the sealing plug. The whole sealing double check detector can be widely used in the area of the detector.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

Method and apparatus for leak-testing electroluminescent device

InactiveCN1529820AQuick leak detectionNon-destructiveSemiconductor/solid-state device testing/measurementElectroluminescent light sourcesNon destructiveOrganic electroluminescence

A method of detecting the leak-in of oxygen in an organic electroluminescent device via the extent of photo-degradation of the electroluminescent organic material is described. The photo-degradation of the electroluminescent organic material is induced by the presence of oxygen, and can be detected by comparing the photo luminescence of the material, before and after illumination of the material with light (e.g. form a laser). Photo-degradation due to the presence of oxygen in an encapsulated organic electroluminescent device is evidence for a leak in the device, which leak will result in a shorter lifetime of the device. The invention provides a fast, non-destructive method of inspecting organic electroluminescent devices on leakage, immediately after their production. Leak devices can be identified and discarded, even on-line.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com