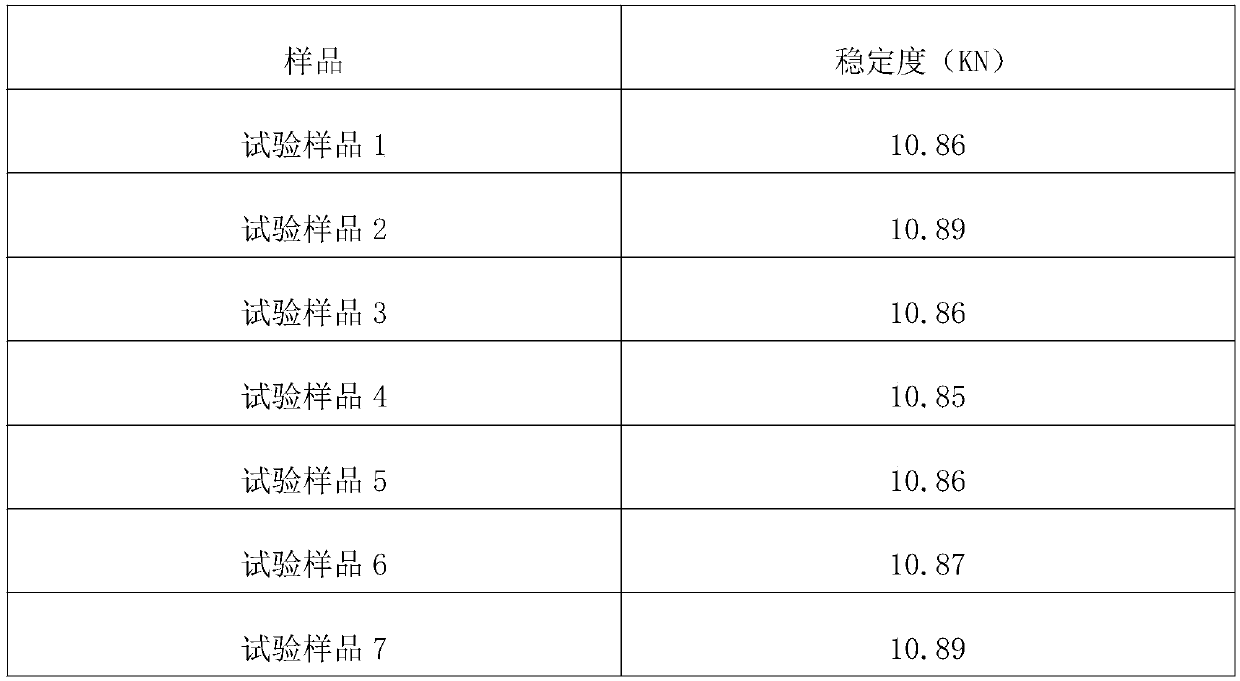

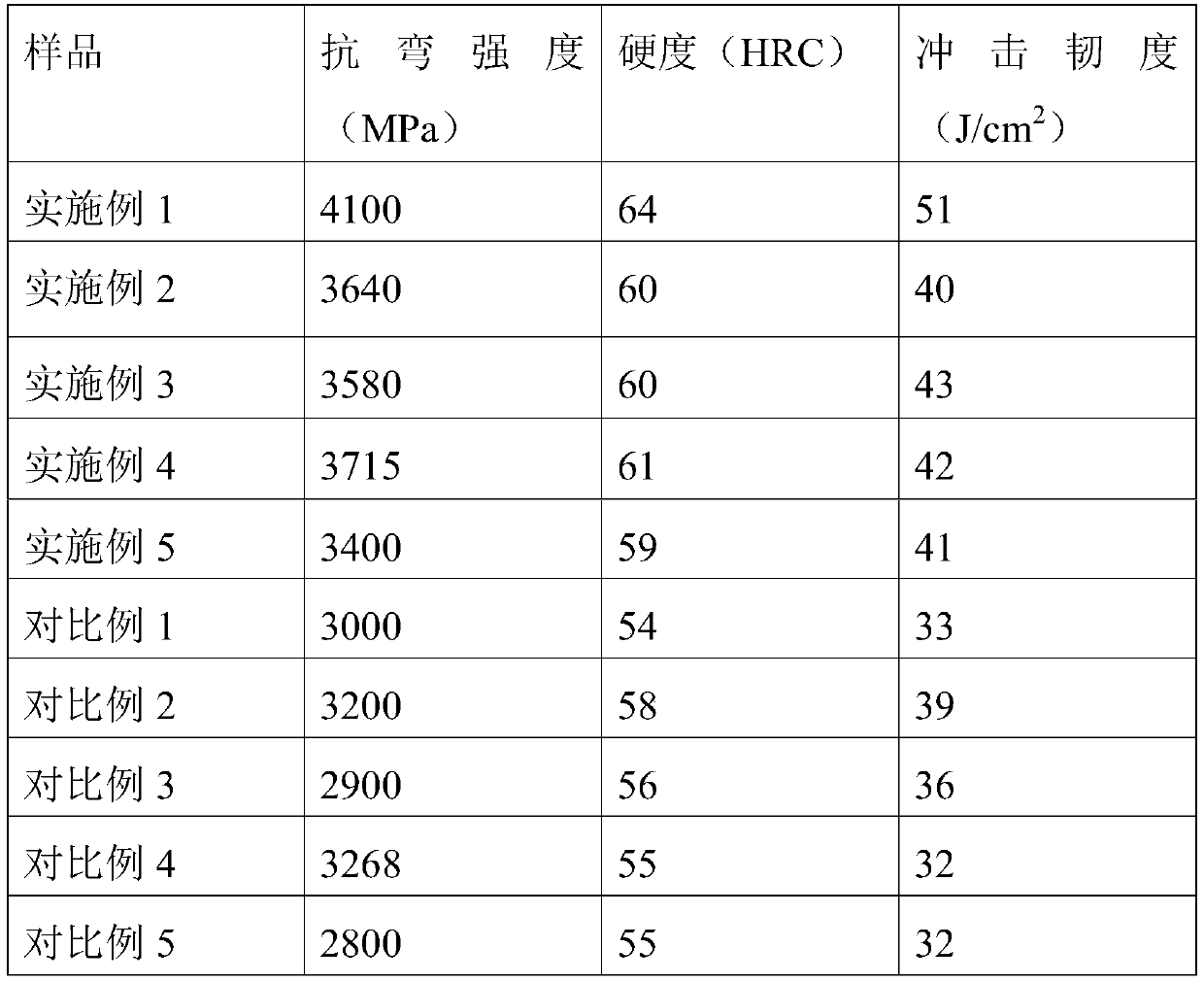

Patents

Literature

138results about How to "Reduce internal porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

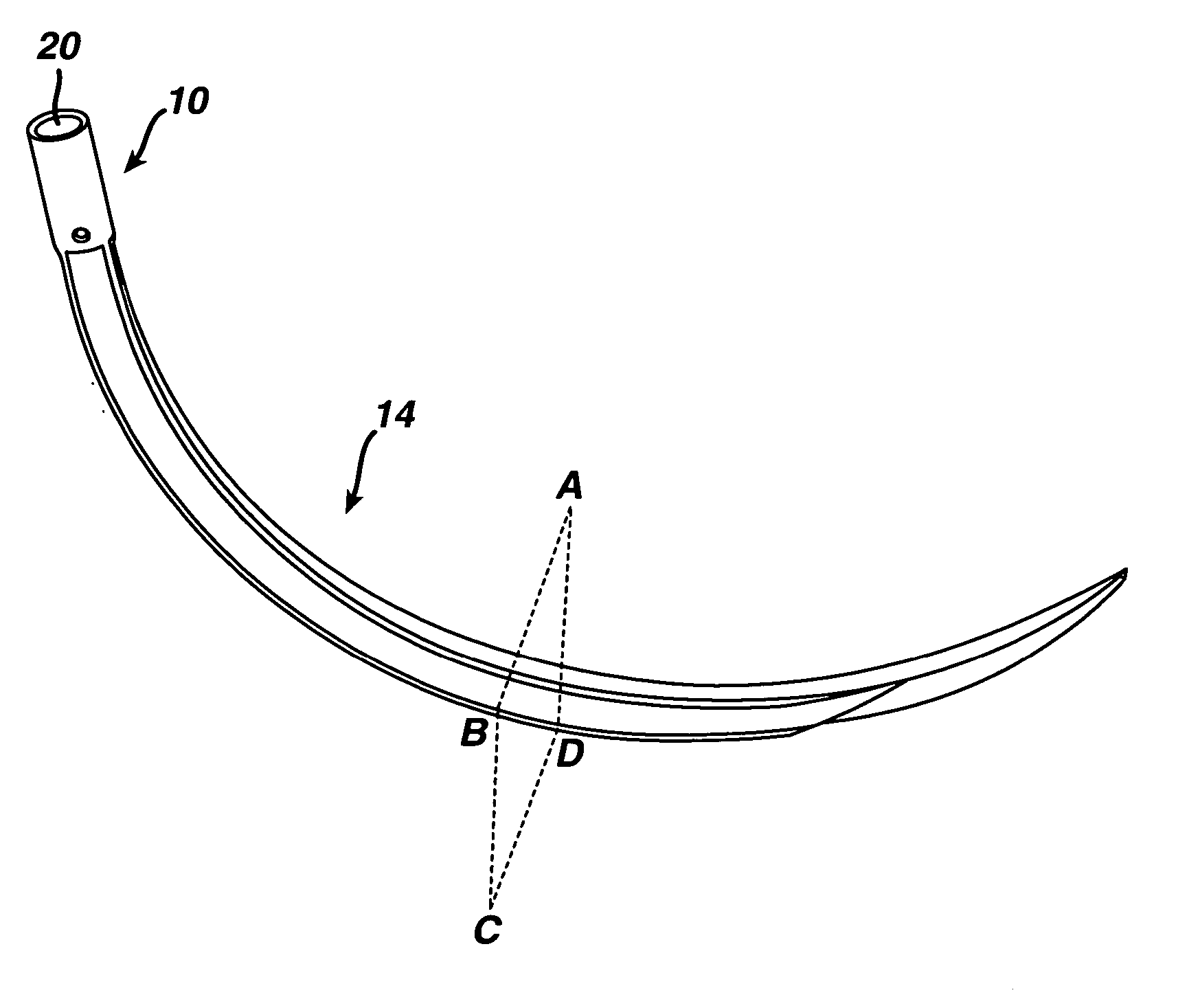

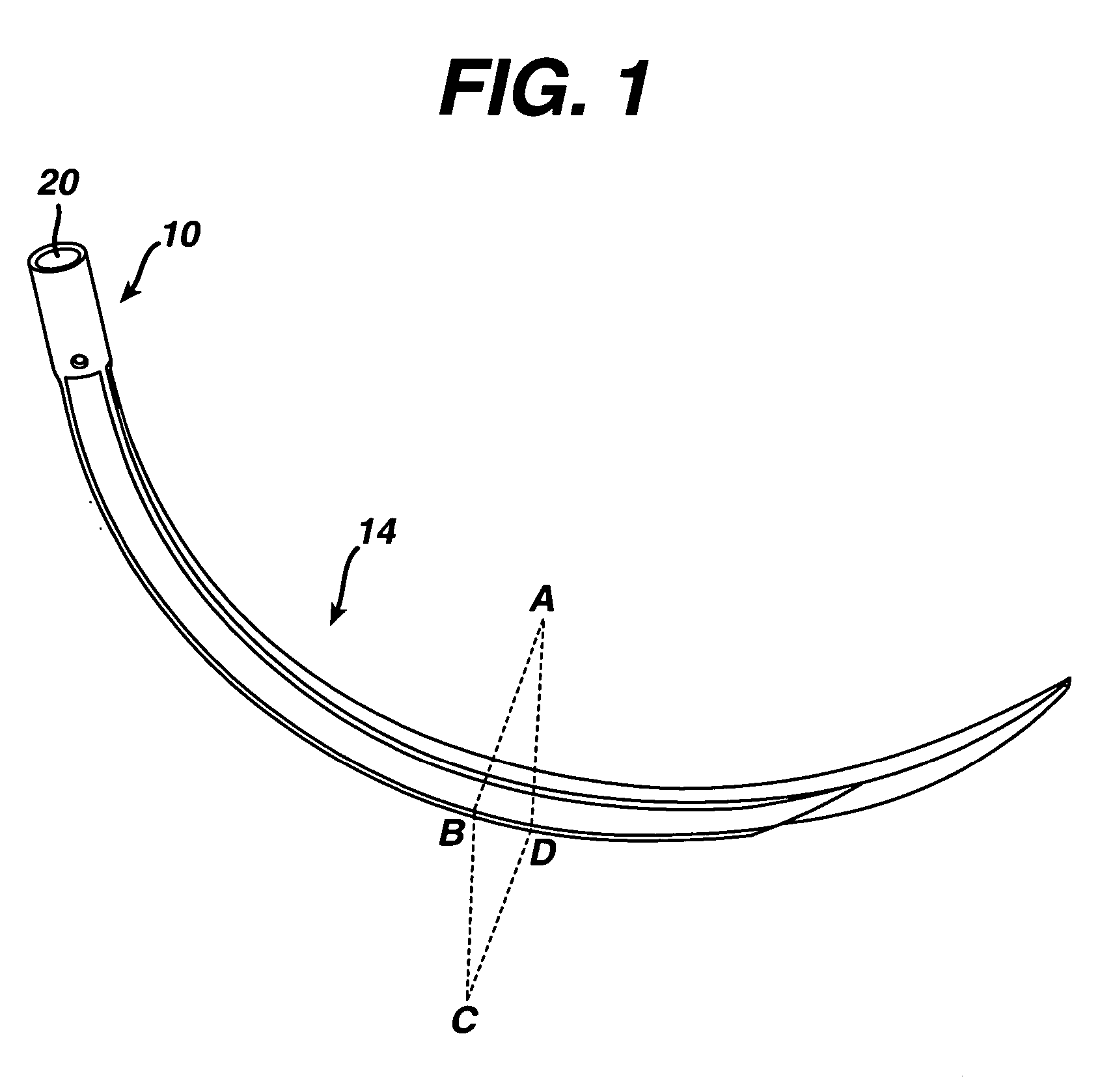

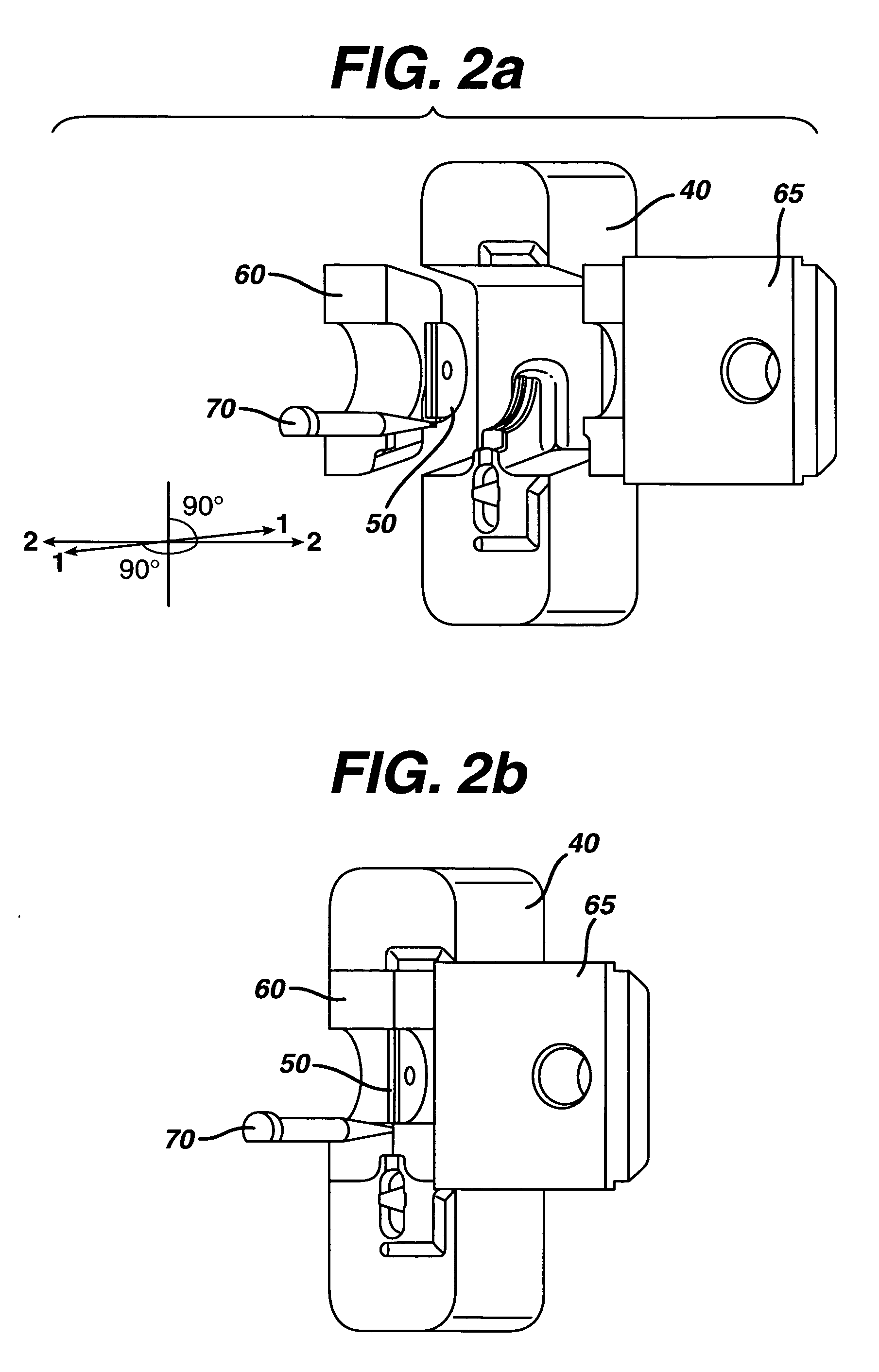

Metal injection molded suture needles

The metal-injection molding (MIM) process offers distinct advantages over conventional wire-based methods for producing suture needles. Methods for producing unique suture receiving holes that accommodate large diameter sutures and facilitate adhesive attachment of said sutures are described herein. Additionally, methods for producing cutting edge suture needles that exhibit exemplary tissue penetration performance are described. Finally, the ductility of suture needles produced via the MIM process have been enhanced substantially by employing processes that reduce the internal porosity of the suture needle component.

Owner:ETHICON INC

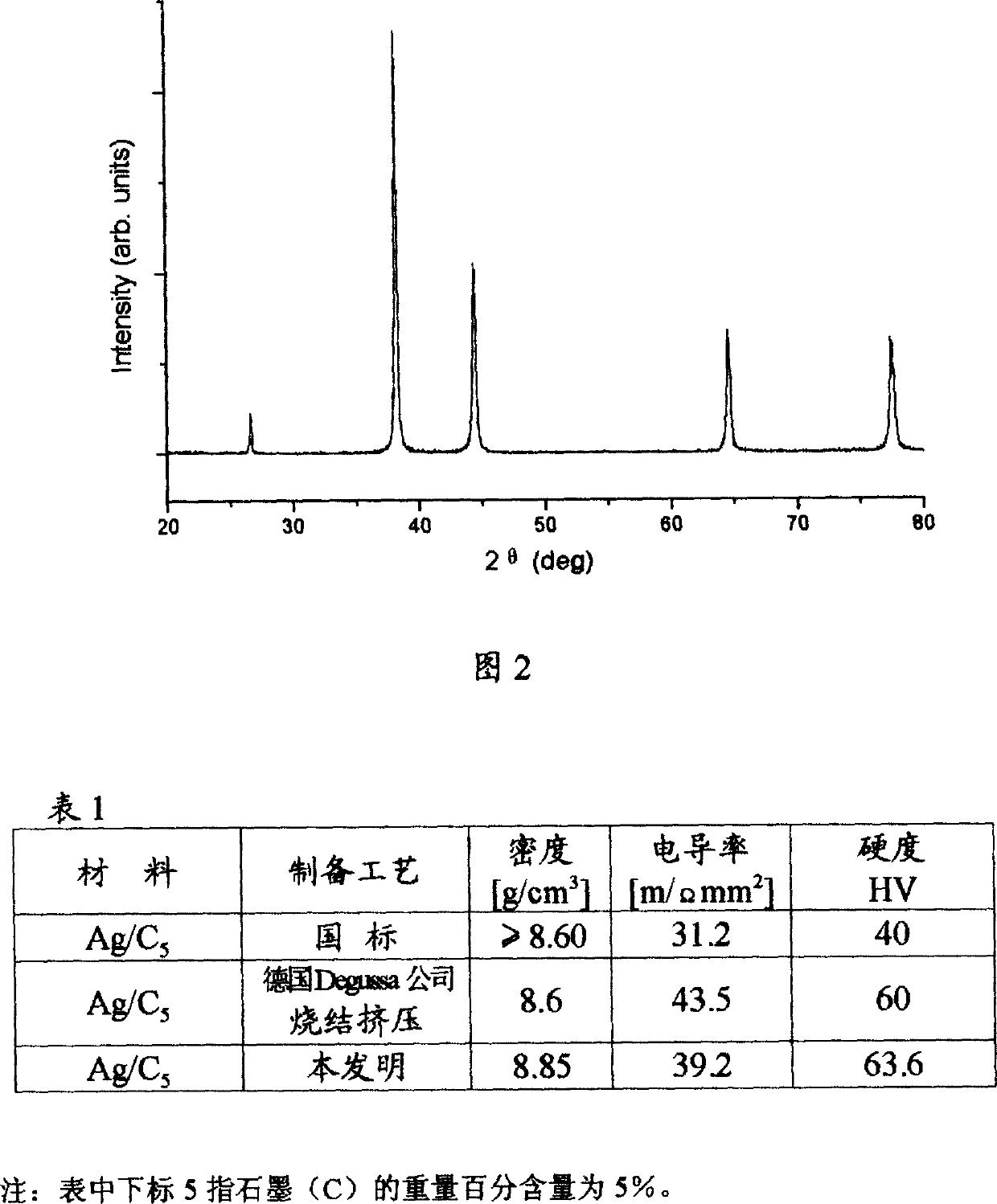

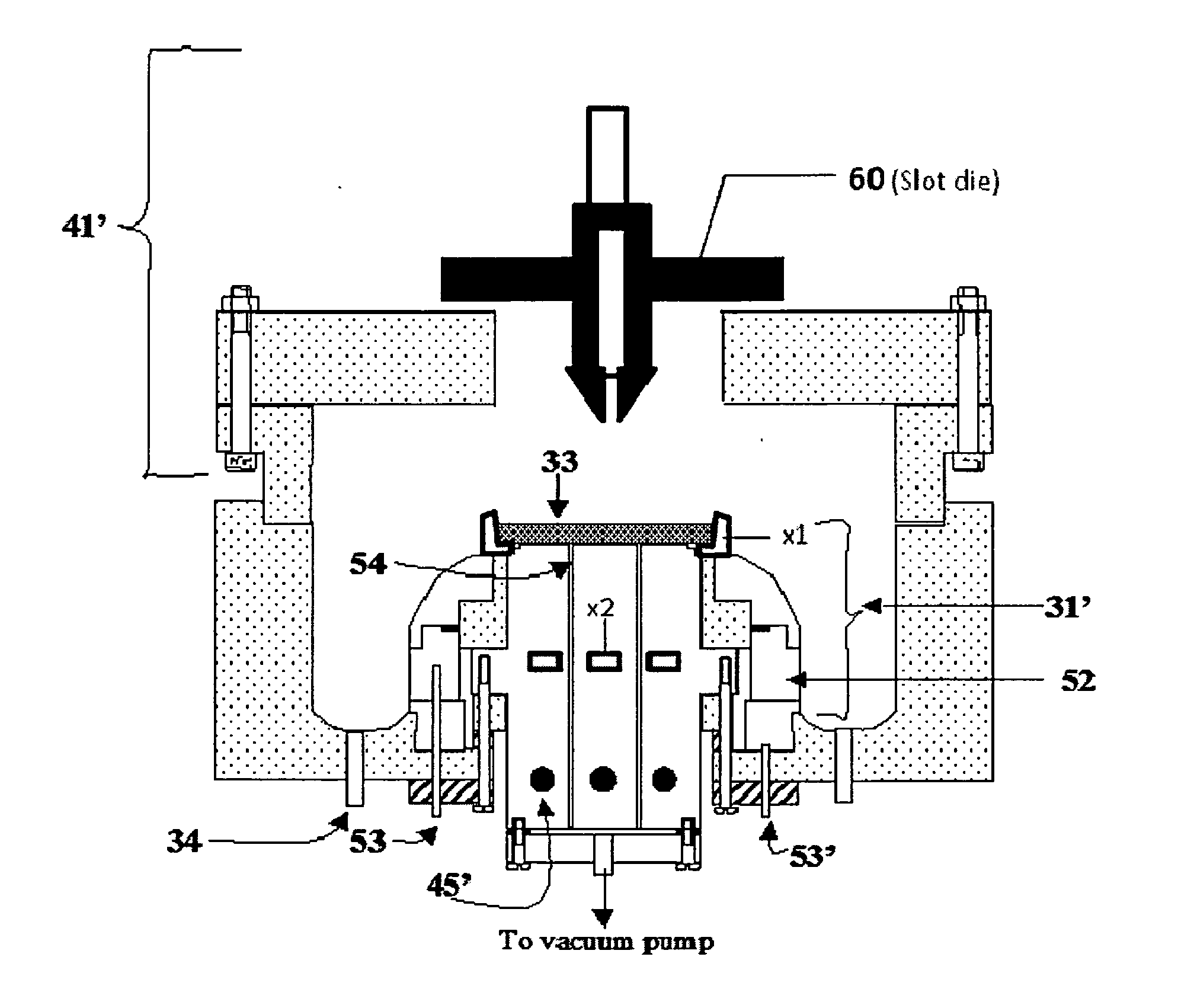

Process for preparing electric silver/graphite contact material by nano technique

InactiveCN1396025AImprove sinterabilityImprove the bonding strength of the interfaceContact materialsGraphiteNanometre

A process for preparing the silver / graphite material as electric contact by use of nanometre technique includes such steps as preparing graphite nanometre powder; adding silver nitrate solution; chemical coating; washing with water; drying and sintering. Its advantages are simple process, low cost and high quality of product.

Owner:EAST CHINA NORMAL UNIV

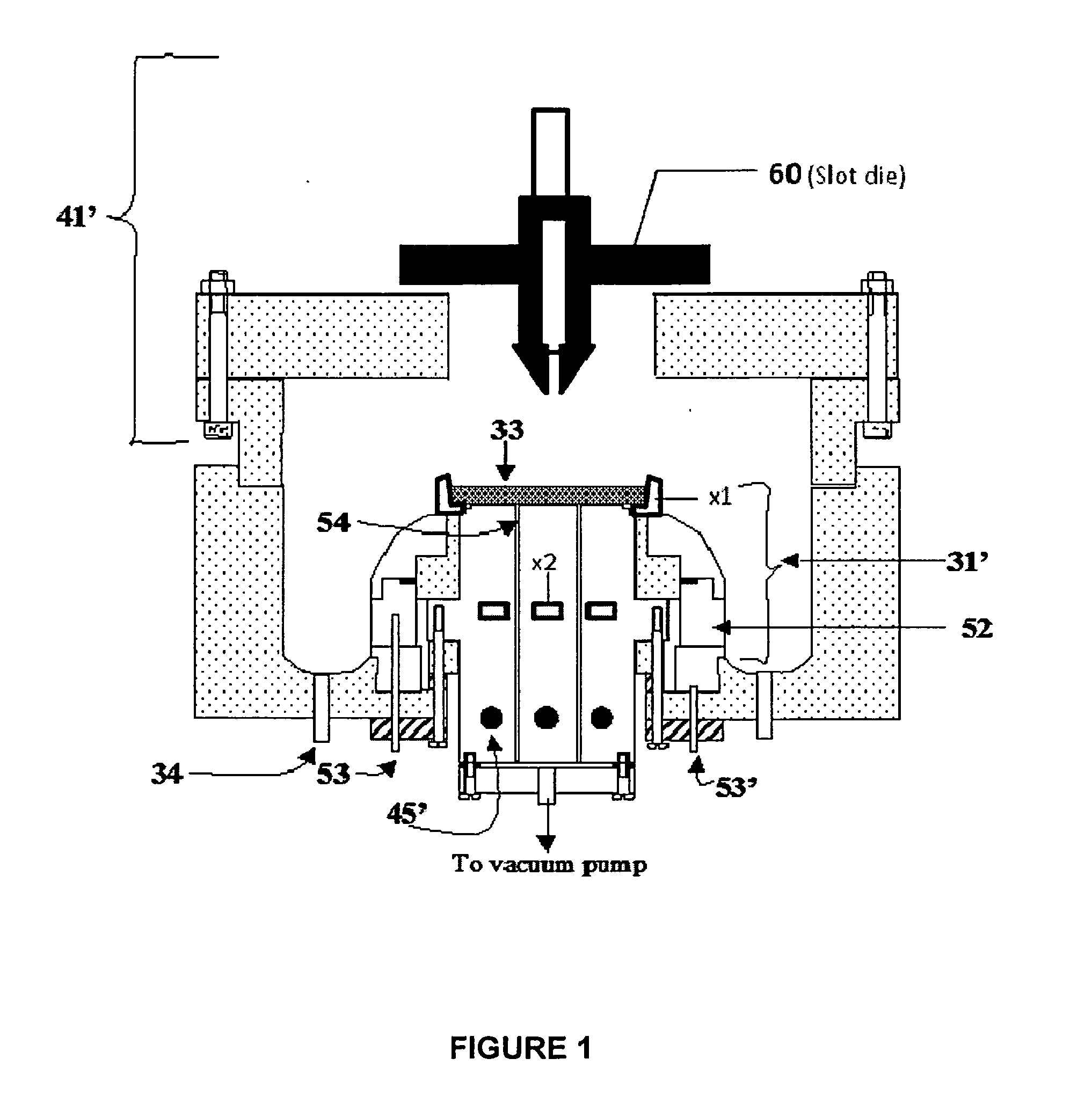

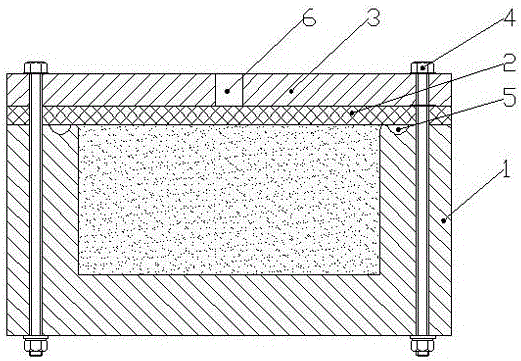

Composite electrodes for lithium ion battery and method of making

InactiveUS20130108920A1Reduce internal porosityElectrode rolling/calenderingElectrode thermal treatmentPorositySodium-ion battery

A method for making a composite electrode for a lithium ion battery comprises the steps of: preparing a slurry containing particles of inorganic electrode material(s) suspended in a solvent; preheating a porous metallic substrate; loading the metallic substrate with the slurry; baking the loaded substrate at a first temperature; curing the baked substrate at a second temperature sufficient to form a desired nanocrystalline material within the pores of the substrate; calendaring the cured composite to reduce internal porosity; and, annealing the calendared composite at a third temperature to produce a self-supporting multiphase electrode. Because of the calendaring step, the resulting electrode is self-supporting, has improved current collecting properties, and improved cycling lifetime. Anodes and cathodes made by the process, and batteries using them, are also disclosed.

Owner:QUANTUMSCAPE CORP

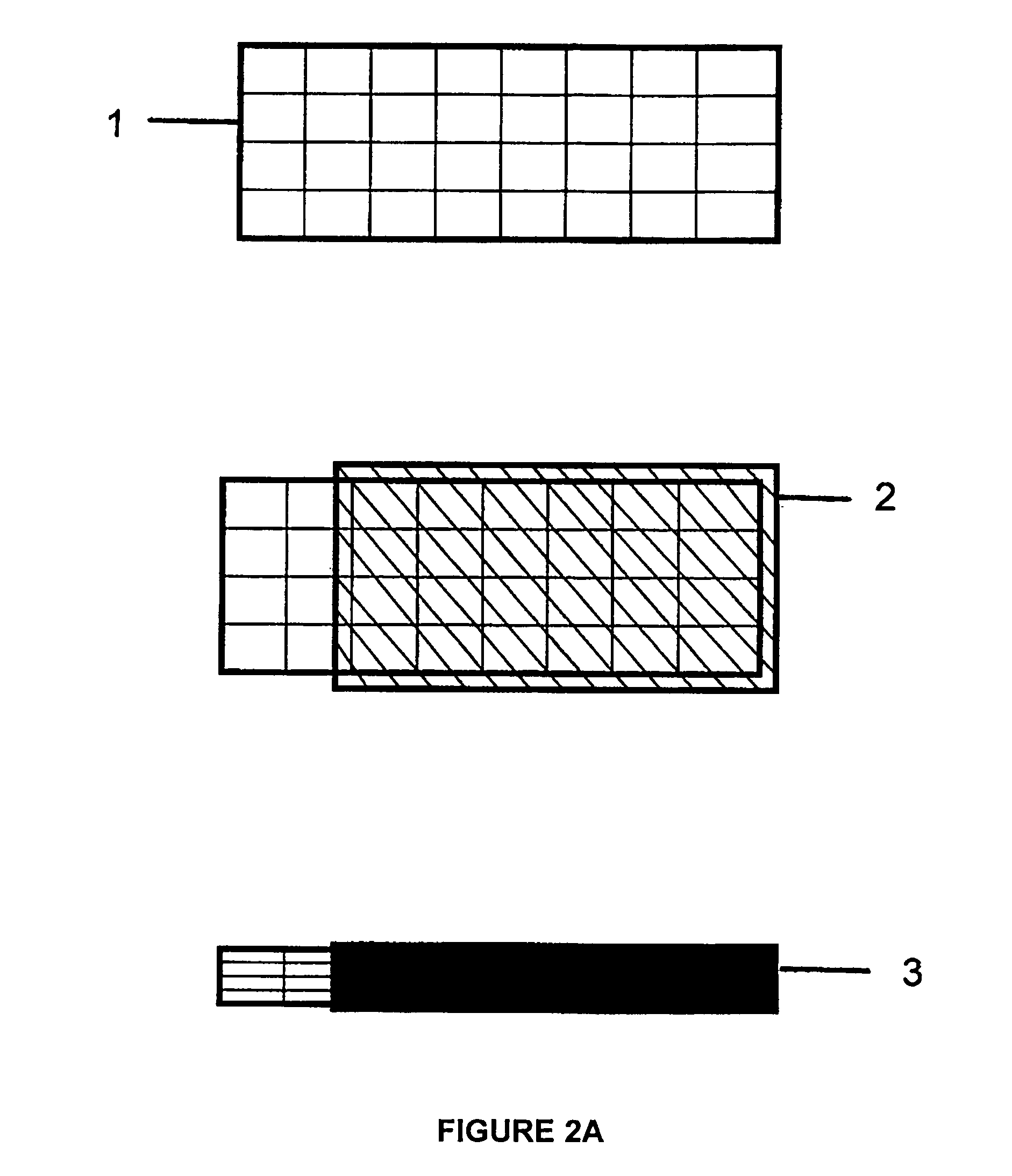

Manufacturing method of carbon fiber composite material rectangular hollow pipe for mechanical arm

The invention provides a manufacturing method of a carbon fiber composite material rectangular hollow pipe for a mechanical arm, and the obtained rectangular hollow pipe. A carbon fiber composite material serves as a raw material and is carbon fiber prepreg; the prepreg comprises one-way and fabric prepregs and the rectangular hollow pipe is manufactured by a mould pressing inflation forming method. According to the manufacturing method of the carbon fiber composite material rectangular hollow pipe, a rectangular thin-walled hollow pipe is manufactured by performing mould pressing inflation combined forming on the carbon fiber prepreg serving as the raw material. Compared with the prior art, the invention has the advantages that the carbon fiber composite material rectangular hollow pipe has high bearing capacity, high rigidity and light weight; during operation, the arm is more stable in action and moves and stops more quickly; the arm can be quickly positioned by the vibration damping characteristic of the carbon fiber composite material; the carbon fiber composite material is applicable to precision equipment due to the zero thermal expansion coefficient; equipment investment is small; a mould is simple to manufacture; production energy consumption is low; production period is short; automatic production is realized.

Owner:HENGSHEN

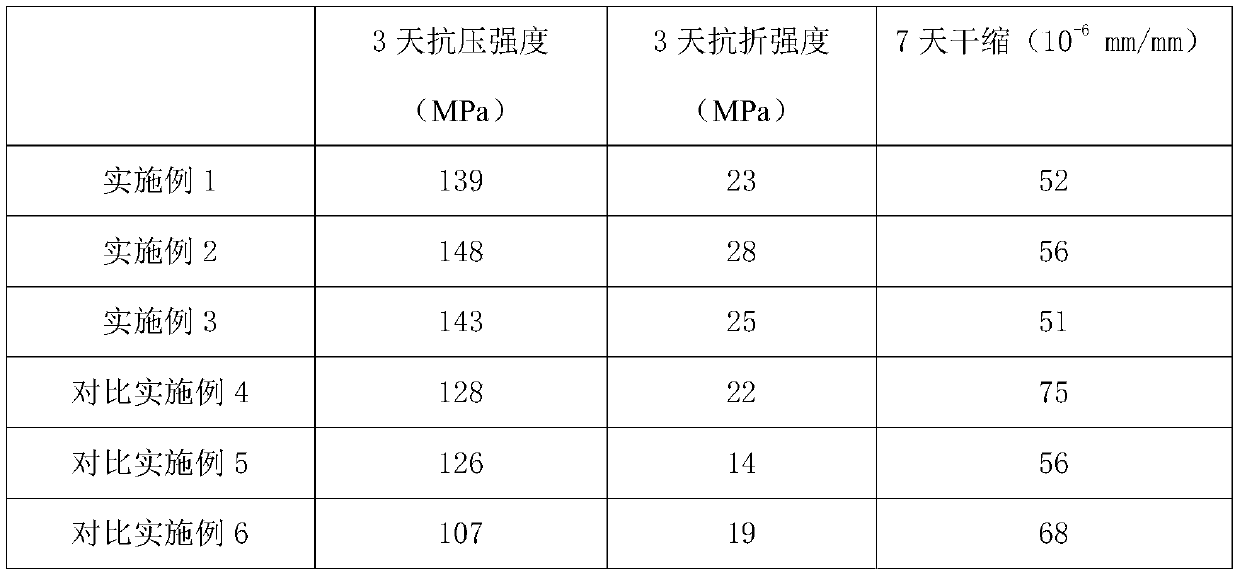

High-strength and high-toughness geopolymer material and preparation method thereof

ActiveCN111018435AHigh bonding strengthImprove mechanical propertiesCement productionFiberKaolin clay

The invention discloses a high-strength and high-toughness geopolymer material. The high-strength and high-toughness geopolymer material comprises, by weight, 500-700 parts of silicon-aluminum mineralraw materials, 600-800 parts of an alkali activator, 70-150 parts of a nanoscale efficient modifier, 2-5 parts of super absorbent resin, 2-6 parts of a hybrid fiber, 4-10 parts of a surfactant, 700-1000 parts of fine aggregates and 100-150 parts of deionized water, the silicon-aluminum mineral raw materials comprise 200-300 parts of metakaolin, 150-200 parts of fly ash, 50-100 parts of red mud, 40-60 parts of mineral slag, 40-60 parts of silica fume and 20-40 parts of Portland cement, and the nanoscale efficient modifier comprises 20-50 parts of condensed phosphate, 20-40 parts of nano-silica, 20-40 parts of nano-alumina and 10-20 parts of zeolite. The invention further discloses a preparation method of the high-strength and high-toughness geopolymer material. The problems of large earlyself-shrinkage and easy cracking of the geopolymer are solved, and the obtained geopolymer has strong toughness and high strength.

Owner:ZHEJIANG UNIV

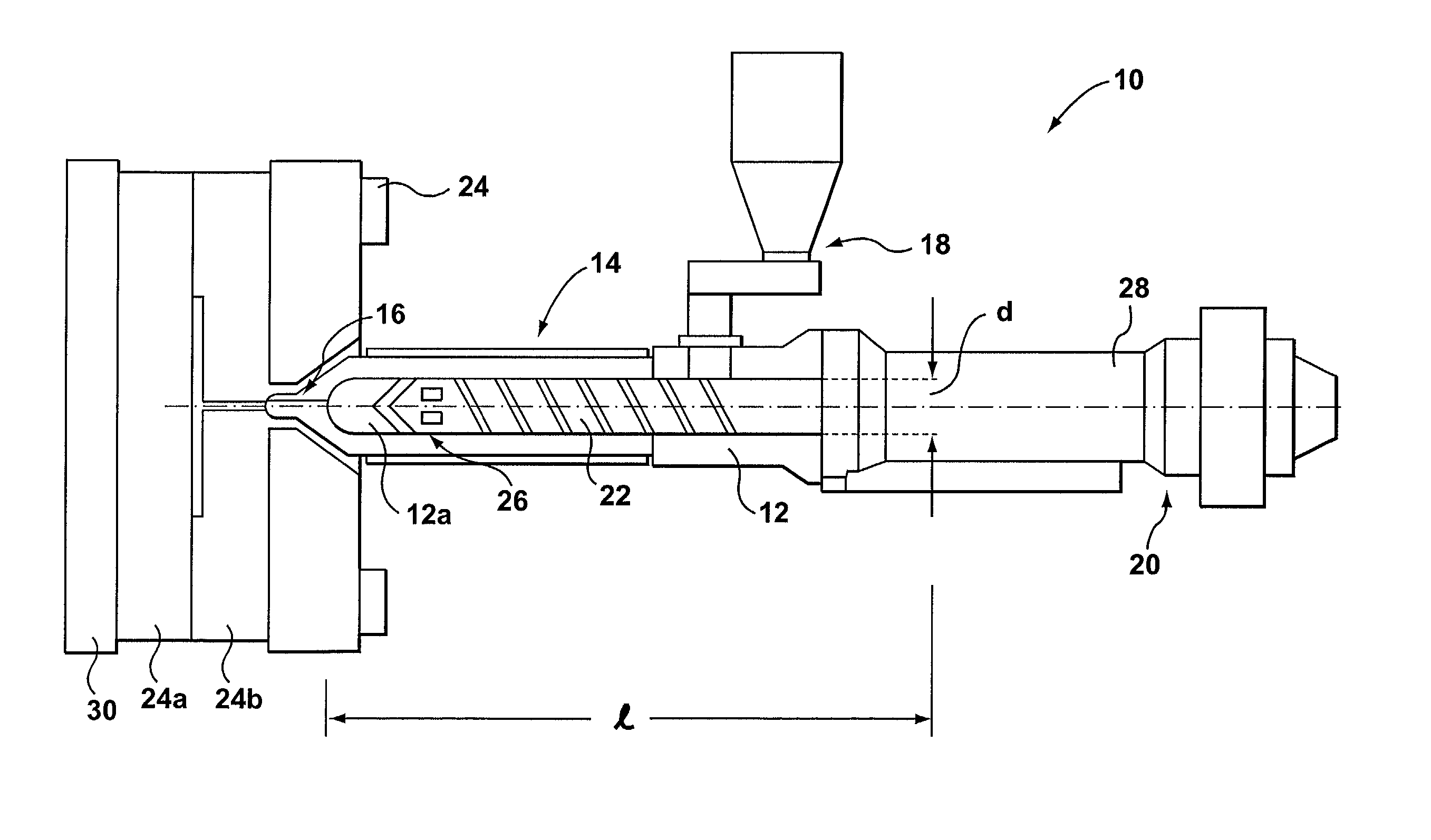

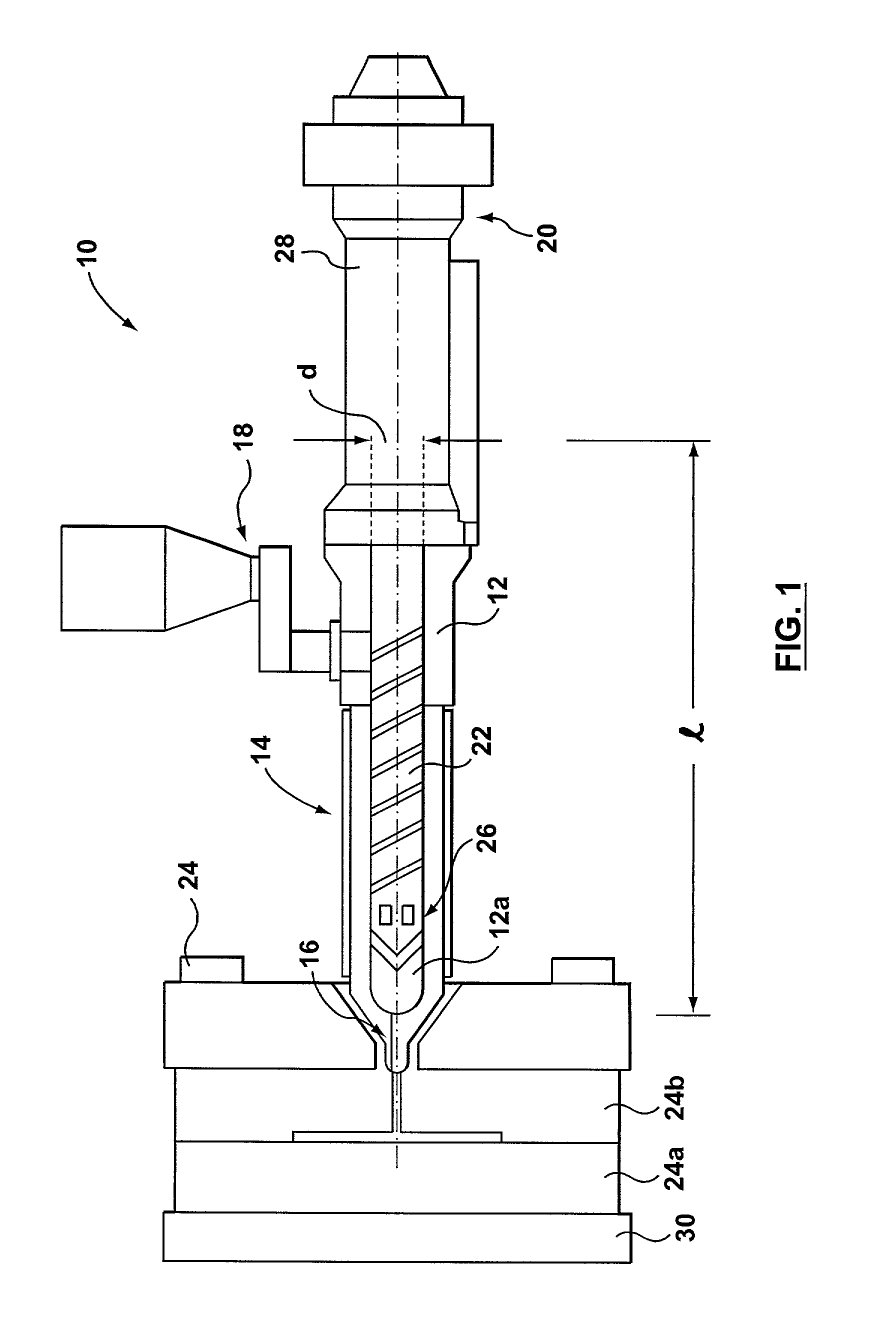

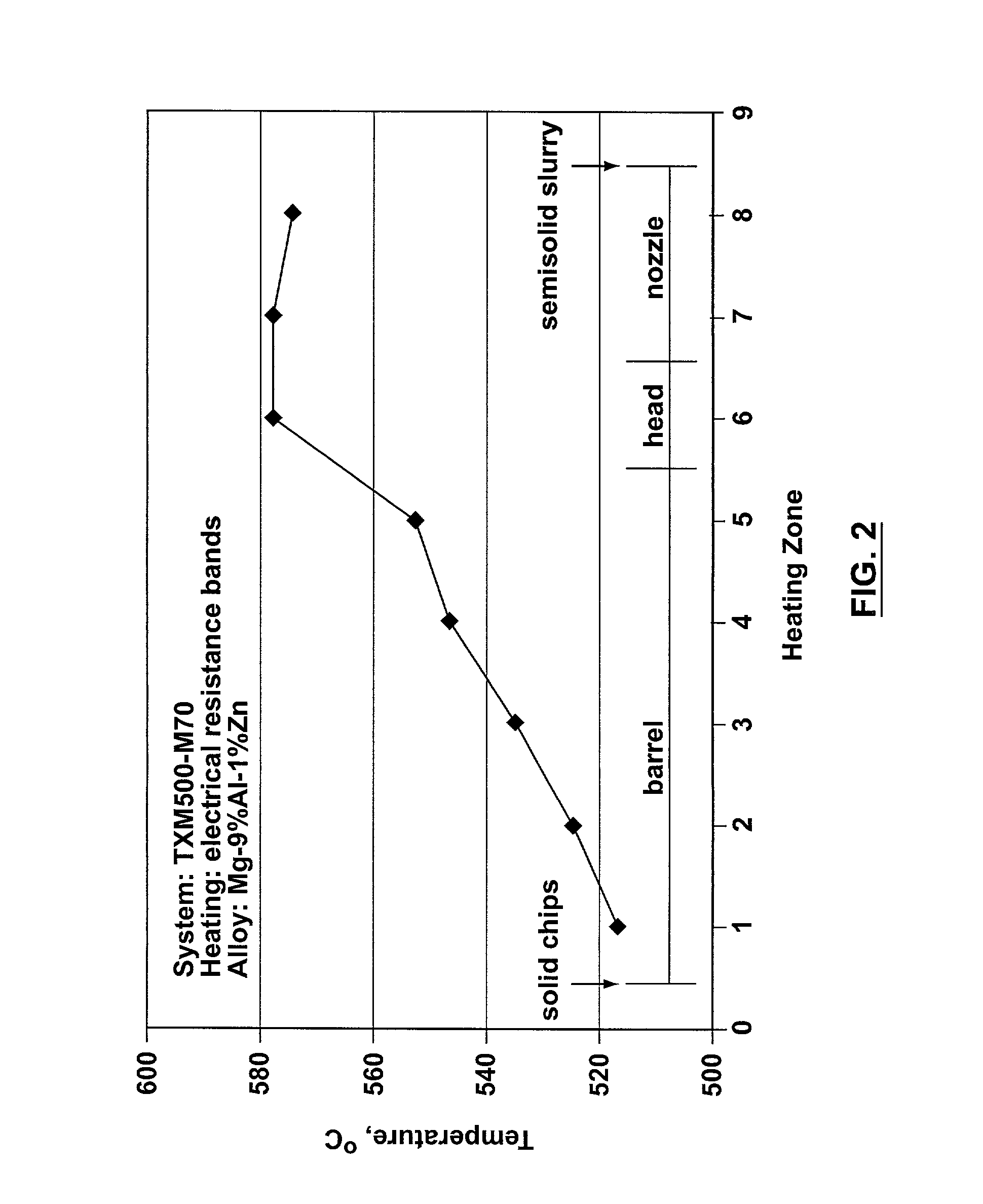

Process for injection molding semi-solid alloys

A injection-molding process injects a semi-solid slurry with a solids content ranging from approximately 60% to 85% into a mold at a velocity sufficient to completely fill the mold. The slurry is injected under laminar or turbulent flow conditions and produces a molded article that has a low internal porosity.

Owner:HUSKY INJECTION MOLDING SYST LTD

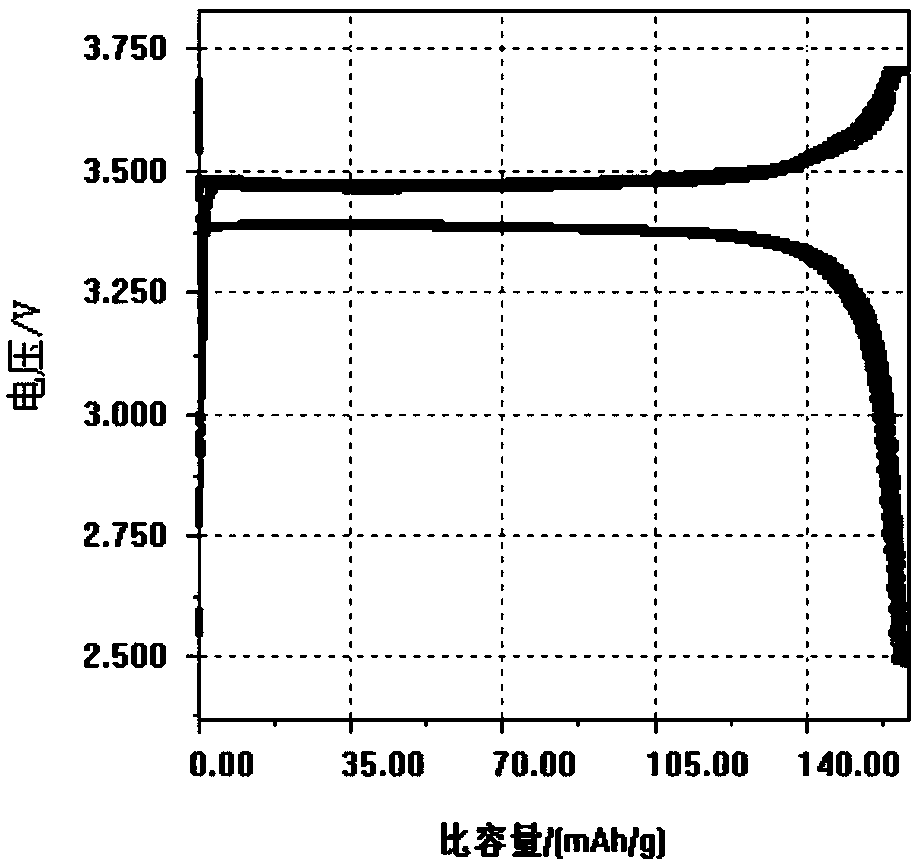

Lithium iron phosphate-based composite material with capacity higher than theoretical capacity of lithium iron phosphate, preparation method and use of lithium iron phosphate-based composite material

ActiveCN108735997AReduce internal porosityIncrease compaction densityFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithium iron phosphatePhosphate

The invention discloses a lithium iron phosphate-based composite material with capacity higher than theoretical capacity of lithium iron phosphate, a preparation method and a use of the lithium iron phosphate-based composite material. The lithium iron phosphate-based composite material comprises an inner core and a composite coating layer for wrapping the inner core; the inner core is composed ofan inorganic carbon substrate and lithium iron phosphate attached to the inorganic carbon substrate; the composite coating layer comprises trivanadium heptoxide monohydrate particles and inorganic carbon. The method comprises the following steps of 1) preparing a composite precursor which is composed of the inorganic carbon substrate and ferrous phosphate attached on the inorganic carbon substrate; 2 ) performing mixing on the composite precursor and a lithium source and a phosphorus source, and carrying out roasting to obtain the inner core; 3 ) performing mixing on the inner core, a vanadiumsource, a soluble organic carbon source, a surfactant and a solvent to obtain a slurry, and carrying out hydrothermal reaction to obtain the lithium iron phosphate-based composite material. The lithium iron phosphate-based composite material disclosed by the invention is high in tap density, the buckling capacity can reach 170mAh / g or above, and the rate performance is high.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

MC nylon engineering plastics and production process thereof

The invention relates to MC nylon engineering plastics and production process thereof. The MC nylon engineering plastics include 100 parts of masterbatch caprolactam, 1-2 parts of nanometer samarium oxide, 0.15-0.25 part of an accelerant sodium hydroxide, 0.5-1 liter of a curing agent TDI, 3-4 parts of a solid lubricant MoS2, 0.8-1.5 parts of graphite and 0.5-0.8 part of boron nitride. The production process comprises the specific steps of mould heating, feeding, curing molding, stress treatment and machining. The product of the invention can effectively transfer the external stress, and can lead to matrix yielding and consume a large amount of impact energy, so as to enhance the toughness and strength of the product. The production process of the invention employs a centrifugal casting technology, eliminates the inner pores of the product, overcomes the product quality problems of steel slider caused by internal pores and inclusion.

Owner:徐崇娣

Preparation method of large-size and fine-grain molybdenum tantalum alloy sputtering target material

ActiveCN105714253AEvenly distributedAvoid defectsVacuum evaporation coatingSputtering coatingSputteringLarge size

A preparation method of a large-size and fine-grain molybdenum tantalum alloy sputtering target material comprises steps of cold isostatic pressing molding through combination of a steel mold with a rubber plate, sintering, levelling and reshaping, hot isostatic pressing treatment, rolling and machining. The grain size of the produced target material is smaller than 50 microns, the change of the grain size is maintained within 20%, and grains are evenly distributed in the plane direction and the thickness direction of the target material; the relative density of the target material is higher than 97%; besides, the large-size sputtering target material with the length being about 2 m and the width being about 1.3 m can be produced.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

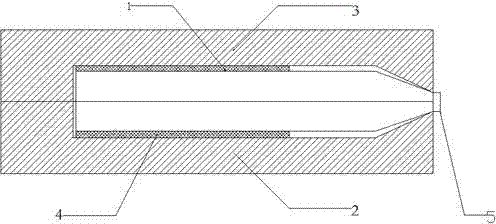

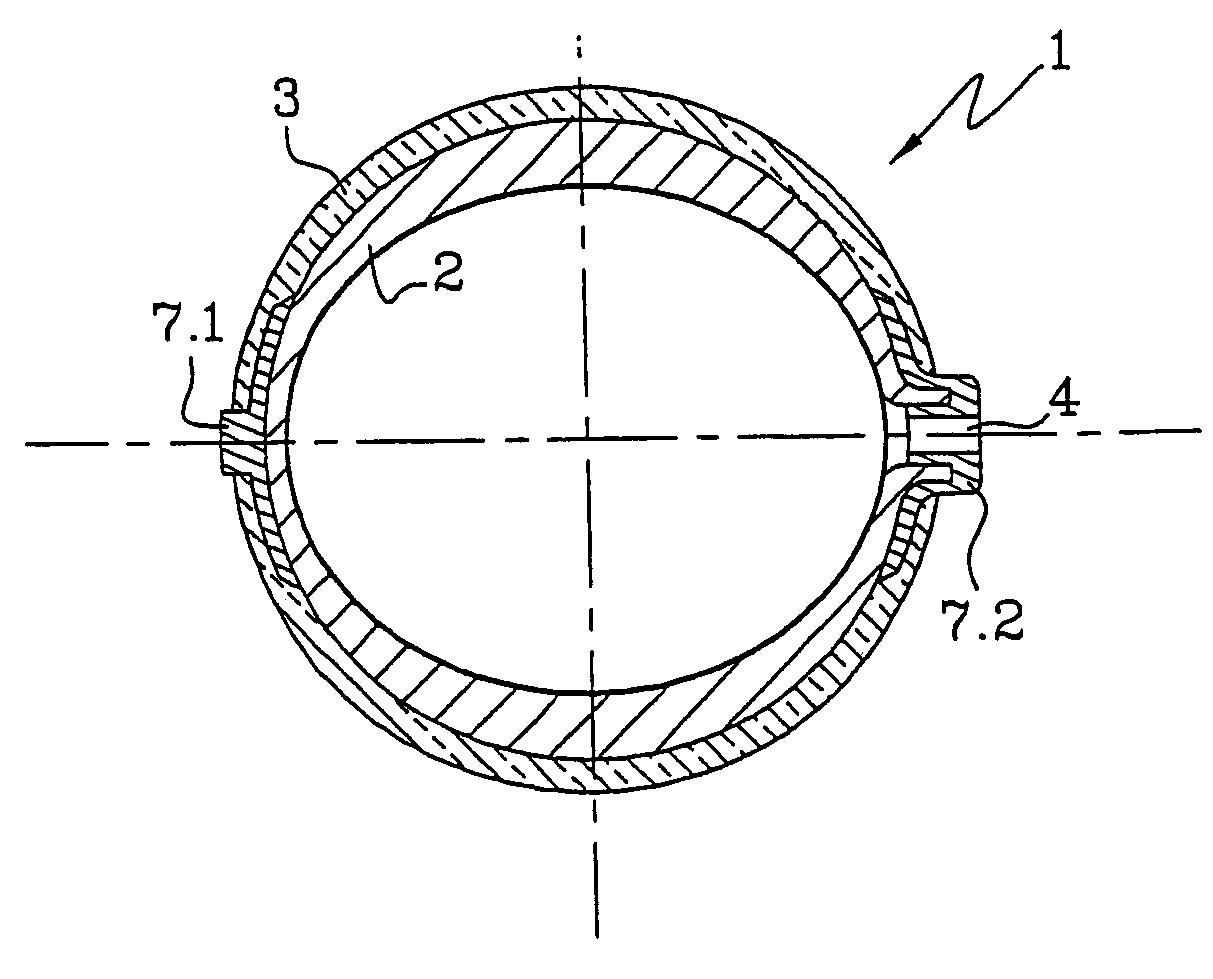

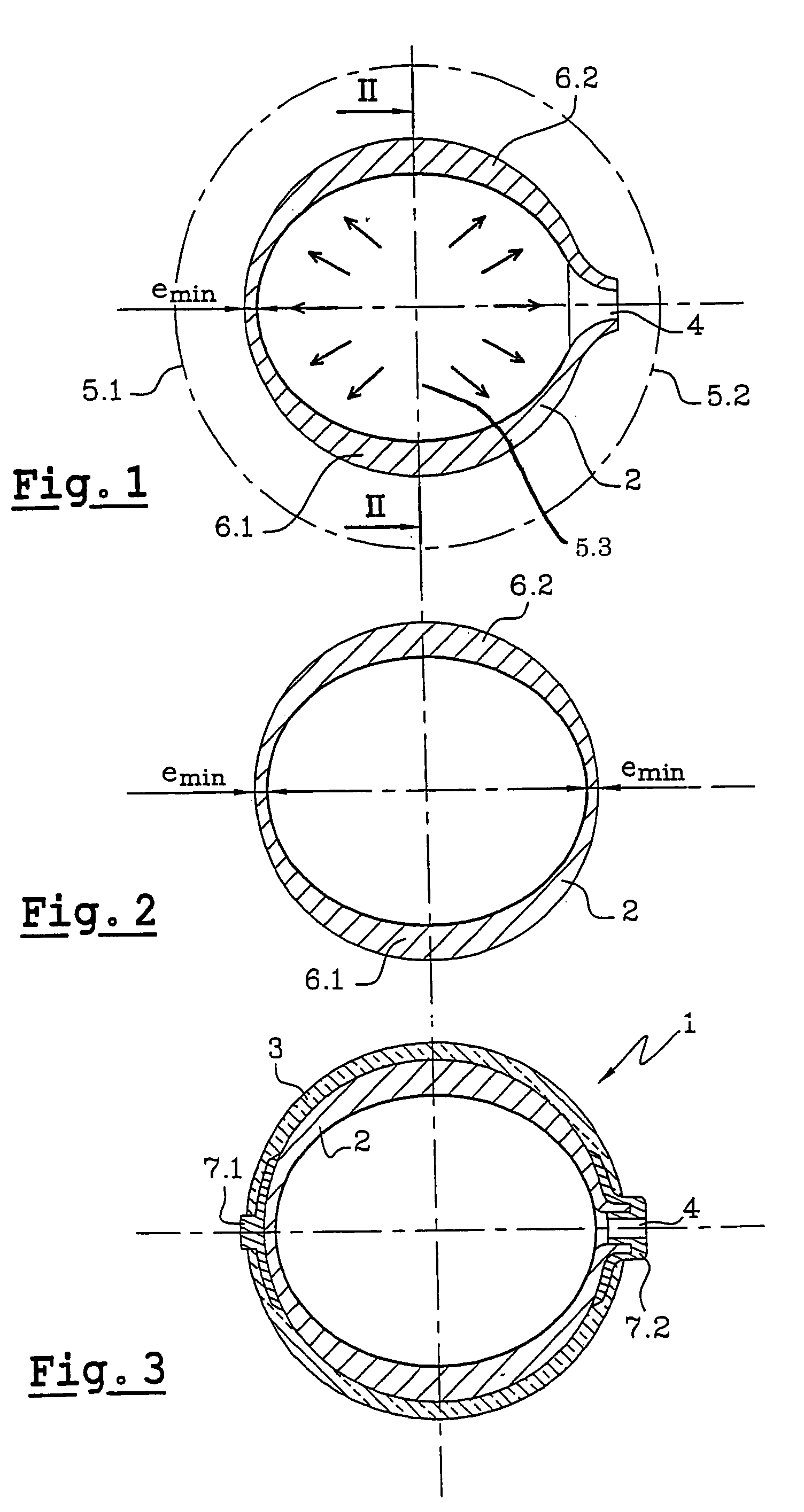

Process for the production of a high pressure vessel particularly for a space engine and vessel obtained therby

InactiveUS6962672B2Reduce internal porosityContainer filling methodsGas handling applicationsPolyamideShort lifetime

A process for the production of a vessel for high pressure gas, particularly helium, for a space launcher or for a satellite with a short lifetime, includes the steps of: a production of an internal skin of a plastic material selected from polyethylene and crystallized polyamide, a winding a reinforcement of fibers and resins, and a providing the obtained vessel with the necessary conduits and control valves.

Owner:EADS LAUNCH VEHICLE

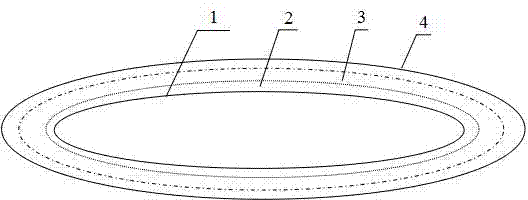

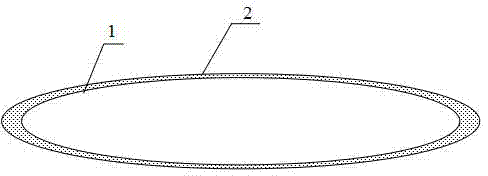

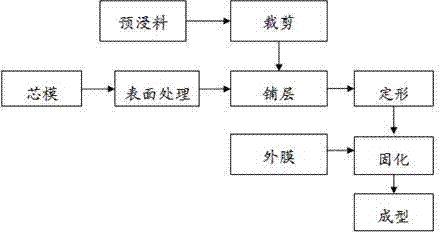

Manufacturing process of lightweight high-strength carbon fiber composite material rudder and obtained rudder

InactiveCN103587126ASmooth manufacturing processReduce internal porositySteering ruddersCarbon fiber compositeMain bearing

The invention provides a manufacturing process of a lightweight high-strength carbon fiber composite material rudder and the obtained rudder. The manufacturing process comprises the following steps: moulding a rudder shape on a rudder core mould to form a pre-forming body; placing a vacuum sealing bag in the pre-forming body; placing the pre-forming body in a rudder outer mould; performing sealing curing formation by using the vacuum sealing bag and the external vacuum bag to obtain carbon fiber composite material rudder. According to the manufacturing process of the lightweight high-strength carbon fiber composite material rudder, the used materials are prepregs, so compared with the common composite material rudder, the lightweight high-strength carbon fiber composite material rudder can precisely control the resin content of the rudder and reduce the porosity of the interior of the rudder. The prepregs consist of a one-way prepreg and a fabric prepreg, wherein the one-way prepreg can provide relatively high strength and rigidity in the main bearing direction; the fabric prepreg can provide longitudinal strength and shear strength and also can provide attractive surface so as to improve the toughness and the handfeel comfortable degree of the rudder.

Owner:HENGSHEN

Novel reinforcement technique of 6XXX aluminum alloy welding joint

InactiveCN103572180AIncrease densityImprove mechanical propertiesSolution treatmentUltimate tensile strength

The invention discloses a novel reinforcement technique of a 6XXX aluminum alloy welding joint, mainly solves the defects such as high cost, large equipment and noise, complex operation, workpiece damage, additional consumption of materials and energy, additional increment of workpiece weight and residual stress, reduction of workpiece plasticity and air hole mingling in the traditional reinforcement methods of the 6XXX aluminum alloy welding joint, and achieves the reinforcement effect to the 6XXX aluminum alloy welding joint. The technique comprises the specific operation steps of solution treatment, subzero treatment and ageing treatment. The technique has the advantages of simple technique, low cost, ideal reinforcement effect, energy conservation, environmental protection and largely improved strength and plasticity, can effectively solve the problems of air holes and mingling inside the joint, and has excellent industrial application prospect.

Owner:葛鹏

Method for preparing aluminium oxide-silicon oxide fibre

InactiveCN1434156ASmaller than surfaceHigh strengthInorganic material artificial filamentsFiberSilicon oxide

The preparation method of aluminia-silica fibre uses water soluble inorganic aluminium salt and metal aluminium as main raw material, uses distilled water as solvent, and adopts the following steps: under the reflux condition utilizing hydrolysis and polymerization to obtain uniform transparent alumina precursor sol, adding a certain quantity of silicide and water soluble polymer as spinning adjuvant into the sol, concentrating to obtain spinning dope with proper rheological property, using blast drawing method to make the spinning dope into precursor fibre, further heat treatment in nitrogengas atmospher to convert the alumina and silica precursor into alumina and silica so as to finally obtain the invented alumina-silica fibre.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Nano samarium oxide-modified monomer casting (MC) nylon sliding block and production process thereof

The invention relates to a nano samarium oxide-modified monomer casting (MC) nylon sliding block and a production process thereof. The nano samarium oxide modified MC nylon sliding block comprises the following materials: 100 parts by weight of master batch hexanolactam, 0.5-1.0 part by weight of nano samarium oxide, 0.12-0.2 part by weight of accelerator sodium hydroxide, 0.3-0.7 liter of curingagent TDI (toluene diisocynate), 2-3 parts by weight of solid lubricant molybdenum disulfide, 0.5-0.8 part by weight of graphite, and 0.3-0.5 part by weight of boron nitride. The production process comprises the specific production steps of: heating up a die, feeding the materials, solidifying for molding, processing internal stress, and machining. The product disclosed by the invention can transfer the born external stress well, as well as can bend a matrix to consume a lot of impact energy, so that an effect for simultaneously increasing the toughness and strength of the product is obtained. According to the production process of the product, disclosed by the invention, a centrifugal casting technology is adopted, so that internal air holes of the product are eliminated, and product quality problems of steel casting sliding blocks caused by defects such as internal air holes, inclusion and the like are solved.

Owner:扬州赛尔达尼龙制造有限公司

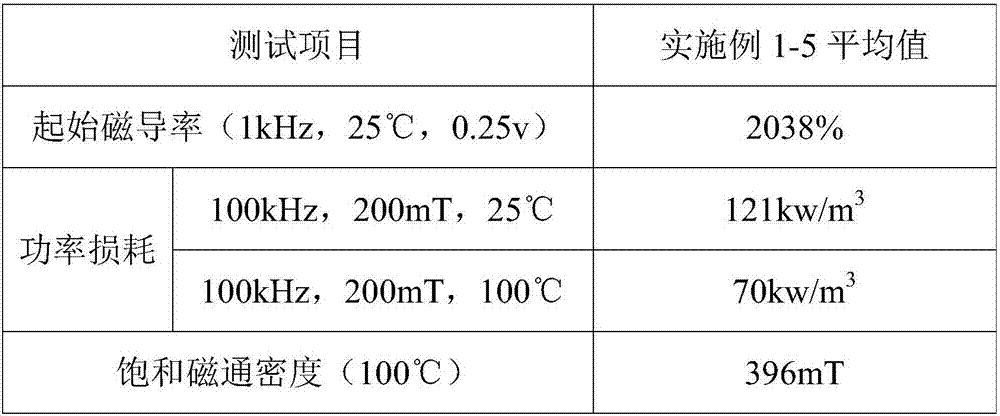

Low-consumption soft magnet ferrite material

ActiveCN107200574ALow melting pointHigh resistivityInorganic material magnetismInductances/transformers/magnets manufactureHigh frequencySoft magnet

The invention discloses a low-consumption soft magnet ferrite material which comprises the following raw materials in parts by weight: 100 parts of a main material, 0.8-0.9 part of an auxiliary material and 6-8 parts of aids, wherein the main material comprises the following raw materials in parts by mole: 56-58 parts of Fe2O3, 30-33 parts of MnO, 8-9 parts of ZnO and 3-4 parts of NiO; the auxiliary material comprises the following raw materials in parts by weight: 2.5-3.5 parts of CaO, 0.8-1.2 parts of V2O5, 0.9-1.1 parts of SnO2, 0.25-0.35 part of TiO2, 0.5-1 part of Co2O3, 0.15-0.25 part of Nb2O5, 0.9-1.1 parts of MoO3, 0.2-0.4 part of Bi2O3 and 0.3-0.5 part of Ta2O5. The low-consumption soft magnet ferrite material has properties of high frequency, high initial magnetic conductivity and low consumption.

Owner:ZHONGDE ELECTRONICS

Technology for forging squeeze roller of cement roller press

InactiveCN103658479AExtended service lifeImprove toughnessMetal-working apparatusFurnace typesReduction rateDiameter ratio

The invention discloses a technology for forging a squeeze roller of a cement roller press. The squeeze roller comprises, by weight, 0.20-0.26% of C, 2.5-2.70% of Mn, 0.60-0.80% of Si, 3.40-3.80% of Cr, 0.10-0.20% of Mo, 0.10-0.20% of Ni, 0.02-0.03% of Ti, 0.005-0.007% of B, and the balance Fe. The forging technology comprises the following steps that firstly, a steel ingot comprising the above materials is heated to the temperature ranging from 1160 DEG C to 1180 DEG C, primary upsetting is carried out on the steel ingot, the steel ingot is drawn out through a WHF method, the height-diameter ratio of the drawn-out steel ingot is controlled within 1.6-1.8, and the total forging ratio is controlled within 2.0-2.2; secondly, the blank obtained in the first step is heated again, the heating temperature ranges from 1140 DEG C to 1160 DEG C, secondary upsetting is carried out on the steel ingot, a wide flat anvil is drawn out to the extreme degree, the forging ratio ranges from 1.5 to 2.0, four times of drawing are carried out, the drawing reduction rate of the first two times is controlled within 12% to 14%, the drawing reduction rate of the later two times is controlled within 24% to 26%, chamfering and rolling are carried out on the squeeze roller, and pressing is carried out; thirdly, heat treatment after forging is carried out.

Owner:AVIC EXCELLENCE FORGING WUXI

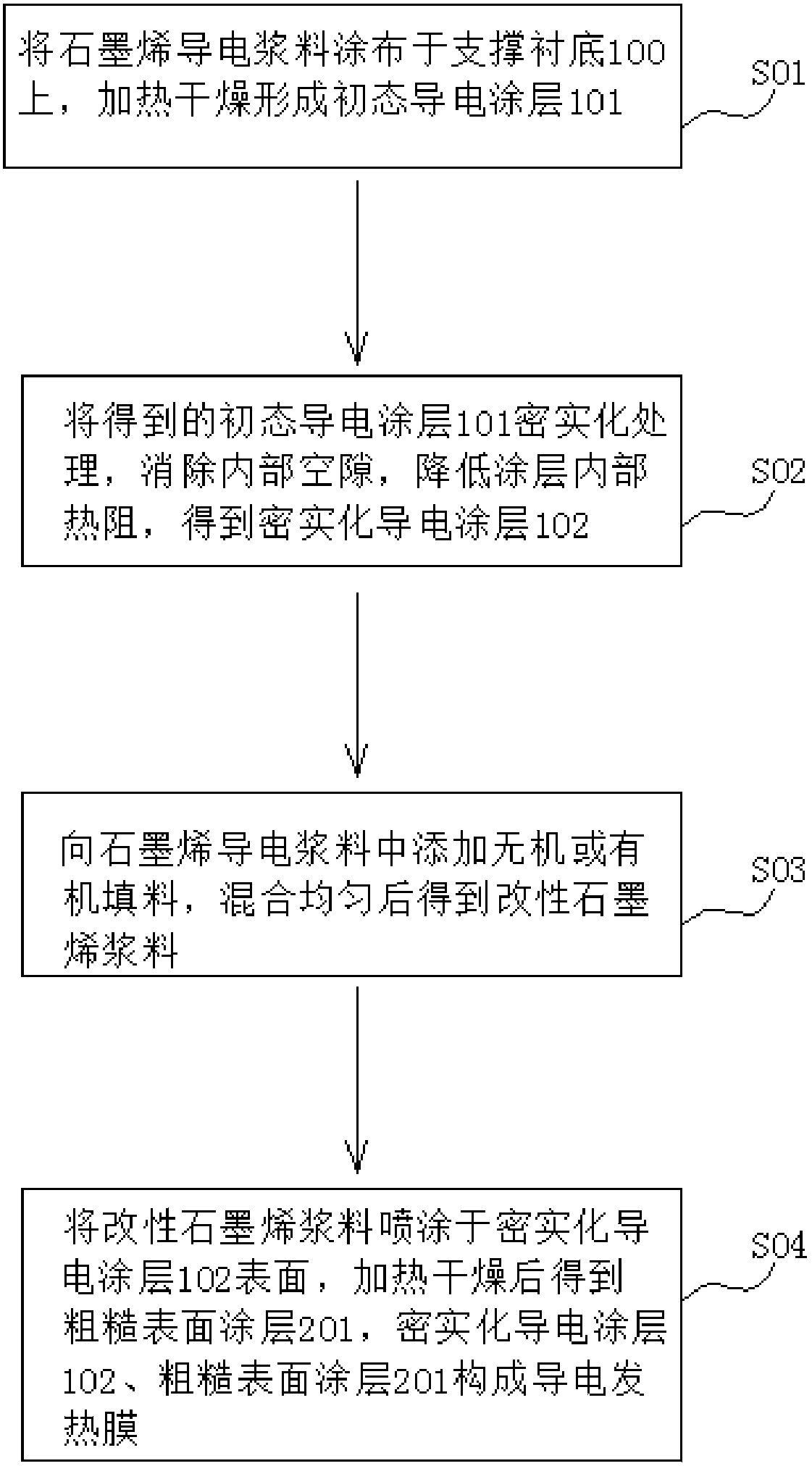

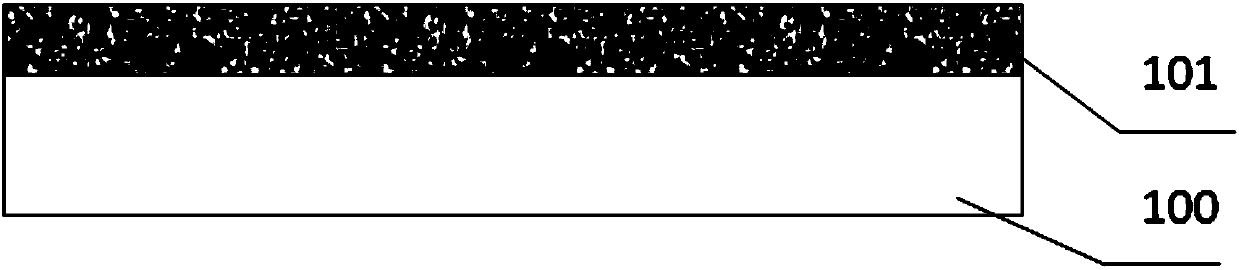

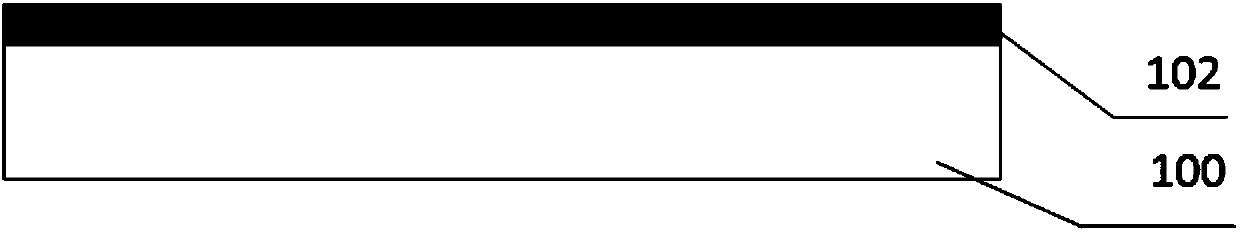

High infrared emitting electrothermal film based on graphene and preparation method of high infrared emitting electrothermal film

ActiveCN107787056AReduce transmission lossReduce internal porosityHeating element materialsFilm baseMaterials science

The invention provides a high infrared emitting electrothermal film based on graphene and a preparation method of the high infrared emitting electrothermal film. The preparation method comprises the following steps that S01, the surface of a supporting substrate is coated with graphene electroconduction slurry, an initial state conductive coating is formed through step-by-step heating and drying;S02, the obtained initial state conductive coating is densified, and the treated densified conductive coating is obtained; S03, inorganic or organic filler is added into the graphene electroconductionslurry obtained in the step S01, and modified graphene slurry is obtained after even mixing is carried out; S04, the surface of the densified conductive coating is coated with the modified graphene slurry, a rough surface coating is obtained after heating and drying are carried out, and the high infrared emitting electrothermal film is formed by the densified conductive coating and the rough surface coating. The electrothermal film is densified, internal holes are removed, the heat conductivity coefficient is increased, and the internal transmission losses of heat are reduced; by means of thesurface ultrathin rough coating, the infrared radiance rate is enhanced, and the radiative heat transfer proportion is increased.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

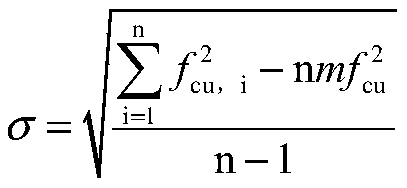

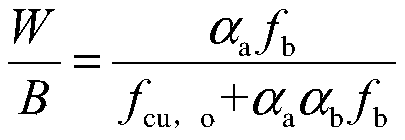

Impermeable concrete and proportioning method thereof

The invention discloses impermeable concrete and a proportioning method thereof. The impermeable concrete comprises cement; PII type Portland cement with strength of not lower than 42.5 grade; coarseaggregate containing 5-25 mm continuous graded broken stone; fine aggregate containing natural river sand; an admixture containing fly ash and mineral powder; and an additive, which comprises a waterreducing agent with a water reducing rate of not lower than 25% and a solid content of not lower than 20%; wherein the cement, the coarse aggregate, the fine aggregate, the admixture and the additiveare mixed and stirred under the action of water to form the impermeable concrete. The technical problems that a conventional impermeable concrete is large in gap, high in manufacturing cost and long in maintenance period due to the material ratio and is not suitable for the secondary lining waterproof requirement in tunnel engineering are solved.

Owner:ROAD & BRIDGE INT +1

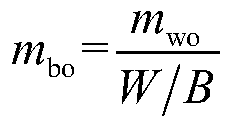

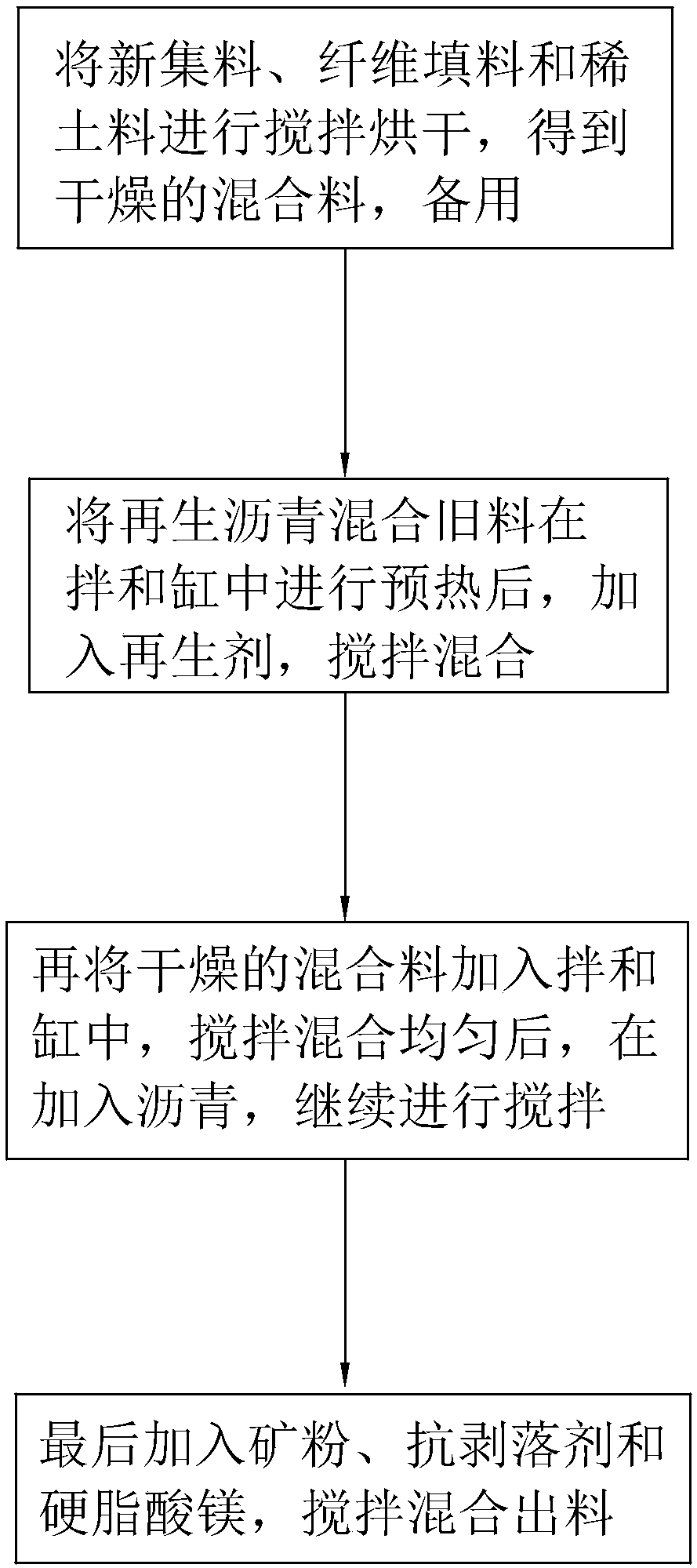

Anti-seepage regenerating asphalt concrete and preparation process thereof

The invention discloses an anti-seepage regenerating asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete production, and solves the problem that theasphalt concrete is easy to damage when being eroded by water due to poor interface bonding strength between asphalt and aggregate. The anti-seepage regenerating asphalt concrete comprises, by weight,80-90 parts of new aggregate; 6-10 parts of asphalt; 0.6-1.2 parts of mineral powder; 20-24 parts of regenerating asphalt mixed waste material; 0.2-0.4 part of a regenerating agent; 1.8-2.6 parts ofa fiber filler; 0.3-0.5 part of an anti-stripping agent; 0.8-1.2 part of a rare earth material; 0.4-0.6 part of a magnesium stearate. In the use process of the anti-seepage regenerating asphalt concrete, the asphalt and aggregate in the anti-seepage regenerating asphalt concrete has a higher interface strength, which plays a good role in resisting water erosion, the asphalt concrete is not easy tocrack, and has longer service life.

Owner:SHANGHAI SHISHEN IND & TRADE CO LTD

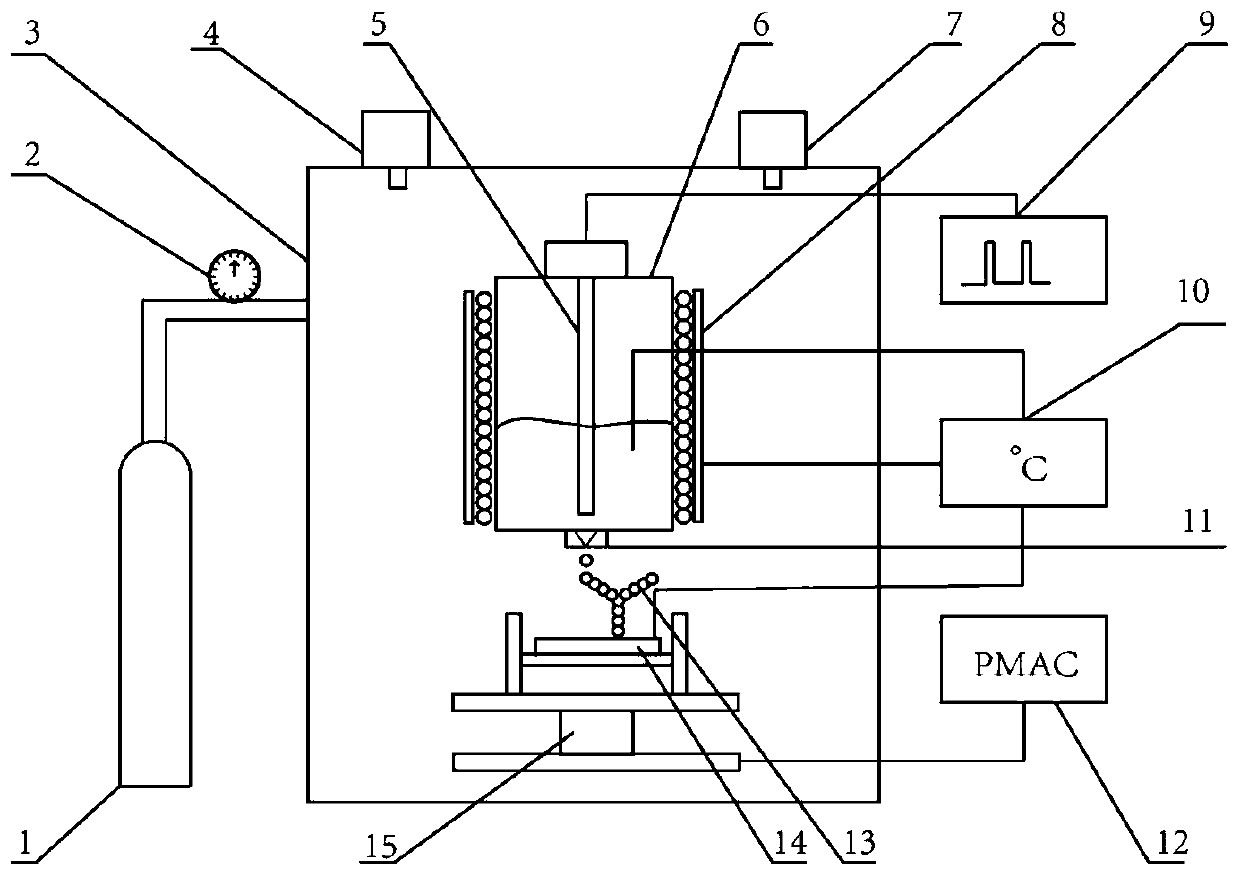

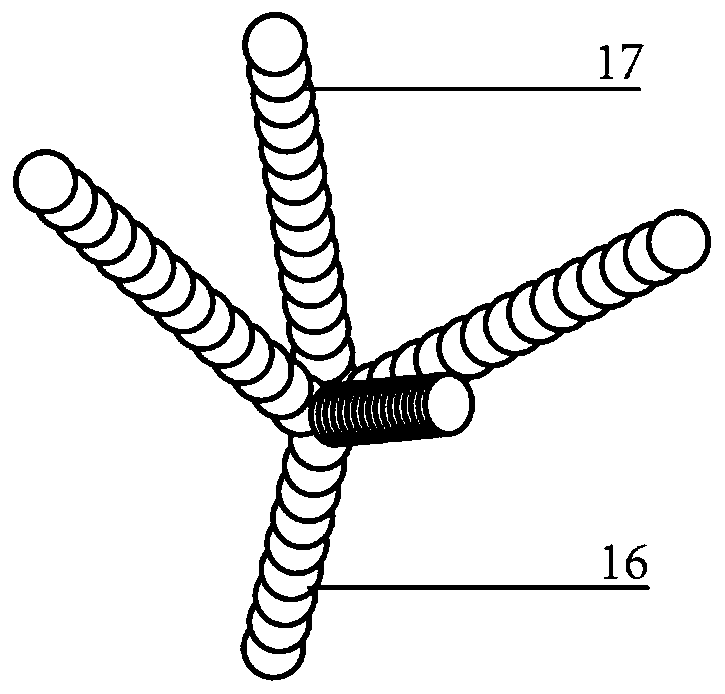

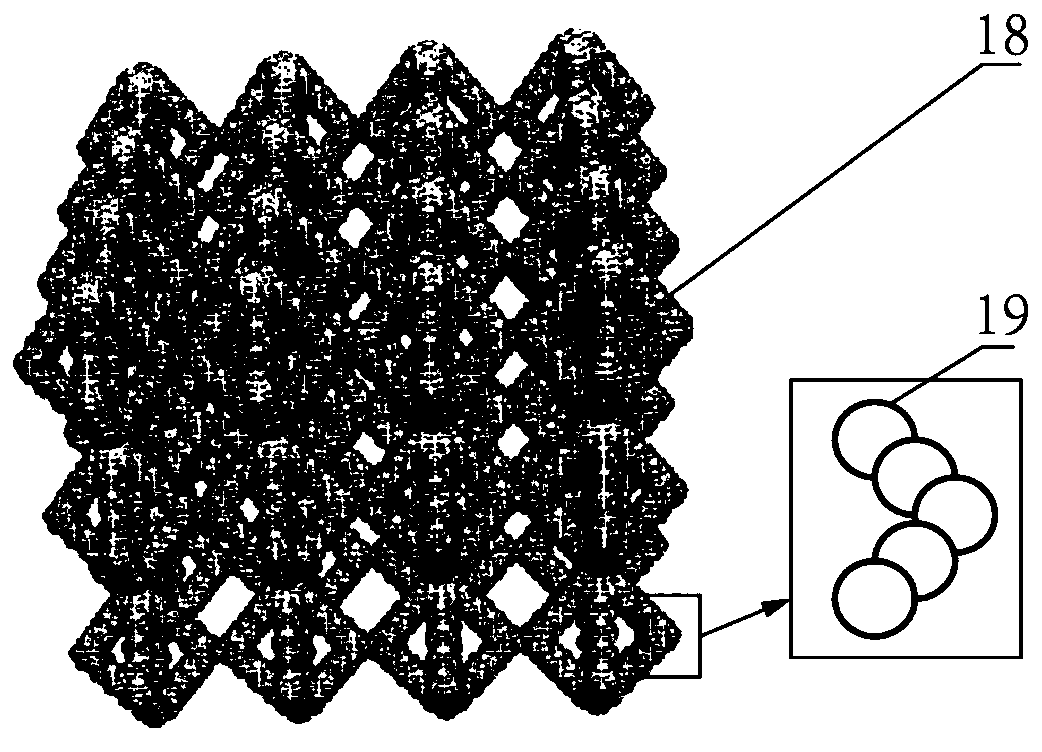

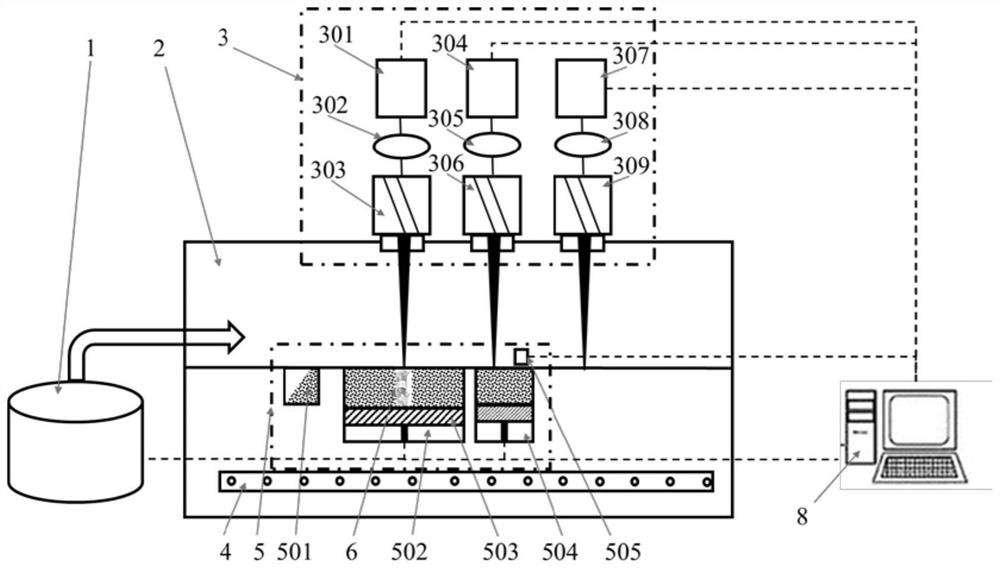

Method for forming low-porosity multi-branch heat dissipation structure through metal droplet printing

ActiveCN109877323AAvoid error accumulationImprove internal qualityAdditive manufacturing apparatusPorosityEngineering

The invention discloses a method for forming a low-porosity multi-branch heat dissipation structure through metal droplet printing. The technical problem that an existing branch heat dissipater preparation method is poor in practicability is solved. According to the technical scheme, metal liquid droplets are produced based on the jet fracture theory, the complex three-dimensional multi-branch profiled heat dissipation structure with the controllable shape and dimension is printed point by point layer by layer by controlling jet of liquid droplets and movement of a movement base plate according to path planning of the profiled heat dissipation structure; and the solidification behavior of the liquid droplets is cooperatively controlled, and the internal quality of the metal droplets is optimized. The limitation that a special manufacturing tool is needed for the profiled structure is avoided, the multi-branch heat dissipation structure is formed through printing of multiple metal liquid droplets, the internal quality of the metal liquid droplets is improved by controlling the solidification behavior of the metal droplets, internal pores of the heat dissipation structure are reduced, and heat conductive performance of the heat dissipation structure can be improved. No laser large-power energy source is needed, and rapid forming of multi-branch profiled heat dissipation structureis achieved without limitation of material varieties and forms.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparing method of graphene steel composite

The invention discloses a preparing method of a graphene steel composite. The preparing method comprises the steps that mixed liquor is provided and comprises an organic solvent, graphene powder and steel powder; the mixed liquor is subjected to drying treatment to obtain mixed powder; the dried mixed powder is loaded in a sheath to be subjected to vacuum pumping degassing treatment, and the sheath is sealed; the sealed sheath loaded with the mixed powder is subjected to hot isostatic pressure treatment, the temperature of the hot isostatic pressure ranges from 920 to 1300 DEG C, and the mixedpowder forms a composite green body; and the composite green body and the sheath are separated.

Owner:北京石墨烯技术研究院有限公司

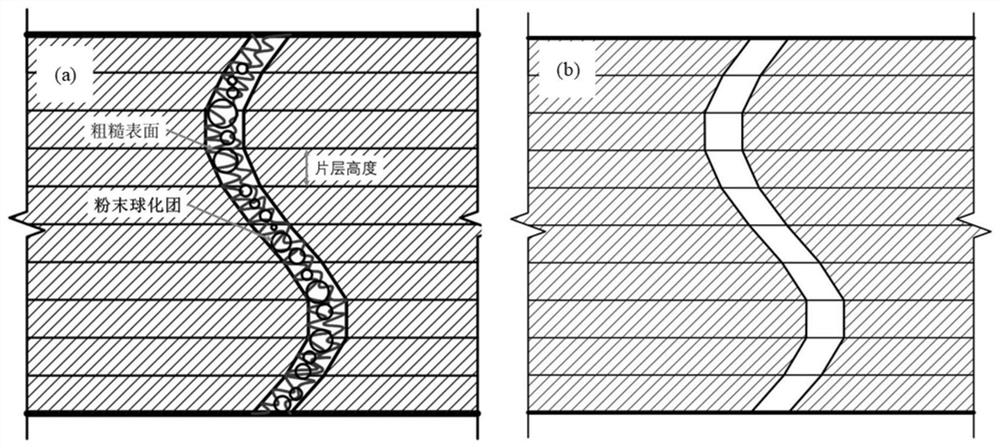

Laser cladding process

ActiveCN107723702AReduce temperature gradientImprove organizationMetallic material coating processesAlcoholLaser processing

The invention discloses a laser cladding process. The laser cladding process comprises the following steps: putting YCF101 powder in a drying box, drying the YCF101 powder for 5h at a constant temperature of 80 DEG C, then pouring the YCF101 powder into a laser cladding powder feeder, and performing powder feeding coaxially for cladding; grinding a substrate, and cleaning the substrate with alcohol to remove impurities so as to obtain a smooth to-be-cladded substrate; and performing laser cladding layer by layer on the smooth to-be-cladded substrate by employing a IPG optical fiber laser according to a certain laser processing parameter and a certain laser scanning policy. According to the laser cladding process disclosed by the invention, defect accumulation as powder is stuck to a lap joint by way of single form interlaminar lap joint is weakened effectively. The extension direction of the defects is consistent to an interlayered scanning track. By crossed longitudinal interlaminar lap of multiple groups, the defects are uniformly distributed on the cladding plane, and the defect degree is reduced effectively; the extension direction of a bath is also consistent to the scanning direction, so that the high temperature of the bath in the next layer also alleviates pores at the lap joint effectively.

Owner:NORTHEASTERN UNIV

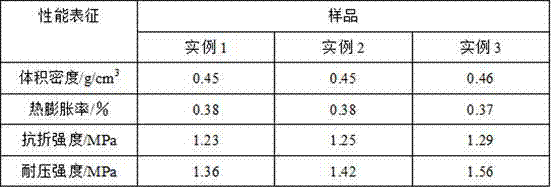

Preparation method of high-strength light-weight refractory material

ActiveCN107963897ALow densityImprove mechanical propertiesCeramic materials productionCeramicwareFiberCellulose

The invention relates to a preparation method of a high-strength light-weight refractory material and belongs to the technical field of refractory material. The method includes the steps of preparinga cellulose gel liquid from moso bamboo fibers, and compounding the cellulose gel liquid with high-viscosity peach gum to prepare composite gel liquid. In the invention, the gel material is filled with expanded perlite granules, so that under a high-temperature calcining environment, the gel lose water to form a solid; meanwhile, the expanded perlite granules continuously increase the volume of the material, so that a plurality of uniform hole structures are formed in the gel granules; finally the gel is calcined in a high temperature environment for being carbonized and is partly decomposed at high temperature, thereby forming the continuous pore structures in an interpenetration manner. Due to the continuous pore structures, mechanical performances of the refractory material are effectively improved, and meanwhile, the material is effectively reduced in density, thus achieving the standard of light-weight materials.

Owner:青岛西海岸高新材料有限公司

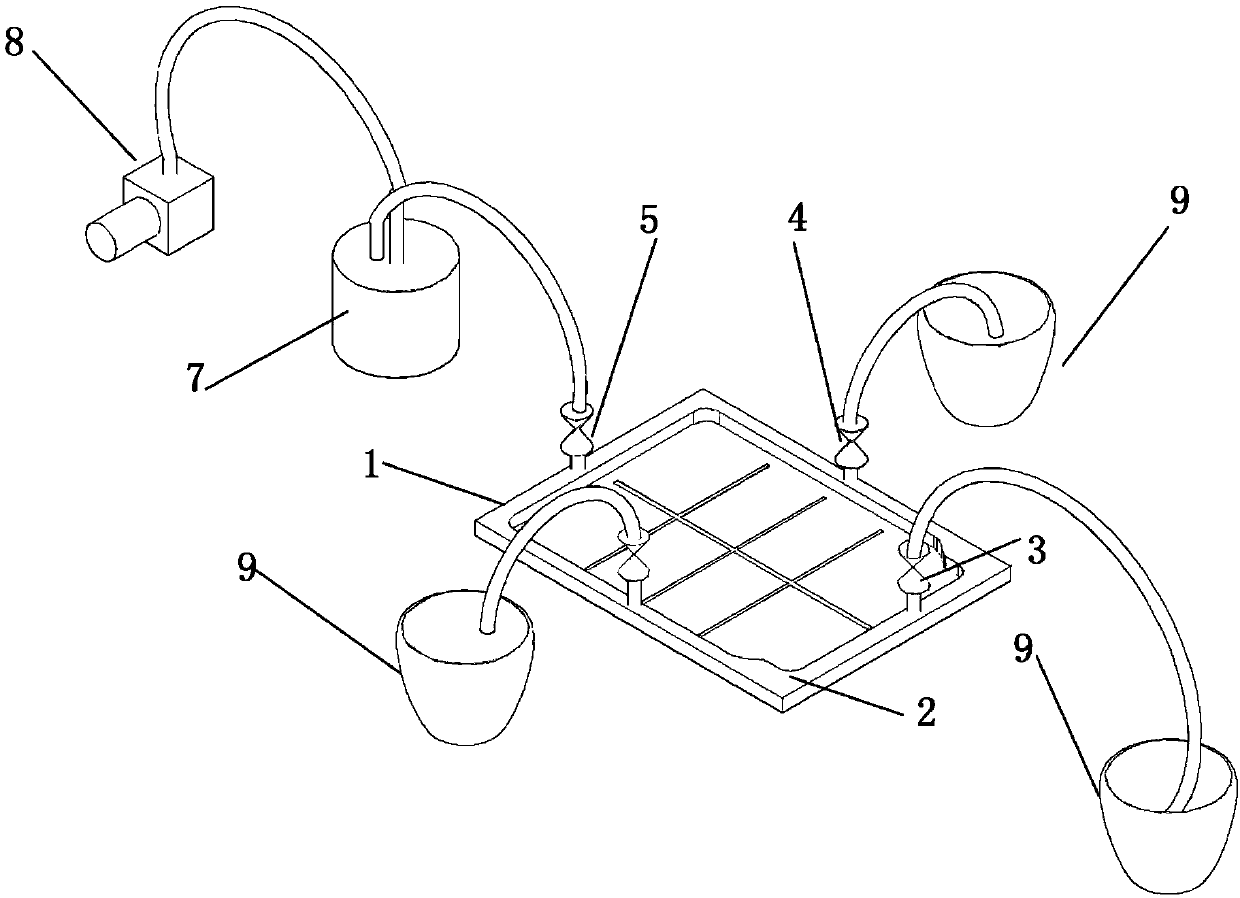

Device conducting composite manufacturing on basis of laser technology

PendingCN111992712AImprove mechanical propertiesImprove the finishAdditive manufacturing apparatusIncreasing energy efficiencyLaser technologyEngineering

The invention discloses a device conducting composite manufacturing on the basis of a laser technology. The device comprises a sealed forming chamber, an inert protective gas source and a machining forming platform. The inert protective gas source is connected with the sealed forming chamber. The machining forming platform is arranged in the sealed forming chamber, and a light path selection system is arranged over the machining forming platform. A machining station is arranged on the machining forming platform, and the machining forming platform is arranged on a guide rail and can slide forwards and backwards through the guide rail. The light path selection system comprises a shock reinforcing independent laser light path, an additive independent laser light path and a subtractive independent laser light path. The light paths are arranged in the direction of the guide rail, and all the independent laser light paths do not share equipment and are arranged over the machining forming platform. According to the device, the laser shock reinforcing technology and the laser additive and subtractive technology are integrated, the forming precision, the surface quality, the organization performance and the residual stress state of a complex fine additive workpiece are improved, and one-stop high-efficiency high-precision and high-performance additive workpiece preparation is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

Environment-friendly preparation technology of baking-free brick

The invention discloses an environment-friendly preparation technology of a baking-free brick. The preparation technology takes iron tailings as a major raw material, has important significance to environmental protection and complies with novel wall material development requirements and the energy conservation and emission reduction policy of China at the present stage; emery is modified by pulverized fuel ash; the surface of the modified emery absorbs much pulverized fuel ash; the pulverized fuel ash can react with free Ca(OH)2 in cement slurry to generate cementitious substances such as calcium aluminosilicate; the compatibility of the emery with a brick body matrix is improved; at the same time, the technology has a positive effect on later strength of the baking-free brick; and the compressive strength of the baking-free brick is greatly improved due to the addition of the modified emery.

Owner:界首市静峰新型建材有限公司

Preparation device for battery tray based on graphene toughened high-performance carbon fiber resin-based composite and preparation method thereof

PendingCN108673911AAchieve weight lossGood adhesionDomestic articlesResin-Based CompositeUltrasonic dispersion

The invention discloses a preparation device for a battery tray based on a graphene toughened high-performance carbon fiber resin-based composite and a preparation method. The method comprises the steps that graphene and a low-viscosity reactive dispersant are subjected to ultrasonic dispersion to obtain graphene dispersion liquid, then the graphene dispersion liquid is directly sprayed uniformlyon the surface of the carbon fiber fabric to prepare a toughened resin of a certain concentration, graphene toughened carbon fibre preprepreg is prepared by continuous impregnation and drying, then the graphene toughened carbon fibre composite is prepared by layer laying, mould pressing and curing. Compared with the prior art, the weight of the battery tray is obviously reduced, and more stabilityis achieved.

Owner:SHANGHAI UNIV +1

High-specific-strength and high-specific-stiffness aluminum-lithium alloy thick-wall annular piece and preparation method thereof

ActiveCN114058912AThe density drop is not obviousImprove microstructureFoundry mouldsFoundry coresThick wallBoron nitride

The invention provides a high-specific-strength and high-specific-stiffness aluminum-lithium alloy thick-wall annular piece and a preparation method thereof, and belongs to the technical field of aluminum-lithium alloy new materials and manufacturing. The aluminum-lithium alloy thick-wall annular piece comprises the following chemical components: 0.8-2.8 wt% of Cu, 2.4-3.8 wt% of Li, 0.8-1.8 wt% of Mg, 0.5-1.5 wt% of Zn, 0.1-0.5 wt% of Er, 0.05-0.2 wt% of Zr, less than or equal to 0.08 wt% of Fe, less than or equal to 0.05 wt% of Si, and the balance of Al and inevitable impurities, wherein the total amount of the alloy elements is less than or equal to 8.5 wt%. The preparation method comprises the steps of alloy proportioning, boron nitride brushing, smelting, refining, centrifugal casting and heat treatment. According to the invention, the forming process of the aluminum alloy annular piece can be simplified, the internal structure is compact, and the specific strength and specific stiffness of the aluminum alloy annular part are remarkably improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Continuous partial roll forming process method for ultra-thin fibrilia composite board

ActiveCN109333900AImprove mechanical propertiesReduce internal porosityFlat articlesRoll formingMechanical property

The invention discloses a continuous partial roll forming process method for an ultra-thin fibrilia composite board, and belongs to the technical field of a fibrilia composite board forming process. The problem that an existing forming process cannot produce the ultra-thin fibrilia composite board with a thickness of 0.2-2 mm is solved. The continuous partial roll forming process method can perform continuous rolling on the ultra-thin fibrilia composite board after a prefabricated body is preheated at a certain temperature to enable the thickness of the ultra-thin fibrilia composite board to gradually reach an ultra-thin thickness of 0.2-2 mm. The ultra-thin fibrilia composite board prepared has the characteristics of compact internal structure, good interface performance, surface decoration, good comprehensive mechanical properties, high molding efficiency and low cost, and can be widely applied to the fields such as building decoration materials, wallpapers and veneer plates of composite panels.

Owner:JILIN UNIV

Novel MC nylon and modification method thereof

The invention relates to a novel MC nylon and a modification method, especially relates to a production method of nanometer samarium oxide modified MC nylon slide blocks, and belongs to the technical field of plastics. The novel MC nylon comprises, by weight, 100 parts of a master batch caprolactam, 0.5-1.0 part of nanometer samarium oxide, 0.12-0.2 parts of an accelerant sodium hydroxide, 0.3-0.7L of a curing agent TDI, 2-3 parts of molybdenum disulfide, 0.5-0.8parts of graphite, and 0.3-0.5 parts of boron nitride, wherein molybdenum disulfide, graphite and boron nitride are used as a solid lubricant. The method concretely comprises the following steps: heating a die, adding materials to the die, carrying out curing molding, carrying out internal press treatment, and machining. The above product can well transmit born external stress, can initiate matrix yielding, and consumes a large amount of impact energy in order to obtain the toughness and the strength. A centrifuge casting technology adopted in the invention eliminates the internal pores of the product, and overcomes the product quality problem caused by internal pores, inclusion and other defects of the cast steel piece slide blocks.

Owner:嵇春霞

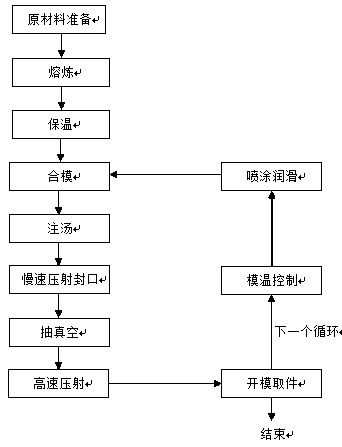

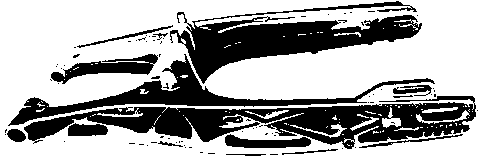

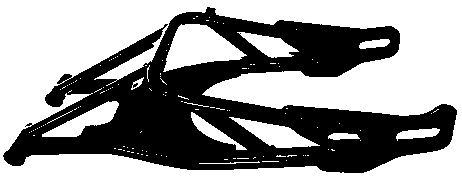

High-vacuum die-casting production process of rear rocker arm of motorcycle

The invention aims to provide a high-vacuum die-casting production process of a rear rocker arm of a motorcycle. The high-vacuum die-casting production process comprises the steps of smelting, heat preservation, mold closing, melting liquid injection, slow-speed sealing, pressure chamber vacuumizing, slow-speed pressing, cavity vacuumizing, high-speed pressing, mold opening and lubrication spraying. According to the rear rocker arm of the motorcycle produced by adopting the high-vacuum die-casting process, the air content in casting can be reduced, the air hole defect is reduced, and the T6 heat treatment can be performed. The casting surface forming quality and the blank size precision are improved, machining is reduced, the casting has higher tensile strength and higher yield strength, the casting quality is lighter, the consumption of resources and energy is reduced, the production cost is reduced, and the economic benefit is improved.

Owner:GUANGDONG TAYO MOTORCYCLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com